Page 1

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

D60656

ATTACK-SPORT

SYSTEM

FP-2NCS/2NCR

•The

ATTACK-SPORT

on the acclaimed ATTACK and has a built-in BEC (Battery Eliminator Circuitry) system.

Thank you for purchasing a Futaba digital proportional radio control set.

Please read this manual carefully before using your set.

CONTENTS

TRANSMITTER PP-T2NCS/FP-T2NCR ..... 2

USING THE FREQUENCY FLAG

LOADING THE PENLIGHT BATTERIES . 3

SERVO

STEERING TRIM LEVER ADJUSTMENT . 3

AND

RATINGS

REVERSE

SWITCHES

is a high

Since the power receiver and servo power is supplied from the running

Nicd battery, there is no troublesome wiring and the vehicle can be made

lighter.

...........

performance 2 channel

CONTENTS

1

......

........

2

3

digital

proportional

CHANGING THE THROTTLE STICK

FROM A SELF-NEUTRAL SYSTEM

TO

A RATCHET SYSTEM

CRYSTAL REPLACEMENT

RECEIVER

AND

WHEN VEHICLE WILL NOT BE USED .

RECEIVER

PP-S148

SPLINED HORNS

SERVOS

ANTENNA

.....................

R/C

..........

..........

............

ROUTING

................

........

set

based

4

4

5

. C4

C4

.C4

C4

Page 2

The ATTACK-SPORT has a BEC function

• The BEC (Battery Eliminator Circuitry) system is a high performance constant voltage

circuit (regulator). Since the running Nicd battery can also be used as the receiver servo

power supply, there is no troublesome wiring and the vehicle can be made lighter.

• Transmitter is Built-in servo reverse switches. (FP-2NCR)

