Page 1

GTS 8XX

Part 23 AML STC Maintenance Manual

with Instructions for Continued Airworthiness

Aircraft Make, Model, Registration Number, and Serial

Number, and accompanying STC configuration

information in Appendix A, must be completed and saved

with aircraft permanent records.

190-01279-01 July 2018 Revision 2

Page 2

© 2014-2018 Garmin International or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual and

of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and to

print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of this

manual or revision must contain the complete text of this copyright notice and provided further that any

unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Garmin

®

, flyGarmin®, and flyGarmin.com

®

are registered trademarks of Garmin International or its

subsidiaries. GDU™, GDL™, GNS™, GTN™, GTS™, and GTX™ are trademarks of Garmin

International or its subsidiaries. These trademarks may not be used without the express permission of

Garmin.

®

Adobe

is a registered trademark of Adobe Systems Incorporated. All rights reserved.

All other product or company names mentioned in this manual are trade names, trademarks, or registered

trademarks of their respective owners.

For aviation product support, visit flyGarmin.com

.

For information regarding the Aviation Limited Warranty

, refer to Garmin’s website.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page i

Page 3

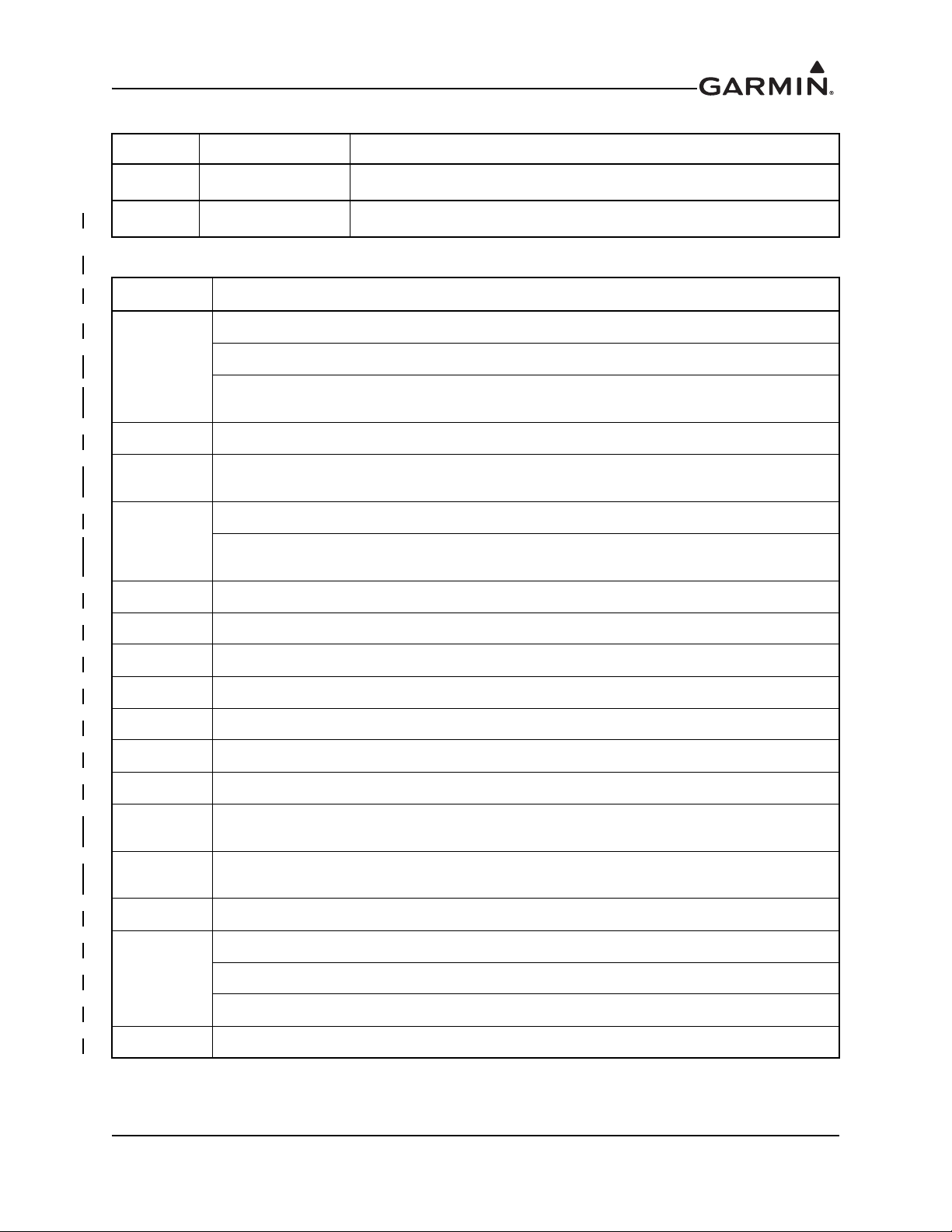

RECORD OF REVISIONS

Revision Revision Date Description

1 05/01/2014 Initial Release.

2

07/25/2018

Added information pertaining to the GTS 800, 820, and 850.

CURRENT REVISION DESCRIPTION

Section Description of Change

Updated “GTS Processor” to “GTS 800/820/850/825/855.”

1.3.1

1.4 Added GTS 8X0/GPA 65 (GTS 800/GTS 820/GTS 850) Installation (P/N 190-00587-00).

2.3

4.3

5.1 Added “GTS 8X0 Install Tool (P/N 006-A0242-00).”

5.3 Updated “Baro Altitude” fault to “Pressure Altitude” in Table 5-1 GTS 8XX System Faults.

6.1 Added Section 6.1 GTS 8X0.

Updated “GTS Processor LRU” to “GTS 825 or 855 LRU.”

Added “GTS 8X0 refers to the GTS 800, 820, or 850 LRU at the core of the GTS 8XX

system.”

Added GTS 800 and GTS 820/850 requirements to Table 2-1 GTX 8XX System Current

Requirements.

Updated procedure for antenna visual inspection to define inspection criteria.

Updated procedure for antenna visual inspection - suspected lightning strike to include

inspection criteria.

6.2 Added Section 6.2 GPA 65.

7.3 Added content for GTS 8X0 Install Tool (P/N 006-A0242-00).

7.3.1 Added note regarding GTS 8XX install tools.

Appendix A Updated title of Appendix A to “Aircraft Installation Record.”

A.2.1

A.3

Appendix B Updated title of Appendix B to “Electrical Bonding Procedures.”

B.3

B.4 Added bonding strap restriction of six inches.

Added GDU 7XX equipment reference to Table A-1 GTS 8XX System Interfaces to

Garmin Equipment.

Updated aircraft profile to Figure A-2 Equipment Location and Wire Routing - Twin

Engine Airplane.

Added flag notes for Figure B-7.

Added 5:1length-to-width ratio requirement.

Added bonding strap restriction of six inches.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page ii

Page 4

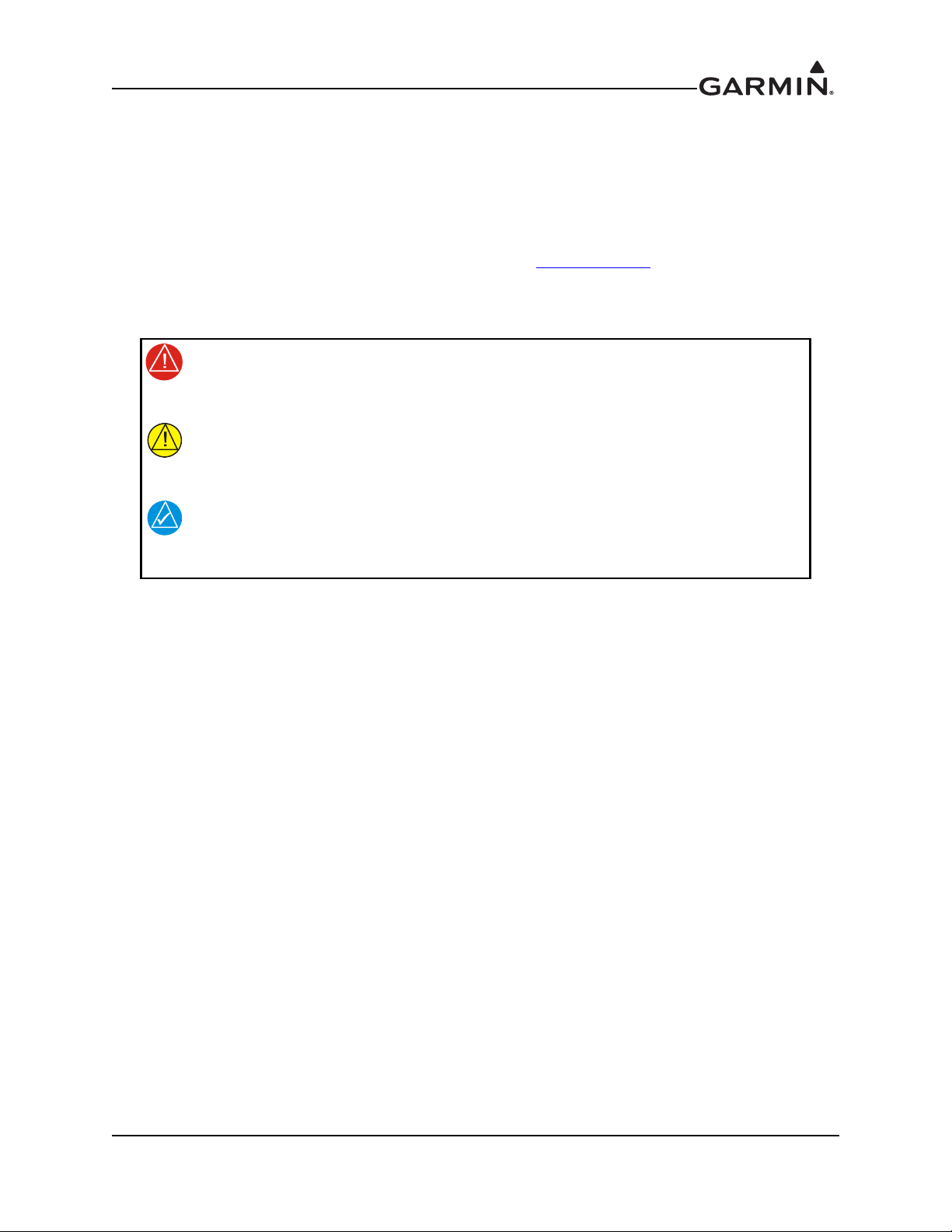

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

WARNING

CAUTION

NOTE

This document may contain information that is subject to the Export Administration Regulations (EAR)

issued by the United States Department of Commerce (15 CFR, Chapter VII, Subchapter C) and may not

be exported, released, or disclosed to foreign nationals inside or outside of the United States without first

obtaining an export license.

