Page 1

RANGE TOP GAS 30”- 36”

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES PARA LA INSTALACIÓN

Page 2

Page 3

Dear Customer,

Thank you for purchasing a Fulgor Milano product. Fulgor Milano is

committed to excellence and our signature technologies provide you with

professional tools for your kitchen. One of our central philosophies is

continuous investment in research that is rooted in developing life enhancing

technology. Our goal is to deliver products that are worthy of your family

recipes and that will breathe life into your kitchen, the heart of your home.

We invite you to enjoy your new Fulgor Milano product with same amount

of care and attention that we have put into creating it.

Your Life | Our Passion

Page 4

Page 5

Pay attention to these symbols present in this manual:

EN

TABLE OF CONTENTS PAGE

1 - Special Warnings 2

Before Starting Installation 2

Mobile Home Installation 2

Recreational Park Trailers 2

2 - Product Dimensions and Cutout Requirements 3

3 - Installation Information 9

4 - Installation Instructions 10

5 - Gas Requirement 11

Pressure Testing 12

Pressure Test Method 12

Gas Connection 13

6 - Conversion for LP or NG Gas 14

Converting Appliance for Use with LP Gas 14

Replace Injectors (two ring flame burner) 14

Converting Appliances for Use with NG Gas 15

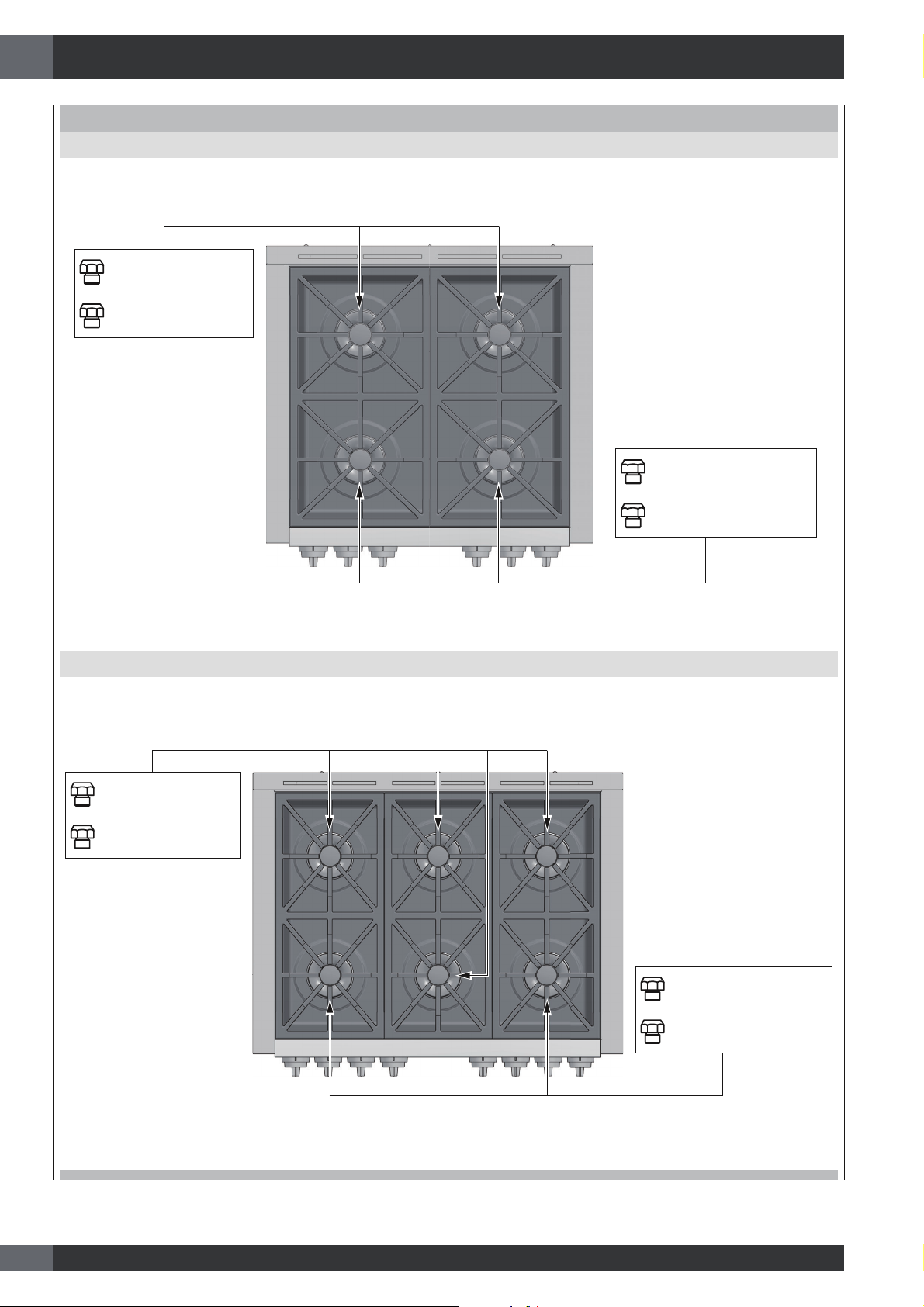

INJECTORS POSITION 16

Low Flame Adjustment 18

Electric Gas Ignition 19

The Burner Flames 19

7 - Electrical Requirements 20

General Information 20

Electrical Connection 20

Electrical Requirements 21

DANGER

You can be killed or seriously injured if you don’t

IMMEDIATELY follow instructions.

WARNING

This is the safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others. You

can be killed or seriously injured if you don’t follow these

instructions.

READ AND SAVE THESE INSTRUCTIONS.

To installer:

Leave these instructions with the appliance.

To customer:

Retain these instructions for future reference.

WARNING

If the information in this manual is not followed exactly, a fire

or explosion may resulting in product and property damage

and / or personal injury or death.

Do not store or use gasoline or other flammable vapours and

liquids in the vicinity of this or any other appliance.

IMPORTANT: Save these instructions for the local

electrical inspector use.

INSTALLER: Please leave this manual with owner

for future reference.

OWNER: Please keep this manual for future

reference.

GLOSSARY OF TERMS: NG - Natural Gas

LP - Liquid Propane

1

Page 6

EN

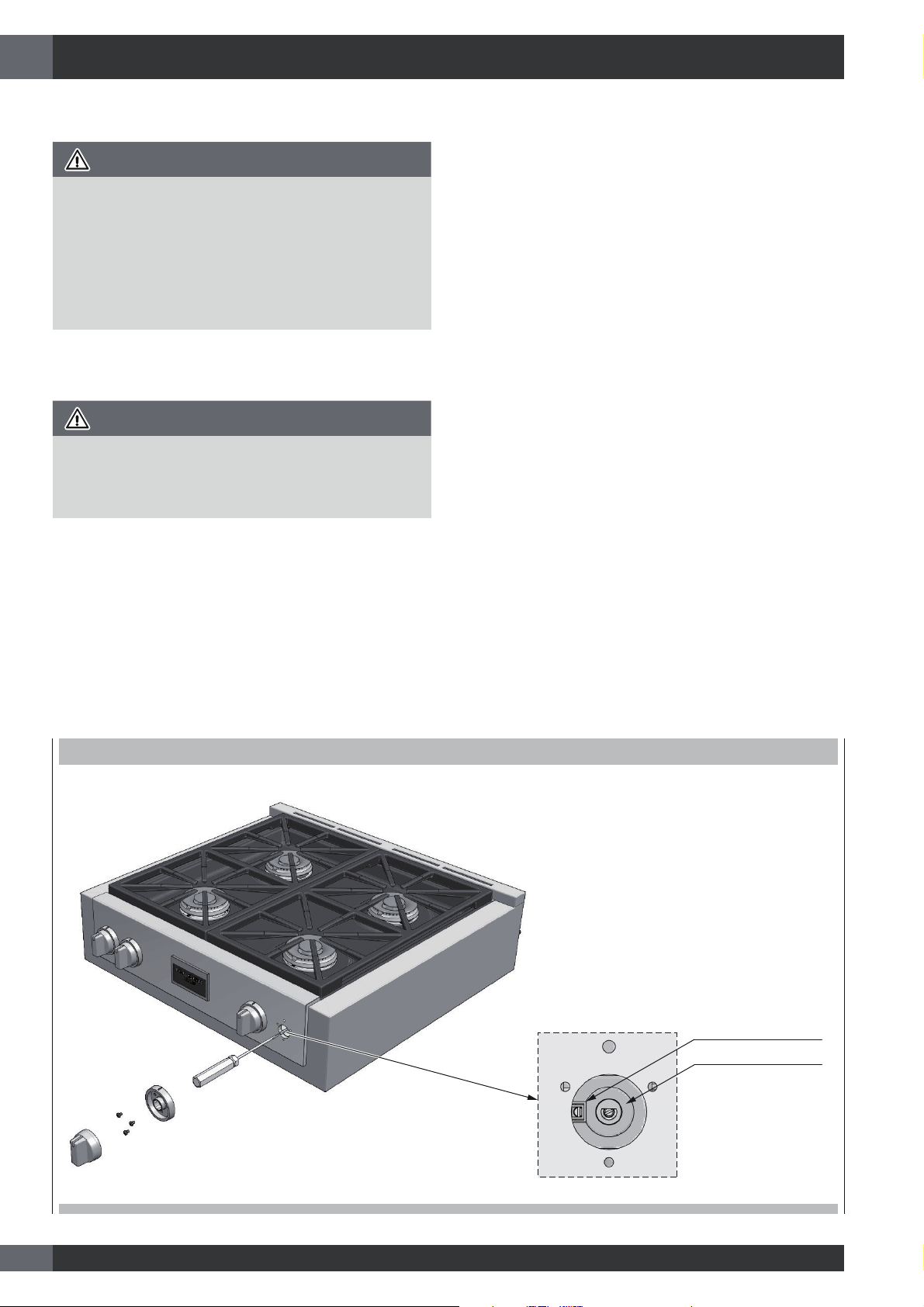

1 - Special Warnings

IMPORTANT INSTRUCTION

Please read all instructions before using this appliance.

Proper installation is your responsibility. Have a qualified

technician install this rangetop.

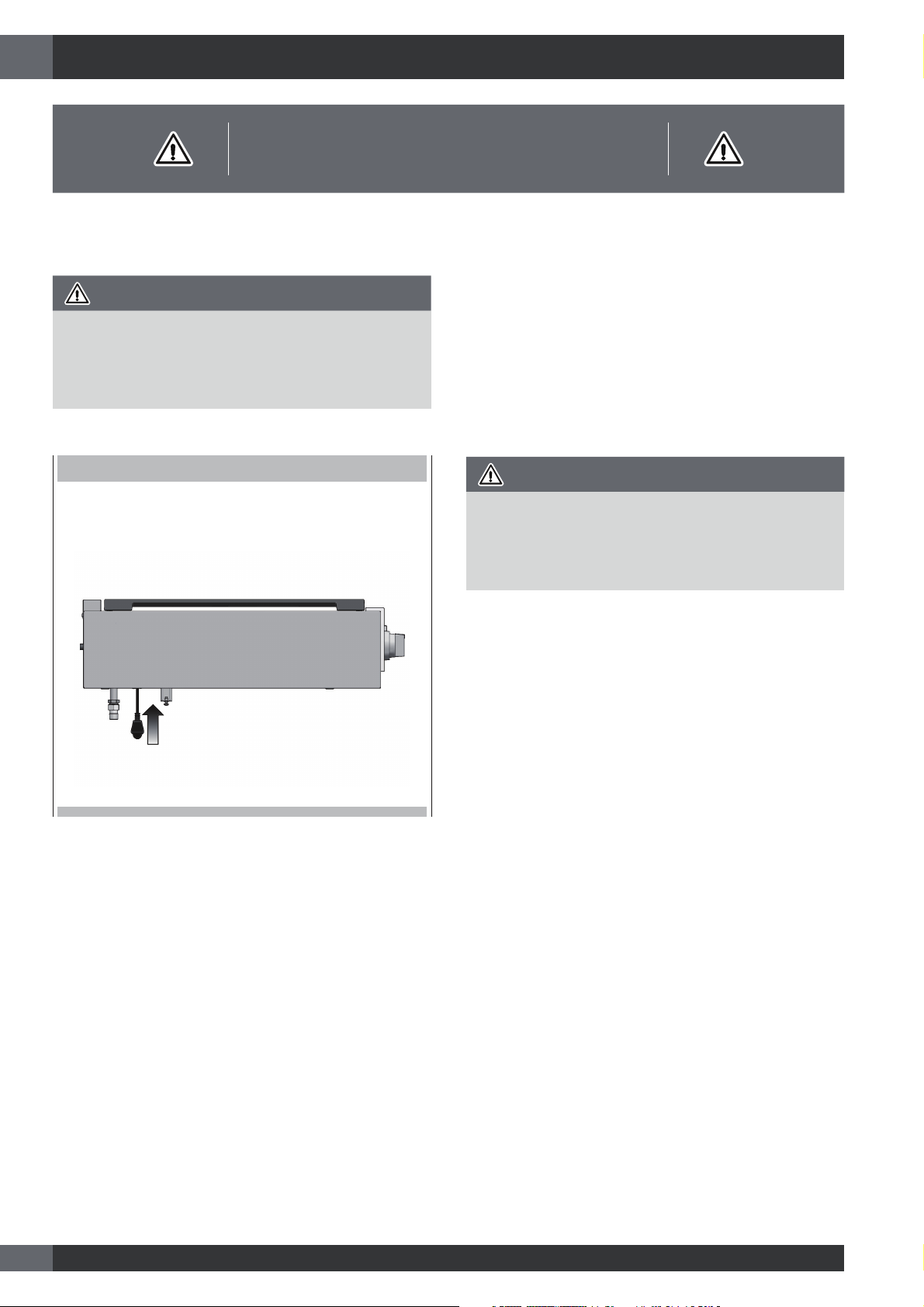

IMPORTANT

- Observe all governing codes and ordinances.

- Write down the model and serial numbers before installing

the rangetop. Both numbers are on the serial rating plate

refer to the illustration below.

LOCATION OF RATING PLATE

Copies of the standards listed may be obtained from:

** National Fire Protection Association One Batterymarch Park

Quincy, Massachusetts 02269

*** CSA International 8501 East Pleasant Valley Rd. Cleveland,

OH 44131-5575

NOTE: This rangetop is manufactured for use with Natural

gas or Propane.

To convert to LP (propane) or NG (natural gas), see

instructions in the gas conversion kit provided in the

literature package. Proper gas supply connection

must be available. See gas supply requirements.

WARNING

Before connecting the appliance to the gas supply line,

ensure that its gas setting is appropriate.

The type of gas adjusted and shipped from the factory is

indicated on the rating plate.

Mobile Home Installation

The installation of this appliances must conform to the

Manufactured Home Construction and Safety Standards, Title

24 CFR, Part 3280 (formerly the Federal Standard for Mobile

Home Construction and Safety; Title 24 HUD part 280); or

when such standard is not applicable, the Standard for

Manufactured Home Installations (Manufactured Home Sites,

Communities and Setups), ANSI A225.1 - latest edition, or

with local codes.

Before Starting Installation

• Check location where rangetop will be installed. The

location should be away from strong drafty areas, such as

windows, doors and strong heating vents or fans.

• Electrical grounding is required. See “Electrical

Requirements”

• Assure that electrical installation is adequate and in

conformance with National Electrical Code, ANSI/

NFPA 70 - latest edition**, or Canadian Electrical Code,

part 1 C22.1 (latest edition)*** and all local codes and

ordinances.

• Assure that gas connection conforms with local codes and

ordinances. In the absence of local codes, installations

must conform with American National Standard, National

Fuel Gas Code ANSI Z223/NFPA 54 - latest edition**

Canadian CAN/ CGA_B 149.1 or CAN/CGA-149.2

latest edition**

2

In Canada, the installation of this appliances must conform

with the current standards CAN/CSA-Z240 - latest edition, or

with local codes.

Recreational Park Trailers

The installation of this appliances designed for Recreational

Park Trailers must conform with state or other codes or, in the

absence of such codes, with the Standard for Recreational

Park Trailers, ANSI A119.5.

