Page 1

OVER THE RANGE MICROWAVE OVEN

INSTALLATION GUIDE

GUIDE D’INSTALLATION

Page 2

EN

Installation GuideInstallation Guide

IMPORTANT–Please Read and Follow!

• Please read all instructions thoroughly before installing the Built-In Microwave Hood. Two people are recommended to

install this product.

• If a new electrical outlet is required, its installation should be completed by a qualified electrician before the Built-In

Microwave Hood is installed. See ELECTRICAL GROUNDING INSTRUCTIONS on page 3.

Unpacking and Examining Your Oven

Open the bottom of the carton, bend the carton flaps back

and tilt the oven over to rest on plastic foam pad. Lift carton

off oven and remove all packing materials, Wall and Top

Cabinet Templates, Turntable and Turntable Support. SAVE

THE CARTON AS IT MAY MAKE INSTALLATION EASIER.

• Remove the feature sticker from the outside of the door,

if there is one.

• DO NOT REMOVE THE WAVEGUIDE COVER, which is

located on the right-side wall of the oven cavity. Check

to see that there is a Wall Template and Top Cabinet

Template. Read enclosures and SAVE the Use and Care

manual.

Check the oven for any damage, such as misaligned or bent

door, damaged door seals and sealing surfaces, broken or

loose door hinges and latches and dents inside the cavity

or on the door. If there is any damage, do not operate the

oven and contact your dealer or AUTHORIZED SERVICER.

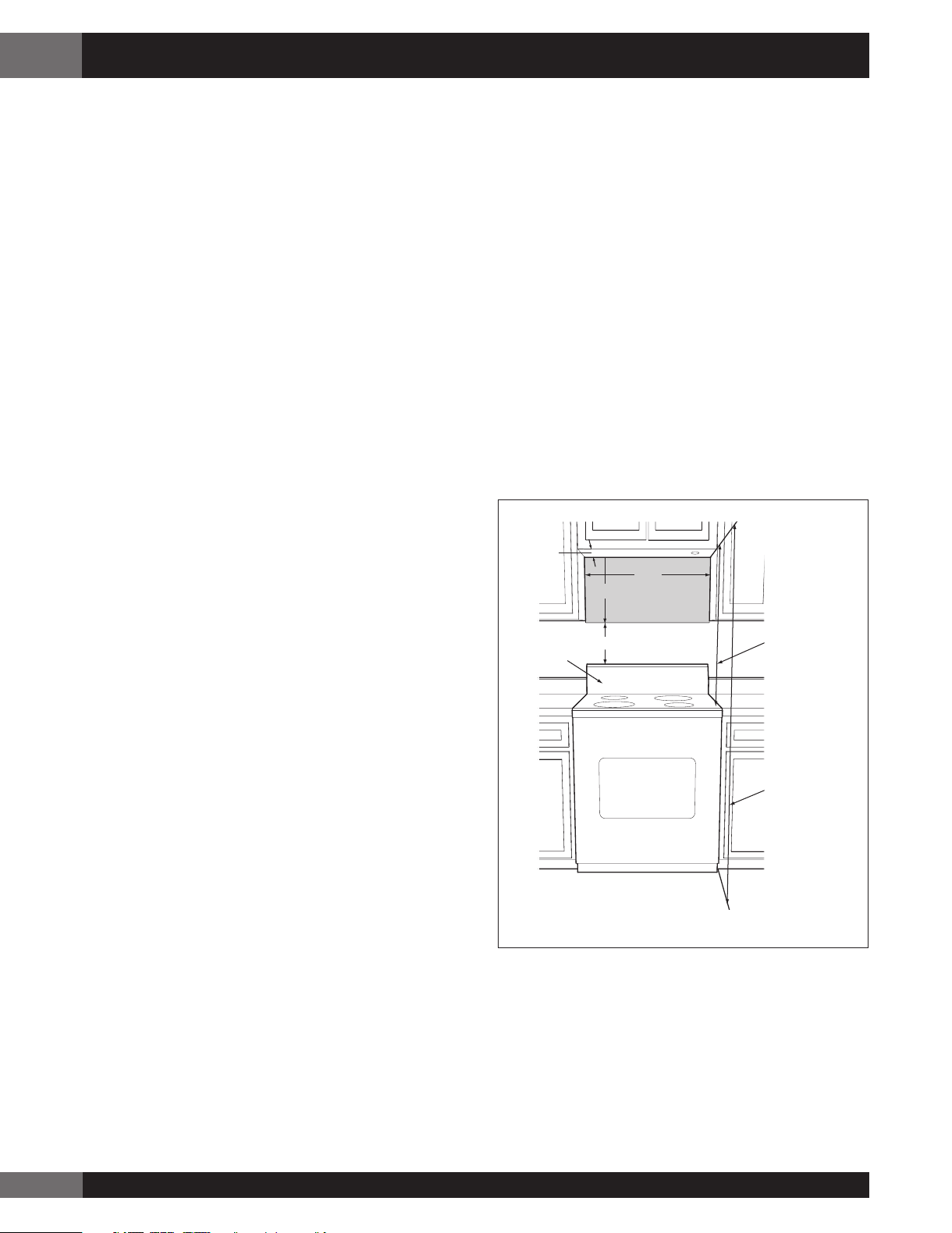

1. Mounting Space

This Built-In Microwave Hood requires a mounting space

on a wall as shown in Figure 1.

If the space between the wall cabinets is greater than

30-inches (36-inches or 42-inches) a Filler Panel may be

used to fill the gap between the Built-In Microwave Hood

and wall cabinets. The Filler Panel Kit should be installed

before the Built-In Microwave Hood is installed.

For proper installation and servicing, a 2-inch space is

necessary between the top of the range backsplash and

the bottom of the Built-In Microwave Hood.

12"

30"

16.3"

30" or more

from cooking

surface

Backsplash

At least 2"

66" or more

from floor

Figure 1

2

Page 3

Installation Guide

EN

2. Wall Construction

This Built-In Microwave Hood should be mounted against

and supported by a flat vertical wall. The wall must be flat

for proper installation. If the wall is not flat, use spacers to

fill in the gaps.

Wall construction should be a minimum of 2” x 4” wood

studding and

The mounting surfaces must be capable of supporting a

weight of 110 pounds—the oven and contents—AND the

weight of all items that would normally be stored in the top

cabinet above the unit. The unit should be attached to a

minimum of one 2” x 4” wall stud.

To find the location of the studs, one of the following methods

may be used:

• Use a stud finder, a magnetic device which locates the

nails in the stud.

• Use a hammer to tap lightly across the mounting surface

to find a solid sound. This will indicate stud location.

The center of the stud can be located by probing the wall

with a small nail to find the edges of the stud and then

placing a mark halfway between the edges. The center of

any adjacent studs will normally be 16” or 24” to either

side of this mark.

3

/8” or more thick drywall or plaster/lath.

3. ELECTRICAL

GROUNDING

INSTRUCTIONS

This appliance must be grounded. This oven is equipped

with a cord having a grounding wire with a grounding

plug. It must be plugged into a wall receptacle that is

properly installed and grounded in accordance with the

National Electrical Code and local codes and ordinances.

In the event of an electrical short circuit, grounding reduces

risk of electric shock by providing an escape wire for the

electric current.

