Page 1

Instruction Manual

DeviceNet Interface Option

"OPC-E1-DEV"

Thank you for purchasing our DeviceNet Interface Option OPC-E1-DEV.

• This product is designed to connect the FRENIC-Multi series of inverters to DeviceNet. Read through this

instruction manual and be familiar with the handling procedure for correct use.

• Improper handling blocks correct operation or causes a short life or failure.

• Deliver this manual to the end user of the product. The end user should keep this manual in a safe place

until the DeviceNet Interface Option is discarded.

• For the usage of inverters, refer to the instruction manual prepared for the FRENIC-Multi series of inverters.

Fuji Electric FA Components & Systems Co., Ltd.

Page 2

Copyright © 2006 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA

Components & Systems Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our DeviceNet Interface Option OPC-E1-DEV.

Mounting this option on your FRENIC-Multi allows you to connect the FRENIC-Multi to a DeviceNet master unit

(e.g., PC and PLC) and control it as a slave unit using the run command, speed command, and access to

function codes.

This option has the following features:

• Data Rate (baud rate): 125 kbps, 250 kbps, 500 kbps

• I/O Message: Polling and Change of State supported

• Applicable Profile: AC Drive profile

• Reading and writing all the function codes applicable to the FRENIC-Multi (User Defined Assembly I/O or

Explicit Message)

This product has been tested by ODVA authorized Independent Test Lab and found to comply with ODVA’s

DeviceNet Conformance Test Version 18.

Certification Logo Mark:

DeviceNet

This instruction manual does not contain inverter handling instructions.

conjunction with the FRENIC-Multi Instruction Manual (INR-SI47-1094-E) and be familiar with proper handling

and operation of this product. Improper handling might result in incorrect operation, a short life, or even a failure

of this product.

Keep this manual in a safe place.

Related Publications

Listed below are the other materials related to the use of the DeviceNet interface option "OPC-E1-DEV." Read

them in conjunction with this manual as necessary.

• RS-485 Communication User's Manual (MEH448)

• FRENIC-Multi Instruction Manual (INR-SI47-1094-E)

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all

safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

is a trademark of Open DeviceNet Vendor Association, Inc. (ODVA).

Read through this instruction manual in

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily

injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

1

Page 4

Installation and wiring

• Turn the inverter's power OFF and wait for at least five minutes. Further, check that the DC link bus

voltage between the P (+) and N (-) terminals is lower than 25 VDC.

• Qualified electricians should carry out wiring.

Otherwise, electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, accident, or injury.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into

the inverter and the option.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

• Noise may be emitted from the inverter, motor and wires. Implement appropriate measure to prevent

the nearby sensors and devices from malfunctioning due to such noise.

Otherwise, an accident could occur.

Operation

• Be sure to install the terminal block cover, front cover of the inverter and option terminal cover before

turning the inverter's power ON. Do not remove the covers while power is applied.

Otherwise electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause electric shock.

• If you set the function codes wrongly or without completely understanding FRENIC-Multi Instruction

Manual (INR-SI47-1094-E) and the FRENIC-Multi User's Manual (MEH457), the motor may rotate

with a torque or at a speed not permitted for the machine. Confirm and adjust the setting of the

function codes before running the inverter.

Otherwise, an accident could occur.

Maintenance and inspection, and parts replacement

• Turn the inverter's power OFF and wait for at least five minutes before starting inspection. Further,

check that the DC link bus voltage between the P (+) and N (-) terminals is lower than 25 VDC.

Otherwise, electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, electric shock or injuries could occur.

2

Page 5

Disposal

• Treat the DeviceNet interface option as an industrial waste when disposing of it.

Otherwise injuries could occur.

Others

• Never attempt to modify the DeviceNet interface option.

Doing so could cause electric shock or injuries.

How this manual is organized

This manual is made up of chapters 1 through 12.

Chapter 1 BEFORE USING THIS OPTION

Lists points to be checked upon delivery of this option. Also this chapter provides information on how to obtain

an EDS file, and describes about applicable inverters.

Chapter 2 BASIC FUNCTIONS AND SETTINGS

Provides inside view of this option and describes on how to specify the communication data rate (baud rate) and

the node address on DeviceNet with the DIP switch. Also this chapter describes about LED status indicators.

Chapter 3 INSTALLATION OF THIS OPTION

Provides instructions and precautions for mounting this option.

Chapter 4 WIRING AND CABLING

Provides wiring instructions around the terminal blocks on this option and the cable specifications.

Chapter 5 CONFIGURING INVERTER'S FUNCTION CODES FOR DeviceNet COMMUNICATION

Describes the inverter's function codes to be set for the DeviceNet communications link. Also this chapter lists

the related function codes.

Chapter 6 ESTABLISHING A DeviceNet COMMUNICATIONS LINK

Guides you to establish a DeviceNet communications link between the DeviceNet master and the inverter.

Chapter 7 I/O MESSAGE

Provides overview of I/O Message and detailed descriptions of I/O assembly instances

Chapter 8 EXPLICIT MESSAGE

Provides overview of Explicit Message and detailed descriptions of objects

Chapter 9 INVERTER REACTION TO DeviceNet COMMUNICATIONS ERRORS

Describes on how the inverter operates if a DeviceNet communications error occurs.

Chapter 10 ALARM CODE LIST

Lists and explains inverter’s alarm codes.

Chapter 11 TROUBLESHOOTING

Provides troubleshooting instructions for certain problems, e.g., when the inverter does not operate as ordered

or when an alarm condition has been recognized.

Chapter 12 SPECIFICATIONS

Lists the general specifications and communications specifications.

3

Page 6

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full

efficiency, as well as information concerning incorrect operations and settings which can result in

accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Table of Contents

Preface ...................................................................................1

How this manual is organized.....................................................3

Chapter 1 BEFORE USING THIS OPTION....................... 5

1.1 Acceptance Inspection ............................................ 5

1.2 Applicable Inverters ................................................. 5

Chapter 2 BASIC FUNCTIONS AND SETTINGS.............. 6

2.1 DeviceNet Interface Option Inside View .................. 6

2.2 DIP Switch ............................................................... 6

2.3 LED Status Indicators.............................................. 7

2.4 RJ-45 Connector ..................................................... 8

2.5 Power Supply Terminal Block and DeviceNet

Terminal Block ......................................................... 8

Chapter 3 INSTALLATION OF THIS OPTION ................... 9

Chapter 4 WIRING AND CABLING ................................. 13

4.1 Basic Connection Diagram .................................... 13

4.2 Wiring for Power Supply Terminal Block ................ 14

4.3 Wiring for DeviceNet Terminal Block ..................... 15

4.4 Turning ON the Optional 24 V Power Supply ........ 16

Chapter 5 CONFIGURING INVERTER'S FUNCTION

Chapter 6 ESTABLISHING A DeviceNet

CODES FOR DeviceNet COMMUNICATION . 17

COMMUNICATIONS LINK ............................. 18

Chapter 7 I/O MESSAGE ................................................ 19

7.1 Overview ............................................................... 19

7.2 I/O Assembly Instances: Selection and Setup ....... 20

7.3 An Example of Actual I/O Communication Data .... 24

7.4 I/O Assembly Instances Assigned to Word

Variables (For reference)....................................... 26

Chapter 8 EXPLICIT MESSAGE ..................................... 28

8.1 Overview ............................................................... 28

8.2 Objects to be Used in Explicit Message................. 28

8.3 Error Code List for Explicit Message Errors........... 33

Chapter 9 INVERTER REACTION TO DeviceNet

Chapter 10 ALARM CODE LIST........................................ 35

Chapter 11 TROUBLESHOOTING.................................... 36

Chapter 12 SPECIFICATIONS .......................................... 37

COMMUNICATIONS ERRORS ...................... 34

12.1 General Specifications........................................... 37

12.2 DeviceNet Specifications....................................... 37

4

Page 7

Chapter 1 BEFORE USING THIS OPTION

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) A DeviceNet interface option and accessories below are contained in the package. (See Figure 1.1.)

• Two option connection cables

One short cable: For inverters with a capacity of 3.7 kW or below

One long cable: For inverters with a capacity of 5.5 kW or above

• One option fixing screw

• DeviceNet Interface Option Instruction Manual (this manual)

(2) The option and accessories have not been damaged during transportation—there should be no dents or

parts missing.

(3) The model name "OPC-E1-DEV" is printed on the nameplate attached to the right side of the option. (See

Figure 1.1.)

If you suspect the product is not working properly or if you have any questions about your product, contact your

Fuji Electric representative.

