FULTON ICS 9.5, ICS 4, ICS 6, ICS 10, ICS 15 Instruction, Operation And Maintenance Manual

...Page 1

Serial Number: _______________________________

Model Number: _______________________________

Fulton Order Number: _______________________________

Instruction, Operation,

and Maintenance

Manual

Sold To: _______________________________

Job Name: _______________________________

Date: _______________________________

Fulton Gas Fired Steam

Boilers

HP to 60 HP

Page 2

Page 3

ProductBulletin

Product Bulletin

2010-001PB

The Fulton Companies

972 Centerville Road

Pulaski, N.Y. 13142

Date: January 22, 2010

Subject: Water Chemistry Requirements for Fulton Steam Products

Products: ICS/ICX, FB-A, FB-F, FB-S, VMP, PVLP, PHP, Electric Steam

Boilers and Unfired Steam Generators

Please note that the water chemistry is different for carbon steel vs. stainless steel

pressure vessels and vertical vs. horizontal orientation.

Effective immediately, please use the limits below. Should you have any questions,

please do not hesitate to contact Fulton at 315-298-5121.

Water Chemistry Requirements for Fulton Steam Products (to 300 psig MAWP)

NOTES:

*This is a minimum temperature. Feedwater temperatures below 200F will require an oxygen scavenger.

** Suspended solids: Take a water sample. After the sample sits for 10 minutes, no solids should be visible.

+ Total Organic Carbon: Take a water sample. Shake vigorously for 30 seconds. No sheen or foam should be visible.

++ Iron: Take a water sample. Hold the sample against a white background. The water should have no visible yellow, red or

orange tinge.

ND: None Detected.

Parameter

Carbon Steel Stainless Steel

Feedwater Vertical

Boiler/Steam

Pac Water

Horizontal

Boiler/Steam

Pac Water

Feedwater Vertical

Boiler/Steam

Pac Water

Horizontal

Boiler/Steam

Pac Water

pH 7.5-9.5 8.5-10.5 8.5-10.5 6.0-9.5 8.5-10.5 8.5-10.5

Feedwater

Temperature

140F* --- --- 140F* --- ---

Hardness as

CaCO

3

<2ppm <10 ppm <15 ppm <2 ppm <10 ppm <15 ppm

Chlorides --- --- --- --- 50 ppm 50 ppm

Tota l

Alkalinity

--- <300 ppm <500 ppm --- <300 ppm <500 ppm

Tota l

Dissolved

Solids

--- <2000 ppm <3000 ppm --- <2000 ppm <3000 ppm

Suspended

Solids

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

Total Organic

Carbon

No sheen

No foam+

No sheen

No foam+

No sheen

No foam+

No sheen

No foam+

No sheen

No foam+

No sheen

No foam+

Iron Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Dissolved

Oxygen

<1ppm* ND ND <5ppm ND ND

Visual Oil ND ND ND ND ND ND

Conducivity

(uS/cm)

--- <2985 <4477 --- <2985 <4477

Page 4

Page 5

Introduction

This manual is provided as a guide

to the correct operation and maintenance of your Fulton Gas Fired

Steam Boiler, and should be permanently available to the staff responsible for the operation of the gas

fired boiler.

These instructions must not be

considered as a complete code of

practice, nor should they replace

existing codes or standards which

may be applicable.

The requirements and instructions

contained in this section generally

relate to the standard Fulton Gas

Fired Steam Boiler. When installing

a packaged unit, this entire section

should be read to ensure that the

installation work is carried out

correctly.

Prior to shipment the following tests

are made to assure the customer the

highest standards of manufacturing:

a) Material inspections.

b) Manufacturing process

inspections.

c) ASME welding inspections.

d) ASME hydrostatic test

inspection.

e) Electrical components

inspection.

f) Operating test.

g) Final Engineering Inspection

h) Crating inspection.

NOTE

The installation of the Fulton Gas

Fired Steam Boiler should be carried out by competent personnel

in accordance with the standards

of the National Fire Protection

Association, National or Canadian

Electrical Code. All state and juris-

dictional codes beyond the scope

of the applicable ASME Boiler and

Pressure Vessel Codes, for its

corresponding classification,

should be followed in all cases.

Jurisdictional authorities must be

consulted prior to installation.

All units are crated for fork lift transport. Once uncrated, all units can be

transported with a forklift. Under no

circumstances should weight be

allowed to bear on the jacket, control panel, or fan housing of any

Fulton Boiler.

Rigging your boiler into position

should be handled by a competent

rigger experienced in handling

heavy equipment.

The customer should examine the

boiler for any damage, especially

the refractories.

Page 6

Page 7

1-G 1/01

Contents

Section

Safety Warnings & Precautions

For Boilers with Low Emissions Burner Only

Description/Instructions

Specifications & Dimensions 4-60 HP

Locating the Boiler

The Gas Supply

Boiler, Condensate Tank, and Blow off Separator Piping

Boiler Installation

The Steam Supply

The Steam Safety Valve

The Steam Pressure Gauge Assembly

The Blow Off Valve

The Feed Water Piping

The Water Column

Water Gauge & Gauge Glass Installation Instructions

Water Supply

Recommended Water Treatment

Glossary of Water Supply Corrosives & Inhibitors

Electrical Requirements

Fresh Air Supply for Boiler

Conventional Venting

Combustion Air Intake (UL and MEA Approved)

Corrosion of Flue Pipe

Installation Checkpoints

Cleaning the Pressure Vessel

Operation

Starting the Gas Fired Boiler

Gas Burner Set Up

Gas Burner Set Up For Boilers Equipped With Modulation

Gas Burner Set Up For Boilers Equipped With High-Low-Off

Primary Air Adjustment

Secondary Air Adjustment

Boiler Controls

Maintenance

Cut Away Gas Boiler

Procedure for Cleaning Water Probes

Flame Rod Adjustment

Flame Scanner Adjustments

Stainless Steel Combustion Ring

Furnace Refractory Replacement

Recommended Daily Maintenance

Recommended Weekly Maintenance

Recommended Monthly Maintenance

Recommended Semi Annual Maintenance

Procedure to Replace Hand Hole Gaskets

Recommended Annual Maintenance

Troubleshooting

Parts

Spare Parts Ordering Instructions

Warranty

Component Data Sheets

1

LE

2

3

4

5

6

7

Page 8

2-G 1/01

Page 9

Safety Warnings/Precautions

1

3-G 1/01

Page 10

4-G 1/01

Page 11

5-G 1/01

Safety Warnings/Precautions

Safety Warnings Cautions &

Notes

The following WARNINGS,

CAUTIONS, and NOTES appear

in various chapters of this manual.

They are repeated on these safety

summary pages as an example and

for emphasis.

WARNINGS must be observed to

prevent serious injury, or death to

personnel.

CAUTIONS must be observed to

prevent damage or destruction of

equipment or loss of operating

effectiveness.

NOTES must be observed for

essential and effective operating

procedures, conditions, and as a

statement to be highlighted.

lt is the responsibility and duty of

all personnel involved in the operation and maintenance of this equipment to fully understand the

WARNINGS, CAUTIONS, and

NOTES by which hazards are to be

reduced or eliminated. Personnel

must become thoroughly familiar

with all aspects of safety and

equipment prior to operation or

maintenance of the equipment.

CAUTION

Some soaps used for leak testing are

corrosive to certain types of metals.

Rinse all piping thoroughly with

clean water after leak check has been

completed.

NOTE

Where a condensate return tank is to

be fitted, this should:

1. Be vented and

2. Have a capacity sufficient to satisfy

boiler consumption as well as maintain proper return tank temperature.

3. Vent pipe should not be downsized (This may cause pressure build

up in the condensate tank.)

4. Return pipes must not be insulated. This can cause overheating the

return system, causing a vapor lock

in the pump.

5. See Return System Instruction

Manual for detailed instructions.

NOTE

Care should be taken to ensure that

the blow off receptacle used meets

the regulations covering such vessels. If in doubt consult a Fulton

Representative for advice.

NOTE

Only properly trained personnel

should install and maintain water

gauge glass and connections. Wear

safety glasses during installation.

Before installing, make sure all parts

are free of chips and debris.

NOTE

Keep gauge glass in original packaging until ready to install.

WARNING

Improper installation or maintenance

of gauge glass and connections can

cause immediate or delayed breakage resulting in bodily injury and/or

property damage.

NOTE

After installation is complete and

prior to operation the pressure vessel should be cleaned.

CAUTION

Do not store halogenated hydrocarbons near or in the boiler room.

NOTE

a) The fused disconnect switch that

controls the feed water pump should

be kept in the “on” position at all

times during the boiler operation as

well as during the non-operating

period of the boiler.

b) This switch should be turned “off”

only when repairs or adjustments

should be made.

NOTE

The pump will continue to operate

until the water reaches the correct

level in the boiler. This level is

approximately the center of the water

gauge glass.

WARNING

Prior to the commencement of any

work requiring the removal of cover

plates and the opening of the control

panel box, the electrical supply to the

boiler must be disconnected.

CAUTION

Do not tamper with the safety features of the low water safety cut off.

WARNING

When stopping the boiler for any

extensive repairs, shut off main disconnect switches on both the boiler

side as well as the feed water side.

