Page 1

Pub.: 42004-701L2F

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model LE200 Series Wall-Mount

Page/Party

®

Line Exte nders

TABLE OF C ONTENTS

Confidentiality Notice.................................................................................................................1

General Information..................................................................................................................1

Product Overview..............................................................................................................................1

System Requirements and Limitations.............................................................................................1

Features and Functions .....................................................................................................................1

Subcomponent Descriptio ns..............................................................................................................4

Enclosure.......................................................................................................................................................4

69441-xxx Audio Terminal PCBA.................................................................................................................4

69442-xxx I/O Terminal PCBA...................................................................................................................... 4

69443-xxx Main PCBA.................................................................................................................................. 4

Fiber Optic Modem Models............................................................................................................................4

+48 Volt Power Supply.......................................................................................................... ........................ 4

+12 Volt Power Supply.......................................................................................................... ........................ 4

Installation................................................................................................................................. 7

Mounting............................................................................................................................................7

Wiring ................................................................................................................................................ 8

Power Connections........................................................................................................................................ 8

Fiber Optic Cable Connections .......................................................................................................12

Operation .................................................................................................................................13

Description of Features ............................................................................................................13

Page Line Audio Transmission........................................................................................................13

Half-Duplex Operation ................................................................................................................................. 13

Training the Echo Cancellation ......................................................................................................13

Overview ....................................................................................................................... .............................. 13

Manual Initiation of Echo Canceling............................................................................................ ................ 13

Page Line Audio 600-ohm Monitor Output....................................................................................15

Page Line Audio Detected Contact Output..................................................................................... 16

Page Line 50 kHz VLC Transmission............................................................................................. 17

Page Line SmartSeries FSK Transmiss ion..................................................................................... 17

Page Line Ground Fa ult Detection and Tra nsmission ................................................................... 18

Page Line G round Fault Detected Contact Output........................................................................ 19

GAI-Tronics Corporation 400 E. Wyomissing Av e. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

Table of Contents Pub.: 42004-701L2F

MODEL LE200 PAGE/PARTY

®

LINE EXTENDER

Party Line Audio Transmission...................................................................................................... 19

Party Line Off-hook Detection and Transmission..........................................................................20

Muting Analog Lines....................................................................................................................... 21

Line Connection Relays................................................................................................................... 21

Page/Party® Line Balance................................................................................................................ 23

Contact Closure Input Transmission............................................................................................. .24

Data Link Technology used with LE200 Line Extenders............................................................... 24

T1/E1 Digital Link....................................................................................................................................... 24

Low Voltage Differential Signaling (LVDS) Data Link................................................................................ 24

Setting up th e Data Link(s)........................................................................................................................... 24

T1 Data Link Settings.......................................................................................................... ........................ 25

LVDS Data Link Settings.............................................................................................................................28

LVDS Port In dicators...................................................................................................................................28

Fiber Optic Modem Set-Up (Models LE200-FSR and LE200-FLR)..............................................29

Loopback Test Switch.................................................................................................................................. 30

Indicators..................................................................................................................................................... 30

Verification of Proper Operation .................................................................................................................. 30

Typical Clock Setting Information.................................................................................................. 31

Point-to-Point Page/Party® System Connection............................................................................................. 31

Point to Multi-point Page/Party® System Connection.................................................................................... 32

Series Connection of Page/Party® System..................................................................................................... 33

Rules for Interconnecting more than Two Model LE200s............................................................. 34

Summary of PC Board Connections and Settings....................................................................36

Frequently Asked Questions.....................................................................................................40

Changing to a LE200 from a LE100........................................................................................41

Changed Features Compared to LE100..........................................................................................41

New Features Compared to LE100................................................................................................. 41

Settings Checklist.....................................................................................................................42

Specifications................................................................................................................. ..........46

Replacement Parts........................................................................................................................... 50

Confidentiality Notice: This document c ont ains s ens it ive business and technical information w hic h is conf ident ial and propriet ary t o t he GAI - T ronic s

Corporation. The inform at ion c ont ained in t his docum ent is intended s olely for internal use by GAI-Tronics personnel, and is not to be disclosed in any form, in

whole or in part, directly or indirect ly , to any third part y.

ii

Page 3

PUB. 42004-701L2F

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

Model LE200 Series Wall-Mount

Page/Party

®

Line Exte nders

Confidentiality Notice

This manua l is provide d sole ly as an operatio nal, installation, and ma inte nance guide and conta ins

sensitive business and t e chnical informatio n tha t is confidentia l and pr opri et ary to GAI- Tronics. GAITronics retains all intellectual property and other rights in or to the information contained herein, and

such information may on ly be u sed in conn e ction with the operatio n of you r GAI-Tr onics p rodu c t or

system. This manu al may not be dis clos e d in any form, in whole or in pa rt, direct ly or i ndir ectly, to a ny

third pa r ty.

General Information

Product Overview

The Model LE200 Series Wall Mount Page/Party® Line Extenders are used in pairs to provide transparent

extension or expansion of both conventional and SmartSeries Page/Party

system by linking a local and distant Page/Party

field devices' line loading to be spread across multiple Page/Party

®

system cable. It can expa nd the system by allowing the

®

®

systems. It ca n extend the

system cables.

System Requirements and Limitations

Two electrically isolated Page/Party® or SmartSeries systems are required.

Features and Functions

The Model LE200 Series Page/Party® Line Extenders provide the following features between Page/Party®

system cables:

• Half-duplex page line audio transmission • A page line ground fault detected contact output

• A page line audio 600-ohm monitor output • One digital link using T1 or E1 technology

• A page line a udio detected contact output • Two digital links using LVDS technology

• Bi-directional page line 50 kHz VLC

transmission

• Bi-directional pa ge line Sma rtSeries FSK

transmission

• Unidirectional page line ground fault

transmission

• Bi-d irectional cont act c losure tr ansmission, for

five contact closure inputs

• Full du plex par ty line au dio trans mis sion, for all

five party lines

• Unidirectional party line off-hook transmission

GAI-Tronics Corporation 400 E. Wyomissing Av e. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 4

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 2 of 50

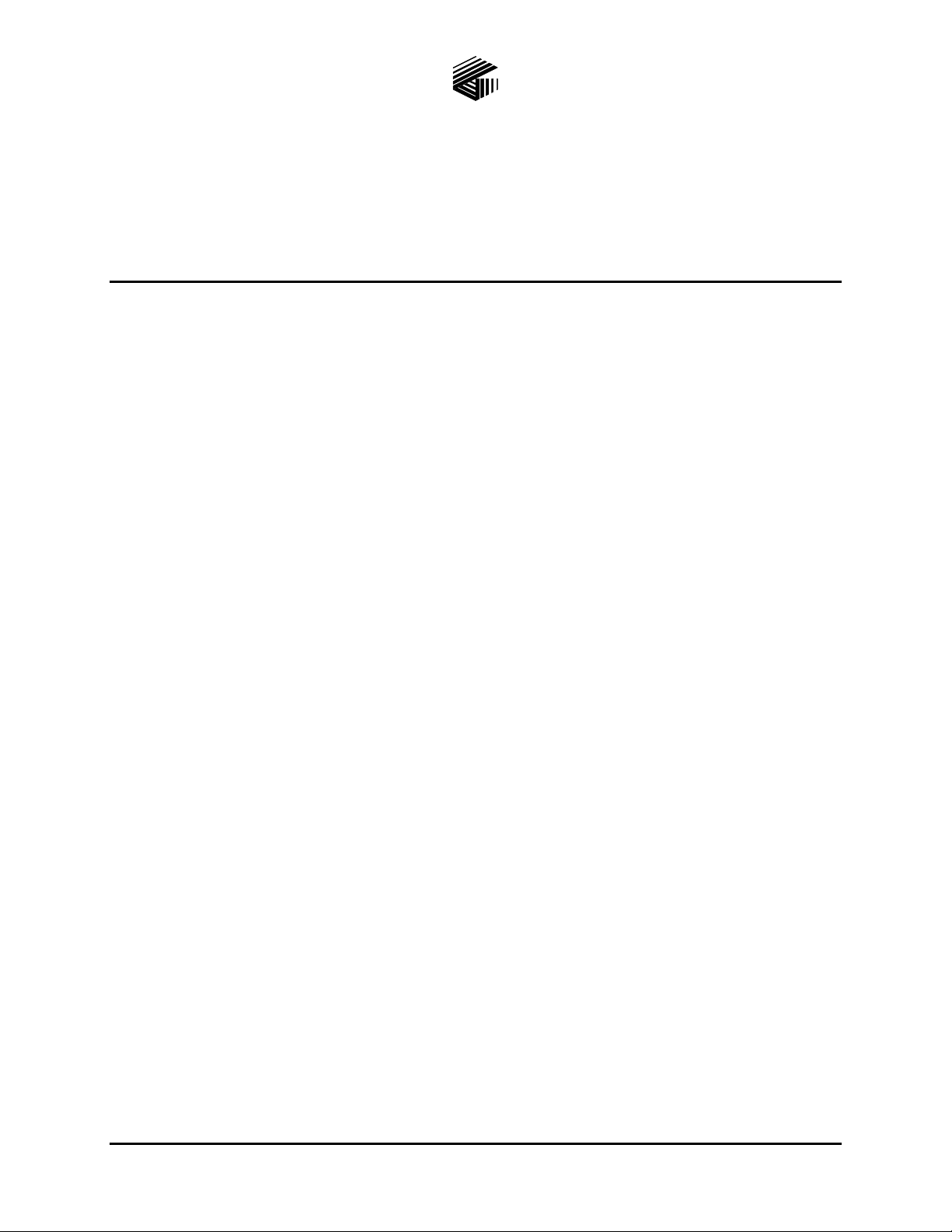

Figure 1. Model LE200 Outline Detail

Figure 2. Interior View of Components - Model LE200 (Enclosure shown open)

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 5

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 3 of 50

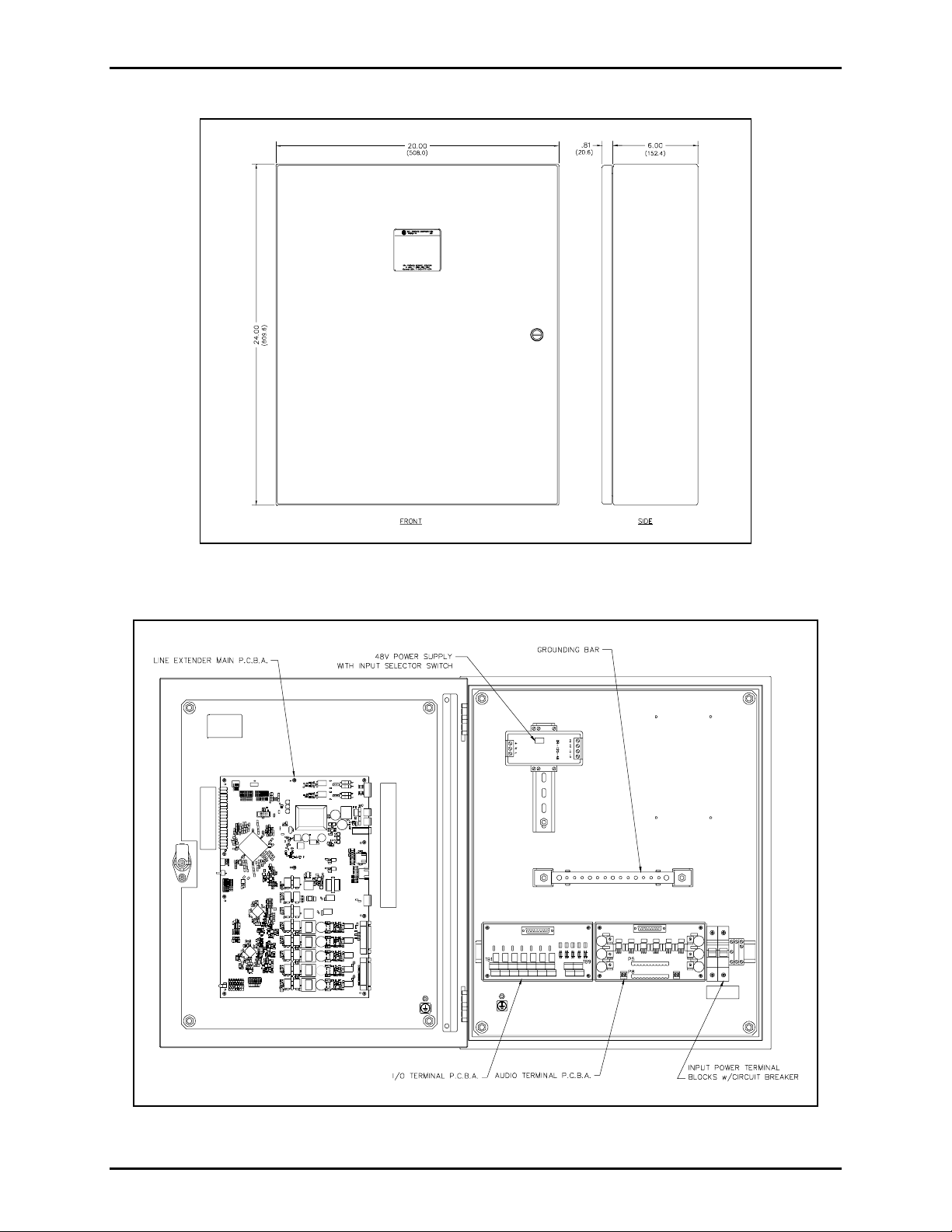

Figure 3. Interior View of Components - Models LE200-FSR and LE200-FLR (Enclosure shown open)