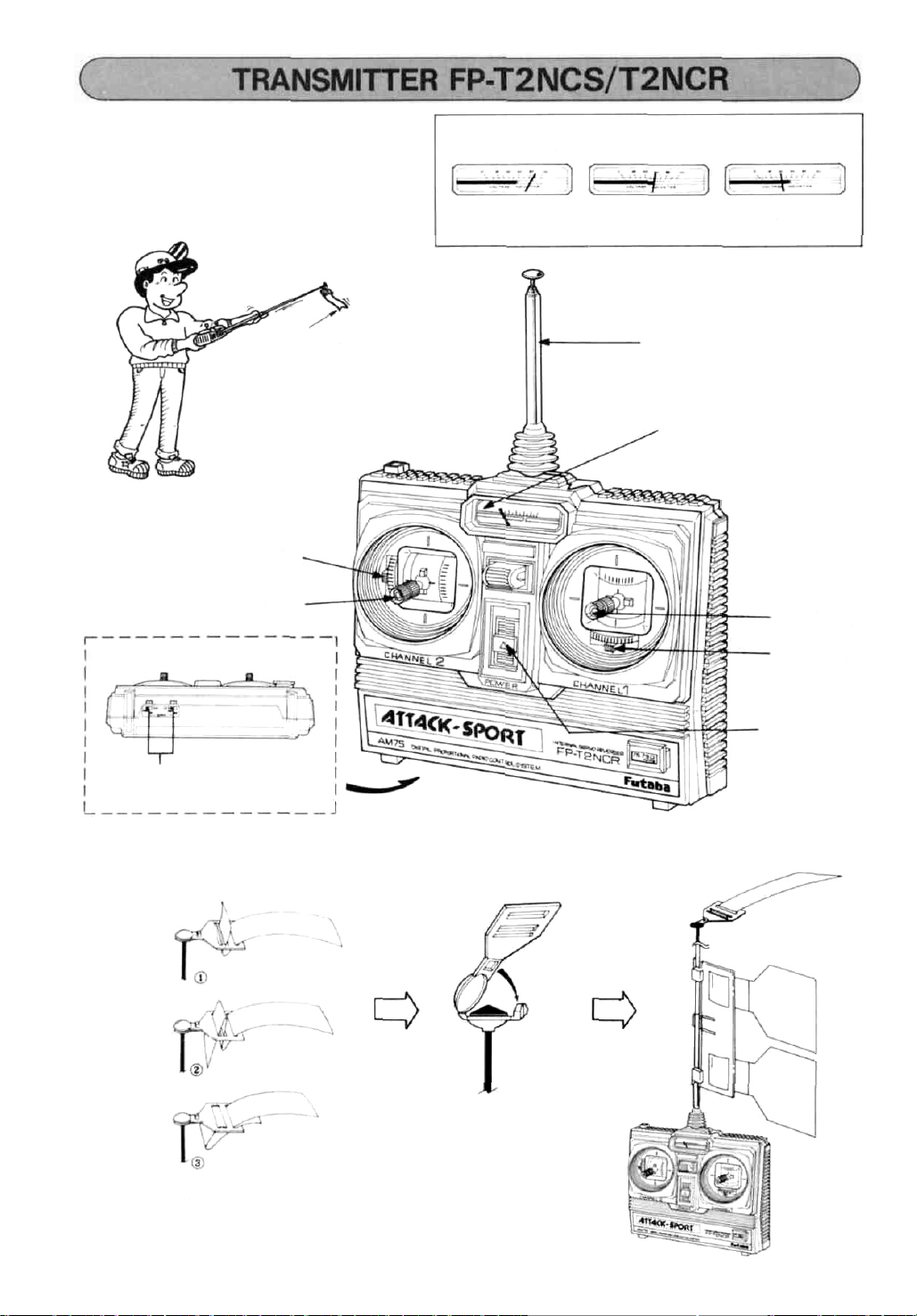

TRANSMITTER FP-T2NCS/T2NCR

•Racing specification short aluminum stick lever makes

operation extremely easy.

•The

stick

can

be

changed

to a ratchet system

by

installing an optional slider.

• Servo reverse switches (steering & throttle).

Since each servo can be switched between forward

and

reverse from the outside of the transmitter, linkage

hookup is extremely easy. (T2NCR)

• Level meter shows the state of the battery at a glance.

•Crystal can be changed from the outside. (Except 72/

75 MHz

in

USA)

RECEIVER FP-R102JE

•Miniature and lightweight high-performance AM

receiver with built-in BEC is realized by using chip parts.

(20% smaller and 35% lighter than our R102GF.)

• Intermodulation interference characteristic improved

substantially by using a new circuit system AIC circuit.

•Reliability is improved further by using the unique

Futaba custom decoder 1C.

• Newly designed case is small and easy-to-use.

• High sensitivity design by built-in RF amp.

•High-performance built-in BEC system can handle

power supply voltages up to 8.4 V.

2CH

SERVO FP-S148

RUGGED, LOW-PROFILE SERVO

•The

PP-S148

design that can be easily mounted in all models.

•Vibration

further by using a direct wiring system which directly

connects the servo amp, motor and potentiometer.

•The

height of

torque, high speed, and smooth movement equal to that

of the coreless servo have been realized by using a new

small, high-performance motor. (Output torque 42

oz-in <3kg, cm), operating speed 0.22 sec/60°).

• New indirect drive/completely sealed potentiometer

substantially improves vibration

and neutral accuracy.

•Unique Futaba power-saving custom 1C provides high

starting torque narrow dead band, and excellent trackability.

•Fiberglass P8T (polybutylene terephthalate) servo case

is mechanically strong and is invulnerable to glow fuel.

•Strong

smooth operation, accurate neutral, and minimal backlash.

•Fiberglass epoxy PC board with THRU-THE-HOLE

plating improves the servo amp vibration and shock

resistance.

•Thick plated connector pins eliminate the problem

faulty contact, improve reliability against shock

vibration, and prevent reverse insertion.

•Special pad grommets simplify mounting

and are extremely vibration-resistant.

•Six kind of special adjustable horns are available.

•High

42

almost all models.

is a low 1.4

and

polyacetyl

oz-in

(3kg-cm)

shock

the

resin

resistance

servo

precision

output

inches

high and

have

has

been

reduced

and shock resistance,

servo

torque

has a thin

been

improved

and high

gear

featuring

of the servo,

is

perfect for

and

of

Transmitter

Receiver

Servo

Others

Transmitter FP.T2NCS/T2NCR

Operating system

Transmitting

frequency

Modulation

Power requirement

Current drain

FP-2NCS

FP-T2NCS x 1

FP-R102JE x 1

FP-S148x 2

2 stick

27MHz bands 1 to 6.72, 75MHz

AM (Amplitude Modulation)

12 0V. penlight battery x 8

170mA

Switch, frequency flag, etc.