Figure 1.1 DeviceNet Interface Option and Accessories

Neither an EDS file nor a terminating resistor comes with this option.

- An EDS file is required for registering this option to the configurator for DeviceNet master node

settings. It is available as a free download from our website at:

http://web1.fujielectric.co.jp/Kiki-Info-EN/User/index.html

(Fuji Electric FA Components & Systems Co., Ltd. Technical Information)

Before downloading, you are requested to register as a member (free of charge).

- A terminating resistor of the following specifications must be used: 121 ohm ±1%, 1/4 watt,

metal-film resistor

1.2 Applicable Inverters

The DeviceNet interface option is applicable to the following inverters and ROM version.

Table 1.1 Applicable inverter and ROM version

Series Inverter type Applicable motor rating ROM version

FRENIC-Multi FRNE1- All capacities 0700 or later

To check the inverter's ROM version, use Menu #5 "Maintenance Information" on the keypad. (Refer to the

FRENIC-Multi Instruction Manual (INR-SI47-1094-E), Chapter 3, Section 3.4.6 "Reading maintenance

information."

Display on LED Monitor Item Description

5_14

Inverter's ROM version Shows the inverter's ROM version as a 4-digit code.

5

Page 8

Chapter 2 BASIC FUNCTIONS AND SETTINGS

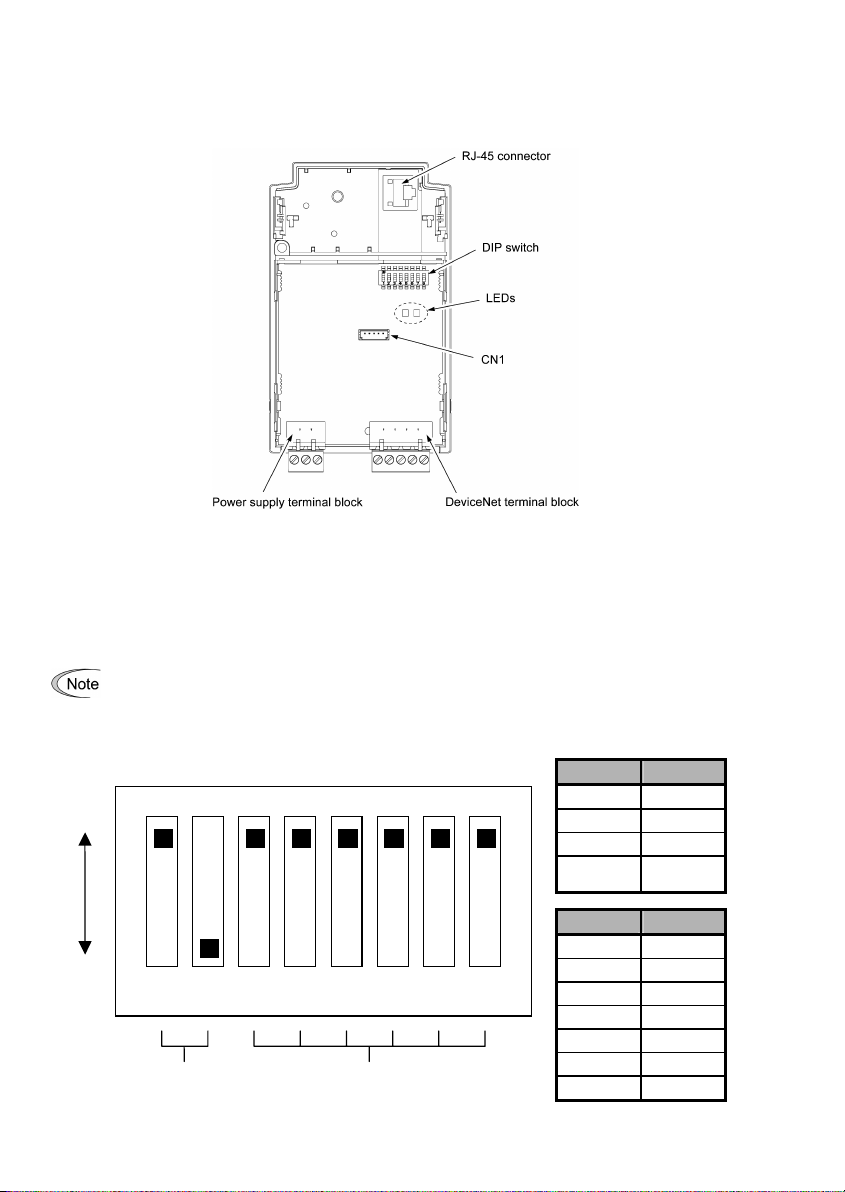

2.1 DeviceNet Interface Option Inside View

Figure 2.1 shows the inside view of the DeviceNet interface option with the option terminal cover (See Figure

3.3) removed.

Figure 2.1 DeviceNet Interface Option Inside View

2.2 DIP Switch

The DIP switch specifies the communication data rate (baud rate) and the node address (MAC ID) on DeviceNet.

It offers a choice of three baud rates (125 kbps, 250 kbps, and 500 kbps) and a choice of node address (MAC

ID) ranging from 0 to 63.

Before accessing the DIP switch, make sure that both the inverter and the option are turned OFF. If

you change the configuration of the DIP switch with the inverter and the option being ON, you need to

restart both the inverter and the option to validate the new settings.

The default settings of the DIP switch at factory shipment are: data rate = 500 kbps, node address = 63.

ON

OFF

1 2 3 4 5 6 7 8

Data Rate (DR) Node Address (NA)

Figure 2.2 DIP Switch Settings (showing an example of Data Rate = 500 kbps and Node Address = 63)

DR (bps) DIP 1-2

125K 00

250K 01

500K 10

Not

allowed

NA DIP 3-8

0 000000

1 000001

2 000010

3 000011

… …

62 111110

63 111111

11

6

Page 9

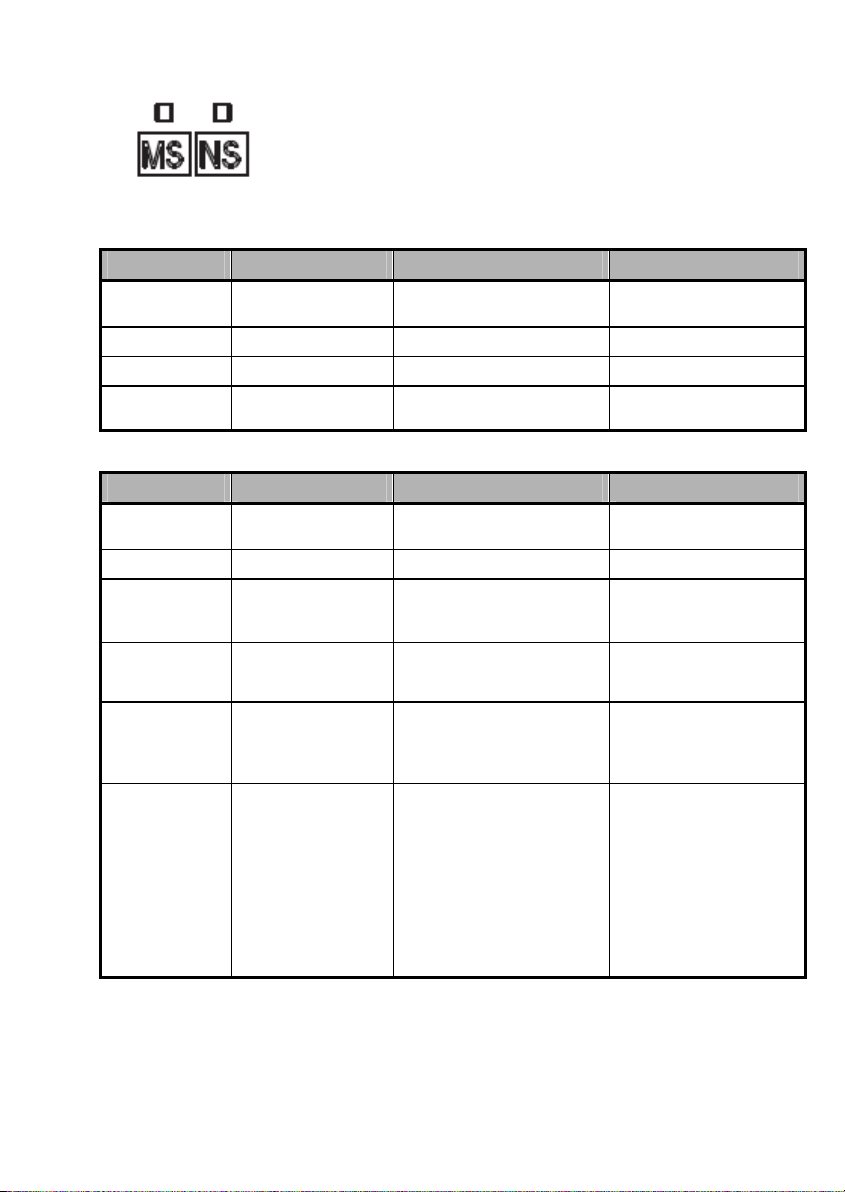

2.3 LED Status Indicators

The two LED status indicators show the status of this option.