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 6

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 4 of 50

Subcomponent Descriptions

Enclosure

The Model LE200 Series enclosures contain:

• The 69441-xxx Audio Terminal PCBA as part of the 13118-011

• The 69442-xxx I/O Terminal PCBA as part of the 13118-012

• The 69443-xxx Main PCBA

• The +48 volt power supply

• A +12 volt power supply (Models LE200-FSR and LE200-FLR only)

• A fiber modem (Models LE200-FSR and LE200-FLR only)

• Grounding connections

• Input power terminals containing 15-amp circuit breakers

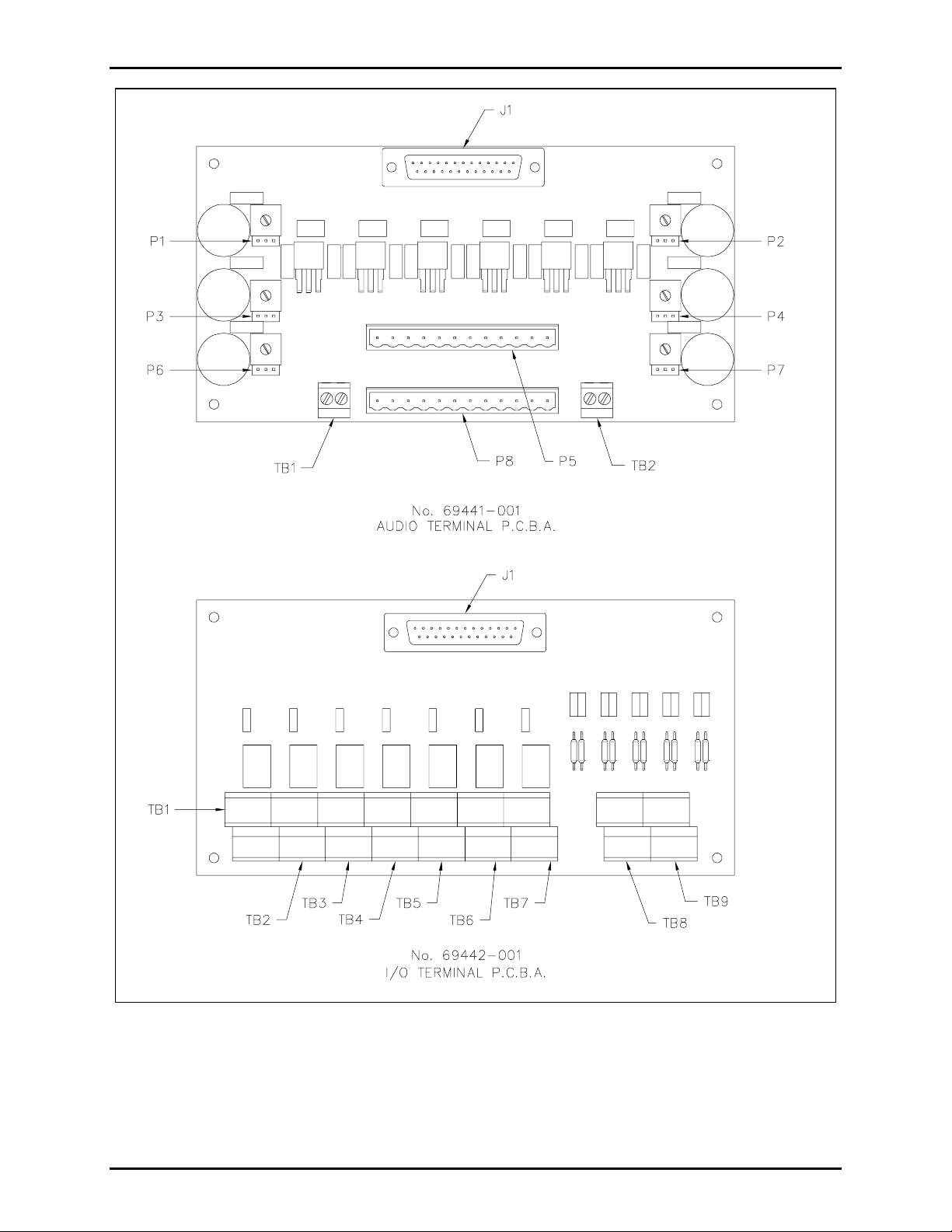

69441-xxx Audio Termin al PCBA

The 69441-xxx printed circuit board is used to terminate the page and party lines of the system cable.

The 69441-xxx includes over voltage protection and line balance potentiometers for the page line and all

five party lines. Refer to Figure 5.

69442-xxx I/O Termin al PCBA

The 69442-xxx printed circuit boa r d is used to terminate the contact inputs and contact outputs. The

69442-xxx contains the relays for the contact outputs, and signal conditioning comp onents for the contact

inputs. Refer to Figure 5.

69443-xxx Main PCBA

The 69443-xxx printed circuit board contains the main logic of the Model LE200. Refer to Figure 4.

Fiber Optic Mod em Models

The Models LE200-FSR, LE200-FSR-E1, LE200-FLR and LE200-FLR-E1 include a third party fiber

modem that converts the copper T1 or E1 signals to fiber optic T1/E1 signals and vice ver sa .

• Model LE200 FSR (Multi-Mode Fiber, T1 signals)

• Model LE200 FLR (Single Mode Fiber, T1 signals)

• Model LE200-FSR-E1 (Multi-Mode Fiber, E1 signals)

• Model LE200-FLR-E1 (Single Mode Fiber, E1 signals)

+48 Volt Power Supply

The Model LE200 is powered by a +48 V power supply. A selector switch allows the power supply to

operate at either 115 V ac or 230 V ac.

+12 Volt Power Supply

The Model LE200-FSR/FLR contains a +12 V power supply for the fiber optic module. It has an

operation range from 90 V ac to 264 V ac.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 7

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 5 of 50

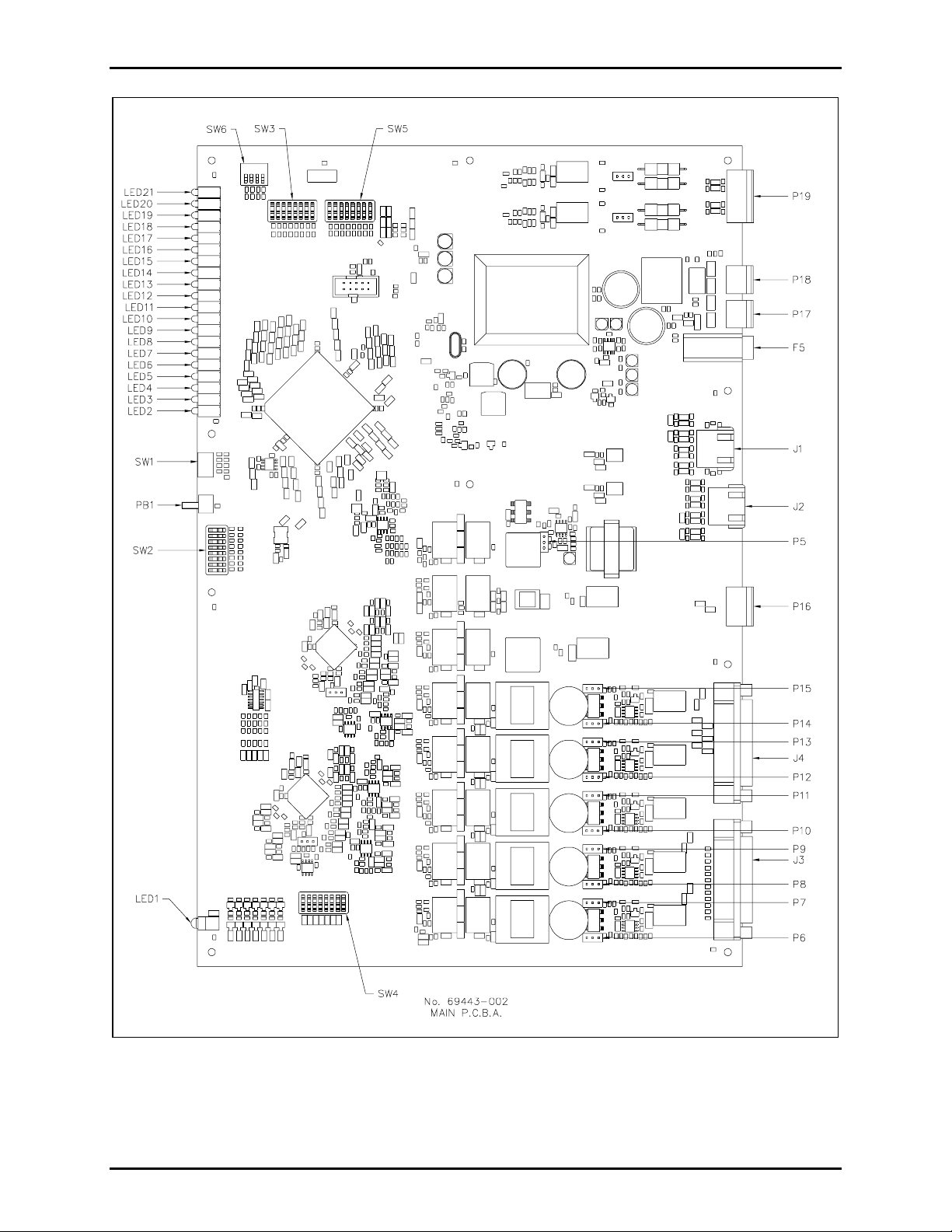

Figure 4. 69443-xxx Main PCBA

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 8

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 6 of 50

Figure 5. 69441-xxx Audio Terminal PCBA and 69442-xxx I/O Terminal PCBA

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 9

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 7 of 50

Installation

ATTENTION

Instal lation s ho uld be performed by qua l ified service perso nnel only in

accordance w it h the Na tional Electri cal Code or applicabl e local codes.

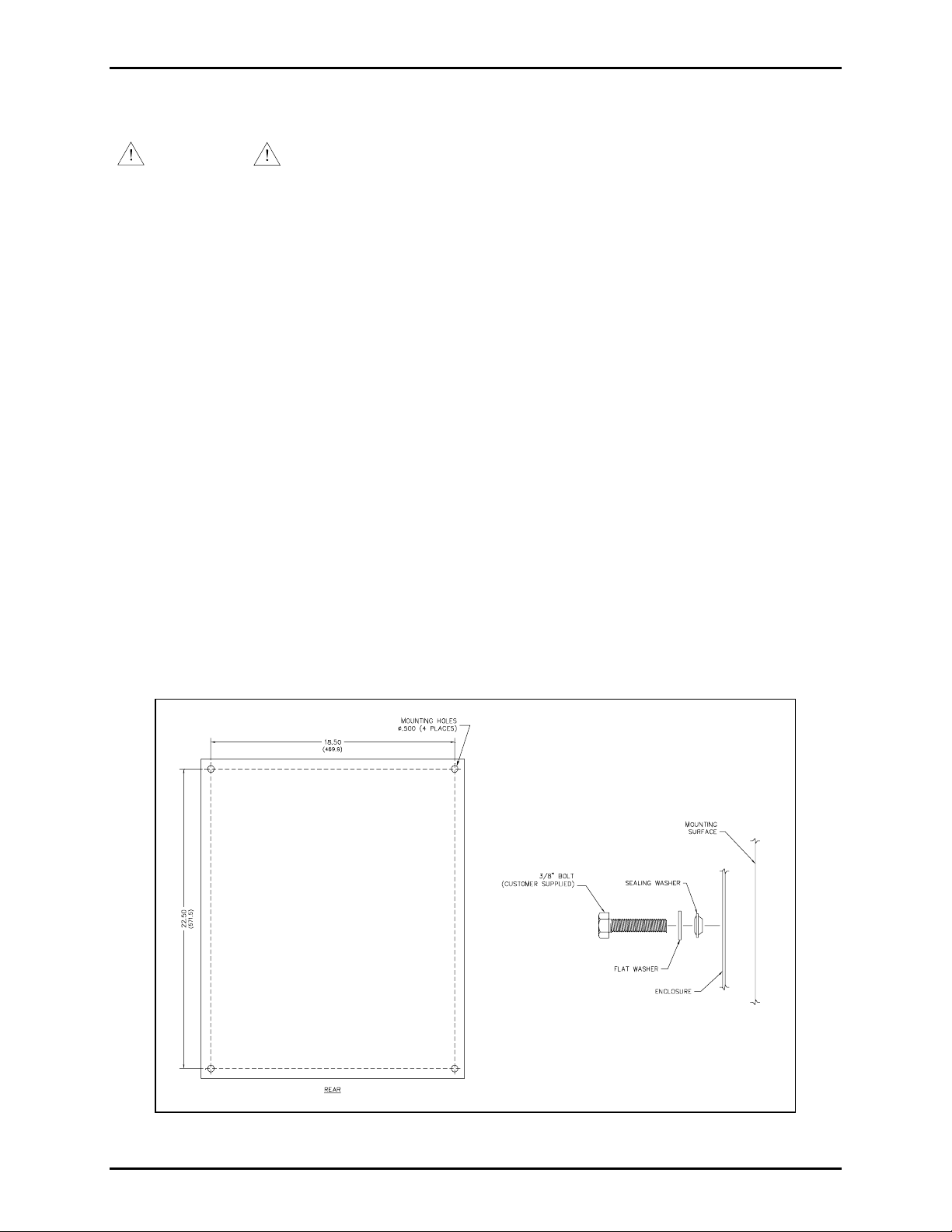

Mounting

1. Unlock the front door of the enclosure using a screwdriver by rotating the lock a quarter turn

counterc loc kwise, and open t he front d oor, which is hinged on the l e ft.

