Page 1

Fuji Instrumentation & Control

Portable Ultrasonic Flowmeter

Quick Reference

ECNO:622HP

Page 2

Page 3

CONTENTS

CONTENTS

1. STANDARD SELECTION OF DETECTOR ....................................

2. CONDITIONS OF DETECTOR MOUNTING POSITIONS..............

3. MEASURABLE FLUID ....................................................................

4. PIPING CONDITIONS ....................................................................

5. MOUNTING METHOD OF DETECTOR ON PIPING......................

6. OPERATION ...................................................................................

6.1 Power ON - How to Select the Language.............................................................................11

6.2 Preparation Prior to Measurement (Zero Adjustment, etc.)...................................................12

6.3 Piping Specification Input Method through Determination of Size for Sensor Spacing .........14

6.4 Error Status Display and Corrective Actions .........................................................................16

6.5 Measurement of Fluid with Unknown Sonic Speed ...............................................................18

7. Q & A.............................................................................................

7.1 How is piping setting made when piping specifications are unknown ? ................................20

7.2 What is the effect of coating outside the piping ? ..................................................................20

7.3 What is the effect of scales in the piping ? ............................................................................20

7.4 What is homogenious fluid through which ultrasonic waves are transmitted ? .....................20

7.5 Is it possible to measure the flow in piping that is not full ?...................................................21

7.6 What happens when the liquid contains air bubbles ? ..........................................................21

7.7 What about mounting the sensor on horizontal piping ? .......................................................22

7.8 What about mounting the sensor on vertical piping ?............................................................22

7.9 When the length of straight piping is short and a pump, valve, orifice, etc. is present,

what is required for measurement ? ......................................................................................22

7.10 How far can the sensor extension cord be extended ? .........................................................22

7.11 What is the approximate accuracy of measurement ? ..........................................................23

7.12 What about error factors ?.....................................................................................................23

7.13 What about comparison with other flowmeters ?...................................................................25

7.14 What is the difference between a Doppler type flowmeter and PORTAFLOW X ? ...............26

7.15 Life span of LCD....................................................................................................................26

20

2

3

5

6

7

8

8. DATA.............................................................................................

(1) Sonic Speed of Solid (at 25°C)..............................................................................................27

(2) Sonic Speed of Water............................................................................................................27

(3) Sonic Speed of Fluid .............................................................................................................28

Note) This manual provides information about the converter type 2.

ECNO: 622

27

1

Page 4

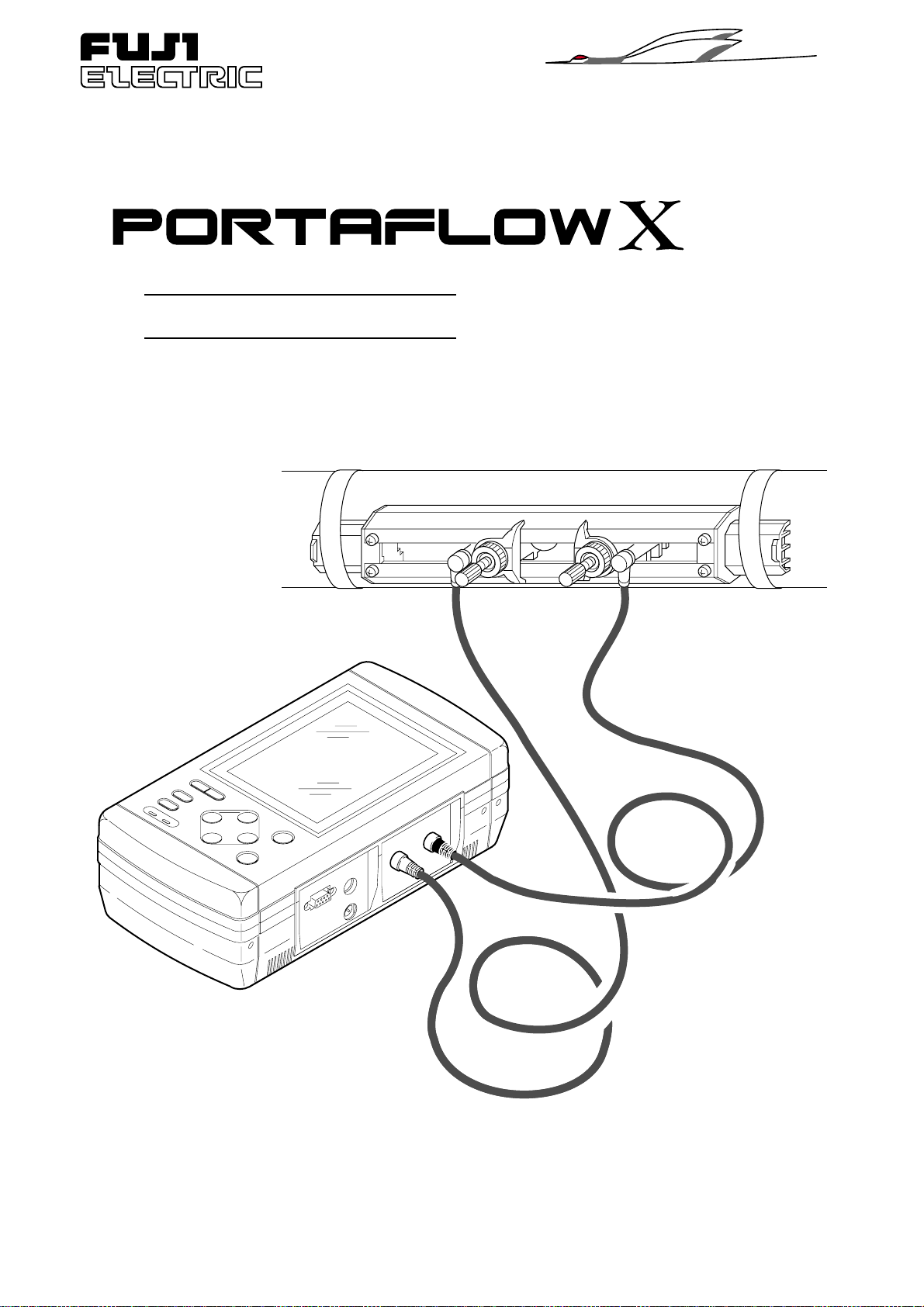

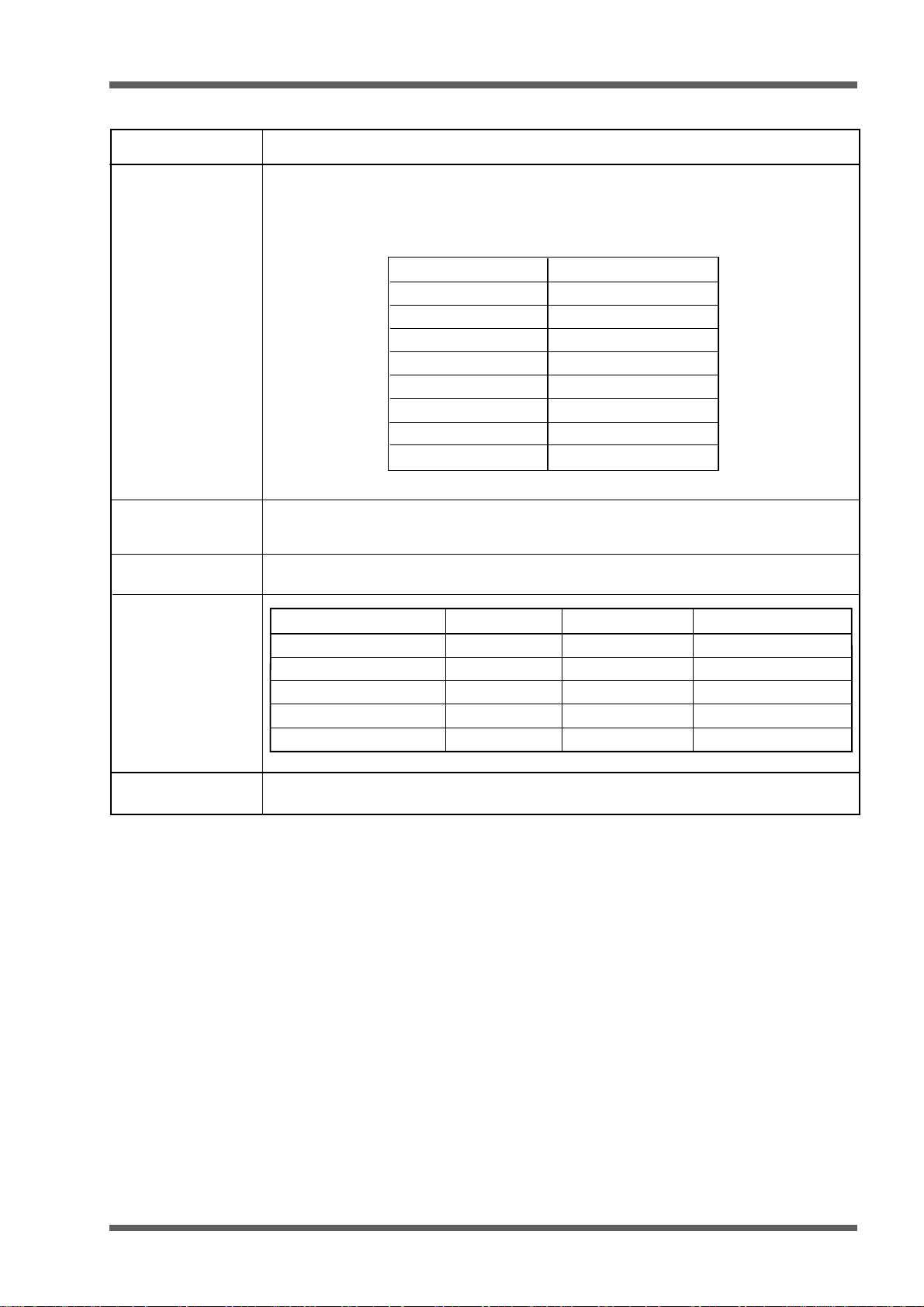

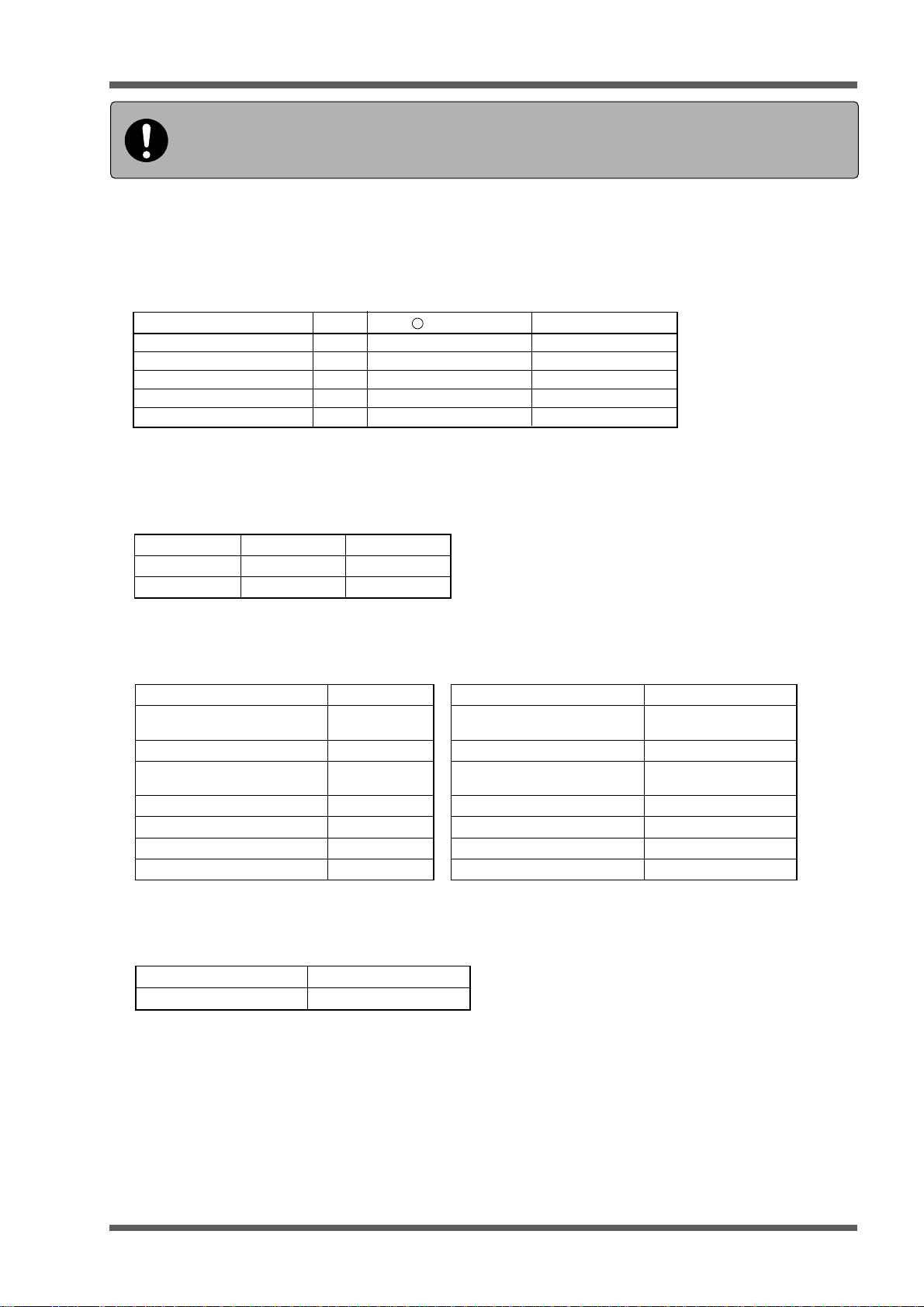

1. STANDARD SELECTION OF DETECTOR

rotceteDepyT)mm(retemaidedisnI(°CegnarerutarepmeT)

rosnesretemaidllamS22DLF001ot31001ot04–

–

–

–

–

001ot04

08ot04

08ot04

002ot04

rosnes

)dradnats(llamS21DLF004ot05

rosnesegraL15DLF0006ot002

0021ot002

rosneserutarepmet-hgiH23DLF004ot05

(1) Selection from 5 types according to applications

Fluid temperature (°C)

