Page 1

取扱説明書 / Instruction Manual

PROFIBUS-DP 通信カード

PROFIBUS-DP Communications Card

Fuji Electric Systems Co., Ltd. INR-SI47-1329a-JE

"OPC-G1-PDP"

日本語

ENGLISH

Page 2

Copyright © 2008 Fuji Electric Systems Co., Ltd.

All rights reserved.

この取扱説明書の著作権は,富士電機システムズ株式会社にあります。

本書に掲載されている会社名や製品名は,一般に各社の商標または登録商標です。

仕様は予告無く変更することがあります。

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric

Systems Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

日

本

日本語版

語

Page 4

まえがき

PROFIBUS-DP 通信カードをお買い上げいただき誠にありがとうございます。

この取扱説明書は,PROFIBUS-DP マスタ(Siemens 社製 PLC 等)と FRENIC-MEGA を PROFIBUS-DP で接続する用途で

ご利用頂くためのものです。この通信カードを FRENIC-MEGA に取 り付 けることで,PLC やパソコンなどの

PROFIBUS-DP マスタ機器と接続し, 運転指令・周波数指令・機能コードアクセス等を使って FRENIC-MEGA をスレ

ーブとしてコントロールすることができます。

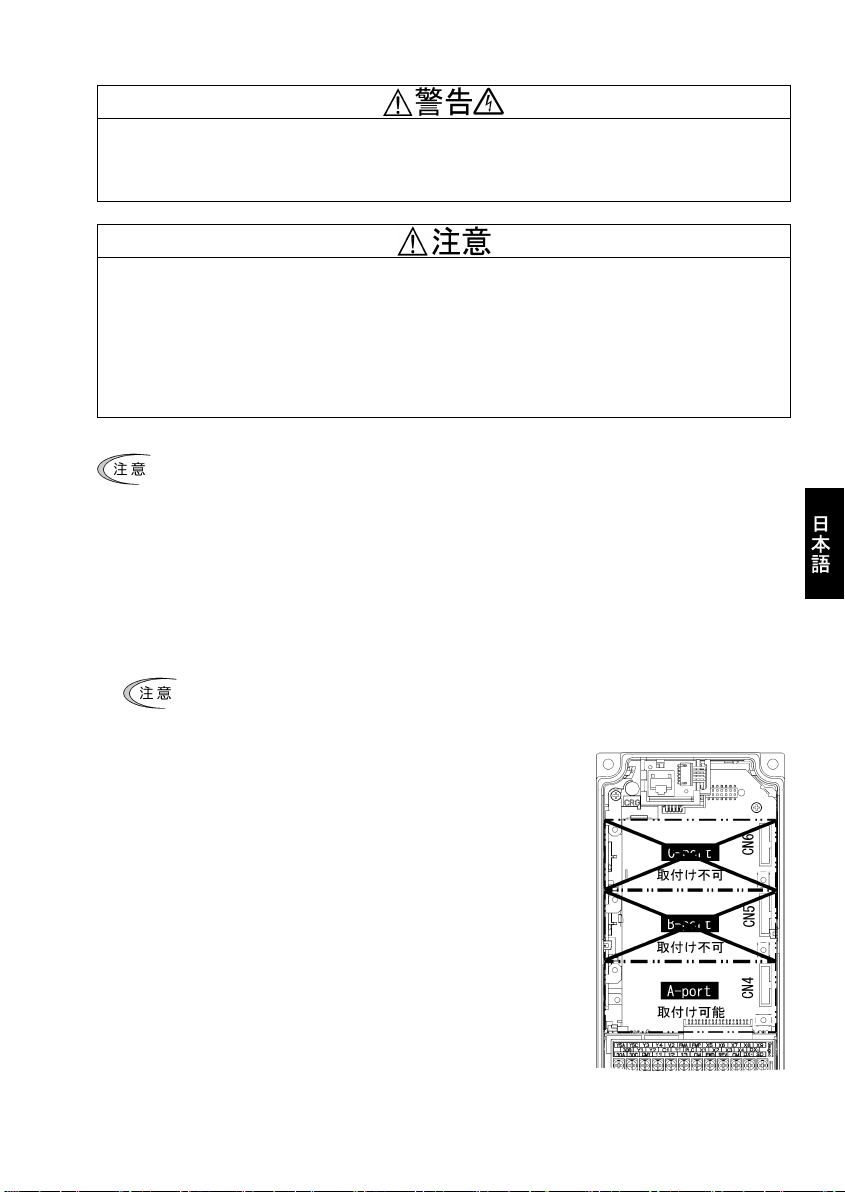

PROFIBUS-DP 通信カードは,FRENIC-MEGA のオプション接続ポート 3 箇所(A,B,C-port)のうち,A-port にのみ

搭載可能です。

本通信カードの特徴を以下に示します。

- PROFIBUS バージョン : DP-V0 対応

- 通信速度 : 9.6Kbit/s~12Mbit/s

- 最大ケーブル長 : 100m (12Mbit/s)~1200m (9.6Kbit/s)

- プロファイル : PROFIDrive V2 準拠

- FRENIC-MEGA が持つ全機能コードを読み書き可能

この取扱説明書にはインバータに関する取扱い方の記載はありませんので,ご使用の前には,この説明書とイン

バータ本体の取扱説明書をお読みになって取扱い方を理解し,正しくご使用ください。間違った取扱いは,正常

な運転を妨げ,寿命の低下や故障の原因になります。

取扱説明書はご使用後も大切に保管してください。

関連資料

OPC-G1-PDP に関連する資料を以下に示します。目的に応じてご利用ください。

・ RS-485 通信ユーザーズマニュアル

・ FRENIC-MEGA 取扱説明書

資料は随時改訂していますので,ご使用の際には最新版の資料を入手してください。

日

本

語

- この取扱説明書を読み,理解したうえで,PROFIBUS-DP 通信カードの取付け,接続(配線),運転,保守

点検を行ってください。

- 間違った取扱いは,正常な運転を妨げたり,寿命の低下や故障の原因になります。

- この取扱説明書は,実際に使用される最終需要家に確実にお届けください。最終需要家はこの取扱説明書

を,PROFIBUS-DP 通信カードが廃棄されるまで大切に保管してください。

■ 安全上のご注意

取付け,配線(接続),運転,保守点検の前に必ずこの取扱説明書を熟読し,製品を正しく使用してください。

更に,機器の知識,安全に関する情報および注意事項のすべてについても十分に習熟してください。

この取扱説明書では,安全注意事項のランクは下記のとおり区別されています。

取扱いを誤った場合に危険な状況が起こる可能性があり,死亡または重傷を負う事故の発生が想

定される場合

取扱いを誤った場合に危険な状況が起こる可能性があり,中程度の傷害や軽傷を受ける事故また

は物的損害の発生が想定される場合

なお,注意に記載した事項の範囲内でも状況によっては重大な結果に結びつく可能性があります。

いずれも重要な内容を記載していますので必ず守ってください。

1

Page 5

取付けおよび配線について

・ インバータの電源を遮断して 22kW 以下は 5 分以上,30kW 以上は 10 分以上経過してから行ってください。

更に LED モニタおよびチャージランプの消灯を確認し,テスターなどを使用して主回路端子 P(+)-N(-)間

の直流中間回路電圧が安全な値(DC+25V 以下)に下がっていることを確認してから行ってください。

・ 配線作業は,資格のある専門家が行ってください。

感電のおそれあり

・ 外部あるいは内部部品が損傷・脱落している製品を使用しないでください。

火災,事故,けがのおそれあり

・ 糸くず,紙,木くず,ほこり,金属くずなどの異物がインバータや通信カード内に侵入するのを防止して

ください。

火災,事故のおそれあり

・ 製品の取付け,取外し時に不適切な作業を行うと,製品が破損するおそれがあります。

故障のおそれあり

・ インバータ,モータ,配線からノイズが発生します。周辺のセンサーや機器の誤動作に注意してください。

事故のおそれあり

操作運転について

・ 必ずインバータ本体の表面カバーを取り付けてから電源 ON(閉)してください。なお,通電中はカバー

を外さないでください。

・ 濡れた手でスイッチを操作しないでください。

感電のおそれあり

・ 機能コードのデータ設定を間違えたり,取扱説明書およびユーザーズマニュアルを十分理解しないで機能

コードのデータ設定を行うと,機械が許容できないトルクや速度でモータが回転することがあります。イ

ンバータの運転の前に各機能コードの確認,調整を行ってください。

事故のおそれあり

保守点検,部品の交換について

・ インバータの電源を遮断して 22kW 以下は 5 分以上,30kW 以上は 10 分以上経過してから行ってください。

更に LED モニタおよびチャージランプの消灯を確認し,テスターなどを使用して主回路端子 P(+)-N(-)間

の直流中間回路電圧が安全な値(DC+25V 以下)に下がっていることを確認してから行ってください。

感電のおそれあり

・ 指定された人以外は,保守点検,部品交換をしないでください。

・ 作業前に金属物,(時計,指輪など)を外してください。

・ 絶縁対策工具を使用してください。

感電,けがのおそれあり

2

Page 6

廃棄について

・ 製品を廃棄する場合は,産業廃棄物として扱ってください。

けがのおそれあり

その他

・ 改造は絶対しないでください。

感電,けがのおそれあり

アイコンについて

本書では以下のアイコンを使用しています。

この表示を無視して誤った取扱いをすると,FRENIC-MEGA が本来持つ性能を発揮できなかったり,その

操作や設定が事故につながることになります。

日

本

語

本製品の操作や設定の際,知っておくと便利な参考事項を示しています。

参照先を示します。

3

Page 7

まえがき ...................................1

■ 安全上のご注意 ........................... 1

第 1 章 ご使用のまえに ..................... 5

1.1 現品の確認 ..........................5

1.2 対象インバータ ...................... 5

第 2 章 各部の名称と機能 ................... 6

2.1 通信カードの外観 .................... 6

2.2 端子台(TERM1) .....................6

2.3 終端抵抗スイッチ(SW3) ............. 7

2.4 アドレススイッチ(SW1,SW2) ........ 7

2.5 通信速度(ボーレート)の設定 ........ 8

2.6 LED インジケータ.....................8

第 3 章 PROFIBUS-DP 通信カードの取付けと

取外し ............................. 9

3.1 通信カードの取付け .................. 9

3.2 通信カードの取外し ................. 10

第 4 章 配線 .............................. 11

4.1 基本接続図 .........................11

4.2 PROFIBUS 端子台の配線...............12

4.3 インバータへの配線 ................. 13

目次

第 5 章 インバータ機能コードの設定 ........ 14

第 6 章 PROFIBUS 通信接続までの手順説明 .... 15

第 7 章 インバータを運転する簡単手順 ...... 16

7.1 事前の設定 ......................... 16

7.2 運転時の実際のデータやりとり例 ..... 16

第 8 章 PROFIBUS プロファイルの詳細説明 .... 19

8.1 サポートする PPO の説明 ............. 19

8.2 PCD の説明 .........................21

8.3 PCV の説明 .........................26

第 9 章 PROFIBUS 通信異常検出時の動作選択 .. 33

第 10 章 アラームコード一覧 ................ 34

第 11 章 トラブルシューティング ............ 35

第 12 章 仕様 .............................. 36

12.1 一般仕様........................... 36

12.2 PROFIBUS-DP 通信仕様................ 36

4

Page 8

第 1 章 ご使用のまえに

1.1 現品の確認

開梱し次の項目を確認してください。

(1) 通信カード,ねじ(M3×8:2 本),取扱説明書(本書)が入っていることを確認してください。

(2) 通信カード上の部品の異常,凹み,反りなど輸送時での破損がないことを確認してください。

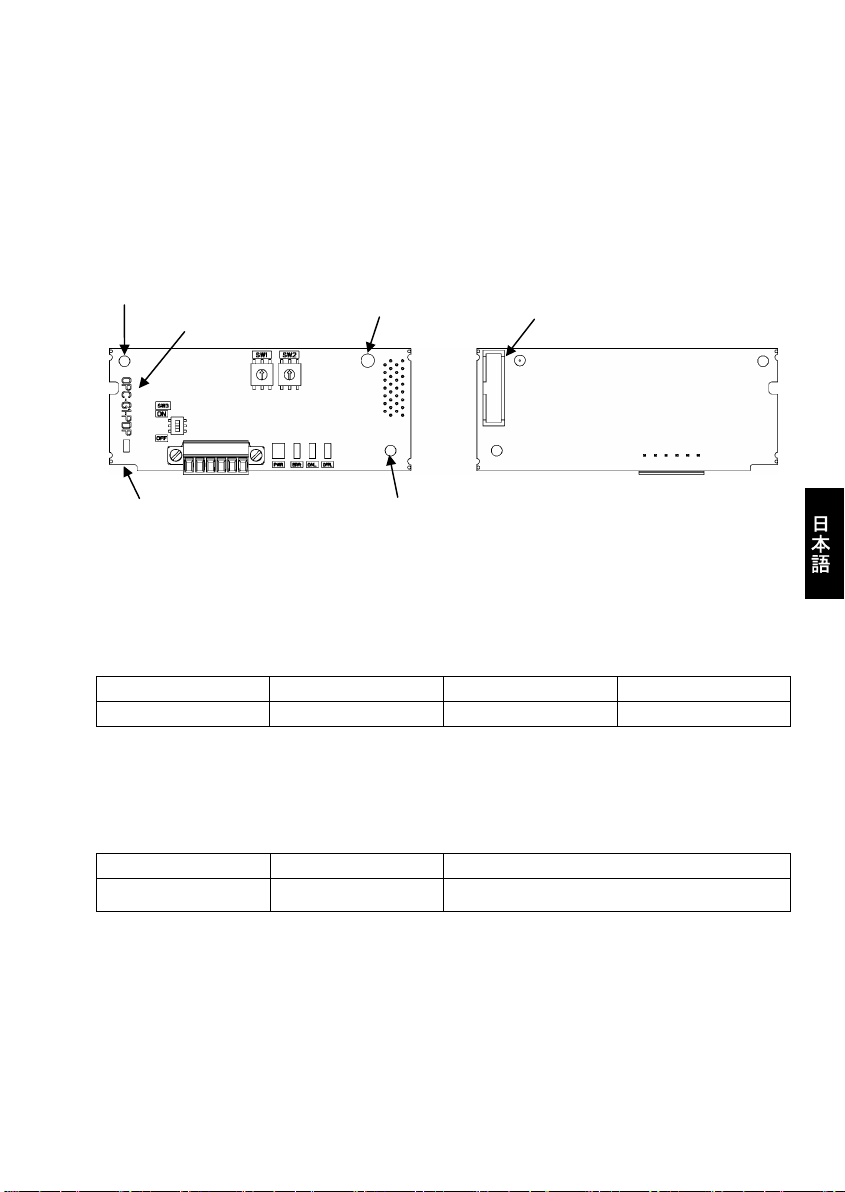

(3) 通信カード上に形式「OPC-G1-PDP」が印刷されていることを確認してください。(図 1.1 参照)

製品にご不審な点や不具合などがありましたら,お買い上げ店または最寄りの弊社営業所までご連絡ください。

ねじ取付け用穴(左)

形式

取外し用つまみ

CN1

(表面) (裏面)

取付け位置決め部

ねじ取付け用穴(右)

