Page 1

MODEL : PXF

INP-TN5A2227a-E

Page 2

Introduction

Thank you for purchasing the Fuji Digital Temperature Controller.

This document describes how to connect the Micro controller PXF Series (referred to below as "Micro controller") to the personal

computer or programmable controller. It also describes communication specifications for controlling and monitoring the

communications with the micro controller, MODBUS protocol, and address map for the micro controller.

In addition to this document, please make sure to read the Instruction Manual (which comes with the product) and the Operations

Manual (packaged separately).

NOTE

■ Exclusions

The contents of this document may change without prior notice.

Although great care has been taken in the accuracy of this document, Fuji Electric takes no responsibility for loss or indirect

damages caused by mistakes, missing information, or use of information in this document.

– 1 –

Page 3

Contents

1. Communication Functions

Overview................................................................................4

Connecting to a programmable controller.......................... 5

Connecting to a personal computer...................................5

2. Specifications

Communication Specifications..............................................8

RS-485...............................................................................8

PC Loader Interface...........................................................8

3. Connection

Communication Terminal Configuration...............................10

Wiring..................................................................................11

4. Setting Communication Parameters

List of Setting Parameters ...................................................16

Parameter Setting Procedure..............................................17

5. MODBUS Communication Protocol

Overview..............................................................................20

Message Composition.........................................................21

Calculating Error Check Code (CRC-16).............................24

Transmission Control Steps.................................................25

Prercautions when Writing Data..........................................26

7. Address Map and Data Format

Data Format.........................................................................38

Internal Calculation Value Data Address Map.....................40

8. Sample Program

Sample Program..................................................................68

9. Cooperative operation

Overview..............................................................................70

Connection...........................................................................71

Setup and related parameters .............................................72

Cooperative operation..........................................................73

List of parameters subject to the cooperative operation......74

10. Programless communication

Overview..............................................................................82

Connection...........................................................................83

Programless communication................................................84

Setup and related parameters .............................................88

Setup for Programless Communication ...............................90

11. Troubleshooting

Troubleshooting..................................................................126

6.

Command and Transmission Frame Details

Reading Data ......................................................................28

Writing Data.........................................................................32

– 2 –

Page 4

Chapter 1

Communication Functions

Overview – 4

– 3 –

Page 5

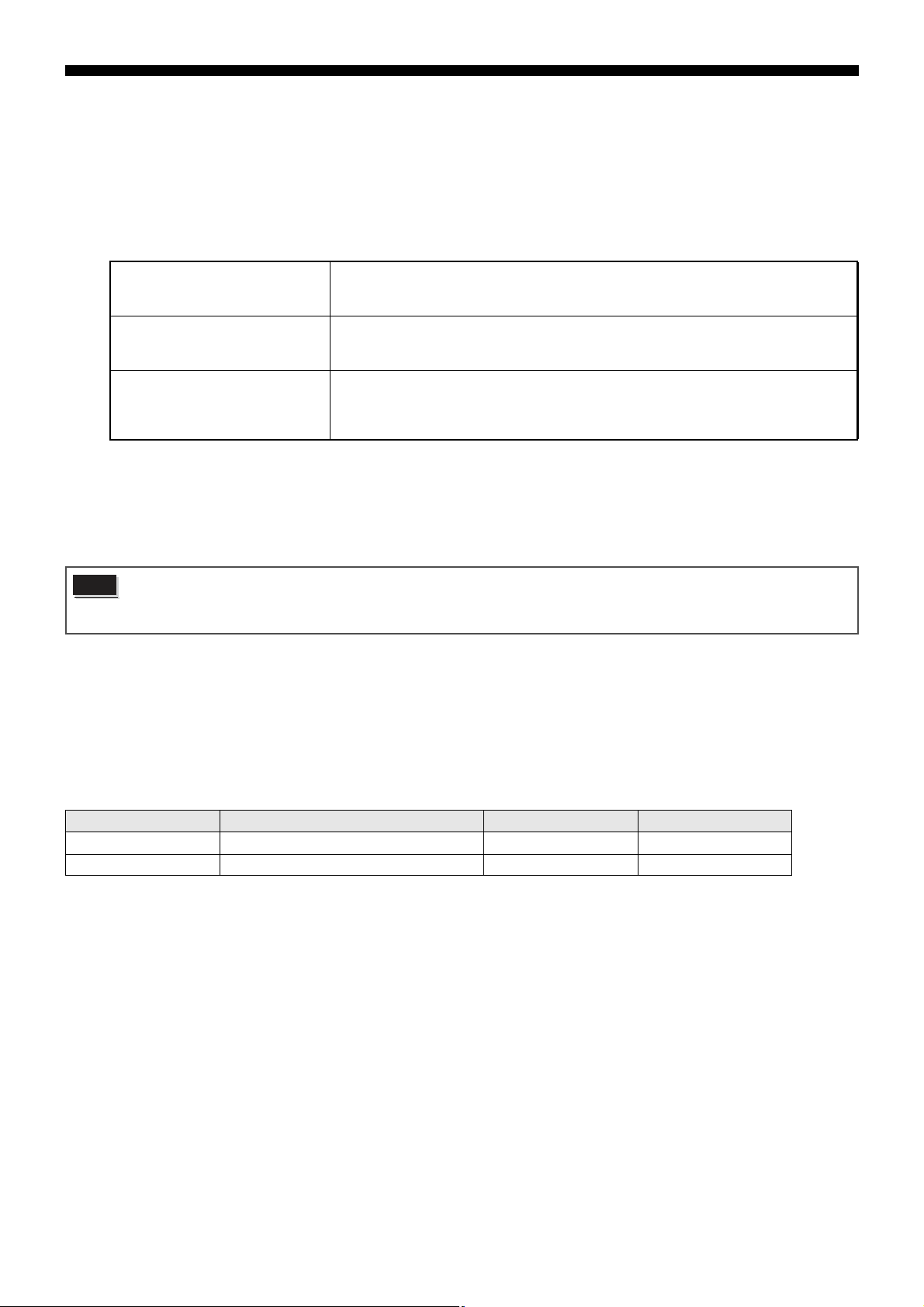

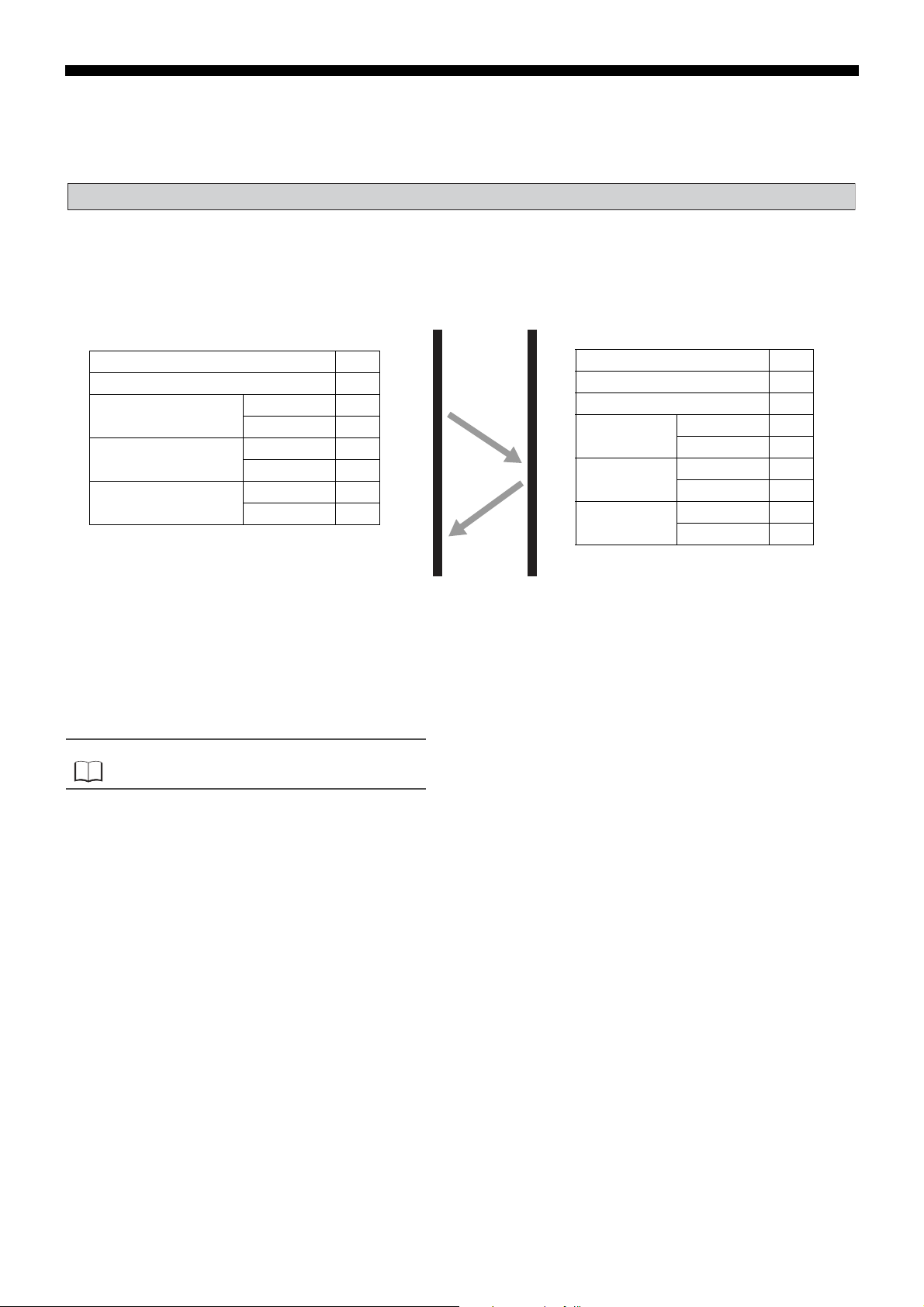

Overview

Caution

• The micro controller is equipped with communication functions fr om the RS-485 interface and PC loader interface, which

enables the transmission and reception of data between such devices as the personal computer, programmable controller,

and graphic panel.

• The version with RS-485 communication can provide the following three function s.

1. MODBUS RTU communication Typical master/stave communication is available. A PC or PLC acts as a master, while multiple

temperature controllers act as slaves. Communication is made in such a way that the master

sends messages to the slaves, and the slaves respond to it.

2. Cooperative operation When you control one temperature controller, the other controllers follow it. The one controller

3. Programless communication Programmable controller (PLC) can read the data of temperature controllers or write data on

The following is the description for MODBUS RTU communication. For cooperative operation and programless

communication, refer to Chapter 9 "Cooperative operation" and/or Chapter 10 "Programless communication".

• The communication system is composed of a master and slave relationship. Up to thirty-one slaves (micro controllers) may

be connected to one master (such as a personal computer) based on a “single master/multiple slave” method.

• However, the master can only communicate with one slave at a time. Therefore, each slave is specified by the "Station No."

setting.With PC loader communication, only one slave can be connected to one master.

Caution

• Systems constructed with the micro controller as slaves do not respond to messages issued by the master

with broadcast queries where the station number is "0".

• PC loader communication is not compatible with the multiple slave method.

acts as a master, while other controllers act as slaves. When you change the settings of the

master controller, a message will be sent to all slave controllers which follow the change.

temperature controllers without preparing a rudder program. One PLC acts as a master, and

multiple temperature controllers act as slaves. Each temperature controller in turn carries out

master-slave communication with PLC. The communication protocol is MODBUS RTU.

• In order to have proper communication between master and slave, the transmission data must be in the same format. This

document explains how to transmit data using the MODBUS protocol format.

• When using equipment with an RS-232C interface, such as a personal computer, as the master, make sure to use an RS-

232C to RS-485 converter.

• When using PC loader communication, you can use communication with the personal computer by connecting the PC loader

interface on the bottom of this unit with the PC loader communication cable (model: ZZP

TQ501923C3) sold separately.

*

RS-232C to RS-485 converter (recommended product)

Model Manufacturer URL Baud rate

KS3C-10 (isolated type) OMRON Corporation http://www.omron.co.jp Maximum 38400 bps

SI-30FA (isolated type) LINEEYE Co., Ltd. http://www.lineeye.co.jp Maximum 115.2 Kbps

– 4 –

Page 6

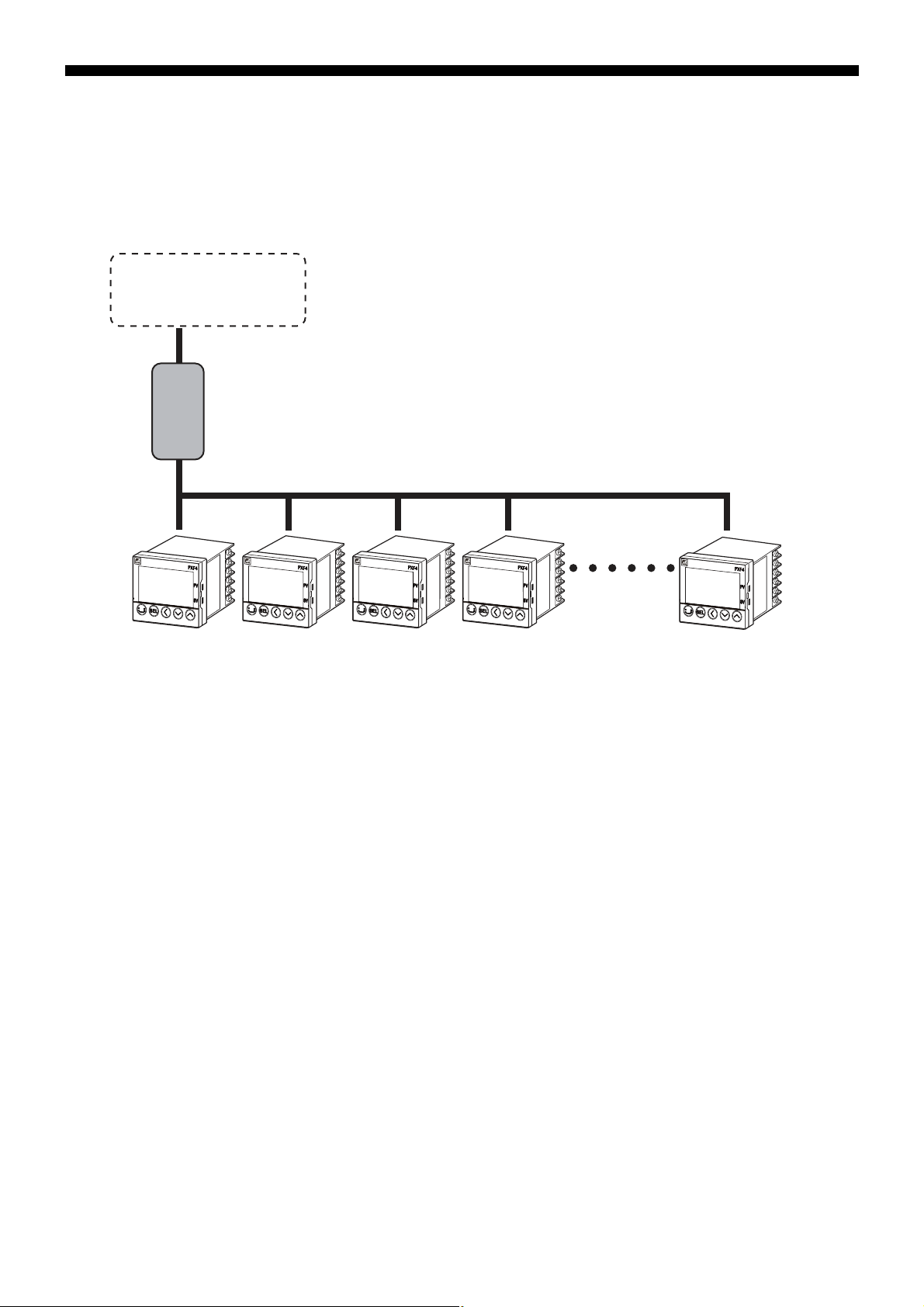

Connecting to a programmable controller

Caution

Programmable

controller

RS-485

PXF Series

Connecting to a personal computer

Personal

computer

PC loader communication cable

RS-232C

RS-232C to RS-485 converter

RS-485

PXF Series

When using the RS-232C to RS-485 converter, check to make sure that the cable is properly connected between the

converter and master. Communication will not work properly if the connection is incorrect.