2. Disconnect the ribbon cables and the ground wire connections from the interior rear panel. Remove

the four bolts that hold the rear panel in place, and set this assemb ly and the bolts aside in a safe

location.

3. Position the enclosure on the mounting surface. The enclosure provides four 0.50-inch mounting

holes. Secure it with four 3/8-inch diameter bolts of the appropriate lengths for the mounting surface,

flat washers and nuts. To ensure proper sealing and enclosure protection rating, use the provided

sealing washers. Install the sealing washers inside the enclosure with the tapered cone against the

enclosure and then add the flat washer s. See Figure 6 for installation details.

4. Prepare the enclosure for cable entry. For example, if conduit is installed, create an access hole using

a metal hole punch that is equivalent in size to the conduit diameter.

5. Re-install the rear panel assembly using the four bolts removed previously. Re-attach the ribbon

cab le connectors and th e grou nd wires.

6. Pull the cables into the enclosure, and make connections per the wiring section.

7. Complete the installation by closing the front door and relocking the enclosure.

Figure 6. Mounting Details

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 10

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 8 of 50

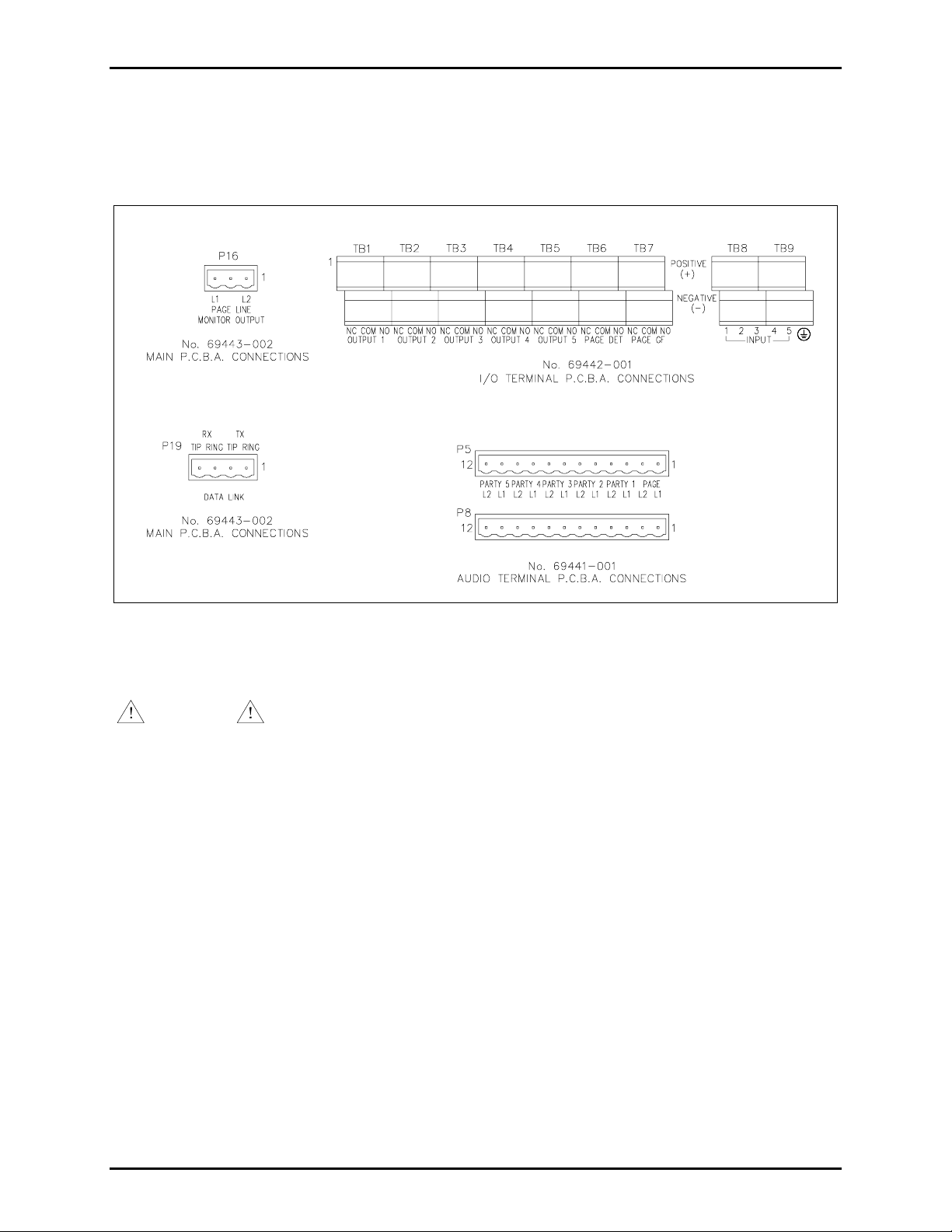

Wiring

The Model LE200 provides the interfaces for customer connections described below. All of the

terminations on the PCBAs support a wire size range of No. 24 AWG to 12 AWG.

Figure 7. Wiring Connections

Power Con nections

WARNING

The input voltage selector switch must be in the appropriate position before

power is ap plied to the Line Extender.

The Line Extender provides a double-pole circuit breaker for the input power. This input voltage may be

set to either 115 V ac at 50/60 Hz or 230 V a c at 50/60 Hz via an input selector switch, which is located

on the +48 V Power Supply.

A ground and spare terminal block are located next to the double-pole circuit breaker. The orange wire

found in GAI-Tronics system cab l e can b e terminated at t his spare terminal.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 11

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 9 of 50

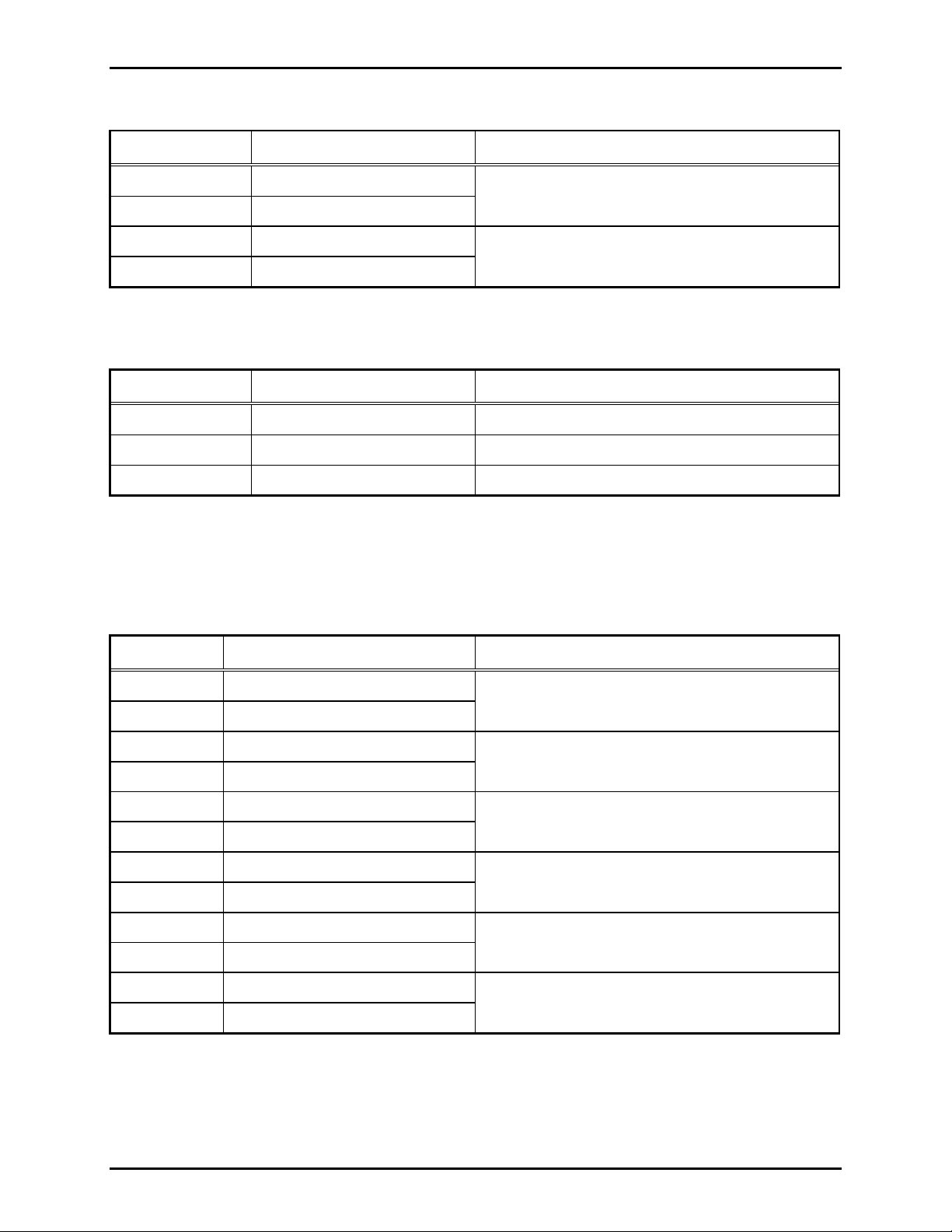

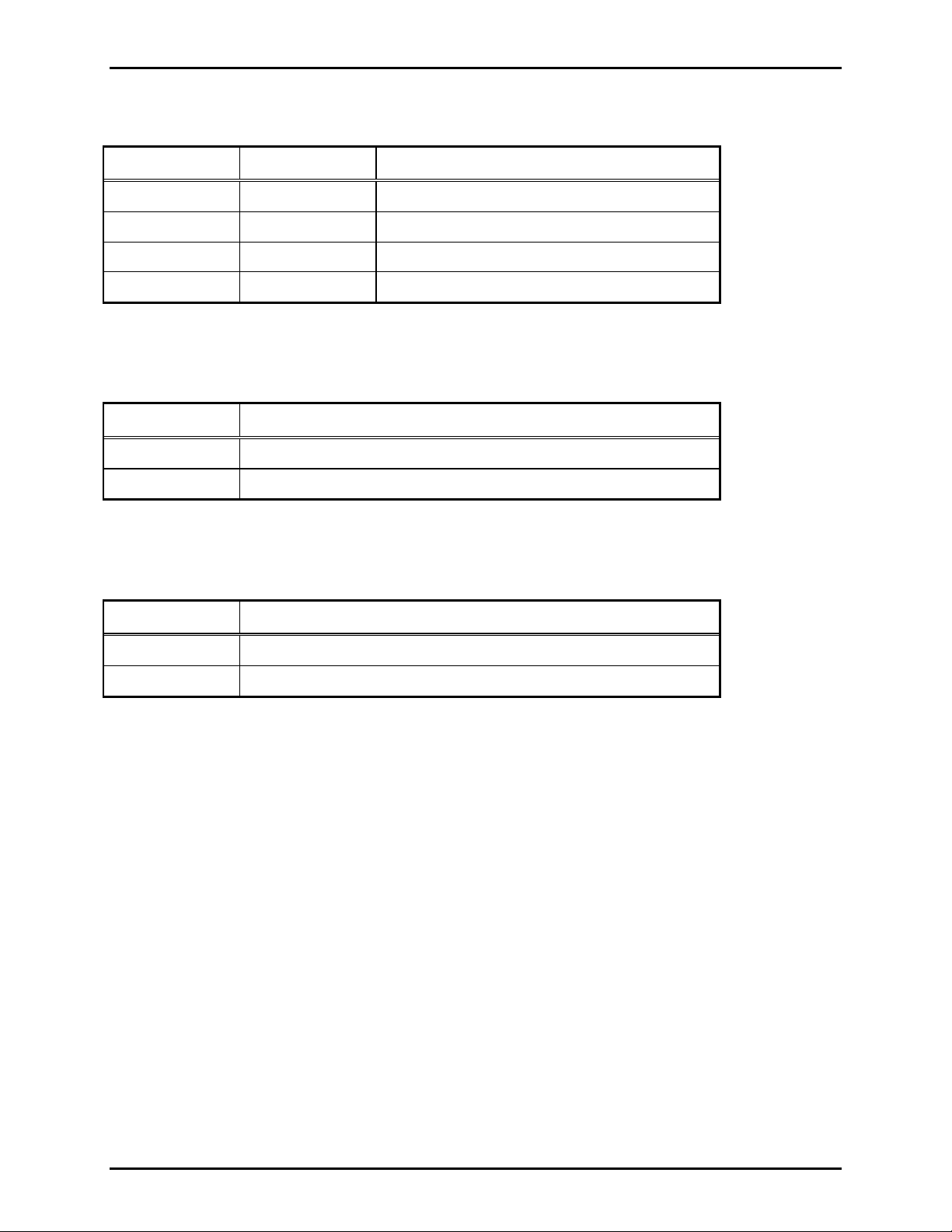

Table 1. Data Link on 69443-xxx PCBA

Terminal Designator Description

P19-1 Data Link TX Ring

Da ta TRANSMIT wir e pair

P19-2 Data Link TX Tip

P19-3 Data Link RX Ring

Data RECEIVE wir e pair

P19-4 Data Link RX Tip

Table 2. Page Line Monitor Output on 69443-xxx PCBA

Terminal Designator Description

P16-1 PG MON L2 Page line monitor audio output (L2)

