Garmin Embraer Prodigy 100 NXI User manual

190-02545-02 December 2020 Revision 4

G1000 NXi

NXi updates to G1000 on Textron Aviation 510

System Maintenance Manual

EMBRAER

Phenom P100

Includes Instructions for Continued Airworthiness

for SA01933WI

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 1

© Copyright 2020

Garmin Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual

and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and

to print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of

this manual or revision must contain the complete text of this copyright notice and provided further that

any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Garmin International, Inc.

1200 E. 151st Street

Olathe, KS 66062 USA

Telephone: 913.397.8200

www.garmin.com

Garmin (Europe) Ltd.

Liberty House, Bulls Copse Road

Hounsdown Business Park

Southampton, SO40 9RB, UK

Phone: +44 (0) 23 8052 4000

Fax: +44 (0) 23 8052 4004

Garmin AT, Inc.

2345 Turner Rd., SE

Salem, OR 97302 USA

Telephone: 503.581.8101

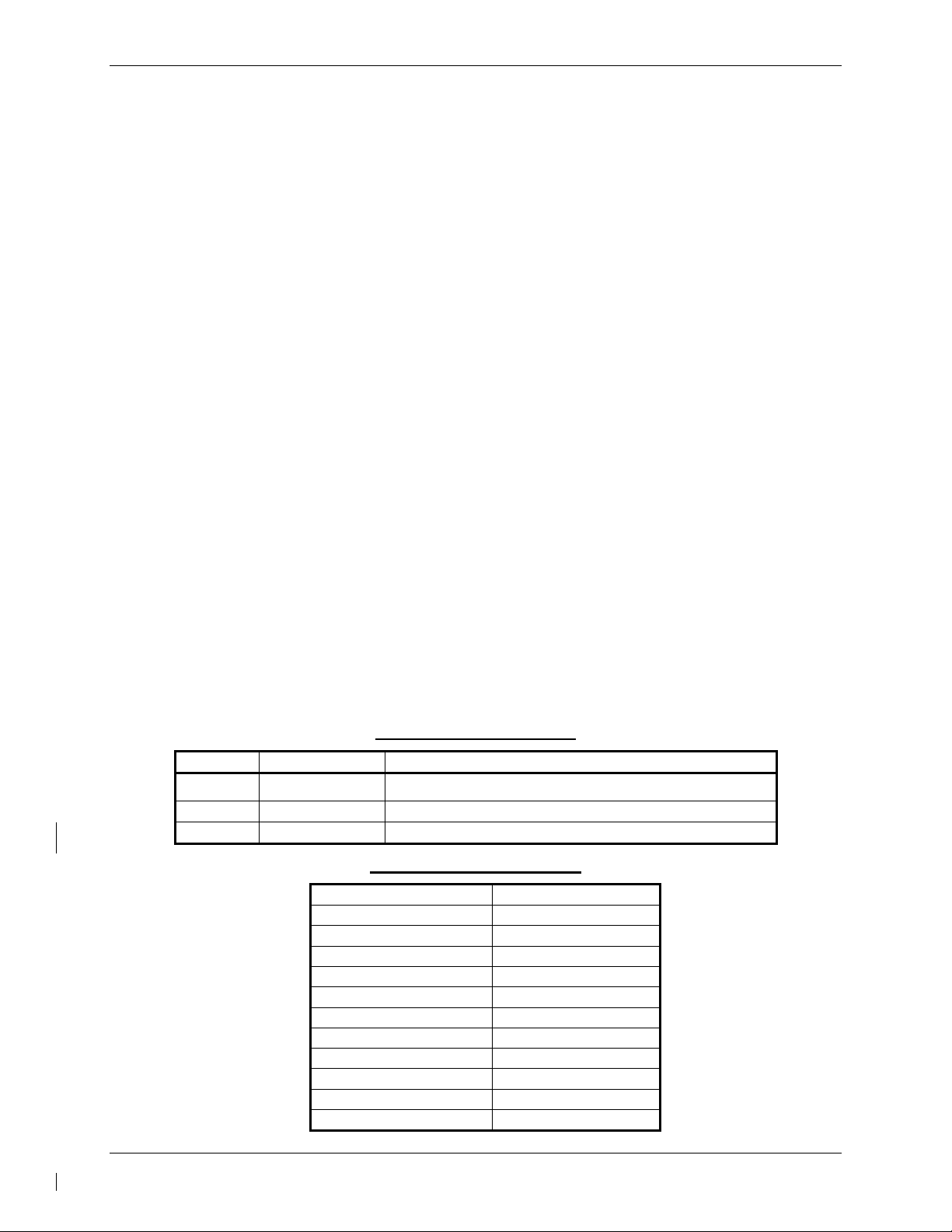

RECORD OF REVISIONS

Revision

Revision Date

Description

2

11/5/19

Update enable card options on page 31

3

6/24/20

Revised 3.5.2, 3.6, 3.8.4. added 8.6

4

12/18/20

Revised section 6.6

DOCUMENT PAGINATION

Section

Pagination

Table of Contents

3-5

Section 1

6-9

Section 2

10-18

Section 3

19-59

Section 4

60-66

Section 5

67-78

Section 6

79-88

Section 7

89-107

Section 8

108-121

Section 9

122-131

Appendix A

132

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 2

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration

Regulations (“EAR”) issued by the United States Department of Commerce (15 CFR, Chapter

VII Subchapter C) and which may not be exported, released or disclosed to foreign nationals

inside or outside the United States without first obtaining an export license. A violation of the

EAR may be subject to a penalty of up to 10 years imprisonment and a fine of up to $1,000,000

under section 2410 of the Export Administration Act of the 1979. The preceding statement is

required to be included on any and all reproductions in whole or in part of this manual.

WARNING

This product, its packaging, and its components contain chemicals known to the State of

California to cause cancer, birth defects, or reproductive harm. This Notice is being provided in

accordance with California's Proposition 65. If you have any questions or would like additional

information, please refer to our web site at www.garmin.com/prop65.

WARNING

Perchlorate Material – special handling may apply, Refer to www.dtsc.ca.gov./hazardouswaste/

perchlorate.

IMPORTANT

All screen shots used in this document are current at the time of publication. Screen shots are

intended to provide visual reference only. All information depicted in screen shots, including

software file names, versions and part numbers, is subject to change and may not be up to

date.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 3

TABLE OF CONTENT

1. INTRODUCTION ......................................................................................................................................... 6

1.1 CONTENT, SCOPE, PURPOSE ................................................................................................................................ 6

1.2 APPLICABILITY .................................................................................................................................................. 6

1.3 ORGANIZATION ................................................................................................................................................. 6

1.4 DEFINITIONS/ABBREVIATIONS ............................................................................................................................. 7

1.5 UNITS OF MEASURE ........................................................................................................................................... 7

1.6 PUBLICATIONS .................................................................................................................................................. 8

1.7 REVISION AND DISTRIBUTION .............................................................................................................................. 9

1.8 GARMIN TECHNICAL SUPPORT ............................................................................................................................. 9

2. SYSTEM DESCRIPTION ............................................................................................................................... 10

2.1 EQUIPMENT DESCRIPTIONS ............................................................................................................................... 10

2.2 SYSTEM INTERFACE SUMMARY ........................................................................................................................... 14

2.3 POWER REQUIREMENTS ................................................................................................................................... 15

2.4 ELECTRICAL BONDING ...................................................................................................................................... 15

3. CONTROL AND OPERATION ....................................................................................................................... 19

3.1 CONFIGURATION MODE OVERVIEW .................................................................................................................... 19

3.2 G1000 SYSTEM SOFTWARE INFORMATION .......................................................................................................... 25

3.3 CONFIGURATION MODE ................................................................................................................................... 26

3.4 G1000 HARDWARE/SOFTWARE COMPATIBILITY CHECK ......................................................................................... 26

3.5 EQUIPMENT VERIFICATION (THIRD PARTY/OPTIONAL EQUIPMENT DOCUMENTATION) ................................................. 27

3.6 CONFIGURATION CHECKLIST .............................................................................................................................. 31

3.7 G1000 SOFTWARE/CONFIGURATION PROCEDURE ................................................................................................ 32

3.8 SYSTEM SOFTWARE AND CONFIGURATION LOAD ................................................................................................... 33

3.9 FEATURE ENABLEMENT .................................................................................................................................... 50

3.10 CONFIGURATION MANAGER .............................................................................................................................. 54

3.11 CLEARING DEFAULT USER SETTINGS .................................................................................................................... 55

3.12 DATABASE LOADING ........................................................................................................................................ 55

3.13 CONFIGURATION OF NAVIGATION MAP FOR TRAFFIC SYSTEM .................................................................................. 58

3.14 FLIGHT STREAM 510 FIRMWARE REVIEW ............................................................................................................ 58

4. INSTRUCTIONS FOR CONTINUED AIRWORTHINESS .................................................................................... 60

4.1 AIRWORTHINESS LIMITATIONS ........................................................................................................................... 60

4.2 SERVICING INFORMATION ................................................................................................................................. 60

4.3 MAINTENANCE INTERVALS ................................................................................................................................ 62

4.4 VISUAL INSPECTION ......................................................................................................................................... 64

4.5 ELECTRICAL BONDING TEST ............................................................................................................................... 65

5. TROUBLESHOOTING .................................................................................................................................. 67

5.1 SYSTEM ANNUNCIATIONS ................................................................................................................................. 68

5.2 AURAL & AUDIO ALERTS .................................................................................................................................. 69

5.3 GDU 1250A TROUBLESHOOTING ...................................................................................................................... 69

5.4 GDU ALERTS ................................................................................................................................................. 70

5.5 GMA 1360D TROUBLESHOOTING ..................................................................................................................... 71

5.6 GCU 475 TROUBLESHOOTING .......................................................................................................................... 72

5.7 GTX TROUBLESHOOTING .................................................................................................................................. 73

5.8 GDL69A SXM TROUBLESHOOTING ................................................................................................................... 74

5.9 GWX 75 TROUBLESHOOTING ........................................................................................................................... 76

5.10 SOFTWARE/CONFIGURATION TROUBLESHOOTING ................................................................................................. 77

5.11 SYSTEM COMMUNICATION HIERARCHY ................................................................................................................ 78

5.12 CONNECTOR LAYOUT ....................................................................................................................................... 78

6. EQUIPMENT REMOVAL & INSTALLATION .................................................................................................. 79

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 4

6.1 GDU 1250A ................................................................................................................................................. 79

6.2 GMA 1360D AUDIO PANEL ............................................................................................................................. 79

6.3 GTX 345R / GTX 345DR TRANSPONDER ........................................................................................................... 80

