Instruction Manual

MICROJET RECORDER

TYPE: PHA

INP-TN4PHAVa-E

PREFACE

Congratulations on your purchase of Fuji Micro-jet Recorder (Type: PHA)

• Read this instruction manual carefully to ensure correct installation, operation and preparation.

Incorrect handling may lead to accident or injury.

• Specifications of this unit is subject to change without prior notice for improvement.

•Modification of this unit without permission is strictly prohibited.

Fuji will not bear any responsibility for a trouble caused by such a modification.

• This instruction manual should be kept by the person who is actually using the unit.

• After reading the manual, be sure to keep it at a place easy to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer : Fuji Electric Instrumentation Co., Ltd.

Type : Shown on nameplate of Micro-jet recorder

Date of manufacture : Shown on nameplate of Micro-jet recorder

Product nationality : Japan

Request

•It is prohibited to transfer part or all of the manual

without Fuji's permission.

• Description in this manual will be changed without prior

notice.

Fuji Electric Systems Co., Ltd. 2000

Issued in Nov., 2000

Rev. 1st edition Nov., 2002

iINP-TN4PHAV-E

CAUTION ON SAFETY

First of all, read this "Caution on safety" before using the unit.

•The cautionary descriptions listed here contain important information about safety, so they should

always be observed.

DANGER

CAUTION

Those safety precautions are ranked to 2 levels, DANGER and CAUTION.

Wrong handling may cause a dangerous situation, in which there

is a risk of death or heavy injury.

Wrong handling may invite a dangerous situation, in which there

is a possibility of medium level trouble or slight injury or only

physical damage is predictable.

Items which must not be done are noted.

PROHIBITION

Caution on Installation

• This unit is not an explosion-proof type. Do not use it in a

DANGER

place with explosive gases to prevent explosion, fire or other

serious accident.

CAUTION

CAUTION

• For installation, select a place observing the operating conditions noted in the instruction manual.

Installation at an unsuited place may cause fall, trouble or

malfunction.

• The unit must be installed correctly as shown in the instruction manual. Incorrect installation may cause fall, trouble or

malfunction.

•During installation work, keep the inside of the unit free from

entry of cable chips or other foreign objects as it may cause

fire, trouble or malfunction.

This unit is a component device used for instrumentation. It is

mounted on a panel or in a rack.

• The unit conforms to IEC1010-1 (1990) Safety Standards, and

is designed for protection class I, overvoltage Category II and

pollution degree 2, except the alarm output terminal (overvoltage category I).

• EMC conforms to EN50081-1 (1992) and EN50082-1 (1992),

(both used for housing areas), except that the noise level of the

power terminal is rated for Class A (used for commercial and

industrial areas).

•Input signals and communication interface should be of SELV

(safety separated from hazardous voltage).

ii INP-TN4PHAV-E

Caution of Wiring

DANGER

Caution on Maintenance

DANGER

•Wiring work must be performed as specified.

If the unit is not earthed, it would result in electric shocks or

malfunction.

•Be sure to connect power source that matches the rating.

Connection of incorrect rating of power source may lead to fire.

• Before starting wiring work, be sure to turn OFF the main power

to prevent electric shocks.

•

Wiring materials to be used must meet the rating. Use of materials

which do not withstand the rating may cause a fire accident.

• When disposing of the recording head, put it in a vinyl bag and

seal it to prevent the diffusion of ink. It should be handled as an

imcombustible object when disposing of it.

• Ink is harmful to human body. Observe the following emergency treatments.

- When ink gets in eyes, wash out for at least 5 minutes immediately with much clean water, and ask your doctor for treatment at once.

- When ink gets on skin, wash out and clean skins with soap

and water.

- When ink is breathed in, move to a clean place immediately.

If necessary, ask your doctor for treatment at once.

• Do not touch the connector at the rear of the carriage mounting

the recording head to avoid the risk of electric shocks.

Caution on Use

DANGER

• If the fault or anomaly of the device may cause serious accident or troubles to other devices, externally install appropriate protective circuit to avoid accidents.

•When fuse is blown out, check and remove the cause of it,

and replace it with new one specified in the instruction manual.

Do not use any other fuse or short it, as it may cause electric

shocks or fire.

iiiINP-TN4PHAV-E

CONTENTS

PREFACE ...................................................................................................................................i

CAUTION ON SAFETY..............................................................................................................ii

1. INTRODUCTION ............................................................................................................. 1-1

1.1 About the microjet recorder ................................................................................................. 1-1

1.2 Product check ....................................................................................................................... 1-1

1.3 Check on type and specification .......................................................................................... 1-2

2. NAMES AND FUNCTIONS OF PARTS........................................................................... 2-1

3. MOUNTING METHOD..................................................................................................... 3-1

3.1 Mounting location ................................................................................................................ 3-1

3.2 External dimensions and panel cut out dimensions ............................................................. 3-1

3.3 Method of mounting onto panel........................................................................................... 3-2

4. WIRING ........................................................................................................................... 4-1

4.1 Before doing the wiring ....................................................................................................... 4-1

4.2 Connection of wires to terminals ......................................................................................... 4-1

5. SET-UP ............................................................................................................................ 5-1

5.1 Loading chart paper ............................................................................................................. 5-1

5.2 Recording head installation (replacement) .......................................................................... 5-4

5.3 Changing the type of input signals....................................................................................... 5-9

6. OPERATION AND ACTIONS .......................................................................................... 6-1

6.1 Before running the equipment: ............................................................................................ 6-1

6.2 Power switch-on and states .................................................................................................. 6-2

6.3 Test pattern print-out ............................................................................................................ 6-3

6.4 Actions during operation...................................................................................................... 6-3

6.5 Displays and print-outs on detection (cancellation) of alarms............................................. 6-5

6.6 Displays and print-outs on occurrence of burnt-out............................................................. 6-5

6.7 Over-range, under-range display and abnormal input display ............................................. 6-6

6.8 Display and record when chart paper runs out..................................................................... 6-6

6.9 Display and record when the recording head ink is low ...................................................... 6-6

6.10 Display when data backup batteries need to be replaced..................................................... 6-7

6.11 Display of fault in recording head carriage.......................................................................... 6-7

6.12 Order of priority of state displays ........................................................................................ 6-7

7. SETTING AND CHECKING PARAMETERS ................................................................... 7-1

7.1 Setting and checking ............................................................................................................ 7-1

7.2 Outline of procedure for setting parameters ........................................................................ 7-3

7.3 Pass code setting .................................................................................................................. 7-4

7.4 Setting the chart speed ......................................................................................................... 7-5

7.5 Setting alarms....................................................................................................................... 7-7

Chapter 3, 4 and chapter 8 should be observed for installation and mainte-

CAUTION

nance of the unit. So, it must be performed by qualified engineers.

iv INP-TN4PHAV-E

7.6 Setting the recording mode .................................................................................................. 7-8

7.7 Setting record ranges.......................................................................................................... 7-12

7.8 Setting kind of input, skip, unit, filter, scaling, subtraction ............................................... 7-13

7.9 Setting T ag Nos. ................................................................................................................. 7-19

7.10 Message print specification................................................................................................ 7-20

7.11 List print-out specification ................................................................................................. 7-23

7.12 Daily report specification................................................................................................... 7-24

7.13 Specifying totalize function ............................................................................................... 7-26

7.14 Transmission specification (option)................................................................................... 7-27

7.15 Setting the time .................................................................................................................. 7-29

7.16 Clearing the ink monitor .................................................................................................... 7-30

7.17 Turning the chart illumination lamp on/off (option) .......................................................... 7-31

8. MAINTENANCE - INSPECTION ..................................................................................... 8-1

9. APPLICATION FUNCTIONS ........................................................................................... 9-1

9.1 Adjustment of backlash........................................................................................................ 9-1

9.2 Zero/span adjustment for analog trend recording position .................................................. 9-2

9.3 Setting of alarm latch and integrated value print-out........................................................... 9-3

9.4 Setting of PV shift................................................................................................................ 9-4

9.5 User definable unit ............................................................................................................... 9-5

9.6 Setting of record error external output ................................................................................. 9-6

9.7 Calibration of measured value ............................................................................................. 9-7

9.8 Change of record color......................................................................................................... 9-8

9.9 Language selection............................................................................................................... 9-8

10. TROUBLESHOOTING................................................................................................... 10-1

11. EXAMPLES OF RECORDS AND PRINT-OUTS ........................................................... 11-1

11.1 Periodic print-outs, scale print-outs ................................................................................... 11-1

11.2 Digital print-out (instantaneous values) ............................................................................. 11-2

11.3 Parameter list print-out....................................................................................................... 11-3

11.4 Test pattern ......................................................................................................................... 11-3

11.5 Scale print-outs .................................................................................................................. 11-3

11.6 Daily report print-out ......................................................................................................... 11-4

11.7 Data sum list print-out ....................................................................................................... 11-5

11.8 Message print (manual print) ............................................................................................. 11-5

11.9 Logging .............................................................................................................................. 11-6

11.10 Alarm print-outs ................................................................................................................. 11-6

11.11 Burn-out print-out .............................................................................................................. 11-6

11.12 Ink dry-up warning print-out.............................................................................................. 11-6

11.13 Record start mark ............................................................................................................... 11-7

11.14 Chart speed change mark ................................................................................................... 11-7

11.15 Auto-range change mark .................................................................................................... 11-7

12. SPECIFICATION............................................................................................................ 12-1

vINP-TN4PHAV-E

1. INTRODUCTION

Before using the Micro-jet recorder, read this manual carefully as it describes its installation, operation,

maintenance, etc.

1.1 About the microjet recorder

(1) This recorder is a multirange input recorder 180mm wide which can record up to a maximum of 12

points using thermocouler/resistance bulb and DC voltage input signals.

(2) It effects high-speed recording and gives clear analog trend records and digital print-outs in 6

colors.

(3) The analog trend records can be given as continuous record type or as intermittent (dot) records.

(See Section 1.3, Format specification.)

(4) As well as providing records of measurement values, the standard unit has a wide range of print-

out functions comprising, e.g., the print-out of dates, chart speed, measurement ranges, Tag Nos.,

daily reports and integrated totals.

(5) Operation of the equipment is simple thanks to an easy-view display section which permits key-in

of various items of set data.

