Page 1

30" MICROWAVE OVEN TRIM KIT

INSTALLATION GUIDE

GUIDE D’INSTALLATION

Page 2

EN

(76 MM)

Standard Installation Guide

This kit is ul approved to allow certain microwave ovens to

be installed above any electric wall oven. Please see the use

& care manual regarding approved built-in applications.

IMPORTANT This Trim Kit is designed for and approved

only for Fulgor Milano Microwave Oven specifying Trim

Kit F4TK30MWO.

PLEASE READ THESE INSTRUCTIONS THOROUGHLY

BEFORE BEGINNING INSTALLATION!

• Be sure to DISCONNECT THE PLUG of the microwave

oven from the electrical outlet before installing the Trim

Kit. Remove the turntable from the oven cavity.

• Because the kit includes metal parts, due caution should

be used in handling and installation to avoid the possibility of injury.

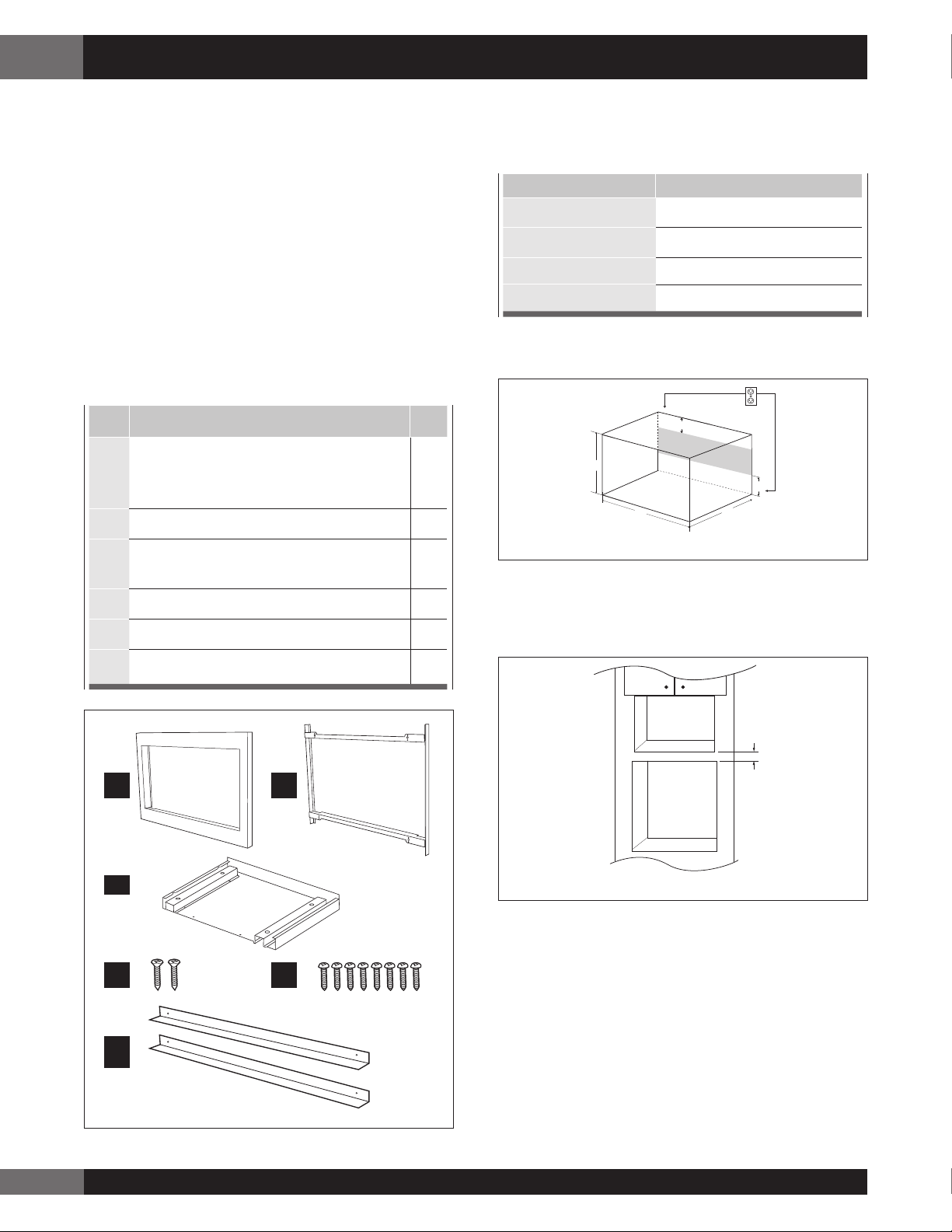

ITEM PART NAMES QTY

Front Frame: FDECAB265MRK0

A

W x H x D: 29

7

⁄8” x 18 1⁄2” x 1 3⁄16”