図 1.1 各部名称

1.2 対象インバータ

本通信カードは,下表のインバータ形式および ROM バージョンで使用できます。

表 1.1 適用インバータ形式と ROM バージョン

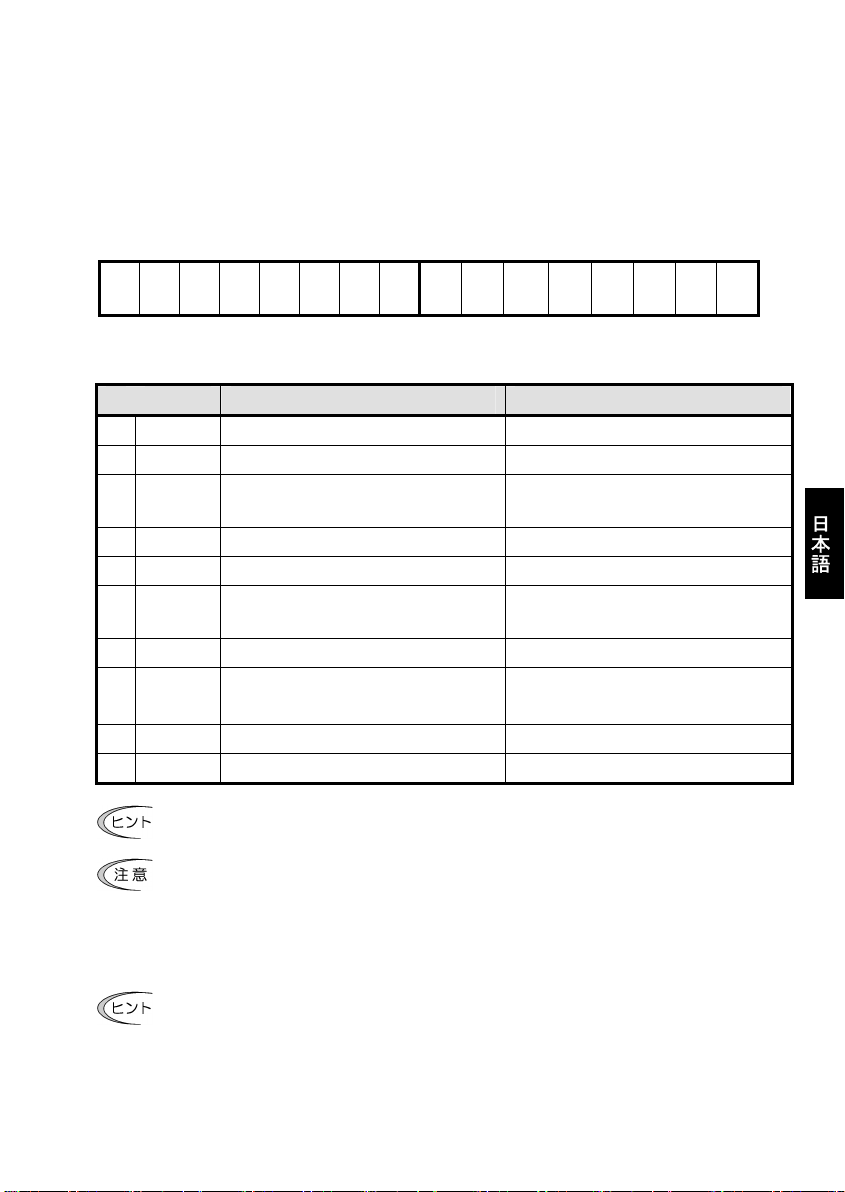

機種 形式 インバータ容量 ROM バージョン

FRENIC-MEGA FRN□□□G1□-□□□ 全容量 1000 以降

※ □には,インバータ容量,タイプ,電圧シリーズなどを示す英数字が入ります。

5_14

インバータの ROM バージョンは,プログラムモードのメニュー番号5「メンテナンス情報」の

ることができます。詳細は,FRENIC-MEGA 取扱説明書の第 3 章「3.4.6 メンテナンス情報を見る」を参照してく

ださい。

LED モニタの表示 項目 表示内容

5_14

インバータ ROM バージョン インバータの ROM バージョンを4桁で表示します。

表 1.2 ROM バージョンの確認方法

で確認す

日

本

語

5

Page 9

第 2 章 各部の名称と機能

2.1 通信カードの外観

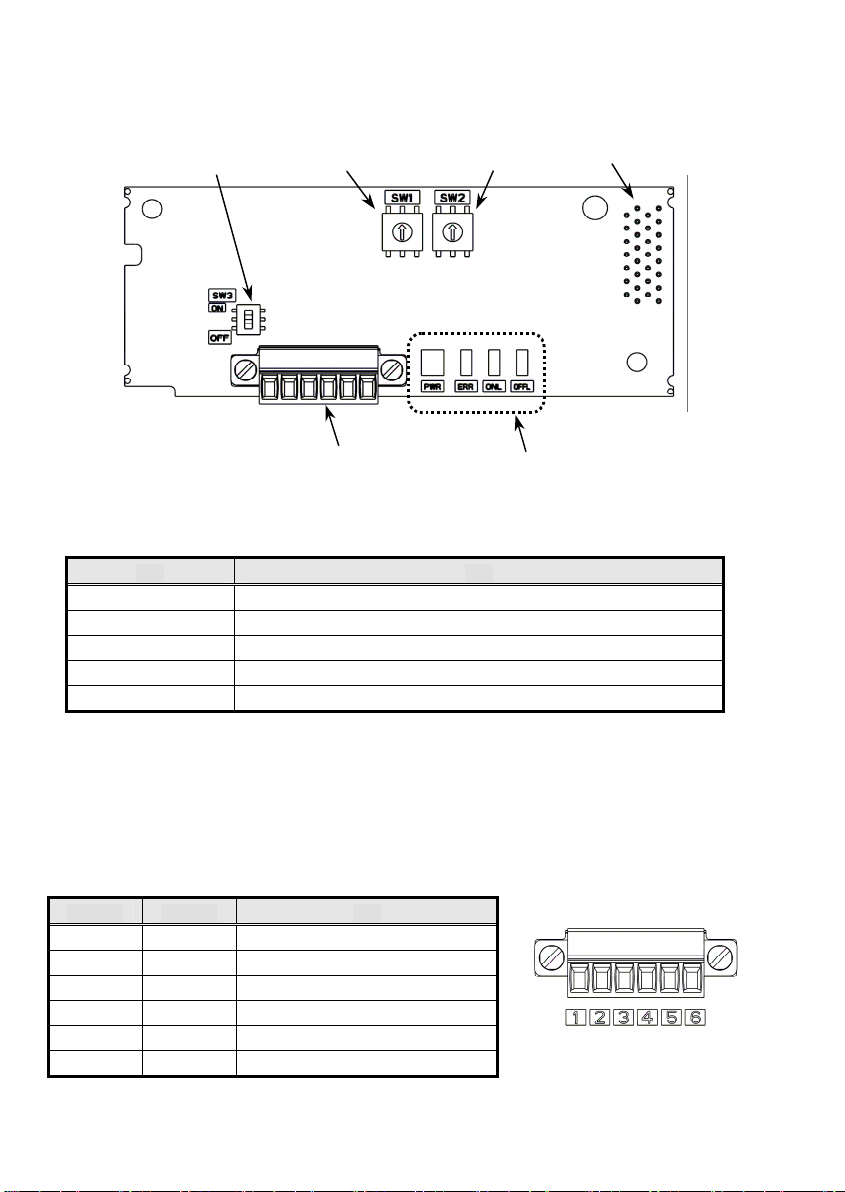

本通信カードの外観および主要部品をそれぞれ,図 2.1 および表 2.1 に示します。

SW3

SW1

SW2

TERM1

図 2.1 OPC-G1-PDP の外観

表 2.1 主要部品の説明

部品 説明

TERM1 PROFIBUS 端子台コネクタ(3.5mm ピッチ) (2.2 項を参照)

CN1 通信カード-インバータ本体の接続コネクタ

SW1,SW2 アドレススイッチ (2.4 項を参照)

SW3 終端抵抗スイッチ (2.3 項を参照)

LED 状態表示 LED インジケータ(PWR,ERR,ONL,OFFL) (2.6 項を参照)

CN1(裏面)

LED

2.2 端子台(TERM1)

着脱可能な6ピン端子台を使用しており,端子台のピン配置は下の表 2.2 のとおりです。

適合する端子台コネクタはフェニックスコンタクト製 MC1.5/6-STF-3.5 です。

PROFIBUS ケーブルの電線の被覆をむいて接続してください。また,シールド線は撚って接続してください。

端子番号 端子名称 説明

1 Shield ケーブルのシールド接続端子

2 GND 使用しません

3 +5V 使用しません

4 A-Line 伝送データのマイナス側(緑電線)

5 B-Line 伝送データのプラス側(赤電線)

6 RTS リピータの制御信号(方向制御)

表 2.2 端子台のピン配置

図 2.2 PROFIBUS 端子台

6

Page 10

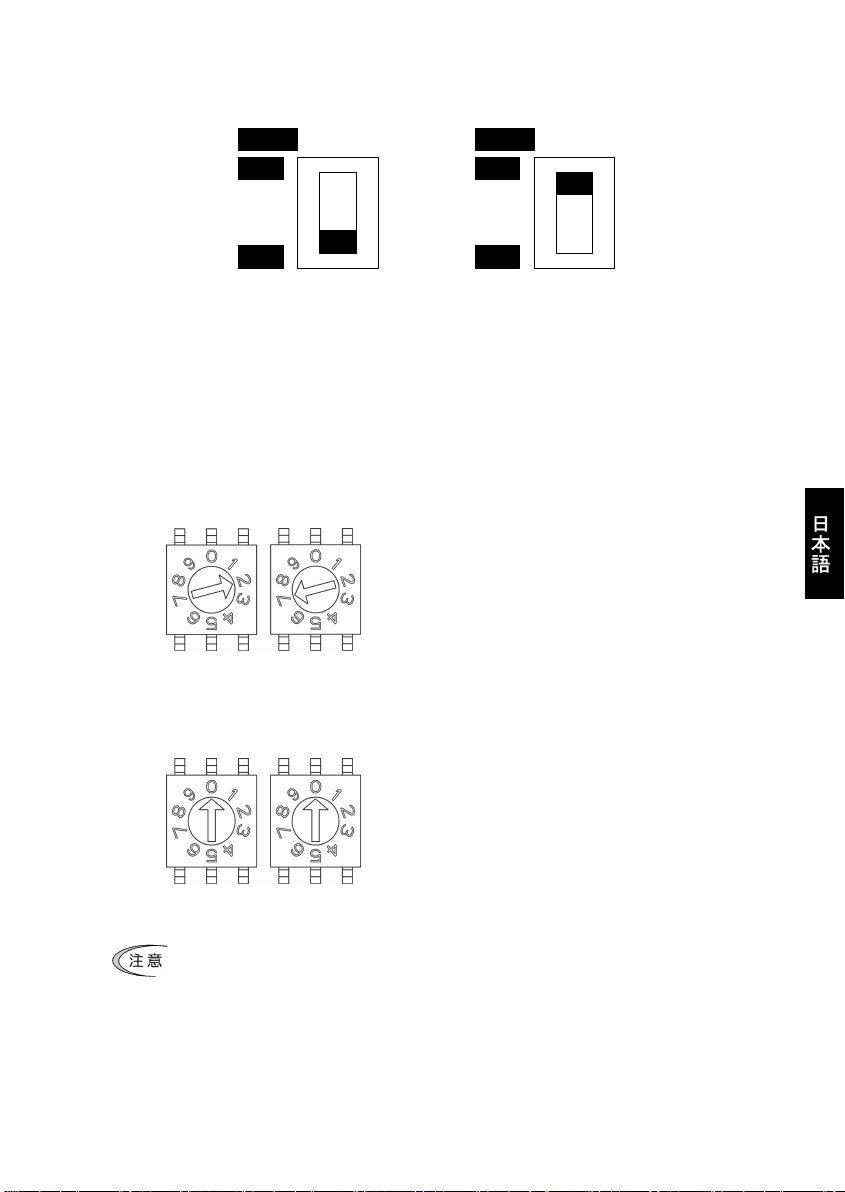

2.3 終端抵抗スイッチ(SW3)

PROFIBUS-DP ネットワークの両端には終端抵抗が必要です。通信カードが PROFIBUS-DP ネットワークのどちらか

一端に取り付けられる場合は,このスイッチを ON することで内蔵の終端抵抗が接続されます。

SW3

ON

SW3

ON

OFF

終端抵抗なし(スイッチ OFF)

図 2.3 終端抵抗 ON/OFF スイッチの設定

OFF

終端抵抗あり(スイッチ ON)

2.4 アドレススイッチ(SW1,SW2)

PROFIBUS-DP 通信上のノードアドレス(局番)を設定するロータリスイッチです。10 進数で 0~99 まで設定可能

です。通信カ-ド上の SW1 が十の位,SW2 が一の位の設定を行います。

なお,ノードアドレスはインバータ機能コード o31 でも設定可能です(10 進数で 0~125 まで設定可能)。o31

で指定したノードアドレス設定を有効にするためには,アドレススイッチを"00"とする必要があります。

例1:ノードアドレス 27 を設定する場合(アドレススイッチで設定)

SW1 SW2

図 2.4 アドレススイッチの設定例1

例2:ノードアドレス 125 を設定する場合(インバータ機能コード o31 で設定)

SW1 SW2

1. インバータの電源 OFF 状態で,

SW1 の設定を"2"にします。

SW2 の設定を"7"にします。

2. インバータの電源を ON すると,アドレス設定完了です。

1. インバータの電源 OFF 状態で,

アドレススイッチの設定を,"00"にします。

2. インバータの電源を ON し,o31 に"125"を設定します。

3. 電源を再投入すると,アドレス設定完了です。

日

本

語

図 2.5 アドレススイッチの設定例2

1. アドレススイッチの設定はインバータの電源を OFF した状態で実施してください。電源 ON 中に

設定を変更した場合は,電源の再投入が必要です。

2. o31 によるノードアドレス設定後は,設定を反映するためにインバータの電源を再投入してくだ

さい。

3. o31 に 126 以上を設定すると,エラーとなり,通信カード上の ERR LED が赤点滅し,インバータ

er5

となります。

は

7

Page 11

2.5 通信速度(ボーレート)の設定

PROFIBUS-DP マスタの通信速度を設定することで,通信カードの通信速度も自動的に設定されます。インバータ

側での設定は必要ありません。

通信カードがサポートする通信速度(ボーレート)は以下のとおりです。

9.6, 19.2, 45.45, 93.75, 187.5, 500 Kbit/s,

1.5, 3, 6, 12 Mbit/s

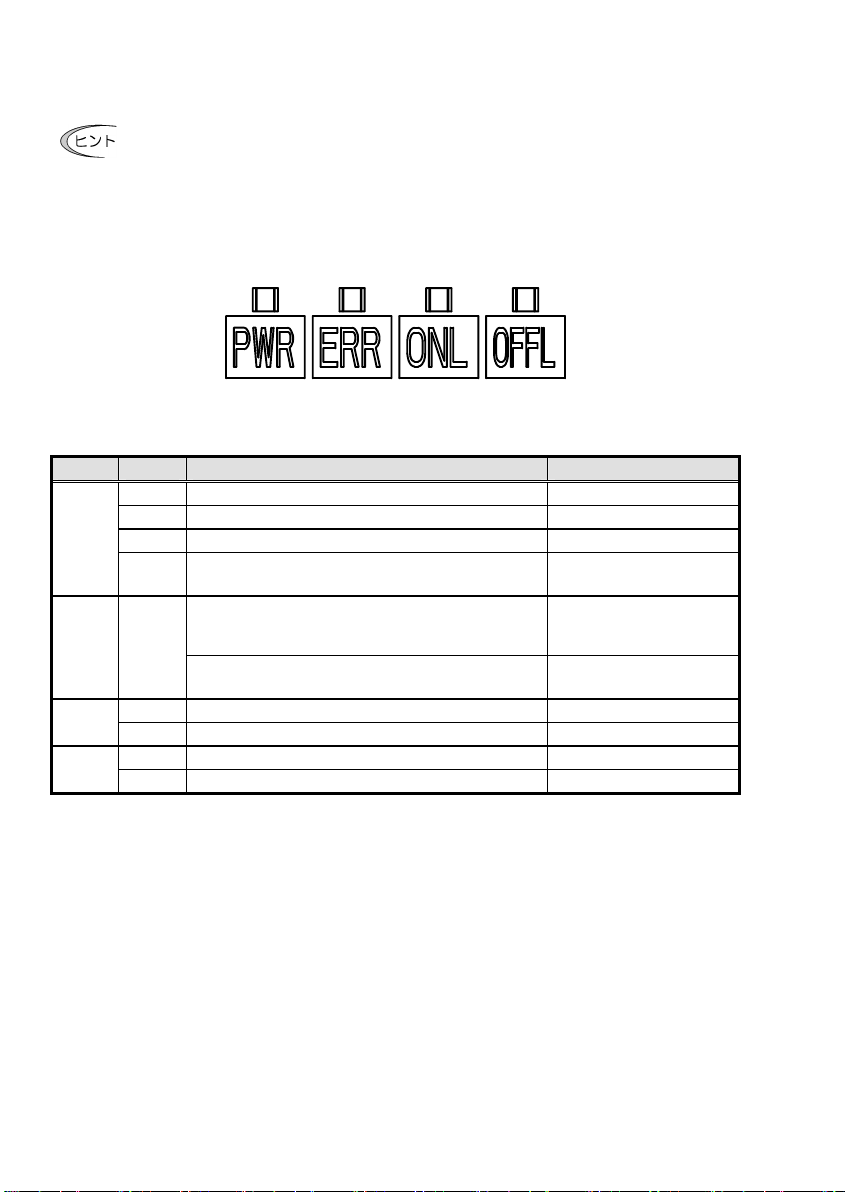

2.6 LED インジケータ

通信カードの状態を示します。LED インジケータには,次の4種類があります。

図 2.6 LED の種類

表 2.3 LED の状態

名称 LED 状態 内容 備考

PWR

緑点滅 電源投入時の自己診断および初期化中 約 0.5s 間実施

赤点滅 PROFIBUS 通信異常 インバータに

ERR 赤点滅 PROFIBUS 設定エラー

ONL 緑 オンライン状態(正常に PROFIBUS 通信している状態)

消灯 オンライン状態でない

OFFL 赤 オフライン状態(PROFIBUS に接続していない状態)

消灯 オフライン状態でない

*1

*2 PPO タイプは PROFIBUS-DP のマスタ設定と通信カードで一致させる必要があります。通信カードの PPO タイ

緑 正常通信中 ―

発生

発生

発生

*

*

er5

赤 ハードウェア異常

(オプション取付け不良またはオプション故障)

