Garmin GNC 420, GNS 430 User Manual

400 SERIES

MAINTENANCE MANUAL

(GNS¥430, GNC¥420, GPS 400)

GNS 430 Shown

GARMIN International, Inc.

1200 E. 151

Olathe, KS 66062 USA

190-00140-05, Revision C

October 2002

st

Street

© Copyright 1999-2002

GARMIN Ltd. or its subsidiaries

All Rights Reserved

GARMIN International, Inc.

1200 East 151st Street, Olathe, Kansas 66062, U.S.A.

GARMIN (Europe) Ltd.

Unit 5, The Quadrangle, Abbey Park Industrial Estate, Romsey, SO51 9AQ, U.K.

GARMIN Corporation

No. 68, Jangshu 2nd Road, Shijr, Taipei County, Taiwan

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of GARMIN. GARMIN hereby grants permission to download a single copy of this

manual and of any revision to this manual onto a hard drive or other electronic storage medium to be

viewed and to print one copy of this manual or of any revision hereto, provided that such electronic or

printed copy of this manual or revision must contain the complete text of this copyright notice and

provided further that any unauthorized commercial distribution of this manual or any revision hereto is

strictly prohibited.

Information in this document is subject to change without notice. GARMIN reserves the right to change or

improve its products and to make changes in the content without obligation to notify any person or

organization of such changes or improvements.

GARMIN International, Inc.

1200 E. 151

st

Street

Olathe, KS 66062 USA

Telephone: 913-397-8200

Aviation Panel-Mount Technical Support Line (Toll Free): 1-888-606-5482

www.garmin.com

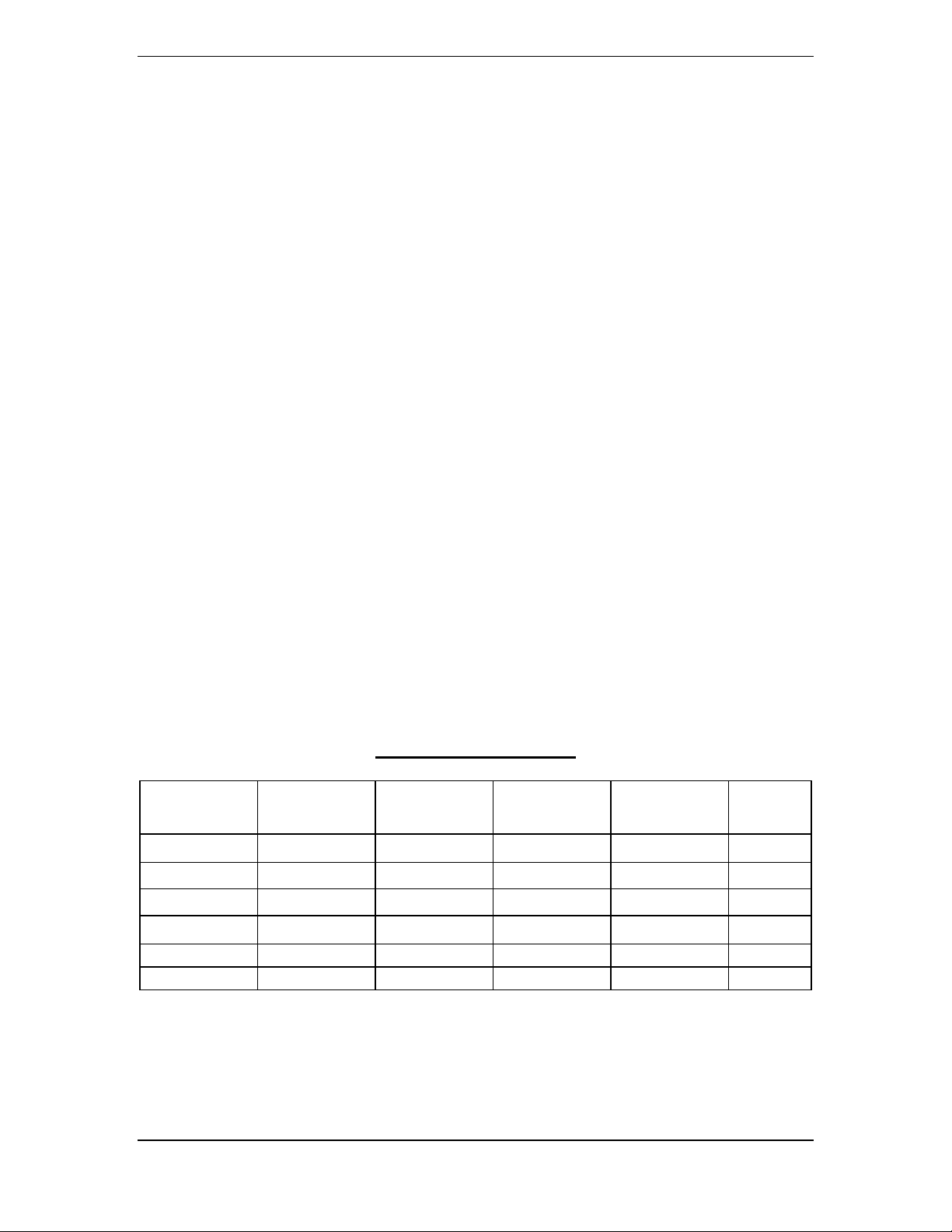

RECORD OF REVISIONS

REVISION REVISION

DATE

A 07/06/99 Initial Release -----

B 01/26/01 Redraw 15007

C 10/22/02 Redraw 19319

Description ECO # Insertion Date By

GNC and GNS are trademarks of GARMIN Ltd. or its subsidiaries and may not be used without the express permission of GARMIN.

Page A 400 SERIES MAINTENANCE MANUAL

Rev. C P/N 190-00140-05

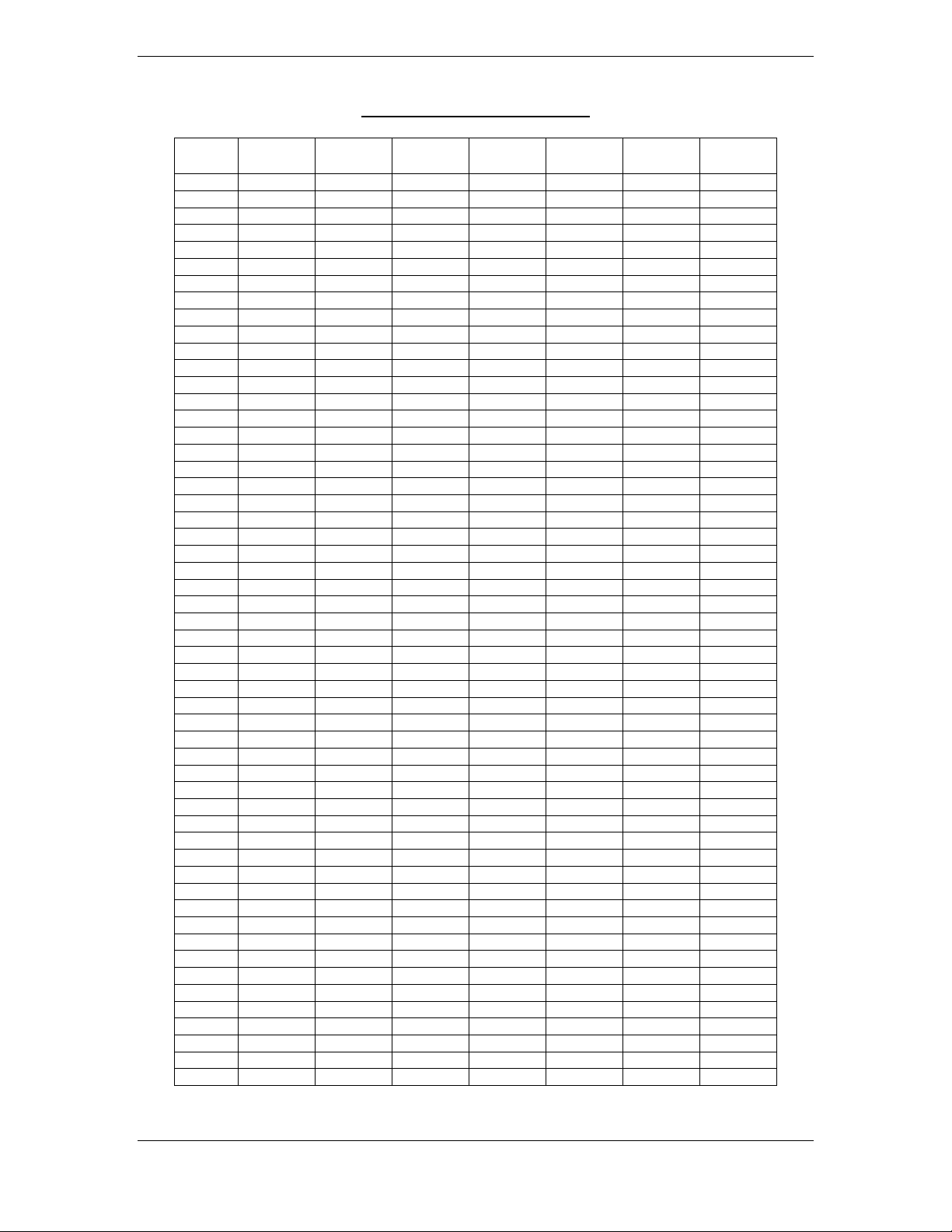

LIST OF EFFECTIVE PAGES

Page Revision Page Revision Page Revision Page Revision

A C 4-8 C 5-54 BLANK F7-24 BLANK

i C 5-1 C 6-1 C A-1 C

ii C5-2 C6-2 CA-2 C

iii C5-3 C6-3 CB-1 C

iv C5-4 C6-4 CB-2 C

v C 5-5 C 6-5 C B-3 C

vi C5-6 C6-6 CB-4 C

vii C 5-7 C 6-7 C B-5 C

viii C5-8 C6-8 CB-6 C

ix C5-9 C6-9 CB-7 C

x C 5-10 C 6-10 C B-8 C

xi C 5-11 C 6-11 C B-9 C

xii C 5-12 C 6-12 C B-10 C

1-1 C 5-13 C 6-13 C B-11 C

1-2 C 5-14 C 6-14 C B-12 C

1-3 C 5-15 C 6-15 C B-13 C

1-4 C 5-16 C 6-16 C B-14 C

1-5 C 5-17 C 6-17 C B-15 C

1-6 C 5-18 C 6-18 C B-16 C

2-1 C 5-19 C 6-19 C B-17 C

2-2 BLANK 5-20 C 6-20 C B-18 C

F2-3 C 5-21 C 6-21 C

F2-4 BLANK 5-22 C 6-22 C

F2-5 C 5-23 C 6-23 C

F2-6 BLANK 5-24 C 6-24 C

F2-7 C 5-25 C 6-25 C

F2-8 BLANK 5-26 C 6-26 C

F2-9 C 5-27 C 6-27 C

F2-10 BLANK 5-28 C 6-28 C

3-1 C 5-29 C 6-29 C

3-2 C 5-30 C 6-30 C

3-3 C 5-31 C 7-1 C

3-4 C 5-32 C 7-2 C

3-5 C 5-33 C F7-3 C

3-6 C 5-34 C F7-4 BLANK

3-7 C 5-35 C F7-5 C

3-8 C 5-36 C F7-6 BLANK

3-9 C 5-37 C F7-7 C

3-10 C 5-38 C F7-8 BLANK

3-11 C 5-39 C F7-9 C

3-12 C 5-40 C F7-10 BLANK

3-13 C 5-41 C F7-11 C

3-14 C 5-42 C F7-12 BLANK

3-15 C 5-43 C F7-13 C

3-16 BLANK 5-44 C F7-14 BLANK

F3-17 C 5-45 C F7-15 C

F3-18 BLANK 5-46 C F7-16 BLANK

4-1 C 5-47 C F7-17 C

4-2 C 5-48 C F7-18 BLANK

4-3 C 5-49 C F7-19 C

4-4 C 5-50 C F7-20 BLANK

4-5 C 5-51 C F7-21 C

4-6 C 5-52 C F7-22 BLANK

4-7 C 5-53 C F7-23 C

(F) INDICATES FOLDOUT PAGES-PRINT ONE SIDE ONLY

400 SERIES MAINTENANCE MANUAL Page i

P/N 190-00140-05 Rev. C

The following are General Safety Precautions that are not related to any specific procedure and

therefore do not appear elsewhere in this maintenance manual. These are recommended

precautions that personnel should understand and apply during the many phases of maintenance

and repair.

