Fuji Electric FRENIC-Mega Instruction Manual

High Performance, Multifunction Inverter

Instruction Manual

This product is designed to drive a three-phase induction motor. Read through this manual to become familiar with proper

handling and correct use.

Improper handling might result in incorrect operation, short life cycle, or failure of this product as well as the motor.

Deliver this manual to the end user of this product. Keep this manual in a safe place until this product is discarded.

For instructions on how to use an optional device, refer to the instruction and installation manuals for that optional device.

Fuji Electric Systems Co., Ltd.

Fuji Electric Corp. of America INR-SI47-1457-E

Copyright © 2010 Fuji Electric Corp. of America

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from

Fuji Electric Corp. of America.

All products and company names mentioned in this manual are trademarks or registered

trademarks of their respective holders.

The information contained herein is subject to change without prior notice for improvement.

Preface

This product is designed to drive a three-phase induction motor. Read through this manual to become familiar with proper handling

and correct use.

Improper handling might result in incorrect operation, shorter life cycle, or failure of this product as well as the motor.

Have this manual delivered to the end user of this product. Keep this manual in a safe place until this product is discarded.

Listed below are the other materials related to the use of the FRENIC-MEGA. Read them in conjunction with this manual as

necessary.

• FRENIC-MEGA User's Manual

• RS-485 Communication User's Manual

These materials are subject to change without notice. Be sure to obtain the latest editions for use.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or maintenance and inspection.

Ensure you have sound knowledge of the device and familiarize yourself with all safety information and precautions before

proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to dangerous conditions,

possibly resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to dangerous conditions,

possibly resulting in minor or light bodily injuries and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences. These safety

precautions are of utmost importance and must be observed at all times.

Application

• The FRENIC-MEGA is designed to drive a three-phase induction motor. Do not use it for single-phase motors or for other

purposes.

Fire or an accident could occur.

• The FRENIC-MEGA may not be used for a life-support system or other purposes directly related to the human safety.

• Though the FRENIC-MEGA is manufactured under strict quality control, install safety devices for applications where

serious accidents or property damages are foreseen in relation to the failure of it.

An accident could occur.

Installation

• Install the inverter on a base made of metal or other non-flammable material.

Otherwise, a fire could occur.

• Do not place flammable object nearby.

Doing so could cause fire.

• Inverters with a capacity of 50 HP or above, whose protective structure is IP00, involve a possibility that a human body may

touch the live conductors of the main circuit terminal block. Inverters to which an optional DC reactor is connected also

involve the same. Install such inverters in an inaccessible place.

Otherwise, electric shock or injuries could occur.

i

• Do not support the inverter by its front cover during transportation.

Doing so could cause a drop of the inverter and injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the inverter or from

accumulating on the heat sink.

• When changing the positions of the top and bottom mounting bases, use only the specified screws.

Otherwise, a fire or an accident might result.

• Do not install or operate an inverter that is damaged or lacking parts.

Doing so could cause fire, an accident or injuries.

Wiring

• If no zero-phase current (earth leakage current) detective device such as a ground-fault relay is installed in the upstream

power supply line in order to avoid the entire power supply system's shutdown undesirable to factory operation, install a

residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB) individually to inverters to break

the individual inverter power supply lines only.

Otherwise, a fire could occur.

• When wiring the inverter to the power source, insert a recommended molded case circuit breaker (MCCB) or

residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB) (with overcurrent protection) in the

path of each pair of power lines to inverters. Use the recommended devices within the recommended current capacity.

• Use wires of the specified size.

• Tighten terminals with specified torque.

Otherwise, a fire could occur.

• When there is more than one combination of an inverter and motor, do not use a multiconductor cable for the purpose of

running the leads together.

• Do not connect a surge killer to the inverter's output (secondary) circuit.

Doing so could cause a fire.

• Be sure to connect an optional DC reactor (DCR) when the capacity of the power supply transformer exceeds 500 kVA and

is 10 times or more the inverter rated capacity.

Otherwise, a fire could occur.

• Ground the inverter in compliance with the national or local electric code.

• Be sure to ground the inverter's grounding terminals

G.

Otherwise, an electric shock or a fire could occur.

• Qualified electricians should carry out wiring.

• Be sure to perform wiring after turning the power OFF.

Otherwise, an electric shock could occur.

• Be sure to perform wiring after installing the inverter unit.

Otherwise, an electric shock or injuries could occur.

• Ensure that the number of input phases and the rated voltage of the product match the number of phases and the voltage of

the AC power supply to which the product is to be connected.

Otherwise, a fire or an accident could occur.

• Do not connect the power supply wires to output terminals (U, V, and W).

• When connecting a DC braking resistor (DBR), never connect it to terminals other than terminals P(+) and DB.

Doing so could cause fire or an accident.

• In general, the insulation of the control signal wires are not specifically designed to withstand a high voltage (i.e., reinforced

insulation is not applied). Therefore, if a control signal wire comes into direct contact with a live conductor of the main

circuit, the insulation may break down, which would expose the signal wire to the high voltage of the main circuit. Make

sure that the control signal wires will not come into contact with live conductors of the main circuit.

Doing so could cause an accident or an electric shock.

ii

• Before changing the switches or touching the control circuit terminal symbol plate, turn OFF the power and wait at least

five minutes for inverters of 40 HP or below, or at least ten minutes for inverters of 50 HP or above. Make sure that the

LED monitor and charging lamp are turned OFF. Further, make sure, using a multimeter or a similar instrument, that the DC

link bus voltage between the terminals P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• The inverter, motor and wiring generate electric noise. This may cause the malfunction of nearby sensors and devices. To

prevent malfunctioning, implement noise control measures.

Otherwise an accident could occur.

Operation

• Be sure to mount the front cover before turning the power ON. Do not remove the cover when the inverter power is ON.

Otherwise, an electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause electric shock.

• If the auto-reset function has been selected, the inverter may automatically restart and drive the motor depending on the

cause of tripping. Design the machinery or equipment so that human safety is ensured at the time of restarting.

Otherwise, an accident could occur.

• If the stall prevention function (current limiter), automatic deceleration (anti-regenerative control), or overload prevention

control has been selected, the inverter may operate with acceleration/deceleration or frequency different from the

commanded ones. Design the machine so that safety is ensured even in such cases.

• If any of the protective functions have been activated, first remove the cause. Then, after checking that the all run commands

are set to OFF, release the alarm. If the alarm is released while any run commands are set to ON, the inverter may supply the

power to the motor, running the motor.

Otherwise, an accident could occur.

• If you enable the "Restart mode after momentary power failure" (Function code F14 = 3 to 5), then the inverter

automatically restarts running the motor when the power is recovered.

Design the machinery or equipment so that human safety is ensured after restarting.

• If the user configures the function codes wrongly without completely understanding this Instruction Manual and the

FRENIC-MEGA User's Manual, the motor may rotate with a torque or at a speed not permitted for the machine.

An accident or injuries could occur.

• Even if the inverter has interrupted power to the motor, if the voltage is applied to the main circuit input terminals L1/R,

L2/S and L3/T, voltage may be output to inverter output terminals U, V, and W.

• Even if the run command is set to OFF, voltage is output to inverter output terminals U, V, and W if the servo-lock command

is ON.

• Even if the motor is stopped due to DC braking or preliminary excitation, voltage is output to inverter output terminals U, V,

and W.

An electric shock may occur.

• The inverter can easily accept high-speed operation. When changing the speed setting, carefully check the specifications of

motors or equipment beforehand.

Otherwise, injuries could occur.

iii

• Do not touch the heat sink and braking resistor because they become very hot.

Doing so could cause burns.

• The DC brake function of the inverter does not provide any holding mechanism.

Injuries could occur.

• Ensure safety before modifying the function code settings.

Run commands (e.g., "Run forward" FWD), stop commands (e.g., "Coast to a stop" BX), and frequency change commands

can be assigned to digital input terminals. Depending upon the assignment states of those terminals, modifying the function

code setting may cause a sudden motor start or an abrupt change in speed.

• When the inverter is controlled with the digital input signals, switching run or frequency command sources with the related

terminal commands (e.g., SS1, SS2, SS4, SS8, Hz2/Hz1, Hz/PID, IVS, and LE) may cause a sudden motor start or an abrupt

change in speed.

• Ensure safety before modifying customizable logic related function code settings (U codes and related function codes) or

turning ON the "Cancel customizable logic" terminal command CLC. Depending upon the settings, such modification or

cancellation of the customizable logic may change the operation sequence to cause a sudden motor start or an unexpected

motor operation.

An accident or injuries could occur.

Maintenance and inspection, and parts replacement

• Before proceeding to the maintenance/inspection jobs, turn OFF the power and wait at least five minutes for inverters

of 40 HP or below, or at least ten minutes for inverters of 50 HP or above. Make sure that the LED monitor and charging

lamp are turned OFF. Further, make sure, using a multimeter or a similar instrument, that the DC link bus voltage between

the terminals P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, an electric shock or injuries could occur.

• Never modify the inverter.

Doing so could cause an electric shock or injuries.

Disposal

• Treat the inverter as an industrial waste when disposing of it.

Otherwise injuries could occur.

GENERAL PRECAUTIONS

Drawings in this manual may be illustrated without covers or safety shields for explanation of detail parts. Restore the covers and

shields in the original state and observe the description in the manual before starting operation.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the inverter not operating to full efficiency, as well as

information concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

iv

Conformity to the Low Voltage Directive in the EU

If installed according to the guidelines given below, inverters marked with CE are considered as compliant with the Low Voltage

Directive 2006/95/EC.

Compliance with European Standards

Adjustable speed electrical power drive systems (PDS).

Part 5-1: Safety requirements. Electrical, thermal and energy. EN61800-5-1: 2007

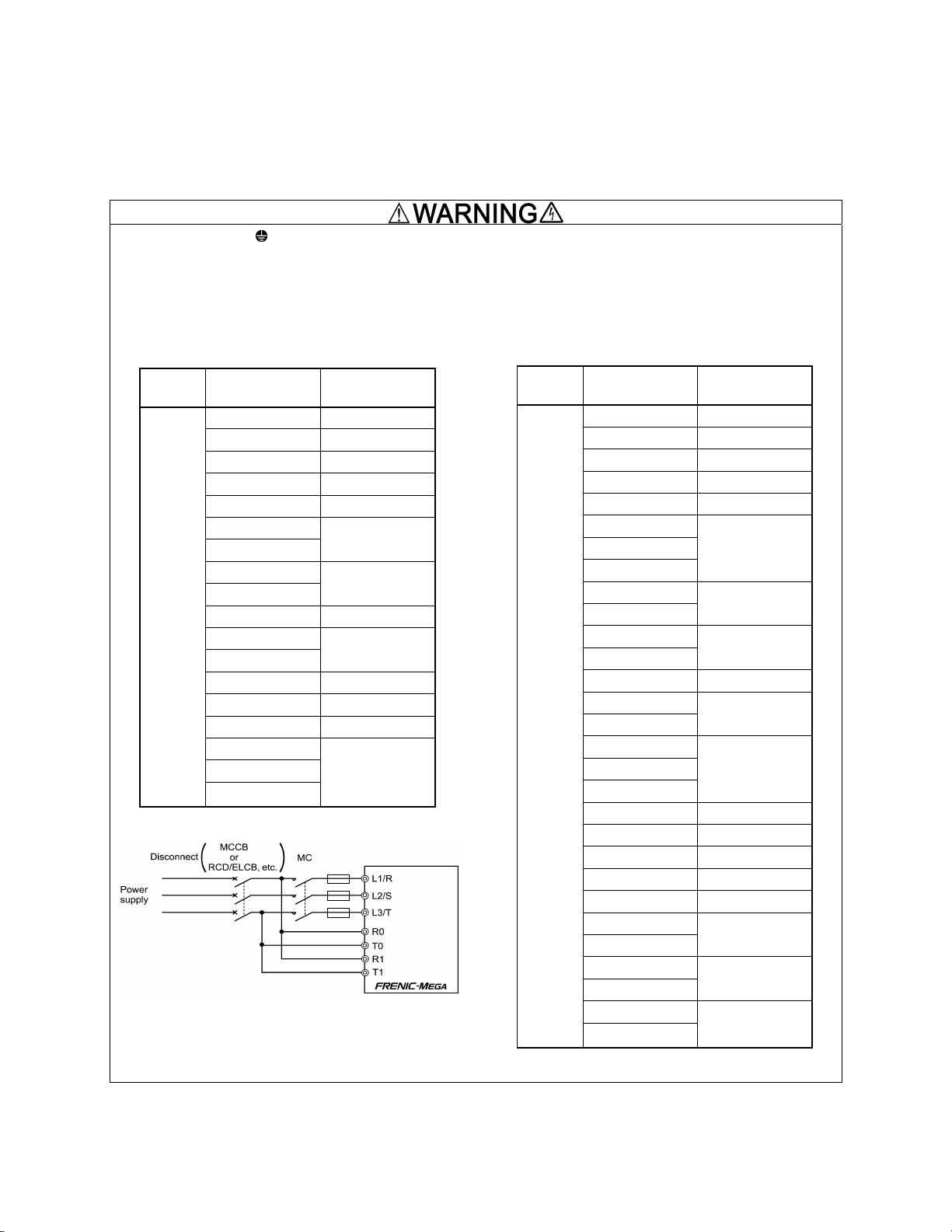

1. The ground terminal G should always be connected to the ground. Do not use only a residual-current-operated protective

device (RCD)/earth leakage circuit breaker (ELCB)* as the sole method of electric shock protection. Be sure to use ground

wires whose size is greater than power supply lines.

*With overcurrent protection.

2. To prevent the risk of hazardous accidents that could be caused by damage of the inverter, install the specified fuses in the

