Gast 0523 User Manual

www.gastmfg.com

ISO 9001 & 14001 CERTIFIED

ART NO. 70-350 G386PL (Rev. F)

WARNING

PLEASE READ THIS MANUAL COMPLETELY BEFORE INSTALLING AND USING

THIS MOTOR. SAVE THIS MANUAL FOR FUTURE REFERENCE AND

KEEP IN THE VICINITY OF THE MOTOR.

P

GAST LUBRICATED LABORATORY 23 SERIES ROTARY

VANE VACUUM PUMPS & COMPRESSORS

PERATION & MAINTENANCE MANUAL

O

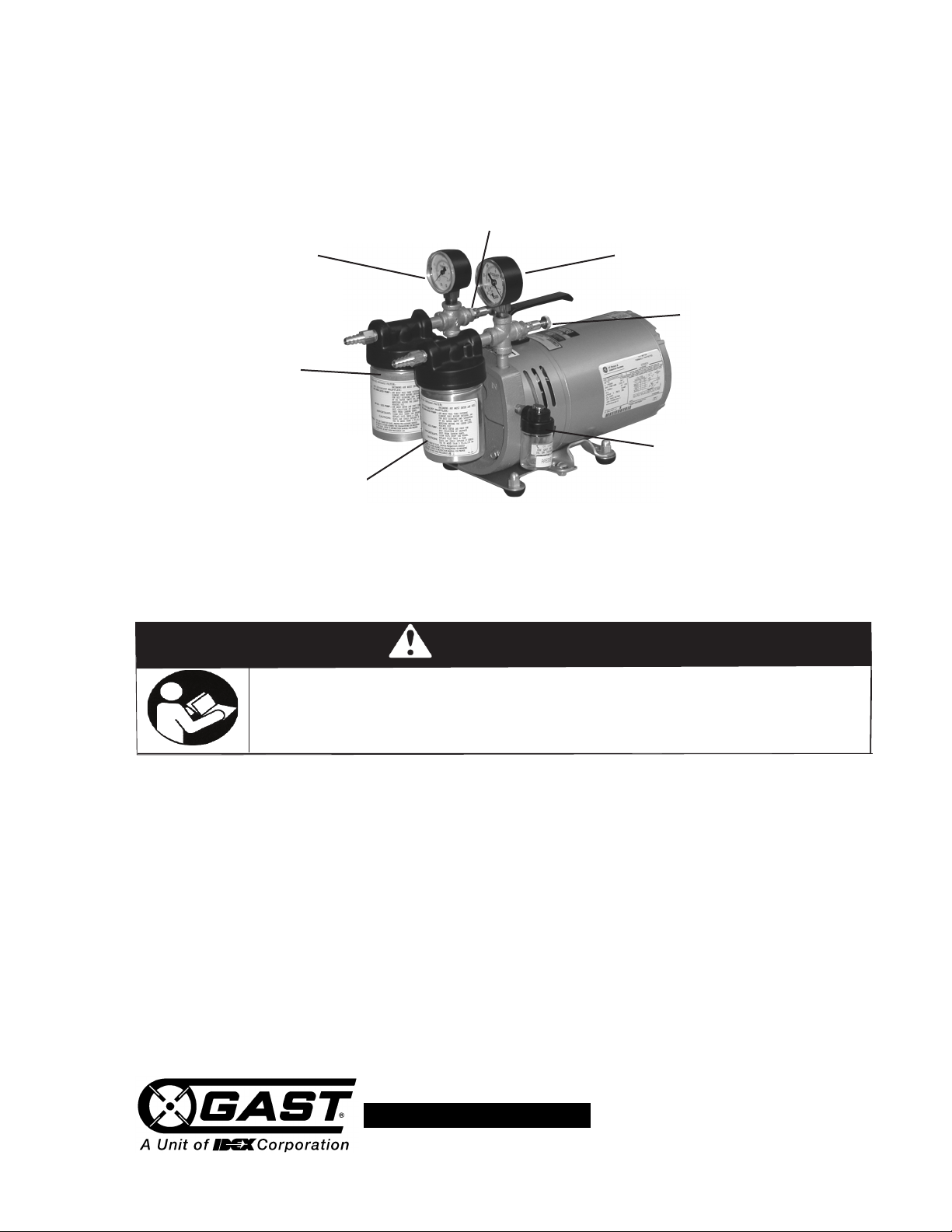

Relief Valve (hidden)

Pressure Gauge

The pressure gauge shows the

utput pressure..

o

Turn the regulator screw

clockwise to increase pressure.

