GasGas EC Racing 2011 Owner's manual

EC 2 STROKES RACING 2011

EC 2 STROKES RACING 2011

ENGLISH

Foreword

GAS GAS thanks you for the trust you have placed in us.

By choosing the new GAS GAS EC 2011 you have become part of the great GAS GAS family and, as a user

of the number one manufacturer of off-road motorbikes, you deserve the distinguished treatment that we wish

to offer to you both in our after-sale relationship and in the explanations that we provide in this manual.

Our EC 2011 is a motorcycle conceived for the practice of high-competition. It is actually the fruit of many

years of competition and experimentation in this demanding discipline, as well as the many great successes

achieved thanks to great trial riders who have contributed with their expertise to the basic data that have

allowed us to create motorcycles of the highest level, GAS GAS unique motorcycles which count on important

key factors: reliability, high features and a good stability.

Congratulations for making the right choice. With your skills at the command of this motorcycle, its adequate

preparation and the corresponding indispensable servicing, this motorcycle will prove to be highly reliable, and

you will be able to enjoy the most comfortable and rewarding practice of your favorite sport.

Thank you for your trust in us, and welcome to GAS GAS Motos, S.A.

February 2011

-3-

HOW TO USE THIS MANUAL

Read this Manual carefully. You will find it contains all the necessary

information for your safety, and that of other persons, as well as

guaranteeing the correct conservation and maintenance of the GAS

GAS motorcycle that you have just acquired.

You will find all the necessary instructions for the correct riding and

control of this vehicle are set out below. Each message is preceded

by a symbol with the following meaning: .

WARNING

This warning symbol identifies special instructions or procedures

which, if not correctly followed, could result in personal injury or even

death.

Motorcycle riding, if improverly conducted, has the potential to cause

environmental problems as well as conflicts with other people.

Responsible riding use of your motorcycle will ensure that these

problems and conflicts do not develop.

TO PROTECT THE FUTURE OF YOUR SPORT MAKE SURE YOU

USE YOUR MOTORCYCLE WHITHIN THE LAW , SHOW CONCERN

FOR THE ENVIRONMENT, AND RESPECT THE RIGHTS OF

OTHER PEOPLE.

Motorcycle riding is a wonderful sport, and we hope you will enjoy

it to the fullest.

CAUTION

This symbol identifies instructions or procedures which, if not followed

strictly, could result in damage to or destruction of equipment.

NOTE

This note symbol indicates points of particular interest for more

efficient and convenient operation.

RECOMMENDS THE USE OF OIL:

-4-

TABLE OF CONTENTS

Foreword...........................................................................................3

How to use this manual.....................................................................4

Table of contents...............................................................................5

Specifications....................................................................................6

Location of components....................................................................8

Side Stand ......................................................................................10

Fuel.................................................................................................10

Serial Number.................................................................................12

Homologation Plate.........................................................................12

Starting the engine..........................................................................12

Shifting gears..................................................................................13

Stopping the motorcycle .................................................................14

Riding during the Break-In Period...................................................14

Maintenance Schedule ...................................................................15

Electronic Ignition............................................................................17

Cooling System...............................................................................17

Spark Plug ......................................................................................20

Transmission...................................................................................20

Air Cleaner......................................................................................22

Throttle Cable .................................................................................23

Carburetor.......................................................................................23

Clutch..............................................................................................24

Exhaust System..............................................................................24

Drive Chain Guide...........................................................................25

Handlebar .......................................................................................27

Brakes.............................................................................................28

Steering...........................................................................................29

Steering blockage...........................................................................30

Front Fork .......................................................................................31

Rear suspension.............................................................................34

Wheels............................................................................................36

Cleaning..........................................................................................37

Bolts and nuts tightening.................................................................38

Lubrication ......................................................................................40

Tunning (Carburetor and Suspension)............................................41

Final recommendatios.....................................................................49

Homologation..................................................................................50

Preparation for competition.............................................................51

Storage ...........................................................................................52

GAS GAS Multifunction Instructions ..............................................53

Troubleshooting..............................................................................60

Electric Schemas............................................................................65

Warranty Manual.............................................................................66

-5-

SPECIFICATIONS

ENGINE 2 cycles, single cylinder, crankcase intake, liquid cooled

125 cc Engine

Bore and stroke 54 x 54.5 mm

Displacement 124 cc

200 cc Engine

Bore and stroke 62.5 x 65 mm

Displacement 199.4 cc

250 cc Engine

Bore and stroke 66.4 x 72 mm

Displacement 249.3 cc

300 cc Engine

Bore and stroke 72 x 72 mm

Displacement 294.7 cc

Carburettor, diameter of diffusor 38 (125 cc : 36)

Lubrication system Mixture

Starting system Starting lever

Ignition system CDI system

Ignition timing 1 mm BTDC

TRANSMISSION

Transmission type 6 speed in cascade

Clutch type Hydraulic operated multi-plate in oil bath

Secondary drive Chain driven

Gear ratio (200 cc, 250 cc, 300 cc) 1st 2.071 (29/14)

100% Synthetic Oil 50:1 = 2%

Mineral Oil (Only USA) 32:1 = 3%

2nd 1.625 (26/16)

3rd 1.333 (24/18)

4th 1.100 (22/20)

5th 0.913 (21/23)

6th 0.791 (19/24)

(125cc)

1st. 2,308 (30/13)

2nd. 1,867 (28/15)

3rd. 1,529 (26/17)

4th. 1,286 (27/21)

5th. 1,130 (26/23)

6th. 1,000 (24/24)

-6-

Primary reduction 2.85 (57/20) (250 cc, 300 cc); 3,32 (63/19) (125cc)

Final reduction 3.692 (48/13) (125 cc, 250 cc, 300 cc); 3,667 (44/12) (200cc)

Transmission oil Capacity 750 cc (125 cc)

900 cc (200 cc / 250 cc / 300 cc)

Type 10W30 API SF or SG

CHASSIS

Type Tubular, semi-double cradle

Tire size Front EC - 90/90 x 21

Rear EC - 140/80 x 18

Suspension Front Inverted telescopic fork ø 45 mm (EC 125, 200 )

Inverted telescopic fork ø 48 mm (EC 250, 300 )

Rear Progressive system with single multi-adjustable shock

Suspension stroke Front ø45: 290mm / ø48: 305mm

Rear 320 mm

Front fork oil SAE 5 - 7.5

Quantity of oil in front fork ø45: 595cc / ø48: 320cc

Level of oil in front fork ø45: 100mm ( without spring, without preload tube and compressed )

ø48: not possible to measure

BRAKES

Type Front, Rear Disc brake

Effective disc diameter Front 260 mm

Rear 220 mm

DIMENSIONS

Overall height 1260 mm

Overall length 2135 mm

Overall width 810 mm

Seat height 940 mm

Minimum height 340 mm

Wheelbase 1475 mm

Fuel tank capacity 9.5 l

(Specifications are subject to change without notice and probably do not apply to all countries).