NOTE

To ensure that your Fulton Steam

Boiler is kept operating safely and

efficiently, follow the maintenance

procedures set forth in Section 4

of this manual.

NOTE

To ensure the continued safety and

efficiency of the boiler, the schedule

of maintenance outlined in this section should be adhered to.

WARNING

Prior to the commencement of any

work requiring the removal of cover

plates and the opening of the control

panel box, the electrical supply to the

boiler must be disconnected.

NOTE

The scanner is located on the

outside edge of the burner top plate

for 20-60 HP.

NOTE

If only the top refractory is to be

changed, the bottom refractory need

not be broken.

NOTE

If the boiler is being operated automatically on a time clock, the blow

off operation may be done once during the working day and once at the

end of the day when at 10 PSIG or

less.

NOTE

Fulton recommends that the feedwater treatment should be added

between the pump and the boiler.

WARNING

Make sure main power switch is off

before starting work.

CAUTION

Do not clean the gauge or glass while

pressurized or in operation.

NOTE

After a new Fulton Boiler has been in

operation for several months, pieces

of burned metal will be found in the

space at the bottom of the boiler.

These pieces of metal are the

remains of a light gauge metal form

which was used during manufacture

for forming the boiler insulation. This

is a normal condition and does not

affect the efficiency or the life of the

boiler in any way.

Page 12

6-G 1/01

Page 13

7-G 1/01

Description/Instructions

LE

Page 14

8-G 1/01

Page 15

Standard Models ICS/FB-A 9.5 10 15 20 25 30

Models ICX/FB-F 9.5 10 15 20 30

Unit Size: BHP 9.5 10 15 20 25 30

A. Boiler Height IN 67.5 63.5 69 72.5 74.5 82

MM 1715 1613 1753 1842 1892 2083

B. Boiler Height With Trim* IN 85 80.5 93 97 97 106.5

& Fuel Train Assembly MM 2159 2045 2362 2364 2364 2705

C. Overall Depth Stack IN 44 48 50 61 59 65.5

to Burner Fan Housing MM 1118 1219 1270 1549 1499 1664

D. Boiler Diameter IN 26 28 30 39 39 46

MM 660 710 760 990 990 1170

E. Overall Width IN 33 33.5 35.5 43 43 49

with Water Column MM 838 851 902 1091 1091 1244

F. Flue Outlet Diameter IN 6 6 8 10 10 12

MM 152 152 203 254 245 305

G. To Center of Flue Outlet IN 61.5 57.5 63 66 68 73

MM 1562 1465 1600 1675 1728 1854

H. Feedwater Inlet IN 33 33 33 34 34 34

MM 838 838 838 865 865 865

I. Handholes IN 18.5 18.5 19.5 19.5 19.5 19.5

MM 470 470 495 495 495 495

J. Blowdown Outlet IN 15.25 15 15 16.5 16.5 16.5

MM 387 381 381 420 420 420

K. Water Column Extension IN 14 14 14 14 14 14

MM 355 355 355 355 355 355

L. Gas Train Extension IN 25 21.5 20.5 25 25 27

(CSD-1) MM 635 546 521 635 635 686

M. Clearance Required IN 94 86 108 111 110 121

for Burner Removal MM 2388 2184 2743 2819 2794 3073

Weights

Approx. Shipping Weight LB 1900 2000 2280 3400 3500 4780

KG 862 910 1036 1545 1591 2173

All measurements are subject to +/- 0.5”. Please refer to component drawings for actual measurements.

NOTE: Recommended minimum clearance is 24” to the side and back of unit; 36” in front

Dimensions

Fulton Gas & Oil Fired

Vertical Tubeless

Steam Boilers

(Low Emissions Burner)

Product Data Submittal

Fulton Models: ICS/FB-A and ICX/FB-F

9-G 1/01

CLEARANCE REQUIRED FOR

C

D

O

M

Q

G

R

H

J

S

I

A

BURNER REMOVAL

L

P

B

K

ON/OFF GAS HEAD

CAN PIVOT 360°

MODULATED GAS HEAD IS

FIXED ABOVE FAN HOUSING

F

N

E

Top Vi e wFront ViewSide View

Page 16

Specifications

Models ICS/ICX/FB 9.5 10 15 20 25 30

Boiler Connections

N. Steam Outlet 15 PSI N/A 1.5” 2” 3” 3” 3”

NPT NPT CL150# CL150# CL150#

Flange Flange Flange

N. Steam Outlet 150 PSI 1” 1” 1.25” 1.5” 2” 2”

NPT NPT NPT NPT NPT NPT

O. Safety Valve Outlet 15 PSI IN N/A 0.75 1 1.5 1.5 1.5

MM 19 32 38 38 38

O. Safety Valve Outlet 150 PSI+ IN 1 1 1 1 1 1

(9.5 HP 100 PSI) MM 25 25 25 25 25 25

P. Safety Valve Inlet 15 PSI++ IN N/A 0.75 1 1.25 1.25 1.25

MM 19 25 32 32 32

P. Safety Valve Inlet 150 PSI IN 0.75 0.75 0.75 0.75 0.75 0.75

(9.5 HP 100 PSI) MM 19 19 19 19 19 19

Q. Feedwater Inlet IN 1 1 1 1 1 1

MM 25 25 25 25 25 25

R. Blowdown Outlet IN 1 1 1 1.25 1.25 1.25

MM 25 25 25 32 32 32

S. Water Column Blowdown IN 1 1 1 1 1 1

MM 25 25 25 25 25 25

Ratings* (Sea level to 3000 ft.)

Output 1000 BTU/HR 318 335 503 670 838 1005

1000 KCAL/HR 80.1 84.4 127 169 211 253

Steam Output LB/HR 328 345 518 690 863 1035

KG/HR 149 157 235 313 392 470

Approximate Fuel Consumption at Rated Capacity+++

Natural Gas (ICS) FT3/HR 398 419 628 837 1047 1256

(9” - 13” w.c. req’d) M3/HR 11.3 11.9 17.8 23.7 29.7 35.4

Natural Gas (ICX) FT3/HR 384 403 606 807 1009 1210

(9” - 13” w.c. req’d) M3/HR 10.8 11.4 17.2 22.9 28.6 34.3

Natural Gas Boiler IN 1 1 1 1.25 1.25 1.5

Connection Size (Std CSD-1) MM 25 25 25 32 32 38

Oil Inlet Size IN 1/4 1/4 1/4 1/4 1/4 1/4

MM 6 6 6 6 6 6

Burner 3450 RPM/60 CY

Motor HP 2850 RPM/50 CY .75 .75 1.5 1.5 1.5 1.5

Electric Power Requirements - Burner Only (in Amps) ***

120V,60 CY, 1 Phase 9.2 9.2 -- -- -- --

240V, 50/60 CY, 1 Phase 4.6 4.6 8.9 8.9 8.9 8.9

208V, 50/60 CY, 3 Phase 3.1 3.1 4.4 4.4 4.4 4.4

240V, 50/60 CY, 3 Phase 2.8 2.8 4.2 4.2 4.2 4.2

480V, 50/60 CY, 3 Phase 1.4 1.4 2.1 2.1 2.1 2.1

Water Content

U.S. GAL 16 24 39 77 82 170

LITERS 61 91 148 292 311 644

Specifications and Dimensions are approximate. We reserve the right to change specifications and/or dimensions..+ High pressure boilers purchased with low pressure

openings may have larger than specified opening sizes, consult factory for correct opening sizes.++ 50 and 60 HP have two safety valves on low pressure.

+++Consumption based on Natural Gas 1000 BTU/ft.3. *All ratings from 0 PSIG and at 212 degrees F. *** Control circuit electrical requirement will vary with the system

voltage, please consult factory. --Consult factory.

ffsle-pds-2011-1223

The Fulton Companies

972 Centerville Road

Pulaski, NY 13142

Call 315-298-5121

Fax 315-298-6390

www.fulton.com

10-G 1/01

Page 17

11-G 1/01

Operation

LE

Page 18

12-G 1/01

Page 19

13-G 1/01

Starting the Gas Fired Boiler

See page 44-G

Gas Burner Set Up

a. Open the manual gas cocks on

the pilot and main lines of the gas

head.

b. Switch on the main power to the

burner. The water level relay is

equipped with a manual reset.

Depress the button on the box.

c. The flame programmer is the

main control in the panel box. The

programmer in conjunction with a

UV scanner “supervises” the ignition

sequence - proves the flame is satisfactory, and finally “monitors” the

established flame. Should any fault

occur, either during the ignition

sequence or during normal running,

the programmer will immediately go

to “lock-out” and the burner will shut

down.

d. When the pilot flame is established, the ultra-violet scanner senses the flame. This signal is transmitted back to the flame programmer

which opens the main gas valve giving a main flame.

e. If the installation is new or the

burner has been disassembled, the

burner may not fire at the first

attempt due to air which must be

purged from the gas lines. This will

result in the burner flame programmer going to lockout. Repeat the

procedure for starting the burner.

f. The main gas valve will remain

open as long as there is a demand

for heat and the flame is carrying a

sufficient signal to the flame programmer.

g. If the flame is not established at

the start, the safety switch in the

flame programmer control will open

the contacts and shut off the burner.

h. Push the reset button on the control to reset. If trouble persists, it

may be necessary to check the UV

scanner. See Maintenance Section

for procedure to check UV Scanner.

