Page 1

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

Solid State Fingerprint Sensor

Overview

The Fujitsu MBF200 Solid-State Fingerprint Sensor is a direct

contact, fingerprint acquisition device. It is a high performance,

low power, low cost, capacitive sensor composed of a twodimensional array of metal electrodes in the sensing array.

Each metal electrode acts as one plate of a capacitor and the

contacting finger acts as the second plate. A passivation layer on the

device surface forms the dielectric between these two plates. Ridges

and valleys on the finger yield varying capacitor values across the

array, and the resulting varying discharge voltages are read to form

an image of the fingerprint.

The MBF200 is manufactured in standard CMOS technology.

The 256 X 300 sensor array has a 50 µm pitch and yields a 500-dpi

image. The sensor surface is protected by a patented, ultra-hard,

abrasion and chemical resistant coating.

Features

• Capacitive solid-state device

Packages

Applications

• Secure access for databases, networks, local storage

• 500-dpi resolution (50 µm pitch)

• 1.28 cm x 1.50 cm (0.5” x 0.6”) sensor area

• 256 x 300 sensor array

• Smart Cards

• 3.3V to 5V operating range

• Exceptionally hard protective coating

• Integrated 8-bit analog to digital converter

• One of three bus interfaces:

8-bit microprocessor bus interface

Integrated USB Full-Speed Interface

Integrated Serial Peripheral Interface

• Standard CMOS technology

• Low power, less than 70 mW operating at 5V

• Automatic finger detection

• Portable fingerprint acquisition

• Smart Cards

• Identity verification for ATM transactions

• Cellular phone-based security access

• Access control and monitoring (home, auto, office, etc.)

Page 2

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

Table of Contents

Chip Operation .....................................................................................................................................................................1

Block Diagram......................................................................................................................................................................1

Connection Diagram..............................................................................................................................................................2

Pin List................................................................................................................................................................................3

Pin Descriptions....................................................................................................................................................................4

Device Bus Operation.............................................................................................................................................................7

Microprocessor Bus Interface............................................................................................................................................7

Serial Peripheral Bus Interface (SPI) Slave ................................................................................................................................8

SPI Bus Mode.................................................................................................................................................................8

SPI Slave Mode...............................................................................................................................................................8

Register Read Command in SPI Slave Mode ........................................................................................................................8

Register Write Command for SPI Slave Mode......................................................................................................................8

USB Interface Mode, Using Internal ROM ................................................................................................................................8

Endpoint 0 ....................................................................................................................................................................8

Endpoint 1 ....................................................................................................................................................................8

Endpoint 2 ....................................................................................................................................................................8

USB Interface Mode, Using External ROM ...............................................................................................................................8

SPI Master Mode ............................................................................................................................................................9

Function Register Descriptions ...............................................................................................................................................9

Function Register Map...........................................................................................................................................................9

RAH 0x00 .....................................................................................................................................................................9

RAL 0x01....................................................................................................................................................................10

CAL 0x02....................................................................................................................................................................10

REH 0x03....................................................................................................................................................................10

REL 0x04....................................................................................................................................................................10

CEL 0x05 ....................................................................................................................................................................10

DTR 0x06....................................................................................................................................................................11

DCR 0x07....................................................................................................................................................................11

CTRLA 0x08 ...............................................................................................................................................................11

CRTLB 0x09................................................................................................................................................................13

CTRLC 0x0A ...............................................................................................................................................................14

SRA 0x0B....................................................................................................................................................................14

PGC 0x0C ...................................................................................................................................................................15

ICR 0x0D ....................................................................................................................................................................15

ISR 0x0E.....................................................................................................................................................................16

THR 0x0F ...................................................................................................................................................................16

Fujitsu Microelectronics America, Inc.

Fujitsu Microelectronics America, Inc.

-1

Page 3

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Solid State Fingerprint Sensor

CIDH 0x10 ................................................................................................................................................................. 17

CIDL 0x11.................................................................................................................................................................. 17

TST 0x12.................................................................................................................................................................... 17

Sensor Initialization............................................................................................................................................................ 18

Image Retrieval .................................................................................................................................................................. 18

Microprocessor Interface ............................................................................................................................................... 18

Get Row ............................................................................................................................................................... 18

Get Whole Image ................................................................................................................................................... 19

Get Sub-Image ...................................................................................................................................................... 20

Serial Peripheral Interface ...................................................................................................................................... 21

Get Image............................................................................................................................................................. 21

USB Interface........................................................................................................................................................ 22

Get Image............................................................................................................................................................. 22

Absolute Maximum Ratings ................................................................................................................................................. 23

Operating Range ................................................................................................................................................................ 23

DC Characteristics .............................................................................................................................................................. 23

Power Supply Consumption ................................................................................................................................................. 24

AC Characteristics .............................................................................................................................................................. 25

Microprocessor Bus Mode.............................................................................................................................................. 25

Read Cycle............................................................................................................................................................ 25

Write Cycle........................................................................................................................................................... 25

SPI Slave Mode...................................................................................................................................................... 26

SPI Master............................................................................................................................................................ 26

Timing Diagrams................................................................................................................................................................ 27

Physical Dimensions............................................................................................................................................................ 31

Recommended Land Pattern................................................................................................................................................. 32

Array Orientation............................................................................................................................................................... 33

Appendix A ........................................................................................................................................................................ 34

Recommended Power and Ground Connections ................................................................................................................ 34

Appendix B........................................................................................................................................................................ 35

Recommended MBF200 Sensor Orientation..................................................................................................................... 35

Fujitsu Microelectronics America, Inc.

Fujitsu Microelectronics America, Inc.

0

Page 4

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

Chip Operation

The sensor array includes 256 columns and 300 rows of sensor plates.

Associated with each column are two sample-and-hold circuits.

A fingerprint image is sensed or captured one row at a time. This

“row capture” occurs in two phases. In the first phase, the sensor

plates of the selected row are pre-charged to the VDD voltage.

During this pre-charge period, an internal signal enables the first

set of sample-and-hold circuits to store the pre-charged plate

voltages of the row.

In the second phase, the row of sensor plates is discharged with a

current source. The rate at which a cell is discharged is proportional

Block Diagram

P0

P1

D[7:0]

DATA

REGISTER

to the “discharge current.” After a period of time (referred to as

the “discharge time”), an internal signal enables the second set

of sample-and-hold circuits to store the final plate voltages.

The difference between the precharged and discharged plate voltages

is a measure of the capacitance of a sensor cell. After the row capture,

the cells within the row are ready to be digitized.

The sensitivity of the chip is adjusted by changing the discharge

current and discharge time. The nominal value of the current source

is controlled by an external resistor connected between the ISET pin

and ground. The current source is controlled from the Discharge

Current Register (DCR). The discharge time is controlled by the

Discharge Time Register (DTR).

A0

RD

WR

WAIT

CS0

CS1

MOSI

MISO

DP

DM

EXTINT

INTR

TEST

INDEX

REGISTER

CONTROL

SPI

USB

FUNCTION

REGISTERS

SAMPLE AND HOLD

A/D CONVERTER

ANALOG

MULTI-

VIBRATOR

256 X 300

SENSOR

ARRAY

AIN

ISET

FSET

MODE1

MODE0

XTAL

OSC

XTAL1

XTAL2

Fujitsu Microelectronics America, Inc.

