Page 1

Page 2

9-52 Ashihara-cho,9-52 Ashihara-cho,

A

A

*00080756800**00080756800*

*00080756800**00080756800*

*OME72410M00**OME72410M00*

Nishinomiya, JapanNishinomiya, Japan

Telephone :Telephone : 0798-65-21110798-65-2111

Telefax :Telefax : 0798-65-42000798-65-4200

ll rights reserved.

ll rights reserved.

PUB.No.PUB.No. OME-72410OME-72410

Printed in JapanPrinted in Japan

Your Local Agent/DealerYour Local Agent/Dealer

IRST EDITION :

IRST EDITION : APR.APR. 19961996

MM :: FEB.FEB. 12,200312,2003

(( DAMIDAMI ))

DS-50DS-50

* 0 0 0 8 0 7 5 6 8 0 0 ** 0 0 0 8 0 7 5 6 8 0 0 *

*OME72410M00**OME72410M00*

* O M E 7 2 4 1 0 M 0 ** O M E 7 2 4 1 0 M 0 *

Page 3

SAFETY INSTRUCTIONS

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

Only qualified personnel

should work inside the

equipment.

Immediately turn off the power at the

switchboard if water leaks into the

equipment or an object is dropped into

the equipment.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Do not place liquid-filled containers on

the top of the equipment.

Fire or electrical shock can result if the

liquid spills into the equipment.

Do not disassemble or modify the

equipment.

CAUTION

Do not use the equipment for other than

its intended purpose.

Improper use of the equipment can result

in personal injury or equipment damage.

Turn off the equipment immediately if

you feel it is abnormal.

Turn off the power from the switchboard if

the equipment is emitting strange noises

or becomes excessively hot. Contact your

dealer for advice.

The useable ambient temperature range

is 15°C

Do not use the equipment out of the

above temperature range.

Do not place objects around the

equipment.

Overheating may result.

to

55°C.

Fire, electrical shock or serious injury can

result.

Keep the equipment away from rain

and water splash.

Fire or electrical shock can result if the

rain or water gets into the equipment.

Do not operate the equipment with wet

hands.

Electrical shock can result.

Keep heater away from equipment.

A heater can melt the equipment's power

cord, which can cause fire or electrical

shock.

Use the proper fuse.

Fuse rating is shown on the equipment.

Use of a wrong fuse can result in damage

to the equipment.

Do not power the equipment when the

transducer is in air.

The transducer may become damaged.

Handle all units carefully.

Damage can lead to corrosion.

Do not use chemical cleaners such as

alcohol, acetone and benzine to clean

the equipment.

Chemical cleaners can remove paint and

markings. Use only a soft, dry cloth. For

stubborn dirt, use a soft cloth moistened

with water-diluted mild detergent.

When dry docked remove marine life

from the transducer.

Remove marine life to maintain good

sensitivity.

Do not paint the transducer face.

Further, handle the transducer with

care.

Paint will affect equipment performance.

i

iiiiiiiiiiiii

Page 4

WARNING LABEL

A warning label is attached to the

units shown right. Do not remove the

labels. If a label is missing or is illegible,

contacta FURUNO dealer or agent about

replacement.

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

Name: Warning Label (1)

Type: 86-003-1011

Code No.: 100-236-230

MAIN DISPLAY UNIT

DS-500

PROCESSOR UNIT

DS-510, DS-511

Warning

label

TRANSCEIVER UNIT

DS-520

ii

iiiiiiiiiiiiiiiiiiiiiiiiii

Page 5

TABLE OF CONTENTS

INTRODUCTION................................................................................................................1

SPECIFICATIONS .............................................................................................................2

SYSTEM CONFIGURATION .........................................................................................5

OPERATION ........................................................................................................................6

Controls and Indications on the Main Display Unit ........................................................... 6

Turning on the Power, Adjusting Panel Brilliance..............................................................8

Selecting Speed Tracking Mode .........................................................................................9

Selecting Unit of Speed Measurement................................................................................9

Displaying Distance Run or Keel Clearance ......................................................................9

Setting Distance Run ........................................................................................................10

System Settings.................................................................................................................11

CONTROL BOX (option) OPERATION ..................................................................13

MAINTENANCE & TROUBLESHOOTING ............................................................14

Preventive Maintenance....................................................................................................14

Troubleshooting ................................................................................................................15