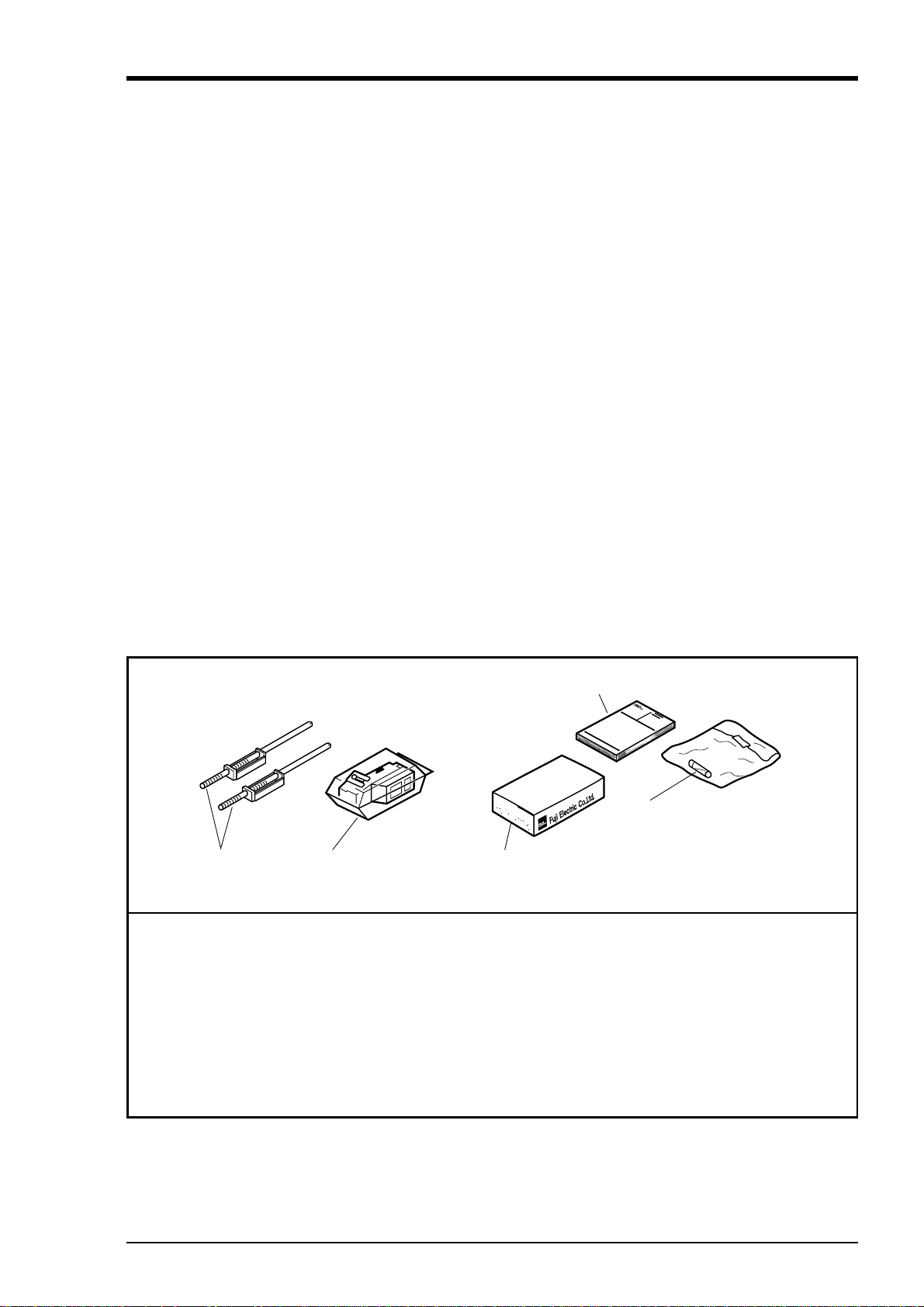

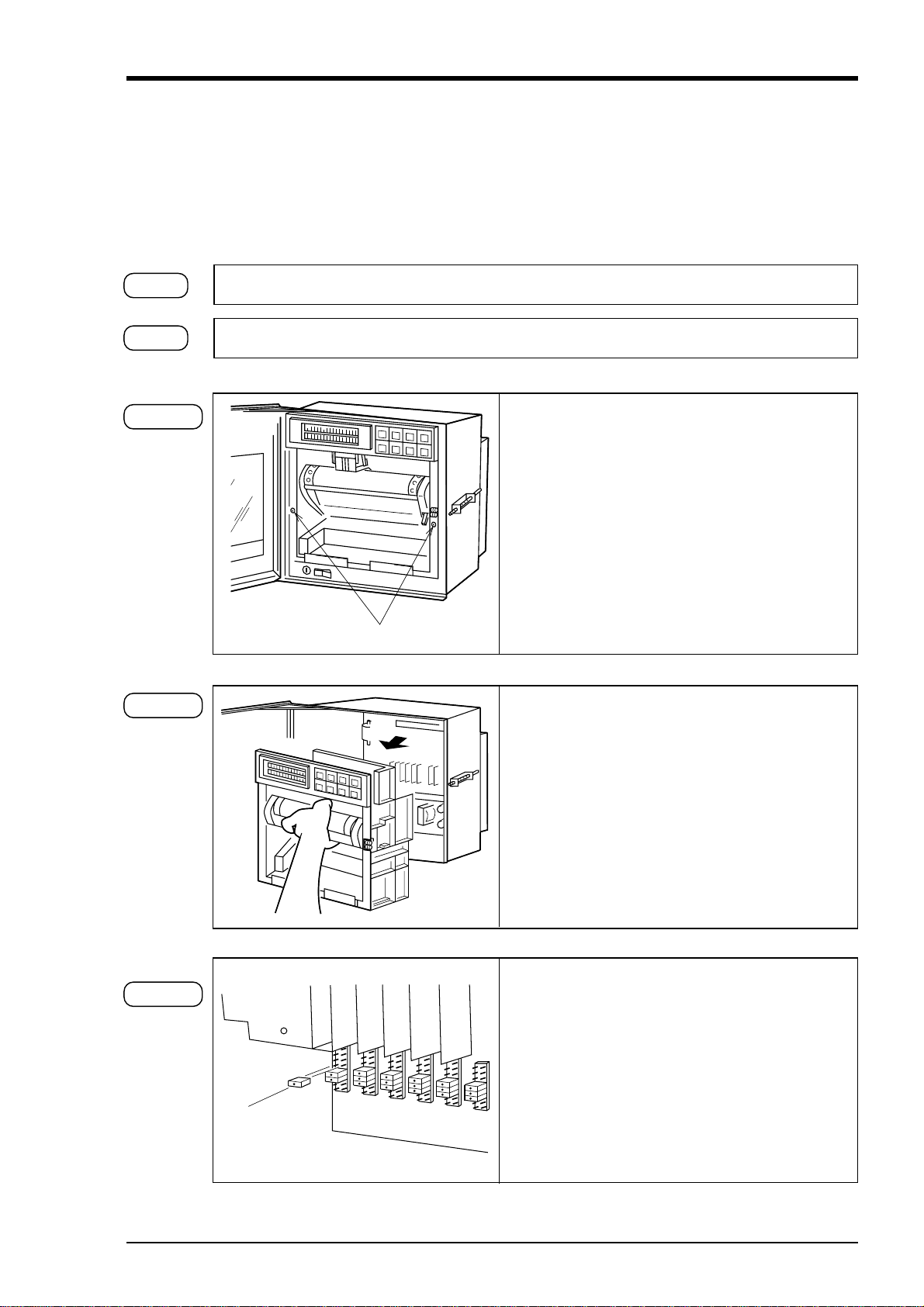

1.2 Product check

Check on accessories.

The unit comes with the accessories shown in Fig. 1-1. Please check that they are all there.

(4) Instruction manual

Instruction Manual

F

u

ji E

le

c

tr

ic

C

o

.,L

td

.

(5) Fuse

(1) Panel fitting

(2) Recording head

(with cloth for blotting ink)

(1) Panel fitting ................................................................................................. 2

(2) Recording head (with cloth for blotting ink) ...............................................1

(3) Recording paper ..........................................................................................1 pack

(The format of standard recording paper is PEX00BL1-1000B.)

(4) Instruction manual .......................................................................................1

(5) Fuse (250V/1A AC) .................................................................................... 1

Note: Item 5 is appended on the back side of the main unit.

(3) Recording paper

Fig. 1-1 Accessories

1 - 1INP-TN4PHAV-E

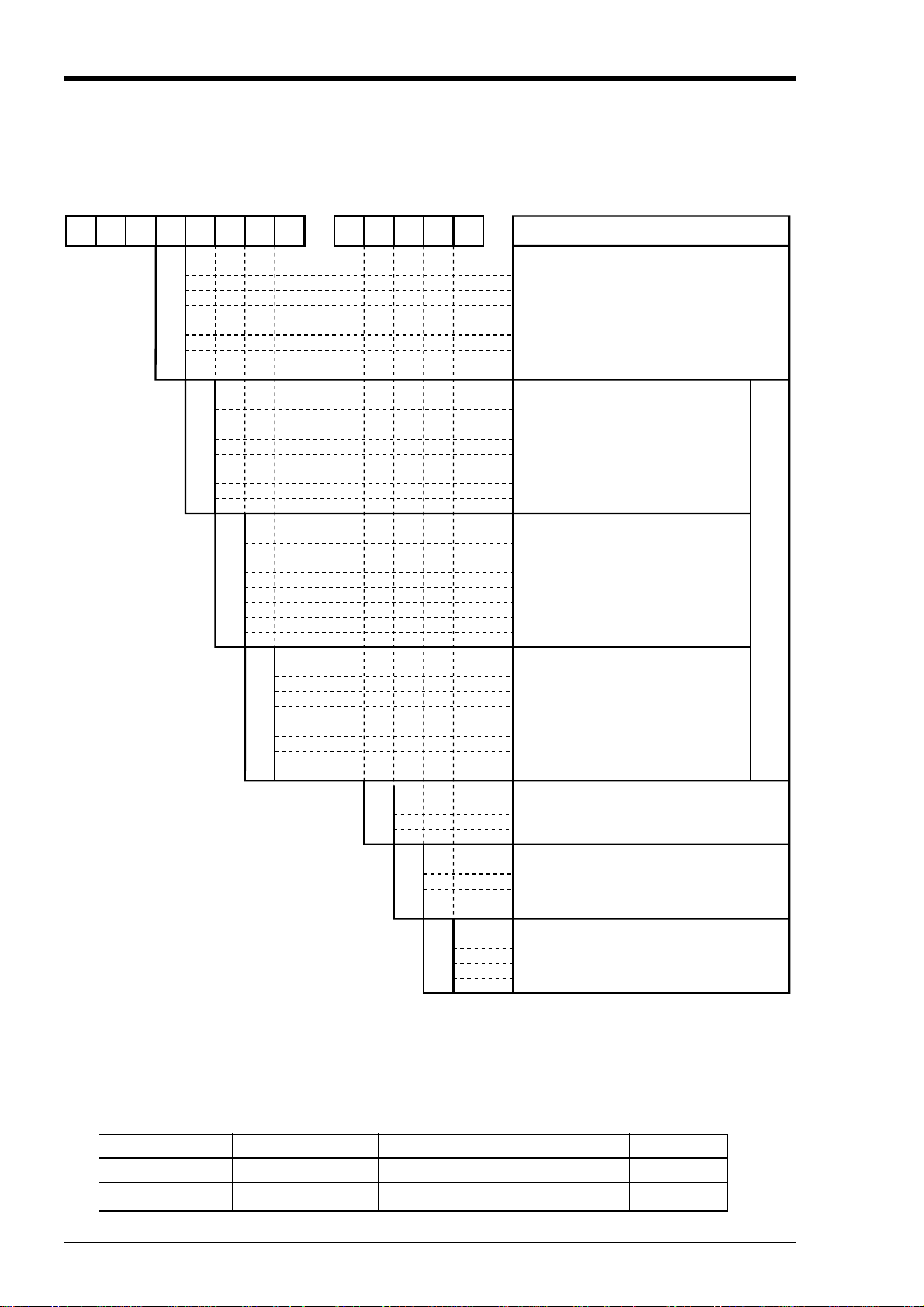

1.3 Check on type and specification

The data plates note the type name, etc. Please check to see that you have got a unit with the specification

you ordered. (There are data plates on the top surface of the case and in the main unit.)

1 2 3 4 5 6 7 8 9 10 11 12 13 places

P H A E

1

2

3

6

7

8

9

0

1

2

3

6

8

Z

0

1

2

3

6

8

Z

–

4

V

/

Y

Number of recording points

1 continuous record

2 continuous record

3 continuous record

6 continuous record

6 dot records

12 dot records

12 continuouous record

Number of input signal points

None

1 point

2 points

3 points

6 points

12 points

Other specification

Number of input signal poiints

None

1 point

2 points

3 points

6 points

12 points

Other specification

Meaning

(thermocouples)

(resistance bulbs)

0

1

2

3

6

8

Z

• Ex-works values of input signals

Thermocouple: K 0 to 1200°C

Resistance bulbs: Pt 100 0 to 500°C

DC voltage: -5 to +5V DC

• Relations between input signal specifications

and recording channels

Ex.: If 3 thermocouple points, 6 resistance bulb

points and 3 DC voltage points are specified.

Channels 1 to 3 are thermocouple

Channels 4 to 9 are resistance bulbs.

Channels 10 to 12 are DC voltage.

A

B

0

1

2

Y

R

T

Number of input signal points

None

1 point

2 points

3 points

6 points

12 points

Other specification

Chart illumination*

Without

With

Alarm output/external control*

None

6-point alarm output, with 3-point external control

12-point alarm output, with 3-point external control

Communication*

None

With RS-485

with T-link

Asterisks * indicate options.

Note: The "Z" in places 5, 6 and 7 indicates a non-standard specification. Please check by the

positions of the input signal type setting pins indicated in Section 5.3.

Note: After purchasing the unit, the type of input signal can be changed within the number of the

record pins (See Item 5.3).

(DC voltage)

The total number of points must be equal to the number of

points in place 4.

• Supplementary supplies

Product name Type Specification Sales units

Recording head PHZH1002 1 per unit 1

Recording paper PEX00BL1-1000B Approximately 20m (6 packs/box) 6 packs

1 - 2 INP-TN4PHAV-E

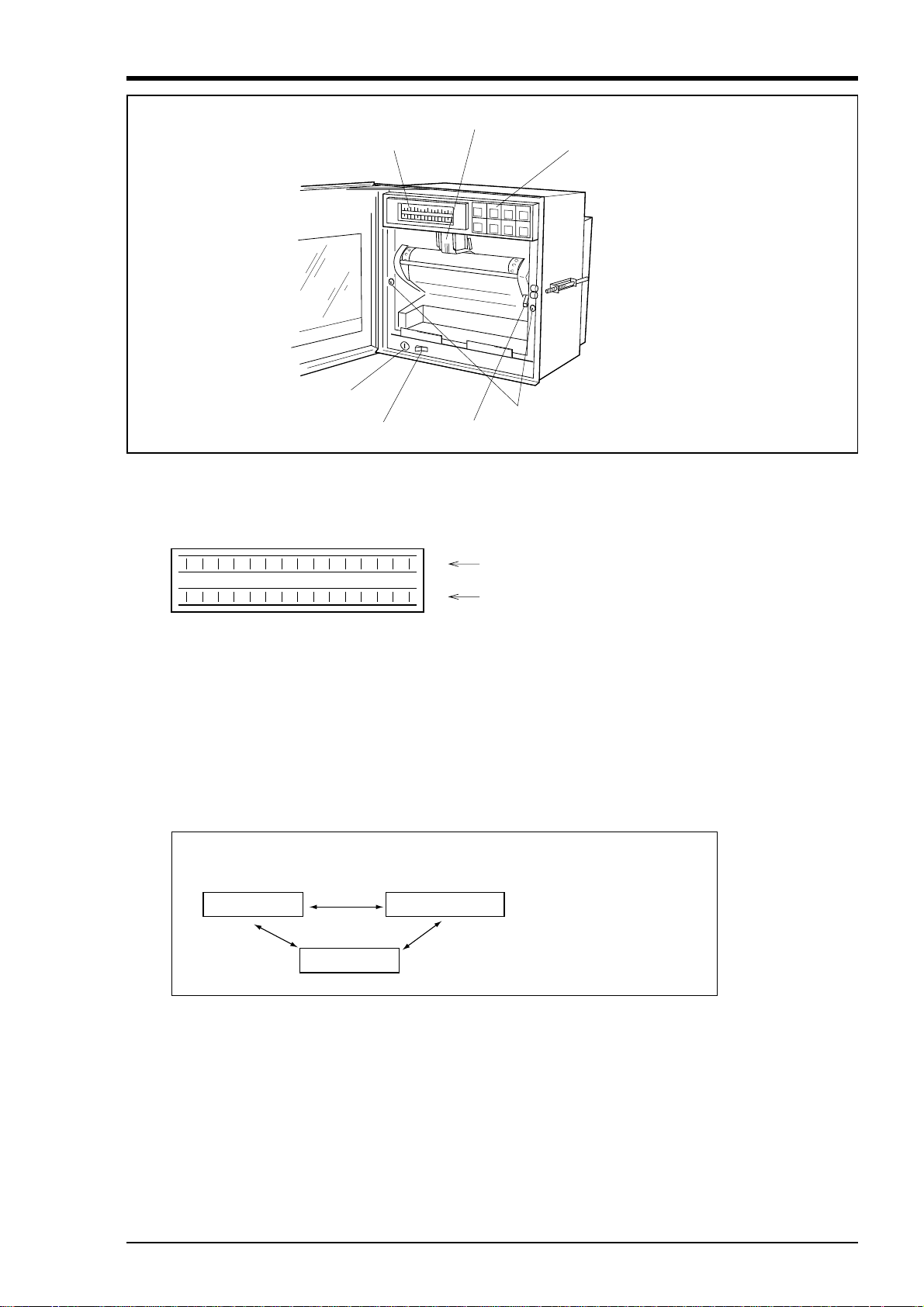

2. NAMES AND FUNCTIONS OF PARTS

(2) Recording head

(1) Display section

(5) Fuse

(7) Key actuation section

(6) Power supply switch

(4) Lever

(3) Lock screws

(1) Display section

For displays such as measurement data, units and displays of various parameters and comments

display of units and data for each channel display of various parameters, comments

display of units and data for each channel

display of varous parameters, comments

(2) Recording head

This is a recording head which serves for analog trend recording and digital print-outs. As this is

not installed in the main unit at the time of delivery, please install it referring to Section 5.2.