200

High-temperature

sensor

100

80

Small

diameter

sensor

0

–40

13 50 100 200 400

Middle sensor

(2) Shape of each sensor

FLD41

Small

sensor

(standard)

Pipe size (mm)

Middle sensor

1200

Large

sensor

6000

Large type (2pcs)

(Type: FLD51)

Middle type (2pcs)

(Type: FLD41)

Small type (standard)

(Type: FLD12)

(3) Example of sensors mounted on pipe

Cloth belt

2

Piping

Element holder

Small diameter

(Type: FLD22)

Exclusive cable

High-temperature

(Type: FLD32)

ECNO: 622

Page 5

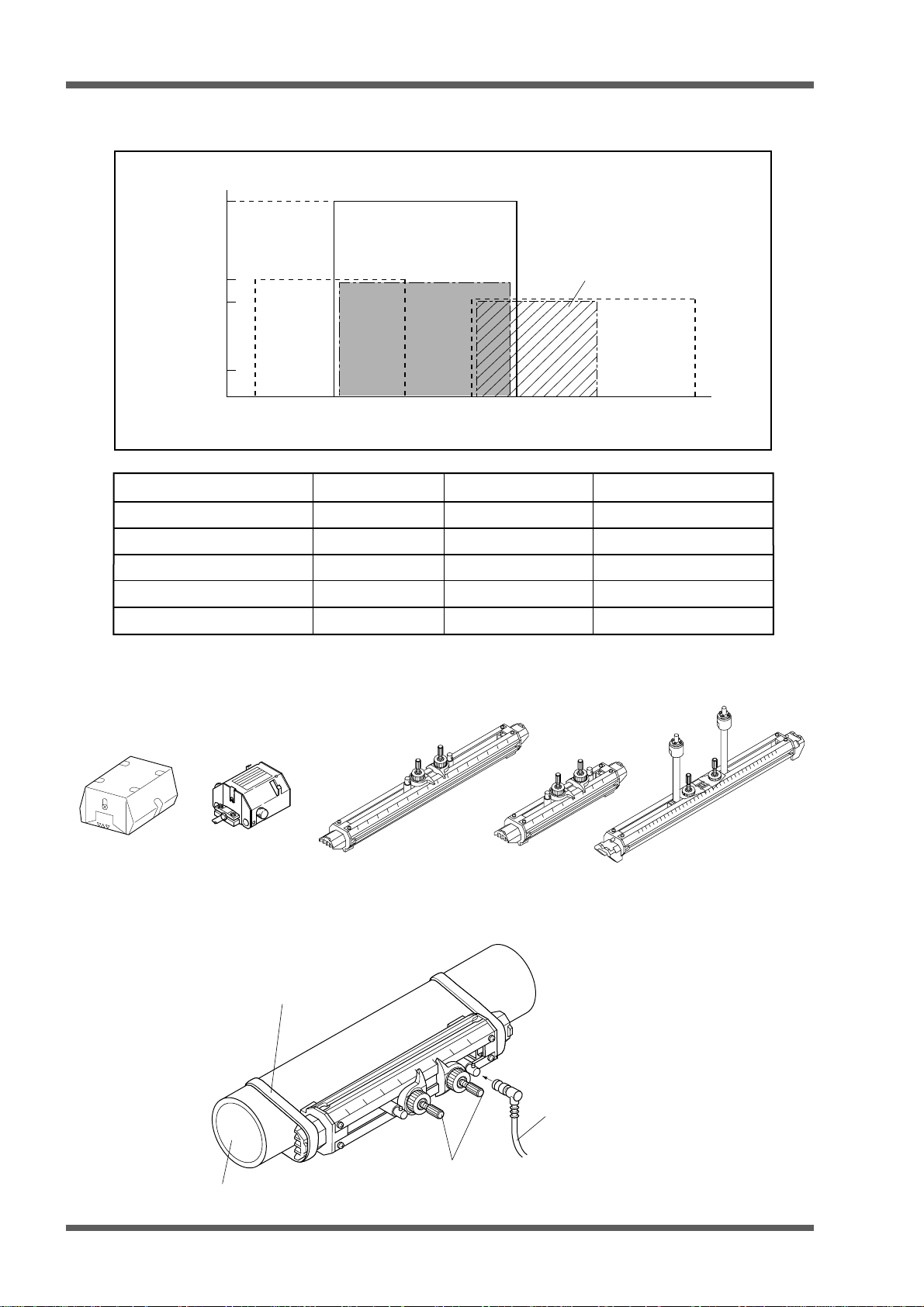

2. CONDITIONS OF DETECTOR MOUNTING POSITIONS

• The piping must be filled with fluid which is free from air bubbles and foreign objects.

• Straight piping greater than 10D must exist on the upstream side and greater than 5D

on the downstream side.

• Elements (pump, valve, etc) on the upstream side must be greater than 30D away to

prevent disturbances.

(1) Necessary straight pipe length

Classification For upstream side For downstream side

90° bend

Tee

Diffuser

Reducer

More than 10D

More than

More than

10D

0.5D

More than

Detector

10D

D

Valves

Pump

ECNO: 622

Flow control valve exists on upstream side.

Stop valve

Check valve

P

Flow control valve exists on downstream side.

3

Page 6

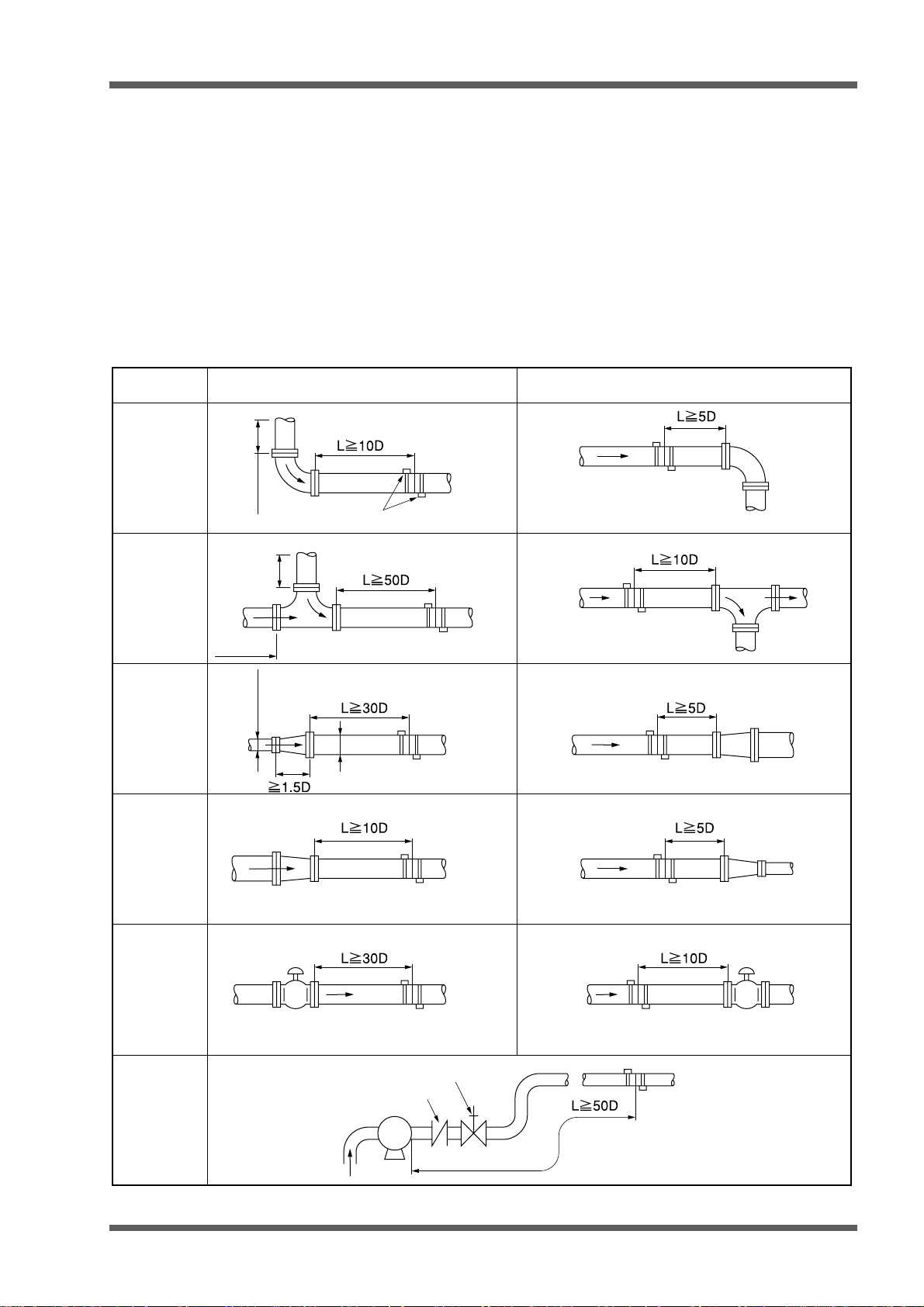

2. CONDITIONS OF DETECTOR MOUNTING POSITIONS

(2) Detector mounting considerations

1) For horizontal piping, the detector should be mounted within ±45° from the water level.

For vertical piping, the detector can be mounted in any external position.

Piping

°

45

Horizon

°

45

2) Avoid mounting the detector at positions with piping distortion, flange or welds.

Welds

Detector

Flange or welds

Welds

Detector

No good No good Good

4

ECNO: 622

Page 7

3. MEASURABLE FLUID

Item

Measurable fluid

Fluid

turbidity

Ultrasonic propagative homogeneous fluids (water, seawater, oil or fluid even

with unknown sonic speed), including the following liquids.

