Page 1

Pub. 43004-027A

GAI-TRONICS® CORPORATION

A HUBBELL COMPANY

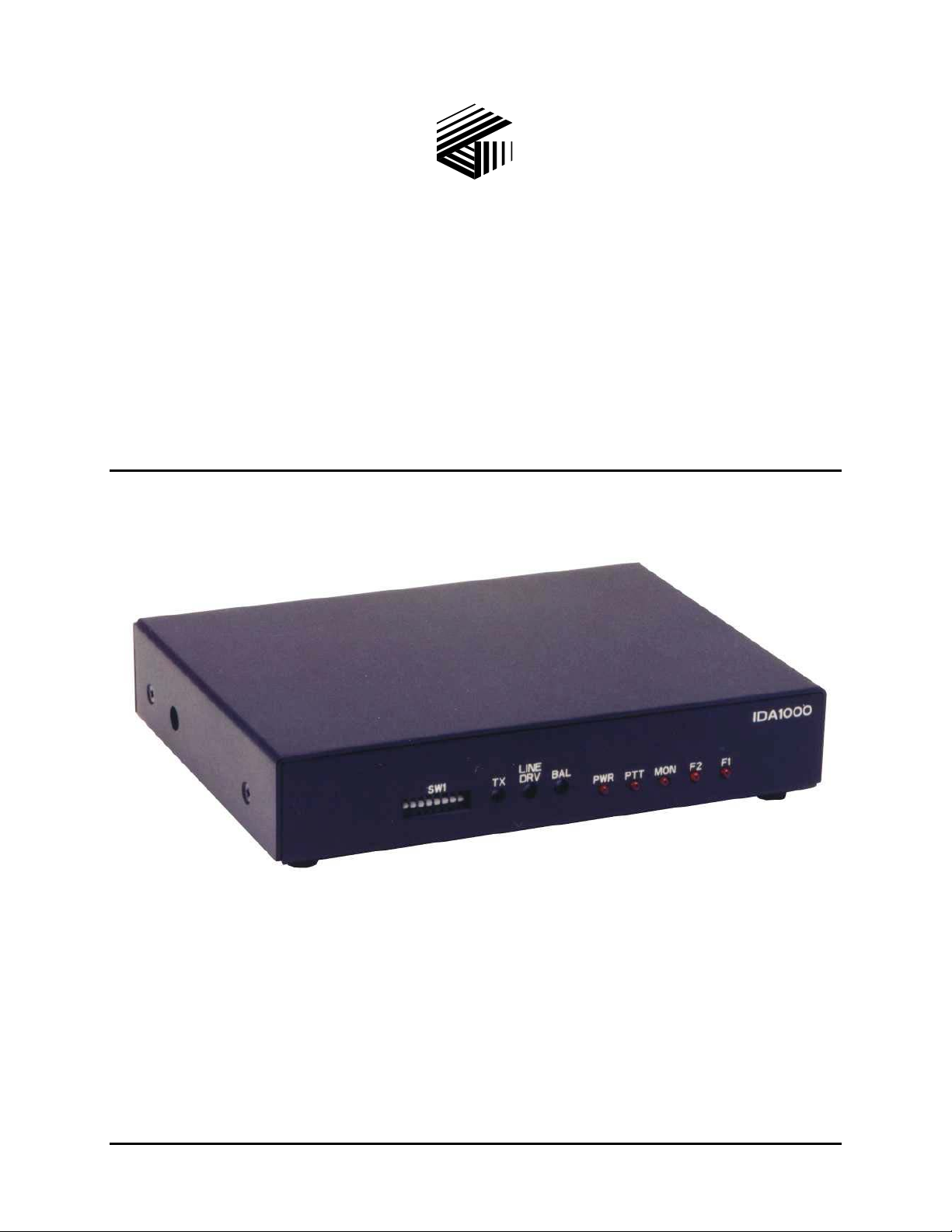

Model IDA1000A DC Remote

Adapter

Installation and Service Manual

GAI-Tronics Corporation 400 E. Wyomissing Ave. Mohnton, PA 19540 USA

610-777-1374 800-492-1212 Fax: 610-796-5954

V

ISIT WWW.GAI-TRONICS.COM FOR PRODUCT LITERATURE AND MANUALS

Page 2

CONFIDENTIALITY NOTICE

This manual is provided solely as an operational, installation, and maintenance guide and contains

sensitive business and technical information that is confidential and proprietary to GAI-Tronics.

GAI-Tronics retains all intellectual property and other rights in or to the information contained herein,

and such information may only be used in connection with the operation of your GAI-Tronics product or

system. This manual may not be disclosed in any form, in whole or in part, directly or indirectly, to any

third party.

COMPUTER SOFTWARE COPYRIGHTS

This product contains copyrighted computer programs stored in semiconductor memory. These programs

are copyrighted by GAI-Tronics Corporation and may not be reproduced in any form without express

written permission from GAI-Tronics.

WARRANTY

GAI-Tronics warrants for a period of one (1) year from the date of shipment, that any GAI-Tronics equipment supplied

hereunder shall be free of defects in material and workmanship, shall comply with the then-current product specifications and

product literature, and if applicable, shall be fit for the purpose specified in the agreed-upon quotation or proposal document. If

(a) Seller’s goods prove to be defective in workmanship and/or material under normal and proper usage, or unfit for the purpose

specified and agreed upon, and (b) Buyer’s claim is made within the warranty period set forth above, Buyer may return such

goods to GAI-Tronics’ nearest depot repair facility, freight prepaid, at which time they will be repaired or replaced, at Seller’s

option, without charge to Buyer. Repair or replacement shall be Buyer’s sole and exclusive remedy, and the warranty period on

any repaired or replacement equipment shall be one (1) year from the date the original equipment was shipped. In no event shall

GAI-Tronics’ warranty obligations with respect to equipment exceed 100% of the total cost of the equipment supplied hereunder.

The applicability of any such third-party warranty will be determined solely by GAI-Tronics.

Services. Any services GAI-Tronics provides hereunder, whether directly or through subcontractors, shall be performed in

accordance with the standard of care with which such services are normally provided in the industry. If the services fail to meet

the applicable industry standard, GAI-Tronics will, for a period of one (1) year from the date of completion, re-perform such

services at no cost to the Buyer. Re-performance of services shall be Buyer’s sole and exclusive remedy, and in no event shall

GAI-Tronics’ warranty obligations with respect to services exceed 100% of the total cost of services provided hereunder.

Limitations/Exclusions. The warranty on any equipment supplied hereunder is subject to Customer’s use in compliance

with applicable FCC regulations and manufacturer specifications. The warranties herein shall not apply to, and GAI-Tronics

shall not be responsible for, any damage to the goods or failure of the services supplied hereunder, to the extent caused by

accident, misuse, abuse, neglect, system design, product modification, failure to follow instructions contained in the product

manual, repair, or attempted repair by anyone not authorized by GAI-Tronics, improper installation, installation of parts that do

not conform to the quality or specifications of the original parts or accessories, damage or loss occurred during shipment, or any

unit which is not new when sold or upon which the serial number has been defaced, modified or removed. The warranty does

not extend to damage incurred by natural causes including Force Majeure. The warranty does not cover microprocessors if

failure is due to static damage or application of improper voltage.

