Page 1

High Performance Compact Inverters

MEH531

Page 2

With advanced technology built in, these new

Gentler on the environment

!

Complies with European regulations that limit the use of specific hazardous substances (RoHS).

These inverters are gentle on the environment.

Use of 6 hazardous substances is limited.(except for

interior soldering in the power module.)

<Six Hazardous Substances>

Lead, Mercury, Cadmium, Hexavalent Chromium,

Polybrominated biphenyl (PBB), Polybrominated

diphenyl ether (PBDE)

<About RoHS>

The Directive 2002/95/EC, promulgated by the

European Parliament and European Council, limits

the use of specific hazardous substances included in

electrical and electronic devices.

Long-life design!

The design life of each

internal component with

limited life has been

extended to 10 years.

This helps to extend the

maintenance cycle for

your equipment.

Limited Life Component Service Life

Main circuit capacitors 10 years

Electrolytic capacitors

on the printed circuit board

Cooling fan 10 years

Conditions: Ambient temperature is 40 C(104 F) and load

factor is 80% of the inverter's rated current.

10 years

Noise is reduced by the built-in EMC filter.

Use of a built-in EMC filter that reduces noise generated by

the inverter makes it possible to reduce the effect on

peripheral equipment.

Expanded capacity range and abundant model variation

●Standard Series

Input power

supply

3-phase

230V

3-phase

460V

1-phase

230V

●Semi-Standard type

●

EMC filter built-in type

●Option card

●

PG interface card (5V type)(12V type)

●

RS-485 communication card

●

Synchronized operation card

●

Device Net card

●

Profibus-DP card

●

DIO card

●

CC-Link card

1/8 1/4 1/2 1 32107.551520

Nominal applied motor (HP)

!

Capacity

expanded

to 20HP

Page 3

inverters can be used for multiple purposes

!

The highest standards of control and performance in its class

Shortened setting time in slip compensation control

Through "slip compensation control" + "voltage tuning," speed

control accuracy at low speeds is improved. This minimizes

variations in speed control accuracy at times when the load

varies, and since the time at creep speeds is shortened,

single cycle tact times can be shortened.

Rotational

speed

Load

torque

Current

200ms

500r/min

Time

200%

Speed

Creep speed

0

Variations according to load

Conveying distance

Equipped with the highest level CPU for its class!

The highest level CPU of any inverter is used. Computation

and processing capacity is doubled over the previous

inverter, improving speed control accuracy.

●CPU speed comparison

32MHz

64MHz

has doubled processing

capacity compared with

the previous model.

<Example of conveyor operation pattern>

Speed

0

■

Improved speed control accuracy

improves conveyor positioning

accuracy.

■

Positioning time can be shortened.

■

Improves measuring accuracy on a

scale.

The inverter controls the

energy level generated

and the deceleration time,

and so deceleration stop

can be accomplished

without tripping due to

overvoltage.

!

Specifications

Compatible with PG feedback control

■ Without speed feedback

The speed just before positioning

varies, so positioning accuracy drops.

Conveying distance

■ With speed feedback

The speed just before positioning is

stabilized, and so positioning accuracy

is improved.

Tripless deceleration by automatic deceleration control

ON

Run

command

Rotational

speed

DC link

bus voltage

Current

OFF

1500r/min

50V

400ms

20A

Load: Small

Load: Large

540V

External

Dimensions

Keypad

Operations

Basic

Wiring Diagram

Terminal

Functions

Functions

Protective

Optimum for the operations specific to vertical and horizontal conveyance

Hit-and-stop control is realized more easily!

Impacts are detected mechanically and not only can the

inverter's operation pattern be set on coast-to-stop or

deceleration stop, but switching from torque limitation to

current limitation and generating a holding torque (hit-andstop control) can be selected, making it easy to adjust brake

application and

release timing.

2s

Current

Rotational

speed

Holding torque generation

Time

10A

600r/min

Time

Settings

Functions

!

Connection Diagrams

Inclusion of a brake signal makes it even more convenient.

■ At brake release time

After the motor operates, torque generation is detected and

signals are output.

■ At brake application time

Brake application that matches the timing can be done,

and so mechanical brake wear is reduced.

Limit operations can be selected to match your equipment!

Inverters are equipped with two limit operations, "torque

limitation" and "current limitation," so either can be selected to

match the equipment you are using the inverter with.

■ Torque limitation

In order to protect mechanical systems, this function

accurately limits the torque generated by the motor.

(Instantaneous torque cannot be limited.)

■ Current limitation

This function limits the current flowing to the motor to

protect the motor thermally or to provide rough load

limitation. (Instantaneous current cannot be limited. Auto

tuning is not required.)

Peripheral Equipment

Options

Warranty

Page 4

Simple and thorough maintenance

!

The life information on each of the inverter's limited life components is displayed.

Main circuit capacitor capacity

Cumulative running time of the electrolytic

capacitor on the printed circuit board.

Simple cooling fan replacement!

Construction is simple, enabling quick removal of the top

cover and making it easy to replace the cooling fan. (7.5HP or

higher models)

Cooling fan replacement procedure

The cover on top of the inverter can

be quickly removed.

Simply disconnect the power

connector and replace the cooling

fan.

Simple operation, simple connection

Cooling fan cumulative running time

Inverter cumulative running time

Information that contributes to equipment maintenance is displayed!

In addition to inverter maintenance information, data that also

take equipment maintenance into consideration are displayed.

Item

Motor

cumulative

running

time (hr)

Number

of starts

(times)

The actual cumulative running time of the equipment (motor) the

inverter is being used with is calculated.

<Example of use>

If the inverter is used to control a fan, this information is an indication

of the timing for replacing the belt that is used on the pulleys.

The number of times the inverter starts and stops can be counted.

<Example of use>

The number of equipment starts and stops is recorded, and so this

information can be used as a guideline for parts replacement timing

in equipment in which starting and stopping puts a heavy load on the

machinery.

Purpose

The alarm history records the latest four incidents.

Detailed information can be checked for the four most recent

alarms.

!

A removable keypad is standard equipment.

The keypad can be

easily removed and

reset, making remote

operation possible. If the

back cover packed with

the inverter is installed and

a LAN cable is used, the

keypad can be easily mounted

on the equipment's control

panel.

A removable interface card is adapted.

Wiring is quite easy

because the interface card

can be attached and

detached as a terminal

base for control signals.

The following option cards

are available.

Option card names

RS-485 communication card

PG interface card (for 5V)

PG interface card (for 12V)

CC-Link card

DeviceNet card

DIO card

SY (synchronized operation) card

PROFIBUS-DP card

Note) The inverter that can be used with the SY card includes special

specifications. When ordering the SY card, please order together

with the inverter in a set.

Built in the inverter (replaced with the standard interface card)

Built in the inverter (replaced with the standard interface card)

Built in the inverter (replaced with the standard interface card)

Front installation type

Front installation type

Front installation type

Front installation type

Front installation type (Available soon)

Installation method

A multi-function keypad which enables a wide variety of operations is available.

A multi-function keypad is available as an

option. This keypad features a large 7-segment

LED with five digits and large back-lighted liquid

crystal panel. Its view-ability is high, and

guidance is displayed on the liquid crystal panel,

therefore operations can be conducted simply. (A

copy function is included.)

Inverter support loader software is available.

Windows compatible loader software is available to simplify

the setting and management of function codes.

RS-485 communications

(RJ-45 connector)

USB/RS-485 converter

(made by System

Sacom Sales Corp.)

USB cable

(supplied with the converter)

Personal computer

(On sale soon)

Simulated failure enables peripheral device operation checks.

The inverter has the function for outputting dummy alarm

signals, enabling simple checking of sequence operations of

peripheral devices from the control panel where the inverter is

used.

Page 5

Consideration of peripheral equipment, and a full range of protective functions!

Side-by-side mounting saves space!

If your control panel is designed to use multiple inverters,

these inverters make it possible to save space through their

horizontal side-by-side installation. (5HP or smaller models)

!

Resistors for suppressing inrush current are built in, making it

possible to reduce the capacity of peripheral equipment.

When FRENIC-Multi Series (including FRENIC-Mini Series,

FRENIC-Eco Series and 11 Series) is used, the built-in resistor

suppresses the inrush current generated when the motor starts.

Therefore, it is possible to select peripheral equipment with

lower capacity when designing your system than the equipment

needed for direct connection to the motor.

4.72(120)

3.15(80) 3.15(80) 3.15(80)

(The 3-phase 230V, 1HP

model is shown here.)

unit:inch(mm)

Outside panel cooling is also made possible using

the mounting adapter for external cooling (option).

The mounting adapter for external cooling (option) can be

installed easily as an outside panel cooling system.

You can use an inverter equipped with functions like these

First time in

the industry

New system for more energy-efficient operation!

Previous energy saving operation functions worked only to

control the motor's loss to keep it at a minimum in accordance

with the load condition. In the newly developed FRENIC-Multi

Series, the focus has been switched away from the motor

alone to both the motor and the inverter as electrical products.

As a result, we incorporated a new control system (optimum

and minimum power control) that minimizes the power

consumed by the inverter itself (inverter loss) and the loss of

the motor.

Previous

Power

supply

Optimum

motor

control

Way of thinking concerning power used

Power

supply

New control system (FRENIC-Multi)

Optimum

control of the

entire system

Smooth starts through the pick-up function!

In the case where a fan is not

being run by the inverter but

is turning free, the fan's

speed is checked, regardless

of its rotational direction, and

operation of the fan is picked

up to start the fan smoothly.

This function is convenient in

such cases as when

switching instantaneously

from commercial power

supply to the inverter.

Power

supply

voltage

Rotational

speed

Output

frequency

Current

Instantaneous power cut

500ms

1500r/min

50Hz

20A

Equipped with a full range of PID control functions!

Differential alarm and absolute value alarm outputs have been

added for PID adjusters which carry out process controls such as

temperature, pressure and flow volume control. In addition, an

anti-reset windup function to prevent PID control overshoot and

other PID control functions which can be adjusted easily through

PID output limiter, integral hold/reset signals are provided. The

PID output limiter and integral hold/reset signals can also be

used in cases where the inverter is used for dancer control.

Operating signal trouble is avoided by the command loss detection function!

If frequency signals connected to the inverter (0 to 10V, 4 to

20mA, Multi-speed signals, communications, etc.) are

interrupted, the missing frequency commands are detected as a

"command loss." Further, the frequency that is output when

command loss occurs

can be set in

advance, so operation

can be continued

even in cases where

the frequency signal

lines are cut due to

mechanical vibrations

of the equipment, etc.

If the load on equipment

suddenly becomes great

while controlled by the

inverter, the inverter can

be switched to

deceleration stop or to

coast-to-stop operation to

prevent damage to the

equipment.

If foreign matter gets wrapped around a fan or pulley and the

load increases, resulting in a sudden temperature rise in the

inverter or an abnormal rise in the ambient temperature, etc.

and the inverter becomes overloaded, it reduces the motor's

speed, reducing the load and continuing operation.

!

400ms

f1

Analog frequency

command

Command loss

detection

"REF OFF"

Output frequency

x

f1

0.1

f1

x

E65

f1

x

0.1

f1

0

An overload stop function protects equipment from over-operation!

Detection

level

Load

0

Operation

frequency

0

Continuous equipment operation with overload avoidance control!