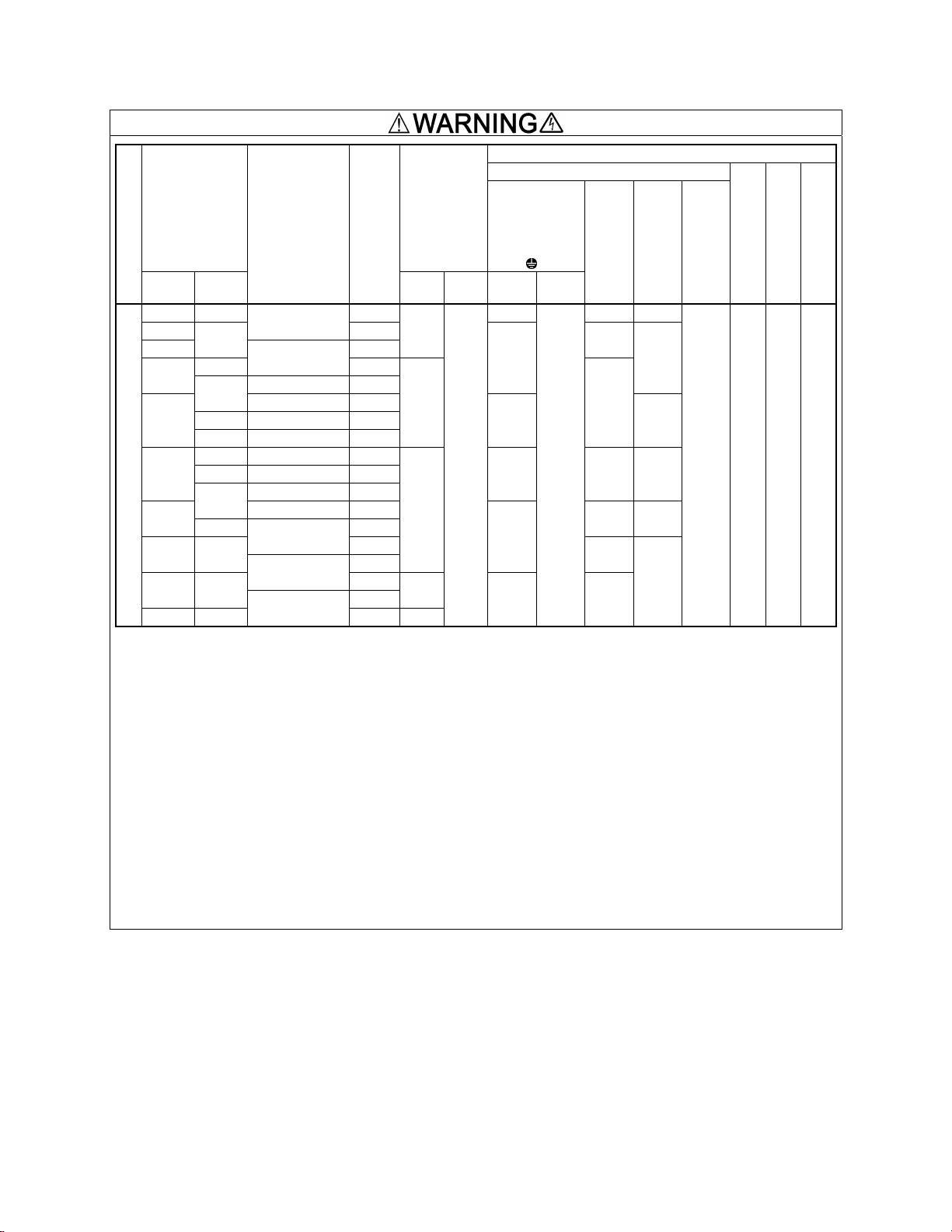

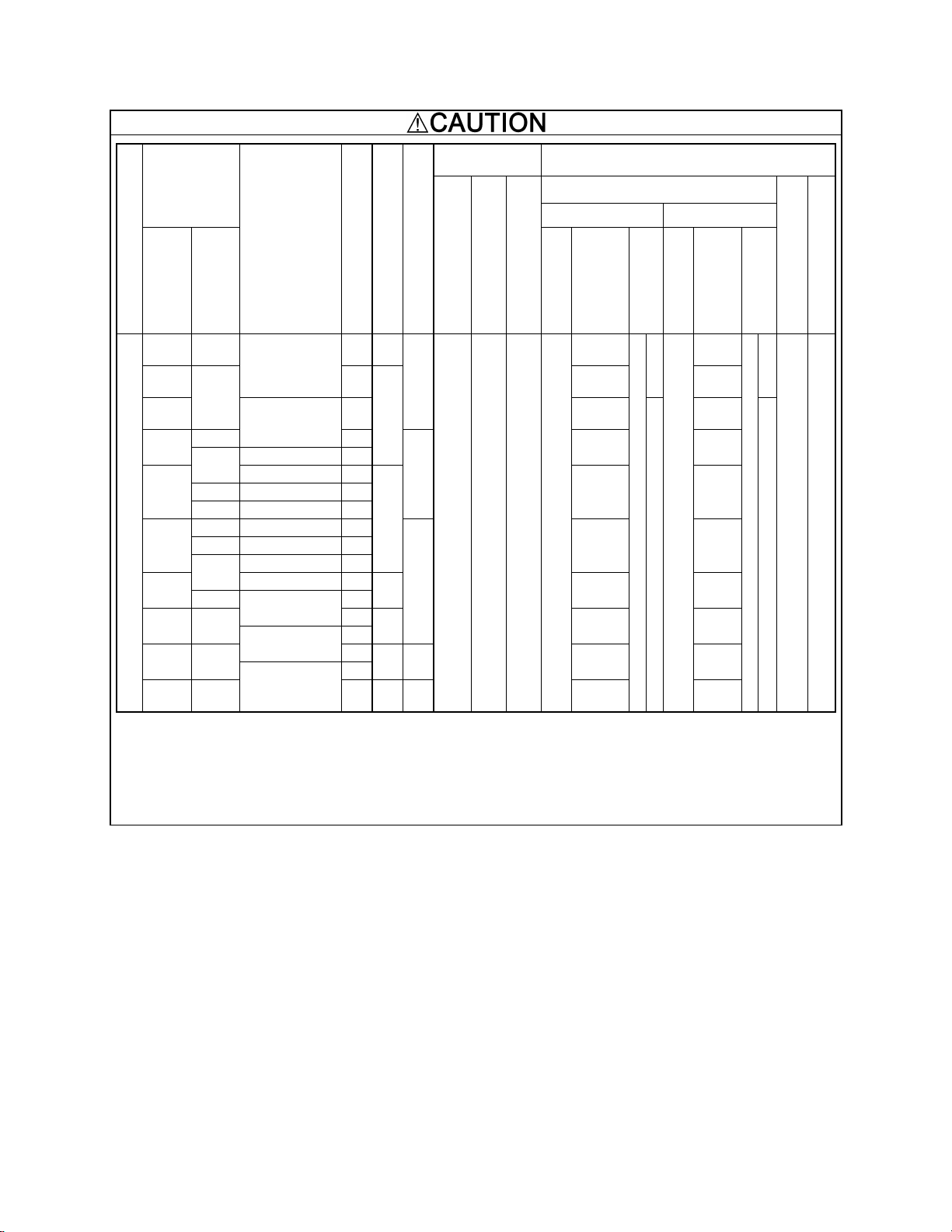

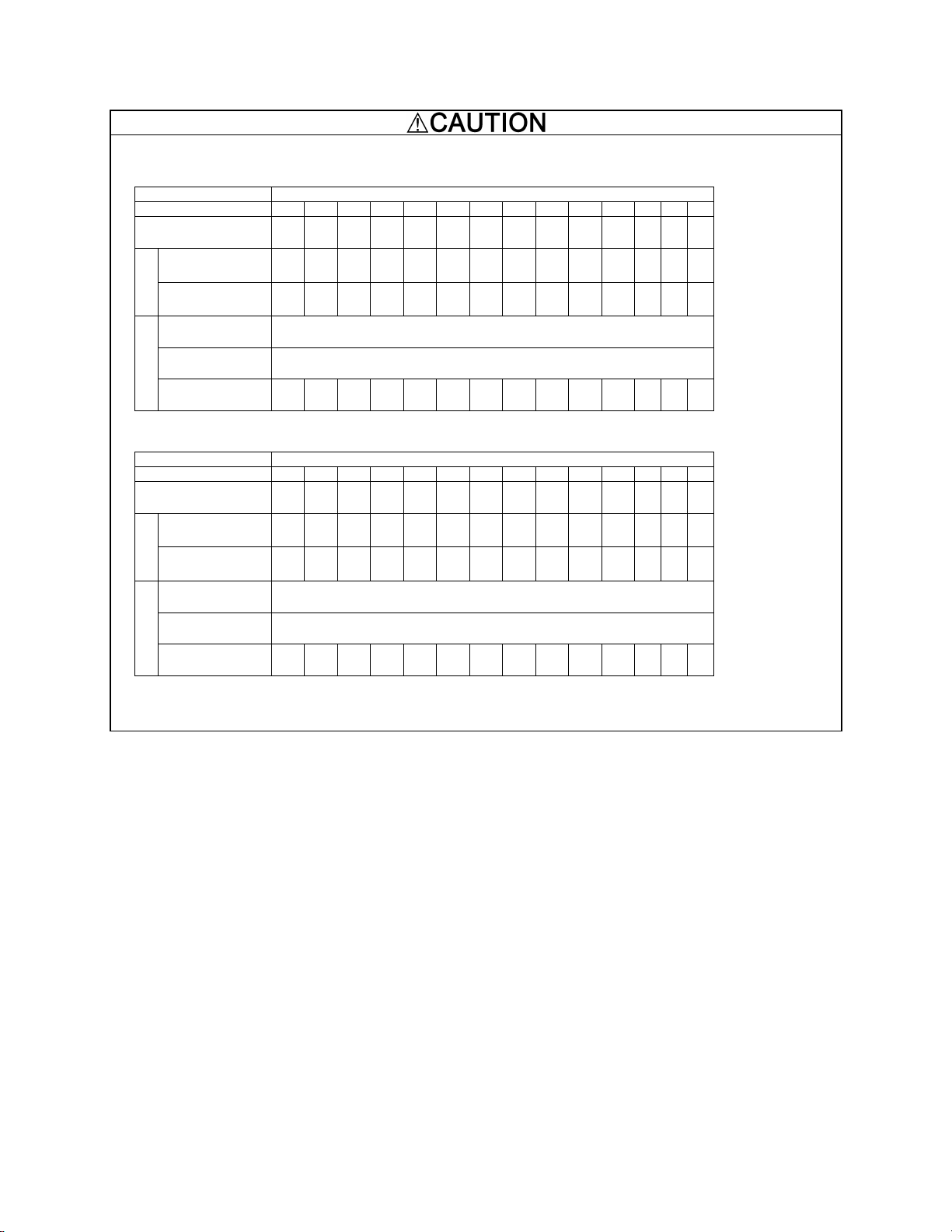

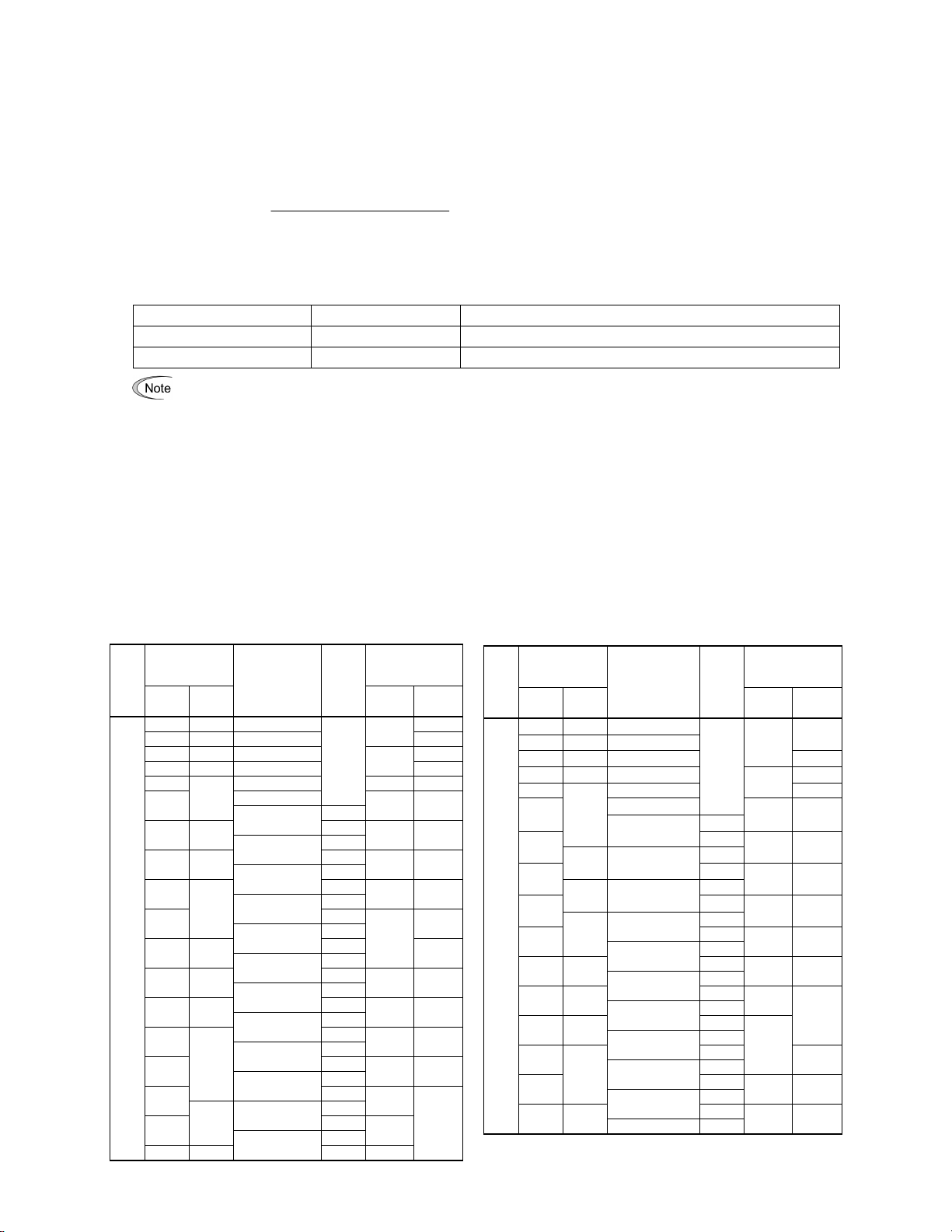

supply side (primary side) according to the following tables.

- Breaking capacity: Min. 10 kA

- Rated voltage: Min. 500 V

Power

supply

voltage

230 V

Note: A box () in these tables replaces S or H depending on the enclosure.

Note: When using the inverter on single-phase input power also, use fuses suitable

for the inverter type as specified on this page.

Inverter type

FRNF50G1S-2U 10 (IEC60269-2)

FRN001G1S-2U 15 (IEC60269-2)

FRN002G1S-2U 20 (IEC60269-2)

FRN003G1S-2U 30 (IEC60269-2)

FRN005G1S-2U 40 (IEC60269-2)

FRN007G1-2U

FRN010G1-2U

FRN015G1-2U

FRN020G1-2U

FRN025G1-2U 200 (IEC60269-4)

FRN030G1-2U

FRN040G1-2U

FRN050G1-2U 350 (IEC60269-4)

FRN060G1-2U 400 (IEC60269-4)

FRN075G1-2U 450 (IEC60269-4)

FRN100G1-2U

FRN125G1S-2U

FRN150G1S-2U

Fuse rating

(A)

125 (IEC60269-4)

160 (IEC60269-4)

250 (IEC60269-4)

500 (IEC60269-4)

Fuses

Power

supply

voltage

460 V

Inverter type

FRNF50G1S-4U 3 (IEC60269-2)

FRN001G1S-4U 6 (IEC60269-2)

FRN002G1S-4U 10 (IEC60269-2)

FRN003G1S-4U 15 (IEC60269-2)

FRN005G1S-4U 20 (IEC60269-2)

FRN007G1-4U

FRN010G1-4U

FRN015G1-4U

FRN020G1-4U

FRN025G1-4U

FRN030G1-4U

FRN040G1-4U

FRN050G1-4U 250 (IEC60269-4)

FRN060G1-4U

FRN075G1-4U

FRN100G1-4U

FRN125G1S-4U

FRN150G1S-4U

FRN200G1S-4U 400 (IEC60269-4)

FRN250G1S-4U 450 (IEC60269-4)

FRN300G1S-4U 500 (IEC60269-4)

FRN350G1S-4U 550 (IEC60269-4)

FRN450G1S-4U 630 (IEC60269-4)

FRN500G1S-4U

FRN600G1S-4U

FRN700G1S-4U

FRN800G1S-4U

FRN900G1S-4U

FRN1000G1S-4U

Fuse rating

(A)

80 (IEC60269-4)

125 (IEC60269-4)

160 (IEC60269-4)

315 (IEC60269-4)

350 (IEC60269-4)

900 (IEC60269-4)

1250

(IEC60269-4)