THE WARRANTIES AND REMEDIES CONTAINED

HEREIN ARE IN LIEU OF AND EXCLUDE ALL OTHER WARRANTIES AND REMEDIES, WHETHER

EXPRESS OR IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING ANY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Operational and Maintenance Procedures. Buyer acknowledges that any improper use, maintenance, or

modification of the equipment provided hereunder, or use of unqualified maintenance or service technicians will severely impair

the operational effectiveness of the entire communication system. Buyer hereby agrees to indemnify, defend and hold GAITronics harmless from and against any and all third party claims arising, in any manner, out of: (a) Buyer’s neglect of the

equipment; (b) Buyer’s use of technicians not authorized by GAI-Tronics to service the equipment; or (c) Buyer’s improper use

or modification of the equipment or failure to follow the operational and maintenance procedures provided with the equipment.

Limitation of Liability/Damages. In no event (even should circumstances cause the exclusive warranties and remedies

set forth in the Warranty section to fail of their essential purpose) shall either party be liable for any indirect, incidental, special

or consequential damages (including, but not limited to, loss of use, loss of anticipated profits, or damages arising from delay)

whether such claims are alleged to have arisen out of breach of warranty, breach of contract, strict or absolute liability in tort, or

other act, error or omission, or from any other cause whatsoever, or any combination of the foregoing.

01/05 Publication 43004-027A i

Page 3

Table of Contents

FOREWORD...............................................................................................................................................................1

COPE OF MANUAL ....................................................................................................................................................1

S

OMENCLATURE........................................................................................................................................................1

N

RDERING REPLACEMENT PARTS ..............................................................................................................................1

O

ERVICE AND REPAIR.................................................................................................................................................1

S

NTERFERENCE WARNING..................................................................................................................................1

FCC I

AFE HANDLING OF CMOS INTEGRATED CIRCUIT DEVICES .....................................................................................2

S

DESCRIPTION ...........................................................................................................................................................3

F

EATURES AND BENEFITS OF THE MODEL IDA1000A DC REMOTE ADAPTER ..........................................................3

HYSICAL DESCRIPTION.............................................................................................................................................3

P

RONT PANEL ............................................................................................................................................................4

F

Programming Switches.........................................................................................................................................4

Front Panel LEDs.................................................................................................................................................4

INE LEVEL ADJUSTMENTS........................................................................................................................................4

L

TX Adjustment.......................................................................................................................................................4

Line DRV Adjustment ...........................................................................................................................................4

BAL Adjustment....................................................................................................................................................4

EAR PANEL ..............................................................................................................................................................5

R

CCESSORIES.............................................................................................................................................................5

A

ERFORMANCE SPECIFICATIONS ................................................................................................................................6

P

OPERATION...............................................................................................................................................................7

O

PERATIONAL DESCRIPTION......................................................................................................................................7

RONT PANEL LED OPERATION ................................................................................................................................8

F

PWR LED..............................................................................................................................................................8

PTT LED...............................................................................................................................................................8

MON LED.............................................................................................................................................................8

F2 LED .................................................................................................................................................................8

F1 LED .................................................................................................................................................................8

INSTALLATION ........................................................................................................................................................9

LANNING THE INSTALLATION...................................................................................................................................9

P

ECHANICAL RECEIPT INSPECTION ...........................................................................................................................9

M

OUNTING.................................................................................................................................................................9

M

NTERFERENCE WARNINGS................................................................................................................................9

FCC I

QUIPMENT REQUIRED...............................................................................................................................................9

E

ABLE INSTALLATION SAFETY CONSIDERATIONS....................................................................................................10

C

ELEPHONE LINE LIGHTNING AND OVER-VOLTAGE PROTECTION............................................................................10

T

OWER CONNECTIONS .............................................................................................................................................10

P

Power Connections Pin-out................................................................................................................................10

ADIO CONNECTIONS ..............................................................................................................................................11

R

Receive Audio – P1-11, Audio Ground; P1-3, to de-emphasized RX audio source...........................................11

Mic High and Mic Low – P1-12, Hi; P1-4, Low ................................................................................................11

Duplex Control – P1-2........................................................................................................................................11

F1 – P1-8............................................................................................................................................................11

PTT Output – P1-13 Active High; P1-6 Active Low...........................................................................................11

Monitor – P1-14 Active High; P1-7 Active Low.................................................................................................11

F2- P1-15............................................................................................................................................................11

01/05 Publication 43004-027A ii

Page 4

Table of Contents Model IDA1000A DC Remote Adapter

ACCESSORY CONNECTIONS......................................................................................................................................12

INE CONNECTIONS .................................................................................................................................................12

L

Radio and Accessory Connection Chart.............................................................................................................13

WITCH POSITIONS.........................................................................................................................................14

SW1 S

SW1 Switch Settings Table..................................................................................................................................14

UMPER POSITIONS...................................................................................................................................................15

J

Jumper Position Table........................................................................................................................................15

INE INPUT GAIN SELECT SWITCHES .......................................................................................................................15

L

EVEL SETTINGS AND ADJUSTMENTS ......................................................................................................................16

L

Line Drive Level .................................................................................................................................................16

Transmit Level....................................................................................................................................................16

DC Threshold Calibration..................................................................................................................................16

Balance Adjustment............................................................................................................................................16

THEORY OF OPERATION....................................................................................................................................17

OWER SUPPLY ........................................................................................................................................................17

P

ONTROL CURRENT DETECTION .......................................................................................................................17

DC C

UDIO CIRCUIT........................................................................................................................................................18

A

TROUBLESHOOTING............................................................................................................................................19

T

ROUBLESHOOTING THE MODEL IDA1000A DC REMOTE ADAPTER......................................................................19

USE REPLACEMENT ................................................................................................................................................20

F

MAIN CIRCUIT BOARD........................................................................................................................................21

SCHEMATICS..........................................................................................................................................................25

DEFINITIONS AND ACRONYMS.........................................................................................................................31

01/05 Publication 43004-027A iii

Page 5

Foreword

Scope of Manual

This manual offers descriptive data and service information for Model IDA1000A DC Remote Adapter

Service diagrams and printed circuit board details are a part of this service manual.

Nomenclature

The model number, located on the nameplate on the bottom, specifically identifies GAI-Tronics

equipment. If additional options are ordered, the option will be identified on the circuit board.

Ordering Replacement Parts

When ordering replacement parts or requesting equipment information, please include the complete

identification number. This applies to all components, kits, and chassis. If the component part number is

not known, the order should include the number of the chassis or kit of which it is a part and sufficient

description of the desired component to identify it. Order parts from:

Customer Service

GAI-Tronics Corporation

400 E. Wyomissing Ave.

Mohnton, PA 19540

US: 800-492-1212

Outside US: 610-777-1374

Service and Repair

Inoperative or malfunctioning equipment should be returned to the factory for repair. Please call

1-800-492-1212 to obtain a Return Authorization number, published repair prices, and shipping

instructions.