Page 7

7” (17.9)

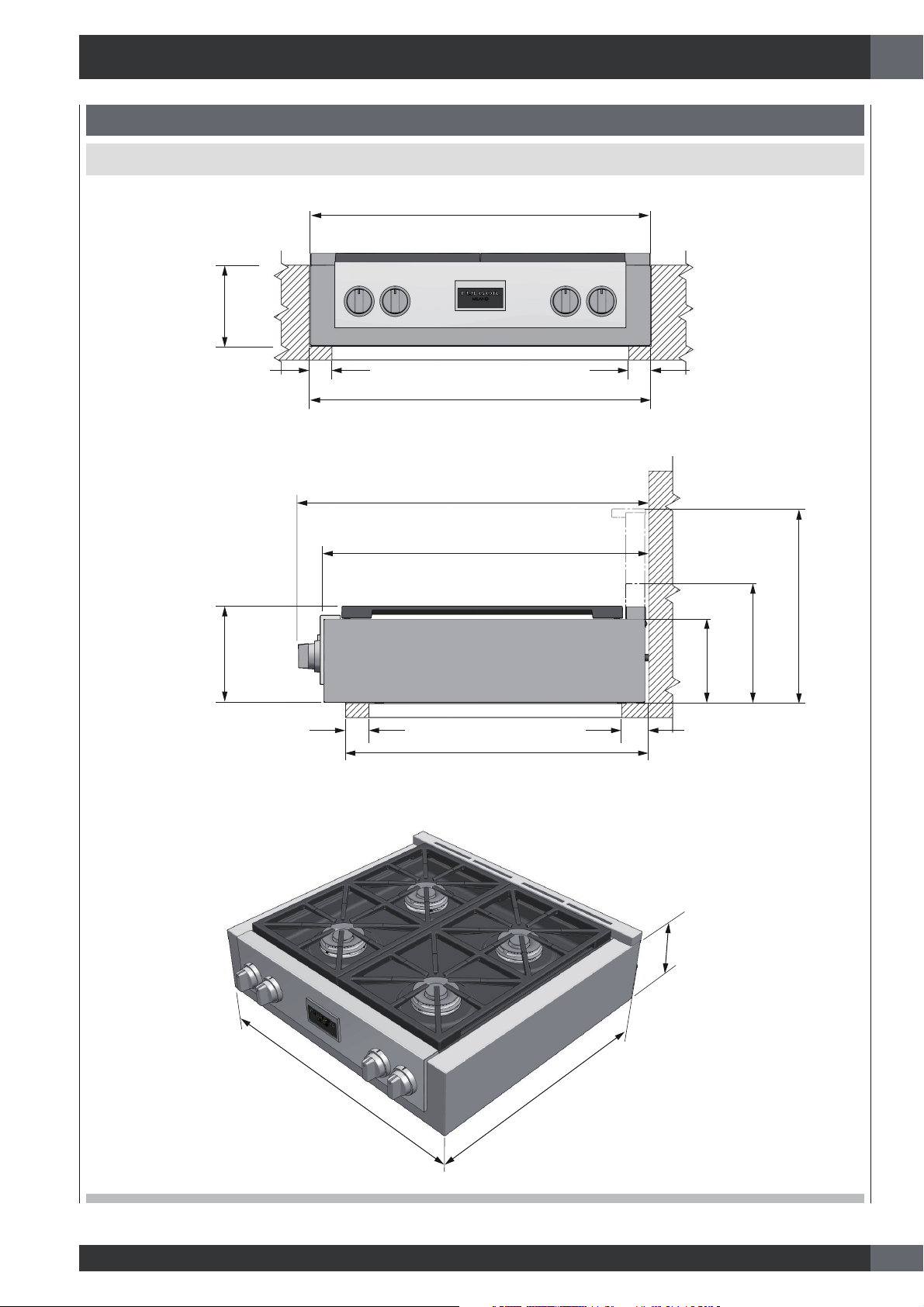

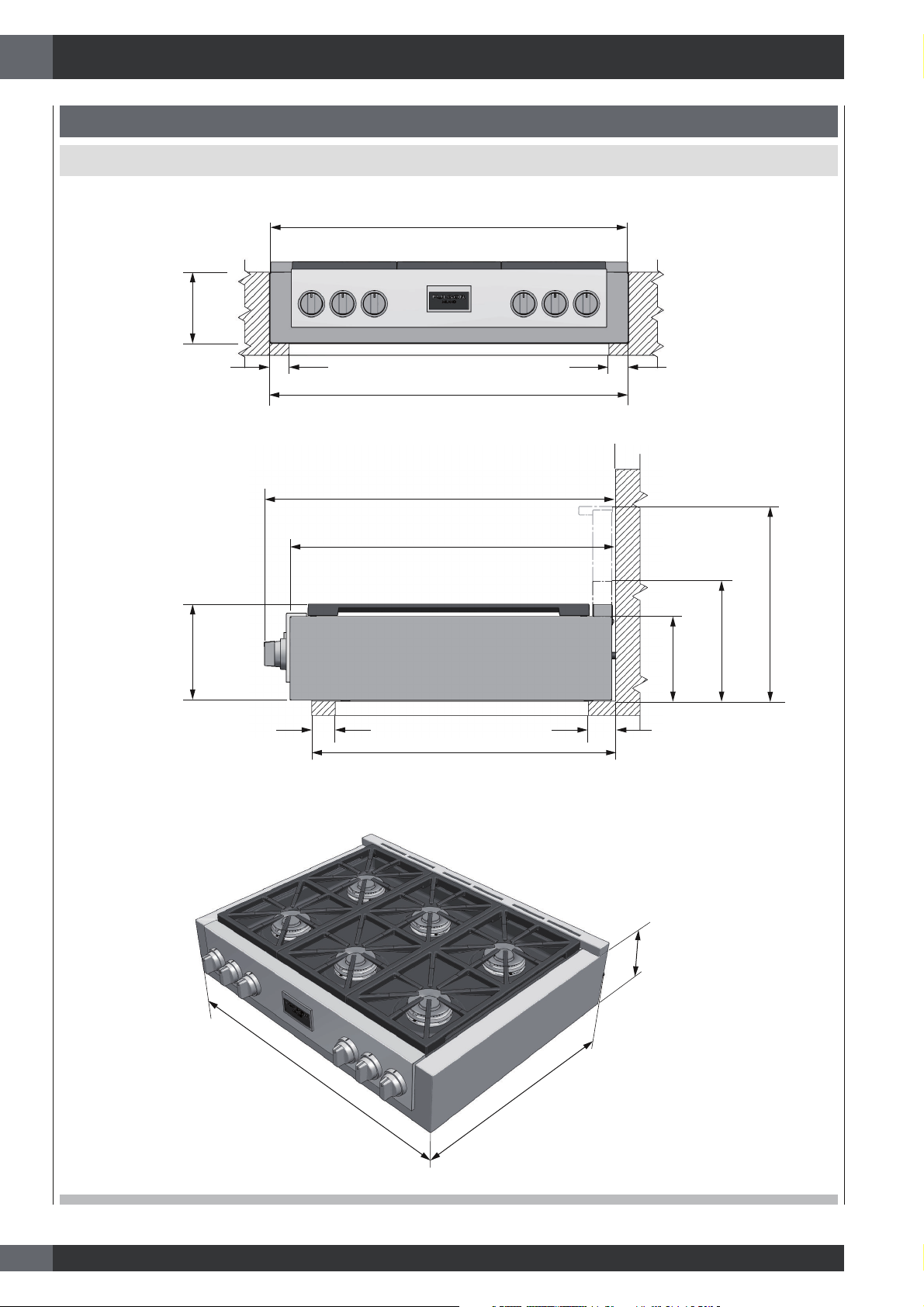

2 - Product Dimensions and Cutout Requirements

PRODUCT DIMENSIONS

30” Wide Rangetop Models

29 3/4” (75.8)

EN

8 1/8” (20.6)

2” (5)

2” (5)

30” (76.2)

29 1/2” (75.1)

27 3/8” (69.7)

min. 24” (61)

max. 25 5/8” (65)

2” (5)

7” (17.9)

2” (5)

10” (25.5)

16 3/8” (41.5)

29 3/4” (75.8)

7” (17.9)

27 3/8” (69.7)

3

Page 8

EN

2 - Product Dimensions and Cutout Requirements

PRODUCT DIMENSIONS

36” Wide Rangetop Models

35 3/4” (91.0)

7” (17.9)

8 1/8” (20.6)

2” (5)

2” (5)

36” (91.4)

29 1/2” (75.1)

27 3/8” (69.7)

min. 24” (61)

max. 25 5/8” (65)

2” (5)

7” (17.9)

2” (5)

10” (25.5)

16 3/8” (41.5)

7” (17.9)

35 3/4” (91.0)

4

27 3/8” (69.7)

Page 9

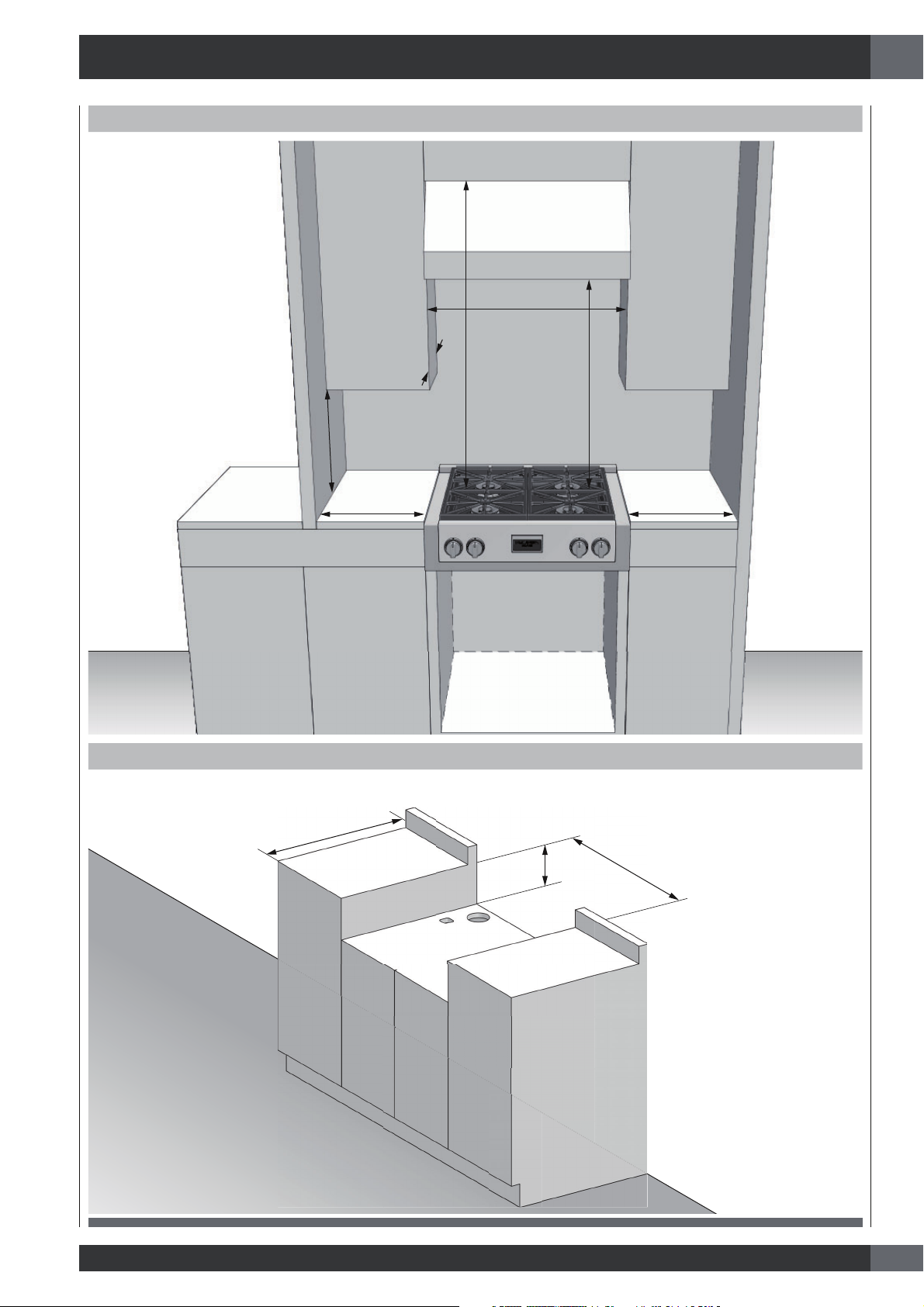

2 - Product Dimensions and Cutout Requirements

CUTOUT REQUIREMENTS

min 48” (122)

Minimum to

Combustibles

A

max 13” (33)

min 30” (76.2)

min 18” (45.7)

min 6” (15.2) min 6” (15.2)

to bottom of

ventilation hood

EN

INSTALLATION WITH SEPARATOR SHEET

(61)

min 24”

max 25 1/2” (65)

Electrical and Gas

connections

in this area

17.9)

(

7”

A

5

Page 10

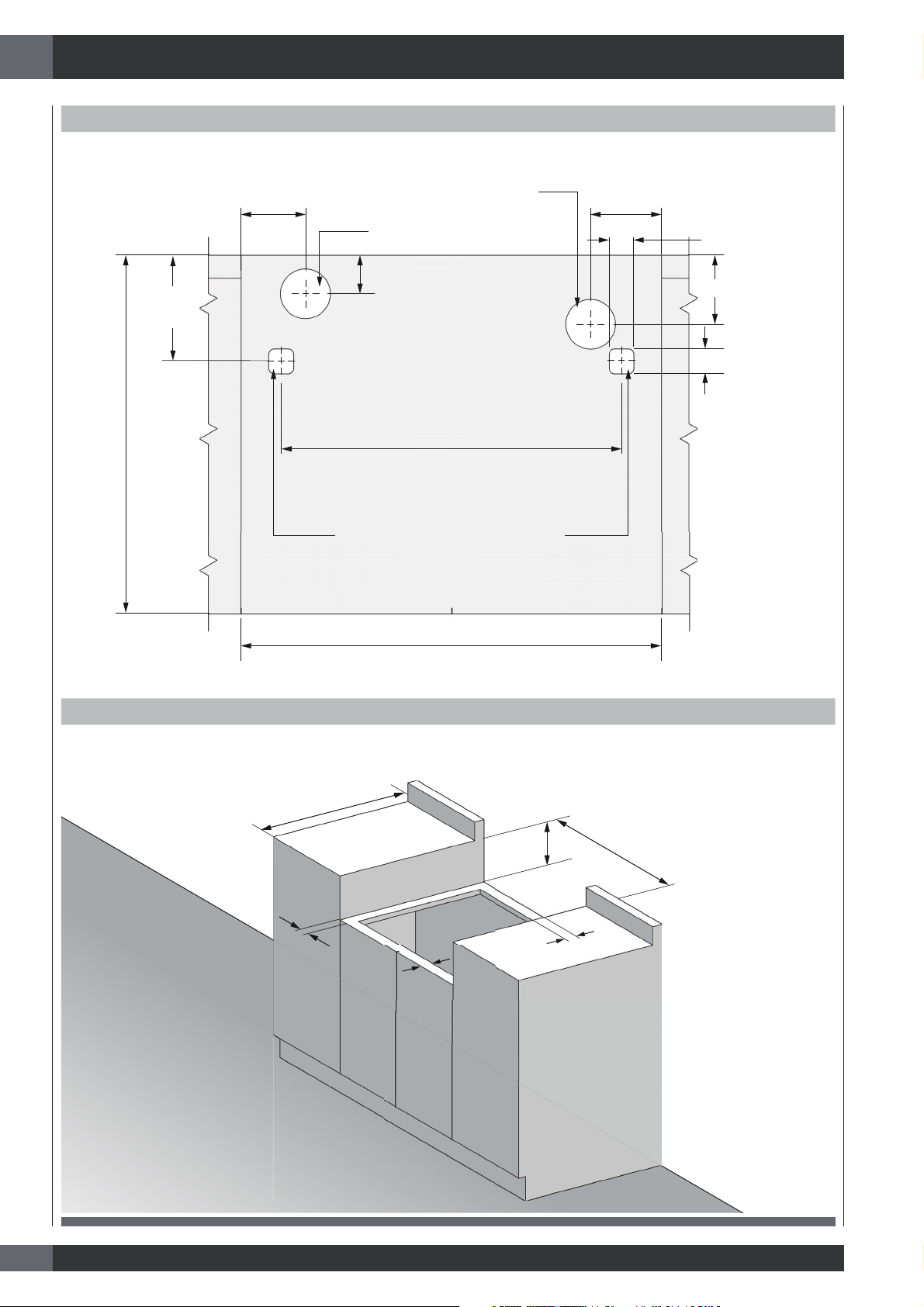

EN

2 - Product Dimensions and Cutout Requirements

INSTALLATION ON SOLID SURFACE

7 1/2”

(19.2)

min 24” (61)

max 25 1/2” (65)

4 5/8” (11.6)