2000

(IEC60269-4)

v

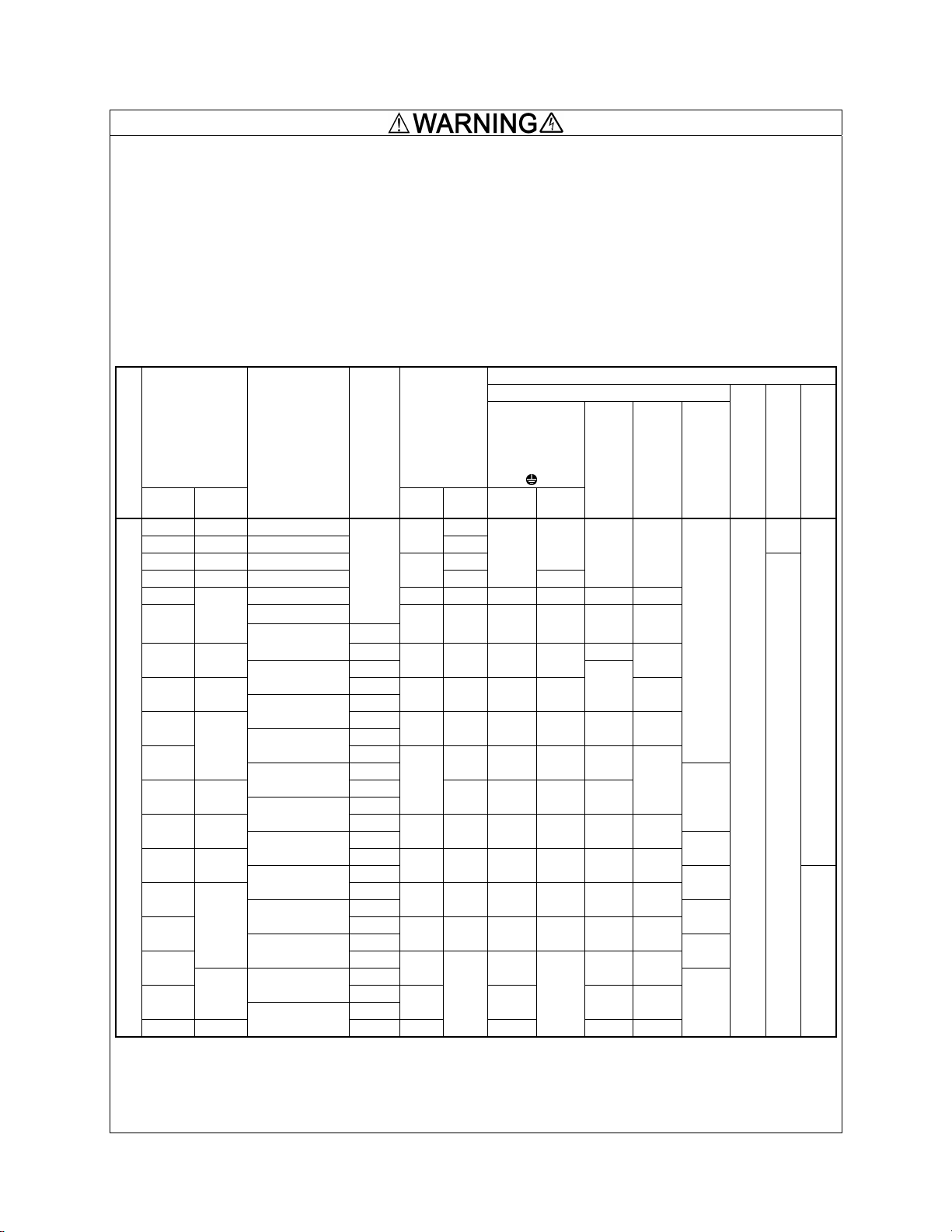

Conformity to the Low Voltage Directive in the EU (Continued)

3. When used with the inverter, a molded case circuit breaker (MCCB), residual-current-operated protective device

(RCD)/earth leakage circuit breaker (ELCB) or magnetic contactor (MC) should conform to the EN or IEC standards.

4. When you use a residual-current-operated protective device (RCD)/earth leakage circuit breaker (ELCB) for protection from

electric shock in direct or indirect contact power lines or nodes, be sure to install type B of RCD/ELCB on the input (primary)

of the inverter if the power supply is three-phase 200/400 V.

5. The inverter should be used in an environment that does not exceed Pollution Degree 2 requirements. If the environment

conforms to Pollution Degree 3 or 4, install the inverter in an enclosure of IP54 or higher.

6. Install the inverter, AC or DC reactor, input or output filter in an enclosure with minimum degree of protection of IP2X (Top

surface of enclosure shall be minimum IP4X when it can be easily accessed), to prevent human body from touching directly

to live parts of these equipment.

7. Do not connect any copper wire directly to grounding terminals. Use crimp terminals with tin or equivalent plating to connect

them.

8. Use wires listed in IEC60364-5-52.

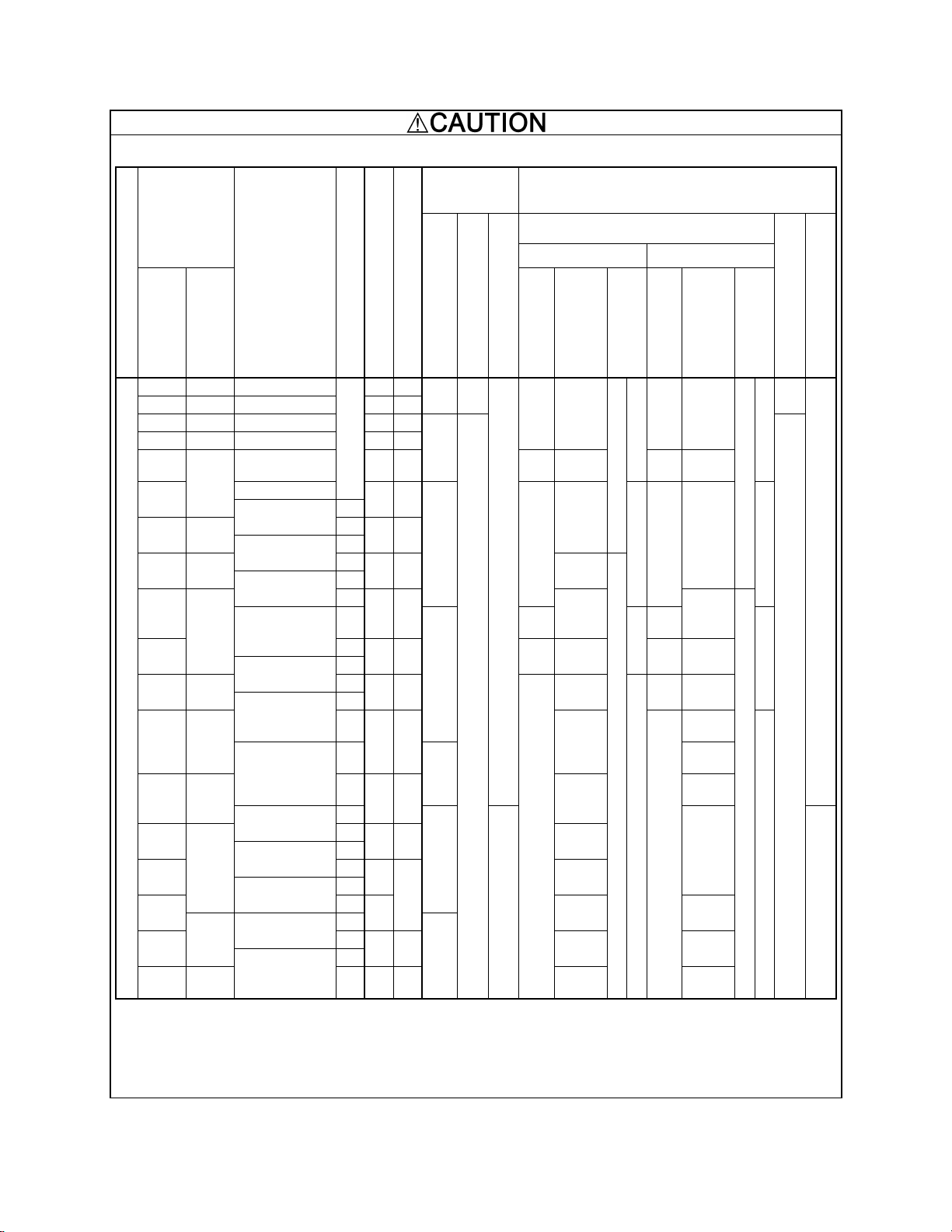

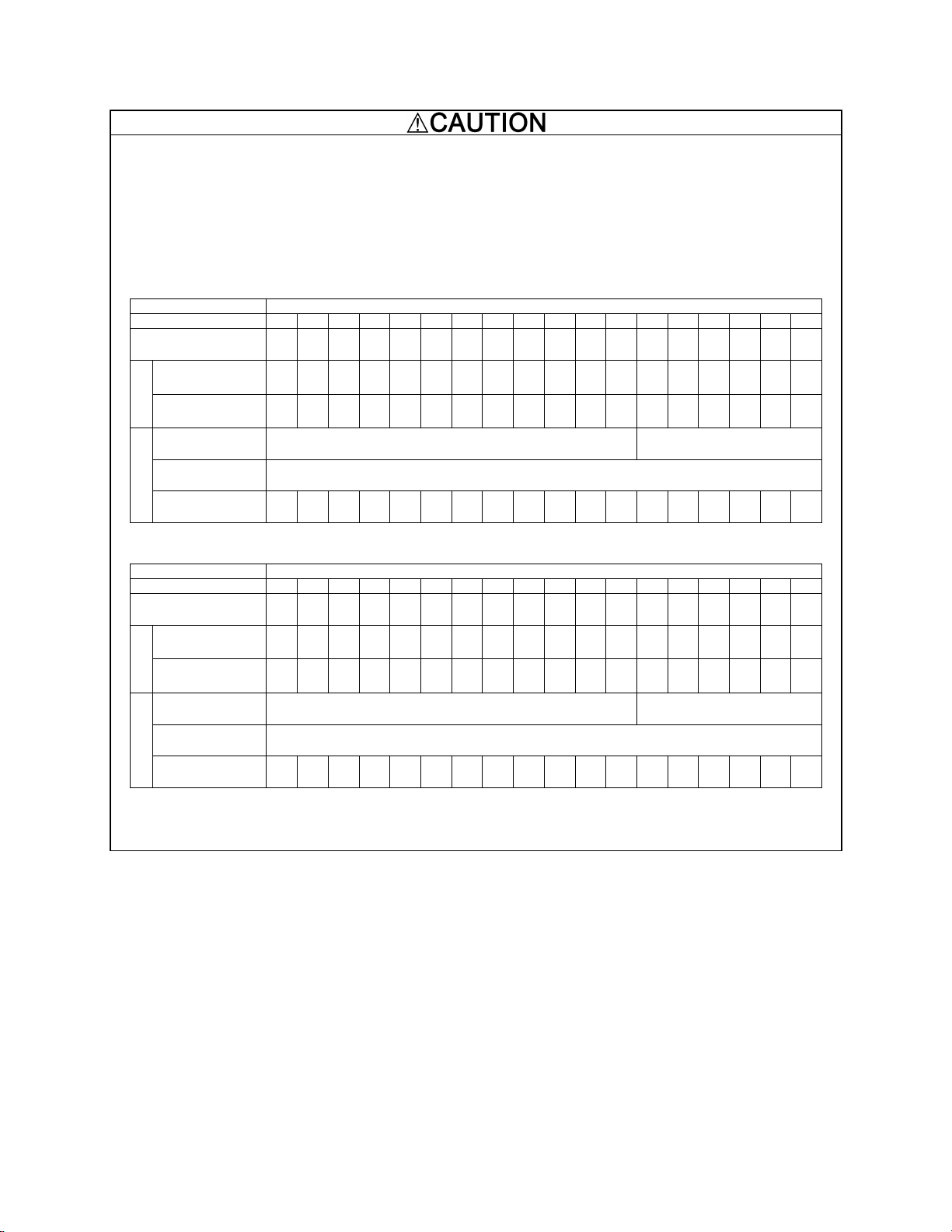

Recommended wire size (mm2)

Main circuit

Nominal applied

motor

(HP)

Power supply voltage

Three-

phase

10 5

15 7.5

20

25

230 V

30 15

40 20

50 25

60

75

100

125

150 50

Note: A box () in the above table replaces S or H depending on the enclosure.

*1 The frame size and model of the MCCB or RCD/ELCB (with overcurrent protection) will vary, depending on the power transformer capacity. Refer

to the related technical documentation for details.

*2 The recommended wire size for main circuits is for the 70°C (158°F) 600 V PVC wires used at a surrounding temperature of 40°C (104°F).

*3 Grounding terminal can accept one wire only.

Single-

phase

0.5 0.25 FRNF50G1S-2U 5

1 0.5 FRN001G1S-2U

2 1 FRN002G1S-2U 15

3 1.5 FRN003G1S-2U

5 FRN005G1S-2U 20 30 2.5 4 2.5 2.5

7.5

3

10

30

40

Inverter type

FRN007G1-2U

FRN010G1-2U

FRN015G1-2U

FRN020G1-2U

FRN025G1-2U

FRN030G1-2U

FRN040G1-2U

FRN050G1-2U

FRN060G1-2U

FRN075G1-2U

FRN100G1

FRN125G1S-2U

FRN150G1S-2U

-2U

HD/LD

HD

LD 6

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD 500

MCCB or

RCD/ELCB *1

Rated current

HD / LD mode

W/

W/o

DCR

DCR

5

10

30 50 4 6 4 4

40 75 6 10 6

50 100 10 16

75 125 16 25 16 25

150 25 35 25

100

175 35 50 35

150 200 50 70 50 70

175 250 70 95 70 95

200 300 95 70×2 95 50×2

250 350 50×2 95×2 70×2 70×2

350 95×2 95×2 95×2

400 120×2 120×2 120×2

Main power

[L1/R, L2/S, L3/T]

Inverter’s

grounding *3

W/

DCR

10

20

1

-

150×2

input *2

G]

[

DCR

W/o

1

1.5

-

DC reactor

[U, V, W] *2

Inverter outputs

1 1

10

150×2 150×2

16

35

[P1, P(+)] *2

Braking resistor

1

1.5

2.5

4

6

10

-

[P(+), DB] *2

0.65

to

0.82

Control circuit

supply [R0, T0]

Aux. control power

-

2.5

2.5

Aux. fan power

supply [R1, T1]

