Page 1

Pub. 42004-392G

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model LE200-RM

®

Rack-Mount Page/Party

T ABLE OF C ONTENTS

Confidentiality Notice .....................................................................................................................1

General Information .......................................................................................................................1

Line Extender and Sub-Component Details ......................................................................................... 2

PCBA Access ........................................................................................................................................................ 3

Audio Termination Connection Module – Optional Model 12118-011 Kit .......................................................... 4

Input/Output (I//O) Termination Connection Module – Optional Model 12118-012 Kit ..................................... 5

Main PCBA........................................................................................................................................................... 6

Features and Functions ..................................................................................................................7

Page Line Audio Transmission .............................................................................................................. 7

Page Line Audio Monitoring Output .................................................................................................... 8

Line Extender

Page Line Audio Detect Output Contact .............................................................................................. 9

Page Line FSK Data Transmission (SmartSeries Systems) ................................................................ 9

Page Line 50 kHz VLC Transmission ................................................................................................. 10

Page Line Ground Fault Detection ...................................................................................................... 10

Page Line Ground Fault Re-generation .............................................................................................. 11

Page Line Ground Fault Output Contact ........................................................................................... 11

Party Line Audio Transmission ........................................................................................................... 12

Party Line Off-Hook Regeneration ..................................................................................................... 12

Party Line Off-Hook Detection ............................................................................................................ 13

Audio Line Connection Relays ............................................................................................................ 14

Audio Line Muting ................................................................................................................................ 15

®

Page/Party

Contact Closure Inputs & Relay Outputs (I /0) .................................................................................. 17

Echo Cancellation ................................................................................................................................. 17

Manual Initiation of Echo Canceling .................................................................................................................. 17

Line Balance ..................................................................................................................... 16

Data Links between Line Extenders .............................................................................................18

T1/E1 Data Link .................................................................................................................................... 18

Low Voltage Differential Signaling (LVDS) Data Link ..................................................................... 18

Configuring the Data Links ................................................................................................................. 19

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

Table of Contents Pub. 42004-392G

M

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER

T1/E1 Data Format Selection .............................................................................................................................. 19

T1 Line Build-out Settings .................................................................................................................................. 19

T1/E1 Receiver Equalization Gain Limit ............................................................................................................ 20

T1/E1 Clock Source ............................................................................................................................................ 20

T1/E1 Data Line Grounding ............................................................................................................................... 21

LVDS Data Link Settings ................................................................................................................................... 21

LVDS Port Indicators ......................................................................................................................................... 22

Typical Data Link Settings ................................................................................................................... 23

Point-to-Point Page/Party® System Connection .................................................................................................. 23

Point to Multi-point Page/Party® System Connection ........................................................................................ 24

Series Connection of Page/Party® System .......................................................................................................... 25

Rules for Interconnecting More than Two Model LE200-RMs .......................................................................... 26

Installation ....................................................................................................................................28

Mounting ................................................................................................................................................ 28

Tabletop Mounting ............................................................................................................................................. 28

Wiring .................................................................................................................................................... 28

Power Connections ............................................................................................................................................. 28

Page/Party® System Cable Connection ............................................................................................................... 28

T1/E1 Data Connections ..................................................................................................................................... 29

Contact Closure Input Connections .................................................................................................................... 30

Contact Closure Output Connections .................................................................................................................. 31

Page Line Audio Monitoring Connections ......................................................................................................... 33

Verifying the Proper Line Balance Resistance ................................................................................................... 34

Distributing Line Balance Resistance ................................................................................................................. 34

Fiber Optic Cable Connections ............................................................................................................ 35

Fiber Optic Transceiver Set-Up........................................................................................................... 36

Verification of Proper Operation ........................................................................................................................ 40

Summary of PC Board Connections and Settings .......................................................................41

Recording the Settings ..................................................................................................................45

Testing and Troubleshooting ........................................................................................................48

Generating Audio Test Signals ............................................................................................................ 48

Function Testing.................................................................................................................................... 49

Specifications ................................................................................................................................50

Replacement Parts ................................................................................................................................ 55

Frequently Asked Questions .........................................................................................................56

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

ii

Page 3

PUB. 42004-392G

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model LE200-RM

®

Rack-Mount Page/Party

Confidential ity Notice

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and such

information may only be used in connection with the operation of your GAI-Tronics product or system.

This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any third party.

Line Extender

General Information

The Model LE200-RM Rack-Mount Page/Party® Line Extender is used in pairs to extend the operating

distance of Page/Party

connected through the Line Extender using either a two-pair copper cable or fiber optic cable depending on

the distance required. The local and remote cable segments are electrically isolated through the Line

Extenders. Refer to Figure 1 for a typical block diagram.

®

, SmartSeries or ICS Page/Party® systems. Two system cable segments are

Figure 1. Typical System Block Diagram

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 4

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 2 of 56

M

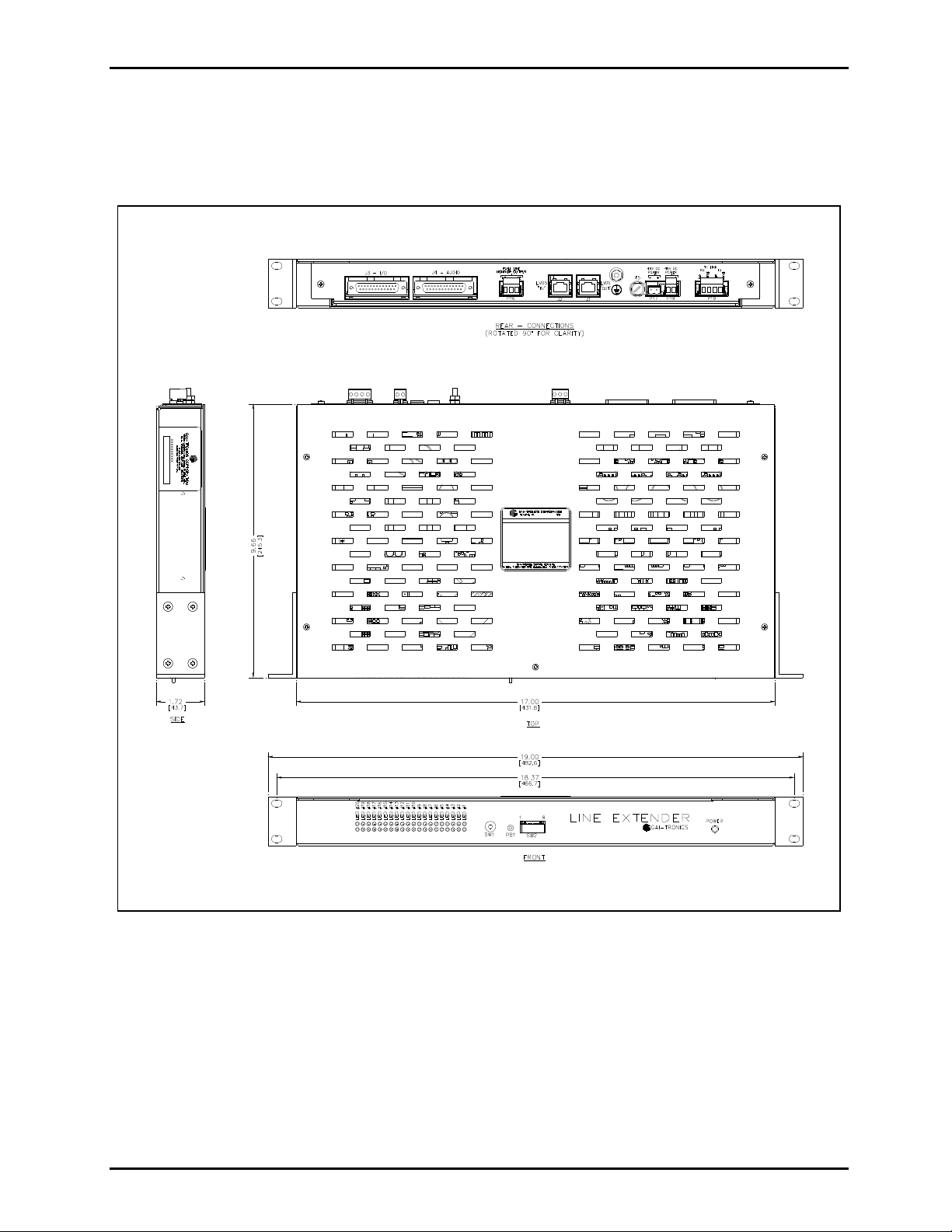

Line Extender and Sub-Component Details

Refer to Figure 2 below for dimensional information and sub-component layout of the LE200-RM Line

Extender.

Figure 2. Model LE200-RM Line Extender Outline

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 5

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 3 of 56

M

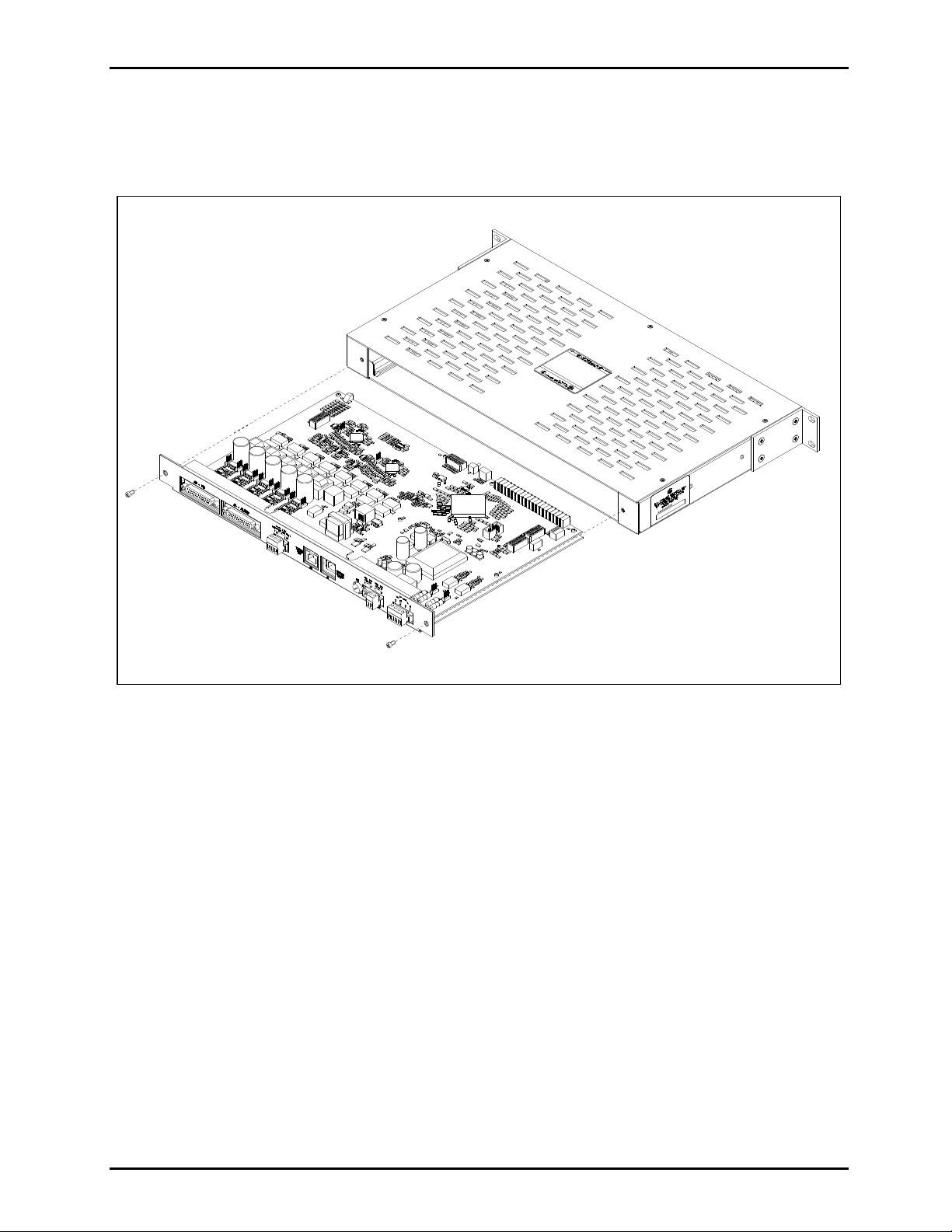

PCBA Access

The Main PCBA can be easily accessed to set up switches and jumpers. Remove the two #6-32 screws

from the rear of the unit. Slide the PCBA support plate and PCBA out of the unit. See Figure 3.

