FUJIFILM FinePix F460 Service Manual

DIGITAL CAMERA

FinePix F460

SERVICE MANUAL

US/EU/EG/EE/AS/CH/JP-Model

CAUTION

BECAUSE THIS PRODUCTIS RoHS LEAD-FREE COMPLIANT, USE THE DESIG-

NATED AFTER-SELES PARTS AND THE DESIGNATED LEAD-FREE SOLDER WHEN

PERFORMING REPAIRS. (Refer to page 3 to page 5)

WARNING

THE COMPONENTS IDENTIFIED WITH THE MARK “ ” ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST ARE CRITICAL FOR SAFETY.

PLEASE REPLACE ONLY WITH THE COMPONENTS SPECIFIED ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST.

IF YOU USE PARTS NOT SPECIFIED, IT MAY RESULT IN A FIRE AND AN

ELECTRICAL SHOCK.

FUJI PHOTO FILM CO., LTD.

Ref.No.:ZM00611-104

Printed in Japan 2006.03

FinePix F460 Service Manual

SAFETY CHECK-OUT

After correcting the original problem, perform the following

safety check before return the product to the customer.

1. Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface

for solder splasher and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair.

Point them out to the customer and recommend their

replacement.

4. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

5. Check the B + voltage to see it is at the values

specified.

6. Make leakage - current measurements to determine

that exposed parts are acceptably insulated from the

supply circuit before returning the product to the

customer.

7. CAUTION: FOR CONTINUED

PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH

SAME TYPE 2.5 AMPERES 125V

FUSE.

2.5A 125V

2.5A 125V

8. WARNING:

RISK OF FIREREPLACE FUSE

AS MARKED

ATTENTION: AFIN D'ASSURER

UNE PROTECTION

PERMANENTE CONTRE LES

RISQUES D'INCENDIE,

REMPLACER UNIQUEMENT

PAR UN FUSIBLE DE MEME,

TYPE 2.5 AMPERES, 125 VOLTS.

TO REDUCE THE ELECTRIC

SHOCK, BE CAREFUL TO

TOUCH THE PARTS.

WARNING!

HIGH VOLTAGE

2

FinePix F460 Service Manual

RoHS lead-free compliance

Because this product is RoHS lead-free compliant, use the designated after-sales parts and the designated lead-free solder

when performing repairs.

<Background & Overview>

With the exception of parts and materials expressly excluded from the RoHS directive (*1), all the internal connections and

component parts and materials used in this product are lead-free compliant (*2) under the European RoHS directive.

*1: Excluded items (list of the main lead-related items)

• Lead included in glass used in fluorescent tubes, electronic components and cathode-ray tubes

• Lead in high-melting-point solder (i.e. tin-lead solder alloys that contain 85% lead or more)

• Lead in ceramic electronic parts (piezo-electronic devices)

• Mercury contained in fluorescent tubes is also excluded.

*2: Definition of lead-free

A lead content ratio of 0.1 wt% or less in the applicable locations (solder, terminals, electronic components, etc.)

<Reference>

RoHS: The name of a directive issued by the European Parliament aimed at restricting the use of

certain designated hazardous substances included in electrical and electronic equipment.

Designated substances (6): Lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs) and

polybrominated diphenyl ether (PBDE)

<Lead-free soldering>

When carrying out repairs, use a designated lead-free solder, bearing in mind the differing work practices for conventional

solder (eutectic) and lead-free solder.

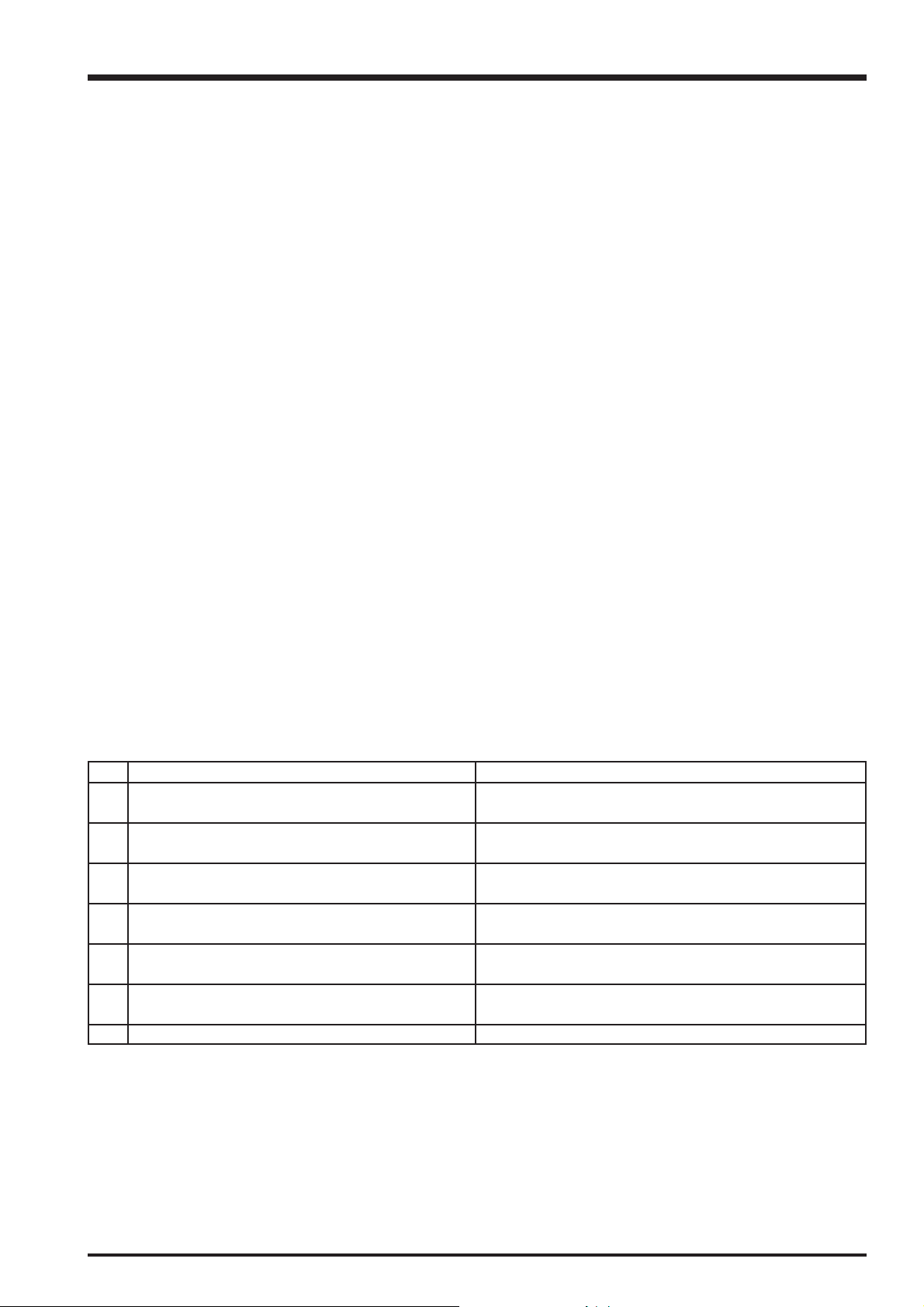

Differences in the soldering work for lead-free and eutectic solder

When the soldering work practices for eutectic solder and lead-free solder are compared, the main differences are as shown

below. In particular, when lead-free solder is used, the solder tends to be less workable than when eutectic solder is used.

Accordingly, the soldering techniques used must take that into account.

Difference

The solder starts melting later.

1

Poor wetting

2

Solder feed rate is difficult to control.

3

Wetting the insides of through holes is especially

4

difficult.

5

During repairs (or modifications) removing solder

from inside through holes is difficult.

6

There is serious carbonization of the soldering iron.

The surface is not glossy.

7

The initial melting point of lead-free solder is high, so you

have to get used to it.

Move the tip of the soldering iron around to heat the entire

connection to the melting temperature and assist wetting.

Use the solder (wire) diameter and soldering iron that are

best suited to connection being soldered.

First apply solder to the area immediately around the

through hold and then feed the solder into the hole.

Use a suitable wicking wire (with a suitable method and

heating) and a suction tool.

Either put solder onto the soldering iron tip after completing

the work, or turn the iron off frequently.

Learn to recognize the appearance of the surface.

Countermeasure

3

FinePix F460 Service Manual

Setting temperature during lead-free soldering

• Lead-free solder melting temperature

The melting point of eutectic (Sn-Pb) solder is 183°C, while the melting point of lead-free solder (Sn-Ag-Cu) is 30°C higher

at 220°C.

• Soldering iron tip temperature

The temperature setting for the soldering iron used should be such that the tip of the soldering iron is at the correct

bonding temperature for the connection. This temperature is normally set at around 100°C higher than the melting point of

the solder.

However, the actual temperature should take into account the shape and size of the soldering iron tip, the heat tolerance

of the connection and the workability of that temperature.

• Correct bonding temperature

The correct bonding temperature refers not to the temperature of the heat source, but to the bonding temperature that will

give the best bond strength.

Precautions when soldering with lead-free solder

• Soldering iron maintenance

Because of the high soldering iron temperature in lead-free soldering, there is rapid carbonization of the flux adhering to

the tip of the soldering iron.

(1) Always cover the tip of the soldering iron with solder when it is not being used.

(2) If the tip is black from carbonization, wipe it gently with a paper towel soaked in alcohol until the solder will wet.

• Uniform heating of the board and components

To ensure that the lead-free solder wets the entire surface of the pattern and the lands despite its poor wetting

characteristics, you must move the tip of the soldering iron over a wide area to raise the temperature of the entire

connection.

Soldering iron

A soldering iron with a temperature control is best.