Also be sure to correctly set the communication settings (such as communication speed and parity) on the RS-2 32C

to RS-485 converter. Communication will not work properly if the settings are incorrect.

– 5 –

Page 7

MEMO

– 6 –

Page 8

Chapter 2

Specifications

Communication Specifications – 8

– 7 –

Page 9

Communication Specifications

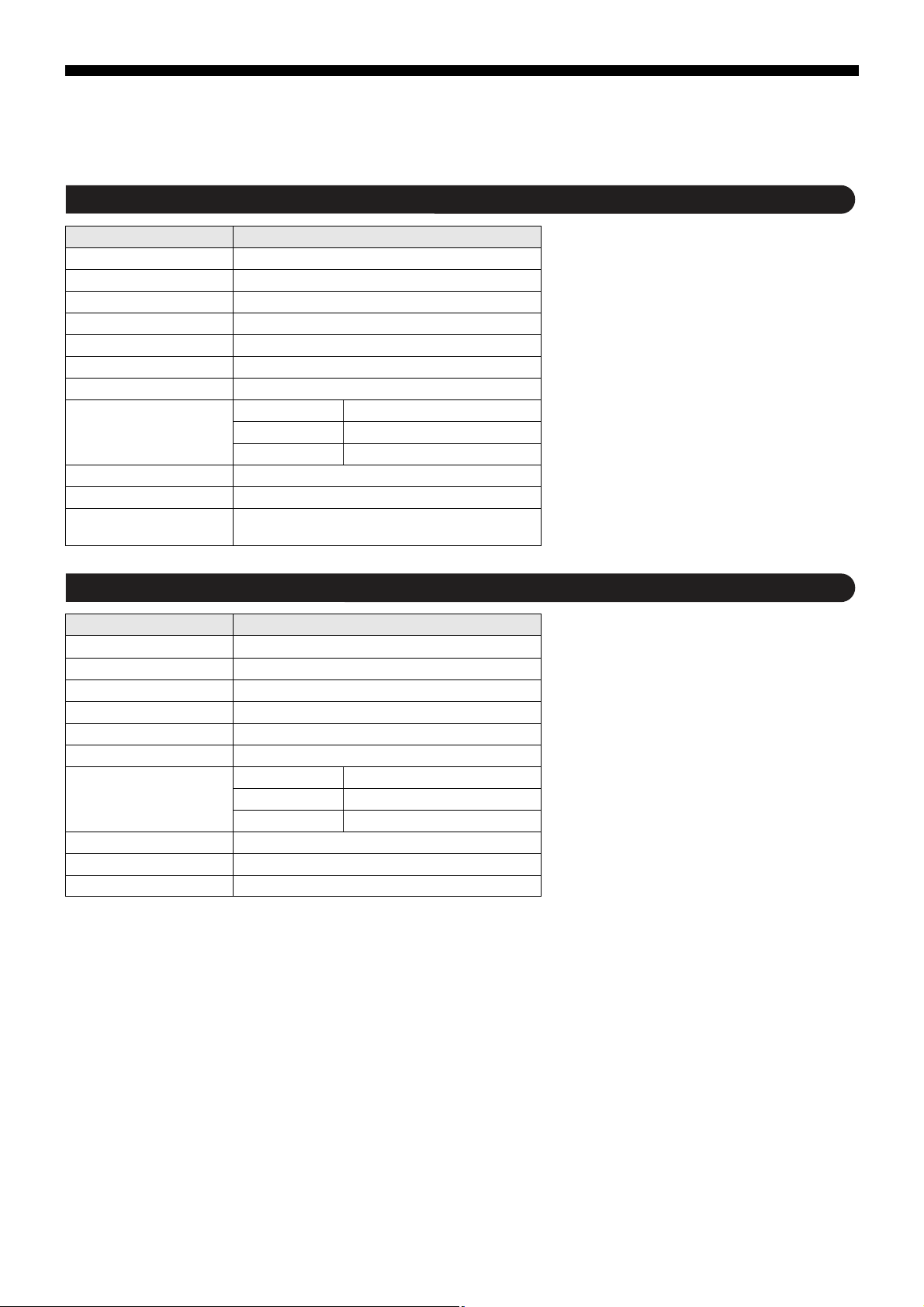

RS-485

Item Specifications

Electrical specifications EIA RS-485 compliant

Communication method Two wire system, half double-bit serial

Synchronous method Asynchronous

Connection status 1:N

Max. no. of connections 31 units

Communication distance Max 500m (total length)

Communication speed 9600bps, 19200 bps, 38.4kbps, 115.2kbps

Data format Data length 8 bits

Stop bit 1 bit

Parity None/Even/Odd (Selectable)

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Insulation Functional insulation for the transmission area and

other areas (withstanding AC 500V)

PC Loader Interface

Item Specifications

Electrical specifications TTL Level

Communication method 3wire system, half double-bit serial

Synchronous method Asynchronous

Connection status 1:1

Station No. 1 (Not to be changed)

Communication speed 38.4kbps (Not to be changed)

Data format Data length 8 bits

Stop bit 1 bit

Parity none (Not to be changed)

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Insulation Non-insulated internal circuit

– 8 –

Page 10

Chapter 3

Connection

Communication Terminal Configuration – 10

●

Wiring – 11

– 9 –

Page 11

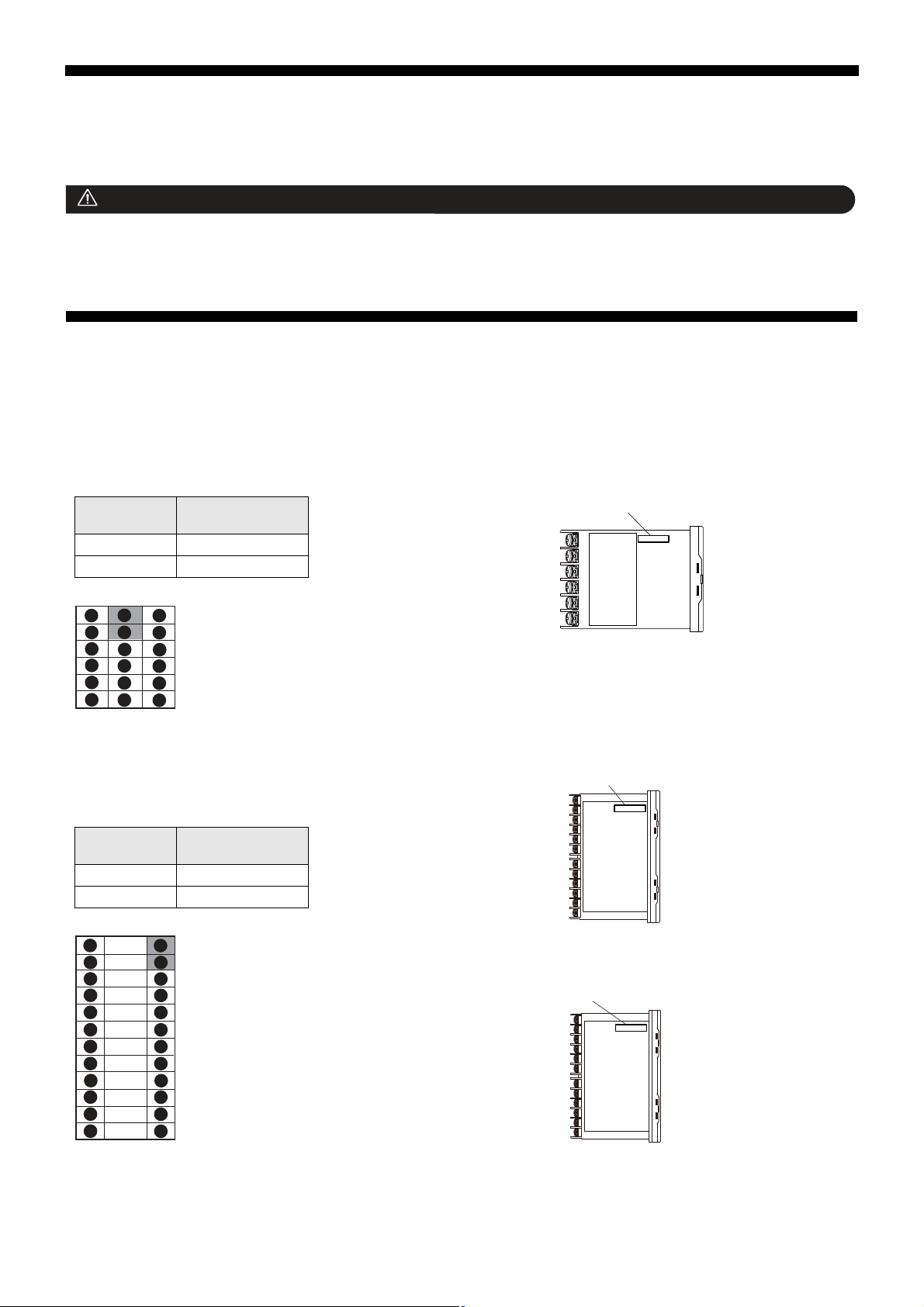

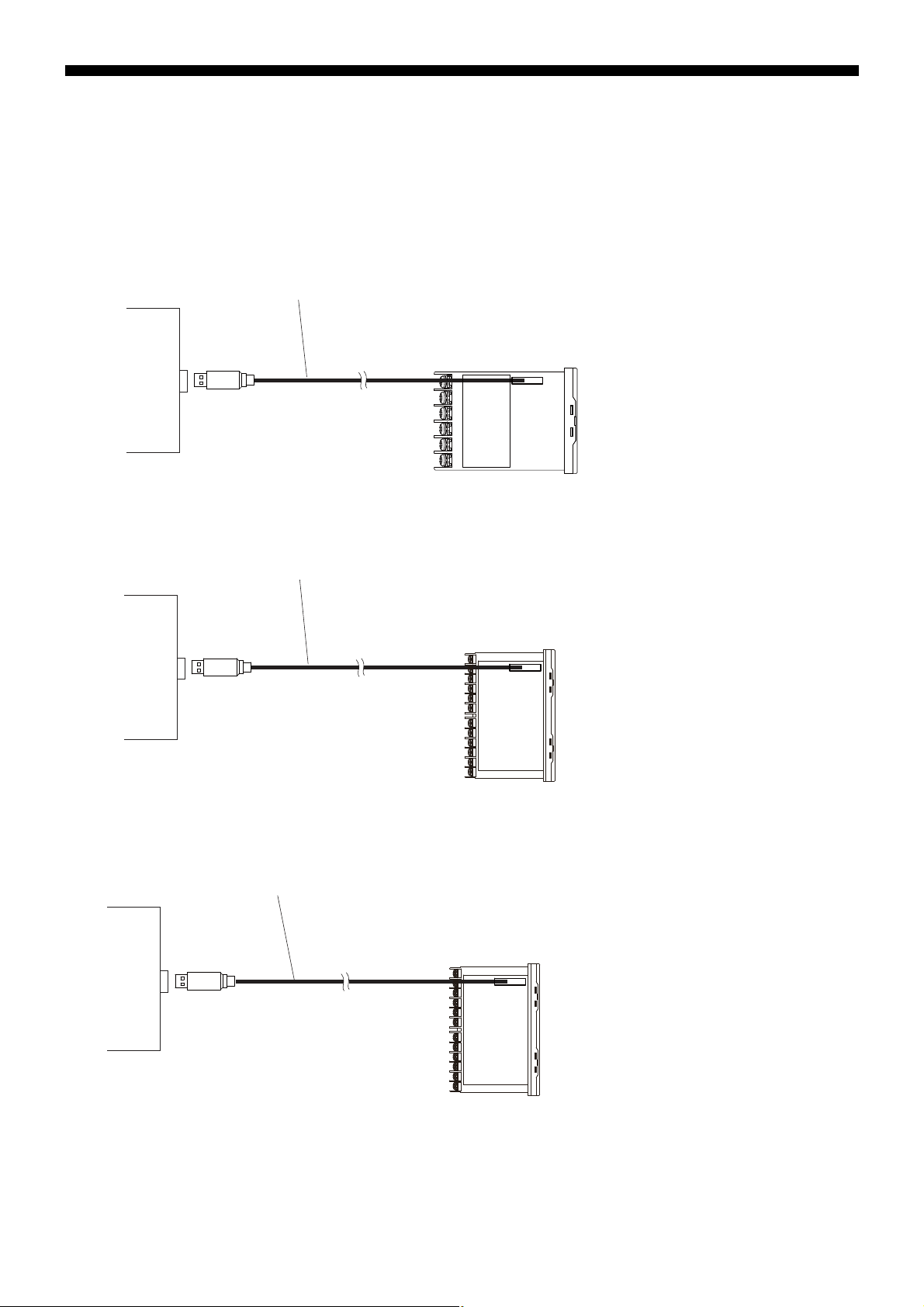

Warning

■ RS-485 (rear terminal)

PXF4

PXF5, PXF9

Terminal

Number

Signal Name

7 RS-485 +

8 RS-485 -

Terminal

Number

Signal Name

25 RS-485 +

26 RS-485 -

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

25

26

27

28

29

30

31

32

33

34

35

36

■ PC Loader Interface

PXF4

PXF5

PXF9

Do not turn on power until all of the wiring is completely finished.

There is a risk of electrical shock or damage.

