Page 1

GTX 23

Transponder

Installation Manual

190-00906-01 January, 2018 Revision G

Page 2

© 2018

Garmin Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied,

transmitted, disseminated, downloaded or stored in any storage medium, for any purpose without

the express prior written consent of Garmin. Garmin hereby grants permission to download a

single copy of this manual and of any revision to this manual onto a hard drive or other electronic

storage medium to be viewed and to print one copy of this manual or of any revision hereto,

provided that such electronic or printed copy of this manual or revision must contain the complete

text of this copyright notice and provided further that any unauthorized commercial distribution of

this manual or any revision hereto is strictly prohibited.

Garmin International, Inc.

1200 E. 151st Street

Olathe, KS 66062 USA

Telephone: 913.397.8200

Aviation Panel-Mount Technical Support Line (Toll Free) 1.888.606.5482

www.garmin.com

Garmin (Europe) Ltd.

Liberty House, Hounsdown Business Park

Southampton, Hampshire SO40 9LR U.K.

+44/ (0) 370 850 1243

Garmin AT, Inc.

2345 Turner Rd., SE

Salem, OR 97302 USA

Telephone: 503.581.8101

AVIATION LIMITED WARRANTY

GTX 23 warranty information is available at garmin.com/aviationwarranty.

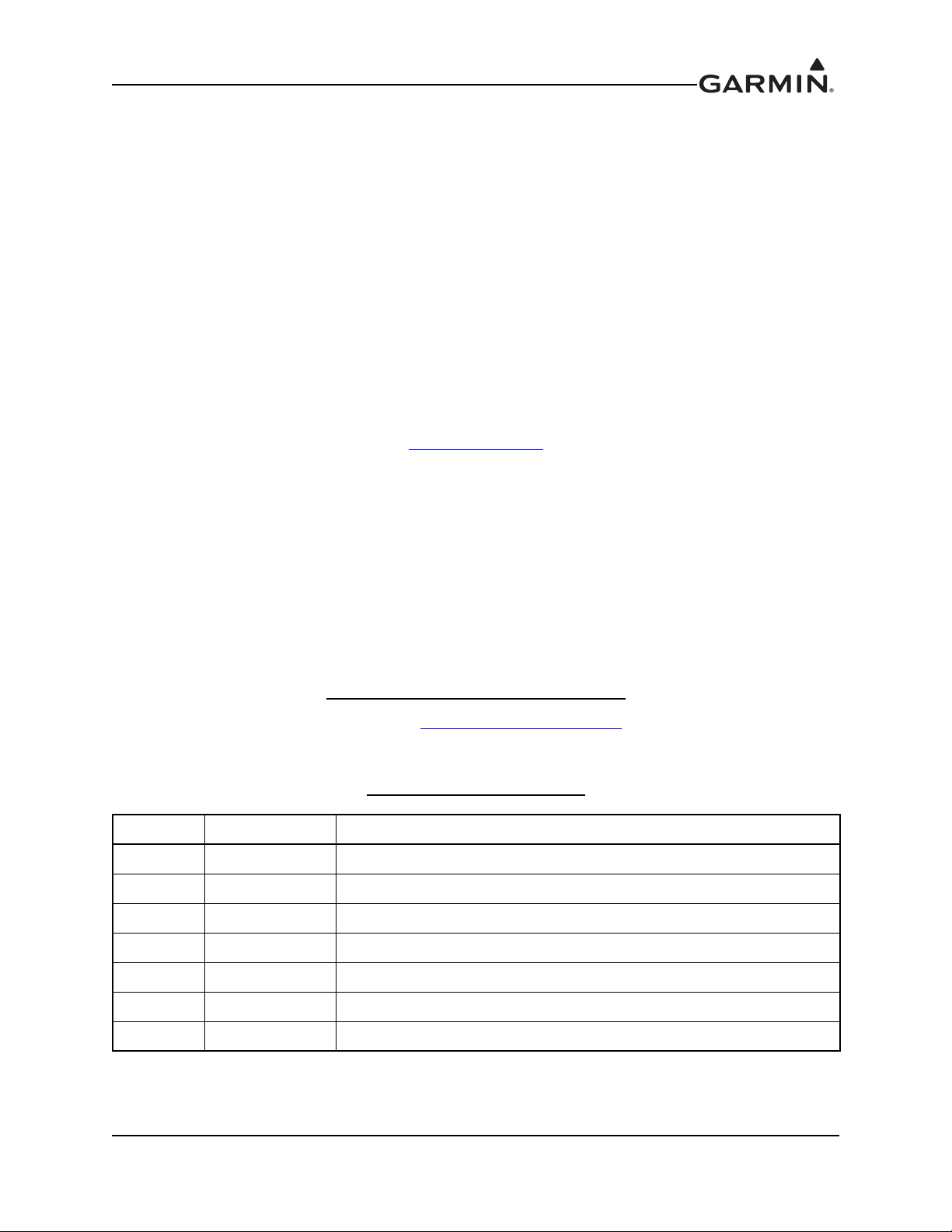

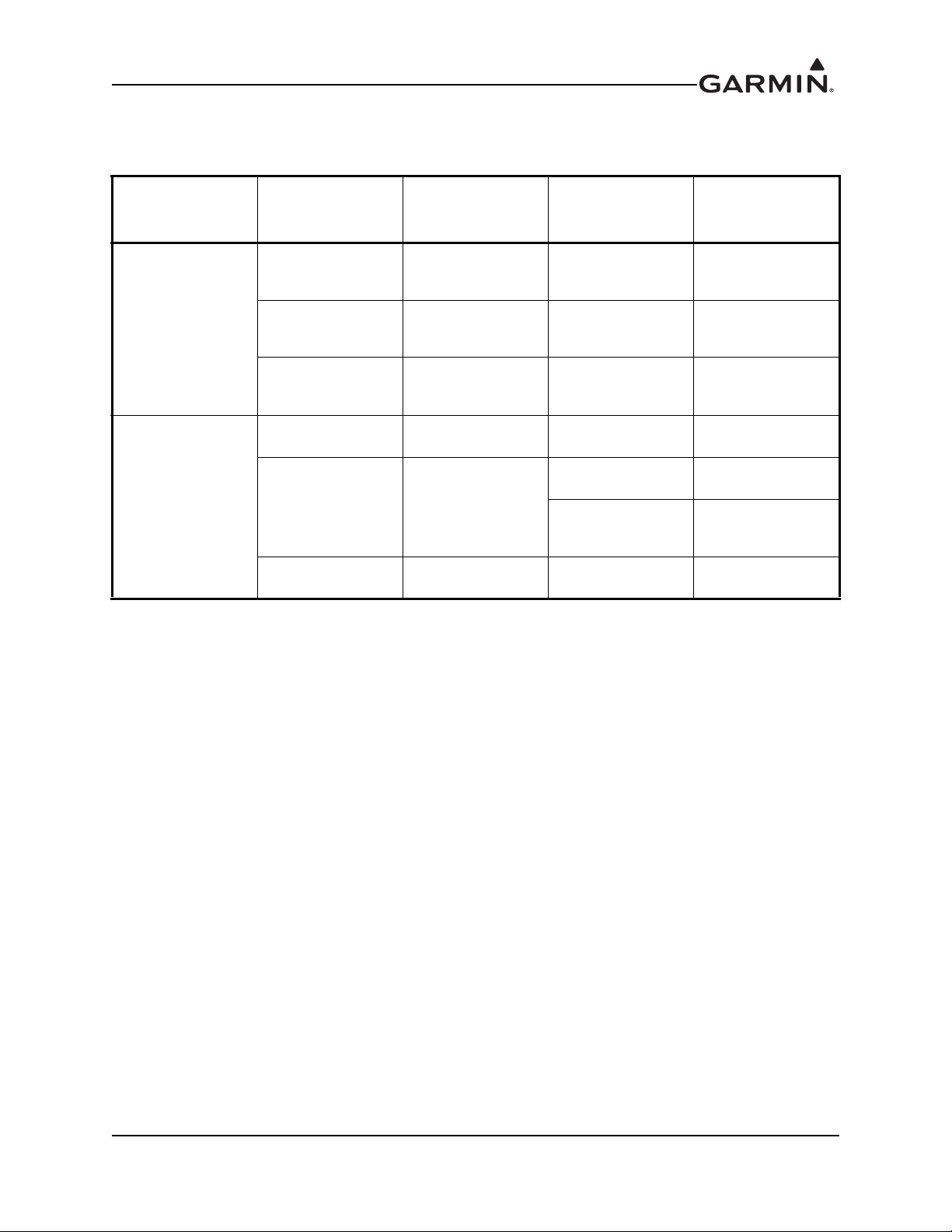

RECORD OF REVISIONS

Revision Revision Date Description

A 08/31/2011 Initial release

B 09/11/2012 Updated for SW v7.01

C 06/06/14 Updated mounting rack info

D 09/22/14 Updated TSO and configuration info

E 04/08/15 Corrected SW part numbers

F 10/20/15 Updated SW and CLD part numbers

G 01/03/18 Updated Transponder Capabilities info

190-00906-01 GTX 23 Installation Manual

Rev. G Page A

Page 3

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration Regulations

("EAR") issued by the United States Department of Commerce (15 CFR, Chapter VII, Subchapter C) and

which may not be exported, released, or disclosed to foreign nationals inside or outside of the United States

without first obtaining an export license. The preceding statement is required to be included on any and all

reproductions in whole or in part of this manual.