(3) Lock screws

To change the type of input signals, remove the lock screws on the left and right, detach the main

unit and make changes inside the instrument (replace the input signal setting pins).

Note that changes in the type of thermocouple can be effected by front panel key operations.

* 'Changes in the type of input signals' means changes as indicated below.

Thermocouple

Resistance bulbs

DC voltage

For details, see Section 5.3.

However, change to the thermocouple model or switching between new JIS and old JIS for resistance bulb can be performed by key operation on the front face.

(4) Lever

This is a lock lever for opening and closing the recording paper holder.

(5) Fuse holder

The holder contains a 250V/1A AC power supply fuse.

2 - 1INP-TN4PHAV-E

(6) Power supply switch

Used to turn on and off the power.

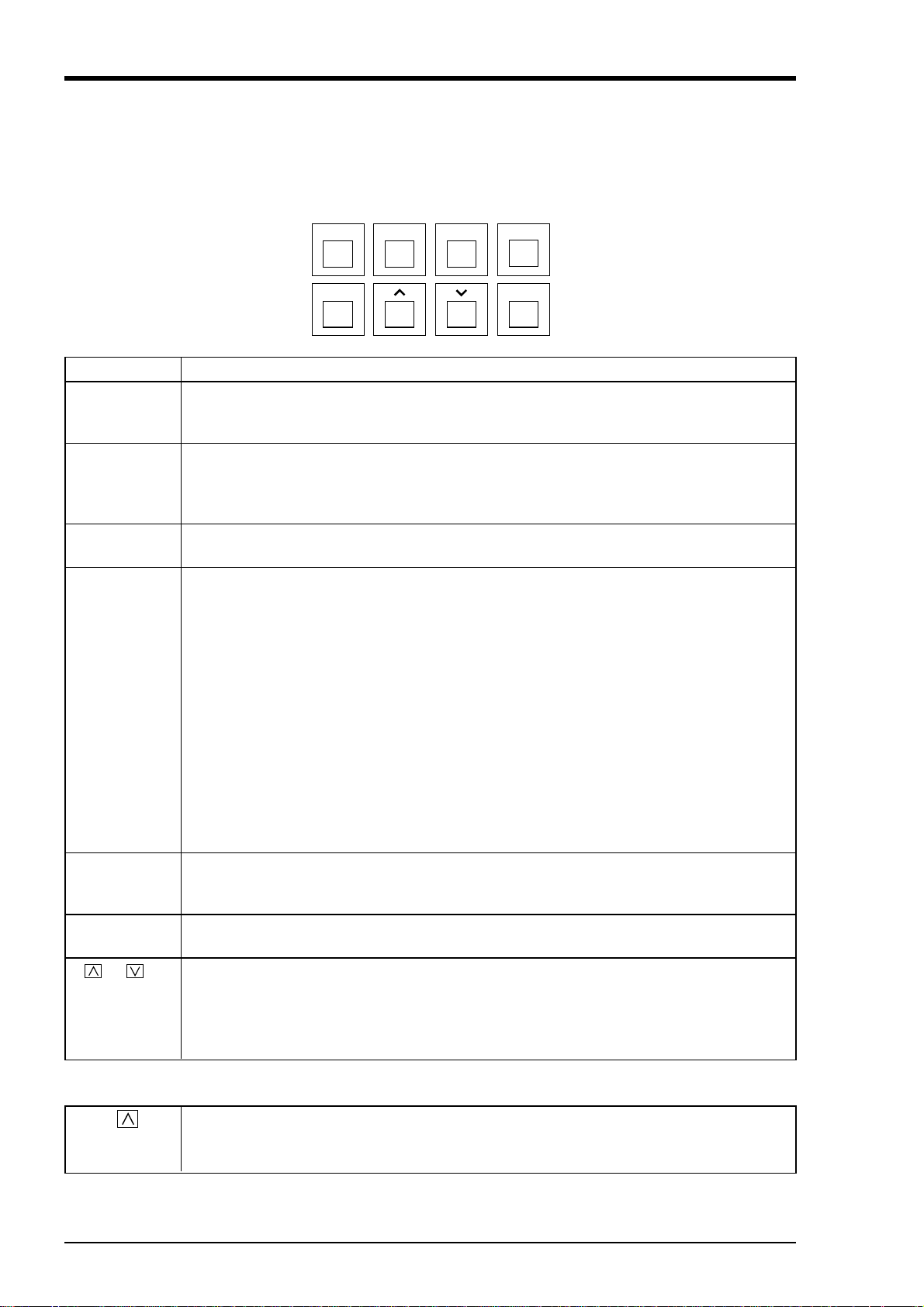

(7) Keying operation section

This is used for setting various parameters, making checks and running the equipment.

FEED LIST DISPLAY

SELECT ENTRY

RECORD

Name of key Function

RECORD Operation key for starting and stopping recording.

Recording starts when the key is pressed once and stops when the key is pressed again. This

key is ineffective during print-out of data or lists.

LIST This is used for effecting print-out of data (instantaneous values).

If you wish to stop the print-out partway through, press the key again.

The recording paper fast feed key.

This key is always valid.

FEED The speed is 3mm/sec during the first second that the key is held depressed and goes to

8mm/sec after the elapse of 1 second.

DISPLAY 1. This is used for changing the contents of displays. Successively pressing the key and

releasing it brings about the following 5 changeovers.

(1) Sequential display of the data of all channels.

However, there is no display for skip channels.

The data display is updated once every 3 seconds.

(2) Display only of the data of specific channels.

The data display is updated once every second.

(3) No 1 to 6 channels are display simultaneously, and data display is updated at 1 sec-

ond intervals.

(4) 7 - 12 channels are displayed simultaneously.

(This panel is not displayed when the number of recorded points is up to six.)

Data display is updated once every second.

(5) Display of the data and time.

2. This key is used for shifting from a set mode to the data display mode.

This key is ineffective during print-out of data or lists.

SELECT 1. Used for shifting from the data display mode to a set mode.

2. Is used for effecting sequential read-out of parameters during operation in a set mode.

This key is ineffective during print-out of data or lists.

ENTRY Is used to register set data.

This key is effective only during set mode operation.

Used to scroll numerical values up and down.

(up) (down) The values are scrolled up or down 1 count each time the relevant key is pressed. Holding a

key depressed for more than 0.5 seconds results in a fast up/down scroll at a rate of 5 counts/

second and holding it depressed for a further 2 seconds results in an ultra-fast scroll of 55

counts/second.

Special keying operations

Press

key Used for reversing the recording paper feeding direction.

while pressing (However, continuous feed is permitted up to about 25 mm.)

the FEED key.

2 - 2 INP-TN4PHAV-E

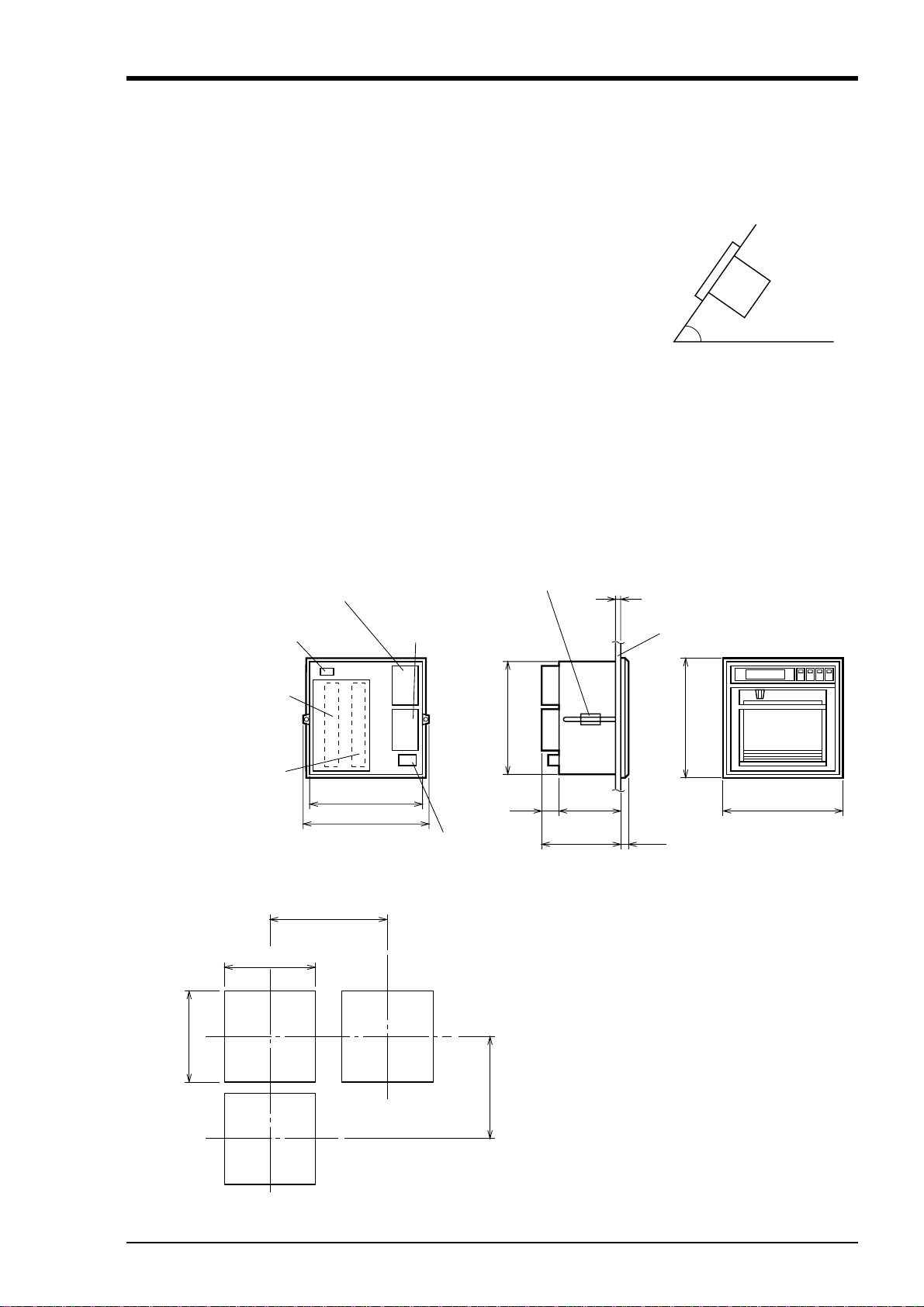

3. MOUNTING METHOD

This unit is designed to be panel mounted.

3.1 Mounting location

Select the following location for mounting the unit.

(1) A place that is not subject to vibration or impact.

(2) A place where there is no corrosive gas.

(3) A place that is subject to little temperature variation and is

close to normal temperature (23°C)

(4) A place that is not struck directly by strong radiant heat.

(5) As humidity affects the ink and recording paper, select a place

that is in the range 45 to 80% RH.

(6) Mount the unit horizontally, with no tilt to the left or right.

(The forward tilt should be 0 (but the unit may be inclined 0 to

30° rearwards.)