Figure 3. Access to the Model LE200-RM Line Extender’s Main PCBA

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 6

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 4 of 56

M

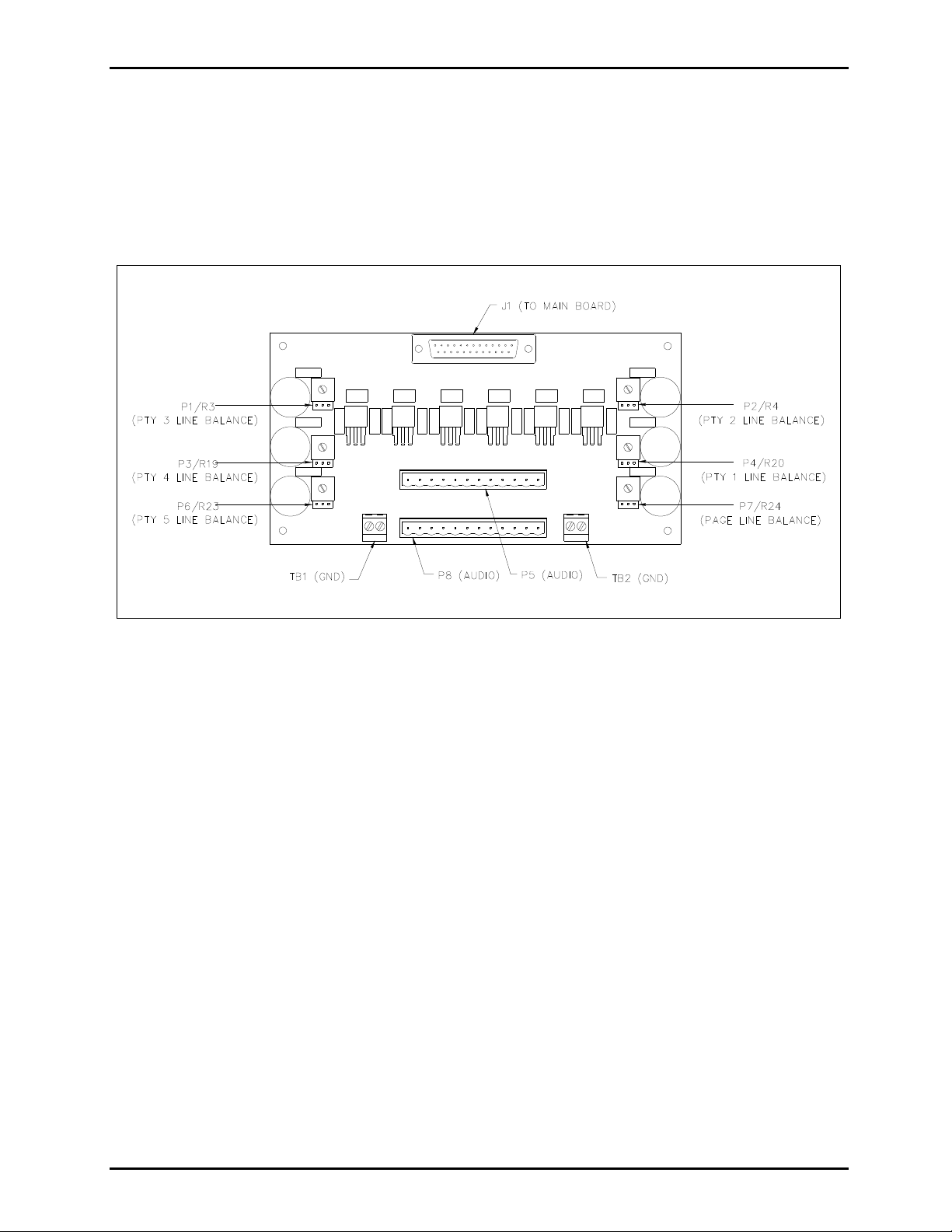

Audio Termination Connection Module – Optional Model 12118-011 Kit

The GAI-Tronics Model 12118-011 Kit must be used if the LE200-RM is to be connected directly to a

Page/Party

Termination Connection Module for connection to the Page/Party

page line and party line 1–5 conductors of the Page/Party

®

system. This kit consists of a ribbon cable for connection to the LE200-RM, an Audio

®

system cable connect to the Audio Termination

®

system and mounting hardware. The

Connection Module. This module also can provide the 33-ohm line balance resistance needed for the

audio lines. Audio line functions are described later in this manual.

Figure 4. Audio Termination Connection Module

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 7

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 5 of 56

M

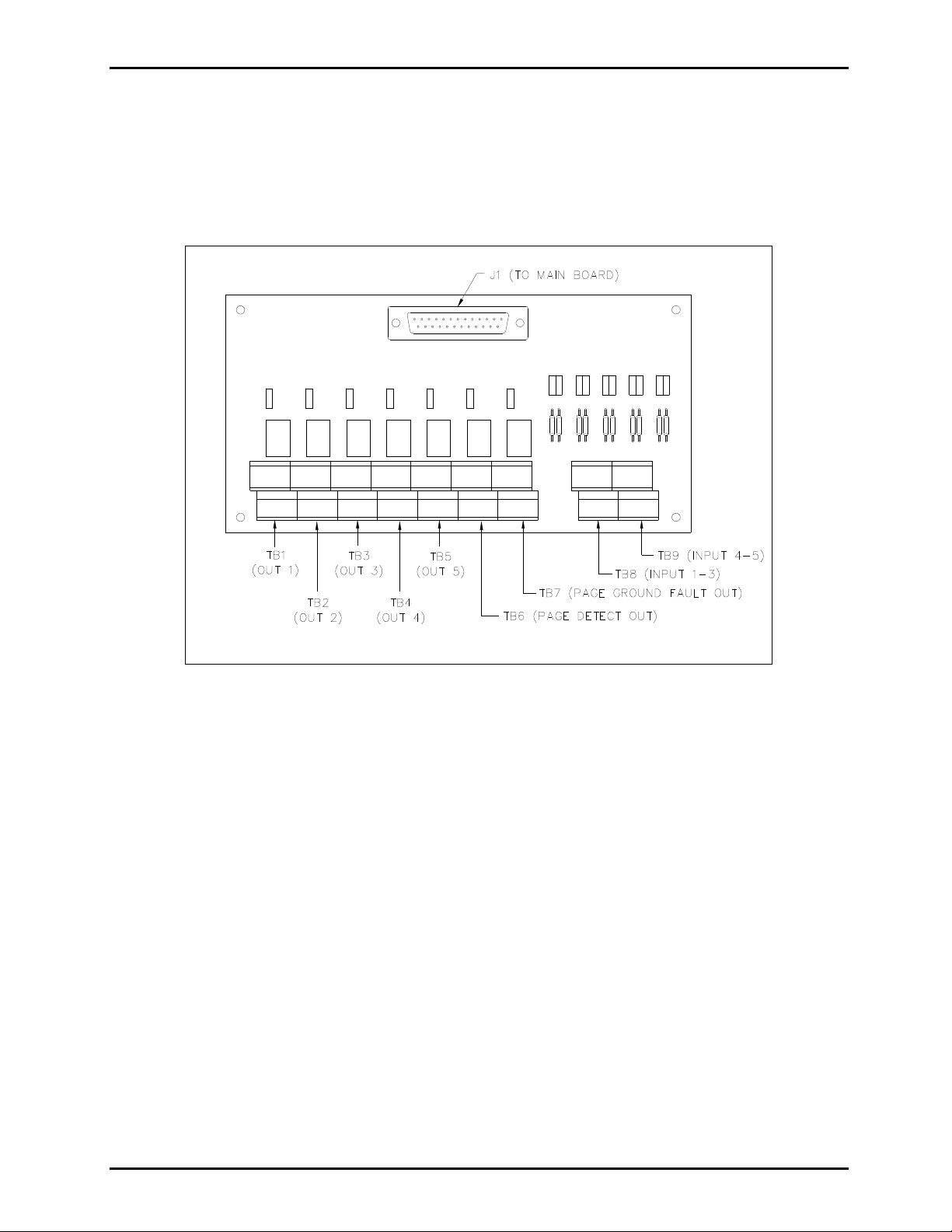

Input/Output (I//O) Termination Connection Module – Optional Model 12118-012 Kit

If the LE200-RM is to be connected directly to I/O wiring then the GAI-Tronics Model 12118-011 Kit is

required. This kit consists of a ribbon cable for connection to the LE200-RM, an I/O Termination

Connection Module and mounting hardware. The I/O Termination Connection Module is for connecting

the control wiring needed to send contact closures across the Line Extenders. I/O features and functions

are described later in this manual.

Figure 5. Input/Output (I/O) Connection Module

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 8

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 6 of 56

M

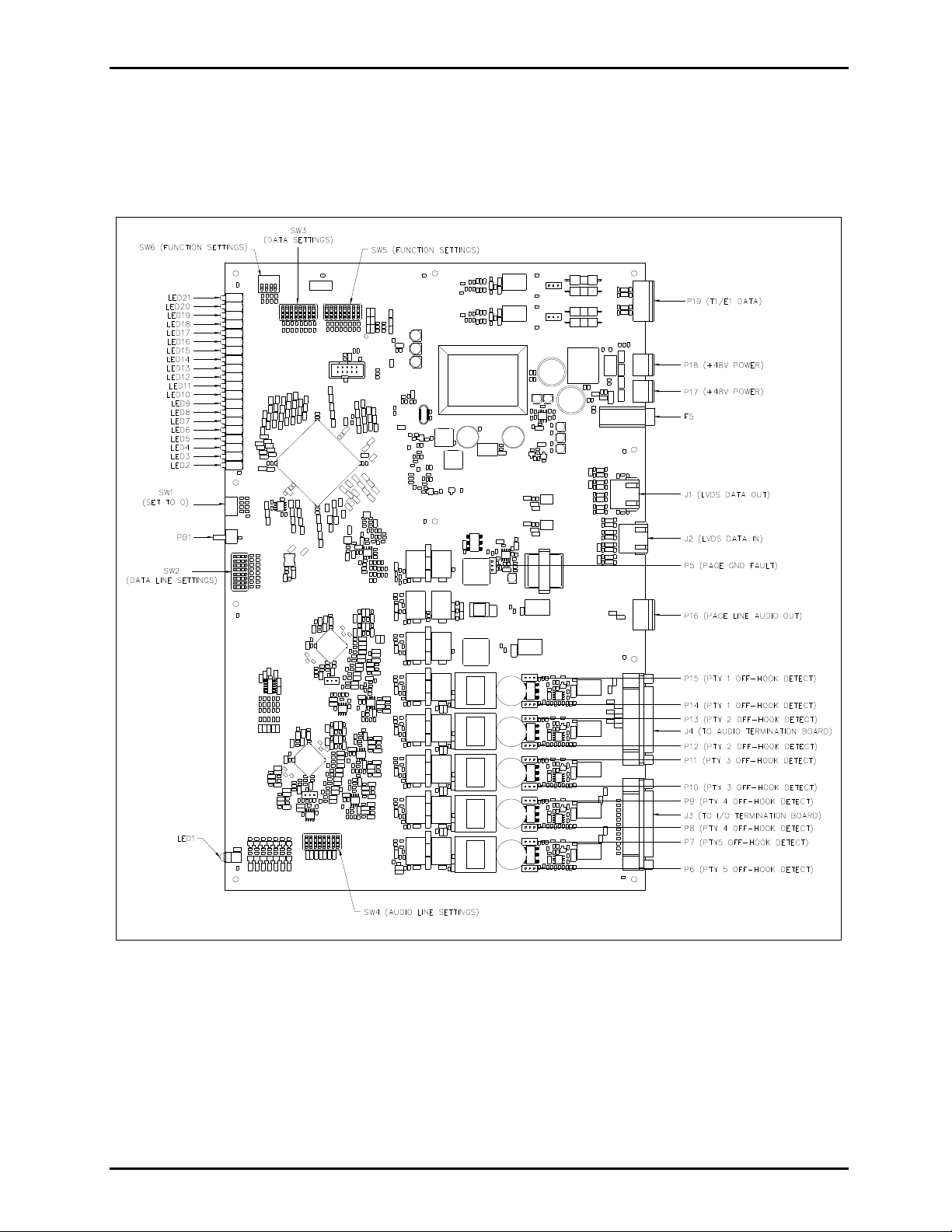

Main PCBA

The Main PCBA contains all the central processing and line driver circuitry for the Line Extender. The

board contains numerous connectors, switches and jumpers for setting the Line Extender operating

parameters. Figure 6 below identifies the various components on the Main PCBA. Features and functions

of each are described later in this manual.

Figure 6. 69443-xxx Main PCBA

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 9

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 7 of 56

M

Fea tures and Functions

The Model LE200-RM Page/Party® Line Extenders provide the following features between Page/Party®

system cables.

Page Line Audio Transmission

A pair of Model LE200-RMs provides page line audio transmission between two Page/Party® system

cables. This transmission is half-duplex operation.

When the Line Extender detects a peak audio level equal or above a

Threshold

Time.

, it immediately switches audio “on” in that direction for the Transmission Direction Hold

Audio from the other direction is muted and ignored during that time. Audio is not switched “off”

Peak Voltage Level Detection

until it is continuously below the Peak Voltage Level Detection Threshold for the Transmission Direction

Hold Time. The DIP switch SW2 positions 5–7, located on the Main PCBA, selects Peak Voltage Level

Detection Threshold and Transmission Direction Hold Time. Refer to Figure 6 for the location of switch

SW2 on the Main PCBA and Table 1 and Table 2 below for setting options.

