Fuji Electric PHR Service Manual

Instruction Manual

PAPERLESS RECORDER

TYPE: PHR

INP-TN4PHRa-E

PREFACE

Congratulations on your purchase of Fuji Paperless Recorder (Type: PHR).

• Read this instruction manual carefully to ensure correct installation, operation and preparation.

Incorrect handling may lead to accident or injury.

• Specifi cations of this unit is subject to change without prior notice for improvement.

• Modifi cation of this unit without permission is strictly prohibited.

Fuji will not be bear any responsibility for a trouble caused by such a modifi cation.

• This instruction manual should be kept by the person who is actually using the unit.

• After reading the manual, be sure to keep it at a place easy to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer : Fuji Electric Instrumentation Co., Ltd.

Type : Shown on nameplate of Paperless Recorder

Date of manufacture : Shown on nameplate of Paperless Recorder

Product nationality : Japan

(Note) Windows 2000/XP, Excel, WORD PAD are registered trademarks of Microsoft Corporation.

(Note) Compact Flash is a trademark of Sandisk Corporation.

Request

• It is prohibited to transfer part or all of the manual without

Fuji’s permission.

• Description in this manual will be changed without prior

notice.

INP-TN4PHR-E

i

© Fuji Electric Systems Co., Ltd. 2006

Issued in March, 2006

Rev. 1st edition April, 2008

CAUTION ON SAFETY

Read this “Caution on Safety” carefully before using the instrument.

• Be sure to observe the instructions shown below, because they describe important information on safety.

The degree of danger is classifi ed into the following two levels: “DANGER” and “CAUTION.”

The signs and their meanings are as follows:

Improper handling may cause dangerous situations that may

DANGER

result in death or severe injury.

CAUTION

Improper handling may cause dangerous situations that may

result in moderate or light injuries or property damage.

DANGER

• When there is a possibility that the abnormality of this instrument may cause a major accident or

damage to other instruments, externally install an adequate emergency stop circuit or a protection

circuit to prevent accidents.

• This product is provided with a built-in fuse that cannot be replaced by the customer. Therefore, we

recommend you to separately provide adequate fuses externally. (Rating: 250V, 1A)

The details of the built-in fuse are as follows.

Type: TR-5 19372, 3.15A (Manufactured by Wickmann-Werke GmbH)

Rating: 250V, 3.25A, Type: T (Slow-blow type)

• Feed the power-supply voltage to specifi cations to prevent damages to and breakdown of the instrument.

• Never turn on the power before all the mounting and wiring work are fi nished to prevent electric

shock, malfunction or failure of the instrument.

• Never use this instrument in an environment where fl ammable or explosive gases exist, since this is

not of intrinsically safe construction.

• Never disassemble, remodel, modify, or repair this instrument. Otherwise malfunction, electric

shock, or failure may result.

• Never touch the terminal while the instrument is being energized. Otherwise electric shock or malfunction may result.

• Turn off the power before attaching/detaching the module/unit. Otherwise electric shock, malfunction or failure may result.

• We recommend you to perform periodic maintenance for the safe and continuous use of this instrument, because consumable parts or those which deteriorate with time are mounted in this instrument.

• Do not block the ventilation holes at the top and the bottom of this instrument. Otherwise a failure,

malfunction, shortened service life, or fi re may result.

ii

INP-TN4PHR-E

CAUTION

• Never use the instrument if it is found damaged or deformed when unpacked. Otherwise a fi re, malfunction, or failure may result.

• Check that the instrument is to the proper specifi cations. Otherwise damage or failure may result.

Do not give a shock to the instrument by falling or toppling it. Otherwise damage or failure may result.

•

• Operate the instrument paying attention to prevent foreign matters such as scraps, electric wire chips,

and iron powder from entering in the instrument.

• Check every six months that the terminal screws and mounting screws are securely fastened. Loose

screws may cause fi re or malfunction.

• When changing the setting during the operation or forcibly outputting, starting or stopping the instrument, be sure to check that safety is ensured. Improper operation may result in damage or failure of

the instrument.

• Be sure to keep the attached terminal cover mounted on the terminal block during the operation.

Otherwise electric shock or fi re may result.

• Never install this instrument in the following environments.

A place where the ambient temperature goes beyond the range from 0 to 50°C (0 to 40°C when

the instrument is mounted with its side face closely contacted, or in the case of portable type, or

provided with Ethernet function)

A place where the ambient humidity goes beyond the range from 20 to 80% RH

A place where condensation occurs

A place where corrosive gases (sulfuric gases or ammonia, etc., in particular) or fl ammable gases

exist

A place where vibration or impact may be applied to the instrument (permissible continuous vibration condition: 2.45 m/s

A place subjected to water, oil, chemicals, vapor, or steam

A place subjected to dust and high in salt or iron content

A place where inductive interference may have a great effect, thus causing static electricity, magnetism, or noises

A place subjected to heat accumulation by radiant heat or the like

If the instrument is installed near other electronics instruments, such as TV in particular, noises

may be caused. Take the following measures in these cases.

• Place the instrument as far from the TV or the radio as possible (1m or more)

• Change the orientation of the antenna of the TV or the radio.

• Use separate receptacles.

• When mounting this instrument against the panel, pay attention not to apply stress to the case. Otherwise the case may be damaged.

• Stop using the instrument if it is immersed in water. Otherwise electric leak, electric shock, or fi re

may result.

• Do not use the wires other than the specifi ed compensation conducting wires for the thermocouple

input connection. Otherwise improper indication or malfunction may result.

2

or lower)

INP-TN4PHR-E

iii

CAUTION

• Use a wire material with low wire resistance and with small resistance difference among the three

wires for the resistance bulb input connection. Otherwise improper indication or malfunction may

result.

• If a large noise is generated from the power supply, provide an isolating transformer and use a noise

fi lter.

• Never use organic solvents such as alcohol or benzene when cleaning this instrument. Do not directly water the main unit. Otherwise deterioration, failure, electric leak, electric shock, or fi re may

result. When cleaning the main unit, wipe with a dry cloth.

• Dispose the instrument as an industrial waste.

• Be sure to ground the instrument. Otherwise electric shock or malfunction may result.

• Only authorized workers should perform wiring. Improper wiring may cause fi re, failure, or electric

shock.

• At this equipment, the electrostatic discharge is evaluated as performance criteria B in EN61326.

iv

INP-TN4PHR-E

CONTENTS

PREFACE ...................................................................................................................... i

CAUTION ON SAFETY .............................................................................................ii

CONTENTS ................................................................................................................. v

1. INTRODUCTION .............................................................................................1-1

1.1 Paperless recorder ...............................................................................................1-1

1.2 Product check ......................................................................................................1-1

1.3 Check on type and specifi cation .......................................................................... 1-2

1.4 Handling memory card (Compact Flash) – Cautions on handling ......................1-2

1.5 Ethernet communication function .......................................................................1-4

2. NAMES AND FUNCTIONS OF PARTS ..........................................................2-1

2.1 Names and functions of parts .............................................................................. 2-1

2.2 Inserting and removing the memory card ...........................................................2-3

2.3 Recording data to memory card ..........................................................................2-4

3. MOUNTING METHOD ....................................................................................3-1

3.1 Mounting location ............................................................................................... 3-1

3.2 External dimensions and panel cutout dimensions (unit: mm) ...........................3-1

3.3 Method of mounting onto panel .......................................................................... 3-2

4. WIRING .............................................................................................................4-1

4.1 Before wiring ......................................................................................................4-1

4.2 Connection to terminals ......................................................................................4-2

4.3 Connection the recorder to loader .....................................................................4-12

5. PORTABLE .......................................................................................................5-1

5.1 Portable ...............................................................................................................5-1

5.2 Handling ..............................................................................................................5-1

5.3 Outline (unit: mm) .............................................................................................. 5-2

5.4 Wiring..................................................................................................................5-2

6. DISPLAY FUNCTION ........................................................................................6-1

6.1 Basic composition of Data Display screen ......................................................... 6-1

6.2 Real time trend display of measured data ...........................................................6-3

6.3 Display of measured data in bar graphs or analog meters ..................................6-5

6.4 Digital display of measured data ......................................................................... 6-6

6.5 Totalizing data display ........................................................................................6-6

6.6 Event summary display .......................................................................................6-8

6.7 Ethernet log display .......................................................................................... 6-10

6.8 Historical trend display ..................................................................................... 6-11

6.9 Message that appears when main unit failure occurs ........................................ 6-13

INP-TN4PHR-E

v

6.10 Cautions about power ON/OFF ........................................................................6-13

7. OPERATION AND ACTIONS .........................................................................7-1

7.1 Before running the recorder ................................................................................7-1

7.2 Power ON and state .............................................................................................7-2

7.3 Stopping and starting the recording operation ....................................................7-3

7.4 Switching data display screens ........................................................................... 7-5

7.5 Display of alarm ................................................................................................. 7-6

8. SETTING AND CHECKING PARAMETERS ................................................8-1

8.1 Setting and checking ........................................................................................... 8-1

8.2 Outline of parameter setting procedure ............................................................... 8-5

8.3 Basic operation of setting screens .......................................................................8-7

8.4 Setting for input types, skip, scaling, units, square rooter,

logarithmic display and unit code table ..............................................................8-9

8.5 Setting for input fi lter (time constant), PV shift, and subtraction ..................... 8-15

8.6 Alarm setting .....................................................................................................8-18

8.7 Setting for F value calculation (Setting common to all channels) ....................8-19

8.8 Parameter copy ..................................................................................................8-21

8.9 Setting for display refreshment cycles ..............................................................8-23

8.10 Setting for TAG. No., display range, and record mode .................................... 8-25

8.11 Setting for messages ..........................................................................................8-29

8.12 Setting for data display screen ..........................................................................8-31

8.13 Background color setting for the real time trend screen and

historical trend screen .......................................................................................8-35

8.14 Registering method of set values (saving to fl ash memory) .............................8-36

8.15 Setting for LCD OFF time ................................................................................8-37

8.16 Unit defi ne .........................................................................................................8-38

8.17 Setting for DI (external control unit) function .................................................. 8-39

8.18 Alarm setting (whole, memory FULL, battery) ................................................8-41

8.19 Adjustment method of clock ............................................................................. 8-43

8.20 Setting for record data format ...........................................................................8-44

8.21 Setting for RS485 communication function ......................................................8-45

8.22 Setting the Ethernet function .............................................................................8-46

8.23 Setting E-mail function .....................................................................................8-49

8.24 Setting E-mail trigger function ......................................................................... 8-50

8.25 Setting the user account ....................................................................................8-51

8.26 Password setting ................................................................................................8-52

8.27 Displaying record data of memory card ............................................................ 8-53

8.28 Removing memory card (compact fl ash) ..........................................................8-56

8.29 Reading settings ................................................................................................8-58

8.30 Writing settings .................................................................................................8-59

vi

INP-TN4PHR-E

8.31 Totalize calculation setting ................................................................................ 8-60

8.32 Setting for daily totalizing .................................................................................8-60

8.33 Setting for channel setting 1 (Daily) ................................................................. 8-62

8.34 Setting for channel setting 2 (Daily) ................................................................. 8-64

8.35 Setting for monthly totalizing ...........................................................................8-66

8.36 Setting for annual totalizing ..............................................................................8-67

8.37 Setting for external input totalizing................................................................... 8-69

8.38 Setting for totalize start/stop .............................................................................8-71

8.39 Setting for totalized value reset ......................................................................... 8-72

8.40 Setting of calculation channel ........................................................................... 8-73

8.41 Setting arithmetic operation for math channel ..................................................8-77

8.42 Input setting for math channel .......................................................................... 8-79

8.43 Calculation setting for math channel ................................................................ 8-80

8.44 Alarm setting for math channel ......................................................................... 8-81

8.45 Setting for TAG No., display range and record mode for math channel ...........8-82

8.46 Math channel parameter copy ........................................................................... 8-83

8.47 Math timer setting .............................................................................................8-84

8.48 Constant setting ................................................................................................. 8-85

9. MAINTENANCE AND INSPECTION ............................................................9-1

9.1 Recommended replacement cycle of parts ..........................................................9-1

9.2 Calibration ...........................................................................................................9-1

9.3 Formatting the memory card ............................................................................... 9-1

10. CALIBRATION ...............................................................................................10-1

10.1 Calibration method of measured values ............................................................ 10-1

10.2 Setting for date format ......................................................................................10-4

10.3 Initializing the set value ....................................................................................10-5

11. TROUBLESHOOTING....................................................................................11-1

12. SPECIFICATIONS ...........................................................................................12-1

APPENDICES .......................................................................................................... A-1

Appendix 1 Recording format (ASCII) ....................................................................... A-1

Appendix 2 Difference between Micro Jet Recorder (PHC) and PHR ....................... A-3

Appendix 3 Parameters that cannot be set during recording ....................................... A-5

Appendix 4 Parameters that cannot be set during totalizing ....................................... A-6

Appendix 5 Opening the PHR record data in ASCII format on Excel ........................ A-7

Appendix 6 Timing of recording ................................................................................. A-8

Appendix 7 Screen confi guration ................................................................................ A-9

CAUTION

INP-TN4PHR-E

Refer to chapters 3 and 4 only when installing this instrument. Only qualifi ed workers should carry out mounting and wiring of this instrument.

vii

1. INTRODUCTION

We thank you for purchasing Fuji Paperless Recorder PHR.

The instruction manual describes installation, operation, and maintenance of Paperless Recorder. Read this

manual carefully before use.

1.1 Paperless recorder

(1) This recorder displays measured data in real time on the liquid crystal display. It is a paperless

type that is also capable of saving the measured data to a compact fl ash card.

(2) It can set up to 18 channels for the input types such as thermocouple, resistance bulb, and DC

voltage (or current).

(3) It allows the measured data saved to the compact fl ash card to be displayed on the display unit.

Use of the support software attached to the recorder allows the saved data to be displayed on a

personal computer.