Receiver—

FP-R102JE

Receiving

frequency

Intermediate

frequency

Power requirement

Current drain

Dimensions

Weight

Range

27 MHz and 72/75 MHz band

455 kHz

4.8 V to

8.4 V (BEC

8.4V/12mA,4.8V/33mA

(no signal)

1.23x 1.87 x 0.78

133x47.4 x 19.8mm)

0.88

oz

125

300 m on the ground with

FP-T2NCS T2NCR

(At the best radio wave condition

of environment) -

1

FP-2NCR

FP-T2NCR x 1

FP-R102JE x 1

FP-S148 x 2

built-in)

in

g)

Control system

Operating angle

Powar

requirement

Current drain

(IDLE)

Output torques

Operating sp—ed

Dimensions

Weight

Specifications are subject to

change without prior notice.

SERVO FP-S148

+pulse width control

One side 45° or more

4.8V-6V

6.0V, 8mA (at idle)

42 oz.

in.

(3

kg

0.22 sec/60°

1 .59x0.77 x 1.4 in.

(40.4 x 19.8 x 36

1.5 oz.(44.4g)

cm)

mm)

Page 3

• Nomenclature

•The

name

of

each

shown in the figure. Learn them before ope-

part of the

rating your set.

When running the vehicle, extend the antenna

fully.

transmitter

is

Before using the set, check the remaining

battery capacity by checking the level meter.

Good

Caution No good

Change the battery.

Throttle trim

Throttle stick

Servo reverse switches

(FP-2NCR)

Frequency flag

Antenna

Level meter

Steering stick

Steering trim

Power switch

•USING THE FREQUENCY FLAG

Attach the frequency flag

the flag holder as shown in the

figure.

First

digit

Second

digit

The flag can be attached to

and removed from, the antenna with one touch.

