Garmin GTX 320, GTX 320A INSTALLATION MANUAL

GTX 320/320A

TRANSPONDER

INSTALLATION

MANUAL

(GTX 320 Shown)

GARMIN International, Inc.

1200 E. 151

Olathe, KS 66062 USA

190-00133-01 Revision L

st

June 2001

Street

££££

© Copyright 1999-2002

GARMIN Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of GARMIN. GARMIN hereby grants permission to download a single copy of this

manual and of any revision to this manual onto a hard drive or other electronic storage medium to be

viewed and to print one copy of this manual or of any revision hereto, provided that such electronic or

printed copy of this manual or revision must contain the complete text of this copyright notice and provided

further that any unauthorized commercial distribution of this manual or any revision hereto is strictly

prohibited.

Information in this document is subject to change without notice. GARMIN reserves the right to change or

improve its products and to make changes in the content without obligation to notify any person or

organization of such changes or improvements.

GARMIN International, Inc.

1200 E. 151

Olathe, KS 66062 USA

Telephone: 913-397-8200

Dealer Line: 1-800-800-1420

Web Site Address: www.garmin.com

st

Street

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration Regulations

(“EAR”) issued by the United States Department of Commerce (15 CFR, Chapter VII, Subchapter C) and

which may not be exported, released, or disclosed to foreign nationals inside or outside of the United States

without first obtaining an export license. A violation of the EAR may be subject to a penalty of up to 10

years imprisonment and a fine of up to US$1,000,000 under Section 2410 of the Export Administration Act

of 1979. Include this notice with any reproduced portion of this document.

RECORD OF REVISIONS

Revision Revision

Date

A

B

C

D

E

F

G

H

J

K

L

02/10/97 Initial Rel --05/30/97 Clarify Antenna Requirements 7096

07/08/97 Lengthens Mount Screws, Add Notes 7344

08/21/97 Depth Behind Panel 7539

09/18/97 Wiring Diagram Corrections 7673

01/23/98 Add Spring Washer 8310

06/05/98 Correct reference to 50 ohm match bushing 8808

05/14/99 Updates and Corrections 10985

09/25/00 Redraw 14199

11/05/01 Updates and Clarifications 16878

06/06/02 Updated unit and accessory part numbers 18314

Description ECO #

Page A GTX 320/320A Installation Manual

Rev. L 190-00133-01

TABLE OF CONTENTS

PARAGRAPH PAGE

1 GENERAL DESCRIPTION .................................................................................................................1

1.1 INTRODUCTION.................................................................................................................................1

1.2 EQUIPMENT DESCRIPTION.............................................................................................................1

1.3 TECHNICAL SPECIFICATIONS........................................................................................................1

1.3.1 Transponder Specifications .......................................................................................................1

1.3.2 Physical Characteristics-GTX 320 ............................................................................................2

1.3.3 Physical Characteristics-GTX 320A..........................................................................................2

1.4 EQUIPMENT AVAILABLE................................................................................................................2

1.4.1 Configurations Available...........................................................................................................2

1.4.2 Installation Accessories .............................................................................................................3

1.5 ADDITIONAL EQUIPMENT REQUIRED.........................................................................................3

1.6 INSTALLATION APPROVAL............................................................................................................3

1.7 ATC TRANSPONDER TESTS AND INSPECTIONS ........................................................................4

1.8 LIMITED WARRANTY ......................................................................................................................4

2. INSTALLATION ..................................................................................................................................5

2.1 INTRODUCTION.................................................................................................................................5

2.2 UNPACKING AND INSPECTING EQUIPMENT..............................................................................5

2.3 ANTENNA INSTALLATION..............................................................................................................5

2.3.1 Location Considerations ............................................................................................................5

2.3.2 Antenna Installation...................................................................................................................5

2.3.3 Installation Approval Considerations for Pressurized Aircraft .................................................6

2.3.4 Antenna Cable Installation ........................................................................................................7

2.3.5 Antenna Cable Connectors ........................................................................................................7

2.4 GTX 320/320A INSTALLATION........................................................................................................9

2.5 ELECTRICAL CONNECTIONS .......................................................................................................10

2.6 CHECK EXISTING COAX AND ANTENNA..................................................................................12

2.7 INSTALLATION USING EXISTING NARCO AT 150 INSTALLATION RACK .........................12

2.8 INSTALLATION USING EXISTING BENDIX/KING 76A/78A INSTALLATION RACK...........13

3. POST INSTALLATION CONFIGURATION & CHECKOUT PROCEDURE................................14

3.1 AIRCRAFT STATION LICENSING REQUIREMENTS .................................................................14

3.2 OPERATION ......................................................................................................................................14

3.2.1 Function Selection Switches....................................................................................................15

3.2.2 Code Selection .........................................................................................................................15

3.2.3 IDENT Button..........................................................................................................................16

3.2.4 Reply Light ..............................................................................................................................16

