Page 1

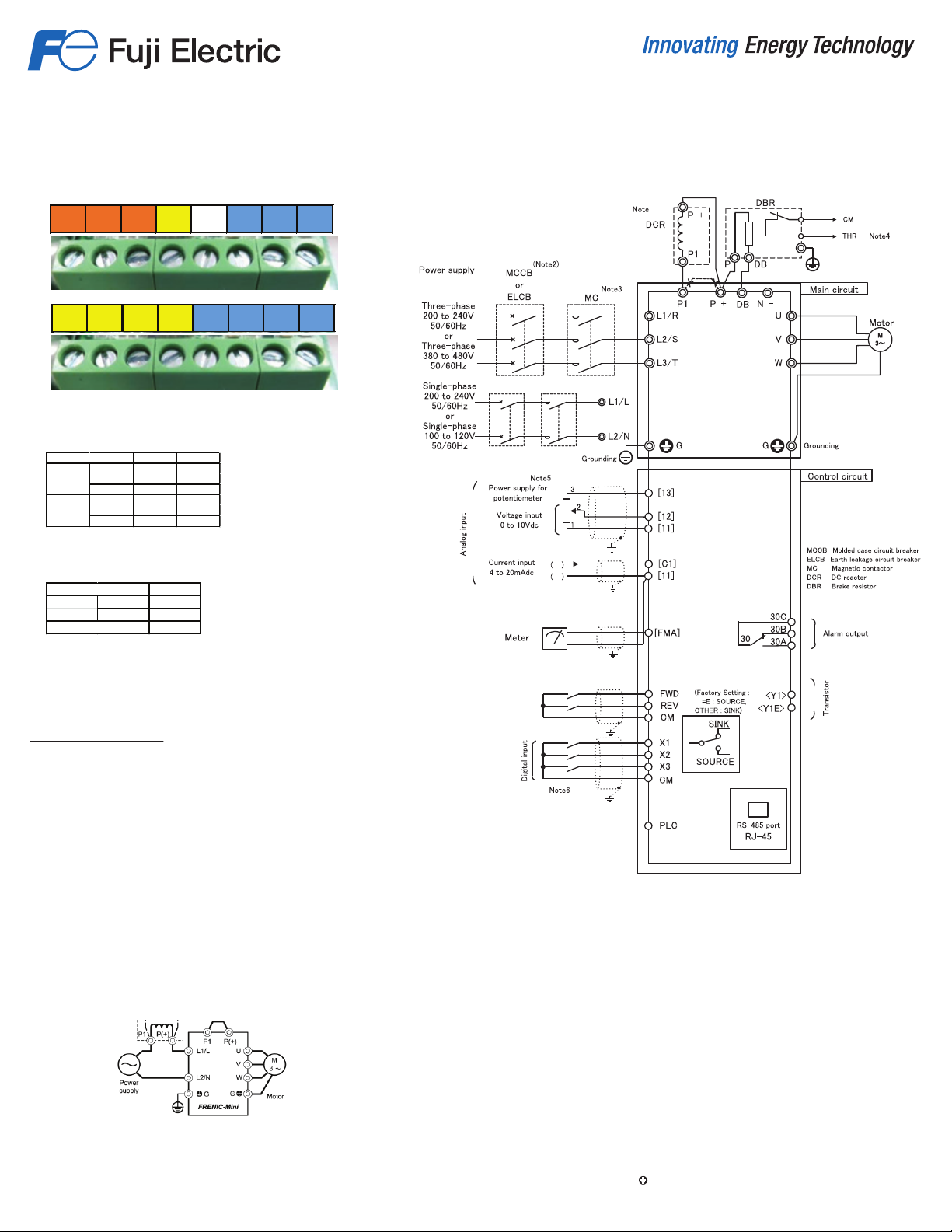

FRENIC-Mini (C2) Quick Reference Guide

Min. Max.

Operang

Voltage

(Sink) Off level 22V 27V

Operang

Voltage

(Sink) Off level 0V 2V

Item

Max.

Operang ON level 2V

Voltage Off level 27V

50m A

Item

Maximum Current at on.

Control Card Terminals

Y1 Y1E FMA C1 PLC X1 X2 X3

11 12 13 11 CM FWD REV CM

Orange = Outputs, Yellow = Analog Inputs, Blue = Digital Inputs

• FWD, Rev, plus 3 Digital inputs configurable for Source or Sink.

