Page 1

PAMPERA 125-07

Page 2

Page 3

INTRODUCTION

GAS GAS would like to thank you for your confidence.

By choosing a new PAMPERA 125 2007 you have become part of the great GAS GAS family and, as a user

of the number one manufacturer of off-road motorbikes, you deserve the best treatment we can offer you both

in our after-sales relations and in the information given in this manual.

The new PAMPERA 125 2007 is a motorcycle that has been designed for your leisure. In fact, it is the result

of many years of competition and experience in this highly demanding discipline and of the many excellent

results obtained by the great riders who have provided the fundamental data to enable us to create excellent

GAS GAS motorcycles with several key advantages: reliability, high-performance and stability.

Congratulations for making, without a doubt, the right choice. With skill at the commands of this motorbike,

an adequate preparation and the corresponding essential servicing, this GAS GAS will remain highly reliable

and you will be able to enjoy the most comfortable and rewarding motor sport.

Thank you for your confidence and welcome to GAS GAS motos S.A.

3

Page 4

IMPORTANT WARNING

Read this manual carefully. This manual covers aspects that will

contribute to your safety and to that of others, as well as guaranteeing

a correct preservation and maintenance of your new GAS GAS

motorcycle.

All the instructions required in order to correctly drive and handle

the motorcycle are listed below. Each message will be preceded by

a symbol.

DANGER

This warning symbol identifies special instructions or procedures

that, if not correctly followed, could result in personal injury,

or even death.

WARNING

This symbol identifies special instructions or procedures that,

if not strictly observed, could result in damage to or destruction

of the machine.

Note

This symbol indicates points of particular interest for more

efficient and convenient operation.

Inadequate driving skill could cause environmental problems and

conflicts with other people. Responsible use of your motorcycle will

ensure that these problems and conflicts do not arise.

TO PROTECT THE FUTURE OF YOUR SPORT, MAKE SURE

YOU USE YOUR BIKE LEGALLY, WITH CONCERN FOR THE

ENVIRONMENT, AND RESPECT THE RIGHTS OF OTHER

PEOPLE.

Motorcycle riding is a fantastic sport, and we hope you will enjoy it

to the fullest.

USE OF OIL RECOMMENDED:

4

Page 5

INDEX

INTRODUCTION .......................................................................... 3

IMPORTANT WARNING ..............................................................4

INDEX .......................................................................................... 5

IDENTIFICATION ..........................................................................7

Motorcycle identification code ........................................................7

Authorization plate .........................................................................7

LOCATION OF COMPONENTS - OPERATION ...........................8

Locating components ....................................................................8

Clutch ..........................................................................................10

Front brake ..................................................................................10

Ignition key and steering lock ......................................................10

Multi-function instrument panel and indicator lights .....................12

Electric start button .................................................................... 15

Engine stop button .......................................................................15

Lights and indicators ....................................................................16

Horn .............................................................................................17

Fuel tank ......................................................................................18

Fuel tap ........................................................................................18

Recommended fuel ......................................................................18

Choke ..........................................................................................19

Gear changer ..............................................................................19

Brake pedal .................................................................................20

Stand ......................................................................................... 20

DRIVING INSTRUCTIONS ..........................................................21

Starting the engine .......................................................................21

Starting a cold engine ..................................................................21

What to do when the engine is "flooded" .....................................22

Stopping the engine ....................................................................22

Stopping the motorcycle ..............................................................22

Running-in period.........................................................................23

MAINTENANCE INSTRUCTIONS ..............................................24

Maintenance chart .......................................................................24

Clutch ...........................................................................................25

- Adjustment ..........................................................................25

Brakes .........................................................................................26

- Position and play of the front brake lever ............................26

- Position and play of the rear brake pedal ...........................26

Brake fluid ....................................................................................27

- Brake fluid level inspection ..................................................28

- Brake pad wear check ........................................................28

Handle bars .................................................................................28

- Adjustment ..........................................................................28

Steering........................................................................................29

Engine oil .....................................................................................30

- Oil level ...............................................................................30

- Changing the oil ..................................................................30

- Cleaning the strainer ...........................................................32

5

Page 6

Carburettor ...................................................................................32

- Adjusting the accelerator control cable ............................. 32

- Adjusting idle speed ............................................................33

Spark plug ...................................................................................34

Air filter ........................................................................................ 35

Wheels .........................................................................................36

- Tyre pressure ......................................................................36

- Adjusting the wheel spokes ................................................37

Secondary transmission chain .....................................................37

- Chain slack – Checking .......................................................37

- Chain slack – Adjusting .......................................................38

- Chain wear ..........................................................................38

- Chain guides – Checking.....................................................39

Battery .........................................................................................39

Exhaust system ...........................................................................41

- Removing the silencer .........................................................41

Front forks .................................................................................. 41

- Height adjustment ...............................................................41

Rear suspension ..........................................................................42

- Checking..............................................................................42

Lubrication ...................................................................................42

Tighten bolts and nuts .................................................................43

Tightening torque table ................................................................45

Fault diagnosis ............................................................................46

CLEANING AND STORAGE.......................................................52

Cleaning .......................................................................................52

Storage....................................................................................... 52

Starting after storage....................................................................52

TECHNICAL DATA .....................................................................53

Engine ........................................................................................ 53

Chassis ........................................................................................53

GUARANTEE MANUAL .............................................................55

Guarantee ....................................................................................55

INDEX

6

Page 7

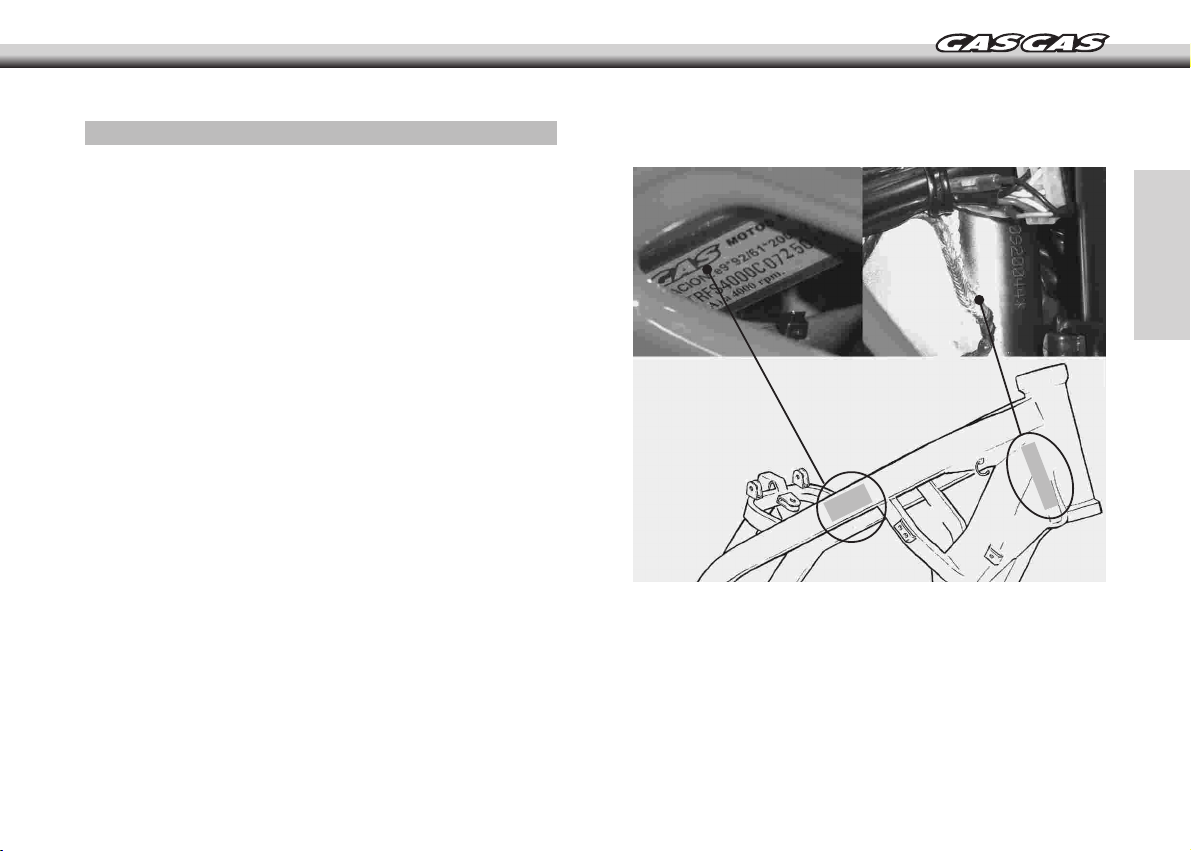

IDENTIFICATION

MOTORCYCLE IDENTIFICATION CODE

The motorcycle identification code is engraved on the steering stem.

AUTHORIZATION PLATE

The motorcycle has its own corresponding authorization plate

including information such as the identification Code. The information

on the authorization plate must correspond to the data in the vehicle

documents.