GTX 320/320A Installation Manual Page i

190-00133-01 Rev L

PARAGRAPH PAGE

APPENDIX A. CERTIFICATION DOCUMENTS....................................................................................17

A.1 CONTINUED AIRWORTHINESS ....................................................................................................17

A.2 ENVIRONMENTAL QUALIFICATION FORM - (GTX 320).........................................................20

A.3 ENVIRONMENTAL QUALIFICATION FORM - (GTX 320A)......................................................22

APPENDIX B. ASSEMBLY AND INSTALLATION DRAWINGS ........................................................24

APPENDIX C. STC PERMISSION-GTX 320 ...........................................................................................39

LIST OF ILLUSTRATIONS

FIGURE PAGE

2-1 DB-25 Pin-Out Definitions .................................................................................................................11

3-1 Transponder Front Panel.....................................................................................................................14

B1 GTX 320/320A Outline Drawing........................................................................................................25

B2 GTX 320/320A Connector/Rack Kit Assembly Drawing ..................................................................27

B3 GTX 320/320A Recommended Panel Cutout Dimensions.................................................................29

B4 GTX 320/320A Interconnect Wiring Diagram ...................................................................................31

B5 Dual Transponder Interconnect Wiring Diagram ...............................................................................33

B6 NARCO AT 150 Installation Adapter Assembly Drawing.................................................................35

B7 KING KT 76A/78A Installation Adapter Assembly Drawing............................................................37

Page ii GTX 320/320A Installation Manual

Rev L 190-00133-01

1. GENERAL DESCRIPTION

1.1 INTRODUCTION

This manual provides the installation and operating instructions for the GARMIN GTX 320 and the GTX 320A

Transponders. Information pertaining to the maintenance, alignment, and procurement of replacement parts is

found in the GTX 320 Maintenance Manual, P/N 190-00133-02 and the GTX 320A Maintenance Manual, P/N

190-00133-08. After installation of the GTX 320/ GTX 320A, FAA Form 337 must be completed by an

appropriately certificated agency and ATC transponder tests required by 14 CFR, Part 91.413 must be completed

to return the aircraft to service.

1.2 EQUIPMENT DESCRIPTION

The GARMIN GTX 320/320A Transponder is a radio transmitter and receiver that operates on radar frequencies.

Receiving ground radar interrogations at 1030 MHz, it transmits a coded response of pulses to ground-based

radar on a frequency of 1090 MHz.

As with other Mode A/Mode C transponders, the GTX 320/320A replies with any one of 4,096 codes, which

differ in the position and number of pulses transmitted. By “replying” to ground transmissions, your

GTX 320/320A enables ATC computers to display aircraft identification, altitude and ground speed on ATC

radar screens. The GTX 320/320A is equipped with IDENT capability that activates the Special Position

Identification Pulse (SPI) for approximately 20 seconds (18 seconds for the GTX 320A) identifying your

transponder return from other aircraft on the controller’s scope.