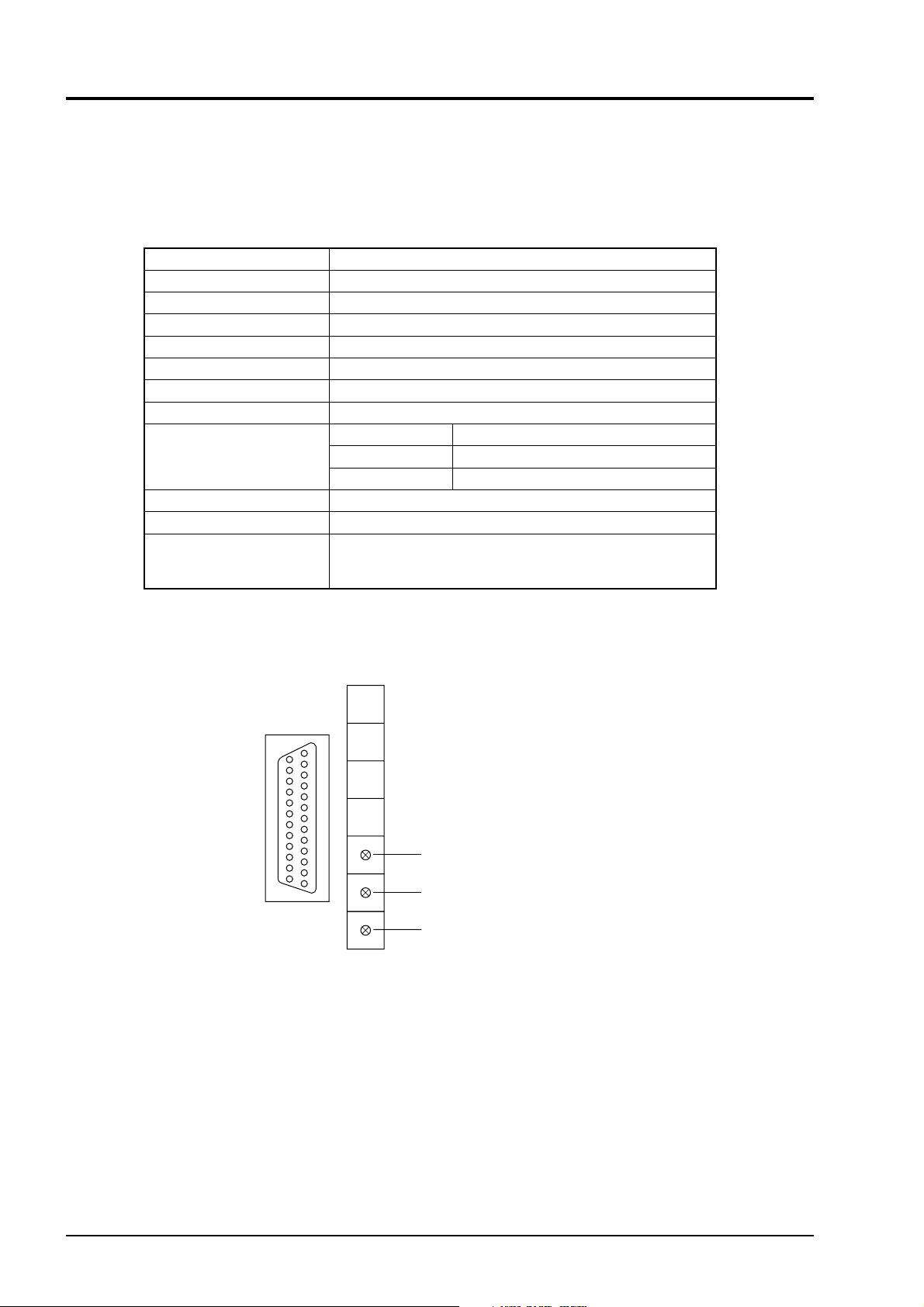

1.2 Product check

Upon receiving the recorder unit, check the appearance for damage, and if the correct quantity of the

accessories are supplied.

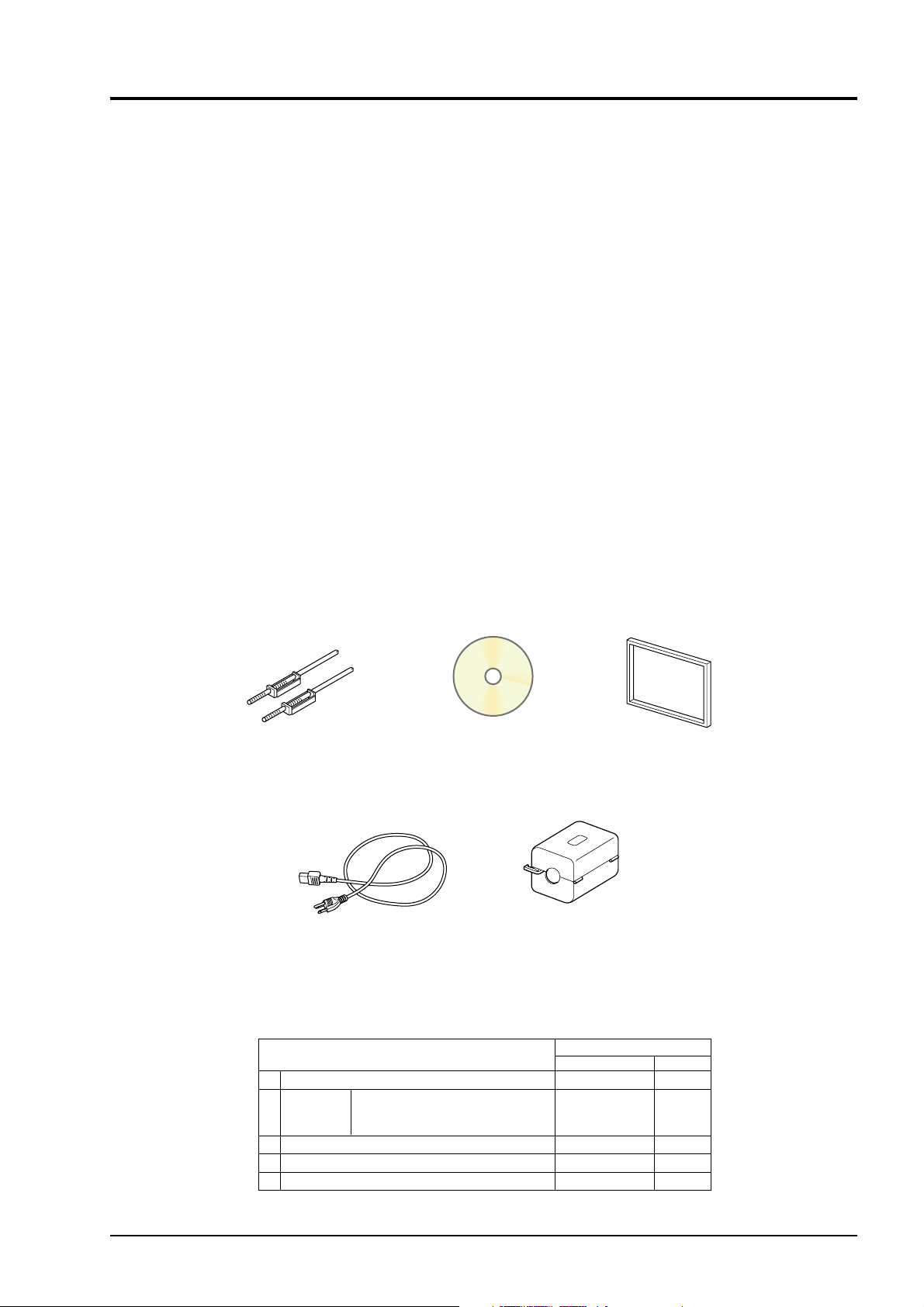

Check on accessories

This recorder comes with the accessories shown in Fig. 1-1. Check that they are all present.

(1) Panel-mounting

bracket

(4) AC power cord

(2) PC support software

(CD-ROM)

(5) Power supply

noise filter

(3) Panel packing

Fig. 1-1 Accessories

INP-TN4PHR-E

Product name

(1)

Panel-mounting bracket

CD-ROM PC support software instruction

(2)

(3)

Panel packing for front face

(4)

AC power cord (2m)

(5)

Power supply noise filter

manual (both in Japanese and

English)

-1

1

Quantity

2

1

1

1

1

PortablePanel-mounted

–

1

–

1

1

1.3 Check on type and specifi cation

Code symbols are marked on specifi cation nameplates. Check the type as ordered. (The specifi cation

nameplates are attached to the right of the case and at the rear of the display unit).

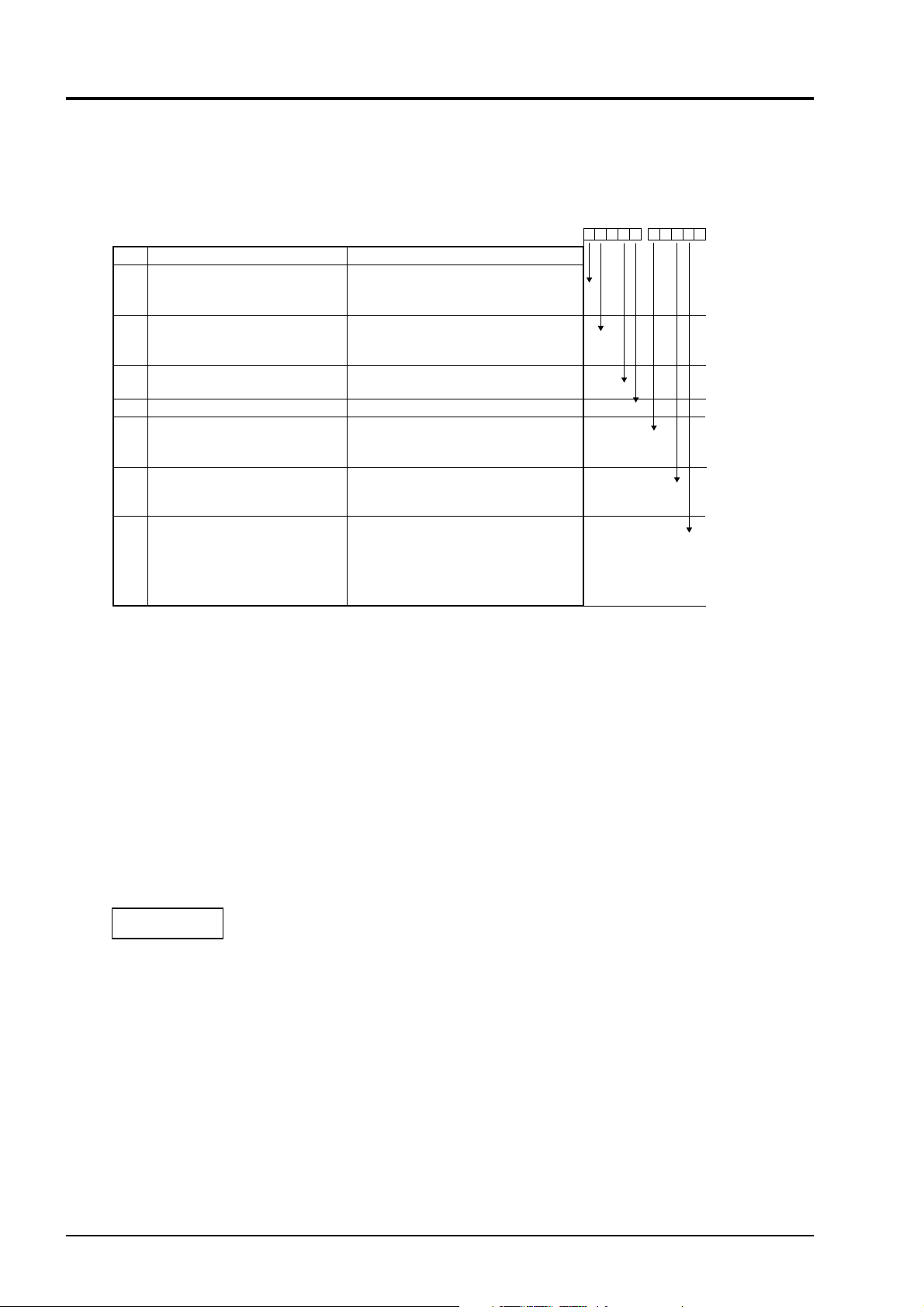

PHR

Digit Note

<Number of input points>

4

9

18

<Mounting>

5

Panel mounted

Portable (desktop)

<Compact flash>

7

Without

<Improvement No. (Fixed)>

8

<Display (instruction manual)>

9

Japanese

English

<Alarm relay output/DI input>

11

Without

With

Communication/alarm

12

(open collector) output/

DI input/Ethernet

Note 1: If you select 2 (18-point input) for the 4th digit of the code symbol,

you cannot select 1 for the 11th digit (alarm output/DI input board).

Note 2: If alarm output/DI input for 18-point input is required, select R or W for the 12th digit

(communication/alarm output/DI input/Ethernet).

Note 3: Portable type is not approved by UL and CE marking.

Portable type cannot be selected with Ethernet.

Specifications

(Note 3)

(Note 1)

Without

RS485+DI+DO (Note 2)

Ethernet (Note 3)

Ethernet+RS485 +DI+DO (Note 2, 3)

45678

1

2

1

2

-

41

1

B

1

4

N

E

9 10111213

0

1

Y

Y

R

E

W

1.4 Handling memory card (Compact Flash) – Cautions on handling

(1) For the memory card, use Sandisk’s compact fl ash memory (URL: http://www.sandisk.co.jp).

Other memory cards may case trouble to the recorder.

1) Be sure to format the memory card with the PC you use.

Format it as FAT16 or FAT. If it is formatted as NTFS, for example, it cannot

CAUTION

be used because the PHR does not recognize it.

2) The memory card should be inserted in the proper direction and fi xed securely

to the slot.

3) Don’t turn OFF the power or remove the card from the slot while data is being

written in or read from the card, or recorded data may be damaged or lost.

4) Measured data saved to the memory card should be backed up, if necessary.

If the CF card should be broken, important record data will be lost. Be sure to

backup the data.

Before using a CF card adaptor, check the capacity of the adaptor. If the capacity of the memory card to be formatted is larger than that of the adaptor, do

no format the card. Otherwise the PHR does not recognize it even if it could

be formatted on Windows.