Vacuum Gauge

he vacuum gauge shows the intake

T

pressure.

10 Micron Filter Element

Check muffler element each time oil

reservoir is filled; clean with soap and

water as needed, or replace. (See page 7

for Ordering Information).

10 Micron Filter Element

Check filter element each time oil

reservoir is filled; clean with soap and

water as needed, or replace. (See

page 7 for Ordering Information).

NOTE: Removes solid particles only.

Install a moisture trap if liquids could

be drawn into the pump.

Relief Valve

Turn the regulator screw clockwise to

increase vacuum. NOTE: Maximum

pressure and vacuum cannot be

produced at the same time.

Siphon Oiler

Models 0323, 0523: Check the oil level at

each use to ensure safe operation.

Constant Level Oiler (not shown)

Models 0823, 1023: Large oil reservoir;

check the oil level at longer intervals.

Product Use Criteria:

• Operate at 32ºF - 104ºF (0ºC - 40ºC).

• Protect unit from dirt & moisture.

• Protect all surrounding items from hot exhaust

air. This exhaust air can become very hot.

• Product is not a consumer product and is for

commercial applications only.

• Do not pump flammable or explosive gases or use

in an atmosphere that contains such gases.

• Corrosive gases and particulate material will

damage unit. Water vapor, oil-based contaminants

or other liquids must be filtered out.

• Consult your Gast Distributor/Representative

before using at high altitudes.

• Use Gast #AD220 or a detergent SAE#10

automotive engine oil for lubricating.

c

Disconnect electrical power at the circuit breaker

or fuse box before installing this product.

Install this product where it will not come into

contact with water or other liquids.

Install this product where it will be weather

protected.

Electrically ground this product.

Failure to follow these instructions can result in

death, fire or electrical shock.

WARNING

Electrical Shock Hazard

WARNING

DANGER

Your safety and the safety of others

i

s extremely important.

We have provided many important safety messages

in this manual and on your product. Always read

and obey all safety messages.

This is the safety alert symbol. This symbol

alerts you to hazards that can kill or hurt you and

others. The safety alert symbol and the words

“DANGER” and “WARNING” will precede all safety

m

essages. These words mean:

Y

ou will

b

e killed or seriously injured if you don’t

follow instructions.

You can

be killed or seriously injured if you don’t

follow instructions.

All safety messages will identify the hazard, tell you

how to reduce the chance of injury, and tell you

what can happen if the safety instructions are not

followed.