Load state

Inverter temperature

Output frequency

0

OH trip

f1 x E65

ON

Correct frequency setting

Time

Timer

Deceleration stop Coast-to-stop

Time

Page 6

Fully compatible with network operation

!

RS-485 communications (connector) is standard!

A connector (RJ-45) that is compatible with RS-485

communications is standard equipment (1 port, also used for

keypad communications), so the inverter can be connected

easily using a LAN cable (10BASE).

RJ-45 Connector

Wiring is easy with the RS-485 communications card (optional)!

The RS-485 communications card is also available as an

option. When it is installed, you can add a branch connection

that is separate from the communications port provided as

standard equipment (RJ-45 connector), and have two

communications ports.

■

Example of connection configuration with peripheral equipment

Complies with optional networks using option cards.

Installation of special interface cards (option) makes it possible

to connect to the following networks.

●

DeviceNet

●

PROFIBUS-DP

●

CC-Link

POD

■ Important Points

(1) A separate branch adaptor is

not required because of two

ports.

The built-in terminating resistor

(2)

makes provision of a separate

terminating resistor unnecessary.

Global compatibility

Europe North America/Canada

Safety

Precautions

UL Standard (cUL Certified)EC Directives (CE Mark)

1. Use the contents of this catalog only for selecting product types and models. When using a product, read the

Instruction Manual beforehand to use the product correctly.

2. Products introduced in this catalog have not been designed or manufactured for such applications in a system

or equipment that will affect human bodies or lives. Customers, who want to use the products introduced in this

catalog for special systems or devices such as for atomic-energy control, aerospace use, medical use, and

traffic control, are requested to consult the Fuji's Sales Division. Customers are requested to prepare safety

measures when they apply the products introduced in this catalog to such systems or facilities that will affect

human lives or cause severe damage to property if the products become faulty.

!

● Complies with standards

● Sink/Source switchable

● Wide voltage range

● The multi-function keypad displays multiple languages (Japanese,

English, German, French, Spanish, Italian, Chinese, Korean).

* This product supports multiple languages such as Japanese, English, German,

French, Spanish and Italian. Another multiple language version is also available,

which supports Japanese, English, Chinese, Korean and simplified Chinese.

(Contact us for the detail separately.)

Page 7

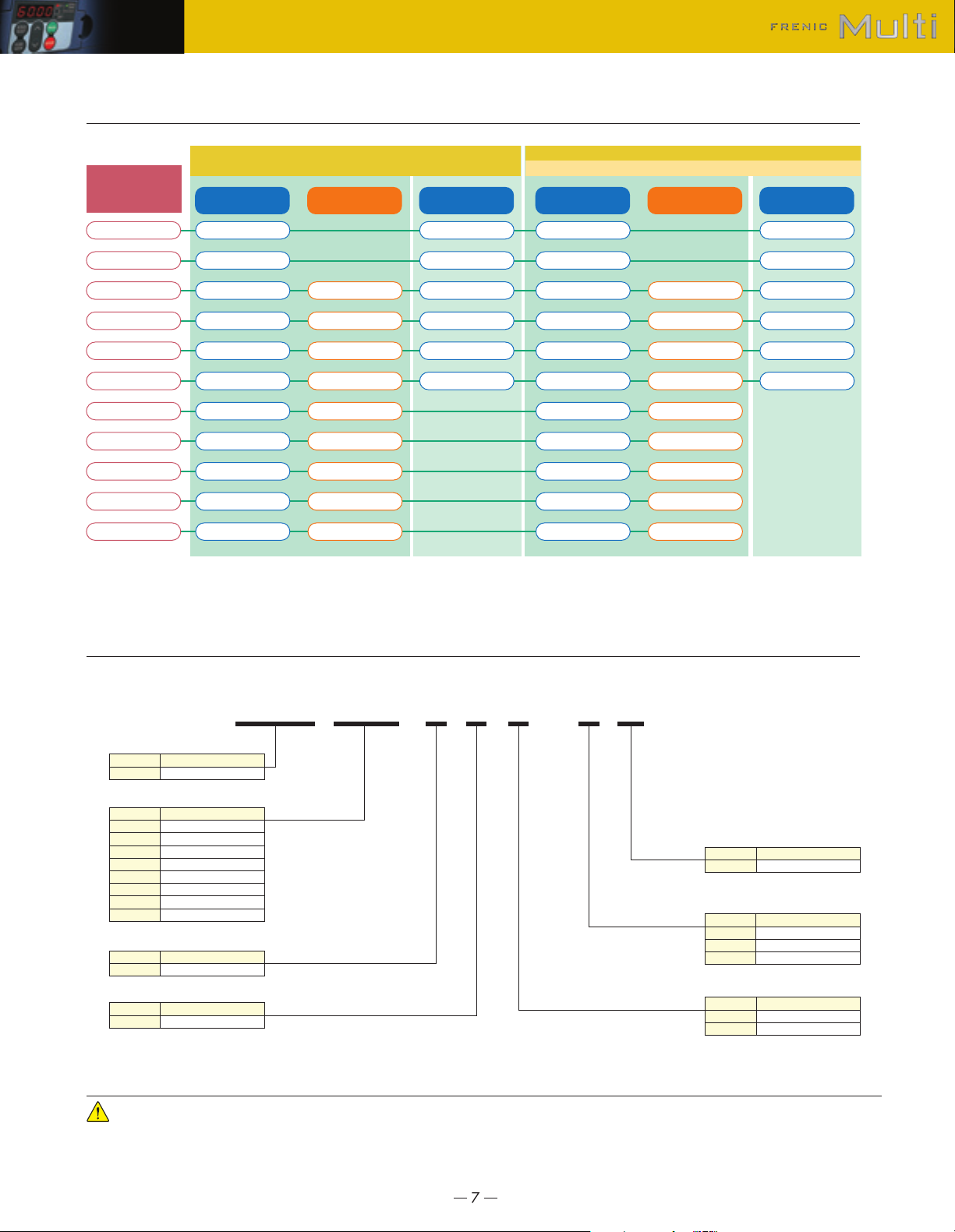

Variation

Model List

Applicable motor

(HP)

rating

1/8

1/4

1/2

1

2

3

5

7.5

10

15

20

Three-phase

230V

FRNF12E1S-2U

FRNF25E1S-2U

FRNF50E1S-2U

FRN001E1S-2U

FRN002E1S-2U

FRN003E1S-2U

FRN005E1S-2U

FRN007E1S-2U

FRN010E1S-2U

FRN015E1S-2U

FRN020E1S-2U

Standard type

Three-phase

460V

FRNF50E1S-4U

FRN001E1S-4U

FRN002E1S-4U

FRN003E1S-4U

FRN005E1S-4U

FRN007E1S-4U

FRN010E1S-4U

FRN015E1S-4U

FRN020E1S-4U

Single-phase

230V

FRNF12E1S-7U

FRNF25E1S-7U

FRNF50E1S-7U

FRN001E1S-7U

FRN002E1S-7U

FRN003E1S-7U

EMC filter built-in type

Three-phase

230V

FRNF12E1E-2U

FRNF25E1E-2U

FRNF50E1E-2U

FRN001E1E-2U

FRN002E1E-2U

FRN003E1E-2U

FRN005E1E-2U

FRN007E1E-2U

FRN010E1E-2U

FRN015E1E-2U

FRN020E1E-2U

Semi-standard type

Three-phase

460V

FRNF50E1E-4U

FRN001E1E-4U

FRN002E1E-4U

FRN003E1E-4U

FRN005E1E-4U

FRN007E1E-4U

FRN010E1E-4U

FRN015E1E-4U

FRN020E1E-4U

Single-phase

230V

FRNF12E1E-7U

FRNF25E1E-7U

FRNF50E1E-7U

FRN001E1E-7U

FRN002E1E-7U

FRN003E1E-7U

How to read the inverter model

FRN 001 E 1 S - 2 U

Code

FRN

Code Applicable motor rating

F12

F25

F50

001

~

010

015

020

Code

E

Code1Developed inverter series

Series name

FRENIC series

1/8HP

1/4HP

1/2HP

1HP

~

10HP

15HP

20HP

Application range

High performance/Compact

Series

CodeUDestination, Instruction manuals

North America / Canada

2

4

7

S

E

Input power source

Three-phase 230V

Three-phase 460V

Single-phase 230V

Enclosure

Standard type (IP20)

EMC filter built-in type

Code

Code

Caution The contents of this catalog are provided to help you select the product model that is best for you. Before actual use, be sure to read the User's Manual

thoroughly to assure correct operation.

Page 8

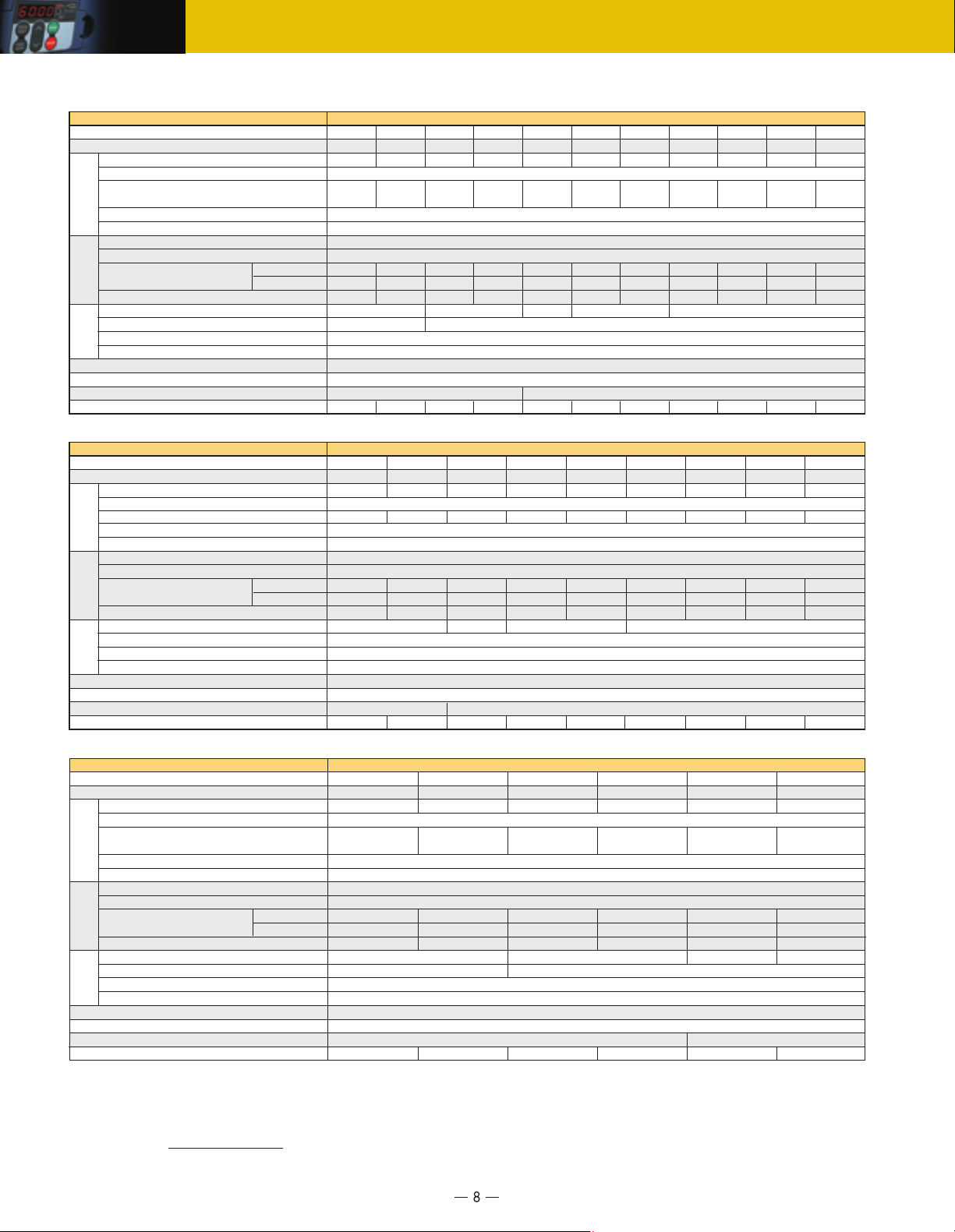

Specifications

●Standard type

■Three-phase 230V (1/8 to 20HP)