インバータ機能コード o30 で設定する PPO タイプと

マスタの PPO タイプが一致していない。 *2

PROFIBUS 設定エラー

ノードアドレスに 126 以上の値が設定されている。

er5

を無視するように設定することも可能です。第 9 章「PROFIBUS 通信異常検出時の動作選択」を参照し

てください。

プはインバータ機能コード o30 で設定します。マスタ側の設定はマスタ用の設定ソフトウェア等で実施しま

す。

インバータに

インバータに

er4

er5

1

1

マスタ側の PPO 設定についてはマスタのマニュアル等を参照してください。

PPO タイプについての詳細は,第 8 章「PROFIBUS プロファイルの詳細説明」を,機能コード o30 につ

いての詳細は第 5 章「インバータ機能コードの設定」を参照してください。

8

Page 12

第 3 章 PROFIBUS-DP 通信カードの取付けと取外し

インバータの電源を遮断して 22kW 以下は 5 分以上,30kW 以上は 10 分以上経過してから行ってください。更に LED

モニタおよびチャージランプの消灯を確認し,テスターなどを使用して主回路端子 P(+)-N(-)間の直流中間回路電圧

が安全な値(DC+25V 以下)に下がっていることを確認してから行ってください。

感電のおそれあり

・ 外部あるいは内部部品が損傷・脱落している製品を使用しないでください。

火災,事故,けがのおそれあり

・ 糸くず,紙,木くず,ほこり,金属くずなどの異物がインバータや通信カード内に侵入するのを防止してくださ

い。

火災,事故のおそれあり

・ 製品の取付け,取外し時に不適切な作業を行うと,製品が破損するおそれがあります。

故障のおそれあり

インバータ本体の主回路端子および制御回路端子の配線は,通信カードを取り付ける前に行ってくだ

さい。

3.1 通信カードの取付け

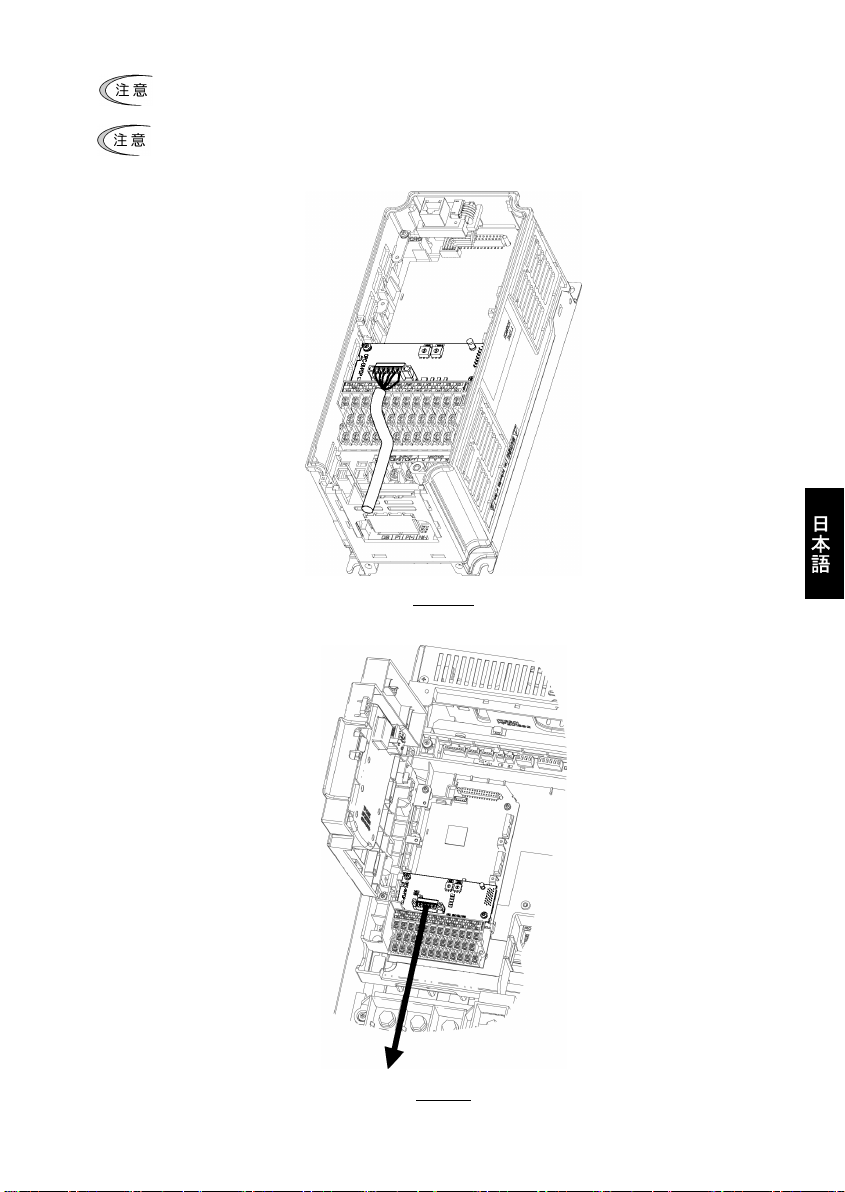

(1) インバータ本体の表面カバーを取り外し,制御プリント基板を露出してください。通信カードは,インバー

タ本体のオプション接続ポート 3 箇所(A,B,C-port)のうち,A-port にのみ取付け可能です。(図 3.1)

FRENIC-MEGA 取扱説明書の「2.3 配線」を参照してカバーを取り外してください。(30kW 以上はタッチ

パネルケースも開けてください。)

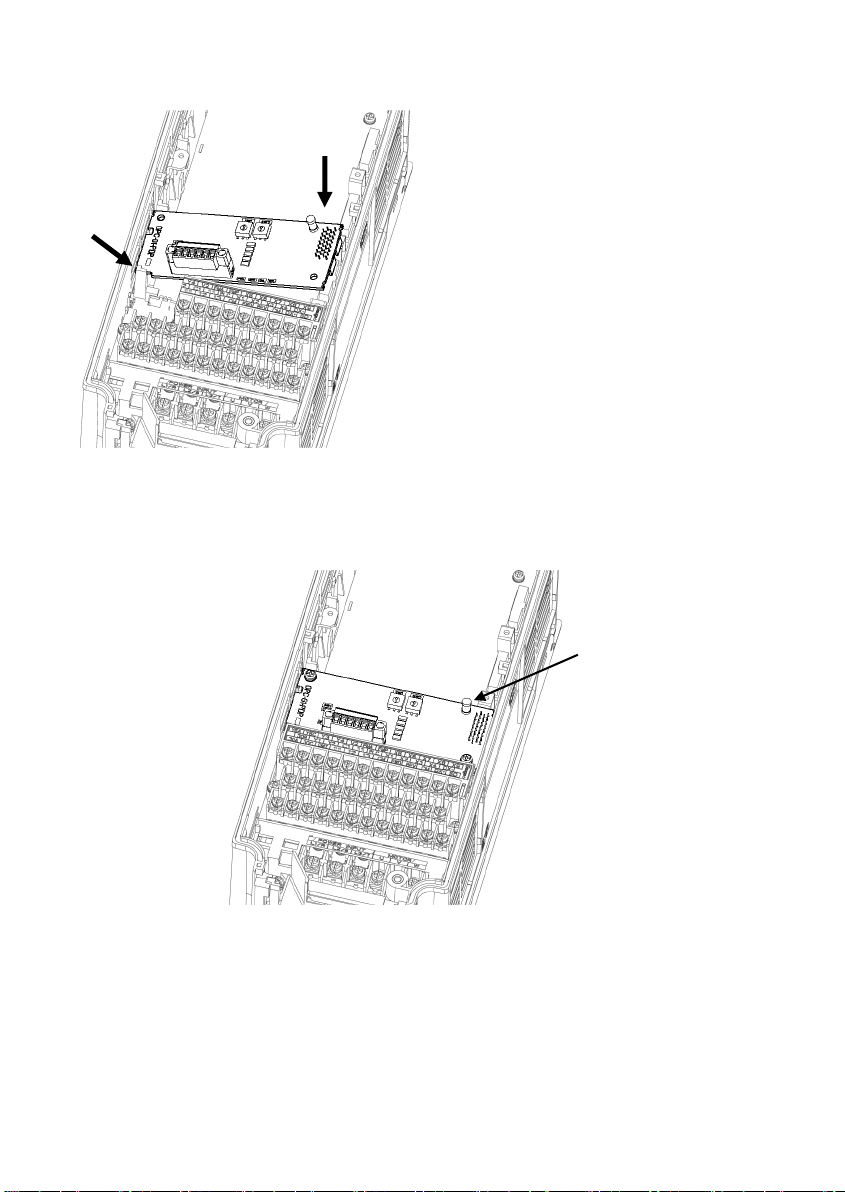

(2) 通信カードの裏面(図 1.1)の CN1 を,インバータ本体の制御プリント基板の A-port(CN4)へ差し込み,付

属ねじで固定してください。(図 3.3)

通信カードの取付け位置決め部(図 1.1)がツメ(図 3.2 の①)にセットされ,CN1(図 3.2 の②)

が確実に差し込まれていることを確認してください。図 3.3 は取付け完了を示します。

日

本

語

(3) 通信カードの配線を行います。

第 4 章「配線」を参照してください。

(4) インバータ本体の表面カバーを元に戻してください。

FRENIC-MEGA 取扱説明書の「2.3 配線」を参照してカバーを取り付

けてください。(30kW 以上はタッチパネルケースも閉じてくださ

い。)

9

図 3.1 0.4kW の例

Page 13

②

①

① カードをツメに引っ掛けるようにしな

がらインバータ本体へ位置決めする。

② コネクタをインバータ本体へ挿入する。

注: 先にコネクタ側を挿入した場合,挿入が不

十分で接触不良となる可能性があります。

図 3.2 カードの取付け

(取外し用つまみ)

図 3.3 取付け完了

3.2 通信カードの取外し

通信カードを取り外す際は,ねじを2ヶ所外し,取外し用つまみ(上図を参照)を引っぱって取り外してくださ

い。

10

Page 14

第 4 章 配線

・ インバータの電源を遮断して 22kW 以下は 5 分以上,30kW 以上は 10 分以上経過してから行ってください。

更に LED モニタおよびチャージランプの消灯を確認し,テスターなどを使用して主回路端子 P(+)-N(-)間

の直流中間回路電圧が安全な値(DC+25V 以下)に下がっていることを確認してから行ってください。

・ 配線作業は,資格のある専門家が行ってください。

感電のおそれあり

・ 一般的に制御信号線の被覆は強化絶縁されていませんので,主回路活電部に制御信号線が直接触れると,

何らかの原因で絶縁被覆が破壊されることがあります。この場合,制御信号線に主回路の高電圧が印加さ

れる危険性がありますので,主回路活電部に制御信号線が触れないように注意してください。

事故のおそれあり,火災のおそれあり

・ インバータ,モータ,配線からノイズが発生します。周辺のセンサーや機器の誤動作に注意してください。

事故のおそれあり

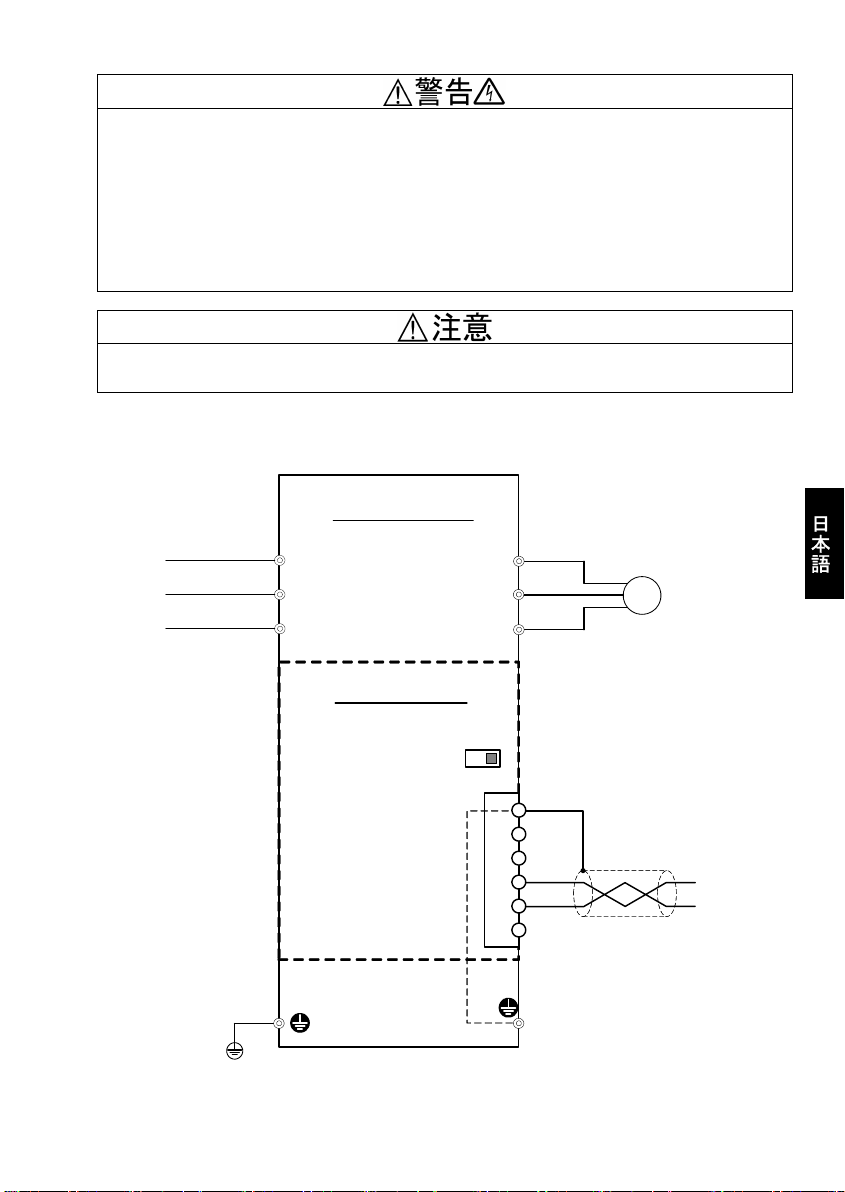

4.1 基本接続図

FRENIC-MEGA

L1/R U

L2/S

L3/T

V

W

モータ

M

OPC-G1-PDP

終端抵抗スイッチ

(SW3)

PROFIBUSコネクタ

(TERM1)

(*)

G

(*) 通信カードをインバータに取り付けることで,この部分が接続されます。

Shield

GND

+5V

A-Line

B-Line

RTS

G

PROFIBUSケーブル

日

本

語

図 4.1 基本接続図

11

Page 15

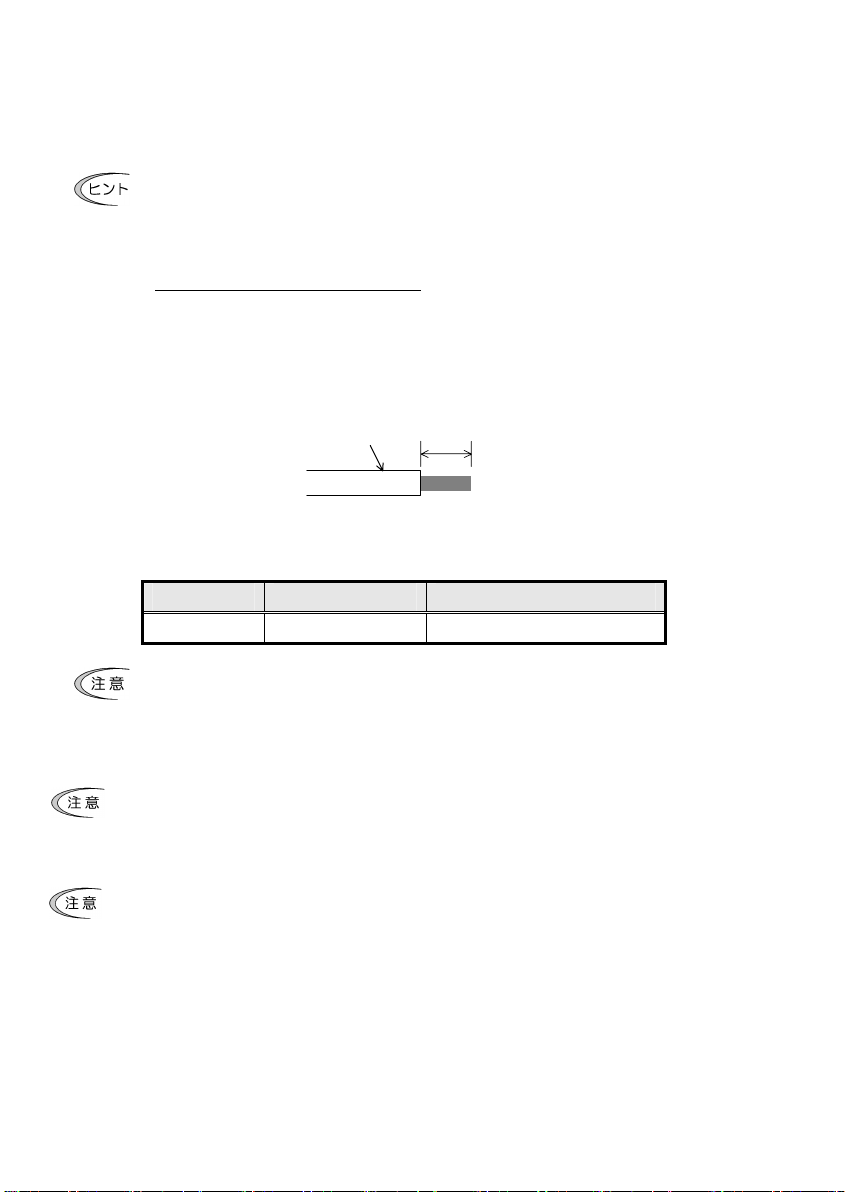

4.2 PROFIBUS 端子台の配線

基本接続図(図 4.1)および配線例(図 4.3)を参考に,以下の注意事項を守って通信カードへの配線を行って

ください。

(1) 電源を OFF(開)してください。

(2) 通信ケーブルは必ず PROFIBUS 仕様に準拠したシールド付きツイストペアケーブルを使用してください。

推奨ケーブルは,シーメンス製 PROFIBUS FC 標準ケーブル 形式 6XV1 830-0EH10 です。

PROFIBUS の配線全般に関する詳細は PROFIBUS 協会発行の「PROFIBUS-DP ケーブルと機器設置の解説」

(3) PROFIBUS 端子台コネクタ(TERM1)への配線

PROFIBUS ケーブルの電線の被覆をむいて接続してください。電線の被覆むきサイズは図 4.2 に従ってくださ

端子台の推奨締め付けトルクと推奨電線サイズを表 4.1 に示します。

および「PROFIBUS 配線作業ガイド」を参照してください。PROFIBUS 協会の Web サイトから無料でダウ

ンロード可能です。

URL: http://www.profibus.jp/tech/downld.htm

い。シールド線は撚って接続してください。

電線

約 6.0mm

図 4.2 PROFIBUS ケーブル電線の推奨被覆むきサイズ

表 4.1 PROFIBUS 端子台の推奨締め付けトルクと電線サイズ

ねじサイズ 締め付けトルク 電線サイズ

M2 0.22~0.25 N・m AWG28~16 (0.14~1.5mm2 )