1

Page 5

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Solid State Fingerprint Sensor

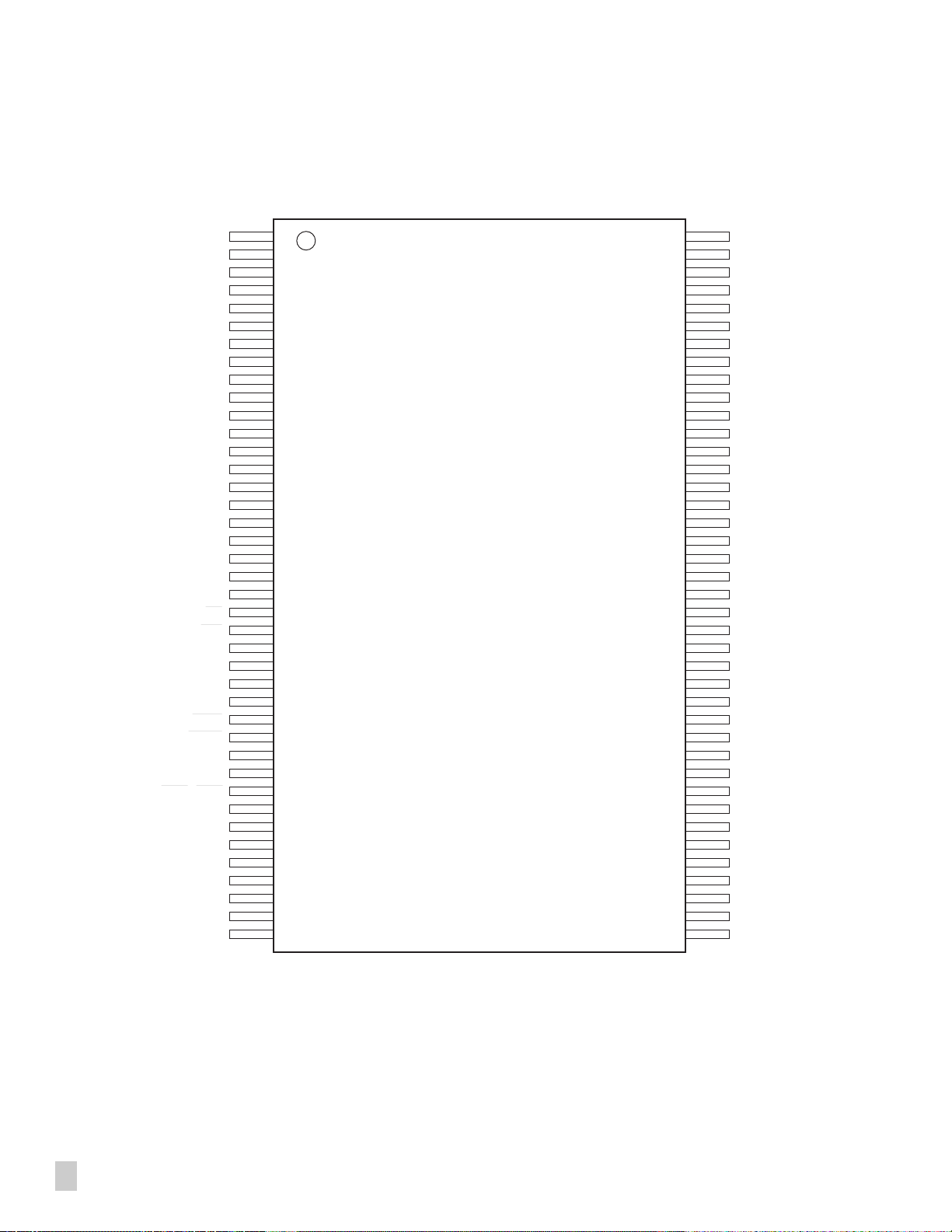

Connection Diagram

VDDA1

VSSA1

ISET

AIN

FSET

VSSA2

VDDA2

TEST

P0

P1

D7

D6

D5

D4

VSS1

VDD1

D3

D2

D1

D0

A0

RD

WR

VSS2

VDD2

XTAL2

XTAL1

INTR

WAIT

EXTINT

CS1/SCLK

CS0/SCS

MOSI

MISO

MODE1

MODE0

DM

DP

VDD3

VSS3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

MBF200

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

N/C

Fujitsu Microelectronics America, Inc.

2

Page 6

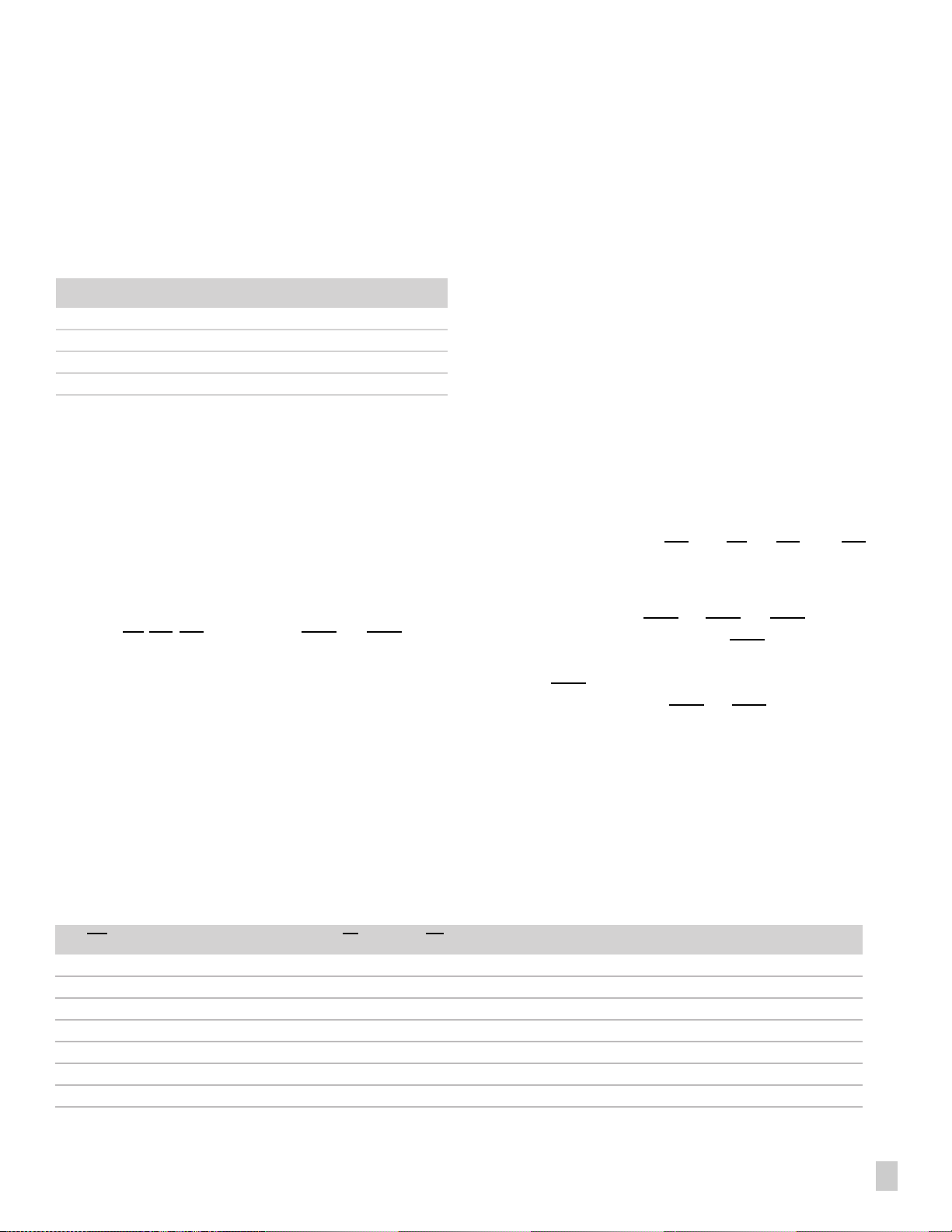

Pin List

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

Pin

Number

1 VDDA1 PWR Analog Power Supply

2 VSSA1 GND Analog Ground

3 ISET O Sets Reference Current

4 AIN I Analog Input

5 FSET O Sets Internal Multi-vibrator Frequency

6 VSSA2 GND Analog Ground

7 VDDA2 PWR Analog Power Supply

8 TEST I Test Mode Enable

9 P0 O 8mA 4mA Output Port 0

10 P1 O 8mA 4mA Output Port 1

11 D7 I/O 8mA 4mA Data Bit 7

12 D6 I/O 8mA 4mA Data Bit 6

13 D5 I/O 8mA 4mA Data Bit 5

14 D4 I/O 8mA Data Bit 4

15 VSS1 GND Digital Ground

16 VDD1 PWR Digital Power Supply

17 D3 I/O 8mA 4mA Data Bit 3

18 D2 I/O 8mA 4mA Data Bit 2

19 D1 I/O 8mA 4mA Data Bit 1

20 D0 I/O 8mA 4mA Data Bit 0

21 A0 I Address Input

22 RD I 8mA 4mA Read Enable, Active Low

23 WR I 8mA 4mA Write Enable, Active Low

24 VSS2 GND Digital Ground

25 VDD2 PWR Digital Power Supply

26 XTAL2 O Internal Oscillator Output

27 XTAL1 I Internal Oscillator Input

28 INTR

29 WAIT O 8mA Wait, Active Low

30 EXTINT I External Interrupt Input

31 CS1/SCLK I/O Chip Select, Active High

32 CS0/SCS I/O Chip Select, Active Low

33 MOSI I/O 8mA 4mA SPI Master Output / Slave Input

34 MISO I/O 8mA 4mA SPI Master Input / Slave Output

35 MODE1 I Mode Select 1

36 MODE0 I Mode Select 0

37 DM I/O USB D-

38 DP I/O USB D+

39 VDD3 PWR Digital Power Supply

40 VSS3 GND Digital Ground

[41:80] N/C No Connect

Name Type IOL (5.0 V) IOH (5.0 V) Description

O 8mA Interrupt Output, Active Low

Fujitsu Microelectronics America, Inc.

