GasGas EC 250-300-F 2013 Owner's manual

Use of incorrect coolant solutions will cause severe engine and

CAUTION

cooling system damage.

Use coolant containing corrosion inhibitors made specifically for

aluminium engines and radiators in accordance with the instructions

of the manufacturer.

WARNING

Coolant chemicals are harmful to the human body. Follow coolant

manufacturer warnings and coolant handing instructions.

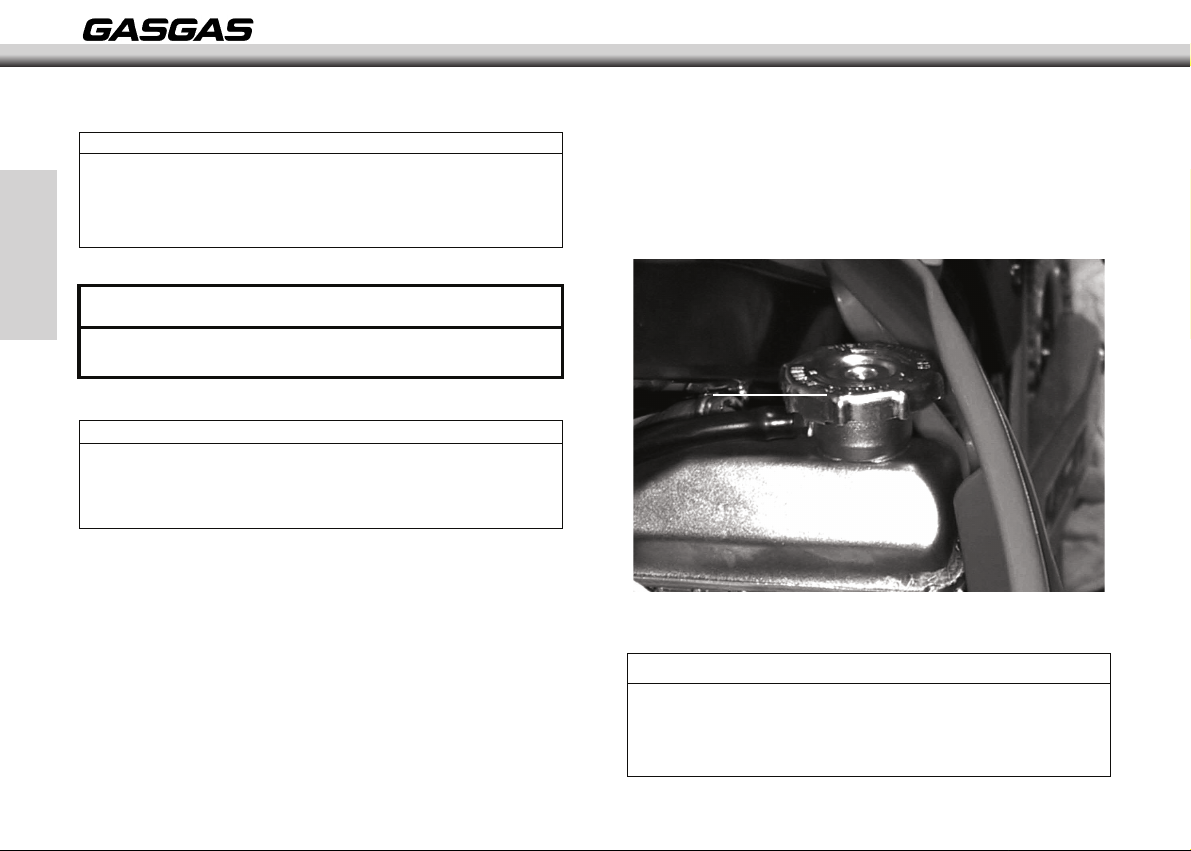

Coolant Level

- Situate the motorcycle so that it is perpendicular to the ground.

- Remove the radiator cap in two stages. First turn the cap anti-clock

wise and wait for a few seconds. Then push and turn it further in the

same direction to remove the cap.

(A)

Soft or distilled water must be used with the inhibitor chemicals and

CAUTION

the antifreeze in the cooling system.

If normal water is used in the system, it the cooling system tubes

may become blocked.

If the lowest ambient temperature encountered falls below the freezing

point of water, protect the cooling system against freezing.

Use a permanent type of anti-freeze (soft water and ethylene glycol

plus corrosion and rust inhibitor chemicals for aluminium engines

and radiators) in the cooling system.

For the coolant mixture ratio under extreme conditions, choose the

mixture ratio listed on the container for the lowest ambient temperature.

(A). Radiator Cap.

CAUTION

Permanent types of antifreeze on the market have anticorrosion and

anti-rust properties. When diluted excessively these lose their

antifreeze and anticorrosion properties. These must be diluted in

accordance with the instructions of manufacturer.

-16-

Check the level when the engine is cold.

NOTE

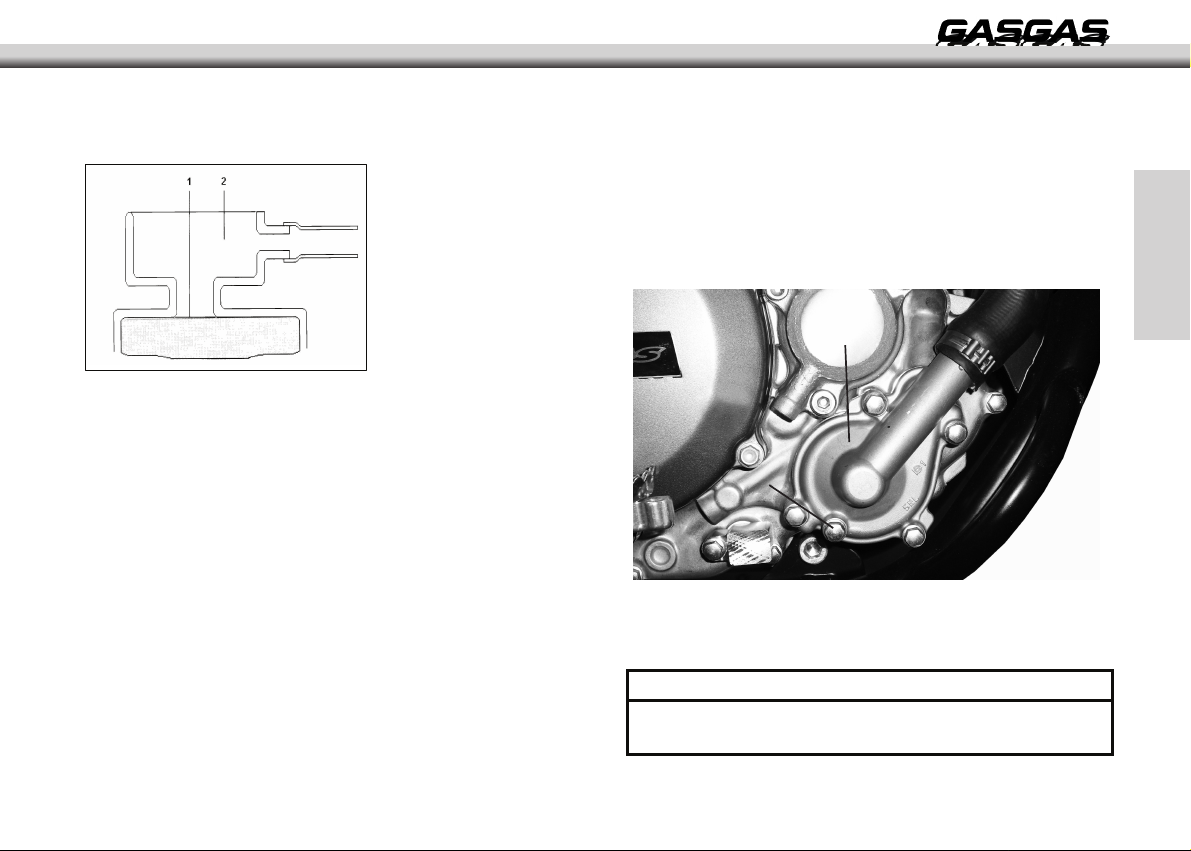

Changing the coolant

- The coolant should be changed periodically to ensure long engine life.

