Page 1

Pub. 43004-010H

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

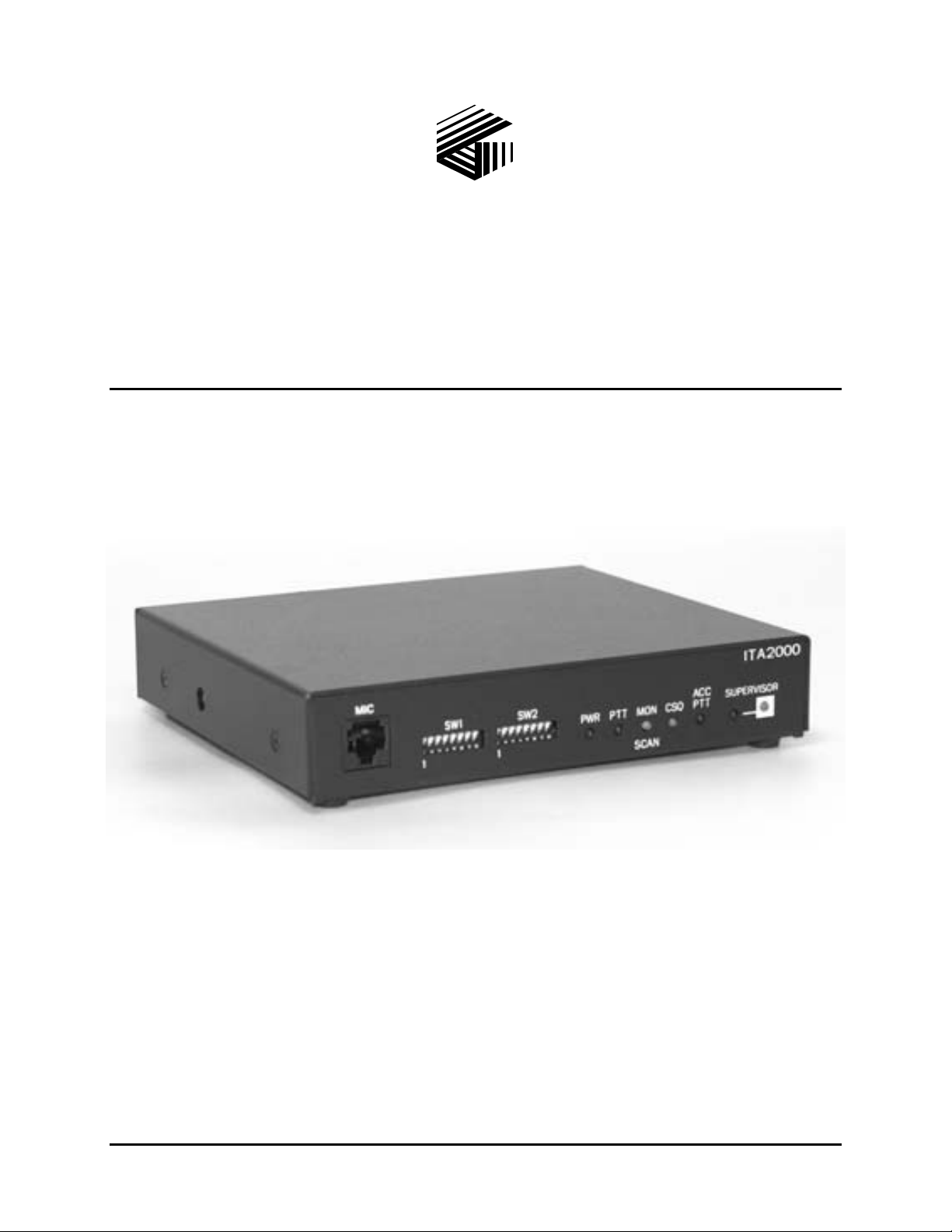

ITA2000A Series Tone Remote Adapter

with Scanning

User and Installation Manual

*U.S. Patent 6,950,653

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

V

Page 2

CONFIDENTIALITY NOTICE

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics.

GAI-Tronics retains all intellectual property and other rights in or to the information contained herein,

and such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

COMPUTER SOFTWARE COPYRIGHTS

This product contains copyrighted computer programs stored in semiconductor memory. These programs

are copyrighted by GAI-Tronics Corporation and may not be reproduced in any form without express

written permission from GAI-Tronics.

WARRANTY

GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any GAI-Tronics equipment supplied hereunder

shall be free of defects in material and workmanship, shall comply with the then-current product specifications and product

literature, and if applicable, shall be fit for the purpose specified in the agreed-upon quotation or proposal document. If (a)

Seller’s goods prove to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above, Buyer may return such

goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time they will be repaired or replaced, at Seller’s

option, without charge to Buyer. Repair or replacement shall be Buyer’s sole and exclusive remedy, and the warranty period on

any repaired or replacement equipment shall be one (1) year from the date the original equipment was shipped. In no event shall

GAI-Tronics’ warranty obligations with respect to equipment exceed 100% of the total cost of the equipment supplied hereunder.

The applicability of any such third-party warranty will be determined solely by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors, shall be performed in

accordance with the standard of care with which such services are normally provided in the industry. If the services fail to meet

the applicable industry standard, GAI-Tronics will, for a period of one (1) year from the date of completion, re-perform such

services at no cost to the Buyer. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall

GAI-Tronics’ warranty obligations with respect to services exceed 100% of the total cost of services provided hereunder.

Limitations/Exclusions. The warranty on any equipment supplied hereunder is subject to Customer’s use in compliance

with applicable FCC regulations and manufacturer specifications. The warranties herein shall not apply to, and GAI-Tronics

shall not be responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent caused by

accident, misuse, abuse, neglect, system design, product modification, failure to follow instructions contained in the product

manual, repair, or attempted repair by anyone not authorized by GAI-Tronics, improper installation, installation of parts that do

not conform to the quality or specifications of the original parts or accessories, damage or loss occurred during shipment, or any

unit which is not new when sold or upon which the serial number has been defaced, modified or removed. The warranty does not

extend to damage incurred by natural causes including Force Majeure. The warranty does not cover microprocessors if failure is

due to static damage or application of improper voltage.

THE WARRANTIES AND REMEDIES CONTAINED

HEREIN ARE IN LIEU OF AND EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER

EXPRESS OR IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Operational and Maintenance Procedures. Buyer acknowledges that any improper use, maintenance, or

modification of the equipment provided hereunder, or use of unqualified maintenance or service technicians will severely impair

the operational effectiveness of the entire communication system. Buyer hereby agrees to indemnify, defend and hold GAITronics harmless from and against any and all third party claims arising, in any manner, out of: (a) Buyer’s neglect of the

equipment; (b) Buyer’s use of technicians not authorized by GAI-Tronics to service the equipment; or (c) Buyer’s improper use

or modification of the equipment or failure to follow the operational and maintenance procedures provided with the equipment.

Limitation of Liability/Damages. In no event (even should circumstances cause the exclusive warranties and remedies

set forth in the Warranty section to fail of their essential purpose) shall either party be liable for any indirect, incidental, special

or consequential damages (including, but not limited to, loss of use, loss of anticipated profits, or damages arising from delay)

whether such claims are alleged to have arisen out of breach of warranty, breach of contract, strict or absolute liability in tort, or

other act, error or omission, or from any other cause whatsoever, or any combination of the foregoing.

Motorola and MAXTRAC are trademarks of Motorola, Inc.

03/13 Publication 43004-010H i

Page 3

Table of Contents

FOREWORD ............................................................................................................................................................... 1

SCOPE OF MANUAL .................................................................................................................................................... 1

NOMENCLATURE ........................................................................................................................................................ 1

ORDERING REPLACEMENT PARTS .............................................................................................................................. 1

SERVICE AND REPAIR ................................................................................................................................................. 1

FCC INTERFERENCE WARNING .................................................................................................................................. 1

SAFE HANDLING OF CMOS INTEGRATED CIRCUIT DEVICES ...................................................................................... 2

DESCRIPTION............................................................................................................................................................ 3

FEATURES AND BENEFITS OF THE ITA2000A TONE REMOTE ADAPTER..................................................................... 3

ADDITIONAL FEATURES AND BENEFITS OF THE ITA2000A TONE REMOTE ADAPTER IN SCAN MODE ....................... 4

PRODUCT OVERVIEW ................................................................................................................................................. 5

ITA2000A ACCESSORIES ........................................................................................................................................... 5

SPECIFICATIONS ......................................................................................................................................................... 6

OPERATION ............................................................................................................................................................... 7

FRONT PANEL LED OPERATION ................................................................................................................................. 7

PWR LED .......................................................................................................................................................................... 7

PTT LED ............................................................................................................................................................................ 7

MON/SCAN LED .............................................................................................................................................................. 7

CSQ LED ........................................................................................................................................................................... 7

ACC PTT LED ................................................................................................................................................................... 7

SUPERVISOR LED ........................................................................................................................................................... 7

SUPERVISOR BUTTON ................................................................................................................................................. 8

DESK MICROPHONE PORT .......................................................................................................................................... 8

Desk Microphone Port Pinout .............................................................................................................................. 8

TONE CONTROL INTERFACE ....................................................................................................................................... 9

Scan Start/Stop in the Scan Mode ....................................................................................................................... 10

Radio Monitor in Scan Mode .............................................................................................................................. 10

SUPERVISOR MODE .................................................................................................................................................. 11

ACCESSORY OPERATION .......................................................................................................................................... 11

TEST MODE .............................................................................................................................................................. 12

INSTALLATION ....................................................................................................................................................... 13

PLANNING THE INSTALLATION .................................................................................................................................. 13

MOUNTING ............................................................................................................................................................... 13

EQUIPMENT REQUIRED ............................................................................................................................................. 14

Test Equipment ................................................................................................................................................... 14

Documentation .................................................................................................................................................... 14

CABLE INSTALLATION SAFETY CONSIDERATIONS..................................................................................................... 14

TELEPHONE LINE LIGHTNING AND OVER-VOLTAGE PROTECTION............................................................................. 14

POWER CONNECTIONS.............................................................................................................................................. 15

CONVENTIONAL TO SCANNING OPERATION CONVERSION ........................................................................................ 16

RADIO CONNECTOR (J2)........................................................................................................................................... 17

Input/Output Radio Connector Table ................................................................................................................. 17

ACCESSORY CONNECTOR (J3) .................................................................................................................................. 20

Input/Output Accessory Connector Table ........................................................................................................... 20

ITA2000A to Kenwood TK-790/890 Series Radio Connection Chart ................................................................. 21

ITA2000A to RPG Radio Connection Chart ....................................................................................................... 23

ITA2000A Tone Remote Adapter to MCS2000 Radio Connection Chart (Conventional Mode Only) ............... 24

03/13 Publication 43004-010H ii

Page 4

Table of Contents ITA2000A Series Tone Remote Adapter

RADIO TIE LINE (TELEPHONE) CONNECTIONS .......................................................................................................... 25

Analog Facility Interface Codes ......................................................................................................................... 25

Telephone Line Connection Table ...................................................................................................................... 25

JUMPERS .................................................................................................................................................................. 26

Jumper Table ...................................................................................................................................................... 26

CHANNEL REVERT (CONVENTIONAL MODE ONLY) .................................................................................................. 27

