Page 1

PRIMERGY

PRIMERGY RX200 S2

Serversystem

Options Guide

Joachim Pichol

Fujitsu Siemens Computers GmbH Paderborn

33094 Paderborn

e-mail: email: manuals@fujitsu-siemens.com

Tel.: (05251) 8-148 84

Fax: 0 700 / 372 00001

Sprachen: En

Edition October 2004

Page 2

Comments… Suggestions… Corrections…

The User Documentation Department would like to

know your opinion of this manual. Your feedback helps

us optimize our documentation to suit your individual

needs.

Fax forms for sending us your comments are included in

the back of the manual.

There you will also find the addresses of the relevant

User Documentation Department.

Certified documentation

according to DIN EN ISO 9001:2000

To ensure a consistently high quality standard and

user-friendliness, this documentation was created to

meet the regulations of a quality management system

which complies with the requirements of the standard

DIN EN ISO 9001:2000.

cognitas. Gesellschaft für Technik-Dokumentation mbH

www.cognitas.de

Copyright and Trademarks

Copyright © 2004 Fujitsu Siemens Computers GmbH.

All rights reserved.

Delivery subject to availability; right of technical modifications reserved.

All hardware and software names used are trademarks of their respective manufacturers.

This manual is printed on

paper treated with

chlorine-free bleach.

Page 3

Preface

Procedure

Safety Instructions

Preparation

Main Memory

Processors

Accessible Drives

Controllers in Non-Hot-Plug PCI Slots

RemoteView Components

Completion

Continued

Page 4

Page 5

Abbreviations

Related publications

Index

Page 6

Page 7

Contents

1 Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview of the documentation . . . . . . . . . . . . . . . . . . 1

1.2 Extensions and conversions . . . . . . . . . . . . . . . . . . . . 3

1.3 Notational conventions . . . . . . . . . . . . . . . . . . . . . . . 5

2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Opening the server . . . . . . . . . . . . . . . . . . . . . . . 15

5Main Memory . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Installation rules . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Upgrading / exchanging main memory . . . . . . . . . . . . . 18

6 Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Installing a second processor . . . . . . . . . . . . . . . . . . 19

6.2 Exchanging the processor . . . . . . . . . . . . . . . . . . . 24

6.3 Exchanging the heat sink . . . . . . . . . . . . . . . . . . . . 27

7 Accessible Drives . . . . . . . . . . . . . . . . . . . . . . . 29

7.1 Installing the LocalView Module . . . . . . . . . . . . . . . . . 30

7.2 Installing a CD-ROM/DVD drive . . . . . . . . . . . . . . . . . 32

7.3 Installing a floppy disk drive . . . . . . . . . . . . . . . . . . . 35

8 Controllers in Non-Hot-Plug PCI Slots . . . . . . . . . . . . 39

8.1 Installing controllers . . . . . . . . . . . . . . . . . . . . . . . 40

9 RemoteView Components . . . . . . . . . . . . . . . . . . . 43

9.1 Installing the RemoteView Service Board S2 LP . . . . . . . . 43

10 Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.1 Closing the server . . . . . . . . . . . . . . . . . . . . . . . . 45

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Options Guide

Page 8

Page 9

1 Preface

The PRIMERGY RX200 S2 is an Intel-based server for mid-tier applications in

server farms. The server is well suited for front end services as well as for use

as an e-mail server, Internet server, or general applications server.

1.1 Overview of the documentation

I PRIMERGY manuals are available in PDF format on the ServerBooks

CD which is supplied as part of the ServerView Suite package for every

server system.

These PDF files can also be downloaded free of charge from the

Internet: At http://manuals.fujitsu-siemens.com you will find an overview

page showing the online documentation available on the Internet. You

can go to the PRIMERGY Server documentation by clicking on “intel

based Servers”.

Concept and target groups

This Options Guide shows you how you can expand and upgrade the server.

V Caution!

The activities described in this manual may only be performed by

specialist personnel with technical training.

I How to install/remove the hot-plug components is described in the

Operating Manual for the server.

Additional documentation about the server

The PRIMERGY RX200 S2 documentation comprises the following additional

manuals:

– The “Security” manual (printed copy always supplied with the server, and

available as a PDF file on the ServerBooks CD supplied)

– The “Guarantee” manual (printed copy always supplied with the server, and

available as a PDF file on the ServerBooks CD supplied)

– The Operating Manual for PRIMERGY RX200 S2 (PDF available on the

ServerBooks CD supplied)

– The Technical Manual for the system board D1790 (PDF available on the

ServerBooks CD supplied)

Options Guide 1

Page 10

Overview of the documentation Preface

– The “BIOS Setup” manual (PDF available on the ServerBooks CD supplied)

– The “Service Supplement for PRIMERGY RX200 S2” (PDF available on the

ServerBooks CD supplied)

– The “ServerView Suite” manual (printed copy always supplied with the

server, and available as PDF file on the ServerBooks CD supplied)

– The “Adaptec HostRAID User’s Guide” (PDF available on the ServerBooks

CD supplied)

– The “Ergonomics” manual (PDF available on the ServerBooks CD supplied).