HOLE FOR ELECTRICAL 3½” (9)

HOLE FOR GAS 3½” (9)

2 3/4” (7.0)

B

CUTOUT FOR FIXING BRAKETS

A

5” (12.8)

1 3/4” ( 4.5)

4 7/8” (12.5)

1 3/4” ( 4.5)

INSTALLATION WITHOUT SEPARATOR SHEET

min 24” (61)

max 25 1/2” (65)

7” (17.9)

2”

(

5

)

2” (5)

A

)

5

(

”

2

6

Page 11

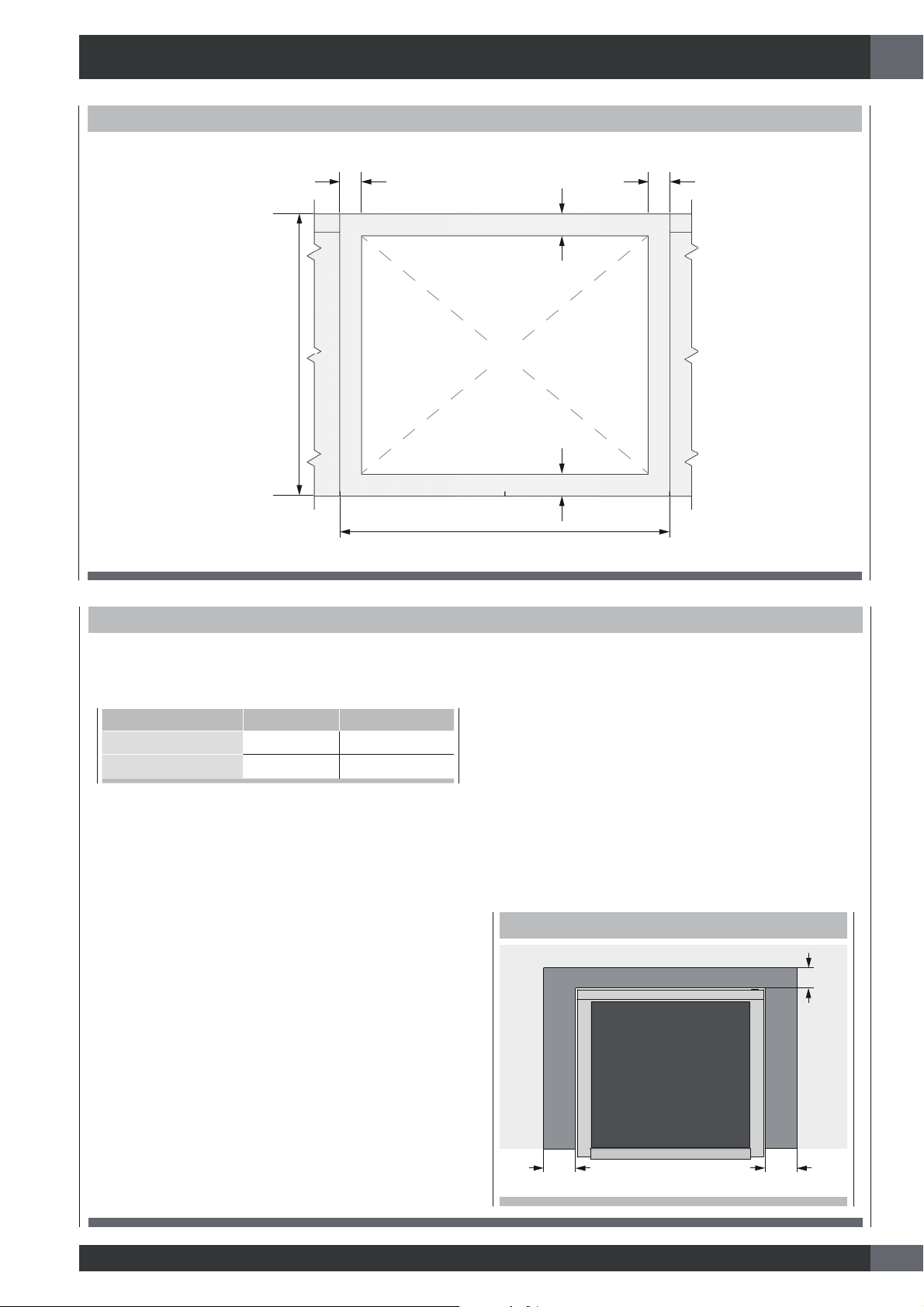

2 - Product Dimensions and Cutout Requirements

INSTALLATION ON OPEN FRAME

2” (5) 2” (5)

max 25 1/2” (65)

min 24” (61)

EN

2” (5)

EMPTY SPACE

2” (5)

A

CUTOUT REQUIREMENTS

The surface of the entire back wall above the range and below the hood must be covered with a noncombustible material.

*Consult local code for exact location requirements.

OPENING WIDTH A B

Rangetop 30” 30" (76.2) 24 1/4 (61.7)

Rangetop 36” 36" (91.4) 30 3/8 (77.1)

ADDITIONAL CLEARANCES:

For island installation, maintain 2-½ in. minimum from

cutout to back edge of countertop and 3 in. minimum from

cutout to side edges of countertop (see top view).

For installation in a stepped island, 12” (30.5 cm) minimum

Note: Clearances from non-combustible materials are not

part of the ANSI Z21.1 scope and not certied.

Clearances to non-combustible materials must

conform with local codes or, in the absence of local

clearance is required from the back or sides of the rangetop

to a combustible riser.

The island installation is not part of the ANSI Z21.1 scope

and not certified.

codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

Minimum clearances:

Above cooking surface (above 36” [91.4 cm])

FLUSH ISLAND INSTALLATION

BACK

• Sides - 6” (15.2 cm)

• Within 6” (15.2 cm) side clearance, wall cabinets no

deeper than 13” (33.0 cm) must be minimum 18” (45.7

cm) above cooking surface

• Wall cabinets directly above product must be a minimum

of 48” (122 cm) above cooking surface.

• Rear - 0” with 9 ” backguard; 0” with non-combustible

rear wall.

min 2 1/2” (6.3)

Below cooking surface (36” [91.4 cm] and below)

• Install with zero clearance between adjacent combustible

construction below the cooking surface and the back

and sides of the appliance.

min 3” (7.6) min 3” (7.6)

7

Page 12

EN

2 - Product Dimensions and Cutout Requirements

Vent hood Combinations:

It is recommended that these rangetops be installed in

conjunction with a suitable overhead vent hood.

Install a hood with at least 450 CFM.

Due to the high heat capacity of this unit, particular attention

should be paid to the hood and ductwork installation to assure

it meets local building codes.

WARNING

Air curtain or other overhead hoods, which operate by

blowing a downward air flow on to a rangetop, shall not be

used in conjunction with rangetop with gas cooktop other than

when the hood and rangetop have been designed, tested

and certified by an independent test laboratory for use in

combination with each other.

Clearances to horizontal surfaces above the rangetop,

measured to the cooking surface are below. Failure to

comply may result in fire hazard.

• Installations without a hood require 48” (122) minimum

to combustibles.

• A custom hood installation with exposed horizontal

combustible surfaces must have an Auto-On feature.

• For other installations with a hood, refer to the hood

installation instructions for specific hood clearances.

CAUTION

Due to the weight and size of the rangetop and to reduce the

risk of personal injury or damage to the product:

TWO PEOPLE ARE REQUIRED FOR PROPER INSTALLATION.

8

Page 13

3 - Installation Information

EN

WARNING

• Excessive Weight Hazard

Use two or more people to move and install rangetop.

Failure to do so can result in back or other injury.

• Cut Hazard

Beware of sharp edges. Use the polystyrene ends when

carrying the product. Failure to use caution could result in

minor injury or cuts.

CHOOSING RANGETOP LOCATION

Carefully select the location where the rangetop will be placed.

The rangetop should be located for convenient use in the

kitchen, but away from strong drafts.

Strong drafts may be caused by open doors or windows, or by

heating and/or air conditioning vents or fans.

IMPORTANT NOTE

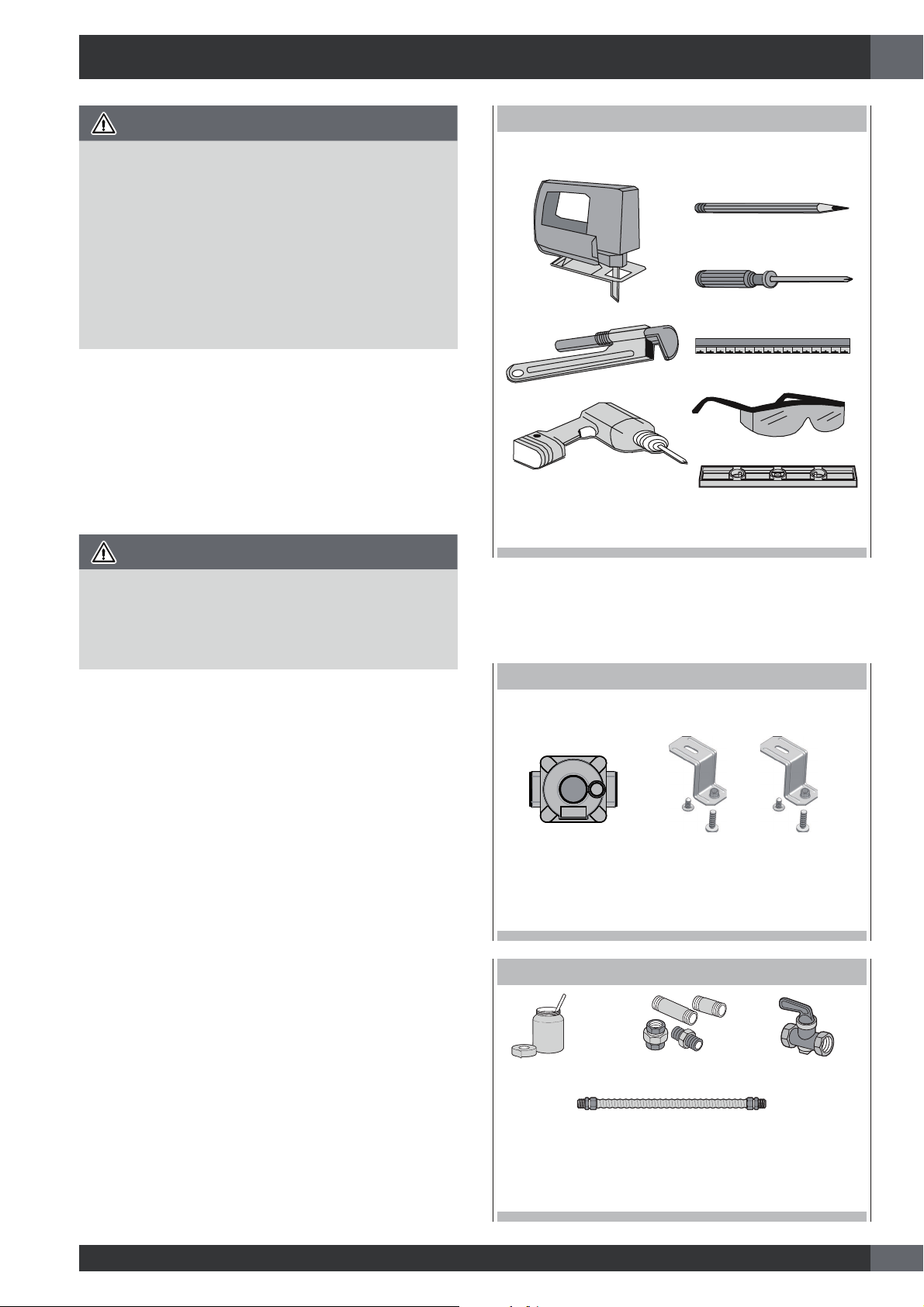

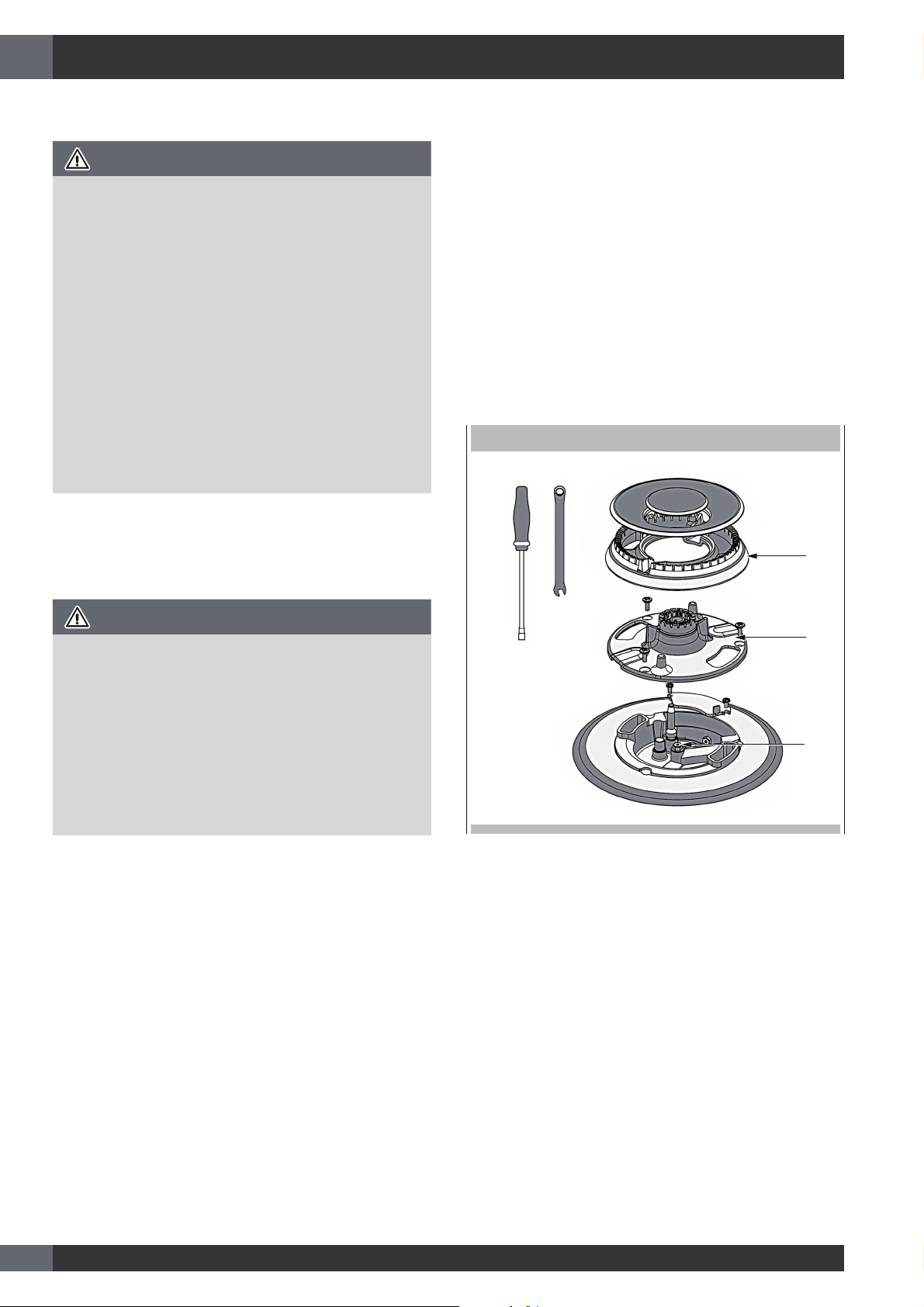

TOOLS WILL YOU NEED

When installing against a combustible surface, a minimum

riser is required for a the rangetop, Follow all minimum

clearances to combustible surfaces shown in the illustration

on the previous pages.

To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the surface

units should be avoided. If cabinet storage is to be provided,

the risk can be reduced by installing a rangetop hood that

projects horizontally a minimum of inches beyond the bottom

of the cabinets.

Remove packaging materials and literature package from the

cooktop before beginning installation.

Remove Installation Instructions from the literature pack and

read them carefully before you begin

MATERIALS PROVIDED

Appliance

pressure

regulator

Fixing brackets

Flare union Gasket

MATERIALS REQUIRED (not provided)

Joint Sealant

5-foot maximum length, 5/8” O.D. CSA-approved flexible

metal gas supply (3-foot maximum length in Massachusetts only)

NOTE: Purchase new flexible line; do not use previously used

flexible gas line.