P16-2 - No connection

P16-3 PG MON L1 Page line monitor audio output (L1)

®

Table 3. Page/Party

System Cable Connection on 69441-xxx PCBA

Refer to Figure 2 on page 2 for location of the 69441-xxx PCBA.

Terminal Designator Description

P5-1/P8-1 PAGE L1

Pa ge line audio

P5-2/P8-2 PAGE L2

P5-3/P8-3 PL1 L1

Party Line 1 audio

P5-4/P8-4 PL1 L2

P5-5/P8-5 PL2 L1

Party Line 2 audio

P5-6/P8-6 PL2 L2

P5-7/P8-7 PL3 L1

Party Line 3 audio

P5-8/P8-8 PL3 L2

P5-9/P8-9 PL4 L1

Party Line 4 audio

P5-10/P8-10 PL4 L2

P5-11/P8-11 PL5 L1

Party Line 5 audio

P5-12/P8-12 PL5 L2

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 12

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 10 of 50

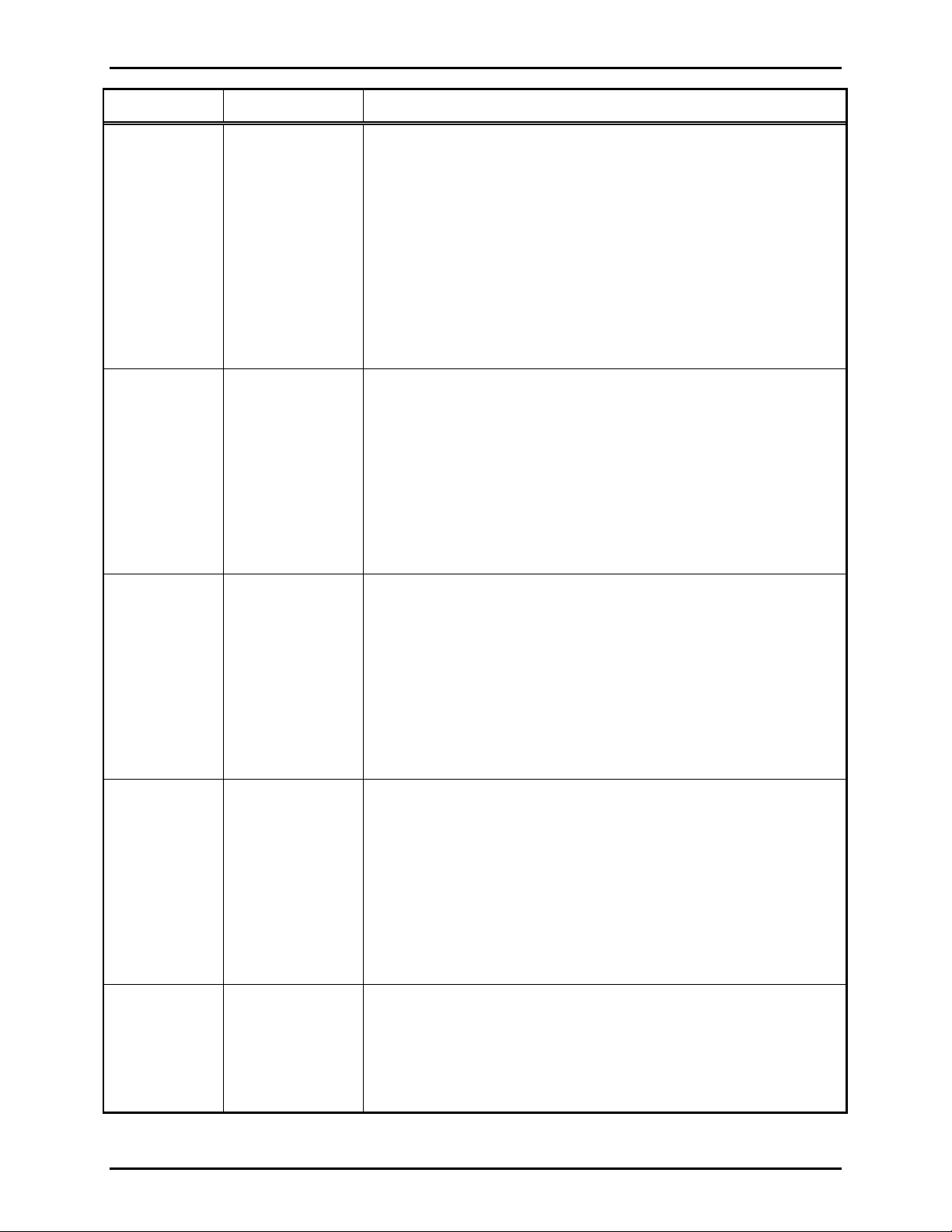

Table 4. Auxiliary Inputs on 69442-xxx PCBA

Refer to Figure 2 on page 2 for location of the 69442-xxx PCBA.

Terminal Designator Description

TB8 Input 1 (+)

Auxiliary input contact 1

TB8 Input 1 (-)

TB8 Input 2 (+)

Auxiliary input contact 2

TB8 Input 2 (-)

TB8 Input 3 (+)

Auxiliary input contact 3

TB8 Input 3 (-)

TB9 Input 4 (+)

Auxiliary input contact 4

TB9 Input 4 (-)

TB9 Input 5 (+)

Auxiliary input contact 5

TB9 Input 5 (-)

Table 5. Page Line Audio Detector Output on 69442-xxx PCBA

Terminal Designator Description

TB6 Output 1 N.C.

TB6 Output 1 COM

Page line audio detector output contact #1

TB6 Output 1 N.O.

TB6 Output 2 N.C.

TB6 Output 2 COM

Page line audio detector output contact #2

TB6 Output 2 N.O.

Table 6. Page Line Ground-Fault Detector Output on 69442-xxx PCBA

Terminal Designator Description

TB7 Output 1 N.C.

TB7 Output 1 COM

Pa ge line ground fault d etector output contact #1

TB7 Output 1 N.O.

TB7 Output 2 N.C.

TB7 Output 2 COM

Pa ge line ground fault d etector output contact #2

TB7 Output 2 N.O.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 13

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 11 of 50

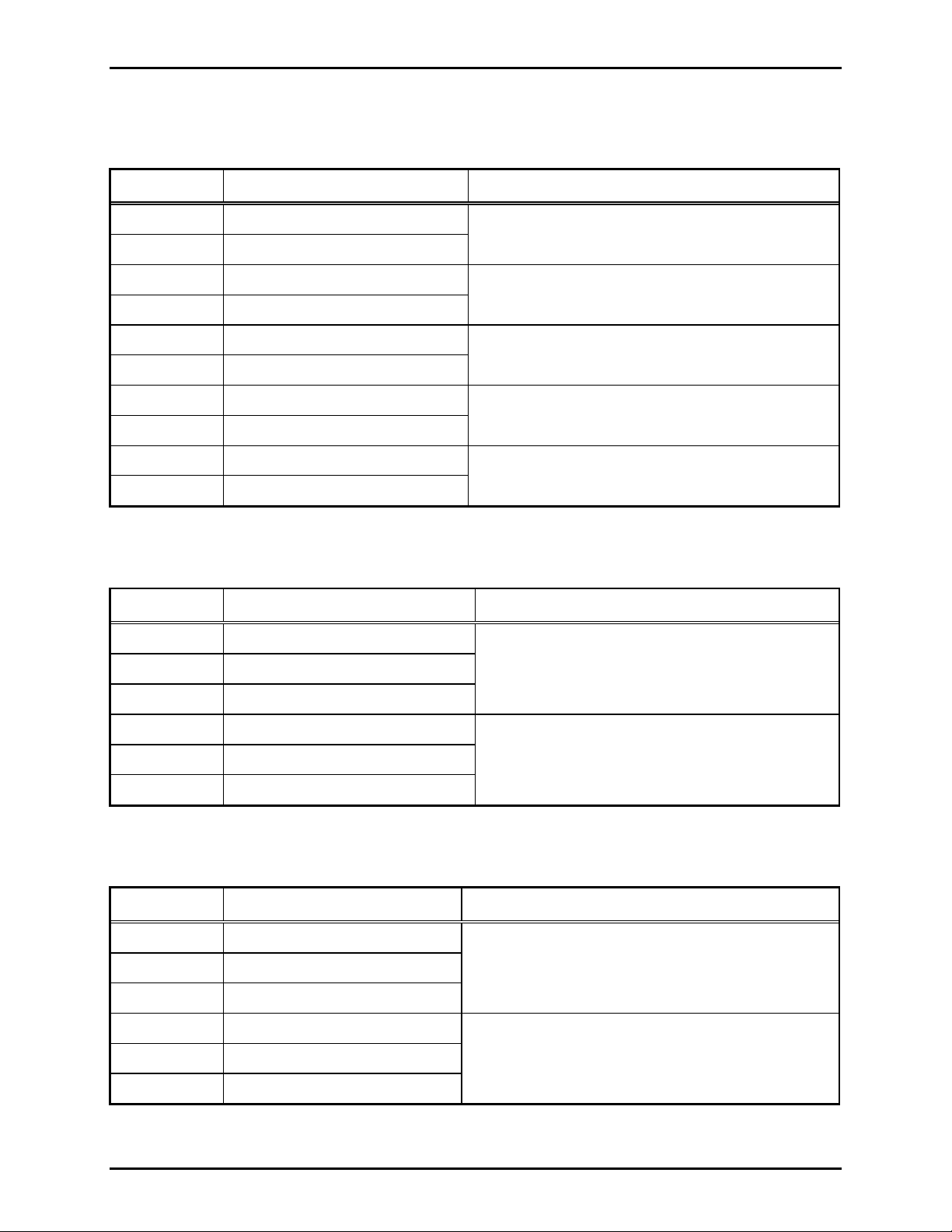

Table 7. Auxiliary Outputs on 69442-xxx PCBA

Terminal Designator Description

TB1 Output 1 N.C.

TB1 Output 1 COM

TB1 Output 1 N.O.

TB1 Output 1 N.C.

TB1 Output 1 COM

TB1 Output 1 N.O.

TB2 Output 2 N.C.

TB2 Output 2 COM

TB2 Output 2 N.O.

TB2 Output 2 N.C.

TB2 Output 2 COM

TB2 Output 2 N.O.

TB3 Output 3 N.C.

TB3 Output 3 COM

TB3 Output 3 N.O.

TB3 Output 3 N.C.

Auxiliary output 1 - contact #1

Auxiliary output 1 - contact #2

Auxiliary output 2 - contact #1

Auxiliary output 2 - contact #2

Auxiliary output 3 - contact #1

TB3 Output 3 COM

TB3 Output 3 N.O.

TB4 Output 4 N.C.

TB4 Output 4 COM

TB4 Output 4 N.O.

TB4 Output 4 N.C.

TB4 Output 4 COM

TB4 Output 4 N.O.

TB5 Output 5 N.C.

TB5 Output 5 COM

TB5 Output 5 N.O.

TB5 Output 5 N.C.

TB5 Output 5 COM

TB5 Output 5 N.O.