Information in this document is subject to change without notice. For updates and supplemental

information regarding the operation of Garmin products, visit

flyGarmin.com.

DEFINITIONS OF WARNINGS, CAUTIONS, AND NOTES

A Warning means injury or death is possible.

A Caution means that damage to the equipment is possible.

A Note provides additional information.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page iii

Page 5

TABLE OF CONTENTS

1 INTRODUCTION..............................................................................................................................1-1

1.1 Scope ..........................................................................................................................................1-2

1.2 Organization ...............................................................................................................................1-2

1.3 Definitions and Abbreviations ...................................................................................................1-3

1.4 Related Publications...................................................................................................................1-3

1.5 Distribution.................................................................................................................................1-4

2 GENERAL DESCRIPTION.............................................................................................................2-1

2.1 System Overview .......................................................................................................................2-2

2.2 Equipment Description...............................................................................................................2-2

2.3 Electrical Current Requirements ................................................................................................2-2

2.4 Interface Summary .....................................................................................................................2-3

2.5 Ground Plane..............................................................................................................................2-4

3 CONTROL AND OPERATION.......................................................................................................3-1

4 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS.........................................................4-1

4.1 Airworthiness Limitations..........................................................................................................4-2

4.2 Servicing Information ................................................................................................................4-2

4.3 Maintenance Intervals ................................................................................................................4-3

5 TROUBLESHOOTING ....................................................................................................................5-1

5.1 Troubleshooting Software ..........................................................................................................5-2

5.2 Assert Log Diagnosis .................................................................................................................5-3

5.3 System Faults .............................................................................................................................5-4

6 EQUIPMENT REMOVAL AND RE-INSTALLATION...............................................................6-1

6.1 GTS 8X0 ....................................................................................................................................6-2

6.2 GPA 65.......................................................................................................................................6-2

6.3 GTS Processor............................................................................................................................6-3

6.4 Configuration Module ................................................................................................................6-3

6.5 Antenna Coaxial Cable...............................................................................................................6-4

6.6 Directional Antenna ...................................................................................................................6-6

6.7 Omni-directional (Monopole) Antenna......................................................................................6-7

7 RETURN TO SERVICE ...................................................................................................................7-1

7.1 Maintenance Records .................................................................................................................7-2

7.2 Return to Service Requirements.................................................................................................7-2

7.3 Configuration and Checkout ......................................................................................................7-3

7.4 System Checkout........................................................................................................................7-8

APPENDIX A AIRCRAFT INSTALLATION RECORD...................................................................A-1

A.1 General Installation Information ...............................................................................................A-2

A.2 Interfaced Equipment ................................................................................................................A-3

A.3 Equipment Locations and Wire Routing...................................................................................A-5

A.4 Configuration Log .....................................................................................................................A-8

A.5 Aircraft Wiring Diagrams .........................................................................................................A-9

APPENDIX B ELECTRICAL BONDING PROCEDURES...............................................................B-1

B.1 Considerations for Untreated or Bare Dissimilar Metals .......................................................... B-2

B.2 Preparation of Aluminum Surfaces ...........................................................................................B-3

B.3 Composite Aircraft ....................................................................................................................B-4

B.4 Tube and Fabric Aircraft ........................................................................................................... B-9

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page iv

Page 6

LIST OF FIGURES

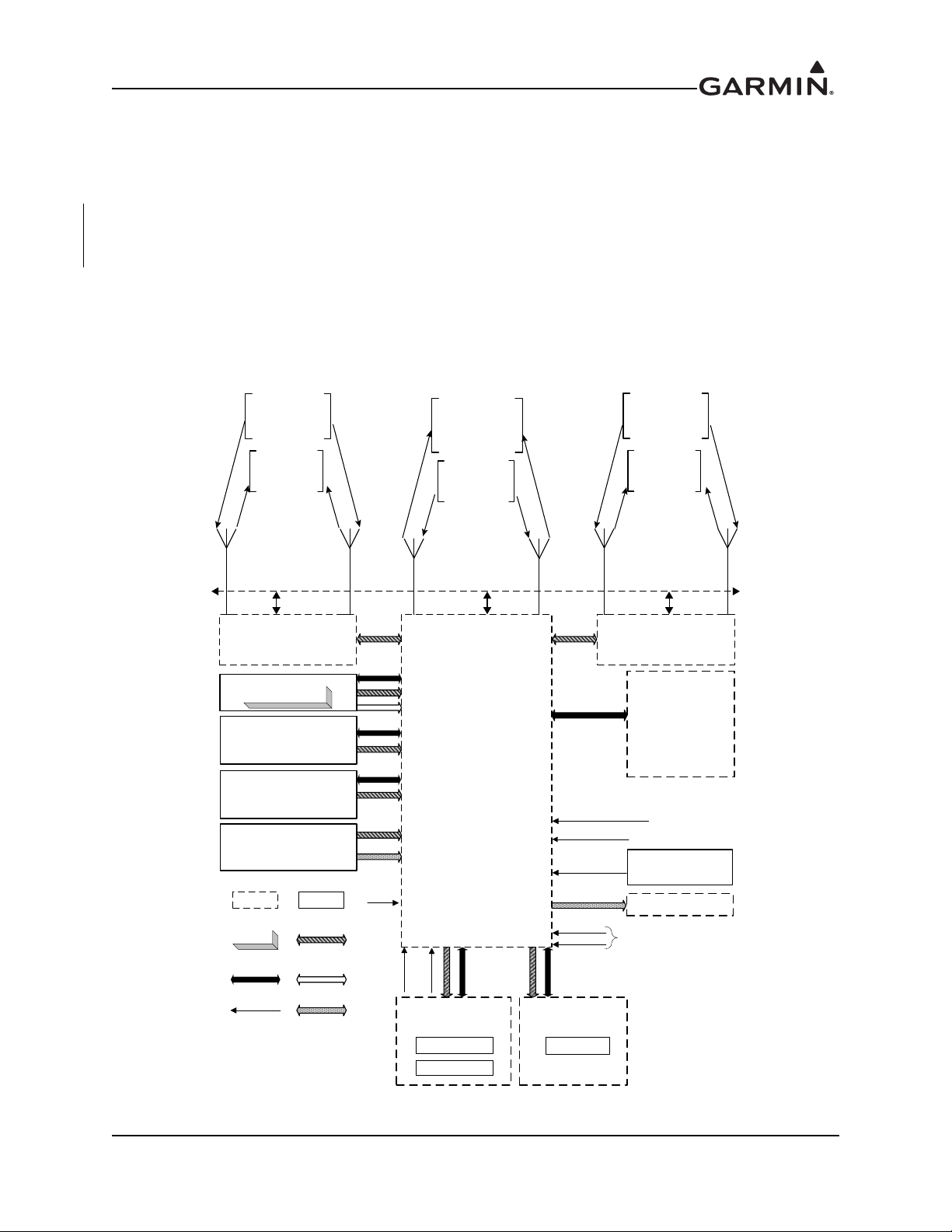

Figure 2-1 GTS 8XX System Interface Diagram ..................................................................................2-3

Figure 3-1 GTS 8XX Traffic System Controls ......................................................................................3-1

Figure 5-1 GTS Assert Log Diagnosis Tool ..........................................................................................5-3

Figure 7-1 GTS Processor Install Tool - Normal Tab ...........................................................................7-4

Figure 7-2 GTS Processor Install Tool - Configuration Tab .................................................................7-6

Figure 7-3 GTS Processor Install Tool - Upload Tab ............................................................................7-7

Figure 7-4 GTS Processor Install Tool - Assert Tab .............................................................................7-7

Figure 7-5 GTS Processor Install Tool - Normal Tab ...........................................................................7-9

Figure 7-6 Target Aircraft Position for Traffic Display Flight Check ................................................7-11

Figure A-1 Equipment Location and Wire Routing - Single-Engine Airplane ....................................A-6

Figure A-2 Equipment Location and Wire Routing - Twin Engine Airplane ......................................A-7

Figure A-3 GTS 8XX System Configuration Log ................................................................................A-8

Figure B-1 Electrical Bonding Preparation – Nut Plate .......................................................................B-2

Figure B-2 Electrical Bonding Preparation – Bolt/Nut Joint ................................................................B-2

Figure B-3 Electrical Bond Preparation – Terminal Lug .....................................................................B-2

Figure B-4 Fiberglass Insulation for Carbon Material ......................................................................... B-4

Figure B-5 Aluminum Tape Joint ......................................................................................................... B-6

Figure B-6 Aluminum Tape Ground Termination ................................................................................B-6

Figure B-7 GTS Processor Aluminum Tape Installation ..................................................................... B-7

Figure B-8 Electrical Bonding Using Conductive Clamp .................................................................. B-11

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page v

Page 7

LIST OF TABLES

Table 2-1 GTS 8XX System Current Requirements .............................................................................2-2

Table 2-2 Ground Plane Definitions and Ground Path Resistance Requirements ................................2-4

Table 5-1 GTS 8XX System Faults .......................................................................................................5-4

Table 6-1 Recommended Coaxial Cable Length ...................................................................................6-5

Table 7-1 GTS 8XX System Flag Status ............................................................................................... 7-5

Table 7-2 Data Source Status Icons .......................................................................................................7-6

Table 7-3 Ramp Test Intruder Scenario ...............................................................................................7-10

Table A-1 GTS 8XX System Interfaces to Garmin Equipment ............................................................A-3

Table A-2 GTS 8XX System Interfaces to Other Equipment ...............................................................A-4

Table A-3 GTS 8XX Equipment Locations ..........................................................................................A-5

Table B-1 Composite Airframe Bonding Strap Assembly .................................................................... B-5

Table B-2 Bonding Strap Assembly for Air-craft with Tubular Airframes ........................................ B-10

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page vi

Page 8

1 INTRODUCTION

1.1 Scope................................................................................................................................... 1-2

1.2 Organization........................................................................................................................ 1-2

1.3 Definitions and Abbreviations ............................................................................................ 1-3

1.3.1 Definitions .................................................................................................................................1-3

1.3.2 Abbreviations .............................................................................................................................1-3

1.4 Related Publications ........................................................................................................... 1-3

1.5 Distribution ......................................................................................................................... 1-4

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 1-1

Page 9

1.1 Scope

This document provides maintenance instructions and Instructions for Continued Airworthiness (ICA) for

the GTS 8XX Traffic System as installed under STC SA02121SE. This document satisfies the requirements

for continued airworthiness as defined by 14 CFR Part 23.1529 and 14 CFR Part 23 Appendix G.

1.2 Organization

The following outline briefly describes the organization of this manual:

Section 2: System Description

This section provides a description of the equipment installed by this STC. An overview of the GTS 8XX

system interface is also provided.