Mounting

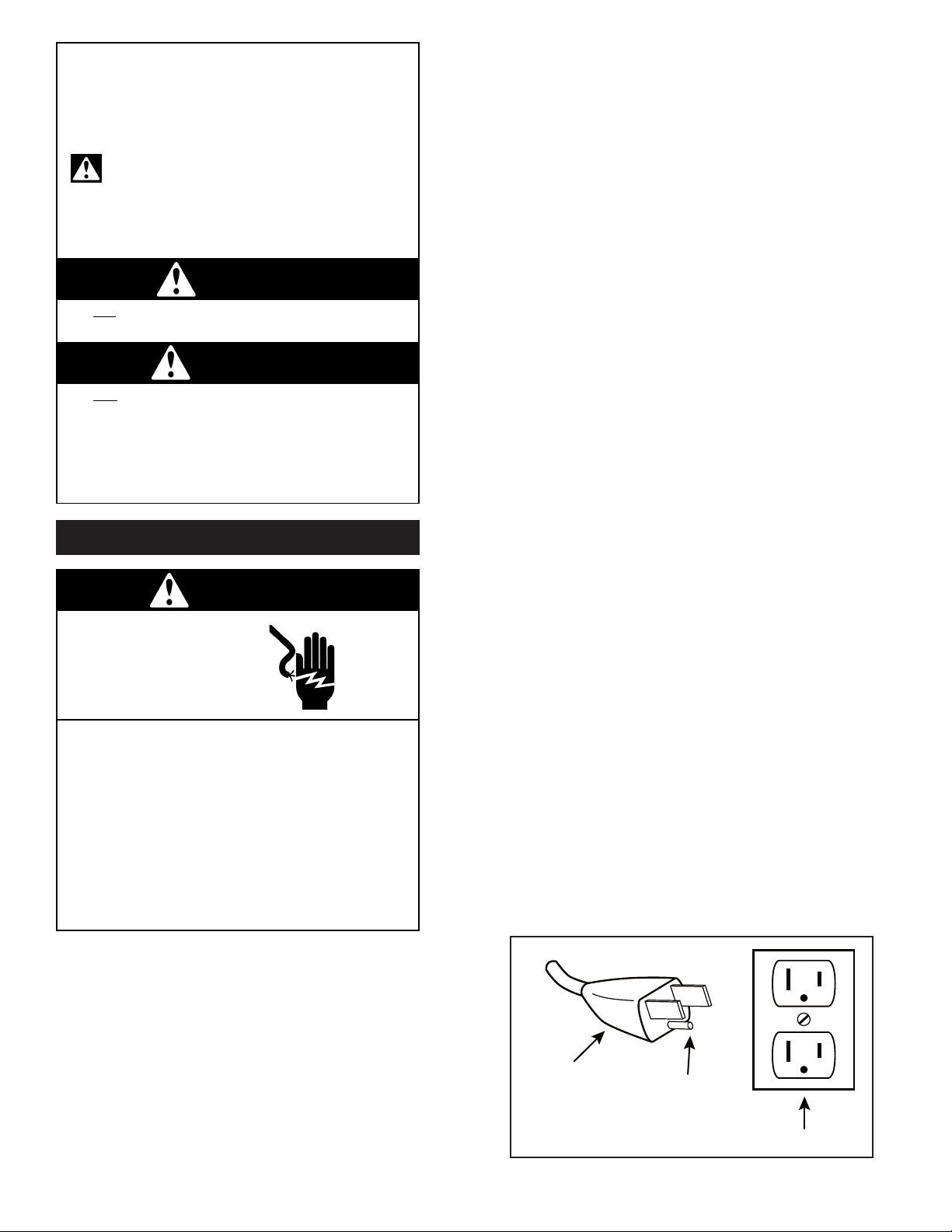

Grounded Plug

Grounding Pin

Grounded Outlet

120-volt grounded connectors

shown. 220/240-volt grounded

connectors will differ in shape.

DIAGRAM A

he pump and its solid base (preferably metal) should be

T

anchored to either a shelf, the floor, or another piece of

machinery. To save time and avoid inconvenience,

position the pump to provide easy access to all

ubricators, filters and mufflers.

l

Moisture Trap

Liquid or moisture vapor will damage the pump. Install a

oisture trap if liquids could be drawn into the pump. For

m

the correct type and size, contact your local Distributor or

the factory.

lumbing

P

To prevent air flow restriction, use pipe and fittings that

are the same size or larger than the threaded ports of the

pump. The ports are marked "IN" and "OUT". If the

istance is great, use lines with a larger diameter than

d

the connections. Give lines a uniform slope, place drain

cock at low point, and avoid extra elbows. For ease of

servicing, use a union or hose with clamps near the

pump (a hose helps eliminate noise and vibration). If a

vacuum/pressure supply tank is used, slope the line

towards tank, provide a drain at the bottom, and place a

check valve between the tank and pump so the pump will

not run backwards when turned off.

INSTALLATION

Correct installation is your responsibility. Make sure you

have the proper installation conditions and that

installation clearances do not block air flow. Proper

guards should be installed to prevent contact with

moveable parts of this pump. Do Not lift the unit by the

fan shroud.

Blocking air flow over the product in any way can cause

the product to overheat.

Mounting

Position the mounting the product to a stable, rigid

operating surface and using shock mounts will reduce

noise and vibration.

Motor Control

It is your responsibility to contact a qualified

electrician to assure that the electrical installation is

adequate and in conformance with all national and local

codes and ordinances.