Auxiliary output 3 - contact #2

Auxiliary output 4 - contact #1

Auxiliary output 4 - contact #2

Auxiliary output 5 - contact #1

Auxiliary output 5 - contact #2

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 14

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 12 of 50

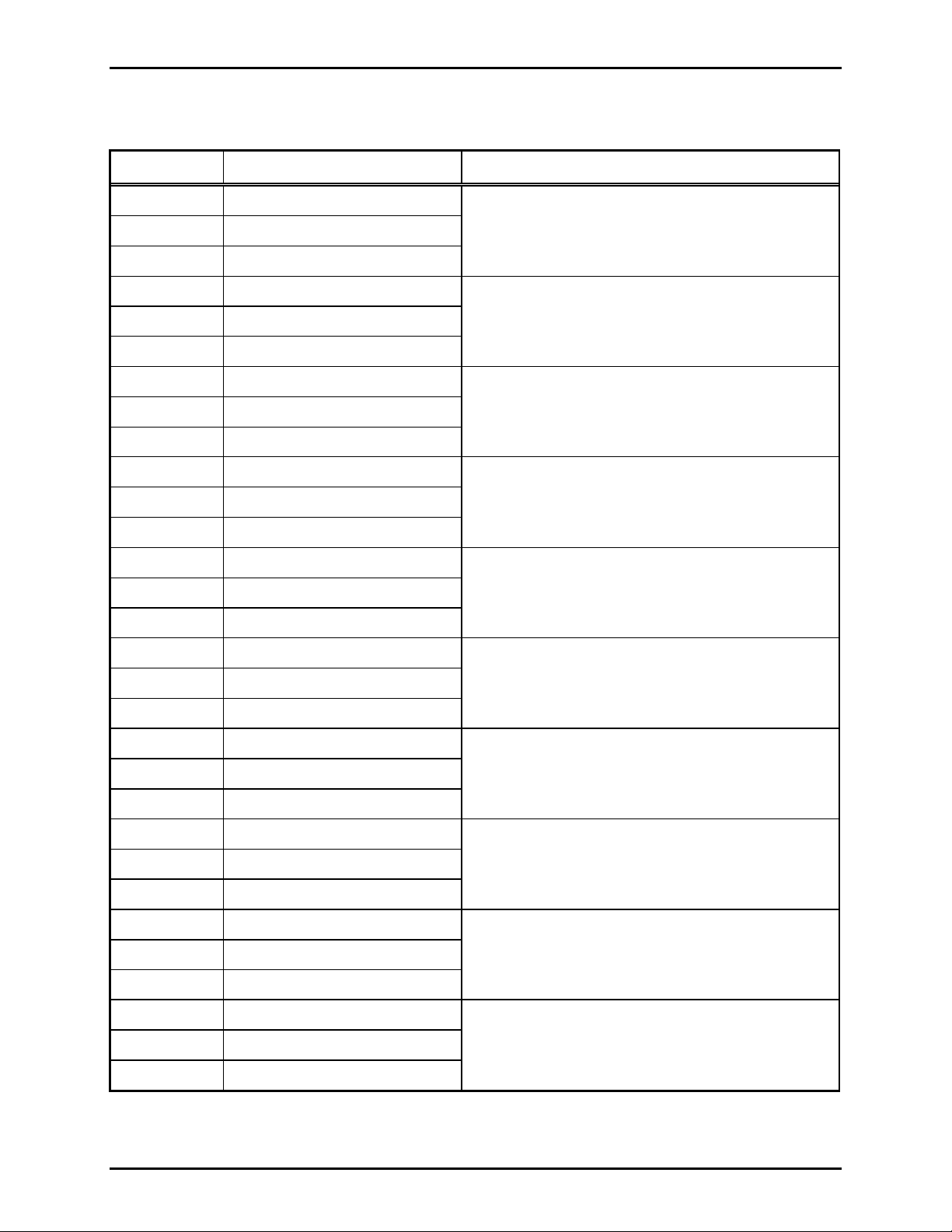

Fiber Optic Cable Connections

The Line Extender provides a pair of ST fiber optic connectors (one for the transmit fiber and one for the

receive fiber). Typical connections for this method are shown in Figure 9.

Figure 8. Fiber Optic Transceiver

Figure 9. Typical Fiber Optic Data Link Connection

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 15

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 13 of 50

Operation

The Model LE200 Page/Party® Line Extender r equires no user interface after successful installation and

testing.

Description of F eatures

Page Line Audio Transmission

A pair of Model LE200s provides page line audio transmission between two Page/Party® system cables.

This transmiss ion is half-dupl ex oper atio n.

Half-Dupl ex Operation

When the Model LE200 detects a peak audio level equal or above a Peak Voltage Level Detection

Threshold

Time.

until it is continuously below the Peak Voltage Level Detection Threshold for the Transmission Direction

Hold Time. The DIP s w itch, SW2, loc ate d on the Main P C boar d select s Peak Voltage Level Detecti o n

Threshold and Transmission Direction Hold Time. Refer to Table 8 and Table 9 for switch setting

options.

, it immediately switches audio “on” in that direction for the Transmission Direction Hold

Audi o f rom the other direct ion is muted and ignored during that time. Audio is not switched “of f”

Training the Echo Cancellation

Overview

Line echo (also known as electric or hybrid echo) is created by the electrical circuitry connected to a twowire (full duplex) audio system. Echo is inherent in all full-duplex audio systems and is affected by the

audio line length and line impedance mismatches. The presence of audible echoes results in undesirable

audio qua lity. This kind of qual ity degradati on is inhere nt in t h e netw ork equip me nt an d e nd-u ser phone

devices.

To minimize echo, the Model LE200 performs an echo cancellation training sequence on party lines 1

through 5 . The echo ca ncellatio n training tak es approxi mate ly 15 seconds and is perf ormed aut omatically

one minute after power is applied to the LE200. This delay allows all power levels to stabilize prior to

perfor mi ng ech o c ancellation tra i ning. Echo cancellat i on can be manu all y initiated as described below.

OTE: Signal impulses are transmitted onto the audio lines during the echo cancellation training

N

sequence. Handset stations that are in use on a party line will hear the signa ls in the handset receiver. For

troubleshooting purposes, the one-minute delay may be disabled by closing DIP switch SW6-1.

Manual In itiation of E cho Cancelin g

Press and release push button PB1 on the main PC board three times. The push button must be pr essed

for at lea st one quarter second and no more than two seconds each time. The timing requirement is meant

to prevent accidental requests. If an error is made with the push-button timing, the sequence must be

repeated from the beginning.

The main board LEDs will indicate the progress of the echo canceling sequence. One column of LEDs

turns on after each push button press or release until the sequence is started. Once the sequence is started,

those LED s rema in on, and a c ountd own timer is disp layed on th e rema ining L EDs. The LED s return t o

normal op eration after the echo c ancellat ion training seque nce is complete.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 16

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 14 of 50

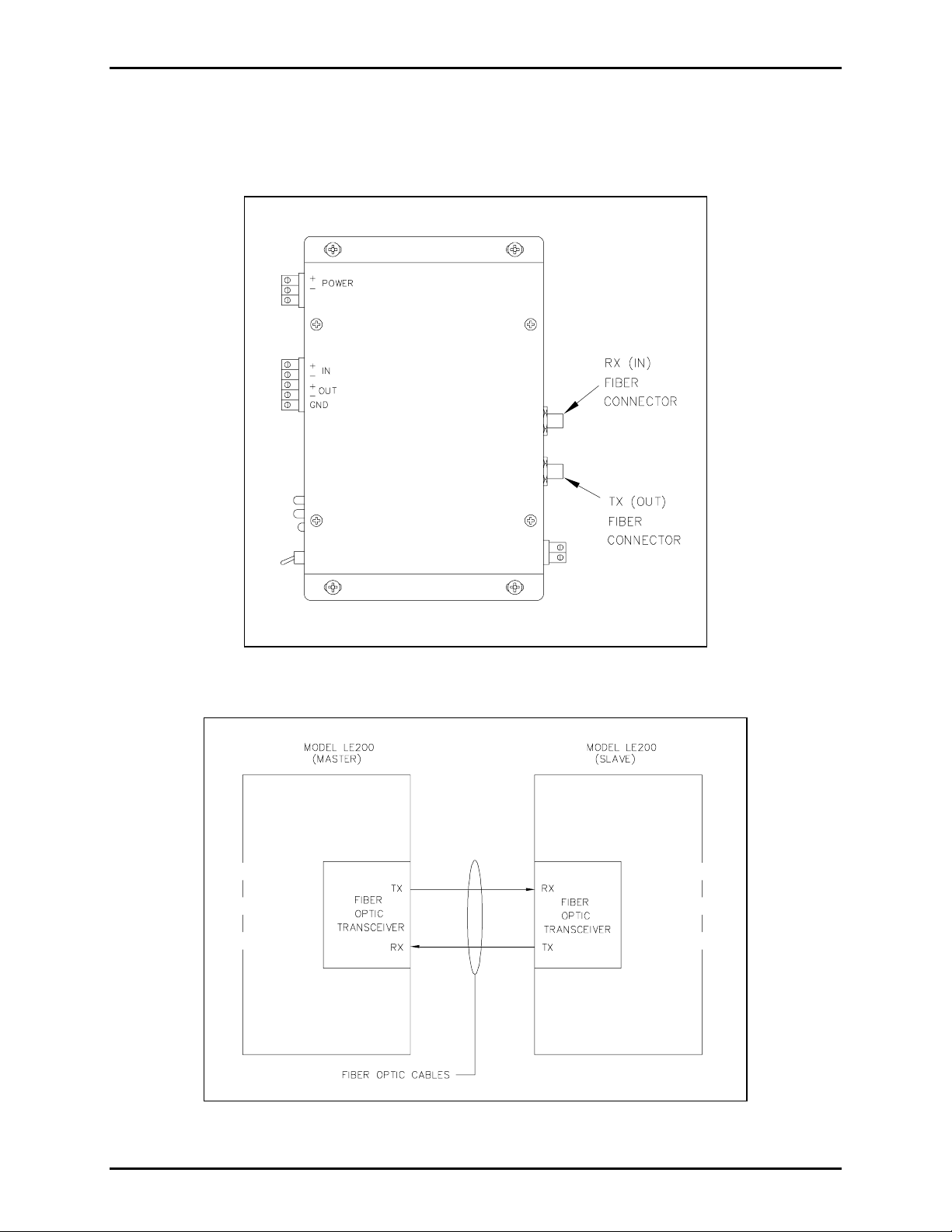

Table 8. Transmission Direction Hold Time on 69443-xxx PCBA

SW2-5 SW2-6 Transmission Direction Hold Time

Open (up)* Open (up)* 1280 milliseconds

Closed (down) Open (up) 640 milliseconds

Open (up) Closed (down) 160 milliseconds

Closed (down) Closed (down) 40 milliseconds

NOTE: Changes to this parameter take effect without cyc ling power.

Table 9. Peak Voltage Level Detection Threshold on 69443-xxx PCBA

SW2-7 Peak Voltage Level Detection Threshold

Open (up)* -12 dB relative to nominal

Closed (down) -24 dB relative to nominal

NOTE: Changes to this parameter take effect without cyc ling power.

Table 10. Echo Cancellation Power-On Delay Setting on 69443-xxx PCBA

SW6-1 Echo Cancellation Power-On Delay

Open* One minute

Closed No delay

NOTES: 1. Changes to this parameter take effect when cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 17

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 15 of 50

Page Line Audio 600-ohm Monitor Output

The Model LE200 mixes the local and remote page line audio and broadcasts it out a 600-ohm monitor

output. For the output voltage to be at the expected level, the device attached to the monitor output

should have an input impedance of 600 ohms. DIP switch SW3 selects the monitor output’s gain.

Table 11. Monitor Output Gain Setting on 69443-xxx PCBA

SW3-8 SW3-7 SW3-6 SW3-5 Monitor Output Gain

Open* Open* Open* Open* 0 dB

Open Open Open Closed -30 dB

Open Open Closed Open -27 dB

Open Open Closed Closed -24 dB

Open Closed Open Open -21 dB

Open Closed Open Closed -18 dB

Open Closed Closed Open -15 dB

Open Closed Closed Closed -12 dB

Closed Open Open Open -9 dB

Closed Open Open Closed -6 dB

Closed Open Closed Open -3 dB

Closed Open Closed Closed 0 dB

Closed Closed Open Open +3 dB

Closed Closed Open Closed +6 dB

Closed Closed Closed Open +9 dB

Closed Closed Closed Closed +12 dB

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 18

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 16 of 50

Page Line Audio Detected Contact Output

The Model LE200 provides a contact closure output that activates whenever audio is detected on the pa ge

line. The contact can be set to close on audio detection of either the local page line, the remote page line

audio, or both. The contact remains active f or one second after the audio is no longer detected. DIP

switch SW5 enables or disables the local and remote page line audio detection contact output. Refer to

Table 12 and Table 13 below for switch setting.

Table 12. Local Page Line Audio Detect Contact on 69443-xxx PCBA

SW5-6 Page Line Audio Detect Contact Uses Local Page Audio

Open* Local page line audio activates the contact.