4

FinePix F460 Service Manual

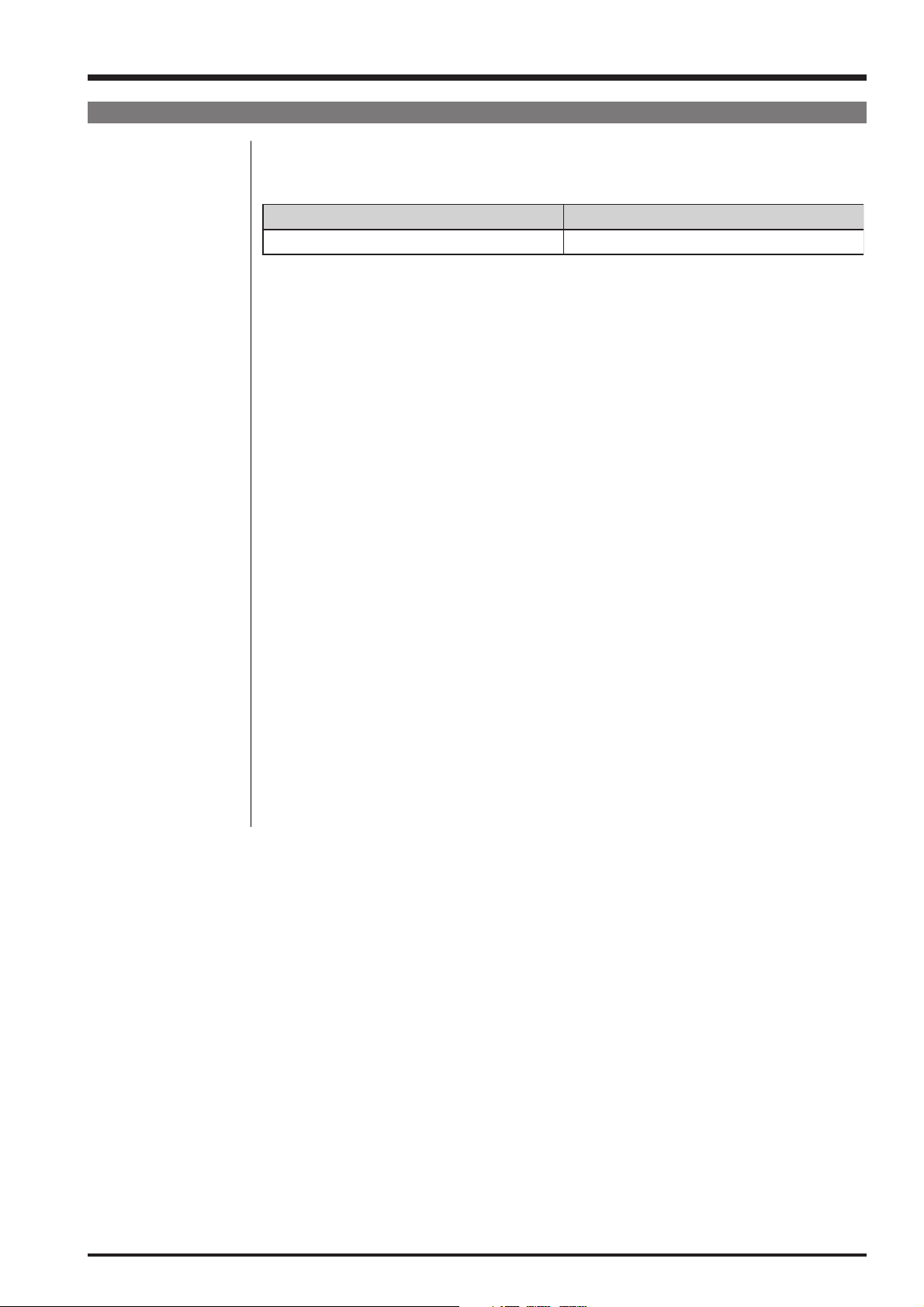

Solder wire (thread)

Use the lead-free solders specified below.

Solder type: Sn96.5Ag3Cu0.5 (Displayed symbol: SnAgCu)

Wire diameter: 0.6, 0.8 or 1.0 mm

Sample:

lead-free

Wire diameter 0.8mm

Solder type (Displayed symbol)

SnAgCu

Flux

Conventional flux can be used.

Solder application wires (mesh, wicking wire, etc.)

Conventional application wires can be used.

5

CONTENTS

FinePix F460 Service Manual

CONTENTS

1. General ........................................................... 7

1-1. Product specification .............................................. 7

1-2. Explanation of Terms ............................................ 11

1-3. Names of External Components .......................... 12

2. Disassembly ................................................. 13

2-1. Names of internal Components ............................13

2-2. Removing the CABI REAR ASSY ........................ 14

2-3. Disassembling the CABI REAR ASSY ................. 15

2-4. Removing the LCD monitor .................................. 16

2-5. Removing the LENS ASSY .................................. 17

2-6. Removing the CCD PWB ASSY ........................... 18

2-7. Removing the MAIN PWB ASSY .......................... 19

2-8. Removing the BATTERY HOLDER ......................20

2-9. Removing the FLASH PWB ASSY .......................20

3. Schematics ................................................... 21

3-1. Description of CCD circuit operation .................... 21

3-1-1. Outline .................................................... 21

3-1-2. IC903 (CCD imager) ...............................21

3-1-3. IC901, IC902 (V driver) and IC905 (H

driver) ...................................................... 21

3-1-4. IC905 (CDS, AGC, A-D conversion) ....... 21

3-2. Description of CP1 circuit operation ..................... 22

3-2-1. Circuit Description ................................... 22

3-2-2. Outline of Operation ................................ 22

3-2-3. LCD Block ............................................... 22

3-2-4. Lens Drive Block ..................................... 23

3-3. Description of PWA power circuit operation ......... 23

3-3-1. Outline .................................................... 23

3-4. Description of ST1 flash circuit operation .............24

3-4-1. Charging circuit ....................................... 24

3-4-2. Flash Circuit ............................................ 25

3-5. Description of SYA circuit operation .....................26

3-5-1. Configuration and Functions ................... 26

3-5-2. Internal Communications Paths .............. 27

3-5-3. Key Operations ....................................... 27

3-5-4. Power Supply Control ............................. 28

3-6. Block Diagram ...................................................... 29

3-7. Overall connection Diagram ................................. 30

3-8. Circuit Diagrams ...................................................31

3-8-1. CCD BLOCK ........................................... 31

3-8-2. FLASH BLOCK .......................................32

3-8-3. MAIN BLOCK .......................................... 33

3-8-4. POWER BLOCK .....................................34

3-8-5. SYSTEM CONTROL BLOCK ................. 35

3-8-6. CA1 BLOCK ............................................ 36

3-8-7. CP1 BLOCK ............................................ 37

3-8-8. DMA BLOCK ...........................................38

3-8-9. PWA BLOCK ........................................... 39

3-8-10. ST1 BLOCK ............................................ 40

3-8-11. ST2 BLOCK ............................................ 41

3-8-12. LENS BLOCK ......................................... 42

3-9. Mounted Parts Diagrams ...................................... 43

3-9-1. ST1/ST2 PWB ASSY .............................. 43

3-9-2. CA1 PWB ASSY .....................................44

3-9-3. CP1 PWB ASSY .....................................46

4. Adjustments .................................................. 48

4-1. Important point Adjustment when Replacing

Major Parts ...........................................................48

4-2. Measuring Instruments Used ............................... 48

4-3. Use Jig list ............................................................ 48

4-4. Calibration method of pattern box ........................ 49

4-5. Adjustment software installation ........................... 49

4-5-1. Various downloading software

decompressions, preservation methods,

and notes ................................................49

4-6. Connecting to the PC for Adjustment ................... 50

4-7. Adjustment Software Description ......................... 51

4-8. MAIN PWB ASSY initialization ............................. 52

4-9. AWB Adjustment .................................................. 56

4-10. LENS Adjustment .................................................58

4-11. CCD Defect Detection .......................................... 60

4-12. CCD Black Defect Detection ................................ 62

4-13. Updating the Firmware .........................................64

4-14. Completion Settings .............................................66

5. Inspection ..................................................... 68

5-1. Required Measuring Equipment ...........................68

5-2. Connection of Measuring Equipment ................... 68

5-3. Inspection and Factory Settings ........................... 69

6. Parts List....................................................... 73

6-1. Packing and Accessories ..................................... 73

6-1-1. US-model ................................................ 73

6-1-2. EU-model ................................................ 74

6-1-3. EG-model ................................................ 75

6-1-4. EE-model ................................................76

6-1-5. AS-model ................................................77

6-1-6. CH-model ................................................ 78

6-1-7. JP-model ................................................. 79

6-2. Mecha Block .........................................................81

6-2-1. US/CA/EU/EG/EE/AS/CH-model ............ 81

6-2-2. JP-model ................................................. 82

6-3. Electrical parts ......................................................83

7. Appendix....................................................... 84

7-1. List of Related Technical Updates Issued ............ 84

6

FinePix F460 Service Manual

1. General

1. General

1-1. Product specification

System

Model Digital camera FinePix F460

Effective pixels 5.1 million pixels

CCD 1/2.5-inch square pixel CCD

Storage media Internal memory (approx. 13 MB) /

xD-Picture Card (16/32/64/128/256/512 MB/1 GB)

