Page 1

Back

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080839301**00080839301*

*00080839301**00080839301*

*IME34690L00**IME34690L00*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. IME-34690-LIME-34690-L

Printed in JapanPrinted in Japan

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION : OCT.OCT. 19981998

LL :: JUL.JUL. 10,200310,2003

(( TENITENI ))

FR-2135SFR-2135S

* 0 0 0 8 0 8 3 9 3 0 1 ** 0 0 0 8 0 8 3 9 3 0 1 *

*IME34690L00**IME34690L00*

* I M E 3 4 6 9 0 L 0 0 ** I M E 3 4 6 9 0 L 0 0 *

Page 3

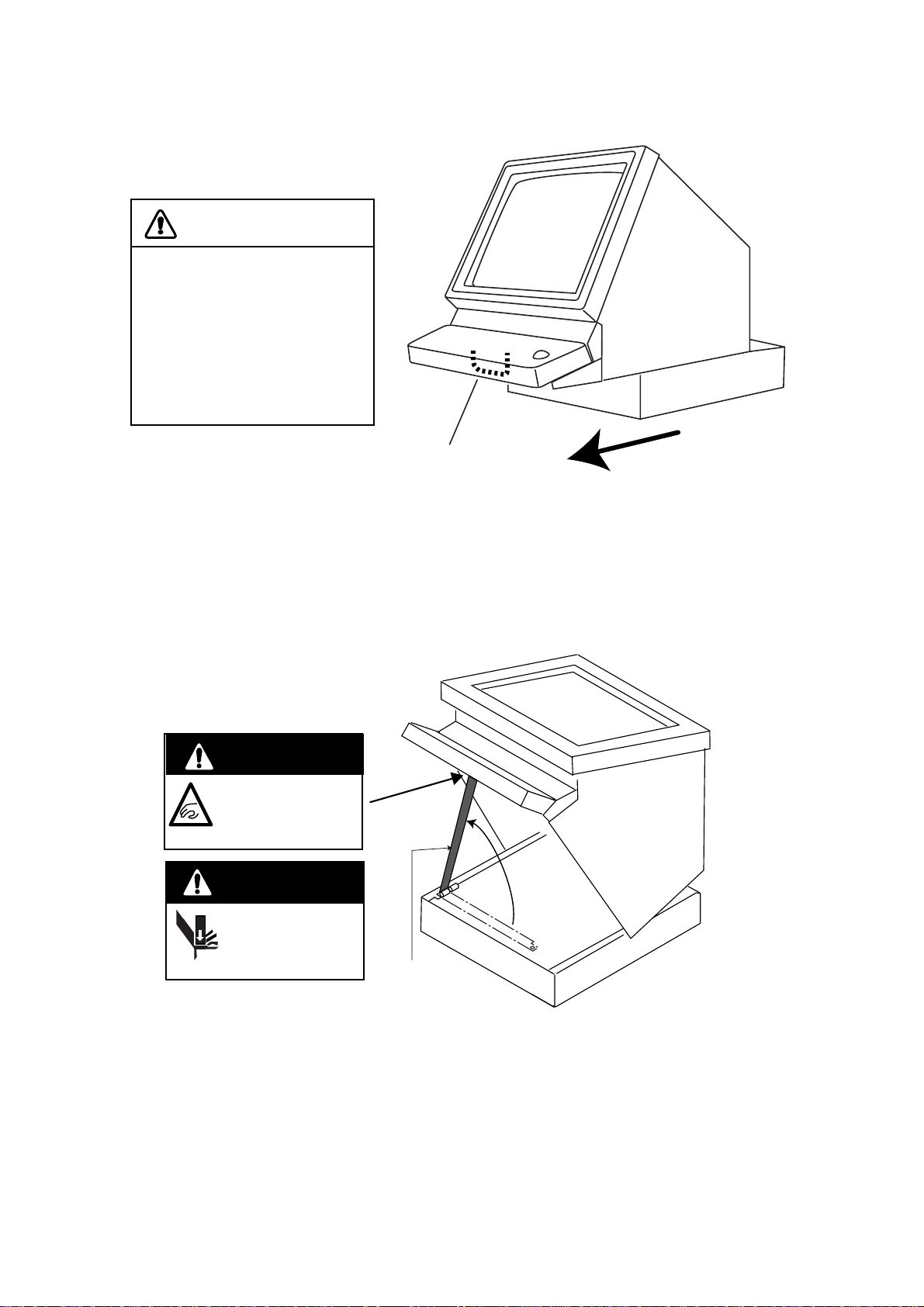

SAFETY INSTRUCTIONS

WARNING

WARNING

WARNING

Radio Frequency Radiation

Hazard

The radar scanner emits electromagnetic

radio frequency (RF) energy which can be

harmful, particularly to your eyes. Never

look directly into the scanner aperture from

a close distance while the radar is in operation or expose yourself to the transmitting

scanner at a close distance.

Distances at which RF radiation levels of

100 and 10 W/m

table below.

Note: If the scanner unit is installed at a

close distance in front of the wheelhouse,

your administration may require halt of

transmission within a certain sector of

scanner revolution. This is possible—Ask

your FURUNO representative or dealer to

provide this feature.

ledoM

S5312-RF

2

exist are given in the

rotaidaR

epyt

FA03NS—m7.0

FA63NS—m5.0

otecnatsiD

2

m/W001

tniop

m/W01

tniop

WARNING

Do not open the equipment

unless totally familiar with

electrical circuits and

service manual.

ELECTRICAL

SHOCK

HAZARD

Construct a suitable service platform

from which to install the scanner unit.

Serious injury or death can result if someone falls from the radar scanner mast.

otecnatsiD

2

Turn off the power at the mains switchboard before beginning the installation.

Fire, electrical shock or serious injury can

result if the power is left on or is applied

while the equipment is being installed.

Only qualified personnel

should work inside the

equipment.

Wear a safety belt and hard

hat when working on the

scanner unit.

Serious injury or death can

result if someone falls from

the radar scanner mast.

Do not install the display unit where it

may get wet from rain or water splash.

Water in the display unit can result in fire,

electrical shock or equipment damage.

i

Page 4

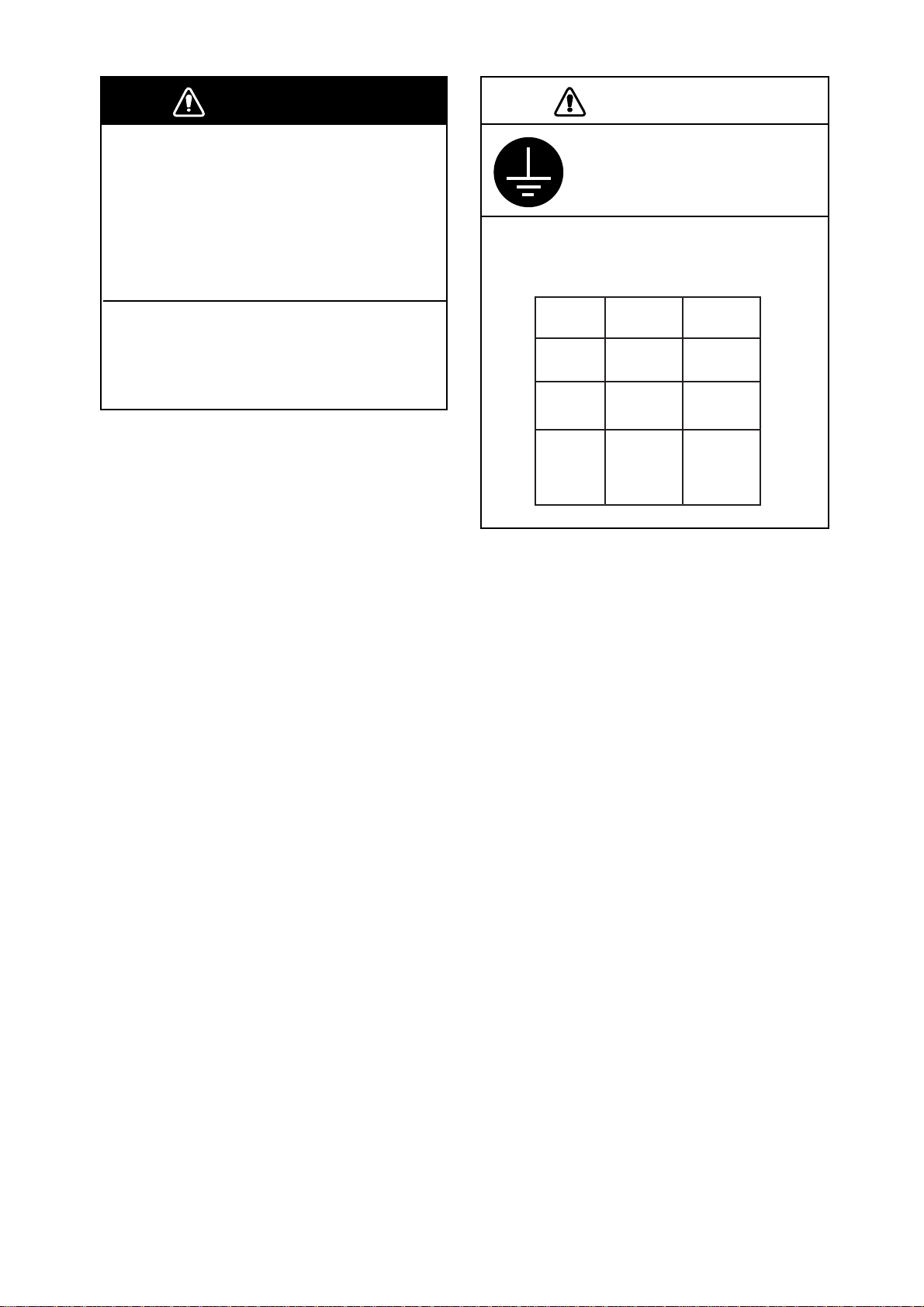

WARNING

CAUTION

Be sure that the power supply is

compatible with the voltage rating of

the equipment.

Connection of an incorrect power supply

can cause fire or equipment damage. The

voltage rating of the equipment appears

on the label above the power connector.

Use only the specified power cable.

Fire or equipment damage can result if a

different cable is used.

Ground the equipment to

prevent electrical shock and

mutual interference.

Observe the following compass safe

distances to prevent deviation of a

magnetic compass:

Display

Unit

Scanner

Unit

Power

supply

unit

PSU-004

Standard

compass

1.70 m 0.90 m

5.00 m 2.80 m

0.50 m 0.30 m

Steering

compass

ii

Page 5

TABLE OF CONTENTS

EQUIPMENT LISTS............................................................................iv

SYSTEM CONFIGURATION...............................................................vi

MOUNTING

1.1 Scanner Unit ............................................................................................................. 1-1

1.2 Display Unit ............................................................................................................... 1-7

1.3 Power Supply Unit................................................................................................... 1-15

WIRING

2.1 Display Unit ............................................................................................................... 2-1

2.2 Scanner Unit ............................................................................................................. 2-6

2.3 Changing AC Power Specification of Display Unit ...................................................2-11

2.4 Power Supply Unit................................................................................................... 2-12

INITIALIZATION AND ADJUSTMENT

3.1 Tuning Initialization.................................................................................................... 3-1

3.2 Accessing Menus for Initialization and Adjustment................................................... 3-1

3.3 Adjusting Video Signal Level..................................................................................... 3-1

3.5 Adjusting Sweep Timing............................................................................................ 3-3

3.6 Suppressing Main Bang ............................................................................................ 3-3

3.7 Confirming Magnetron Heater Voltage...................................................................... 3-4

3.8 Initial Setting Menus.................................................................................................. 3-5

INSTALLATION OF OPTIONAL EQUIPMENT

4.1 Gyro Converter GC-8 ................................................................................................ 4-1

4.2 ARP Board ARP-26 ................................................................................................... 4-7

4.3 RP Board RP-26...................................................................................................... 4-10

4.4 Performance Monitor PM-50 ................................................................................... 4-14

4.5 Alarm Kit.................................................................................................................. 4-15