OTE: A purchase order or credit card number is required prior to processing non-warranty repairs.

N

FCC Interference Warning

The FCC requires that manuals pertaining to Class A and Class B computing devices must contain

warnings about possible interference with local residential radio and TV reception. This warning reads as

follows:

OTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

N

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

1 01/05

Page 6

Foreword Model IDA1000A DC Remote Adapter

Safe Handling of CMOS Integrated Circuit Devices

Many of the integrated circuit devices used in communications equipment are of the Complementary

Metal Oxide Semiconductor (CMOS) type. Because of their high open circuit impedance, CMOS

integrated circuits are vulnerable to damage from static charges. Care must be taken handling, shipping,

and servicing them and the assemblies in which they are used.

Even though protection devices are provided in CMOS integrated circuit inputs, the protection is effective

only against overvoltage in the hundreds of volts range such as is encountered in an operating system. In

a system, circuit elements distribute static charges and load the CMOS circuits, decreasing the chance of

damage. However, CMOS circuits can be damaged by improper handling of the modules, even in a

system.

To avoid damage to circuits, observe the following handling, shipping, and servicing precautions:

1. Prior to and while servicing a circuit module, particularly after moving within the service area,

momentarily touch both hands to a bare metal, earth-grounded surface. This will discharge any static

charge that may have accumulated on the person doing the servicing.

OTE: Wearing a conductive wrist strap will minimize static build-up during servicing.

N

2. Whenever possible, avoid touching any electrically conductive parts of the circuit module with your

hands.

3. Power down the unit before installing or removing the circuit module.

4. When servicing a circuit module, avoid carpeted areas, dry environments, and certain types of

clothing (silk, nylon, etc.) because they contribute to static build-up. Similarly, disconnect the test

probe prior to removing the ground lead.

5. All electrically powered test equipment should be grounded. Apply the ground lead from the test

equipment to the circuit module before connecting the test probe.

6. If a circuit module is removed from the system, it is desirable to lay it on a conductive surface (such

as a sheet of aluminum foil) which is connected to ground through 100K of resistance.

7. When soldering, be sure the soldering iron is grounded and has a grounded tip.

8. Prior to connecting jumpers, replacing circuit components, or touching CMOS pins (if this becomes

necessary in the replacement of an integrated circuit device), be sure to discharge any static build-up

as described in procedure 1. Since voltage differences can exist across the human body, it is

recommended that only one hand be used if it is necessary to touch pins on the CMOS device and

associated board wiring.

9. When replacing a CMOS integrated circuit device, leave the device in its conductive rail container or

conductive foam until it is to be inserted into the printed circuit module.

10. All low impedance test equipment (such as pulse generators, etc.) should be connected to CMOS

device inputs after power is applied to the CMOS circuitry. Similarly, such low impedance

equipment should be disconnected before power is turned off.

11. Replacement modules shipped separately from the factory will be packaged in a conductive material.

Any modules being transported from one area to another should be wrapped in a similar material

(aluminum foil may be used). Never use non-conductive material for packaging these modules.

01/05 2

Page 7

Description

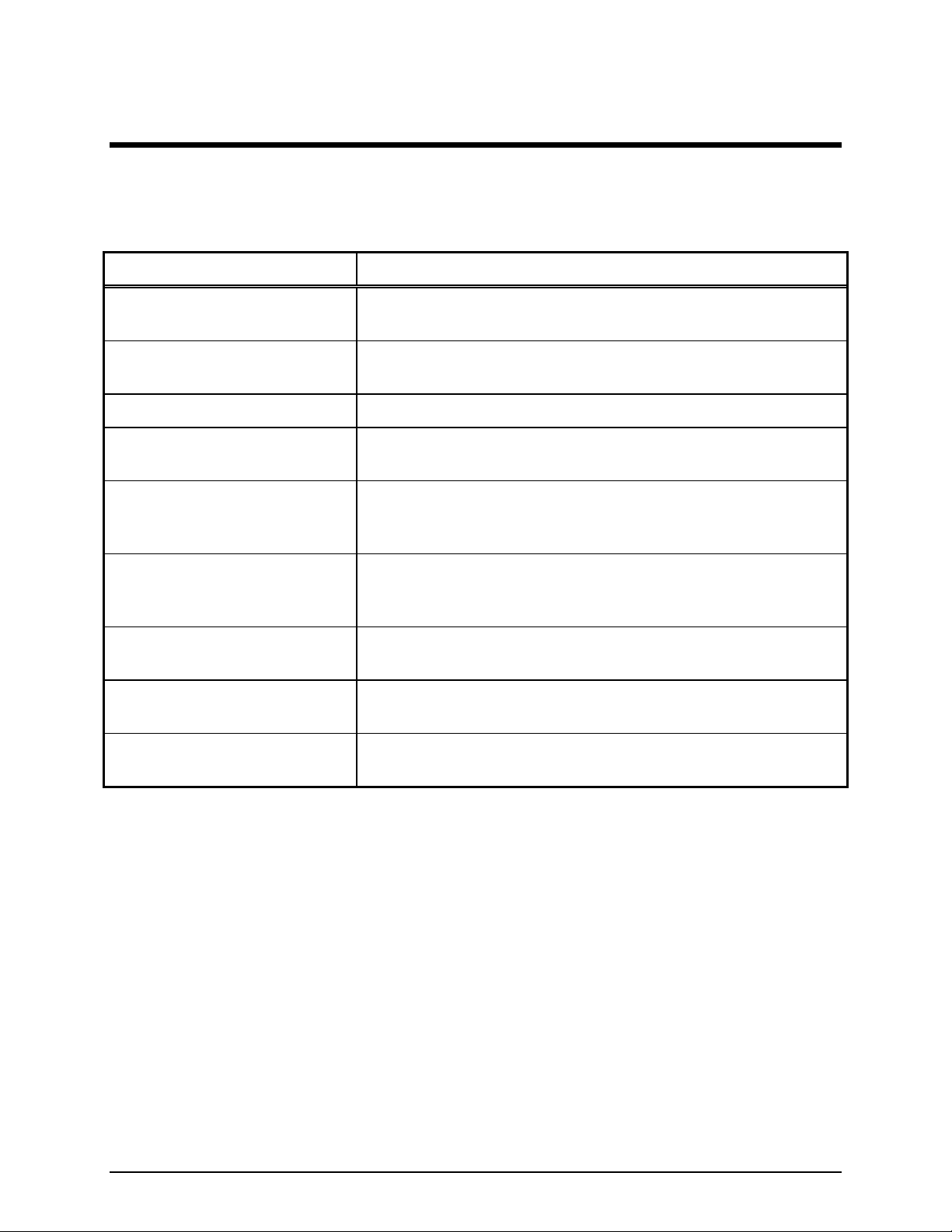

Features and Benefits of the Model IDA1000A DC Remote Adapter

Feature Benefit

Multiple dc remote support System flexibility and productivity are enhanced when several desk

sets are connected.