Type (FRN

Applicable motor rating [HP] (*1)

Rated capacity [kVA] (*2)

Rated voltage [V] (*3)

Rated current [A] (*4)

Overload capability

Output ratings

Rated frequency [Hz]

Phases, voltage, frequency

Voltage/frequency variations

Rated current [A] (*9)

(without DCR)

Input powerBraking

Required power supply capacity [kVA] (*5)

Torque [%] (*6)

Torque [%] (*7)

DC injection braking

Braking transistor

Applicable safety standards

Enclosure (IEC60529)

Cooling method

Weight / Mass [lbs(kg)]

■Three-phase 460V (1/2 to 20HP)

Type (FRN

Applicable motor rating [HP] (*1)

Output ratings

Input powerBraking

Applicable safety standards

Enclosure (IEC60529)

Cooling method

Weight / Mass [lbs(kg)]

Rated capacity [kVA] (*2)

Rated voltage [V] (*3)

Rated current [A] (*4)

Overload capability

Rated frequency [Hz]

Phases, voltage, frequency

Voltage/frequency variations

Rated current [A] (*9)

(without DCR)

Required power supply capacity [kVA] (*5)

Torque [%] (*6)

Torque [%] (*7)

DC injection braking

Braking transistor

■Single-phase 230V (1/8 to 3HP)

Type (FRN

Applicable motor rating [HP] (*1)

Output ratingsInput powerBraking

Applicable safety standards

Enclosure (IEC60529)

Cooling method

Weight / Mass [lbs(kg)]

(*1) Fuji's 4-pole standard motor

(*2) Rated capacity is calculated by assuming the output rated voltage as 230V for three-phase 230V series and 460V for three-phase 460V series.

(*3) Output voltage cannot exceed the power supply voltage.

(*4) When setting the carrier frequency (F26) to 3 kHz or less. Use the current ( ) or below when the carrier frequency setting is higher than 4kHz and continuously operating at 100%.

(*5) Obtained when a DC REACTOR is used.

(*6) Average braking torque obtained when reducing the speed from 60Hz with AVR control OFF (Varies with the efficiency of the motor.)

(*7) Average braking torque obtained by use of external braking resistor (standard type available as option)

(*8) Voltage unbalance [%] =

Three-phase average voltage [V]

If this value is 2 to 3%, use AC REACTOR (ACR: option).

(*9) The value is calculated on assumption that the inverter is connected with a power supply capacity of 500kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50kVA) and %X is 5%.

Rated capacity [kVA] (*2)

Rated voltage [V] (*3)

Rated current [A] (*4)

Overload capability

Rated frequency [Hz]

Phases, voltage, frequency

Voltage/frequency variations

Rated current [A] (*9)

(without DCR)

Required power supply capacity [kVA] (*5)

Torque [%] (*6)

Torque [%] (*7)

DC injection braking

Braking transistor

Item Specifications

E1S-2U)

F12

1/8

0.3

F25

1/4

0.6

F50

1/2

1.2

001

1

2.0

002

2

3.2

003

4.4

Three-phase 200V to 240V (with AVR function)

0.8

1.5

(1.4)(0.7)

3.0

(2.5) (10)(7.0) (23.5)(16.5) (31) (57)(44)

5.0

(4.2)

8.0

11

150% of rated current for 1min, 200% - 0.5s

50, 60Hz

Three-phase, 200 to 240V, 50/60Hz

Voltage: +10 to -15% (Voltage unbalance (*8): 2% or less) Frequency: +5 to -5%

(with DCR)

1.1

0.2

0.93

1.8

0.3

1.6

3.1

0.6

3.0

5.3

1.1

5.7

9.5

2.0

13.2

0.57

150 100 70 2040

Starting frequency: 0.1 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100% of rated current

Built-in

UL508C, C22.2No.14, EN50178:1997

IP20, UL open type

Natural cooling

1.3(0.6)

1.3(0.6) 1.5(0.7) 1.8(0.8) 3.7(1.7) 3.7(1.7) 5.1(2.3) 7.5(3.4) 7.9(3.6) 13(6.1) 16(7.1)

Fan cooling

Item Specifications

E1S-4U)

F50

1/2

1.2

001

2.0

1

2

2.9

002

003

4.4

3

005

7.2

Three-phase 380V to 480V (with AVR function)

1.5 2.5 3.7 5.5 13 18 24 30

9.0

150% of rated current for 1min, 200% - 0.5s

50, 60Hz

Three-phase, 380 to 480V, 50/60Hz

Voltage: +10 to -15% (Voltage unbalance (*8): 2% or less) Frequency: +5 to -5%

(with DCR)

0.85

1.7

0.6

1.6

3.1

1.1

3.0

5.9

2.0

4.4

8.2

2.9

13.0

150

Starting frequency: 0.1 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100% of rated current

Built-in

UL508C, C22.2No.14, EN50178:1997

IP20, UL open type

Natural cooling

Fan cooling

2.4(1.1) 2.6(1.2) 3.7(1.7) 3.7(1.7) 5.1(2.3) 7.5(3.4) 7.9(3.6) 13(6.1) 16(7.1)

Item Specifications

E1S-7U)

F12

1/8

0.3

F25

1/4

0.6

F50

1/2

1.2

Three-phase 200V to 240V (with AVR function)

0.8

(0.7) (1.4) (2.5) (4.2) (7.0) (10)

1.5

150% of rated current for 1min, 200% - 0.5s

50, 60Hz

Single-phase, 200 to 240V, 50/60Hz

Voltage: +10 to -10%, Frequency: +5 to -5%

(with DCR)

1.1

1.8

0.3

2.0

3.3

0.4

3.5

5.4

0.7

150 100

-

Starting frequency: 0.1 to 60.0Hz, Braking level: 0 to 100% of rated current, Braking time: 0.0 to 30.0s

Built-in

UL508C, C22.2No.14, EN50178:1997

IP20, UL open type

Natural cooling

1.3(0.6) 1.3(0.6) 1.5(0.7) 2.0(0.9) 4.0(1.8) 5.3(2.4)

Max voltage [V] - Min voltage [V]

x 67 (IEC 61800-3)

3

5

7.3

4.9

8.3

2.9

005

5

6.8

17

14.0

22.2

4.9

150

001

1

2.0

6.4

9.7

1.3

007

7.5

10

10.6

17.3

7.4

007

7.5

10

25

21.1

31.5

7.4

150

010

10

13

33

28.8

42.7

10

010

10

14

14.4

23.2

10

204070100

002

2

3.2

8.0 113.0 5.0

11. 6

16.4

2.4

70 40

Fan cooling

015

15

19

21.1

33.0

15

015

15

19

47

42.2

60.7

15

020

20

24

60

57.6

80

20

020

20

24

28.8

43.8

20

003

3

4.4

17.5

24.8

3.5

Page 9

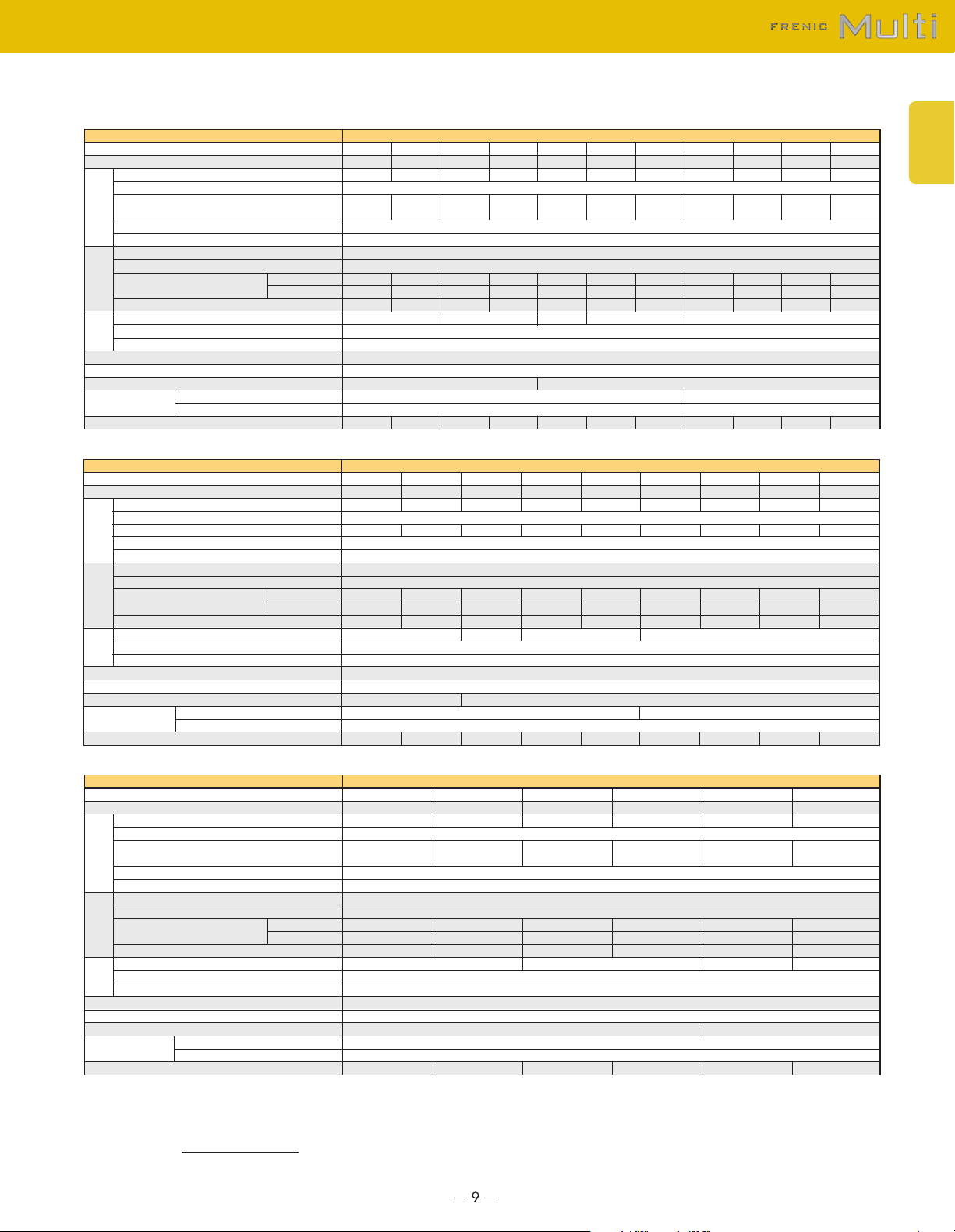

●Semi-standard type

EMC filter built-in type

■Three-phase 230V (1/8 to 20HP)

