Page 1

1M23N25101

Backplate Sensor For

Governor

BPS-1

Instruction Manual

WARNING

Always use the BPS-1 with a BPS-1

compatible engine backplate.

Be careful of the connector polarity.

■ Because of the case construction, reversing the polarity

may cause trouble or sparking from the wiring.

Mount the BPS-1 when the engine is

sufficiently cool.

■ If you touch the engine immediately after use, you may

receive a burn.

Mount the senso r in accordance

w i th t h e inst al lat ion m e t h od

described below.

■ If the BPS-1 drops out during flight, it cases erratic

operation or loss of control.

Grommet

< BPS-1 >

Sensor

To engine

backplate

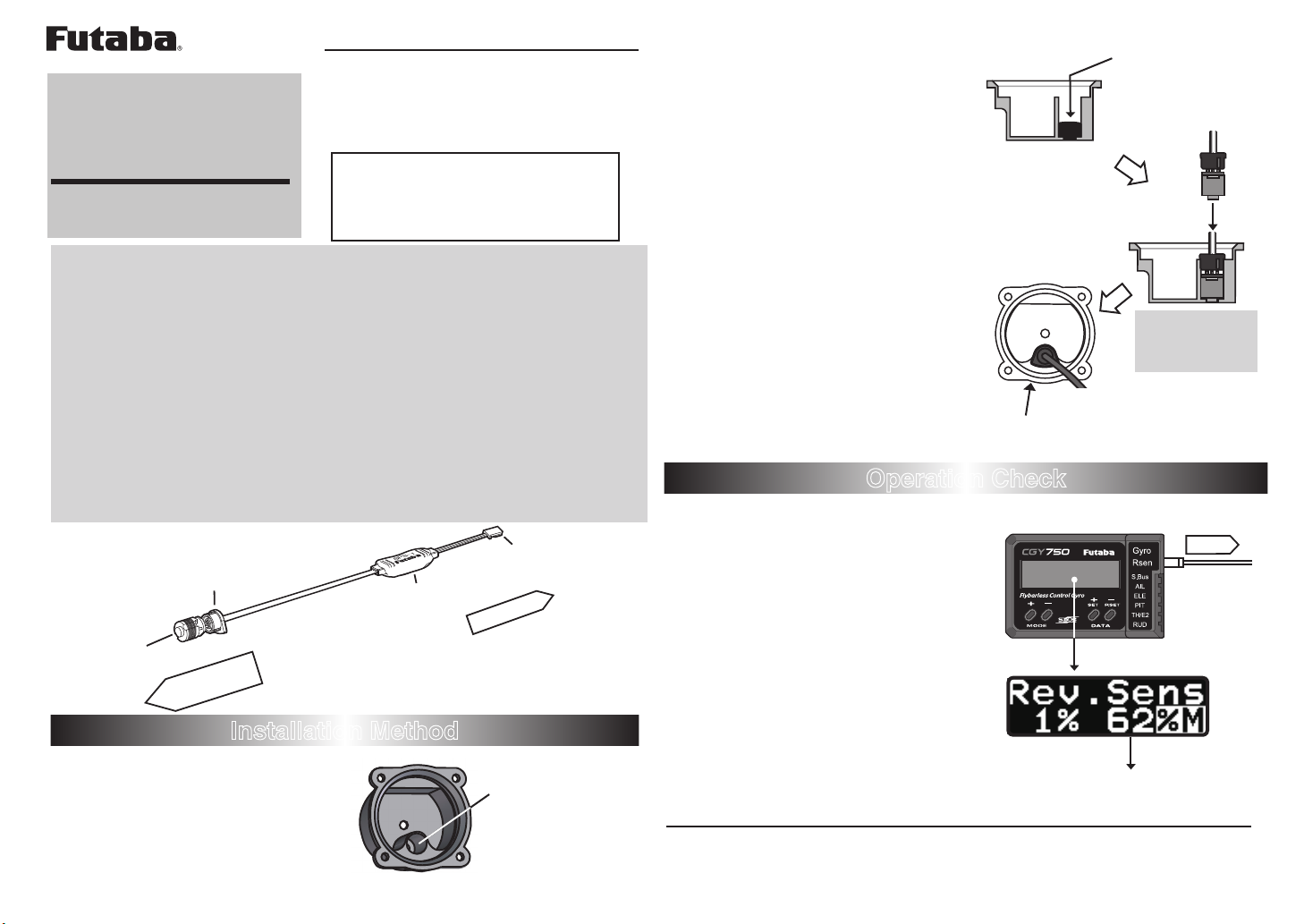

Installation Method

Degrease the engine backplate with

1

alcohol, etc.

*Oil residue on the backplate will

cause faulty adhesion.

Thank you for purchasing a BPS-1 Backplate Sensor

for governor. Before using your new sensor, please

read this manual together with the instruction manuals

of the governor, transmitter, and engine used and use

the BPS-1 properly. After reading this manual, store it

in a safe place.

●The BPS-1 is designed for use with

Futaba GY701, CGY750, and GV-1

governors.

●The BPS-1 can be used only with a

BPS-1 compatible engine backplate.

Vibration-proof the PC board and

mount the BPS-1 where it will not be

exposed to fuel and water.

■ Electronic parts are used at the PC board. Take

protective measures against vibration, shock, high

temperature, and so forth.

When mounting the BPS-1 to the

fu selage, be sure there is some

slack in the wiring cable.

■ If the cable is too tight, vibration may cause the wire

to break or the connector to be dislodged and cause a

malfunction.

Always perform an operation check

after assembling.

■ Do not fly until inspection is complete.

Do not use the BPS-1 with anything

other than an R/C model helicopter.

Connector

PCBoard

To Governor

Overall length: approx. 655mm

Weight: 8g

Sensor mounting

section

Special engine

backplate

Inject silicone resin into the special

2

engine backplate up to about 1/3

(approximately 0.3cc) from the bottom

of the sensor mounting section of the

backplate.

Use non-solvent alcohol-release type silicone

*

adhesive.

Insert the sensor perpendicularly and

3

push in the grommet fully.

*Until adhesive is squeezed out from the

grommet is a sufcient.

Wipe off the squeezed out adhesive.

Special engine

backplate

Silicone adhesive

Insert sensor

perpendicularly

4

WARNING

*So that the adhesive does not enter the engine.

Adhesive in the engine will cause engine

trouble.

Fasten the grommet so that it will

5

not move and allow the adhesive to

harden.

Make the grommet

direction like this.

Operation Check

After assembling is complete, check operation as follows:

Connect the sensor to the governor

1

used and call the governor revolution

sensor test screen. (Revolution sensor

monitor for the GV-1.)

*Connect and operate the sensor in accordance

with the governor instruction manual.

Using a starter, rotate the engine

2

without starting it and check if the

sensitivity is 60% or greater.

*Rotate with only the starter without plug

heater attached.

*If the sensitivity is less than 60%, re-check the

installation.

FUTABA CORPORATION

1080 Yabutsuka, Chosei-mura, Chosei-gun, Chiba-ken, 299-4395, Japan

Phone: +81 475 32 6982, Facsimile: +81 475 32 6983

©FUTABA CORPORATION 2011, 3 (1)

OK at more than 60% by

rotating the starter.

Push in fully.

BPS-1

Loading...

Loading...