-2

1

INP-TN4PHR-E

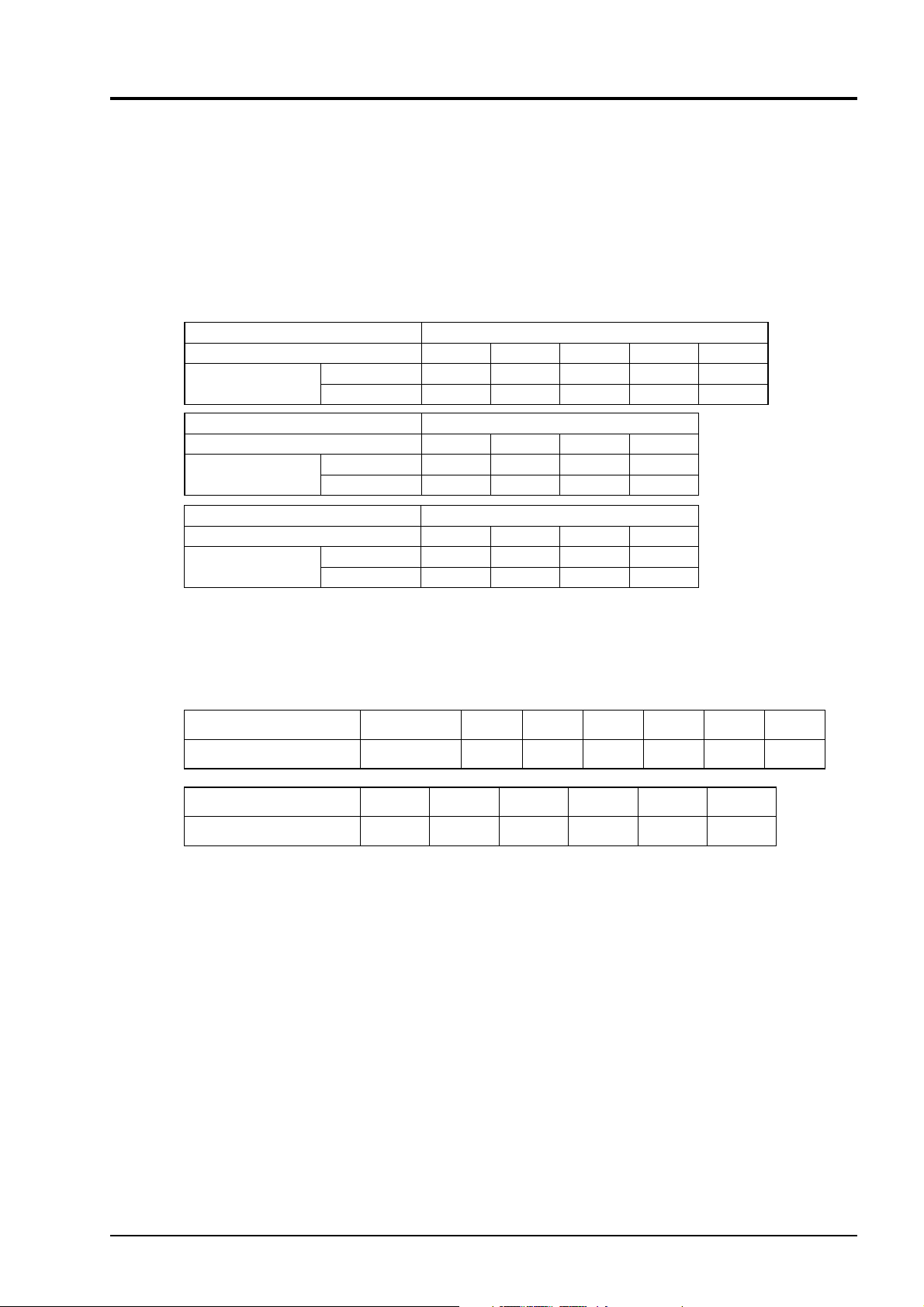

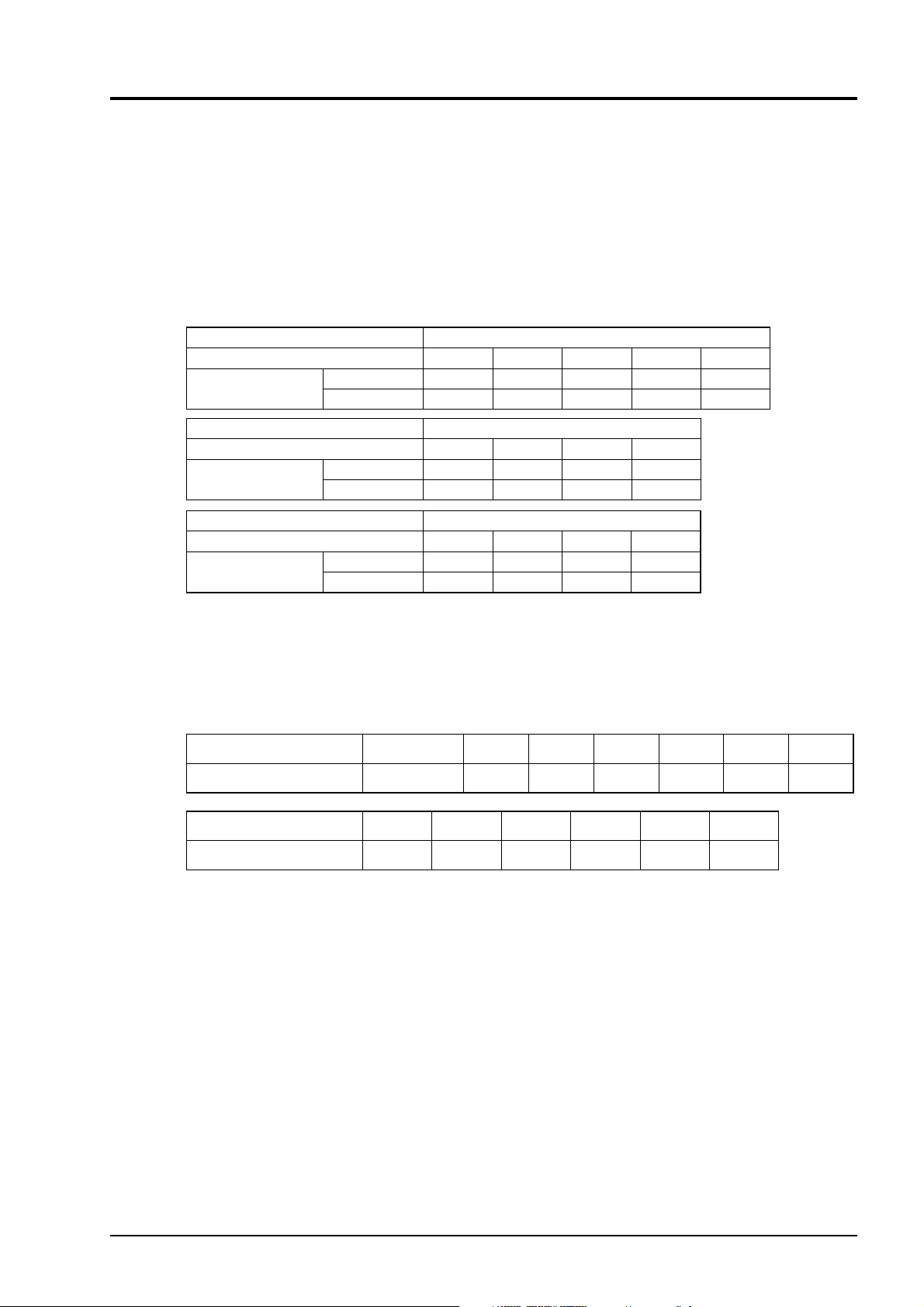

(2) Compact fl ash in the capacity range from 8MB to 1GB can be used.

Refer to the following tables for the storage capacity in the case of 9-channel recording (on condi-

tion that no events such as alarms or messages are occurring, and that integration is stopped).

(The number of days required for 18-channel recording is approximately one half of those shown

in the table.)

(The number of days required for average value recording and instantaneous value recording is

approximately twice of those shown in the table.)

Compact flash size

Display refresh cycle

Recordable capacity

(about)

Compact flash size

Display refresh cycle

Recordable capacity

(about)

Compact flash size

Display refresh cycle

Recordable capacity

(about)

Note: Refer to Item 8.19 “Setting method of record data format” for the selection of ASCII or binary format

for data recording.

ASCII format

Binary format

ASCII format

Binary format

ASCII format

Binary format

1 sec 10 sec 30 sec 1 min 10 min

112 hours 46 days 140 days 280 days 7.7 years

448 hours 184 days 560 days 1,120 days 30.8 years

1 sec 10 sec 30 sec 1 min

226 hours

932 hours

1 sec 10 sec 30 sec 1 min

18 days 187 days 1.5 years 3 years

72 days 748 days 6 years 12 years

94 days 282 days 565 days

388 days 3.2 years 6.4 years

64MB

128MB

256MB

(3) Data write to the memory card is performed according to the following timing. If the power is

OFF in the writing cycle, note that the data will not be recorded.

Display refresh cycle 1 sec to 1min 2 min 3 min 5 min 10 min 30 min

Write cycle 1 min 2 min 3 min 5 min 10 min 30 min

20 min

20 min

Display refresh cycle 1 hour 2 hours 3 hours 4 hours 6 hours

Write cycle

1 hour 2 hours 3 hours 4 hours 6 hours 12 hours

12 hours

(4) The data recorded in the compact fl ash can be regenerated on the PC by using the data viewer

(contained in the attached CD-ROM).

If the data is recorded in ASCII format, it can be directly opened in a spreadsheet such as EXCEL.

However, large-amount data cannot be opened (about 10MB or larger in the case of 9-point input,

and about 5MB or larger in the case of 18-point input).

In those cases, read in data with the data viewer (contained in the attached CD-ROM), and per-

form CSV conversion to divide the fi le, which allows the data to be read in.

The data recorded in binary format cannot be directly opened in a spreadsheet such as EXCEL.

See “

8.20 Setting for record data format

” for details.

Note: Be careful not to make the size of a fi le too large even if a large-capacity CF card is

used. (Keep it to less than 10MB if possible.)

INP-TN4PHR-E

-3

1

(5) Removing memory card

By prohibiting the writing on the memory card, the card can be taken out even if the recording or

integration is not stopped. Refer to Item 8.28 “Removing memory card (compact fl ash)” for the

procedure.

CAUTION

Make sure to prohibit writing before removing the memory card, when using FTP

server function.

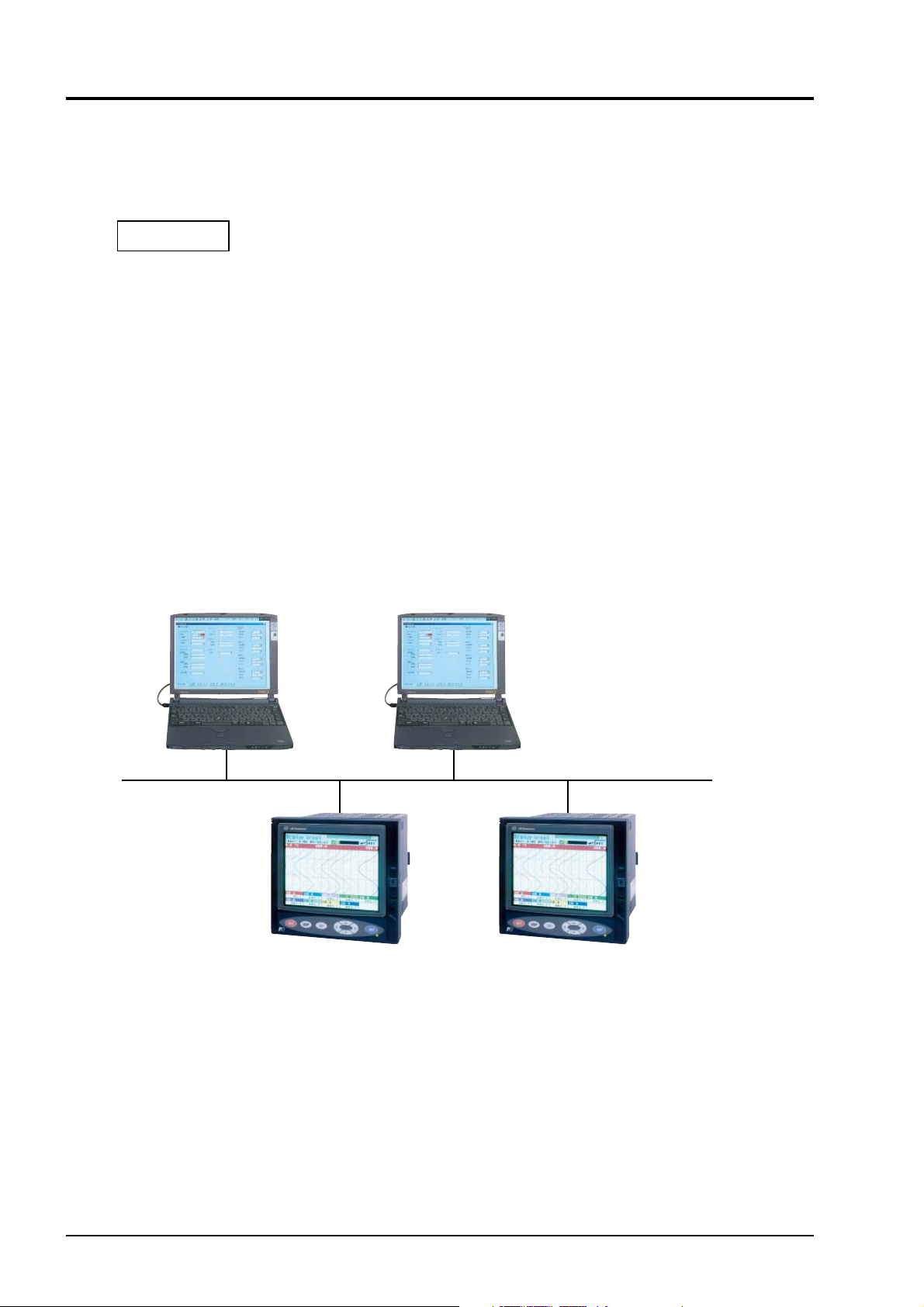

1.5 Ethernet communication function

By connecting the paperless recorder to Ethernet, the following function can be used (when E or W is

selected for the 12th digit of the code symbols).

• FTP server function: Record fi les stored in the compact fl ash of the recorder can be downloaded

from the PC on the network using Web browser (Microsoft Internet Explorer) or DOS prompt.

• Web server function: Measurements of the recorder or event log on the network can be displayed

using Web browser (Microsoft Internet Explorer).

• E-mail function: E-mails can be sent to specifi ed addresses with the measurement of the recorder

attached.

• MODBUS TCP/IP function: Settings of the recorder can be read or written from the PC on the network using MODBUS TCP/IP function.

Ethernet

-4

1

INP-TN4PHR-E

2. NAMES AND FUNCTIONS OF PARTS

2.1 Names and functions of parts

(1) Display unit

(6) Function keyboard

(1) Display unit

Allows the Real time trend screen, Bar Graph Display screen, Analog Meter Display screen,

Digital Display screen, Totalized Value Display screen, Historical trend screen and other various

Parameter Set screens to be displayed.

(2) Power switch

Used to turn the power ON or OFF.

(3) Memory card slot

Used for inserting the memory card

(4) Memory card ejection button

To remove the memory card from the slot, press this button.

CAUTION

(5) Connector to parameter loader

When changing parameters by using a loader, connect the exclusive cable (optional cable:

PHZP1801) to the connector.

(6) Function keyboard

Used for operation, or setting and verifying each parameter.

1) Do not remove the memory card while recording is in progress (while REC in

the display unit is highlighted) or during totalizing. Otherwise, the data cannot be recorded correctly, or the past data may be damaged. Be sure to stop

recording and totalizing before removing the memory card. (If the memory card

is removed and inserted again while recording or totalizing is in progress, it is

recorded as a new fi le.)

2) While the compact fl ash of the paperless recorder is accessed by FTP communication, do not take out the compact fl ash.

Furthermore, when the FTP server function is used, inhibit access to the compact fl ash in the “Memory card abstract” screen, before taking out the compact

fl ash.