CURRENT REVISION DESCRIPTION

Revision

G

Page

Number(s)

iii Front Added Software License Agreement

1-1 1.2 Updated Equipment Description

1-5 1.7.1 Added continuous operation spec to Table 1-2

1-6 1.7.2 Updated Table 1-3

2-5 2.5 Added Electrical Bonding section

3-4, 3-5 3.8.1.1 Added Configuration Considerations section

4-4 4.2.2 Updated active low description in Table 4-4

4-5 4.3.1 Updated RS-232 description

C-1–C-12 Appdx C

C-2 Appdx C Updated Figure C-2

Section

Number

Description of Change

Removed Appendix C (Compliance Matrix) from previous

revision

190-00906-01 GTX 23 Installation Manual

Rev. G Page i

Page 4

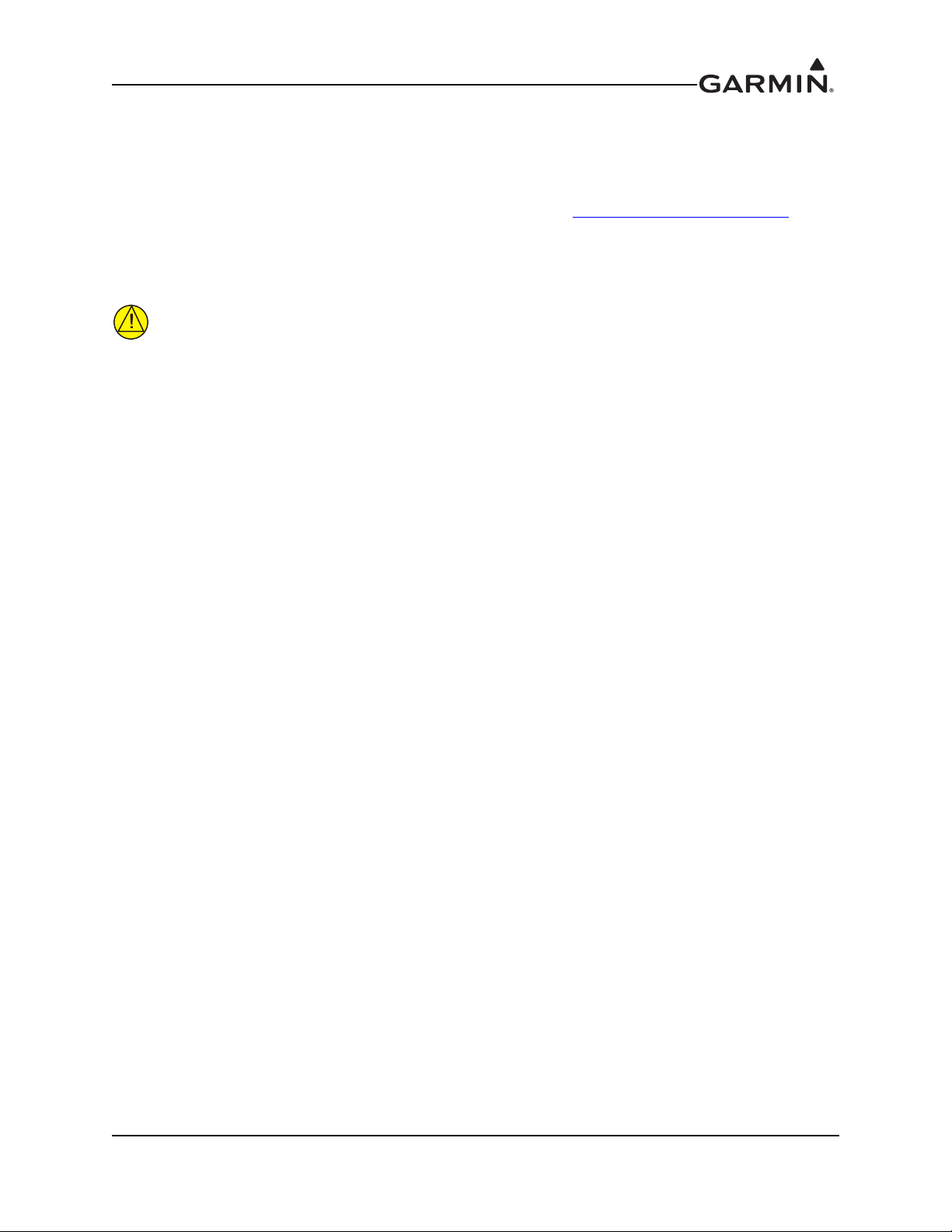

DEFINITIONS OF WARNINGS, CAUTIONS, AND NOTES

WARNING

WARNING

WARNING

Warni ngs are used to bring to the installer’s immediate attention that not only

damage to the equipment but personal injury may occur if the instruction is

disregarded.

CAUTION

Cautions are used to alert the individual that damage to equipment may

result if the procedural step is not followed to the letter.

NOTE

Notes are used to expand and explain the preceding step and provide further

understanding of the reason for the particular operation.

This product, its packaging, and its components contain chemicals known to the State of

California to cause cancer, birth defects, or reproductive harm. This Notice is being

provided in accordance with California's Proposition 65. If you have any questions or

would like additional information, please refer to our web site at www.garmin.com/prop65

Perchlorate Material – special handling may apply. See www.dtsc.ca.gov/hazardouswaste/

perchlorate.

.

190-00906-01 GTX 23 Installation Manual

Rev. G Page ii

Page 5

SOFTWARE LICENSE AGREEMENT

BY USING THE DEVICE, COMPONENT OR SYSTEM MANUFACTURED OR SOLD BY GARMIN

(“THE GARMIN PRODUCT”), YOU AGREE TO BE BOUND BY THE TERMS AND CONDITIONS

OF THE FOLLOWING SOFTWARE LICENSE AGREEMENT. PLEASE READ THIS AGREEMENT

CAREFULLY. Garmin Ltd. and its subsidiaries (“Garmin”) grants you a limited license to use the

software embedded in the Garmin Product (the “Software”) in binary executable form in the normal

operation of the Garmin Product. Title, ownership rights, and intellectual property rights in and to the

Software remain with Garmin and/or its third-party providers. You acknowledge that the Software is the

property of Garmin and/or its third-party providers and is protected under the United States of America

copyright laws and international copyright treaties. You further acknowledge that the structure,

organization, and code of the Software are valuable trade secrets of Garmin and/or its third-party providers

and that the Software in source code form remains a valuable trade secret of Garmin and/or its third-party

providers. You agree not to reproduce, decompile, disassemble, modify, reverse assemble, reverse

engineer, or reduce to human readable form the Software or any part thereof or create any derivative works

based on the Software. You agree not to export or re-export the Software to any country in violation of the

export control laws of the United States of America.

190-00906-01 GTX 23 Installation Manual

Rev. G Page iii

Page 6

TABLE OF CONTENTS

PARAGRAPH PAGE

Section 1 GENERAL DESCRIPTION .............................................................1-1

1.1 Introduction...................................................................................................................... 1-1

1.2 Equipment Description .................................................................................................... 1-1

1.3 ADS-B Capabilities ......................................................................................................... 1-2

1.4 TIS System Capabilities................................................................................................... 1-3

1.5 Mutual Suppression Pulses .............................................................................................. 1-4

1.6 Interface Summary...........................................................................................................1-4

1.7 Technical Specifications .................................................................................................. 1-5

1.8 License Requirements...................................................................................................... 1-8

1.9 Certification ..................................................................................................................... 1-8

1.10 Operating Instructions.................................................................................................. 1-12

1.11 Reference Documents .................................................................................................. 1-12

Section 2 INSTALLATION OVERVIEW........................................................2-1

2.1 Introduction...................................................................................................................... 2-1

2.2 Installation Materials ....................................................................................................... 2-1

2.3 Installation Considerations .............................................................................................. 2-3

2.4 Cabling and Wiring..........................................................................................................2-4

2.5 Electrical Bonding ........................................................................................................... 2-5

2.6 Cooling Air ...................................................................................................................... 2-5

2.7 GTX 23 Mounting Requirements .................................................................................... 2-5

Section 3 INSTALLATION PROCEDURE.....................................................3-1

3.1 Unpacking Unit................................................................................................................ 3-1

3.2 Wiring Harness Installation ............................................................................................. 3-1

3.3 Electrical Connections ..................................................................................................... 3-1

3.4 Backshell Assembly......................................................................................................... 3-2

3.5 Weight and Balance ......................................................................................................... 3-2

3.6 Electrical Load Analysis.................................................................................................. 3-2

3.7 Final Installation .............................................................................................................. 3-3

3.8 Post Installation Configuration and Checkout ................................................................. 3-4

3.9 Continued Airworthiness ................................................................................................. 3-6

Section 4 SYSTEM INTERCONNECTS..........................................................4-1

4.1 Pin Function List.............................................................................................................. 4-1

4.2 Discrete Functions ........................................................................................................... 4-3

4.3 Serial Data Electrical Characteristics .............................................................................. 4-5

4.4 RS-232 Input/Output, Software Update Connections...................................................... 4-6

Appendix A CONSTRUCTION AND VALIDATION OF STRUCTURES A-1

A.1 Static Test Loading ........................................................................................................ A-1

190-00906-01 GTX 23 Installation Manual

Rev. G Page iv

Page 7

A.2 Determining Static Load Capability .............................................................................. A-1

Appendix B SHIELD BLOCK INSTALLATION INSTRUCTIONS ..........B-1

B.1 Shield Block Installation Parts ........................................................................................B-1

B.2 Shield Termination Technique – Method A.1 (Standard)...............................................B-3

B.3 Shield Termination Technique - Method A.2 (Daisy Chain).........................................B-7

B.4 Shield Termination – Method B.1 (Quick Term)............................................................B-7

B.5 Shield Termination-Method B.2 (Daisy Chain-Quick Term) .........................................B-9

B.6 Daisy Chain between Methods A and B .......................................................................B-10

B.7 Splicing Signal Wires....................................................................................................B-10

Appendix C INTERCONNECT DRAWINGS (Example Only)....................C-1

Appendix D OUTLINE AND INSTALLATION DRAWINGS.....................D-1

190-00906-01 GTX 23 Installation Manual

Rev. G Page v

Page 8

LIST OF FIGURES

FIGURE PAGE

Section 1 GENERAL DESCRIPTION .............................................................1-1

Section 2 INSTALLATION OVERVIEW........................................................2-1

Figure 2-1. Antenna Installation Considerations ................................................................... 2-3

Figure 2-2. GTX 23 Remote Rack (115-00629-00) .............................................................. 2-6

Figure 2-3. GTX 23 Modular Rack (115-00438-00) ............................................................. 2-6

Figure 2-4. GTX 23 Remote Rack, Suggested Mounting Locations..................................... 2-7

Section 3 INSTALLATION PROCEDURE.....................................................3-1

Figure 3-1. Aircraft Length and Width Determination.......................................................... 3-4

Figure 3-2. Combined GPS Antenna Containment ............................................................... 3-5

Section 4 SYSTEM INTERCONNECTS..........................................................4-1

Figure 4-1. J2301 Connector ................................................................................................. 4-1

Figure 4-2. GTX 23 Software Update Connections .............................................................. 4-6

Appendix A CONSTRUCTION AND VALIDATION OF STRUCTURESA-1

Figure A-1. Upward static Load Test ................................................................................... A-2

Figure A-2. Forward Static Load Test .................................................................................. A-2

Appendix B SHIELD BLOCK INSTALLATION INSTRUCTIONS.......... B-1

Figure B-1 Shield Block Installation (78 pin example).........................................................B-2

Figure B-2 Method A.1 for Shield Termination ....................................................................B-3

Figure B-3 Insulation/Contact Clearance ..............................................................................B-5

Figure B-4 Method A.2 (Daisy Chain) for Shield Termination ............................................B-7

Figure B-5 Method B.1 (Quick Term) for Shield Termination .............................................B-8

Figure B-6 Method B.2 (Daisy Chain-Quick Term) for Shield Termination........................B-9

Figure B-7 Daisy Chain between Methods A and B ...........................................................B-10