Acetone

Aniline

Ether

Ethylene glycol

Chloroform

Glycerin

Acetic acid

Methyl acetate

Ethyl acetate

Heavy water

Carbon tetrachloride

Mercury

Nitrobenzene

Carbon bisulfide

n. pentane

n. hexane

Spindle oil

Gasoline

10000 (mg/L) or less

Flow condition

Full-filled,axisymmetric and well developed flow

Fluid temperature

per detector

Velocity range

–

32 to 0 to +32m/s

Specifications

rotceteDepyT)mm(retemaidedisnI(°CegnarerutarepmeT)

rosnesretemaidllamS22DLF001ot31001ot04–

–

–

–

–

001ot04

08ot04

08ot04

002ot04

rosnes

)dradnats(llamS21DLF004ot05

rosnesegraL15DLF0006ot002

0021ot002

rosneserutarepmet-hgiH23DLF004ot05

FLD41

Middle sensor

ECNO: 622

5

Page 8

4. PIPING CONDITIONS

Item

Piping diameter

Piping materials

Lining materials

(coating materials

for piping interior)

Specifications

Small diameter sensor

Small sensor (standard)

Middle sensor

Large sensor

High-temperature sensor

Iron

Copper

Ductile cast iron

Cast iron

Stainless steel

Steel

Lead

Aluminum

None

Tar epoxide

Mortar

Rubber

Teflon

Pilex glass or materials with known sonic speed

φ13 to φ100mm

:

φ50 to φ400mm

:

φ200 to φ1200mm

:

φ200 to φ6000mm

:

φ50 to φ400mm

:

Brass

Polyvinyl chloride

Acrylic resin

Mortar

Tar epoxide

Polyethylene

Teflon

FRP

6

ECNO: 622

Page 9

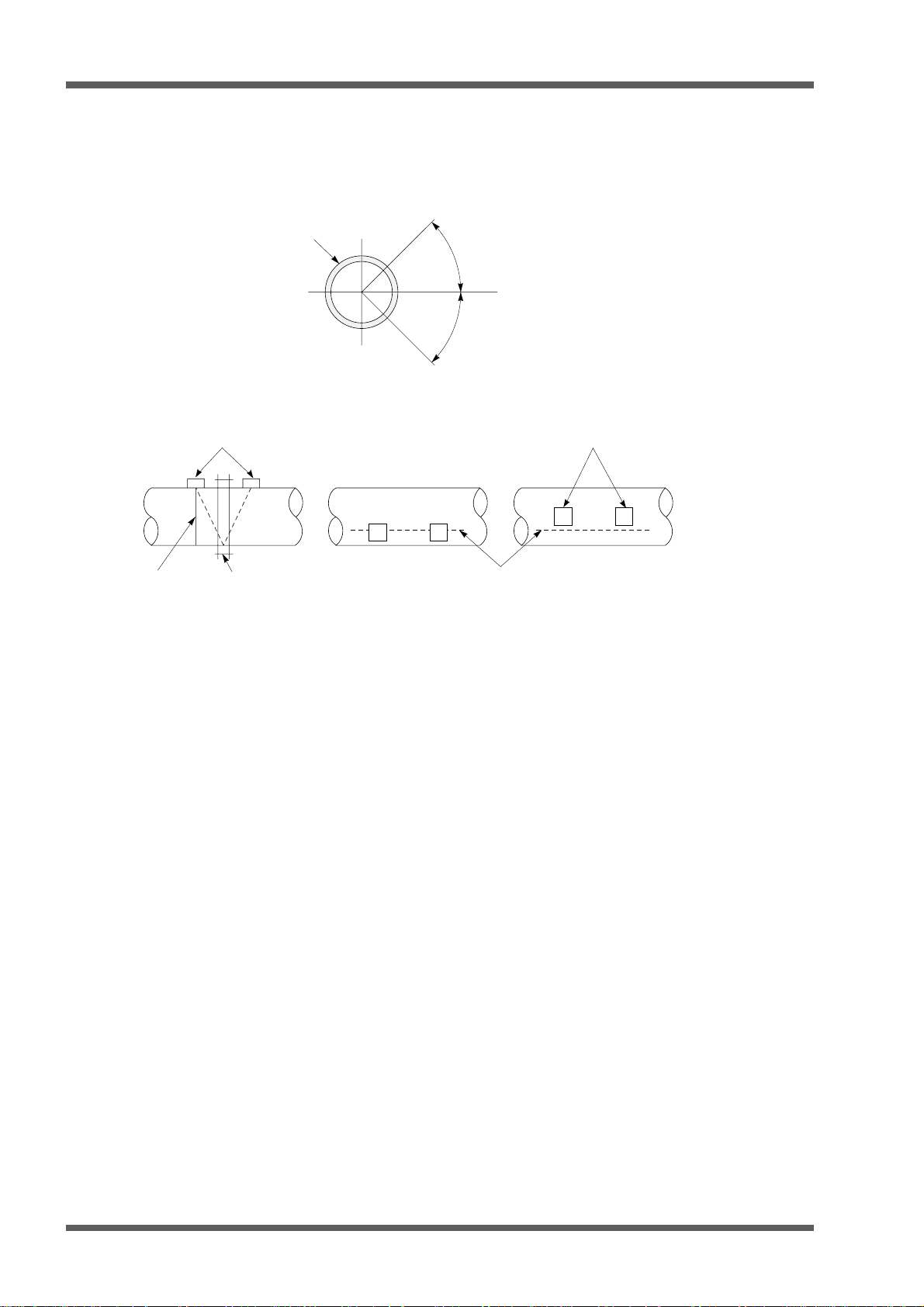

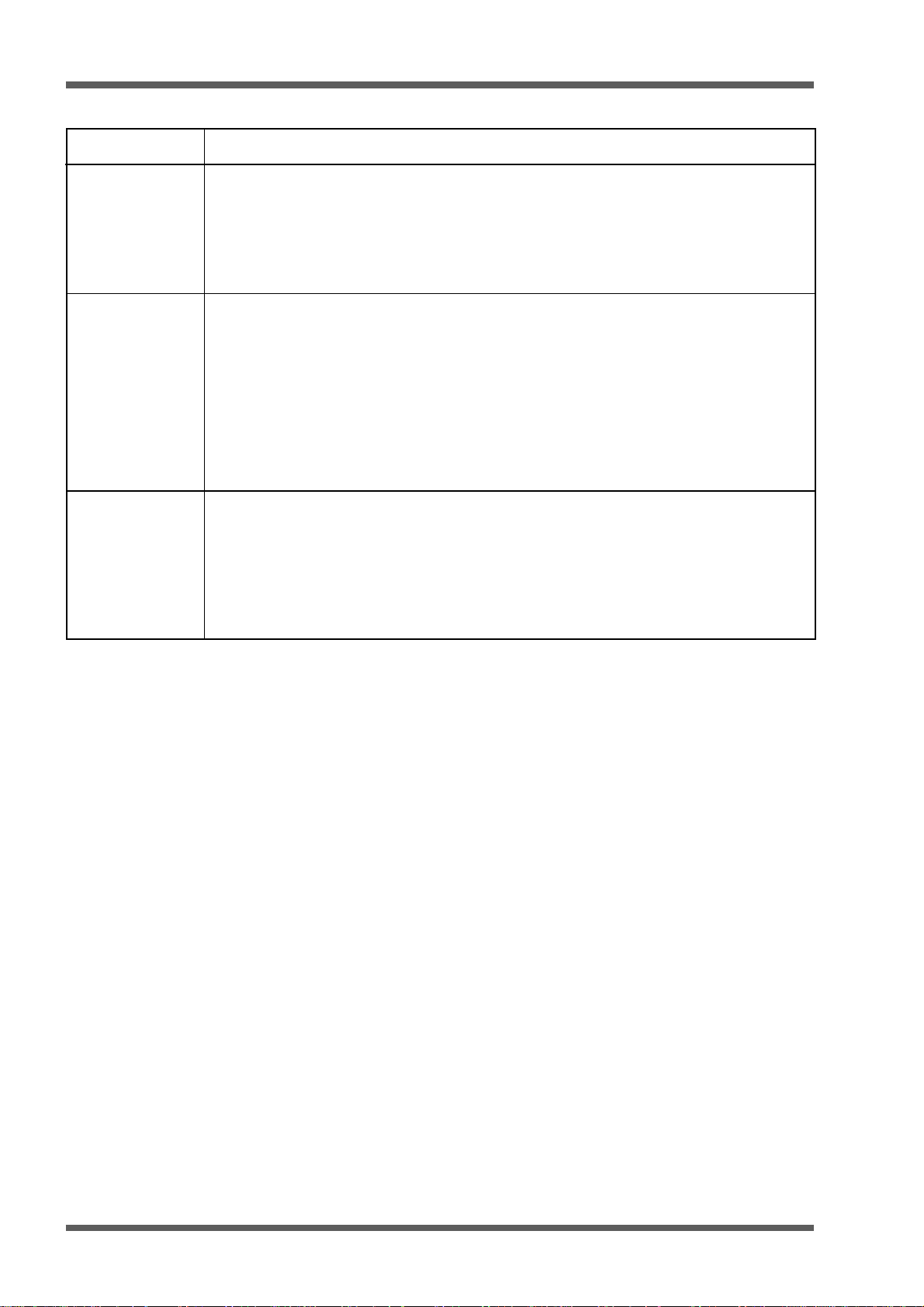

5. MOUNTING METHOD OF DETECTOR ON PIPING

Enter the piping specifications in the parameter of the converter to determine the sensor mounting

dimension and then mount the sensor on the piping.

Loosen the lock nut and slide the sensor so as to

(1)

meet the specified mounting dimension (by

rounding off the displayed mounting dimension

value of the converter below the decimal point),

and then tighten the nut.

Apply the attached silicone grease to the

(2)

transmitting surface of the sensor. Spread the

compound over the entire area.

Element holder

BNC connector

Scale

Lock nut

Cursor

Frame

Saddle

Mounting dimension

(L)

Element holder

Cloth belt

Transmitting

surface

Keep the sensor retracted by turning the element

holder counterclockwise.

After cleaning the surface of the pipe, the sensor

should be mounted.

Fix both ends (saddles) of the sensor to the pipe

(3)

by the attached cloth belts. Mounting will be

facilitated by winding the cloth belts on the pipe in

advance.

Cloth belts are usable at 80°C or lower.

If above 80°C, stainless steel belts should be

used.

ECNO: 622

Element holder

Exclusive cable

(4)

Make sure the sensor is mounted in parallel with

the pipe axis and the mounting dimension is

correct. Then, turn the element holder clockwise

until the sensor comes in close contact with

the pipe.

Stop turning the element holder when it tightens

as the transmitting surface comes in contact with

the pipe surface. Be careful not to tighten the

holder excessively.

7

Page 10

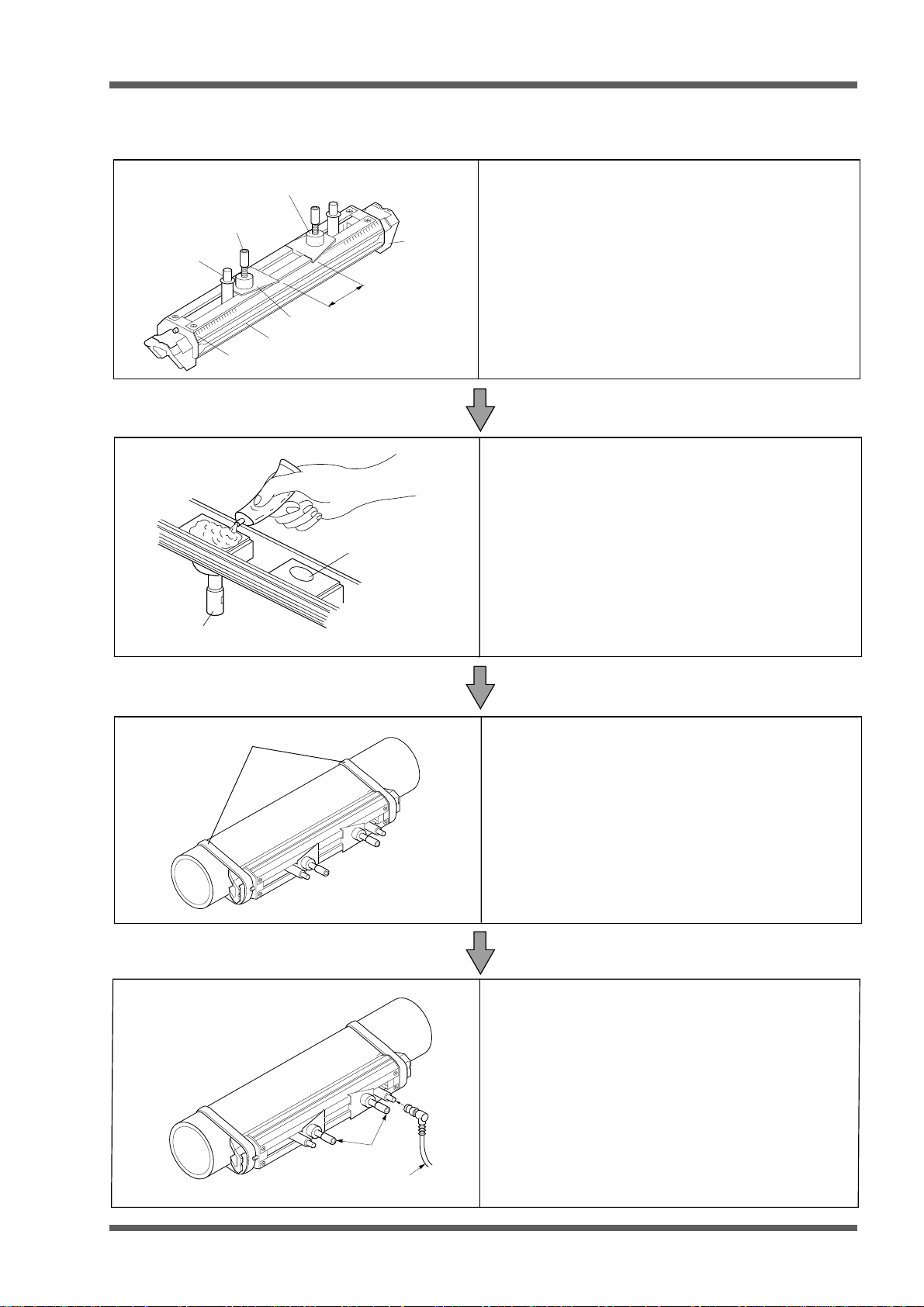

6. OPERATION

Be sure to read the following items and record (check) the next page before

using the flowmeter. Read these data together with the instruction manual.

