Page 1

User's Manual

24A7-E-0023d

Page 2

Page 3

Compact Inverter

User's Manual

Page 4

Copyright © 2013-2014 Fuji Electric Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric

Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 5

Preface

This manual provides all the information on the FRENIC-Mini series of inverters including its operating

procedure, operation modes, and selection of peripheral equipm ent. Carefully read this m anual for proper use.

Incorrect handling of the inverter may prevent the inverter and/or related equipment from operating correctly,

shorten their lives, or cause problems.

The table below lists the other materials related to the use of the FRENIC-Mini. Read them in conjunction

with this manual as necessary.

Name Material No. Description

Catalog 24A1-E-0011

Instruction Manual INR-SI47-1729-E

RS-485 Communication

User's Manual

MEH448

Product scope, features, specifications, external

drawings, and options of the product

Acceptance inspection, mounting & wiring of the

inverter, operation using th e keypad, running the

motor for a test, troubleshooting, and maintenance

and inspection

Overview of functions implemented by the use of

RS-485 communication, the communications

specifications, Modbus RTU/Fuji general-purpose

inverter protocol, related function codes, and data

formats

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

Guideline for Suppressing Harmonics in Home Electric and General-purpose

Appliances

Our three-phase, 200 V class series inverters of 3.7 kW or less (FRENIC-Mini series) were the products of

which were restricted by the "Guideline for Suppressing Harmonics in Home Electric and General-purpose

Appliances" (established in September 1994 and revised in October 1999) issued by the Ministry of

Economy, Trade and Industry.

The above restriction, however, was lifted when the Guideline was revised in January 2004. Since then, the

inverter makers have individually imposed voluntary restrictions on the harmonics of their products.

We, as before, recommend that you connect a reactor (for suppressing harmonics) to your inverter. As a

reactor, select a "DC REACTOR" introduced in this manual. For use of the other reactor, please inquire of us

about detailed specifications.

Japanese Guideline for Suppressing Harmonics by Customers Receiving

High Voltage or Special High Voltage

Refer to this manual, Appendix B for details on this guideline.

i

Page 6

Safety precautions

Read this manual and the FRENIC-Mini Instruction Manual (INR-SI47-1729-E) thoroughly before

proceeding with installation , connections (wiring), operation, or maintenance and inspection . Ensure you

have sound knowledge of the product and familiarize yourself with all safety information and precautions

before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bo dily injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

This product is not designed for use in appliances and m achinery on which lives de pend. Consult yo ur Fuji

Electric representative before considering the FRENIC-Mini series of inverters for equipment and

machinery related to nuclear power control, aerospace uses, medical uses or transportation. When the

product is to be used with any machinery or equipment on which lives depend or with machinery or

equipment which could cause serious loss or damage should this product malfunction or fail, ensure that

appropriate safety devices and/or equipment are installed.

ii

Page 7

Precautions for Use

Driving a 400 V

general-purpose

motor

Torque

characteristics and

temperature rise

In running

generalpurpose

motors

Vibration

Noise

When driving a 400 V general-purpose motor with an inverter using

extremely long wires, damage to the insulation of the motor may occur. Use

an output circuit filter (OFL) if necessary after checking with the motor

manufacturer. Fuji motors do not require the use of output circuit filters

because of their reinforced insulation.

When the inverter is used to run a general-purpose motor, the temperature

of the motor becomes higher than when it is operated using a commercial

power supply. In the low-speed range, the cooling effect will be weakened,

so decrease the output torque of the motor. If constant torque is required in

the low-speed range, use a Fuji inverter motor or a motor equipped with an

externally powered ventilating fan.

When an inverter-drive n m otor i s m ounte d to a m achine, resona nce m ay be

caused by the natural frequencies of the machine system.

Note that operation of a 2-pole motor at 60 Hz or higher may cause

abnormal vibration.

* The use of a rubber coupling or vibration-proof rubber is recommended.

* Use the inverter's jump frequency control feature to skip the resonance

frequency zone(s).

When an inverter is used with a general-purpose motor, the motor noise

level is higher than that with a commercial power supply. To reduce noise,

raise carrier frequency of the inverter. Operation at 60 Hz or higher can als o

result in higher level of wind roaring sound.

In running

special

motors

High-speed

motors

Explosion-proof

motors

Submersible

motors and pumps

Brake motors

Geared motors

Single-phase

motors

If the reference frequency is set to 120 Hz or more to drive a high-speed

motor, test-run the combination of the inverter and motor beforehand to

check for safe operation.

When driving an explosion-proof motor with an inverter, use a combination

of a motor and an inverter that has been approved in advance.

These motors have a higher rated current than general-purpose motors.

Select an inverter whose rated output current is higher than that of the

motor.

These motors differ from general-purpose motors in thermal characteristics.

Set a low value in the thermal time constant of the motor when setting the

electronic thermal overcurrent protection (for motor).

For motors equipped with parallel-connected brakes, their power supply for

brake must be supplied from the inverter’s primary circuit. If the power

supply for brake is connected to the inverter's output circuit by mistake, the

brake will not work.

Do not use inverters for driving motors with series-connected brake coils.

If the power transmission mechanism uses an oil-lubricated gearbox or

speed changer/reducer, then continuous motor operation at low speed may

cause poor lubrication. Avoid such operation.

Single-phase motors are not suitable for inverter-driven variable speed

operation. Use three-phase motors.

Environmental

conditions

Installation

location

Use the inverter within the ambient temperature range from -10 to +50°C.

The heat sink and braking resistor of the inverter may become hot under

certain operating conditions, so install the inverter on nonflammable

material such as metal.

Ensure that the installation location meets the environmental conditions

specified in Chapter 8, Section 8.4 "Operating Environment and Storage

Environment."

iii

Page 8

Install a recommended molded case circuit breaker (MCCB) or

Installing an

MCCB or

RCD/ELCB

residual-current-operated protective device (RCD)/earth leakage circuit

breaker (ELCB) (with overcurrent protection) in the primary circuit of each

inverter to protect the wiring. Ensure that the circuit breaker capacity is

equivalent to or lower than the recommended capacity.

If a magnetic contactor (MC) is installed i n the inverter's output (seconda ry)

Installing an MC

in the secondary

circuit

circuit for switching the motor to commercial power or for any other

purpose, ensure that both the inverter and the motor are completely stopped

before you turn the MC on or off.

Remove a surge killer integrated with the magnetic contactor in the

inverter's output (secondary) circuit.

Combination with

peripheral

devices

Installing an MC

in the primary

circuit

Protecting the

motor

Discontinuance of

power-factor

correcting

capacitor

Discontinuance of

surge killer

Reducing noise

Do not turn the magnetic contactor (MC) in the primary circuit on or off

more than once an hour as an inverter failure may result.

If frequent starts or stops are required during motor operation, use terminal

[FWD]/[REV] signals or the

key.

/

The electronic thermal feature of the inverter can protect the motor. The

operation level and the motor type (general-purpose motor, inverter motor)

should be set. For high-speed motors or water-cooled motors, set a small

value for the thermal time constant.

If you connect the motor thermal relay to the motor with a long wire, a

high-frequency current may flow into the wiring stray capacitance. This

may cause the thermal relay to trip at a current lower than the set value. If

this happens, lower the carrier frequency or use the output circuit filter

(OFL).

Do not connect power-factor correcting capacitors to the inverter’s primary

circuit. (Use the DC reactor to improve the inverter power factor.) Do not

use power-factor correcting capacitors in the inverter’s output (secondary)

circuit. An overcurrent trip will occur, disabling motor operation.

Do not connect a surge killer to the inverter's output (secondary) circuit.

Use of a filter and shielded wires is typically recommended to satisfy EMC

Directive.

Refer to Appendices, App. A "Advantageous Use of Inverters (Notes on

electrical noise)" for details.

If an overvoltage trip occurs while the inverter is stopped or operated under

Measures against

surge currents

light load, it is assumed that the surge current is generated by open/close of

the phase-advancing capacitor in the power system.

* Connect a DC reactor to the inverter.

When checking the insulation resistance of the inverter, use a 500 V megger

Megger test

and follow the instructions contained in the FRENIC-Mini Instruction

Manual (INR-SI47-1729-E), Chapt er 7, Section 7.5 "Insulation Test."

iv

Page 9

Wiring

Control circuit

wiring length

Wiring length

between inverter

and motor

Wire size

When using remote control, limit the wiring length between the inverter and

operator panel to 20 m or less and use twisted pair or shielded wire.

If long wiring is used between the inverter and the motor, the inverter may

overheat or trip due to overcurrent because a higher harmonics current

flows into the stray capacitance between each phase wire. Ensure that the

wiring is shorter than 50 m. If this length must be exceeded, lower the

carrier frequency or install an output circuit filter (OFL).

Select wires with a sufficient capacity by referring to the current value or

recommended wire size.

Selecting

inverter

capacity

Transportation and

storage

Wire type

Do not share one multi-core cable in order to connect several inverters with

motors.

Grounding Securely ground the inverter using the grounding terminal.

Select an inverter according to the nominal applied motor ratings listed in

Driving

general-purpose

motor

the standard specifications table for the inverter.

When high starting torque is required or quick acceleration or deceleration

is required, select an inverter with one rank larger capacity than the

standard. Refer to Chapter 7, Section 7.1 "Selecting Motors and Inverters"

for details.

Driving special

motors

Select an inverter that meets the following condition:

Inverter rated current > Motor rated current

For transportation and storage instructions, see the FRENIC-Mini Instruction Manual

(INR-SI47-1729-E), Chapter 1, Section 1.3 "Transportation" and Section 1.4 "Storage

Environment."

v

Page 10

How this manual is organized

This manual contains Chapters 1 through 9, and Appendices.

Chapter 1 INTRODUCTION TO FRENIC-MINI

This chapter describes the features and control system of the FRENIC-Mini series, and the recommended

configuration for the inverter and peripheral equipment.

Chapter 2 PARTS NAMES AND FUNCTIONS

This chapter contains external views of the FRENIC-Mini series and an overview of terminal blocks,

including a description of the LED display and keys on the keypad.

Chapter 3 OPERATION USING THE KEYPAD

This chapter describes inverter operation using the keypad. The inverter features three operation modes

(Running, Programming and Alarm modes) which enable you to run and stop the motor, monitor running

status, set function code data, display run ning i nform ation require d for m aintena nce, an d dis play a larm data.

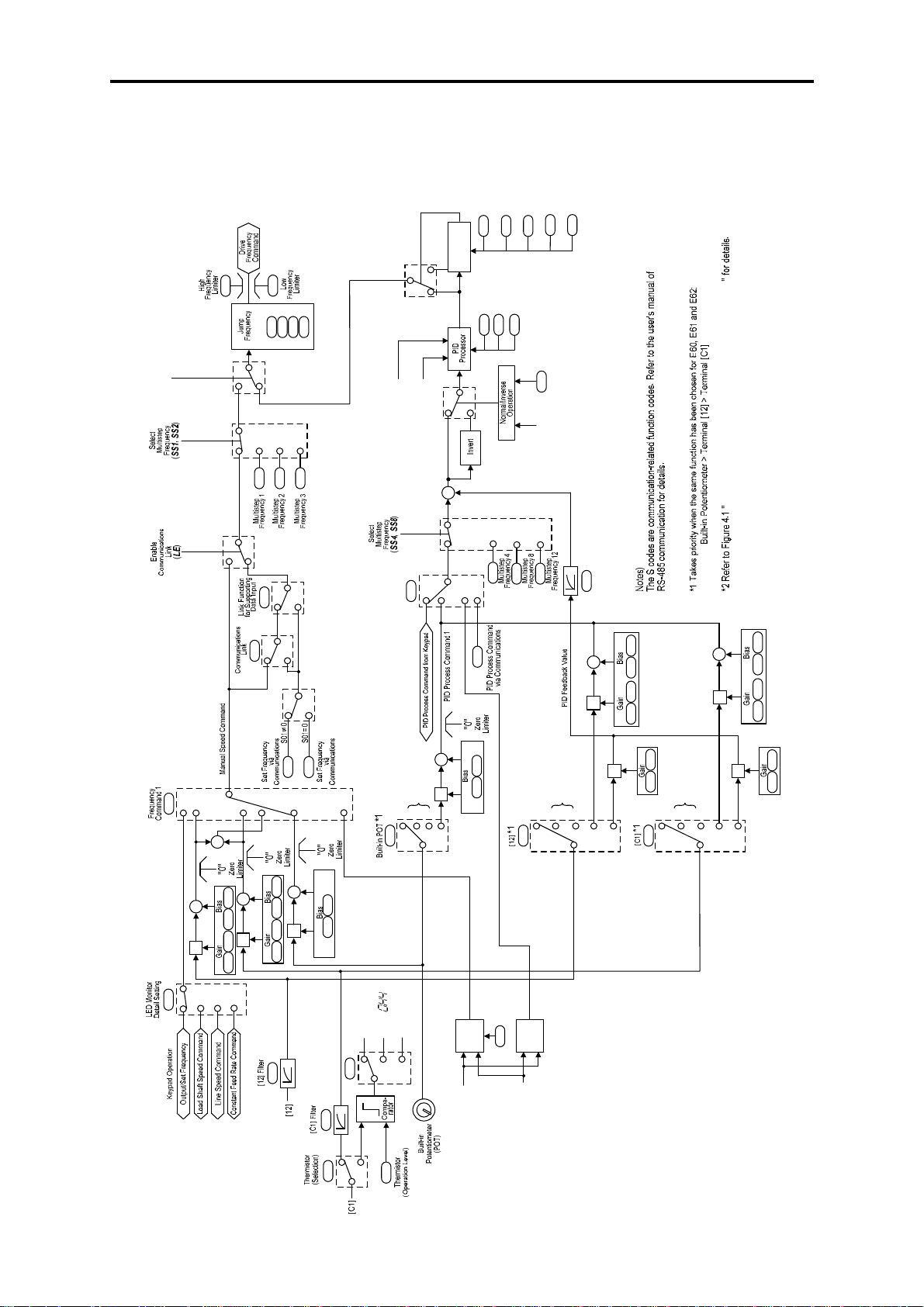

Chapter 4 BLOCK DIAGRAMS FOR CONTROL LOGIC

This chapter describes the main block diagram s for the control logic of the FRENIC-Mini series of inverters.

Chapter 5 RUNNING THROUGH RS-485 COMMUNICATIONS

This chapter describes an overview of inverter operation through the R S-485 comm unications facil ity. Refer

to the RS-485 Communication User's Manual (MEH448) for details.

Chapter 6 SELECTING PERIPHERAL EQUIPMENT

This chapter describes how to use a range of peripheral equipment and options, FRENIC-Mini's

configuration with them, and requirements and precautions for selecting wires and crimp terminals.

Chapter 7 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

This chapter provides you with information about the inverter output torque characteristics, selection

procedure, and equations for calculating capacities to help you select optimal motor and inverter models. It

also helps you select braking resistors.

Chapter 8 SPECIFICATIONS

This chapter describes specifications of the output ratings, control system, and terminal functions for the

FRENIC-Mini series of inverters. It also provides descriptions of the operating and storage environment,

external dimensions, examples of basic connection diagrams, and details of the protective functions.

Chapter 9 FUNCTION CODES

This chapter contains overview lists of seven groups of f unction cod es available f or the FRENIC-Mini series

of inverters and details of each function code.

Appendices

App. A Advantageous Use of Inverters (Notes on electrical noise)

App. B Japanese Guideline for Suppressing Harmonics by Customers Receiving High Voltage or Special

High Voltage

App. C Effect on Insulation of General-purpose Motors Driven with 400 V Class Inverters

App. D Inverter Generating Loss

App. E Conversion from SI Units

App. F Allowable Current of Insulated Wires

App. G Replacement Information

vi

Page 11

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the inverter not operating to

full efficiency, as well as information concerning incorrect operations and settings which can

result in accidents.

This icon indicates information that can prove handy when performing certain settings or

operations.