The tables below show the states of the LEDs and their meanings.

MS LED Stat us Meaning Note

Blinks between

green and red*

1

OFF

Lights in green

Lights in red

NS LED Stat us Meaning Note

Blinks between

green and red*

OFF

Blinks in green

Lights in green

Blinks in red

Lights in red

1

Blinks in the pattern specified in the DeviceNet specifications.

*

2

*

er5

cannot be reset until the NS LED comes to stay on in green. A setting for ignoring

a connection error is detected. For details, refer to Chapter 9, Section 1 "INVERTER REACTION TO DeviceNet

COMMUNICATIONS ERRORS."

Self-diagnostic test

1

Offline

Online

Connection established

Connection timeout

Connection error

- MS (Module Status)

Indicates the hardware status of the DeviceNet interface option.

- NS (Network Status)

Indicates the communication status on DeviceNet.

Table 2.1 MS LED state

Self-diagnostic test

Running self-diagnostic test

upon power-on

Power OFF Powered OFF

Hardware normal Hardware working normally

Hardware error

Option not properly mounted

or the option is faulty

Table 2.2 NS LED state

Running self-diagnostic test

upon power-on

DeviceNet being offline –

DeviceNet cabling correct

Option not communicating on

the DeviceNet network

Option communicating

normally on the DeviceNet

network

Connection timeout between

the option and the master

- Too short communication

cycle time

Improper DeviceNet cabling, or

improper settings

- Node address double

assigned

- Data rate mismatch

- Bus-off state detected

- Power supply cable for the

DeviceNet unconnected

- Improper wiring for the

DeviceNet terminal block

This test takes 1 second.

The inverter issues

er4

–

The inverter issues

er4

This test takes 1 second.

Waiting for a request from

the master

–

The inverter issues

The inverter issues

er5

is also available even if

er5

er5

.

.

*2

*2

7

Page 10

2.4 RJ-45 Connector

The RJ-45 connector is used to connect the keypad of the FRENIC-Multi to this option.

The keypad can be detached from the option and mounted on a panel wall. For details, refer to the

FRENIC-Multi Instruction Manual (INR-SI47-1094-E), Chapter 2, Section 2.4 "Mounting and Connecting a

Keypad."

2.5 Power Supply Terminal Block and DeviceNet Terminal Block

The power supply terminal block and DeviceNet terminal block are used to connect the 24V power cable and

DeviceNet cable, respectively, in order to operate this option.

For details, refer to Chapter 4 "WIRING AND CABLING."

8

Page 11

Chapter 3 INSTALLATION OF THIS OPTION

Turn the inverter's power OFF and wait for at least five minutes. Further, check that the DC link bus voltage

between the P (+) and N (-) terminals is lower than 25 VDC.

Otherwise, electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, accident, or injury.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into

the inverter and the option.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

When handling this option, take any antistatic measure or hold the plastic parts taking care not to directly touch

the circuit board; otherwise, the static electricity charged in your body may damage it.

9

Page 12

Before mounting the option, perform the wiring for the main circuit terminals and control circuit

terminals.

(1) Remove the terminal cover from the inverter.

Note: For inverters with a capacity of 5.5 to 15 kW, you need to remove the terminal cover fixing screw to remove

the terminal cover.

For details on how to remove the terminal cover, refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E), Chapter 2, Section 2.3 "Wiring."

(2) Connect the option connection cable to the CN1 connector on the interface printed circuit board (interface

PCB) on the inverter.

Use the short cable for inverters with a capacity of 3.7 kW or below, and the long cable for the ones with a

capacity of 5.5 kW or above.

(3) Mount the terminal cover.

For details on how to mount the terminal cover, refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E), Chapter 2, Section 2.3 "Wiring."

(4) Push the hooks provided on both sides of the keypad and pull the keypad up and out of the inverter.

For details on how to remove the keypad, refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E), Chapter 2, Section 2.4 "Mounting and Connecting a Keypad."

Figure 3.1 Connecting the Option Connection Cable to the Interface PCB and Removing the Keypad

(For inverters with a capacity of 11 and 15 kW)

10

Page 13

(5) Mount the option on the inverter, making the RJ-45 connector on the back side of the option engage with

the RJ-45 connector on the inverter (to which the keypad had been connected).

(6) Connect the keypad to the RJ-45 connector on the front side of the option, then secure the keypad and

option to the inverter with the option fixing screw (that comes with the option).

When using the keypad at a remote site, secure the option without the keypad to the inverter with the

screw.

Tightening torque: 0.6 N·m

Take care not to tighten the option fixing screw too much. Doing so could make the screw defective.

Figure 3.2 Mounting the DeviceNet Interface Option and the Keypad

11

Page 14

(7) Slightly pull the bottom of the option terminal cover towards you and remove it downward.

(8) Connect the other end of the option connection cable (whose end has been connected to the interface PCB

on the inverter in step (2) above) to the CN1 connector on the interface option printed circuit board

(interface option PCB).

(9) Mount the option terminal cover.

First fit the bosses on the top of the cover into the square holes provided in the option, and then push the

bottom of the cover until it snaps into place.

Figure 3.3 Connecting the Option Connection Cable to the Interface Option PCB

12

Page 15

Chapter 4 WIRING AND CABLING

• Before starting installation, turn off the power to the inverter and wait for at least five minutes. Further,

check the DC link circuit voltage between the P (+) and N (-) terminals to be lower than 25 VDC.

• Qualified electricians should carry out wiring.

Otherwise, electric shock could occur.

The inverter, motor, and wiring emit electrical noise. Take appropriate measures to prevent the nearby

sensors and devices from malfunctioning due to such noise.

Otherwise, an accident could occur.

4.1 Basic Connection Diagram

FRENIC-Multi

Grounding

terminal

L1/R

L2/S

L3/T

PLC

+DC24V

CM

0V

OPC-E1-DEV

Power supply

terminal block

24V

0V

E

G

DeviceNet

terminal block

V-

CAN L

Shield

CAN H

V+

U

V

W

DeviceNet cable

Motor

M

G

To

DeviceNet

Figure 4.1 Basic Connection Diagram

13

Page 16

約

A

4.2 Wiring for Power Supply Terminal Block

This terminal block is used to supply this option with 24 V power to operate it. Perform wiring for the terminal

block as described blow.

(1) Wiring for the power supply terminal block (TERM3)

The terminal block uses a pluggable 3-pin connector as shown in Figure 4.2. Table 4.1 shows the pin

assignment.

A typical connector that matches this terminal block is Phoenix Contact MSTB 2.5/3-ST-5.08.

Table 4.1 Pin Assignment on Power Supply Terminal Block

Pin # Terminal

1 24V Power supply

2 0V Power supply

3 E Grounding

name

Description Remarks

The PLC terminal of the

(24 VDC, + side)

(24 VDC, - side)

terminal

FRENIC-Multi is available as

a 24V power source. Connect

the PLC terminal to this "24V"

terminal and CM terminal to

this "0V" terminal.

Connect the ground terminal

of the inverter (

terminal.

G) to this

Figure 4.2 Connectors on the Power

For protection against external noise and prevention of failures, be sure to connect a grounding

wire.

Table 4.2 lists the recommended wire size, terminal screw size and its tightening torque.

Table 4.2 Recommended Wire Size, Terminal Screw Size, and Its Tightening Torque

Wire size Terminal screw size Tightening torque

AWG20 to AW G16 (0.5 to 1.5mm2 ),

wire with rated temperature 105 °C (UL)

recommended

for the Power Supply Terminal Block

M3 0.5 to 0.6 N・m

pprox.

6.0 mm

Cable wire

電線

6mm

1 2 3

Supply Terminal Block

Figure 4.3 Recommended Strip Length of the Cable Wire End

for Terminal Connection

14

Page 17

(2) Input power requirements

It is recommended that the PLC and CM terminals on the FRENIC-Multi be used for the power supply

terminal block. When using an external power source, however, select the input power supply that meets

the specifications listed in Table 4.3.