Section 3: Control and Operation

This section provides basic control and operation information in relation to maintenance practices. Basic

GTS configuration and software loading is also described.

Section 4: Instructions for Continued Airworthiness

This section provides instructions to maintain continued airworthiness of the GTS 8XX system and system

airworthiness limitations.

Section 5: Troubleshooting

This section provides troubleshooting information to diagnose and resolve problems with GTS 8XX

system equipment.

Section 6: Equipment Removal and Reinstallation

This section provides instructions for the removal and re-installation of GTS 8XX system equipment.

Section 7: Return to Service

This section specifies return to service procedures to be performed upon completion of maintenance of

GTS 8XX system equipment.

Appendix A: Aircraft Installation Record

This appendix is used to record information for a specific GTS 8XX system installation.

Appendix B: Electrical Bonding Procedures

This appendix provides special bonding procedures for non-metallic aircraft.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 1-2

Page 10

1.3 Definitions and Abbreviations

1.3.1 Definitions

“GTS 8XX system” refers to the complete system, including GTS 800/820/850/825/855, antennas, and

associated equipment.

“GTS Processor” refers to the GTS 825 or 855 LRU at the core of the GTS 8XX system.

“GTS 8X0” refers to the GTS 800, 820, or 850 LRU at the core of the GTS 8XX system.

1.3.2 Abbreviations

The following terminology is used within this document:

AML Approved Model List

ADS-B Automatic Dependent Surveillance-Broadcast

CFR Code of Federal Regulations

DME Distance Measuring Equipment

FAA Federal Aviation Administration

HSDB High Speed Data Bus

ICA Instructions for Continued Airworthiness

LRU Line Replaceable Unit

MFD Multi-Function Display

SL Sensitivity Level

STC Supplemental Type Certificate

TA Traffic Advisory

TAS Traffic Advisory System

TCAS Traffic Alert and Collision Avoidance System

TSO Technical Standard Order

In this manual, references to GTS 8XX Part 23 AML STC Installation Manual

abbreviated as the “STC IM.”

1.4 Related Publications

Part Number Document

005-00738-01

005-00738-02

190-00587-00

190-00587-02

190-00587-50

190-00587-51

190-01279-00

700704

700784

Master Drawing List, GTS 8XX Part 23 AML STC

Equipment List, GTS 8XX Part 23 AML STC

GTS 8X0/GPA 65 (GTS 800/GTS 820/GTS 850) Installation Manual

GTS Traffic Systems Pilot’s Guide

GTS Processor (GTS 825/855/8000) Installation Manual

GTS Processor Maintenance Manual

GTS 8XX Part 23 AML STC Installation Manual

L-Band/DME Blade Antenna P/N L10-611-( ) Limitations and Installation Instructions

Dayton-Granger Inc. General Installation Instructions for Antennas

(P/N 190-01279-00) may be

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 1-3

Page 11

1.5 Distribution

This document contains instructions required to maintain continued airworthiness of the GTS 8XX system.

When this

dealers may

document is revised, every page will be revised to indicate the current revision level. Garmin

obtain the latest revision of this document on the Garmin Dealer Resource Center website.

Owner/operators may obtain the latest revision of this document from

A Garmin Service Bulletin describing the revision to this document will be sent to Garmin dealers if the

revision is determined to be significant.

flyGarmin.com.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 1-4

Page 12

2 GENERAL DESCRIPTION

2.1 System Overview................................................................................................................ 2-2

2.2 Equipment Description .......................................................................................................2-2

2.3 Electrical Current Requirements......................................................................................... 2-2

2.4 Interface Summary.............................................................................................................. 2-3

2.5 Ground Plane ...................................................................................................................... 2-4

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 2-1

Page 13

2.1 System Overview

The GTS 8XX system is designed to use active interrogations of Mode S and Mode C transponders to

provide Traffic Advisories (TA) to the pilot. Traffic is displayed on a multifunction display (MFD) via

ARINC 429 and/or High Speed Data Bus (HSDB). An overview of the GTS 8XX system

and its interfaces

are shown in Figure 2-1.

2.2 Equipment Description

The GTS 8XX is a microprocessor-based Line Replaceable Unit (LRU) that uses active interrogations of

Mode S and Mode C transponders to provide Traffic Advisories (TAs) to the pilot.

When properly configured, the GTS 8XX system will utilize passive surveillance to provide ADS-B In

traffic. The GTS ADS-B In capability allows the unit to receive traffic data through its 1090 MHz

Extended Squitter (1090 ES) receiver. Using the received ADS-B Out broadcasts, the system provides

correlated information about target aircraft, including identification, speed, and direction. GPS and

magnetic heading inputs to the GTS 8XX are required for ADS-B In to operate. Although ADS-B In relies

on 1090ES ADS-B Out broadcasts from other aircraft, it is not necessary for the GTS-equipped aircraft to

broadcast an ADS-B Out signal.

Aural alerts are provided to inform the crew of TAs. A top-mounted directional antenna is used to derive

bearing of the intruder aircraft, which is displayed with relative altitude to own aircraft. Top antenna

transmitted interrogations are directional, reducing the number of transponders that receive the

interrogation, thus reducing potential garble on the 1090 MHz band. An optional bottom antenna transmits

omni directional interrogations. A bottom directional antenna installation gives the benefit of intruder

bearing visibi

be degraded on fixed gear aircraft with a bottom directional antenna.

lity for targets that are shaded from the top directional antenna. Target bearing accuracy may

2.3 Electrical Current Requirements

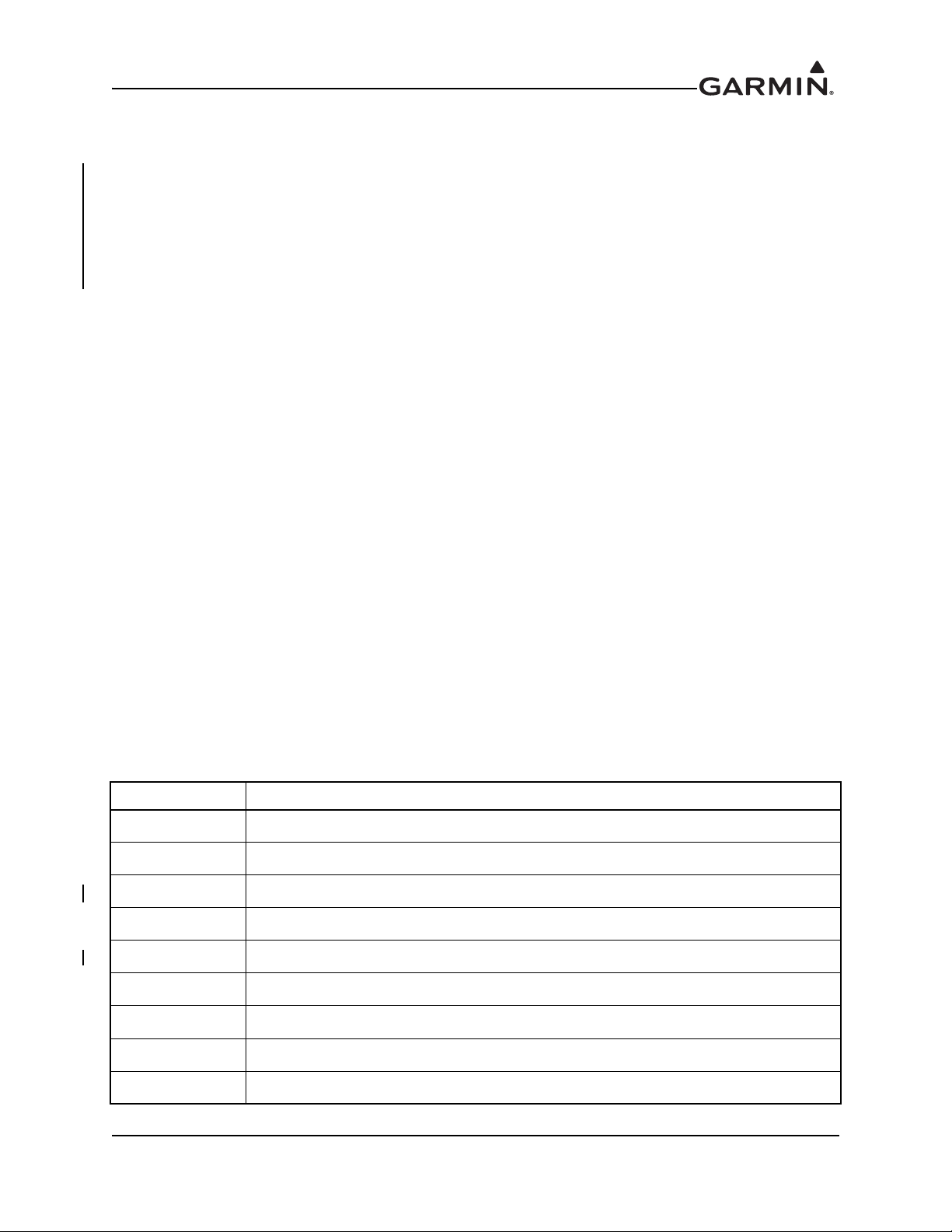

Table 2-1 shows current requirements for the GTS 8XX system.

Table 2-1 GTS 8XX System Current Requirements

LRU

GTS 800 2.2 A 2.6 A 1.1 A 1.5 A

GTS 820/850 2.7 A 3.2 A 1.3 A 1.6 A

GTS Processor 3.5 A 7.5 A 1.7 A

14V Current Draw 28V Current Draw

Typical Maximum Typical Maximum

3.1 A

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 2-2

Page 14

2.4 Interface Summary

Mode S Transponder

Compatible TX/RX interface

required for power programming

GTS TRAFFIC SYSTEM

Top

Directional

Antenna

Mode C Replies

Mode S Replies

Mode S Squitters

Mode C Interrogations

Broadcast Messages

Mode S Interrogations

1

0

9

0

M

H

z

R

X

1

0

9

0

M

H

zR

X

1

0

3

0

M

H

z

T

X

Optional

Top

Antenna

Bottom

Antenna

Mode A/C/S

Replies

Mode S Squitter

Mode A/C

Interrogations

Mode S Interrogations

Broadcast Messages

1

0

9

0

M

H

zTX

1

0

9

0

M

H

zTX

1

0

3

0

M

H

z

R

X

1

0

3

0

M

H

zR

X

Suppression Bus

Audio Inhibit

Audio Output

Pressure Altitude*

OR

OR

OR

Transponder

Serializer

Magnetic Heading*

(optional)

Radar Altimeter

(optional)

GPS PVT*

(optional)

Data Source

Options

HSDB

Analog I/O

Discrete I/O

RS-232

ARINC 429

LRU Data

OPR/SBY

Self Test

Control/Display*

Unit

Color Display

Knobs/Buttons

Mode S Transponder

(Optional Second Unit)

Compatible TX/RX interface

required for power programming

Optional

Top

Antenna

Bottom

Antenna

Mode A/C/S

Replies

Mode S Squitter

Mode A/C

Interrogations

Mode S Interrogations

Broadcast Messages

1

0

9

0

M

H

zTX

1

0

9

0

M

H

z

T

X

1

0

3

0

M

H

zR

X

1

0

3

0

M

H

z

R

X

Display Unit*

Color Display

Pressure Altitude

Magnetic Heading

GPS PVT

Radio Altitude

Air /Gnd Status

Ldg Gear Position

Mode S TX/RX interface

Control/Display

Ldg Gear Position

Air/Gnd Status

OR

Optional

Bottom

Directional or

Monopole

Antenna

GTS 800 TAS

GTS 820 TAS

GTS 825 TAS

GTS 850 TCAS I

GTS 855 TCAS I

Self Test /

Alt Filter

OPR/SBY

External control inputs required

if Display Unit is only unit installe

d

Audio Panel

High-Priority

Audio Source

(e.g. ,TAWS)

(Optional)

(Req’d for retractable ldg gear)

*The HSDB interface can perform all

of the listed interface functions in

place of separate analog/digital

interfaces.