6.4 GCU 475 CONTROLLER ................................................................................................................................... 81

6.5 GWX 75 WEATHER RADAR .............................................................................................................................. 81

6.6 GDL 69A SXM RECEIVER ................................................................................................................................ 86

6.7 CONFIGURATION MODULES .............................................................................................................................. 87

7. GARMIN G1000 LRU REPLACEMENT/CONFIGURATION & TESTING ............................................................. 89

7.1 GIA BOOT BLOCK LOAD ................................................................................................................................... 89

7.2 .GDU 1250A DISPLAY .................................................................................................................................... 90

7.3 GMA 1360D AUDIO PANEL ............................................................................................................................. 93

7.4 GTX 345R / GTX 345DR TRANSPONDER ........................................................................................................... 97

7.5 GCU 475 FMS CONTROLLER .......................................................................................................................... 100

7.6 GWX 75 WEATHER RADAR ............................................................................................................................ 103

8. SUBSYSTEM FUNCTIONAL CHECKS........................................................................................................... 108

8.1 TAWS FUNCTIONAL CHECK ............................................................................................................................ 108

8.2 FLITECHARTS FUNCTIONAL CHECK .................................................................................................................... 110

8.3 CHARTVIEW FUNCTIONAL CHECK ..................................................................................................................... 111

8.4 SAFETAXI FUNCTIONAL CHECK ......................................................................................................................... 112

8.5 GTS 850 TRAFFIC SYSTEM FUNCTIONAL CHECK .................................................................................................. 113

8.6 TCAS 3000 TRAFFIC SYSTEM FUNCTIONAL CHECK .............................................................................................. 114

8.7 GWX 68 / 70 SYSTEM FUNCTIONAL CHECK ....................................................................................................... 115

8.8 DME FUNCTIONAL CHECK .............................................................................................................................. 116

8.9 ADF FUNCTIONAL CHECK ............................................................................................................................... 119

8.10 HF RADIO FUNCTION CHECK ........................................................................................................................... 119

8.11 RADIO ALTIMETER FUNCTION CHECK ................................................................................................................ 121

9. G1000 SYSTEM RETURN TO SERVICE PROCEDURE .................................................................................... 122

9.1 DISPLAY TEST ............................................................................................................................................... 122

9.2 G1000 BACKUP PATH TEST ............................................................................................................................ 125

9.3 DISPLAY FAILURE TEST ................................................................................................................................... 125

9.4 REVERSION MODE CHECK ............................................................................................................................... 126

9.5 AIRCRAFT BASIC EMPTY WEIGHT INITIALIZATION ................................................................................................. 128

9.6 GPS SIGNAL ACQUISITION .............................................................................................................................. 129

9.7 FIELD ELEVATION INITIALIZATION ...................................................................................................................... 129

9.8 EICAS VERIFICATION ..................................................................................................................................... 130

9.9 TEST PANEL ................................................................................................................................................. 130

9.10 MAINTENANCE RECORDS ................................................................................................................................ 131

APPENDIX A - GARMIN UNIT PART AND SERIAL NUMBER CROSS REFERENCE ................................................... 132

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 5

TABLE OF FIGURES

FIGURE 2-1 – GCU 475 .................................................................................................................................................... 12

FIGURE 2-2 – GDU 1250A ............................................................................................................................................... 12

FIGURE 2-3 – GMA 1360D .............................................................................................................................................. 12

FIGURE 2-4 – GTX 345R .................................................................................................................................................. 12

FIGURE 2-5 – GTX 345DR ................................................................................................................................................ 12

FIGURE 2-6 – FS 510 ....................................................................................................................................................... 12

FIGURE 2-7 – GWX 75 ..................................................................................................................................................... 13

FIGURE 2-8 – GDL 69A SXM ............................................................................................................................................ 13

FIGURE 2-9 – G1000 NXI SYSTEM OVERVIEW ....................................................................................................................... 14

FIGURE 2-10 – ELECTRICAL BONDING PREPARATION – NUT PLATE ............................................................................................ 16

FIGURE 2-11 – ELECTRICAL BONDING PREPARATION – BOLT/NUT JOINT .................................................................................... 17

FIGURE 2-12 – ELECTRICAL BONDING PREPARATION – TERMINAL LUG ....................................................................................... 17

FIGURE 3-1, SET>ACTV DIAGRAM ..................................................................................................................................... 21

FIGURE 3-2, LOSS OF COMMUNICATION ............................................................................................................................... 21

FIGURE 3-3, CONFIGURATION STATUS .................................................................................................................................. 22

FIGURE 3-4, DATA TRANSMISSION INDICATORS ...................................................................................................................... 22

FIGURE 3-5, GARMIN UNIT S/N LOCATION ........................................................................................................................... 27

FIGURE 3-6, SOFTWARE/CONFIGURATION OVERVIEW ............................................................................................................. 32

FIGURE 3-7, MFD AUX – DATABASE PAGE DB TRANSFER (EXAMPLE) ........................................................................................ 57

FIGURE 5-1, AUX – SYSTEM STATUS PAGE ............................................................................................................................ 67

FIGURE 5-2, SYSTEM ANNUNCIATIONS ................................................................................................................................. 68

FIGURE 6-1, RADAR ANTENNA INNER SCREWS ....................................................................................................................... 82

FIGURE 6-2, RADAR ANTENNA OUTER SCREWS. ..................................................................................................................... 83

FIGURE 6-3, CABLE BUNDLE POSITION ................................................................................................................................. 84

FIGURE 6-4, RADAR MOUNTING ADAPTERS .......................................................................................................................... 85

FIGURE 6-5, CONFIGURATION MODULE INSTALLATION ............................................................................................................ 87

FIGURE 7-1, G1000 NORMAL MODE CHECK ........................................................................................................................ 93

FIGURE 7-2, AIRCRAFT REGISTRATION EXAMPLE ..................................................................................................................... 98

FIGURE 9-1, MFD POWER UP PAGE .................................................................................................................................. 122

FIGURE 9-2, PFD POWER-UP SYSTEM ANNUNCIATIONS ........................................................................................................ 123

FIGURE 9-3, PFD NORMAL OPERATION ............................................................................................................................. 124

FIGURE 9-4, GDU REVERSIONARY MODE ........................................................................................................................... 127

FIGURE 9-5, BASIC EMPTY WEIGHT ENTRY .......................................................................................................................... 128

FIGURE 9-6, AUX-GPS STATUS PAGE ................................................................................................................................ 129

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 6

1. Introduction

1.1 Content, Scope, Purpose

This document provides maintenance instructions and Instructions for Continued Airworthiness

(ICA) for the changes to the G1000 Integrated Flight Deck as installed in the Embraer Model

EMB-500 Phenom P100. Throughout this document, this aircraft model will be referred to as

“Phenom 100”, unless otherwise specified. The change under STC SA01933WI upgrades the

system to the NXi configuration of the Garmin G1000 Integrated Flight Deck including the

GFC700 Automatic Flight Control System (AFCS). This document satisfies the requirements for

continued airworthiness as defined by 14 CFR Part 23.1529 and Appendix G. Information in

this document is required to maintain the continued airworthiness of the G1000 and GFC700.

Throughout this document, the GFC 700 autopilot system is included in the G1000NXi system

description and is identified separately only when needed.

1.2 Applicability

This document applies to Embraer Phenom 100 aircraft equipped with the G1000 NXi system.

All G1000NXi Phenom 100 aircraft are configured per General Arrangement drawing

005-01385-01, Rev 1 or subsequent approved revision.

Modification of an aircraft by Supplemental Type Certificate STC SA01933WI obligates the

aircraft operator to include the maintenance information provided by this document in the

operator’s Aircraft Maintenance Manual and the operator’s Aircraft Scheduled Maintenance

Program. The scope of maintenance information in this document is limited to aspects

pertaining to the Garmin G1000 NXi upgrade only. For other G1000 and aircraft level

maintenance items, refer to the Embraer Phenom 100 Maintenance Manual.

1.3 Organization

The following outline briefly describes the organization of this manual:

Section 2: System Description

Provides a complete description of the type design change associated with installing the G1000

NXi on Embraer Phenom 100 aircraft. Also provides an interface summary, power

requirements, and instructions on electrical bonding.

Section 3: Control and Operation

Provides brief instructions on controls and operation of the G1000 NXi system.

Section 4: Instructions for Continued Airworthiness

Provides maintenance procedures and instructions for continued airworthiness of the G1000

NXi system.

Section 5: Troubleshooting

Provides troubleshooting information to aid in diagnosing and resolving potential problems with

G1000 NXi system.

Section 6: Equipment Removal & Replacement

Gives instructions for the removal and replacement of G1000 NXi equipment.

Section 7: LRU Configuration & Testing

Gives instructions for loading software, configuring, and testing of the G1000 NXi system.

Section 8: Sub-System Functional Checks

Gives instructions for loading software and configuring the G1000 NXi system.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 7

Section 9: G1000 System Return to Service Procedures

Specifies return-to-service procedures to be performed upon completion of maintenance of the

G1000 NXi system.

1.4 Definitions/Abbreviations

ADI: Attitude Director Indicator

AML: Approved Model List

ARP: Aerospace Recommended Practice

ASTM: American Society for Testing and Materials

CDI: Course Deviation Indicator

CFR: Code of Federal Regulations

CWS: Control Wheel Steering

DDM: Difference in Depth of Modulation

DTK: Desired Track

FAA: Federal Aviation Administration

GPS: Global Positioning System

ICA: Instructions for Continued Airworthiness

ILS: Instrument Landing System

LRU: Line Replaceable Unit

MFD: Multifunction Flight Display

n/a: Not Applicable

NXi: Next Generation Integrated

OBS: Omni-Bearing Selector

PED: Personal Electronic Device

PFD: Primary Flight Display

PFT: Pre-Flight Test

SAE: Society of Automotive Engineers

SD: Secure Digital

SXM: SiriusXM

STC: Supplemental Type Certificate

VOR: VHF Omnidirectional Radio

1.5 Units of Measure

Unless otherwise stated, all units of measure are English units.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 8

1.6 Publications

All Garmin documents listed in Table 1-1 and Table 1-2 are available for download through the

Dealer Resource Center section of the Garmin web site. Refer to Section 1.7 for details.

The documents listed in Table 1-1 are required by this maintenance manual to perform

maintenance on the G1000 NXi system on the Embraer Phenom 100 aircraft. It is the

responsibility of the owner/operator to ensure that the latest versions of these documents are

used during operation, servicing or maintenance of the airplane. Refer to the Master Drawing

List 005-01385-00 for applicability.