Table 4.3 Input Power Requirements

Item Specifications

Input power voltage range 21.6 to 27.0 V

Power consumption Maximum 35 mA

Do not use the 24 V power supply designed for DeviceNet communication (i.e., power supply fed

to the DeviceNet cable) for the power supply terminal block. Doing so may affect negatively on the

noise resistance in DeviceNet communication.

It is convenient to use the PLC terminal on the control circuit terminal block on the FRENIC-Multi

as a 24 V power supply. Connect the PLC terminal to the "24 V" terminal of this option, and the CM

terminal, to the "0 V" terminal.

For details about the PLC and CM terminals, refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E), Chapter 2, Section 2.3 "Wiring."

4.3 Wiring for DeviceNet Terminal Block

(1) To connect this option to DeviceNet, use a DeviceNet thin cable complying with the DeviceNet

specifications. Also observe the wiring lengths specified in the DeviceNet specifications.

The recommended DeviceNet cable is TDN24U made by SWCC Showa Device Technology, Co.,

Ltd.

Proper installation of the cable requires specialist knowledge. Be sure to refer to the DeviceNet

specifications (published by ODVA) beforehand.

(2) Wiring around the DeviceNet terminal block (TERM1)

The terminal block uses a pluggable 5-pin connector as shown in Figure 4.4. It has five labels

corresponding to the five pins. Each label has an ID color corresponding to the wire (core) to be connected

to its pin. Make sure that the ID colors of the wires and labels match. Table 4.4 shows the correspondence

between the pin numbers and the ID colors.

A typical connector that matches this terminal block is Phoenix Contact MSTB 2.5/5-ST-5.08 AU.

The Phoenix Contact TMSTBP 2.5/5-ST-5.08 AU and TFKC 2.5/5-STF-5.08 AU (spring-cage

connection type) connectors for multidrop connection are also usable. Note that, however, the

former can be used only for FRENIC-Multi 3.7 kW or below.

Table 4.4 Layout of Terminal Pins

Pin #

ID Color of

Wire Sheath

1 Black V- Power supply

2 Blue CANL Signal line (- side)

3 Metallic SD Cable shield

4 White CANH Signal line (+ side)

5 Red V+ Power supply

Pin

Assignment

Description

(24 VDC, - side)

(24 VDC, + side)

1 2 3 4 5

Figure 4.4 Connectors on the

DeviceNet Terminal Block

15

Page 18

約

A

Table 4.5 lists the recommended terminal screw size and its tightening torque, and Figure 4.5 shows the

recommended strip length of the cable wire end.

Table 4.5 Recommended Tightening Torque

of the Terminal Screws for the

DeviceNet Terminal Block

Terminal screw size

M3 0.5 to 0.6 N·m

Tightening torque

Cable wire

電線

Figure 4.5 Recommended Strip Length of the

Cable Wire End for Terminal

Connection

pprox.

6mm

6.0 mm

(3) Terminating resistor

DeviceNet requires a terminating resistor to be installed externally on each end of the trunk line. Check that

the trunk line is terminated on both ends; if not, install a terminating resistor(s) on the missing end(s).

Terminating resistors do not come with this option. A pair of resistors with the following

specifications is separately necessary.

121 ohm ±1%, 1/4 watt, metal-film resistor

4.4 Turning ON the Optional 24 V Power Supply

Observe the following instructions about the ON/OFF timing of this option and the inverter.

(1) Power ON

It is recommended that this option be turned ON at the same time as or before the inverter. Turning the

inverter ON first may detect no operation of the option, causing a trip with

er4

alarm. The

er4

trip can be

reset after this option is turned ON.

(2) Power OFF

It is recommended that this option be turned OFF at the same time as or after the inverter. Turning the

option OFF first may cause the inverter to detect no operation of the option, causing a trip with

Turning the inverter OFF resets the

er4

trip.

er4

alarm.

When the PLC terminal on the FRENIC-Multi control circuit terminal block is used as a 24V power

source, turning ON or OFF of the inverter interlocks with that of the option. It is convenient.

16

Page 19

Chapter 5 CONFIGURING INVERTER'S FUNCTION CODES FOR DeviceNet

COMMUNICATION

Before starting DeviceNet communication between the inverter equipped with this option and the DeviceNet

master device, configure the inverter's function codes listed in Table 5.1.

Table 5.2 lists other related function codes to be configured if necessary.

Table 5.1 Inverter's Function Codes for DeviceNet Communication

Function

codes

o31 *1

o32 *1

y98 *2

*1

After conf iguring the function code o31 or o32, turn the power of the inverter and the option OFF and then ON to validate the

new setting. For details about these functions, refer to Chapter 7 "I/O MESSAGE."

Input and output assembly instances should not be necessarily set to the same instance type. (Ex. Output assembly instance =

Extended speed control output, Input assembly instance = User defined assembly input.)

*2 If the extended speed control input/output is selected (o31 = 0 or 21), bit operation in the instance can select the run/frequency

command source, requiring no prior configuration of y98. For details, refer to Chapter 7, Section 7.2 "(2) Extended Speed

Control Instance."

Description

Select output assembly

instance

(From master to slave)

Select input assembly

instance

(From slave to master)

Select run/frequency

command source

Factory

default

setting

Available data is:

0

20 : Basic speed control output

0, 21 : Extended speed control output

100 : Fuji drive assembly output

102 : User defined assembly output

Available data is:

0

70 : Basic speed control input

0, 71 : Extended speed control input

101 : Fuji drive assembly input

103 : User defined assembly input

Available data is:

0

Table 5.2 Other Related Function Codes

Function code data Remarks

Frequency

command

0 Inverter Inverter

1 DeviceNet Inverter

2 Inverter DeviceNet

3 DeviceNet DeviceNet

Run

command

See Chapter 7.

The factory default is

"Extended speed

control output."

See Chapter 7.

The factory default is

"Extended speed

control input."

If there is no special

problem with your

system, setting y98 =

3 is recommended.

Function

codes

o27 *1

o28 *1

o40 to o43

o48 to o51

*1 For details about function codes o27 and o28, refer to Chapter 9 "INVERTER REACTION TO DeviceNet COMMUNICATIONS

ERRORS."

*2 For details about function codes o40 to o43 and o48 to o51, refer to Chapter 7, Section 7.2 (4) "User Defined Assembly

Instance."

Select the inverter’s operation mode to

apply when a DeviceNet

communications error occurs.

Set the operation timer to apply when a

DeviceNet communications error occurs.

Assign the function code writing data

cyclically.

*2

Assign the function code reading data

cyclically.

*2

Description

Factory default

setting

0 0 to 15

0.0 s 0.0 to 60.0 s

0

(No assignment)

0

(No assignment)

17

Function code

setting range

0000 to FFFF (hex)

0000 to FFFF (hex)

Remarks

Valid only when

"User defined

assembly

input/output" is

selected (o31 = 102,

o32 = 103).

Page 20

r

r

Chapter 6 ESTABLISHING A DeviceNet COMMUNICATIONS LINK

This chapter guides you to establish a DeviceNet communications link in I/O Message transmission between the

DeviceNet master and the inverter (slave).

I/O Message is a communication process that cyclically transfers data between the DeviceNet master and

slave. For details about I/O Message, refer to Chapter 7, "I/O MESSAGE."

(1) Configure the inverter's function codes described in Chapter 5.

- Set the I/O assembly instances with the inverter's function codes o31 and o32. It is not necessary to set

the same type of I/O assembly instances to input and output.

- Configure the inverter's function codes o27 and o28 with your need. If the instances for user defined

assemblies have been set, configure the function codes o40 to o43 and o48 to o51.

- After completion of the settings above, restart the inverter and this option in order to validate the settings.

For details about the inverter's function codes o31, o32, o40 to o43, and o48 to o51, refer to Chapter 7

"I/O MESSAGE."

(2) Set up the DeviceNet master (PLC, PC tool, or Configurator).

- Set a unique MAC ID (node address), so that it does not coincide with any other nodes.

- Set the baud rate. Make sure that all the nodes have the same baud rate.

- If necessary, install the EDS file of this option to the setup tool of the master.

- Allocate an I/O area corresponding to the I/O assembly instance set for this option. The I/O area is either

2 words or 4 words in length.

- Specify the I/O connection type--"Poll" or "Change of state." Specify the communications scan cycle if

necessary.

The communications scan cycle to this option should be 10 ms or longer. If a single slave is

connected to a master, the cycle should be 10 ms or longer; if two slaves are connected, 5 ms o

longer. To minimize the data conflicts and maximize the system reliability, the cycle of 20 ms o

longer is recommended.