3

Page 7

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Solid State Fingerprint Sensor

Pin Descriptions

VDDA1, VDDA2 (Pins 1 and 7)

Power Supply to the analog section of the sensor. VDDA1 powers the array, row drivers, column receivers, A/D converter, and sample/hold

amplifier. VDDA2 powers the multi-vibrator and bias circuits.

VSSA1, VSSA2 (Pins 2 and 6)

Ground for the analog section of the sensor. VSSA1 is the ground return for the array, row drivers, column receivers, A/D converter, and

sample hold amplifier. VSSA2 is the ground return for the multi-vibrator and bias circuits.

VDD1, VDD2, VDD3 ( Pins 25, 16, and 39)

Power supply to the digital logic and I/O drivers. VDD2 powers the core digital logic, oscillators, phase-locked loops, and digital inputs.

VDD1 and VDD3 supply power to the digital output circuits and USB transceivers.

VSS1, VSS2, VSS3 (Pins 24, 15, and 40)

Ground for the digital logic and I/O drivers.

VSS2 is the ground connection for the core digital logic, oscillators, phase-locked loops, and digital inputs. VSS1 and VSS3 are the ground

connections for the digital outputs and USB transceivers.

ISET (Pin 3)

Connect a 200k ohm resistor between ISET and analog ground VSSA1 to set the internal reference current. The discharge current is a scalar

function of the internal reference current.

AIN (Pin 4)

Alternate analog input to the A/D converter. Set the AINSEL bit in register CTRLA to select AIN as the input to the A/D converter. Pull this

pin to ground, preferably with a resistor.

FSET (Pin 5)

Connect a resistor between FSET and ground to set the internal multi-vibrator and automatic finger detection frequency. Use a 56k ohm

resistor for standard 12 MHz (±20%) multi-vibrator operation and 120KHz (±20%) automatic finger detection sampling rate.

XTAL1 (Pin 27)

Input to the internal oscillator. To use the internal oscillator, connect a crystal circuit to this pin. If an external oscillator is used, connect its

output to this pin.

XTAL2 (Pin 26)

Output from the internal oscillator. To use the internal oscillator, connect a crystal circuit to this pin. If an external oscillator is used, leave this

pin unconnected.

D[7:0] (Pins 11-14, 17-20)

Bi-directional data bus. D[7:0] have weak latches that hold the bus’s state when not being driven. These pins may be left unconnected in SPI or

USB mode.

A0 (Pin 21)

Address input. Drive A0 low to select the address index register. Drive A0 high to select the data buffer. A0 has a weak latch that holds the pin

state when not being driven. This pin may be left unconnected in SPI or USB mode.

Fujitsu Microelectronics America, Inc.

4

Page 8

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

(Pin 22)

RD

Read enable, active low. To read from the chip, drive RD

resistor and may be left unconnected in SPI or USB mode.

(Pin 23)

WR

Write enable, active low. To write to the chip, drive WR

and may be left unconnected in SPI or USB mode.

/ SCS (Pin 32)

CS0

Chip select, active low. The CS0

USB mode if not using an external serial ROM. The function of the CS0

MODE[1:0] = 00b (Microprocessor Bus Interface Mode)

/SCS functions as an active-low chip select input. Drive CS0/SCS low while CS1 is high to select the chip.

CS0

/SCS pin has a weak latch that holds the pin’s state when not being driven. CS0/SCS may be left unconnected in

low while WR is high and the chip is selected. RD has an internal, weak pull-up

low while RD is high and the chip is selected. WR has an internal, weak pull-up resistor

MBF200

/SCS pin depends on the MODE1 and MODE0 pins.

MODE[1:0] = 01b (SPI Slave Mode)

CS0

/SCS functions as an active-low slave chip select input. Connect a pull-up resistor between CS0/SCS and VDD.

MODE[1:0] = 10b (USB Interface Mode, Using Internal ROM)

CS0

/SCS has no function.

MODE[1:0] = 11b (USB Interface Mode, Using External ROM)

CS0

/SCS functions as the master chip select output, active low to the slave serial ROM chip select. Connect a pullup resistor between

/SCS and VDD.

CS0

CS1 / SCLK (Pin 31)

Chip select, active high. The CS1/SCLK pin has a weak latch that holds the pin’s state when not being driven. CS1/SCLK may be left

unconnected in USB mode if not using an external serial ROM. The function of this pin depends on the MODE1 and MODE0 pins.

MODE[1:0] = 00b (Microprocessor Bus Interface Mode)

CS1/SCLK functions as an active-high chip select input. Drive CS1/SCLK high while CS0-/CSC- is low to select the chip.

MODE[1:0] = 01b (SPI Slave Mode)

CS1/SCLK functions as the slave serial clock input.

MODE[1:0] = 10b (USB Interface Mode, Using Internal ROM)

CS1/SCLK has no function.

MODE[1:0] = 11b (USB Interface Mode, Using External ROM)

CS1/SCLK functions as the master serial clock output to the slave serial ROM clock input. Connect a pull-up resistor between

CS1/SCLK and VDD.

EXTINT (Pin 30)

External Interrupt input. This pin can be programmed to be edge or level sensitive, active-high or active-low. EXTINT has a weak pull-up and

may be left unconnected in MCU, SPI, or USB mode.

INTR

(Pin 28)

Interrupt output, active low. INTR

be enabled if the sensor is in MCU or SPI mode. In USB mode leave this pin unconnected.

is high impedance when it is not active and is driven low when an enabled interrupt event occurs. INTR can

Fujitsu Microelectronics America, Inc.

5

Page 9

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Solid State Fingerprint Sensor

AIT (Pin 29)

W

Wait output, active low. W

an A/D conversion is in progress. W

MOSI (Pin 33)

SPI Master Output/Slave input. The MOSI pin has a weak latch that holds the pin’s state when not being driven. MOSI may be left

unconnected in MCU mode or USB mode if not using an external serial ROM. The function of this pin depends on the MODE1 and MODE0

pins.

MODE[1:0] = 00b (Microprocessor Bus Interface Mode)

MOSI has no function.

MODE[1:0] = 01b (SPI Slave Mode)

MOSI functions as the slave serial input.

AIT is driven low when active and high-impedance when not active. WAIT goes low if the A/D converter is read while

AIT will remain low until the A/D conversion is completed.

MODE[1:0] = 10b (USB Interface Mode, Using Internal ROM)

MOSI has no function.

MODE[1:0] = 11b (USB Interface Mode, Using External ROM)

MOSI functions as the master serial data output to the slave serial ROM data input. Unlike standard SPI, MOSI is actively driven high

and low when transmitting data and is high impedance when idle. Connect a pull-up resistor between MOSI and VDD to pull MOSI

high when idle.

MISO (Pin 34)

SPI Master Input/Slave Output. The MISO pin has a weak latch that holds the pin’s state when not being driven. MISO may be left

unconnected in MCU mode or USB mode if not using an external serial ROM. The function of this pin depends on the MODE1 and MODE0

pins.

MODE[1:0] = 00b (Microprocessor Bus Interface Mode)

MISO has no function.

MODE[1:0] = 01b (SPI Slave Mode)

MISO functions as the slave serial data output. Unlike standard SPI, the MISO connection is actively driven high and low when

transmitting data and is high impedance when idle. Connect a pull-up resistor between MISO and VDD to pull MISO high when idle.