Two-channel control Model IDA1000A can be used to change channels and other

functions on certain radios.

Monitor Allows user to hear co-channel activity; CTCSS/CDCSS is disabled.

Full-duplex capable When used with a 2/4-wire capable desk set, provides full-duplex

operation for use with most full-duplex and trunking radio systems.

Adjustable receive input

sensitivity and transmit output

level

Selectable input/output logic

control

Accessory port Easily connects other devices such as a local desk set and telephone

Modular phone line connection on

back

AC or dc capable Uses power from radio or ac source (using optional wall transformer

Interfaces to most radio systems and line conditions.

The Model IDA1000A is flexible for many radio systems. Outputs

can be individually selected to go active high or to ground,

depending on the radio.

interconnect.

Provides easy-to-install phone line cable connection.

Part. No. 3308-00750-00).

Physical Description

The Model IDA1000A adapts remote desk set or console dc control to most radio systems with features

that exploit maximum functionality.

Adjustable input and output functions such as line input, transmit output level and selectable input/output

logic control provide flexibility. Easy connections and support of multiple desk sets make this dc adapter

the ideal choice for simple or complex desk set arrangements. One dc remote adapter can interface

several dc remote desk sets to the base station, depending on system design.

3 01/05

Page 8

Description Model IDA 1000A DC Remote Adapter

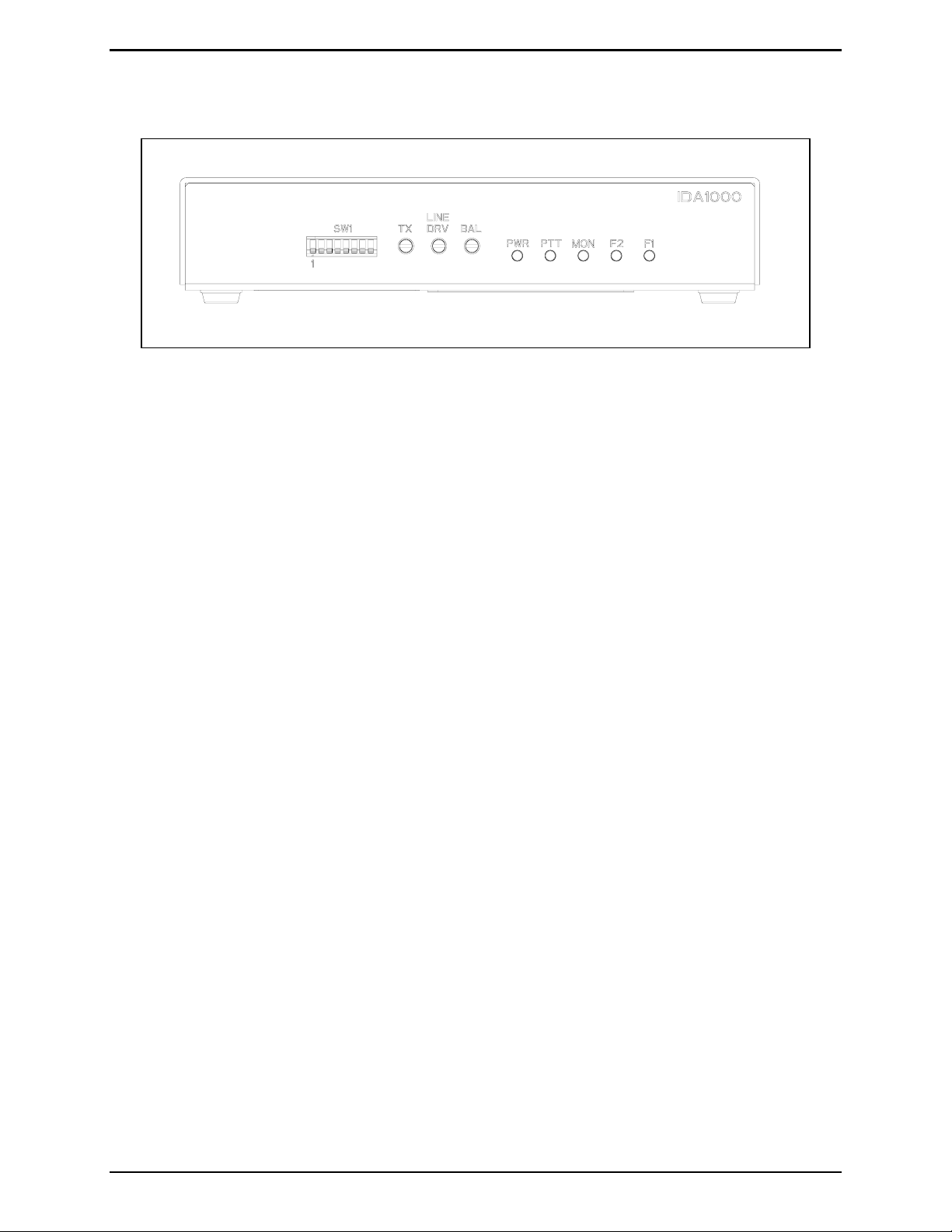

Front Panel

Figure 1. Front View of the Model IDA1000A DC Remote Adapter

Programming Switches

The programming switches (SW1) are used to set up and interface with the radio system. They are

numbered from left to right when viewed from the front.

Front Panel LEDs

The PWR LED indicates the remote adapter is on. The PTT LED illuminates when a valid transmit

request has been decoded. The

IDA1000A is in monitor mode. The

MON (timed or constant monitor) LED illuminates when the Model

F1 and F2 LEDs indicate current frequency and/or other functions.

Line Level Adjustments

TX Adjustment

The TX adjustment pot sets the level of the transmit audio to that required to properly modulate the base

station’s transmitter.

Line DRV Adjustment

The LINE DRV adjustment is used to set the telephone (audio) line level or “drive” to the remote desk set

or console.

BAL Adjustment

The balance potentiometer (BAL) allows optimizing the hybrid RX to TX isolation of the internal hybrid

in the 2-wire mode.