∠ α

∠ α = 60 to 90

3.2 External dimensions and panel cut out dimensions (unit: mm)

Mounting

Alarm unit (option)

(Alarms 7 to 12)

Transmission terminal

(option)

Input terminals

(inputs 7 to 12)

Input terminals

(inputs 1 to 6)

Panel cut dimensions (unit: mm)

360MIN

+2

281

0

+2

0

281

Alarm, external

control unit

(option) (Alarms 1 to 6)

280

312

Power supply terminal

attachment 2≤t≤30

Panel

280

16039

288

18199

Mass: Approximately 6kg (without options)

Approximately 7kg (with all options)

Power consumption: Approximately 22VA

(100V AC without options)

Approximately 37VA

(100V AC with all options)

288

320MIN

3 - 1INP-TN4PHAV-E

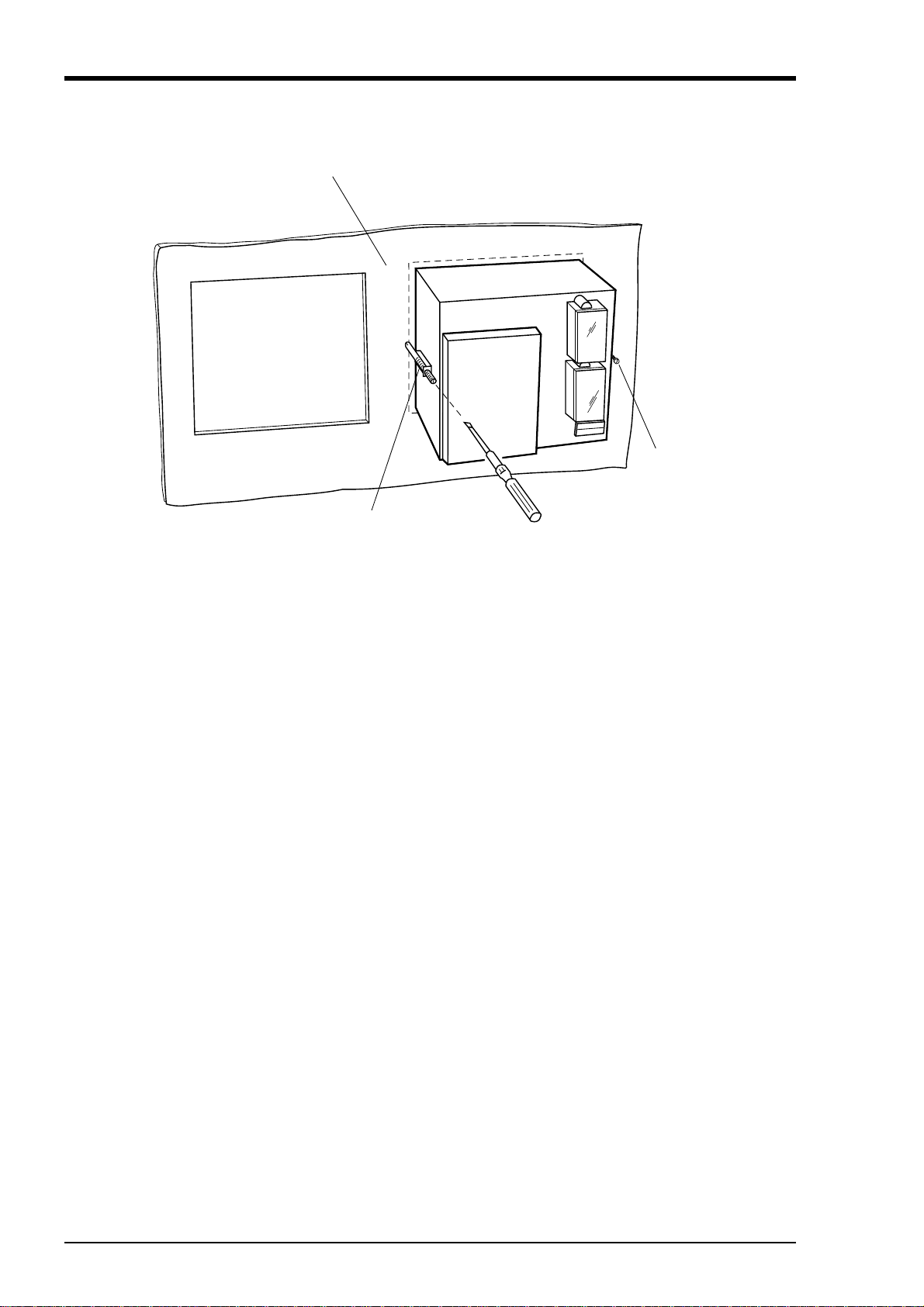

3.3 Method of mounting onto panel

Panel

Screw

Screw

• Tighten and fix the mounting screw attachments on the left and right.

• Use a panel that is 2mm or more thick.

3 - 2 INP-TN4PHAV-E

4. WIRING

(6)

(3)

(2)

(4)

(5)

(1)

(Inputs 7 to 12)

(1)

(Inputs 1 to 6)

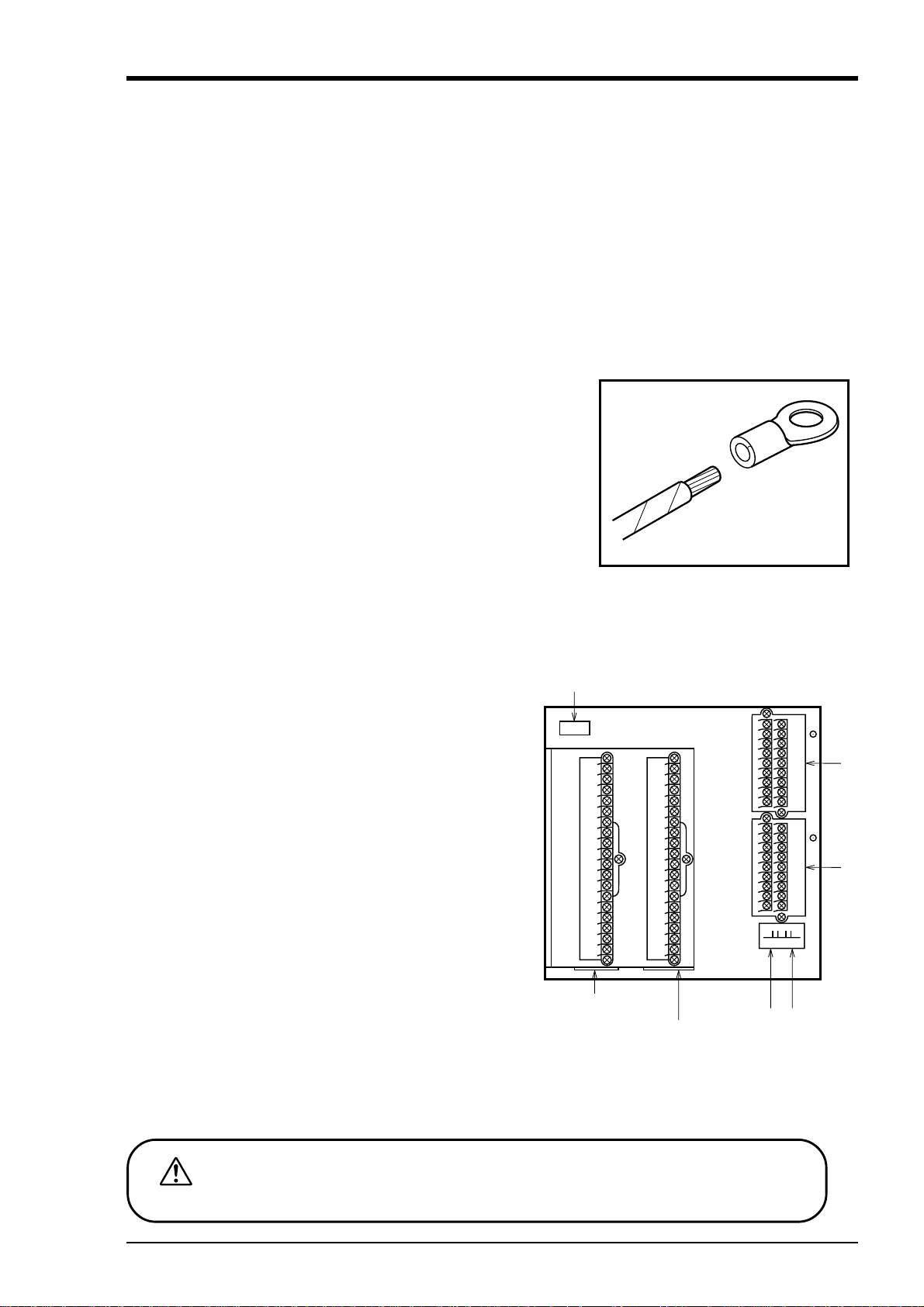

4.1 Before doing the wiring

To carry out wiring, remove the unit's rear cover (Notes).

(1) For the power cable, use a 600V vinyl-insulated cable (JIS C 3307) or a cable with equal or supe-

rior performance to this.

(2) Use compensating leads for thermocouple inputs.

(3) To avoid the effects of induction noise, keep input signal leads as far away as possible (at least

30cm) from power supply lines and lines carrying heavy current. Also, wherever possible use a

shieled cable and earth one point of the shield.

(4) For wiring the terminals, use a maximum of 2 crimp style terminals.

Notes

(1) To remove the rear cover, put a finger in a cable

through-hole in the cover, gently raise the cover

and then pull outwards.

(2) After wiring up the input terminals, always re-

place the rear cover in its original position so as

to ensure proper compensation of reference contacts for thermocouple inputs.

(3) We recommend the use of insulation-sleeve

solderless terminals (using M4 thread) for connecting wires to terminals.

4.2 Connection of wires to terminals

(1) Input terminals

➪ Connect signal leads for each channel.

(2) Alarm, external control unit (option)

➪ Connect the alarm signal outputs and ex-

ternal control signal inputs (for alarms 1

to 6, external controls 1 to 3).

(3) Alarm unit (option)

➪ Connect the alarm signal outputs (for

alarms 7 to 12).

(4) Power supply terminal

➪ Connect the power cables to AC/AC ter-

minals. Connect to a noise-free, stabilized power supply.

This is an 100 to 240V AC free power supply.

(5) Ground terminal ➪ Effect type 3, Grounding (not more than 100Ω) of the G terminal.

(6) Transmission terminal (option) ➪ Connect the transmission signals.

CAUTION

Alarm unit are of overvoltage category I.

Other signal (input, communication interface) should be SELV (safety separated from

hazardous voltage).