MODE1/MODE0 = 10b (USB Interface Mode, Using Internal ROM)

MISO has no function.

MODE1/MODE0 = 11b (USB Interface Mode, Using External ROM)

MISO functions as the master serial data input from the slave serial ROM data output.

P0 (Pin 9)

Port Output 0. This output is controlled by bit 0 of the CTRLC register.

P1 (Pin 10)

Port Output 1. This output is controlled by bit 1 of the CTRLC register.

DP (Pin 38)

USB D+ data line. In USB mode, connect a 1.5k ohm resistor between DP and VDD3, which must be between 3.3V and 3.6V in this mode.

Use a 43 ohm series resistor. In MCU or SPI mode, either pull-up this pin with a resistor or tie it to ground.

Fujitsu Microelectronics America, Inc.

6

Page 10

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

DM (Pin 37)

USB D- data line. Use 43 ohm series resistor. In MCU or SPI mode, either pull-up this pin with a resistor or tie it to ground.

MODE[1:0] (Pins 35 and 36)

Mode Select pins. MODE[1:0] select one of four operating modes.

MBF200

MODE[1:0]

00b Microprocessor Bus Mode

01b SPI Bus Mode

10b USB Mode, Using Internal ROM

11b USB Mode, Using External ROM

Description

TEST (Pin 8)

Test Mode Enable. It is intended for factory use only. Connect this pin to VSS.

No Connect (Pins 41-80)

Unconnected pins.

Device Bus Operation

Microprocessor Bus Interface

The microprocessor bus interface mode uses the following pins:

D[7:0], A0, RD

the internal multi-vibrator or the XTAL1/XTAL2 oscillator can be

selected to provide the clock to the chip. The SPI and USB interfaces

are disabled.

The fingerprint sensor chip uses an indexed addressing scheme to

access its function registers. The chip has eight data lines (D[7:0]) and

one address line (A0). The address line selects between the index

register and the data register. Drive A0 low to select the index

register. Drive A0 high to access the function register selected by the

index register. The index register retains its value until it is rewritten

or the chip is reset.

, WR, CS0, CS1, EXTINT, INTR, and WAIT. Either

The chip has four control inputs: CS0

low and CS1 high to select the chip. Data is latched on the rising edge

of WR-.

The chip has two status lines: INTR

asserted when an interrupt event occurs. The W

when the A/D converter is read while an A/D conversion is in

progress. The W

conversion is completed. Both the W

impedance when they are not active. As a result, they can be activelow WIRE-ORed in conjunction with other interrupts or wait

signals.

The SPI and USB interfaces are disabled when the microprocessor

bus interface is selected. A truth table for the microprocessor bus

interface is shown below:

, CS1, RD, and WR. Drive CS0

and WAIT. The INTR signal is

AIT signal goes low

AIT signal will be high impedance when the A/D

AIT and INTR outputs are high

Truth Table for the Microprocessor Bus Interface

CS0

H X X X X De-selected High Impedance

X L X X X De-selected High Impedance

L H X H H Standby High Impedance

L H L L H Read Index Register Output

L H L H L Write Index Register Input

L H H L H Read Data Register Output

L H H H L Write Data Register Input

CS1 A0 RD WR Mode Data Lines

Fujitsu Microelectronics America, Inc.

7

Page 11

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Serial Peripheral Bus Interface (SPI)

Slave

SPI Bus Mode

SPI (Slave) bus mode uses the following pins: SCLK, SCS

MISO, and EXTINT. Either the internal multivibrator or the

XTAL1/XTAL2 oscillator can be selected to provide the clock to the

chip. The microprocessor bus and USB interface are disabled.

SPI Slave Mode

In SPI Slave Mode, the sensor can operate in either SPI mode (0, 0)

where CPOL = 0 and CPHA = 0 or SPI mode (1, 1) where CPOL = 1

and CPHA = 1. T he SPI Master may clock in commands and clock out

data up to 12 Mbits per second. The SPI Master can write and read the

registers of the sensor even when the internal 12 MHz multivibrator or

XTAL1/XTAL2 oscillator is halted.

• MOSI bits are sampled on the rising edge of SCK

• MISO bits change on the falling edge of SCK

• SCK can be idle in either a high or low state

• The most significant bits are shifted out first

, MOSI,

USB Interface Mode, Using Internal

ROM

This USB mode uses the following pins: DP, DM, EXTINT, XTAL1,

and XTAL2. XTAL1 must be driven from a 12 MHz source or XTAL1

and XTAL2 must be connected to a 12 MHz crystal circuit. The

internal 12 MHz multivibrator, the microprocessor bus, and SPI

interface are disabled. The internal USB descriptor ROM will be

accessed in response to a USB GET_DESCRIPTOR command.

The sensor’s USB interface uses three endpoints:

Endpoint 0

Endpoint 0 is a control endpoint used for device enumeration and

configuration. The sensor function registers are written and read

using control transfers of vendor specific commands to endpoint 0.

Endpoint 1

Endpoint 1 is a bulk-in endpoint specifically for reading the CTRLA

register, which is the output buffer of the A/D converter. Data is

transmitted in 64-byte packets except for the last packet of a

GETROW operation which may be 64-bytes or less, depending on

the row length.

Register Read Command in SPI Slave Mode

The Register Read command includes a command byte and address

byte. The command sequence begins when the SPI master drives SCS

low and sends the Read Command byte (encoded as 0x03) on the

MOSI pin. Following the command byte, the master sends the

address byte, which is the index to the register to be read. After

receiving the least significant bit (LSB) of the address byte, the SPI

slave sensor sends the contents of the selected register on the MISO

pin. Finally, the master drives SCS

of the data byte. When reading the A/D converter, the Master may

keep SCS

row. A new Register Read command must be issued to read the next

row. The SPI Master must drive SCS

command.

low to read consecutive pixels up to the end of the current

high after it has sampled the LSB

high before beginning another

Register Write Command for SPI Slave Mode

The Register Write command includes a command byte and address

byte followed by the data to be written. The command sequence

begins when the SPI Master drives SCS

Command byte (encoded as 0x02) on the MOSI pin. Then the master

sends the address byte, which is the index to the register to be

written. Finally, the master sends the data byte and thereafter drives

high.

SCS

low and sends the Write

Endpoint 2

Endpoint 2 is an interrupt endpoint. In the event of an interrupt,

the contents of the ISR (Interrupt Status Register) are transfered to

endpoint 2.

USB Interface Mode, Using External

ROM

This USB mode the uses following pins: DP, DM, SCLK, SCS

MOSI, MISO, EXTINT, XTAL1, and XTAL2. XTAL1 must be

driven from a 12 MHz source or a 12 MHz crystal circuit must be

connected to XTAL1 and XTAL2. The internal 12 MHz multivibrator and the microprocessor bus are disabled.

The SPI interface is enabled as an SPI Master. The external SPI serial

ROM will be accessed in response to a USB GET_DESCRIPTOR

command. The internal USB descriptor ROM is disabled. This mode

allows an external serial ROM to override the internal descriptor ROM.

Note: When the MBF200 is directly connected to USB in either of

the modes above, the VDD and VDDA pins must be powered

between 3.3V and 3.6V so that the MBF200 DP and DM pins do

not drive the USB beyond 3.6V.

,

Fujitsu Microelectronics America, Inc.

8

Page 12

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

SPI Master Mode

In SPI Master Mode the sensor operates in SPI mode (1,1) where

CPOL = 1, and CPHA = 1. SCK is limited to 1 MHz.

• MOSI bits change on the falling edge of SCK

• MISO bits are sampled on the rising edge of SCK

• SCK is idle in the high state

• The most significant bits are shifted out first

Function Register Map

Index

0x00 RAH Row Address, High R/W

0x01 RAL Row Address, Low R/W

0x02 CAL Column Address, Low R/W

0x03 REH Row Address End, High R/W

0x04 REL Row Address End, Low R/W

0x05 CEL Column Address End, Low R/W

0x06 DTR Discharge Time Register R/W

0x07 DCR Discharge Current Register R/W

0x08 CTRLA Control Register A R/W

0x09 CTRLB Control Register B R/W

0x0A CTRLC Control Register C R/W

0x0B SRA Status Register A R

0x0C PGC Programmable Gain Control Register R/W

0x0D ICR Interrupt Control Register R/W

0x0E ISR Interrupt Status Register R/W

0x0F THR Threshold Register R/W

0x10 CIDH Chip Identification, High R

0x11 CIDL Chip Identification, Low R

0x12 TST Test Mode Register R/W

Name Description Read/Write Access

Function Register Descriptions

The function registers are accessed by indexed addressing. Write the

index register to select a function register. Read or write the data

register to access the contents of the function register. All registers

can be read and written except as noted in the following

descriptions.