Pipe Fittings

Shut-Off Valve

9

Page 14

EN

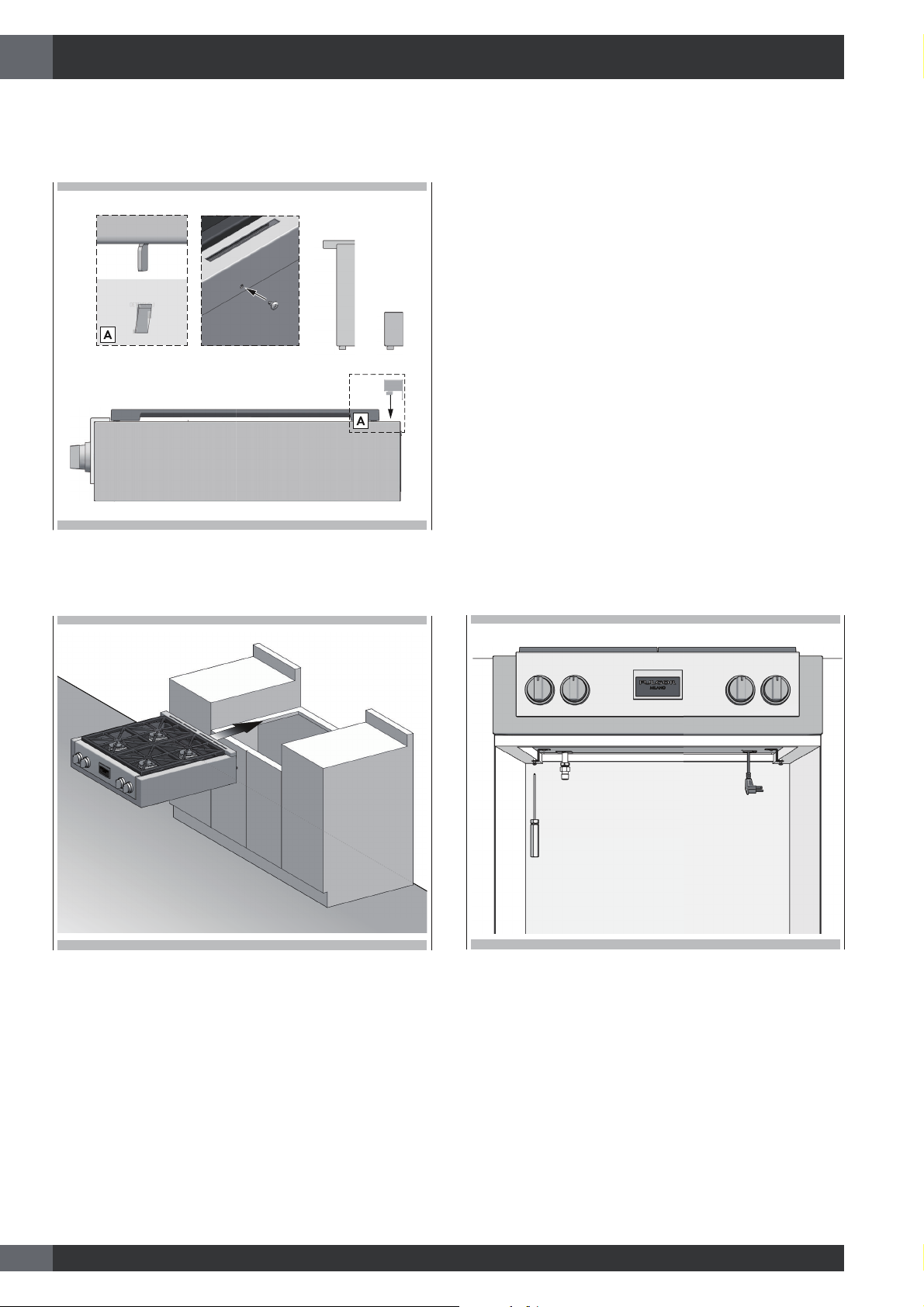

4 - Installation Instructions

STEP 1

Install the backsplash (if provided) by the three screws on the

back and the toe kick

3”9”

STEP 2

STEP 3

Two clamp brackets are provided with your unit.

After rangetop has been installed into the countertop, install the

brackets on the burner box as shown.

step A place the clamping screws into brackets

step B attach brackets by using the attachment screws on the

selected location of burner box, tighten screws just

enough to hold brackets in place

step C position brackets so that they are with the clamp screw

in contact with the counter top bottom

step D tighten attachment screws securely.

step E check that the front edge of the rangetop is parallel

to the front edge of the countertop tighten the screw

clamping against the countertop.

DO NOT OVER TIGHTEN

Slide the rangetop top into place.

10

Page 15

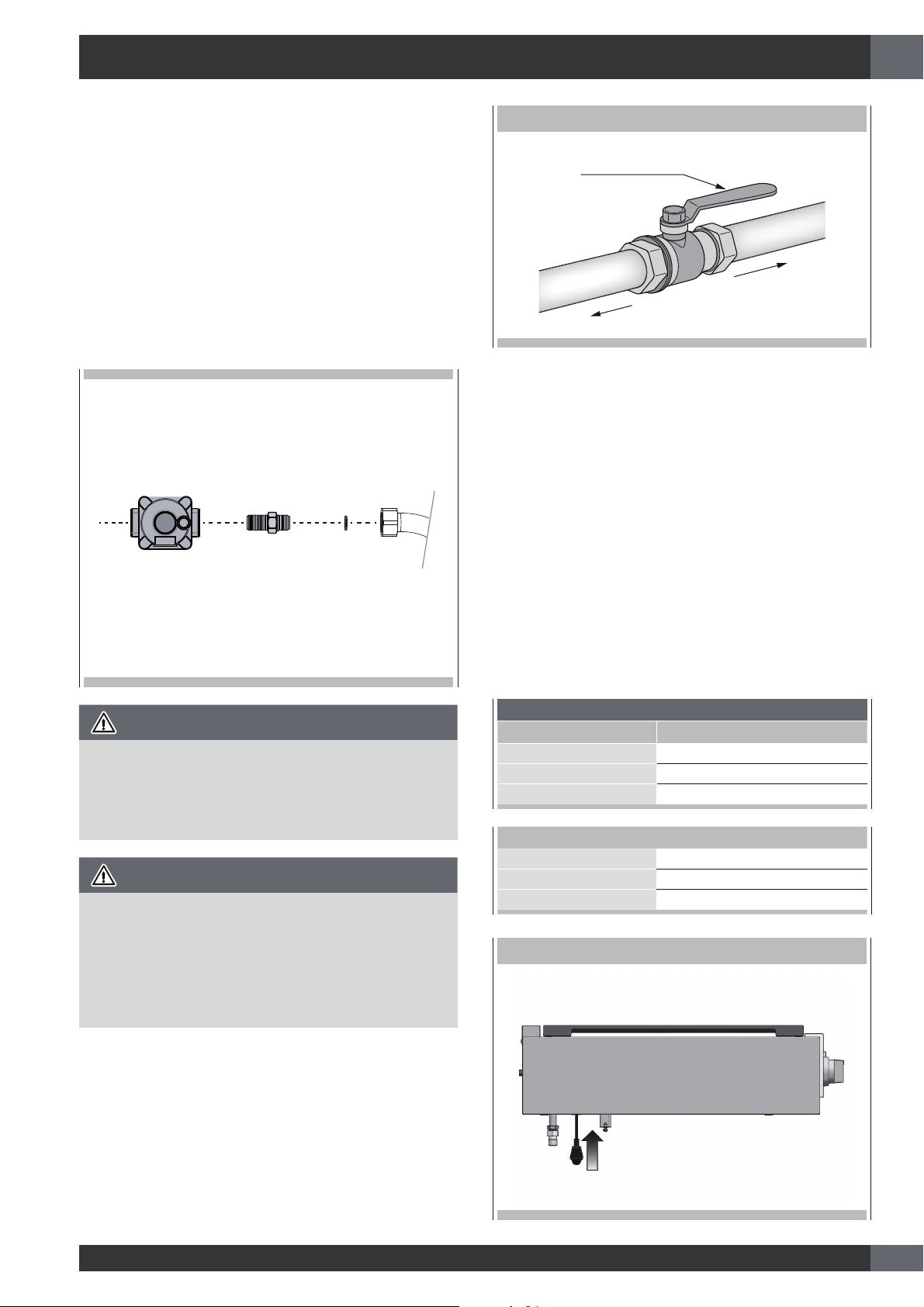

5 - Gas Requirement

EN

QUALIFIED SERVICE MAN OR GAS APPLIANCE INSTALLER

MUST MAKE THE GAS SUPPLY CONNECTION.

Leak testing of the appliance shall be conducted by the installer

according to the instructions given.

You must install the supplied connection parts seen here in

this configuration to the main gas manifold on the appliance.

Issues arising from a failure to do so will not be covered by

warranty.

Do not install the pressure regulator backwards as the gas will

not flow correctly. Check that the arrow on the back points in

the direction of gas flow.

Parts required for connection from gas supply to regulator are

the responsibility of the installer / owner

Appliance

GAS SHUT OFF VALVE

OPEN POSITION

AS SUPPLY

G

E

C

N

IA

L

TO APP

All supply piping, except as noted, should use common

National Pipe Thread (N.P.T.). For all pipe connections use an

approved pipe joint compound resistant to the action of LP gas.

This appliance is designed for use with NG gas or LP gas.

The gas pressure regulator is supplied with this appliance.

It must be installed in the gas ahead of the manifold entrance.

It is pre-set for use with natural gas. To use it with different

gas it must be converted, as described in the Gas Conversion

paragraph.

Appliance

pressure regulator

Flare union

adaptor

Gasket

ATTENTION

Use Teflon tape rated for gas applications at all threaded

connections.

Do not overtighten the connection at the manifold or you

could damage the gasket causing a leak.

WARNING

If the line pressure supplying the appliance pressure regulator

exceeds 14 inches W.C. (any gas), an external regulator

must be installed in the gas line ahead of the appliance

regulator to reduce the pressure to no more than 14 inches

W.C. Failure to do this can result in malfunction and damage

to the appliance.

If at any time the appliance is to be used with a different type

of gas, all the conversion adjustments must be made by a

qualified technician before attempting to operate the rangetop

with that gas.

The gas should be supplied to the appliance’s pressure regulator

at line pressure between 6 and 14 inches of water column for

NG, and between 11 and 14 inches of water column for LP.

GAS REQUIREMENTS

NATURAL GAS WC

Manifold Pressure 5" (12.5 mb)

Min Line Pressure 6" (15 mb)

Max Line Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

LP GAS WC

Manifold Pressure 10” (25 mb)

Min Line Pressure 11” (27.4 mb)

Max Line Pressure 14” (34.9 mb), .5 psi (3.5 kPa)

LOCATION OF GAS RATING PLATE

Important Notes for Gas Connection

The appliance and its individual gas shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2

psi (3.5 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.5 kPa).

11

Page 16

EN

5 - Gas Requirement

Pressure Testing

IMPORTANT

NEVER REUSE OLD CONNECTORS WHEN INSTALLING

THIS RANGETOP.

To reduce the likelihood of gas leaks, apply teflon tape or a

thread compound approved for use with LP or Natural gases

to all threaded connections.

Apply a non-corrosive leak detection fluid to all joints and

fittings in the gas connection between the supply line shut-off

valve and the cooktop inlet.

Check for leaks!

Bubbles appearing around fittings and connections will

indicate a leak. If a leak appears, turn off supply line gas

shut-off valve, tighten connections, turn on the supply line gas

shutoff valve, and retest for leaks. Never test for gas leaks

with an open flame.

NEVER TIGHTEN TO MORE THAN 35 ft lbs OF TORQUE

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG (3.5 kPa).

This appliance, as well as its individual shut-off valve, must be

disconnected from the gas supply piping system during any

pressure testing of the system at test pressures in excess of 1/2

PSIG (3.5 kPa).

When checking appliance regulator function, make certain

pressure of natural gas supply is between 6 and 14 inches of

water column or, if converted for LP gas, between 11 and 14

inches.

THE PRESSURE TESTING SHOULD BE PERFORMED BY

MEANS OF THE INJECTOR THREAD ZONE

EXPLODED VIEW OF BURNER

1

CAUTION

Do not attempt to attach the flexible connector directly to an

external pipe thread.

Connection requires flare union adapters.

For Massachusetts Installations:

1. Shut-off valve must be a “T” handle gas valve.

2. Flexible gas connector must not be longer than 36 inch.

3. Not approved for installation in a bedroom or a bathroom

unless unit is direct vent.

2

A

Pressure Test Method

• Remove grate and burner cap (1).

• Remove aluminum gas spreader (2).

• Temporarily remove the injectors (A).

• Connect the pressure Test instrument into injector holder

thread zone (M6x0,75).

• Check if the cooktop has the correct pressure.

• Fix the injector removed for testing and replace the parts in

the right position.

12

Page 17

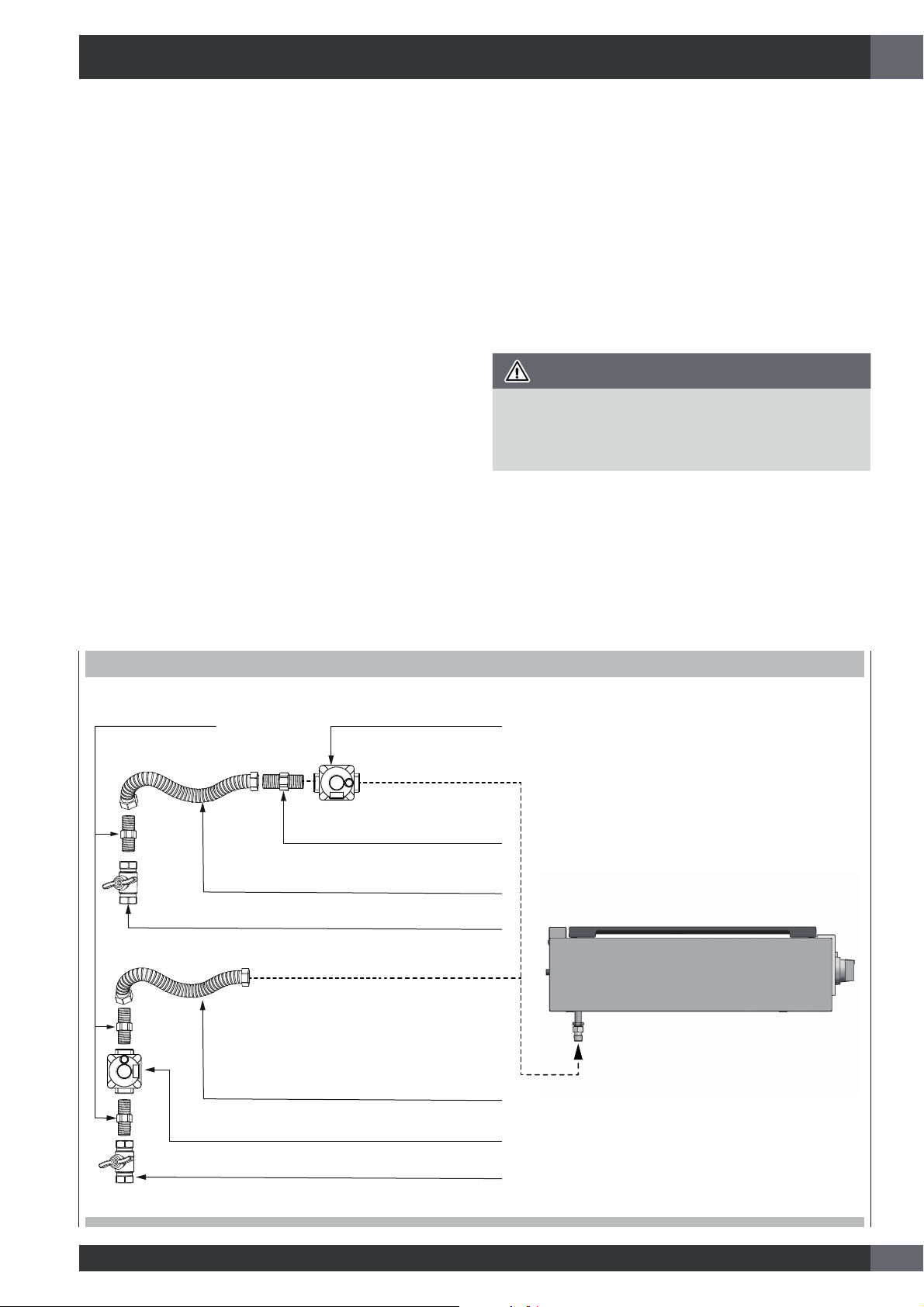

Gas Connection

5 - Gas Requirement

EN

• Thread the appliances pressure regulator with 1/2” male

end connection both supplied with this appliance.