Channel Revert Settings Table ............................................................................................................................ 27

CONFIGURATION SWITCH SETTINGS FOR CONVENTIONAL MODE OPERATION .......................................................... 28

Switch Settings for SW1 (Conventional) ............................................................................................................. 28

Switch Settings for SW2 (Conventional) ............................................................................................................. 29

CONFIGURATION SWITCH SETTINGS FOR SCAN MODE OPERATION ........................................................................... 30

Switch Settings for SW1 (Scan) ........................................................................................................................... 30

Switch Settings for SW2 (Scan) ........................................................................................................................... 31

LEVEL SETTINGS AND ADJUSTMENTS ....................................................................................................................... 32

Receive Audio Level ............................................................................................................................................ 32

Line Output Level ................................................................................................................................................ 32

Transmit Audio Level .......................................................................................................................................... 33

TEST DIAGNOSTICS .................................................................................................................................................. 34

THEORY OF OPERATION .................................................................................................................................... 35

TECHNICAL OVERVIEW ............................................................................................................................................ 35

Transmit Audio ................................................................................................................................................... 35

Radio Audio ........................................................................................................................................................ 35

Accessory Transmit ............................................................................................................................................. 36

Desk Mic Transmit .............................................................................................................................................. 36

Reset Circuit ....................................................................................................................................................... 36

TROUBLESHOOTING ............................................................................................................................................ 37

TROUBLESHOOTING THE ITA2000A TONE REMOTE ADAPTER ................................................................................ 37

FUSE REPLACEMENT ................................................................................................................................................ 38

MAIN CIRCUIT BOARD ........................................................................................................................................ 39

SCHEMATICS .......................................................................................................................................................... 41

DEFINITIONS AND ACRONYMS ......................................................................................................................... 49

03/13 Publication 43004-010H iii

Page 5

Foreword

Scope of Manual

This manual offers descriptive data and service information for the ITA2000A Tone Remote Adapter

with Scanning. The unit is shipped as a conventional tone remote adapter but can easily be converted to

a scanning tone remote adapter with a simple switch setting change. Please refer to the switch settings

located in the Installation section of this manual.

Nomenclature

The model number, located on the nameplate on the bottom, specifically identifies GAI-Tronics

equipment. If additional options are ordered, the option will be identified on the circuit board.

Many ITA2000A features are the same in both Conventional and Scan modes. If a feature is particular to

either mode, the mode will be identified.

Ordering Replacement Parts

When ordering replacement parts or requesting equipment information, please include the complete

identification number. This applies to all components, kits, and chassis. If the component part number is

not known, the order should include the number of the chassis or kit of which it is a part and sufficient

description of the desired component to identify it. Order parts from:

Customer Service

GAI-Tronics Corporation

400 E. Wyomissing Ave.

Mohnton, PA 19540

US: 800-492-1212

Outside US: 610-777-1374

Service and Repair

Inoperative or malfunctioning equipment should be returned to the factory for repair. Please call

1-800-492-1212 to obtain a Return Authorization number, published repair prices, and shipping

instructions. A Return Authorization can also be obtained by visiting our website at

www.gai-tronics.com.

OTE: A purchase order or credit card number is required prior to processing non-warranty repairs.

N

FCC Interference Warning

The FCC requires that manuals pertaining to Class A and Class B computing devices must contain

warnings about possible interference with local residential radio and TV reception. This warning reads

as follows:

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

1 03/13

Page 6

Foreword ITA2000A Series Tone Remote Adapter

Safe Handling of CMOS Integrated Circuit Devices

Many of the integrated circuit devices used in communications equipment are of the Complementary

Metal Oxide Semiconductor (CMOS) type. Because of their high open circuit impedance, CMOS

integrated circuits are vulnerable to damage from static charges. Care must be taken handling, shipping,

and servicing them and the assemblies in which they are used.

Even though protection devices are provided in CMOS integrated circuit inputs, the protection is

effective only against overvoltage in the hundreds of volts range such as is encountered in an operating

system. In a system, circuit elements distribute static charges and load the CMOS circuits, decreasing the

chance of damage. However, CMOS circuits can be damaged by improper handling of the modules, even

in a system. To avoid damage to circuits, observe the following handling, shipping, and servicing

precautions:

1. Prior to and while servicing a circuit module, particularly after moving within the service area,

momentarily touch both hands to a bare metal, earth-grounded surface. This will discharge any static

charge that may have accumulated on the person doing the servicing.

N

OTE: Wearing a conductive wrist strap will minimize static build-up during servicing.

2. Whenever possible, avoid touching any electrically conductive parts of the circuit module with your

hands.

3. Power down the unit before installing or removing the circuit module.

4. When servicing a circuit module, avoid carpeted areas, dry environments, and certain types of

clothing (silk, nylon, etc.) because they contribute to static build-up. Similarly, disconnect the test

probe prior to removing the ground lead.

5. All electrically powered test equipment should be grounded. Apply the ground lead from the test

equipment to the circuit module before connecting the test probe.

6. If a circuit module is removed from the system, it is desirable to lay it on a conductive surface (such

as a sheet of aluminum foil) which is connected to ground through 100k of resistance.

7. When soldering, be sure the soldering iron is grounded and has a grounded tip.

8. Prior to connecting jumpers, replacing circuit components, or touching CMOS pins (if this becomes

necessary in the replacement of an integrated circuit device), be sure to discharge any static build-up

as described in procedure 1. Since voltage differences can exist across the human body, it is

recommended that only one hand be used if it is necessary to touch pins on the CMOS device and

associated board wiring.

9. When replacing a CMOS integrated circuit device, leave the device in its conductive rail container or

conductive foam until it is to be inserted into the printed circuit module.

10. All low impedance test equipment (such as pulse generators, etc.) should be connected to CMOS

device inputs after power is applied to the CMOS circuitry. Similarly, such low impedance

equipment should be disconnected before power is turned off.

11. Replacement modules shipped separately from the factory will be packaged in a conductive material.

Any modules being transported from one area to another should be wrapped in a similar material

(aluminum foil may be used). Never use non-conductive material for packaging these modules.

