Page 1

High Performance Inverter

Solar Pumping

Instruction Manual

Thank you for purchasing our multifunction FRENIC-Ace series of inverters.

• This product is desig ne d to dri ve a thr e e-phase motor under var iab le s p eed c ontr ol. Read through

this user's manual and become familiar with the handling procedure for correct use.

• Improper handling might result in incorrect operation, a short life, or even a failure of this product as

well as the motor.

• Deliver this manual t o the end user of this product. Kee p this manual in a safe place until t his

product is discarded.

• For how to use an optional device, refer to the instruction and installation manuals for that optional

device.

Jde085-00031a

Page 2

Copyright © 2014 Fuji Electric Co., Ltd.

All rights reserved.

No part of this publ ication m ay be reproduc ed or copi ed without pr ior writte n perm ission

from Fuji Electric Co., Ltd.

All products and company nam es m entioned in t his manua l are tr adem ark s or r egistered

trademarks of their respective holders.

The information contained herein is subject to change without prior notice for

improvement.

The purpose of this user's manual is to provide accurate information in handling, setting up

and operating of the FRENIC-Ace series of inverters. Please feel free to send your

comments regarding any errors or omissions you may have found, or any suggestions you

may have for generally improving the manual.

In no event will Fuji Electric Co., Ltd. be liable for any direct or indirect damages resulting

from the application of the information in this manual.

Page 3

Preface

Thank you for purchasing our m ultifunction FRENIC-Ace series of inverters for Solar Pum ping

application. This product is designed to drive three-phase induction motors or three-phase

permanent magnet synchronou s m otors under variable speed control.

This manual provides the i nformation on the FRENIC-Ace series of inverters including its

operating procedure when used in Solar Pumping application. B efore use, carefully read this

manual for proper use. Improper ha ndling might res ult in incorrect operat ion, a short life, or ev en a

failure of this product as well as t he motor .

The table below lists the other materials related to the use o f the FRENIC-Ace. Read the m in

conjunction with this manual if necessary.

Name Material No. Description

Catalog

24A1-E-0042

Product scope, features, specifications, external drawings,

and options of the product

RS

-485 Communication User' s

Manual

24A7-E-0021*

Overview of functions implemented by using FRENIC-Ace

RS-485 communications facility, its communications

specifications, Modbus RTU/Fuji general-p urpo se inv ert er

protocol, function codes and related data formats

User

’s Manual for China model 24A7-E-0043x This manual is written in English.

User

’s Manual for China model. 24A7-C-0043x This manual is written in simplified Chinese.

User

’s Manual for Japanese

model.

24A7-J-0043x This manual is written in Japanese.

*Available soon

x Is the index letter that indicates the manual version. Please refer to the latest one.

The materials are subject to c hange without notice. Be sure to obtain the latest editions for use.

i

Page 4

Introduction of FRENIC Ace Solar Pumping

In the Solar Pumping applicat ion the inv ert er drives an electrical motor (pump), while the power is

supplied usually from a PV panel. FRENIC Ace Solar Pumping inverter speci fication is equipped

with dedicated functions for t he cor r ect oper ation under these spec ia l conditions:

Solar Panel voltage set point calculation at every start (depending on current irradiance

and panel temperatur e)

True M aximum Power Point Tracking (MPP T) function

Detection of sudden changes of conditions (irradiance)

Stop criteria selectable (frequency and/or power)

Star t c rit er ia by s olar panel voltage and time (to limit the number of starts)

Dry pump detection funct i on

Water t ank maximum level detection fu nc t io n

Low power detection funct ion

Two sets of PID gains

ii

Page 5

Index

Chapter 1 SAFETY PRECAUTIONS

This chapter describes the safety precautions that should be considered during t he w hol e li fe o f

the product.

Chapter 2 INSTALLATION AND WIRING

This chapter describes the i mportant points in installing and wiring the inver t er.

Chapter 3 OPERATION USING THE KEYP AD

This chapter describes keypad operation of the inv er t er.

Chapter 4 SET UP PROCEDURE

This chapter describes the set up pr ocedure of FRENIC Ace for Solar Pumping application.

Chapter 5 FUNCTION CODES

This chapter explains the function codes relevant for Sol ar pumping application. For other

parameters not descr ib ed in this manual please refe r t o FRE NIC Ace User M anual.

Chapter 6 TROUBLESHOOTING

This chapter describes troubleshooting procedures t o be fo llowed when the invert er malfunctions

or detects an alarm or a light alarm condition. In this c hapter , first chec k whether any alarm code o r

the "light alarm" indicatio n (

l-al

) is displayed or not, and then pro ceed to the troubleshooting items.

Chapter 7 SPECIFICATIONS

This chapter describes the pow er circuit input and output r at ings and basic constructive

specifications of FRENIC Ace standard model.

iii

Page 6

1-1

Chapter 1 SAFETY PRECAUTIONS

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or maintenance

and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all safety information

and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to dangerous

conditions, possibly resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to dangerous

conditions, possibly resulting in minor or light bodily injuries and/or substantial

property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences. These

safety precautions are of utmost importance and must be observed at all times.

Application

• The FRENIC-Ace is designed to drive a three-phase induction motor. Do not use it for single-phase motors

or for other purposes.

Fire or an accident could occur.

• The FRENIC-Ace may not be used for a life-support system or other purposes directly related to the human

safety.

• Though the FRENIC-Ace is manufactured under strict quality control, install safety devices for applications

where serious accidents or property damages are foreseen in relation to the failure of it.

An accident could occur.

Installation

• Install the inverter on a base made of metal or other non-flammable material.

Otherwise, a fire could occur.

• Do not place flammable object nearby.

Doing so could cause fire.

• Inverters FRN0085E2■-4G or above, whose protective structure is IP00, involve a possibility that a human

body may touch the live conductors of the main circuit terminal block. Inverters to which an optional DC

reactor is connected also involve the same. Install such inverters in an inaccessible place.

Otherwise, electric shock or injuries could occur.

• Do not support the inverter by its front cover during transportation.

Doing so could cause a drop of the inverter and injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the

inverter or from accumulating on the heat sink.

• When changing the positions of the top and bottom mounting bases, use only the specified screws.

Otherwise, a fire or an accident might result.

• Do not install or operate an inverter that is damaged or lacking parts.

Doing so could cause fire, an accident or injuries.

Page 7

1-2

Wiring

• If no zero-phase current (earth leakage current) detective device such as a ground-fault relay is installed in

the upstream power supply line, in order to avoid the entire power supply system's shutdown undesirable to

factory operation, install a residual-current-operated protective device (RCD)/earth leakage circuit breaker

(ELCB) individually to inverters to break the individual inverter power supply lines only.

Otherwise, a fire could occur.

• When wiring the inverter to the power source, insert a recommended molded case circuit breaker (MCCB) or

residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB) (with overcurrent

protection) in the path of each pair of power lines to inverters. Use the recommended devices within the

recommended current capacity.

• Use wires in the specified size.

• Tighten terminals with specified torque.

Otherwise, a fire could occur.

• When there is more than one combination of an inverter and motor, do not use a multicore cable for the

purpose of handling their wirings together.

• Do not connect a surge killer to the inverter's output (secondary) circuit.

Doing so could cause a fire.

• Be sure to connect an optional DC reactor (DCR) when the capacity of the power supply transformer exceeds

500 kVA and is 10 times or more the inverter rated capacity.

Otherwise, a fire could occur.

• Ground the inverter in compliance with the national or local electric code.

• Be sure to ground the inverter's grounding terminals G.

Otherwise, an electric shock or a fire could occur.

• Qualified electricians should carry out wiring.

• Be sure to perform wiring after turning the power OFF.

Otherwise, an electric shock could occur.

• Be sure to perform wiring after installing the inverter unit.

Otherwise, an electric shock or injuries could occur.

• Ensure that the number of input phases and the rated voltage of the product match the number of phases and

the voltage of the AC power supply to which the product is to be connected.

Otherwise, a fire or an accident could occur.

• Do not connect the power supply wires to output terminals (U, V, and W).

• When connecting a DC braking resistor (DBR), never connect it to terminals other than terminals P(+) and

DB.

Doing so could cause fire or an accident.

• In general, sheaths of the control signal wires are not specifically designed to withstand a high voltage (i.e.,

reinforced insulation is not applied). Therefore, if a control signal wire comes into direct contact with a live

conductor of the main circuit, the insulation of the sheath might break down, which would expose the signal

wire to a high voltage of the main circuit. Make sure that the control signal wires will not come into contact with

live conductors of the main circuit.

Doing so could cause an accident or an electric shock.

• Before changing the switches or touching the control circuit terminal symbol plate, turn OFF the power and

wait at least five minutes for inverters FRN0115E2■-2G / FRN0072E2■-4G or below, or at least ten

minutes for inverters FRN0085E2■-4G or above. Make sure that the LED monitor and charging lamp are

turned OFF. Further, make sure, using a multimeter or a similar instrument, that the DC link bus voltage

between the terminals P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• The inverter, motor and wiring generate electric noise. Be careful about malfunction of the nearby sensors

and devices. To prevent them from malfunctioning, implement noise control measures.

Otherwise an accident could occur.

Page 8

1-3

Operation

• Be sure to mount the front cover before turning the power ON. Do not remove the cover when the inverter

power is ON.

Otherwise, an electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause electric shock.

• If the auto-reset function has been selected, the inverter may automatically restart and drive the motor

depending on the cause of tripping. Design the machinery or equipment so that human safety is ensured at

the time of restarting.

Otherwise, an accident could occur.

• If the stall prevention function (current limiter), automatic deceleration (anti-regenerative control), or

overload prevention control has been selected, the inverter may operate with acceleration/deceleration or

frequency different from the commanded ones. Design the machine so that safety is ensured even in such

cases.

• The key on the keypad is effective only when the keypad operation is enabled with function code F02 (=

0, 2 or 3). When the keypad operation is disabled, prepare an emergency stop switch separately for safe

operations.

Switching the run command source from keypad (local) to external equipment (remote) by turning ON the

"Enable communications link" command LE disables the key. To enable the key for an emergency

stop, select the STOP key priority with function code H96 (= 1 or 3).

• If any of the protective functions have been activated, first remove the cause. Then, after checking that the

all run commands are set to OFF, release the alarm. If the alarm is released while any run commands are set

to ON, the inverter may supply the power to the motor, running the motor.

Otherwise, an accident could occur.

• If you enable the "Restart mode after momentary power failure" (Function code F14 = 3 to 5), then the

inverter automatically restarts running the motor when the power is recovered.

Design the machinery or equipment so that human safety is ensured after restarting.

• If the user configures the function codes wrongly without completely understanding this User's Manual, the

motor may rotate with a torque or at a speed not permitted for the machine.

• Starting auto-tuning involves motor rotation. Sufficiently check that motor rotation brings no danger

beforehand.

An accident or injuries could occur.

• Even if the inverter has interrupted power to the motor, if the voltage is applied to the main circuit input

terminals L1/R, L2/S, L3/T, L1/L and L2/N, voltage may be output to inverter output terminals U, V, and W.

• Even if the motor is stopped due to DC braking or preliminary excitation, voltage is output to inverter output

terminals U, V, and W.

An electric shock may occur.

• The inverter can easily accept high-speed operation. When changing the speed setting, carefully check the

specifications of motors or equipment beforehand.

Otherwise, injuries could occur.

• Do not touch the heat sink and braking resistor because they become very hot.

Doing so could cause burns.

• The DC brake function of the inverter does not provide any holding mechanism.

Injuries could occur.

• Ensure safety before modifying the function code settings.

Run commands (e.g., "Run forward" FWD), stop commands (e.g., "Coast to a stop" BX), and frequency

change commands can be assigned to digital input terminals. Depending upon the assignment states of

those terminals, modifying the function code setting may cause a sudden motor start or an abrupt change in

speed.

• When the inverter is controlled with the digital input signals, switching run or frequency command sources

with the related terminal commands (e.g., SS1, SS2, SS4, SS8, Hz2/Hz1, Hz/PID, IVS, and LE) may cause

a sudden motor start or an abrupt change in speed.

• Ensure safety before modifying customizable logic related function code settings (U codes and related

function codes) or turning ON the "Cancel customizable logic" terminal command CLC. Depending upon the

settings, such modification or cancellation of the customizable logic may change the operation sequence to

cause a sudden motor start or an unexpected motor operation.

An accident or injuries could occur.

Page 9

1-4

Maintenance and inspection, and parts replacement

• Before proceeding to the maintenance/inspection jobs, turn OFF the power and wait at least five minutes

for inverters FRN0115E2■-2G / FRN0072E2■-4G or below, or at least ten minutes for inverters

FRN0085E2■-4G or above. Make sure that the LED monitor and charging lamp are turned OFF. Further,

make sure, using a multimeter or a similar instrument, that the DC link bus voltage between the terminals

P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, an electric shock or injuries could occur.

• Never modify the inverter.

Doing so could cause an electric shock or injuries.

Disposal

• Treat the inverter as an industrial waste when disposing of it.

Otherwise injuries could occur.

GENERAL PRECAUTIONS

Drawings in this manual may be illustrated without covers or safety shields for explanation of detail parts. Restore

the covers and shields in the original state and observe the description in the manual before starting operation.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the inverter not operating to full efficiency,

as well as information concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can be useful when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Page 10

Page 11

Chapter 2 INSTALLATION AND WIRING

2.1 Installation

(1) Installation Environment

Please install FRENIC-Ace in locations which meet the conditions specified in “Chapter 1 1.3.1 Usage

environment” of the User Manual.

(2) Installation Surface

Please install the inver ter on non-combustible matter such as metals. Also, do not mount it up si de down or

horizontally.