Communication Terminal Configuration

PC Loader Interface

PC Loader Interface

PC Loader Interface

– 10 –

Page 12

Wiring

Master

SG

Slave

+

–

+

–

Shielded twist pair cable

Terminating resistance

100W (1/2W)

Terminating resistance

100W (1/2W)

PXF Series

PXF Series

PXF Series

RS-485 interface

or

RS-485 side of

RS-232C to RS-485 converter

+

–

+

–

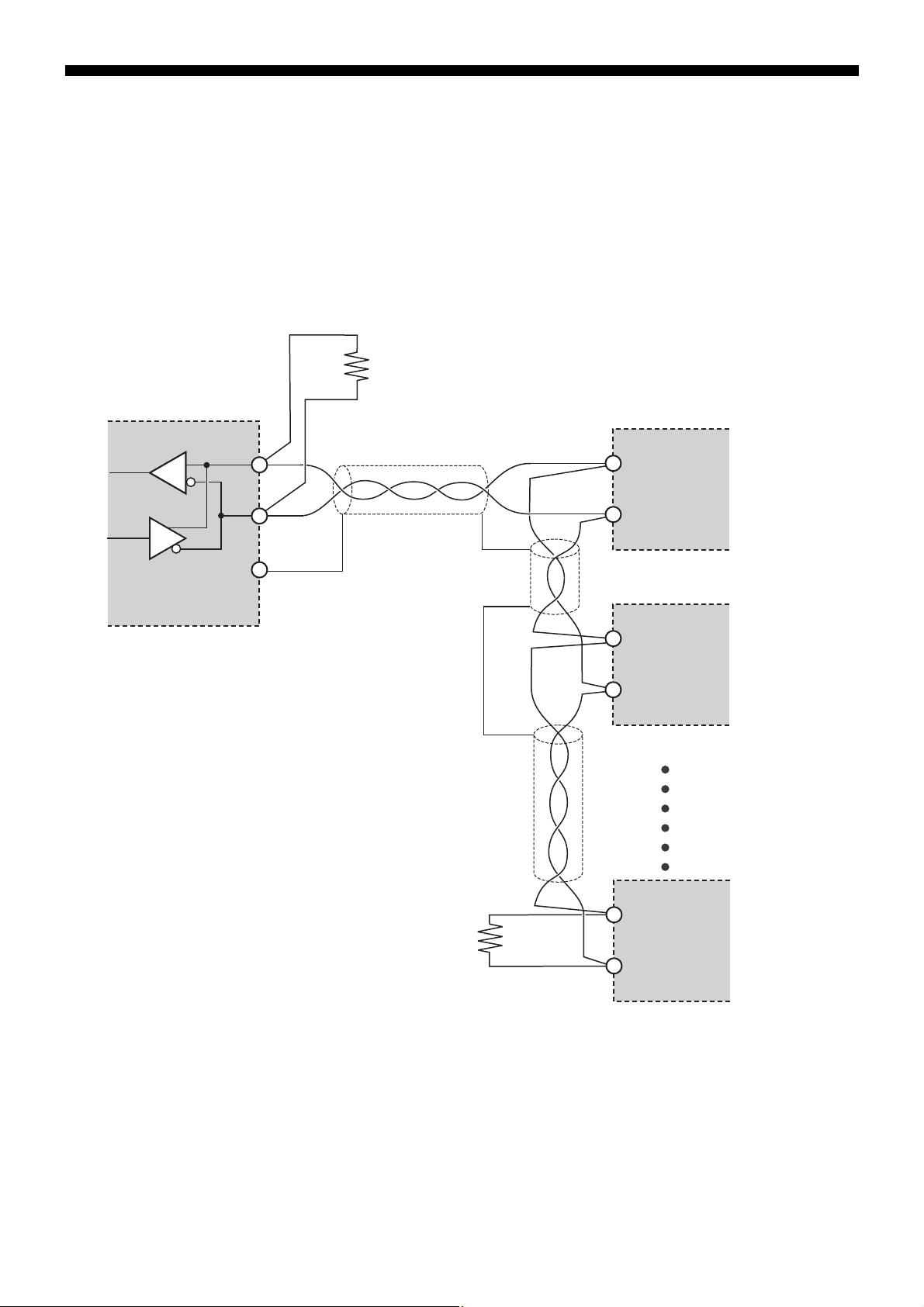

■ RS-485

• Please use a shielded twist pair cable. (Recommended cable: KPEV-SB (made by The Furukawa Electric Co., Ltd.))

• The maximum cable length should be 500m. One master and up to thirty-one micro controllers (slaves) can be connected per

circuit.

• Terminate both ends of the circuit with a terminating resistance of 100Ω (1/2W or more).

• Ground the shielded cable once towards the master side.

• SG does not have to be connected, but it can be used as an effective countermeasure against communication errors due to

noise.

– 11 –

Page 13

• When using the micro controller in an area where the imp ose d noise level is expected to exceed 1000V, we recommend using

Noise filter

Programmable controller

or

Personal computer

+ RS-232C to RS-485 converter

RS-485

PXF Series

a noise filter on the master side as seen in the figure b el ow.

[Noise filter] (recommended): ZRAC220 3-1 1 (ma de by TDK Corporation)

• If there are problems with EMC during communication, the noise l evel can be reduced by using a communication cable with a

ferrite core.

Ferrite core (recommended): ZCAT series (made by TDK Corporation)

MSFC series (made by Morimiya Electric Co., Ltd.)

– 12 –

Page 14

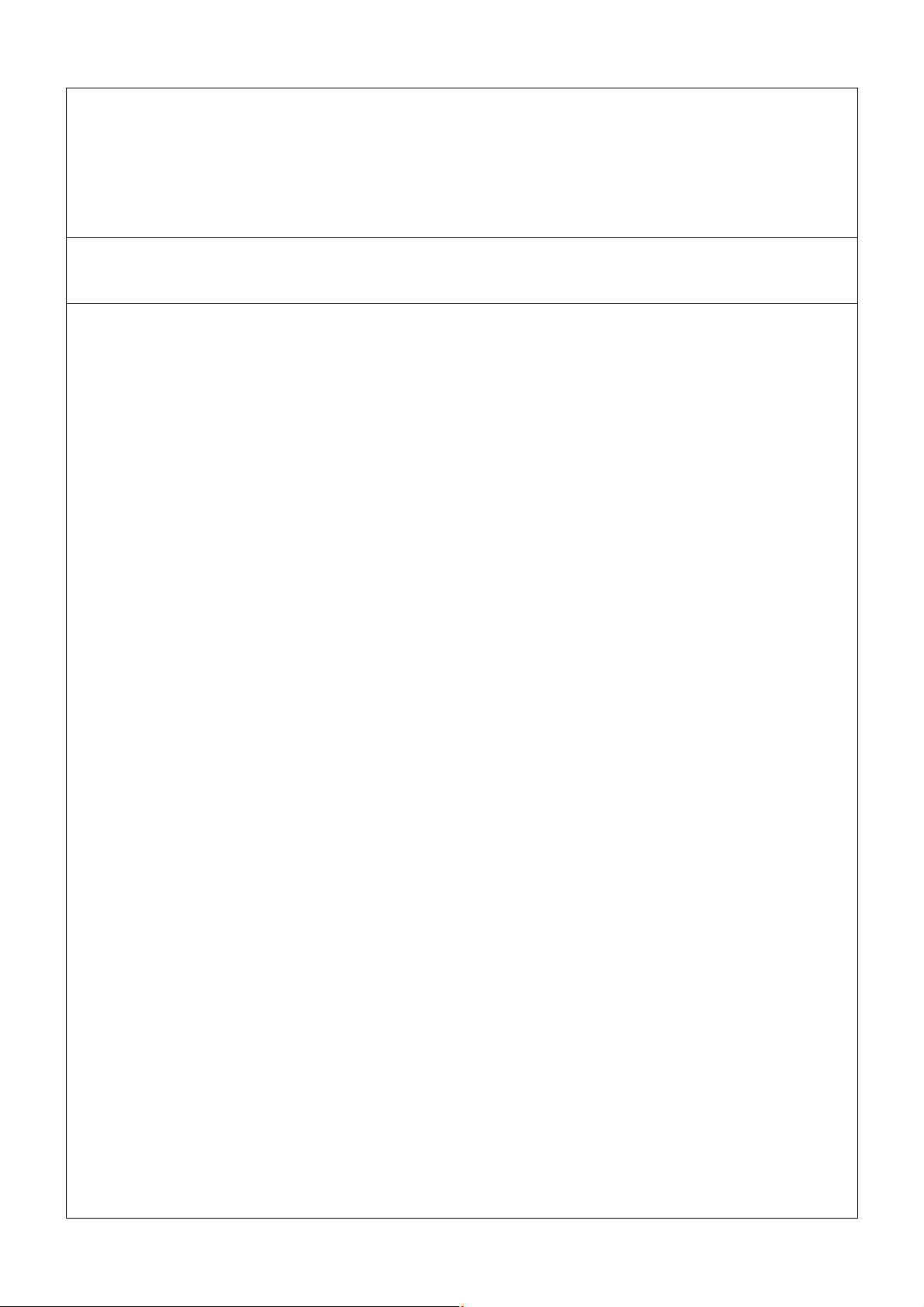

■ PC Loader Interface

PC loader communication cable

Master side

USB

PXF4 Left view

Personal

computer

etc.

ZZP

*

TQ501923C3

Master side

PXF5 Left view

Personal

computer

etc.

PC loader communication cable

ZZP

*

TQ501923C3

USB

• Use the PC loader communication cable sold separately.

PXF4

PXF5

PXF9

Master side

Personal

computer

etc.

USB

PC loader communication cable

TQ501923C3

ZZP

*

PXF9 Left view

– 13 –

Page 15

MEMO

– 14 –

Page 16

Chapter 4

Setting Communication Parameters

List of Setting Parameters – 16

●

Parameter Setting Procedure – 17

– 15 –

Page 17

The following settings are required for proper communication between the master and micro controller units.

• The communication parameters for the master and all of the units must be set the same.

• During RS-485 communication, all of the micro controllers on a circuit must b e set with different "Station No. (STno)" other

than "0 (zero)". (Multiple micro controllers must not have the same "Station No.".)

• When using the PC loader interface, settings are not necessary on the main unit (the micro controller).

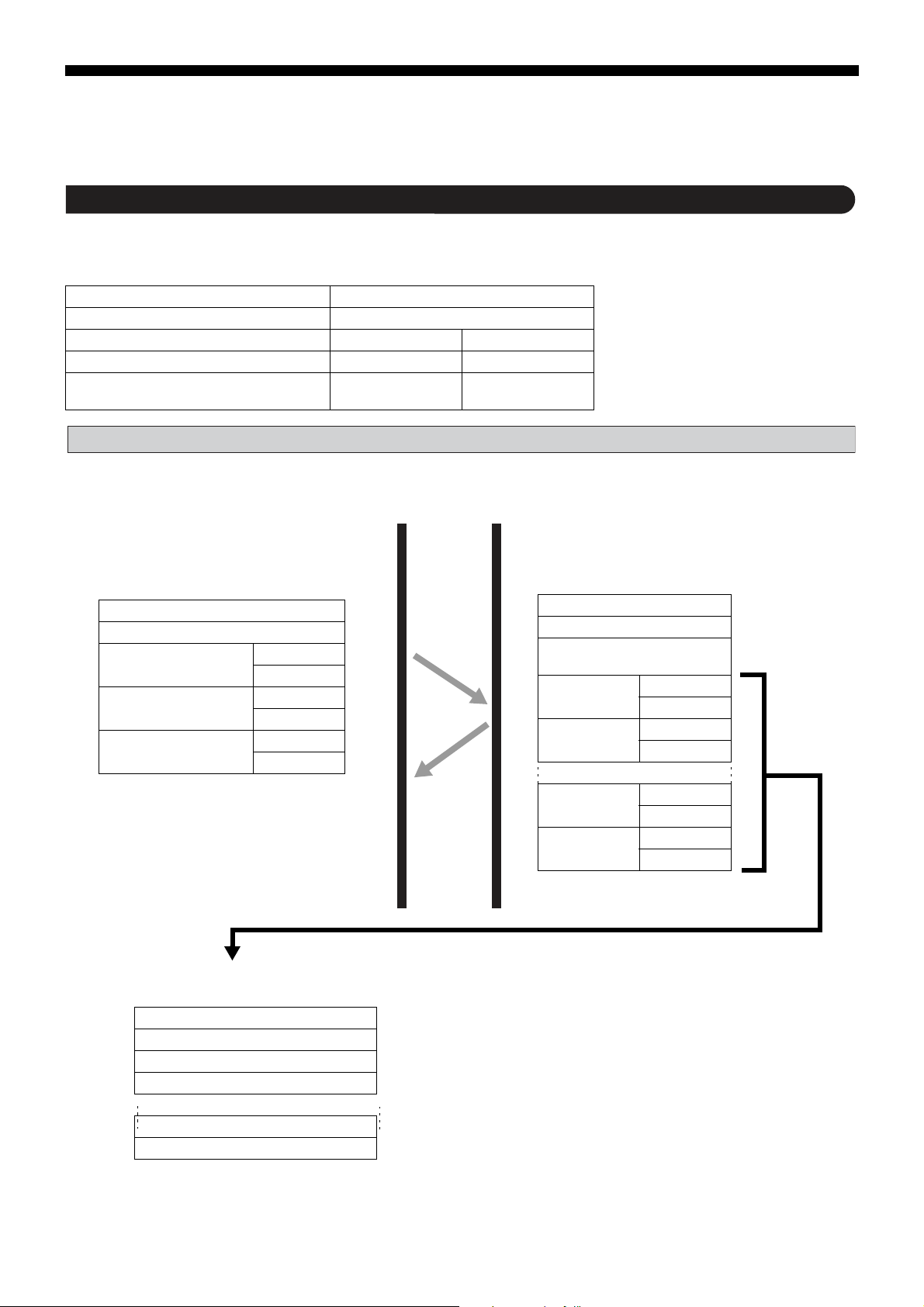

List of Setting Parameters

The setting parameters are shown in the chart shown below. Change the settings using the keys on the front of the micro

controller.