03/13 2

Page 7

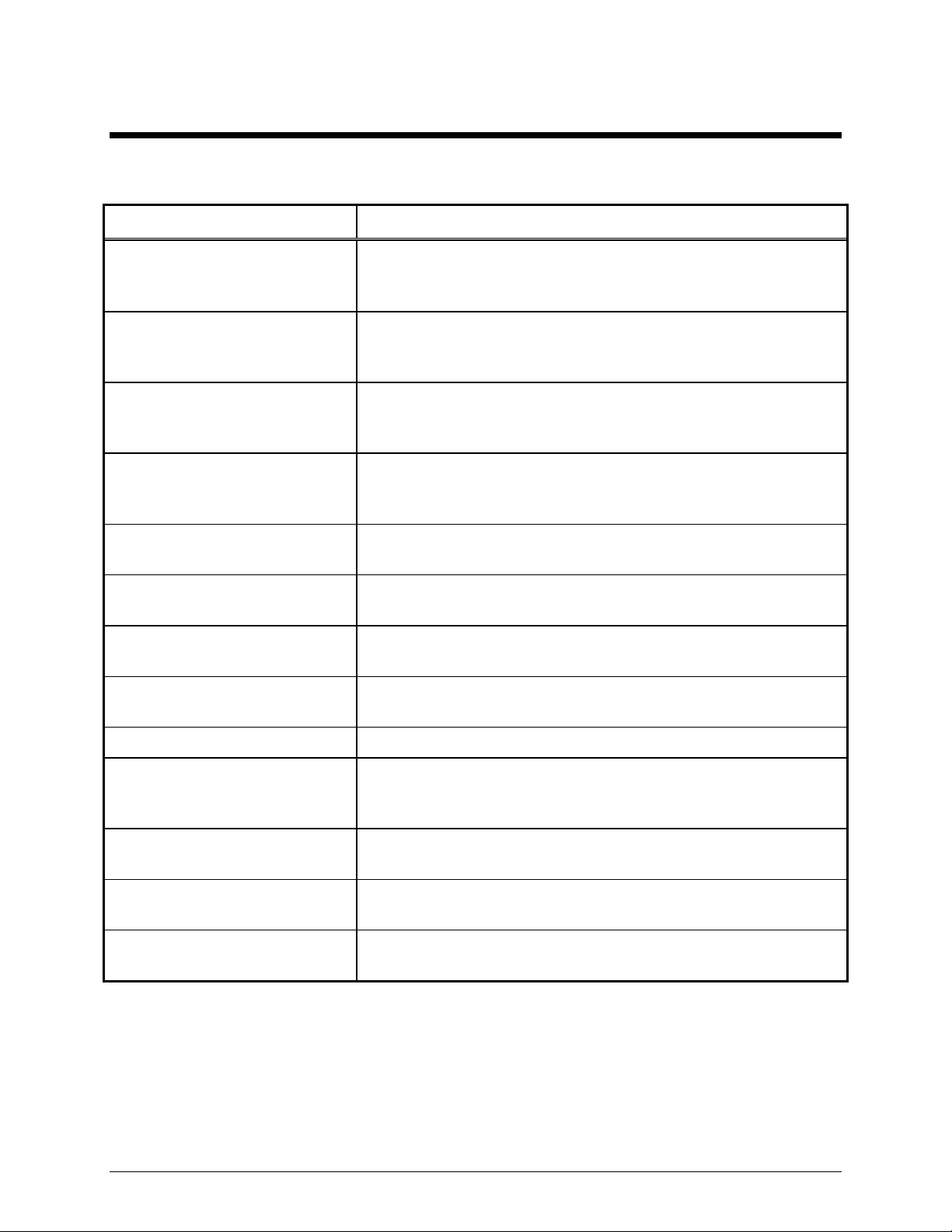

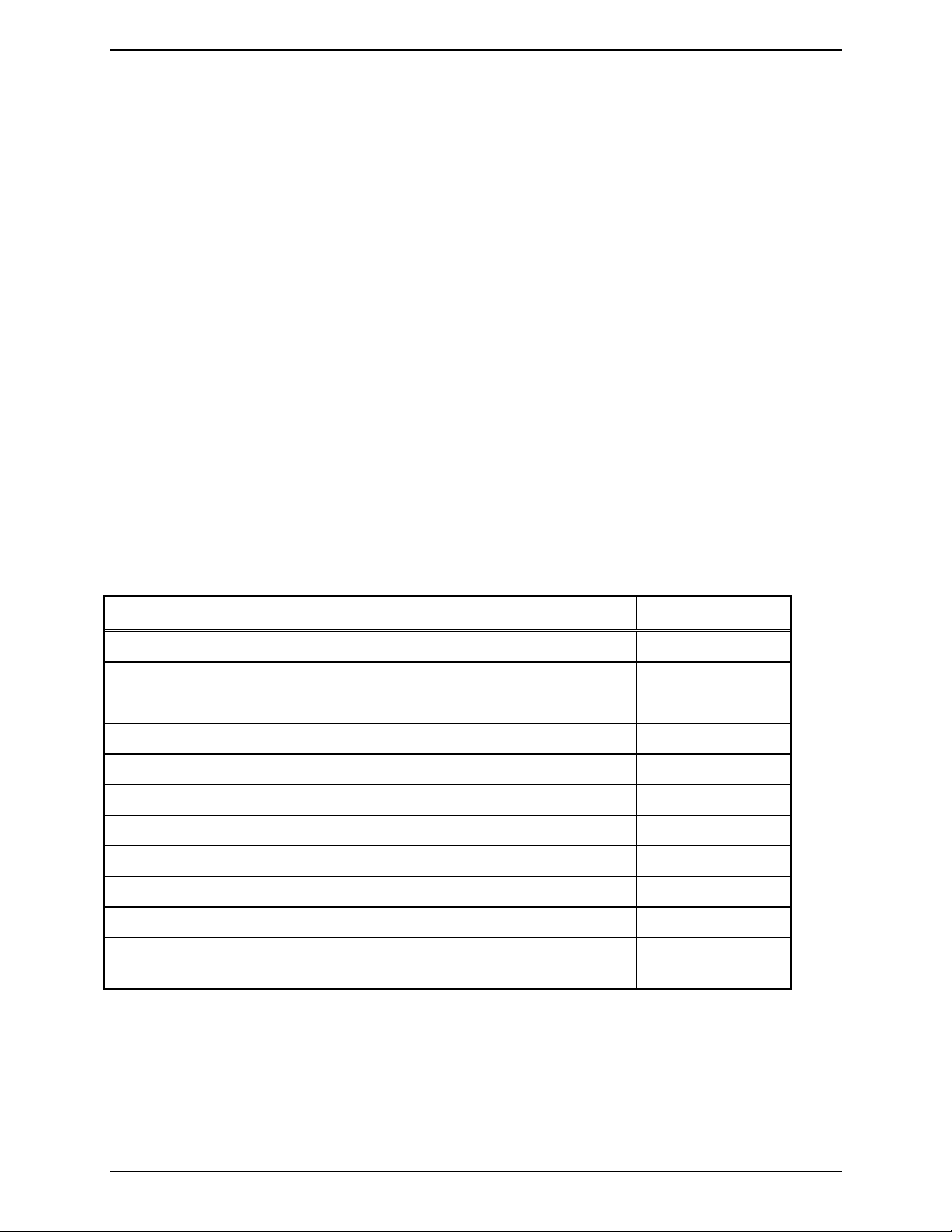

Features and Benefits of the ITA2000A Tone Remote Adapter

Feature Benefit

Description

Adjustable receive input

sensitivity and transmit output

level

Allows flexibility with different radio systems and user

environments, where radio output levels, line losses, and noise

factors vary.

Autolevel Reduces the need for site visits to adjust audio pots. Mobiles

receive consistently high receive sound level, with fewer repeat

requests.

Selectable input/output logic

control

All inputs/outputs can be individually selected to go active high or

to ground, depending on the radio, offering compatibility with many

radio systems.

Full-duplex capable with 2- or

4-wire

With 2-wire capable desk set (such as an ITR2000A), gives fullduplex operation for use with most full-duplex and trunking radio

systems.

Modular telephone line

Easy-to-install telephone line cable.

connection on back

Selectable timed or continuous

monitor

2

Flexible monitoring option.

Multiple parallel desk set support System flexibility and productivity are enhanced when several desk

sets are connected.

16-channel control1 Each of the five-channel steer outputs can be used to change

channels and other functions on certain radios.

Courtesy tones Sends a tone to the desk set when a mobile has stopped transmitting.

Selectable 2175 Hz guard tone

2

keying

High and low level guard tones and function tones are sent in

applications where tones are needed. (e.g. wireless phone line

extension).

Supervisor control Allows the dispatcher at the ITA2000A to override remote desk sets

and accessory.

Front panel mic jack Allows dispatch control with desk microphone, headset, handset,

etc.

Accessory port Allows connection of other devices, such as a local desk set or

telephone interconnect.

1

16-channel control is available only when configured for Conventional mode. When configured for

Scan mode, only 15-channel control is available.

2

Available only when configured for Conventional mode.

3 03/13

Page 8

Description ITA2000A Series Tone Remote Adapter

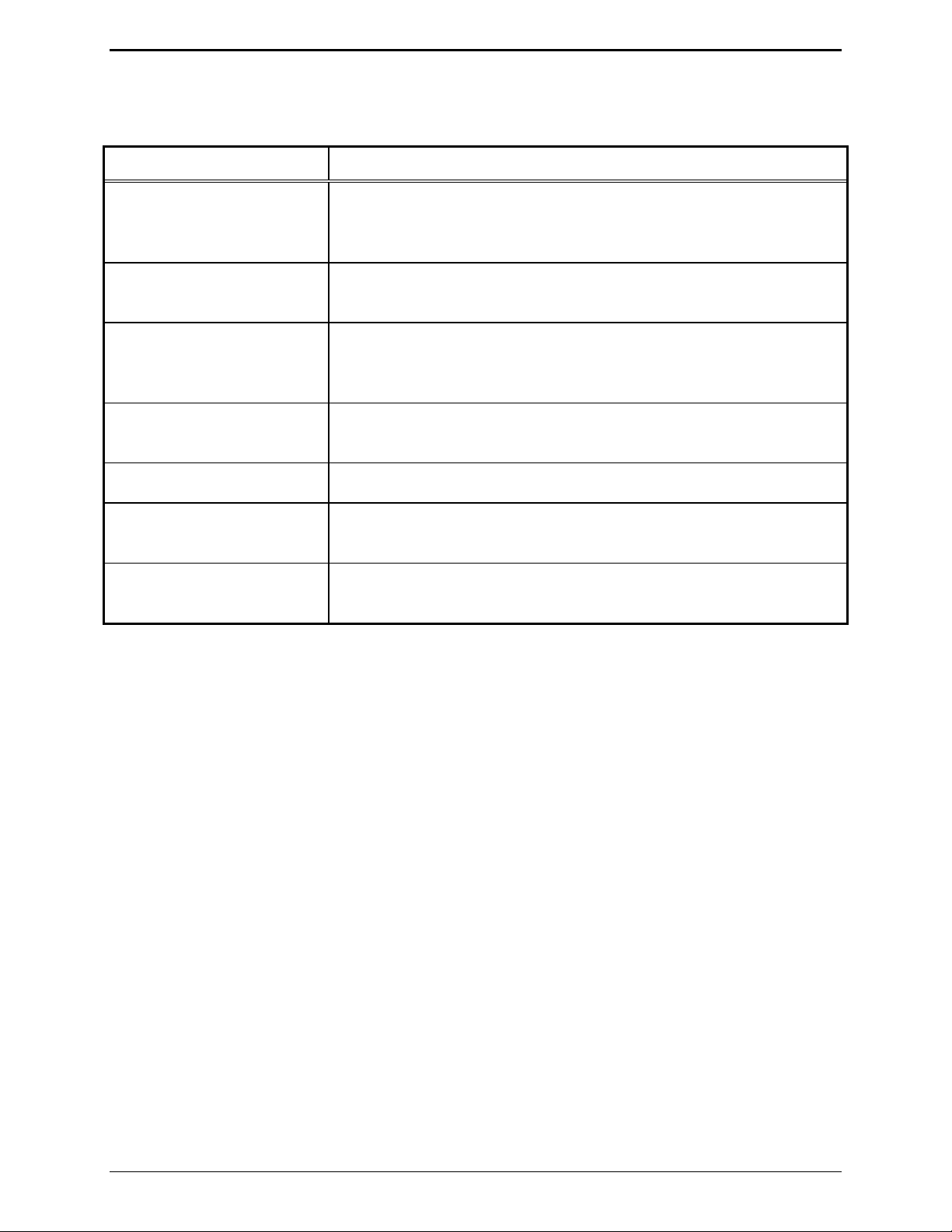

Additional Features and Benefits of the ITA2000A Tone Remote Adapter in Scan Mode

Feature Benefit

Adds scanning capability to

conventional multi-channel

radios

Scanning of up to 15

frequencies

Allows remote scanning and

radio control from multiple

dispatch points

Flexible scanning

configuration

Talk-back scanning Allows dispatcher to transmit on last active receive channel.

Remote scan on/off Scanning can be remotely turned on or off. Properly equipped parallel

15-channel control Each of the five channel steer outputs can be used to change channels

Enhances radio functionality by using channel steering capability of

both non-scanning and scanning radios. Reduces overall system cost.

A single multi-channel radio can remotely monitor multiple frequencies,

reducing the number of radios required for dispatch applications.

Using regular leased lines, multiple dispatchers can monitor and control

scanning capability. Each dispatch point displays currently active

receive channel.

Number of channels, scan rate, scan-stop time, and scan resume can all

be easily configured using readily accessible DIP switches.

dispatch devices are updated with the status.

and other functions on certain radios.

03/13 4

Page 9

ITA2000A Series Tone Remote Adapter Description

Product Overview

The ITA2000A Tone Remote Adapter uses a state-of-the-art digital signal processor (DSP) to ensure

highly accurate and fast tone encoding/decoding and audio filtering. It allows a radio to be remotely

controlled through dedicated, leased telephone lines or in-house wiring using standard EIA tone keying

sequences.

The advantages include flexible configuration, front panel controls and status indicators for set-up

convenience, automatic level control (ALC), and a dispatcher/service mic jack. It is compact, measuring

7.03 W 6.3 L 1.5 H inches, and supports full-duplex or simplex, 2- or 4-wire desk set stations. The

ITA2000A has an accessory connector that supports local control devices, such as a telephone

interconnect, extended local desk set, or a secondary radio.

Using GAI-Tronics’ ITR2000A or IPE2500A Tone Remote Desk Set, the ITA2000A programmed for

Scan mode (using patented techniques), adds tone remote scanning and scan start/stop capability to

conventional, multi-channel, steering-capable radios. Dispatch points are updated using these techniques

through the use of the parallel status update feature found in the GAI-Tronics Model ITR2000A and

IPE2500A Desk Sets.

To accommodate radios that vary in their active input logic, the ITA2000A can be set up to provide

discrete active output logic functions. Active low or active high outputs can be set for each radio and

accessory Channel Selection Output, Monitor, Push-to-Talk, Push-to-Talk Sense, and CSQ Detect.

ITA2000A Accessories

Description Part No.

GM300/MAXTRAC or Motorola GR1225 Radio Interface Cable 61531-007

Kenwood Radio Interface Cable (KCT-19) 61531-004

Radio Interface Cable (bare leads), 3-foot (included with unit) 97C160-0003

Power Supply, 100-240 V ac/12 V dc1 40419-008

Power Supply Adapter, European 40420-001

Power Supply Adapter, UK 40420-002

Power Supply Adapter, Australia 40420-003

Power Supply Adapter, Korea 40420-004

Fuse, F2, (Telco line only) Bussmann C515S 1.25A 4612-23015-25

Fuse, F1, (Power) Bussmann Type GMA-1A 4612-23500-01

Dual 19-inch Rack Mount, 1.75-inch high (Can hold two ITA2000A

units.)

1

Power (12 V dc) may be obtained directly from the controlled radio. A local power supply, if required,

must be ordered separately.

XAC0005A

5 03/13

Page 10

Description ITA2000A Series Tone Remote Adapter

Specifications

Color ...................................................................................................................................................... Black

Physical size ................................................................................................... 7.03 W 6.3 L 1.5 H inches

Weight .................................................................................................................................................... 4 lbs.