7

Page 8

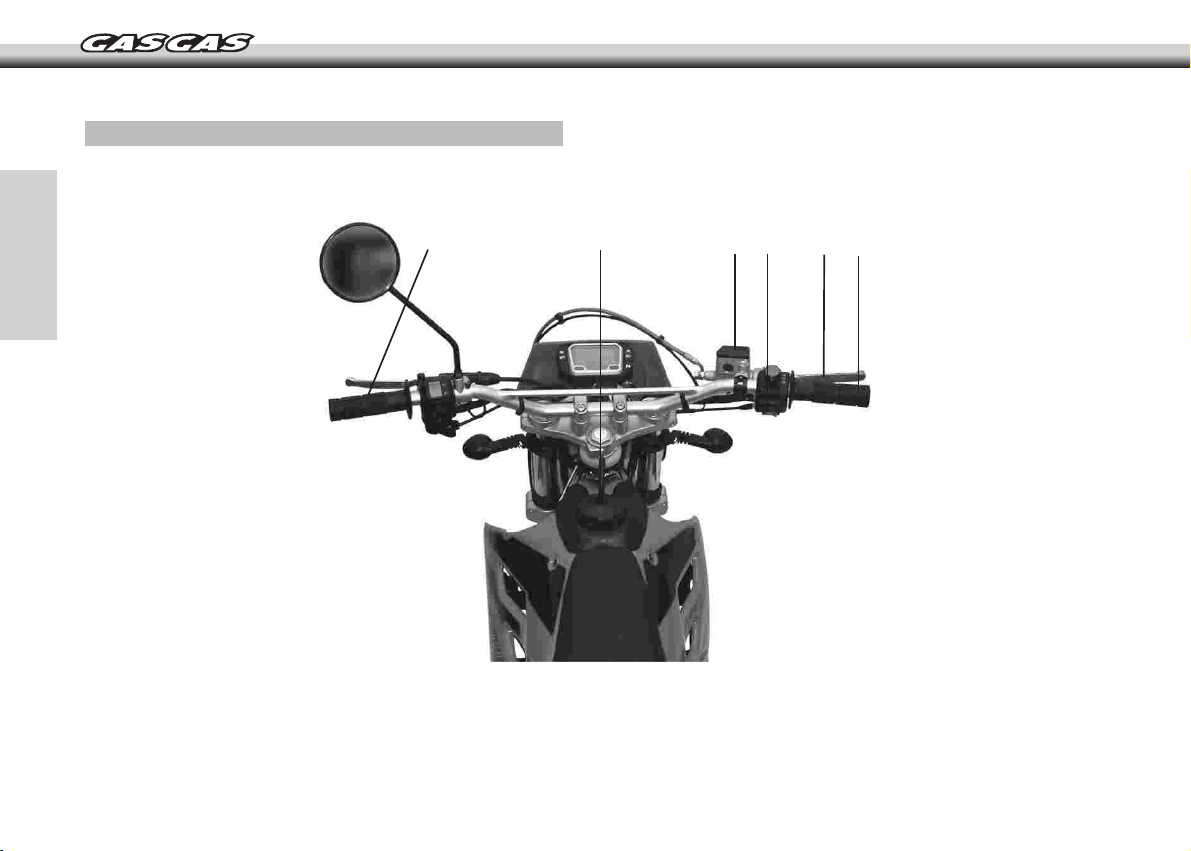

LOCATION OF COMPONENTS – OPERATION

LOCATION OF COMPONENTS

1 2

4

3

6

5

1- Clutch lever

2- Fuel tank cap

3- Front brake fluid tank

4- Engine start button

5- Front brake lever

6- Accelerator control

8

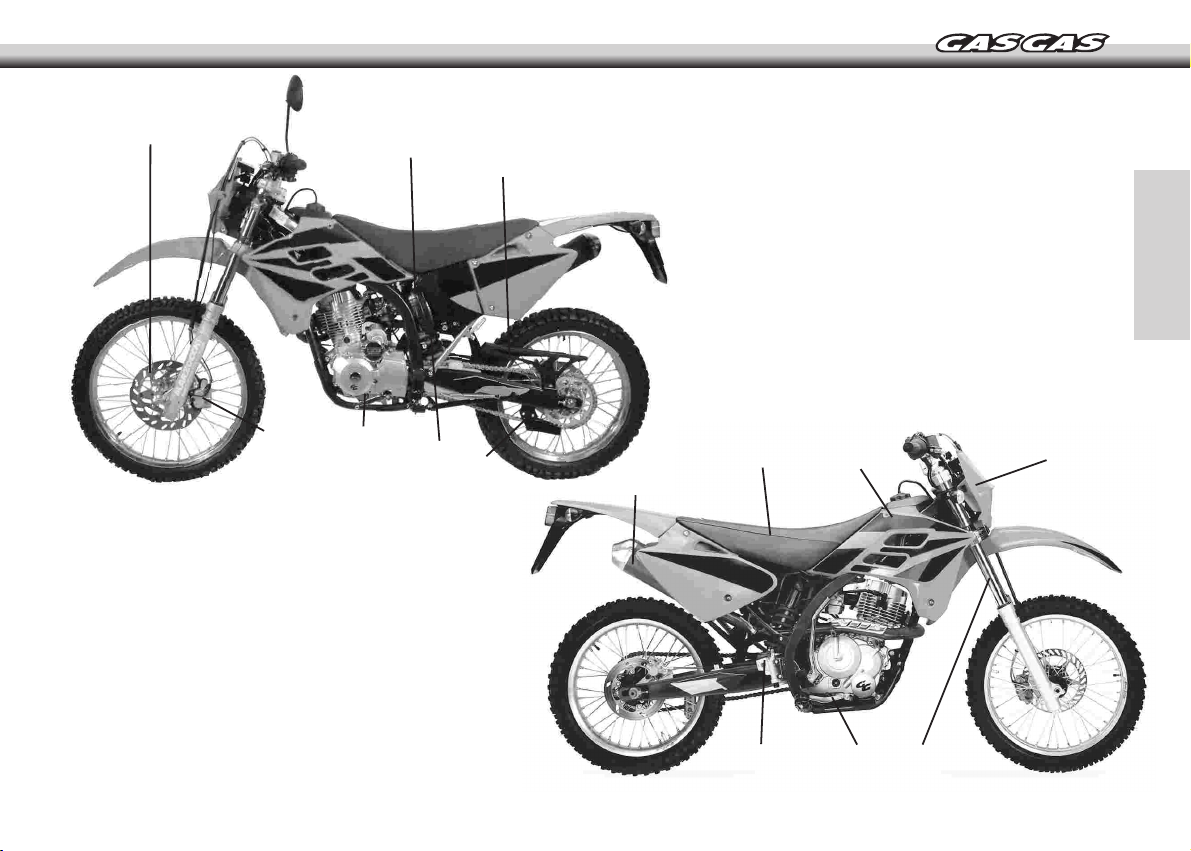

Page 9

1

2

3

8- Silencer

9- Seat

10- Fuel tank

11- Headlight assembly

12- Front suspension

13- Rear brake pedal

14- Rear brake fluid tank

7

1- Front brake disk

2- Air filter

3- Chain

4- Chain guide

5- Rear shock absorber

6- Gear shift pedal

7- Front brake callipers

6

5

4

8

9

14

LOCATION OF COMPONENTS – OPERATION

10

13

12

11

9

Page 10

CLUTCH

FRONT BRAKES

The clutch lever A is located on the left hand side of the handlebars.

To adjust the cable, see the section "maintenance instructions".

A

The front brake lever A is located on the right hand side of the

handlebars.

A

IGNITION KEY AND STEERING LOCK

The ignition key A comes with the motorcycle and is inserted into

the lock cylinder B located at the front of the handle bars.

A

B

LOCATION OF COMPONENTS – OPERATION

10

Page 11

In the position everything is off and neither the lights or the horn

will function. The battery is not used. In this position the hazard lights

will not work either.

In the position the ignition is turned on, the engine may be started

and both the lights and the horn may be used.

The battery is used. In this position the hazard lights will operate.

Note

The motorcycle is fitted with a safety device allowing the engine

to be started while the gear is engaged. See the section "Starting

the engine".

The ignition key also operates the steering lock.

To activate the lock, insert the ignition key then:

- rotate the handlebars all the way to the left.

- from the position rotate the key to the left while pressing down

to the position.

- remove the key; the steering is now locked.

LOCATION OF COMPONENTS – OPERATION

11

Page 12

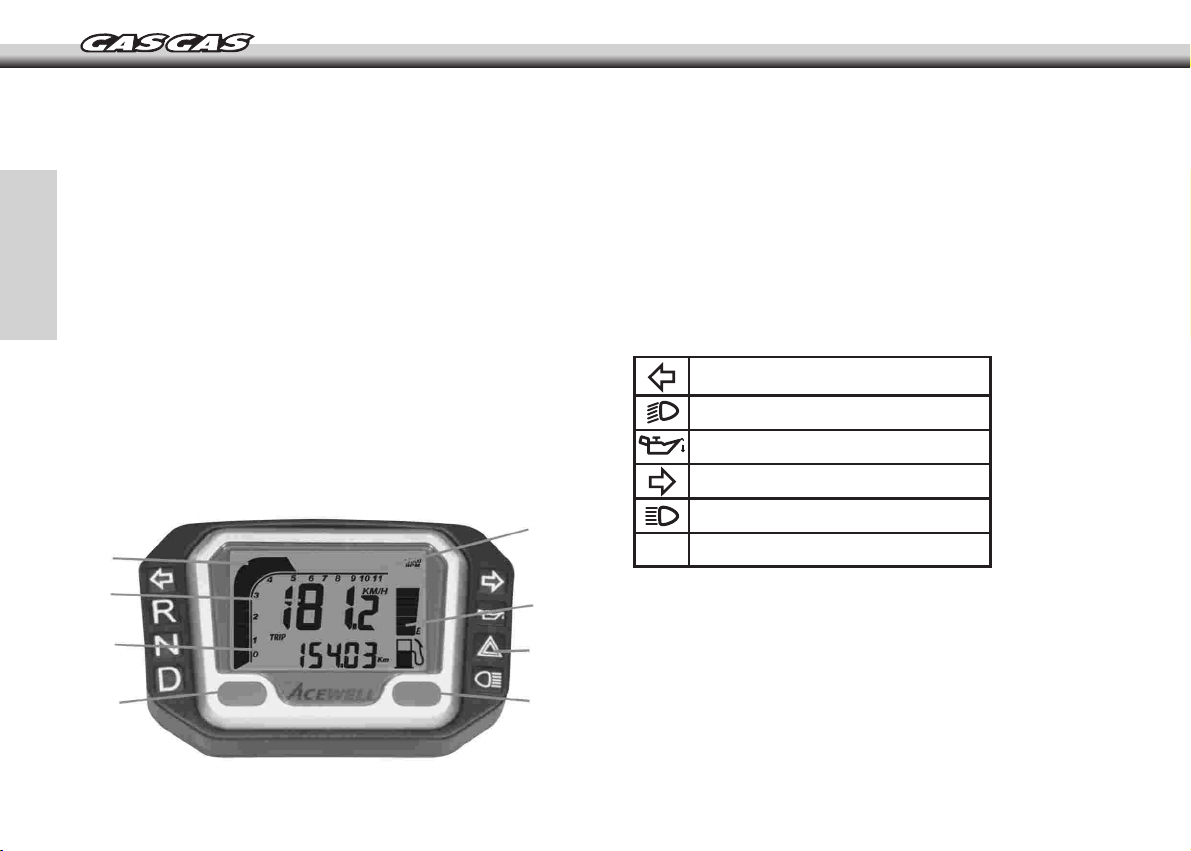

MULTI FUNCTION INSTRUMENT PANEL

AND INDICATOR LIGHTS

The multifunction apparatus, which is waterproof, has 4-8 LED

indicators on both sides of a central indicator screen

This central indicator screen, made of liquid crystal and with

illumination, gives information about the rpm, speed, journey,

kilometres travelled, time, average speed, maximum speed, length

of time with motor running and total time. The data relative to the

distance travelled and total time of use is stored in the memory,

even when the apparatus is switched off. When the multifunction

apparatus is not activated, it displays a clock.

The wheel circumference value is adaptable, as is the measuring

system (metric or imperial).

The number and distribution of the LED indicators, and the amount

of information on screen may vary according to model.