This icon indicates a reference to more detailed information.

vii

Page 12

CONTENTS

Chapter 1 INTRODUCTION TO FRENIC-Mini

1.1 Features.....................................................................................................................................................1-1

1.2 Control System.......................................................................................................................................1-10

1.3 Recommended Configuration................................................................................................................. 1-11

Chapter 2 PARTS NAMES AND FUNCTIONS

2.1 External View and Term inal Blocks .........................................................................................................2-1

2.2 Names and Functions of Keypad Components......................................................................................... 2-2

Chapter 3 OPERATION USING THE KEYPAD

3.1 Overview of Operation Modes .................................................................................................................3-1

3.2 Running Mode..........................................................................................................................................3-3

3.2.1 Run/stop the motor.............................................................................................................................. 3-3

3.2.2 Set up the reference frequency and PID process command ................................................................ 3-3

3.2.3 Monitor the running status..................................................................................................................3-5

3.2.4 Jog (inch) the motor............................................................................................................................3-7

3.3 Programming Mode.................................................................................................................................. 3-8

3.3.1 Setting the function codes--"Data Setting"..........................................................................................3-9

3.3.2 Checking changed function codes--"Data Checking".......................................................................3-13

3.3.3 Monitoring the running status--"Drive Monitoring".........................................................................3-14

3.3.4 Checking I/O signal status--"I/O Checking"..................................................................................... 3-17

3.3.5 Reading maintenance information--"Maintenance Information"...................................................... 3-21

3.3.6 Reading alarm information--"Alarm Information"............................................................................3-24

3.4 Alarm Mode............................................................................................................................................ 3-28

3.4.1 Releasing the alarm and transferring the inverter to Running mode.................................................3-28

3.4.2 Displaying the alarm history.............................................................................................................3-28

3.4.3 Displaying the running information when an alarm occurs .............................................................. 3-29

3.4.4 Transferring to Programming mode..................................................................................................3-29

Chapter 4 BLOCK DIAGRAMS FOR CONTROL LOGIC

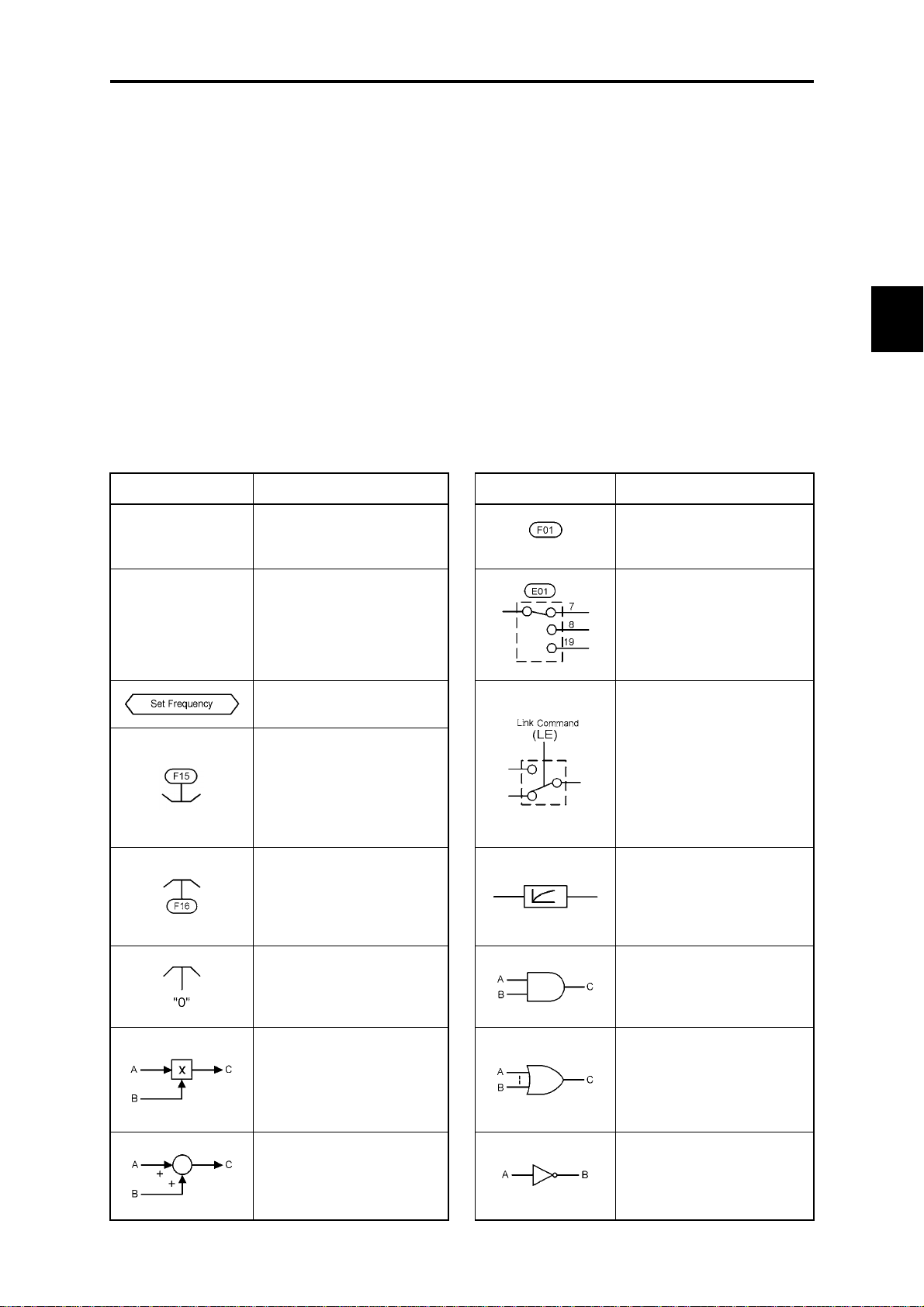

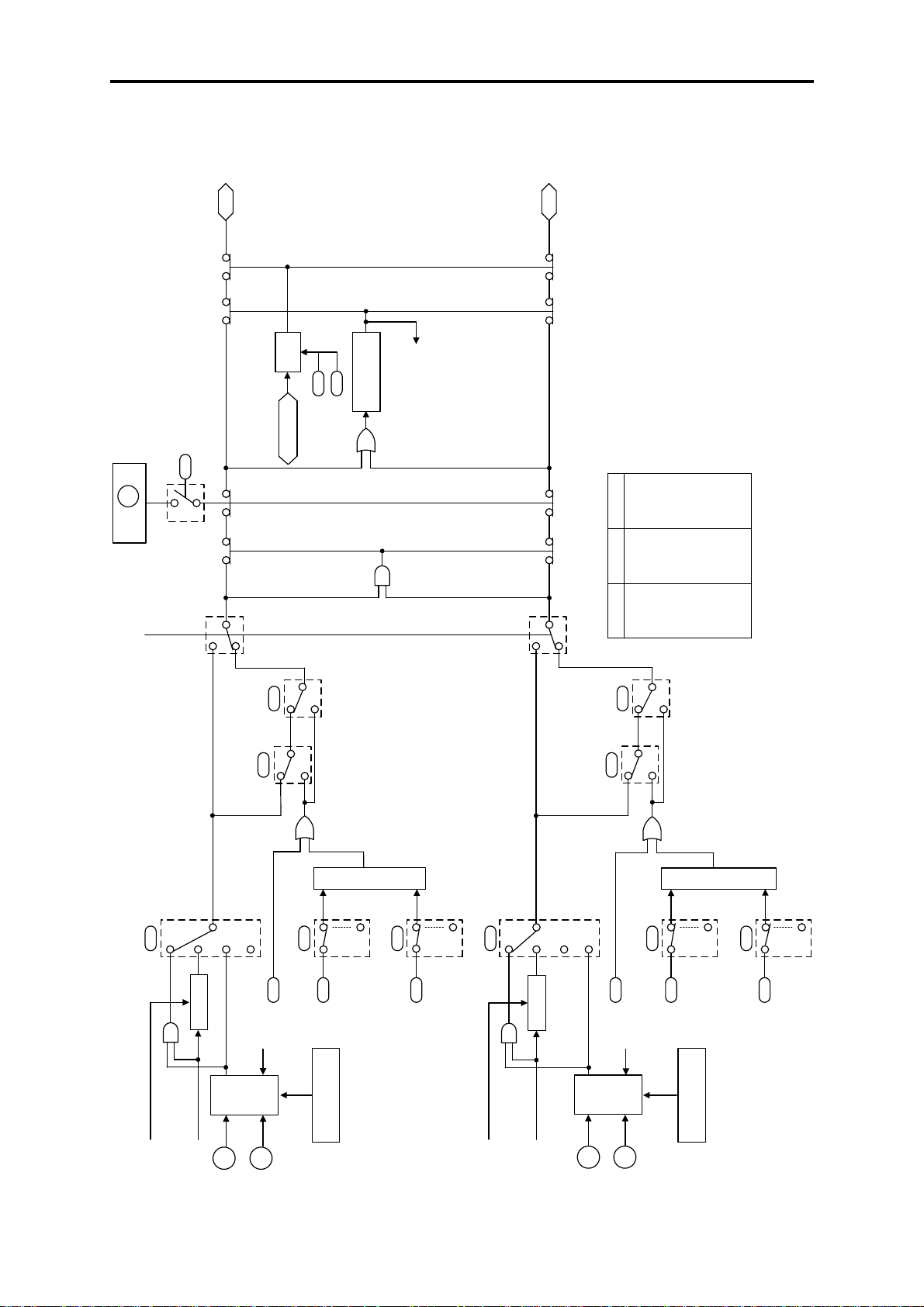

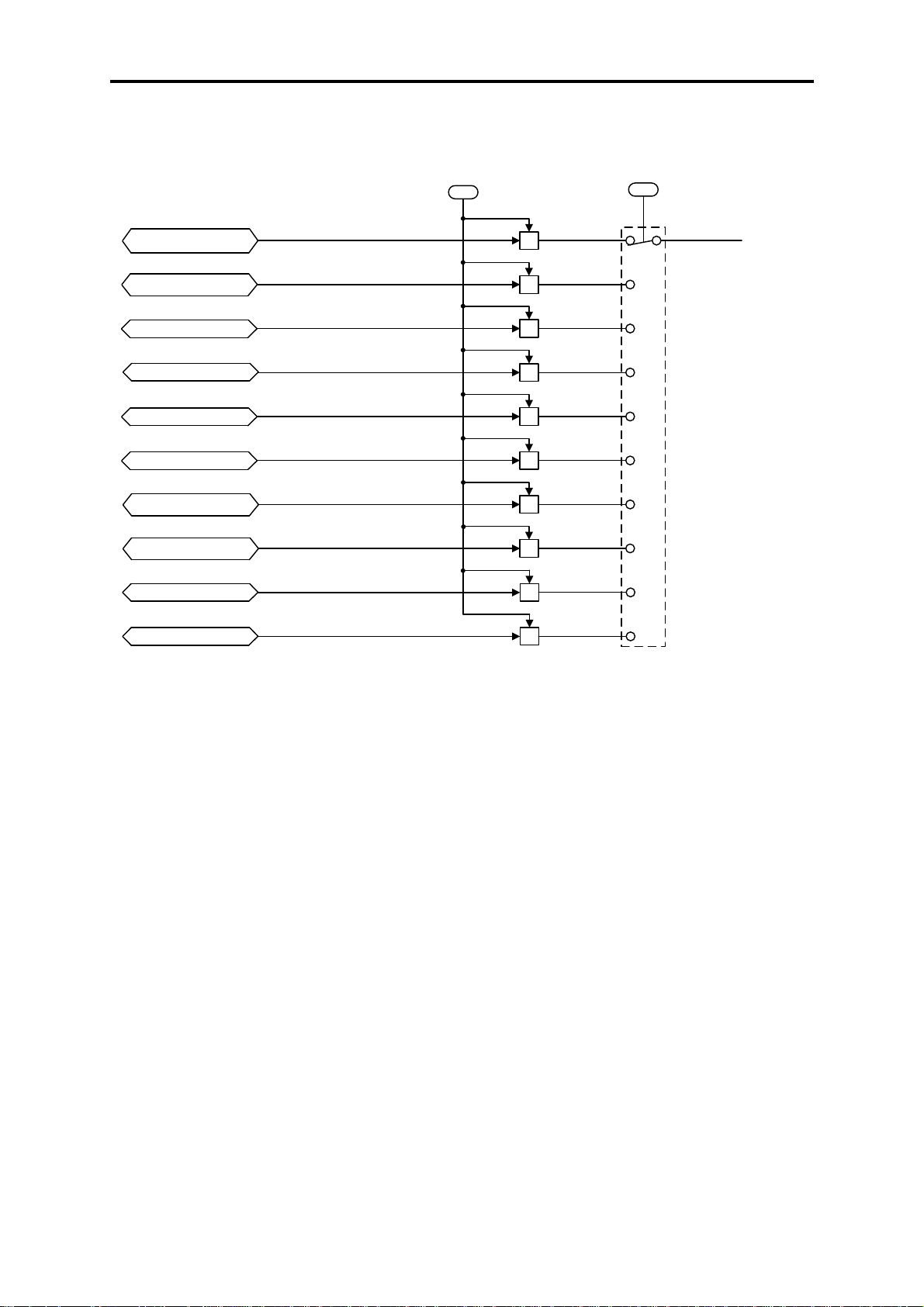

4.1 Symbols Used in the Block Diagrams and their Meanings.......................................................................4-1

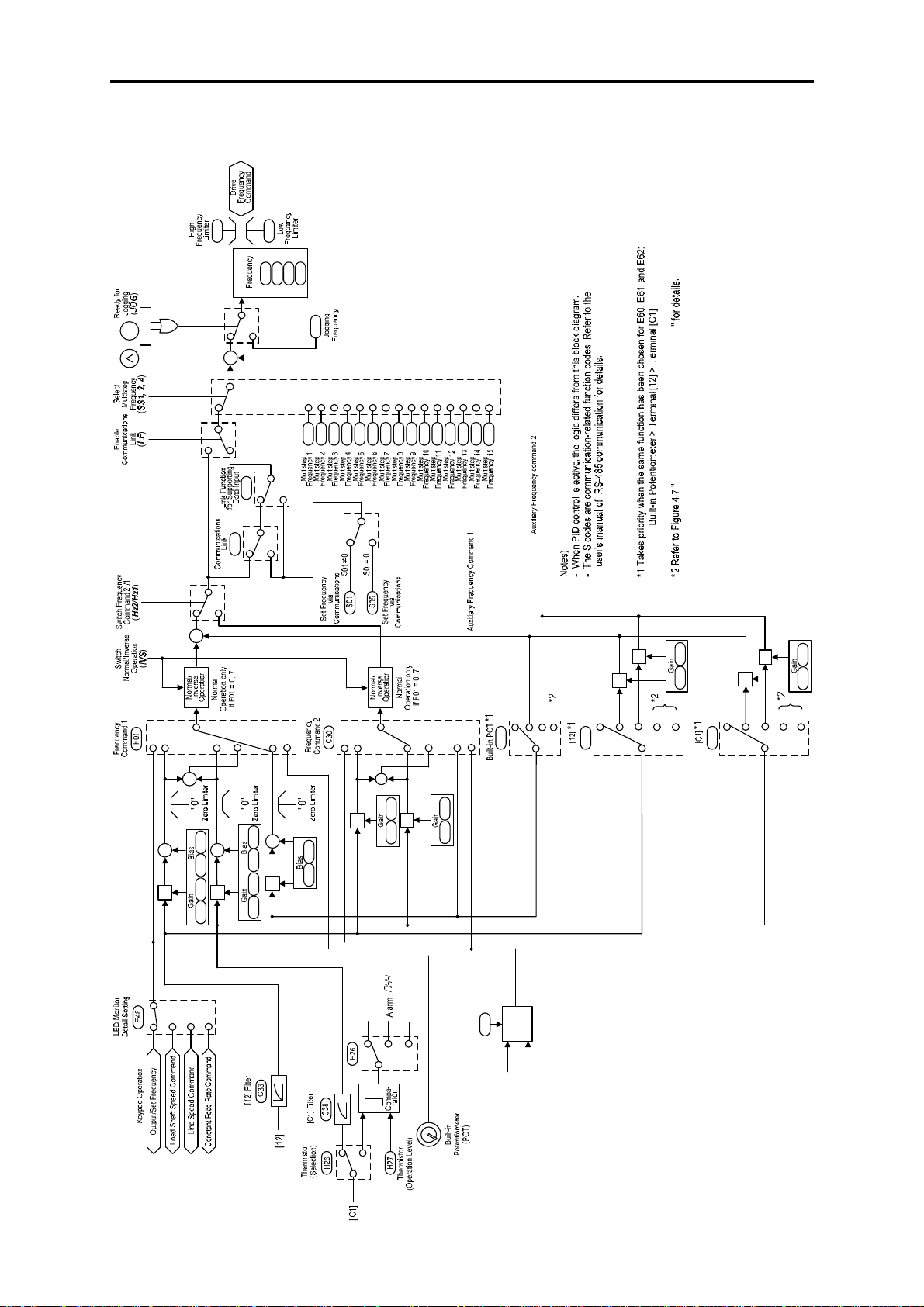

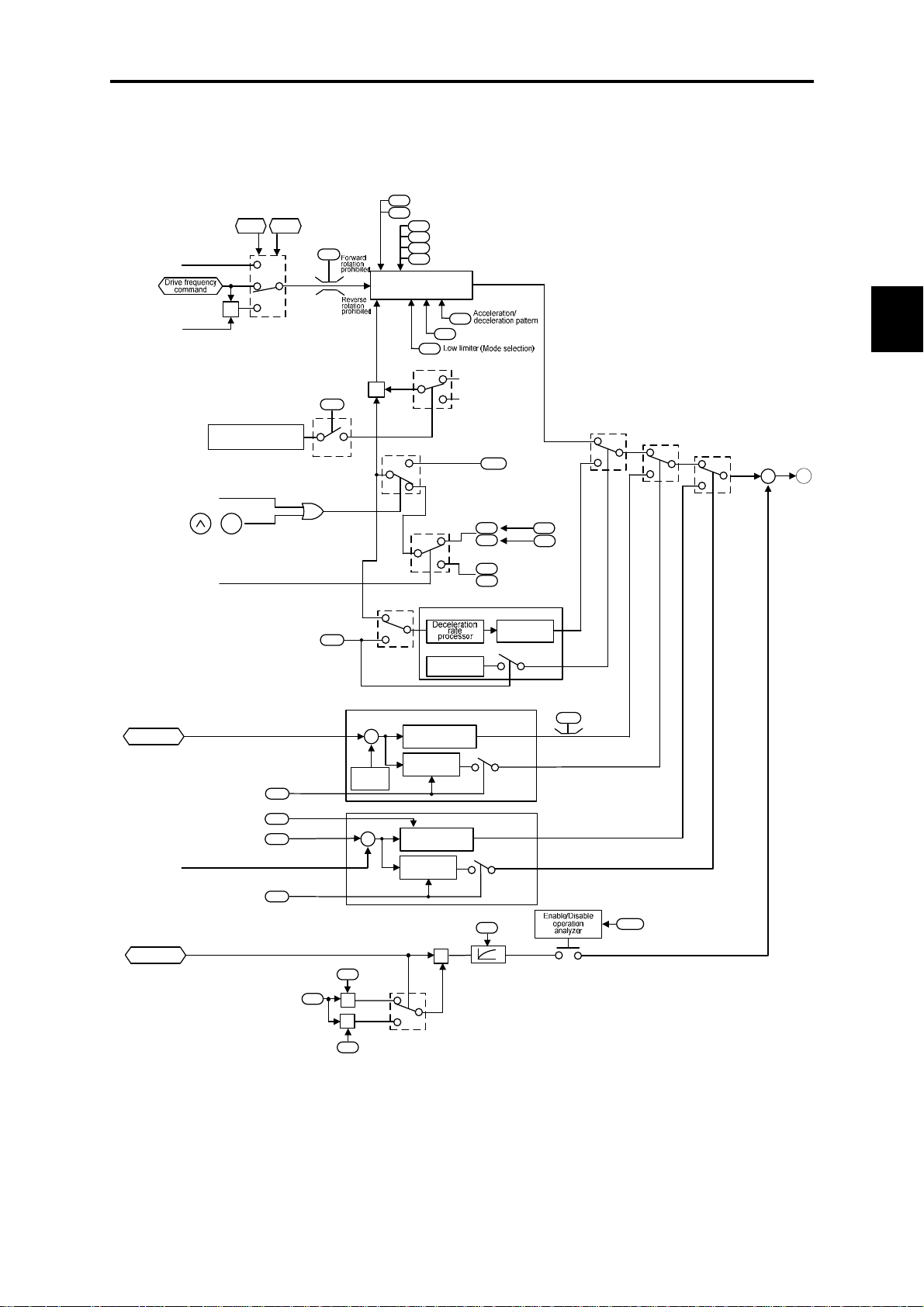

4.2 Drive Frequency Command Generator.....................................................................................................4-2

