Gaylord GX2-BDL Service Manual

THE

GAYLORD VENTILATOR

EFFECTIVE DA TE 4-05

TECHNICAL MANUAL

FOR THE GRAND “GX2” SERIES

NON WATER-WASH VENTILATORS

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • TUALATIN, OREGON 97062-1149 U.S.A.

800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES, INC.

World Headquarters: 10900 S.W. Av erry Street • Tualatin, Oregon 97062-1149 U.S .A.

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. W e are proud to be ab le

to provide you with a quality product that incorporates

the latest engineering concepts and is a result of over

50 years of experience in the foodservice kitchen

exhaust industry.

If you have other Gaylord equipment such as a Gaylord

Utility Distribution System, Quencher Fire Protection Sys-

tem, or Roof Top Air Handling Equipment, etc., please

refer to the corresponding supplementary equipment

manuals.

If you have further questions, please call us toll free at

1-800-547-9696 or email:info@gaylordusa.com. We are

more than happy to help.

Sincerely,

Gaylord Industries

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: gaylord@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062-8549 U.S.A.

TABLE OF CONTENTS

“GX2” SERIES PRINCIPLE OF OPERATION........................................................ 3

STANDARD MODELS ............................................................................................ 6

MAINTENANCE AND CLEANING INSTRUCTIONS.............................................. 7

TROUBLESHOOTING ........................................................................................... 8

MEASURING INLET SLOT VELOCITY ................................................................. 10

WIRING DIAGRAMS.............................................................................................. 13

PARTS LIST ........................................................................................................... 17

START-UP INSPECTION REPORT ....................................................................... 20

WARRANTY................................................................................. Inside back cover

PATENT NUMBERS

U.S.A.: 4,266,529

4,281,635

4,356,870

CANADA: 1,139,151

1,155,366

GERMANY: 8,034,240

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED

IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR O THERWISE WITHOUT PRIOR

WRITTEN PERMISSION OF GAYLORD INDUSTRIES, INC. COPYRIGHT 2003.

© Copyright 2005, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product improvement or the availability of new materials.