-

vi

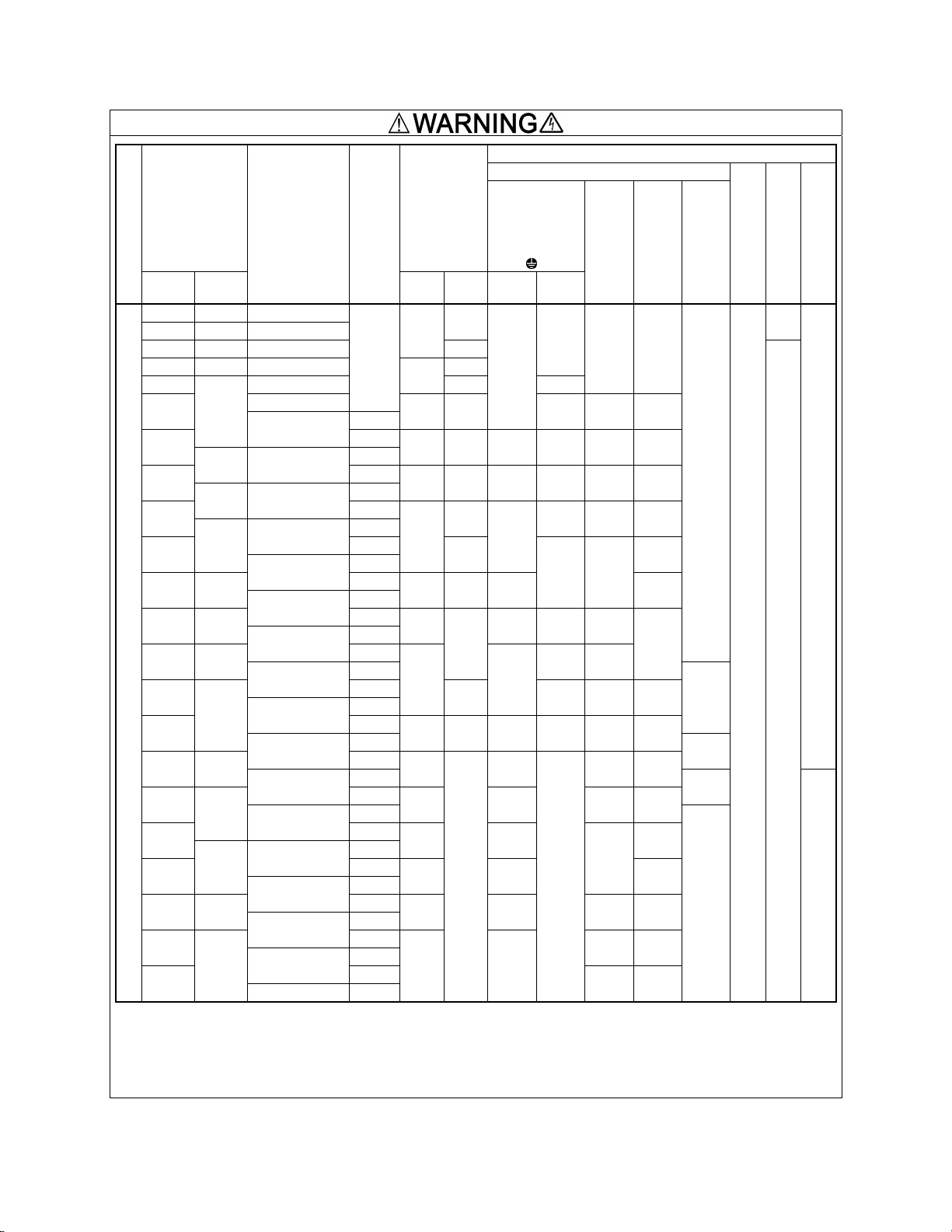

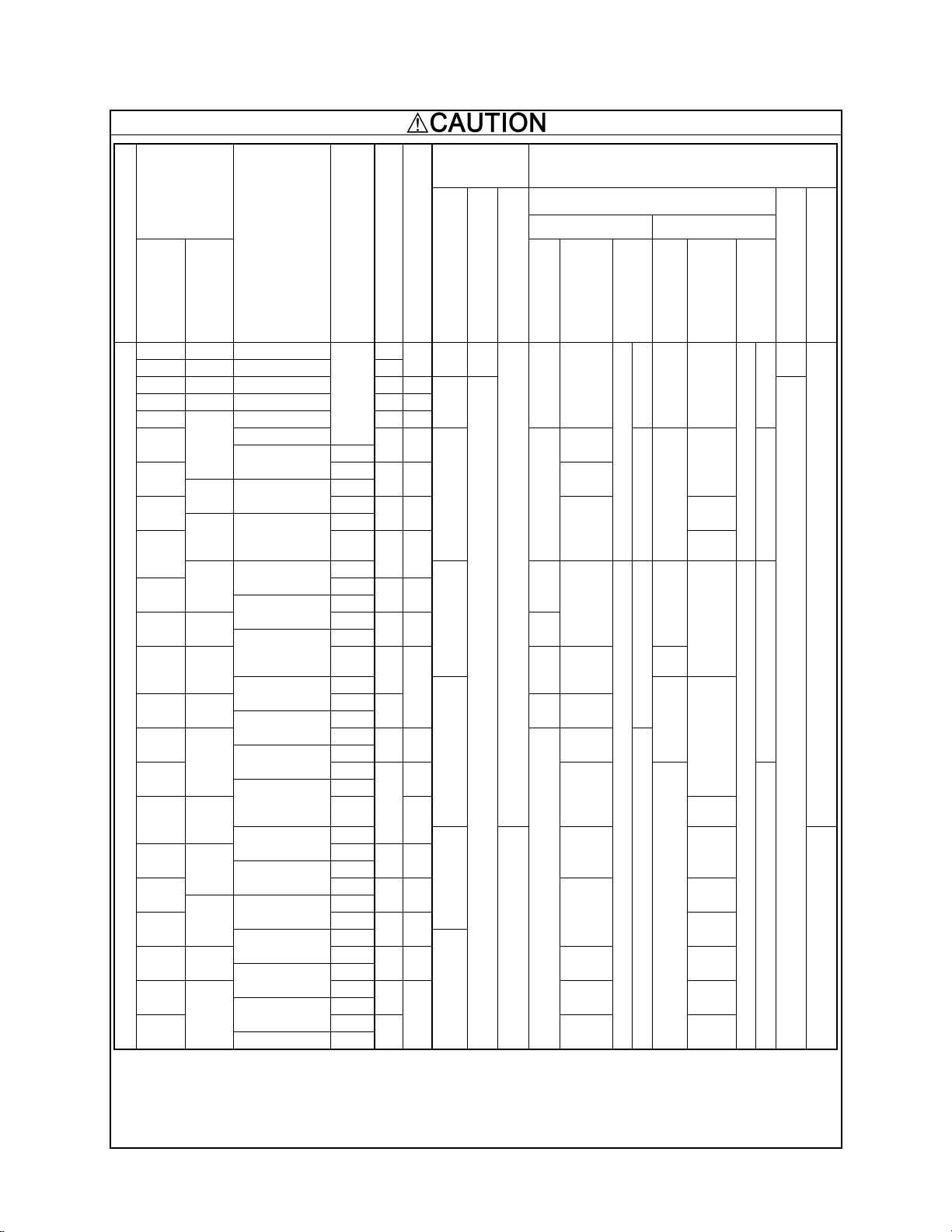

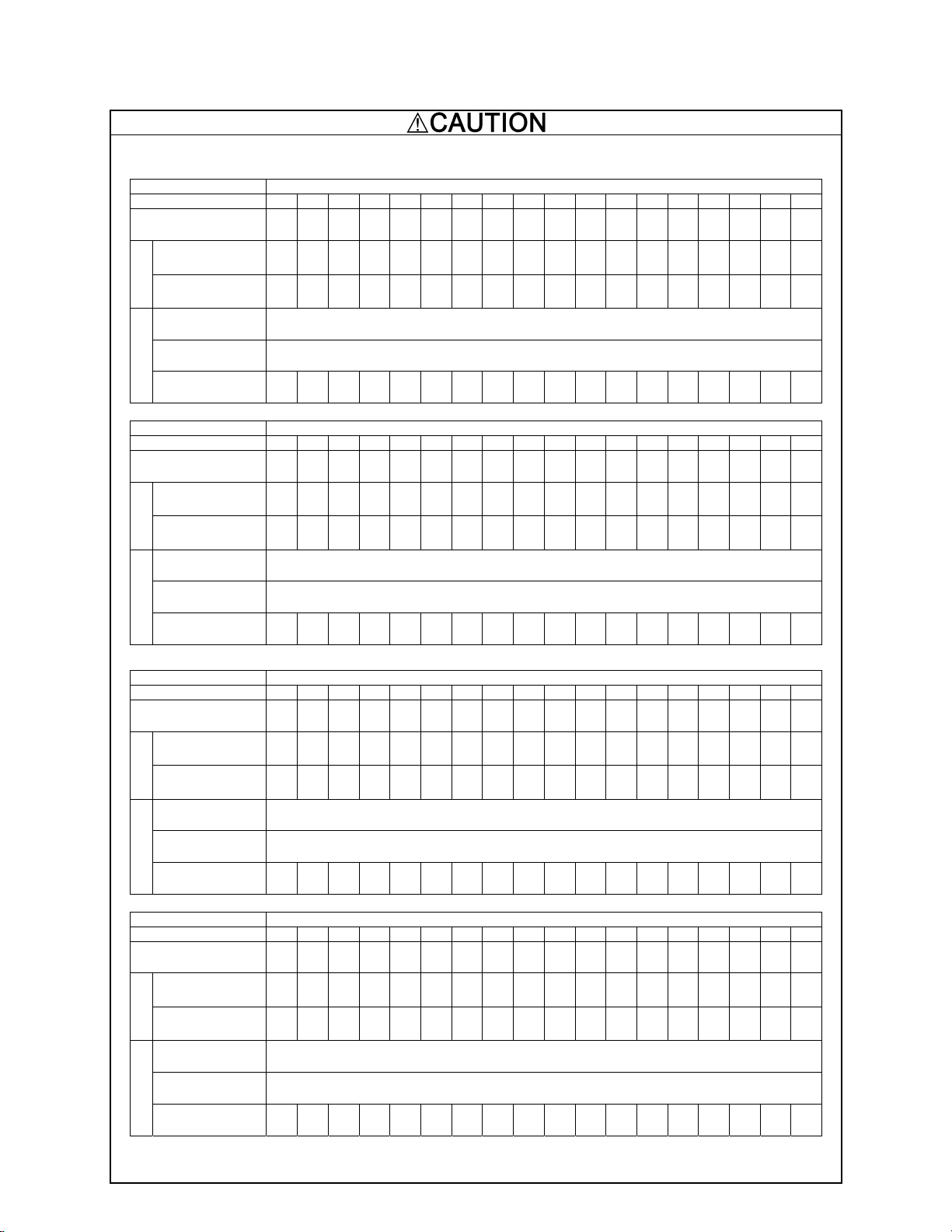

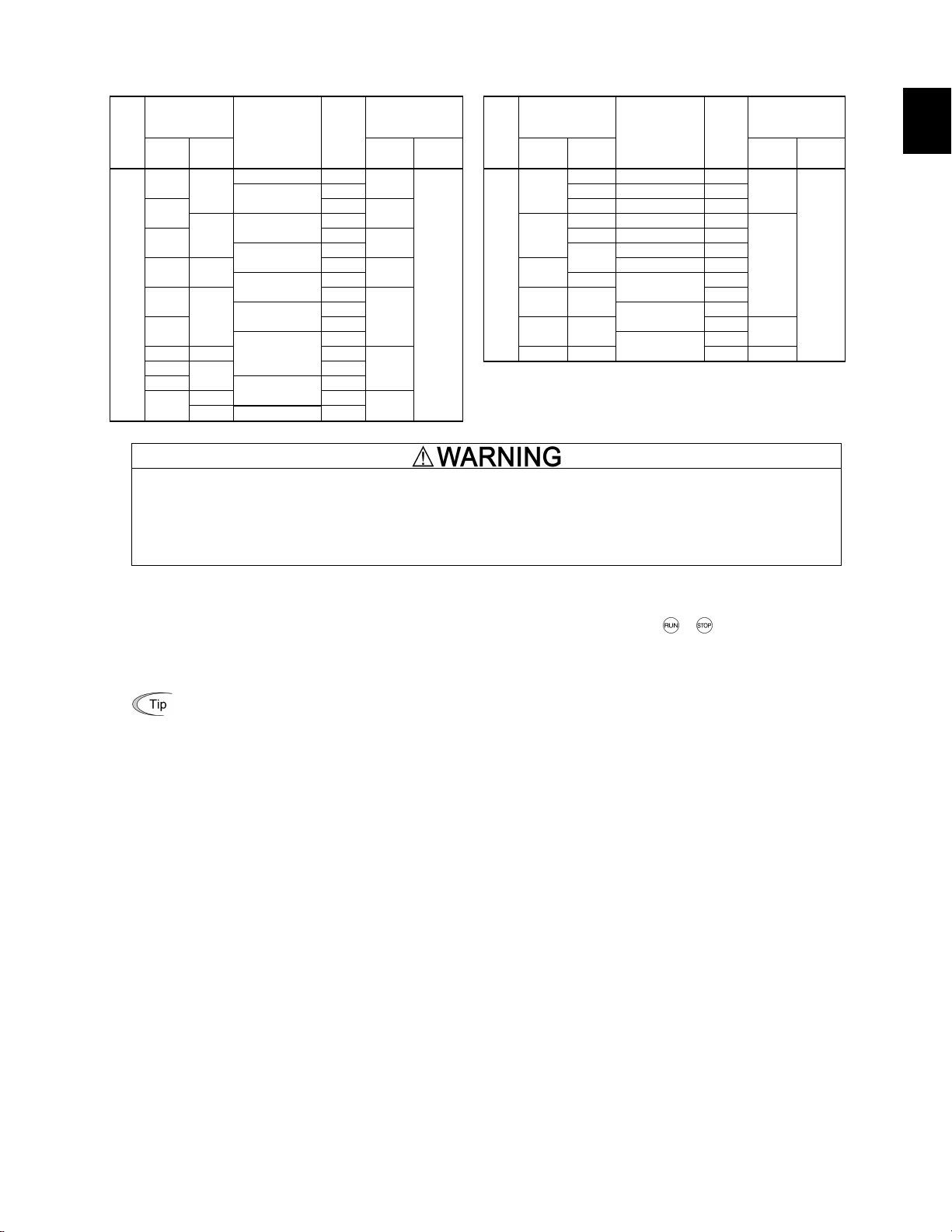

Conformity to the Low Voltage Directive in the EU (Continued)

Recommended wire size (mm2)

Main circuit

Nominal applied

motor

(HP)

Inverter type

MCCB or

RCD/ELCB *1

Rated current

Main power

input *2

[L1/R, L2/S, L3/T]

Inverter’s

grounding *3

G]

Power supply voltage

Three-

phase

Single-

phase

0.5 0.25 FRNF50G1S-4U

1 0.5 FRN001G1S-4U

2 1 FRN002G1S-4U

3 1.5 FRN003G1S-4U 15

5 FRN005G1S-4U

FRN007G1-4U

7.5

3

FRN010G1

-4U

10

5 FRN015G1-4U

15

7.5 FRN020G1-4U

20

FRN025G1-4U

25

10

FRN030G1-4U

30 15

FRN040G1-4U

40 20

FRN050G1-4U

50 25

460 V

FRN060G1-4U

60

30

FRN075G1-4U

75

FRN100G1-4U

100 40

FRN125G1S-4U

125

50

FRN150G1S-4U

150

FRN200G1S-4U

200

60

FRN250G1S-4U

250 75

FRN300G1S-4U

300

100

350

Note: A box () in the above table replaces S or H depending on the enclosure.

*1 The frame size and model of the MCCB or RCD/ELCB (with overcurrent protection) will vary, depending on the power transformer capacity. Refer

to the related technical documentation for details.

*2 The recommended wire size for main circuits is for the 70°C (158°F) 600 V PVC wires used at a surrounding temperature of 40°C (104°F).

*3 Grounding terminal can accept one wire only.

FRN350G1S-4U

FRN450G1S-4U HD

HD/MD/LD mode

HD/LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

MD/LD

HD

MD/LD

HD

MD/LD

HD

MD/LD

HD

MD/LD

W/

W/o

DCR

DCR

5 -

5

10

10

20 1.5

15 30

20 40 1.5 4 2.5 2.5

30 50 4 6 4 4

60 10 6 6

40

75

50 100 10

75 16 25 16

125

100

150

125 200 35 70 50 70

175 70 70 95

200 95 95 120

250 50×2 150

300 70×2

-

350 185 240 300

500

W/

DCR

1

6

25

300

[

W/o

Inverter outputs

DCR

1

1 1

2.5 1.5 1.5

16 10

35 25

50 35 35

70×2

-

300 120×2

150×2 150×2

DC reactor

[U, V, W] *2

[P1, P(+)] *2

Braking resistor

Control circuit

[P(+), DB] *2

supply [R0, T0]

Aux. control power

1

10

16

25

0.65

to

0.82

2.5

1.5

2.5

4

70×2

-

2.5

Aux. fan power

supply [R1, T1]

-

vii

Conformity to the Low Voltage Directive in the EU (Continued)

Nominal applied

motor

(HP)

Power supply voltage

Three-

phase

350 - MD 185×2 185×2 185×2

450

400

450

500

600

460 V

700

800 250

900 300

1000 400

*1 The frame size and model of the MCCB or RCD/ELCB (with overcurrent protection) will vary, depending on the power transformer capacity. Refer

to the related technical documentation for details.

*2 The recommended wire size for main circuits is for the 70°C (158°F) 600 V PVC wires used at a surrounding temperature of 40°C (104°F).

*3 Grounding terminal can accept one wire only.

Single-

phase

125

-

150

- FRN600G1S-4U MD

150 FRN700G1S-4U HD

200 FRN600G1S-4U LD

- FRN700G1S-4U MD

200

- MD

Inverter type

FRN450G1S-4U

FRN500G1S-4U

FRN600G1S-4U HD

FRN500G1S-4U LD

FRN800G1S-4U HD

FRN700G1S-4U LD

FRN800G1S-4U

FRN900G1S-4U

FRN1000G1S-4U

LD

HD

MD

LD

HD

LD

HD

LD 1600

RCD/ELCB *1

Rated current

HD/MD/LD mode

W/

DCR

600

800

1200

1400

MCCB or

[L1/R, L2/S, L3/T]

W/o

DCR

-

Recommended wire size (mm2)

Main circuit

Main power

input *2

Inverter’s

grounding *3

G]

[

W/

DCR

240×

300×2

240×3 240×3 300×3

300×3

300×4

W/o

DCR

2

-

Inverter outputs

240×2

300×2

300×3 240×4

240×4

300×4

[U, V, W] *2

DC reactor

240×2

300×2

300×4

Control circuit

[P1, P(+)] *2

[P(+), DB] *2

Braking resistor

0.65

-

to

0.82

supply [R0, T0]

Aux. control power

2.5 2.5

9. When you use an inverter at an altitude of more than 6600 ft (2000 m), you should apply basic insulation for the control

circuits of the inverter. The inverter cannot be used at altitudes of more than 9800 ft (3000 m).