Operation Checks..............................................................................................................15

Error Displays.........................................................................................................................17

Program Number ..............................................................................................................17

PRINCIPLE OF DOPPLER SPEED LOG...............................................................18

DIGITAL INTERFACE (IEC 61162-1 EDITION 2) ..................................... 19

Declaration of Conformity

iii

Page 6

SPECIFICATIONS

General Specifications

1. Ultrasonic frequency 440 kHz

2. Number of beams 3 beams for dual-axis speed indication

3. Measuring range and accuracy

Ship's speed Fore/aft: -10.0 to +40.0 kt

Port-Starboard: -9.9 to +9.9 kt

Working depth Ground tracking: 1 to 200 m beneath the keel

Water tracking: 3 to 25 m below hull bottom. (It will

change by installation conditions and surrounding water

conditions of transducer. The measuring accuracy will be

reduced for the depth shallower than 30 m.)

Total distance run 0 to 99999.99 nm

Accuracy (ship's speed) 1.0% or 0.1 kt, whichever is greater. Rolling ±10°, pitching

±5°

4. Display

Main display unit LED

Digital indicator LCD or LED

5. Input/Output signals

Input External keying pulse: 2 ports

Output Ship's speed: 2 ports (digital) 1 port (analog or through

distribution box)

Distance signal: 1 port (400 p/nm, forward data only)

Distance signal: 6 ports with contact closure signal,

200 p/ nm, contact capacity 30 V,

max 0.2A, forward data only.

Alarm signal: 1 port (contact closure signal, contact

capacity 30 V, max 0.2 A)

Keying pulse: 1 port

Digital interface IEC 61162-1 2nd Edition: 2 ports

VBW, VTG, VHW, VLW (VTG is not output when the

seabed is not acquired. Heading data in VTG and VHW is

"null".)

6. Power supply 100/110/115/220 230 VAC, 50/60 Hz

7. Environmental conditions Standards: IEC 945 test methods

In-bridge units -15°C to +55°C

Relative humidity 95% at 40°C

Note: Performance may be affected by air bubbles, interference and other factors.

2

Page 7

Specifications of DS-350/351 Digital Display (option)

1. Display device DS-350: LCD, DS-351: LED

2. Indication

Speed Fore/Aft: ❐❐.❐❐

Port/Starboard: ❐.❐❐

Unit Knots or meters/second

Direction cd (Fore/Aft), [ \ (Port/Starboard)

Mode Ground or Water tracking

Depth (clearance) ❐❐ .❐ m

3. Other features Dimmer controls, Mode selector, Unit of speed selector

4. Power consumption DS-350: 12 VA, DS-351: 44 VA

Specifications of DS-370 Distribution Box (option)

1. Input signal (TTL level) Digital speed signal

Log signal (400 p/nm)

Alarm signal

Power on/off signal

2. Output signal The following output boards are available optionally.

(1) OTX board Serial signal for DS-350/351 Digital Indicator and/or

cascade connection of DS-370 Distribution Box (1 port /1

board)

(2) ODD board BCD serial signal for DS-720/DS-370/DS-377 Digital

Display (Analog current signal for analog display, 1 board),

-2.5 mA to 10.0 mA/-10 kt to 40 kt or -3.33 mA to 10.0

mA/ - 10 kt to 30 kt

(3) OAD board Analog current signal for analog display, 1 board, -2.5 mA

to 10.0 mA/-10 kt to 40 kt or -3.33 mA to 10.0 mA/-10 kt

to 30 kt

(4) OLG board For Distance Indicator (1 port /1 board) and Log signal

(3 ports /1 board, 200/400 p/nm contact closure signal, 30

V/0.2A or RS-422 current loop signal). One Log signal

port can be modified for Fore/aft status signal port (contact

closure signal, 30 V/0.2A or RS-422 current loop signal).