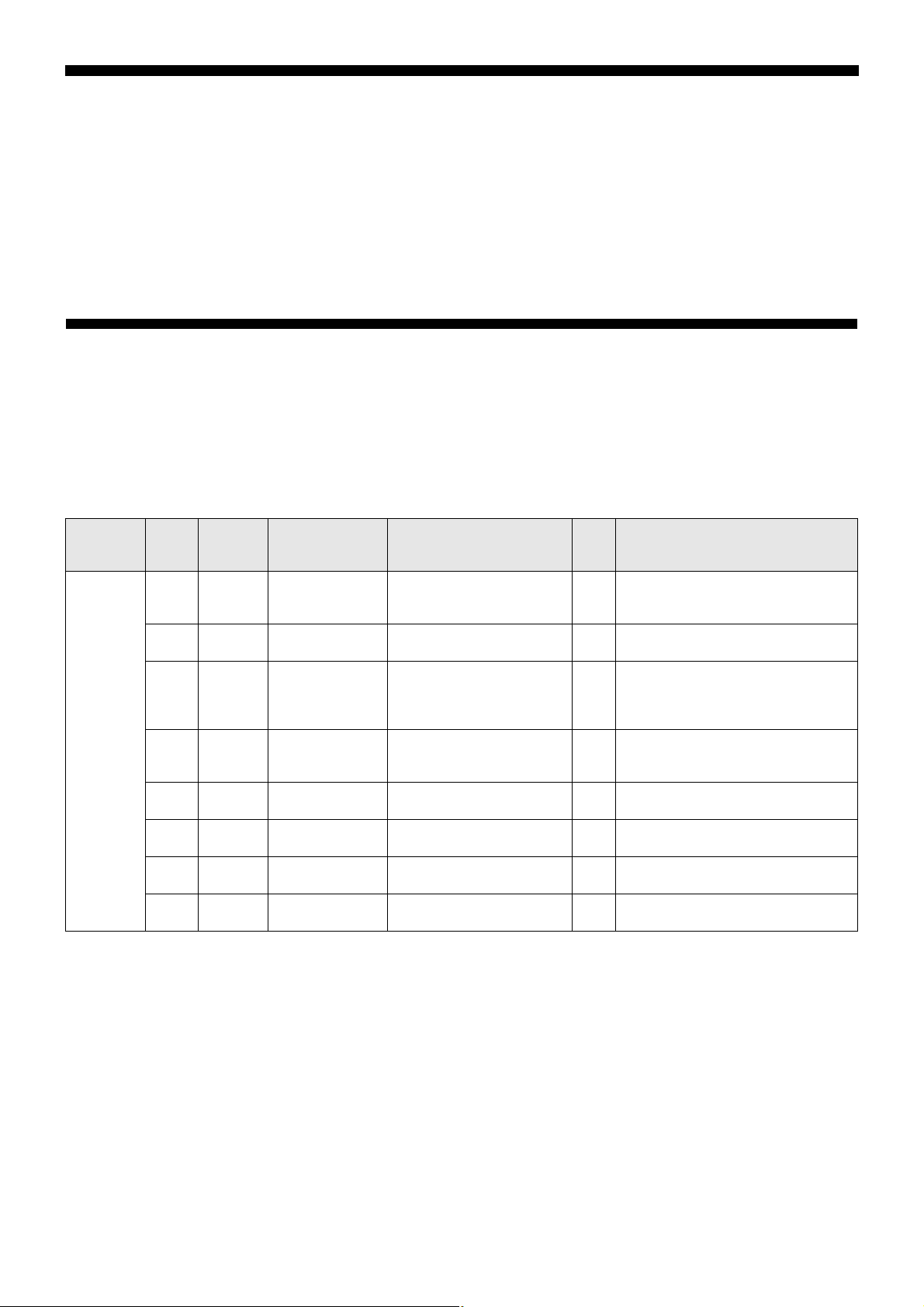

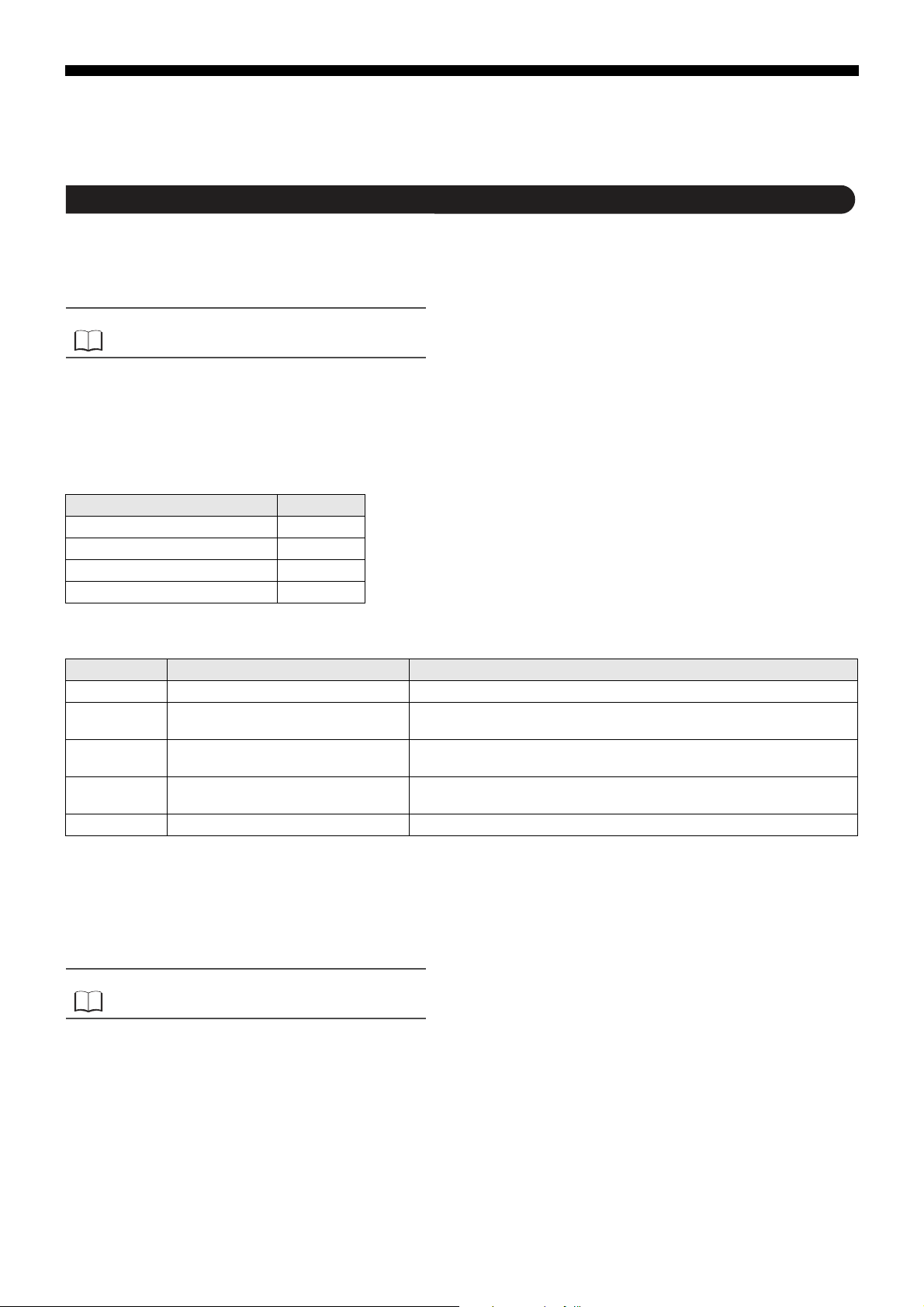

■ RS-485 (controller side)

Parameter

channel

CoM CH9

Screen

Parameter

No.

760

761

762

763

764

767

display

symbol

CTYP Communication

StNo Station No. 0 to 255 (0: unresponsive

SPEd RS-485 baud rate 96: 9600 bps

PRty RS-485 parity none

iNtV RS-485 response

SCC Communication

–

–

– Data length Fixed (cannot be changed) 8 bits Set the master and all of the slaves with

– Stop bit Fixed (cannot be changed) 1 bits Set the master and all of the slaves with

Name Setting range

0: MODBUS RTU

type

interval

permissions

1: Cooperative operation

2: Programless communication

communication)

192: 19200 bps

384: 38400 bps

115K: 115 Kbps

odd

even

0 to 100 1 Widen the time interval of receiving

r: read only

rW: read/writable

Initial

value

0 Select "0: MODBUS RTU".

1 Sets the station number.

96 Sets the baud rate

odd Sets the parity check

response. (Set value x 20 ms)

rW Sets whether or not overwriting is

possible from the master side (PC, etc.)

the same settings.

the same settings.

Remarks

■ Loader interface (main unit side)

The parameters do not need to be set. Set the loader software (master) with the following settings.

• Communication speed: 38400 bps

• Parity: none

– 16 –

Page 18

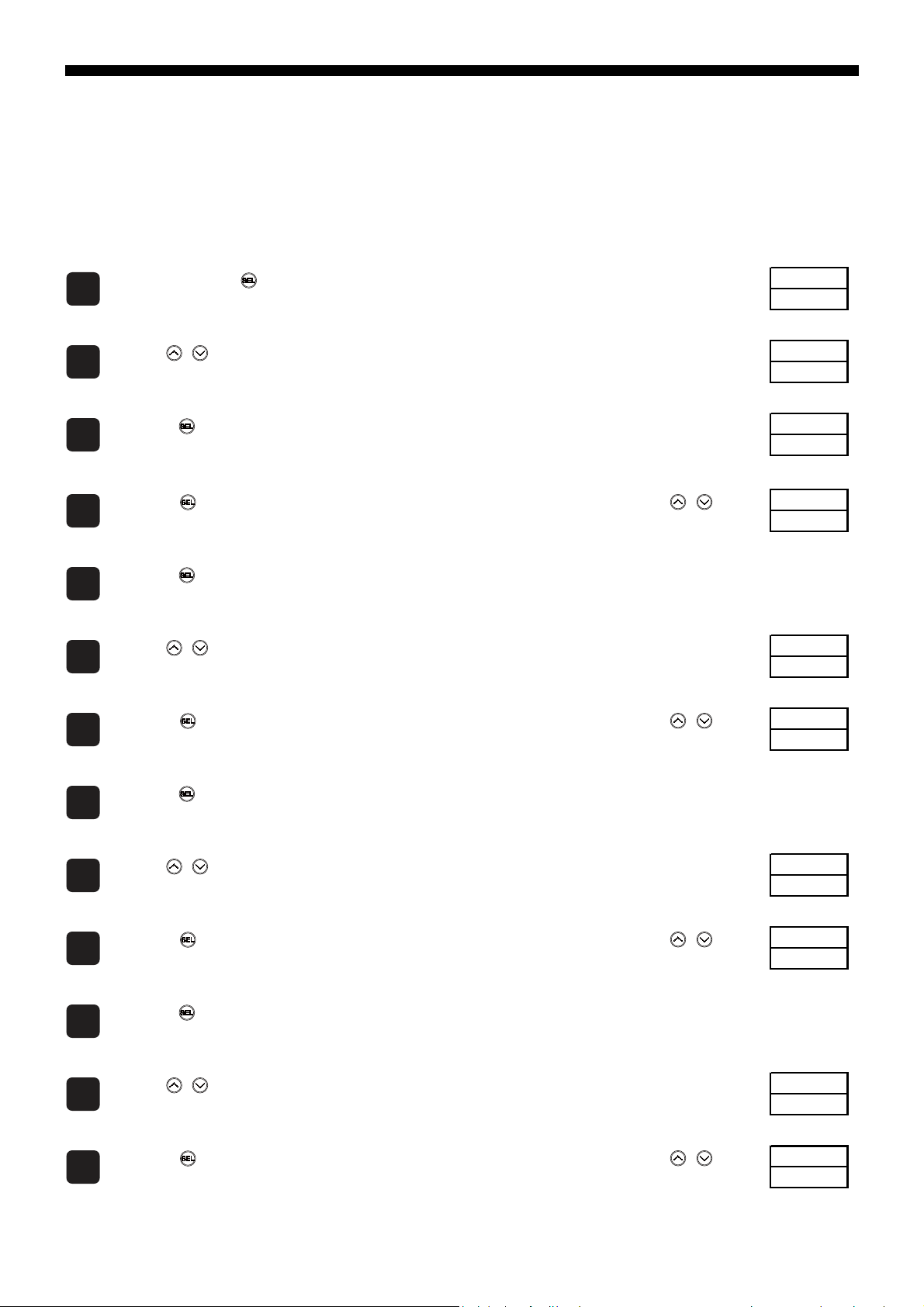

Parameter Setting Procedure

Pid

1

CoM

2

0

3

"3"

4

5

96

6

"96"

7

8

odd

9

"NoNE"

10

11

R

12

"WR"

13

The following steps explain how to change the settings to station number "3", parity setting "9600bps/none", and communication

permissions "read and writable" as an example.

Press and hold the key to move to "channel selection mode".

Use the keys to select "CoM CH9".

Press the key to display "StNo".

Press the key, and whe n the bottom part of the display begins to blink, use the

keys to select "3".

The station number "3" is selected.

Press the key to set.

Use the keys to select "SPEd".

Press the key, and whe n the bottom part of the display begins to blink, use the

keys to select "96".

The RS-485 baud rate is set to "9600 bps".

CH 1

CH 9

StNo

StNo

SPEd

SPEd

Press the key to set.

Use the keys to select "PRty".

Press the key, and whe n the bottom part of the display begins to blink, use the

keys to select "NoNE".

The RS-485 parity is set to "none".

Press the key to set.

Use the keys keys to select SCC ("SCC").

Press the key, and whe n the bottom part of the display begins to blink, use the

keys to select "WR".

Communication permissions is set to "read/writable".

PRty

PRty

SCC

SCC

– 17 –

Page 19

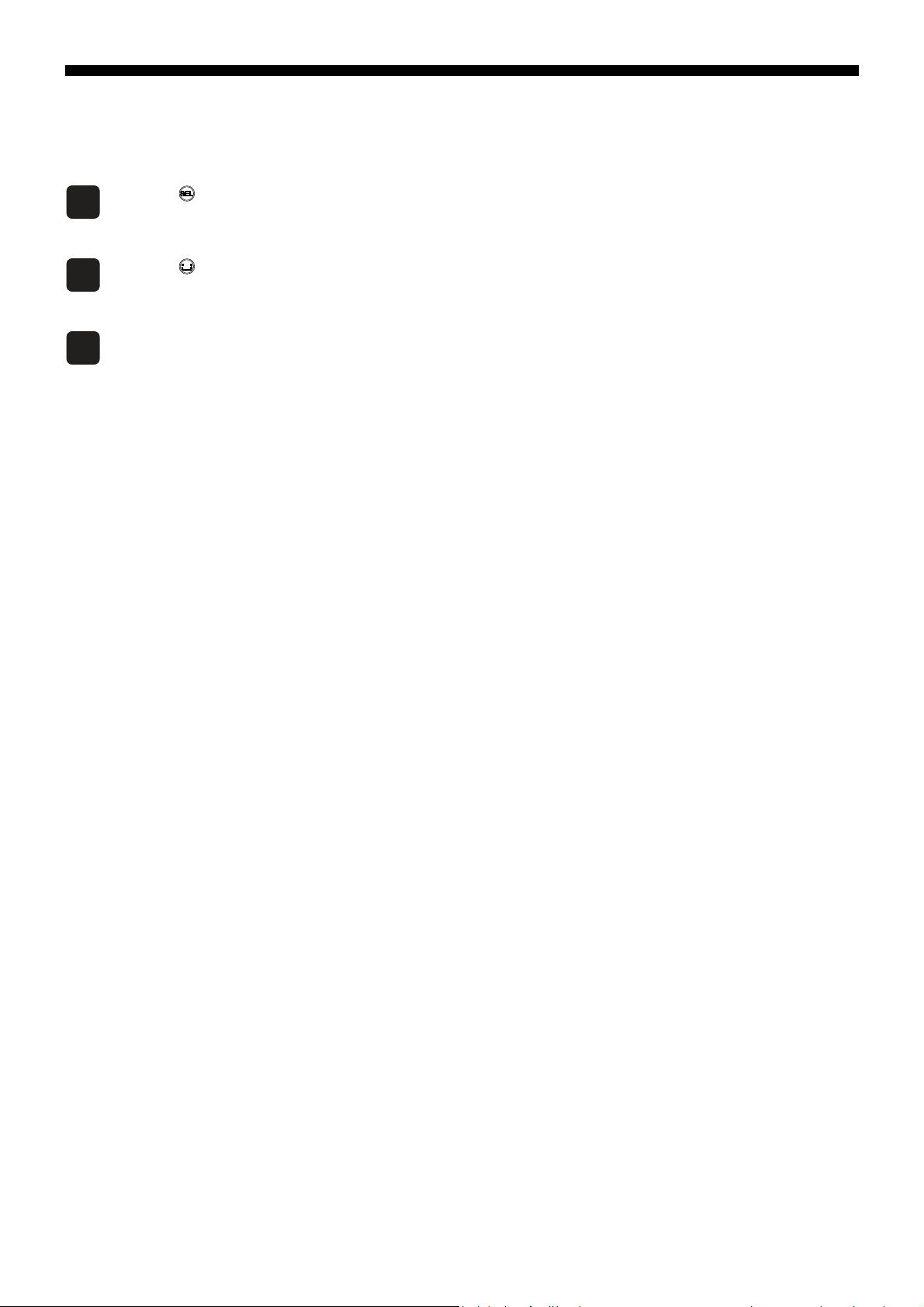

Press the key to set.

14

15

16

Press the key to return to the operation mode PV/SV screen.

Turn the power to the micro controller off and on a g ain.

The changes to the communication parameters become effective after the power turns off and on

again.