-7-

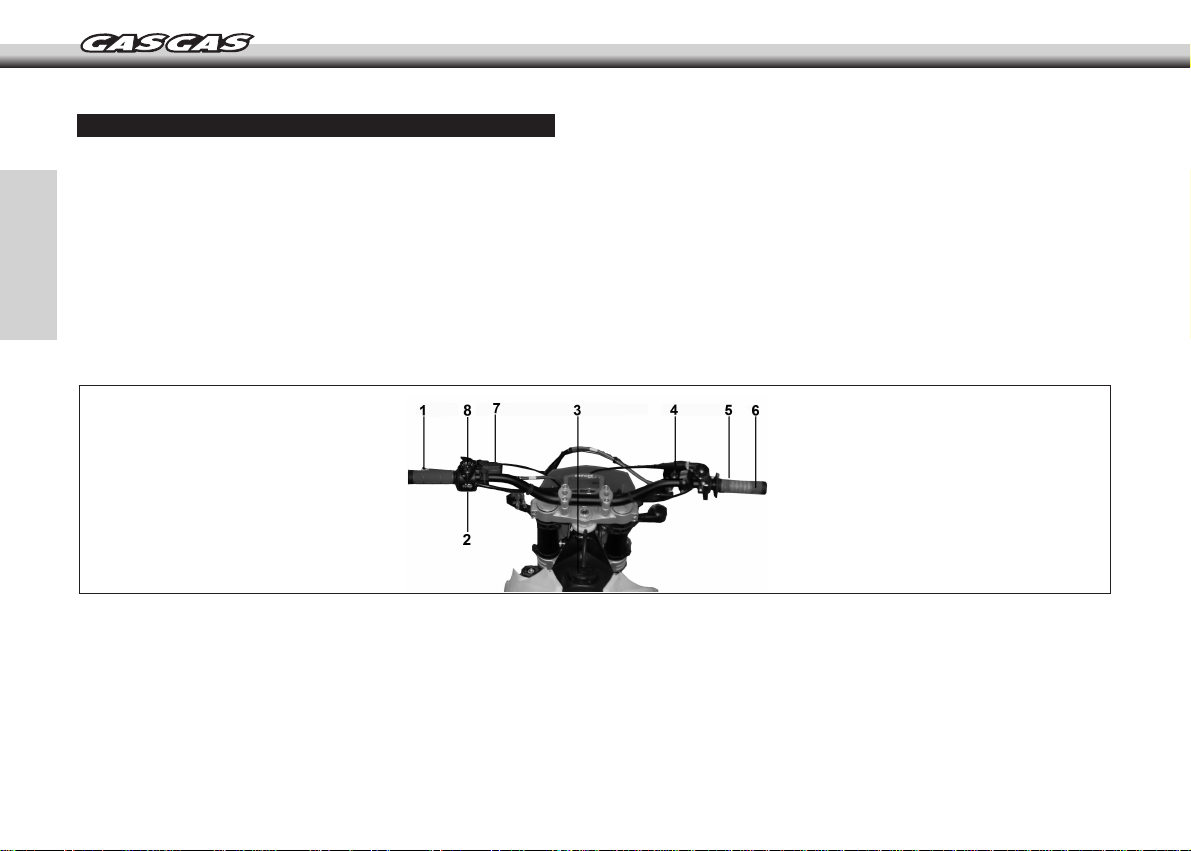

LOCATION OF COMPONENTS

GAS GAS EC 2010

1- Clutch lever

2- Steering, lights, horn and

headlamp controls

3- Fuel tank cap

4- Brake fluid reservoir

5- Front brake lever

6- Throttle grip

7- Clutch fluid reservoir

8- Choke Trigger

-8-

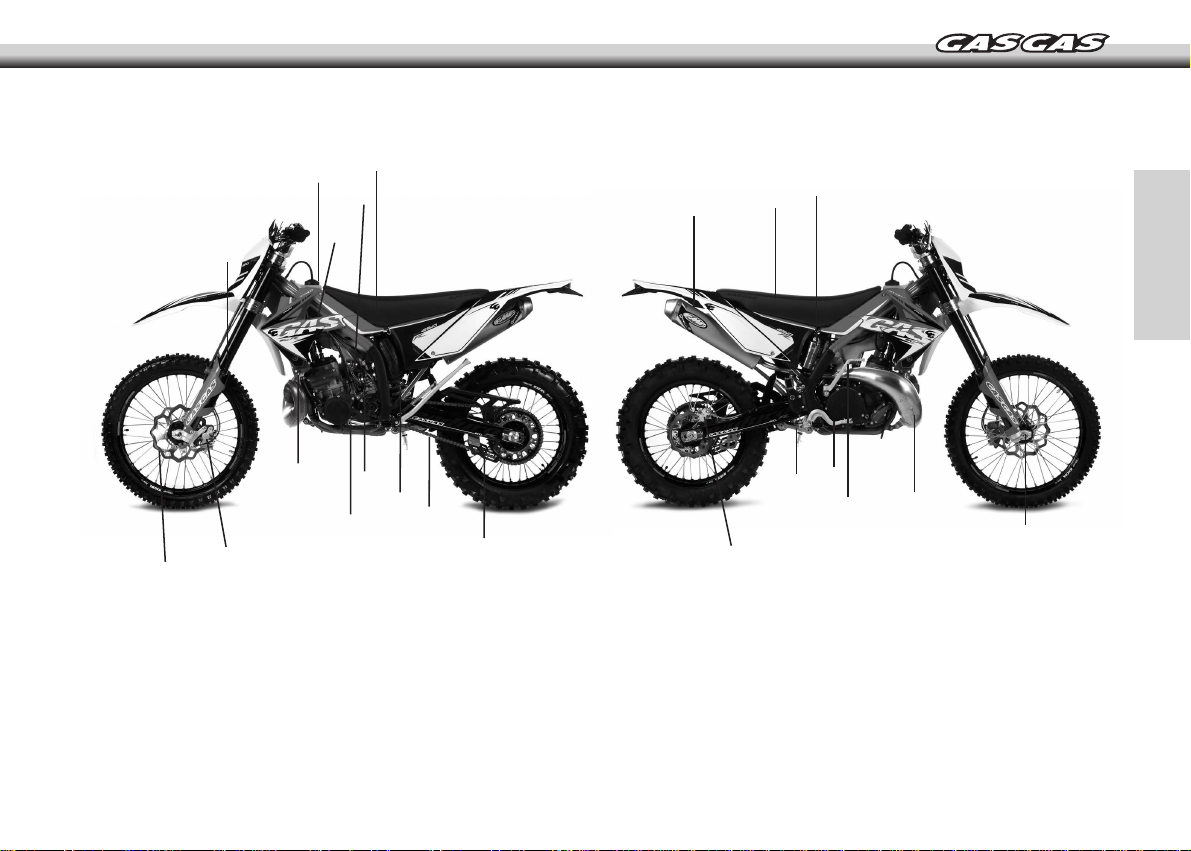

GAS GAS EC

27

17

16

12

8

20

19

23

14

25- Kick-start pedal

26- Exhaust

27- CDI switch

28- Front axe puller

24

25

26

28

13

18

22

21

17- Shift pedal

18- Muffler

19- Seat

20- Gas reservoir

21- Chain guide

22- Chain

23- Suspension linkage

and swingarm

11

10

15

14

9

9- Brake disc

10- Front suspension

11- Fuel tank

12- Carburetor

13- Rear shock absorber

14- Brake caliper

15- Radiator

16- Gasoline cock

24- Rear brake pedal

-9-

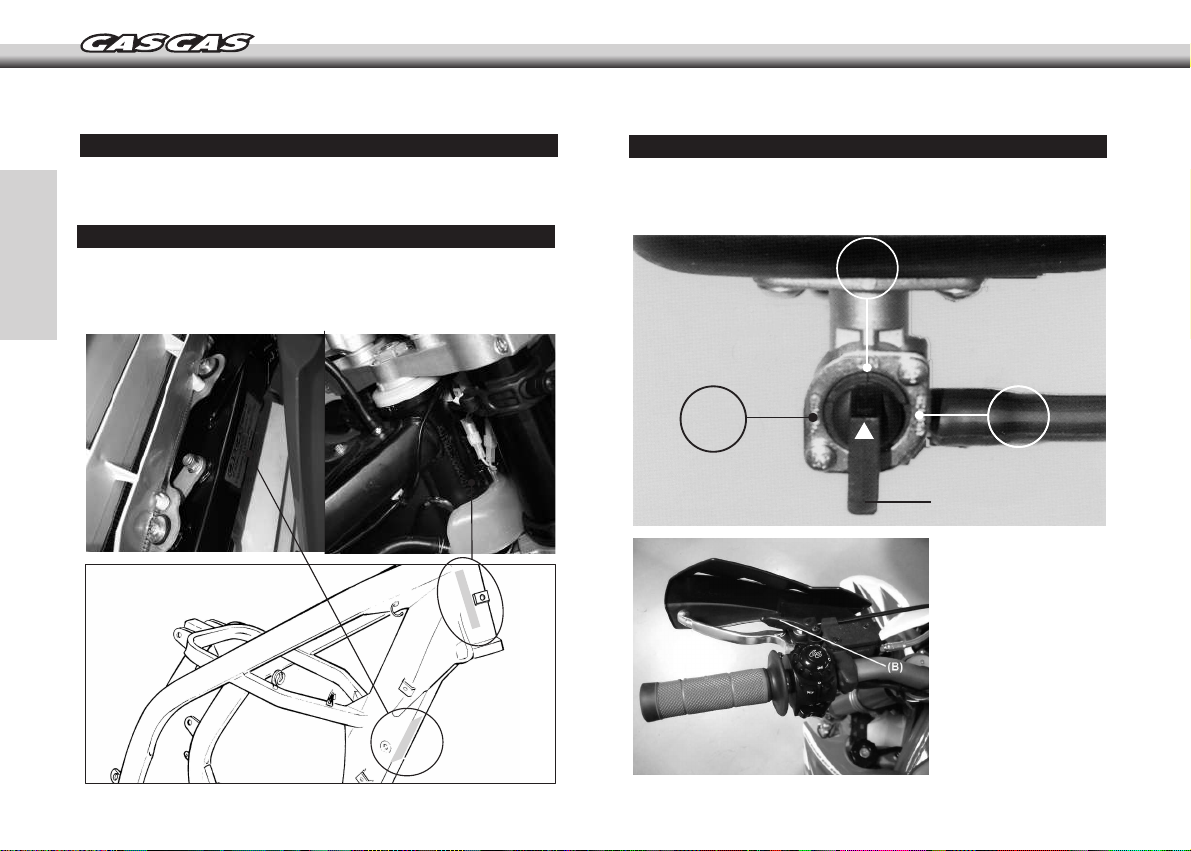

SIDE STAND

FUEL

To set the side stand only turn it until it contacts the stopper, then

the side stand will be parallel to the ground and rest securely.

The side stand will return to its original position by means of the

double spring. The function of the double spring insures that, when

the side stand is down, the rest position is stable and above all

secure; moreover, it also returns the side stand to its original position.

EC

(A). Side stand.

(B). Double

spring.

(A). Side stand.

(A)

NOTE

Do not start the engine or ride the motorcycle when the side

stand is down.

The GAS GAS EC models have 2-cycle engines that require a

mixture of gasoline and oil.

Gas Tank Capacity

9,5 L

(B)

(A)

(A). Fuel tank cap.

(B). Vapor outlet tube.

The fuel tank cap is of the quick-release type.

To open the fuel tank cap, lift the plated latch and turn cap counterclockwise.

To close it, turn the cap clockwise and lower the latch.