Note: In the following descriptions, “sub-image” means a rectangular region of the sensor array, up to and including the entire array.

RAH 0x00

Row Address Register High.

Reset State: 0x00

This register holds the high order bit of the address of the first row of a sub-image.

Bit Number

[7:1] - Reserved. Write 0 to these bits.

0 RA[8] Most Significant Bit of Row Address Register

Bit Name Function

Fujitsu Microelectronics America, Inc.

9

Page 13

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

RAL 0x01

Row Address Register Low.

Reset State: 0x00

This register holds the low order byte of the address of the first row of a sub-image.

Bit Number

[7:0] RA[7:0] Low eight bits of Row Address Register

Bit Name Function

CAL 0x02

Column Address Register.

Reset State: 0x00

This register holds the address of the first column of a sub-image.

Bit Number

[7:0] CA[7:0] Column Address Register

Bit Name Function

REH 0x03

Row Address End Register High.

Reset State: 0x00

This register holds the most significant bit of the address of the last row of a sub-image.

Bit Number

[7:1] - Reserved. Write 0 to these bits.

0 REND[8] Most Significant Bit of Row Address Register

Bit Name Function

REL 0x04

Row Address End Register Low.

Reset State: 0x00

This register holds the least significant byte of the address of the last row of a sub-image.

Bit Number

[7:0] REND[7:0] Low eight bits of Row Address Register

Bit Name Function

CEL 0x05

Column Address End Register.

Reset State: 0x00

This register holds the address of the last column of a sub-image.

Bit Number Bit Name Function

[7:0] CEND[7:0] Column Address Register

Fujitsu Microelectronics America, Inc.

10

Page 14

DTR 0x06

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Discharge Time Register

Reset State: 0x00

MBF200

Bit Number

[7] - Reserved. Write 0 to these bits.

[6:0] DT[6:0] Sets the discharge time in oscillator clock periods.

Bit Name Function

DCR 0x07

Discharge Current Register

Reset State: 0x00

Bit Number

[7:5] - Reserved. Write 0 to these bits.

[4:0] DC[4:0] Sets the discharge current rate.

Bit Name Function

CTRLA 0x08

Control Register A.

Reset State: 0x00

Write this register to initiate image conversion. Read this register to read the A/D converter.

Bit Number

7 - Reserved. Write 0 to this bit.

6 - Reserved. Write 0 to this bit.

5 - Reserved. Write 0 to this bit.

4 - Reserved. Write 0 to this bit.

3 AINSEL

2 GETSUB Initiates Auto-increment for sub-image

1 GETIMG Initiates Auto-increment for whole image

0 GETROW Initiates Auto-increment for selected row

Bit Name Function

0=Select Array for Conversion

1=Select External Analog Input Pin and Start Conversion

The GETSUB, GETIMG, and GETROW bits select an image access mode and initiate an A/D conversion sequence. The AINSEL bit selects

the input source to the A/D converter.

Set the GETSUB bit to initiate the capture of a rectangular sub-image defined by the RAH, RAL, CAL, REH, REL, and CEL registers.

In CPU or SPI mode, the sub-image can be an arbitrary rectangle ranging from a single pixel to the entire array. In USB mode, the number of

columns in the sub-image must be an integral multiple of 64.

Set the GETIMG bit to initiate the capture of a whole image starting from row zero and column zero through row 299 and column 255,

regardless of the RAH, RAL, CAL, REH, REL, and CEL registers.

Set the GETROW bit to initiate the capture of a row specified by the RAH and RAL registers.

Writing a 1 to any of GETSUB, GETIMG, or GETROW abandons the current image access operation and restarts at the beginning of the

sub-image, image, or row. Set at most one of these three bits. If more than one these three bits are set, image conversion will not start.

Fujitsu Microelectronics America, Inc.

11

Page 15

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Setting the GETROW bit causes the following events to happen:

• Row address loaded with contents of RAH and RAL register.

• Column address resets to zero

• Row capture automatically starts

• Analog to digital conversion of first pixel automatically starts

Setting the GETIMG bit causes the following events to happen:

• Row address resets to zero

• Column address resets to zero

• Row capture automatically starts

• Analog to digital conversion of first pixel automatically starts

Setting the GETSUB bit causes the following events to happen:

• Row address loaded with contents of RAH and RAL register

• Column address loaded with contents of CAL

• Row capture automatically starts

• Analog to digital conversion of first pixel automatically starts

Set the AINSEL bit along with one of the other three bits to begin the analog to digital conversion of the voltage on the AIN pin instead of the

sensor array.

Writing 0 to the CTRLA register has no effect other than clearing AINSEL; the current image access operation is not abandoned.

Read CTRLA for the result of the A/D conversion. The rising edge of RD

Parameter Description

Rising Edge of WR to First Data Valid 28 + DT[6:0] Clock Cycles

Rising Edge of RD

Note: DT[6:0] refers to the contents of the Discharge Time Register.

to Next Data Valid 6 Clock Cycles

causes the next A/D conversion to start.

Max Units

Fujitsu Microelectronics America, Inc.

12

Page 16

CRTLB 0x09

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Control Register B.

Reset State: CTRLB[7:6] = state of MODE[1:0].

CTRLB[5] = 1.

CTRLB [4:0] = 0, Chip is disabled, oscillator is stopped.

MBF200

Bit Number

[7:6] MODE[1:0] Reflects the state of the MODE[1:0] pins. These bits are read-only. Writing to these bits has no effect. Write 0 to these bits.

5 RDY

4 - Reserved. Write 0 to this bit.

3 AFDEN

2 AUTOINCEN

1 XTALSEL

0 ENABLE

Bit Name Function

This is a read-only bit that indicates the status of the A/D Converter.

0 = A/D Conversion is in progress.

1 = A/D Converter is idle.

Writing this bit has no effect. Write 0 to this bit.

Set this bit to enable the automatic finger detection circuit.

In USB mode, automatic finger detection will generate an interrupt on endpoint 2.

In CPU or SPI mode, automatic finger detection will generate a finger detect interrupt on the INTR pin as controlled by the Interrupt

Control Register (ICR). In any mode, the automatic finger detection can be combined with ENABLE=0 to save power.

0 = Column and row addresses do not automatically increment after the A/D converter is read.

1 = Column addresses increment and another A/D conversion is initiated after the A/D converter is read. The row address

increments at the end of each column.

In USB mode this bit has no function. In CPU and SPI mode this bit selects the clock source for the digital logic.

0 = Selects the internal 12 MHz multi-vibrator.

1 = Selects the XTAL1 pin.

0 = Place the sensor array, digital, and analog block into low-power state (12 MHz clock is halted, A/D Converter is shut down).

1= Enable the sensor array, digital, and analog blocks (12 MHz clock and A/D Converter are enabled).

Fujitsu Microelectronics America, Inc.

13

Page 17

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

CTRLC 0x0A

Control Register C. This register controls the behavior of general output port pins P0 and P1.

Reset State: 0x00

Bit Number Bit Name Function

Programs the toggle rate of the P1 pin.

If PT1[2:0] = 000, then the P1 pin follows the state of the P1 bit. Otherwise PT1[2:0] selects the clock divisor to generate a square

wave on the P1 pin.

000 = P1 pin follows state of bit P1.

[7:5] PT1[2:0]

[4:2] PT0[2:0]

1 P1

0 P0

001 = clock divided by 2

010 = clock divided by 223.

011 = clock divided by 222.

100 = clock divided by 221.

101 = Reserved.

110 = Reserved.

111 = Reserved.

Programs the toggle rate of the P0 pin.

If PT0[2:0] = 000, then the P0 pin follows the state of the P0 bit. Otherwise PT0[2:0] selects the clock divisor to generate a square

wave on the P0 pin.