I You can order a supplementary ServerBooks CD by sending an e-mail to

the following address, quoting your server data:

Reklamat-PC-LOG@fujitsu-siemens.com

Further sources of information:

– Technical Manual on the relevant rack

– Manual on the monitor

– Manual on ServerView Server Management

– Manual on the RemoteView Remote Test and Diagnostics System

– Documentation on boards and drives

– Documentation on your operating system

– Information files on your operating system

(see also “Related publications” on page 53)

2 Options Guide

Page 11

Preface Extensions and conversions

1.2 Extensions and conversions

Second processor

The system board can be upgraded with a second processor. Only processors

of the same type may be used on the system board. The second processor must

have the same clock frequency as the first processor.

Extension of the main memory

The eight slots for the main memory are suitable for PC2-3200 DDR DIMM

memory modules. Their organization in four memory banks, 0 to 3, allows fast

memory access with two-way interleaving.

Memory modules must always be installed in pairs. A memory bank must

always be fully equipped and with the same type of memory modules.

Additional accessible drives

The accessible drives available are a floppy disk drive and a CD-ROM/DVD

drive. The drives can be installed in the two top bays. The left-hand bay is

intended for a 3.5 x 0.5 inch floppy drive or a LocalView module, while the righthand bay takes a 5.25 x 0.5 inch CD-ROM/DVD drive.

LocalView module (alphanumeric system display)

The LocalView module gives you the option of displaying system information

and hardware system faults alphanumerically. This is an intelligent module with

a microcontroller and its own memory, which functions independently of the

server system.

The LocalView module consists of an LCD display panel and a toggle switch,

both accommodated in a suitable mount. The mechanism used allows the LCD

display panel to be pulled out and opened out.

For more information on operation and display modes, see the documentation

for the LocalView module [6].

Options Guide 3

Page 12

Extensions and conversions Preface

Additional controllers in non-hot-plug PCI slots

The system board offers two PCI-X slots:

– PCI-X slot 1: 64 bit/133 MHz, max. length 315 mm

– PCI-X slot 2: 64 bit/66 MHz, low profile, max. length 175 mm

I Both slots are not hot-pluggable.

RemoteView

RemoteView provides you with a comprehensive remote test and diagnostics

package.

RemoteView Service Board S2 LP

The RemoteView Service Board S2 “low profile” (RSB S2 LP) is a PCI board

with a completely independent system, i.e. it has its own operating system with

Web server and SNMP agents and can optionally be equipped with an external

power supply.

The RSB S2 LP is inserted into a standard-PCI slot via a riser card and

connected to the system board by means of a cable.

The RSB S2 LP permits remote diagnosis for system analysis, remote system

configuration and remote restart even in the event of operating system failure or

hardware faults. It has its own LAN connection and its own COM port. All the

functions of the RSB S2 LP are thus available either via LAN or via modem.

4 Options Guide

Page 13

Preface Notational conventions

1.3 Notational conventions

The following notational conventions are used in this manual:

Italics indicate commands, menu items or software programs.

“Quotation marks” indicate names of chapters and terms that should be

emphasized.

Ê text which follows this symbol describes activities that

must be performed in the order shown.

V CAUTION! pay particular attention to text marked with this symbol.

Failure to observe this warning may endanger your life,

damage the server, or lead to loss of data.

I supplementary information, remarks and tips follow this

symbol.

Table 1: Notational conventions

Options Guide 5

Page 14

Page 15

2Procedure

V CAUTION!

● The actions described in this manual should only be performed by

engineers, service personnel or technical specialists.

● Equipment repairs should only be performed by authorized, qualified

staff.

● Any failure to observe the guidelines in this manual, and any unautho-

rized openings and improper repairs could expose the user to risks

(e.g. electric shock, fire hazards) and could also damage the

equipment.

● Please note that any unauthorized opening of the device will result in

the invalidation of the warranty and exclusion from all liability.

Ê First of all please familiarize yourself with the safety instructions in the

chapter “Safety Instructions” on page 9ff.

Ê Make sure that all required manuals (see “Additional documentation about

the server” on page 1) are available, printing out the PDF files if necessary.

You will definitely need

– the Operating Manual for the server and

– the Service Supplement for the server

– the Technical Manual for the system board.

Ê Shut down the server correctly, switch it off, pull out the power plug, and

open the server as described in the chapter “Preparation” on page 15ff.

Ê Extend or upgrade your server as described in the relevant chapter.

I How to install/remove the hot-plug components is described in the

Operating Manual for the server.

Ê Close the server, plug all mains plugs into the power outlets, and switch on

the server as described in the chapter “Completion” on page 45ff.

Ê Start the operating system and, if necessary, configure it as required (see

the Operating Manual).

Options Guide 7

Page 16

Page 17

3 Safety Instructions

I The following safety instructions can also be found in the manual entitled

“Safety”.

This device complies with the relevant safety regulations for data processing

equipment, including electronic office machines for use in an office

environment.

If you have any questions as to whether you can set up the device in your

particular environment, please contact your sales outlet or our customer service

centre.

V CAUTION!

● The actions described in this manual should only be performed by

engineers, service personnel or technical specialists.

● Equipment repairs should only be performed by qualified staff.

● Any failure to observe the guidelines in this manual, and any unautho-

rized openings and improper repairs could expose the user to risks

(e.g. electric shock, fire hazards) and could also damage the

equipment.

● Please note that any unauthorized opening of the device will result in

the invalidation of the warranty and exclusion from all liability.

Before setting up

V CAUTION!

● During installation and before operating the device, observe the

instructions on environmental conditions for you device.

● If the device is brought in from a cold environment, condensation may

form both inside and on the outside of the machine.