Type (FRN

Nominal applied motor [HP] (*1)

Rated capacity [kVA] (*2)

Rated voltage [V] (*3)

Rated current [A] (*4)

Overload capability

Output ratingsInput ratings

Rated frequency [Hz]

Phases, voltage, frequency

Voltage/frequency variations

Rated current [A] (*8)

(without DCR)

Required power supply capacity [kVA] (*5)

Torque [%] (*6)

DC injection braking

Braking transistor

Braking

Applicable safety standards

Enclosure

Cooling method

EMC standard

compliance

Weight / Mass [lbs(kg)]

■Three-phase 460V (1/2 to 20HP)

Type (FRN

Nominal applied motor [HP] (*1)

Output ratings

Input ratings

Braking

Applicable safety standards

Enclosure

Cooling method

EMC standard

compliance

Weight / Mass [lbs(kg)]

Rated capacity [kVA] (*2)

Rated voltage [V] (*3)

Rated current [A] (*4)

Overload capability

Rated frequency [Hz]

Phases, voltage, frequency

Voltage/frequency variations

Rated current [A] (*8)

(without DCR)

Required power supply capacity [kVA] (*5)

Torque [%] (*6)

DC injection braking

Braking transistor

■Single-phase 230V (1/8 to 3HP)

Type (FRN

Nominal applied motor [HP] (*1)

Applicable safety standards

Enclosure

Cooling method

EMC standard

compliance

Weight / Mass [lbs(kg)]

*1) Fuji's 4-pole standard motor

*2) Rated capacity is calculated by regarding the output rated voltage as 230V for three-phase 230V series_lb24.Tdmprfpcc+nf_qc24.Tqcpgcq,

*3) Output voltage cannot exceed the power supply voltage.

*4) The load shall be reduced so that the continuous operating current is the rated current in parenthesis or less if the carrier frequency is set to 4kHz or above.

*5) Obtained when a DC REACTOR is used.

*6) Average braking torque when a motor of no load decelerates.(Varies with the efficiency of the motor.)

*7) Voltage unbalance [%] =

Three-phase average voltage [V]

If this value is 2 to 3%, use an AC REACTOR.

*8) The currents are calculated on the condition that the inverters are connected to power supply of 500kVA, %X=5%.

Rated capacity [kVA] (*2)

Rated voltage [V] (*3)

Rated current [A] (*4)

Overload capability

Output ratingsInput ratingsBraking

Rated frequency [Hz]

Phases, voltage, frequency

Voltage/frequency variations

Rated current [A] (*8)

(without DCR)

Required power supply capacity [kVA] (*5)

Torque [%] (*6)

DC injection braking

Braking transistor

Item Specifications

E1E-2U)

F12

1/8

0.30

F25

1/4

0.57

F50

1/2

1.1

001

1

1.9

Three-phase 200 to 240V (with AVR)

0.8

(1.4)(0.7)

1.5

3.0

(2.5) (10)(7.0) (23.5)(16.5) (31) (57)(44)

5.0

(4.2)

150% of rated current for 1min or 200% of rated current for 0.5s

50, 60Hz

Three-phase, 200 to 240V, 50/60Hz

(with DCR)

Voltage: +10 to -15% (Voltage unbalance : 2% or less (*7)) Frequency: +5 to -5%

3.0

0.57

1.1

0.2

0.93

1.80

0.30

1.6

3.1

0.6

5.3

1.1

150 100 70 2040

Starting frequency: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Built-in

UL508C, C22.2No.14(pending), EN50178:1997

IP20(IEC60529)/UL open type(UL50)

Natural cooling

Emission

Immunity

Class 1A (EN55011:1998/A1:1999)

2nd Env. (EN61800-3:1996/A11:2000)

1.5(0.7)

1.5(0.7) 1.8(0.8) 2.0(0.9) 5.3(2.4) 5.3(2.4) 6.4(2.9) 11.2(5.1) 11.7(5.3)

Item Specifications

E1E-4U)

F50

1/2

1.1

001

1.9

1

2

2.8

002

Three-phase 380 to 480V (with AVR)

1.5 2.5 3.7 5.5 13 18 24 30

150% of rated current for 1min or 200% of rated current for 0.5s

50, 60Hz

Three-phase, 380 to 480V, 50/60Hz

Voltage:+10 to -15% (Voltage unbalance: 2% or less (*7)), Frequency: +5 to -5%

(with DCR)

0.85

1.7

0.6

1.6

3.1

1.1

3.0

5.9

2.0

Starting frequency: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Built-in

UL508C, C22.2No.14 (pending), EN50178:1997

IP20 (IEC60529)/UL open type (UL50)

Emission

Immunity

Natural cooling

Class 1A (EN55011:1998/A1:1999)

2nd Env. (EN61800-3:1996/A11:2000)

Fan cooling

3.3(1.5) 3.5(1.6) 5.5(2.5) 5.5(2.5) 6.6(3.0) 10.6(4.8) 11.0(5.0) 17.9(8.1) 20.0(9.1)

Item Specifications

E1E-7U)

F12

1/8

0.3

Three-phase 200 to 240V (with AVR)

0.8

(0.7) (1.4) (2.5) (4.2) (7.0) (10)

F25

1/4

0.57

1.5

150% of rated current for 1min or 200% of rated current for 0.5s

50, 60Hz

Single-phase, 200 to 240V, 50/60Hz

(with DCR)

Voltage: +10 to -10%, Frequency: +5 to -5%

1.1

1.8

0.3

2.0

3.3

0.4

150 100

Starting frequency: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Built-in

UL508C, C22.2No.14 (pending),EN50178:1997

IP20 (IEC60529)/UL open type (UL50)

Emission

Immunity

Natural cooling

Class 1A (EN55011:1998/A1:1999)

2nd Env. (EN61800-3:1996/A11:2000)

1.5(0.7) 1.5(0.7) 1.8(0.8) 2.9(1.3) 5.5(2.5) 6.6(3.0)

Max. voltage [V] - Min. voltage [V]

x 67 (IEC61800-3(5.2.3))

002

2

3.0

8.0

5.7

9.5

2.0

Fan cooling

003

3

4.1

4.4

8.2

2.9

F50

1/2

1.1

3.5

5.4

0.7

003

3

4.1

11

8.3

13.2

2.9

005

5

6.8

9.0

7.3

13.0

4.9

005

6.4

14.0

22.2

007

5

7.5

9.5

17

25

21.1

31.5

4.9

7.4

010

10

12

33

28.8

42.7

10

015

15

17

47

42.2

60.7

15

2nd Env. (EN61800-3:1996+A11:2000)

22.7(10.3) 24.9(11.3)

007

7.5

9.9

10.6

17.3

7.4

010

10

13

14.4

23.2

10

015

15

18

21.1

33.0

15

204070100

2nd Env. (EN61800-3:1996+A11:2000)

001

1

1.9

002

2

3.0

8.0 113.0 5.0

6.4

9.7

1.3

11. 6

16.4

2.4

70 40

Fan cooling

003

4.1

17.5

24.8

3.5

3

020

57.6

80

20

020

20

22

28.8

43.8

20

20

22

Specifications

60

Page 10

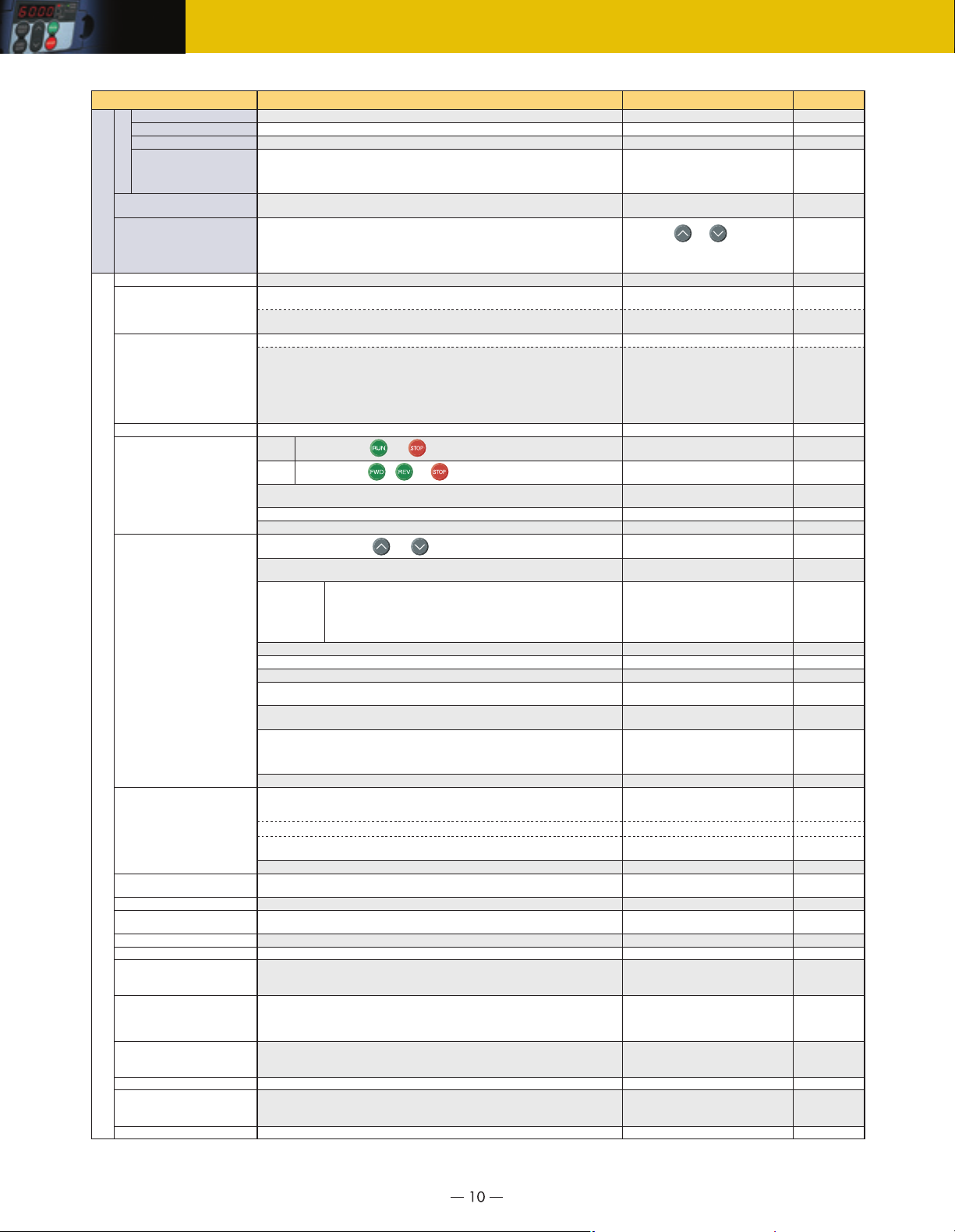

Specifications

●Common specifications

Item Explanation

Maximum frequency

Base frequency

Starting frequency

Carrier frequency

Setting range

Accuracy (Stability)

Output frequencyControl

Setting resolution

Control method

Voltage/freq. characteristic

(Non-linear V/f setting)

Torque boost

Starting torque

Start/stop

Frequency setting

Acceleration/deceleration time

Frequency limiter

(Upper limit and lower limit frequencies)

Bias

Gain

Jump frequency

Timer operation

Jogging operation

Auto-restart after momentary

power failure

Torque limit

Current limit

Slip compensation

Droop control

(Load selection)

25 to 400Hz variable setting

25 to 400Hz variable setting

0.1 to 60.0Hz variable setting, Duration: 0.0 to 10.0s

0.75 to 15kHz variable setting

• Analog setting:

• Keypad setting:

• Analog setting: 1/3000 of maximum frequency (ex. 0.02Hz at 60Hz, 0.4Hz at 120Hz)

Keypad setting: 0.01Hz (99.99Hz or less), 0.1Hz (100.0Hz or more)

•

• Link setting: Selectable from 2 types

• 1/2000 of maximum frequency (ex. 0.003Hz at 60Hz, 0.006Hz at 120Hz)

• 0.01Hz (fixed)

• V/f control • Dynamic torque-vector control (magnetic flux estimator) • V/f control (with sensor, when the PG interface card (option) is installed)

Possible to set output voltage at base frequency and at maximum output frequency (common spec).