10. The inverter has been tested with IEC61800-5-1 2007 5.2.3.6.3 Short-circuit Current Test under the following conditions.

Short-circuit current in the supply: 10 kA

Maximum 240 V for 200 V series with 40 HP or below

Maximum 230 V for 200 V series with 50 HP or above

Maximum 480 V for 400 V series

11. Connect the inverter to a power system which has a grounded neutral-point. In case of a non-grounded system (ex.

Delta-Delta), the control interface of the inverter is basic insulation, thus do not connect SELV circuit from external

controller directly. See Basic connection diagram (2.3.4).

Aux. fan power

supply [R1, T1]

viii

Conformity with UL standards and CSA standards (cUL-listed for Canada)

UL/cUL-listed inverters are subject to the regulations set forth by the UL standards and CSA standards (cUL-listed for Canada) by

installation within precautions listed below.

1. Solid state motor overload protection (motor protection by electronic thermal overload relay) is provided in each model.

Use function codes F10 to F12 to set the protection level.

2. Use Cu wire only.

3. Use Class 1 wire only for control circuits.

4. Short circuit rating

"Suitable For Use On A Circuit Of Delivering Not More Than 100,000 rms Symmetrical Amperes, 240 Volts Maximum for

230 V class input 40 HP or below, 230 Volts maximum for 230 V class input 50 HP or above when protected by Class J

Fuses or a Circuit Breaker having an interrupting rating not less than 100,000 rms Symmetrical Amperes, 240 Volts

Maximum." Models FRN; rated for 230 V class input.

"Suitable For Use On A Circuit Of Delivering Not More Than 100,000 rms Symmetrical Amperes, 480 Volts Maximum

when protected by Class J Fuses or a Circuit Breaker having an interrupting rating not less than 100,000 rms Symmetrical

Amperes, 480 Volts Maximum." Models FRN; rated for 460 V class input.

"Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection must be

provided in accordance with the National Electrical Code and any additional local codes."

5. Field wiring connections must be made by a UL Listed and CSA Certified closed-loop terminal connector sized for the wire

gauge involved. Connector must be fixed using the crimp tool specified by the connector manufacturer.

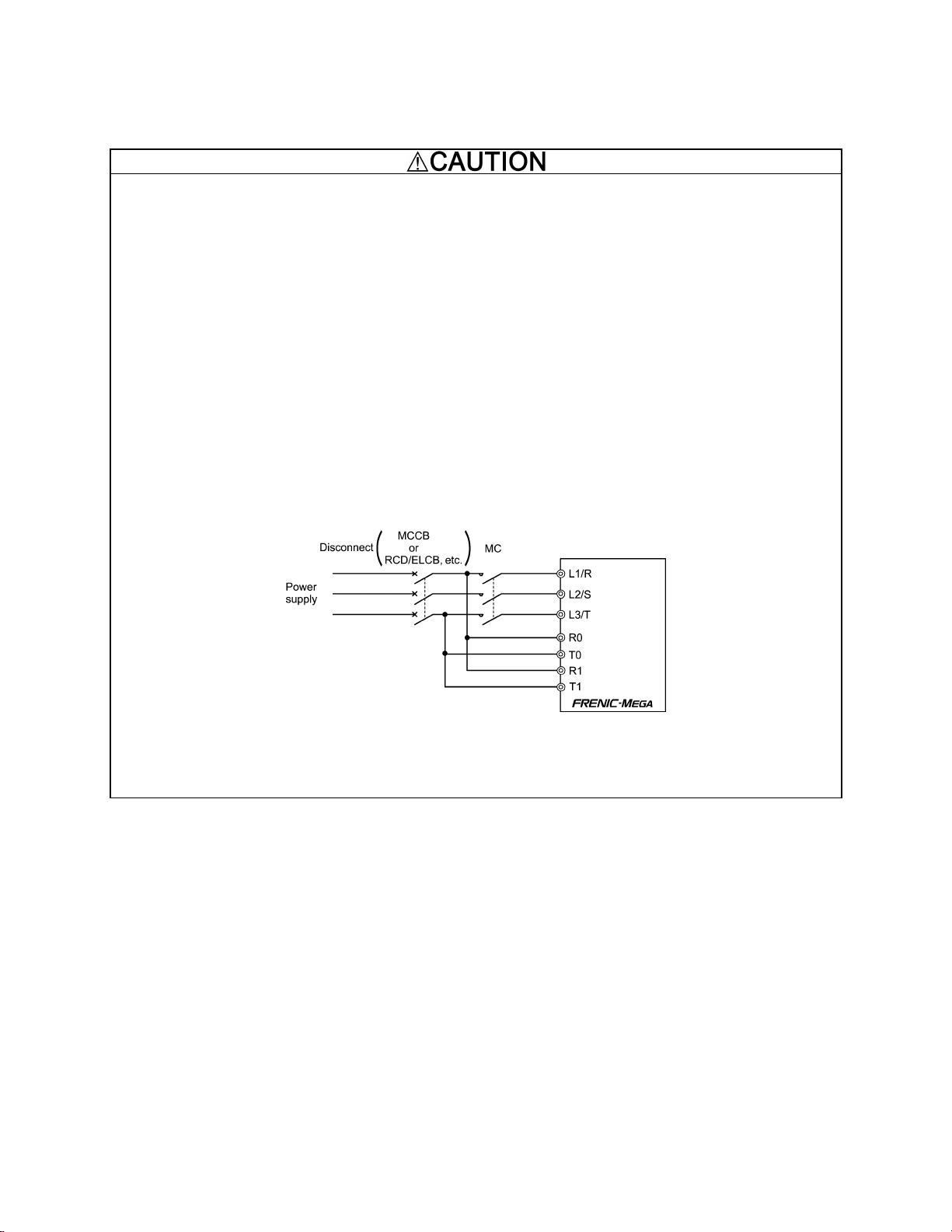

6. All circuits with terminals L1/R, L2/S, L3/T, R0, T0, R1, T1 must have a common disconnect and be connected to the same

pole of the disconnect if the terminals are connected to the power supply.

7. When using the inverter as a UL Enclosed Type (UL TYPE1), purchase Type 1 kit (option) and mount it on the inverter as

instructed.

ix

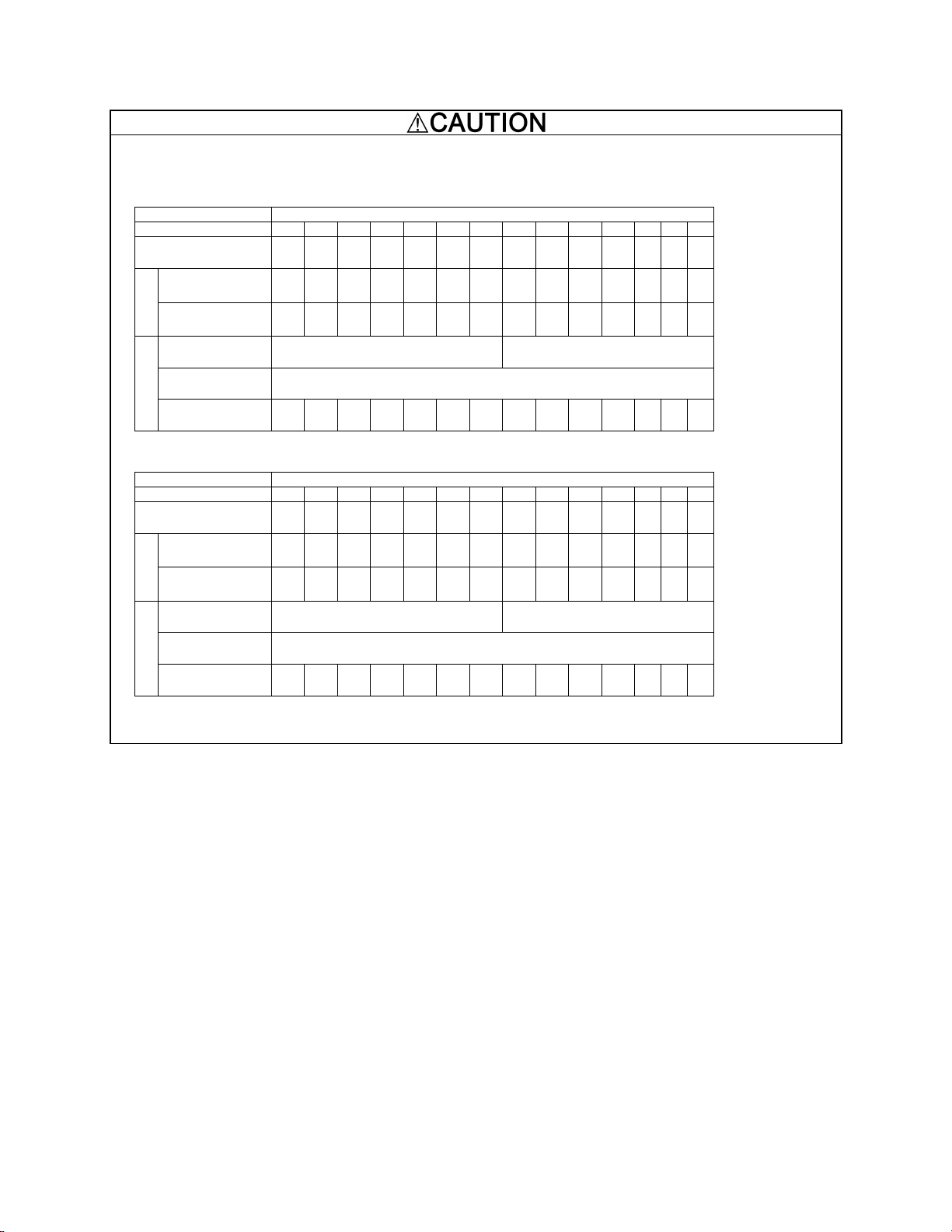

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

8. Install UL certified fuses or circuit breaker between the power supply and the inverter, referring to the table below.

Nominal applied

motor

(HP)

Required

torque

lb-in (Nm)

Wire size

AWG ( mm

Main terminal

2

)

L1/R, L2/S, L3/T U, V, W

Inverter type

HD/LD mode

Three-

Power supply voltage

230 V

Note 1: Control circuit terminals Tightening torque: 6.1 lb-in (0.7 Nm), Recommended wire size: AWG 19 or 18 (0.65 to 0.82 mm2)

Note 2: A box (

*1 No terminal end treatment is required for connection.

*2 Use 75°C (167°F) Cu wire only.

*3 The wire size of UL Open Type and Enclosed Type are common. Please contact us if UL Open Type exclusive wire is necessary.

phase

Single-

phase

Class J fuse size (A)

0.5 0.25 FRNF50G1S-2U 10 5

1 0.5 FRN001G1S-2U 15 10

2 1 FRN002G1S-2U 20 15

3 1.5 FRN003G1S-2U 30 20

HD/

LD

5 FRN005G1S-2U 40 30

3

7.5

10 5

15 7.5

20

25

30 15

40 20

FRN007G1-2U

FRN010G1-2U

FRN015G1-2U

FRN020G1-2U

FRN025G1-2U

10

FRN030G1-2U

FRN040G1-2U

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

60 50

75 75

100 100

150 125

175 150

200 175

250 200

HD

FRN050G1-2U

-2U

LD

350 250

HD

LD

400 300

HD

LD

450

HD

LD

500

HD

LD

600 400

HD

LD 700 500

50 25

60

75

30

100

125

40

150 50

FRN060G1-2U

FRN075G1-2U

FRN100G1

FRN125G1S-2U

FRN150G1S-2U

) in the above table replaces S or H depending on the enclosure.

Circuit breaker trip size (A)

350

Main terminal

Aux. control power supply

10.6

- -

(1.2)

15.9

(1.8)

Aux. Fan power supply

60°C (140°F)

14

(2.1)

10

(5.3)

Cu wire

14

(2.1)

10

(5.3)

Cu wire

75°C (167°F)

*1

Remarks

-

60°C (140°F)

14

(2.1)

12

(3.3)

Cu wire

75°C (167°F)

14

(2.1)

12

(3.3)

Cu wire

*1

8

30.9

(3.5)

(8.4)

-

6

*2

*3

8

(8.4)

-

(13.3)

-

51.3

(5.8)

119.4

(13.5)

238.9

(27)

424.7

(48)

10.6

(1.2)

10.6

(1.2)

3

(26.7)

1

(42.4)

-

4

(21.2)

3

(26.7)

2

(33.6)

2/0

(67.4)

3/0

(85)

4/0

(107.2)

2/0×2

(67.4×2)

3/0×2

(85×2)

4/0×2

(107.2×2)

300×2

(152×2)

-

-

*2

*3

(21.2)

(26.7) 4 (21.2)

(33.6) 3 (26.7)

4

3

2

-

6

(13.3)

2

(33.6)

1

(42.4)

1/0

(53.5)

4/0

(107.2)

3/0×2

(85×2)

4/0×2

(107.2×2)

300×2

(152×2)

-

Remarks

-

*2

*3

-

*2

*3

14

(2.1)

*1

*2

Aux. control power supply

-

14

(2.1)

Aux. fan power supply

x

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

Nominal applied

motor

(HP)

Required

torque

lb-in (Nm)

Wire size

AWG ( mm

2

)

Main terminal

L1/R, L2/S, L3/T U, V, W

Inverter type

Three-

Power supply voltage

460 V

Note 1: Control circuit terminals Tightening torque: 6.1 lb-in (0.7 Nm), Recommended wire size: AWG 19 or 18 (0.65 to 0.82 mm2)

Note 2: A box (

*1 No terminal end treatment is required for connection.

*2 Use 75°C (167°F) Cu wire only.

*3 The wire size of UL Open Type and Enclosed Type are common. Please contact us if UL Open Type exclusive wire is necessary.

phase

Single-

phase

HD/MD/LD mode

0.5 0.25 FRNF50G1S-4U 3

1 0.5 FRN001G1S-4U 6

2 1 FRN002G1S-4U 10 10

3 1.5 FRN003G1S-4U 15 15

HD/

LD

5 FRN005G1S-4U 20 20

7.5

10

15

20

25

30 15

40 20

50 25

60

75

100 40

125

150

200

250 75

300

350

FRN007G1-4U

3

FRN010G1

-4U

5 FRN015G1-4U

7.5 FRN020G1-4U

FRN025G1-4U

10

FRN030G1-4U

FRN040G1-4U

FRN050G1-4U

FRN060G1-4U

FRN075G1-4U

30

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

30 30

40 40

60 50

70 60

90 75

100 100

125

175

200 150

HD

FRN100G1-4U

FRN125G1S-4U

50

60

100

FRN150G1S-4U

FRN200G1S-4U

FRN250G1S-4U

FRN300G1S-4U

FRN350G1S-4U

MD/LD

MD/LD

MD/LD

MD/LD

MD/LD

FRN450G1S-4U HD

) in the above table replaces S or H depending on the enclosure.