NOTE

It is recommended that the rubber seal should be checked

thoroughly to insure it is airtight.

-10-

RECOMMENDED FUEL

Use gasoline with an octane rating equal to or higher than that shown

in the table.

Recommended oil:

2-CYCLE SYNTHETIC

OCTANE RATING METHOD MINIUM

RATING

Antiknock Index (RON+MON)/2 90

Research Octane No. (RON) 98

NOTE

If knocking or pinging occurs, try a different brand of gasoline

or higher octane grade.

WARNING

Gasoline is extremely flammable and can be explosive under certain

conditions. Always stop the engine and do not smoke. Make sure

the area is well ventilated and free from any source of flame or

sparks; this includes any appliance with a pilot light.

Mixing oil inside the engine

Oil must be mixed with gasoline to lubricate the piston, cylinder,

crankshaft, and connecting rod bearings.

If the recommended oil is not available, use only oil designed

NOTE

for racing with 2-cycle engines.

Gasoline and engine oil mixing proportions:

Synthetic oil 100%: gasoline 50, engine oil 1 = 2%

Semi-synthetic oil: gasoline 50, engine oil 1 = 2%

Mineral oil: gasoline 32, engine oil 1 = 3%

CAUTION

Do not mix vegetable and mineral based oils.

Too much oil will cause excessive smoking and spark plug fouling.

Too little oil will cause engine damage or premature wear.

CAUTION

Below 0 ºC do not use 100% synthetic oil.

To prepare the mixture, first pour oil and half of the gasoline used

into a container and stir the mixture thoroughly. Then add the rest

of the gasoline and stir the mixture well.

NOTE

At low temperature, oil will not easily mix with gasoline. Take

time to ensure a well-blended mixture.

The lubrication quality of this mixture deteriorates rapidly; use

a fresh mixture for each day of operation.