PACKING LISTS........................................................................................................A-1

OUTLINE DRAWINGS............................................................................................D-1

INTERCONNECTION DIAGRAM ...................................................................... S-1

SCHEMATIC DIAGRAMS ..................................................................................... S-2

iii

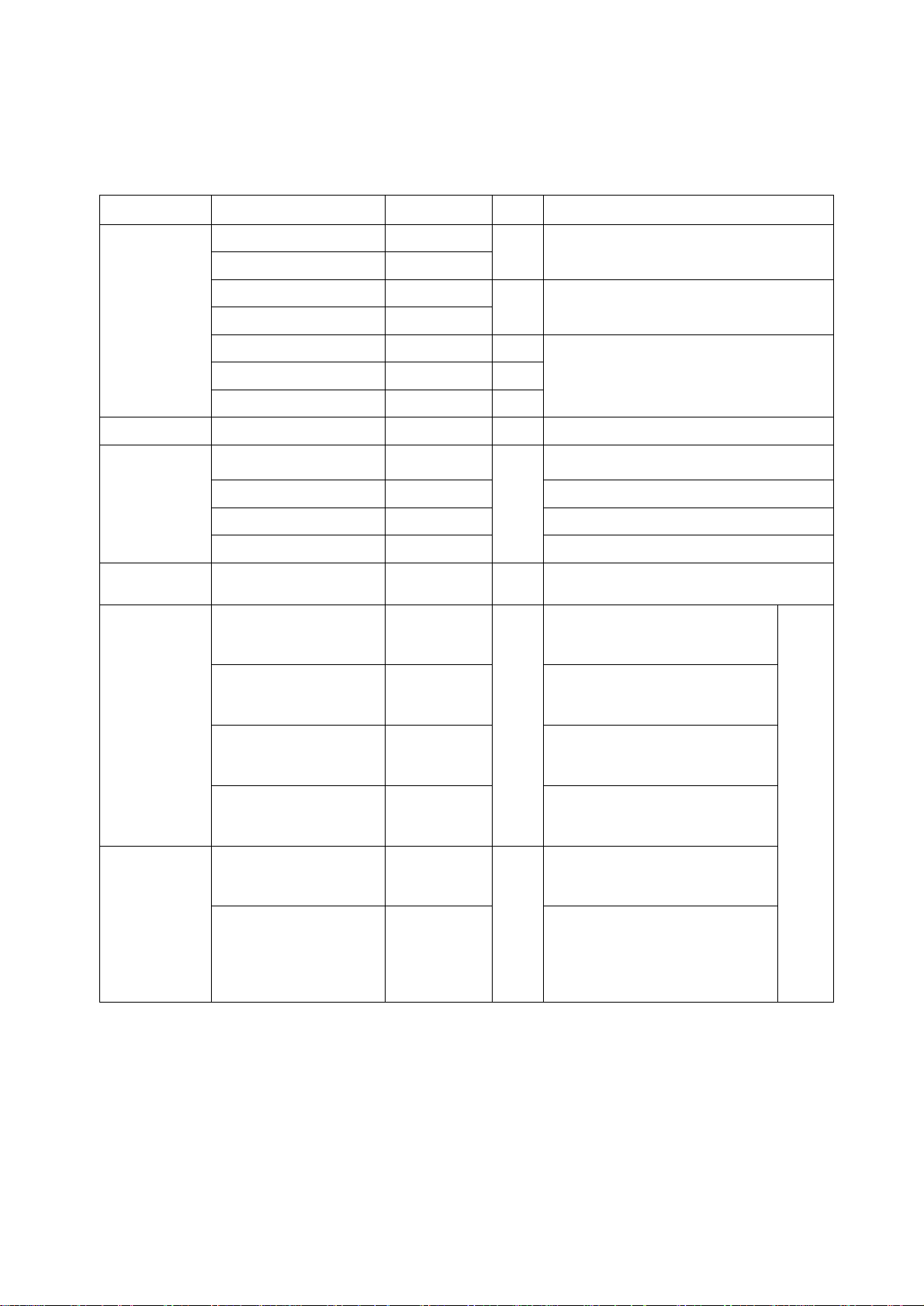

Page 6

Standard Supply

emaNepyT.oNedoCytQskrameR

EQUIPMENT LISTS

FA03NSFA63NS-

6200-BSR-

tinUrennacS

tinUyalpsiD421-PDR-1

ylppuSrewoP

tinU

straPerapS00131-30PS896-780-0001

noitallatsnI

slairetaM

seirosseccA

1300-BSR8800-BSR-

0900-BSR-

S-32-07-400-USPS-01-08-400-USP-3φ,CAV044/083

KH-32-07-400-USP-3φ,CAV032/022

KH-32-08-400-USP-3φ CAV044/083,

00002-30PC996-780-000

01002-30PC007-780-000

02002-30PC107-780-000

03002-30PC207-780-000

01660-30PF407-780-000

03660-30PF417-780-000

1rotaidaR

1reciedtuohtiwrohtiw,sissahcannetnA

3φ V032/022,CA

1

1

1

CSHrofsissahcannetnA9800-BSR-

,)tinUyalpsiD(60521-30PS

)tinUylppuSrewoP(02301-30PS

,50191-30PC,30641-30PC

elbaclangiS70931-30PC

)m51(51-47-30S

,50191-30PC,30641-30PC

elbaclangiS70931-30PC

)m02(02-47-30S

,50191-30PC,30641-30PC

elbaclangiS70931-30PC

)m03(03-47-30S

,50191-30PC,30641-30PC

elbaclangiS70931-30PC

)m06(06-47-30S

,20560-30PF,10260-30PF

01720-30PF,30560-30PF

revoctsuD

:epytelosnocroF

,40560-30PF,10260-30PF

,30560-30PF,20560-30PF

01720-30PF

revoctsuD

S

E

E

P

A

C

K

I

N

G

L

I

S

T

S

iv

Page 7

Optional Equipment

emaNepyT.oNedoCytQskrameR

yalpsiDetomeR0108-DMF–1

retrevnoCoryG2-8-CG025-644-800tes1redroetarapeS

hctiwsretnI7-JR–1

hctiwsretnI8-JR–1

rotinoMecnamrofreP05-MP–1 radarOMIrofyrotadnaM

3965-UR654-030-0001

3081-UR794-030-0001

remrofsnarT

tinU

tiKnoitallatsnIMP051-30PO094-584-800tes1

APRA62-PRA005-584-800tes1

rettolPoediV

daeHlortnoCetarapeS

tiKgnitnuoM

tiKmralA651-30PO056-005-8001

2256-UR014-030-0001

5033-UR844-030-0001reciedroF

1-6645-UR354-030-0001

T-62-PR015-584-800

tes1

Z-62-PR025-584-800

151-30PO035-584-8001

V011 → 3,V022 φ

tinurennacsrof

V044 → 1,V001 φ

tinuyalpsidrof

V022 → 3,V002 φ

tinurennacsrof

V044 → 3,V002 φ

tinurennacsrof

epytelosnoc,potelbaT

lortnocetarapesroF

daeh

tinUecafretnI0032-FI–1 radarOMIrofyrotadnaM

v

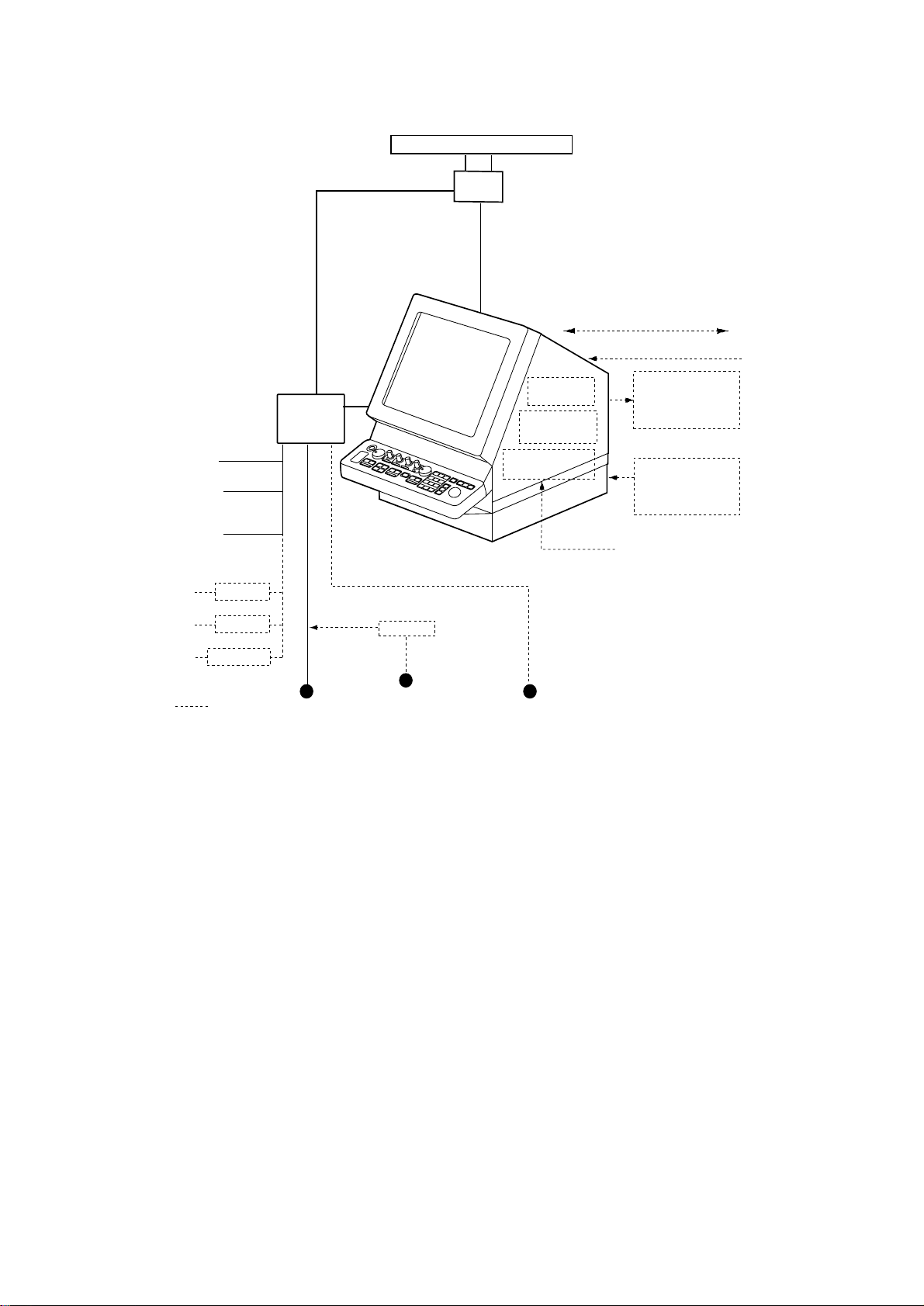

Page 8

SYSTEM CONFIGURATION

POWER SUPPLY

UNIT PSU-004

220 VAC, 3φ, 60 Hz

200 VAC, 3φ, 50 Hz

440 VAC, 3φ, 60 Hz

380 VAC, 3φ, 50 Hz

For HSC

220 VAC, 3φ, 50 Hz

220 VAC, 3φ, 60 Hz

440 VAC, 3φ, 60 Hz

110 VAC, 3φ,

60 Hz

220 VAC, 3φ,

50 Hz

440 VAC, 3φ,

50 Hz

RU-5466-1

SCANNER UNIT

RU-5693

RU-6522

OPTION

For SCANNER UNIT

For DISPLAY UNIT

For DE-ICER

RU-1803

SHIP’S MAINS

100/110/115/

220/230 VAC

1φ, 50/60 Hz

DISPLAY UNIT

RDP-124

Gyro Converter

440 VAC

1φ, 50/60 Hz

100 VAC

1φ, 50/60 Hz

SN30AF/SN36AF

RSB-0026/0031

RSB-0088/0089/0090 (For HSC)

IEC 61162-1 (Input/Output)

IEC 61162-1 (Input)

ARPA Board

ARP-26

Video Plotter

RP-26

GC-8

Slave Display

FMD-8010

Performance

Monitor

PM-50

Gyrocompass

Navigator

Speed Log

vi

Page 9

1.1 Scanner Unit

Mounting considerations

• The scanner unit is generally installed either on top of the wheelhouse or on the

radar mast, on a suitable platform. Locate the scanner unit where there is a

good all-round view.

• No funnel, mast or derrick should be within the vertical beamwidth of the scanner in the bow direction, especially zero degrees ±5°, to prevent blind sectors

and false echoes on the radar picture.

• It is rarely possible to place the scanner unit where a completely clear view in

all directions is available. Thus, you should determine the angular width and

relative bearing of any shadow sectors for their influence on the radar at the

first opportunity after fitting.

• Locate the antenna of a direction finder clear of the scanner unit to prevent

interference to the direction finder. A separation of more than two meters is

recommended.

MOUNTING

• T o lessen the chance of picking up electrical interference, avoid where possible

routing the signal cable near other onboard electrical equipment. Also avoid

running the cable in parallel with power cables.

• A magnetic compass will be affected if placed too close to the scanner unit.

Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 5.0 m, Steering compass, 2.80 m.

• Do not paint the radiator aperture, to ensure proper emission of the radar waves.

• The signal cable run between the scanner and the display is available in lengths

of 15 m (standard), 20 m, 30 m and 60 m. Whatever length is used it must be

unbroken; namely, no splicing allowed.

• Deposits and fumes from a funnel or other exhaust vent can adversely affect

the aerial performance and hot gases may distort the radiator portion. The scanner unit must not be mounted where the temperature is more than 70°C.

• The scanner base is made of cast aluminum. To prevent electrolytic corrosion

of the scanner base, use the seal washers and corrosion-proof rubber mat and

ground the unit with the ground wire (supplied).

• Leave sufficient space around the unit for maintenance and servicing. See the

scanner unit outline drawing for recommended maintenance space.

1-1

Page 10

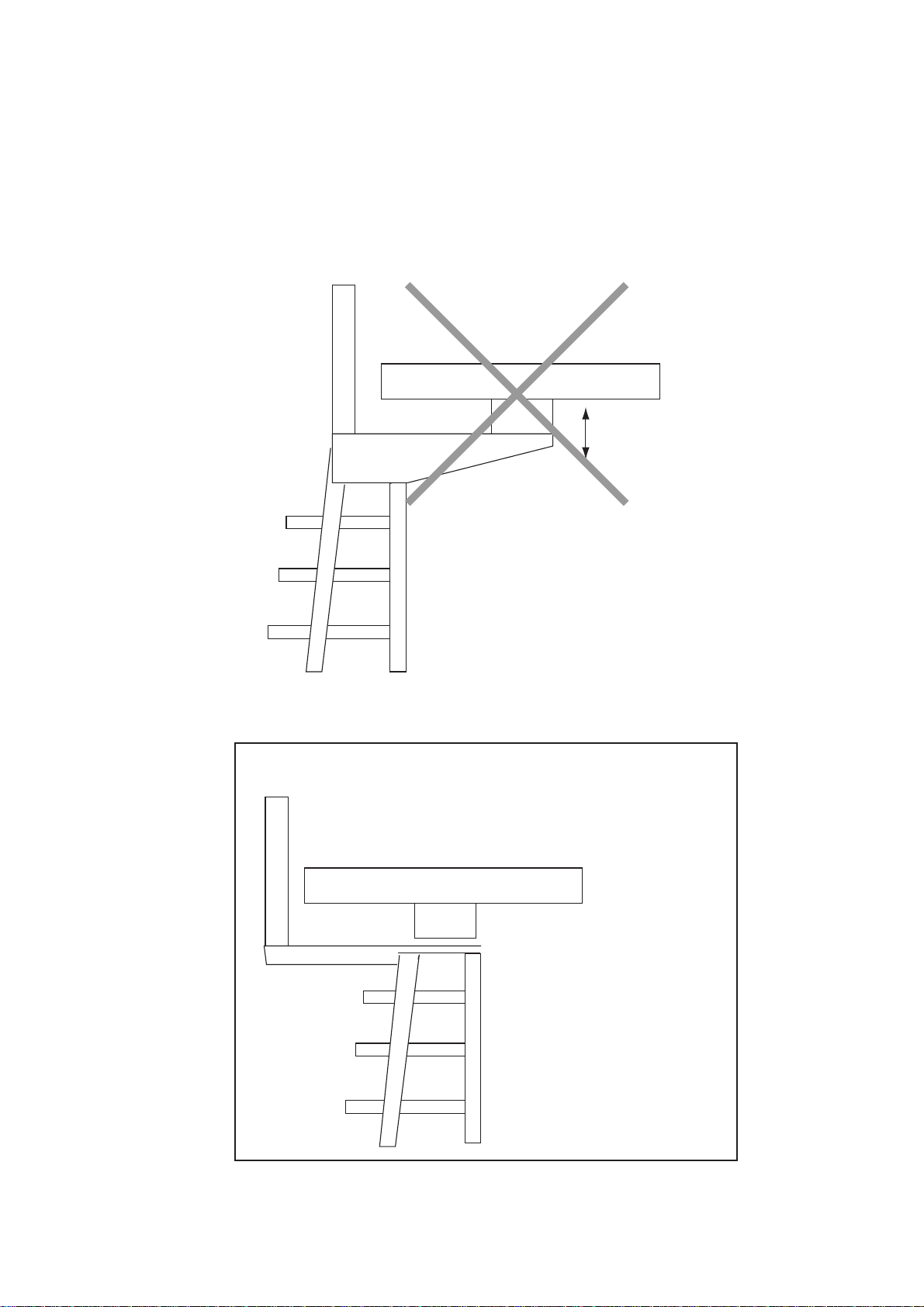

Installation precaution for S-band scanner unit

If an S-band scanner unit is mounted near the end of a platform to provide sufficient rotation clearance for the radiator, the scanner unit, because of its weight,

swings up and down by ship’s vibration and rolling, exerting excessive levels of

stress at the base of the radiator , which can damage the radiator. To prevent this,

relocate the scanner unit, or if relocation is not possible, reinforce the platform.

Pole for DF, etc.

Remarkable vibration

(pitching)

Mounting

position

EXAMPLE

Pole for DF

Mount the scanner unit

Directly on the mast or

on the platform, as near

as possible to the center

of the mast.