Before operating the device, wait until it is absolutely dry and has

reached approximately the same temperature as the installation site.

Failure to observe these guidelines can lead to material damage of

the device.

● Transport the device only in its original packaging or in packaging

which protects it from knocks and jolts.

Options Guide 9

Page 18

Safety Instructions

Installation and operation

V CAUTION!

● If the rack model is integrated in an installation that receives power

from an industrial (public) power supply network with the IEC309

connector, the (public) power supply protection must comply with the

requirements for the non-industrial (public) power supply networks for

the type A connector.

● The server automatically adjusts to a mains voltage between 100 V

and 240 V. Make sure that the local mains voltage is neither above nor

below this range.

● This device has safety-tested power cables and must only be

connected to properly grounded power outlets.

● Make sure that the power socket on the device or the grounded mains

outlet is freely accessible.

● The power switch does not disconnect the device from the mains

voltage. To completely disconnect it from the mains voltage, you must

remove the power plug from the power outlet.

● Always connect the device and the attached peripherals to the same

power circuit. Otherwise you run the risk of losing data if, for example,

a power outage occurs and the central processing unit is still running

but the peripheral device (e.g. a storage subsystem) has failed.

● Data cables must be adequately shielded to avoid interference.

● For the LAN wiring, the requirements according to standards EN

50173 and EN 50174-1/2 apply. The minimum requirement is the use

of a protected LAN line of category 5 for 10/100 Mbps Ethernet,

and/or of category 5e for Gigabit Ethernet. The requirements of the

specification ISO/IEC 11801 must also be taken into account.

● Route the cables in such a way that they do not form a potential

hazard (tripping) and that they cannot be damaged. When connecting

the device, refer to the relevant notes in the operating manual.

● Do not connect or disconnect any data transmission cables during a

thunderstorm (lightning hazard).

10 Options Guide

Page 19

Safety Instructions

V CAUTION!

● Be careful to ensure that no objects (e.g. jewelry, paper clips etc.) or

liquids get inside the device (electric shock, short circuit).

● In emergencies (e.g. damaged casing, elements, or cables,

penetration of liquids or foreign bodies), switch off the device immediately, remove the power connector from the grounded power outlet,

and contact your customer service centre.

● Proper operation of the device (in accordance with IEC 60950/DIN

EN 60950) is only ensured if the casing is completely assembled and

the rear covers for the installation openings have been put in place

(electric shock, cooling, fire protection, interference suppression)

● Install only system extensions that satisfy the requirements and rules

governing safety, electromagnetic compatibility, and telecommunications terminal equipment.

If you install other extensions, you may damage the system or violate

these safety regulations.

Information on which system extensions are suitable can be obtained

from the customer service centre or your sales outlet.

●

The components marked with a warning label (e.g. lightning symbol)

may only be opened, removed, or exchanged by authorized, qualified

personnel.

●

The warranty is invalidated if the device is damaged during the installation or replacement of system extensions.

●

You may set only those resolutions and refresh rates specified in the

operating manual for your monitor.

Otherwise, you may damage the monitor. If you are in any doubt, contact your sales outlet or customer service centre.

Options Guide 11

Page 20

Safety Instructions

Batteries

V CAUTION!

● Incorrect replacement of batteries may lead to risk of explosion. The

batteries may only be replaced with identical batteries or with a type

recommended by the manufacturer (see the Technical Manual for the

system board under “Related publications” on page 67).

● Do not throw batteries into the trash can. They must be disposed of

in accordance with local regulations concerning special waste.

● Replace the lithium battery on the system board in accordance with

the instructions in the Technical Manual for the system board (see

“Related publications” on page 67).

● All batteries containing pollutants are marked with a symbol (a

crossed-out garbage can). The marking also contains the chemical

symbol of the heavy metal that determines the classification as a

pollutant:

Cd Cadmium

Hg Mercury

Pb Lead

Notes on handling CDs in CD-ROM/DVD drives

V CAUTION!

● Use only CDs in proper condition in the CD-ROM/DVD drive of your

server to prevent data loss, damage to the device, or injuries.

Therefore, check each CD for damage, cracks, breakage etc. before

inserting it in the drive.

● Please note that any additional labels applied may change the

mechanical properties of a CD and cause imbalance.

● Damaged and imbalanced CDs can break at high drive speeds (data

loss).

● Under certain conditions, sharp-edged pieces of broken CDs can

penetrate the cover of the drive (cause damage to the device) and be

thrown out of the device (therefore causing injury to uncovered body

parts, particularly the face or neck).

12 Options Guide

Page 21

Safety Instructions

I To protect the CD-ROM/DVD drive and prevent mechanical damage, as

well as premature wearing of the CDs, you should observe the following

advice:

– Only insert the CDs in the drive when needed and remove them after

use.

– Store the CDs in suitable sleeves.

– Protect the CDs from exposure to heat and direct sunlight.

Note on the laser

The CD-ROM/DVD drive contains a light-emitting diode (LED) classified

according to IEC 825-1:1993:LASER CLASS 1.

Modules with electrostatic-sensitive devices

Electrostatic-sensitive components are identified by the following sticker:

Figure 1: ESD label

V CAUTION!

When you handle components fitted with ESDs, you must observe the

following points under all circumstances:

● Remove the power plug from the power socket before inserting or

removing components containing ESDs.

● You must always discharge static build-up (e.g. by touching a

grounded object) before working with such components.

● The equipment and tools you use must be free of static charge.