(1) Make sure that the inside diameter of the piping being measured comforms to the

sensor type.

Middle sensor

rotceteDepyT)mm(retemaidedisnI(°CegnarerutarepmeT)

rosnesretemaidllamS22DLF001ot31001ot04

rosnes

rosnesegraL15DLF0006ot002

)dradnats(llamS21DLF004ot05

FLD41

rosneserutarepmet-hgiH23DLF004ot05

0021ot002

–

–

–

–

–

001ot04

08ot04

08ot04

002ot04

(2) Check the lengths of the straight pipe upstream and downstream of the sensor mount-

ing position.

•

Straight piping greater than 10D must exist on the upstream side and greater than 5D on the

downstream side.

•

Elements (pump, valve, etc) on the upstream side must be greater than 30D away to prevent

disturbances.

(3) Check if the piping setting (outside diameter , material, thic kness , etc.) is correct.

•

If the sensor mounting size is not calculated correctly, errors will occur such as window scan

(reception range-over) or no received signal.

(4) Check if the sensor is mounted correctly.

•

If the transmission side of the sensor is not coated sufficiently with silicone grease, receiving

signals will become unstable or errors will occur such as window scans (receiving range-over),

no received signals, etc.

•

If the upstream and downstream side connectors are reversed, a negative flow rate will be

indicated.

(5) Make sure that the zero point adjustment is completed.

•

Fill the piping with measuring fluid, then stop the flow of the fluid to perform a manual zero

adjustment.

(6) Check to see if more than 2 indicators on the upper right of the measurement screen

are working to indicate wave reception.

•

If no indicator is displayed, or if only one is displayed, increase the level of the transmission

voltage.

(7) Check if the analog output range is set correctly.

•

Even when the analog output is not used, an error of analog scale-over will occur unless the

analog output range has been set properly.

* Preparations for measurement have been completed.

Set the integrator, logger, printer, etc., as necessary. Check whether the flow rate is indicated

correctly. If an error message is indicated, display the system check screen and press the

ENT key while setting the cursor on the error checker.

At this time, the error data, the cause of the error and procedures to correct the error are

indicated. Operate the flowmeter according to the instructions.

8

ECNO: 622

Page 11

6. OPERATION

Be sure to record (check) the following items before using the flowmeter.

Date of recording [ day month year] Place of measurement ______________________

Recorded by ___________________________ ________________________________________

(1) Check the inside diameter of the piping to insure it conforms to the sensor type.

Detector Type (Mark on sensor in use) Piping inside diameter

Small diameter sensor FLD22

Small sensor (standard) FLD12

Middle sensor FLD41

Large sensor FLD51

High-temperature sensor FLD32

(2) Check for sufficient lengths of straight pipe upstream and downstream of the sensor

mounting position.

mm

mm

mm

mm

mm

gnipipthgiartS.cte,evlav,pmuP

edismaertspUDtuohtiW/htiW

edismaertsnwoDDtuohtiW/htiW

(3) Check for correct piping settings (outer diameter size, material, thickness, etc.).

.1emanetiSdiulffodniK.7)(/retaw-aeS/retaW

ezisretemaidretuognipiP.2mm

lairetamgnipiP.3 deepsdnuosdiulF/rehtO*s/m

)gnittesdeepsicnos(rehtO*s/m

)mm(ssenkcihtgnipiP.4mmdohtemgnitnuomrosneS.8dohtemZ/dohtemV

lairetamgniniL.5 rosnesfoepyT.9

)gnittesdeepsicnos(rehtO*s/megatlovnoissimsnarT.01

ssenkcihtgniniL.6mmezisgnitnuoM.11mm

fotneiciffeoC/retaw-aeS*

ytisocsivcitamenik

fotneiciffeoC/rehtO*

ytisocsivcitamenik

×1 / ×2 / ×4 / ×8

m

m

(4) Check for correct sensor mounting.

Silicone grease coating No / Yes

No / YesConnector connection check

2

s/

2

s/

(5) Check the zero point adjustment.

Zero point adjustment method: Manual zero clear (stop the flow of fluid for manual zero operation.)

ECNO: 622

9

Page 12

6. OPERATION

(6) Check that more than 2 indicators on the upper right of the measurement screen are

working to indicate received waves.

Number of working indicators: [ ] (If neither indicator or only one indicator is working, increase

the transmission voltage.)

(7) Check if the analog output range is set properly.

Output range set value: M .MMMEM

* Recording (check) has been finished. Set the integrator, logger, printer, etc., as necessary.

Check if the flow rate is indicated correctly. If an error message is indicated, display the system check screen and press the ENT key while setting the cursor on the error check.

At this time, the error data, the cause of the error and corrective action are indicated. Follow

the operating instructions displayed on the screen.

10

ECNO: 622

Page 13

6. OPERATION

6.1 Power ON - How to Select the Language

At the time of purchase of the flowmeter, English is used as the display language. To change it into

Japanese, German or French, use the following procedure.

Once a language is set, it is stored in memory and it is not necessary to reset every time the power

OFF.

Power switch

PORT AFLOW

ON OFF

English

*

ESC

Default display is in English.

To choose a different language,

ESC key while “English”

press

is Flashing for 10 seconds.

If key is not pressed

ESC

within 10 seconds, the main

display in English will

appear.

Select language

Wahle Sprache

Choix de la langue

ENT

FLOW RATE

UNIT:1/s

0.000 0

MEASURE

VELOCITY

UNIT:m/s

0.000 0

+TOTAL

UNIT:ml

0000000

-TOTAL

UNIT:ml

0000000

NO RECEIVED SIGNAL

ENT

The selected language will

appear at start up the next

time.

RESET

RESET

ECNO: 622

11

Page 14

6. OPERATION

6.2 Preparation Prior to Measurement (Zero Adjustment, etc.)

rotceteDepyT)mm(retemaidedisnI(°CegnarerutarepmeT)

rosnesretemaidllamS22DLF001ot31001ot04

rosnes

Middle sensor

*

Straight piping greater than 10D must exist on the upstream side and greater than

5D on the downstream side.

*

Elements (pump, valve, etc) on the upstream side must be greater than 30D away

to prevent disturbances.

)dradnats(llamS21DLF004ot05

rosnesegraL15DLF0006ot002

FLD41

rosneserutarepmet-hgiH23DLF004ot05

0021ot002

–

001ot04

–

08ot04

–

08ot04

–

002ot04

–

Detector selection standard

Power ON

When the power is ON, the

language select screen is

displayed. Select the

Piping specification input

Sensor mounting

language to be used and

then press the ENT key.

x10 0 = 0

x10 1 =10

Measurement start

Measurement end

/Power OFF

Measurement

x10

2

Example)

1.200

Battery alarm

Measurement

99-05-11 11:49

FLOW RATE UNIT:

VELOCITY UNIT:

MEASURE

+

TOTAL UNIT:

–

TOTAL UNIT:

NORMAL

=100

Status display

x10 2 corresponds to l.2 x 100 = 120m /h.

(Measurement cycle: Once/sec)

M3/h

x10

m/s

x10

ml

STOP

RESET

ml

STOP

RESET

More than 2 indicators for standard

measurement. When one or no indicator

is working, the transmission voltage

should be raised.

×1

×2

×4

×8

Zero Adjustment

3

Indicator (receiving wave strength)

ENT

Site setup

Data logger

System setup

Analog

Printer

System check

Description of key symbols

ENT

: ENTRY key (data registration)

ESC

: ESCAPE key (setting suspension)

: Cursor up-shift (set value feed)

: Cursor down-shift (set value return)

: Cursor left-shift (scale change)

: Cursor right-shift (scale change)

PRINT

: Display screen printout (hard copy)

Important!

(1)

Selection of detector mounting

position

1)

Straight piping greater than 10D must exist

on the upstream side and greater than 5D

on the downstream side.

2)

Elements (pump, valve, etc) on the

upstream side must be greater than 30D

away to prevent disturbances

3) The piping must be filled with fluid free from

air bubbles and foreign objects.

(2)

Selection of mounting method

Small diameter sensor and small type (standard)

sensor should be mounted by the V method.

In the following cases, the Z method should be

used for mounting.

• Insufficient mounting space (about 1/2 of the size of

the V method)

• Piping with mortar lining

• Piping is old and presumed to have a deposit of a thick

layer of scales inside the piping.

L = About D

D

V method

L: Mounting size

L = About D/2

D

Z method

(3)

Treatment of detector mounting side

•

Using thinner and sand-paper, remove the

pitches, rust and uneven surface of the detector

mounting piping over the entire mounting area

of (L) + 200mm wide.

•

When the piping exterior is wrapped with jute,

remove the jute and then perform the above

treatment.

•

Horizontal piping should be mounted within

±45° from the horizon.

•

Vertical piping can be mounted at any external

position.

°

45

°

45

(4)

Method of mounting for small sensor

(standard) and small diameter

sensors

(refer to Page 7 of this manual)

1)Loosen the lock nut. After setting to the

mounting position, tighten the lock nut.

2)Coat the sensor transmission side with a

sufficient amount of silicone grease.

3)Attach both ends (saddle) to the piping

using a cloth belt.

4)Make sure that the sensor is mounted in

parallel with the piping and that the

mounting position is correct. Then, turn the

element holder clockwise until the sensor is

firmly fitted to the piping (clockwise;

element moves down, anti-clockwise;

element moves up).

12

ECNO: 622

Page 15

SITE SETUP

SITE SETUP

ZERO ADJUST

MANUAL ZERO

CALIBRATION

SPAN

100.00%

ZERO ADJUST

MANUAL ZERO

SITE SETUP

SITE SETUP

CALIBRATION

Adjustment with “Site

setting/Transmission

voltage”

Important !

(1)

Insufficient coating of grease on the sensor

(2)

Air stays in the piping.

(3)

When the inside of the piping is rusted or the lining material is

peeled off, the number of indicators will not increase even if the

transmission voltage is raised.

(4)

When transmission voltage is raised unnecessarily, the battery

power will be consumed quickly during battery drive

(no problems with measurement ).

Site setup

6. OPERATION

Stop the flow for

zero adjustment

This is the result of automatic calculation.

It can be changed by piping specification input.

SITE SETUP

SITE MEMORY

PIPE PARAMETER

ZERO ADJUST

RESPONSE SET

SITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

MANUAL ZERO

--- SENSOR SPACING ---

255.1mm

Site setup

ENT

Important !

ZERO ADJUST

Under the flow stop condition,

set the cursor for manual zero

adjustment and press the

ENT key

(compulsory zero adjustment).

MANUAL ZERO

CLEAR

ENT

This is used when the flow cannot be stopped.

Since the exact zero adjustment cannot be obtained

(output is within the range of allowable error), the

manual zero adjustment should be

performed after stopping the flow.

ECNO: 622

SITE SETUP

SITE MEMORY

PIPE PARAMETER

ZERO ADJUST

RESPONSE SET

SITE SETUP

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING --

255.1mm

MANUAL ZERO

Important !

ENT

CALIBRATION

ZERO

SPAN

In general, 0.000m/s is used for zero, and

100.00% is used for span.

Note that when this value changes, the output

deviates by the amount of the change.

Example) When the span is set to 0.0%, the

100.00%

instantaneous value 0.0 remains

unchanged.

13

Page 16

6. OPERATION

SITE NAME

PIPE MATERIAL

CARBON STEEL

KIND OF FLUID

WATER

WATER

KINEMATIC VISCOSITY

SOUND VELOCITY

PIPE PARAMETER

6.3 Piping Specification Input Method through Determination

of Size for Sensor Spacing

rotceteDepyT)mm(retemaidedisnI(°CegnarerutarepmeT)

rosnesretemaidllamS22DLF001ot31001ot04

rosnes

Middle sensor

*

Straight piping greater than 10D must exist on the upstream side and greater than

5D on the downstream side.

*

Elements (pump, valve, etc) on the upstream side must be greater than 30D away

to prevent disturbances.

)dradnats(llamS21DLF004ot05

rosnesegraL15DLF0006ot002

FLD41

rosneserutarepmet-hgiH23DLF004ot05

0021ot002

–

001ot04

–

08ot04

–

08ot04

–

002ot04

–

Detector selection standard

Power ON

When the power is ON, the

language select screen is

displayed. Select the

Piping specification input

language to be used and

then press the ENT key.