File format Still image: DCF-compliant

Compressed: Exif ver.2.2 JPEG, DPOF-compatible

* Design rule for Camera File System compliant DPOF compatible

Movie: AVI format, Motion JPEG

Audio: WAVE format, Monaural sound

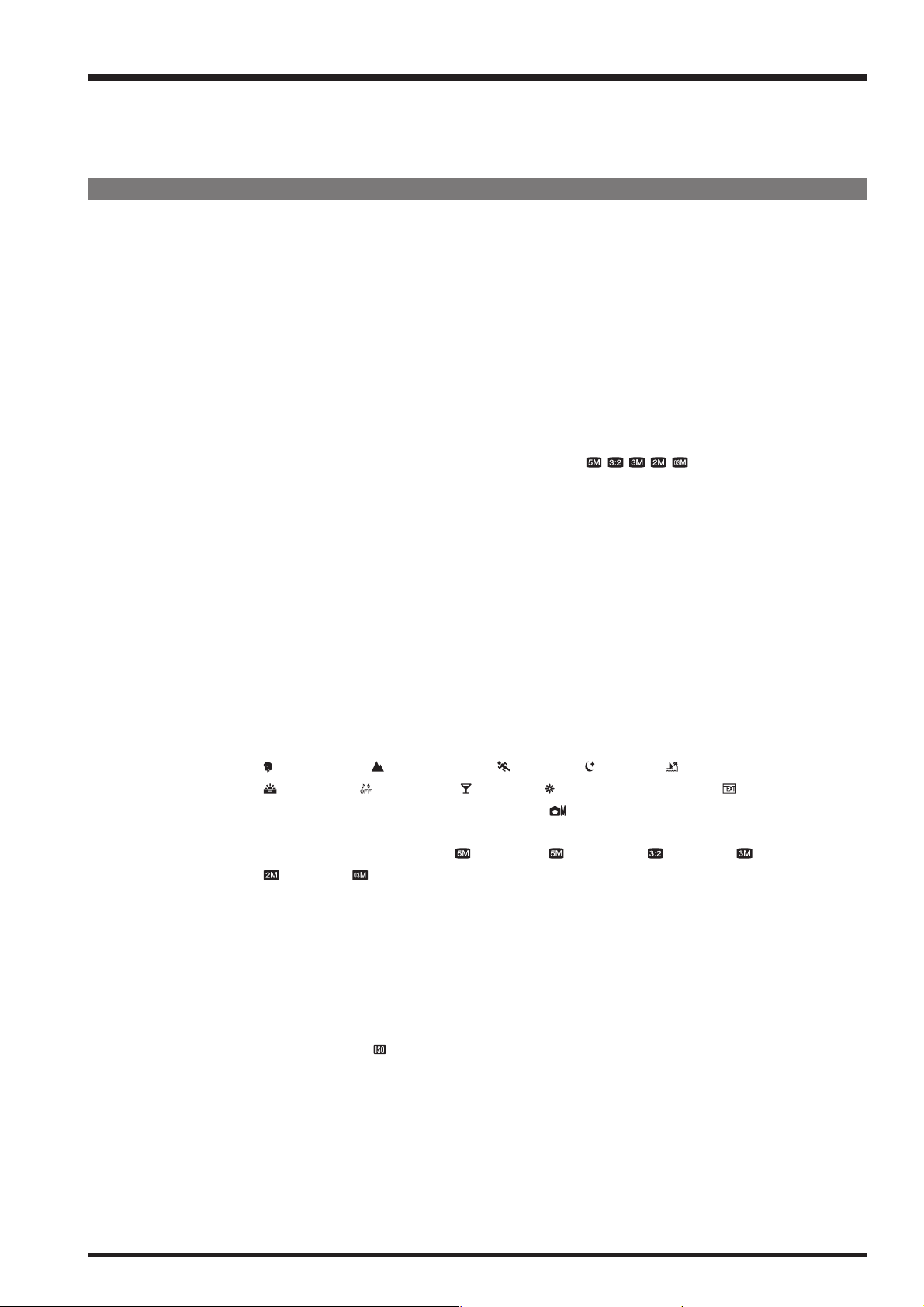

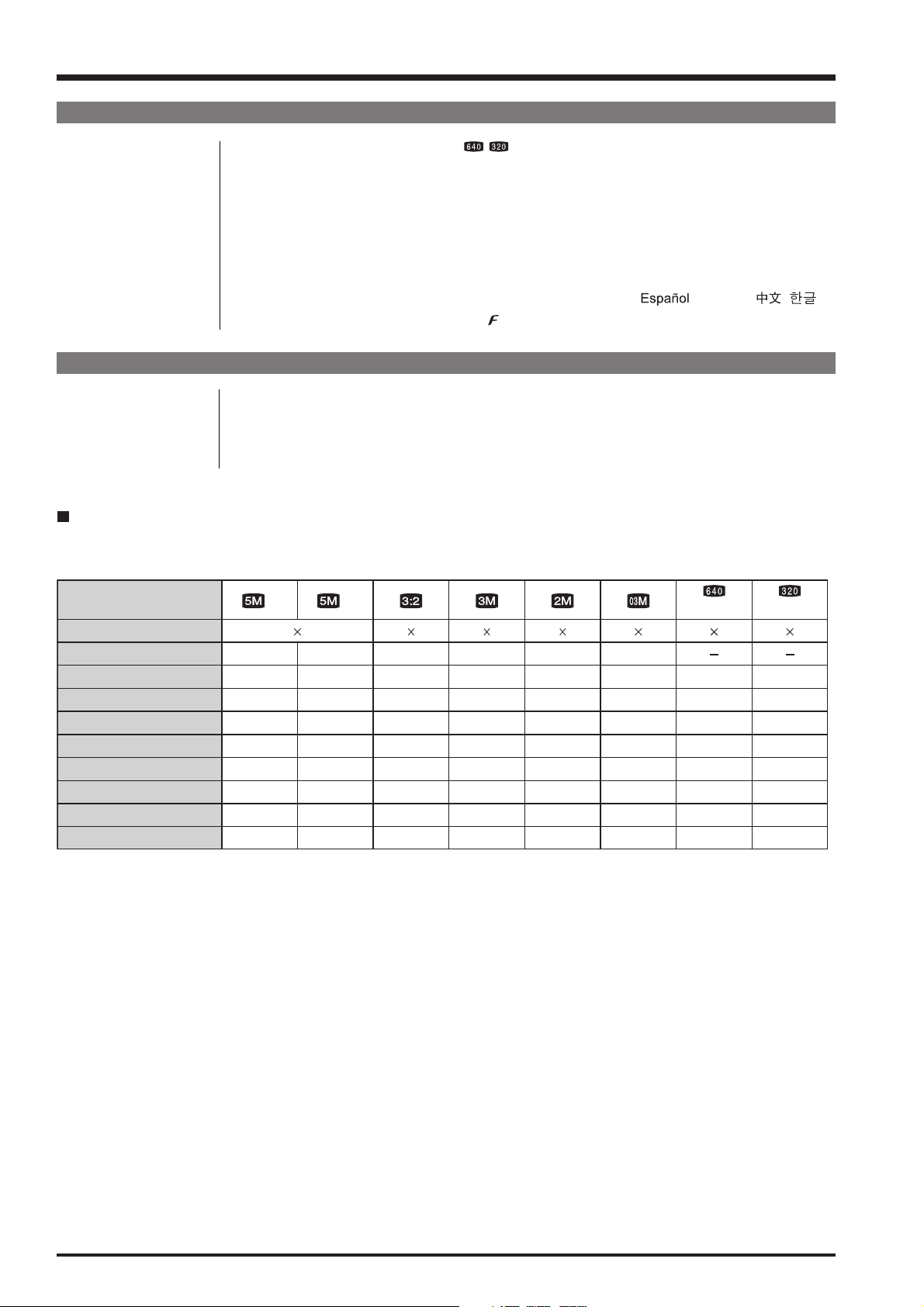

Number of recorded pixels

Lens Fujinon 3

Focal length f=5.8 mm-17.4 mm

Digital zoom Approx. 4.1

Aperture (Wide-angle) F2.8 to F7.0

Focal range Normal: approx. 70 cm (2.3 ft.) to infinity

Sensitivity AUTO/Equivalent to ISO 64/100/200/400

Photometry TTL 256-zones metering

Exposure control Program AE

Scene position

Exposure compensation -2 EV to +2 EV in 1/3 EV-step increments (

Shutter speed 2 sec. to 1/1500 sec. (depend on Exposure mode)

Continuous shooting Number of recorded frames:

Focus Mode: Auto focus

White balance Automatic scene recognition/Preset (Fine, Shade, Fluorescent (Daylight), Fluorescent

Self-timer Approx. 10 sec./2 sec.

Flash type Auto flash

Flash mode Auto, Red-Eye Reduction, Forced Flash, Suppressed Flash, Slow Synchro, Red-Eye

LCD monitor 2.5 inches, Aspect ratio: 4:3; 115,000 pixels Amorphous silicon TFT,

Still image: 2592 × 1944 pixels/2592 × 1728 pixels/2048 × 1536 pixels/

1600 × 1200 pixels/640 × 480 pixels ( / / / / )

×

optical zoom lens

F2.8-F4.9

(Equivalent to approx. 35 mm-105 mm on a 35 mm camera)

×

(3× optical zoom lens is used together: Max. zoom scale: approx. 12.2×)

Macro: approx. 10 cm (3.9 in.) to 80 cm (2.6 ft.) (wide-angle)

approx. 40 cm (1.3 ft.) to 80 cm (2.6 ft.) (telephoto)

(PORTRAIT), (LANDSCAPE), (SPORT), (NIGHT), (BEACH & SNOW),

(SUNSET), (MUSEUM), (PARTY), (FLOWER CLOSE-UP), (TEXT)

)

F 2 frames/ N 4 frames/ 5 frames/ 7 frames/

9 frames/ 44 frames (Max. 1.9 frames/sec.)

AF system: TTL contrast-type

AF frame selection: AF (CENTER)

(Warm White), Fluorescent (Cool White), Incandescent)

Effective range (

Reduction + Slow Synchro

Approx. 97% coverage

: AUTO): Wide-angle: approx. 70 cm-4.6 m (2.3 ft.-15.1 ft.)

Telephoto: approx. 70 cm-2.6 m (2.3 ft.-8.5 ft.)

Macro: approx. 30 cm-80 cm (1.0 ft.-2.6 ft.)

7

1. General

FinePix F460 Service Manual

System

Movie 640 × 480 pixels/320 × 240 pixels ( / )

(30 frames per second with monaural sound)

A series of continuous image can be recorded depending on the available space on an

xD-Picture Card or internal memory. Zoom cannot be used during movie recording.

Photography functions Best framing, Frame No. memory

Playback functions Trimming, Image rotate, Automatic playback, Multi-frame playback, Sorting by date, Voice

memo

Other functions PictBridge, Exif print, Language (English, Francais, Deutsch,

Time difference, FinePix photo mode (

-mode)

, Italiano, , ),

Input/Output Terminals

A/V OUT NTSC/PAL-type (with monaural sound)

(Audio/Visual output)

Digital input/output USB

DC input socket AC Power Adapter AC-5VX (sold separately)

Standard number of available frames/recording time per xD-Picture Card / internal memor y

The number of available

that the divergence between standard number of

xD-Picture Card s with higher capacities.

Quality setting

Number of recorded pixels

Image data size

Internal memory (approx. 13 MB)

DPC-16 (16 MB)

DPC-32 (32 MB)

DPC-64 (64 MB)

DPC-128 (128 MB)

DPC-256 (256 MB)

DPC-512/M512 (512 MB)

DPC-M1GB (1 GB)

, recording time or file size varies slightly depending on the subjects photographed. Note also

frames

and the actual number of

640 480 640 480 320 240

780 KB

630 KB

130 KB

frames

F

2592

2.5 MB

1944

1.3 MB

frames

N

2592 1728 2048 1536 1600 1200

1.2 MB

511121722108

12

25

51

103

206

6

12

25

51

102

205

409

14

28

57

114

228

456

20

40

81

163

326

652

25

51

102

204

410

819

124

249

499

999

1999

3995

412 820 913 1305 1640 7996

is greater for

(30 fps) (30 fps)

15 sec. 24 sec.

17 sec.

34 sec.

70 sec.

140 sec.

280 sec.

9.3 min.

18.7 min. 29.6 min.

27 sec.

55 sec.

110 sec.

221 sec.

7.4 min.

14.7 min.

8

FinePix F460 Service Manual

Power Supply and Others

Power supply Use one of the following

• Rechargeable Battery NP-40N (included)/NP-40 (sold separately)

• AC Power Adapter AC-5VX (sold separately)

Guide to the number of

available frames for battery

operation

According to the CIPA (Camera & Imaging Products Association) standard procedure for

measuring digital still camera battery consumption (extract):

When using a battery, use the battery supplied with the camera. The storage media should

be xD-Picture Card.

Pictures should be taken at a temperature of +23

on, the optical zoom moved from full wide-angle to full telephoto (or vice-versa) and back

again to its original position every 30 seconds, the flash used at full power every second

shot and the camera turned off and then on again once every 10 shots.

• Note: As the number of available shots varies depending on the level of charge in

battery, the figures shown here for the number of available shots using battery is

not guaranteed. The number of available shots will also decline at low tempera-

tures.

Camera dimensions 91.9 mm

(W/H/D) (not including accessories and attachments)

Camera mass (weight) Approx. 122 g/4.3 oz.

(not including accessories, batteries and xD-Picture Card)

Weight for photography Approx. 142 g/5.0 oz. (including batteries and xD-Picture Card)

Operating conditions Temperature: 0

80% humidity or less (no condensation)

Accessories included z Rechargeable Battery NP-40N (1) Soft case included

z Strap (1)

z A/V cable for FinePix F460 (1) Included plug to pin-plug

z USB cable for FinePix F460 (1)

z Battery Charger BC-40 (1)

z CD-ROM (1) Software for FinePix CX

z Owner’s Manual (1)

Battery Type Number of frames

NP-40N Approx. 200

o

C (+73oF), with the LCD monitor turned

×

58.1 mm × 19.7 mm/3.6 in. × 2.3 in. × 0.8 in.

o

C to +40oC (+32oF to +104oF)

×

2

1. General

9

1. General

Power Supply and Others

Optional accessories z xD-Picture Card

DPC-16 (16 MB)/DPC-32 (32 MB)/DPC-64 (64 MB)/DPC-128 (128 MB)/

DPC-256 (256 MB)/DPC-512 (512 MB)/DPC-M512 (512 MB)/DPC-M1GB (1 GB)

z Battery Charger BC-65

z Rechargeable Battery NP-40 (750 mAh)

z AC Power Adapter AC-5VX

z AC Power Adapter AC-5VH/AC-5VHS

z Soft Case SC-FX455

z Image Memory Card Reader DPC-R1

• Compatible with Windows 98/98 SE, Windows Me, Windows 2000 Professional,

Windows XP or iMac, Mac OS 8.6 to 9.2.2, Mac OS X (10.1.2 to 10.2.2) and

models that support USB as standard.

• Compatible with xD-Picture Card of 16 MB to 512 MB, and SmartMedia of 3.3 V, 4

MB to 128 MB.

z PC Card Adapter DPC-AD

• Compatible with xD-Picture Card of 16 MB to 512 MB, and SmartMedia of 3.3 V, 2

MB to 128 MB.

z CompactFlash Card Adapter DPC-CF

• Windows 95/98/98 SE/Me/2000 Professional/XP

• Mac OS 8.6 to 9.2/X (10.1.2 to 10.1.5)

z xD-Picture Card USB Drive DPC-UD1

• Compatible with xD-Picture Card of 16 MB to 512 MB

• Windows 98/98 SE/Me/2000 Professional/XP

• Mac OS 9.0 to 9.2.2/X (10.0.4 to 10.2.6)

FinePix F460 Service Manual

10

FinePix F460 Service Manual

1. General

1-2. Explanation of Terms

EV: A number denotes Exposure Value. The EV is determined by the brightness of the subject

and sensitivity (speed) of the film or CCD. The number is larger for bright subjects and

smaller for dark subjects. As the brightness of the subject changes, a digital camera

maintains the amount of light hitting the CCD at a constant level by adjusting the aperture

and shutter speed.