PROFIBUS ケーブルは,ノイズによる誤動作を防止するため,インバータ本体の主回路配線,モー

タ配線,その他の動力線とは可能な限り離し,同一ダクト内に入れないでください。また,シール

ド線は必ず接続してください。

(4) インバータの電源投入前に配線を完了してください。

・ 制御回路端子への配線は,主回路の配線とは可能な限り離して配線してください。ノイズによる誤

動作の要因となります。

・ インバータ内部の制御回路配線は,主回路活電部(例えば主回路端子台部)に直接接触しないよう

に内部で束線固定などの処理を行ってください。

線種,配線本数によっては,インバータの表面カバーが浮き上がり,タッチパネルが正しく動作しな

い場合があります。その際は,線種・線径等の変更が必要です。

12

Page 16

4.3 インバータへの配線

PROFIBUS 配線は,主回路の配線とは可能な限り離して配線してください。ノイズによる誤動作の要因

となります。

通信カードからの配線は,インバータ本体の制御端子台上部と表面カバーの間を通してください。

・22kW 以下の場合

・30kW 以上の場合

0.4kW の例

日

本

語

75kW の例

図 4.3 配線例

13

Page 17

第 5 章 インバータ機能コードの設定

通信カードと PROFIBUS-DP マスタ間の通信を行うためには,下記の表 5.1 に示すインバータの機能コードの設定

が必要です。

また,関連するインバータ機能コードを表 5.2 に示します。必要に応じて設定してください。

インバータ機能コードの詳細につきましては,FRENIC-MEGA 取扱説明書の第5 章「機能コード」および RS-485

通信ユーザーズマニュアルの第 5 章「機能コードとデータフォーマット」を参照してください。

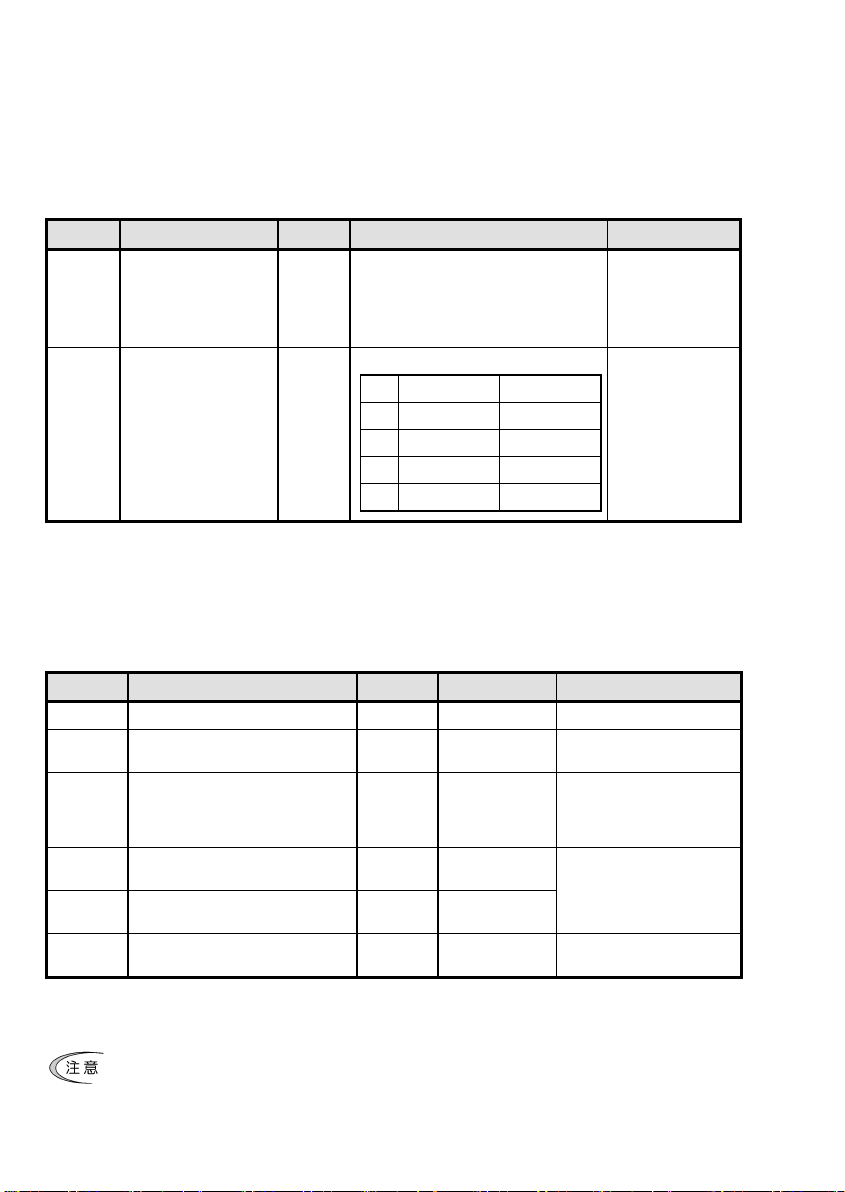

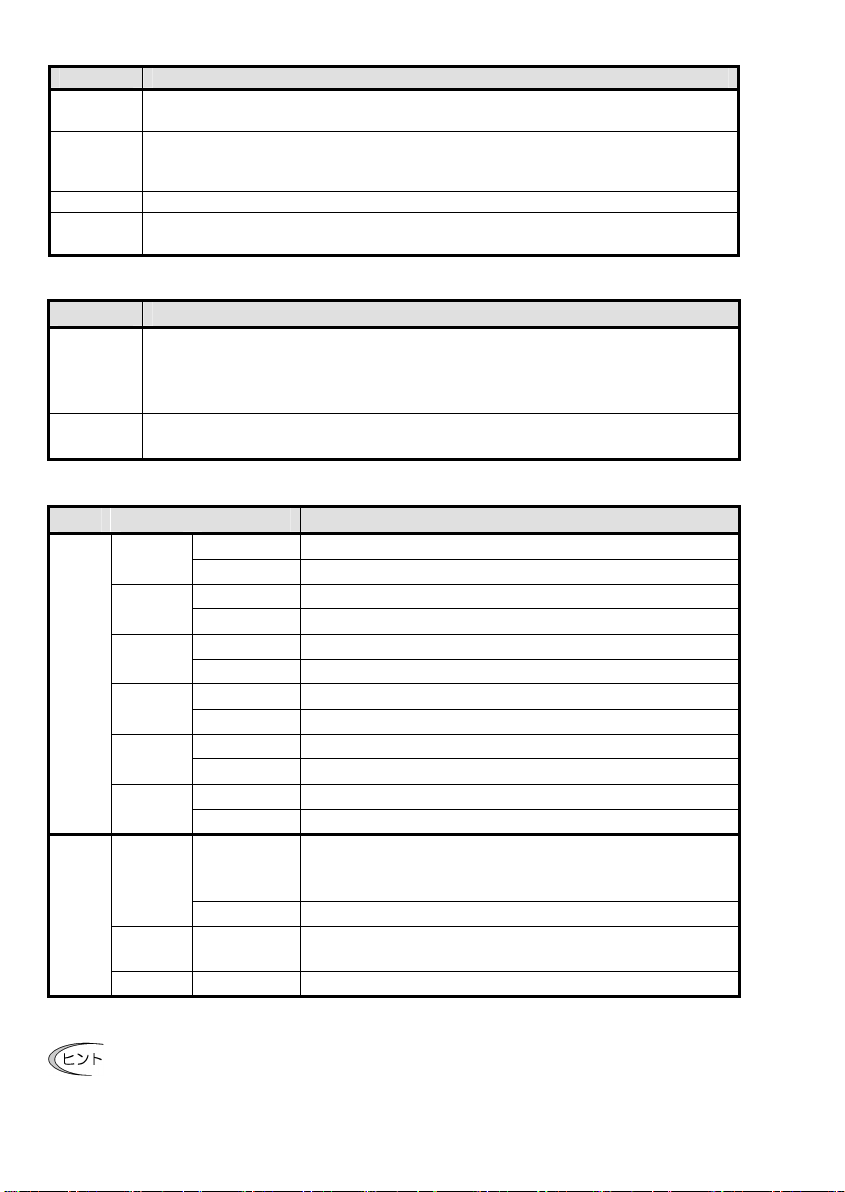

表 5.1 PROFIBUS 通信を行うために必要なインバータ機能コード設定

機能コード 説明 工場出荷値 設定変更値 備考

o30 *1 PPO タイプ(データフォー

y98 *2 運転・周波数指令元の選択 0 下記から選択

*1

o30 を設定後は, インバータに設定を反映させるために, インバータの電源を再投入してください。o30 の

マット)の選択

設定内容についての詳細は,第 8 章「PROFIBUS プロファイルの詳細説明」を参照してください。

*2

運転・周波数指令元の選択を設定するインバータ機能コードは,y98 の他にもあります。それらの設定によ

り,より細やかに運転・周波数指令元の選択が可能となります。詳細につきましては,FRENIC-MEGA 取扱説

明書の第 5 章「機能コード」の H30,y98 の項を参照してください。

機能コード 説明 工場出荷値 設定範囲 備考

o27 *1 PROFIBUS 通信異常検出時の動作選択 0 0~15

o28 *1 PROFIBUS 通信異常検出時の動作タイ

o31 *2 ノードアドレス設定 0 0~255

o40~o43 *3 定周期で書込みを行う機能コードの

o48~o51 *3 定周期で読出しを行う機能コードの

W90 PROFIBUS オプション

1

*

o27,o28 についての詳細は,第 9 章「PROFIBUS 通信異常検出時の動作選択」を参照してください。

2

*

o31 についての詳細は,第 2 章「2.4 アドレススイッチ」を参照してください。

3

*

o40~o43 および o48~o51 の詳細は,第 8 章「8.2 (4) PCD1~PCD4」を参照してください。

マー

割付け

割付け

ソフトバージョン

o40~o43 および o48~o51 の設定後は, インバータに設定を反映させるために,インバータの電源を

再投入してください。

0 下記から選択

0,1,6~255 : PPO タイプ1

2,5 : PPO タイプ2

3 : PPO タイプ3

4 : PPO タイプ4

y98 周波数指令元 運転指令元

0 インバータ インバータ

1 PROFIBUS インバータ

2 インバータ PROFIBUS

3 PROFIBUS PROFIBUS

表 5.2 その他関連機能コード

0.0s 0.0s~60.0s

(有効範囲 0~125)

0000

(割付なし)

0000

(割付なし)

オプション

による

0000~FFFF(hex)

0000~FFFF(hex)

-(モニタ専用) 4桁の 10 進数

マスタ側の設定と必

ず一致させてくださ

い

特に問題がなければ

y98=3 を推奨します。

アドレススイッチが"00"の

時に有効。126 以上を設定時

は,ERR LED 点滅および

発生

PPO Type2 または Type4 の時

に有効

V1.23 の場合,"123"と表示

er5

14

Page 18

第 6 章 PROFIBUS 通信接続までの手順説明

本章では, PROFIBUS-DP マスタとインバータを PROFIBUS 通信接続するまでの手順について説明します。

手順は以下の 1~3 です。

1. PROFIBUS-DP マスタ側の設定

2. 通信カードの設定およびインバータ機能コード設定

3. インバータの電源再投入 ⇒ PROFIBUS-DP データの送受信開始

以降,上記の手順 1~3 について説明します。

1. PROFIBUS-DP マスタ側の設定

- マスタ側のノードアドレス,通信速度(ボーレート)を設定します。

- 通信カード用の GSD ファイルを使用し,通信カードをマスタに登録します。

- マスタに登録した通信カードに適用する PPO Type(データフォーマット)を Type1~4 の中から1つ選択

します。

PROFIBUS-DP マスタについての設定方法詳細については,ご使用のマスタのユーザーズマニュアル等を

参照してください。

PPO Type の詳細については,第 8 章「PROFIBUS プロファイルの詳細説明」を参照してください。

本通信カードには GSD ファイルは付属していません。

GSD ファイルは次の Web サイトにてダウンロードください。(会員登録が必要(無料))

富士電機システムズ 技術情報ページ

URL : https://web1.fujielectric.co.jp/Kiki-Info/User/guestlogin.asp

2. 通信カードの設定およびインバータ機能コード設定

- ノードアドレスを設定します。マスタに登録した通信カードのアドレスと必ず一致させてください

- 必要に応じて, インバータ機能コード o27,o28 の設定を行ってください。

- インバータ機能コード o30 で PPO Type を Type1~4 の中から1つ選択します。

必ずマスタで設定した PPOType と一致させてください。また,o30 変更後は, 必ずインバータの電源を再

投入してください。

ノードアドレスの設定方法については,第 2 章「各部の機能・設定」を参照してください。

o27,o28 についての詳細は,第 9 章「PROFIBUS 通信異常検出時の動作選択」を参照してください。

3. インバータの電源再投入 ⇒ PROFIBUS-DP データの送受信開始

o30 の設定後, インバータの電源を再投入した段階で,PROFIBUS-DP マスタ側と通信カードの設定が正しく,

かつ, 適正に配線されていれば,自動的に PROFIBUS-DP の通信が確立し, データの送受信が行われます。

この状態で通信カードの LED 状態は PWR LED 緑点灯, ONL LED 緑点灯となっています。マスタから通信カー

ドに対し, 周波数指令および運転指令等を送信してください。

具体的なデータフォーマットやデータのやりとりについては,第 7 章「インバータを運転する簡単手

順」および第 8 章「PROFIBUS プロファイルの詳細説明」を参照してください。

配線方法については,第 4 章「配線」を参照してください。

。

日

本

語

15

Page 19

第 7 章 インバータを運転する簡単手順

本章では, PROFIBUS-DP マスタからインバータを運転するための最もシンプルなフォーマット(PPO Type3)を

使用した例について, 手順に従って簡単に説明します。PPO Type3 は PROFIBUS からの周波数指令と運転指令に

特化したシンプルなフォーマットです。

他の PPO Type でもフォーマットの割付領域が異なるだけで, 内容的には共通です。

本章は説明の簡単化のためインバータを運転することのみに特化した説明を行っています。更に詳細な説

明については,第 8 章「PROFIBUS プロファイルの詳細説明」を参照してください。

7.1 事前の設定

(1) PROFIBUS-DP マスタ側の設定で通信カードの PPO Type を Type3 にしてください。

PROFIBUS-DP マスタ側での PPO Type の設定方法については, お使いのマスタのユーザーズマニュアル等を

参照してください。

(2) インバータの機能コードを以下の通りに設定します。

F03=60(最高周波数(Hz)),y98=3(PROFIBUS から周波数指令・運転指令有効),o30=3(PPO Type3)

また,必要に応じて o27,o28 の設定をしてください。

設定後,インバータの電源を再起動してください。

o27,o28 についての詳細は,第 9 章「PROFIBUS 通信異常検出時の動作選択」を参照してください。

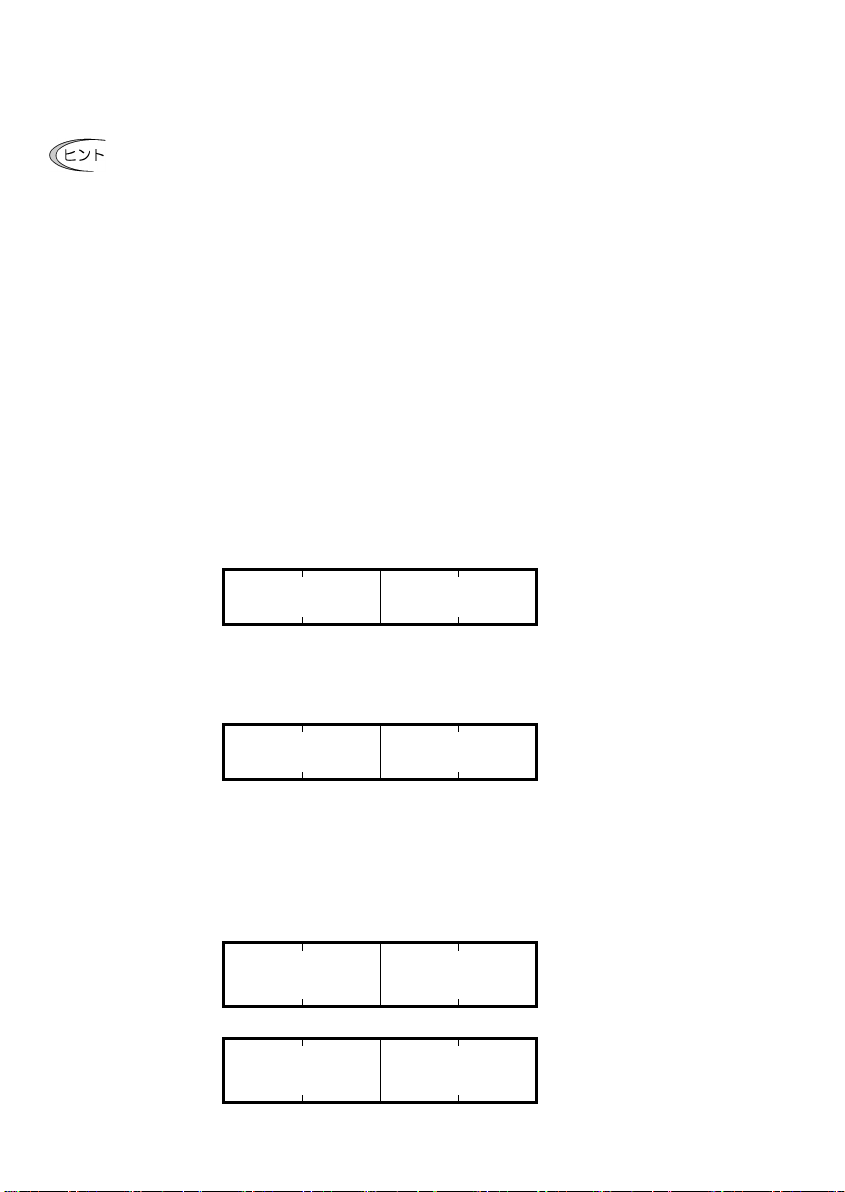

7.2 運転時の実際のデータやりとり例

説明の前に PPO Type3 のデータフォーマットを以下に示します。以降の説明はこのフォーマットに基づき行いま

す。

要求

(マスタ→スレーブ)

CTW : コントロールワード(2byte)。運転指令を行います。(最下位 bit が運転指令 ON/OFF)

MRV : 周波数指令を行います。最高周波数 F03(Hz)を 4000hex とした時の割合を指定

応答

(スレーブ→マスタ)