Sensor mounting

Measurement start

SITE SETUP

Site setup

SITE SETUP

PARAMETER MEMORY

PIPE PARAMETER

ZERO ADJUST

MANUAL ZERO

RESPONSE SET

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING ---

0.0mm

ENT

Measurement end

/Power OFF

ENT

Measurement

Site setup

Data logger

System setup

Analog

Printer

System check

Description of key symbols

ENT

: ENTRY key (data registration)

ESC

: ESCAPE key (setup suspension)

: Cursor up-shift (set value feed)

: Cursor down-shift (set value return)

: Cursor left-shift (scale change)

: Cursor right-shift (scale change)

PRINT

: Display screen printout (hard copy)

Site name input

(1)

Measurement is possible

without input.

SITE SETUP

PIPE PARAMETER

SITE NAME

(7)

Kind of fluid

KIND OF FLUID

SEA WATER

WATER

KINEMATIC VISCOSITY

1.004E-6 m /s

*

Designation of coefficient of kinematic

viscosity, Table 2

*

When selecting "OTHER", select sonic

speed and coefficient of kinematic viscosity

from Table 2, and enter them.

WATER

OTHER

(2)

(Setting range:13 to 6100mm)

Note) Input the actually

ENT

OTHER

SOUND VELOCITY

KINEMATIC VISCOSITY

Piping outer diameter

(unit: mm)

PIPE PARAMETER

SITE NAME

OUTER DIAMETER

ENT ENT

0013.0 mm

Digit shift

Numeric

value input

After input

measured external size.

Selection of sensor

(8)

mounting method

PIPE PARAMETER

SENSOR MOUNTING

Z

TABLE 2

In general, the V method is used.

But, the Z method is used in the following

cases.

* Mounting space cannot be obtained.

* High turbidity

* Weak receiving wave

* Deposit of thick scale inside the piping

(3)

Piping material

PIPE MATERIAL

CARBON STEEL

STAINLESS STEEL

CAST IRON

COPPER

PVC

ALUMINUM

ASBESTOS

FRP

OTHER

DUCTILE IRON

"Other": Input of sound

speed value, Table

(Setting range:

1000

to 3700m/s

)

ENT

ENT

1

14

ECNO: 622

Page 17

6. OPERATION

ENT

ENT ENT

Numeric

value input

(Setting range :

0.01 to 100.00mm)

ENT ENT

(Setting range :

0.01 to 100.00mm)

ENT

"Other": Input of sound speed

value, Table 1

(Setting range :

1000 to 3700m/s)

20 0.7905 1190 0.407

20 1.0216 1659 1.762

20 0.7135 1006 0.336

20 1.1131 1666 21.112

20 1.4870 1001 0.383

20 1.2613 1923 1188.500

20 1.0495 1159 1.162

20 0.9280 1181 0.411

20 0.9000 1164 0.499

20 1.1053 1388 1.129

20 1.5942 938 0.608

20 13.5955 1451 0.114

20 1.2070 1473 1.665

20 1.2634 1158 0.290

20 0.6260 1032 0.366

20 0.6540 1083 0.489

32 0.9050 1324 15.700

34 0.8030 1250 0.4~0.5

13.5 1.0000 1460 1.004 (20°C)

3230

3206

3000

2460

3206

2260

2170

3080

2050

2640

2644

2505

2500

2505

1900

1240

Vm/s

Fluid name T

°C ρg/cm

3

Vm/s

ν

(×10-6m2/s)

Site setup

Piping thickness

(Unit: mm)

Lining thickness

(4)

Kind of sensor

(9)

Lining material

(5) (6)

Determination of

mounting size

Transmission voltage

(10 )

(11)

PIPE PARAMETERPIPE PARAMETER

PIPE NO.1

SITE NAME

Error of 1mm deviation at φ50: About 1%.

Error of 1mm deviation at φ500: About 0.1%

ENT

ENT

ENT

FLD51

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING ------ SENSOR SPACING ---

255.1mm255.1mm

Important !

SITE SETUP

SITE SETUP

OUTER DIAMETER

PIPE MATERIAL

WALL THICKNESS

LINING MATERIAL

KIND OF FLUID

SENSOR MOUNTING

CARBON STEEL

PIPE PARAMETERPIPE PARAMETER

NO LINING

SENSOR TYPE

LINING THICKNESS

0.01mm

WATER

SITE NAMESITE NAME

×

1

TRANS, VOLTAGE

Entry of site name

Outer diameter

dimension of piping

Pipe material

Pipe thickness

Lining material

Lining thickness

Kind of fluid

Selection of sensor installation

Kind of sensor

Transmission voltage

000.0 mm

PIPE MATERIAL CAST IRON

LINING MATERIAL NO LINING

WALL THICKNESSWALL THICKNESS

TAR EPOXY

MORTAR

RUBBER

TEFLON

PYREX GLASS

OTHER

LINING MATERIALLINING MATERIAL

2000 m/s

NO LININGNO LINING

000.0 mm

LINING MATERIAL MORTAR

LINING THICKNESSLINING THICKNESS

KIND OF FLUID WATER

FLD12

FLD22

FLD32/FLW32

FLD41/FLW41

FLD50/FLW50

FLD51/FLW51

FLW12

FLG1S/FLG2S

FLG1L

FLG2L

SENSOR TYPESENSOR TYPE

FLD11/FLW11

×2

×

1

×8

TRANS. VOLTAGETRANS. VOLTAGE

×4

Selection of

(1)

through

(10)

.

Table 1: Sonic speed

of piping material

Material

Iron

Copper

Ductile cast iron

Cast iron

Stainless steel

Steel

Lead

Aluminum

Brass

Polyvinyl chloride

Acrylic resin

FRP

Mortar

Tar epoxide

Polyethylene

Teflon

V: Sonic speed

Table 2: Coefficient of kinematic viscosity

of various fluids

Note) For other fluids, see "DATA" given in Chapter 8.

Acetone

Aniline

Ether

Ethylene glycol

Chloroform

Glycerin

Acetic acid

Methyl acetate

Ethyl acetate

Heavy water

Carbon tetrachloride

Mercury

Nitrobenzene

Carbon bisulfide

n. pentane

n. hexane

Spindle oil

Gasoline

Water

T: Temperature ρ: Density V: Sonic speed

n: Coefficient of kinematic viscosity

(Unit: mm)

Digit shift

After input

Setting prior to delivery: ×4

Numeric

value input

Digit shift

After input

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

ESC

ECNO: 622

15

Page 18

6. OPERATION

SYSTEM CHECK

SYSTEM CHECK

6.4 Error Status Display and Corrective Actions

rotceteDepyT)mm(retemaidedisnI(°CegnarerutarepmeT)

rosnesretemaidllamS22DLF001ot31001ot04

rosnes

Middle sensor

*

Straight piping greater than 10D must exist on the upstream side and greater than

5D on the downstream side.

*

Elements (pump, valve, etc) on the upstream side must be greater than 30D away

to prevent disturbances.

Detector selection standard

Piping specification input

)dradnats(llamS21DLF004ot05

rosnesegraL15DLF0006ot002

Power ON

FLD41

rosneserutarepmet-hgiH23DLF004ot05

When the power is ON, the

language select screen is

displayed. Select the

language to be used and

then press the ENT key.

0021ot002

–

001ot04

–

08ot04

–

08ot04

–

002ot04

–

SYSTEM CHECK

System check

ERROR CHECK

SIGNAL CHECK

OUTPUT CHECK 0.00%

ENT

Sensor mounting

Measurement start

Measurement end

/Power OFF

Measurement

Site setup

Data logger

System setup

Analog

Printer

System check

Important !

The error check screen is used to display error status

and the corrective actions, it is not used to display the

state of occurrence of errors.

(Do not misunderstand it for occurrence of too

many errors.)

(1)

Module-to-module communication failure (major fault)

Internal data communication is abnormal.

• Reset the power source. (SW ON - OFF)

• If the instrument does not recover, it is an indication of malfunction. Contact your

dealer for repair.

(2)

Measurement module failure

ENT

Measurement module is abnormal and cannot be used for measurement.

• Reset the power source. (SW ON - OFF)

• If the instrument does not recover, it is an indication of malfunction. Contact your

dealer for repair.

(3)

Calculation failure

Measurement calculation is abnormal.

• Confirm the set data.

• Reset the power source. (SW ON - OFF)

• If the instrument does not recover, it is an indication of malfunction. Contact your

dealer for repair.

SYSTEM CHECK

Description of key symbols

ENT

: ENTRY key (data registration)

ESC

: ESCAPE key (setting suspension)

: Cursor up-shift (set value feed)

: Cursor down-shift (set value return)

: Cursor left-shift (scale change)

: Cursor right-shift (scale change)

PRINT

: Display screen printout (hard copy)

16

(4)

Printer failure

The printer has a problem and cannot be used for printing.

• Is the printer power turned on?

• Check to see if paper is jammed. Also, make sure that the printer is connected

correctly to the main unit.

• Reset the power source for the main unit and printer.

(5)

Receiving signal fluctuation

Measurement is impossible due to fluctuation of received ultrasonic waveform.

• Check to see if a large quantity of air bubbles or foreign objects have entered

the piping.

• Change the sensor mounting position.

• Remove the cause of air bubbles or foreign objects.

• Check if the dedicated cable is improperly plugged in or disconnected.

ECNO: 622

Page 19

System check

SITE SETTING

TRANS. VOLTAGE

SYSTEM CHECK

INSIDE COMMUNICATION FAIL

SYSTEM CHECK

ERROR CHECK

INSIDE COMMUNICATION FAIL

MEASURING MODULE FAULT

CALCULATION ERROR

PRINTER FAIL

RECEIVED SIGNAL ERROR

WINDOW SCANNING

NO RECEIVED SIGNAL

TOO STRONG RECEIVED SIGNAL

ANALOG OUTPUT ERROR

BACKUP BATTERY FAIL

SYSTEM CHECK

0.00%

0.00%

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

ENT

Selection of

(1)

through (10)

6. OPERATION

(6)

Window scan

Received signal is lost in the measurement window. It is being searched.

• Check the setting of piping data.

• Open the PIPE PARAMETER screen. Measurement operation is reset

and window scanning will start (It is not an error).

(7)

No received signal

Ultrasonic waveform is lost.

• Check the setting of piping data.

• Check the sensor mounting size.

• Check the connection of the cable.

• Raise the transmission voltage.

(8)

Receiving signal overflow

Overflow of the strength of ultrasonic received signal

• Change the sensor mounting method.

Z method - V method

(9)

Analog over-scale

Over-scale of analog output

• Change the range setting. Refer to analog input/output setting.

(10)

Backup failure

• Backup battery power is lost. The battery needs to be replaced.

Contact our office for replacement.

• Measurement can be made but data backup cannot be made.

Error is cleared when it passes through this panel.

SITE SETTING

PIPE PARAMETER

SITE NAME PIPE

OUTER DIAMETER

PIPE MATERIAL CAST IRON

WALL THICKNESS

LINING MATERIAL MORTAR

SITE SETTING

LINING THICKNESS

KIND OF FLUID WATER

SENSOR MOUNTING

TRANS. VOLTAGE

ENT

TRANS. VOLTAGE

×

1

×

2

×

4

×

8

ENT

NO.1

318.50mm

1.25mm

1.25mm

V

FLD12SENSOR TYPE

×

1

Delivered with × 4 setting

ECNO: 622

17

Page 20

6. OPERATION

SIT SETUP

SITE SETUP

KIND OF FLUID

WATER

WATER

KINEMATIC VISCOSITY

OTHER

SOUND VELOCITY

6.5 Measurement of Fluid with Unknown Sonic Speed

(operation after inputting the piping input/output specifications)

Site setup

SITE SETUP

(1) (2) (3)

(4)

(5)

(6)

(7)

Measurement

Site setup

Data logger

System setup

Analogy

Printer

System check

NO

Normal

YES

(8)

(9)

(4) (5) (6)

(10)

(11)

PARAMETER MEMORY

PIPE PARAMETER

(4)

Measurement of unknown fluid

ZERO ADJUST

RESPONSE SET

SIT SETUP

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING---

126.7mm

MANUAL ZERO

Temporarily set the sonic speed and the coefficient of kinematic viscosity of an approximate fluid

(water soluble fluid is regarded as water), and obtain a measured value of sonic speed.

If the sonic speed is not known at all, temporarily set the sonic speed by the following steps within

the range 500 to 2500m/s.