• Join the pressure regulator to the entrance threads of the

Gas Manifold with gasket supplied with this appliance.

The regulator is marked with a directional arrow indicating

correct direction of gas flow. Ensure the appliance regulator

is installed with the arrow pointing toward the gas manifold

entrance.

• Connect a manual shut-off valve to the gas supply in an

accessible location for turning on or shutting off gas to the

appliance.

• Install a coupling between the regulator and the shutoff

valve to complete the connection.

• Assure all pipe joint connections are gas tight.

• Check alignment of valves after connecting the cooktop to

the gas supply to be sure the manifold pipe has not been

moved.

FOR ALTERNATIVE PIPING METHODS TO CONNECT THE

APPLIANCE TO THE GAS SUPPLY, A TRAINED SERVICE

TECHNICIAN OR GAS APPLIANCE INSTALLER MUST

MAKE THE GAS SUPPLY CONNECTION. Leak testing of the

appliance shall be conducted by the Installer according to the

Instructions given.

Unless prohibited by local codes or ordinances, a new A.G.A.

- Certified, flexible metal appliance connector may be used to

connect this appliance to its gas supply.

The connector must have an internal diameter not less than

nominal 1/2” NPT pipe and be no more than 5 feet in length.

A 1/2” NPT x 1/2” flare union adapter is required at each

end of the flexible connector.

If a flexible connector is used assure that both the appliance

pressure regulator and manual shut-off valve are joined solidly

to other permanent hard piping (either gas supply or the

appliance manifold) so as to be physically stationary.

CAUTION

Do not attempt to attach the flexible connector directly to an

external pipe thread.

Connection requires flare union adapters.

For Massachusetts Installations:

1. Shut-off valve must be a “T” handle gas valve.

2. Flexible gas connector must not be longer than 36 inches.

3. Not approved for installation in a bedroom or a bathroom

unless unit is direct vent.

FLARE UNION ADAPTOR

GAS CONNECTION

APPLIANCE PRESSURE REGULATOR

FLARE UNION ADAPTOR

FLEXIBLE APPLIANCE CONNECTOR

(5 FT.) MAX, (1.52 m) MAX

MANIFOLD SHUTOFF VALVES

FLEXIBLE APPLIANCE CONNECTOR

(5 FT.) MAX, (1.52 m) MAX

APPLIANCE PRESSURE REGULATOR

MANIFOLD SHUTOFF VALVES

13

Page 18

EN

6 - Conversion for LP or NG Gas

Converting Appliance for Use with LP Gas

WARNING

Conversion is to be performed by an AUTHORIZED

SERVICER (or other qualified agency) in accordance with the

manufacturer’s instructions and all codes and requirements of

the authority having jurisdiction. Failure to follow instructions

could result in serious injury or property damage.

The qualified agency performing this work assumes

responsibility for this conversion.

CAUTION

Before proceeding with the conversion, shut off the gas

supply to the appliance prior to disconnecting the electrical

power

If this appliance is to converted for use with gas LP (propane

or butane), each of the following modifications must be

performed:

Gas conversion label (aluminium) to be placed on the back of

the appliance, near the data plate, after conversion has been

carried out;

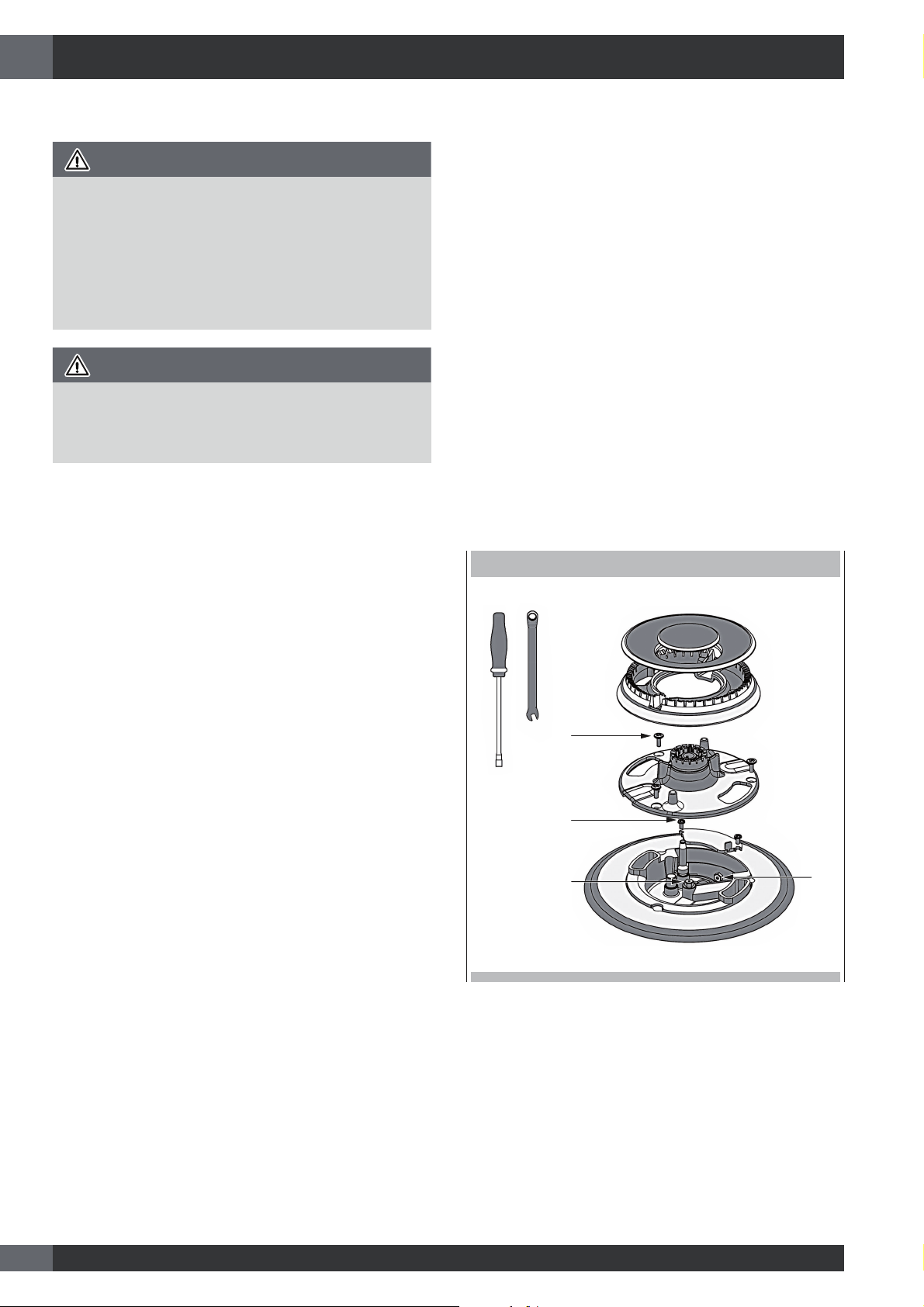

Replace Injectors (two ring flame burner)

1. Remove the grates and burner caps.

2. Remove aluminium gas spreader.

3. Remove the three screws from the simmer gas spreader (1).

4. Remove the two screws of the injector cover (2).

5. Remove injector (A) by using a 9-32” (7 mm) nut driver

counter clockwise.

6. Remove injector (B) by using a 9-32” (7 mm) box wrench

counter clockwise.

7. Install the injectors supplied with this appliance in the

appropriate burner. The injectors have small numbers

stamped on the side, this number corresponds with the

orifice diameter and its correct burner location (refer to

illustrations in the section: “Injectors Position”).

8. Turn clockwise to tighten (tighten to a torque of 15 to 20

inch-lbs).

9. Replace all parts following the reverse order.

10. Save the injectors removed from the appliances for future

use.

EXPLODED VIEW OF BURNER

1

2

A

B

14

Page 19

6 - Conversion for LP or NG Gas

EN

Proceed to Pressure Regulator Conversion noting the

LP / Propane position to complete the conversion.

After replacing the injectors adjust the burner flame (see Low

Flame Adjustment paragraph).

Check the appearance of each burner’s flame at HILO settings,

if the flame appears too large or too small make sure that all

steps were completed correctly.

Converting Appliances for Use with NG Gas

If this appliance should be converted for use with gas NG

(natural gas), each of the following modifications must be

performed.

1. Convert the pressure regulator to NG position as per the

section “Pressure Regulator Conversion”.

2. Replace all injectors following the step described on the

previous pages, observe the number stamped on the side,

this number corresponds to the orifice diameter and its

correct burner location (refer to the illustrations in section:

“Injectors Position”).

3. Adjust the burner flame (see Low Flame Adjustment section).

Check the appearance of each burner’s flame at HI - LO

settings, if the flame appears too large or too small make

sure that all steps were completed correctly.

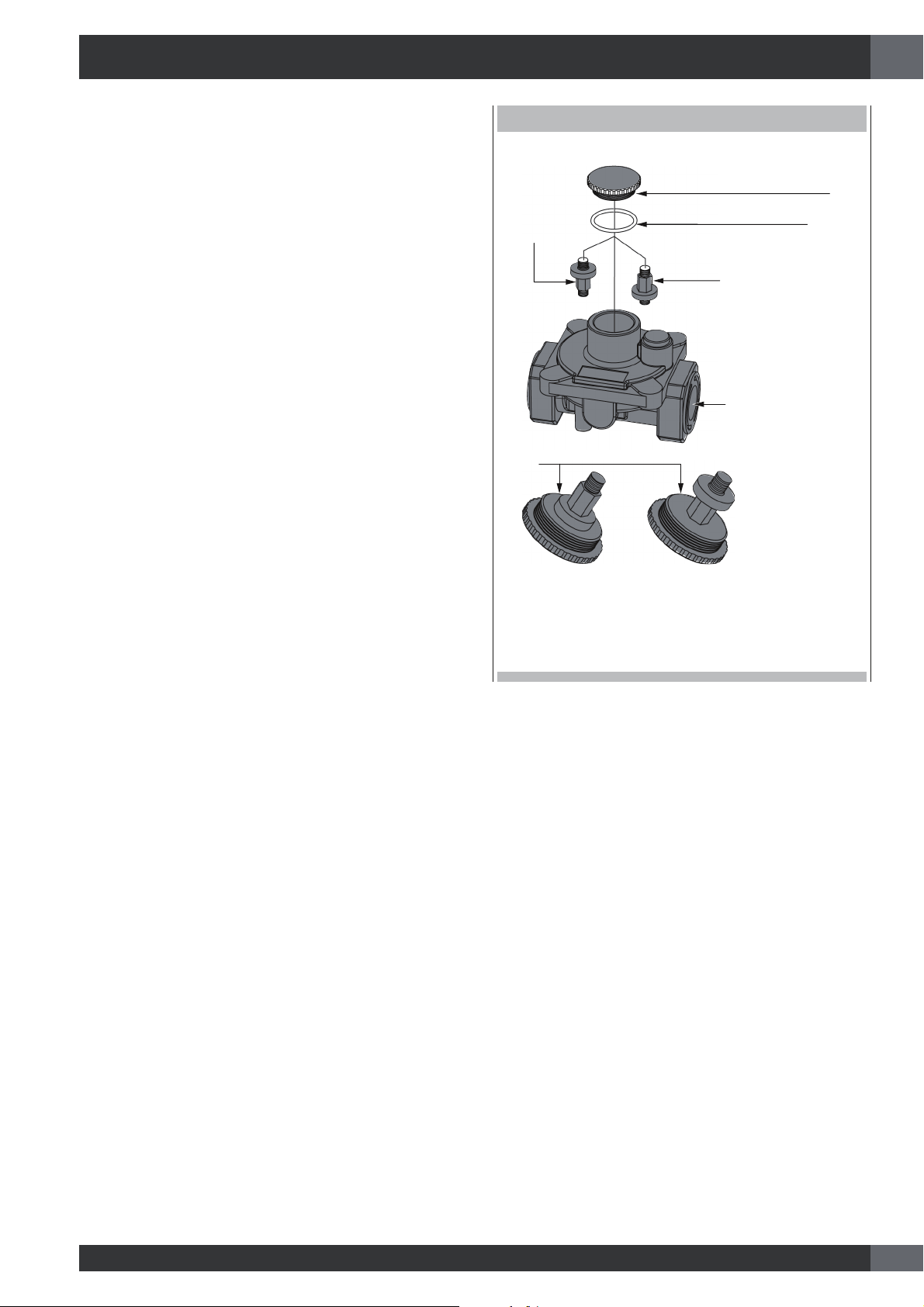

Pressure regulator conversion

The appliances is designed for use with NG gas or LP gas. The

gas pressure regulator is supplied. It must be installed in the

gas supply line ahead of the manifold entrance.

It is pre-set for use with the gas as indicated on the appliance

label supplied with the appliance. For use with different gas

the appliance must be converted.

For the pressure regulator conversion follow the instructions

below:

• Disconnect all electrical power, at the main circuit breaker

or fuse box.

• Shut off the gas supply to the cooktop by closing the manual

shut-off valve.

• Adjust the pressure regulator, by following the instruction

(see figure)

1. Unscrew the regulator cap

2. Unscrew the plastic conversion plug from the cap turn

over and screw back (wide section away from cap for

LP and against cap for NG) see figures below.

3. Replace the regulator cap ensuring gasket is in place.

PRESSURE REGULATOR CONVERSION

CAP

NG POSITION

PLUG

NG

LP/PROPANE POSITION

PRESSURE REGULATOR

LP

GASKET

Before replacing the regulator cap, check if the position

of plug is suitable for the gas

15

Page 20

EN

6 - Conversion for LP or NG Gas

INJECTORS POSITION

NG- DUAL FLAME RING 30”

SIMMER 72

MAIN FLAME 180

SIMMER 72

*MAIN FLAME 180 or

*MAIN FLAME 192

SIMMER 72

MAIN FLAME 180

NG- DUAL FLAME RING 36”

SIMMER 72

*MAIN FLAME 180 or

*MAIN FLAME 192

* depending on the model

16

Page 21

6 - Conversion for LP or NG Gas

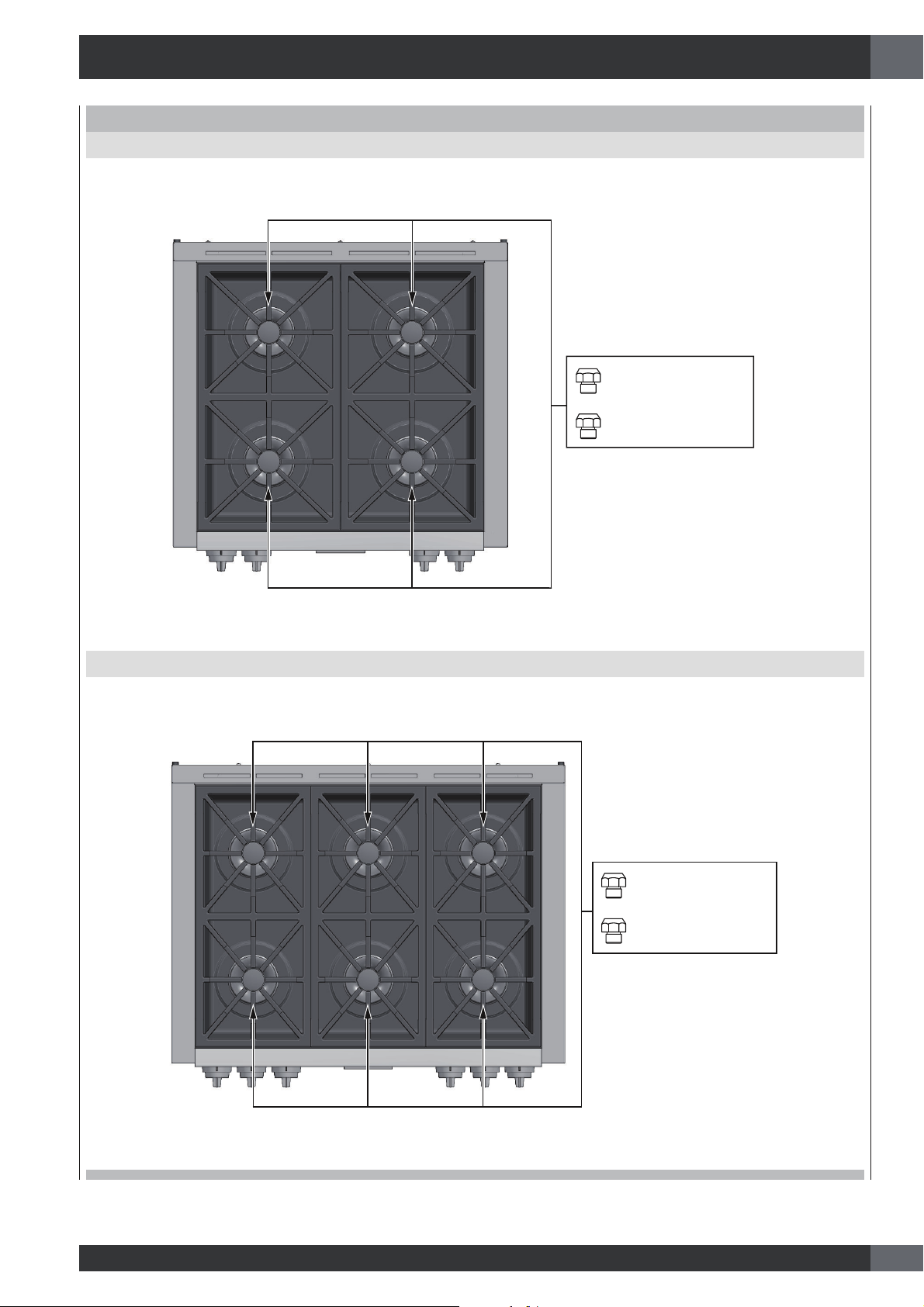

INJECTORS POSITION

LP- DUAL FLAME RING 30”

EN

SIMMER 50

MAIN FLAME 105

LP- DUAL FLAME RING 36”

SIMMER 50

MAIN FLAME 105

17

Page 22

EN

6 - Conversion for LP or NG Gas

Low Flame Adjustment

DANGER

Lighting gas burners with a match is dangerous.