STW : ステータスワード(2byte)。インバータの運転状態をモニタします。

MAV : 出力周波数モニタ。最高周波数 F03(Hz)を 4000hex とした時の割合を出力

以降,インバータを 60Hz で正転運転するまでの例を説明します。

(1) インバータの電源を ON すると PROFIBUS-DP 通信が始まります。電源 ON 直後のデータの状態は下記の様にな

っています。

要求

(マスタ→スレーブ)

応答

(スレーブ→マスタ)

STW : 02=PROFIBUS から周波数・運転指令有効, 40=運転指令 ON 準備未完了

MAV : 出力周波数 0Hz

0 1 2 3 (Byte)

CTW MRV

0 1 2 3 (Byte)

STW MAV

0 1 2 3 (Byte)

00 00 00 00

(CTW) (MRV)

0 1 2 3 (Byte)

02 40 00 00

(STW) (MAV)

16

Page 20

(2) 最初の状態では,運転指令 ON の準備ができていない状態(STW=運転指令 ON 準備未完了)になっています。

まず, 運転指令 ON の準備を完了する要求"04 7E"を CTW に入力します。 また, 下の例では同時に周波数指

令 60Hz(=4000h)を MRV に入力しています。

要求

(マスタ→スレーブ)

0 1 2 3 (Byte)

04 7E 40 00

(CTW) (MRV)

CTW : 04=本フレーム内容イネーブル, 7E=運転指令 ON 準備完了要求

MRV : 周波数指令 4000h(周波数指令=F03(Hz))

上記の要求を受け, 通信カードは次の応答をします。

応答

(スレーブ→マスタ)

0 1 2 3 (Byte)

02 31 00 00

(STW) (MAV)

STW : 02=PROFIBUS から周波数・運転指令有効, 31=運転指令 ON 準備完了

MAV : 出力周波数 0Hz

(3) スレーブが運転指令 ON 準備完了になったので CTW に運転指令 CTW="04 7F"を入力してください。

要求

(マスタ→スレーブ)

0 1 2 3 (Byte)

04 7F 40 00

(CTW) (MRV)

CTW : 04=本フレーム内容イネーブル, 7F=運転指令 ON

MRV : 周波数指令 4000h(周波数指令=F03(Hz))

上記の要求を受け, インバータが運転を始めます。通信カードの応答は下記のとおりです。

応答

(スレーブ→マスタ)

0 1 2 3 (Byte)

02 37 ** **

(STW) (MAV)

STW : 02=PROFIBUS から周波数・運転指令有効, 37=運転状態

MAV : 出力周波数加速中

(4) 運転を停止する場合は, CTW="04 7F"→"04 7E"としてください。

要求

(マスタ→スレーブ)

0 1 2 3 (Byte)

04 7E 40 00

(CTW) (MRV)

CTW : 04=本フレーム内容イネーブル, 7E=運転指令 OFF

MRV : 周波数指令 4000h(周波数指令=F03(Hz))

上記の要求を受け, インバータが減速, 停止します。通信カードの応答は下記のとおりです。

応答

(スレーブ→マスタ)

0 1 2 3 (Byte)

02 33/31 ** **

(STW) (MAV)

STW : 02=PROFIBUS から周波数・運転指令有効, 33=減速中/31=運転指令 ON 準備完了(停止時)

MAV : 出力周波数減速中

日

本

語

17

Page 21

(5) 再び運転する場合は, CTW="04 7F"を入力します。ここで, もしも逆転させる場合は, CTW="0C 7F"とします。

下の例では, 逆転指令で, 周波数に 2000h(=30Hz)を設定しています。

要求

(マスタ→スレーブ)

0 1 2 3 (Byte)

0C 7F 20 00

(CTW) (MRV)

CTW : 0C=本フレーム内容イネーブル&逆転, 7F=運転指令 ON

MRV : 周波数指令 2000h(周波数 Hz=F03×2000h/4000h)

上記の要求を受け, インバータが逆転で運転開始します。下の例は, 逆転で速度到達したときの応答です。

応答

(スレーブ→マスタ)

0 1 2 3 (Byte)

03 37 E0 00

(STW) (MAV)

STW : 03=PROFIBUS から周波数・運転指令有効&周波数到達, 37=運転状態

MAV : 出力周波数 E000h(2000h の2の補数表記) (周波数 Hz=F03×(-2000h)/4000h)

(6) MRV に負の値を入力することでも逆転は可能です。下の例では 2000h の2の補数である E000h を入力してい

ます。

要求

(マスタ→スレーブ)

0 1 2 3 (Byte)

04 7F E0 00

(CTW) (MRV)

CTW : 04=本フレーム内容イネーブル, 7F=運転指令 ON

MRV : 周波数指令 E000h(-2000h)(周波数 Hz=F03×(-2000h)/4000h)

上記の要求を受け, インバータが逆転で運転開始します。下の例は, 速度到達したときの応答です。

応答

(スレーブ→マスタ)

0 1 2 3 (Byte)

03 37 E0 00

(STW) (MAV)

STW : 03=PROFIBUS から周波数・運転指令有効&周波数到達, 37=運転状態

MAV : 出力周波数 E000h (周波数 Hz=F03×(-2000h)/4000h)

(7) トリップが発生した場合は,トリップ原因解消後 CTW="0480" を入力するとトリップが解除されます。トリ

ップが解除されたら, CTW="0400"としてください。(CTW の byte1 の最上位 bit がトリップ解除ビットです。)

要求

(マスタ→スレーブ)

0 1 2 3 (Byte)

04 80 10 00

(CTW) (MRV)

CTW : 04=本フレーム内容イネーブル, 80=トリップ解除要求

MRV : 周波数指令 1000h(周波数 Hz=F03×1000h/4000h)

トリップ解除すると, 電源 ON 直後の状態に戻ります。再び運転する場合は, 手順(2)に戻ってください。

応答

(スレーブ→マスタ)

0 1 2 3 (Byte)

02 40 00 00

(STW) (MAV)

STW : 02=PROFIBUS から周波数・運転指令有効, 37=運転状態

MAV : 出力周波数 0000h

18

Page 22

第 8 章 PROFIBUS プロファイルの詳細説明

本通信カードは PROFIBUS 協会が規定したモータコントロール用のプロファイルである PROFIdrive V2 をサポー

トしています。本章では,この PROFIdrive プロファイルについて説明します。

8.1 サポートする PPO の説明

PROFIdrive では, PPO(Parameter Process-data Object)と呼ばれるデータフォーマットを複数定義しています。

通信カードがサポートする PPO は図 8.1 に示す 4 種類です。PPO Type の選択はインバータ機能コード o30 で設

定してください(表 8.1)。各 PPO の特徴を表 8.2 に,PPO の各要素についての説明を表 8.3 および表 8.4 に示し

ます。

PCV PCD

CTW

PCA IND PVA

1 2 3 4 5 6 (word)

PPO Type1

1 2 3 4 5 6 7 8 9 10 (word)

PPO Type2

1 2 (word)

PPO Type3

1 2 3 4 5 6 (word)

PPO Type4

図 8.1 サポートする PPO のフォーマット

表 8.1 インバータ機能コード o30 による PPO Type 選択

o30 PPO 備考

0, 1, 6~255 PPO Type1 工場出荷状態での PPO Type

2, 5 PPO Type2

3 PPO Type3

4 PPO Type4

インバータ機能コード o30 を設定後は, インバータに設定を反映させるために, インバータの電源を

再投入してください。

STW

MRV

PCD1 PCD2 PCD3 PCD4

MAV

日

本

語

19

Page 23

表 8.2 各 PPO Type の特徴

PPO 特徴

PPO Type1 標準的なフォーマット。運転指令/運転状態モニタと周波数指令/出力周波数モニタに

加えて, インバータ機能コードの単発的なアクセスが可能です。

PPO Type2 全ての機能を網羅したフォーマット。運転指令/状態モニタ, 周波数指令モニタ, イン

バータ機能コードの単発アクセス, 事前に割付した 4 種類のインバータ機能コードの

定周期アクセスが可能です。

PPO Type3 運転指令/状態モニタと周波数指令/モニタに特化したシンプルなフォーマットです。

PPO Type4 運転指令/状態モニタ, 周波数指令/モニタと事前に割付した 4 種類のインバータ機能

コードの定周期アクセスが可能なフォーマットです。

表 8.3 PPO 内の各要素の説明

要素 説明

PCD

PCV

要素 説明

PCD CTW/STW 要求 CTW: コントロールワード。マスタから運転指令を行います。

応答 STW: ステータスワード。インバータの運転状態応答です。

MRV/MAV 要求 MRV: 設定周波数。最高周波数 F03 を 4000(Hex)とする割合で指定。

応答 MAV: 出力周波数。最高周波数 F03 を 4000(Hex)とする割合で応答。

PCD1 要求 o40 で割付したインバータ機能コードを書込みします。

応答 o48 で割付したインバータ機能コードを常時モニタします。

PCD2 要求 o41 で割付したインバータ機能コードを書込みします。

応答 o49 で割付したインバータ機能コードを常時モニタします。

PCD3 要求 o42 で割付したインバータ機能コードを書込みします。

応答 o50 で割付したインバータ機能コードを常時モニタします。

PCD4 要求 o43 で割付したインバータ機能コードを書込みします。

応答 o51 で割付したインバータ機能コードを常時モニタします。

PCV PCA 要求

応答 指定されたパラメータとアクセス結果を応答します。

IND 要求・応答

PVA 要求・応答 パラメータの書込み値/読出し値を表示します。

o40~o43,o48~o51 についての詳細は,本章の「8.2 (4) PCD1~PCD4」を参照してください。

PROFIBUS-DP マスタと常時データ通信を行う領域です。運転指令/運転状態モニタ, 周波数

指令/出力周波数モニタが該当します。また, PPO Type2 および Type4 では, 任意のインバ

ータ機能コードを割付けて, 常時書込み/モニタする機能もサポートしています。(書込み,

読出しでそれぞれ 4 種類まで)

パラメータ(インバータ機能コード, PROFIdrive 固有パラメータ)への単発的なアクセス

を行う領域です。この領域は PPO Type1 および Type2 がサポートしています。

表 8.4 PCV 部と PCD 部の各要素の説明

パラメータ(インバータ機能コードおよび PROFIBUS パラメータ)

要求は PROFIBUS-DP マスタから通信カードへのデータ送信を, 応答は通信カードから PROFIBUS-DP

マスタへのデータ送信を意味します。

の指定と, そのパラメータに対してアクセス方法(読出し/書込み

等)の指定をします。

配列型パラメータのインデックス指定に使用します。また, イン

バータ機能コードの番号指定に使用します。

20

Page 24

8.2 PCD の説明

PCD は PROFUBUS-DP マスタと通信カード間で常時データをやり取りする領域です。運転指令/運転状態モニタ, 周

波数指令/周波数モニタおよび, 事前に割付けた 4 種類のインバータ機能コードに対する常時アクセスを行う

PCD1~4 の領域からなります。

(1) CTW(コントロールワード)

PROFIBUS-DP マスタからインバータに運転指令等を行うワード領域です。

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 (bit)

0 0 0 0

運転

方向

PCD

有効

00

ALM

RST設定有効

Ramp

Ramp有効運転可能ON3/

非固定

OFF3

ON2/

OFF2

ON/

OFF

表 8.5 CTW のビット説明

bit False (0) True (1)

0 ON/OFF 運転指令 OFF 運転指令 ON

1 ON2/OFF2 フリーラン停止指令(OFF2) 運転指令 ON 準備完了要求その1(ON2)

2 ON3/OFF3 機能コード H56 の減速時間による停止指令

運転指令 ON 準備完了要求その2(ON3)

(OFF3)

3 運転可能 インバータ運転無効 インバータ運転可能

4 Ramp 有効 出力周波数 0 固定 ランプジェネレータ(加減速器)有効指令

5 Ramp

非固定

ランプジェネレータ(加減速器)フリーズ。

出力周波数はその時点の値で固定

加減速フリーズ状態解除指令

6 設定有効 停止 ON ビット有効

7 ALM RST アラームリセットしない

アラームリセット(リセット後, 運転指令

ON 準備未完了の状態になります)

10 PCD 有効 PCD 部(CTW+MRV)の入力無効 PCD 部(CTW+MRV)の入力有効

11 運転方向 正転方向 逆転方向

通常の使用状況においては, bit1~6 および bit10 は常時1で問題ないと思われます。

PROFIdrive プロファイルは状態遷移させて制御を行います。従って単に運転指令を ON してもインバ

ータは運転しません。 インバータを運転させるためには PROFIdrive プロファイルの状態遷移条件に

従い, しかるべき状態になった上で運転指令を ON する必要があります。状態は次項で説明する STW

(ステータスワード)で判断可能です。

PROFIdrive の状態遷移条件については, 次項「(2) STW(ステータスワード)」および図 8.2 を参照し

てください。

状態遷移による厳密な制御は特に必要ないという方は,第 7 章「インバータを運転する簡単手順」で

説明している内容に従って頂いて問題ありません。

日

本

語

21

Page 25

(2) STW(ステータスワード)

インバータの運転状態等をモニタするワード領域です。

STW は PROFIdrive の状態遷移を表します。状態遷移については,図 8.2 を参照してください。

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 (bit)

0 0 0 0 0 FDT R/L FAR 0

表 8.6 STW のビット説明

bit False (0) True (1)

0 ON 準備完 運転指令 ON 準備未完了状態 運転指令 ON 準備完了状態

1 運転準備完 運転準備未完了状態 運転準備完了状態

2 運転状態 運転不能状態 運転中

3 ALM インバータトリップなし インバータトリップ中

4 ON2/OFF2 CTW の ON2 ビット=0 (OFF2) CTW の ON2 ビット=1 (ON2)

5 ON3/OFF3 CTW の ON3 ビット=0 (OFF3) CTW の ON3 ビット=1 (ON3)

6 ON 禁止 運転指令 ON 準備完了状態

(bit0 を論理反転したもの)

8 FAR 設定周波数に未到達 設定周波数に到達

9 R/L PROFIBUS からの周波数指令・運転指

令が共に無効

10 FDT 出力周波数が, インバータ機能コー

ド E31 で設定した周波数未満である。

ON禁止ON3/

ON2/

OFF3

OFF2

運転指令 ON 準備未完了状態

(bit をの論理反転したもの)

PROFIBUS-DP からの周波数指令・運転指令

いずれかが有効

出力周波数が, インバータ機能コード

E31 で設定した周波数以上である。

ALM

運転状態運転

準備完

準備完

ON

22

Page 26

以下に PROFIdrive の状態遷移図を示します(図 8.2)。

インバータの電源 ON 直後は「S1:運転指令 ON 準備未」から始まり, 順次 CTW の bit 操作を行うことで, 「S2:

運転指令 ON 準備完」→「S3:運転準備完」へ遷移し, 「S4:運転状態」に遷移した状態で, インバータ運転

状態となります。S4 の状態から, 運転指令を OFF すると「S5:運転指令 OFF」に遷移し, モータ停止後 S2 あ

るいは S1 に遷移します。

図8.2では, 説明の簡単化のため CTW の bit4~6 および bit10 は常時1としています。これらの

bit 値が1でないと状態遷移が正しくても, インバータは運転状態となりません。

インバータ電源ON

アラームリセット

→(CTW: bit7=0 1)

STW:xxxx xxxx xxxx 1000

モータ停止検出

or

運転可能=0

(CTW: xxxx x1xx x111 0110)

)OFF2(フリーラン指令

任意の状態で

トリップ発生

トリップ中

モータ停止検出

(CTW: xxxx x1xx x111 001x)

(CTW: xxxx x1xx x111 110x)

(CTW: xxxx x1xx x111 1100)

or

運転可能=0

or

)OFF2(フリーラン指令

)OFF2(フリーラン指令

STW:xxxx xxxx x1xx x000

OFF and ON2 and ON3

(CTW: xxxx x1xx x111 x110)

STW:xxxx xxxx x0xx x001

ON

(CTW: xxxx x1xx x111 x111)

STW:xxxx xxxx x0xx x011

運転可能=1

( CTW: xxxx x1xx x111 1111)

:S1 運転指令ON

準備未

S2:運転指令ON

準備完

S3:運転準備完

OFF2 or OFF3

(CTW: bit2=0 or bit3=0)

OFF

(CTW: xxxx x1xx x111 x110)

(CTW: xxxx x1xx x111 0111)

運転可能=0

OFF2 or OFF3

(CTW: bit2=0 or bit3=0)

(CTW: xxxx x1xx x111 1101)

日

本

語

(CTW: xxxx x1xx x111 1110)

OFF3

(CTW: xxxx x1xx x111 1011)

インバータ機能コード S06/S01,S05,S19 による運転指令および周波数/速度指令について

S06 による運転指令(bit0,1)および S01,S05,S19 による周波数・速度指令は,状態 S1 の時に可能

です。これらの指令を行っている時に状態 S1 以外に遷移させた場合は,即時 CTW および MRV による指

令に従います。なお,S06 の bit2~15 は,どの状態でも使用可能です。

状態 S4 または状態 S5 で OFF2(フリーラン停止)または OFF3(急減速停止)によって状態 S1 に遷移させ

た場合,状態 S1 であってもインバータ機能コード S06 による運転指令は無効(正確には,0Hz で運転

状態)となります。この場合,ON2 あるいは ON3 を入力することで,S06 による運転指令を有効にする

ことができます。

:S4 運転状態

STW:xxxx xxxx x0xx x111

OFF

OFF3

(CTW: xxxx x1xx x111 1010)

ON

(CTW: xxxx x1xx x111 1111)

:S5 運転指令OFF

減速停止中

急減速停止中

STW:xxxx xxxx x0xx x011

図 8.2 PROFIdrive の状態遷移図

23

注意

1. bitの状態を示す記号の意味

0 : False

1 : True

x : Don’t care

2. CTWのbit状態の下線部は, 状態遷移

。 のトリガとなるbitを示す

Page 27

PROFIBUS-DP からオートチューニング(インバータ機能コード P04/A18/b18/r18)を実施した場合は,

状態遷移に関わらず,規定の周波数でインバータが運転します。

オートチューニングについては,FRENIC-MEGA 取扱説明書の第 4 章「4.1.7 機能コードの基本設定・チュ

ーニング<2>」を参照してください。

(3) MRV(設定周波数)/MAV(出力周波数)