– 18 –

Page 20

Chapter 5

MODBUS Communication Protocol

Overview – 20

●

Message Composition – 21

●

Calculating Error Check Code (CRC-16) – 24

●

Transmission Control Steps – 25

●

Prercautions when Writing Data – 26

– 19 –

Page 21

Overview

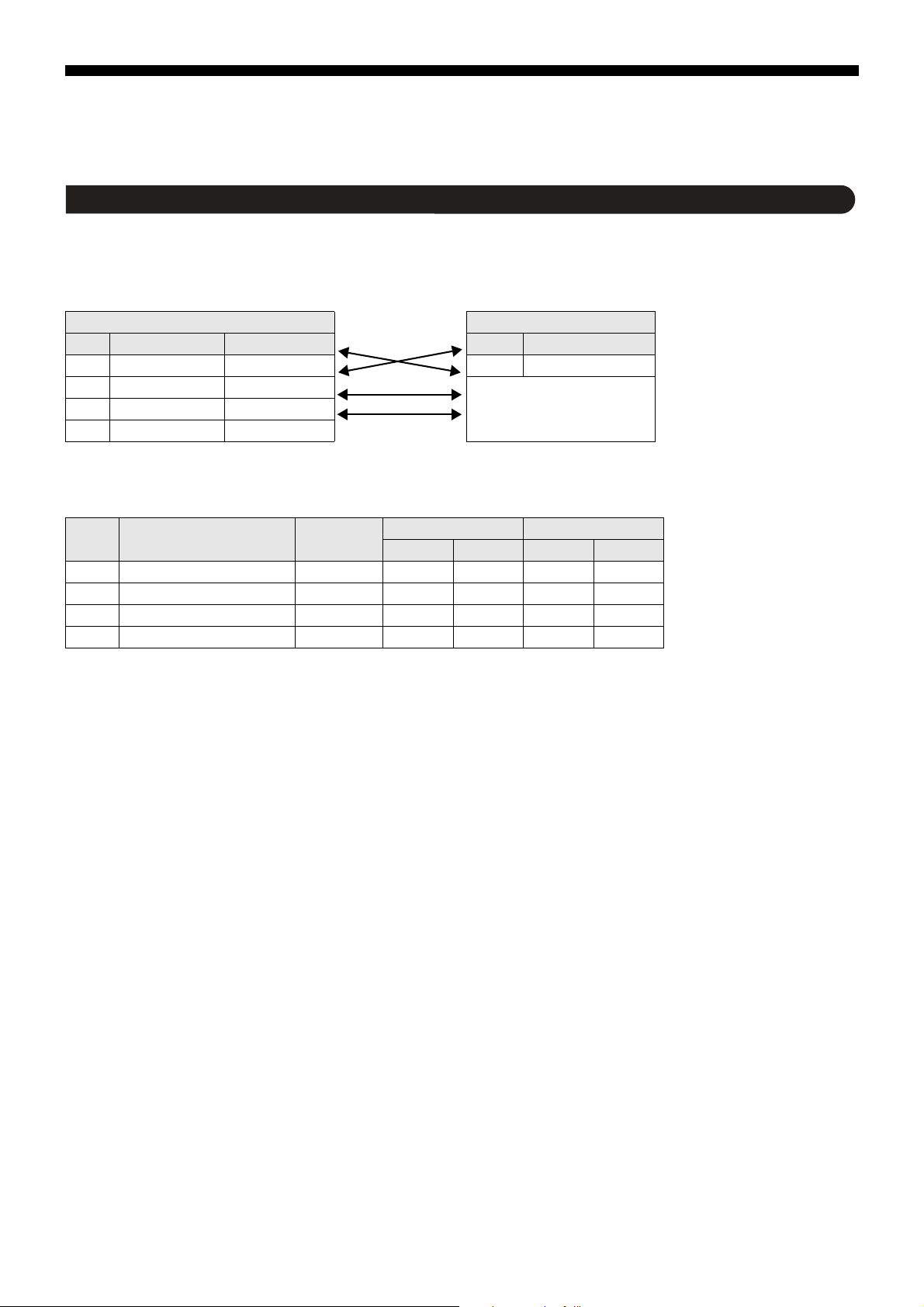

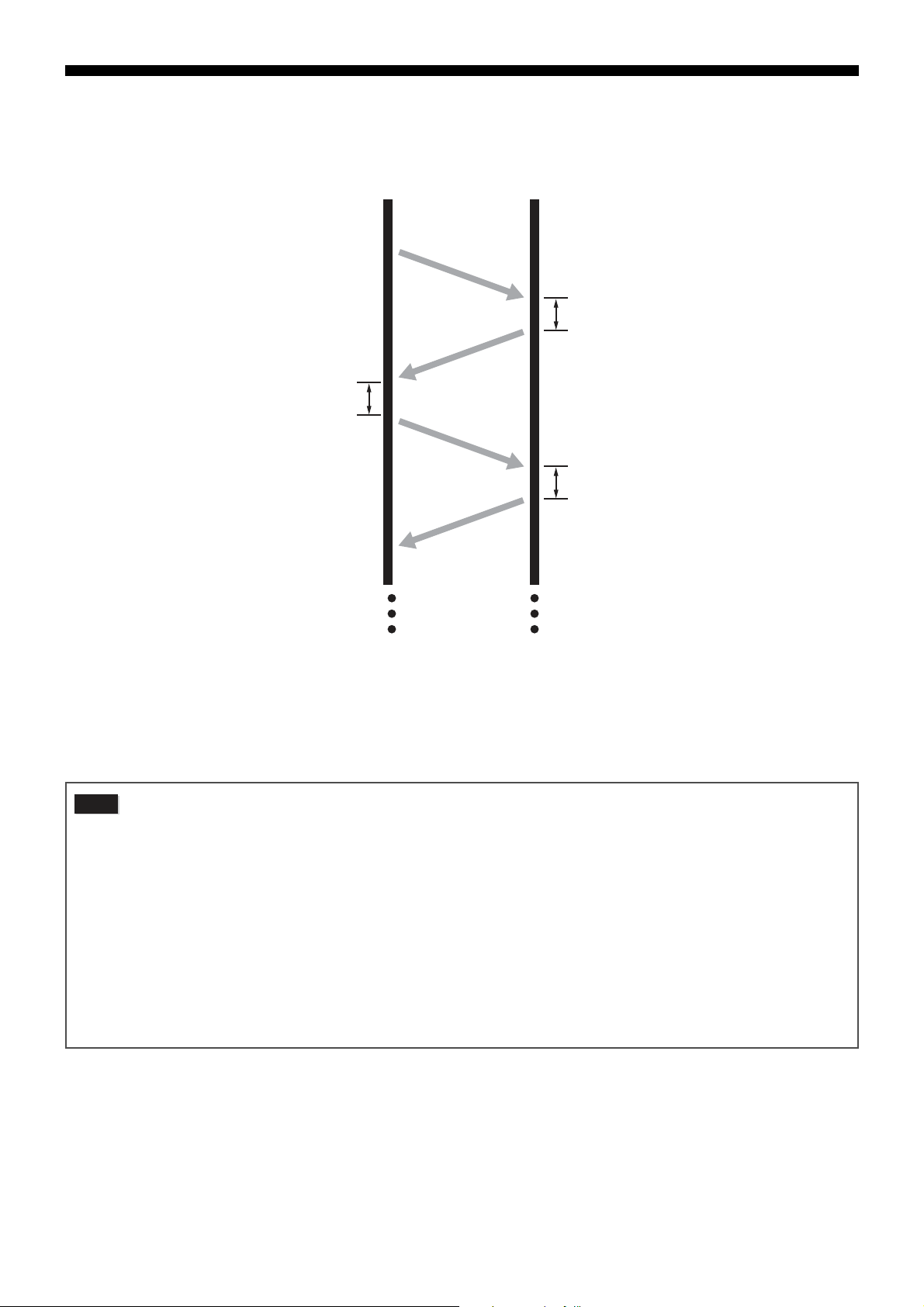

Master Slave

Command Message

Response Message

Station number is the same

The communication system with the MODBUS protocol always operates using a method where the master first sends a command

message and the applicable slav e re plys with a respo nse message .

The following describes the communication steps.

Master sends the command

message for the slave.

The slave checks whether the station

number in the received message is

the same as its own station number.

When it’s the same When it’s not the same

The slave runs the command and

sends a response message.

The slave throws out the received

message and waits for the next

command message. (No reply.)

● When the station number in the command message is the same as the unit’s station number

● When the station number in the command message is not the same as the unit’s station number

Master Slave

The master can communicate with an individual slave when multiple slaves are connected on the same circuit by the station

number specified in the master’s command message.

Command Message

Station number is not the same

– 20 –

Page 22

Message Composition

Refer to

Refer to

Refer to

Refer to

The command message and response message are composed of four parts: the station number, function code, data part, and

error check code. These four parts are sent in that order.

Field name No. of bytes

Station No. 1 byte

Function Code 1 byte

Data Part 2 to 125 bytes

Error Check Code (CRC-16) 2 bytes

The following describes each part of the message.

Station No.

This is the number specifying the slave. Commands can only be processed by slaves that have the same value set in the "STno"

parameter.

For more about setting the "STno" parameter, see "Chapter 4,

Setting Communication Parameters" (p. 15).

Function Code

This code specifies the function for the slave to perform.

For more about function codes, see "Function Code" (p. 23).

Data Part

This data is required to run the function code. The composition of the data part is different depending on the function code.

See "Chapter 6, Command and Transmission Frame Details"

(p. 27).

The data in the micro controller is assigned a coil number or resistor number. This coil number or resistor number is specified

when the data is read or written through communication.

The coil number or resistor number used by the message employs a relative address.

The relative address is calculated using the following formula.

Relative address = (last four digits of the coil number or resistor number) – 1

(Ex.) When a function code specifies resistor number "40003"

Relative address = (the last four digits of 40003) – 1

= 0002

is used in the message.

Error Check Code

This code detects whether there are errors (changes in the bits) dur ing the signal transmission processes. MODBUS protocol

(RTU mode) uses CRC-16 (Cyclic Redundancy Check).

For more about calculating CRC, see Section 5,

"Calculating Error Check Code (CRC-16)" (p. 24).

– 21 –

Page 23

Slave Response

Refer to

Refer to

■ Normal Slave Response

The slave creates and replies with a response message for each command message. The response message has the same

format as the command message.

The contents of the data part are different depending on the function code.

See "Chapter 6, Command and Transmission Frame Details".

■ Irregular Slave Response

If there are problems (such as specification of a nonexistent function code) with the contents of the command message other than

transmission error, the slave creates and replies with an error response message without following the command.

The composition of the error response message uses the value of the function code in the command message plus 80

below.

Field name No. of bytes

Station No. 1 byte

Function Code +80

H 1 byte

Error Code 1 byte

Error Check Code (CRC-16) 2 bytes

The error code is shown as follows.

Error Code Contents Explanation

H Faulty function code A nonexistent function code was specified. Please check the function code.

01

H Faulty address for coil or resistor The specified relative address for the coil number or resistor number cannot be

02

used by the specified function code.

03

H Faulty coil or resistor number The specified number is too large and specifies a range that does not contain

04

H Write inhibited Data writing via communication is prohibited. “SCC” parameter is set to “R: read

06

H Busy EEPROM is busy in writing. Wait for a few seconds, and then retry writing.

coil numbers or resistor numbers.

only”.

H, as seen

■ No Response

In the following situations, the slave will ignore the command message and not send a response message.

• The station number specified by the command message is not the same as the slave’s specified station number.

• The error check code does not correspond, or a transmission error (such as parity error) is detected.

• The interval between the data comprising the message is empty for more than 24 bit time.

See Section 5 "Transmission Control Steps" (p. 25).

• The slave station number is set to "0".

– 22 –

Page 24

Function Code

For MODBUS protocol, coil numbers or resistor numbers are assigned by the function code, and each function code

only works for the assigned coil number or resistor number.

The correspondence between the function code and the coil number or resistor number is as follows.

Function Code Coil Number, Resistor Number

Code Function Target Number Contents

H Read (continuous) Hold resistor 3xxxx Read word data

03

04

H Read (continuous) Input resistor

H Write Hold resistor

06

H Write (continuous) Retention resistor

10

The message length for each function is as follows.

Code Contents

H Read word data 60 words

03

H Read word data (read-only) 60 words

04

06

H Write word data 1 word 8888

H Continuously write word data 60 words

10

Assignable

Data Number

*1

*1

*1

Command Message Response Message

Minimum Maximum Minimum Maximum

4xxxx

Read/write word data

[unit: byte]

887125

887125

11 129 8 8

*1: "Assignable Data Number" above is limited by the data number that the micro controller assigned to the coil number or

address number.

(Excluding function code 06

H).

– 23 –

Page 25

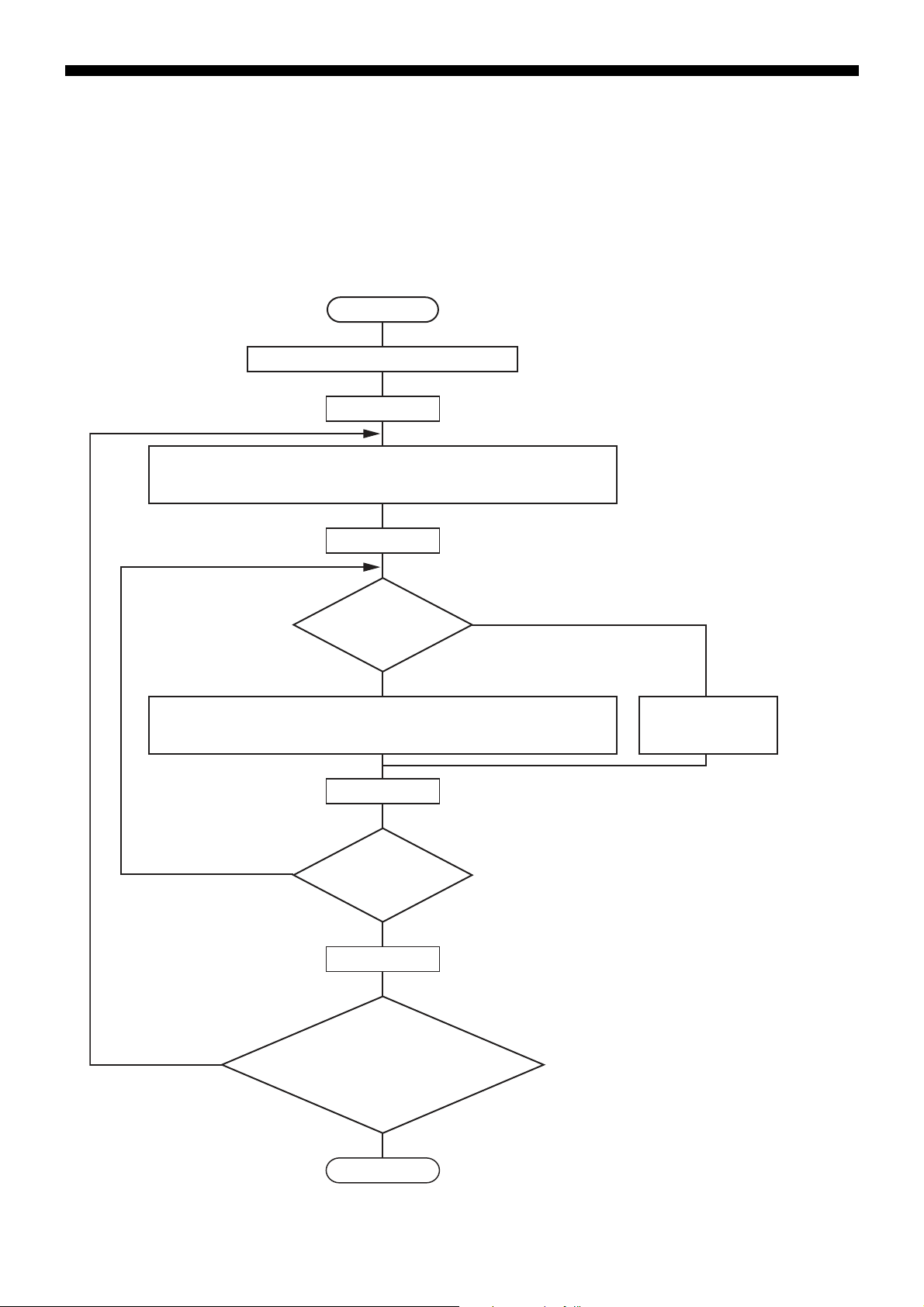

Calculating Error Check Code (CRC-16)

YES

YES

NO

NO

YES

* Description of Variables

CR : CRC error check data (2 byte)

J : Command message calculation

character digit

K : No. of times to check CR calculation

Start

Set J = 1

Set K = 1

Add 1 to K

Complete

Add 1 to J

Set CR to FFFF

H (hexadecimal)

Exclusive-or (XOR) runs on each character of J (one byte) for CR

and the specified message, and sets that result to CR.

After CR has been adjusted one bit to the right, A001

H and XOR

run and set that result to CR.

Is the right-hand

bit for CR 1?

NO

Adjust CR one bit

to the right.

Has calculation

finished 8 times ?

J > 8

Has every character

been calculated ?

J > Number of characters

(Calculations occur in the order

command message station number,

function code, and data.)

The CR calculation result is added

onto the end of the command

message in LOW or HIGH order.

CRC-16 is a 2-byte (16-bit) error check code. The calculation range extends from the start of the message (station number) to the

end of the data part.