Panel description

1. RESET button

2. 2nd row of indicators

3. 1st row of indicators

4. Tachometer with bar graph

5. Tachometer scale

6. Fuel indicator bars (optional)

7. LED indicator symbols

8. MODE button

Description of symbols

Left indicator / Green

Dipped headlights / Green

Motor oil / Red

Panel

4

3

2

1

LOCATION OF COMPONENTS – OPERATION

12

Right indicator / Green

Full headlights / Blue

5

Neutral / Green (Optional)

N

6

7

8

Page 13

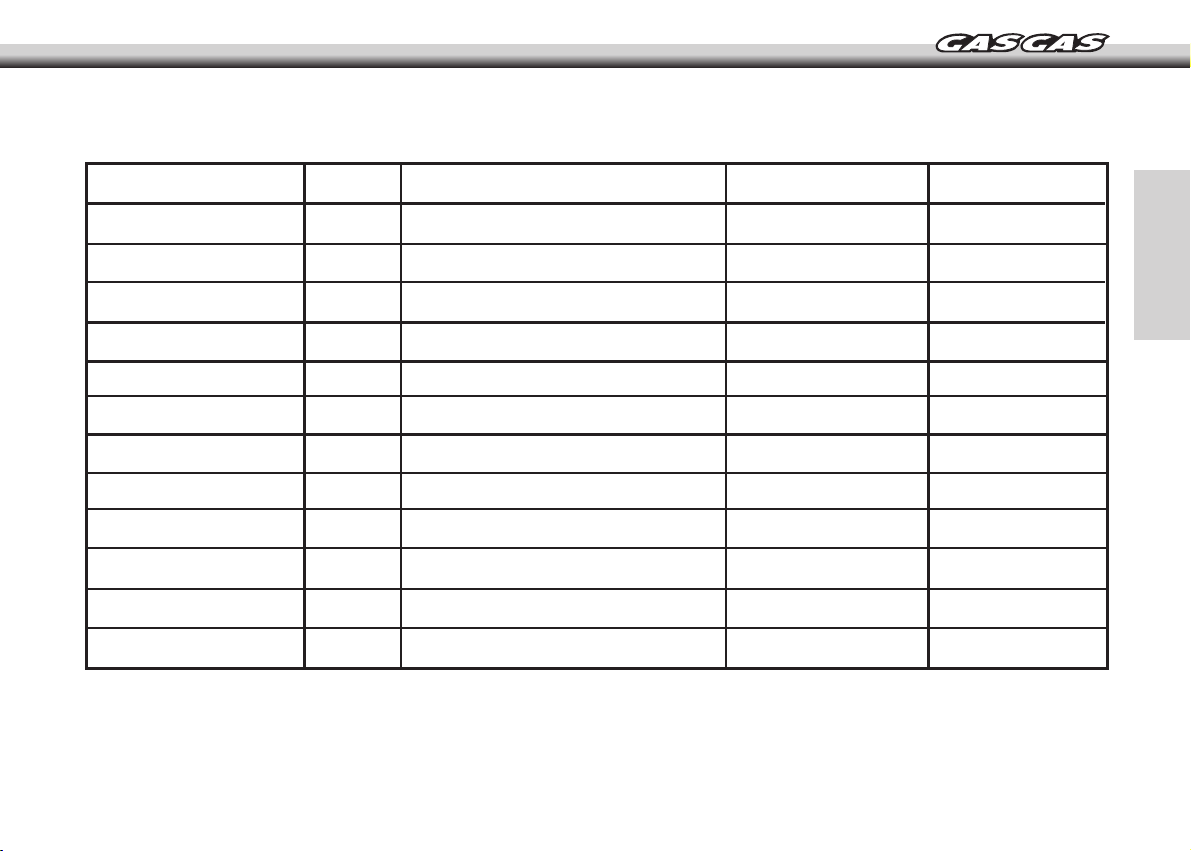

Technical characteristics

FUNCTIONS Symbol TECHNICAL CHARACTERISTICS INCREMENTS PRECISION

Bar tachometer 500 - 11,000 rpm 500 rpm

Digital Tachometer RPM 100 - 19,900 rpm 100 rpm

Gear change indicator RPM 100 - 19,900 rpm 100 rpm

Maximum tachometer value 100 - 19,900 rpm 100 rpm

Speedometer 2.3 - 300 kmph (187.5 mph) 0.1 kmph o mph

Maximum speed gauge MAX 2.3 - 300 kmph (187.5 mph) 0.1 kmph o mph

Average speed gauge AVG 2.3 - 300 kmph (187.5 mph) 0.1 kmph o mph

Trip counter 1 and 2 TRIP 1&2 0 - 999.9 km o 0 - 624.9 miles 0.01 km o miles

Mileometer ODO 0 - 999,999 km o 0 - 624,999 miles 0.1 km o millas

± 1% o ± 0,1

km/h / m/h

± 1% o ± 0,1

km/h / m/h

± 1% o ± 0,1

km/h / m/h

± 0.1 %

± 0.1%

Operation time RT 0:00'00" - 99:59' 59" 1 second

Total time TT 0:00' - 9999:59' 1 minute

Clock 0:00'00" - 23:59' 59" 1 second/1 minute

Initial voltage: 12v CC.

Speed sensor: Non-contact magnetic sensor.

Tachometer input: CDI (capacitor discharge ignition) or ignition coil signal.

Wheel circumference adjustment: 1 mm - 3.999 mm (1 mm increments).

Working temperature: -10 ºC - + 80 ºC (engine casing interior).

Fuel sensor resistance: 100 (only in models with fuel level indicator).

LOCATION OF COMPONENTS – OPERATION

± 50 PPM

± 50 PPM

± 50 PPM

13

Page 14

Functions

RPM: Bar

Tachometer with bar graph. The bar graph of the tachometer displays

up to 11,000 rpm.

RPM: Digital Tachometer

The rpm is shown in the second row. The digital tachometer displays

up to 19,900 rpm The tachometer signal can be read from the CDI

(Capacitor Discharge Ignition) or the ignition coil.

TRIP: Journey counter

This appears in the second line of the screen. The TRIP function

contains the vehicle's accumulated mileage since the last RESET

operation.

ODO: Mileometer

It shows the total mileage accumulated by the vehicle. The data is

stored in the memory, even when the device is not running.

Gear change indicator according to rpm

This function permits setting an indicator for changing gear at a

specific rpm level The tachometer bar flashes when the rpm reaches

the specific level and stops flashing when the gear is changed.

MAX RPM: Maximum tachometer value

It appears in the 2nd row. It shows the highest level reached by the

tachometer since the last resetting of the data.

SPD: Speedometer

The speedometer information appears in the first line of the screen

It shows up to 300 km/h or 187.5 mph.

MAX: Maximum speed gauge

The MAX value appears in the 1st line. It shows the highest speed

reached since the last resetting of the data.

AVG: Average driving speed

The AVG value appears in the 1st line. It calculates the average

speed since the last RESET operation.

LOCATION OF COMPONENTS – OPERATION

14

RT: Time of use controller

It calculates the total time in use since the last RESET operation. It

starts counting from the moment that movement begins.

TT: Total time of use controller

It calculates the vehicle's total time in use. It starts counting from the

moment that movement begins. The data is stored in the memory,

even when the device is not running.

12/24 hour clock

It shows the time in either 12 or 24 hour formats.

Fuel level indicator (only vehicles with this function)

It has 7 bars showing the amount of fuel remaining in the fuel tank.

The last bar flashes to indicate that the fuel level is too low.

Page 15

ELECTRIC START BUTTON

Note

The motorcycle is fitted with a safety device allowing the engine

to be started while the gear is engaged. See the section "Starting

the engine".

The electric starter button A is located on the right-hand side of the

handlebars and only operates if:

- the ignition key is in the position .

- if the clutch is pressed in or the gear change pedal is in neutral.

ENGINE STOP BUTTON

The switch A is located on the right-hand side of the handlebar and

has three positions:

- Engine off

A

- Engine running

- Engine off

A

To stop the engine, moved the switch A 21 of the two positions

indicated by the symbol .

LOCATION OF COMPONENTS – OPERATION

15

Page 16

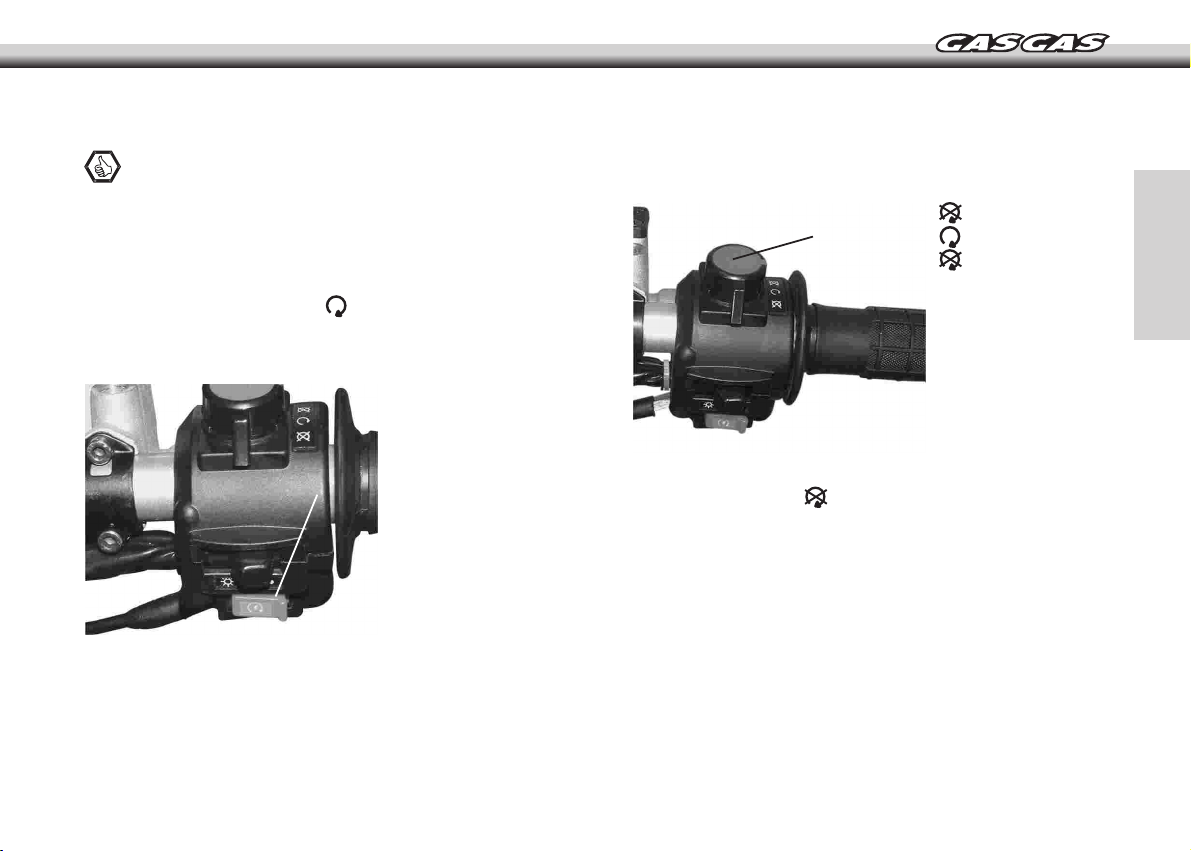

LIGHTS AND INDICATORS

Note

With the ignition in position it is not possible to activate the

lights or the horn. In this position the hazard lights will not work

either.