Figure B-8 D-Sub Spliced Signal Wire illustration .............................................................B-11

Appendix C INTERCONNECT DRAWINGS (Example Only) ...................C-1

Figure C-1 Core Interconnect Examples ...............................................................................C-1

Figure C-2 ADS-B Interconnect Examples ...........................................................................C-2

Figure C-3 TIS Display Options Example.............................................................................C-3

Appendix D OUTLINE AND INSTALLATION DRAWINGS ....................D-1

Figure D-1 GTX 23 in Remote Rack, Outline Drawing....................................................... D-1

Figure D-2 GTX 23 Connector/Remote Rack Assembly Drawing ...................................... D-2

Figure D-3 GTX 23 in Modular Rack, Outline Drawing ..................................................... D-3

Figure D-4 GTX 23 Connector/Modular Rack Assembly Drawing..................................... D-4

190-00906-01 GTX 23 Installation Manual

Rev. G Page vi

Page 9

LIST OF TABLES

TABLE PAGE

Section 1 GENERAL DESCRIPTION .............................................................1-1

Table 1-1 ADS-B Versions.................................................................................................... 1-2

Table 1-2 General Specifications........................................................................................... 1-5

Table 1-3 Transponder Capabilities....................................................................................... 1-6

Table 1-4 Physical Characteristics......................................................................................... 1-7

Table 1-5 Power Requirements.............................................................................................. 1-7

Table 1-6 TSO/ETSO/RTCA/ICAO Compliance ................................................................. 1-9

Table 1-7 TSO/ETSO Deviations ........................................................................................ 1-10

Table 1-8 Additional TSO/ETSO Deviations Specific to Software Versions ..................... 1-11

Table 1-9 Non TSO Functions............................................................................................. 1-11

Table 1-10 Other Regulatory Criteria.................................................................................. 1-11

Table 1-11 Reference Documents........................................................................................ 1-12

Section 2 INSTALLATION OVERVIEW........................................................2-1

Table 2-1 Installation Materials............................................................................................. 2-1

Table 2-2 Equipment Available............................................................................................. 2-1

Table 2-3 GTX 23 Connector Kit (011-01012-01)................................................................ 2-2

Table 2-4 Cable Specifications .............................................................................................. 2-4

Section 3 INSTALLATION PROCEDURE.....................................................3-1

Table 3-1 Pin Contact Part Numbers (High Density) ............................................................ 3-1

Table 3-3 Unit Power Loads.................................................................................................. 3-2

Table 3-2 Recommended Crimp Tools (High Density)......................................................... 3-2

Section 4 SYSTEM INTERCONNECTS..........................................................4-1

Table 4-1 J2301 Pin Assignments ......................................................................................... 4-1

Table 4-2 Aircraft Power ....................................................................................................... 4-3

Table 4-3 Discrete Outputs .................................................................................................... 4-3

Table 4-4 Discrete Inputs.......................................................................................................4-4

Table 4-5 RS-232 Input/Output ............................................................................................. 4-5

Table 4-6 ARINC 429 Input/Output...................................................................................... 4-5

Appendix A CONSTRUCTION AND VALIDATION OF STRUCTURESA-1

Table A-1 Static Test Load................................................................................................... A-1

Appendix B SHIELD BLOCK INSTALLATION INSTRUCTIONS.......... B-1

Table B-1 Parts Supplied for a Shield Block Installation (011-01012-01)............................B-1

Table B-2 Parts Not Supplied for a Shield Block Installation (Figure B-1)..........................B-1

Table B-3 Shielded Cable Preparations for Garmin Connectors...........................................B-3

Table B-4 Shielded Cable Preparations – (Quick Term).......................................................B-9

Appendix C INTERCONNECT DRAWINGS (Example Only) ...................C-1

Appendix D OUTLINE AND INSTALLATION DRAWINGS ....................D-1

190-00906-01 GTX 23 Installation Manual

Rev. G Page vii

Page 10

1 GENERAL DESCRIPTION

NOTE

1.1 Introduction

This manual is intended to provide mechanical and electrical information for use in the planning and

design of an installation of the GTX 23 into an aircraft. This manual is not a substitute for an approved

airframe-specific maintenance manual, installation design drawing, or complete installation data package.

Attempting to install equipment by reference to this manual alone and without first planning or designing

an installation specific to your aircraft may compromise your safety and is not recommended. The content

of this manual assumes use by competent and qualified avionics engineering personnel and/or avionics

installation specialists using standard aviation maintenance practices in accordance with Title 14 of the

Code of Federal Regulations and other relevant accepted practices. This manual is not intended for use by

individuals who do not possess the competencies and abilities set forth above.

Garmin recommends installation of the GTX 23 by a Garmin-authorized installer. To the

extent allowable by law, Garmin will not be liable for damages resulting from improper or

negligent installation of the GTX 23. For questions, please contact Garmin Aviation

Product Support at 1-888-606-5482.

1.2 Equipment Description

The Garmin GTX 23 rack-mounted Mode S Transponder is a radio transmitter and receiver that operates

on radar frequencies, receiving ground radar and TCAS interrogations at 1030 MHz and transmitting a

coded response of pulses on a frequency of 1090 MHz. The GTX 23 is equipped with IDENT capability

that activates the Special Position Identification (SPI) pulse for 18 seconds.

The GTX 23 replies to Mode A, Mode C and Mode S interrogations. Mode A replies consist of framing

pulses and any one of 4,096 codes, which differ in the position and number of pulses transmitted. Mode C

replies include framing pulses and encoded altitude. Mode S interrogations are selective. The Mode S

transponders can respond to a single directed interrogation from the ground station or another aircraft.

The GTX 23 with Extended Squitter Enabled provides Automatic Dependent Surveillance-Broadcast

(ADS-B) technology that improves situational awareness and flight safety. With ADS-B capabilities,

position, velocity, and heading information are automatically transmitted to other aircraft and ground

stations. The current air traffic control system depends on the transmission of interrogations for pertinent

aircraft information at a slower update rate. ADS-B provides immediate surveillance of air-to-air traffic

and aircraft in remote or inhospitable areas not currently covered by radar.

The GTX 23 is a Level 2 transponder, providing downlink of aircraft information. Ground stations can

interrogate Mode S Transponders individually using a 24-bit ICAO Mode S address, which is unique to the

particular aircraft. In addition, ground stations may interrogate a GTX 23 for its Transponder data

capability and the aircraft's Flight ID, which is the registration number or other call sign. The GTX 23

makes the maximum airspeed capability (set during configuration setup) available to TCAS systems

on-board nearby aircraft to aid in the determination of TCAS advisories. The GTX 23 also supports

receiving TIS services from ground stations.

The GTX 23 meets Mode S Enhanced Surveillance (EHS) requirements. Mode S Enhanced Surveillance is

used predominantly in European airspace. It provides information consisting of additional aircraft

parameters (see CS-ACNS and AMC 20-13) to ground radar systems. Compliance with Enhanced

Surveillance may require additional interface between aircraft systems and the GTX 23.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-1

Page 11

1.3 ADS-B Capabilities

NOTE

The GTX 23 provides the capabilities of Automatic Dependent Surveillance-Broadcast (ADS-B)

technology, which improves situational awareness and flight safety. With ADS-B capabilities, position,

velocity, and heading information are automatically transmitted to other aircraft and ground stations. The

current air traffic control system depends on a transponder request for pertinent aircraft information.

ADS-B provides automatic transmission of aircraft information without a request.

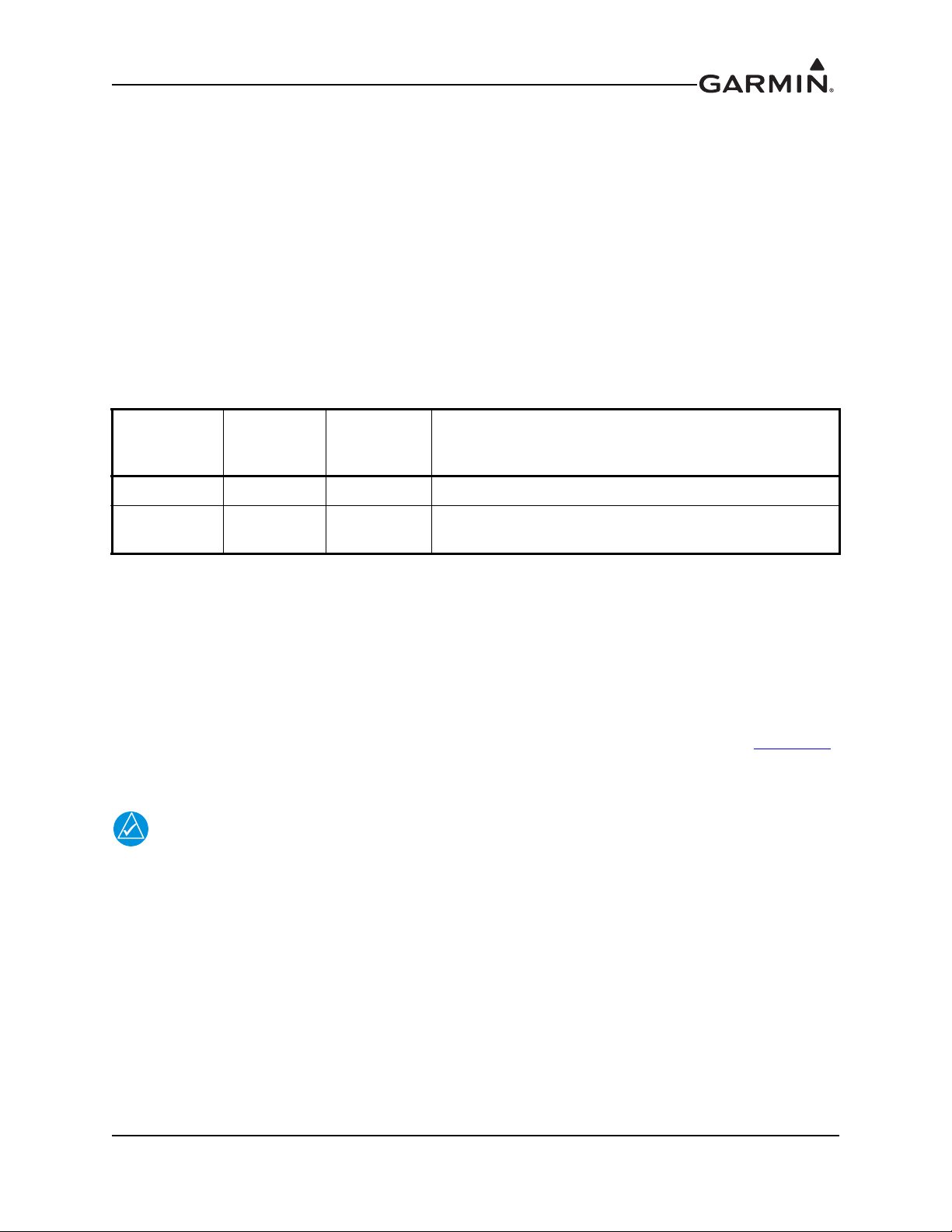

1.3.1 ADS-B Versions

There are three distinct ADS-B versions recognized by regulatory authorities. As shown in the table

below, the Garmin GTX 23 w/ES currently supports ADS-B Out 1090MHz Extended Squitter capability

meeting ‘Version 1’ or ‘Version 2' ADS-B system requirements depending on software version

(Table 1-1).