The Electric Data Sheet (EDS) file defines parameters on the slave. Using it quickly accesses the

desired parameters. For this option, the file makes it easier to access the inverter's function codes.

For how to obtain the EDS file, refer to Chapter 2 "Acceptance Inspection."

For details about the setup procedure of the DeviceNet master, refer to the user’s manual of the

corresponding master.

(3) Configure the node address and baud rate with the DIP switch on this option.

- Before accessing the DIP switch, make sure that both the inverter and this option are turned OFF.

- Set a unique node address, so that it does not coincide with any other nodes.

- Set the same baud rate as the master.

For details about setting the DIP switch, refer to Section 2.2 "DIP Switch."

(4) Have an I/O connection request issued from the DeviceNet master.

- Turn ON the inverter and this option.

- Have an I/O connection request issued from the DeviceNet master.

For details about issuing I/O connection requests from the master, refer to the user's manual of the

connected master device. In many PLCs, an I/O connection request is automatically issued at the time

of powering ON.

(5) Start I/O Message.

If both the master and this option have been set correctly and the wiring is proper, I/O message connection

will be established in response to the connection request and data transmission starts. At this stage, the MS

and NS LEDs on this option light in green. It is ready to control the inverter according to the specified I/O

assembly instances.

18

Page 21

Chapter 7 I/O MESSAGE

7.1 Overview

I/O Message is a communication process that cyclically transfers data between the DeviceNet master and

slave.

This option supports two types of I/O Message connections--Poll and Change-of-State connections. It also

supports four types of I/O assembly instances as data formats in I/O Message, as listed in Table 7.1. One of the

four instances can be selected for input and output each.

The I/O assembly instances should be specified using inverter's function codes o31 and o32.

- Poll connections allow the master to periodically poll the slave for data. In response to the

request, the slave sends data. In Change-of-State connections, the slave sends data only

when the data has changed.

- Input and output assembly instances should not be necessarily set to the same instance type.

(Ex. Output assembly instance = Extended speed control output, Input assembly instance =

User defined assembly input.)

Table 7.1 Configuring I/O Assembly Instances

o31, o32 Type Instance ID Description

o31=20 20 Basic Speed Control Output 2

o31=0 or 21 21 Extended Speed Control Output

o31=100 100 Fuji Drive Assembly Output 2

o31=102

o32=70 70 Basic Speed Control Input 2

o32=0 or 71 71 Extended Speed Control Input

o32=101 101 Fuji Drive Assembly Input 2

o32=103

Output

(from master

to slave)

Input

(from slave

to master)

(Factory default)

102 User Defined Assembly Output 4

(Factory default)

103 User Defined Assembly Input 4

Length

(words)

2

2

19

Page 22

7.2 I/O Assembly Instances: Selection and Setup

(1) Basic speed control instance

Output (from master to this option): o31=20

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

20

0 - - - - - Fault

1 (Fixed at 00)

2 Speed Reference (lower byte) (r/min)

3 Speed Reference (upper byte) (r/min)

Reset

Run Forward: 1 = Run forward command

Fault Reset: 1 = Reset the alarm condition

Speed Reference: Speed command (in r/min)

Input (from this option to master): o32=70

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

70

0 - - - - - Running

Forward

1 (Fixed at 00)

2 Speed Actual (lower byte) (r/min)

3 Speed Actual (upper byte) (r/min)

Faulted: 1 = The inverter has (and remains) tripped

Running Forward: 1 = The motor is running forward.

Speed Actual: Actual rotation speed (in r/min)

- Run

- Faulted

Forward

20

Page 23

(2) Extended Speed Control Instance (factory default)

Output (from master to this option): o31=0 or 21

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

21

0 - NetRef NetCtrl - - Fault

1 (Fixed at 00)

2 Speed Reference (lower byte) (r/min)

3 Speed Reference (upper byte) (r/min)

Reset

Run

Reverse

Run Forward: 1 = Run forward command

Run Reverse: 1 = Run reverse command

Fault Reset: 1 = Reset the alarm condition

NetCtrl: 1 = Request for enabling run command sent from DeviceNet;

0 = Request for enabling run command sent from other than DeviceNet

NetRef: 1 = Request for enabling speed reference sent from DeviceNet;

0 = Request for enabling speed reference sent from other than DeviceNet

Speed Reference: Speed reference (in r/min)

Input (from this option to master): o32=0 or 71

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

71

0 At

Reference

1 Drive State

2 Speed Actual (lower byte) (r/min)

3 Speed Actual (upper byte) (r/min)

Ref

FromNet

Ctrl

FromNet

Ready Running

Reverse

Running

Forward

- Faulted

Faulted: 1 = The inverter has (and remains) tripped.

Running Forward: 1 = The motor is running forward.

Running Reverse: 1 = The motor is running backward (in the reverse direction).

Ready: 1 = Ready to run

CtrlFromNet: 1 = Run command sent from DeviceNet being enabled

0 = Run command sent from other than DeviceNet being enabled

RefFromNet: 1 = Speed reference sent from DeviceNet being enabled

0 = Speed reference sent from other than DeviceNet being enabled

At Reference: 1 = The motor is running at the reference speed.

Drive State: 1 = Startup, 2 = Not Ready, 3 = Ready, 4 = Enabled, 5 = Stopping,

6 = Fault stop, 7 = Faulted

Speed Actual: Actual rotation speed (in r/min)

Run

Forward

21

Page 24

(3) Fuji Drive Assembly Instance

Output (from master to this option): o31=100

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

100

0 - X5 X4 X3 X2 X1 REV FWD

1 RST XR XF - - - - -

2 Frequency command p.u. (lower byte)

3 Frequency command p.u. (upper byte)

FWD: 1 = Run forward command

REV: 1 = Run reverse command

X1 to X5: Communication terminal block command

(The function to be performed is specified by E01 to E05).

XF, XR: Communication terminal block command

(The function to be performed is specified by E98 and E99).

RST: 1 = Reset the alarm (fault) condition.

Frequency command p.u.: Specifies the ratio of the frequency relative to the maximum frequency

(defined by F03 in Hz) being assumed as 20000.

Frequency command p.u. = Frequency command (Hz)/F03 (Hz) × 20000.

Input (from this option to master): o32=101

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

101

0 VL TL NUV BRK INT EXT REV FWD

1 BUSY ERR - RL ALM DEC ACC IL

2 Frequency output p.u. (lower byte)

3 Frequency output p.u. (upper byte)

FWD: During forward rotation

REV: During reverse rotation

EXT: During DC braking (or during pre-exciting)

INT: Inverter shut down

BRK: During braking

NUV: DC link bus voltage established (0 = undervoltage)

TL: During torque limiting

VL: During voltage limiting

IL: During current limiting

ACC: During acceleration

DEC: During deceleration

ALM: Alarm relay (for any fault)

RL: Run or speed command from communication enabled

ERR: Function code access error

BUSY: During function code data writing

Frequency output p.u.: Specifies the ratio of the frequency relative to the maximum frequency (defined by

F03 in Hz) being assumed as 20000.

22

Page 25

(4) User Defined Assembly Instance

Output (from master to this option): o31=102

User Defined Assembly Output offers a format which allows the user to freely set or modify the function

code defined by the user using the function codes o40 to o43 beforehand. Four function codes are provided

for the user to define.

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 User-defined function code 1 (write) (lower byte) (data of function code specified by o40)

102

1 User-defined function code 1 (write) (upper byte) (data of function code specified by o40)

2 User-defined function code 2 (write) (lower byte) (data of function code specified by o41)

3 User-defined function code 2 (write) (upper byte) (data of function code specified by o41)

4 User-defined function code 3 (write) (lower byte) (data of function code specified by o42)

5 User-defined function code 3 (write) (upper byte) (data of function code specified by o42)

6 User-defined function code 4 (write) (lower byte) (data of function code specified by o43)

7 User-defined function code 4 (write) (upper byte) (data of function code specified by o43)

User-defined function code 1 (write): Write data for the function code specified by o40

User-defined function code 2 (write): Write data for the function code specified by o41

User-defined function code 3 (write): Write data for the function code specified by o42

User-defined function code 4 (write): Write data for the function code specified by o43

If you assign the same function code to more than one "o" code, only the one with the smallest "o"

code number will become effective, and all the rest will be ignored (treated as "not assigned").

(For example, if the same function code is assigned to o40 and o43, o40 becomes effective and o43

does not.)

For details about configuring the inverter's function codes using o40 to o43, refer to the next page.