KEEP AWAY FROM LIVE CIRCUITS.

Maintenance personnel shall observe all safety

regulations at all times. Do not replace components inside the equipment when potentially lethal

voltages are present. Turn off system power before making or breaking electrical connections.

Regard any exposed connector, terminal board, or circuit board as a possible shock hazard.

Components which retain a charge shall be discharged only when such grounding does not result

in equipment damage. If a test connection to energized equipment is required, make the test

equipment ground connection before probing the voltage or signal to be tested.

DO NOT SERVICE ALONE.

Personnel shall not under any circumstances reach into or enter

any enclosure for the purpose of servicing or adjusting the equipment without immediate

presence or assistance of another person capable of rendering aid.

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration

Regulations (“EAR”) issued by the United States Department of Commerce (15 CFR, Chapter

VII, Subchapter C) and which may not be exported, released, or disclosed to foreign nationals

inside or outside of the United States without first obtaining an export license. A violation of the

EAR may be subject to a penalty of up to 10 years imprisonment and a fine of up to

US $1,000,000 under Section 2410 of the Export Administration Act of 1979. Include this notice

with any reproduced portion of this document.

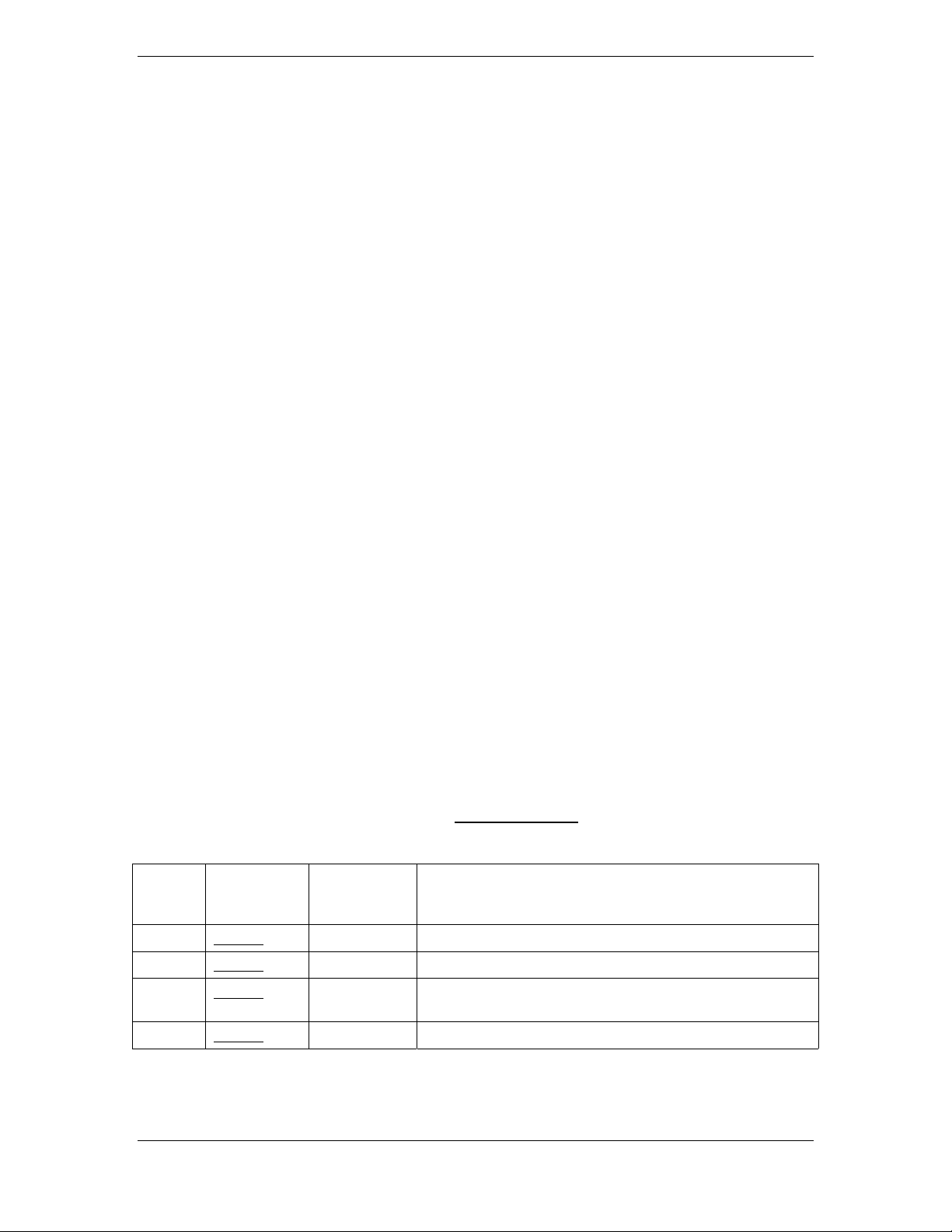

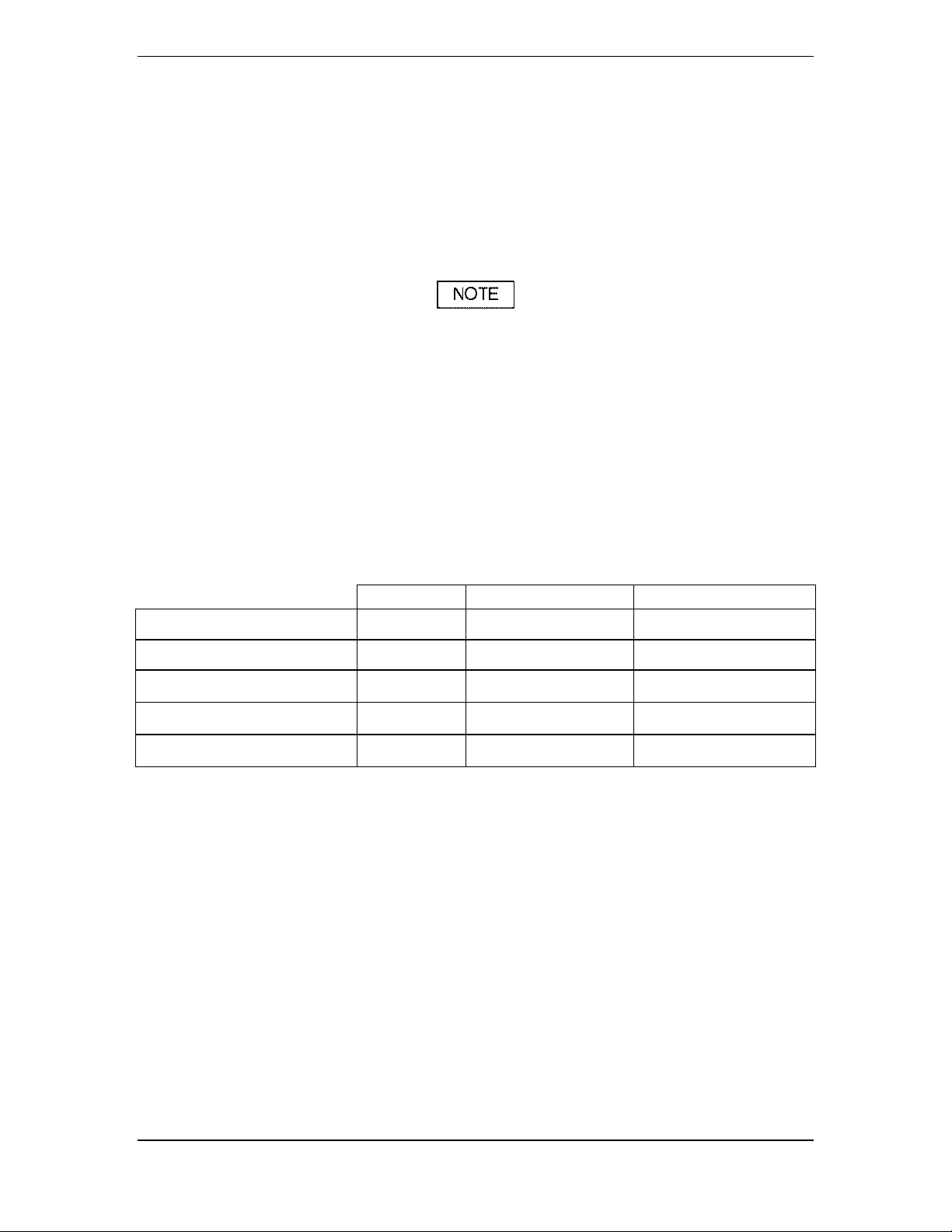

400 SERIES HARDWARE MOD LEVEL HISTORY

The following table identifies hardware modification (Mod) Levels for the 400 Series.

Mod Levels are listed with the associated service bulletin number, service bulletin date, and the

purpose of the modification. The table is current at the time of publication of this manual (see

date on front cover) and is subject to change without notice. Authorized GARMIN Sales and

Service Centers are encouraged to access the most up-to-date bulletin and advisory information

on the GARMIN Dealer Resource web site at www.garmin.com using their GARMIN-provided

user name and password.

Mod

Level

1 SB0019 Nov 7, 2000 14/28V only, Comm Transmitter Fuse

2 SB0101 Feb 16, 2001 14/28V only, Remote COM Transfer

3 SB0203 Feb 1, 2002 430/420; 14/28V only (-10 and –30), Receiver Audio

4 SB0207 Apr 2, 2002 430/420; Remove excessive solder from Comm Board vias

Service

Bulletin

Number

Service

Bulletin Date

Purpose of Modification

Compressor (recommended only if problem exists)

Page ii 400 SERIES MAINTENANCE MANUAL

P/N 190-00140-05 Rev. C

TABLE OF CONTENTS

SECTION 1

DESCRIPTION AND OPERATION

Paragraph Page

1.1 INTRODUCTION....................................................................................................1-1

1.1.1 Versions Covered by this Manual....................................................................1-1

1.2 FUNCTIONAL SUMMARY......................................................................................1-3

1.2.1 GPS 400..........................................................................................................1-3

1.2.2 GNC 420 .........................................................................................................1-3

1.2.3 GNS 430..........................................................................................................1-3

1.3 REPAIR PLAN........................................................................................................1-4

1.4 SPECIFICATIONS..................................................................................................1-4

1.5 GENERAL DESCRIPTION.....................................................................................1-4

1.5.1 Main Board......................................................................................................1-4

1.5.2 Com Board .....................................................................................................1-5

1.5.3 Nav Board ......................................................................................................1-5

1.5.4 GPS Module ...................................................................................................1-5

1.5.5 Glideslope Board ............................................................................................1-6

1.5.6 Inverter Board..................................................................................................1-6

1.5.7 CDU Assembly................................................................................................1-6

1.5.8 Map Board.......................................................................................................1-6

SECTION 2

SPECIAL TOOLS AND TEST EQUIPMENT

Paragraph Page

2.1 INTRODUCTION....................................................................................................2-1

2.2 SPECIAL TOOLS AND TEST EQUIPMENT ..........................................................2-1

2.3 TEST PANELS AND CABLES................................................................................2-1

400 SERIES MAINTENANCE MANUAL Page iii

P/N 190-00140-05 Rev. C

SECTION 3

TROUBLESHOOTING

Paragraph Page

3.1 TROUBLESHOOTING EQUIPMENT .....................................................................3-1

3.2 TROUBLESHOOTING ORDER..............................................................................3-1

3.3 TROUBLESHOOTING PROCEDURES .................................................................3-2

3.3.1 Fuses...............................................................................................................3-2