You should match light the burners only in an emergency.

Light a match and hold the flame near the burner you want

to light. Wooden matches work best.

Push in and turn the control knob slowly.

Be sure you are turning the correct knob for the burner you

are lighting.

NOTE: If the burner does not light within five seconds, turn the

knob off and wait one minute before trying again.

CAUTION

If you attempt to measure the inner cone of the flame, please

use caution.

Burns could result.

This appliance is shipped from the factory with low and

medium flame settings adjusted.

If further adjustment is necessary, proceed as follows:

Adjustment for Burners with one or two flame rings:

1. Light burner and set control knob for low flame.

2. Remove control knob from valve stem.

3. Remove knob seat from control panel.

4. Insert a slender, thin-blade screwdriver into the recess

behind the control knob (A or B) and engage blade with

slot in adjusting screw.

5. Turn adjusting screw to set flame size:

• clockwise to reduce

• counterclockwise to increase

6. Replace control knob when adjustment is completed.

ADJUSTMENT FOR COOKTTOP BURNERS

A

B

MAIN FLAME

SIMMER

18

Page 23

Proper adjustment will produce a stable, steady blue flame of

minimum size.

The final adjustment should be checked by turning the knob

from high to low several times without extinguishing the flame.

This adjustment, at low setting, will automatically provide the

proper flame size at medium setting.

After Conversion steps have been completed, check the

appearance of each burner’s flame at the HI and LO settings,

if the flames appear too large or too small

review each step to make sure it was completed correctly.

NOTE: To obtain the correct minimum setting with LP gas,

turn clockwise tightening the valve(s) fully with the thin-blade

screwdriver into the recess behind control knob (A and / or B).

6 - Conversion for LP or NG Gas

EN

Electric Gas Ignition

The gas burners use an electric ignition device located near

each burner ensures burners ignite automatically.

ELECTRIC IGNITION

The Burner Flames

Turn each burner on. Flames should be blue in color with no

trace of yellow. The burner flames should not flutter or blow

away from the burner The inner cone of the flame should be

between 1/2” and 3/4” long.

BURNER FLAMES

1/2” to 3/4”

BURNER

See Use & Care manual for better explanation and its control.

19

Page 24

EN

7 - Electrical Requirements

General Information

This appliance must be supplied with the proper voltage and

frequency and connected to an individual, properly grounded

branch circuit, protected by a circuit breaker or fuse having

amperage as noted on the rating plate. We recommend you

have the electrical wiring and hookup of your appliance

connected by a qualified electrician.

After installation, have the electrician show you where your

main appliance disconnect is located. Check with your local

utilities for electrical codes which apply in your area. Failure to

wire your cooktop according to governing codes could result

in a hazardous condition.

If there are no codes, your appliance must be wired and fused

to meet the requirements of the National Electrical Code,

ANSI/NFPA No. 70 - Latest edition.

You can get a copy by writing:

National Fire Protection Association

Battery march Park

Quincy. MA 02269

In Canada your appliance must be wired and fused to meet

the requirements of the Canadian Electrical Code.

Be sure the installation of this product in a mobile home

conforms with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280.

If this standard does not apply, you must follow the standard

for Manufactured Home Installations, ANSI A225.1 and

Manufactured Home Installations, Sites and Communities and

ANSI/NFPA 501A or with local codes.

Electrical Connection

An adequate electrical supply and outlet must be used to

operate the electrical parts of your appliance.

WARNING

Electrical Grounding Instruction Plug into a grounded 3

prong outlet.

- Do not remove ground prong.

- Do not use an adapter.

- Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or

electrical shock.

You can get a copy of the Federal Standard by Writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

LOCATION OF RATING PLATE

IMPORTANT

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

The power cord of this appliance is equipped with a 3-prong

(grounding) plug which must be used with a properly grounded

3-hole outlet with a standard 120 Volt, 60 cycle AC household

current. If you do not have a 3-hole grounded outlet, have a

qualified electrician change your old one.

A grounding adaptor will be needed to convert the old one

until the outlet can be replaced. This method is only temporary,

and a qualified electrician should test it to be sure it meets

requirements.

20

Page 25

Electrical Requirements

7 - Electrical Requirements

EN

Do not under any circumstances cut or remove grounding

prong from the appliance cord.

PLUG POWER SUPPLY CORD

N

L

Grounding prong

WARNING

• If cold water pipe is interrupted by plastic, non metallic

gaskets, union connections or other insulating materials,

DO NOT use for grounding.

• DO NOT ground to a gas pipe.

• DO NOT have a fuse in the NEUTRAL or GROUNDING

circuit. A fuse in the NEUTRAL or GROUNDING circuit

could result in an electrical shock.

• Check with a qualified electrician if you are in doubt as to

whether the appliance is properly grounded.

• Failure to follow these instructions could result in serious

injury or death.

CAUTION

Do not repair or replace any part of the appliance unless

specifically recommended in the manual. All other servicing

should be done by a qualified technician. This may reduce

the risk of personal injury and damage to the appliance.

Never modify or alter the construction of the appliance by

removing panels, wire covers, screws, or any other part of

the product.

21

Page 26

EN

22

Page 27

Veuillez prêter attention à ces symboles que vous rencontrerez

dans ce manuel :

FR

TABLES DES MATIERES PAGE

1 - Avertissement Spéciaux 2

Avant de Procéder à l’Installation 2

Installation autocaravane 2

Micro-maisons préfabriquées 2

2 - Dimensions et Dispositions pour la Découpe 3

3 - Consignes d’installation 9

4 - Instructions d’Installation 10

5 - Conditions Requires Gaz 11

Vérification de la Pression 12

Méthode de Test de Pression 12

Raccordement du Gaz 13

6 - Conversion Gaz PL ou Gaz Naturel 14

Conversion de l’Appareil pour Fonctionner au

Gaz PL 14

Remplacez un injecteur (brûleur avec deux

anneaux de flamme) 14

Conversion des Appareils pour Une Utilisation

avec Gaz Naturel 15

Position des Injecteurs 16

Réglage Petite Flamme 18

Allumage à gaz électrique 19

Les Flammes du Brûleur 19

7 - Conditions Requises Electricité 20

Information Général 20

Branchement Electrique 20

Requises Electricité 21

DANGER

Si vous ne suivez pas IMMEDIATEMENT ces instructions,

vous courez le risque de mourir ou d’être sérieusement

blessé.

AVERTISSEMENT

Ce symbole signifie que la sécurité est en danger. Il signale

les risques potentiels qui peuvent entraîner la mort ou des

blessures à l’opérateur ou aux autres.

Si vous ne suivez pas ces instructions à la lettre, vous courez

le risque de mourir ou d’être sérieusement blessé.

BIEN LIRE CES INSTRUCTIONS ET LES CONSERVER.

À l’installateur :

Laissez ces instructions avec l’appareil.

Au client :

Gardez ces instructions comme référence future.

AVERTISSEMENT

Le respect minutieux des indications fournies dans ce manuel

est indispensable pour éviter le risque de feu ou d’explosion

susceptible d’endommager les biens et les produits et de

provoquer des blessures, voire même la mort.

Ne pas stocker ou utiliser de l’essence ou d’autres liquides

inflammables à proximité de cet appareil ou de tout autre

appareil électroménager.

IMPORTANT: Gardez ces instructions pour une utilization

d’inspection électrique locale

INSTALLATEUR: Veuillez laisser ce manuel au propriétaire

pour de futures références.

PROPRIETAIRE: Veuillez garder ce manuel pour de futures

références.

LEXIQUE: NG - Gaz naturel

LP - Propane liquide

1

Page 28

FR

1 - Avertissement Spéciaux

INSTRUCTION IMPORTANT

Veuillez lire les instructions avant toute utilisation.

Il est de votre responsabilité d’installer l’appareil correctement.

Confiez l’installation de cette cuisinières à un technicien

qualifié.

AVERTISSEMENT

- Respecter les règlements et ordonnances en vigueur.

- Avant l’installation de la cuisinière, noter le modèle et

les numéros de série. Les deux numéros se trouvent sur

la plaque de données dans la position indiquée dans la

figure ci-dessous.

POSITION DE LA PLAQUE SIGNALÉTIQUE

être conforme au Standard National Américain, à la

Réglementation Nationale Essence Gaz ANSI Z223.1

– NFPA 54 dernière édition** ou CAN/CGA-149.2

dernière édition***.

Vous pouvez demander une copie des standards répertoriés à:

** National Fire Protection Association One Batterymarch

Park Quincy, Massachusetts 02269

*** CSA International 8501 East Pleasant Valley Rd.

Cleveland, OH 44131 – 5575

NOTE: Cette cuisinières est fabriquée pour fonctionner au gaz

naturel*.

Si elle doit être raccordée au gaz propane/PL, ffectuez

la conversion en suivant les instructions rapportées dans

le kit de conversion gaz fourni avec les explications.

Une canalisation de fourniture de gaz correcte doit être

disponible. Voir «Conditions requises fourniture gaz».

WARNING

Avant de raccorder le dispositif à la ligne d’amenée du gaz,

vérifier que le type de gaz est réglé correctement. Le type de

gaz programmé et envoyé de l’usine est indiqué sur la plaque

signalétique.

Avant de Procéder à l’Installation

• Vérifiez l’endroit où la cuisinières sera installée. La table de

cuisson ne doit pas se trouver dans une zone de courants

d’air forts, par exemple de fenêtres ou de portes ni près de

calorifères ou de ventilateurs.

• L’appareil doit nécessairement être relié à la terre. Voir

«Conditions requises électricité».

• Veuillez vous assurer que l’installation électrique est

adéquate et conforme à la Réglementation Électrique

Nationale ANSI/NFPA 70 – dernière édition** ou à la

Réglementation Électrique du Canada, C22.1 – 1982 et

C22.2 N° 01982 (ou dernière édition)*** et à tous les

règlements et ordonnances en vigueur localement.

• Assurez-vous que le raccordement de gaz est conforme

aux règlements et ordonnances en vigueur localement.

En l’absence de règlements locaux, l’installation doit

Installation autocaravane

L’installation de cette table de cuisson doit être conforme

aux Normes de Construction et de Sécurité des Habitations,

titre 24 CFR, Partie 3280 (jadis la Norme Fédérale pour la

Construction et la Sécurité des Autocaravanes; titre 24HUD

partie 280); ou lorsque de telles normes ne sont pas

applicables, la Norme pour les Installations des Habitations

(Emplacements, Communautés et Structures Habitations),

ANSI 225.1 - dernière édition ou aux réglementations locales.

Au Canada, l’installation de cette table de cuisson doit être

conforme aux normes en vigueur CAN/CSA-Z240 - dernière

édition ou aux réglementations locales.

Micro-maisons préfabriquées

L’installation de ces dispositifs conçus pour micro-maisons

préfabriquées doit se faire conformément aux réglementations

nationales ou autres ou, à défaut, à la norme en matière de

micro-maisons préfabriquées ANSI A119.5.

2

Page 29

7” (17.9)

2 - Dimensions et Dispositions pour la Découpe

DIMENSIONS DU PRODUIT

Modèles de cuisinière 30”

29 3/4” (75.8)

FR

8 1/8” (20.6)

2” (5)

2” (5)

30” (76.2)

29 1/2” (75.1)

27 3/8” (69.7)

min. 24” (61)

max. 25 5/8” (65)

2” (5)

7” (17.9)

2” (5)

10” (25.5)

16 3/8” (41.5)

29 3/4” (75.8)

7” (17.9)

27 3/8” (69.7)

3

Page 30

FR

2 - Dimensions et Dispositions pour la Découpe

DIMENSIONS DU PRODUIT

Modèles de cuisinière 36”

35 3/4” (91.0)

7” (17.9)

8 1/8” (20.6)

2” (5)

2” (5)

36” (91.4)

29 1/2” (75.1)

27 3/8” (69.7)

min. 24” (61)

max. 25 5/8” (65)

2” (5)

7” (17.9)

2” (5)

10” (25.5)

16 3/8” (41.5)

7” (17.9)

35 3/4” (91.0)

4

27 3/8” (69.7)

Page 31

2 - Dimensions et Dispositions pour la Découpe

DISPOSITIONS POUR LA DÉCOUPE

min 48'' (122)

minimum par rapport

aux matériaux combustibles

A

max 13” (33)

min 30” (76.2) de

distance avec le

min 18” (45.7)

min 6” (15.2) min 6” (15.2)

fond de la hotte

d'aération

FR

INSTALLATION AVEC PLAQUE DE SEPARATION

(61)

min 24”

max 25 1/2” (65)

Raccordements pour

électricité et gaz

dans cette zone

17.9)

(

7”

A

5

Page 32

FR

2 - Dimensions et Dispositions pour la Découpe

INSTALLATION SUR UNE SURFACE SOLIDE

7 1/2”

(19.2)

min 24” (61)

max 25 1/2” (65)

4 5/8” (11.6)

TROU POUR CÂBLAGE 3½” (9)

2 3/4” (7.0)

B

DECOUPES POUR ETRIERS DE FIXATION

A

5” (12.8)

1 3/4” ( 4.5)TROU POUR LE GAZ 3½” (9)

4 7/8” (12.5)

1 3/4” ( 4.5)

INSTALLATION SANS PLAQUE DE SEPARATION

min 24” (61)

max 25 1/2” (65)

7” (17.9)

2” (

5

)

2” (5)

A

)

5

(

”

2

6

Page 33

2 - Dimensions et Dispositions pour la Découpe

INSTALLATION SUR UNE STRUCTURE OUVERTE

2” (5) 2” (5)

max 25 1/2” (65)

min 24” (61)

FR

2” (5)

VIDE

2” (5)

A

DISPOSITIONS POUR LA DÉCOUPE

La totalité de la surface du mur arrière ainsi que la surface se trouvant au-dessus de la table de cuisson doit être faite d’une

matière ignifuge.

*Consulter les réglementations locales pour les exigences exactes de localisation.

LARGEUR

A B

D’OUVERTURE

Cuisinière 30 po 30" (76.2) 24 1/4 (61.7)

Cuisinière 36 po 36" (91.4) 30 3/8 (77.1)

• Installation à dégagement nul entre la construction

combustible adjacente sous la surface de cuisson et les

parties arrière et latérale de l’appareil.

ESPACE SUPPLÉMENTAIRES:

Pour une installation en îlot, maintenir une distance minimum

Remarque: Les distances par rapport aux matières non

combustibles n’entrent pas dans le cadre de

l’ANSI Z21.1 et ne sont pas certiées.

La distance par rapport aux matériaux non

combustible doit respecter les réglementations

locales ou, en l’absence de celles-ci, avec le

« National Fuel Gas Code », ANSI Z223.1/

NFPA 54.

Dégagements minimums d’une construction:

Au-dessus de la surface de cuisson [au-dessus de 36 po (91.4 cm)]

de 6.3 cm (2 ½ po) entre le bord et le dos du comptoir et

7.6 cm (3 po) minimum sur les côtés du comptoir (voir vue

de dessus).