1.3 TECHNICAL SPECIFICATIONS

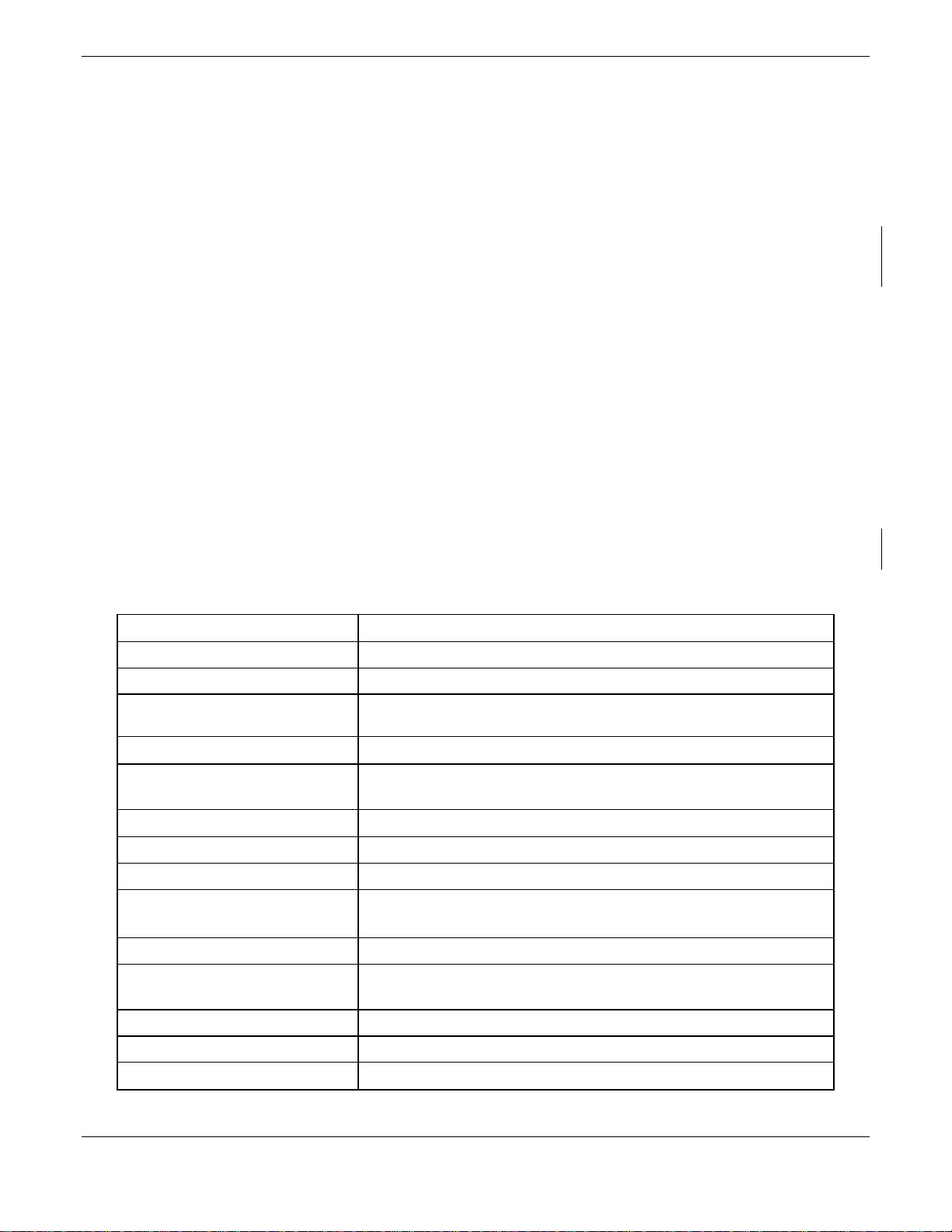

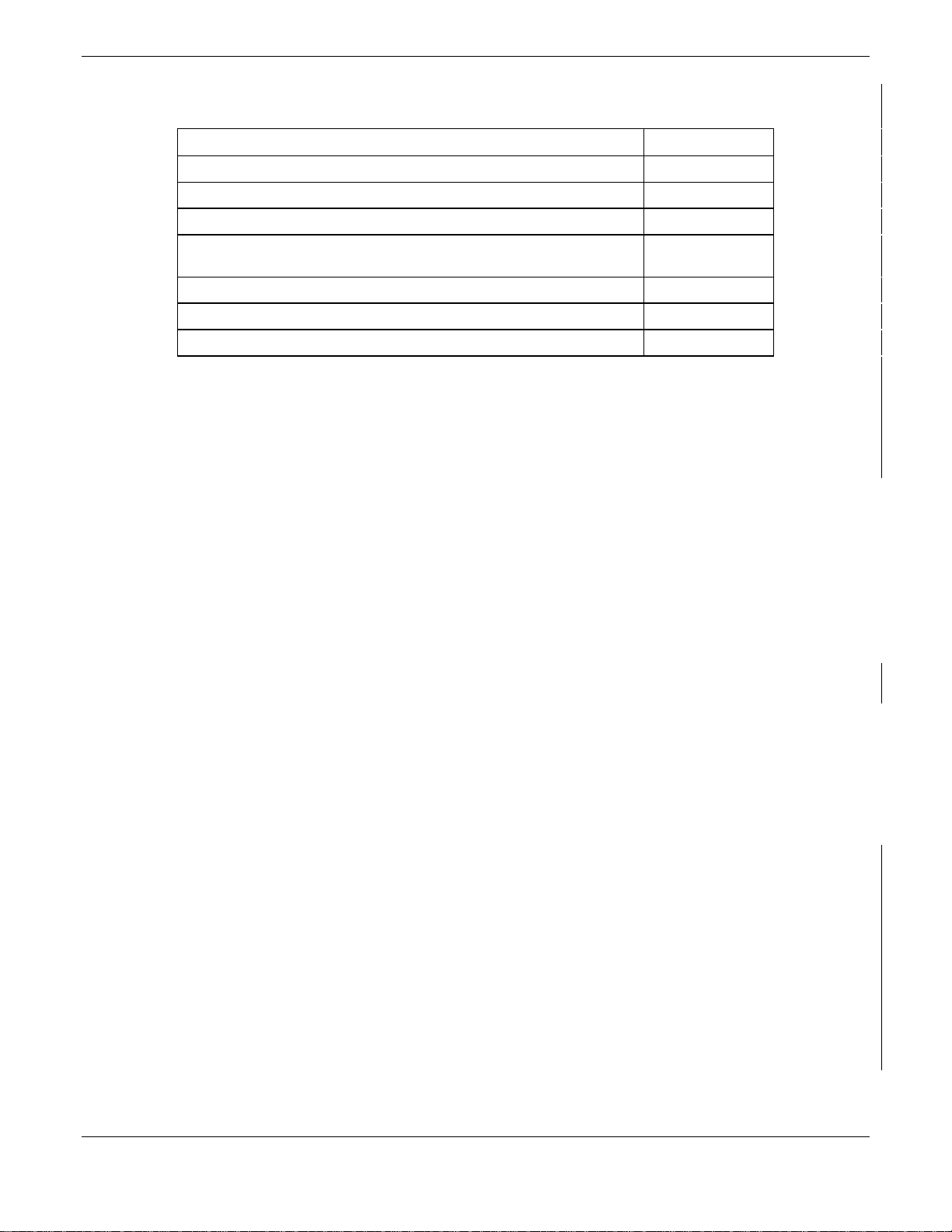

1.3.1 Transponder Specifications

SPECIFICATION CHARACTERISTIC

TSO, JTSO TSO C74c Class 1A, JSTO C74C Class 1A

TSO ENV CAT (A1D1)-CA(BMN)XXXXXXZBABAUZXXXXXX

Applicable Documents

Temperature Range

Power Requirements

Humidity

Altitude 50,000 Feet

Transmitter Frequency 1090 MHz

Transmitter Power

Receiver Frequency 1030 MHz

Receiver Sensitivity

Mode A Capability 4096 Identification Codes

Mode C Capability 100 Foot Increments from -1000 to 63,000 Feet

External Suppression Input

GTX 320: FAA TSO C74c; RTCA DO-160C, JTSO C74c

GTX 320A: FAA TSO C74c; RTCA DO-160D, JTSO C74c

-20°C to +55°C (Continuous Operation)

GTX 320: +11.0 to +33.0 VDC: 12 Watts Max.

GTX 320A: +11.0 to +33.0 VDC: 20 Watts Max.

95% @ +55°C for 16 Hours; 85% @ +38°C for 32 Hours

125 Watts minimum, 150 Watts nominal at the antenna with 1.5

coaxial cable loss at 1090 MHz

GTX 320: -72 dBm Nominal for 90% replies

GTX 320A: -74 dBm Nominal for 90% replies

Low ≤ 0.5 V; High ≥ 8 V

dB

GTX 320/320A Installation Manual Page 1

190-00133-01 Rev L

1.3.2 Physical Characteristics-GTX 320