3.3.2 Power Supply Checks .....................................................................................3-4

3.3.2.1 Current Measurements....................................................................................3-4

3.3.2.2 Com Board .....................................................................................................3-5

3.3.2.3 Glideslope Board.............................................................................................3-6

3.3.2.4 Nav Board .......................................................................................................3-6

3.3.3 Processor Clock Check...................................................................................3-6

3.3.3.1 Internal Clock CheckMain Processor...........................................................3-6

3.3.3.2 Internal Clock CheckGPS Processor...........................................................3-6

3.4 STATIC MESSAGES..............................................................................................3-7

3.5 TESTING FAILURES............................................................................................3-10

3.6 EXTERNAL CONNECTORS ................................................................................3-15

3.7 CONNECTOR I/O DESCRIPTIONS.....................................................................3-15

3.8 BLOCK DIAGRAM................................................................................................3-15

SECTION 4

DISASSEMBLY AND ASSEMBLY

Paragraph Page

4.1 INTRODUCTION...................................................................................................4-1

4.2 REQUIRED TOOLS ..............................................................................................4-1

4.3 NAV DATA CARD REMOVAL AND INSERTION..................................................4-2

4.4 UNIT DESIGN ......................................................................................................4-3

4.5 DISASSEMBLY PROCEDURE.............................................................................4-3

4.5.1 Remove the Top Cover ...................................................................................4-3

4.5.2 Remove the CDU Assembly ...........................................................................4-3

4.5.2.1 Disassemble the CDU Assembly ...................................................................4-4

4.5.3 Separate the Main and Nav Chassis...............................................................4-4

4.5.4 Remove Faulty Boards from the Main Chassis Top Cavity ............................4-5

4.5.5 Remove Faulty Boards from the Main Chassis Underside Cavity...................4-5

4.5.6 Remove Faulty Boards from the Nav Chassis ...............................................4-6

4.6 REASSEMBLY......................................................................................................4-7

4.7 MEMORY BATTERY REPLACEMENT.................................................................4-7

4.7.1 Remove the Memory Battery...........................................................................4-8

Page iv 400 SERIES MAINTENANCE MANUAL

P/N 190-00140-05 Rev. C

SECTION 5

ALIGNMENT, CALIBRATION, AND TESTING

Paragraph Page

5.1 INTRODUCTION.................................................................................................5-1

5.2 RECOMMENDED TEST EQUIPMENT ...............................................................5-1

5.3 TEST SETUP.......................................................................................................5-3

5.4 STANDARD SIGNALS AND TEST LOADS.........................................................5-3

5.4.1 VHF Com Transceiver.....................................................................................5-3

5.4.1.1 Standard Loads...............................................................................................5-3

5.4.1.2 Standard Signals.............................................................................................5-4

5.4.2 Glideslope .......................................................................................................5-4

5.4.2.1 Standard Loads...............................................................................................5-4

5.4.2.2 Standard Signals.............................................................................................5-4

5.4.3 NAV Receiver..................................................................................................5-5

5.4.3.1 Standard Loads...............................................................................................5-5

5.4.4 VOR Standard Signals ....................................................................................5-6

5.4.4.1 Standard Test Signals.....................................................................................5-6

5.4.5 Localizer Standard Signals..............................................................................5-7

5.4.5.1 Standard Test Signals.....................................................................................5-7

5.5 ALIGNMENT........................................................................................................5-9

5.6 CALIBRATION.....................................................................................................5-9

5.6.1 Com Setup Page Fields ................................................................................5-10

5.6.1.1 Com Frequency.............................................................................................5-10

5.6.1.2 Frequency Spacing .......................................................................................5-10

5.6.1.3 SQ 250..........................................................................................................5-10

5.6.1.4 SQ 833..........................................................................................................5-10

5.6.1.5 Sidetone........................................................................................................5-11

5.6.1.6 MIC Gain.......................................................................................................5-11

5.7 TEST PROCEDURES.......................................................................................5-12

5.7.1 Test Mode .....................................................................................................5-12

5.7.2 Com Testing..................................................................................................5-14

5.7.2.1 Power Input Check........................................................................................5-14

5.7.2.2 RF Power Out................................................................................................5-15

5.7.2.3 Frequency Stability and Tolerance................................................................5-16

5.7.2.4 Modulation Capability Test............................................................................5-16

5.7.2.5 Carrier Noise Level........................................................................................5-17

5.7.2.6 Demodulated Audio Distortion.......................................................................5-17

5.7.2.7 Demodulated Audio Response......................................................................5-17

400 SERIES MAINTENANCE MANUAL Page v

P/N 190-00140-05 Rev. C

SECTION 5

ALIGNMENT, CALIBRATION, AND TESTING

(continued)

5.7.2.8 Sidetone........................................................................................................5-18

5.7.2.9 MIC Intercom Test.........................................................................................5-18

5.7.2.10 Receiver Sensitivity.......................................................................................5-18

5.7.2.11 TX Interlock...................................................................................................5-19

5.7.2.12 AGC Test.......................................................................................................5-19

5.7.2.13 Selectivity (25 kHz Mode) .............................................................................5-19

5.7.2.14 Selectivity (8.33 kHz Mode) ..........................................................................5-20

5.7.2.15 Volume Control (Audio Output).....................................................................5-21

5.7.2.16 Audio Distortion Test.....................................................................................5-21

5.7.2.17 Audio Frequency Response..........................................................................5-22

5.7.2.18 Receiver Audio Compressor Test .................................................................5-22

5.7.2.19 Squelch Test .................................................................................................5-23

5.7.2.20 Frequency Modulation...................................................................................5-24

5.7.2.21 Com Remote Transfer Input..........................................................................5-24

5.7.3 Navigation Receiver Final Tests ...................................................................5-25

5.7.3.1 Voice/Ident Audio Output Level.....................................................................5-25

5.7.3.2 Voice/Ident Audio Frequency Response.......................................................5-25

5.7.3.3 Voice/Ident Audio Distortion..........................................................................5-26

5.7.3.4 VOR AGC......................................................................................................5-26

5.7.3.5 VOR Audio Sensitivity...................................................................................5-26

5.7.3.6 Receiver Quieting..........................................................................................5-27

5.7.3.7 Ident/Voice Tone Ratio..................................................................................5-27

5.7.3.8 Harmonic Distortion.......................................................................................5-27

5.7.3.9 VOR Flag Sensitivity .....................................................................................5-28

5.7.3.10 LOC Flag Sensitivity......................................................................................5-28

5.7.3.11 VOR/LOC Composite Test............................................................................5-28

5.7.3.12 VOR Course Deviation Sensitivity.................................................................5-29

5.7.3.13 Localizer Course Deviation Sensitivity..........................................................5-29

5.7.3.14 TO-FROM Indicator.......................................................................................5-29

5.7.3.15 Centering Accuracy.......................................................................................5-29

5.7.3.16 Course Deviation Accuracy Test...................................................................5-30

5.7.3.17 VOR OBS Bearing Accuracy.........................................................................5-30

5.7.3.18 Selectivity......................................................................................................5-30

5.7.3.19 Spurious Response—VOR/LOC...................................................................5-31

Page vi 400 SERIES MAINTENANCE MANUAL

P/N 190-00140-05 Rev. C

SECTION 5

ALIGNMENT, CALIBRATION, AND TESTING

(continued)

5.7.4 Navigation Assembly I/O Tests ....................................................................5-32

5.7.4.1 Localizer Course Deviation Test ...................................................................5-32

5.7.4.2 To/From Deflection Output Characteristic Test.............................................5-32

5.7.4.3 To/From Deflection Accuracy Test................................................................5-32

5.7.4.4 Course Deviation Flag Output Characteristic Test........................................5-33

5.7.4.5 Course Deviation Flag Test...........................................................................5-33

5.7.4.6 VOR/LOC Super Flag Output Test................................................................5-33

5.7.4.7 NAV Input Lines ............................................................................................5-34

5.7.4.8 NAV OBI Outputs..........................................................................................5-34

5.7.4.9 Nav Serial DME Outputs...............................................................................5-35

5.7.4.10 NAV Parallel DME Outputs ...........................................................................5-35

5.7.5 Glideslope Final Tests...................................................................................5-37

5.7.5.1 Glideslope Course Deviation Output Characteristic Test..............................5-37

5.7.5.2 Course Deviation Deflection Accuracy Test..................................................5-37

5.7.5.3 Course Deviation Flag Test...........................................................................5-37

5.7.5.4 Glideslope Superflag Output Test.................................................................5-38

5.7.5.5 Receiver Sensitivity.......................................................................................5-38

5.7.5.6 Centering Accuracy.......................................................................................5-39

5.7.5.7 AGC...............................................................................................................5-39

5.7.5.8 Selectivity (Bandwidth)..................................................................................5-39

5.7.5.9 Nose Bandwidth............................................................................................5-40

5.7.5.10 Skirt Bandwidth .............................................................................................5-40

5.7.5.11 Spurious Response.......................................................................................5-40

5.7.5.12 Status Tests ..................................................................................................5-41

5.7.6 Main Board Final Tests .................................................................................5-42

5.7.6.1 Push Button Response..................................................................................5-42

5.7.6.2 Rotary Knobs.................................................................................................5-42

5.7.6.3 Map ID and Data Card Test ..........................................................................5-42

5.7.6.4 Photocell........................................................................................................5-43

5.7.6.5 Lighting Bus Input .........................................................................................5-43

5.7.6.6 Memory Battery Voltage................................................................................5-44

5.7.6.7 Display Pattern Test......................................................................................5-45

5.7.6.8 Fan Test........................................................................................................5-45

5.7.6.9 Unit Configuration Test..................................................................................5-45

5.7.6.10 GPS Antenna Bias ........................................................................................5-45

5.7.6.11 GPS Noise.....................................................................................................5-45

5.7.6.12 Satellite Tracking Test...................................................................................5-46

5.7.6.13 MAIN Lateral LEFT, RIGHT Outputs.............................................................5-47

400 SERIES MAINTENANCE MANUAL Page vii

P/N 190-00140-05 Rev. C

SECTION 5

ALIGNMENT, CALIBRATION, AND TESTING

(continued)

5.7.6.14 MAIN Vertical UP, DOWN Outputs................................................................5-47

5.7.6.15 MAIN To/From Output...................................................................................5-47

5.7.6.16 MAIN Lateral Flag Output..............................................................................5-48

5.7.6.17 MAIN Vertical Flag Output.............................................................................5-48

5.7.6.18 MAIN Lateral Super Flag Output...................................................................5-48

5.7.6.19 MAIN Vertical Super Flag Output..................................................................5-48

5.7.6.20 Annunciate Outputs.......................................................................................5-49

5.7.6.21 OBI Serial Interface.......................................................................................5-50

5.7.6.22 Discrete Switch and Altitude Inputs...............................................................5-51

5.7.6.23 ARINC 429 Transmitters and Receivers.......................................................5-52

5.7.6.24 RS232 Ports..................................................................................................5-53

5.7.6.25 OBS...............................................................................................................5-54

SECTION 6

PARTS AND ASSEMBLIES

Paragraph Page

6.1 INTRODUCTION....................................................................................................6-1

6.2 TABLES..................................................................................................................6-1

SECTION 7

ASSEMBLY DRAWINGS

7.1 INTRODUCTION....................................................................................................7-1

7.2 DRAWING LIST......................................................................................................7-1