4.3 Drive Command Generator.......................................................................................................................4-4

4.4 Terminal Command Decoders ..................................................................................................................4-6

4.5 Digital Output Selector...........................................................................................................................4-10

4.6 Analog Output (FMA) Selector.............................................................................................................. 4-12

4.7 Drive Command Controller....................................................................................................................4-13

4.8 PID Frequency Command Generator......................................................................................................4-16

Chapter 5 RUNNING THROUGH RS-485 COMMUNICATIONS

5.1 Overview on RS-485 Communication......................................................................................................5-1

5.1.1 Common specifications.......................................................................................................................5-2

5.1.2 Connector specifications.....................................................................................................................5-3

5.1.3 Connection..........................................................................................................................................5-4

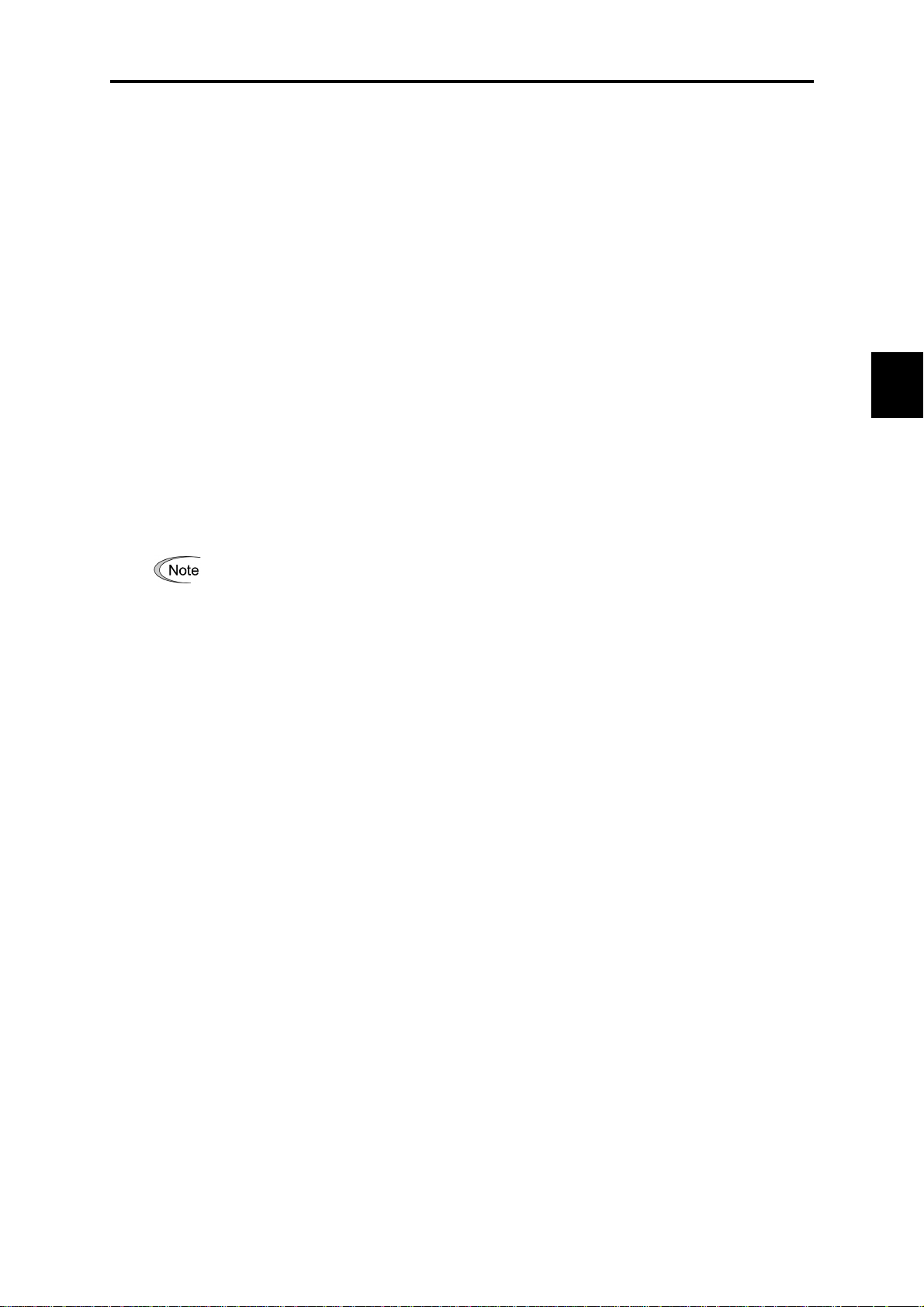

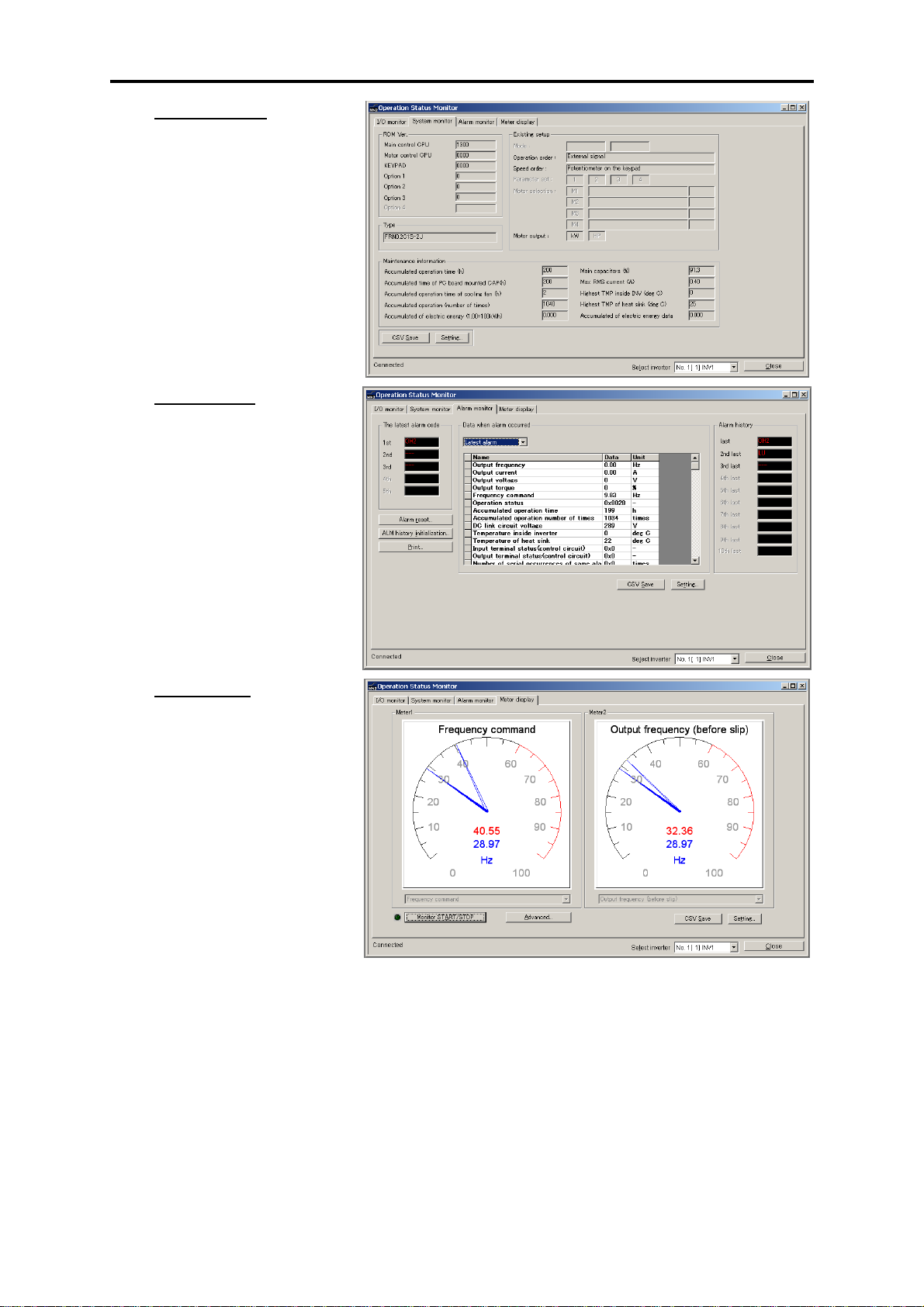

5.2 Overview of FRENIC Loader................................................................................................................... 5-5

5.2.1 Specifications......................................................................................................................................5-5

5.2.2 Connection..........................................................................................................................................5-6

5.2.3 Function overview...............................................................................................................................5-6

5.2.3.1 Setting of function code..............................................................................................................5-6

5.2.3.2 Running status monitor...............................................................................................................5-7

5.2.3.3 Test-running ................................................................................................................................5-9

viii

Page 13

Chapter 6 SELECTING PERIPHERAL EQUIPMENT

6.1 Configuring the FRENIC-Mini................................................................................................................. 6-1

6.2 Selecting Wires and Crimp Terminals.......................................................................................................6-2

6.2.1 Recommended wires........................................................................................................................... 6-4

6.2.2 Crimp terminals.................................................................................................................................6-12

6.3 Peripheral Equipment ............................................................................................................................. 6-13

6.4 Selecting Options.................................................................................................................................... 6-20

6.4.1 Peripheral equipment options............................................................................................................6-20

6.4.2 Options for operation and communications ......................................................................................6-33

6.4.3 Extended installation kit options....................................................................................................... 6-37

6.4.4 Meter options ....................................................................................................................................6-40

Chapter 7 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

7.1 Selecting Motors and Inverters................................................................................................................. 7-1

7.1.1 Motor output torque characteristics.....................................................................................................7-1

7.1.2 Selection procedure............................................................................................................................. 7-4

7.1.3 Equations for selections ......................................................................................................................7-7

7.1.3.1 Load torque during constant speed running................................................................................7-7

7.1.3.2 Acceleration and deceleration time calculation........................................................................... 7-8

7.1.3.3 Heat energy calculation of braking resistor............................................................................... 7-11

7.1.3.4 Calculating the RMS rating of the motor..................................................................................7-12

7.2 Selecting a Braking Resistor................................................................................................................... 7-13

7.2.1 Selection procedure........................................................................................................................... 7-13

7.2.2 Notes on selection.............................................................................................................................7-13

Chapter 8 SPECIFICATIONS

8.1 Standard Models....................................................................................................................................... 8-1

8.1.1 Three-phase 200 V series.................................................................................................................... 8-1

8.1.2 Three-phase 400 V series.................................................................................................................... 8-2

8.1.3 Single-phase 200 V series...................................................................................................................8-3

8.1.4 Single-phase 100 V series...................................................................................................................8-4

8.2 Semi-standard Models..............................................................................................................................8-5

8.2.1 EMC filter built-in type in three-phase 400 V series........................................................................... 8-5

8.2.2 EMC filter built-in type in single-phase 200 V series......................................................................... 8-6

8.3 Common Specifications............................................................................................................................ 8-7

8.4 Terminal Specifications .......................................................................................................................... 8-11

8.4.1 Terminal functions ............................................................................................................................ 8-11

8.4.2 Location of terminal blocks...............................................................................................................8-19

8.4.3 Terminal arrangement diagram and screw specifications..................................................................8-20

8.4.3.1 Main circuit terminals ...............................................................................................................8-20

8.4.3.2 Control circuit terminals............................................................................................................8-22

8.5 Operating Environment and Storage Environment.................................................................................8-24

8.5.1 Operating environment......................................................................................................................8-24

8.5.2 Storage environment.........................................................................................................................8-25

8.5.2.1 Temporary storage..................................................................................................................... 8-25

8.5.2.2 Long-term storage.....................................................................................................................8-25

8.6 External Dimensions............................................................................................................................... 8-26

8.6.1 Standard models................................................................................................................................ 8-26

8.6.2 EMC filter built-in type..................................................................................................................... 8-32

8.7 Connection Diagrams .............................................................................................................................8-37

8.7.1 Keypad operation..............................................................................................................................8-37

8.7.2 Operation by external signal inputs................................................................................................... 8-38

8.8 Details of Protective Functions............................................................................................................... 8-39

ix

Page 14

Chapter 9 FUNCTION CODES

9.1 Function Code T ables...............................................................................................................................9-1

9.2 Details of Function Codes.......................................................................................................................9-20

9.2.1 F codes (Fundamental functions)......................................................................................................9-20

9.2.2 E codes (Extension terminal functions).............................................................................................9-47

9.2.3 C codes (Control functions)..............................................................................................................9-71

9.2.4 P codes (Motor 1 parameters) ...........................................................................................................9-77

9.2.5 H codes (High performance functions).............................................................................................9-81

9.2.6 A codes (Motor 2 parameters)......................................................................................................... 9-107

9.2.7 J codes (Application functions)....................................................................................................... 9-109

9.2.8 y codes (Link functions).................................................................................................................. 9-119

9.3 Notes in Driving PMSM....................................................................................................................... 9-124

Appendices

App. A Advantageous Use of Inverters (Notes on electrical noise)................................................................... A-1

A.1 Effect of inverters on other devices....................................................................................................... A-1

A.2 Noise...................................................................................................................................................... A-2

A.3 Noise prevention.................................................................................................................................... A-4

App. B Japanese Guideline for Suppressing Harmonics by Customers Receiving High Voltage or

Special High Voltage ........................................................................................................................... A-12

B.1 Application to general-purpose inverters.............................................................................................A-12

B.2 Compliance to the harmonic suppression for customers receiving high voltage or

special high voltage............................................................................................................................. A-13

App. C Effect on Insulation of General-purpose Motors Driven with 400 V Class Inverters.......................... A-17

C.1 Generating mechanism of surge voltages............................................................................................A-17

C.2 Effect of surge voltages....................................................................................................................... A-18

C.3 Countermeasures against surge voltages ............................................................................................. A-18

C.4 Regarding existing equipment............................................................................................................. A-19

App. D Inverter Generating Loss.....................................................................................................................A-20

App. E Conversion from SI Units.................................................................................................................... A-21

App. F Allowable Current of Insulated Wires................................................................................................. A-23

App. G Replacement Information .................................................................................................................... A-25

G.1 Compatibility and differences between FRENIC-Mini series FRNC1- and

FRNC2- ......................................................................................................................A-25

G.2 External dimensions comparison tables............................................................................................... A-26

G.3 Terminal arrangements and symbols ................................................................................................... A-29

G.4 Function codes..................................................................................................................................... A-31

x

Page 15

Chapter 1

INTRODUCTION TO FRENIC-Mini

This chapter describes the features and control system of the FRENIC-Mini series, and the recommended

configuration for the inverter and peripheral equipment.

Contents

1.1 Features.......................................................................................................................................................1-1

1.2 Control System..........................................................................................................................................1-10

1.3 Recommended Configuration................................................................................................................... 1-11

Page 16

Page 17

1.1 Features

Upgraded FRENIC-Mini (FRNC2-) functions

• Dynamic torque vector control providing bumped-up torque performance

Fuji's original dynamic torque vector control broadens the range of applications.

• RS-485 communications port provided as standard to facilitate system configuration

While the original FRENIC-Mini series has an RS-485 communications port as an option, the

upgraded one has it as standard, making it easy to connect the upgraded one to a PLC and facilitating

system configuration.

• Slow flowrate stop function under PID control for further energy saving

Under PID control for constant pump discharge pressure, the slow flowrate stop function stops the

inverter when the pump discharge pressure is high, which achieves further energy saving.

• Braking signal function making the FRENIC-Mini applicable to simple vertical lift

applications

The upgraded FRENIC-Mini series supports brake ON/O FF signals that are conventi onally su pported

by the upper inverter series only. The braking signal fun ction enables t he FRENIC-Mini to be applied

to simple vertical lift applications.

• Motor switching function

Turning the Di terminal ON and OFF switches between parameters specified for the 1st motor and

those for the 2nd motor. This further broadens the range of applications.

1.1 Features

Chap. 1 INTRODUCTION TO FRENIC-Mini

• Motor auto-tuning

The auto-tuning function enables the dynamic torque vector control, automatic energy saving

operation, and other advanced motor controls to be applied also to non-Fuji general purpose motors.

• Long-life DC link bus capacitors, control printed circuit board capacitors and cooling fans

adopted

• Optional USB-equipped remote keypad

Data copying and connection to FRENIC Loader are easy.

• Permanent magnet synchronous motor (PMSM) supported

A PMSM is more efficient than an induction motor (IM) so that further energy saving c an be achieved.

• Available capacity range up to 15 kW (20 HP)

The capacity range has been spread.

1-1

Page 18

Optimum performance for traversing conveyors

• High starting torque, at 150% or more

Equipped with Fuji's original dynamic torque-vector control system and the automatic torque boost

function, these inverters ensure consistent and powerful operation (when automatic torque boost and

slip compensation control are ON and start frequency is set at 3 Hz).