Bezel Height 1.63 inches (41 mm)

Bezel Width 6.25 inches (159 mm)

Rack Height (Dimple to Dimple) 1.71 inches (43 mm)

Rack Width 6.30 inches (160 mm)

Depth Behind Panel with

Connectors (measured from face of

aircraft panel to rear of connector

backshells)

Weight (Unit Only) 1.7 lbs. (0.8 kg)

Weight (Installed with rack and

connectors)

1.3.3 Physical Characteristics-GTX 320A

Bezel Height 1.63 inches (41 mm)

Bezel Width 6.25 inches (159 mm)

Rack Height (Dimple to Dimple) 1.71 inches (43 mm)

Rack Width 6.30 inches (160 mm)

Depth Behind Panel with

Connectors (measured from face of

aircraft panel to rear of connector

backshells)

Weight (Unit Only) 2.3 lbs. (1.1 kg)

Weight (Installed with rack and

connectors)

8.78 inches (223 mm)

2.3 lbs. (1.1 kg)

8.78 inches (223 mm)

2.9 lbs. (1.3 kg)

1.4 EQUIPMENT AVAILABLE

1.4.1 Configurations Available

ITEM GARMIN P/N

GARMIN GTX 320 Transponder 010-00135-00

GARMIN GTX 320A Transponder 010-00247-00

GARMIN GTX 320 Transponder includes GARMIN installation kit, P/N 010-10161-00 010-00135-03

GARMIN GTX 320A Transponder includes GARMIN installation kit, P/N 010-10161-01 010-00247-02

