Page 1

General Specifications

C2

FECA-TE-2015

Page 2

2

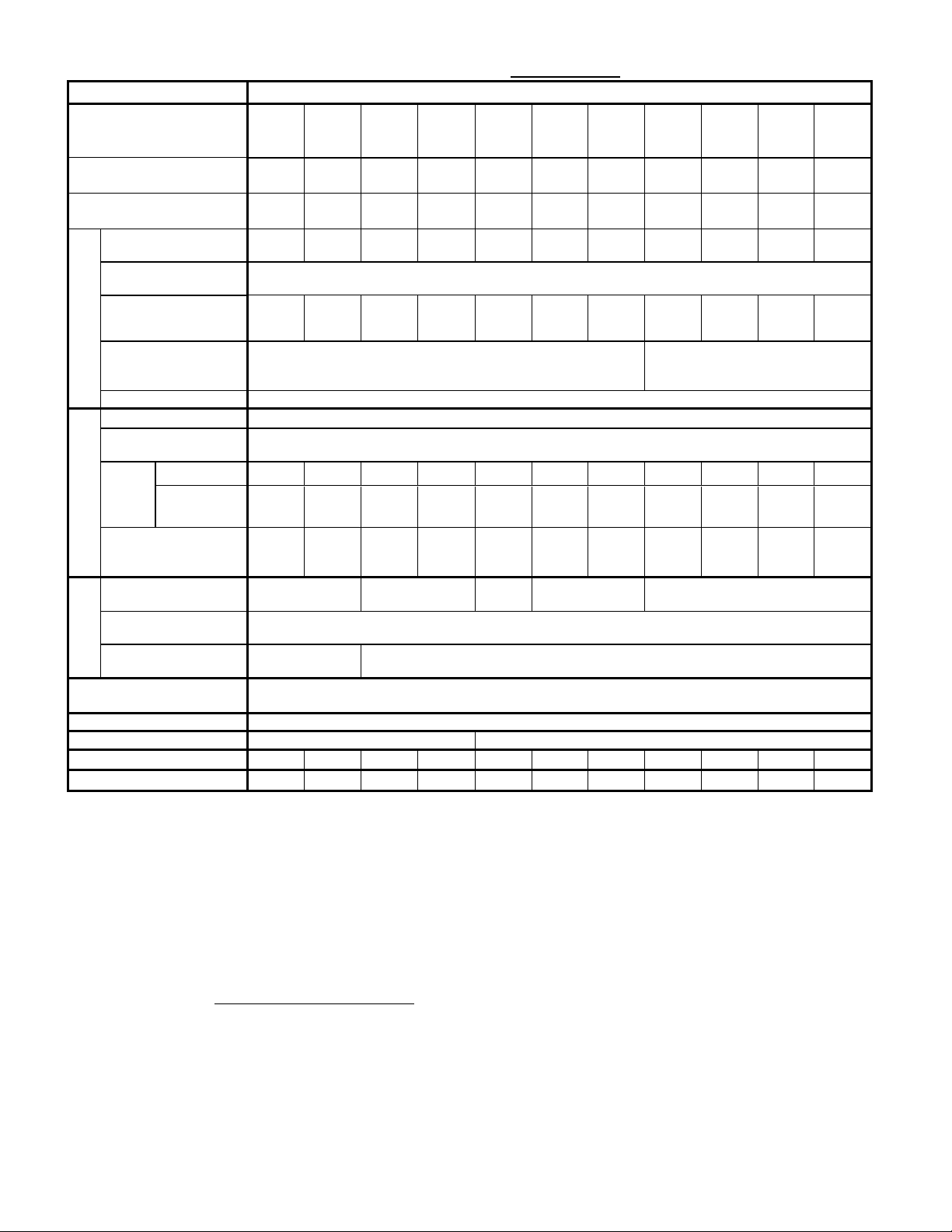

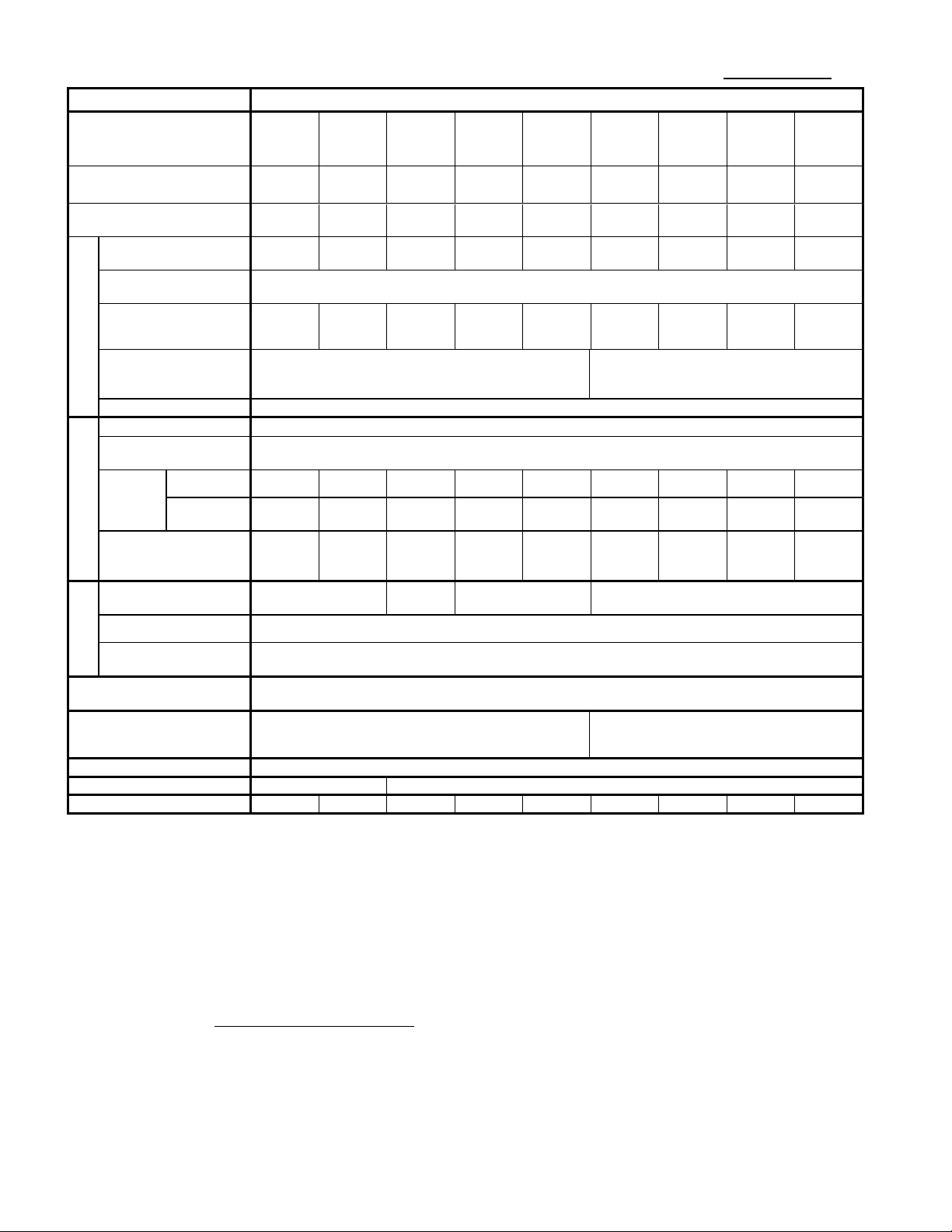

1. Standard Specifications

Items

Specifications

Type

(FRN□□□C2S-2△、

△ = A,U)

0001

0002

0004

0006

0010

0012

0020

0025

0033

0047

0060

Nominal applied motor

*1)

[kW]

(△=A)

0.1

0.2

0.4

0.75

1.5

2.2

3.7

5.5

7.5

11

15

Nominal applied motor

*1)

[HP]

(△=U)

1/8

1/4

1/2 1 2 3 5

7.5

10

15

20

Output ratings

Rated capacity

*2)

[kVA]

0.30

0.57

1.3

2.0

3.5

4.5

7.2

9.5

12

17

22

Rated voltage

*3)

[V]

Three-phase 200~240V (With AVR)

Rated current [A]

0.8

(0.7)

*4)

1.5

(1.4)

*4)

3.5

(2.5)

*4)

5.5

(4.2)

*4)

9.2

(7.0)

*4)

12.0

(10.0)

*4)

19.1

(16.5)

*4)

25.0

(23.5)

*10)

33.0

(31.0)

*10)

47.0

(44.0)

*10)

60.0

(57.0)

*10)

Overload capability

150% of rated current for 1min

150% of rated current for 1min or 200% of rated current for 0.5s (If

the rated current is in parenthesis)

150% of rated current for 1min or

200% of rated current for 0.5s

Rated frequency

50, 60Hz

Input ratings

Main power supply

Three-phase 200~240V,50/60Hz

Voltage/frequency

variations

Voltage: +10 to -15% (Voltage unbalance: 2% or less

*7)