-11

-

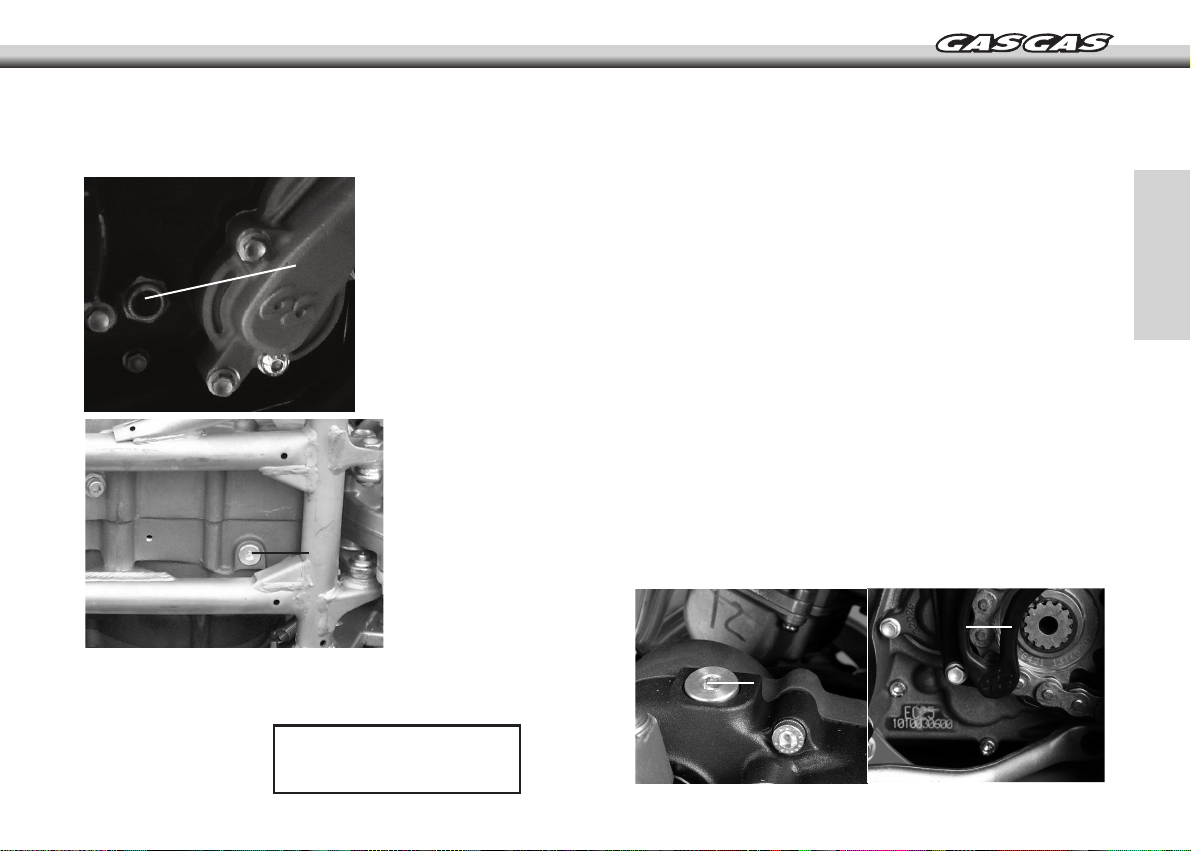

SERIAL NUMBER (A)

STARTING THE ENGINE

It is stamped on the steering pipe. It indicates the frame number

registered for this motorcycle.

HOMOLOGATION PLATE (B)

This motorcycle carries its corresponding homologation plate where

it also shows the serial number, and this data must match the

information registered in the motorcycle documents.

(A)

(B)

1. Make sure the motorcycle is in the neutral position.

2. Turn the gasoline cock (A) clockwise to the "ON" position.

ON

Open

OFF

Close

RES

Reserve

(A)

(B)

3. If the engine is

cold, pull up the

choke trigger (B).

-12-

- When the engine is already warm or on hot days, open

NOTE

the throttle instead of using the choke knob.

- If the engine is flooded, kick with the throttle fully open.

- If the clutch lever is pulled, the motorcycle can be

started while in any gear.

4. Start the

motorcycle with

kick-start pedal (C).

5. Even after the engine starts, keep the choke knob pulled up.

Stopping the engine

1. Shift the transmission into neutral.

SHIFTING GEARS

The transmission is a 6-speed, of the return shift type. A return shift

means that to go from first gear to third gear it must go first through

the second gear, that is to say that it upshifts gears one by one. To

engage first gear from neutral, pull the clutch lever in and push down

on the gearshift pedal, then release the gearshift pedal and gently

release the clutch lever.

CAUTION

When shifting gears, press firmly on the gearshift pedal to ensure

a positive shifting. Careless, incomplete shifts can cause the

transmission to jump out of gear and cause engine damage.

(D)

2. After racing the

engine slightly,

close the throttle

completely and

depress the engine

stop button (D).

(A). Gearshift pedal.

-13-

STOPPING THE MOTORCYCLE

For maximum deceleration, close the throttle (A) and apply both

front and rear brakes. Disengage the clutch as the motorcycle comes

to a stop. Independent use of the front or rear brake may be

advantageous under certain conditions.

Downshift progressively as speed is reduced to ensure good engine

response when you want to accelerate.

inspection of the spark plug shows this to be the case, replace

the standard spark plug with another of a higher heat range.

Perform the break-in period following these steps:

1. Start the engine and let it run at idle until the engine is warm.

2. Stop and let the engine cool completely.

3. Start the engine and ride for 10 minutes at moderate speed -

NEVER ACCELERATE HARD.

4. Stop and let the engine cool completely. Be sure to check and

adjust chain slack and spoke tightness and cxarry out a general

inspection.

5. Start the engine and ride for 20 minutes at moderate speed. -

NEVER ACCELERATE HARD.

6. Stop and let the engine cool completely. Check and adjust as

needed (Refer to the table of adjustments).

7. Install the parts removed.

8. Fill the radiator with the recommended coolant. Before starting

the motorcycle, bleed the air from the cooling system.

9. Start the engine and ride for 30 minutes at moderate speed.

10. Stop and let the engine cool completely. Check and adjust.

11. After the break-in procedure has been properly carried out, the

motorcycle is ready for regular operation.

CAUTION

RIDING DURING THE BREAK-IN PERIOD

A break-in period is necessary to ensure a smooth operation and

obtain an optimum engine and the transmission responses. During

the first hour or 20 km of operation, run the engine at low and

moderate speeds and revolutions per minute (RPM).

NOTE

The slow riding necessary during the break-in period may cause

carbon deposits to build up on the spark plug and foul it. If

However, avoid accelerating recklessly that can lead to engine failure.

Be careful to use the necessary skills and techniques while operating

the motorcycle.

NOTE

After the break-in period, install a new set of standard spark

plugs.