WARNING - Improper use of the grounding plug can result

in a risk of electric shock.

The Power Supply Cord and plug must be connected to a

separate 120 Volt AC, 60 Hz, 15 Amp, or more branch

circuit, single grounded receptacle.

Ground

Receptacle

2"x 4" Wood Studs

16" or 24"

3/8" Dry Wall

or Plaster/Lath

Figure 2

NOTE: In the event that the unit will be unable to be

supported by any stud, it will be necessary to use special

care in the placement of the toggle bolts and top cabinet

screws. See Wall Template for details. The top cabinet

should be tested to ensure it is securely attached to the

wall. Place extra weight up to 110 pounds inside the top

cabinet to test the support.

Opening for

Power Cord

Figure 3

NOTE:

1. If you have any questions about the grounding or

electrical instructions, consult a qualified electrician or

serviceperson.

2. Neither Fulgor Milano nor the dealer can accept any

liability for damage to the oven or personal injury

resulting from failure to observe the correct electrical

connection procedures.

3

Page 4

EN

Installation Guide

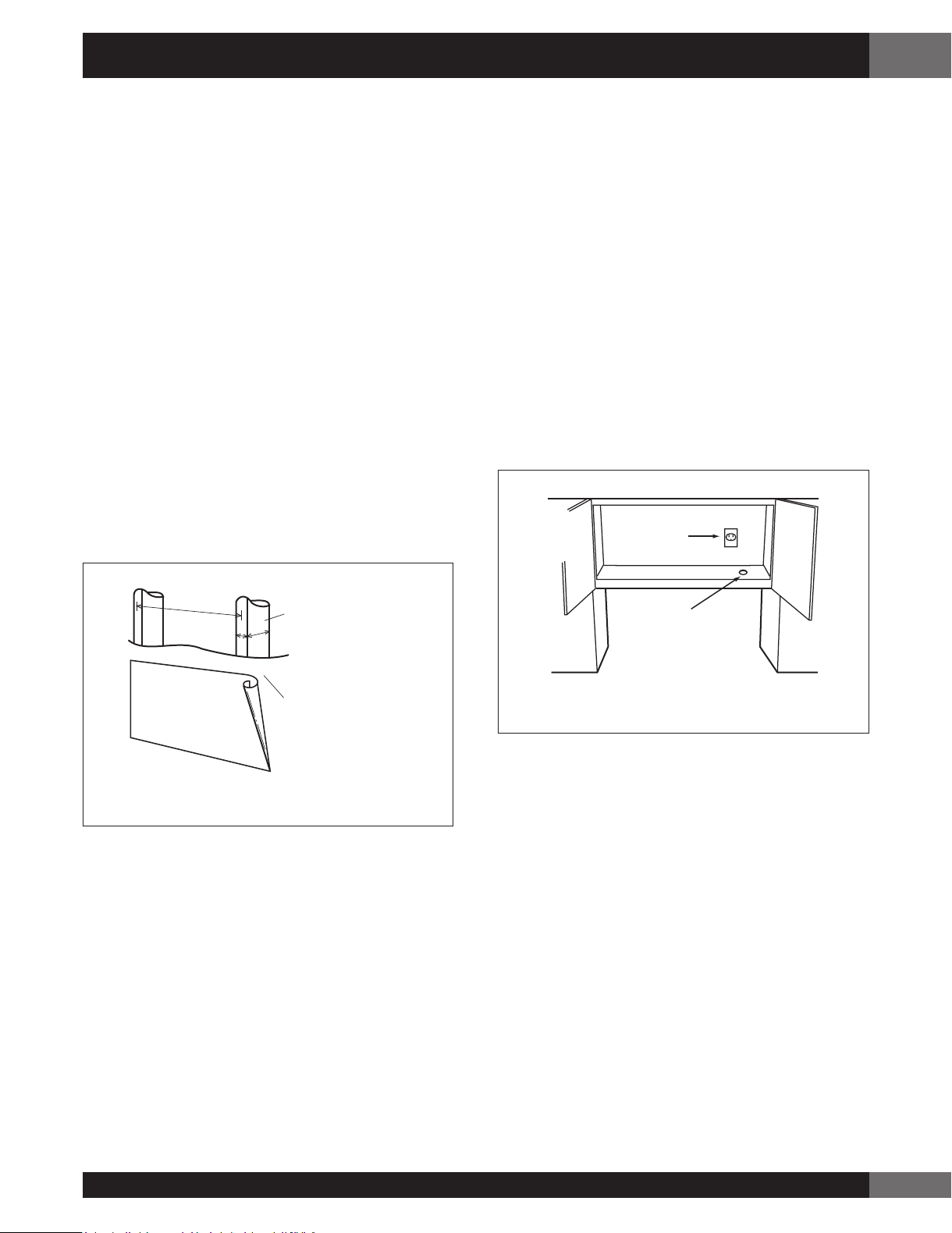

4. Hood Exhaust Duct

When the hood is vented to the outside, a hood exhaust

duct is required. All ductwork must be metal; absolutely do

not use plastic duct. Check that all connections are made

securely. Please read the following carefully:

Exhaust Connection: The hood exhaust has been

designed to connect to a standard 3

duct. If round duct is required, a rectangular-to-round

adapter must be used.

Rear Exhaust: If a rear or horizontal exhaust is to be

used, care should be taken to align the exhaust with the

space between the studs, or wall should be prepared at

the time it is constructed by leaving enough space between

wall studs to accommodate exhaust.

Maximum Duct Length: For satisfactory air movement,

the total duct length of 3

diameter round duct should not exceed 140 feet.

Elbows, adapters, wall, roof caps, etc. present additional

resistance to air flow and are equivalent to a section of

straight duct which is longer than their actual physical

size. When calculating the total length, add the equivalent

lengths of all transitions and adapters plus the length of all

straight duct sections. Figure 4 shows the approximate feet

of equivalent length of some typical ductwork parts.

Use the values in parentheses for calculating air flow

resistance equivalent, which should total less than 140 feet.

1

/4” x 10” rectangular or 6”

1

/4” x 10” rectangular

5. Tools Recommended for Installation

• Phillips Screwdriver

• Electric Drill

• Scissors

• Saw to cut exhaust

opening (if needed)

1

/2” Wood Bit or

• 1

Metal Hole Cutter (if

metal cabinet is used)

• Pencil

• Measure

• Tape

1

•

/2”, 5/8” and 3/32”

Drill Bits

• Protective Drop Cloth

for product and

range—you may

also use carton for

protection

6. Installation Hardware

The following is a list of parts you may need for installing

your Built-In Microwave Hood. You will find the installation

hardware contained in a packet with the unit. Check to

make sure you have all these parts. Use this time to become

familiar with each piece.

ITEM PART NAME & CODE QTY

1

Lag screws (

1

9KC7117604511

Toggle Bolts and Nuts

2

9KC3516003200, 9KC3516003300

Cabinet Mounting Bolts

3

9KC7045607011

Washer (

4

Nylon Grommet (for metal cabinets)

5

9KC3517503200

/4” x 1.8”)

3

/16” x 2.7”

1

/4” x 31/8”

3

/4”) 9KC3516003100

2

2

2

2

1

Figure 4

Damper 9KC3515400500

6

Mounting Plate 9KC351060009300

7

Figure 5

1

1

4

Page 5

Installation Guide

EN

7. Ventilation System

This Built-In Microwave Hood is designed for adaptation

to three types of hood ventilation systems. Select the type

required for your installation.