Input (from this option to master): o32=103

User Defined Assembly Input offers a format which allows the user to monitor the function codes defined by

the user using the function codes o48 to o51 beforehand. Four function codes are provided for the user to

define.

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

103

0 User-defined function code 1 (read) (lower byte) (data of function code specified by o48)

1 User-defined function code 1 (read) (upper byte) (data of function code specified by o48)

2 User-defined function code 2 (read) (lower byte) (data of function code specified by o49)

3 User-defined function code 2 (read) (upper byte) (data of function code specified by o49)

4 User-defined function code 3 (read) (lower byte) (data of function code specified by o50)

5 User-defined function code 3 (read) (upper byte) (data of function code specified by o50)

6 User-defined function code 4 (read) (lower byte) (data of function code specified by o51)

7 User-defined function code 4 (read) (upper byte) (data of function code specified by o51)

User-defined function code 1 (read): Monitored value of the function code specified by o48

User-defined function code 2 (read): Monitored value of the function code specified by o49

User-defined function code 3 (read): Monitored value e of the function code specified by o50

User-defined function code 4 (read): Monitored value of the function code specified by o51

For details about configuring the inverter's function codes using o48 to o51, refer to the next page.

Each function code defined has its own data format. For details about the data format of each code,

refer to the RS-485 Communication Use's Manual (MEH448), Chapter 5, Section 5.2 "Data Formats."

23

Page 26

F

How to set o40 to o43 and o48 to o51

Specifying the function code type (shown in Table 7.2) and number in a 4-digit hexadecimal notation.

Function code number (hexadecimal)

Function code type (in accordance with Table 7.2)

Table 7.2 Function Code Type

Type Type Code Function Code Ty pe Type Code Function Code

S 2 02h Command/function data A 9 09h Motor 2 function

M 3 03h Monitored data o 10 0Ah Optional function

F 4 04h Fundamental function J 14 0Eh Application function

E 5 05h Terminal function y 15 0Fh Link function

C 6 06h Control function W 16 10h Monitor 2

P 7 07h Motor 1 function X 17 11h Alarm 1

H 8 08h

High performance

function

Z 18 12h Alarm 2

Example: For F26: F ⇒ Type Code 04

26 ⇒ 1A (hexadecimal)

041a

Once you have modified the settings for o40 to o43 and o48 to o51, be sure to restart both the inverter

and this option in order to validate the new settings.

7.3 An Example of Actual I/O Communication Data

Presented herein is an actual communication data in the format of Extended Speed Control Instance, the factory

default format.

(1) Driving pattern example

Given below is an example of the driving pattern for controlling the inverter. Its corresponding I/O data is

shown in (2) on the next page.

orward

Reverse

1800 r/min

Figure 8 Driving Pattern

300 r/min

1800 r/min

Tim e (s )

24

Page 27

(2) Description of I/O Data (The I/O data are in hexadecimal notation.)

Request: Run command is OFF. Speed command = 1800 r/min (= 0708h). The run command and speed

command via DeviceNet are enabled.

60 00 08 07

Response: Stopping. The inverter is ready.

70 03 00 00

Request: Run forward command. Speed command = 1800 r/min (= 0708h). The run command and speed

command via DeviceNet are enabled.

61 00 08 07

Response: The motor is running forward and accelerating. The actual speed is increasing.

74 04 ** **

Request: Run forward command. Speed command = 1800 r/min (= 0708h). The run command and speed

command via DeviceNet are enabled.

61 00 08 07

Response: Running forward. The actual speed has reached the Reference

F4 04 08 07

Request: Run command is OFF. Speed command = 1800 r/min (= 0708h). The run command and speed

command via DeviceNet are enabled.

60 00 08 07

Response: The motor is running forward and decelerating. The actual speed is decreasing.

74 05 ** **

Request: No run command. Speed command is changed to 300 r/min (= 012Ch). The run command and

speed command via DeviceNet are enabled.

60 00 2C 01

Response: Stopping. The inverter is ready.

70 03 00 00

Request: Run reverse command. Speed command = 300 r/min (= 012Ch). The run command and speed

command via DeviceNet are enabled.

62 00 2C 01

Response: The motor is running backward (in the reverse direction) and accelerating. The actual speed is

increasing.

78 04 ** **

Request: Run reverse command. Speed command = 300 r/min (= 012Ch). The run command and speed

command via DeviceNet are enabled.

62 00 2C 01

Response: Running in the reverse direction. The actual speed has reached Reference

F8 04 2C 01

Request: Run reverse command. Speed command is changed to 1800 r/min (= 0708h). The run

command and speed command via DeviceNet are enabled.

62 00 08 07

Response: The motor is running backward (in the reverse direction) and accelerating. The actual speed is

increasing.

78 04 ** **

Request: Run reverse command. Speed command = 1800 r/min (= 0708h). The run command and speed

command via DeviceNet are enabled.

62 00 08 07

Response: Running in the reverse direction. The actual speed has reached Reference

F8 04 08 07

Request: Run command is OFF. Speed command = 1800 r/min (= 0708h). The run command and speed

command via DeviceNet are enabled.

60 00 08 07

Response: The motor is running backward (in the reverse direction) and decelerating. The actual speed is

decreasing.

78 05 ** **

25

Page 28

7.4 I/O Assembly Instances Assigned to Word Variables (For reference)

Some masters assign an I/O assembly instance area to a word variable. Shown below are the formats for each

I/O assembly instance assigned to a word variable. For details about the definition of bits in the formats, refer to

Section 7.2, "I/O ASSEMBLY INSTANCES: SELECTION AND SETUP."

(1) Basic Speed Control Instance

Output (from master to this option): o31=20

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 - - - - - - - - - - - - - Fault

1 Speed Reference (r/min)

Reset

- Run

Forward

Input (from this option to master): o32=70

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 - - - - - - - - - - - - - Running

1 Speed Actual (r/min)

Forward

- Faulted

(2) Extended Speed Control Instance

Output (from master to this option): o31=21

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 - - - - - - - - - Net

1 Speed Reference (r/min)

Ref

Net

Ctrl

- - Fault

Reset

Run

Reverse

Run

Forward

Input (from this option to master): o32=71

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 - - - - - - - - At

Reference

1 Speed Actual (r/min)

*2 *1 Ready Running

Reverse

Running

Forward

- Faulted

*1 CtrlFromNet

*2 RefFromNet

(3) Fuji Drive Assembly Instance

Output (from master to this option): o31=100

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 RST XR XF - - - - - - X5 X4 X3 X2 X1 REV FWD

1 Frequency command p.u.

Input (from this option to master): o32=101

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 BUSY ERR - RL ALM DEC ACC IL VL TL NUV BRK INT EXT REV FWD

1 Frequency command p.u.

26

Page 29

(4) User Defined Assembly Instance

Output (from master to this option): o31=102

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 User-defined function code 1 (write) (data of function code specified by o40)

1 User-defined function code 2 (write) (data of function code specified by o41)

2 User-defined function code 3 (write) (data of function code specified by o42)

3 User-defined function code 4 (write) (data of function code specified by o43)

Input (from this option to master): o32=103

word

bit15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 bit0

0 User-defined function code 1 (read) (data of function code specified by o48)

1 User-defined function code 2 (read) (data of function code specified by o49)

2 User-defined function code 3 (read) (data of function code specified by o50)

3 User-defined function code 4 (read) (data of function code specified by o51)

27

Page 30

Chapter 8 EXPLICIT MESSAGE

8.1 Overview

Explicit Message is a communication process that accesses DeviceNet variables at arbitrary (event-driven)

timing. Using this option is capable of accessing not only standard DeviceNet variables but also all inverter's

function codes. Explicit Message lacks realtime performance, but it allows many variables to be set or referred

to. It is, therefore, suited for initial setting.

Refer to the user's manual of the connected master for Explicit Message.

- Variables usable in Explicit Message are grouped using three codes--Class (major key), Instance

(medium key) and Attribute (minor key). These three codes should be used for specifying a variable.

- A group of all variables contained in Class is called "Object."

8.2 Objects to be Used in Explicit Message

This section describes objects relating to this option and the inverter. Other objects that are automatically

executed by the master device are excluded in this manual.

(1) Identity object (Class 01 hex.)

This object refers to the product information of this option. It is a group of read-only variables.

Instance Attribute Name Description Value (hex.) R/W Data size

0 01 Revision Revision number of Identity

1 01 Vender ID Manufacturer's ID code 013F (=319):

02 Device Type Applied device profile 0002: AC drive R Word

03 Product Code ID code of this option 2402 R Word

04 Revision Software version

05 Status Status of this option Depends on DeviceNet

06 Serial Number Serial number of the product Differs with the product. R DWord

07 Product Name Model name

object

(Major and minor versions)

0001 R Word

Fuji Electric

Display of version

Example: 01, 0A

(=Ver. 1.10)

specifications.