ADDITIONAL COPIES $10.00

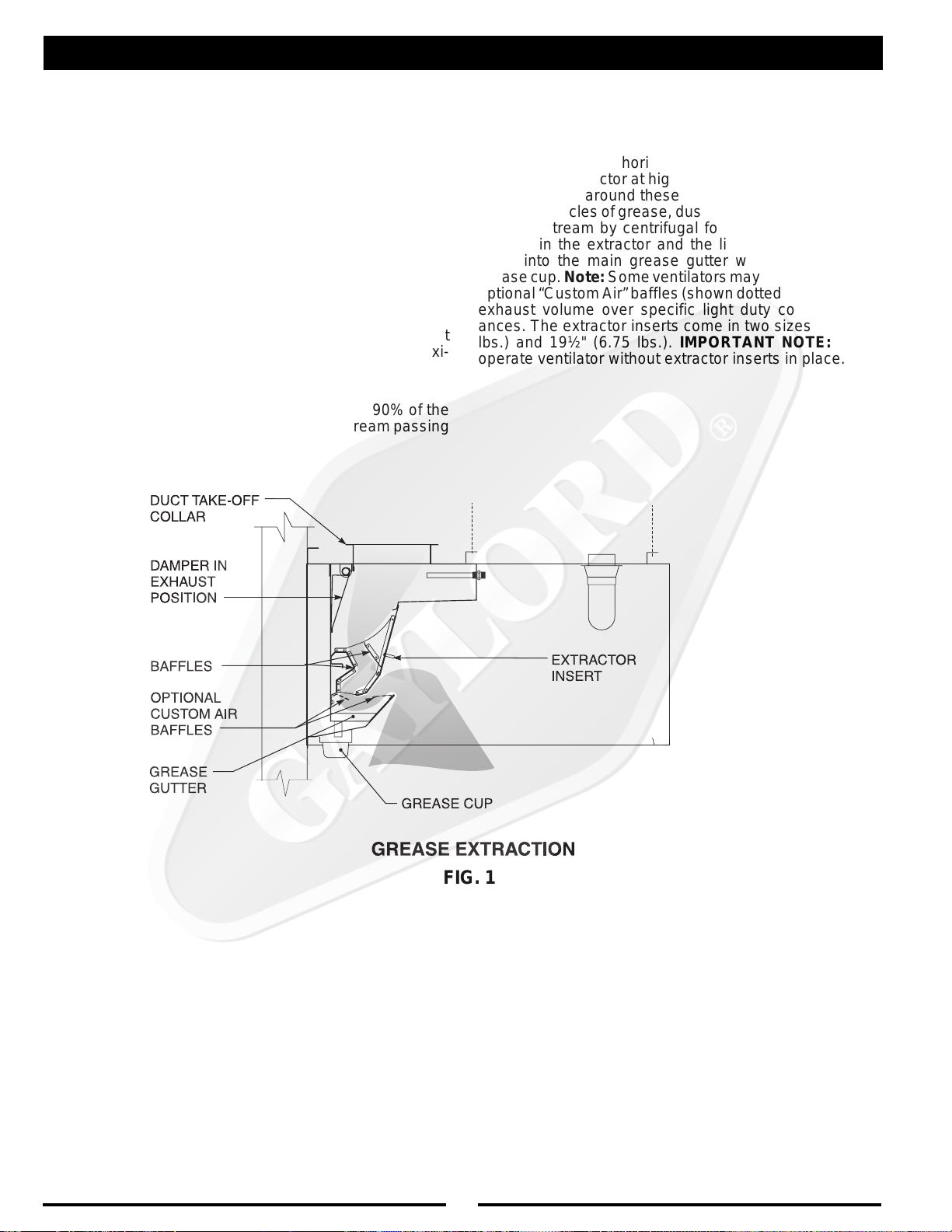

“GX2” SERIES PRINCIPLE OF OPERATION

The Gaylord “GX2” Series Non Water-Wash Ventilator

offers simplicity, economy and performance that no other

ventilator can offer. The unique “extractor insert” gives a

grease extraction efficiency far superior to that of a typical

baffle filter. The Gaylord “GX2” Series Ventilators are UL

Listed and meet all the requirements of NFPA #96 and the

International Mechanical Code.

EXHAUST FAN OPERATION

The exhaust fan is controlled by the Gaylord C-150

“Exhaust Fan Start/Stop Switch”, an optional switch, or a

standard wall switch. The switch is usually located on a

wall near the ventilator. When the switch is flipped up to the

on position, the damper begins opening to the exhaust

position (refer to Fig. 1). After the damper opens (approxi-

mately 80 seconds) the exhaust fan will come on.

GREASE EXTRACTION

The Gaylord “GX2” Series Ventilator extracts 90% of the

grease, dust, and lint particles from the airstream passing

through it. Grease extraction is accomplished by unique,

removable stainless steel “extractor inserts” which incorporates a series of horizontal baffles. As the air moves

through the extractor at high speed, it is forced to make a

series of turns around these baffles, forcing the heavierthan-air particles of grease, dust, and lint to be thrown out

of the airstream by centrifugal force. The sticky grease

collects in the extractor and the liquified grease drains

down into the main grease gutter which slopes to the

grease cup. Note: Some ventilators may be equipped with

optional “Custom Air” baffles (shown dotted) to reduce the

exhaust volume over specific light duty cooking appliances. The extractor inserts come in two sizes15½" (5.6

lbs.) and 19½" (6.75 lbs.). IMPORTANT NOTE: Never

operate ventilator without extractor inserts in place.