Temperature range ................................................................................................................. −30º C to 70º C

Humidity .................................................................................................................................... 95% at 50º C

Input power (main or aux.) .................................................................... 10.5 to 16 V dc; 100 mA maximum

Frequency response............................ +

Hum and noise ..................................................................................... More than -45 dB below rated output

Line audio input ........................... Microprocessor automatically compensates for line loses of up to 24 dB

Audio distortion ............................................................................................................... Less than 3% THD

RX input ............................................................. 32 mV ac to 4.5 V ac into 600 ohms (nominal 300 mV ac)

TX input ........................................................... 32 mV ac to 800 mV ac into 600 ohms (nominal 80 mV ac)

Line input ........................................................... −25 dBm to 0 dBm AGC to reference (nominal −10 dBm)

Line output ......................................... −15 dBm to +10 dBm adjustable into 600 ohms (nominal −10 dBm)

Logic outputs ........................................................................ PTT, CH-STEER; 20 mA, 100 mW dissipated

Maximum number of desk sets supported (practical limit) ........................................................................ 10

Microphone connections ..................................................................................................... Desk microphone

Input tone tolerance ................................................................................................................................. +

Safety .................................................................................................... Class III SELV powered equipment.

Powered by optional UL-listed (E104603)

and CSA certified (LR67888) ac adapter.

EMI ................................................................................................. USA: FCC Part 15, Sub. B-Verification

Canada: ICES-003

Line Interface ......................................................................... FCC Part 68 Exempt (Category II Tariff #260

service for private/leased line applications)

IC: Designed to meet CS03-8. (Cert. Pending)

Category: Voice-band metallic private line channel interface.

3 dB, 300 to 3000 Hz (except TX and RX audio notch at 2175 Hz)

2%

F1

F2

F3

F4

1

Scan operation only

2

Conventional operation only - Monitor/F16 is switch-selectable. See the programmable switch settings

1950 Hz

1850 Hz

1750 Hz

1650 Hz

F5

F6

F7

F8

1550 Hz

1450 Hz

1350 Hz

1250 Hz

F9

F10

F11

F12

1150 Hz

1050 Hz

950 Hz

850 Hz

F13

F14

F15

Scan Start/Stop1

or,

Monitor/F162

750 Hz

650 Hz

550 Hz

2050 Hz

in the “Installation” section of this manual.

03/13 6

Page 11

Front Panel LED Operation

PWR LED

Operation

ITA2000

Front View of the ITA2000A

The PWR LED illuminates to indicate that the ITA2000A power is on and the DSP is operating.

PTT LED

The push-to-talk LED, labeled PTT, illuminates when a valid transmit request has been decoded or the

mic PTT is actuated.

MON/SCAN LED

Conventional: The timed or constant monitor LED, labeled MON, illuminates when the ITA2000A is in

the monitor mode.

Scan: The SCAN LED blinks at the scan rate when the ITA2000A is scanning, and is lit steadily when in

monitor mode.

CSQ LED

The CSQ LED illuminates when a carrier detect input is active.

ACC PTT LED

The ACC PTT LED illuminates when the accessory PTT input is active.

SUPERVISOR LED

The SUPERVISOR LED illuminates when the ITA2000A is placed into supervisor mode.

7 03/13

Page 12

Operation ITA2000A Series Tone Remote Adapter

Supervisor Button

The SUPERVISOR button with the associated LED indicator provide full dispatcher control of the radio

system. This button is used to enter the supervisor mode or the test mode. Refer to the Operation section

for more information.

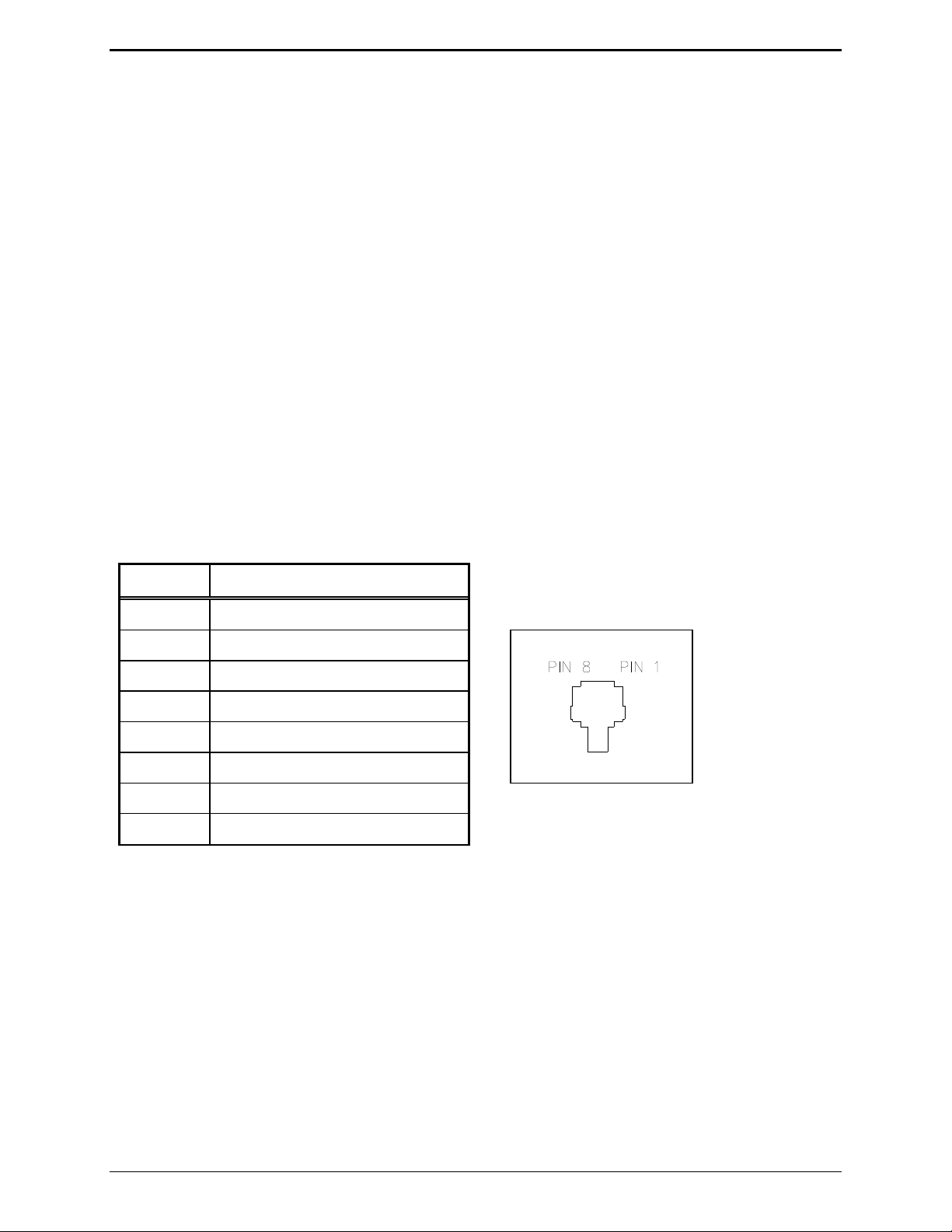

Desk Microphone Port

The front panel desk microphone port (MIC), is an 8-pin modular connector that supports an external

connection for local dispatch control. (Possible accessories include desk, gooseneck, or boom

microphones, or a headset or footswitch via the GAI-Tronics XAAB002A Audio Accessory Box).

Audio from this microphone is routed to the station transmit and receive audio and the telephone line

while push-to-talk is applied from the external microphone. The front-panel mic audio does not have a

guard tone notch applied. Station receive audio is also provided at the

allows a handset or similar device to be used in place of a desk microphone.

An external microphone monitor function places the ITA2000A in the monitor mode while asserting

PL/DPL disable at the radio connector. The microphone input type is passive, with an input impedance

of less than 2 k and a nominal input level of −20 dBm. The GAI-Tronics XDM004A Desk Microphone

is an acceptable example.

MIC connector. This feature

Desk Microphone Port Pinout

Pin No. Function

1 B+ OUT (through 10 ohms)

2 N/C

3 Monitor IN (closure to ground)

4 AGND

5 Mic IN (with bias voltage)

6 PTT IN (closure to ground)

7 N/C Desk Mic Port Pinout

8 RX audio OUT (handset audio)

03/13 8

Page 13

ITA2000A Series Tone Remote Adapter Operation

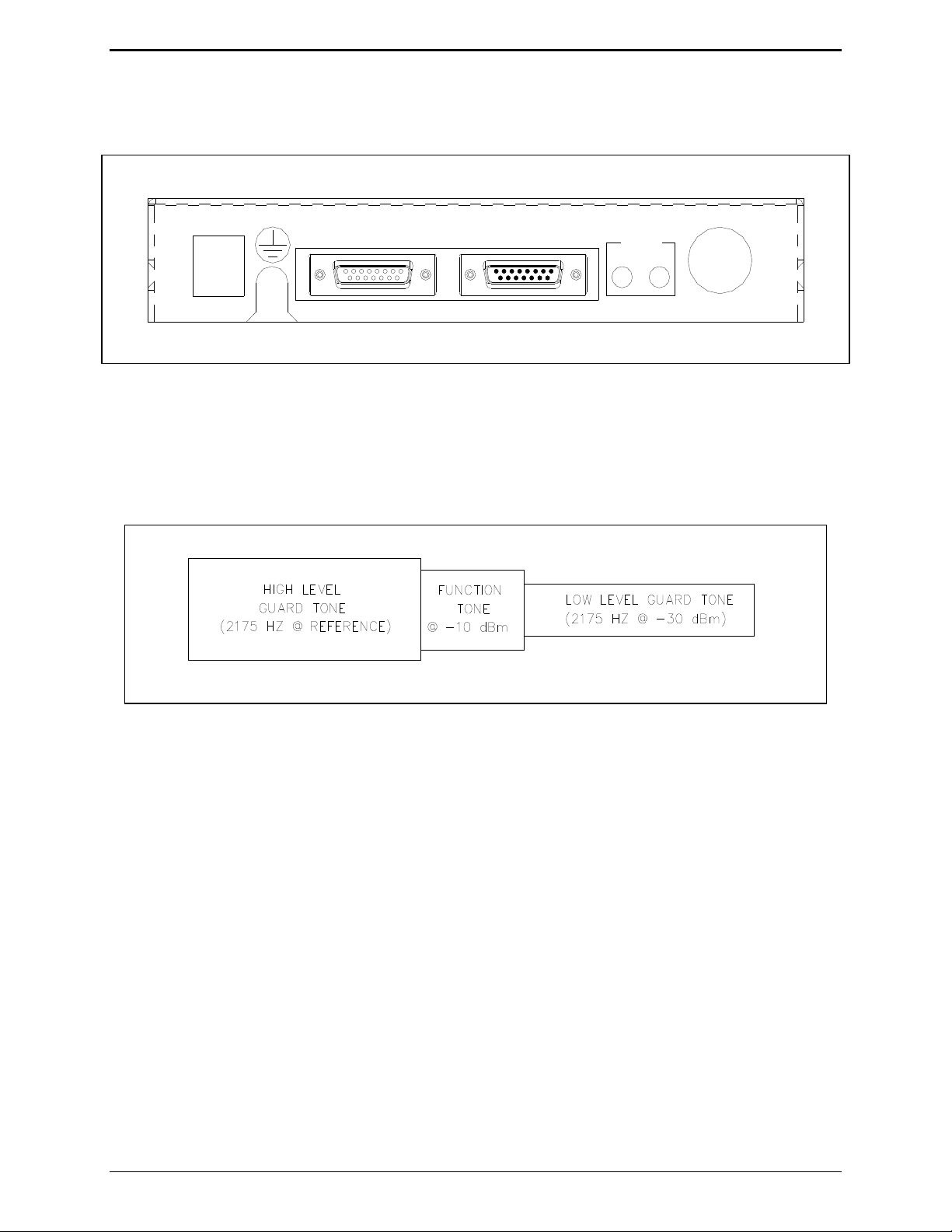

The rear view of the ITA2000A shows the line, accessory, radio, and power connector locations. Also

shown are the

TX and RX level adjustment pots, and the location of the internal fuse.