LD

HD

LD

HD

HD

HD

HD

HD

250

300 200

350 250

400 300

500 350

600

700

Class J fuse size (A)

Circuit breaker trip size (A)

5

125

200

175

500

Main terminal

Aux. control power supply

10.6

- -

(1.2)

15.9

Aux. Fan power supply

60°C (140°F)

14

(2.1)

Cu wire

75°C (167°F)

14

(2.1)

Cu wire

Remarks

-

60°C (140°F)

14

(2.1)

Cu wire

75°C (167°F)

14

(2.1)

Cu wire

(1.8)

12

(3.3)

30.9

(3.5)

*1

10

(5.3)

-

*2

*3

8

(8.4)

12

(3.3)

10

(5.3)

8

(8.4)

6

-

51.3

(5.8)

119.4

(13.5)

10.6

(1.2)

(13.3)

(21.2)

(26.7)4 (21.2)

(33.6)3 (26.7)

6

(13.3)

4

3

2

2

(33.6)

-

6

(13.3)

4

(21.2)

2

(33.6)

6

(13.3)

2

(33.6)

1/0

(53.5)

-

1/0

(53.5)

238.9

(27)

424.7

(48)

10.6

(1.2)

-

2/0

(67.4)

1/0×2

(53.5×2)

3/0×2

(85×2)

4/0×2

(107.2×2)

250×2

(127×2)

*2

*3

-

4/0

(107.2)

1/0×2

(53.5×2)

2/0×2

(67.4×2)

3/0×2

(85×2)

250×2

(127×2)

300×2

(152×2)

*1

Remarks

-

*2

*3

-

(2.1)

-

*2

*3

Aux. control power supply

14

*1

*2

Aux. fan power supply

-

14

(2.1)

*1

*2

xi

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

Nominal applied

motor

HP

Required torque

lb-in (Nm)

L1/R, L2/S, L3/T

Wire size

AWG ( mm

Main terminal

U, V, W

Inverter type

Three-

Power supply voltage

phase

phase

350 - MD 800

FRN450G1S-4U

450

125

Single-

400

450

500

FRN500G1S-4U

-

FRN600G1S-4U HD

150

FRN500G1S-4U LD

- FRN600G1S-4U MD

150 FRN700G1S-4U HD

460 V

600

700

200 FRN600G1S-4U LD

- FRN700G1S-4U MD

FRN800G1S-4U HD

200

FRN700G1S-4U LD

- MD

FRN800G1S-4U

800 250

FRN900G1S-4U

900 300

1000 400

Note: Control circuit terminals Tightening torque: 6.1 lb-in (0.7 Nm), Recommended wire size: AWG 19 or 18 (0.65 to 0.82 mm2)

*1 No terminal end treatment is required for connection.

*2 Use 75°C (167°F) Cu wire only.

*3 The wire size of UL Open Type and Enclosed Type are common. Please contact us if UL Open Type exclusive wire is necessary.

*4 It is showing the wire size for UL Open Type.

See additional material INR-SI47-1365-JE for UL Enclosed Type (Pack with TYPE1 kit).

FRN1000G1S-4U

HD/MD/LD mode

Class J fuse size (A)

LD

HD

600

1000

MD

800

1200

1200

1400

LD

1600

HD

LD

2000 1400

HD

LD 2200 1600

Circuit breaker trip size (A)

424.7

(48)

Main terminal

Aux. control power supply

10.6

10.6

(1.2)

(1.2)

Aux. Fan power supply

60°C (140°F)

-

Cu wire

300×2

(152×2)

400×2

(203×2)

250×2

(127×2)

300×2

(152×2)

400×2

(203×2)

500×2

(253×2)

600×2

(304×2)

350×3

(177×3)

500×3

(253×3)

600×3

(304×3)

75°C (167°F)

Cu wire

-

*2

*3

*2

*4

Cu wire

Remarks

60°C (140°F)

350×2

(177×2)

400×2

(203×2)

300×2

(152×2)

350×2

(177×2)

400×2

(203×2)

500×2

(253×2)

600×2

(304×2)

400×3

(203×3)

600×3

(304×3)

500×4

(253×4)

2

)

Cu wire

75°C (167°F)

Remarks

Aux. control power supply

Aux. fan power supply

*2

*3

14

14

(2.1)

*1

*2

(2.1)

*1

*2

-

*2

*4

xii

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

When applying single-phase to a three-phase drive, the applied motor must not exceed the specifications in the table below.

Specifications other than those shown below are the same as those in the "Three-phase 230 V series" and "Three-phase 460 V

series."

For precautions for single-phase use, refer to Section 1.3.4.

Standard Model 1 (Basic Type)

(1) Single-phase 230 V series

LD (Low Duty)-mode inverters for light load

Type (FRN_ _ _G1S-2U) F50 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125 150

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

0.25 0.5 1 1.5 3 3 5 7.5 10 10 15 20 25 30 30 30 40 50

Rated capacity (kVA)

*2

Rated current (A) 1.9 3.1 4.7 6.3 11 17 23 30 32 39 44 58 74 93 95 102 131 149

Output ratings

Voltage, frequency Single-phase, 200 to 240 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(with DCR) (kVA) *3

0.8 1.3 1.9 2.6 4.4 6.8 9.2 12 13 16 18 23 30 37 38 41 52 59

Single-phase, 200 to 220 V, 50 Hz

Single-phase, 200 to 230 V, 60 Hz

Voltage: +10 to -10% , Frequency: +5 to -5%

0.5 0.9 1.6 2.2 4.0 5.8 7.9 11 13 16 18 25 32 40 41 47 59 67

HD (High Duty)-mode inverters for heavy load

Type (FRN_ _ _G1S-2U) F50 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125 150

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

0.25 0.5 1 1.5 3 3 3 5 7.5 10 10 15 20 25 30 30 40 40

Rated capacity (kVA)

*2

0.8 1.3 1.9 2.6 4.4 6.8 6.8 9.2 10 13 15 18 24 30 37 38 44 52

Rated current (A) 1.9 3.1 4.7 6.3 11 17 17 23 26 33 38 45 61 75 93 95 109 131

Output ratings

Voltage, frequency Single-phase, 200 to 240 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(with DCR) (kVA) *3

*1 US 4P-standard induction motor

Voltage: +10 to -10% , Frequency: +5 to -5%

0.5 0.9 1.6 2.2 4.0 5.8 5.8 7.7 9.7 13 16 18 26 33 40 42 50 58

Single-phase, 200 to 220 V, 50 Hz

Single-phase, 200 to 230 V, 60 Hz

*2 Rated capacity is calculated assuming the rated output voltage as 230 V for 230 V series and 460 V for 460 V series.

*3 Required when a DC reactor (DCR) is used.

xiii

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

(2) Single-phase 460 V series

LD (Low Duty)-mode inverters for light load

Type (FRN_ _ _G1S-4U) F50 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100

Nominal applied motor (HP)

(Output rating) *1

(50 to 400 HP)

Type (FRN_ _ _G1S-4U) 125 150

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

0.25 0.5 1 1.5 3 3 5 7.5 10 10 15 20 25 30 30 40

Rated capacity (kVA)

*2

Rated current (A) 0.9 1.5 2.4 3.0 5.6 8.0 11 15 17 20 23 29 37 46 54 59

Output ratings

Voltage, frequency Single-phase, 380 to 480 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(with DCR) (kVA) *3

Item Specifications

Rated capacity (kVA)

*2

Rated current (A) 70 82 99 121 146 161 202 250 288 326 384 462 579

Output ratings

Voltage, frequency

Allowable

voltage/frequency

Input ratings

Required capacity

(with DCR) (kVA) *3

0.8 1.2 2.0 2.4 4.5 6.4 8.8 12 14 16 18 23 30 37 43 47

Voltage: +10 to -10% , Frequency: +5 to -5%

0.5 0.9 1.7 2.2 4.0 5.4 7.3 11 13 16 18 25 32 39 46 51

200 250 300 350 450 500 600 700 800 900 1000

50 50 60 75 100 100 125 150 200 200 250 300 400

55 65 78 96 116 128 160 198 229 259 305 368 461

Single-phase, 380 to 440 V, 50 Hz

Single-phase, 380 to 480 V, 60 Hz

Voltage: +10 to -10% , Frequency: +5 to -5%

61 73 87 105 130 143 181 227 257 291 330 404 488

(0.25 to 40 HP)

HD (High Duty)-mode inverters for heavy load (0.25 to 30 HP)

Type (FRN_ _ _G1S-4U) F50 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

0.25 0.5 1 1.5 3 3 3 5 7.5 10 10 15 20 25 30 30

Rated capacity (kVA)

*2

0.8 1.2 2.0 2.4 4.5 6.4 6.4 9.6 10 14 16 18 24 30 36 44

Rated current (A) 0.9 1.5 2.4 3.0 5.6 8.0 8.0 12 13 17 20 23 30 38 45 55

Output ratings

Voltage, frequency Single-phase, 380 to 480 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(with DCR) (kVA) *3

Voltage: +10 to -10% , Frequency: +5 to -5%

0.5 0.9 1.7 2.2 4.0 5.4 5.4 7.8 9.9 13 16 19 26 32 39 49

(40 to 300 HP)

Type (FRN_ _ _G1S-4U) 125 150 200 250 300 350 450 500 600 700 800 900 1000

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

40 50 60 60 75 100 100 125 150 150 200 250 300

Rated capacity (kVA)

*2

Rated current (A) 61 72 86 103 122 149 167 204 231 259 297 384 469

Output ratings

Voltage, frequency

Allowable

voltage/frequency

Input ratings

Required capacity

(with DCR) (kVA) *3

48 57 68 82 97 118 133 162 184 206 236 305 373

Single-phase, 380 to 440 V, 50 Hz

Single-phase, 380 to 480 V, 60 Hz

Voltage: +10 to -10% , Frequency: +5 to -5%

53 63 76 89 108 132 147 182 206 236 265 325 410

*1 US 4P-standard induction motor

*2 Rated capacity is calculated assuming the rated output voltage as 230 V for 230 V series and 460 V for 460 V series.

*3 Required when a DC reactor (DCR) is used.

xiv

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

Standard Model 2 (DCR Built-in Type)

(1) Single-phase 230 V series

LD (Low Duty)-mode inverters for light load

Type (FRN_ _ _ G1H-2U) 007 010 015 020 025 030 040 050 060 075 100

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

3 5 7.5 10 10 15 20 25 30 30 30

Rated capacity (kVA)

*2

Rated current (A) 14 17 24.2 31 36 46.2 59.4 75 91 95 102

Output ratings

Voltage, frequency Single-phase, 200 to 240 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(kVA)

5.0 6.1 8.7 11 12 16 21 27 32 34 36

Single-phase, 200 to 220 V, 50 Hz

Single-phase, 200 to 230 V, 60 Hz

Voltage: +10 to -10%, Frequency: +5 to -5%

4.1 6.6 9.3 12.8 13.2 19.1 26 33 39 40 41

HD (High Duty)-mode inverters for heavy load

Type (FRN_ _ _ G1H-2U) 007 010 015 020 025 030 040 050 060 075 100

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

3 3 5 7.510101520253030

Rated capacity (kVA)

*2

5.0 5.0 6.8 9.3 11 14 16 21 27 32 34

Rated current (A) 14 14 19 26 33 39 47 59.4 75 91 95

Output ratings

Voltage, frequency Single-phase, 200 to 240 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(kVA)

*1 US 4P-standard induction motor

*2 Rated capacity is calculated assuming the rated output voltage as 230 V for 230 V series and 460 V for 460 V series.

Voltage: +10 to -10%, Frequency: +5 to -5%

4.1 4.1 6.8 9.6 13.2 13.4 19.3 27 33 40 40

Single-phase, 200 to 220 V, 50 Hz

Single-phase, 200 to 230 V, 60 Hz

xv

Conformity with UL standards and CSA standards (cUL-listed for Canada) (continued)

(2) Single-phase 460 V series

LD (Low Duty)-mode inverters for light load

Type (FRN_ _ _ G1H-4U) 007 010 015 020 025 030 040 050 060 075 100

Nominal applied motor (HP)

(Output rating) *1

Item Specifications

3 5 7.5 10 10 15 20 25 30 30 40

Rated capacity (kVA)

*2

Rated current (A) 8.5 11 14 18 22 25 32 39 46 54 59

Output ratings

Voltage, frequency Single-phase, 380 to 480 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(kVA)

6.7 8.7 11 14 17 20 25 31 36 43 47

Voltage: +10 to -10%, Frequency: +5 to -5%

4.1 6.6 9.3 12.8 13.2 19.1 26 33 39 40 54

HD (High Duty)-mode inverters for heavy load

Type (FRN_ _ _G1H-4U) 007 010 015 020 025 030 040 050 060 075 100

Nominal applied motor (HP)

(Output rating) *1

*1 US 4P-standard induction motor

*2 Rated capacity is calculated assuming the rated output voltage as 230 V for 230 V series and 460 V for 460 V series.

Item Specifications

3 3 5 7.510101520253030

Rated capacity (kVA)

*2

Rated current (A) 8.5 8.5 12 15 18 23 26 33 42 49 59

Output ratings

Voltage, frequency Single-phase, 380 to 480 V, 50/60 Hz

Allowable

voltage/frequency

Input ratings

Required capacity

(kVA)

6.7 6.7 9.5 11 14 18 20 26 33 39 47

Voltage: +10 to -10%, Frequency: +5 to -5%

4.1 4.1 6.8 9.6 13.2 13.5 19.4 27 33 40 41

xvi

Table of Contents

Preface ............................................................................... i

Safety precautions................................................................. i

Conformity to the Low Voltage Directive in the EU................ v

Conformity with UL standards and CSA standards

(cUL-listed for Canada).......................................................... ix

Chapter 1 BEFORE USING THE INVERTER ...................1-1

1.1 Acceptance Inspection .............................................1-1

1.2 External View and Terminal Blocks ......................... 1-2

1.3 Precautions for Using Inverters................................ 1-4

1.3.1 Precautions in introducing inverters.................. 1-4

1.3.2 Precautions in running inverters........................1-9

1.3.3 Precautions in using special motors ..................1-9

1.3.4 Precautions for use on single-phase power .....1-10

Chapter 2 MOUNTING AND WIRING THE INVERTER .2-1

2.1 Operating Environment............................................ 2-1

2.2 Installing the Inverter...............................................2-1

2.3 Wiring......................................................................2-4

2.3.1 Removing and mounting the front cover and

the wiring guide ................................................ 2-4

2.3.2 Screw specifications and recommended wire

sizes ..................................................................2-5

2.3.3 Wiring precautions............................................2-8

2.3.4 Wiring of main circuit terminals and

grounding terminals ........................................2-11

2.3.5 Wiring for control circuit terminals................. 2-18

2.3.6 Setting up the slide switches ........................... 2-25

2.4 Mounting and Connecting the Keypad................... 2-27

Chapter 3 OPERATION USING THE KEYPAD ................3-1

3.1 LED Monitor, LCD Monitor, and Keys....................3-1

3.2 Overview of Operation Modes.................................3-3

3.3 Running Mode .........................................................3-4

3.3.1 Running or stopping the motor .........................3-4

3.3.2 Monitoring the running status on the LED

monitor..............................................................3-5

3.3.3 Monitoring light alarms ....................................3-7

3.4 Programming Mode .................................................3-8

3.4.1 Setting up function codes quickly using

Quick Setup -- Menu #0 "Quick Setup" -- ........3-9

3.4.2 Setting up function codes

-- Menu #1 "Data Setting" --............................. 3-9

3.4.3 Checking changed function codes

-- Menu #2 "Data Checking" --....................... 3-12

3.4.4 Monitoring the running status

-- Menu #3 "Drive Monitoring" --...................3-12

3.4.5 Checking I/O signal status

-- Menu #4 "I/O Checking" -- ......................... 3-15

3.4.6 Reading maintenance information

-- Menu #5 "Maintenance Information" -- ...... 3-18

3.4.7 Reading alarm information

-- Menu #6 "Alarm Information" --.................3-24

3.4.8 Viewing causes of alarm

-- Menu #7 "Alarm Cause" --.......................... 3-27

3.4.9 Data copying -- Menu #8 "Data Copying" -- ..3-29

3.4.10 Measuring load factor

-- Menu #9 "Load Factor Measurement" --..... 3-36

3.4.11 Changing function codes covered by

Quick Setup -- Menu #10 "User Setting" -- .... 3-39

3.4.12 Helping debugging for communication

3.5 Alarm Mode...........................................................3-41

Chapter 4 RUNNING THE MOTOR ..................................4-1

4.1 Running the Motor for a Test ...................................4-1

-- Menu #11 "Communication Debugging" --. 3-40

4.1.1 Test run procedure.............................................4-1

4.1.2 Checking prior to powering on ......................... 4-1

4.1.3 Powering ON and checking .............................. 4-2

4.1.4 Switching between LD, MD and HD drive

modes................................................................ 4-2

4.1.5 Selecting a desired motor drive control.............4-3

4.1.6 Function code basic settings < 1 >....................4-6

4.1.7 Function code basic settings and tuning < 2 > ..4-7

4.1.8 Function code basic settings and tuning < 3 >.. 4-9

4.1.9 Function code basic settings < 4 >.................. 4-13

4.1.10 Function code basic settings and

tuning < 5 > .................................................... 4-14

4.1.11 Running the inverter for motor operation

check .............................................................. 4-16

4.1.12 Preparation for practical operation ................. 4-18

4.2 Special Operations................................................. 4-19

4.2.1 Jogging (inching) the motor............................ 4-19

4.2.2 Remote and local modes................................. 4-19

4.2.3 External run/frequency command................... 4-20

Chapter 5 FUNCTION CODES.......................................... 5-1

5.1 Function Code Tables .............................................. 5-1

5.2 Details of Function Codes...................................... 5-35

5.2.1 Fundamental Functions ..................................

5.2.2 E codes (Extension Terminal Functions) ........

5.2.3 C codes (Control functions)..........................

5.2.4 P codes (Motor 1 Parameters).......................

5.2.5 H codes (High Performance Functions)........

5.2.6 A codes (Motor 2 Parameters),

b codes (Motor 3 Parameters),

r codes (Motor 4 Parameters) .......................