4 - 1INP-TN4PHAV-E

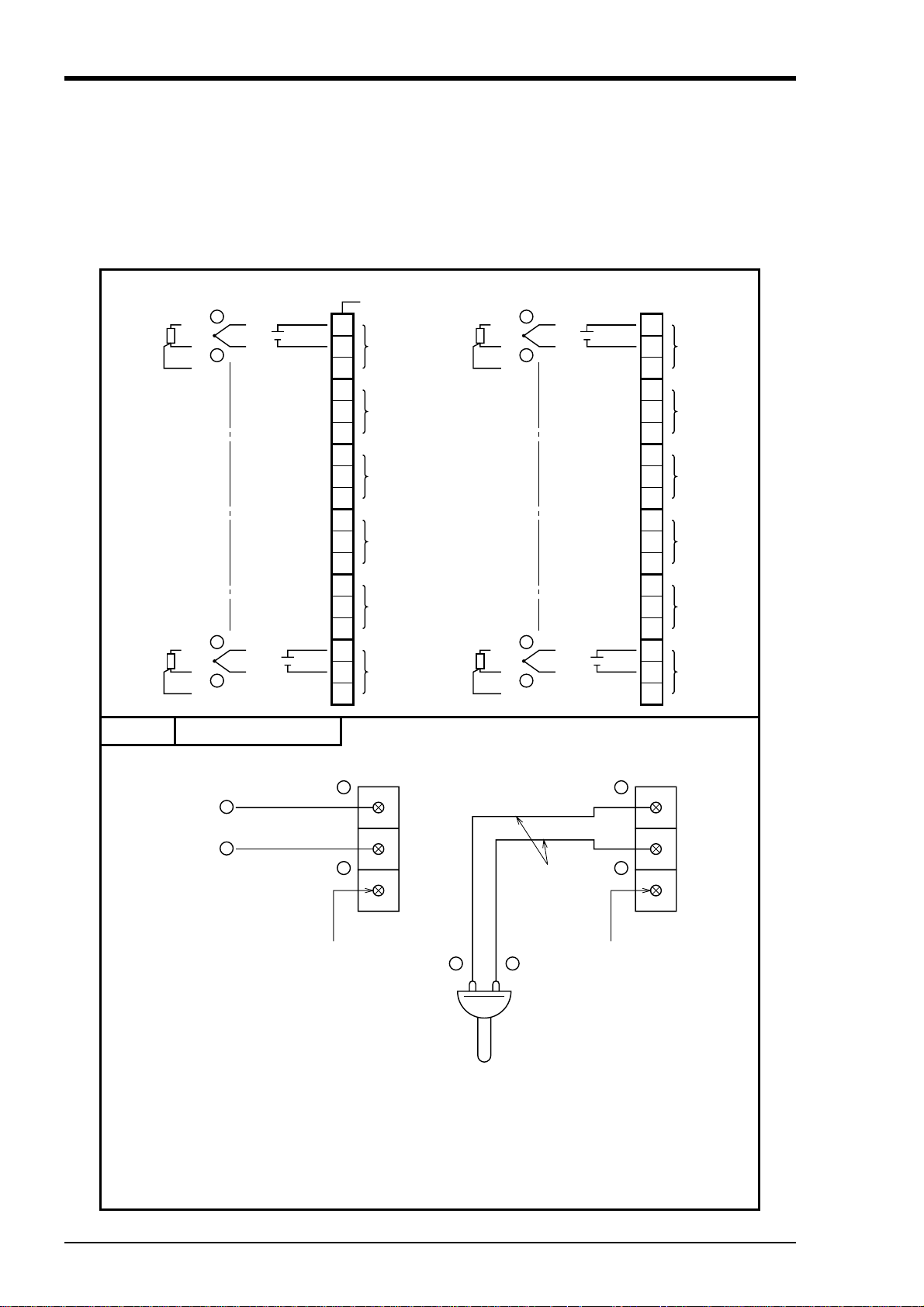

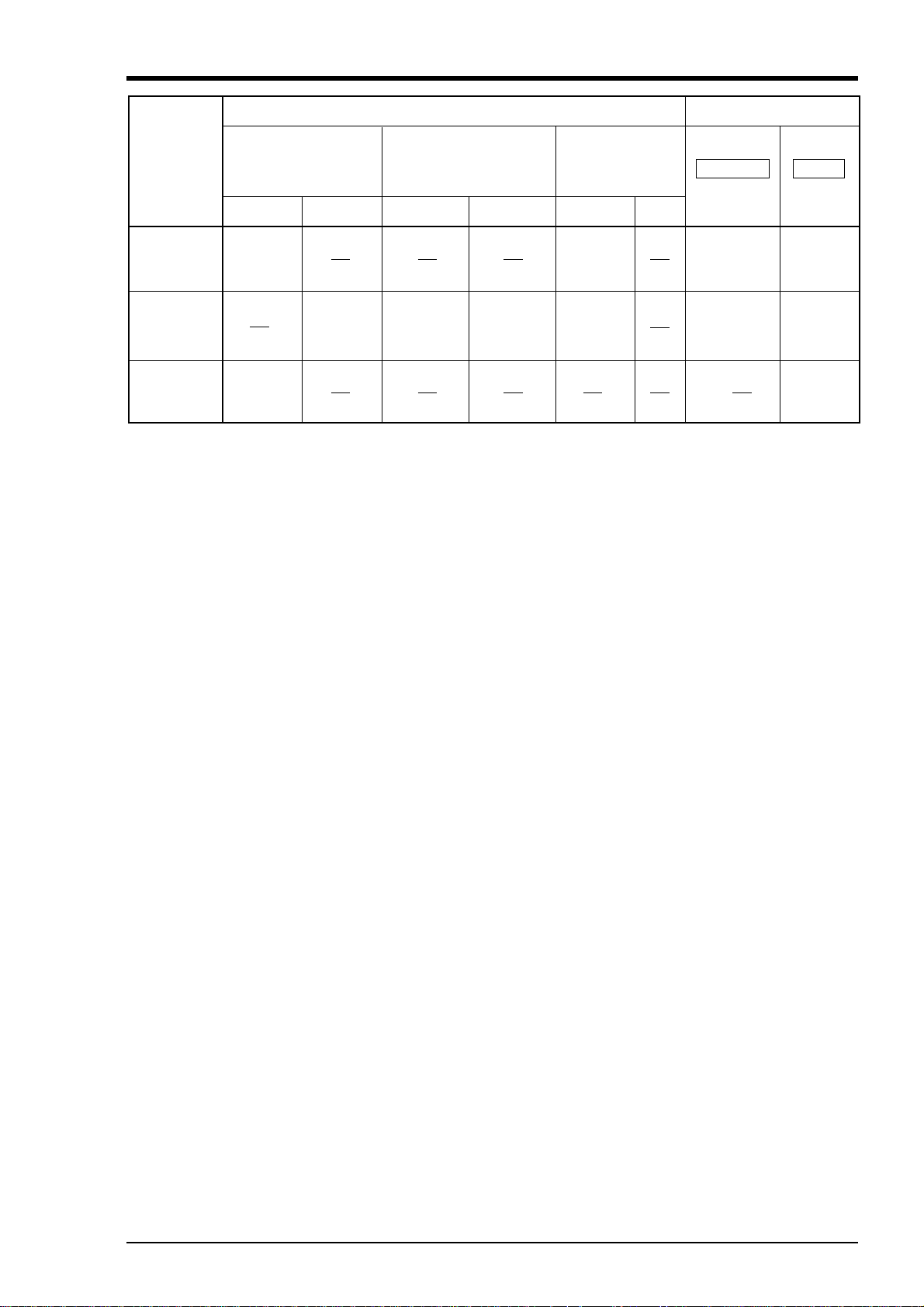

(1) Wiring of input terminals

(1) There are individual input terminal numbers for different channels.

(2) Make connection in accordance with the relation between number of input signals by type designa-

tion and channels (see section 1.3).

(3) If you decide to change the type of input signals after your purchase, be sure to remember to wire

up the requisite channel accordingly.

Resistance

bulb

A

b

A

b

Thermocouple

B

B

DC

voltage

+

–

+

–

Example Input terminal wiring

Terminal number

71

Input 7

72

(CH7)

73

81

Input 8

82

(CH8)

83

91

Input 9

92

(CH9)

93

101

Input 10

102

(CH10)

103

111

Input 11

112

(CH11)

113

121

Input 12

122

(CH12)

123

A

A

+

B

–

b

+

B

–

b

11

12

13

21

22

23

31

32

33

41

42

43

51

52

53

61

62

63

Input 1

(CH1)

Input 2

(CH2)

Input 3

(CH3)

Input 4

(CH4)

Input 5

(CH5)

Input 6

(CH6)

DC voltage input

DC voltage input

+

+

–

–

Blank Blank

11

12

13

Compensating

leads

+

–

Thermocouple input

+

21

22

–

23

Thermocouple

Note: Avoid using thermocpoule inputs with

wiring parallel to other instruments.

4 - 2 INP-TN4PHAV-E

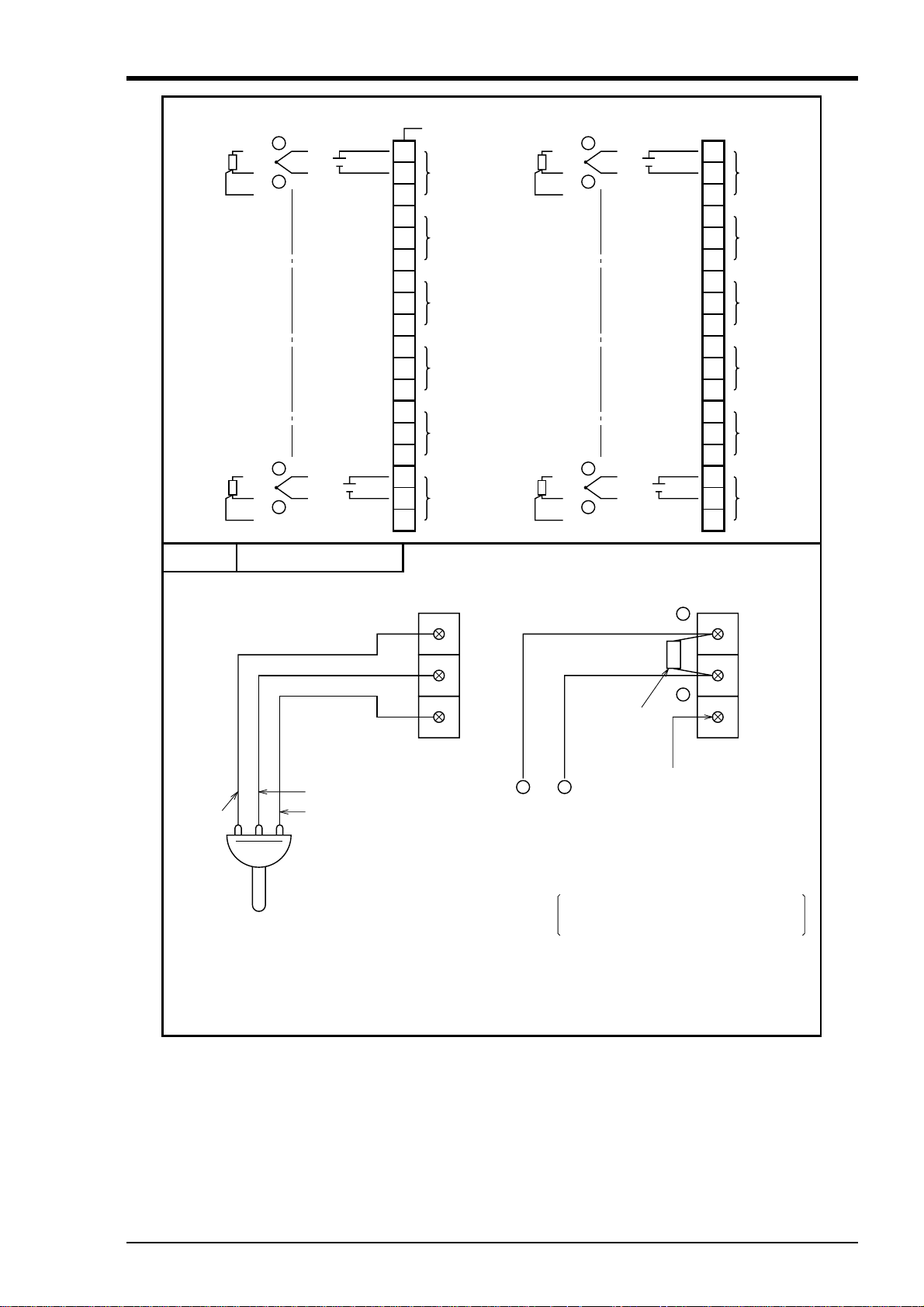

Resistance

bulb

A

b

A

b

Thermocouple

B

B

DC

voltage

+

–

+

–

Example Input terminal wiring

Terminal number

71

Input 7

72

(CH7)

73

81

Input 8

82

(CH8)

83

91

Input 9

92

(CH9)

93

101

Input 10

102

(CH10)

103

111

Input 11

112

(CH11)

113

121

Input 12

122

(CH12)

123

A

A

+

B

–

b

+

B

–

b

11

12

13

21

22

23

31

32

33

41

42

43

51

52

53

61

62

63

Input 1

(CH1)

Input 2

(CH2)

Input 3

(CH3)

Input 4

(CH4)

Input 5

(CH5)

Input 6

(CH6)

Resistance bulb input DC current input

A

B

b

B

A

b

31

32

33

+

DC current input

Shunt

resistance

–

+

–

Blank

Example: A 10Ω±0.1% shunt resistance is

used for 4 to 20mA, 10–50mA input.

Resistance bulb

In this case, ±500mV input range is

available. See Section 5-3.

Note: DC current input is converted into voltage by

shunt resistor (10Ω):

In 4 to 20mA DC : 40 to 200mV DC range

In 10 to 50mA DC :100 to 500mV DC range

4 - 3INP-TN4PHAV-E

(2) Alarm output/remote control unit (option)

About alarm outputs :

(1) Alarms can be set at 4 points in each channel and alarm outputs are provided as an option for up to

a maximum of 12 points.

(2) When an alarm is detected, the relevant terminals are shorted.

Relay contact capacity 240V/3A AC, 30V/3A DC (resistive load), 1a contact

14 24

15 25

16 26

17 27

18 28

19 29

Alarm 1

Alarm 2

Alarm 3

Alarm 4

Alarm 5

Alarm 6

31 41

32 42

33 43

34 44

35 45

36 46

Alarm 7

Alarm 8

Alarm 9

Alarm 10

Alarm 11

Alarm 12

Note: If lamps are used on the outside, insert a resistor to prevent surge current. Also, if relays or

solenoids are used, insert elements for contact protection (diodes, surge killers, etc.)

About remote control inputs

(1) This performs the functions 'Recording operation start/stop', 'Two-stage changeover of recording

paper speed' and 'Data (instantaneous value) print-out' in response to contact signals from outside

the instrument.

(2) There are separate wiring terminals for the different functions.

11 21

(DI1) Record start .................. Recording starts when the contact is closed and

stops when the contact is open.

12 22

(DI2) Chart speed change ...... The chart speed is the remote mode speed when

the contact is closed and the normal operation

speed when the contact is open.

13 23

(DI3) Data print ...................... Print-out starts when the contact is closed and

goes on right to the end even if the contact is

opened partway through the print-out. If you

wish to stop print-out partway through, press the

LIST key on the front panel.

Note 1: As the external control unit is not insulated, use it with interposition of an external relay.

External contact capacity 12V DC/0.05A 1a contact

Note 2: Operations effects by the external control unit and the front panel switches are as in the table

below. (A - in a box of the table indicates that no effect at all is had on the main unit operation.)

Note 3: When using the message print function or alarm latch function, the meaning of control input is

different. Refer to "7.10 List print-out setting" and "9.3 Alarm latch specification".

4 - 4 INP-TN4PHAV-E

Remote control

Front panel switch

While

recording

is stopped

During

recording

List

printout

Recording starts

(across terminals

(11) to (21))

ON OFF ON OFF ON OFF

Recording

starts

Recording

stops

Recording

starts

Chart speed change

(across terminals

(12) to (22))

Remote

mode chart

speed

Normal

operation

chart speed

Data printout

(across terminals

(13) to (23))

List

printout

starts

List

printout

starts

RECORD

Recording

starts

Recording

starts

LIST

List

printout

starts

List

printout

starts

List

printout

stops

(3) Caution on connection of input signal through barrier

A) Thermocouple input and resistance bulb input

Perform "Calibration of measured value" with the input connected to the barrier recorder because

the barrier internal resistance is added and causes an error in the measured value.

For the calibration method, refer to Item 9.4.

B) When using Fuji Zener Barrier (PWZ), a power source 100V AC line (85 to 132V AC) should be

used to ensure safe operation of the unit.