- Wait for the engine to cool completely.

- Situate the motorcycle so that it is perpendicular to the ground.

- Remove the radiator cap.

- Place a bowl under the water pump cover and remove all the liquid

in the radiator and engine, uclock the drain screw (B). Immediately

wipe or wash off any coolant that spills on the frame, engine, or

wheels.

(1). Coolant level.

(2). Filler opening.

If the coolant level is low, add the correct amount of coolant through

the filler opening.

Recommended liquid

Permanent type of antifreeze (distilled water and ethylene glycol)

with corrosion and rust inhibitor chemicals for aluminium engines

and radiators).

NOTE

Initially a permanent type of antifreeze is installed in the cooling

system by the manufacturer. This is green in colour, containing

30 % ethylene glycol with a freezing point of –18°C.

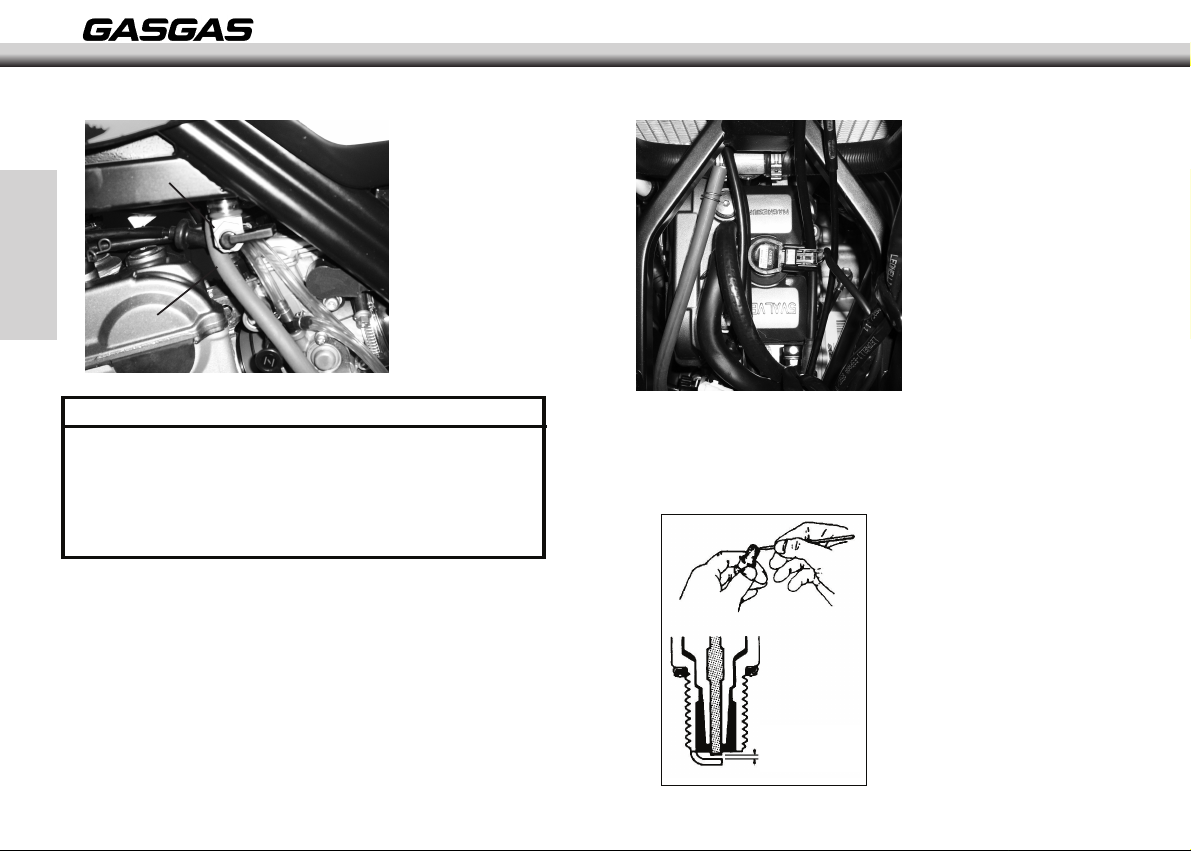

(A)

(A)

(B)

(A). Water pump cover.

(B). Screw to drain.

WARNING

If coolant gets on the tyres this will make them slippery and could

result in an accident.

-17-

- Examine the used coolant. If white cotton-like patches appear in

the liquid then this means that the aluminium elements of the cooling

system are corroded. If the liquid is brown then this means that the

steal or iron parts of the system are oxidized. In either case clean

out the system.

- Check the cooling system for damage, loose joints, or leaks.

- Put the drain screw on the water pump cover and lock it with the

indicated torque. Change the copper washer by a new one.

between electrodes using a gauge and adjust in case that it is not

correct by bending the outer electrode. If the spark plug electrodes

are oxidised, damaged or the insulation is broken then replace the

plug.

NOTE

Inspect every 30 hours. Replace every 60 hours.

Screw torque:

Drain screw on the water pump cover: 9 Nm.

- Fill the radiator up to the edge and install the radiator cap.

- Check the cooling system for leaks.

- Start the engine, warm up the engine, and then stop it.

- Check the coolant level after the engine cools down. Add

coolant up to the bottom of the radiator filler neck.

SPARK PLUG

The standard spark plug is indicated inside the table and the torque

to lock it is 13 Nm.

Standard spark plug

Standard spark plug Gap between electrodes: 0.7-0.8 mm.

The spark plug should be taken out periodically to check the electrode

gap. If the plug is oily or has carbon build up on it the clean it with

a sand blaster. Following abrasive particle cleaning, the spark plug

should be cleaned with a wire brush or similar. Measure the distance

To find the correct heat grade spark plug is being used, take it out

and examine the insulation around the electrode. If the ceramic is

light brown, the spark plug is correctly matched to engine temperature.

If the ceramic is white, the plug should be replaced with the next

coldest plug. If the ceramic is black, the plug should be replaced

with the next hottest plug.

NOTE

If the engine output decreases, replace the spark plug to regain

performance.

Spark plug maintenance

COMMENTS

If the standard spark plug is wet then replace it.

If the standard spark plug looks glassy or has a white

colour, replace it(

-18-

An incorrectly fitted spark plug, or an incorrect temperature can lead

WARNING

to severe damage to the engine, and this damage is not covered by

the warranty.

Always use the manufacturer's recommended brand of spark plug.