周波数を設定/モニタするワード領域です。

MRV: 設定周波数。PROFIBUS-DP マスタからインバータの周波数を設定します。

MAV: 出力周波数。インバータの現在の出力周波数を応答します。

共に, 最高周波数 F03(Hz)を 4000(hex)とした場合の割合で表記しています。換算式は以下の通りです。

MAV or MRV ×=×=

周波数(Hz)

(Hz)機能コードF03

(Hz)機能コードF03周波数(Hz) あるいは 4000(hex)

4000(hex)

MAV or MRV

負の値は2の補数表現となります。逆転時は, MAV(出力周波数)は負の値として出力されます。

MRV(設定周波数)に負の値を設定すると, 正転運転しても, 運転方向は逆転になります。

(4) PCD1~PCD4

PPO Type2 および Type4 のみがサポートしているワード領域で, 事前に割付けしたインバータ機能コードに

対して, 常時書込み/モニタが可能です。書込み/モニタでそれぞれ個別に4種類ずつの機能コードの割付け

が可能です。

割付けしたインバータ機能コードの書込み/モニタされる値は, 機能コードごとにインバータで

規定されたフォーマットに従っています。

インバータ機能コードのそれぞれのフォーマットについては,RS-485 通信ユーザーズマニュアルの

第 5 章「5.2 データフォーマット」を参照してください。

機能コードの割付けは, インバータ機能コード o40~o43 および o48~o51 で行います(表 8.7)。また, o40

~o43 および o48~o51 を使った機能コードの割付方法については, 次ページの表 8.8 に示します。

表 8.7 PCD1~4 に割付けするための機能コード

PCD 領域 機能コード 備考

要求 PCD1 o40 PNU915, index1 でも割付可 *1

(機能コード書込み) PCD2 o41 PNU915, index2 でも割付可 *1

PCD3 o42 PNU915, index3 でも割付可 *1

PCD4 o43 PNU915, index4 でも割付可 *1

応答 PCD1 o48 PNU916, index1 でも割付可 *1

(機能コードモニタ) PCD2 o49 PNU916, index2 でも割付可 *1

PCD3 o50 PNU916, index3 でも割付可 *1

PCD4 o51 PNU916, index4 でも割付可 *1

*1 PNU915, PNU916 とは PROFIdrive 固有パラメータのことです。それらについての詳細は,

本章の「8.3 (4) PROFIdrive 固有パラメータ」を参照してください。

o40~o43およびo48~o51 を使用した機能コードの割付方法については,次ページを参照してください。

24

Page 28

インバータ機能コード o40~o43 および o48~o51 による機能コードの割付けは, 4桁の 16 進数で機能コー

ド種別(表 8.8)と番号を指定することで行います。

□□□□

インバータ機能コード S06 による運転指令(bit0, 1)および S01,S05,S19 による周波数・速度

指令は,状態 S1 の時に可能です。これらの指令を行っている時に状態 S1 以外に遷移させた場合

は,即時 CTW および MRV による指令に従います。なお, S06 の bit2~15 は,どの状態でも使用可

インバータ通信専用機能コード S01, S05, S19 については, RS-485 通信ユーザーズマニュアルの第 5

能です。

章「5.1 通信専用機能コード」を参照してください。

種別 種別コード 機能コード名称 種別 種別コード 機能コード名称

S 2 02h 指令・機能データ r 12 0Ch モータ 4 機能

M 3 03h モニタデータ J 14 0Eh アプリケーション機能 1

F 4 04h 基本機能 y 15 0Fh リンク機能

E 5 05h 端子機能 W 16 10h モニタデータ 2

C 6 06h 制御機能 X 17 11h アラーム 1

P 7 07h モータ 1 機能 Z 18 12h アラーム 2

H 8 08h ハイレベル機能 b 19 13h モータ 3 機能

A 9 09h モータ 2 機能 d 20 14h アプリケーション機能 2

o 10 0Ah オプション機能

例:F26 の場合 F ⇒ 種別コード 04

26 ⇒ 1A(16 進表記)

o40~o43 および o48~o51 の設定後は, インバータに設定を反映させるために,インバータの電源

を再投入してください。

書込みの割付(o40~o43)に同じ機能コードを複数割付した場合, o コードの番号が一番小さいも

のへの割付だけが有効となり, 残りは割付なしと判断します。

異なる機能コード割付けであっても,インバータ機能コード S01,S05,S19(周波数・速度指令)

のうち 2 つ以上を同時割付けした場合, o コードの番号が一番小さいものへの割付だけが有効とな

り,残りは割付なしと判断します。(内部的にはこれら3つの機能コードは同一の扱いとなってい

ます。)

機能コード番号(16進表記)

機能コード種別(表 8.8 による)

表8.8 機能コード種別

"041A"

日

本

語

25

Page 29

8.3 PCV の説明

PCV はパラメータ(インバータ機能コード, PROFIdrive 固有パラメータ)の単発的なアクセスを行う領域です。

この領域は PPO Type1 および Type2 がサポートしています。PCV 部の構成を図 8.3 に示します。

1 2 3 4 (word)

PCV 部 PCA IND

図 8.3 PCV 部の全体構成

PVA

(H) (L)

(1) PCA および IND

2つの領域でパラメータの指定を行います。PCA と IND は更に以下の構成からなります。

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 (bit)

PCA RC SPM PNU

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 (bit)

IND SubIndex 使用しません

RC: 要求コード/応答コード(表 8.9)

SPM: 使用しません。0 固定。

PNU: アクセスするパラメータの番号を指定。

SubIndex: インバータ機能コードの番号(機能コード種別に続く数字)を指定。もしくは,

配列型 PROFIdrive 固有パラメータのインデックス番号を指定。

インバータ機能コードの指定は, PNU 領域と SubIndex 領域を使って行います。PNU 領域には(機

能コード種別(表 8.8)+100h)の値を, SubIndex の領域には機能コード番号を入力します。

インバータ機能コードの指定方法, 読出し/書込み方法については, 本章の「8.3 (3)インバータ機能

コードおよび PROFIdrive 固有パラメータへのアクセス方法」を参照してください。

表 8.9 RC の説明

RC 要求/応答 内容

0 要求 要求無し

1 (マスタ→スレーブ) パラメータ値読出し

2 パラメータ値書込み(word)

3~5 使用しません

6 配列型パラメータの値の読出し

7 配列型パラメータの書込み(配列 word)

8 使用しません

9 配列型パラメータの配列要素数読出し

10~15 使用しません

0 応答 応答なし

1 (スレーブ→マスタ) パラメータ値(word)を正常転送した

2, 3 使用しません

4 パラメータ値(配列 word)を正常転送した

5 使用しません

6 配列要素数の正常応答

7 転送エラー(PVA にエラー番号が格納)*1

8~15 使用しません

*1 エラー番号の内容については,表 8.10 を参照してください。

26

Page 30

表 8.10 パラメータアクセスエラー時のエラー番号一覧

エラ―番号

RC

(PVA に表示)

7 0 存在しないパラメータを指定

1 パラメータ書込み不可

2 パラメータ設定範囲外

3 無効な SubIndex 指定

11 運転中あるいは端子台 ON 中パラメータ書込み不可エラー

17 読出し処理実行不可能

101 リンク優先エラー

104 パラメータ書込み中 busy エラー

(2) PVA

書込み/読出しパラメータ値を示す2ワード領域です。本通信カードでは, PVA の下位 1 ワードのみ(PCV 部

の頭から数えて4ワード目)を使用します。

パラメータの書込みの場合は, マスタから書込み値を入力します。読出しの場合は, 応答時にこの領域に読

出し値が出力されます。パラメータアクセスにエラーがある場合(応答 RC=7 の時)は, 応答時にこの領域に

エラー番号(表 8.10)が出力されます。

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 (bit)

PVA

使用しません

(H)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 (bit)

PVA

書込み値/読出し値 or エラー番号(表 8.10)

(L)

内容

日

本

語

27

Page 31

(3) インバータ機能コードおよび PROFIdrive 固有パラメータへのアクセス方法

1. PNU 領域と SubIndex 領域で, アクセスするパラメータを指定します(図 8.4 参照)。インバータ機能コ

ードを指定する場合は, PNU に 100(hex)+機能コード種別(表 8.8 参照), Subindex に機能コード番号(機

能コード種別に続く番号。F01 ならば"01"の部分)を指定します。

2. RC 領域で, 指定したパラメータに対してのアクセス方法(書込み, 読出しなど)を指定します。RC の

詳細は表 8.9 を参照してください。

3. パラメータの書込みの場合は, PVA 領域に書込み値を入力します。読出しの場合は, 応答時に指定した

パラメータの値がスレーブから出力されます。アクセス結果がエラーだった場合は, 応答時の RC が 7

となり, PVA 領域に表 8.10 に示すエラー番号が出力されます。

インバータ機能コード S06 による運転指令(bit0,1)および S01,S05,S19 による周波数・速度指

令は,状態 S1 の時に可能です。これらの指令を行っている時に状態 S1 以外に遷移させた場合は,

即時 CTW および MRV による指令に従います。なお,S06 の bit2~15 は,どの状態でも使用可能で

す。

インバータ通信専用機能コード S01,S05,S06,S19 については,RS-485 通信ユーザーズマニュアル

の第 5 章「5.1 通信専用機能コード」を参照してください。

インバータ機能コードごとにそれぞれ規定のフォーマットが定められています。それぞれのフォーマ

ットについては, RS-485 通信ユーザーズマニュアルの第 5 章「5.2 データフォーマット」を参照して

ください。

15 12 10 8 7 0 (bit)

PCA

RC

(表 8.9 による)

0 PNU

インバータ機能コード指定時:

PROFIdrive 固有パラメータ:

指定時

100(hex)+表 8.8 の値

PNU 番号(表 8.11)

15 8 7 0 (bit)

IND SubIndex 使用しない。00(hex)固定

インバータ機能コード指定時: 機能コード番号

PROFIdrive 固有パラメータ:

(配列型)指定時

インデックス番号

(表 8.11)

15 8 7 0 (bit)

PVA

(H)

使用しない。0000(hex)固定

15 8 7 0 (bit)

PVA

(L)

書込み値/読出し値 or エラー番号(表 8.10)

図 8.4 パラメータのアクセス方法

次ページ以降に実際にパラメータにアクセスした例を示します。

28

Page 32

例1. インバータ機能コード F26 に値として 15 を書込みする場合

① マスタから F26 に 15 を書込む要求を送信します。

RC=2(hex) → パラメータ書込み(word)

PNU=104(hex), SubIndex=1A(hex) → F26 を指定(100h+種別 04h=104h, 機能コード番号=1Ah)

PVA=0000 000F(hex) → 書込み値15(=000Fh)を入力

15 8 7 0 (bit)

要求

(マスタ→スレーブ)

IND 1A(hex) (00h 固定)

PVA(H) (0000h 固定)

PVA(L) 000F(hex)

PCA 2(hex) 104(hex)

② 通信カードからの応答例です。(正常応答)

RC=1(hex) → パラメータ値の正常転送

PNU=104(hex), SubIndex=1A(hex) → アクセスしたパラメータは機能コード F26

PVA=0000 000F(hex) → 書込まれた値は15

応答

(スレーブ→マスタ)

IND 1A(hex) (00 固定)

PVA(H) (0000 固定)

PVA(L) 000F(hex)

15 8 7 0 (bit)

PCA 1(hex) 104(hex)

③ 書込みエラーがあった場合の応答例(範囲外エラー時)

RC=7(hex) → パラメータの転送エラー

PNU=104(hex), SubIndex=1A(hex) → アクセスしたパラメータは機能コード F26

PVA=0000 0002(hex) → エラーコード2(パラメータ範囲外エラー)

応答

(スレーブ→マスタ)

IND 1A(hex) (00 固定)

PVA(H) (0000 固定)

PVA(L) 0002(hex)

15 12 11 8 7 0 (bit)

PCA 7(hex) 104(hex)

日

本

語

29

Page 33

例2. インバータ機能コード y98 の値を読出しする場合

① マスタから y98 の読出し要求を送信します。

RC=1(hex) → パラメータ読出し

PNU=10F(hex), SubIndex=62(hex) → y98(100h+種別 0Fh=10Fh, 機能コード番号=62h)を指定

PVA=0000 0000(hex) → PVA には特に何も入力する必要なし

15 8 7 0 (bit)

要求

(マスタ→スレーブ)

IND 62(hex) (00h 固定)

PVA(H) (0000h 固定)

PVA(L) 0000(hex)

PCA 1(hex) 10F(hex)

② 通信カードからの応答例です。(正常応答)

RC=1(hex) → パラメータ値の正常転送

PNU=10F(hex), SubIndex=62(hex) → アクセスしたパラメータは機能コード y98

PVA=0000 0003(hex) → 読出し値 3

応答

(スレーブ→マスタ)

IND 62(hex) (00 固定)

PVA(H) (0000 固定)

PVA(L) 0003(hex)

15 8 7 0 (bit)

PCA 1(hex) 10F(hex)

③ 読出しエラーがあった場合の応答例(機能コードが存在しない)

RC=7(hex) → パラメータの転送エラー

PNU=10F(hex), SubIndex=64(hex) → アクセスしたパラメータはインバータ機能コード y100

PVA=0000 0000(hex) → エラーコード 0(存在しないパラメータを指定)

応答

(スレーブ→マスタ)

IND 64(hex) (00 固定)

PVA(H) (0000 固定)

PVA(L) 0000(hex)

15 8 7 0 (bit)

PCA 7(hex) 10F(hex)

30

Page 34

例3. 配列型の PROFIdrive 固有パラメータ PNU947(アラーム履歴)を読出しする場合

① マスタから PNU947 の読出し要求を送信します。(下記の例はインデックス1を読出し)

RC=6(hex) → 配列型パラメータ読出し

PNU=3B3(hex), SubIndex=1(hex) → PNU947(=3B3h),インデックス 1 を指定

PVA=0000 0000(hex) → PVA には特に何も入力する必要なし

15 8 7 0 (bit)

要求

(マスタ→スレーブ)

IND 01(hex) (00h 固定)

PVA(H) (0000h 固定)

PVA(L) 0000(hex)

PCA 6(hex) 3B3(hex)

② 通信カードからの応答例です。(正常応答)

RC=4(hex) → 配列型パラメータ値の正常転送

PNU=3B3(hex), SubIndex=01(hex) → アクセスしたパラメータ PNU947(=3B3h),インデックス1

PVA=0000 7511(hex) → 読出し値 7511(hex) ; PROFIBUS 通信エラー(

PNU947 の値については,第 10 章「アラームコード一覧」を参照してください。

応答

(スレーブ→マスタ)

IND 01(hex) (00 固定)

PVA(H) (0000 固定)

PVA(L) 7511(hex)

15 8 7 0 (bit)

PCA 4(hex) 3B3(hex)

er5

③ 読出しエラーがあった場合の応答例(配列型読出しで読出ししなかった時)

RC=7(hex) → パラメータの転送エラー

PNU=3B3(hex), SubIndex=01(hex) → アクセスしたパラメータはインバータ機能コード y100

PVA=0000 0003(hex) → エラーコード 3(無効な SubIndex 指定)

応答

(スレーブ→マスタ)

IND 1A(hex) (00 固定)

PVA(H) (0000 固定)

PVA(L) 0003(hex)

15 8 7 0 (bit)

PCA 7(hex) 3B3(hex)

)

日

本

語

31

Page 35

(4) PROFIdrive 固有パラメータ

通信カードでサポートする PROFIdrive 固有パラメータを表 8.11 に示します。Index の欄に記載がある PNU

は, 配列型パラメータであるこということを示します。

表 8.11 PROFIdrive 固有パラメータ一覧

PNU Index 内容 範囲 R/W 備考

915 1~4 PCD1~4(要求)への機能コード割付け

(機能コード書込み)

916 1~4 PCD1~4(応答)への機能コード割付け

(機能コードモニタ)

0000~

FFFF(hex)

0000~

FFFF(hex)

R/W o40~o43 と同一

R/W o48~o51 と同一

918 なし ノードアドレス 0~125 R

927 なし PCV 領域のアクセス権限

0 : 書込禁止

1 : 書込許可

947 1 故障履歴(最新)

9 故障履歴(1回前)

17 故障履歴(2回前)

25 故障履歴(3回前)

上記

0 固定

以外

0, 1 R/W 書込禁止後はこの

PNU のみ書込み可と

なります。

表 10.1 による R PROFIdrive 用のアラ

ームコード(マルフ

ァンクションコー

ド)で表示されます。

機能コード M16~M19

によるアラームコー

ドとは別のフォーマ

ットです。*1

現在のボーレート 963 なし

0 : 不定

2 : 19.2 kbit/s

4 : 93.75 kbit/s

6 : 500 kbit/s

8 : 3Mbit/s

1 : 9.6 kbit/s

3 : 45.45 kbit/s

5 : 187.5 kbit/s

7 : 1.5Mbit/s

9 : 6Mbit/s

0~10 R

10 : 12Mbit/s

965 なし PROFIdrive のバージョン 2 固定 R PROFIdrive V2

を示す。

967 なし 最後に送信した CTW 0000~

R

FFFF(hex)

968 なし 最新の STW 0000~

R

FFFF(hex)

970 なし インバータの初期化

0, 1 R/W H03 と同等機能

(1→0 で初期化実行)