000 = P0 pin follows state of bit P0.

001 = clock divided by 2

010 = clock divided by 223.

011 = clock divided by 222.

100 = clock divided by 221.

101 = Reserved.

110 = Reserved.

111 = Reserved.

General Purpose Output Port. When PT1[2:0] bits are 000, this bit controls the P1 pin.

0 = P1 pin low.

1 = P1 pin high.

General Purpose Output Port. When PT0[2:0] bits are 000, this bit controls the P0 pin.

0 = P0 pin low.

1 = P0 pin high.

24

.

24

.

SRA 0x0B

Status Register A. Read Only. This register shadows the state of CTRLA.

Reset State: 0x00

Bit Number Bit Name Function

7 - Reserved. Returns 0.

6 - Reserved. Returns 0.

5 - Reserved. Returns 0.

4 - Reserved. Returns 0.

3 AINSEL This bit is set or cleared when the AINSEL bit (CTRLA bit 3) is set or cleared by software.

2 GETSUB This bit is set when the GETSUB bit (CTRLA bit 2) is set by software. This bit is cleared after the last byte is read.

1 GETIMG This bit is set when the GETIMG bit (CTRLA bit 1) is set by software. This bit is cleared after the last byte is read.

0 GETROW This bit is set when the GETROW bit (CTRLA bit 0) is set by software. This bit is cleared after the last byte is read.

14 Fujitsu Microelectronics America, Inc.

Page 18

PGC 0x0C

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Programmable Gain Control Register.

Reset State: 0x00

Bit Number Bit Name Function

[7:4] - Reserved. Write 0 to these bits. Returns 0 when read.

Sets the gain of the amplifier.

0000 = 1.0 (default)

0001 = 0.25

0010 = 0.50

0011 = 0.75

0100 = 1.0

0101 = 1.25

0110 = 1.50

[3:0] PG[3:0]

0111 = 1.75

1000 = 4.0

1001 = 1.0

1010 = 2.0

1011 = 3.0

1100 = 4.0

1101 = 5.0

1110 = 6.0

1111 = 7.0

MBF200

ICR 0x0D

Interrupt Control Register.

Reset State 0x00.

This register controls the behavior of the two interrupt sources of the fingerprint sensor. Interrupt request 0 corresponds to the finger detect

interrupt. Interrupt request 1 corresponds to the external interrupt pin EXTINT.

Set bits IE[1:0] to enable the corresponding interrupt. Disabling an interrupt prevents the interrupt event from causing the chip to assert

or to send a packet on USB endpoint 2. However, the interrupt event is not prevented from setting its corresponding bit in the ISR

INTR

register.

Set bits IM[1:0] to prevent an interrupt event from setting the corresponding bit in the ISR. Setting or clearing IM[1:0] will not clear ISR bits

IR[1:0].

Set bits IT[1:0] to program the interrupts as edge or level sensitive. If IT1 is programmed as edge triggered, then IR1 (interrupt request 1) will

be set by the falling edge of EXTINT.

IP[1:0] select the polarity of the interrupt source. To detect finger down and finger up states with the internal finger detect circuit, set the IP0

bit to detect finger down (rising or high signal). After the finger down interrupt occurs, clear the IP0 bit to detect finger up (falling or low

signal). Similarly, IP1 can be programmed to select the polarity of the EXTINT signal.

Fujitsu Microelectronics America, Inc. 15

Page 19

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Bit Number Bit Name Function

7 IP1

6 IP0

5 IT1

4 IT0

3 IM1

2 IM0

1 IE1

0 IE0

ISR 0x0E

Interrupt Status Register.

Reset State ISR[7:2] = 0.

ISR[1:0] = X. State is indeterminate after reset.

0=EXTINT Interrupt Polarity is Falling Edge or Active Low

1=EXTINT Interrupt Polarity is Rising Edge or Active High

0=Finger Detect Interrupt Polarity is Falling Edge or Active Low

1=Finger Detect Interrupt Polarity is Rising Edge or Active High

0=EXTINT Interrupt is Edge Triggered

1=EXTINT Interrupt is Level Triggered

0=Finger Detect Interrupt is Edge Triggered

1=Finger Detect Interrupt is Level Triggered

0=EXTINT Interrupt Not Masked

1=EXTINT Interrupt Masked

0=Finger Detect Interrupt Not Masked

1=Finger Detect Interrupt Masked

0=EXTINT Interrupt Disabled

1=EXTINT Interrupt Enabled

0=Finger Detect Interrupt Disabled

1=Finger Detect Interrupt Enabled

Read this register to determine source(s) of interrupt(s).

Write a 1 to IR[1:0] to acknowledge and clear the corresponding interrupt bit.

Bits IS[1:0] reflect the state of the finger detect sensor and the EXTINT pin, regardless of the bit settings in the ICR register. When the finger

detect sensor is not triggered, the IS0 bit will be constantly low. However the IS0 bit may not be constantly high when a finger is present; the

bit may be repeatedly changing from a low to high state.

Bit Number Bit Name Function

[7:4] - Reserved. Write 0 to these bits. Returns 0 when read.

3 IS1 Reflects the state of the EXTINT Pin. Write 0 to this bit.

2 IS0 Reflects the state of the Finger Detect Sensor. Write 0 to this bit.

1 IR1 EXTINT Interrupt Request Pending.

0 IR0 Finger Detect Interrupt Request Pending.

THR 0x0F

Threshold Register.

Reset State 0x00.

This register controls the threshold at which a finger is detected by the automatic finger detection circuit.

Bit Number Bit Name Function

7 - Reserved. Write 0 to this bit.

[6:4] THV[2:0] Threshold voltage level.

[3:0] THC[3:0] Sharing capacitor size.

16 Fujitsu Microelectronics America, Inc.

Page 20

CIDH 0x10

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Chip Identification Register High. This register holds the high order byte of the chip identification word.

Bit Number Bit Name Function

[7:0] CIDH[7:0] Returns 0x20 when read.

CIDL 0x11

Chip Identification Register Low. This register holds the low order byte of the chip identification word.

Bit Number Bit Name Function

[7:0] CIDL[7:0] The return value depends on the Revision of the chip.

TST 0x12

Test Mode Register. Reserved for factory use only.

Reset State 0x00.

Bit Number Bit Name Function

[7:0] TST[7:0] Reserved. Write only 0 to these bits.

MBF200

Fujitsu Microelectronics America, Inc. 17

Page 21

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Sensor Initialization

The sensor should be enabled and its image parameters adjusted

before beginning a GETIMG, GETROW, or GETSUB operation.

Enable ADC

Write CTRLB with bits

2 and 0 set.

Wait 30 µS.

Sensor Enabled.

If using an external clock,

then set bit 1 also.

Other registers (DTR and

DCR for example) can be

initialized during this time.

Image Retrieval

Microprocessor Interface

Get Row

First load the RAH and RAL registers with the address of the row to

be fetched. Then write the CTRLA register to initiate a GETROW

operation. Finally, read the CTRLA register 256 times to retrieve

the row data.

Setup Row Address

(MCU Mode)

Write RAH.

Write RAL.

Row Selected.

Set Row Address

High Order bit.

Set Row Address

Low Order byte.

Adjust Parameters

Write DTR.

Write DCR.

Write PGC.

Parameters Adjusted.

(MCU Mode)

Write CTRLA with

Wait Row Capture

Read CTRLA.

Conversion Time.

No

of Row was

Row Captured.

GetRow

0x01.

Time.

Wait A/D

Last Cell

Read?

Yes

18 Fujitsu Microelectronics America, Inc.

Page 22

MBF200

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Get Whole Image

No row or column registers need to be loaded prior to starting a GETIMG operation. The sensor will automatically begin A/D conversion at

row zero, column zero.

Image Capture

(MCU Mode)

Write CTRLA with

0x02.

Wait Row Capture

Time.

Read CTRLA.

Wait A/D

No

Conversion Time.

No

Last Cell

of Row was

Read?

Yes

Last Cell

of Image

was Read?

Yes

Image Captured.

Fujitsu Microelectronics America, Inc. 19

Page 23

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Get Sub-Image

First, load the RAH, RAL, and CAL registers with the starting row and column address of the sensor sub-region. Then load registers REH,

REL, and CEL with the ending row and column address of the sensor sub-region. Write the CTRLA register to initiate a GETSUB operation.