Figure 1-1 Mounting of S-band scanner unit

1-2

Page 11

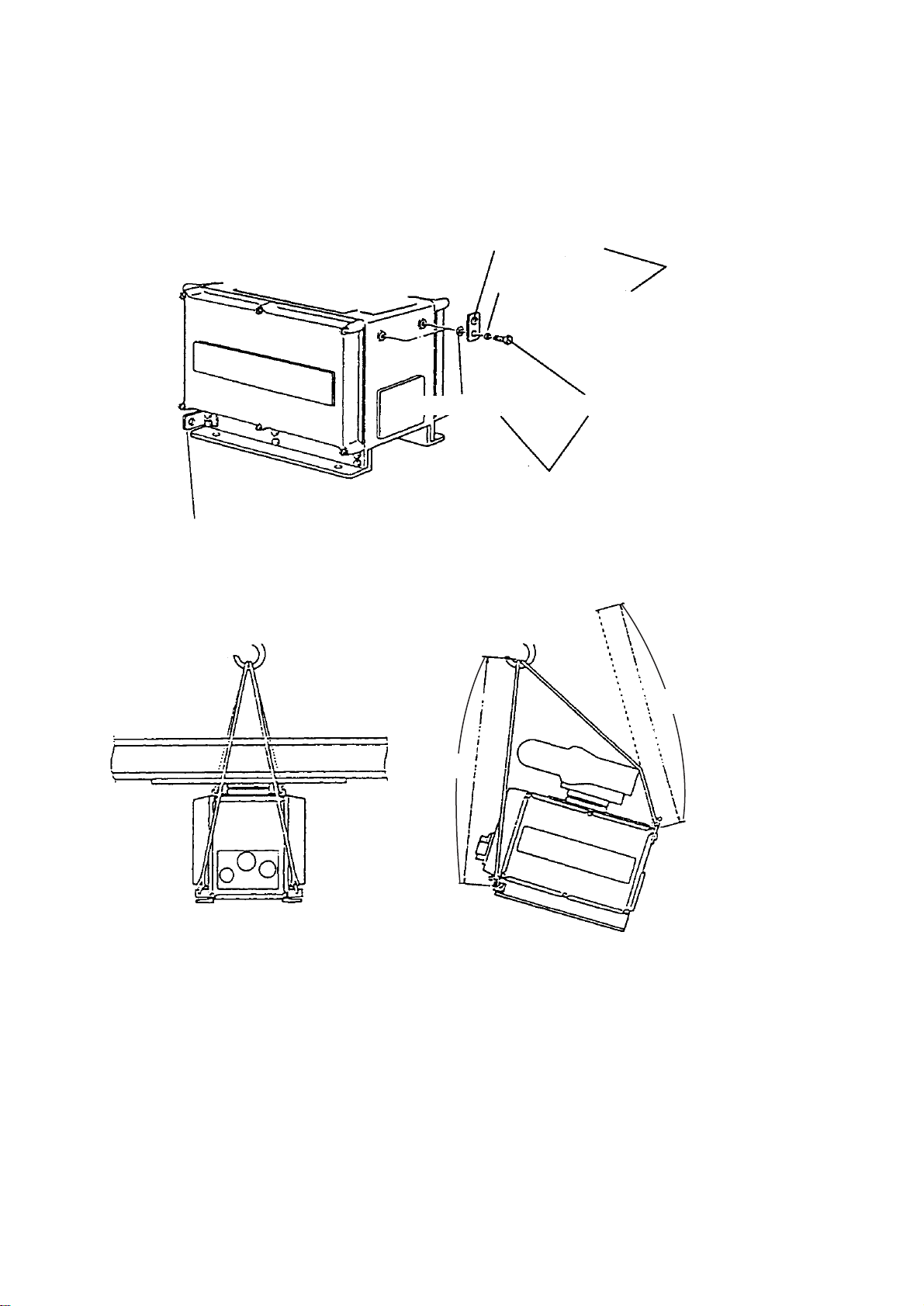

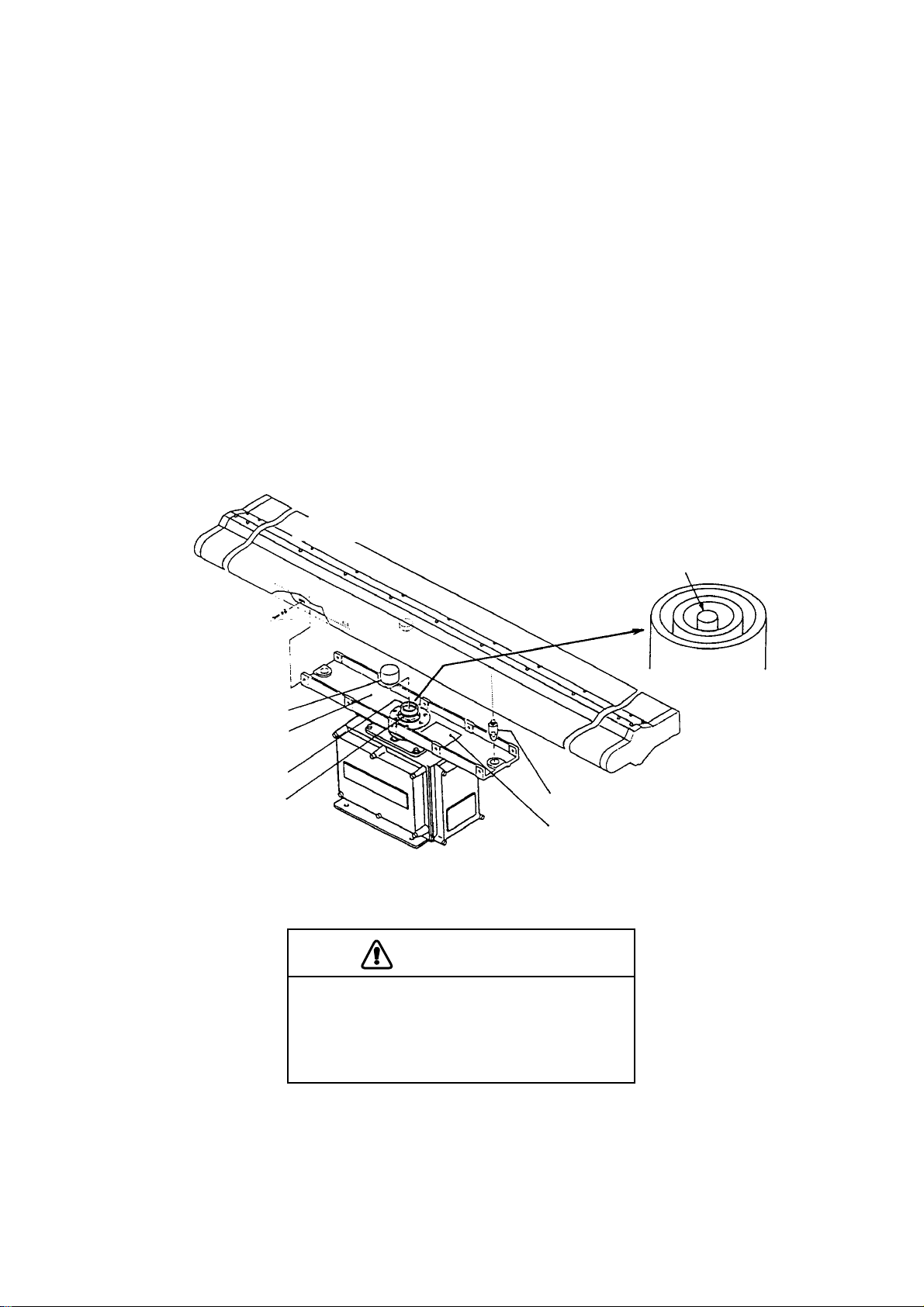

How to lift scanner unit

1. Fix the scanner radiator to the scanner unit chassis.

2. Attach the lifting fixtures and collars as shown in Figure 1-2 and 1-3.

3. Position the radiator as shown in Figure 1-3 and arrange the ropes A

and B

.

=

1.8m.

.

=

.

.

2m

Lifting hook (2 pcs.)

Figure 1-2 Attachment of lifting fixtures and collar

Lifting fixture

Collar for fixing

Spring washer (M12)

Remove lifting fixture, coat threads

of hex bolts with silicone grease, and

then insert bolts in scanner body.

Supplied as installation

materials. Remove after

installation.

Hex bolt (M12X20)

.

B=1.8m

.

.

A=2.0m

.

*

Figure 1-3 Attachment of ropes

*

* Protect radiator with

cardboard or cloth at

locations marked with

asterisk.

1-3

Page 12

Scanner unit assembling

The scanner radiator and the scanner housing are shipped in separate packages.

Assemble them as below . The scanner unit may be assembled before hoisting it to

the mounting platform. However, do not lift the scanner unit by the radiator.

Scanner unit assembling procedure

1. Screw the guide pins (2 pcs.) in the radiator.

2. Remove the protective cap from the choke guide.

3. Grease O-ring and set it to groove of the choke guide.

4. Place the radiator on the radiator bracket. (Radiator direction is shown by the

logo on the bracket. If reversely oriented the radiator cannot be set to the bracket.)

5. Loosely fix the radiator to the radiator bracket with hex bolts (M10 x 25), spring

washers and flat washers.

6. Remove the guides pins and tighten hexagon bolts.

Spring washer,

flat washer,

10 pcs. each,

M10 x 25

Protective cap

Radiator bracket

Choke guide

O-ring

(JIS B24011A-G60, 2 pcs.)

Scanner radiator

Do not remove the teflon tube from

the center conductor.

Guide pin (2 pcs.)

Instruction label for scanner

aperature direction

Figure 1-4 Assembling the radiator

CAUTION

Be sure to remove the guide pins.

Injury may result if the guide pins loosen

and fall.

1-4

Page 13

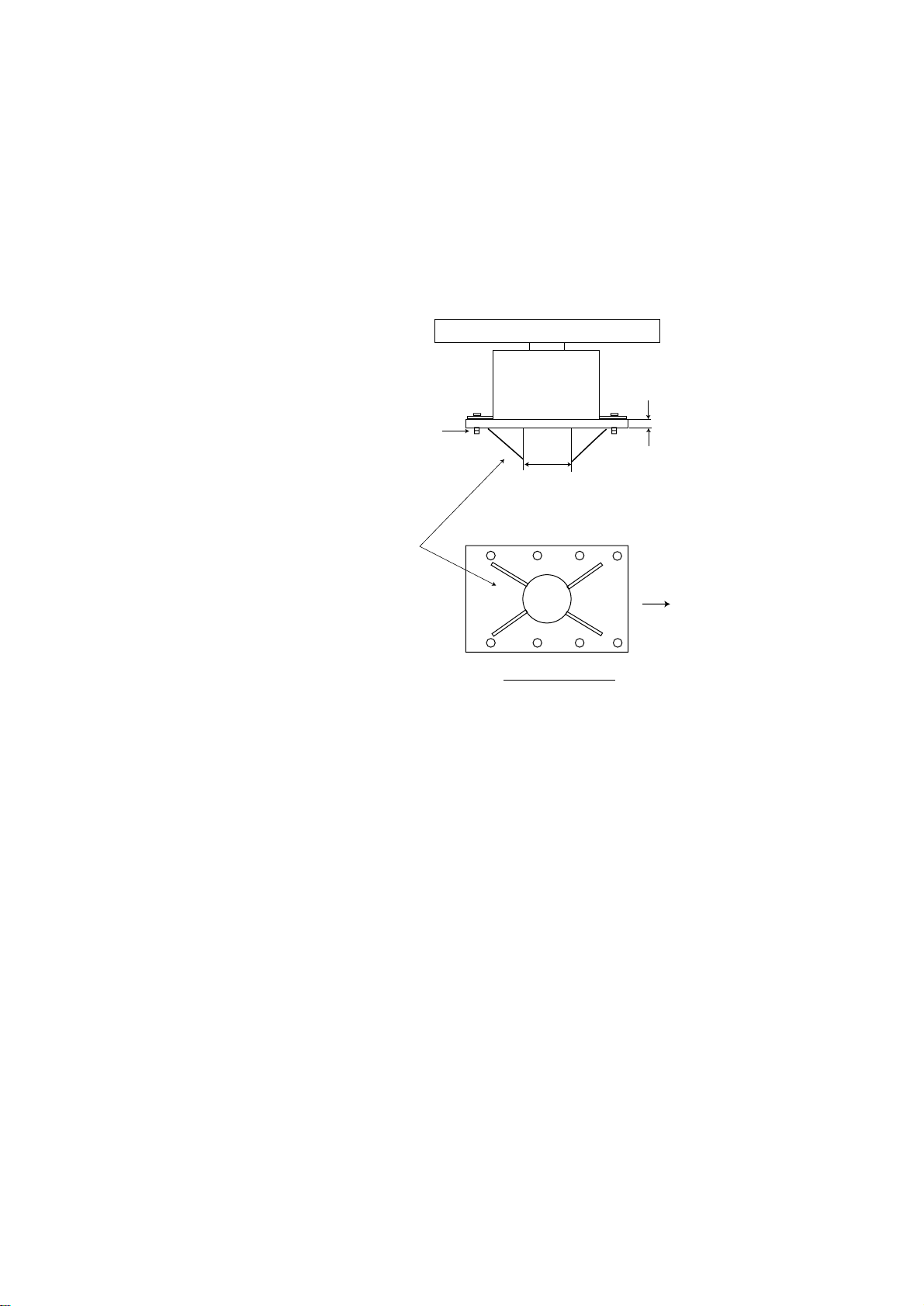

Fastening the scanner unit to the mounting platform

See the figure on the next page for scanner unit mounting.

1. Referring to the scanner outline drawing, drill four bolt holes (15 mm dia.) in the

radar mast platform or the deck.

• The diameter of the mast for fixing the scanner unit platform must be over 15

mm.

• The thickness of the scanner unit platform must be over 15 mm.

• The reinforcement ribs must be installed diagonally as shown below.

Over 15 mm

Use two nuts.

250 mm diameter or more,

6 mm thick or more

Install the reinforcement

ribs diagonally.

Ship’s bow

BOTTOM VIEW

Figure 1-5 Installation of reinforcement ribs

2. Place the corrosion-proof rubber mat (supplied) on the mounting platform.

3. Hoist the scanner unit as shown on page 1-3 and place it on the rubber mat.

Orient the cable gland toward the ship’s stern (or port, starboard). Remove the

lifting fixtures and collars.

4. Fix the scanner base to the mounting platform with four M12x70 hex bolts,

nuts, washers and seal washers (supplied).

5. Arrange the grounding terminal at the nearest grounding spot with the M6x25

hex bolt, nut and washers (supplied). Then, fix a ground wire (RW-4747, 340

mm long) to the terminal.

6. Connect the other end of the ground wire to the ground terminal of the scanner

unit.

7. Coat grounding terminal and fixing bolts on the scanner unit with silicone sealant (supplied).

1-5

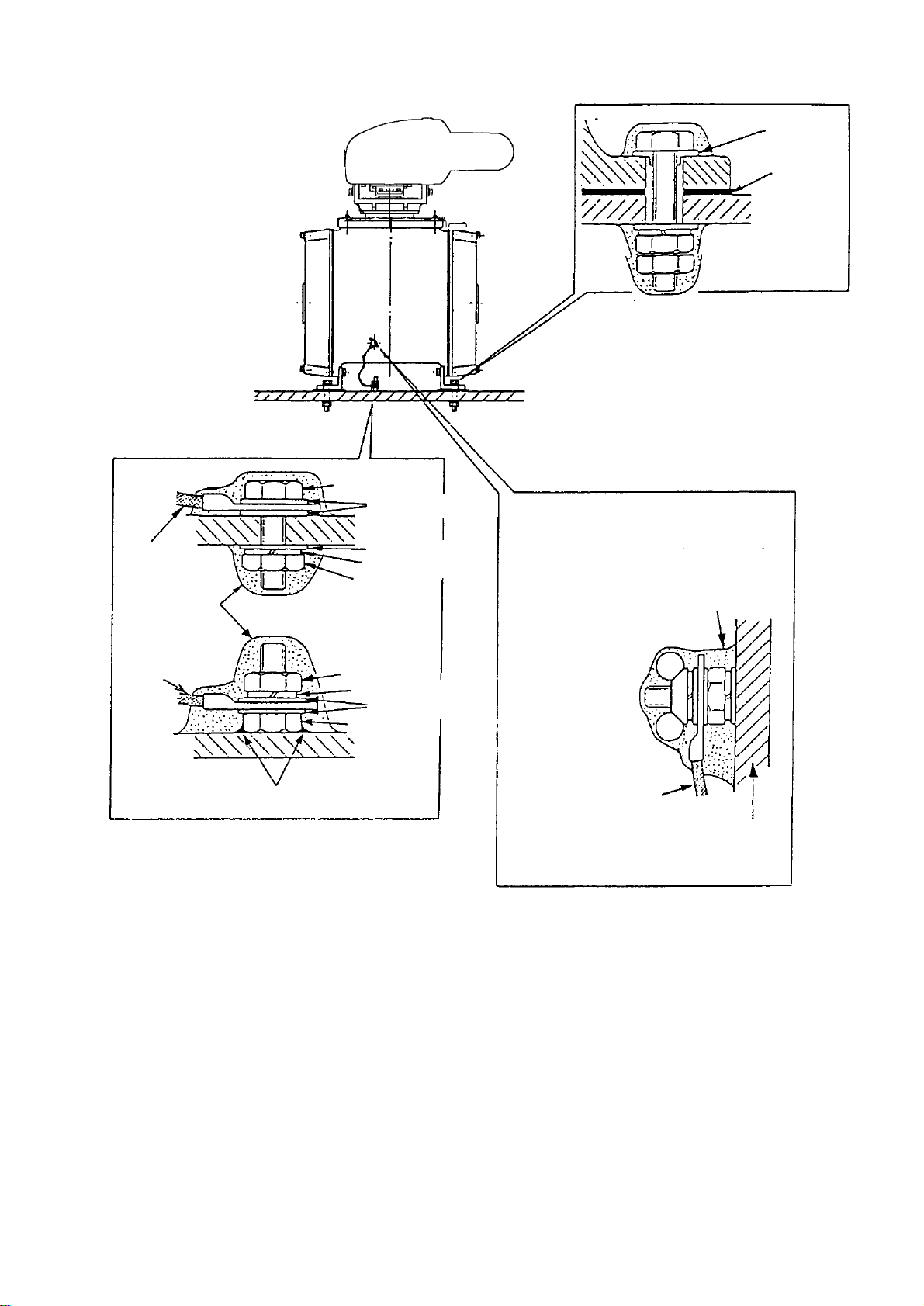

Page 14

Hex bolt

Flat washer

Seal washer

Corrosionproof

rubber

mat

Use two nuts.

Set corrosion-proof rubber mat,

bolt scanner unit to mounting

location, and coat exposed

hardware with silicone sealant.

Ground wire

Coat with

silicone

sealant.

Ground wire

Arrange ground terminal as close

as possible to scanner unit.

OR

Welding

Figure 1-6 Mounting of scanner unit

Flat washer

Spring washer

Hex nut

Hex nut

Spring washer

Flat washer

Hex bolt

Coat with silicone sealant after

fastening ground wire.

Ground wire

Scanner body

Ground terminal provided on scanner base.

1-6

Page 15

1.2 Display Unit

Before mounting the display unit

If Gyro Converter GC-8 (option) is to be used, install and setup the GYRO CONVERTER Board before mounting the display unit, because of the difficulty involved

in doing it after the display unit is installed. Instructions for installation and setup

are in Chapter 4.

