Gaylord ELXC-BBC-CL User Manual

MODEL “ELXC-BBC-CL”

HIGH EFFICIENCY EXTRACTOR VENTILATOR

WITH CLEAN-IN-PLACE TECHNOLOGY

GENERAL SPECIFICATIONS AND DESCRIPTION

Furnish Gaylord Ventilator Model “ELXC-BBC-CL___________” as shown

on plans and in accordance with the following specications:

HIGH EFFICIENCY EXTRACTION: Each ventilator shall contain “XGS” High

Eciency Extractors utilizing the “capture and drain” principle. Extractor

eciencies shall be determined using ASTM F2519-2005 testing procedures

as accepted by ASHRAE TC 5.10 and ASHRAE Standard 154-2011 - 4.7.2.

The “capture and drain” principle shall prevent water from entering the

plenum and duct areas during “FAN ON” wash cycles, thus providing 24/7

operators the full eect of clean-in-place technology. The High Eciency

Extractors shall not exceed 55 db, on typical cooking lines, as measured

at the chef’s ear so fatigue is minimized and productivity is optimized.

CAPTURE AND CONTAINMENT: Each ventilator shall achieve capture

and containment using the lowest possible airow rates through “passive”

versus “active” design features, thus eliminating the wiring or adjustment

of internal motors, plenums or jets. The lowest possible airow rates shall

be tested to ASTM 1704-09 by the Food Service Technology Center and

published on their website for easy conrmation.

http://www.shnick.com/publications/appliancereports/hoods/

CLEAN-IN-PLACE WASH TECHNOLOGY: Each ventilator shall include two

full length stainless steel wash manifolds with brass nozzles; one to power

wash the inlet face and internal passages of the extractors during “FAN ON”

mode and one to wash the plenum chamber, during the “FAN OFF” mode

as programmed by the Gaylord Command Center. Each wash manifold on

each ventilator section shall operate independently so wash cycles may

be programmed at dierent frequencies and dierent durations to reduce

water and detergent usage and optimize cleaning ecacy according to

load and demand. Each ventilator section shall drain to sloping gutters

with 2” outlets.

CONSTRUCTION: Each ventilator shall include full length access panels that

are non-tool entry, non-gasketed and non-removable to ease inspection of

extractors, plenum and re extinguishing system. The ventilator shall be of

all stainless steel construction, not less than 18 gauge, type 300 series. All

exposed surfaces shall be a number 4 nish. The use of aluminized steel or

galvanized steel is not acceptable. The Ventilator shall include a “V” bank

arrangement of “XGS” High Ecienc y Extractors. The Ventilator shall include

a static pressure port in each section to be used in balancing exhaust air

volumes. Continuous front and rear mounting brackets shall be provided

to facilitate mounting to the wall and hanging from the overhead building

structure. Each duct collar shall include as standard a Gaylord Balancing

Damper (GBD) with opposed blades that adjust manually through access

from within the canopy. Ventilators built in end-to-end multiple sections

shall have as standard “Continuous Capture” from one end to the other to

ease cleaning and improve capture and containment.

ELXC

SERIES

ITEM NO. _______________

ACCEPTANCE & APPROVALS: Each ventilator shall include an integral

“Autostart” controller and sensors to meet current IMC standards (optional outside North America). Each ventilator shall include a built-in 1”

air space at the rear that is Listed for reduced clearance to combustibles,

and is NFPA-96 and IMC compliant when mounting against a combustible

wall. Each ventilator shall be Listed to UL Standard 710, ETL Sanitation,

comply with all requirements of NFPA-96, IMC, UMC, BOCA, and SBCCI

mechanical codes and be capture tested to ASTM 1704-09 with High

Eciency Extractors tested to ASTM 2519-2005.

APPLICATION

Wall mounted canopy for use over all types of equipment; ovens, broilers, griddles, fryers, ranges, steam equipment, etc.

DESIGN FEATURES

• Internal Canopy Radius

• Enhanced “XGS” Extractor Angle and Slot Spacing

• Faceted “Super Capture”™ Lip

• Integrated Capture Wall

OPTIONAL EQUIPMENT

1. Decorative Facings and Trim

2. Demand Control Ventilation

3. Fire Extinguishing Systems

4. Pollution Control Systems

5. Utility Distribution Systems

6. “XGS” Spark Arrestor Extractors

LIGHT FIXTURES: The ventilator shall be equipped with:

o Recessed LED 6 Watts/Ft. Min.

o Recessed uorescent 12 Watts/Ft. Min.

o 100 watt surface mounted incandescent 24 Watts/Ft. Min.

o 150 watt recessed incandescent 36 Watts/Ft. Min.

Light xtures shall be factory pre-wired to a single connection point.

Ventilators built in multiple sections shall be furnished with coiled ex

conduit for interconnecting sections.

GAYLORD INDUSTRIES

10900SWAVERYST•TUALATIN,OREGON97062U.S.A.