A. Recirculating

Non-Vented, Ductless Operation

The unit is shipped assembled for recirculating.

NOTE:

1. The Exhaust Damper Assembly is not required for

recirculating operation.

2. The Charcoal Filter should be replaced every 6

months, depending on use.

3. The Charcoal Filter is also sold as an accessory. See

Use and Care Manual for ordering information.

B. Horizontal Ventilation System

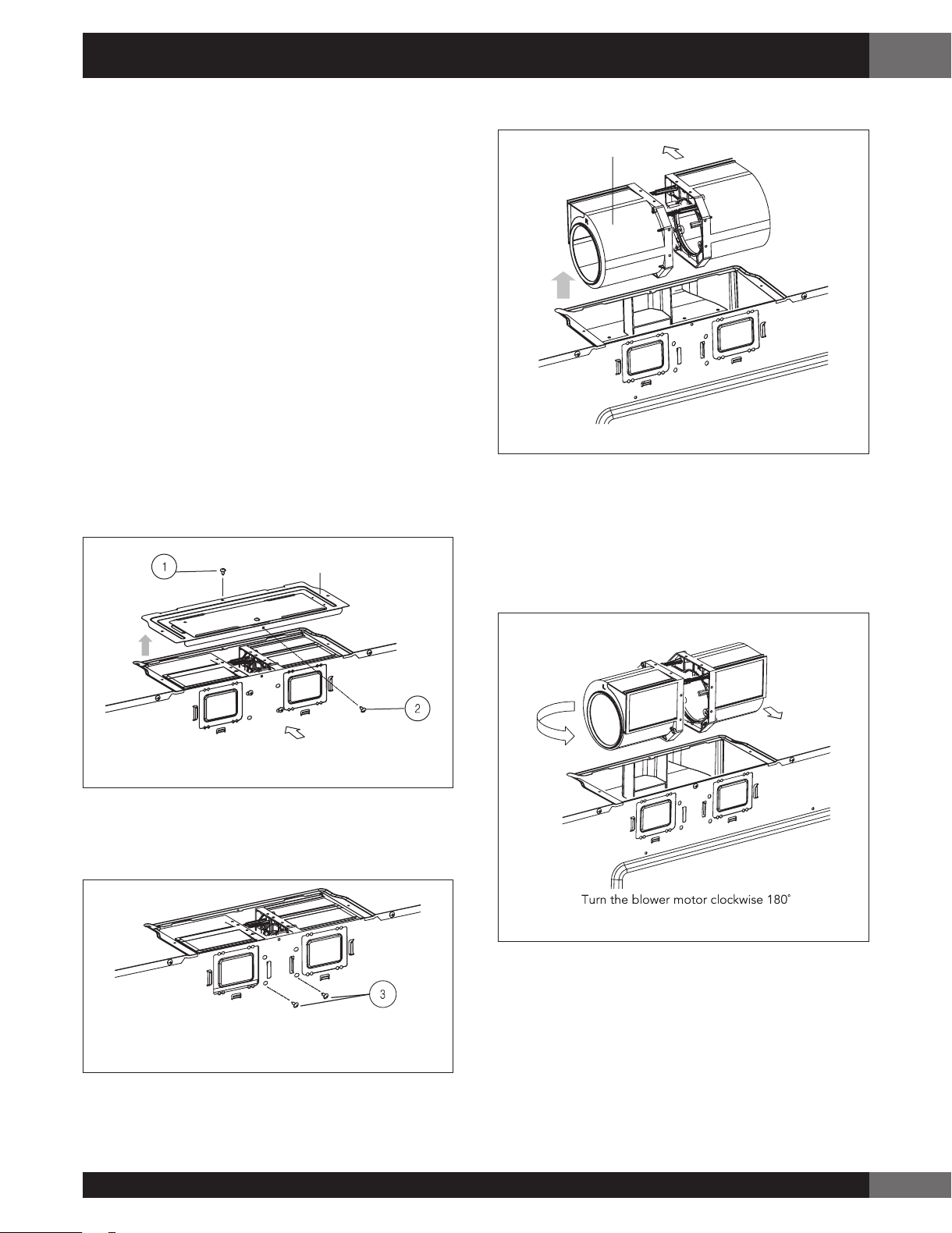

STEP 1

• Remove the screws (1) and (2) for opening the blower

motor cover and save screws. Remove cover. See

Figure 6.

Blower motor cover

• Lift blower unit out of mounting location. See Figure 8.

Blower motor

Figure 8

CAUTION: Do not pull or stretch blower wiring.

STEP 3

• Turn the blower unit so that the fan blade openings are

facing back (rear of unit). See Figure 9.

CAUTION: Wires to blower unit must be routed properly to

avoid pinching wires before reinstallation of cover plate.

Back of OVEN

Figure 6

STEP 2

• Remove the screws (3) for Blower attachment and save

screws. See Figure 7.