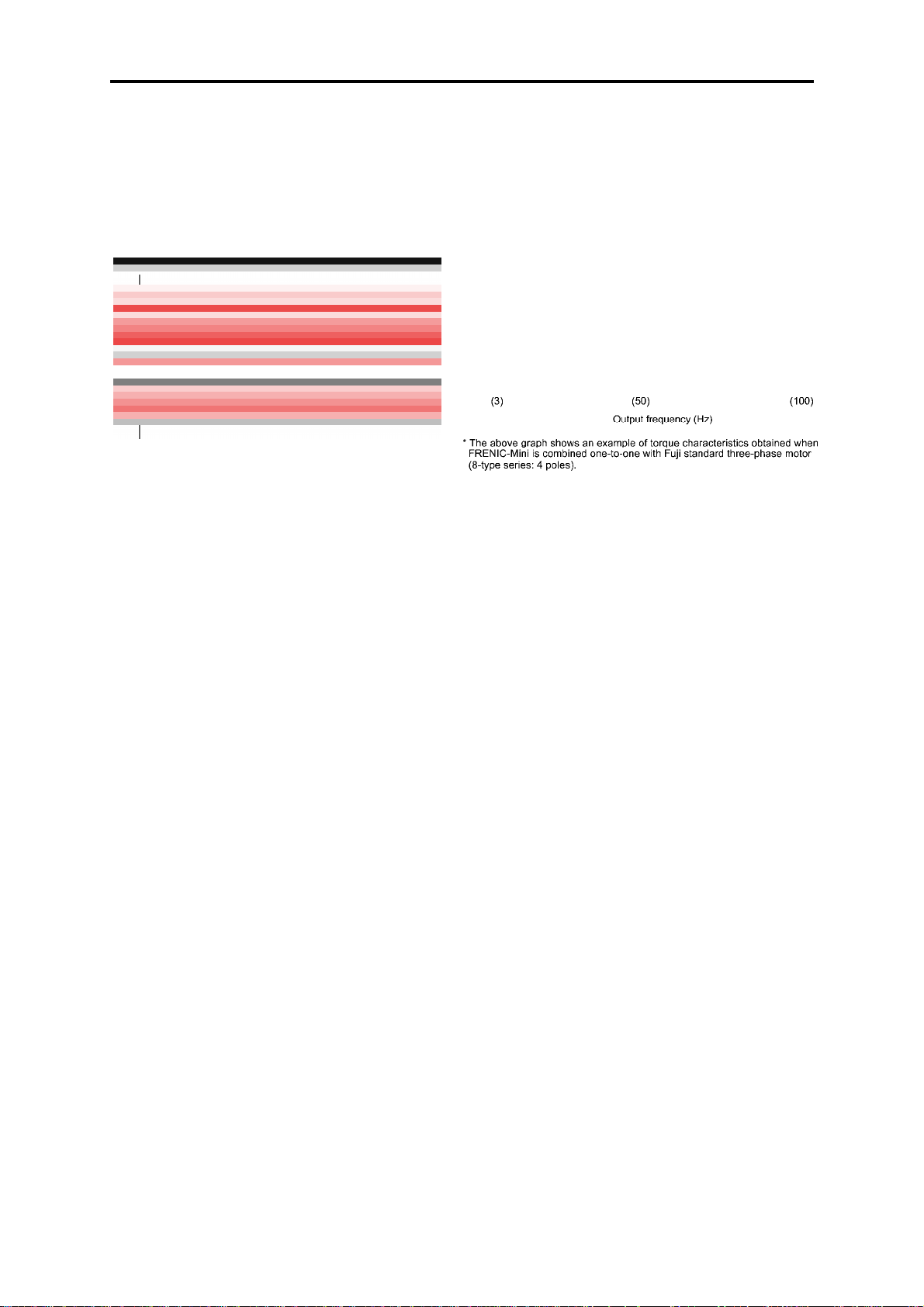

Figure 1.1 Torque Characteristics Data

(Dynamic torque vector control: ON)

Figure 1.2 Example of Output Torque Characteristics

• Braking resistor connectable to the inverter

FRENIC-Mini series of inverters features a built-in braking transistor (for inverters of 0.4 kW (1/2

HP) or larger), which makes it possible for an opt ional braki ng resistor to be connecte d to increase t he

regenerative braking ability for conveya nce and transpor tation machin ery that req uires stro ng braking

power.

• Trip-free operation

The remarkably improved current limiting function (stall prevention) ensures trip-free operation even

for impact loads.

Figure 1.3 Example of Response for Impact Load Torque

• Stable operation even for a step load

The slip compensation function ensures stable operation even when the motor load fluctuates (step

load).

Figure 1.4 Example of Response for Step Load Torque (Refer to the note in Figure 1.2 for the test configuration.)

1-2

Page 19

• Inclusion of a brake signal makes it even more convenient

At brake release time

After the motor runs, the inverter detects torque generation and outputs signals.

1.1 Features

Chap. 1 INTRODUCTION TO FRENIC-Mini

At brake application time

Brake application that matches the timing can be done, so mechanical brake wear is reduced.

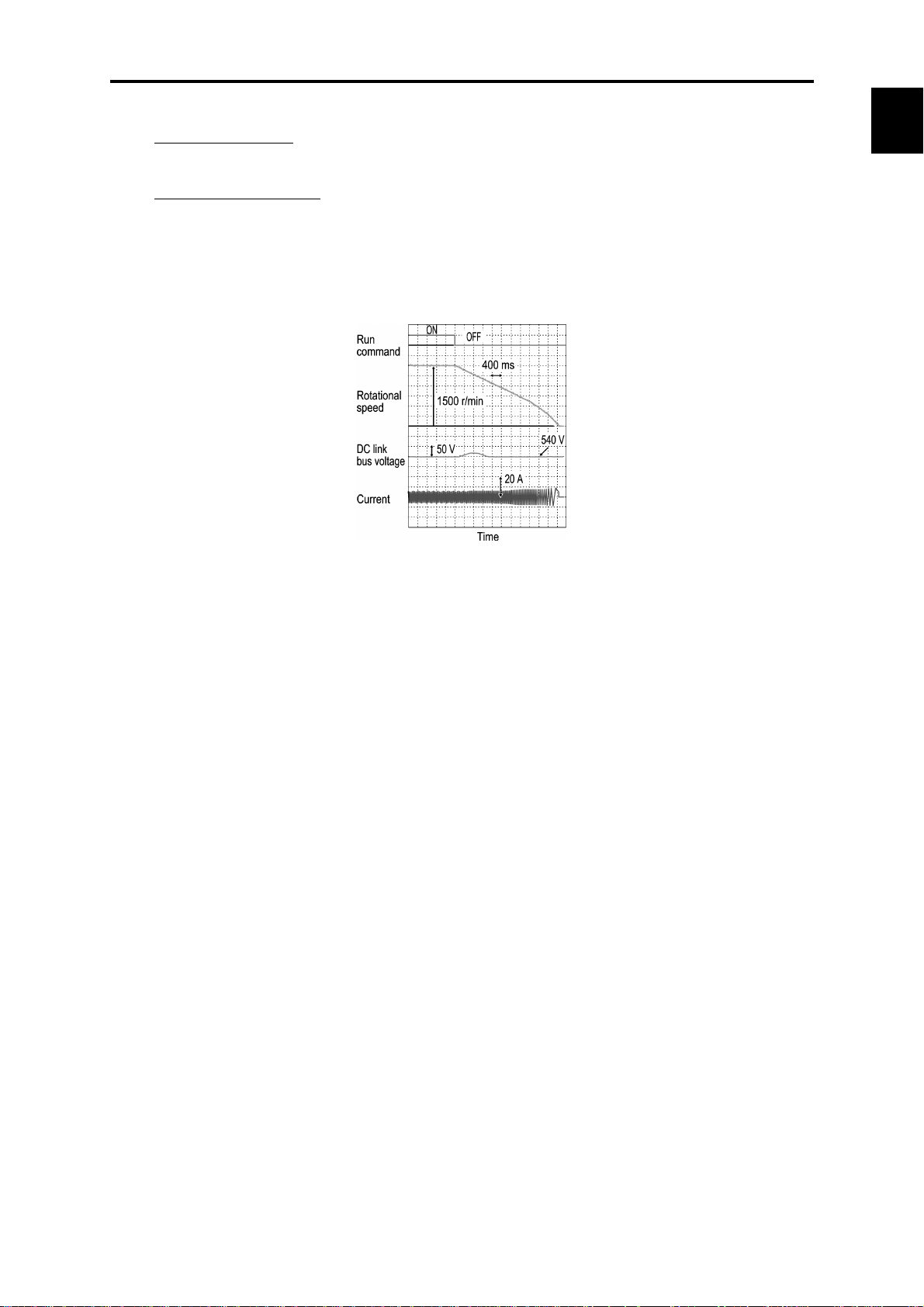

• Tripless deceleration by automatic deceleration control

The inverter controls the energy level generated and the deceleration time to decelerate to stop the

motor without tripping due to overvoltage.

Figure 1.5

Default functions for fans and pumps

• Automatic energy-saving function provided as standard

To minimize the total loss (motor loss plus inverter loss), rather than just the motor loss as in the

predecessor models, FRENIC-Mini saves even more power when used with fans or pumps.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

* Energy savings vary depending on the motor characteristics.

Figure 1.6 Example of Energy Savings

1-3

Page 20

• PID control function

Permits motor operation while controlling temperature, pressure, or flow rate without using an

external device such as a temperature regulator. Under the constant pump discharge pressure control,

the slow flowrate stop function is available.

Refer to Chapter 4, Section 4.8 "PID Frequency Command Generator" for details.

• Cooling fan ON/OFF control function

The inverter's cooling fan can be turned off while the fan or pump is stopped for noise reduction and

energy savings.

The ideal functions to serve a multiplicity of needs for small-capacity inverters

• Compatible with a wide range of frequency settings

You can select the optimum frequency setti ng method that m atches your m achine or equipm ent via the

/

keypad (

1 to 5 V), 16 multistep speed settings (0 to 15 steps) or via RS-485 communications.

• A transistor output is provided

This enables an overload early warning, lifetime forecast or other information signals to be output

during operation.

Refer to function code E20 in Chapter 9, Section 9.2.2 " E codes (Extension terminal functio ns)."

• High output frequency - up to 400 Hz

The inverter can be used with equipment such as centrifugal separators that require a high motor speed.

In this case, you need to check whether the machine operation in combination with the motor is

compatible or not.

• Three points can be set for a non-linear V/f pattern.

The addition of an extra point (total 3 points) for the non-linear V/f pattern, which ca n be set as desired,

improves the FRENIC-Mini's drive capability, because the V/f pattern can be adjusted to match a

wider application area.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

keys or potentiometer), analog input (4 t o 20 mA , 0 to 2 0 m A, 0 to +1 0 V , 0 to +5 V ,

Compact size

• Side-by-side mounting

More than one FRENIC-Mini inverter can be mounted side-by-side without any gap inside your

system control panel, thereby reducing the amount of space required for installation. (Ambient

temperature: 40°C (104°F) or lower)

Unit: mm (inch)

(Example: Inverters of 3-phase 200 V, 0.75 kW (1 HP) or less)

1-4

Page 21

• External dimensions compatible with Fuji FVR-C11S series,

externals compatible with original FRENIC-Mini series (FRNC1-)

The external differences (improved points) from the conventional FRNC1- are as

follows.

Screw added to the control circuit terminal bl ock cover, which prevents the cover from coming off due

to vibration or unexpected incident.

Control circuit terminal block using commonly used slotted screws instead of Phillips-head ones,

which standardizes tools.

1.1 Features

Chap. 1 INTRODUCTION TO FRENIC-Mini

Simplified operation and wiring

• Frequency setting potentiometer provided as standard

The frequency can be adjusted easily by hand.

• Easy-to-remove terminal block covers (for control circuit and main circuit) that are secured

with a single screw.

As shown below, the terminal block covers for the control circuit and main circuit can be removed

easily by removing the single screw from the control circuit terminal block cover.

Control circuit terminal block cover

Main circuit terminal

block cover

1-5

Page 22

• LED monitor on the keypad displaying all types of data

You can access and monitor all types of inverter's data and information including output frequency,

reference frequency, load shaft speed, output current, output voltage, alarm history, input power etc.

using built-in keypad with LED.

Refer to Chapter 3, "OPERATION USING THE KEYPAD."

• Menu mode accessible from the keypad

You can easily access the menu mode includi ng "Data s etting," "Data checki ng," "Drive m onit oring,"

"I/O checking," "Maintenance information," and "Alarm information."

Refer to Chapter 3, "OPERATION USING THE KEYPAD."

Maintenance

FRENIC-Mini series features the following facilities useful for maintenance.

Refer to Chapter 3, Section 3.3.5 "Reading Maintenance Information" and the FRENIC-Mini

Instruction Manual, Chapter 7 "MAINTENANCE AND INSPECTION" for details.

• The lifetime of the DC link bus capacitor (reservoir capacitor) can be estimated

The capacitor's condition compared with its initial state can be confirmed.

• Recording and displaying of cumulative running time of the inverter

The inverter records and displays the accumulated running time of the inverter itself, the printed

circuit board and cooling fan.

• Displaying Information that contributes to equipment maintenance

In addition to inverter maintenance information, the inverter displays data that also take equipment

maintenance into consideration.

Item Purpose

Motor cumulative

running time (hr)

The actual cumulative running time of the equipment (motor) using the inverter is

calculated.

<Example of use>

If the inverter is used to control a fan, this information is an indication of the timing

for replacing the belt that is used on the pulleys.

Number of starts

(times)

The number of the inverter start and stop times can be counted.

<Example of use>

The number of equipment start and stop times is recorded, so this information can

be used as a guideline for parts replacement timing in equipment in which starting

and stopping puts a heavy load on the machinery.

1-6

Page 23

1.1 Features

• Alarm history for up to 4 latest alarms

The inverter records detailed information for up to 4 alarms that occurred most recently, which can

also be displayed on the LED.

Refer to Chapter 3, Section 3.3.6 "Reading alarm information."

• Lifetime forecast signal via transistor output

This signal is output when the reserv oir capaci tor i n the DC link bus, the electrolytic capacit ors on the

printed circuit board, or the cooling fans have been nearing the end of their service life.

Refer to function code E20 in Chapter 9, Section 9.2.2 "E codes (Exte nsion term inal functions)"

for details.

Interface for peripheral devices and comprehensive protective functions

• All models are equipped with an inrush current suppression circuit.

FRENIC-Mini series features an inrush current suppression circ uit as standard in all m odels to reduce

the cost of peripheral devices such as input magnetic contactor.

• Terminals for a DC reactor (DCR) provided as standard

Terminals for connection of a DCR, which are necessary for suppressing harmonics, are provided as

standard in all models.

• Input/output phase loss protective function

FRENIC-Mini series can detect output phase loss at all times during starting and running. This fe ature

assists you for keeping operation of your system stable.

• Switchable sink/source

The input/output mode (sink/source) of the digital input terminals can be switched by means of an

internal jumper switch. No engineering change is required in other control devices including PLC.

• Motor can be protected by a PTC thermistor

The motor is protected by PTC (Positive Temperature Coefficient) thermistor which detects the

motor's temperature and stops the inverter before the motor is overheated.

Flexible through options

Chap. 1 INTRODUCTION TO FRENIC-Mini

• Function code copy function

The optional remote keypad inc ludes a built-in copy facility , so you can copy function code data set i n

a source inverter and duplicate it into a destination inverter.

• Inverter support software FRENIC Loader available

The inverter support loader program (Windows-base d), which sim plifies the configu ration of function

codes, is available as a free-of-charge option. It can be downloaded from our Website.

Refer to Chapter 5, "RUNNING THROUGH RS-485 COMMUNICATION" for details.

1-7

Page 24

• Optional USB-equipped remote keypad (Available soon)

A variety of data about the inverter unit can be saved in the keypad memory, allowing you to check the

information in any place.

Features

1. The keypad can be directly connected to a computer through

a commercial USB cable (mini B) without using a converter.

The computer can be connected online with the inverter.

USB

<Example of use in the office>

2. With the FRENIC Loader, the inverter can support the

following functions (1) to (4).

(1) Editing, co mparing, and copying the function code data

(2) Real-time operation monitor

(3) Trouble history (indicating the latest four troubles)

(4) Maintenance information

Data can be transferred from the USB port of the keypa d directly to the computer (FRENIC Loader) at

the site of production.

Periodical collection of life information can be carried out efficiently.

< Example of use at the site of production >

• Mounting on DIN rail

Using the rail-mounting base (option), t he inverter can ea sily be mounte d on a DIN rail (35 mm wide).

Refer to Chapter 6, "SELECTING PERIPHERAL EQUIPMENT" for details.

• Easy replacement of older models with new ones

Using the mounting adapter (optio n) m akes it possible t o m ount the la test m odels witho ut drilli ng any

additional holes.

Refer to Chapter 6, "SELECTING PERIPHERAL EQUIPMENT" for details.

1-8

Page 25

• Remote operation

Using the remote keypad (option) toget her with remote operation e xtension cable enables you to easily

operate the inverter from a remote location.

Refer to Chapter 5, "RUNNING THROUGH RS-485 COMMUNICATION" and Chapter 6,

"SELECTING PERIPHERAL EQUIPMENT" for details.

Wide variations

The wide range of models available in the FRENIC-Mini series of i nve rters is cert ain to fl exibly m eet

your various system needs.

• Three-phase 200/230 V series; 0.1 to 15 kW (1/8 to 20 HP)

• Three-phase 400/460 V series; 0.4 to 15 kW (1/2 to 20 HP)

• Single-phase 200/230 V series; 0.1 to 2.2 kW (1/8 to 3 HP)

• Single-phase 115 V series; 0.1 to 0.75 kW (1/8 to 1 HP)

• Model with a built-in EMC filter is available on order

Refer to Chapter 8, "SPECIFICATIONS" for details.

1.1 Features

Chap. 1 INTRODUCTION TO FRENIC-Mini

Global products

The FRENIC-Mini series of inverters is designed for use in global market in conformity with the

global standards listed below.

• All standard models conform to the EC Directive (CE Marking), UL standards (UL-Listed)

and Canadian standards (cUL-Listed).

All standard FRENIC-Mini inverters conform to European and North American/Canadian standards,

enabling standardization of the specifications for machines and equipment used at home and abroad.

• If a model with a built-in EMC filter is used, the model conforms to the European EMC

Directive.

1-9

Page 26

1.2 Control System

This section gives you a general overview of inverter control systems and features specific to the

FRENIC-Mini series of inverters.