Install on non-combustible matter such as metals.

Risk of fire exists

(3) Surrounding Space

Secure the space shown in Figure 2.1

-1 and Table 2.1-1. When

enclosing

FRENIC-Ace in cabinets, be sure to provide adequate

ventilation

to the cabinet, as the surround ing te mpera ture ma y rise. Do

not contain

it in small enclosures with low heat dissipation capacity.

Installation of Multiple Inverters

When installing 2 or m

ore units in the same equipment or cabinet,

generally mount

them to the side of each other, not above each other.

When the inverters are mounted

above each other, attach partitioning

boards to prevent

that the heat dissipated from the lower inverter to

affect

s the upper inverter.

For

types FRN0072E2-4G, FRN0220E2-2G or below and for

ambient temperature below 4

0°C only, the units can be installed

side by

side without any spacing between them

(30°C or lower for ND and HD).

Table 2.1-1 Surrounding Space mm (inch)

Applicable Capacity A B C

200 V class: FRN0001 to 0220E2-2G

200 V class: FRN0001 to 0012E2-7G

400 V class: FRN0002 to 0072E2-4G

10

(0.39)

100

(3.9)

0

*1

400 V class: FRN0085 to 0590E2-4G

50

(1.97)

100

(3.9)

*1 A clearance of 50 mm is required to use RJ45 connector .

C: Space in front of the inverter unit

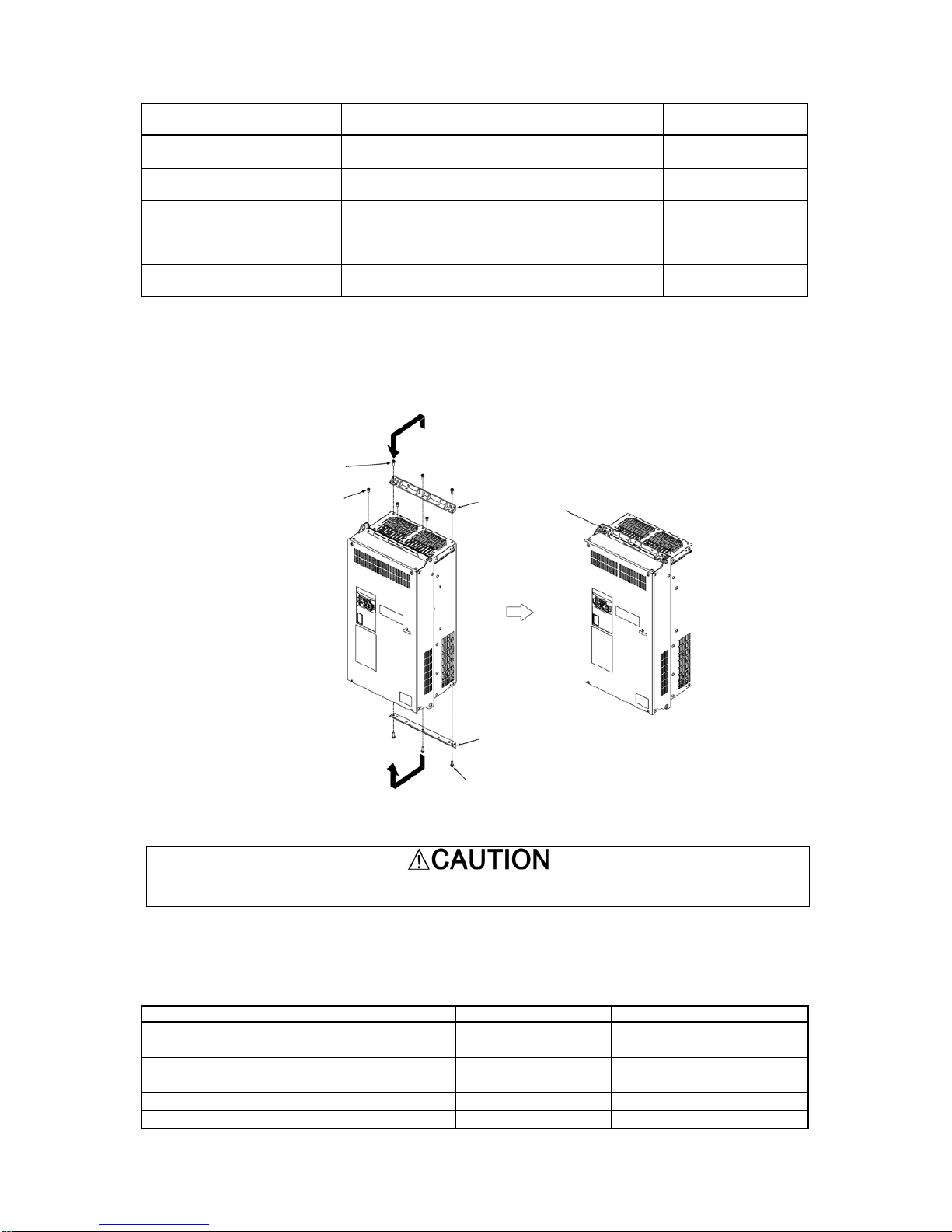

Installation with External Cooling

The

external cooling installation reduces the generated heat inside the

panel

by dissipating approximately 70% of the total heat generated

(total heat loss)

by mounting the cooling fins protruding outside the

equipment or cabinet.

Installation with external co

oling is possible for types FRN0069E2■-2G

and

FRN0072E2■-4G or below by adding attachments (optional) for

external cooling,

and for types FRN0085E2■-4G or above by moving

the

mounting bases.

Figure 2.1-2 Installation with External

Cooling

Please refer to User Manual Chapter 11 Item 11.15 for the external

dimensions

drawing of the external cooling attachment (optional).

Prevent lint, wastepaper, wood shavings, dust, metal scrap, and

other foreign material from entering the inv erter or fro m att ac hing to

the cooling fins.

Risk of fire and risk of accidents exist

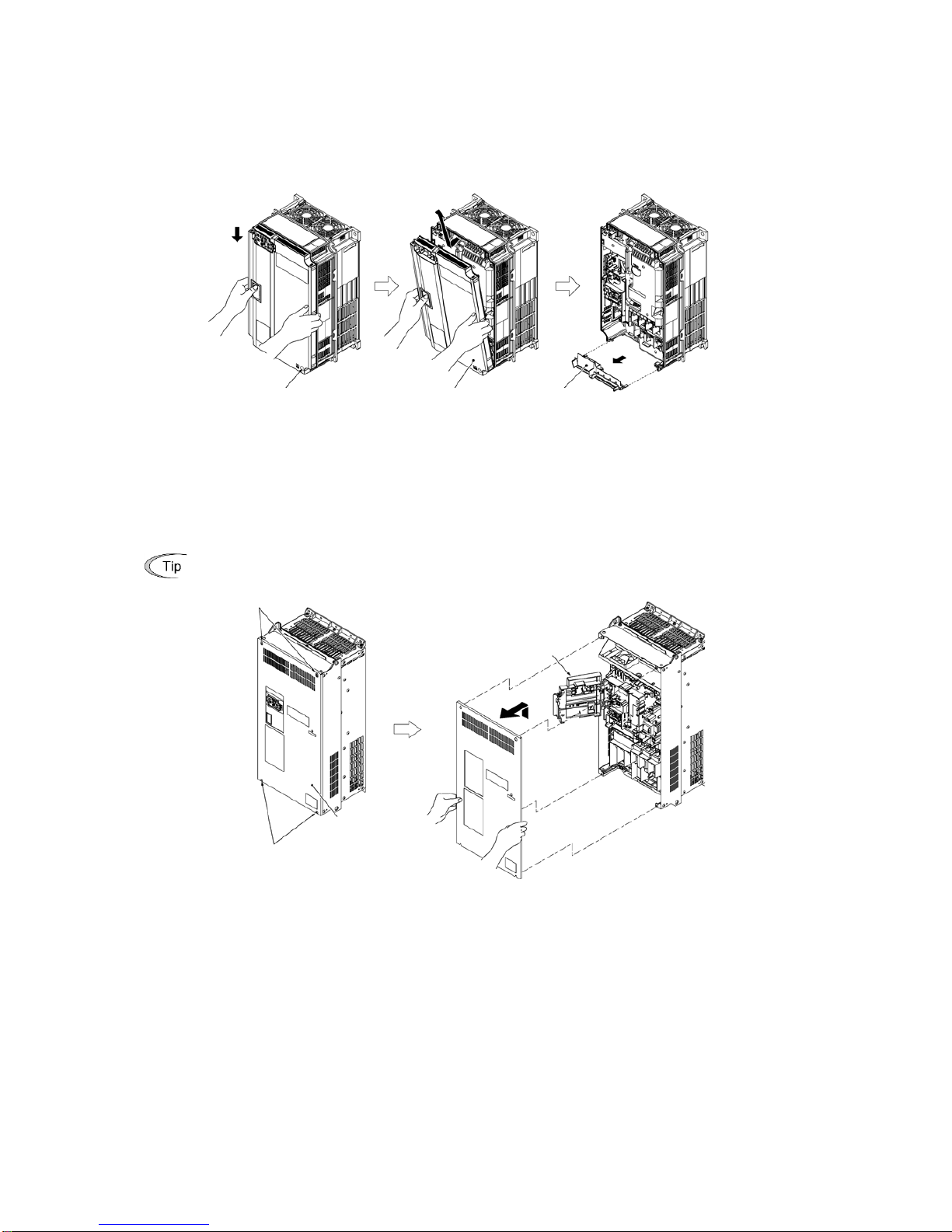

To install the FRN0085E2■-4G inverter with external cooling, change the mounting position of the mounting bases

following the procedure in Figure 2.1-3.

As the type and number of screws differ by inverter type, please review the following table.

Figure 2.1-1 Installation Direction

2-1

Page 12

Table 2.1-2 Type and Number of Screws, and Tightening Torque

Inverter type

Mounting base fixation screw Case attachment screw

Tightening torque

Nm (Ib-in)

FRN0085E2■-4G

to FRN0168E2■-4G

M6×20 (5 screws on top,3

screws on bottom)

M6×20

(2 screws on top only)

5.8 (51.3)

FRN0203E2■-4G

M6×20 (3 screws on top and

bottom each)

M6×12

(3 screws on top only)

5.8 (51.3)

FRN0240E2■-4G

to FRN0290E2■-4G

M5×12 (7 screws on top and

bottom each)

M5×12

(7 screws on top only)

3.5 (31.0)

FRN0361E2■-4G

to FRN0415E2■-4G

M5×16 (7 screws on top and

bottom each )

M5×16

(7 screws on top only)

3.5 (31.0)

FRN0520E2■-4G

to FRN0590E2■-4G

M5×16 (8 screws on top and

bottom each)

M5×16

(8 screws on top only)

3.5 (31.0)

1) Remove all of the mounting base fixation screws and the case attachment screws on the top of the inverter.

2) Fix the mounting bases to the case attachment screw holes using the mounting base fixation screws. A few

screws should remain after changing the position of the mounting bases.

3) Change the position of the mounting bases on the bottom side following the procedure in 1) and 2).

Figure 2.1-3 Method to Change the Mounting Base Positions

Use the specified screws in changing the mounting bases.

Risk of fire and risk of accidents exist

Inverter unit installation screw size.

Select the bolt size, considering the thickness of the mounting feet and installation surface so that the bolt

protrudes from the nut by 2 threads or more.

Inverter type

Inverter fixation screw

Tightening torque Nm (Ib-in)

200V class:FRN0030/0040E2■-2G

400V class:FRN0022/0029E2■-4G

M5 (4 screws) 3.5 (31.0)

200V class:FRN0056/0069E2■-2G

400V class:FRN0037E2■-4G to RN0203E2■-4G

M8 (4 screws) 13.5 (119)

400V class:FRN0240E2■-4G to RN0415E2■-4G

M12 (4 screws)

48 (425)

400V class:FRN0520E2■-4G to RN0590E2■-4G

M12 (6 screws)

48(425)

Mounting base fixation screw

Mounting base

(upper side)

Mounting base

(lower side)

Mounting base fixation screw

Case attachment screw

2-2

Page 13

2.2 Wiring

This chapter describes the basic connection diagram alternatives for Solar Pumping application.

2.2.1 Input and output control signals.

T

able 2.2-1 describes the input control signals to the inverter.

T

able 2.2-1 Input control signals to the inverter.

INPUT DESCRIPTION SYMBOL

[12]

Water tank level analog signal. The signal from the water level sensor of the tank can

be connected to this input. The inverter will stop when the tank level becomes higher

than the level programmed in parameter U128. In order to use this signal, connect the

sensor to this input and set the desired tank level above which the pump has to stop. If

this signal is not used, set a high level in parameter U128 to avoid that the inverter

stops.

TANK LEVEL

[FWD] Run command in the FWD direction FWD

[REV] Run command in the REV direction REV

[X1]

Water tank high level digital signal. This signal is ON when the level of the tank is high.

The inverter will stop when this signal is ON. In order to use this signal, simply connect

it to the inverter; it is not required to enable it by function code.

TANK HL

T

able 2.2-2 describes the outp ut control signals f rom the inverter. The assignment of the out puts can

be changed if required. To do so, change the settings of parameters E20, E21, E27.

T

able 2.2-2 Output control signals from the inverter.

OUTPUT DESCRIPTION SYMBOL

[Y1]

Tank full output signal. This signal indicates that the water tank is full. In this situation

the inverter will not be allowed to RUN, therefore this signal is useful to

indicate/diagnose the cause of the stop.