ON level 0V 2V

ON level 22V 27V

• 0-10VDC analog inputs.

• 4-20mA analog input.

• Transistor outputs.

( )

FRENIC-Mini (C2) Control Wiring

( 1)

( )

+

−

()

( ) ( )

:

:

:

:

:

( )

( )

( )

〜

• Form C contact relay

o (250VAC 0.3A, cosØ=0.3), (48VDC, .5A).

• 24VDC max 200mA DC output power.

• 10VDC output for potentiometer.

• 24 VDC 50mA power source

Other Control Terminal

• RJ-45 keypad connection port.

Note 1:

When connecting a DC REACTOR (DCR) (option), remove the jumper

bar from across the terminals [P1] and [P (+)].

For single-phase 100V input series, DCR shall be connected to the

point that is shown below.

( )

( )

)

(

( )

(

)

( )

( )

Note 2:

Install a recommended molded-case circuit breaker (MCCB) or an earth leakage circuit breaker (ELCB) (with an

overcurrent protection function) in the primary circuit of the inverter to protect wiring. At this time, ensure that the

circuit breaker capacity is equivalent to or lower than the recommended capacity.

Note 3:

Install a magnetic contactor (MC) recommended for each inverter to separate the inverter form the power supply,

apart from the MCCB or ELCB, when necessary. Connect a surge suppressor in parallel when installing a coil such

as the MC or solenoid near the inverter.

Note 4:

(THR) is available when one of terminal functions for X1 to X3, FWD, REV (function code E01 to E03, E98 or E99)

is set to the data “9”.

Note 5:

Frequency can be set by connecting a frequency setting device (external potentiometer) among the terminals 11, 12

and 13 instead of inputting voltage signal (0 to +10V DC, 0 to +5V DC or +1 to +5V DC) between the terminals 12

and 11.

Note 6:

For the control signal wires, use shielded or twisted wires. Ground shielded wires. To prevent malfunction due to

noise, keep the control circuit wiring away from the main circuit wiring as far as possible (recommended:

10cm(3.94inches) or more), and never set them in the same wire duct. ⓔ

When crossing the control circuit wiring with the main circuit wiring, set them at right angles.

Note 7:

Three –phase 4wire cable is recommended for motor wiring to reduce the noise emitted. Connect the motor

grounding wire to the inverter grounding terminal G

( )

( )

‐

( )