Determine the correct overload setting required to

protect the motor (see motor starter manufacturerʼs

recommendations). Select fuses, motor protective

switches or thermal protective switches to provide

protection. Fuses act as short circuit protection for the

motor, not as protection against overload. Incoming line

fuses help to withstand the motorʼs starting current.

Motor starters with thermal magnetic overload or circuit

breakers protect motor from overload or reduced

voltage conditions.

The wiring diagram supplied with the product provides

required electrical information. Check that power

source is correct to properly operate the dual-voltage

motors.

Electrical Connection

2

c

Disconnect electrical power supply cord before

performing maintenance on this product.

If product is hard wired into system, disconnect

electrical po

wer at the circuit breaker or fuse box

before performing maintenance on this product.

F

ailure to follow these instructions can result in

death, fire or electrical shock.

Electrical Shock Hazard

WARNING

WARNING

Injury Hazard

Air stream from product may contain solid or liquid

m

aterial that can result in eye or skin damage.

Wear hearing protection. Sound level from product

may exceed 85 db(A).

Failure to follow these instructions can result in eye

injury or other serious injury.

P

ump only clean dry air.

Do not pump flammable or explosive gases or use

i

n an atmosphere that contains such gases.

Install proper safety guards as needed. Pumps with

g

lass jars need safety guards to protect against

breaking glass.

Use only recommended air handling parts acceptable

for pressure not less than 70 psi.

Keep fingers and objects away from openings and

r

otating parts.

When provided, motor terminal covers must be in

place for safe operation.

Check that coupling guard and shroud are in place

before operating.

Product surfaces may become hot during operating,

allow product surfaces to cool before handling.

Do not direct air stream at body. Air stream from

product may contain solid or liquid material that can

result in eye or skin damage, wear proper eye

protection.

Do not spray flammable or combustible liquid.

Model with a power supply cord:

This product must be grounded. For either 120-volt or

220/240-volt circuits connect power supply cord

rounding plug to a matching grounded outlet. Do not

g

use an adapter. (See DIAGRAM A)

In the event of an electrical short circuit, grounding

reduces the risk of electric shock by providing an

scape wire for the electric current. This product may

e

be equipped with a power supply cord having a

grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly

nstalled and grounded in accordance with all local

i

codes and ordinances.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood,

or if you are not sure whether the product is properly

grounded. Do not modify the plug provided. If it will not

fit the outlet, have the proper outlet installed by a

qualified electrician.

Model that is permanently wired:

This product must be connected to a grounded,

metallic, permanent wiring system, or an equipment

grounding terminal or lead on the product.

OPERATION

Power supply wiring must conform to all required safety

codes and be installed by a qualified person. Check

that supply voltage agrees with that listed on product

nameplate.

Extension cords:

Use only a 3-wire extension cord that has a 3-blade

grounding plug. Connect extension cord plug to a

matching 3-slot receptacle. Do not use an adapter.

Make sure your extension cord is in good condition.

Check that the gage wire of the extension cord is the

correct size wire to carry the current this product will

draw.

Minimum gage for extension cords

Amps Volts Length of cord in feet

120v 25 50 100 150 200 250 300 400 500

240v 50 100 200 300 400 500 600 800 1000

0-2 18 18 18 16 16 14 14 12 12

2-3 18 18 16 14 14 12 12 10 10

3-4 18 18 16 14 12 12 10 10 8

4-5 18 18 14 12 12 10 10 88

5-6 18 16 14 12 10 10 888

6-8 18 16 12 10 10 8666

8-10 18 14 12 10 88664

10-12 16 14 10 886644

12-14 16 12 10 866642

14-16 16 12 10 866442

16-18 14 12 8864422

18-20 14 12 8664422

3

It is your responsibility to operate this product at

recommended pressures or vacuum duties and room

ambient temperatures. Do Not start against a vacuum

or pressure load.

Start Up

If pump is extremely cold, let it warm up to room

temperature before starting. If motor fails to start or

slows down significantly under load, shut off and

disconnect from power supply. Check that the voltage

is correct for motor and that motor is turning in the

proper direction. Turning in the wrong direction will

drastically reduce vane life. Vane life will be drastically

reduced if motor is not operating properly. Vanes can

break or be damaged if motor/pump runs in the wrong

direction.

MAINTENANCE

Loading...

Loading...