TANK FULL

[Y2]

Low power output signal. This signal indicates that the output power is low. In case

that this signal is ON and the solar irradiance is high, it is useful to detect/diagnose that

there is a problem in the PV solar panel (for example dust, or the panel has been

covered).

LOW POWER

[30A/B/C]

This relay output is used to indicate that the inverter has tripped by alarm. The alarm

code is displayed in the inverter keypad.

ALM

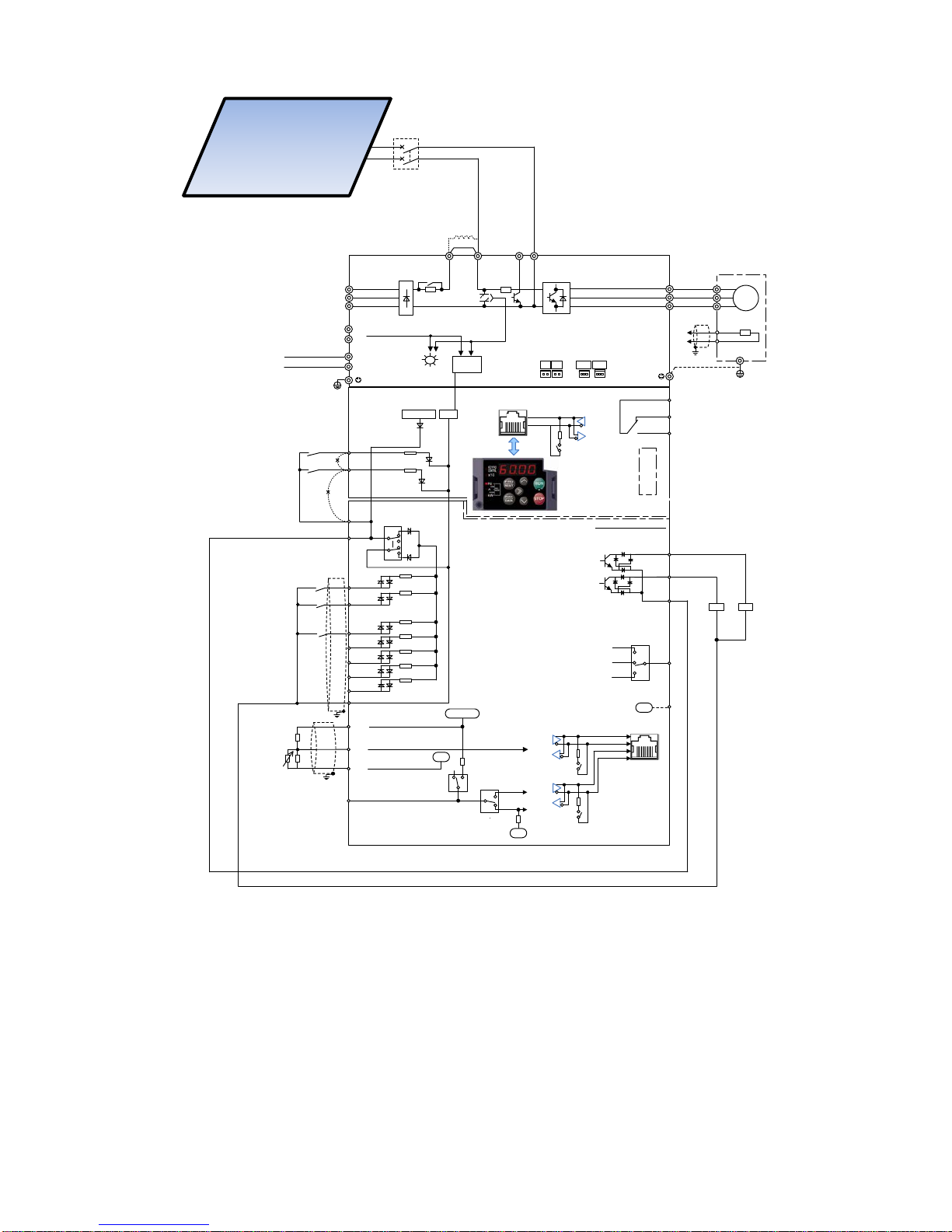

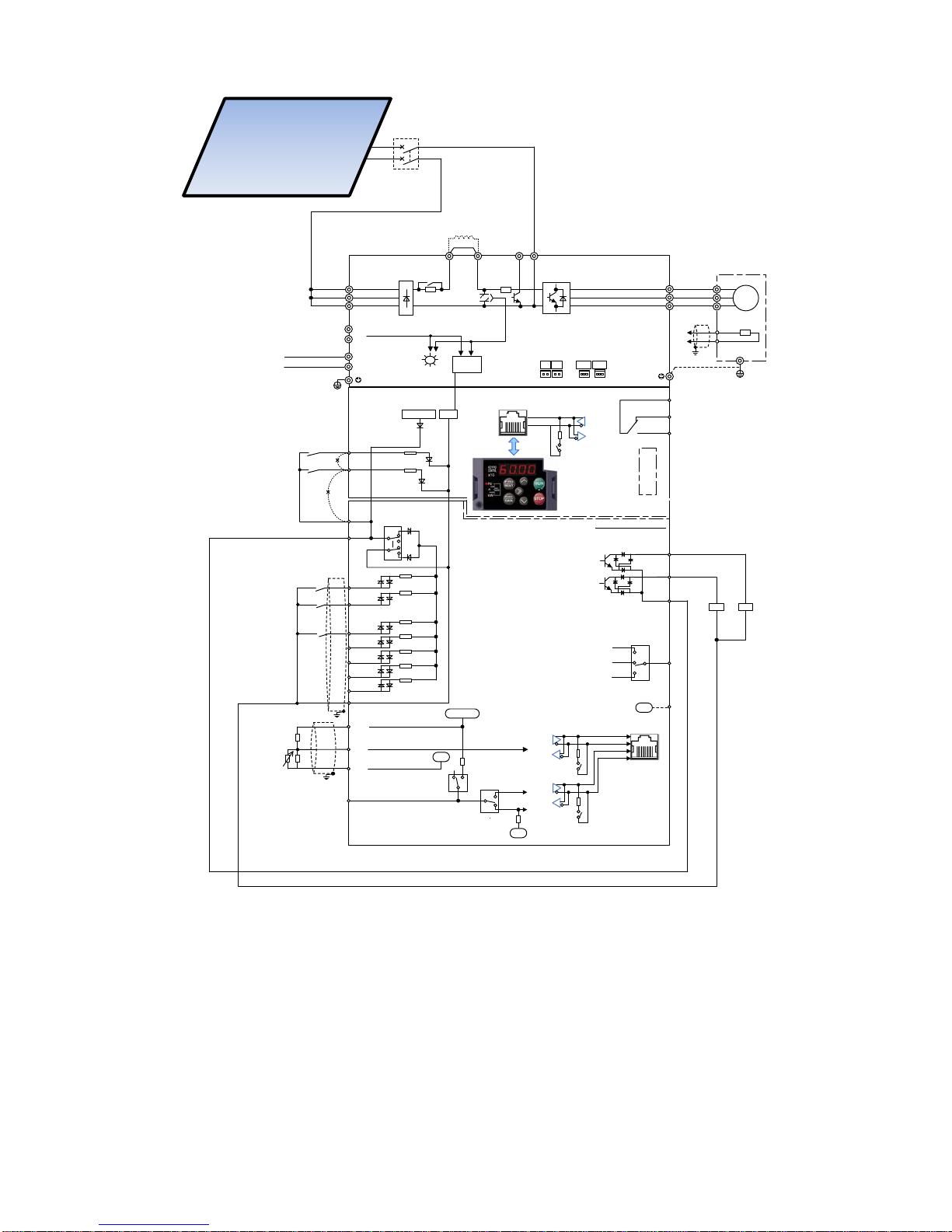

2.2.2 Inverter supplied from PV panel only

There are two alternatives of connecting the PV panel to the inverter:

(1) Connected to the DC bus terminals P(+), N(-). I n this case the pre charging ci rcuit of the inve rter is not

used. Therefore, when the PV panel is connected to the inverter, high current may flow through at the

initial stage because the inverter DC link capacitor is discharged. In order to avoid the high charging

current, there are some alternatives:

o do not make the connection when the PV panel is already receiving strong irradiat ion, or

o insert a pre-charging circuit in the connection between (+) (PV panel positive pole) and P(+), or

o use the connection alternative (2) described in following pages.

2-3

Page 14

R

F

Direct current

reactor (option)

DB

N(-)

P(+)P1

U

V

W

U

V

W

M

3~

C

L1/R

L2/S

L3/T

G

Ground

terminal

(Note 6)

TH1

THC

PTC

thermistor

To [11]

To [C1]

)

R1

T1

R0

T0

Auxiliary power

input for fan

(Note 5)

{

(Note 11)

DC/DC

(PLC)

(FWD

)

(REV

)

(X1)

(X2)

(X3)

(X4)

(X5)

(CM)

(EN1)

SINK

SOURCE

(EN2)

0V

+24VDC

<Y1>

<Y2>

<CMY>

[FM]

[11]

0V

G

E

DX+

DX-

SW6

(Note 12)

SW1

(Note 12)

(Note 8)

(Note 9)

(Note 10)

(Note 10)

Safety signal

SW5

(Note 12)

30C

30B

30A

30

Current output

(4(0) to 20 mA DC)

Voltage output

(0 to +10 V DC)

Pulse output

(25 to 32kp/s)

・Power supply voltage switching

connector “CN UX”

・Fan power supply connector “CN R” /

“CN W”

(Note 10)

CAN+

CAN-

SW6

(Note 12)

RJ45 Connector

(Note 9)

(Note 14)

(PLC)

Charge

lamp

RJ45 connector

SW2

(Note 12)

Option

connector

FMI

FMV

FMP

Motor

Data transmission and

reception (RS-485)

Keypad

Detachable terminal block

Voltage input V2

(0 to +10 V DC)

〔11〕

〔12〕

〔13〕

(Note 9)

+10VDC

Current input C1

(4(0) to 20 mA DC)

PTC thermistor input

0V

〔C1〕

Voltage input 12

(0 to +10VDC)

(0 to ±10VDC)

SW4

PTC

AI

(Note 12)

(Note 12)

SW3

C1

V2

0V

Grounding

terminal

(Note15)

(Note 15)

(Note 15)

U1

U2

CN UX

FAN

NC

CN R

CN W

Circuit breaker

(MCCB)

R1

R2

Rx

(+)

(-)

Run forward command (FWD)

Run reverse command (REV)

Tank High Level

detection (TANK HL)

Alarm output

(ALM)

Tank level

detection (TANK

LEVEL)

TANK FULL

LOW POWER

(Note 4)

Figure 2.2-1 Wiring diagram when inverter is supplied from PV panel connected to DC bus terminals.

When using this wiring please ensure that the motor is not regenerating. In case of regeneration the DC link

voltage of the inverter will rise damaging the PV panels. In order to avoid regeneration when operation command

is removed please set function code H11=1 (Coast to a stop). If regeneration cannot be avoided (for example,

controlled deceleration is always required), please use connection alternative (2) below.

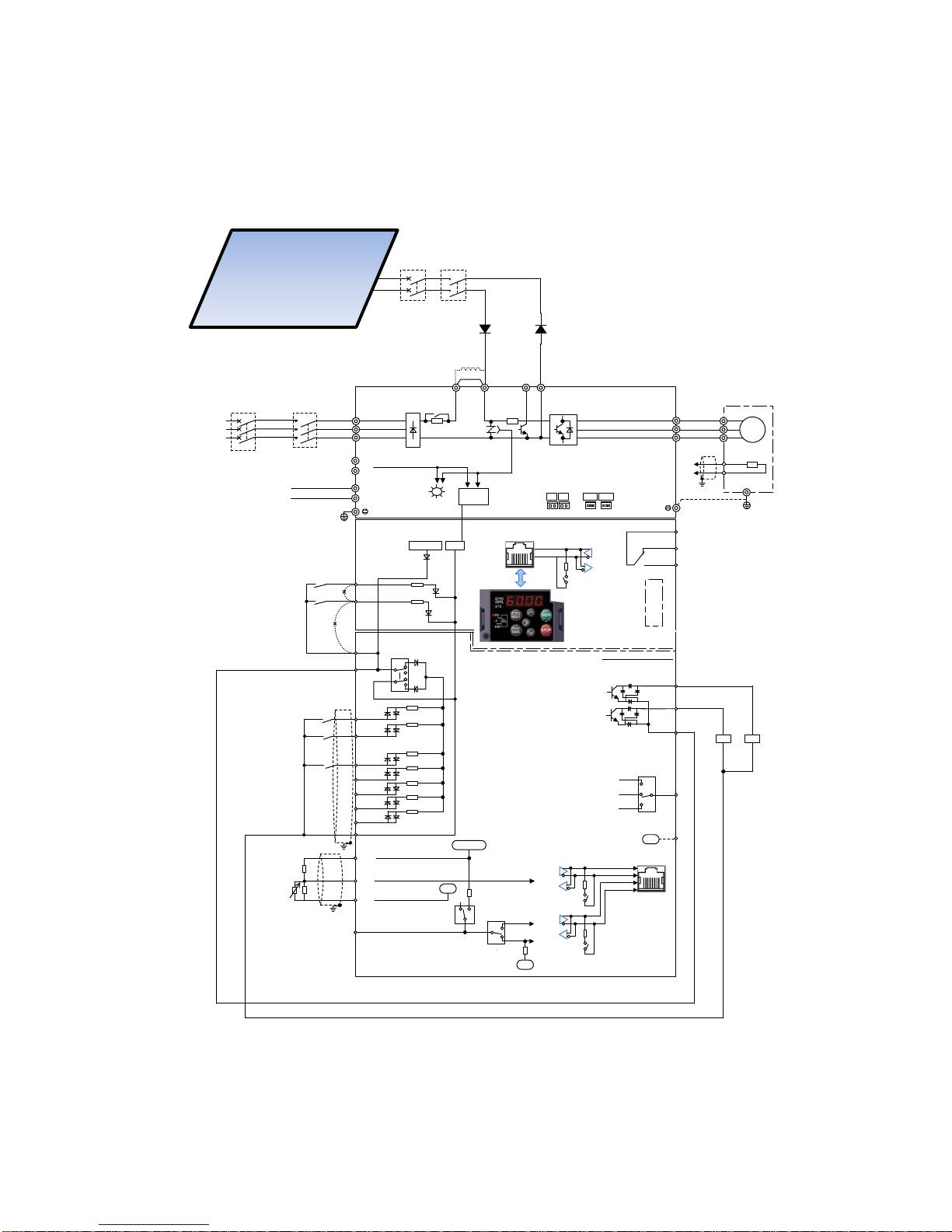

(2) Connected to the AC supp ly input s and N(-). In this case the precharging circuit of the inverter is used,

limiting the initial charging current of the inverter DC link capacitor. In this case be aware that the

maximum frequency of charging cycles is two times per hour. When using this connection the current

rating of the input rectifier must be considered. Please consult Fuji Electric to make the inverter

selection.