When the amount of light striking the CCD doubles, the EV increases by 1. Likewise, when

the light is halved, the EV decreases by 1.

Frame rate (fps): The frame rate refers to the number of images (frames) that are photographed or played

back per second. For example, when 10 frames are continuously photographed in a 1-

second interval, the frame rate is expressed as 10 fps.

For reference, TV images are displayed at 30 fps (NTSC).

JPEG: Joint Photographic Experts Group

A file format used for compressing and saving color images. The higher the compression

rate, the greater the loss of quality in the decompressed (restored) image.

Motion JPEG: A type of AVI (Audio Video Interleave) file format that handles images and sound as a

single file. Images in the file are recorded in JPEG format. Motion JPEG can be played

back by QuickTime 3.0 or later.

Smear: A phenomenon specific to CCDs whereby white streaks appear on the image when there

is a very strong light source, such as the sun or reflected sunlight, in the photography

screen.

WAVE: A standard format used on Windows systems for saving audio data. WAVE files have the

“.WAV” file extension and the data can be saved in either compressed or uncompressed

format. Uncompressed recording is used on this camera.

WAVE files can be played back on a personal computer using the following software:

Windows: MediaPlayer

Macintosh: QuickTime Player

* QuickTime 3.0 or later

White Balance: Whatever the kind of the light, the human eye adapts to it so that a white object still looks

white. On the other hand, devices such as digital cameras see a white subject as white by

first adjusting the color balance to suit the color of the ambient light around the subject.

This adjustment is called matching the white balance.

Exif Print: Exif Print Format is a newly revised digital camera file format that contains a variety of

shooting information for optimal printing.

11

1. General

)

r

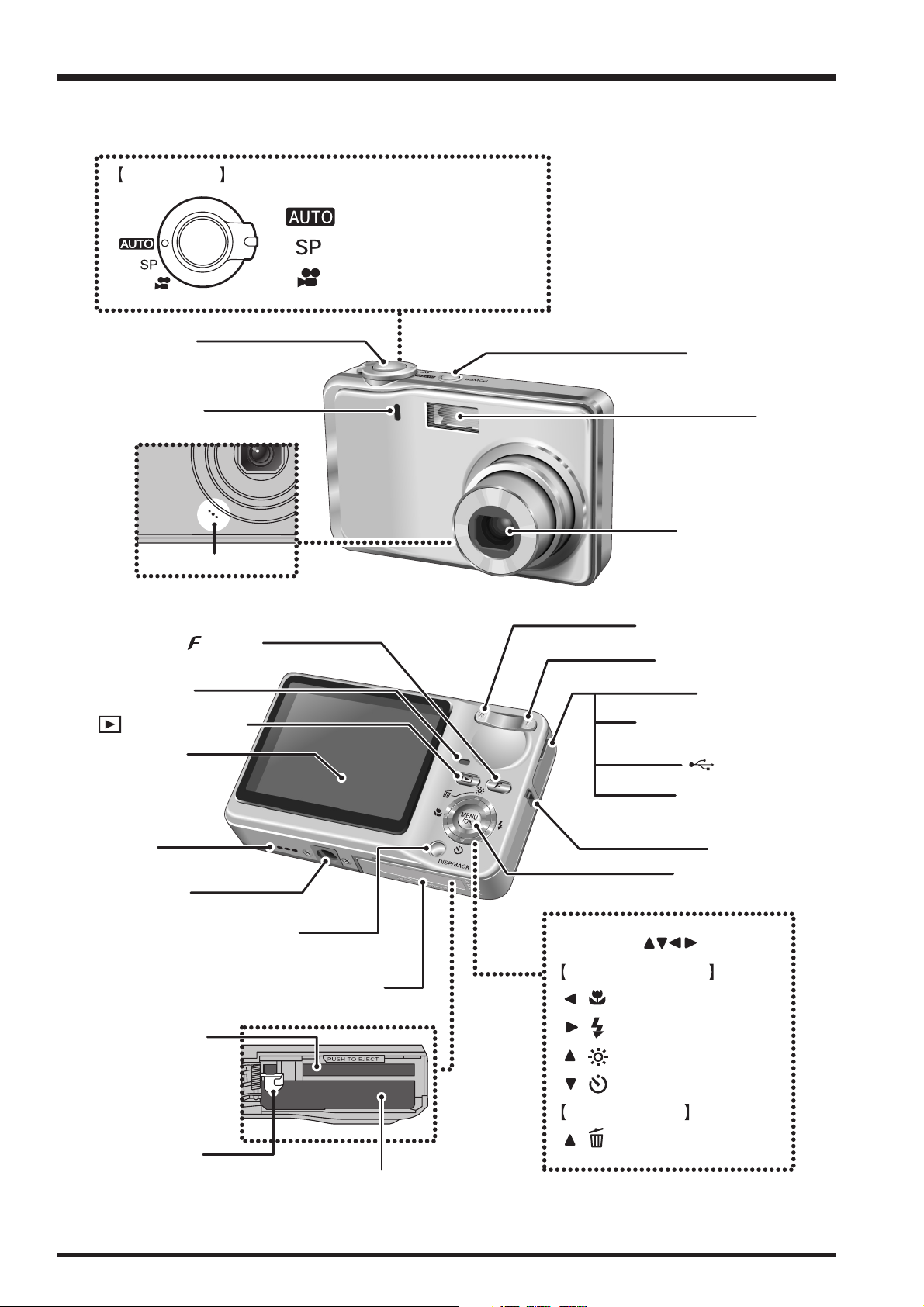

1-3. Names of External Components

Mode switch

Auto

Scene position

Movie

FinePix F460 Service Manual

Shutter button

Self-timer lamp

Microphone

Photo mode( ) button

Indicator lamp

(Playback) button

LCD monitor

POWER button

Flash

Lens (lens cover

W (Wide zoom ) button

T (Tele zoom)button

Terminal cove

DC IN 5V (power input)