Lights

A

B

The switch A is located on the right-hand side of the handlebar and

has three positions:

- Off

- Side lights

- Low beam / high beam

To switch from low beam to high beam operate the switch B located

on the left hand side of the handlebars.

- Low beam

- High beam

Light burst

To operate the light burst, press the switch B to the position

.

Note

The switch A does not need to be activated to use the light

burst. However the ignition key must be in the position .

LOCATION OF COMPONENTS – OPERATION

16

Page 17

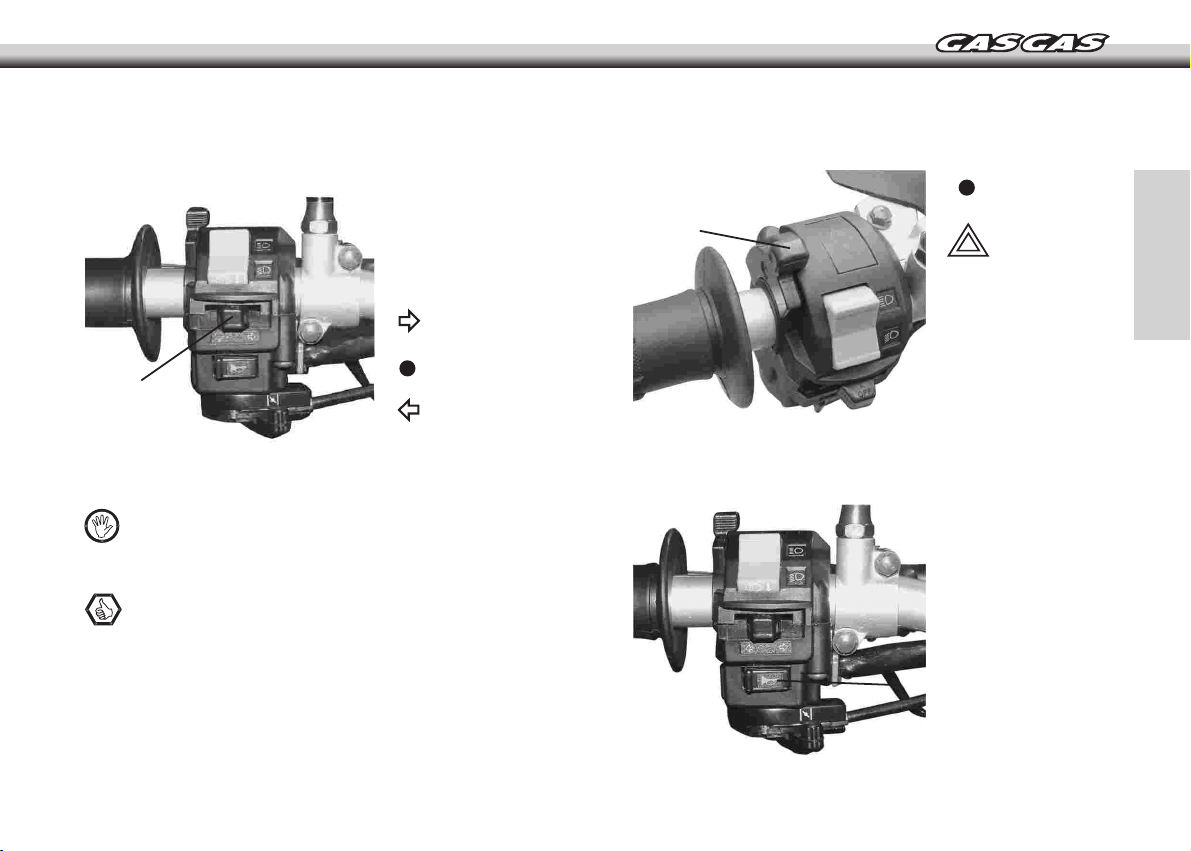

Turn indicators

The switch A is located on the left-hand side of the handlebar and

has three positions:

Right hand side

indicator

Indicator

A

Hazard lights

WARNING

Regarding the use of these lights, follow the legal requirements

of each country.

Note

The hazard lights only operate when the ignition is turned on.

off

Left hand side

indicator

The switch A is located on the left-hand side of the handlebar and

has two positions:

Hazard

lights off

A

Hazard

lights on

HORN

The button A, located on the left hand side of the handlebars,

operates the horn.

A

LOCATION OF COMPONENTS – OPERATION

17

Page 18

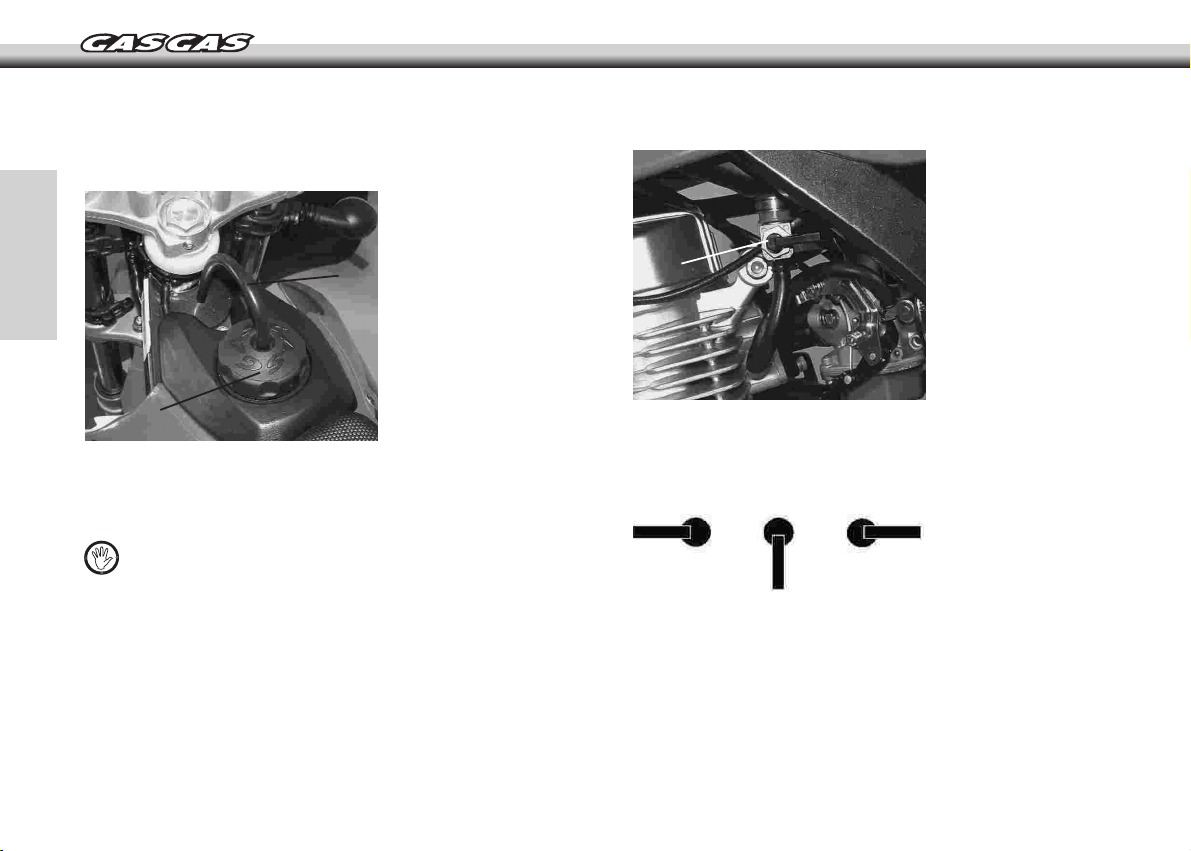

FUEL TANK

The fuel tank holds 7.4 l.

FUEL CUTOFF

B

A

The tank has a rapid access cap A and a tube for ventilation B to

clear and vapours that may form.

- Turn the cap to the left to open.

WARNING

Regularly check the cap seal and vent hose to ensure they are

leak proof. Risk of spillage!

LOCATION OF COMPONENTS – OPERATION

18

A

This has three positions:

The diagrams below show the position of the fuel tap (A) for each

case.

1 2 3

RECOMMENDED FUEL

Use lead-free petrol with an octane rating of 95 or higher.

1- Reserve

2- Open

3- Closed

Page 19

WARNING

If knocking occurs, try a different brand of petrol or higher

octane grade.

DANGER

Always stop the engine and do not smoke. Gasoline is extremely

flammable and can be explosive under certain conditions. Make

sure the area is well ventilated and free from any source of

flame or sparks; this includes any appliance with a pilot light.

THROTTLE CONTROL

A

GEARBOX

The motorcycle has 5 gears. It is a sequential gearbox, which

means that in order to reach third gear from first gear, second

gear must first be engaged, that is, the gears go up or down

gear by gear.

To engage the first gear from neutral, press on the clutch,

press the gearshift pedal all the way down then release the

clutch slowly.

Neutral is located between first gear and second gear.

2, 3, 4, 5

N

1

Moving the control A to the left will close the throttle and restrict

the flow of air in the carburettor jet. While the control A remains in

this position, the air/fuel mixture is enriched and this will facilitate

cold starting. See also "Starting a cold engine".

WARNING

To ensure correct gear engagement, operate the gearshift pedal

firmly so that the transition is complete.

Incomplete or erratic insertion of gears could cause damage to

the transmission system. Accident risk!

LOCATION OF COMPONENTS – OPERATION

19

Page 20

BRAKE PEDAL

WARNING

Do not start the engine or ride the motorcycle when the stand

is down.

B

A

The rear brake pedal is located in front of the right hand side footrest

and may be adjusted to the position of the driver.

SEE MAINTENANCE INSTRUCTIONS.

STAND

DANGER

Danger, risk of physical injury! Use the stand with care.

The uncontrolled return of the stand to its rest position could

cause injury to the user or to others

LOCATION OF COMPONENTS – OPERATION

20

A - Rear brake pedal

A

- Push the stand A downwards to the ground by foot until it supports

the weight of the motorcycle.

Ensure that the surface on which the stand rests is sufficiently hard

so that the motorcycle remains in a stable position.

- To take up the stand, remove the weight of the motorcycle by

inclining it - the spring B will return the stand to its resting position.

Page 21

DRIVING INSTRUCTIONS

STARTING THE ENGINE

DANGER

Do not start or leave the engine idling in closed spaces.

Exhaust fumes are highly toxic and may result in loss of

consciousness or even death. When the engine is running,

ensure that there is always adequate ventilation.

Note

The motorcycle is fitted with a safety device allowing the engine

to be started while the gear is engaged.

To start the motorcycle, proceed as follows.

- Open the fuel tap.

- Put the gearbox into neutral or even hold in the clutch lever during

the starting operation.

- Rotate the ignition key A clockwise to the position , the electric

circuits are activated and the motorcycle may start.

- Without using the throttle, press the electric start button B.

A

WARNING

When the key remains in the engine start position: If the

engine is not started then a loss of battery electrical potential

may occur.