Before : Fan blade openings facing Front

Figure 7

After : Fan blade openings facing Rear

Figure 9

5

Page 6

EN

Installation Guide

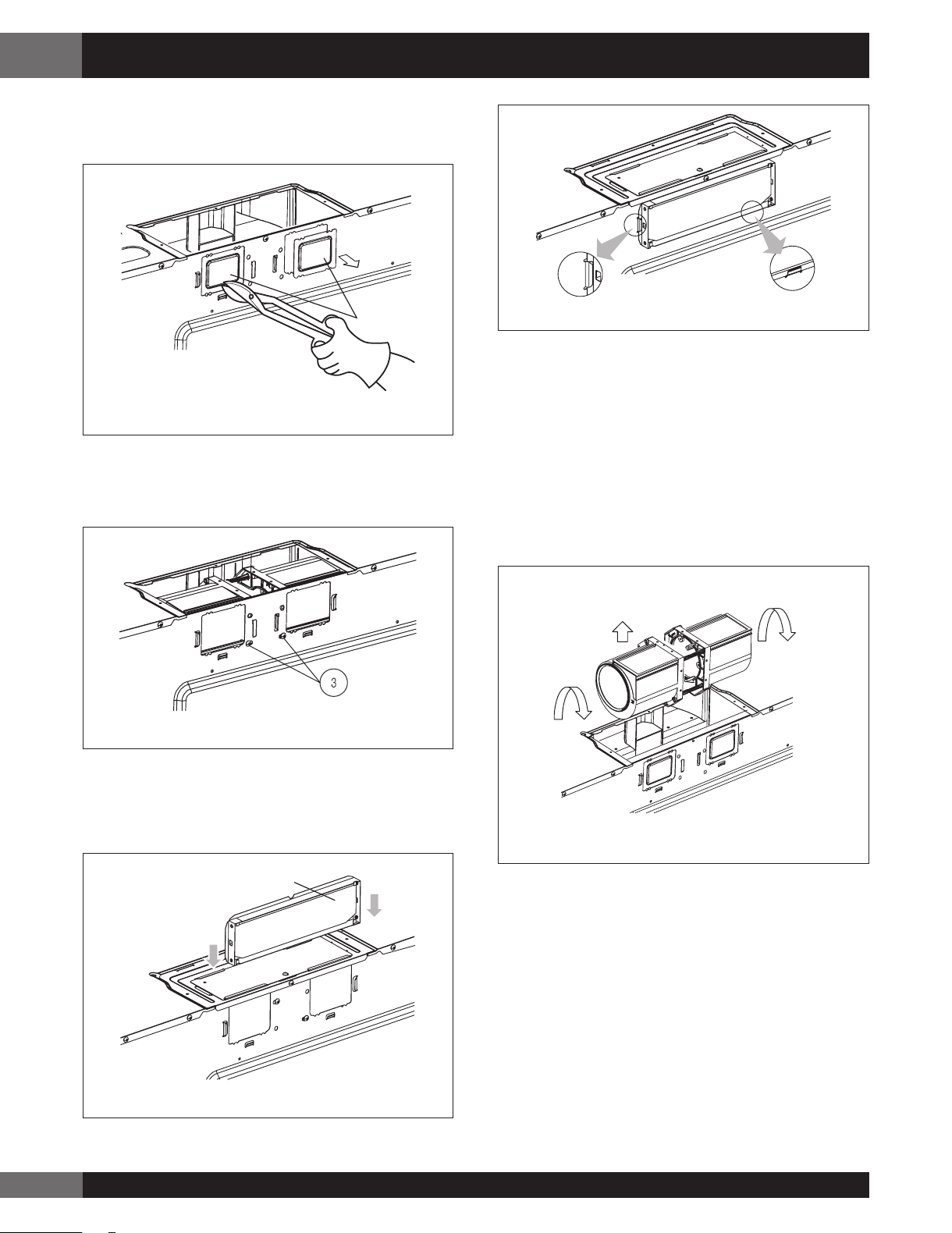

• Use side cutters or tin snips to cut and remove parts B

from back plate. Be careful not to distort the plate. See

Figure 10.

Parts B

Figure 10

STEP 4

• Place the blower unit into the opening and secure it to

the oven with the screws (3) from step 2. See Figure 11.

Figure 11

Figure 13

Be sure that the damper hinge is on the top and the damper

swings free into the wall outlet.

C. Vertical Ventilation System

The unit is shipped assembled for recirculating.

STEPS 1 & 2

• A-1 Ventilation motor. See Figure 8.

STEP 3

• Turn the blower unit so that the fan blade openings are

facing upward. See Figure 14.

Fan Blade Openings Facing Up

After Turning

• Carefully match the exhaust opening location of the

microwave and attach the damper to the rear plate by

sliding it into the guides at the rear plate. See Figures

12,13.

Damper

Figure 12

6

Back of Oven

Figure 14

Page 7

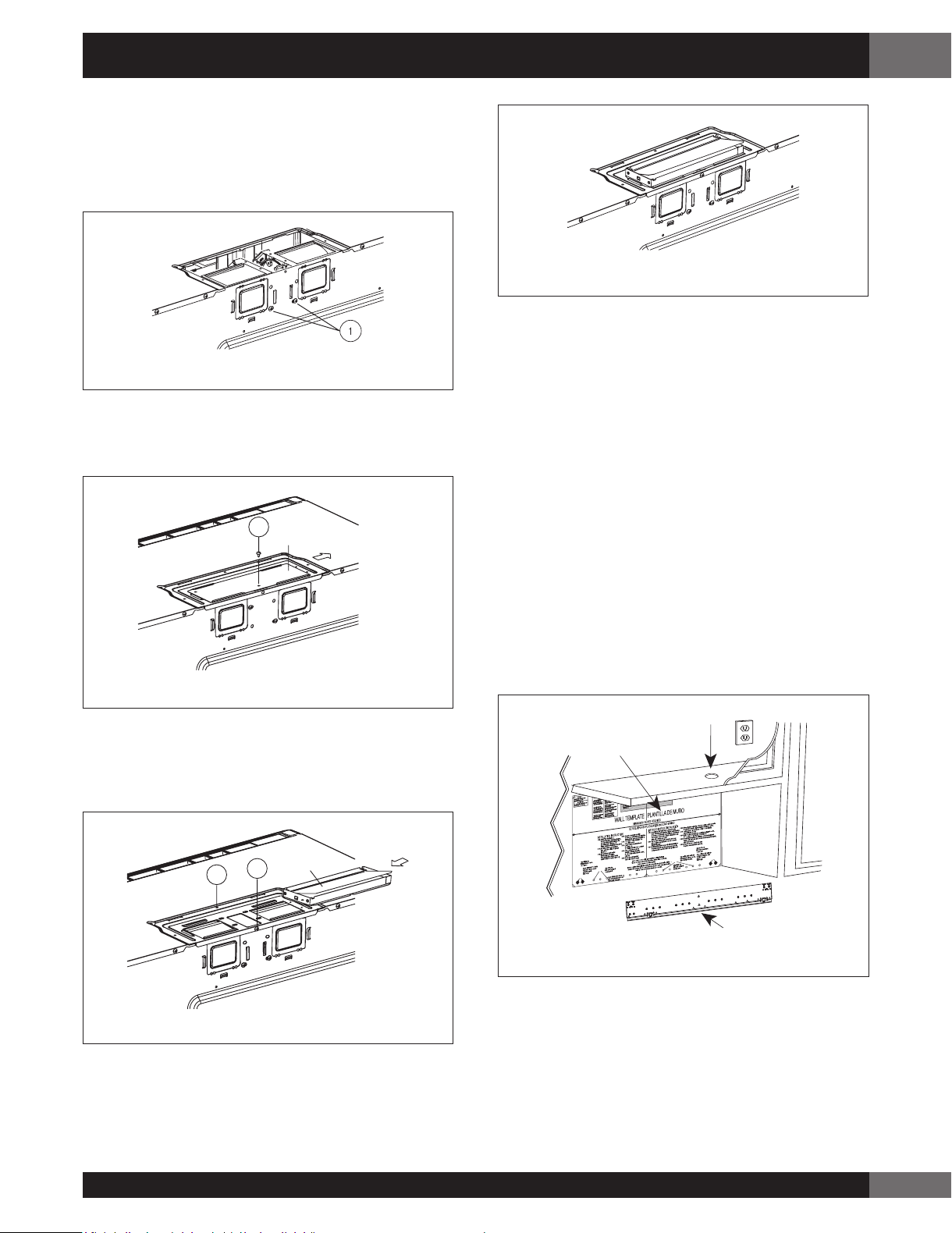

STEP 4

• Place the blower unit into the opening.

• Secure the Blower Motor Cover to the microwave oven

with the screw (1, 2 and 3) from step 1 and 2. See Figure

15.

Figure 15

Installation Guide

Figure 17

Be sure that the damper hinge is on the front and the

damper swings free into the wall outlet.

8. Oven Installation

EN

• Remove the screw (4) for the Blower Motor Cover and

save screws. Remove the Cover Motor Hole from Blower

Motor Cover. See Figure 16-1.

4

Cover Motor Hole

Figure 16-1

• Carefully match the exhaust opening location of the

microwave and attach the damper to blower motor cover

by sliding it into the guides at the blower motor cover.

See Figure 16-2, 17.

Damper

2

3

THIS OVEN CANNOT BE PROPERLY INSTALLED WITHOUT

REFERRING TO THE MOUNTING INSTRUCTIONS FOUND

ON BOTH TEMPLATES.