Air adjustment for Fulton LE Gas

Fired Steam Boilers.

a. The primary air adjustment or

main air control is located at the fan

housing inlet. This control is used to

supply the burner with air needed to

facilitate good combustion. Too

much or too little air will result in

poor combustion. Using a CO

2

or O

2

tester, it is possible to determine the

percent of excess air in the combustion mixture. Refer to Factory Test

Fire Report for acceptable ranges.

LE Operation

Page 20

14-G 1/01

Page 21

15-G 1/01

Maintenance

LE

Page 22

16-G 1/01

Page 23

17-G 1/01

Pilot Adjustment for Fulton

LoNOx Burner.

a. Close downstream main shut off

valve.

b. Start boiler and check flame signal on pilot, lock programmer into

pilot hold.

c. Adjust gas regulator as needed

to obtain a strong pilot signal.

d. Slowly open downstream shut off

valve and take the flame programmer off of hold.

Main Flame Adjustment

a. Place a combustion analyzer in

the exhaust of the boiler.

b. Adjust main gas regulator until

last elbow pressure matches the

test fire sheet.

NOTE: Adjust air accordingly to

ensure stable combustion during

gas adjustments.

c. Adjust air setting until combustion readings are within specifications and stable combustion is present. Refer to Fulton test fire report

for acceptable ranges.

Burner Tile Replacement

a. Remove scroll assembly.

b. Break off top holding clips.

c. Remove ceramic fiber burner tile.

d. Replace burner tile bottom holding clips if needed.

e. Replace with new burner tile.

f. Carefully replace scroll assembly

so that the ceramic fiber burner tile

is not damaged.

LE Maintenance

Page 24

18-G 1/01

Troubleshooting

a. The following troubleshooting

guide will assist in the diagnosis and

the correction of minor field problems. It contains instruction and

information necessary to locate and

isolate possible troubles which

occur during normal operation. It

should be used in conjunction with

the unit wiring diagram and the

component literature provided in

Section 7 of this manual.

b. The following lists cover the most

common troubles that may occur on

the Fulton gas fired boilers. Refer

to left hand column of the chart to

locate the problem. Determine

which cause, listed in the center column, that represents the problem by

performing the corrective action as

listed in the right hand column titled

“REMEDY”.

Troubleshooting Gas-Fired Boilers

Problem Cause Remedy

Ignition Failure 1. Power Supply Check fuse or circuit breaker. Reset or

replace, as necessary.

2. Ignition Electrodes Check electrodes for carbon buildup and clean if necessary.

Check for proper adjustments. Readjust if necessary.

Check for cracks in porcelain. If found, replace.

3. Transformer Check voltage between transformer leads at terminal block

to be sure transformer is being powered.

4. Flame Safeguard Check voltage between ignition terminal and neutral.

Control Check must be made before control locks out on safety.

If no power, replace control.

5. Faulty Air Switch Check for bad air switch by jumpering the two air switch

leads at the terminal block. If the boiler starts and runs with

these terminals jumpered, the air switch should be

replaced.

6. Gas Valve Sticking Check for dirt in valve or orifice and clean if necessary.

(Pilot) Check for faulty actuator or valve and replace if necessary.

7. Gas Supply Check for gas pressure and for intermittent supply

problems. See test fire sheet for last elbow.

8. Loose wire connection Check connections to all components.

Flame Failure 1. Power Supply Check fuse or circuit breaker. Reset or replace, as

necessary.

2. Gas Supply Check for gas pressure and for intermittent supply

problems.

3. Ignition Electrodes Check electrodes for carbon buildup and clean if necessary.

Check for proper adjustment. Readjust if necessary.

Check for cracks in porcelain; if found, replace.

4. Primary Air Adjustment Check air adjustment. Air may be blowing flame away

from burner head.

LE Maintenance

Page 25

19-G 1/01

Problem Cause Remedy

Flame Failure 5. Scanner Check for dirt on flame scanner and clean. Check for

proper location of detector.

6. Flame Safeguard Control Check voltage at terminal leading to main gas valve.

If no power, replace the control.

7. Loose wire at fuel Tighten wiring connections.

valve circuit

8. Contact open on air Adjust to proper setting.

safety switch

9. Scanner wiring reversed Change to correct terminals.

at panel box

Burner Cut-Off 1. Power Supply Check fuse or circuit; reset or replace, as necessary.

2. Gas Supply Check to be sure main gas cock is not closed. Check coil

in gas valve with OHM meter. Replace if faulty. Check gas

regulator setting and readjust as necessary. Check inlet

gas pressure and increase or decrease as necessary.

3. Ignition Electrodes Check electrodes for carbon buildup and clean if

necessary.Check for proper adjustment. Readjust if

necessary. Check for cracks in porcelain; if found, replace.

4. Scanner Check for dirt on flame scanner and clean.

Check for proper location of detector.

5. Air Switch Check for bad air switch by jumpering the two air switch

leads as the terminal block. If the boiler starts and runs

with these terminals jumpered, the air switch should be

replaced.

6. Gas Valve Sticking Check for dirt in valve or orifice and clean if necessary.

(Pilot) Check for faulty actuator or valve and replace if necessary.

7. Weak Amplifier Replace.

8. Weak Pilot Adjust to larger pilot by adjusting pilot gas pressure

regulator.

9. Faulty Liquid Level Control Check to see if there is power to terminal number 10

when the sight glass shows the proper water level.

If there is no power at this terminal, the control is bad and

must be replaced.

10. Dirty or defective Clean or replace.

UV Scanner

LE Maintenance

Page 26

20-G 1/01

Problem Cause Remedy

Poor Combustion 1. Refractories Check refractories to see if they are plugged with soot or

broken in pieces. Clean or replace as necessary.

2. Air Adjustment Check main air adjustment to see if it is loosened up.

Adjust as necessary and tighten plate in position. Check

CO2and O2levels.

3. Draft Check draft with a gauge. Draft should be a -.02” to -.04”

W.C. with burner off or -.04” to -.06” when operating. May

need to install a barometric damper.

4. Dirty Flue Check flue for carbon buildup or blockage. Clean flue

passages with brush.

5. Negative Room Pressure Make sure no exhaust fans are running in the boiler room.

Burner back fires 1. Refractories Check refractories to see if they are plugged with soot or

broken in pieces. Replace as necessary.

2. Ignition Electrodes Check electrodes for carbon buildup and clean if necessary.

Check for proper adjustment. Readjust if necessary. Check

for cracks in porcelain; if found, replace.

3. UV Scanner Check for dirt on flame scanner and clean.

Check for proper location of detector.

4. Draft Check draft with a gauge. Draft should be a -.02” to -.04”

W.C. with burner off or -.04” to -.06” when operating. May

need to install a barometric damper.

5. Negative Room Pressure Make sure no exhaust fans are running in the boiler room.

Boiler will not 1. Gas Supply Check gas pressure coming into gas train. If low, contact

maintain pressure gas company. Should be 7” to 11” W.C. Check coil in

gas valve with AMP meter. Replace if bad. Check gas

regulator setting and readjust as necessary.

2. Dirty Flue Check flue for carbon buildup or blockage. Clean flue

passages with brush.

3. Pressuretrol Disconnect all power to the controller. Disconnect the wires

from the controller. Put an OHM meter between the switch

terminals. Lower the set point and recheck with OHM meter.

Switch should break. If the controller operates improperly,

replace it.

4. Scale Built up in boiler Refer to Section 2 “Pressure Vessel Cleaning”.

5. Refractories Check refractories to see if they are cracked or broken

in pieces. Replace as necessary.

6. Steam traps Check traps to see if they are clean or replace as necessary.

blowing through

7. Boiler size Boiler may be undersized.

LE Maintenance

Page 27

21-G 1/01

Problem Cause Remedy

Boiler is Surging 1. Steam traps blowing Check traps to see if they are clean or replace as necessary.

through

2. Perc (cleaning solvent Clean boiler with washing soda per instruction manual.

in boiler)

3. Scale build-up or lime Call water treatment professional and consult factory.

deposits

4. Too much compound in Dump return tank and flush system. Have water tested by

system (water treatment) water treatment company.

5. Too much water Have water tested by water treatment company.

softener (high PH)

6. Too much of a load Check total equipment horsepower required against

horsepower of boiler being used. Decrease amount of

equipment being used at one time.

7. Boiler new (not Clean per instructions in instruction manual.

cleaned)

Boiler Rumbles and 1. Draft problem Check draft with a gauge. Draft should be a -.02” to -.04”

Pulsates W.C. with burner off or -.04” to -.06” when operating. May

need to install a barometric damper.

Boiler pushing water 1. Steam Traps Chech traps. Clean or replace as necessary.

with the steam

2. Too much boiler Dump return tank and flush system. Have water

compound tested by water treatment company.

Pump will not cut off 1. Dirty Probes Clean or replace as necessary.

2. Relay failed Make sure relay is plugged in tightly. If so, replace

water level relay.