STARTING A COLD ENGINE

WARNING

Do not fully load the motorcycle while the engine is cold.

Allow the engine to run at idle speed or drive slowly until the

engine reaches normal operation speed.

B

21

Page 22

A

After some seconds, and depending on the outside temperature, the

engine will reach a higher and more stable speed. This means that

it has reached normal operation temperature. At this moment remove

the choke by turning the control A to the right hand side.

WHAT TO DO WHEN THE ENGINE IS FLOODED

Note

If the engine will not start, remove the spark plug and dry it.

See "Removing the spark plug".

- Once the engine is running, open the fuel tap.

Stopping the engine

- Brake the motorcycle and put the gearshift pedal in neutral.

- Completely close the accelerator pedal and use the engine stop

button.

- Rotate the ignition key anticlockwise to the position .

- Close the fuel tap.

STOPPING THE MOTORCYCLE

DANGER

When driving in wet conditions or after washing the motorcycle,

the brakes may be wet. If so, then the braking capacity is reduced

until the braking elements are dry. Drive carefully and lightly apply

both brakes in order to dry them.

- Close the fuel tap.

- Following the instructions described in STARTING THE ENGINE,

operate the starter button with the throttle completely open (full

throttle) and the choke control all the way to the right; release the

throttle control as soon as the engine starts.

DRIVING INSTRUCTIONS

22

WARNING

If the ground is slippery or loose then give preference to the

rear brake.

Depending on circumstances and ground surface, it may be

better to use the front or rear brakes independently.

Gear down gradually using the engine braking capacity.

Page 23

For maximum deceleration, close the throttle A and apply both front

and rear brakes.

A

RUNNING IN PERIOD

WARNING

Brutal acceleration during the run in period may cause engine

damage.

All of the moving parts in the engine have been made to a high level

of precision in order to obtain a quality contact surface and correct

positioning.

However, correct engine care during the first hours of use is vital for

obtaining the best from your motorcycle.

Therefore, we recommend:

- Start the engine and let it run at idle until the engine is thoroughly

warmed up.

- Stop the engine and wait for it to completely cool.

- Start the engine once again. For the first hour of use or for the first

100 Km, use the engine at a moderate speed.

- Never run the engine at maximum rpm.

- Vary the engine speed consistently using the throttle control.

Note

The spark plug may be soiled if the engine is used at a low

speed during the running in period. If this occurs then replace

the standard spark plug by a higher temperature spark plug for

the running in period only. See the section regarding extraction

of the spark plug.

Following the run-in period, fit a new standard spark plug.

DRIVING INSTRUCTIONS

23

Page 24

MAINTENANCE INSTRUCTIONS

MAINTENANCE CHART

Article Period Period Period

First 5 hours every 30 hours every 60 hours

Air filter Inspect the following every time that the motorcycle has been used or when necessary

*Bolts on the silencer and the connections

for the silencer T T T

*Valve tolerances I - I

Spark plug - I R

Fuel lines I I I

*Change every 4 years

Engine oil R R R

Oil strainer C - C

Clutch I I I

Chain Clean, lubricate and inspect each time the motorcycle has run

*Brakes I I I

Brake lines I I I

*Revise every 4 years

Brake fluid I I I

*Change every 2 years

Tyres

*Steering assembly I - I

*Front forks I - I

*Rear suspension I - I

*Chassis bolts and nuts T T T

Note: I = Inspect and clean, adjust, replace or lubricate if necessary; R= Replace; T= Tighten; C= Clean

Inspect tyres for damage and check the tyre pressure every time the motorcycle has run

24

Page 25

CLUTCH

Correct clutch cam play is 2-3 mm.

Adjusting

Correct clutch lever play is 2-3 mm.

WARNING

Lower play than that indicated will reduce the clutch effectiveness

and the clutch useful life.

To adjust the clutch lever play, proceed as follows:

- Remove the cap A.

- Loosen the lock nut C.

- Rotate the adjustment B in one direction to achieve the indicated

play.

- Tighten the lock nut C to lock the adjustment B in position.

- Fit the protection cap.

C

B

A

A- Protection cap

B- Adjustment

D

Note

If the clutch lever adjustment is at its limit, play must be adjusted

by using the clutch cam.

C- Lock nut

D- Clutch lever

WARNING

Lower play than that indicated will reduce the clutch effectiveness

and the clutch useful life.

To adjust the clutch cam play, proceed as follows:

- Loosen the adjustment nuts B and rotate in one direction until the

correct play is achieved.

- Tighten the adjustment nuts B to lock the adjustment in position.

A

A- Cam

B- Adjustment nuts

B

MAINTENANCE INSTRUCTIONS

25

Page 26

BRAKES

Brake disc wear is automatically compensated mechanically and

has no effect on the front brake lever or on the rear brake pedal.

The only adjustments that need to be made are: Position and play

both on the front brake lever and the rear brake pedal.

If the front brake has a spongy feeling then it is possible that

there is air in the hydraulic circuit. We recommend that you visit

a GAS GAS workshop immediately.

- Ensure that front brake lever adjustment is correctly suited to

your hand.

Position and play of the front brake lever

- Adjust the position of the front brake lever according to the size of

your hand. Note that the front brake lever should have a play of at

least 3 mm when in rest position. Adjust the position and play of

the brake lever using the bolt A.

A

A - Adjustment bolt

DANGER

Never reduce the play of the front brake lever to less than

3 mm. If the play is reduced then the brake cylinder acts on the

front brake pads which then remain in permanent contact with

the brake disc; this could result in brake failure due to

overheating.

MAINTENANCE INSTRUCTIONS

26

Position and play of the rear brake pedal

The rear brake pedal should have a play of between 1 to 3 mm when

in rest position.

- Loosen the bolt A and adjust the play using the pin B.

- Tighten the nut A once again.

C

A - Nut

B

A

- Ensure that the rear brake pedal adjustment is correct; if necessary

repeat the adjustment until it is correct.

- Ensure that the pedal operates correctly and that it does not rub

on any element of the motorcycle.

B - Pin

C - Play

Page 27

DANGER

Never reduce the play of the rear brake pedal to less than 10

mm. If the play is reduced then the brake cylinder acts on the

rear brake pads, which then remain in permanent contact with

the brake disc; this could result in brake failure due to

overheating.

If the rear brake has a spongy feeling then it is possible that

there is air in the hydraulic circuit. We recommend that you visit

a GAS GAS workshop immediately.

BRAKE FLUID

- Check the condition of the brake fluid using the level inspection

windows on both the front brake tank A and rear brake tank B. If the

brake fluid is dark or appears dirty then go immediately to an approved

GAS GAS workshop to replace the fluid.

A B

WARNING

Brake fluid absorbs ambient humidity and degrades with time.

So that the brake fluid retains its specifications, use only fluid

from sealed containers and respect the replacement periods as

shown in the MAINTENANCE CHART.

Brake fluid is corrosive to paintwork. Avoid contact between

the fluid and paintwork.

- Only use fluid in accordance with DOT 3 or DOT 4.

MAINTENANCE INSTRUCTIONS

27

Page 28

Brake fluid level inspection

- Check the brake fluid level using the inspection windows on both

the front A and rear B brake tanks. The level should at least reach

halfway up the inspection window.

If brake fluid is required:

- Ensure that brake fluid is not leaking from: front and rear brake

cylinder seals, hoses and joints. If there is any leak, visit a GAS

GAS workshop immediately.

- Add brake fluid, complying to the DOT 3 or DOT 4 standards, to

the corresponding brake fluid tank in order to re-establish the correct

level.

Checking brake pad wear

- Check the thickness of both the front and rear brake pads.

- Minimum brake pad thickness A: 1 mm

- If any brake pad is less than 1mm thick then replace the complete

set.

1 mm

HANDLEBARS

Adjustment

In order to better suit the driver size and preferences, the handlebar

position may be adjusted forwards or backwards.

Loosen the handlebar A clamp bolts B then place the handlebars

in the required position.

B

A

Tighten the bolts to 25 Nm, firstly the forward bolts then the rear

bolts. If the handlebars are correctly installed, there will be a minimal

gap at the front and rear of the clamp after tightening A.

A

MAINTENANCE INSTRUCTIONS

28

Page 29

STEERING

Steering - adjustment

DANGER

Handlebars with excessive play or an incorrect adjustment are

extremely dangerous for driving.

Steering - verification

The steering should always be kept adjusted so that the handlebar

will turn freely but without excessive play

To check the steering adjustment, proceed as follows:

- lift the motorcycle off the ground using a support under the chassis

so that both wheels are suspended.

- move the steering gently from side to side.

If the steering continues to turn when released then this means that

the some play has resulted from use.

Make a final test:

- with the motorcycle firmly attached to the supports and with the

wheels suspended, stand in front of the motorcycle; pull and push

the handlebars forward and back.

- Stabilise the motorcycle using a solid support under the chasis.

- Keep the front wheel off the ground.

- Remove the handlebar by loosening the handlebar clamp bolts A.

WARNING

Always work with the handlebars in such a way that cables and

hydraulic lines are not damaged.

-Loosen the steering stem bolt B.

-Loosen the steering stem bolt C.

A

B

C

If the steering shaft moves

then the steering must be

adjusted.

MAINTENANCE INSTRUCTIONS

29

Page 30

E

D

- Loosen the bolts D on both sides then remove the upper suspension

plate E.

- Rotate the steering adjustment nut using the special spanner in

order to obtain the appropriate adjustment.

- Fit the upper suspension plate E.

- Fit the washers, tighten the steering shaft bolt C, the steering shaft

nut B and the bolts D to the correct torques below:

Steering nut: 44 Nm (4.5 Kgm)

Suspension plate bolts: 22 Nm (2.25 Kgm)

- Check the steering once more and adjust again if necessary.

- Refit all removed parts.

ENGINE OIL

The oil must comply with the SAE 10W-50 standard, classification

API SF or SG.

Note

If you are using the motorcycle in climates with extreme

temperatures then choose the most suitable engine oil using

the attached table as a guide.

20W-50

ENGINE OIL

ºC -30 -20 -10 0 10 20 30

TEMP.

ºF -22 -4 -14 32 50 68 86

15W-40 15W-50

10W-40 10W-50

10W-30

Oil level

Note

- To keep your engine in perfect working order, regularly check

the oil level and change the oil.

- The engine oil increases in volume when it is hot. Check and

adjust the level when the oil is cold.

- Initially replace the oil after 5 hours of operation and then

every 60 hours. See the maintenance table.

Changing the oil

DANGER

- The engine oil and the exhaust manifold can be very hot and

cause burns. Wait until the oil and the exhaust manifold are cool.

- Exhaust fumes are highly toxic and may result in loss of

consciousness or even death. When the engine is running, ensure

that there is always adequate ventilation.

MAINTENANCE INSTRUCTIONS

30

Page 31

WARNING

- Avoid all contact with the engine oil; this is a health risk and

may cause irritations.

- Keep new or used oil away from the reach of children and

animals.