), Frequency: +5 to -5%

Rated

current

*8)

[A]

With DCR

0.57

0.93

1.6

3.0

5.7

8.3

14.0

21.1

28.8

42.2

57.6

Without DCR

1.1

1.8

3.1

5.3

9.5

13.2

22.2

31.5

42.7

60.7

80.0

Required power

supply capacity

*5)

[kVA]

0.2

0.3

0.6

1.1

2.0

2.9

4.9

7.4

10

15

20

Braking

Braking torque

*6)

[%]

150

100

50

30

20

DC braking

Starting frequency

*9)

: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Transistor for

braking resistor

-

Built-in

Applicable safety

standards

UL508C, EN 61800-5-1:2007

Enclosure

IP20 (IEC 60529:1989) / UL open type (UL50)

Cooling method

Natural cooling

Fan cooling

Mass [kg] (△=A)

0.6

0.6

0.7

0.8

1.7

1.7

2.5

3.1

3.1

4.5

4.5

Mass [lbs] (△=U)

1.3

1.3

1.5

1.8

3.7

3.7

5.5

6.8

6.8

9.8

9.8

2004):361800 (IEC 67%

[V] voltageaverage phase-Three

[V] voltageMin.[V] voltageMax.

unbalance Voltage

1) Three-phase 200V series(0.1 to 15kW / 1/8 to 20HP) (△ = A, U only)

*1) Fuji Electric's/US 4-pole standard motor.

*2) Rated capacity is calculated by regarding the output rated voltage as220V for three-phase 200V series.

*3) Output voltage cannot exceed the power supply voltage.

*4) The load shall be reduced so that the continuous operating current is the rated current in parenthesis or less if the carrier frequency

is set to 3kHz or above or ambient temperature exceeds 40℃(104°F).

*5) Obtained when a DC REACTOR is used.

*6) Average braking torque when a motor of no load decelerates from 60Hz.(Varies with the efficiency of the motor).

*7)

If this value is 2 to 3%, use an AC REACTOR.

*8) The currents are calculated on the condition that the inverters are connected to power supply of 500kVA (In the case of inverter

capacity is more than 50kVA, it is 10 times of the inverter capacity), %X=5%.

*9) Effective function only in induction motor drive.

*10) The load shall be reduced so that the continuous operating current is the rated current in parenthesis or less if the carrier frequency

is set to 4kHz or above or ambient temperature exceeds 40℃(104°F).

Page 3

3

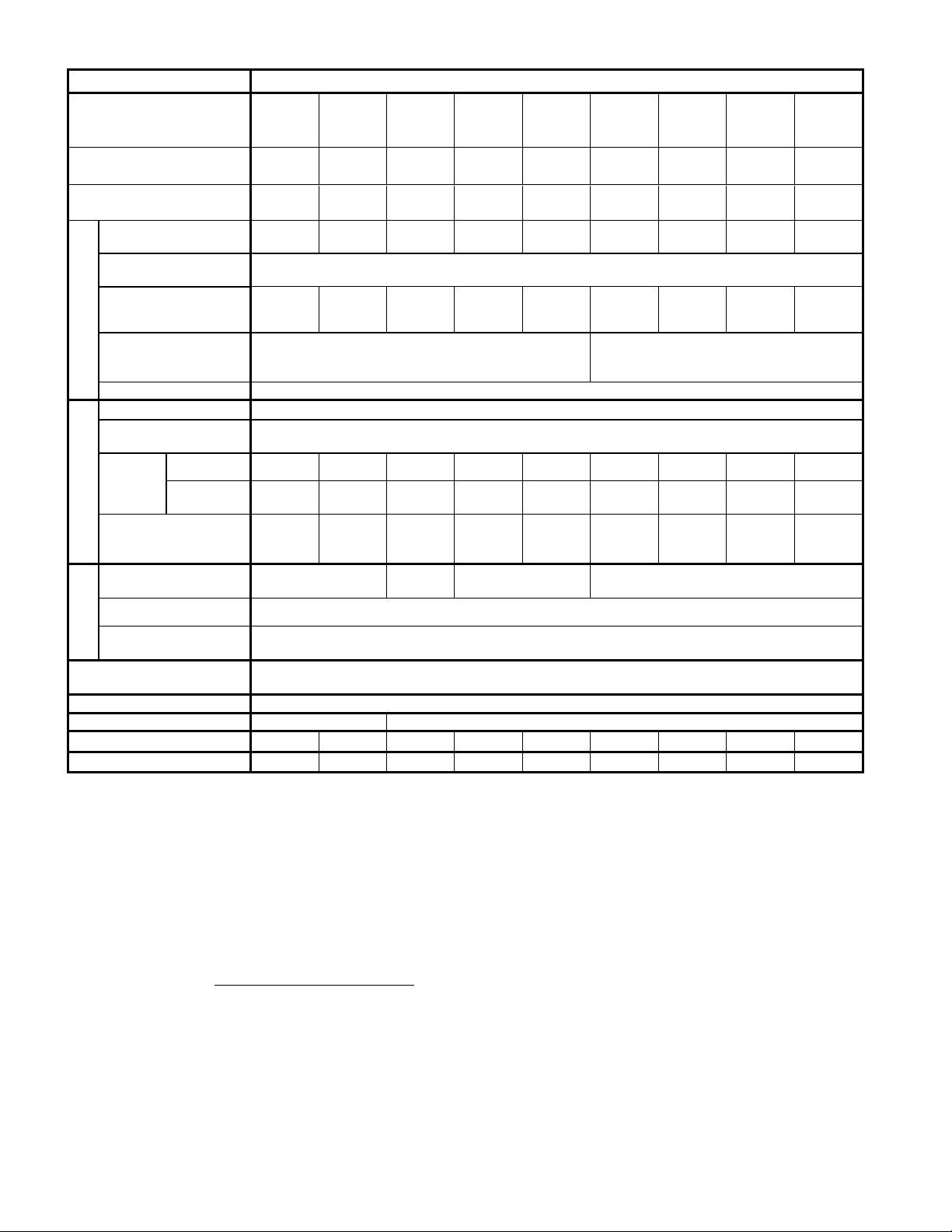

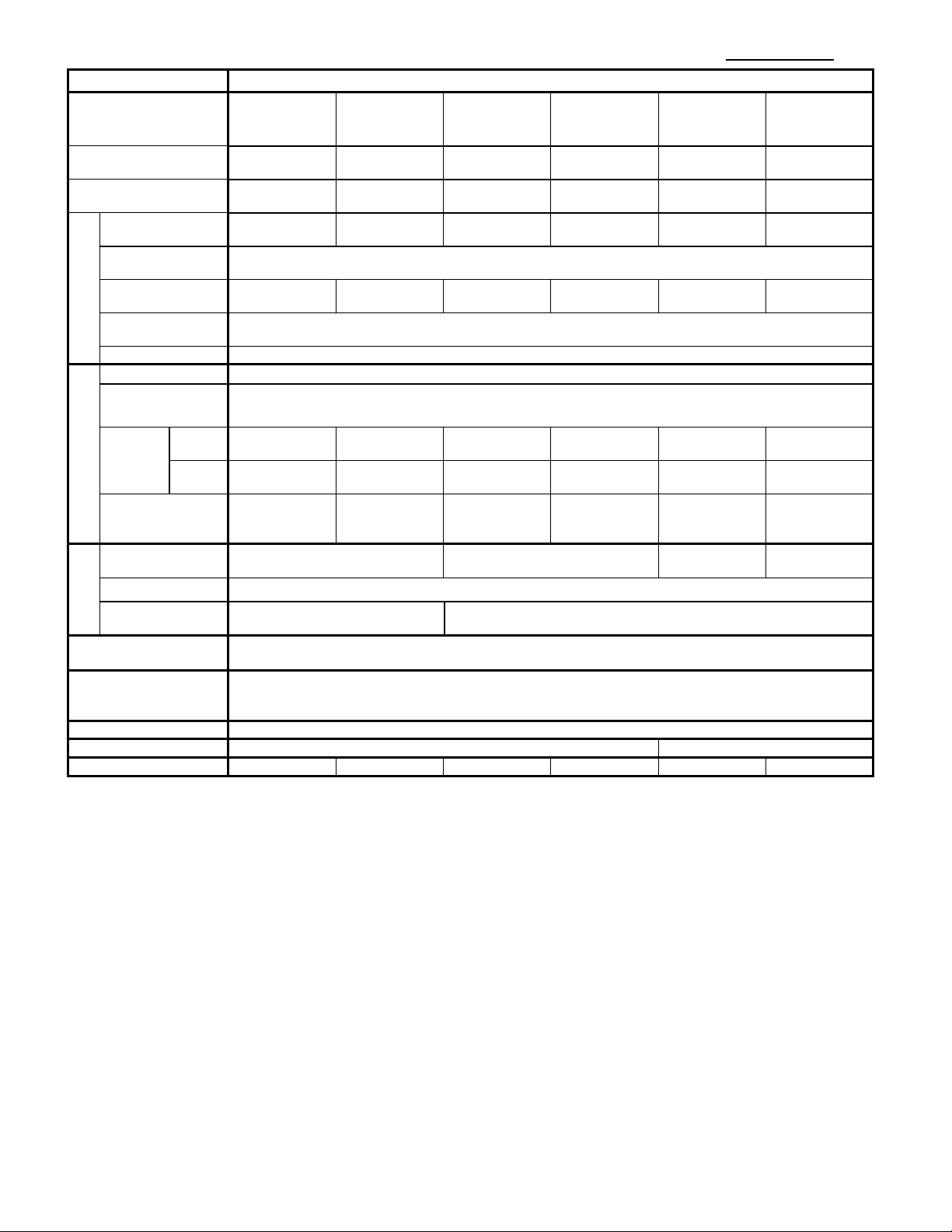

2) Three-Phase 400V Series(0.4 to 15kW / 1/2 to 20HP)