Table 1-1 ADS-B Versions

ADS-B

Version

Version 1 Yes 6.00 - 6.20 Equipment designed to (E)TSO-166a / RTCA DO-260A

Version 2* Yes

*Version required by 2020 ADS-B Out mandate defined in 14 CFR 91.225

GTX 23

w/ES

Compliant

Supported

SW Version

7.01

and later

Regulatory Standard/Minimum Performance

Specification

Equipment designed to TSO-166b / RTCA DO-260B

1.3.1.1 Installation Approval of Version 2 ADS-B Systems

GTX 23 w/ES transponders running software versions v7.01 and later support Version 2 ADS-B Out

functionality.

There are two options for installers wanting to install GTX 23 w/ES transponders running software

versions v7.01 and later:

1. Installers may elect to disable the ADS-B Extended Squitter function, as described in Section 3.8

2. Installers must utilize a Supplemental Type Certificate (STC) for the GTX 23 with the Version 2

ADS-B Extended Squitter activated.

It is the installer’s responsibility to ensure the ADS-B Out system is compliant with

AC 20-165 and to ensure compatibility between the GTX 23 and the ADS-B Out position

source equipment. See Garmin ADS-B Out Compatible Equipment (190-01533-00) for

compatible equipment shown to be eligible for 14 CFR 91.227-compliant installations in

accordance with AC 20-165

.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-2

Page 12

1.4 TIS System Capabilities

Traffic Information Service (TIS) provides a graphic display of traffic advisory information in the cockpit

for non-TCAS equipped aircraft.

TIS is a ground-based service providing relative location of all transponder equipped aircraft within a

specified service volume. The TIS ground sensor uses real time track reports to generate traffic

notification.

Traffic display is available to aircraft equipped with a Mode S data link such as the Garmin GTX 23

transponder. Traffic can then be displayed on a Garmin GDU Primary Flight Display, or GNS 400W/

500W-series unit.

Surveillance data includes all transponder equipped aircraft within the coverage volume. Aircraft without

an operating transponder are invisible to TIS. TIS displays traffic within seven nautical miles from 3000

feet below to 3500 feet above the requesting aircraft.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-3

Page 13

1.5 Mutual Suppression Pulses

Other equipment on board the aircraft may transmit in the same frequency band as the transponder. DME,

TCAS, or another transponder are examples of equipment that operate in the same frequency band. Mutual

suppression is a synchronous pulse that is sent to the other equipment to suppress transmission of a

competing transmitter for the duration of the transmission. The transponder transmission is suppressed by

an external source, and other equipment on board that transmit in the same frequency band are suppressed

by the GTX 23 transponder. This feature is designed to limit mutual interference.

1.6 Interface Summary

The GTX 23 provides the following interface connections via the rear connector. See Section 4 and

Appendix C for connection details.

• External IDENT input

• External STBY input (useful for dual transponder installations)

• External mutual suppression pulse input/output

• Aircraft power input (14/28 Vdc)

• RS-232 input #1 connection for altitude and unit control data

• RS-232 output #1 connection for TIS and unit status

• RS-232 input #2 connection for GPS data for ADS-B

• Supports Comm-A and Comm-B protocol

• ARINC 429 outputs for TIS data

• ARINC 429 input

The GTX 23 supports the following list of Comm-B Definition Subfield (BDS) registers:

• BDS (0,0) Air Initiated Comm-B (AICB)

• BDS (0,5) Extended Squitter Airborne Position (ES Enable Units Only)

• BDS (0,6) Extended Squitter Surface Position (ES Enable Units Only)

• BDS (0,7) Extended Squitter Status Position (ES Enable Units Only)

• BDS (0,8) Extended Squitter Aircraft Identification and Category (ES Enable Units Only)

• BDS (0,9) Extended Squitter Airborne Velocity – Subtypes 1 and 3 (ES Enable Units Only)

• BDS (0,A) Extended Squitter Event Driven Data (ES Enable Units Only)

• BDS (1,0) Data Link Capability Report

• BDS (1,7) Common Usage Ground Initiated Comm-B (GICB) Capability Report

• BDS (1,8) Mode S Specific Services GICB Capability Report

• BDS (1,9) Mode S Specific Services GICB Capability Report

• BDS (1,D) Mode S Specific Services Protocols (MSP) Capability Report

• BDS (2,0) Aircraft Identification

• BDS (4,0) Selected Vertical Intention

• BDS (5,0) Track and Turn Report

• BDS (6,0) Heading and Speed Report

• BDS (6,1) Emergency/Priority Status (ES Enable Units Only)

• BDS (6,2) Target State and Status (ES Enabled Units Only, software versions v8.01 and later)

• BDS (6,5) Aircraft operational Status (ES Enable Units Only)

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-4

Page 14

1.7 Technical Specifications

1.7.1 General Specifications

Table 1-2 General Specifications

Characteristic Specification

Environmental Qualification

Form

FCC Authorization Emission Designator 12M0M1D

FCC Authorization ID IPH-0046400

Temperature Range -45°C to +70°C (continuous operation)

Humidity

Altitude 55,000 Feet

Transmitter Frequency 1090 MHz ±1 MHz

Transmitter Power 125 Watts minimum, 250 Watts nominal.

Receiver Frequency 1030 MHz

Receiver Sensitivity -74 dBm nominal for 90% replies

External Suppression Input

External Suppression Output

Audio Output 4.04 Vrms to 7.85 Vrms into a 500 Ω load

Maximum Days of Continuous

Operation

005-00131-03

95% @ +50°C for 6 hours; 85% @ +38°C for 16 hours;

Tested to Category A in DO-160D

Low 0.5 V; High 8 V, maximum is +33 Vdc

Output: minimum is +18 V (for 300 Ω load) and maximum of +23 V (for

2000 Ω load).

48

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-5

Page 15

1.7.2 Transponder Capabilities

Table 1-3 Transponder Capabilities

Characteristic Specification

Mode A Capability 4096 Identification Codes

Mode C Altitude Capability 100 Foot increments from -1000 to 62,700 feet.

Mode S Altitude Capability

Mode S Uplink Capability UF0, UF4, UF5, UF11, UF16, UF20, UF21 - see Note 1

Mode S Downlink Capability DF0, DF4, DF5, DF11, DF16, DF17, DF20, DF21

Data Link Capability

Diversity No

Extended Squitter Yes, see Note 2 and Note 3

Elementary Surveillance Yes, see Note 3

Enhanced Surveillance Yes, see Note 3

Selective Identification Code

Support

TSO-C112d Class 1

Note 1: Each supported UF Format interrogation will illicit the corresponding DF format response. There

is no response to the following UF formats: 1, 2, 3, 6, 7, 8, 9, 10, 12, 13, 14, 15, 17, 18, 19, 22, 23, 24.

The following are exceptions to the responses:

• If UF4 is received with RR of 16 through 31 the unit will respond with DF 20.

• If UF5 is received with RR of 16 through 31 the unit will respond with DF 21.

• If UF20 is received with RR of 0 through 15, the unit will respond with DF4.

• If UF21 is received with RR of 0 through 15, the unit will respond with DF5.

• If UF16 Broadcast interrogation is received, the unit will not reply. If UF16 non-Broadcast interrogation

is received, the unit will reply with DF16 if RL indicates a request for a long reply, otherwise it will reply

with DF0.

• IF UF0 is received with RL=1 the unit will respond with a DF16.

Note 2: The GTX 23 does not source the data for extended squitter / ADS-B messages. The GTX 23

must receive this data from other equipment in order to provide extended squitter / ADS-B functionality.

Also, ADS-B must be configured on.

Note 3: Compliance with elementary surveillance, enhanced surveillance, and extended squitter ADS-B

is shown at the installation-level per EASA CS-ACNS. The GTX 23 implements the technical

requirements necessary of a transponder that CS-ACNS requires, but installation of a GTX 23 by itself

does not constitute compliance with elementary surveillance, enhanced surveillance, or extended

squitter ADS-B requirements. Also, in order for the GTX 23 to meet the technical requirements of

CS-ACNS for enhanced surveillance or extended squitter ADS-B, the GTX 23 must have the feature

configured on and it must receive data to populate the relevant BDS registers.

25 Foot increments from -1000 to 50,175 feet with suitable serial

data altitude. 100 Foot increments from -1000 to 62,700 feet.

