Page 1

Fuji Electric

PXG WINE Controller

Temperature Controller with Micro-Oxygenation

Function Especially Designed for Oenology

Key Features: 0/150°C

¾ AC/DC 24V Power Supply

¾ 1 relay output (remounting/pumping over)

¾ 1 relay output (oxygenation)

¾ Format 48x96 depth 79mm

¾ ON/OFF or PID control mode

Fuji Electric Systems Co., Ltd. April 2006

Page 2

Fuji Electric, in consultation with leading oenologists, has developed a precise temperature

controller, the PXG Wine, uniquely suited to the demands of the winemaking industry. Featuring

exacting standards for temperature control and the ability to regulate oxygenation, the Fuji

Electric PXG Wine is a smart, cost-effective way to control the critical functions of winemaking.

Grapes to glass, the process of crafting fine wines is dependant upon maintaining precise control

over temperatures during critical junctures. At every moment in the process of winemaking, there

is an optimal temperature that must be maintained to control the biological and chemical

processes involved with winemaking. Accurate control of these temperatures contributes to the

improvement in the final character and quality of the wine. Simply put, maintaining optimal

temperatures during the process of vinification influences:

• Development of the flavors of the grape

• Clarification of musts and wines

• Optimal development then inhibition of yeasts and bacteria

• Extraction of the pellicle compounds; tannins and anthocyanins

• Optimization of oxydo-reduction and etherification

• Blooming of the olfactive and gustatory characters of the wine

Advanced heating and cooling systems allow vintners to intervene in an active way in the

processes being held in the vat during the wine making. Heating and cooling systems can modify

these processes if necessary and direct them in the desired direction. The Fuji Electric PXG Wine

allows precision temperature control for exacting vinification standards.