Mounting considerations

When selecting a mounting location, keep in mind the following points:

• Select a location where the display unit can be viewed and operated conveniently and where the screen can be viewed while facing towards the bow.

• Locate the unit out of direct sunlight and away from heat sources because of

heat that can build up inside the cabinet.

• Locate the equipment away from places subject to water splash and rain.

• The display unit is very heavy . Be sure the mounting location is strong enough

to support the weight of the unit under the continued vibration which is normally

experienced on the ship. If necessary reinforce the mounting location.

• Determine the mounting location considering the length of the signal cable between the scanner unit and the display unit and the power cable between the

display unit and Power Supply Unit PSU-004.

• Leave sufficient space on the sides and rear of the unit to facilitate maintenance. Also, leave a foot or so of “service loop” in cables behind the unit so it

can be pulled forward for servicing or easy removal of connectors.

• A magnetic compass will be affected if placed too close to the display unit.

Observe the following compass safe distances to prevent deviation of a magnetic compass: Standard compass, 1.70 m, Steering compass, 0.90 m.

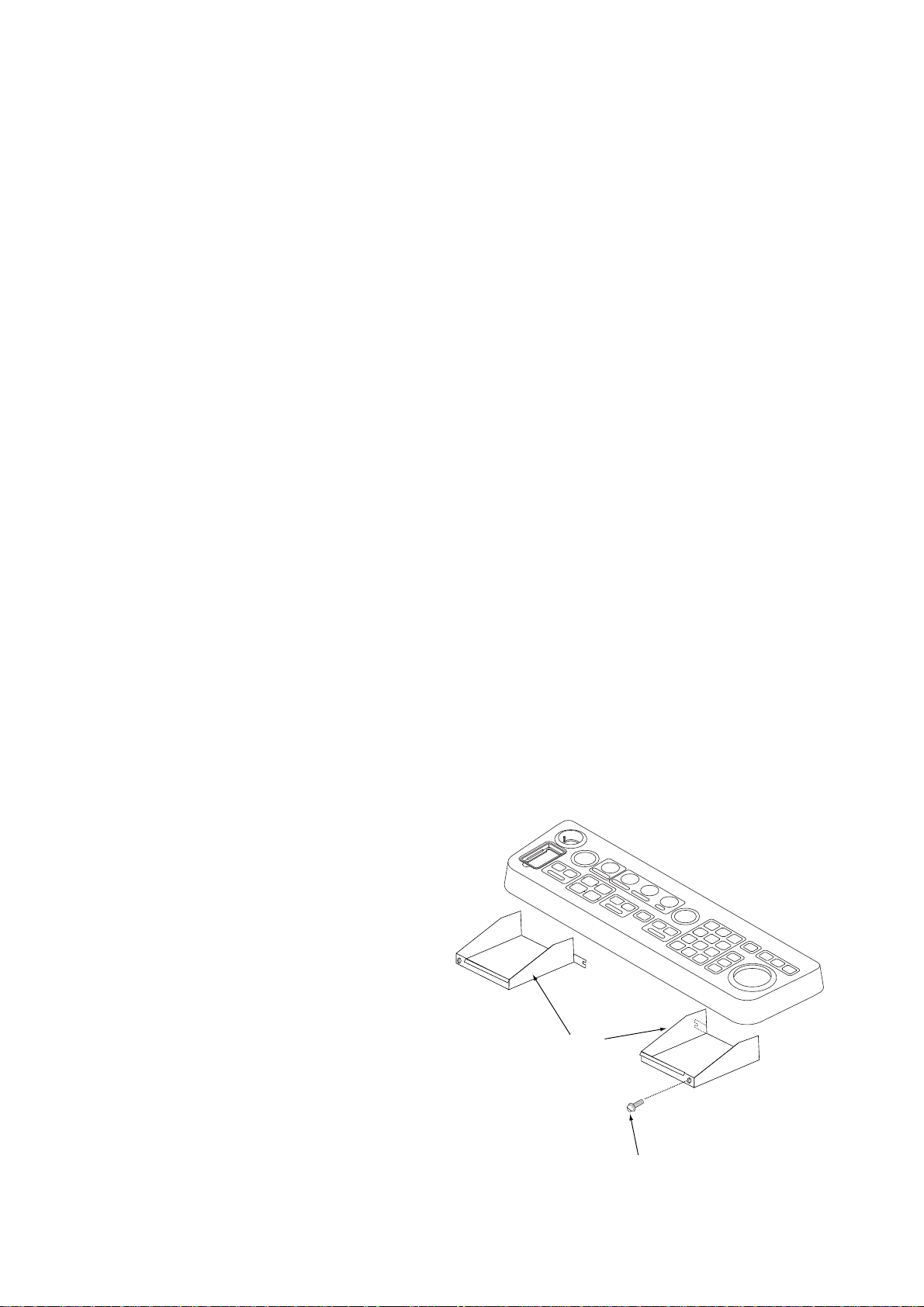

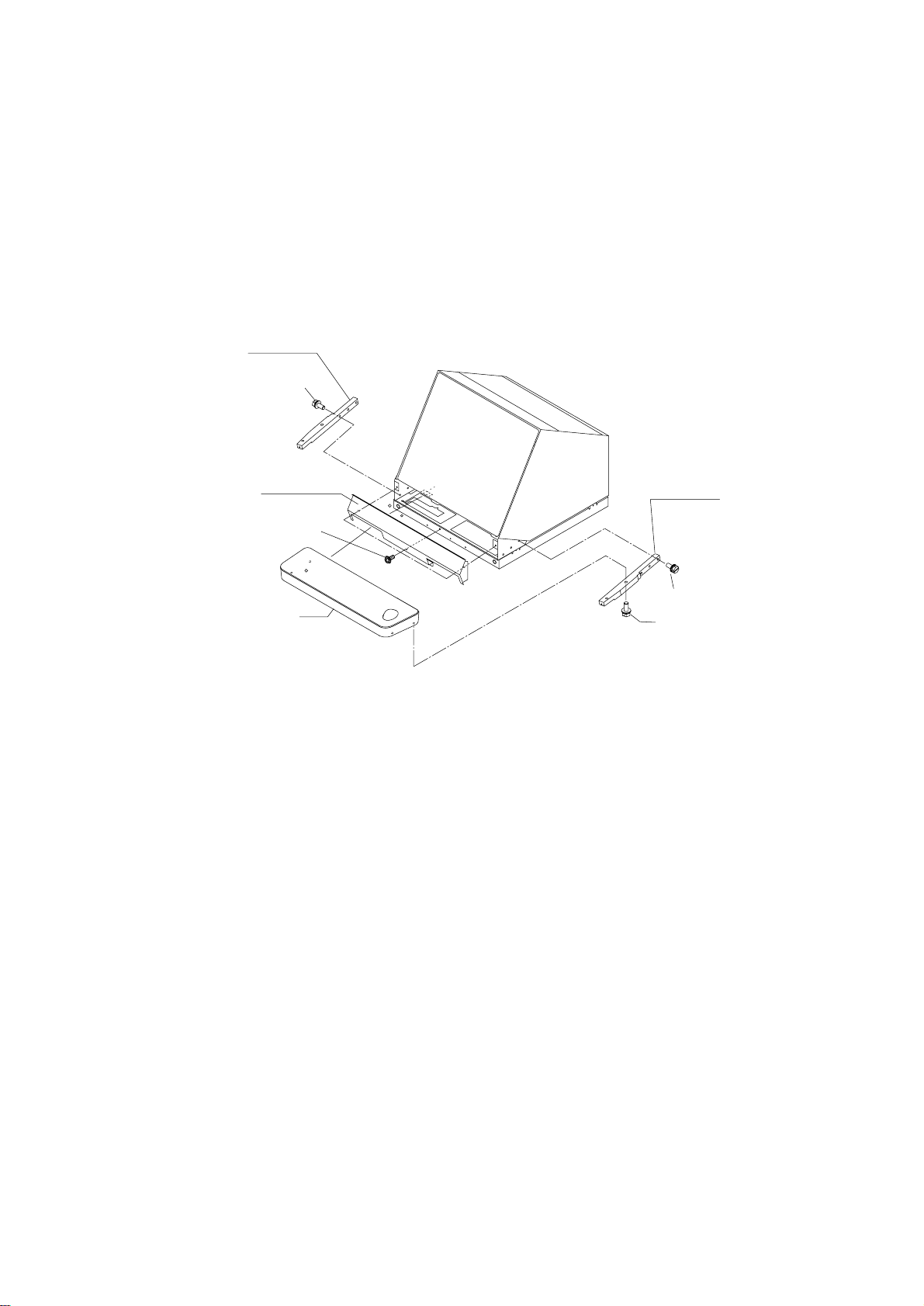

Mounting procedure

Tabletop mounting

This procedure requires two

people to complete.

1. Make four holes of 12 mm diameter referring to the outline

drawing at end of this manual.

2. Unfasten the screws fixing the

right and left brackets on the

control head

Left, right

arm cover

3. Unfasten bolts (four total) in the

brackets.

M4x10

Figure 1-7 Control head

1-7

Page 16

4. While one person is holding the mounting base at the sides, pull the handle on

the underside of the control head to draw the display unit toward you until you

hear a click.

CAUTION

Use two people to complete

this step.

The display unit may fall to

the deck when it is pulled

forward, since the mounting

base is not yet fastened to

the mounting location.

Handle

Pull forward

Figure 1-8 Display unit

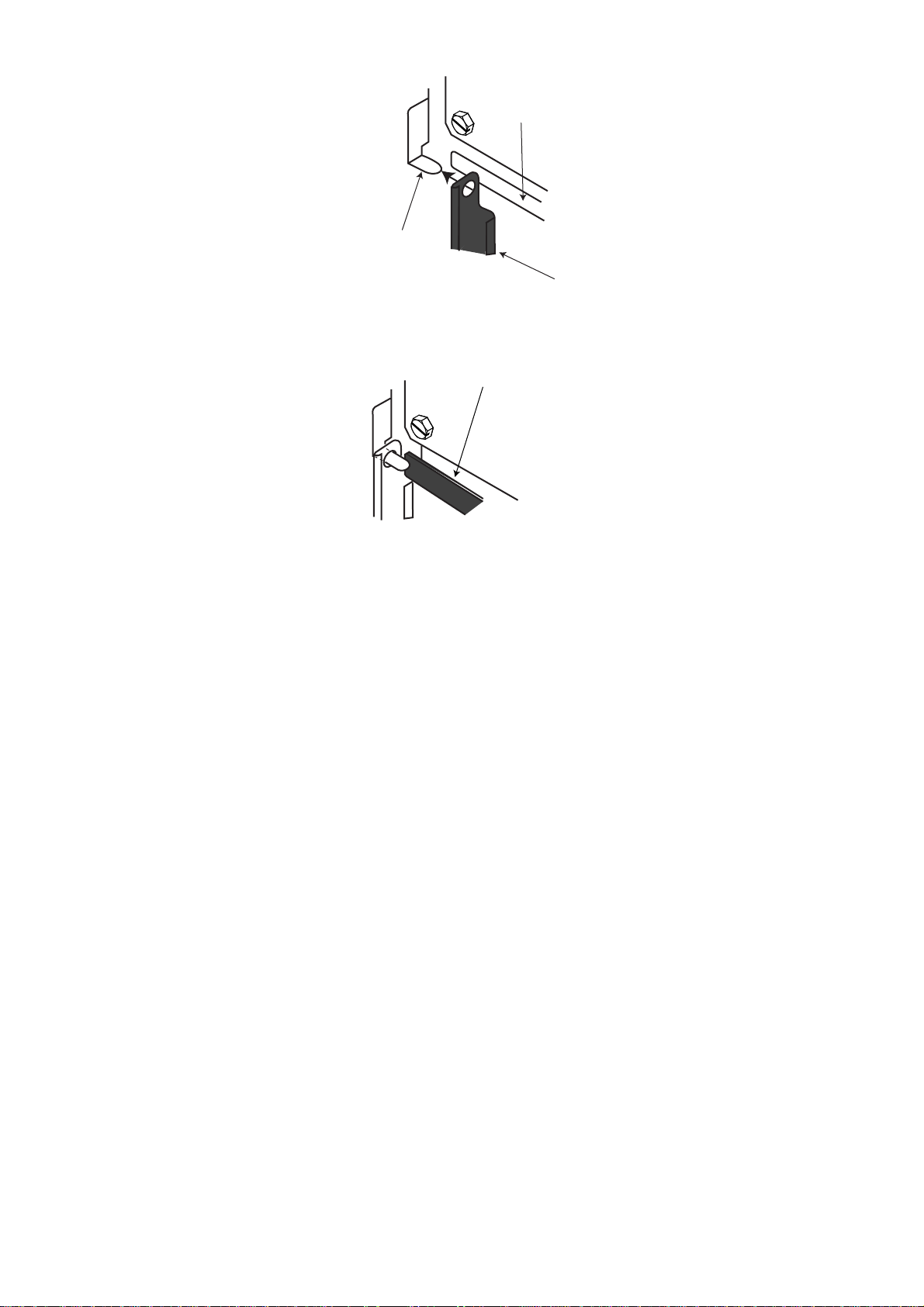

5. This step requires two people to complete. While raising the monitor until the

CRT is horizontal, fix the stay as follows:

a)Raise the stay as shown below.

Two warning labels on

the underside of monitor

HORIZONTAL

WARNING

Possibility of injury.

Hold handle when

mounting display unit.

WARNING

Display unit may fall.

Lock stay before

servicing.

Stay

Figure 1-9 Display unit, inside view

b)While pushing the stopper, set the catch on the display unit in the hole at the

front edge of the stay.

1-8

Page 17

Catch

Figure 1-10 Setting catch to hole in stay

c)Release hand from stopper.

Figure 1-11 Stay fixed

Stopper

Stay

Release stopper;

fix stay.

6. Fasten the display unit to the mounting location at front fixing holes (2 points)

with M10 bolts, nuts and flat washers, using the pipe box spanner (supplied).

You cannot fasten the display unit at the rear fixing holes while the monitor is

raised.

7. Retract the stay and lower the monitor.

8. Fasten the display unit to the mounting locations at rear fixing holes (2 points)

with M10 bolts, nuts and flat washers, using the pipe box spanner (supplied).

The rear left hole is hid under the PTU cover. Remove the cover as follows:

(1) Unfasten five M3x8 screws at the top of the PTU cover and two M4x8

screws at the front of the cover to slide the cover toward the front side.

(2) Remove the cover by grasping the knob on the top of the cover.

1-9

Page 18

*M3x8, 5 pcs.

Fixing hole (rear)

J106

J105

Knob

*

Slide forward.

J104

J103

*

M4x8, 2 pcs.

Fixing hole (front)

J446

J466

J462

J465

*

*

Figure 1-12 How to remove the PTU cover

9. Push the monitor forward until you hear a click.

10.Fix the brackets with the M10 bolts removed at step 2.

Console type mounting

1. Make six holes of 15 mm diameter and a cable entrance hole through the deck

referring to the outline drawing at end of this manual.

2. Open the front cover.

3. Fix the equipment with M12 bolts, nuts and washers.

4. Hoist the console to the deck by using the eye bolts attached to the console.

Remove the eye bolts and set the cosmetic caps to the eye bolt holes.

Separating the control head

The control head connects to the display unit with a connection cable, thus it can

be located where desired, using the separate control head kit (option). Follow the

procedure on the next page to separate the control head from the display unit.

1-10

Page 19

Separate type control head kit (Type: OP03-151, No.: 008-485-530)

emaNepyTytQ.onedoCskrameR

.yssAelbaCP1/P02BS642LU1218-041-0002249S30,m01

teeFrebbuR3005-JS4787-108-000epat/w

revoCtnorFrotinoM1631-552-301043-362-001

etalPgnixiFBK1961-441-301049-362-001

etalPeldnaH2361-441-301140-862-001

BKrevoctsuD3961-441-301067-172-001

wercS01x4M3644-188-000

lebaL1101-300-681032-632-001

rebbuRpihsnoN4961-441-301067-172-001

Display unit modification procedure

1. Raise the monitor unit referring to procedure for tabletop mounting on page 1-

8.

2. Unplug two connectors from the control head cable (P412 from MOTHER Board

and J583 and unfasten two earth wires.

PTU COVER

Control Head

Cable

P412

J583

J418

Earth Wire

MB 03P9251

Figure 1-13 Display unit, inside view

3. Lower the monitor.

INT

03P9252

1-11

Page 20

4. Unfasten the M4 screw fixing the ground terminal of the connection cable.

5. Push the monitor forward until you hear a click.

6. Unscrew four screws fixing the top cover of the display unit.

7. Remove three clamps fixing the connection cable in the monitor unit.

8. Unfasten four screws fixing the right and left brackets on the control head.

9. Unfasten four screws fixing the right and left covers of the display unit.

10.Unfasten six screws fixing the right and left KB arms.