Table 1-1 – Required Documents

GARMIN PUBLICATIONS

Document Number

Document Title

005-01385-00

Master Drawing List Embraer Phenom Garmin G1000 Integrated Avionics System

Updates

005-01385-01

General Arrangement, G1000 NXi, Embraer Phenom P100

005-01385-19

Equipment Installation, Phenom 100 NXi Upgrade

005-01385-18

Wire Harness Routing/Install Embraer Phenom P100

005-W0042-00

Wiring Diagram, G1000 NXi, Embraer Phenom P100

EMBRAER PUBLICATIONS

AMM-2432

Phenom By Embraer Aircraft Maintenance Manual

The documents listed in Table 1-2 are recommended to be available during the performance of

maintenance activities.

Table 1-2 –Reference Publications

GARMIN PUBLICATIONS

Document Number

Document Title

190-02545-01

Airplane Flight Manual Supplement, G1000 Integrated Avionics System and GFC 700

AFCS in Embraer Model EMB-500 (Phenom 100)

190-02547-00

Prodigy Nxi Flight Deck 100 Cockpit Reference Guide Embraer Phenom 100

190-02546-00

Prodigy Nxi Flight Deck 100 Pilot's Guide Embraer Phenom 100

190-00355-04

GDL 69 Series SiriusXM Satellite Radio Activation Instructions

190-00903-00

G1000 System Maintenance Manual (LJ/VLJ Aircraft)

190-00303-93

GDU 1250A Installation Manual

190-03813-00

GMA 1360 Installation Manual

190-01499-02

GTX 3X5 Transponder TSO Installation Manual

190-02009-00

GWX Processor Installation Manual.

190-00355-07

GDL 69 Series TSO Installation Manual

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 9

Table 1-3 – Other Reference Documents

Document Number

Title

AC 43.13-1B

FAA Advisory Circular, Acceptable Methods, Techniques, and Practices

– Aircraft Inspection and Repair

AC 43.13-2B

FAA Advisory Circular, Acceptable Methods, Techniques, and Practices

– Aircraft Alterations

SAE ARP1870

Aerospace Systems Electrical Bonding and Grounding for Electromagnetic

Compatibility and Safety

SAE AS4461

Assembly and Soldering Criteria for High Quality/High Reliability Soldered Wire and

Cable Termination in Aerospace Vehicles

SAE AS50881

Wiring, Aerospace Vehicle

ASTM F 2490-05

Standard Guide for Aircraft Electrical Load and Power Source Capacity Analysis

1.7 Revision and Distribution

This document is required for maintaining the continued airworthiness of the G1000 NXi system

on the Embraer Phenom 100 aircraft. When this document is revised, every page will be

updated to indicate current revision level. Garmin Dealers may obtain the latest revision of this

document on the Garmin Dealer Resource Center website.

Owner/operators may obtain the latest revision of this document from the https://fly.garmin.com

Support page, or by contacting a Garmin dealer, contacting Garmin Product Support at 913397-8200, toll free 866-739-5687, or using around the world contact information on

https://fly.garmin.com/.

A Garmin Service Bulletin describing the revision to this document will be sent to Garmin

dealers if the revision is determined to be significant.

1.8 Garmin Technical Support

For technical support contact, Garmin Aviation Product Support at 913-397-8200 (toll free 866739-5687) or by using the around-the-world contact information on www.flygarmin.com.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 10

2. System Description

The G1000 NXi system components described in this section are additions or updates to

existing components on the Embraer Phenom 100. This section briefly describes the function of

these components.

2.1 Equipment Descriptions

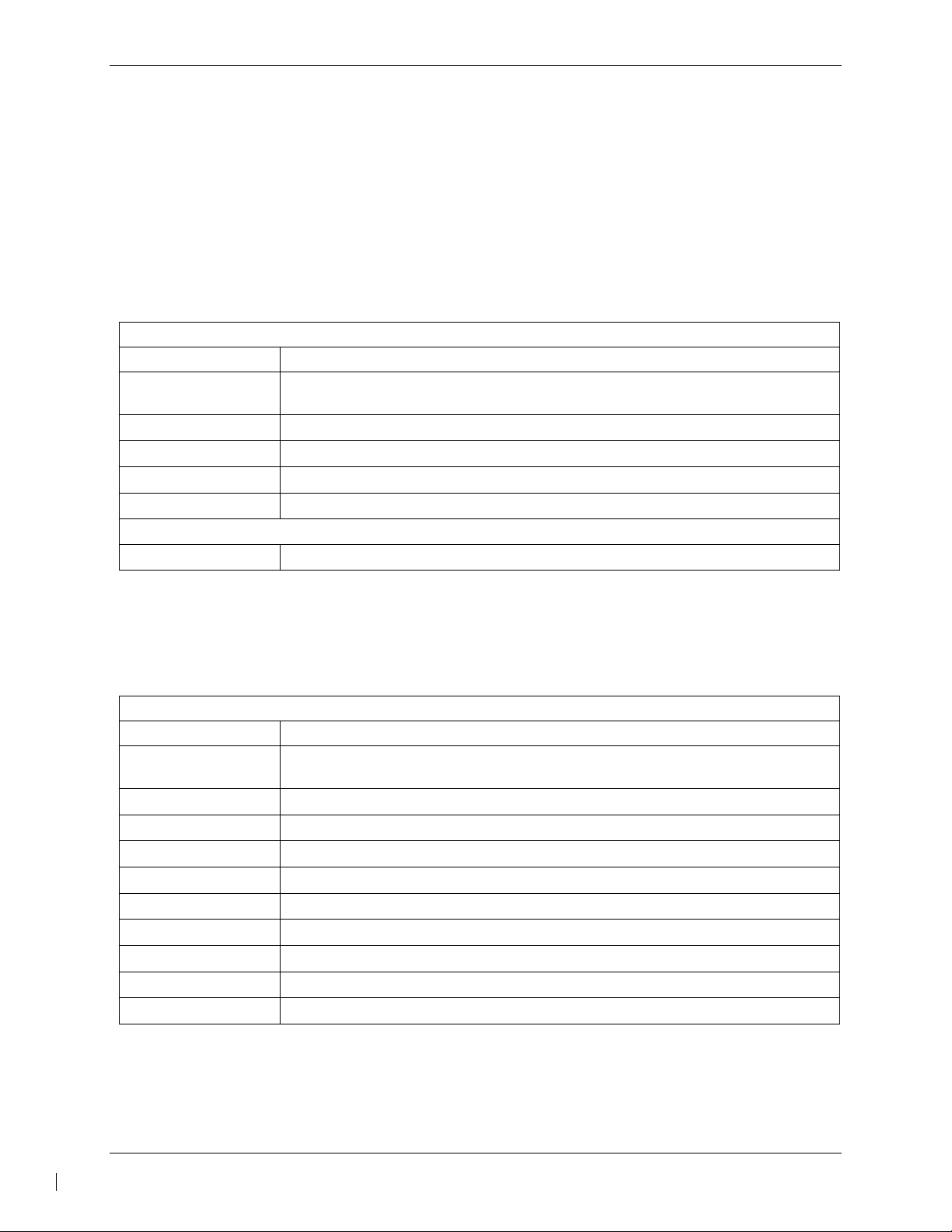

2.1.1 GCU 475

The GCU 475 controller is shown in Figure 2-1. This is an updated version of the existing GCU

475 controller. The controller is updated with improved joystick function. This is a drop-in

replacement.

2.1.2 GDU 1250A

The GDU 1250A display unit is shown in Figure 2-2. The GDU 1250A is used as primary flight

displays (PFDs) and multifunction display (MFD), mounted in the cockpit. The GDU 1250As are

an update to the existing GDU 1240As that were originally installed. The new displays have the

same overall dimensions as the previous generation hardware, with physical controls and

labeling being identical to the previous versions. The new GDU 1250A displays contain a new

LED backlight, and updated electronics, including a multi-core microprocessor.

Electronic Checklist

The Electronic Checklists (ECL) function allows the user to view and interact with aircraft

checklists. The Checklist contents are displayed on the GDUs and the checklist control is

performed using the GCU 475. The Garmin Checkset tool is provided by Garmin at no charge to

the aircraft operator to generate and edit the custom checklist files which are saved in the .gcl

format.

NOTE

For the G1000 NXi update, the checklist has to be saved as a “.gcl” file for

the checklist function to work.

The Checkset tool can be downloaded from the Fly.Garmin website under the Tools menu

(https://fly.garmin.com/fly-garmin/). The checklist is created or edited by the OEM/End user

without involvement from Garmin. Once the electronic checklist is created by the OEM/end user,

it is then downloaded onto an SD card and inserted into the top or bottom MFD card slot. Upon

power-up, the G1000 system checks the MFD SD cards for any checklist files and then

transfers the electronic checklist to the GDU internal memory. Once the Checklist is transferred

to the GDU, the SD card containing the checklist files can be removed and is no longer

required.

Please note that operational usage of the checklist file may require regulatory approval. The

OEM/Operator is expected to obtain the required approval.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 11

2.1.3 GMA 1360D (optional)

The GMA 1360D audio panel is shown in Figure 2-3. This unit replaces the GMA 1347D audio

panel and there are two per aircraft. The GMA 1360D brings 3D audio and Bluetooth

connectivity.

2.1.4 GTX 345R (optional)

The GTX 345R transponder is shown in Figure 2-4. The GTX 345R replaces the existing #1

GTX 33 w/ES Mode S transponder with a GTX 345R ADS-B transponder when there is only one

transponder on the aircraft, or when a GTX 33DR is in the #2 transponder position. The GTX

345R provides ADS-B Out. The GTX 345R also provides ADS-B In for TIS-B and air-to-air

traffic and FIS-B weather data to the G1000 NXi system for display to the flight crew.

2.1.5 GTX 345DR (optional)

The GTX 345DR transponder is shown in Figure 2-5. The GTX 345DR replaces the existing #2

GTX 33D w/ES Mode S transponder (if installed) with a GTX 345DR ADS-B transponder when

there is a GTX 33 in the #1 transponder position. The GTX 345DR is a dual-link diversity ADSB In receiver, capable of receiving 1090 MHz and 978 MHz Universal Access Transceiver (UAT)

data. The GTX 345DR’s datalink provides traffic (TIS-B and air-to-air) and weather (FIS-B) data

for display on the PFD’s and MFD.

2.1.6 FS 510

The FS 510 (Flight Stream 510) wireless data card is shown in Figure 2-6. The FS 510 is an

SD card that installs into the MFD in the aircraft cockpit. The FS510 offers the addition of Wi-Fi

and Bluetooth connectivity for activities such as flight plan transfers and data output to carry-on

devices such as tablets and electronic flight bags. This data may be in the form of GPS

information, weather, aircraft traffic, or other items for flight crew use.