Closed Local page line audio does not activate the contact.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Table 13. Remote Page Line Audio Detect Contact on 69443-xxx PCBA

SW5-7 Page Line Audio Detect Contact Uses Remote Page Audio

Open* Remote page line audio activates the contact.

Closed Remote page line audio does not activate the contact.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 19

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 17 of 50

Page Line 50 kHz VLC Transmission

A pair of Model LE200s provides page line 50 kHz VLC transmission between two Page/Party® system

cables. The two connected Model LE200s must both be configured for 50 kHz VLC operation, and not

be configured for SmartSeries FSK transmission. If both 50 kHz VLC and SmartSeries FSK are enabled,

then neither is transmitted. DIP switch SW5 configur es page line 50 kHz VLC transmission.

Table 14. Page Line 50 kHz VLC Transmission Setting on 69443-xxx PCBA

SW5-2 Page Line 50 kHz VLC Transmission

Open* 50 kHz VLC is disabled

Closed 50 kHz VLC is enabled

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Page Line SmartSeries FSK Transmissi on

A pair of Model LE200s provides page line SmartSeries FSK transmission between two Page/Party®

system cables. The two connected Model LE200s must both be configured for SmartSeries FSK

oper atio n, and not be conf igured for 50 kH z VLC transmission. If bot h 50 kHz VL C and SmartS eries

FSK are enabled, then neither is transmitted. DIP switch SW5 configures page line SmartSeries FSK

transmission.

Table 15. Page Line SmartSeries FSK Transmission Setting on 69443-xxx PCBA

SW5-1 Page Line SmartSeries FSK Transmission

Open* SmartSer ies FSK is disabled.

Closed SmartSeries FSK is enabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 20

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 18 of 50

Page Line Ground Fault Detection and Transmission

The Model LE200 Line Extenders provide page line ground fault detection on the local Page/Party®

system cable. Additionally, when a ground fault is detected, the LE200 can transmit the ground fault to

the more remote LE200 so that it is duplicated on the remote Page/Party

LE200s are connected to the same Page/Party

®

system cable segment, only one page line ground fault

dete ctor may b e enabl e d. A three-posi tion header, P5, a nd its short ing cl ip cont rol p age line ground f ault

detection. DIP switch SW5 controls page line ground fault regeneration.

Table 16. Page Line Gro und Fault Detectio n Set ting on 69443-xxx PCBA

P5 Shorting Clip Page Line Ground Fault Detection

Pins 1-2* Page line ground fault detection is disabled.

Pins 2-3 Pa ge l ine groun d f ault detection is enabled.

Removed Page line ground fault detection is disabled.

NOTES:

1. If connecting an LE200 to the same system cable segment as an ADVANCE Page/P a r ty

(PPI) card, disable the LE200 page line ground fault detector and enable the PPI card ground fault

dete c tor. If both ground fault c ircuits a re enabled s imultaneously, intermittent Sma rtSeries FSK data

err ors wi ll occur b et w e en th e PPI c a rd and SmartSer ies s tatio ns.

2. Changes to this parameter take effect without cycling power.

3. *Indicates default pos ition.

®

system cable. If multiple

®

Interface

Table 17. Page Line Gro und Fault Regeneration Setti ng on 69443-xxx PCBA

SW5-3 Page Line Ground Fault Regeneration

Open* Pa ge l ine ground faults a re not regen erat e d locally.

Closed Page l ine groun d f aults are regen erated loc ally.

NOTES:

1. The expected use of the ground fault regeneration feature is within ADVANCE systems. If used in

Page/Party

®

systems, this feature should be disabled.

2. Changes to this parameter take effect without cycling power.

3. *Indicates default pos ition.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 21

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 19 of 50

Page Line Ground Fault Detected Conta ct Output

The Model LE200 provides a contact output that activates whenever it detects a ground fault on the page

line. The DIP switch SW5 configures which page line ground faults activate this contact.

Table 18. Page Line Ground Fault Contact S e tt i ng o n 69443-xxx PCBA

SW5-4 Page Line Ground Fault Contact Uses Local Ground Fault

Open* Local page line ground faults activate the contact

Closed Local page line ground faults do not activate the contact

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Table 19. Page Line Ground Fault Contact S et ting on 69443-xxx PCBA

SW5-5 Page Line Ground Fault Contact Uses Remote Ground Fault

Open* Remote page line ground faults activate the contact

Closed Remote page line ground faults do not activate the contact

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Party Line Audio Transmission

A pair of Model LE200 Line Extenders provides full duplex party line audio transmission between two

Page/Party

During on-hook conditions of the party lines, the LE200 will mute the local party line analog circuits. If

it is necessary to have party line audio present at an LE200 even when no stations are off-hook, DIP

switch SW6-3 may be closed to disable this muting feature. This switch affects the on-hook muting

function of all five party lines.

Table 20. Party Line On-Hook M uting Setting on 69443-xxx PCBA

SW6-3 Party Line On-Hook Muting

Open* On-hook muting of local party lines is enabled.

Closed On-hook muting of local party lines is disabled.

®

system cables, for up to five party lines.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 22

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 20 of 50

Party Line Off-hook Detection and Tran smission

The Model LE200 Line Extenders provides off-hook detection on the local Page/Party® system cable for

party lines 1 through 5. Additionally, when an off-hook condition is detected, the LE200 transmits the

off-hook condition to the more remote LE200 so that it is duplicated on the remote Page/Party

cable. If mult iple LE200s are connected to the same Page/Party

®

system cable segment, only one off-

hook detector may be enabled.

Several three-position headers and their shorting clips control party line 1 through 5 off-hook detection.

Both shorting clips associated with a particular party line must be set to the same position for proper

operation. The party lines 1-5 are configured independently.

Table 21. Party Line Off-H o ok Detection Setting on 69443-xxx PCBA

Header Pair Shorting Clip Party Line Off-Hook Detection

P15, P14 P ins 1-2* Party line #1 off-hook detection disabled.

Pins 2-3 Party line #1 off-hook detection enabled.

Removed P ar ty line #1 off-hook detection disabled.

®

system

P13, P12 P ins 1-2* Party line #2 off-hook detection disabled.

Pins 2-3 Party line #2 off-hook detection enabled.

Removed P ar ty line #2 off-hook detection disabled.

P11, P10 P ins 1-2* Party line #3 off-hook detection disabled.

Pins 2-3 Party line #3 off-hook detection enabled.

Removed P ar ty line #3 off-hook detection disabled.

P9, P8 Pins 1-2* Party line #4 off-hook detection disabled.

Pins 2-3 Party line #4 off-hook detection enabled.

Removed P ar ty line #4 off-hook detection disabled.

P7, P6 Pins 1-2* Party line #5 off-hook detection disabled.

Pins 2-3 Party line #5 off-hook detection enabled.

Removed P ar ty line #5 off-hook detection disabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 23

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 21 of 50

If it is not necessary to have a Model LE200 regenerate the off-hook condition locally. DIP switch SW62 may be closed to disable this feature. This switch affects the off-hook regeneration function of all five

party lines.

Table 22. Off-Hook Regeneration on 69443-xxx PCBA

SW6-2 Off-Hook Regeneration Setting

Open* Regeneration of off-hook to local party lines is enabled.

Closed Regeneration of off-hook to local par ty lines is disabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Muting Analog Lines

Pa ge and Pa rty li ne audio is muted when SW 6-4 is c lose d. This feat u re enhanc es syst e m operation in

some configurations where no page and party lines are attached to the LE200.

Table 23. Mute Analog Lines Setting on 69443-xxx PCBA

SW6-4 Mute Analog Lines Setting

Open* Muting of the analog lines is disabled.

Closed Muting of the analog lines is enabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

Line Connection Relays

The Model LE200 has relays that disconnect the page and party line connections from the main PC board

for s pecial appl ications. This would apply to sin gle party l ine systems or any applic ati on in which a

page/5-party cable is not connected to the line extender. The DIP switch, SW4, controls audio line

connections. Also, if no Page/Party

analog circuits.

N

OTE: When a par ty line is disconne c ted from the field wirin g, that pa r ty line ’s off-hook detect or should

be disable d. Otherwise, t hat pa r ty line will appear permanently of f-hook.

®

cable is connected, DIP switch SW6-4 should be closed to mute the

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 24

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 22 of 50

Table 24. Line Connection Relay Enable SW4 DIP Switch Setting on 69443-xxx PCBA

SW4 Switch Setting Field Wiring Connection

SW4-1 Open Party line #5 is not connected to the field wiring.

Closed* Party line #5 is connected to the field wiring.

SW4-2 Open Party line #4 is not connected to the field wiring.

Closed* Party line #4 is connected to the field wiring.

SW4-3 Open Party line #3 is not connected to the field wiring.

Closed* Party line #3 is connected to the field wiring.

SW4-4 Open Party line #2 is not connected to the field wiring.

Closed* Party line #2 is connected to the field wiring.

SW4-5 Open Party line #1 is not connected to the field wiring.

Closed* Party line #1 is connected to the field wiring.

SW4-6 Open The page line is not connected to the f i eld wiring.

Closed* The page line is connected to the field wiri ng.

SW4-7 Open The monitor output is not connected to the f i eld wiring.

Closed* The monitor outpu t is connected to the field wiring.

SW4-8 Open Not used.

Closed* Not used.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 25

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 23 of 50

Page/Party® Line Balance

For proper operation, th e l ine resistanc e for t he page and part y lines s hould be set c lose to 33 o hms. The

Model LE200 provides the line balance resistors needed on the page line and five party lines. These line

balance resistors are located on the 69441-xxx board next to the pa ge and party line terminal blocks. The

line balance resistors are adjustable or can be disabled. Several headers, shorting clips, and

potentiometers control the line balance settings.

®

Table 25. Page/Party

Header Shorting Clip Line Balance Setting

P6 Pins 1-2* Party line #5 line balance resistor disabled.

Pins 2-3 Party line #5 line balance resistor enabled.

Removed Party line #5 line balance resistor disabled.

P3 Pins 1-2* Party line #4 line balance resistor disabled.

Pins 2-3 Party line #4 line balance resistor enabled.

Line Balance Setting on 69441-xxx PCBA

Removed Party line #4 line balance resistor disabled.

P1 Pins 1-2* Party line #3 line balance resistor disabled.

Pins 2-3 Party line #3 line balance resistor enabled.

Removed Party line #3 line balance resistor disabled.

P2 Pins 1-2* Party line #2 line balance resistor disabled.

Pins 2-3 Party line #2 line balance resistor enabled.

Removed Party line #2 line balance resistor disabled.

P4 Pins 1-2* Party line #1 line balance resistor disabled.

Pins 2-3 Party line #1 line balance resistor enabled.

Removed Party line #1 line balance resistor disabled.

P7 Pins 1- 2* Pa ge l ine li ne balance resis tor disabled.

Pins 2-3 Page lin e line balance r es i stor enabled.

Removed Page line line balance resistor disabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 26

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 24 of 50

Contact Closure Input Transmission

A pair of Model LE200s provides contact closure detection and transmission for five contact closure

inputs. An input contact closure on the local Model LE200 results in the corresponding output contact

becoming active on the remote Model LE200.

N

OTE: Should the data link between the two LE200s break, any active output contacts will deactivate.

Data Link Technology used with LE200 Line Extenders

The LE200 contains two different data link types for connecting line extenders. The connection scheme

of the line extenders determines which data link(s) should be used. The two data types are T1/E1 and

Low Voltage D i ffere ntial Signal ing (LVDS) . It i s possible to use both types at the same time to achieve

complex system architectures. Each data type, intended use, and the applicable switch settings are

described below.

T1/E1 Digital Lin k

The T1/E1 data link connection is the most common and is used when one pair of Model LE200s is

connected together. The T1/E1 carrier technology uses dedicated copper cable or fiber optic cable when

equipped with a T1/E1 fiber optic modem. The distance between line extenders determines the type of

connection needed. Copper wire connections require a 2-pair cable and will operate at up to 6000 feet

using No. 22 AWG wire. For distances greater than 6000 feet, a T1/E1 fiber optic modem and fiber optic

cable must be used.

OTE: The Model LE200 is NOT designed for use with the public switched telephone network.

N

Low Voltage Diff erential Signaling ( LVDS) Data Link

The LVDS data link connection is used to connect two or more LE200s located within 10 meters of each

oth er. The L VD S dat a link requ ires a straight-through shiel d e d CAT 5e cab le between line exten d ers.

Each line extender contains an LVDS data “in” port and an LVDS data “out” port. The “out” port of the

first line extender to the “in” port of the next line extender. This connection scheme is repeated to link

mult ipl e li ne ext e nd ers . Typicall y th is con ne ct io n sc heme is us ed when mu lt ip le li ne ext e nd ers ar e

installed in a central location.