AVR control can be turned ON or OFF (Factory setting: OFF).

2 points (Desired voltage and frequency can be set.)

Torque boost can be set with the function code F09. Set when 0, 1, 3, or 4 is selected at F37.

Select application load type with the function code F37.

0: Squared variable torque load

1: Constant torque load

2: Auto torque boost

3: Auto energy-save operation (variable torque load in deceleration)

4: Auto energy-save operation (constant torque load)

5: Auto energy-save operation (auto torque boost)

200% or over (Auto torque boost in 0.5Hz operation, slip compensation and auto torque boost)

Keypad

operation

External signals (7digital inputs): FWD (REV), RUN, STOP commands (3 wire operation possible),

coast-to-stop, external alarm, alarm reset, etc.

Linked operation: Operation through RS-485 or field buss (option) communications

Switching operation command: Link switching, switching between communication and inverter (keypad or external signals)

Key operation: Can be set with and keys

External volume: Can be set with external potentiometer (1 to 5kΩ1/2W)

Analog input

Multistep frequency: Selectable from 16 steps (step 0 to 15)

UP/DOWN operation: Frequency can be increased or decreased while the digital input signal is ON.

Linked operation: Frequency can be set through RS-485 or field buss (optional) communications.

Switching frequency setting: Frequency setting can be switched (2 settings) with external signal (digital input).

Switching to frequency setting via communication and multi-frequency setting are available.

Auxiliary frequency setting: Terminal 12 input and terminal C1 input (terminal V2 input) can be added

to main setting as auxiliary frequency.

Inverse operation: Normal/inverse operation can be set or switched with digital input signal and

function code setting.

• +10 to 0V DC /0 to 100% (terminal 12, C1 (V2))

• +20 to +4mA DC/0 to 100% (terminal C1)

Pulse train input: 30kHz (max.)/ Maximum output frequency

0.00 to 3600s

*If 0.00s is set, the time setting is cancelled and acceleration and deceleration is made

according to the pattern given with an external signal.

Acceleration and deceleration time can be independently set with 2 types and selected with digital input signal (1 point).

(Curve)

Acceleration and deceleration pattern can be selected from 4 types:

Linear, S-curve (weak), S-curve (strong), Non-linear

Deceleration with coasting can be stopped with operation stop command.

High and Low limiters can be set. (Setting range: 0 to 400Hz)

Bias of set frequency and PID command can be independently set (setting range: 0 to

Analog input gain can be set between 0 and 200%.

Three operation points and their common jump width (0 to 30.0Hz) can be set.

The inverter operates and stops for the time set with the keypad (1-cycle operation).

• Can be operated using digital input signal or keypad.

• Acceleration and deceleration time (same duration used only for jogging) can be set.

• Jogging frequency: 0.00 to 400.0Hz

• Restarts the inverter without stopping the motor after instantaneous power failure.

• Select "Continuous motor mode" to wait for the power recovering with low output frequency.

Restart at 0Hz, restart from the frequency used before momentary power failure, restart at the set frequency can be selected.

•

• Motor speed at restart can be searched and restarted.

• Controls the output torque lower than the set limit value.

• Can be switched to the second torque limit with digital input signal.

• Soft start (filter function) is available when switching the torque control to 1/2.

Keeps the current under the preset value during operation.

• Compensates for decrease in speed according to the load, enabling stable operation.

• Time constant can be changed. Possible to enable or disable slip compensation during

acceleration/deceleration or in constant output range.

Decrease the speed according to the load torque.

±0.2% of maximum frequency (at 25±10˚C(at 77±50˚F))

±0.01% of maximum frequency (at -10 to +50˚C(at 14 to +122˚F))

Start and stop with and keys

Start and stop with / and keys

Analog input can be set with external voltage/current input

• 0 to

• +4 to +20mA DC/0 to 100% (terminal C1)

±10V DC (0 to ±5V DC)/0 to ±100% (terminal 12, C1 (V2))

±100%).

Remarks

Frequency may drop automatically to protect the

inverter depending on environmental

temperature and output current.This protective

operation can be canceled by function code H98.

Setting with and keys

Three-phase 230V, single-phase 230V: 80 to 240V

Three-phase 460V: 160 to 500V

Three-phase and single-phase 230V: 0 to 240V/0 to 400Hz

Three-phase 400V: 0 to 500V/0 to 400Hz

Keypad (standard)

Multi-function keypad

With data protection

Connected to analog input terminals 13, 12,

and 11. Potentiometer must be provided.

• 0 to +5V DC can be used depending on the

analog input gain (200%). +1 to +5V DC can

be adjusted with bias and analog input gain.

• Voltage can be input (terminal V2) to the

terminal 1.

When the PG interface card (optional) is installed.

If the set frequency is lower than lower limit, continuous

motor running or stop running motor can be selected.

Voltage signal from terminal 12, C1 (V2) and current

signal (from terminal C1) can be set independently.

Related

function code

F03

F04

F23,F24

F26

F27

H98

F03 to F06

H50 to H53

F09, F37

F09, F37

H68, F37

F02

F02

E01 to E05

E98, E99

H30, y98

F01, C30

F18, C50,

C32 to C34,

C37 to C39,

C42 to C44

C05 to C19

F01, C30

H30, y98

F01, C30

E61 to E63

C53

F07, F08

E10,E11

H07

H11

F15, F16

H63

F18, C50 to C52

C32, C34, C37

C39, C42, C44

C01 to C04

C21

H54

C20

F14

H13 to H16

H92, H93

F40, F41

E16, E17

H76

F43, F44

H68

P09 to P12

H28

H28

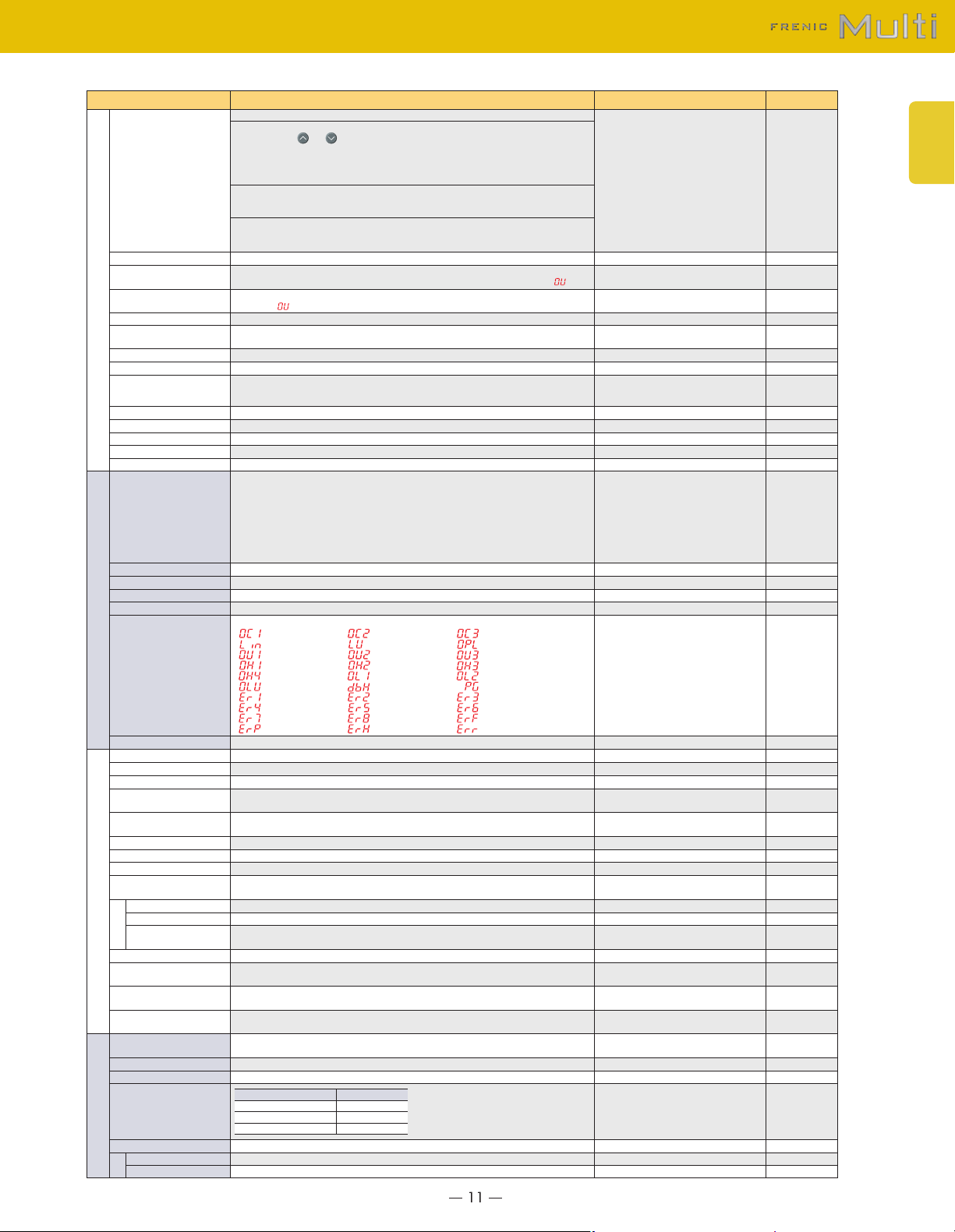

Page 11

Item Explanation

PID control

Pick-up

Automatic deceleration

Deceleration characteristic

Automatic energy-saving operation

Overload Prevention Control

Auto-tuning

Cooling fan ON/OFF control

Secondary motor setting

Universal DI

Universal AO

Speed control

Positioning control

Rotation direction control

Running/stopping

Life early warning

Cumulative run hours

I/O check

Power monitor

Trip mode

Indication ControlProtection

Running or trip mode

Overcurrent protection

Short circuit protection

Grounding fault protection

Overvoltage protection

Undervoltage

Input phase loss

Output phase loss

Overheating

Overload

Electronic thermal

PTC thermistor

Overload early warning

Motor protectionStorage

Stall prevention

Momentary power failure

protection

Retry function

Command loss detection

Installation location

Ambient temperature

Ambient humidity

Altitude

Environment

Vibration

Ambient temp.