2-4

Page 15

R

F

Direct current

reactor (option)

DB

N(-)

P(+)P1

U

V

W

U

V

W

M

3~

C

L1/R

L2/S

L3/T

G

Ground

terminal

(Note 6)

TH1

THC

PTC

thermistor

To [11]

To [C1]

)

R1

T1

R0

T0

Auxiliary power

input for fan

(Note 5)

{

(Note 11)

DC/DC

(PLC)

(FWD)

(REV)

(X1)

(X2)

(X3)

(X4)

(X5)

(CM)

(EN1)

SINK

SOURCE

(EN2)

0V

+24VDC

Run forward command (FWD)

Run reverse command (REV)

Tank High Level

detection (TANK HL)

<Y1>

<Y2>

<CMY>

[FM]

[11]

0V

G

E

DX+

DX-

SW6

(Note 12)

SW1

(Note 12)

(Note 8)

(Note 9)

(Note 10)

(Note 10)

Safety signal

SW5

(Note 12)

30C

30B

30A

Alarm output

(ALM)

30

Current output

(4(0) to 20 mA DC)

Voltage output

(0 to +10 V DC)

Pulse output

(25 to 32kp/s)

・Power supply voltage switching

connector “CN UX”

・Fan power supply connector “CN R” /

“CN W”

(Note 10)

CAN+

CAN-

SW6

(Note 12)

RJ45 Connector

(Note 9)

(Note 14)

(PLC)

Charge

lamp

RJ45 connector

SW2

(Note 12)

Option

connector

FMI

FMV

FMP

Motor

Data transmission and

reception (RS-485)

Keypad

Detachable terminal block

Voltage input V2

(0 to +10 V DC)

〔11〕

〔12〕

〔13〕

(Note 9)

+10VDC

Current input C1

(4(0) to 20 mA DC)

PTC thermistor input

0V

〔C1〕

Voltage input 12

(0 to +10VDC)

(0 to ±10VDC)

SW4

PTC

AI

(Note12)

(Note 12)

SW3

C1

V2

0V

Grounding

terminal

Tank level

detection (TANK

LEVEL)

(Note 15)

(Note 15)

(Note 15)

U1

U2

CN UX

FAN

NC

CN R

CN W

Circuit breaker

(MCCB)

R1

R2

Rx

TANK FULL

LOW POWER

(+)

(-)

(Note 4)

Figure 2.2-2 Wiring diagram when inverter is supplied from PV panel connected to AC input and N(-) terminals.

2-5

Page 16

2.2.3 Inverter supplied from PV panel and AC supply

When the inverter can be supplied from PV panel and AC supply at the same time, as shown in figure 2.2-4,

please insert magnetic contactors in both PV panel supply and AC supply and make the necessary interlock to

avoid that both supplies are connected at the same time. Additionally to the magnetic contactors, insert blocking

diodes with the suitable rating between the PV panel and the inverter.

R

F

Direct current

reactor (option)

DB

N(-)

P(+)P1

U

V

W

U

V

W

M

3~

C

L1/R

L2/S

L3/T

Magnetic

contactor (MC)

Circuit breaker

(MCCB) or earth

leakage breaker

(ELCB)

G

Ground

terminal

(Note 2, 3)

(Note 6)

TH1

THC

PTC

thermistor

To [11]

To [C1]

)

R1

T1

R0

T0

Auxiliary power

input for fan

(Note 5)

{

(Note 11)

DC/DC

(PLC)

(FWD)

(REV)

(X1)

(X2)

(X3)

(X4)

(X5)

(CM)

(EN1)

SINK

SOURCE

(EN2)

0V

+24VDC

<Y1>

<Y2>

<CMY>

[FM]

[11]

0V

G

E

DX+

DX-

SW6

(Note 12)

SW1

(Note 12)

(Note 8)

(Note 9)

(Note 10)

(Note 10)

Safety signal

SW5

(Note 12)

30C

30B

30A

30

Current output

(4(0) to 20 mA DC)

Voltage output

(0 to +10 V DC)

Pulse output

(25 to 32kp/s)

・Power supply voltage switching

connector “CN UX”

・Fan power supply connector “CN R” /

“CN W”

(Note 10)

CAN+

CAN-

SW6

(Note 12)

RJ45 Connector

(Note 9)

(Note 14)

(PLC)

Charge

lamp

RJ45 connector

SW2

(Note 12)

Option

connector

FMI

FMV

FMP

Motor

Data transmission and

reception (RS-485)

Keypad

Detachable terminal block

Voltage input V2

(0 to +10 V DC)

〔11〕

〔12〕

〔13〕

(Note 9)

+10VDC

Current input C1

(4(0) to 20 mA DC)

PTC thermistor input

0V

〔C1〕

Voltage input 12

(0 to +10VDC)

(0 to ±10VDC)

SW4

PTC

AI

(Note12)

(Note 12)

SW3

C1

V2

0V

Grounding

terminal

(Note 15)

(Note 15)

(Note 15)

U1

U2

CN UX

FAN

NC

CN R

CN W

200V system

200V to 240V

50/60 Hz

400V system

380V to 480V

50/60 Hz

Circuit breaker

(MCCB)

R1

R2

Rx

(+)

(-)

Magnetic

contactor (MC)

(Note 2, 3)

Run forward command (FWD)

Run reverse command (REV)

Tank High Level

detection (TANK HL)

Alarm output

(ALM)

Tank level

detection (TANK

LEVEL)

TANK FULL

LOW POWER

(Note 4)

Figure 2.2-3 Wiring diagram when inverter is supplied from PV panel and AC supply.

2-6

Page 17

• The PV panel is a DC voltage/current source. Therefore in all cases please ensure that the polarity is

respected when performing the connection between the inverter and the PV panel, otherwise either

equipment may be damaged

Risk of fire and risk of damage exist.

Notes for all drawings:

(Note 1) Install recommended circuit breakers (MCCB) or residual-current-operated protective device (RCD)/

earth leakage breakers (ELCB) (with overcurrent protective function) on the inputs of each inverter

(primary side) for wiring protection. Do not use breakers which exceed the recommended rated current

.

(Note 2) Install recommended magnetic contactors (MC) as necessary on each inverter as these will be used to

disconnect the inverter from the power supply separately from the MCCB or the RCD / ELCB.

Additionally, when installing coils such as MC or solenoid close to the inverter, connect surge absorbers

in parallel.

(Note 3) Make the necessary interlock to avoid that both PV panel supply and AC supply are connected at the

same time. Not preventing this may cause damage to the equipment.

(Note 4) Used for the protection of the PV panel and the wiring. Alternatively fuses can be also used. Please

use recommended types by the PV panel maker. The use of additional protection devices (like surge

protection devices) may be also recommended by the PV panel maker.

(Note 5) Use this terminal when supplying the inverter with DC voltage from the PV panel. Applicable for types

FRN0203E2■-4G or above. Please consult Fuji Electric.

(Note 6) Remove the shorting bar between the inverter main circuit terminals P1-P(+) before connecting the

direct current reactor (DCR) (option).

It must be connected in the following cases:

ND mode: T y pes FRN0139 E2■-4G or above, HD/ HND mode: T y pes FRN01 68E2■-4G or above, HHD

mode: Types FRN0203E2■-4G or above.

Use the direct current reactor (option) when the power supply transformer capacity is above 500 kVA

and the transformer capacity is over 10 times the rated capacity of the inverter, or when “thyristor load

exists” in the same power system. In case of PV panel supply only, DCR is not required for any

capacity.

(Note 8) This terminal is used for grounding the motor. Grounding the motor using this terminal is recommended

in order to suppress inverter noise.

(Note 9) Use twisted lines or shielded lines for the control signals.

Generally, the shielded line requires grounding, but when the effect of externally induced noise is large,

connecting to [CM] may suppress the eff ect of noise. Separate the line from the main circuit wiring and

do not enclose in the same duct. Separation distance of over 10 cm is recommended. When crossing

the main circuit wiring, make the intersection perpendicular.

(Note 10) The various functions listed for terminals [X1] to [X5] (digital inputs), terminals [Y1] to [Y2] (transistor

outputs), and terminal [FM] (monitor output) show the recommended functions for Solar Pumping

application.

(Note 11) These are conne ctors for switching the main circuit. For details, refer to “2.2.7 Switching connectors”.

(Note 12) The various switches on the control printed circuit board define the settings for the inverter operation.

For details, refer to “2.2.6 Operating slide switches”.

(Note 14) Shorting bars are connected between the safety function terminals [EN1], [EN2], and [PLC] as factory

default. Remove the shorting bars when using this function.

(Note 15)

and are separated and insulated.

(Note 16) Charge lamp does not exist in the inverters FRN0069E2■-2G/FRN0044E2■-4G/FRN0012E2■-7G or

below.

0V

0V

2-7

Page 18

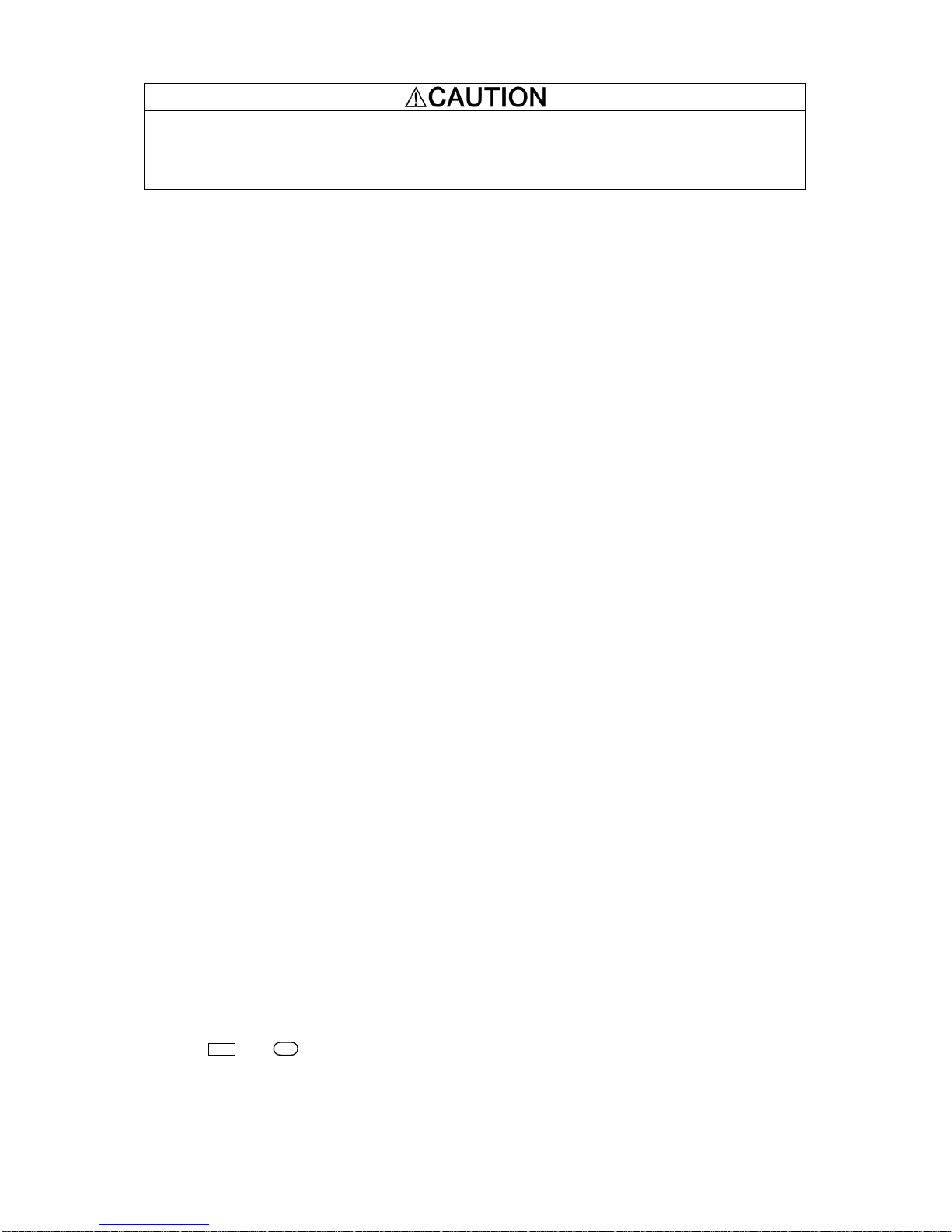

2.2.4 Removal and attachment of the front cover/terminal cover and wiring guide

Always remove the RS-485 communication cable from the RJ-45 connector before removing the front cover.