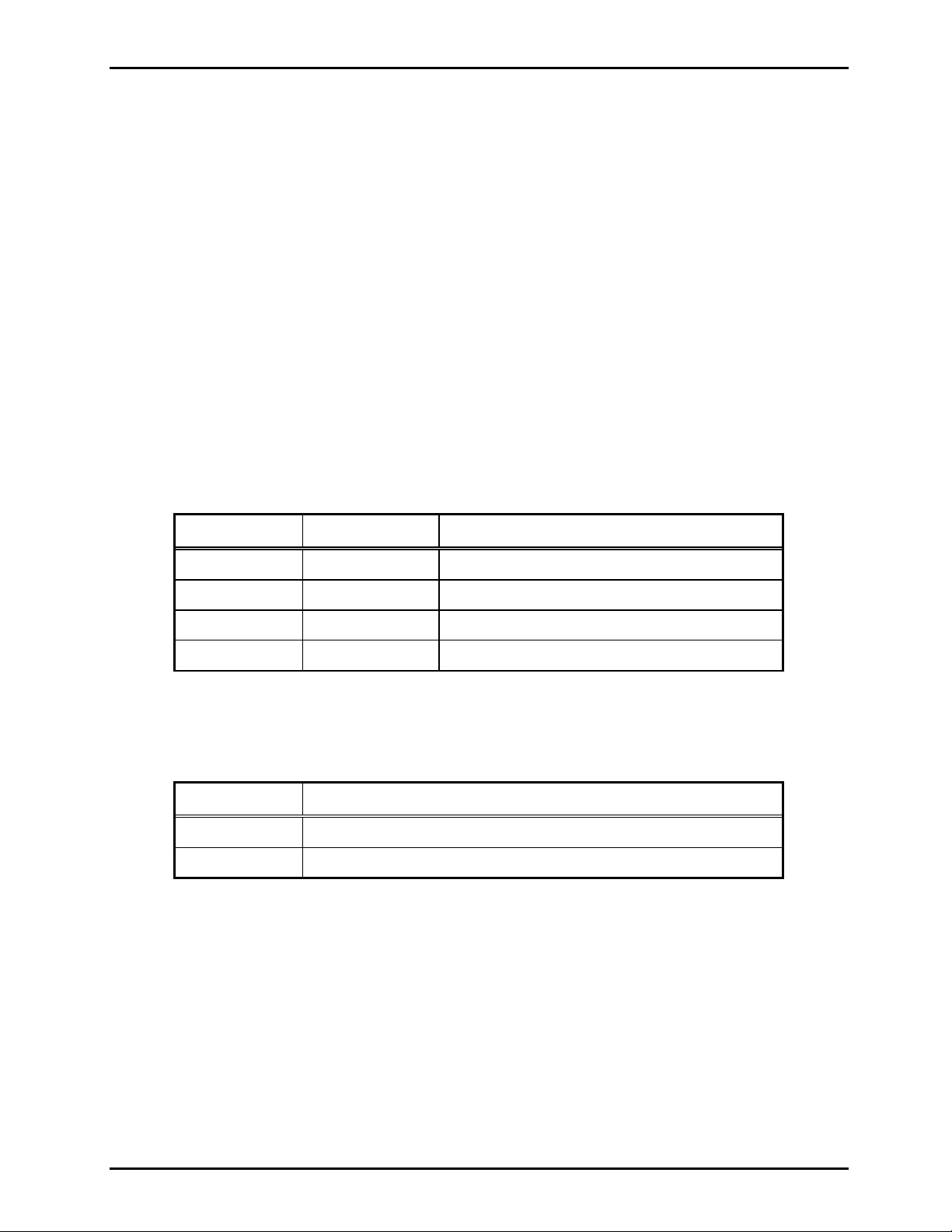

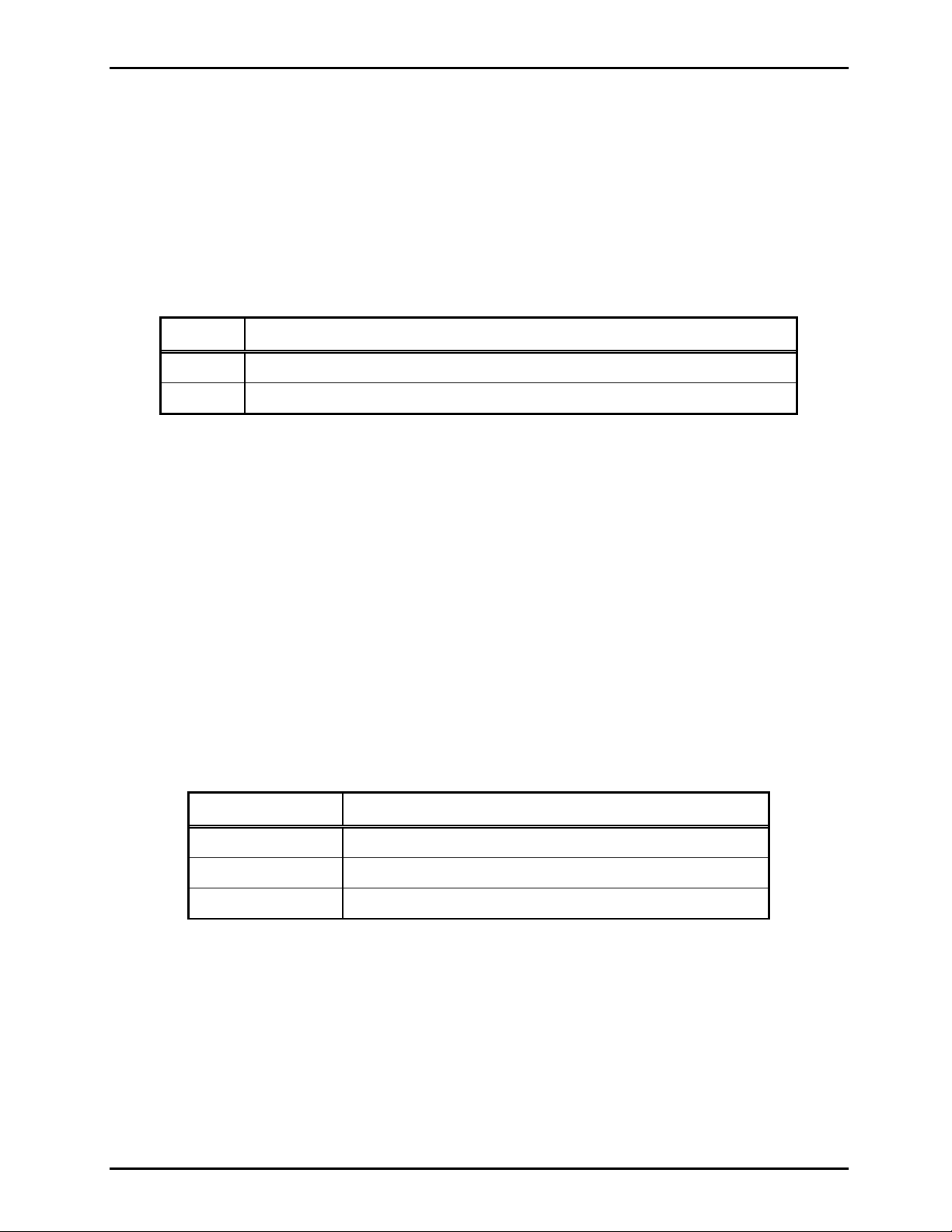

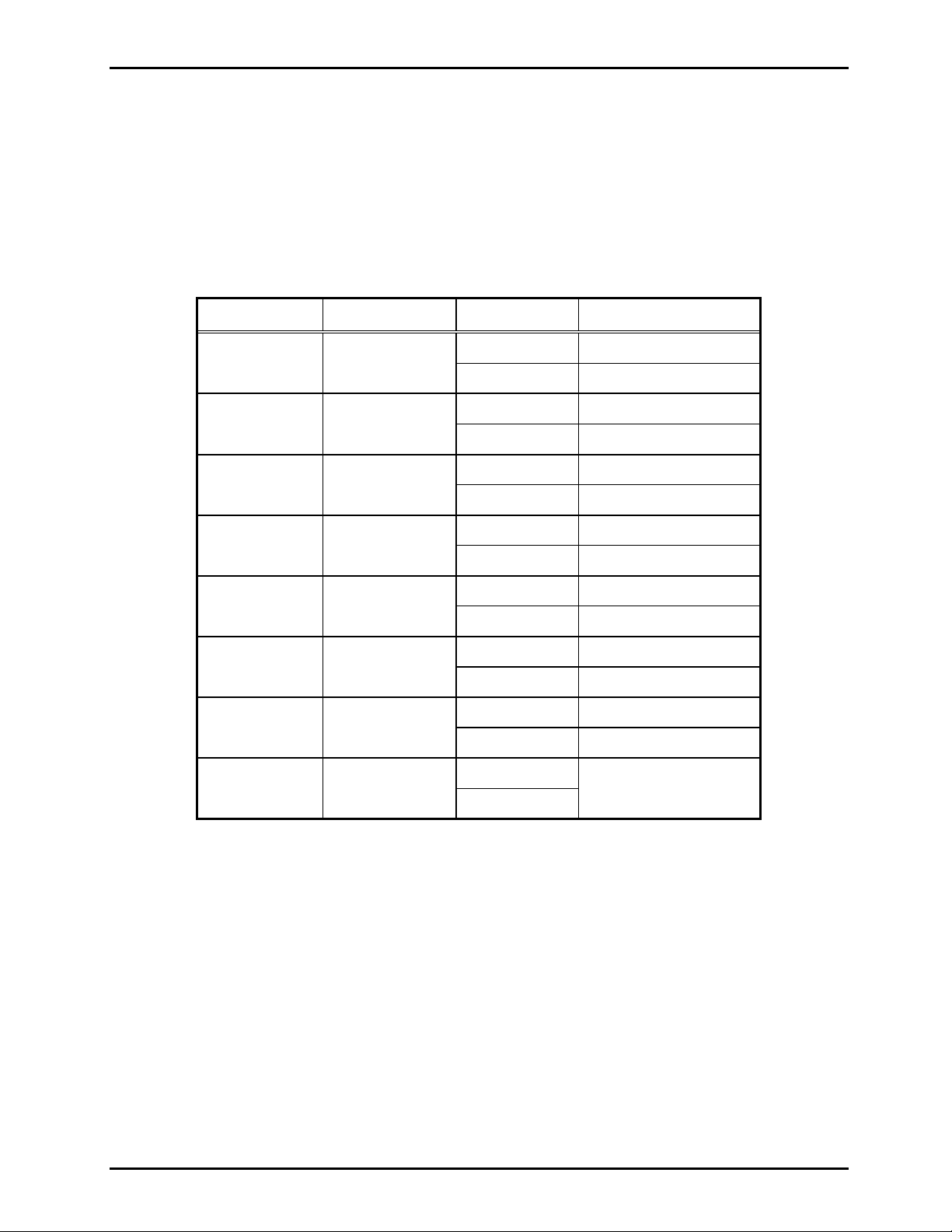

Table 1. Transmission Direction Hold Time Settings on Main PCBA

SW2-5 SW2-6 Transmission Direction Hold Time

Open* Open * 1280 milliseconds

Closed Open 640 milliseconds

Open Closed 160 milliseconds

Closed Closed 40 milliseconds

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Table 2. Peak Voltage Level Detection Threshold on Main PCBA

SW2-7 Peak Voltage Level Detection Threshold

Open* −12 dB relative to nominal

Closed −24 dB relative to nominal

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 10

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 8 of 56

M

Page Line Audio Monitoring Output

The Model LE200-RM provides a balanced 600-ohm audio output for monitoring audio on both the local

and remote page lines. LE200-RM mixes the local and remote page line audio and routes it to the 600ohm audio output terminals. This audio can be sent to any external audio device (recorder, radio

transmitter, amplifier, etc.) with an input impedance equal to or greater than 600 ohms. The audio output

gain is adjustable using DIP switch SW3 positions 5–8 on the Main PCBA. Refer to Figure 6 for the

location of switch SW3 on the Main PCBA and Table 3 below for setting options.

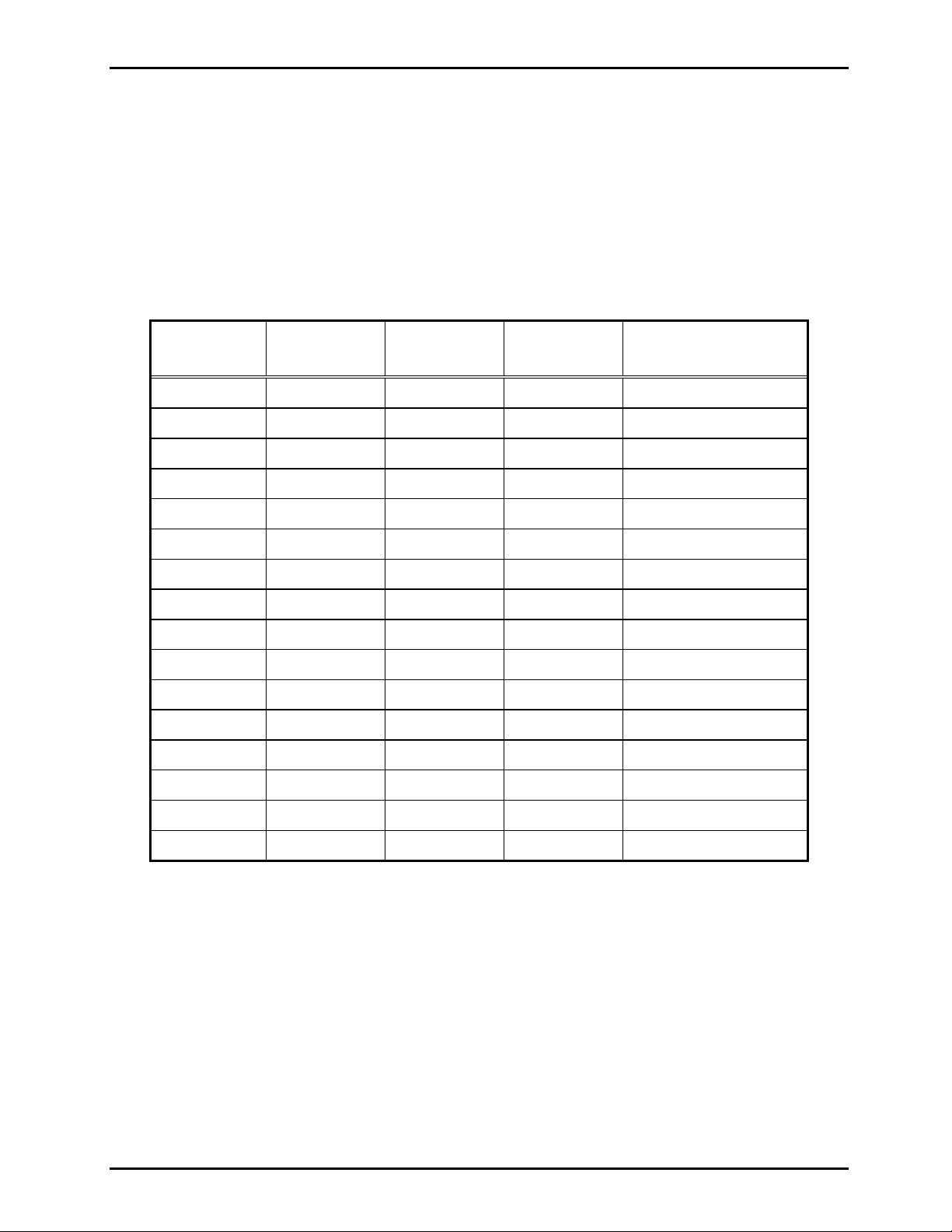

Table 3. Page Line Monitor Output Gain Setting on Main PCBA

SW3-5

SW3-6

SW3-7

SW3-8

Monitor Output

Gain

Open* Open* Open* Open* 0 dB

Closed Open Open Open −30 dB

Open Closed Open Open −27 dB

Closed Closed Open Open −24 dB

Open Open Closed Open −21 dB

Closed Open Closed Open −18 dB

Open Closed Closed Open −15 dB

Closed Closed Closed Open −12 dB

Open Open Open Closed −9 dB

Closed Open Open Closed −6 dB

Open Closed Open Closed −3 dB

Closed Closed Open Closed 0 dB

Open Open Closed Closed +3 dB

Closed Open Closed Closed +6 dB

Open Closed Closed Closed +9 dB

Closed Closed Closed Closed +12 dB

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 11

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 9 of 56

M

Page Line Audio Detect Output Contact

The Model LE200-RM provides a contact closure output that activates whenever audio is detected on the

page line. The contact can be set to close when audio is detected at the local page line, the remote page

line, or both. Typically this contact is used in conjunction with the Page Line Audio Monitoring Output to

provide a control contact to external devices or systems when page line audio is present. The contact

remains active for 1 second after the audio is no longer detected. DIP switch SW5 positions 6 and 7

enables or disables the output contact. Refer to Figure 6 for the location of switch SW5 on the Main

PCBA and Table 4 below for setting options.