(5) OAC board Ship's speed current voltage signal (1 port /1 board), Cur-

rent signal (4.0 mA to 20.0 mAI-10 kt to max, speed, max

impedance: 250 ohms)

3

Page 8

(6) OAV board Ship's speed voltage signal (1 port / 1 board), voltage

signal (-2.50 to 10.0 V/-10 kt to 40 kt, -3.33 V to 10.0 V/

-10 kt to 30 kt, -4.00 V to 10.0 V/-10 kt to 25 kt, -5.00 V to

10.0 V/-10 kt to 20 kt, max, impedance: l kohm) + Fore aft

status signal (RS-422 current loop)

3. Power supply and power 115/230 VAC, 1ø, 50/60 Hz, 50 VA max

consumption

Specifications of DS-381 Series Analog Display (option)

1. Indication system Dual range system

2. Panel dimensions ø200 mm

3. Power consumption 5 VA approx.

Specifications of DS-382 Series Analog Display (option)

1. Indication system Dual range system

2. Panel dimensions ø200 mm

3. Power consumption 5 VA approx.

Specifications of DS-501 Control Box (option)

1. Installation method Flush mount

2. Power consumption 200 mW max

3. Illumination LED

Specifications of DS-730 Distance Indicator (option)

1. Distance run indication ❐❐❐❐❐.❐ nm

2. Indication system LCD with dimmer

3. Power consumption 2.5 VA approx.

Specifications of DS-760 Series Analog Display (option)