Page 2 GTX 320/320A Installation Manual

Rev L 190-00133-01

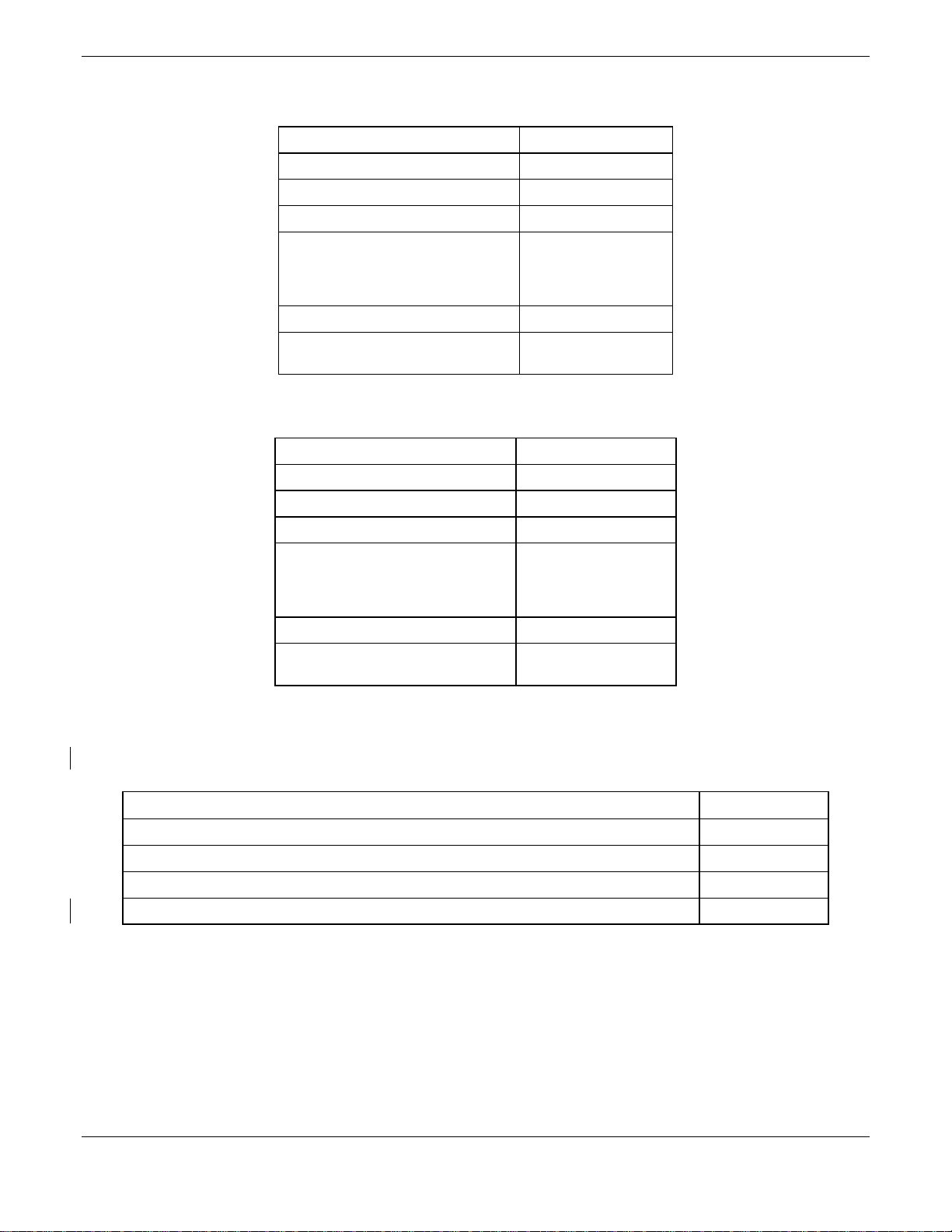

1.4.2 Installation Accessories

ITEM GARMIN P/N

Mounting Rack 115-00285-00

Connector Kit 011-00651-01

Rear Backplate 011-00677-01

Mounting Rack, Rear Backplate and Connector Kit

(Includes 115-00285-00, 011-00677-01 and 011-00651-01)

GARMIN GTX 320/320A Narco Adapter 010-10158-00

GARMIN GTX 320/320A KT76A Adapter 010-10159-00

GARMIN GTX 320/320A Antenna kit* 010-10160-00

010-10161-01

* Note: A transponder antenna approved to TSO C66( ) or C74( ) that has been installed to meet the

requirements of this manual may be approved for use with the GTX 320/320A.

1. 5 ADDITIONAL EQUIPMENT REQUIRED

• Antenna Sealant - Use antenna manufacturer’s instructions, install according to FAA

AC 43.13-2A.

• Cables - The installer will supply all system cables. Cable requirements and fabrication is

detailed in Section 2 of this manual.

• Hardware - #6 Flat Head Screw (6 ea.) and #6-32 Self Locking Nut (6 ea.). Hardware required to

mount installation rack is not provided.

1.6 INSTALLATION APPROVAL

The conditions and tests required for TSO approval of the GTX 320/320A Transponder and antenna are

minimum performance standards. It is the responsibility of those desiring to install this transponder and antenna

either on or within a specific type or class of aircraft to determine that the aircraft installation standards are

within the TSO standards. The GTX 320/320A and antenna may be installed only if further evaluation by the

applicant documents an acceptable installation and is approved by the administrator. For GTX 320/320A TSO

compliance, see Appendix A. For antenna TSO compliance, refer to antenna manufacturer’s literature.

1.7 ATC TRANSPONDER TESTS AND INSPECTIONS

The ATC transponder tests required by 14 CFR, Part 91.413 may be conducted using a bench check or portable

test equipment and must meet the requirements prescribed in Part 43 Appendix F.

If portable test equipment with appropriate coupling to the aircraft antenna system is used, operate the test

equipment for ATCRBS transponders at a nominal rate of 235 interrogations per second to avoid possible

ATCRBS interference. An additional 3 dB loss is allowed to compensate for antenna coupling errors during

receiver sensitivity measurements conducted in accordance with Part 43 Appendix F, Paragraph (c)(1) when

using portable test equipment.