Check with your dealer or a qualified mechanic to determine the

correct spark plug for your motorbike.

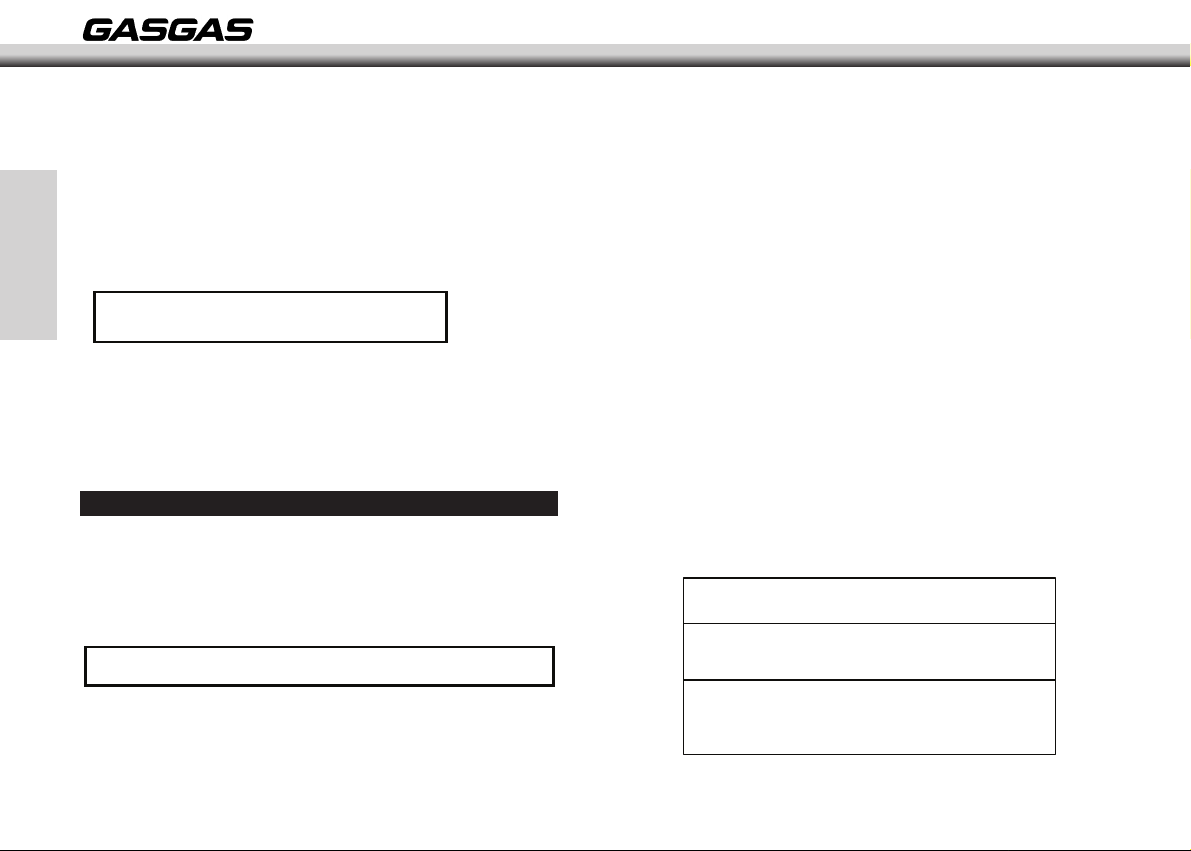

Removing the spark plug

To remove the spark plug, follow these steps:

(A)

(C)

(C)

2. Remove the bolts

(C) (left and right).

3. Remove the tank

securing bolt (E).

(B)

1. Remove the bolt (A)

and remove the seat (B).

(E)

(D)

-19-

(G)

(F)

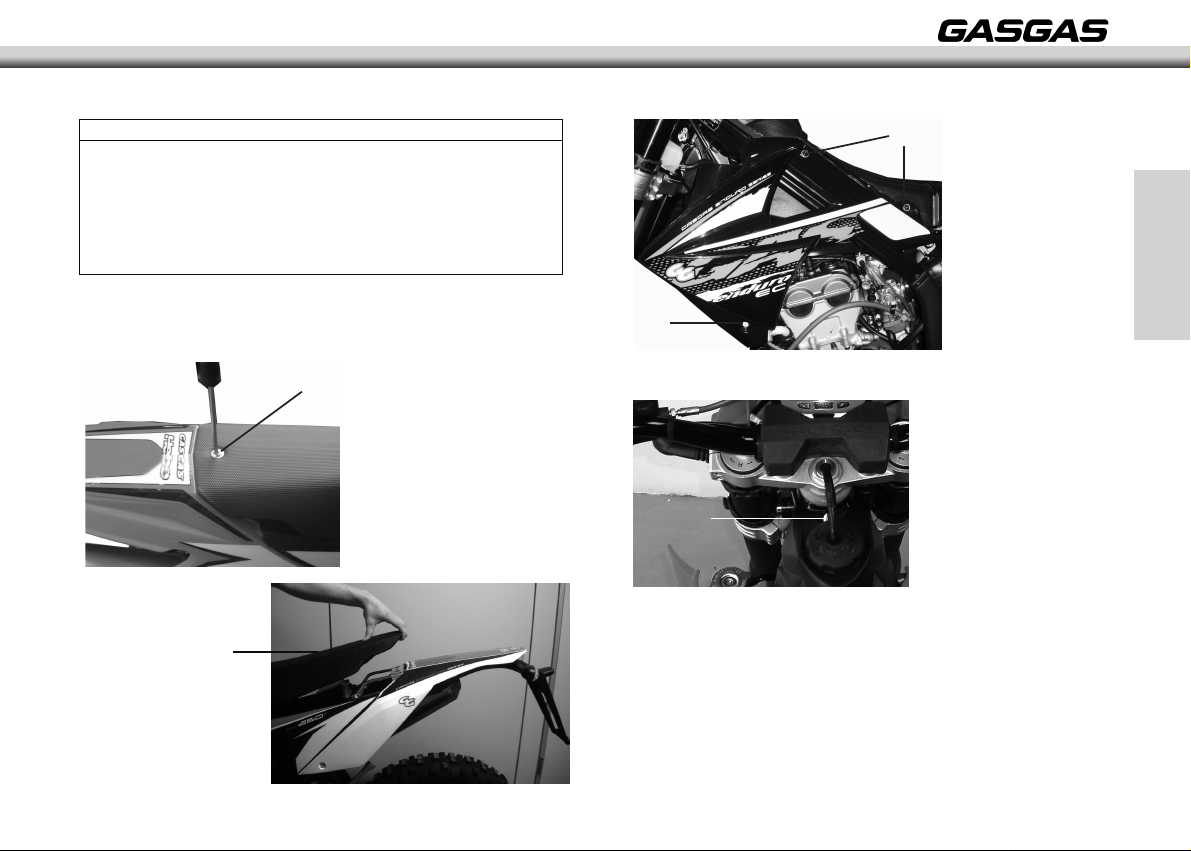

4. Close the fuel tap

F and remove the fuel

tub G.

5. Remove the spark

plug hood.

WARNING

Becareful to the fuel loss when you remove the fuel tub, the fuel is

highly flammable.