Level 2, Comm-A (TIS), Comm-B (GICB, Comm-B Broadcast),

TCAS Crosslink, Subnetwork Version 5

Yes

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-6

Page 16

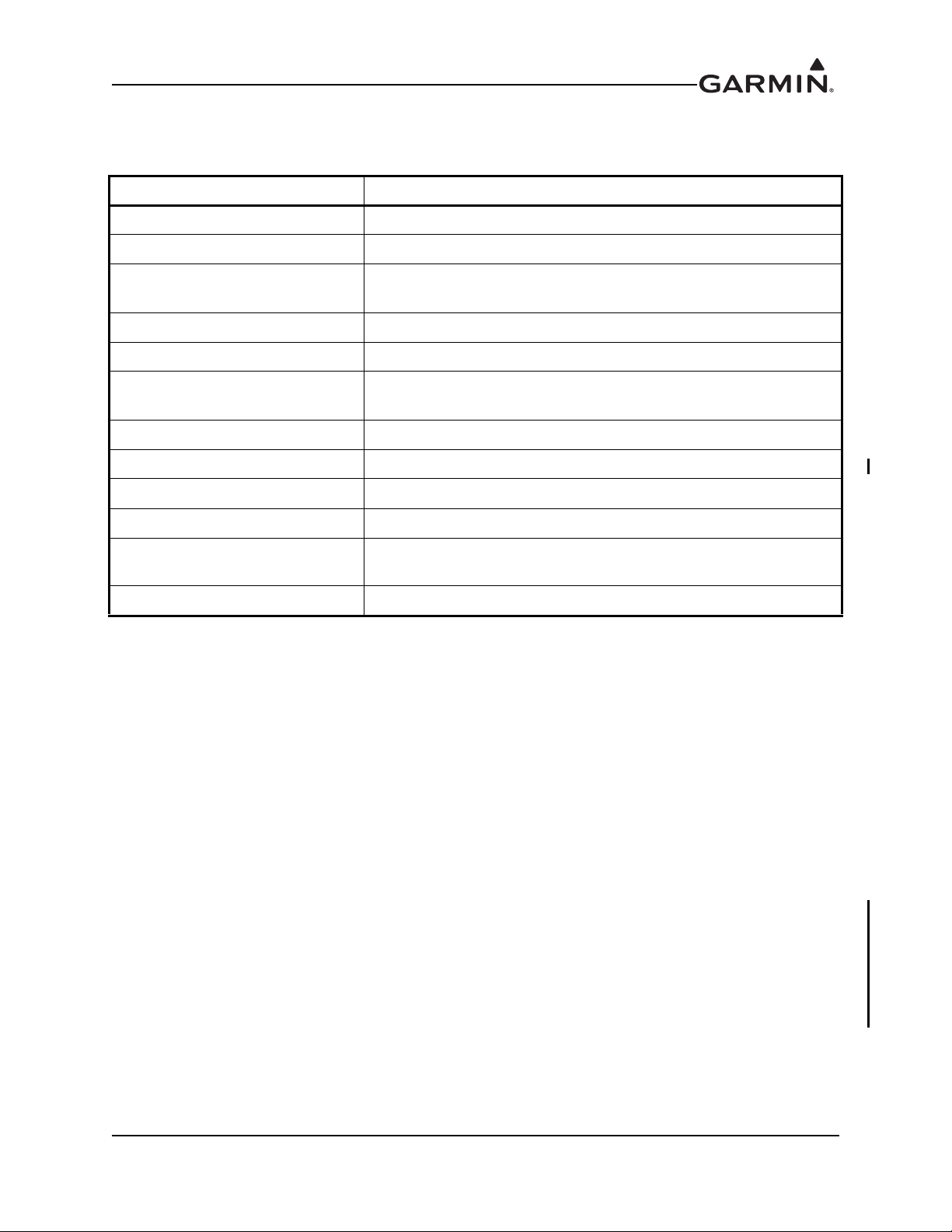

1.7.3 Physical Characteristics

Table 1-4 Physical Characteristics

Characteristic Specification

Modular Rack Width 1.72 inches [44 mm]

Modular Rack Height 6.30 inches [160 mm]

Modular Rack Weight 0.4 lbs [0.18 kg]

Remote Rack Width 1.78 Inches (45 mm)

Remote Rack Height 6.92 Inches (176 mm)

Remote Rack Weight 0.9 lbs. (0.41 kg)

Depth Including Connectors (measured from front face of unit to rear of

connector backshells)

Depth Including Connectors and Shield Blocks (measured from front face of

unit to rear of shield blocks)

Connecter Weight (including backshell) 0.4 lbs (0.18 kg)

GTX 23 Unit Weight 3.1 lbs. (1.41 kg)

11.05 Inches (281 mm)

11.44 inches (291 mm)

1.7.4 Power Requirements

Table 1-5 Power Requirements

Characteristic Specification

Input Voltage

Power Input 22 Watts Typical, 45 Watts Maximum

Maximum Full TSO Reply Rate;

Mode C, 1200 PRF, Code 7777

Maximum Quiescent 0.85 A @ 28 Vdc, 1.1A @ 14 Vdc

14/28 Vdc See the Environmental Qualification Form for details

on surge ratings and minimum/maximum operating voltages.

1.6 A @ 28 Vdc, 3.1 A @14 Vdc

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-7

Page 17

1.8 License Requirements

CAUTION

The Telecommunications Act of 1996, effective February 8, 1996, provides the FCC discretion to

eliminate radio station license requirements for aircraft and ships. The GTX 23 installation must comply

with current transmitter licensing requirements. To find out the specific details on whether a particular

installation is exempt from licensing, please visit the FCC web site http://wireless.fcc.gov/aviation.

If an aircraft license is required, make application for a license on FCC form 404, Application for Aircraft

Radio Station License. The FCC also has a fax-on-demand service to provide forms by fax. The GTX 23

owner accepts all responsibility for obtaining the proper licensing before using the GTX 23.

The UHF transmitter in this equipment is guaranteed to meet federal

communications commission acceptance over the operating temperature range.

Modifications not expressly approved by Garmin could invalidate the license and

make it unlawful to operate the equipment.

1.9 Certification

The conditions and tests required for TSO approval of this article are minimum performance standards. It

is the responsibility of those installing this article either on or within a specific type or class of aircraft to

determine that the aircraft installation conditions are within the TSO standards. The article may be

installed only if performed under 14 CFR Part 43 or the applicable airworthiness requirements.

It is the installer’s responsibility to ensure the ADS-B Out system is compliant with AC 20-165 and to

ensure compatibility between the GTX 23 and the ADS-B Out position source equipment. See Garmin

ADS-B Out Compatible Equipment (190-01533-00) for compatible equipment shown to be eligible for

14 CFR 91.227-compliant installations in accordance with AC 20-165.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-8

Page 18

1.9.1 GTX 23 TSO/ETSO/RTCA/ICAO Compliance

Table 1-6 TSO/ETSO/RTCA/ICAO Compliance

Function

Air Traffic Control Radar

Beacon System/Mode

Select

(ATCRBS/MODE S)

Airborne Equipment

Extended Squitter

Automatic Dependent

Surveillance –

Broadcast (ADS-B) and

Traffic Information

Services – Broadcast

(TIS-B)

1. Complies with ICAO Annex 10, Amendment 77 Tables: 2-64, 2-80, 2-96 functionality only when the Enhanced Surveillance

function is enabled during configuration.

2. Complies with TSO-C166a/ETSO-C166a functionality only when the Extended Squitter function is enabled during

configuration.

3. Complies with TSO-C166b functionality only when the Extended Squitter function is enabled during configuration.

Performance

Standard

TSO-C112 Class 2A

TSO-C112d Class 1 Level 2ens

ETSO-2C112b

TSO-C166a

(See Note 2)

TSO-C166b

(See Note 3)

ETSO-C166a

(See Note 2)

Category

2C112b Class 1 Level

2es

B0 006-B1417-00 (v6.20) 006-C0034-21

B1S

B0 006-B1417-00 (v6.20) 006-C0034-21

Applicable LRU

SW Part Numbers

006-B1417-00

(v6.20 through v7.XX

except v7.00)

006-B0172-1( )

except -10

(v8.XX except v8.00)

006-B1417-00

(v6.20 through v7.XX

except v7.00)

006-B1417-00

(v7.XX except v7.00)

006-B0172-1( )

except-10

(v8.XX except v8.00)

Applicable LRU

CLD

Part Numbers

006-C0034-21

006-C0034-2()

except -20

006-C0034-21

006-C0034-21

006-C0034-2()

except -20

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-9

Page 19

1.9.2 TSO/ETSO Deviations

Table 1-7 TSO/ETSO Deviations

TSO/ETSO Deviation

1. Garmin was granted a deviation from TSO-C112 to use RTCA DO-178B instead of RTCA DO-178A.

2. Garmin was granted a deviation from TSO-C112 to use RTCA DO-160D instead of RTCA DO-160B.

TSO-C112

TSO-C112d

TSO-C166a

ETSO-C166a

3. Garmin was granted a deviation from TSO-C112 to use RTCA DO-181C instead of RTCA DO-181.

4. Garmin was granted a deviation from RTCA DO-160D, Section 20.3.d to perform RF Susceptibility testing at

50 mV/m for frequencies between 980 MHz to 1080 MHz.

5. Garmin was granted a deviation from DO-181C Section 2.2.16.2.6.2 to not provide Mode-S Extended

Squitter for an ADS-B system (for non-ES transponders only).

1. Garmin was granted a deviation from TSO-C112d to use RTCA/DO-160D instead of RTCA/DO-160G.

2. Garmin was granted a deviation from RTCA/DO-181E Section 2.3.1 Environmental Test Conditions to

perform DO-160D Section 20 RF Susceptibility testing at 50 mV/m for frequencies between 980 MHz to 1080

MHz.

3. Garmin was granted a deviation from RTCA/DO-181E Section 2.2.2.4.G Sensitivity and Dynamic Range.

4. Garmin was granted a deviation from RTCA/DO-181E Section 2.2.8.6 Response in the Presence of CW

Interference.

5. Garmin was granted a deviation from RTCA/DO-181E Section 2.2.11 Response to Mutual Suppression

Pulses Paragraph B.

1. Garmin was granted a deviation from TSO-C166a to use RTCA DO-160D instead of RTCA DO-160E.

2. Garmin was granted a deviation from TSO-C166a to place relevant TSO marking information within the

installation manual, rather than on the equipment.

1. Garmin was granted a deviation from ETSO-C166a to use RTCA/DO-160D instead of RTCA/DO- 160E as

the standard for Environmental Conditions and Test Procedures for Airborne Equipment.

2. Garmin was granted a deviation from ETSO-C166a, section 4.1 and 4.2 to reference the installation manual

for the equipment's ETSO compliance and class for this ETSO.

1. Garmin was granted a deviation from RTCA DO-260B Section 2.1.10 to meet the transponder function

requirements of RTCA DO-181C instead of RTCA DO-181D. (For TSO-C112 compliant versions)

2. Garmin was granted a deviation from TSO-C166b Section 4.b to not mark the TSO number on the unit.

3. Garmin was granted a deviation from TSO-C166b Section 4.c to reference the installation manual for

TSO-C166b

ETSO-2C112b

granted TSO deviations.

4. Garmin was granted a deviation from TSO-C166b Section 4.e to reference the installation manual for

equipment class.

5. Garmin was granted a deviation from RTCA/DO-260B Section 2.1.10 to meet the transponder function

requirements of RTCA/DO-181E instead of RTCA/DO-181D. (For TSO-C112d compliant versions)

6. Garmin was granted a deviation from RTCA/DO-260B Section 2.3 to use RTCA/DO-160D (including

Change 1, 2, and 3) instead of RTCA/DO-160F.

1. Garmin was granted a deviation from RTCA DO-160D, Section 20.3.d to perform RF Susceptibility testing at

50 mV/m for frequencies between 980 MHz to 1080 MHz.

2. Garmin was granted a deviation from ED-73B, Section 1.4.2.2 to mark the equipment's functional level on

the chassis in a location not visible when the transponder is mounted in the aircraft.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-10

Page 20

1.9.3 Additional TSO/ETSO Deviations Specific to Software Versions

Table 1-8 Additional TSO/ETSO Deviations Specific to Software Versions

TSO/ETSO Deviation

Applicable

Software

Versions

TSO-C112

TSO-C166b

1. Garmin was granted a deviation from RTCA DO-181C Section 2.2.17.1.13.e to

remove the requirement to report the new aircraft identification to the ground by use of

the Comm-B Broadcast Message protocol if the aircraft identification reported in the AIS

subfield is changed in flight.

