Page 1

G1000

System Maintenance Manual

Hawker Beechcraft G36

Contains Instructions

For Continued Airworthiness

For STC SA1595WI-D

190-01259-00 January 2012 Rev. 5

Page 2

This page intentionally left blank

Page 3

© Copyright 2012

Garmin Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual

and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and

to print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of

this manual or revision must contain the complete text of this copyright notice and provided further that

any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Garmin International, Inc.

1200 E. 151

Olathe, KS 66062 USA

Telephone: 913-397-8200

www.garmin.com

Garmin (Europe) Ltd.

Liberty House

Bulls Copse Road

Hounsdown Business Park

Southampton, SO40 9RB, UK

Phone: +44 (0) 23 8052 4000

Fax: +44 (0) 23 8052 4004

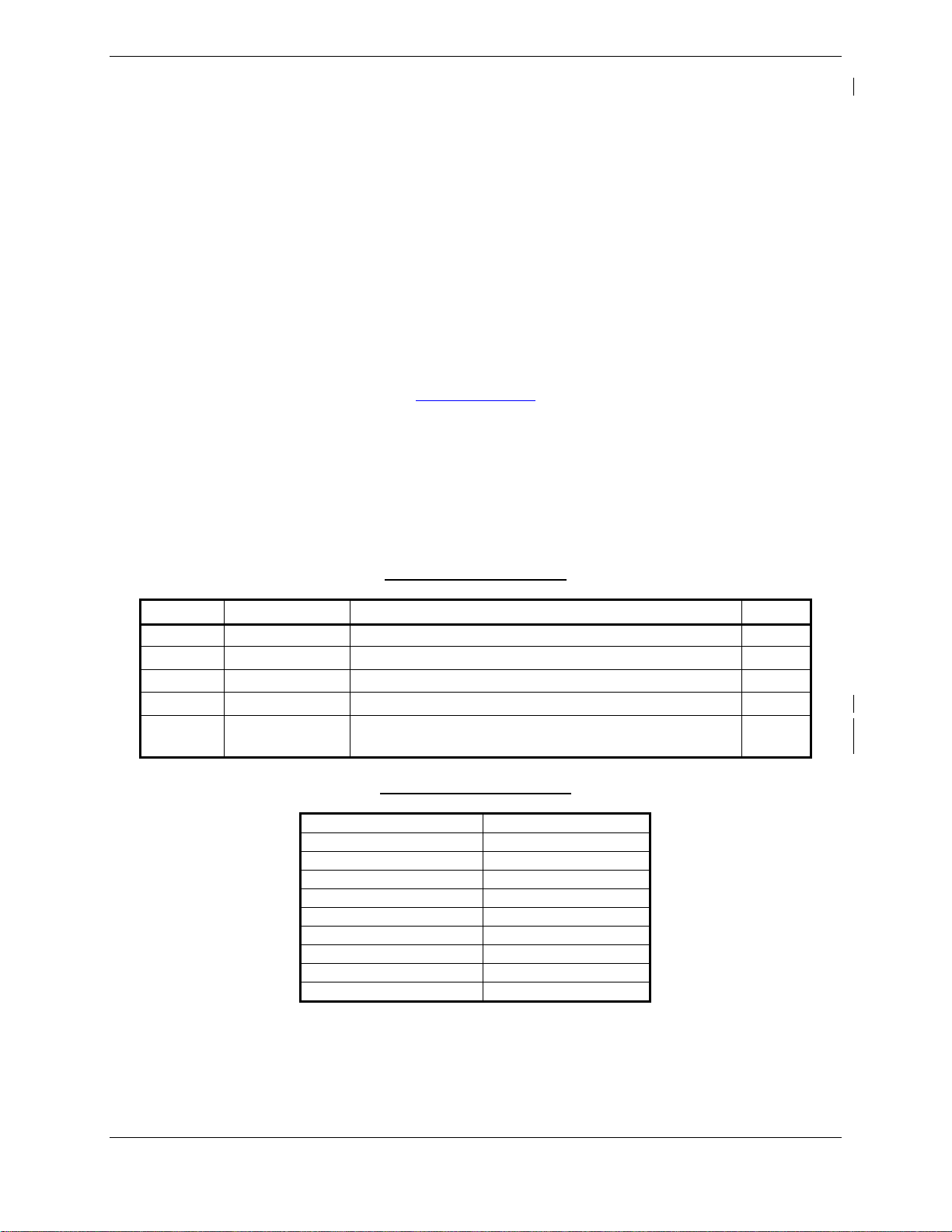

RECORD OF REVISIONS

Revision Revision Date Description ECO #

1 6/9/10 Initial release -----2 9/3/10 Updated Figure 3.10 75110

3 3/8/11 Revised to add -20 GIA63W 82831

4 9/21/11 Added UPDT CFG step to Section 3.7.2 85076

5 1/6/12

Added -09 software image and updated loader card

creation procedures in Section 3

DOCUMENT PAGINATION

Section Pagination

Table of Contents i – iv

Section 1 1-1 – 1-4

Section 2 2-1 – 2-6

Section 3 3-1 – 3-24

Section 4 4-1 – 4-6

Section 5 5-1 – 5-6

Section 6 6-1 – 6-6

Section 7 7-9 – 7-4

Section 8 8-1 – 8-11

st

Street

89692

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page A

Rev. 5 190-01259-00

Page 4

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration Regulations (“EAR”)

issued by the United States Department of Commerce (15 CFR, Chapter VII Subchapter C) and which

may not be exported, released or disclosed to foreign nationals inside or outside the United States

without first obtaining an export license. The preceding statement is required to be included on any and

all reproductions in whole or in part of this manual.

This product, its packaging, and its components contain chemicals known to the State of California to

cause cancer, birth defects, or reproductive harm. This Notice is being provided in accordance with

California's Proposition 65. If you have any questions or would like additional information, please refer to

our web site at www.garmin.com/prop65.

The GDU lens is coated with a special anti-reflective coating that is very sensitive to skin oils, waxes and

abrasive cleaners. CLEANERS CONTAINING AMMONIA WILL HARM THE ANTI-REFLECTIVE

COATING. It is very important to clean the lens using a clean, lint-free cloth and an eyeglass lens

cleaner that is specified as safe for anti-reflective coatings.

WARNING

CAUTION

All G1000 screen shots used in this document are current at the time of publication. Screen shots are

intended to provide visual reference only. All information depicted in screen shots, including software file

names, versions and part numbers, is subject to change and may not be up to date.

IMPORTANT

Page B G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 5

TABLE OF CONTENTS

PARAGRAPH PAGE

1 INTRODUCTION ................................................................................................................. 1-1

1.1 C

1.2 O

1.3 D

1.4 P

1.5 D

ONTENT, SCOPE, PURPOSE .......................................................................................... 1-1

RGANIZATION ............................................................................................................... 1-1

EFINITIONS/ABBREVIATIONS .......................................................................................... 1-2

UBLICATIONS ................................................................................................................ 1-3

ISTRIBUTION ................................................................................................................. 1-4

2 SYSTEM DESCRIPTION .................................................................................................... 2-1

2.1 E

2.2 O

QUIPMENT DESCRIPTIONS ............................................................................................. 2-1

PTIONAL FEATURES ...................................................................................................... 2-6

3 G1000 CONTROL & OPERATION ..................................................................................... 3-1

3.2 G1000

3.3 R

3.4 C

3.5 C

3.6 G1000

3.7 G1000

3.8 S

3.9 A

3.10 SVS

3.11 C

3.12 TAWS-B

3.13 A

3.14 C

NORMAL MODE ................................................................................................... 3-1

EVERSIONARY MODE .................................................................................................... 3-2

ONFIGURATION MODE OVERVIEW ................................................................................. 3-3

ONFIGURATION MODE NAVIGATION ............................................................................... 3-3

SOFTWARE INFORMATION .................................................................................... 3-5

SOFTWARE/CONFIGURATION PROCEDURE ......................................................... 3-10

OFTWARE LOAD CONFIRMATION .................................................................................. 3-16

VIATION DATABASE LOADING PROCEDURES ................................................................ 3-18

/ PATHWAYS ACTIVATION (OPTION)..................................................................... 3-19

HARTVIEW ENABLE PROCEDURE .............................................................................. 3-21

ENABLE PROCEDURE .................................................................................. 3-22

IRCRAFT REGISTRATION NUMBER ENTRY ................................................................. 3-23

LEARING DEFAULT USER SETTINGS ......................................................................... 3-23

4 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS ................................................... 4-1

4.1 A

4.2 S

4.3 M

IRWORTHINESS LIMITATIONS ......................................................................................... 4-1

ERVICING INFORMATION ................................................................................................ 4-1

AINTENANCE INTERVALS ............................................................................................... 4-3

5 TROUBLESHOOTING ........................................................................................................ 5-1

5.1 SVS/P

5.2 GTS

5.3 S

5.4 GRT

5.5 S

5.6 B

ATHWAYS TROUBLESHOOTING .............................................................................. 5-1

820 TROUBLESHOOTING ......................................................................................... 5-2

OFTWARE/CONFIGURATION TROUBLESHOOTING ............................................................ 5-3

10 / GRC 10 XM REMOTE CONTROL TROUBLESHOOTING ........................................ 5-4

YSTEM COMMUNICATION HIERARCHY ............................................................................ 5-4

ACKSHELL/BACKPLATE CONNECTORS ........................................................................... 5-5

6 EQUIPMENT REMOVAL & INSTALLATION ..................................................................... 6-1

6.1 GTS

6.2 GPA

6.3 TAS

6.4 GRT

6.5 GDU

6.6 GMU

6.7 GTX

6.8 GIA

820 TAS PROCESSOR ............................................................................................ 6-1

65 LNA/PA ............................................................................................................ 6-2

ANTENNAS .............................................................................................................. 6-2

10 XM REMOTE CONTROL TRANSCEIVER................................................................. 6-3

REMOVAL & REPLACEMENT .................................................................................... 6-4

44 REMOVAL & REPLACEMENT .............................................................................. 6-5

33ES TRANSPONDER REMOVAL & REPLACEMENT ................................................... 6-6

63W REMOVAL & REPLACEMENT ............................................................................. 6-7

7 G1000 EQUIPMENT CONFIGURATION & TESTING ........................................................ 7-9

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page i

190-01259-00 Rev. 5

Page 6

7.1 TRANSPONDER TESTING ................................................................................................. 7-9

7.2 GTS

TRAFFIC SYSTEM .................................................................................................... 7-9

8 SYSTEM RETURN TO SERVICE PROCEDURE ............................................................... 8-1

8.1 D

8.2 GIA

8.3 GFC

8.4 M

ISPLAY TESTING ........................................................................................................... 8-1

63W INTEGRATED AVIONICS UNIT ............................................................................ 8-6

700 AUTOPILOT GROUND CHECKS .................................................................. 8-8

AINTENANCE RECORDS .............................................................................................. 8-13

Page ii G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 7

LIST OF ILLUSTRATIONS

FIGURE PAGE

Figure 2.1. Display Unit .............................................................................................................. 2-1

Figure 2.2. Transponder ............................................................................................................ 2-2

Figure 2.3. Magnetometer .......................................................................................................... 2-2

Figure 2.4. GTS Receiver .......................................................................................................... 2-3

Figure 2.5 GPA 65 PA/LNA Module .......................................................................................... 2-3

Figure 2.6 G36 Traffic Antenna ................................................................................................. 2-4

Figure 2.7 GRT 10 Transceiver ................................................................................................ 2-4