5.2.7 J codes (Application Functions 1) ................

5.2.8 d codes (Application Functions 2)................

5.2.9 U codes (Application functions 3)................

5.2.10 y codes (Link Functions)..............................

Chapter 6 TROUBLESHOOTING...................................... 6-1

6.1 Protective Functions ................................................ 6-1

6.2 Before Proceeding with Troubleshooting................. 6-4

6.3 If Neither an Alarm Code Nor "Light Alarm"

Indication (

6.3.1 Abnormal motor operation ............................... 6-5

6.3.2

6.4 If an Alarm Code Appears on the LED Monitor .... 6-12

6.5 If the "Light Alarm" Indication (

on the LED Monitor............................................... 6-25

6.6 If an Abnormal Pattern Appears on the LED

Monitor except Alarm Codes and "Light Alarm"

Indication (

6.7 If the Inverter is Running on Single-Phase

Power..................................................................... 6-27

Chapter 7 MAINTENANCE AND INSPECTION.............. 7-1

7.1 Daily Inspection....................................................... 7-1

7.2 Periodic Inspection .................................................. 7-1

7.3 List of Periodic Replacement Parts.......................... 7-3

7.3.1 Judgment on service life................................... 7-3

7.4 Measurement of Electrical Amounts in

Main Circuit............................................................. 7-6

7.5 Insulation Test.......................................................... 7-7

7.6 Inquiries about Product and Guarantee.................... 7-7

7.6.1 When making an inquiry .................................. 7-7

7.6.2 Product warranty .............................................. 7-8

Chapter 8 SPECIFICATIONS............................................. 8-1

8.1 Standard Model 1 (Basic Type)................................ 8-1

8.1.1 Three-phase 230 V series.................................. 8-1

8.1.2 Three-phase 460 V series.................................. 8-2

8.2 Standard Model 2 (DCR Built-in Type) ................... 8-5

8.2.1 Three-phase 230 V series.................................. 8-5

8.2.2 Three-phase 460 V series.................................. 8-6

8.3 Common Specifications........................................... 8-7

8.4 External Dimensions.............................................. 8-10

8.4.1 Standard models ............................................. 8-10

8.4.2 Panel cutting of standard model

8.4.3 DC reactor (DCR) .......................................... 8-12

8.4.4 DCR built-in type ........................................... 8-15

8.4.5 Standard models with NAMA1 kit (option).... 8-16

8.4.6 Keypad (TP-G1W-J1)..................................... 8-17

xvii

l-al

) Appears on the LED Monitor... 6-5

Problems with inverter settings...................6-11

l-al

) Appears

l-al

) ................................................ 6-26

(50 HP or above) ............................................ 8-11

5-35

5-80

5-108

5-112

5-117

5-138

5-141

5-160

5-168

5-177

Chapter 9 CONFORMITY WITH STANDARDS ............... 9-1

9.1 Compliance with UL Standards and Canadian

Standards (cUL certification) ...................................9-1

9.1.1 General..............................................................9-1

9.1.2 Considerations when using FRENIC-MEGA

in systems to be certified by UL and cUL ......... 9-1

9.2 Compliance with European Standards......................9-1

9.3 Compliance with EMC Standards ............................9-1

9.3.1 General..............................................................9-1

9.3.2 Recommended installation procedure ............... 9-2

9.4 Compliance with EN954-1, Category 3 ...................9-3

9.4.1 General..............................................................9-3

9.4.2 Notes for compliance to En954-1 category 3....9-3

9.4.3 EN954-1............................................................9-4

xviii

Chapter 1 BEFORE USING THE INVERTER

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) An inverter and instruction manual (this book) are contained in the package.

The FRN100G1S-2/4U and higher types come with a DC reactor (DCR). Be sure to connect the DCR.

(2) The inverter has not been damaged during transportation—there should be no dents or parts missing.

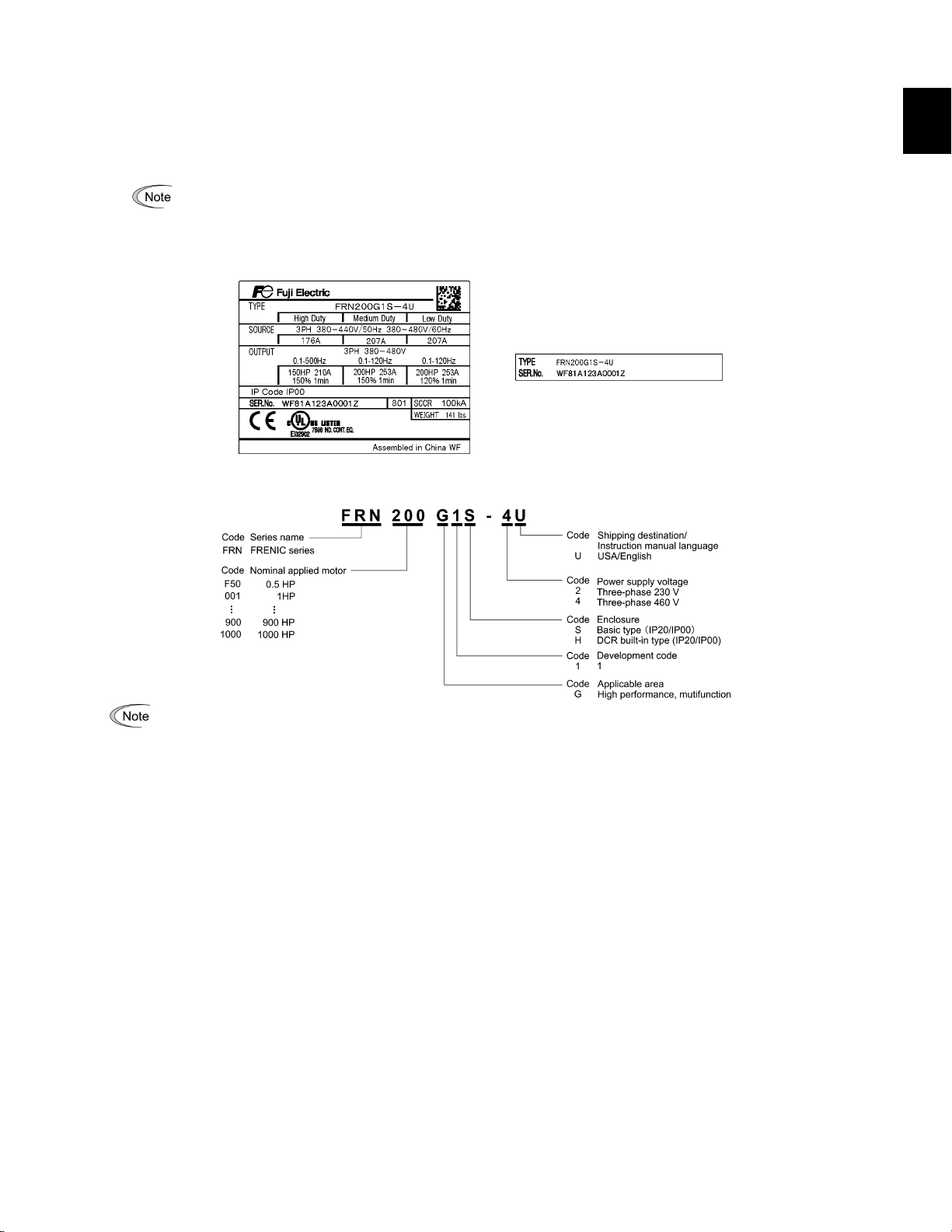

(3) The inverter is the type you ordered. You can check the type and specifications on the main nameplate. (Main and sub

TYPE: Type of inverter

nameplates are attached to the inverter and are located as shown on the next page.) For inverters of 50 HP or above, the mass

is printed on the main nameplate.

(a) Main Nameplate (b) Sub Nameplate

Figure 1.1 Nameplates

Chap. 1

BEFORE USING THE INVERTER

In tables given in this manual, inverter types are denoted as "FRN_ _ _G1-2U/4U." The box replaces an alphabetic

letter depending on the enclosure.

The FRENIC-MEGA is available in two or three drive modes depending upon the inverter capacity: Low Duty (LD) and High

Duty (HD) modes or Low Duty (LD), Medium Duty (MD) and High Duty (HD) modes. One of these modes should be selected to

match the load property of your system. Specifications in each mode are printed on the main nameplate. For details, see Chapter 8

"SPECIFICATIONS."

Low Duty: LD mode designed for light duty load applications. Overload capability: 120% for 1 min. Continuous ratings =

Inverter ratings

Medium Duty: MD mode designed for medium duty load applications. Overload capability: 150% for 1 min. Continuous ratings

= Inverter rating or one rank lower capacity of inverters

High Duty: HD mode designed for heavy duty load applications. Overload capability: 150% for 1 min, 200% for 3 s.

Continuous ratings = One rank or two ranks lower capacity of inverters

SOURCE: Number of input phases (three-phase: 3PH), input voltage, input frequency, input current (each for LD, MD and

HD modes)

OUTPUT: Number of output phases, rated output voltage, output frequency range,

rated output capacity, rated output current, overload capability (each for LD, MD and HD modes)

SCCR: Short-circuit capacity

WEIGHT: Mass of the inverter in lbs

SER. No.: Product number

If you suspect the product is not working properly or if you have any questions about your product, contact your Fuji Electric

representative.