3. Ground Connection Check for tightness and clean.

Pump runs but does 1. Vapor locking of pump Allow system to cool down, check steam traps and check

not put water into to be sure return lines are not insulated. Check return tank

boiler temp. If it is above 180°F., (82°C.) vapor locking of pump

will occur. Inspect check valves. Clean and replace as

needed. Replace pump with multistage centrifugal good

for 250°F. (121°C.).

2. Impeller Adjustment Check for impeller wear and adjust per component

information in instruction manual (Burks only).

3. Back pressure on pump Need to install repair kit on pump.

4. Plugged feed water Check and clean or replace as necessary.

nipple

LE Maintenance

Page 28

22-G 1/01

Problem Cause Remedy

Water pump will not 1. Scale on probes Check and clean or replace as necessary.

come on at times

2. Bad Pump Contactor Check to see if contactor is being powered.

Check to see if contactor coil is pulling in. Replace if

necessary.

3. Bad Pump Motor Check the incoming power to the pump to be sure it

is receiving power. If power is present but motor does

not run, replace it.

Low Fuel pressure 1. Gas pressure regulator Check and replace.

Boiler Flooding 1. Pump does not shut off Dirty probes. Clean or replace as necessary.

2. Relay failed Make sure relay is plugged in tightly. If so, replace

water level relay.

3. Ground Connection Check for tightness and clean.

4. Vacuum created with As the boiler cools off, it pulls water from the system

boiler off piping. To prevent this, add a 1/4” check valve on the

steam gauge assembly piping, which closes under

pressure and opens under vacuum.

LE Maintenance

Page 29

23-G 1/01

Parts

LE

Page 30

24-G 1/01

Page 31

25-G 1/01

Spare Parts

a. It is important that the correct

replacement part is fitted to your

Fulton Gas Fired Steam Boiler.

b. When ordering replacement or

spare parts, make sure that the full

information given in the Parts List

is supplied, together with the following details as shown on your

boiler identification plate:

1. Boiler Number

2. Boiler Type

3. Electrical Specifications

NOTE:

The policy of Fulton Boiler

Works, Inc. is one of continuous

improvement, and therefore, we

reserve the right to change

prices, specifications, and

equipment without notice.

LE Parts

Replacement Parts Listing (available from authorized Fulton Representative)

Approx. Approx.

Part No. Description Net Weight Net Weight

(lbs.) (kgs.)

2-12-219 Furnace Burner Tile (9.5 HP) 2 .91

2-12-253 Furnace Burner Tile (10 HP) 2 .91

2-12-221 Furnace Burner Tile (15 HP) 2 .91

2-12-254 Furnace Burner Tile (20-30 HP) 15 6.8

5-21-6009 Burner Scroll (9.5 HP) 30 13.6

5-21-6010 Burner Scroll (10 HP) 45 20.4

5-21-6015 Burner Scroll (15 HP) 55 24.9

5-21-6030 Burner Scroll (20 HP) 65 29.5

5-21-6031 Burner Scroll (30 HP) 65 29.5

2-30-1330 Blower Assembly (9.5 - 10 HP) 22 9.98

2-30-1331 Blower Assembly (15 - 20 HP) 30 13.6

2-30-1339 Blower Assembly (30 HP) 35 15.9

2-20-18 Ignition Electrode (9.5 - 10 HP) .5 .23

2-20-30 Ignition Electrode (15, 20, 30 HP) .4 .18

5-10-610 Burner Assembly LoNOx (9.5 - 10 HP) 35 15.9

7-30-571 Burner Assembly LoNOx (15 HP) 45 20.4

7-30-672 Burner Assembly LoNOx (20 HP) 55 24.9

7-30-673 Burner Assembly LoNOx (30 HP) 55 24.9

2-30-819 O ring for Pilot Tube LoNOx - 1.76 ID x .070) .01 .005

2-30-813 O ring for Pilot Tube LoNOx - 8.7 mm x 1.78 mm) .01 .005

2-40-631 Temperature Limit LoNOx 3 1.37

2-40-803 Thermocouple High Limit LoNOx .2 .09

Page 32

26-G 1/01

Page 33

Boiler Description/Instructions Gas Fired Boiler

2

27-G 1/01

Page 34

Description/Instructions

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;

QQQQQQQQQQQQQQQQQQQQ

QQQQQQQQQQQQQQQQQQQQ

¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢

¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢¢

Transformer Scroll

Gaskets

Steam Gauge

Assembly

Gauge Glass

Valve

To

O.P .C.

*

To

H.P .C.

*

Burner Motor

Gauge Glass

Valve

Gauge Glass

And Protector

Water Column

Control Box

High Density

Insulation

Outside Jacket

Handhole

Blowdown

Outlet

Boiler Runners

(4-30 HP)

Feedwater

Inlet

Flue Outlet

Lifting Hook(s)

Flue Blanket

Flue Rope

Gasket

Flue Plate

Cover

Top Plate

Assembly

Gas Train

Assembly

Secondary

Air Damper

Burner

Plate

Assembly

Stainless

Steel Ring

Bottom

Refractory

Top

Refractory

Castable

Refractory

Insulation

*

O.P.C. = Operating Pressure Control

*

H.P.C. = High Pressure Control

28-G 1/01

Page 35

Standard Models ICS/FB-A 4 6 9.5 10 15 20 25 30 50 60

Models ICX/FB-F 4 6 9.5 10 15 20 25 30

Unit Size: BHP 4 6 9.5 10 15 20 25 30 50 60

A. Boiler Height IN 47.5 57.5 67.5 63.5 69.5 72.5 75 82.5 87.5 93.5

MM 1207 1461 1715 1613 1765 1842 1905 2069 2223 2375

B. Boiler Height With Trim* IN 65 75 85 80.5 86.5 92.5 95 102 106.5 120

& Fuel Train Assembly MM 1651 1905 2159 2045 2197 2350 2413 2591 2705 3048

C. Overall Depth Stack IN 44 44 44 46 47 58 59 67 78 78

to Burner Fan Housing MM 1118 1118 1118 1168 1194 1474 1499 1702 1981 1981

D. Boiler Diameter IN 26 26 26 28 30 39 39 46 55 55

MM 660 660 660 710 760 990 990 1170 1400 1400

E. Overall Width IN 33 33 33 33.5 35.5 43 43 49 57 57

with Water Column MM 838 838 838 851 902 1091 1091 1244 1448 1448

F. Flue Outlet Diameter IN 6 6 6 6 8 10 10 12 12 12

MM 152 152 152 152 203 254 245 305 305 305

G. To Center of Flue Outlet IN 42 52 62 58 63 66 68 73.5 79 85

MM 1070 1320 1575 1473 1600 1675 1728 1867 2007 2159

H. Feedwater Inlet IN 27 33 33.5 33 33.5 34 34 34 35 35

MM 685 840 851 840 851 865 865 865 890 890

I. Handholes IN 19 19 19 19 19 19 19 19 20 20

MM 485 485 485 485 485 485 485 485 510 510

J. Blowdown Outlet IN 15 15 15.5 15.5 15.5 16.5 16.5 16.5 17.5 17.5

MM 380 380 394 394 394 420 420 420 445 445

K. Water Column Extension IN 14 14 14 14 14 14 14 14 14 14

MM 355 355 355 355 355 355 355 355 355 355

L. Gas Train Extension IN 22.5 22.5 25 21.5 20.5 25 25 27 22.5 34

(CSD-1) MM 572 572 635 546 521 635 635 686 572 867

M. Clearance Required IN 72 82 92 86 92 96 98 106 114 124

for Burner Removal* MM 1828 2083 2337 2184 2337 2438 2490 2692 2896 3150

Weights

Approx. Shipping Weight LB 1400 1700 1900 2000 2280 3400 3500 4780 6526 7280

KG 635 773 862 910 1036 1545 1591 2173 2966 330

Approx. Operating Weight LB 1516 1833 2200 2200 2605 4042 4184 6197 8569 9531

KG 688 831 998 998 1182 1833 1898 2811 3887 4323

*This dimension is 6” less for oil fired units 4-50 HP and 12” less for oil fired units 60 HP.