01/05 4

Page 9

Model IDA 1000A DC Remote Adapter Description

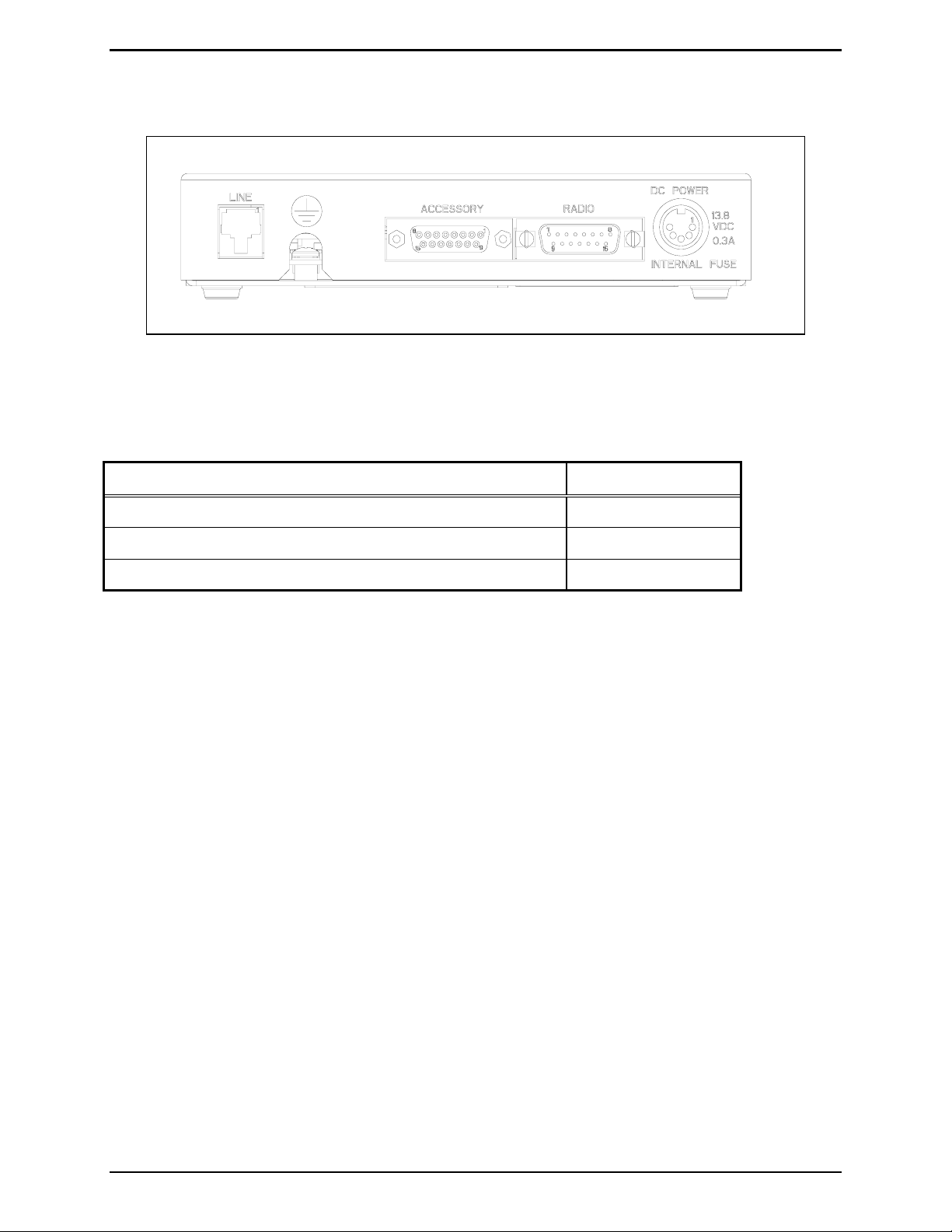

Rear Panel

Figure 2. Rear View of the Model IDA1000A DC Remote Adapter

Accessories

Description Part No.

AC Wall Transformer 3308-00750-00

Rack-Mount Kit (Standard 19-inch W × 1.75-inch H)

4-Wire Field Install Kit XDA0001A

XAC0005A

5 01/05

Page 10

Description Model IDA 1000A DC Remote Adapter

Performance Specifications

Color ......................................................................................................................................................Black

Physical size.............................................................................................................7.02 W × 5.3 L × 1.35 H

Weight.....................................................................................................................................................4 lbs.

Temperature range..................................................................................................................-30º C to 70º C

Humidity.......................................................................................................95% at 50º C (non-condensing)

Power input..........................................................................................10.5 to 16 V dc at 300 mA maximum

Hum and noise ..................................................................................... Less than –45 dB below rated output

Audio distortion................................................................................................................Less than 3% THD

RX input.....................................................................................32 mV ac to 4.5 V ac (nominal 300 mV ac)

TX input.............................................................. 32 mV ac to 800 mV ac in 560 ohms (nominal 80 mV ac)

Line input.........................................................................-25 to 0 dB ALC to reference (nominal –10 dBm)

Line output................................................... -15 to +10 dBm adjustable into 560 ohms (nominal –10 dBm)

Maximum desk sets supported...................................................................10 maximum (per system design)

DC current defaults......................................................................................................................F1: 5.5 mA

F2: 12.5 mA

Monitor: -2.5 mA

01/05 6

Page 11

Operation

Operational Description

The Model IDA1000A DC Remote Adapter is for use with base stations or repeaters controlled from a

remote desk set or console by dc line currents. One adapter can interface up to ten dc remote desk sets to

the base station or repeater, depending on the system design.

The Model IDA1000A incorporates all necessary circuit interfacing to translate single-frequency

(5.5 mA) transmit and monitor (-2.5 mA) commands into signals to control base station operation. Where

applicable, F2 transmit (12.5 mA) commands are also supported when used with a two-frequency base

station. Frequency outputs are jumper-selectable for open collector, 5 V pull up, or pull down. The

Model IDA1000A can be programmed to revert to F1 or F2 receive after transmit. See the SW1 Switch

Settings Table on page 14.

Monitor operation can be either latching or non-latching. The adapter routes audio signals between the

wire line and base station circuitry. Transmit audio from the wire line is amplified before being input to

the station. Receiver audio from the base station is amplified before being output to the wire line.

The amount of gain set by the adapter will operate full duplex with either 2-wire or 4-wire. The balanced

inputs cancel ac line noise.

Five LED function indicators are included on the front panel. When illuminated, they indicate wire line

push-to-talk command, a monitor command, and presence of 5 V dc power. Two LEDs indicate detection

of line current levels of 5.5 mA (

F1) or 12.5 mA (F2).

7 01/05

Page 12

Operation Model IDA 1000A DC Remote Adapter

Front Panel LED Operation

The operation of the IDA1000A DC Remote Adapter front panel LEDs is as follows:

PWR LED

The PWR LED illuminates to indicate that the IDA1000A DC Remote Adapter dc power is on.

PTT LED

The push-to-talk LED, labeled PTT, illuminates when a valid transmit request has been decoded.

MON LED

The timed or constant monitor LED, labeled MON, illuminates when the IDA1000A is in the monitor

mode, and indicates detection of a line current level of -2.5 mA.

F2 LED

The front panel F2 LED indicates detection of line current level of 12.5 mA (F2). It illuminates to

indicate that the unit is programmed to use the F2 transmit (12.5 mA) command, which is supported when

used with a two-frequency base station.

F1 LED

The front panel F1 LED illuminates to indicate that the unit is programmed to translate the singlefrequency (5.5 mA) transmit command into signals to control base station operation. The IDA1000A

may be programmed to revert to F1 or F2 receive after transmit.