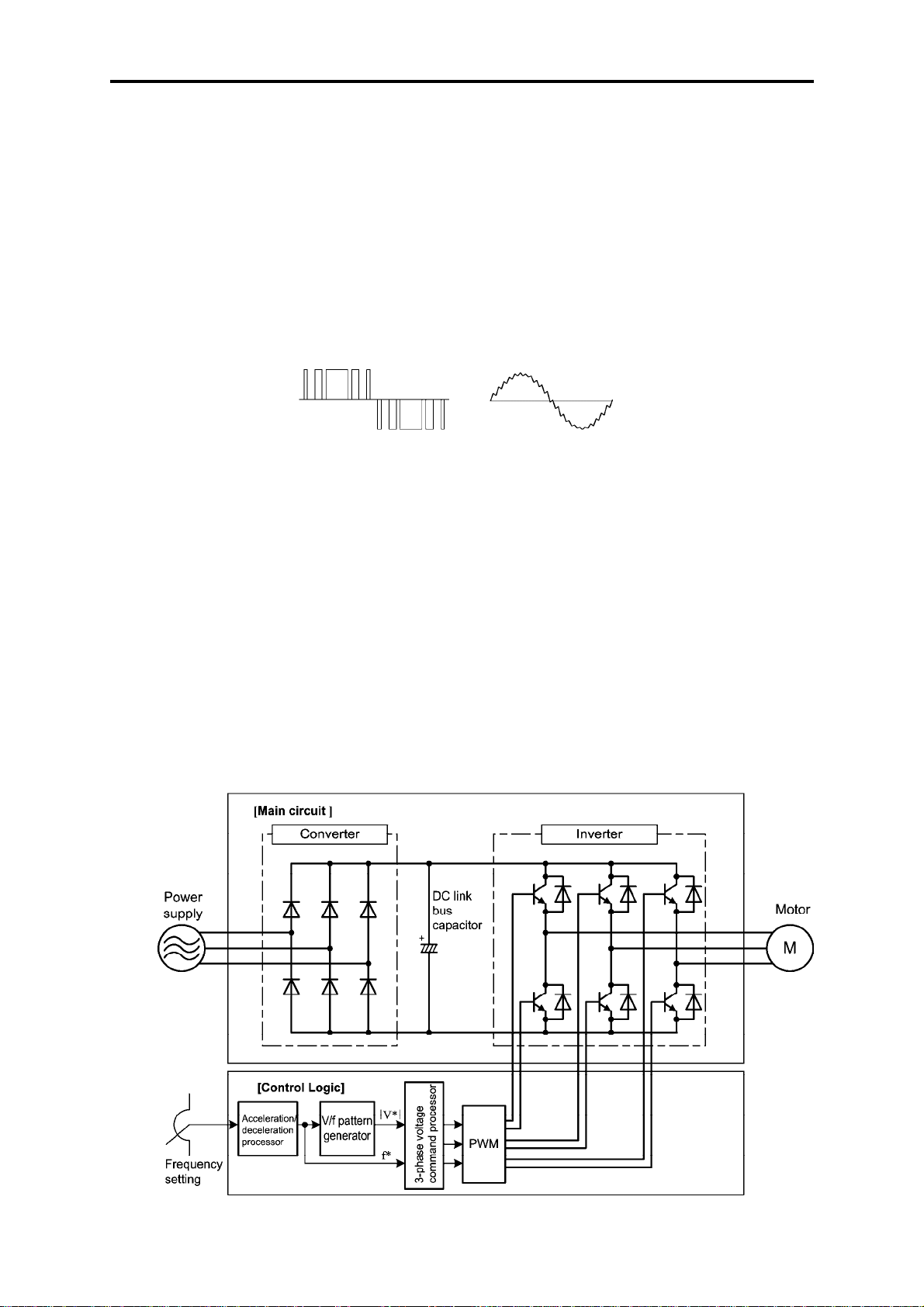

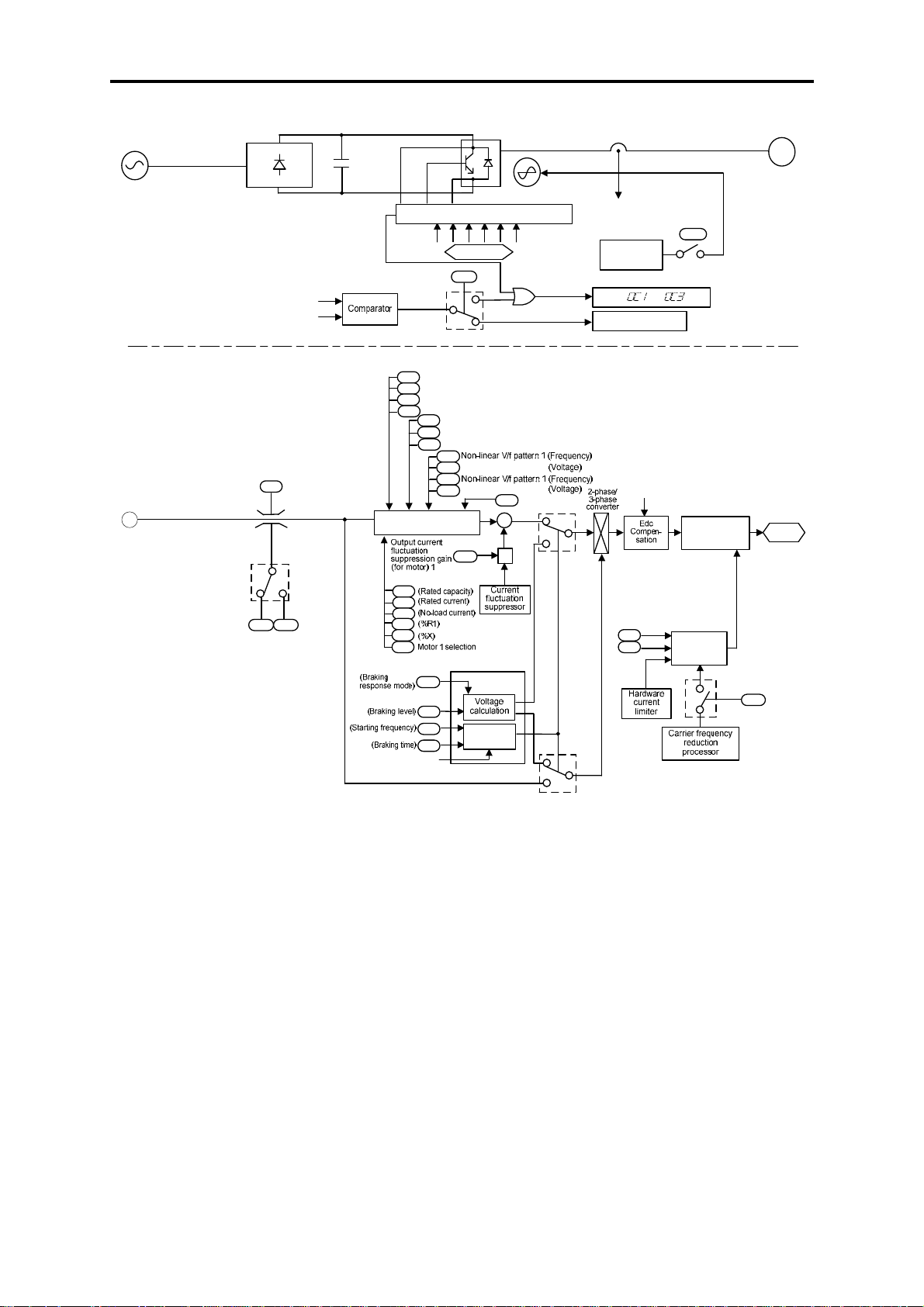

As shown in Figure 1.8, single- or three-phase commercial power is converted to DC power in the

converter section, which is then used to charge the capacitor on the DC link bus. Accor ding to co ntrol

commands or signals generated in the control logic, the inverter modulates the electricity charged in

the capacitor to PWM (Pulse Width Modulation) format and feeds the output to the motor. The

modulation frequency is called "carrier frequency." As shown in Figure 1.7, the voltage waveform of

the modulated power source produces pulse train with positive and negative polarity synchronized

with the inverter's output comm and frequ e ncy . The inverter feeds the produced output as drive power

with sinusoidal current waveform like that of ordinary commercial power lines.

PWM voltage waveform Current waveform

Figure 1.7 Output Voltage and Current Waveform of the Inverter

For the reference frequency given in the control logic, the accelerator/decelerator pr ocessor calculate s

the acceleration/deceleration rate required by run/stop control of the m otor and transfers the calc ulated

results to the 3-phase voltage command processor directly or via the V/f pattern generator.

Refer to Chapter 4, Section 4.7 "Drive Command Controller" for details.

The FRENIC-Mini series changes the voltage control from the "Simplified Torque-Vector Control"

using a magnetic flux estimator in conventiona l inverter series, to the Dynam ic Torque Vector Control

adopted in upper inverter series. Accordingly, the FRENIC-Mini series assures high start torque that

the conventional series cannot obtain, broadening the range of applications.

The control logic section, which is the very brain of the invert er, allows you to customize the i nverter's

driving patterns using the function code settings.

Refer to Chapter 4 "BLOCK DIAGRAMS FOR CONTROL LOGIC" for details.

Figure 1.8 Simplified Control System Diagram of FRENIC-Mini

1-10

Page 27

r

r

1.3 Recommended Configuration

1.3 Recommended Configuration

To control a motor with an inverter correctly, you should consider the rated capacity of both the m otor

and the inverter and ensure that the combination matches the specifications of the machine or system

to be used. Refer to Chapter 7, "SEL ECTING OPTIMAL MOTOR AND I NVERTER CAPACI TIES"

for details.

After selecting the rated capacity, select appropriate peripheral equipment for the inverter, then

connect them to the inverter.

Refer to Chapter 6, "SELECTING PERIPHERAL EQUIPMENT" and Chapter 8, Section 8.7

"Connection Diagrams" for details on the selection and connection of peripheral equipment.

Figure 1.9 shows the recommended configuration for an inverter and peripheral equipment.

Chap. 1 INTRODUCTION TO FRENIC-Mini

Three-phase or single-phase

power supply

Molded case circuit breaker

or

Earth leakage circuit breaker

(with overcurrent protection)

Magnetic contacto

Braking resistor

Moto

DC reactor (DCR)

Figure 1.9 Recommended Configuration Diagram

1-11

Page 28

Page 29

Chapter 2

PARTS NAMES AND FUNCTIONS

This chapter contains external views of the FRENIC-Mini series and an overview of terminal blocks,

including a description of the 7-segment LED monitor and keys on the keypad.

Contents

2.1 External V ie w and Terminal Blocks............................................................................................................2-1

2.2 Names and Functions of Keypad Components...........................................................................................2-2

Page 30

Page 31

r

2.1 External View and Terminal Blocks

2.1 External View and Terminal Blocks

(1) External view

Keypad

Nameplate

Control circuit terminal

bock cover

Main circuit

terminal block cover

Control circuit terminal

block cover

(2) Wiring section

Barrie

for the RS-485

communications port*

Control circuit wire

port

DB, P1, P (+) and

N (-) cable port

L1/R, L2/S, L3/T, U, V, W,

and grounding wire port

L1/R, L2/S, L3/T, P1, P (+),

and N(-) wire port

DB, U, V, W,

and grounding

wire port

(a) FRN0006C2S-2 (b) FRN0010C2S-2

(*When connecting the RS-485 communications cable, remove the control circuit terminal block cover and snip off the barrier

provided in it using nippers.)

Note: A box () in model names replaces A, C, E, or U depending on shipping destination.

Figure 2.1 External View of FRENIC-Mini

Cooling fan

Chap. 2 PARTS NAMES AND FUNCTIONS

Terminating resistor

ON/OFF jumper switch

Control circuit terminal block

Grounding terminal

RJ-45 connecotr

Power input terminal block

SINK/SOURCE jumper switch

DC reactor, braking resistor and

DC link bus terminal block

Grounding terminal

Inverter output terminal block

(FRN0010C2S-2)

Figure 2.2 Enlarged View of Terminal Blocks

The above figures show three-phase power source models. The term inal alloca tion of the power i nput

terminals L1/R, L2/S, L3/T, and grounding term inals for sing le-phase models differs from that show n

in above figures.

Refer to Chapter 8 "SPECIFICATIONS" for details on terminal functions, allocation and

connection and to Chapter 6, Section 6.2.1 "Recommended wires" when selecting wires.

For details on the keys and their functions, refer to Section 2.2 " LED Monitor, Potentiometer and

Keys on the Keypad." For details on keying operation and function code setting, refer to Chapter

3 "OPERATION USING THE KEYPAD."

2-1

Page 32

2.2 Names and Functions of Keypad Components

7-segment

As shown at the right, the keypad

consists of a four-digit, 7-segment

LED monitor, a potentiometer (POT),

and six keys.

The keypad allows you to run and stop

the motor, monitor running status,

configure the function code data,

check I/O signal states, and display

maintenance information and alarm

information.

Table 2.1 Overview of Keypad Functions

Program/Reset key

LED monitor

Down key Up key Function/Data key

Figure 2.3 Keypad

PotentiometerRUN key

STOP key

Monitor, Potentiometer

and Keys

/

Functions

Four-digit, 7-segment LED monitor which displays the running status, data

settings, and alarm status of the inverter according to the operation modes*.

In Running mode, the monitor displays running status information (e.g.,

output frequency, current, and voltage). In Programming mode, it displays

menus, function codes and their data. In Alarm mode, it displays an alarm

code which identifies the error factor if the protective function is activated.

Potentiometer (POT) which is used to manually set frequency, auxiliary

frequencies 1 and 2 or PID process command.

RUN key. Press this key to run the motor.

STOP key. Press this key to stop the motor.

UP/DOWN keys. Press these keys to select the setting items and change the

function data displayed on the LED monitor.

Program/Reset key. Press this key to switch the operation modes* of the

inverter.

Pressing this key in Running mode switches the inverter to Programming

mode and vice versa.

In Alarm mode, pressing this key after removing the error factor will switch

the inverter to Running mode.

Function/Data key.

Pressing this key in Running mode switches the information displayed

(output frequency (Hz), current (Amps) or voltage (V)).

Pressing this key in Programming mode displays the function code and sets

the data entered using

keys or the POT.

/

Pressing this key in Alarm mode displays information concerning the alarm

code currently displayed on the LED monitor.

* FRENIC-Mini features three operation modes--Running, Programming, and Alarm modes. Refer to

Chapter 3, Section 3.1 "Overview of Operation Modes."

2-2

Page 33

LED monitor

2.2 Names and Functions of Keypad Components

In Running mode, the LED monitor displays running status information (output frequency, current or

voltage); in Programming mode, it displays menus, function codes and their data; in Alarm mode, it

displays an alarm code which identifies the error factor if the protective function is activated.

If one of LED4 through LED1 is blinking, it means that the cursor is at this digit, allowing you to

change it.

If the decimal point of LED1 is blinking, it means that the currently displayed data is a PID process

command, not the frequency data usually displayed.