1. Indication range -10 to 30 kt

2. Panel dimensions DS-761/762: ø200 mm

DS-763: ø100 mm

3. Power consumption 5 VA approx.

4

Page 9

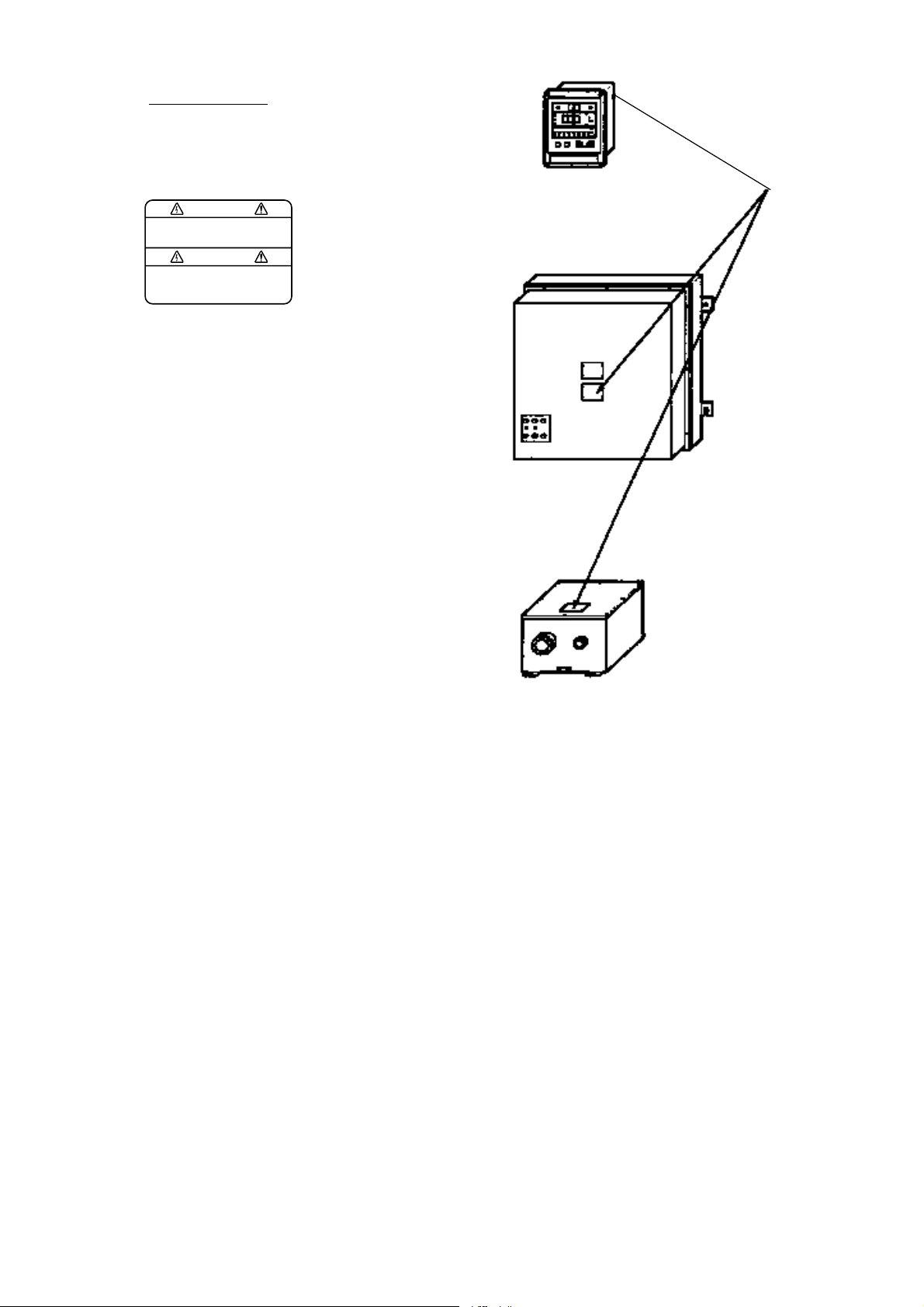

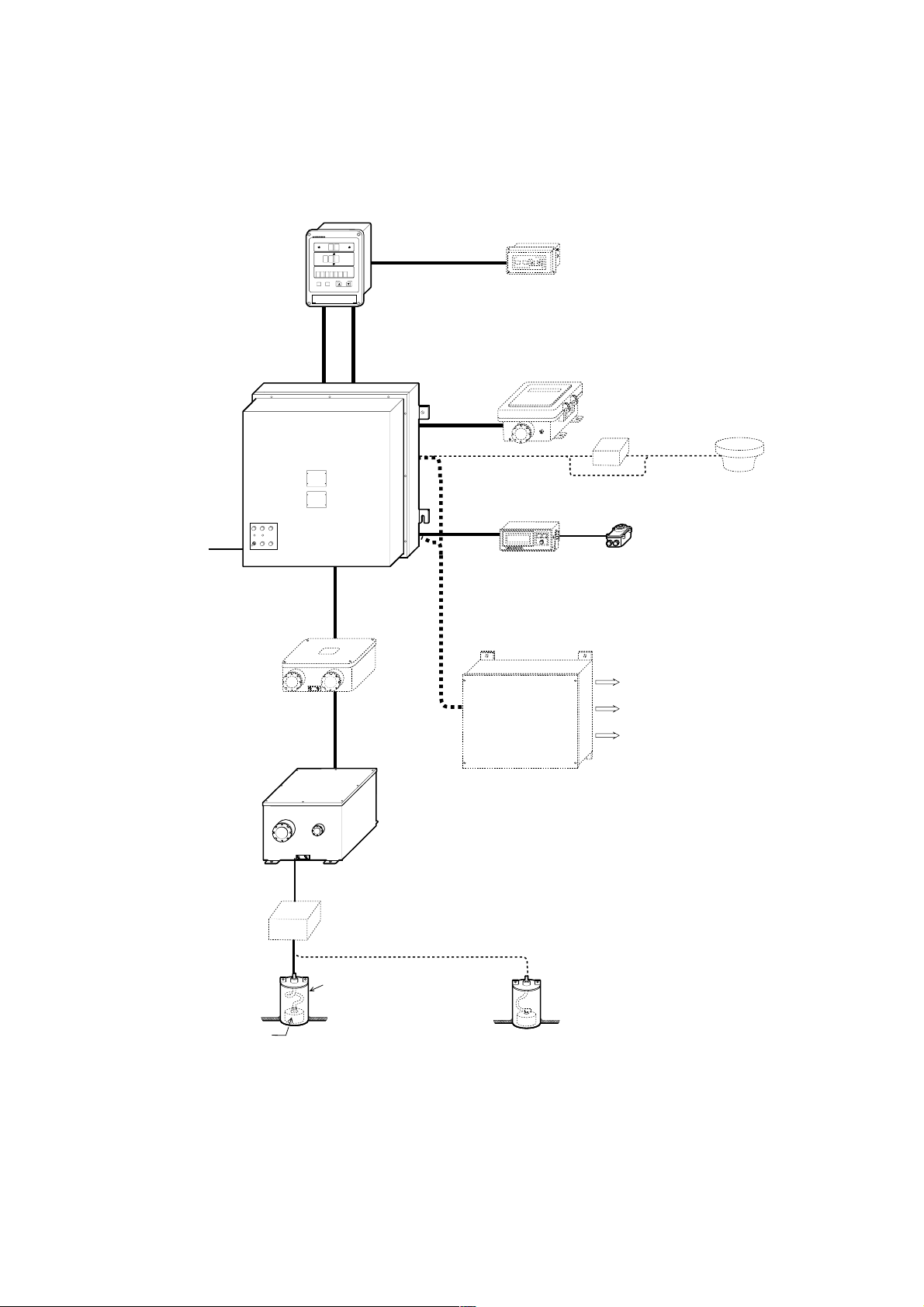

PROCESSOR

UNIT DS-511/510

SHIP'S MAINS

115/230 VAC,

50/60 Hz, 1¿

SYSTEM CONFIGURATION

MAIN DISPLAY UNIT

SIGNAL

cable

DS-50

G

G

W

W

A

A

T

T

kt

kt

m/s

m/s

AL

AL

f t

f t

f a

f a

nm

nm

POWER cable

CONTROL BOX

DS-501 (option)

DIGITAL DISPLAY

DS-350/351 (option)

DISTANCE

INDICATOR

DS-730 (option)

RANGE

SWITCH BOX

DS-389, HF-22A

DIMMER MF-22L

ANALOG INDICATOR

DS-381/382

MF-22A

JUNCTION BOX

DS-360 (option)

TRANSCEIVER UNIT

DS-520

TRANSDUCER

DS-530

DISTRIBUTION BOX

DS-370 (option)

DISTANCE RUN INDICATOR

DIGITAL DISPLAY

ANALOG DISPLAY

Note: When Processor Unit DS-510

is used Transceiver Unit is

incorporated in the DS-510.

JUNCTION BOX

CI-630

(option)

TRANSDUCER TANK

DS-531 or

GATE VALVE DS-532

TRANSDUCER TANK DS-331 /

TRANSDUCER DS-330

or

GATE VALVE for TRANSDUCER DS-335

5

Page 10

OPERATION

Controls and Indications on the Main Display Unit

Port or starboard speed

Port and starboard

direction indicators

Fore or aft

speed

Tracking mode

indicator

Ground

Water

Automatic

MODE selector

Selects tracking

mode.

Distance/Keel

Clearance selector

Displays distance run

or keel clearance.

speed measurement.

FURUNOFURUNO

G

W

A

D

istance

MODE

Kt/ m/s selector

Selects unit of

DOPPLER SONAR

DS-50

T

kt

m/s

AL

DIMMER

▲

ft

fa

nm

▲

Keel Clearance

Distance

Keel

Clearance

▲

▲

SET and arrow keys

Set distance run.

Fore and aft

direction indicators

Test mode indicator

Unit of speed (knot or

meters/second)