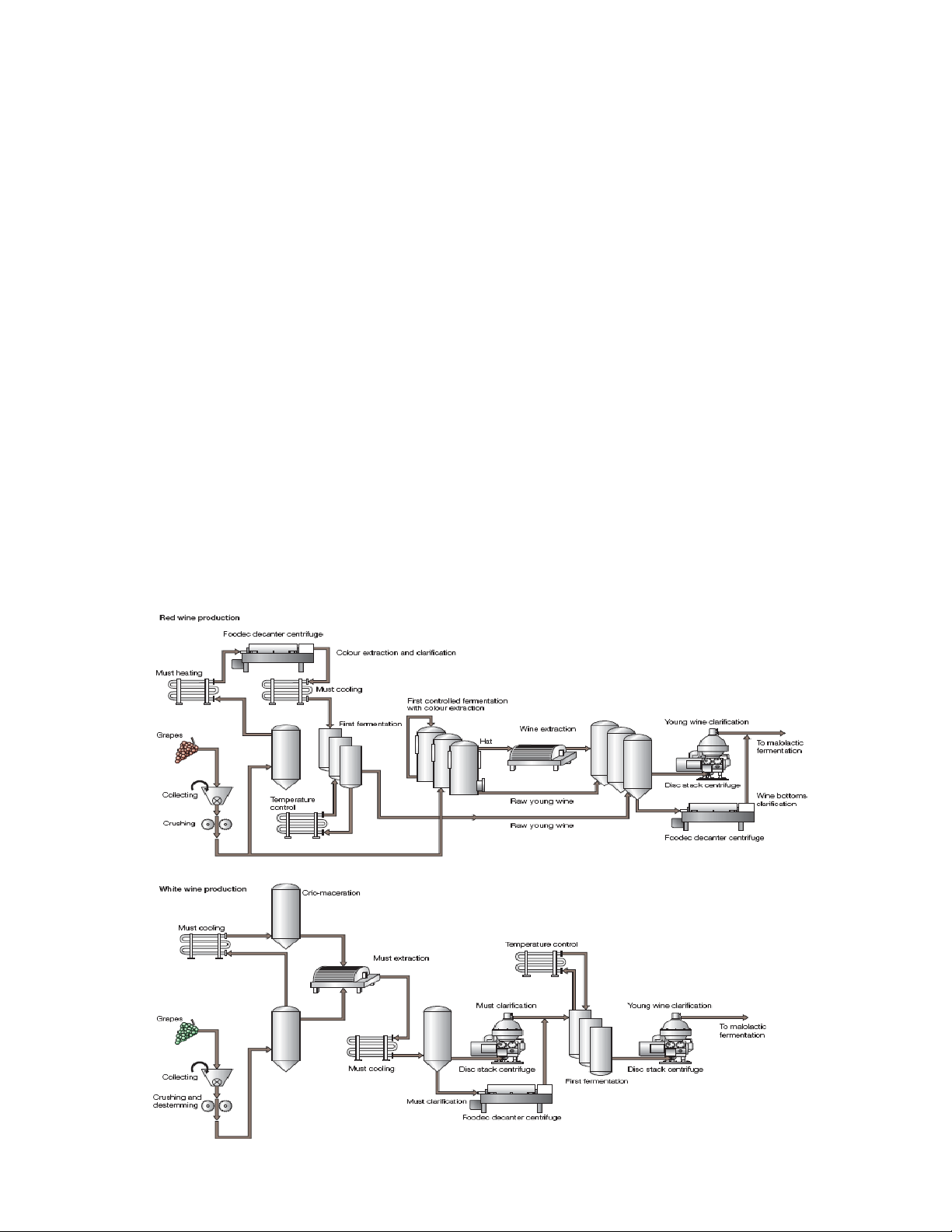

The Process of Making Wines:

Page 3

Steps of Wine Making that Require Precise Temperature Control:

Cryoextraction: The process by which grapes are frozen prior to pressing. The

temperature of the grapes is lowered to around -7º C and pressed while still

frozen. Ice crystals remain in the press while concentrated juice flows out.

Pre-Fermentation Cold Maceration: By keeping temperatures cool (around

8ºC) during maceration, the period can be extended without fermentation.

Maceration determines much about the color, flavor, tannin content and aroma of

the resulting wine.

Fermentation: The process by which grape juice is transformed into wine

through yeast cells that convert the sugars in the juice to alcohol and carbon

dioxide. The initial application of heat controls the start and intensity of

fermentation.

Cold fermentation: This is fermentation of mainly white wines in temperature-

controlled tanks, usually at around 13 to 16 degrees Celsius.

Cold Stabilization: A process to remove tartrate cystals in wine. Temperatures

are reduced to near freezing for up to 2 weeks. This causes the crystals to

separate from the wine and cling to the sides of the holding vessel. The wine is

then poured off leaving the tartrates behind.

Heat Stabilization: The heating of wines to a high temperature allows the

destruction of yeasts and bacteria and ensures biological stabilization

(pasteurization) while preventing precipitates in the wine.

Storage: The wine industry has long considered that a constant temperature

between 55 °F and 60 °F (13.0 °C and 15.5 °C) is optimum for the storage and

aging of wine.

Micro-Oxygenation Function

In addition to its ability to carefully regulate temperatures during the process of winemaking, the

Fuji Electric PXG Wine also features the micro-oxygenation function.

Wines are typically held in barrels or tanks for a period of 12 to 24 months prior to bottling.

During this time, a natural maturation of the wine occurs, as harsh young tannins soften and other

complex changes take place.

The right amount of oxygen is vital in this maturation process. While excess oxygen can lead to

premature ageing or spoilage, insufficient amounts can also be a problem. Wines can take a long

time to develop, retaining under-ripe characters and lacking fullness and complexity.

The micro-oxygenation technique allows a controlled introduction of oxygen into the wine at

precise levels, assisting the wine to breathe and develop at an optimum rate.

Micro-oxygenated wines invariably show greater purity of fruit, enhanced palate structure,

richness and more supple mouth-feel without in any way compromising their longevity.

Page 4

Micro-oxygenation can help to:

• Improve structure and body

• Remove sulphide/reduced characters and remove tendency to reduction

• Stabilise colour/oxidative potential

• Reduce green, herbaceous characters

• Improve fruit profile

This technique is fully compatible with ultra-premium barrel maturation or oak alternatives.

Micro-oxygenation provides the winemaker with control over oxygen uptake in wine in order to

best manage its subtle and complex changes.

The Fuji Electric PXG Wine can control the micro-oxygenation process via a relay output able to

activate the oxygenation valve. Additionally, the frequency and running time of the oxygenation

can be adjusted on the controller.

Technical Specifications:

The Fuji Electric PXG Wine is base upon the popular PXG model and contains many of the same

features and specifications.

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Fuji Electric Systems Co., Ltd. April 2006

Loading...

Loading...