1. Garmin was granted a deviation from RTCA DO-260B Section 2.2.3.3.1.4.2 to remove

the requirement to change the broadcast rate of the Operational Status Message (OSM)

for a period of 24+/- 1 seconds after a change in NIC

information.

SUPP

006-B1417-00

(v6.20 through

v7.02, except for

v7.00)

006-B1417-00

(v7.01 and v7.02)

1.9.4 Non-TSO Functions

Table 1-9 Non TSO Functions

Function

Traffic Information

Service (TIS)

Enhanced Surveillance

1. Complies with ICAO Annex 10, Amendment 77 Tables: 2-64, 2-80, 2-96 functionality only when the Enhanced Surveillance

function is enabled during configuration.

Performance

Standard

RTCA DO-239 N/A

ICAO Annex 10,

Amendment 77

Tables: 2-64,2-80, 2-96

(See Note 1)

Category

N/A

Applicable LRU

SW Part Numbers

006-B1417-00

(v6.20 through v7.XX)

006-B0172-1( ) (v8.XX)

006-B1417-00

(v6.20 through v7.XX)

Applicable LRU

CLD

Part Numbers

006-C0034-21

006-C0034-2()

except -20

N/A

1.9.5 Other Regulatory Criteria

Table 1-10 Other Regulatory Criteria

Applicable LRU

CLD

Part Numbers

N/A

006-C0034-21

Function

RTCA DO-178B

Compliance

RTCA DO-254

Compliance

Performance

Standard

DO-178B Level C

DO-254 Level C

Category

Applicable LRU

SW Part Numbers

006-B1417-00

(v6.20 through v7.XX)

006-B0172-1( ) (v8.XX)

006-B1417-00

(v6.20 through v7.XX)

006-B0172-1( ) (v8.XX) 006-C0034-2()

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-11

Page 21

1.10 Operating Instructions

NOTE

The GTX 23 is a remote-mount LRU with no user controls or indicators. All user interface is accomplished

through a compatible display device. Although different displays will handle the transponder interface

differently, all will typically have the following user inputs:

Mode Selection

1. Standby Mode: In Standby Mode, the GTX 23 will not reply to interrogations.

2. ON Mode: In ON mode, the GTX 23 will generate Mode A and Mode S replies, but Mode C altitude

reporting is inhibited.

3. Altitude Mode: In Altitude Mode, Mode C altitude reporting is enabled.

Code Selection

1. Entering a Code: A total of 4096 discrete identification codes can be entered.

2. VFR Code: Selecting VFR changes the Code to the pre-programmed VFR code.

Ident Function

Selecting the Ident function sends an ID indication to ATC for 18 seconds. This ID indication distinguishes

your transponder from all others on the air traffic controller’s radar screen.

For detailed operating instructions, refer to the pilot’s guide for the equipment that

provides the GTX 23 user interface. The G3X Pilot’s guide (190-01115-00) provides

information for operating a GTX 23 in a G3X system.

:

:

:

1.11 Reference Documents

The following publications are sources of additional information for installing the GTX 23. Before

installing the unit, the technician should read all relevant referenced materials along with this manual.

Table 1-11 Reference Documents

Part Number Document

190-01115-01 G3X Installation Manual

190-00906-01 GTX 23 Installation Manual

Rev. G Page 1-12

Page 22

2 INSTALLATION OVERVIEW

2.1 Introduction

This section provides hardware equipment information for installing the GTX 23 Mode S transponder,

related hardware, and optional accessories. Installation of the GTX 23 should follow the data detailed in

this manual. Cabling is fabricated by the installing agency to fit each particular aircraft. The guidance of

FAA advisory circulars AC 43.13-1B and AC 43.13-2B, where applicable, may be found useful for making

retro-fit installations that comply with FAA regulations.

Refer to Appendix D for rack drawings and dimensions.

2.2 Installation Materials

The GTX 23 is available as a single unit under the following part numbers:

Table 2-1 Installation Materials

Item Catalog Part Number

GTX 23 w/ES, Unit Only, (011-02803-02) 010-01014-02

GTX 23 w/ES and Install Kit, (011-02803-02) 010-01014-03

GTX 23 w/ES, Standard, w/System Rack (011-02803-02) 010-01014-04

2.2.1 Equipment Available

Each of the following accessories is provided separately for the GTX 23 unit. The rack and the remainder

of the accessories are required for installation.

Table 2-2 Equipment Available

Item Garmin Catalog Part Number

Garmin Transponder Antenna kit** 010-10160-00

Connector Kit, GTX 23 (see Table 2-3) 011-01012-01

Back-plate Assembly, GTX 23, BNC* 011-00582-00

Back-plate Assembly, GTX 23, TNC* 011-00582-04

GTX 23 Modular Install Rack 115-00438-00

Or

GTX 23 Remote Install Rack 115-00629-00

*Only one Backplate Assembly required, installer’s choice of BNC or TNC connector.

**Note: A transponder antenna approved to TSO C66( ) or C74( ) that has been installed to meet the

requirements of this manual may be used with the GTX 23.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 2-1

Page 23

Table 2-3 GTX 23 Connector Kit (011-01012-01)

Item Garmin Part Number Quantity

37/62 Pin Backshell w/Hardware 011-00950-03 1

Ground Adapter Shell, Size 4 & 5 011-01169-01 1

Screw, 4-40x.437, FLHP100, SS/P, Nyl 211-63234-11 2

High Density Connector, D-Sub, Mil Crimp 62 ckt 330-00185-62 1

Contact Pin, Mil Crimp, Size 22D 336-00021-00 20

2.2.2 Additional Equipment Required

The following installation accessories are required but not provided:

• Cables – The installer will supply all system cables including circuit breakers. Cable requirements

and fabrication is detailed in Section 3 of this manual.

• Hardware – #6-32 x 100° Flathead SS Screw [(MS24693, AN507R or other approved fastener)

(4 ea.)] for horizontal mounting of the remote rack.

• Hardware – #8-32 Panhead Machine Screw [(MS35206, AN526 or other approved fastener) (4

ea.)] for vertical mounting of the remote rack.

• Hardware – #6-32 x 100° Flathead SS Screw [(MS24693, AN507R or other approved fastener)

(8 ea.)] for mounting of the remote modular rack.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 2-2

Page 24

2.3 Installation Considerations

NOTE

Mount Antenna on

Bottom of Aircraft

2.3.1 Preservation of Previous Systems

It is the installer’s responsibility to preserve the essential characteristic of the aircraft being modified with

this equipment to be in accordance with the aircraft manufacturer’s original design. This includes the

preservation of multiple power buses, which reduces the probability of interrupting power to essential

instruments and avionics.

2.3.2 Antenna Location Considerations

The antenna should be installed in accordance with AC 43.12-2A Chapter 3.

Figure 2-1. Antenna Installation Considerations

a. The antenna (Garmin P/N 010-10160-00 or equivalent) should be mounted away from major pro-

trusions, such as engine(s), propeller(s), and antenna masts. It should also be as far as practical

from landing gear doors, access doors, or other openings that could shadow (block) the signal

between the transponder antenna and ATC radar on TCAS.

b. The antenna should be mounted vertically on the bottom of the aircraft (Figure 2-1).

c. Antenna Separation: DME and TCAS receive signals in the same frequency range that aviation

transponders transmit at, so their antennas should be separated from the transponder antenna by as

much as feasible. Six feet of separation is a guideline. Radar altimeters (should one be installed

on an aircraft with a GTX 23) also have some potential to receive interference from a transponder

(the transponders’ fourth harmaonic), so it is good practice to separate transponder and radar

altimeter antennas by as much as practical also. Avoid mounting the antenna within three feet of

the ADF sense antenna or any other communication antenna.

d. To prevent RF interference, the antenna must be physically mounted a minimum distance of three

feet from the GTX 23.

If the antenna is being installed on a composite aircraft, sufficient ground plane material

must be added. Conductive wire mesh, radials, or thin aluminum sheets embedded in the

composite material provide the proper ground plane allowing the antenna gain pattern to

be maximized for optimum transponder performance.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 2-3

Page 25

2.4 Cabling and Wiring

Refer to the interconnect examples in Appendix C for wire gauge guidance.

Ensure that routing of the wiring does not come in contact with sources of heat, RF or EMI interference.

Check that there is ample space for the cabling and mating connectors. Avoid sharp bends in cabling and

routing near aircraft control cables. It is also good practice to avoid routing cables near sharp edges

because aircraft vibration might wear away the insulation on the wires, which will leave them exposed to

moisture and potentially create arcing or intermittent short circuits.

The GTX 23 back-plate assembly utilizes a BNC-type (bayonet connection) coaxial connector.

The maximum attenuation at 1090 MHz between the unit and the antenna must not exceed 1.5 dB. This

loss specification includes connector loss; for example, through a bulkhead connector. The following table

lists examples of recommended antenna cable. One can determine the length of cable needed to connect

the transponder to the antenna, and then use the table to look up a recommended cable manufacturer and

part number that will meet the 1.5 dB loss spec. The table assumes a loss figure of 0.2 dB per connector.

Note that any 50 Ω, double shielded coaxial cable assembly that meets airworthiness requirements and the

1.5 dB maximum loss figure (including connectors) may be used.

Table 2-4 Cable Specifications

Max. Length

(feet – [m])

6' 1.3" [1.86m] 18.0

7' 7.3" [2.32m] 14.45 3C142B

9' 2.0" [2.79m] 12.00

12' 6.0" [3.81m] 8.80 311601

15' 5.4" [4.71m] 7.12 311501

19' 9.4" [6.03m] 5.56 311201

30' 3.6" [9.24m] 3.63 310801

Supplier

Information

Insertion loss

(dB/100ft)

Carlisle IT Type MIL-C-17 Type RG Type

Vendor: Carlisle

Interconnect Technologies

100 Tensolite Drive

St. Augustine, FL 32092

Tel: 800-458-9960

904-829-3447

Fax: 904-829-3447

www.carlisleit.com

M17/128-

RG400

M17/112-

RG304

M17/127-

RG393

See current

issue of

Qualified

Products List

QPL-17.

RG-400

RG-304

RG-393

RG types are

obsolete and

are shown for

reference only;

replaced by

M17 type

numbers.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 2-4

Page 26

2.4.1 Cable Routing Considerations

After the cable assemblies are made and wiring installed to the rack back plate, route wiring bundle as

appropriate. Use cable ties to secure the cable assemblies and coax to provide strain relief for the cable

assemblies. When routing cables, observe the following precautions:

• All cable routing should be kept as short and as direct as practical.

• Avoid sharp bends to prevent insulation from being breached.