READ AND FOLLOW MOUNTING INFORMATION ON

BOTH TOP CABINET AND WALL TEMPLATES.

Mounting Plate

STEP 1 - SETUP POSITION

• Draw a line down the middle of the studs (see Wall

Construction, page 3).

• Draw a vertical line on the wall at the center of the 30”

wide space. See Figure 18.

NOTE: Use the wall template for the rear wall. Reference

Wall Template prior to proceeding. Installation of this

product requires 2 people.

Power Supply Cord Hole

House Duct

C

A

C

B

C

C

Figure 16-2

Mounting Plate

Figure 18

7

Page 8

EN

Installation Guide

STEP 2 - DRILLING

Reference the Wall Template.

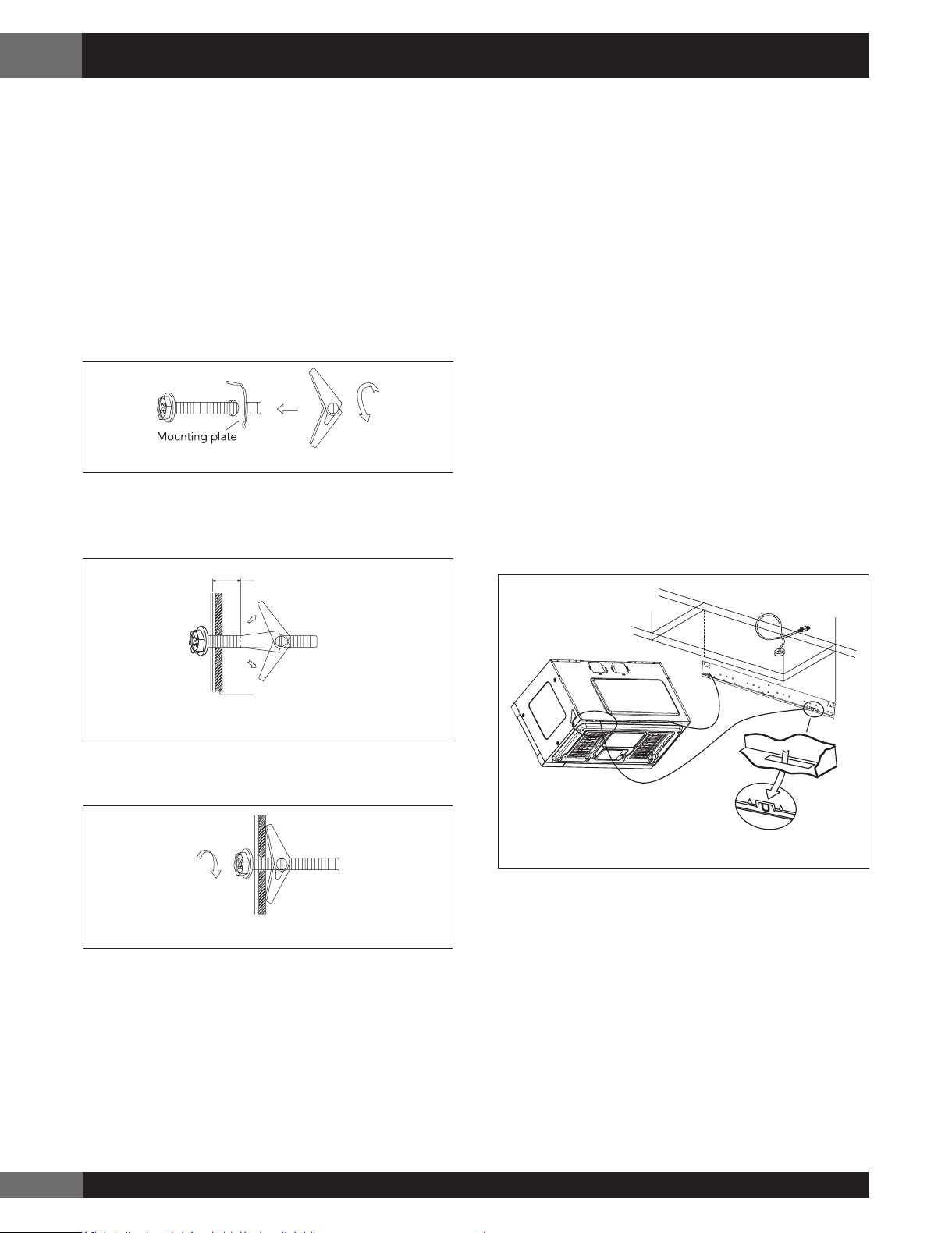

STEP 3 - TIGHTENING THE SCREWS

To attach the mounting plate to the wall using the toggle

bolt assemblies and/or lag screws:

• Insert toggle bolts through mounting plate at required

locations and add the spring loaded toggles. See

Figure 19.

Be sure you leave space at least the thickness of the wall

between the mounting plate and the end of the toggle

nut, (in closed position). If you do not leave this space,

the toggle nut will not open on the other side of the wall.

Figure 19

• Position mounting plate on wall and insert toggle bolt

assemblies through the drywall holes or start the lag

screw(s) through the wall stud(s). See Figure 20.

Space more than

wall thickness

Mounting Oven to The Wall

NOTE: IT IS VERY IMPORTANT THAT THIS OVEN BE

INSTALLED BY TWO PEOPLE.

IMPORTANT: DO NOT GRIP OR USE HANDLE DURING

INSTALLATION.

Preparation of Top Cabinet

You need to drill holes for the top support screws and a hole

large enough for the power cord to fit through.

Read the instructions on the TOP CABINET TEMPLATE.

Tape it underneath the top cabinet.

Drill the holes, following the instructions on the template.

NOTE: TOP CABINET TEMPLATE instruction must be installed

to proceed.

STEP 1

• Protect the top of your range by placing a portion of the

carton or some other heavy material over the cooking

surface before mounting your oven.

STEP 2

• Lift the microwave oven and tilt it forward.

• Hang the unit on two tabs at the bottom of the mounting

plate. See Figure 22.

Dry Wall

Figure 20

• Next, secure mounting plate to the wall by tightening

toggle bolt assemblies or lag screw(s). See Figure 21.

Figure 21

3

• Drill

(Remember, you must have at least one lag screw

• Tighten the lag screw(s) into wall stud(s).

/16” diameter lag screw hole(s), into one or more

wall studs.

secured to a wall stud.) For stud location refer to WALL

CONSTRUCTION, see page 3.

Figure 22

8

Page 9

Installation Guide

EN

STEP 3

• Thread power cord through the hole at the bottom of the

top cabinet.

• Swing the unit upward to meet the top of the mounting

plate and hold it securely. See Figure 23.

Figure 23

Connecting Ductwork

• Extend the house duct down to connect to the exhaust

adapter. Seal exhaust duct joints using duct tape. See

Figure 25.

House Duct

Figure 25

How to Replace the Charcoal filter

1. Unplug the oven or turn off the power at the main power

supply.

2. Remove the grille air mounting 3 screws and open the

door. See Figure 26.

STEP 4

• Insert a bolt down through each hole in the upper cabinet

bottom.

• Tighten the bolts until the gap between the upper cabinet

and microwave oven is closed. See Figure 24.