OPC-E1-DEV R 11 bytes

R Word

R Byte,

R Word

Byte

(2) Motor Data object (Class 28 hex.)

This object refers to and sets up the motor rated current and voltage. When Motor 2 is selected, this object

automatically switches to the one for Motor 2.

Instance Attribute Name Description Value (hex.) R/W Data size

0 01 Revision Revision number of Motor

1 03 Motor Type Type of motor connected 07: Squirrel-cage,

06 Rated

07 Rated

Current

Voltage

Data object

Rated current in units of 0.1 A Depends on the

Rated voltage in units of 1 V

(base voltage)

0001 R Word

induction motor

inverter setting.

Depends on the

inverter setting.

R Byte

R/W Word

R/W Word

28

Page 31

(3) Control Supervisor object (Class 29 hex.)

This object monitors the current run command settings and the running status of the inverter, and configures the

running-related settings.

Instance Attribute Name Description Value (hex.) R/W Data size

0 01 Revision Revision number of Control

1 03 Run1 Run forward command 00: OFF

04 Run2 Run reverse command 00: OFF

05 NetCtrl Switching run command

06 State Current inverter status 01: Inverter running

07 Running1 Running forward 00: Stopped/Running

08 Running2 Running reverse 00: Stopped/Running

09 Ready Inverter ready to run/Inverter

0A Faulted Tripped state 00: Not tripped

0B Warning Warning. Fixed at 0. 00: No warning R Byte

0C FaultRst Reset of tripped (alarm) state 00→01: Request for

0F CtrlFromNet Current run command source 00: Inverter

10 DNFaultMode Inverter reaction to DeviceNet

Supervisor object

source

running

(Synchronized with State

above)

communications errors

0001 R Word

01: ON

01: ON

00: Inverter

01: DeviceNet

02: Inverter not ready

to run

03: Inverter ready to

run

04: Inverter running

05: During

deceleration

06: Stop due to

communication

broken

07: Tripped

reverse

01: Running forward

forward

01: Running reverse

00: State = Value

except below

01: State = 03 to 05

01: Tripped

reset

01: DeviceNet

Refer to Chapter 9. R/W Byte

R/W Byte

R/W Byte

R/W Byte

R Byte

R Byte

R Byte

R Byte

R Byte

R/W Byte

R Byte

29

Page 32

(4) AC/DC Drive object (Class 2A hex.)

This object monitors the current speed command settings and the current speed of the inverter, and configures

their related settings. It also monitors the output data issued from the inverter.

Instance Attribute Name Description Value (hex.) R/W Data size

0 01 hex Revision Revision number of AC/DC

Drive object

1 03 hex AtReference Speed arrival 00: Stopped/

0001 R Word

Accelerating or

decelerating

R Byte

01: Speed arrival

04 hex NetRef Switching speed command

source

00: Inverter

01: DeviceNet

R/W Byte

06 hex DriveMode Run mode. Fixed at 0. 00: Unique to vendor R Byte

07 hex SpeedActual Speed monitor (r/min) Actual speed R Word

08 hex SpeedRef Speed command (r/min) -32768 to 32767 r/min R/W Word

09 hex CurrentActual Output current

Output current R Word

(in units of 0.1 A)

11 hex OutputVoltage Output voltage (V) Output voltage R Word

12 hex AccelTime Acceleration time (ms) 0 to 65535 ms R/W Word

13 hex DeccelTime Deceleration time (ms) 0 to 65535 ms R/W Word

14 hex LowSpdLimit Lower limit speed (r/min) 0 to 32767 r/min R/W Word

15 hex HighSpdLimit Maximum speed (r/min) 0 to 32767 r/min R/W *1Word

16 hex SpeedScale Change the speed scale

17 hex CurrentScale Change the current scale

1B hex VoltageScale Change the voltage scale (V)

1C hex TimeScale Change the time scale (ms)

(r/min) all at once, as

calculated below.

r/min

SpeedScale

2

(0.1 A) all at once, as

calculated below.

A0.1

leCurrentSca

2

all at once, as calculated

below.

V

leVoltageSca

2

all at once, as calculated

-15 to 15

(Factory default: 0)

-15 to 15

(Factory default: 0)

-15 to 15

(Factory default: 0)

-15 to 15

(Factory default: 0)

R/W Byte

R/W Byte

R/W Byte

R/W Byte

below.

ms

TimeScale

2

1D hex RefFromNet Current speed command

1

*

"Read-only" while the inverter is running.

source

00: Inverter

01: DeviceNet

R Byte

30

Page 33

(5) Inverter Function Code object (Class 64 hex.)

This object configures or refers to inverter's function codes.

Instance corresponds to function code group and Attribute, to function code number.

Example: To configure F26 data, specify 04 hex for Instance and 1A hex (=26) for Attribute.

Inverter's function codes have individually specified data formats. For details about the data formats, refer

to the RS-485 Communication User's Manual (MEH448), Chapter 5 "Function Codes and Data Formats."

For details about function code data, refer to the FRENIC-Multi Instruction Manual (INR-SI47-1094-E),

Chapter 5, "Function Codes."

Instance Attribute Name Description Value (hex.) R/W Data size

00 01 Revision Revision number of Inverter

0001 R Word

Function Code object

02 01 S01 Communication function code S01 0 to FFFF R/W Word

(S codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) S99 Communication function code S99 0 to FFFF R/W Word

03 01 M01 Communication function code M01 0 to FFFF R Word

(M codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) M99 Communication function code M99 0 to FFFF R Word

04 01 F01 Inverter function code F01 0 to FFFF R/W Word

(F codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) F99 Inverter function code F99 0 to FFFF R/W Word

05 01 E01 Inverter function code E01 0 to FFFF R/W Word

(E codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) E99 Inverter function code E99 0 to FFFF R/W Word

06 01 C01 Inverter function code C01 0 to FFFF R/W Word

(C codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) C99 Inverter function code C99 0 to FFFF R/W Word

07 01 P01 Inverter function code P01 0 to FFFF R/W Word

(P codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) P99 Inverter function code P99 0 to FFFF R/W Word

08 01 H01 Inverter function code H01 0 to FFFF R/W Word

(H codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) H99 Inverter function code H99 0 to FFFF R/W Word

09 01 A01 Inverter function code A01 0 to FFFF R/W Word

(A codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) A99 Inverter function code A99 0 to FFFF R/W Word

0A (10) 01 o01 Option function code o01 0 to FFFF R/W Word

(o codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) o99 Option function code o99 0 to FFFF R/W Word

0E (14) 01 J01 Inverter function code J01 0 to FFFF R/W Word

(J codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) J99 Inverter function code J99 0 to FFFF R/W Word

31

Page 34

Instance Attribute Name Description Value (hex.) R/W Data size

0F (15) 01 y01 Inverter function code y01 0 to FFFF R/W Word

(y codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) y99 Inverter function code y99 0 to FFFF R/W Word

10 (16) 01 W01 Communication function code W01 0 to FFFF R Word

(W codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) W99 Communication function code W99 0 to FFFF R Word

11 (17) 01 X01 Communication function code X01 0 to FFFF R Word

(X codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) X99 Communication function code X99 0 to FFFF R Word

12 (18) 01 Z01 Communication function code Z01 0 to FFFF R Word

(Z codes)

:

:

:

:

:

:

:

:

:

:

:

:

63 hex (99) Z99 Communication function code Z99 0 to FFFF R Word

32

Page 35

8.3 Error Code List for Explicit Message Errors

If an explicit message sent from the master contains any error, this option responds to the master with "94" in

the service code and "error code" (see Table 8.1) in the data.

An error code is two bytes long, consisting of a general code and additional code. Some error codes have no

additional code and have "FF" instead.

Table 8.1 Error Code List for Explicit Message Errors

Error code

General

Additional

code

08 FF Service not supported Invalid service code Correct service code.

0E FF Invalid attribute value Attempted to change a

13 FF Not enough data Attempted to write Byte

14 FF Attribute not supported Access to a nonexistent

15 FF Too much data Attempted to write Word

16 FF Object does not exist Access to a nonexistent

1F See blow. Vender specific error Error unique to vendor See below.

20 FF Invalid parameter Attempted to write a value

code

02 No function code

03 Function code not

06 Not allowed to change

07 Not allowed to change

08 Data entry range error Attempted to write data out

0F Function code data

21 No function code

Error name Description Error recovery

(Read: 0E hex, Write:10 hex)

Check the specified variable

again.