-14-

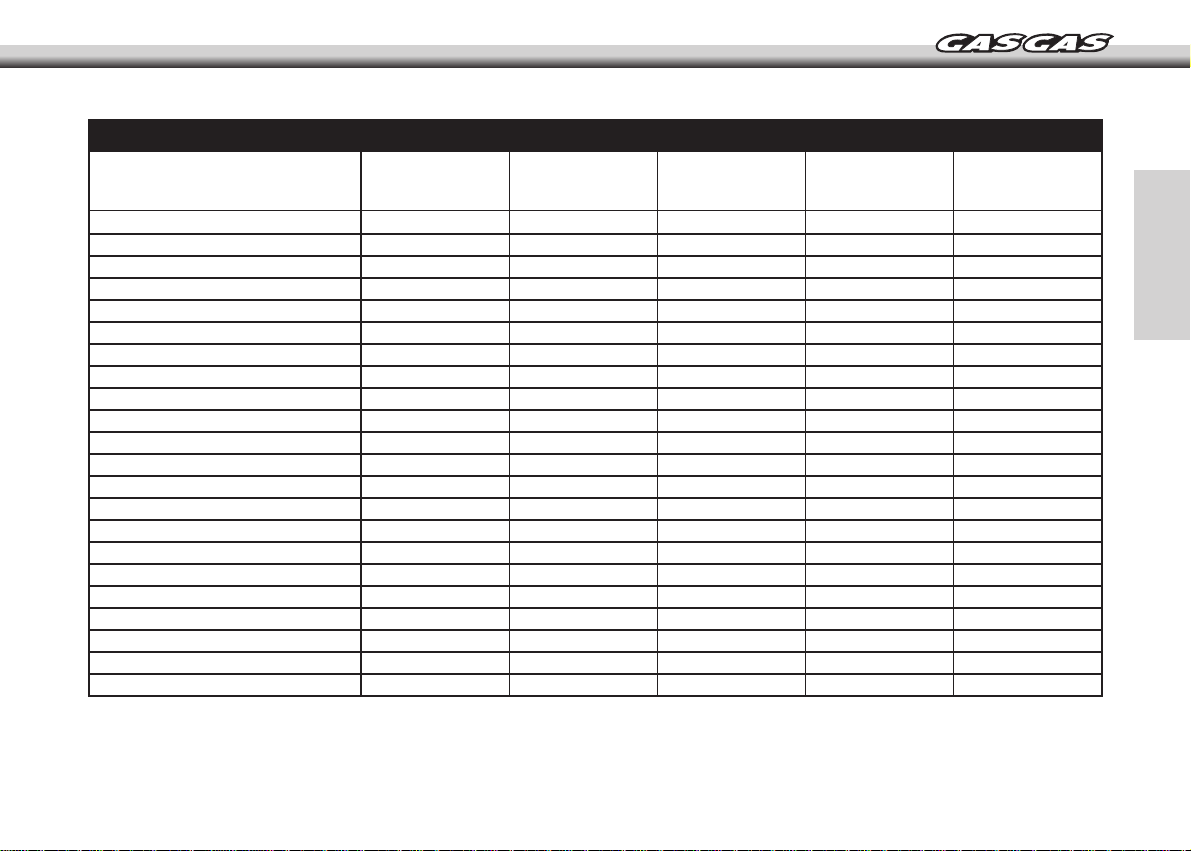

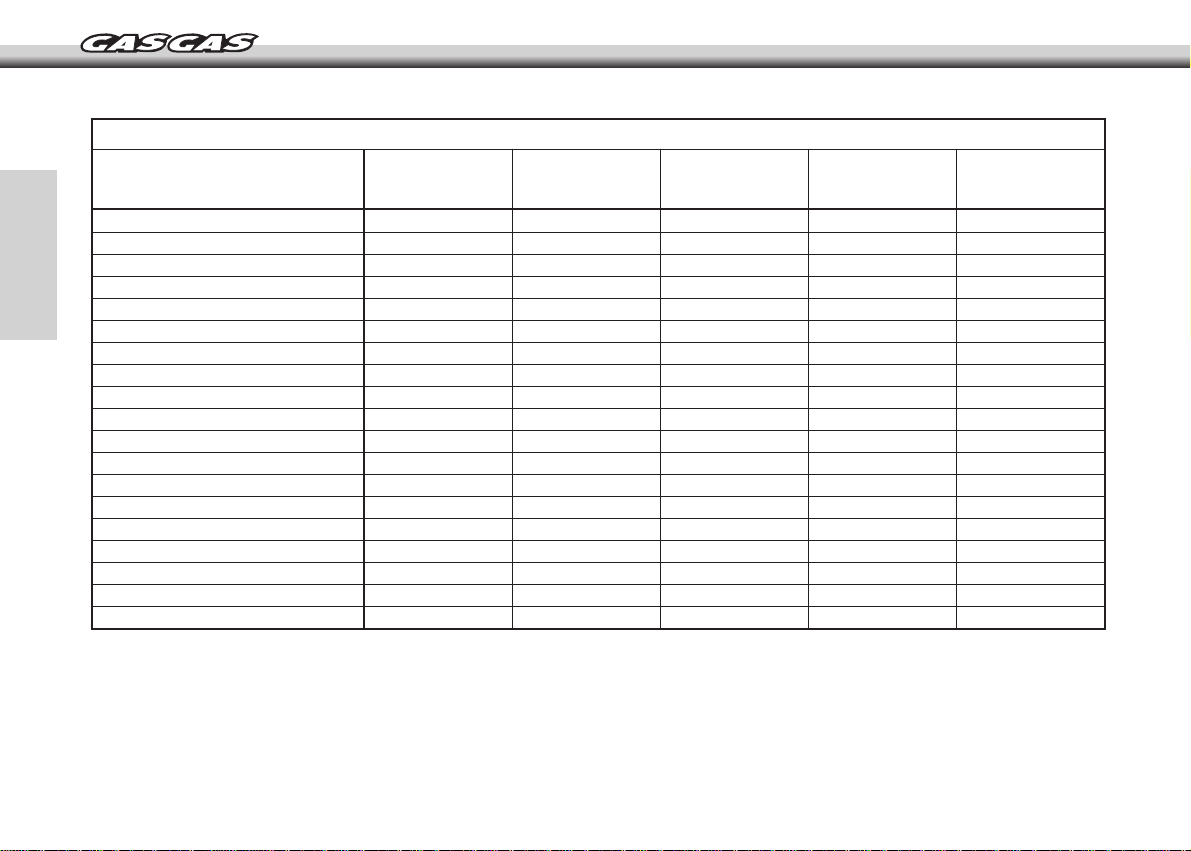

Item

MANTENANCE SCHEDULE

Check / Inspect Change / Replace Apply grease /

Adjust

Clean

Lubricate

Clutch

Discs

Throttle cable

Spark plug

Air cleaner element

Carburetor

Transmission oil

Piston and piston ring

Cylinder head, cyl. & exhaust valves

Exhaust

Muffler gasket

Piston bearing

Kick-start pedal and gearshift pedal

Exhaust pipe o'ring

Engine bearings

Coolant

Radiator tube and connections

Brake adjustment

Brake pads wear

Brake fluid level

Brake fluid

Brake pump piston & dust cover

At each fill up

3 fill ups

-

-

-

1 fill up

3 fill ups

3 fill ups

1 fill up

3 fill ups

-

-

10 fill ups

3 fill ups

1 fill up

3 fill ups

5 fill ups

3 fill ups

-

-

At each fill up

3 fill ups*

1 fill up

-

-

1 fill up

3 fill ups*

3 fill ups*

1 fill up*

10 fill ups*

3 fill ups*

-

-

10 fill ups*

3 fill ups*

1 fill up*

3 fill ups*

5 fill ups*

3 fill ups*

-

-

At each fill up*

3 fill ups*

-

-

When damaged

-

3 fill ups

3 fill ups*

3 fill ups*

1 fill up*

10 fill ups

10 fill ups

-

3 fill ups

10 fill ups*

3 fill ups*

1 fill up*

3 fill ups*

5 fill ups*

3 fill ups*

Every 2 years

Every 2 years

-

-

1 fill up

1 fill up

-

-

3 fill ups

1 fill up

-

-

-

-

-

-

-

-

-

-

-

-

At each fill up

-

-

-

-

-

-

-

-

-

-

3 fill ups

1 fill up

-

-

-

-

-

-

-

-

-

The maintenance and adjustments in this table are easy to follow and must be carried out to keep the motorcycle in good running condition.

NOTE: (*) Inspect and carry out these operations only if it is necessary.