FIG. 1

3

“GX2” SERIES PRINCIPLE OF OPERATION

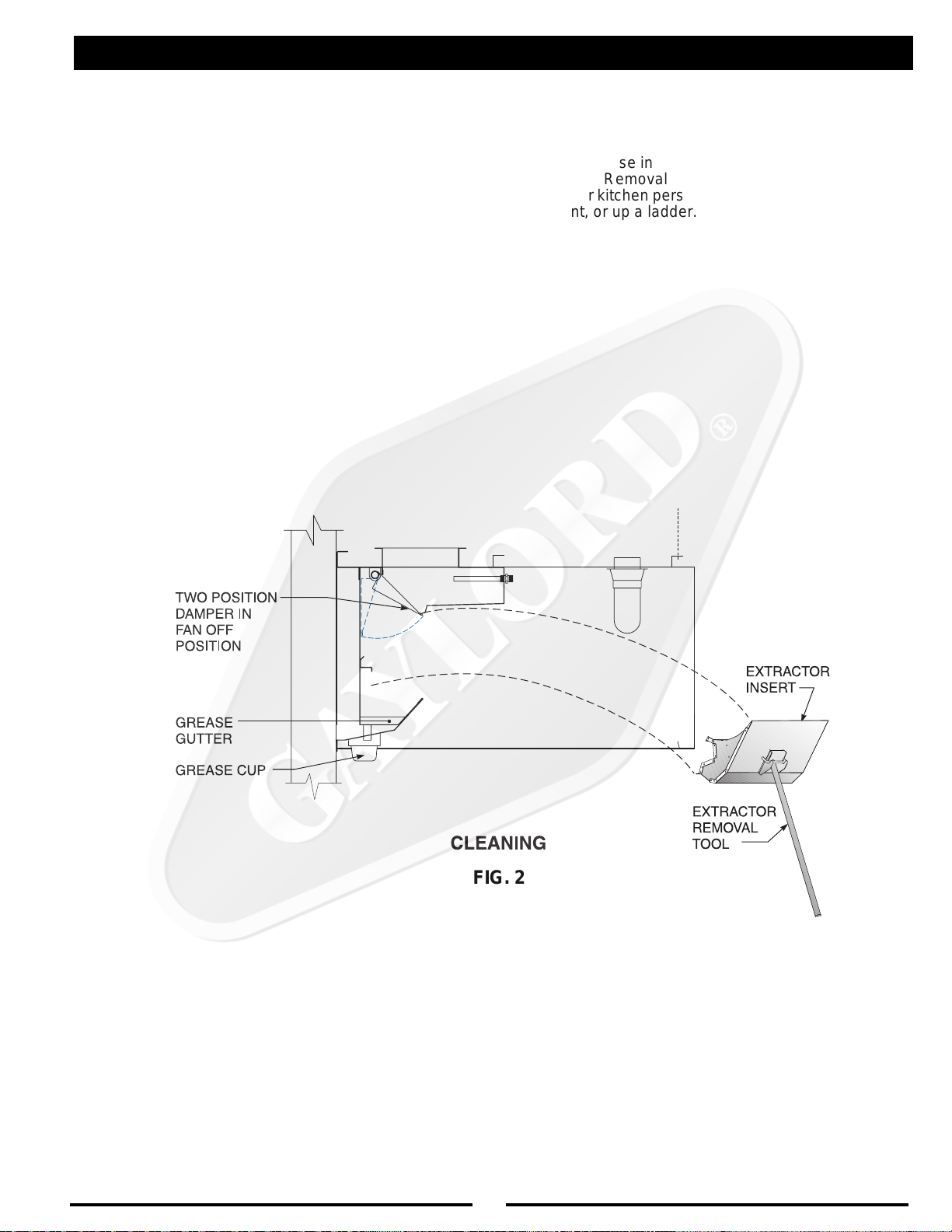

CLEANING

At the end of the cooking day the exhaust fan is turned off

by the “Exhaust Fan Start/ Stop Switch.” In addition to the

fan going off, the two position damper moves to the fan off

position (See Fig 2.). This prevents conditioned air from

going up the exhaust system during off hours. After the fan

has been turned off, the extractor inserts are removed and

can be washed either in a dishwasher or soaked and

rinsed off. The grease cup is also removed and emptied at

this time. To ease in the removal of the extractor inserts,

an “Extractor Removal Tool” is available which eliminates

the need for kitchen personnel to climb up on the cooking

equipment, or up a ladder.