4 - 5INP-TN4PHAV-E

5. SET-UP

5.1 Loading chart paper

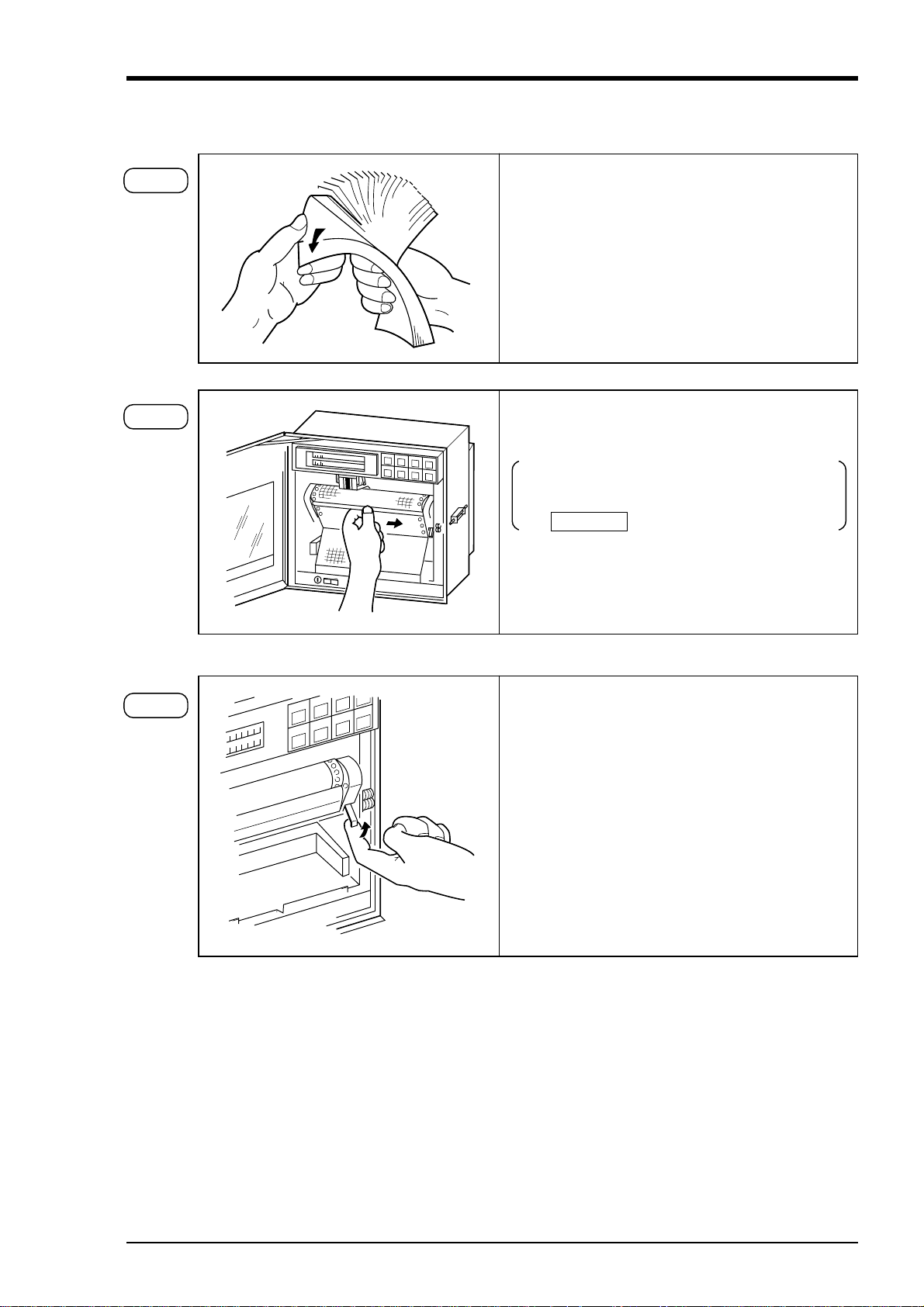

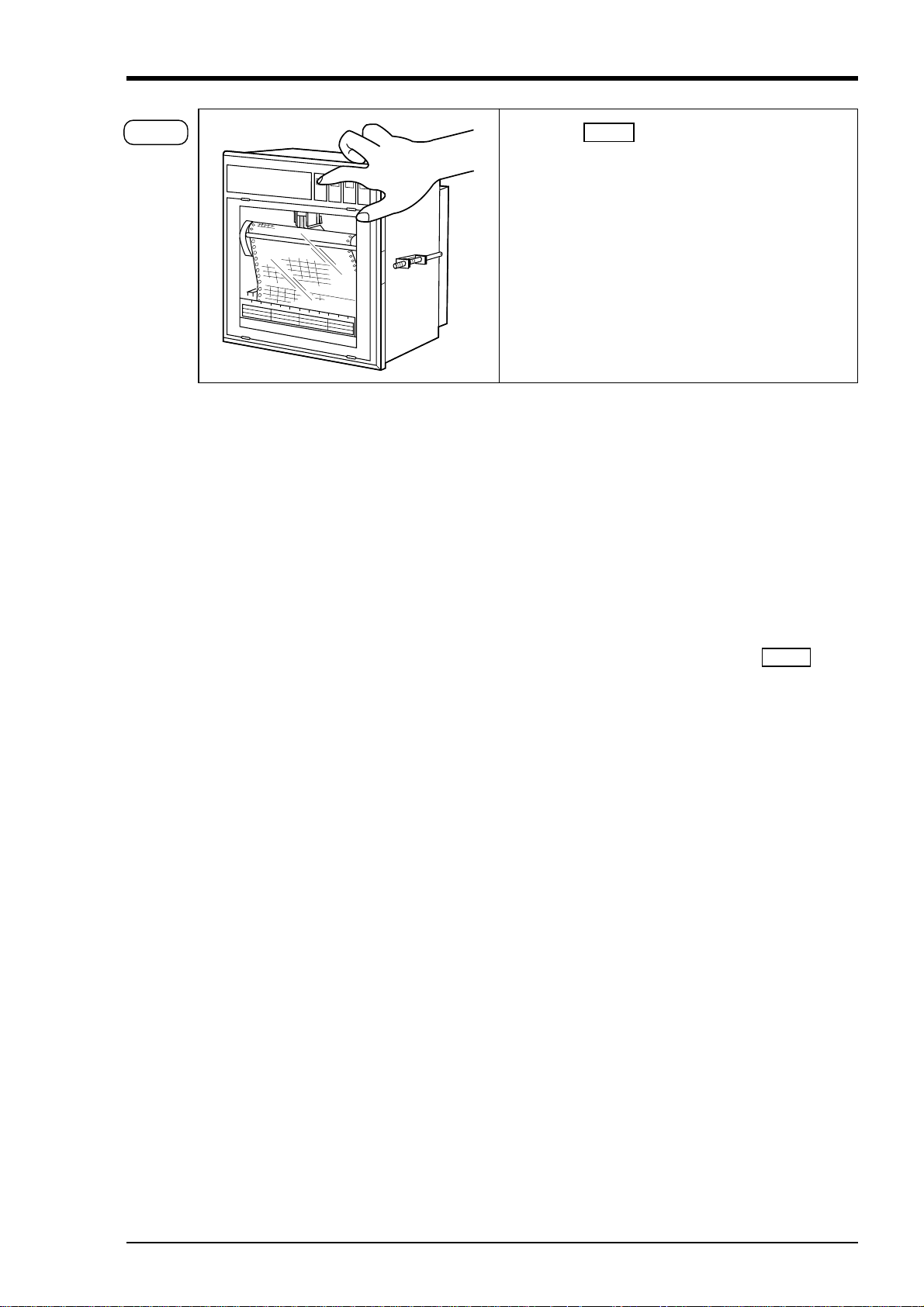

Step 1 Riffle and loosen the recording paper so as to

prevent overlapping feed.

Step 2 Open the front flap, push the paper hold-down

roller to the right and detach it.

To replace chart paper while recording is in

progress, carry out the above after pressing

the RECORD key to stop recording.

Step 3 Raise the lever that is on the right.

This releases the lock, the paper feeder moves

downward and paper holder can be seen.

5 - 1INP-TN4PHAV-E

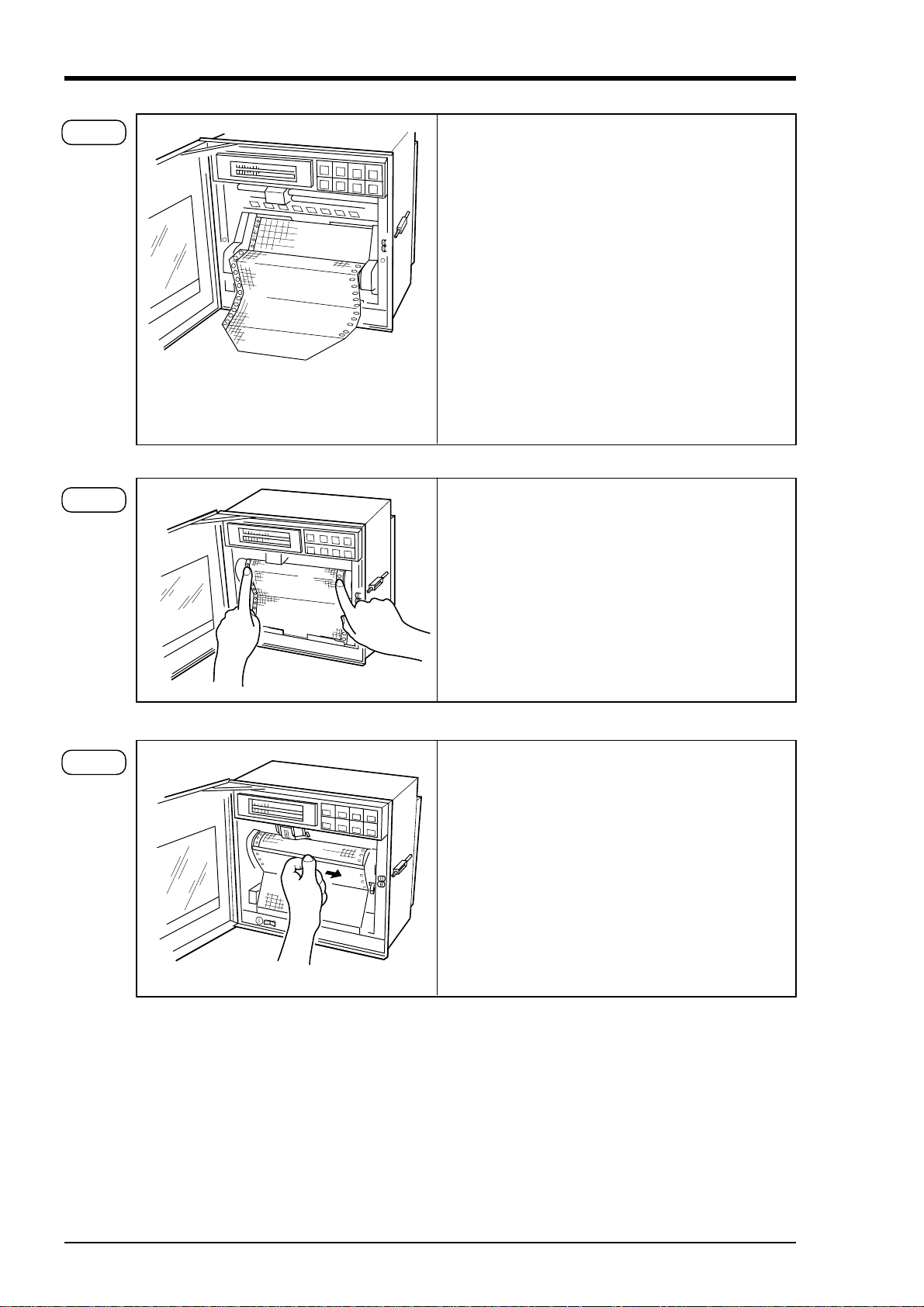

Step 4 With round holes (small holes) in the recording

paper located on the left-hand side, set the recording paper so that its leading edge with both

corners cut off comes to this side. Then insert

the leading edge into the container with the printing face located upward.

Butt the recording paper to the left-hand end and

set the recording paper in this position at this

time. Furthermore, be careful so that the recording

paper will not be located aslant. In addition, droop

the first two or three folds of the recording paper into the recording paper receiver.

Step 5 Press the chart paper so that its holes engage with

the sprockets and then, without further adjustment, return the paper holder to its original place.

Make sure that the chart paper does not lift up.

Note: If chart paper lifts up and contacts the re-

cording head, it can prevent ink coming

out. It can also cause improper paper feed.

Step 6 Return the paper hold-down roller to its original

position.

Check to make sure that the chart paper is straight

and that its holes are properly engaged with the

sprockets.

In order to prevent the chart paper slipping to the

left or right,

per folds into the middle of the paper catcher.

Turn the power supply switch on.

position equipment so that the pa-

5 - 2 INP-TN4PHAV-E

Step 7 Press the FEED key and check that the chart

paper is fed out smoothly. (Feed out about 2 folds

of paper.)

<If the paper is not fed out smoothly, go through

the procedure from Step 2 again.>

Note 1: Selection of chart paper

The chart paper greatly affects the quality of the printed recording and it is also related to problems such as paper jamming, etc.

Please be sure to use the pure-quality chart paper specified by us.

Chart paper type:PEX00BL1-1000B (100 equal divisions, no time lines)

Note 2: Use of the recorder after it has been left unused for a long time

If the recorder is left unused for a long time with chart paper still in the main unit, the paper 'packs

down' and if the recorder is used straightway there can be problems of paper jamming, etc.

If you use the equipment after it has been left unused for a long time, first press the FEED key to

feed out 2 to 3 folds of the paper.

Reference 1: Chart paper length

The chart paper is approximately 20m long. This permits about 31 days continuous printout at a paper feed speed of 25mm/h.

Reference 2: Chart paper end mark

The amount of chart paper remaining is indicated by digits (units : cm) on the right-hand

side of the paper. When there is only a small amount left, red letters appear on the righthand edge.

If the recording paper runs out completely, a recording paper end indicator displays 'Chart

end' in the display section and recording automatically stops.

5 - 3INP-TN4PHAV-E

5.2 Recording head installation (replacement)

The recording head has ink and a head for recording in an integral assembly.

If the ink gets used up or if it happens that there is a fault, the head can easily be replaced.

As the recording head is a very delicate element, please carefully read the 'Precautions" that are noted

later and handle the head with care during replacement work.