(5) Connector for

parameter loader

(3) Memory card slot

(4) Memory card ejection button

(2) Power switch

INP-TN4PHR-E

-1

2

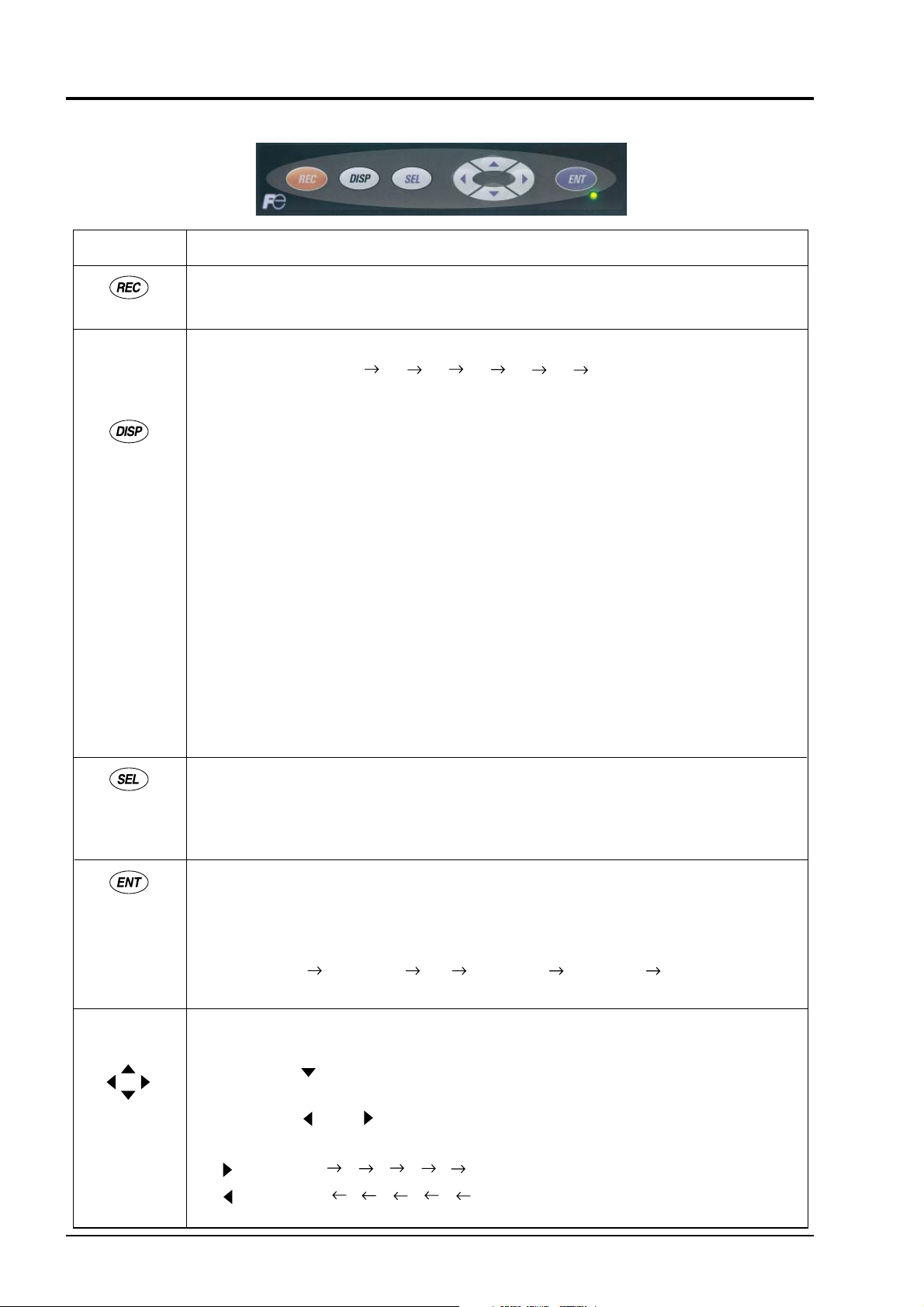

Key name

(Record)

(Display)

Function

Used to start or stop recording.

Pressing once starts recording, and pressing once again stops recording.

Used to switch displayed contents. Every time it is pressed, the display is switched

in the following order: (1) (2) (3) (4) (5) (6) (7) and back to (1).

(1) Real time trend display

Displays the measurement data of an arbitrary channel

(2) Key guidance display

Displays the guide for key operation.

(3) Bar graph/analog meter display

Displays the measured data of the channel in a bar graph (or analog meter)

(4) Digital display.

Displays the measured data of the channel in numerical values.

(5) Totalizing data display

Displays the totalizing data of an arbitrary channel in numerical values.

(6) Event summary display

Displays the alarm summary or message summary.

(7) Ethernet log display

Displays the FTP communication and E-mail sending log.

Used to switch the parameter setting screen to the data display screen.

Pressing the key on the historical trend screen, historical jump window appears.

(Select)

(Entry)

(Cursor)

Used to switch from the data display screen to the parameter setting screen.

Pressing the key on the parameter setting screen switches to the screen one step up.

Pressing the key on the historical trend screen switches to the real time trend screen.

Note, however, that pressing the key on the menu screen does not change screens.

(1) Used for selection on the setting screen or registration of the set data.

(2) If the key is pressed while the scales are displayed on the real time trend display screen,

historical trend display screen (*1), or recorded data display screen, the channels for which

scales are to be displayed can be switched.

(Scale of ch1 scale of ch2 ….. scale of ch9 scale of ch1 scale of ch2…..)

*1: The screen in the past of the data currently recorded

(1) Used to select setting items.

(2) Used to increase or decrease numerical values.

(3) Pressing the key on the real time trend displays the historical trend screen (*1).

At this time, the window can be scrolled using the cursor key.

(4) Pressing the or the key on the real time trend display, bar graph/analog meter display,

digital display, or totalized value display screen switches group screens as follows.

key: Group 1 2 3 4 1 ...

key: Group ... 1 4 3 2 1

*1: The screen in the past of the data currently recorded

-2

2

INP-TN4PHR-E

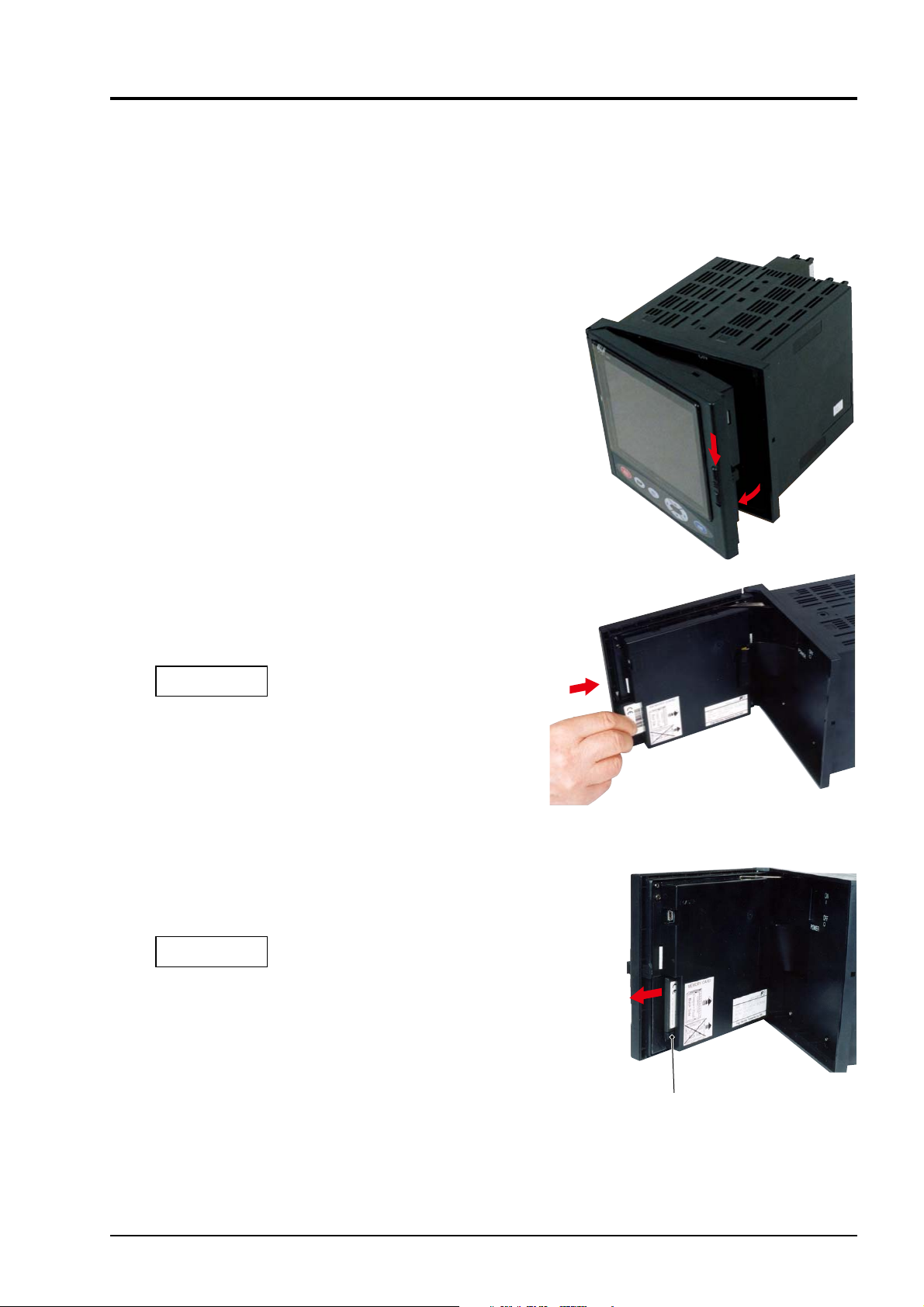

2.2 Inserting and removing the memory card

The memory card is used for saving measured data. Before attempting to use the recorder, set it in the

recorder slot securely.

This section explains how to insert the memory card into or remove it from the slot.

(1) To insert memory card

Step 1) Open the panel unit.

Step 2) Insert the memory card into the slot at the

right side of the panel unit as shown in

Photo.

Insert the card straight into the

CAUTION

slot as shown by the photo at

right.

Be careful not to forcibly press

the card if it is inserted obliquely.

Otherwise the pin on the PHR

may be damaged.

(2) To remove memory card

Step 1) Press the memory card ejection button to remove the

memory card from the slot.

CAUTION

INP-TN4PHR-E

(1) Do not remove the memory card

while data is written in it (while the

lamp indicating writing status is kept

on). Refer to Item 8.28 “Removing

memory card (compact fl ash)” for the

removal of the memory card while

recording is in progress.

(2) After inserting the memory card into

the slot, don’t remove the card until

the recorder can acknowledge it.

(3) Be careful with static electricity when

removing the memory card.

Memory card ejection button

-3

2

2.3 Recording data to memory card

(1) Folder confi guration of the memory card:

The following folders are created in the memory card.

Folder name

Root folder

S000000

S******.FDT Record file

A******.FDT Event file

Folder name File name

T000000

Folder name

PA RA M

T******.FDT Daily totalizing data file

D******.FDT Monthly totalizing data file

M******.FDT Annual totalizing data file

E******.FDT External signal totalizing data file

PA00000.PHR Setting value file

(2) Recorded data:

Data can be recorded in the following four formats. Either ASCII or binary format can be selected

for recording. Refer to Item 8.20 “Setting for record data format.”

Trend data : Records the maximum and the minimum values of the measured

value sampled at display update cycles.

Trend data fi le name to be created: S00****.FDT (**** is substi-

tuted by four-digit numerical value.)

Refer to “Appendix 1 (1) Trend data fi le” for recording format.

Event data : Records the information on occurrence or release of alarms and mes-

sage issuing information.

Event data fi le name to be created: A00****.FDT (**** is substi-

tuted by four-digit numerical value.)

Refer to “Appendix 1 (2) Event data fi le” for recording format.

Totalizing data : Records the totalizing data every totalize recording cycle.

The name of the totalizing data fi le created is as follows.

Daily report: T000000.FDT

Monthly report: D000000.FDT

Annual report: M000000.FDT

External input: E000000.FDT

Setting value fi le : The setting value of the recorder can be stored in a memory card.

Name of the confi guration fi le to be created: *******. PHR (Substi-

tute arbitrary capital letters or numerical value for *******.)

-4

2

INP-TN4PHR-E

(3) Recording capacity:

It depends on the capacity of the memory card.

Refer to the following tables for the storage capacity in the case of 9-channel recording (on condi-

tion that no events such as alarms or messages are occurring, and that integration is stopped).

(The number of days required for 18-channel recording is approximately one half of those shown

in the table.)

(The number of days required for average value recording and instantaneous value recording is approximately twice of those shown in the table.)

Compact flash size

Display refresh cycle

Recordable capacity

(about)

Compact flash size

Display refresh cycle

Recordable capacity

(about)

Compact flash size

Display refresh cycle

Recordable capacity

(about)

Note: Refer to Item 8.20 “Setting for record data format” for the selection of ASCII or binary format

for data recording.

ASCII format

Binary format

ASCII format

Binary format

ASCII format

Binary format

1 sec 10 sec 30 sec 1 min 10 min

112 hours 46 days 140 days 280 days 7.7 years

448 hours 184 days 560 days 1,120 days 30.8 years

1 sec 10 sec 30 sec 1 min

226 hours

932 hours

1 sec 10 sec 30 sec 1 min

18 days 187 days 1.5 years 3 years

72 days 748 days 6 years 12 years

94 days 282 days 565 days

388 days 3.2 years 6.4 years

64MB

128MB

256MB

(4) Recording cycle:

The following tables show the timing of writing the trend data to the compact fl ash.

The event data is written in the compact fl ash by the minute.

Display reflesh cycle 1 sec to 1min 2 min 3 min 5 min 10 min 30 min

Writing cycle 1 min 2 min 3 min 5 min 10 min 30 min

20 min

20 min

Display reflesh cycle 1 hour 2 hours 3 hours 4 hours 6 hours

Writing cycle

1 hour 2 hours 3 hours 4 hours 6 hours 12 hours

(5) Timing to start recording:

The event data cannot be written in the compact fl ash before the initial display update cycle.

INP-TN4PHR-E

-5

2

12 hours

3. MOUNTING METHOD

This unit is designed to be panel mounted.

3.1 Mounting location

Select the following location for mounting the unit.

(1) A place that is not subject to vibration or shock.

(2) A place where there is no dust, dirt or corrosive gas.

(3) A place where ambient temperature falls within 0 to 50°C range with minimum temperature fl uc-

tuation (Recorder provided with Ethernet function: 0 to 40°C).

(4) A place that is not struck directly by strong radiant heat.

(5) A place that is free from water drip or dew condensation in the range of 20 to 80%RH.

(6) A place that is well ventilated for the dispersion of heat generated from other devices.

(7) A space that is accessible for wiring, and maintenance and check.

(8) A place that is not affected by electromagnetic wave from wireless machine or

portable telephones.

(9) Mount the unit horizontally, with no tilt to the left or right (The forward tilt

should be 0° but the unit may be inclined 0 to 30° rearwards.