Stop the engine, before to remove the fuel tank. Take care to be

inside a well-ventilated area that there is no

sparks or flame anywhere near the working zone.

NOTE

A cap protects the spark plug.

Keep this clean and dry.

-20-

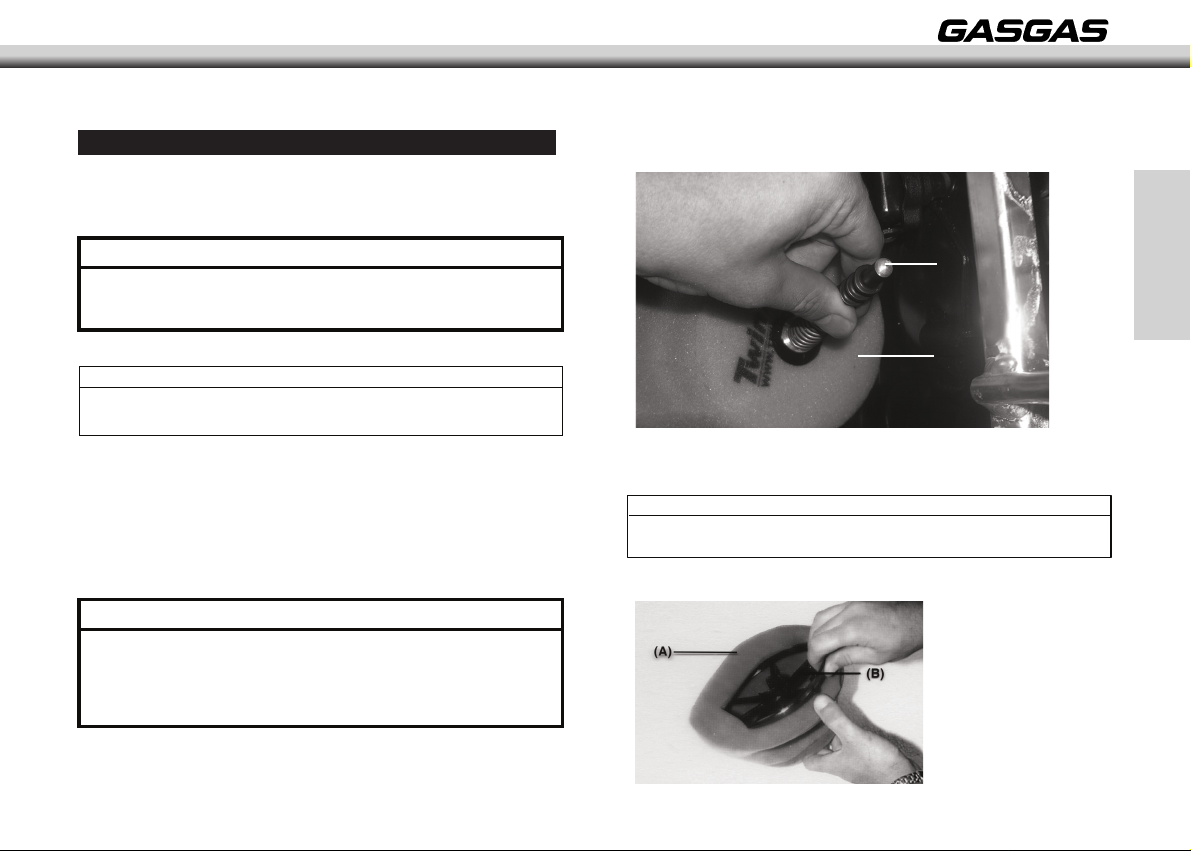

(A)

6. Take out the spark plug

and clean carbon deposits

from the spark plug with a

small tip or a metallic brush.

Readjust the gap (A) in the

plug between 0.7 and 0.8

mm. (0.028 – 0.031 in).

Before removing the carbon

deposits, check its colour; this

colour tells us whether the

standard plug is the best for

our use.

AIR FILTER

An obstructed air filter restricts the air intake of the engine, increasing

the petrol consumption and reducing the engine power as well as

the destruction of the spark plug.

- Remove the seat.

- Remove the bracket (A) and remove the filter (B).

WARNING

An obstructed air filter may allow dirt to enter into the injector blocking

it open; this could lead to an accident.

CAUTION

An obstructed air filter will allow dirt to enter the engine causing

excess wear and engine damage.

Inspect this without fault, before and after each race or session.

Clean if necessary.

Cleaning the air filter

WARNING

Clean the filter in a well-ventilated zone and ensure that there are

no sources of naked flame or sparks near the work area (including

the focus of a powerful light). Do not use petrol to clean the filter as

this could result in an explosion.

(A)

(B)

Stuff a clean, lint-free towel into the intake manifold so that no dirt

is allowed to enter.

CAUTION

Do not spin the filter on its cage. It is possible to tear or damage the

filter.

- Clean inside the filter housing using a damp cloth.

Remove the cage (B)

from the air filter (A).

-21-

- Clean the filter in a

filter bath using a soft

brush.

- Squeeze it and take it

out with a clean cloth.

- Check the air filter for damage such as scraping, hardening, shrinkage

If it is damaged then replace otherwise dirt will enter the throttle body.

- Grease all of the connections and bolts of the air filter and inlets.

– Install the filter in the

cage and cover the filter

lip (A) with a thick layer

of grease to ensure a

seal and to avoid dust

penetration.

- Fit the air filter to the motorcycle and ensure that it is correctly

connected.