- Wash yourself with neutral soap if oil comes in contact with

your skin.

- Used oil should be kept in an appropriate recipient for

subsequent recycling according to current legislation.

B

Note

- Change the oil when the engine is warm; this will facilitate the

drainage of the oil from the drain in the lower part of the engine.

- Always use genuine GAS GAS parts.

To change the oil, take the following steps:

- Ensure that the motorcycle is on a suitable, solid, horizontal surface,

for example a stand.

- Place an adequately sized container underneath the engine.

- Remove the bolt from the drain A.

A

C

- Remove the oil level rod B.

- Allow the used oil to completely drain out.

- Replace the seal washer and replace the drain bolt A.

- Add oil in small quantities (for example 150 ml) and check the oil

level using the oil level rod as usual (clean before checking).

Note

The engine has a visor on the right hand side cover – on the

clutch side, close to the brake pedal – this can be used to check

the approximate oil level.

- The oil level should never exceed the upper mark indicated by the

grooved zone C on the oil level rod.

- Start the engine and keep it running for several minutes to ensure

that oil is not leaking from the drain plug.

- Stop the engine.

- Ensure that the oil level is correct and if necessary add more oil.

MAINTENANCE INSTRUCTIONS

31

Page 32

Cleaning the strainer

Note

- The engine oil circuit, has a strainer to filter out particles that

may contaminate the oil.

- The oil strainer should be cleaned as indicated in the

Maintenance table.

WARNING

Used oil should be kept in an appropriate recipient for subsequent

recycling according to current legislation.

- Empty the engine oil as indicated in the section Changing the

engine oil.

- Remove the plug A located on the left hand side of the engine.

A

- Remove the spring B and the oil strainer C.

- Clean the strainer using petrol and dry using compressed air in

order to remove the remains of petrol.

B

C

B- oil strainer

C- spring

- Fit the strainer, the spring and the cap.

- Refill the oil and ensure that there are no leaks as indicated in the

section regarding oil changes.

CARBURETTOR

Adjusting the throttle control cable

The throttle control should have a play of 2-3 mm.

If the play is not as indicated then proceed as follows:

A

C

A - Throttle control

B

B - Lock nut

C - Adjustment

MAINTENANCE INSTRUCTIONS

32

Page 33

- Check that the throttle grip turns smoothly.

- Loosen the lock nut B.

- Rotate the adjustment bolt C until the indicated play is reached.

- Tighten the locknut B.

Adjusting idle speed

DANGER

The exhaust gasses are highly toxic. The idle adjustment

operation must be carried out in open spaces or in suitably

ventilated premises.

The carburettor has an idle adjustment screw A, which acts on the

fuel opening cylinder in the carburettor.

The bolt B adjusts the supply of air-fuel for the deceleration system.

A

B

To set the engine speed to a minimum or slow the engine down then

take the following steps:

- Use the motorcycle until the normal operation temperature is

reached.

- Stop the engine and secure the motorcycle (for example on a

support stand).

- Start the engine.

- Rotate the bolt A until the engine runs continuously.

Note

- Rotating the screw A clockwise will increase the engine speed.

- Rotating the screw A anticlockwise will decrease the engine

speed.

- Rotate the bolt B until the engine reaches the highest speed.

Note

- Tightening the screw B will restrict the flow of air-fuel mixture

- Loosening the screw B will open the flow of air-fuel mixture

- Tighten the screw B about 1/4 of a turn.

Rotate the bolt A until the engine reaches the required idle speed.

MAINTENANCE INSTRUCTIONS

33

Page 34

SPARK PLUG

Note

- The spark plug should be regularly checked, according to the

"Maintenance table" or if the engine has a problem. See the

section "Trouble shooting".

- Note that if the engine performance falls then this could be

due to the spark plug.

Standard spark plug TORCH D8RTC

Electrode spacing 0.7 to 0.8 mm (0.028 – 0.031 in)

WARNING

Incorrect installation of the spark plug or the choice of an

incorrect temperature grade may cause serious damage to the

engine. This damage is not covered by the guarantee.

Always use spark plugs recommended by GAS GAS. Consult

the dealers or a qualified mechanic to know which spark plug

is best for your bike.

Spark plug - removing

To remove the spark plug, take the following steps:

- Remove the cap A from the spark plug.

- Remove the spark plug B from its allotment using the special spark

plug wrench.

Note

Check the colour and the appearance of deposits on the spark

plug. These deposits indicate if the standard spark plug is the

most suitable for your motorcycle or if it should be replaced by

another of a different temperature grade.

A

B

- If there is soot on the spark plug then clean using a metal brush.

- Check and, if necessary, adjust the electrode spacing to between

0.7 - 0.8 mm (0.028 - 0.031 in).

WARNING

If the spark plug electrodes are oxidised, damaged or the

insulation is broken then replace the plug.

MAINTENANCE INSTRUCTIONS

34

Page 35

- Fit the spark plug and tighten to the specified torque of 11 Nm (1.0

kgm). See also the "Tightening torques table".

- Refit the hood for the spark plug.

Note

To ensure correct operation of the spark plug, keep the protection

hood clean and dry.

AIR FILTER

A clean air filter will provide good engine performance and prolong

its useful life.

An obstructed air filter restricts the air intake of the engine, increasing

the petrol consumption and reducing the engine power as well as

causing the destruction of the spark plug.

WARNING

If dirt enters the engine then this will lead to excessive wear

and engine damage. Inspect the air filter regularly as indicated

in the Maintenance table.

Air Filter - Cleaning

DANGER

When cleaning the air filter, ensure the area is well ventilated

and free from any source of flame or sparks; this includes any

appliance with a pilot light.

Do not use petrol to clean the filter as this could result in an

explosion.

To remove the air filter, proceed as follows:

-Remove the cover A by rotating the clip B.

B

A

-Remove the retention rod C.

- Remove the filter element assembly

- Stuff a clean, lint-free towel into the intake manifold so no dirt is

allowed to enter.

- Clean inside the filter housing using a damp cloth.

MAINTENANCE INSTRUCTIONS

35

Page 36

- Remove the cage B from the air filter A.

- Clean the filter in a bath of filter cleaning liquid using a gentle brush.

- Check the filter for damage such as rupture, scratching, hardening,

or shrinkage. If it is damaged then replace it, otherwise dirt will

enter the carburettor.

- Grease all of the connections and bolts of the air filter and inlets.

- Re-install the air filter in the motorcycle and make sure it is correctly

secured.

WHEELS

Tyre pressure

Tyre pressure affects traction, handling, and tyre life.

- Adjust the tyre pressure to suit ground conditions and rider

preference, but do not deviate excessively from the recommended

pressure.

- Squeeze it and dry it with a clean cloth. Do not twist the filter or

expose it to pressurized air otherwise it will be damaged.

MAINTENANCE INSTRUCTIONS

36

Note

Tyre pressure should be tested when the tyre is cold before

driving.

Page 37

Ground conditions

SECONDARY TRANSMISSION CHAIN

- Wet, sandy, muddy and slippery ground: reduce tyre pressure.

- Hard ground, stony ground: increase tyre pressure.

Adjusting the wheel spokes

DANGER

The wheel spokes must be evenly tightened.

One or more loose or incorrectly tightened wheel spokes may

put the rim off-centre and put extra tension on the remaining

spokes which may in turn rupture. Accident risk!

Centring the rim

Note

If the rim is bent or crooked then it must be replaced.

In case of small deformations of the rim, go to an approved GAS

GAS workshop or specialist workshop.

DANGER

A chain in bad condition, inadequately maintained or incorrectly

adjusted may jump or rupture leading to a loss of control of the

motorcycle.

Note

The chain should be regularly examined, according to the

maintenance table or when the motorcycle is used in adverse

conditions, for example in mud, rain or humid conditions.

Chain slack - Checking

Note

Under muddy or humid conditions, the chain will be under more

tension. Eliminate mud from the chain before checking the play.

The distance between the chain B and the chain pad A should be

about 30 a 50 mm.

A- Wheel spoke

adjustment tool

MAINTENANCE INSTRUCTIONS

37

Page 38

- To check this, rotate the rear wheel until the chain becomes more

tense.

- Lift the chain B by hand in the area of the pad A and measure the

distance between the pad surface and the lower part of the chain

links.

- If the indicated specification is not reached then adjust the chain

as described below.

Note

When checking the chain tension, rotate the rear wheel to check

for damaged links and lost connections as well as worn or

damaged teeth on the drive pinion and sprocket.

Chain slack - Adjusting

Note

The operation is described from the swinging arm side.

- Loosen the axle nut C.

- Loosen the lock nuts B.

- Rotate the chain adjustment bolt A to reach the measurement

indicated in the section "Chain slack - Checking".

WARNING

The operations described should be repeated on the opposite

side given that the rear wheel must be aligned with the front

wheel. To align both wheels, use the string method and adjust,

if necessary, the adjustment bolts as described above.

DANGER

An incorrectly aligned wheel will cause abnormal tyre wear and

may be dangerous for driving.

-Tighten the lock nuts.

-Tighten the rear axle nut to 98 Nm.

DANGER

An incorrectly tightened rear axle nut will be extremely dangerous

for driving.

B

C

A

MAINTENANCE INSTRUCTIONS

38

A - Adjustment bolt

B - Lock nut

C - Axle nut

Rear

- Rotate the wheel and measure the position when the chain is most

tense. Re-adjust if necessary.

Chain wear

WARNING

Replace the chain when the length excedes 2% of its original

length*.

Only use original replacement parts.

Page 39

When the chain is replaced, the engine output pinion and the rear

sprocket should also be replaced. If the teeth on these element are

worn then this will lead to a rapid wear of the new chain.

Check the engine output pinion and rear sprocket teeth and replace

them if they are worn.

* the chain must be removed by opening the connection link. The

length is measured from the two ends of the chain.

WARNING

Whenever the chain is removed, ensure that the clip on the chain

connection link is correctly installed with the closed part of the

"U" in the direction of rotation.

A

B

A

Chain guides - Checking

Check the chain guide A as well as the upper and lower parts of the

chain pad B. If there is any serious damage then replace these

elements.

A - Clip

B - Direction of

rotation of the chain

Note

Only use original replacement parts.

BATTERY

Note

This battery is maintenance free and checking the fluid level is

not required. It is advisable to check the charge of the battery

periodically.

Battery - removing

To remove the battery, follow these steps:

MAINTENANCE INSTRUCTIONS

39

Page 40

B

A

C D

E

If the battery voltage is above 12.6 V, the battery can be installed

on the vehicle without having to recharge it.

Constant voltage charge mode

- Constant voltage = 14.4 - 14.7 V

- Initial charge current = 0.1 - 0.5 Cn

- Charge duration = 6 hours minimum / 24 hours maximum.

Constant power charge mode

- Maximum charge current = 0.1 Cn

- Recommended charge time = 5 - 8 hours.

- The product (charge current) x (charge duration) must be within

the range: 0.5 - 0.8 Cn.

- Remove the bolts A and remove the seat B.