Items

Specifications

Type

(FRN□□□C2S-4△、

△ = A,C,E,U)

0002

0004

0005

0007

0011

0013

0018

0024

0030

Nominal applied motor

*1)

[kW]

(△=A,C,E)

0.4

0.75

1.5

2.2

3.7(△=A,C)/

4.0(△=E)

5.5

7.5

11

15

Nominal applied motor

*1)

[HP]

(△=U)

1/2 1 2 3 5

7.5

10

15

20

Output ratings

Rated capacity

*2)

[kVA]

1.3

2.3

3.2

4.8

8.0

9.9

13

18

22

Rated voltage

*3)

[V]

Three-phase 380~480V (With AVR)

Rated current [A]

1.8

(1.5)

*4)

3.1

(2.5)

*4)

4.3

(3.7)

*4)

6.3

(5.5)

*4)

10.5

(9.0)

*4)

13.0

18.0

24.0

30.0

Overload capability

150% of rated current for 1min

150% of rated current for 1min or 200% of rated current for

0.5s (If the rated current is in parenthesis)

150% of rated current for 1min or

200% of rated current for 0.5s

Rated frequency

50, 60Hz

Input ratings

Main power supply

Three-phase 380~480V,50/60Hz

Voltage/frequency

variations

Voltage: +10 to -15% (Voltage unbalance: 2% or less

*7)

), Frequency: +5 to -5%

Rated

current

*8)

[A]

With DCR

0.85

1.6

3.0

4.4

7.3

10.6

14.4

21.1

28.8

Without

DCR

1.7

3.1

5.9

8.2

13.0

17.3

23.2

33.0

43.8

Required power

supply capacity

*5)

[kVA]

0.6

1.1

2.0

2.9

4.9

7.4

10

15

20

Braking

Braking torque

*6)

[%]

100

50

30

20

DC braking

Starting frequency

*9)

: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Transistor for

braking resistor

Built-in

Applicable safety

Standards

UL508C, EN 61800-5-1:2007

Enclosure

IP20 (IEC 60529:1989) / UL open type (UL50)

Cooling method

Natural cooling

Fan cooling

Mass [kg] (△=A,C,E)

1.2

1.3

1.7

1.7

2.5

3.1

3.1

4.5

4.5

Mass [lbs] (△=U)

2.6

2.9

3.7

3.7

5.5

6.8

6.8

9.8

9.8

2004):361800 (IEC 67%

[V] voltageaverage phase-Three

[V] voltageMin.[V] voltageMax.

unbalance Voltage

*1) Fuji Electric's/US 4-pole standard motor.

*2) Rated capacity is calculated by regarding the output rated voltage as440V for three-phase 400V series.

*3) Output voltage cannot exceed the power supply voltage.

*4) The load shall be reduced so that the continuous operating current is the rated current in parenthesis or less if the carrier frequency

is set to 3kHz or above or ambient temperature exceeds 40℃(104°F).

*5) Obtained when a DC REACTOR is used.

*6) Average braking torque when a motor of no load decelerates from 60Hz. (Varies with the efficiency of the motor).

*7)

If this value is 2 to 3%, use an AC REACTOR.

*8) The currents are calculated on the condition that the inverters are connected to power supply of 500kVA (In the case of inverter

capacity is more than 50kVA, it is 10 times of the inverter capacity), %X=5%.

*9) Effective function only in induction motor drive.

Page 4

4

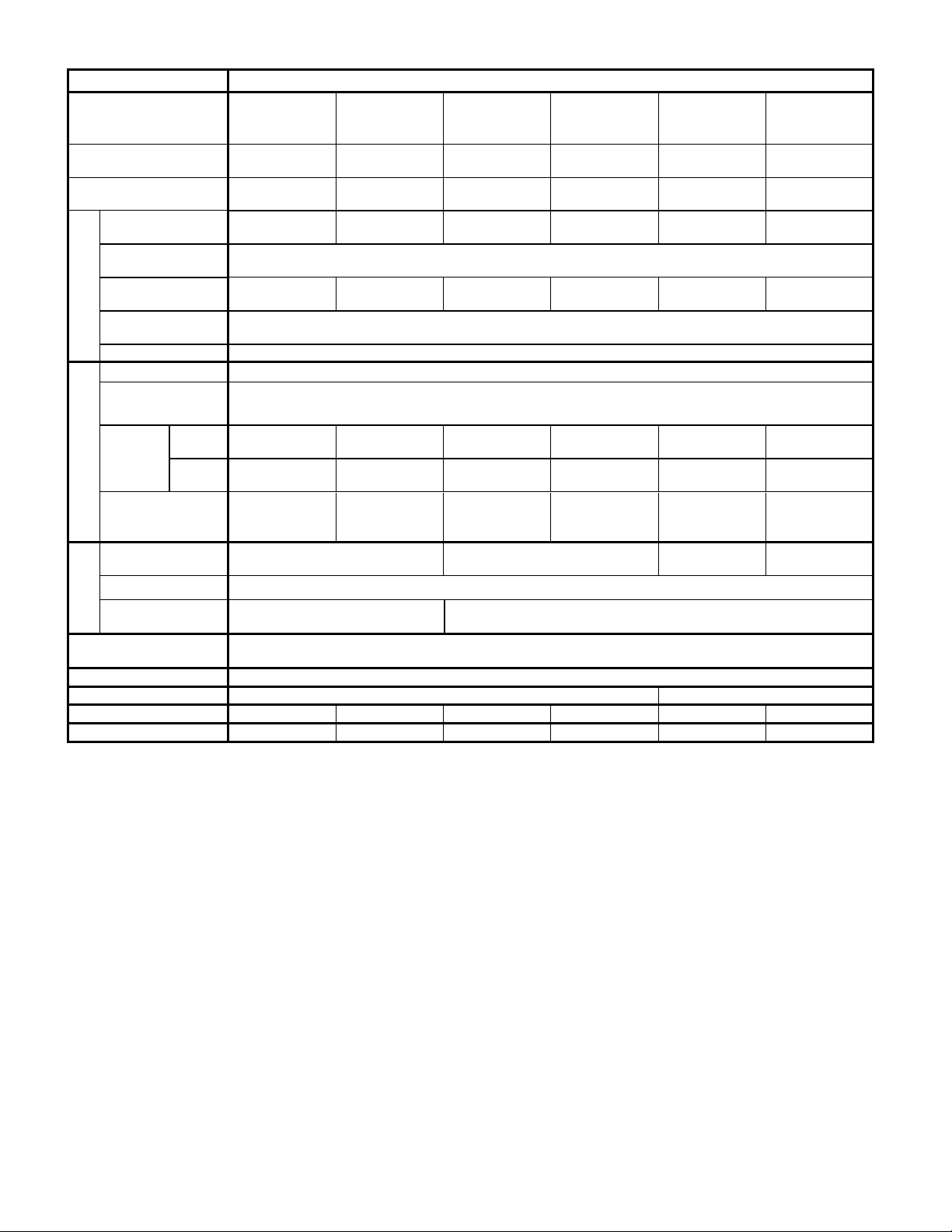

3) Single-Phase 200V Series(0.1 to 2.2kW / 1/8 to 3HP)

Items

Specifications

Type

(FRN□□□C2S-7△、

△ = A,C,E,U)

0001

0002

0004 ⓐ

0006

0010

0012

Nominal applied motor

*1)

[kW]

(△=A,C,E)

0.1

0.2

0.4

0.75

1.5

2.2

Nominal applied motor

*1)

[HP]

(△=U)

1/8

1/4

1/2 1 2

3

Output ratings

Rated capacity

*2)

[kVA]

0.30

0.57

1.3

2.0

3.5

4.5

Rated voltage

*3)

[V]

Three-phase 200~240V (With AVR)

Rated current [A]

*4)

0.8

(0.7)

1.5

(1.4)

3.5

(2.5)

5.5

(4.2)

9.2

(7.0)

12.0

(10.0)

Overload capability

150% of rated current for 1min

150% of rated current for 1min or 200% of rated current for 0.5s (If the rated current is in parenthesis)

Rated frequency

50, 60Hz

Input ratings

Main power supply

Single-phase 200~240V,50/60Hz

Voltage/frequency

variations

Voltage: +10 to -10%, Frequency: +5 to -5%

Rated

current

*7)

[A]

With

DCR

1.1

2.0

3.5

6.4

11.6

17.5

Without

DCR

1.8

3.3

5.4

9.7

16.4

24.0

Required power

supply capacity

*5)

[kVA]

0.3

0.4

0.7

1.3

2.4

3.5

Braking

Braking torque

*6)

[%]

150

100

50

30

DC braking

Starting frequency

*9)

: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Transistor for

braking resistor

-

Built-in

Applicable safety

standards

UL508C, EN 61800-5-1:2007

Enclosure

IP20 (IEC 60529:1989) / UL open type (UL50)

Cooling method

Natural cooling

Fan cooling

Mass [kg] (△=A,C,E)

0.6

0.6

0.7

0.9

1.8

2.5

Mass [lbs] (△=U)

1.3

1.3

1.5

2.0

4.0

5.5

*1) Fuji Electric’s/US 4-pole standard motor.