Ambient humidity

Control with PID regulator or dancer controller.

■ Process command

• Key operation ( and keys) : 0 to 100%

• Analog input (terminal 12, C1 (V2)) : 0 to

• Analog input (terminal C1) : 4 to 20mA DC/0 to 100%

• UP/DOWN (digital input) : 0 to 100%

• Communication (RS-485, bus option) : 0 to 20000/0 to 100%

■ Feedback value

• Analog input from terminal 12, C1 (V2) : 0 to

• Analog input (terminal C1) : 4 to 20mA DC/0 to 100%

■ Accessory functions

• Alarm output (absolute value alarm, deviation alarm) • Normal operation/inverse operation

• PID output limiter • Anti-reset wind-up function • Integration reset/hold

Operation begins at a preset pick-up frequency to search for the motor speed to start an idling motor without stopping it.

When the torque calculation value exceeds the limit level set for the inverter during deceleration, the output

frequency is automatically controlled and the deceleration time automatically extends to avoid an trip.

The motor loss increases during deceleration to reduce the load energy regenerating at the inverter

to avoid an trip upon mode selection.

The output voltage is controlled to minimize the total sum of the motor loss and inverter loss at a constant speed.

The output frequency is automatically reduced to suppress the overload protection trip o inverter

caused by an increase in the ambient temperature, operation frequency, motor load or the like.

The motor parameters are automatically tuned.

Detects inverter internal temperature and stops cooling fan when the temperature is low.

One inverter can be used to control two motors by switching (switching is not available while a motor is running). Base

•

frequency, rated current, torque boost, electronic thermal, slip compensation can be set as data for the secondary motor.

• The second motor constants can be set in the inverter. (Auto-tuning possible)

The presence of digital signal in a device externally connected to the set terminal can be sent to the master controller.

The output from the master controller can be output from the terminal FM.

The motor speed can be detected with the pulse encoder and speed can be controlled.

Only one program can be executed by setting the number of pulses to the stop position and deceleration point.

Select either of reverse prevention or forward rotation prevention.

• Speed monitor, output current [A], output voltage [V], torque calculation value, input power [HP],

PID reference value, PID feedback value, PID output, load factor, motor output, period for timer operation [s]

◆Select the speed monitor to be displayed from the following:

Output frequency [Hz], Output frequency 1 [Hz] (before slip compensation),

Output frequency 2 (after slip compensation) [Hz],

Motor speed (set value) [r/min],

Motor speed [r/min], Load shaft speed (set value) [r/min],

Load shaft speed (r/min),

Line speed (set value), Line speed (r/min)

The life early warning of the main circuit capacitors, capacitors on the PC boards and the cooling fan can be displayed.

The cumulative motor running hours, cumulative inverter running hours and cumulative watt-hours can be displayed.

Displays the input signal status of the inverter.

Displays input power (momentary), accumulated power, electricity cost (accumulated power x displayed coefficient).

Displays the cause of trip by codes.

(Overcurrent during acceleration)

•

• (Input phase loss) •

• (Overvoltage during acceleration)

• (Overheating of the heat sink) •

• (Motor protection (PTC thermistor))

• (Inverter overload) •

• (Memory error) •

•

(Optional communication error) •

• (Tuning error) •

• (RS485 communication error (option))

Trip history: Saves and displays the last 4 trip codes and their detailed description.

The inverter is stopped upon an overcurrent caused by an overload.

The inverter is stopped upon an overcurrent caused by a short circuit in the output circuit.

The inverter is stopped upon an overcurrent caused by a grounding fault in the output circuit.

An excessive DC link circuit voltage is detected to stop the inverter.

Stops the inverter by detecting voltage drop in DC link circuit.

Stops or protects the inverter against input phase loss.

Detects breaks in inverter output wiring at the start of running and during running, stopping the inverter output.

The temperature of the heat sink of the inverter or that inside the inverter unit is detected to stop the inverter, upon a failure or overload of the cooling fan.

The inverter is stopped upon the temperature of the heat sink of the inverter or the temperature of the

switching element calculated from the output current.

The inverter is stopped upon an electronic thermal function setting to protect the motor.

A PTC thermistor input stops the inverter to protect the motor.

Warning signal can be output based on the set level before the inverter trips.

The output frequency decreases upon an output current exceeding the limit during acceleration or constant speed operation, to avoid overcurrent trip.

•

A protective function (inverter stoppage) is activated upon a momentary power failure for 15msec or longer.

•

If restart upon momentary power failure is selected, the inverter restarts upon recovery of the voltage within the set time.

When the motor is tripped and stopped, this function automatically resets the tripping state and

restarts operation.

A loss (broken wire, etc.) of the frequency command is detected to output an alarm and continue

operation at the preset frequency (set at a ratio to the frequency before detection).

Shall be free from corrosive gases, flammable gases, oil mist, dusts, and direct sunlight.

(Pollution degree 2 (IEC60664-1)). Indoor use only.

-10 to +50˚C(at +14 to +122˚F)

5 to 95% RH (without condensation)

Altitude [ft(m)]

Lower than 3,300(1,000 )

3,301 to 6,600(1,001 to 2,000)

6,601 to 9,800(2,001 to 3,000)

3mm (vibration width): 2 to less than 9Hz, 9.8m/s

-25 to +65˚C(-13 to +149˚F)

5 to 95%RH (without condensation)

Output decrease

None

Decreases

Decreases*

±10V DC/0 to ±100%

±10V DC/0 to ±100%

•

(Overcurrent during deceleration)

(Undervoltage) •

•

(Overvoltage during deceleration)

(External alarm) •

•

(Motor 1 overload) •

(Overheating of braking resistor)

(Keypad communication error) •

(Option error)

(RS-485 communication error) •

•

(Power LSI error) •

2

: 9 to less than 20Hz, 2m/s2: 20 to less than 55Hz, 1m/s2: 55 to less than 200Hz

•

(Overcurrent at constant speed)

(Output phase loss)

•

(Overvoltage at constant speed)

(Inverter overheat)

(Motor 2 overload)

•

(PG disconnection)

(CPU error)

•

(Operation error)

(Data save error due to undervoltage)

(Simulation error)

Remarks

Trip may occur due to load conditions.

Mode that the motor rotates and mode that the motor does not rotate can be selected.

An external output is issued in a transistor output signal.

When the PG interface card (optional) Is installed.

When the PG interface card (optional) Is installed.

An external output is issued in a transistor output signal.

3-phase 230V / 400V DC, Single-phase 230V/400V DC

3-phase 460V / 800V DC

3-phase 230V / 200V DC, Single-phase 230V/200V DC

3-phase 460V / 400V DC

The protective function can be canceled with function code 99.

The protective function can be canceled with function code 99.

Thermal time constant can be adjusted (0.5 to 75.0min.)

Waiting time before resetting and the number

of retry times can be set.

-10 to 40˚C(+14 to +104˚F)when inverters are installed side by side without clearance.

* If the altitude exceeds 6,600ft(2,000m)

insulate the interface circuit from the

main power supply to conform to the

Low Voltage Directives.

Related

function code

E61 to E63

J01 to J06

J10 to J19

H09, H13, H17

H69, F08

H71

F37, F09

H70

P04

H06

E43

E48

E52

F14

H98

H98

H43

F10 to F12, P99

H26, H27

F10, F12, E34,

E35, P99

H12

H13 to H16

F14

H04, H05

E65

Specifications

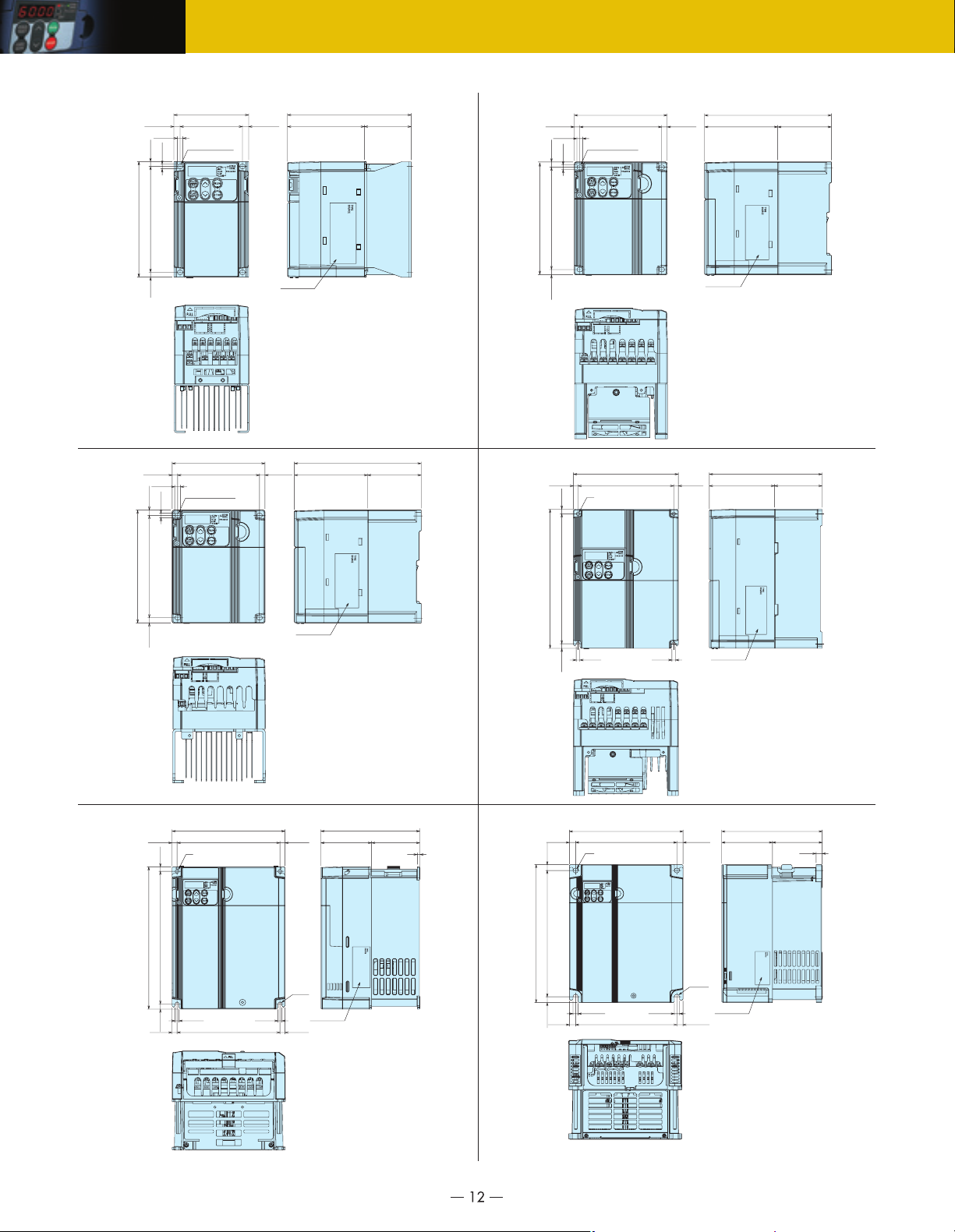

Page 12

External Dimensions

●Inverter outline (standard type)

Fig. a Fig.b

Fig. c Fig. d

0.26&6.5) 0.26&6.5)

0.24(6)

0.2(5)

0.2(5)

H

H1

0.2(5)

0.26(6.5)

0.28(7)

0.24(6)

0.2(5)

W

W1

C

(elongated hole)

W

W1

C

(elongated hole)

Name plate

0.26(6.5)

D

D1 D2

D

D1 D2

W

C

(elongated hole)

C

W1

W

W1

0.26(6.5)

0.28(7)

0.24(6)

0.2(5)

H

H1

0.24(6)

0.24(6) 0.24(6)

0.26(6.5)

Name plate

D

D1 D2

D

D2D1

H

H1

0.24(6)

Name plate

2-R0.12

(2-R3)

0.31(8)

Name plate

D

D2D1

5

0.24(6)

C

0.24(6)

W

W1

6.46(164)

Fig. e Fig. f

0.31(8) 0.31(8)

H

H1

0.31(8) 0.28(7)

0.31(8)

H

H1

0.47(12)

2-R0.2

(2-R5)

0.47(12)

Name plate

Name plate

D

D2 D1

11.2

0.2(5) 0.2(5)

0.24(6) 0.24(6)

W

C

0.39(10)

W1

7.72(196)

0.39(10)

0.47(12)

0.43(11)

H

H1

0.47(12)

0.43(11)

Page 13

Power supply

voltage

Three-phase

230V

Three-phase

460V

Single-phase

230V

Inverter type Fig.