Pour une installation sur un îlot, un espace de minimum 12”

(30.5 cm) est nécessaire de l’arrière ou des côtés de la

cuisinière pour le brûleur.

L’installation de îlot ne fait pas partie de la norme ANSI

Z21.1 portée et pas certié.

INSTALLATION ÉBARBER

DOS

• Côtés - 6 po (15.2 cm)

• Avec un dégagement latéral de 6 po (15.2 cm) ou moins,

les placards muraux ne mesurant pas plus de 13 po (33

cm) de profondeur doivent se trouver à 18 po (45.7 cm)

minimum au-dessus de la surface de cuisson

• Les armoires murales juste au-dessus du produit doivent

se trouver à 48 po (122 cm) minimum au-dessus de la

surface de cuisson

• Arrière - 0 po avec dosseret de 9 po ou étagère

supérieure; 0 po avec paroi arrière non combustible.

min 2 1/2” (6.3)

Sous la plaque de cuisson (36” [91.4 cm] et au-dessous)

min 3” (7.6) min 3” (7.6)

7

Page 34

FR

2 - Dimensions et Dispositions pour la Découpe

Disposition de hotte d’extraction:

Il est recommandé d’installer nos cuisinières avec une hotte

d’extraction suspendue.

Installez une hotte disposant d’une capacité d’évacuation d’au

moins 450 CFM.

Cet appareil produisant une importante quantité de chaleur,

vous devez porter une attention toute particulière à l’installation

de la hotte et de la conduite d’aération afin de vous assurer

qu’elle répond aux normes de construction en vigueur dans

votre region.

AVERTISSEMENT

Les rideaux d’air ou les hottes de cuisinières qui projettent

un courant d’air descendant vers la table de cuisson, ne

doivent pas etres utilises avec des appareils à gaz, sauf si

la hotte et l’appareil ont ete concus, testes et repertories par

un laboratoire d’essai independant pour pouvoir fonctionner

conjointement.

Il faut prévoir les dégagements ci-dessous par rapport

aux surfaces horizontales qui se trouvent au-dessus de la

cuisinière.

Le non-respect de cette consigne pourrait présenter un risque

d’incendie.

• Pour les installations dépourvues de hotte, prévoyez un

espace minimum de 48” (122) entre l’appareil et tout

élément inflammable situé au-dessus de celui-ci.

• Il est possible d’installer une hotte spéciale à proximité

d’éléments horizontaux inflammables dans la mesure

où celle-ci dispose d’une fonction de mise en marche

automatique.

• Pour obtenir les spécifications relatives aux espaces

d’autres installations pourvues d’une hotte, veuillez vous

reporter aux instructions fournies avec celle-ci

ATTENTION

Afin d’éviter tout risque de blessure ou d’endommagement

de l’appareil et compte tenu du poids et de la taille de la

cuisinière:

DEUX PERSONNES SONT NÉCESSAIRES POUR UNE

INSTALLATION ADÉQUATE DES CUISINIÈRES.

8

Page 35

3 - Consignes d’installation

FR

AVERTISSEMENT

• Risque du fait du poids excessif

Soyez à deux personnes ou plus pour porter et installer la

cuisinières. Sinon, vous risquez de vous blesser au dos ou

de subir d’autres blessures.

• Risque de coupure

Méfiez-vous des bords tranchants et des extrémités du

polystyrène lorsque vous portez le produit. Sinon, vous

risquez de vous couper ou de vous faire légèrement mal.

CHOIX DE LA POSITION DE LA CUISINIÈRE

Choisissez attentivement l’emplacement d’installation de la

cuisinière.

La cuisinière doit être positionnée pour être utilisée dans la

cuisine, mais loin des courants d’air.

Une porte ou une fenêtre ouvertes, l’air mis en mouvement par

les ventilateurs de chauffage/climatisation peuvent causer des

courants d’air forts.

NOTE IMPORTANTE

Avant de commencer l’installation, enlevez les matériaux

d’emballage et les manuels d’explication sur la table de

cuisson; puis retirez du manuel d’explication, les instructions

concernant l’installation et lisez-les avec attention.

MATÉRIEL FOURNI

Régulateur de

pression appareil

Etriers de fixation

Adaptateur de

Joint

MATÉRIEL FOURNI (non fourni)

Si vous installez la cuisinière contre une surface combustible,

veillez à prévoir un minimum de rehausse.

Respectez toutes les distances par rapport aux surfaces

combustibles qui sont indiquées dans les pages précédentes

Pour éliminer le risque de brûlure ou d’incendie à cause

d’une surchauffe de la surface des unités, évitez de placer

une armoire de rangement au-dessus de l’unité. Si vous avez

une armoire au-dessus de la cuisinière, vous pouvez réduire

le risque en installant à une certaine distance au-dessous de

la partie inférieure de l’armoire un écran de protection qui

projette horizontalement.

LES OUTILS DONT VOUS AUREZ BESOIN

Scellant à joint

Tuyau métallique flexible d’alimentation de gaz agréé CSA de

1.58 cm de diamètre et d’une longueur maximale de 1.5 m (5

pieds) (Longueur maximum de 90 cm (3 pieds) dans le

Massachusetts uniquement)

NOTE: procurez-vous un tuyau flexible neuf, n’utilisez pas un tuyau

ayant déjà été utilisé.

Raccords de tuyau

Clapet de fermeture

9

Page 36

FR

4 - Instructions d’Installation

ÉTAPE 1

Installez le dosseret (si fourni) au moyen de trois vis dans la

partie postérieure et la plinthe

3”9”

ÉTAPE 2

Faire glisser la cuisinière pour la mettre en place.

ÉTAPE 3

2 étriers de fixation sont fournis avec l’unité.

Une fois la table de cuisson encastrée dans le plan de travail,

fixez les étriers sur la caisse du brûleur comme indiqué.

Etape A: placez les vis de fixation dans les étriers.

Etape B: attachez les étriers par des vis de fixation aux

endroits choisis sur la boîte du brûleur, serrez les vis

juste assez pour tenir en place les étriers.

Étape C: positionnez les étriers et les vis de fixation de sorte

qu’ils soient au contact du bas du plan de travail.

Étape D: bien serrer les vis de fixation.

Étape E: vérifiez que le bord antérieur de la table de cuisson

est bien parallèle au bord du plan de travail, serrez

la vis de fixation contre le plan de travail.

BIEN SERRER MAIS PAS TROP FORT

10

Page 37

5 - Conditions Requires Gaz

FR

LE RACCORDEMENT À LA CONDUITE DE GAZ DOIT ÊTRE

EFFECTUÉ PAR UN TECHNICIEN D’ENTRETIEN QUALIFIÉ OU UN

INSTALLATEUR DE GAZ.

La vérification de fuites de l’appareil doit être effectuée par

l’installateur selon les instructions données.

Vous devez installer les pièces de raccordement fournies

indiquées ici au collecteur principal de gaz de l’appareil. Les

problèmes résultant de la non application de ceci ne seront

pas couverts par la garantie.

Ne pas installer le régulateur de pression en contre-courant car

le gaz ne passera pas correctement. Vérifier que la flèche à

l’arrière pointe en direction du flux de gaz.

Les pièces nécessaires pour le raccordement à l’alimentation en

gaz sont de la responsabilité de l’installateur/du propriétaire

Appareil

Régulateur de

pression

de l’appareil

Adaptateur

raccordement

brûleur

Joint

individuel de fermeture du gaz, lors de toute vérification de

pression du système de canalisation de gaz à des pressions

de test égales ou inférieures à ½ psi (3.5 kPa).

ROBINET D’ARRET DU GAZ

POSITION OUVERT

ALIMENTATION EN GAZ

VERS L’APPAREIL

Toutes les canalisations, sauf celles spécifiées diversement,

doivent utiliser du Filetage Conduite National normal (N.P.T.).

Pour tous les raccordements de conduite, utilisez un compound

de joint de conduite homologué résistant à l’action du gaz PL.

Cet appareil est conçu pour être utilisé avec le régulateur de

pression du gaz qui vous est fourni.

Il doit être installé sur la canalisation, en avant de l‘entrée du

tuyau de gaz. Il est préréglé pour fonctionner au gaz naturel

et doit être converti, comme décrit en ‘’Conversion Gaz’’, s’il

doit fonctionner au gaz PL.

ATTENTION

Utiliser du ruban Téflon adapté pour les applications avec

gaz sur tous les raccords filetés.

Ne pas trop serrer le raccord au collecteur. Cela pourrait

endommager le joint et causer des fuites.

AVERTISSEMENT

Si la conduite fournissant le régulateur de pression de

l’appareil a une pression de plus de 14 pouces C.E. (pour

n’importe quel gaz), il est nécessaire d’installer un régulateur

externe sur la conduite de gaz, en avant du régulateur de

l’appareil, afin de réduire la pression à 14 pouces C.E.

ou moins. Si vous ne le faisiez pas, vous risqueriez des

dysfonctionnements de l’appareil et des dommages.

Notes importantes pour le raccordement à la canalisation

du gaz

L’appareil et son robinet individuel de fermeture du gaz

doivent être débranchés des canalisations de gaz durant toute

vérification de pression de ce système, à des pressions de

test allant au-delà de ½ psi (3.5 kPa). Vous devez également

isoler l’appareil des canalisations de gaz en fermant le robinet

Cet appareil est conçu pour fonctionner à une pression de 5

pouces de colonne d’eau sur le gaz naturel ou s’il fonctionne

au gaz PL (propane ou butane) à une pression de 10 pouces

de colonne d’eau. Bien s’assurer que cet appareil est livré et

équipé avec le type de gaz pour lequel il a été conçu. Cet

appareil a été réglé en usine pour fonctionner au gaz naturel.

Si pour une raison ou une autre, vous deviez utiliser un autre

type de gaz, n’essayez pas de faire fonctionner la cuisinièr

avec le gaz différent mais appelez un technicien spécialisé

qui effectuera tous les réglages de conversion décrits en

‘’Conversion Gaz’’.

Le gaz naturel doit arriver au régulateur de pression de

l’appareil à une pression de conduite entre 6 et 14 pouces de

colonne d’eau ou si converti au gaz PL entre 11 et 14 pouces.

EXIGENCES D’ALIMENTATION EN GAZ

GAZ NATUREL CE (Colonne d’eau)

Indicateur de Pressure 5 po (12,5 mb)

Pression min. de la conduite 6 po (15 mb)

Pression max. de ligne 14 po CE (34.9 mb),

0.5 lb/po² ( 3.5 kPa)

GAZ PL CE (Colonne d’eau)

Indicateur de Pressure 10 po (25 mb)

Pression min. de la conduite 11 po (27,4 mb)

Pression max. de ligne 14 po CE (34.9 mb),

0.5 lb/po² ( 3.5 kPa)

11

Page 38

FR

5 - Conditions Requires Gaz

ENDROIT DE LA PLAQUE DE GAZ

IMPORTANT

NE JAMAIS RÉUTILISER DE VIEUX RACCORDS POUR

INSTALLER CET APPAREIL.

Afin de limiter les fuites de gaz possibles, appliquez un

ruban adhésif téflon ou un compound de filetage homologué

pour l’emploi avec du gaz naturel ou du gaz PL sur tous les

raccords filetés.

Appliquez un fluide non-corrosif de détection de fuite sur tous

les joints et raccords de la conduite de gaz entre le robinet de

fermeture du gaz et l’entrée de la table de cuisson. Vérifiez

qu’il n’y a pas de fuites! Des bulles qui se forment autour

des joints et des raccords indiquent la présence d’une fuite.

Dans ce cas, fermez le robinet de fermeture du gaz, serrez

les raccords, ouvrez à nouveau le robinet de fermeture et

vérifiez s’il y a encore des fuites. Ne jamais vérifier s’il y a

des fuites avec une flamme directe.

NE JAMAIS SERRER À PLUS DE 35 ft Ibs (pieds livre) DE

TORSION.

Vérification de la Pression

Vous devez isoler l’appareil des canalisations de gaz en

fermant le robinet individuel de fermeture du gaz lors de tout

test de pression du système de canalisation de gaz à des

pressions de test égales ou inférieures à ½ psig (3,5kPa).

Cet appareil et son robinet individuel de fermeture du gaz

doivent être débranchés des canalisations de gaz durant tout

test de pression de ce système à des pressions de test allant audelà de ½ psig (3.5kPa). Lorsque vous vérifiez la fonction du

régulateur de l’appareil, bien vous assurer que le gaz naturel

est fourni à une pression entre 6 et 14 pouces de colonne

d’eau et si converti au gaz PL entre 11 et 14 pouces.

LE TEST DE PRESSION SOIT ETRE EFFECTUE EN EMPLOYANT

LA ZONE DE FILETAGE DE L’INJECTEUR

VUE EXPLOSÉE DU BRÛLEUR

1

2

A

CAUTION

N’essayez pas de raccorder le connecteur flexible

directement à un tuyau fileté extérieur.

Il est nécessaire d’utiliser des adaptateurs évasés.

Pour Massachusetts Installations :

1. La vanne de fermeture doit être un robinet à gaz à

poignée en T.

2. Le connecteur gaz flexible ne doit pas avoir plus de 36

pouces de long.

3. L’installation dans une chambre ou une salle de bains

n’est pas permise si l’unité n’est pas à évent direct.

12

Méthode de Test de Pression

• Enlevez la grille et le chapeau du brûleur (1).

• Enlevez le diffuseur aluminium de gaz (2).

• Enlevez les injecteurs temporaires (A).

• Connectez l’instrument de test sur la zone de filetage du

porte-injecteur(M6x0.75).

• Vérifiez si la table de cuisson a une pression correcte.

• Fixez l’injecteur enlevé pour le test et replacez les pièces

dans leur bonne position.

Page 39

Raccordement du Gaz

5 - Conditions Requires Gaz

FR

• Taraudez le régulateur de pression de l’appareil à l’aide

des deux extrémités mâles de ½’’ en dotation avec cet

appareil.

• Assemblez le régulateur de pression aux filetages

d’entrée du tuyau de gaz avec le joint en dotation. Sur le

régulateur, vous pouvez voir une flèche indiquant le bon

sens de circulation du gaz. Assurez vous que le régulateur

de l’appareil est bien installé avec la flèche pointée vers

l’entrée du tuyau de gaz;

• Raccordez au tuyau de gaz, un robinet de fermeture qui

soit facile d’accès pour ouvrir ou fermer l’arrivée de gaz à

l’appareil.

• Installez un emmanchement entre le régulateur et le robinet

de fermeture pour compléter le raccordement.

• Bien vérifier que tous les joints de raccordement sur la

conduite de gaz sont étanches.

• Une fois le raccordement à la table de cuisson effectué,

bien vérifier l’alignement des soupapes pour être sûr que le

tuyau n’a pas bougé.

AUTRES POSSIBILITÉS DE RACCORDEMENT DE L’APPAREIL

À UNE CONDUITE DE GAZ UN TECHNICIEN D’ENTRETIEN

QUALIFIÉ OU UN INSTALLATEUR FOURNISSEUR DE GAZ

DOIVENT EFFECTUER LE RACCORDEMENT DU GAZ. La

recherche de fuites possibles sur l’appareil doit être réalisée par

l’installateur selon les instructions données.

Vous pouvez utiliser un connecteur d’appareil en métal flexible

récemment certifié A.G.A pour raccorder cet appareil à la

conduite de gaz. Le connecteur doit avoir un diamètre interne

d’au moins ½ NPT nominal et n’être pas plus long que 5 pieds.

Il faut un adaptateur raccord évasé de ½’’ NPT x ½’’ à chaque

extrémité du connecteur flexible. Si vous utilisez un connecteur

flexible, veillez à ce que le régulateur de pression de l’appareil

ainsi que le robinet de fermeture soient solidement raccordés

à une autre conduite rigide permanente (la conduite de gaz

ou le tuyau de l’appareil) de façon à être physiquement fixe.

ATTENTION

N’essayez pas d’attacher directement le connecteur flexible

à un filetage de tuyau externe.

Le branchement requiert des adaptateurs de raccord évasés

Pour des installations Massachusetts:

1. Le robinet de fermeture doit être un robinet de gaz à «T».

2. La longueur du connecteur de gaz flexible ne doit pas

dépasser 36 pouces.

3 N’est pas approuvé pour être installé dans des chambres

ou une salle de bain sauf si la pièce est ventilée directement.

ADAPTATEUR D’UNION ÉVASÉ

RACCORD GAZ

RÉGULATEUR DE PRESSION APPAREIL

ADAPTATEUR D’UNION ÉVASÉ

CONNECTEUR D’APPAREIL FLEXIBLE (5 PIEDS MAX.)