-15-

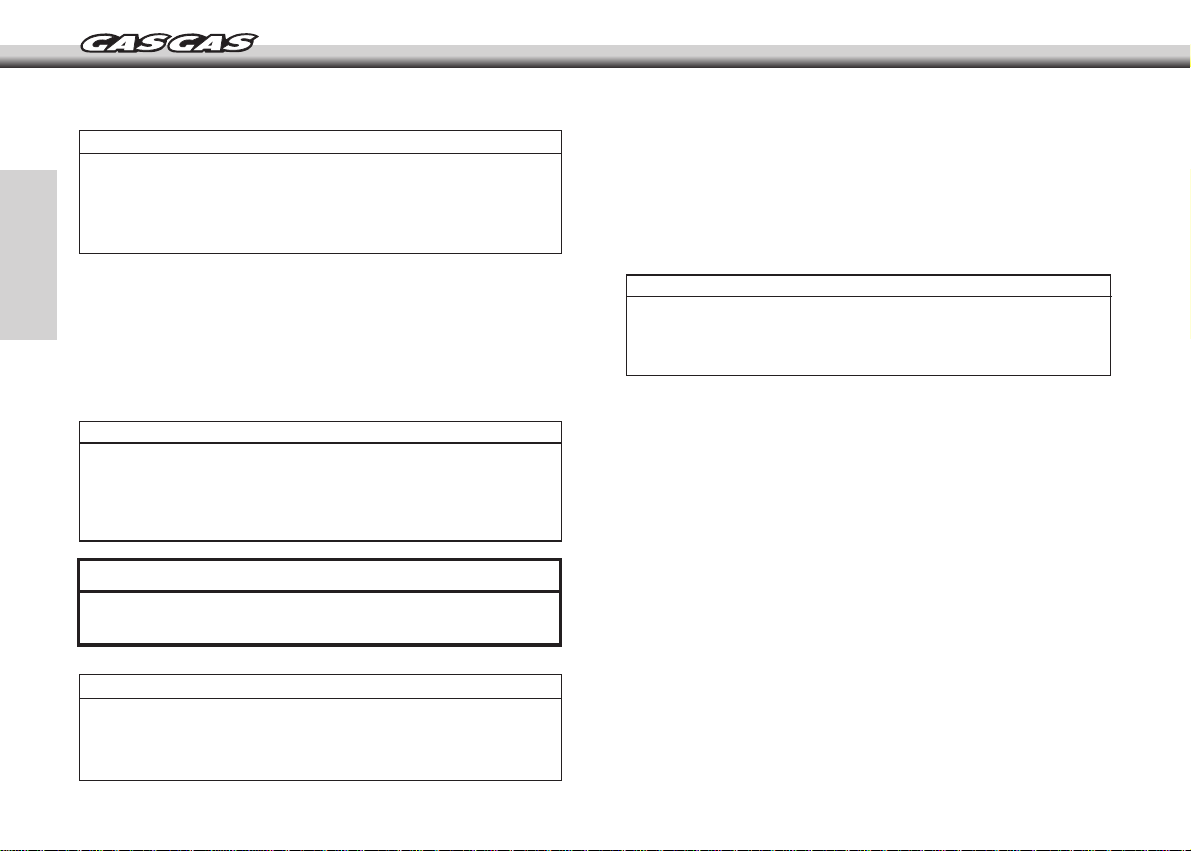

Item

MANTENANCE SCHEDULE

Check / Inspect Change / Replace Apply grease /

Adjust

Clean

Lubricate

Brake caliper piston seal & dust seal

Brake hose and pipe

Spoke tightness and rim runout

Lubricate drive chain

Drive chain

Drive chain wear

Chain slider

Front fork

Front fork oil

Nuts, bolt, fasteners

Fuel hose

Fuel system

Steering play

Rear sprocket

General lubrication

Steering bearing

Wheel bearing

Swingarm and linkages

Rear shock absorber oil

-

-

1 fill up

-

1 fill up

-

5 fill ups

1 fill up

5 fill ups

7 fill ups

-

1 fill up

5 fill ups

5 fill ups

-

10 fill ups

5 fill ups

Every 2 years

-

-

1 fill up*

-

-

5 fill ups

5 fill ups*

When necessary

5 fill ups*

7 fill ups*

-

5 fill ups*

-

-

10 fill ups*

5 fill ups*

2 years*

Every 2 years

Every 4 years

1 fill up*

-

-

5 fill ups

5 fill ups*

When damaged

Every year

5 fill ups*

7 fill ups

10 fill ups

-

5 fill ups*

-

-

10 fill ups*

5 fill ups*

2 years*

-

-

-

-

-

-

-

When necessary

-

-

-

When necessary

-

-

-

-

-

-

-

-

-

-

1 fill up

-

-

-

-

-

-

-

-

-

-

5 fill ups

10 fill ups

-

5 fill ups

-

The maintenance and adjustments in this table are easy to follow and must be carried out to keep the motorcycle in good running condition.

NOTE: (*) Inspect and carry out these operations only if it is necessary.

-16-

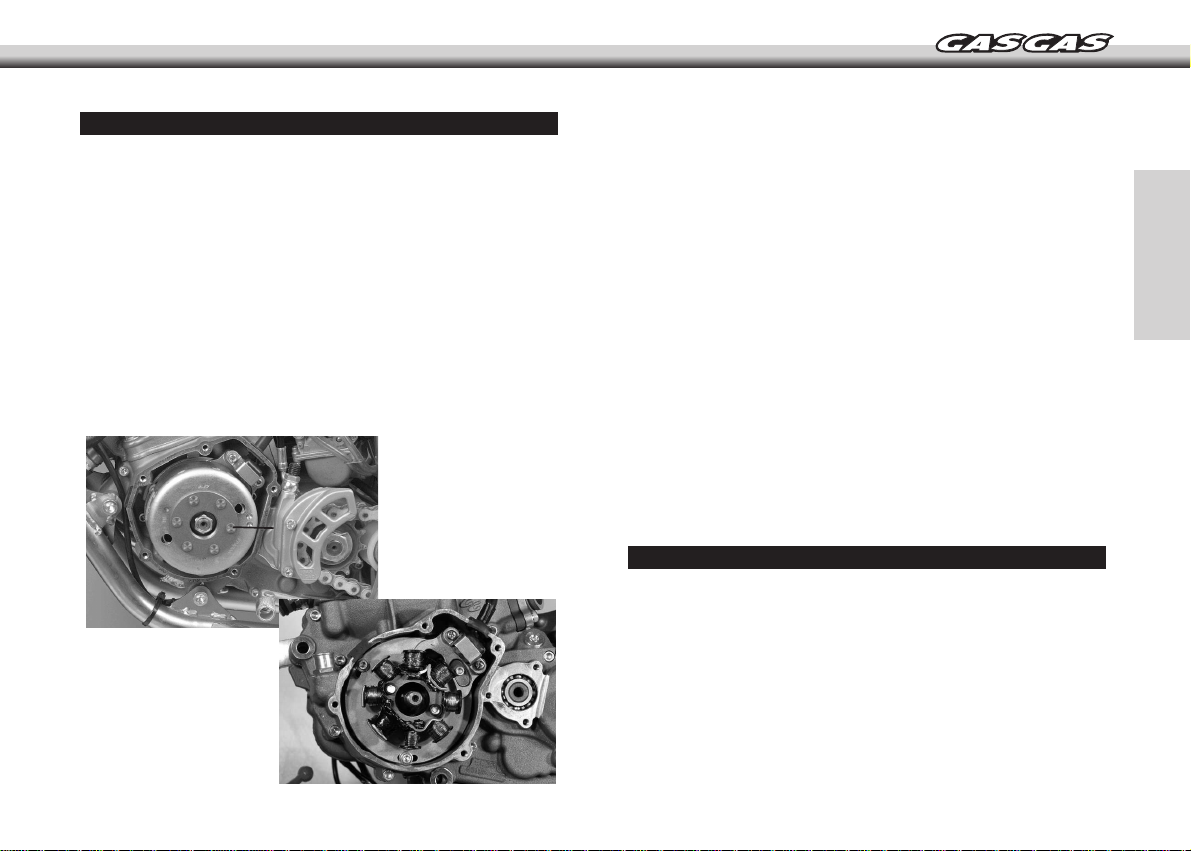

ELECTRONIC IGNITION

This motorcycle uses a capacitor discharge ignition system (CDI).

The ignition system should never require adjustment unless the

stator of the magnetic flywheel was incorrectly installed during engine

reassembly.