FIG. 2

4

“GX2” SERIES PRINCIPLE OF OPERATION

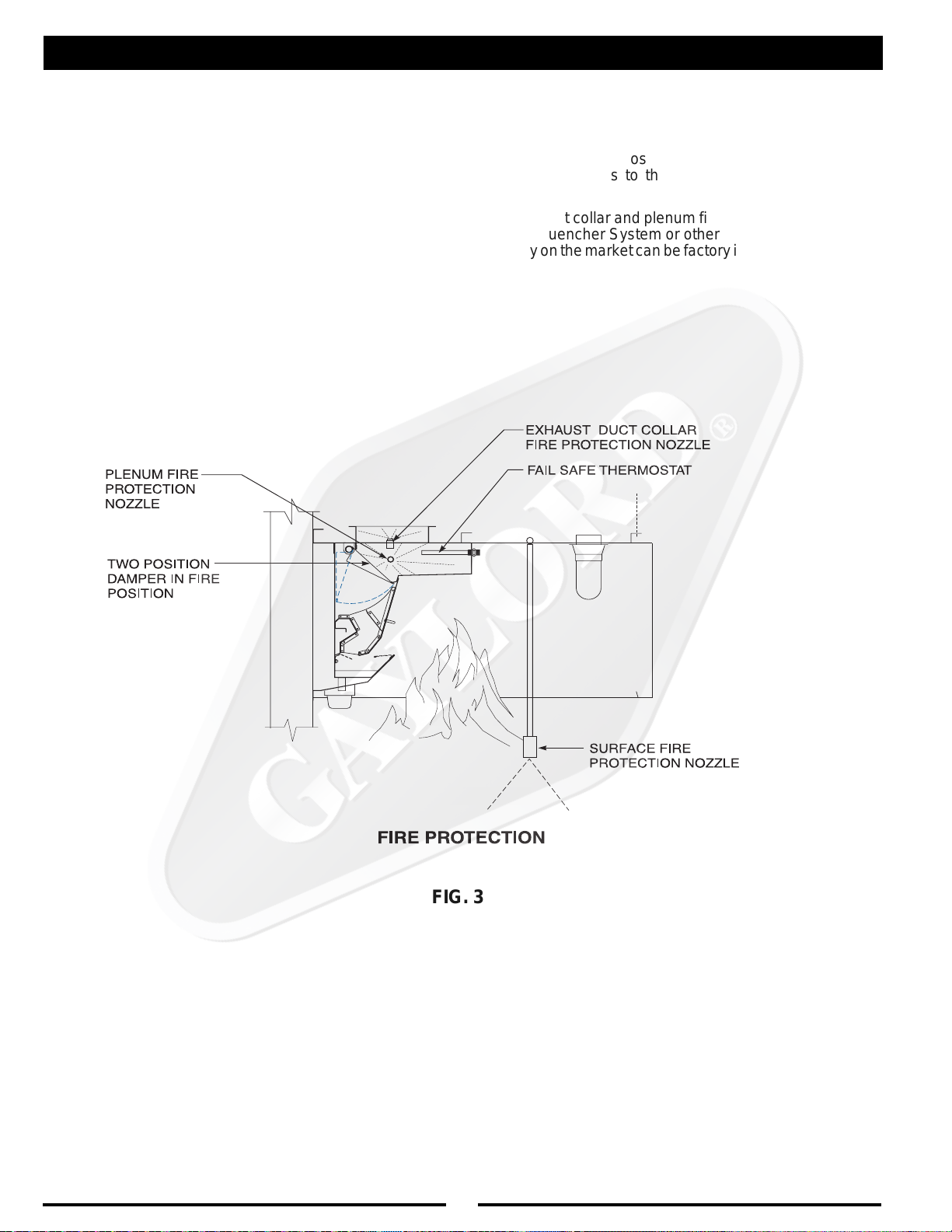

FIRE PROTECTION

NFPA #96 requires the use of surface, duct and plenum

protection on all hoods. It is these systems that are the first

line of defense against equipment fires.

The “GX2” Series ventilator incorporates a two position

damper, a fail safe damper control and a fail safe thermostat.

In the event of a fire, should the thermostat located at the duct

collar reach 250°F, the damper control is de-energized

closing the damper to the fire position (See Fig. 3) and the

exhaust fan shuts off. This prevents the flames from entering

the ductwork and spreading to other parts of the building. The

fire is contained in the kitchen area where it can be properly

fought. After the thermostat cools below 250°F, the damper

automatically opens to the exhaust position and the fan

re-starts.

Surface, duct collar and plenum fire protection utilizing The

Gaylord Quencher System or other fire protection systems

currently on the market can be factory installed as an option.