×0.84 ×0.84

2500 → 2100 → 1764 → 1482 → 1245 → 1046 → 878 → 738 → 620 → 521m/s

Table 2: Coefficient of kinematic viscosity

of various fluids

20 0.7905 1190 0.407

20 1.0216 1659 1.762

20 0.7135 1006 0.336

20 1.1131 1666 21.112

20 1.4870 1001 0.383

20 1.2613 1923 1188.500

20 1.0495 1159 1.162

20 0.9280 1181 0.411

20 0.9000 1164 0.499

20 1.1053 1388 1.129

20 1.5942 938 0.608

20 13.5955 1451 0.114

20 1.2070 1473 1.665

20 1.2634 1158 0.290

20 0.6260 1032 0.366

20 0.6540 1083 0.489

32 0.9050 1324 15.700

34 0.8030 1250 0.4~0.5

13.5 1.0000 1460 1.004 (20°C)

T: Temperature ρ: Density V: Sonic speed

ν: Coefficient of kinematic viscosity

WATER

KINEMATIC VISCOSITY

KIND OF FLUID

WATER

SEA WATER

OTHER

1.004E-6 m2/s

Important !

ENT

OTHER

SOUND VELOCITY

KINEMATIC VISCOSITY

TABLE 2

Fluid name T°C ρg/cm3Vm/s

Acetone

Aniline

Ether

Ethylene glycol

Chloroform

Glycerin

Acetic acid

Methyl acetate

Ethyl acetate

Heavy water

Carbon tetrachloride

Mercury

Nitrobenzene

Carbon bisulfide

n. pentane

n. hexane

Spindle oil

Gasoline

Water

Note) For other fluids, see "DATA" given in Chapter 8.

ν

(×10-6m

ENT

2

/s)

Description of key symbols

ENT

: ENTRY key (data registration)

ESC

: ESCAPE key (setting suspension)

: Cursor up-shift (set value feed)

: Cursor down-shift (set value return)

: Cursor left-shift (scale change)

: Cursor right-shift (scale change)

PRINT

: Display screen printout (hard copy)

18

(9)

Setting of "Sonic speed"

and "Coefficient of

kinematic viscosity" of

unknown fluid

•

Open "SITE SETUP" page.

•

Change the setting from

"Kind of fluid" to "Other".

Important !

1) Fluid sonic speed: Set m/s in

Item (8) .

2) Coefficient of kinematic viscosity:

Referring to Table 1 “Coefficient of

kinematic viscosity”, set the coefficient of

kinematic viscosity of an unknown fluid

approximate to the fluid name (kind of fluid).

(Note that this is not the coefficient of

kinematic viscosity of fluid approximate

to the sonic speed of the measured fluid.)

ECNO: 622

Page 21

6. OPERATION

PIPE PARAMETER

--- SENSOR SPACING ---

255.1mm

PIPE PARAMETER

SENSOR MOUNTING

SENSOR TYPE

ERROR CHECK

Piping setting

For details, refer to the

piping input specifications

(Page 6).

(5)

Display of mounting

size

PIPE PARAMETER

PIPE NO.1SITE NAME

CALIBRATION

CUT OFF

TOTALIZE

--- SENSOR SPACING ---

255.1mm

Error of 1mm deviation at φ50:

About 1%.

Error of 1mm deviation at φ500:

About 0.1%

(2)

Selection of sensor

(1)

Kind of sensor Transmission

mounting method

PIPE PARAMETER

SENSOR MOUNTING

Z

In general, the V method is used.

But, the Z method is used in the

following cases.

* Mounting space cannot be

obtained.

* High turbidity

* Weak receiving wave

* Deposit of thick scale inside the

piping

(6)

Mounting of sensor

ENT

Refer to page 7 .

ENT

(7)

Starting the flow

SENSOR TYPE

FLD11/FLW11

FLD12

FLD22

FLD32/FLW32

FLD41/FLW41

FLD50/FLW50

FLD51/FLW51

FLW12

FLG1S/FLG2S

FLG1L

FLG2L

ENT

measurement

• No received signal

• Window scan

(3)

voltage

TRANS. VOLTAGE

Important !

Setting prior to delivery:

Opening the system

(8)

check panel

System check

SYSTEM CHECK

ERROR CHECK

SIGNAL CHECK

OUTPUT CHECK 0.00%

×

1

×

2

ENT

×

4

×

8

×

4

• Received signal overflow

When the above errors appear,

repeat (4), (5), (6) procedures

until it becomes “Normal”.

SYSTEM CHECK

• Measurement panel status display

→ “Normal”

• More than 2 indicators are “ON” on

the upper right of the screen.

1) Select “Signal check”.

2) Read measured value m/s

of “Fluid sonic speed” on the upper

side of the panel.

(10)

Stopping the flow for

zero adjustment

SITE SETUP

SITE MEMORY

PIPE PARA,METER

ZORO ADJUST

RESPONSE SET

ECNO: 622

MANUAL ZERO

(11)

Starting the flow

measurement

Stop the flow and perform zero

adjustment.

SITE SETUP

SITE MEMORY

PIPE PARAMETER

ZERO ADJUST

RESPONSE SET

MANUAL ZERO

Measurement

start

Important !

Measurement accuracy

Fluid sonic speed is entered

approximately so the measurement

accuracy is almost the same as

"Accuracy of fluid with known sonic

speed". But, the accuracy is

slightly worse to the extent that the

coefficient of kinematicviscosity is

not actual but approximate.

19

Page 22

7. Q & A

7.1 How is piping setting made when piping specifications are unknown ?

Flow rate can be measured within the range of the specifications of PORTAFLOW X by entering

the standard value, but the accuracy cannot be guaranteed.

* Outer diameter can be confirmed by measuring the outside circumference.

* Thickness can be confirmed by using a piping thickness gauge available optionally.

* Lining material and its thickness can generally be estimated from the above-mentioned specifi-

cations and the standard specifications.

7.2 What is the effect of coating outside the piping ?

In general, when the outside wall of the piping is rusted and contaminated with deposits of foreign

objects, coating materials, etc., so the sensor is not fitted firmly to the piping, measurement cannot

be made if there is an air gap which prevents the passage of ultrasonic waves.

In this case, the sensor should be mounted after removing the contamination.

Measurement at a point with uniform coating can be made without problems.

There are no problems with a thick coating (more than several mm), but the measurement accuracy can be improved by adding the lining thickness to the coating thickness and entering it prior to

measurement.

When wrapped with jute, the jute should be removed before measurement.

7.3 What is the effect of scales in the piping ?

Measurement can be made even when there are scales in the piping, but the amount of reduction

of the sectional area due to scaling will become an error.

Therefore, the flow indicated is a little larger than the actual flow.

When the scale thickness is known, it can be compensated by adding it to the lining thickness and

entering it for measurement. In general, the state of deposit of scales in old piping is not uniform,

and shows an uneven surface. Therefore, an accurate cross-sectional area of flow passage cannot

be measured.

Also, the flow profile is not uniform, and an accurate measurement of flow cannot be expected,

strictly speaking.

7.4 What is homogenious fluid through which ultrasonic waves are transmitted ?

Municipal water can be measured over the range from raw water to clean water without problems.

Sewage flows can be measured up to return sludge.

If the flow contains many air bubbles, it cannot be measured. In general, the less foreign objects

(including air bubbles) the flow contains, the more easily can it be measured.

20

ECNO: 622

Page 23

7. Q & A

7.5 Is it possible to measure the flow in piping that is not full?

In horizontal piping, if the pipe is filled with liquid up to 2/3 of inside diameter D as shown below,

the flow velocity can be measured. In this case, the flow rate indicated is the assumed one under

filled pipe conditions.

Therefore, the flow indicated is larger than the actual flow.

If sludge is accumulated on the bottom of the piping, the flow velocity can be measured up to 1/3 of

inside diameter D. In this case, the flow rate indicated is the assumed one under filled pipe conditions without any sludge.

D

2D/3

D

1D/3

7.6 What happens when the liquid contains air bubbles ?

When liquid contains excessive air bubbles, no measurement can be made because of transmission failure of the ultrasonic waves. When air bubbles enter the liquid momentarily, the output is

retained by the self-check function, thereby causing no problems. Air bubbles easily enter liquid in

the following cases.

(1) Suction of air due to low liquid level of pump well

(2) Occurrence of cavitation

(3) Pressure in the piping becomes negative and air enters from piping connection.

P

P

ECNO: 622

Negative pressure

qe

21

Page 24

7. Q & A

7.7 What about mounting the sensor on horizontal piping ?

The sensor should be mounted in the horizontal direction on the piping circumference to prevent

the effects of accumulated sludge (lower) and air bubbles (upper).

Upper

Sensor

Lower

Sensor

7.8 What about mounting the sensor on vertical piping ?

The sensor can be mounted on any external position of vertical piping.

The recommendable flow direction is upward to avoid the interference of bubbles.

7.9 When the length of straight piping is short and a pump,

valve, orifice, etc. is present, what is required for

measurement ?

In general, the length of straight piping on upstream side should be longer than 10D, and that on

downstream side should be longer than 5D. When a pump, valve, orifice, etc. is present, measurement should be made at a location greater than 30D away on the upstream side and greater than

5D away on the downstream side. (See page 3 for detail.)

7.10 How far can the sensor extension cord be extended ?

Extension cords can be connected and extended up to 100m.

(Special cable with BNC connector: 10m x 2 or 50m x 2 available optionally)

22

ECNO: 622

Page 25

7. Q & A

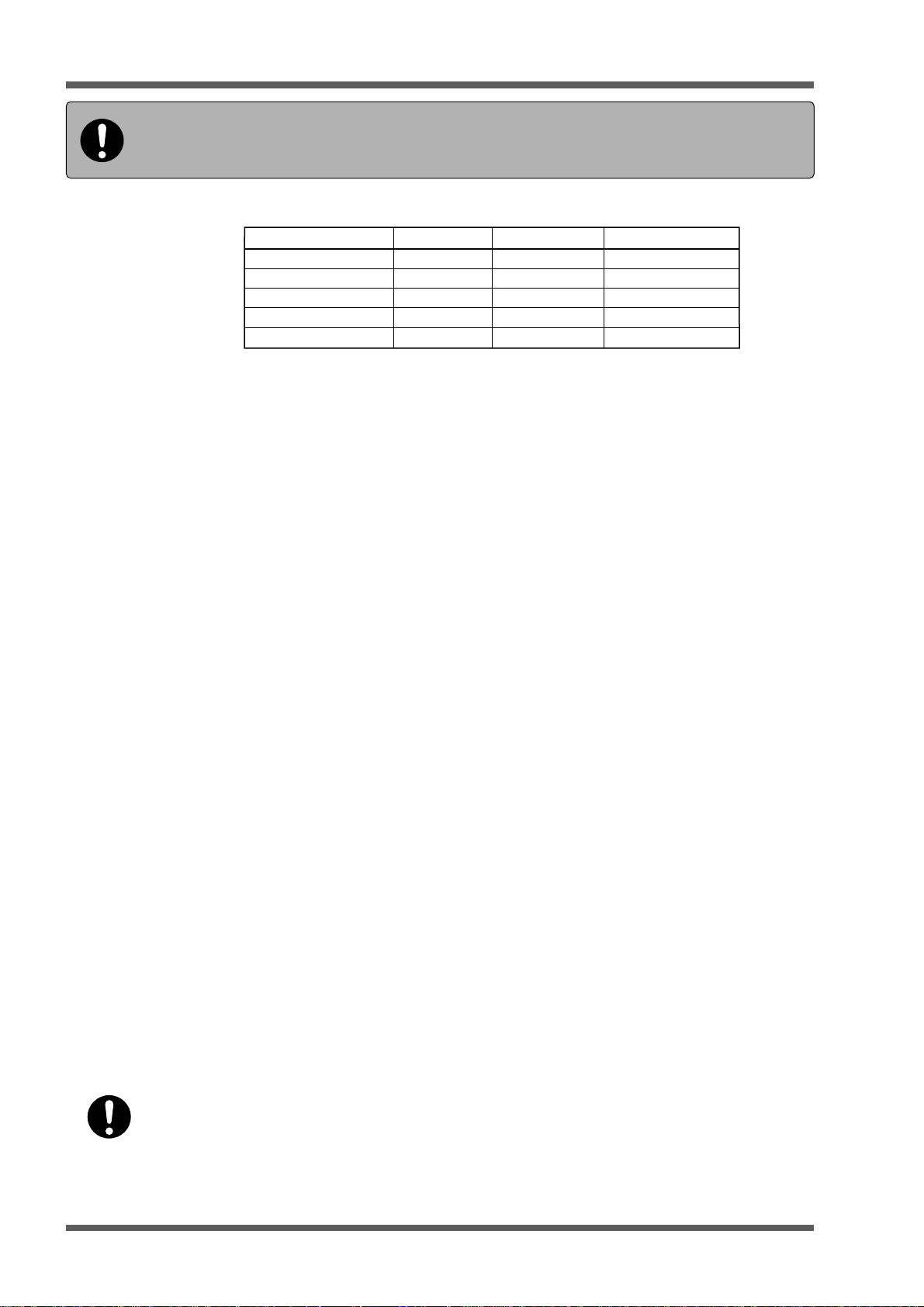

7.11 What is the approximate accuracy of measurement ?

Specifications:

Inside diameter

φ13 to φ50 or less

φ50 to φ300 or less

φ300 to φ6000

*1: Example of calculation

Error at 2m/s

Error at 1m/s? / ±0.03 × 100/1 = ±3.0%

? / ±0.03 × 100/2 = ±1.5%

Flow velocity

2 to 32 m/s

0 to 2 m/s

2 to 32 m/s

0 to 2 m/s

1 to 32 m/s

0 to 1 m/s

Accuracy

±1.5% of measured flow

±0.03 m/s*

±1.0% of measured flow

±0.02 m/s

±l.0% of measured flow

±0.01 m/s

1

Formerly, the expression KK% of full scale was often used. But, in the recent age of digital

system, it is more frequently expressed in % of the displayed value. Under the condition of low

flow velocity, the absolute value of error is used as a standard of accuracy in consideration of the

threshold of device performance.