Speed alarm

Unit of keel clearance

or distance run:

ft (feet), fa (fathoms), or

nm (nautical miles)

DIMMER controls

Adjust brilliance.

Push here to

open lid.

POWER

switch

Note: Performance may be affected by air bubbles, interference and other factors.

6

Page 11

Control description

Main controls

MODE selector Selects tracking mode among ground, water and automatic. Each time the

key is pressed the tracking mode changes in the sequence of ground, water

and automatic. Current tracking mode is denoted by the tracking mode

lamps.

Distance/Keel Displays distance run or depth below keel at each pressing.

Clearance selector "Distance" or "Keel Clearance" lights to show current selection.

DIMMER controls Adjust panel brilliance.

Controls in compartment

Kt / m/s

SET

ts

Distance Set

▲

▼

POWER

Kt/ m/s selector Selects the unit of speed measurement; knots or meters/second.

SET key Sets distance run display.

Arrow keys Set the distance run indication.

POWER switch Turns power on and of f.

7

Page 12

Turning on the Power, Adjusting Panel Brilliance

1. Press the [POWER] switch to turn on the power. The equipment is tested in the sequence

below:

1) Communications test between main display unit and the processor unit is conducted.

Three zeroes blink about 30 s.

MODE

G

W

A

DOPPLER SONAR

Distance

Keel

Clearance

Keel Clearance

DS-50

DIMMER

T

kt

m/s

AL

Zeroes blink for

about 30 s.

ft

fa

nm

FURUNOFURUNO

Distance

Power switch behind

the cover

2) Testing of main display and processor unit begins. Memory, LEDs and buzzer are tested

in order, each tested eight times consecutively. Then the program version number of

both the main display unit and the processor unit appear.