TRFC Mute

(Optional)

1

0

3

0

M

H

z

T

X

G950/G1000 System*

OR

The GTS 8XX system is designed as an open architecture system that uses ARINC 429, RS-232, and

HSDB communications interfaces, as well as analog and discrete inputs and outputs. GTS 8XX interfaces

include:

• Three RS-232 Inputs/Outputs • Alert Audio Output

• Two RS-422 Input/Output • Ten Active Low Discrete Inputs

• Twelve ARINC 429 Inputs/Outputs • Two Active High Discrete Inputs

• Configuration Module • External Suppression Input/Output

• Aircraft Power Input • Four Annunciator Outputs

• Analog Radar Altimeter Input • HSDB Input/Output

• 26 VAC Heading Reference Input

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 2-3

Figure 2-1 GTS 8XX System Interface Diagram

Page 15

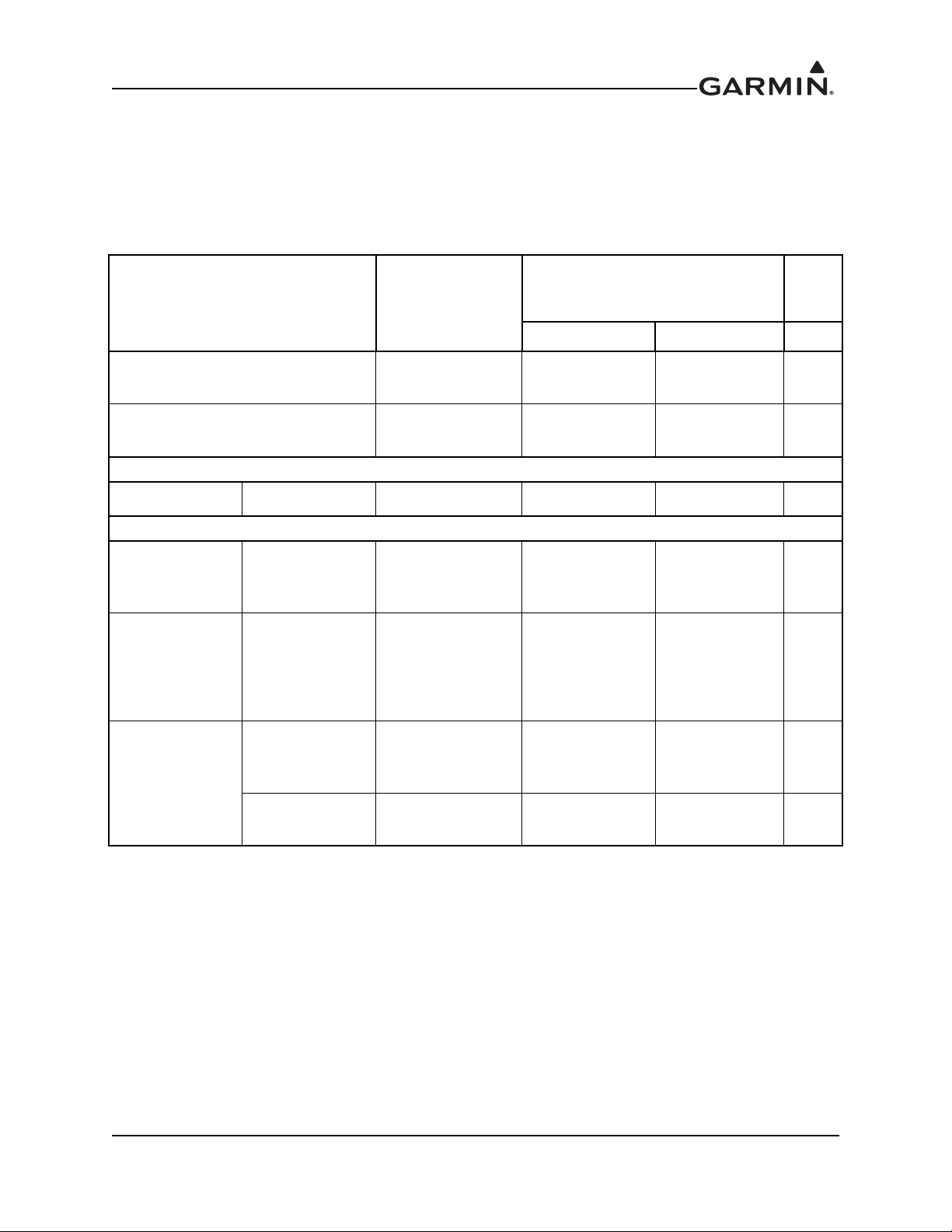

2.5 Ground Plane

Ground plane definition varies with airframe type and aircraft model, as defined in Table 2-2. Refer to the

periodic test and reconditioned resistance values corresponding to these ground plane definitions when

performing the equipment bonding test per Section 4.3. Ensure that all GTS 8XX system antenna coaxial

cables are disconnected during resistance checks.

Table 2-2 Ground Plane Definitions and Ground Path Resistance Requirements

Maximum Resistance Between

Aircraft Type/Model

Ground

Reference

GTS 8XX

Reference (mΩ)

Periodic Test Reconditioned

Chassis and Ground

Notes

Metal airframe

Tube airframe with fabric cover

Composite VFR-only Models

Diamond

Composite IFR Models

Cessna

Cirrus

Diamond

DA 40, DA 40F Instrument panel 50.0 25.0

LC40-550FG,

LC41-550FG,

LC42-550FG

SR20,

SR22,

SR22T

DA 40,

DA 40F

DA 42,

DA 42 N-MG

Nearby metallic

structure

Nearby metallic

structure

Nearby aluminum

lightning

bar/strip

Local grounded

structure

seat support

structure, entry

step)

Nearby structure

lightning

tube

Nearby lightning

ground

ground

(such as

ground

10.0 2.5

10.0 2.5

10.0

10.0

10.0 5.0 [1]

10.0 5.0

5.0

5.0

Notes:

[1] Diamond DA 40 and DA 40F with Diamond OSB 40-004/3 incorporated, or aircraft with

similar factory-installed lightning protection supporting IFR operation.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 2-4

Page 16

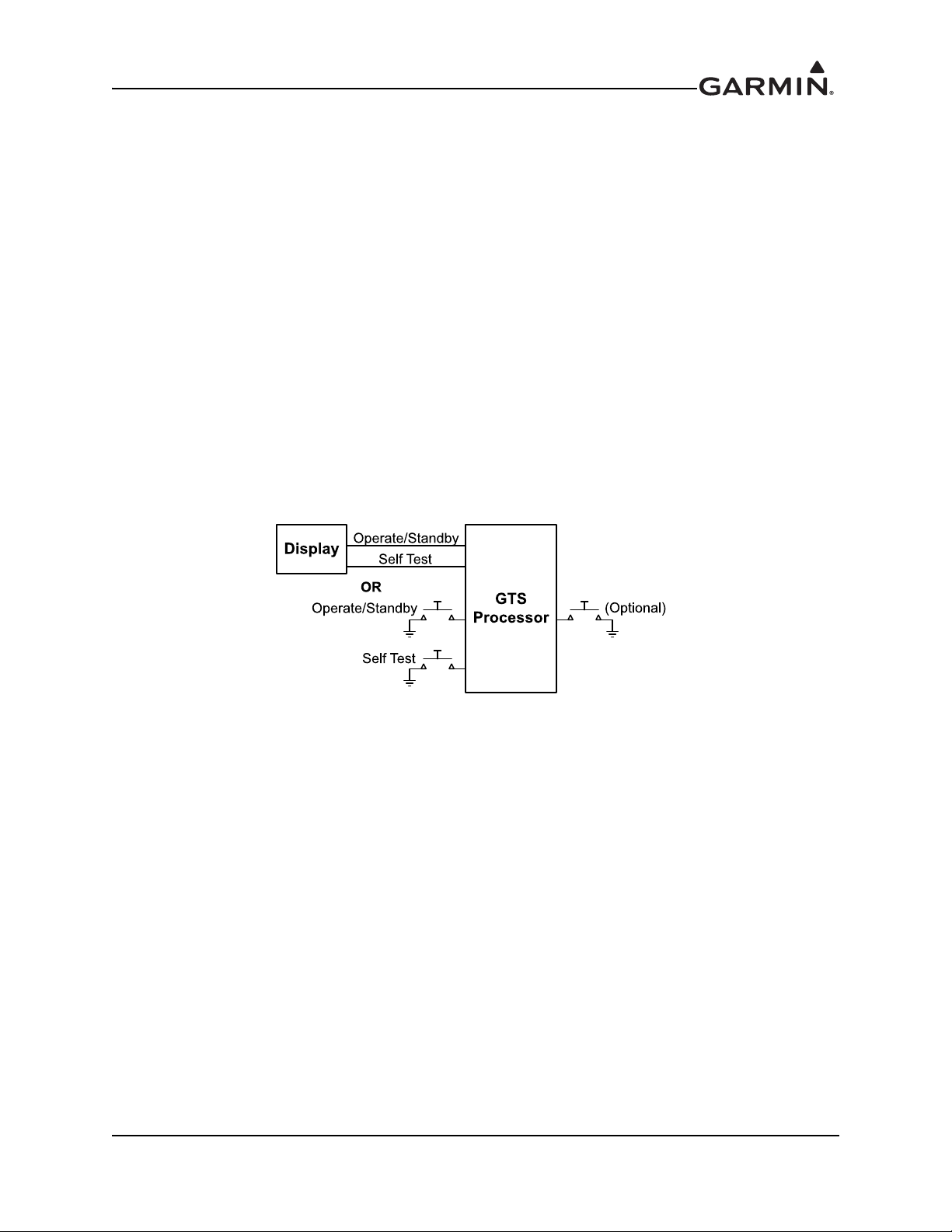

3 CONTROL AND OPERATION

Traffic Mute

The GTS 8XX system includes functions that can be controlled via configured displays or external

switches. Figure 3-1 summarizes GTS 8XX system control. Refer to display documentation for traffic

system control details.