*2) Rated capacity is calculated by regarding the output rated voltage as 220V.

*3) Output voltage cannot exceed the power supply voltage.

*4) The load shall be reduced so that the continuous operating current is the rated current in parenthesis or less if the carrier frequency

is set to 3kHz or above or ambient temperature exceeds 40℃(104°F).

*5) Obtained when a DC REACTOR is used.

*6) Average braking torque when a motor of no load decelerates from 60Hz. (Varies with the efficiency of the motor).

*8) The currents are calculated on the condition that the inverters are connected to power supply of 500kVA (In the case of inverter

capacity is more than 50kVA, it is 10 times of the inverter capacity), %X=5%.

*9) Effective function only in induction motor drive.

Page 5

5

4) Single-Phase 100V Series(0.1 to 0.75kW / 1/8 to 1HP) (△ = U only)

Items

Specifications

Type

(FRN□□□C2S-6△、

△ = U)

0001

0002

0003

0005

Nominal applied

motor

*1)

[HP]

1/8

1/4

1/2

1

Output ratings

Rated capacity

*2)

[kVA]

0.26

0.53

0.95

1.6

Rated voltage

*3)

[V]

Three-phase 200~240V (With AVR)

Rated current [A]

0.7

1.4

2.5

4.2

Overload capability

150% of rated current for 1min or 200% of rated current for 0.5s

Rated frequency

50, 60Hz

Input ratings

Main power supply

Single-phase 100~120V,50/60Hz

Voltage/frequency

variations

Voltage: +10 to -10%, Frequency: +5 to -5%

Rated

current

*8)

[A]

With

DCR

2.2

3.8

6.4

12.0

Without

DCR

3.6

5.9

9.5

16.0

Required power

supply capacity

*5)

[kVA]

0.3

0.5

0.7

1.3

Braking

Braking torque

*6)

[%]

150

100

DC braking

Starting frequency

*9)

: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Transistor for

braking resistor

-

Built-in

Applicable safety

standards

UL508C

Enclosure

IP20 (IEC 60529:1989) / UL open type (UL50)

Cooling method

Natural cooling

Mass [kg]

0.7

0.7

0.8

1.3

Mass [lbs]

1.5

1.5

1.8

2.9

Shaft output (%)

Maximum torque (%)

w/o DC reactor (DCR)

90

150

w/ DC reactor (DCR)

85

120

*1) Fuji Electric's/US 4-pole standard motor.

*2) Rated capacity is calculated by regarding the output rated voltage as 220V.

*3) Output voltage cannot exceed the twice of power supply voltage.

*5) Obtained when a DC REACTOR is used.

*6) Average braking torque when a motor of no load decelerates from 60Hz. (Varies with the efficiency of the motor).

*8) The currents are calculated on the condition that the inverters are connected to power supply of 50kVA, %X=5%.

*9) Effective function only in induction motor drive.

Note

When driven by 100 VAC, the single-phase 100 V series of inverters limit their shaft output and maximum output torque as listed

below. This is to prevent their output voltage from decreasing when load is applied.

Page 6

6

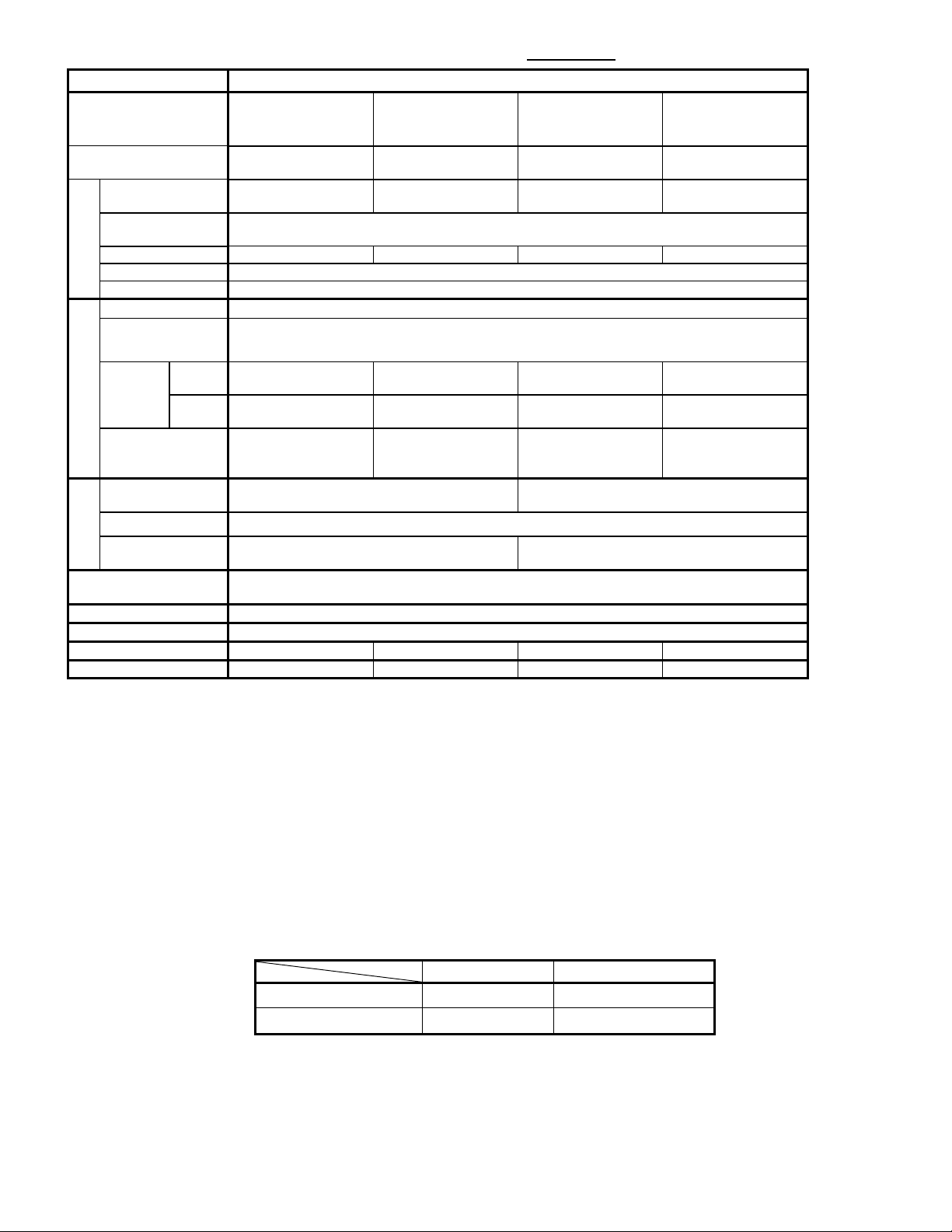

2. Semi-Standard Specifications

Items

Specifications

Type

(FRN□□□C2E-4△、

△ = C,E)

0002

0004

0005

0007

0011

0013

0018

0024

0030

Nominal applied motor

*1)

[kW]

0.4

0.75

1.5

2.2

3.7(△=C)/

4.0(△=E)

5.5

7.5

11

15

Nominal applied motor

*1)

[HP]

1/2 1 2 3 5

7.5

10

15

20

Output ratings

Rated capacity

*2)

[kVA]

1.3

2.3

3.2

4.8

8.0

9.9

13

18

22

Rated voltage

*3)

[V]

Three-phase 380~480V (With AVR)

Rated current [A]

1.8

(1.5)

*4)

3.1

(2.5)

*4)

4.3

(3.7)

*4)

6.3

(5.5)

*4)

10.5

(9.0)

*4)

13.0

18.0

24.0

30.0

Overload capability

150% of rated current for 1min

150% of rated current for 1min or 200% of rated current for

0.5s (If the rated current is in parenthesis)

150% of rated current for 1min or

200% of rated current for 0.5s

Rated frequency

50, 60Hz

Input ratings

Main power supply

Three-phase 380~480V,50/60Hz

Voltage/frequency

variations

Voltage: +10 to -15% (Voltage unbalance: 2% or less

*7)

), Frequency: +5 to -5%

Rated

current

*8)

[A]

With DCR

0.85

1.6

3.0

4.4

7.3

10.6

14.4

21.1

28.8

Without

DCR

1.7

3.1

5.9

8.2

13.0

17.3

23.2

33.0

43.8

Required power

supply capacity

*5)

[kVA]

0.6

1.1

2.0

2.9

4.9

7.4

10

15

20

Braking

Braking torque

*6)

[%]

100

50

30

20

DC braking

Starting frequency

*9)

: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Transistor for

braking resistor

Built-in

Applicable safety

Standards

UL508C, EN 61800-5-1:2007

Applicable EMC standards

(EN61800-3:2004 +A1:2012)

(in progress)

Immunity : Second Environment (Industrial)

Emission : Category C2

Immunity : Second Environment (Industrial)

Emission : Category C3

Enclosure

IP20 (IEC 60529:1989) / UL open type (UL50)

Cooling method

Natural cooling

Fan cooling

Mass [kg]

1.5

1.6

3.0

3.1

3.2

(T.B.D.)