Setting up the Da ta Link(s)

The data links between line extenders must be configured using multiple DIP switch settings to determine

the clock source. Each LE200 must have exactly one clock source for its main processing logic. There

ar e three choices for the cloc k: an inter nal oscilla tor, a T1/E1 clock, or the LVD S “in” clock.

There are three possible choices for the source of this clock: the local Model LE200, the remote Model

LE200, or an external clock source on the T1/E1 link connecting two Model LE200s. If more than two

Model LE200s are connected using the T1/E1 data link and LVDS data link, then all must have their

clock derived from a single source.

An unused T1/E 1 conn ect i o n can be left open (not termina t ed).

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 27

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 25 of 50

The T1/E1 and LVDS data link settings are described in the following paragraphs.

T1 Data Link Settings

DIP switch, SW2, on the main PC board selects two line-length related parameters for the T1 format.

Line length refers to the distance between the two LE200s connecting over copper cable or the cable

distance between the LE200 and the fiber optic modem if using fiber optics to connect the line extenders.

Table 26. T1/E1 Line Length Setting on 69443-xxx PCBA

SW2-1 SW2-2 SW2-3 T1 Line Length

Open (up)* Open (up)* Open (up)* DSX-1 (0 to 133 feet)

Closed (down) Open (up) Open (up) DSX-1 (133 to 266 feet)

Open (up) Closed (down) Open (up) DSX-1 (266 to 399 feet)

Closed (down) Closed (down) Open (up) DSX-1 (399 to 533 feet)

Open (up) Open (up) Closed (down) DSX-1 (533 to 655+ feet)

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

3. These switches have no effect in E1 mode.

Table 27. Receive Equalizer Gai n Limit Setting on 69443-xxx PCBA

SW2-4

Receive Equalizer Gain Limit

T1 Mode E1 Mode

Open (up)* -36 dB (long haul) -12 dB (short haul)

Closed (down) -15 dB (limited long haul) -43 dB (long haul)

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 28

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 26 of 50

DIP switch SW3 selects T1/E1 clock related parameters. For each pair of line extenders, only one line

ext e nder c an be c lock s ource (master).

Table 28. Use T1/E1 Clock as Board’s Master Clock Source Setting on 69443-xxx PCB A

SW3-1 T1/E1 Clock as Board’s Master Clock Source

Open * The recovered clock is not t he boa rd’s master clo ck source.

Closed The recovere d clock is the board's master cl ock source.

NOTES: 1. Changes to this parameter take effect after cycling power.

2. *Indicates default position.

Table 29. Use the Board’s Master Clock as the T1/E1 Transmit Clock Setting on 69443-xxx PCBA

SW3-2 Use the Board’s Master Clock as the T1/E1 Transmit Clock

Open * T he board’s master c lock is the t rans mit clock (clock mast er).

Closed The remote (recovered) c lock is the transmit clock (cloc k sla v e) .

NOTES: 1. Changes to this parameter take effect after cycling power.

2. *Indicates default position.

DIP switch, SW5, on the main PC board provides the selection of which data link format is to be used for

the digital audio transmission. The T1 (1.544 Mbps) format is most commonly used in North America.

The E1 (2.048 Mbps) format is most commonly used in Europe. It is important that these settings match

between the connected LE200s and any interface equipment between.

Table 30. Digital Audio Format Setting on 69443-xxx PCBA

SW5-8 Digital Audio Format

Open* T1 Mode (1.544Mbps, 24-channel)

Closed E1 Mode (2.048Mbps, 32-channel)

NOTES: 1. Changes to this parameter take effect after cycling power.

2. *Indicates default position.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 29

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 27 of 50

Headers P20 and P21 control the grounding of the T1/E1 lines. Grounding the T1/E1 lines may reduce

emissions if that is an instal lation conc ern.

Table 31. T1/E1 Line Grounding on 69443-xxx PCBA

Header Shorting Clip Grounding Condition

P20 1-2 * T1/E1 Rx line floati ng.

2-3 T1/E 1 R x line gr ound e d.

Removed T1/E1 Rx lin e floa ting.

P21 1-2* T1/E1 Tx line floating.

2-3 T1/E1 Tx line grounded.

Removed T1/E1 Tx line floating.

*Indicates default pos ition.

NOTE

Do not connect t he T1/ E1 transmit signal to the T1/E1 receive signal on the same

Model LE200. Doing so creates a feedback path that usually results in extremely loud oscillations

on the page line and the party lines. The contact outputs may a lso act ivate.

NOTE

Do not ground the T1/E1 lines at bo th ends. Doing so will create a g round loop.

An unused T1 connection can be left open (n ot t erminated).

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 30

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 28 of 50

LVDS Data Link Se ttings

DIP switch, SW3, selects the LVDS related para meters which are the LVDS “in” clock and the LVDS

“out” port ena ble or disable. The LVDS “in” port is disabled unless it is receiving a signal from LVDS

“out” of a different Model LE200.

Table 32. Use the LVDS “in” Clock as Board’s Master Clock Source Setting on 69443-xxx PCBA

SW3-3 LVDS “in” as Board’s Master Clock Source

Open * The L VD S “in” clock is not the board’s ma ster clock source.

Closed The LVD S “in” clock is the boa rd’s master clo ck sou rce.

NOTES: 1. Changes to this parameter take effect after cycling power.

2. *Indicates default position.

Table 33. Enable LVDS “out” Setting on 69443-xxx PCB A

SW3-4 Enable LVDS “out”

Open* LVDS “out” is disabl ed.

Closed LVDS “out” is enabled.

NOTES: 1. Changes to this parameter take effect without cycling power.

2. *Indicates default position.

NOTE

Do not connect LVDS “in” to LVDS “out” on the same Model LE200. Doing so

creates a feedback path that usually results in (extremely loud) oscillations on the page line, all party

lines, and poss i bly the co ntact outputs.

Unused LVDS ports can be left open.

LVDS Port I ndicators

Each LVDS port has two LEDs. The green LED is ON when the LE200 detects a signal from the remote

LE200 on that LVDS port. The yellow/orange LED is ON when the local LE200 is the source of page

line data (Sma rtSeries FSK or 50 kHz VLC) ou t of that L VD S port.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 31

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 29 of 50

Fiber Optic Modem Set-Up (Models LE2 00-FSR and LE200-FLR)

The Fiber Optic Transceiver contains a 9-position DIP switch on the front panel that is ma r ked SET UP.

These switches must be set according to the following table to insure proper operation of the Model

LE200-FSR or LE200-FLR Line Extender.

Table 34. Front Panel DIP Switch Settings Model 9637/T1 or Model 9637/E1

Switch # Function Correct Setting

1 Sets the signal encoding format:

• UP or OFF – B8ZS (T1 only); HDB3 (E1 only)

• DOWN or ON – AMI

2 Enables the TAOS test mode:

• UP or OFF – N ormal operation

• DOWN or ON – Unit will transmit all logic ones

from the data port

3 Enables Local Loopback Test Mode:

• UP or OFF – N ormal operation

• DOWN or ON – Used only for testing purposes. The

data input is looped back to the data output. Use the

front panel toggle switch to enable the loopback test.

Switches 4–6 are the Line Build-out selection for T1.

They must be set according to the twisted pair cable

length between the data port and the LE200 Main PCBA.

Length S4 S5 S6

0–133 feet OFF ON ON

4, 5, 6

134–266 feet ON OFF OFF

267–399 feet ON OFF ON

400–533 feet ON ON OFF

UP or OFF – B8ZS (T1);

HDB3 (E1)

UP or OFF – N ormal operation

UP or OFF – N ormal operation

T1 S4 S5 S6

0–133 feet OFF ON ON

E1 S4 S5 S6

Not used OFF OFF OFF

534–655 feet ON ON ON

This feature is not available for E1. However, switches

must be in th e O FF positi on for proper opera tion.

7

Not used for T1 or E1 but must be OFF for proper

operation.

8

Selects b etween B iphase-M and Bipha se-L optical

cloc k/da ta enc oding:

• UP or OFF – Biphase M encoding

• DOWN or ON – Biphase L encoding

9

Master/Slave S witch ( T1 onl y):

• UP or OFF – Master

• DOWN or ON – Slave

Not used (E1)

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

OFF

UP or OFF – Biphase M

encoding

DOWN or ON – Slave (T1)

UP or OFF (E1)

Page 32

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 30 of 50

Loopback T est Switch

A 3-position toggle switch marked LPBK TEST is loca ted on the fr o nt pane l. This s witch must b e set to

the center position labeled OPR to insure proper operation of the Model LE200-FSR or LE200-FLR Line

Extender.

Indicators

Table 35. Model 9637/T1 or Model 9637/E1 Indicator Function Table

Indicator Function

OPT CD This is the optical carrier detect indicator.

• RED - indicates t he abs e nce of a good optical signal.

• GREEN - indicates the presence of a good optical signal.

DATA IN This is the data input detect indicator.

• RED - indicates t he abs e nce of an inpu t si gnal.

• GREEN - indicates the presence of an input signal.

BPV

When illuminated RE D , it indi c ates the pr esence of Bipolar Violations on

the input signal. This could be a result of a faulty input cable or that the

modem’s signal encoding switch (S1) is set incorrectly.

DATA AIS OUT

When illuminated YELLOW, all logic ones are being transmitted from the

Data I/O Output port. Switch 2 is set to DOWN position.

DATA AIS IN

When illuminated YELLOW, all logic ones are being received at the Data

I/O Input port. Switch 2 is set to DOWN position.

OPT AIS IN

When illuminated YELLOW, an optical AIS signal is being received.

Typically an indication of a successful loopback test

TEST When illuminated YELLOW, the unit is in a Test mode.

Verificatio n of Proper Operation

Under normal operating conditions, the DATA IN and OPT CD indicators will be GREEN. All other

LED indicators will be OFF.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 33

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 31 of 50

Typical Clock Setting Information

The following section shows the most common line extender connection schemes and the expected T1/E1

and LVDS data line parameters for each. Consult the applicable tables above to determine the correct

switch settings. Consult GAI-Tronics for technical support of connection schemes not shown in this

manual.

Point-to-P oint Page/P arty® System Connection

®

Figure 10. Point -to- Point Page/Party

Table 36. Point-to- Point Page/Party

®

System Connection Table

System Connection

Parameter Switch Configuration Description

T1 Line

SW2 Determined by installation distance between LE200s.

Length

T1 /E1 Cl oc k

Source

SW3-1

SW3-2

• Unit A is the master clock source: SW3-1 (open) SW3-2 (open)

• Unit B uses the T1/E1 clock from Unit A: SW3-1 (closed) SW3-2

(closed)

LVDS Clock

Source

SW3-3

SW3-4

Not used - disable both LVDS “in” and “out”: SW3-3 (open) SW3-4 (open)

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 34

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 32 of 50

Point to Multi- point Page/Party® System Connection

Figure 11. Point to Multi-point Page/Pa r ty

®

System Connection

Table 37. Point to Multi-point Page/Party

®

System Connection Table

Parameter Switch Configuration Description

T1 Line

Length

SW2

Determined by installation distance between each pair of line extenders:

• A to D

• B to E

• C to F

T1 /E1 Cl oc k

Source

SW3-1

SW3-2

• Units A, B, and C are the master clock sources: SW3-1 (open) SW3-2

(open)

• Unit D uses the T1/E1 clock from Unit A: SW3-1 (closed) SW3-2 (closed)

• Unit E uses the T1/E1 clock from Unit B: SW3-1 (closed) SW3-2 (closed)

• Unit F uses the T 1/E1 clock from Unit C: SW3-1 (closed) SW3-2 (closed)

LVDS

Clock

Source

SW3-3

SW3-4

LVDS clock is used b etween u n its A, B and C.

• Unit A - “in” disabled, “out” enabled: SW3-3 (open) SW3-4 (closed)

• Unit B - “in” enabled, “out” enabled: SW3-3 (closed) SW3-4 (closed)

• Unit C - “in” enabled, “out” disabled: SW3-3 (closed) SW3-4 (open)

Mute

Analog

SW6-4

Units B and C are muted since no Page/Party® cable is connected:

SW6-4 (closed).

Lines

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 35

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 33 of 50

Series Connec tion of Page/Party® System

Figure 12. Series Connection of Page/Party

®

System

®

Table 38. Series Connection o f Page/ P ar ty

System Table

Parameter Switch Configuration Description

T1 Line

Length

SW2 Determined by installation distance between each pair of line extenders:

• A to B

• C to D

T1 /E1 Cl oc k

Source

SW3-1

SW3-2

• Units A and C are the master clock sources: SW3-1 (open) SW3-2 (open)

• Unit B uses the T1/E1 clock from Unit A: SW3-1 (closed) SW3-2

(closed)

• Unit D uses the T1/E1 clock from Unit C: SW3-1 (closed) SW3-2

(closed)

LVDS Clock

Source

SW3-3

SW3-4

LVDS clock is used b etween u n its B and C:

• Unit B - “in” disabled, “out” enabled: SW3-3 (open) SW3-4 (closed)

• Unit C - “in” enabled, “out” disabled: SW3-3 (closed) SW3-4 (open)

Mute Analog

Lines

SW6-4

Unit C is muted since no Page/Party

SW6-4 (closed).