Table 4. Page Line Audio Detect Contact Main PCBA

SW5-6 SW5-7 Audio Detect Contact Operati on

Closed Closed Disabled

Open Closed Local page line audio activates the contact

Closed Open Remote page line audio activates the contact

Open* Open* Both local and remote page line audio activates the contact

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Page Line FSK Data Transmission (SmartSeries System s)

A pair of Model LE200-RM Line Extenders re-generates the FSK data transmission between two

SmartSeries Page/Party

SmartSeries Page/Party

both Line Extenders must have this feature enabled by setting DIP switch SW5 position 1. Refer to Figure

6 for the location of switch SW5 on the Main PCBA and Table 5 below for setting options.

SW5-1 Page Line FSK Transmission

Open* FSK data is disabled.

Closed FSK data is enabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

OTE: FSK operation and VLC operation (described below) cannot be enabled at the same time.

N

FSK operation is only used with SmartSeries systems.

VLC operation is only used within NON-SmartSeries systems. If both VLC and FSK are enabled at

the same time, neither feature will function correctly.

®

system cables. FSK data transmission occurs on the page line allowing

®

stations to communicate with the system control cabinet. For proper operation,

Table 5. Page Line FSK Transmission on Main PCBA

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 12

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 10 of 56

M

Page Line 50 kHz VLC Transmission

A pair of Model LE200-RM Line Extenders re-generates the 50 kHz VLC control signal between two

Page/Party

speaker volume of Page/Party

on/off control functions on some Page/Party

®

system cables. 50 kHz VLC signaling occurs on the page line and is typically used to alter the

®

stations equipped VLC receivers. VLC signals may also be used for other

®

systems. For proper operation, both Line Extenders must

have this feature enabled by setting DIP switch SW5 position 2. Refer to Refer to Figure 6 for the location

of switch SW5 on the Main PCBA and Table 6 below for setting options.

Table 6. Page Line 50 kHz VLC Transmission Setting on Main PCBA

SW5-2 Page Line 50 kHz VLC Transmission

Open* 50 kHz VLC is disabled.

Closed 50 kHz VLC is enabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

OTE: FSK operation and VLC operation (described above) cannot be enabled at the same time.

N

FSK operation is only used with SmartSeries systems.

VLC operation is only used within NON-SmartSeries systems. If both VLC and FSK are enabled at

the same time, neither feature will function correctly.

Page Line Ground Fault Detection

The Model LE200-RM Line Extenders provide page line ground fault detection on the local Page/Party®

system cable. If multiple LE200-RMs are connected to the same Page/Party

one page line ground fault detector may be enabled. A shorting clip setting at header P5 on the Main

PCBA enables the page line ground fault detection. Refer to Figure 6 for the location of header P5 on the

Main PCBA and Table 7 below for setting options:

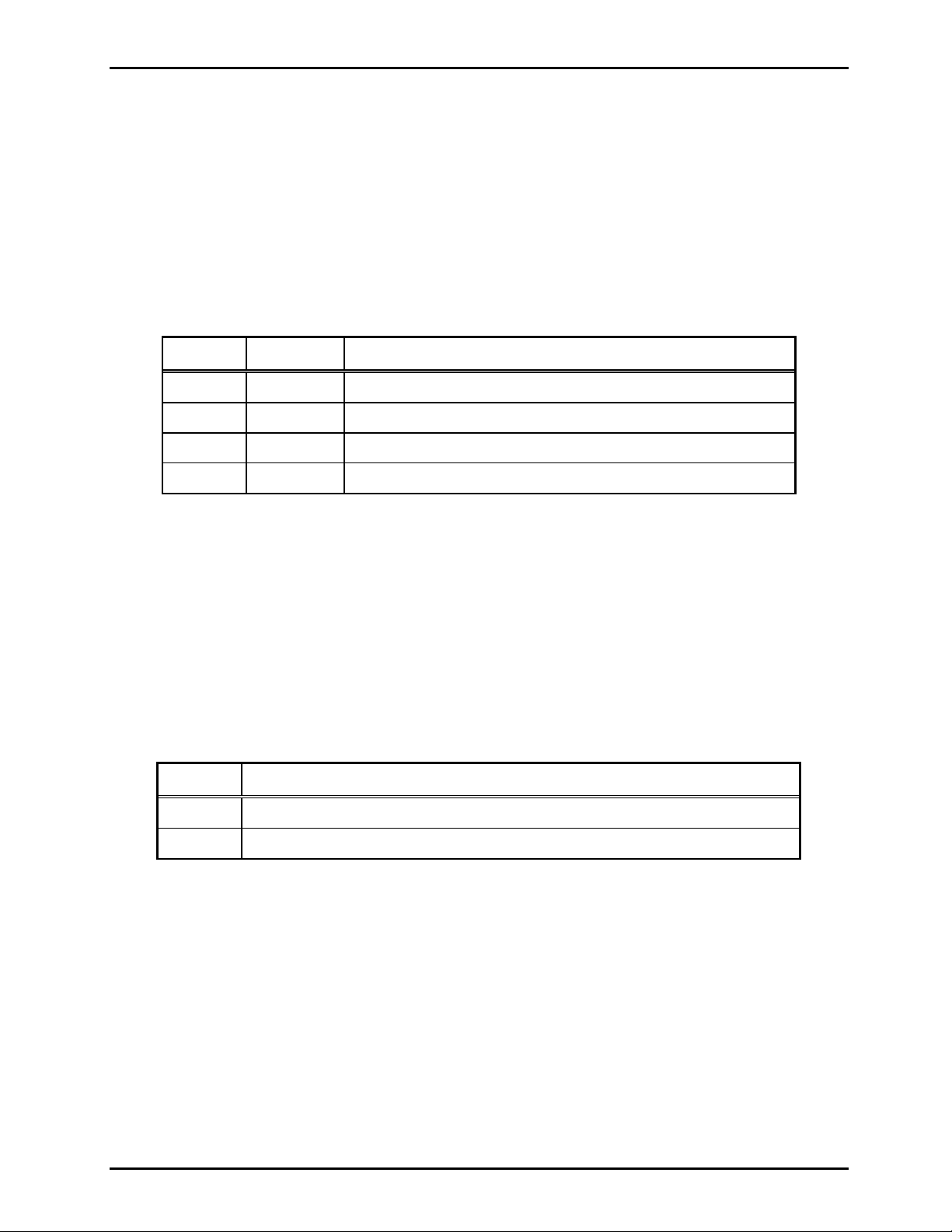

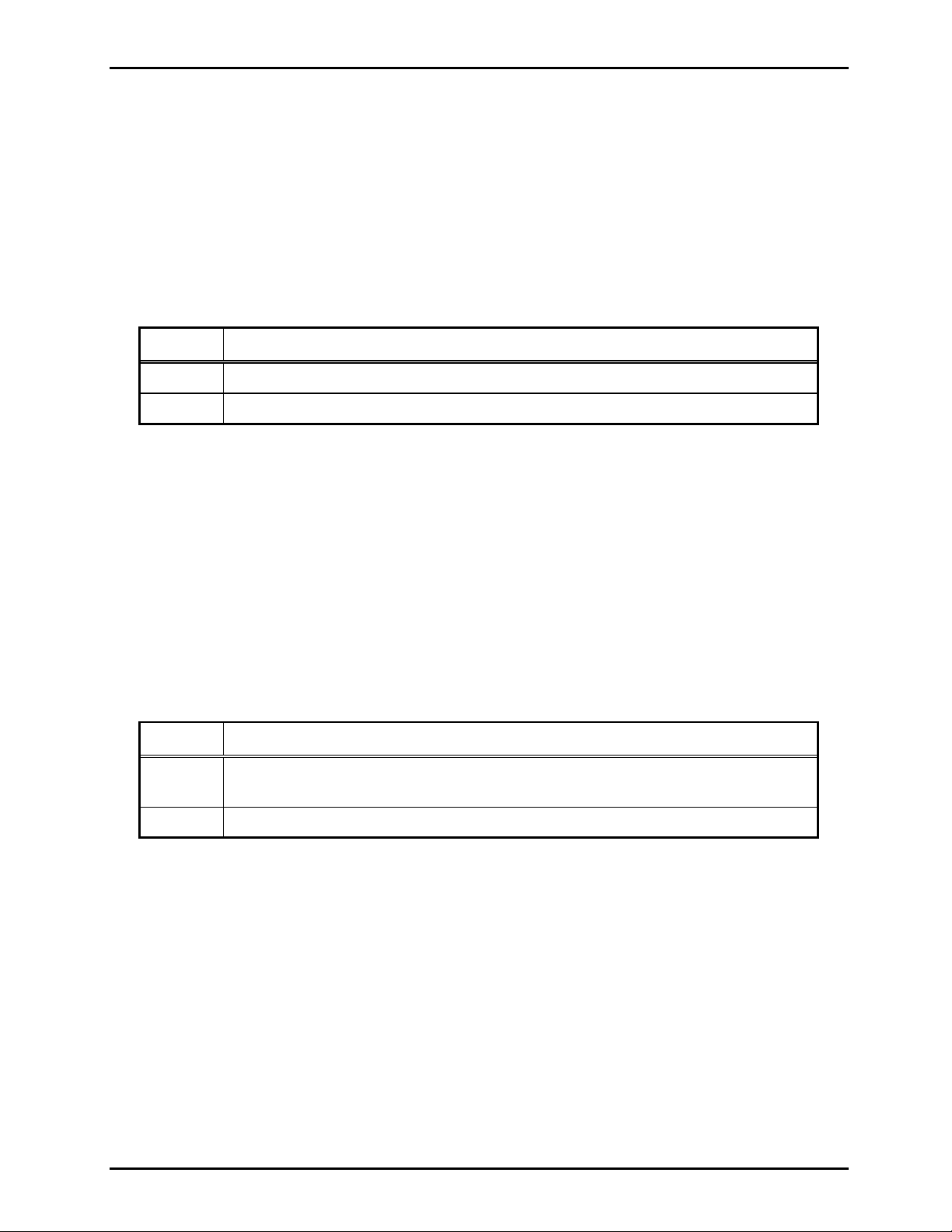

Table 7. Page Line Ground Fault Detection Setting on Main PCBA

P5 Shorting Clip Page Line Ground Fault Detection

Pins 1–2* Page line ground fault detection is disabled.

Pins 2–3 Page line ground fault detection is enabled.

Removed Page line ground fault detection is disabled.

NOTES:

1. If connecting an LE200-RM to the same system cable segment as an ADVANCE Page/Party

Interface (PPI) card, disable the LE200-RM page line ground fault detector. The PPI card contains the

ground fault detector. If both ground fault circuits are enabled simultaneously, intermittent

SmartSeries FSK data errors will occur between the PPI card and SmartSeries stations.

2. Changes to this parameter take effect without cycling power.

3. *Indicates default position.

®

system cable segment, only

®

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 13

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 11 of 56

M

Page Line Ground Fault Re-generation

When a ground fault is detected at a remote LE200-RM Line Extender, the ground fault can be duplicated

on the local Page/Party

®

system cable. DIP switch SW5 position 3 enables regeneration of the ground

fault. Refer to Figure 6 for the location of switch SW5 on the Main PCBA and Table 8 below for setting

options.

Table 8. Page Line Ground Fault Regeneration Setting on Main PCBA

SW5-3 Page Line Groun d Fault Regeneration

Open* Disabled - Page line ground faults detected on the remote system cable are NOT

regenerated on the local system cable.

Closed Enabled - Page line ground faults detected on the remote system cable are regenerated on

the local system cable.

NOTES:

1. The ground fault regeneration feature is used in SmartSeries systems to allow a ground fault on the

remote cable segment to be detected by the system control cabinet. Disable this feature if the Line

Extender is not installed in this type system.

2. Changes to this parameter take effect without cycling power.

3. *Indicates default position.

Page Line Ground Fault Output Contact

The Model LE200-RM provides a relay contact that activates whenever a ground fault is detected on the

local page line, remote page line or both the page lines. The ground fault detection feature (described

above) must be enabled. The contact output can be used to activate an external device or system which

annunciates the fault condition. The DIP switch SW5 positions 4 and 5 configure which page line ground

faults activate this contact. Refer to Figure 6 for the location of switch SW5 on the Main PCBA and Table

9 below for setting options.

Table 9. Page Line Ground Fault Contact Setting on Main PCBA

SW5-4 SW5-5 Page Line Ground Fault Contact

Closed Closed Disabled

Closed Open Remote page line ground fault activates the contact.

Open Closed Local page line ground fault activates the contact.

Open* Open* Both Local and Remote page line ground faults activate the contact.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 14

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 12 of 56

M

Party Line Audio Transmission

A pair of Model LE200-RM Line Extenders provides full duplex party line audio between two Page/Party®

system cables, for party lines 1–5. During on-hook conditions of the party lines (meaning no handset

stations are in use), the LE200-RM will mute the local party line analog circuits. If it is necessary to have

party line audio enabled even when no stations are off-hook, DIP switch SW6-3 may be closed to disable

this muting feature. This switch affects the on-hook muting function of all five party lines simultaneously.