01/05 8

Page 13

Planning the Installation

Sample Installation Diagram - Shown connected in parallel within one building.

Installation

Mechanical Receipt Inspection

The Model IDA1000A DC Remote Adapter is shipped in a cardboard container with inserts. Thoroughly

inspect it as soon as possible after delivery. In-transit damage should be immediately reported to the

transportation company.

Mounting

The Model IDA1000A can be installed in a custom-supplied rack or cabinet (with XAC0005A RackMount Kit) or can be placed on a desk for convenience when used with accessories.

FCC Interference Warnings

The FCC requires that manuals pertaining to Class A and Class B computing devices contain warnings

about possible interference with local and residential radio and TV reception. Please read these warnings

and all safety information in the Foreword section of this manual.

Equipment Required

Test Equipment

• RF service monitor

• AC voltmeter with dB ranges for measuring audio levels

• #1 Phillips screwdriver

• 1/8-inch flat blade screwdriver

Documentation

• base station's tone remote adapter manual

• these installation instructions

9 01/05

Page 14

Installation Model IDA 1000A DC Remote Adapter

Cable Installation Safety Considerations

Interconnecting, communications, and Class 2 dc power cables should be separated from electrical light

or other Class I circuits by at least 2 inches. The exception is where Class I wiring or power circuits are

run in a raceway, or are metal-sheathed or metal-clad, or are permanently separated from the conductors

of the other circuitry by a continuous and firmly fixed nonconductor such as porcelain tubes or flexible

tubing in addition to the insulation on the wire. Communications cables and in-building wiring should be

listed and marked for the purpose according to NEC Article 800.

Telephone Line Lightning and Over-voltage Protection

For maximum surge and lightning protection, building primary (over-voltage) protectors should be

installed at the point where the phone lines enter the radio equipment building. Primary protectors are

usually required by local codes and should be provided by your local exchange carrier.

The Model IDA1000A has over-current phone line fuses F2 (main) and F3 (4-wire option board), which

protect against occasional extreme fault conditions that may get past the primary protectors. An example

of such a fault condition is a power line cross. If the fuse requires replacement, replace it with the same

type Bussmann C515S 1.25A SB fuse.

Power Connections

Connections should be made to a 10.5 to 16 V dc source capable of supplying up to 300 mA. An optional

120 V ac wall transformer (Part No. 3308-00750-00) should be used if a suitable dc source is not

available.

The Model IDA1000A provides active low outputs referenced to system ground (negative ground

system). To interface with a positive ground radio station, or a radio needing active high signals, requires

relays or opto-isolators, which translate the adapter outputs.

Power Connections Pin-out

Pins Position

Pins 3 and 5 +IN

Pins 1 and 4 -IN

Pin 2 Battery +

Figure 3. Optional 5-Pin DIN

Power Supply

01/05 10

Page 15

Model IDA1000A DC Remote Adapter Installation

Radio Connections

Radio connections are made via P1. See Figure 4 on page 13. The supplied radio cable can be removed

if not needed, and a connector or terminal appropriate for the station used can be installed.

Receive Audio – P1-11, Audio Ground; P1-3, to de-emphasized RX audio source.

This input uses dc blocking capacitors on each side; reference level input at 2/3 radio system modulation

is 600 mV ac. Receive “audio in” can be configured for balanced or single-ended audio.

• If balanced, both pins should be connected. If single-ended audio is used, P1-11 should be grounded

to audio or chassis ground.

• Receive input audio can be configured for 32 to 150 mV ac, 150 to 400 mV ac, 400 mV ac to 1.7 V

ac, or 1.7 V ac to 4.5 V ac using SW1-3 and JU3. See the Jumper Position Table on page 15.

• To determine the correct setting, measure the receive audio output with 2/3 maximum deviation

applied where pins P1-11 and P1-3 will be connected.

Mic High and Mic Low – P1-12, Hi; P1-4, Low

This output uses a dc blocking capacitor. P1-12 goes to the capacitor’s + side and is connected to the

station transmit audio. Common mode noise is detected by internal circuitry, correcting the mic high

signal.

• The return, P1-4, should connect to mic low or station audio ground.

• The reference output is 80 mVac into 560 ohms.

Duplex Control – P1-2

This is an input that routes radio supervisory talk permit and button-acknowledge tones to the adapter.

Connect to RX audio enable high/disable low output from the radio.

F1 – P1-8

In a multi-frequency radio, connect to the F1 oscillator ground or enable. In single-channel radios, this

input is normally not connected. This uncommitted collector transistor switch is capable of driving 100

mA, and is Zener-protected to +5 V.

PTT Output – P1-13 Active High; P1-6 Active Low

Connect to radio station PTT (TX) input. These are uncommitted collector transistor switches, capable of

driving 100 mA maximum and Zener-protected to +15 V.

Monitor – P1-14 Active High; P1-7 Active Low

This uncommitted collector transistor switch is capable of driving 100 mA maximum and Zener-protected

to +15 V.

• Connect P1-7 to radio station monitor input if GND is required for monitor.

• Connect P1-14 if high is requested.

F2- P1-15

In a multi-frequency radio, connect to the F2 oscillator ground or enable. This is an uncommitted

collector transistor switch, capable of driving 100 mA maximum and Zener-protected to +5 V.

11 01/05

Page 16

Installation Model IDA 1000A DC Remote Adapter

Accessory Connections

Accessory connections are made to the 15-pin accessory connector, located on the rear of the unit.

Numeric designations and functions are parallel to the radio pin numbers and functions as described

above. Input and output signals are opposite those of the radio connections.

Line Connections

The landline RJ11/RJ14 connector to J1 is polarity sensitive and must be wired to the modular connector

as follows:

• Pins 3 (dc control negative) and 4 (dc control positive) for 2-wire TX/RX operation.

• Pins 2 and 5 connect to the 4-wire receive landline pair if the E376AG 4-wire option has been

installed. The 4-wire receive-only pair is not polarity sensitive.

• Pins 1 and 6 are not used on the RJ11 (2-wire) or RJ14 (4-wire) connector.

OTE: Pin 1 is on the right-hand side looking into the modular connector.

N

01/05 12

Page 17

Model IDA1000A DC Remote Adapter Installation

Radio and Accessory Connection Chart

Radio connections are made via P1-1 to P1-15. J3-1 to J3-15 accessory connections correspond

numerically and functionally.

Pin Wire Input/ Output Nominal

# Color Description Radio Acc. Range Default

1 Blk/Wht dc+ (not used) JU12 Power input B+ V dc

2 Blu/Wht Duplex control JU10

I

3 Green RX audio + I O Range 1: 32 mV–400 mVRMS

I Enable high (+5 V dc)

Disable low (0 V dc) RX audio

0 V dc

300 mV

RMS

Range 2: 400 mV–4.5 VRMS

See Jumper Position Table.