GTX 320/320A Installation Manual Page 3

190-00133-01 Rev L

1.8 LIMITED WARRANTY

GARMIN warrants this product to be free from defects in materials and manufacture for one year from the date

of purchase. GARMIN will, at its sole option, repair or replace any components that fail in normal use. Such

repairs or replacement will be made at no charge to the customer for parts or labor. The customer is, however,

responsible for any transportation costs. This warranty does not cover failures due to abuse, misuse, accident or

unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES EXPRESS OR IMPLIED OR STATUTORY, INCLUDING ANY LIABILITY

ARISING UNDER ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

WHICH MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL GARMIN BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE, OR INABILITY TO

USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT. SOME STATES DO NOT ALLOW THE

EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY

NOT APPLY TO YOU.

To obtain warranty service, call the GARMIN Customer Service department (913-397-8200) for a returned

merchandise tracking number. The unit should be securely packaged with the tracking number clearly marked on

the outside of the package and sent freight prepaid and insured to a GARMIN warranty service station. A copy

of the original sales receipt is required as the proof of purchase for warranty repairs. GARMIN retains the

exclusive right to repair or replace the unit or software or offer a full refund of the purchase price at its sole

discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF

WARRANTY.

Page 4 GTX 320/320A Installation Manual

Rev L 190-00133-01

2. INSTALLATION

2.1 INTRODUCTION

This section provides the necessary information for installing the GTX 320/320A Transponders, and where

required, optional accessories. Installation of the GTX 320/320A will differ according to equipment location and

other factors. Cabling will be fabricated by the installing agency to fit these various requirements. This section

contains interconnect diagrams, mounting dimensions, and information pertaining to installation. Each

installation shall be accomplished to meet the requirements of FAA AC 43.13-2A.

2.2 UNPACKING AND INSPECTING EQUIPMENT

Carefully unpack the equipment and make a visual inspection of the unit for evidence of damage incurred during

shipment. If the unit is damaged, notify the carrier and file a claim. To justify a claim, save the original shipping

container and all packing materials. Do not return the unit to GARMIN until the carrier has authorized the claim.

Retain the original shipping containers for storage. If the original containers are not available, a separate

cardboard container should be prepared that is large enough to accommodate sufficient packing material to

prevent movement.

2.3 ANTENNA INSTALLATION

2.3.1 Location Considerations

A. The antenna (GARMIN P/N 010-10160-00) should be well removed from any major protrusions, the

engine(s), propeller(s), and antenna masts. It should also be as far removed as practical from

landing gear doors, access doors, or other openings that could alter its radiation pattern.

B. The antenna should be mounted on the underside of the aircraft and in a vertical position when the

aircraft is in level flight.

C. Avoid mounting the antenna within three feet of the ADF sense antenna or any other

communication antenna and six feet from the DME antenna.

D. To prevent RF interference, the antenna must be physically mounted a minimum distance of three

feet from the GTX 320/320A.

If the antenna is being installed on a composite aircraft, ground planes must sometimes be added.

Conductive wire mesh, radials, or thin aluminum sheets embedded in the composite material provide

the proper ground plane allowing the antenna pattern (gain) to be maximized for optimum

transponder performance.

2.3.2 Antenna Installation

Install the antenna according to the antenna manufacturer’s instructions and FAA AC 43.13-2A.

NOTE

GTX 320/320A Installation Manual Page 5

190-00133-01 Rev L

2.3.3 Installation Approval Considerations for Pressurized Aircraft

Antenna and cable installations on pressurized cabin aircraft require FAA approved installation design and

engineering substantiation data whenever such installations incorporate alteration (penetration) of the cabin

pressure vessel by connector holes and/or mounting arrangements.

For needed engineering support pertaining to the design and approval of such pressurized aircraft antenna

installations, it is recommended that the installer proceed according to any of the following listed alternatives:

1. Obtain approved antenna installation design data from the aircraft manufacturer.

2. Obtain an FAA approved Supplemental Type Certificate (STC) pertaining to and valid for the subject

antenna installation.

3. Contact the FAA Aircraft Certification Office in the appropriate Region and request identification of FAA

Designated Engineering Representatives (DERs) who are authorized to prepare and approve the required

antenna installation engineering data.

4. Obtain FAA Advisory Circular AC-183C and select (and contact) a DER from the roster of individuals

identified there under.

Contact an aviation industry organization such as the Aircraft Electronics Association and request their

assistance.

Page 6 GTX 320/320A Installation Manual

Rev L 190-00133-01

2.3.4 Antenna Cable Installation

When routing antenna cables, observe the following precautions:

• All cable routing should be kept as short as possible and as direct as possible.

• Avoid sharp bends.

• Avoid routing cables near power sources (e.g., 400 Hz generators, trim motors, etc.) or near

power for fluorescent lighting.

• Avoid routing cable near ADF antenna cable (allow at least a 12-inch separation).