Risk of fire and risk of accidents exist.

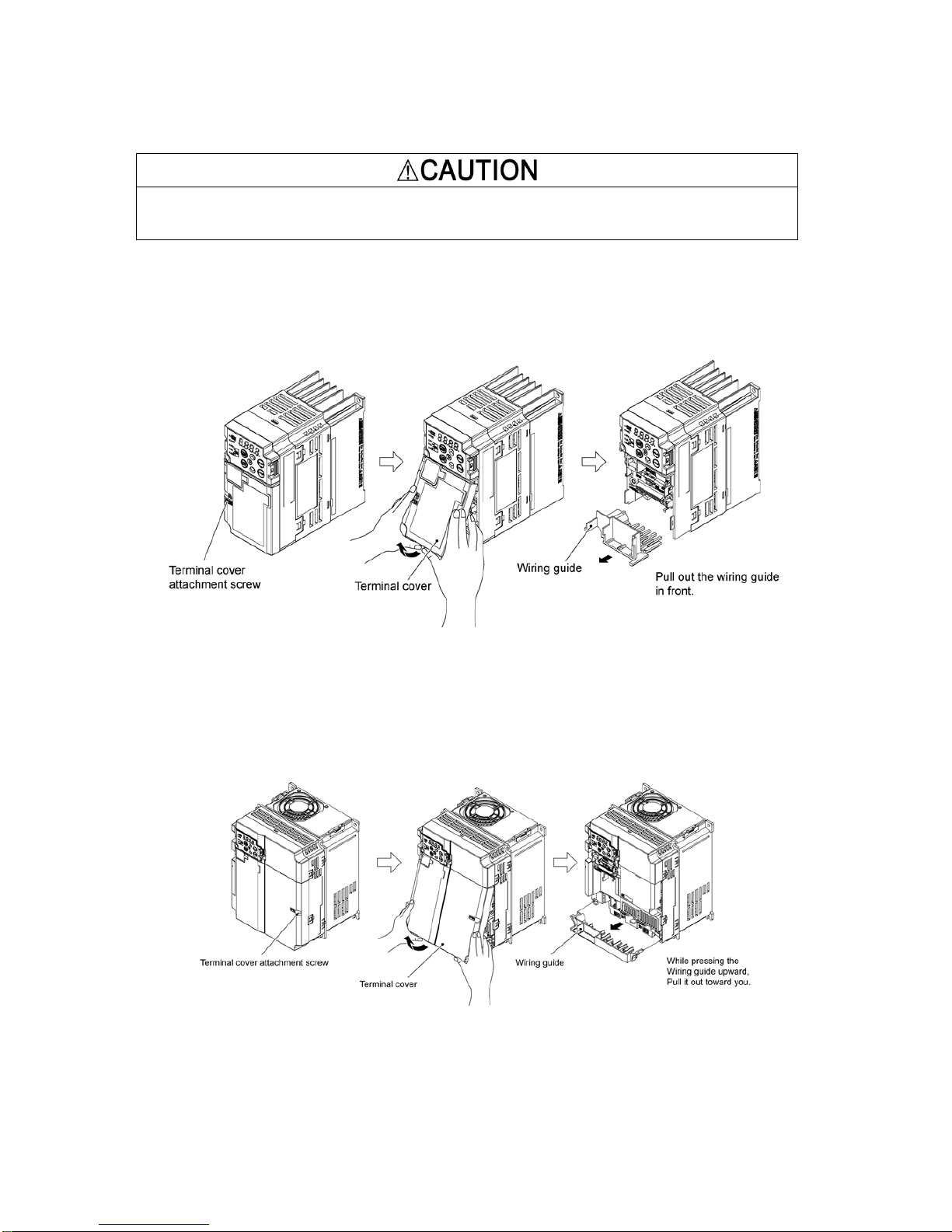

(1) Types FRN0020E2■-2/ FRN0012E2■-4/ FRN0011E2■-7 or below

1) Loosen the screws of the terminal cover. To remove the terminal cover, put your finger in the dimple of the

terminal cover and then pull it up toward you.

2) Pull out the wiring guide toward you.

3) After routing the wires, attach the wiring guide and the terminal cover reversing the steps above.

Figure 2.2-1 Removal of the Terminal Cover and the Wiring Guide (for FRN0006E2S-2)

(2) Types FRN0030E2■-2 to FRN0069E2■-2 and FRN0022E2■-4 to FRN0044 E2■-4

1) Loosen the screws of the terminal cover. To remove the terminal cover, put your finger in the dimple of the

terminal cover and then pull it up toward you.

2) Pull out the wiring guide toward you.

3) After routing the wires, attach the wiring guide and the terminal cover reversing the steps above.

Figure 2.2-2 Removal of the Terminal Cover and the Wiring Guide (for FRN0069E2■-2)

2-8

Page 19

(3) Types FRN0088E2■-2/ FRN0115E2■-2/ FRN0072E2■-4/ FRN0085E2■-4

1) Loosen the screws of the front cover. Hold both sides of the front cover with the hands, slide the cover

downward, and pull. Then remove it to the upward dir ect ion.

2) Push the wiring guide upward and pull. Let the wiring guide slide and remov e it.

3) After routing the wires, attach the wiring guide and the front cover reversing the steps above.

Figure 2.2-3 Removal of the Front Cover and the Wiring Guide (for FRN0072E2■-4)

(4) Types FRN0085E2■-4 or above

1) Loosen the screws of the front cover. Hold both sides of the front cover with the hands and slide it upward to

remove.

2) After routing the wires, align the front cover top edge to the screw holes and attach the cover reversing the

steps in Figure 2.2-4.

Open the keypad case to view the control printed circuit board.

Tightening torque: 1.8 N·m(15.9 Ib-in) (M4)

3.5 N·m(31.0 Ib-in) (M5)

Figure 2.2-4 Removal of the front cover (for FRN0203E2■-4)

Screw

Screw

Front cover

Keypad case

Front

cover attachment screw

Front cover

Wiring guide

Push upward and pull.

Let the guide slide.

2-9

Page 20

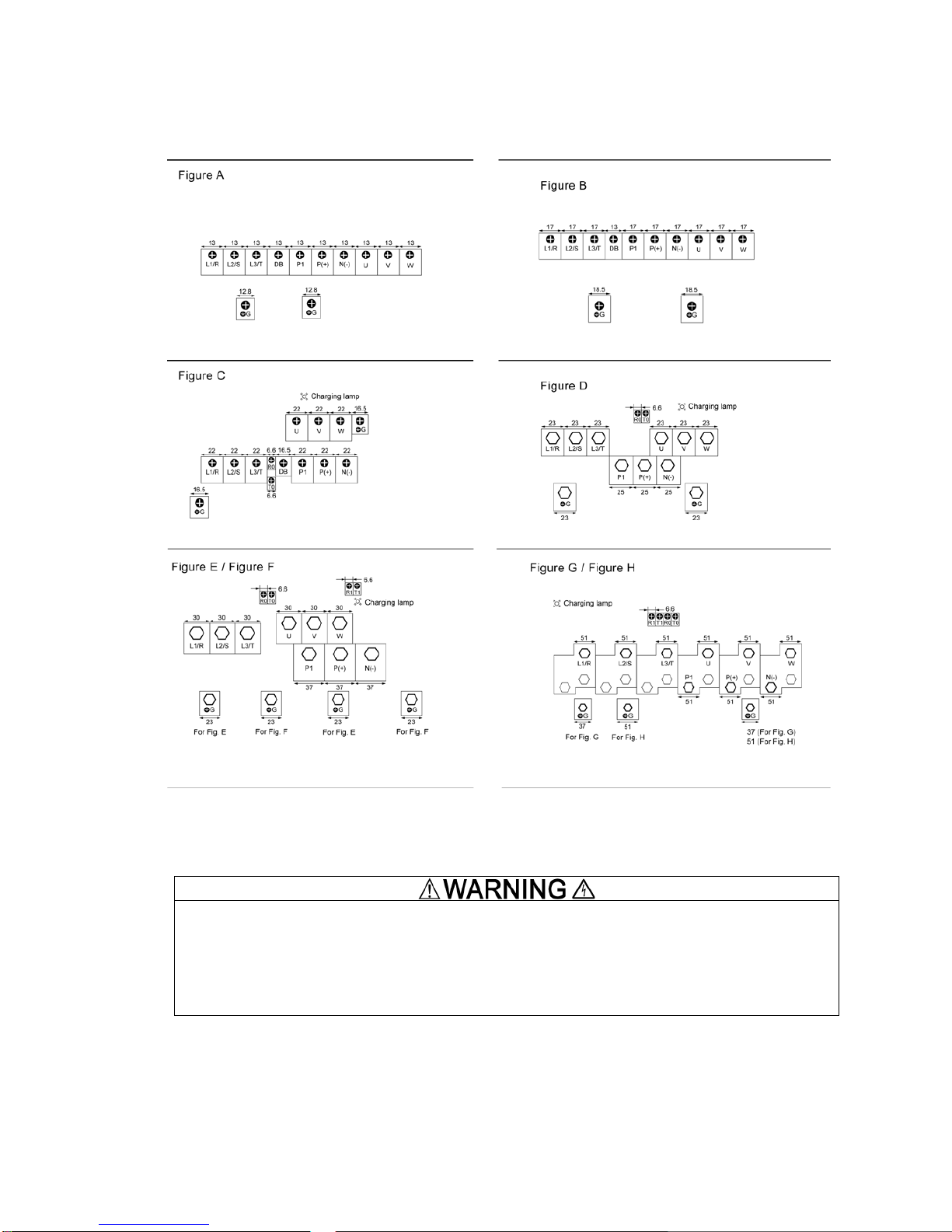

2.2.5 Main circuit terminals

Terminal layout diagram (main circuit terminals)

Figure 2.2-7 Main circuit terminals layout

The following terminals will have high voltage when power is ON.

Main circuit: L1/R, L2/S, L3/T, P1, P(+), N(-), DB, U, V, W, R0, T0, R1, T1

Insulation level

Main circuit - Casing : Basic insulation (overvoltage category III, degree of contamination 2)

Main circuit - Control circuit : Enhanced insulation (overvoltage category III, degree of contamination 2)

Risk of electric shock exists

For recommended wire sizes please refer to the User Manual.

2-10

Page 21

[ 1 ] Description of terminal functions (main circuit terminal)

Classification

Terminal

symbol

Terminal name Specification

Main circuit

L1/R, L2/S,

L3/T

Main power

input

Terminals to connect three-phase power source.

L1/L, L2/N

Main power

input

Terminals to connect single-phase power source.

U, V, W Inverter output Terminals to connect three-phase motors.

P (+), P1

For direct

current reactor

connection

Terminals to connect DC reactor (DCR) for power factor enhancement.

It must be connected in the following cases:

ND mode: Types FRN0139E2■-4G or above.

HD/HND mode: Types FRN0168E2■-4G or above.

HHD mode: Types FRN0203E2■-4G or above.

It is not required to connect a DC reactor when supplying the inverter only from PV

panel.

P (+), N (-)

For direct

current bus

connection

Terminals to connect to DC supply voltage from PV panel.

P (+), DB

For braking

resistor

connection

Terminals to connect a braking resistor (optional). Wiring length: Below 5 meters.

(Types FRN0220E2■-2G/FRN0072E2■-4G or below)

G

For inverter

chassis (case)

grounding

Grounding terminal for inverter chassis (case).

R0, T0

Auxiliary power

input for control

circuit

When it is desired to retain the alarm signal for the activation of the protective

function at even inverter main power supply sh

ut off or when continuous display of

the keypad is desired, connect this terminal to the power supply.

(Types FRN0185E2■-2G/FRN0059E2■-4G

or above)

R1, T1

Auxiliary power

input for fan

Ordinarily, these terminals do not need to be connected. Connect these terminals

to AC power supply when operating with direct current power input (such as in

combination with PWM converters).

(Types FRN0203E2■-4G or above)

Follow the sequence below when wiring.