1

(759 x 470 x 30.2 mm)

B

Back Frame: FDECAB266MRK0 1

Exhaust Duct Assembly:

C

PDUC-B185MRP0A

D

Screw D: XTSS740P20000 2

E

Screw E: XOPS740P16000 8

1

STEP 1 - CABINET OR WALL OPENING

The opening in the wall or cabinet must be within the

following dimensions:

CUT OUT DIMENSIONS

A (Height)

B (Width)

C (Minimum Depth)

D

Outlet should NOT be in the shaded area as indicated on

Sketch 1.

A

B

Sketch 1

NOTES

• Please allow minimum 3" (76 mm) wood gap between

the microwave oven cutout and the appliance cutout

below the microwave oven. See Sketch 2.

17” (432 mm)

1

25

20” (508 mm)

4” (101.6 mm)

D

C

⁄4” (641 mm)

D

F

Air Deflector: PREF-B035MRP0 2

A B

C

D

E

F

Microwave cutout

3"

Wall oven cutout

Min.

Sketch 2

• If the dimension of DEPTH (C) is more than 21" (533.4

mm), the outlet location may be any area on the rear wall.

• The floor of the opening should be constructed of

plywood strong enough to support the weight of the oven

and floor load (about 100 pounds/45 KG). The floor

should be level and 90˚ with the face of the cabinet for

proper installation and operation of the oven. Be sure

to check the local building code as it may require that

the opening be enclosed with sides, ceiling and rear

partition. The proper functioning of the oven does not

require the enclosure.