4 Black Mic low (AGND) 0 V dc

5 Wht/Blk Not used.

6 White PTT (push-to-talk) O I Active low (GND)

0 V dc

(B+ unkeyed)

7 Orange Monitor O I Active low (GND)

0 V dc

(B+ unkeyed)

8Red F1 O I

Low (0 V dc) or high (+5 V dc) 0 V dc

JU15

9 Red/Wht dc– (not used) JU13 Power input 0 V dc

10 Grn/Wht Not used

11 Grn/Blk RX audio - I O

12 Blue TX audio (Mic Hi) O I 32 mV–800 mVRMS 560 ohms 80 mVRMS

13 Blu/Blk PTT (push-to-talk) O I Active high (B+) (GND

B+ V dc

unkeyed)

14 Org/Blk Monitor JU11

O

I Active high (B+) (GND

unkeyed)

B+ V dc

15 Rd/Blk F2 O I

Low (0 V dc) or high (+5 V dc) 0 V dc

JU14

*NOTE: Colors apply to the supplied GAI-Tronics cable.

Possible accessories include external speaker, telephone interconnect, local desk set, tone remote adapter,

or paging encoder.

1

9

8

15

Figure 4. P1 Radio Connector Mating Side Pin

Contacts

8

15

Figure 5. J3 Accessory Connector Mating Side

Socket Contacts

1

9

13 01/05

Page 18

Installation Model IDA 1000A DC Remote Adapter

SW1 Switch Positions

There are eight section switches (SW1) on the front panel of the Model IDA1000A housing. See Figure 1

on page 4. A switch is closed when in the down position, and open in the up position. Refer to the tables

that follow for switch position and function information.

SW1 Switch Settings Table

SW1

Section Position Function

1Down

Up

2Up

Down

3 Up with JU3 Out

Down with JU3 Out

Up with JU3 In

Down with JU3 In

4Down

Up

5 & 6 5 & 6 down

Duplex hybrid enabled

Duplex hybrid disabled (default)

Transmit output range -15 dBm to 0 dBm

Transmit output range -25 dBm to -15 dBm (default)

Line input range: 32 mV ac to 150 mV ac

Line input range: 150 mV ac to 400 mV ac (default)

Line input range: 400 mV ac to 1.7 V ac

Line input range: 1.7 V ac to 4.5 V ac

Monitor function enabled only for duration of monitor command

(default).

Monitor function remains enabled after receiving a monitor command

and until a transmit command is received.

Special application: neither frequency is selected during receive

condition (default).

5 & 6 up

5 down

Radio remains on whatever frequency the last transmission occurred.

Radio reverts to frequency F1 after every transmission regardless of

frequency of previous broadcast (when SW1 section 6 is up).

6 down

Radio reverts to frequency F2 after every transmission regardless of

frequency of previous broadcast (when SW1 section 5 is up).

7Down

Up

8Down

Up

Provides line termination for incoming signals (default).

Does not terminate line.

Half-duplex operation (default).

Allows remote user to hear supervisory talk permit and button

acknowledge tone from the radio (requires SW1 section 1 to be down

and appropriate adjustment of Pot 3).

01/05 14

Page 19

Model IDA1000A DC Remote Adapter Installation

Jumper Positions

The IDA circuit board contains nine jumpers, JU1 through JU5, and JU10 through 13. See board layout

in the Main Circuit Board section. The default setting provides normal operation. It should be changed

only for special applications.

Jumper Position Table

Jumper Position Function

JU1 3

1*

JU2 Out

In*

JU3 Out*

In

JU4 A

B*

JU5 A

B*

JU10-13 Out* Special applications only.

Line driver disable

Line driver enable

4-wire (if XDA0001A option is installed)

2-wire

SW1-3 Up - Line input range: 32 mV ac to 150 mV ac

SW1-3 Down – Line input range: 150 mV ac to 400 mV ac

SW1-3 Up – Line input range: 400 mV ac to 1.7 V ac

SW1-3 Down – Line input range: 1.7 V ac to 4.5 V ac

High output for F1

Low output for F1

High output for F2

Low output for F2

*Indicates the default positions.

Line Input Gain Select Switches

For SW1 sections 2 and 3, the default setting is down. These should be changed only if one of the remote

units has wire line losses of 10 dB or more. Select a gain setting to compensate for the unit with the most

loss. Adjust all other units to give identical transmit levels. To make adjustments:

1. Apply a 1000 Hz tone at the desired line level, e.g. 0 dBm at the remote end of the wire line to be

tested.

CAUTION

Do not exceed the recommended operating level of the line. Consult the line provider for this

information.

2. Measure and record the level at the remote adapter end with the adapter connected to the line. Do this

for each line attached.

3. Select the gain that best compensates for the line with the most loss. Start with the desk set that has

the most line loss and use the recommended mic input level from the desk set adjustment instructions.

Adjust the line driver on each desk set to obtain a 2/3 system deviation (nominally 80 to 165 mV ac).

15 01/05

Page 20

Installation Model IDA 1000A DC Remote Adapter

Level Settings and Adjustments

Line Drive Level

Set the line drive level as follows:

1. With a service monitor connected to the receiver with maximum allowable system deviation, measure

the audio across P1-11 and P1-3.

2. Set jumper JU3 and switch SW1-3 for the level indicated. See the Jumper Position Table on page 15.

3. While measuring the input to the line J1-3 and J1-4 (on 4-wire installations, J1-2 and J1-5), adjust

Pot 1, the adapter

allowable.

Transmit Level

Setting the transmit level compensates for any losses in the audio control line. The transmit level is set as

follows:

1. Apply a 1000 Hz signal to the mic circuit of the remote desk set. This signal should be enough to

provide the desired reference level across the audio control line at the desk set end, normally

-10 dBm.

LINE DRV level pot, for the desired level of drive, but no greater than the maximum

2. Adjust Pot 2, the adapter TX level pot, to obtain 2/3 system deviation from the base station

transmitter. If it is not possible to obtain the correct level near the center of the control’s travel, use

the opposite position for Gain Select, SW1-2.

DC Threshold Calibration

The dc threshold level is factory set and should not require adjustment unless field service is required. If

field service is necessary, complete the following steps:

1. Apply a –2.5 mA source to the control line.

2. Slowly adjust Pot 4, the calibration pot, to illuminate the

3. Remove the –2.5 mA current. The

Balance Adjustment

MON LED should extinguish.

MON LED.

The hybrid adjustment is factory-set and should not require adjustment. If field service is necessary,

complete the following steps:

1. Set switch SW1-8 up and SW1-1 down.

2. Adjust Pot 4 to full clockwise position.

3. Apply a 1000 Hz signal to P1-3/P1-11.

4. Measure the audio across P1-12/P1-4 and adjust Pot 3, the adapter

01/05 16

BAL pot, to null (minimum).

Page 21

Theory of Operation

Power Supply

The power supply for the remote adapter operates in the linear serial-pass mode. Programmable Zener U4

serves as reference for the 5 V digital power supply. The reference voltage is 5.00 V dc, +/- 0.1 V dc

measured at emitter Q5. Op-amp U1a controls the series pass element Q5 to provide 5 V dc at the 5 V

source point and the power LED provides indication of this voltage level. The reference voltage from U4

is scaled and isolated through U1b to provide a 2.5 V source.