FIG. 3

5

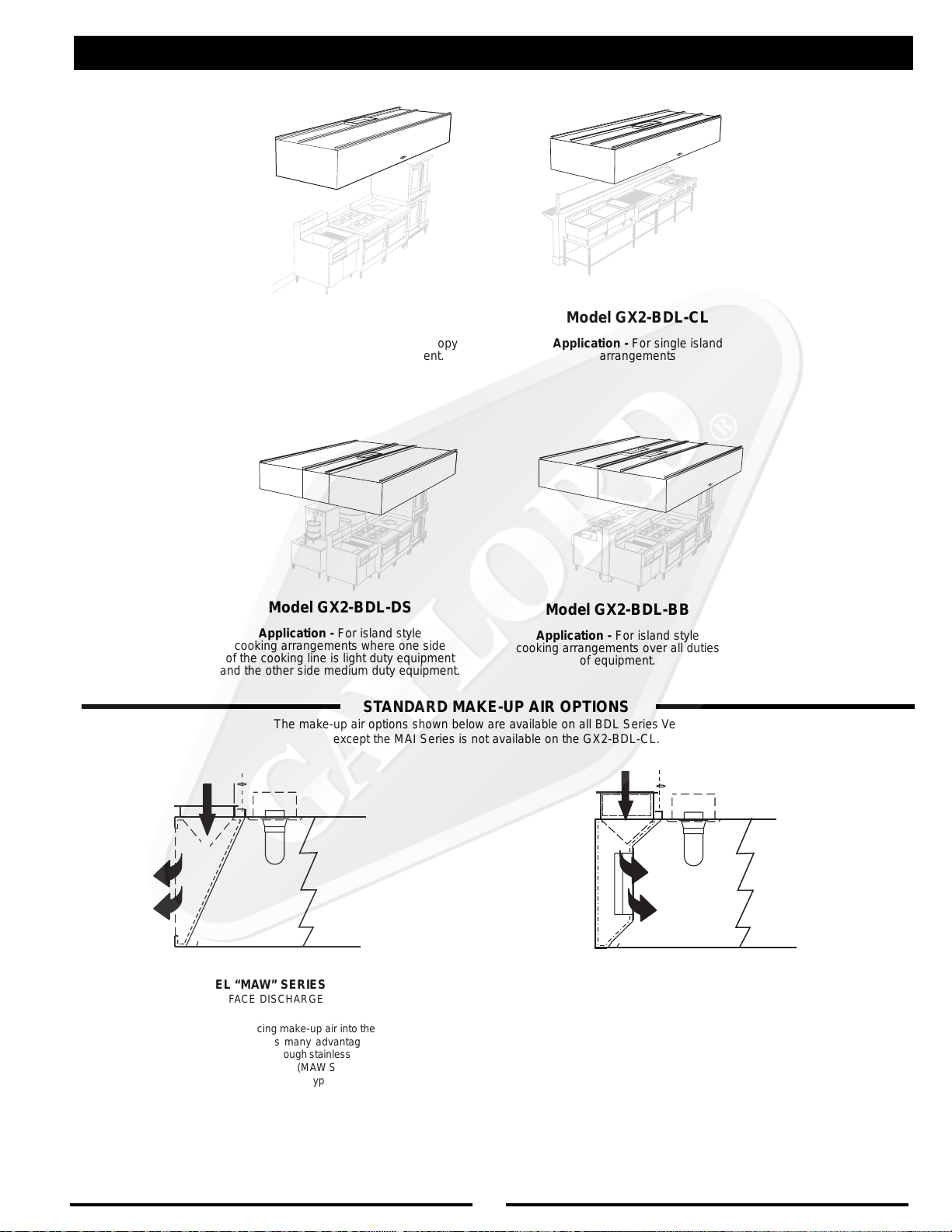

STANDARD VENTILATOR MODELS

Model GX2-BDL

Application - Wall mounted canopy

style for all types of equipment.

Model GX2-BDL-DS

Application - For island style

cooking arrangements where one side

of the cooking line is light duty equipment

and the other side medium duty equipment.