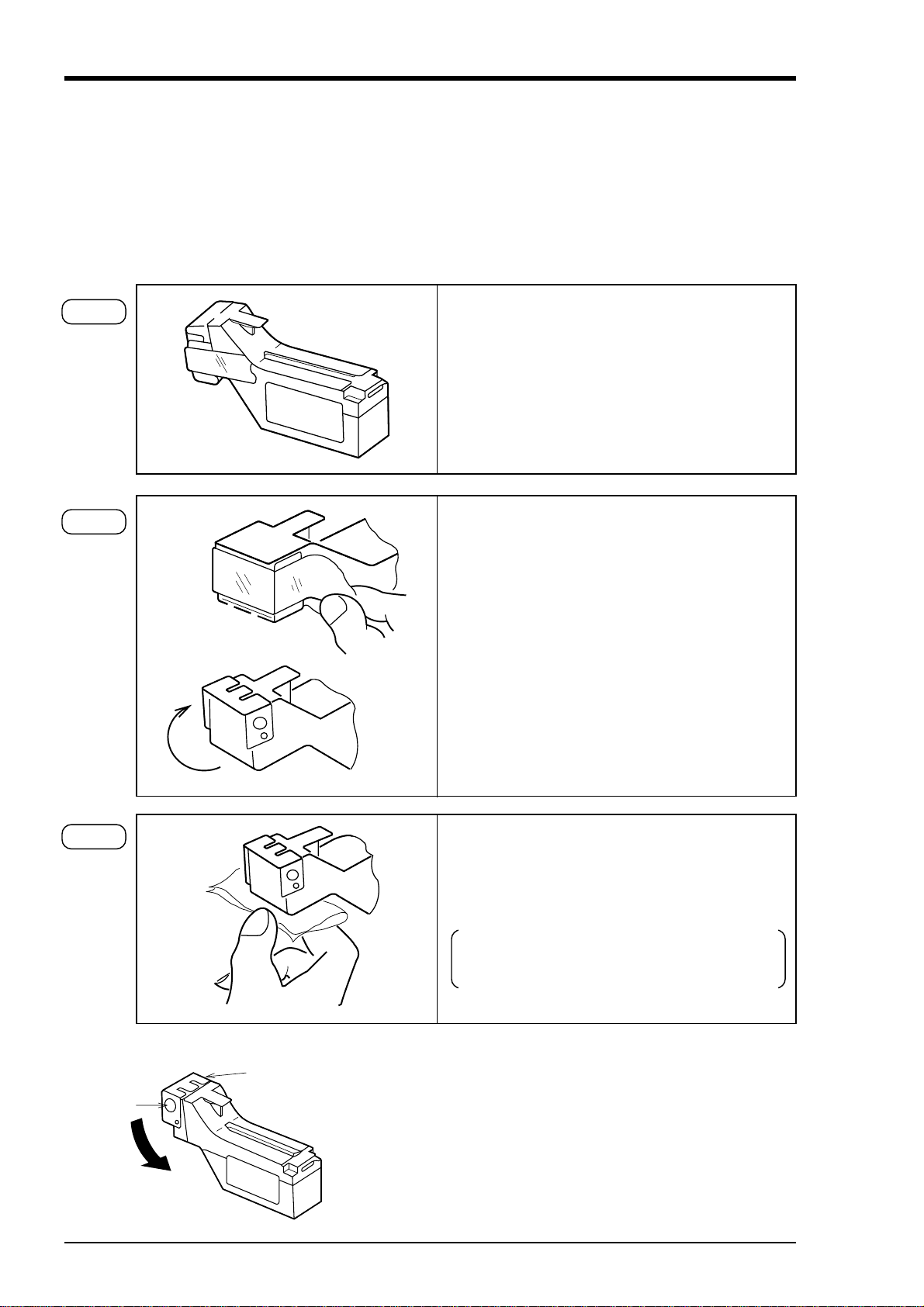

Step 1 Get the recording head ready by taking it out of

its aluminium pack.

Step 2 Tear the tape.

Open the cap by turning it in the direction indicated by the arrow.

(If the head is not going to be used for a long

time, close the cap back in its original position.)

The cap is integral with the head unit. Turn it

about 180° until it stops against the tope of the

head.

Step 3 Lightly press the nozzle surface (the surface

from which ink is discharge). Make sure that

the cloth is properly impregnated with the 4

colors blue, red, yellow and black.

First press the cloth against the surface for 2

to 3 second; if the 4 colors ooze out, it is OK.

How to close the cap

Cap

Stopper

• Turn the cap in the direction indicated by the arrow and

press it firmly until it is retained by the stopper.

• Ink may leak out if the cap is not properly in place.

5 - 4 INP-TN4PHAV-E

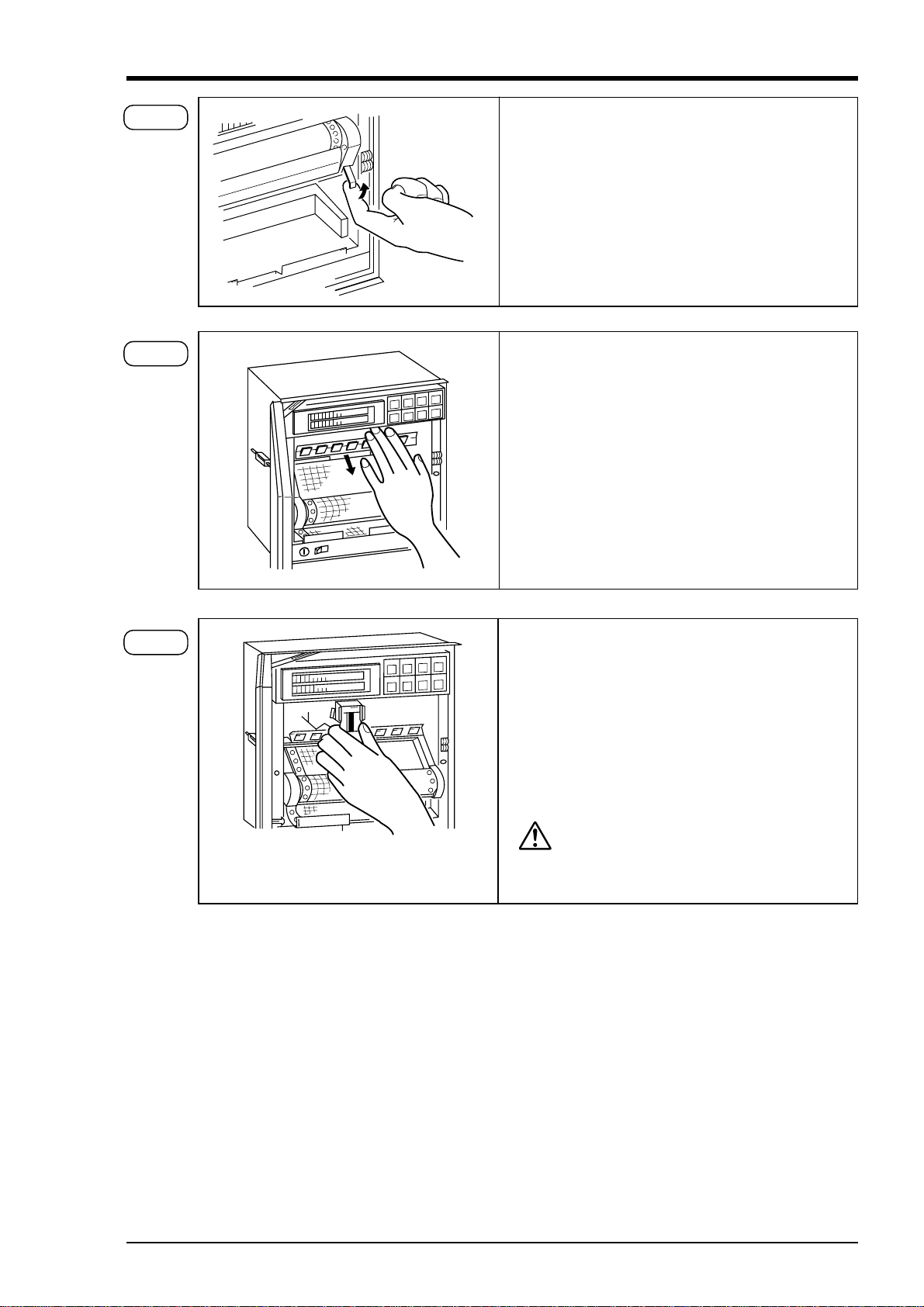

Step 4 • If recording is in progress, stop it by pressing

CAUTION

the RECORD key.

• Raise the lever that is on the right. This releases the lock comma only, the recording paper feed section pulls forward an recording paper holder can be seen.

Step 5 Push the chart paper hold-down plate spring

down.

Step 6 Hold the recording head horizontal, line it up

with the carriage in the main unit slide it in

slowly and press it firmly until it does not go in

any further. Take care not to bang the nozzle

surface of the hand.

Also, avoid touching the nozzle surface with your

hand.

Do not touch the connector at the rear

of the carriage to avoid the risk of minor electric shocks.

5 - 5INP-TN4PHAV-E

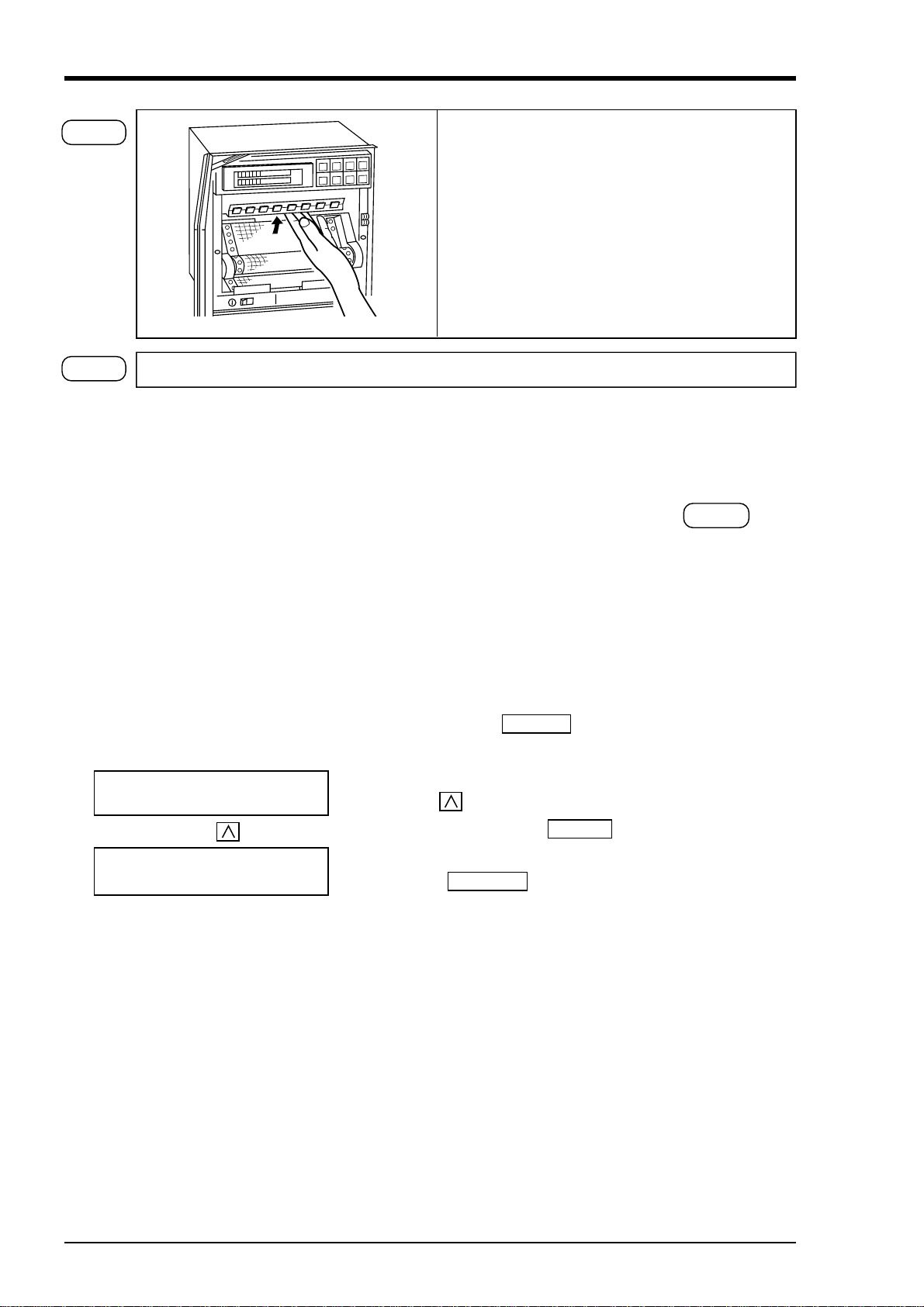

Step 7 Move the chart paper hold-down plate spring

back up to its original position.

(Check that the plate spring is not contacting the

recording head.)

Step 8 Return the chart paper holder to its original setting.

The above completes installation of the recording head.

The recording head is a consumable part. Replace it with a new one when the ink it contains is used up.

Recording head replacement

Draw out the recording head in the manner that is opposite to what is described in Step 6 of the

recording head setting procedure, and place it with a new recording head.

Always carry out the following procedure after replacing a recording head.

(1) Setting the ink monitor

Perform the following keying actions in order to get correct performance of the ink dry-up warning-detection function.

As in "Clearing the ink monitor' of Section 7.16, press the SELECT key to give an 'Ink monitor

clear" display.

INK MONITOR CLEAR

NO

↓

INK MONITOR CLEAR

YES

(2) Test patter print-out

Print out a test pattern to check that normal recording is possible. Set Section 6.3 for the way of printing

out a test pattern.

(3) Adjustment of analog trend recording positions

Referring to Section 9.2, readjust the zero and span on the recording paper.

Press the key to change the flickering "NO" to "YES".

Next, press ENTRY the ENTRY key.

This completes the setting.

Press the DISPLAY key to return to a data display

5 - 6 INP-TN4PHAV-E

Precautions in handling recording heads

Note 1: If recording is halted and the recorder is not used for a long time

Carry out the following in order to prevent jamming and drying-up of the ink.

Remove the recording head from the main unit, make absolutely sure the cap is closed

properly and store the head in a cool, dark place (average temperature 5 to 30°C).

If the head is left installed in the recorder:

Do not switch off the power to the recorder and do not close the cap.

* Periodically, there is an automatic discharge of ink to prevent drying-up.

Leave the recording paper in place in the recorder.

If it is not possible to keep the power switched on, make sure that the cap is closed.

In this case, follow Step 4 and Step 5 of 'Recording head installation' to lower the recording

paper holder and hold-down plate spring and tighten the cap.

Note 2: At the start of use of a recording head

If you are starting to use a new recording head or if the recorder has been left unused for a long time,

always wipe the head's nozzle surface lightly with the accessory cloth and check that the 4 colors black,

blue, red and yellow ooze out properly into the cloth. (See Section 5.2.) Also, after normal recording

is possible. See Section 6.3 for the way of printing out a test pattern.