● Use a grounding cable designed for this purpose to connect yourself

to the system unit as you install components.

Options Guide 13

Page 22

Safety Instructions

V CAUTION!

● Always hold components with ESDs at the points marked green

(touch points).

● Do not touch any exposed pins or conductors on a component.

● Place all components on a static-free base.

I You will find a detailed description of handling ESD components in the

relevant European or international standards (EN 61340-5-1,

ANSI/ESD S20.20).

14 Options Guide

Page 23

4 Preparation

V CAUTION!

Please observe the safety information in the chapter “Safety Instructions”

on page 9ff.

4.1 Opening the server

Ê Exit all applications and shut down the server correctly.

Ê Press the on/off button.

Ê Unplug the power plugs.

1

2

1

Figure 2: Removing the server

Ê Undo the knurled screws (1) and pull the server carefully out of the

rack (2) as far as possible.

Options Guide 15

Page 24

Opening the server Preparation

In the majority of cases it makes sense to remove the server from the rack.

V CAUTION!

There is no cable management for the server in the rack!

Before you remove the server from the rack, you must therefore

unplug all cables connected to the server from their sockets.

I How to remove the server from the rack is described in the operating

manual.

Figure 3: Removing the cover

Ê Undo the knurled screw on the back of the device (see figure).

Ê Pull the server cover back a few centimeters.

Ê Lift up the server cover and remove it.

16 Options Guide

Page 25

5Main Memory

V CAUTION!

Please observe the safety information in the chapter “Safety Instructions”

on page 9ff.

The eight slots for the main memory are suitable for PC2-3200 DDR-II DIMM

memory modules. The board supports a maximum of 13-16 Gbytes of main

memory (depending on the configuration). Organization in four memory banks,

0 to 3, enables fast memory access with two-way interleaving.

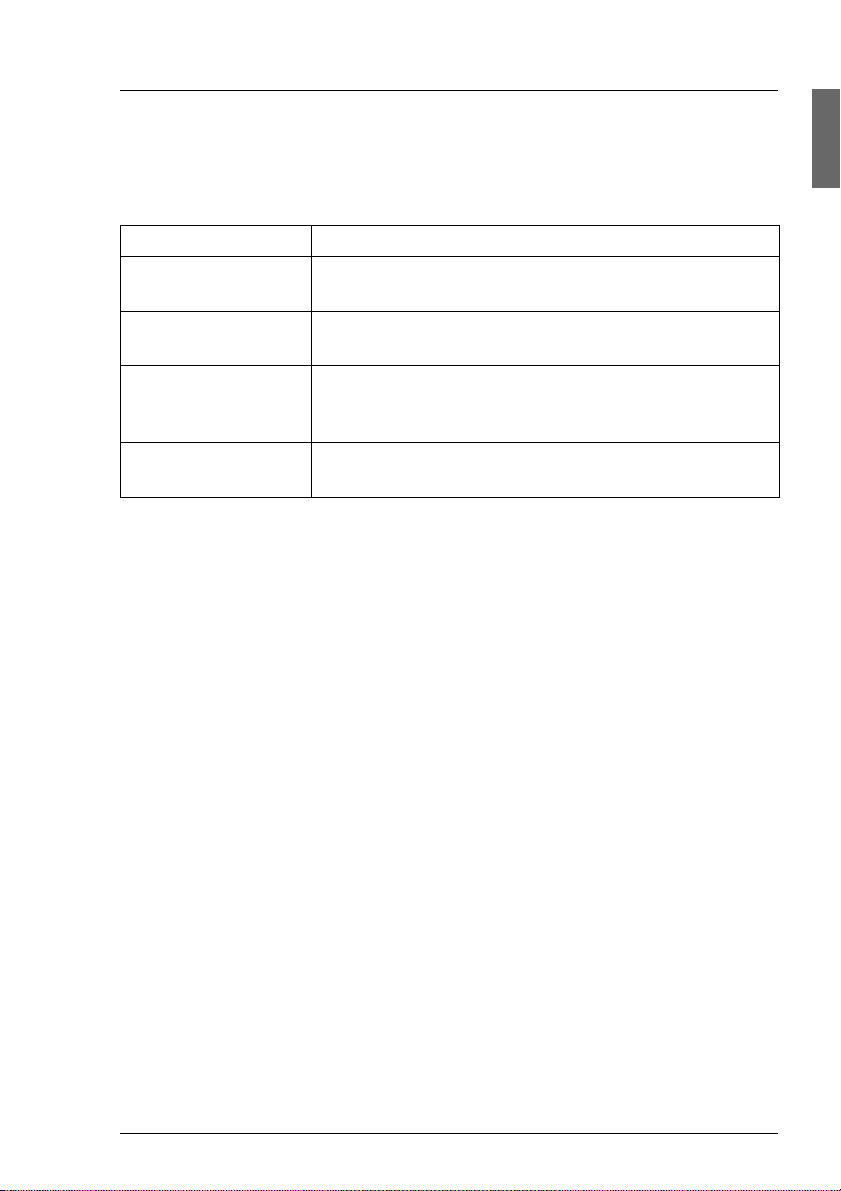

5.1 Installation rules

V CAUTION!

Memory modules have to be installed in pairs. Each memory bank must

always be fully equipped with the same type of modules.

The following memory configurations are permitted:

1

2

3

4

5

6

Mem. module

Bank/DIMM no.