Finally, read CTRLA register until the sub-image has been retrieved. The RAH, RAL, CAL, REH, REL, and CEL registers do not have to be

loaded before each GETIMG operation unless a different sensor sub0region is to be captured.

Setup Sub Region

(MCU Mode)

Write RAH.

Write RAL.

Write CAL.

Write REH.

Write REL.

Write CEL.

Set Starting Row Address,

High Order bit.

Set Starting Row Address,

Low Order byte.

Set Starting Column Address.

Set Ending Row Address,

High Order bit.

Set Ending Row Address,

Low Order byte.

Set Ending Column Address.

No

No

Get Sub Image

(MCU Mode)

Write CTRLA with

0x04.

Wait Row Capture

Time.

Read CTRLA.

Wait A/D

Conversion Time.

Last Cell

of Row was

Read?

Yes

Sub Region Selected.

20 Fujitsu Microelectronics America, Inc.

Last Cell

of Image

was Read?

Yes

Image Captured.

Page 24

MBF200

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Serial Peripheral Interface

The “Get Image,” “Get Sub-Image,” and “Get Row” operations are initiated by writing the same registers as described in the microprocessor

interface, except that the commands are written to the MOSI pin and the data is read back on the MISO pin. However, in SPI mode, an image

or sub-image cannot be retrieved by issuing a single Register Read Command and shifting in the entire image; a separate Register Read

Command must be issued prior to reading each row.

Get Image

Image Capture

(SPI Mode)

Drive SCS- Low.

Send Write Opcode.

Send CTRLA Address.

Send Data 0x02.

Drive SCS- High.

Wait Row Capture

Time.

No

Drive SCS- Low.

Send Read Opcode.

Send CTRLA Address.

Read Data.

No

Converted

Last Cell of

Row?

Yes

Drive SCS- High.

Converted

Last Cell of

Image?

Yes

Image Captured.

Fujitsu Microelectronics America, Inc. 21

Page 25

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

USB Interface

The “Get Image,” “Get Sub-Image,” and “Get Row” operations are initiated by writing the same registers as described in the microprocessor

interface, except that the registers are written and read on endpoint 0 and the image data is read from endpoint 1.

Get Image

Image Capture

(USB Mode)

At Endpoint 0,

Write CTRLA with

0x02.

From Endpoint 1,

Read 64-byte packet.

No

Final

packet of Image

was Read?

Yes

Image Captured.

22 Fujitsu Microelectronics America, Inc.

Page 26

MBF200

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Absolute Maximum Ratings

Symbol Rating Value Unit

VDD Power Supply Voltage +7.0 V

VIN, VOUT Voltage on Any Pin Relative to VSS -0.5V to +7.0V V

IOUT Output Current per I/O 8.0 mA

TSTG Storage Temperature -65°C to +150°C °C

Stresses above those listed under Absolute Maximum Ratings may cause permanent device failure. Functionality at or above these limits is not

implied. Exposure to Absolute Maximum Ratings for extended periods may affect device reliability.

Operating Range

Symbol Description Min Max Unit

VDD Supply Voltage

TA Ambient Temperature 0°C 60°C °C

USB Mode 3.3 3.6 V

DC Characteristics

3.3 5.5 V

(VDD=5.0V)

Symbol Description Test Conditions Min Max Units

VIL Input LOW Voltage VDO = 4.5V -0.5 0.8 V

VIH Input HIGH Voltage – 2.0 VDD V

VOL Output LOW Voltage VDD = MIN, IOL = 8 mA - 0.4 V

VOH Output HIGH Voltage VDD = MIN, IOH = -4 mA 2.4 - V

ILI Input Leakage Current VDD = MAX, VIN = VSS to VDD -5.0 5.0 µA

ILO Output Leakage Current VDD = MAX, VOUT = VSS to VDD, CE0- = VIH or CE1 = VIL -5.0 5.0 µA

(VDD=3.3V)

Symbol Description Test Conditions Min Max Units

VIL Input LOW Voltage VDD = 3.0V -0.5 0.6 V

VIH Input HIGH Voltage 2.0 VDD V

V

OL Output LOW Voltage VDD = 3.6V, IOL = 4 mA - 0.4 V

OH Output HIGH Voltage VDD = 3.0V, IOH = -2 mA 2.4 - V

V

ILI Input Leakage Current VDD = 3.6V VIN = VSS to VDD -5.0 5.0 µA

I

LO Output Leakage Current VDD = 3.6V, VOUT = VSS to VDD, CE0- = VIH or CE1 = VIL -5.0 5.0 µA

Fujitsu Microelectronics America, Inc. 23

Page 27

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Power Supply Consumption

Symbol Description Test Conditions Max Units

(Microprocessor Mode, VDD=5.0V f

I

DD

I

Digital Current, Standby 1 mA

DDSB

I

Digital Current, Power Down with Auto Finger Detection Enabled 10 µA

DDPDF

I

Digital Current, Power Down 10 µA

DDPD

I

Analog Current, Dynamic 20 mA

DDA

I

Analog Current, Standby 12 mA

DDASB

I

Analog Current, Power Down with Auto Finger Detection Enabled 200 µA

DDAPDF

I

Analog Current, Power Down 10 µA

DDAPD

Digital Current, Dynamic 5 mA

= 20MHz)

OSC

(SPI Slave Mode, VDD=5.0V)

I

DD

Digital Current, Standby 1mA

IDDSB

I

DDPDF

I

DDPD

I

Analog Current, Dynamic 20 mA

DDA

I

Analog Current, Standby 12 mA

DDASB

I

Analog Current, Power Down with Auto Finger Detection Enabled 200 µA

DDAPDF

I

Analog Current, Power Down 10 µA

DDAPD

Digital Current, Dynamic 5mA

Digital Current, Power Down with Auto Finger Detection Enabled 10 µA

Digital Current, Power Down 10 µA

(Microprocessor Mode, VDD=3.3V)

IDD Digital Current, Dynamic 5mA

I

Digital Current, Standby 1mA

DDSB

I

Digital Current, Power Down with Auto Finger Detection Enabled 10 µA

DDPDF

I

Digital Current, Power Down 10 µA

DDPD

I

DDA

I

DDASB

I

DDAPDF

I

DDAPD

Analog Current, Dynamic 15 mA

Analog Current, Standby 8mA

Analog Current, Power Down with Auto Finger Detection Enabled 200 µA

Analog Current, Power Down 10 µA

(SPI Slave Mode, VDD=3.3V)

I

DD

I

DDSB

I

DDPDF

I

DDPD

I

DDA

I

DDASB

I

DDAPDF

I

DDAPD

Digital Current, Dynamic 5mA

Digital Current, Standby 1mA

Digital Current, Power Down with Auto Finger Detection Enabled 10 µA

Digital Current, Power Down 10 µA

Analog Current, Dynamic 15 mA

Analog Current, Standby 8mA

Analog Current, Power Down with Auto Finger Detection Enabled 200 µA

Analog Current, Power Down 10 µA

24 Fujitsu Microelectronics America, Inc.

Page 28

MBF200

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Power Supply Consumption (continued)

Symbol Description Test Conditions Max Units

(USB Mode, VDD=3.3V)