When the working environment is 15°C or less, perform print-out of "test pattern" after period of

several minutes has elapsed since the recording head was mounted. (The recording head has a built-in

heater.)

Note 3: Handling recording heads

• Do not knock or shake recording heads as this can cause faults.

• The inks are not harmful but they are very difficult to remove if they adhere to the skin or to clothes,

so handle heads carefully in order to avoid staining. Also, do not disassemble them.

• If, by accident, it happens that ink gets into your eyes, wash thoroughly with water as an emergency

measure and then immediately consult a specialist doctor.

Note 4: Storage of recording heads

When they are delivered, recording heads are in aluminium packs.

If you are not going to use a head straight-away, leave it sealed and store it in a cool, dark place with an

average temperature of 5 to 30°C.

5 - 7INP-TN4PHAV-E

Note 5: Shipping of recording head

• Do not ship the unit recording head after the aluminum pack was opened up.

If it is necessary to ship the unit recording head under avoidable circumstances, be sure to close the

cap, and ship it as contained in a boxboard in the state where vibration and impact are eased using

cushioning materials.

• Always close the cap if you are transporting a head while it is still installed in the recorder main unit.

Note 6: If the ink is not sprayed.

(1) Hold the recording head with turning the nozzle surface down-

ward and push the side strong till spilling two drops.

(2) Absorb the standing ink on the nozzle surface with the cloth at-

tached.

(3) Hold the cloth to the nozzle surface again to find all colors flowed

onto cloth.

* When working environment is 15°C or less, perform print-out

of "record" or "test pattern" after a period or several minutes

has elapsed since the recording head was mounted. (The recording head has a built-in heater.)

Reference: Ink consumption

This varies depending on the conditions of use but with a chart speed of 25mm/h and recording of

constant input, the amount of consumption is as follows.

About 1 year..............................in the case of 1, 2, 3 continuous records

About 6 months.........................in the case of 6 continuous records

About 3 months.........................in the case of 12 continuous records

An ink dry-up warning-detection function produces a warning display in the display section and a

warning print-out the recording paper.

(See Section 11.12 for an example of print-out.)

5 - 8 INP-TN4PHAV-E

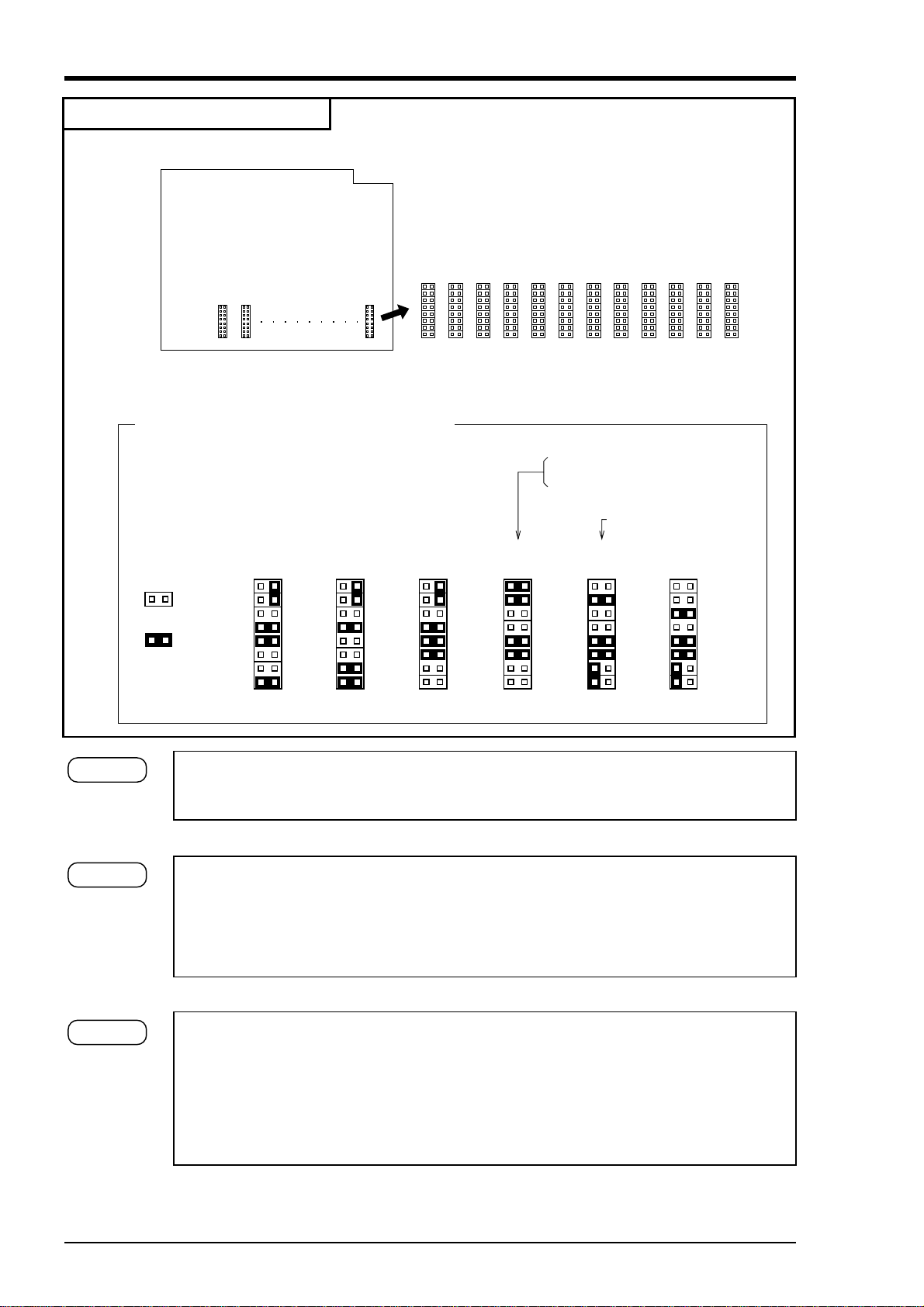

5.3 Changing the type of input signals

This recorder is a multi-input type which permits the input for any channel to be changed to thermocouple, resistance bulb or DC voltage input.

Follow the procedure described below if you with to change the type of input signals subsequent to

purchase.

Step 1 Turn off the power.

Step 2 Open the front flap and remove the main unit in the manner shown in the drawings below.

Step 2-1 Loosen the lock screws on the left and right and

remove them.

Lock screws

Step 2-2 Grip the paper feed frame and pull it firmly to-

wards you. This detaches it from the main unit.

Step 2-3 Change the settings of the pins for individual

channels on the internal printed circuit board.

(See the method of changing pin positions on the

next page.)

* If there are not enough pins, use the accessory

Input signal

setting pins

input signal setting pins.

* Use pliers, to remove the insert pins.

5 - 9INP-TN4PHAV-E

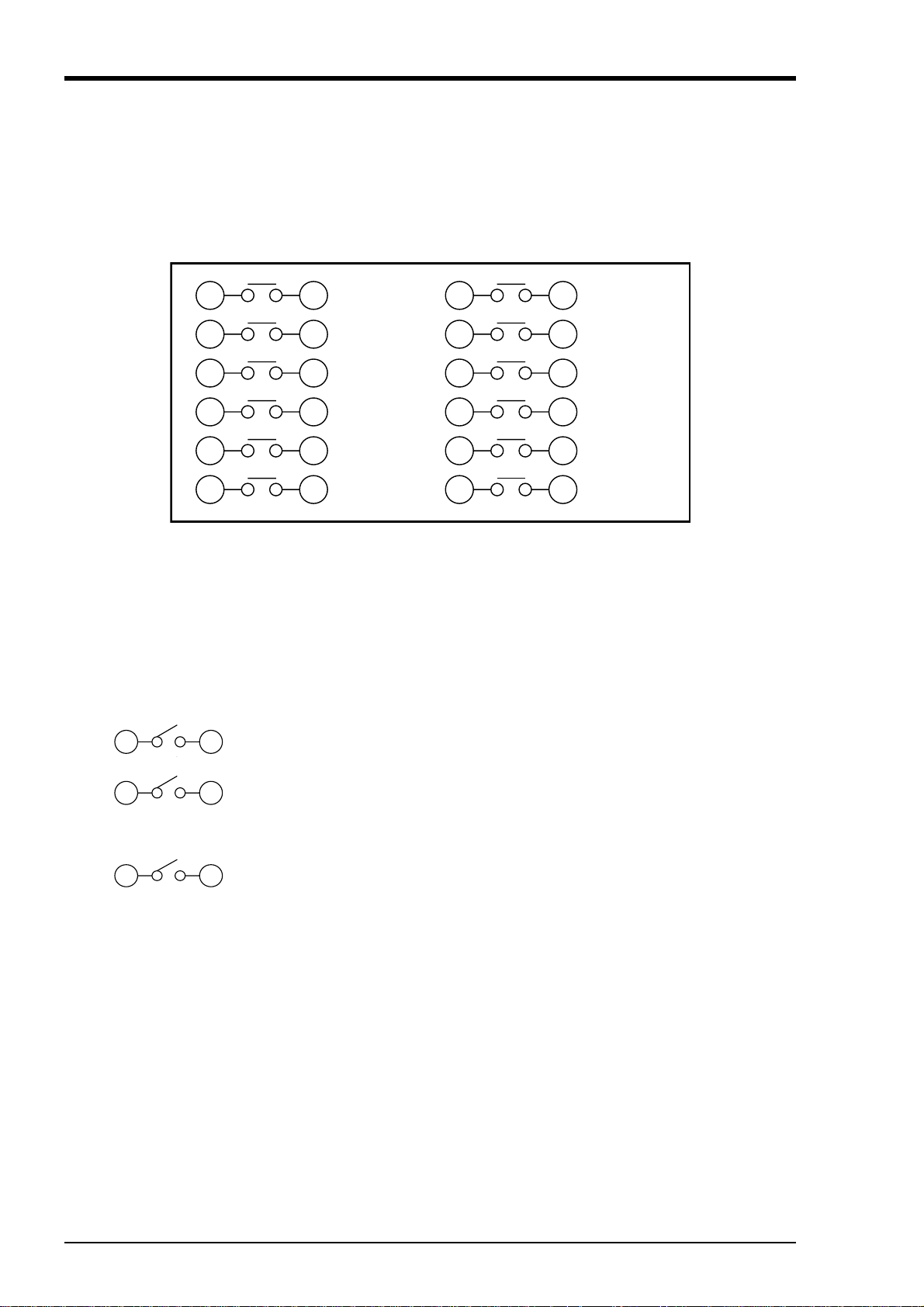

Method of changing pin position

Large PC board installed in deepth of the case.

CH6 CH5 CH7

Changeover pins

(maximum 12)

Pin position for different types of inputs

Correspondence between pin line-up

and input channels

CH6

5 4 3 2 1 121110 9 8 7

Pin setting is required in correspondence

with types of inputs for each channel.

4 to 20mA DC at input

10 to 50mA DC at input

The set position is as shown below.

1 to 5V DC at input

MAX.

Thermocouple

Resistance

bulb

±

50mV

MAX.

±

500mV

MAX.

±

5V

MAX.

±

50V

OPEN

SHORT

Step 2-4 After completing the change, push the main unit back into its original place and fix it

with the left and right lock screws.

Step 2-5 Change the input terminal wiring to make it correspond to the new input signal type.

For DC voltage input, provide the input terminals with shunt resistors.

Example: In the case of 4 to 20mA DC input, fit the separately sold shund resistors

(10Ω) and set to ±500mV range input pin positions.

Step 2-6 Refer to Section 7.8 and carry out front-panel keyboard operations in order to change

setting in correspondence to change types of input signals.

[Note] DC current input is converted into voltage by shunt resistor (10Ω):

In 4 to 20mA DC : 40 to 200mV DC range

In 10 to 50mA DC : 100 to 500mV DC range

5 - 10 INP-TN4PHAV-E

6. OPERATION AND ACTIONS

6.1 Before running the equipment:

Check the following points before starting operation.

1. Recording paper, recording head installation

(1) Loading chart paper....................................................... See Section 5.1

(2) Installation of recording head........................................ See Section 5.2

2. Wiring

(1) Input terminals .............................................................. See Section 4.2

(2) Alarm terminals (option) ............................................... See Section 4.2

(3) Power supply, ground terminals.................................... See Section 4.2

3. Do the input types and channels match?

(1) Type specification ......................................................... See Section 1.3

(2) Changing the type of input terminals ............................ See Section 5.3

6 - 1INP-TN4PHAV-E

6.2 Power switch-on and states

(1) Open the front flap.

(2) The power supply switch is at the above left; switch it on.

(1) Initial switch-on of power

↓

—

↓

The recording head moves slowly to the left-hand end (the 0% side).

↓

When the 0% point is detected, the recording head moves to a position that is

about 50mm from the left-hand end and stops.

↓

Ch1. 100°C

(2) If the power is switched off while recording is stopped and switched on again:

The state becomes 'Recording stopped'.

(3) If the power is switched off during recording operation and switched on again:

The state becomes 'Recording in progress'.

Recording in progress

↓

Power supply cut off

↓

Display disappears Recording stops

↓

Power turned on again

↓

(A cursor appears in the upper left of the display section.)

The input data and Tag No. are displayed in the display section.

(No recording takes place.)

—

↓

The recording head moves slowly to the left-hand end (the 0% side).

↓

When the 0% point is detected, the recording head moves to a position that is about 50mm

from the left-hand end (0%), moves back again to the left-hand end and is on standby

↓

Ch1. 100°C

Record ON

(Cursor appears in top left of display section)

The input data is displayed in the display section and recording restarts.

6 - 2 INP-TN4PHAV-E

Loading...

Loading...