to

2

Page 4

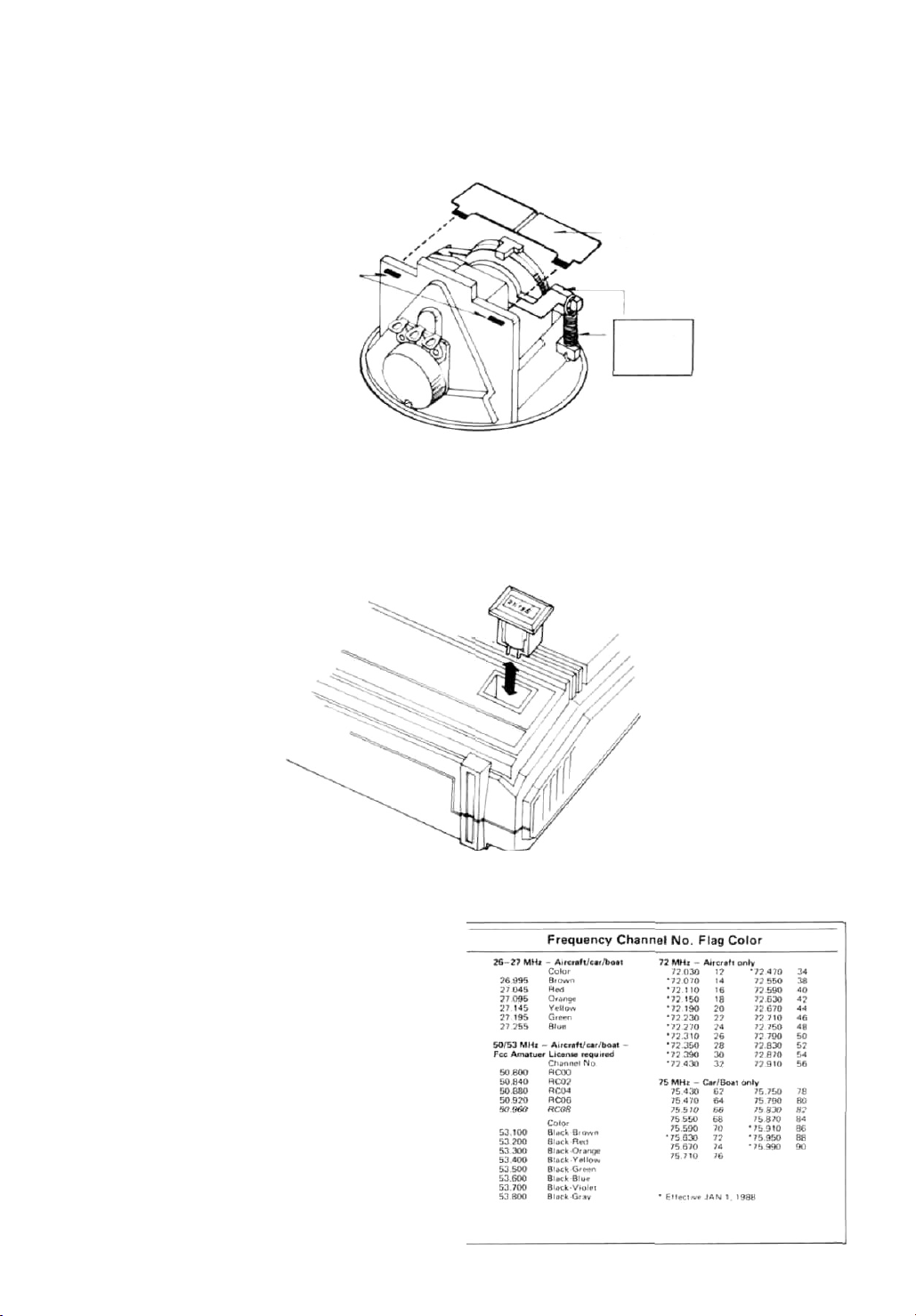

•LOADING THE PENLIGHT BATTERIES

• Remove the battery cover at the rear and insert eight penlight batteries in the correct polarity.

Rear cover mounting screws

Servo reverse

switches

(FP-T2NCR)

Slide in the direction of the

arrow while pushing here.

• Extend the antenna fully and set the power switch to ON.

The

level

er does not move, or moves very little, check for poor battery contact, incorrect battery polarity, or faulty batteries.

• If the pointer of the level meter deflects to the red zone, the range of

the radio waves will become short. When the pointer drops to the

boundary between the silver and red zones, change the batteries.

•The

used to adjust the neutral position and for correcting the running

posture after the mechanism is mounted. After test running, make

corrections with the rod adjuster, etc. and operate the set with the

trim

meter pointer should deflect to the

trim

levers

are

used

to fine

levers

in the neutral position

adjust

as

much

the

as

silver

steering

possible.

zone.

angle.

If

the

They

point-

•SERVO REVERSE SWITCHES

(FP-2NCR)

•This

switch makes

direction.

• After fixed servos onto your model, and found

that rotation is wrong-way, switch to another

direction.

•Servo reverse switches are located at bottom of

Transmitter case like drawing below:

•STEERING TRIM LEVER ADJUSTMENT

servo

rotation to

When vehicle was run straight.

another-

are

The batteries can be easily

loaded by inserting them

four at a time from the back.

Steering servo

reverse

switch

Normal Reverse

• When vehicle was run straight-

Throttle

servo reverse

switch

Normal Reverse

When vehicle turns

to the right

Move the trim lever slowly

to the left so that the ve-

hicle runs straight.

*Adjust the trim lever so that the vehicle runs straight on a smooth road.

The throttle trim lever is used to fine adjust the speed controller stop position, etc.

Move the trim lever slowly

to the right so that the

vehicle runs straight.

3

When vehicle turns

to the left

Page 5

•CHANGING THE THROTTLE STICK FROM A SELF-NEUTRAL SYSTEM TO A RATCHET SYSTEM

•When changing the throttle stick from a self-neutral

system to a ratchet system, install the optional slider.

Then, remove the spring and swing arm.

Install the optional

slider.

Twist with long-nose

pliers.

Remove the

spring and

swing arm.

•CRYSTAL REPLACEMENT

• When changing the band, remove the crystal holder and

change the crystal. (Except 72.75 MHz in USA)

•Futaba Digital Proportional Frequencies (FOR

U.S.A.)

•The

frequency

changed within their own band. There are 4 different

bands for you to choose from (27 MHz, 50—53 MHz,

72 MHz, and 75 MHz.) Please see chart listed below for

specific frequency and its intended use. Please note there

are specific frequencies allocated for aircraft only and

surface only use.