NOTE: Recommended minimum clearance is 24” to the side and back of unit; 36” in front

Dimensions

Fulton Gas & Oil Fired

Vertical Tubeless

Steam Boilers

(Standard Burner)

Product Data Submittal

Fulton Models: ICS/FB-A and ICX/FB-F

29a-G 1/01

O

CLEARANCE REQUIRED FOR

C

D

BURNER REMOVAL

ON/OFF GAS HEAD

CAN PIVOT 360°

MODULATED GAS HEAD IS

FIXED ABOVE FAN HOUSING

L

F

N

M

Q

G

R

H

J

S

I

A

B

P

K

E

Top ViewFront ViewSide View

Page 36

ffsstd-pds-2011-1222

Specifications

Models ICS/ICX/FB 4 6 9.5 10 15 20 25 30 50 60

Boiler Connections

N. Steam Outlet 15 PSI 1” 1” N/A 1.5” 2” 3” 3” 3” 4” 4”

25 NPT NPT NPT CL150# CL150# CL150# CL150# CL150#

Flange Flange Flange Flange Flange

N. Steam Outlet 150 PSI 0.75” 0.75” 1” 1” 1.25” 1.5” 2” 2” 3” 3”

19 NPT NPT NPT NPT NPT NPT NPT CL150# CL150#

Flange Flange

O. Safety Valve Outlet 15 PSI IN 0.75 0.75 N/A 0.75 1 1.5 1.5 1.5 2 2

MM 19 19 19 32 38 38 38 38 38

O. Safety Valve Outlet 150 PSI+ IN 1 1 1 1 1 1 1 1 1.25 1.25

(9.5 HP 100 PSI) MM 25 25 25 25 25 25 25 25 32 32

P. Safety Valve Inlet 15 PSI++ IN 0.75 0.75 N/A 0.75 1 1.25 1.25 1.25 1.5 2

MM 19 19 19 25 32 32 32 32 32

P. Safety Valve Inlet 150 PSI IN 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75 1 1

(9.5 HP 100 PSI) MM 19 19 19 19 19 19 19 19 25 25

Q. Feedwater Inlet IN 0.75 0.75 1 1 1 1 1 1 1 1

MM 19 19 25 25 25 25 25 25 25 25

R. Blowdown Outlet IN 1 1 1 1 1 1.25 1.25 1.25 1.5 1.5

MM 25 25 25 25 25 32 32 32 38 38

S. Water Column Blowdown IN 1 1 1 1 1 1 1 1 1 1

MM 25 25 25 25 25 25 25 25 25 25

Ratings* (Sea level to 3000 ft.)

Output 1000 BTU/HR 134.40 201 318 335 503 670 838 1005 1674 2009

1000 KCAL/HR 33.8 50.7 80.1 84.4 127 169 211 253 422 506

Steam Output LB/HR 138 207 328 345 518 690 863 1035 1725 2070

KG/HR 63 94 149 157 235 313 392 470 785 942

Approximate Fuel Consumption at Rated Capacity+++

Light Oil GPH 1.2 1.8 2.8 3.0 4.5 6.0 7.5 9.0 15.0 17.9

LPH 4.5 6.8 10.6 11.4 17 22.7 28.4 34.1 56.8 67.8

Propane Gas (ICS) FT3/HR 67.2 100 159 168 251 335 419 502 837 1004

(14” w.c. req’d) M3/HR 1.9 2.8 4.5 4.8 7.1 9.5 11.9 14.2 23.7 28.4

Propane Gas (ICX) FT3/HR 63 97 161 242 323 404 484

(14” w.c. req’d) M3/HR 2.2 2.7 N/A 4.6 6.9 9.1 11.4 13.7

Natural Gas (ICS) FT3/HR 168 257 398 419 628 837 1047 1256 2093 2511

(7” - 11” w.c. req’d) M3/HR 4.8 7.1 11.3 11.9 17.8 23.7 29.7 35.4 59.3 71.1

Natural Gas (ICX) FT3/HR 159 242 384 403 606 807 1009 1210

(7” - 11” w.c. req’d) M3/HR 5.6 6.9 10.8 11.4 17.2 22.9 28.6 34.3

Natural Gas Boiler IN 1 1 1 1 1 1.25 1.25 1.5 1.5 2

Connection Size (Std CSD-1) MM 25 25 25 25 25 32 32 38 38 51

Oil Inlet Size IN 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

MM 6 6 6 6 6 6 6 6 6 6

Burner 3450 RPM/60 CY 1/3 gas 1/3 gas 1.5 gas 1.5 gas

Motor HP 2850 RPM/50 CY 1/3 1/3 1/3 1/3 1/3 3/4 oil 3/4 oil 3/4 2 oil 2 oil

Electric Power Requirements - Burner Only (in Amps) ***

120V,60 CY, 1 Phase 5.2 5.2 5.2 5.2 5.2 5.2 gas 5.2 gas 9.2 -- --

9.2 oil 9.2 oil

240V, 50/60 CY, 1 Phase 2.6 2.6 2.6 2.6 2.6 2.6 gas 2.6 gas 4.6 8.9 gas 8.9 gas

4.6 oil 4.6 oil 9.5 oil 9.5 oil

208V, 50/60 CY, 3 Phase 1.9 1.9 1.9 1.9 1.9 1.9 gas 1.9 gas 3.1 4.4 gas 4.4 gas

3.1 oil 3.1 oil 5.7 oil 57 oil

240V, 50/60 CY, 3 Phase 1.6 1.6 1.6 1.6 1.6 1.6 gas 1.6 gas 2.8 4.2 gas 4.2 gas

2.8 oil 2.8 oil 5.4 oil 5.4 oil

480V, 50/60 CY, 3 Phase 0.8 0.8 0.8 0.8 0.8 0.8 gas 0.8 gas 1.4 2.1 gas 2.1 gas

1 .4 oil 1.4 oil 2.7 oil 2.7 oil

Water Content

U.S. GAL 14 16 16 24 39 77 82 170 245 270

LITERS 53 61 61 91 148 292 310 644 927 1022

Specifications and Dimensions are approximate. We reserve the right to change specifications and/or dimensions..+ High pressure boilers purchased with low pressure

openings may have larger than specified opening sizes, consult factory for correct opening sizes.++ 50 and 60 HP have two safety valves on low pressure.

+++Consumption based on light Oil 140,000 BTU/G; Natural Gas 1000 BTU/ft.3; Propane 2500 BTU/ft3. *All ratings from 0 PSIG and at 212 degrees F. *** Control

circuit electrical requirement will vary with the system voltage, please consult factory. --Consult factory.

The Fulton Companies

972 Centerville Road

Pulaski, NY 13142

Call 315-298-5121

Fax 315-298-6390

www.fulton.com

29b-G 1/01

Page 37

30-G 1/01

Description/Instructions

K

K

F

K

D

C

I

E

J

H

B

A

G

Page 38

Description/Instructions

31-G 1/01

SEE PRODUCT DATA SUBMITTAL ON

PREVIOUS PAGES

72

1828

4

Locating the Boiler

a) The boiler should be located in dry

surroundings on a level base, making

sure that there is sufficient room

around the boiler to enable the operator and/or the maintenance engineer

to gain access to all parts of the boiler.

Check location for ease of water supply and electrical connections.

b) Place the boiler on a non combustible floor with clearances to unprotected combustible materials, including plaster or combustible supports.

c) It is necessary to have the following vertical clearance from the floor to

the ceiling for removal of the burner

for servicing:

Minimum Vertical Clearances

BHP IN MM

6 82 2083

9.5 86 2184

10 86 2184

15 92 2337

20 92 2438

30 106 2692

40 104 2642

50 114 2896

60 124 3150

The Gas Supply

a) Gas Piping should be installed in

accordance with National Fuel Gas

Code, ANSI-Z223-1-1984 or latest

addenda and any other local codes

which may apply. In Canada gas

installations must be in accordance

with the current CAN/CGA B149.1

and .2 and/or local codes.

b) Install a dirt trap ahead of all of the

gas valves.

c) The pipe and the fittings used

must be new and free of dirt or other

deposits.

d) The piping must be of the proper

size to ensure adequate gas supply to

the gas head assembly. Consult your

gas company for specific recommendations.

e) For natural gas a pressure of 7" to

11" (178mm to 279mm) of water column pressure at the gas train is

required with burner firing. Do not

exceed 13" of water column.

f) For propane or butane gas the

pressure required is 11" (279 mm) of

water column pressure. Again, do not

exceed 13" of water column.

g) When making gas piping joints,

use a sealing compound resistant to

the action of liquefied petroleum

gases. Do not use teflon tape on

gas line threads.

h) The main and the pilot gas pressure regulators must be vented to the

atmosphere.

i) After gas piping is completed carefully check all piping connections, (factory and field), for gas leaks. Use a

soap and water solution.

CAUTION

Some soaps used for leak testing

are corrosive to certain types of

metals. Rinse all piping thoroughly

with clean water after leak check

has been completed.

j) The boiler must be disconnected at

the boiler shut off valve from the gas

supply piping system during any pressure testing of the system at pressure

in excess of 1/2 PSIG--14" W.C.

k) The boiler must be isolated from

the gas supply piping system by closing the shut-off cock during any pressure testing of the gas supply piping

system at pressures equal to or less

than 1/2 PSIG--14" W.C.