G

T

kt

W

A

m/s

AL

Program Version NO.

of main display unit

Distance

Keel Clearance

ft

fa

Program Version NO.

nm

of processor unit

The equipment is normal if the program version nos. appear. If an error is found an error

message appears instead of a program version number. Error messages are described on

page 16.

3) The normal display appears, showing speed and distance run (or depth below keel).

2. Adjust panel brilliance with the [DIMMER] controls. Eight levels of brilliance are available. Selected brilliance appears below the distance run and depth display for 0.5 seconds.

8

Page 13

Selecting Speed Tracking Mode

Press the [MODE] selector to select speed tracking mode among water, ground or automatic.

Select the mode considering depth and speed. "G", "W" or "A" lights to show mode selected.

G: Measures and displays a speed relative to ground. The depth range usable for this mode is 1

to 200 meters below the keel.

W:Measures and displays a speed relative to the watermass. The depth from the keel to the

seabed should be three meters or more.

Note: It is recommended to use the water tracking mode in operation with an ARPA for

collision avoidance task.

A: Automatically selects ground tracking mode or water tracking speed mode depending on

depth. Water tracking mode is selected when the keel clearance exceeds 200 meters.

Note: Actual working depth in the ground tracking mode depends on seabed and water condi-

tions, and the reflecting properties for sonic pulses.

Selecting Unit of Speed Measurement

Speed can be measured in knots or meters/second. Press the [Kt/ m/s] selector to select the unit.

"Kt" or "m/s" lights to show the selection.

Displaying Distance Run or Keel Clearance

Press the [Distance/Keel Clearance] selector to display distance run or keel clearance (depth).

Distance run is always displayed in nautical miles. Keel clearance is the depth from the transducer to the seabed, and can be displayed in meters, feet or fathoms. See page 11 for how to

select unit of keel clearance measurement.

9

Page 14

Setting Distance Run

The distance run indication is backed up with an internal battery when the power is off. To reset

or change the distance run, do the following:

1. Open the lid at the bottom of the display unit and press the [SET] key. The display should

look like the illustration below, with the highest digit of distance run blinking.

0 0

1 2 3 0 0

1 2 3 0 0

Blinking

nm: Before pressing [SET] key

nm: After pressing [SET] key

2. Press t or s to place the blinking cursor on the digit to change.

3. Press ▲ or ▼ to set.

4. Repeat steps 2 and 3 to change other digits.

Note 1: Distance run can be reset to zero by entering all zeroes.

Note 2: T o restore previous distance run setting, do not operate arrow keys or [SET] key for

more than 10 seconds. When this is done the distance run indication stops blinking and then

the previous setting is restored. Note that if the ship is moving at this time the distance run

indication will change.

5. Press the [SET] key.

10

Page 15

System Settings

The system settings do not require frequent adjustment. The table below shows setting range

and default setting for each parameter.

.oNmetIegnaRgnitteSgnitteStluafeD

1tesffodeepsdnuorGspets%1.0,%7.21+ot8.21-%0

2tesffodeepsretaWspets%1.0,%7.21+ot8.21-%0

3tesffonoitallatsnirecudsnarT7.21+ot8.21-°1.0,°spets0°

4tesffoelgnamirT7.21+ot8.21-°1.0,°spets0.0°

5tesffoelgnaleeH7.21+ot8.21-°1.0,°spets0.0°

6gnigarevadeepSces09,06,03,51ces51

7htpeddeepsretawecnerefeRspetsm1,m0.52ot0.2m2

8ecnatsid1PKlanretxEspetsm1.0,m0.003+ot0.00.0

9ecnatsid2PKlanretxEspetsm1.0,m0.003+ot0.00.0

01tnemerusaemecnaraelcleekfotinUaf/tf/mm

Note: The above settings are retained with an internal battery when the power is off.

11

Page 16

Setting procedure

1. Turn off the main display unit. Turn on the power while pressing and holding down the

[Distance/Keel Clearance] selector. "1" indicates system setting no. 1 at the center of the

display.

FURUNOFURUNO

D

MODE

G

W

A

istance

DOPPLER SONAR

Distance

Keel

Clearance

Keel Clearance

DS-50

DIMMER

T

kt

m/s

AL

"1" appears.

ft

fa

nm

Setting

(The number corresponds to that on

the table on page 11.)