*1 マルファンクションコードおよびアラームコードについては, 第 10 章「アラームコード一覧」を参照

してください。

32

Page 36

第 9 章 PROFIBUS 通信異常検出時の動作選択

PROFIBUS-DP マスタは,通信状態を監視するために,通信タイムアウト検出時間であるウオッチドッグタイマ(以

下,WDT と記載)を設定することができます。通信カードは,いったんデータを受信してから,この WDT で設定

した時間を超えても次のデータ受信がない場合,通信異常と判断します。通信異常と判断した後のインバータの

動作は,インバータ機能コード o27,o28 で設定することが可能です(表 9.1)。

PROFIBUS-DP マスタの WDT の設定については,お使いのマスタのユーザーズマニュアル等を参照してくだ

さい。

通信異常時の通信カードの LED 状態については, 第 2 章「2.6 LED インジケータ」を参照してください。

er5

インバータの電源 ON 直後に通信異常があっても

も受信した後に, 通信異常を検出した場合に

表 9.1 PROFIBUS 通信異常検出時の動作選択

o27 o28 異常検出時の動作 備考

0,

4 ~ 9

1 0.0s~60.0s

2 0.0s~60.0s

3,

13~15

10 -

11 0.0s~60.0s

12 0.0s~60.0s

-

-

er5

を軽故障対象に選択した場合は, 機能コード o27 の設定に関わらず, 通信異常があっても運

転を継続します。

即時フリーラン&

o28 で設定した時間経過後,フリーラン&

o28 で設定した時間内に通信リンクが復帰すれば異常

を無視。タイムアウトならフリーラン&

通信異常を無視して現状維持。

er5

は発生しません。)

(

即時強制減速。停止後

o28 で設定した時間経過後,強制減速し,停止後

o28 で設定した時間内に通信リンクが復帰すれば異常

を無視。タイムアウトなら強制減速後,

er5

トリップ。

er5

。 強制減速の時間はインバ

トリップとなりません。正常データを1回で

er5

トリップとなります。

er5

。

er5

。

通信異常を検出した場

合, LED は通信異常表示

となります。

(PWR 赤点滅, OFFL 赤)

ータ機能コード F08 によ

ります。

er5

。 同上

同上

er5

。

軽故障選択については,FRENIC-MEGA 取扱説明書の第 5 章「機能コード」の H81 を参照してください。

日

本

語

33

Page 37

第 10 章 アラームコード一覧

インバータがトリップした時の要因をアラームコードとして PROFIBUS 通信で確認することができます。

アラームコードは以下の 2 つの方法で確認することができます。

1. PROFIdrive 固有パラメータ PNU947 で確認する。

2. インバータ機能コード M16, M17, M18 および M19(最新アラーム, 1 回前, 2 回前および 3 回前)で確認する。

表 10.1 に上記 1 および 2, それぞれの場合のアラームコード一覧を示します。

上記の 1 および 2 で確認できるコードはフォーマットが異なっています。

PNU947 については, 第 8 章「8.3 (4) PROFIdrive 固有パラメータ」を参照してください。

表 10.1 マルファンクションコード(アラームコード)一覧

マルファ

ンクショ

ンコード

PNU947

0000 0

2301 1

2302 2

2303 3

2330 5

3211 6

3212 7

3213 8

3220 10

3130 11

5450 14

5440 16

4310 17

9000 18

4110 19

4310 20

4210 22

2211 23

2212 24

2200 25

7310

7301

アラーム

コード

M16~M19

アラームなし

過電流(加速中)

過電流(減速中)

過電流(一定速中)

地絡

過電圧(加速中)

過電圧(減速中)

過電圧

(一定速中または停止中)

不足電圧

入力欠相

ヒューズ断

充電回路異常

冷却フィン過熱

外部アラーム

インバータ内過熱

モータ保護

(PTC/NTC サーミスタ)

制動抵抗器過熱

モータ 1 過負荷

モータ 2 過負荷

インバータ過負荷

27 過速度保護

28 PG 断線

内容

マルファ

ンクショ

ンコード

PNU947

--- 7300

0c1

5500 31

0c2

7520 32

0c3

5220 33

ef

7510 34

0u1

7511 35

0u2

F004 36

0u3

7200 37

lu

B100 38

lIn

2212

fus

2212

pbf

3300 46

0h1

8400

0h2

6300 51

0h3

7520 53

0h4

5220 54

dbh

8500

0l1

5430

0l2

7200

0lu

5400

FF00

0s

pg

アラーム

コード

M16~M19

29 NTC サーミスタ断線

メモリエラー

タッチパネル通信エラー

CPU エラー

オプション通信エラー

(通信カードハードエラー)

オプションエラー

(PROFIBUS 通信エラー)

運転動作エラー

チューニングエラー

RS-485 通信エラー

(通信ポート 1)

44 モータ 3 過負荷

45 モータ 4 過負荷

出力欠相

47 速度不一致

(速度偏差過大)

不足電圧時

データセーブエラー

RS-485 通信エラー

(通信ポート 2)

ハードウェアエラー

56 位置制御エラー

57 EN 回路異常

58 PID フィードバック断線

検出

59 制動トランジスタ故障

254 模擬故障

内容

nrb

er1

er2

er3

er4

er5

er6

er7

er8

0l3

0l4

0pl

ere

erf

erp

erh

ero

ecf

cof

dba

err

34

Page 38

第 11 章 トラブルシューティング

通信カードに何らかのトラブルが発生した場合は,下記に従ってトラブルシューティングを行ってください。

No

現象 原因

1 通信カードの LED が全て点灯しない。

er4

2

3

4

5

6

7

8

9

トリップが解除できない。

(PWR LED が赤点灯)

PROFIBUS 通信できない。PWR LED が赤

点滅, OFFL LED が赤点灯のままであ

る。

PROFIBUS 通信できない。ERR LED が点

滅のままである。

er5

トリップが解除できない。ある

いはすぐに

まう。

(PWR LED が赤点滅, OFFL LED が赤)

CTW あるいは MRV がインバータ反映さ

れない。

PP0 Type2 あるいは Type4 の PCD1~4

が正しく動作しない。

ノードアドレスを 0 に設定しても, 0

にならない。

速度指令は反映されたが,実際の回転

速度が指令とは異なっている。

er5

トリップとなってし

• インバータの電源が ON していない。

• 通信カードが正しく取り付けられていない。

• 通信カードの故障。

• 通信カードが正しく取り付けられていない。

• 通信カードの電源が ON していない。

• 通信カードの故障。

• GSD ファイルをマスタに登録していない。

• マスタに登録したノードアドレスと通信カードのノードア

ドレスが不一致である。

• ノードアドレスが他のノードと重複している。

• ケーブルが正しく配線されていない。

• PROFIBUS-DP 専用のケーブルを使用していない。

• ネットワークの両端に終端抵抗が接続されていない。

• インバータ機能コード o30 を設定していない。マスタで登

録した PPO Type と一致させること。

• o30 設定後, インバータの電源を再起動していない。

• マスタのウオッチドッグタイマ(タイムアウト時間)の設

定が短い。

• インバータ機能コード o31 に 126 以上の値を設定している。

• PROFIBUS-DP 専用のケーブルを使用していない。

• 通信カードをアースしていない。

• インバータ機能コード y98 が 3 に設定されていない。

• インバータの機能コードで優先順位が高い運転指令・速度

指令が有効になっている。(y99, [LE]端子, [LOC]端子)

• 選択した PPO Type のフォーマットを確認する。

• インバータ機能コード o30 を設定していない。または, o30

設定後, インバータの電源を再起動していない。

• インバータ機能コード o40~o43, o48~o51 を設定後, イン

バータの電源を再起動していない。

• ノードアドレス変更後, インバータの電源を再起動してい

ない。

• インバータ機能コード o31 に 0 以外の値が設定されている。

• FRENIC-MEGA 取扱説明書の第 6 章「6.3.1 モータの異常動作」

を参照してください。

日

本

語

35

Page 39

第 12 章 仕様

12.1 一般仕様

本通信カード搭載のインバータの使用環境を表 12.1 に示します。記載のない項目については,インバータ本体

の仕様に準じます。

項目 仕様

場所 屋内

動作周囲温度 FRENIC-MEGA 取扱説明書の第 2 章を参照してください。

動作周囲湿度 5~95%(結露しないこと)

雰囲気

標高 1,000m 以下

気圧 86~106 kPa

振動 FRENIC-MEGA 取扱説明書の第 2 章を参照してください。

対応インバータ FRENIC-MEGA ROM Ver.1000 以降

(注) 糸屑や湿り気を帯びた塵埃など冷却フィンの目詰まりが生じる環境に据え付けないでください。このような環境で使う場合,

糸屑などが入らない制御盤内に据え付けてください。

12.2 PROFIBUS-DP 通信仕様

本通信カードの PROFIBUS-DP 仕様を表 12.2 に示します。記載のない項目については,PROFIBUS-DP の仕様に準

じます。

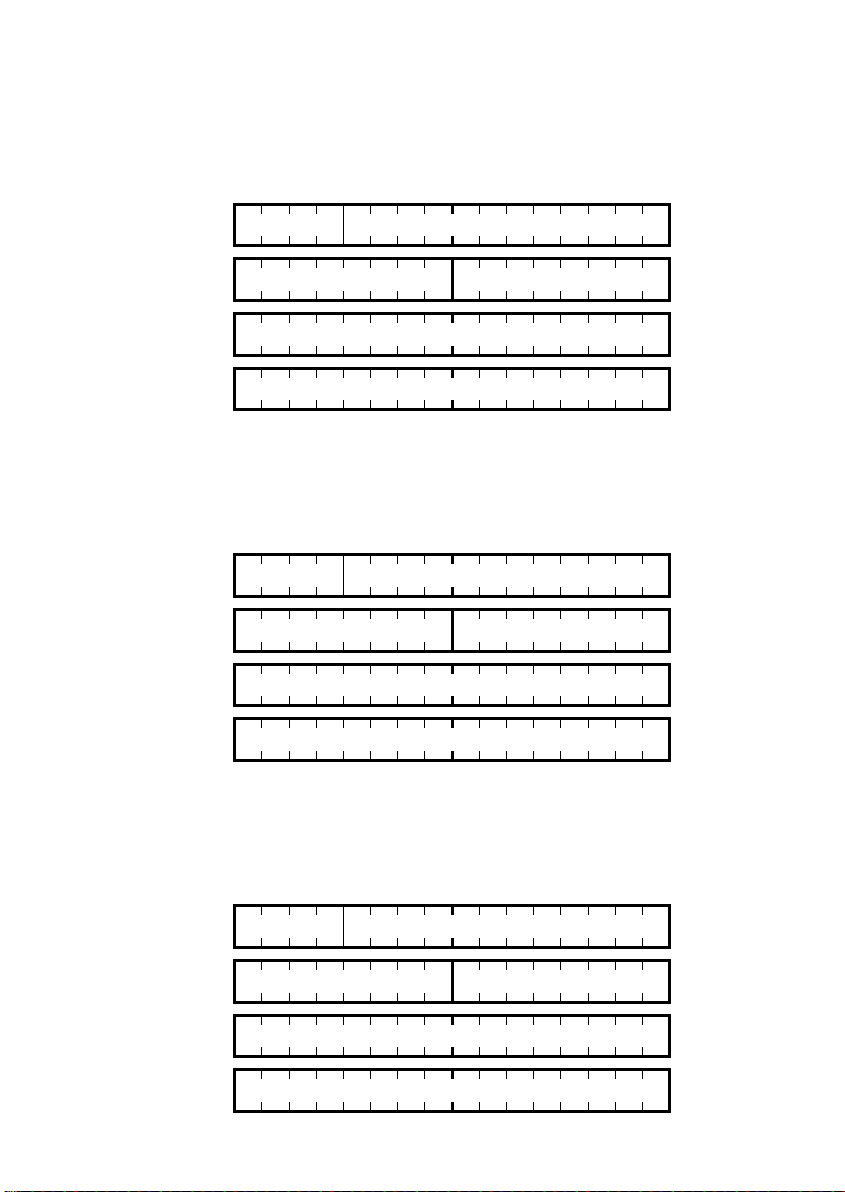

項目 仕様 備考

伝送部

接続コネクタ 着脱式6極端子台

アドレス

PROFIBUS-DP 用ケーブルを用いた場合の 1 セグメントあたりの最大電送距離

通信速度(bit/s) セグメント当たりの最大長(m)

回線 RS-485 (絶縁)

接続長 下表参照

伝送速度 9.6Kbit/s ~ 12Mbit/s (自動検出) マスタ側で設定

伝送規約 PROFIBUS-DP (DP-V0) IEC 61158, 61784

コントローラ SPC3 (Siemens) 制御部

伝送バッファ 1472byte(SPC3 内蔵メモリ)

表 12.3 PROFIBUS-DP ケーブル最大配線長

9.6k 1200

19.2k 1200

45.45k 1200

93.75k 1000

187.5k 1000

500k 400

1.5M 200

3M 100

6M 100

12M 100

表 12.1 インバータ使用環境

塵埃,直射日光,腐食性ガス,可燃性ガス,オイルミスト,蒸気,水滴がない

こと。(汚染度 2(IEC60664-1))(注)

塩分があまり含まれていないこと。(年間 0.01 mg/cm

急激な温度変化による結露が生じないこと。

表 12.2 PROFIBUS-DP 仕様

アドレススイッチにより設定 (0~99)

または, インバータ機能コード o31 により

設定(0~125)

断線検出 OFFL LED による 診断機能

コンフィグレーション異常検出 ERR LED による

36

2

以下)

フェニックスコンタクト社製

MC1.5/6-STF-3.5

o31 はアドレススイッチが 0

設定時に有効

Page 40

English Version

ENGLISH

Page 41

Preface

Thank you for purchasing our PROFIBUS-DP Communications Card OPC-G1-PDP.

This manual has been prepared to help you connect your FRENIC-MEGA to a PROFIBUS-DP master (Siemens

PLC, computer, etc.) via PROFIBUS-DP.

Mounting the communications card on your FRENIC-MEGA allows you to connect the FRENIC-MEGA to a

PROFIBUS-DP master node and control it as a slave unit using run and frequency commands, and access to

function codes.

The communications card can be connected to the A-port only, out of three option connection ports (A-, B-, and

C-ports) provided on the FRENIC-MEGA.

It has the following features:

- PROFIBUS version: DP-V0 compliant

- Transmission speed: 9,600 bps to 12 Mbps

- Maximum network cable length per segment: 100 m (12 Mbps) to 1200 m (9.6 kbps)

- Applicable Profile: PROFIDrive V2 compliant

- Able to read and write all function codes supported in the FRENIC-MEGA

This instruction manual does not contain inverter handling instructions. Read through this instruction manual in

conjunction with the FRENIC-MEGA Instruction Manual and be familiar with proper handling and operation of

this product. Improper handling might result in incorrect operation, a short life, or even a failure of this product.

Keep this manual in a safe place.

Related Publications

Listed below are the other materials related to the use of the PROFIBUS-DP Communications Card

OPC-G1-PDP. Read them in conjunction with this manual as necessary.

• RS-485 Communication User's Manual

• FRENIC-MEGA Instruction Manual

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

• Read through this instruction manual and be familiar with the PROFIBUS-DP communications card

before proceeding with installation, connections (wiring), operation, or maintenance and inspection.

• Improper handling might result in incorrect operation, a short life, or even a failure of this product as

well as the motor.

• Deliver this manual to the end user of this product. Keep this manual in a safe place until this product

is discarded.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all

safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

1

ENGLISH

Page 42

Installation and wiring

• Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters

with a capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or

above. Make sure that the LED monitor and charging lamp are turned OFF. Further, make sure,

using a multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+)

and N(-) has dropped to the safe level (+25 VDC or below).

• Qualified electricians should carry out wiring.

Otherwise, an electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, an accident, or injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into

the inverter and the communications card.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

• Noise may be emitted from the inverter, motor and wires. Implement appropriate measure to prevent

the nearby sensors and devices from malfunctioning due to such noise.

Otherwise, an accident could occur.

Operation

• Be sure to install the front cover before turning the inverter's power ON. Do not remove the cover

when the inverter power is ON.

Otherwise, an electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause an electric shock.

• If you configure the function codes wrongly or without completely understanding FRENIC-MEGA

Instruction Manual and the FRENIC-MEGA User's Manual, the motor may rotate with a torque or at a

speed not permitted for the machine. Confirm and adjust the setting of the function codes before

running the inverter.

Otherwise, an accident could occur.

Maintenance and inspection, and parts replacement

• Before proceeding to the maintenance/inspection jobs, turn OFF the power and wait at least five

minutes for inverters with a capacity of 22 kW or below, or at least ten minutes for inverters with a

capacity of 30 kW or above. Make sure that the LED monitor and charging lamp are turned OFF.

Further, make sure, using a multimeter or a similar instrument, that the DC link bus voltage between

the terminals P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, an electric shock or injuries could occur.

2

Page 43

Disposal

• Treat the communications card as an industrial waste when disposing of it.

Otherwise injuries could occur.

Others

• Never modify the communications card.

Doing so could cause an electric shock or injuries.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full

efficiency, as well as information concerning incorrect operations and settings which can result in

accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

ENGLISH

3

Page 44

Table of Contents

Preface .......................................................................... 1

Safety precautions............................................................ 1

Chapter 1 BEFORE USE................................................... 5

1.1 Acceptance Inspection ............................................ 5

1.2 Applicable Inverters ................................................. 5

Chapter 2 NAMES AND FUNCTIONS ............................... 6

2.1 External Appearance ............................................... 6

2.2 Terminal Block (TERM1).......................................... 6

2.3 Terminating Resistor Switch (SW 3) ......................... 7

2.4 Node Address Switches........................................... 7

2.5 Setting the Transmission Speed (Baud Rate).......... 8

2.6 LED Status Indicators.............................................. 8

Chapter 3 INSTALLATION AND REMOVAL OF THE

Chapter 4 WIRING AND CABLING ..................................11

Chapter 5 CONFIGURING INVERTER'S FUNCTION

PROFIBUS-DP COMMUNICATIONS CARD.... 9

3.1 Installing the Communications Card ........................ 9

3.2 Removing the Communications Card.................... 10

4.1 Basic Connection Diagram .....................................11

4.2 Wiring for PROFIBUS Terminal Block.................... 12

4.3 Wiring to Inverter ................................................... 13

CODES FOR PROFIBUS COMMUNICATION 14

Chapter 6 ESTABLISHING A PROFIBUS

Chapter 7 QUICK SETUP GUIDE FOR RUNNING THE

Chapter 8 DETAILS OF PROFIBUS PROFILES.............. 19

Chapter 9 ERROR PROCESSING FOR PROFIBUS

Chapter 10 LIST OF INVERTER ALARM CODES.............34

Chapter 11 TROUBLESHOOTING .................................... 35

Chapter 12 SPECIFICATIONS...........................................36

COMMUNICATIONS LINK.............................. 15

INVERTER...................................................... 16

7.1 Before Proceeding to Data Exchange.................... 16

7.2 Data Transaction Examples in Running an

Inverter................................................................... 16

8.1 Description of PPO Types Supported .................... 19

8.2 PCD Word Area .....................................................21

8.3 PCV Word Area...................................................... 26

NETWORK BREAKS ......................................33

12.1 General Specifications........................................... 36

12.2 PROFIBUS-DP Specifications ............................... 36

4

Page 45

Chapter 1 BEFORE USE

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) A communications card, two screws (M3 × 8), and the PROFIBUS-DP Communications Card Instruction

Manual (this document) are contained in the package.