(T.B.D.)

(T.B.D.)

(T.B.D.)

2004):361800 (IEC 67%

[V] voltageaverage phase-Three

[V] voltageMin.[V] voltageMax.

unbalance Voltage

1) EMC Filter Built-in Type in Three-Phase 400V Series(0.4 to 15kW / 1/2 to 20HP) (△ = C, E only)

*1) Fuji Electric's/US 4-pole standard motor.

*2) Rated capacity is calculated by regarding the output rated voltage as440V for three-phase 400V series.

*3) Output voltage cannot exceed the power supply voltage.

*4) The load shall be reduced so that the continuous operating current is the rated current in parenthesis or less if the carrier frequency

is set to 3kHz or above or ambient temperature exceeds 40℃(104°F).

*5) Obtained when a DC REACTOR is used.

*6) Average braking torque when a motor of no load decelerates from 60Hz. (Varies with the efficiency of the motor).

*7)

If this value is 2 to 3%, use an AC REACTOR.

*8) The currents are calculated on the condition that the inverters are connected to power supply of 500kVA (In the case of inverter

capacity is more than 50kVA, it is 10 times of the inverter capacity), %X=5%.

*9) Effective function only in induction motor drive.

Page 7

7

2) EMC Filter Built-in Type in Single-Phase 200V Series(0.1 to 2.2kW / 1/8 to 3HP) (△ = C, E only)

Items

Specifications

Type

(FRN□□□C2E-7△、

△ = C,E)

0001

0002

0004

0006

0010

0012

Nominal applied motor

*1)

[kW]

0.1

0.2

0.4

0.75

1.5

2.2

Nominal applied motor

*1)

[HP]

1/8

1/4

1/2 1 2

3

Output ratings

Rated capacity

*2)

[kVA]

0.30

0.57

1.3

2.0

3.5

4.5

Rated voltage

*3)

[V]

Three-phase 200~240V (With AVR)

Rated current [A]

*4)

0.8

(0.7)

1.5

(1.4)

3.5

(2.5)

5.5

(4.2)

9.2

(7.0)

12.0

(10.0)

Overload capability

150% of rated current for 1min

150% of rated current for 1min or 200% of rated current for 0.5s (If the rated current is in parenthesis)

Rated frequency

50, 60Hz

Input ratings

Main power supply

Single-phase 200~240V,50/60Hz

Voltage/frequency

variations

Voltage: +10 to -10%, Frequency: +5 to -5%

Rated

current

*7)

[A]

With

DCR

1.1

2.0

3.5

6.4

11.6

17.5

Without

DCR

1.8

3.3

5.4

9.7

16.4

24.0

Required power

supply capacity

*5)

[kVA]

0.3

0.4

0.7

1.3

2.4

3.5

Braking

Braking torque

*6)

[%]

150

100

50

30

DC braking

Starting frequency

*9)

: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s, Braking level: 0 to 100%

Transistor for

braking resistor

-

Built-in

Applicable safety

standards

UL508C, EN 61800-5-1:2007

Applicable EMC

standards

EN61800-3:2004 +A1:2012

Immunity : Second Environment (Industrial)

Emission : Category C2

Enclosure

IP20 (IEC 60529:1989) / UL open type (UL50)

Cooling method

Natural cooling

Fan cooling

Mass [kg]

0.7

0.7

0.8

1.2

3.0

3.0

*1) Fuji Electric's/US 4-pole standard motor.

*2) Rated capacity is calculated by regarding the output rated voltage as 220V.

*3) Output voltage cannot exceed the power supply voltage.

*4) The load shall be reduced so that the continuous operating current is the rated current in parenthesis or less if the carrier frequency

is set to 3kHz or above or ambient temperature exceeds 40℃(104°F).

*5) Obtained when a DC REACTOR is used.

*6) Average braking torque when a motor of no load decelerates from 60Hz. (Varies with the efficiency of the motor).

*8) The currents are calculated on the condition that the inverters are connected to power supply of 500kVA (In the case of inverter

capacity is more than 50kVA, it is 10 times of the inverter capacity), %X=5%.

*9) Effective function only in induction motor drive.

Page 8

8

3. Common Specifications

Items

Specifications

Remark

Output frequency

adjustment

Max. output

frequency

25 to 400Hz adjustable

Base

frequency

25 to 400Hz adjustable

Starting

frequency

0.1 to 60.0Hz

Carrier

frequency

・0.75 to 16kHz adjustable

Note) (*1) In the case of the carrier frequency is 6kHz or above, the carrier frequency may

drop automatically according to the ambient temperature or output current to protect

the inverter. (It has a stop function of automatic reduction.)

・ Carrier frequency modulation: Motor noise may reduced by modulating the carrier

frequency.

Accuracy

Analog setting: ±2% of max freq. (at 25°C), temperature drift: ±0.2% of max freq. (at 25±10°C)

Keypad setting: ±0.01% of max freq. (at 25°C), temperature drift: ±0.01% of max freq. (at 25±10°C)

Setting resolution

・Analog setting :1/1000 of maximum frequency

・Keypad setting :0.01Hz(99.99Hz or below),0.1Hz(100.0 to 400.0Hz)

・Link setting :1/20000 of maximum frequency or 0.01Hz(Fixed)

Control

Control method

Induction Motor

・V/f control, ・Slip compensation, ・Auto-torque boost,

・Dynamic torque vector control, ・Automatic energy saving

Synchronous Motor (*2)

・Synchronous motor drive(without speed/position sensor)

Speed control range : 10% or higher of base frequency

Voltage/freq.

characteristic

200V

series

Possible to set output voltage at base frequency and at maximum respectively

from 80 to 240V. AVR control (*1) can be turned ON or OFF.

2 points (Arbitrary voltage and frequency (*1) can be set.)

Arbitrary voltage (0 to 240V), Arbitrary frequency(0 to 400Hz)

400V

series

Possible to set output voltage at base frequency and at maximum respectively

from 160 to 500V. AVR control (*1) can be turned ON or OFF.

2 points (Arbitrary voltage and frequency (*1) can be set.)

Arbitrary voltage (0 to 500V), Arbitrary frequency(0 to 400Hz)

Torque boost (*1)

・Auto-torque boost(For constant torque load)

・Manual torque boost: Torque boost value can be set 0.0 to 20.0 percent.

・Selectable by load characteristics

(Constant torque load, Variable torque load)

Starting torque (*1)

150% or more at setting frequency 1.0Hz with Slip compensation and auto-torque boost.

Start/Stop

Keypad operation :Start/Stop with RUN, STOP keys (Standard keypad)

Start/Stop with RUN, STOP keys (Remote keypad: Option)

External signals : Forward (Reverse) rotation, stop command (capable of 3-wire operation)

(Digital input) coast-to-stop command, external alarm, alarm reset, etc.

Link operation : RS-485communications(Equipped as standard)

Operation command switch: Link switch

Frequency setting

Key operation: Can be set with , keys(Possible to lock the setting data)

Also can be set with function code (only via communication) and be copied. (*2)

Built-in potentiometer

Analog input : DC0 to +10V/0 to 100%(Terminal 12)

: DC4 to 20mA/0 to 100%, DC0 to 20mA/0 to 100% (Terminal C1)

Multi-frequency: 16 frequencies at maximum are selectable.

UP/DOWN operation: The frequency rises or lowers while the digital input signal is turned

on.

Link operation: Can be set with RS-485 communications.

Frequency setting change: Two types of frequency settings can be switched with an external

signal (Digital input).

Frequency setups through communications or Multi-frequency

are also possible.

Auxiliary frequency setting: Built-in potentiometer, Inputs at terminal 12, C1 can be added to

the main setting as auxiliary frequency settings.

*1 : Effective function only in induction motor drive.

*2 : These functions can be supported by the inverters having a ROM version 0500 or later.