Figure 2.8 GRC 10 Remote Control .......................................................................................... 2-5

Figure 2-9 GIA unit ..................................................................................................................... 2-5

Figure 3.1 - G1000 Softkeys ...................................................................................................... 3-1

Figure 3.2 - Normal Mode (with SVS enabled) .......................................................................... 3-2

Figure 3.3 - Normal Mode (without SVS enabled) ..................................................................... 3-2

Figure 3.4 - Display Reversionary Mode .................................................................................... 3-2

Figure 3.5, Configuration Status ............................................................................................... 3-4

Figure 3.6, Data Transmission Indicators ................................................................................. 3-4

Figure 3.8, Software/Configuration Overview ......................................................................... 3-10

Figure 3.9 - Configuration/Software Load Page ....................................................................... 3-13

Figure 3.10 - Option Selection ................................................................................................. 3-14

Figure 5.1 - GTS 820 Mating Connector .................................................................................... 5-5

Figure 5.2 - GTS 820 Mating Connector .................................................................................... 5-5

Figure 5.3 - GPA 65 Connector ................................................................................................. 5-6

Figure 5.4 - GRT 10 Mating Connector ..................................................................................... 5-6

Figure 6.1 - Battery Compartment ............................................................................................. 6-3

Figure 8.1 – MFD Initial Power Up page (format reference) ...................................................... 8-1

Figure 8.2 – PFD Power Up System Annunciations .................................................................. 8-2

Figure 8.3 – Normal Display (without SVS enabled) .................................................................. 8-2

Figure 8.4 – Normal Display (with SVS enabled) ....................................................................... 8-3

Figure 8.5 – PFD Display without SVS enabled ........................................................................ 8-4

Figure 8.6 – PFD with SVS enabled .......................................................................................... 8-5

Figure 8-7, AUX – GPS STATUS Page (MFD) ......................................................................... 8-6

Figure 8.8 - GFC 700 Pre-Flight Test ........................................................................................ 8-9

LIST OF TABLES

TABLE PAGE

Table 1.1 - Required Documents .............................................................................................. 1-3

Table 1.2 - Reference Publications ............................................................................................ 1-3

Table 3.1 - Required Loader Cards ........................................................................................... 3-5

Table 3.2 – SVS Enable Card .................................................................................................. 3-19

Table 4.1 - Maintenance Intervals .............................................................................................. 4-3

Table 5.1 – SVS Troubleshooting .............................................................................................. 5-1

Table 5.2 – SVS Alert Messages ............................................................................................... 5-2

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page iii

190-01259-00 Rev. 5

Page 8

This page intentionally left blank

Page iv G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 9

1 INTRODUCTION

1.1 Content, Scope, Purpose

This document provides Instructions for Continued Airworthiness (ICA) for the Garmin G1000

integrated avionics as installed in the Hawker Beechcraft G36 as modified under STC

SA1595WI-D. This document satisfies the requirements for continued airworthiness as defined

by 14 CFR Part 23.1529 and Appendix G. Information in this document is required to maintain

the continued airworthiness of the G1000. This document is intended to be used in conjunction

with the existing Hawker Beechcraft Bonanza 36 Maintenance Manual and the Hawker

Beechcraft Bonanza (Model G36) Maintenance Manual Supplement listed in Table

1.1.

1.1.1 Applicability

This document applies to all G36 aircraft that have been modified in accordance with STC

SA1595WI-D. The data defining this modification is contained in the Master Drawing List 00500620-18.

Modification of an aircraft by this Supplemental Type Certificate (STC) obligates the aircraft

operator to include the maintenance information provided by this document in the operator’s

Aircraft Maintenance Manual and the operator’s Aircraft Scheduled Maintenance Program.

1.2 Organization

The following outline briefly describes the organization of this manual:

Section 2: System Description

Provides a complete description of the type design change associated with updating the G1000

system in the Hawker Beechcraft G36 .

Section 3: G1000 Control & Operation

Presents basic control and operation information specifically tailored to maintenance practices.

Basic G1000 Configuration Mode operation is also described.

Section 4: Instructions for Continued Airworthiness

Provides maintenance instructions for continued airworthiness of the G1000 systems.

Section 5: Troubleshooting

Provides troubleshooting information to aid in diagnosing and resolving potential problems with

the G1000.

Section 6: G1000 Equipment Removal & Replacement

Gives instructions for the removal and replacement of G1000 equipment associated with this

modification.

Section 7: G1000 Equipment Configuration & Testing

Gives instructions for loading software, configuring, and testing of G1000 equipment.

Section 8: System Return to Service Procedure

Specifies return-to-service procedures to be performed upon completion of maintenance of the

G1000 system.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 1-1

190-01259-00 Rev. 5

Page 10

1.3 Definitions/Abbreviations

AFCS: Automatic Flight Control System

CFR: Code of Federal Regulations

DME: Distance Measuring Equipment

VHF: Very High Frequency

AC: Advisory Circular

AFMS: Airplane Flight Manual Supplement

FPGA: Field Programmable Gate Array

FPM: Flight Path Marker

HSDB: High Speed Data Bus

GDU: Garmin Display Unit

GDC: Garmin Air Data Computer

GTS: Garmin Traffic System

GRT: Garmin Remote Transceiver

GTX: Garmin Transponder

GDL: Garmin Datalink

GMU: Garmin Magnetometer

GA: Garmin Antenna

GIA: Garmin Integrated Avionics

GMA: Garmin Audio Panel

GPS: Global Position System

GRS: Garmin AHRS

HSI: Horizontal Situation Indicator

LCD: Liquid Crystal Display

LRU: Line Replaceable Unit

MDL: Master Drawing List

MFD: Multi-Functional Display

PFD: Primary Flight Display

STC: Supplemental Type Certificate

SVS: Synthetic Vision System

TCAS: Traffic Collision Avoidance System

TAWS: Terrain Awareness and Warning System

WAAS: Wide Area Augmentation System

1.3.1 Units of Measure

Unless otherwise stated, all units of measure are English units.

Page 1-2 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 11

1.4 Publications

The following documents are required by this maintenance manual to perform maintenance. It

is the responsibility of the owner / operator to ensure latest versions of these documents are

used during operation, servicing or maintenance of the airplane.

Table 1.1 - Required Documents

P/N Description

005-00620-06 General Arrangement, G1000 Update with Options, G36

005-W0225-00 Wiring Diagram, Optional GRT 10, Hawker Beechcraft G36 Update

005-W0224-00 Wiring Diagram, Optional GTS 820, Hawker Beechcraft G36 Update

005-00620-07 GRT 10 Equipment Install, Hawker Beechcraft G36

005-00620-08 GTS 820 Equipment Install, Hawker Beechcraft G36

005-00620-09 GTS 820 Wire Harness Installation, Hawker Beechcraft G36

005-00620-10 GRT 10 Wire Harness Installation, Hawker Beechcraft G36

320-00609-XX Harness and Coax Fabrication, GTS 820 Option, Hawker Beechcraft G36

320-00610-XX Harness Fabrication, GRT 10 Option, Hawker Beechcraft G36

36-590001-11B *

(or subsequent

revision)

36-590001-15C *

(or subsequent

revision)

36-590001-9C1 *

(or subsequent

revision)

Hawker Beechcraft Bonanza (Model G36) Maintenance Manual

Supplement for Airplanes with Garmin G1000 Equipment Installed

Hawker Beechcraft Bonanza G36 Avionics Wiring Diagram Manual

Hawker Beechcraft Bonanza (A36/B36TC/G36) Maintenance Manual

* Hawker Beechcraft document

The following publications are recommended to be on hand during the performance of

maintenance activities.

Table 1.2 - Reference Publications

P/N Description

FAA Approved Airplane Flight Manual Supplement, G1000 Integrated

190-01258-00

190-00525-03 Cockpit Reference Guide for the Hawker Beechcraft G36

190-01257-00 Post Installation Checkout Procedures Hawker Beechcraft G36

Avionics Update with Options Including Synthetic Vision/Pathways on

Hawker Beechcraft G36

190-00355-04 GDL 69/69A XM Satellite Radio Activation Instructions

190-00907-00 G1000 System Maintenance Manual

190-00587-00 GTS 8XX/GPA 65 Installation Manual

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 1-3

190-01259-00 Rev. 5

Page 12

Generic installation manuals for individual Garmin LRUs are also available through the ‘Dealers

Only’ section of the Garmin web site; refer to Section 1.5 for details.

1.5 Distribution

This document is required for maintaining the continued airworthiness of the aircraft. When this

document is revised, every page will be revised to indicate current revision level.

Garmin Dealers may obtain the latest revision of this document on the Garmin Dealer Resource

Center website.

Owner/operators may obtain the latest revision of this document from the https://fly.garmin.com/

Support page, or by contacting a Garmin dealer, contacting Garmin Product Support at 913397-8200, toll free 866-739-5687, or using around the world contact information on

https://fly.garmin.com/.

A Garmin Service Bulletin describing the revision to this document will be sent to Garmin

dealers if the revision is determined to be significant.

Page 1-4 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 13

2 SYSTEM DESCRIPTION

2.1 Equipment Descriptions

The following subparagraphs provide a brief description and picture of each Garmin LRU installed

or replaced by this STC. For all other G1000/GFC 700 LRUs, refer to the Hawker Beechcraft

Bonanza (Model G36) Maintenance Manual Supplement for Airplanes with Garmin G1000

Equipment Installed listed in Table 1.1.