Hinged cover

2. Press ▲ or ▼ to select system setting number to be changed.

3. Press t or s to change setting.

4. Press ▲ or ▼ to verify the data entered.

5. Turn off the power, and the new settings are entered in memory.

12

Page 17

CONTROL BOX (option) OPERATION

The DS-501 Control Box provides remote operation of the main display unit. The [MODE],

[Distance/ Keel Clearance] and [DIMMER] controls function the same as those found on the

main display unit.

DS-50

DS-50

DIMMER

DIMMER

MODE

Distance

Keel

Clearance

REMOTE CONTROL

REMOTE CONTROL

13

Page 18

MAINTENANCE & TROUBLESHOOTING

WARNING

Do not open the equipment.

High voltage which can shock,

burn or cause serious injury

exists inside the equipment.

Do not work inside the equipment unless familiar with

electrical circuits.

Preventive Maintenance

Monthly checks

Check the following monthly:

• All connectors and cables are securely connected.

• Check ground of main display unit and processor unit for rust. Clean if necessary.

• Check that power voltage is within prescribed rating.

• Conduct the diagnostic program.

Cleaning

Display unit

Dust and dirt may be wiped off the main display unit with a soft cloth. Mild detergent may be

used if necessary. Do not use chemical cleaners to clean the unit—they may remove paint and

markings.

Transducer

Marine life (barnacles, etc.) on the transducer can cause a considerable drop in sensitivity.

When the ship is docked, carefully remove any marine life from the transducer . Paint the transducer yearly with Marine Star 20C (no other paint allowed) anticorrosion paint.

14

Page 19

Troubleshooting

Below are simple troubleshooting procedures the operator can follow to restore normal operation.

Power cannot be turned on.

• Try adjusting brilliance (power may be on but brilliance is too low).

• Check the power cable for damage.

• Check that the power connector is firmly fastened.

• Check if fuse(s) on the processor unit have blown. If a fuse has blown, find out the cause

before replacing it. Be sure to use proper fuse. Fuse rating appears below fuse holder.

Poor accuracy.

• Check if ground has corroded or ground connection has loosened.

• Check if cables of other equipment are near the transducer cable.

Operation Checks

Main display unit

1. Turn on the power while pressing and holding down the [MODE] selector. The following

appears when the equipment is normal:

Port/starboard speed: 0.5 kt \

Fore/aft speed: c 18.9 kt

Distance run: 12345.67

Depth: 12.3 (unit according to system settings)

2. Operate the [MODE], [Distance/Keel Clearance] and [Kt / m/s] controls one by one. Confirm that mode or indications changes with each pressing.

3. Confirm that distance run setting can be changed.

Interconnection between main display unit and remote indicators

1. Turn on the power while pressing and holding down the [SET] key . 10.0 kt for fore/aft speed

appears. "T" appears to denote the test mode.

2. Confirm that the remote indicators display 10.0 kt. If not, there may be some problem between the processor unit and remote indicators.

15

Page 20

Main display unit diagnostic program

The diagnostic program checks the main display unit for proper operation and is automatically

conducted at start up. It may also be conducted when necessary . The program checks the memory

(ROM, RAM, EEPROM), LEDs and buzzer and then shows the program version number . The

equipment is normal if the program version no. appears.

1. To run the diagnostic program, turn on the power while pressing the [Kt / m/s] selector . The

program checks the LEDs, ROM, RAM, EEPROM and buzzer and displays the program

version number. This is done continuously.

2. To escape from the diagnostic program, turn off the power.

Error display

FURUNOFURUNO

D

MODE

G

W

A

istance

DOPPLER SONAR

Distance

Keel

Clearance

Keel Clearance

DS-50

DIMMER

T

kt

m/s

AL

Main display unit

error indications

1: ROM error

2: RAM error

3: EEPROM error

ft

fa

nm

16

Page 21

Error Displays

Processor unit

error indications

1: MCP Board

error

Program Number

FURUNOFURUNO

DOPPLER SONAR

G

W

A

Distance

Distance

Keel

MODE

Clearance

2: MFT Board

error

Keel Clearance

DS-50

T

kt

m/s

AL

ft

fa

nm

DIMMER

3: MCP Board

error

Main display unit

error indications

1: ROM error

2: RAM error

3: EEPROM error

4: MIF Board

error

,.oNbuP

.oNmargorPerawfoS

,noitacifidoM

etaD

K-01427-EMO

xifotdeifidoM

005-SD

300-0040-566draobPC

ecnetnesGTV

015-SD

2002/7

700-0140-566draobPC

000-0210-566draobTF

100-2210-566draobFI

17

Page 22

PRINCIPLE OF DOPPLER SPEED LOG

A doppler speed log measures ship's speed by utilizing the principle of the Doppler effect, which defines

that a signal emitted from a moving object is heard

with its frequency shifted at stationary locations and

the degree of the frequency shift is proportional to the

speed of the moving object.