Page viii 400 SERIES MAINTENANCE MANUAL

P/N 190-00140-05 Rev. C

APPENDIX A

GNC 420A AND GNS 430A

A.1 DESCRIPTION....................................................................................................A-1

A.2 ‘A’ VERSION PART NUMBERS..........................................................................A-1

A.3 TROUBLESHOOTING.........................................................................................A-1

A.4 DISASSEMBLY AND ASSEMBLY.......................................................................A-2

A.5 ALIGNMENT, CALIBRATION, AND TESTING....................................................A-2

A.6 REPLACEABLE PARTS AND ASSEMBLIES......................................................A-2

A.7 ASSEMBLY DRAWING.......................................................................................A-2

APPENDIX B

CONNECTOR I/O DESCRIPTIONS

B.1 I/O DESCRIPTION...............................................................................................B-1

B.2 INTERNAL AND EXTERNAL CONNECTORS....................................................B-1

B.3 MAIN BOARD CONNECTORS............................................................................B-2

B.4 COM BOARD CONNECTORS..........................................................................B-11

B.5 NAV BOARD CONNECTORS...........................................................................B-12

B.6 GLIDESLOPE BOARD CONNECTORS............................................................B-15

B.7 KEYBOARD CONNECTORS............................................................................B-15

B.8 INVERTER BOARD CONNECTORS ................................................................B-16

B.9 GPS MODULE CONNECTORS........................................................................B-17

B.10 INTERFACE BOARD CONNECTORS..............................................................B-17

B.11 DISPLAY MODULE CONNECTORS.................................................................B-18

B.12 DATA BASE CARD CONNECTORS.................................................................B-18

B.13 MAP BOARD CONNECTORS...........................................................................B-18

400 SERIES MAINTENANCE MANUAL Page ix

P/N 190-00140-05 Rev. C

LIST OF FIGURES

Figure Page

2-1 Com Chassis Nut.................................................................................................2-1

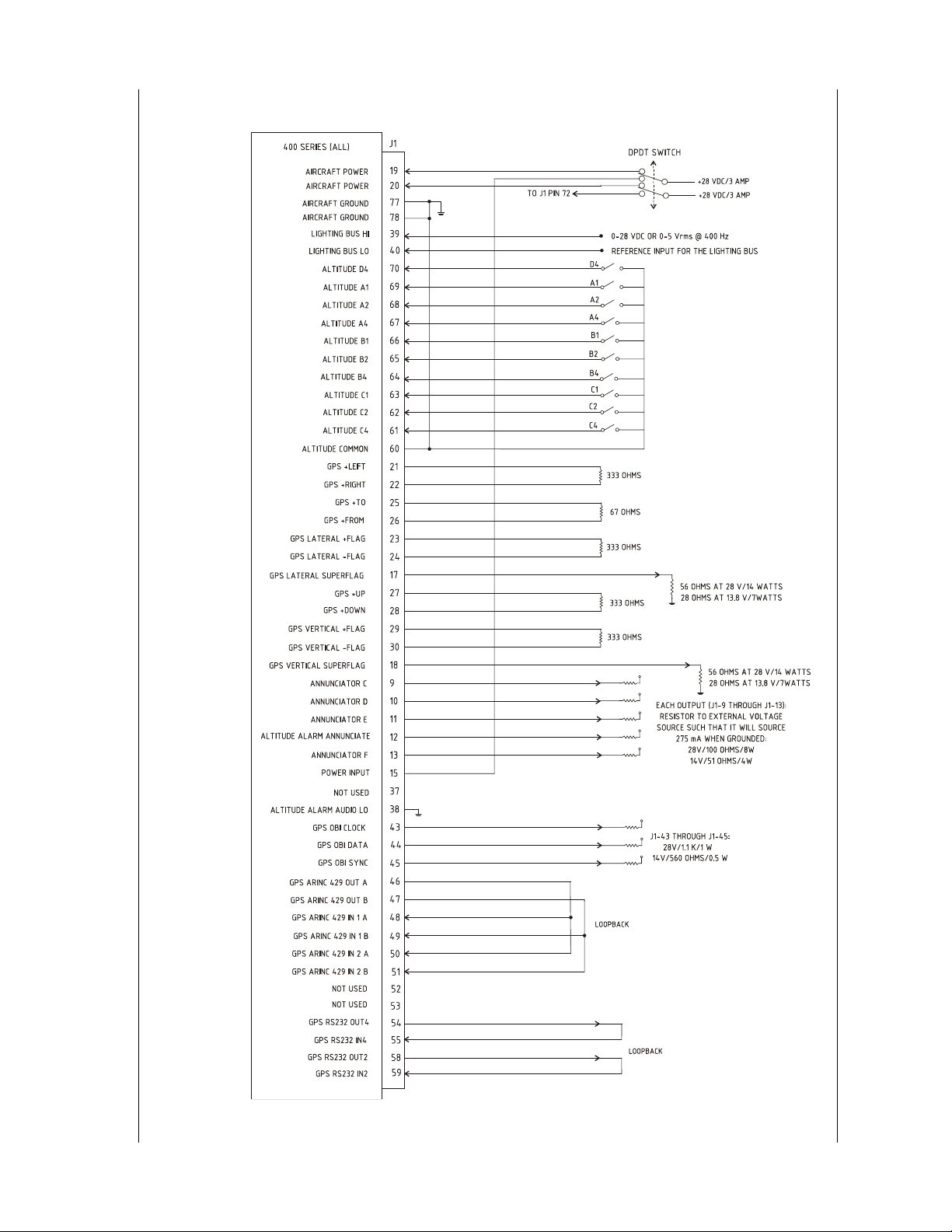

2-2 Signal And Load Drawing-J1 (Sheet 1 of 2) ........................................................2-3

2-3 Signal And Load Drawing-J1 (Sheet 2 of 2) ........................................................2-5

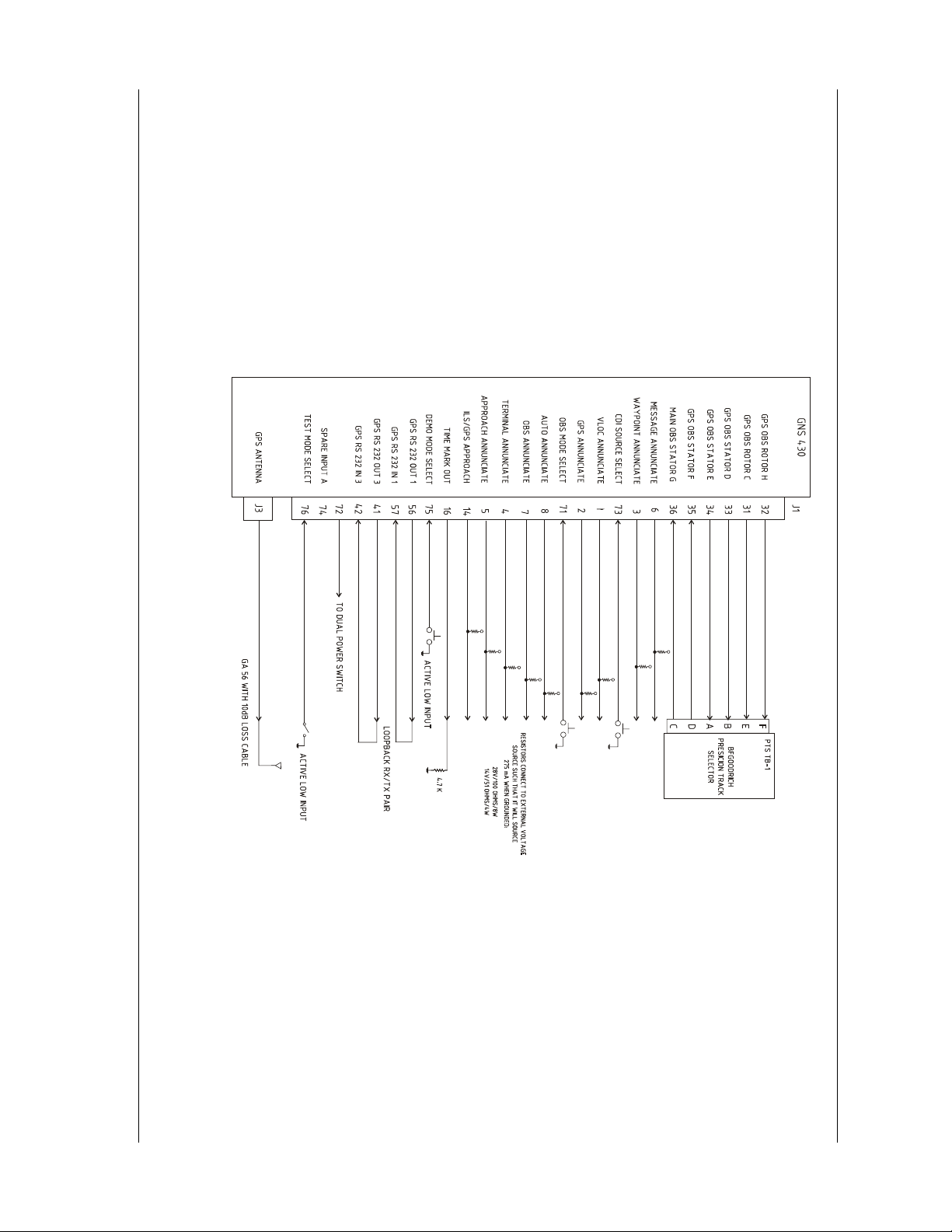

2-4 Signal And Load Drawing-J2 ...............................................................................2-7