Operate/Standby

The Operate/Standby function toggles the GTS 8XX system between Operate and Standby modes.

Operate/Standby may be controlled through a compatible display or external switch.

Self-Test

The GTS 8XX built-in self-test function may be controlled either through a compatible display or an

external switch.

Traffic Mute (optional)

The optional Traffic Mute function mutes traffic audio alerts and is controlled by an external switch.

Figure 3-1 GTS 8XX Traffic System Controls

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 3-1

Page 17

4 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

4.1 Airworthiness Limitations .................................................................................................. 4-2

4.2 Servicing Information ......................................................................................................... 4-2

4.2.1 Periodic Maintenance ................................................................................................................. 4-2

4.2.2 Special Tools ..............................................................................................................................4-2

4.3 Maintenance Intervals......................................................................................................... 4-3

This document is designed for use by the installing agency of the Garmin GTS 8XX Traffic System as

Instructions for Continued Airworthiness in response to 14 CFR 23.1529 and 14 CFR 23 Appendix G. This

ICA includes information required by the operator to adequately maintain the GTS 8XX system installed

under the Approved Model List (AML) STC.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 4-1

Page 18

Page 19

4.3 Maintenance Intervals

Maintenance Item Interval Description/Procedure

Antenna visual inspection 12 calendar months

Visually inspect the GTS 8XX system antenna(s) for the following:

• Environmental seal damage or decomposition

• Cracks in the antenna body

• Mounting structure damage or deformation

• Corrosion on metallic structures

If the antenna is not properly attached, or the antenna seal shows signs of damage or deterioration,

the following procedure:

1. Remove, clean, and reattach the antenna.

2. Complete the antenna electrical bonding test as described below.

3. Reseal the antenna.

If the antenna is damaged or cracked, remove and replace the antenna in accordance with Section 6

(antenna(s) installed under this STC), or the antenna installation data (antenna(s) not installed under this

STC). After installing antenna, complete the antenna electrical bonding test described below (if applicable).

If aircraft structure, at location of the antenna, is deformed or damaged, remove the antenna and repair

aircraft structure in accordance with aircraft model-specific structural repair manual. After the aircraft repair

is complete, perform the following:

1. Clean and reattach the antenna.

2. Complete the antenna electrical bonding test as described below (if applicable).

3. Reseal the antenna.

complete

Antenna visual inspection suspected lightning strike

Suspected or actual

lightning strike

In the event of a suspected or actual lightning strike to the aircraft, the GTS 8XX system antenna(s) and

antenna cable installation must be inspected.

1. Inspect the antenna(s) and surrounding area for structural damage.

a. If the antenna is damaged, replace the antenna in accordance with Section 6.

b. If the aircraft structure supporting the antenna installation is deformed or damaged,

2. Inspect the antenna and coaxial cable connector ends for damage. If any damage is found on any

3. Ensure that the coaxial cable connectors are securely attached to the antenna connectors.

4. Perform the GTS 8XX system checkout procedure in accordance with Section 5.

remove the antenna and repair in accordance with procedures detailed in the aircraft

model-specific structural repair manual. When repair is complete, continue with the

following steps.

antenna or coaxial cable connector, replace the antenna(s) or coaxial cable(s) in accordance with

Section 6.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 4-3

Page 20

Maintenance Item Interval Description/Procedure

An electrical bonding test must be performed on all GTS 8XX system antennas. The test procedure is:

Antenna electrical bonding test

(Not applicable to

VFR-only

Equipment electrical bonding

test

models)

composite

Every 2000 flight

hours

or ten years,

whichever

Following removal

and

the

rack or bonding

components

AND

Every 2000 flight

hours

whichever

is first

replacement of

GTS 8XX install

or ten years,

is first

1. Gain access to the antenna.

2. Disconnect the coaxial cable connector(s) from the antenna.

3. Measure the resistance between the antenna coaxial connector body and a nearby exposed portion

of aircraft metallic structure (e.g., exposed rivet on fuselage stringer).

4. Verify the resistance is less than or equal to 10 mΩ.

5. Reconnect the antenna connector(s).

In the event of bonding test failure, perform the following procedure:

1. Remove the antenna, clean, and re-install in accordance with Section 6.

2. Measure the resistance between the antenna coaxial connector body and a nearby exposed portion

of aircraft structure (e.g., exposed rivet on fuselage stringer).

3. Verify the resistance is less than or equal to 2.5 mΩ.

1. Disconnect the coaxial cable connector(s) from the GTS 8XX.

2. Disconnect P8001, P8002, and P8003 connectors from the GTS 8XX.

3. Measure the DC resistance between the GTS 8XX chassis and the aircraft ground, as defined in

Table 2-2. Verify the resistance is less than or equal to the appropriate periodic test resistance value

listed in Table 2-2.

In the event of bonding test failure, perform the following procedure:

1. Remove GTS 8XX and install rack from the aircraft per instructions in Section 6.

2. Ensure that the GTS 8XX and install rack are clean and free of dirt and debris.

3. Ensure that all ground path components are in good condition and properly connected and attached

to the aircraft.

4. Re-install the GTS 8XX and install rack in accordance with Section 6.

5. Measure the resistance between the GTS 8XX chassis and the aircraft ground,

as defined in Table 2-2.

6. Verify the resistance is less than or equal to the appropriate reconditioned resistance value listed in

Table 2-2.

Equipment removal and

replacement

On condition

Remove and replace the GTS 8XX and/or GTS 8XX system antenna.

See Section 6 for equipment removal and re-installation instructions.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 4-4

Page 21

Maintenance Item Interval Description/Procedure

In the event of a suspected or actual lightning strike to the aircraft, the bonding components for the

Equipment bonding visual

inspection – suspected

lightning strike

Suspected or

actual lightning

strike

GTS 8XX: bonding straps and associated hardware (if applicable) must be inspected. If any damage is

found, the damaged components must be replaced in accordance with specifications and procedures

shown in Appendix B. If any bonding components are replaced, complete the equipment electrical

bonding test as described above.

Equipment visual inspection

12 calendar months

Conduct a visual inspection of the GTS 8XX installation in accordance with 14 CFR 43

Preventative Maintenance, Rebuilding and Alteration, Appendix D. If the equipment fails the visual

inspection, complete the following procedure:

1. Correct improper installations and ensure that all mounting racks and fasteners are secure.

2. Correct improper wire routing and ensure that the wire harness is securely mounted. Replace the

install rack or any wiring, bonding, or shielding component with obvious defects.

3. If the install rack or any bonding components are replaced, complete the equipment electrical

bonding test as described above.

Maintenance,

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 4-5

Page 22

5 TROUBLESHOOTING

5.1 Troubleshooting Software................................................................................................... 5-2

5.1.1 GTS Install Tool.........................................................................................................................5-2

5.1.2 GTS Assert Log Diagnosis Tool ................................................................................................5-2

5.2 Assert Log Diagnosis.......................................................................................................... 5-3

5.3 System Faults...................................................................................................................... 5-4

This section provides information to assist troubleshooting if problems occur after completing the

maintenance. Refer to the GTS 8XX System Configuration Log, retained in the aircraft permanent records,

for a list of the interfaced equipment and system configuration data. When troubleshooting the GTS 8XX

system, refer to wire routing drawings and interconnect diagrams retained with the aircraft’s permanent

records.

Before troubleshooting the GTS 8XX system, use the GTS Install Tool’s Configuration tab to ensure that

system configuration settings match those recorded in the completed GTS 8XX System Configuration Log

that is retained in the aircraft’s permanent records. See Appendix A for system configuration information.

GTS 8XX system troubleshooting is performed using the following tools:

• Assert Diagnosis

• System Faults

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 5-1

Page 23

5.1 Troubleshooting Software

The GTS Processor Install Tool (P/N 006-A0242-10) and GTS 8X0 Install Tool (P/N 006-A0242-00)

display GTS 8X5 and GTS 8X0 system faults and generate assert logs. Assert logs can be analyzed using

the GTS Assert Log Diagnosis Tool (P/N 006-A0244-00).

5.1.1 GTS Install Tool

Complete the following procedure to install the GTS Install Tool.

From the Garmin

(P/N 006-A0242-10) for the GTS 825/855 or the GTS 8X0 Install Tool (P/N 006-A0242-00) for the

GTS 800/820/850.

1. Double-click the 32-bit or 64-bit .msi file (depending on PC operating system) to begin

installation.

2. Follow installer prompts and allow driver installation if prompted.

3. Click Close to exit the installer. The GTS Install Tool is now ready to use.

5.1.2 GTS Assert Log Diagnosis Tool

1. Complete the following procedure to install the GTS Assert Log Diagnosis Tool.

2. Download the GTS Assert Log Diagnosis Tool (P/N 006-A0244-00) from the

Garmin

3. Double-click the .msi file to begin installation and follow installer prompts.

4. Click Close to exit the installer. The GTS Assert Log Diagnosis Tool is now ready to use.

Dealer Resource Center, download either the GTS Processor Install Tool

Dealer Resource Center.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 5-2

Page 24

5.2 Assert Log Diagnosis

The GTS Assert Log Diagnosis Tool, shown in Figure 5-1, is used with the GTS assert log to assist in the

diagnosis and resolution of asserts generated from the GTS Processor Install Tool or GTS 8X0 Install Tool.

This tool allows for

Windows XP or later and

the Garmin

Diagnosis Tool. See Section 7.3.1.4 for assert log generation instructions.

Dealer Resource Center. A detailed user guide is found under the Help menu of the Assert

troubleshooting the GTS Assert Log using a computer (installed with Microsoft

Microsoft, NET Framework 2.0 SP2 or later) and is available for download from

Figure 5-1 GTS Assert Log Diagnosis Tool

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 5-3

Page 25

5.3 System Faults

NOTE

GTS 8XX system faults will annunciate on interfaced compatible displays, such as the GDU 620 and on the GTS Install Tool’s Normal tab. Fault descriptions and

corrective actions are listed in Table 5-1.

If any system fault persists after performing the associated troubleshooting actions, return the GTS 8XX to Garmin for service.

Table 5-1 GTS 8XX System Faults

Fault Description Corrective Action

Calibration Data

Configuration Data

FPGA

ROM

Execution CPU execution fault has occurred.

Electrical

Whisper Shout Transmit power is out of tolerance.

Transmit Power

Stored factory calibration parameters are

invalid.