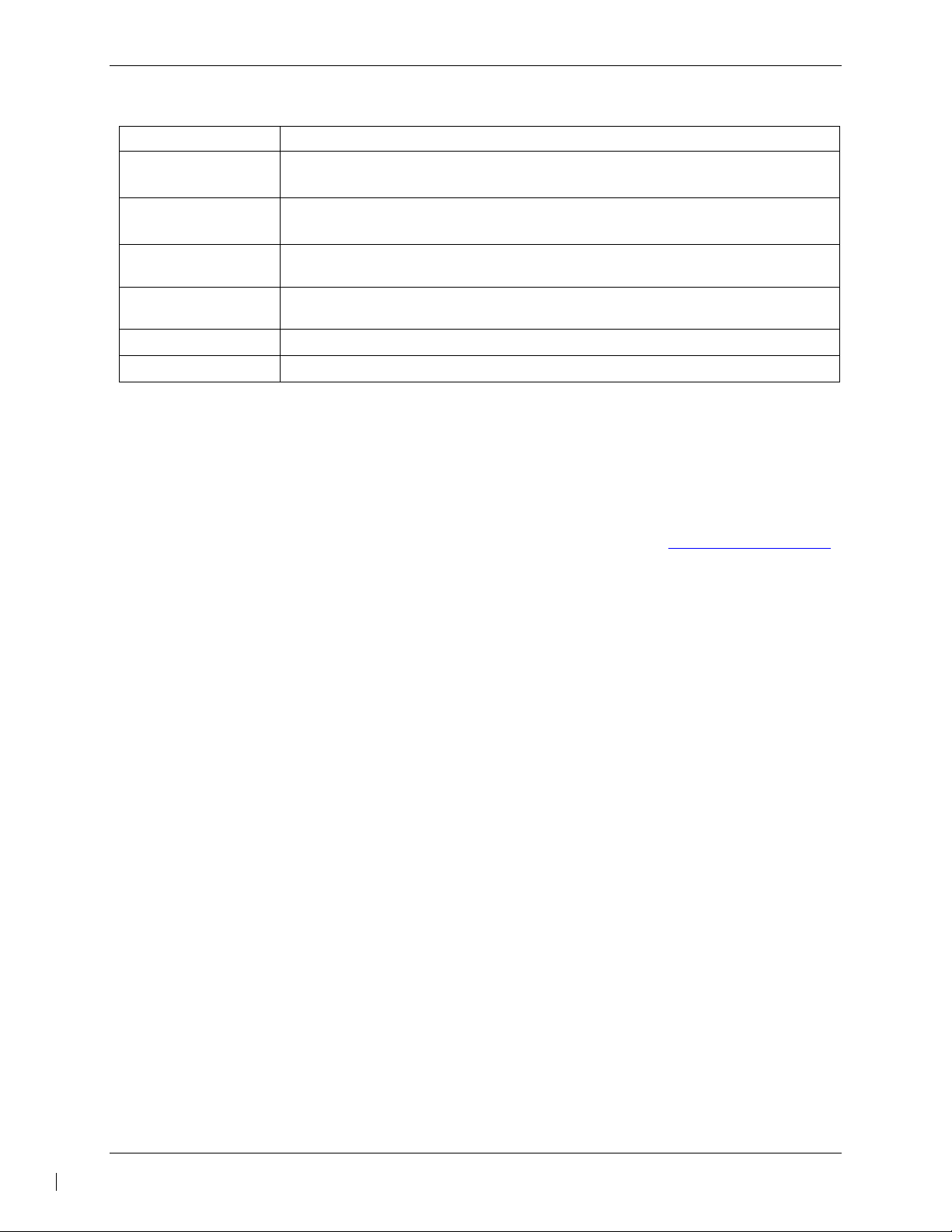

2.1.7 GWX 75 (Optional)

The optional GWX 75 weather radar is shown in Figure 2-7. The GWX 75 replaces the existing

weather radar and provides turbulence detection and ground clutter suppression, not available

with the GWX 68.

2.1.8 GDL 69A SXM (Optional)

The optional GDL 69A SXM receiver is shown in Figure 2-8. The GDL 69A SXM replaces the

existing GDL 69 XM receiver and is required if either optional GTX 345R or a GTX 345DR

transponder is installed in the aircraft. The GDL 69A SXM unit provides the same functions and

interfaces as the legacy GDL 69A it replaces and is designed to be compatible with the updated

SiriusXM G4 satellite network.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 12