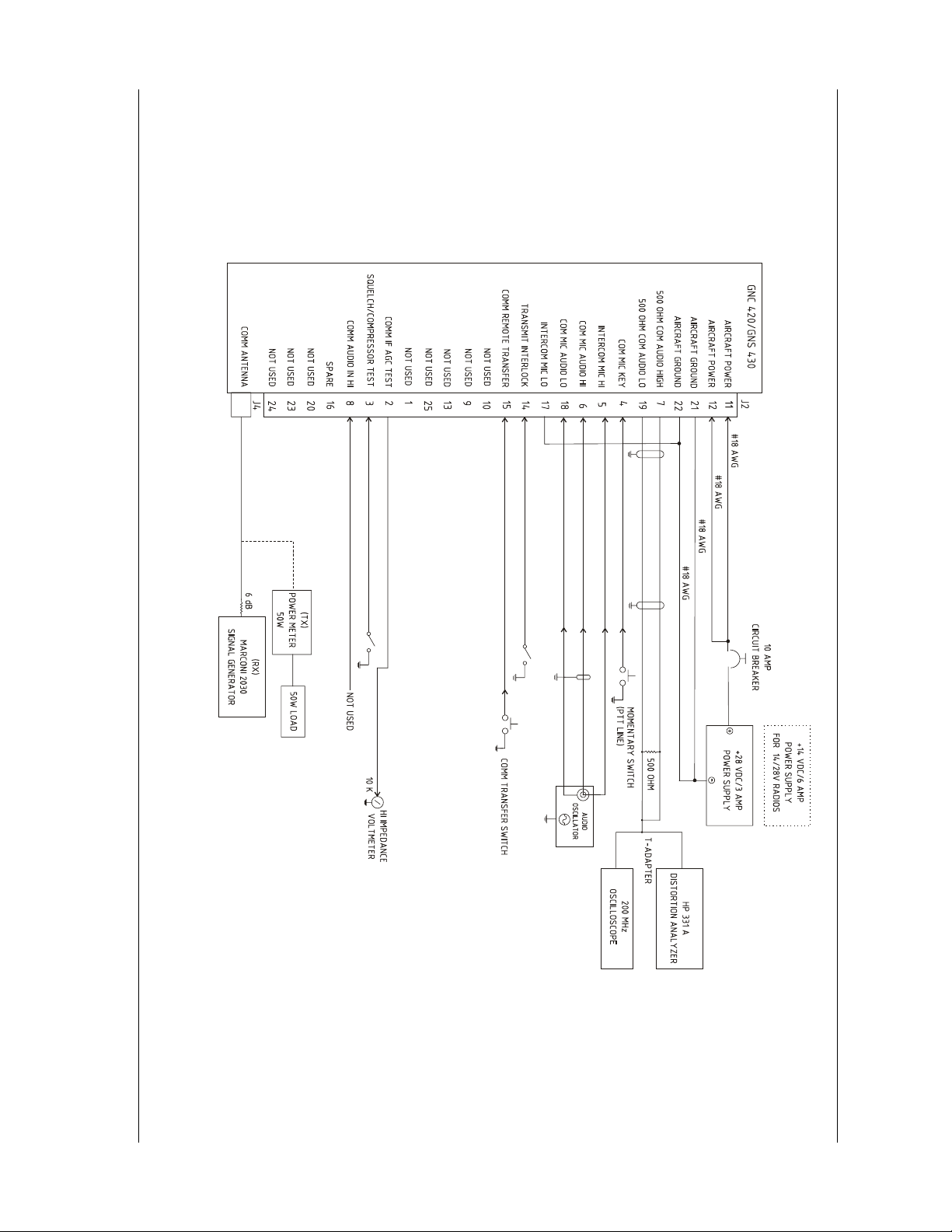

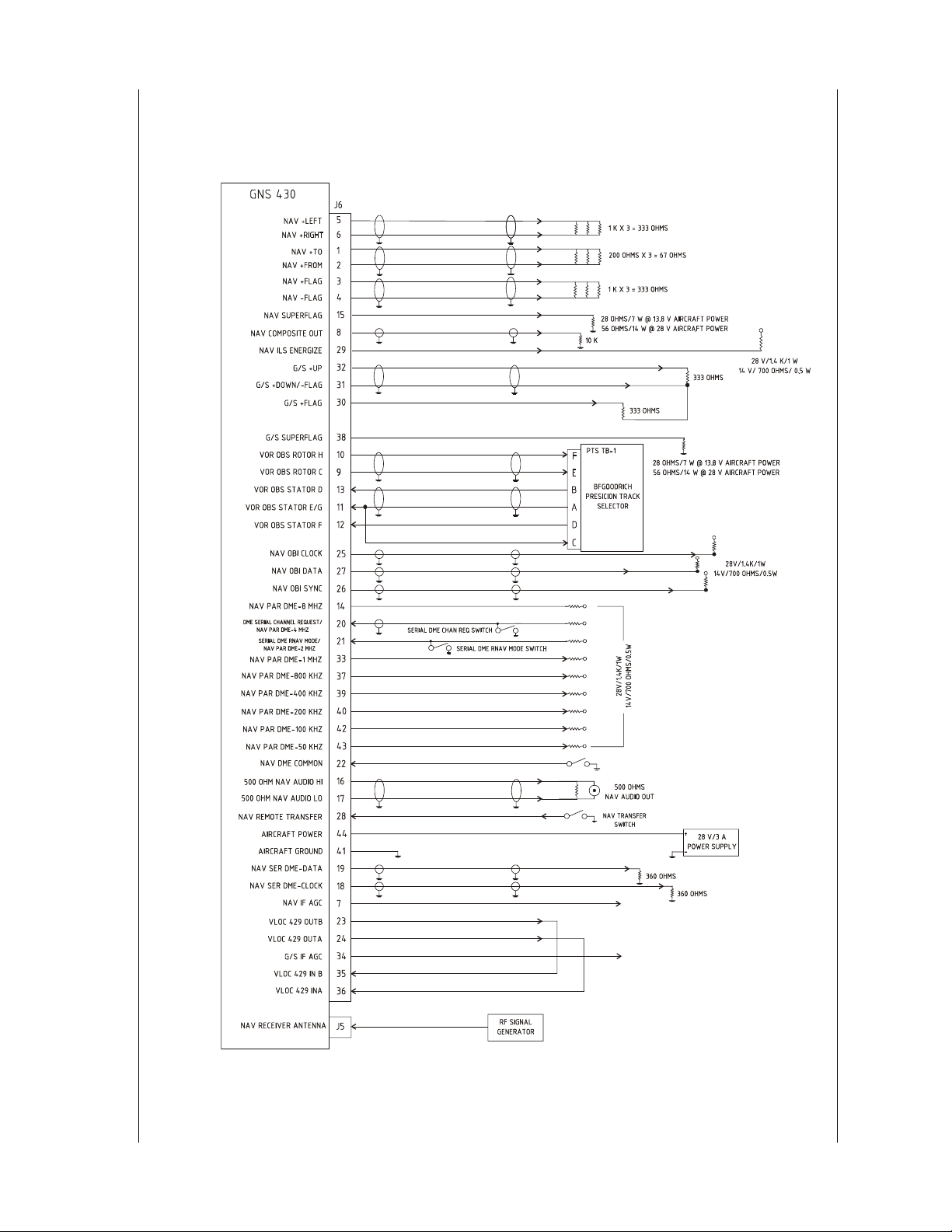

2-5 Signal And Load Drawing-J6 ...............................................................................2-9

3-1 Main Board Fuse Locations.................................................................................3-2

3-2 Com Board Fuse Location/F600..........................................................................3-3

3-3 Com Board Fuse Location/F600 (Replaced by R611).........................................3-3

3-4 Nav Board Fuse Locations ..................................................................................3-4

3-5 Processor Location (Main Board) ........................................................................3-7

3-6 External Connectors ..........................................................................................3-15

3-7 400 Series Block Diagram .................................................................................3-17

4-1 Nav Data Card Installation And Removal ............................................................4-2

4-2 Memory Battery Location (Main Board)...............................................................4-7

5-1 40dB Attenuator Circuit........................................................................................5-3

5-2 Com Setup Page .................................................................................................5-9

5-3 R558 (Com Board).............................................................................................5-11

5-4 Test Pages.........................................................................................................5-13

5-5 Modulation Measurement ..................................................................................5-16

5-6 VOR/LOC/GS CDI Test Page............................................................................5-32

5-7 Main Lighting and Main Analog Test Pages ......................................................5-44

5-8 GPS Test Page..................................................................................................5-45

5-9 Main CDI/OBS Configuration Test Page ...........................................................5-47

5-10 Main Discrete Outputs Test Page......................................................................5-49

5-11 Main Discrete Inputs Test Page.........................................................................5-51

5-12 Main Status/Loopback Test Page......................................................................5-52

5-13 Main CDI/OBS Configuration Page ...................................................................5-54

7-1 Sub-Assembly, GNS 430 (Dwg. No. 015-00280-XX, Rev. P)..............................7-3

7-2 Main Chassis Assembly, GNS 430(A) (Dwg. No. 015-00283-00, Rev. Q) ..........7-5

7-3 Nav Chassis Assembly, GNC 400 (Dwg. No. 015-00282-00, Rev. K).................7-7

7-4 GNC 4XX CDU Assembly (Sheet 1 of 2) (Dwg. No. 015-00281-XX, Rev. F)......7-9

7-4 GNC 4XX CDU Assembly (Sheet 2 of 2) (Dwg. No. 015-00281-XX, Rev. F)....7-11

7-5 Sub-Assembly, GNC 420 (Dwg. No. 015-00506-XX, Rev. N) ...........................7-13

7-6 Main Chassis Assembly, GNC 420(A) (Dwg. No. 015-00283-01, Rev. J )........7-15

7-7 Sub-Assy, GNC 420 Nav Chas, W/O Nav (Dwg. No. 015-00282-01, Rev. E ).7-17

7-8 Sub-Assy, GNC 420A (Dwg. No. 015-00837-XX, Rev. A )................................7-19

7-9 Main Chassis Assembly, GPS 400 (Dwg. No. 015-00283-03, Rev. J) ..............7-21

7-10 Assy Dwg, GPS 400 (Dwg. No. 015-00504-XX, Rev. G)...................................7-23

Page x 400 SERIES MAINTENANCE MANUAL

P/N 190-00140-05 Rev. C

LIST OF TABLES

Table Page

1-1 Unit Configuration................................................................................................1-1

3-1 Unit Board Power Supply Max Current Allowed ..................................................3-5

3-2 Com Board Power Supply Tolerances................................................................. 3-5

3-3 Glideslope Board Power Supply Tolerances .......................................................3-6

3-4 Nav Board Power Supply Tolerances..................................................................3-6

3-5 Static Messages ..................................................................................................3-8

3-6 Testing Failures-Main Board..............................................................................3-10

3-7 Testing Failures-COM Board.............................................................................3-12

3-8 Testing Failures-NAV Board..............................................................................3-13

3-9 Testing Failures-Glideslope...............................................................................3-13

3-10 Testing Failures-NAV Receiver .........................................................................3-14

5-1 Channel ID And Frequency ...............................................................................5-14

6-1 Sub-Assy, GNS 430 28V, Black (Unit P/N 011-00280-00, Figure 7-1)................6-4

6-2 Sub-Assy, GNS 430 14/28V, Black (Unit P/N 011-00280-10, Figure 7-1)...........6-4

6-3 Sub-Assy, GNS 430 14/28V, Gray (Unit P/N 011-00280-30, Figure 7-1)............6-5

6-4 Sub-Assy GNS 430A, 28V, Black (Unit P/N 011-00836-00, Figure 7-1)..............6-5

6-5 Sub-Assy GNS 430A, 28V, Gray (Unit P/N 011-00836-10, Figure 7-1)...............6-6

6-6 Main Chassis Assy, GNS 430, 14/28V (Unit P/N 011-00283-10, Figure 7-2)......6-7

6-7 Main Chassis, GNS 430, 14/28V, (Unit P/N 011-00283-30, Fig. 7-2)..................6-8

6-8 Main Chassis Assy, GNS 430, 28V, (Unit P/N 011-00283-00, Fig. 7-2)..............6-9

6-9 Main Chassis Assy, GNS 430A, 28V (Unit P/N 011-00283-20, Figure 7-2) ......6-10

6-10 Nav Chassis Sub Assy, GNS 430/430A (Unit P/N 011-00282-00, Figure 7-3)..6-11

6-11 Sub-Assy, CDU, GNS 430 Black (Unit P/N 011-00281-00, Figure 7-4).............6-12

6-12 Sub-Assy, CDU, GNS 430, Gray (Unit P/N 011-00281-04, Figure 7-4).............6-13

6-13 Sub-Assy, CDU, GNS 430A, Black (Unit P/N 011-00281-00, Figure 7-4) .........6-14

6-14 Sub-Assy, CDU, GNS 430A, Gray (Unit P/N 011-00281-04, Figure 7-4) ..........6-15

6-15 Sub-Assy, GNC 420, 28V, Black (Unit P/N 011-00506-00, Figure 7-5).............6-16

6-16 Sub-Assy, GNC 420, 14/28V, Black (Unit P/N 011-00506-10, Figure 7-5)........6-16

6-17 Sub-Assy, GNC 420, 14/28V, Gray (Unit P/N 011-00506-30, Fig 7-5)..............6-17

6-18 Sub-Assy, GNC 420A, 28V, Black (P/N 011-00837-00, Figure 7-8)..................6-17

6-19 Sub-Assy, GNC 420A, 28V, Gray (Unit P/N 011-00837-10, Figure 7-8) ...........6-18

6-20 Main Chassis Assy, GNC 420, 28V (P/N 011-00283-01, Figure 7-6)................6-19

6-21 Main Chassis Assy, GNC 420, 14/28V (Unit P/N 011-00283-11, Fig 7-6).........6-20

6-22 Main Chassis Assy, GNC 420, 14/28V DO (Unit P/N 011-00283-31, Fig 7-6) ..6-21

6-23 Main Chassis Sub-Assy, GNC 420A, 28V (Unit P/N 011-00283-21, Fig 7-6)....6-22

6-24 Nav Chassis Sub-Assy, GNC 420/420A (Unit P/N 011-00282-01, Figure 7-7) .6-22

400 SERIES MAINTENANCE MANUAL Page xi

P/N 190-00140-05 Rev. C

LIST OF TABLES

(con’t.)