Stored system configuration parameters

are

invalid or Mode S address is invalid (all

zeros

configuration is

FPGA image check failed. Fault will

persist

Internal non-volatile memory failure or

invalid

One or more internal electrical voltages

are

power is

One or more internal transmitter power

source

will persist

or F’s). Fault will persist until

corrected.

until valid FPGA image is loaded.

data image detected.

out of range. Fault will persist until

cycled.

voltages are out of range. Fault

until power is cycled.

Return unit to Garmin for service.

Analyze the assert log. See Section 5.2.

1. Load a valid FPGA image. See Section 7.3.1.3.

2. If an audio or Magnetic Variation image was recently uploaded, retry the upload.

1. Cycle GTS 8XX power. Run self-test. Ensure that self-test occurs in an area free of

buildings and large structures that might reflect signals. [1]

2. Analyze the assert log. See Section 5.2.

1. Cycle GTS 8XX power. Run self-test. [1]

2. Check aircraft power supply.

3. Analyze the assert log. See Section 5.2.

1. Check cable loss configuration.

2. Check antenna installation and all cable connections.

3. Analyze the assert log. See Section 5.2.

1. Cycle GTS 8XX power and run self-test. [1]

2. Check aircraft power supply.

3. Analyze the assert log. See Section 5.2.

1030 MHz

Transmit frequency synthesizer is not

locked.

1. Cycle GTS 8XX power and run self-test. [1]

2. Analyze the assert log. See Section 5.2.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 5-4

Page 26

Fault Description Corrective Action

1090 MHz

Receiver Cal GTS 8XX receiver is out of calibration.

Transmitter Cal GTS 8XX transmitter is out of calibration.

Receive frequency synthesizer is not

locked.

1. Cycle GTS 8XX power and run self-test. [1]

2. Analyze the assert log. See Section 5.2.

1. Check antenna installation and all cable connections and run self-test. Ensure that self-test

occurs in an area free of buildings and large structures that might reflect signals. See

Section 7.3.1.3. Receiver self-calibration and test is performed prior to transmitter calibration

and test. In the event that a receiver calibration fault occurs, transmitter self-calibration and

testing will not be performed.

2. Analyze the assert log. See Section 5.2.

1. Check antenna installation and all cable connections and run self-test. Ensure that self-test

occurs in an area free of buildings and large structures that might reflect signals. See

Section 7.3.1.3. Receiver self-calibration and test is performed prior to transmitter calibration

and test. In the event that a receiver calibration fault occurs, transmitter self-calibration and

testing will not be performed.

2. Analyze the assert log. See Section 5.2.

Pressure Altitude

Temperature

TCAS Equipage

Radio Altitude

Notes:

[1] If self-test is controlled through a compatible display, refer to display documentation for self-test procedures.

Ownship barometric altitude calculation

is

invalid or has timed out.

Main board or RF receiver temperature is

higher than 100° Celsius or lower than

-60° Celsius. Fault will persist until

internal

acceptable range.

GTS 8XX is not receiving TCAS

Equipage data.

GTS 8XX is not receiving radar altimeter

data.

temperature returns to

Check wiring to the barometric altitude source and ensure that the source is operating. The fault will

clear as soon as valid barometric altitude data is received.

1. Ensure that the GTS 8XX has adequate ventilation and the fan is not obstructed.

2. Analyze the assert log. See Section 5.2.

1. Ensure that transponder is operating properly.

2. Check GTS 8XX wiring to the transponder. This fault will clear as soon as valid TCAS

source data is received.

1. Ensure that radar altimeter is operating properly.

2. Check GTS 8XX wiring to radar altimeter. This fault will clear as soon as valid radio altitude

data is received.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 5-5

Page 27

6 EQUIPMENT REMOVAL AND RE-INSTALLATION

WARNING

6.1 GTS 8X0 ............................................................................................................................. 6-2

6.2 GPA 65 ............................................................................................................................... 6-2

6.3 GTS Processor .................................................................................................................... 6-3

6.4 Configuration Module......................................................................................................... 6-3

6.5 Antenna Coaxial Cable .......................................................................................................6-4

6.6 Directional Antenna............................................................................................................ 6-6

6.7 Omni-directional (Monopole) Antenna .............................................................................. 6-7

This section contains procedures and requirements for removal and re-installation of GTS 8XX equipment.

After removal and re-installation, the GTS 8XX system must be checked in accordance with Section 7.

Prior to removal or re-installation of any component of the GTS 8XX system, always ensure

that the aircraft power is off. Unplug any auxiliary power supply.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 6-1

Page 28

6.1 GTS 8X0

Removal

1. Ensure there is no power supplied to the GTS 8X0.

2. Gain access to the GTS 8X0. See Appendix A for equipment locations.

3. Disconnect the D-sub and QMA antenna coaxial cable connectors from the GTS 8X0.

4. Loosen the mounting screw on the front of the GTS 8X0 LRU mounting tray.

5. Remove the GTS 8X0 from the install rack.

Re-installation

1. Ensure there is no power supplied to the GTS 8X0.

2. Place the GTS 8X0 in the install rack.

3. Tighten the mounting screw on the front of the GTS 8X0 LRU mounting tray.

4. Connect the D-sub and QMA antenna coaxial cable connectors to the GTS 8X0.

5. Complete the appropriate return to service procedures in Section 7.

6.2 GPA 65

Removal

1. Ensure there is no power supplied to the GPA 65.

2. Gain access to the GPA 65. See Appendix A for equipment locations.

3. Disconnect the QMA antenna coaxial cable connectors from the GPA 65.

4. Disconnect the pigtail connector.

5. Remove the four mounting screws on the GPA 65.

6. Retain the screws for re-installation.

7. Remove the GPA 65.

Re-installation

1. Ensure there is no power supplied to the GPA 65.

2. Install the GPA 65.

3. Attach the GPA 65 with the four mounting screws.

4. Connect the pigtail connector.

5. Connect the antenna connectors on the GPA 65 ensuring each QMA connector is secured.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 6-2

Page 29

6.3 GTS Processor

CAUTION

Removal

1. Ensure there is no power supplied to the GTS 8XX.

2. Gain access to the GTS 8XX. See Appendix A for equipment locations.

3. Disconnect the D-sub and antenna coaxial cable connectors from the GTS 8XX.

4. Unscrew the lockdown knob(s).

5. Remove the GTS 8XX from the install rack.

Re-installation

1. Ensure there is no power supplied to the GTS 8XX.

2. Place the GTS 8XX in the install rack with its connectors facing the same side of the rack as

lockdown knob(s).

3. Screw the rack lockdown knob(s) onto the unit lockdown hook(s). Tighten until ratchet clicking

stops.

4. Connect the D-sub and antenna coaxial cable connectors to the GTS 8XX.

5. Complete the appropriate return to service procedures in Section 7.

6.4 Configuration Module

Removal

1. Ensure there is no power supplied to the GTS 8XX.

2. Gain access to the GTS 8XX. See the completed copy of Appendix A retained with the

permanent record for equipment locations.

3. Disconnect D-sub connector P8001 from the GTS 8XX.

4. Remove the two 4-40 x 0.187” countersunk screws from the backshell cover.

5. Remove the three 4-40 x 0.375” pan head screws from the strain relief clamp and remove the clamp.

6. Remove the single screw securing the configuration module.

7. Disconnect the configuration module harness and remove the configuration module.

aircraft

the

Re-installation

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 6-3

1. Ensure there is no power supplied to the GTS 8XX.

2. Reverse steps 2-7 of the removal procedure above.

Be sure to install the strain relief clamp with its flanges facing AWAY from the wiring

harness. Failure to do so may cause damage to the wiring harness.

3. Complete the appropriate return to service procedures in Section 7.

Page 30

6.5 Antenna Coaxial Cable

NOTE

The GTS 8XX system has stringent coaxial cable requirements. Any damaged or malfunctioning section of

antenna coaxial cable must be replaced. The replacement must include the entire cable length from

connector to connector. See Table 6-1.

To avoid attenuation issues, replace coaxial cables with identical part numbers.

Removal

1. Ensure there is no power supplied to the GTS 8XX.

2. Gain access to the antenna coaxial cable section being removed.

3. Disconnect the QMA or TNC connector at both ends of the coaxial cable section being removed.

4. Remove the coaxial cable section.

Re-installation

1. Ensure there is no power supplied to the GTS 8XX.

2. Route and secure the coaxial cable section.

3. Connect the QMA or TNC connectors at both ends of the coaxial cable section.

4. Complete the appropriate return to service procedures in Section 7.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 6-4

Page 31

Coaxial Cable Assembly Repair and Replacement

An individual coaxial cable may be repaired with a maximum reduction in length of two inches from the

length specified in Table 6-1.