Figure 2-1 – GCU 475

Figure 2-2 – GDU 1250A

Figure 2-3 – GMA 1360D

Figure 2-4 – GTX 345R

Figure 2-5 – GTX 345DR

Figure 2-6 – FS 510

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 13

Figure 2-7 – GWX 75

Figure 2-8 – GDL 69A SXM

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 14

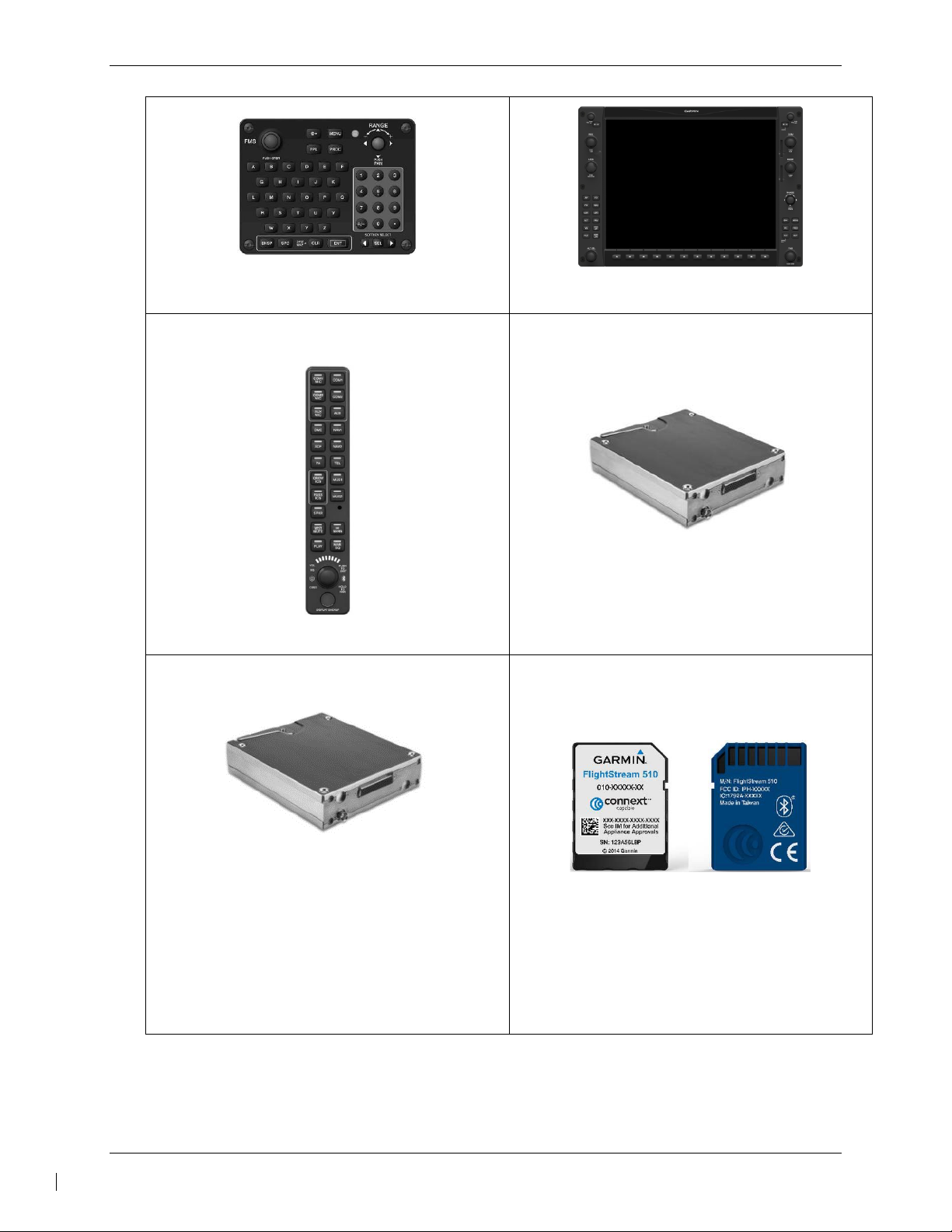

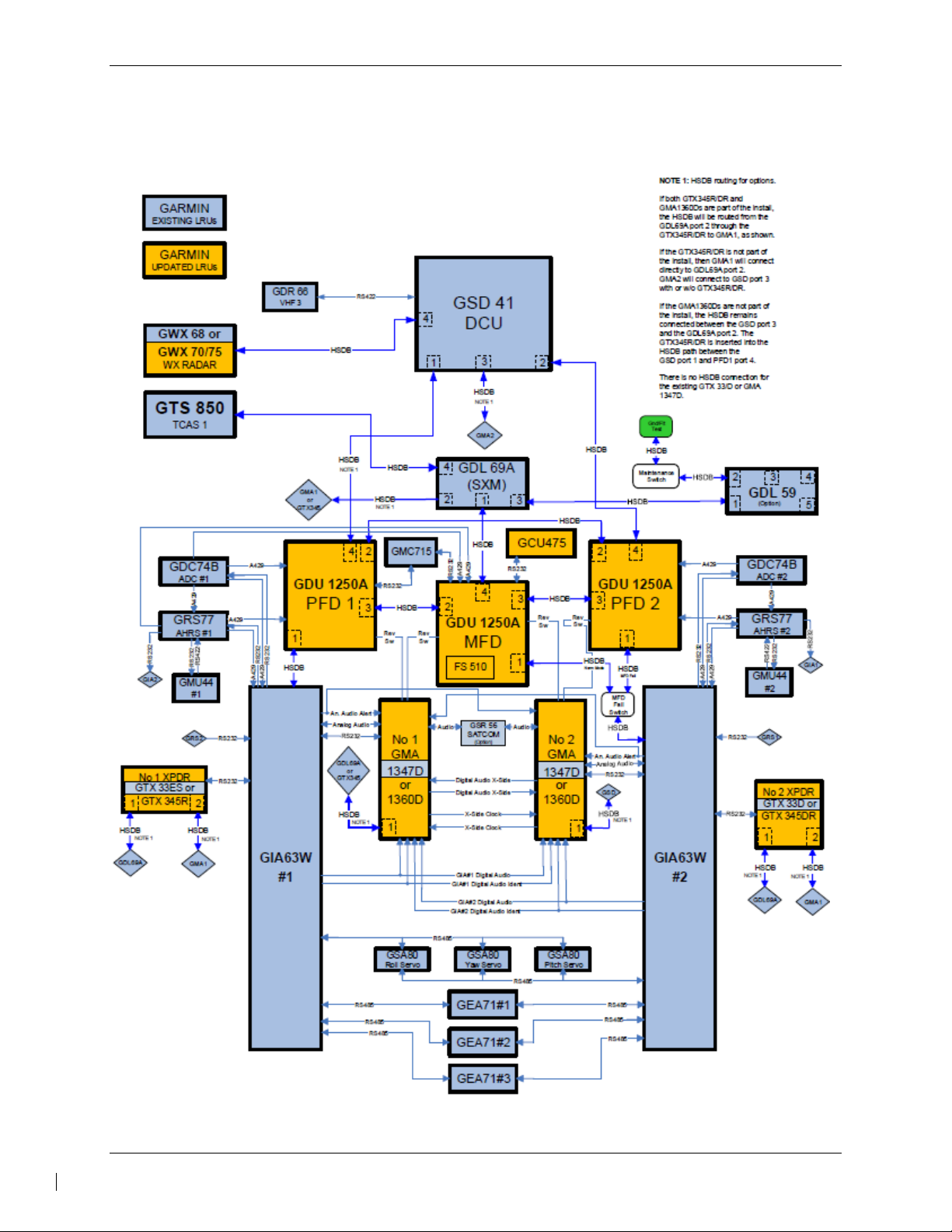

2.2 System Interface Summary

The following figure provides a high-level summary of G1000 NXi on the Embraer Phenom 100.

Aircraft. Yellow blocks signify new or updated equipment.

Figure 2-9 – G1000 Nxi System Overview

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 15

2.3 Electrical Load Requirements

Table 2-1 below summarizes the electrical load requirements for the LRUs installed by this STC.

Table 2-1 – Electrical Load Requirements

LRU

Characteristics

Specifications

Notes

GCU 475

Max Current Draw @ 28 VDC

0.05 A

GDU 1250A

Max Current Draw @ 28 VDC

0.9 A

At or below -15° = 1.9A

GMA 1360D

Max Current Draw @ 28 VDC

1.00 A

GTX 345R

Max Current Draw @ 28 VDC

0.65 A

GTX 345DR

Max Current Draw @ 28 VDC

0.65 A

FS 510

Max Current Draw @ 28 VDC

n/a

Powered by GDU 1250A

GWX 75

Max Current Draw @ 28 VDC

2.5 Amps

GDL 69A

Max Current Draw @ 28 VDC

0.35 Amps

2.4 Electrical Bonding

For the purposes of this STC, aircraft ground reference definitions vary according to airframe

type, as defined in Table 2-2. Refer to the periodic test and reconditioned resistance values

corresponding to these ground reference definitions when performing the equipment bonding

tests in Section 4.5.

The periodic test value is the value allowed during the bonding checks specified in Section 4.5.

The reconditioned value is the value allowed on initial installation or if the bond must be

reworked if the periodic test value is exceeded.

Refer to SAE ARP 1870 Section 5 when surface preparation is required to achieve electrical

bond.

NOTE

Bonding checks are performed with harness connectors connected for all

equipment except for the GWX 75 (If installed). GWX 75 bonding checks

are to be accomplished with the harness connectors disconnected.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 16

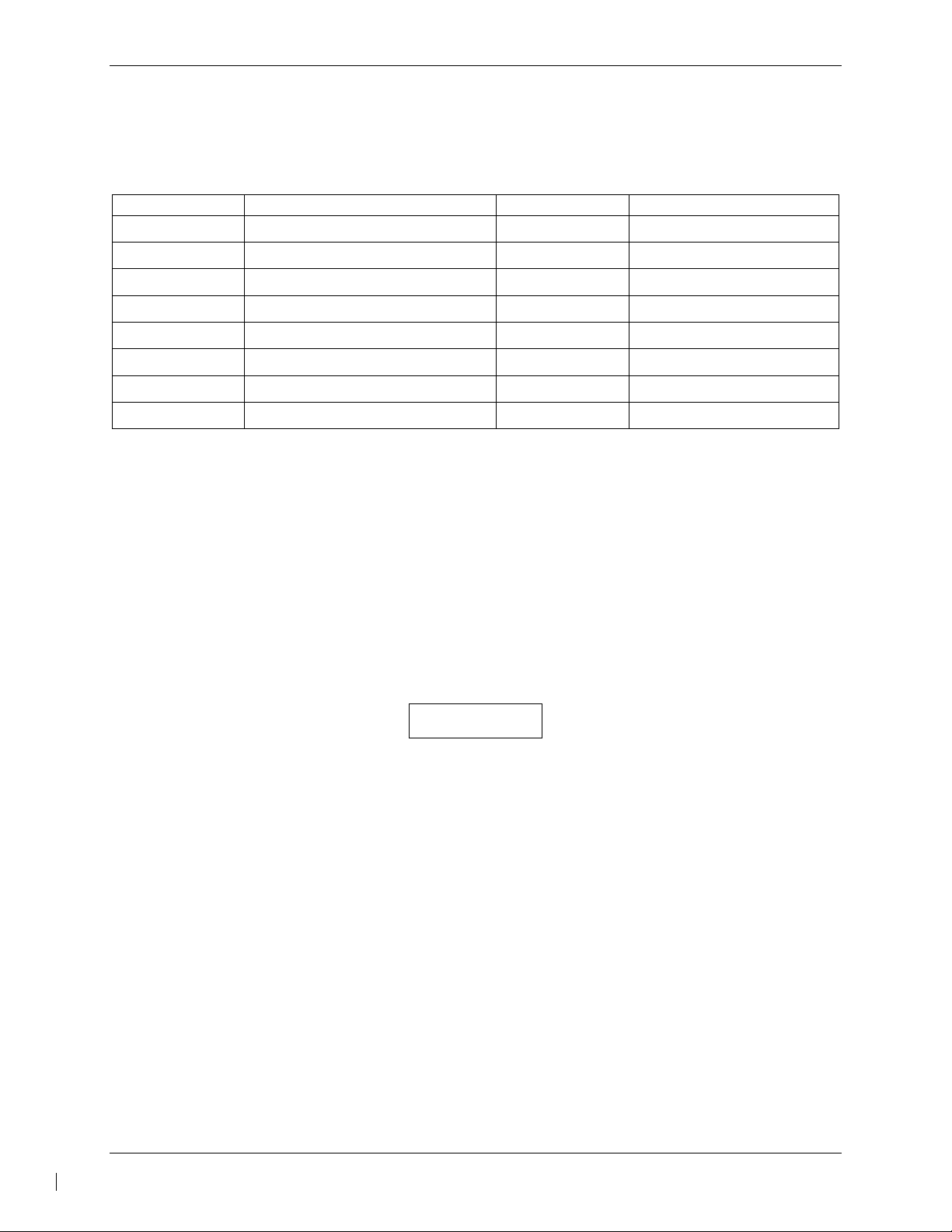

Table 2-2 – Electrical Bonding

Aircraft Type

Ground Reference

Maximum Resistance Between LRU

Equipment Chassis and Ground

Reference (mΩ)

Periodic Test

Reconditioned

Metallic Airframe

Nearby metal structure

or

Instrument panel for LRU

30.0 for PFD1,

MFD, PFD2, GCU,

or GMA 1360D (if

installed)

20.0 for PFD1,

MFD, PFD2, GCU,

or GMA 1360D (if

installed)

5.0 for GTX 345R

(if installed),

GDL69A SXM (if

installed), or GWX

75 (if installed)

2.5 for GTX 345R

(if installed),

GDL69A SXM (if

installed), or GWX

75 (if installed)

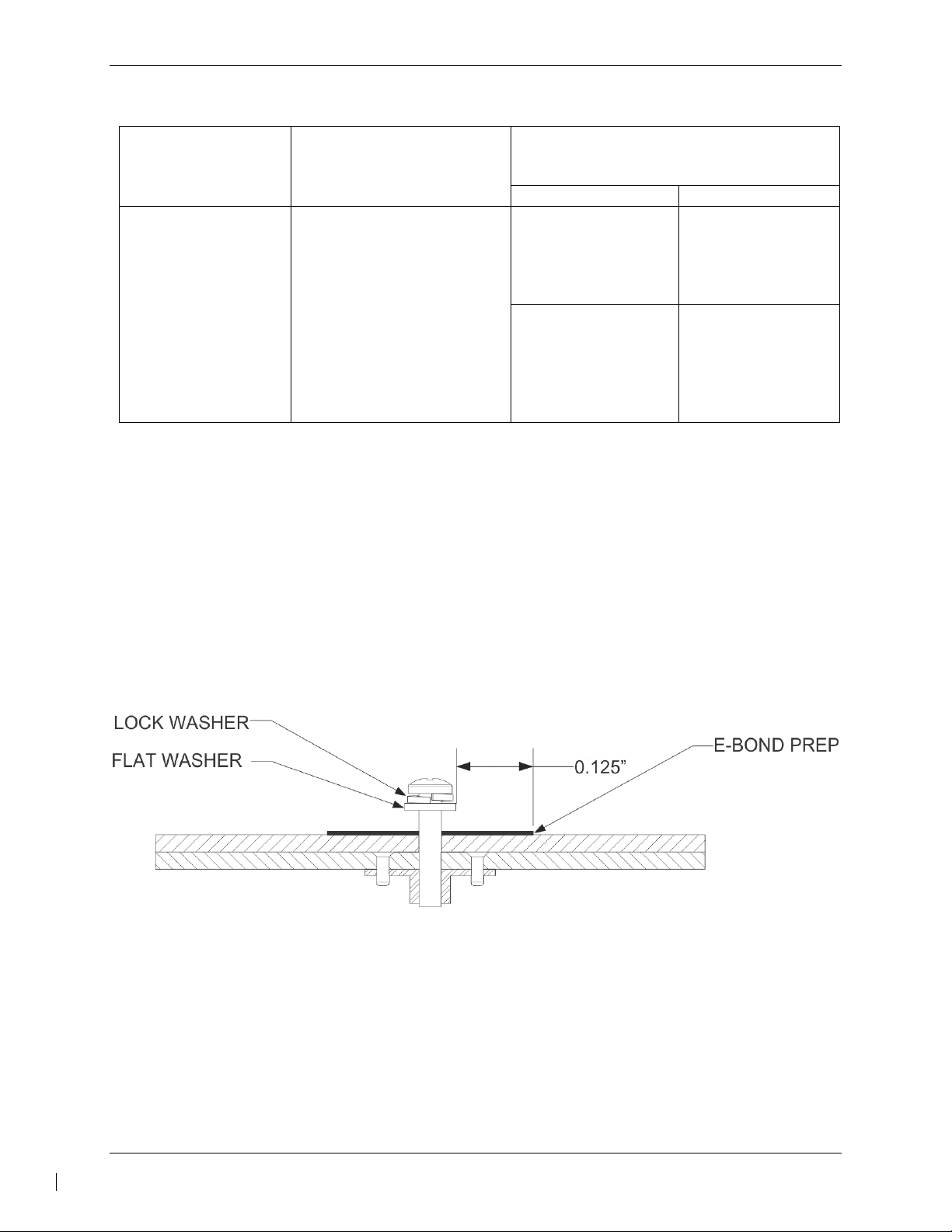

2.4.1 Consideration for Untreated or Bare Dissimilar Metals

The correct material finish is important when mating untreated or bare dissimilar metals.