2

Page 3

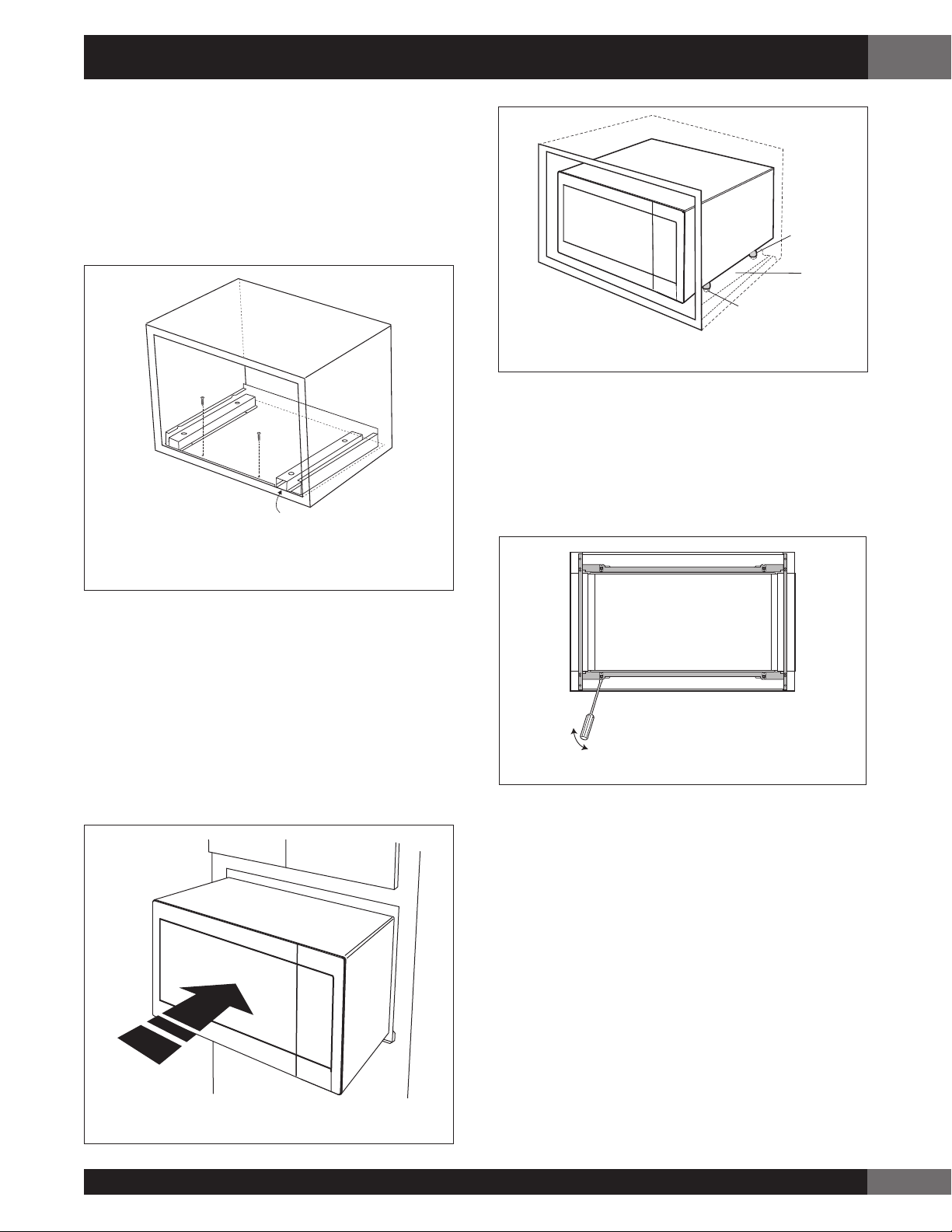

STEP 2 - EXHAUST DUCT ASSEMBLY

INSTALLATION

1. Place the Exhaust Duct Assembly in the center of the

opening. Align the front edge of the duct with the front

of the cabinet.

2. Secure the Exhaust Duct Assembly with two Screws D.

See Sketch 3.

Standard Installation Guide

Foot

Exhaust

duct

assembly

Duct recess

Sketch 5

EN

Screw D

Screw D

Exhaust duct assembly

right side aligns to front

edge of shelf

Sketch 3

STEP 3 - FRAME INSTALLATION

1. Place the oven adjacent to the wall or cabinet opening.

Plug the power cord into the electrical outlet.

2. Carefully guide the assembled oven into the prepared

opening. Slide the oven on the Exhaust Duct Assembly.

See Sketch 4. Avoid pinching the cord between the

oven and the wall. Adjust the position of the oven so

that the feet of the oven are fitted into the recesses of the

Exhaust Duct Assembly and door will open properly. See

Sketch 5.

3. Disassembly: The Front Frame and Back Frame come

pre-assembled with ball studs engaged in the receivers.

Separate the Front Frame from the Back Frame. Place

the assembly face down on a protected surface. At the

location of the ball stud, insert a flat head screwdriver

between the Front Frame and the Back Frame and gently

pry up to disengage the ball stud from the receiver.

Repeat for each corner. See Sketch 6.

Sketch 6

Sketch 4

3

Page 4

EN

Standard Installation Guide Flush Installation Guide

4. Back Frame Installation: Position back frame equal space

top to bottom, side to side. Mark for 4 holes, center

punch and pre-drill with 1⁄16” drill bit. Secure frame with

4 Screws (E). See Sketch 7.

Screw E

Screw E

Mounting holes

Equal gap

side to side

Mounting holes

Equal gap top, bottom

Mounting holes

Screw E

Screw E

Mounting holes

Sketch 7

5. Front Frame Installation: Place the Front Frame

onto the Back Frame and align ball studs and

receivers. Secure the Front Fram to the Back Frame

by firmly pushing the front frame onto the back

frame engaging the four (4) snap attachments. See

Sketch 8.

STEP 1 - CABINET OR WALL OPENING

The opening in the wall or cabinet must be within the

following dimensions:

CUT OUT DIMENSIONS

1

⁄4” (641.4 mm)

A

B

C

D

E

F

G

Outlet should NOT be in the shaded area H as indicated

on Sketch 1.