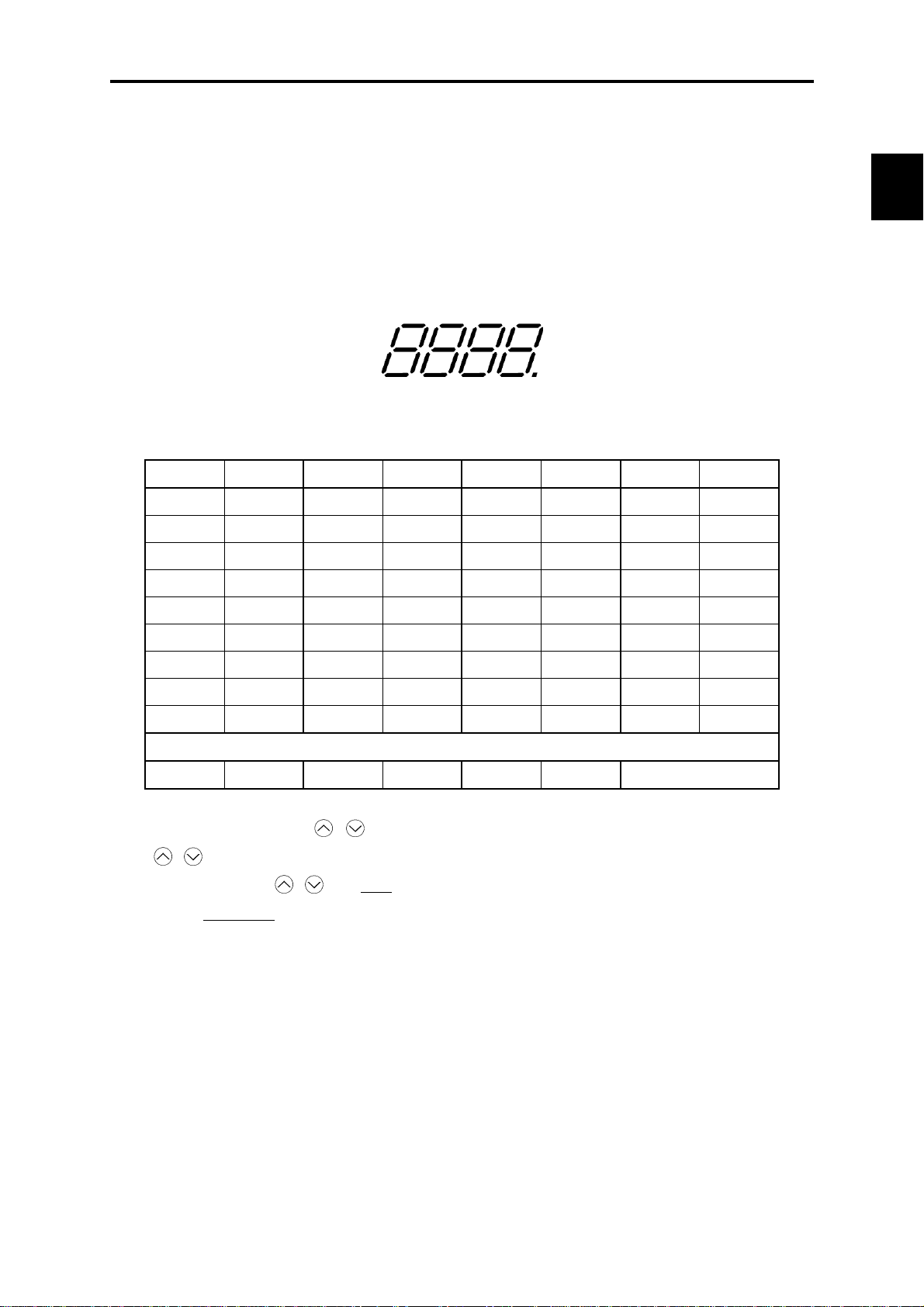

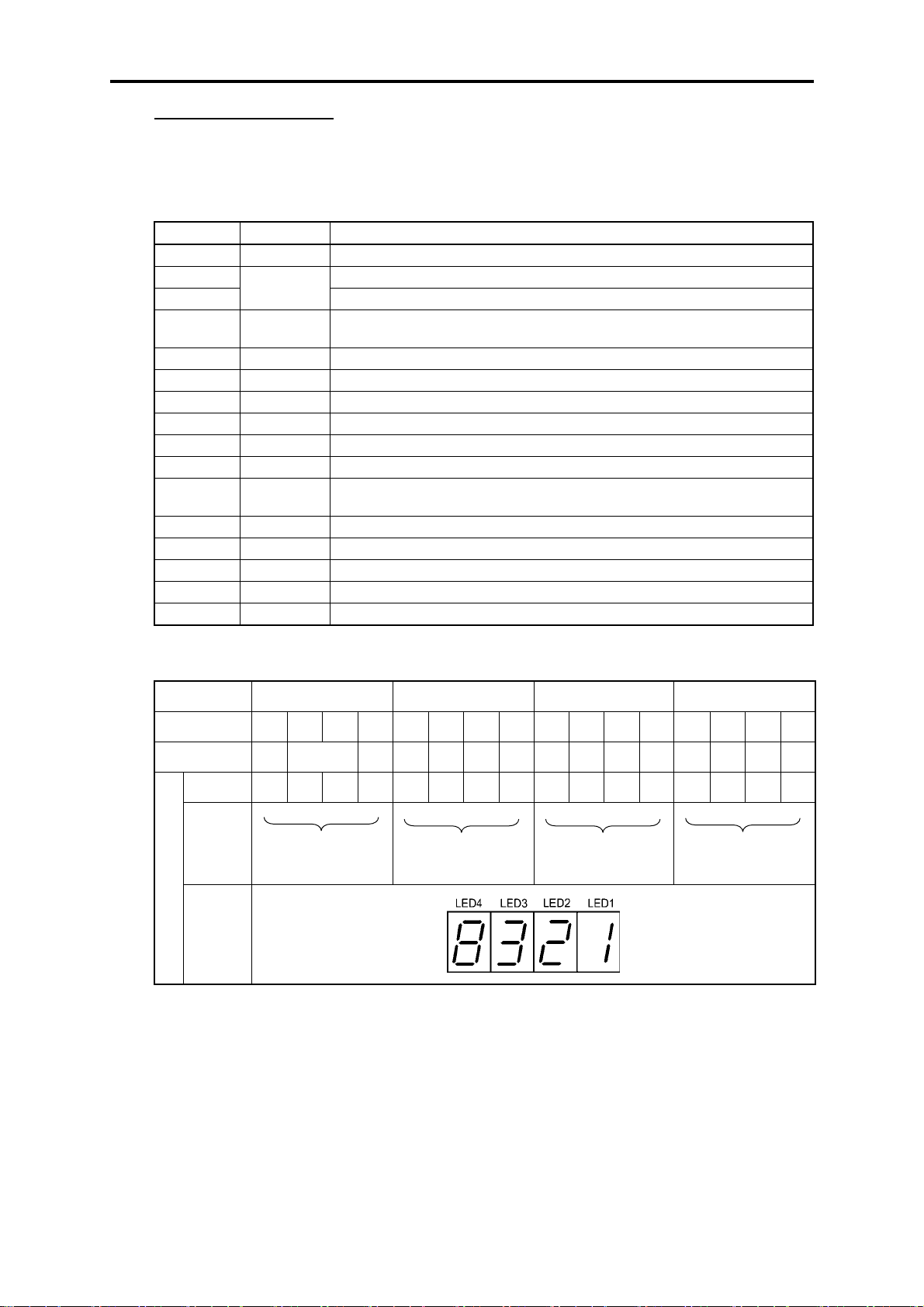

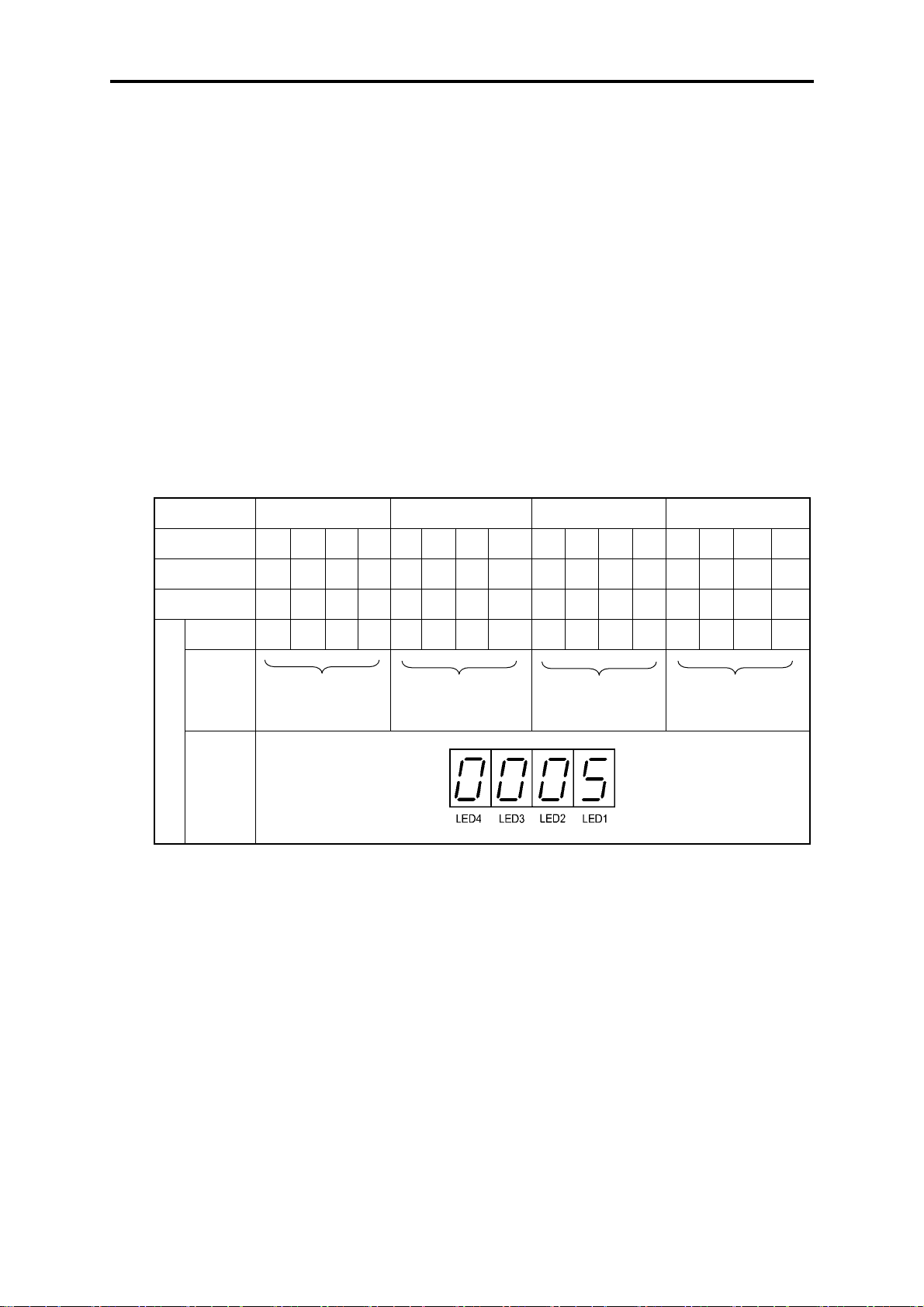

Table 2.2 Alphanumeric Characters on the LED Monitor

Character 7-segment Character 7-segment Character 7-segment Character 7-segment

0

1

2

3

0

1

2

3

9

A

b

C

LED4 LED3 LED2 LED1

Figure 2.4 7-Segment LED Monitor

9

Aa

b

Cc

i

J

K

L

i

Jj

-

Ll

S

T

u

r

r

Ss

-

-

Chap. 2 PARTS NAMES AND FUNCTIONS

4

5

6

7

8

Special characters and symbols (numbers with decimal point, minus and underline)

0. - 9.

4

5

6

7

8

0

. – 9. - - _ _

d

E

F

G

H

d

Ee

Ff

Gg

Hh

M

n

o

P

q

n

o

Pp

q

V

W

X

y

Z

u

-

y

-

Repeat function of / keys

/ keys have a repeat function which helps you change displayed data speedily as follows:

Usually you press

If you hold down

/ keys once to increase or decrease the displayed value by 1, respectively.

either key so as to activate the repeat function, the displayed value will keep

changing in steps of 1 speedily. Note that when changing some function code data during running of

the inverter (not always possible), the displayed data will keep c hanging more slowly. This is to ensure

safe and stable operation.

2-3

Page 34

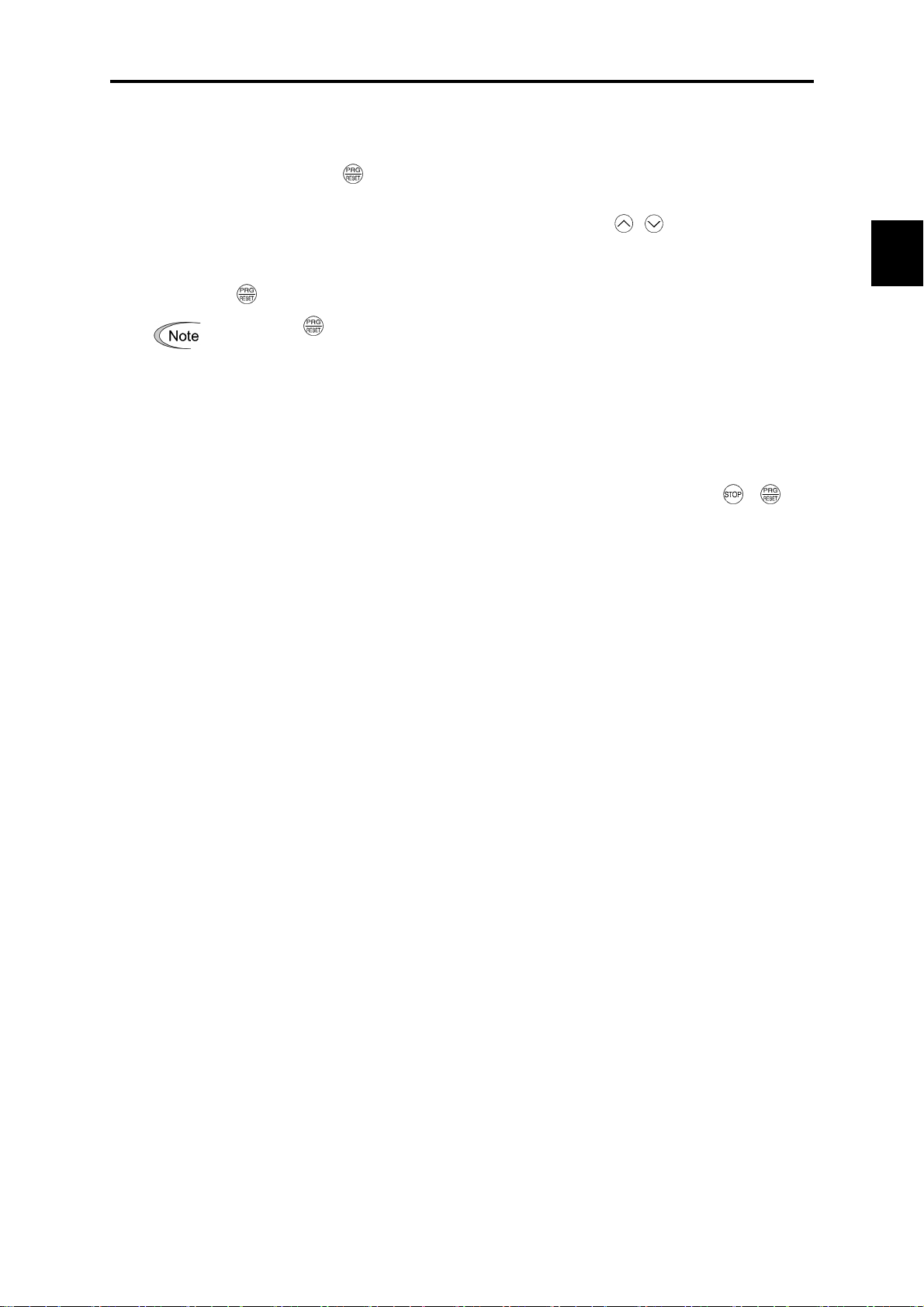

Continuous holding-down function for Program/Reset key

Holding down the key longer (approx. one second or longer) moves the cursor on th e LED monitor.

In Running mode, the cursor moves alon g digits; in Programm ing mode, it moves not only along digits

but to the next function code.

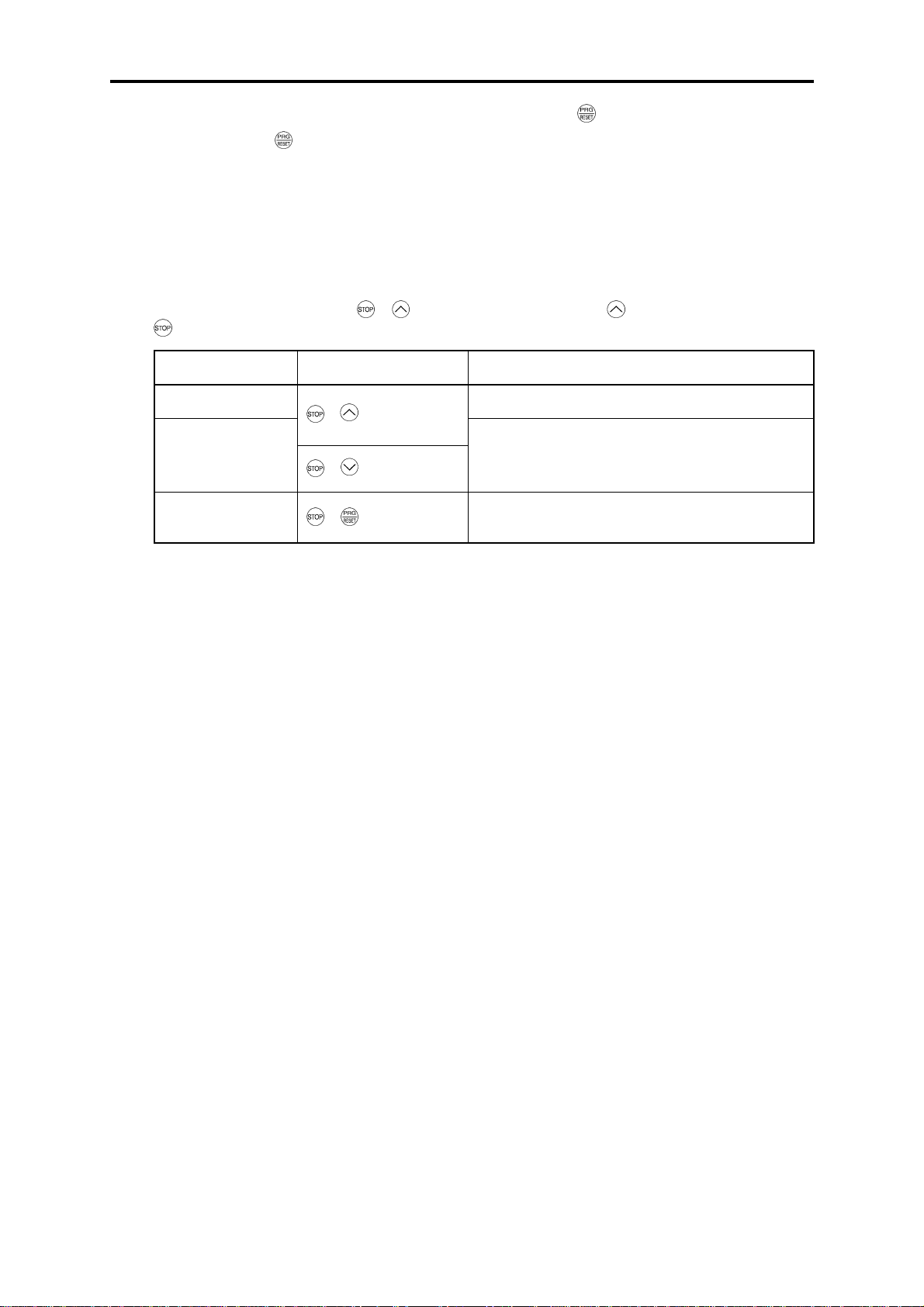

Simultaneous keying

Simultaneous keying means depressing two keys at the same time (expressed by "+"). FRENIC-Mini

supports simultaneous keying as listed below.

(For example, the expression "

+ keys" stands for pressing the key while holding down the

key.)