1-1

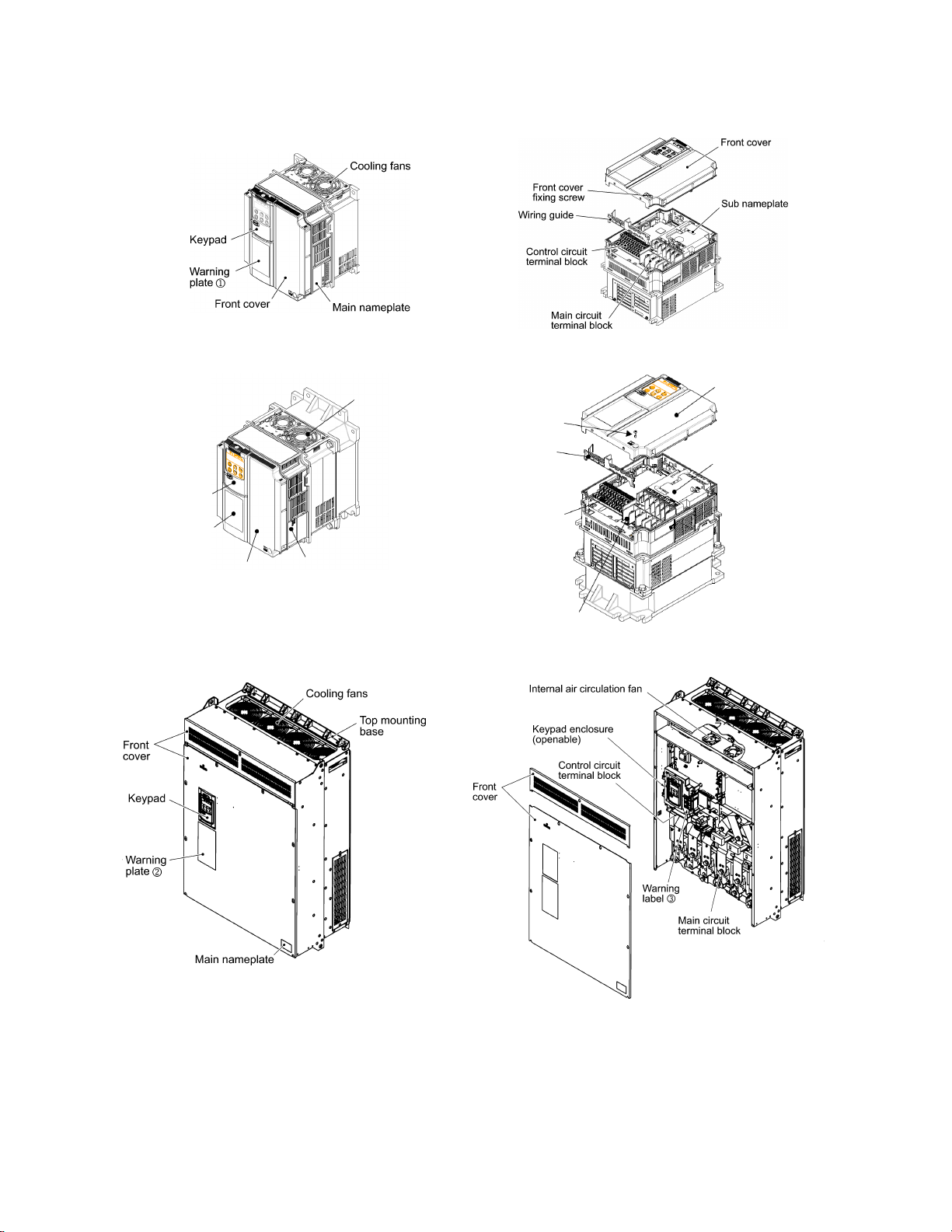

1.2 External View and Terminal Blocks

r

c

r

(1) Outside and inside views

Keypad

Warning plate

Front cove

Main nameplate

Cooling fans

(a) e.g. FRN020G1S-4U

Front cover

fixing screw

Wiring guide

Control circuit

terminal block

Front cove

Sub nameplate

Main circuit

terminal block

(b) e.g. FRN020G1H-4U

(c) e.g. FRN450G1S-4U

Figure 1.2 Outside and Inside Views of Inverters

1-2

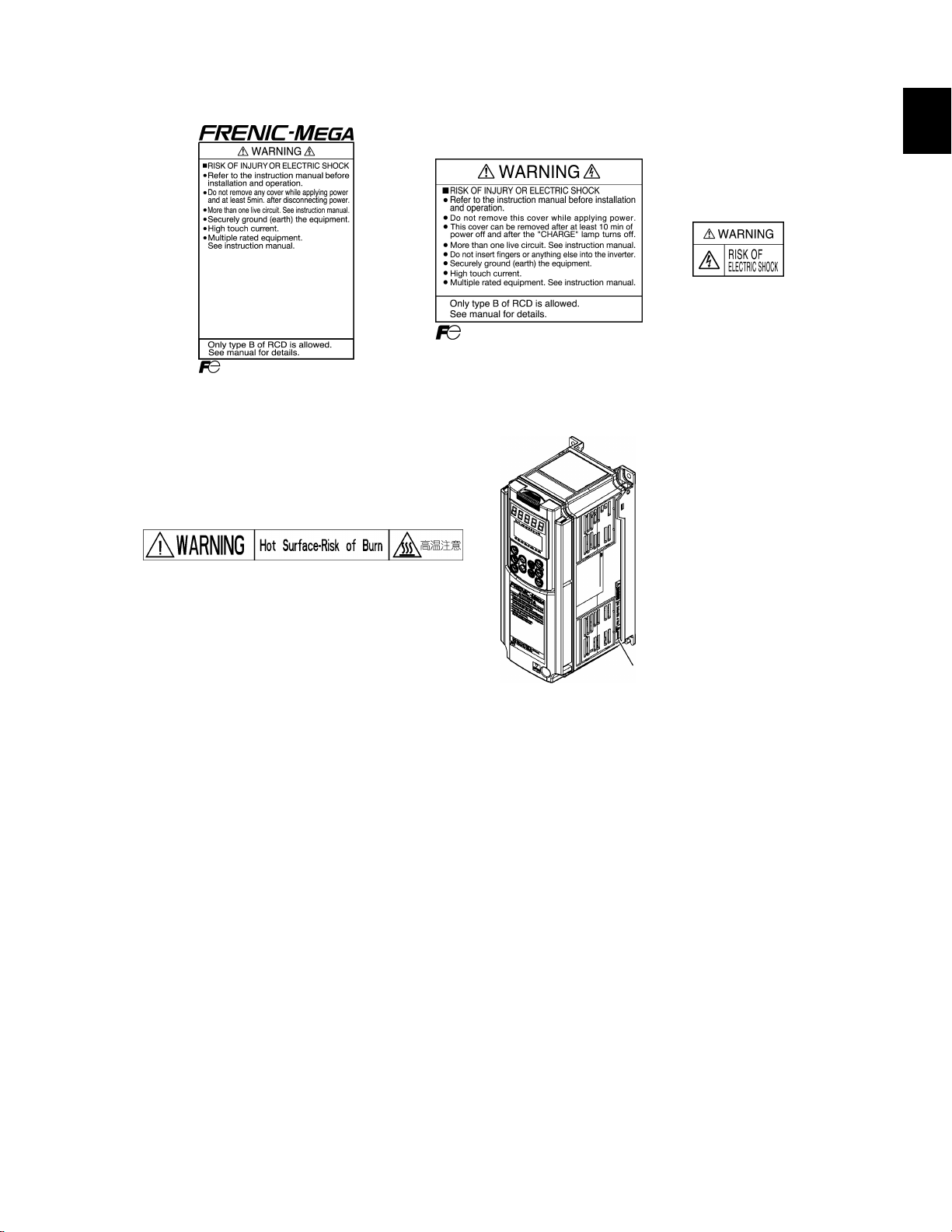

(2) Warning plates and labels

Warning plate c Warning plate

Chap. 1

BEFORE USING THE INVERTER

Warning label

d

e

Warning label

f

Figure 1.3 Warning Plates and Labels

Warning label f

(on heat sink)

1-3

1.3 Precautions for Using Inverters

1.3.1 Precautions in introducing inverters

This section provides precautions in introducing inverters, e.g. precautions for installation environment, power supply lines,

wiring, and connection to peripheral equipment. Be sure to observe those precautions.

Installation environment

Install the inverter in an environment that satisfies the requirements listed in Table 2.1 in Chapter 2.

Fuji Electric strongly recommends installing inverters in a panel for safety reasons, in particular, when installing the ones whose

enclosure rating is IP00.

When installing the inverter in a place out of the specified environmental requirements, it is necessary to derate the inverter or

consider the panel engineering design suitable for the special environment or the panel installation location. For details, refer to

the Fuji Electric technical information "Engineering Design of Panels" or consult your Fuji Electric representative.

The special environments listed below require using the specially designed panel or considering the panel installation location.

Environments Possible problems Sample measures Applications

Highly concentrated

sulfidizing gas or

other corrosive gases

A lot of conductive

dust or foreign

material (e.g., metal

powders or shavings,

carbon fibers, or

carbon dust)

A lot of fibrous or

paper dust

High humidity or

dew condensation

Vibration or shock

exceeding the

specified level

Fumigation for

export packaging

Corrosive gases cause parts

inside the inverter to corrode,

resulting in an inverter

malfunction.

Entry of conductive dust into

the inverter causes a short

circuit.

Fibrous or paper dust

accumulated on the heat sink

lowers the cooing effect.

Entry of dust into the inverter

causes the electronic circuitry

to malfunction.

In an environment where a

humidifier is used or where

the air conditioner is not

equipped with a dehumidifier,

high humidity or dew

condensation results, which

causes a short-circuiting or

malfunction of electronic

circuitry inside the inverter.

If a large vibration or shock

exceeding the specified level

is applied to the inverter, for

example, due to a carrier

running on seam joints of rails

or blasting at a construction

site, the inverter structure gets

damaged.

Halogen compounds such as

methyl bromide used in

fumigation corrodes some

parts inside the inverter.

Any of the following measures may be

necessary.

- Mount the inverter in a sealed panel

with IP6X or air-purge mechanism.

- Place the panel in a room free from

influence of the gases.

Any of the following measures may be

necessary.

- Mount the inverter in a sealed panel.

- Place the panel in a room free from

influence of the conductive dust.

Any of the following measures may be

necessary.

- Mount the inverter in a sealed panel

that shuts out dust.

- Ensure a maintenance space for

periodical cleaning of the heat sink

in panel engineering design.

- Employ external cooling when

mounting the inverter in a panel for

easy maintenance and perform

periodical maintenance.

- Put a heating module such as a

space heater in the panel.

- Insert shock-absorbing materials

between the mounting base of the

inverter and the panel for safe

mounting.

- When exporting an inverter built in

a panel or equipment, pack them in

a previously fumigated wooden

crate.

- When packing an inverter alone for

export, use a laminated veneer

lumber (LVL).

Paper manufacturing, sewage

disposal, sludge treatment,

tire manufacturing, gypsum

manufacturing, metal

processing, and a particular

process in textile factories.

Wiredrawing machines, metal

processing, extruding

machines, printing presses,

combustors, and industrial

waste treatment.

Textile manufacturing and

paper manufacturing.

Outdoor installation.

Film manufacturing line,

pumps and food processing.

Installation of an inverter

panel on a carrier or

self-propelled machine.

Ventilating fan at a

construction site or a press

machine.

Exporting.

1-4

Storage environment

The storage environment in which the inverter is stored after purchase is different from the operation environment. For details,

refer to the FRENIC-MEGA User's Manual, Chapter 2.

Wiring precautions

(1) Route the wiring of the control circuit terminals as far from the wiring of the main circuit as possible. Otherwise electric noise

may cause malfunctions.

(2) Fix the control circuit wires inside the inverter to keep them away from the live parts of the main circuit (such as the terminal

block of the main circuit).

(3) If more than one motor is to be connected to a single inverter, the wiring length should be the sum of the length of the wires to

the motors.

(4) Drive output terminals (U, V, W)

1) Connect these terminals to a 3-phase motor in the correct phase sequence. If the direction of motor rotation is incorrect,

exchange any two of the U, V, and W phases.

2) Do not connect a power factor correction capacitor or surge absorber to the inverter output.

3) If the cable from the inverter to the motor is very long, a high-frequency current may be generated by stray capacitance

between the cables and result in an overcurrent trip of the inverter, an increase in leakage current, or a reduction in current

indication precision.

When a motor is driven by a PWM-type inverter, the motor terminals may be subject to surge voltage generated by inverter

element switching. If the motor cable (with 460 V series motors, in particular) is particularly long, surge voltage will

deteriorate motor insulation. To prevent this, use the following guidelines:

Inverter 7.5 HP and larger

Motor Insulation Level 1000 V 1300 V 1600 V

460 VAC Input Voltage 66 ft (20 m) 328 ft (100 m) 1312 ft (400 m)*

230 VAC Input Voltage 1312 ft (400 m)* 1312 ft (400 m)* 1312 ft (400 m)*

Inverter 5 HP and smaller

Motor Insulation Level 1000 V 1300 V 1600 V

460 VAC Input Voltage 66 ft (20 m) 165 ft (50 m)* 165 ft (50 m)*

230 VAC Input Voltage 328 ft (100 m)* 328 ft (100 m)* 328 ft (100 m)*

* For this case the cable length is determined by secondary effects and not voltage spiking.

• When a motor protective thermal O/L relay is inserted between the inverter and the motor, the thermal O/L relay

may malfunction (particularly in the 460 V series), even when the cable length is 165 ft (50 m) or less. To correct,

insert a filter or reduce the carrier frequency. (Use function code F26 "Motor sound".)

• For the vector control mode, wiring length is 328 ft (100 m) or less.

(5) When an output circuit filter is inserted in the secondary circuit or the wiring between the inverter and the motor is long, a

voltage loss occurs due to reactance of the filter or wiring so that the insufficient voltage may cause output current oscillation

or a lack of motor output torque. To avoid it, select the constant torque load by setting the function code F37 (Load

Selection/Auto Torque Boost/Auto Energy Saving Operation 1) to "1" and keep the inverter output voltage at a higher level by

configuring H50/H52 (Non-linear V/f Pattern, Frequency) and H51/H53 (Non-linear V/f Pattern, Voltage).

Precautions for connection of peripheral equipment

(1) Phase-advancing capacitors for power factor correction

Do not mount a phase-advancing capacitor for power factor correction in the inverter's input (primary) or output (secondary)

circuit. Mounting it in the input (primary) circuit takes no effect. To correct the inverter power factor, use an optional DC

reactor (DCR). Mounting it in the output (secondary) circuit causes an overcurrent trip, disabling operation.

An overvoltage trip that occurs when the inverter is stopped or running with a light load is assumed to be due to surge current

generated by open/close of phase-advancing capacitors in the power system. An optional DC/AC reactor (DCR/ACR) is

recommended as a measure to be taken at the inverter side.

Input current to an inverter contains a harmonic component that may affect other motors and phase-advancing capacitors on

the same power supply line. If the harmonic component causes any problems, connect an optional DCR/ACR to the inverter.

In some cases, it is necessary to insert a reactor in series with the phase-advancing capacitors.

Chap. 1

BEFORE USING THE INVERTER

1-5

(2) Power supply lines (Application of a DC/AC reactor)

Use an optional DC reactor (DCR) when the capacity of the power supply transformer is 500 kVA or more and is 10 times or

more the inverter rated capacity or when there are thyristor-driven loads. If no DCR is used, the percentage-reactance of the

power supply decreases, and harmonic components and their peak levels increase. These factors may break rectifiers or

capacitors in the converter section of the inverter, or decrease the capacitance of the capacitors.

If the input voltage unbalance rate is 2% to 3%, use an optional AC reactor (ACR).

(%) unbalance Voltage = -

(V)voltageMin - (V) voltageMax

(V) voltage average phase-Three

3)61800 (IEC 67×

(3) DC reactor (DCR) for correcting the inverter input power factor (for suppressing harmonics)

To correct the inverter input power factor (to suppress harmonics), use an optional DCR. Using a DCR increases the reactance

of inverter’s power source so as to decrease harmonic components on the power source lines and correct the power factor of

the inverter.

DCR models Input power factor Remarks

DCR2/4-/A/B Approx. 90% to 95% The last letter identifies the capacitance.

DCR2/4-C Approx. 86% to 90% Exclusively designed for inverters of 50 HP or above.

For selecting DCR models, refer to Chapter 8 "SPECIFICATIONS."

(4) PWM converter for correcting the inverter input power factor

Using a PWM converter (High power-factor, regenerative PWM converter, RHC series) corrects the inverter power factor up

to nearly 100%. When combining an inverter with a PWM converter, disable the main power down detection by setting the

function code H72 to "0." If the main power loss detection is enabled (H72 = 1 by factory default), the inverter interprets the

main power as being shut down, ignoring an entry of a run command.

(5) Molded case circuit breaker (MCCB) or residual-current-operated protective device (RCD)/earth leakage circuit breaker

(ELCB)

Install a recommended MCCB or RCD/ELCB (with overcurrent protection) in the primary circuit of the inverter to protect the

wiring. Since using an MCCB or RCD/ELCB with a lager capacity than recommended ones breaks the protective coordination

of the power supply system, be sure to select recommended ones. Also select ones with short-circuit breaking capacity suitable

for the power source impedance.

Power

supply

voltage

Nominal applied

motor

Three-

phase

Residual-Current-Operated Protective Device (RCD)/Earth Leakage Circuit Breaker (ELCB)

(HP)

Single-

phase

Inverter type

0.5 0.25 FRNF50G1S-2U 5

1 0.5 FRN001G1S-2U

2 1 FRN002G1S-2U 15

3 1.5 FRN003G1S-2U

5 FRN005G1S-2U 20 30

3

7.5

FRN007G1-2U

FRN010G1-2U

10 5

FRN015G1-2U

15 7.5

FRN020G1-2U

20

10

FRN025G1-2U

25

230 V

FRN030G1-2U

30 15

FRN040G1-2U

40 20

FRN050G1-2U

50 25

FRN060G1-2U

60

75

FRN100G1

-2U

FRN075G1-2U

30

100

FRN125G1S-2U

40

125

Note: A box () in the above table replaces S or H depending on the enclosure.

150 50

FRN150G1S-2U

Molded Case Circuit Breaker (MCCB) and

Rated current of

HD/MD/

LD mode

MCCB and

RCD/ELCB (A)

w/ DCR w/o DCR

5

HD/LD

HD

LD

HD

LD

HD

LD

HD

10

30 50

40 75

50 100

75 125

LD

HD

LD

100

HD

LD

LD

LD

LD

LD

LD

150 200

175 250

200 300

250 350

350

400

HD

HD

HD

HD

HD

HD

LD 350

10

20

150

175

--

Power

supply

voltage

460 V

1-6

Nominal applied

Three-

phase

motor

(HP)

Single-

Inverter type

phase

HD/MD/

LD mode

0.5 0.25 FRN0F50G1S-4U

1 0.5 FRN001G1S-4U

2 1 FRN002G1S-4U

3 1.5 FRN003G1S-4U 15

HD/LD

5 FRN005G1S-4U

7.5

FRN007G1-4U

3

FRN010G1

-4U

10

5 FRN015G1-4U

15

7.5 FRN020G1-4U

20

FRN025G1-4U

10

25

FRN030G1-4U

30 15

FRN040G1-4U

40 20

FRN050G1-4U

50 25

FRN060G1-4U

60

30

FRN075G1-4U

75

FRN100G1-4U

100 40

FRN125G1S-4U HD

w/ DCR w/o DCR

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

HD

LD

Rated current of

MCCB and

RCD/ELCB (A)

5

5

10

10

20

15 30

20 40

30 50

40 60

40 75

50 100

75

125

100

150

125 200

175 --

d

Power

supply

voltage

460 V

Nominal applied

motor

(HP)

Three-

Single-

phase

phase

125

150

200

250 75

300

100

350

350 - MD

450

125

400

450

150 FRN600G1S-4U HD

Inverter type

FRN125G1S-4U LD

50

FRN150G1S-4U

FRN200G1S-4U

60

FRN250G1S-4U

FRN300G1S-4U

FRN350G1S-4U

FRN450G1S-4U

FRN500G1S-4U

-

HD/MD/

LD mode

HD

MD/LD

HD

MD/LD

HD

MD/LD

HD

MD/LD

HD

MD/LD

HD

LD

HD

MD

Rated current of

MCCB and

RCD/ELCB (A)

w/ DCR w/o DCR

200

250

300

350

--

500

600

800

Power

supply

voltage

460 V

Nominal applied

motor

(HP)

Three-

Single-

phase

phase

500

600

700

800 250

900 300

1000 400

150 FRN500G1S-4U LD

- FRN600G1S-4U MD

150 FRN700G1S-4U HD

200 FRN600G1S-4U LD

- FRN700G1S-4U MD

200

- MD

Inverter type

FRN800G1S-4U HD

FRN700G1S-4U LD

FRN800G1S-4U

FRN900G1S-4U

FRN1000G1S-4U

HD/MD/

LD mode

LD

HD

LD

HD

LD 1600

Rated current of

MCCB and

RCD/ELCB (A)

w/ DCR w/o DCR

800

1200

1400

--

If no zero-phase current (earth leakage current) detective device such as a ground-fault relay is installed in the upstream

power supply line in order to avoid the entire power supply system's shutdown undesirable to factory operation, install a