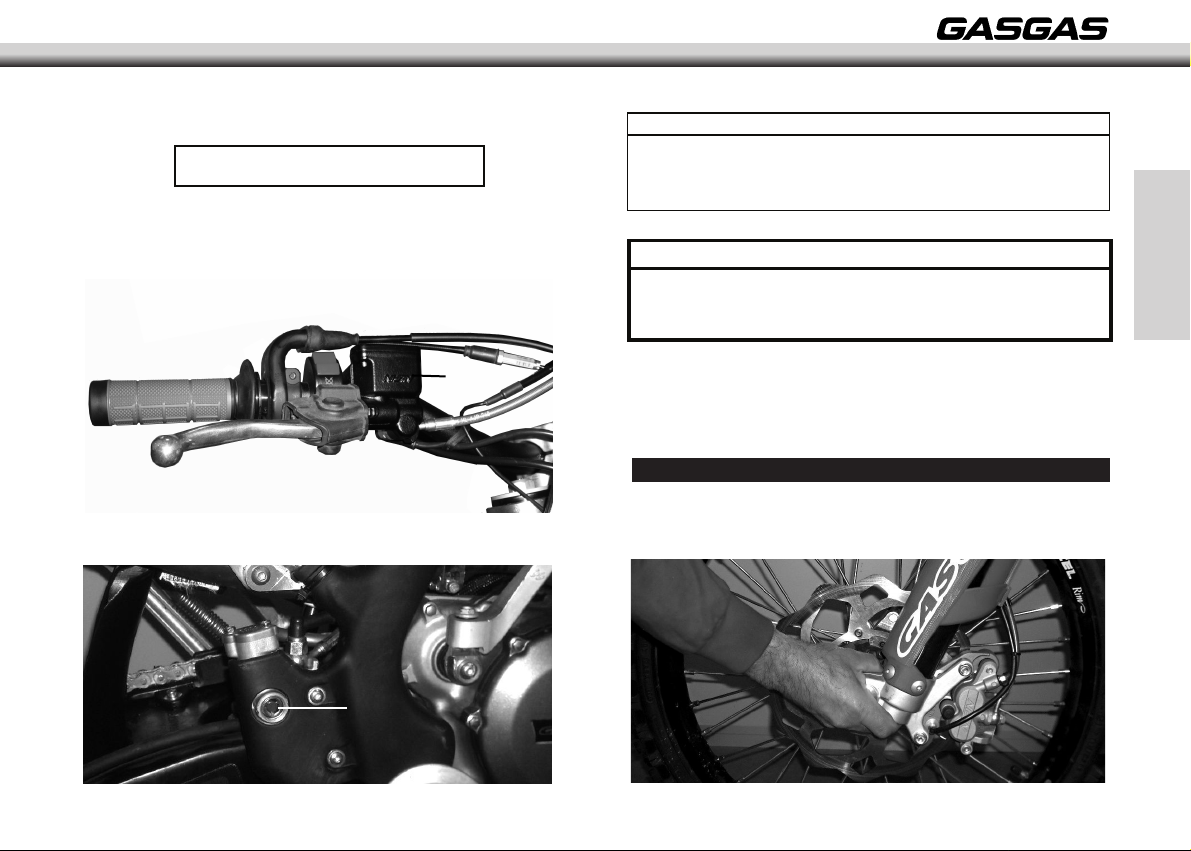

THROTTLE CABLE

- Check that the throttle grip turns smoothly

- Check that the throttle grip has 2-3 mm of play.

- If the clearance is incorrect, pull out the rubber protection from the

tensioner (A), unlock the locknut (B) and adjust the tolerance with

the tensioner. Lock after the locknut and push the rubber protection

on it.

(C)

- If the play can not be

established by adjusting

the cable, remove the

cable protection from the

throttle, adjust this using a

tensioning device at the

end of the cable, tighten

the lock nut and refit the

protection.

NOTES:

Before the cable adjustment, you must adjust the idle.

WARNING:

After the adjustment, start the engine and turn the handlebar left

and right at the maximum, to check if the idle increase.

(D)

(A). Adjustment.

(B). Lock nut.

(C). Throttle grip.

(D). Brake fluid reservoir.

(A)

(B)