If necessary, inspect and adjust as follows:

Adjustment

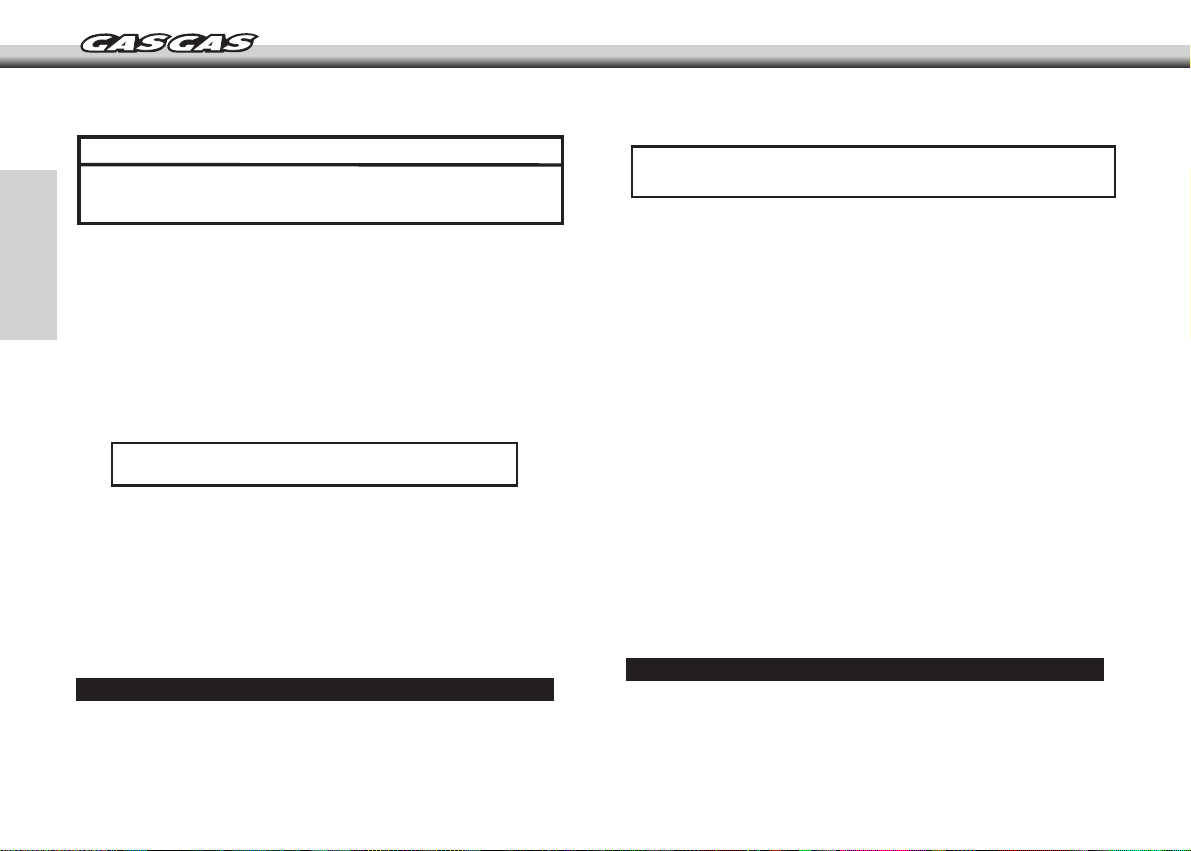

- Remove the magnetic flywheel cover (A).

- Make sure that the mark on the stator plate is aligned with the

mark on the crankcase.

- If the marks are not aligned, loosen the magnetic inertia wheel

screws and turn it.

- Tighten the screws securely.

- Install the magnetic flywheel cover.

NOTE

Engine tune-up can be adjusted to match the rider´s preferences

and skills.

- Remove the magnetic flywheel cover.

- Loosen the stator screws.

- Adjust the engine tune-up by changing the position of the stator

within prudent limits

NOTE

For the best engine performance, it is very important to adjust

the engine tune-up within the set of limits described.

(A)

125 cc

200 / 250 / 300 cc

- Tighten the stator screws.

- Install the magnetic flywheel cover.

- Test ride the motorcycle and readjust the engine tune-up, if

necessary.

COOLING SYSTEM

Radiator Hoses

Check the radiator hoses for cuts or deterioration, and the connections

for looseness and leaks.

Radiator

Check the radiator fins for obstructions (insects or mud). Remove

any obstructions with a stream of low water pressure.

-17-

If high water pressure is used the radiator fins could be damaged

CAUTION

and impair the radiator effectiveness.

Do not obstruct or deflect airflow through the radiator by installing

unauthorized accessories. Any interference with the radiator airflow

can lead to engine overheating and damage.

Coolant information

To protect the cooling system aluminum parts (engine and radiator)

from rust and corrosion, the use of corrosion and rust inhibitors

chemicals in the coolant is essential. If rust inhibitors were not used,

over a period of time the radiator will be corroded. This will clog the

tubes of the cooling system.

If the lowest ambient temperature encountered falls below the freezing

point of water, protect the cooling system. Use a permanent type of

antifreeze in the cooling system (distilled water and ethylene glycol

and corrossion inhibitors for aluminium engines and radiators).

For the coolant mixture ratio under extreme conditions, choose the

mixture ratio listed on the container for the lowest ambient temperature.

CAUTION

Permantent types of antifreeze have anticorrosion and anti-rust

properties. When it is diluted excessively, it loses its antifreeze and

anticorrosion properties. Mix in accordance with the instructions of

manufacturer.

Liquid recommended

Use of incorrect coolant solutions will cause engine and cooling

CAUTION

system damage.

Use coolant containing corrosion inhibitors made specifically for

aluminum engines and radiators in accordance with the instructions

of the manufacturer.

WARNING

Chemical liquids are harmful to the human body. Follow manufacturer

instructions.

CAUTION

Distilled water must be used with corrosion inhibitors and the

antifreeze in the cooling system. If tap water is used in the system,

the cooling tubes can be clogged and reduce the cooling system

efficiency.

Permanent type of antifreeze (distilled water and ethylene glycol)

plus corrossion inhibitors for aluminium engines and radiators.

NOTE

Initially, at the factory a permanent type of antifreeze is installed

in the cooling system. It is colored green, it contains a 30%

solution of ethylene glycol, and has a freezing point of –18 ºC.

Coolant recommended

Coolant absorbs excessive heat from the engine and transfers it to

the air at the radiator. If the coolant level is low , the engine overheats

and may suffer severe damage. Check the coolant level each day

before riding the motorcycle. Add liquid recommended if the level is

low (see next page).

-18-

WARNING

To prevent severe scalding do not remove the radiator cap or try to

change liquid, when the engine is still hot. Wait until it cools.

Total quantity

Mix antifreeze and distilled water 1:1 (distilled water 50%, antifreeze

50%).