Table Page

6-25 Sub-Assy, CDU, GNC 420, Black (Unit P/N 011-00281-01, Figure 7-4) ...........6-23

6-26 Sub-Assy, CDU, GNC 420, Gray (Unit P/N 011-00281-05, Figure 7-4) ............6-24

6-27 Sub-Assy, CDU GNC 420A, Black (Unit P/N 011-00281-01, Figure 7-4).........6-25

6-28 Sub-Assy, CDU, GNC 420A, Gray (Unit P/N 011-00281-05, Figure 7-4)..........6-26

6-29 Sub-Assy, GPS 400, 14/28V Black (Unit P/N 011-00504-00, Figure 7-1) .........6-27

6-30 Sub-Assy, GPS 400, 14/28V Gray (Unit P/N 011-00504-10, Figure 7-1) .........6-27

6-31 Main Chassis Assy, GPS 400, 14/28V (Unit P/N 011-00283-03, Figure 7-9)....6-28

6-32 Main Chassis Assy, GPS 400, 14/28V, DO (Unit P/N 011-00283-33, Fig 7-9)..6-28

6-33 Nav Chassis Sub-Assy, GPS 400 (Unit P/N 011-00281-03, Fig 7-7) ................6-28

6-34 Sub-Assembly, CDU, GPS 400, Black (Unit P/N 011-00281-03, Fig 7-4) .........6-29

6-35 Sub-Assembly, CDU, GPS 400, Gray (Unit P/N 011-00281-06, Fig 7-4) ..........6-30

A-1 Unit Main Board Power Supply Maximum Current ..............................................A-1

A-2 Voltage and Current Supply Requirements.........................................................A-2

B-1 I/O Descriptions...................................................................................................B-1

B-2 Internal and External Connectors........................................................................B-1

B-3 J1 Descriptions....................................................................................................B-2

B-4 J8 Descriptions....................................................................................................B-4

B-5 J9 Descriptions....................................................................................................B-5

B-6 J11 Descriptions..................................................................................................B-5

B-7 J12 Descriptions..................................................................................................B-6

B-8 J14 Descriptions..................................................................................................B-7

B-9 J16 Descriptions..................................................................................................B-9

B-10 J17 Descriptions................................................................................................B-10

B-11 P13 Descriptions................................................................................................B-10

B-12 J2 Descriptions..................................................................................................B-11

B-13 J26 Descriptions................................................................................................B-12

B-14 J6 Descriptions..................................................................................................B-12

B-15 J10 Descriptions................................................................................................B-14

B-16 J24 Descriptions................................................................................................B-14

B-17 J25 Descriptions................................................................................................B-15

B-18 J13 Descriptions................................................................................................B-15

B-19 J26 Descriptions................................................................................................B-16

B-20 J27 Descriptions................................................................................................B-17

B-21 J101 Descriptions..............................................................................................B-17

B-22 P16 Descriptions................................................................................................B-18

Page xii 400 SERIES MAINTENANCE MANUAL

P/N 190-00140-05 Rev. C

SECTION 1

DESCRIPTION AND OPERATION

1.1 INTRODUCTION

References made to the GNS 430 and the GNC 420 throughout

this manual equally apply to the GNS 430A and the GNC 420A

except where specifically noted.

This manual provides board-level maintenance information for the GARMIN 400 Series of

products. Table 1-1 shows each unit in the 400 series and their configurations. The system allows

the Main Processor software to recognize which of the optional components (VHF

Communications Transceiver, VOR/LOC receivers, and Glideslope receiver) are present.

Table 1-1. Unit Configuration

GPS 400 GNC 420 GNS 430

Main Processor

GPS Receiver

VHF Com Transceiver

VOR/ILS Localizer Receivers

ILS Glideslope Receiver

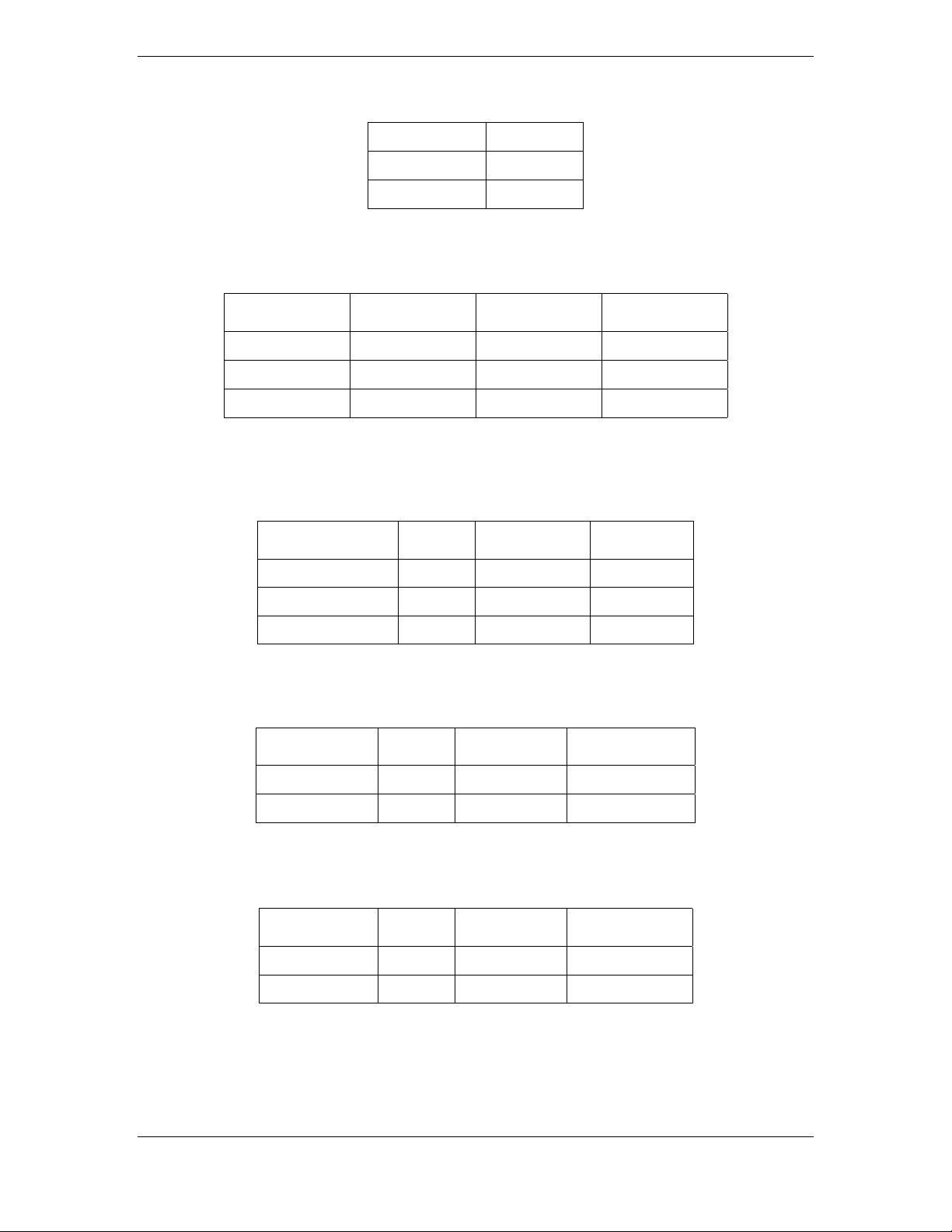

1.1.1 Versions Covered by this Manual

This manual applies to the GPS 400, GNC 420, and the GNS 430. It also applies to the

GNC 420A and the GNS 430A. The “A” identifies the 16 watt VHF COM transmitter as opposed

to the 10 watt version. Appendix A describes the GNC 420A and the GNS 430A. For ease of

identification, the following tables contain part number information relative to the different

versions of the 400 Series:

400 SERIES MAINTENANCE MANUAL Page 1-1

P/N 190-00140-05 Rev. C

GPS 400:

GNC 420:

UNIT P/N COLOR

011-00504-00 Black

011-00504-10 Gray

GNS 430:

GNC 420A:

UNIT P/N COLOR OPERATING

VOLTAGE

011-00506-00 BLACK 28 V 10 W

011-00506-10 BLACK 14 or 28 V 10 W

011-00506-30 GRAY 14 or 28 V 10 W

UNIT P/N COLOR OPERATING

VOLTAGE

011-00280-00 BLACK 28 V 10 W

011-00280-10 BLACK 14 or 28 V 10 W

011-00280-30 GRAY 14 or 28 V 10 W

UNIT P/N COLOR OPERATING

VOLTAGE

011-00837-00 BLACK 28 V only 16 W

MINIMUM

XMIT PWR

MINIMUM

XMIT PWR

MINIMUM

XMIT PWR

011-00837-10 GRAY 28 V only 16 W

GNS 430A:

UNIT P/N COLOR OPERATING

VOLTAGE

011-00836-00 BLACK 28 V only 16 W

011-00836-10 GRAY 28 V only 16 W

Page 1-2 400 SERIES MAINTENANCE MANUAL

Rev. C P/N 190-00140-05

MINIMUM

XMIT PWR

Each of the configurations includes a color display providing graphical moving map capability.

Navigation, communication, and mapping functions are supported by a navigation database

provided by a removable database card. The mapping function has additional support provided

by a built-in ground features base map which may be supplemented by a detailed map provided

on a second removable database card.

Information relative to the installation and operation of the 400 Series is found in the 400 Series

Installation Manual, P/N 190-00140-02.

1.2 FUNCTIONAL SUMMARY

1.2.1 GPS 400

ƒ Position and velocity determination using signals transmitted by Global Positioning

System (GPS) Satellites.

ƒ Display of the stored navigation and map database for use by the pilot/flight crew.

ƒ Area navigation functions using the determined position/velocity and stored

navigation data.

ƒ Approach navigation functions and the associated database.

ƒ Interfacing with other flight instruments such as a moving map, autopilot, CDI/HSI

(including OBS), indicators, altitude encoder/serializer, fuel management system, and

annunciators.

ƒ 14 or 28 volt operation.

1.2.2 GNC 420

ƒ Performs all functions of a GPS 400.

ƒ Communications transceiver tuning from 118.000 to 136.9916 MHz in 25 kHz or

8.33 kHz increments.

ƒ Com audio output.

ƒ 10 or 16-watt transmitter.

ƒ 14 or 28 volt operation for 10 watt transmitter;

28 V only for 16 watt transmitter.

1.2.3 GNS 430

ƒ Performs all functions of a GNC 420.

ƒ VOR and ILS Localizer Receivers.

ƒ ILS Glideslope Receiver.

400 SERIES MAINTENANCE MANUAL Page 1-3

P/N 190-00140-05 Rev. C

1.3 REPAIR PLAN

This manual is designed to allow the user to perform board-level repair. If necessary, the unit can

be returned to GARMIN for complete service work. Contact GARMIN at the address given on

Page A (inside cover) for further service information.

1.4 SPECIFICATIONS

Technical specifications for each unit are given in the 400 Series Installation Manual,

P/N 190-00140-02.

1.5 GENERAL DESCRIPTION

To help understand the general description, Appendix B lists all

external and internal I/O signal descriptions for each unit. Also,

see Figure 3-7 for a block diagram, which shows all of the

external and internal connectors for each board.

1.5.1 Main Board

The Main Board is the functional center of the unit. The Main Board communicates with all the

components of the unit, and provides the interface with the pilot and other avionics installed in

the aircraft.

The Main Board performs the following functions:

1. Communicates with all components of the unit.

2. Displays and controls interface with the pilot.

3. Displays the navigation database via a removable memory card for use by the

pilot/flight crew.

4. Area navigation functions using the determined position/velocity and stored

navigation data.

5. Interfaces with other flight instruments such as a moving map autopilot, CDI/HSI,

indicators, altitude encoder, fuel management system, and annunciators.