RX

DC POWER

INTERNAL

FUSE

13.8VDC

0.3A

LINE

ACCESSORY

RADIO

LEVEL

TX

Rear View of the ITA2000A

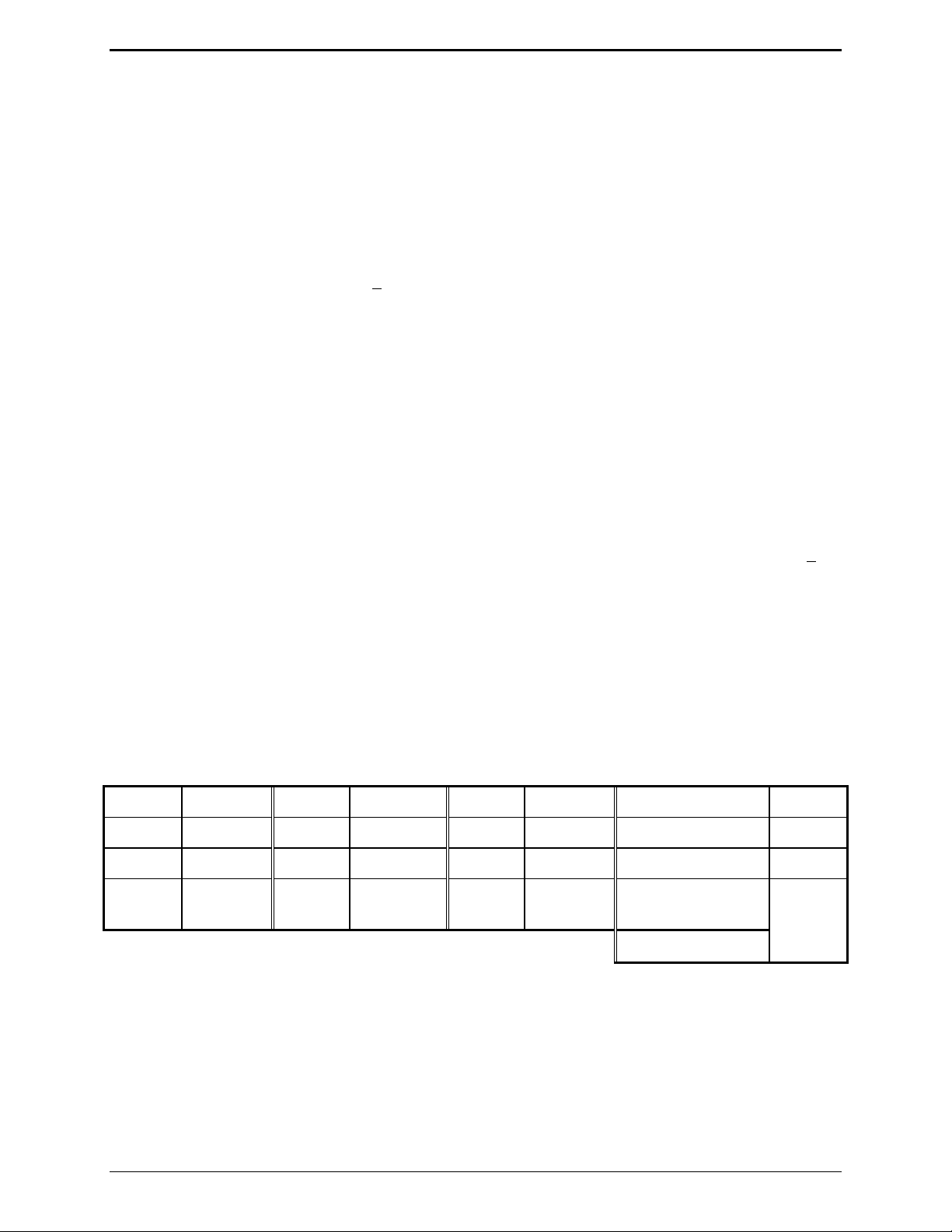

Tone Control Interface

The ITA2000A decodes standard EIA tone keying control tones for controlling the radio system. The

control tone convention can be seen below.

Standard EIA Tone Control Sequence

The function tone frequency ranges from 550 Hz to 2050 Hz in 100 Hz increments. 2050 Hz represents

monitor in Conventional mode and scan start/stop in Scan mode, 1950 Hz for F1, 1850 Hz for F2 down

to 550 Hz for F15.

When scanning and carrier is detected, a similar tone sequence is generated to the phone line where

HLGT is generated for 40 ms followed by a 20 ms function tone representative of the current channel.

This tone sequence will be decoded by desk sets capable of fast parallel status update, such as the GAITronics ITR2000A and IPE2500A. The use of products that are not capable of decoding this fast tone

sequence is not advisable, as the reliability of the operator information may be less than desirable.

9 03/13

Page 14

Operation ITA2000A Series Tone Remote Adapter

Scan Start/Stop in the Scan Mode

Upon power-up, the ITA2000A will automatically start scanning. While in scan mode, the ITA2000A

asserts, in sequence, the channel steer pins at the configured scan rate. Upon detection of carrier, the unit

stops scan and generates the appropriate tone sequence to the phone line. Upon loss of carrier, the unit

resumes scan after the configured scan stop time, or until manually started by that attached desk set,

depending on the configuration of the unit. When the unit resumes scan, a monitor function tone burst is

generated indicating to the attached desk sets that scan has resumed. If the operator wishes to stop the

scan resume before the scan stop time expires, the scan should be stopped using the scan stop feature.

The ITA2000A supports a remote scan start/stop toggle feature via the monitor function tone or 2050 Hz.

Pressing the desk set

MONITOR button causes a 2050 Hz tone sequence to be generated. When in scan

mode, if a valid 2050 Hz tone sequence is decoded, the unit stops scan on the current scan channel and

generates a tone burst to the phone line indicating to the attached desk set(s) the channel on which the

scan was stopped.

Likewise, when not in scan mode, if a valid 2050 Hz tone sequence is detected, the unit will resume scan.

The decoding of this 2050 Hz tone sequence by parallel desk sets indicates that scan has been resumed.

While in scan mode, if a channel steer is done by the desk set, the unit will cease scan. If the unit is

configured to resume scan after PTT, the unit will do so after the first PTT from the desk set. If the

operator wishes to remain on the channel indefinitely, scan must be stopped prior to issuing the channel

steer.

Radio Monitor in Scan Mode

The ITA2000A does not use a monitor function tone for assertion of monitor that may be required in

some installations, when in scan mode. To place the ITA2000A into monitor mode, the desk set must

force a channel steer to the desired channel by generating the appropriate function tone burst. This

causes the ITA2000A to stop scan and assert the PL/DPL disable output to the radio placing the radio in

monitor mode. When in this mode, the SCAN LED is lit. Subsequent transmissions by the desk set will

cause this assertion to be cleared until the desk set, again, generates an appropriate function tone burst.

An example of this operation using an IPE2500A Tone Remote Desk Set is as follows:

1. While scanning, the desk set operator wishes to transmit on channel 3. Before doing so, the operator

must ensure that the channel is clear by placing the radio in monitor mode on channel 3. The

operator presses the “3” key on the IPE25000A causing the desk set to generate a tone burst

consisting of HLGT followed by a function tone of 1750 Hz. Note that no low-level guard tone is

generated. The ITA2000A stops scan, switches to channel 3, asserts the PL/DPL output placing the

radio in monitor mode, and lights the SCAN LED.

2. The operator monitors the channel for activity and, upon assuring there is none, presses the

TRANSMIT key on the IPE2500A. The desk set generates a tone burst of HLGT followed by a

function tone of 1750 Hz, which is followed by LLGT. The ITA2000A asserts the radio PTT, clears

the assertion of the PL/DPL output and extinguishes the SCAN LED.

3. The operator releases the

radio. The ITA2000A does not

TRANSMIT key on the IPE2500A and the ITA2000A releases PTT from the

reassert the PL/DPL output to the radio. The operator carries on a

conversation with the field unit normally. If the unit is configured to resume scan after PTT, the unit

will do so after the scan-stop time has passed upon releasing PTT unless scan was halted prior to the

transmission.

4. If the operator wishes to again place the radio in monitor mode on channel 3, he must press the “3”

key again. The ITA2000A will decode the tone burst and place the radio into monitor mode as in

number 1 above.

03/13 10

Page 15

ITA2000A Series Tone Remote Adapter Operation

Supervisor Mode

The ITA2000A is placed in the supervisor mode by pressing the SUPERVISOR button for less than four

seconds, or by pressing either the MONITOR or PTT buttons of an attached desk-mic accessory. This

feature can be disabled in Conventional mode. When supervisor mode is entered, the SUPERVISOR

LED illuminates and the ITA2000A enters home-mode state. This is useful when a dispatcher needs to

disable control of the radio from all desk set operators and the accessory input. Pressing the

SUPERVISOR button again for less than four seconds is the only method used to exit supervisor mode

and return the ITA2000A to normal operation.

In the home-mode state, the ITA2000A clears all channel steer lines to the radio and generates

continuous guard tone to the phone line. In addition, the ITA2000A ceases scanning if in Scan mode.

The generation of guard tone serves two purposes. First, all LOTL-equipped desk sets such as the

ITR2000A or IPE2500A connected to the ITA2000A will recognize the base station is now in use and

will effectively lock out any operations. Second, when using the Scan mode, the generation of the guard

tone will clear the scan (monitor) indicator of these connected desk sets indicating that scan has stopped.

When home-mode is exited, the ITA2000A returns to the previously selected channel, or if in Scan mode,

returns to the previous scan state. If scan were active prior to entering the home-mode state, the

ITA2000A returns to scan upon exiting home-mode state and generates a tone burst to the phone line to

update the connected desk sets appropriately. If scan were not active prior to entering home-mode state,

the ITA2000A will not resume scan upon exiting home-mode state.

Accessory Operation

The ITA2000A includes an accessory connector to allow access to the radio from other devices such as

an ILD1000A Local Control Desk Set, a PL1877A Telephone Interconnect, or an additional ITA2000.

With such devices, control of the radio is limited to monitor and PTT. When an accessory device

requires access to the radio, it will assert the appropriate input on the accessory connector. When this

assertion is detected, the ITA2000A enters home-mode state. This feature can be disabled when in

Conventional mode.