∠α = 60 to 90°

∠α

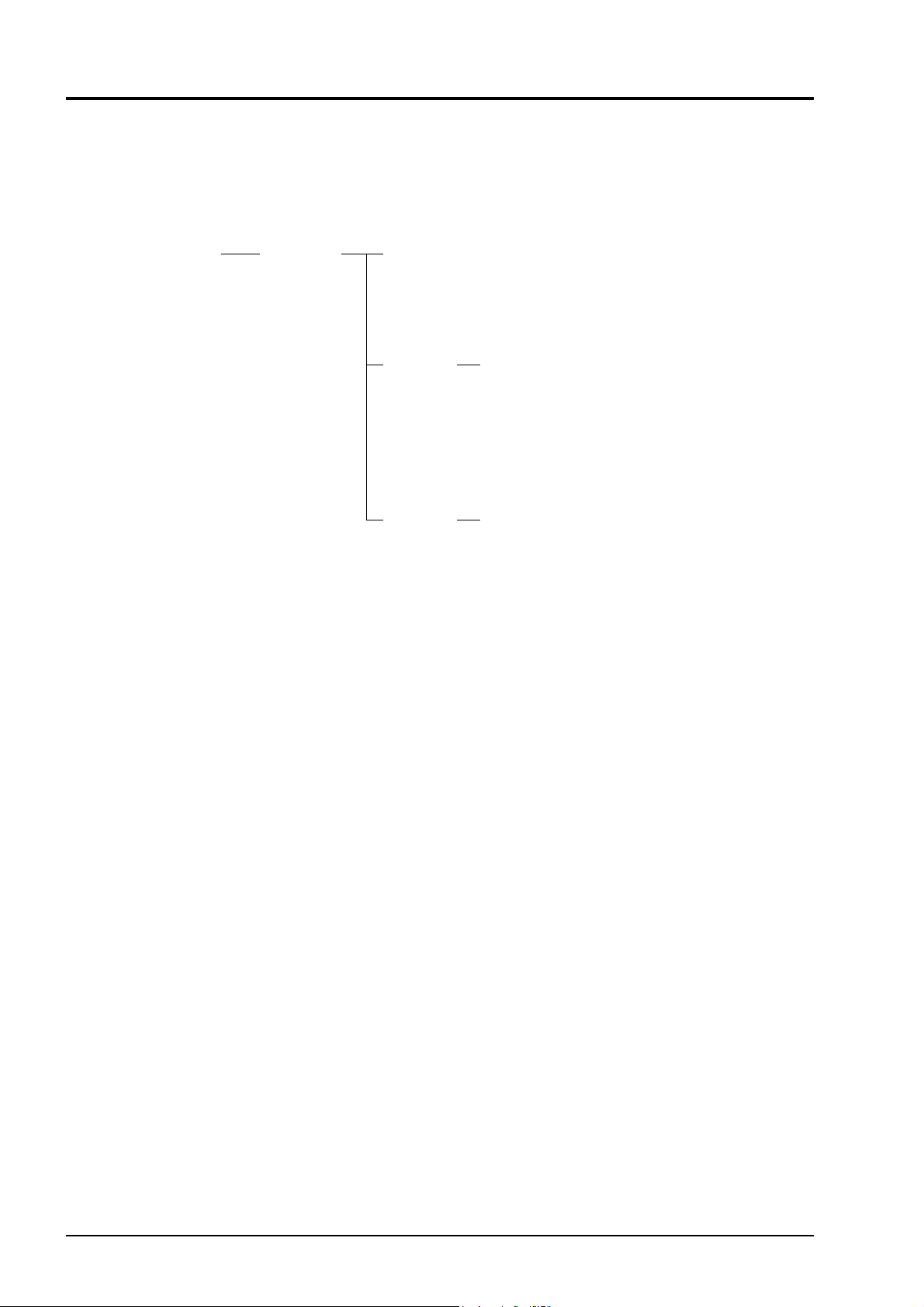

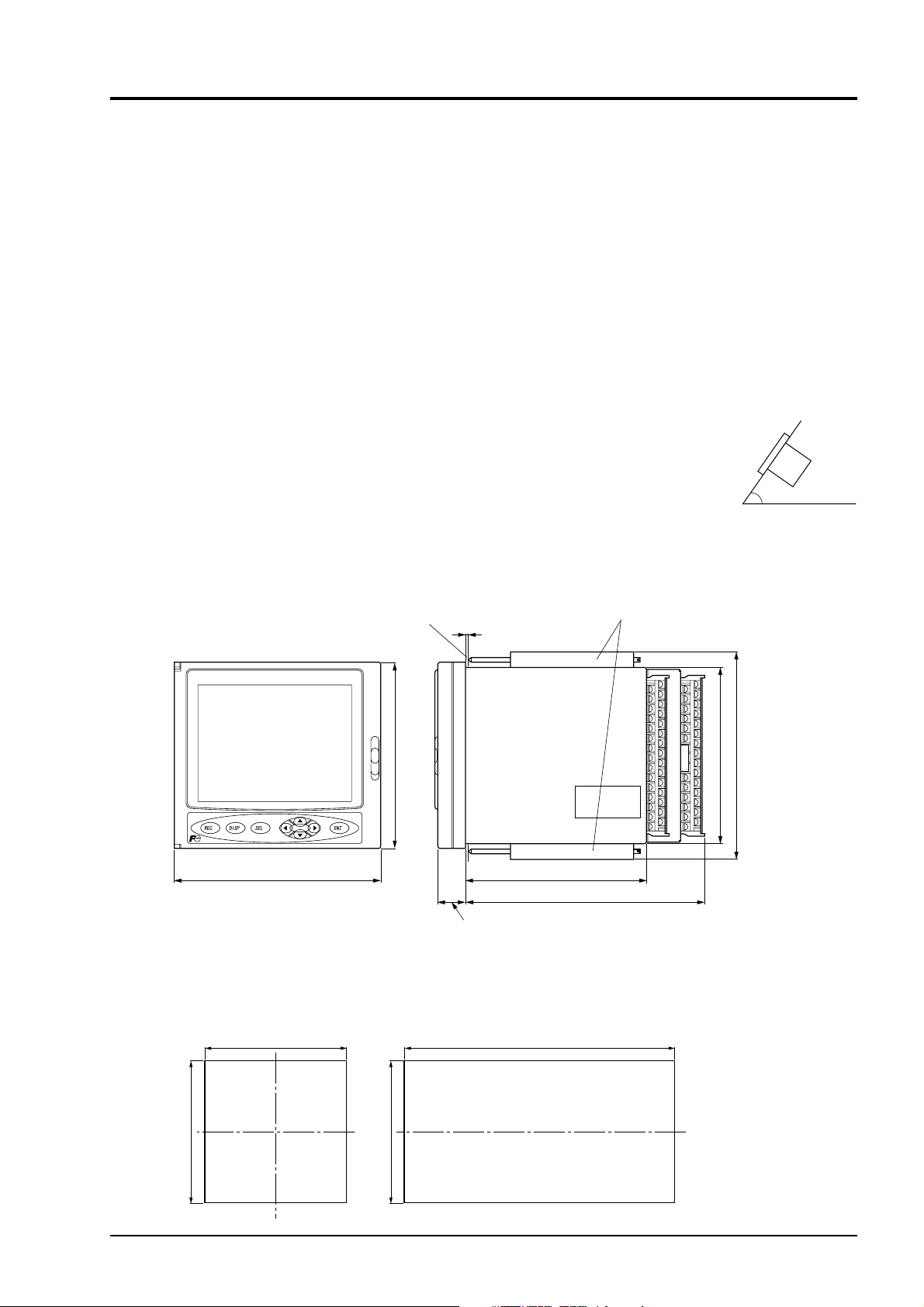

3.2 External dimensions and panel cutout dimensions (unit: mm)

161

136.5

External dimensions

160 140

Note) If other instruments are placed under the recorder unit,

provide a space of 100 mm or more from the instrument or floor.

Panel cutout dimensions

Mounting 1 unit Mounting n units

+1.5

137

0

Pane l

144

2 ≤ T ≤ 26

T

21.6

24.6 when packing is used

(160 × n–22)

Mounting bracket

185

+2

0

+1.5

0

137

INP-TN4PHR-E

+1.5

0

137

Note) When mounting n units, don't use packing.

-1

3

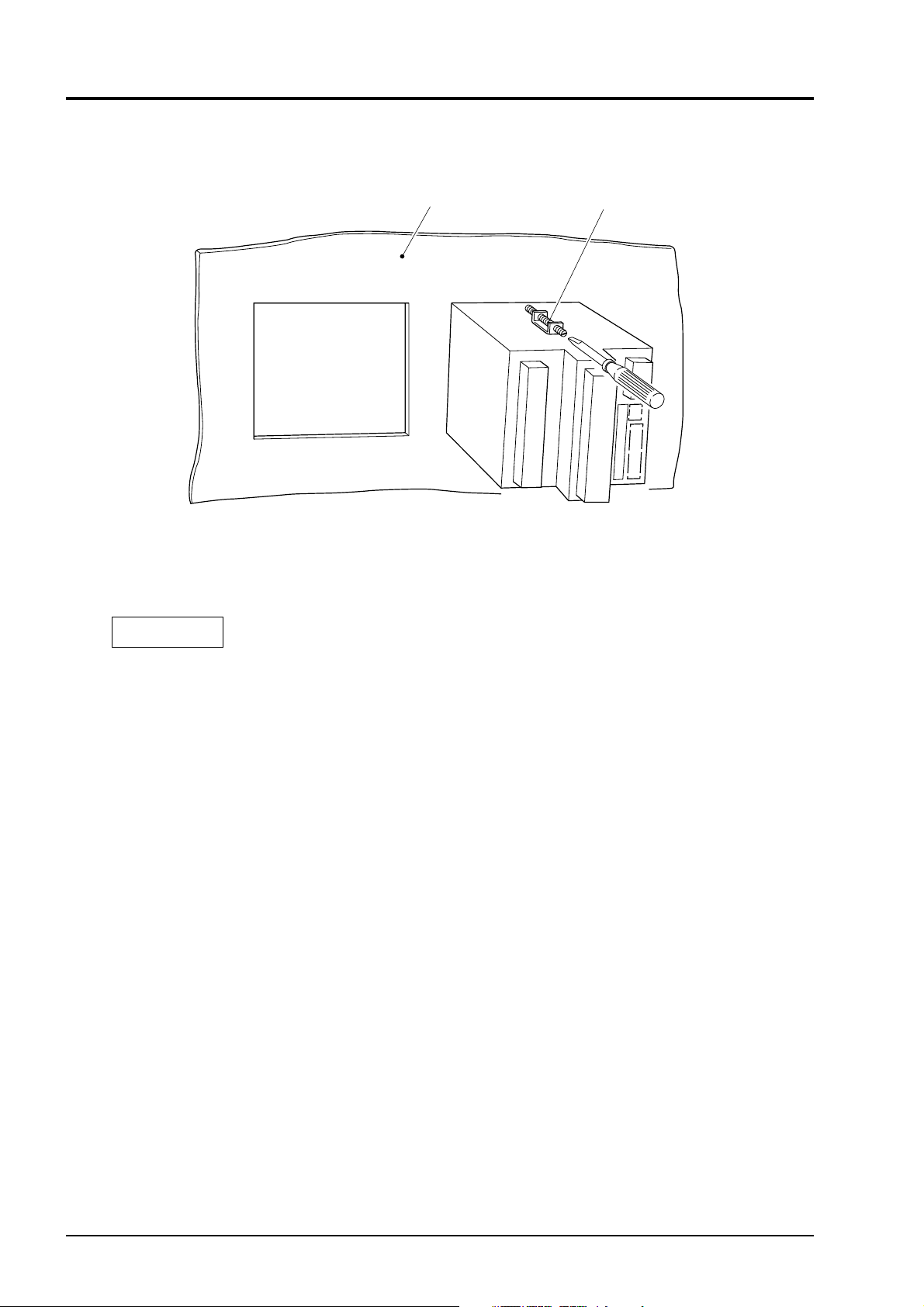

3.3 Method of mounting onto panel

Panel

• Using the supplied mounting bracket, tighten the upper and lower screws unit the panel is fi xed.

• The panel to be used should be more than 2 mm thick.

CAUTION

Excessive torque will cause damage to front panel frame or result in case de-

formation.

Torque: 0.2 N·m

Mounting bracket

• If the panel front is subject to water splashes, use panel packing between the unit and panel.

-2

3

INP-TN4PHR-E

4. WIRING

4.1 Before wiring

(Note) When cables are connected to terminals of the recorder unit, don’t apply pulling force to them

excessively. Excessive force to the terminal may result in damage to the terminal or cable.

(1) Use the power cable that has the performance equivalent to or higher than 600-V vinyl insulated

power cable (IEC227-3). Install the attached noise fi lter within approximately 20cm from the

power terminal of this instrument. (Wind the power cable 1 to 2 turns.)

(2) For the thermocouple input, be sure to use a compensated lead wire.

(3) Input signal cables should be wired separately as far as possible (30 cm or more) from power lines

and high-voltage lines to minimize the effect of inductive noise. Shielded cables should preferably be used. In this case, the shield braids should be earthed at one point.

(4) Up to 2 solderless terminals should be used when connecting cables to terminals. Be sure to use

an insulation cap.

(Note)

1) At the completion of wiring of the input terminals, be sure to close the rear cover to ensure

the compensation of reference contact when thermocouple input is used.

In case of thermocouple input, follow the steps to stabilize temperature at the terminal.

• Be sure to attach input terminal cover.

• Don’t use a thick cable to prevent the effect of radiation. It is recommended that the cable

with a diameter of 0.5 mm or less should be used.

• Don’t mount other instruments near a fan to keep temperature stable.

2) For connection of lead wires to terminals, use of sleeve-insulated clamping terminals is recommended.

3) This unit has no power fuse. Mount a power fuse outside the unit

as needed.

Recommended fuse rating: 250V AC, 1A

4) Don’t loosen screws that are secured to the terminal case and

power terminal.