The slave calculates the CRC of the received message and ignores the message if this value is not the same as the received

CRC code.

CRC-16 is calculated as follows.

– 24 –

Page 26

Transmission Control Steps

Caution

Master Communication Method

Start communication from the master while following the rules below.

1. The command message, must be sent after an empty space of at least 48 bit time.

2. The interval between each byte in a command message should be less than 24 bit time.

3. After sending a command message, for less than 24 bit time the master will enter receiving standby.

4. After receiving the response message, the next command message must be sent after at least 48 bit time. (Similar to #1.)

5. For safety reasons, create a framework where the master checks the response message, and if there is no response or an

error occurs, retry at least three times.

The definitions written above are for the minimum required value. For safety reasons, we recommend creating a

master side program that keeps margins two to three times as large. For a concrete example, with 9600 bps, we

recommend programming a blank state (#1 above) of at least 10ms, and the interval between bytes (#2 above) and

switching time from sending to receiving (#3 above) within 1 ms.

Explanation

■ Frame Detection

This communication system uses a two-wire RS-485 interface, and the circuit can therefore enter one of the following two states.

• Empty state (no data on the circuit)

• Communication state (data running on the circuit)

The units connected on the circuit start in receiving state and monitor the circuit. When a blank state appears on the circuit f or at least

24 bit time, the unit detects the end of the previous frame, and within the next 24 bit time, enters receiving standby. When data

appears on the circuit, the unit begins receiving data, and once another blank state of at least 24 bit time is detected, that frame is

ended. In other words, the data on the circuit from the first time that a 24 bit time blank state appears to the second time one appears

is loaded as one frame (a bundle of data). Therefore, one frame (command message) must be sent while following the rules below.

• Before sending the command message, leave an empty space of at least 48 bit time.

• The interval between each byte in a command message should be less than 24 bit time.

■ Micro controller Response

After the micro controller detects the frame (detects blank states at least 24 bit time long), that frame is used to send a command

message. When a command message is sent locally, the response message is returned, but the processing time is about 1 to 30

ms. (The time may change depending on the contents of the command message. ) Therefore, one frame (command message)

must be sent while following the rules below.

– 25 –

Page 27

• After sending a command message, for less than 24 seconds the master will enter receiving standby.

Caution

Master

POL1

POL1 response data

POL2 response data

Slave

POL2

1 to 30ms

1 to 30ms

Interval of at least 10ms required

(at least 20ms recommended)

Prercautions when Writing Data

PXF contains internal nonvolatile memory (EEPROM) that is used to save the setting parameters. The data written to the

nonvolatile memory (EEPROM) remains even after the power for PXF is turned off. Parameters that are written via

communication are automatically saved in the internal nonvolatile memory (EEPROM). However, please note that there are two

limitations as follows.

1. There is a limit to the number of times that data can be transferred to the nonvolatile memory (EEPROM)

(100,000 times). Data cannot be guaranteed if written more than 100,000 times.

Be careful not to transfer unnecessary data when writing data via communication.

In particular, when constructing a communication system with master POD (such as a touch panel), make sure

that the POD writing and trigger settings are appropriate.

Avoid writing at fixed cycles.

2. Writing to the nonvolatile memory (EEPROM) takes seve ral milliseconds . If the pow er f or PXF is turned off during

this operation, the data saved to the nonvolatile memory (EEPROM) may be corrupted.

Wait several seconds after writing data before turning off the power.

In particular, when writing data in a cycle from master device, there is a greater danger of the writing timing and

power shutoff timing coinciding.

Avoid writing at fixed cycles.

– 26 –

Page 28

Chapter 6

Command and Transmission Frame

Details

Reading Data – 28

●

Writing Data – 32

– 27 –

Page 29

Reading Data

Master Slave

Command Message Composition

(bytes)

Station No.

Function Code

No. to Start Reading

(Relative Address)

Upper

Lower

No. of Words to Read

(1 to 60 words)

Upper

Lower

CRC Data

Upper

Lower

Reply Message Composition (bytes)

Station No.

Function Code

No. of Bytes to Read

(No. of Words to Read x 2)

First Word Data

Contents

Upper

Lower

Next W ord Da ta

Contents

Upper

Lower

Last Word D a t a

Contents

Upper

Lower

CRC Data

Upper

Lower

■ Meaning of Read Word Data

MSB LSB

First Word Data upper byte

First Word Data lower byte

Next Word Data upper byte

Next Word Data lower byte

Last Word Data upper byte

Last Word Data lower byte

Reading Word Data (Function Code: 03H)

The unit reads word data continuously for the specified number of words from the first number to start reading from.

The slave forwards the read word data from the upper number of bytes to the lower number.

Function Code 03H

Max. No. of Words to Read in One Message 60 words

Relative Address 0000H to 07CFH

Resistor Number 40001 to 42000 42001 to 45032

Contents

Internal Calculation

Value

Message Composition

H to 013AH

07D0

Engineering Unit

– 28 –

Page 30

Example of Transmitting a Message (For Engineering Unit)

Refer to

Master Slave

Command Message (bytes)

Station No. 02H

Function Code 03H

No. to Start Reading

(Relative Address)

Upper 07H

Lower E7H

No. of Words to Read

Upper 00H

Lower 02H

CRC Data

Upper 78H

Lower 95H

Response Message (bytes)

Station No. 02H

Function Code 03H

No. of Bytes to Read 04H

First Word Data

Contents

Upper 00H

Lower 00H

Next Word

Data Contents

Upper 01H

Lower 90H

CRC Data

Upper C8H

Lower CFH

The message is composed as fo ll ows when reading the PV input lower limit and PV input upper limit from station number 2.

• PV Lower Limit Relative Address: 07E1H

■ Meaning of Read Data

PV Input Lower Limit 00 00H = 0

PV Input Upper Limit 01 90H = 400

If Decimal Point Position = 0, then the PV input upper limit and lower limit are as follows.

PV Lower Limit = 0°C

PV Upper Limit = 400°C

For more about the internal calculation value, engineering unit,

and decimal point see

"Chapter 7, Address Map and Data Format" (p. 39).

– 29 –

Page 31

Reading Read-Only Word Data (Function Code: 04H)

Master Slave

Command Message Composition

(bytes)

Station No.

Function Code

No. to Start Reading

(Relative Address)

Upper

Lower

No. of Words to Read

(1 to 60 words)

Upper

Lower

CRC Data

Upper

Lower

Reply Message Composition (bytes)

Station No.

Function Code

No. of Bytes to Read

(No. of Words to Read x 2)

First Word Data

Contents

Upper

Lower

Next W ord Data

Contents

Upper

Lower

Last Word Data

Contents

Upper

Lower

CRC Data

Upper

Lower

■ Meaning of Read Word Data

MSB LSB

First Word Data upper byte

First Word Data lower byte

Next Word Data upper byte

Next Word Data lower byte

Last Word Data upper byte

Last Word Data lower byte

The unit reads word data continuously for the specified number of words from the first number to start reading from.

The slave forwards the read word data from the upper number of bytes to the lower number.

Function Code 04H

Max. No. of Words to Read in One Message 60 words

Relative Address 0000H to 07CFH

Resistor Number 30001 to 32000 32001 to 32240

Contents Internal Calculation Value Engineering Unit

Message Composition

H to 08BFH

07D0

– 30 –

Page 32

Example of Transmitting a Message (Internal Calculation Data)

Refer to

Refer to

Master Slave

Command Message (bytes)

Station No. 01H

Function Code 04H

No. to Start Reading

(Relative Address)

Upper 00H

Lower 00H

No. of Bits to Read

Upper 00H

Lower 01H

CRC Data

Upper 31H

Lower CAH

Response Message (bytes)

Station No. 01H

Function Code 04H

No. of Bytes to Read 02H

First Word Data

Contents

Upper 03H

Lower 46H

CRC Data

Upper 38H

Lower 32H

Master Slave

Command Message (bytes)

Station No. 01H

Function Code 04H

No. to Start Reading

(Relative Address)

Upper 07H

Lower D0H

No. of Words to Read

Upper 00H

Lower 01H

CRC Data

Upper 47H

Lower 31H

Response Message (bytes)

Station No. 01H

Function Code 04H

No. of Bytes to Read 02H

First Word Data

Contents

Upper 01H

Lower 4FH

CRC Data

Upper F9H

Lower 54H

The message is composed as follows when reading the PV input value from station number 1.

• PV value relative address: 0000H Number of data: 01H

■ Meaning of Read Data

Word Data Contents 03 46H = 838 (8.38% FS)

When the input range is 0 to 400°C

PV = 33.5°C (= 8.38% FS x 400 (input range width)

For more about the internal calculation value, engineering unit,

and decimal point see

"Chapter 7, Address Map and Data Format" (p. 39).

Example of Transmitting a Message (For Engineering Unit)

The message is composed as follows when reading the PV value from station number 1.

• PV value relative address: 07D0H Number of data: 01H

■ Meaning of Read Data

Word Data Contents 01 4FH = 335

When the decimal point position = 1

PV = 33.5°C

For more about the internal calculation value, engineering unit,

and decimal point see

"Chapter 7, Address Map and Data Format" (p. 39).

– 31 –

Page 33

Writing Data

Master Slave

Command Message Composition

(bytes)

Station No.

Function Code

Specified Write Number

(Relative Address)

Upper

Lower

Word Data to Write

Upper

Lower

CRC Data

Upper

Lower

Response Message Composition

(bytes)

Station No.

Function Code

Specified Write

Number

(Relative Address)

Upper

Lower

Word Data to

Write

Upper

Lower

CRC Data

Upper

Lower

Writing Word Data (1 word, function code: 06H)

This writes the specified data to the specified number for word data. The master sends the data to be written from the upper

number of bytes to the lower number.

Function Code 06H

Max. No. of Bits to Read in One Message 1 words

Relative Address 0001H to 07CFH 07D0H to 13A7H

Resistor Number 40004 to 42000 42001 to 45032

Contents Internal Calculation

Value

Message Composition

Engineering Unit

– 32 –

Page 34

Example of Transmitting a Message

Point

Master Slave

Command Message (bytes)

Station No. 01H

Function Code 06H

Specified Write

Number

(Relative Address)

Upper 00H

Lower 05H

Word Data to Write

Upper 03H

Lower E8H

CRC Data

Upper 99H

Lower 75H

Response Message (bytes)

Station No. 01H

Function Code 06H

Specified Write

Number

(Relative Address)

Upper 00H

Lower 05H

Write Specification

State

Upper 03H

Lower E8H

CRC Data

Upper 99H

Lower 75H

This example explains how to set PID parameter "P" to 100.0 (1000D = 03E8H) on station number 1.

Parameter "P" relative address: 0005H (internal calculation value table)

07D5H (initial value table)

For more about the internal calculation value, engineering unit, and decimal point see "Sent Data Format" (p. 40).

– 33 –

Page 35

Writing Continuous Word Data (Function code: 10H)

Master Slave

Command Message Composition (bytes)

Station No.

Function Code

Specified Write

Number (Relative

Address)

Upper

Lower

No. of Words to Write Upper

Lower

No. of Bytes to Write

First Word Data to

Write

Upper

Lower

Next Word Data to

Write

Upper

Lower

Last Word Data to

Write

Upper

Lower

CRC Data Upper

Lower

Reply Message Composition (bytes)

Station No.

Function Code

Specified Write

Number (Relative

Address)

Upper

Lower

No. of Words to

Write

Upper

Lower

CRC Data Upper

Lower

■ Meaning of Read Word Data

MSB LSB

First Word Data upper byte

First Word Data lower byte

Next Word Data upper byte

Next Word Data lower byte

Last Word Data upper byte

Last Word Data lower byte

}

1 to 60

} No. of Words

to Write x 2

This writes continuous word information for a number of written words from the first number for writing.

The master sends the data to be written from the upper number of bytes to the lower number.

Function Code 10H

Max. No. of Bits to Read in One Message 60 words

Relative Address 0000H to 07CFH

Resistor Number 40001 to 42000 42001 to 45032

Contents Internal Calculation

Message Composition

Value

H to 13A7H

07D0

Engineering Unit

– 34 –

Page 36

Example of Transmitting a Message (Internal Calculation Data)

Point

Refer to

Master Slave

Command Message (bytes)

Station No. 01H

Function Code 10H

Specified Write

Number (Relative

Address)

Upper 00H

Lower 05H

No. of Words to

Write

Upper 00H

Lower 03H

No. of Bytes to Write 06H

First Word Data to

Write

Upper 03H

Lower E8H

Next Word Data to

Write

Upper 00H

Lower 64H

Last Word Data to

Write

Upper 00H

Lower 32H

CRC Data Upper 56H

Lower BEH

Response Message (bytes)

Station No. 01H

Function Code 10H

Specified Write

Number

(Relative Address)

Upper 00H

Lower 05H

Write Specification

State

Upper 00H

Lower 03H

CRC Data

Upper 90H

Lower 09H

The message is composed as follows when writing the following PID parameters to station number 1.

P = 100.0 (= 1000D = 03E8H)

I = 10 (= 100D = 0064)

D = 5.0 (= 50D = 0032H)

• Parameter “P” relative address: 0005H, Data number: 03H

The decimal point cannot be included in the sent data, so data such as “100.0” above is sent as “1000”.

For each type of send data format, see “Chapter 7, Address

Map and Data Format” (p. 39).

– 35 –

Page 37

MEMO

– 36 –

Page 38

Chapter 7

Address Map and Data Format

Data Format – 38

●

Internal Calculation Value Data Address Map – 40

– 37 –

Page 39

Data Format

Refer to

Caution

Sent Data Format

The MODBUS protocol used by this equipment employs RTU (Remote Terminal Unit) mode. The data is sent as "numerical

value", not as ASCII code.

Internal Calculation Value and Engineering Unit

In this unit, parameter data and data dependent on an input range can handle the following two types of data.

Internal Calculation Value: Values listed as percentages of the input range (0.00 to 100.00, without decimal point)

Engineering Unit: Values subjected to scaling to actual values depending on the input range

"Engineering Unit" data is handled as the address (resister num ber) of 2000 added to th e address (resiste r number) for "Internal

Calculation Value".

(Ex.) The value is calculated as follows when the full scale is 400°C and the PV value is "150".

Class Resistor Number Data (HEX) Data

Internal Calculation Value 30001 0EA6 (H)

Engineering unit 32001 0096 (H) 150

→

3750 (37.5%)

The PV value is received as follows.

37.50 (%) x 400 (full scale °C) = 150 °C

Data not dependent on an input range the same data in both addresses.

For more about data dependent on an input range, see

"Chapter 7 Address Map and Data Format" (page 39).

Pay attention to the position of the decimal point when changing the input range by writing with communication. When

changing the position of the decimal point by writing with communication, change the lower limit and upper limit of the

input range at the same time.

(Ex.) When changing the input range from 0 to 400 to 0.0 to 400.0

■ Operating the keys on the front of the equipment

Change the position of the decimal point ("Pvd") in the setup menu ("SET Ch 6").

"Pvd" = 0 → 1 (or 2)

■ Changing by communication

Set the decimal position parameter ("Pvd"), as well as the corresponding values for PF input lower limit ("Pvb") and PV input upper

limit ("PvF").

"Pvd" = 0 → 1

"Pvb" = 0 → 0

"PvF" = 400 → 4000

Managing the Decimal Point

Some of the internally stored data may contain may digits lower than the decimal point on the front display . Also , the decimal point

is not added to sent data.

Carry out processes for the decimal point position (erasing the d ecimal point when sending data and add ing the decimal point

when receiving data).

Attention must be paid to the position of the decimal point for data where the parameters are dependent on a range in "Chapter 7

Address Map and Data Format". Refer to Address Map.

– 38 –

Page 40

Data during Input Error

For situations such as overrange, underrange, and input breaks where "UUUU" or "LLLL" display on the front, read PV value

becomes 105% or -5% of the input range.