Refer to Figure 6 for the location of switch SW6 on the Main PCBA and Table 10 below for setting

options.

Table 10. Party Line On-Hook Muting Setting on Main PCBA

SW6-3 Party Line On-H ook Muting

Open* Enabled – local party lines are muted when no handset stations are in-use.

Closed Disabled – party line audio is never muted.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Party Line Off-Hook Regeneration

When an off-hook handset station is detected, the LE200-RM can transmit the off-hook condition to

remote Line Extenders so that it is duplicated on the remote Page/Party

feature is used in systems that contain a telephone interface device so that the caller is transferred to the

party line when a handset station answers the call. DIP switch SW6 position 2 is used to enable this

feature. This switch affects the off-hook regeneration function of all five party lines. Refer to Figure 6 for

the location SW6 on the Main PCBA and the Table 11 below for setting options.

Table 11. Off-Hook Regeneration on Main PCBA

SW6-2 Off-Hook Regeneration Setting

Open* Enabled – an off hook condition on the local party line is regenerated at the

remote Line Extender.

Closed Disabled

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

®

system cable. Typically this

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 15

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 13 of 56

M

Party Line Off-Hook Detection

The Model LE200-RM Line Extenders provide off-hook detection on the local Page/Party® system cable

for party lines 1 through 5. An off-hook condition means a handset station is in use. If multiple Line

Extenders are connected to the same Page/Party

enabled. If connecting an LE200-RM to the same system cable segment as an ADVANCE Page/Party

Interface (PPI) card, disable the LE200-RM off-hook detection for party lines 1 and 2. The PPI card

contains off-hook detection for party lines 1 and 2.

Several shorting clips (P6–P15) are used to enable the off-hook detection feature on party line 1 through 5.

Two shorting clips are associated with each party line and must be set to the same position for proper

operation. The party lines 1–5 are configured independently. Refer to Figure 6 for the location of P6–P15

on the Main PCBA and Table 12 below for setting options.

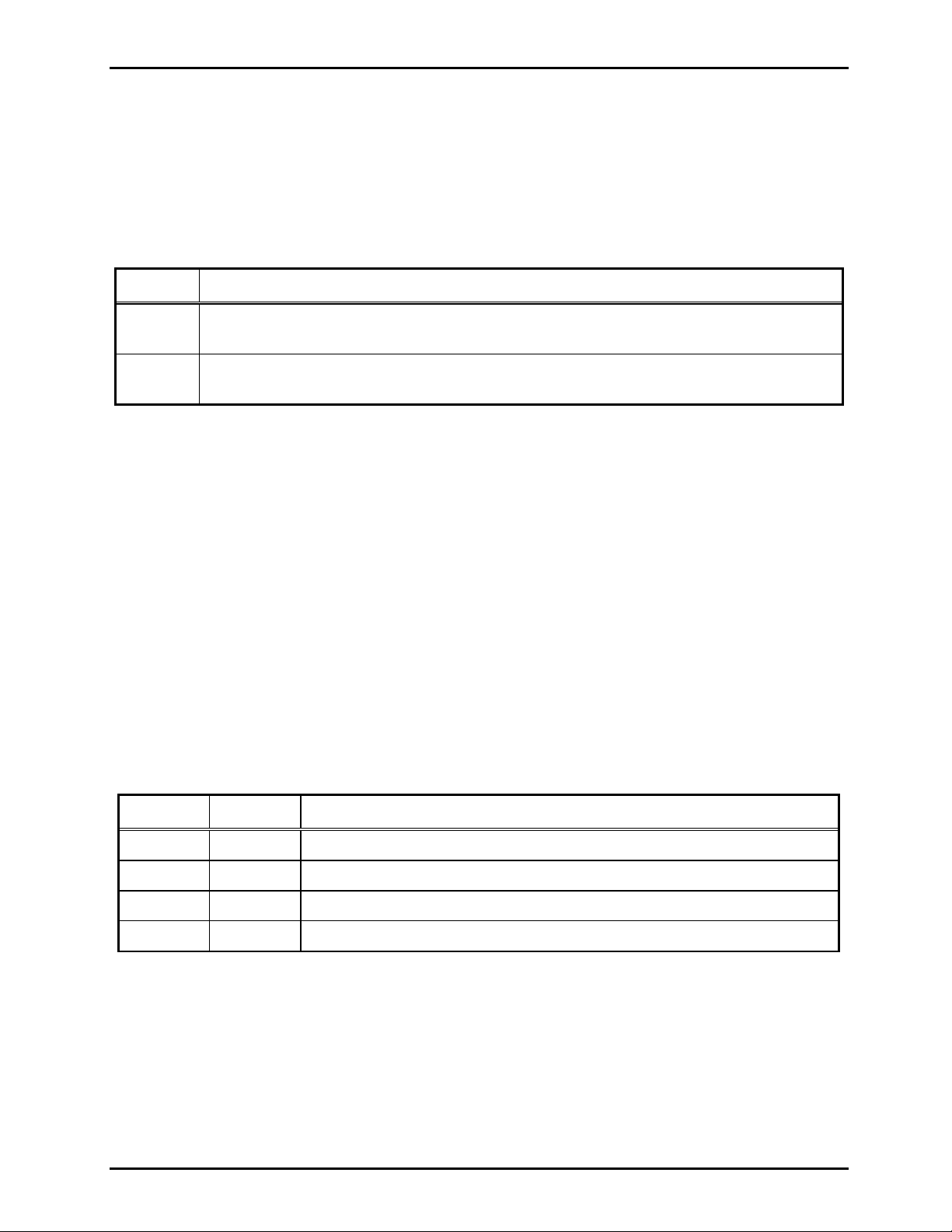

Table 12. Party Line Off-Hook Detection Setting on Main PCBA

Party Line Headers Shorting Clip Off-Hook Dete ction

®

system cable segment, only one off-hook detector can be

Pins 1–2* Disabled

NOTES:

Party Line 1 P15, P14

Party Line 2 P13, P12

Party Line 3 P11, P10

Party Line 4 P9, P8

Party Line 5 P7, P6

Pins 2–3 Enabled

Removed Disabled

Pins 1–2* Disabled

Pins 2–3 Enabled

Removed Disabled

Pins 1–2* Disabled

Pins 2–3 Enabled

Removed Disabled

Pins 1–2* Disabled

Pins 2–3 Enabled

Removed Disabled

Pins 1–2* Disabled

Pins 2–3 Enabled

Removed Disabled

1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 16

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 14 of 56

M

Audio Line Connection Relays

The Model LE200-RM has relays that disconnect the page, party lines 1–5 and the page monitoring output

connections from the Main PCBA. The disconnect feature is used for special applications such as

connection of a single party line system or other scenarios in which a particular audio line is not physically

connected to the Line Extender. DIP switch SW4 is used to control the audio line disconnect feature.

Refer to Figure 6 for the location of SW4 on the Main PCBA and Table 13 below for setting options.

Table 13. Audio Line Connection Relay Settings on Main PCBA

Audio Line Switch SW4 Setting Field Wiring

Party line 5 SW4-1

Party line 4 SW4-2

Party line 3 SW4-3

Party line 2 SW4-4

Party line 1 SW4-5

Page line SW4-6

Page monitor SW4-7

N/A SW4-8

Open Disconnected

Closed* Connected

Open Disconnected

Closed* Connected

Open Disconnected

Closed* Connected

Open Disconnected

Closed* Connected

Open Disconnected

Closed* Connected

Open Disconnected

Closed* Connected

Open Disconnected

Closed* Connected

Open

Not used

Closed*

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 17

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 15 of 56

M

Audio Line Muting

In some system configurations, the Page/Party® system cable is not connected to the Line Extender. In this

case, all audio lines (page and party lines 1–5) should be muted since they are not physically connected.

DIP switch SW6 position 4 on the Main PCBA enables this feature. If this feature is enabled, it is

unnecessary to disconnect the audio lines using the audio line relays (mentioned above). Refer to Figure 6

for the location of SW6 on the Main PCBA and Table 14 below for setting options.

Table 14. Audio Line Mute Setting on Main PCBA

SW6-4 Mute Analog Lines Setting

Open* Disabled - Party lines 1–5 and page line are operational.

Closed Enabled - Party lines 1–5 and page line are muted.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 18

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 16 of 56

M

Page/Party® Line Balance

For proper system operation, the page line and party lines 1–5 must be terminated with a resistance of

approximately 33 ohms. The Model LE200-RM provides potentiometers to set the line balance resistance

on the page line and five party lines. The line balance resistors are located on the Audio Termination

Connection Module (part of Model 12118-011 Kit) next to the page and party line terminal blocks. The

line balance resistors are adjustable or can be disabled using shorting clips P1–P7.

If connecting an LE200-RM to the same system cable segment as an ADVANCE Page/Party Interface

(PPI) card, disable the line balance for party lines 1, 2 and the page line. The PPI card provides the line

balance resistors for these audio lines. Refer to Figure 4 for the location of the jumpers and potentiometers

on the Audio Termination Connection Module and the Table 15 for setting details.

®

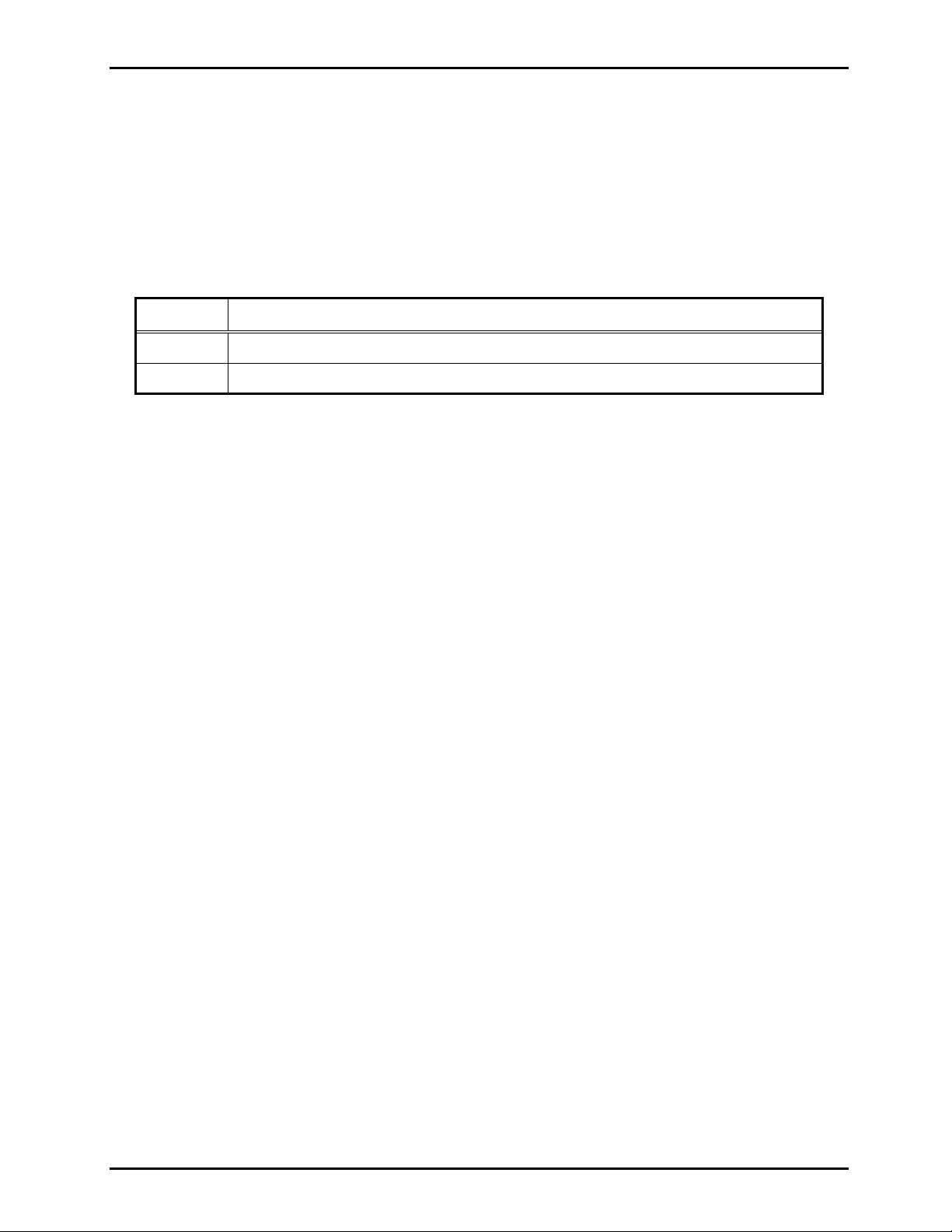

Table 15. Page/Party

Line Balance Settings on Audio Termination Connection Module

Audio Line Header Shorting Clip Line Balance

Pins 1–2* Disabled

Party line 5 P6

Removed Disabled

Pins 1–2* Disabled

Party line 4 P3

Removed Disabled

Pins 1–2* Disabled

Party line 3 P1

Removed Disabled

Pins 1–2* Disabled

Party line 2 P2

Removed Disabled

Pins 1–2* Disabled

Party line 1 P4

Adjustment

Potentiometer

R23 Pins 2–3 Enabled

R19 Pins 2–3 Enabled

R3 Pins 2–3 Enabled

R4 Pins 2–3 Enabled

R20 Pins 2–3 Enabled

Removed Disabled

Pins 1–2* Disabled

Page line P7

R24 Pins 2–3 Enabled

Removed Disabled

NOTES: *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 19

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 17 of 56

M

Contact Closure Inputs & Relay Outputs (I/0)

Five independent contact closures can be transmitted across a pair of Line Extenders meaning that an

active input contact on the local Line Extender results in the corresponding output relay contact energizing

on the remote Line Extender. Contact closures are bi-directional.

Example: Closing a switch contact across input #1 of the local Line Extender results in relay output #1

activating on the remote Line Extender and vice versa. When the input contact is removed the

corresponding output relay de-activates. No switch or jumper setting is required on the Main PCBA for

configuring the I/O feature.