Materials should be galvanically compatible. When corrosion protection is removed to make an

electrical bond any exposed area after the bond is completed should be protected again.

Additional guidance can be found in SAE ARP 1870 Section 5. Typical electrical bonding

preparation examples are shown in Figure 2-10, Figure 2-11, and Figure 2-12.

Figure 2-10 – Electrical Bonding Preparation – Nut Plate

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 17

Figure 2-11 – Electrical Bonding Preparation – Bolt/Nut Joint

Figure 2-12 – Electrical Bonding Preparation – Terminal Lug

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 18

2.4.2 Preparation of Aluminum Surfaces

The following general procedure is recommended to prepare an aluminum surface for proper

electrical bonding.

1. Clean grounding location with solvent.

2. Remove non-conductive films or coatings from the grounding location.

3. Apply a chemical conversion coat such as Alodine 1200 to the bare metal.

4. Once the chemical conversion coat is dry, clean the area.

5. Install bonding equipment at grounding location.

6. After bond is complete, if any films or coatings were removed from the surface, reapply a

suitable film or coating to the surrounding area within 24 hours.

After satisfactory electrical bond is achieved, when it has been necessary to remove any highresistance protective coating, the area from which the coating has been removed should be

refinished with the same finish as is on the rest of the part within 24 hours. In cases where the

parts come in with certain areas spot-faced, or if there is no finish on the part (bare metal), apply

conformal coating over the bond joint and hardware per MIL-I-46058 or clear lacquer per TT-L20A to facilitate future inspection. Refer to the model specific Aircraft Maintenance Manual or

Standard Practices Manual for surface protection requirements applicable to affected areas.

The correct material finish is important when mating untreated or bare dissimilar metals. They

should be galvanically compatible. When corrosion protection is removed to make an electrical

bond, any exposed area after the bond is completed should be protected again. Additional

guidance can be found in SAE ARP 1870 Section 5.

For a more detailed procedure, refer to SAE ARP 1870 Sections 5.1 and 5.5.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 19

3. Control and Operation

3.1 Configuration Mode Overview

Throughout this document, references are made to the PFD1, PFD2, and/or MFD being in

configuration mode. The configuration mode exists to provide the avionics technician with a

means of configuring, checking, and calibrating various G1000 Nxi sub-systems.

Troubleshooting and diagnostics information can be viewed in this mode.

To start the G1000 Nxi system in configuration mode, follow these steps;

1. With the G1000 Nxi system off, open the MFD PWR 1, MFD PWR 2, PFD 1 and PFD 2

circuit breakers.

2. In accordance with AFM electrical system recommendation, connect external power to

the aircraft and energize the battery electrical busses.

3. Press and hold the ENT key on PFD 2 (copilot) and close the PFD 2 circuit breaker.

4. Release the ENT key after ‘INITIALIZING SYSTEM’ appears in the upper left corner of

PFD 2.

5. Press and hold the #12 (far right) softkey on the MFD and close the MFD PWR 1 circuit

breaker.

6. Release the #12 softkey after ‘INITIALIZING SYSTEM’ appears in the upper left corner

of MFD.

7. Press and hold the ENT key on PFD 1 (pilot) and close the PFD 1 circuit breaker.

8. Release the ENT key after ‘INITIALIZING SYSTEM’ appears in the upper left corner of

PFD 1.

IMPORTANT

The Configuration Mode contains certain pages and settings that are

critical to aircraft operation and safety. These pages are protected and

cannot be modified unless the technician is properly authorized and

equipped. Most protected page content is viewable to allow system

awareness for troubleshooting.

NOTE

If the specific procedure requires an SD card to be in the top slot of the

PFD/MFD, this card must be inserted prior to applying power to the

PFD/MFD. Any time a card is inserted, the power to the PFD/MFD must

be cycled.

If a software loader card is inserted in the top slot of the display before it is

powered on, the display will automatically enter configuration mode and the

technician does not need to press and hold a softkey at power-on.

For a complete description and breakdown of each Configuration Mode page, refer to the

G1000 System Maintenance Manual listed in Table 1-2.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 20

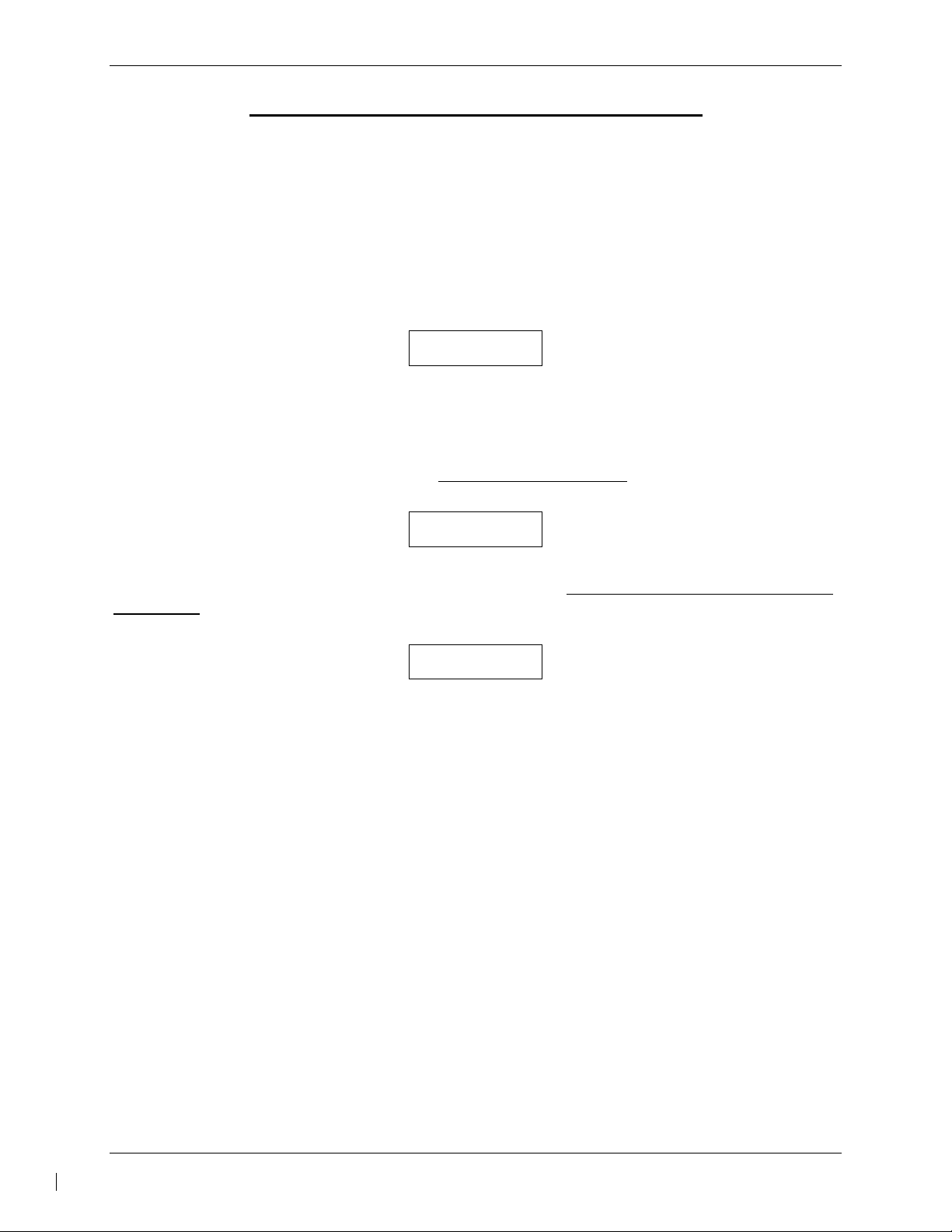

3.1.1 SET>ACTV Configuration

Throughout the configuration mode pages, there are SET and ACTIVE columns for input/output

settings and other parameters.

SET: Refers to a setting or group of settings that reside in PFD Internal Memory and/or the

Master Configuration Module.

ACTIVE: Refers to an ‘active’ setting or parameter currently being used by the LRU. LRUs

store the ‘active’ settings within internal memory.

Data can be manually copied from one column to the other (and consequently from PFD

memory to the LRU memory and vice-versa) by using the following two softkeys, when

available:

• SET>ACTV (read ‘Set to Active’) softkey: Allows the installer to send the information in

the SET column (data stored in the master config module) to the ACTV column (data

used by LRU).

• ACTV>SET (read ‘Active to Set’) softkey: Causes the LRUs current settings to be

copied to the master configuration module as SET items.

CAUTION

The ACTV>SET softkey must be used with caution. If an improperly

configured unit is installed, this softkey causes the wrong configuration to

replace the correct aircraft configuration.