INP-TN4PHR-E

-1

4

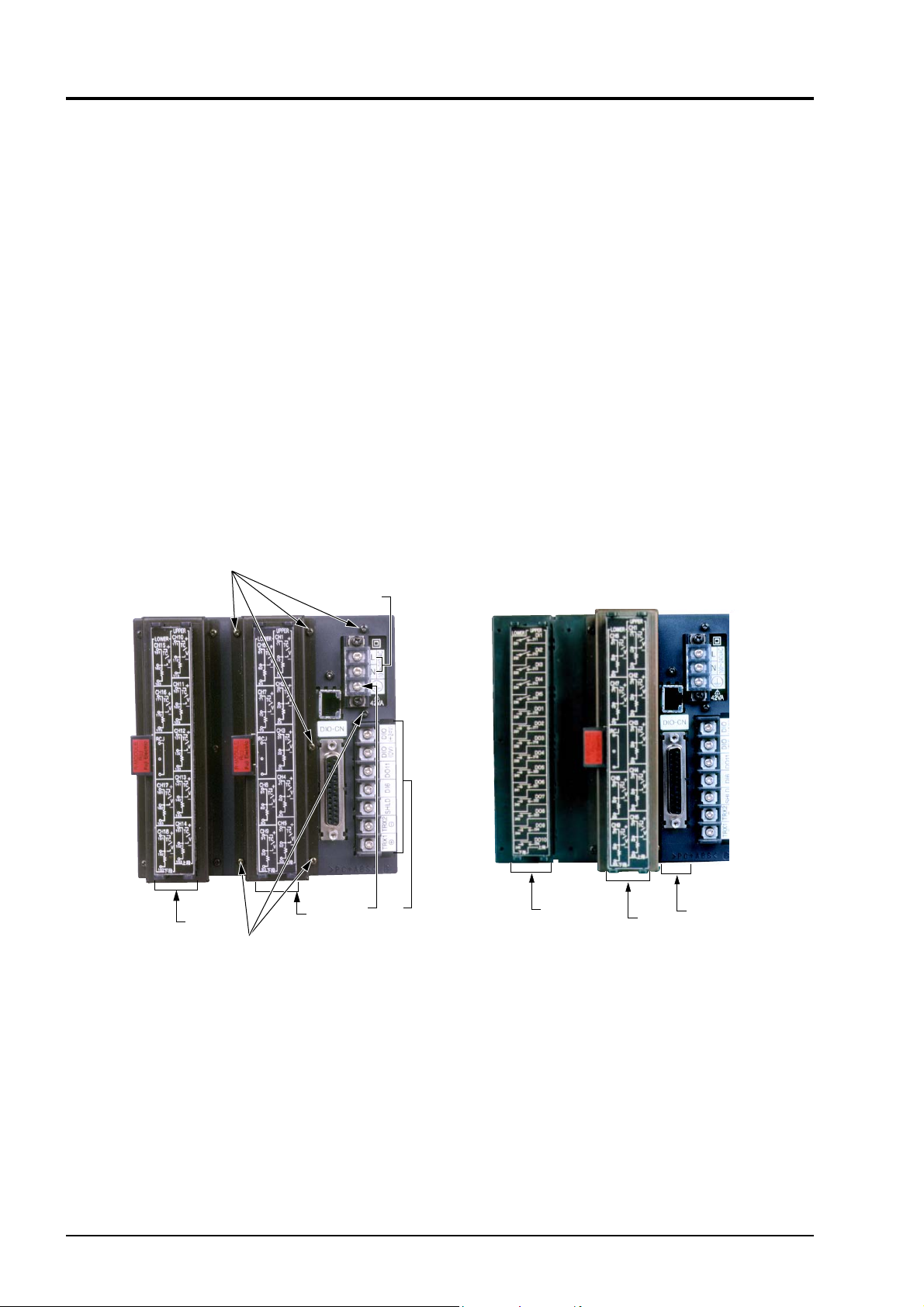

4.2 Connection to terminals

(1) Input terminal:

Connect signal cable for each channel.

(2) Alarm (DO)/DI (External control unit):

Connect the output of alarm signals and the input of DI (external control) signals (for alarm [DO]

1 to 10 and DI [external control] 1 to 5)

(3) Power terminal:

Connect power cable to L/N terminals. Power source to be connected should be free from noise.

(4) Earth terminal:

Connect to “G” terminal (Class-D, 100Ω or less).

(5) Communication, alarm (open collector) output and DI terminal:

Connect the input of alarm output (DO11) and DI (external control: D16) signals.

-

Connect communication signal cable to TRX (+) and TRX (

(6) Alarm (open collector) output and DI input:

Connect the input of alarm output (DO12 to 28) and DI (external control: DI7 to 10) signals.

Do not loosen.

).

(3)

(1)

Do not loosen.

(1)

(4) (5)

(2)

(1)

(6)

Note: Do not loosen the screws. Otherwise accurate measurement may not be carried out with

thermo-couple input.

-2

4

INP-TN4PHR-E

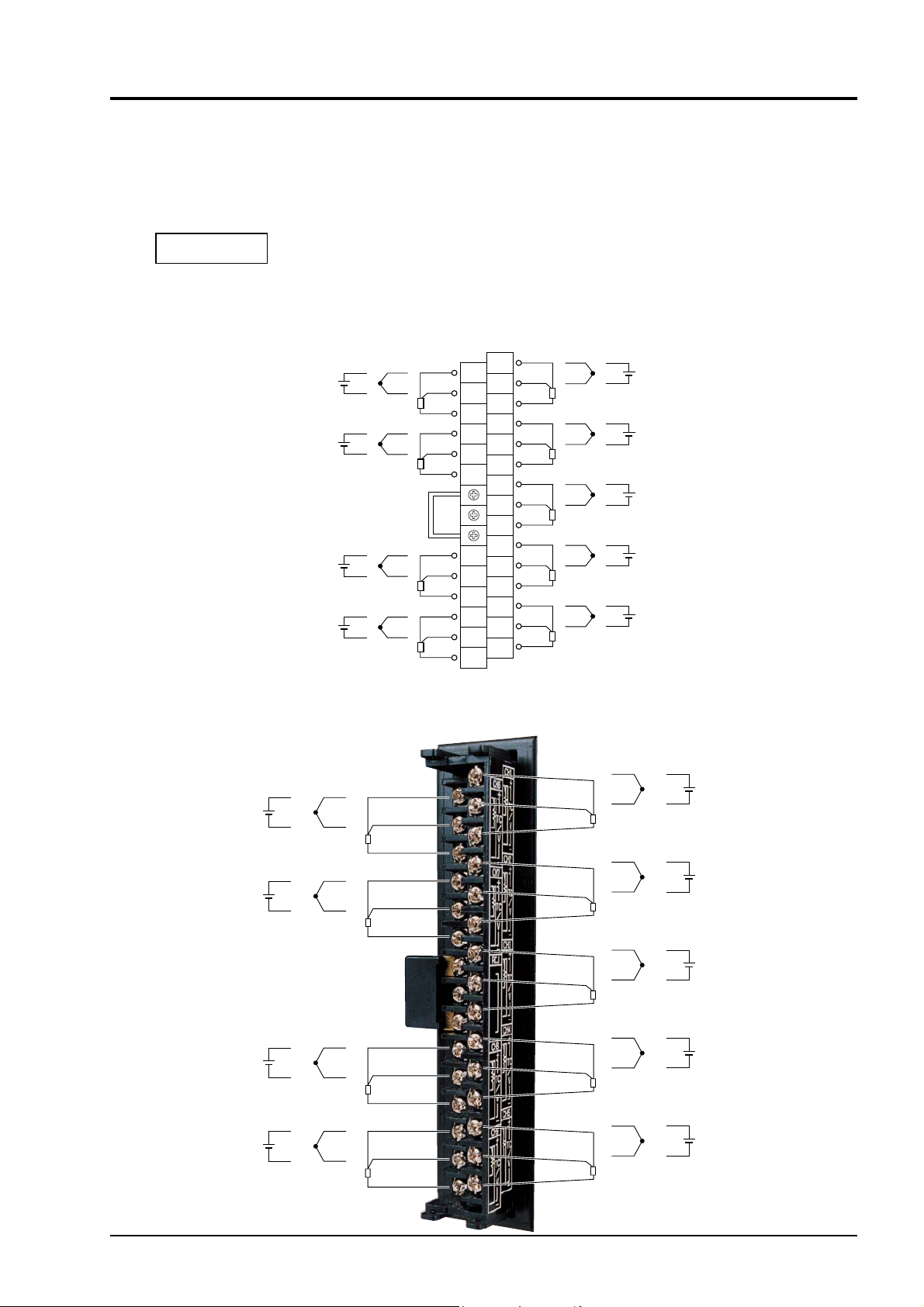

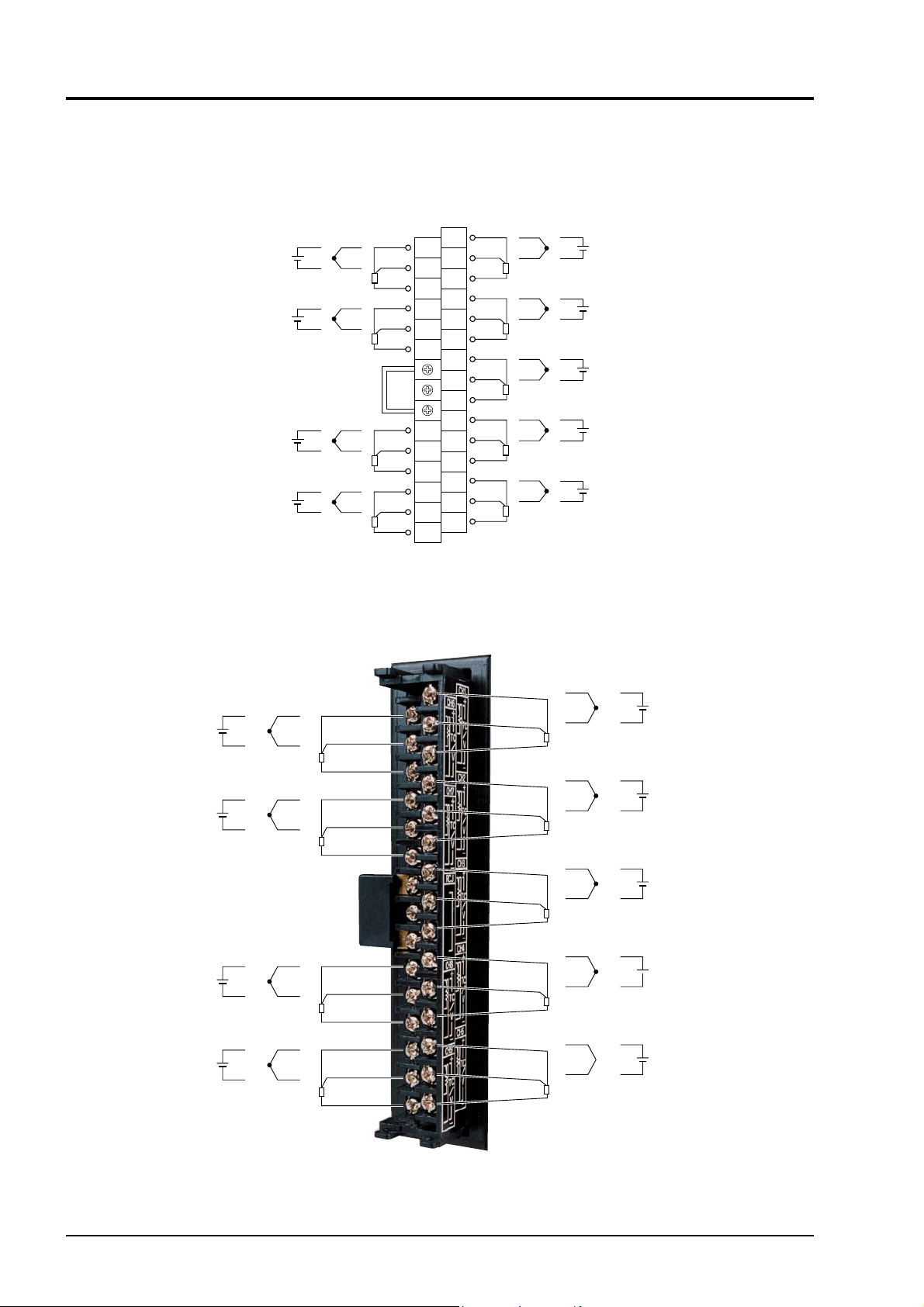

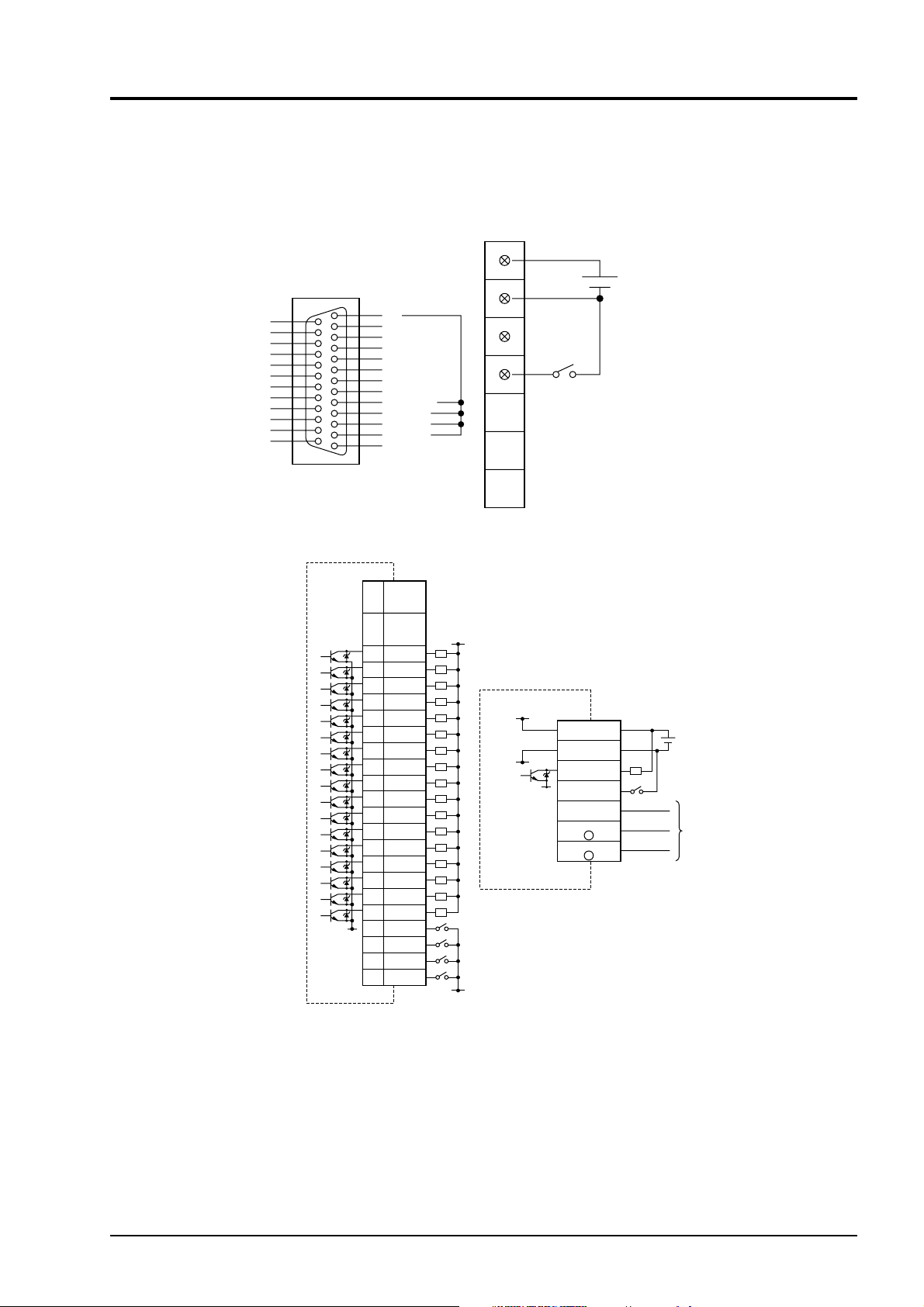

(1) Wiring of input terminal

1) Input terminal No. is determined for each channel.