When an accessory asserts the accessory monitor input, the ITA2000A enters home-mode state. When

the accessory releases the accessory monitor input, the ITA2000A exits home-mode state. If in Scan

mode, the ITA2000A resumes scan after the scan stop time if scan were active prior to the assertion of

the accessory monitor input.

When the accessory asserts the accessory PTT input, the ITA2000A enters home-mode state for the

duration of the assertion when in Scan mode. When the accessory releases the accessory PTT input,

Conventional mode exits home-mode state, and Scan mode immediately returns to the previous scan

state.

11 03/13

Page 16

Operation ITA2000A Series Tone Remote Adapter

Test Mode

To enter the test mode, press the SUPERVISOR button for more than four seconds. All LEDs illuminate

for two seconds indicating the ITA2000A has entered the test mode.

While the ITA2000A is in test mode, pressing the

SUPERVISOR button momentarily (less than four

seconds) causes the ITA2000A to step up to the next test.

WARNING

Disconnect the ITA2000A from the radio and disconnect all accessories from the ITA2000A when

performing Diagnostic Tests 2, 3, and 4. These diagnostics are used for factory testing only and

perform input/output configuration tests that may damage the interface to the radio and/or any

accessories connected to the ITA2000A.

Pressing the button again for at least four seconds

takes the ITA2000A out of the test mode.

03/13 12

Page 17

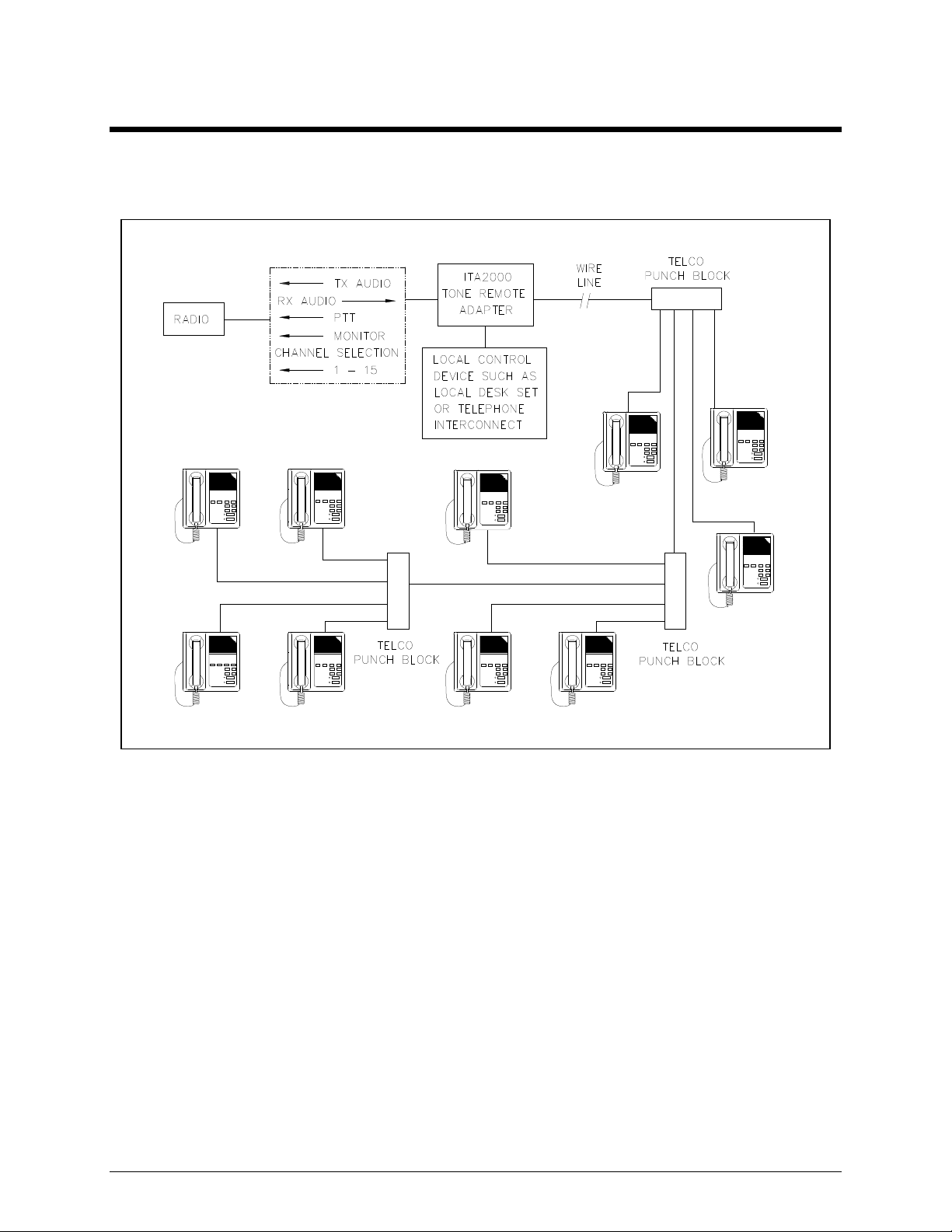

Planning the Installation

Installation

Typical ITA2000A Installation

Mounting

The ITA2000A Tone Remote Adapter can be installed in a customer-supplied rack or cabinet, or can be

placed on a desk for convenience when used with microphones and other accessories. A 19-inch

standard rack panel, 1.75 inches high, is also available. The GAI-Tronics part number is XAC0005A.

13 03/13

Page 18

Installation ITA2000A Series Tone Remote Adapter

Equipment Required

Test Equipment

RF service monitor, or Communications Service Analyzer such as the Motorola R-2600 with

RTL-1003A transformer

audio ACVM

multimeter or VOM

#1 Phillips screwdriver

8-pin modular plug with 'pigtail' leads

Documentation

this installation manual

associated radio installation/technical manual

service monitor manual

Cable Installation Safety Considerations

Interconnecting, communications, and Class 2 dc power cables should be separated from electrical light

or other Class 1 circuit by at least 2 inches. The exception is where Class 1 wiring or power circuits are

run in a raceway, or are metal-sheathed or metal–clad, or are permanently separated from the conductors

of the other circuitry by a continuous and firmly fixed nonconductor, such as porcelain tubes or flexible

tubing, in addition to the insulation on the wire.

Communications cables and in-building wiring should be listed and marked for the purpose according to

NEC Article 800. Optional cabling kits comply with these requirements and are recommended.

Telephone Line Lightning and Over-voltage Protection

The ITA2000A employs over-current phone line fuses F1 and F2. These fuses protect against occasional

extreme fault conditions that may get past the primary protectors. An example of a fault condition is a

power line cross. If these fuses ever require replacement, replace F1 or F2 only with the same type

Bussmann C515S 1.25A fuse.

For maximum surge and lightning protection, building primary (over-voltage) protectors must be

installed at the point where the phone lines enter the radio equipment building. Primary protectors are

usually required by local codes and should be provided by your leased line provider.

03/13 14

Page 19

ITA2000A Series Tone Remote Adapter Installation

Power Connections

The ITA2000A is supplied with a dc power cable. Plug the cable’s DIN connector into the dc power

receptacle on the rear of the unit. Connect the red lead to the positive terminal and the black lead to the

negative terminal of the station’s dc power supply. This supply must be capable of supplying the 0.3 A

current required by the ITA2000A.

The ITA2000A operates properly on input voltages from 10.5 to 16 V dc. The optional 40419-008

UL-listed/CSA-certified Class 2 ac wall transformer should be used if a suitable dc source such as the

station’s dc supply is not available. The power connection pinout is as follows:

Pins Function

Pin 1 –IN

Pin 2 N/C

Pin 3 +IN

Pin 4 –IN

Pin 5 +IN

CAUTION

For safe operation, use only a listed or certified Class 2 ac adapter.

15 03/13

Page 20

Installation ITA2000A Series Tone Remote Adapter

Conventional to Scanning Operation Conversion

NOTE: The ITA2000A includes an LED labeled MON (top) and SCAN (bottom). It is the third LED

from the left when looking at the unit from the front. In Conventional mode, the LED indicates monitor

operation. In Scan mode, the LED will flash at the scan rate and illuminates steadily when the adapter

locks onto a channel (monitor).

Locate SW1-7 on the unit’s front panel, and place it in the down position.

The unit will perform a reboot and begin operation in the Scan mode. When the unit is powered up or

when exiting diagnostics, the hybrid balance tone will be heard twice. This will not cause any harm to

the system.

N

OTE: The scan or scanning features of the radio must not be programmed or selected. The ITA2000A

will not function properly if the radio is programmed with scan functions.

03/13 16

Page 21

ITA2000A Series Tone Remote Adapter Installation

Radio Connector (J2)

The radio connector is located on the rear of the ITA2000A. The connector pinout appears below:

Input/Output Radio Connector Table

Pin

J2-1 Black/

J2-2 Blue/

Wire

Color Description

Channel Steer 3 O JU4 B position = Lo (0 V dc)*

white

CSQ Detect (SW1-1 must be

white

Down) Refer to Switch

Input/

Output Range

JU4 A position = Hi (B+)

I SW1-2 UP = Lo (0 V dc)*

SW1-2 DOWN = Hi (B+)

Table.

J2-3 Green RX Audio + (Selectable)

300 mV

RMS nominal/default

I Range 1: −20 dB Jumper = OUT

32 mV

RMS–1.6 VRMS

Range 2: −20 dB Jumper = IN

1.5 V

RMS–4.5 VRMS

J2-4 Black AGND

J2-5 White/

black

Channel Steer 2 O JU5 B position = Lo (0 V dc)*

JU5 A position = Hi (B+)

J2-6 White PTT O JU2 B position = Lo (0 V dc)*

JU2 A position = Hi (B+)

J2-7 Orange RX PL Disable O Closure between pins 7 and 14

J2-8 Red Channel Steer 0 O JU7 B position = Lo (0 V dc)*

JU7 A position = Hi (B+)

J2-9 Red/

white

J2-10 Green/

white

Channel Steer 4 O JU3 B position = Lo (0 V dc)*

JU3 A position = Hi (B+)

CSQ and CTCSS Detect

(SW1-1 must be Down.)

I SW1-2 UP = Lo (0 V dc)*

SW1-2 DOWN = Hi (B+)

Refer to Switch Table.

J2-11 Green/

Black

RX Audio – (AGND) I Connected internally to pin 4 at radio

end of cable.

J2-12 Blue TX Audio O 32 mVRMS–800 mVRMS 560 ohms

J2-13 Blue/

black

J2-14 Orange/

PTT Sense I SW1-3 UP = Lo (0 V dc)*

SW1-3 DOWN = Hi (B+)

RX PL Disable O Closure between pins 7 and 14

black

J2-15 Red/

black

Channel Steer 1 O JU6 B position = Lo (0 V dc)*

JU6 A position = Hi (B+)

*default from the factory

Radio Connector Pinout

17 03/13

Page 22

Installation ITA2000A Series Tone Remote Adapter

Transmit Audio – Pin 12

Connect this single-ended output to a microphone input circuit or exciter input of the transmit section.

The radio should be capable of a level from 32 mV

to 800 mV

RMS

RMS

.