I

DD

I

DDSB

I

DDPDF

I

DDPD

I

DDSPF

I

DDSP

I

DDA

I

DDASB

I

DDAPDF

I

DDAPD

AC Characteristics

Digital Current, Dynamic 5 mA

Digital Current, Standby 1 mA

Digital Current, Power Down with Auto Finger Detection Enabled 10 µA

Digital Current, Power Down 10 µA

Digital Current, USB Suspend with Auto Finger Detection Enabled 10 µA

Digital Current, USB Suspend 10 µA

Analog Current, Dynamic 30 mA

Analog Current, Standby 20 mA

Analog Current, Power Down with Auto Finger Detection Enabled 200 µA

Analog Current, Power Down 10 µA

Microprocessor Bus Mode

Read Cycle

Symbol Description Min Max Units

t

ACC

t

CE

t

OE

t

OH

t

DF

t

DF

Write Cycle

Symbol Description Min Max Units

Address Setup to WR low 0 - ns

t

AS

t

CS

t

CS

t

AH

t

CH

t

CH

t

WP

t

WPH

t

DS

t

DH

Address to Output Delay 5 35 ns

Chip Select to Output Delay 5 35 ns

Read Enable to Output Delay 5 35 ns

Output Hold Time from Address, CS0, CS1, or RD, which ever occurs first 5 - ns

RD high to Output High Z - 10 ns

CS0 high or CS1 low to Output High Z - 10 ns

CS0 Setup to WR low 0 - ns

CS1 Setup to WR low 0 - ns

Address Hold Time from WR high 5 - ns

CS0 Hold Time from WR high 0 - ns

CS1 Hold Time from WR high 0 - ns

WR Pulse Width Low 10 - ns

WR Pulse Width High 10 - ns

Data Setup Time to WR low 8 - ns

Data Hold Time to WR high 0 - ns

Fujitsu Microelectronics America, Inc. 25

Page 29

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

SPI Slave Mode

Symbol Description Min Max Units

f

SCK

t

CSS

t

CSH

t

WL

t

WH

t

CS

t

SU

t

H

t

V

t

HD

t

DIS

SPI Master

Symbol Description Min Max Units

f

SCKM

t

CSSM

t

CSHM

t

WLM

t

WHM

t

CSM

t

SUM

t

HM

t

VM

t

HDM

t

DISM

SCLK Clock Frequency - 12 MHz

SCS Setup Time 40 - ns

SCS Hold Time 40 - ns

SCLK Low 40 - ns

SCLK High 40 - ns

SCS High Time 40 - ns

Data-In Setup Time 20 - ns

Data-In Hold Time 20 - ns

Data-Out Valid Time 20 30 ns

Data-Out Hold Time 0 - ns

Data-Out Disable Time - 100 ns

SCLK Clock Frequency - 2 MHz

SCS Setup Time 250 - ns

SCS Hold Time - 250 ns

SCLK Low - 250 ns

SCLK High - 250 ns

SCS High Time - 250 ns

Data-In Setup Time - 100 ns

Data-In Hold Time - 250 ns

Data-Out Valid Time - 200 ns

Data-Out Hold Time - 200 ns

Data-Out Disable Time - 300 ns

26 Fujitsu Microelectronics America, Inc.

Page 30

Timing Diagrams

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

A0

CS1

CS0

RD

t

ACC

MBF200

t

CE

t

OE

WR

D[7:0]

Figure 1. Microprocessor Mode Read Cycle

t

OH

t

DF

Fujitsu Microelectronics America, Inc. 27

Page 31

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

A0

CS1

CS0

RD

WR

D[7:0]

t

AS

t

CS

t

WP

t

AH

t

WPH

t

DS

Figure 2. Microprocessor Mode Write Cycle

t

DH

t

CH

SCS

SCK

MOSI

MISO

28 Fujitsu Microelectronics America, Inc.

t

CSS

t

SU

t

WL

t

H

data in

Figure 3. SPI Slave Mode Timing

t

V

t

WH

data out

t

CS

t

CSH

t

HD

t

DIS

For read operations only.

Page 32

SCS

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

SCK

MOSI

MISO

SCS

SCK

MOSI

MISO

Command Stage

0

Op Code

00

0

Op Code

x0

Command Stage Data Stage

Op Code Op Code

0

00

0

x0

Address Stage

Register Address

1

10

a4

a3 a2

a1

a0

0

0

Data Stage

Don't Care

x

Data Out

d7 d6 d5

d4

d2

Figure 4. SPI Slave Mode Read Operation

Address Stage

Register Address

0

1

a4

a3

a2

a1

a0

0

0

d7

0

High Impedance

Data In

d4d6 d5

d2

d1

d1

d0d3

d0d3

SCS

SCK

MOSI

MISO

t

CSSM

t

SUM

Figure 5. SPI Slave Mode Write Operation

t

WLM

t

HM

data out

t

VM

Figure 6. SPI Master Timing

t

WHM

data in

t

HDM

t

CSM

t

CSHM

t

DISM

Fujitsu Microelectronics America, Inc. 29

Page 33

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

SCS

SCK

MOSI

MISO

Command Stage Data Stage

Op Code Op Code

0

00

00

0

Address Stage

ROM Address

1

a7 a6 a5 a4 a3

1

Figure 7. SPI Master Read Operation

a2 a1

a0

d7 d6

Data In

d0

d7

d6

d0

30 Fujitsu Microelectronics America, Inc.

Page 34

Physical Dimensions

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

Fujitsu Microelectronics America, Inc. 31

Page 35

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Recommended Land Pattern

P

SEE DETAIL

Z

FULL RADIUS

TYPICAL

L

A

W

DETAIL Z

140

Symbol Description Dimension

N Pin Count 80

A Tip to Tip Dimension 1.074 (27.30)

P Pitch .0197 (.50)

L Pad Length .065 (1.65)

W Pad Width .012 (.30)

Note: Dimensions are in inches (mm)

32 Fujitsu Microelectronics America, Inc.

Page 36

Array Orientation

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

MBF200

PIN 40 PIN 1

(0, 0) (255, 0)

MBF200

(0, 299)

PIN 41 PIN 80

(255, 299)

Fujitsu Microelectronics America, Inc. 33

Page 37

Solid State Fingerprint Sensor

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Appendix A

Recommended Power and Ground Connections

The following describes the recommended method for reducing

image noise to get the best image from the sensor.

VDDA1 (Pin 1) and VDDA2 (Pin 7) are the analog power supply

pins. VSSA1 (Pin 2) and VSSA2 (Pin 6) are the ground returns.

Connect one bulk capacitor (4.7µF to 10µF) and two 0.1µF

capacitors in parallel between analog power and ground to provide

filtering of low and high frequency noise. Place the bulk capacitor

near VDDA1. Separate VDDA1 and VDDA2 from the digital power

pins through a 10 ohm resistor.

VDD

0.1 µF 0.1 µF 0.1 µ F 0.1 µF

VSS3

VDD3

VDD2 VSS2

VDD1 VSS1 VDDA2 VSSA2 VSSA1 VDDA1

VDD1 (Pin 16), VDD2 (Pin 25), and VDD3 (Pin 39) are the digital

power supply pins. VSS1 (Pin 15), VSS2 (Pin 24), and VSS3 (Pin

40) are the ground returns. Place 0.1µF capacitors between digital

power and ground, as close to the pins as possible.

Input signals that are to be tied high should not be shorted directly

to VDD, but connected through a 1K to 10K ohm resistor in order

to maximize ESD immunity of the sensor. A single resistor may be

used for all inputs that are tied high.

10Ω

0.1 µF

4.7 to 10 µF

1267151624253940

34 Fujitsu Microelectronics America, Inc.

Page 38

MBF200

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

APPENDIX B

Recommended MBF200 Sensor Orientation

Mount the MBF200 such that pins 1 through 40 point away the user

and pins 41 through 80 point toward from the user. When a finger is

placed on the sensor, the tip of the finger should be near pins 1

through 40, the cuticle should be centered over the sensor, and the

knuckle should be near pins 41 through 80. This orientation ensures

that fingerprint images will be captured right-side up, not sideways

nor upside down, using Fujitsu’s standard software.

The sensor should be mounted flush with the surrounding surface to

allow the finger to rest flat on the sensor surface and increase the

contact area between the finger and the sensor. If the sensor is

recessed too deeply, only the tip of the finger will be imaged.

It is also recommended that there be a groove or channel to guide the

finger into the proper position so that images are captured with a

uniform orientation.

PIN 1PIN 40

PIN 41 PIN 80

Fujitsu Microelectronics America, Inc. 35

Page 39

FUJITSU MICROELECTRONICS AMERICA, INC.

SUNSTAR传感与控制 http://www.sensor-ic.com/ TEL:0755-83376549 FAX:0755-83376182 E-MAIL:szss20@163.com

SUNSTAR自动化 http://www.sensor-ic.com/ TEL: 0755-83376489 FAX:0755-83376182 E-MAIL:szss20@163.com

Corporate Headquarters

1250 E. Arques Ave. Sunnyvale, CA 94088-3470

Tel: (800) 866-8608 Fax: (408) 737-5999

E-mail: inquiry@fma.fujitsu.com Web Site: http://www.fma.fujitsu.com

©2001 Veridicom, Inc. All rights reserved.

All company and product names are trademarks or registered