socket

USB socket

Speaker

Tripod mount

DISP (Display) / BACK button

xD-Picture Card

slot

Battery release

catch

Battery compartment

Battery cover

A/V OUT (audio /

visual output) socket

Strap mount

MENU/OK button

4-direction ( ) button

Photography mode

/ (Macro) button

/ (Flash) button

/ (Low light view) button

/ (Self-timer) button

Playback mode

/ (Erase) button

12

FinePix F460 Service Manual

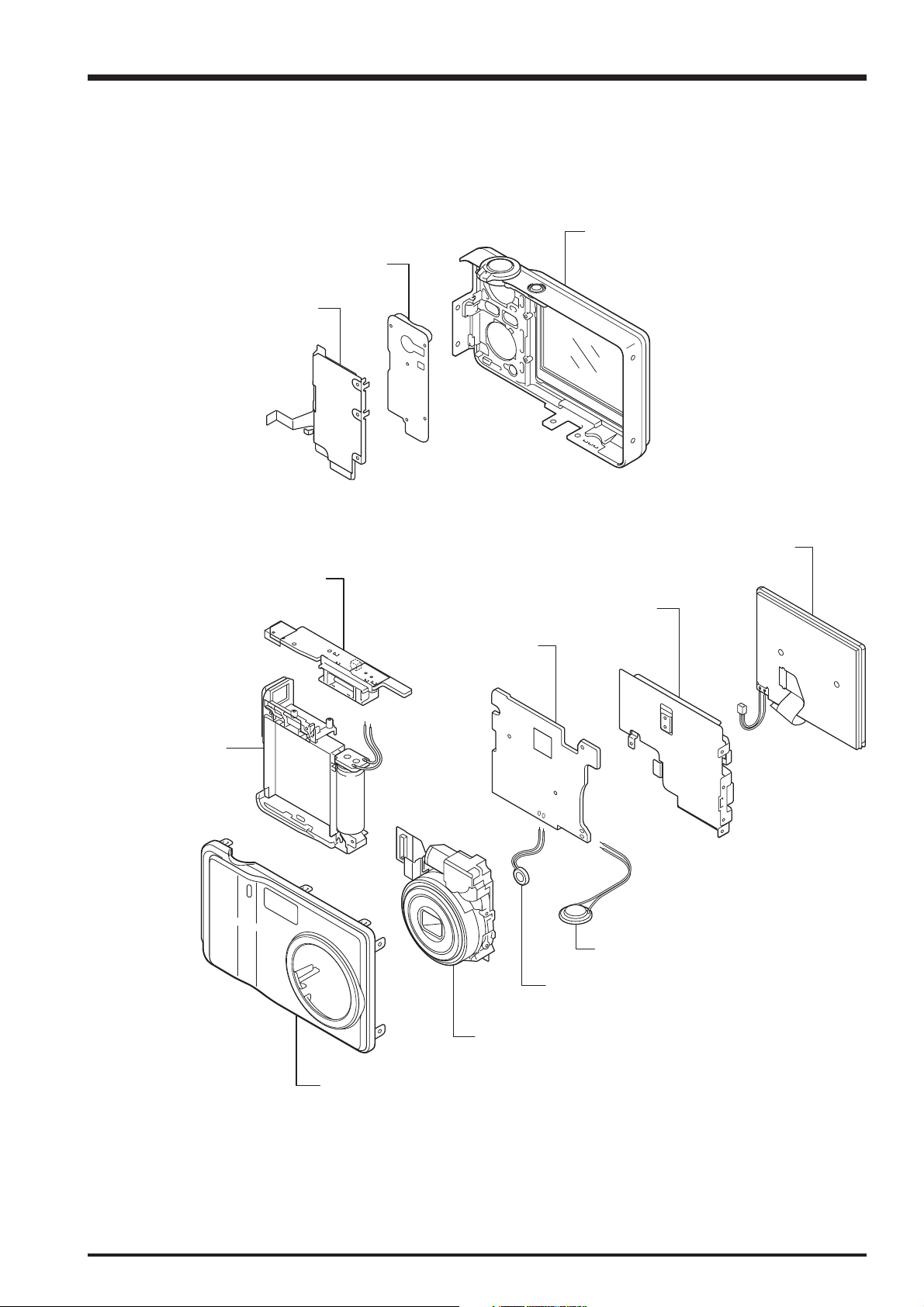

2. Disassembly

2-1. Names of internal Components

OPERATION BUTTON

KEY UNIT

2. Disassembly

CABI R ASSY

FLASH PWB ASSY

BATTERY

HOLDER ASSY

LCD

MONITOR HOLDER

MAIN PWB ASSY

SPEAKER

MICROPHONE

CABI F ASSY

LENS ASSY

13

2. Disassembly

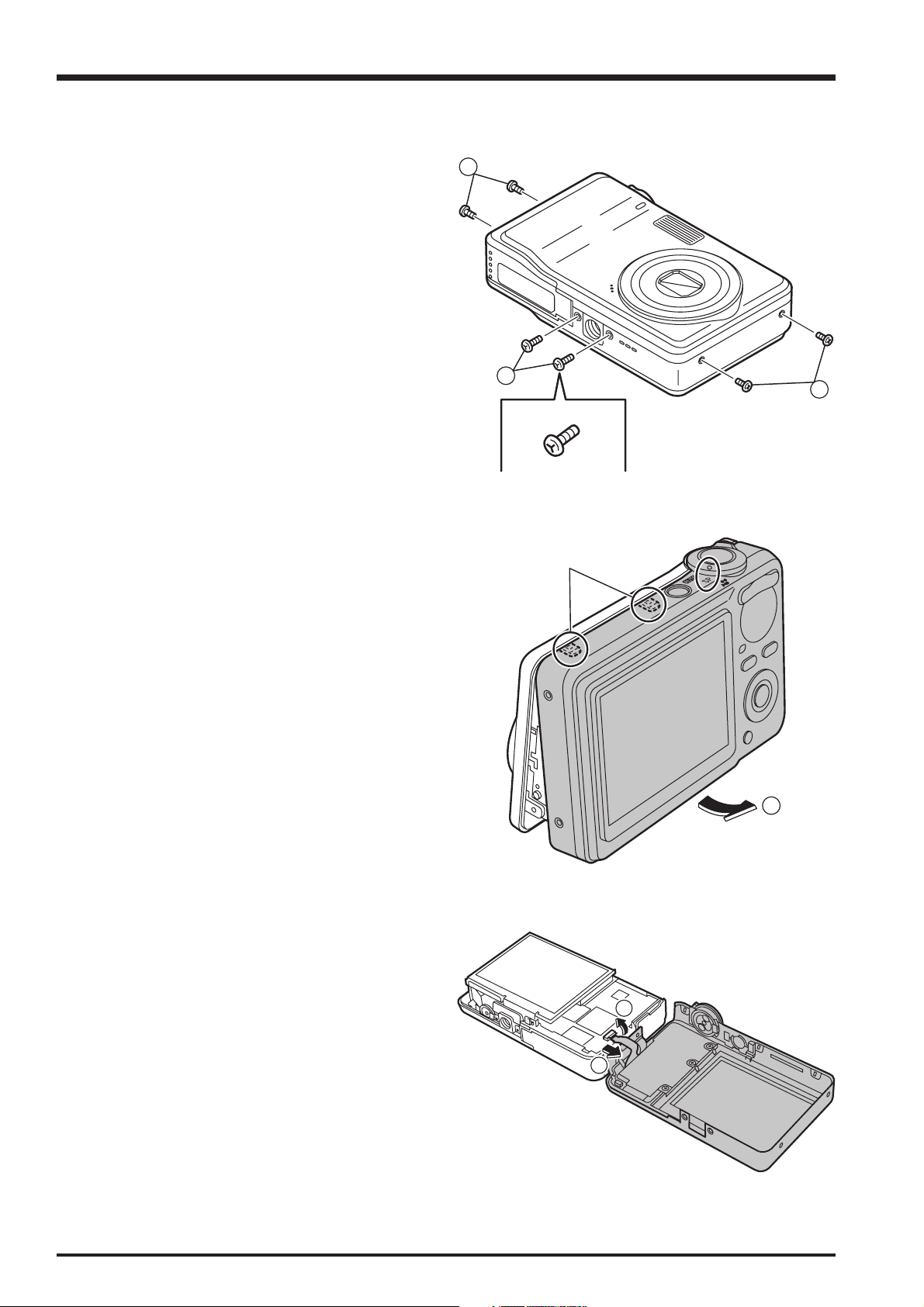

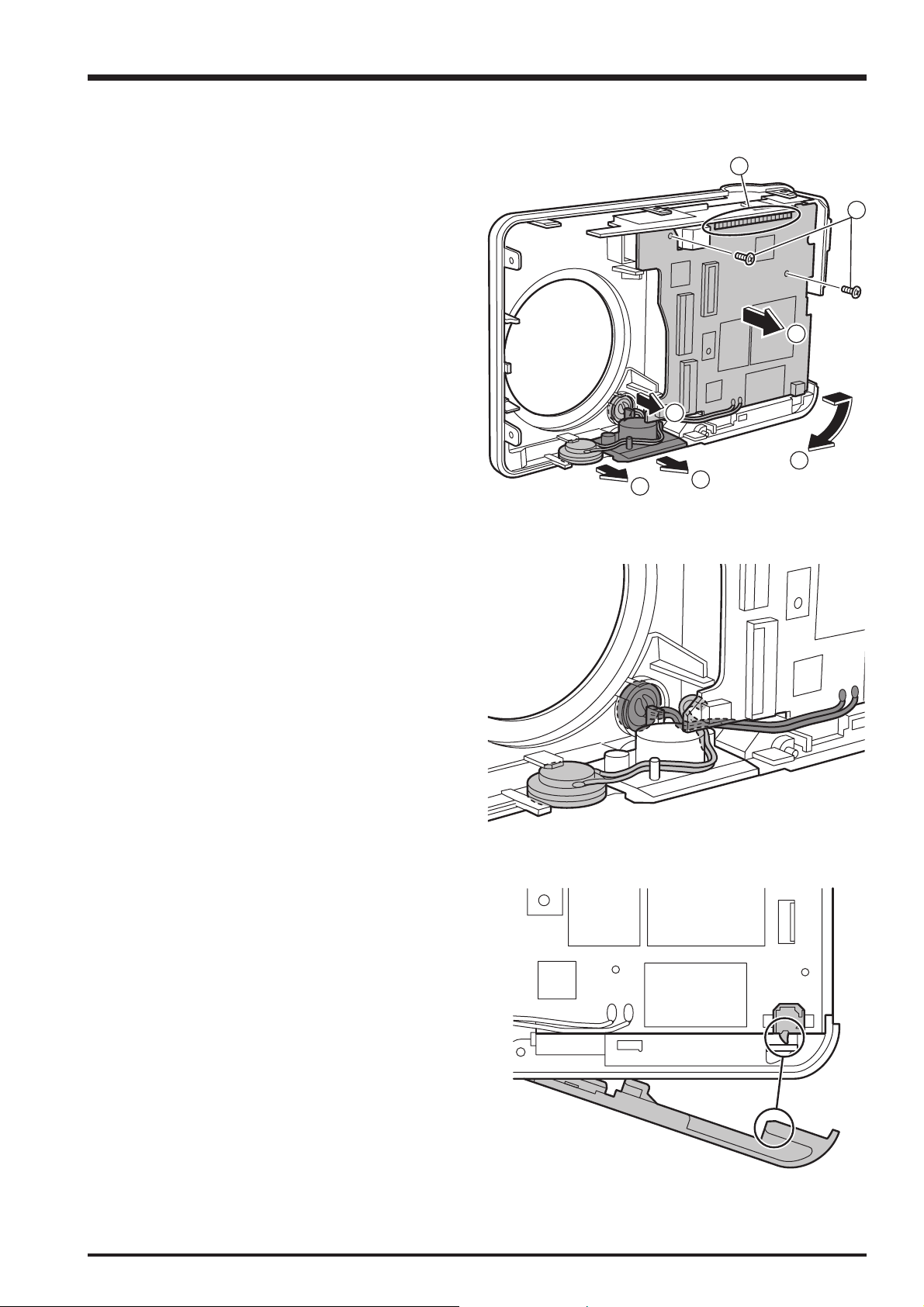

2-2. Removing the CABI REAR ASSY

FinePix F460 Service Manual

(1) Remove the 2 special screws (M1.7 x 4).

(2) Remove the 4 screws (M1.4 x 2.5).

(3) Set the mode switch to the “SP” position and disengage

the 2 hooks as you remove the CAB REAR ASSY in

the direction of the arrow. (Set the mode switch to the

“SP” position for assembly also.)

2

1

2

Hook

(4) Release the lock on connector CN301.

(5) Remove the FPC.