Page 39

32-G 1/01

Description/Instructions

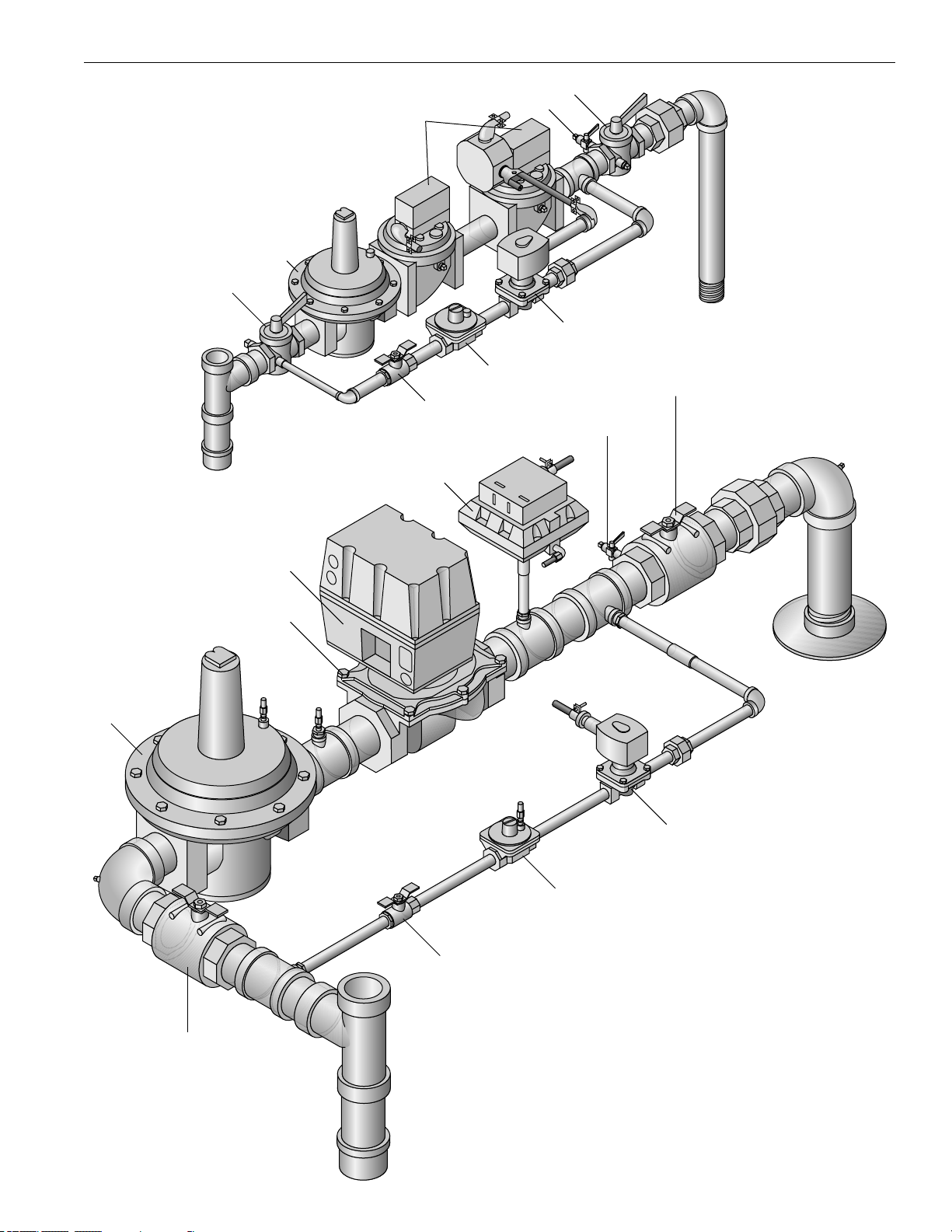

Vent

Vent

Return

Cold

Water

Supply

Sight

Glass

Union

Pump/

Strainer

Thermometer

Aquastat

Drain

Condensate

Return

T ank

Blowdown

Separator

Outlet

To Drain

Check

Valve

Shut

Off

Valve

Cold Water

Inlet

Basic Boiler,

Condensate Tank,

and Blow off

Separator

NOTE

Where a condensate return tank is

to be fitted, this should:

1) Be vented to a safe

location, and

2) Have a capacity sufficient to

satisfy boiler consumption as well

as maintain proper return tank

temperature.

3) Vent pipe should not be downsized (this may cause pressure

build up in the condensate tank).

4) Return pipes must not be insulated. This can cause overheating

the return system, causing a vapor

lock in the pump.

5) See Return System Instruction

Manual for detailed instructions.

Page 40

Description/Instructions

Safety

Valve

Water

Column

and

Sight

Glass

Electric

Control

Panel

Gas Fired

Steam Boiler

Shut

Off

Valve

Check

Valves

Fast

Opening

Valve

Blowdown

Valve

Union

NOTE

Care should be taken to ensure

that the blow off receptacle used

meets the regulations covering

such vessels. If in doubt consult

a Fulton Representative for

advice.

a) Make sure two check valves are

installed between the boiler and

pump (one check valve is supplied

with the unit).

b) In a closed system an end of the

line trap should be installed.

c) There are three blow off valves

on the boiler: the main valve at the

rear of the boiler, the gauge glass

blow off valve, and the water column blow off valve. The boiler blow

off valve supplied with the boiler

should be screwed to the blow off

pipe at the rear of the boiler and

connected to a blow off receptacle

of approved design.

All these procedures should be

done in accordance with state

and/or local codes. The water column blow off valve and the gauge

glass blow off valve should be connected to the main blow off line.

33-G 1/01

Page 41

Description/Instructions

Boiler Installation

The Steam Supply — Pipe the

steam supply line from the top right

side of the boiler.

The Steam Safety Valve

1) Before installing, be sure that all

pipes and connections have been

blown clean. Pipe compound or

dope is used on external threads

only. Be sure inlet of valve is free of

any foreign material.

2) Do not use a pipe

wrench! When making

installation, use proper

type and size wrench.

3) The valve should be

installed in a vertical upright

position in the connection provided

on the top left side of the boiler

with no unnecessary inter-

vening pipe. Under no circumstances should there be

a shut off valve or restriction

of any kind between the

safety valve and the con-

nection provided.

4) Do not cap or plug drain

hole in the side of valve body.

5) Since the purpose of this

safety valve is to protect

against an overpressure situation, it will loudly discharge hot

steam in doing so. Therefore, it is

recommended that a discharge pipe

be securely installed and run to a

safe point of disposal.

6) When a discharge pipe is used,

it must be of a pipe size equal to or

greater than that of the valve outlet.

Use schedule 40 discharge pipe

only. Do not use schedule 80, extra

strong or double extra strong discharge pipe or connections. It must

be as short and straight

as possible and so

arranged as to avoid undue

stress on the valve. It must

have an ample provision for draining condensate at or near the valve

outlet. It must terminate freely to

atmosphere with no intervening

valve of any description and it must

be securely anchored and supported.

The Steam Pressure Gauge

Assembly — The gauge should be

facing front towards the panel box

and/or operator of the boiler.

Except as noted, each assembly or

any of its component parts may be

oriented, other than as shown to

provide improved operating clearances and/or view of gauge.

Before installing steam gauge on

the siphon, add a small amount of

water to the siphon to create a

water seal to buffer the gauge element. This must be done to prevent

inaccurate pressure readings and

/or premature failure of the gauge.

Install the steam gauge into the

siphon on the water column.

Saftey Valve

Outlet

Steam Outlet

Steam

Pressure

Gauge

Inspection/

Test Valve

(Shown Open)

Steam

Siphon Loop

To

High Limit

Pressure

Control

To

Operating

Pressure

Control

Ball

Valve

(Open)

(Closed)

34-G 1/01

Page 42

Description/Instructions

35-G 1/01

4

1/2

12.5

The Blow-Off Valve — There are two

blow off valves on the boiler: The

main valve at the rear of the boiler

and the water gauge glass blow off

valve. The boiler blow off valve supplied with the boiler should be

screwed to the blow off pipe at the

rear of the boiler and connected to a

blow off receptacle of approved

design. This should be done in accordance with state and local codes.

4) Do not use the pump as a piping

support. It is critical that the pipe be

independently supported near the

pump so no strain will be transmitted to the unit.

5) Connect the feed water stop

valve to the feed water pipe at the

rear of the boiler and pipe it to the

return system.

The Water Column

Install the piping from the water

column and water gauge glass to a

safe blow-off point.

The Feed Water Piping

1) Provisions must be made for ade-

quate water supply and properly

sized piping. Piping must be done in

compliance with all local codes. The

following chart may be used as a

guideline for sizing.

BHP Minimum Water

Supply Piping Size

Inches Millimeters

6 1/2 12.5

9.5 1/2 12.5

10 1/2 12.5

15 3/4 19

20 3/4 19

30 1 25

40 1 25

50 1 25

60 1 25

2) When feeding the boiler using a

return system, the city water pressure

should not exceed 40 PSI. A pressure reducing valve should be

installed a head of the return tank

when above this pressure.

3) It is important that all piping be

lined up and not forced into place. It

is recommended that you begin piping at the pump. If the lines are

ended at the pump, particularly if the

last piece is cut too short or long, the

pump will be forced to meet the pipe

and strain or distortion will result.

Page 43

36-G 1/01

Water Gauge & Gauge Glass

Installation instructions

NOTE

Only properly trained personnel

should install and maintain water

gauge glass and connections.

Wear safety glasses during

installation. Before installing,

make sure all parts are free of

chips and debris.

NOTE

Keep gauge glass in original packaging until ready to install.

1) Verify the proper gauge has been

supplied.

2) Examine the gauge glass and

packings carefully for damage before

installation. Do not use the glass if it

contains any scratches, chips, or any

other visible signs of damage.

3) Do not subject the gauge glass to

bending or torsional stresses.

4) Apply teflon tape or pipe dope to

pipe threads. Install top gauge fitting

(fitting without a drain valve) into the

uppermost tapping. Wrench tighten

the fitting until it is snug and the glass

outlet is pointing at five o’clock (about

1/8 turn from its final downward vertical position).