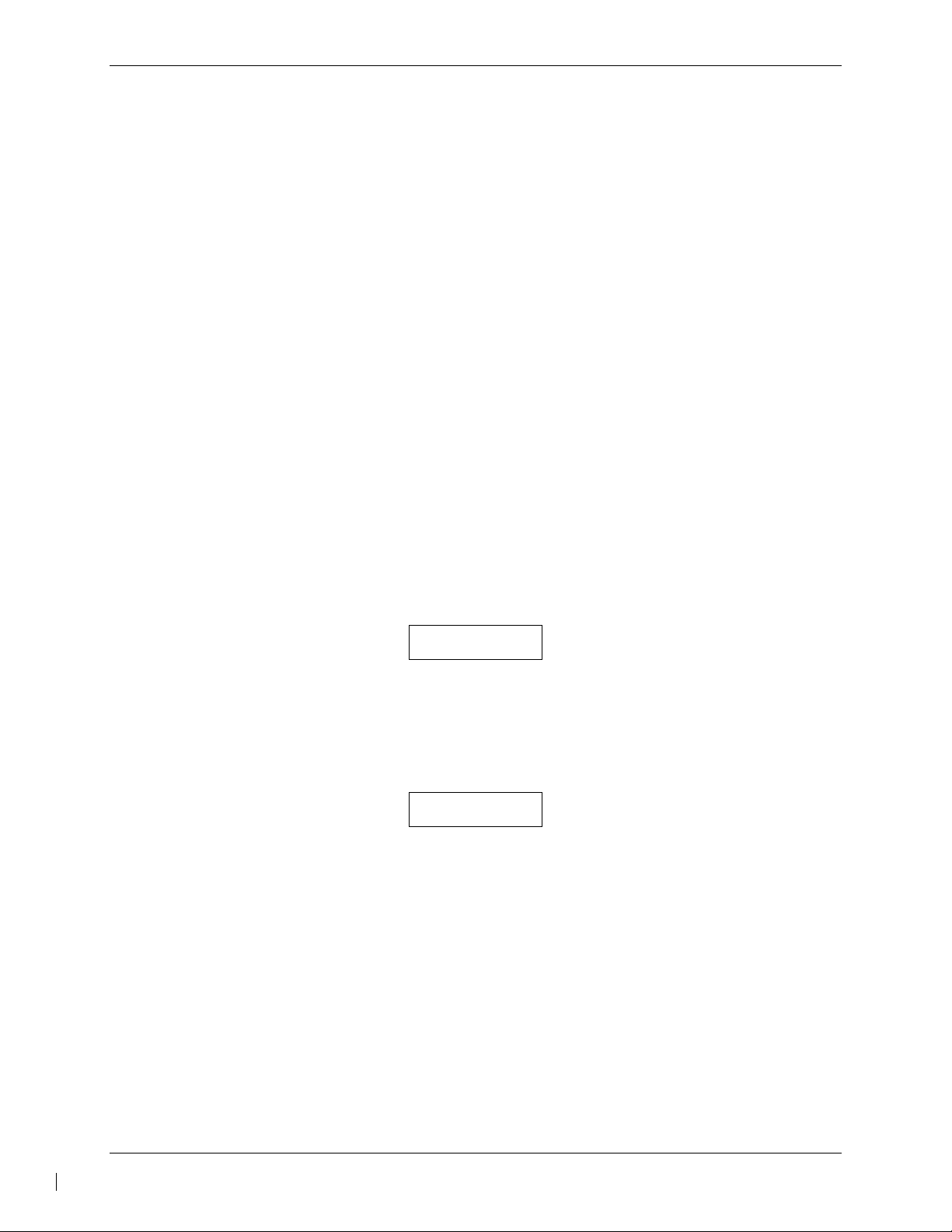

In the first example shown in Figure 3-1 the SET columns do not match the ACTIVE columns.

The inequality between SET and ACTIVE indicates a configuration mismatch. By pressing the

SET>ACTV softkey, this copies the SET column to the LRU unit’s configuration memory. The

settings then become the ACTIVE settings for the LRU being configured.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 21

Figure 3-1, SET>ACTV Diagram

When troubleshooting the system, technicians can look for inequalities between SET and

ACTIVE columns. Certain problems can be resolved simply by pressing the SET>ACTV

softkey, which reloads settings to the specific LRU from the PFD. (Note that this can also be

accomplished by reloading the configuration files for the LRU. Section 7 describes this process

for each LRU).

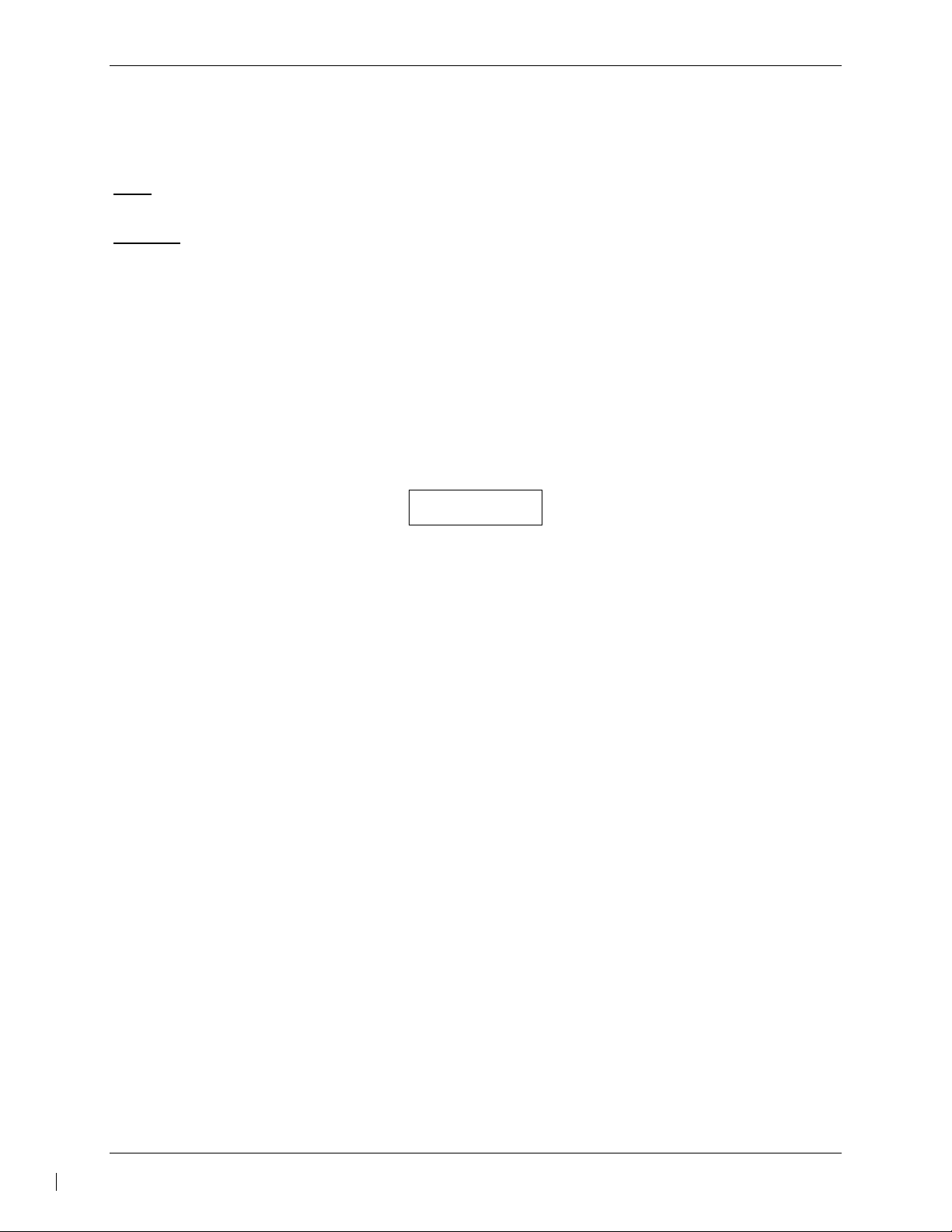

A blank active column, as shown in Figure 3-2, represents loss of communication between the

display and the particular unit. See Section 5 for more details on troubleshooting.

Figure 3-2, Loss of Communication

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 22

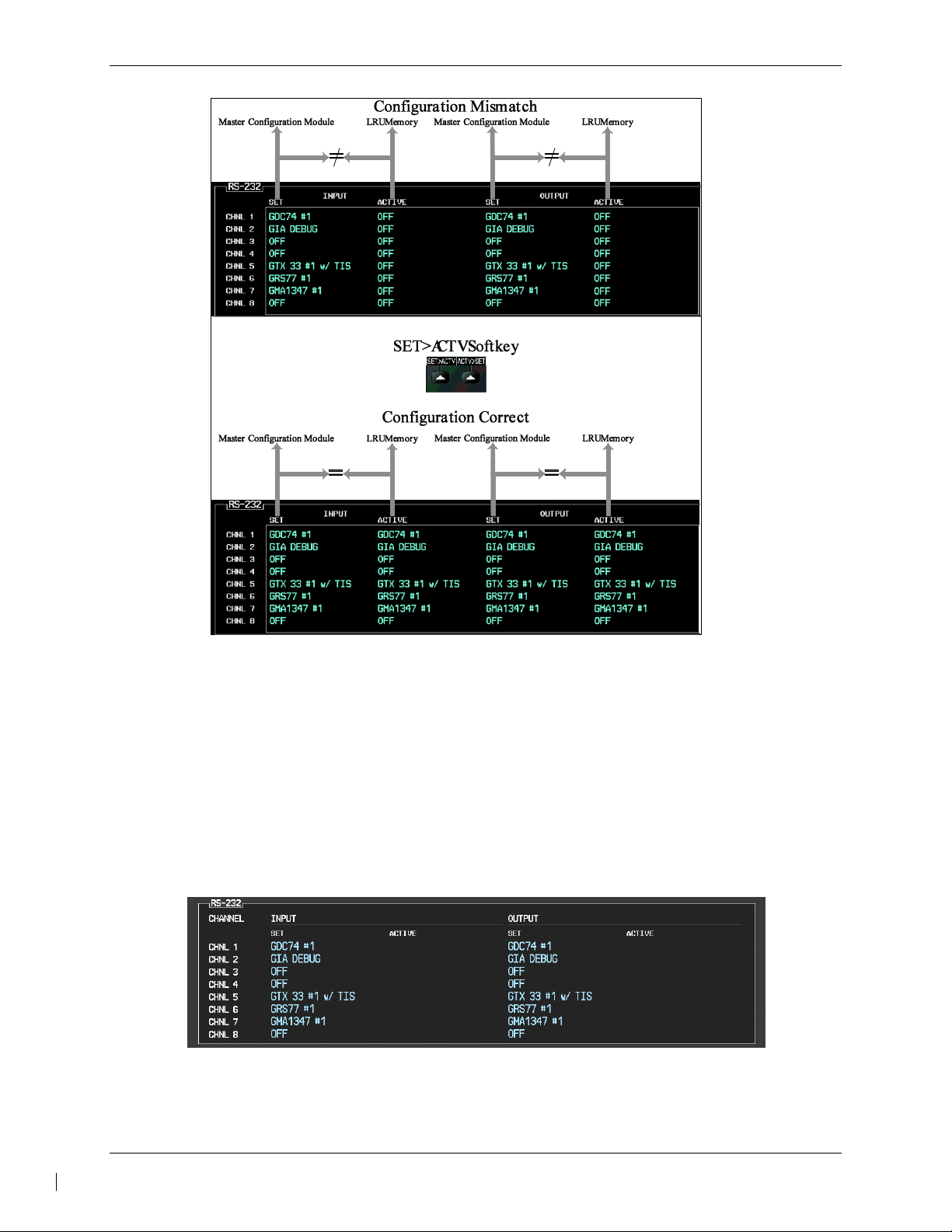

3.1.2 Configuration Prompts

When configuration settings are changed, the technician receives on-screen prompts and/or

confirmations such as those shown in Figure 3-3.