• Avoid routing close to sharp edges to prevent insulation from being breached due to vibration or

handling the cable.

• Avoid routing cables near power sources (e.g., 400 Hz generators, trim motors, etc.) or near power

for fluorescent lighting.

• Avoid routing antenna cables near DME, TCAS, radar altimeter, and ADF antenna cables (allow at

least a 12-inch separation).

2.5 Electrical Bonding

Electrical equipment, supporting brackets, and racks should be electrically bonded to the aircraft’s main

structure. Refer to SAE ARP 1870 section 5 when aluminum surface preparation is required to achieve

electrical bond. An equivalent OEM bonding procedure may also be substituted. The electrical bond

should achieve direct current (DC) resistance less than or equal to 2.5 milliohms to local structure to where

the equipment is mounted. Compliance should be verified by inspection using a calibrated milliohm

meter.

2.6 Cooling Air

Cooling air is generally not required. However, if the unit is located in a confined space or near a source of

heat, cooling air is recommended for maximizing the life of the GTX 23. A 5/8 inch air fitting is provided

on the rear of the backplate for the purpose of admitting cooling air. If a form of forced air cooling is

installed, make certain that rainwater or condensation cannot enter and be sprayed on the equipment.

2.7 GTX 23 Mounting Requirements

The GTX 23 mounting surface must be capable of providing structural support and electrical bond to the

aircraft to minimize radiated EMI and provide protection from High-Intensity Radiation Fields (HIRF).

The GTX 23 can be mounted using either a modular rack or a remote rack. Ensure that the GTX 23 chassis

has a ground path to the airframe by having at least one rack mounting screw in contact with the airframe.

The racks can be installed in a variety of locations, such as the electronics bay, under a seat or on an

avionics shelf behind the rear baggage area. Refer to Figure 2-4 for suggested locations. The racks should

be mounted to a surface known to have sufficient structural integrity to withstand additional inertia forces

imposed by the GTX 23 unit, rack, and connectors (see Section 1.7.1 for weight information). If it is

necessary to build a shelf or bracket to mount the GTX 23 racks, or it is not certain that the chosen location

is of sufficient structural integrity, refer to Appendix A for validation of rack mounting structures and

determining static load capability. Leave sufficient clearance between the GTX 23 and any obstruction.

Consider installing the rack in accordance with AC 43.13-2B Chapter 2 “Communication, Navigation, and

Emergency Locator Transmitter System Installations”.

2.7.1 Remote Rack Considerations

Figures 2-2, D-1, and D-2 show the GTX 23 remote-mounted remote rack. Figure D-1 gives the remote

rack dimensions for the GTX 23. The rack can be mounted vertically using four 8-32 pan head screws

(MS35206, AN526 or other approved fastener). It can also be mounted horizontally using four 6-32 100°

counter-sunk flathead screws (MS24693, AN507R or other approved fastener). If more water-resistance is

desired, the rack should be installed in the upright vertical orientation only, otherwise, the rack may be

mounted in either vertical or horizontal orientation.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 2-5

Page 27

2.7.2 Modular Rack Considerations

Figures 2-3, D-3, and D-4 show the GTX 23 remote-mounted modular rack. Figure D-3 gives the modular

rack dimensions for the GTX 23. The modular rack can be mounted in any orientation and must be secured

to the airframe using a minimum of eight 6-32 100° counter-sunk flathead screws (MS24693, AN507R or

other approved fastener), two per position as indicated in Figure D-4.

Figure 2-2. GTX 23 Remote Rack (115-00629-00)

Figure 2-3. GTX 23 Modular Rack (115-00438-00)

190-00906-01 GTX 23 Installation Manual

Rev. G Page 2-6

Page 28

Figure 2-4. GTX 23 Remote Rack, Suggested Mounting Locations

190-00906-01 GTX 23 Installation Manual

Rev. G Page 2-7

Page 29

3 INSTALLATION PROCEDURE

CAUTION

CAUTION

3.1 Unpacking Unit

Carefully unpack the equipment and make a visual inspection of the unit for evidence of damage incurred

during shipment. If the unit is damaged, notify the carrier and file a claim. To justify a claim, save the

original shipping container and all packing materials. Do not return the unit to Garmin until the carrier has

authorized the claim.

Retain the original shipping containers for storage. If the original containers are not available, a separate

cardboard container should be prepared that is large enough to accommodate sufficient packing material to

prevent movement.

3.2 Wiring Harness Installation

Allow adequate space for installation of cables and connectors. The installer shall supply and fabricate all

cables. All electrical connections to the GTX 23 are made through one 62-pin D-subminiature connector.

Section 4 defines the electrical characteristics of all input and output signals. Required connectors and

associated hardware are supplied with the connector kit.

See Appendix C for examples of interconnect wiring diagrams.

Check wiring connections for errors before inserting the GTX 23 into the rack.

Incorrect wiring could cause internal component damage.

3.3 Electrical Connections

All electrical connections, except for the antenna and shield ground, are made through a single 62 pin

D-subminiature connector (see Figure 4-1). Table 4-1 lists the electrical connections of all input and

output signals. See Appendix C for interconnect wiring diagrams and cable requirements for each signal.

Required connector and associated hardware are supplied in the connector kit (P/N 011-01012-01).

Check wiring connections for errors before inserting the GTX 23 into the rack.

Incorrect wiring could cause internal component damage.

Table 3-1 Pin Contact Part Numbers (High Density)

Manufacturer*

18-20 AWG (Power Only) 22-28 AWG

Garmin P/N 336-00044-00 336-00021-00

Military P/N N/A M39029/58-360

*Non-Garmin part numbers shown are not maintained by Garmin and consequently are subject to

change without notice.

62 pin connector (P2301)

190-00906-01 GTX 23 Installation Manual

Rev. G Page 3-1

Page 30

Table 3-2 Recommended Crimp Tools (High Density)

18-20 AWG 22-28 AWG

Manufacturer

(note 1)

Military P/N M22520/2-01 N/A M81969/1-04 M22520/2-09 M81969/1-04

Positronic 9507-0 9502-11 M81969/1-04 9502-4 M81969/1-04

AMP 601966-1 N/A 91067-1 601966-6 91067-1

Daniels AFM8 K774 M81969/1-04 K42 M81969/1-04

Astro 615717 N/A M81969/1-04 615725 M81969/1-04

1) Non-Garmin part numbers shown are not maintained by Garmin and consequently are subject to

change without notice.

2) Extracting the #18 or #20 contact requires that the expanded wire barrel be cut off from the contact.

It may also be necessary to push the pin out from the face of the connector when using an extractor due

to the absence of the wire. A new contact must be used when reassembling the connector.

Hand

Crimping

Tool

Positioner

Insertion/

Extraction Tool

(note 2)

Positioner

Insertion/

Extraction

Tool

3.4 Backshell Assembly

The GTX 23 connector kit includes one Garmin backshell assembly. Garmin’s backshells give the installer

the ability to quickly and easily terminate shield grounds at the backshell housing.

Refer to Appendix B for Shield Block Installation Instructions.

3.5 Weight and Balance

Weight and balance computation is required after the installation of the GTX 23. Follow the guidelines as

established in AC 43.13-1B, Chapter 10, Section 2. Make appropriate entries in the equipment list

indicating items added, removed or relocated along with the date accomplished. Include your name and

certificate number in the aircraft records. Section 1.7.1 identifies the weight of the new GTX 23

equipment and the drawings in Appendix D shows the center of gravity.

3.6 Electrical Load Analysis

An electrical load analysis should be completed on each aircraft prior to installation in accordance with

AC43.13-1B, Chapter 11. Use the following values for computation:

Table 3-3 Unit Power Loads

GTX 23 Input

Typical Max. Typical Max.

GTX 23 Main Power 1.6 A 3.1 A 0.85 A 1.6 A

14 Vdc 28 Vdc

190-00906-01 GTX 23 Installation Manual

Rev. G Page 3-2

Page 31

3.7 Final Installation

CAUTION

CAUTION

For final installation and assembly, refer to the outline and installation drawings shown in Appendix D of

this manual.

a. Assemble the connector backshell as described in Appendix B.

b. Attach the connector to the rear plate using the screws provided in the connector kit.

c. Mount the unit rack to a mounting location that considers the mounting requirements in Section

2.6.

d. Assemble the rear plate into the GTX 23 unit rack using screws provided with the rear plate.

e. Insert the GTX 23 into the rack, noting proper orientation as shown on the installation drawing in

Appendix D.

Do not use excessive force when inserting the GTX 23 into the rack. This may

cause damage to occur to the connectors, unit, and/or unit rack. If heavy

resistance is felt during installation, stop! Remove the GTX 23 and identify the

source of resistance.

f. Lock the GTX 23 in place using the lever-locking handle. Fasten the handle to the GTX 23 body

using the provided Phillips screw.

Start the handle screw into the hole carefully, to avoid cross-threading. Do not

apply torque in excess of 14 in-lbs to the handle screw. The application of torque

exceeding 14 in-lbs to the screw will damage the LRU case and/or retaining

hardware.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 3-3

Page 32

3.8 Post Installation Configuration and Checkout

NOTE

The GTX 23 Mode S Transponder will not provide valid outputs until the aircraft post

installation configuration procedures are completed.

3.8.1 Configuration

Since the GTX 23 is remote mount, it is installed with other equipment that provides a user interface. For

information on configuring the GTX 23, please see the installation manual for the equipment that provides

the user interface for the GTX 23. The G3X install manual (190-01115-01) is an example of a manual that

provides information for how to configure a GTX 23 in a G3X system.

3.8.1.1 Configuration Considerations

When configuring the aircraft size and GPS antenna offsets it is important to ensure that the enclosing box

fully contains the aircraft as shown in Figure 3-1.

Figure 3-1. Aircraft Length and Width Determination

In installations with multiple GPS sources tied to a single transponder, it is recommended that the GPS

antenna furthest aft from the nose is used when configuring the GPS antenna offsets. Further, the

configured aircraft length and width parameters may need to be adjusted such that the containing box fully

encloses the aircraft when any of the GPS antennas are sourcing data to the transponder. The example in

Figure 3-2

such that the containment box fully encloses the aircraft when GPS 1 is the selected GPS source.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 3-4

of two GPS sources demonstrates the need to expand the aircraft length and width parameters

Page 33

Figure 3-2. Combined GPS Antenna Containment

NOTE

Based on Figure 3-2, the following would be used to configure the transponder:

Values used to configure Aircraft Length and Width:

Combined Aircraft Width = Actual Aircraft Width + 2 * (x1+ x2)

Combined Aircraft Length = Actual Aircraft Length + (y2 – y1)

The equation “x1+x2” simply represents the lateral distance between the two antennas.