Socket label

Populated with 2

DIMMs

Populated with 4

DIMMs

Populated with 6

DIMMs

Populated with 8

DIMMs

Options Guide 17

1.1

1.2

1.2

1.2

1.2

DIMM

DIMM

DIMM

DIMM

A1

B1

A2

B2

DIMM

A3

XX 1

XXXX 2

XXXXXX 3

XXXXXXXX 4

1.2

DIMM

B3

7

1.2

DIMM

A4

8

1.2

DIMM

B4

Mounted

memory

banks

ß

Page 26

Upgrading / exchanging main memory Main Memory

5.2 Upgrading / exchanging main memory

Ê Open the server as described in the chapter “Preparation” on page 15f.

1

Figure 4: Removing a memory module

2

1

Ê Flip the ejector tabs on each side of the slot outward (1). This levers an

installed memory module out of its slot.

Ê Remove the memory module from the slot (2).

2

2

Figure 5: Installing a memory module

Ê Carefully press the memory module into the slot (1) until the ejector tabs on

both sides of it engage (2).

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45f.

18 Options Guide

Page 27

6 Processors

V CAUTION!

Please observe the safety information in the chapter “Safety Instructions”

on page 9ff.

V CAUTION!

Processors are components which are extremely sensitive to electrostatic discharge and must be handled with caution.

When you take a processor out of its protective wrapper or out of a

socket, place it on an insulated, antistatic surface with the smooth side

down.

Never slide a processor over a surface.

6.1 Installing a second processor

The system board can be upgraded with a second processor.

V CAUTION!

You may only use processors of the same type. The second processor

must have the same clock frequency as the first. For dual-processor

mode use a suitable multiprocessor operating system.

Ê Open the server as described in the chapter “Preparation” on page 15f.

Options Guide 19

Page 28

Installing a second processor Processors

Removing the ventilation duct

Figure 6: Removal of the ventilation duct

Ê Lift off the ventilation duct upwards.

20 Options Guide

Page 29

Processors Installing a second processor

Removing the heat sink dummy

Figure 7: Removing the heat sink dummy

Ê Remove the heat sink dummy.

Installing the processor

Figure 8: Opening the socket lever

Ê Release the socket lever by pressing it sideways and lifting it up as far as it

will go.

Options Guide 21

Page 30

Installing a second processor Processors

1

2

Figure 9: Installing the processor

Ê Position the new processor over the socket and fit it into the socket by

carefully pushing it downwards (1).

V CAUTION!

The processor can only be installed in one direction. Pay attention to

the marking on one of the corners for the correct alignment (see

figure). To avoid damaging the pins or the processor, do not force the

processor into the socket.

Ê Lock the processor into place in the socket by pushing the socket lever back

into its original position (2).

22 Options Guide

Page 31

Processors Installing a second processor

Installing the heat sink

2

1

Figure 10: Installing the heat sink

Ê Fit the heat sink on the processor such that the side labeled “FRONT” (see

arrow (1) in figure above) is facing the front of the server.

Ê Attach the heat sink with four screws. Tighten the screws in diagonally

opposite sequence (2).

V CAUTION!

Never install a processor without a heat sink! The processor is likely to

overheat, which may cause damage to the processor and the system

board.

Installing the ventilation duct

Ê Reinstall the ventilation duct (see page 20).

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45.

Options Guide 23

Page 32

Exchanging the processor Processors

6.2 Exchanging the processor

V CAUTION!

You may only use processors of the same type on the system board.

Ê Open the server as described in the chapter “Preparation” on page 15f.

Ê Remove the ventilation duct (see page 20).

Figure 11: Removing the processor heat sink

Ê Remove the four screws of the heat sink in diagonally opposite sequence

(see figure).

Ê Turn the heat sink carefully back and forth to loosen it. Then lift it out to

remove it.

Ê Remove the residual thermal paste from the underside of the heat sink.

Ê Clean the underside of the heat sink using a lint-free cloth.

24 Options Guide

Page 33

Processors Exchanging the processor

2

1

Figure 12: Removing the old processor

Ê Release the socket lever by pressing it sideways and lifting it up as far as it

will go (1).

Ê Lift the installed processor carefully out of its socket (2).

1

2

Figure 13: Installing the new processor

Ê Position the new processor above the socket, and press it carefully into the

socket (1).

V CAUTION!

The processor can only be installed in one direction. Pay attention to

the marking on one of the corners for the correct alignment. To avoid

damaging the pins or the processor, do not force the processor into

the socket.

Ê Lock the processor into place in the socket by pushing the socket lever back

into its original position (2).

Options Guide 25

Page 34

Exchanging the processor Processors

Ê Apply a small amount of thermal paste to the top of the new processor.

Ê Spread the paste thinly and evenly.

Ê Fit the heat sink on the processor such that the side labeled “FRONT” is

facing the front of the server (see page 23).

Ê Attach the heat sink with four screws. Tighten the screws in diagonally

opposite sequence (see page 23).

Ê Reinstall the ventilation duct (see page 20).

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45.

26 Options Guide

Page 35

Processors Exchanging the heat sin

k

6.3 Exchanging the heat sink

Ê Open the server as described in the chapter “Preparation” on page 15f.

Ê Remove the ventilation duct (see page 20).

Ê Remove the four screws of the heat sink in diagonally opposite sequence

(see page 24).

Ê Turn the heat sink carefully back and forth to loosen it. Then lift it out to

remove it.