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

3

4

5

14

FinePix F460 Service Manual

1

2

3

Hook

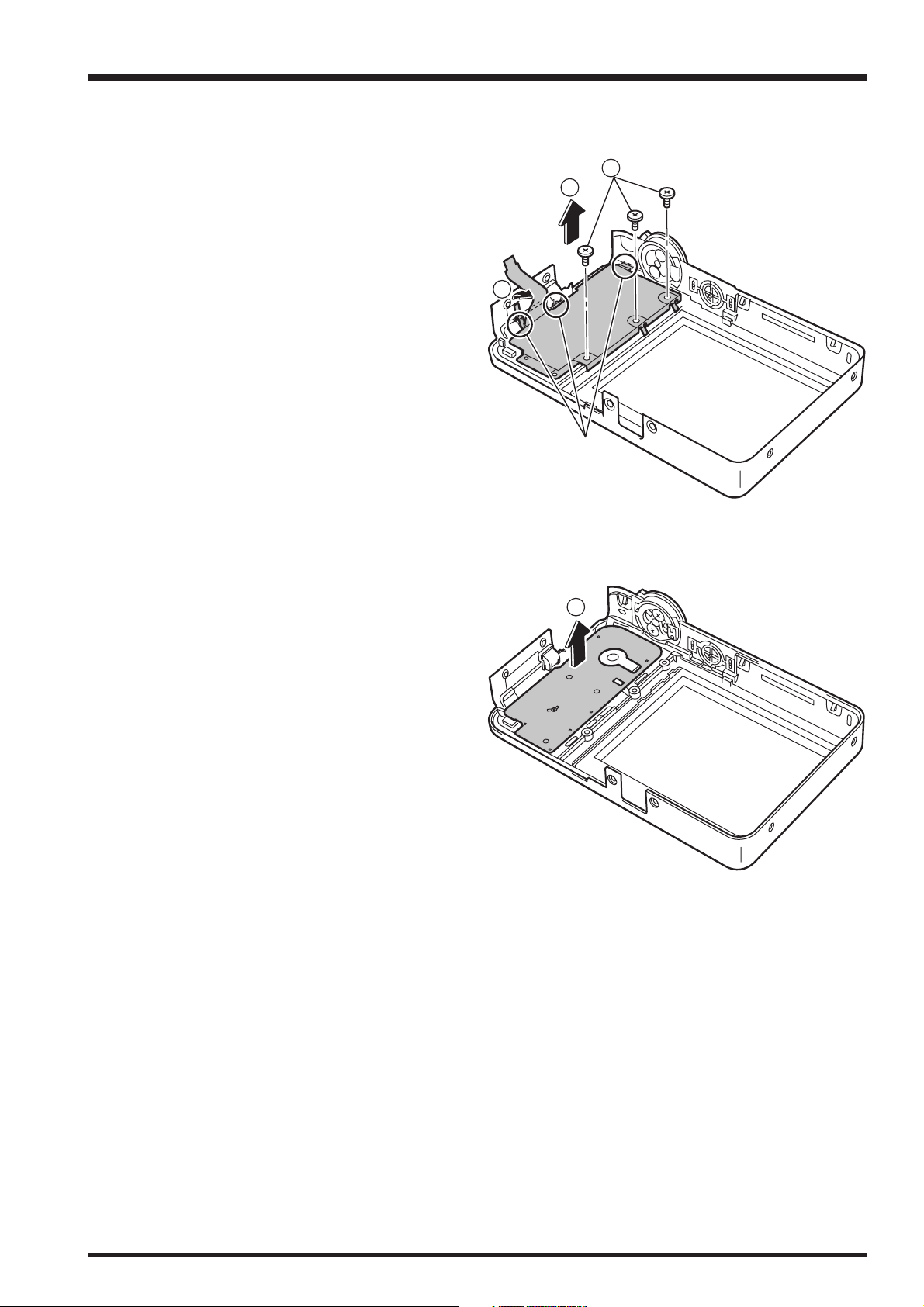

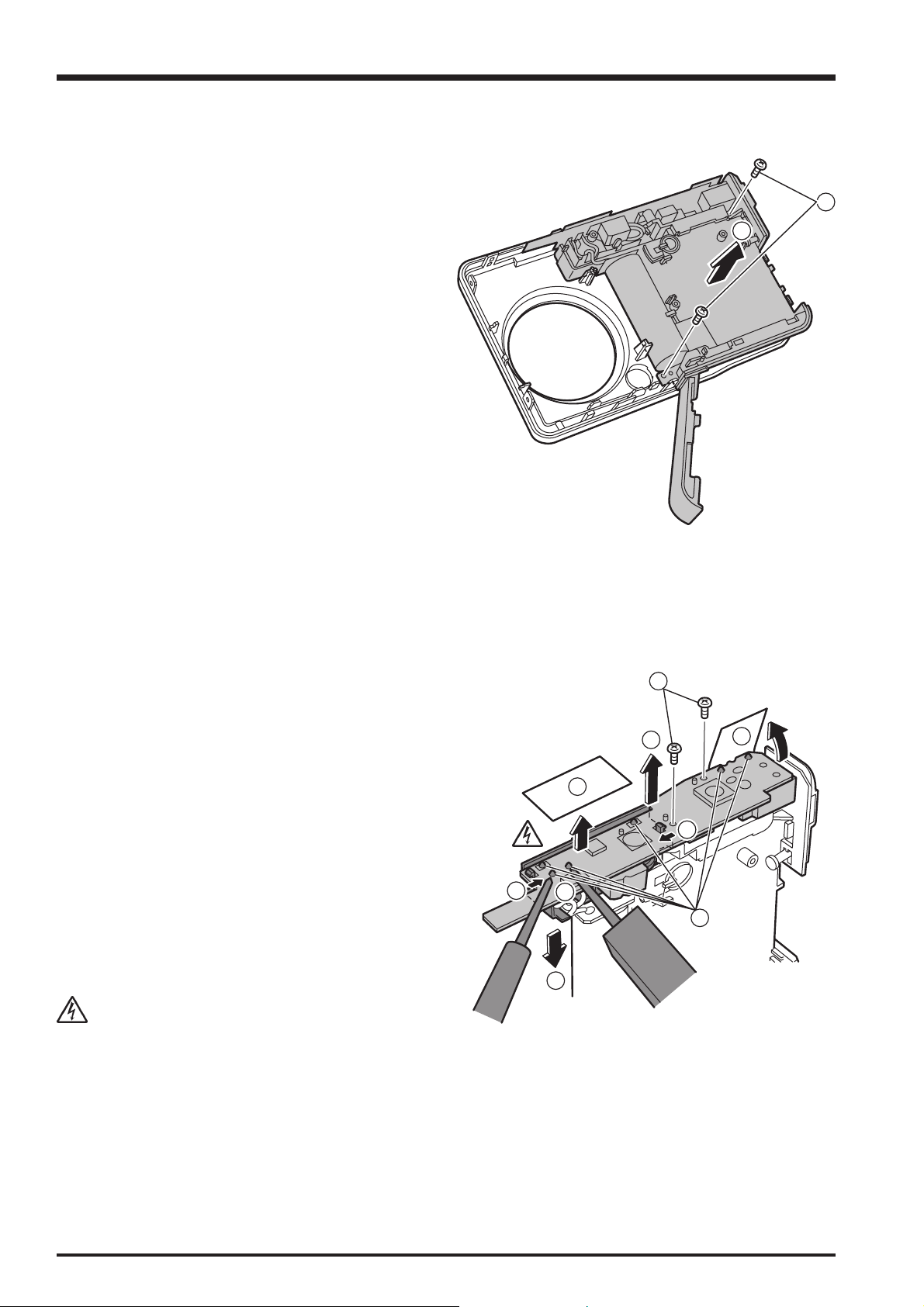

2-3. Disassembling the CABI REAR ASSY

(1) Remove the 3 screws (M1.4 x 2).

(2) Peel off the KEY UNIT SHIELD TAPE.

(3) Disengage the 3 hooks as you remove the KEY UNIT.

2. Disassembly

(4) Remove the OPERATION BUTTON.

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

4

15

2. Disassembly

2-4. Removing the LCD monitor

FinePix F460 Service Manual

(1) Peel off the double-sided tape as you remove the LCD

monitor in the direction of the arrow.

(2) Remove connector CN172.

(3) Release the lock on connector CN171.

(4) Remove the FPC in the direction of the arrow.

1

TAPE W FACE

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

4

2

3

16

FinePix F460 Service Manual

3

2

1

A

B

C

4

5

5

6

7

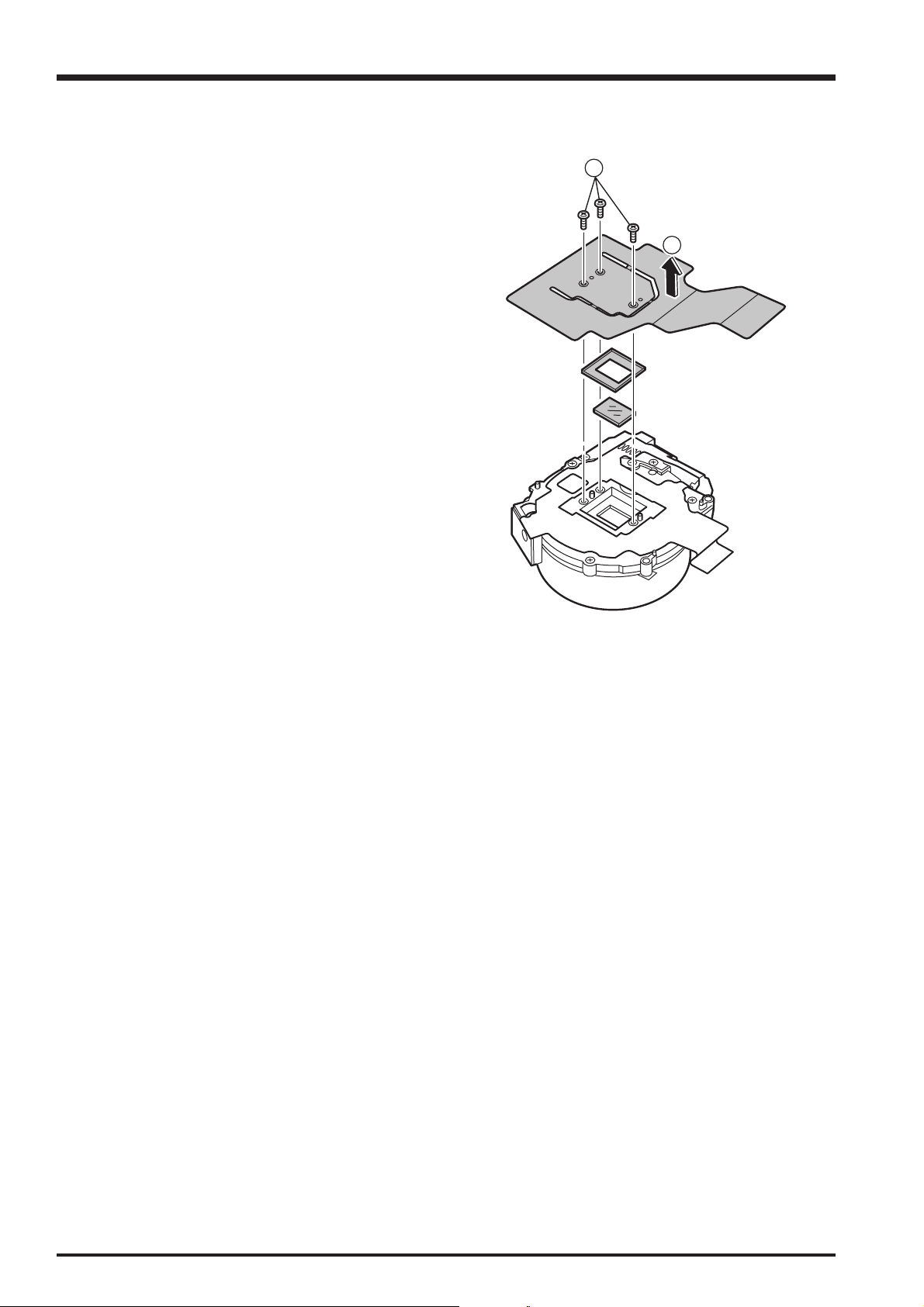

2-5. Removing the LENS ASSY

(1) Remove the 2 screws (M1.4 x 3).

(2) Remove the screw (M1.4 x 2.5).

(3) Remove the MONITOR HOLDER.

2. Disassembly

(4) Remove connector CN101.

(5) Release the lock on connector CN951.

(6) Remove the FPC in the direction of the arrow.

(7) Remove the LENS ASSY in the direction of the arrow.

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

[Notes on assembly]

Tighten the MONITOR HOLDER lock screws in the A>B>C

sequence.

17

2. Disassembly

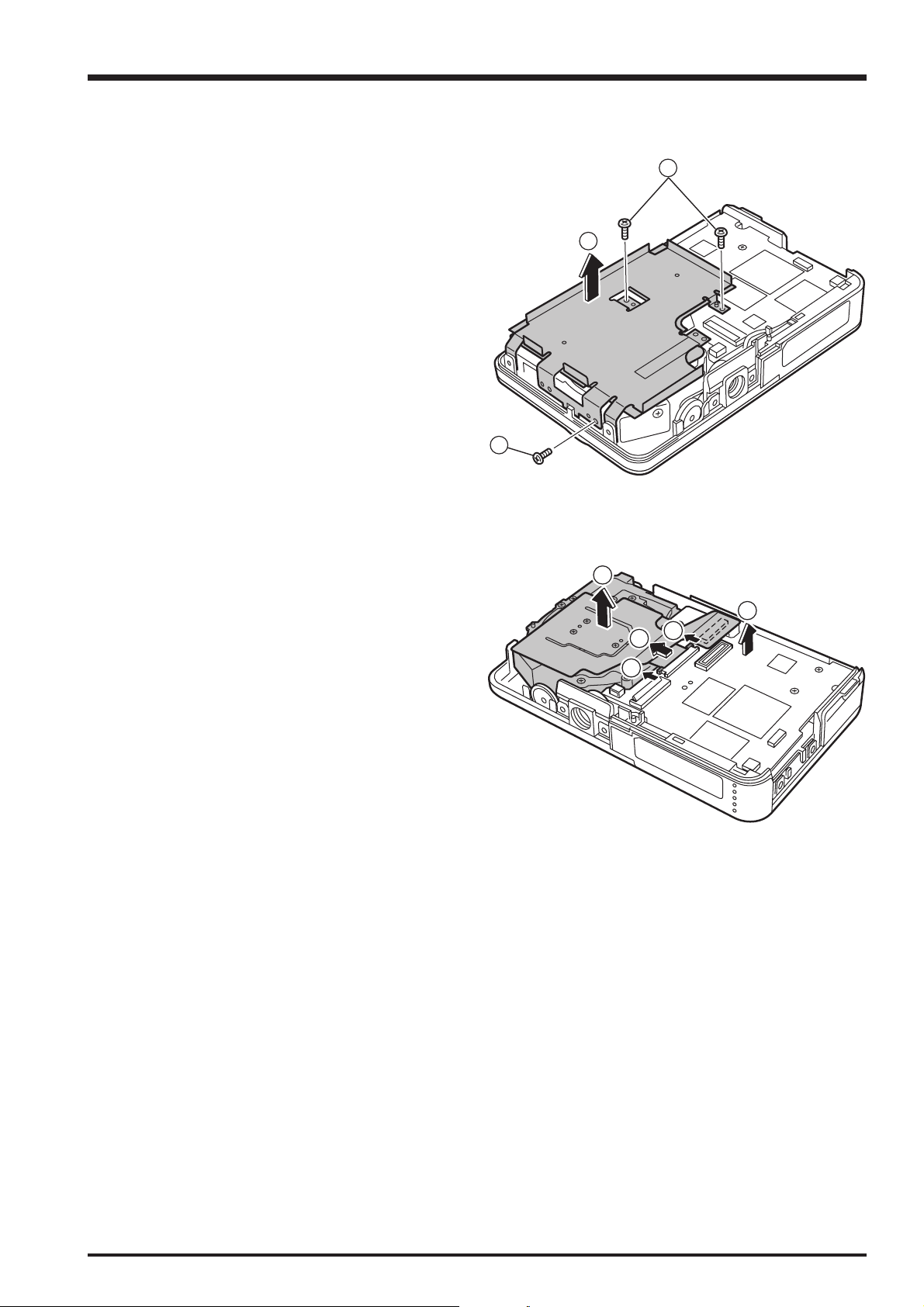

2-6. Removing the CCD PWB ASSY

FinePix F460 Service Manual

(1) Remove the 3 screws (M1.4 x 3.5).