-22-

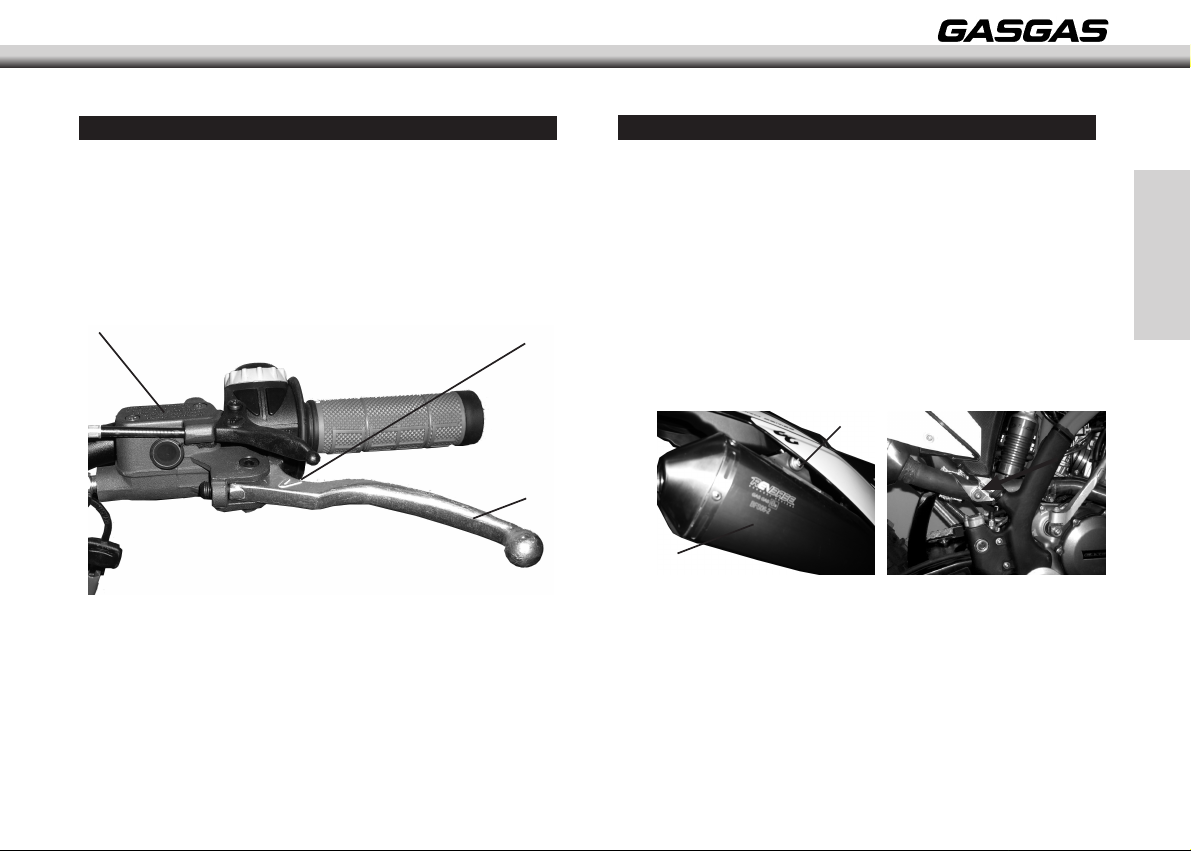

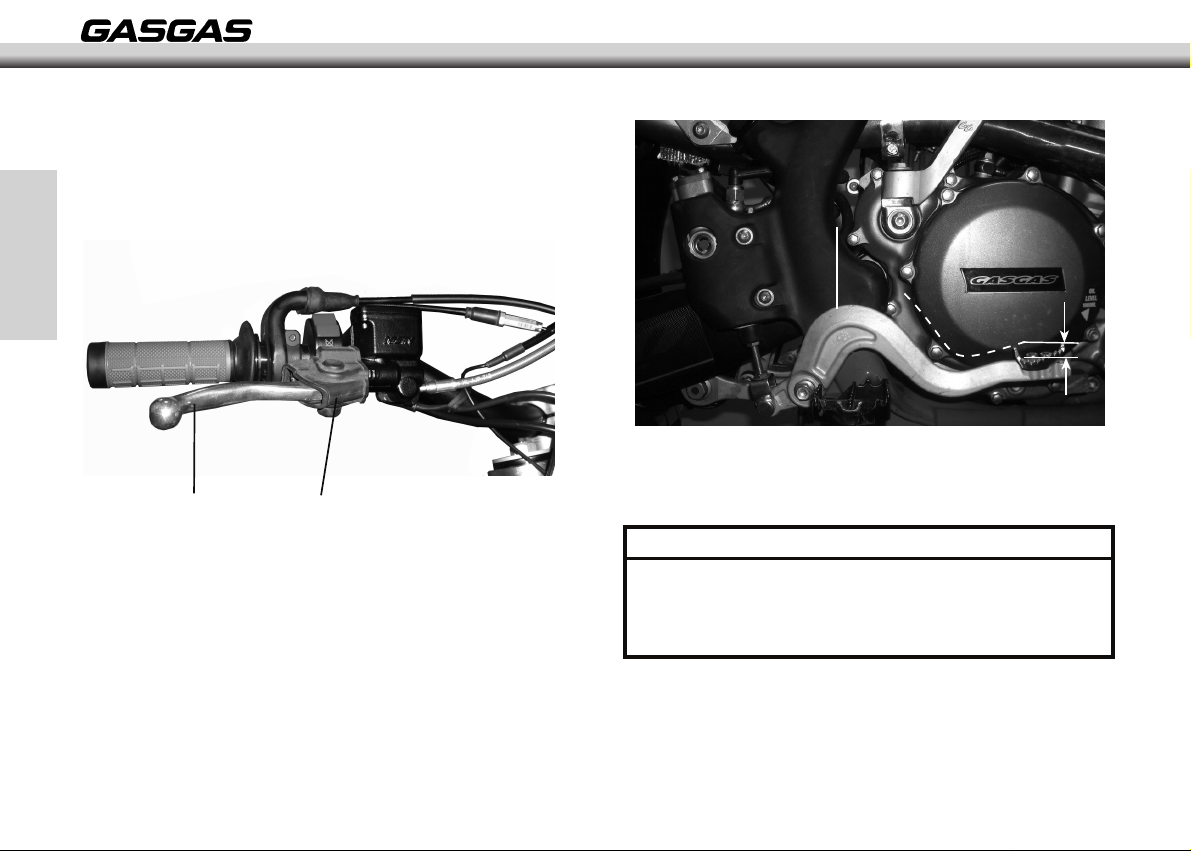

CLUTCH

THE EXHAUST SYSTEM

Proper clutch lever play is 2-3 mm. Play increases with the clutch

wear and thus requires adjustment.

When there is too much play, first try to adjust the level of the clutch

lever.

Tighten the adjustment bolt to obtain the optimal play.

(C)

(B)

(A)

(A). Clutch Lever.

(B). Clutch cylinder piston rod.

(C). Hydraulic fluid tank.

If the adjustment of the clutch lever has reached its limit, then play

must be adjusted by the clutch cylinder piston rod.

The exhaust and the silencer reduce noise and carry the gasses

away from the driver.

If the exhaust is damaged, rusted, dented or split then change it.

Change the silencer packing if the noise begins to be too loud or if

the engine performance drops.

Changing the silencer

- Release the exhaust flange.

(B)

(A)

(A). Silencer.

(B). Silencer attachment bolts.

-23-

Changing the silencer packing

(A)

- Remove the cover rivets (A).

- Extract the silencer cover (B).

- Pull out the inner silencer.

- Change the silencer packing by wrapping around the inner tube.

- Refit the assembly.

WARNING

A chain that breaks or jumps off the sprockets could snag on the

engine sprocket or lock the rear wheel, severely damaging the

motorcycle and causing it to go out of control.

Checking tension

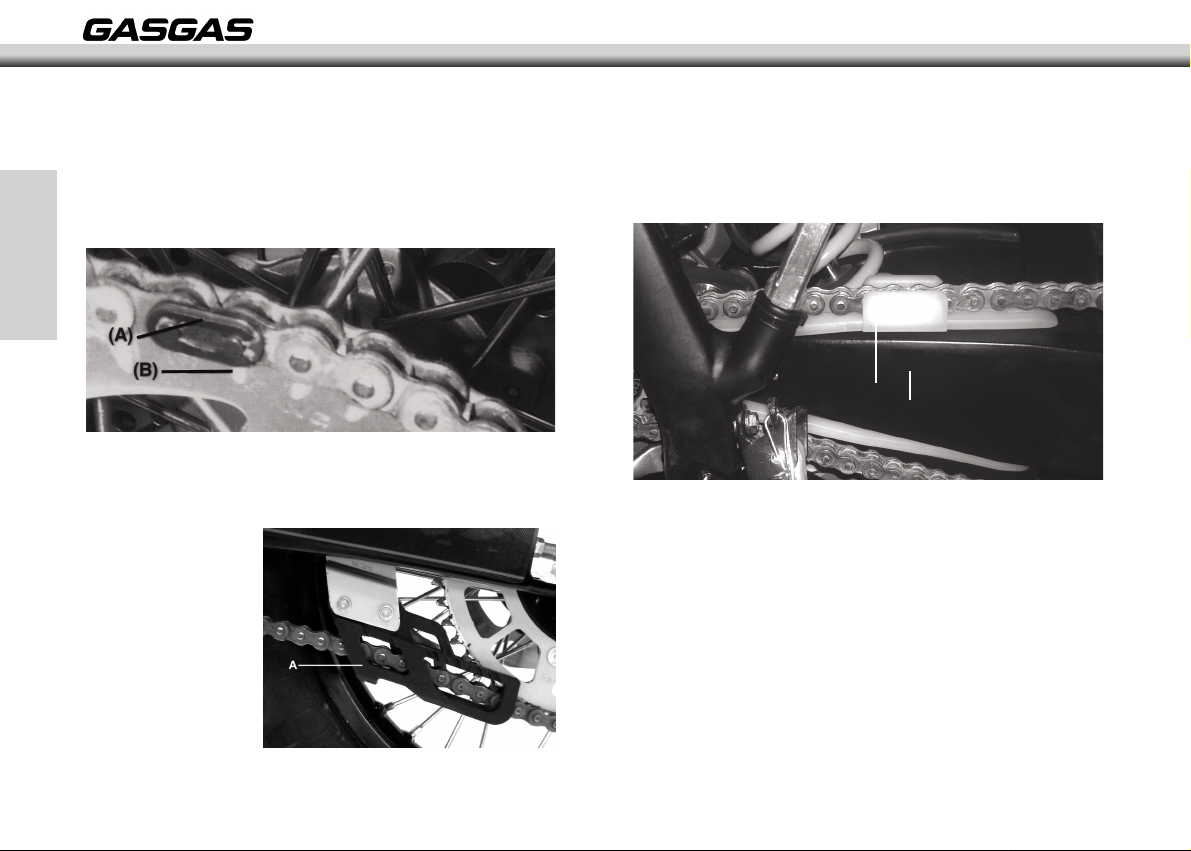

(A)

(B)

(A). Rivets.

(B). Cover.