(1) Inverter ground terminal (zG)

(2) Inverter output terminals (U, V, W), motor ground terminal (zG)

(3) Direct current reactor connection terminals (P1, P(+))*

(4) Braking resistor connection terminals (P(+), DB)*

(5) Direct current bus connection terminals (P(+), N(-))*

(6) Main power supply input terminals (L1/R, L2/S, L3/T) or (L1/L, L2/N)

*

Connect if necessary

2-11

Page 22

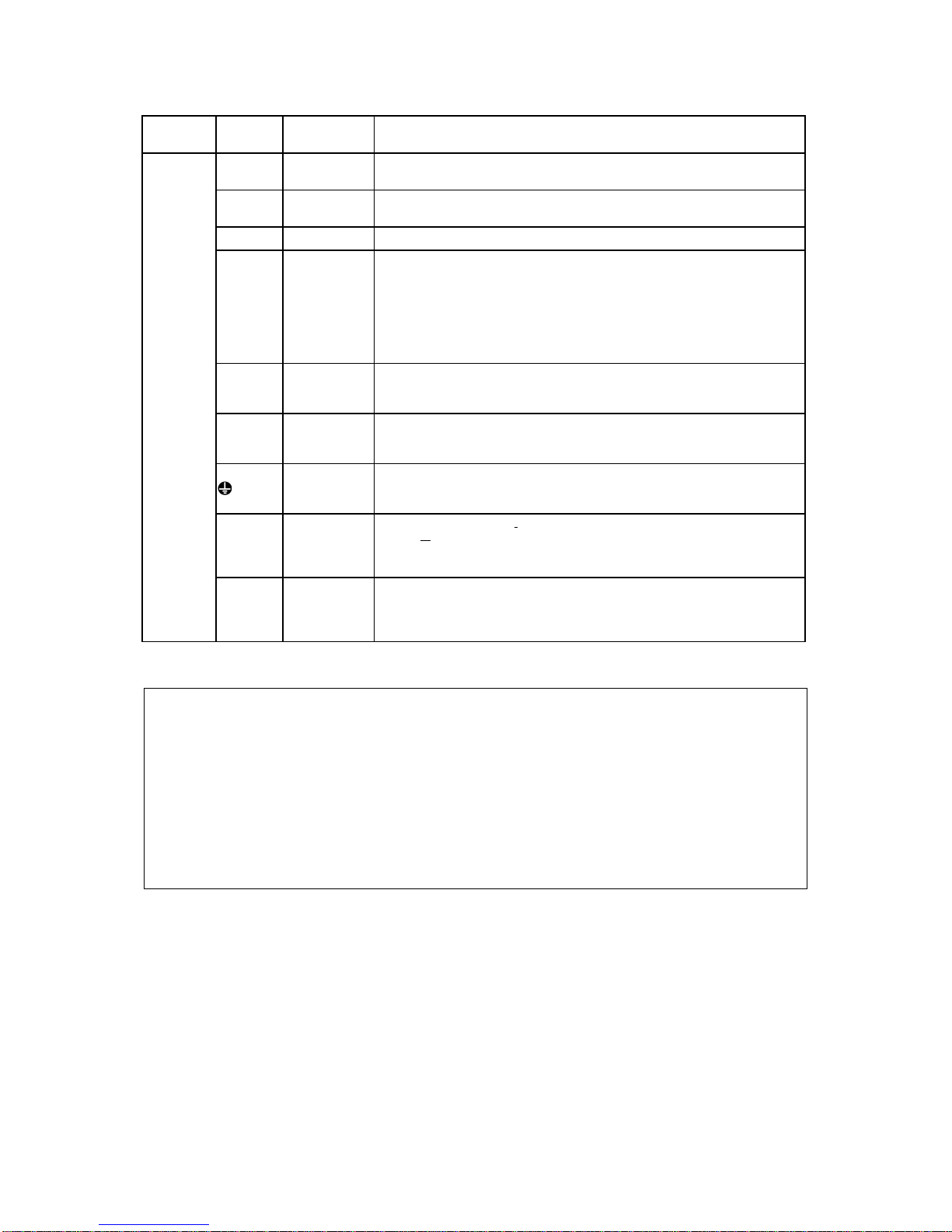

2.2.5 Control circuit terminals (common to all models)

[ 2 ] Terminal layout diagram (control circuit terminals)

FRNE2-A, E, K, U

FRNE2-C

Figure 2.2-8 Control circuit terminals layout

The following terminals will have high voltage when the power is ON.

Control terminals: AUX-contact (30A, 30B, 30C, Y5A, Y5C)

Insulation level

Contact output – control circuit : Enhanced insulation (overvoltage category II, degree of contamination 2)

Risk of electric shock exists

[ 3 ] Description of terminal functio ns ( control circuit terminal)

Table 2.2.6-3 Functional Description of Control Circuit Terminals (continued)

Classification

Terminal

symbol

Terminal name

Functional description

Digital input

[EN1]

[EN2]

Enable input

(1) When terminals [EN1]-[PLC] or terminals [EN2]-[PLC] are OFF, the inverter output

transistors stop functioning. (Safe Torque Off: STO)

Be sure to operate terminals [EN1] and [EN2] simultaneously; otherwise an ecf ala rm is

issued and the operation of the inverter will be disabled.

To enable the Enable function, remove the short bar.

(2) T he input mode for terminals [EN1] and [EN2] is fixed to source. The mode cannot be

switched to sink.

(3) Short-circuit terminals [EN1]-[PLC] and [EN2]-[PLC] with short bars when the Enable

input function is not used. (Keep the short bar connected).

<EN terminal circuit specification>

PLC

Photo coupler

CM

<Control circuit block>

6.6 kΩ

DC+24 V

EN1

6.6 kΩ

EN2

Shorting

bar

[PLC] Programma-

ble controller

signal power

source

(1) T he termi nal is used for c onnecting the output signal power source of the programm able

controller (rated voltage DC +24 V (power supply voltage fluctuation range: DC +22 to

+27 V) maximum 100 mA).

(2) The terminal can also be used for the power source for the load connected to the

transistor output. For details, refer to the page on transistor output.

Contact output

Enhanced insulation

(Max. 250 VAC overvoltage category II,

degree of contamination 2)

Contact output

Enhanced insulation

(Max. 250 VAC overvoltage category II,

degree of contamination 2)

Item Min. Max.

Operating

voltage

(SOURCE)

ON level 22 V 27 V

OFF level 0 V 2 V

Operating current at ON

(at input voltage 24 V)

- 4.5 mA

Allowable leak current at OFF - 0.5 mA

2-12

Page 23

Table 2.2.6-3 Functional Description of Control Circuit Terminals (continued)

Classification

Terminal

symbol

Terminal name Functional description

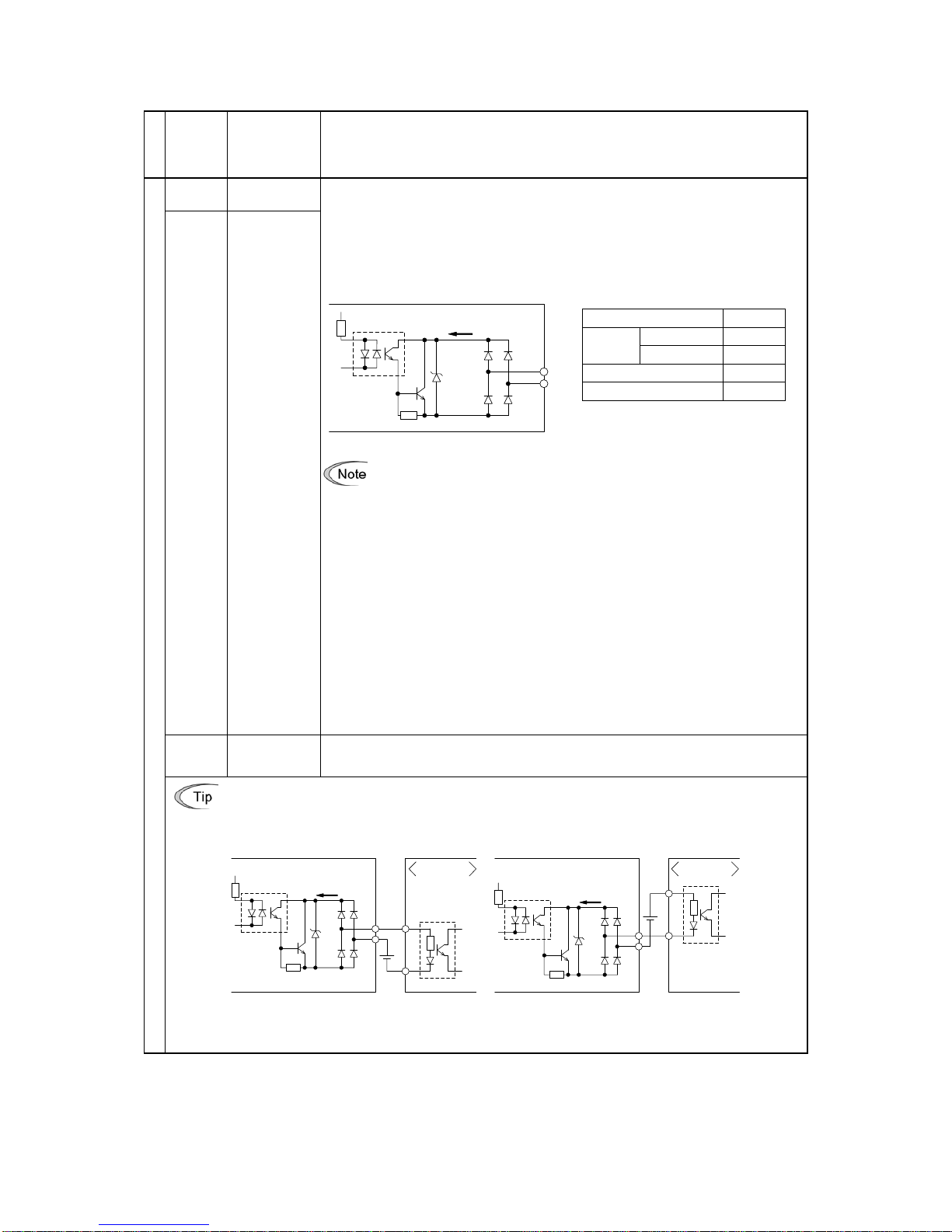

Transistor output

[Y1] Transistor

output 1

(1) Various signals (running signal, frequency reached signal, overload forecast signal,

etc) set up by function code E20, E21 can be output. For details, refer to “Chapter 5

Function Codes”.

(2) The operating mode between transistor output terminals [Y1], [Y2] and terminal CMY

can be switched to “ON (active ON) at signal output” or “OFF (active OFF) at signal

output”.

<Transistor output circuit specification>

Photo coupler

<Control circuit block>

Y1 to

Y2

CMY

31 to 35V

Voltage

Current

Figure 2.2-14 Transistor Output Circuit

• Connect surge absorbing diode on both ends of the excitation coil when

c

onnecting control relays.

• When a power source is needed for the circuit to be connected, terminal PLC

can be used as a power source terminal (DC24 V (power supply volt

age

f

luctuation range: DC22 to 27 V), maximum 50 mA). In this case, terminal

[CMY] must be shorted to terminal [CM].

SW8 switches the [Y2] terminal output between a general-purpose output assigned by

function code E21 and a functional safety circuit failure output SRCF. The factory default

of SW8 is a general-purpose output.

When SRCF is assigned to terminal [Y2]:

if terminal [Y2] is ON, it means "No ecf alarm."

if terminal [Y2] is OFF, it means "ecf alarm has occurred."

Note that when SRCF is assigned, the operating mode between terminals [Y2] and [CMY]

is fixed at "active ON" (ON at signal output).

For details about an ecf alarm, refer to Section 6.3.2 "Causes, checks and measures of

alarms."

[Y2] Transistor

output 2

[CMY] Transistor

output common

This terminal is the common terminal for transistor output signals.

This terminal is insulated against terminals [CM] and [11].

When connecting the programmable controller to terminals [Y1], [Y2].

The circuit configuration example for connecting the inverter transistor output to the programmable controller

is shown in Figure 2.2

-15. Circuit (a) in Figure 2.2-15 shows the programmable controller input circuit as sink

input and circuit (b) shows as the source input case.

C0

DC+24 V

Programmable

controller

Sink type input

Photo coupler

<Control circuit block>

Y1,

Y2

CMY

31 to

35 V

Current

C0

Programmable

controller

Source type

input

DC+24 V

Photo coupler

<Control circuit block>

Y1 to

Y2

CMY

31 to

35 V

Current

(a) Connec tion diagram for sink input type

programmable controller

(b) Connection diagram for source input

type programmable controller

Figure 2.2-15 Example of Connection Circuit Configuration with Programmable Controller