Figure 24

Figure 26

3. Slide the grille air to the left, then pull it straight out.

4. Push the charcoal filter backward and remove it.

9

Page 10

EN

Installation Guide

5. Slide a new charcoal filter into place. The filter should

rest at the angle. See Figure 27.

Charcoal Filter

Grille Air

Figure 27

6. Replace the grille air and 3 screws and close the door.

7. Plug the oven in or turn on the power at the main power

supply.

CHECK LIST FOR OPERATION

1 Make sure the unit has been installed according to all

of the Installation Instructions, the Top Cabinet Template

and Wall Template.

2. Remove all packing material from the oven.

3. Plug in the power cord.

4. Read the Use & Care Manual.

5. Keep the Installation Instructions for the local electrical

inspector’s use.

ACCESSORIES

Check with your dealer or order directly from Fulgor Milano.

CHARCOAL FILTER (CFOR3). Filter is used when hood

exhaust is recirculated only.

10

Page 11

Page 12

EN

FR

Installation Guide

Guide d’installation

IMPORTANT – Prière de lire et de suivre!

• Veuillez lire les instructions en entier avant d’installer le système four à micro-ondes et hotte intégrée. La participation de

deux personnes est recommandée pour l’installation de ce produit.

• Si une nouvelle prise de courant est requise, son installation devrait être effectuée par un électricien qualifié avant l’installation

du four à micro-ondes à hotte intégrée. Voir 3 - INSTRUCTIONS DE MISE À LA TERRE à la page 3.

Déballer et examiner votre four

Ouvrez le fond du carton, pliez les rabats du carton et

inclinez le four pour qu’il repose sur un tampon en mousse

plastique. Soulevez le carton du four et retirez tous les

matériaux d’emballage, les modèles d’armoires murale et

supérieure, le plateau tournant et son support. CONSERVEZ

LE CARTON POUR FACILITER L’INSTALLATION.

Retirez l’autocollant de fonction de l’extérieur de la porte,

le cas échéant.

NE RETIREZ PAS LE COUVERCLE DU GUIDE DE CONDUITES,

situé sur la paroi droite de la cavité du four. Vérifiez

qu’il existe un modèle de mur et un modèle d’armoire

supérieure. Lisez les pièces jointes et CONSERVEZ le

manuel d’utilisation et d’entretien.

Vérifiez que le four ne présente aucun dommage, tel qu’une

porte mal alignée ou déformée, des joints d’étanchéité de

la porte et des surfaces d’étanchéité endommagés, des

charnières et des loquets de porte cassés ou desserrés, ainsi

que des bosses dans la cavité ou sur la porte. En cas de

dommage, n’utilisez pas le four et contactez votre revendeur

ou votre réparateur agréé.

Guide d’installation

1. Espace de montage

Ce four à micro-ondes à hotte intégrée nécessite un espace

de montage sur le mur tel qu’illustré dans la Figure 1.

Si l’espace entre les armoires est supérieur à 30 pouces

(36 ou 42 pouces), un panneau de finition peut être utilisé

pour fermer l’espace vide entre le four à micro-ondes à hotte

intégrée et les armoires. Le panneau de finition devrait être

installé avant le four à micro-ondes à hotte intégrée.

Pour une installation et un entretien adéquats, un espace

minimum de deux pouces est nécessaire entre le dessus du

dosseret de la cuisinière et le dessous du système four à

micro-ondes et hotte intégrée.

12 po

30 po

16.3 po

Dosseret

Au moins 2 po

30 po ou plus,

de la surface

de cuisson

66 po ou plus,

du plancher

Figure 1

2

2

Page 13

Installation Guide

Guide d’installation

EN

FR

2. Construction du mur

Ce four à micro-ondes à hotte intégrée devrait être monté

sur et soutenu par un mur vertical plat. Le mur doit être plat

pour une installation adéquate. Si le mur n’est pas plat,

utilisez des entretoises pour remplir les écarts.

Le mur devrait comprendre au minimum des montants en

bois de 2 po x 4 po et une cloison sèche de 3/8 po ou plus

ou une cloison de plâtre sur lattes. Les surfaces de montage

doivent avoir la capacité de soutenir un poids de 110 livres

(50 kg) (le four et son contenu) PLUS le poids de tous les

articles normalement rangés dans l’armoire au-dessus du

four à micro-ondes.

L’appareil doit être fixé à au moins un montant mural de

2 po x 4 po.

Pour trouver l’emplacement des montants, vous pouvez

utiliser l’une des méthodes suivantes :

Utiliser un détecteur de montant, un appareil magnétique

qui détecte les clous dans le montant.

Utiliser un marteau pour taper doucement la surface de

montage jusqu’à ce qu’il produise un son solide. Ceci

indique l’emplacement du montant.

Vous pouvez trouver le centre du montant en sondant le

mur avec un petit clou pour trouver les rebords du montant,

puis tracer une marque au centre. Le centre des montants

adjacents se trouve normalement à 16 ou 24 pouces de

chaque côté de cette marque.

3. INSTRUCTIONS POUR LA

MISE À LA TERRE

Cet appareil doit être mis à la terre. Ce four est équipé d’un

cordon avec fil de mise à la terre et une fiche pour mise à

la terre. Il doit être branché dans une prise murale installée

correctement et mise à la terre conformément au Code

national de l’électricité ainsi qu’aux codes et règlements

locaux. Dans l’éventualité d’un court-circuit, la mise à la

terre réduit le risque d’électrocution en fournissant un fil de

sortie pour le courant électrique.

AVERTISSEMENT - L’utilisation inappropriée de la prise

de mise à la terre peut entraîner un risque d’électrocution.

Le cordon d’alimentation et la fiche doivent être connectés

à une prise de courant séparée, mise à la terre, avec circuit

de dérivation de 120 volts alternatif, 60 Hz, 15 ampères

ou plus.

Prise avec

mise à la terre

Orifice pour le

cordon d’alimentation

16 po ou 24 po

Montants en

bois de

2 po x 4 po

Cloison sèche

de 3/8 po ou

plâtre sur lattes

Figure 2

REMARQUE : S’il est impossible de fixer l’appareil à un

montant du mur, il faudra porter une attention particulière au

placement des ancrages à boulon et des vis pour l’armoire

supérieure. Consultez le Gabarit mural pour les détails.

L’armoire supérieure devrait être testée pour vérifier qu’elle

est solidement fixée au mur. Placez jusqu’à 110 livres (50

kg) de poids supplémentaire dans l’armoire supérieure pour

tester sa capacité de soutien.

Figure 3

REMARQUE :

1. Si vous avez des questions concernant la mise à la terre

ou les instructions sur l’électricité, consultez un électricien

ou technicien qualifié.

2. Ni Fulgor Milano ni le revendeur ne peuvent être tenus

responsables des dommages causés au four ou des

blessures personnelles résultant du non-respect des

procédures adéquates de branchement électrique.

3

3

Page 14

EN

FR

Installation Guide

Guide d’installation

4. Conduit de sortie

de la hotte

Si la hotte est ventilée vers l’extérieur, un conduit de sortie

est nécessaire. Tous les conduits doivent être en métal;

n’utilisez absolument jamais de tuyauterie en plastique.