Page 9

9

Items

Specifications

Remark

Control

Frequency setting

Inverse action: The digital input signal and function code setting sets or switches between the

normal and inverse actions

DC0 to +10V/0 to 100% can be switched to DC+10 to 0V/0 to 100%

DC4 to +20mA ”DC0 to +20mA” /0 to 100% can be switched to DC+20 to 0mA

“DC+20 to 0mA” /0 to 100%

Acceleration /

Deceleration time

・0.00 to 3600s

・Two kinds of acceleration and deceleration time can be set and selected individually

(A changeover is possible during operation)

・Acceleration and deceleration pattern can be selected from 4 types: Linear,

・S-curve (weak), S-curve (strong), Curvilinear (constant output max. capacity)

・Shutoff of the operation command coasts the motor to decelerate and stop.

・ACC./DEC time for Jogging operation can be set. (0.00 to 3600s)

S-curve

(free area

setting is

hided

function)

Frequency limiter

(Upper / lower)

・Upper and lower limiters can be set. ( setting range: 0 to 400Hz)

Bias frequency

Bias of set frequency and PID command can be set in the range between 0 and ±100%.

Gain for frequency

setting

The analog input gain can be set in the range from 0 to 200%.

Jump frequency

setting

3 operation points and their common jump hysteresis width (0 to 30Hz) can be set. (ROM version 0499 or earlier)

6 operation points and their common jump hysteresis width (0 to 30Hz) can be set. (ROM version 0500 or later)

Timer operation

Operate and stop by the time set with keypad. (1 cycle operation)

Jogging operation

(*1)

Jogging operation is possible by RUN key(Standard keypad)or digital input.

(ACC./DEC. time for Jogging operation can be set. (ACC. and DEC. time is common.)

Restart after

momentary

power failure (*1)

・Trip at power failure: The inverter trips immediately after power failure.

・Trip at power recovery: Coast-to-stop at power failure and trip at power recovery

・Deceleration stop: Deceleration stop at power failure, and trip after stoppage (*2)

・Start at the frequency selected before momentary stop: Coast-to-stop at power failure and start

after power recovery at thefrequency selected before momentary stop.

・Start at starting frequency: Coast-to-stop at power failure and start at the starting frequency after

power recovery.

Current limit (*1)

(Hardware current

limiting)

Hardware current limiting is used avoiding overcurrent tripping of the inverter, when impact load

change or momentary power failure that can be responded software current limiting. (Hardware

current limiting can be inactive.)

Slip compensation (*1)

・Compensate the lowering the motor speed and get the stabilized operation.

Current limiter

・Control output current so that output current is preset limiting value or less.

PID control

PID control for process control is possible.

・PID command: Keypad, Analog input (Terminal 12,C1), RS-485 communications

・Feed back value: Analog input (Terminal 12,C1)

・Accessory functions

Stop for Slow flowrate function, Normal operation/inverse operation

Integration reset/hold

Automatic

Deceleration

・ If the calculated torque exceeds automatic deceleration level, the inverter avoids

overvoltage trip by automatically controlling the frequency. (*1)

・If the DC link bus voltage exceeds the overvoltage limitation level during deceleration,

the inverter automatically prolongs the deceleration time to three times to avoid

overvoltage trip.

Deceleration

Characteristics

Make the motor loss increase during deceleration so as to reduce the regenerative

energy from motor and avoid Overvoltage trip.

Auto-energy

saving operation (*1)

Control the output voltage so as to minimize the sum of motor loss and inverter loss at

constant speed.

Active drive

The output frequency is automatically reduced to suppress the overload protection trip of the

inverter caused by an increase in the IGBT junction temperature or the ambient temperature,

motor load or the like.

Off-line tuning

(*1)

The motor parameters are automatically tuned. “r1, Xσ, no-load current” (ROM version 0499 or earlier)

The motor parameters are automatically tuned. “r1, Xσ, no-load current, rated slip frequency” (ROM version 0500 or later)

Cooling fan

ON/OFF control

Detects inverter internal temperature and stops cooling fan when the temperature is low.

Second motor

parameters

・One inverter can drive the another motor changing from a motor.

Only induction motor can be set as second motor.

The function data set for second motor are base frequency, rated current, torque boost,Electronic

overload protection for motor, slip compensation, etc…

・Second motor parameters can be preset in the inverter. Auto-tuning is possible.

Limiting the

direction of the

motor rotation

Reverse rotation inhibited,/Forward rotation inhibited selectable

*1: Effective function only in induction motor drive.

*2: These functions can be supported by the inverters having a ROM version 0500 or later.

Page 10

10

Items

Specifications

Remark

Indication

Running

/stopping

・Speed monitor, output current [A], output voltage [V], input power [kW], PID reference value,

PID feedback value, PID output, Time [s] for timer operation, Integrating electric energy

・Select the speed monitor to be displayed among the following.

Output frequency[Hz](Before slip compensation), Output frequency2 [Hz](After slip

compensation), Set frequency, , motor speed [min-1], Line speed [m/min], Constant Feeding

Rate Time [min]

Life early

warning

The life early warning of the main circuit capacitors, capacitors on the PC boards and the

cooling fan can be displayed.

Cumulative run

hours

The cumulative motor running hours, cumulative inverter running hours and cumulative

watt-hours can be displayed.

Page 11

11

Items

Specifications

Remark

Indication

I/O checking

Indicate the status of the Di, Do on the control circuit.

Energy saving

monitor

Input power, Input power×coefficient are indicated.

Trip mode

Displays the cause of trip by codes.

・OC1 (Overcurrent:during acceleration)

・OC2 (Overcurrent:during deceleration)

・OC3 (Overcurrent:at constant speed)

・Lin (Input phase loss)

・LU (Undervoltage)

・OPL(Output phase loss)

・OU1 (Overvoltage:during acceleration)

・OU2 (Overvoltage:during deceleration)

・OU3 (Overvoltage:at constant speed)

・OH1(Overheating of the heat sink)

・OH2(External alarm)

・OH4 (Motor protection (PTC thermistor))

・dbH (Braking resistor overload)

・CoF (PID feedback breaking)

・OL1 (Motor 1 overload)

・OL2 (Motor 2 overload)

・OLU (Inverter overload)

・Er1 (Memory error)

・Er2 (Keypad communications error)

・Er3 (CPU error)

・Er6 (Operation action error)

・Er7 (Tuning error)

・Er8 (RS-485 communications error)

・ErF (Data save error due to undervoltage)

・Erd (Step-out detection(for synchronous

motor drive)) (*2)

・Err (Mock alarm)

Running or trip

mode

Trip history: Saves and displays the last 4 trip codes and their detailed description

Protection

Overcurrent

protection

The inverter is stopped for protection against overcurrent caused by an overload.

LED

indication

OC1

OC2

OC3

Shirt circuit

protection

The inverter is stopped for protection against overcurrent caused by a short circuit in the

output circuit.

Grounding fault

protection

The inverter is stopped only upon start-up for protection against overcurrent caused by a

grounding fault in the output circuit.

Overvoltage

protection

An excessive voltage (3-phase 200V series: 400VDC, 3-phase 400V series: 800VDC) in the

DC link circuit is detected and the inverter is stopped. If a remarkably large voltage is applied

by mistake, the protection cannot be made.

OU1

OU2

OU3

Undervoltage

protection

The voltage drop (3-phase 200V series: 200VDC, 3-phase 400V series: 400VDC) in the DC

link circuit is detected to stop the inverter. However, when "F14: 4 or 5" is selected, an alarm

is not issued even upon a voltage drop in the DC link circuit.

LU

Input phase

loss

The input phase loss is detected to shut off the inverter output. This function protects the

inverter from being broken by adding extreme stress caused by a power phase loss or

unbalance between phases. When the load to be connected is small or DC Reactor is

connected even in the case of an input phase loss, a phase loss is not detected.

Lin

Output phase

loss

Detects breaks in inverter output wiring at the start of operation and during running, to shut off

the inverter output.

OPL

Overheating

The temperature of the heat sink in the event of cooling fan trouble and overload is detected

to stop the inverter.

OH1 Braking resistor is protected from overheat setting Electronic Thermal Overload Protection

for braking resistor appropriately.

dbH

Overload

The temperature inside the IGBT is calculated from the detection of output current and internal

temperature, to shut off the inverter output.

OLU

External alarm

input

With the digital input signal (THR), the inverter is stopped as for an alarm.

OH2

Motor protection

Electronic

thermal

The inverter is stopped upon an electronic thermal function setting to protect the motor.

• The standard motor and inverter motor is protected in the range of all the frequencies.

• Protection for send motor is also possible.

*The operation level and thermal time constant ( 0.5 to 75.0 min) can be set.

OL1

OL2

PTC

thermistor

A PTC thermistor input stops the inverter to protect the motor.

• The PTC thermistor is connected between terminals C1 and 11, a resisitor is connected

between terminals 13 and C1 and setting function codes.