•The

frequency

using a precisely matched pair of Futaba crystals.

However, Futaba recommends that you return your

system to our factory service department for frequency

changing, as turning may be necessary for proper operation. Changing frequency from one band to another is

NOT possible.

•Always change frequency flag when frequency is changed.

The frequency flag is to be attached to the top of antenna

and the channel designation to the base. (See Drawing)

• It

is illegal to change crystals of 72—75 MHz bands in the

U.S.A.

of Futaba

can be changed

digital

proportional

within

the

same

sets

BAND

can be

by

4

Page 6

The

system

sets

Receiver FP-R102JE

mark is displayed on the front of the receiver of BEC

with a receiver

with

shared

power

supply

regulator.

Receiver crystal

OFF

ON

Throttle servo

Steering servo

Antenna wire

Red common 2P

connector (male pins)

Connect the servo and switch as

shown in the figure and extend

the transmitter and receiver antenna fully.

(3) When motor car uses an ordi-

nary common power supply

chassis

Red common

2P

connector

(Female pins)

Buy the red common 2P

connector from the kit

manufacturer and connect to

the controller.

Pin 1: Minus

Pin 2: Plus

Switch

Connection to this connector

Red common 2P

connector

(Female pins)

Red common 2P

connector

(Female pins)

(1) When chassis power supply of

engine or motor car is separate

(2) When motor car uses a speci-

al BEC system chassis (common power supply specifi-

cations)

Controller

Connect to the red common

2P connector of the controller.

Wrapped with

rubber bands.

The Futaba BEC system can also use a common power supply with the conventional four penlight batteries system

(separate power supply).

•A

common

ing

on

the

power

vehicle

supply

kit.

Since

regulator

they

and

diode

cause a voltage

may

drop,

also

be

supplied

always

remove

with

them.

the

speed

controller,

depend-

5

Page 7

•Set

the transmitter power switch

position. Operate the transmitter sticks and check if each servo faithfully follows operation of the sticks.

to

ON,

then

set

the

receiver

power

switch

to

ON.

The servos

stop

near

the

neutral

From transmitter

when

switch turned

on

• Connect the pushrod to each servo horn, then check if the direction of travel of each servo matches the transmitter

Operation.

When transmitter

stick lever set to the

right

• Operate each servo over its full travel and check if the pushrod binds or is too loose. Applying unreasonable force to

the

servo

horn

will

•Always make the full stroke (including trim) of the servo horns somewhat larger than the full travel. Adjust the

servo horns so that they move smoothly even when the trim lever and stick are operated simultaneously in the same

direction.

• Be alert for noise.

Always solder a noise killing capacitor to the running motor. If metal parts touch each other due to vibration, noise

will

be generated and

•

Even

though

adversely

the

receiver antenna

affect the servo and

cause

the

receiver

wire

servos

is

long,

quickly

drain

to

operate erroneously.

do

not

cut

or

bundle

the

battery.

We

it.

The range

Be

especially careful

recommend

of

the

use

the

radiowaves

From receiver when

switch turned off

Vehicle also steers

to the right

when

of

noiseless parts.

will

be

using 8.4V.

shortened.

R102JE

Scissors

• A spare horn is provided. Use it as required.

•Wrap the receiver in sponge rubber and wrap rubber bands around the sponge rubber. Mount the receiver so it is

not exposed to vibration, does not touch the frame, and does not move.

•When the receiver is installed on a board or used where it may be splashed with mud and water, place it in a plastic

bag, etc. and wrap a rubber band around the open end of the bag to waterproof and dustproof the receiver. After use,

remove the receiver from the bag to prevent condensation.

• Use the rubber bands wrapped around the receiver to hold the servo and switch leads.

•After mounting is complete, recheck each part, then check the transmitting range by making the transmitter antenna

as short as possible and extending the receiver antenna fully and operating the set from a distance of 20m to 30m. The

movement of each servo should follow the movement of the transmitter sticks.

• The crystal can be changed from the outside of the receiver case. (Except 72/75MHz in U.S.A) Always use a Futaba

transmitter and receiver crystal pair as the replacement crystals.