®

cable is connected:

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 36

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 34 of 50

Rules for Interconnecting more than T wo Model LE200s

When connecting more than two Model LE200s together, these rules must be followed.

• A maximum of two Model LE200 pairs can be connected in series when the series connections are

made using Page/Party

®

cable as shown below.

Figure 13 . Maximum S eries C onnections

When Model LE200s are connected in series, a problem can arise when training echo cancellation. If

more than one Model LE200 is training echo cancellation on a signal line at the same time, then none

of them will train echo canc ellation properly. To prevent this, power each line extender one at a time.

Wait for the echo cancellation to complete on the first line extender before powering the second.

• A maximum of eight

pairs of Model LE200s can be connected in parallel. Parallel connections must

be made using the LVDS link and the T1/E1 link as shown below.

Figure 14. Maximum Parallel Connections

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 37

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 35 of 50

• A maximum of 16 Model LE200s can be connected within a single z one or Page/Party® subsystem

®

• Avoid having more than one Model LE200 connected to a particular Page/Party

ca ble. Instead, use

th e LVD S link w hen ever p o ssi bl e.

• Line extenders can NOT be wired in a loop architecture for redundant connections as shown below:

Figure 15. Inva lid Loop Conne c tio n of Page/Party

®

Systems

• All contact input states are ORed together to determine a contact output state.

• All remote page line audio detected states are ORed together to determine the remote page line audio

detected st ate used by that contact output .

• All remote page line ground fault states are ORed together to determine the remote page line ground

fault state used by that contact output.

• When enabled, 50 kHz VLC signal on any page line is transmitted to all page lines.

• SmartSeries FSK data on any page line is transmitted to all page lines.

• Manual retraining of echo cancellation at one Model LE200 also requests it at all digitally

interconnected Model LE200s.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 38

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 36 of 50

Summary of PC Board Connections and Settings

Table 39. Page/Party Termination PCBA (Model 69441-xxx)

Refer to Figure 5 for comp onent locations.

Designator Type Function

J1 DB-25 connector Connect to J4 on Main PCBA (69443-xxx) via ribbon cable.

P1 Jumper clip Part y line #3 line balance resistor enabled/disabled

P2 Jumper clip Part y line #2 line balance resistor enabled/disabled

P3 Jumper clip Part y line #4 line balance resistor enabled/disabled

P4 Jumper clip Part y line #1 line balance resistor enabled/disabled

P6 Jumper clip Part y line #5 line balance resistor enabled/disabled

P7 J umper c lip Page line balance resistor e nable d/disable d

P5 & P8 Ter minal b lock Pa ge L ine - T ermi nals 1 and 2

Party Line 1 - Terminals 3 and 4

Party Line 2 - Terminals 5 and 6

Party Line 3 - Terminals 7 and 8

Party Line 4 - Terminals 9 and 10

Party Line 5 - Terminals 11 and 12

R3 Potentiometer Party line #3 line balance resistance

R4 Potentiometer Party line #2 line balance resistance

R19 Potentiometer Party line #4 line balance resistance

R20 Potentiometer Party line #1 line balance resistance

R23 Potentiometer Party line #5 line balance resistance

R24 Potentiometer Page line, line balance resistance

TB1 T erminal block C hassis ground - Terminals 1 and 2

TB2 T erminal block C hassis ground - Terminals 1 and 2

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 39

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 37 of 50

Table 40. Input/Output Terminations PCBA (Model 69442-xxx)

Refer to Figure 5 for comp onent locations.

Designator Type Function

J1 DB-25 connector Connect to J3 on Main PCBA (69443-xxx) via ribbon cable

TB1 Terminal block

Field connections for contact output #1

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB2 Terminal block

Field connections for contact output #2

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB3 Terminal block

Field connections for contact output #3

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB4 Terminal block

Field connections for contact output #4

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB5 Terminal block

Field connections for contact output #5

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB6 Terminal block

Field connections for page audio detected contact output

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB7 Terminal block

Field connections for page ground fault contact output

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB8 Terminal block

Field connections for contact inputs #1, #2, and #3

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

TB9 Terminal block

Field connections for contact inputs #4 a nd #5

Field connections for chassis ground

The board’s silkscreen indicates the connections; the pin

numb ers a re not la bel e d.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 40

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 38 of 50

Table 41. Main Processing PCBA (Model 69443-xxx)

Refer to Figure 4 for comp onent locations.

Designator Type Function

J1 RJ45 receptacle LVDS data “out”

J2 RJ45 receptacle LVDS data “in”

J3

J4

DB-25

connector

DB-25

connector

Connect to J1 on Input/Output Termination PCBA (Model 69442xxx) via 25-pin ribbon cable.

Connect to J1 on Page/Pa rty

®

Termination PCBA (Model 69441-

xxx) via 25-pin ribbon cable.

P1 N/A Not installed

P2 Post header No connection - used during production testing of PC board)

P3 N/A Not installed

P4 Post header No connection - used during production testing of PC board)

P5 J umper c lip P age line ground f ault detector e nabled/dis abl e d.

P6, P7 Jumper clip Party line #5 off-hook detector enabled/disabled.

P8, P9 Jumper clip Party line #4 off-hook detector enabled/disabled.

P10, P11 Jumper clip Party line #3 off-hook detector enabled/disabled.

P12, P13 Jumper clip Party line #2 off-hook detector enabled/disabled.

P14, P15 Jumper clip Party line #1 off-hook detector enabled/disabled.

P16 Terminal block

Page line monitor output - Terminals 1 and 3

No connection - Terminal 2

P17, P18 Terminal block

P19 Terminal block

Power 48 V dc (+) - Terminal 1

Power 48 V dc (-) - Terminal 2

T1/E1 Data TX (ring) - Terminal 1

WARNING

Turn off power before connecting

and disconnect i ng.

T1/E1 Data TX (tip) - Terminal 2

T1 /E1 Data RX ( ring) - Ter minal 3

T1/E1 Data RX (tip) - Terminal 4

P20 Jumper clip T1/E1 receive transformer center tap floating/grounded.

P21 Jumper clip T1/E1 transmit transformer center tap floa ting/grounded.

PB1

Push-button

Used to retrain the echo cancellation circuit.

switch

SW1

Rotary HEX

Used for diagnostic purposes. Set to 0 during normal operation

switch

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 41

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 39 of 50

Designator Type Function

SW2

SW3

SW4

8-position

DIP switch

8-position

DIP switch

8-position

DIP switch

Position 1 - T1 line build out bit 0

Position 2 - T1 line build out bit 1

Position 3 - T1 line build out bit 2

Position 4 - T1/E1 receive equalizer gain limit

Position 5 - Page audio hold ti me ( bit 1)

Test waveform select (bit 1)

Position 6 - Page audio hold ti me ( bit 2)

Test waveform select (bit 1)

Positio n 7 - Page audio detect thr eshold

Position 8 - Test waveform enable

Positio n 1 - Board T 1/E1 c lock s ource

Positio n 2 - Board T 1/E1 c lock s ource

Position 3 - LVDS “in” enable/disable

Position 4 - LVDS “out” enable/disable

Position 5 - 600-ohm audio monitor volume (bit 1)

Position 6 - 600-ohm audio monitor volume (bit 2)

Position 7 - 600-ohm audio monitor volume (bit 3)

Position 8 - 600-ohm audio monitor volume (bit 4)

Position 1 - Party Line 5 (connect/disconnect)

Position 2 - Party Line 4(connect/disconnect)

Position 3 - Party Line 3 (connect/disconnect)

Position 4 - Party Line 2 (connect/disconnect)

Position 5 - Party Line 1 (connect/disconnect)

Position 6 - Page line (connect/disconnect)

Position 7 - Page line monitor output (connect/disconnect)

Position 8 - Not used

SW5

8-position

DIP switch

Position 1 - SmartSeries Page Line FSK data (enable/disable)

Position 2 - 50 kHz Page Line VLC signal (enable/disable)

Position 3 - Regenerate page line ground fault (enable/disable)

Position 4 - GND fault contact activates on local page line fault.

Position 5 - GND fault contact activates on remote page line fault.

Position 6 - Page au dio co ntact activates on l oc al pa ge line au dio.

Position 7 - Page audio co ntact activates on remot e p age line au dio.

Position 8 – T1 or E1 mode selection

SW6

4-position

DIP switch

Position 1 - One minute startu p delay of e c ho can cellatio n training

(enable/disable)

Position 2 - Local party line off-hook regeneration (enable/disable)

Position 3 - On-hook party line muting (enable/disable)

Position 4 - Mute analog circuit (enable/disable)

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 42

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 40 of 50

F requently Asked Questions

Q: Why does it take so long for the propagation of off-hook to on-hook transitions?

A: The line balance ac coupling capacitors take some t ime to charge. Also, the delay helps to prevent

audio from looking like an on-hook condition.

Q: Why does it take so long for the propagation of the page line ground fault transitions?

A: If the delay was not there, then page line audio might appear to be a ground fault.

Q: I am upgrading an LE100 to an LE200, and am using a CAT 3 cable c onnection. Do I need to replace

the CAT 3 cable with CAT 5 cable?

A: No.

Q: Why is shielded cabl e sp ecified for the LVDS cab l e?

A: To improve the link’s noise immunity. Most likely, the clock signal that controls one of the LE200s

pass es over t he L V DS c ab le.

Q: Is the LE200 compatible with the public switched telephone network?

A: No.

Q: Does the LE200 have on-board prima ry protection for the T1/E1 cable?

A: No.

Q: Why is the LE200 not compatible with the public switched telephone network?

A: (1) It is not approved for such use. (2) At a minimum, it does not support the facility data link

transmission required for such use.

Q: What does LVDS stand for?

A: Low Voltage Differential Signaling

Q: Can I connect a Model LE200 to an LE100?

A: The T1 connection cannot be used to connect an LE200 to an LE100. However, an analog connection

can be used, i.e., an LE200 and an LE100 can both connect to the same system cable.

Q: Can I have Model LE100 and LE200 Line Extenders in the same system?

A.: Yes, but the LE100s must be connected to other LE100s and the LE200s must be connected to

LE200s.

Q: What happens if the line balance is not installed?

A: A loud osc illation is hea rd on t he audio line.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 43

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 41 of 50

Changing to a LE200 from a LE100

Changed Features Compared to LE100

An echo cancellation routine is added.

The LE200’s off-hook detector must be the only off-hook detector installed on a particular party line.

The LE200 supports only unidirectional off-hook propagation, while the LE100 supported bi-directional

off-hook prop agation.

For copp er T1/E1 conne ctions, CAT 5 ca ble is specified instead of CAT 3 cable.

OTE: The LE200 should work with CAT 3 cable; use CAT 5 cable, or better, for all new installations.

N

• The LE200 provides true relay outputs instead of polarized solid-state relay outputs.

• The LE200 is not able to connect to the LE100. The LE200 pairs must replace the LE100 in pairs.

• There exists an additional consideration related to echo cancellation when connecting Model LE200s

in series.

New Features Compared to LE100

• The LE200 has a LVDS interface expected to be used to avoid paralleling multiple LE200s on the

same Page/Party

• Page line ground faults can be propagated from the remote connection.

• The LE200 can report remote page line ground faults.

• The LE200 has an array of LEDs tha t can sometimes aid in troubleshooting.

• The LE200 has isolation relays that disconnect it from its (audio line) field wiring when it is not

powered.

• The LE200 has the ability to select either T1 or E1 signal spec ifications

®

cable.

f:\standard ioms - current releas e\ 42004 ins t r. manuals\42004-701l2f.doc

04/09

Page 44

Pub. 42004-701L2F

M

ODEL LE200 SERIES WALL-MOUNT PAGE/PARTY® LINE EXTENDERS PAGE 42 of 50

Settings Checklist

The following tables (Table 42 through Table 48) have been included to ser ve as a system setting

checklist. After determining the appropriate settings for your system, you may record them below for

future reference.

Table 42. Line Balance Resistor Enable on 69441-xxx PCBA

Header Setting Note

P1 Party Line #3

P2 Party Line #2

P3 Party Line #4

P4 Party Line #1

P6 Party Line #5

P7 Page Line

Table 43. Line Balance Resistance on 69441-xxx PCBA

Potentiometer Setting Note

R3 Party Line #3

R4 Party Line #2

R19 Party Line #4

R20 Party Line #1

R23 Party Line #5

R24 Page Line

Table 44. Off-hoo k and Gr ound Fault D et ectio n o n 69443-xxx PCBA

Header Setting Note

P5 Page line ground fault d etector

P6, P7 Part y line #5 off-hook detector

P8, P9 Part y line #4 off-hook detector

P10, P11 Party line #3 off- hook detector

P12, P13 Party line #2 off- hook detector

P14, P15 Party line #1 off- hook detector