(2) The communications card is not damaged during transportation--no defective parts, dents or warps.

(3) The model name "OPC-G1-PDP" is printed on the communications card. (See Figure 1.1.)

If you suspect the product is not working properly or if you have any questions about your product, contact the

shop where you bought the product or your local Fuji branch office.

Screw hole (left)

Model name

Release knob

CN1

(Front) (Back)

Positioning cutout

Figure 1.1 Names of Parts on PROFIBUS-DP Communications Card (OPC-G1-PDP)

1.2 Applicable Inverters

The communications card is applicable to the following inverters and ROM version.

Table 1.1 Applicable Inverters and ROM Version

Series Inverter type Applicable motor rating ROM version

FRENIC-MEGA FRNG1- All capacities 1000 or later

* The boxes replace alphanumeric letters depending on the nominal applied motor, enclosure, power supply voltage, etc.

To check the inverter's ROM version, use Menu #5 "Maintenance Information" on the keypad. (Refer to the

FRENIC-MEGA Instruction Manual, Chapter 3, Section 3.4.6 "Reading maintenance information."

Display on LED Monitor Item Description

5_14

Inverter's ROM version Shows the inverter's ROM version as a 4-digit code.

Screw hole (right)

Table 1.2 Checking the Inverter ROM Version

ENGLISH

5

Page 46

Chapter 2 NAMES AND FUNCTIONS

2.1 External Appearance

The external appearance and the components of the PROFIBUS-DP communications card are shown in Figure

2.1 and Table 2.1, respectively.

SW3

SW1

TERM1

Item Description

TERM1 PROFIBUS-DP terminal block (3.5 mm pitch) (See Section 2.2.)

CN1 Connector for joint with inverter

SW1, SW2 Node address switches (Rotary switches) (See Section 2.4.)

SW3 Terminating resistor switch (See Section 2.3.)

LEDs LED status indicators (PWR, ERR, ONL and OFFL) (See Section 2.6.)

Figure 2.1 External View and Component Names

Table 2.1 Components on the PROFIBUS-DP Communications Card

SW2

LEDs

CN1 (on the back)

2.2 Terminal Block (TERM1)

The terminal block TERM1 uses a pluggable 6-pin terminal block as shown in Figure 2.2. Table 2.2 lists the pin

assignment. A typical connector that matches this terminal block is Phoenix Contact MC1.5/6-STF-3.5.

Before connecting the PROFIBUS cable to the terminal block, strip the wire ends and twist the shield wires.

Table 2.2 Pin Assignment on the PROFIBUS Terminal Block

Pin # Pin Assignment Description

1 Shield Terminal for connecting the cable shield

2 GND NC

3 +5V NC

A-Line

4

5 B-Line Terminal for the positive (+) line (red wire)

RTS

6

Terminal for the negative (-) line of

PROFIBUS cable (green wire)

Data transmission control for the repeater

(direction control)

Figure 2.2 PROFIBUS-DP

Terminal Block

6

Page 47

2.3 Terminating Resistor Switch (SW3)

The PROFIBUS-DP communications network requires insertion of line terminating resistors at its both ends.

When the communications card is mounted on the inverter at either end of the network, turn this switch ON to

insert the terminating resistor.

SW3

ON

SW3

ON

OFF

OFF: No insertion of terminating resistor ON: Insertion of terminating resistor

Figure 2.3 Terminating Resistor Switch Settings

OFF

2.4 Node Address Switches

The node address switches (SW1 and SW2) on the communications card are rotary ones that are used to

specify the PROFIBUS-DP communications network node address (station address) of the communications

card. The setting range is from 0 to 99 in decimal. The SW1 specifies a 10s digit of the node address and the

SW2, a 1s digit.

The node address can also be specified with the inverter's function code o31. The setting range is from 0 to 125

in decimal. Note that validating the node address specified with the function code o31 requires setting the node

address switches to "00."

Example 1: Setting the node address 27 using the node address switches

SW1 SW2

Figure 2.4 Node Address Setting Example 1

Example 2: Setting the node address 125 using the function code o31

SW1 SW2

Figure 2.5 Node Address Setting Example 2

1. The node address switches should be accessed with the inverter being OFF. Setting these

switches with the inverter being ON requires restarting it to enable the new settings.

2. To enable the node address setting using the function code o31, restart the inverter.

3. Setting the function code o31 data to "126" or greater will cause an error, blinking the ERR LED

on the communications card in red and issuing the alarm code

1. When the inverter is powered OFF:

Set SW1 to "2."

Set SW2 to "7."

2. Turn the inverter ON to complete the setting

procedure.

1. When the inverter is powered OFF:

Set both the SW1 and SW2 to "0."

2. Turn the inverter ON and set the function code o31

data to "125."

3. Restart the inverter to complete the setting

procedure.

er5

from the inverter.

ENGLISH

7

Page 48

2.5 Setting the Transmission Speed (Baud Rate)

No transmission speed setting is required on the communications card (slave). Setting the transmission speed

in the PROFIBUS-DP network master node automatically configures the transmission speed of the

communications card.

The communications card supports the following transmission speeds.

9.6, 19.2, 45.45, 93.75, 187.5, and 500 kbps

1.5, 3, 6, and 12 Mbps

2.6 LED Status Indicators

The communications card has four LED status indicators shown in Figure 2.6. They indicate the operation status

of the communications card as listed in Table 2.3.

Figure 2.6 LED Status Indicators

Table 2.3 LED Indications and Operation Status

Name LED state Meaning Note

Lights in green Normally communicating ---

PWR

Blinks in green

Blinks in red PROFIBUS communications error The inverter shows

Lights in red

Self-diagnostic test running or initialization in

progress during powering on sequence

Hardware error

(Communications card not properly mounted or

This test takes approx. 0.5

second.

er5

. *1

The inverter shows

er4

.

faulty)

Blinks in red

ERR

Wrong configuration of PROFIBUS protocol

(Discrepancy between PPO type defined by the

inverter's function code o30 and the one defined

in the PROFIBUS master node)*

2

Wrong configuration of PROFIBUS protocol

(The node address is set to 126 or greater.)

---

The inverter shows

er5

. *1

Online

ONL

Lights in green

(The communications card communicates

normally on the PROFIBUS network.)

---

OFF Not online ---

Offline

OFFL

Lights in red

(The communications card is not connected to

PROFIBUS)

---

OFF Not offline ---

*1 Configuration for ignoring

NETWORK BREAKS."

*2 PPO (Parameter Process-data Object) type defined in the communications card should be consistent with that in the

PROFIBUS-DP master node. To define the PPO type in the communications card, use the inverter's function code

o30; to define that in the master node, use a configuration tool designed for the master node.

er5

is possible. For details, refer to Chapter 9, "ERROR PROCESSING FOR PROFIBUS

For defining the PPO type in the master node, refer to the documentation of the master node.

For details about the PPO type, see Chapter 8, "DETAILS OF PROFIBUS-DP PROFILES." For details

about the function code o30, see Chapter 5 "CONFIGURING INVERTER'S FUNCTION CODES FOR

PROFIBUS-DP COMMUNICATION."

8

Page 49

Chapter 3 INSTALLATION AND REMOVAL OF THE PROFIBUS-DP

COMMUNICATIONS CARD

Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters with a

capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or above. Make

sure that the LED monitor and charging lamp are turned OFF. Further, make sure, using a multimeter or a

similar instrument, that the DC link bus voltage between the terminals P(+) and N(-) has dropped to the safe

level (+25 VDC or below).

Otherwise, an electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, an accident, or injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the

inverter and the communications card.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

Before mounting the communications card, perform the wiring for the main circuit terminals and

control circuit terminals.

3.1 Installing the Communications Card

(1) Remove the front cover from the inverter and expose the control printed circuit board (control PCB). As

shown in Figure 3.1, the communications card can be connected to the A-port only, out of three option

connection ports (A-, B-, and C-ports) on the control PCB.

To remove the front cover, refer to the FRENIC-MEGA Instruction Manual, Chapter 2, Section 2.3.

For inverters with a capacity of 30 kW or above, open also the keypad enclosure.

(2) Insert connector CN1 on the back of the communications card (Figure 1.1) into the A-port (CN4) on the

inverter's control PCB. Then secure the communications card with the two screws that come with the card.

(Figure 3.3)

Check that the positioning cutout (shown in Figure 1.1) is fitted on the tab (c in Figure 3.2) and

connector CN1 is fully inserted (

correctly mounted.

(3) Perform wiring on the communications card.

d in Figure 3.2). Figure 3.3 shows the communications card

Refer to Chapter 4 "WIRING AND CABLING."

(4) Put the front cover back into place.

To put back the front cover, refer to the FRENIC-MEGA

Instruction Manual, Chapter 2, Section 2.3. For inverters with

a capacity of 30 kW or above, close also the keypad

enclosure.

ENGLISH

Figure 3.1 In the case of 0.4 kW

9

Page 50

d

c

Figure 3.2 Mounting the Communications Card

c

Fit the positioning cutout of the communications

card over the tab on the inverter to determine

the mounting position.

d Insert connector CN1 on the communications

card into the A-port on the inverter's control

PCB.

Note: Be sure to follow the order of c and d.

Inserting CN1 first may lead to insufficient

insertion, resulting in a contact failure.

(Release knob)

Figure 3.3 Mounting Completed

3.2 Removing the Communications Card

Remove the two screws that secure the communications card and pull the release knob (shown above) to take

the communications card out of the inverter.

10

Page 51

Chapter 4 WIRING AND CABLING

• Before starting installation and wiring, turn the power OFF and wait at least five minutes for inverters with

a capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or above.

Make sure that the LED monitor and charging lamp are turned OFF. Further, make sure, using a

multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+) and N(-) has

dropped to the safe level (+25 VDC or below).

• Qualified electricians should carry out wiring.

Otherwise, an electric shock could occur.

• In general, the covers of the control signal wires are not specifically designed to withstand a high voltage

(i.e., reinforced insulation is not applied). Therefore, if a control signal wire comes into direct contact with

a live conductor of the main circuit, the insulation of the cover might break down, which would expose the

signal wire to a high voltage of the main circuit. Make sure that the control signal wires will not come into

contact with live conductors of the main circuit.

Failure to observe this precaution could cause an electric shock or an accident.

Noise may be emitted from the inverter, motor and wires.

Take appropriate measures to prevent the nearby sensors and devices from malfunctioning due to such

noise.

An accident could occur.

4.1 Basic Connection Diagram

FRENIC-MEGA

L1/R U

L2/S

L3/T

V

W

OPC-G1-PDP

Terminating

resistor switch

(SW3)

PROFIBUS

connector

(TERM1)

(*)

G

(*) Mounting the communications card on the inverter forms this connection.

Figure 4.1 Connection Diagram

11

Shield

GND

+5V

A-Line

B-Line

RTS

G

PROFIBUS cable

Motor

M

ENGLISH

Page 52

A

4.2 Wiring for PROFIBUS Terminal Block

Perform wiring for the communications card observing the precautions below. Refer to the connection diagram

shown in Figure 4.1 and the wiring examples shown in Figure 4.3.

(1) Turn the inverter's power OFF.

(2) To connect the communications card to a PROFIBUS-DP network, use a shielded twist pair cable that

complies with the PROFIBUS specifications.

The recommended cable is a PROFIBUS FC standard cable 6XV1 830-0EH10 manufactured by

(3) Wiring for the PROFIBUS terminal block (TERM1)

Before connecting the PROFIBUS cable to the terminal block, strip the wire ends. For the recommended

Table 4.1 lists the recommended terminal screw size and the tightening torque.

(4) Complete wiring before turning the inverter ON.

Siemens AG.

For details about wiring for PROFIBUS, refer to the "Installation Guideline for PROFIBUS-DP/FMS"

and "Handbook PROFIBUS Installation Guideline" published by the PROFIBUS Organization. It can

be downloaded for free from the PROFIBUS Organization's website at:

http://www.profibus.com/pall/meta/downloads/

strip length, see Figure 4.2. Twist the shield wires before connection.

Cable wire

Figure 4.2 Recommended Strip Length of the Cable Wire End for Terminal Connection

Table 4.1 Recommended Tightening Torque of Terminal Screws and Wire Size

Terminal screw size Tightening torque Wire size

on the PROFIBUS-DP Terminal Block

M2 0.22 to 0.25 N·m AWG28 to 16 (0.14 to 1.5 mm2 )

To prevent malfunction due to noise, keep the wiring of the PROFIBUS cable away from the main

circuit wiring, motor wiring, and other power lines as far as possible. Never install them in the

same wire duct. Be sure to connect the shield wires.

• Route the wiring for the control circuit terminals as far from that for the main circuit terminals as

possible. Otherwise electric noise may cause malfunctions.

• Fix the control circuit wires inside the inverter with a cable tie to keep them away from the live parts

of the main circuit (such as main circuit terminal block).

Depending upon the wire type and the number of wires used, the front cover may be lifted by the

wires, which impedes normal keypad operation. If it happens, change the wire type or size.

pprox.

6.0 mm

12

Page 53

4.3 Wiring to Inverter

Route the wiring of the PROFIBUS cable as far from the wiring of the main circuit as possible.

Otherwise electric noise may cause malfunctions.

Pass the wires from the communications card between the control circuit terminal block and the

front cover.

• For inverters with a capacity of 22 kW or below

• For inverters with a capacity of 30 kW or above

Figure 4.3 Examples of Wiring

In the case of 0.4 kW

In the case of 75 kW

ENGLISH

13

Page 54

Chapter 5 CONFIGURING INVERTER'S FUNCTION CODES FOR PROFIBUS

COMMUNICATION

To perform data transmission between the inverter equipped with the communications card and the

PROFIBUS-DP master node, configure the function codes listed in Table 5.1.

Table 5.2 lists inverter's function codes related to PROFIBUS-DP communication. Configure those function

codes if necessary.

For details about function codes, refer to the FRENIC-MEGA Instruction Manual, Chapter 5 "FUNCTION

CODES" and the RS-485 Communication User's Manual, Chapter 5, Section 5.2 "Data Formats."

Table 5.1 Inverter's Function Code Settings Required for PROFIBUS Communication

Function

codes

o30 *1

y98 *2

*1

After configuring the function code o30, restart the inverter to enable the new settings. For details about the function

code o30, refer to Chapter 8 "DETAILS OF PROFIBUS PROFILES."

*2 In addition to y98, the FRENIC-MEGA has other function codes related to the run/frequency command source.

Configuring those codes realizes more precise selection of the command sources. For details, refer to the

descriptions of H30 and y98 in the FRENIC-MEGA Instruction Manual, Chapter 5 "FUNCTION CODES."

Function

codes

o27 *1

o28 *1

o31 *2

o40 to o43

*3

o48 to o51

*3

W90

*1 For details about function codes o27 and o28, refer to Chapter 9 "ERROR PROCESSING FOR PROFIBUS

NETWORK BREAKS."

*2 For details about function code o31, refer to Chapter 2, Section 2.4 "Node Address Switches."

*3 For details about function codes o40 to o43 and o48 to o51, refer to Chapter 8, Section 8.2 (4) "PCD1 to PCD4."

Description

Select PPO type

(data format)

Select run/frequency

command sources

Select error processing for

PROFIBUS network breaks.

Set the operation timer to be used in

error processing for network breaks.

Set the PROFIBUS network node

address.

Specify function codes for cyclical

write.

Specify function codes for cyclical

read.

Show the software version of the

PROFIBUS-DP communications card

on the LED monitor.

After configuring function codes o40 to o43 and o48 to o51, restart the inverter to enable the new

settings.

Description

Factory

default

Select from the following:

0

0, 1, 6 to 255: PPO type 1

2 and 5: PPO type 2

3: PPO type 3

4: PPO type 4

Select from the following choices:

0

y98

0 Inverter Inverter

1 PROFIBUS Inverter

2 Inverter PROFIBUS

3 PROFIBUS PROFIBUS

Table 5.2 Other Related Function Codes

Function code data Remarks

Frequency

command source

Factory

default

0 0 to 15

0.0 s 0.0 to 60.0 s

0 0 to 255

0000

(No

assignment)

0000

(No

assignment)

Depends on

the communications card

(Setting range: 0 to

125)

0000 to FFFF (hex)

0000 to FFFF (hex)

---

(Only for monitoring)

The selected PPO

type should be

consistent with that

of the master node.

If there is no special

Run command

source

Setting range Remarks

problem with your

system, setting y98 =

3 is recommended.

Valid only when address

switches SW1 and SW2

are set to "00." Setting

126 or greater causes an

error, flashing the ERR

LED and issuing an

Valid only when PPO type

2 or 4 is selected.

4-digit decimal

If the version is V.1.23,

the LED shows "123."

er5

.

14

Page 55

Chapter 6 ESTABLISHING A PROFIBUS COMMUNICATIONS LINK

This chapter guides you to establish a PROFIBUS-DP communications link between the PROFIBUS-DP master

node and the communications card mounted on the inverter (slave node).

Follow the steps below.

Step 1 Configuring the PROFIBUS-DP master node equipment

Step 2 Configuring the communications card and inverter's function codes

Step 3 Restarting the inverter

Each of the above steps is detailed below.

Step 1 Configuring the PROFIBUS-DP master node equipment