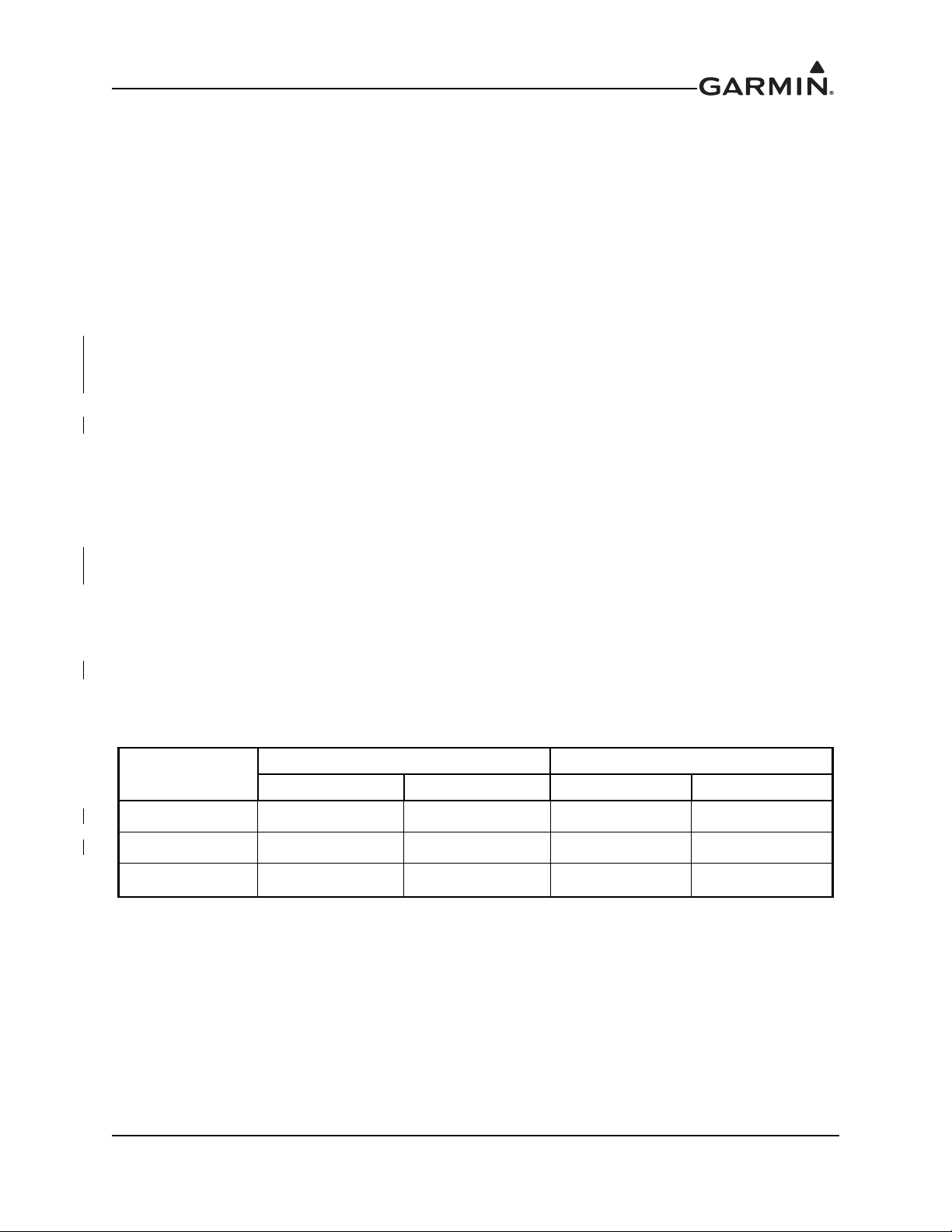

Table 6-1 Recommended Coaxial Cable Length

Cable Type

M17/128RG400

PIC 83204 16.7

M17/60-RG142 15.5

PIC S44191 12.2

Carlisle 311901 12.16

PIC S44193 11.8

Carlisle 311601 8.7

PIC S67163 7.5

Carlisle 311501 7.12

Cable Loss

(dB/100ft)

17.2

Connector

Type(s)

Unit/Antenna

TNC/TNC 0.08/0.08 1.98 7.79 10.70 13.60 16.51

TNC/QMA 0.08/0.035 2.24 8.05 10.96 13.87 16.77

TNC/TNC 0.08/0.08 2.04 8.02 11.02 14.01 17.01

TNC/QMA 0.08/0.035 2.31 8.29 11.29 14.28 17.28

TNC/TNC 0.08/0.08 2.19 8.65 11.87 15.10 18.32

TNC/QMA 0.08/0.035 2.48 8.94 12.16 15.39 18.61

TNC/TNC 0.08/0.08 2.79 10.98 15.08 19.18 23.28

TNC/QMA 0.08/0.035 3.16 11.35 15.45 19.55 23.65

TNC/TNC 0.08/0.08 2.80 11.02 15.13 19.24 23.36

TNC/QMA 0.08/0.035 3.17 11.39 15.50 19.61 23.73

TNC/TNC 0.08/0.08 2.88 11.36 15.59 19.83 24.07

TNC/QMA 0.08/0.035 3.26 11.74 15.97 20.21 24.45

TNC/TNC 0.08/0.08 3.91 15.40 21.15 26.90 32.64

TNC/QMA 0.08/0.035 4.43 15.92 21.67 27.41 33.16

TNC/TNC 0.08/0.08 4.53 17.87 24.53 31.20 37.87

TNC/QMA 0.08/0.035 5.13 18.47 25.13 31.80 38.47

TNC/TNC 0.08/0.08 4.78 18.82 25.84 32.87 39.89

TNC/QMA 0.08/0.035 5.41 19.45 26.47 33.50 40.52

Connector

Loss

(dB)

Length

(ft) for

0.5 dB

Length

(ft) for

1.5 dB

Length

(ft) for

2.0 dB

Length

(ft) for

2.5 dB

Length

(ft) for

3.0 dB

Notes:

[1] Actual cable lengths may vary depending on manufacturer’s cable attenuation and

connector specifications.

[2] The values listed include the maximum attenuation of both the maximum length of coaxial

cable and two RF coaxial connectors at a frequency of 1090 MHz.

[3] Vendor: Carlisle Interconnect Technologies

100 Tensolite Drive

St. Augustine, FL 32092

Telephone: 800.458.9960

Fax: 904.829.3447 Website: www.carlisleit.com

[4] Vendor: PIC Wire and Cable

N53 W24747 S Corporate Circle

Sussex, WI 53089-0330

Telephone 800.742.3191 or 262.246.0500

Fax: 262.246.0450 Website: www.picwire.com

[5] See current issue of Qualified Products List, QPL-17.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 6-5

Page 32

6.6 Directional Antenna

NOTE

CAUTION

Removal

1. Ensure there is no power supplied to the GTS 8XX.

2. Remove sealant from the antenna’s fasteners.

3. Remove the fasteners attaching the antenna to the fuselage.

4. Remove environmental seal between the antenna and fuselage skin and pull the antenna away from

the fuselage.

5. Disconnect the antenna coaxial cables from the antenna connectors.

6. Remove the antenna from the aircraft. Retain the antenna backing plate (if used) and O-ring.

Re-installation

Ensure the electrical bond meets requirements in Table 2-2.

1. Ensure there is no power supplied to the GTS 8XX.

2. Inspect the antenna O-ring for damage. If necessary, replace the O-ring with a new O-ring.

Otherwise, re-install the O-ring in the groove on the antenna baseplate.

3. Position the antenna backing plate (if used) on the aircraft structure.

4. Reconnect the antenna coaxial cables to the corresponding antenna connectors.

5. Position the antenna on the fuselage and re-install antenna fasteners. Torque 0.164-32 fasteners

10-12 in-lbf.

6. Seal the antenna base to fuselage skin by applying MIL-S-8802 sealant around entire perimeter of

antenna base in a uniform fillet.

7. Ensure that the antenna connector is not contaminated with sealant.

8. Seal the mounting screws with sealant.

Do not use construction grade RTV sealant or sealants containing acetic acid. These

sealants may damage the electrical connections to the antenna. Use of these sealant types

may void the antenna warranty.

9. Complete the appropriate return to service procedures in Section 7.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 6-6

Page 33

6.7 Omni-directional (Monopole) Antenna

NOTE

CAUTION

Removal

1. Ensure there is no power supplied to the GTS 8XX.

2. Remove sealant from the antenna’s fasteners.

3. Remove the fasteners attaching the antenna to the fuselage.

4. Remove environmental seal between the antenna and fuselage skin and pull the antenna away from

the fuselage.

5. Disconnect the antenna coaxial cable from the antenna connector.

6. Remove the antenna from the aircraft. Retain the antenna backing plate (if used) and O-ring.

Re-installation

Ensure the electrical bond meets requirements in Table 2-2.

1. Ensure there is no power supplied to the GTS 8XX.

2. Inspect the antenna O-ring for damage. If necessary, replace the O-ring with a new O-ring.

Otherwise, re-install the O-ring in the groove on the antenna baseplate.

3. Position the antenna backing plate (if used) on the aircraft structure.

4. Reconnect the coaxial cable to the antenna connector.

5. Position the antenna on the fuselage and re-install antenna fasteners. Torque the 8-32 fasteners

12-15 in-lbf.

6. Seal the antenna base to fuselage skin by applying MIL-S-8802 sealant around entire perimeter of

antenna base in a uniform fillet.

7. Ensure that the antenna connector is not contaminated with sealant.

8. Seal the mounting screws with sealant.

Do not use construction grade RTV sealant or sealants containing acetic acid. These

sealants may damage the electrical connections to the antenna. Use of these sealant types

may void the antenna warranty.

9. Complete the appropriate return to service procedures in Section 7.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 6-7

Page 34

7 RETURN TO SERVICE

7.1 Maintenance Records.......................................................................................................... 7-2

7.2 Return to Service Requirements ......................................................................................... 7-2

7.2.1 GTS 8XX....................................................................................................................................7-2

7.2.2 GTS 8XX Configuration Module...............................................................................................7-2

7.2.3 Antenna ......................................................................................................................................7-2

7.3 Configuration and Checkout............................................................................................... 7-3

7.3.1 GTS 8XX Install Tools ..............................................................................................................7-3

7.4 System Checkout ................................................................................................................ 7-8

7.4.1 System Test and Audio Check ...................................................................................................7-8

7.4.2 Interface Check ..........................................................................................................................7-9

7.4.3 Ramp Test and Return To Service Test .....................................................................................7-9

This section provides procedures for returning the GTS 8XX system to service after removal and

re-installation of system components. The aircraft may be returned to service after accomplishing the

required procedures prescribed in this section.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-1

Page 35

7.1 Maintenance Records

NOTE

NOTE

Record the following information in the appropriate aircraft maintenance logs:

Version number(s) of software loaded during maintenance

Part and serial numbers of any replacement equipment

Database updates performed during maintenance

Other relevant aircraft maintenance information

7.2 Return to Service Requirements

7.2.1 GTS 8XX

Original GTS 8XX Re-installed

No action is necessary.

New, Repaired, or Exchanged GTS 8XX Installed

If the GTS 8XX configuration module is left in place, no configuration is necessary.

7.2.2 GTS 8XX Configuration Module

Original Configuration Module Re-installed

No action is necessary.

New Configuration Module Installed

Installation of a used configuration module is not recommended.

Feature control of the GTS 8XX as a TAS or TCAS I is stored in the GTS P8001 backshell

configuration module. Replacement of the configuration module will require that the TAS

or TCAS I feature be re-enabled. Contact Garmin

See front matter of this manual for contact information.

The GTS 8XX system configuration must match the original configuration settings recorded in the

completed configuration and checkout log kept with the aircraft’s permanent records.

7.2.3 Antenna

Perform the Ramp Test and Return to Service Test per Section 7.4.3 or the Alternate Flight Test per

Section 7.4.3.1.

Aviation Product Support for details.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-2

Page 36

7.3 Configuration and Checkout

NOTE

NOTE

The GTS 8XX system configuration and software loading is performed using a computer (installed with

Microsoft Windows XP or later) and the GTS Processor Install Tool (P/N 006-A0242-10) for the

GTS 825/855 or the GTS 8X0 Install Tool (P/N 006-A0242-00) for the GTS 800/820/850. The tool is

available for download from the Garmin Dealer Resource Center

the USB pigtail installed in the wiring harness.

A USB-A to USB-B cable (not provided) is required to interface between a computer

USB-A receptacle and the GTS 8XX USB-B receptacle installed in the wiring harness.

7.3.1 GTS 8XX Install Tools

The GTS Processor Install Tool (P/N 006-A0242-10) and GTS 8X0 Install Tool

(P/N 006-A0242-00) will be referred to as the GTS 8XX Install Tool. Functionality is the

same between the two tools except for TCAS II, which is not approved.