OTE: Any active output contacts will deactivate if the data link is broken between the Line Extenders.

N

Echo Cancellation

Line echo (also known as electric or hybrid echo) is created by the electrical circuitry connected to a twowire (full duplex) audio system. Echo is inherent in all full-duplex audio systems and is affected by the

audio line length and line impedance mismatches. The presence of audible echoes results in undesirable

audio quality. This kind of quality degradation is inherent in network equipment and end-user phone

devices.

To minimize echo, the Model LE200-RM performs an echo cancellation sequence on party lines 1 through

5. The echo cancellation process takes approximately 15 seconds and is performed automatically one

minute after power is applied to the LE200-RM. This delay allows all power levels to stabilize prior to

performing echo cancellation.

OTE: Signal impulses are transmitted onto the party lines during the echo cancellation process. Handset

N

stations that are in use on a party line will hear the signals in the handset receiver. For troubleshooting

purposes, the 1-minute delay may be disabled by closing DIP switch SW6 position 1. Refer to Figure 6 for

the location of SW6 on the Main PCBA and Table 16 below for setting details.

Table 16. Echo Cancellation Power-On Delay Setting on Main PCBA

SW6-1 Echo Cancellation Power-On Delay

Open* 1 minute

Closed No delay

NOTES: 1. Changes to this parameter take effect when cycling power.

2. *Indicates default position.

Manual Initiation of Echo Canceling

Echo cancellation can be manually initiated as described below.

Press and release push button PB1 on the Main PCBA three times. The push button must be pressed for at

least 0.25 second and no more than 2 seconds each time. The timing requirement is meant to prevent

accidental requests. If an error is made with the push-button timing, the sequence must be repeated from

the beginning.

The LEDs on the Main PCBA will indicate the progress of the echo canceling sequence. One column of

LEDs turns on after each push button press release until the sequence is started. Once the sequence is

started, those LEDs remain on, and a countdown timer is displayed on the remaining LEDs. The LEDs

turn OFF after the echo cancellation training sequence is complete.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 20

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 18 of 56

M

Data Links between Line Extenders

The LE200-RM is equipped with two different data link types for connecting to another Line Extender.

The two data types are T1/E1 and Low Voltage Differential Signaling (LVDS). The type of data

connection(s) required is determined by the system architecture. It is possible to use both types at the

same time to achieve complex system architectures. Each data type, the intended use, and the applicable

switch settings are described below.

T1/E1 Data Link

The T1/E1 data link connection is the most common and is used when one pair of Model LE300 Line

Extenders are connected in point to point system architecture over a long distance. The T1/E1 carrier

technology uses dedicated copper cable or fiber optic cable when equipped with a T1/E1 fiber optic

modem. The distance between Line Extenders determines the type of connection needed. Copper wire

connections between the Line Extenders require a two-pair cable and will operate at a distance of up to

6000 feet using No. 22 AWG wire. For distances greater than 6000 feet, a T1/E1 fiber optic transceiver

and fiber optic cable must be used.

OTE: The Model LE200-RM is NOT designed for use with the public switched telephone network.

N

Low Voltage Differential Signaling (LVD S) Data Link

The LVDS data link connection is used to connect two or more LE200-RM Line Extenders in a “daisy

chain” fashion when the Line Extenders are located within 10 meters of each other. The LVDS data link

requires a straight-through CAT5e cable between Line Extenders. Each Line Extender contains an LVDS

data “in” port and an LVDS data “out” port. The “out” port of the first Line Extender connects to the “in”

port of the next Line Extender. This connection scheme can be used to link up to a maximum of eight Line

Extenders and is typically used when multiple Line Extenders are installed in a central location.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 21

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 19 of 56

M

Configuring the Data Links

The T1/E1 and LVDS data link parameters between Line Extenders must be configured using multiple

DIP switch settings on the Main PCBA. The following sections describe each parameter and the switch

settings.

T1/E1 Data Format Selection

The LE200-RM supports both T1 and E1data line connections between units. T1 is a digital circuit that

uses the DS-1 (Digital Signaling level 1) signaling format to transmit voice/data at 1.544 Mbps. T1 can

carry up to 24 digital channels for voice or data. E1 is the European equivalent of the T1, except E1

carries information at the rate of 2.048 Mbps. E1 is used to transmit 30 digital channels for voice or data

plus one channel for signaling, and one channel for framing and maintenance.

DIP switch SW5 position 8 on the Main PCBA selects the data link format for the digital audio

transmission between Line Extenders. Both Line Extenders must be set to the same format. Refer to

Figure 6 for the location of SW5 on the Main PCBA and Table 17 below for setting details.

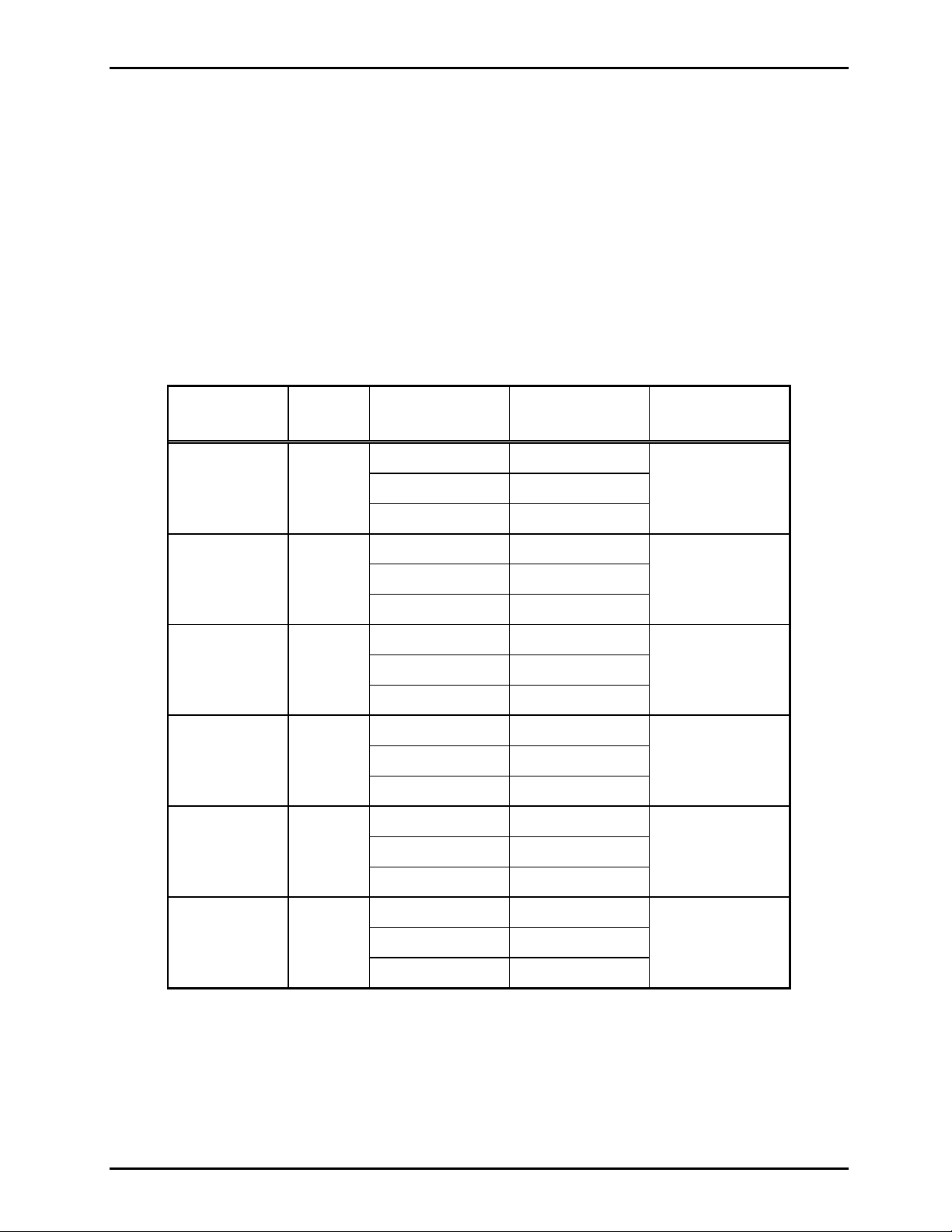

Table 17. Data Format Setting on Main PCBA

SW5-8 Format

Open* T1 Mode (1.544 Mbps, 24-channel)

Closed E1 Mode (2.048 Mbps, 32-channel)

NOTES: 1. Changes to this parameter take effect after cycling power.

2. *Indicates default position.

T1 Line Build-out Settings

This option allows the user to control the wave shape being output by the transmitter. This helps to correct

problems related to long copper cables. Improperly setting this switch will cause signal degradation. The

proper setting refers to the cable distance between two LE200-RM Line Extenders. If connecting to a fiber

optic transceiver, it refers to the copper cable distance between the LE300-RM Main PCBA and the fiber

optic transceiver and should be set to 0–133 feet (default setting). DIP switches SW2 positions 1–3 on the

Main PCBA selects line-build out parameters. Refer to Figure 6 for the location of SW2 on the Main

PCBA and Table 18 below for setting details.

Table 18. T1 Line Length Setting on Main PCBA

SW2-1 SW2-2 SW2-3 T1 Line Length

Open (up)* Open (up)* Open (up)* 0 to 133 feet

Closed (down) Open (up) Open (up) 133 to 266 feet

Open (up) Closed (down) Open (up) 266 to 399 feet

Closed (down) Closed (down) Open (up) 399 to 533 feet

Open (up) Open (up) Closed (down) 533 to 655 feet

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

3. These switches have no effect in E1 mode.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 22

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 20 of 56

M

T1/E1 Receiver Equalization Gain Limit

This option allows the user to compensate for diminishing signal intensity over the data line by adjusting

the sensitivity of the receiver. By setting the Receive Equalizer Gain Limit, very long copper lines can be

utilized. DIP switch SW2 position 4 on the Main PCBA selects the parameter. Refer to Figure 6 for the

location of SW2 on the Main PCBA and Table 19 below for setting details.

Table 19. Receive Equalizer Gain Limit Setting on Main PCBA

SW2-4

Receive Equalization Gain Limit

T1 Mode E1 Mode

Open (up)* −36 dB (long haul) −12 dB (short haul)

Closed (down) −15 dB (limited long haul) −43 dB (long haul)

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

T1/E1 Clock Source

For each pair of Line Extenders, one Line Extender must be the master clock source. The other unit must

be the slave. The slave unit receives the clock from the master. DIP switch SW3 positions 1 and 2 on the

Main PCBA selects T1/E1 clock parameters. Refer to Figure 6 for the location of SW3 on the Main PCBA

and Table 20 below for setting details.

Table 20. Master Clock Setting on Main PCBA

SW3-1 SW3-2 Clock Source

Open* Open* LE200-RM is the T1/E1 Master (generates the T1/E1 clock).

Closed Closed LE200-RM is the T1/E1 Slave (receives the T1/E1 clock from master).

NOTES: 1. Changes to this parameter take effect after cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 23

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 21 of 56

M

T1/E1 Data Line Grounding

T1/E1 data line can be floating or grounded. When floating, neither conductor of the data line cable pair is

connected to ground. Headers P20 and P21 control the grounding of the T1/E1 lines. Grounding the

T1/E1 lines may reduce emissions if it becomes an installation concern. Refer to Figure 6 for the location

of P20 and P21 on the Main PCBA and Table 21 below for setting details.

Table 21. T1/E1 Data Line Grounding setting on Main PCBA

Header Shorting Cl i p Grounding Condition

P20 1–2* T1/E1 Rx line - floating

2–3 T1/E1 Rx line - grounded

Removed T1/E1 Rx line - floating

P21 1–2* T1/E1 Tx line - floating

2–3 T1/E1 Tx line - grounded

Removed T1/E1 Tx line - floating

*Indicates default position.

NOTE

LVDS Data Link Settings

Do not ground the T1/E1 lines at both ends. Doing so will create a ground loop.

The LVDS “in” port is disabled unless it is receiving a signal from LVDS “out” from another Line

Extender. Switch SW3 position 3 enables the LVDS “in” port. Refer to Figure 6 for the location of SW3

on the Main PCBA and Table 22 below for setting details.

Table 22. LVDS “IN” Setting on Main PCBA

SW3-3 Enable/Disable LVDS “IN” Port

Open* The LVDS “in” port is disabled (no cable connection from another LE200-RM.)

Closed The LVDS “in” port is enabled (cable is connected to LVDS “out” cable connection

from anther to LVDS.

NOTES: 1. Changes to this parameter take effect after cycling power.

2. *Indicates default position.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 24

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 22 of 56

M

The LVDS “out” port is disabled unless the Line Extender is transmitting an LVDS signal to another Line

Extender’s LVDS “in” port. Switch SW3 position 4 enables the LVDS “out” port. Refer to Figure 6 for

the location of SW3 on the Main PCBA and Table 23 below for setting details.

Table 23. LVDS “OUT” Setting on Main PCBA

SW3-4 Enable/Disable LVDS “OUT” Port

Open* LVDS “out” is disabled.

Closed LVDS “out” is enabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

NOTE

Do not connect LVDS “in” to LVDS “out” on the same Model LE200-RM. Doing so

creates a feedback path that usually results in (extremely loud) oscillations on the page line, all party lines,

and possibly the contact outputs.