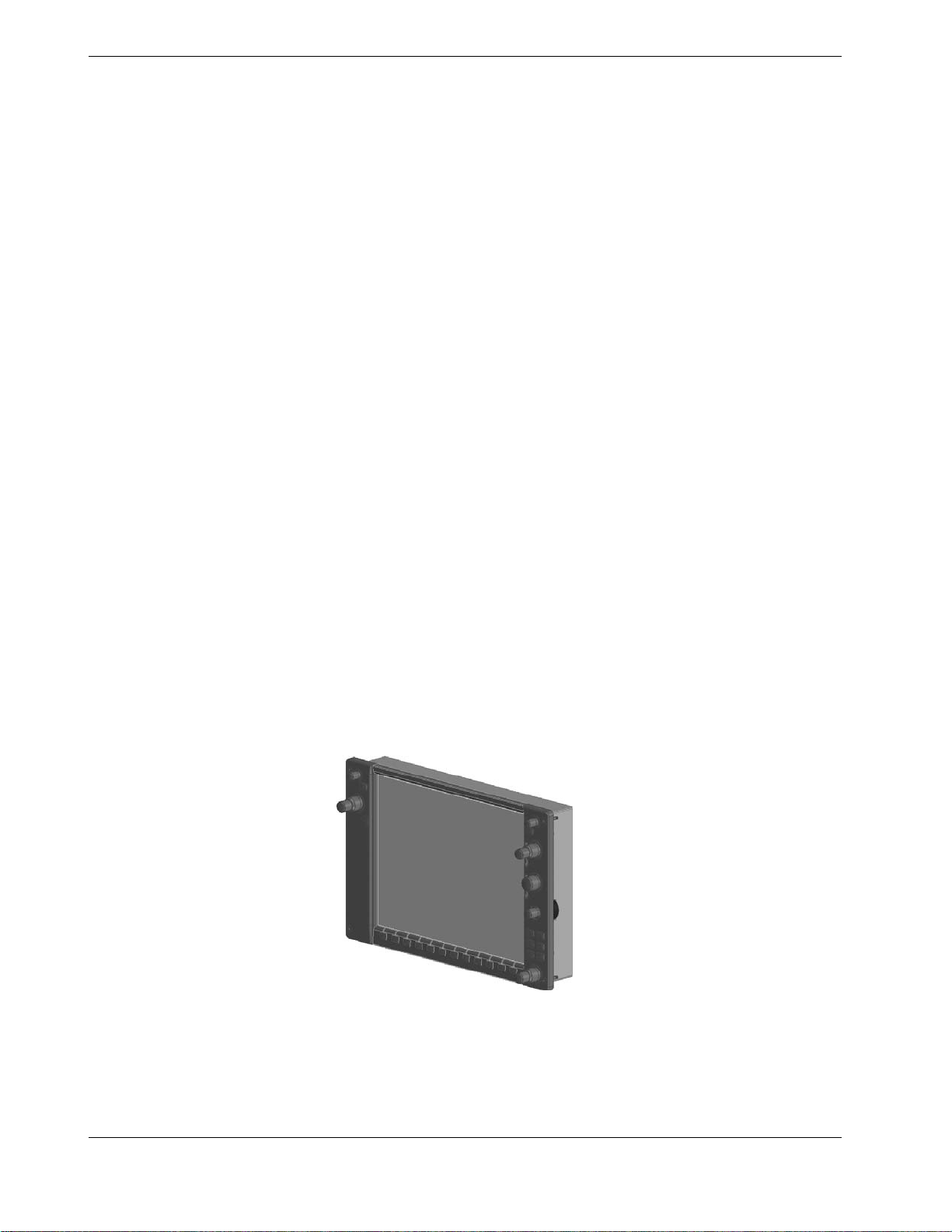

2.1.1 GDU 1040 PFD & GDU 1045 MFD

One Garmin GDU 1040 display and one GDU 1045 display is installed in the Bonanza instrument

panel. The GDU 104X units, 10.4 inch LCD displays with 1024x768 resolution, are configured as

PFD and an MFD. Both displays provide control and display of nearly all functions of the G1000

integrated cockpit system. The PFD is located on the left side of the MFD.

The GDU 1045 communicates with the GDU 1040, and the GDL 69A through a high-speed data

bus (HSDB) Ethernet connection. The GDU 1045 also communicates with the GTS 820 through

the HSDB via the GDL 69A. The GRS 77 and GDC 74A send information to the GDU 1045 via

ARINC 429 data bus. The display units communicate with each other and the GIA 63W units

through a high-speed data bus (HSDB) Ethernet connection.

This STC installation approves alternate part numbers for these displays that accept external video

input and have an additional HSDB Ethernet connection. There are no mechanical or electrical

interface changes needed for these new part number displays. Refer to the General Arrangement

Drawing 005-00620-06 listed in Table 1.1 for part number information.

NOTE

While the alternate part numbers of displays authorized by this STC include an

external video input and HDSB Ethernet connection, this STC does not approve any

interfaces to these ports. Any interfaces to these ports will require additional

airworthiness approvals.

Figure 2.1. Display Unit

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 2-1

190-01259-00 Rev. 5

Page 14

2.1.2 GTX 33 Transponder

The Garmin GTX 33 transponder communicates with the on-side GIA 63W through RS-232 digital

interface. This STC provides for the optional installation of a GTX 33ES transponder that provides

extended squitter functionality. The unit is mounted on the back side of the instrument panel.

There are no mechanical or electrical interface changes needed GTX 33ES option and is installed

in place of the existing GTX 33 if selected. Refer to the General Arrangement Drawing 00500620-06 listed in Table 1.1 for part number information.

Figure 2.2. Transponder

2.1.3 GMU 44 Magnetometer

The GMU 44 provides horizontal and vertical magnetic field information to the GRS 77 AHRS.

This allows heading to be calculated and provides assistance during AHRS alignment. The

GMU 44 unit is mounted in L/H wing tip. This STC approved an alternate part number of the

GMU 44. There are no mechanical or electrical interface changes needed for the new

magnetometer and it is installed in place of the existing part if selected. Refer to the General

Arrangement Drawing 005-00620-06 listed in Table 1.1 for part number information.

Figure 2.3. Magnetometer

Page 2-2 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 15

2.1.4 GTS 820 Traffic System

The optional GTS 820 system is designed to use active interrogations of Mode S and Mode C

transponders to provide Traffic Advisories (TA) to the pilot. Passive surveillance is available only

when installed with a GTX 33 with extended squitter. Traffic is displayed on the MFD via Ethernet

High Speed Data Bus routed through the existing GDL 69A. The GTS receiver is installed at FS

190. It is powered from the 5 amp Traffic Alert circuit breaker fed from the 28 Vdc Avionics bus.

The GPA 65 is a power amplifier / low noise amplifier (PA/LNA) module installed between the top

antenna and the GTS receiver just forward of FS 140 behind the headliner. A top GA 58 antenna

is installed on the top of the aircraft just forward of FS 106.25. A lower GA 58 antenna is installed

on the bottom of the aircraft between FS 131.00 and FS 151.00.

Figure 2.4. GTS Receiver

Figure 2.5 GPA 65 PA/LNA Module

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 2-3

190-01259-00 Rev. 5

Page 16

Figure 2.6 G36 Traffic Antenna

2.1.5 XM remote control system

The optional XM remote control system consists of the GRT 10 transceiver and the GRC Remote

Control. This system allows for remote control of the XM satellite radio function provided by the

existing GDL 69A. The GRT 10 is installed behind the instrument panel on the top of the MFD

system rack. It is powered from the existing 3 amp Datalink circuit breaker off the 28 Vdc Avionics

Bus.

Figure 2.7 GRT 10 Transceiver

Page 2-4 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 17

Figure 2.8 GRC 10 Remote Control

2.1.6 GIA 63W Integrated Avionics Unit (2)

Two Garmin GIA 63W Integrated Avionics Units (IAUs) contain the VHF COM/NAV receivers,

WAAS GPS receiver, Flight Director, and system integration microprocessors. The GIAs also

serve as a communication interface to all other G1000 LRUs in the system. Each GIA 63W

communicates directly with the on-side GDU display using a HSDB Ethernet connection. Both

GIAs are mounted in the systems rack behind the MFD.

GIA 1 is powered through Bus 2 and immediately powers up when the battery 1 or Battery 2

master switch is turned on. GIA #2 receives power through the Avionics Bus and powers up when

the avionics master switch is turned on.

Figure 2-9 GIA unit

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 2-5

190-01259-00 Rev. 5

Page 18

2.2 Optional features

The following optional features are included with this STC. These features are enabled via

individual Enable cards that are to be retained with the aircraft.

• Synthetic Vision and Pathways

• TAWS-B

• Chartview

These features will need to be re-enabled after replacement of a display unit.

Page 2-6 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 19

3 G1000 CONTROL & OPERATION

All control and operation of G1000 equipment as normally used in flight occurs through the PFD,

MFD, and GMA audio panel.

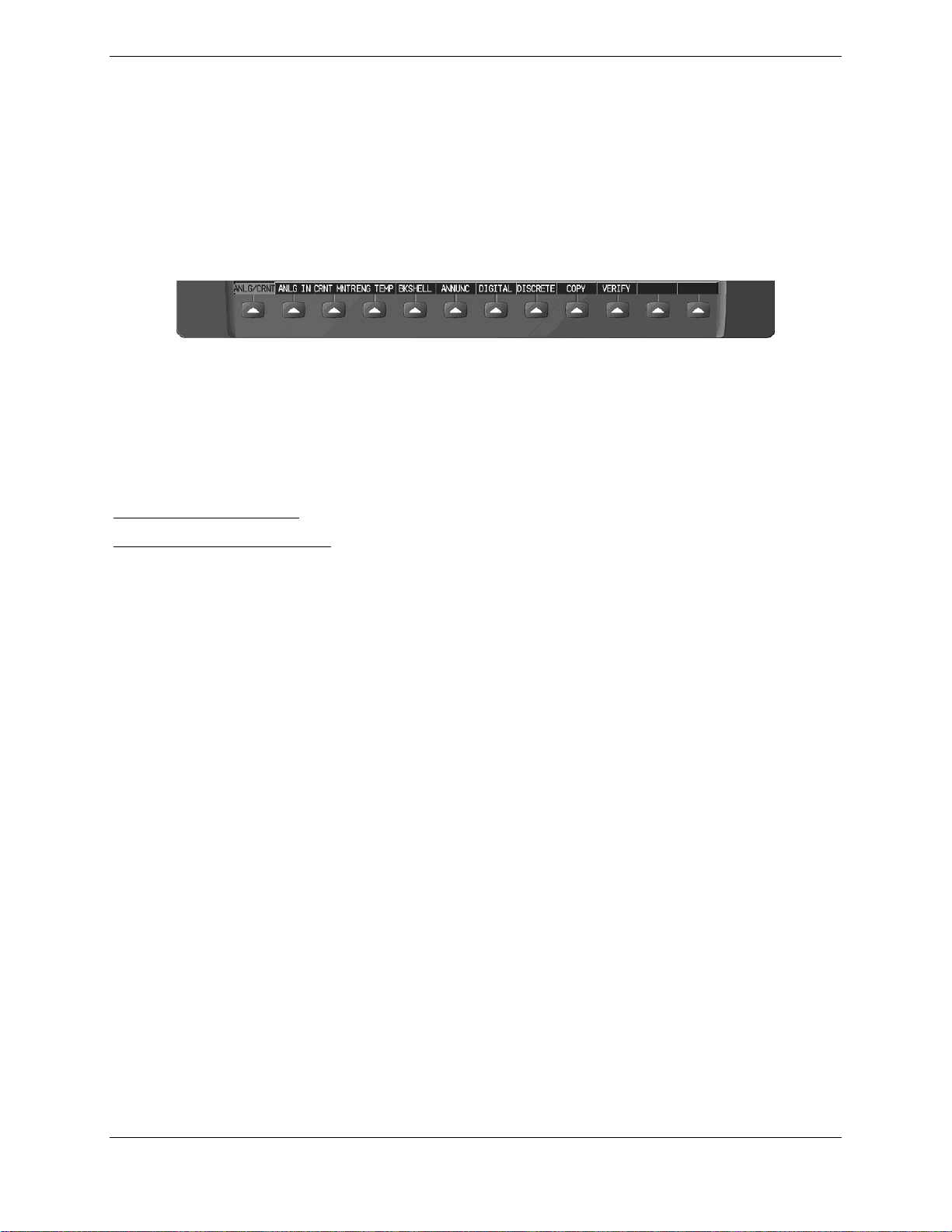

3.1.1 Softkeys

Some pages have commands or selections that are activated by the GDU softkeys. If a softkey

is associated with a command, that command will be displayed directly above the key. A

grayed-out softkey shows a command that is unavailable. A softkey that is highlighted shows

the current active selection.

Figure 3.1 - G1000 Softkeys

3.1.2 FMS Knob

The FMS knob is the primary control for the G1000 system. Operation is similar to the Garmin

400/500 Series units.

To cycle through different configuration screens:

To change page groups:

To change pages in a group:

To activate the cursor for a page, press the small FMS knob directly in, as one would push a

regular button.

To cycle the cursor through different data fields, rotate the large FMS knob.

To change the contents of a highlighted data field, rotate the small FMS knob. This action

either brings up an options menu for the particular field, or in some cases allows the operator to

enter data for the field.

To confirm a selection, press the ENT key.

To cancel a selection, press the small FMS knob in again, deactivating the cursor. The CLR

key may also be used to cancel a selection or deactivate the cursor.