Ê Clean the surface of the processor with a lint-free cloth.

Ê Fit the heat sink on the processor such that the side labeled “FRONT” is

facing the front of the server (see page 23).

Ê Attach the heat sink with four screws. Tighten the screws in diagonally

opposite sequence (see page 23).

Ê Reinstall the ventilation duct (see page 20).

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45f.

Options Guide 27

Page 36

Page 37

7 Accessible Drives

V CAUTION!

Please observe the safety information in the chapter “Safety Instructions”

on page 9ff.

The PRIMERGY RX200 S2 server offers a total of two slots for accessible

drives. Available are a floppy disk drive and a CD-ROM/DVD drive. Instead of

the floppy drive a LocalView module can be installed.

The drives can be installed into the two top bays. The left-hand bay is intended

for a 3.5 x 0.5 inch floppy drive or a LocalView module, while the right-hand bay

takes a 5.25 x 0.5 inch CD-ROM/DVD drive.

Options Guide 29

Page 38

Installing the LocalView Module Accessible Drives

7.1 Installing the LocalView Module

The LocalView module is an optional extra for servers in the PRIMERGY series.

It allows you to read status messages directly from the server on the LocalView

display panel. These status messages provide system information and

warnings of hardware errors (e.g. fan failure, CPU overvoltage, etc.)

The LocalView module can be pulled out like a drawer. You can also angle the

LCD panel downwards.

In the RX200 S2 server, the LocalView module can be installed next to the 5.25

x 0.5 inch CD-ROM/DVD drive bay instead of a floppy disk drive.

Figure 14: LocalView module

Ê Open the server as described in the chapter “Preparation” on page 15f.

30 Options Guide

Page 39

Accessible Drives Installing the LocalView Module

Ê Remove the dummy cover with a screwdriver.

V CAUTION!

Keep the dummy cover for future use. If you remove the LocalView

module without installing a new one, you must reinstall the dummy

cover to comply with EMC regulations and to satisfy cooling require-

ments and fire protection measures.

Ê Push the LocalView module into its bay until it engages.

Figure 15: Connecting the LocalView module

Ê Connect the CN6 plug of the SCSI/fan board (see figure) using the IPMB

cable with the connector on the rear of the LocalView module.

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45.

I For information on operation and display modes, see the user documen-

tation for the LocalView module [6].

Options Guide 31

Page 40

Installing a CD-ROM/DVD drive Accessible Drives

7.2 Installing a CD-ROM/DVD drive

You can install a CD-ROM/DVD drive in the top right bay (seen from the front).

If the bay is empty, a dummy cover will have been fitted.

Removing the dummy cover

Figure 16: Dummy cover

Ê Remove the dummy cover with a screwdriver.

V CAUTION!

Keep the dummy cover for future use. If you remove the drive without

installing a new one, you must reinstall the dummy cover to comply with

EMC regulations and to satisfy cooling requirements and fire protection

measures.

32 Options Guide

Page 41

Accessible Drives Installing a CD-ROM/DVD drive

Installing a CD-ROM/DVD drive

Figure 17: Mounting the drive in its frame

Ê Insert the CD-ROM/DVD drive in its frame and secure it with four screws.

Ê Push the CD-ROM/DVD drive into its bay from the front until it engages.

Options Guide 33

Page 42

Installing a CD-ROM/DVD drive Accessible Drives

2

1

Figure 18: Installing the CD-ROM/DVD drive

Ê Plug the data cable (1) and the power cable (2) into the CD-ROM/DVD drive.

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45f.

34 Options Guide

Page 43

Accessible Drives Installing a floppy disk drive

7.3 Installing a floppy disk drive

You can install a floppy disk drive in the top left bay (seen from the front). If the

bay is empty, a dummy cover will have been fitted.

Removing the dummy cover

Figure 19: Dummy cover

Ê Remove the dummy cover with a screwdriver.

V CAUTION!

Keep the dummy cover for future use. If you remove the drive without

installing a new one, you must reinstall the dummy cover to comply with

EMC regulations and to satisfy cooling requirements and fire protection

measures.

Options Guide 35

Page 44

Installing a floppy disk drive Accessible Drives

Removing/installing a floppy disk drive

Figure 20: Mounting the drive in its frame

Ê Insert the floppy disk drive in its frame and secure it with two screws.

Ê Push the floppy disk drive in its frame into the bay from the front until it

engages.

36 Options Guide

Page 45

Accessible Drives Installing a floppy disk drive

Figure 21: Connecting the data cable

Ê Remove the capton foil from the data cable and connect the cable to the rear

of the floppy drive (see figure).

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45f.

Options Guide 37

Page 46

Page 47

8 Controllers in Non-Hot-Plug PCI

Slots

V CAUTION!

Please observe the safety information in the chapter “Safety Instructions”

on page 9ff.

If you want to replace components which are not hot-pluggable, you must

proceed as follows:

Ê Shut down the operating system

Ê Switch off the server, and

Ê Unplug the power plugs.

The system board contains two PCI-X slots, which can only be used via a riser

card because of the height of the server:

– PCI-X slot 1: 64 bit/133 MHz, max. length 315 mm

– PCI-X slot 2: 64 bit/66 MHz, low profile, max. length 175 mm

I Both slots are not hot-pluggable.

Options Guide 39

Page 48

Installing controllers Controllers in Non-Hot-Plug PCI Slots

8.1 Installing controllers

Ê Open the server as described in the chapter “Preparation” on page 15f.