- Remove the terminals D carefully so that they do not come into

contact with metal elements.

- Unhook the rubber element E.

- Remove the battery C from its allotment.

DANGER

Hydrogen gas produced by the battery may explode if exposed

to open flame or sparks.

Keep the area ventilated and free from naked flames.

The operating instructions for the battery are as follows:

- Check the battery voltage in open circuit status (disconnected).

- If the battery voltage is below 12.6 V, or if the storage period has

exceeded 6 months, the battery has to be recharged following the

instructions in paragraph 3.

MAINTENANCE INSTRUCTIONS

40

DANGER

Inverting the polarity of the battery terminals may cause battery

charge problems and cause damage to the battery system.

The red terminal is positive ( + ) and the black terminal is

negative ( - ).

WARNING

Not using the standard manner of charging may seriously

shorten the battery life.

Never exceed the standard charge.

Note

In case that a different mode of charging is used to those

established here, never exceed the maximum allowed

currents nor the maximum charge duration of 24 hours.

Page 41

THE EXHAUST SYSTEM

The exhaust and the silencer reduce noise and carry the gasses

away from the driver.

If the exhaust is damaged, rusted, dented or split then change it.

Removing the silencer

- Remove the right hand side number plate carrier by removing the

attachment bolts.

- Remove the silencer B attachment bolts A.

A

A

- Loosen the bolt A on the exhaust pipe clamp.

- Remove the silencer assembly

B

FRONT FORKS

Height adjustment

The flat surface around the front fork bars nut-cap should be flush with

the surface of the upper plate.

MAINTENANCE INSTRUCTIONS

A- Clamp

for exhaust pipe

41

Page 42

REAR SUSPENSION

Checking

The rear suspension is fitted with a hydraulic telescopic shock

absorber fitted to the chassis and to the swinging arm by ball joints.

Maintenance of this system consists only of inspecting the ball joints

and the swinging arm joint on the chassis.

LUBRICATION

Note

- Before lubricating each part, clean off any rusty spots with

rust remover and wipe off any grease, oil, dirt, or grime.

- Lubricate the points shown here, with either motor oil or regular

grease, periodically or whenever the vehicle is wet, and

especially after using a high-pressure spray washer.

General lubrication

Lubricate the points indicated with an arrow

- Clutch lever.

- Front brake lever.

- Rear brake pedal.

MAINTENANCE INSTRUCTIONS

42

Note

In order to lubricate the control cables (for example the throttle

control) several lubricants in aerosols are available on the market.

Ask for information from your approved GAS GAS workshop.

Page 43

Lubricating the secondary transmission chain

Lubricate the chain according to the intervals indicated in the

maintenance charge or whenever the motorcycle is used in adverse

conditions such as mud or rain.

Note

Several chain lubricants in aerosols are available on the

market.

- Lubricate both sides of the chain links with chain lubricant. Dry the

excess lubricant.

TIGHTENING NUTS AND BOLTS

Every day before using the bike, rapidly ensure that all bolts and

nuts are tightened. Also make certain that all of the other fastenings

are in place and in good condition.

MAINTENANCE INSTRUCTIONS

43

Page 44

3

2

1

4

6

5

1

16

17

18

20

19

21

22

15

14

11

10

7

9

8

12

13

23

24

25

1- Front and rear wheels

2- Front forks

3- Handle bars

4- Upper plate nut

5- Air filter housing bolts

6- Seat bracket bolts

7- Spokes

8- Front axle bolt

MAINTENANCE INSTRUCTIONS

44

9- Brake hose bolt

10- Bolts and nuts of the

engine brackets.

11- Shift pedal bolts

12- Subframe support bolt

13- Chain guide bolts

14- Chain adjustment nut

15- Drive sprocket bolts

16- Silencer bracket bolts

17- Sub chassis bolts

18- Shock absorber bolts

(rear)

19- Exhaust clamp bolt

20- Upper plate bolts

(suspension)

21- Brake lever bolt

22- Handlebar bolts

23- Rear axle nut

24- Rear brake pedal bolt

25- Swinging arm nut

Page 45

TIGHTENING TORQUE TABLE

PART NUMBER Nm Kgm

E

N

G

I

N

E

C

H

A

S

S

I

S

Tighten all of the bolts and nuts using the correct spanners. If not correctly tightened then motorcycle damage or even an accident could occur.

Engine drain plug 20 2.0

Shift pedal bolt 10 1.0

Spark plug 11 1.0

Calliper mounting bolts 25 2.5

Disc plate mounting screws 10 1.1

Engine mounting bolts 36 3.6

Front axle bolt 51 5.1

Front brake lever support bolt 6 0.6

Fork flange bolt 29 3.0

Steering nut 98 10.0

Rear axle nut 98 10.0

Rear brake pedal bolt 9 0.9

Subframe support bolt 26 2.7

Rear shock absorber bolt 39 4.0

Rear disc wheel drive bolt 29 3.0

Spokes 1.5 0.15

Steering axle bolt 4 4.5

MAINTENANCE INSTRUCTIONS

45

Page 46

TROUBLE SHOOTING

Note

This is not an exhaustive list, it is meant simply as a rough guide to assist troubleshooting for some of the more common difficulties.

SOLUTIONCAUSEFAULT

1

The starter motor does not work

2

The engine does not rotate

- The fuse for the starter relay is

blown.

- Battery discharged.

- Crankshaft locked.

- Remove the number plate on the right hand side and

the air filter cover then change the starter motor relay

fuse.

- Charge the battery and investigate the causes for discharging.

- Visit an approved GAS GAS workshop.

3

Engine rotates but does not

start

MAINTENANCE INSTRUCTIONS

46

- Cylinder/ piston/ crankpin journal

seizure.

- Transmission assembly seizure.

- Incorrect fuel supply.

- The motorcycle has been

out of operation for a long period

of time.

- Spark plug soiled or humid.

- Engine flooded.

- The CDI pin connector,

generator or coil oxidised or in

bad condition.

- Petrol / gas mixture incorrect.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Ensure that the fuel tap is not damaged or obstructed.

- Drain the old fuel from the fuel tank.

- Fill the fuel tank with new fuel.

- Clean and dry the spark plug.

- Clean the inside of the spark plug hood and apply an antihumidity spray.

- Move the accelerator to full position and press the electric

start button twice within five seconds. Then start the engine

as described before. If the engine does not start, remove the

spark plug and dry it.

- Clean the inside of the CDI, generator or coil connectors. If the

engine still does not start then visit an approved GAS GAS

workshop.

- Clean the petrol tank ventilation.

Page 47

SOLUTIONCAUSEFAULT

The engine starts but does not

4

stop

The engine overheats

5

The engine does not run

6

smoothly

The engine is not powerful or

7

accelerates badly

High oil consumption

8

Abnormal engine noise

9

- Air supply incorrect.

- Fuel insufficient.

- Engine cooling blades damaged,

dirty or bent.

- Fuel system maladjusted

.

- Valve adjustment incorrect.

- Fuel supply faulty.

- Air filter dirty.

- Exhaust deteriorated with leaks.

- Valve play too low.

- Incorrect piston ring-cylinder

tolerances.

- Engine oil level is too high.

- The quality or viscosity of the oil

is insufficient.

- Ignition problem.

- Valve play adjustment.

- Over heating.

- Close the choke. Clean the petrol tank ventilation.

- Fill the fuel tank with fuel.

- Clean the engine cooling blades or replace.

- Adjust the fuel system correctly. Visit an approved GAS GAS

workshop.

- Adjust the valve play. Visit an approved GAS GAS workshop.

- Clean the fuel system and check for leaks.

- Clean or change the air filter.

- Check if the exhaust system is deteriorated. Change if

necessary.

- Adjust the valve play. Visit an approved GAS GAS

workshop.

- Adjust the tolerance by changing the piston rings.

- Correct the engine oil level by draining the required amount.

- Empty the engine oil and fill with oil of the recommended viscosity.

- Visit an approved GAS GAS workshop.

- Adjust the valve play. Visit an approved GAS GAS workshop.

- See chapter 5.

MAINTENANCE INSTRUCTIONS

47

Page 48

SOLUTIONCAUSEFAULT

Detonations in the exhaust

10

11

Brown fumes from the exhaust

Gears do not engage

12

13

Gears jump

- Carbon in combustion chamber.

- The carburetion system is

maladjusted.

- Incorrect or poor gasoline or

wrong octane rating.

- Damaged or Incorrect spark

plug.

- Exhaust system joints

deteriorated.

- Air filter obstruction.

- The clutch does not

disengage.

- Shift fork worn or locked.

- Gear locked in transmission.

- Gear change lever damaged.

- Selector position spring loose or

broken.

- Down shift selector mechanism

spring broken.

- Gearbox cylinder broken.

- Gear ratchet spring broken.

- Gear fork worn

in gears.

- Gear fork shaft:

worn.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Drain the low quality fuel from the fuel tank.

- Fill the fuel tank with fresh fuel with the correct octane rating.

- Change the spark plug for a new one with the correct

specifications.

- Check if the exhaust system is deteriorated. The joints must be

in perfect condition. If necessary replace them.

- Clean or change the air filter.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Replace the gear operation lever.

Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

MAINTENANCE INSTRUCTIONS

48

Page 49

SOLUTIONCAUSEFAULT

Gears jump13

- Gear selection rail worn.

- Gear selection heads damaged.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

Clutch slipping

14

Bike unstable

15

Shock absorption too hard

16

- Gear drum groove worn.

- No play in the clutch lever.

- Clutch plate worn.

- Clutch hub worn.

- Clutch spring broken or weak.

- Clutch plates worn.

- Electrical installation, control

cable or brake line interfere

with steering.

- Steering shaft nut

too tight.

- Steering bearings damaged

or worn.

- Steering shaft bent.

- Excessive oil level in front

forks.

- Front fork oil viscosity too

high.

- Front forks twisted.

- Tyre pressure to high.

- Rear shock absorber maladjusted.

- Visit an approved GAS GAS workshop.

- Check the adjustment of the clutch lever. Visit an approved

GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Check that the electrical installation support, the control

cables or fuel lines are not interfering with the handlebar

movement.

- Ensure that all of the electrical installation attachments,

the control cables or the brake lines are fitted and in good

condition.

- Check the adjustment of the steering shaft nut. Visit an

approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Visit an approved GAS GAS workshop.

- Eliminate the excess oil to an adequate level. Visit an

approved GAS GAS workshop.

- Empty the fork oil and fill with oil of the recommended viscosity.

Visit an approved GAS GAS workshop.

- Replace the front forks. Visit an approved GAS GAS

workshop.

- Verify tyre pressure.

- Adjust the rear shock. Visit an approved GAS GAS

workshop.

MAINTENANCE INSTRUCTIONS

49

Page 50

SOLUTIONCAUSEFAULT

Shock absorption too soft

17

The bike makes unusual noise

18

- Insufficient oil level in front

forks.

- Front fork oil viscosity too low.

- Tyre pressure to low

- Rear shock absorber

maladjusted.