Rotate the large FMS knob.

Rotate the small FMS knob.

3.2 G1000 Normal Mode

To start the G1000 system in Normal Mode:

1. With a ground power unit connected to the external power receptacle, set the L and R BAT

switch to ‘ON’.

2. Set the AVIONICS MASTER switch to ‘ON’.

The G1000 system is now powered in the normal mode. In the normal operating mode, data

fields that are invalid have large red X’s through them. A valid field does not display a red X.

Allow the displays to initialize for approximately one minute. The PFD and MFD will function as

specified in the Cockpit Reference Guide for the Hawker Beechcraft G36 when the system has

been correctly installed and configured.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-1

190-01259-00 Rev. 5

Page 20

Figure 3.2 - Normal Mode (with SVS enabled)

Figure 3.3 - Normal Mode (without SVS enabled)

3.3 Reversionary Mode

Reversionary mode allows for display of information related to safe flight in the event of a

display communication or hardware failure. As installed in the G36, both manual and automatic

reversionary modes are possible. Manual reversionary mode allows the operator to force the

PFD or MFD into reversionary mode by pressing the large red button labeled ‘DISPLAY

BACKUP’ on the GMA audio panel. In addition to the manual mode, the system will detect

when a display failure has occurred and will put the still functioning display into reversionary

mode automatically.

NOTE

When the ‘DISPLAY BACKUP’ button is pushed to exit reversionary mode, there

is a 5-second debounce (or the GDU waits for 5 consecutive seconds) and then

returns to normal mode if no other input is received. If the ‘DISPLAY BACKUP’

button is pushed again during this 5-second interval, the timer will repeat the

count.

Figure 3.4 - Display Reversionary Mode

Page 3-2 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 21

3.4 Configuration Mode Overview

The Configuration Mode exists to provide the avionics technician with a means of configuring,

checking, and calibrating various G1000 sub-systems. Troubleshooting and diagnostics

information can also be viewed in this mode.

To start the system in Configuration Mode:

a. Press and hold the ENT key on the MFD while resetting power using the MFD circuit

breaker.

b. Release the ENT key after ‘INITIALIZING SYSTEM’ appears in the upper left corner of the

MFD.

c. Press the ENT key or the YES softkey to update system files if prompted.

d. Repeat steps a through c on the PFD using the PFD circuit breaker to apply power.

CAUTION:

The Configuration Mode contains certain pages and settings that are critical to

aircraft operation and safety. These pages are protected and cannot be

modified, unless the technician is properly authorized and equipped. However,

most protected pages are viewable to allow system awareness for

troubleshooting.

NOTE

For a complete description and breakdown of each Configuration Mode page,

refer to the G1000 System Maintenance Manual listed in Table 1.2.

3.5 Configuration Mode Navigation

Using the FMS knob, a user can navigate through different pages and page groups in the

Configuration Mode. For complete description and breakdown of each page, refer to the G1000

Line Maintenance & Configuration manual.

System Page Group

1. System Status 6. File Manager 11. System Setup

2. Time Configuration 7. Diagnostics Terminal 12. Manifest Configuration

3. Lighting Configuration 8. OEM Diagnostics 13. Maintenance Log

4. System Audio 9. System Configuration

5. System Upload 10. System Data Path Configuration

GDU Page Group

1. Serial Configuration 4. Diagnostics 7. Airframe Configuration

2. CDU Status Page 5. Ethernet Test 8. TAWS Configuration

3. Key Test 6. Alert Configuration

GIA Page Group

1. Serial Configuration 3. GIA I/O Configuration 5. GIA Status Page

2. GIA RS-485 Configuration 4. GIA Configuration 6. GIA CAN Configuration

GEA Page Group

1. Engine Data 2. GEA Status Page 3. GEA Configuration

GTX Page Group

1. Serial Configuration 2. Transponder Configuration

GRS Page Group

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-3

190-01259-00 Rev. 5

Page 22

1. Inputs Configuration 2. GRS / GMU Calibration

ADC Page Group

1. ADC Configuration 2. GDC Configuration

GFC Page Group

1. GFC Configuration 2. GFC Status

GMA Page Group

1. GMA Configuration

GDL Page Group

1. GDL 69 Config

GTS Page Group

1. GTS Configuration

OTHER Page Group *

1. Stormscope

CAL Page Group

1. Fuel Tank Calibration 2. Flap and Trim Calibration 3. HSCM Calibration

* OTHER Page Group will not be present unless Stormscope is configured ON.

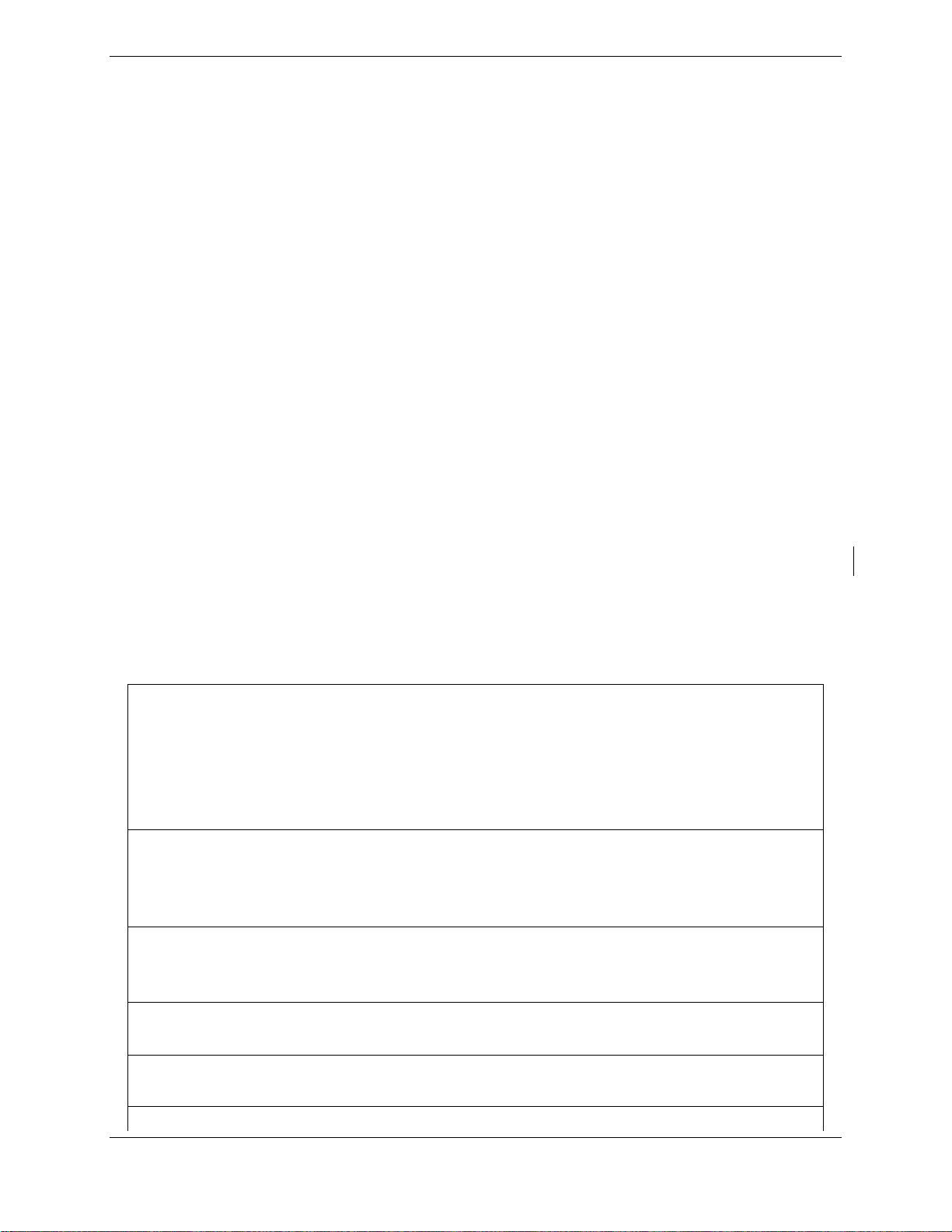

3.5.1 Configuration Prompts

When configuration settings are changed, the technician receives on-screen prompts and/or

confirmations such as those shown in Figure 3.5. Section 7 shows other prompts encountered

during the configuration process.

Figure 3.5, Configuration Status

3.5.2 Data Transmission Indicators

Several configuration screens utilize an indicator light system to show discrete (ON/OFF) data

and/or hardware component status. Unless otherwise noted, the following applies to all such

status indicators:

• Green Checkmark: Expected data is successfully received and is ON. A green check

could also indicate that the parameter/component is working correctly.

• Red X: Expected data is not received. A red X could also indicate that a

parameter/component is invalid.

• White N/A: Expected data is OFF, or no data is expected.

• Amber ?: Data is unknown.

Figure 3.6, Data Transmission Indicators

Page 3-4 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 23

3.6 G1000 Software Information

The following sections provide a detailed description of loading all G1000

software and configuration files, which may be excessive for individual

LRU removal and replacement. If removing and replacing individual

LRUs, refer to Section 5.6 of this manual for the necessary steps.

3.6.1 Loader cards

The G1000 has various features that require the use of unlock/enable

cards to activate the feature. Throughout this document these cards are

generically referred to as enable cards. In some cases, the actual label

on the physical card may say unlock. If uncertain, the technician should

verify the card part number prior to use.

Table 3.1 - Required Loader Cards

NOTE

NOTE

010-00726-07 ¹

or

010-00726-08 ²

or

010-00726-09

G1000/G36 Loader card (contains 006-B0858-07 Software Image)

or

G1000/G36 Loader card (contains 006-B0858-08 Software Image)

3

G1000/G36 Loader card (contains 006-B0858-09 Software Image)

or

(2 Required) Terrain/Obstacle/Airport/Supplemental Data plus

010-00330-43

Garmin Safe Taxi and NOS Flight Charts (Remains in the bottom

slot of the PFD and MFD)

010-00330-50

010-00330-51

010-00330-54

ChartView Enable Card (see note)

TAWS Enable Card (see note)

SVS Enable Card (see note)

¹ 010-00726-07 Loader card contains the 006-B0858-07 software image and is only

compatible with aircraft that have GIA63W P/N: 011-01105-01 installed.

² 010-00726-08 Loader card contains the 006-B0858-08 software image.

3

010-00726-09 Loader card contains the 006-B0858-09 software image.

3.6.2 G1000 Software Image

All software and configuration files were certified by Garmin as part of the FAA-approved Type

Design data. Approved software and hardware definitions are defined on the General

Arrangement drawing 005-00620-06.

G1000 software and configuration files are controlled via the approved software image part

number listed on the General Arrangement drawing 005-00620-06. This software image is

loaded into the G1000 using a software loader card.

NOTE

Installers may obtain the G1000 software image already on a loader

card by ordering the Garmin Part Number listed in the General

Arrangement Drawing 005-00620-06 referenced in Table 1.1

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-5

190-01259-00 Rev. 5

Page 24

IMPORTANT

To satisfy the requirements of this STC it is critical that the technician

install correct software image part number when servicing the G1000

system. Approved software image part numbers are defined on the

General Arrangement Drawing 005-00620-06 listed in Table 1.1

CAUTION

Be cautious when using software loader cards during maintenance. The

G1000 system immediately initializes the card upon power-up. Onscreen prompts must be given careful attention in order to avoid

potential loss of data.