Removing the riser card holder

Figure 22: Removing the riser card holder

Ê Undo the two knurled screws (see figure).

Ê Pull out the riser card holder upwards.

Installing a PCI board

Ê Please read the documentation supplied with the PCI board.

Ê Plug any necessary cables into the PCI board.

Ê Remove the slot cover from the PCI board.

I Keep the slot cover for future use. If you remove the board without

installing a new one, you must reinstall the slot cover to comply with

EMC regulations (regulations on electromagnetic compatibility) and

to satisfy cooling requirements and fire protection measures.

40 Options Guide

Page 49

Controllers in Non-Hot-Plug PCI Slots Installing controllers

Low-profile slot (#2)

Figure 23: Mounting the board

Ê Plug the board into the PCI slot on the riser card that is suitable for the height

of the board.

I Make sure that the slot cover fits into the appropriate recess.

Ê If necessary, plug in the cables on the board and other components.

Reinstalling the riser card holder

Ê Plug the riser card holder into the system board.

Ê Attach the riser card holder to the rear of the housing with two knurled

screws (see page 40).

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45f.

Options Guide 41

Page 50

Page 51

9 RemoteView Components

V CAUTION!

Please observe the safety information in the chapter “Safety Instructions”

on page 9ff.

9.1 Installing the RemoteView Service Board S2 LP

I How to install/remove and configure the RSB S2 LP is described in detail

in the manual “RemoteView Service Board S2/S2 LP 1.x, Mounting and

Setting Up”.

The RemoteView Service Board S2 LP (RSB S2 LP) is a PCI board including a

completely independent system, i.e. it has a separate operating system with a

Web server and SNMP agent and can be driven by an external power supply.

The RSB S2 LP should preferably be installed in the low-profile PCI slot, but can

also be installed in the full-height slot.

It is connected to the system board via a data cable and a power cable. The

RSB S2 LP enables remote diagnostics for system analysis, remote system

configuration, and a remote restart if the operating system fails or if a hardware

error occurs.

Ê Open the server as described in the chapter “Preparation” on page 15f.

Ê Remove the riser card holder (see page 40).

Ê Plug the supplied power cable into the J302 connector on the RSB S2 LP.

Ê Plug the supplied data cable into the J104 connector on the RSB S2 LP.

Options Guide 43

Page 52

Installing the RemoteView Service Board S2 LP RemoteView Components

Low-profile slot (#2)

Figure 24: Installing the RSB S2 LP

Ê Remove the slot cover.

I Keep the slot cover for future use. If you remove the RSB S2 without

installing a new one, you must reinstall the slot cover to comply with

EMC regulations (regulations on electromagnetic compatibility) and

to satisfy cooling requirements and fire protection measures.

Ê Install the RSB S2 LP in the low-profile PCI slot (#2) of the riser card. The

procedure is described in the section “Installing controllers” on page 40.

Ê Plug the power cable into the CN7 connector of the system board.

I The position of the connectors is described in the “Technical Manual

of the System Board D1790”.

Ê Plug the data cable into the CN6 socket (IPMB) of the system board.

Ê Install the riser card holder (see page 41).

Ê Close the server, plug in the power plugs, and switch on the server as

described in the chapter “Completion” on page 45f.

44 Options Guide

Page 53

10 Completion

V CAUTION!

Please observe the safety information in the chapter “Safety Instructions”

on page 9ff.

10.1 Closing the server

Figure 25: Installing the cover

Ê Position the cover in such a way that the rear edge protrudes 3-4 cm from

the housing.

Ê Push the cover to the front as far as it will go.

Ê Attach the cover with the knurled screw (see circle in figure) at the back of

the housing.

Ê Install the server in the rack.

I How to install the server in the rack is described in the operating

manual.

Options Guide 45

Page 54

Closing the server Completion

2

1

2

Figure 26: Installing the server

Ê Slide the server into the rack (1).

I After you have inserted the server, you should pull it out again as far

as it will go and then push it back in. This ensures that the server runs

cleanly on the telescopic rails.

Ê Fasten the server at the front using the two knurled screws (2).

Ê Plug in the power plugs and switch the server on.