Receive Audio – Pin 3 RX High (+), Pin 11 RX Low (−)

Connect to a speaker or detector audio source from a radio receiver capable of supplying a level in the

range of 250 mV

N

OTE: It is best to connect to a point not controlled by a volume potentiometer to avoid the receive

RMS

to 4.5 V

. Ensure that SW2-1 is set properly.

RMS

audio being affected by someone adjusting the volume control.

If connecting to a volume potentiometer, connect to the high side so the level can not be changed.

Connect pin 11 to audio ground (AGND) if a receive return is not provided. Pin 11 should be shorted

with Pin 4 on the radio connector.

Push-to-Talk (PTT) Output – Pin 6

This output must be connected to a point in the radio that causes it to transmit when active. When this

input on the radio is active, ensure that the microphone input circuit where the transmit audio of the desk

set (pin 12) is connected will be active also.

Monitor – Pin 7, Pin 14

These pins provide a closure output for receive PL/DPL disable (monitor), and is activated when the

ITA2000A decodes a function tone of 2050 Hz from a tone remote desk set when in Conventional mode.

These pins are activated by a channel steer sequence until a PTT or scanning is resumed in Scan mode.

Connect to the radio receive PL/DPL disable input so the radio will go into carrier squelch mode. Since

this connection is a closure, one side of the closure can be connected to B+ or ground, depending on the

desired activation function logic. If receive PL/DPL disable is not supported by the radio, or is not

desired, disregard this connection.

Carrier Detect Input – Pin 2

The ITA2000A can be set up to accept an active low or high logic level for routing radio audio to

accessory and remotes when carrier is detected. Connect pin 2 to a radio output that goes active when a

valid receive carrier is present.

Carrier and PL/DPL Detect – Pin 10

Connect pin 10 to an output in the radio that goes active when a valid receive carrier and PL/DPL is

present. This indicates channel activity when the radio has been placed in monitor mode.

Push-to-Talk (PTT) Sense Input – Pin 13

Connect pin 13 to a point in the radio that goes active (set by SW1-3) when the radio is keyed from a

source other than the ITA2000A. When the ITA2000A senses the radio is keyed, it holds off any remote

or accessory transmit until the PTT sense clears.

N

OTE: If this function is not available, disregard this connection.

Channel Select – Pins 1, 5, 8, 9, and 15

Connect pins 1, 5, 8, 9, and 15 to the points in the radio that will cause it to change channels when the

active logic is present. The active level of these outputs can be set to active low or high as determined by

jumpers JU3 through JU7.

03/13 18

Page 23

ITA2000A Series Tone Remote Adapter Installation

These pins output the binary equivalent of the decoded function tone from the tone remote or the current

scan selected channel. The chart that follows shows the pin designation and output for the decoded

function tone. These outputs can be used to control other logic-driven functions of radios that support

such features.

Channel Select Pin Designation/Output Chart

Pin 9 Pin 1 Pin 5 Pin 15 Pin 8

F# Frequency MSB Bit 3 Bit 2 Bit 1 LSB

F1 1950 Hz High High High High Low

F2 1850 Hz High High High Low High

F3 1750 Hz High High High Low Low

F4 1650 Hz High High Low High High

F5 1550 Hz High High Low High Low

F6 1450 Hz High High Low Low High

F7 1350 Hz High High Low Low Low

F8 1250 Hz High Low High High High

F9 1150 Hz High Low High High Low

F10 1050 Hz High Low High Low High

F11 950 Hz High Low High Low Low

F12 850 Hz High Low Low High High

F13 750 Hz High Low Low High Low

F14 650 Hz High Low Low Low High

F15 550 Hz High Low Low Low Low

F16* 2050 Hz Low High High High High

*F16 is switch selectable between a monitor and channel steer function (Conventional) or scan on/off

function (Scan).

N

OTE: The logic is inverted if the ITA2000A channel selection outputs are set for active high.

If programmable or N/C pins are not used, clip off or secure in a fashion to prevent leads from

shorting together, thus preventing damage to the adapter or the radio.

19 03/13

Page 24

Installation ITA2000A Series Tone Remote Adapter

Accessory Connector (J3)

The accessory connector is located on the rear of the ITA2000A Tone Remote Adapter.

Input/Output Accessory Connector Table

Pin Wire Color Description

J3-1 Black/white Channel Steer 3 O

Input/

Output Range

JU11 B position = Lo (0 V dc)*

JU11 A position = Hi (B+)

J3-2 Blue/

white

Carrier Squelch Detect OUT O

JU8 B position = Lo (0 V dc)*

JU8 A position = Hi (B+)

J3-3 Green RX Audio +300 mVRMS O

J3-4 Black AGND

J3-5 White/black Channel Steer 2 O

JU12 B position = Lo (0 V dc)*

JU12 A position = Hi (B+)

J3-6 White PTT I

Lo (0 V dc)

J3-7 Orange RX PL Disable O Closure between pins 7 and 14

J3-8 Red Channel Steer 0 O

JU14 B position = Lo (0 V dc)*

JU14 A position = Hi (B+)

J3-9 Red/white Channel Steer 4 O

JU10 B position = Lo (0 V dc)*

JU10 A position = Hi (B+)

J3-10 Green/white CSQ and CTCSS Detect I

SW1-2 UP = Lo (0 V dc)*

SW1-2 DOWN = Hi (B+)

J3-11 Green/black RX Audio O Connected internally to pin 4 at radio

end of cable.

J3-12 Blue TX Audio 80 mV ac I

J3-13 Blue/black PTT OUT O

JU9 B position = Lo (0 V dc)*

JU9 A position = Hi (B+)

J3-14 Orange/black RX PL Disable I Closure between pins 7 and 14

J3-15 Red/black Channel Steer 1 O JU13 B position = Lo (0 V dc)*

JU13 A position = Hi (B+)

*default from the factory

Accessory Connector Pinout

03/13 20

Page 25

ITA2000A Series Tone Remote Adapter Installation

ITA2000A to Kenwood TK-790/890 Series Radio Connection Chart

Adapter

Pin

Adapter

Function

Wire Color

Radio

Connector Pin Radio Function

1 Channel steer 3 Blk w/white stripe 5 Auxiliary input 4 (programmable)

2 CSQ Detect IN Blue w/white stripe 8, 20 , 21, 22 Auxiliary output 2

(program to COR)

3 RX audio + Green 17 RX audio signal output

4 AGND Black 7 Earth

5 Channel steer 2 White w/blk stripe 4 Auxiliary input 3 (programmable)

6 PTT White 6 Auxiliary input 5

(program to PTT)

7 Monitor Orange 5 Auxiliary input 4

(program to MON)

8 Channel steer 0 Red 2 Auxiliary input 1 (programmable)

9 Channel steer 4 Red w/white stripe 5 Auxiliary input 4 (programmable)

10 CTCSS IN Grn w/white stripe N/C

11 RX audio – Grn w/black stripe 7 Earth. Connected internally to

15D pin 4 at radio end of cable.

12 TX audio + Blue 13 MIC/Data input signal 1

13

14 Monitor low Orange w/blk stripe 7 Earth. Connected internally to

15D pin 4 at radio end of cable.

15 Channel steer 1 Red w/black stripe 3 Auxiliary input 2 (programmable)

Connector

Housing

Shield

Connected

internally to 15D

pin 4 at radio end

of cable.

NOTES:

The Carrier Detect Signal (COR) must be programmed to an auxiliary output pin. The Radio

Connection Chart shows COR programmed to auxiliary output 2, which is pin 8 of the radio

connector. Carrier Detect is Active High (SW1-2 = DN).

The PTT signal must be programmed to an auxiliary input 5, as per the Radio Connection Chart.

If the monitor function is required, the MON signal must be programmed to auxiliary input 4, as per

the Radio Connection Chart. Programming the MON signal alters the maximum number of channels

that can be scanned. Normally, a maximum of 15 channels can be scanned, however, use of the

MON function limits the maximum to 8 channels. Pin 7 of the adapter must be connected to the RX

CTCSS Disable Input (MON) pin of the radio. Pin 14 of the adapter must be connected to GRND.

21 03/13

Page 26

Installation ITA2000A Series Tone Remote Adapter

WARNING

If programmable or N/C pins are not used, clip off or secure in a fashion to prevent leads from

shorting together, thus preventing damage to the adapter or the radio.

Adapter Radio Connector

Connector Termination with Internal Jumpers

Connecting Pins 4 - 11- 14.

03/13 22

Page 27

ITA2000A Series Tone Remote Adapter Installation

ITA2000A to RPG Radio Connection Chart

Adapter

Pin

Adapter

Function

Wire Color

Radio

Connector Pin Radio Function

1 Channel steer 3 Black w/white stripe 6, 8, 9, 12, or 14 Programmable

2 CSQ Detect IN Blue w/white stripe 4, 8, 12, or 14 Programmable

3 RX audio + Green 11 RX audio

4 AGND Black 7 GND

5 Channel steer 2 White w/black stripe 6, 8, 9, 12, or 14 Programmable

6 PTT White 3 Mic PTT

7 Monitor Orange 14, or 6, 8, 9, 12 PL disable (monitor)

8 Channel steer 0 Red 6, 8, 9, 12, or 14 Programmable

9 Channel steer 4 Red w/white stripe 6, 8, 9, 12, or 14 Programmable

10 CTCSS IN Green w/white stripe 4, 8, 12, or 14 Programmable

11 RX audio − Connected internally to

15D pin 4 at radio end of

cable.

12 TX audio + Blue 2 Mic audio

13 PTT Sense IN Blue w/black stripe N/C

14 Monitor low Connected internally to

15D pin 4 at radio end of

cable.

15 Channel steer 1 Red w/black stripe 6, 8, 9, 12, or 14 Programmable

Connector

Housing

Shield Connected internally to

15D pin 4 at radio end of

cable.

OTE: The radio must be programmed to disable emergency functions from pin 9.

N

RPG includes: DESKTRAC, GM300, M1225 (four-channel only).

WARNING

If programmable or N/C pins are not used, clip off or secure in a fashion to prevent leads from

shorting together, thus preventing damage to the adapter or the radio.

Adapter Radio Connector

Radio Connector

23 03/13

Page 28

Installation ITA2000A Series Tone Remote Adapter

ITA2000A Tone Remote Adapter to MCS2000 Radio Connection Chart (Conventional Mode Only)

15-Pin

Pin #

Adapter

Function

Wire Color

Radio

Connector Pin # Radio Function

1 Channel Steer 3 Black w/white stripe N/C Programmable

2 CSQ Detect IN Blue w/white stripe 8 Programmable

3 RX audio + Green 11 RX audio

4 AGND Black 10 GND

5 Channel Steer 2 White w/black stripe N/C Programmable

6 PTT White 21 Mic PTT

7 Monitor Orange 7 CTCSS disable

(monitor)

8 Channel Steer 0 Red N/C Programmable

9 Channel Steer 4 Red w/white stripe N/C Programmable

10 CTCSS IN Green w/white stripe 8 Programmable

11 RX audio – Connected internally to 15D

pin 4 at radio end of cable.

12 TX audio + Blue 23 Mic audio

13

14 Monitor low Connected internally to 15D

pin 4 at radio end of cable.