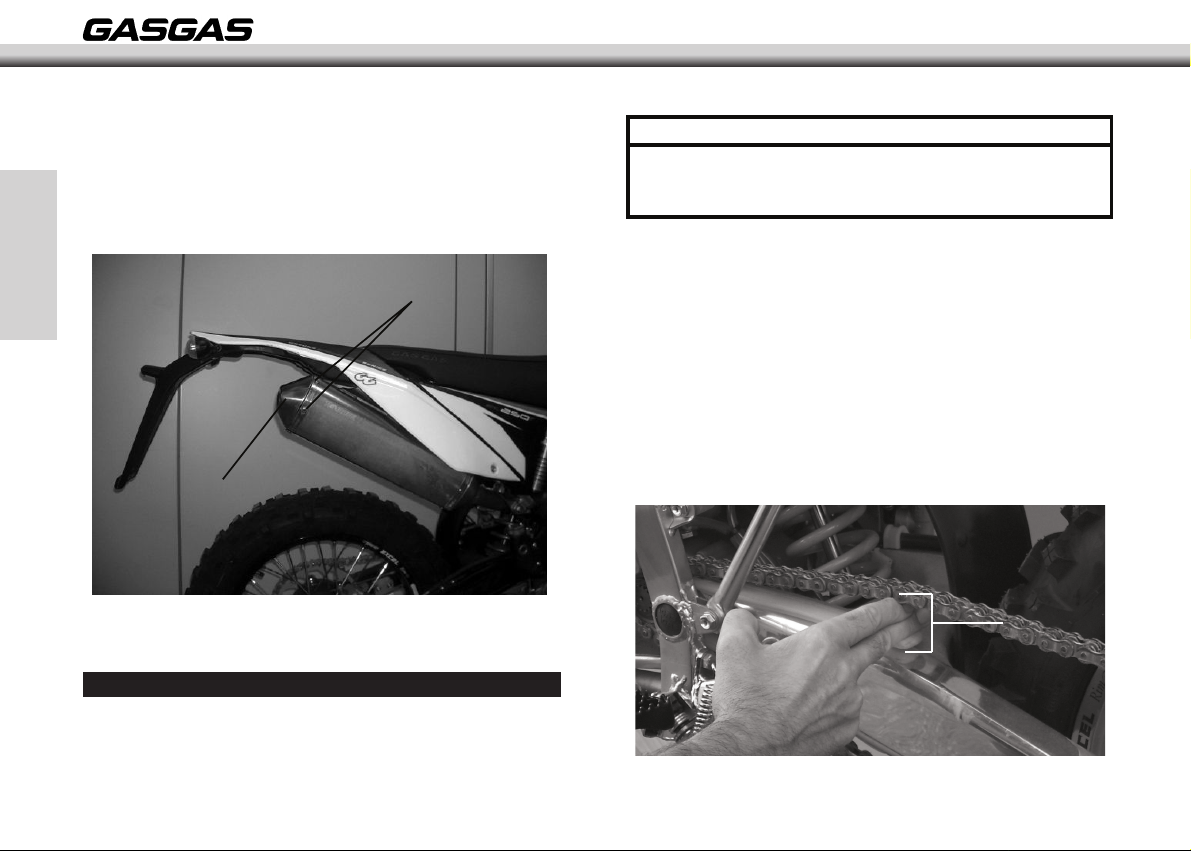

CHAIN GUIDE

The drive chain must be checked, adjusted, and lubricated in

accordance with the Periodic Maintenance table in order to prevent

excessive wear. If the chain is worn or badly adjusted (to tight or

loose) then it may jump off the sprockets or break.

The space between the chain and the swing arm at the rear of the

chain slider should be 30-50 mm. Rotate the rear wheel to find the

place where the chain is tightest. Adjust the drive chain if it has

too much or too little slack.

NOTE

In muddy or humid conditions, the mud gets inside the chain

increasing tension and may cause the chain to break. To prevent

this, adjust the chain to 30-50 mm of space between the chain

and rocker arm whenever necessary.

(A). 30 - 50 mm.

-24-

In addition to checking the slack, rotate the rear wheel to inspect

the drive chain and sprockets for damaged rollers, loose pins and

links, unevenly or excessively worn and damaged teeth.

Wheel alignment can also be checked using the straightedge

NOTE

or string method.

TENSION ADJUSTMENT

-Loosen the rear axle nut.

- Turn the nuts on the chain adjusting bolts evenly until there is 3050 mm of space between the chain and the swing arm. To keep the

chain and wheel aligned, the adjustment on the left of the chain

should be equal to that on the right.

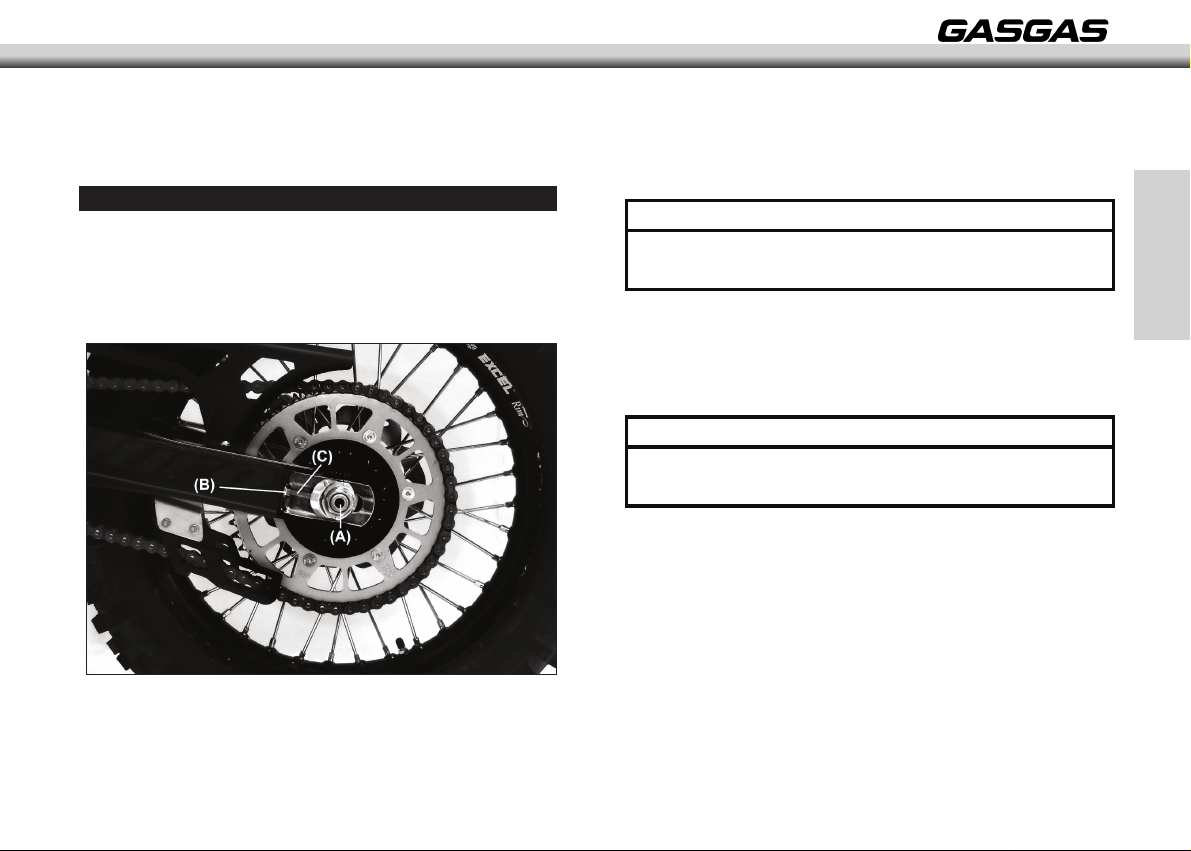

(C)

(B)

(A)

(A). Rear axle.

(B). Adjustment nut.

(C). Chain adjustment.

WARNING

Misalignment of the wheel will result in abnormal wear and may

result in an unsafe riding condition.

- Tighten the chain adjustment nuts.

- Tighten the axle nut to 98 N-m.

- Rotate the wheel, measure the chain slack again at the tightest

position, and readjust if necessary.