11.Unfasten three screws fixing the panel cover.

KB arm (L)

03-144-1341

M5X25 SUS 3 pcs.

Panel cover

03-144-1345

M4X10, 3 pcs.

Control head

KB arm (R)

03-144-1342

M5X25 SUS 3 pcs.

M5X25 SUS 4 pcs.

Figure 1-14 Detaching the control head

1-12

Page 21

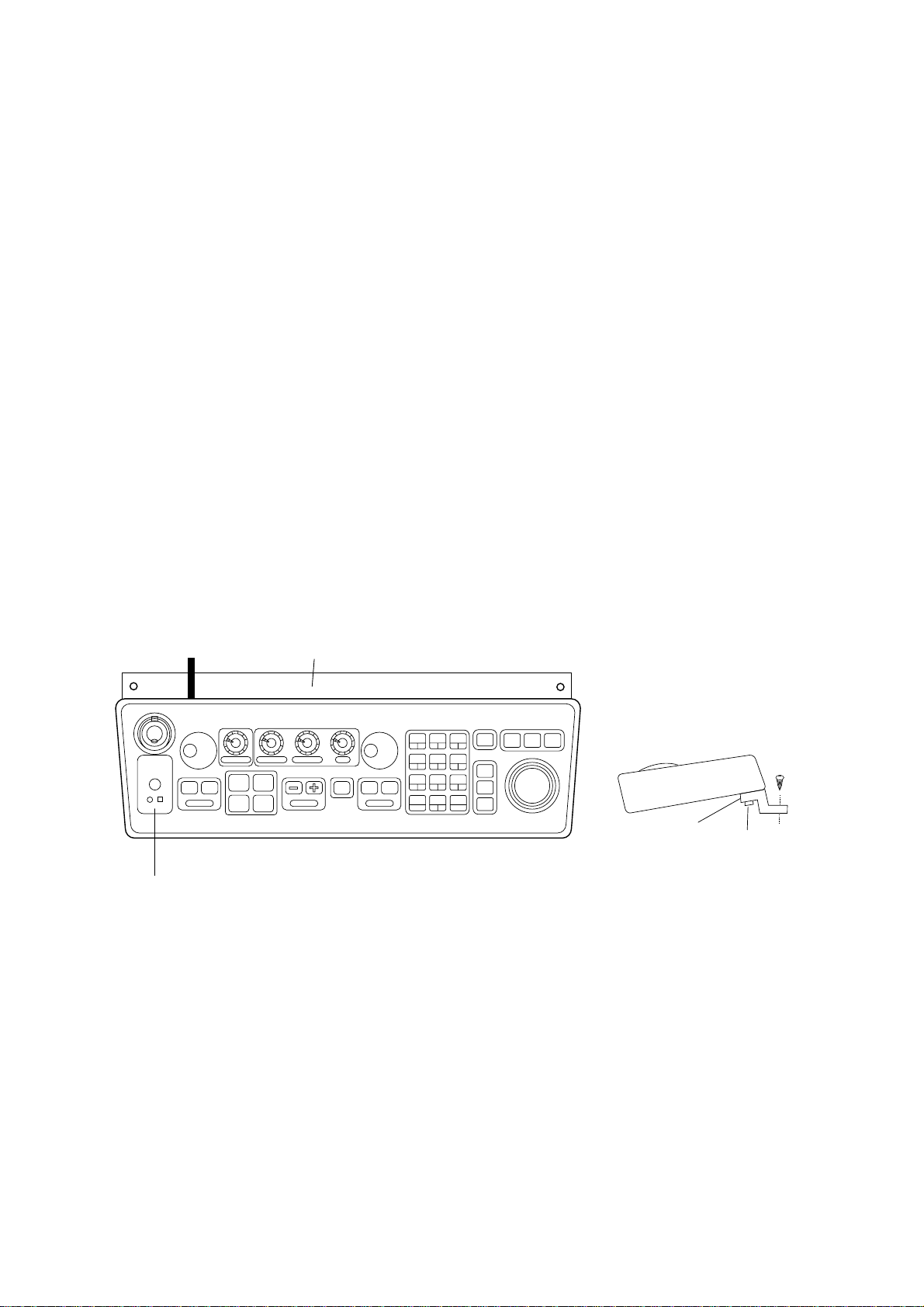

Control head modification procedure

1. Unfasten eight screws (M4X8) on the underside of the control head. Unplug

connectors P314, P312 and P317 from the control head. Separate the KB bottom plate from the control head.

2. Unfasten the screw (M4) fixing the ground terminal and two screws (M4X8)

fixing the clamp. Remove the connection cable assy.

3. Unfasten two screws (M6X12) from the inside of the bottom plate of the control

head to dismount the handle.

4. Replace the cable assy. with cable assy. UL2464SB2-0P/1P (10 m, supplied)

as below and reassemble the control head.

5. Paste warning label to the bottom plate.

Warning label

Screw

M4X8 (8 pcs.)

P312 FX Connector

KB BOTTOM

PLATE

Earth Wire

Upset Screw

M6X12 (2 pcs.)

KB Clamp

Handle

Replace with

cable assy. in

kit.

Spacer

Pan-head Screw M4X8 (2 pcs.)

Be careful not to pinch cable between

KB clamp and spacer.

Figure 1-15 Control head

Connection of display unit to control head

J317 (underside)

J314 (underside)

J312 (underside)

P314 XH3P

Lay cable in slot.

1-13

Page 22

Connection of display unit to control head

1. Attach the handle to the handle plate, using the screws for the handle and

bottom cover of the control head.

2. Attach the handle plate to location where the KB arms were fastened.

3. Pull the monitor toward you until you hear click.

4. Lead in the cable assy. (option) from the rear entrance of the display unit. See

Chapter 2.

5. Raise the monitor and fix the stay.

6. Inside the display unit, fasten ground wire of the cable assembly with an M4

screw on the chassis.

7. Plug in two connectors of connection cable (P412, J583: See illustration on the

previous page.)

8. Lower the monitor.

9. Attach the monitor front cover (option) to the place the panel cover have been,

using the screw for the panel cover.

10.Attach rubber to feet to the bottom of the keyboard if the keyboard is not going

to be permanently fixed. To fix the keyboard to a desired location, f asten the KB

fixing plate to the keyboard and desired location with two upset scre ws (M5X25,

formerly used to fasten KB arms) and two tapping screws (φ6.5, local supply)

as below.

KB Fixing Plate

CONTROL HEAD

SIDE VIEW

KB Fixing

Plate

CONTROL HEAD TOP VIEW

Tuning compartment

(Performance Monitor

SW inside)

φ6.5

Tapping

Screw

M5X25

Upset

Screw

Figure 1-16 How to attach KB fixing plate

11.Set dust cover KB (supplied) on the control head.

Attachment of hood

1. Set two spacers (supplied) to the lower two of the four M5 holes in the CRT

panel.

2. Screw two screws (supplied) into the holes in the hood.

3. Set the bottom of the hood to the screws at the bottom of the CRT panel, and

then fasten the two screws at the top of the hood to the CRT panel.

1-14

Page 23

1.3 Power Supply Unit

The Power Supply Unit PSU-004 does not contain usual operating controls. Therefore, it can be installed in any recessed place either in vertical or horizontal position. (For the console mount display unit, the PSU-004 can be installed inside the

console.) However, select a dry and well-ventilated location and observe the compass safe distances below to prevent deviation of a magnetic compass: Standard

compass, 0.50 m, Steering compass, 0.30 m. Fasten the unit to chosen location

with four M6 screws.

1-15

Page 24

This page is intentionally left blank .

Page 25

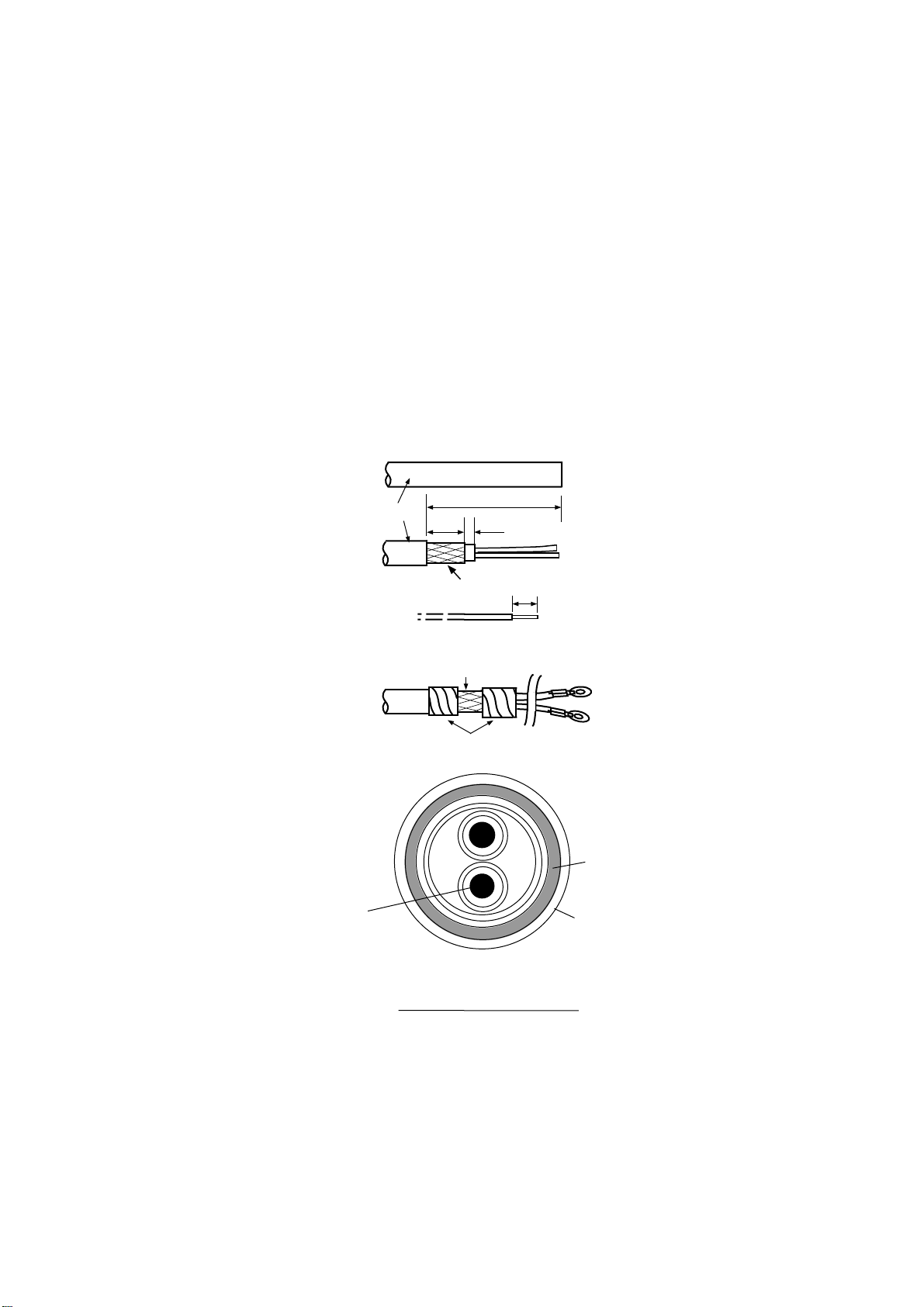

2.1 Display Unit

Fabricating the power cable DPYCY-3.5 (JIS cable)

1. Remove the vinyl sheath by 80 mm.

2. Cut off jute tape wrapped around the armor.

3. Unravel the armor to expose the cores by about 35 mm.

4. Remove insulation of cores by about 10 mm. Fix crimp-on lugs to the cores and

armor .

5. Cover the armor with vinyl tape, leaving the portion which will lie inside the

cable clamp untaped.

WIRING

(a)

Vinyl sheath

(b)

(c)

Lay this part in cable clamp.

(d)

Core

S = 3.5 mm

∅ = 2.4 mm

DPYCY-3.5

About 80 mm

40 mm

2

5 mm

Armor

Taping

10 mm

Armor

Vinyl

sheath

DPYCY-3.5 sectional view

Figure 2-1 Fabrication of power cable DPYCY-3.5 (JIS cable)

2-1

Page 26

Leading in cables to the display unit

The cable clamp may be positioned inside the display unit (default arrangement),

outside the display unit or at the bottom of the display unit (when using console

mount). When the cable clamp is located outside or beneath the display unit, use

the bottom clamp front plate and bottom clamp rear plate (supplied with installation materials).

Also, use the shielding foam (supplied) to protect against noise radiation.

Cable fed from back of display unit (default method)

Nav equipment

(Gyrocompass)

Keyboard

Log

(C) Signal cable

(Aluminum)

PWR

SCAN

Cable position in clamp

(Display unit, rear view)

Nonslip rubber

If speed log and navigator

are not connected, paste

the nonslip rubber to the

clamp and secure cables.

(D) Rear clamp plate

Slave display

Navigation

External CRT

Make sure shielding foam contacts rear chassis.

Hex bolt

M5X12 SUS

2 pcs

Hex bolt

M5X35 SUS

2 pcs

Hex bolt

M5X35 SUS

2 pcs

(Construction of

cable clamp)

Rear cable entrance

Panhead screw

M4X8

(D) Rear clamp

plate

(C) Signal clamp

(Aluminum)

(B) Power clamp

(Aluminum)

(A) Rear clamp

base

(B) Power clamp

(Aluminum)

(A) Rear clamp base

(Display unit, right-hand side view)

Figure 2-2 Default cable clamp position

• Place shielding foam between cables, and then attach the foam to aluminum

clamps.

• Fill unused clamp holes with shielding foam.

Cable

Shielding foam

(Display unit, rear view)

2-2

Page 27

Cable fed from outside display unit

Shielding foam

(D) Rear clamp plate

(C) Signal clamp

(Aluminum)

(B) Power clamp

(A) Rear clamp base

M5x10 (2 pcs)

(Installation materials)

Bottom clamp front plate

(Installation materials)

(Aluminum)

Back cable entrance

(Display unit, right-hand side view)

Figure 2-3 Clamp position outside display unit

• Place shielding foam between cables inside of display unit, and then attach

foam to chassis.

• Fill unused clamp holes with shielding foam.

Cables fed from bottom of display unit (console mount)

Lead in cables through the cable clamp at the rear of the console and ground their

shields in the cable clamp. For signal cable, remove vinyl sheath where cable lies

in cable clamp. Fasten cables with cable ties.

Seventh hole

from the top

Power Cable

(For display unit)

Close shutter door and cover

Close shutter and cover

with aluminum tape to

it with aluminum tape to keep

keep foreign objects out

foreign objects out of the

of the display unit.

display unit.

Performance

Monitor

Cable Arrangement in the Console (Top view)

SIGNAL CABLE:

Remove the vinyl sheath here.

(1300 mm from display unit end

of cable remove sheath by 70 mm.)