STANDARD MAKE-UP AIR OPTIONS

The make-up air options shown below are available on all BDL Series Ventilators

except the MAI Series is not available on the GX2-BDL-CL.

Model GX2-BDL-CL

Application - For single island

arrangements

Model GX2-BDL-BB

Application - For island style

cooking arrangements over all duties

of equipment.

MODEL “MAW” SERIES

FRONT FACE DISCHARGE

This method of introducing make-up air into the

kitchen is flexible and has many advantages.

Make-up air is discharged through stainless steel

perforated panels as illustrated (MA W Series) or

optional registers (MAR Series). Typical supply

volume is 80% of the exhaust or more, depending on air balance desired. Supply air temperatures should range from 60 to 65°F (16 to 18°C),

but may be as low as 50°F (10°C) depending on

air volume, distribution, and internal heat load.

MODEL “MAI” SERIES

INTERNAL DISCHARGE

This method of introducing air into the hood is

typically referred to as the “short circuit” method.

This design has very limited applications and the

amount of supply air able to be introduced varies

considerably with the type of cooking equipment.

This air may be untempered air in most areas

depending upon climatic conditions and the type

of cooking equipment. The difference between

the quantity of air being introduced and the

amount of air being exhausted must be supplied

through a traditional make-up air system.

6

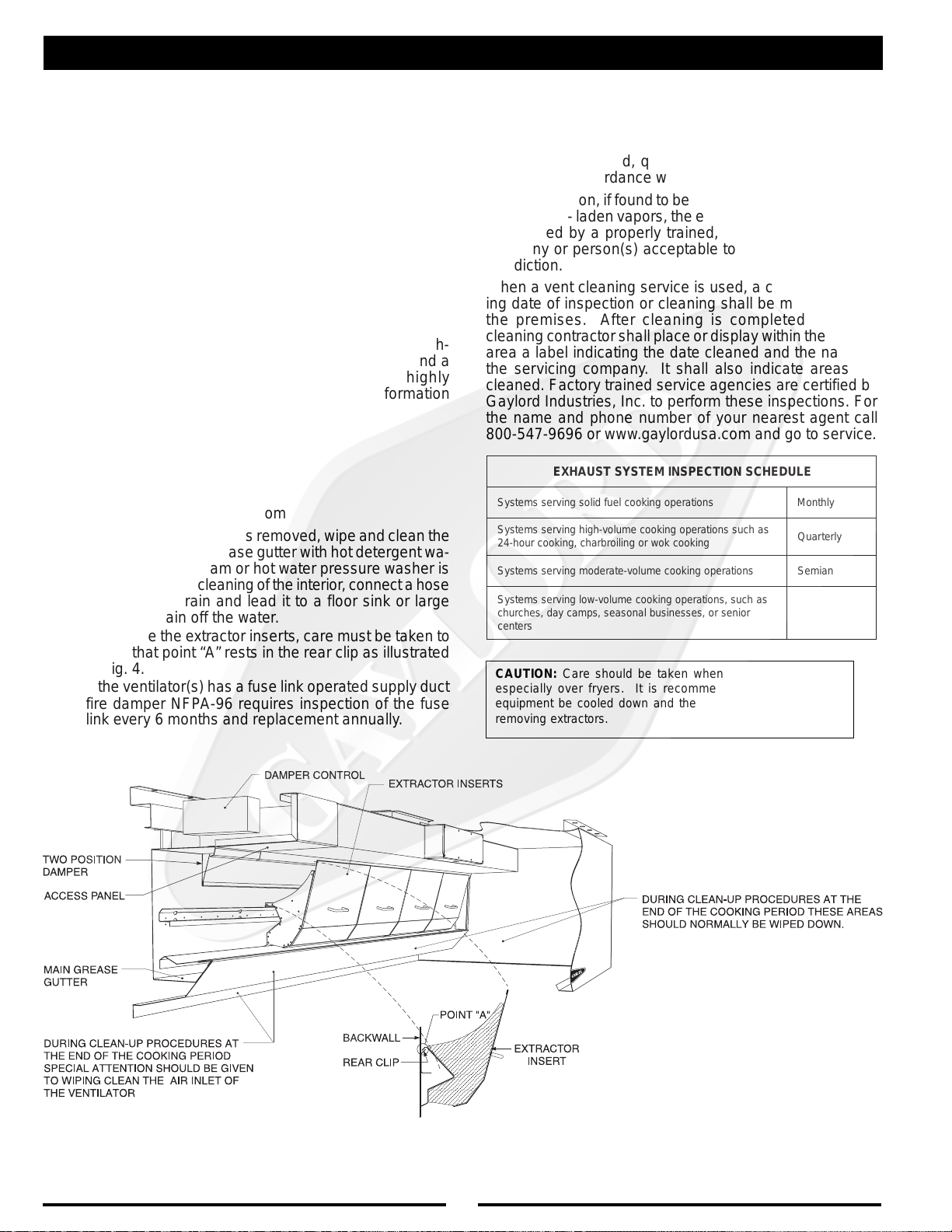

MAINTENANCE AND CLEANING INSTRUCTIONS

CLEANING

At the end of each cooking day, the exposed interior

surfaces of the ventilator should be wiped down and the

grease cup emptied. During the course of operation, grease

particles are gradually collecting inside the extractor inserts.

Daily , or at periodic intervals, depending on the type of cooking, the extractor inserts must be removed and cleaned.

To clean, proceed as follows:

1.Remove extractor inserts by hand or by using the

extractor removal tool. CAUTION: Care should be

taken when removing extractors, especially over fryers. It is recommended that the cooking equipment be

cooled down and the fryers be covered prior to removing

extractors. To remove, lift up slightly on extr actor insert

and pull straight out.

2.Extractor inserts may be cleaned either by using a dish-

washer or by washing in a sink using hot water and a

degreasing detergent. Formula G-510 is highly

recommended for this application. For information

contact:

20/10 Products Inc.

P.O. Box 7609

Salem, OR 97303

Phone: 800-286-2010

Fax: 503-363-4296

E-mail: twentyten@juno.com

3.With the extractor inserts removed, wipe and clean the

back wall and the grease gutter with hot detergent wa-

ter. NOTE: If a steam or hot w ater pressure washer is

used for periodic cleaning of the interior, connect a hose

to the gutter drain and lead it to a floor sink or large

buck et to drain off the water.

4.T o replace the extractor inserts, care must be taken to

insure that point “A” rests in the rear clip as illustrated

in Fig. 4.

5.If the ventilator(s) has a fuse link operated supply duct

fire damper NFPA-96 requires inspection of the fuse

link every 6 months and replacement annually.

INSPECTION AND CLEANING REQUIREMENTS

The 2001 edition of NFP A-96 (Standard for V entilation Control and Fire Protection of Commercial Cooking Operations)

require that hoods, ducts and exhaust fans be inspected

by a properly trained, qualified and certified company or

person(s) in accordance with the following table.

Upon inspection, if found to be contaminated with deposits

from grease- laden vapors, the entire exhaust system shall

be cleaned by a properly trained, qualified, and certified

company or person(s) acceptable to the authority having

jurisdiction.

When a vent cleaning service is used, a certificate showing date of inspection or cleaning shall be maintained on

the premises. After cleaning is completed, the vent

cleaning contractor shall place or display within the kitchen

area a label indicating the date cleaned and the name of

the servicing company. It shall also indicate areas not

cleaned. Factory trained service agencies are certified by

Gaylord Industries, Inc. to perform these inspections. For

the name and phone number of your nearest agent call

800-547-9696 or www.ga ylordusa.com and go to service.

ELUDEHCSNOITCEPSNIMETSYSTSUAHXE

snoitarepognikoocleufdilosgnivressmetsySylhtnoM

gnikoockowrogniliorbrahc,gnikoocruoh-42

sahcussnoitarepognikoocemulov-hgihgnivressmetsyS

snoitarepognikoocemulov-etaredomgnivressmetsyS yllaunnaimeS

sahcus,snoitarepognikoocemulov-wolgnivressmetsyS

roinesro,sessenisublanosaes,spmacyad,sehcruhc

sretnec

CAUTION: Care should be taken when removing extractors,

especially over fryers. It is recommended that the cooking

equipment be cooled down and the fryers be covered prior to

removing extractors.

ylretrauQ

yllaunnA

FIG. 4

7

Loading...

Loading...