7.12 What about error factors ?

On PORTAFLOW X, ultrasonic waves are emitted from the outside of the piping and the time is

measured while the waves are passing through the piping material - fluid - piping material.

Therefore, the flow coefficient is determined according to the piping material, size and the angle of

propagation of sound waves. As mentioned on the previous page, the following points become the

error factors to be considered when evaluating the measured values.

Piping size

(1)

When the value set for piping size is different from the actual size of piping, and if the difference

from the inside diameter is about 1% in size, the error is about 3% of deviation obtained by flow

conversion.

(The following shows an example of 1mm deviation in inside diameter)

[%]

–2

–4

–6

6

4

2

0

+1mm

–1mm

100

200

Inside diameter

400 500

300 mm φ

Flow error

ECNO: 622

23

Page 26

7. Q & A

(2) Difference in sensor mounting length

As a general standard, when the error in mounting length is ±1mm, the error of flow is within

1%.

[%]

Flow error

1

+1mm

L

Flow in piping is deviated

(3)

–1

0

–1mm

400 500

300 mm φ

200

100

Inside diameter

When the straight piping is short (particularly upstream side), the flow has become skewed and

some deviation error will occur, or fluctuation of indicated value will occur when the flow is

swirling.

(4)

Inside diameter different from set value due to deposits of scales inside the piping

The error is the same as noted in 1). If scales are badly deposited, receiving waves are not

available and measurement may be disabled.

(5)

Change in water temperature

Temperature is compensated, but there is a slight error when temperature changes.

70°C

(Setting of flow with water)

0°C

35°C

200

Inside diameter

400 500300 mm φ

20°C

Flow error

[%]

1.0

0.5

–0.5

–1.0

0

100

24

(6)

Weak received wave due to improper mounting condition and piping condition

Measurement may be possible. But, if received wave is weak, it may result in a large error due

to the effect of external noise.

ECNO: 622

Page 27

7.13 What about comparison with other flowmeters ?

Although thermometers and pressure gauges can easily be calibrated at a site, flowmeters are

generally very difficult to calibrate at a site.

Therefore, PORTAFLOW X is often used for checking other flowmeters. After checking, the

result of comparison of flowmeters should be evaluated with care while considering to the

following points.

Consideration of error of each flowmeter

(1)

3

In case of 5000m

can be considered at any range.

The error of PORTAFLOW X should also be added when evaluating the total error.

When the error range is the same for both the result of the check is considered normal.

(2) Study data systematically, if an error is found.

Check points of flowmeter are the following 3 factors.

(1) Zero point

(2) Span (flow range)

(3) Linearity

Do not compare values only at 1 point of flow. Draw many samples on a graph and arrange

them systematically. Determine the error in the above 3 points and perform calibrations.

/h full-scale flowmeter with performance of ±1% full-scale, an error of ±5m3/h

7. Q & A

(3)

Thoroughly chec k the piping system.

If fluid flows into or out of a branch pipe in the middle of a piping system, the comparison data of

each side of such a pipe-junction may not match each other.

When there is storage in the middle of piping system and it becomes a buffer for the flow, the

liquid level of the storage area should be taken into consideration.

(4) Comparison of 2 different sets of flowmeters is difficult.

When there is a difference between 2 sets of flowmeters, it is difficult to judge the correct one.

So, another judgement criteria needs to be considered.

ECNO: 622

25

Page 28

7. Q & A

7.14 What is the difference between a Doppler type

flowmeter and PORTAFLOW X?

A Doppler type flowmeter emitts ultrasonic waves and receives the waves reflected from foreign

objects in the fluid.

Velocity is measured utilizing the principle that the frequency deviation of the received waves from

the emitted ones is in proportion to the flow velocity (Doppler effect).

Therefore:

(1) The fluid must contain foreign objects (including air bubbles). It is not suited for clean water

but is suited for sewage.

Since the position in the fluid where the reflection occurs is obscure, the amount and nature of

(2)

foreign objects in the fluid affect the measuring accuracy together with the velocity profile in

the piping.

PORTAFLOW X is designed to measure the velocity with ultrasonic waves passing through piping.

As it measures an average velocity in the piping, it measures flow rate highly accurately.

The Doppler system has the above-mentioned disadvantage, but it is used to measure an approximate flow from the outside of the piping, permitts liquids with large amount of foreign objects, and

is effectively used for liquids with slurry or air bubbles.

7.15 Life span of LCD

The life span of LCD is considered to be about l0 years under general operating conditions, according to the manufacturer’s catalogue. Generally, it is about 5 to 6 years in actual service.

The life span is not so much related to the number of displaying operations.

26

ECNO: 622

Page 29

8. DATA

(1) Sonic Speed of Solid (at 25°C )

Material Sound Material Sound

Speed Speed

(m/s) (m/s)

Steel 1% Carbon, 3150 Iron(Armco) 3230

hardened

Carbon Steel 3206 Ductile Iron 3000

Mild Steel 3235 Monel 2720

Steel 1% Carbon 3220 Nickel 2960

Stainless Steel 302 3120 Tin, rolled 1670

Stainless Steel 303 3120 Titanium 3125

Stainless Steel 304 3206 Tungsten,annealed 2890

Stainless Steel 316 3175 Tungsten, drawn 2640

Stainless Steel 347 3100 Tungsten, carbide 3980

Stainless Steel 410 2990 Zinc, rolled 2440

Stainless Steel 430 3360 Glass, Pyrex 3280

Aluminum 3080 Glass, heavy 2380

silicate flint

Aluminum(rolled) 3040 Glass, 2840

light borate crown

Copper 2260 Nylon 2400

Copper(annealed) 2325 Nylon,6-6 1070

Copper(rolled) 2270 Polyethylene(HD) 2310

CuNi 2540 Polyethylene(LD) 1940

(70%Cu 30%Ni)

CuNi 2060 PVC, CPVC 2400

(90%Cu 10%Ni)

Brass(Naval) 2050 Acrylic 2730

Gold(hard-brawn) 1200 Asbestos Cement 2200

Inconel 3020 Tar Epoxy 2000

Iron(electrolytic) 3240 Mortar 2500

Cast Iron 3230 Rubber 1900

Lead 2170 FRP 2505

Teflon 1240

(2) Sonic Speed of Water

Temperature Sound Temperature Sound

(°C) Speed (°C) Speed

(m/s) (m/s)

0 1402.74 52 1544.95

2 1412.57 54 1546.83

4 1421.96 56 1548.51

6 1430.92 58 1550.00

8 1439.46 60 1551.30

10 1447.59 62 1552.42

12 1455.34 64 1553.35

14 1462.70 66 1554.11

16 1469.70 68 1554.70

18 1476.35 70 1555.12

20 1482.66 72 1555.37

22 1488.63 74 1555.47

24 1494.29 76 1555.40

26 1499.64 78 1555.18

28 1504.68 80 1554.81

30 1509.44 82 1554.30

32 1513.91 84 1553.63

34 1518.12 86 1552.82

36 1522.06 88 1551.88

38 1525.74 90 1550.79

40 1529.18 92 1549.58

42 1532.37 94 1548.23

44 1535.33 96 1546.75

46 1538.06 98 1545.14

48 1540.57 100 1543.41

50 1542.84

ECNO: 622

27

Page 30

8. DATA

(3) Sonic Speed of Fluid

Substance Form Temp. Sound Kinematic

Acetic acid CH3COOH 20 1159

Acetic anhydride (CH3CO)2O 20 1180 0.769

Acetic acid, (CH3CO)2O 20 1180 0.769

anhydride

Acetonitrile C2H3N 25 1290 0.441

Ethyl acetate C4H8O

Methyl acetate C3H6O

Acetone C3H6O 20 1190 0.407

Acetonitrile C2H3N 25 1290 0.441

Acetonylacetone C6H10O

Acetylen dichloride C2H2Cl

Acetylene C2H2Br

tetrabromide

Acetylene C2H2Cl

tetracloride

Ethyl alcohol C2H6O 25 1207 1.396

Alkazene-13 C15H

Alkazene-25 C10H12Cl

2-amino-ethanol C2H7NO 25 1724

2-aminotolidine C7H9N 25 1618 4.394 (20°C)

4-aminotolidine C7H9N 25 1480 1.863 (50°C)

Ammonia NH

t-amyl alcohol C5H12O 25 1204 4.374

Aminobenzene C6H5NO

Aniline C6H5NO

Azine C6H5N 25 1415 0.992

Benzene C6H

Benzol C6H

Bromine Br

Bromobenzene C6H5Br 25 1170 0.693

1-bromo-butane C4H9Br 20 1019 0.49 (15°C)

Bromoethane C2H5Br 20 900 0.275

Bromoform CHBr

n-butane C4H

2-butanol C4H10O 25 1240 3.239

sec-butylalcohol C4H10O 25 1240 3.239

n-butyl bromide C4H9Br 20 1019 0.49 (15°C)

n-butyl chloride C4H9Cl 25 1140 0.529

tert butyl chloride C4H9Cl 25 984 0.646

Butyl oleate C22H42O

2,3 butylene glycol C4H10O

Carbinol CH4O 25 1076 0.695

Carbitol C6H14O

Carbon dioxide CO

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

25 1085 0.467

2

25 1211 0.407

2

25 1399

2

25 1015 0.400

2

25 1027

4

25 1147 1.156 (15°C)

4

24

3

6

6

2

10

2

25 1317

25 1307

2

-33 1729 0.292

25 1639 3.63

2

20 1659 1.762

2

25 1306 0.711

25 1306 0.711

25 889 0.323

20 918 0.654

3

-5 1085

25 1404 0.529

2

25 1484

2

25 1458

3

-37 839 0.137

1/4

Substance Form Temp. Sound Kinematic

Carbon dioxide CO

Carbon disulphide CS

Carbon tetrachloride CCl

Cetane C16H

Chlorobenezene C6H5Cl 20 1289 0.722 (25°C)

1-Chlorobutane C4H9Cl 25 1140 0.529

Chloroform CHCl

1-chloropropane C3H7Cl 25 1058 0.378

Cinnamaldehyde C9H8O 25 1554

Cinnamic aldehyde C9H8O 25 1554

Colamine C2H7NO 25 1724

o-cresol C7H8O 20 1541 4.29 (40°C)

m-cresol C7H8O 20 1500 5.979 (40°C)

Cyanomethane C2H3N 25 1290 0.441

Cyclohexane C6H

Cyclohexanol C6H12O 25 1454 0.071 (17°C)

Cyclohexanone C6H10O 25 1423

Decane C10H

1-decene C10H

n-decylene C10H

Diacetyl C4H6O

Diamylamine C10H23N 25 1256

1, 2-dibromo-ethane C2H4Br

trans-1, 2- C2H2Br

dibromoethene

Dibutyl phthalate C6H22O

Dichloro-t-butyl C4H8Cl2O 25 1304

alcohol

2, 3-dichlorodixane C2H6Cl2O

dichlorodi- CCl2F

fluoromethane

(Freon 12)

1, 2-dichloro ethane C2H4Cl

cis1, 2-dichloro- C2H2Cl

ethane

trans 1, 2-dichloro- C2H2Cl

ethane

Dichlorofluoro- CHCl2F 0 891

methane (Freon21)

1-2-dichlorohexa- C4Cl2F

fluorocyclobutane

1-3-dichloro- C4H8Cl

isobutane

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

-37 839 0.137

2

2

12

20 1158 0.290

20 938 0.608

4

20 1338 4.32

34

20 931 0.383

3

20 1284 1.31 (17°C)