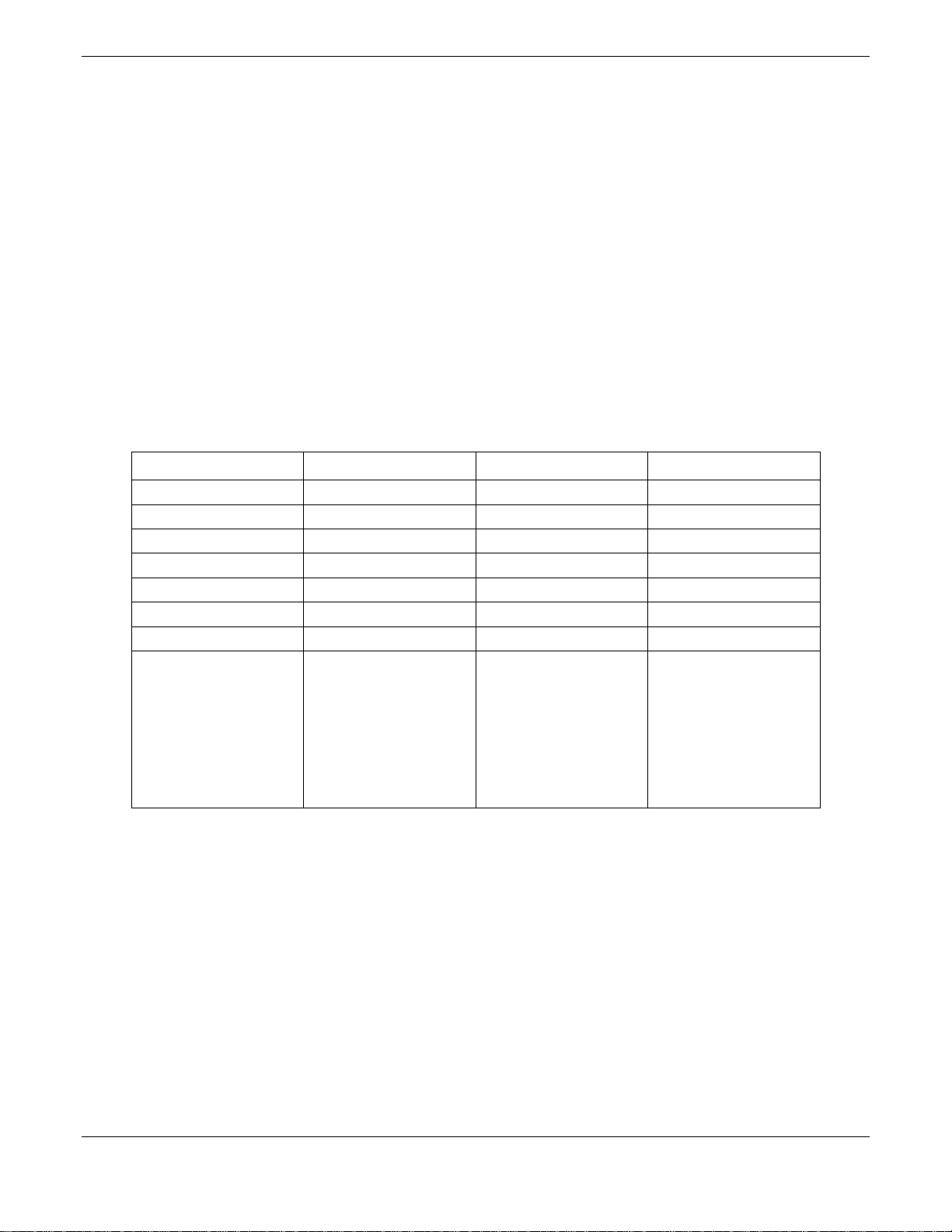

The table below lists the recommended 50 ohm double shielded coax antenna cable vendor and the type to be

used for specific lengths of cable. Adherence to this table will ensure that the coax installation will not exceed

the maximum allowable 1.5 dB attenuation at the transmitter operating frequency of 1090 MHz.

Max. Length (feet) ECS Type MIL-C-17 Type RG Type

8.8 M17/128 RG400

10.0 3C142B

12.5 M17/112 RG304

17.0 311601 M17/127 RG393

21.0 311501

27.0 311201

41.0 310801

Supplier Information

Vendor: Electronic

Cable Specialists

5300 W. Franklin Drive

Franklin, WI 53132

Tel: 800-327-9473

414-421-5300

Fax: 414-421-5301

MIL-C-17 types: See

current issue of

Qualified Products List

QPL-17.

RG types: See current

issue of Qualified

Products List QPL-17.