Input errors can be detected via communication using "resistor number 30008 (or 31008): Input/Unit Error Status".

Written Data

When writing data to each parameter, set that written data within the range for the data. PXF can accept wr itten data outside of

the range, but do so with care as correct operations are not guaranteed.

Addresses Not Written

Do not write to addresses that are not public. Doing so may cause damage.

– 39 –

Page 41

Internal Calculation Value Data Address Map

DisplayNo. Name Internal

Engineering

unit

Value

Function

Relative

address

Register No.

Read data Written data range

Factory-set

value

Dependent

on range

Remarks

1MAn Switchover between auto

and manual mode

Switches between auto and manual

modes

0084H40133 42133 0: oFF (auto)

1: on (manual)

oFF

2 STby Switchover between RU N

and standby

Switches the operation mode between

RUN and standby

0003

H

40004 42004 0: oFF (RUN)

1: on (standby)

oFF

4PrG

Ramp soak control command

Changes ramp soak run states 0051H40082 42082 0: oFF (stop)

1: rUn (during run)

2: hLd (during hold)

3: ENd (end)

4: GS

(during guarantee soak)

0: oFF (stop)

1: rUn (run)

2: hLd (hold)

oFF

5AT Auto-tuning run command Runs auto-tuning. 0004H40005 42005 0: oFF (stop/fini sh)

1: on (normal type)

2: Lo (low PV type)

oFF

6LACh Alarm output latch release

command

Cancels the alarm output latch state 00A0

H

40161 42161 0: oFF

1: rST (latch reset)

oFF

7 Svn SV selecti on Chooses the SV No. to be used for

control.

00DC

H

40221 42221 0: LoCL (local SV)

1: Sv1 (SV = SV1)

2: Sv2 (SV = SV2)

3: Sv3 (SV = SV3)

4: Sv4 (SV = SV4)

5: Sv5 (SV = SV5)

6: Sv6 (SV = SV6)

7: Sv7 (SV = SV7)

8: di (according to DI)

LoCL

8 PLn1 PID selection Chooses the PID No. to be used for

control.

00DDH40222 42222 0: LoCL (local PID group)

1: Pid1 (PID group No.1)

2: Pid2 (PID group No.2)

3: Pid3 (PID group No.3)

4: Pid4 (PID group No.4)

5: Pid5 (PID group No.5)

6: Pid6 (PID group No.6)

7: Pid7 (PID group No.7)

8: di (according to DI)

LoCL

9AL1 00A2

H

40163 42163

2.50%FS

10 AL1L ALM1 set value

11 AL1h 00A3

H

40164 42164

12 AL2 00A9

H

40170 42170

2.50%FS

13 AL2L

ALM2 set value

14 AL2h 00AA

H

40171 42171

15 AL3 00B0

H

40177 42177

2.50%FS

16

AL3L

ALM3 set value

17

AL3h 00B1H40178 42178

27 WCMd Electric power calculation

command

Switches the electric power calculation

status

031F

H

40800 42800

oFF

28 LoC Key lock Sets the key lock to prevent wrong

operation

0027

H

40040 42040 0: oFF (no lock)

1: ALL (all lock)

2: PArA (all but SV locked)

oFF

Sets the alarm value for ALM 3.Absolute value alarm: 0 to 100% FS

Deviati on alarm: -100 to 100% FS

0: oFF (off)

1: rUn (run)

2: hLd (hold)

Sets the alarm value for ALM 1. Absolute value alarm: 0 to 100% FS

Deviati on alarm: -100 to 100% FS

Sets the alarm value f

or ALM2. Absolute value alarm: 0 to 100% FS

Deviati on alarm: -100 to 100% FS

3 REM Local/remote switchover Switches SV between local/remote. 0074H40117 42117 LoCL (local)/

rEM (remote)

LoCL

When changing the

SV with the front key,

do not change the

“Svn” parameter via

communication.

Otherwise, the

changed SV may not

be stored correctly.

18 AL4 00B7H40184 42184

2.50%FS

19 AL4L

ALM4 set value

20 AL4h 00B8

H

40185 42185

21 AL5 00BE

H

40191 42191

2.50%FS

22 AL5L

ALM5 set value

23 AL5h 00BFH40192 42192

Sets the alarm value for ALM 5. Absolute value alarm: 0 to 100% FS

Deviati on alarm: -100 to 100% FS

Sets the alarm value for ALM 4. Absolute value alarm: 0 to 100% FS

Deviati on alarm: -100 to 100% FS

Handles data dependent on an input range as an internal value before scaling (0.00 to 100.00%).

See "Operation Manual" for more details about individual parameter fun cti ons and settings ranges.

Word Data (read/write): function code [03 (H), 06 (H), 10 (H)]

Operation control parameter

– 40 –

Page 42

Ch1 PID (control parameters)

DisplayNo. Name Internal

Engineering

unit

Value

Function

Relative

address

Register No.

Read data Written data range

Factory-set

value

Dependent

on range

Remarks

50 P Proportional band (%) 0005

H

40006 42006 5.0%

51 i Integration time Sets the integration ti me of the PID

parameter. Setting "0" will turn off

integrati on.

0006

H

40007 42007 240 sec

52 d Differential time Sets the differential band of the PID

parameter. Setting "0" will turn off

differentiation.

0007

H

40008 42008 60.0 sec

53 hyS ON/OFF control hysteresisSets the hysteresis width for the

ON/OFF control.

0008

H

40009 42009 0.25%FS

54 CoL Cooling proportional band

coefficient

Sets the proportional band coefficient

for cooling.

Setting "0.0" will turn the cooling into

an ON/OFF control.

0009

H

40010 42010 1.0

55 db Dead band (%) Shifts the cooling proportional band

from the set value

000A

H

40011 42011 0.0%

56 bAL Output convergence value

(%)

Offset value which is added to the MV

output value

000C

H

40013 42013Single

control: 0.0%

Dual control:

50.0%

57 Ar Anti-reset windup Sets the range of integration control 000B

H

40012 42012 100% FS

58 rEv Normal/reverse

operations

Selects single control or dual control.

Sets the control action (normal or

reverse).

0057H40088 42088 Single

control: rv--

Dual control:

rvno

[RESET]

59 SvL SV limi t (l ower) Sets the lower limit of SV 40031 420310.00%FS

Note 1)

60 Svh SV limi t (upper) Sets the upper limit of SV 40032 42032100.00%FS

Note 1)

61 TC1 OUT1 proportion cycle

Sets the proportion cycle of the control

output (OUT1)

(contacts, SSR drive)

40089 42089 30 (relay)

2 (SSR)

1 (current)

62 TC2 OUT2 proportion cycle

Sets the proportion cycle of the control

output (OUT2)

(contacts, SSR drive)

40090 42090 30 (relay)

2 (SSR)

1 (current)

63 PLC1 OUT1 lower limit

Sets the lower limit of the control output

(OUT1)

40025 42025 -5.0%

64 PhC1 OUT1 upper limit

Sets the upper li mi t o f the control output

(OUT1)

40026 42026 105.0%

65PLC2 OUT2 lower limit

Sets the lower limit of the control output

(OUT2)

40027 42027 -5.0%

66 PhC2 OUT2 upper limit

Sets the upper li mi t o f the control output

(OUT2)

40028 42028 105.0%

67 PCUT Type of output limiter Type of output limiter 40024 42024 0

73 ALPA Alpha

Sets 2-degrees-of-freedom coefficient α

40436 4243640.0%

74 bEtA Beta

Sets 2-degrees-of-freedom coefficient β

40437 42437 100.0%

0 to 50%FS

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

-1000 to 1000 (-100.0 to 100.0%)

0 to 100% FS

0: rv-- (heat (reverse)/cool (none))

1: no-- (heat (normal)/cool (none))

2: rvno (heat (reverse)/cool (normal))

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

0 to 9999 (0.0 to -999.9 sec)

-500 to 10500 (-5.0 to 105.0%)

-500 to 10500 (-5.0 to 105.0%)

0 to 15

-1999 to 3000 (-199.9 to 300.0%)

0 to 9999 (0.0 to 999.9%)

0 to 100%FS

0 to 100%FS

1 to 150 (1 to 150 sec)

1 to 150 (1 to 150 sec

)

-500 to 10500 (-5.0 to 105.0%)

-500 to 10500 (-5.0 to 105.0%)

001E

001F

0058

0059

0018

0019

001A

001B

0017

01B3

01B4

H

H

H

H

H

H

H

H

H

H

H

Sets the proportional band of the PID

parameter.

Note 1:"SvL" and "Svh" must be set so that SvL < Svh. When you change the values for "SvL" and "Svh", check SV 1 ("Sv1 Ch2") through SV 7

("Sv7 Ch2").

– 41 –

Page 43

Ch2 PLT (PID palette parameters)

DisplayNo. Name Internal

Engineering

unit

Value

Function

Relative

address

Register No.

Read data Written data range

Factory-set

value

Dependent

on range

Remarks

100 Sv1 SV1

Sets the SV (set value)

00F0H40241 42241 0%FS Note 1)

101 P1 Proportional band 1 (%)

Sets the proportional band.

00F1H40242 42242 5.0%

102 i1 Integration time 1

Sets the i ntegration ti me.

00F2H40243 42243 240 sec

103 d1 Differential time 1

Sets the differential time.

00F3H40244 42244 60.0 sec

104 hyS1

ON/OFF control hysteresis 1

Sets the hysteresis when using the

ON/OFF control.

00F4H40245 42245 0.25%FS

105 CoL1

Cooling proportional band 1

(%)

Sets the cooling proportional band.

00F5H40246 42246 1.0

106 db1Dead band 1 (%)

Sets the dead band

00F6H40247 42247 0.0%

107 bAL1

Output convergence value 1

(%)

Offset value whi ch is added to the

control output

00F7H40248 42248Single control:

0.0%

Dual control:

50.0%

108 Ar1 Anti-reset windup 1

Sets the anti-reset wi ndup

00F8H40249 42249 100%FS

109 rEv1 Normal/reverse 1

Selects single control or dual control.

Sets the control action (normal or

reverse).

00F9H40250 42250 Single control:

rv--

Dual control:

rvno

Note 2)

[RESET]

110 Sv2 SV 2 00FA

H

40251 42251 0.00%FS Note 1)

111 P2 Proportional band 2 (%)00FB

H

40252 42252 5.0%

112 i2 Integration time 2 00FC

H

40253 42253 240 sec

113 d2 Differential time 2 00FD

H

40254 42254 60.0 sec

114 hyS2

ON/OFF control hysteresis 2

00FEH40255 42255 0.25%FS

115 CoL2

Cooling proportional band 2

(%)

00FF

H

40256 42256 1.0

116 db2Dead band 2 (%) 0100

H

40257 42257 0.0%

117 bAL2

Output convergence value 2

(%)

0101H40258 42258Single control:

0.0%

Dual control:

50.0%

118 Ar2 Anti-reset windup 2 0102

H

40259 42259 100.00%FS

119 rEv2 Normal/reverse 2 0103H40260 42260 Single control:

rv--

Dual control:

rvno

Note 2)

[RESET]

120 Sv3SV 3 0104

H

40261 42261 0.00%FS Note 1)

121 P3 Proportional band 3 (%) 0105

H

40262 42262 5.0%

122 i3 Integration time 3 0106

H

40263 42263 240 sec

123 d3 Differential time 3 0107H40264 42264 60.0 sec

124 hyS3

ON/OFF control hysteresis 3

0108H40265 42265 0.25%FS

125 CoL3

Cooling proportional band 3

(%)

0109

H

40266 42266 1.0

126 db3 Dead band 3 (%) 010A

H

40267 42267 0.0%

127 bAL3

Output convergence value 3

(%)

010B

H

40268 42268Single control:

0.0%

Dual control:

50.0%

128 Ar3 Anti-reset windup 3 010CH40269 42269 100.00%FS

129 rEv3 Normal/reverse 3 010D

H

40270 42270 Single control:

rv--

Dual control:

rvno

Note 2)

[RESET]

130 Sv4 SV 4 010E

H

40271 42271 0.00%FS Note 1)

131 P4 Proportional band 4 (%) 010FH40272 42272 5.0%

132i4 Integration time 4 0110

H

40273 42273 240 sec

133 d4 Differential time 4 0111

H

40274 42274 60.0 sec

134hyS4

ON/OFF control hysteresis 4

0112H40275 42275 0.25%FS

135 CoL4

Cooling proportional band 4

(%)

0113

H

40276 42276 1.0

136db4Dead band 4 (%) 0114

H

40277 42277 0.0%

137 bAL4

Output convergence value 4

(%)

0115H40278 42278Single control:

0.0%

Dual control:

50.0%

138 Ar4 Anti-reset windup 4 0116

H

40279 42279 100.00%FS

139rEv4 Normal/reverse 4 0117

H

4028042280 Single control:

rv--

Dual control:

rvno

Note 2)

[RESET]

SV limit (lower)(SVL) to SV li mit (upper)(SVH) %FS

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

0: rv-- (heat (reverse)/cool ( non e))

1: no-- (heat (normal)/cool (none))

2: rvno (heat (reverse)/cool (normal))

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

SV limit (lower)(SVL) to SV li mit (upper)(SVH) %FS

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

0 to 9999 (0.0 to -999.9 sec

)

0 to 50%FS

0 to 9999 (0.0 to -999.9 sec)

0 to 50%FS

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

-1000 to 1000 (-100.0 to 100.0%)

0 to 100%FS

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

0 to 9999 (0.0 to -999.9 sec)

0 to 50%FS

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

-1000 to 1000 (-100.0 to 100.0%)

0 to 100%FS

0: rv-- (heat (reverse)/cool ( non e))

1: no-- (heat (normal)/cool (none))

2: rvno (heat (reverse)/cool (normal))

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

SV limit (lower)(SVL) to SV li mit (uppe

r)(SVH) %FS

0 to 9999 (0.0 to -999.9 sec)

0 to 50%FS

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

-1000 to 1000 (-100.0 to 100.0%)

0 to 100%FS

-1000 to 1000 (-100.0 to 100.0%)

0 to 100%FS

0: rv-- (heat (reverse)/cool ( non e))

1: no-- (heat (normal)/cool (none))

2: rvno (heat (reverse)/cool (normal))

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

SV limit (lower)(SVL) to SV li mit (upper)(SVH) %FS

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

0: rv-- (heat (reverse)/cool ( non e))

1: no-- (heat (

normal)/cool (none))

2: rvno (heat (reverse)/cool (normal))

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

140 Sv5 SV 5 0118H40281422810.00%FS

Note 1)

SV li mit (lower )(SVL) to SV l imit (upper)(SVH) %FS

141 P5 Proportional band 5 (%) 0119H40282422825.0%

142 i5 Integration ti me 5 011A

H

40283 42283 240 sec

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

143 d5 Differential time 5 011BH40284 4228460.0 sec

144 hyS5

ON/OFF control hysteresis 5

011CH40285 422850.25%FS

0 to 9999 (0.0 to -999.9 sec)

0 to 50%FS

– 42 –

Page 44

Value

DisplayNo. Name Internal

145 CoL5

146 db5Dead band 5 (%)011E

147 bAL5

148 Ar5 Anti-reset windup 5 0120

149 rEv5 Normal/reverse 5 0121H40290 42290 Single control:

150 Sv6 SV 6 0122

151 P6 Proportional band 6 (%)0123

152 i6 Integration time 6 0124

153 d6 Differential time 6 0125

154 hyS6

155 CoL6

156 db6Dead band 6 (%)0128H40297 42297 0.0%

157 bAL6 Output convergence value 6

158 Ar6 Anti-reset windup 6 012A

159 rEv6 Normal/reverse 6 012B

160 Sv7 SV 7 Sets the SV (set value) 012C

161 P7 Proportional band 7 (%) Sets the proportional band. 012DH40302 42302 5.0%

162 i7 Integration time 7 Sets the integration time. 012E

163 d7 Differential time 7 Sets the differential time. 012F

164 hyS7

165 CoL7 Cooling proportional band 7

166 db7Dead band 7 (%) Sets the dead band 0132

167 bAL7 Output convergence value7

168 Ar7 Anti-reset windup 7 Sets the anti-reset windup013440309 42309 100.00%FS

169 rEv7 Normal/reverse 7 Selects single control or dual control.