25 1252 1.26 (20°C)

22

25 1235

20

25 1235

20

25 1236

2

25 995 0.79 (20°C)

2

25 935

2

25 1408

4

25 1391

2

25 774.1

2

25 1193 0.61

2

25 1061

2

25 1010

2

25 669

6

25 1220

2

28

ECNO: 622

Page 31

8. DATA

2/4

Substance Form Temp. Sound Kinematic

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

Dichloro methane CH2Cl

25 1070 0.31

2

1, 1-dichloro- CClF2-CClF225 665.3

1, 2, 2, 2-tetra

fluoroethane

Diethyl ether C4H10O 25 985 0.311

Diethylene glycol C4H10O

Diethylene glycol, C6H14O

3

3

25 1586

25 1458

monoethyl ether

Diethylenimide C4H9NO 25 1442

oxide

1, 2-bis C4H8(NF2)225 1000

(difluoramino)

butane

1, 2-bis C4H9(NF2)225 900

(difluoramino) 2-methylpropane

1, 2-bis C3H6(NF2)225 960

(difluoramino)

propane

2, 2-bis C3H6(NF2)225 890

(difluoramino)

propane

2, 2-dihydroxy- C4H10O

3

25 1586

dilethyrther

Dihdroxyethane C2H6O

1, 3-dimethyl- C8H

10

25 1658

2

20 1343 0.749 (15°C)

benzene

1, 2-dimethyl- C8H

10

25 1331.5 0.903 (20°C)

benzene

1, 4-dimethyl- C8H

10

20 1334 0.662

benzene

2,2-dimethyl- C6H

14

25 1079

butane

Dimethyl ketone C3H6O 25 1174 0.399

Dimethyl pentane C7H

16

25 1063

(47)

Dimethyl phthalate C8H10O

Diiodo-methane CH2l

Dioxane C4H8O

Dodecane (23) C12H

1, 2-ethanediol C2H6O

26

25 1463

4

25 980

2

25 1376

2

25 1279 1.80

25 1658

2

Ethanenitrile C2H3N 25 1290 0.441

Ethanoic anhydride (CH3CO)2O 25 1180 0.769

(22)

Substance Form Temp. Sound Kinematic

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

Ethanol C2H6O 25 1207 1.39

Ethanol amide C2H7NO 25 1724

Ethoxyethane C4H10O 25 985 0.311

Ethyl acetate C4H8O

20 1164 0.499

2

Ethyl alcohol C2H6O 25 1207 1.396

Ethyl benzene C8H

10

20 1338 0.797(17°C)

Ethyl Bromide C2H5Br 20 900 0.275

Ethyliodide C2H5l 20 876 0.29

Ether C4H10O 20 1006 0.336

Ethyl ether C4H10O 25 985 0.311

Ethylene bromide C2H4Br

Ethylene chloride C2H4Cl

Ethylene glycol C2H6O

25 995 0.79

2

25 1193 0.61

2

20 1666 21.112

2

50% glycol/ 25 1578

50% H2O

d-fenochone C10H16O 25 1320 0.22

d-2- fenochone C10H16O 25 1320 0.22

Fluoro-benzene (46) C6H5F 25 1189 0.584

Formaldehyde, C2H4O

2

25 1127

methylester

Formamide CH3NO 25 1622 2.91

Formic asid, amide CH3NO 25 1622 2.91

Freon R12 25 774.2

Furfural C5H4O

Furfuryl alcohol C5H6O

Fural C5H4O

2-furaldehyde C5H4O

2-furancarboxalde- C5H4O

2

2

2

2

2

25 1444

25 1450

25 1444

25 1444

25 1444

hyde

2-furyl-methanol C5H6O

2

25 1450

Gallium Ga 30 2870

Glicerin C3H8O

Glycerol C3H8O

Glycol C2H6O

Heptane C7H

n-heptane C7H

Hexachloro- C5Cl

16

16

20 1923 1188.5

3

25 1904 757.1

3

25 1658

2

25 1131 0.598(20°C)

25 1180

25 1150

6

cyclopentadiene

Hexadecane C16H

Hexalin C16H

Hexane C6H

n-hexane C6H

2, 5-hexanedione C6H10O

34

12

14

14

25 1338 4.32(20°C)

25 1454 70.69(17°C)

25 1112 0.446

20 1083 0.489

25 1399

2

n-hexanol C6H14O 25 1300

ECNO: 622

29

Page 32

8. DATA

3/4

Substance Form Temp. Sound Kinematic

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

Hexahydrobenzene C6H

12

25 1248 1.31(17°C)

Hexahydrophenol C6H12O 25 1454

Hexamethylene C6H

12

25 1248 1.31

2-hydroxy-toluene C7H8O 20 1541 4.29 (40°C)

3-hydroxy-toluene C7H8O 20 1500 5.979 (40°C)

Iodo-benzene C6H5l 20 1114 0.954

Iodo-ethane C2H5l 20 876 0.29

Iodo-methane CH3l 25 978 0.211

Isobutyl acetate C6H12O 27 1180

Isobutanol C4H10O 25 1212

Iso-butane 25 1219.8 0.34

Isopentane C5H

12

25 980 0.34

Isopropanol (46) C3H8O 20 1170 2.718

Isopropyl alcohol C3H8O 20 1170 2.718

Kerosene 25 1324

Ketohexamethylene C6H10O 25 1423

Mercury Hg 20 1451 0.114

Mesityloxide C6H16O 25 1310

Methanol CH4O 25 1076 0.695

Methyl acetate C3H6O

20 1181 0.411

2

o-methylaniline C7H9N 25 1618 4.394 (20°C)

4-methylaniline C7H9N 25 1480 1.863 (50°C)

Methyl alcohol CH4O 25 1076 0.695

Methyl benzene C7H

2-methyl-butane C5H

8

12

20 1328 0.644

25 980 0.34

Methyl carbinol C2H6O 25 1207 1.396

Methyl-chloroform C2H3Cl

25 985 0.902 (20°C)

3

Methyl-cyanide C2H3N 25 1290 0.441

3-methyl C7H14O 25 1400

cyclohexanol

Methylene chloride CH2Cl

Methylene iodide CH2l

Methyl formate C2H4O

25 1070 0.31

2

25 980

2

25 1127

2

Methyl iodide CH3l 25 978 0.211

α-methyl napthalene C11H

10

25 1510

2-methylphenol C7H8O 20 1541 4.29 (40°C)

3-methylphenol C7H8O 20 1500 5.979 (40°C)

Milk, homogenized 25 1548

Morpholine C4H9NO 25 1442

Naphtha 25 1225

Nitrobenzene C6H5NO

Nitromethane CH3NO

20 1473 1.665

2

25 1300 0.549

2

Nonane C9H2O 25 1207 0.99(20°C)

1-nonene C9H

18

25 1207

Substance Form Temp. Sound Kinematic

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

Octane C8H

n-octane C8H

1-octene C8H

18

18

16

25 1172 0.73

20 1192 0.737(25°C)

25 1175.5

Oil of camphor 25 1390

Sassafrassy

Oil, car(SAE 20a.30) 25 870 190

Oil, castor C11H10O

25 1477 0.670

10

Oil, diesel 25 1250

Oil, fuel AA gravity 25 1485

Oil (Lubricating X200) 25 1530

Oil (olive) 25 1431 100

Oil (peanut) 25 1458

Oil (sperm) 25 1440

Oil, 6 22 1509

2, 2-oxydiethanol C4H10O

Pentachloroethane C2HCl

Pentalin C2HCl

Pentane C5H

n-pentane C5H

Perchlorocyclo- C5Cl

12

12

25 1586

3

25 1082

5

25 1082

5

25 1020 0.363

20 1032 0.366

25 1150

6

pentadiene

Perchloroethylene C2Cl

Perchloro-1-hepten C7F

Perfluoro-n-hexane C6F

Phene C6H

14

14

25 1036

4

25 583

25 508

25 1306 0.711

6

β-phenyl acrolein C9H8O 25 1554

Phenyl amine C6H5NO

25 1639 3.63

2

Phenyl bromide C6H5Br 20 1170 0.693

Phenyl chloride C6H5Cl 25 1273 0.722

Phenyl iodide C6H5l 20 1114 0.954(15°C)

Phenyl methane C7H

20 1328 0.644

8

3-Phenyl propenal C9H8O 25 1554

Phthalardione C8H4O

3

152 1125

Pimelic ketone C6H10O 25 1423

Plexiglas, lucite, 25 2651

acrylic

Refrigerant 11 CCl3F 0 828.3

Propane C3H

1, 2, 3-propanetriol C3H8O

-45 1003

8

25 1904 0.757×10

3

1-propanol C3H8O 20 1222

2-propanol C3H8O 20 1170 2.718

2-propanone C3H6O 25 1174 0.399

Propene C3H

n-propyl acetate C5H10O

6

2

-13 963

2 1280

-3

30

ECNO: 622

Page 33

8. DATA

4/4

Substance Form Temp. Sound Kinematic

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

n-propyl alcohol C3H8O 20 1225 2.549

Propylchloride C3H7Cl 25 1058 0.378

Propylene C3H

6

-13 963

Pyridine C6H5N 25 1415 0.992(20°C)

Refrigerant 11 CCl3F 0 828.3

Refrigerant 12 CCl2F

2

-40 774.1

Refrigerant 21 CHCl2F 0 891

Refrigerant 22 CHClF

2

50 893.9

Refrigerant 113 CCl2F-CClF20 783.7

Refrigerant 114 CClF2-CClF2-10 665.3

Refrigerant 115 C2ClF

Refrigerant C318 C4F

8

5

-50 656.4

-10 574

Silicone (30cp) 25 990 30

Solvesso #3 25 1370

Spirit of wine C2H6O 25 1207 1.396

Sulfuric Acid H2SO

1, 1, 2, 2-tetrabromo- C2H2Br

25 1257.6 11.16

4

25 1027

4

ethane

1, 1, 2, 2-tetrachloro- C2H2Cl

25 1147 1.156 (15°C)

4

ethane

T etrachloroethane C2H2Cl

T etrachloroethene C2Cl

T etrachloro- CCl

4

20 1170 1.19

4

25 1036

4

25 926 0.607

Methane

T etradecane C14H3O 20 1331 2.86

T etraeth ylene glycol C8H18O

5

25 1586

T etrah ydro-1, C4H9NO 25 1442

4-isoxazine

T oluene C7H

8

20 1328 0.644

o-toluidine C7H9N 25 1618 4.394 (20°C)

p-toluidine C7H9N 25 1480 1.863 (50°C)

T oluol C7H

T ribromomethane CHBr

1, 1, 1-trichloro- C2H3Cl

8

25 1308 0.58

25 918 0.654

3

25 985 0.902 (20°C)

3

ethane

T richloro-ethene C2HCl

3

25 1028

T richloro- CCl3F 0 828.3

fluoromethane

(Freon 11)

Tr ichloro-methane CHCl

25 979 0.55

3

1, 1, 2-trichloro- CCl2F-CClF20 783.7

1, 2, 2-trifluoro etham

T riethylamine C6H15N 25 1123

Substance Form Temp. Sound Kinematic

Index (°C) Speed Viscosity

(m/s) (m2/s ×10-6)

T rieth ylene glycol C6H14O

1, 1, 1-trifluoro- C2HClBrF

4

3

25 1608

25 693

2-chloro-2-bromo ethane

1, 2, 2-trifluorotrichlo- CCl2F-CClF20 783.7

ethane (Freon 113)

d-1,3,3- C10H16O 25 1320 0.22

trimethylnorcamphor

T rinitrotoluene C7H5(NO2)381 1610

T urpentine 25 1255 1.4

Unisis 800 25 1346

Water, distilled H2O 20 1482 1.00

Water, heavy D2O 20 1388 1.129

Water, sea 20 1520 1.00

Wood alcohol CH4O 25 1076 0.695

m-xylene C8H

o-xylene C8H

p-xylene C8H

Xylene hexafluoride C8H4F

10

10

10

20 1343 0.749 (15°C)

25 1331.5 0.903 (20°C)

20 1334 0.662

25 879 0.613

6

ECNO: 622

31

Page 34

Head office

Osaki 1-chome, Sinagawa-ku, Tokyo,

11-2

Phone :

81-3-5435-7111

141-0032

Japan

http://www.fujielectric.co.jp/eng/sg/KEISOKU /welcome.htm

Sales Div.

International Sales Dept.

, Fuji-machi, Hino-city, Tokyo,

No.1

Phone :

81-42-585-6201,6202

Fax:81-42-585-6187,6189

191-8502

Japan

Information in this catalog is subject to change without notice.

Printed in Japan 2000-3/10 FIS

Loading...

Loading...