The GTS 8XX Install Tools allow for configuration, diagnostics, and upload of GTS 8XX software. See

Section 5.1.1 for download and installation instructions.

The following GTS 8XX system tabs are accessible on both the GTS Processor Install Tool and GTS 8X0

Install Tool.

Normal tab – Allows selection of Traffic mode to Standby, Operate, or Test. Reports system faults,

status flags, and operation status. Allows Ground Test Mode to be enabled or disabled

Configuration tab – Allows selection of installation options

Upload tab – Allows upload of software to the GTS 8XX

Assert tab – Retrieves and displays the contents of the assert log from the GTS 8XX

. The GTS 8XX system is interfaced with

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-3

Page 37

7.3.1.1 Normal Tab

Figure 7-1 GTS Processor Install Tool - Normal Tab

The Normal tab, shown in

Figure 7-1, displays GTS 8XX

system status during normal

operation, including operating

status, antenna alpha values,

system faults, and status flags. The

Normal tab is also used to enable

or disable GTS 8XX system

ground test. When the Normal tab

is selected, the GTS 8XX reboots

into Normal System mode.

Operating Status

The Normal tab’s Operating

Status portion displays the

GTS 8XX total power-on count

and time, as well as the current

temperature of the GTS 8XX.

Alpha Values

Alpha values are phase measurement values for the top and bottom antennas used to determine if the

installation has an adequate ground plane for each antenna. Alpha values are updated after a self-test is

performed.

System Faults

GTS 8XX system faults are listed in the System Faults column of the Normal tab, shown in Figure 7-1.

Red bold text indicates an active fault. Gray text indicates an inactive fault. See Section 5.3 for GTS 8XX

system fault descriptions.

Status Flags

GTS 8XX system status flags are listed in the Status Flags column of the Normal tab, shown in

Figure 7-1. Black bold text indicates a status flag that has been set. Gray text indicates a status flag that has

not been set. Status flags are described in Table 7-1.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-4

Page 38

Ground Test

NOTE

NOTE

The Ground Test feature simulates aircraft flight conditions of 50,000 feet altitude and 0º heading for the

purpose of conducting the ramp and return to service tests described in Section 7.4.3.

Table 7-1 GTS 8XX System Flag Status

Flag Active Flag Description

Transponder #1 Active Transponder #1 is active.

Transponder #2 Active Transponder #2 is active.

Magnetic Variation

GPS Available

Display #1 Active Traffic display #1 discrete input is active.

Display #2 Active Traffic display #2 discrete input is active.

Radio Altitude Available Radio altitude source is configured, and valid data is available. [1]

Mag Heading Available Magnetic heading source is configured, and valid data is available. [1]

Airborne Self Test Allowed Self-test can be initiated while airborne. [2]

Notes:

[1] If the status flag is not active, the source is not configured or data is unavailable or invalid.

[2] If the status flag is not active, self-test can only be initiated on the ground.

Magnetic variation data (difference between “true” North and magnetic

North) is available.

GPS Position, Velocity, and Time source is configured and valid data is

available. [1]

7.3.1.2 Configuration Tab

The Configuration tab displays configuration data and allows the maintenance technician to configure the

GTS 8XX to the original configuration settings after maintenance has been performed (e.g., removal and

replacement). Refer to the aircraft records for a copy of the original configuration settings. The

Configuration tab also displays the status of each data source. Table 7-2 depicts status icons that can be

displayed to the left of each data source field.

When the Configuration tab is selected, the GTS 8XX reboots into Configuration mode. Changed

configuration options will be highlighted yellow until the Set Active key is clicked. Configuration items

not applicable to the GTS 8XX system are disabled in the install tool.

After the configuration changes are complete, make sure the Set Active key is selected.

Then return to the Normal tab on the Install Tool to allow the GTS 8XX to go into Operate

mode.

Configuration settings will be lost if the Set Active key is not selected prior to switching to

a different tab.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-5

Page 39

Table 7-2 Data Source Status Icons

Figure 7-2 GTS Processor Install Tool - Configuration Tab

Icon Status

Active

Inactive

Unknown

Saving or Canceling Configuration Settings

•The Set Active key saves highlighted configuration settings to the GTS 8XX configuration

module and reboots the GTS 8XX with the configuration settings

•The Revert Changes key resets all highlighted configuration settings to those saved on the

GTS 8XX configuration module

•The Exit key closes the GTS Install Tool and causes the GTS 8XX to reboot into Normal mode

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-6

Page 40

7.3.1.3 Upload Tab

Figure 7-3 GTS Processor Install Tool - Upload Tab

Figure 7-4 GTS Processor Install Tool - Assert Tab

The Upload tab displays current

software version information for

Boot Block, Region List, System,

FPGA, Audio, and Magnetic

Variation software, and can be

used to upload new versions of all

software except for Boot Block.

To upload a new software version:

1. Type the software file

path in the appropriate

Upload tab window or

click the Browse key.

2. Click the appropriate

Upload key.

3. Click the Normal tab to

return the GTS 8XX to

Normal mode.

7.3.1.4 Assert Tab

The Assert tab retrieves and

displays the contents of the assert

log from the GTS 8XX. The

contents of the assert log from the

GTS 8XX can be retrieved and

displayed on the Assert tab.

The Assert tab can be used to

generate an assert log, which can

be diagnosed using the Assert

Log Diagnosis Tool

(P/N 006-A0244-00) or submitted

to Garmin Technical Support for

troubleshooting. See Section 5.2

for download and installation

instructions.

1. Select Get Assert Log to

retrieve the assert log

from the GTS 8XX.

2. Select Save Assert Log

to File to save the

received log to a text file.

3. Files can be submitted to Garmin Product Support

issue.

to aid in diagnosing a failure or operational

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-7

Page 41

7.4 System Checkout

NOTE

NOTE

This section details aspects of the GTS 8XX system checkout. It includes traffic audio and system interface

checks, plus detailed procedures for conducting Ramp and Return to Service Test procedures. An alternate

flight check procedure is also provided.

7.4.1 System Test and Audio Check

Verify that the GTS 8XX system produces aural alerts.

1. While on the ground, turn on the GTS 8XX system and audio panel following normal power-up

procedures.

2. Connect a headset to the audio panel and set the volume to a typical in-flight volume level.

3. Command the GTS 8XX system into Self-test mode. If switches are used to control the mode of

the GTS 8XX system, this is done by activating the Traffic Test switch.

4. When the self-test is completed, the aural announcement “TAS SYSTEM TEST PASSED” or

“TCAS ONE SYSTEM TEST PASSED” should be heard. Evaluate the audio for acceptable

volume and intelligibility.

The traffic system audio volume can be adjusted, if necessary. Use the following flight

check to ensure the audio volume configuration is acceptable after adjustments.

7.4.1.1 Traffic Audio Flight Check

The traffic audio volume should be loud enough to ensure aural alerts are audible under

all anticipated noise environmental conditions. This check verifies traffic audio can be

heard during flight.

1. Perform the traffic flight evaluation for the following scenarios:

◦ Not wearing a headset during a normal climb with maximum power

◦ Wearing a noise-attenuating headset during cruise flight

◦ Not wearing a headset during cruise flight

◦ Not wearing a headset during a normal descent at high airspeed

2. When the aircraft is in the necessary flight configuration, place the GTS 8XX system in Standby

mode, then initiate a GTS 8XX system self-test.

3. Evaluate the volume of the audio message. Ensure the GTX 8XX traffic system audio can be heard

clearly and intelligibly. If the volume is too high or low, adjust to an acceptable level.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-8

Page 42

7.4.2 Interface Check

NOTE

Using the applicable install tool, verify there are no system faults (bold red text) shown on the Normal tab

of the GTS Processor Install Tool (P/N 006-A0242-10) or GTS 8X0 Install Tool (P/N 006-A0242-00).

Then verify status flags are present (bold black text) for interfaces that are connected and valid. See

Figure 7-5.

Figure 7-5 GTS Processor Install Tool - Normal Tab

7.4.3 Ramp Test and Return To Service Test

GDU 1XXX software version 11.10 and later allows the Ramp Test and Return to Service

Tests to be accomplished via the GIFD.

Connect a laptop computer to the USB dongle and, using the GTS Install Tool, perform the following test:

Use a TCAS ramp tester and the following procedure to verify GTS 8XX system operation and

surveillance functionality. See Section 7.4.3.1 if a TCAS ramp tester is unavailable.

The following procedure requires the GTS 8XX system to be placed into Ground Test mode. Ground Test

mode simulates being airborne at 50,000 feet with a heading of 0°. Ground Test mode can be selected on

the Normal tab of the GTS Install Tool or from the G950/G1000 Traffic page (GDU software versions

11.10 and later only).

1. If a radar altimeter is installed and interfaced to the GTS 8XX, temporarily disable the radar

altimeter interface for the duration of the test.

a. Pull the radar altimeter circuit breaker.

190-01279-01 GTS 8XX Part 23 AML STC Maintenance Manual

Rev. 2 Page 7-9

Page 43

2. Using the Configuration tab of GTS Install Tool, set all A429/Analog Radar Altitude Sources to

NOTE

Disabled (see Figure 7-2).The GTS 8XX inputs must be in an on-ground state to enter Ground

Test mode. This may be accomplished by one of the following methods:

a. Squat switch input indicates on-ground.

b. GPS groundspeed is less than 30 knots (valid GPS position required).

c. HSDB input from G950/G1000 indicates on-ground.

d. If none of the above inputs are available, use the Configuration tab of the GTS Install Tool

to temporarily configure the SQUAT ‘ON-GROUND’ SENSE to Open for the duration of

the test (see Figure 7-2).

3. Select the Ground Test mode using one of the following methods:

a. Select Enable key in the Ground Test field on the Normal tab of the GTS Install Tool.

b. G950/G1000 with GDU software version 11.10 or later only: On the Traffic page, press

the soft key sequence 3-4-4-3, then press the GND TEST soft key that appears.

4. Position the test set directional antenna with a clear line of sight to the GTS 8XX antenna at 90º.

5. Set the TRAFFIC SYSTEM to the Operate mode.

6. Set the TCAS ramp tester to the scenario in Table 7-3.

Table 7-3 Ramp Test Intruder Scenario

Intruder Type Intruder Start Distance Intruder Start Altitude Vertical Speed Velocity

ATCRBS 10 NM 50,000 ft 0 fpm 0 Kts

7. Initiate the intruder scenario and observe the following:

◦ The intruder should be displayed at approximately 10 NM, 90º bearing, with a relative

altitude of “00” (same altitude as ownship).

If the bearing is not as anticipated or multiple targets are displayed during tests, verify the

following:

◦ Coax cable connectors are securely connected in place at the GTS 8XX and

associated antennas