FRNF12E1S-2U

FRNF25E1S-2U

FRNF50E1S-2U

FRN001E1S-2U

FRN002E1S-2U

FRN003E1S-2U

FRN005E1S-2U

FRN007E1S-2U

FRN010E1S-2U

FRN015E1S-2U

FRN020E1S-2U

FRNF50E1S-4U

FRN001E1S-4U

FRN002E1S-4U

FRN003E1S-4U

FRN005E1S-4U

FRN007E1S-4U

FRN010E1S-4U

FRN015E1S-4U

FRN020E1S-4U

FRNF12E1S-7U

FRNF25E1S-7U

FRNF50E1S-7U

FRN001E1S-7U

FRN002E1S-7U

FRN003E1S-7U

Dimensions [Unit: inch (mm)]

WW1HH1 DD1D2 C

a

b

d

e

f

c

b

d

e

f

a

b

d

3.15(80)

4.33(110)

5.51(140)

7.09(180)

8.66(220)

4.33(110)

4.33(110)

5.51(140)

7.09(180)

8.66(220)

3.15(80)

4.33(110)

5.51(140)

2.64(67)

3.82(97)

5.04(128)

6.46(164)

7.72(196)

3.82(97)

3.82(97)

5.04(128)

6.46(164)

7.72(196)

2.64(67)

3.82(97)

5.04(128)

4.72(120)

5.12(130)

7.09(180)

8.66(220)

10.24(260)

5.12(130)

5.12(130)

7.09(180)

8.66(220)

10.24(260)

4.72(120)

5.12(130)

7.09(180)

4.33(110)

4.65(118)

6.61(168)

8.07(205)

9.37(238)

4.65(118)

4.65(118)

6.61(168)

8.07(205)

9.37(238)

4.33(110)

4.65(118)

6.61(168)

3.62(92)

4.21(107)

5.20(132)

5.91(150)

5.94(151)

6.22(158)

7.68(195)

4.96(126)

5.91(150)

5.91(150)

5.94(151)

6.22(158)

7.68(195)

3.62(92)

4.21(107)

5.98(152)

5.91(150)

5.94(151)

3.23(82)

3.39(86)

3.43(87)

3.19(81)

3.88(98.5)

3.39(86)

3.39(86)

3.43(87)

3.19(81)

3.88(98.5)

4.02(102)

3.39(86)

3.43(87)

0.39(10)

0.98(25)

1.97(50)

2.52(64)

2.52(64)

3.03(77)

3.80(96.5)

1.57(40)

2.52(64)

2.52(64)

2.52(64)

3.03(77)

3.80(96.5)

0.39(10)

0.98(25)

1.97(50)

2.52(64)

2.52(64)

4-0.20x0.24 (4-5x6)

(elongated hole)

4-0.20x0.28 (4-5x7)

(elongated hole)

φ0.20 (φ5)

φ0.24 (φ6)

φ0.39 (φ10)

4-0.20x0.24 (4-5x6)

(elongated hole)

4-0.20x0.28 (4-5x7)

(elongated hole)

φ0.20 (φ5)

φ.24 (φ6)

φ0.39 (φ10)

4-0.20x0.24 (4-5x6)

(elongated hole)

4-0.20x0.28 (4-5x7)

(elongated hole)

φ0.20 (φ5)

External

Dimensions

●Keypad

0.2

(5.2)

0.19(4.7)

1.65(41.8)

1.28(32.4)

0.19(4.7)

* Dimensions when installing the supplied rear cover

2.03(51.44)

3.12(79.2)

2.71(68.8)

2.01(51.05)

0.53

(13.5)

0.59

(15.08)

0.2

(5.2)

A

0.65

(16.6)

0.39

(10)

0.16

(4.1)

Inside panel

0.17

0.67

(4.25)

(17.1)

0.6

0.88

(22.46)

(15.24)

0.19

(4.7)

0.2(5.2)

1.28(32.4)

[Unit: inch (mm)]

3.12(79.2)

2.71(68.8)

2xM3

Dimensions of panel cutting

(viewed from "A")

cutout

0.67(17)1.77(45)

Panel

0.11

0.08(2)

1.44(36.5)

(2.7)

1.65(41.8)

Page 14

External Dimensions

●Inverter outline (EMC filter built-in type)

Fig. g Fig. h

W

0.26(6.5) 0.26(6.5)

2.64(67)

4-0.2

x0.24(

(elongated hole)

4-5x6)

D

D1 D2

WD

3.82(97)0.26(6.5) 0.26(6.5)

4-0.2Ļ.,06&4-5

(elongated hole)

x

7)

D1 D2

H

4.33(110) 0.2(5)

H1

0.2(5)

2.36(60) D30.39(10)

H1

Fig. i Fig. j

W

5.04(128)0.24(6)

2- 0.2(2- 5)

(6)

0.24

H

6.61(168)

H1

0.2

(5)

0.24(6)

0.36(92)

0.24(6)

7.48(190)

D

D1 D2

D31.06(27)0.41(10.5)

H

H

4.65(118) 0.24(6)0.24(6)

0.28(7)

10.1(256.5)

3.5(89) D30.41(10.5)

WD

5.91(150)

x0.26

(2x6.5)

A

2.17(55)

0.26(6.5)2

1.08(27.5)

(7)

0.28

10.1(256.5)

Detailed drawing A

0.33(8.5)

2.6

( 6.5)

0.47

( 12)

Fig. k Fig. l

0.49

H

12.8(325)

(12.5)

W

7.09(180)

A

2

x0.33

(2x8.4)

D

1.28(32.5)

2.56

(65)

0.33

(8.4)

0.49(12.5)

12.8(325)

0.35(9)

Detailed drawing A

0.33

( 8.4)

0.55

( 14)

H

11.91(302.5) 0.39(10)

W

7.09(180)

x0.33

2

(2x8.3)

D

2.17

(55)

A

1.08

(27.5)

0.33

(8.3)

0.39(10)11.91(302.5)

0.33

( 8.3)

0.35(9)

Detailed drawing A

0.55

( 14)

Page 15

Power supply voltage

Three-phase 230V

Three-phase 460V

Single-phase 230V

Inverter type Fig.

FRNF12E1S-2U

FRNF25E1S-2U

FRNF50E1S-2U

FRN001E1S-2U

FRN002E1S-2U

FRN003E1S-2U

FRN005E1S-2U

FRN007E1S-2U

FRN010E1S-2U

FRN015E1S-2U

FRN020E1S-2U

FRNF50E1S-4U

FRN001E1S-4U

FRN002E1S-4U

FRN003E1S-4U

FRN005E1S-4U

FRN007E1S-4U

FRN010E1S-4U

FRN015E1S-4U

FRN020E1S-4U

FRNF12E1S-7U

FRNF25E1S-7U

FRNF50E1S-7U

FRN001E1S-7U

FRN002E1S-7U

FRN003E1S-7U

g

i

j

k

h

i

j

l

g

h

i

Dimensions [Unit: inch (mm)]

W H H1 D D1 D2 D3

0.39

(10)

0.98(25)

1.97(50)

2.52

(64)

-

-

1.57(40)

2.52(64)

2.52

(64)

-

-

0.39

(10)

0.98(25)

1.57(40)

2.52

(64)

3.15

(80)

5.51

(140)

7.15

(181.5)

8.66

(220)

4.33

(110)

5.51

(140)

7.15

(181.5)

8.66

(220)

3.15

(80)

4.33(110)

5.51

(140)

4.72

(120)

7.09

(180)

11.22

(285)

13.78

(357)

5.12

(130)

7.09

(180)

11.22

(285)

13.07

(332)

4.72

(120)

5.12(130)

7.09

(180)

6.69

(170)

9.65

(245)

-

-

7.09

(180)

9.65

(245)

-

-

6.69

(170)

7.09(180)

9.65

(245)

4.41

(112)

5.00(127)

5.98(152)

7.64

(194)

8.39

(213)

10.24

(260)

6.65(169)

7.60(193)

7.64

(194)

8.19

(208)

9.98

(250)

4.41

(112)

5.00(127)

5.91(150)

7.64

(194)

4.02

(102)

5.12

(130)

-

-

5.08

(129)

5.12

(130)

-

-

4.02

(102)

4.33(110)

5.12

(130)

0.83

(21.2)

1.43(36.2)

2.41(61.2)

3.37

(85.5)

-

-

2.42(61.5)

3.37(85.5)

3.37

(85.5)

-

-

0.83

(21.2)

1.43(36.2)

2.17(55.2)

3.37

(85.5)

External

Dimensions

Page 16

Keypad Operations

■ Keypad switches and functions

LED monitor

When the motor is running or stopped:

The monitor displays speeds, such as output frequency, set

frequency, motor speed and load shaft speed, output voltage,

output current, and power consumption.

Alarm mode:

The monitor shows the alarm description with a fault code.

Program/Reset key

Used to change the mode.

Programming mode:

Used to shift the digit (cursor movement)

to set data.

Alarm mode:

Resets trip prevention mode.

Function/Data select key

Used to change the LED monitor and to store the

function code and data.

Up/Down keys

During operation: Used to increase or decrease the

frequency or motor speed.

In data setting: Used to indicate the function code number

or to change data set value.

Unit display

The unit of the data displayed at the LED monitor is indicated.

Use the key to switch the displayed data.

Operation mode display

During keypad operation:

When function code is, ,

or (keypad operation), the green KEYPAD

CONTROL LED lights up.

Run key

While the motor is stopped:

Used to start the operation.

This key is invalid if the function code

(operation by external signals) is

set to .

During operation:

The green RUN LED lights up.

Stop key

Used to stop the operation.

During operation:

This key is invalid if the function code (operation by

external signals) is set to .

The inverter stops when the function code is set to

or .

■

Monitor display and key operation

Operation mode

Monitor, keys

Function

Display

Function

Hz

r/min

A

PRG.MODE

m/min

kW

Display

MonitorKeys

KEYPAD

CONTROL

RUN

Function

Display

Indicates absence of operation commands.