3.6.3 Software Loader Card Creation

The software image is an executable self-extracting file which builds the correct file structure

onto an SD card for use loading software to the G1000 and GFC700. To obtain the current file

follow the procedures outlined below.

NOTE

In order to create a loader card, the installer completing these

procedures must be an authorized Hawker Beechcraft service center to

gain access to the necessary data via the Garmin website.

NOTE

Screenshots contained in this section is dependent upon the computer

being used to download the updates and its operating system.

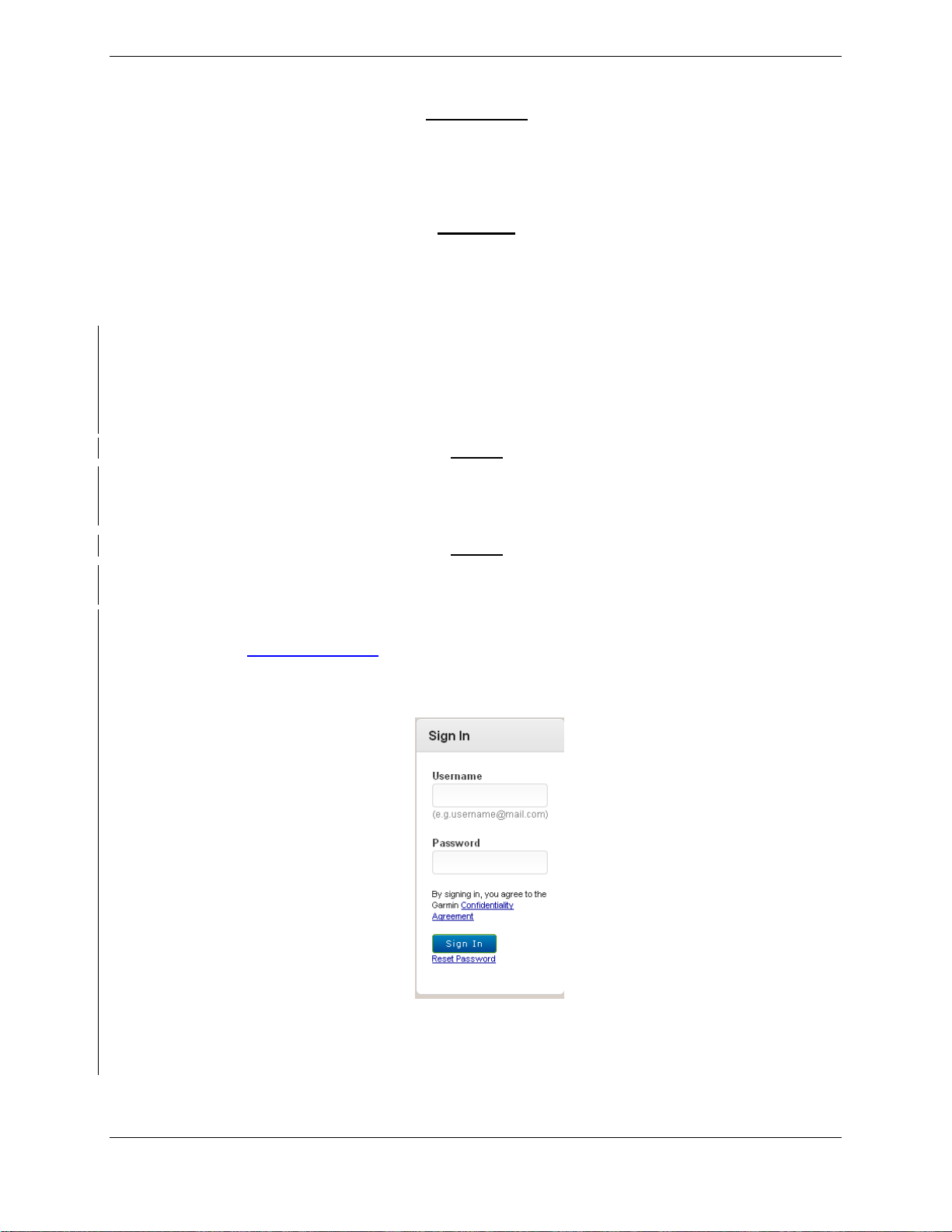

a. Go to www.garmin.com and click on the Dealer Resource Center link in the lower

portion of the home page. Enter User name and Password in the Sign In area at the

left of the page.

b. Click the Agree button on the confidentiality agreement page.

c. Select the Download Software link.

Page 3-6 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 25

d. Select the Software Downloads hyperlink on the left hand edge of the page.

e. Scroll down until the appropriate software image is visible. Note: the software image

version number will be listed in the name column. Select the appropriate software

image based upon the information provided in Garmin GA Drawing 005-00606-12.

f. Select the Download hyperlink and save the file to the local hard drive. Note: part

number shown below is for reference only.

g. Double-click the .exe file that was downloaded. The following window will pop-up on

the screen. Click Yes.

h. Ensure that there is an empty SD card in the card reader and then click Next.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-7

190-01259-00 Rev. 5

Page 26

NOTE

When the extraction begins, the program automatically deletes all

current files on the SD card and copies the selected files to it, regardless

of the file format on the SD card. Ensure files are not necessary or card

is empty before proceeding

i. Ensure the card and correct drive letter is used, and click next. A window will pop-up

onto the screen to indicate file progress.

Page 3-8 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 27

j. Once successfully completed, the following message/window will pop-up. Click

Finish to finalize SD card.

3.6.4 Software Files

Software files are defined by part number and version number on the General Arrangement

Drawing 005-00620-06. Each G1000 LRU reports the software version it currently contains to

the user in two places.

• Normal System Mode: The AUX – SYSTEM STATUS page lists each LRU and the

reported software version.

• Configuration Mode: The SYSTEM STATUS page (SYSTEM page group) reports more

detailed LRU information, including software version, part number, and LRU status.

Software files are loaded to LRUs from the SYSTEM UPLOAD page in configuration mode.

3.6.5 Configuration File Descriptions

There are configuration files for baseline settings and various options. Configuration files

contain preset selections for input/output channels, aircraft-specific settings, and LRU-specific

settings.

IMPORTANT!

Certain software and configuration files are REQUIRED to be re-loaded

during maintenance that involves removal and replacement of G1000

equipment. Refer to Section 7 for re-configuration requirements for each

G1000 LRU. Pay special attention to the configuration of options for the

G1000.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-9

190-01259-00 Rev. 5

Page 28

3.7 G1000 Software/Configuration Procedure

This section summarizes the procedures required to load software and configuration files to the

G1000. It is intended to work as a central guide for technicians to use while performing

maintenance on the aircraft. In sections of this manual where software is required to be

reloaded, these sections will make reference back to this Section for instructions. The

technician should use proper judgment regarding the context of maintenance required while

following this section.

The following diagram depicts an overview of the software/configuration sequence for the

G1000 system. This applies mostly to a new G1000 system which has not previously been

powered up and is for informative purposes only.

Figure 3.7, Software/Configuration Overview

Page 3-10 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 29

3.7.1 MFD & PFD Software Load

IMPORTANT!

When replacing a display, it is REQUIRED to update the system files

with the new display in the MFD slot regardless of intended final

configuration, PRIOR to loading configuration files. Failure to do so could

result in loss of any existing calibration/configuration data.

a. Apply power to the G1000 by doing the following: Connect a ground power unit to the

external power receptacle, and turn on the ground power unit.

b. Turn on the BAT 1, BAT 2, and AVIONICS MASTER switches. At this moment, all G1000

equipment is receiving power.

c. Pull the MFD and PFD circuit breakers.

d. Insert the loader card into the MFD top card slot.

e. While holding the ENT key on MFD, restore power by closing the MFD circuit breaker.

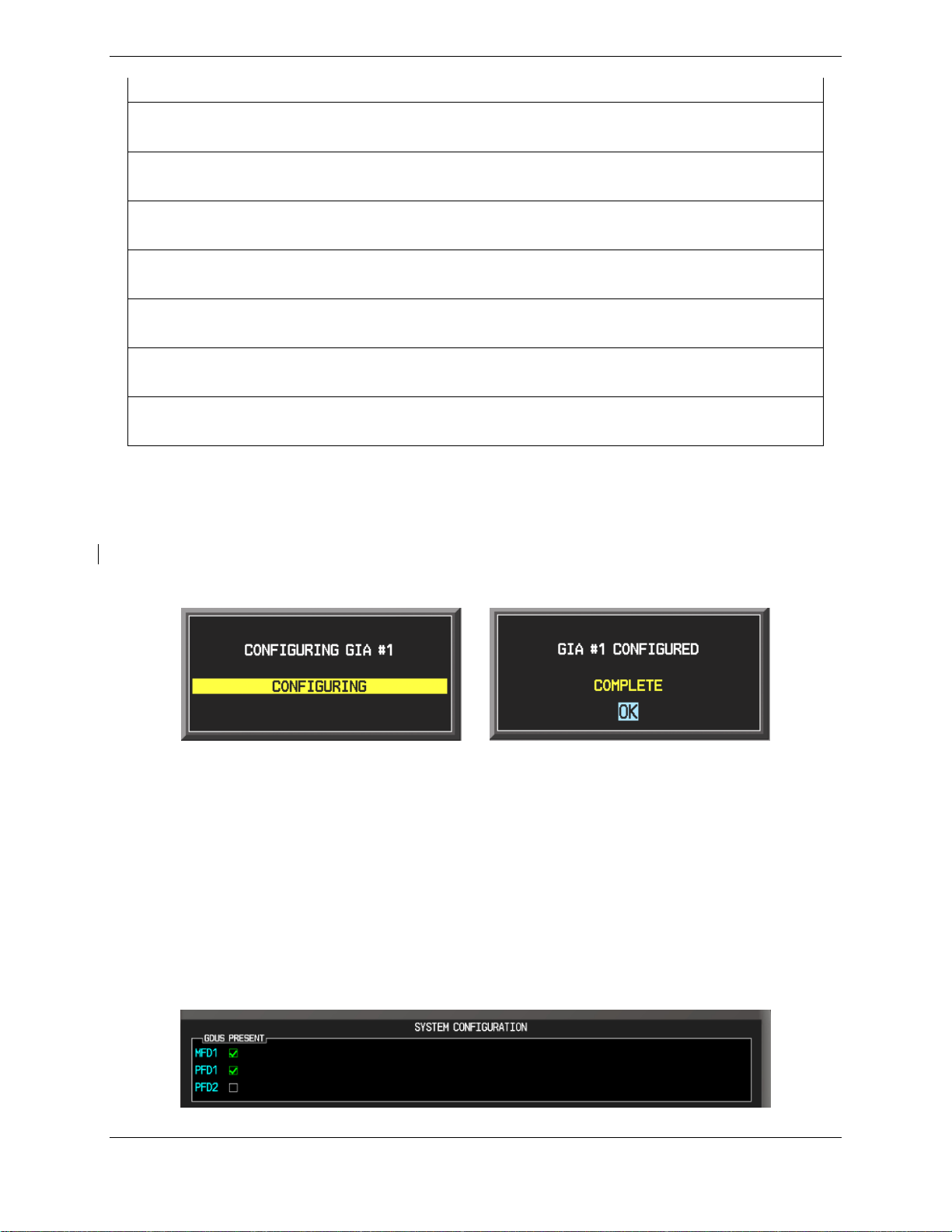

f. When the words

the MFD ENT key.

g. Press the MFD ENT key to acknowledge the following prompt (NOTE: A softkey labeled

YES appears in the lower right corner and may be used in lieu of the ENT key):

appear in the upper left corner of MFD, release

h. The following screen is displayed.

i. New software is loaded to MFD. When complete, the MFD starts in configuration mode

displaying the System Status page . Do not remove power.

j. Remove the loader card from MFD and insert it into the top card slot on the PFD. Repeat

Steps e through h for the PFD.

k. When PFD update is complete, it starts in the configuration mode. Do not remove power.