Receiver antenna

wire

- Wood screw

Rubber

bushing

Grommet

• Install the servos firmly. Install

the servo to the servo tray as

shown in the figure. In other

cases, install the servo as described in the model manufacturer's manual.

6

Page 8

Your NEW FUTABA Digital Proportional R/C Sys-

tern is guaranteed against defects in workmanship

and material for 180 days from the date of purchase

when the attached registration card is returned to

us within ten days of purchase.

This Guarantee is null and void if the R/C system

has been improperly handled, damaged in a crash, or

tampered with and does not cover the replacement

of plastic housings or electronic components

damaged due to the use of improper voltages.

When service is required, please take your equipment to your local authorized service station or ship

it directly to us. All postage, shipping, and insurance

charges must be paid by the user.

•WHEN VEHICLE WILL NOT BE USED

Be sure and release the connector of running

Nicd battery except when you are on the way

to the starting line.

When not using the

connector, set the

switch to OFF.

To obtain the best possible range (car to transmitter

distance) and reduce the possibility of interference,

please observe these antenna routing instructions.

Failure to follow these guidelines can result in loss

of control or limited range

1) NEVER cut your receiver's antenna wire.

Your system

length of the stock antenna.

2)

Excess

coiled. To safely store the excess wire make

an antenna shortener from a small piece of stiff

cardboard. This will provide maximum reception

and prevent tangling and breakage of the wire.

3) When routing the antenna wire to the antenna

tube keep the wire away from battery and speed

control wiring. The high power of the NiCd

battery creates electrical "noise" which can cause

interference.