(2) Remove the CCD PWB ASSY.

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

[Notes on assembly]

Tighten the screws in the A>B>C sequence.

1

A

C

B

2

18

FinePix F460 Service Manual

5

2

3

4

7

6

1

2-7. Removing the MAIN PWB ASSY

(1) Remove the solder.

(2) Remove the SPEAKER.

(3) Remove the TRIPOD SCREW.

(4) Remove the MIC.

(5) Remove the 2 screws (M1.4 x 3).

(6) Open the BATTERY COVER.

(7) Remove the MAIN PWB ASSY.

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

[Notes]

{

When replacing the MAIN PWB ASSY, execute the

procedure described in “4-8. MAIN PWB ASSY

initialization”.

2. Disassembly

[Notes on assembly]

Run the MIC and SPEAKER wire harnesses as shown in

the figure on the right.

Install the MAIN PWB ASSY with the BATTERY COVER

open (to prevent S3001 breakage).

Revised: 09. Mar. 2006

{

19

2. Disassembly

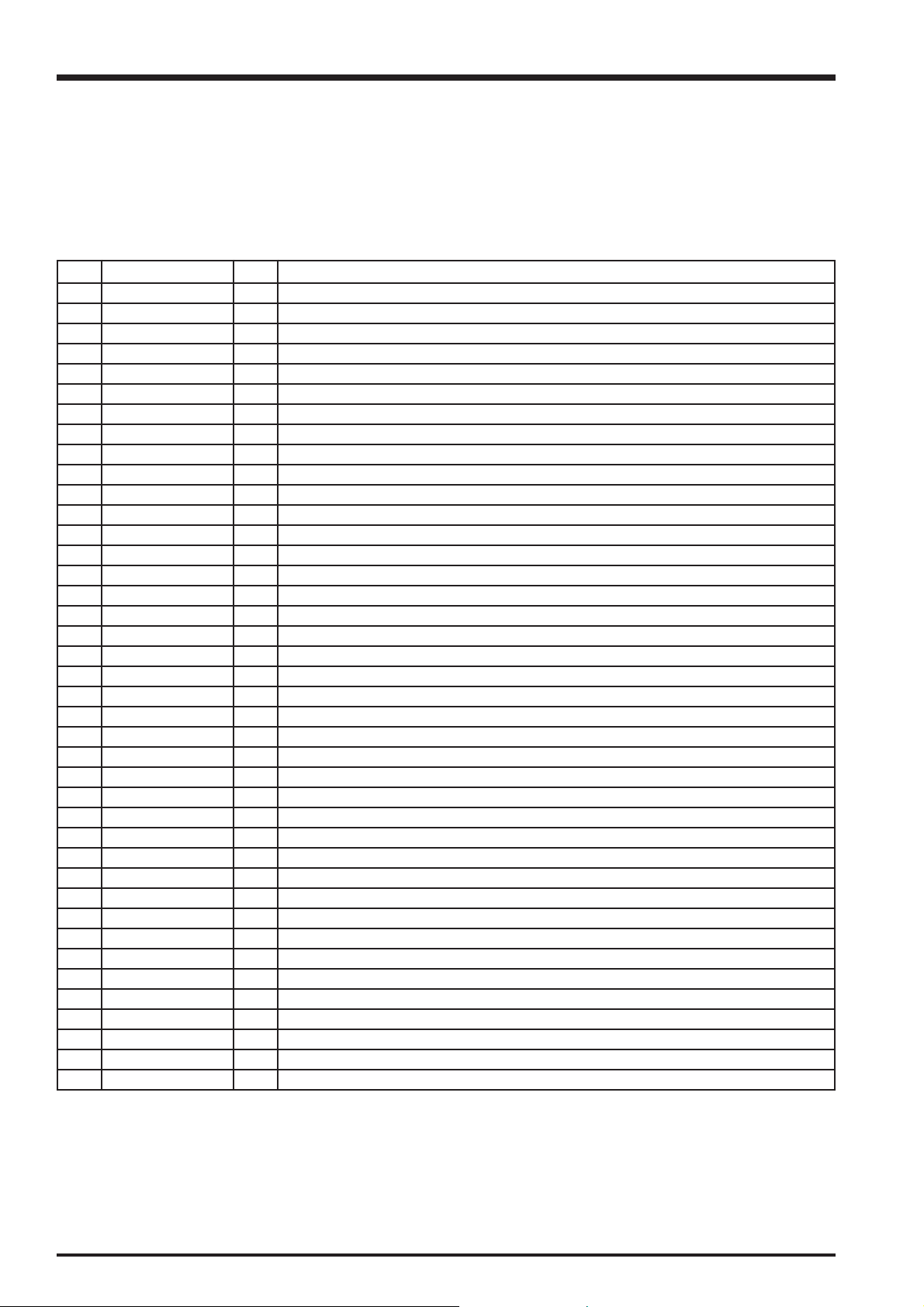

2-8. Removing the BATTERY HOLDER

(1) Remove the 2 screws (M1.4 x 3).

(2) Remove the BATTERY HOLDER.

FinePix F460 Service Manual

1

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

2-9. Removing the FLASH PWB ASSY

(1) Peel off the FLASH PWB SPACER.

(2) Discharge the current across the (+) RD and (-) BK

terminals.

(3) Remove the solder.

(4) Remove the 2 screws (M1.4 x 3).

(5) Remove the FLASH PWB ASSY.

(6) Push the FLASH UNIT claw in the direction of the

arrow.

(7) Remove the FLASH UNIT in the direction of the arrow.

2

4

5

1

6

1

[Assembly]

Assemble by performing the disassembly procedure in

reverse.

Take care not to touch the terminals as this could

cause an electric shock.

20

6

2

3

7

FinePix F460 Service Manual

3. Schematics

3. Schematics

3-1. Description of CCD circuit

Ø7B

Ø8

V

V

14

13

12

Ø7A

V

ØHLD

Ø6

V

V

10

11

Ø4

Ø5A

Ø5B

V

V

V

7

8

9

Ø3A

Ø3B

ØST

V

V

V

6

4

5

Ø1A

Ø1B

Ø2

V

V

V

1

3

2

operation

3-1-1. Outline

The CCD peripheral circuit block is primarily composed of

the following ICs:

IC903 (ICX495BQF) CCD imager

IC905 (AD9948AKCPZ) H driver, CDS, AGC, A-D conversion

IC901, IC902 (CXD3440EN-1), V drivers

3-1-2. IC903 (CCD imager)

• Interline-type CCD image sensor

• Image size: 7.19 mm diagonal (1/2.5-inch)

G

R

G

R

G

R

G

R

Vertical register

G

R

G

R

Horizontal register

B

G

B

G

B

G

B

G

B

G

B

G

• Total pixels: 2168 (H) x 1970 (V)

• Recorded pixels: 2592 (H) x 1944 (V)

16

15

DD

OUT

V

V

19

20

18

17

RG

Ø1B

Ø

H

Ø2B

H

GND

21

23

22

GND

GND

<Fig 3-1. CCD block diagram>

Terminal no. Terminal symbol Terminal description Terminal no. Terminal symbol Terminal description

1VØ1AVertical register transfer clock

2VØ1BVertical register transfer clock

3VØ2Vertical register transfer clock

4VØ3AVertical register transfer clock

5VØ3BVertical register transfer clock

6VØSTHorizontal addition control clock

7VØ4Vertical register transfer clock

8VØ5AVertical register transfer clock

9VØ5BVertical register transfer clock

10 VØ

11 VØ

12 VØ

13 VØ

14 VØ

HLD

7A

7B

Horizontal addition control clock

6

Vertical register transfer clock

Vertical register transfer clock

Vertical register transfer clock

8

Vertical register transfer clock

15 V

16 V

17 ØRG Reset gate clock

18 HØ

19 HØ

20 GND GND

21 GND GND

22 GND GND

23 ØSUB Board clock

24 C

25 NC –

26 V

27 HØ

28 HØ

out

DD

SUB

Signal output

Circuit power supply

1B

Horizontal register transfer clock

2

Horizontal register transfer clock

Board bias

L

1A

2A

Protective transistor bias

Horizontal register transfer clock

Horizontal register transfer clock

<Table 3-1. Explanation of the CCD terminals>

B

G

G

R

B

G

G

R

B

G

G

R

B

G

G

R

B

G

G

R

B

G

(Note)

G

R

25

26

24

SUB

SUB

C

Ø

(Note): Photosensor

NC

27

L

V

Ø1A

H

28

Ø2A

H

3-1-3. IC901, IC902 (V driver) and IC905 (H driver)

The H driver and V driver are necessary to generate the

clocks that drive the CCD (vertical register transfer clock,

horizontal register transfer clock and electronic shutter

clock). IC 901 and IC902 comprise the V driver, XV1-XV6

output from IC101 comprises the vertical register transfer

clock, and XSG is superposed in IC901 and IC902 to

generate a 3-value pulse. The XSUB output by IC101 serves

as the clearing pulse for the electronic shutter. The H driver

is built into IC905 and the clocks for H1, H2 and RG are

created by IC905.

3-1-4. IC905 (CDS, AGC, A-D conversion)

Video signals output from the CCD are input via pin 27 on

IC905. Inside the IC are a sampling hold block, AGC block

and A-D conversion block. The sampling phase and AGC

amplifier settings are specified using serial data to pin 32.

The video signals are A-D converted and output as 10-bit data.

CCDIN

RG

H1-H4

VRB

VRT

VREF

2~36 dB

VGA

PxGA

CDS

HORIZONTAL

4

DRIVERS

CLAMP

INTERNAL

CLOCKS

PRECISION

TIMING

CORE

SYNC

GENERATOR

VD

HD

CLAMP

<Fig 3-2. IC905 block diagram>

ADC

INTERNAL

REGISTERS

SL

SCK

10

SD ATA

DOUT

CLI

21

3. Schematics

FinePix F460 Service Manual

3-2. Description of CP1 circuit

operation

3-2-1. Circuit Description

Digital clamp

The black levels for the CCD output data are evened up

across the line by subtracting the averaged value for the

optical black sections of the CCD from the subsequent data.

The average value for the optical black sections of the CCD

is obtained by multiplying the value for the previous line by a

coefficient k and multiplying the value for the current line by a

coefficient k-1 and then taking the sum of the multiples.

Signal processor

γγ

γ (gamma) correction circuit: γ (gamma) correction is

γγ

performed to ensure that there is a linear relationship

between the optical input to the camera and the optical

output of the screen receiving the image.