2) When changing the type of input signal (see Item 8.4) after purchasing the unit, connect input

terminals according to the relation between terminal No. and channel No.

CAUTION

Channel 1 to 9

Do not apply excessive voltage. Otherwise the PHR circuit may be damaged,

and proper operation may not be performed.

Input terminal

Thermocouple

Resistance

bulb

Voltage

+

+

–

–

CH1

+

+

–

–

CH2

+

+

–

–

CH3

+

+

–

–

CH4

+

+

–

–

CH5

CH6

CH7

CH8

CH9

Thermocouple

Voltage

+

–

+

–

+

–

+

–

Resistance

bulb

+

–

+

–

RCJ

+

–

+

–

61

62

63

71

72

73

81

82

83

91

92

93

11

12

13

21

22

23

31

32

33

41

42

43

51

52

53

Note) For current input, connect optional shunt resitors to the voltage input terminals.

Resistance

bulb

ThermocoupleThermocouple

+

–

+

–

+

–

+

–

+

–

CH6

CH7

CH8

CH9

Resistance

bulb

+

–

+

–

+

–

+

–

+

–

+

–

RCJ

+

–

+

–

VoltageVoltage

+

CH1

–

+

CH2

–

+

CH3

–

+

CH4

–

+

CH5

–

INP-TN4PHR-E

-3

4

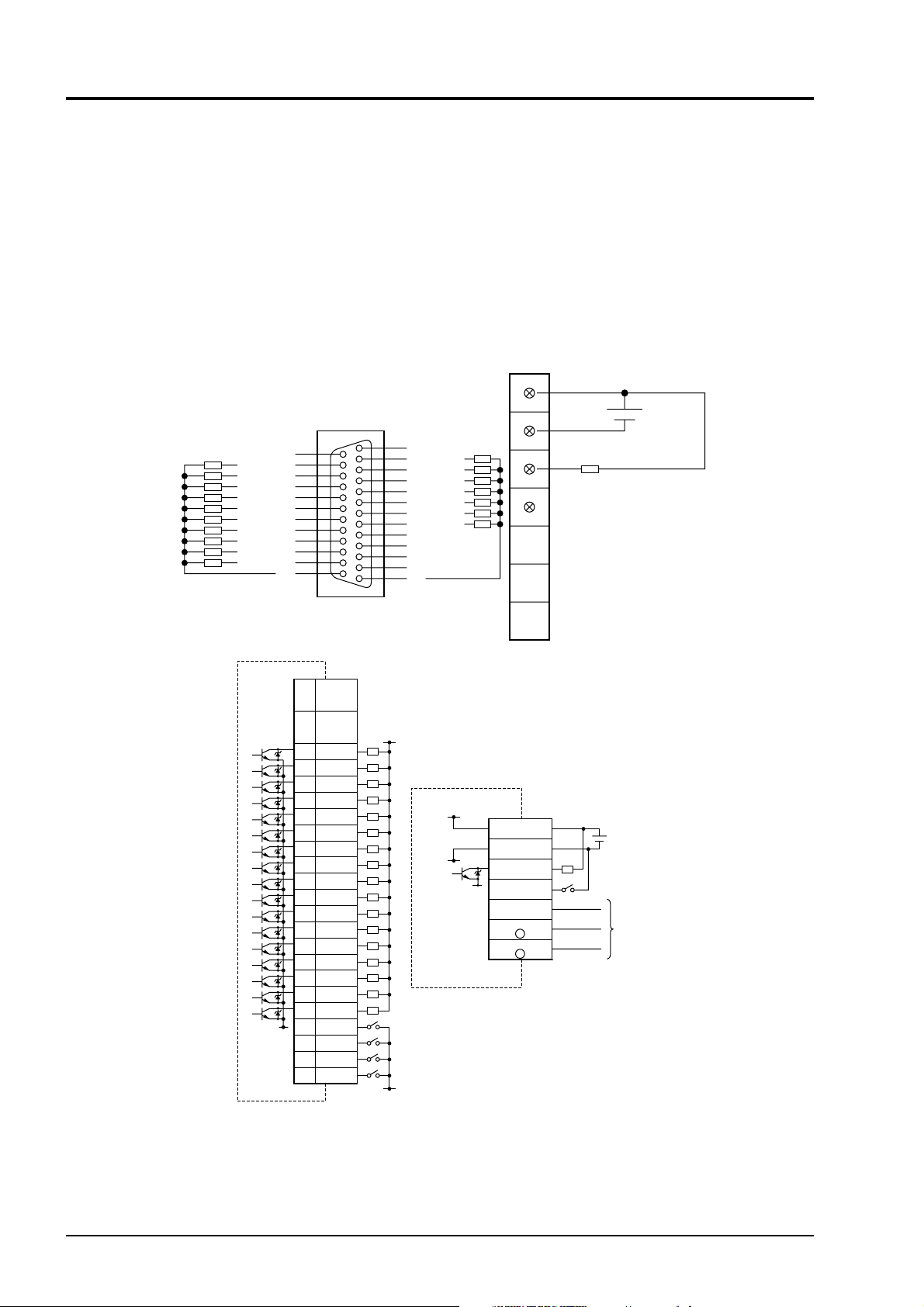

Channel 10 to 18

Note) For current input, connect optional shunt resitors to the voltage input terminals.

CH15

CH16

CH17

CH18

Voltage

+

–

+

–

+

–

+

–

Thermocouple

Resistance

+

–

+

–

RCJ

+

–

+

–

Input terminal

bulb

161

162

163

171

172

173

181

182

183

191

192

193

111

112

113

121

122

123

131

132

133

141

142

143

151

152

153

Thermocouple

Resistance

bulb

Voltage

+

+

–

–

CH10

+

+

–

–

CH11

+

+

–

–

CH12

+

+

–

–

CH13

+

+

–

–

CH14

CH15

CH16

CH17

CH18

Resistance

bulb

+

–

+

–

+

–

+

–

+

–

+

–

RCJ

+

–

+

–

Resistance

bulb

ThermocoupleThermocouple

VoltageVoltage

+

–

+

–

+

–

+

–

+

–

+

CH10

–

+

CH11

–

+

CH12

–

+

CH13

–

+

CH14

–

-4

4

INP-TN4PHR-E

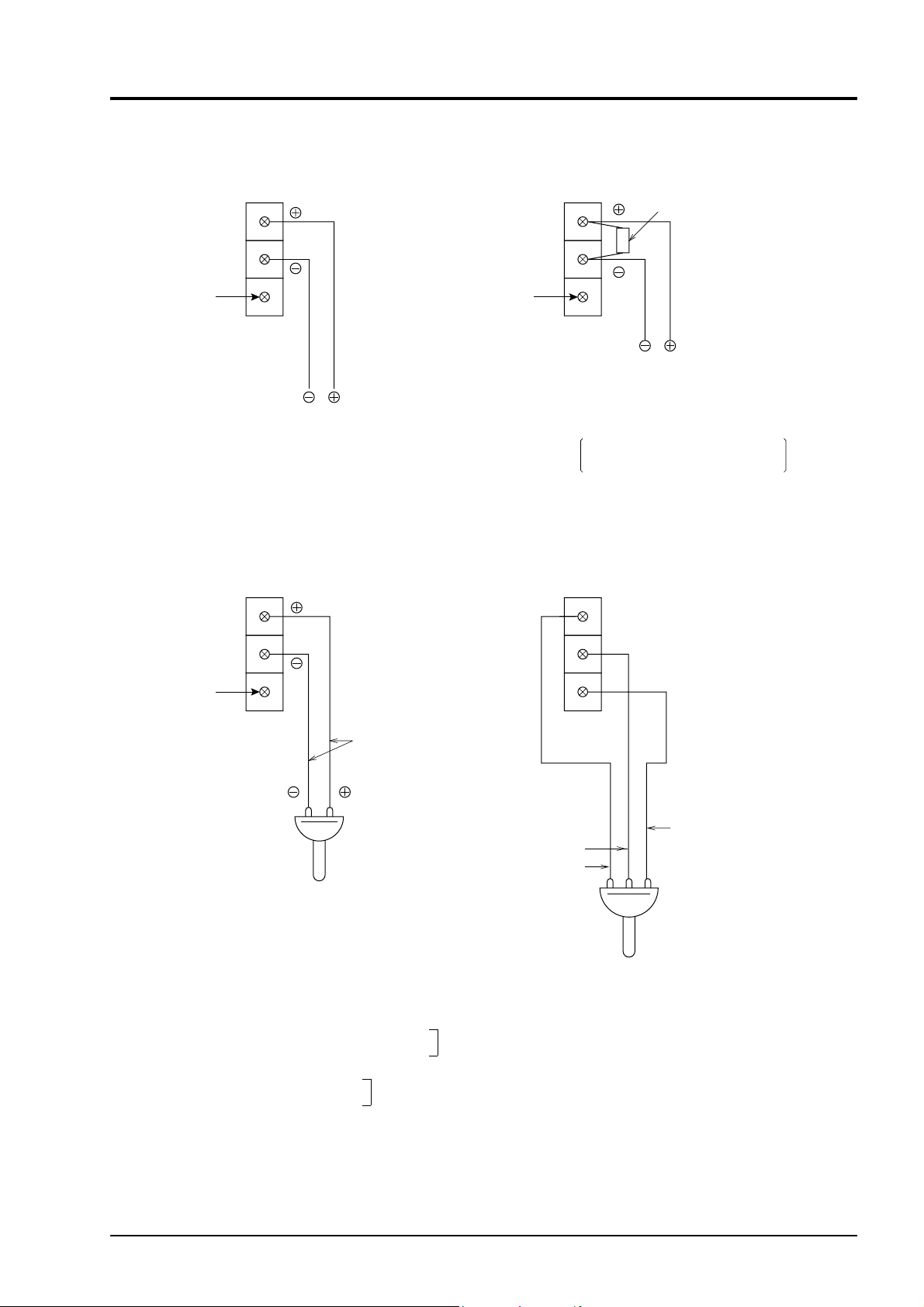

Wiring of input terminals

(1) DC voltage input

ex)

11

12

Not used

(3) Themocouple input

13

DC voltage input

ex)

11

(2) DC current input

ex)

11

12

Not used

(4) Resistance input

13

DC current input

Example 1) For 4 to 20mA and 10 to 50mA input,

10Ω±0.1% shunt resistance is used.

In this case, set the input range

to ±500mV (see Item 8.4).

Voltage conversion by shunt resistance of 10Ω

4 to 20mA DC : 40 to 200mV DC

10 to 50mA DC : 100 to 500mV DC

ex)

11

b

Shunt resistor (option)

12

Not used

13

Compensating leads

Thermocouple

Note) Avoid using thermocouple input with wiring

parallel to other instruments.

Note)

1) Input signals should be the same for every 2 channels.

Example) ch1: thermocouple

Any type of thermocouple can be set.

ch2: thermocouple

ch3: 5V

1 to 5V or 0 to 5V can be set.

ch4: 5V

For the setting method, see Item 8.4.

2) Don’t remove RCJ module.

12

13

White(B)

White(b)

B

A

Red(A)

Resistance bulb

INP-TN4PHR-E

-5

4

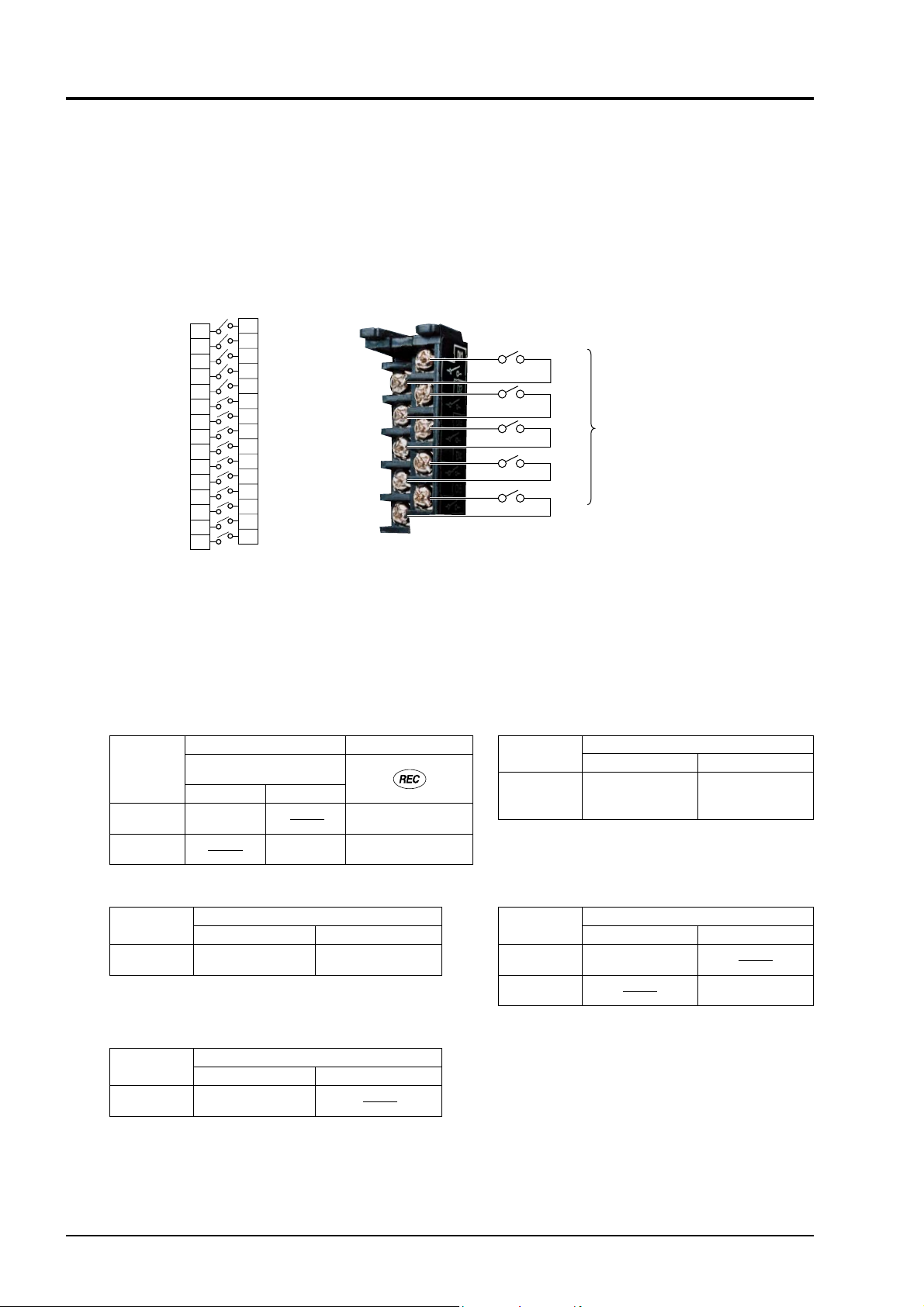

(2) Wiring of alarm output (DO)/DI (external control unit) (Option)

Note: This option cannot be mounted if the number of input points is 18.