5) Install the bottom gauge fitting

(the fitting with a drain valve) until it is

snug and the glass outlet is pointing

directly upward. Verify top and bottom fittings are threaded into the tappings the same number of turns (distance A=distance B).

6) Remove glass packing nut, friction

washer and glass packing from the

fittings, and place them, in the same

order, on to both ends of the gauge

glass. Push both packings about an

inch up the gauge glass.

7) Gently insert one end of the

glass into the top gauge fitting.

Keeping the glass inside the top fitting, gently rotate the top gauge fitting clockwise until vertically aligned

with the bottom gauge fitting, then

inset glass into bottom fitting until

glass bottoms out on the shoulder

inside the bottom fitting.

8) Carefully raise glass about 1/16”

and slide lower glass packing down

until the glass packing contacts the

lower gauge fitting. DO NOT allow

the glass to remain in contact with

any metal!

9) Carefully slide upper glass packing up as far as possible.

10) Hand tighten both glass packing

nuts, then tighten 1/2 turn more by

wrench. Tighten only enough to prevent leakage. DO NOT OVER

TIGHTEN! If any leakage should

occur, tighten slightly, a quarter turn

at a time, checking for leakage after

each turn.

11) Install the protective guard, and

utilize automatic ball checks where

necessary to help prevent injury in

case of glass breakage.

WARNING

Improper installation or maintenance of gauge glass and connections can cause immediate or

delayed breakage resulting in bodily injury and/or property damage.

Description/Instructions

Top Gauge

Fitting

Gauge Glass

Guard Rod

Glass Packing Nut

Friction Washer

Glass Packing

Bottom Gauge

Fitting

A

Vessel

Wall

B

Drain

Valve

Page 44

Water Supply

a) Feed water contains solids and

dissolved gases. These may promote

incrustation of scale; foaming, priming, surging, and solids in steam; corrosion and pitting; or caustic embrittlement. To prevent this, feedwater must

be studied individually and treated

accordingly by reputable professionals specializing in this field. It is

strongly recommended that a competent water treatment company be consulted prior to the installation of the

boiler.

b) The purpose of this treatment

should be to provide quality feedwater

to the boiler such that corrosion and

deposition in the boiler will be minimized. Dissolved oxygen, high chloride levels and low pH can all be

major causes of corrosion. Untreated

hardness is the major cause of

deposits. Poor quality feedwater

requires increased blow off and

increased chemical treatment costs to

prevent boiler corrosion and scaling.

c) One way to lower the amount of

dissolved oxygen in the boiler feed

water is the sparge tube option. This

option injects live steam into the

feedwater to increase the water

temperature to 180 degrees F

(82 degrees C) which removes

oxygen from the water.

d) Chlorides can be controlled by

increasing the number of blow downs

per day from one to four.

e) The Fulton Warranty does not

cover damage or failure that can be

attributed to corrosion, scale or dirt

accumulations. Oxygen is a corrosive. See the Warranty Section of

this manual for full details.

Recommended Water Treatment

a) Following are recommendations

for feed water and boiler water.

Contact your local water treatment

professional for testing and treatment

recommendations. It is very important

that a strict water treatment program

be followed.

Feedwater:

Dissolved Oxygen.............less than 0.05 ppm

pH Value............................9-11 (tested at room

temperature)

*Hardness..........................less than 70 ppm

in the form of CACO

3

Oil.......................................none

Suspended Solids.............none

Organic Matter ..................less than 5.0 ppm

Chloride .............................less than 50.0 ppm

Total Dissolved Solids .......less than 300ppm

Boiler Water:

Phosphate....................30 to 50 ppm

in the form of PO

4

Alkalinity .......................less than 300 ppm in

the form of CACO3

Chloride ........................less than 500 ppm

pH Value.......................9 to 11 tested

at room temperature)

Total Dissolved Solids..400 to 2,000 ppm

Iron................................1 ppm maximum

Silica .............................180 ppm max. as SIO

2

Hardness......................less than 50.0 ppm

Dissolved Oxygen........none

ppm = parts per million; CACO3=Calcium

Carbonate; PO4=Phosphate; SiO2=silicon

dioxide; * 1 Grain Hardness = 17.118 ppm

Therefore: 70 ppm = 4.10 grains hardness

b) It is critical that the boiler pH be

alkaline (9-11) whenever water is in

the boiler. Solids that enter in with the

feed water concentrate in the boiler.

Daily boiler blow down is recommended to prevent corrosion and/or

deposits from forming.

Glossary of Water

Supply Corrosives

and Inhibitors

Dissolved Oxygen: Oxygen that is

dissolved in the feedwater will cause

the steel in the boiler and the feedwater system to be attacked by the water

in a manner described as “pitting”.

The pits that are produced can vary

from tiny depressions to holes large

enough to penetrate the boiler metal

and are usually covered with tubercles of iron oxide. Once pitting starts,

it may be extremely hard to arrest.

Pitting can proceed at a surprisingly

rapid rate and can occur not only in

the boiler proper, but also in pre-boiler

equipment such as economizers,

feedwater heaters, and feedwater

lines.

Sodium Sulfite: Its purpose is to

chemically remove the dissolved oxygen left in the feedwater.

Sodium Sulfite reacts chemically

with dissolved oxygen, producing

sodium sulfate. Since it is desirable to

remove dissolved oxygen from the

feedwater before it reaches a boiler.

Sodium sulfite is best introduced continuously at some suitable point in the

feedwater system. Chemical residual

control is based on the maintenance

of a specific excess of sodium sulfite

in the boiler water. The essential

requirement being to maintain in the

feedwater at all times slightly more

than enough sodium sulfite to consume all of the dissolved oxygen.

When sodium sulfite is not fed contin-

uously, protection of the boiler against

oxygen attack must depend on the

reserve of sodium sulfite that is present in the boiler water. In this case, it

is important that the feedwater and

the boiler water are mixed thoroughly

and as quickly as possible so that

boiler water sodium sulfite may consume feedwater oxygen before the

latter can cause damage to the boiler.

Sulfite as a treatment represents

a second line of defense against oxygen corrosion. A vigorous maintenance program to safe guard against

oxygen leakage into the pre-boiler

system should be followed.

Suspended Solids: Suspended

solids are the undissolved matter in

water, including dirt, silt vegetation,

and any other insoluble organic matter. Normally suspended solids are

expressed in terms of turbidity.The

presence of suspended solids in cooling water can increase impingement

type corrosion. Suspended solids may

also deposit in low velocity areas and

create differential aeration cells.

Pitting can result. The most common

cause of high suspended solids is

high hardness feedwater. Of the

agents which cause foaming, suspended solids probably have the least

effect. Reasons for the increased

hardness or other suspended solids

should be determined.

In line filters, or various types of

pretreatment can be used to lower

the suspended solids level. Various

polymers assist in holding solids in

suspension.

Alkalinity: Alkalinity is the capacity of

a water to neutralize acids.

Common water alkalinities consist of

bicarbonate, carbonates, hydroxide,

phosphate, and silicate. These alkalinities, especially bicarbonates and

carbonates, break down to form carbon dioxide in steam, which is a major

factor in the corrosion on condensate

lines. High alkalinity also causes

foaming and carry over in boilers.

Both foaming and carry over cause

erratic boiler operation. When foaming

occurs an anti-foam should be added

or increased. The reason for the high

alkalinity should be determined. It

may result from lack of sufficient blow

off. Pretreated makeup water and

condensate should also be checked.

Quite often the source of alkalinity is

an overdose of alkaline internal water

treatment chemical.

Description/Instructions

37-G 1/01

Page 45

38-G 1/01

pH: pH is a measure of the degree

of acid or base of solution. Normal

pH ranges of 6.5-9.0 will have little

influence on the corrosion rate of

cooling waters. If for some reason,

pollution, etc., the pH is lowered into

the acid range, increased corrosion

can be expected. The solution lies in

determining the cause of the low pH

and correcting that condition. A low

pH can result in corrosion of metals,

while a high pH can result in scale

formation.

In order to control boilers and

equipment used for the external

treatment of make up water, it is

essential that reliable pH measurements be made.

Phosphates: Ground or surface

waters seldom contain large amounts

of phosphates. If present, it generally

indicates fertilizer runoff or pollution.

Phosphate from raw water can be the

cause of scale problems in open recirculating cooling water systems after

the water is concentrated.

Chlorides: Chlorides are involved in

most cooling water corrosion cells.

Other factors being equal, it can be

assumed the higher the chloride content, the more corrosive the water.

When pits or cracks occur on stainless steel or other metals, chlorides

are always suspect.

High chloride levels can cause severe

corrosion. Corrosion from chlorides

can be controlled by increasing the

amount of corrosion inhibitor or

changing to a more effective inhibitor.

Oil: Oil is not a natural constituent of

boiler water; still it can frequently enter

a system through leaks in a condenser or other heat exchanger. Oil

can also enter a system through the

lubrication of steam driven reciprocating equipment. Whatever the source,

the presence of oil in boiler water is

undesirable. Oil can act as a binder to

form scale. In high heat-transfer

areas oil can carbonize and further

contribute to the formation of scale.