LVDS Port Indicators

Each LVDS port has two LEDs. The green LED is ON when the LE200-RM detects a signal connection

from the other LE200-RM connected to that port. The yellow/orange LED is ON when the LE200-RM

detects page line data (SmartSeries FSK or 50 kHz VLC) on the LVDS port.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 25

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 23 of 56

M

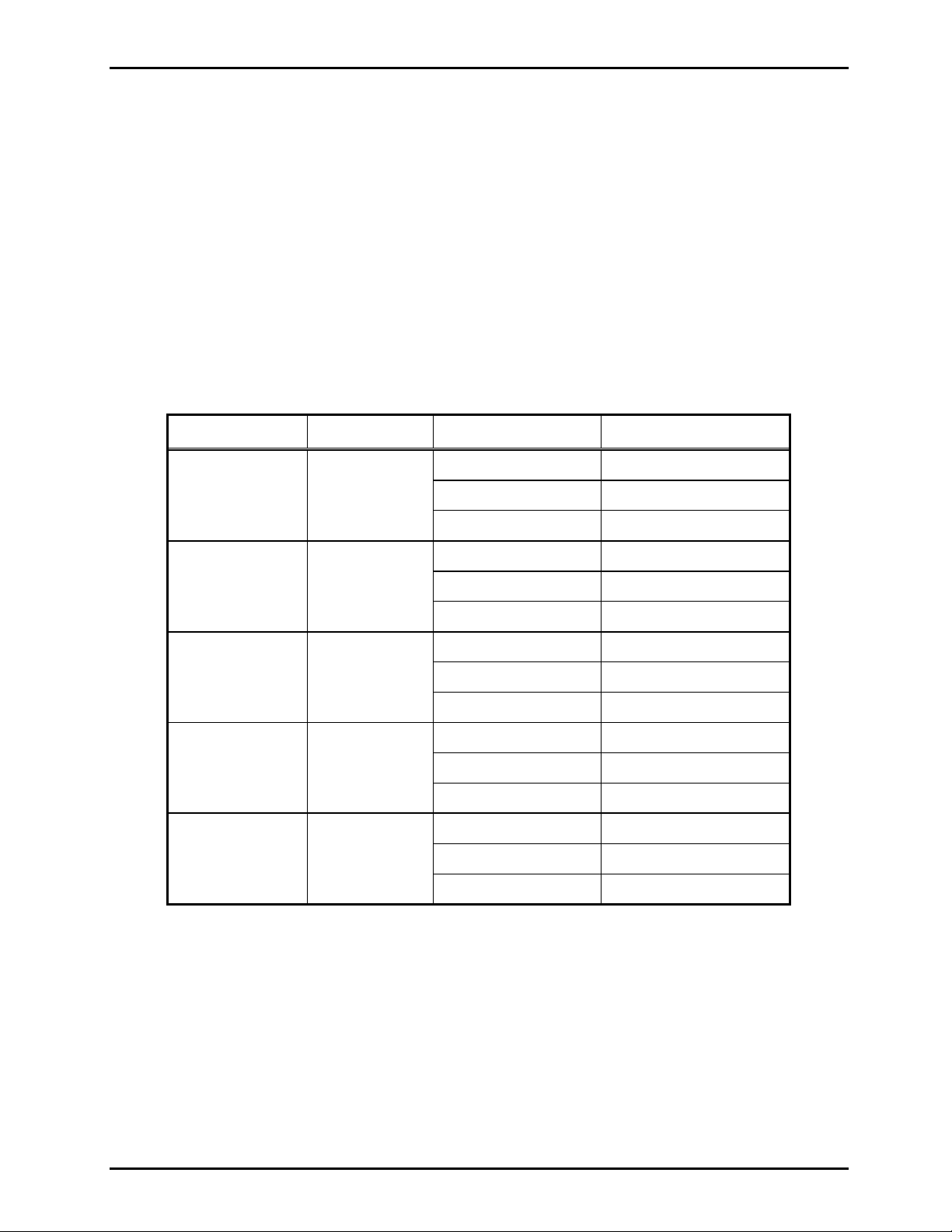

Typical Data Link Settings

The following section shows the most common Line Extender connection schemes and the expected T1/E1

and LVDS data line parameters for each. Consult the applicable tables above to determine the correct

switch settings. Consult GAI-Tronics for technical support of connection schemes not shown in this

manual.

Point-to-Point Page/Party® System Connection

Figure 7. Point-to-Point Page/Party

®

System Connection

®

Table 24. Point-to-Point Page/Party

Parameter Switch Configuration Description

System Connection Table

T1 Line Length SW2 Determined by installation distance between LE200-RMs.

T1/E1 Clock Source SW3-1

SW3-2

Unit A is the master clock source:

SW3-1 (open) SW3-2 (open)

Unit B is the slave and uses the T1/E1 clock from Unit A:

SW3-1 (closed) SW3-2 (closed)

LVDS Clock Source SW3-3

SW3-4

Not used - disable both LVDS “in” and “LVDS out”:

SW3-3 (open) SW3-4 (open)

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 26

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 24 of 56

M

Point to Multi-point Page/Party® System Connection

Figure 8. Point to Multi-point Page/Party

®

System Connection

Table 25. Point to Multi-point Page/Party

Parameter Switch Configuration Description

®

System Connection Table

T1 Line Length SW2 Determined by installation distance between each pair of Line Extenders:

A to D

B to E

C to F

T1/E1 Clock

Source

SW3-1

SW3-2

Units A, B, and C are the master T1/E1 clock sources:

SW3-1 (open) SW3-2 (open)

Unit D is a slave and uses the T1/E1 clock from Unit A:

SW3-1 (closed) SW3-2 (closed)

Unit E is a slave and uses the T1/E1 clock from Unit B:

SW3-1 (closed) SW3-2 (closed)

Unit F is a slave and uses the T1/E1 clock from Unit C:

SW3-1 (closed) SW3-2 (closed)

LVDS Data

Line

SW3-3

SW3-4

LVDS data link is used between units A, B and C.

Unit A - “LVDS in” disabled, “LVDS out” enabled:

SW3-3 (open) SW3-4 (closed)

Unit B - “LVDS in” enabled, “LVDS out” enabled:

SW3-3 (closed) SW3-4 (closed)

Unit C - “LVDS in ” enabled, “LVDS out” disabled:

SW3-3 (closed) SW3-4 (open)

Mute Analog

Lines

SW6-4 Units B and C are muted since there is not a Page/Party® cable connected:

SW6-4 (closed)

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 27

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 25 of 56

M

Series Connection of Page/Party® System

Figure 9. Series Connection of Page/Party

®

System

Table 26. Series Connection of Page/Party

Parameter Switch Configuration Description

®

System Table

T1 Line Length SW2 Determined by installation distance between each pair of Line Extenders:

A to B

C to D

T1/E1 Clock

Source

SW3-1

SW3-2

Units A and C are the master T1/E1 clock sources:

SW3-1 (open) SW3-2 (open)

Unit B is the slave and uses the T1/E1 clock from Unit A:

SW3-1 (closed) SW3-2 (closed)

Unit D is the slave and uses the T1/E1 clock from Unit C:

SW3-1 (closed) SW3-2 (closed)

LVDS Clock

Source

SW3-3

SW3-4

LVDS clock is used between units B and C:

Unit B - “in” disabled, “out” enabled:

SW3-3 (open) SW3-4 (closed)

Unit C - “in” enabled, “out” disabled:

SW3-3 (closed) SW3-4 (open)

Mute Analog

Lines

SW6-4 Unit C is muted since there is not a Page/Party® cable connected:

SW6-4 (closed)

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 28

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 26 of 56

M

Rules for Interconnecting More than Two Model LE200-RMs

When connecting more than two Model LE200-RMs together, these rules must be followed.

A maximum of two Model LE200-RM pairs can be connected in series when the series connections

are made using Page/Party

®

cable as shown below.

Figure 10. Maximum Series Connections

When the Model LE200-RMs are connected in series, a problem can arise when training the echo

cancellation. If more than one Model LE200-RM is training echo cancellation on a signal line at the

same time, then none of them will train echo cancellation properly. To prevent this, power each Line

Extender one at a time. Wait for the echo cancellation to complete on the first Line Extender before

powering the second.

A maximum of eight pairs of Model LE200-RMs can be connected in parallel. Parallel connections

must be made using the LVDS link and the T1/E1 link as shown below.

Figure 11. Maximum Parallel Connections

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 29

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 27 of 56

M

A maximum of 16 Model LE200-RMs can be connected within a single zone or Page/Party

®

subsystem.

®

Avoid having more than one Model LE200-RM connected to a particular Page/Party

cable. Instead,

use the LVDS link whenever possible.

Line extenders can NOT be wired in a loop architecture for redundant connections as shown below:

Figure 12. Invalid Loop Connection of Page/Party

®

Systems

All contact input states are ORed together to determine a contact output state.

All remote page line audio detected states are ORed together to determine the state of the page line

audio detected relay contact output.

All remote page line ground fault states are ORed together to determine the state of the page line

ground fault relay contact output.

When enabled, 50 kHz VLC signal on any page line is transmitted to all page lines.

SmartSeries FSK data on any page line is transmitted to all page lines.

Manual retraining of echo cancellation at one Model LE200-RM also requests it at all digitally

interconnected Model LE200-RMs.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 30

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 28 of 56

M

Installation

ATTENTION

Installation should be performed by qualified service personnel only in

accordance with the National Electric al Code or applicable local codes.

Mounting

The Model LE200-RM Rack-Mount Line Extender can be placed on a table or desk, or it can be mounted

in a standard EIA 19-inch electronic equipment rack. The LE200-RM unit requires 1U (1.75 inches) in a

standard 19-inch rack. If the LE200-RM is installed in an electronic equipment rack, complete the

following steps:

1. Install the mounted brackets with the eight 8-32 3/8-inch screws provided.

2. Mount the LE200-RM into the rack using the four 10-32 3/4-inch screws provided.

Tabletop Mounting

If the Model LE200-RM is to be placed on a table or desk, install the five stabilizing feet.

Wiring

Pressure-type terminal blocks are provided on the optional Model 12118-011 and 12118-012 Connection

Module Kits for connecting the incoming field wiring. The terminal blocks can support a wire size of No.

24 AWG to 12 AWG. It is recommended that the installer crimp ferrules on the end of each wire before

inserting the wire into the terminal block to ensure a reliable termination. Wiring connections to the

connection modules are described below.

Power Connections

Connect input power of 48 V dc to P17 on the rear panel of the LE200-RM. Common must be connected

to earth ground at the power supply.

Page/Party® System Cable Connection

Connect the audio conductors (page line and party line 1–5) of the Page/Party® system cable to either P5 or

P8 on the Audio Termination Connection Module of the Model 12118-011 Kit. Each connection point is

labeled next to the terminal block as shown below.

Figure 13. Page/Party

®

Cable Terminals

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 31

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 29 of 56

M

When using GAI-Tronics 60029 Series system cable, follow the wiring color code as shown in Table 27

below:

Table 27. Color Codes for GAI-Tronics 60029 Series System Cable

Terminal

Designator

GTC System

Cable Color Code

Description

P5-1/P8-1 PAGE - L1 Red/blue

Page line audio

P5-2/P8-2 PAGE - L2 Blue/red

P5-3/P8-3 PARTY 1 - L1 Red

Party line 1 audio

P5-4/P8-4 PARTY 1 - L2 Tan/red

P5-5/P8-5 PARTY 2 - L1 Violet

Party line 2 audio

P5-6/P8-6 PARTY 2 - L2 Tan/violet

P5-7/P8-7 PARTY 3 - L1 Blue

Party line 3 audio

P5-8/P8-8 PARTY 3 - L2 Tan/blue

P5-9/P8-9 PARTY 4 - L1 Brown

Party line 4 audio

P5-10/P8-10 PARTY 4 - L2 Tan/brown

P5-11/P8-11 PARTY 5 - L1 Yellow

Party line 5 audio

P5-12/P8-12 PARTY 5 - L2 Tan/yellow

T1/E1 Data Connections

A two-pair cable is required for the T1/E1 data line connection between Line Extenders. Connect the

T1/E1 data cable to P19 on the Main PCBA. The transmit (TX) and receive (RX) pairs between Line

Extenders must be wired in a cross-over fashion such that the TX terminals of Line Extender #1 are

connected to the RX terminals of Line Extender #2 and vice-versa. Each data cable connection point is

labeled next to the terminal block P19 as shown below.

Figure 14. Data Line Terminals

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 32

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 30 of 56

M

Table 28. Terminal Block P19

Terminal Designator Description

P19-1 TX Ring

Data TRANSMIT wire pair

P19-2 TX Tip

P19-3 RX Ring

Data RECEIVE wire pair

P19-4 RX Tip

NOTE

Do NOT connect the TX (transmit) signal to the RX (receive) signal on the same

Model LE200-RM Line Extender. Doing so creates a feedback path that usually results in extremely

loud oscillations on the page line and the party lines. The contact outputs may also activate.

Contact Closure Input Connections

Contact inputs are typically connected to switches or mechanical relay contacts. Five inputs are available

on Model 12118-012 Kit with each input requiring two conductors. Connect the normally open contact

across the top and bottom. If using a solid state switch as the input device, observe polarity of the

connection (−) on bottom, (+) on top. Each input cable connection point is labeled next to the terminal

block TB8 and 9 as shown in Figure 15 below.

Figure 15. Input Contact Terminals

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 33

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 31 of 56

M

Table 29. TB8 and TB9

Terminal Designator Description

TB8 Input 1 (+)

Input contact 1

TB8 Input 1 (−)

TB8 Input 2 (+)

Input contact 2

TB8 Input 2 (−)

TB8 Input 3 (+)

Input contact 3

TB8 Input 3 (−)

TB9 Input 4 (+)

Input contact 4

TB9 Input 4 (−)

TB9 Input 5 (+)

Input contact 5

TB9 Input 5 (−)

Contact Closure Output Connections

Seven relay outputs are provided. Each relay output provides two contact sets and each contact set

consists of normally open (NO), common (C) and normally closed (NC) contacts. Outputs 1–5 are

activated by inputs 1–5 on the remote Line Extender. Output 6 is activated when page line audio is

detected and output 7 is activated when a page line ground fault is detected. Terminals are provided on the

Model 12118-012 Kit for each relay contact and are labeled with the relay contact description next to the

terminal block TB1-7 as shown below.

Figure 16. Relay Output Terminals

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 34

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 32 of 56

M

Table 30. Contact Closure Output Connections

Terminal Designator Description

N.C.

TB1 (Top)

TB1 (Bottom)

TB2 (Top)

TB2 (Bottom)

TB3 (Top)

Output 1 – contact #1 COM

N.O.