ROBINET DE FERMETURE TUYAU

CONNECTEUR D’APPAREIL FLEXIBLE (5 PIEDS MAX.)

RÉGULATEUR DE PRESSION APPAREIL

ROBINET DE FERMETURE TUYAU

13

Page 40

FR

6 - Conversion Gaz PL ou Gaz Naturel

Conversion de l’Appareil pour Fonctionner au

Gaz PL

AVERTISSEMENT

La conversion au gaz propane doit être effectuée par UN

TECHNICIEN D’ENTRETIEN AUTORISÉ (ou un autre centre

autorisé) selon les instructions du fabricant et les normes et

réglementations des autorités de juridiction. Le non-respect

de ces instructions peut entraîner des blessures graves ou des

dommages à la propriété. Le centre autorisé ayant effectué

la conversion s’en assume la responsabilité.

ATTENTION

Avant de procéder à la conversion, couper l’alimentation en

gaz de l’appareil avant de couper l’alimentation.

Cet appareil a été prédisposé en usine pour fonctionner au

gaz naturel. Pour le convertir au gaz PL (propane ou butane),

vous devez effectuer chacune des modifications suivantes:

Étiquette de conversion de gaz (aluminium) à placer à l’arrière

de l’appareil, en proximité de la plaque signalétique, à

conversion effectuée;

Remplacez un injecteur (brûleur avec deux

anneaux de flamme)

1. Enlevez les grilles et les bagues de brûleur

2. Enlevez le diffuseur de gaz en aluminium

3. Enlevez les trois vis du diffuseur de gaz pour cuisson douce

(1)

4. Enlevez les deux vis du couvercle de l’injecteur (2)

5. Desserrez l’injecteur (A) en tournant la clé à douille de

9-32” (7 mm) dans le sens inverse des aiguilles d’une

montre

6. Desserrez l’injecteur (B) en tournant la clé polygonale de

9-32” (7 mm) dans le sens inverse des aiguilles d’une

montre

7. Installez les injecteurs fournis avec les appareils sur le

brûleur approprié. Les injecteurs ont un petit numéro gravé

sur le côté, ces chiffres codent le diamètre de l’orifice et

l’emplacement correct du brûleur (consulter les illustrations

à la section “Position des injecteurs”).

8. Tournez dans le sens des aiguilles d’une montre pour serrer

(couple de serrage 15 à 20 inch-lbs)

9. Replacez les pièces suivantes dans l’ordre inverse

10. Gardez les injecteurs enlevés des appareils pour un usage

postérieur.

VUE EXPLOSÉE DU BRÛLEUR

1

2

A

B

14

Page 41

6 - Conversion Gaz PL ou Gaz Naturel

FR

Procéder à la conversion du régulateur de pression en

prenant note de la position LP/Propane pour achever la

conversion.

Après le remplacement des injecteurs, réglez la flamme

des brûleurs (voir ‘’Réglage de la flamme basse’’). Vérifiez

l’apparence de chaque flamme des brûleurs sur les réglages

HI-LO, si la flamme semble trop grande ou trop petite, vérifiez

si les étapes on bien été suivies correctement.

Conversion des Appareils pour Une Utilisation

avec Gaz Naturel

Si les appareils devaient être convertis pour une utilisation

avec le gaz naturel, il faut effectuer chacune des modifications

suivantes.

1. Commuter le régulateur de pression à la position NG

conformément aux indications de la section “Conversion

du régulateur de pression”.

2. Remplacez tous les injecteurs suivant l’étape décrite dans

les pages précédentes, observez le chiffre gravé sur le côté,

ce chiffre code le diamètre de l’orifice et l’emplacement

correct du brûleur (consulter les illustrations à la section

“Position des injecteurs”).

3. Ajustez la flamme du brûleur (voir “Réglage de la flamme”).

Vérifiez l’apparence de chaque flamme de brûleur sur les

réglages HI-LO, si la flamme semble trop grande ou trop petite,

vérifiez que les étapes ont bien été suivies correctement.

RÉGULATEUR DE PRESSION

CHAPEAU

GAZ NATUREL

BRANCHEMENT

NG

POSITION PROPANE

LP

JOINT

GAZ LIQUEFIE

REGULATEUR

DE PRESSION

Avant de replacer le chapeau du regulateur, verifiez

que la position du branchement est appropriee pour la

conversion du gaz

Conversion du régulateur de pression

Le dispositif est conçu pour être utilisé avec du gaz NG ou LP.

Le régulateur de pression de gaz est fourni. Il doit être installé

sur la ligne d’amenée de gaz devant l’entrée du collecteur.

Il est pré-réglé pour être utilisé avec le gaz indiqué sur l’étiquette

du dispositif fourni avec l’appareil. Pour l’utilisation avec un

gaz différent, il est nécessaire de convertir le dispositif.

Pour la conversion du régulateur de pression, suivez les

instructions ci-dessous:

• Déconnectez tous les branchements électriques, au

disjoncteur principal ou à la boîte de fusible.

• Fermez l’alimentation de gaz à la table de cuisson en

fermant manuellement le robinet de retenue.

• Ajustez le régulateur de pression, en suivant les instructions

(voir figure)

1. Dévissez le couvercle du régulateur.

2. Dévissez la fiche d’alimentation de conversion en

plastique du chapeau tournez et revissez (grande

section retirée du chapeau pour gaz liquéfié et contre le

chapeau pour le gaz naturel) (voir figure.

3. Remplacer le bouchon du régulateur en veillant à ce que

le joint soit en place.

15

Page 42

FR

6 - Conversion Gaz PL ou Gaz Naturel

POSITION DES INJECTEURS

NG- BRÛLEURS AVEC DOUBLE ANNEAU DE FLAMME 30”

FEUX DOUX

FLAMME PRINCIPALE 180

72

FEUX DOUX

*FLAMME PRINCIPALE 180 ou

*FLAMME PRINCIPALE 192

NG- BRÛLEURS AVEC DOUBLE ANNEAU DE FLAMME 36”

72

FEUX DOUX

FLAMME PRINCIPALE 180

* dépend du modèle

16

72

FEUX DOUX

*FLAMME PRINCIPALE 180 or

*FLAMME PRINCIPALE 192

72

Page 43

6 - Conversion Gaz PL ou Gaz Naturel

POSITION DES INJECTEURS

LP- BRÛLEURS AVEC DOUBLE ANNEAU DE FLAMME 30”

FR

FEUX DOUX

FLAMME

PRINCIPALE 105

LP- BRÛLEURS AVEC DOUBLE ANNEAU DE FLAMME 36”

50

FEUX DOUX

FLAMME

PRINCIPALE 105

50

17

Page 44

FR

6 - Conversion Gaz PL ou Gaz Naturel

Réglage Petite Flamme

AVERTISSEMENT

Allumer des brûleurs à gaz avec une allumette est dangereux.

Vous ne devriez allumer un brûleur avec une allumette que

dans un cas urgent. Allumez une allumette et tenir la flamme

près du brûleur que vous voulez allumer.

Ce sont les allumettes en bois qui fonctionnent le mieux.

Enfoncez et tournez le bouton lentement. Assurez- vous que

vous tournez bien le bouton du brûleur que vous voulez

allumer.

NOTE: Si le brûleur ne s’allume pas dans les 5 secondes,

remettez le bouton en position off, attendez une minute

et ré-essayez à nouveau.

AVERTISSEMENT

Si vous essayez de mesurer le cône interne de la flamme,

faites attention. Vous pourriez vous brûler.

Cet appareil est prédisposé en usine pour une flamme petite et

moyenne et fonctionne au gaz naturel.

Si d’autres réglages sont, veuillez procéder de la sorte:

Réglage pour brûleurs avec un ou deux anneaux de

flamme:

1. Allumez le brûleur et positionnez le bouton sur petite

flamme.

2. Enlevez le bouton de commande de la tige de la soupape.

3. Retirez la base du bouton du panneau de commande.

4. Introduire un tournevis fin à pointe plate dans la fente au

centre de la tige de la vanne (A ou B) et introduire la pointe

dans la rainure de la vis de réglage.

5. Tournez la tige du centre pour ajuster la flamme et

déterminer sa taille.

• dans le sens des aiguilles d’une montre, vous réduisez

la flamme

• dans le sens contraire des aiguilles d’une montre, vous

augmentez la flamme

6. Replacez le bouton de commande en fin d’opération.

RÉGLAGE POUR BRÛLEURS TABLE DE CUISSON

A

CHAMPIGNON

B FLAMME PRINCIPALE

18

Page 45

Un ajustement correct produira une flamme bleue de taille

minimum, stable et constante. Vérifiez le réglage final en

tournant plusieurs fois le bouton de la position flamme haute

à flamme basse sans que la flamme ne s’éteigne. Ce réglage

à position faible indiquera automatiquement la taille de la

flamme sur la position moyenne.

Une fois que les étapes de conversion sont terminées, vérifiez

l’aspect de la flamme de chaque brûleur en position HI et LO. Si

les flammes semblent trop larges ou trop hautes, revoir chaque

étape afin de vérifier qu’elles ont été exécutées correctement.

REMARQUE: Pour obtenir le réglage minimum correct avec

le gaz de PL, tourner dans le sens des aiguilles

d’une montre en serrant totalement la vanne

avec le tournevis plat dans la rainure au centre

de la tige de vanne (A ou B).

6 - Conversion Gaz PL ou Gaz Naturel

FR

Allumage à gaz électrique

Les brûleurs à gaz utilisent un appareil à allumage électrique

situé près de chaque brûleur qui assure que les brûleurs

s’allument automatiquement.

ALLUMAGE À GAZ ÉLECTRIQUE

Les Flammes du Brûleur

Allumez chaque brûleur. Les flammes devraient être de couleur

bleu sans aucune trace de jaune. Les flammes du brûleur ne

devraient pas tressaillir ou s’écarter du brûleur.

Le cône interne de la flamme devrait être long de ½‘’ à ¾‘’.

FLAMMES DU BRÛLEUR

1/2” to 3/4”

BRÛLEUR

Voir le Manuel d’utilisation et d’entretien pour une meilleure

explication de fonctionnement de la table de cuisson.

19

Page 46

FR

7 - Conditions Requises Electricité

Information Général

Le voltage et la fréquence de cet appareil doivent être

conformes à ceux du réseau; en outre, il doit être correctement

relié à la terre et protégé par un disjoncteur général ou un

fusible ayant un ampérage comme spécifié sur la plaque

signalétique. Nous vous recommandons de faire exécuter le

branchement électrique de votre appareil par un électricien

compétent. Après l’installation, demandez-lui de vous montrer

où se situe l’interrupteur général de la appareil. Vérifiez auprès

des autorités locales les normes d’électricité qui s’appliquent à

votre zone d’habitation. Un branchement électrique incorrect

est synonyme de risque. Dans le cas où il n’y aurait pas de

normes spéciales, votre appareil sera branchée et protégée par

des fusibles aux termes des Normes d’Électricité Nationales,

ANSI/NFPA N°70-dernière édition.

Vous pouvez obtenir une copie en écrivant à:

National Fire Protection Association

Battery march Park

Quincy. MA 02269

Au Canada, le branchement électrique de votre appareil et

les fusibles doivent être conformes aux Normes d’Électricité du

Canada. Assurez-vous que l’installation de ce produit dans une

autocaravane est conforme aux Normes de Construction et de

Sécurité des Habitations, Titre 24CFR, Partie 3280, ou lorsque

de telles normes ne sont pas applicables, à la Norme pour les

Installations d’Habitations, ANSI A225.1, à la Norme pour les

Installations des Habitations, Emplacements et Communautés

et ANSI/NFPA 501A ou aux réglementations locales.

Branchement Electrique

Vous devez disposer d’une fourniture et d’une sortie électrique

adéquate pour que les pièces électriques de votre tappareil

fonctionnent.

AVERTISSEMENT

RISQUE D’ÉLECTROCHOC

Branchez dans une prise à 3 fils avec mise à la terre.

- Ne pas enlever le conducteur de mise à la terre.

- Ne pas utiliser un adaptateur.

- Ne pas utiliser un câble d’extension.

La non-observation de ces instructions peut entraîner la mort,

un incendie ou un électrochoc.

Vous pouvez obtenir une copie de la Norme Fédérale en

écrivant à:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

POSITION DE LA PLAQUE SIGNALÉTIQUE

IMPORTANT

POUR VOTRE SÉCURITÉ PERSONNELLE, CET APPAREIL

DOIT NÉCESSAIREMENT ÊTRE RELIÉ À LA TERRE.

Le câble d’alimentation de cet appareil est équipé d’une fiche

à 3 fils (mise à la terre) qui doit être branchée dans une prise

à 3 fils mise à la terre correctement et disposant d’un courant

alternatif standard de 120 Volt et 60 cycles. Si votre prise n’est

pas reliée à la terre, demandez à un électricien de vous la

remplacer; et en attendant, utilisez un adaptateur reliant à la

terre pour convertir la vieille prise.

Cette solution ne peut être que temporaire et un électricien

compétent devrait la tester pour être sûr qu’elle correspond

aux normes.

20

Page 47

Requises Electricité

7 - Conditions Requises Electricité

FR

Ne jamais en aucun cas couper ou enlever la mise à la terre

du câble électrique de la appareil.

CÂBLE D’ALIMENTATION AVEC FICHE

N

L

Mise à la terre

WARNING

• Si un tuyau d’eau froide est interrompu par un plastique,

des joints non métalliques; des connexions d’union ou

d’autres matériaux isolants. NE L’UTILISEZ pas pour

mettre à la masse.

• Ne branchez pas la masse à un tuyau à gaz.

• N’AYEZ PAS de fusible en position neutre ou un circuit à

la masse.

• Un fusible dans un circuit neutre ou à la masse pourrait

entraîner une électrocution.

• Vérifiez avec un électricien qualifié si vous avez un doute

si votre appareil est correctement raccordé à la masse.

• Si vous ne suivez pas bien ces instructions, cela peut

entraîner des blessures graves ou la mort.

CAUTION

Ne réparez ou ne remplacez pas des pièces de l’appareil

si ce n’est pas spécifiquement recommandé dans le manuel.

Tous les autres dépannages doivent être effectués par un

technicien qualifié. Ce qui réduirait les risques de blessures

et d’endommagements du apareil.

Ne modifiez jamais ou n’altérez jamais la construction de

l’appareil en enlevant des panneaux, des couvertures de fil,

des vis, ou toute autre pièce du produit.

21

Page 48

FR

22

Page 49

Preste la debida atención a los siguientes símbolosque

encontrará en el manual:

ES

TABELA DE CONTENIDO

1 - Advertencias Especiales 2

Antes de comenzar la instalación 2

Instalación en Casas Móviles 2

Micro-casas prefabricadas 2

2 - Dimensiones del Producto y de Encastre 3

3 - Información de instalación 9

4 - Instrucciones para la Instalación 10

5 - Conexión del Gas - Requisitos 11

Prueba de Presión 12

Método de la prueba de presión 12

Conexión del Gas 13

6 - Conversión a Gas LP o NG 14

Conversión del Electrodoméstico para su Uso con

Gas LP 14

Sustitución de los inyectores (quemadores de

doble corona de combustión) 14

Conversión de los Electrodomesticos para

Utilizarlos con Gas NG 15

Posición de los Inyectores 16

Graduación de la Llama Baja 18

Ignición eléctrica del gas 19

Las llamas del quemador 19

7 - Conexión Eléctrica - Requisitos 20

Information Général 20

Conexión Eléctrica 20

Conexión Eléctrica - Requisitos 21

PAG E

PELIGRO

Si no sigue estas instrucciones de forma INMEDIATA, puede

correr peligro de muerte o de resultar gravemente herido.

ADVERTENCIA

Este es el símbolo de los avisos relacionados con la

seguridad: alerta sobre potenciales peligros que pueden

derivar en muerte o daños a las personas.

Si no sigue estas instrucciones, puede correr peligro de

muerte o de resultar gravemente herido.

LEA Y CONSERVE ESTAS INSTRUCCIONES.

Instalador:

Deje las instrucciones con el electrodoméstico.

Cliente:

Conserve las instrucciones como referencia futura.

ADVERTENCIA

Respetar minuciosamente las indicaciones aportadas en este

manual es indispensable para evitar el riesgo de incendio

o de explosión que podrían estropear los bienes y los

productos y provocar heridas, y hasta provocar la muerte.

No almacene ni utilice gasolina u otros vapores o líquidos

inflamables cerca de este ni otro electrodoméstico.

IMPORTANTE: Guarde estas instrucciones para el uso del