Item Maximum

Operating

voltage

ON level

3 V

OFF level

27 V

Max load current at ON

50 mA

Leak current at OFF

0.1 mA

2-13

Page 24

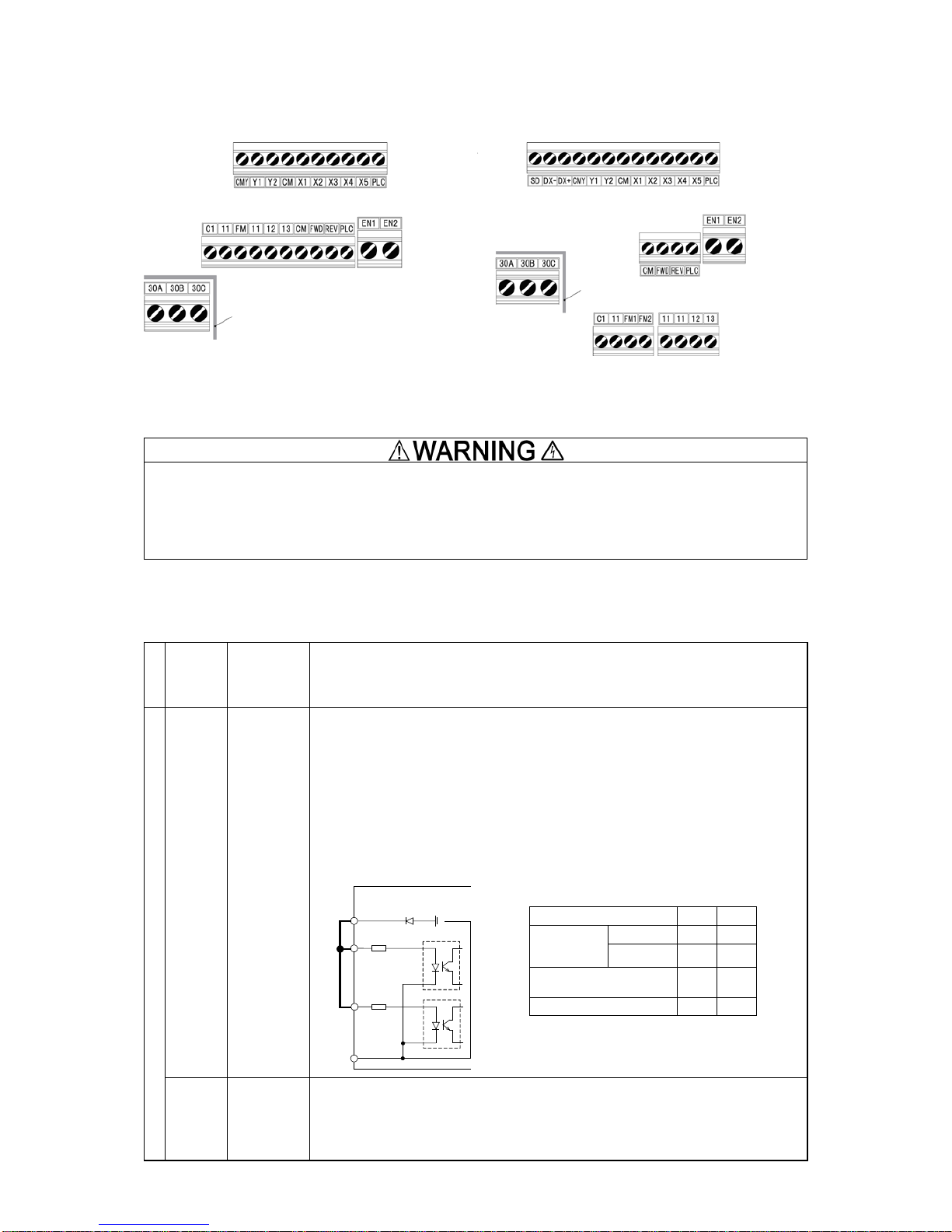

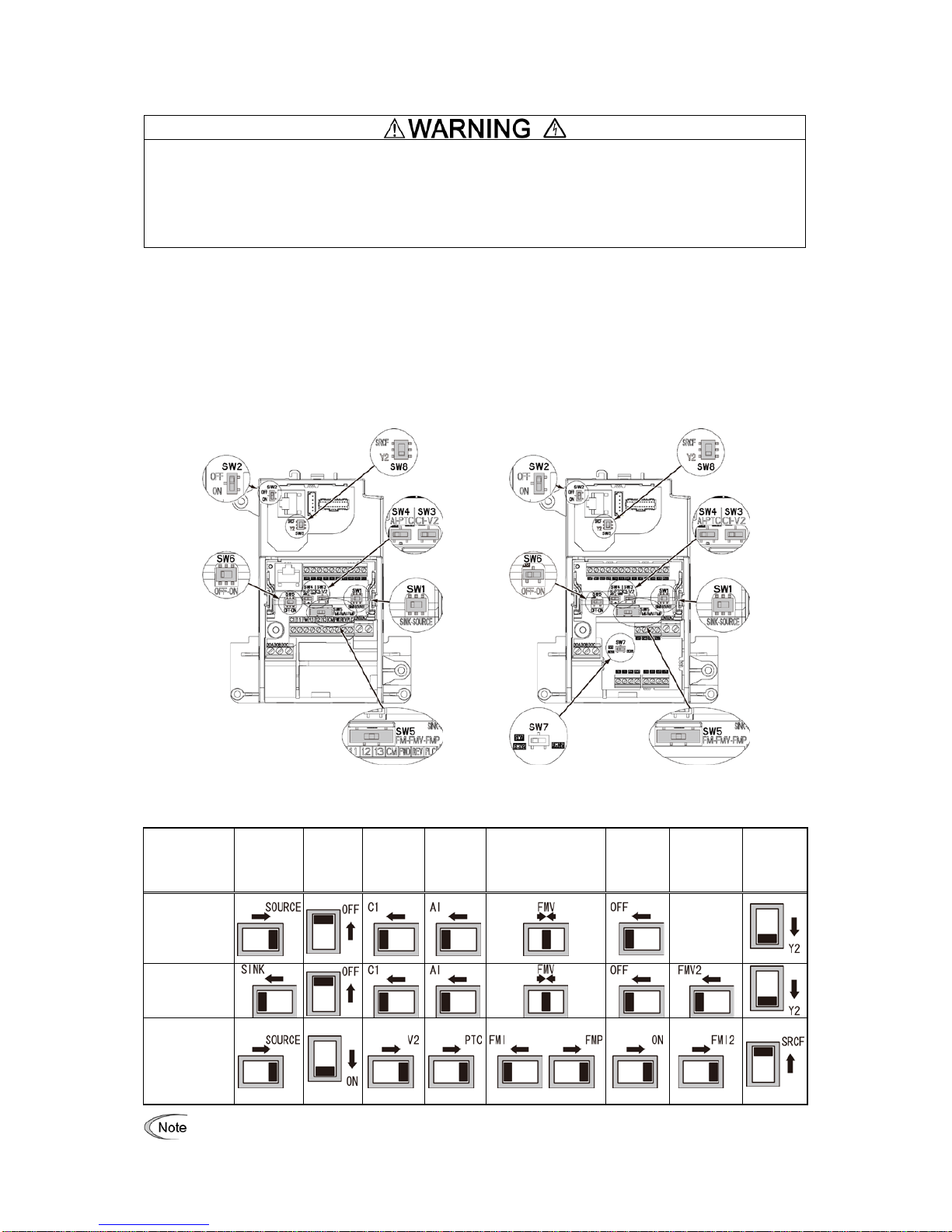

2.2.6 Operating slide switches

Operation of the various switches should be conducted after more than 5 minutes has elapsed since power

is shut off for types smaller than FRN0069E2

-2

and FRN0072E2-4 and after more than 10 minutes

has elapsed for types larger than FRN0085E2

-4

. Confirm that the LED monitor and the charge lamp are

turned off, and that the direct current intermediate circuit voltage between the main circuit terminals P(+) - N(-)

is below the safe voltage (below DC+25 V) with the tester before operating the switches.

Risk of electric shock exists.

The I/O terminal specification can be changed, such as switching the analog output form, by operating the various

slide switches on the printed circuit board (Figure 2.2-22 Slide Switches Positions on the Control Printed Circuit

Board).

To operate the various slide switches, remove the front cover and make the control printed circuit board visible.

(For types larger than FRN0085E2-4, also open the keypad case).

Refer to Section 2.2.2 "Removal and attachment of the front cover and wiring guide" to remove the front

cover and to open/close the keypad case.

The slide switches positions on the control printed circuit board are shown below.

FRNE2-A, E, K, U FRNE2-C

Figure 2.2-9 Slide Switches Locations on the Control Printed Circuit Board

SW1 SW2 SW3 SW4 SW5 SW6

SW7

only on

FRN

E2

-

C

SW8

Factory default

FRN

E2

-E

―

Factory default

FRN

E2

-A, C, K, U

―

Use pointed devices (such as tweezers) to operate the switches. Avoid touching other electronic parts

when moving the switches. The switch will be at open state when the slider is in the middle, so make

sure to push the slider to the ends.

2-14

Page 25

Functional description of the slide switches is given in Table 2.2.8-1 "Functional Description of Various Switches."

Table 2.2.8-1 Functional Description of Slide Switches

Switch

symbol

Functional description

SW1

<Switch to change sink/source setting of digital input terminals>

• This switch determines the type of input (sink or source) to use for digital input terminals [X1] to [X5],

FWD, and REV.

SW2

<Switch to change the RS-485 communication termi nating resist or (RS-485 communication port (on the

control PCB))>

• Move to the ON side when RS-485 communication is used and this inverter is connected to the

termination.

SW3

SW4

<Switch to change terminal [C1] input setting to current/voltage/PT C thermist or >

This switch changes the input type for terminal [C1].

Input type

SW3 SW4 E59 H26

Current input (factory default)

C1 side

AI side 0 0

Voltage input

V2 side

AI side 1 0

PTC thermistor input

C1 side

PTC side

0

1

SW5

<Switch to change terminal [FM] output setting to current/voltage/pulse>

This switch changes the output type for terminal [FM]. When operating this switch, also change function

code F29.

Output type

SW5 F29

Current output

FMI side

1 or 2

Voltage output (factory default)

FMV side 0 Pulse output

FMP side

3

SW6

<Switch to change the RS-485 communication terminating resistor (RS-485 c ommunicat i on port (on the

terminal board))>

FRNE2-A, E, K, U

• Used for the RS-485/CANopen communication. Move the switch to the ON position when the inverter is

connected to the terminal. They cannot be used simultaneously.

FRNE2-C

• Used for the RS-485 communication. Move the switch to the ON position when the inverter is connecte

d

t

o the termination.

SW7

<Switch to change terminal [FM2] output setting to voltage/current> The terminal is used only on the

FRNE2-C.

This switch changes the output type for terminal [FM2]. When operating this switch, also change function

code F32.

Output type

SW7 F32

Voltage output

FMV2 side

0

Current output

FMI2 side

1 or 2

SW8

<Switch to change terminal [FM2] output setting to general-purpose/SRCF >

This switch changes the output for terminal [Y2].

Output

SW8

General-purpose output

Y2 side

SRCF output

SRCF side

Exercise caution as expected operation may not result

if the setting above is not conducted accurately.

2-15

Page 26

2.3 Attachment and Connection of Keypad

2.3.1 Parts required for connection

The following parts are necessary when attaching the keypad to locations other than the inverter main body.

Part name Type Remarks

Keypad extension cable (note 1) CB-5S, CB-3S, CB-1S Three lengths available (5 m, 3 m, 1 m) (3.3ft, 9.8ft, 16.4ft)

Keypad fixing screws

M3x

(note 2)

2 screws required (prepared by user)

(Note 1) When using commercially avai labl e LAN cabl e, use 10BA SE-T/100BASE-TX straight cables (below 20

meters) which meet the ANSI/TIA/EIA-568A category 5 standards of U.S.A.

Recommended LAN cable

Manufacturer: Sanwa Supply, Inc.

Type: KB-10T5-01K (for 1 meter)

KB-STP-01K (for 1 meter) (shielded cable when conforming to EMC directive)

(Note 2) When attaching to the cabinet, use a fixing screw of appropriate length to the cabinet thickness.

2.3.2 Attachment procedure

The keypad can be attached in the following forms.

Attach to the inverter main body (refer to figure 2.3-1(a), (b), (c))

Attach to the cabinet (refer to figure 2.3-2)

Operate the panel remotely, on the hand (refer to Figure 2.3-3)

(a) FRN0069E2■-2G

(b) FRN0072E2■-4G

(c) FRN0203E2■-4G

Figure 2.3-1 Attaching the Keypad to the Inverter Main Body

Figure 2.3-2 Attaching the Keypad

on the Cabinet

Figure 2.3-3 Operating the Keypad Remotely,

on the Hand

Keypad

Keypad

Cabinet

Extension cable for

remote operation

Extension cable for

remote operation

Inverter main

body

Keypad

Keypad fixing

screws

Keypad

Inverter main

body

Keypad

2-16

Page 27

Attachment to the cabinet

(1) Squeeze the hooks at the arrows and pull as shown in the figure below.

Figure 2.3-4 Removal of the Keypad

(2) Attach the keypad rear cover to the keypad using the included keypad rear cover fixing screw.

Figure 2.3-5 Attachment of the Keypad

Keypad rear cover fixing

screw

Keypad rear cover

Keypad

2-17

Page 28

(3) Cut the cabinet to attach the keypad, as shown in figure 2.3-6

(Units: mm [inch])

Figure 2.3-6 Fixing Screw Positions and the Dimensions of the Cabinet to Cut

2-18

Page 29

(4) Fix the keypad to the cabinet using 2 keypad rear cov er fixing screws. Refer to figure 2.3-7 (tightening torque:

0.7 N•m(6.2lb-in)).

Figure 2.3-7 Attachment of the Keypad

(5) Connect the extended cable for remote operation (CB-5S, CB-3S, CB-1S) or the commercially available LAN

cable (straight) to the keypad RJ-45 connector and the inverter main body RJ-45 connector (modular jack).

Refer to Figure 2.3-8.

Figure 2.3-8 Connection of the Extension Cable or the Commercially Available LAN Cable between the Keypad

and the Inverter Main Body

• The RJ-45 connector for keypad connection is specializ ed fo r keypad communication and does not support

RS-485 communication. Connection with the PC loader is not possible.

• Do not connect the inverter to PC LAN ports, Ethernet hubs, or tel ephone lines. The inverter and the

connected instrument may be damaged.

Risk of fire and risk of accidents exist.

Operating remotely, on the hand

Connect following the procedure (5) in “Attachment to the cabinet”.

Cabinet

Keypad fixing

screws

Cabinet

Keypad

RJ-45 connector

RJ-45 connector

(modular jack)

Connect to the RJ-45

connector of

the

inverter main body

Extended cable for remote

operation (CS

-5S, CB-3S,

CB

-1S) or LAN cable

2-19

Page 30

2.4 RJ-45 Cover

The opening for the RS-485 communi cat ion cab le con nec tion (RJ-45 connector) is located below the keypad, as

shown in figure 2.4-1(a), (b).

Types FRN0069E2■-2G / FRN0044E2■-4G or below

To connect the RS-485 communication cable, open the RJ-45 cover as shown in the figure below.

Figure 2.4-1 (a) Connection of the RS-485 Communication Cable

Types FRN0185E2■-2G / FRN0059E2■-4G or above

To connect the RS-485 communication cable, open the RJ-45 cover until the “click” can be heard and connect the

cable as shown in the figure below.

Figure 2.4-1 (b) Connection of the RS-485 Communication Cable

Connect with the PC via the RS-485 converter using the RS-485 communication cable. The PC loader allows

editing, confirmation, and management of the inverter function codes, and monitoring of operation data remotely.