Vérifiez que tous les raccords sont fixés solidement. Veuillez

lire attentivement ce qui suit :

Raccordement du conduit de sortie : L’échappement

de la hotte a été conçu pour être raccordé à un tuyau

rectangulaire standard de 3

rond est utilisé, un adaptateur de tuyau rectangulaire à

tuyau rond devra être utilisé.

Échappement à l’arrière : Si un échappement

horizontal ou vers l’arrière est utilisé, il faut faire attention

d’aligner l’échappement avec l’espace entre les montants,

ou le mur doit être préparé au moment de sa construction

pour laisser suffisamment d’espace entre les montants pour

accommoder l’échappement.

Longueur maximale des tuyaux : Pour permettre un

mouvement d’air satisfaisant, la longueur totale d’un tuyau

rectangulaire de 3

1/4

de 6 po de diamètre ne devrait pas dépasser 140 pieds.

Les coudes, adaptateurs, sorties murales et de toit, etc.,

offrent une résistance supplémentaire au mouvement de l’air

et équivalent à une section de tuyau droit plus longue que

leur longueur réelle. Lors du calcul de la longueur totale,

ajoutez la longueur équivalente de toutes les transitions

et des adaptateurs à la longueur de toutes les sections de

tuyau droites. La Figure 4 montre la longueur équivalente

approximative en pieds des pièces de conduit communes.

Utilisez les valeurs entre parenthèses pour calculer la

longueur totale équivalente, qui devrait être inférieure à

140 pieds.

1

/4 po x 10 po. Si un tuyau

po par 10 po ou d’un tuyau rond

5. Outils recommandés pour

l’installation

• Tournevis Phillips

• Perceuse électrique

• Ciseaux

• Scie pour découper

l’orifice d’échappement

(si nécessaire)

• Foret pour bois ou foret

emporte-pièce pour le

métal (si armoire en

1

métal) de 1

/2 po

• Crayon

• Ruban à mesurer

• Ruban adhésif

3

/32 po

1

/2 po, 5/8 po

• Forets de

et

• Linge ou tissu de

protection pour

l’appareil et la

cuisinière; vous pouvez

aussi utiliser un carton

6. Quincaillerie d’installation

La liste qui suit comprend les pièces dont vous pourriez

avoir besoin pour installer votre four à micro-ondes à hotte

intégrée. La quincaillerie d’installation est fournie dans

un sac accompagnant l’appareil. Assurez-vous d’avoir

toutes ces pièces en votre possession. Profitez-en pour vous

familiariser avec chacune des pièces.

ARTICLE NOM DE LA PIÈCE ET CODE QTÉ

1

Vis tire-fond (

1

9KC7117604511

Boulons et écrous à ailettes

3

2

/16 po x 2,7 po

9KC3516003200, 9KC3516003300

Boulons de montage à l’armoire

3

1

/4 po x 31/8 po 9KC7045607011

Rondelle (

4

Passe-câble en nylon (pour armoires

5

en métal) 9KC3517503200

/4 po x 1,8 po)

3

/4 po) 9KC3516003100

2

2

2

2

1

1

1

COUDE 90 º

(10 PI)

COUDE 10 PO DE

COUDE 90 º

(25 PI)

LARGE (10 PI)

COUDE 45 º

(5 PI)

COUDE 45 º

(5 PI)

ADAPTATEUR

SORTIE DE TOIT

(24 PI)

SORTIE MURALE

(40 PI)

(5 PI)

Clapet 9KC3515400500

6

Plaque de montage

7

9KC351060009300

Figure 4

Figure 5

4

4

Page 15

Installation Guide

Guide d’installation

EN

FR

7. Système de ventilation

Cette hotte intégrée pour micro-ondes est conçue pour

s’adapter à trois types de systèmes de ventilation de hotte.

Sélectionnez le type requis pour votre installation.

A. Recirculation

Fonctionnement non ventilé et sans tuyau

L’appareil est expédié prêt à être utilisé en mode de

recirculation.

REMARQUE :

1. Le clapet de sortie n’est pas nécessaire pour le

fonctionnement en mode de recirculation.

2. Le filtre à charbon devrait être remplacé tous les six

mois, selon la fréquence d’utilisation.

3. Le filtre à charbon est aussi vendu en tant qu’accessoire.

Voir le Manuel d’utilisation pour des détails sur le

processus de commande.

B. Système de ventilation horizontal

ÉTAPE 1

• Retirez les vis (1) et (2) pour ouvrir le couvercle du moteur

du ventilateur et conservez ces vis. Retirez le couvercle.

Voir la Figure 6.

Couvercle du moteur

du ventilateur

• Soulevez le ventilateur et retirez-le de l’emplacement de

montage. Voir la Figure 8.

Moteur du ventilateur

Figure 8

MISE EN GARDE : Ne tirez pas et n’étirez pas les fils du

ventilateur.

ÉTAPE 3

• Tournez le ventilateur afin que les ouvertures du

ventilateur soient tournées vers l’arrière (de l’appareil).

Voir la Figure 9.

MISE EN GARDE : Les fils du ventilateur doivent être

acheminés correctement avant la réinstallation de la plaque

pour éviter les pincements.

Arrière du FOUR

Figure 6

ÉTAPE 2

• Retirez les vis (3) de fixation du ventilateur et conservez

les vis. Voir la Figure 7.

Avant : Ouvertures du ventilateur

orientées vers l’avant

Figure 7

Après : Ouvertures du ventilateur vers l’arrière

Tournez le moteur du ventilateur 180° en sens horaire

Figure 9

5

5

Page 16

EN

FR

Installation Guide

Guide d’installation

• Utilisez une pince coupante diagonale ou une cisaille à

tôle pour découper et retirer les pièces B de la plaque

arrière. Faites attention de ne pas déformer la plaque.

Voir la Figure 10.

Pièces B

Figure 13

Assurez-vous que la charnière du clapet est en

haut et que le clapet bascule librement dans la

sortie murale.

Figure 10

ÉTAPE 4

• Placez le ventilateur dans l’ouverture et fixez-le au four

avec les vis (3) de l’étape 2. Voir la Figure 11.

Figure 11

• Alignez précisément l’ouverture du four à micro-ondes

et le clapet et fixez ce dernier à la plaque arrière en le

glissant dans les guides de la plaque arrière. Voir les

Figures 12 et 13.

Clapet

C. Système de ventilation vertical

L’appareil est expédié prêt à être utilisé en mode de

recirculation.

ÉTAPES 1 & 2

• A-1 Moteur du ventilateur. Voir la Figure 8

ÉTAPE 3

• Tournez le ventilateur afin que les sorties soient tournées

vers le haut. Voir la Figure 14.

Sorties du ventilateur orientées

vers le haut

Après l’avoir

tourné

Arrière du four à

micro-ondes

Figure 14

Figure 12

6

6

Page 17

ÉTAPE 4

• Placez le ventilateur dans l’ouverture.

• Fixez le couvercle du moteur du ventilateur au four à

micro-ondes avec les vis (1, 2 et 3) des étapes 1 et 2.

Voir la figure 15.

Figure 15

• Retirez la vis (4) du capot du moteur du ventilateur

et conservez les vis. Retirez le trou du couvercle du

couvercle du moteur de la soufflante. Voir la figure 16-1.