Values used to configure GPS antenna offsets:

Longitudinal Offset = y2

Lateral Offset = x2

190-00906-01 GTX 23 Installation Manual

Rev. G Page 3-5

Page 34

3.8.2 Interference Check

CAUTION

Turn on and verify operation of all avionics equipment except GTX 23. Then power the GTX 23 on, and

verify there is no interference with any other equipment in the aircraft. The operation/performance checks

should be made with all other avionics turned on. Verify that there is no interference during any mode of

transponder operation.

3.8.3 Performance (Ramp) Test

If the unit is removed from the aircraft and operated, always connect J2302 to an

antenna or a 50 Ω, 5-Watt load. The GTX 23 transmits Mode S acquisition

squitters about once per second whether interrogations are received or not. The

unit may become damaged if J2302 is not connected to a 50 Ω, 5-Watt load when

the unit squitters,

Installations require verification of proper operation of the transponder by testing as specified in

Appendix F of 14 CFR, Part 43, to AC 43-6B, and/or other appropriate regulations. The test is typically

done as a ramp test using a transponder ramp test set, such as the TIC TR-220, IFR ATC-601 or other

suitable Mode S transponder test set. The ramp test includes checks as follows:

Reference Part 43 Appendix F:

a. Reply Frequency

b. Suppression

c. Receiver Sensitivity

d. Reply RF Output Power

e. Mode S Diversity Channel Isolation (if applicable)

f. Mode S Address

g. Mode S Formats

h. Mode S All-Call

i. ATCRBS –Only All Call

j. Squitter

Reference AC 43-6B and 14 CFR Part 43, Appendix E (c):

3.9 Continued Airworthiness

Installations are required to test according to Title 14 CFR §§ 91.411 and 91.413 as well as Part 43

Appendix F. Otherwise, maintenance of the GTX 23 is ‘on condition’ only.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 3-6

a. Altitude Reporting

Page 35

4 SYSTEM INTERCONNECTS

123456789101112131415

222324252627282930313233343536

44464748495051

525354

5556

161718192021

373839404142

57

5859

6061

62

4.1 Pin Function List

4.1.1 J2301

Figure 4-1. J2301 Connector

Table 4-1 J2301 Pin Assignments

Pin Pin Name I/O

1 NOT USED --

2 NOT USED --

3 NOT USED --

4 NOT USED --

5 NOT USED --

6 NOT USED --

7 NOT USED --

8 NOT USED --

9 NOT USED --

10 NOT USED --

11 NOT USED --

12 EXTERNAL IDENT SELECT* In

13 EXTERNAL STANDBY SELECT* In

14 NOT USED --

15 NOT USED --

16 NOT USED --

17 NOT USED --

18 NOT USED --

19 NOT USED --

20 NOT USED --

21 AIRCRAFT POWER 1 In

22 RS-232 IN 1 In

23 RS-232 OUT 1 Out

24 RS-232 IN 2 In

25 RS-232 OUT 2 Out

26 NOT USED --

27 NOT USED --

28 ARINC 429 OUT 2 B Out

29 NOT USED --

30 ARINC 429 OUT 2 A Out

*Denotes active low (ground to activate)

190-00906-01 GTX 23 Installation Manual

Rev. G Page 4-1

Page 36

Table 4-1 J2301 Pin Assignments

Pin Pin Name I/O

31 MUTUAL SUPPRESSION I/O I/O

32 NOT USED --

33 NOT USED --

34 ARINC 429 OUT 1 B Out

35 NOT USED --

36 NOT USED --

37 ARINC 429 OUT 1 A Out

38 NOT USED --

39 POWER GROUND --

40 NOT USED --

41 NOT USED --

42 AIRCRAFT POWER 1 In

43 RS-232 GROUND --

44 NOT USED --

45 NOT USED In

46 TIS CONNECT SELECT* In

47 NOT USED --

48 NOT USED --

49 NOT USED --

50 RS-232 GROUND 2 --

51 NOT USED --

52 NOT USED --

53 NOT USED --

54 NOT USED --

55 NOT USED --

56 AIRCRAFT POWER 2 In

57 NOT USED --

58 POWER GROUND --

59 NOT USED --

60 AIRCRAFT POWER 2 In

61 NOT USED --

62 NOT USED --

*Denotes active low (ground to activate)

190-00906-01 GTX 23 Installation Manual

Rev. G Page 4-2

Page 37

4.1.2 Aircraft Power

Power input requirements are listed in the following tables. The power input pins accept 14/28 Vdc. Refer

to Figure C-1 and C-2 for power interconnections.

Table 4-2 Aircraft Power

Pin Name Connector Pin I/O

AIRCRAFT POWER 1 J2301 21 In

AIRCRAFT POWER 1 J2301 42 In

AIRCRAFT POWER 2 J2301 56 In

AIRCRAFT POWER 2 J2301 60 In

POWER GROUND J2301 39 --

POWER GROUND J2301 58 --

4.2 Discrete Functions

4.2.1 Discrete Outputs

External suppression should be connected if a DME or TCAS is installed in the aircraft avionics system.

The GTX 23 suppression I/O pulses may not be compatible with all models of DME or TCAS. Known

incompatible DME units include the Bendix/King KN 62, KN 64 and KNS 80. These models have an

output-only suppression port and can be damaged by the GTX 23 mutual suppression output. In this case,

do not connect the GTX 23’s suppression pin to the incompatible unit’s suppression pin; however, do

connect the GTX 23’s suppression pin to any other compatible unit’s suppression pin.

Table 4-3 Discrete Outputs

Pin Name Connector Pin I/O

EXTERNAL SUPPRESSION I/O (TXP/DME) J2301 31 I/O

190-00906-01 GTX 23 Installation Manual

Rev. G Page 4-3

Page 38

4.2.2 Discrete Inputs

Sink current is internally limited to 200 uA max for a grounded input

EXTERNAL IDENT SELECT (remote IDENT) is a momentary input. When grounded, it activates the

IDENT pulse for 18 seconds in Mode A replies.

EXTERNAL STANDBY SELECT (remote STANDBY) is not a momentary input. When EXTERNAL

STANDBY SELECT is grounded, the GTX 23 operates in standby mode. In this mode, the transponder

will not squitter or reply to interrogations.

TIS CONNECT SELECT is a momentary input. When grounded, it toggles whether TIS is in standby or

operating.

Table 4-4 Discrete Inputs

Pin Name Connector Pin I/O

EXTERNAL IDENT SELECT* J2301 12 In

EXTERNAL STANDBY SELECT* J2301 13 In

TIS CONNECT SELECT J2301 46 In

*Denotes active low (ground to activate)

190-00906-01 GTX 23 Installation Manual

Rev. G Page 4-4

Page 39

4.3 Serial Data Electrical Characteristics

4.3.1 RS-232 Input/Output

RS-232 input #1 is used to receive pressure altitude control commands. RS-232 output #1 provides unit

status and TIS data. RS-232 #1 input and output are also used for software upgrades.

For installations that enable ADS-B, RS-232 input #2 should be connected to a GNS 400W/500W-series

WAAS enabled unit, a GTN 6XX/7XX series unit, or other ADS-B position source listed in Garmin

ADS-B Out Compatible Equipment (190-01533-00). This connection provides the GTX 23 with GPS data

for ADS-B. The RS-232 output #2 is unused on the GTX 23.

The RS-232 outputs conform to EIA Standard RS-232C with an output voltage swing of at least ±5 V

when driving a standard RS-232 load. Refer to figures in Appendix C

interconnect.

Table 4-5 RS-232 Input/Output

Pin Name Connector Pin I/O

RS-232 OUT 1 J2301 23 Out

RS-232 GROUND 1 J2301 43 --

RS-232 IN 1 J2301 22 In

RS-232 OUT 2 J2301 25 Out

for the RS-232 serial data

RS-232 IN 2 J2301 24 In

RS-232 GROUND 2 J2301 50 --

4.3.2 ARINC 429 Input/Output

The ARINC 429 outputs conform to ARINC 429 electrical specifications when loaded with up to five

standard ARINC 429 receivers.

Table 4-6 ARINC 429 Input/Output

Pin Name Connector Pin I/O

ARINC 429 OUT 1A J2301 37 Out

ARINC 429 OUT 1B J2301 34 Out

ARINC 429 OUT 2A J2301 30 Out

ARINC 429 OUT 2B J2301 28 Out

SIGNAL GROUND J2301 51 --

SIGNAL GROUND J2301 58 --

190-00906-01 GTX 23 Installation Manual

Rev. G Page 4-5

Page 40

4.4 RS-232 Input/Output, Software Update Connections

CAUTION

GTX 23GTX 23

50Ω50Ω

5 WATT5 WATT

J2301 P2301J2301 P2301

J2302 P2302J2302 P2302

GTX 23 software is updated using the RS-232 #1 interface. When wiring the RS-232 #1 interface to the

rest of the system, it may be useful to splice in a pigtail connector that could be plugged into a laptop

computer. Also when wiring, consider that the GTX 23 must be turned on (during software update) and

the other avionic equipment attached to the RS-232 #1 interface (e.g. GSU or GDU) must be turned off.

Instead of turning the other avionic equipment off, a relay can be installed that disconnects the avionic

equipment and connects the laptop to the GTX 23. This connector may be useful for updating software to

comply with new ADS-B regulation.

The connector can be mounted anywhere convenient for access, such as under the instrument panel, on a

remote avionics shelf next to the unit, or in the instrument panel itself. Label the connector “For Software

Update”. Do not include the Test Mode Select switch in the aircraft. See Figure 4-2 for software update

connections.

Updating the GTX 23 software to version 8.01 or later requires marking the unit with "TSO-C112d". The

preferred method is to mark the connector panel containing the existing product tag. However, if access to

the connector panel requires removal of the unit, it is acceptable to mark the unit anywhere on the housing.

Marking can be accomplished using a new Garmin tag or an indelible marker. It is not necessary to

remove the old marking if the product tag contains the statement "See Inst Mnl for Addtl TSOs/ETSOs" or

similar.

If the unit is removed from the aircraft and operated, always connect J2302 to an

antenna or a 50 Ω, 5-Watt load (Figure 4-2). The GTX 23 transmits Mode S

acquisition squitter replies about once per second whether interrogations are

received or not. The unit may become damaged if J2302 is not connected to a

50 Ω, 5-Watt load when the unit transmits.

190-00906-01 GTX 23 Installation Manual

Rev. G Page 4-6

Figure 4-2. GTX 23 Software Update Connections

Page 41

APPENDIX A CONSTRUCTION AND VALIDATION OF STRUCTURES

A.1 Static Test Loading

This appendix includes information necessary for testing load-carrying capabilities of equipment mounting

structures, such as shelves, mounting plates and mounting brackets, used to mount the GTX 23 remote

mounting racks.