DC Control Current Detection

Audio and dc control line currents are input to the circuit board through pins 3 and 4 of modular

connector J1. AC current is shunted across the transformer secondary by C1, and dc current is developed

across R1. The dc current is translated to a voltage (referenced to 6 V) by amplifier U5 and fed to U6a, b,

c, and associated components.

If the translated voltage were produced by a line current greater than or equal to 4.4 mA (indicating a

transmit command), then U6-1 would output a high level voltage; if the translated voltage were produced

by a line current greater than or equal to 9 mA, then U6-7 would output a high level voltage. If the

translated voltage were produced by a line current of negative polarity and greater than or equal to 2 mA

(indicating a monitor command), then U6-14 would output a high level voltage.

A high signal on U6-1 forces a low at U7-1 (illuminating LED 2) and U8-1, resulting in a high at U7-4

(after a delay through R71 and C20, C52) which then opens the audio path from the wire lines to the

station, drives Q1(Q6) and thus forces transmission on F1 (in a multi-frequency station), and forces

Q3(Q8) to output an active low (high) on the push-to-talk line. The low at U7-1 disables the receive

audio path from the station when SW1 section 8 is down.

In a 2-frequency station, a high on U6-7 drives Q2(Q7) through NOR gates U9b and U9c and thus forces

transmission on F2. The circuitry consisting of latch U8b and U8c, U8a, U8d, U9 guarantees that the F1

line will be disabled in the event of an F2 command. Switch SW1–5 may be pushed down (with SW1-6

up) to cause the transmit frequency to revert to F1 subsequent to every transmit command; switch SW1-6

may be pushed down (with SW1-5 up) to cause the transmit frequency to revert to F2 subsequent to every

transmit command.

A high signal on U6-14 forces U7-10 low (illuminating LED 3) and U7-13 high, thus enabling transistor

Q4(Q9) to output an active low on the monitor line. If switch SW1-4 is up, the monitor function will

remain enable subsequent to a monitor command and until a transmit command is received. This function

is accomplished by the latch configuration of U7c and U7d.

A low on U9-4 (indicating detection of a line current greater than or equal to 9 mA) illuminates LED 4; a

low on U9-13 (indicating detection of a line current greater than or equal to 4.4 mA) illuminates LED 5.

17 01/05

Page 22

Theory of Operation Model IDA1000A DC Remote Adapter

Audio Circuit

Receiver audio to be output on the control lines at J1 is input to the circuit board on P1-11, 3. These

signals are scaled through amplifier U2a, U10b and fed through the line audio adjustment, pot 1. The

resulting signal is gated to the line driver U11, U10a, and associated components.

Transmitter audio is input to the remote adapter through J1-3, 4, routed through transformer T1, and

scaled through U1c, U1a, U2c, and associated components. The line output gain may be set by proper

configuration of switch SW1-2.

The signal exiting U2c is fed through the line output adjustment, pot 2 and gated through U3a to the mic

hi input to the base station on P1-12.

01/05 18

Page 23

Troubleshooting

Troubleshooting the Model IDA1000A DC Remote Adapter

The following is a list of potential problems you may encounter and possible solutions.

Problem Possible Solution

General problems Ensure that there is a valid circuit line path from the desk set to the dc remote

adapter.

Check for a blown fuse and ensure that the dc remote adapter is connected to

a properly functioning dc power source (if using a dc power supply option).

The IDA1000A will not

key the radio.

Radio is keyed constantly

while the IDA1000A is

connected.

RX audio is low or

distorted.

There is constant white

noise in RX audio.

There is no RX audio. Check fuse F3 (4-wire option)

There is no TX audio. Verify that the radio is being keyed when transmitting to the IDA1000A from

Ensure that one of the IDA1000A PTT outputs is connected to the radio.

Check the telephone line continuity from the desk set to the remote adapter.

Reversed phone line pins 3 and 4.

Ensure that the telephone line is generating a current that the IDA1000A uses

for keying the radio.

Ensure that the PTT is in the proper active state:

P1-6 Ground keying

P1-13 B+ keying

Ensure that the IDA1000A receive sensitivity is set properly.

Ensure that there is no more than 20 dB loss in the telephone line.

Obtain RX audio from a muted source in the station and not ‘raw

detector/disc. audio.’ See radio manuals.

Check radio cable connections to radio’s RX audio source.

a dc remote.

Verify that the IDA1000A output level is properly set and there is not more

than 20 dB of loss in the telephone line.

Open fuse F2. (See fuse replacement information below.)

TX audio is distorted. Verify that the dc adapter transmit audio output is not set too high for the

radio’s expected input level. Adjust the TX audio level pot for proper setting.

TX level is set too high or SW1-2 is set to wrong position.

IDA1000A does not

transmit or receive.

Ensure that there is a telephone line audio path from the IDA1000A to the dc

desk set.

19 01/05

Page 24

Troubleshooting Model IDA1000A DC Remote Adapter

Fuse Replacement

CAUTION

For continued safe operation, replace fuses with the same type:

• F1 is a Bussmann 0.5A Type GMA, FB fuse.

• F2 on the main board and F3 on the 4-wire option board are Bussmann C515S 1.25A 2AG SB.

01/05 20

Page 25

Main Circuit Board

21 01/05

Page 26

Main Circuit Board Model IDA1000A DC Remote Adapter

22

Page 27

Model IDA1000A DC Remote Adapter Main Circuit Board

23

Page 28

Main Circuit Board Model IDA1000A DC Remote Adapter

24

Page 29

Schematics

25 01/05

Page 30

Schematics Model IDA1000A DC Remote Adapter

Schematic - Sheet 1

26

Page 31

Model IDA1000A DC Remote Adapter Installation and Service Manual Schematics

Schematic Diagram - Sheet 2

27

Page 32

Schematics Model IDA1000A DC Remote Adapter

Schematic Diagram - Sheet 3

28

Page 33

Model IDA1000A DC Remote Adapter Installation and Service Manual Schematics

Schematic Diagram - Sheet 4

29

Page 34

Schematics Model IDA1000A DC Remote Adapter

Notes:

30

Page 35

Term Definition

Definitions and Acronyms

CSQ

CTCSS

CDCSS

HLGT

LLGT

PTT

Carrier squelch

A means of grouping users of a common radio channel. Subaudible tones are transmitted

with audio; a particular radio's speaker (or the speakers of a group of radios) will unmute

to broadcast a transmission only if the associated subaudible tone identifies it as

belonging to the radio's user group.

A system analogous to CTCSS but using low speed digital signaling instead of subaudible

tones.

High level guard tone

Low level guard tone

Push-to-talk

31 01/05

Page 36

Notes: Model IDA 1000A DC Remote Adapter

32

Loading...

Loading...