Page 1-4 400 SERIES MAINTENANCE MANUAL

Rev. C P/N 190-00140-05

1.5.2 Com Board

The Com Board contains the VHF COM Transceiver that provides voice communication in the

118.000 to 136.992 MHz general aviation band. The transceiver consists of a 10 or 16 watt (“A”

versions) amplitude modulated transmitter (see the unit matrix tables on page 1-1), and a single

conversion superhetrodyne AM receiver. The 10 watt transmitters are Class 4 and 6 devices as

described in RTCA DO-186A, indicating that they have channel spacing modes of 25 kHz and

8.33 kHz, and are intended for a communications range of 100 nautical miles. The 16 watt

transmitters are class 3 and 5 devices as described in RTCA DO-186A, indicating that they have

channel spacing modes of 25 kHz and 8.33 kHz and are intended for a communications range of

200 nautical miles.

The receiver is a Class C and E device as described in RTCA DO-186A, indicating that it has

channel spacing modes of 8.33 kHz and 25 kHz, with offset carrier capability in 25 kHz mode.

The Com Board contains connectors J2 and J26. J4 is the Com BNC antenna connector.

1.5.3 Nav Board

The Nav Board contains the processor controlled navigation receiver for VOR and Localizer

signals from 108.00 MHz to 117.95 MHz in 50 kHz increments providing 200 channels.

Functionally, the Nav Board performs the following:

1. Tunes a VOR or localizer frequency as commanded by the Main Board.

2. Communicates VOR/LOC receiver sub-system status to the Main Board.

3. Communicates VOR radial or localizer deviation, TO/FROM flag state and

navigation flag state to the Main Board.

4. Drives horizontal deviation, flag and TO/FROM electrical outputs.

5. Receives glideslope data from the Main Board to be sent out in ARINC 429 format.

6. Toggles the VOR/LOC identifier filter as commanded by the Main Board.

7. Communicates to the Main Board the detection of a remote frequency transfer key

press.

8. Drives electrical outputs for OBI.

9. Channels a remote DME if connected to the VOR/LOC Receiver Board.

10. Transmits ARINC 429 labels.

11. Receives ARINC 429 labels.

12. Provides signal pass-through for G/S flags and drivers to NAV Board Connectors.

1.5.4 GPS Module

The GPS Module contains a twelve channel parallel receiver that is capable of tracking and using

up to twelve visible satellites for position, velocity, and time calculations. The GPS Receiver is

designed to operate with the GARMIN GA 56 antenna (P/N 011-00134-00). The GPS Module

interfaces with the Main Board via connector J101.

400 SERIES MAINTENANCE MANUAL Page 1-5

P/N 190-00140-05 Rev. C

1.5.5 Glideslope Board

The Glideslope Board contains a processor controlled Glideslope Receiver which operates from

329.15 MHz to 335.00 MHz in 150 kHz increments for 40 Glideslope channels.

1.5.6 Inverter Board

The Inverter Board supplies high voltage for display operation.

1.5.7 CDU Assembly

The main components of the CDU Assembly are the Liquid Crystal Display (LCD), Keyboard

Assembly, and the Interface Board. The display portion consists of a 3-color RGB DSTN type

LCD, 128 x 240 pixels. The keyboard assembly consists of the snap-dome keys, photocell and

LED’s for backlighting display operation. The Interface Board is simply an interconnect

containing no active components. Unit switches and volume pots are mounted in the CDU.

1.5.8 Map Board

The Map Board is physically connected to the Main Board via P16. The Map Board consists of a

map data storage device (ROM or flash). The map storage device contains base map data used to

store topographical information (highways, lakes, rivers, and railroads).

Page 1-6 400 SERIES MAINTENANCE MANUAL

Rev. C P/N 190-00140-05

SECTION 2

SPECIAL TOOLS AND TEST EQUIPMENT

2.1 INTRODUCTION

This section identifies the special tools and test equipment needed to maintain the 400 Series

Units. Standard equipment is not listed. For any questions regarding special tools and test

equipment contact GARMIN at the following address:

GARMIN

1200 E. 151st Street

Olathe, KS 66062 USA

Telephone: 913-397-8200

Aviation Panel Mount Technical Support Line (Toll Free): 1-888-606-5482

Website Address: www.garmin.com

2.2 SPECIAL TOOLS AND TEST EQUIPMENT

x Test Panel—See paragraph 2.3.

x Test Cables—See paragraph 2.3.

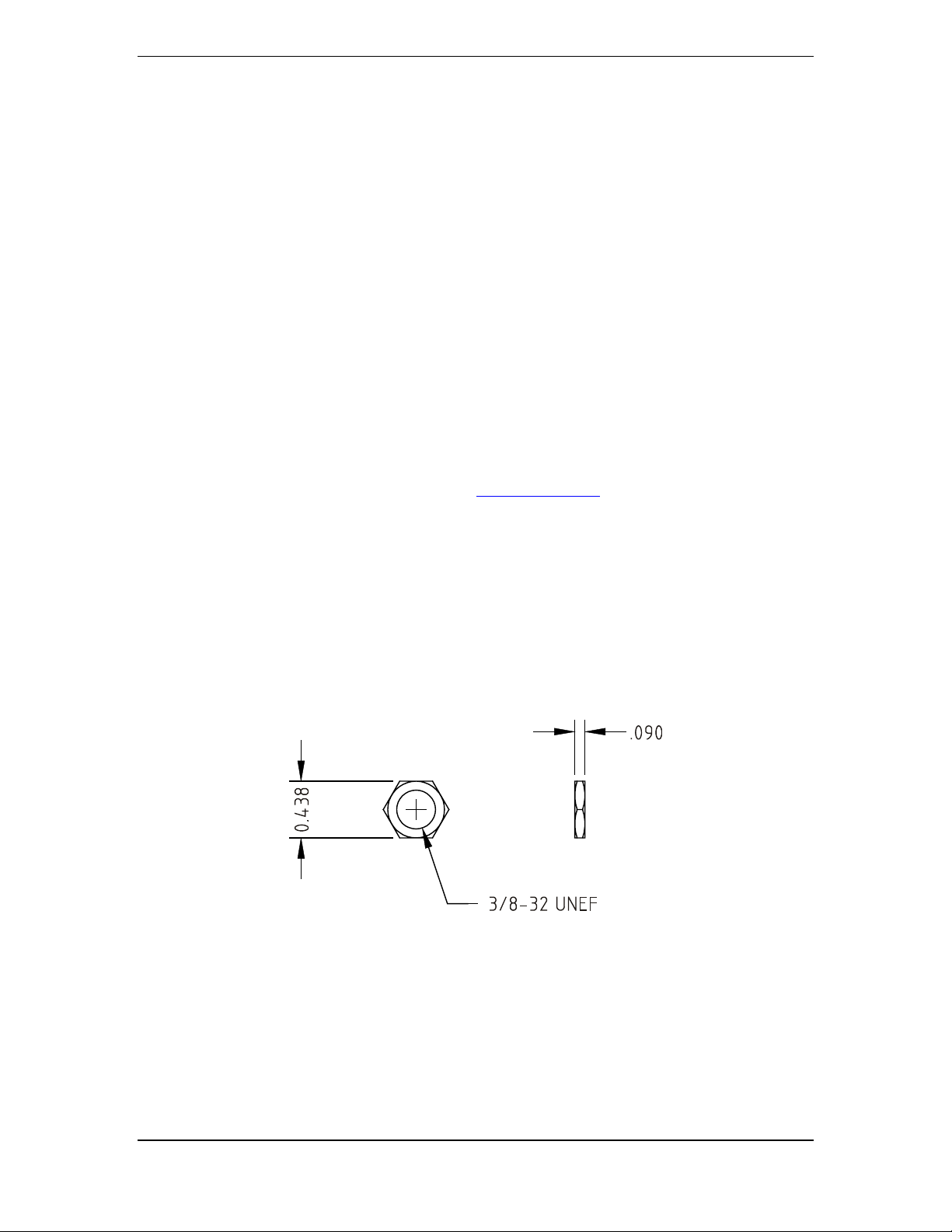

x Thinly Ground Open End Wrench for removing COM BNC Chassis Nut (on units

with serial numbers of approximately 96303300 and lower).

Figure 2-1. COM Chassis Nut

2.3 TEST PANELS AND CABLES

Test panels and cables are to be supplied by the repair facility. Load and signal information

given in Figures 2-2 through 2-5 and the information listed in Appendix B can help in their

fabrication.

400 SERIES MAINTENANCE MANUAL Page 2-1

P/N 190-00140-05 Rev. C

This page left intentionally blank.

Page 2-2 400 SERIES MAINTENANCE MANUAL

Rev. C P/N 190-00140-05

400 SERIES MAINTENANCE MANUAL Page 2-3 (Page 2-4 blank)

P/N 190-00140-05 Rev. C

Figure 2-2. J1 Signal and Load Drawing (Sheet 1 of 2)

400 SERIES MAINTENANCE MANUAL Page 2-5 (Page 2-6 blank)

P/N 190-00140 Rev. C

Figure 2-3. J1 Signal and Load Drawing (Sheet 2 of 2)

400 SERIES MAINTENANCE MANUAL Page 2-7 (Page 2-8 blank)

P/N 190-00140-05 Rev. C

Figure 2-4. J2 Signal and Load Drawing

400 SERIES MAINTENANCE MANUAL Page 2-9 (Page 2-10 blank)

P/N 190-00140-05 Rev. C

Figure 2-5. J6 Signal and Load Drawing

SECTION 3

TROUBLESHOOTING

Each unit in the 400 Series contains static sensitive components.

Observe proper anti-static procedures when testing the unit.

Hazardous voltages exist on the Inverter Board (all units).

Under normal operating conditions the voltages range up to

2500 Vac peak to peak. Under open circuit conditions voltages

can range over 8000 Vac peak to peak. Exercise extreme

caution during unit troubleshooting. Death or serious injury

could result from electrical shock. See other general

maintenance warnings and cautions on page ii.

3.1 TROUBLESHOOTING EQUIPMENT

The equipment used in testing a unit can be used to troubleshoot a faulty unit. See Sections 2 and

5.

3.2 TROUBLESHOOTING ORDER

Start troubleshooting a unit by following steps one through three listed below (not necessarily in

the order listed). Once it has been determined that these three items are not the cause of failure,

proceed with troubleshooting using the static messages and performance testing (paragraphs 3.4

and 3.5). To help in the troubleshooting process, a block diagram and external connectors are

shown at the end of this section. In addition, Appendix B describes all of the input/output signals

for all of the unit’s internal and external connectors.

1. Fuses (Paragraph 3.3.1).

2. Power Supply Checks (Paragraph 3.3.2).

3. Processor Clock Check (Paragraph 3.3.3).

400 SERIES MAINTENANCE MANUAL Page 3-1

P/N 190-00140-05 Rev. C

3.3 TROUBLESHOOTING PROCEDURES

0

3.3.1 Fuses

Check for blown fuses on the Main Board, Com Board, and Nav Board as shown in Figures 3-1

through 3-4. If blown fuses are found, try to determine the cause of the fuse failure before

installing a new fuse.