OH4

Overload

early

warning

Warning signal is output at the predetermined level before stopping the inverter with the

electronic thermal function to protect the motor

―

Memory error

Data is checked upon power-on and data writing to detect any fault in the memory and to stop

the inverter.

Er1

*2: These functions can be supported by the inverters having a ROM version 0500 or later.

Page 12

12

Items

Specifications

Remark

Protection

Keypad

communications

error

The remote keypad (optional) is used to detect a communications fault between the keypad

and inverter main body during operation and to stop the inverter.

Er2

CPU error

Detects a CPU error caused by noise and so on and stops the inverter.

Er3

Operation error

STOP key

priority

Pressing the STOP key on the keypad forcibly decelerates and stops

the motor even if the operation command is given through a terminal

block or communications. (Er6 will be displayed after stoppage.)

Er6

Start check

If the operation command is entered in the following cases, Er6 will be

displayed on the LED monitor to prohibit operation.

•Power-on

•Alarm reset (PRG/RESET key ON)

•The link operation selection "LE" is used to switch operation.

Tuning error (*1)

Stop the inverter output when tuning failure, interruption, or any fault as a result of tuning is

detected during tuning for motor constant.

Er7

RS-485

communications

error

When the connection port of the keypad is connected via RS485 communications to the

network to detect a communications error, the inverter is stopped to display the error.

Er8

Data save error

upon

undervoltage

When the undervoltage protection works, an error is displayed if data cannot be stored.

ErF

Step-out

detection (*2)

Stop the inverter when the step-out of the synchronous motor is detected.

Erd

PID feedback

breaking

detection

Stop the inverter output detecting a breaking when the input current is allocated to the PID

control feedback. (Select valid/invalid.)

CoF

Stall

prevention

This is protected when the instantaneous overcurrent limitation works.

Instantaneous overcurrent limitation: operates when the inverter output current goes

beyond the instantaneous overcurrent limiting level, and avoids tripping (during acceleration

and constant speed operation).

Alarm relay

output

(for any fault)

The relay signal is output when the inverter stops upon an alarm. <Alarm reset>

The PRG/RESET key or digital input signal (RST) is used to reset the alarm stoppage state.

Retry function

When the motor is tripped and stopped, this function automatically resets the tripping state

and restarts operation. (The number of retries and the length of wait before resetting can

be set.)

Surge

protection

The inverter is protected against surge voltages intruding across the main circuit power

cable and ground.

Momentary

power failure

protection

A protective function (inverter stoppage) is activated upon a momentary power failure for

15ms or longer.

If restart upon momentary power failure is selected, the inverter restarts upon recovery of

the voltage within the set time.

Mock alarm

Simulated alarm is output by the keypad operation. To check the alarm sequence, simulated

alarm can be output by the keypad operation.

Err

Environment

Installation

location

Shall be free from corrosive gases, flammable gases, oil mist, dusts, and direct sunlight.

(Pollution degree 2 (IEC60664-1:2007)). Indoor use only.

Surrounding air

temperature

-10 to +50°C (14 to 122°F) (IP20)

Ambient

humidity

5 to 95%RH (no condensation)

Altitude

1000m (3300ft) or less (Output derating is not necessary.)

Above 1000m (3300ft) to 3000m (9800ft) or less (Output derating is necessary.)

Above 1000m (3300ft) to 1500m (4900ft) or lower :0.97、

Above 1500m (4900ft) to 2000m (6600ft) or lower:0.95

Above 2000m (6600ft) to 2500m (8200ft) or lower:0.91、

Above 2500m (8200ft) to 3000m (9800ft) lower:0.88

Vibration

3mm(0.12inch) (vibration width) : 2 to less than 9Hz,

9.8m/s2 (32ft/s2) : 9 to less than 20Hz

2m/s2 (6.6ft/s2) : 20 to less than 55Hz

1m/s2 (3.3ft/s2) : 55 to less than 200Hz

Storage

temperature

-25 to +70°C (-13 to 158°F)

Storage

temperature

5 to 95%RH (no condensation)

*1: Effective function only in induction motor drive.

*2: These functions can be supported by the inverters having a ROM version 0500 or later.

Page 13

13

4. Terminal Functions

Symbol

Terminal name

Specification

Remark

Main

circuit

L1/R,L2/S

L3/T

Power input

Connect a three-phase power supply.

(Three-phase 200V, 400V input)

L1/L,L2/N

Connect a single-phase power supply.

(Single-phase 200V input)

U,V,W

Inverter output

Connect a three-phase motor.

P(+),P1

For DC REACTOR

Connect the DC reactor (DCR).

P(+),N(-)

For DC bus

connection

Used for DC bus connection.

P(+),DB

For braking resistor

Connect a external braking resistor

0.4kW(1/2HP) or more

only

(No effection if use at

0.2kW(1/4HP) or less)

G

Grounding

Terminal for inverter grounding

Two terminals are

provided.

Frequency settings

13

Potentiometer power

supply

Used for frequency setting device power supply (variable

resistance: 1 to 5kΩ)

DC10V

12

Voltage input

(Inverse operation)

(PID control)

(Frequency aux.

setting)

・Used as a frequency setting voltage input.

DC 0V to +10V/ 0 to 100%

・DC+10 to 0V // 0 to 100%

・Used for setting signal (PID command value) or feedback

signal.

・Used as additional auxiliary setting to various frequency

settings.

C1

Current input

・Used as a frequency setting current input.

DC4 to 20mA “DC0 to 20mA” / 0 to 100%

(Inverse operation)

(PID control)

(Frequency aux.

setting)

・DC20 to 4mA “DC20 to 0mA” /0 to 100%

・Used for setting signal (PID command value) or feedback

signal

・Used as additional auxiliary setting to various frequency

settings.

For PTC thermistor

connection

・Connect a PTC thermistor for a motor protection.

11

Common for analog

input

Common for Frequency setting input/output signals.

(12,13,C1,FMA)

Two terminals are

provided.

Terminal 11 is isolated

from terminal CM,

Y1E.

Page 14

14

Symbol

Terminal name

Specification

Remark

Digital inputs

X1

Digital input 1

The following functions can be set at terminals X1 to X3, FWD and REV for

signal input.

<Common function>

• Sink and source are changeable using the built-in sliding switch.

• Input logic can be changed between short-circuit of terminals X1 and CM

and open circuits of them. The same setting is possible between CM and

any of the terminals among X2, X3, FWD and REV.

X2

Digital input 2

X3

Digital input 3

FWD

Forward operation

command

REV

Reverse operation

command

(FWD)

Forward operation

command

The motor runs in the forward direction upon ON across (FWD) and CM.

The motor decelerates and stops upon OFF.

This function can be set only

for the terminals FWD and

REV.

Only an active ON signal is

acceptable.

(REV)

Reverse operation

command

The motor runs in the reverse direction upon ON across (REV) and CM.

The motor decelerates and stops upon OFF.

(SS1)

(SS2)

(SS4)

(SS8)

Select Multi-frequency

16 frequencies can be selected with ON/OFF signals at (SS1) to (SS8).

(RT1)

Select ACC/DEC time

ACC1/DEC1 is select when (RT1) is OFF and ACC2/DEC2 is select when

(RT1) is ON.

(HLD)

3-wire operation stop

command

Used for 3-wire operation.

ON across (HLD) and CM: The inverter self-holds FWD or REV signal.

OFF across (HLD) and CM: The inverter releases self-holding.

(BX)

Coast to a stop

The inverter output is shut off immediately and the motor coasts to a stop

when (BX) is ON.

(RST)

Reset alarm

Faults are reset when (RST) is ON.

0.1s or more signal required.

(THR)

External alarm trip

The inverter output is shut off immediately and the motor coasts-to-stop

when (THR) is OFF.

(JOG)

Ready for jogging

Operation mode is changed to Jogging mode and frequency, ACC/DEC

time are changed to those for Jogging operation when (JOG) is ON.

(*1)

(Hz2/Hz1)

Select frequency

command 2/1

Frequency setting 2 is selected when (Hz2/Hz1) is ON.

(M2/M1)

Motor2/Moor1

Motor 1 is effective when (M2/M1) is OFF and Motor 2 is

effective when (M2/M1) is ON.

(DCBRK)

Enable DC braking

DC braking is enable when (DCBRK) is ON.

(WE-KP)

Enable data change with

keypad

Enable data change with keypad when (WE-KP) is ON.

(UP)

UP command

The output frequency increases while (UP) is ON.

(DOWN)

DOWN command

The output frequency decreases while (DOWN) is ON.

(Hz/PID)

Cancel PID control

PID control is canceled when (Hz/PID) is ON/

(Inverter runs with a selected frequency by Multi-frequency, Keypad, analog

input, etc…)

(IVS)

Switch normal/inverse

operation

The frequency setting or PID control output signal (frequency setting) action

mode switches between normal and inverse actions according to (IVS)

ON/OFF status.

(LE)

Enable communication link

via RS-485 or field bus

Enable communication link via RS-485 or field bus when (LE) is ON.