Color signal generation circuit: This circuit converts the

CCD data to R, G and B signals.

Matrix circuit: This circuit uses the R, G and B signals to

generate Y, R-G and B-G signals.

Horizontal/vertical aperture circuit: This circuit generates

the aperture signal.

3-2-2. Outline of Operation

When the shutter is released, the microprocessor sends a

reset signal and a serial signal (TAKE A PICTURE

instruction) to the ASIC and CPU and operation begins.

When the TG/SG drives the CCD, the image data passes

through A-D conversion and CDS and is sent to the ASIC as

12-bit data. The received (input) data is then input to SDRAM

via the digital clamp.

This data is used to calculate the AF, AE, AWB, shutter and

AGC values, and then 3 exposures are normally taken to

obtain the best possible image. The data for the images

stored in SDRAM is loaded into the CPU and the colors are

generated. Each pixel in the R, G and B data is interpolated

from the surrounding data to generate the R, G and B pixel

data. After AWB and γ (gamma) correction, a matrix is

generated and aperture compensation is applied for the Y

signal. The resulting data is then subjected to JPEG

compression and recorded onto card memory (xD-Picture

card). When the data is output to an external device, the data

is fetched from memory and output serially via USART. When

the image is played back on an LCD or monitor, the data is

transferred from memory to SDRAM, expanded into the

SDRAM display area and then displayed.

AE/AWB/AF calculation circuit

This circuit calculates the AE and AWB values by dividing the

screen into 64 zones and calculates the AF value by dividing

the screen into 6 zones.

SDRAM controller circuit

This circuit outputs the address, RAS, CAS and AS used for

SDRAM control. This circuit also refreshes the SDRAM.

Communication control

SIO: This is the interface with the 8-bit microprocessor.

SIO for LCD, PWM and PIO: This makes it possible to

switch between PWM output and individual I/O in 8-bit

parallel I/O.

TG/SG

This controls and generates timing for the 5-megapixel CCD.

Digital encoder

This generates chroma signals from the color difference

signals.

3-2-3. LCD Block

The LCD display circuit is located on the CP1 board and

includes its own power supply circuit.

Signals from the ASIC are input directly to the LCD as 8-bit

digital signals and are converted to RGB signals by the driver

circuit built into the LCD. The LCD is a 3-wire serial device

and controls parameters such as the brightness and image

quality.

The larger the difference in potential between VCOM

(common terminal voltage: AC) and R, G and B, the more the

LCD elements close and the display darkens. Conversely,

the smaller the potential difference, the more the LCD

elements open and the display brightens. In addition to the

video signals, timing pulses are also input directly to the LCD

from the ASIC.

22

FinePix F460 Service Manual

3. Schematics

3-2-4. Lens Drive Block

Focus drive

The focus is operated by the focus stepping motor, which is

driven (AFSPM (1) +A, AFSPM (2) -A, AFSPM (3) +B,

AFSPM (4) -B) by the motor driver (IC951) in response to 4

control signals (FIN1, FIN2, FIN3 and FIN4) output by the

ASIC (IC101). The focus reference position is detected by a

photo-interrupter (AFPI_E) inside the lens unit.

Zoom drive

The zoom is operated by the zoom DC motor, which is driven

(ZM (+), ZM(-)) by the motor driver (IC951) in response to 2

control signals (ZIN1 and ZIN2) output by the ASIC (IC101).

The zoom reference position is detected by a photo-reflector

(ZMPR_E) inside the lens unit. The zoom position is also

acquired using a count kept for a photo-interrupter (ZMPI_E)

inside the lens unit.

Shutter drive

The mechanical shutter is opened and closed by a fixedcurrent drive (SHUT (+), SHUT (-)) from the motor driver

(IC951) in response to 2 control signals (SIN1 and SIN2)

output by the ASIC (IC101).

Aperture (ND) drive

The aperture is operated by the ND filter motor, which is

driven (IRIS (+), IRIS (-)) by the motor driver (IC951) in

response to 2 control signals (IIN1 and IIN2) output by the

ASIC (IC101).

3-3. Description of PWA power

circuit operation

3-3-1. Outline

The power circuit consists primarily of the following blocks:

• Switching power controller (IC501)

• VDD 5V power output (L5001)

• VDD 3V (digital 3.25-volt) power output (L5008)

• VDD 1.2V (digital 1.2-volt) power output (L5007)

• CCD 15.0V power output (L5003)

• CCD -7.5V power output (L5005)

• LCD backlight power output (L5002)

• CCD 3.45V output (IC502)

• LCD 12V output (IC504)

Switching power controller (IC501)

Built into this controller are the basic circuits that drive and

control the 8 types of current used in the DSC. These

currents are comprised of the channels (CH) for SU, M, SD,

BST, INV, LED, AFE and AUX. On this model, CH AFE and

CH AUX are not used. The channel-to-output

correspondence is as shown below.

• SU - VDD 5V

• M - VDD 3V

• SD - VDD 1.2V

• BST - CCD 15.0V

• INV - CCD -7.5V

• LED - LCD backlight

The output from each type is fed back to IC501.

IC501 monitors the feedback voltages and performs PWM

control so as to maintain the designated voltages for each

channel.

Short-circuit protection

When a short-circuit of 100 msec or longer occurs on any of

the outputs, IC501 detects the short-circuit and sets all

output to OFF. Operation can be recovered by re-imposing

control via the ONSU terminal (pin 46).

VDD 5V power output

The switching power controller IC501 generates VDD 5V by

stepping up and controlling the voltage supplied from the

battery. The VDD current is the drive power supply used by

IC501 and is fed back to IC501 (pin 42) and subjected to

PWM control. The VDD 5V power output is also the supply

source for the VDD 3V and CCD 3.45V circuits.

VDD 3V power output

IC501 generates the VDD 3V power output by stepping down

and controlling the VDD 5V power output. VDD 3V is fed

back to IC501 (pin 2) and subjected to PWM control.

23

3. Schematics

FinePix F460 Service Manual

VDD 1.2V power output

IC501 generates the VDD 1.2V power output by stepping

down and controlling the power supplied from the battery.

VDD 1.2V is fed back to IC501 (pin 12) and subjected to

PWM control.

CCD 15V power output

IC501 generates the CCD 15V power output by stepping up

and controlling the power supplied from the battery. CCD

15V is fed back to IC501 (pin 26) and subjected to PWM

control. The CCD 15V power output is also the supply source

for the LCD 12V circuit.

CCD -7.5V power output

IC501 generates the CCD -7.5V power output by reversing

the polarity and controlling the power supplied from the

battery. CCD -7.5V is fed back to IC501 (pin 25) and

subjected to PWM control.

LCD backlight power output

A set current is output to the backlight LED for the LCD.

The backlight power output is fed back to IC501 (pin 37) and

subjected to PWM control to ensure that the current flowing

to R5024 is constant.

CCD 3.45V power output

Series regulator IC502 generates the CCD 3.45V power

output by stepping down the VDD 5V output.

LCD 12V power output

Series regulator IC504 generates the LCD 12V power output

by stepping down the CCD 15V output.

3-4. Description of ST1 flash

circuit operation

3-4-1. Charging circuit

When UNREG power is supplied to the charging circuit and

the CHG signal from the microprocessor is Hi (3.3 volt), the

charging circuit starts operating and charges the main

electrolytic capacitor with direct current at high voltage. If the

CHG signal is Lo (0 volt), the charging circuit does not

operate.

Power switch

When the CHG signal is Hi, IC542 is set to ON and charging

starts.

Power filter

C5407 acts as a power filter that smoothes out current

ripples caused by oscillation transformer switching.

Oscillation circuit

This circuit generates an AC voltage (pulses) for stepping up

the DC low-voltage UNREG power supply. The oscillation

circuit generates drive pulses with frequencies from

approximately 50 KHz to 100 KHz. Because the circuit is

self-oscillating, the oscillation frequency varies depending on

the drive conditions.

Oscillation transformer

The oscillation transformer converts the low-voltage AC

current generated by the oscillation control circuit to a highvoltage AC current.

Rectifier circuit

This circuit rectifies high-voltage AC current occurring on the

secondary side of T5401 so that it becomes high-voltage DC

current and stores the charge in the main electrolytic

capacitor (C5412).

24

Voltage monitor circuit

This circuit is used to maintain the voltage stored in C5412 at

a set level. Once the charging voltage has been divided and

reduced by R5405 and R5406, it is output as the monitor

voltage VMONIT.

When the VMONIT voltage reaches the stipulated value, the

CHG signal is set to Lo and charging stops.

FinePix F460 Service Manual

3-4-2. Flash Circuit

When an FLCLT signal is input to this circuit from the ASIC

expansion board, the flash fires.

Flash control circuit

When a Hi FLCLT signal is input to the flash control circuit,

Q5409 is set to ON and the flash is readied for firing. If the

FLCLT signal is Lo, firing stops.

Trigger circuit

When Q5409 is set to ON by the FLCLT signal and the flash

is ready to fire, at the same time a high-voltage pulse of

several kilovolts is generated by the trigger coil and applied

to the flash unit.

Flash element

When the high-voltage pulse from the trigger circuit is

applied to the flash unit, the current flows into the flash

element and the flash fires.

3. Schematics

* Beware of electric shocks.

25

3. Schematics

FinePix F460 Service Manual

3-5. Description of SYA circuit operation

3-5-1. Configuration and Functions

Refer to the block diagram for the overall configuration of the SYA block. At the core of the SYA block is an 8-bit

microprocessor (IC301). The functions handled by the 8-bit microprocessor are: 1. Operation key input; 2. Clock management

and backup; 3. Power ON/OFF; and 4. Flash charging control.

<Table 3-2. 8-bit microprocessor port specifications>

Pin Signal name I/O Description

1 BAT OFF I Battery OFF detection signal

2 NOT USED - 3 VF.LED (g) O VF. LED (green) (H = lit)

4 NOT USED - 5 SW 3.2 ON O SW 3.2V control signal (L = ON)

6 RESET I Reset input

7 XCOUT O Clock oscillation terminal

8 XCIN I Clock oscillation terminal (32.768kHz)

9 IC (FLMD0) I Power supply for program writing

10 XOUT O Main clock oscillation terminal

11 XIN I Main clock oscillation terminal (4MHz)

12 REGC - Stable-capacity connection terminal for regulator output (2.5V) for internal operations

13 VSS - GND

14 VSS - GND

15 VDD - VDD

16 VDD - VDD

17 MAIN RESET O System reset (MRST)

18 NOT USED - 19 VF.LED (R) O VF. LED (red) (L = lit)

20 SELF LED O SELF LED (red) (L = lit)

21 CARD SW I Card cover open/close detection signal (L = open)

22 COMREQ I ASIC serial communication request signal

23 NOT USED - 24 PLLEN O PLL operation mode control signal (H = oscillation)

25 S2 I Shutter 2nd detection signal (L = ON)

26 S1 I Shutter 1st detection signal (L = ON)

27 NOT USED - 28 SCAN IN1 I Key matrix input

29 SCAN IN0 I Key matrix input

30 P ON O D-D converter (digital) control signal (H = ON)

31 NOT USED - 32 USB CONNECT I USB power detection terminal

33 P31 - On-chip debugging port

34 SCAN OUT0 O Key matrix output

35 SCAN OUT1 O Key matrix output

36 SCAN OUT2 O Key matrix output

37 SCAN OUT3 O Key matrix output

38 SREQ I Serial communication request signal

39 NOT USED - 40 LCD PWM O LCD backlight brightness current control

26

Loading...

Loading...