The operating status and alarms can also be monitor ed.

RJ-45 cover

RJ-45 cover

2-20

Page 31

3-1

Chapter 3 OPERATION USING THE KEYPAD

3.1 Names and Functions of Keypad Components

The keypad allows you to run and stop the motor, display various data, configure function code data, and

monitor I/O signal states, maintenance information and alarm information.

Table 3.1-1 Overview of Keypad Functions

Item

LED Monitor,

Keys, and

LED Indicators

Functions

LED Monitor

Four-digit, 7-segment LED monitor which displays the followings according to the

operation modes.

In Running mode: Running status information (e.g., output frequency,

current, and voltage)

When a light alarm occurs,

l-al

is displayed.

In Programming mode: Menus, function codes and their data

In Alarm mode: Alarm code, which identifies the alarm factor that has

activated the protective function.

Operation

Keys

P

rogram/Reset key which switches the operation modes of the inverter.

In Running mode: Pressing this key switches the inverter to Programming

mode.

In Programming mode: Pressing this key switches the inverter to Running mode.

In Alarm mode: Pressing this key after removing the alarm factor resets

the alarm and switches back to Running mode.

Function/Data key which switches the operations you want to do in each mode as

follows:

In Running mode: Pressing this key switches the information to be

displayed concerning the status of the inverter (output

frequency (Hz), output current (A), output voltage (V),

etc.).

When a light alarm is displayed, holding down this key

resets the light alarm and switches back to Running

mode.

In Programming mode: Pressing this key displays the function code or

establishes the data entered with and keys.

In Alarm mode: Pressing this key displays the details of the problem

indicated by the alarm code that has come up on the

LED monitor.

RUN key. Press this key to run the motor.

STOP key. Press this key to stop the motor.

and

UP and DOWN keys. Press these keys to select the setting items and change the

function code data displayed on the LED monitor.

Shift key. Press this key to shift the cursor to the right for entry of a numerical value.

LED indicators

DOWN key

STOP key

UP key

Function/Data

key

RUN key

7-segment

LED monitor

Program/Reset key

RUN LED

Shift key

Page 32

3-2

Table 3.1-1 Overview of Keypad Functions (continued)

Item

LED Monitor,

Keys, and

LED Indicators

Functions

LED

Indicators

RUN LED

Lights when running with a run command entered by the

key, by terminal

command FWD or REV, or through the communications link.

KEYPAD

CONTROL LED

Lights when the inverter is ready to run with a run command entered by the key

(F02 = 0, 2, or 3). In Programming and Alarm modes, however, pressing the key

cannot run the inverter even if this indicator lights.

Unit LEDs

(3 LEDs)

These three LED indicators identify the unit of numeral displayed on the LED monitor in

Running mode by combination of lit and unlit states of them.

Unit: Hz, A, kW, r/min and m/min

Refer to Section ¡Error! No se encuentra el origen de la referencia. "¡Error! No se

encuentra el origen de la referencia." for details.

While the inverter is in Programming mode, Hz

the LEDs of Hz and kW light. A

kW

x10 LED

Lights when the data to display exceeds 9999. When this LED lights, the "displayed

value x 10" is the actual value.

Example:

If data is "12,345," the LED monitor displays

1234

and the x10 LED lights, meaning

that "1,234 × 10 = 12,340."

LED monitor

In Running mode, the LED monitor displays running status information (output frequency, current or

voltage); in Programming mode, it displays menus, function codes and their data; and in Alarm mode, it

displays an alarm code which identifies the alarm factor that has activated the protective function.

If one of LED4 through LED1 is blinking, it means that the cursor is at this digit, allowing you to change it.

If the decimal point of LED1 is blinking, it means that the currently displayed data is a value of the PID

command, not the frequency data usually displayed.

Figure 3.1-1 7-Segment LED Monitor

Table 3.1-2 Alphanumeric Characters on the LED Monitor

Character 7-segment Character 7-segment Character 7-segment Character 7-segment

0

0000

9

9999

i

IIII

r

rrrr

1

1111

A

aaaa

J

JJJJ

S

ssss

2

2222

b

Bb

BbBb

Bb

K

KKKK

T

TTTT

3

3333

C

Cc

CcCc

Cc

L

llll

u

UUUU

4

4444

d

dddd

M

mmmm

V

uuuu

5

5555

E

eeee

n

nnnn

W

wwww

6

6666

F

ffff

o

oooo

X

xxxx

7

7777

G

gggg

P

pppp

y

yyyy

8

8888

H

hhhh

q

qqqq

Z

ZZZZ

Special characters and symbols (numbers with decimal point, minus and underscore)

0. - 9.

*

* *

* – ))))

-

-

_

_

Page 33

3-3

3.2 Overview of Operation Modes

The FRENIC-Ace features the following three operation modes.

Table 3.2-1 Operation Modes

Operation mode

Description

Running mode

When powered ON, the inverter automatically enters this mode.

This mode allows you to specify the reference frequency, PID command value and etc., and

run/stop the motor with the / keys.

It is also possible to monitor the running status in real time.

If a light alarm occurs, the

l-al

appears on the LED monitor.

Programming

mode

This mode allows you to configure function code data and check a variety of information

relating to the inverter status and maintenance.

Alarm mode

If an alarm condition arises, the inverter automatically enters Alarm mode in which you can

view the corresponding alarm code* and its related information on the LED monitor.

* Alarm code: Indicates the cause of the alarm condition. For details, first see Table 6.1

"Abnormal States Detectable ("Heavy Alarm" and "Light Alarm" Objects)" in Chapter 6,

Section 6.1 "Protective Function," and then read the troubleshooting of each alarm.

Figure 3.2-1 shows the status transition of the inverter between these three operation modes.

Programming mode

Configuration of function

code data and monitor of

maintenance/alarm info

and various status

Alarm mode

Display of alarm status

Occurrence of

a heavy alarm

(Press this key if

an alarm has

occurred.)

+

Running mode

Release of

a light alarm

Monitor of running status

Light alarm displayed

Run/Stop of motor

Run/Stop of motor

Detection of

a light alarm

Power ON

Release of

a heavy alarm

Figure 3.2-1 Status Transition between Operation Modes

Simultaneous keying

Simultaneous keying means pressing two keys at the same time. The simultaneous keying operation is

expressed by a "+" letter between the keys throughout this manual.

For example, the expression " + keys" stands for pressing the key with the key held down.

Page 34

3-4

Figure 3.2-2 illustrates the transition of the LED monitor screen during Running mode, the transition between menu

items in Programming mode, and the transition between alarm codes at different occurrences in Alarm mode.

(*1) The speed monitor allows you to select the desired one from the speed monitor items by using function code

E48.

(*2) Applicable only when PID control is active (J01 = 1, 2 or 3).

(*3) The analog input monitor can appear only when the analog input monitor function is assigned to one of the

analog input terminals by one of function codes E61 to E63 (= 20).

(*4)

0

appears under the V/f control.

(*5) The Timer screen appears only when the timer operation is enabled with function code C21 (C21 = 1).

(*6) Applicable only when the full-menu mode is selected (E52 = 2).

Figure 3.2-2 Transition between Basic Screens in Individual Operation Mode

Page 35

4-1

Chapter 4 SET UP PROCEDURE

This chapter describes a simple step by step set up procedure of FRENIC-Ace for solar pumping application.

Please refer to:

- chapter 2 for detailed information about installation and wiring

- chapter 3 for the information about the operation of the keypad

- chapter 5 for detailed description of the function codes.

In order to set up FRENIC-Ace for solar pumping application, please proceed with the following step by step

procedure:

1. Install the inverter as described in chapter 2 of this manual.

2. Set up the motor parameters and, whenever possible, execute the auto tuning procedure. If the

motor is already coupled with the load (pump) please execute static auto-tuning (P04=1). If the

motor can be dismounted from the load please execute dynamic auto-tuning (P04=2), which

measures more motor parameters than the static auto-tuning (for details, please refer to chapter 5).

Some functions like the dry pump detection and low power detection will work with the best

accuracy only if the motor parameters are correctly set.

3. Set up the parameter F02 (Operation method) to 1 (External signal).

4. Set up the parameter H11 (Deceleration mode) to 1 (Coast to a stop).

5. Set the PID control related parameters:

o J01 (Mode selection) to 2 (inverse operation)

o J02 (Remote command) to 1 (PID process command 1)

o J06 (Feedback filter) to 0.0s (No filter).

6. Set up the following parameters related to the PV panel specifications:

o Function code U126 (PV panel open circuit voltage) is used to set the PV panel open circuit

voltage

o Function code U127 (PV panel MPP voltage) is used to set the PV panel MPP voltage

7. Set up the following parameters related to the MPP search (tracking) function:

o Function code U121 (Enable MPP search) must be set to “1.00” to enable the MPP search

function

o Function code U135 (Voltage/PID set point increase/decrease step for MPP search) to set the

set point increase/decrease at each step of the MPP search function.

8. Set up the parameters related to the sleep function:

o Function code J15 (Sleep frequency) to set the minimum frequency level to keep running,

because the pump is not anymore effective when rotating at lower speeds than the value set in

this function code. This setting depends mainly on the pump specifications.

o Function code U134 (Power level to keep running) to set the minimum power level to keep

running. If the power level is very small, it means that the pump may not be effective anymore.

This setting depends mainly on the pump specifications.

It is important to note that it is not compulsory to set both parameters. The inverter can use either the

sleep frequency or the minimum power as the stop (sleep) criteria. In other words, it is not required to

fulfill both conditions.

Do not change the value of function code J17 from factory default value, otherwise it would interfere

with the sleep and wake up functions.

9. Set up the following parameters related to the wake up function:

o Function code U131 (DC link voltage level to start) to set the minimum voltage level of the PV

panel (DC link) to allow the operation of the inverter. This parameter is very important to avoid

that the inverter (pump) starts operation when there is not enough available power from the PV

panel. The value of this parameter can be set from PV panel specification or from tests at very

low irradiance conditions (for example during sunset).

Do not change the value of function code J17 from factory default value, otherwise it would interfere

with the sleep and wake up functions.

Page 36

4-2

10. Set up the initial parameters of the PID regulator:

o PID controller gains J59 (P Gain 2) and J60 (I integral time 2), used when the PID feedback

value is higher than the PID set point value. As initial values set the values recommended in

chapter 5.

o PID controller gains U132 (P Gain 1) and U133 (I integral time 1), used when the PID feedback

value is lower than the PID set point value. As initial values set the values recommended in

chapter 5.

11. Check that the function codes related to the digital inputs [FWD] and [REV] are set to “No function

assigned”.

( Function code E98, E99 data = 100)

12. If tank high level digital detection signal is used, check that the function code related to the digital

input [X1] is set to “No function assigned”.

( Function code E01 data = 100)

13. If tank level analog detection signal is used, set function code U128 (High level) to the desired

maximum level of the tank. If this signal is not used, set function code U128 to 100%, to ensure that

the pump starts (inverter operates) regardless of the value on the analog input of the inverter.

14. Ensure that function code U00 (Mode Selection) is set to 1, in order to enable the Solar Pumping

application.

• When setting U00 to 1 the operation of the inverter may start (if all necessary conditions are fulfilled).

Please ensure that it is safe to start operation.

An accident or physical injury may result.

Page 37

5-1

Chapter 5 FUNCTION CODES

This chapter describes the function codes used to set FRENIC-Ace for Solar Pumping application.

5.1 Function Codes Table

The table below describes the function codes used to set up FRENIC Ace inverter for Solar Pumping application.

For other function codes not described in this manual refer to FRENIC Ace User’s Manual. In case of using PMS

motor please refer to the FRENIC Ace User’s Manual for the correct setting of motor parameters.

Code Keypad code Name Data setting range

Factory

default

Setting

F02 F02 Operation method

0: Keypad operation (rotation direction input:

terminal block)

1: External signal (digital input)

2: Keypad operation (forward rotation)

3: Keypad operation (Reverse rotation)

2 1

F03 F03 Maximum output frequency 1 25.0 to 500.0 Hz

200V class

AJKU:60.0

400V class

ACE:50.0

JKU:60.0

App.

(Note 1)

F04 F04 Base frequency 1 25.0 to 500.0Hz

200V class

J:50.0

AUK:60.0

400V class

ACEJ:50.0

UK:60.0

App.

(Note 1)

F05 F05 Rated voltage at base frequency 1

0: AVR disable (output voltage proportional to

power voltage)

80 to 240 V: AVR operation (200V class)

160 to 500V: AVR operation (400V class)

App.

(Note 1)

F06 F06 Maximum output voltage 1

80 to 240V: AVR operation ( 200V class)

160 to 500V: AVR operation ( 400V class)

App.

(Note 1)

F07 F07 Acceleration time1 6.00

F08 F08 Deceleration time1 0.50

F09 F09 Torque boost 1

0.0 to 20.0% (% value against base frequency

voltage 1)

(Note 7)

App.

(Note 1)

F10 F10

Electronic thermal overload

protection for motor 1 (Select motor

characteristics)

1: Enable (For a general-purpose motor with selfcooling fan)

2: Enable (For an inverter-driven motor (FV) with

separately powered cooling fan)

1

App.

(Note 1)

F11 F11

Electronic thermal overload

protection for motor 1 (Overload

detection level)

0.00 (disable), current value of 1 to 135% of

inverter rated current

(Inverter rated current dependent on F80)

(Note 3)

App.

(Note 1)

F12 F12

Electronic thermal overload

protection for motor 1 (Thermal time

constant)

0.5 to 75.0 min (Note 4)