- Drive chain incorrectly adjusted.

- Chain worn.

- Rear sprocket worn.

- Chain lubrication insufficient.

- Rear wheel misaligned.

- 17-Insufficient oil level in front

forks.

- Front fork spring(s) weak or

broken.

- Brake disc excessively worn.

- Brake pads, incorrect position

or crystallised.

- Engine cylinder damage.

- Brackets, nuts, bolts not properly

tightened.

- Add oil to the forks as required. Visit an approved

GAS GAS workshop.

- Empty the fork oil and fill with oil of the recommended viscosity.

Visit an approved GAS GAS workshop.

- Verify tyre pressure.

- Adjust the rear shock. Visit an approved GAS GAS workshop.

- Adjust the chain.

- Replace the chain, rear sprocket and secondary transmission

pinion. Visit an approved GAS GAS workshop.

- Change the rear sprocket. Visit an approved GAS GAS

workshop.

- Apply a suitable chain lubricant.

- Align the rear wheel.

- Add oil to the forks as required. Visit an approved GAS GAS

workshop.

- Replace the springs in the front forks. Visit an approved GAS

GAS workshop.

- Replace the brake disc. Visit an approved GAS GAS workshop.

- Check the brake pad wear.

- Replace the brake pads. Visit an approved GAS GAS

workshop.

- Replace the damaged cylinder. Visit an approved GAS GAS

workshop.

-Check all brackets, nuts and bolts and apply the correct torques.

Visit an approved GAS GAS workshop.

MAINTENANCE INSTRUCTIONS

50

Page 51

SOLUTIONCAUSEFAULT

The handlebars vibrate

19

Motorcycle pulls to one side

20

The brakes do not function

21

correctly

The bulbs blow constantly

22

The lighting system does not

23

work

- Tyre worn, swing arm or its

needle bearing worn.

- Rim off-centre.

- Handlebar bracket or steering

shaft nut loose.

- Chassis twisted.

- Steering incorrectly adjusted.

- Steering shaft bent.

- Front forks twisted.

- Wheels misaligned.

- Brake disc wear excessive.

- Brake liquid leak.

- Brake fluid degraded.

- Brake cylinder worn or damaged.

- Brakes incorrectly adjusted.

- Voltage regulator defective.

- Lighting installation fuse is

blown.

- Replace the worn parts. Visit an approved GAS GAS workshop.

- Centre the wheel. Visit an approved GAS GAS workshop.

- Verify the tension of the wheel spokes. Adjust if necessary.

- Tighten the handlebar bracket and the steering shaft nut to

the correct tightening torques. Visit an approved GAS GAS

workshop.

- Replace the chassis. Visit an approved GAS GAS workshop.

- Adjust the steering. Visit an approved GAS GAS workshop.

- Replace the steering shaft. Visit an approved GAS GAS

workshop.

- Change front forks. Visit an approved GAS GAS

workshop.

- Align the wheels. Visit an approved GAS GAS workshop.

- Replace the brake discs. Visit an approved GAS GAS workshop.

- Ensure that brake fluid is not leaking from: front and rear brake

cylinder seals, hoses and joints. If there is any leak, visit a GAS

GAS workshop immediately.

- Replace the brake fluid. Visit an approved GAS GAS

workshop.

- Replace the brake cylinder. Visit an approved GAS GAS

workshop.

- Adjust the position and play of the front brake lever.

- Remove the left hand side cover from the fuel tank and check

the voltage regulator connections, the voltage regulator itself

and all fuses.

- Remove the front headlights cover and check the fuse.

MAINTENANCE INSTRUCTIONS

51

Page 52

CLEANING AND STORAGE

Cleaning

Note

Before cleaning the motorcycle, prepare the machine so that

water does not penetrate certain areas of the bike.

Exhaust: Once this is cold, cover it with a plastic bag attached with

rubber.

Clutch and brake levers, handgrips, engine stop button: cover with a

plastic bag.

Air filter intake: Cover the opening with tape or stuff a cloth in it.

Where to be most careful

Avoid applying high-pressure water to:

Brake pump cylinder and callipers and under the petrol tank: If water

enters the electric coil or the spark plug hood then the engine will

not start and the affected parts must be dried.

Front and rear wheel hubs.

Steering pivots (steering tube).

Rear suspension system.

Swing arm pivots.

WARNING

Never wax or lubricate the brake disk, this could lead to brake

failure and could provoke an accident. Clean the disc using

trichloroethylene or acetone.

Storage

When the motorcycle is to be stored for any length of time, it should

be prepared for storage as follows:

- Clean the entire vehicle thoroughly.

- Start the engine, and allowed to run for five minutes to teach the

transmission oil then drain as indicated in the section about oil

changes.

- Put in fresh transmission oil.

- Empty the fuel tank. If fuel is left for a long time it will deteriorate.

- Disconnect the battery.

- Lubricate the drive chain and all the cables.

- Spray oil on all unpainted metal surfaces to prevent rusting. Avoid

getting oil on rubber parts or in the brakes.

- Set the motorcycle on a box or stand so that both wheels are raised

off the ground. (If this cannot be done, put boards under the front

and rear wheels to keep dampness away from the tire rubber).

- Tie a plastic bag over the exhaust pipe to prevent moisture from

entering.

- Put a cover over the motorcycle to keep dust and dirt from collecting

on it.

After washing

- Remove the plastic bags and clean the air filter intake.

- Lubricate the locations listed in the lubrication section.

- Start the engine and let it heat for 5 minutes.

- Check the brakes before driving the bike.

52

Starting after storage

- Remove plastic bag from exhaust.

- Tighten spark plug.

- Fill the fuel tank with fuel.

- Check all the points listed in the Daily Pre-ride Inspection Section.

- General lubrication

- Connect the battery.

Page 53

TECHNICAL DATA

ENGINE

Engine 4-stroke, 2-valve, air-cooled single cylinder

Displacement in cubic centimetres 123 cc

Bore and stroke 53 x 50 mm

Spark plug TORCH D8RTC

Fuel supply Carburettor Keihin 22

TRANSMISSION

Transmission type 5 speed

Clutch type Cable operated, multi-disc in oil bath

Secondary transmission Chain 5/8 x 1/4

Gear ratio 1st 2.76 (13/36)

2nd 1.88 (17/32)

3rd 1.4 (20/28)

4th 1.13 (23/26)

5th 0.96 (25/24)

Primary transmission 4,05 (18/73)

Transmission oil Capacity 1000 cc

Type 10W50 API SF or SG

CHASSIS

Type Double-beam, rectangular and 28 mm circular steel tubes with chrome alloy finish.

Steel swinging arm

Tyre sizes Front 2.75 x 21"

Rear 4.10 x 18"

53

Page 54

Suspension Front Marzocchi telescopic fork 40mm

Suspension stroke Front 202 mm

Front suspension oil MARZOCCHI SAE 7.5

Front fork oil level Marzocchi: 200 mm (compressed, without spring)

BRAKES

Front 260 mm diameter Disc Double piston calliper AJP*

Rear 220 mm diameter Disc Cylinder with incorporated tank, single piston calliper AJP*

DIMENSIONS

Overall height 1,120 mm

Overall length 2,135 mm

Overall width 820 mm

Wheel base 1,450 mm

Minimum ground clearance 300 mm

Fuel tank capacity 7.4 litres

Weight 119 Kg

Specifications may not be valid for all countries and may change without prior notice.

Rear Single shock absorber system

Rear 220 mm

TECHNICAL DATA

54

Page 55

GUARANTEE MANUAL

(According to law 23/2003 of the 10 of July, regarding Consumer Goods Sales Guarantees.)

Manufacturer's guarantee regulations for GAS GAS Motos S.A.

The Company GAS GAS Motos S.A. (hereafter referred to as GG) hereby guarantees the final purchaser of a vehicle manufactured by GG that

both materials and workmanship are free from defects according to the maximum quality standards. Consequently, GG hereby warrants to the

final purchaser (hereinafter referred to as the "purchaser"), subject to the conditions stated below, to remove any defects in material or production

detected in a new motorcycle free of charge within the agreed period of warranty without any limitation whatsoever in terms of the number of

kilometres travelled or the number of operating hours.

Period of warranty

The period of warranty shall commence on the day of delivery of the vehicle by a licensed GG dealer to the purchaser, or in the case of demonstration

models, on the date on which the vehicle is put into operation for the first time.

The vendor will respond to any conformity faults that appear within the period established by the Law 23/2003 of the 10th of July regarding

Consumer Goods Sales Guarantees from the delivery of goods and in accord with the directive 1999/44/CE for the remainder of the European

Community Member States. For those countries outside of the European Community the guarantee will be regulated by the relevant current

legislation. However, if the conformity fault appears during the first six months following delivery of the motorcycle, it will be assumed that this

fault existed when the motorcycle was delivered; from the sixth month, the purchaser must show that the fault existed at the moment the goods

were delivered.

During the six months following the delivery of the repaired goods, the vendor will respond to the faults requiring repairs.

Any defect detected in the product must be brought to the attention of the authorized GG dealer within the period of the guarantee. If the last day

of the warranty period is a Sunday or public holiday, the warranty period shall be extended in such a way that the last day of the warranty period

is the next working day following the respective Sunday or public holiday.

Warranty claims shall be excluded for any defects not brought to the attention of a licensed GG dealer by the end of the warranty period.

55

Page 56

Purchaser obligations

GG shall be entitled to refuse to accept warranty claims if and to the extent that:

a) The purchaser has failed to subject the vehicle to any of the inspections and/or maintenance work prescribed in the operating manual or has

exceeded the date stated for such inspections or maintenance work, also excluding from the warranty defects that appear before the prescribed

date of such inspection or maintenance work not performed or performed after the prescribed date.

b) the inspection, maintenance and repair of the vehicle is carried out by third parties unauthorized or not recognised by GG.

c) Any maintenance or repair work has been performed on the vehicle in violation of the technical requirements, specifications and instructions

indicated by the manufacturer.

d) Spare parts not released for use by GG have been used to perform maintenance or repair work on the vehicle, or if and to the extent that the

vehicle has been operated using other fuels, lubricants or operating fluids (including but not limited to cleaning agents) other than those expressly

stated in the specifications in the operating manual;

e) The vehicle has been altered or modified in any way or equipped with other components than those expressly released by GG as admissible

vehicle components.

f) The vehicle has been stored or transported in a way that does not meet the corresponding technical requirements.

g) The vehicle has been used for extraordinary use such as for competitions, races or attempts at any record whatsoever.

h) The vehicle has suffered a fall or accident provoking the damage indirectly or directly.

Exclusions from the warranty

The following items will be excluded from the warranty:

a) normal wear and tear on parts including, without limitation, spark plugs, batteries, fuel filters, oil filter elements, drive chains (secondary), engine

pinions, rear sprockets, air filters, brake discs, brake pads, clutch discs, lamps, fuses, carbon brushes, footrest rubbers, tires, tubes, cables

and other rubber components.