PHONE:800.547.9696•FAX:503.692.6048•email:info@gaylordventilation.com

www.gaylordventilation.com

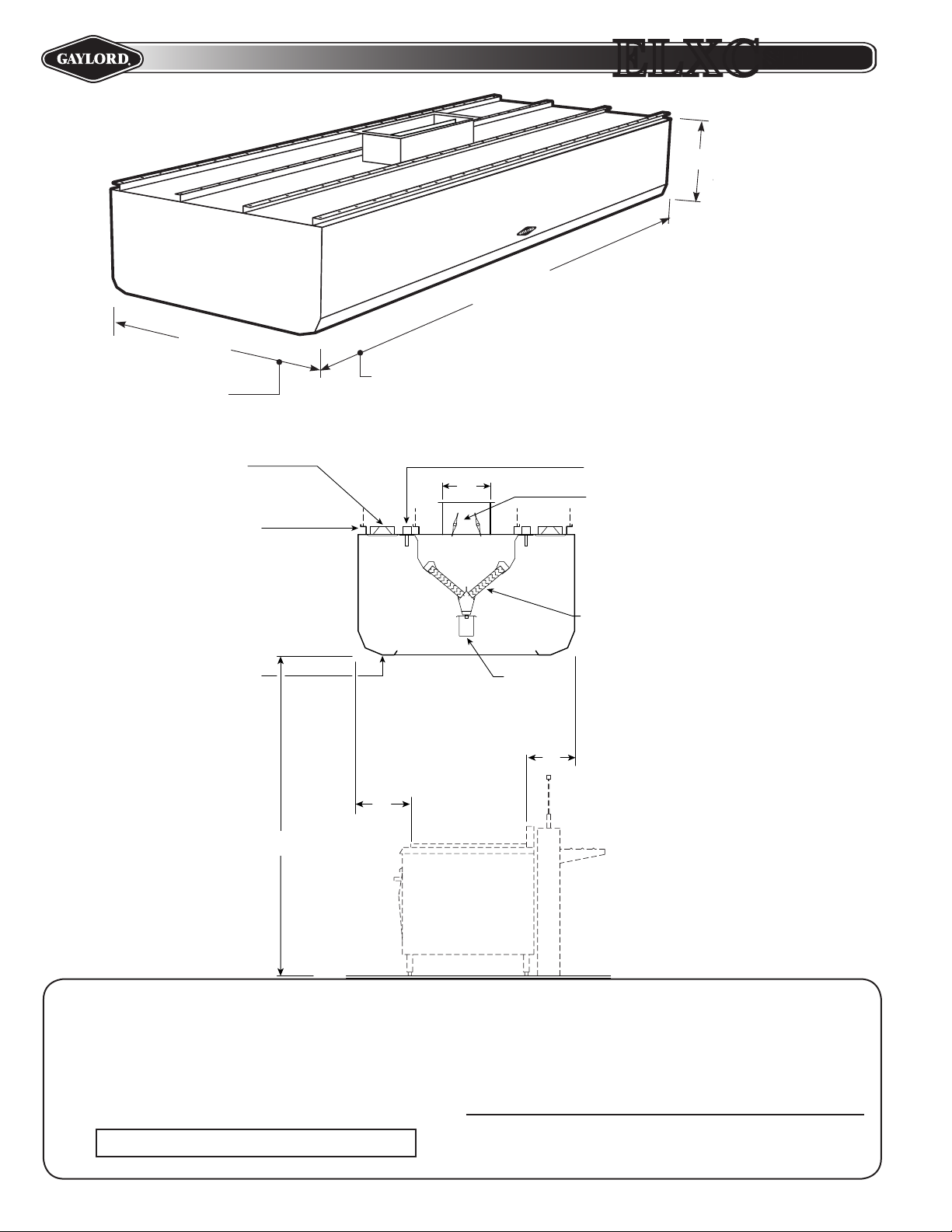

54” MINIMUM.

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT.

LIGHT FIXTURE

*16’ -0” MAX. UNIT LENGTH.

FOR GREATER LENGTH, JOIN TWO OR MORE

SECTIONS TOGETHER. ALLOW 12” MIN.

OVERHANG AT EACH END.

“AUTOSTART ” SENSOR

10”

OR 12”

GAYLORD BALANCING DAMPER (LISTED)

ELXC

30” STANDARD

ALSO AVAILABLE

24” HIGH

SERIES

CONTINUOUS

HANGING BRACKET

SUPERCAPTURE™ LIP

6’-8”

MTG. HT.

12”

MIN.

0.5 GALLON

GREASE CUP

“XGS” SUPER HIGH EFFICIENCY

FILTRATION EXTRACTOR

12”

MIN.

MECHANICAL REQUIREMENTS

The amount of exhaust volume required is dependent upon the type of cooking

equipment and the type and volume of cooking. Contact factory for exhaust

volumes, duct sizes, and static pressures.

ELECTRICAL

Provide 120 volt 50/60Hz circuit to lights, 220/240 volt optional. Refer to Wash

Control Cabinet for its electrical requirements.

The manufacturer reserves the right to modify the materials and specifications resulting

from a continuing program of product improvement or the availability of new materials

Form No. ELXC -BBC-CL 0214-20408 © Copyright 2012, Gaylord Industries Litho USA

ENGINEERING DATA

Ventilator Lengths

Maximum unit length 16’-0”. For greater lengths, join two or more sections together.

Check to ensure that there is adequate access into building and kitchen area.

NOTE: Ventilators manufactured outside North America; maximum unit length

*

10’-0”.

Hanging Weight

Ventilator Width 54” 60” 66”

Wt. / Lineal Ft. Lbs. 100 105 110

Loading...

Loading...