Figure 3-3, Configuration Status

3.1.3 Data Transmission Indicators

Several configuration screens utilize an indicator light system to show discrete (ON/OFF) data

and/or hardware component status. Unless otherwise noted, the following applies to all such

status indicators:

• Green Checkmark: Expected data is successfully received and is ON. A green check

could also indicate that the parameter/component is working correctly.

• Red X: Expected data is not received. A red X could also indicate that a

parameter/component is invalid.

• White N/A: Expected data is OFF, or no data is expected.

Figure 3-4, Data Transmission Indicators

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 23

3.1.4 Configuration Mode Navigation

Using the FMS knob, a user can navigate through different pages and page groups in the

Configuration Mode. For complete description and breakdown of each page, refer to the G1000

System Maintenance Manual listed in Table 1-2

System Page Group

1. System Status

7. Transaction Log

12. System Data Path

Configuration

2. Time Configuration

8. Aircraft Configuration

13. System Setup

3. Lighting Configuration

9. Diagnostics Terminal

14. Manifest Configuration

4. System Audio

10. OEM Diagnostics

15. Log Utilities

5. System Upload

11. System Configuration

16. Configuration Manager

6. LRU Replacement

GDU Page Group

1. Serial Configuration

6. Diagnostics

11. Airframe Configuration

2. CDU Status Page

7. Ethernet Test

12. TAWS Configuration

3. Key Test

8. Video Test

13. SurfaceWatch

Configuration

4. FS 510 Test

9. Alert Configuration

14. Connext Connections

5. CDU Calibration

10. DAT Configuration

GIA Page Group

1. Serial Configuration

3. GIA I/O Configuration

5. GIA Status Page

2. GIA RS-485 Configuration

4. GIA COM Setup Page

6. GIA CAN Configuration

GSD Page Group

1. GSD ARINC 429

Configuration

3. GSD I/O Configuration

4. GSD Status Page

2. GSD RS-485 Configuration

GEA Page Group

1. Engine Configuration

2. GEA Status Page

3. GEA Configuration

GTX Page Group*

1. Transponder Serial

Configuration

2. Transponder Configuration

GTX 3X5 Page Group*

1. Transponder Airframe Config

2. Transponder Diagnostics

3. Transponder Wiring Config

GRS Page Group

1. Inputs Configuration

2. GRS / GMU Calibration

3. GRS Flight Data Log*

ADC Page Group

1. ADC Configuration

2. GDC Configuration*

GFC Page Group

1. GFC Configuration

2. GFC Status

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 24

GMA X36X Page Group

1. GMA Discrete In

4. GMA Marker

8. GMA Squelch

2. GMA Discrete Out

5. GMA Misc

9. GMA Status

3. GMA Fast Volume

Configuration

6. GMA Noise

10. GMA Volume

7. GMA Options

11 GMA Wiring

GDL Page Group

1. GDL 69 Configuration

RMT Page Group

1. Remote Controller Status

GWX Page Group

1. GWX Configuration

GTS* Page Group

1. GTS Configuration

* Appears only if option is installed.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 25

3.2 G1000 System Software Information

NOTE

The following sections provide a detailed description of loading all G1000

software and configuration files, which may be excessive for individual LRU

removal and replacement. If removing and replacing individual LRUs, refer

to Section 6 of this manual for the necessary steps.

3.2.1 G1000 Software Image

G1000 software and configuration files are controlled via the approved software image part

number listed on the General Arrangement drawing listed in Table 1-1. This software image is

loaded into the G1000 using a software loader card. Approved software loader cards may be

purchased from Garmin. Refer to the General Arrangement drawing for the part number.

NOTE

The following sections provide a detailed description of loading all G1000

software and configuration files, which may be excessive for individual LRU

removal and replacement. If removing and replacing individual LRUs, refer

to Section 6 of this manual for the necessary steps.

NOTE

Only SanDisk brand SD cards are recommended for use with the G1000

system. Other brand cards have not been tested by Garmin.

IMPORTANT

To satisfy the G1000 Nxi System STC requirements for the Embraer

Phenom P100, it is critical that the technician installs the correct software

image part number when servicing the G1000 Nxi system. Approved

software loader card and image part numbers are defined on the General

Arrangement drawing.

IMPORTANT

Be cautious when using software loader cards during maintenance. The

G1000 system immediately initializes the card upon power-up. On-screen

prompts must be given careful attention in order to avoid potential loss of

data. Always read through procedures given in Sections 5, 6 and 7 before

attempting to use the software loader cards.

3.2.2 Loader Card

Obtain the software loader SD card listed on the General Arrangement drawing in Table 1-1.

This SD card contains the loader image for use in the PFD1 top slot.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 26

3.2.3 Software Files

Software files are defined by part number and version number on the General Arrangement

drawing listed in Table 1-1. Each G1000 system LRU reports the software version it currently

contains to the user in two places.

• Normal System Mode: The Aux – System Status page lists each LRU and the

reported software version.

• Configuration Mode: The System Status page (System page group) reports more

detailed LRU information, including software version, part number, and LRU status.

Software files are loaded to LRUs from the PFD1 System Upload page in configuration mode.

3.3 Configuration Mode

1. Refer to Section 3.1 for the procedure to start the G1000 Nxi system in Configuration

mode.

NOTE

If a software loader card is inserted in the top slot of the display before it is

powered on, the display will automatically enter configuration mode and it

is not needed to press and hold a softkey at power-on.

3.4 G1000 Hardware/Software Compatibility Check

Before installing software, the technician must first ensure that hardware part numbers and mod

status levels are compatible with the G1000 Nxi system software image to be used. The

General Arrangement drawing shows all available combinations of hardware and software part

numbers.

A G1000 Nxi system loader card is required to install software and configuration settings to a

newly installed G1000 Nxi system. The part number of the loader card and software image is

directly associated with the combination of software file part numbers and version levels that

are defined on the General Arrangement drawing. Should software part numbers or versions

change, a new software image part number is issued.

IMPORTANT

After verifying hardware/loader card compatibility, record the software

image part number and all LRU hardware part numbers in the appropriate

aircraft records before proceeding.

NOTE

Throughout the next section of this document, screen shots and examples

are used to illustrate the software and configuration loading process.

These screen shots are provided as reference only. Always refer to the

General Arrangement drawing listed in Table 1-1 for the correct software

file names, versions and part numbers.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 27

3.5 Equipment Verification (Third Party/Optional Equipment Documentation)

Use the configuration/software checklist in Section 3.6 to determine what configuration software

files to load for the aircraft installation. It is extremely important to know exactly what equipment

the aircraft is equipped with and how it is connected before loading any files. Loading the

incorrect files could lead to longer down time and unplanned removal of equipment.

• Garmin optional equipment (i.e. GTX 33 or GTX 3X5 transponder, etc.). Section 3.5.1

helps find which units are installed without a physical inspection.

• Third party avionics equipment interfaced to G1000 (ADF, DME, non-Garmin traffic

systems, etc.). To determine if the third-party equipment is installed, check the circuit

breaker panel for circuit breakers for the units, and check for G1000 controls for the

third-party devices.

3.5.1 Determining Installed Garmin Units

Use the table in Appendix A to determine what the unit part number is based on the unit’s serial

number reported on the MFD Aux – System Status page in Normal mode or PFD1 System

Status page in Config mode. This table lists the units that have different loader card option files

so the installer can choose the correct file without requiring the unit to be physically inspected.

Figure 3-5, Garmin Unit S/N Location

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 28

3.5.2 Aircraft Configuration Survey

IMPORTANT

These procedures must be carried out prior to maintenance of the aircraft, requiring that

any G1000 hardware is replaced that would require reloading the baseline software,

and/or if the G1000 baseline software is reloaded.

1. Conduct a pre-maintenance aircraft survey. Record the following information:

Date: _____________________

Aircraft S/N: __________________

Aircraft Registration: __________________

2. In accordance with AFM electrical system recommendation, apply ground external

power the aircraft. Turn the BATT 1 and BATT 2 switches to the ON position. On the

Electrical Control panel verify the external power ‘AVAIL’ light is illuminated. Select the

GPU button and verify the ‘AVAIL’ annunciation changes to ‘IN USE’.

3. Allow G1000 displays to initialize.

4. On the MFD power-up page, record the System Software version shown in the upper

right corner of the display here:

System Software Version: __________________

5. Acknowledge the MFD power-up page by pressing the right-most softkey, then use the

GCU 475 FMS knob and navigate to the Aux - System Status page.

6. Record the G1000 System ID shown in the upper right corner of the display here:

G1000 Legacy System ID: __________________

7. Remove electrical power from the aircraft by selecting the AVN PWR switch to OFF and

selecting the BATT master switch to OFF.

Garmin G1000 NXi System Maintenance Manual 190-02545-02

Embraer Phenom P100 Revision 4

Page 29

Optional Equipment Survey

1. Embraer offered several factory equipment options during the span of Phenom P100

production.

2. If reloading the G1000 NXi baseline software, the technician must conduct an options

equipment survey and record the installed equipment here:

L3 TRC 899 TCAS

Collins ADF

Honeywell KN63 DME

Honeywell KHF 1050 HF Radio

Honeywell KRA 405B Radio Altimeter

Honeywell KRX 1053 HF Radio

Inmarsat Aviator 300

Spoilers

Ice Detector System

Garmin GDR 66 (CPDLC)

Garmin GDL 59 with GSR 56

Garmin GDL 59 (no voice)

Garmin GWX 68 or GWX 70 (Weather Radar)

Garmin GTS 850 TCAS

ACSS TCAS 3000 w/ RCZ852 (NXT600) Transponders

IMPORTANT

If the aircraft is equipped with Sky Watch (L3 TRC 899 TCAS) option, it is

up to the installer to provide regulatory approval for the Sky Integration in

the G1000 Nxi installation.

Loading...

Loading...