170 rEF1 PID switching point 1

171 rEF2 PID switching point 2

172 rEF3 PID switching point 3

173 rEF4 PID switching point 4

174 rEF5 PID switching point 5

175 rEF6 PID switching point 6

176 rEF6 PID switching point 7

177 SvMX Max SV selection number Sets the maximum SV number that the

178 PL1M Max PID selection number Sets the maximum PID number that

Cooling proportional band 5

(%)

Output convergence value 5

(%)

ON/OFF control hysteresis 6

Cooling proportional band 6

(%)

(%)

ON/OFF control hysteresis 7

(%)

(%)

Sets the hysteresis when using the

ON/OFF control.

Offset value which is added to the

control output

Sets the control action (normal or

reverse).

Sets the PID switching point for palette 1.

Sets the PID switching point for palette 2.

Sets the PID switching point for palette 3.

Sets the PID switching point for palette 4.

Sets the PID switching point for palette 5.

Sets the PID switching point for palette 6.

Sets the PID switching point for palette 7.

USER key can select.

the USER key can select.

Function

Relative

address

011D

0126H40295 42295

0127

0129

0130H40305 42305 0.25%FS

0131

0133

013540310 42310 Single control:

0136H40311 42311 0%FS

0137H40312 42312 0%FS

0138H40313 42313 0%FS

0139H40314 42314 0%FS

013AH40315 42315 0%FS

013BH40316 42316 0%FS

01A0H40417 42417 0%FS

00DF

Register No.

Engineering

H

H

011FH40288 42288 Single control:

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

00E0H40225 42225 0: LoCL (PID group local)

unit

40286422861.0

40287422870.0%

4028942289100.00%FS

40291 42291 0.00%FS

40292 42292 5.0%

40293 42293 240 sec

40294 42294 60.0 sec

40296 42296 1.0

40298 42298Single control:

40299 42299 100.00%FS

40300 42300 Single control:

40301 42301 0.00%FS

40303 42303 240 sec

40304 42304 60.0 sec

40306 42306 1.0

40307 42307 0.0%

40308 42308Single control:

40224 42224 0: LoCL (local SV)

Read data Written data range

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

-1000 to 1000 (-100.0 to 100.0%)

0 to 100%FS

0: rv-- (heat (reverse)/cool (none))

1: no-- (heat (normal)/cool (none))

2: rvno (heat (reverse)/cool (normal))

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

SV limit (lower)(SVL) to SV limit (upper)(SVH) %FS

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

0 to 9999 (0.0 to -999.9 sec)

0 to 50%FS

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

-1000 to 1000 (-100.0 to 100.0%)

0 to 100%FS

0:

rv-- (heat (reverse)/cool (none))

1: no-- (heat (normal)/cool (none))

2: rvno (heat (reverse)/cool (normal))

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

SV limit (lower)(SVL) to SV limit (upper)(SVH) %FS

0 to 9999 (0.1 to 999.9%)

0 to 32000 (0 to 3200 sec)

0 to 9999 (0.0 to -999.9 sec)

0 to 50%FS

0 to 1000 (0.0 to 100.0)

-5000 to 5000 (-50.0 to 50.0%)

-1000 to 1000 (-100.0 to 100.0%)

0 to 100%FS

0: rv-- (heat (reverse)/cool (none))

1: no-- (heat (normal)/cool (none))

2: rvno (heat (reverse)/cool (nor

3: norv (heat (normal)/cool (reverse))

4: rvrv (heat (reverse)/cool (reverse))

5: nono (heat (normal)/cool (normal))

0 to 100%FS

0 to 100%FS

0 to 100%FS

0 to 100%FS

0 to 100%FS

0 to 100%FS

0 to 100%FS

1: Sv1 (SV = SV1)

2: Sv2 (SV = SV2)

3: Sv3 (SV = SV3)

4: Sv4 (SV = SV4)

5: Sv5 (SV = SV5)

6: Sv6 (SV = SV6)

7: Sv7 (SV = SV7)

8: di (according to DI)

1: Pid1 (PID group No.1)

2: Pid2 (PID group No.2)

3: Pid3 (PID group No.3)

4: Pid4 (PID group No.4)

5: Pid5 (PID group No.5)

6: Pid6 (PID group No.6)

7: Pid7 (PID group No.7)

8: di (according to DI)

mal))

Factory-set

value

0.0%

Dual control:

50.0%

rv--

Dual control:

rvno

0.25%FS

0.0%

Dual control:

50.0%

rv--

Dual control:

rvno

0.0%

Dual control:

50.0%

rv--

Dual control:

rvno

Sv7

Pid7

Dependent

on range

Remarks

Note 2)

[RESET]

Note 1)

Note 2)

[RESET]

Note 1)

Note 2)

[RESET]

Note 1: "SvL" and "Svh" must be set so that SvL < Svh. When you change the values for "SvL" and "Svh", check SV 1 ("Sv1 Ch2") through SV 7

("Sv7 Ch2").

Note 2: Set the same value as the one for the Normal/Reverse setting ("rEv Ch1").

– 43 –

Page 45

Ch 3 PRG (ramp soak parameters)

DisplayNo. Name Internal

Engineering

unit

Value

Function

Relative

address

Register No.

Read data Written data range

Factory-set

value

Dependent

on range

Remarks

200 PTn

Ramp soak op erati on pattern

(Step No.)

Sets whi c h steps to use in the ramp

soak operation pattern

0230

H

40561 42561 0 Note 1)

201 TiMU Ramp soak time unitsSets the units of the ramp soak time 0231

H

40562 42562 hh.MM

202 Sv-1 Ramp soak 1 seg/SV 1 Sets the SV 0244

H

40581 425810%FS

203 TM1r

Ramp soak 1 seg ramp time

Sets the ramp ti me. 0245H40582 42582 00:00

204 TM1S

Ramp soak 1 seg soak time

Sets the soak time. 0246H40583 42583 00:00

205 Sv-2 Ramp soak 2 seg/SV 2 Sets the SV 0247

H

40584 425840%FS

206 TM2r

Ramp soak 2 seg ramp time

Sets the ramp ti me. 0248H40585 42585 00:00

207 TM2S

Ramp soak 2 seg soak time

Sets the soak time. 0249H40586 42586 00:00

208Sv-3 Ramp soak 3 seg/SV 3Sets the SV 024AH40587 425870%FS

209 TM3r

Ramp soak 3 seg ramp time

Sets the ramp ti me. 024BH40588 42588 00:00

210 TM3S

Ramp soak 3 seg soak time

Sets the soak time. 024CH40589 42589 00:00

211 Sv-4 Ramp soak 4 seg/SV 4 Sets the SV 024DH40590 42590 0%FS

212 TM4r

Ramp soak 4 seg ramp time

Sets the ramp ti me. 024EH40591 42591 00:00

213 TM4S

Ramp soak 4 seg soak time

Sets the soak time. 024FH40592 42592 00:00

214 Sv-5 Ramp soak 5 seg/SV 5 Sets the SV 0250

H

40593 42593 0%FS

215 TM5r

Ramp soak 5 seg ramp time

Sets the ramp ti me. 0251H40594 42594 00:00

216 TM5S

Ramp soak 5 seg soak time

Sets the soak time. 0252H40595 42595 00:00

217 Sv-6 Ramp soak 6 seg/SV 6 Sets the SV 0253

H

40596 42596 0%FS

218 TM6r

Ramp soak 6 seg ramp time

Sets the ramp ti me. 0254H40597 42597 00:00

219 TM6S

Ramp soak 6 seg soak time

Sets the soak time. 0255H40598 42598 00:00

220 Sv-7 Ramp soak 7 seg/SV 7 Sets the SV 0256

H

40599 42599 0%FS

221 TM7r

Ramp soak 7 seg ramp time

Sets the ramp ti me. 0257H40600 42600 00:00

222 TM7S

Ramp soak 7 seg soak time

Sets the soak time. 0258H40601 42601 00:00

223Sv-8 Ramp soak 8 seg/SV 8Sets the SV 0259

H

40602 42602 0%FS

224 TM8r

Ramp soak 8 seg ramp time

Sets the ramp ti me. 025AH40603 42603 00:00

225 TM8S

Ramp soak 8 seg soak time

Sets the soak time. 025BH40604 42604 00:00

226 Sv-9 Ramp soak 9 seg/SV 9 Sets the SV 025C

H

40605 42605 0%FS

227 TM9r

Ramp soak 9 seg ramp time

Sets the ramp ti me. 0 25DH40606 42606 00:00

228 TM9S

Ramp soak 9 seg soak time

Sets the soak time. 025EH40607 42607 00:00

229 Sv10 Ramp soak 10 seg/SV 10 Sets the SV 025F

H

40608 42608 0%FS

230T10r

Ramp soak 10 seg ramp time

Sets the ramp ti me. 0260H40609 42609 00:00

231T10S

Ramp soak 10 seg soak time

Sets the soak time. 0261H40610 42610 00:00

232 Sv11 Ramp soak 11 seg/SV 11 Sets the SV 0262H40611 42611 0%FS

233 T11r

Ramp soak 11 seg ramp time

Sets the ramp ti me. 0263H40612 42612 00:00

234T11S

Ramp soak 11 seg soak time

Sets the soak time. 0264H40613 42613 00:00

235 Sv12 Ramp soak 12 seg/SV 12 Sets the SV 0265

H

40614 42614 0%FS

236T12r

Ramp soak 12 seg ramp time

Sets the ramp ti me. 0266H40615 42615 00:00

237T12S

Ramp soak 12 seg soak time

Sets the soak time. 0267H40616 42616 00:00

238 Sv13 Ramp soak 13 seg/SV 13Sets the SV 0268

H

40617 42617 0%FS

239T13r

Ramp soak 13 seg ramp time

Sets the ramp ti me. 0269H40618 42618 00:00

240 T13S

Ramp soak 13 seg soak time

Sets the soak time. 026AH40619 42619 00:00

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0 (uses steps 1 to 8)

1 (uses steps 9 to 16)

2 (uses steps 17 to 24)

3 (uses steps 25 to 32)

4 (uses steps 33 to 40)

5 (uses steps 41 to 48)

6 (uses ste

ps 49 to 56)

7 (uses steps 57 to 64)

8 (uses steps 0 to 16)

9 (uses steps 17 to 32)

10 (uses steps 33 to 48)

11 (uses steps 49 to 64)

12 (uses steps 0 to 32)

13 (uses steps 33 to 64)

14 (uses steps 0 to 64)

15 (according to DI)

0: hh.MM (hour:min)

1: MM.SS (min:sec)

0 to 100%FS

0-

5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour

:min/min:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0-5999 (00:00 to 99:59)

(hour:min/mi n:sec)

0 to 100%FS

– 44 –

Page 46

DisplayNo. Name Internal

Engineering

unit

Value

Function

Relative

address

Register No.

Read data Written data range

Factory-set

value

Dependent

on range

Remarks

241 Sv14 Ramp soak 14 seg/SV 14 Sets the SV 026B

H

40620 42620 0%FS

242 T14r

Ramp soak 14 seg ramp time

Sets the ramp time. 026CH40621 42621 00:00

243 T14S

Ramp soak 14 seg soak time

Sets the soak time. 026DH40622 42622 00:00

244 Sv15 Ramp soak 15 seg/SV 15 Sets the SV026E

H

40623 42623 0%FS

245 T15r

Ramp soak 15 seg ramp time

Sets the ramp ti me. 026FH40624 42624 00:00

246 T15S

Ramp soak 15 seg soak time

Sets the soak time. 0270H40625 42625 00:00

247 Sv16 Ramp soak 16 seg/SV 16 Sets the SV 0271

H

40626 42626 0%FS

248 T16r

Ramp soak 16 seg ramp time

Sets the ramp time. 0272H40627 42627 00:00

249 T16S

Ramp soak 16 seg soak time

Sets the soak time. 0273H40628 42628 00:00

250 Sv17 Ramp soak 17 seg/SV 17 Sets the SV 0274H40629 42629 0%FS

251 T17r

Ramp soak 17 seg ramp time

Sets the ramp time. 0275H40630 4263000:00

252 T17S

Ramp soak 17 seg soak time

Sets the soak time. 0276H40631 4263100:00

253Sv18 Ramp soak 18 seg/SV 18Sets the SV 0277H40632 426320%FS

254 T18r

Ramp soak 18 seg ramp time

Sets the ramp ti me. 0278H40633 42633 00:00

255 T18S

Ramp soak 18 seg soak time

Sets the soak time. 0279H40634 4263400:00

256 Sv19 Ramp soak 19 seg/SV 19 Sets the SV 027A

H

40635 426350%FS

257 T19r

Ramp soak 19 seg ramp time

Sets the ramp time. 027BH40636 4263600:00

258 T19S

Ramp soak 19 seg soak time

Sets the soak time. 027CH40637 4263700:00

259 Sv20 Ramp soak 20 seg/SV 20 Sets the SV 027D

H

40638 42638 0%FS

260 T20r

Ramp soak 20 seg ramp time

Sets the ramp ti me. 027EH40639 4263900:00

261 T20S

Ramp soak 20 seg soak time

Sets the soak time. 027FH40640 42640 00:00

262 Sv21 Ramp soak 21 seg/SV 21 Sets the SV0280

H

40641 42641 0%FS

263 T21r

Ramp soak 21 seg ramp time

Sets the ramp ti me. 0281H40642 42642 00:00

264 T21S

Ramp soak 21 seg soak time

Sets the soak time. 0282H40643 42643 00:00

265 Sv22 Ramp soak 22 seg/SV 22 Sets the SV0283

H

40644 42644 0%FS

266 T22r

Ramp soak 22 seg ramp time

Sets the ramp ti me. 0284H40645 42645 00:00

267 T22S

Ramp soak 22 seg soak time

Sets the soak time. 0285H40646 42646 00:00

268Sv23 Ramp soak 23 seg/SV 23Sets the SV0286

H

40647 42647 0%FS

269 T23r

Ramp soak 23 seg ramp time

Sets the ramp ti me. 0287H40648 42648 00:00

270 T23S

Ramp soak 23 seg soak time

Sets the soak time. 0288H40649 42649 00:00

271 Sv24 Ramp soak 24 seg/SV 24 Sets the SV0289

H

40650 42650 0%FS

272 T24r

Ramp soak 24 seg ramp time

Sets the ramp ti me. 028AH40651 42651 00:00

273 T24S

Ramp soak 24 seg soak time

Sets the soak time. 028BH40652 42652 00:00

274 Sv25 Ramp soak 25 seg/SV 25 Sets the SV028C

H

40653 42653 0%FS

275 T25r

Ramp soak 25 seg ramp time

Sets the ramp ti me. 0 28DH40654 42654 00:00

276 T25S

Ramp soak 25 seg soak time

Sets the soak time. 028EH40655 42655 00:00

277 Sv26 Ramp soak 26 seg/SV 26 Sets the SV028FH40656 42656 0%FS

278 T26r

Ramp soak 26 seg ramp time

Sets the ramp time. 0290H40657 42657 00:00

279 T26S

Ramp soak 26 seg soak time

Sets the soak time. 0291H40658 42658 00:00

280 Sv27 Ramp soak 27 seg/SV 27 Sets the SV 0292

H

40659 42659 0%FS

281T27r

Ramp soak 27 seg ramp time

Sets the ramp ti me. 0293H40660 42660 00:00

282T27S