Function

Display

Function

Function

Function

Function

Function

This keypad supports the full menu mode that allows you to set or display the following information. Indication and setting change of changed function code,

drive monitor, I/O check, maintenance information, and alarm information. For the actual operation methods, refer to the FRENIC-Multi Instruction Manual

or User's Manual.

Programming mode Running mode

STOP

Displays the function code and data.

Lighting

Indicates that the program mode is selected.

Hz

r/min

A

PRG.MODE ON

m/min

kW

RUN unlit

Switches to running mode Switches to programming mode

Digit shift (cursor movement) in data setting

Determines the function code, stores and

updates data.

Increases/decreases the function code

and data.

Invalid

Invalid

RUN STOP RUN

Operation selection (keypad operation/terminal operation) is displayed.

Indicates presence of operation commands.

Deceleration stop (switches to

programming mode (STOP)).

The keypad modes are classified into the following 3 modes.

Alarm mode

Displays the output frequency, set frequency, loaded motor

speed, power consumption, output current, and output voltage.

Blinking Lighting Blinking/Lighting

Displays the units of frequency, output current,

power consumption, and rotation speed.

Hz

r/min

Frequency

A

PRG.MODE

PRG.MODE

ON

ON

display

m/min

kW

Hz

r/min

Current

A

display

m/min

kW

Lit in keypad operation mode

Indicates absence of operation commands. Indicates presence of operation commands.

RUN unlit RUN litRUN lit

Switches the LED monitor display. Displays the operation

Increases/decreases the frequency, motor speed

and other settings.

Starts running (switches

to running mode (RUN)).

Invalid

Hz

r/min

Speed

A

m/min

r/min

m/min

kW

Hz

A

kW

PRG.MODE

PRG.MODE

display

Capacity

or

Current

indication

Invalid Invalid

Deceleration stop (switches

to running mode (STOP)).

Displays the alarm description

and alarm history.

None

ON

OFF

blinks

or lit

Indicates that the operation is trip-stopped.

If an alarm occurs during

operation, the lamp is unlit during

keypad operation and lit during

terminal block operation.

Releases the trip and

switches to stop mode

or running mode.

information.

Displays the alarm

history.

Invalid

Page 17

Basic Wiring Diagram

●Wiring diagram

The following diagram is for reference only. For detailed wiring diagrams, refer to the instruction manual.

■ Keypad operation

(Note 2)

MCCB

Power

Three-phase/

single-phase

200 to 240V,

50/60Hz

or three-phase

390 to 480V,

50/60Hz

MCCB: Molded-case circuit breaker

GFCI: Ground-fault circuit interrupter

MC: Magnetic contactor

DCR: DC reactor

DBR: Braking resistor

or

GFCI

Grounding terminal

(Note 3)

MC

(Note 1)

DCR

[13]

[12]

[11]

[C1]

[11]

[FM]

(FWD)

(REV)

(CM)

(X1)

(X2)

(X3)

(X4)

(X5)

(CM)

(PLC)

L1/R

L2/S

L3/T

P1

G

P(

+

)

P1

FMA

FMP

SW6

SOURCE

SW1

PDB

P(+)

SW3

PTC

SW8

C1

30

SINK

RS485 port

(option)

DBR

N(

G

SW7

V2

<Y1>

<Y2>

<CMY>

-)DB

U

V

W

30C

30B

30A

(CM)

(THR)

Main circuit

Motor

Grounding terminal

Control circuit

Alarm output

(for any fault)

Transistor input

■ Run/Stop operation and frequency setting on the keypad

(Note 4)

[Wiring procedure]

(1) Wire the inverter main power circuit.

[Operation method]

(1) Run/Stop: Press or key.

M

(2) Setting frequency: Set the frequency with and keys.

Note1: When connecting a DC REACTOR (DCR option), remove the

jumper bar from across the terminals [P1] and [P (+)].

Note2: Install a recommended molded-case circuit breaker (MCCB) or a

ground-fault circuit interrupter (with an overcurrent protection

function) in the primary circuit of the inverter to protect wiring. At

this time, ensure that the circuit breaker capacity is equivalent to

or lower than the recommended capacity.

Note3: Install a magnetic contactor (MC) for each inverter to separate the

inverter from the power supply, apart from the MCCB or GFCI,

when necessary.

Connect a surge killer in parallel when installing a coil such as the

MC or solenoid near the inverter.

Note4: (THR) function can be used by assigning code "9" (external alarm)

to any of the terminals X1 to X5, FWD or REV (function code; E01

to E05, E98, or E99).

Keypad

Operations

Basic

Wiring Diagram

■ Operation by external signal inputs

Power

Three-phase/

single-phase

200 to 240V,

50/60Hz

or three-phase

390 to 480V,

50/60Hz

Potentiometer power supply

Voltage input for setting

DC0 to

Analog

input

MCCB: Molded-case circuit breaker

GFCI: Ground-fault circuit interrupter

MC: Magnetic contactor

DCR: DC reactor

DBR: Braking resistor

±10V

Current/voltage input

for setting

DC +4 to 20 mA/DC0 to 10V

Digital input

(Note 2)

MCCB

or

GFCI

Grounding terminal

(Note 5)

Meter

(Note 1)

DCR

(Note 3)

MC

L1/R

L2/S

L3/T

G

3

2

1

)

(

+

-

)

(

(Note 6)

[13]

[12]

[11]

[C1]

[11]

[FM]

(FWD)

(REV)

(CM)

(X1)

(X2)

(X3)

(X4)

(X5)

(CM)

(PLC)

P1

P(

+

)

P1

FMA

FMP

SW6

SOURCE

SW1

PDB

P(+)

SW3

PTC

SW8

30

SINK

RS-485 port

(option)

DBR

C1

SW7

V2

<CMY>

-)DB

N(

U

V

W

G

30C

30B

30A

<Y1>

<Y2>

(CM)

(Note 4)

(THR)

Main circuit

Motor

Grounding terminal

Control circuit

Alarm output

(for any fault)

Transistor input

M

■ Run/Stop operation and frequency setting through external signals

[Wiring procedure]

(1) Wire both the inverter main power circuit and control circuit.

(2) Set (external signal) at function code . Next, set (voltage input

(terminal 12) (0 to +10V DC)), (current input (terminal C1) (+4 to

20mA DC)), or other value at function code .

[Operation method]

(1) Run/Stop: Operate the inverter across terminals FDW and CM short-

circuited, and stop with open terminals.

(2) Frequency setting: Voltage input (0 to +10V DC), current input (+4 to

20mA DC)

Note1: When connecting a DC REACTOR (DCR option), remove the

jumper bar from across the terminals [P1] and [P (+)].

Note2: Install a recommended molded-case circuit breaker (MCCB) or a

ground-fault circuit interrupter (with an overcurrent protection

function) in the primary circuit of the inverter to protect wiring. At

this time, ensure that the circuit breaker capacity is equivalent to

or lower than the recommended capacity.

Note3: Install a magnetic contactor (MC) for each inverter to separate the

inverter from the power supply, apart from the MCCB or GFCI,

when necessary.

Connect a surge killer in parallel when installing a coil such as the

MC or solenoid near the inverter.

Note4: (THR) function can be used by assigning code "9" (external alarm)

to any of the terminals X1 to X5, FWD or REV (function code; E01

to E05, E98, or E99).

Note5: Frequency can be set by connecting a frequency-setting device

(external potentiometer) between the terminals 11, 12 and 13

instead of inputting a voltage signal (0 to +10V DC, 0 to +5V DC

or +1 to +5V DC) between the terminals 12 and 11.

Note 6: For the control signal wires, use shielded or twisted wires.

Ground the shielded wires. To prevent malfunction due to noise,

keep the control circuit wiring away from the main circuit wiring as

far as possible (recommended: 3.94inch(10cm) or more). Never

install them in the same wire duct.

When crossing the control circuit wiring with the main circuit wiring,

set them at right angles.

Page 18

Terminal Functions

■ Terminal Functions

Symbol Terminal name Functions Remark

Division

L1/R,L2/S,L3/T

U,V,W

P1,P (+)

P (+),DB

P (+),N (

Main circuitFrequency settingDigital input

G

13

12

C1

11

X1

X2

X3

X4

X5

FWD

REV

(Hz2/Hz1)

(DCBRK)

(TL2/TL1)

(WE-KP)

(PID-RST)

(PID-HLD)

PLC

CM

Power input

Inverter output

For DC REACTOR

For braking resistor

For DC bus connection

-

)

Grounding

Potentiometer power

supply

Analog setting voltage

input

(Inverse operation)

(Frequency aux. setting)

Analog setting current

input

(Inverse operation)

(Frequency aux. setting)

(V2)

Analog setting voltage

input

(Inverse operation)

(Frequency aux. setting)

(PTC)

(PTC thermistor)

Analog common

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Forward operation command

Reverse operation command

Forward operation command

(FWD)

Reverse operation command

(REV)

Multistep

(SS1)

freq. selection

(SS2)

(SS4)

(SS8)

Acceleration time

(RT1)

selection command

3-wire operation stop

(HLD)

command

Coast-to-stop command

(BX)

(RST)

Alarm (error) reset

(THR)

Trip command (External fault)

Freq. set 2/Freq. set 1

(M2/M1)

Motor2/Motor1

DC braking command

Torque limit 2/Torque limit 1

(UP)

UP command

(DOWN)

DOWN command

Write enable for KEYPAD

(Changing data is available.)

(Hz/PID)

PID cancel

(IVS)

Inverse mode

changeover

(LE)

Link enable

(U-DI)

Universal DI

(STM)

Starting characteristic selection

Forcible stop

(STOP)

PID differentiation / integration reset

PID integral hold

Jogging operation

(JOG)

PLC terminal

Digital common

(PID control)

(PID control)

(PID control)

Connect a three-phase power supply.

Connect a three-phase motor.

Connect the DC reactor (DCR).

Connect the braking resistor (option).

Used for DC bus connection.

Terminal for inverter chassis (case) and motor grounding

Used for frequency setting device power supply (variable resistance: 1 to 5kΩ)

(10V DC 10mA DC max.)

Used as a frequency setting voltage input.0 to

DC/0 to 100%)

±10V DC/0 to 100% (0 to ±5V

±10 to 0V DC/0 to ±100%

Used for setting signal (PID process command value) or feedback signal.

Used as additional auxiliary setting to various frequency settings.

Used as a frequency setting current input.4 to 20mA DC/0 to 100%

20 to 4mA DC/0 to 100%

Used for setting signal (PID process command value) or feedback signal.

Two terminals are provided.

Connect the potentiometer with

higher than 1/2W.

Input impedance: 22kΩ

Maximum input: +15V DC

However, the current larger than

±20mA DC is handled as ±20mA

DC.

Input impedance: 250Ω

Maximum input: 30mA DC

However, the voltage higher than

±10V DC is handled as ±0V DC.

Used as additional auxiliary setting to various frequency settings.

Used as a frequency setting voltage input.0 to +10V DC/0 to 100% (0 to +5V

DC/0 to 100%)

+10 to 0V DC/0 to 100%

Used for setting signal (PID process command value) or feedback signal.

Input impedance: 22kΩ

Maximum input:+15V DC

However, the voltage higher than

±10V DC is handled as ±10V DC.

Used as additional auxiliary setting to various frequency settings.

Connect the thermistor used to protect the motor.

Common terminal for frequency setting signals (13, 12, C1, FM)