Page 2

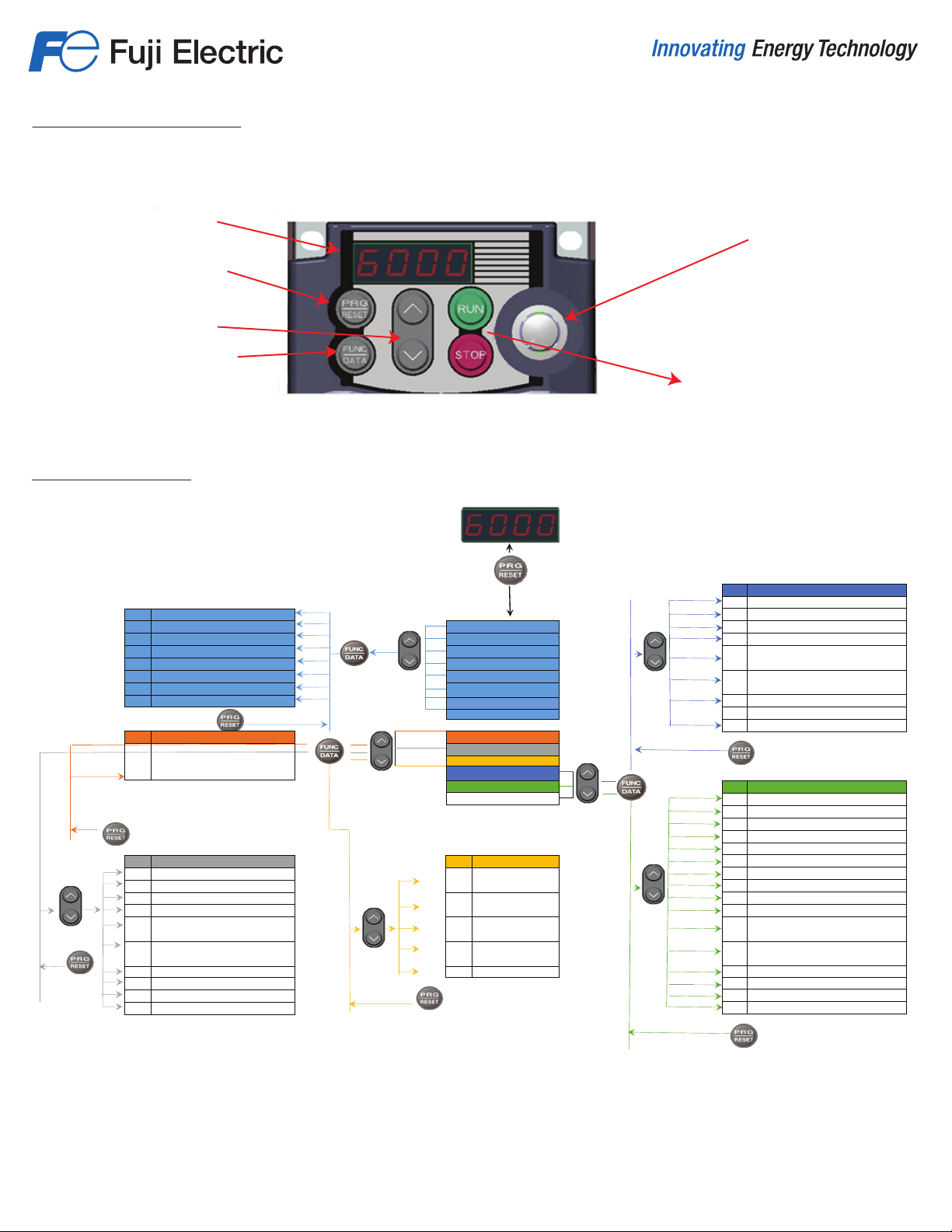

Frenic-Mini (C2) Keypad

1.F Fundamental Funcons

1.E Extension Terminal Funcons

1.C Control Funcons of Frequency

1.P Motor 1 Parameters

1.H High Performance Funcons

1.A Motor 2 Funcons

1.J Applicaon Funcons

1.Y Link Funcons

2. rEP

3. oEP

4. I_O

5. CHE

6. AL

7. CPY

2.

rEP (Data Check)

been changed from factory default.

5. CHE (Maintenance Info)

5_00 Accumulated run time

5_01 DC link bus voltage

5_03 Max temperature of heat sink

5_04 Max effective current

5_05 Capacitance of the DC link bus

capacitance

5_06

Accumulated run time of

electrolyc capacitors on the PCB

5_07 Accumulated run time of cooling fan

5_08 Number of startups

5_09 Input wa-hour

1.F _ _

1.E _ _

1.C _ _

1.P _ _

1.H _ _

1.A _ _

1.J _ _

1.Y _ _

6. AL (Alarm Info)

6_00 Output frequency

6_01 Output current

6_02 Output voltage

6_03 Calculated torque

6_04 Reference frequency

6_05 Rotational detection

6_06 Running status

6_07 Accumulated running time

6_08 Number of startups

6_09 DC link bus voltage

6_11

Max. temperature of heat sink

6_12

Terminal I/O status

6_13 Terminal input signal status in HEX

6_14 Terminal Output status in Hex

6_15 Number of consecutive occurrences

6_16 Overlapping alarm 1

3. oPE (Operations Monitor)

3_00 Output frequency before slip

3_01 Output frequency after slip

3_02 Output Current

3_03 Output Voltage

3_05 Reference frequency

3_06 Rotation direcon

3_07 Running status

3_09 Load Shaft speed

3_10 PID SV

3_11 PID PV

4. I_O (I/O Check)

4_00

I/O Signals on the

control card

4_01

I/O Signals on the

control card

4_02

Input Voltage on

terminal 12

4

Input Current on

terminal C1

4_04

Output voltage of

Digital Display for Operation,

Function Codes & Fault Indication

Programming & Fault Reset

Digital Frequency Adjust

Manual Frequency Command

Adjustment

Function Code Data/Menu

Selection

Quick Start Menus

Displays function codes that have

Manual Run-Stop Command

To access Menes 2-7 change funcon code E52-2

_03

Fuji Electric Corp. of America

47520 Westinghouse Drive, Fremont, CA 94539

Phone: 510-440-1060

www.americas.fujielectric.com

FECA-MINIC2QRG

Loading...

Loading...