About external control unit (DI)

1) This instrument is provided with the function of performing “start/stop of recording operation,”

“F-value computation resetting,” “Start/stop of totalizing,” and “Message display” in response to

the contact signals (DI) received from outside the instrument.

Alarm output/DI input terminal

211

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

Note 1) DI (external control) unit is not insulated and should be used with a relay connected to

the outside.

External contact capacity: 20V/0.05A DC, 1a contact

Note 2) DI (external control) unit is operated as follows when the front switch is pressed.

212

213

214

215

216

217

218

219

220

221

222

223

224

225

DI1

DI2

DI3

DI4

DI5

DO1

DO2

DO3

DO4

DO5

DO6

DO7

DO8

DO9

DO10

DI1

DI2

For DI function,

DI3

see"Setting of DI function".

DI4

DI5

(1) Recording start/stop

External control

Recording start/stop by DI

ON OFF

Recording

suspended

Starts recording

Recording

in progress

(3) Totalizing reset

ON OFF

Totalizing

in progress

Resets

totalized value.

(5) LCD

ON OFF

LCD OFF

LCD ON

Stops recording

External control

Continuous totalizing.

External control

Front key

Starts recording

Stops recording

(2) F value calculation reset

External control

ON OFF

F value

calculation

in progress

Resets F value.

(4) Totalizing start/stop

External control

ON OFF

Totalizing

suspended

Totalizing

in progress

Starts totalizing

Continues

calculation.

Stops totalizing

-6

4

INP-TN4PHR-E

About alarm output (DO)

1) Alarm setting is provided at 4 points for each input channel. Up to 10 points for alarm output can

be set as an option.

2) When an alarm occurs, the relevant terminals are shorted (ON).

1a contact output: Relay contact capacity : 150V AC/3A, 30V DC/3A (resistive load : DO1)

: 240V AC/3A, 30V DC/3A (resistive load : DO2 to

DO10)

DO1

Alarm output/DI input terminal

211

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

212

213

214

215

216

217

218

219

220

221

222

223

224

225

DI1

DI2

DI3

DI4

DI5

DO1

DO2

DO3

DO4

DO5

DO6

DO7

DO8

DO9

DO10

DO2

DO3

DO4

DO5

DO6

DO7

DO8

DO9

DO10

Note: If lamps are provided on the outside, set a resistor to prevent rush current. When

relays or solenoids are used, set elements for contact protection (diodes or surge killers,

etc).

INP-TN4PHR-E

-7

4

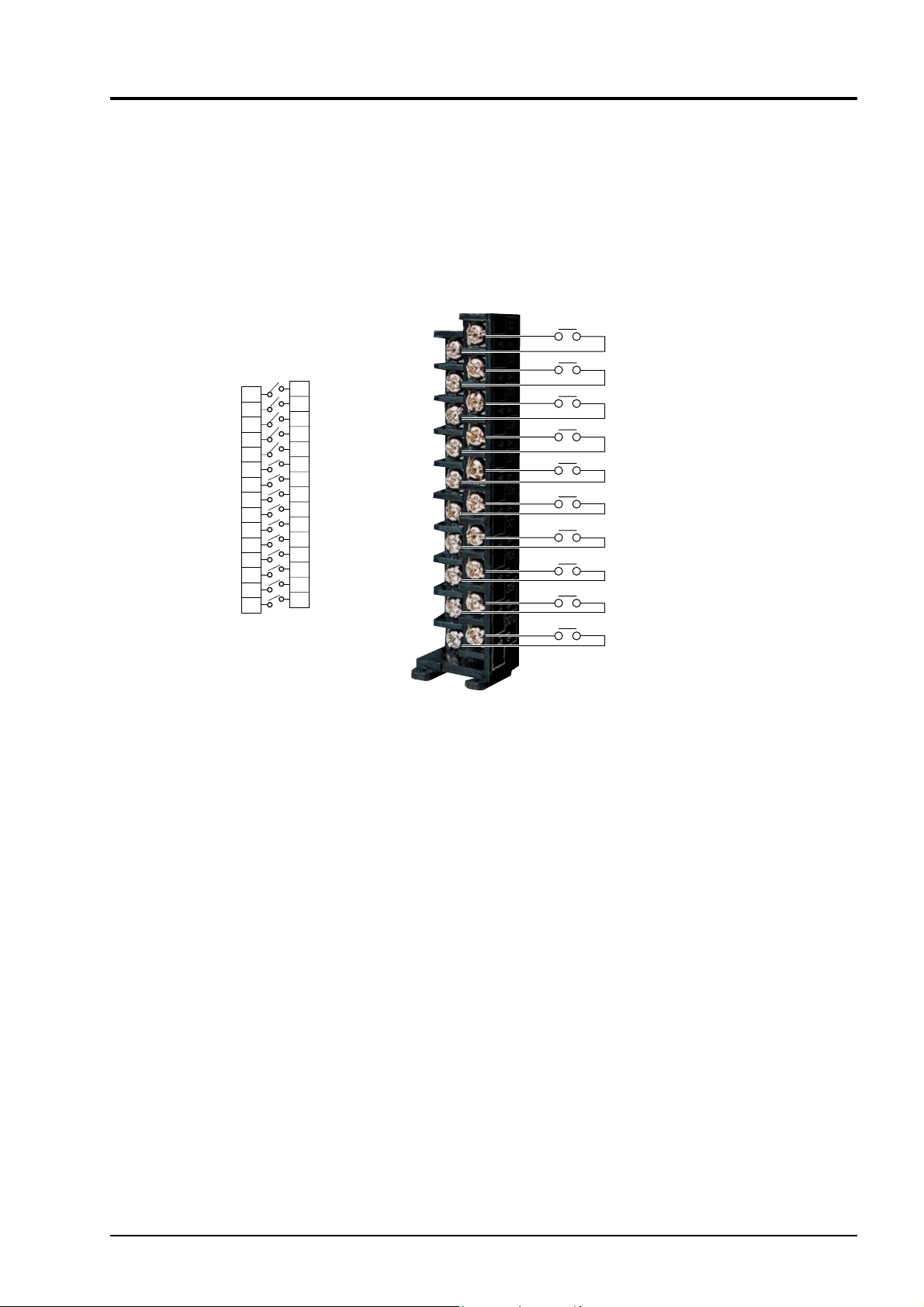

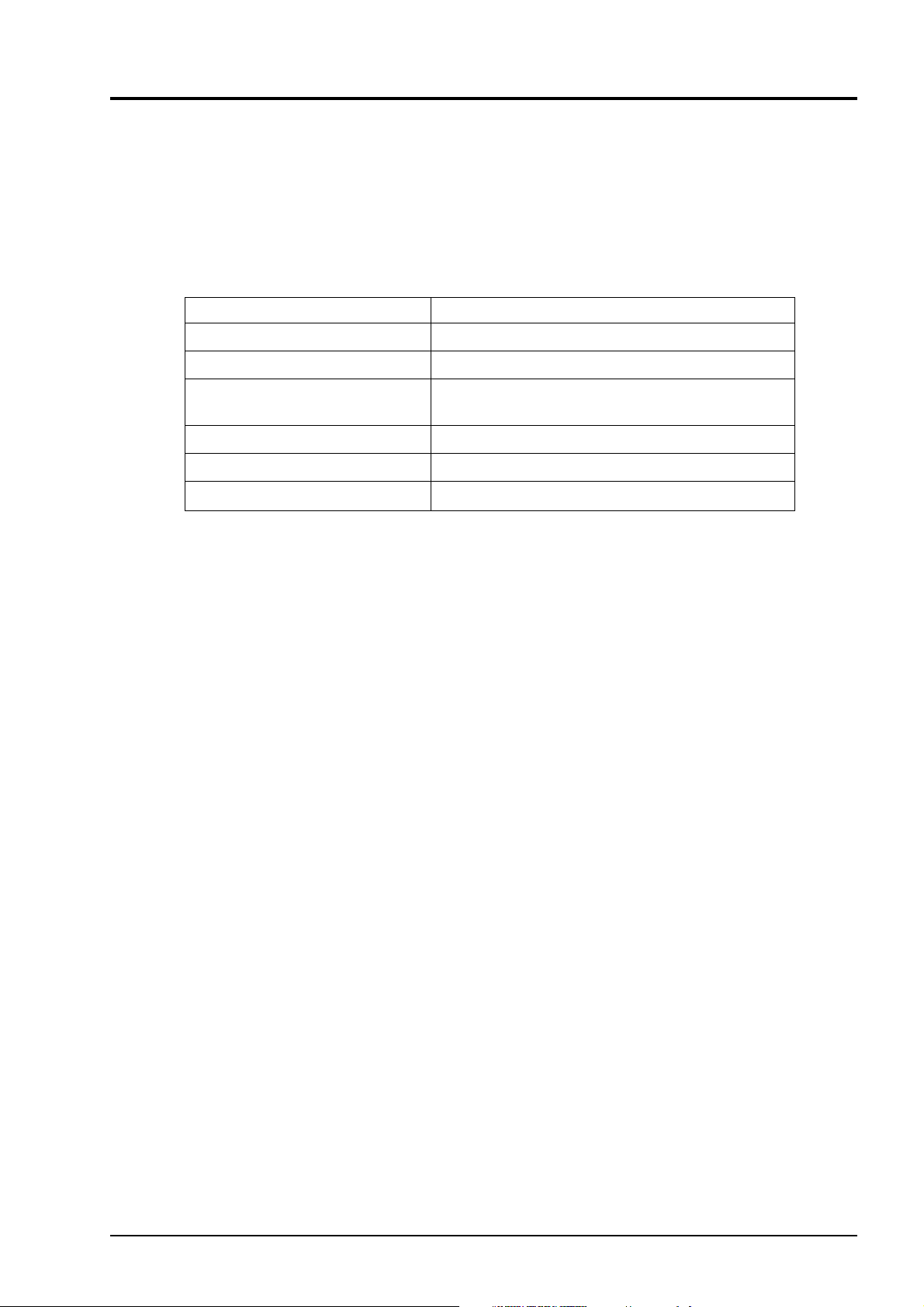

(3) Wiring of communication, alarm output (DO)/DI input

Note: Select R or W for the 12th digit of the code symbols to use this option.

About communication

This is digital communication function with other devices. Specifi cations are as follows.

Item Specifications

Electrical specifications Conforms to EIA RS-485

Communication mode Two-wire half-duplex

Synchronous system Start-stop synchronization

Topology 1 : N

Number of connected units Up to 31

Communication distance Up to 500m (Total distance)

Communication speed 9600, 19200 bps

Data format Data length

Stop bit

Parity

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Insulation The communication section and the ground terminal

are functionally separated.

(Withstand voltage: 500V AC)

8 bits

1 bit

None, Even, Odd (selectable)

Communication terminal

Shield

-

TRX2 (

TRX1 (+)

)

-8

4

INP-TN4PHR-E

About external control unit (DI)

This function is the same as that described on page 4-6.

Alarm output/DI input terminal

24VdC

25

24

23

22

21

20

19

18

17

16

15

14

PCD

13

12

11

10

9

8

7

6

5 (DI10)

4 (DI9)

3 (DI8)

2 (DI7)

1

1

VPD

14

13

PCD

25

6

DO12

7 DO13

8 DO14

9 DO15

10 DO16

11 DO17

12 DO18

15 DO19

16 DO20

17 DO21

18 DO22

19 DO23

20 DO24

21 DO25

22 DO26

23 DO27

24 DO28

2 DI7

3 DI8

4 DI9

5 DI10

VPD

PCD

VPD

PCD

PCD

DIO(+24V)

DIO(0V)

DO11

DI6

SHLD

TRX2

–

TRX1

+

DI6

(Shield)

(

-

(+)

24Vdc

)

MODBUS

communication

Note 1: The DI (external control unit) is not insulated. Connect a relay externally to use the

Note 2: The operation by DI (external control unit) and the switch on the front face is as

INP-TN4PHR-E

unit.

Capacity required for external contact: 20V/0.05A DC, 1a contact, or larger

shown in (1) to (5) of Note 2 on page 4-6.

-9

4

About alarm output (DO)

1) Alarm setting can be made for 4 points per input channel. Alarm output (DO) can be mounted up

to 18 points.

2) On occurrence of an alarm, the internal transistor is turned ON.

Output : Open collector

Rating : 30V/100mA DC (resistance load)

24VdC

25

(DO28) 24

(DO27) 23

(DO26) 22

(DO25) 21

(DO24) 20

(DO23) 19

(DO22) 18

(DO21) 17

(DO20) 16

(DO19) 15

PCD

14

1

14

13

25

6

7 DO13

8 DO14

9 DO15

10 DO16

11 DO17

12 DO18

15 DO19

16 DO20

17 DO21

18 DO22

19 DO23

20 DO24

21 DO25

22 DO26

23 DO27

24 DO28

2 DI7

3 DI8

4 DI9

5 DI10

VPD

PCD

DO12

13

12 (DO18)

11 (DO17)

10 (DO16)

9 (DO15)

8 (DO14)

7 (DO13)

6 (DO12)

5

4

3

2

1

VPD

VPD

PCD

PCD

PCD

DIO(+24V)

DIO(0V)

DO11

DI6

SHLD

TRX2

–

TRX1

+

DO11

(Shield)

(

-

(+)

24Vdc

)

MODBUS

communication

Note: This is not relay output.

Do not apply voltage or feed current larger than the rating.

Otherwise the internal circuit may be damaged, and the instrument stops operating.

-10

4

INP-TN4PHR-E

(4) Ethernet (option)

Note: Select E or W for the 12th digit of code signals to use this option.

Ethernet communiction specifi cations are as follows.

Note: Install the LAN cable far away from the power supply line or strong electric line as possible

to avoid the infl uence of induction noise.

Item Specifi cations 10BASE-T

Communication speed 10 Mbps

Communication mode Base band

Maximum network length or Up to 500 m (4-stage cascade)

maximum node spacing

Maximum segment length Up to 100 m (between node and hub)

Connection cable UTP (Unshielded twisted pair cable) 22-26AWG

Communication protcol TCP/IP

(5) Cautions on connection of input signals via barrier

1) When thermocouple or resistance bulb is used for input

Measurement value error is generated because resistance value within the barrier is added.

Calibrate the measurement value in a state where the input, barrier, and the recorder are connected.

See section 10.1 for details of calibration.

2) Use our Zener barrier (PWZ) with 100V AC series power supply (85 to 150V AC) according the

restrictions placed to maintain safety ratings.

INP-TN4PHR-E

-11

4

Loading...

Loading...