Capacity: 1.1 L

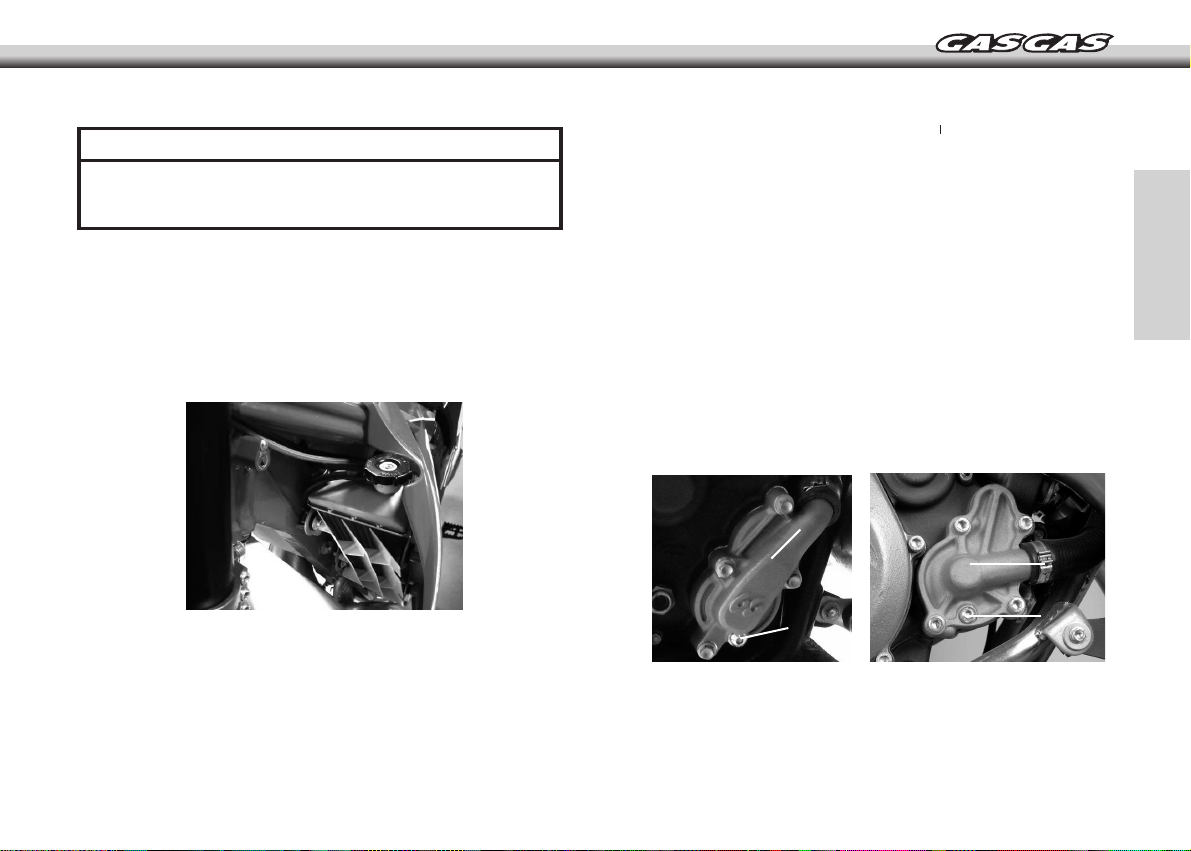

Coolant Replacement

Coolant level

- Place the motorcycle in riding position.

- Turn the radiator cap (A) counterclockwise and wait a few seconds

until vapors inside are released. Then push and turn it further in

the same direction and remove the cap.

NOTE

Check the level when the engine is cold.

- Check the coolant level. The coolant level should be just at a level

below de cap rubber seal.

- If the coolant level is low, add the correct amount of coolant

through the filler opening.

Coolant should be changed periodically to ensure long engine life.

- Wait for the engine to cool completely.

- Place the motorcycle in riding position.

- Remove the radiator cap.

- Place a container under the coolant drain screw, and drain the

coolant from the radiator and engine by removing the drain screw

(B) at the bottom of the water pump cover (A). Wash off immediately

any coolant spilled on the chassis, engine, or wheels.

200/250/300

(A)

(A)

(B)

(B)

-19-

125 cc.200 / 250 / 300 cc.

(A)

(B)

WARNING

If coolant gets on the tires will make them very slippery and can

cause an accident.

- Visually inspect the old coolant. If whitish spots are observed in

the liquid is a clear indication that the aluminum parts in the cooling

system are corroded. If the coolant is brown, iron or steel parts

of the system are rusting. In both cases, flush the cooling system.

- Check the cooling system for damage, leaks or missing gaskets

in the cooling system.

- Install the water pump cover drain screw with the specified torque

values shown in the table. Always replace the gasket with a new

one.

Standard Spark Plug

125 cc Denso W27ESR-U 0.7-0.8 mm OR NGK BR9EG

200 / 250 / 300 cc Denso W24ESR-U 0.7-0.8 mm OR NGK BR8EG

The spark plug should be removed periodically to check its gap. If

the plug is oily or has carbon deposits, clean it with a sandblaster.

After removing the abrasive particles, the spark plug must be cleaned

using a wire brush or a similar tool. Measure the gap with a feeler

gauge, if incorrect adjust the gap by bending the side electrode. If

the spark plug electrodes are corroded or damaged, or if insulator

is cracked, replace the plug.

NOTE

Inspect every 30 hours and change every 60 hours.

Drain plug tightening torque (refer to torque table)

Water pump screw: 9 Nm

- Fill the radiator up to the edge of the cap with coolant, and install

the radiator cap.

- Inspoect the cooling system for leaks.

- Start and warm up the engine, then stop the engine.

- Check the coolant level after the engine cools down. Add coolant

up to the cap.

SPARK PLUG

The standard spark plug is a shown in the table and should be

tightened to 27 Nm.

To find out whether the right heat range plug is being used, remove

it and inspect the ceramic insulator around the center electrode. If

the ceramic is light brown, the spark plug is correctly matched to

engine temperature. If the ceramic is whie, the spark plug should

be replaced with the next colder plug. If the ceramic is black, the

spark plug should be replaced with the next hotter plug.

NOTE

If the engine performance drops, replace the spark plug first to

recover its output.

TRANSMISSION

For the transmission and clutch to function properly, maintain the

transmission oil level at the optimum level and change it periodically.

A motorcycle with insufficient transmission oil, deteriorated or

contaminated can accelerate wear and tear and cause transmission

-20-

Oil level inspection

Oil change

- Wait a few minutes if the motorcycle has been operating.

(A)

(B)

- If the level is low, add the necessary quantity of oil by opening the

plug (C). Use the same type and oil manufacturer used currently

with the engine.

Transmission Oil Viscosity: SAE 10W30

Capacity: 750 cc (EC 125)

900 cc (EC 200-250-300)

- Check the oil level

through the

inspection window

in the lower right

hand side of the

engine (A).

- Oil level must be

kept between the

maximum and

minimum marks.

- If the lever is too

high, you have to

remove the excess

oil through the drain

plug (B).

125 cc.

NOTE

200 / 250 / 300 cc

The engine must be completely cool and then warm up the

engine again for a few minutes to normal operating temperature,

to register the correct engine oil temperature and to obtain an

accurate oil level measurement.

- The transmission oil should be changed periodically to ensure

long engine life.

- Warm up the engine for 5 minutes so any oil sediment will float.

- Stop the engine, and place an oil pan under the engine.

- Remove the drain screw (see previous photo) and place the

motorcycle in riding position to allow the oil to drain out.

- Clean the drain screw magnet of any iron particles.

- Tighten the oil drain screw with its O-ring to 20-Nm.

- Remove the oil filler opening plug (C) and pour 900 cc of new

transmission oil for the models 200 / 250 / 300, and 750 cc for

model 125.

- Check the oil level, after kicking the kick-start pedal 3 or 4 times.

- Install the oil filler opening plug.

(C)

(C)

-21-

Loading...

Loading...