25

1

30

5

20

7

2

⁄16” (62 mm)

3

⁄4” (45 mm)

1

3

1

⁄16” (30.2 mm)

4” (101.6 mm)

Top View

A

B

⁄8” (765.2 mm)

⁄16” (516.7 mm)

Mounting

cleat

Shelf

F

Cabinet

face

Sketch 8

Front View

G

D D

Shelf

Bottom of flush cutout

E

C

H

G

Sketch 1

NOTES

7

Dimension C above will result in

⁄8 ” (23 mm) spaces

above and below the trim to allow for necessary intake and

exhaust air flow to ensure appliance does not overheat. Do

not reduce this spacing as in will void the warranty for any

issues resulting from a lack of airflow.

4

Page 5

Flush Installation Guide

(76 MM)

EN

NOTES

• Please allow minimum 3" (76 mm) wood gap between

the microwave oven cutout and the appliance cutout

below the microwave oven. See Sketch 2.

Microwave cutout

3"

Wall oven cutout

Min.

Sketch 2

• If the dimension of DEPTH (C) is more than 21" (533.4

mm), the outlet location may be any area on the rear wall.

• The floor of the opening should be constructed of

plywood strong enough to support the weight of the oven

and floor load (about 100 pounds/45 KG). The floor

should be level and 90˚ with the face of the cabinet for

proper installation and operation of the oven. Be sure

to check the local building code as it may require that

the opening be enclosed with sides, ceiling and rear

partition. The proper functioning of the oven does not

require the enclosure.

STEP 3 - FRAME INSTALLATION

1. Place the oven adjacent to the wall or cabinet opening.

Plug the power cord into the electrical outlet.

2. Carefully guide the assembled oven into the prepared

opening. Slide the oven on the Exhaust Duct Assembly.

See Sketch 4. Avoid pinching the cord between the

oven and the wall. Adjust the position of the oven so

that the feet of the oven are fitted into the recesses of the

Exhaust Duct Assembly and door will open properly. See

Sketch 5.

Screw D

Screw D

Sketch 4

STEP 2 - EXHAUST DUCT ASSEMBLY

INSTALLATION

1. Place the Exhaust Duct Assembly in the center of the

opening. Align the front edge of the duct with the front

of the cabinet. Align the front edge of the right side of

the duct with the front of the shelf. See Sketch 3.

2. Secure the Exhaust Duct Assembly with two Screws D.

See Sketch 3.

Screw D

Screw D

Exhaust duct assembly

right side aligns to front

edge of shelf

Sketch 3

Sketch 5

Duct recess

Foot

Exhaust

duct

assembly

5

Page 6

EN

Flush Installation Guide

3. Disassembly: The Front Frame and Back Frame come

pre-assembled with ball studs engaged in the receivers.

Separate the Front Frame from the Back Frame. Place

the assembly face down on a protected surface. At the

location of the ball stud, insert a flat head screwdriver

between the Front Frame and the Back Frame and gently

pry up to disengage the ball stud from the receiver.

Repeat for each corner. See Sketch 6.

Sketch 6

4. Back Frame Installation: Position back frame equal

space top to bottom, side to side. Mark for 4 holes on the

1

installed wood cleats, center punch and pre-drill with

⁄16”

drill bit. Secure frame with 4 Screws (E). See Sketch 7.

Mounting holes

Screw E

Mounting holes

Screw E

right) the Air Deflectors above and below the installed

Back Frame. See Sketch 8. Mark holes and pre-drill with

1

⁄16” drill bit.

Sketch 8

6. Front Frame Installation: Place the Front Frame

onto the Back Frame and align ball studs and

receivers. Secure the Front Fram to the Back Frame

by firmly pushing the front frame onto the back

frame engaging the four (4) snap attachments. See

Sketch 9.

Equal gap

side to side

Screw E

Mounting holes

Equal gap top, bottom

Screw E

Mounting holes

Snap

Attachment

Sketch 7

5. Install Air Deflectors top and bottom. Center (left and

Sketch 9

French Translation of this document can be found on our website https://www.fulgor-milano.us/.

6

Page 7

Page 8

YOUR LIFE | OUR PASSION

www.fulgor-milano.com/us

TINSEB574MRR0 _ 09-16-19

Loading...

Loading...