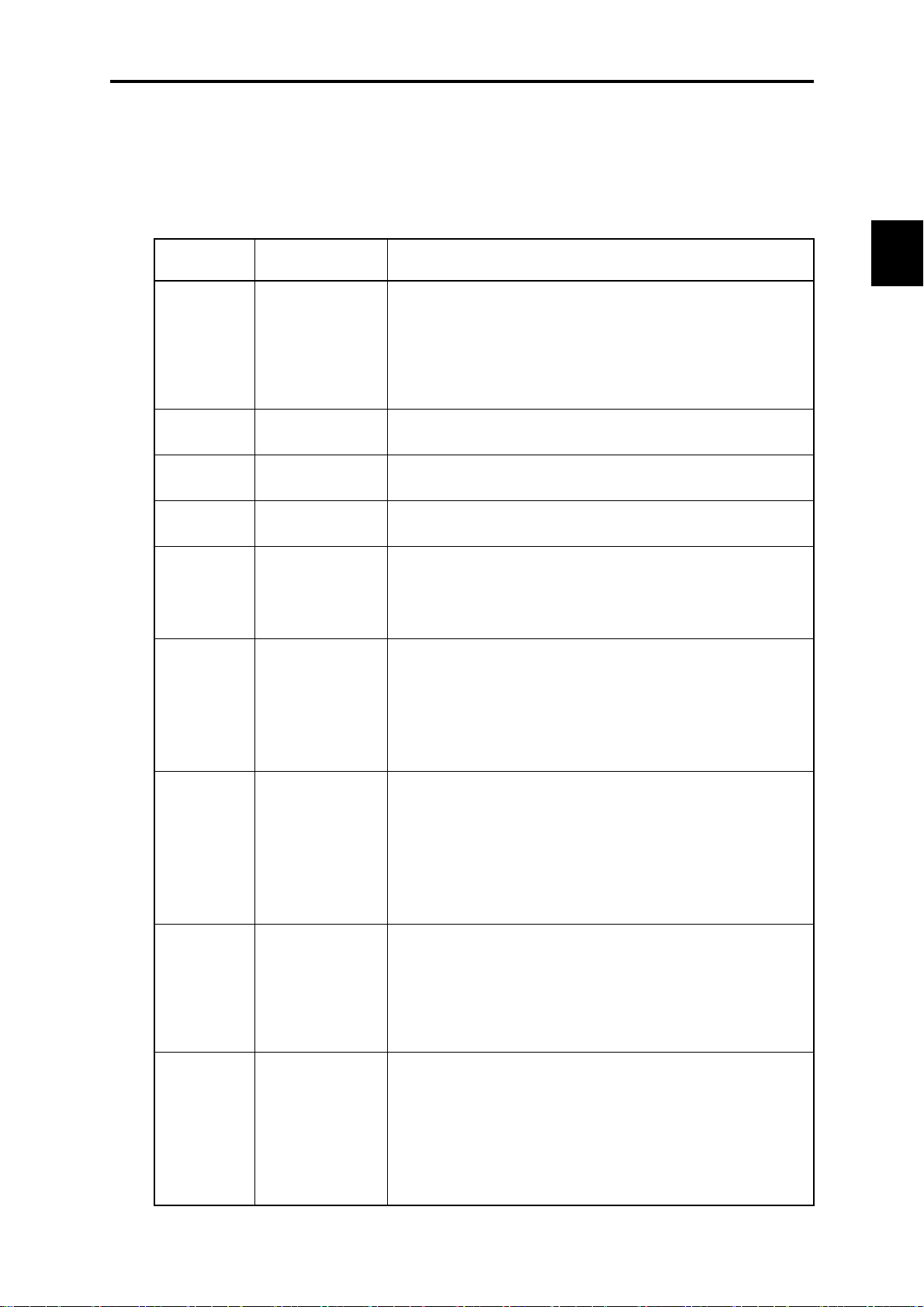

Operation modes Simultaneous keying Used to:

Running mode Control entry to/exit from jogging operation.

Programming mode

Alarm mode + keys

+ keys

+ keys

Change special function code data.

(Refer to function codes F00, H03, H45 and H97 in

Chapter 9 "FUNCTION CODES.")

Switch to Programming mode without clearing

alarms.

About changing of function code data

The function code data can be changed only when the data value displayed on the LED monitor is

flashing.

When the data value is lit, no change is allowed. To change the data, stop the inverter or disable the

data protection.

2-4

Page 35

Chapter 3

OPERATION USING THE KEYPAD

This chapter describes inverter operation using the keypad. The inverter features three operation modes

(Running, Programming and Alarm modes) which enable you to run and stop the motor, monitor running

status, set function code data, display run ning i nform ation require d for m aintena nce, an d dis play a larm data.

Contents

3.1 Overview of Operation Modes....................................................................................................................3-1

3.2 Running Mode ............................................................................................................................................3-3

3.2.1 Run/stop the motor.............................................................................................................................. 3-3

3.2.2 Set up the reference frequency and PID process command................................................................3-3

3.2.3 Monitor the running status.................................................................................................................. 3-5

3.2.4 Jog (inch) the motor............................................................................................................................ 3-7

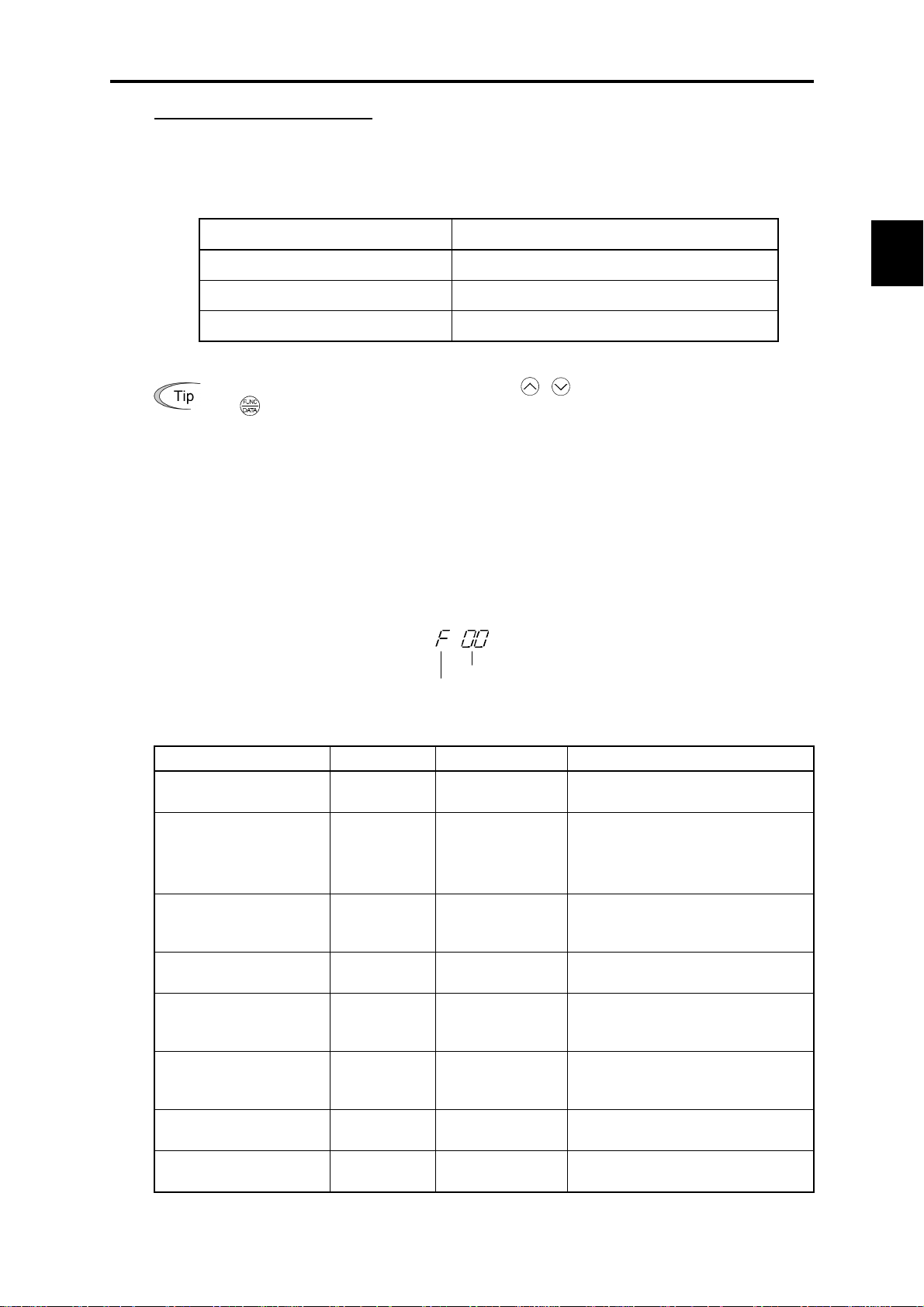

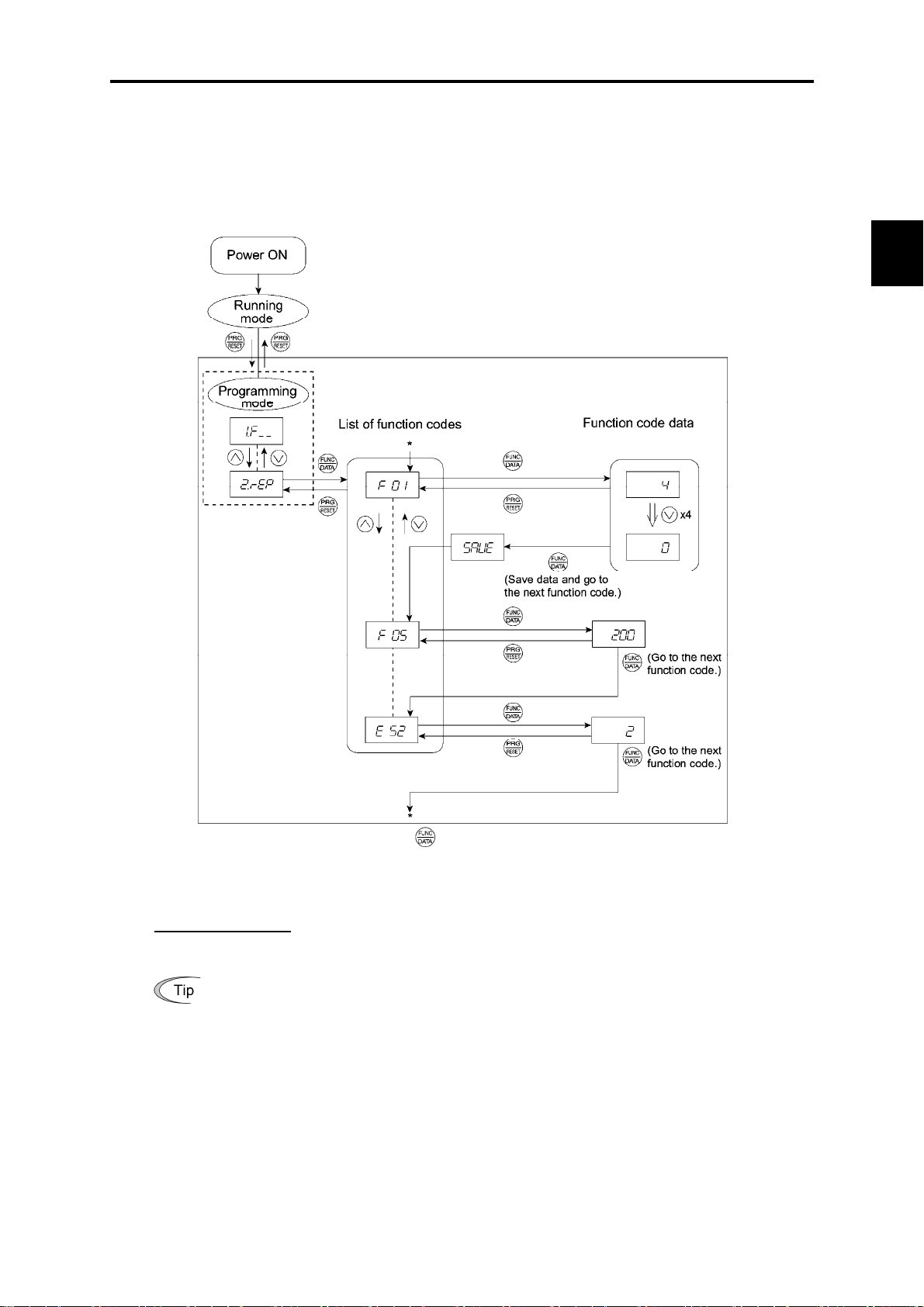

3.3 Programming Mode....................................................................................................................................3-8

3.3.1 Setting the function codes--"Data Setting"..........................................................................................3-9

3.3.2 Checking changed function codes--"Data Checking".......................................................................3-13

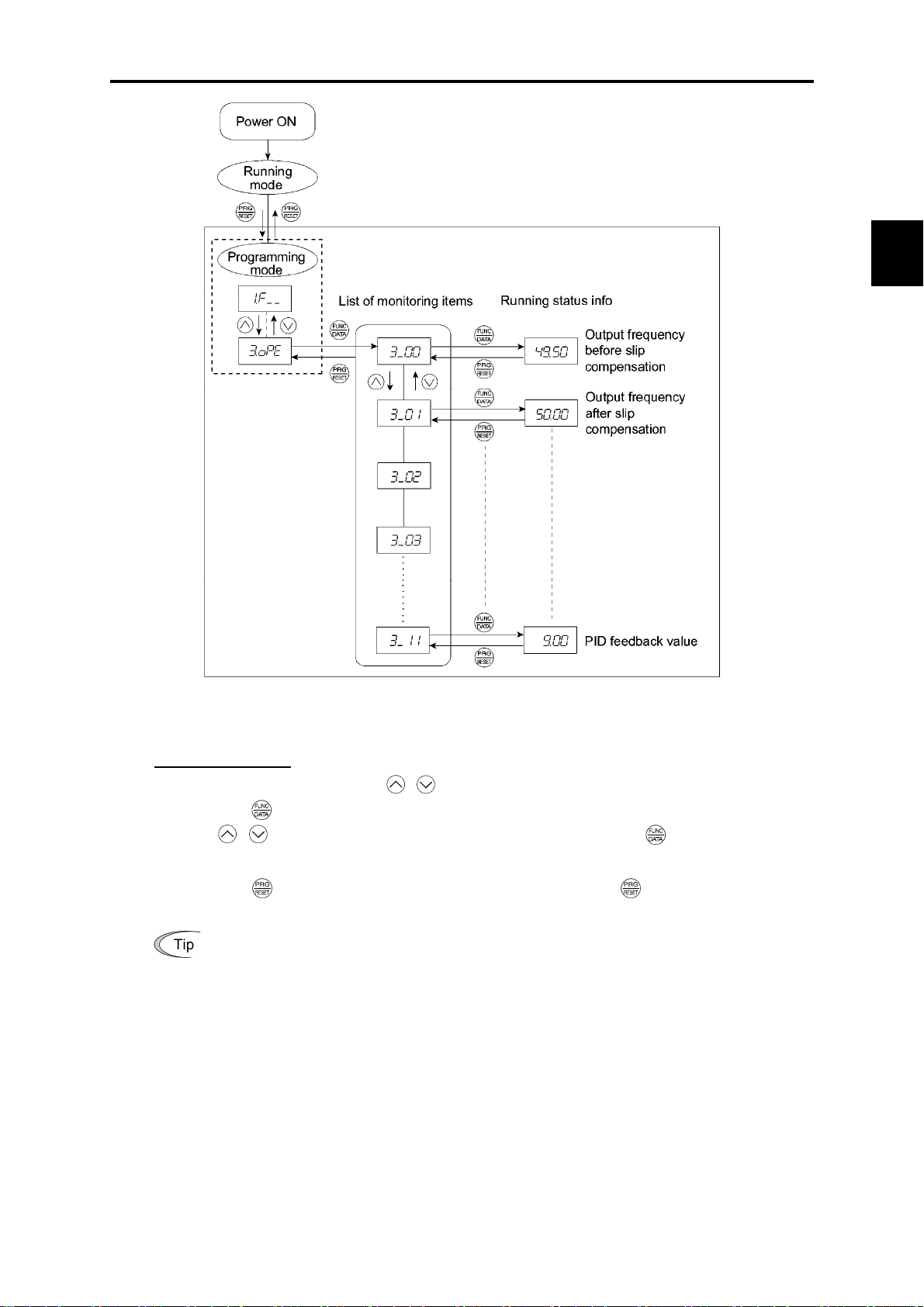

3.3.3 Monitoring the running status--"Drive Monitoring".........................................................................3-14

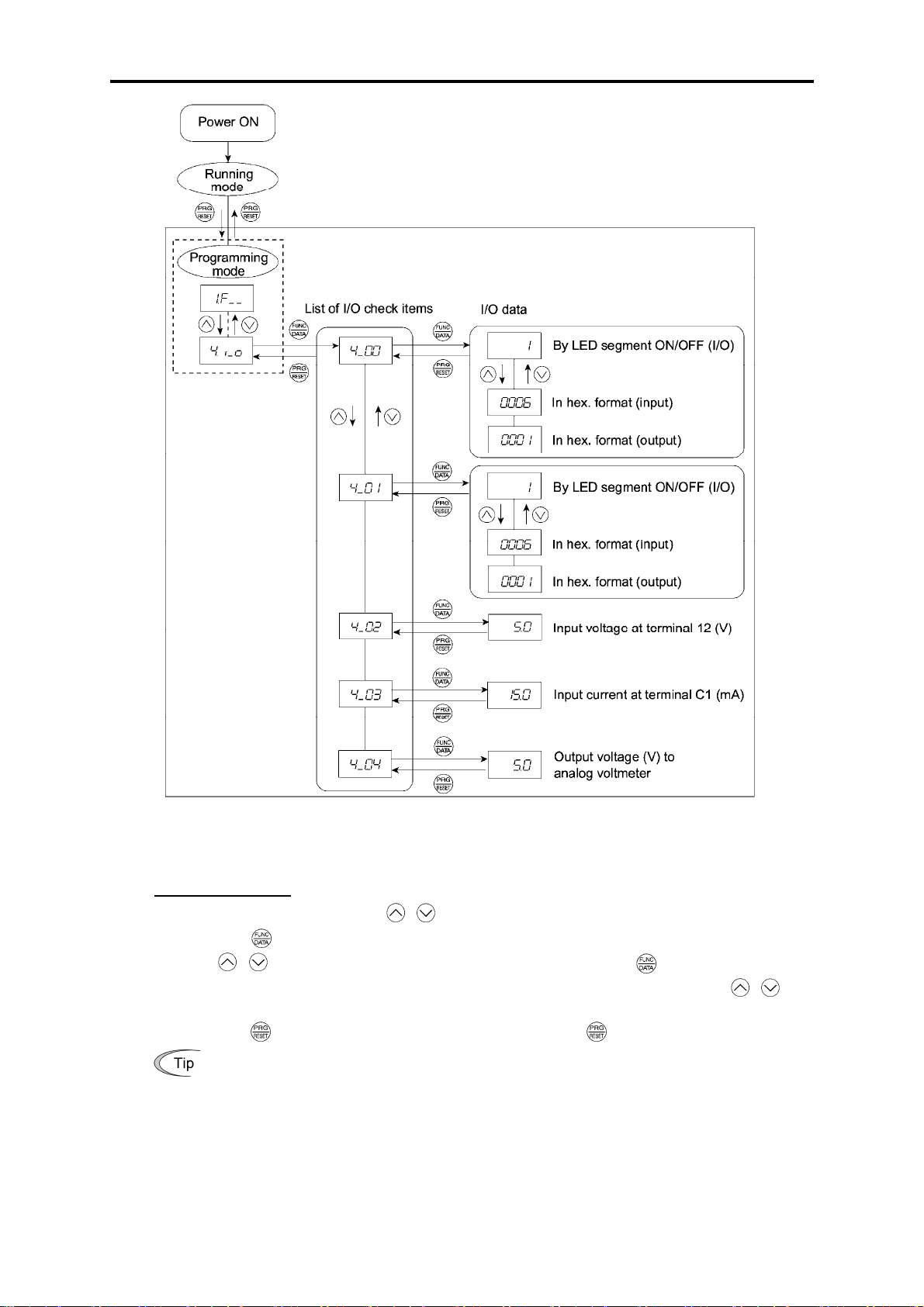

3.3.4 Checking I/O signal status--"I/O Checking".....................................................................................3-17