N.C.

Output 1 – contact #2 COM

N.O.

N.C.

Output 2 – contact #1 COM

N.O.

N.C.

Output 2 – contact #2 COM

N.O.

N.C.

Output 3 – contact #1 COM

N.O.

N.C.

TB3 (Bottom)

TB4 (Top)

TB4 (Bottom)

TB5 (Top)

Output 3 – contact #2 COM

N.O.

N.C.

Output 4 – contact #1 COM

N.O.

N.C.

Output 4 – contact #2 COM

N.O.

N.C.

Output 5 – contact #1 COM

N.O.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 35

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 33 of 56

M

Terminal Designator Description

N.C.

TB5 (Bottom)

Output 5 – contact #2 COM

N.O.

N.C.

TB6 (Top)

Page line audio – contact #1 COM

N.O.

N.C.

TB6 (Bottom)

Page line audio – contact #2 COM

N.O.

N.C.

TB7 (Top)

Page line ground fault – contact #1 COM

N.O.

N.C.

TB7 (Bottom)

Page line ground fault – contact #2 COM

N.O.

Page Line Audio Monitoring Connections

The Model LE200-RM provides a balanced 600-ohm audio output for monitoring audio on both the local

and remote page lines. Connect any external audio input device (audio recorder, radio transmitter,

amplifier, etc.) to the audio line monitoring terminals using a twisted pair cable. The input impedance of

the audio device should be 600 ohms or greater. Terminals are located at connector P16 on the Main

PCBA and are labeled as shown below.

Table 31.

Terminal Designator Description

P16-1 PG MON L2 Page line monitor audio output (L2)

P16-2 − No connection

P16-3 PG MON L1 Page line monitor audio output (L1)

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 36

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 34 of 56

M

Verifying the Proper Line Balance Resistance

For proper Line Extender operation, the line balance resistance, for both page and party lines, should be set

close to 33 ohms. This can be done by enabling and adjusting the line balance potentiometers on the

69441-xxx terminal board using an ohmmeter.

When the line balance potentiometer is enabled, it is possible to measure the selected dc resistance

directly. One side of the ohmmeter should connect to the exposed header pin on the header used to enable

or disable the line balance potentiometer. The other side of the ohmmeter should connect to the side of the

associated 15-ohm series resistor closest to the edge of the printed circuit board. Ensure the 15-ohm

resistor is part of the measurement before adjusting the potentiometer for the correct resistance. All six

circuits are symmetric and their signals have minimal overlap. If the incorrect series resistor is chosen,

then the ohmmeter should read an open circuit.

Distributing Line Balance Resistance

As an increasing length of cable is added from the Line Extender the effects of cable resistance should be

taken into consideration. The farther a Page/Party

®

station is connected to the system cable from the line

balance resistance the greater the chance deficiencies in system behavior may occur. The station farthest

away from the line balance will exhibit increased sidetone audio in the handset earpiece and will place

higher than nominal levels of audio onto the system cable. Stations receiving this audio nearby will have

louder than expected outputs. These same stations receiving audio from other stations near the line

balance resistance will have lower than expected outputs due to the line loss of the cable resistance. A

system showing these characteristics should have distributed line balancing.

For reference, if a line balance is installed at both ends of one mile of 18 gauge cable, then both line

balances should be set to nominally 46.7 ohms. The one mile of cable provides approximately 33 ohms of

resistance in each leg; the resulting series-parallel combination will result in the devices installed at both

ends seeing a line impedance of approximately 33 ohms.

SmartSeries systems utilize FSK for communication on the page line between the stations and the Line

Extender. Since FSK frequencies range between 31 kHz and 33 kHz instead of audio frequencies, the

effects of longer cable lengths will present itself sooner. The higher frequency will lend to a greater

probability that standing waves of the FSK signal will be present. The cable length, in addition to the

number of cable branches present, will combine to determine the severity of these standing waves. Severe

standing waves present on the line can cause a portion of the system devices to be unable to properly

communicate with the Line Extender giving the need for distributing the line balance resistance.

Determining the cable resistance with any accuracy in installed systems is too difficult. Fortunately, the

resistance values to be installed can be determined without using the cable resistance in the calculation, as

precise accuracy is not necessary to achieve acceptable system functionality. The resistance values

installed should always calculate to a nominal parallel resistance of 33 ohms. One of the line balance

resistances can be the resistance included on the 69441-xxx terminal board, but it is not a requirement. It

will provide a resistance up to 115 ohms determined by the position of the potentiometer. Examples of

line balance resistances that could be installed are 51║100 ohms, 68║68 ohms or 100║100║100 ohms. It

is best to install the line balance resistors as far apart from one another in cable distance as possible.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 37

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 35 of 56

M

Fiber Optic Cable Connections

Model LE200-RM can be used with an optional fiber optic interface. This consists of a chassis

(GTRFP6972-102) and either a multimode fiber transceiver (GTRFP6972-201) or a single mode fiber

transceiver (GTRFP6972-202), as shown below in Figure 17.

Figure 17. T1/E1 Fiber Optic Transceiver (top view)

Transceiver GTRFP6972-201 requires multi-mode fiber optic cable and Transceiver GTRFP6972-202

requires single-mode fiber optic cable. With either model, the fibers must be terminated with ST-type

connectors. The fiber optic cables between Line Extenders must be connected in a “cross-over” fashion

meaning the Transmit (XMIT) port of Line Extender #1 connects to the Receive (RCV) port of Line

Extender #2 and vice-versa as shown below.

Figure 18. Fiber Optic Cable Connection

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 38

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 36 of 56

M

Fiber Optic Transceiver Set-Up

The Fiber Optic Transceiver contains two DIP switches as shown below. To access the switches, the

module must be removed from the chassis. Loosen the screw and pull out the transceiver module.

Figure 19. DIP Switches on Fiber Optic Transceiver

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 39

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 37 of 56

M

These switches are factory set according to Table 32 below. It is recommended that the default

configuration (passive mode) is used for most typical applications. Passive mode allows the fiber segment

to pass data unchanged between the T1/E1 segments independent of the actual line coding (AMI, B8ZS, or

HDB3). All errors and fault conditions from one T1/E1 end will pass through the fiber to the other end as

if there were one long T1/E1 connection. Use these settings to insure proper operation of the Model

LE200-RM Line Extender.

Table 32. Factory Settings for the Fiber Optic Transceiver

Function Factory Setting

T1/E1 mode T1

Receive Equalizer Gain Limit (EGL) −30 dB (Limited Long Haul)

Line encoding AMI (passive mode)

Transmit LIU wave shape (Build-out) DSX-1 (0 to 133 feet) 0 dB CSU

Receive LIU termination Receive side 100 ohms enabled

Transmit data source Standard data

Jitter attenuator Place jitter attenuator on TX side

Select remote management Remote management disabled

Loopback selection No loopback

Monitor/boost mode No boost

NRZ selection Disable NRZ (passive mode)

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 40

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 38 of 56

M

Table 33 below outlines the functions settings for DIP switch S2:

Table 33. Function Settings for DIP Switch S2

Function Setting

T1/E1 Selection

Receive

Equalizer Gain

Limit

Line Encoding

Transmit LIU

Wave Shape

(Build-out)

S2-1: OFF; T1 mode selected ( d efau lt se tt ing)

S2-1: ON; E1 mode selected

E1

S2-2: ON; −12 dB Short Haul

S2-2: OFF; −43 dB Long Haul

T1

S2-2: ON; −36 dB Long Haul

S2-2: OFF; −30 dB Limited Long Haul (default setting)

S2-3: ON; B8ZS or T1 or HDB3 for E1

S2-3: OFF; AMI (default setting)

E1

S2-4 S2-5 S2-6

ON ON ON 75 ohms

OFF ON ON 125 ohms

ON ON OFF 75 S ohms with High Return Loss

OFF ON OFF 125 S ohms with High Return Loss

T1

S2-4 S2-5 S2-6

ON ON ON DSX-1 (0 to 133 feet) 0 dB CSU (default setting)

OFF ON ON DSX-1 (133 to 266 feet)

ON OFF ON DSX-1 (266 to 399 feet)

OFF OFF ON DSX-1 (399 to 533 feet)

ON ON OFF DSX-1 (533 to 655 feet)

OFF ON OFF −7.5 dB CSU

ON OFF OFF −15 dB CSU

OFF OFF OFF −22.5 dB CSU

S2-7: ON; S2-8: ON; Receive side termination disabled

Receive LIU

Termination

S2-7: OFF; S2-8: ON; Receive side 120 ohms enabled

S2-7: ON; S2-8: OFF; Receive side 100 ohms enabled (default set ting)

S2-7: OFF; S2-8: OFF; Receive side 75 ohms enabled

S2-9: ON; S2-10: ON; Standard data (default setting)

Transmit Data

Source

S2-9: OFF; S2-10: ON; Transmit pseudo-random bit sequence (PRBS)

S2-9: ON; S2-10: OFF; Transmit alternating ones and zeros

S2-9: OFF; S2-10: OFF; Transmit unframed all ones

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 41

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 39 of 56

M

Table 34 outlines the function settings for DIP switch S3:

Table 34. Function Settings for DIP Switch S3

Function Setting

Jitter

Attenuator

Select

Remote

Management

Loopback

Selection

Monitor/Boost

Mode

NRZ Selection

Fiber Type

S3-1: ON; Place jitter attenuator on RCV side

S3-1: OFF; Place jitter attenuator on XMT side (default setting)

S3-2: ON; Remote management enabled (only at the REMOTE end)

S3-2: OFF; Remote management disabled (only at the LOCAL end) (default setting)

S3-3: ON; S3-4: ON; None (default se tt ing)

S3-3: OFF; S3-4: ON; Local loopback

S3-3: ON; S3-4: OFF; Analog loopback

S3-3: OFF; S3-4: OFF; Remote loopback

S3-5: ON; S3-6: ON; Normal operation (No boost) (default set t ing)

S3-5: OFF; S3-6 ON; 20 dB

S3-5: ON; S3-6 OFF; 26 dB

S3-5: OFF; S3-6 OFF; 32 dB

S3-7: ON; Disable NRZ (Required for Passive Mode) (defau lt se tt ing)

S3-7: OFF; Enable NRZ (Line Terminating Mode)

S3-8: Factory configured; DO NOT CHANGE

S3-9: Factory configured; DO NOT CHANGE

S3-10: Factory configured; DO NOT CHANGE

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 42

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 40 of 56

M

Verification of Proper Operation

This section describes the LEDs and their functions. The fiber port LED RM is the only LED that should

be lit on the modules under normal operating conditions.

Table 35. Copper Port Indicators

Indicator Function

LPBK Glows green when the module is set to one of the loopback modes.

NO LNK Glows green when a link is NOT established.

Only used when the Transmit Data Source option is set to PRBS. This LED will glow

PBEO

amber when the module receives errors and will stay dark when the converter receives

a PRBS without errors.

Table 36. Fiber Optic Port Indicators

Indicator Function

NRZ Glows green when the NRZ mode is enabled.

RM

Glows green on the remote unit when remote management is enabled. Glows green on

the local unit when it has discovered a remote unit with remote management enabled.

NO LNK Glows green when a fiber link has NOT been established.

SYM

Glows amber when a 4-bit to 5-bit (4b/5b) symbol encoding error in the fiber line is

detected.

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 43

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 41 of 56

M

Summary of PC Board Connections and Settings

Table 37. Audio Line Termination Connection Module

Designator Type Function

J1 DB-25 connector Connect to J4 on Main PCBA via ribbon cable.

P1 Jumper clip Party line #3 line balance resistor (enabled/disabled)

P2 Jumper clip Party line #2 line balance resistor (enabled/disabled)

P3 Jumper clip Party line #4 line balance resistor (enabled/disabled)

P4 Jumper clip Party line #1 line balance resistor (enabled/disabled)

P6 Jumper clip Party line #5 line balance resistor (enabled/disabled

P7 Jumper clip Page line balance resistor (enabled/disabled)

P5 & P8 Terminal block Page line - Terminals 1 and 2

Party line 1 - Terminals 3 and 4

Party line 2 - Terminals 5 and 6

Party line 3 - Terminals 7 and 8

Party line 4 - Terminals 9 and 10

Party line 5 - Terminals 11 and 12

R3 Potentiometer Party line #3 line balance resistance

R4 Potentiometer Party line #2 line balance resistance

R19 Potentiometer Party line #4 line balance resistance

R20 Potentiometer Party line #1 line balance resistance

R23 Potentiometer Party line #5 line balance resistance

R24 Potentiometer Page line, line balance resistance

TB1 Terminal block Chassis ground - Terminals 1 and 2

TB2 Terminal block Chassis ground - Terminals 1 and 2

e:\standard ioms - current release\42004 i nstr. manuals\4 2004-392g.doc

09/14

Page 44

Pub. 42004-392G

ODEL LE200-RM RACK-MOUNT PAGE/PARTY® LINE EXTENDER PAGE 42 of 56

M

Table 38. Input/Output Termination Connection Module

Designator Type Function

J1 DB-25 connector Connect to J3 on Main PCBA via ribbon cable

TB1 Terminal block Field connections for contact output #1

The board’s silkscreen indicates the connections; the pin

numbers are not labeled.

TB2 Terminal block Field connections for contact output #2

The board’s silkscreen indicates the connections; the pin

numbers are not labeled.

TB3 Terminal block Field connections for contact output #3

The board’s silkscreen indicates the connections; the pin

numbers are not labeled.

TB4 Terminal block Field connections for contact output #4

The board’s silkscreen indicates the connections; the pin

numbers are not labeled.

TB5 Terminal block Field connections for contact output #5

The board’s silkscreen indicates the connections; the pin

numbers are not labeled.

TB6 Terminal block Field connections for page audio detected contact output

The board’s silkscreen indicates the connections; the pin

numbers are not labeled.

TB7 Terminal block Field connections for page ground fault contact output

The board’s silkscreen indicates the connections; the pin

numbers are not labeled.

TB8 Terminal block Field connections for contact inputs #1, #2, and #3

The board’s silkscreen indicates the connections; the pin