15 Channel Steer 1 Red w/black stripe N/C Programmable

Connector

Housing

Shield Connected internally to 15D

pin 4 at radio end of cable.

WARNING

If programmable or N/C pins are not used, clip off or secure in a fashion to prevent leads from

shorting together, thus preventing damage to the adapter or the radio.

Adapter Radio Connector

HLN6412 Connector Termination with Internal

Jumpers Connecting Pins 1–2 and Pins 4–9.

03/13 24

Page 29

ITA2000A Series Tone Remote Adapter Installation

Radio Tie Line (Telephone) Connections

If leased lines from your local telephone company are used between the remotes and the ITA2000A Tone

Remote Adapter, the telephone company (local exchange carrier) may request a Facility Interface Code

(FIC). Refer to the Analog Facility Interface Code Table that follows for information about codes that

may be available.

Analog Facility Interface Codes

FIC Description

02NO2 2-wire private line; no signaling conversion by LEC. (IN-Band)

02NO4 4-wire private line; no signaling conversion by LEC. (IN-Band)

Metallic 2- or 4-wire metallic private line. (Hoot and Holler circuits)

Within a manufacturing plant, campus, or large building, customer lines referred to as metallic pairs may

be used. To make appropriate phone line connections, refer to the Telephone Line Connection Table

below.

Telephone Line Connection Table

J1 Connector Pins Description Color and Direction

3 and 4 2-wire TX/RX pair Red/green; bi-directional required.

3 and 4 4-wire TX audio control Red/green; may be uni-directional or bi-directional

5 and 2 4-wire RX audio only Yellow/black; may be uni-directional or bi-directional.

25 03/13

Page 30

Installation ITA2000A Series Tone Remote Adapter

Jumpers

The default setting of the circuit board jumpers provide normal operation and should be changed only for

special applications. Remove the cover of the ITA2000A to access these jumpers. The “A” and “B”

positions are indicated on the PCBA.

Jumper Table

A = Active High B = Active Low

Jumper

No.

Default

Value

Description

JU2 B Radio PTT

JU3 B Channel Steer Output 4

JU4 B Channel Steer Output 3

JU5 B Channel Steer Output 2

JU6 B Channel Steer Output 1

JU7 B Channel Steer Output 0

JU8 B Accessory CSQ Output

JU9 B Accessory PTT Output

JU10 B Channel Steer Output 4

JU11 B Channel Steer Output 3

JU12 B Channel Steer Output 2

JU13 B Channel Steer Output 1

JU14 B Channel Steer Output 0

−20 dB Out Reduces radio RX by −20 dB

JU20 2W Select 2-wire/4-wire audio

JU21 2W Select 2-wire/4-wire audio

JU22 In Enables audio hybrid for 2-wire configuration

JU24 2W Select 2-wire/4-wire enable

JU30 Out Converts the B+ supply to a 15 V power supply to increase audio

output.

JU31 Pins 1 and 2

Pins 2 and

Selects Channel Steer 4 Output.

Selects J3-9 as alternate dc input.

3*

*If pins 2 and 3 are selected, Channel Steer Bit 4 will be disabled.

03/13 26

Page 31

ITA2000A Series Tone Remote Adapter Installation

Channel Revert (Conventional Mode Only)

Channel Revert allows the ITA2000A to output a certain value on the four channel selection lines after a

transmit is complete from the remote. The value output on the channel selection lines is determined by

switches SW2-5 through SW2-8.

Channel Revert Settings Table

Switch Determines: Up/Down

SW2-4 Whether channel selections are latched

to last decoded frequency, or revert to

a preprogrammed channel (SW2-5 to

SW2-8) after transmit from land line.

SW2-5

to

SW2-8

The binary representation of the revert

channel.

N

OTE: Revert channel must

correspond to a BCD* code 1 - 15.

Revert to F16 is not

possible.

*Binary coded decimal

Up = Do not revert

Down = Revert based on SW2-5 to SW2-8.

Ch

Home

1

2

3

4

5

6

7

SW2

5 6 7 8

Ch

8

9

10

11

12

13

14

15

SW2

5 6 7 8

27 03/13

Page 32

Installation ITA2000A Series Tone Remote Adapter

Configuration Switch Settings for Conventional Mode Operation

Two sets of programming switches are included on the front panel of the ITA2000A. They are used to

set up and interface with the radio system. The switch function settings are as follows:

Switch Settings for SW1 (Conventional)

Switch Determines: Up Down

SW1-1* The method of carrier detection from

radio.

Uses radio receive

audio (RX VOX

Uses logic output from

radio.

detect).

SW1-2 is ignored.

SW1-2 The active logic levels for carrier detect if

Active Low Active High

SW1-1 is down.

SW1-3 The active input level of radio PTT sense

Active Low Active High

on radio connector pin 13.

SW1-4 Whether courtesy beep generation is

Disabled Enabled

enabled or disabled.

SW1-5 F16 Enable 2050 Hz is used for

monitor

SW1-6 The polarity of monitor input from desk

Active Low Active High

2050 Hz is used for

F16

mic.

SW1-7 Operate in Conventional or Scan mode Operate in

Operate in Scan mode

Conventional mode

SW1-8** Enter Supervisor Mode upon pressing

Disabled Enabled

desk-mic PTT or Monitor buttons.

*When configured for receive vox detect, the radio receive audio is continuously routed to the phone line

regardless of the vox status using firmware TNA1B and later. The CSQ LED and courtesy tone, if

enabled, are still controlled by the vox status.

**Available in firmware TNA2C and later.

03/13 28

Page 33

ITA2000A Series Tone Remote Adapter Installation

Switch Settings for SW2 (Conventional)

Switch Determines: Up Down

SW2-1 The receive audio input for radio

connector pin 3.

SW2-2 Whether tone panel will PTT on HLGT

detect and pass the high and low level

function tones to transmit audio.

SW2-3 The timing of monitor output after a valid

monitor command is detected.

SW2-4 Whether channel selections are latched to

last decoded frequency, or revert to a

preprogrammed channel (SW2-5 to

SW2-8) after transmit from wire line.

SW2-5

to

SW2-8

The binary representation of revert

channel. SW2-5 is MSB and SW2-8 is

LSB.

Example: To revert to channel 3 after

transmit, set the switch as follows:

Speaker level audio

(unsquelched

de-emphasized audio)

PTT after valid

function tone detect

and filter tones to

Detector audio

(squelched, requires

de-emphasis)

PTT on HLGT detect,

pass tones to transmit

audio.

transmit audio.

Monitor output

latched until a valid

transmit command is

detected from the

Monitor output is active

4 seconds after a valid

monitor command is

detected.

wire line.

Stay on last decoded

frequency from wire

line.

Revert to the channel

determined by SW2-5 to

SW2-8.

High Low

SW2-5 = Up, SW2-6 = Up,

SW2-7 = Down, SW2-8 = Down.

See Channel Revert Chart on page 27

OTE: Revert to F16 is not possible.

N

29 03/13

Page 34

Installation ITA2000A Series Tone Remote Adapter

Configuration Switch Settings for Scan Mode Operation

Two sets of configuration switches are included on the front panel of the ITA2000A. The switch

function settings are as follows:

Switch Settings for SW1 (Scan)

Switch Determines: Up Down

SW1-1 The receive audio input for radio

connector pin 3.

Speaker level audio

(unsquelched

de-emphasized audio)

Detector audio

(squelched, requires

de-emphasis)

SW1-2 The active input level for carrier detect. Active Low Active High

SW1-3 The active input level of radio PTT sense

Active Low Active High

on radio connector pin 13.

SW1-4 Whether courtesy beep generation is

Disabled Enabled

enabled or disabled.

SW1-5 How scan resumes after a desk set PTT. The unit will cease

scan and not resume

after a desk set PTT

The unit will resume

scan after the scan-stop

time upon release of

the desk set PTT

SW1-6 The polarity of monitor input from desk

mic.

SW1-7 Operate in Conventional or Scan mode Operates in

Active Low/ Normally

Open

Active High/ Normally

Closed

Operates in Scan mode

Conventional mode

SW1-8 How scanning resumes after loss of

carrier detect

The unit will cease

scan and not resume

after a loss of carrier

detect

The unit will resume

scan after the scan-stop

time upon loss of

carrier detect

03/13 30

Page 35

ITA2000A Series Tone Remote Adapter Installation

Switch Settings for SW2 (Scan)

Switch Determines: Up/Down Settings

SW2-1

to

SW2-4

SW2-5

to

SW2-7

Scan Limit: Maximum number of channels

to be scanned.

Sequence of scanning starts at channel 1

and counts upward to the maximum

number of channels to be scanned. Once

the maximum channel has been reached

the scanning sequence repeats beginning

with channel 1.

N

OTE: The wrap-around time for

scanning the same channel is a function of

the scan limit and the scan rate. For

example, if the scan limit is 10 and the

scan rate is 100 ms, the minimum wraparound time for any one channel is 10

100 ms, or 1 second.

Scan Rate (ms): Time allotted for carrier

detect per channel frequency.

Depending upon the radio and the

programming of the radio used, the time

required for detection of valid carrier can

vary. Factors such as the design of the

radio, use of PL/DPL and quieting can

affect carrier detection time. Consult your

radio manual and manufacturer for specific

carrier-detect times.

N

OTE: The scan rate should be set for the

maximum time any one channel requires

for reliable carrier detection.

Scan

Home

1

2

3

4

5

6

7

Rate

(ms)

100

120

160

200

SW2

1 2 3 4

SW2

5 6 7

Scan

8

9

10

11

12

13

14

15

Rate

(ms)

400

420

460

500

SW2

1 2 3 4

SW2

5 6 7

SW2-8 Scan Stop Time: Time scan halts after a

UP = 4 seconds

desk set PTT (SW1-5) or carrier is no

longer detected (SW1-8).

DN = 2 seconds

NOTE: Scan Rate Setting - Due to the differences in radios, the scan rate should be selected from the

slowest level (500 ms) first. The scan rate can be affected by the PL/DPL decode time within certain

radio transceivers.

31 03/13

Page 36

Installation ITA2000A Series Tone Remote Adapter

Level Settings and Adjustments

Receive Audio Level

The ITA2000A is shipped from the factory set to accept a 300 mV receive audio input level from the

station’s receiver. To accommodate receivers with different audio levels, perform the following steps:

1. After verifying the connections are properly made to the station in accordance with the installation

instructions, apply power to the station and the ITA2000A.

2. Inject a fully quieted (approximately 1000 microvolt) RF signal set to the station receiver’s antenna

connector. Modulate the RF generator with a 1000 Hz tone at rated system deviation.

3. If applicable, enable the proper PL or DPL code on the RF generator at 15% system deviation

(approximately 750 Hz of deviation).

4. Adjust the

RX level pot for −6 dBm (388 mV) at U18 pin 7, or mic jack J4 pin 8.

5. Remove the 1000 Hz tone or use diagnostic Test 1.

Line Output Level

The phone line level has been factory-set to 0 dBm at reference input level. This setting should be

adequate for most installations. Use the following procedure if readjustment is ever required:

N

OTE: For this adjustment, it is necessary to open the housing to gain access to the line out

potentiometer located on the PCBA. It is important that the receive audio level (RX) is set properly prior

to setting the line output level.