For ease of understanding measurement of ship's

fore-aft speed is explained in this paragraph.

Although the DS-50 employs three directional beams,

let's suppose that only two beams are used as shown

at right.

Ultrasonic pulses are emitted at an angle of θ relative

to water line toward ship's fore and aft direction. If

the ship's speed is "V", the source of the ultrasonic

pulse approaches or goes away the reflecting points

on the seabed at a speed of Vcosθ.

This relative motion causes the Doppler shift and the

ultrasonic signals reflected at the seabed are received

at frequencies of "fo + fd" and "fo - fd" by the transducer. In the processor unit of the DS-50, difference

of "fo + fd" and "fo - fd" are computed to extract only

the Doppler shift factor "fd".

(fo+fd) -(fo-fd) = 2fd

Since the 'fd' is theoretically given by

θ

fd = 2Vcos

and fo, C and

Note that the sound velocity in water changes with water temperature and water pressure but

the change by water temperature is automatically compensated for by using temperature sensor .

x fo/C (C: Sound velocity in water)

θ

are known, V can be calculated if the "fd" is given.

18

Page 23

DIGITAL INTERFACE IEC 61162-1

EDITION 2

Output sentences of channel 1, 2 (NMEA/CIF 1, NMEA/CIF 2)

VBW, VTG, VLW, VHW. (VTG is not output when the bottom echo has not been acquired.

Heading data in VTG and VHW is "null.")

Transmission interval

1 s for any sentence

Data transmission

Data is transmitted in serial asynchronous form in accordance with the standard referenced in

2.1 of IEC 61162-1. The first bit is a start bit and is followed by data bits, least-significant-bit as

illustrated below.

The following parameters are used:

Baud rate: 4800

Data bits: 8 (D7 = 0), parity none

Stop bits: 1

D0 D1 D2 D3 D4 D5 D6 D7

Start

bit

Data bits

Stop

bit

19

Page 24

Schematic diagram

Data sentences

VBW - Dual ground/water speed

$--VBW,x.x,x.x,A,x.x,x.x,A,x.x,A,x.x,A*hh<CR><LF>

| | | | | | | | | | |

| | | | | | | | | | +--- 11

| | | | | | | | | +----- 10

| | | | | | | | +-------- 9

| | | | | | | +----------- 8

| | | | | | +-------------- 7

| | | | | +----------------- 6

| | | | +-------------------- 5

| | | +------------------------ 4

| | +--------------------------- 3

| +------------------------------ 2

+---------------------------------- 1

1. Longitudial water speed, knots

2. Transverse water speed, knots

3. Status: water speed, A=data valid V=data invalid

4. Longitudial ground speed, knots

5. Transverse ground speed, knots

6. Status: ground speed, A=data valid V=data invalid

7. Stern transverse water speed, knots

8. Status: stern water speed, A=data valid V=data invalid

9. Stern transverse ground speed, knots

10. Status: stern ground speed, A=data valid V=data invalid

11. Checksum

20

Page 25

VHW - Water speed and heading

$--VHW,x.x,T,x.x,M,x.x,N,x.x,K*hh<CR><LF>

| | | | | | | | |

| | | | | | | | +--------- 5

| | | | | | +--+----------- 4

| | | | +--+----------------- 3

| | +--+----------------------- 2

+--+----------------------------- 1

1. Heading, degrees true

2. Heading, degrees magnetic

3. Speed, knots

4. Speed, km/h

5. Checksum

VLW - Distance traveled through water

$--VLW,x.x,N,x.x,N*hh<CR><LF>

| | | | |

| | | | +--------- 3

| | +--+----------- 2

+--+----------------- 1

1. Total cumulative distance, nautical miles

2. Distance since reset, nautical miles

3. Checksum

VTG - Course over ground and ground speed

21

Page 26

This page is intentionally left blank .

Page 27

Loading...

Loading...