F85

5A

F852

2A

F854

5A

F853

0.75A

F851

3A

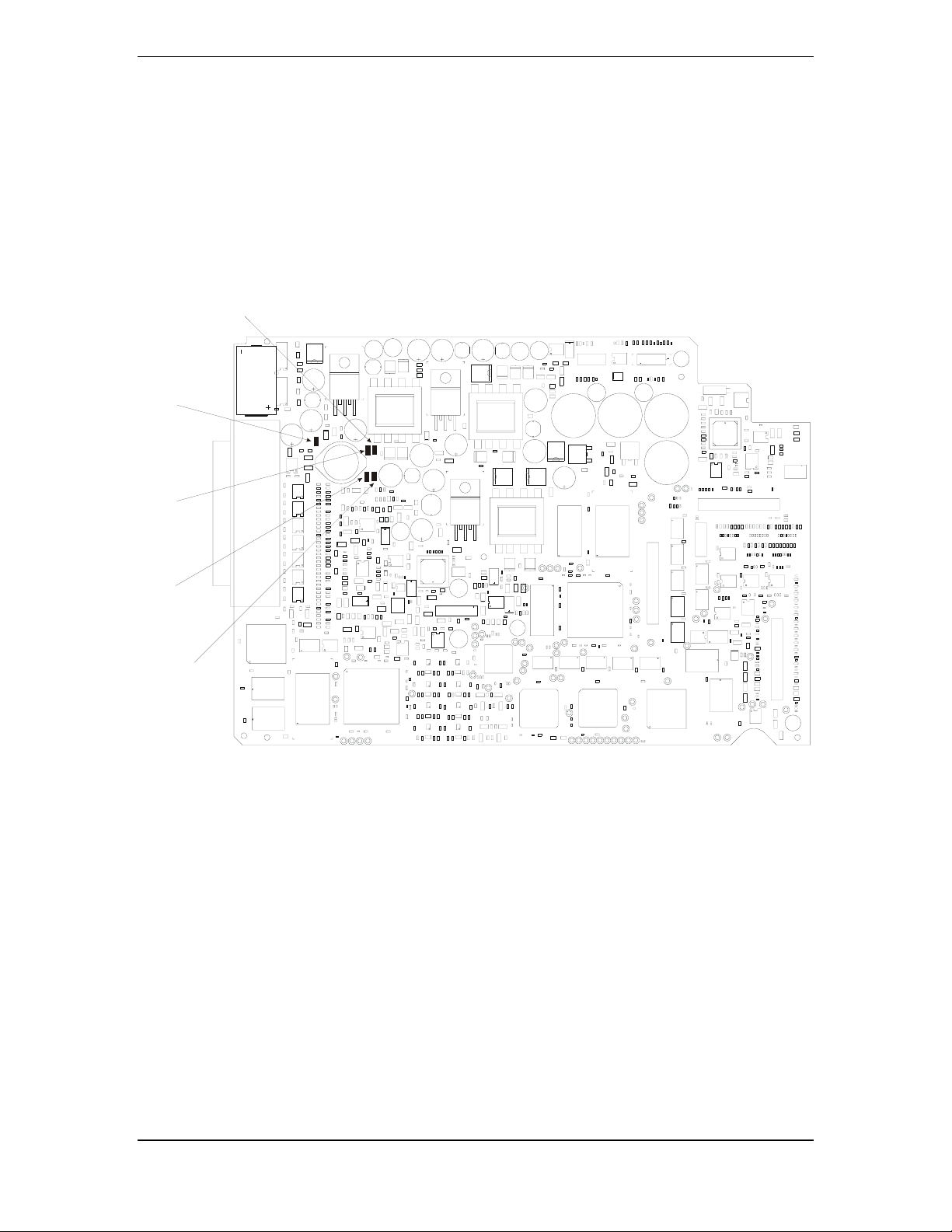

Figure 3-1. Main Board Fuse Locations

Page 3-2 400 SERIES MAINTENANCE MANUAL

Rev. C P/N 190-00140-05

LOCATION OF

)

F600 (7A FUSE

ON -00/-02/-03

COM BOARDS

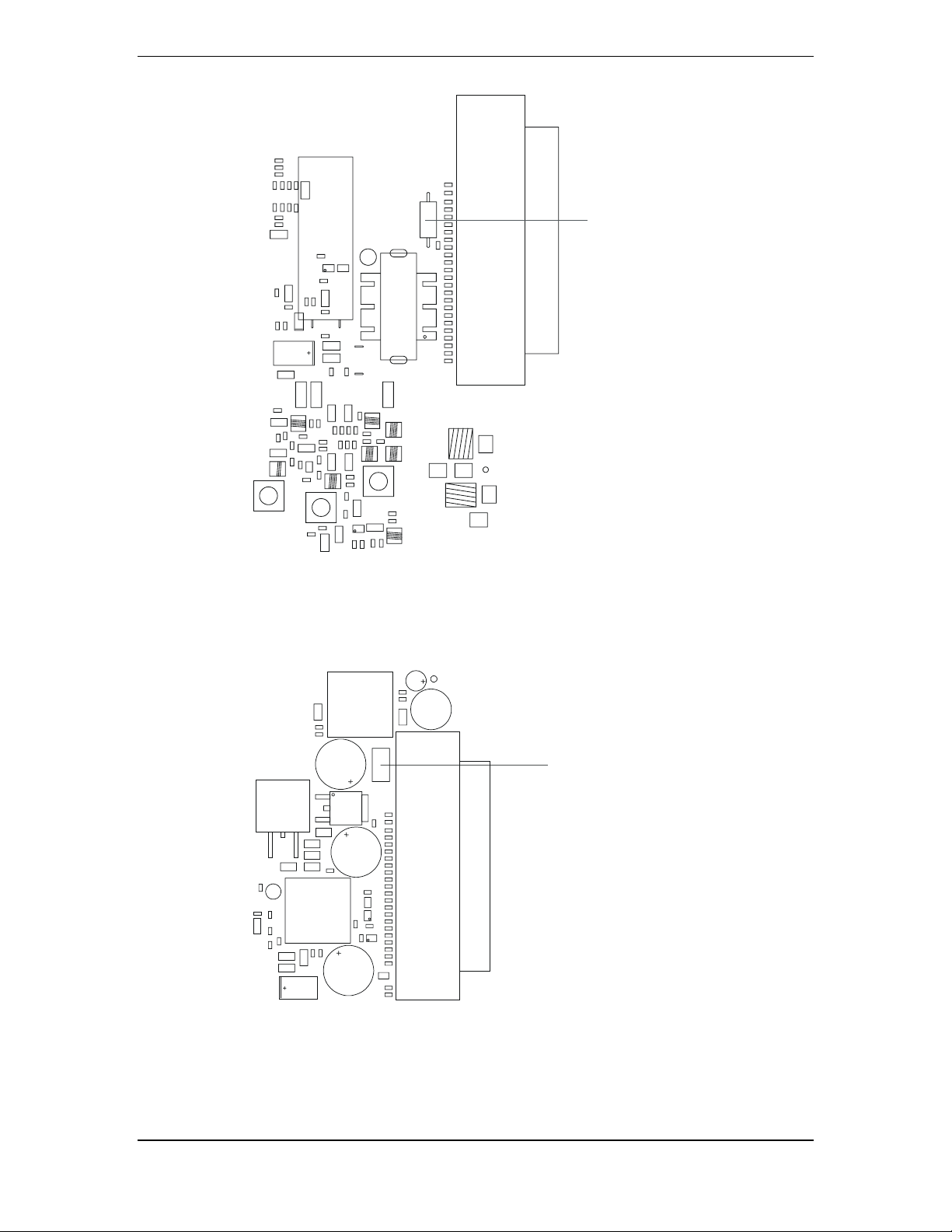

Figure 3-2. Com Board Fuse Location/F600

LOCATION OF

F600 ON

-04 REV C

COM BOARDS

TO PRESENT

(F600 REPLACED

WITH R611, EXCEPT

ON -04 REV A AND B

BOARD)

Figure 3-3. Com Board Fuse Location/F600 (Replaced by R611)

400 SERIES MAINTENANCE MANUAL Page 3-3

P/N 190-00140-05 Rev. C

F501

1 AMP

F502

1 AMP

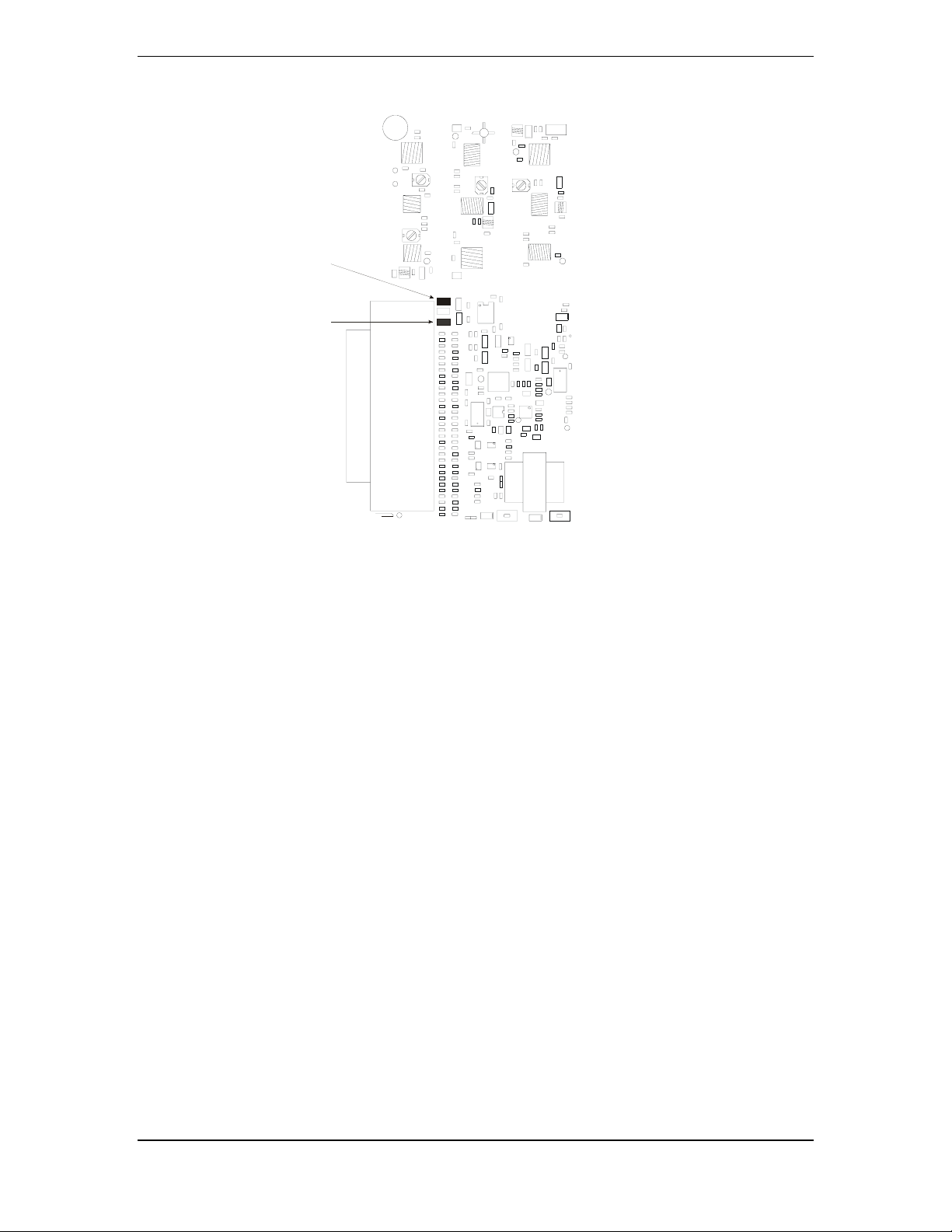

Figure 3-4. Nav Board Fuse Locations

3.3.2 Power Supply Checks

3.3.2.1 Current Measurements

J6

Taking intra-board and external current measurements is one way of determining a faulty board.

To measure the currents, use a spare ribbon cable and spread the cable wires, then use a DC probe

to measure the current in the appropriate wire (connector pin). The following external and

intra-board current measurements can be taken during troubleshooting (the intra-board currents

are given as reference):

x Com Board (Tables 3-2 and 3-3):

J26: Intra-board (Main Board to Com Board)

J2: External Connector

x Glideslope Board (Table 3-4):

J25: Intra-board (Nav Board to Glideslope Board)

x Nav Board (Table 3-4):

J10: Intra-board (Main Board to Nav Board)

J6: External Connector

Page 3-4 400 SERIES MAINTENANCE MANUAL

Rev. C P/N 190-00140-05

Loading...

Loading...