3.3.5 Reading maintenance information--"Maintenance Information"

3.3.6 Reading alarm information--"Alarm Information"............................................................................3-24

3.4 Alarm Mode..............................................................................................................................................3-28

3.4.1 Releasing the alarm and transferring the inverter to Running mode................................................. 3-28

3.4.2 Displaying the alarm history............................................................................................................. 3-28

3.4.3 Displaying the running information when an alarm occurs..............................................................3-29

3.4.4 Transferring to Programming mode..................................................................................................3-29

........................................................3-21

Page 36

Page 37

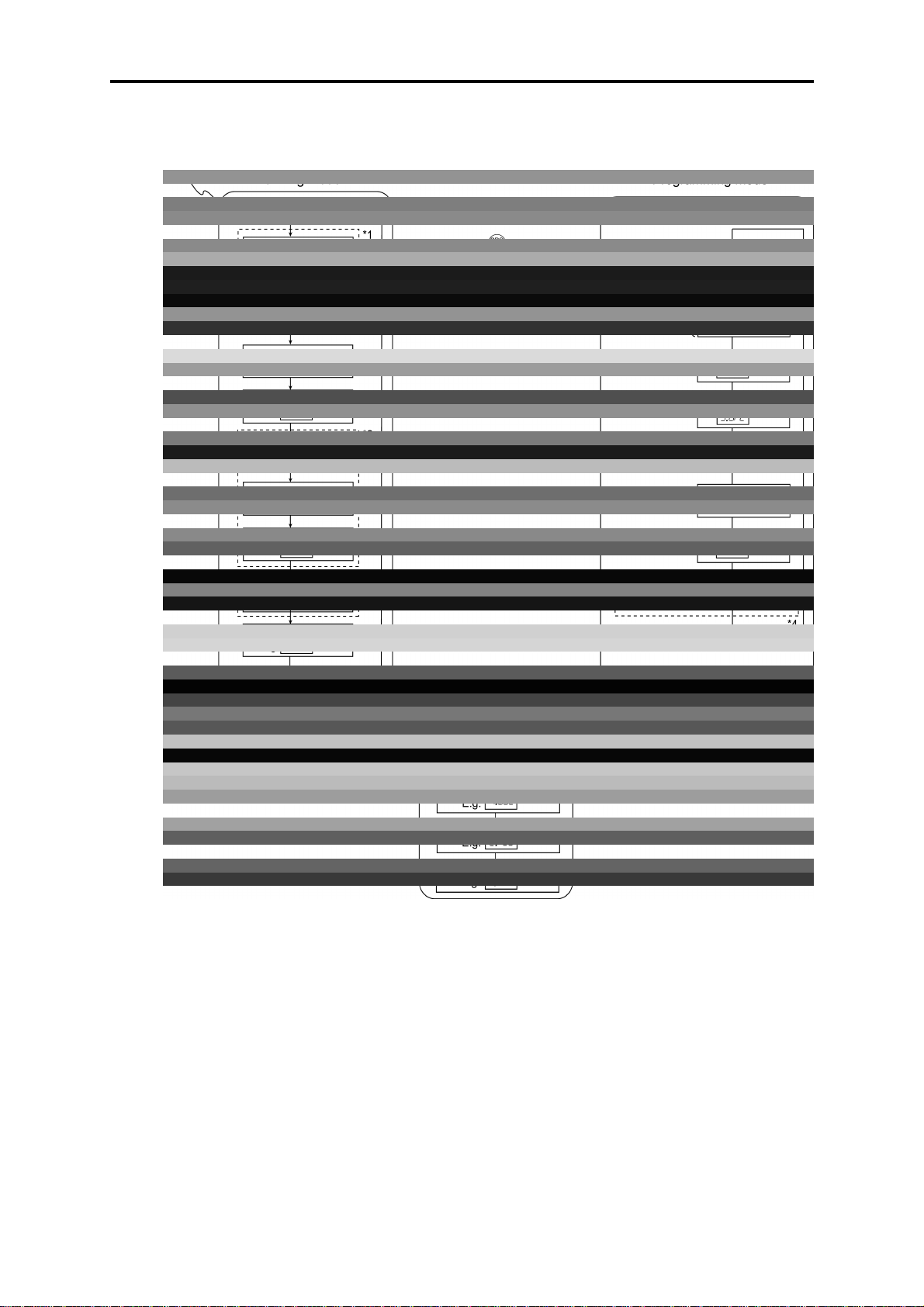

3.1 Overview of Operation Modes

3.1 Overview of Operation Modes

FRENIC-Mini features the following three operation modes:

Running mode : This mode allows you to enter run/stop commands in regular operation. You

may also monitor the running status in realtime.

Programming mode : This mode allows you to set function code data and check a variety of

information relating to the inverter status and maintenance.

Alarm mode : If an alarm occurs, the inverter automatically enters this Alarm mode in

which the corresponding alarm code* and its related information may be

displayed on the LED monitor.

* Alarm code: Shows the error factor that has activated the protective function. For

details, refer to Chapter 8, Section 8.8 "Details of Protective Functions."

Figure 3.1 shows the status transition of the inverter between these three operation modes. If the

inverter is turned ON, it automatically enters Running mode, making it possible to start or stop the

motor.

To make the transition between th ose op eratio n m odes, y ou ne ed to pre ss the sp ecifie d key s as s hown

below, except at the occurrence of an alarm. If an alarm occurs in Running mode, the inverter will

automatically switch to Alarm mode.

Chap. 3 OPERATION USING THE KEYPAD

Figure 3.1 Status Transition between Operation Modes

3-1

Page 38

The figure below shows the transi tion between the runnin g status monitoring screens in Ru nning mode,

that between the menu screens in Programming mode, and that between the alarm code screens in

Alarm mode.

*1 The speed monitor may display the outp ut f r e que nc y (Hz), reference f reque nc y (Hz), load shaft spe ed (r /min), line

speed (m/min.), and constant feeding rate time (min.) which can be selected by setting up function code E48.

*2 These PID-related information will appear only when the inverter is under the PID control. (Refer to Section 3.2.2.)

*3 This appears only when timer operation is enabled by setting up function code C21. (Refer to Chapter 9, Section

9.2.3 "C codes (Control functions of frequency).")

*4 This appears only when the remote keypad (option) is connected with the inverter.

Figure 3.2 Basic Screen Transition in Each Operation Mode

3-2

Page 39

3.2 Running Mode

3.2 Running Mode

If the inverter is turned ON, it automatically enters Running mode in which you may:

(1) Run/stop the motor

(2) Set up the reference frequency and PID process command

(3) Monitor the running status (e.g., output frequency, output current)

(4) Jog (inch) the motor

3.2.1 Run/stop the motor

By factory default, pressing the key starts running the motor in the forward direction and pressing

key brings the motor to a decelerated stop. The key is enabled only in Running mode.

the

Changing function code F02 data makes it possible to run the motor in the reverse direction by

pressing the

and control the motor by pressing

key, determine the motor rotational direction by entering i nput signals to the term inals,

/

keys.

Chap. 3 OPERATION USING THE KEYPAD

3.2.2 Set up the reference frequency and PID process command

By using the potentiometer and

frequency and PID process command. It is also possib le to set up the reference frequency as frequency,

load shaft speed, line speed, and constant feeding rate time by setting function code E48.

Setting up the reference frequency

With the potentiometer on the keypad (factory default)

If you set function code F01 to "4: Potentiom eter on the keypad" (factory default) a nd select frequency

setting-1 with function codes E01 through E03 (Hz2/Hz1 = OFF), then the potentiometer becomes

enabled to set up the reference frequency. Setting function code C30 to "4: Potentiometer on the

keypad" and selecting frequency setting-2 (Hz2/Hz1 = ON) also produce the same effect.

With

If you set function code F01 to "0: Keypad operation" and select frequency setting-1, then

keys become enabled to set up the reference frequency in Running mode. In any other operation

modes, those keys remain disabled.

Pressing

keys again makes it possible to change the reference frequency. The new setting will be saved

internally. Even if the inverter is switched to any other frequency entry method and then returned to

the keypad entry method, the setting will be retained.

Further, even turning OFF the inverter will automatically save the setting into the non-volatile

memory. At the next time when the inverter is turned ON, the setting will become the default

frequency.

/ keys

/

keys calls up the reference frequency with the lowest dig it blinking. Pressi ng

keys on the keypad, you may set up the desired reference

/

/

/

If you set function code F01 to "0: Keypad operation" but do not select frequency setting-1, then

keys cannot be used for setting up the reference frequency. Pressing those keys will just display the

currently selected reference frequency.

To set up the reference frequency from any other d isplayed items, it is depe ndent on function code E48

data (= 4, 5, or 6) "LED monitor details (Select speed monitor)" as listed in the following table.

3-3

/

Page 40

E48 data "LED monitor details

(Select speed monitor)"

Display of reference frequency Conversion of displayed value

0: Output frequency (before slip

compensation)

1: Output frequency (after slip

compensation)

2: Reference frequency Frequency setting

4: Load shaft speed Load shaft speed setting Frequency setting x E50

5: Line speed Line speed setting Frequency setting x E50

6: Constant feeding rate time Constant feeding rate time

Frequency setting

Frequency setting

E50

×

If you set function code C30 to "0: Keypad operation" and select frequency setting-2, then

/

keys become also enabled to set up the reference frequency.

Setting up the PID process command

To enable PID control, you need to set function code J01 to 1 or 2.

/

In the PID control mode, the items that can be set or checked with

keys are different from

those under normal frequency control, depending upon the current LED monitor setting. If the LED

monitor is set to the speed monitor (E43 = 0), you may access manual feed commands (Reference

/

frequency) with

keys; if it is set to any other, you may access PID process commands with

those keys.

Refer to Chapter 4, Section 4.8 "PID Frequency Command Generator" for details on the PID

control.

Setting the PID process command with the built-in potentiometer

Set function code E60 to "3: PID process command 1" and J02 to " 1: PID process comm and 1." After

that, selecting PID control remote process command enables you to set the PID process command

using the built-in potentiometer.

E39 settingFrequency

Setting the PID process command with

/ keys

Set function code J02 to "0: Keypad operation" and set the LED monitor to the setting other than the

speed monitor (E43 = 0) in Running mode. This makes it possible to set the PID process command

using

Pressing

monitor. Pressing

/ keys. This setting is possible only in Running mode.

keys displays the PID process command with the lowest digit blinking on the LED

/

/ keys again makes it possible to change the PID process command. Once the

PID process command is modified, it will be saved internally. Even if the inverter is switched to any

other PID process command entry method and then returned to the keypad entry method, the setting

will be retained.

Further, even turning OFF the inverter will automatically save the setting into the non-volatile

memory. At the next time when the inverter is turned ON, the setting will become the default PID

process command.

Even if the PID process command is selected ((SS4) = ON) in the multistep frequency, it is still

possible to set the process command using the keypad.

When function code J02 has been set to any value except 0, pressing

/ keys displays the PID

process command currently selected (setting is not possible).

When the PID process command is displayed, the decimal point next to the lowest digit on the LED

display blinks to discriminate it from the frequency setting.

3-4

Page 41

3.2 Running Mode

• When setting the frequency and others with

will blink. Change the setting, starting from the lowest digit and the cursor will move

/

keys, the lowest digit on the display

gradually to the next digit to be changed.

• When the data is to be changed rapidly, hold down the

key for 1 second or longer, and

the blinking cursor will move to the next digit where the data can be changed (cursor

movement).

3.2.3 Monitor the running status

In Running mode, the nine items listed below can be monitored. Immediately after the inverter is

turned ON, the monitor item specified by function code E43 is displayed. Press the key to switch

between monitor items.

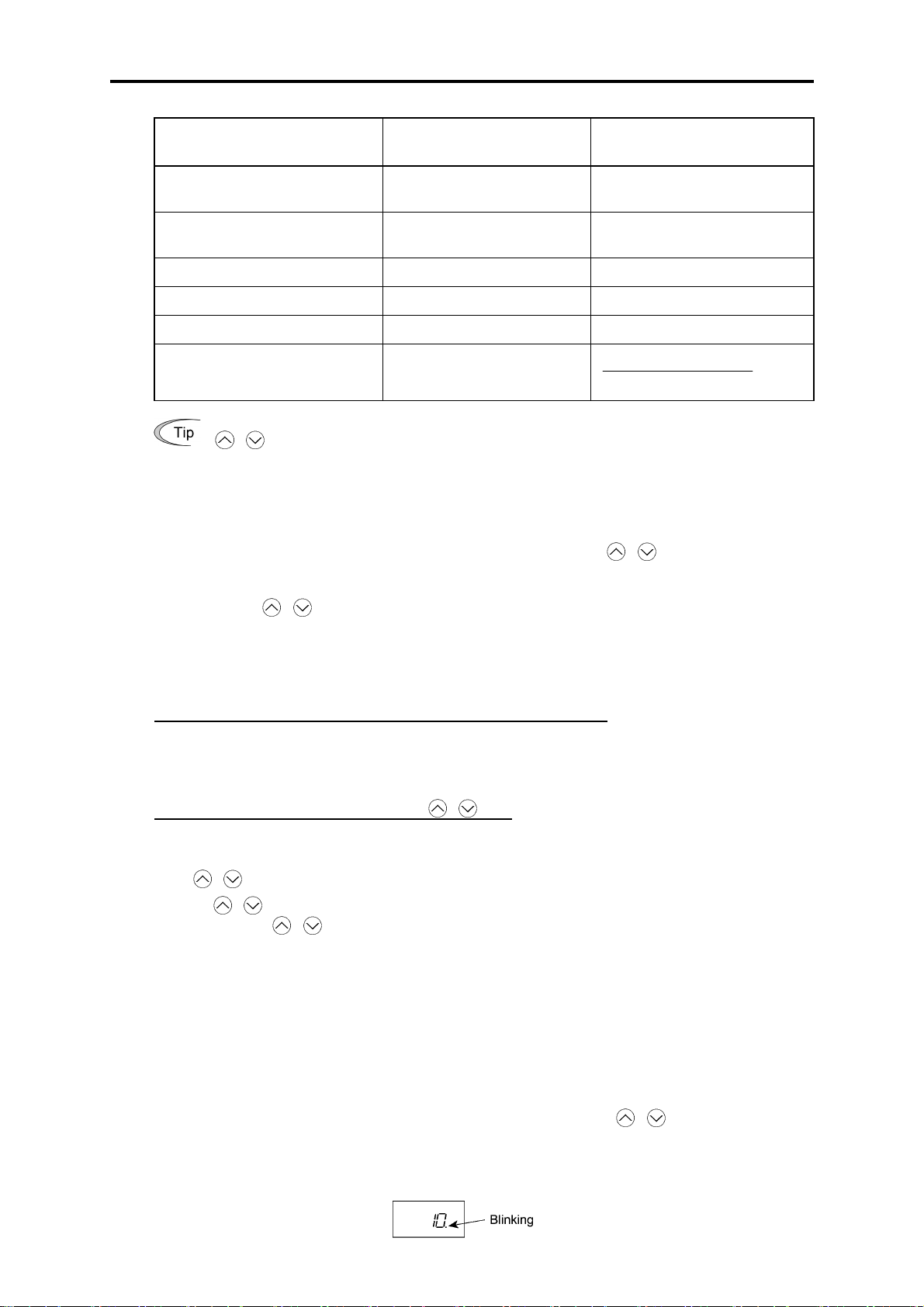

Table 3.1 Monitor Items

Chap. 3 OPERATION USING THE KEYPAD

Monitor Items

Speed monitor

(Hz, r/min, m/min, min)

Output current (A)

Input power (kW)

Output voltage (V) *2

PID command *3 *4

PID feedback value *3 *5

PID output *3 *4

Timer (sec) *3

Input watt-hour

Display Sample on

the LED monitor *

5*00

!90a

Current output from the inverter in RMS

*40p

Input power to the inverter

200u

Voltage output from the inverter in RMS

1*0*

)0*

10**

50

Remaining effective timer count

2*38

1

Refer to Table 3.2.

(PID command or PID feedback value) × (PID

display coefficient A – B) + B

PID display coefficient A and B: Refer to function

codes E40 and E41

PID output in %, assuming the maximum frequency

(F03) as 100%

Display value =

Meaning of Displayed Value

Input watt-hour (kWh)

100

*1 A display value 10000 or above cannot be displayed on the 4-digit LED monitor, so " " appears instead.

u

*2 When the LED monitor displays an output voltage, the 7-segment letter

the voltage "V."