When complete, both displays should be in configuration mode, with the Loader Card

remaining in the top slot of PFD.

IMPORTANT!

For the rest of the software/configuration procedure, do not operate the

MFD while loading software or configuration files unless specifically

instructed to do so. A failed or cancelled load may result.

l. On PFD, verify on the SYSTEM CONFIGURATION PAGE that the following LRUs are

present. (status box is green, as shown below): MFD, PFD, GIA1, GIA2, GDL 69A.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-11

190-01259-00 Rev. 5

Page 30

m. Verify on the SYSTEM STATUS PAGE that the following are valid. (Indicated by a green

checkmark within the status box, as shown above): MFD, PFD, GIA1, GIA2, GDL 69A .

n. Proceed to next section.

Page 3-12 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 31

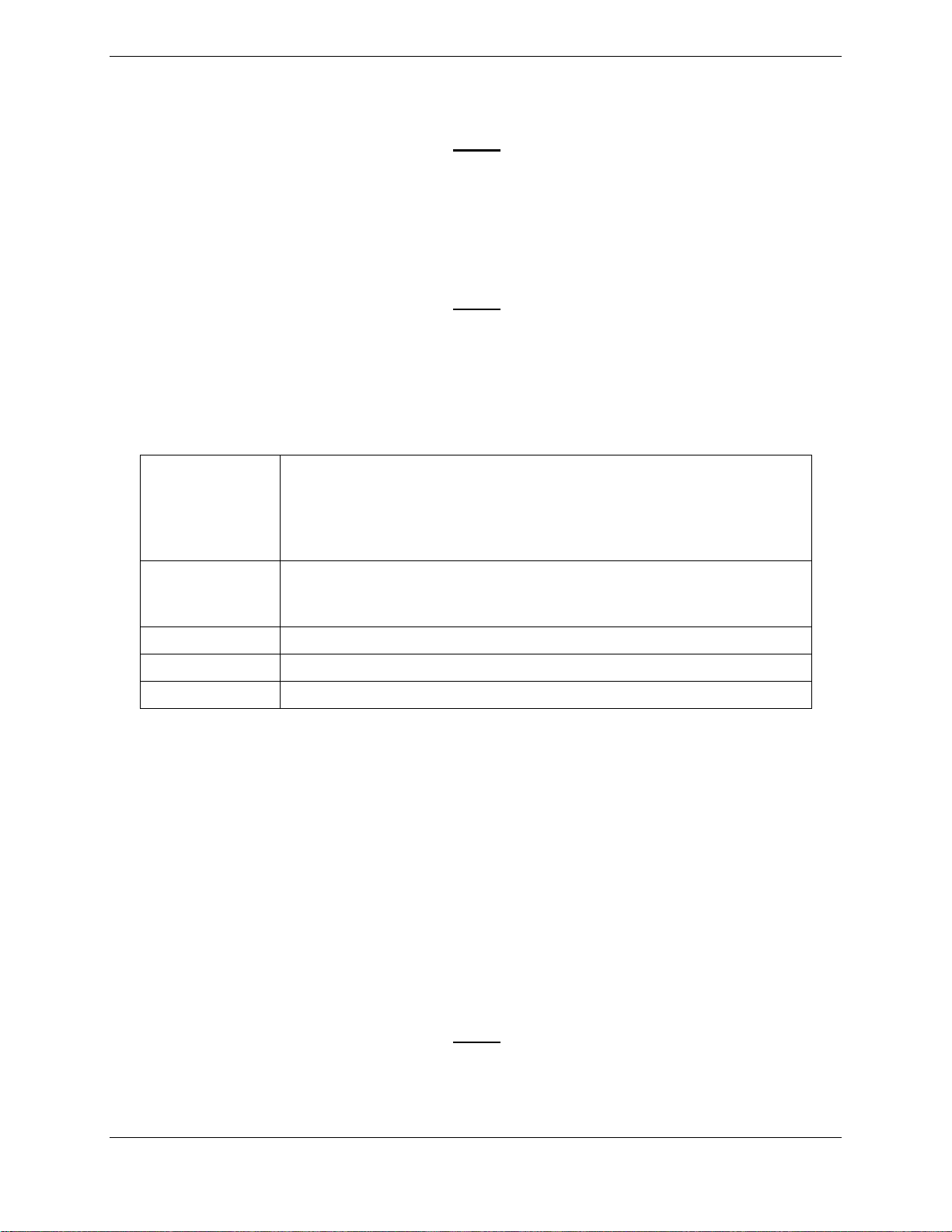

3.7.2 Base Configuration and Software Upload

a. Ensure loader card is inserted into top card slot of PFD. On PFD, select the System Upload

page using the PFD small FMS knob.

b. Activate the cursor and rotate the PFD small FMS knob to highlight BEECHCRAFT G36 in

the AIRFRAME field. Press the PFD ENT key to select the configuration .

c. Once an airframe type is selected the cursor moves to the FILE window. Rotate the PFD

small FMS knob to activate the drop-down menu. Move the cursor to highlight the

appropriate configuration for the aircraft and press ENT on PFD.

The PRODUCT window displays information regarding each G1000

LRU. The LRU column depicts the reported software version of the

LRU, whereas the CARD VERS column shows the LRU software

version stored on the Loader Card. The SOFTWARE and

CONFIGURATION columns default to having all required boxes

checked. Each checked file is automatically loaded to the correct

G1000 LRU.

Figure 3.8 - Configuration/Software Load Page

d. Press the LOAD softkey.

NOTE

e. Observe software loading progress and verify software load completes without errors as

indicated by the following:

f. Green PASS or White N/A in SOFTWARE and CONFIGURATION columns.

g. Upload Complete………….COMPLETE in the summary box.

h. Press PFD ENT key to acknowledge the Upload Complete box.

i. Press the UPDT CFG softkey on PFD and acknowledge prompt by pressing the ENT key on

PFD.

j. Proceed to the next section.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-13

190-01259-00 Rev. 5

Page 32

3.7.3 Optional Equipment Configuration

Perform the following steps if any of the following options are installed:

• GTS 820

• SKY 497 Skywatch

• KN 63 DME

• WX-500 Storm Scope

• GTX 33 with extended squitter

a. Go to the System Upload page and activate cursor. Activate the drop down menu in the

AIRFRAME field by rotating the small FMS knob and select G36 OPTIONS and press ENT.

b. Activate the drop down menu by rotating the small FMS knob and select the desired option,

press ENT.

c. Press the LOAD softkey.

d. Observe software loading progress and verify software load completes without errors as

indicated by the following:

e. Green PASS or White N/A in SOFTWARE and CONFIGURATION columns.

f. Upload Complete………….COMPLETE in the summary box.

g. Press PFD ENT key to acknowledge the Upload Complete box.

h. For other installed options repeat steps b thru e by rotating the large FMS knob and

highlighting the File Field.

i. De-activate the cursor.

Figure 3.9 - Option Selection

Page 3-14 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 33

3.7.4 GRC 10 configuration (Optional)

For installations with the optional GRT 10/GRC 10 wireless remote system, the GRC 10 must

be configured to communicate with the specific GRT 10 that is installed in the aircraft. To

configure the RF Pairing ID of the GRC 10:

NOTE

GRT 10 serial number is required for installation. Serial number is

located on the bottom of the unit.

a. Insert two AA batteries in GRC 10.

b. On the GRC 10 press any key to power the remote.

c. When the “GRT 10 not found” message is displayed on the GRC 10, press the following

buttons in order:

UP, DOWN, LEFT, RIGHT, MINUS (-), PLUS (+), PSET

d. Use the arrow buttons on the GRC 10 to enter the serial number of the GRT 10 transceiver

that is installed in the aircraft. Verify that the correct GRT 10 transceiver serial number has

been entered.

e. Press the XM button to store the GRT 10 serial number.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-15

190-01259-00 Rev. 5

Page 34

3.8 Software Load Confirmation

Go to the Systems Status page. Activate the cursor and toggle to the LRU window. Highlight

each of the following items in the LRU window and verify that the LRU software part number

and software version matches the following information.

NOTE

Verify the software and version levels for the items listed below.

a. Highlight each of the following items in the LRU window by scrolling with the small FMS

knob, and verify that the software part number and version matches the information in

General Arrangement, G1000 Update with Options G36, 005-00620-06 General

Arrangement drawing.

SYSTEM SW VER OK SYSTEM SW VER OK SYSTEM SW VER OK

GDC1 GIA2 GTS

GDC1 FPGA GIA2 AUDIO GTS AUDIO

GDL69 GMA1 GTS FPGA

GEA1 GMU1 GTS MAGNETIC VA

GFC CERT GIA1 GMU1 FPGA GTS RGN LIST

GFC CERT GIA2 GRS1 GTX1

GFC CERT PC GRS1 FPGA MFD1

GFC CERT PM GRS1 MV DB MFD1 FPGA

GFC CERT PT C GSA PTCH CTL PFD1

GFC CERT PT M GSA PTCH MON PFD1 FPGA

GFC CERT RC GSA PTCH TRM C COM 1 *

GFC CERT RM GSA PTCH TRM M COM 2 *

GFC CERT YC GSA ROLL CTL NAV 1 *

GFC CERT YM GSA ROLL MON NAV 1 BB *

GIA1 GSA YAW CTL NAV 1 FPGA *

GIA1 AUDIO GSA YAW MON NAV 2 *

NAV 2 BB * NAV 2 FPGA *

* Only applicable to those installations using GIA 63W P/N: 011-01105-20.

Page 3-16 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 35

b. De-activate the cursor.

c. Remove loader card and power down aircraft.

IMPORTANT

If any software version and/or part number does not match, or is not

successfully loaded, do not continue with post installation procedures.

Troubleshoot and resolve the issue before continuing.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-17

190-01259-00 Rev. 5

Page 36

3.9 Aviation Database Loading Procedures

3.9.1 Terrain Data Card Loading Procedure

a. Remove power from the PFD and MFD by pulling the PFD and MFD circuit breakers.

b. Install a GDU 10XX Terrain Data Base Card 010-00330-43 in the bottom slot of the PFD

and MFD.

c. This completes the installation of the Terrain Data Card.

3.9.2 Aviation Database Loading

a. Remove power from MFD.

b. Insert an SD card containing the latest cycle Jeppesen aviation database (data supplied by

Jeppesen) into the top slot of MFD.

c. Apply power to MFD. The following prompt is displayed in the upper left corner of MFD:

d. Press the MFD ENT key to confirm the database update.

e. A prompt will be displayed. Press ENT for YES.

f. After the update completes, MFD starts in normal mode.

g. Rotate FMS knob to select AUX – SYSTEM STATUS page.

h. Press the SYNC DBS softkey on the MFD.

i. Acknowledge the prompt “Enable automatic database synchronization” by pressing the ENT

key on the MFD.

j. The aviation databases are now updated.

k. Confirm that the correct update cycle is loaded at the power-up page of the MFD.

Page 3-18 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 37

3.10 SVS / Pathways Activation (option)

This section provides the requirements and instructions necessary to enable the G1000

Synthetic Vision / Pathways feature.