(PID-RST)

Reset PID integral and

differential component

Reset PID integral and differential component when (PID-RST) is ON.

(PID-HLD)

Hold PID integral

component

Hold PID integral component when (PID-HLD) is ON.

PLC

PLC terminal

Connect to PLC output signal power supply. Common for 24V power.

+24V(22 to 27V),

Max.50mA

CM

Common for digital inputs

Common for digital inputs

CM is isolated from 11, Y1E.

Two terminals are provided.

*1: Effective function only in induction motor drive.

Page 15

15

Symbol

Terminal name

Specification

Remark

Transistor outputs

(PLC)

Power supply for transistor

outputs

Power supply for transistor outputs (DC24V DC50mA Max.)

(This terminal is same for PLC terminal for digital input.)

Connect CM with Y1E when

this terminal is used for

transistor outputs.

Y1

Transistor outputs

The following functions can be set at terminals Y1, SO for signal output.

• The setting of "short circuit upon active signal output" or "open upon active

signal output" is possible.

Max. voltage:27Vdc,

max. current:50mA,

leak current:0.1mA

max.

,

ON voltage : within 2V

(at 50mA)

(RUN)

Inverter running (speed

exists)

An active signal is issued when the inverter runs at higher than the stop

frequency.

(FAR)

Frequency arrival

An active signal is issued when the difference between output freq. and set

freq. is equal or less than the value of function code E30 Freq. arrival

(Hysteresis width).

(FDT)

Frequency detected

An active signal is issued when output freq. gets equal or higher than the

value specified by function code E31.

The signal is deactivated if the output frequency falls below the freq. less

than function data E31 minus function data E32.

(LU)

Undervoltage detected

An active signal is issued when inverter dc link voltage is undervoltage

detection level or below.

(IOL)

Inverter output limiting

An active signal is issued when the current limiting, Automatic Deceleration

or torque limiting limits inverter output.

(IPF)

Auto-restarting after

momentary power failure

An active signal is issued until restarting is completed after momentary

power failure.

(OL)

Motor overload early

warning

An active signal is issued when the calculated value of electronic thermal

overload exceeds the preset detection level.

(SWM2)

Select Motor 2

An active signal is issued when motor 2 is selected.

(TRY)

Auto-resetting

An active signal is issued when the auto-resetting is in progress.

(LIFE)

Service lifetime alarm

An active signal is issued when the service lifetime of DC link bus capacitor,

capacitor on the PCBs, cooling fans have expired.

(PID-CTL)

Under PID control

This signal comes ON when the PID control is enabled.

(PID-STP)

Motor stopped due to

slow flowrate under PID

control

This signal is ON when the inverter is in a stopped state by the slow flowrate

stopping function under the PID control. (The inverter is stopped even if a

run command is entered.)

(RUN2)

Inverter output on

An active signal is issued when the inverter runs at higher than stop

frequency or is in DC braking.

(OLP)

Overload prevention

control

An active signal is issued when overload prevention function is in effective.

(ID2)

Current detected 2

An active signal is issued when the output current comes to the current

detection level (for ID) or above and the condition continues for the time

specified current detection timer.

(THM)

Motor overheat detecsted

by thermistor

This signal comes ON when the motor overheat is detected with the

PTC/NTC thermistor.

(BRKS)

Brake signal

This signal is issued to make the mechanical brake ON/OFF.

(*1)

(MNT) ⓑ

Maintenance timer

Alarm signal is generated when time passes or start-up

exceeds over the preset value.

(*2)

(FARFDT)

Logical AND signal of

(FAR) and (FDT)

Logical AND signal of (FAR) and (FDT)

(C1OFF)

Terminal [C1] wire break

When Input current to C1 terminal become less than 2mA, this is interpreted

as wire brake and then ON-singal is generated.

(ID)

Current detected

An active signal is issued when the output current comes to the current

detection level (for ID) or above and the condition continues for

the time specified current detection timer.

(IDL)

Low current detected

This output signal comes ON when the output current drops

below the low current detection level specified by E37 for the

period specified by E38 (Low current detection (Timer)).

(ALM)

Alarm output (for any

alarm)

An active signal is issued when the inverter is in alarm mode.

Y1E

Transistor output

common

Common terminal for transistor output.

Y1E is isolated from 11,CM.

*1: Effective function only in induction motor drive.

*2: These functions can be supported by the inverters having a ROM version 0500 or later.

Page 16

16

Symbol

Terminal name

Specification

Remark

Relay output

30A,30B,

30C

Alarm output (for any

alarm)

A no-voltage contact signal (1c) is issued when the inverter is stopped due

to an alarm.

• Multi-purpose relay output; signals similar to above-mentioned signals Y1

can be selected.

• An alarm output is issued upon either excitation or no excitation according

to selection.

Contact rating: AC250V,

0.3A, cosφ=0.3 DC48V, 0.5A

Analog output

FMA

Analog monitor

Output signal: DC voltage (0 to 10V)

The one of the following signals can be monitored at terminal FMA.

・

Output frequency 1 ( Before slip compensation )

・

Output frequency 1 ( After slip compensation )

・

Output current ・Output voltage

・

Input power ・PID feed back value

・

DC link voltage ・Calibration analog output (+)

・

PID reference ・PID output

Gain: 0 to 300%

Communications

Built-in RJ-45

connector (RS-485)

The one of the following protocol can be selectable.

・

Protocol for keypad (Automatically selected)

・

Modbus RTU

・

FGI bus

・

SX protocol for loader software

With power source for

the keypad and the

switch for changeover

of terminating resistor

ON/OFF.

Communication data

storage can be

selected. (*2)

*2 : These functions can be supported by the inverters having a ROM version 0500 or later.

Page 17

17

5. Basic Wiring Diagram

L1/R

L2/S

L3/T

[13]

G

U

V

W

M

3~

(Note3)

MCCB

or

ELCB

(Note2)

Three-phase

200 to 240V

50/60Hz

or

Three-phase

380 to 480V

50/60Hz

Power supply

P(+)P1 N(-)

G

Main circuit

P(+)

P1

MC

(Note1)

DCR

Motor

Grounding

Grounding

[12]

[11]

[C1]

[11]

[FMA]

(FWD)

(CM)

(REV)

3

2

1

Voltage input

0 to 10Vdc

Power supply for

potentiometer

(Note5)

Control circuit

<Y1E>

<Y1>

(+)

(-)

Current input

4 to 20mAdc

Analog input

(Note6)

Digital input

30A

30B

30C

30

MCCB:Molded case circuit breaker

ELCB:Earth leakage circuit breaker

MC :Magnetic contactor

DCR :DC reactor

DBR :Brake resistor

Transistor

Alarm output

DB

P DB

(Note4)

DBR

(CM)

(THR)

SINK

SOURCE

Meter

L1/L

L2/N

Single-phase

200 to 240V

50/60Hz

or

Single-phase

100 to 120V

50/60Hz

(X1)

(X2)

(X3)

RS‐485 port

(RJ-45)

(CM)

(PLC)

(Factory Setting :

△=E : SOURCE,

OTHER : SINK)

* Switch for termination resistor is built-in.

Page 18

18

Note 1:

When connecting a DC REACTOR (DCR) (option), remove the jumper bar from across the terminals [P1] and [P (+)].

For single-phase 100V input series, DCR shall be connected to the point that is shown below.

Note 2:

Install a recommended molded-case circuit breaker (MCCB) or an earth leakage circuit breaker (ELCB) (with an overcurrent

protection function) in the primary circuit of the inverter to protect wiring. At this time, ensure that the circuit breaker capacity is

equivalent to or lower than the recommended capacity.

Note 3:

Install a magnetic contactor (MC) recommended for each inverter to separate the inverter form the power supply, apart from the

MCCB or ELCB, when necessary. Connect a surge suppressor in parallel when installing a coil such as the MC or solenoid near the

inverter.

Note 4:

(THR) is available when one of terminal functions for X1 to X3, FWD, REV (function code E01 to E03, E98 or E99) is set to the

data “9”.

Note 5:

Frequency can be set by connecting a frequency setting device (external potentiometer) among the terminals 11, 12 and 13 instead

of inputting voltage signal (0 to +10V DC, 0 to +5V DC or +1 to +5V DC) between the terminals 12 and 11.

Note 6:

For the control signal wires, use shielded or twisted wires. Ground shielded wires. To prevent malfunction due to noise, keep the

control circuit wiring away from the main circuit wiring as far as possible (recommended: 10cm(3.94inches) or more), and never set

them in the same wire duct. ⓔ

When crossing the control circuit wiring with the main circuit wiring, set them at right angles.

Note 7:

Three –phase 4wire cable is recommended for motor wiring to reduce the noise emitted. Connect the motor grounding wire to

the inverter grounding terminal G.

Page 19

19

6. Outline: Standard Models

Page 20

20

Page 21

21

Page 22

22

Fuji Electric Corp. of America

47520 Westinghouse Drive, Fremont, CA 94539

Phone: 510-440-1060

www.americas.fujielectric.com

Loading...

Loading...