Foaming is one indication of oil in

boiler water. Its presence can also

be confirmed by first shaking a bottle containing boiler water. If oil is

present foam will result. To ensure

the foaming is being caused by oil,

add a small amount of powdered

activated carbon to the bottle containing the boiler water and shake.

Little or no foam will appear if the

foaming is caused by oil.

Often oil in boiler water will originate in the condensate. This contaminated condensate should be

directed to the sewer until the

source of the oil is determined and

corrective steps taken.

Silica: Silica in boiler deposits is usually combined with other constitutents.

Silicates form a number of different

scale complexes with calcium, magnesium, aluminum, sodium, and iron.

Since there is at present no effective

dispersant for silicate deposits, the

scale problem can be alleviated by

maintaining close control of calcium,

aluminum, and iron as well as silica.

Iron (oxides): Iron in any of its oxide

or complex forms is undesirable in

boiler water. It is very difficult to disperse so that it can be removed the

bottom blow off lines.

Iron in its various forms can originate

in the raw water makeup, condensate

return water, or form directly in the

boiler as a result of corrosion. Most

iron oxide originates outside the boiler. It does not concentrate in the boiler and it tends to collect in stagnant

areas. If a boiler is using raw water

makeup, iron is almost certain to be a

major component of developing scale.

Water Hardness: Water hardness

is the measure of calcium and magnesium content as calcium carbonate equivalents. Water hardness is

a primary source of scale in boiler

equipment.

Feedwater: Feedwater is the combination of fresh makeup and returning condensate that is pumped to

the boiler.

Condensate: Condensate is condensed steam that is normally low in

dissolved solids. Hence, it does not

contribute to the dissolved solid content of the feedwater. In addition, condensate is very expensive to waste.

It's been chemically treated, heated,

pumped, converted to steam, and

condensed. This costs money and

when condensate is returned to the

boiler, money is saved.

Description/Instructions

Page 46

39-G 1/01

Description/Instructions

41.09

Electrical Requirements

a) Connect wiring as shown in

the wiring diagram which is furnished

inside the electrical control panel box.

b) Be sure to install a separate

fused disconnect for each. The disconnects should be installed in compliance with the NEC (National

Electric Code) and all local codes.

c) Connections for an optional

audible alarm are provided in the

control panel and are clearly indicated on the diagram.

Fresh Air Supply for

Boiler

a) It is most important to provide

free access of air to the boiler. To

burn fuel properly, it requires one

square inch opening of fresh air for

every 3,000 BTU input of fuel.

(6.4cm2for every 756 Kcal).

b) Proper ventilation of the boiler

room is essential for good

combustion. Install two fresh air

openings, one at a low level (24”—

610mm from floor) and one at a higher level in the boiler room wall.This

will provide a flow of air to exhaust

the hot air from the boiler room.

Room temperature not to exceed

100°F.

c) The following openings are

recommended for each size boiler:

Make Up Air Openings

BHP FT

6 1 .09

10 1 .09

15 1.5 .14

20 4 .37

30 4 .37

40 5 .46

50 5 .46

60 7.5 .69

2

M

2

Be sure total BHP = proper make

up air opening size. For instance

if you have three 10 BHP boilers,

it is a total BHP of 30, and the 30

BHP make up air opening size is

recommended.

These measurements are subject to

state and local regulations. The

installation of exhaust fans in a boiler room is not recommended. An

exhaust fan, or similar equipment

can create down draft in the stack or

restrict the burner’s air supply which

will result In poor combustion. It is

essential that only fresh air is

allowed to enter the combustion air

system. Foreign substances, such

as combustible volatiles and lint, in

the combustion system can create

hazardous conditions.

Page 47

40-G 1/01

Description/Instructions

46152

Conventional Venting

a) The stack should rise continuously

to the connection with the chimney,

and should contain no more than two

bends at 45 angles or less. If required

as the result of space limitations, one

90 elbow can be fitted at the back of

the boiler. There should be two feet of

straight, horizontal flue before any

bends or turns. Any alternative stack

arrangement must supply a negative

.02 to.04” W.C. pressure (0.508 to

1.016 mm) with the burner off.

b) The run in the total distance of

stack ducting, as measured in a

straight line from the outlet of the

boiler to the outlet of the stack,

should not exceed 25% of the rise.

With the exception of a duct run

described in Item a, horizontal sections of ducting must be avoided,

and should not exceed four feet of

total run.

Install

Appropriate

Weather

Cap

c) The stack and chimney material

shall comply with all local codes.

d) Adequate provision must be

made for the support of the weight of

the chimney and stack to avoid having too great a load imparted to the

flue outlet connection of the boiler.

e) The proper flue size and draft

control is most important for proper

burner operation. The flue must be as

large or larger than the outlet on the

boiler. Avoid flue piping and elbows

by placing the boiler as close as possible to the chimney.

f) A mechanical draft regulator

should be installed in the flue

outlet. Do not install the draft regulator prior to the first turn of the flue.

BHP Boiler Flue Size

Inches Millimeters

6 6 152

9.5 6 152

10 6 152

15 8 203

20 10 254

30 12 305

40 12 305

50 12 305

60 12 305

g) The installer should check the

draft with a meter at negative .02 to

.04” W.C. pressure (0.508 to 1.016

mm) with the burner off.

Cleanout

Door

Draft Regulator

(If Necessary)

Horizontal

Run 2'

Support As

Necessary

60°

(45° Min.)

Cleanout

Door

This Distance

Must Not

Exceed 25%

Of Total Rise

Roof

A-A

Expansion Joints

As Required

Stagger

Entrances

Draft Regulator

(If Necessary)

Horizontal

Run 2'

Minimum

6' Above

Any Structure

Within 30'

AA

30°

Max

Baffle

Cleanout

Door

Total

Rise

3'

3'

Page 48

41-G 1/01

Description/Instructions

Exhaust Side Wall Venting (UL and

MEA Approved- MEA File Number

68-79-E Vol. 2 )

a) Boilers for which sidewall venting

may be utilized are No. 2 oil, natural

gas, or combination No. 2 oil and natural gas,sizes 4 to 30 H.P. The following criteria is required for installations using sidewall venting:

1) Flue vent piping shall be pitched

upward at 1/4" per foot of length.

2) A U.L. Approved draft fan must be

installed to provide sufficient draft

(-.02 to -.04 inches WC pressure -

0.508 to -1.016 mm) to safely vent

the products of combustion.

3) The draft fan should be located as

close to the flue outlet as possible.

4) Draft regulation sufficient to

lower the draft to between -.02 and

-.04 inch WC pressure (-.508 to -

1.016mm) may be required. The

draft regulator(s) must be between

the boiler and draft fan.

5) The draft fan shall have an air flow

proving switch wired in series with the

boiler air safety switch.

6) The sidewall vent total length from

boiler exhaust to termination shall not

exceed 35 feet (10.7 m) with 4

elbows maximum.

Combustion Air Intake (UL and

MEA Approved- MEA File Number

68-74-E Vol. 3 )

a) Vertical boilers as described in

MEA 68-79-E Vol. 3 applied with

combustion air intake assembly. This

shall be applicable only to gas fired

units, sizes 4-30 boiler horsepower.

The following criteria is required for

installations using combustion air

intake assemblies.

1) Outside air intake inlet shall be

equipped with a vent cap in order to

prevent flame blow out from excessive wind. This vent cap shall have a

minimum cross sectional opening

equal to an 8 inch vent pipe.

2) All intake ducting shall have a

cross sectional area equal to or

greater than 50 square inches.

3) A mesh screen shall be affixed to

the air inlet with openings of approximately 1/2" x 3/4".

4) The total length from outdoors

to the boiler intake shall not exceed

35 feet (10.7 m) with four elbows

maximum.

Corrosion of flue pipe

a) In the case of a combustion flue

pipe, acid may develop over a long

period of time by the following

process. Chlorine containing gases,

such as halocarbon refrigerants, carbon tetrachloride, trichloroethylene,

or perchloroethylene, when drawn

into combustion air are broken down

into elemental chlorine gas which

exits up the flue pipe. If the flue pipe

is cold, as it would be if the combustion process had been off for some

time, the water vapor condenses in

the flue pipe during the first few minutes of ignition and the chlorine in the

combustion gas dissolves in the

water forming hydrochloric acid. As

the combustion system flue line

increases in temperature, the water

vapor no longer condenses because

the flue temperature is above the dew

point of the combustion gas.

The combustion gas then dries

out (dehydrates) the hydrochloric

acid solution leaving behind dry

chloride salt.

b) When the next cold start-up

occurs, the process repeats except

that more and more chloride collects

and concentrates along the flue. As

the quantity of chloride increases it

does not dehydrate completely as the

flue heats up and a corrosive poultice

develops which attacks the steel and

will also attack the boiler.

c) Concentration levels of only a

few ppm of chlorine containing

compounds in combustion air can

produce serious corrosion over long

periods of time. High chlorine containing compounds such as carbon

tetrachloride or perchloroethylene

would be prime suspects .

Air Flow

Safety Switch

U.L. Approved

Induced Draft Fan

Side Wall

Vent

Termination

(By Others)

Side Wall Vent

(By Others)

Page 49

Installation Check Points

1) Make sure all piping connections

are complete and tight.

2) Make sure the pressure controls