Gyrocompass

Power Cable

(For PM)

Log

NAV

Signal Cable

ARPA

Slave Display

Figure 2-4 Clamp position at bottom of display unit

2-3

Page 28

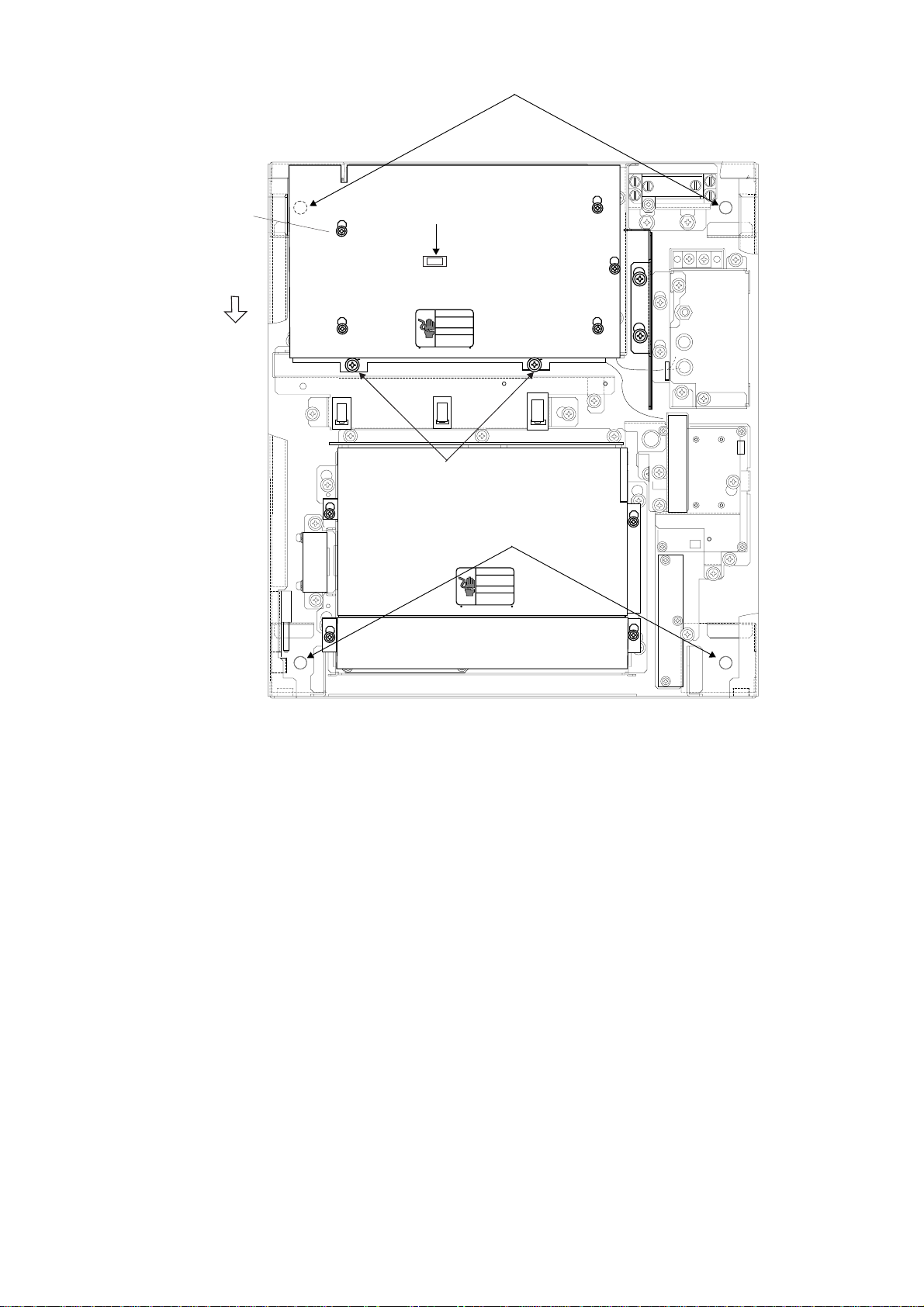

Connections

Open the display unit and fix it with the stay. (For procedure see page 1-6.) Remove the shield cover from the INT Board. Connect signal, power, gyro and log

cables as shown on the next page. Optional equipment are connected to the INT

Board. Be sure to ground the display unit.

Fasten shield here.

PTU BOARD

03P9245

MOTHER BOARD

03P9251

J448

(Tabletop type)

Connect coax

cable here.

DJ1

J5

J4

Gyro

Scanner

Unit

Ship's

Log

Ground terminal

(Tabletop type)

Terminal

board

Fasten shields

here together.

(Console type)

POWER switch

(for maintenance,

always ON)

Fasten TX-HV

line to #1 termanal.

To fasten;

1. Slide terminal.

2. Lift terminal to

remove.

J442

J443

J444

J463

J457

J458

J453

J451

J452

INT BOARD

03P9252

GYRO CONVERTER

BOARD 64P1106

Fix the DJ1 connector with

teo M3x8 screw )supplied).

J450

J445

Location of connectors

on the INT Board. See

next page for connector

J454

J455

J466

J462

J448

J446

J467

J449

description.

Bind the cables so as not to pinch them

between the monitor and mounting base.

Take special care with the high voltage

J456

J465

line.

Figure 2-5 Display unit, inside view

CAUTION

Ground the equipment to

prevent electrical shock

and mutual interference.

2-4

Page 29

Connectors on the INT Board

Table 2-1 Connectors on the INT Board

emanlangiSnoemaN

bcp

langiStupnI

langisoryG5J,4J,nip3,HV

goldeepS

langis

youbradaR

langis

etomeR

lanretxE

APRA

langis

yalpsidevalS

langis

GOL844Jnip3,HN .cte,mn/seslup002

RADAR

YOUB

RADAR-TXE

langisyalpsid

langiStuptuO

7-JRro

APRA-TXE444Jnip8,HN,gniraeb,gnidaeH

EVALS244J

.on

rotcennoC

epyt

nip5,HV

544Jnip4,HN

854Jnip8,HN

nip8,HN,141-DC,041-DC

344J

rotcennoC

,005-DG

08-DMF11*0

elbacilppA

tnempiuqe

,2KM005-DG

,008-DMF

skrameR

bcpnO:*

)noitpo(6011P46A

reggirtxT

,gniraeb,gnidaeH

reggirtxT,oediv

langisrezzuBZUB-TXE154Jnip9,HNpma/wrekaepSlangisrekaepS

langisrotinoM944Jnip01,HN,suonorhcnysREV

C232-SRC232-SR654Jnip4,HN

golanAGOLANA354Jnip3,HN

lanretxE

rezzub

atadSNIATAD.SNI554Jnip5,HN

7-JR7-JR754J

atadvaNATADVAN054Jnip5,HN

)CA(

langiStuptuO/tupnI

MRALATXE

254Jnip3,HN

854J

nip51,HN

nip8,HN

roftinuyalpsiD:1*

seires5012-RF

desuebnacradar

yalpsidevalssa

.tinu

,suonorhcnysROH

-rofCSTN(oediv

)tam

atadAPRAATADAPRA454Jnip5,HN

Note: How to attach NH connector is shown on the next page.

2-5

Page 30

How to attach NH connector

A

HOW TO ATTACH NH CONNECTOR TO SIGNAL CABLE

NH connector wire

NH connector

housing

1

Insert NH connector

wire into NH connector

housing.

Figure 2-6 How to attach NH connector

2.2 Scanner Unit

Fabricating multicore cable 660V-MPYCY-12/250V-MPYCY12 (JIS cable)

1. Shorten the multicore cable making the length from the cable gland to the cable

end inside the scanner unit 450 mm. Remove the vinyl sheath of the cable by

450 mm; the armor by 440 mm.

Shrink tubing

20mm

2

Cut shrink tubing

in 20 mm lengths and

slip onto each wire.

Solder

3 Solder connector

to signal cable.

Heat shrink

4

tubing with soldering iron.

rmor

440 mm

Conductors

450 mm

Armor

Core

φ = 1.25 mm

2

Vinyl sheath

Figure 2-7 Fabrication of multicore cable 660V-MPYCY-12/250V-MPYCY-12

2. Turn off the ANT MOTOR SW on the scanner unit.

ANT MOTOR SW

Signal cable

(S03-74)

Multicore cable

(250V-MPYCY-12 or

660V-MPYCY-12)

Figure 2-8 Scanner unit, bow view

2-6

Page 31

3. Open the left side cover on the scanner unit with the hex wrench (supplied).

4. Unfasten the cable gland for the multicore cable and remove the gasket and

flat washers.

5. As shown in Figure 2-9, slide the clamping gland, flat washers and gasket on

the multicore cable.

6. Fold back armor by 5 mm and pass it through the two flat washers as shown in

Figure 2-9.

Gasket

Seal with putty

after tightening.

Vinyl sheath

Clamping gland

Flat

washer

Armor (folded back)

Cable gland

Flat

washer

Flat

washer

Figure 2-9 Passing clamping gland, washers and gasket on the multicore cable

7. Shorten conductors considering their locations on the terminal board STB-1.

STB-1

RTB-801

Figure 2-10 Scanner unit, port side view

8. Confirm that armor is grounded between two flat washers.

2-7

Page 32

9. Remove the sheath of each conductor by 6 mm. Fix crimp-on lugs (FV1.25-4,

blue, ø4) to each conductor . Make sure each connection is secure both electrically and mechanically.

10.Tighten the clamping gland.

11.Seal the cable gland with putty.

12.Connect the conductors to terminal board STB-1 referring to the interconnection diagram on page S-1.

Fabricating signal cable S03-74

13.At the signal cable gland on the scanner unit, unfasten the clamping gland and

remove gasket and flat washers.

14.Shorten the signal cable making the length from the cable gland to the cable

end 500 mm. Remove the vinyl sheath by 550 mm; the armor by 540 mm.

Approx. 550 mm

Inner shield

Anti-corrosive

vinyl sheath

Armor

Approx. 540 mm

Outer shield

Figure 2-11 Fabricating the signal cable S03-74

15.Unravel the outer shield with a screwdriver or similar tool to expose the cores

beneath the outer shield. Similarly, expose the cores beneath the inner shield.

Mark all cores for future identification.

16.As shown in Figure 2-12, slide the clamping gland, washers and gasket onto

the signal cable. Fold back the armor by 5 mm, and then pass it through the two

flat washers.

Seal with putty

after tightening.

Clamping gland

Gasket

Washer

Armor

Gland body

Washer

Figure 2-12 Passing clamping gland, washers and gasket on signal cable

17.Unfasten the terminal board RTB-801.

18.Pass the signal cable behind the terminal board plate for cable MPYCY -12, and

then pass it through the locking wire saddle.

2-8

Page 33

Terminal board fixing plate for RTB-801

Ground terminal

Figure 2-13 Scanner unit, rear view

Locking wire saddle

Figure 2-14 Scanner unit, rear view

19.Fasten the terminal board fixing plate for RTB-801.

2-9

Page 34

20.Route the signal cable beneath the lower left side of the terminal board fixing

plate for the RTB-801. Shorten conductors of the signal cable considering their

locations on the RTB-801.

Coaxial cable

75 mm

2C-2V

50 mm

Fold back the conductor

as illustrated below.

45 mm

Crimp-on lug

Inner core

Conductor

FVD1.25-3

(Red, ∅3)

Crimp-on lug

6 mm

FV1.25-M3

(Red, ∅3)

Figure 2-15 Fabrication of coaxial cable

21.Shorten the shield considering the distance to the ground terminal on the left

side of the scanner unit chassis. (See Figure 2-13 for location.) Attach the

crimp-on-lug FV5.5-4 (ø4, yellow) to the shield.

22.Remove approx. 6 mm of the vinyl insulation from the end of each conductor

and fix the crimp-on lug FV1.25-M3 (Red) to each conductor . As shown in Figure 2-14, fold back the coaxial cable four times and attach the crimp-on-lug

FVD1.25-3 (ø3, red). Attach the crimp-on-lug FVD1.25 (ø3, red) to the shield.

23. Tighten the clamping gland, and then seal the cable gland with putty.

24.Fasten the shield to the ground terminal on the scanner unit chassis.

25.Connect conductors to the terminal board RTB-801 referring to the interconnection diagram.

When the length of the signal cable is more than 150 m, remove the solder at

terminal Nos. 24 (red) and 26 (black) on the DJ-1 connector . (#24 and #25 are

spares.). Fasten the wires as shown below.

TB801

14

16

SCANNER

UNIT

Length 150 m

or more

HEATER HOT

+12V

DJ-1

14

16

DISPLAY

UNIT

YELLOW, LARGE

WHITE, LARGE

RED, LARGE

BLACK, LARGE

£

Figure 2-16 Wiring on terminal boards when length of signal cable is 150 m or more

2-10

Page 35

26.Check for miswiring, loose screws. Grease the fixing bolts for the cover, gasket, and tap holes in the scanner chassis. Attach the cover.

When the de-icer is installed

1) Before beginning any work on the scanner unit, turn off the breaker for the deicer line at the main switchboard to remove the power (100 V AC, 1ø) to the deicer. (Turning off the power to the display unit has no effect.)

2) The neck of the scanner unit becomes VERY HOT when the de-icer is working.

(The de-icer turns on when ambient temperature is below 0°C.)

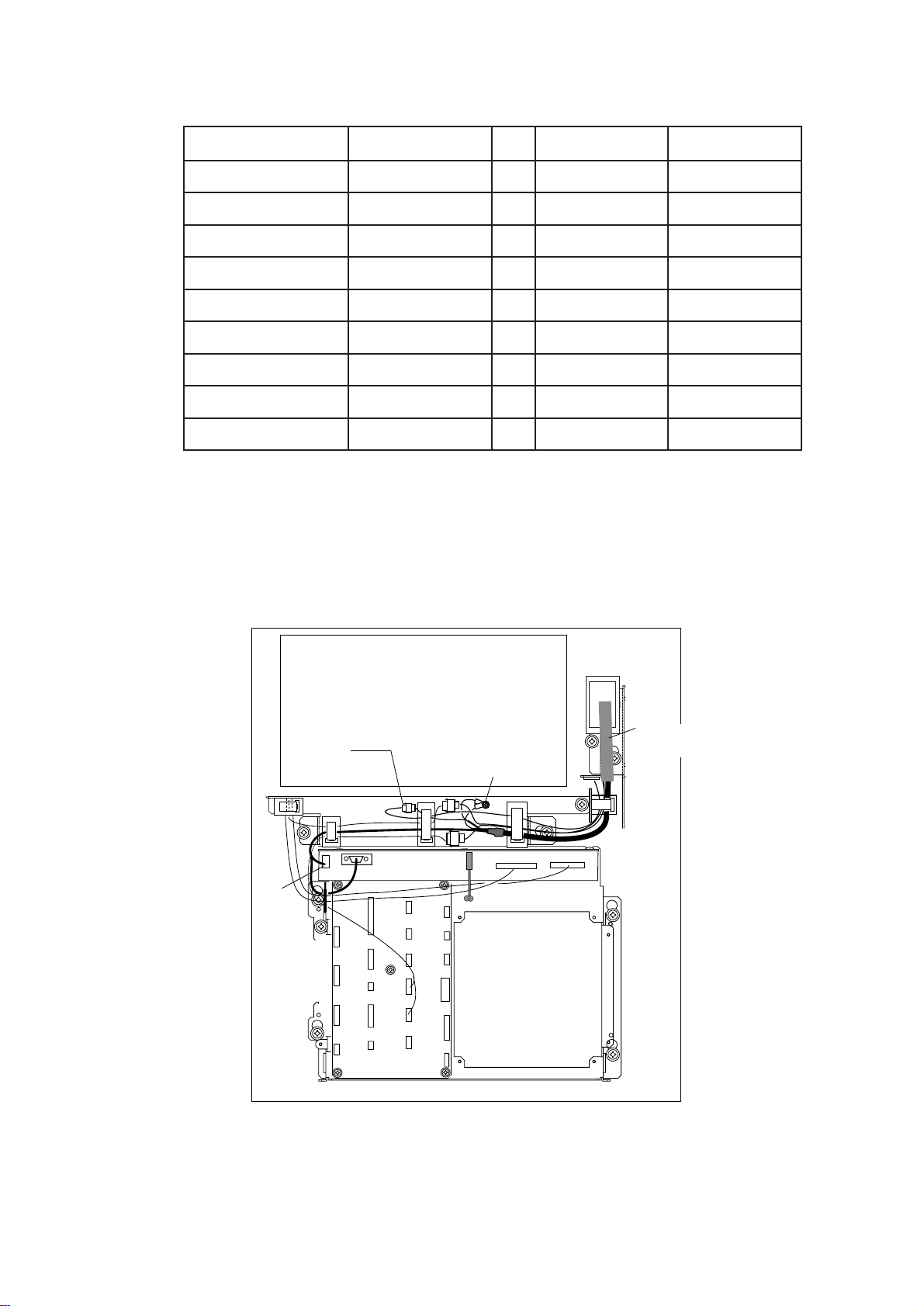

2.3 Changing AC Power Specification of Display Unit

To operate the display unit from 100 VAC or 220 VAC power, add or delete jumper

wires on the PTU Board and change the power fuses inside the display unit as

shown in the table below. The figure below shows the location of the power fuses

and the jumper wires on the PTU Board.

Table 2-2 Jumper wire setting on the PTU board, fuse rating and power specification

BCP.cepSrewoP

A5429P30CAV511/011/001mpr42SEYSEYSEYONONONA01

D5429P30CAV032/022mpr42ONONONSEYONONA5

annetnA

mpr

Jumper wire to use:

JP1: 0.8 dia. gilded wire

JP2, JP3, JP4, JP91, JP92: type ERD-S2TCOV

Fuse

1PJ2PJ3PJ4PJ19PJ29PJ

03P9245

C11

C12

JP1

T1

JP2

T21

JP3

JP4

JP92

JP92

U92

JP91

PTU Board

Figure 2-17 Display unit, inside view

rewoP

sesuF

2-11

Page 36

2.4 Power Supply Unit

Wire the unit as shown in the interconnection diagram.