4

Trou du moteur

Figure 16-1

• Faites correspondre avec soin l’emplacement de l’orifice

d’évacuation du four à micro-ondes et fixez l’amortisseur

au capot du moteur du ventilateur en le faisant glisser

dans les guides situés sur le capot du moteur du

ventilateur. Voir les figures 16-2 et 17.

Installation Guide

Guide d’installation

Figure 17

Assurez-vous que la charnière de l’amortisseur

est à l’avant et que l’amortisseur bascule

librement dans la sortie verticale.

8. Installation du four

CE FOUR NE PEUT PAS ÊTRE INSTALLÉ CORRECTEMENT

SANS CONSULTER LES INSTRUCTIONS DE MONTAGE

IMPRIMÉES SUR LES DEUX GABARITS.

LISEZ ET SUIVEZ LES INFORMATIONS DE MONTAGE

IMPRIMÉES SUR LES GABARITS POUR L’ARMOIRE

SUPÉRIEURE ET LE MUR.

Plaque de montage

ÉTAPE 1 - POSITION DE MONTAGE

• Tracez une ligne le long du centre des montants (voir

Construction du mur, page 1).

• Tracez une ligne verticale sur le mur au centre de l’espace

de 30 po. Voir la Figure 18.

REMARQUE : Utilisez le gabarit mural pour le mur arrière.

Reportez-vous au gabarit mural avant de poursuivre.

L’installation de ce produit nécessite le concours de deux

personnes.

Orifice pour le cordon d'alimentation

Conduit de la maison

EN

FR

2

3

Figure 16-2

Amortisseur

C

A

C

B

C

C

Plaque de montage

Figure 18

7

7

Page 18

EN

FR

Installation Guide

Guide d’installation

ÉTAPE 2 - PERÇAGE DES TROUS

Reportez-vous au gabarit mural.

ÉTAPE 3 - SERRAGE DES VIS

Pour fixer la plaque de montage au mur, utilisez les ensembles

de boulon à ailettes et/ou les vis tire-fond :

• Insérez les boulons à travers la plaque de montage aux

emplacements déterminés et ajoutez les ailettes à ressort.

Voir la Figure 19.

Assurez-vous de laisser un espace d’au moins l’épaisseur

du mur entre la plaque de montage et la fin de l’écrou

à ailettes (en position fermée). Si vous ne laissez pas cet

espace, l’écrou à ailettes ne pourra pas s’ouvrir de l’autre

côté du mur.

Plaque de montage

Figure 19

• Mettez en place la plaque de montage sur le mur et insérez

les boulons à ailettes assemblés dans les trous percés dans

le mur ou commencez à visser les vis tire-fond dans le(s)

montant(s) du mur. Voir la Figure 20.

Espace plus grand que

l’épaisseur du mur

Fixation du four à micro-ondes

au mur

REMARQUE : IL EST TRÈS IMPORTANT QUE LE FOUR SOIT

INSTALLÉ PAR DEUX PERSONNES.

IMPORTANT : NE TENEZ OU N’UTILISEZ PAS LA POIGNÉE

PENDANT L’INSTALLATION.

Préparation de l’armoire supérieure

Vous devez percer des trous pour les vis de montage

supérieures et un trou suffisamment grand pour y passer le

cordon d’alimentation.

Lisez les instructions sur le GABARIT DE L’ARMOIRE

SUPÉRIEURE.

Fixez le gabarit sous l’armoire à l’aide de ruban adhésif.

Percez les trous conformément aux instructions sur le gabarit.

REMARQUE : Les instructions imprimées sur le GABARIT

DE L’ARMOIRE SUPÉRIEURE doivent être complétées avant

de poursuivre.

ÉTAPE 1

• Protégez la surface de votre cuisinière en plaçant une

partie de la boîte en carton ou un autre matériau épais

sur celle-ci avant de procéder à l’installation du four à

micro-ondes.

ÉTAPE 2

• Soulevez le four à micro-ondes et inclinez-le vers l’avant.

• Accrochez-le aux deux languettes situées à la base de

la plaque de montage. Voir la Figure 22.

Cloison sèche

Figure 20

• Ensuite, fixez la plaque de montage au mur en serrant les

boulons à ailettes ou les vis tire-fond. Voir la Figure 21.

Figure 21

• Percez un ou des trous de 3/16 po de diamètre dans le

ou les montants pour le(s) vis tire-fond.

(N’oubliez pas qu’il devrait y avoir au moins une vis tire-

fond dans un montant.) Pour déterminer l’emplacement des

montants, consultez CONSTRUCTION DU MUR en page

3.

• Serrez la/les vis tire-fond dans le(s) montant(s).

Figure 22

8

8

Page 19

Installation Guide

Guide d’installation

EN

FR

ÉTAPE 3

• Acheminez le cordon d’alimentation à travers l’orifice

dans la base de l’armoire supérieure.

• Basculez l’appareil vers le haut pour qu’il rejoigne le

dessus de la plaque de montage et tenez-le fermement.

Voir la Figure 23.

Figure 23

Connecting Ductwork

• Abaissez le conduit de la maison pour le raccorder à

l’adaptateur d’échappement. Scellez les joints du tuyau

de sortie avec du ruban à conduits. Voir la Figure 25.

Conduit de la maison

Figure 25

Comment remplacer le filtre à charbon

1. Débranchez le four à micro-ondes ou coupez le courant

directement au panneau de distribution électrique.

2. Retirez les 3 vis de montage de la grille d’aération et

ouvrez la porte. Voir la Figure 26.

ÉTAPE 4

• Insérez ensuite un boulon dans chacun des trous percés

dans l’armoire supérieure.

• Serrez les boulons jusqu’à ce que l’écart entre l’armoire

et le four à micro-ondes se referme complètement. Voir

la Figure 24.

Figure 24

Figure 26

3. Glissez la grille à air vers la gauche, puis tirez pour

l’enlever.

4. Poussez le filtre à charbon vers l’arrière et retirez-le.

9

9

Page 20

EN

FR

Installation Guide

Guide d’installation

5. Glissez en place un filtre à charbon neuf. Le filtre devrait

reposer avec un angle d’inclinaison. Voir la Figure 27.

Filtre à charbon

Grille

d’aération

Figure 27

6. Replacez la grille d’aération et les 3 vis de montage et

fermez la porte.

7. Rebranchez le four à micro-ondes ou remettez le

courant.

LISTE DE VÉRIFICATION POUR LE

FONCTIONNEMENT

1. Vérifier que l’appareil a été installé conformément à

toutes les Instructions d’installation et celles du Gabarit

de l’armoire supérieure et du Gabarit mural.

2. Le cas échéant, retirer du four le matériel d’emballage

restant.

3. Brancher le cordon d’alimentation.

4. Lire le Manuel d’utilisation.

5. Garder toutes les instructions d’installation à l’intention

de l’inspecteur en électricité.

ACCESSOIRES

Consultez votre revendeur ou commandez directement du

Centre à fournitures et accessoires de Fulgor Milano .

FILTRE À CHARBON (CFOR3). Le filtre est utilisé uniquement

lorsque l’échappement est en mode de recirculation d’air.

10

10

Page 21

Page 22

Page 23

Page 24

YOUR LIFE | OUR PASSION

www.fulgor-milano.com/us

TINSKB287MRR0 _ 6/26/19

Loading...

Loading...