46 Options Guide

Page 55

Abbreviations

AC

Alternating Current

ANSI

American National Standards Institute

ASR&R

Automatic Server Reconfiguration and Restart

BIOS

Basic Input/Output System

BMC

Baseboard Management Controller

CC

Cache Coherency

CD

Compact Disk

CD-ROM

Compact Disk Read-Only Memory

CHS

Cylinder Head Sector

CMOS

Complementary Metal Oxide Semiconductor

COM

Communication

CPU

Central Processing Unit

DC

Direct Current

Options Guide 47

Page 56

Abbreviations

DIMM

Dual Inline Memory Module

DIP

Dual Inline Package

DMA

Direct Memory Access

DMI

Desktop Management Interface

ECC

Error Checking and Correcting

ECP

Extended Capabilities Port

EEPROM

Electrically Erasable Programmable Read-Only Memory

EMC

ElectroMagnetic Compatibility

EMP

Emergency Management Port

EPP

Enhanced Parallel Port

ESD

Electrostatic-Sensitive Devices

FPC

Front Panel Controller

FRU

Field Replaceable Unit

FSB

Front Side Bus

48 Options Guide

Page 57

GAM

Global Array Manager

GUI

Graphical User Interface

HDD

Hard Disk Drive

HSC

Hot-Swap Controller

I²C

Inter-Integrated Circuit

I/O

Input/Output

ICM

Intelligent Chassis Management

ID

Identification

Abbreviations

IDE

Integrated Drive Electronics

IRQ

Interrupt Request Line

LAN

Local Area Network

LBA

Logical Block Address

LCD

Liquid Crystal Display

LUN

Logical Unit Number

Options Guide 49

Page 58

Abbreviations

LV D

Low-Voltage Differential SCSI

MMF

Multi-Mode Fiber

MRL

Manual-Retention Latch

NMI

Non-Maskable Interrupt

NVRAM

Non-Volatile Random Access Memory

OS

Operating System

PCI

Peripheral Component Interconnect

PDA

Prefailure Detection and Analysis

POST

Power-ON Self-Test

RAID

Redundant Arrays of Independent Disks

RAM

Random Access Memory

ROM

Read-Only Memory

RSB

Remote Service Board

RTC

Real-Time Clock

50 Options Guide

Page 59

RTDS

Remote Test and Diagnosis System

SAF-TE

SCSI Accessed Fault-Tolerance Enclosures

SBE

Single-Bit Error

SCA

Single-Connector Attachment

SCSI

Small Computer System Interface

SDR

Sensor Data Record

SDRAM

Synchronous Dynamic Random Access Memory

SEL

System Event Log

Abbreviations

SMI

System Management Interrupt

SSU

System Setup Utility

SVGA

Super Video Graphics Adapter

USB

Universal Serial Bus

VGA

Video Graphics Adapter

ZCR

Zero Channel RAID

Options Guide 51

Page 60

Page 61

Related publications

PRIMERGY manuals are available as PDF file on the ServerBooks CD. The

ServerBooks CD is part of the ServerStart Bundle delivered with each server

system.

The actual version of the necessary manuals can be downloaded free of charge

from the Internet. The overview page showing the online documentation

available in the Internet can be found via the URL:

http://manuals.fujitsu-siemens.com (choose: intel based servers.

[1] Safety

[2] Warranty

[3] 19 inch rack

Technical Manual

[4] DataCenter Rack

Technical Manual

[5] PRIMECENTER Rack

Technical Manual

[6] LocalView

User Manual

[7] ServerView

Server Management

User Manual

[8] ServerView Extension

ServerView Extension for HP OpenView NNM

[9] ServerView/Plus for Tivoli

[10] RemoteView

User Manual

[11] RemoteView Service Board S2/S2 LP 1.x

Mounting and Setting Up

User’s Guide

Options Guide 53

Page 62

Related publications

[12] PRIMERGY ServerView Suite

ServerStart

[13] PRIMERGY RX200 S2

Service Supplement

[14] System Board D1790

Technical Manual

[15] BIOS-Setup

Reference Manual

[16] Integrated Mirroring

User’s Guide

[17] Global Array Manager Client Software

User’s Guide

[18] Global Array Manager Server Software

User’s Guide

[19] Ergonomics

[20] Configurator

For partners and distributors only:

http://extranet.fujitsu-siemens.com/cafe/products/primergy

54 Options Guide

Page 63

Index

A

accessible drives 3

additional documentation 1

B

batteries 12

C

CD-ROM/DVD drive

installation 33

upgrade 32

controller 4

upgrade 40

cover

installation 45

removal 16

D

dual-processor mode 19

dummy cover 32, 35

E

EGB label 13

electrostatic sensitive devices 13

ESD 13

ESD label 13

exchange

main memory 18

processor 24

F

floppy disk drive

upgrade 35

H

heat sink

exchange 27

installation 23

removing the dummy 21

I

information material 2

installation

CD-ROM/DVD drive 33

cover 45

RemoteView Service Board S2 LP

43

riser card holder 41

ventilation duct 23

L

light-emitting diode (LED) 13

lithium battery

exchange 12

LocalView module 3

upgrade 30

M

main memory

exchange 18

upgrade 3, 18

meaning of the symbols 5

multiprocessor operating system 19

N

notational conventions 5

notes

on handling CDs 12

on the laser 13

P

PCI board

upgrade 40

processor

exchange 24

installation 19, 21

module 21

upgrade 3

R

RemoteView 4

RemoteView Service Board S2 LP

installation 43

Options Guide 55

Page 64

Index

introduction 4

removal

cover 16

riser card holder 40

ventilation duct 20

riser card holder

installation 41

removal 40

T

target group 1

U

upgrade

CD-ROM/DVD drive 32

controller 40

floppy disk drive 35

LocalView module 30

main memory 18

PCI board 40

V

ventilation duct

installation 23

removal 20

56 Options Guide

Page 65

Fujitsu Siemens Computers GmbH

User Documentation

33094 Paderborn

Germany

Fax: 0 700 / 372 00001

email: manuals@fujitsu-siemens.com

http://manuals.fujitsu-siemens.com

Submitted by

Comments

Suggestions

Corrections

Comments on PRIMERGY RX200 S2

Serversystem

✁

Page 66

Page 67

Fujitsu Siemens Computers GmbH

User Documentation

33094 Paderborn

Germany

Fax: 0 700 / 372 00001

email: manuals@fujitsu-siemens.com

http://manuals.fujitsu-siemens.com

Submitted by

Comments

Suggestions

Corrections

Comments on PRIMERGY RX200 S2

Serversystem

✁

Page 68

Loading...

Loading...