TB

PTB14

TB

PTB11

Thermal relay

K2

Relay K3

Relay K1

Photo No. 3148

TB

PTB13

TB

PTB12

Figure 2-18 Power supply unit PSU-004

The type and rating of the thermal relay (K2) are as below.

sniaMs'pihStinUrennacS

epyTgnitaR

3,CAV022/002 φ 6200-BSRA7.13/HN0RTA3.2

3,CAV044/083 φ 1300-BSRA8.03/HN0RTA0.1

3,CAV022 φ zH05,8800-BSRA7.13/HN0RT*)XAM(A6.2

3,CAV022 φ zH06,9800-BSRA7.13/HN0RT*)XAM(A6.2

3,CAV044 φ zH06,0900-BSRA8.03/HN0RT*)XAM(A2.1

)2K(yaleRlamrehT

*: Set the rating to maximum ( 2.3A to 2.6A or 1.0A to 1.2A) for HSC radar.

2-12

Page 37

INITIALIZATION AND ADJUSTMENT

3.1 Tuning Initialization

Tune the radar as follows: Press [RADAR MENU] [0] [0] [2] [0] [0] [0] [0] (TUNE

INITIALIZE on RADAR 3 menu) and press the [ENTER] key. Also, confirm that

“2.MODEL” is set to “OTHER S-BAND” in the INTIAL SETTING 4 menu, referring

to page 3-5. If the setting is wrong, trouble may result.

3

.2 Accessing Menus for Initialization and Adjustment

To access them do the following:

1. Turn on the power.

2. Press the [RADAR MENU] key five times while pressing and holding down

the [HL OFF] key.

Restoring default settings

1. Press [RADAR MENU] [0] [0] [0] [2] [0] [0] [0] to display the INITIAL SETTING

4 menu and [0] again.

2. Press the [0] key.

3. Press the [ENTER] key five times, and turn the power off and on again.

4. “Initializing” appears during restoring. It takes about 90 seconds to restore the

default settings, after which the normal display appears.Confirm that

“2.MODEL” is set to “OTHER S-BND” in the INITIAL SETTING 4 menu.

3.3 Adjusting Video Signal Level

When the signal cable is very long, the video amplifier input level decreases,

shrinking target echoes. To prevent this, confirm (and adjust if necessary) video

amplifier input level.

1. Connect an oscilloscope to TP6 on the INT Board (03P9252) in the display

unit.

2. Transmit on the 12 nm range.

3. Adjust R21 on the INT Board so the value of TP6 is 4 Vpp. (For remote display, adjust R134 on the INT Board.)

INT Board

(03P9252)

3-1

TP1

R134

TP6

R21

Figure 3-1 Display pedestal

Page 38

3.4 Heading Alignment

You have mounted the scanner unit facing straight ahead in the direction of the

bow. Therefore, a small but conspicuous target dead ahead visually should appear on the heading line (zero degrees).

In practice, you will probably observe some small bearing error on the display

because of the difficulty in achieving accurate initial positioning of the scanner

unit. The following adjustment will compensate for this error.

Correct bearing

relative to heading

Target

a

270

260

Scanner mounted

error to port

(HDG SW advanced)

000

010

350

020

340

330

320

310

300

290

280

250

240

230

220

210

200

030

140

150

160

190

170

180

Picture appears

deviated clockwise.

040

050

130

a

060

070

080

090

100

110

120

Apparent

position

of target

Scanner mounted

error to starboard

(HDG SW delayed)

Apparent position

of target

Target

b

b

000

010

350

020

340

330

320

310

300

290

280

270

260

250

240

230

220

210

200

030

040

050

060

070

080

090

Correct

100

110

bearing

120

130

relative to

140

150

160

190

170

180

heading

Picture appears

deviated counterclockwise.

Figure 3-2 Heading alignment

1. Turn on the power. Press [RADAR MENU] [0] [0] [0] [2] [2] to select HL ALIGN

on the INITIAL SETTING1 menu.

2. Select a target echo (by gyrocompass, for example) at a range between 0.125

and 0.25 nm, preferably near the heading line.

3. Operate the EBL control to bisect the target echo with the heading line. (The

value shown on the display is scanner position in relation to ship's bow.)

4. Press [ENTER] to finish.

3-2

Page 39

3.5 Adjusting Sweep Timing

Sweep timing differs with respect to the length of the signal cable between the

scanner unit and the display unit. Adjust sweep timing at installation to prevent

the following symptoms:

• The echo of a "straight" target (for example, pier), on the 0.25 nm range, will

appear on the display as being pulled inward or pushed outward. See Figure

3-3.

• The range of target echoes will also be incorrectly shown.

(1) Correct

Figure 3-3 Examples of correct and incorrect sweep timings

1. Turn on the power. Press [RADAR MENU] [0] [0] [0] [2] [3] to select TIMING

ADJ on the INITIAL SETTING1 menu.

2. Transmit on the 0.25 nm range.

3. Adjust radar picture controls to display picture properly.

4. Select a target echo which should be displayed straightly.

5. Adjust the VRM control to straighten the target echo.

6. Press [ENTER].

(2) Target pushed

inward

3.6 Suppressing Main Bang

If main bang appears at the screen center, suppress it as follows.

(3) Target pushed

outward

1. Turn on the power. Transmit on a long range and then wait ten minutes.

2. Adjust [GAIN] control to show a slight amount of noise on the display.

3. Select the 0.25 nm range. Adjust the [A/C SEA] control to suppress sea clutter.

4. Press [RADAR MENU] [0] [0] [0] [2] to open the INITIAL SETTING1 menu.

5. Press [7] to select 7. MBS.

6. Adjust the VRM control to adjust timing; the EBL control to adjust level.

7. Press [ENTER].

3-3

Page 40

3.7 Confirming Magnetron Heater Voltage

h

Magnetron heater voltage is adjusted at the factory . Confirm that magnetron heater

voltage is within the prescribed rating as follows:

1. Turn on the radar and select the 0.125 mile range.

2. Press [RADAR MENU] [0] [0] [0] [2] [0] to

open the INITIAL SETTING2 menu.

ANTENNA

switch

3. Press [5] to select the 5. SCANNER

STOPPED field and the TX option.

ANTENNA

4. Turn off the antenna switch in the display

unit.

5. Connect a multimeter, set to the 10 VDC

range, between #12(+) of P801 and the

chassis.

6. The multimeter should read 9.2-9.4 V . If not,

adjust VR1.

DEGAUSS ERROR

7. “Transmit” on the 48 mile range.

8. The multimeter should read 7.3-8.3V.

Figure 3-5 Antenna switc

in tuning compartment

9. Press [RADAR MENU] [0] [0] [0] [2] [0] [5]

to select the 5. SCANNER STOPPED field and the ROTATE option.

10.Turn on the ANT MOTOR SW on the scanner unit.

ON

OFF

TUNE

PM

Figure 3-6 Scanner unit, bow view

3-4

Page 41

PCB 03P9243

P801

VR1

Figure 3-7 Scanner unit, stern side view

3.8 Initial Setting Menus

The INITIAL SETTING menu (four menus) and the OWN SHIP INFORMATION

menu setup the radar according to expected usage, authorities specification, ship's

characteristics, operator's preference, etc. Set items on each menu in accordance with regulations/operator's preference. After entering initial settings, reset

the power.

3-5

Page 42

Press [RADAR MENU] [0] [0] [0] [2]

[OWN SHIP INFORMATION]

1 [INITIAL SETTING(1)]

2 SHIP’S LENGTH 000m

3 SHIP’S WIDTH 00m

4 RADAR POSN FOR BOW 000m

FOR PORT 00m

5 NAV ANT POSN FOR BOW 000m

FOR PORT 00m

6 TURN RATE 00KT

00.0° / s

00KT

00.0° / s

7 SPEED RATE 00KT

0.00KT/s

00KT

0.00KT/s

Press [0]

[INITIAL SETTING 4]

1 [INITIAL SETTING(3)]

2 MODEL FR-2115, 2125/

OTHER X-BND/

FR-2165DS, 2135SW/

OTHER S-BND

3 TYPE R/N/G/D

4 CTR STC CURVE L/M/H

5 RJ-7 OFF/ON

6 RJ-8 OFF/ON

ANT A

FR-2115, 2125/

OTHER X-BND/

FR-2165DS, 2135SW/

OTHER S-BND

ANT B

FR-2115, 2125/

OTHER X-BND/

FR-2165DS, 2135SW/

OTHER S-BND

7 SHIP’S TYPE DEEP SEA/FISHING/

LONG LINE FISHING

8

9 CABLE LENGTH 500m/5000m

0 FACTORY DEFAULT

Press [6]

[INITIAL SETTING 1]

1 [FUNCTIONS(4)]

2 HL ALIGN

EBL 0.0°

3 TIMING ADJ

VRM 00.00

4 ANT HGT 5m/7m/10m/15m/

20m/30mMORE

5 LOG PULSE 200P

6 [OWN SHIP INFORMATION]

7 MBS MBS TIMING VRM 0

MBS LEVEL EBL 0

8 ON TIME 000000.0H

9 TX TIME 000000.0H

0 [INITIAL SETTING(2)]

Press [0]

[INITIAL SETTING 2]

1 [INITIAL SETTING(1)]

2 LOG GYRO INPUT LOG

PULSE/SERIAL DATA

GYRO

AD/10/SERIAL DATA

3 OWN SHIP VECTOR COMPASS/COURSE

4 KEY BEEP ON/OFF

5 SCANNER STOPPED ST-BY/TX

6 VIDEO SIG ANALOG/DIGITAL

7 ALARM LEVEL 4/5/6/7

8 DISPLAY MAIN/SUB

9 SECTOR BLKG OFF/ON

000° → 000°

000° → 000°

0 [INITIAL SETTING(3)]

Press [0]

[INITIAL SETTING 3]

1 [INITIAL SETTING(2)]

2 TRAILS RESTART OFF/ON

3 ECHO AVG W/O GYRO OFF/ON

4 HEAD UP TB SCALE DEG/16POINT

5 CTR ECHO STRETCH OFF/ON

6 VIDEO CONTRAST 1/2/3

7 MAXIMUM RANGE 72/96/120

8 ECHO FULL COLOR OFF/ON

9 INDEX LINES 2/3/6

0 [INITIAL SETTING(4)]

INITIAL SETTING1 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2]

HL ALIGN: Aligns heading.

TIMING ADJ: Adjusts sweep timing.

ANT HGT: Enter height of scanner above water. Select from 5 m, 7 m, 10 m, 15

m, 20 m, or more than 30 m.

LOG PULSE: Enter speed log's pulse rate.

3-6

Page 43

OWN SHIP INFORMATION: Enter ship's characteristics; length, width, radar

scanner position, navigation antenna position, turn rate, and speed rate. See the

description on the next page for further details.

MBS: Suppresses main bang.

ON TIME, TX TIME: Shows number of hours the radar has been turned on and

transmitted, respectively. Value can be changed.

INITIAL SETTING2 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [0]

LOG GYRO INPUT : Select LOG or GYRO input type. LOG: Select pulse or serial

data. GYRO: Digital from A/D converter or serial data.

OWN SHIP VECTOR: Select reference for own ship vector; compass or course.

KEY BEEP: Turns key response beep on or off.

SCANNER STOPPED: Set to ST-BY in normal use. TX enables transmission

state without scanner rotation.

VIDEO SIG: Set to ANLG (analog) for normal use. Select DIGITAL to adjust QV

(Quantized Video).

ALARM LEVEL: Sets echo strength which triggers guard alarm. "7" is strongest

echo; "4" is medium strength echo.

DISPLAY: Select radar display function; main or sub (slave).

SECTOR BLKG: Sets area (up to 2) where no radar pulses will be transmitted.

For example, set the area where an interfering object at the rear of the scanner

would produce a dead sector (area where no echoes appear) on the display. To

enter an area, select ON and enter relative bearing range of the area.

INITIAL SETTING3 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [0] [0]

TRAILS RESTART: Selects whether to restart or discontinue target trails when

changing the range. ON restarts trailing on newly selected range; OFF discontinues trails.

ECHO A VG W/O GYRO: Echo averaging can be turned on without gyrocompass

connection.

HEAD UP TB SCALE: Bearing scale may be shown in degrees or compass

points in the head-up mode.

CTR ECHO STRETCH: Turn on to enlarge echoes in the range up to the first

range ring.

VIDEO CONTRAST: For factory use. Do not change setting.

MAXIMUM RANGE: For factory use. Do not change setting.

ECHO FULL COLOR: Echoes may be displayed in one color or multi-color. Se-

lect ON for multi-color display.

INDEX LINES: Selects the number of index lines to display; 2, 3, or 6.

3-7

Page 44

INITIAL SETTING4 menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [0] [0] [0]

MODEL: Selects radar model.

TYPE: Selects specification of radar. Select R for R type; G for IMO type.

CTR STC CURVE: Selects level of STC affect; Low, Medium or High.

RJ-7, RJ-8: Selects which Interswitch unit to use.

SHIP'S TYPE: Select class of vessel; deep sea, fishing, long line fishing.

CABLE LENGTH: Set for "500."

FACTORY DEFAULT: Restores all menus' default settings.

OWN SHIP INFORMATION menu

Keying sequence: [RADAR MENU] [0] [0] [0] [2] [6]

SHIP'S LENGTH: Enter ship's length.

SHIP'S WIDTH: Enter ship's width.

RADAR POSN: Enter distance from both bow and port to the radar antenna

location.

NAV ANT POSN: Enter distance from both bow and port to the navigation an-

tenna location.

TURN RATE: Enter ship's turn rate.

SPEED RATE: Enter ship's speed rate.

3-8

Page 45

INSTALLATION OF OPTIONAL EQUIPMENT

4.1 Gyro Converter GC-8

The Gyro Converter GC-8, incorporated inside the radar display unit, converts

analog gyrocompass reading into digital coded bearing data for display on the

radar display.

This section explains how to install and setup the GC-8 (mainly consisting of the

GYRO CONVERTER Board) and set it up according to gyrocompass connected.

Installation and connection of the GYRO

CONVERTER Board

Necessary Parts: GC-8-2 (008-446-520)

emaNepyTytQ.oNedoC

draoBretrevnoCoryG6011P461022-214-400

swercSW0072C,8x3M5404-188-000

rekcitS11202-410-461107-231-001

1) Turn off the power.

2) Open the display unit. See Chapter 1 for instructions.

3) Fasten the GYRO CONVERTER Board inside the display unit with four

washerhead screws (supplied).

PTU BOARD

03P9245A`F

MB BOARD

03P9251

GYRO CONVERTER

BOARD 64P1106

INT BOARD

03P9252

Figure 4-1 Display unit, inside view

4-1

Page 46

4) Connect the GYRO CONVERTER Board to the INT Board (cables supplied

with GC-8) as shown below.

INT Board GYRO CONVERTER Board

J446 (4P) J7 (5P)

J465 (6P) J1 (14P)

J5

To gyro

J4

J446

INT BOARD

03P9252

J7

J1

Fix cable to chassis

with cable tie.

GYRO CONVERTER

BOARD 64P1106

Figure 4-2 Display unit, inside view

5) Confirm gyrocompass specifications and set up the DIP switches and jumper

wires on the GYRO CONVERTER Board according to gyrocompass connected:

• Setting jumper wires and DIP switches by gyrocompass

specifications: page 4-3

• Setting jumper wires and DIP switches by make and

model of gyrocompass: page 4-5

• Location of jumper wires and DIP switches: page 4-6

6) Solder the gyrocompass cable to the VH connector assemblies (supplied).

7) Attach instruction label (supplied).

8) Close the display unit.

9) Turn the power off and on to reset the CPU.

4-2

Page 47

Connection of external power supply

An external power supply is necessary when the repeater signal is step-by-step

type and the step voltage is below 20V or output voltage is less than 5 W.

1. Cut jumper wire JP1 on the GYRO CONVERTER Board when an external power

supply is used.

2. Connect gyro cable and power cable as shown below.

GYRO CONVERTER Board

kAl64P1106

External Power Supply

20 - 135 VAC

20 - 100 VDC

Gyrocompass

(Step type)

S1

S2

S3

COM

F.G.

J5

1 R2

2 R1/COM

Either connection

in case of DC

polarity.

J4

1 S1

2 S2

3 S3

4 T

5 F.G.

Figure 4-3 Connection of external power supply to GYRO CONVERTER Board

DIP switch, jumper wire settings

Default setting

The default setting of all DIP switches is off and all jumpers wire are set to “#1.”

(Note that jumper wire JP1 is set at #1, #2, and #3.) In those settings the gyrocompass having the following characteristics can be directly connected; modification

of the GYRO CONVERTER Board is not necessary.