WARNING

If the axle nut is not securely tightened unsafe riding conditions

may result.

Drive chain, chain guide, chain slide, and rear sprocket

When the chain has worn so much that it is more than 2% longer

than when new, it is no longer safe for use and should be replaced.

Whenever the chain is replaced, inspect both the engine pinion and

rear sprocket, and replace them if necessary. Worn teeth will cause

the chain to wear more quickly.

-25-

For maximum resistance and safety, a genuine part must be

(B)

NOTE

used for replacement.

To minimize any chance of the master link coming apart, the

master link clip must be installed with the closed end of the

«U» points in the direction of chain rotation.

(A). Clip.

(B). Chain direction of rotation.

Chain guide slide

Visually inspect the upper and lower part of the chain slider on the

swing arm. If this is worn then replace it.

(A)

Chain Wear Guide

Visually inspect

the drive chain wear

guide (A); If the guide

is worn excessively

or damaged, replace it.

(A). Chain guide slide.

(B). Rocker arm.

Pinion and sprocket teeth wear

Visually inspect the pinion and sprocket teeth.

If they are worn or damaged, replace the pinion or sprocket.

Lubrication

Lubrication is necessary after riding through rain or in the mud, or

any time that the chain appears dry. A heavy oil is preferred to a

lighter oil because it will stay on the chain longer and provide better

lubrication.

-26-

Apply oil to the side of the links so that it will penetrate better. Wipe

(A)

off any excess oil.

(A) (A)

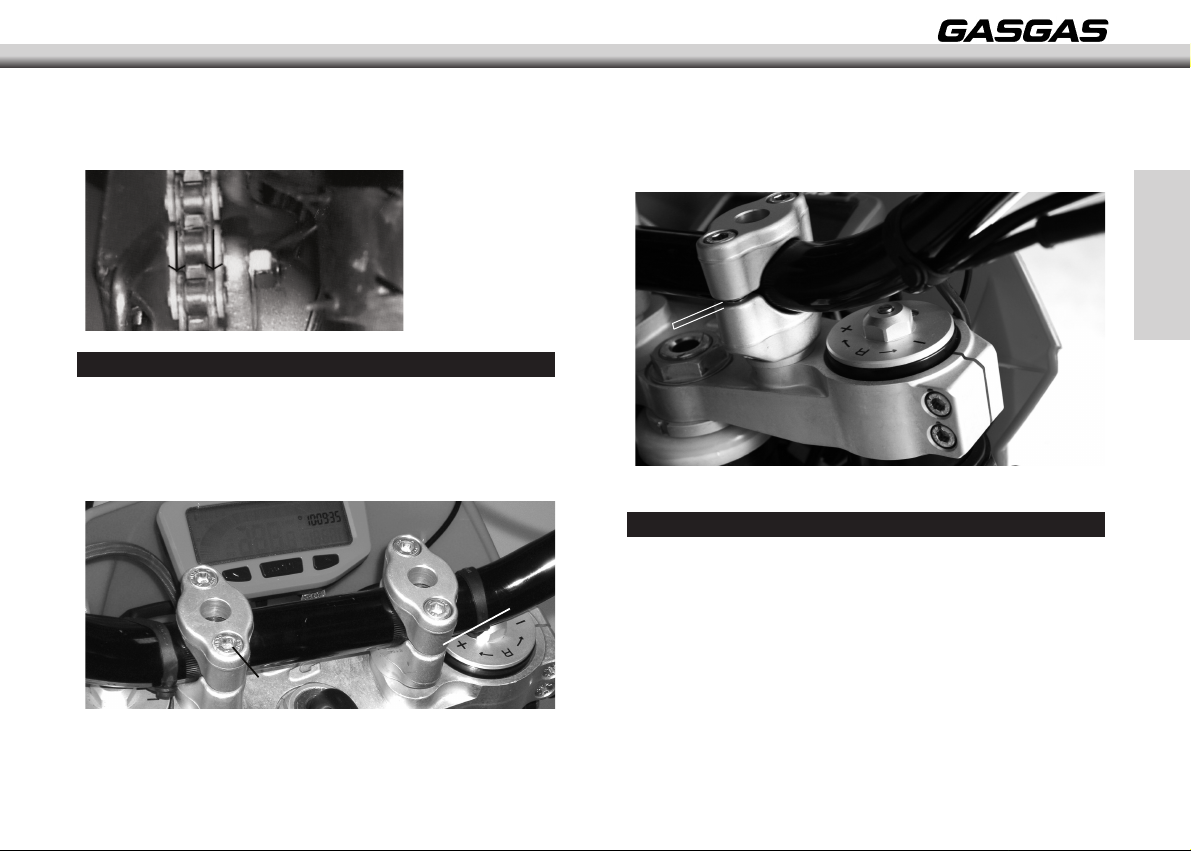

Tighten the bolts securely; first the forward bolts then the rear, to a

torque of 25 Nm. If the handlebar is correctly installed, there will be

a minimal gap at the front and rear of the clamp after tightening (A).

(A). Apply oil.

HANDLEBARS

To suit various riding positions, the handlebar position can be adjusted

front to rear.

Handlebar position adjustment

(A)

(B)

Loosen the handlebar holder bolts (B), of the handlebar holder (A)

then rotate bars to desired position.

(A)

BRAKES

Disc and disc pad wear is automatically compensated for and has

no effect on the brake lever or pedal action. So there are no parts

that require adjustment on the brakes except brake lever play and

the brake pedal position and play.

-27-

Front brake lever

Adjust brake lever to a comfortable position. To adjust, loosen the

nut under the rubber protection (B). Tighten after adjustment. Ensure

that the brake responds correctly.

(A)

(B)

(A). Brake pedal.

(B). 10 mm of play.

(A)

Rear brake pedal

When the brake pedal is in rest position, there should be a play of

10 mm. If not, then adjust this.

Ensure that the brake responds correctly and does not rub.

To adjust the pedal play, loosen the locknut, rotate the bolt and

retighten the locknut.

(B)

(A). Brake lever.

(B). Rubber protection.

WARNING

If the brake lever or pedal feels mushy when it is applied, there might

be air in the brake lines or the brake may be defective. Since it is

dangerous to operate the motorcycle under such conditions, check

the brakes immediately.

Brake fluid

Regularly check the brake fluid and periodically change it. It should

also be changed if it is contaminated by water or dirt.

-28-

(B)

Recommended liquid

Use D.O.T 3 or D.O.T 4

Fluid level inspection

The front (A) and rear (B) reservoirs must be kept more than half

full with brake fluid. If the amount of brake fluid is insufficient, add

brake fluid.

Do not spill brake fluid onto any painted surface. Do not use fluid

CAUTION

from a container that has been left open or that has been unsealed

for a long time. Check for fluid leakage around the fittings. Check

for brake line damage.

WARNING

Do not mix brands of fluid. Change the brake fluid in the brake line

completely if the brake fluid must be refilled with a type other than

the brake fluid already in the reservoirs.

(A)

Brake Wear Inspection

If the thickness of either pad is less than 1 mm, replace both pads

in the calliper as a set. Pad replacement should be done by an

authorized GAS GAS dealer.

STEERING

The steering should always be kept adjusted so that the handlebar

will turn freely but without excessive play.

-29-

Loading...

Loading...