Remember that operating your FX10 on snow

or in wet areas is not recommended. Melted

snow becomes water which will damage or short

out your system's electronics._____

has

antenna wire should

SNOW IS WATER

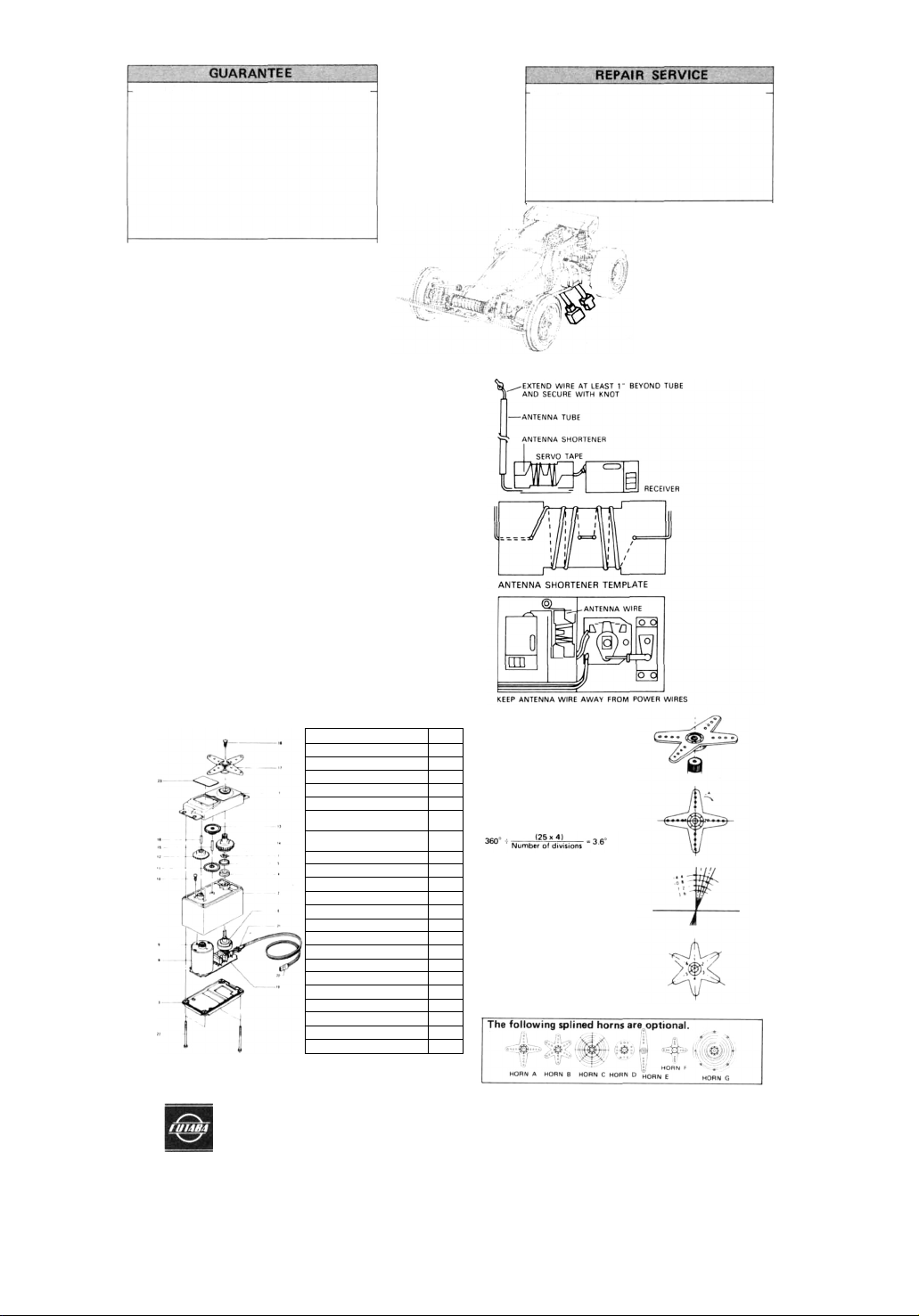

FP-S148

been precisely tuned

NOT

No. Part name

1. Upper case

2. Middle case

3. Bottom case

4. Metal bearing

5. Metal bearing

6. Potentiometer

8. Motor

9. Motor pinion

10. Screw

11. 1st gear

12. 2nd gear

13. 3rd gear

14. Final gear

15. Intermediate shaft

16. 2nd shaft

17. Servo horn A

18. Binding head tapping screw 2.6 x8

19. Printed wiring board S148

20. S148 3PB-WRB300G

21. w gum bush

22. Pan head truss screw

23. Nameplate S148

be

to

the

tightly

full

Part

FCS-48

FCS-48

FCS-48

S04137

S04136

I 39668

S91259

802461

J50002

FOS-48

FGS-48

FGS-48

FGS-48

S02495

S02494

FSH-6X

FSH-4I

AS1157

AT2453

S90045

S50360

S60099

•SPLINED HORNS

This horn permits shifting of the

No.

servo neutral position at the servo

horn. Setting and shifting the neutral

position

1) The splined horn has 25 segments. The amount of change per

segment is; 360-25!e14.4°

2) The minimum adjustable angle is

determined by the number of arms or

number of the holes. For four arms,

the minimum adjustable angle is:

b) Effect

To shift the holes center line to the

right (clockwise) relative to baseline

A, shift arm 2 to the position of arm

1 and set it to the position closet to

baseline A.

angular shift per segment is 14.4°.

The shift to the right is 90° - (14.4 x

6) = 3.6°

To shift by the same angle in the

opposite direction, use the opposite

arm number.

For a six arm horn, turn the arm

counterclockwise and set arm 2 to

the position of arm 1. The adjustable

angle is 60° - (14.4 x 4) =2.4°.

Arm 3 shift 4.8° to the right, arm 6

shifts 2.4° to the left, and aim 4

shifts 7.2° to the right and left

•When requesting repair of trouble that has occurred suddenly of from long use, describe the

trouble symptoms in as much detail as possible.

This will facilitate detection of the trouble point

and shorten the repair period greatly.

•Defects caused by faulty materials or workmanship

will

be

corrected

free

of

•This limited warranty is null and void if the set has

been tampered with or disassembled.

Refer to warranty statement for details.

Release the connector.

charge.

FUTABA CORPORATION OF AMERICA

4 Studebaker, Irvine California 92718, I .S.A.

Phone:714-455-9888 Telex: 23-0691227 Facsimile: 714-455-9899

FUTABA (EUROPE) GmbH

Am Seestern 24, D-4000, Dusseldorf 11, W. Germany.

Phone:021 1-5287-0 Faesimile:0211-593133

FUTABA CORPORATION

Tokyo Office: INAGAKI BLDG., 3F 1-21-3, Kanda sudacho, Chiyoda-ku, Tokyo, Japan.

Phone: (03)255-681 1 Facsimile: (03)255-6880

Loading...

Loading...