AC synchronous signal: 50/60 Hz

Rotor voltage: 60 V to 135 V AC

Stator voltage: 60 V to 135 V AC

Gear ratio: 360x

Supply voltage: 30 V to 135 V AC

If the specifications of the gyrocompass differ from those mentioned above, change

jumper wire and DIP switches settings on the GYRO CONVERTER Board. Settings may be changed according to gyrocompass specifications or make and model

of gyrocompass (see page 4-5). For the location of DIP switches and jumper wires,

see page 4-6.

4-3

Page 48

Setting method 1: by gyrocompass specifications

1) Gyrocompass type 2) Frequency

Gyrocompass

type

AC synchronous OFF OFF OFF #1,

DC synchronous OFF OFF OFF #2,

DC step ON OFF OFF #4,

Full-wave

pulsating current

Half-wave

pulsating current

SW

1-4SW1-5SW1-6

OFF ON OFF #4,

ON ON OFF #4,

JP1 Frequency SW

#2, #3

#3, #4

#5, #6

#5, #6

#5, #6

50/60Hz OFF OFF AC synchronous

400Hz ON OFF AC synchronous

500Hz OFF ON AC synchronous

DC ON ON DC synchronous

Remarks

1-7SW1-8

pulsating current

pulsating current

pulsating current

DC step

3) Rotor voltage

(between R1 & R2)

Rotor voltage SW 2-1 JP3 Stator voltage SW 2-2 SW 2-3 JP2

20 V to 45 VAC ON #2 20 V to 45 VAC, or

30 V to 70 VAC OFF #2

40 V to 90 VAC ON #1 20 V to 45 VAC, or

60 V to 135 VAC OFF #1

4) Stator voltage

(between S1 and S2)

20 V to 60 VDC

20 V to 60 VDC

40 V to 90 VAC ON OFF #1

60 V to 135 VAC OFF OFF #1

ON OFF #2

OFF OFF #2

5) Ratio 6) Supply voltage

Ratio SW1-1 SW 1-2 SW1-3 Supply voltage JP4 JP5

360x OFF OFF OFF 20 V to 45 VAC, or

180x ON OFF OFF

90X OFF ON OFF 30 V to 135 VAC, or

36X ON ON OFF

20 V to 60 VDC

40 V to 100 VDC

#2 #2

#1 #1

7) AD-10 format data

Tx interval

Select data transmitting interval for ports 1 to 6 by jumper wires

JP6 and JP7.

Note: The Tx interval is available in 25 ms or 200 ms.

25 ms is for radar; 200 ms is for all other equipment.

9) NMEA-0183

Version no.

Version no.

2.0 ON

SW3-1

OFF1.5

10) NMEA-0183

Baud rate

Baud rate

38400bps ON

SW3-2

OFF4860bps

4-4

8) NMEA-0183

Tx interval and Output sentence

Tx

interval

1 s

200 ms

100 ms OFF

25 ms

SW

2-5

OFF

ON

ON

SW

2-6

OFF

OFF

ON

ON

Output

sentence

HDT+VHW

HDT

HDT

HDT

11) NMEA-0183

Talker

Talker

HE ON

SW3-3

OFFAG

Page 49

Setting method 2: by make and model of gyrocompass

rekaMsledoMnoitacificepSWS

ONURUF007-YGpetsCD

ztuhcsnA3,2dradnatSsuonorhcnysCA

6,4dradnatSsuonorhcnysCA

02dradnatSpetsCD

awagokoY

cetvaN

htialP(

)epyt

htialPIII/IITAGVANsuonorhcnysCA

cemikoT

yrrepS(

)epyt

ikasawaK18-XGsuonorhcnysCA

nworbamrA1-LKM,01-KM

nostreboR08-RKSpetsCD

3/2/A1/1-C

55-B,55-A

007-ZMCpetsCD

005/X003

003

3/2-SPI

05-ZMC

etoN

11/2/1-SE

002-GT

H/L732RP

12MG

41-KM

T/2/1-DOM

302/

0006-GTpetsCD

11-MGsuonorhcnysCA

4-DOM

/X052-ZMC

/002/001-ZMC

3/1/Z1-D,rJ1-C

/201/101-TLG

701/K601/301

011/A11-SE

0002/R222RP

IE-KN,NE-KN

041/031-RSpetsCD

0005/001-GT

/031/753-RP

71-SE,041

202/102-TLG

61-SE,021-RS

03/02/01-KM

,1531SEIRES

x081V001

zH06/05

x063

zH06/05

x063

x081V53

zH06/05

x063

x081V42

petsCD

x081V53

zH06/05

x063

pets

x081V53

zH06/05

x063

zH06/05

x63

zH06/05

x09

petsCD

x081V07

x081V07

petsCD

x081V07

x081V42

zH06/05

x09

petsCD

x081V53

zH06/05

x09

petsCD

x081V05

x081V53

rotcellocnepo,eriw-5

V06/05:egatlovrotoR

V22:egatlovrotatS

V06/05:egatlovrotoR

V09:egatlovrotatS

)+(eriw-3,)-(MOC

suonorhcnysCA

V06/05:egatlovrotoR

V22:egatlovrotatS

)-(eriw-3,)+(MOC

x063suonorhcnysCDFFOFFOFFOFFOFFOFFONONO-NOFFO-omeR

)-(eriw-3,)+(MOC

suonorhcnysCA

V001:egatlovrotoR

V09:egatlovrotatS

)-(eriw-3,)+(MOC

V06/05:egatlovrotoR

V86:egatlovrotatS

suonorhcnysCA

V011/001:egatlovrotoR

V09:egatlovrotatS

suonorhcnysCA

V011/001:egatlovrotoR

V22:egatlovrotatS

)+(eriw-3,)-(MOC

rotcellocnepo,eriw-5

)-(eriw-3,)+(MOC

V001:egatlovrotoR

V09:egatlovrotatS

V011/001:egatlovrotoR

V09:egatlovrotatS

)-(eriw-3,)+(MOC

)+(eriw-3,)-(MOC

WS

WS

WS

WS

WS

WS

WS

WS

WS

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

1-2

NOFFOFFONOFFOFFONONO- FFOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFONOFFO,1#

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFONOFFO,1#

NOFFOFFONOFFOFFONONO-NOFFO-omeR

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– NOFFO-omeR

FFOFFOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFOFFONOFFOFFOFFO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO-NOFFO,4#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– NOFFO,4#

FFONOFFOFFOFFOFFOFFOFFOFFOFFOFFO,1#

NOFFOFFONOFFOFFONONO– FFOFFO,4#

NOFFOFFONOFFOFFONONO– NOFFO,4#

WS

2-2

3-2

1PJ2PJ3PJ4PJ5PJ

2#-1#1#

6#,5#

2#2#1#1#

3#,2#

2#1#1#1#

3#,2#

2#– 2#2#

6#,5#

2#2#1#1#

3#,2#

2#–

ev

2#–

ev

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#–

ev

2#2#1#1#

3#,2#

1#1#1#1#

3#,2#

1#1#1#1#

3#,2#

2#– 1#1#

6#,5#

2#– 1#1#

6#,5#

2#– 1#1#

6#,5#

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#– 2#2#

6#,5#

1#1#1#1#

3#,2#

2#– 1#1#

6#,5#

2#– 2#2#

6#,5#

∗∗

∗∗

∗∗

*: Set JP4 and JP5 according to the voltage of the external power supply.

Note: If CMZ-50 has 35VDC, set JP1 to #4, #5, #6.

4-5

Page 50

Location of DIP switches, jumper wires on the GYRO CONVERTER

Board

JP2

(Rotor voltage)

JP3

(Stator voltage)

JP1

(Gyro type)

JP5, JP4

(Supply voltage)

64P1106

SW3

DIP switch

J12

(Data output

port #6)

J11

(Data output

port #5)

J10

(Data output

port #4)

SW2

DIP switch

JP6, JP7

(AD formal

Fuse

(2A)

J5

(Rotor signal input,

external power input)

J4

(Stator signal input)

SW1

DIP switch

(IEC-61162-1 output port)

J6

J7

(Data output port #1)

J8

(Data output port #2)

data Tx interval)

J9

(Data output port #3)

Figure 4-4 GYRO CONVERTER Board

Setting the heading readout on the radar display

Confirm that the gyrocompass is giving a reliable readout. Then, set the heading

readout on the radar display with the gyrocompass readout as follows:

1. Press [RADAR MENU] to display the FUNCTIONS 1 menu.

2. Press the [0] key twice to display the FUNCTIONS 3 menu.

3. Press the [9] key to select the GYRO SETTING option.

4. Rotate the EBL control to align the radar’s HDG readout with the gyrocompass.

5. Press [ENTER] to conclude the setting.

4-6

Page 51

4.2 ARP Board ARP-26

The ARP Board ARP-26, which provides ARPA functions, is an optional circuit

board which is accommodated in the display unit of the FR-2105 series radar.

Necessary Parts: ARP-26-2E (008-485-500)

emaNepyTytQ.onedoC

draobPRAB2009P811056-374-800

Installation of the ARP board

1. Remove the bottom cover of the display unit by unfastening four screws.

2. Set the ARP Board in the center slot of the PCB card case.

PCB card case

Top: RP Board (Option)

Middle: ARP Board (Option)

Bottom: SPU Board

Figure 4-5 Display pedestal inside view

3. Adjust the ARP referring to the procedure on the next page.

4-7

Page 52

ARP board adjustment

1. Turn the GAIN, A/C SEA and A/C RAIN controls fully counterclockwise, and

then transmit on the 12 nm range.

2. Connect a digital multimeter between TP7(+) and TP6(-) on the ARP Board.

TP7

TP6

R104

R103

Figure 4-6 ARP Board (18P9002B)

3. Adjust R104 on the ARP Board so the multimeter reads between 0.09 and 0.14

VDC.

4. Set controls and switches as below.

GAIN: fully clockwise (max.)

Interference rejector: OFF

Range: 24 nm

Echo stretch: OFF

5. Press [RADAR MENU] [0] [0] [0] [0] open the INITIAL SETTING3 menu.

6. Set the VIDEO SIG field to DIGITAL and press [ENTER].

7. Adjust R103 on the ARP Board so noise just appears on the display.

Too little noise

Proper noise

Figure 4-7 How to adjust noise

8. Set VIDEO SIG to ANALOG and press [ENTER].

4-8

Too much noise

Page 53

Final check

Connect a gyrocompass and a log to the radar and place the radar under transmit

state. Confirm that LEDs CR9, CR10, CR11, CR12, CR15 and CR16 on the ARP

Board are off. If ship's speed is zero, or other signal is not being input, corresponding LED will light.

CR16 LOG

CR15 GYRO

CR12 TRG

CR11 VID

CR10 BRG

CR9 HDG

S1

4#3#2#1#

FFOFFOFFOFFO

Figure 4-8 ARP Board ARP-26

4-9

Page 54

4.3 RP Board RP-26

The RP Board RP-26, which providesvideo plotter functions, consists of a circuit

board and a card drive both of which are accommodated in the display unit of the

FR-2105 series radar.

Table top/console type

Necessary Parts: RP-26-T-2E (008-485-520)

draobPR8920P411046-784-800

emaNepyTytQ.onedoC

.yssaesacdraC–1–

BwercsdaehnaPW0072C8x4M4544-188-000

BwercsdaehnaPW0072C8x3M2404-188-000

AwercsdaehnaPW0072C5x6.2M2379-008-000

rehsawkcoldehteeT

)hteetedistuO(

.yssaelbaC25-A-A-D001-6FIH1355-731-000

W1915C4M1605-468-000

1. Lift the monitor and fix it with the stay. Refer to Chapter 1 for instructions.

2. Remove the right arm cover from the control head.

3. Fasten the card case to the right arm cover as follows:

a) Fasten the ground wire with an M4x10 screw and washer (supplied) as shown

below.

b) Fasten the arm cover to the card case with three M4x8 screws (supplied).

Panhead screw

M4X10@

Arm cover (right)

Panhead screw

M4X8@3 pcs.@

Ground wire

Washer

M4@

Card case

Figure 4-9 Fastening the card case to the right arm cover

4-10

Page 55

4. Unfasten the front panel from the display pedestal.

5. Pass the connector from the card case through the hole in the display pedestal.

Display pedestal

Front panel

Figure 4-10 Display pedestal

6. Set the RP Board (14P0298) in the top slot of the pcb card case. See page 4-7

for the location of the pcb card case.

7. Run the connector from the card case in front of the GYRO CONVERTER

Board.

8. Plug the connector in J1 on the RP Board.

9. Fasten the ground wire from the connector at the location shown below.

RP connector

INT Board

Fasten ground wire from connector to this screw.

RP Board

GYRO

CONVERTER

Board

FRONT

(TOP VIEW)

ARP Board

SPU Board

J1

Route cable between ARP and SPU Boards.

(FRONT VIEW)

Figure 4-11 Display pedestal, top view

4-11

Page 56

10.Fasten the front panel on the display pedestal.

11.Retract the stay to close the display unit.

12.Fasten the right arm cover.

Separate type control head

Necessary parts: RP-26-Z-2E (Code no. 008-491-400)

emaNepyTytQ.oNedoC

.yssAesaCdraC–1–

draoBPR8920P411046-784-800

BwercSdaeHnaPW0072C8x4M1544-188-000

BwercSdaeHnaPW0072C8x3M2404-188-000

AwercSdaeHnaPW0072C5x6.2M2379-008-000

1. Lift the monitor. See Chapter 1 for instructions.

2. Fasten the mounting base with one M4 x 8 screw as below.

Fasten with

M4 x 8 screws.

Fasten with M3 x 8

screws (2 pcs.)

Figure 4-12 Display unit, inside view

3. Fix the mounting base to front panel with two M3 x 8 screws.

4. Set the M-card case lid to the hole in the front panel and fix with two M2.6 x 5

screws.

4-12

Page 57

Display pedestal

M-card base

Display pedstal

front panel

Pan Head

Screw

M2.6X5

(2 pcs.)

M-card

case lid

Figure 4-13 Display pedestal, front view

5. Loosen six screws to remove the front panel on the display pedestal.

6. Set the RP Board (14P0298) in the top slot of the pcb card case.

7. Run the connector from the card case in front of the GYRO CONVERTER

Board.

8. Plug the connector in J1 on the RP Board.

9. Fasten the ground wire from the connector at the location shown below.

RP connector

INT Board

Fasten ground wire from connector to this screw.

RP Board

ARP Board

SPU Board

GYRO

CONVERTER

Board

FRONT

(TOP VIEW)

J1

Route cable between ARP and SPU Boards.

(FRONT VIEW)

Figure 4-14 Display pedestal, top view

4-13

Page 58

10.Fasten the front panel of the display pedestal.

11.Fasten the ground wire to the location shown in Figure 4-14.

12.Close the monitor.

4.4 Performance Monitor PM-50

Necessary parts: PM-50 and OP03-150 (Code no. 008-485-490)

emaNepyTytQ.oNedoC

draoBMP5229P301

wercSdaeHnaPW0072C8x3M3404-188-000

.yssArotcennoCAA-003L-P3HV2410-141-000

1. Lift the monitor. See Chapter 1 for instructions.

2. Fasten the PM Board 03P9225 to the location shown below with three screws

(M3 x 8).

J402

PM Board

03P9225

J411

J403

J401

Figure 4-15 Display unit, inside view

3. Connect the connector P401 coming from J411 to J401 on the PM Board.

4. Connect two connector assemblies (VH3P-L300-AA) to J402 and J403.

5. Solder the other end of there connector assemblies with external cables, one

from ship’s mains and one from the PM-30.

6. Peel off the seal located to the right of the antenna switch in the tuning compartment on the control head to access PM switch. (Refer to page 1-14 for

location.)

7. Close the monitor.

4-14

Page 59

4.5 Alarm Kit

Necessary parts: OP03-156 (Code no. 008-500-650)

The alarm kit mainly consists of a circuit board and connection cables, and provides alarm output to ship’s bridge alarm system.

Contents of Alarm Kit OP03-156

emaNepyT.oNedoCytQ

draoBMRALA2629P30086-005-8001

.yssArotcennoCHN)P9-9(0991-30007-005-8001

.yssArotcennoCHN)P3(1991-30017-005-8004

dnaBelbaCN3-PH100-075-0001

eiTelbaC001-VC223-075-0003

BwercSdaeh-naPW0072C8X3M404-188-0004

BwercSdaeh-naPW0072C21X4M744-188-0001

Procedure

Refer to the figure below for parts locations.

1. Raise the monitor and fix it with the stay. (See page 1-5 for instructions.)

2. Unfasten four screws to dismount the shield cover for the INT Board.

3. Fasten the ALARM Board to the display unit with four pan-head screws (M3X8,

supplied).