Baseline Software:

The Garmin Synthetic Vision and Pathways feature in the Hawker Beechcraft requires GDU

software version 11.01 (or later) to be installed with the G36-specific software/configuration

image prior to activation. See the STC Master Drawing List for specific installation

requirements.

Database Cards:

The Garmin Synthetic Vision and Pathways feature requires 9 arc-second high resolution terrain

databases to function.

Each G1000 display must be equipped with the P/N 010-00330-43 Terrain/Obstacle/SafeTaxi

database card installed in the lower slot.

SVS / Pathways Enable Card:

The following enable card is required to activate the SVS/Pathways feature for G1000/G36

installations:

Table 3.2 – SVS Enable Card

QTY GARMIN PART NUMBER DESCRIPTION

1 010-00330-54 Synthetic Vision & Pathways Enable, 1 PFD

IMPORTANT!

When the SVS/Pathways option is enabled for the first time, the G1000

writes its unique system ID to the physical card and locks the files to

this unique ID. This prevents the SVS/Pathways enable card from ever

being used to activate the SVS/Pathway feature in other G1000

systems. This card MUST be kept with the aircraft for situations where

SVS/Pathways must be re-activated.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-19

190-01259-00 Rev. 5

Page 38

3.10.1 SVS Activation Procedure

Activate the SVS/Pathways feature by performing the following steps:

a. Apply power to the G1000 system.

b. Pull the MFD and PFD circuit breakers.

c. A special SVS Enable card is required to activate this feature, refer to Table 3.2. Insert this

card in the upper slot of PFD.

d. While holding the ENT key on the PFD and MFD restore power to the displays.

e. When the words

appear in the upper left corner of the displays,

release the ENT key.

f. From PFD, accomplish the following:

g. Go to the System Upload page using the small FMS knob.

• Activate the cursor. Use the small FMS knob to select CONFIGURATION FILES in

the AIRFRAME field and press the ENT key.

• Highlight the FILE field. Use the small FMS knob to select the Enable SVS option

and press the ENT key. Once the option is selected the configuration files in the

PRODUCT field will be displayed. All files should be checked. If not, press the CHK

ALL softkey.

• Press the LOAD softkey.

• Monitor the status of the upload. When the upload is finished, press the ENT key to

acknowledge the upload complete confirmation.

h. View the SUMMARY field and ensure that the item is COMPLETE.

i. De-activate the cursor.

j. Power down the system and remove the SVS Enable card from the PFD.

Page 3-20 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 39

3.11 Chartview Enable Procedure

NOTE

• The Chart Enable card can only enable Charts on one system (one

aircraft). A new Chart Enable card must be used for each aircraft.

• The required ChartView databases are subscription-based and are

to be procured by the installing agency directly from Jeppesen.

• The G1000 can only be configured for FliteCharts or ChartView but

not both. Performing this procedure will automatically disable the

FliteChart option.

a. Apply power to the G1000 system.

b. Pull the PFD and MFD circuit breakers.

c. Insert the Chart Enable card, 010-00330-50 in the upper slot of the PFD.

d. While holding the ENT key on the PFD and MFD restore power to the displays.

e. When the words

appear in the upper left corner of the

displays, release the ENT key.

f. On the PFD, go to the System Upload page.

g. Activate the cursor and rotate the small FMS knob to activate the drop down menu

and select CONFIGURATION FILES in the AIRFRAME field. Press ENT.

h. Rotate the small FMS knob to activate the drop down menu and select ENABLE

CHARTVIEW in the FILE field. Press ENT.

i. Verify there is a check mark in the box in the configuration column for AIRFRAME.

j. Press the LOAD softkey.

k. Monitor the status of the upload. When the upload is finished Complete and Pass is

displayed. Press ENT.

l. De-activate the cursor.

m. Power down the system and remove the ChartView Enable card from the PFD.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-21

190-01259-00 Rev. 5

Page 40

3.12 TAWS-B Enable Procedure

NOTE

The TAWS-B Enable card can only enable TAWS on one system (one

aircraft). A new TAWS Enable card must be used for each aircraft.

a. Remove power from the MFD and PFD by pulling the PFD and MFD circuit breakers.

b. Insert the TAWS Enable card, 010-00330-51 in the upper slot of the PFD.

c. While holding the ENT key on the PFD and MFD restore power to the displays.

d. When the words

displays, release the ENT key.

e. On the PFD, go to the System Upload page.

f. Activate the cursor and use the small FMS knob to activate the drop down menu and

select CONFIGURATION FILES in the AIRFRAME field. Press ENT.

g. Use the small FMS knob to activate the drop down menu and select ENABLE TAWS

in the FILE field. Press ENT.

h. Verify there is a check mark in the box in the configuration column for AIRFRAME.

appear in the upper left corner of the

i. Press the LOAD softkey.

j. Monitor the status of the upload. When the upload is finished, Complete and Pass is

displayed. Press ENT.

k. De-activate the cursor.

l. Power down the system and remove the TAWS-B Enable card from the PFD.

Page 3-22 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 41

3.13 Aircraft Registration Number Entry

NOTE

The large FMS knob changes Groups and the small FMS knob changes

Pages within a Group.

NOTE

If aircraft has a Garmin GTS 8XX Traffic System installed, ensure GTS

8XX system configuration is loaded prior to registration entry for

transponder (See Section 3.7.3).

a. Remove power (if applied) from PFD by pulling the PFD circuit breaker.

b. While holding the ENT key on the PFD, restore power by closing the PFD circuit

breaker.

c. When the words INITIALIZING SYSTEM appear in the upper left corner of the PFD

release the ENT key.

d. Rotate the outer FMS knob to activate the GTX group, then rotate the small FMS

knob to select the TRANSPONDER CONFIGURATION page on PFD.

e. Ensure that the ADDRESS TYPE is US TAIL under the SET and XPDR ACTIVE

columns.

f. Ensure that the FLIGHT ID TYPE is SAME AS TAIL under the SET and ACTIVE

columns.

g. Activate the cursor and highlight the MODE S ADDRESS field. Use the small/large

FMS knob to enter the aircraft registration number.

h. Once the correct registration number is entered, press the ENT key to configure the

transponder.

i. Observe the status window and press the ENT key on PFD to acknowledge the OK

prompt once configuration is complete.

3.14 Clearing Default User Settings

a. Remove power from PFD and MFD.

b. While holding the CLR button on PFD, re-power PFD.

c. When prompted to clear user settings select the YES softkey.

d. Repeat steps a-c for MFD.

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 3-23

190-01259-00 Rev. 5

Page 42

This page intentionally left blank

Page 3-24 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 43

4 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

4.1 Airworthiness Limitations

There are no airworthiness limitations associated with this type design change (STC #

SA1595WI-D).

The previously approved Instructions for Continued Airworthiness defined under TCDS 3A15,

and identified in Table 1-1, remain valid and applicable for all other maintenance and ICA

aspects of the G1000 and GFC 700 systems.

The Airworthiness Limitations section is FAA-approved and specifies maintenance

required under § 43.16 and 91.403 of Title 14 of the Code of Federal Regulations, unless

an alternative program has been FAA-approved.

4.2 Servicing Information

G1000 LRU maintenance is “on condition” only. No component level overhaul is required for

this design change.

4.2.1 On Condition Servicing

‘On Condition’ replacement and/or servicing should occur when an item exhibits conditions,

symptoms, and/or abnormalities defined in Section 5 of this manual. Replacement and/or

servicing should be made only after the technician troubleshoots the system to the extent

determined necessary by using the guidance in this manual along with common avionics

maintenance practices.

IMPORTANT

It is impossible to provide guidance for every conceivable failure scenario

within the scope of this manual. Every effort has been made to provide

comprehensive guidance for possible failures. The information in this

document should always be combined with common sense and a

thorough knowledge of the system. Use sound avionics maintenance

practices when working around or on G1000 equipment.

IMPORTANT

All structural repairs associated with this installation are to be addressed

in accordance with proper Hawker Beechcraft Aircraft Company

standards.

4.2.2 Required Tools

The following tools are needed to perform maintenance tasks on GTS 820 equipment:

• Outdoor line-of-site to GPS satellite signals or GPS indoor repeater

• TIC TR 220 Test set or equivalent

• Headset/microphone

• Ground Power Unit (Capable of supplying 28 Vdc)

• Laptop with Garmin GTS 8XX Installation software installed. The Installation software is available

for download from the dealers only portion of the Garmin website (www.garmin.com)

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 4-1

190-01259-00 Rev. 5

Page 44

The following tools are needed to perform maintenance tasks on GMU 44 equipment:

• #2 non-magnetic Philips screw driver

The following tools are needed to perform maintenance tasks on GTX 33ES transponder:

• Calibrated pitot/static tester

• Calibrated transponder ramp tester

The following tools are needed to perform maintenance tasks on GRT 10 equipment:

• 3/32” Hex tool

• #2 Philips screw driver

The following tools are needed to perform maintenance tasks on GDU 104X equipment:

• 3/32” Hex tool

For any other tools required to maintain the G1000 / GFC 700 refer to the existing Hawker beechcraft ICA

listed in Table 1.1.

.

Page 4-2 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 45

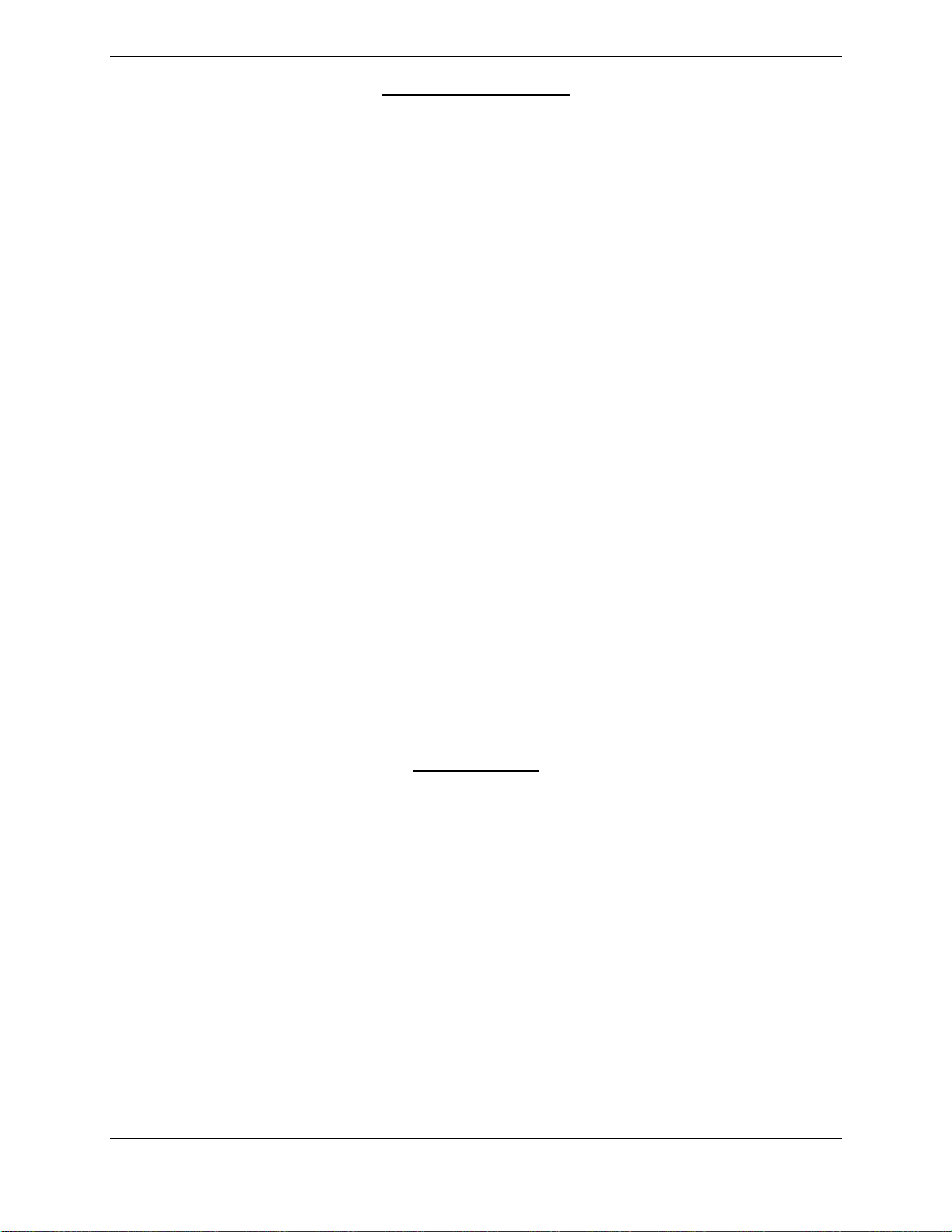

4.3 Maintenance Intervals

Table 4.1 below shows the systems and equipment installed by this STC that must undergo any

maintenance action and identifies the timeframe in which that activity should occur.