Match the data size.

Check the specified variable

again.

Match the data size.

Correct the contents of the

Class.

Correct the function code

number specified.

Correct the function code

number specified.

Write after the inverter is

stopped.

Write after the X terminal is

turned OFF.

Write data within the range.

Request to write after

completion of the current writing

operation.

Correct the function code

number specified.

Correct the value within the

range.

(in writing)

allowed to change

in running

with X terminal being

ON

being written

(in reading)

write-inhibited variable.

data to Word variable.

variable.

data to Byte variable.

object.

Attempted to write to a

nonexistent function code.

Attempted to write to a

read-only function code.

Attempted to write to a

function code not allowed to

change when the inverter is

running.

Attempted to write to a

function code not allowed to

change when X terminal is

ON.

of the range.

Requested to write to a

function code being written.

Attempted to read from a

nonexistent function code.

out of the range.

33

Page 36

Chapter 9 INVERTER REACTION TO DeviceNet COMMUNICATIONS ERRORS

Inverter's function codes o27 and o28 specify the inverter reaction to be taken after an error occurrence. Table

9.1 lists the settings for o27 and o28. The same setting can also be made by the DeviceNet variable

DNFaultMode (Class: 0x29, Instance: 0x01, Attribute: 0x10).

Table 9.2 lists the inverter reaction specified by the DNFaultMode. The setting value of o27 and that of

DNFaultMode are interlocked with each other. Changing either one automatically changes the other one.

Table 9.1 Inverter Reactions to DeviceNet Communications Errors Specified by Function Codes o27 and o28

o27 data o28 data Inverter reaction to DeviceNet communications error Remarks

0,

4 to 9

1 0.0 s to 60.0 s

2 0.0 s to 60.0 s

3,

13 to 15

10 ---

11 0.0 s to 60.0 s

12 0.0 s to 60.0 s

13 ---

14 ---

15 ---

---

---

er5

er5

er5

trip)

.

.

er5

.

Immediately coast to a stop and trip with

After the time specified by o28, coast to a stop and trip

er5

.

with

If the communications link is restored within the time

specified by o28, ignore the communications error. After

the timeout, coast to a stop and trip with

Keep the current operation, ignoring the communications

error. (No

er5

trip)

Immediately decelerate to a stop.

Issue

er5

after stopping.

After the time specified by o28, decelerate to a stop. Issue

er5

after stopping.

If the communications link is restored within the time

specified by o28, ignore the communications error. After

the timeout, decelerate to a stop and trip with

Immediately run command OFF. (No

Force to rotate the motor in forward direction.

er5

trip)

(No

Force to rotate the motor in reverse direction.

er5

trip)

(No

Table 9.2 Inverter Reactions to DeviceNet Communications Errors Specified by DNFaultMode

DNFaultMode Inverter reaction to DeviceNet communications error Remarks o27 data

0 Immediately run command OFF. (No

1 Ignore the communications error. (No

If the communications link is restored within the time

2

specified by o28, ignore the communications error. After

the timeout, decelerate to a stop and trip with

Force to rotate the motor in forward direction.

3

(No

er5

trip)

Force to rotate the motor in reverse direction.

4

(No

er5

trip)

100

101

102

110

111

112 Same as for [DNFaultMode = 2] 12

Immediately coast to a stop and trip with

After the time specified by o28, coast to a stop and trip

with

er5

.

If the communications link is restored within the time

specified by o28, ignore the communications error. After

the timeout, coast to a stop and trip with

Immediately decelerate to a stop.

Issue

er5

after stopping.

After the time specified by o28, decelerate to a stop.

Issue

er5

after stopping.

er5

trip) 13

er5

trip) 3

The inverter's function code

F08 specifies the deceleration

time.

..

Forward rotation is enabled

when NetCtrl = 1.

Reverse rotation is enabled

when NetCtrl = 1.

The inverter's function code

F08 specifies the deceleration

time.

Same as above. 11

er5

er5

er5

.

.

The inverter's function code

F08 specifies the

deceleration time.

Same as above.

Same as above.

Forward rotation is enabled

when NetCtrl = 1.

Reverse rotation is enabled

when NetCtrl = 1.

12

14

15

0

1

2

10

34

Page 37

Chapter 10 ALARM CODE LIST

The information on alarms that have occurred in the inverter can be monitored through DeviceNet.

They are stored in the inverter's function codes M16 to M19 as listed in Table 10.1.

The communication dedicated function codes M16 to M19 store information on the current alarm code, most

recent alarm code, 2nd recent alarm code, and 3rd recent alarm code, respectively.

Table 10.1 Alarm Codes

Alarm codes

in M16 to M19

0 No alarm --- 22 Braking resistor overheated

Overcurrent

1

(during acceleration)

Overcurrent

2

(during deceleration)

Overcurrent

3

(During running at constant

speed)

5 Ground fault

Overvoltage

6

(during acceleration)

Overvoltage

7

(during deceleration)

Overvoltage

8

(during running at constant

speed (stopped))

10 Undervoltage

11 Input phase loss

14 Fuse blown

16 Charger circuit fault

17 Heat sink overheat

18

19 Inverter overheat

20

Alarm issued by an external

device

Motor protection

(PTC thermistor)

Description

0c1

0c2

0c3

ef

0u1

0u2

0u3

lu

lIn

fus

pbf

0h1

0h2

0h3

0h4

Alarm codes

in M16 to M19

23 Motor 1 overload

24 Motor 2 overload

25 Inverter overload

31 Memory error

32 Keypad communications error

33 CPU error

34

35

36 Operation protection

37 Tuning error

38 RS-485 communications error

46 Output phase loss

51

53

54

Interface option

communications error

DeviceNet communications

error

Data saving error during

undervoltage

RS-485 communications error

(option card)

LSI error

(Power printed circuit board)

Description

dbh

0l1

0l2

0lu

er1

er2

er3

er4

er5

er6

er7

er8

0pl

erf

erp

erh

35

Page 38

Chapter 11 TROUBLESHOOTING

If any problem or error occurs during DeviceNet communication, follow the troubleshooting procedures given

below.

No Phenomenon/Symptom Probable Causes

None of the LEDs on the

1

option would light.

er4

2

3

4

5 The NS LED would not light.

6

7

8

alarm cannot be reset

(The MS LED lights in red).

The NS LED lights in red.

(

er5

alarm cannot be reset.)

The NS LED blinks in red.

er5

alarm has occurred.)

(

The NS LED keeps blinking in

green and does not come to

stay on in green.

Even though the NS LED

lights in green, the settings for

run command or speed

command cannot be

validated.

Although the speed command

has been validated, the actual

speed is different from it.

• No 24 VDC power supply is connected to this option.

• The option is faulty.

• The option is not properly mounted.

• The option connection cable is not connected.

• The option is faulty.

• The same node address is double assigned in DeviceNet.

• There is a mismatch in baud (data) rate.

• The network power (24 V) is not properly supplied.

• Cabling for DeviceNet communications is not properly done.

• The inverter and the option have not been powered OFF and

then ON after modifying the DIP switch settings.

• The cable was broken during communication.

• The I/O scan interval is too short.

• The node address for the option is improper.

• The cable for DeviceNet communications was broken.

• The master does not request a connection.

• The I/O scan interval has been set to be too short at the start of

communication.

• The I/O area is invalidly mapped.

• There is no I/O connection.

• Neither NetCtrl nor NetRef is set to "1."

• On the inverter, the higher-priority run command or speed

command is enabled.

• There is a mistake in the selection of I/O Assembly Instances.

• The inverter and the option have not been powered OFF and

then ON after modifying the o31 data.

• Refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E), Section 6.2.1 "Motor is running abnormally."

36

Page 39

Chapter 12 SPECIFICATIONS

12.1 General Specifications

For the items not covered in this section, the specifications of the inverter apply.

Item Specifications

Power input voltage 21.6 to 27.0 V

Input power 35 mA at maximum (24 VDC) (not included network input power)

Operating ambient temperature range -10 to +50°C

Operating ambient humidity range 5 to 95% RH (There shall be no condensation.)

External dimensions 79.6 x 127 x 47.5 mm

Applicable inverter FRENIC-Multi, ROM version: 0700 or later

12.2 DeviceNet Specifications

For the items not covered in this section, the DeviceNet Specifications Release 2.0 apply.

Item Specifications

Network input voltage 11 to 28 V

Network power consumption 75 mA at maximum (24 VDC)

No. of nodes connected 64 at maximum (including the master)

MAC ID 0 to 63