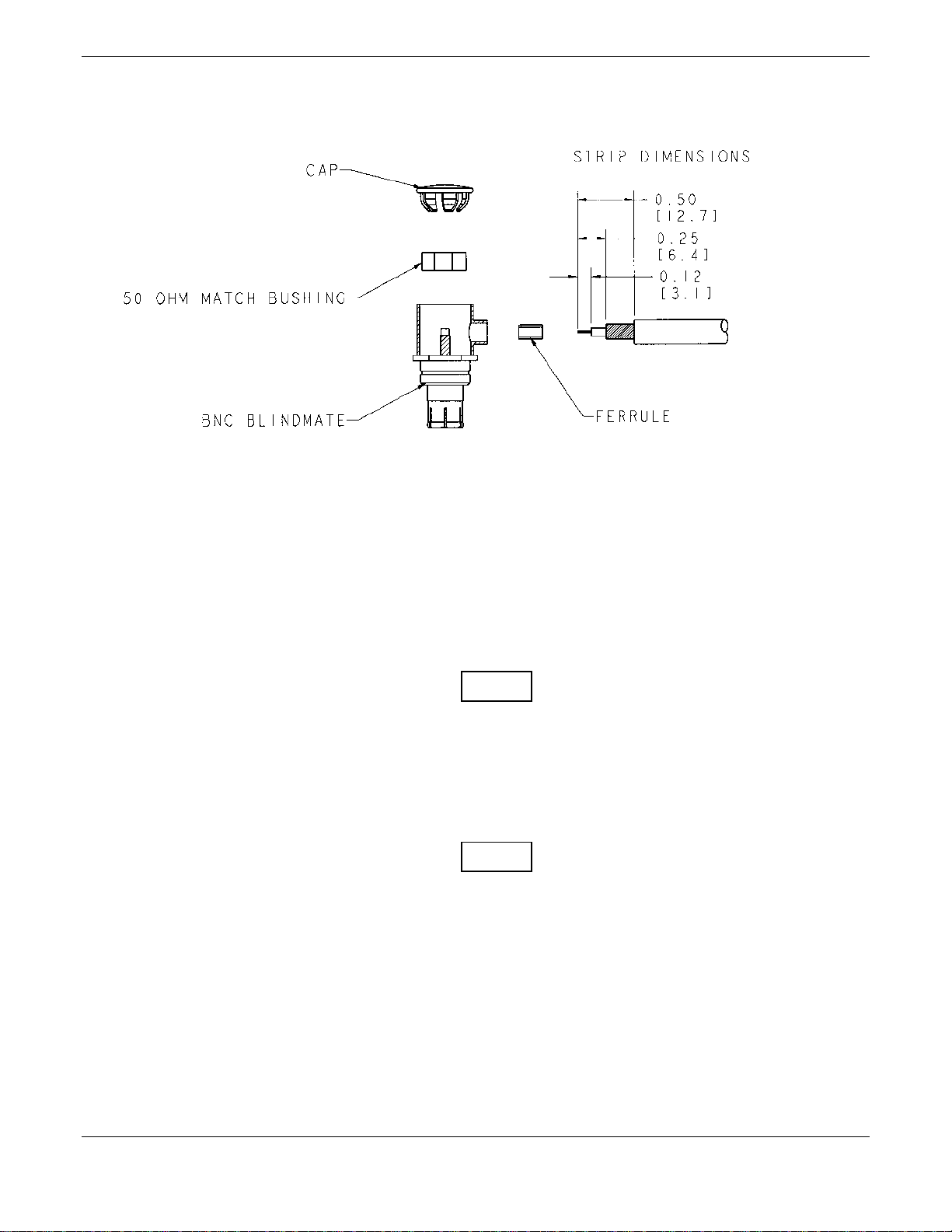

2.3.5 Antenna Cable Connectors

One of two rack connectors is provided (item 6 or 12 in the installation drawing, figure B2). RF Adapter item 12

(P/N 330-00326-00) requires the cable to be terminated to an appropriate type BNC plug (provided by installer),

which is then attached to item 12. Any 50 ohm, double shielded cable may be used, provided it introduces less

than 1.5 dB attenuation at 1 GHz including the connector.

Connector item 6 (P/N 330-00198-00) requires the cable to be terminated directly to it and can accommodate

only M17/128 (RG-400) cable. The completed cable including connectors must introduce no more than 1.5

attenuation at 1 GHz. Instructions for installing the item 6 are shown below (steps A-G).

GTX 320/320A Installation Manual Page 7

190-00133-01 Rev L

dB

A. Trim coax outer insulation back 0.50".

B. Trim braid (not center conductor or insulation) back 0.25".

C. Strip Insulation back 0.120".

NOTE

Place the ferrule over the coax braid, flush against the coax outer insulation before performing the

next step if the outside diameter of the coax braid is smaller than the inside diameter of the center

connector sidewall opening.

D. Insert cable (center conductor, dielectric and shield braid) through the sidewall of the connector and

solder the center conductor to the center pin of the connector.

NOTE

When using low loss cable it may be necessary to flatten the solid wire center conductor slightly so

it can fit the slot on the RF connector center pin. When soldering, avoid applying excess heat to the

connector body, and center conductor insulator.

E. Heat the outside of the connector sleeve and at the same time apply solder between the braid and the

sleeve. Continue to apply heat until the solder flows evenly.

F. Install 50 1 Matching Bushing.

G. Insert connector cap and tack solder in two places.

Page 8 GTX 320/320A Installation Manual

Rev L 190-00133-01

Loading...

Loading...