The previously approved Instructions for Continued Airworthiness defined under TCDS 3A15,

and identified in Table 1-1, remain valid and applicable for all other maintenance and ICA

aspects of the G1000 and GFC 700 systems. This STC does not remove or allieviate any of the

existing maintenance requirements for the Hawker Beechcraft G36 aircraft unless specifically

stated.

Table 4.1 - Maintenance Intervals

Item Description / Procedure Section # Interval

Annual inspection

Visual Inspection

Complete visual inspection of

new equipment and wiring

4.3.1

(in conjunction with existing

visual inspection requirements)

Electrical Bonding

tests

Suspected lightning

strike to GA58

antenna

GDU 1040 PFD Remove and Replacement

GDU 1045 MFD Remove and Replacement On Condition

GIA 63W Remove and Replacement 6.8 On Condition

GMU 44

Magnetometer

GTS 820 Traffic

receiver

Conduct electrical bonding

checks of new LRUs and

Antenna

Inspect antenna and surrounding

structure to ensure there is no

structural damage where

lightning may have attached. If

there is visible damage to the

equipment, then it should be

replaced.

Remove and Replacement 6.6 On Condition

Remove and Replacement 6.1 On Conditon

4.3.3

6.3 On Condition

6.5

Annual inspection

(in conjunction with existing

visual inspection requirements)

On Condition

GPA 65 Traffic

PA/LNA

GA 58 Antenna Remove and Replacement 6.3 On Condition

GRT 10 XM remote

control transceiver

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 4-3

190-01259-00 Rev. 5

Removal and Replacement 6.2 On Condition

Removal and Replacement 6.4 On Condition

Page 46

A

Item Description / Procedure Section # Interval

GRC 10 XM remote

control

Synthethic Vision

/Pathways

GTX 33ES

Tranponder with

Extended Sqitter

Functionality **

Replacement / Reconfiguration

6.4.1

Battery replacement On Condition

Reactivation 3.10

Removal and Replacement 6.7 On Condition

Transponder test

(required for compliance with

Title 14 of the Code of Federal

Regulations (14 CFR) §§ 91.411

and 91.413)

7.1 Every 24 Calendar months

On Condition

On Condition / after GDU

replacement

4.3.1 Visual Inspection Requirements

In conjuction with existing Annual visual inspection requirements, conduct the following:

• Inspect all new appliances, antennas, and electrical connectors and coax connectors for

corrosion or other defects.

• Check the integrity of all shield block ground attachments to the harness connector as

well as integrity of the individuals shields.

• Inspect all exposed wiring for chaffing, damage, proper routing and security of

attachment.

• Signs of corrosion on equipment, racks, aircraft structure relied upon for ground, and

connectors, backshells, wire attachment.

• Conduct a visual inspection of the antennas and mounting. Verify there are no cracks in

the antenna, no deformation in the mounting structure, and that all sealing fillets around

the antennas are in good condition.

• If the antenna is broken, cracked, dented, etc. then it must be replaced.

• If the attachment is not secure, re-work the installation and complete electrical bonding

test based on installation requirements.

• In the event the antenna seal shows sign of damage or decomposition, re-seal and

complete the Electrical bonding test to installation requirements.

4.3.2 Coax Cable Maintenance

CAUTION

fter any maintenance or modification is made to the GTS 820 TAS

cables such as replacing a connector or entire cable, some important

considerations must be made.

Page 4-4 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 47

When making any repairs to GTS coax cables installed under this STC, be sure to adhere to all

of the specifications and limitations such as minimum and maximum cable attenuation,

attenuation balance between cables, phase matching etc. in the Installation Manuals

referenced in Table 1.1

4.3.3 Electrical Bonding Test

The following bonding tests are provided for GTS 820 equipped G36 aircraft as a requirement

beyond what is given in the aircraft maintenance manual.

NOTE

It is recommended that these tests be conducted after visual

inspections of each zone to minimize access requirements

4.3.3.1 Requirements

All GTS equipment must be installed. Gain access for the procedure listed below as

required and in accordance with the Bonanza G36 Maintenance Manual.

4.3.3.2 Test Equipment

A milli-ohm meter and Kelvin probes are recommended for this test. However, a standard

voltmeter, power supply with adjustable current limit, and ammeter may be substituted. The

following procedure is written using the voltmeter, power supply and ammeter. All test

equipment must have valid calibration records.

4.3.3.3 Electrical Bonding Procedure

Test Preparation:

All electrical connectors including coaxial cable connectors must be disconnected during

bonding checks.

1. Connect the positive lead of the power supply to a nearby exposed portion of aircraft

metallic structure, such as a frame, as close as possible to the unit under test. Do not

use the units own installation rack. Connect/touch the positive lead of the voltmeter to

the same point.

NOTE

Ensure that the voltmeter and power supply probes do not touch so as not to

induce contact resistance.

2. Touch negative lead of power supply to each of the test points listed while performing

Step 3. At each point, configure the power supply to produce 1 amp before measuring

voltage. (Use an ammeter to ensure current is within 1 amp ±100 milli-amp at each

point).

3. Set the voltmeter to measure milli-volts and null the reading. Measure the voltage from

ground point (step 1) to each of the following points and record the voltage. (Perform

Step 2 at each point to ensure that 1 amp ±100 milli-amp is present before measuring.)

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 4-5

190-01259-00 Rev. 5

Page 48

Pilot Compartment

• Top metal case of PFD: __________ milli-volts

• Top metal case of MFD: __________ milli-volts

• GTX 33 top: __________ milli-volts

• GIA 1 top: __________ milli-volts

• GIA 2 top: __________ milli-volts

• GMU metal base: __________ milli-volts

Ensure that at each PFD or MFD test point, no more than 20 milli-volts (20 mΩ) are present.

In this case, voltage is equivalent to resistance (Ω), given that precisely 1 amp reference

current is present. For all other LRUs see requirements below.

Cabin Compartment

• Metal case of GPA 65 LNA/PA: __________ milli-volts (part of GTS 820 option)

Empennage

• Metal case of GTS 820: __________ milli-volts (optional equipment)

Aircraft Exterior (Antennas)

• GA 58 Top traffic antenna mounting screw: __________ milli-volts (optional equipment)

• GA 58 Bottom traffic antenna mounting screw: __________ milli-volts (optional

equipment)

Ensure that at each test point, no more than 10 milli-volts (10 mΩ) are present. In this case,

voltage is equivalent to resistance (Ω), given that precisely 1 amp reference current is

present.

TIP: If 1 amp reference current cannot be maintained, note the difference between the

attainable current and 1 amp reference current. Calculate the percentage difference and

apply this to the voltage reading to obtain the equivalent resistance. Example: If the

measured current is 1.2 amps, (20% high from the target 1 amp current), then the allowable

voltage measurement would be 20% high, 2.5 milli-volts would now be 3.0 milli-volts.

If one or more bonding checks fails, i.e. the resistance is higher than those listed above,

then clean and rebond as necessary. Re-attach equipment racks/appliance/antenna and

complete electrical bonding test based on the original installation requirements. Refer to the

applicable installation drawing referenced in Table 1.1 for the bonding requirements.

After bonding checks are complete, ensure all electrical and coaxial cable connectors are

reconnected and all systems are working properly.

Page 4-6 G1000 System Maintenance Manual - Hawker Beechcraft G36

Rev. 5 190-01259-00

Page 49

5 TROUBLESHOOTING

This section provides instructions and guidance for system troubleshooting additional systems /

functions added by this STC. For troubleshooting assistance for all other aspects of the G1000

/ GFC 700 refer to the existing Hawker Beechcraft G36 maintenance supplement listed in Table

1.1.

IMPORTANT

Sections 6, 3.7, and 8 provide detailed instructions on equipment

removal, replacement, configuration, and return-to-service testing.

Anytime a G1000 component or LRU is removed, swapped, or

replaced, the technician must follow the procedures given in

Sections 3.7, and 8 to ensure proper operation of the system.

5.1 SVS/Pathways Troubleshooting

The SVS/Pathways software feature requires the following G1000 sensors/data to be valid:

• AHRS

• Heading

• GPS Position

• 9 Arc-Second Terrain Data

In the event that one the above items fails or is unavailable, the SVS/Pathways feature is

automatically removed from the PFD. The following table describes possible symptoms

associated with the SVS/Pathways feature, and provides corresponding actions for

troubleshooting:

Table 5.1 – SVS Troubleshooting

Symptom Recommended Action

Verify that the PFD and MFD software versions are shown to be 11.01

“SYN VIS” softkey does not

appear on PFD softkey tier.

3D terrain presentation does

not appear on PFD.

or later by checking the AUX – System Status Page on the MFD.

If version 11.01 or later software is installed in the MFD and PFDs,

follow the steps in Section 3.10.1 to reactivate the SVS/Pathways

feature.

Verify that P/N 010-00330-43 terrain datacards are installed in the

lower slot of the PFD and MFD.

Verify that no alert messages are shown in the PFD Alerts Window.

Verify that the G1000 AHRS, and heading data are valid on the PFD.

Verify that a valid GPS 3D position solution is being received.

Troubleshoot these systems in accordance with the existing Piper PA46-500TP Airplane Maintenance Manual as referenced in Table 1-1.

If a terrain database update has just been performed, allow the

system time to initialize and verify the data. When the databases

have been verified, the current database cycle and version are

reported on the MFD AUX – System Status page.

The following table provides SVS/Pathways specific alert messages which may appear in the

Alerts Window on the PFD (press the ALERTS softkey on the PFD to view the Alerts Window):

G1000 System Maintenance Manual - Hawker Beechcraft G36 Page 5-1

190-01259-00 Rev. 5

Page 50

Table 5.2 – SVS Alert Messages

Failure Message Cause Solution

SVS is disabled because the

SVS – SVS DISABLED: Out of

available terrain region.

SVS – SVS DISABLED: Terrain

DB resolution too low

aircraft exceeded the

boundaries of the loaded terrain

database.

SVS is disabled because a 9