Fuji Electric FRENIC-HVAC Series Instruction Manual

Instruction Manual

UL/NEMA Type 1 & Type 12

FRENIC-HVAC

Combination VFD

Fuji Electric Corp. of America FECA-IN-117 / 120715

Information subject to change without notice.

Safety Precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), or

maintenance and inspection. Ensure you have sound knowledge of the device and

familiarize yourself with all safety information and precautions before proceeding to

operate the drive. Refer to the FRENIC-HVAC

1707c-JE) for further safety information.

Safety precautions are classified into the following two categories in this manual.

WARNING

Failure to heed the information indicated by this symbol may lead to dangerous

conditions, possibly resulting in death or serious bodily injuries.

CAUTION

Failure to heed the information indicated by this symbol may lead to dangerous

conditions, possibly resulting in minor or light bodily injuries and/or substantial property

damage.

drive Instruction Manual (INR-SI47-

Page 2 of 37

FRENIC-HVAC Combination VFD Overview

The FRENIC-HVAC Combination VFD is a packaged drive solution in a UL Type 1 or

Type 12 enclosure designed for indoor HVAC applications.

Features

• UL/NEMA Type 1 or Type 12 enclosure – “slim-type”

design

• Non-fusible input disconnect with padlockable through-the-door operator handle

mechanically interlocked with the enclosure cover/door (motor branch circuit

protection required and to be provided by others), also available is an optional input

circuit breaker with padlockable through-the-door operator handle mechanically

interlocked with the enclosure cover/door

• DC link reactor integra l for im pr oved power factor and

harmonic mitigation up to 60 HP at 208/230V and 125 HP

at 460 & 575V. External mounted within the enclosure for

larger sizes.

• Integral EMC filter compliant with IEC/EN61800-3-12

• VFD mounted keypad with backlit LCD for drive set-up,

troubleshooting, local operation control, maintenance

indication, and operational indication. Keypad displays

engineering units for easy-to-understand information.

• Keypad functions as a copy unit

• 0 to 10Vdc or 0/4 to 20mA customer supplied analog input

for speed reference

• 0 to 10Vdc or 0/4 to 20mA analog output for indication

(programmable)

• Run, Enable, and Fireman Override inputs

• Optional damper control output contacts

• Drive Run and Fault status output contacts

• Real Time Clock (RTC) function with alarm history for the

last 10 alarms

• Enhanced automatic energy savings, reduces power

consumption of both the motor and VFD

• Power consumption data available via VFD keypad

• Built-in PID control with sleep function & auto-tuning

• “Catch-a-spinning motor” functionality available

• Built-in communications user selectable between Modbus

RTU, Metasys

communication drive options including; LonWorks

EtherNet [including Modbus/TCP & BACnet/IP]

• UL Listed assembly per UL-508A

®

N2, or BACnet, with additional

®

and

Page 3 of 37

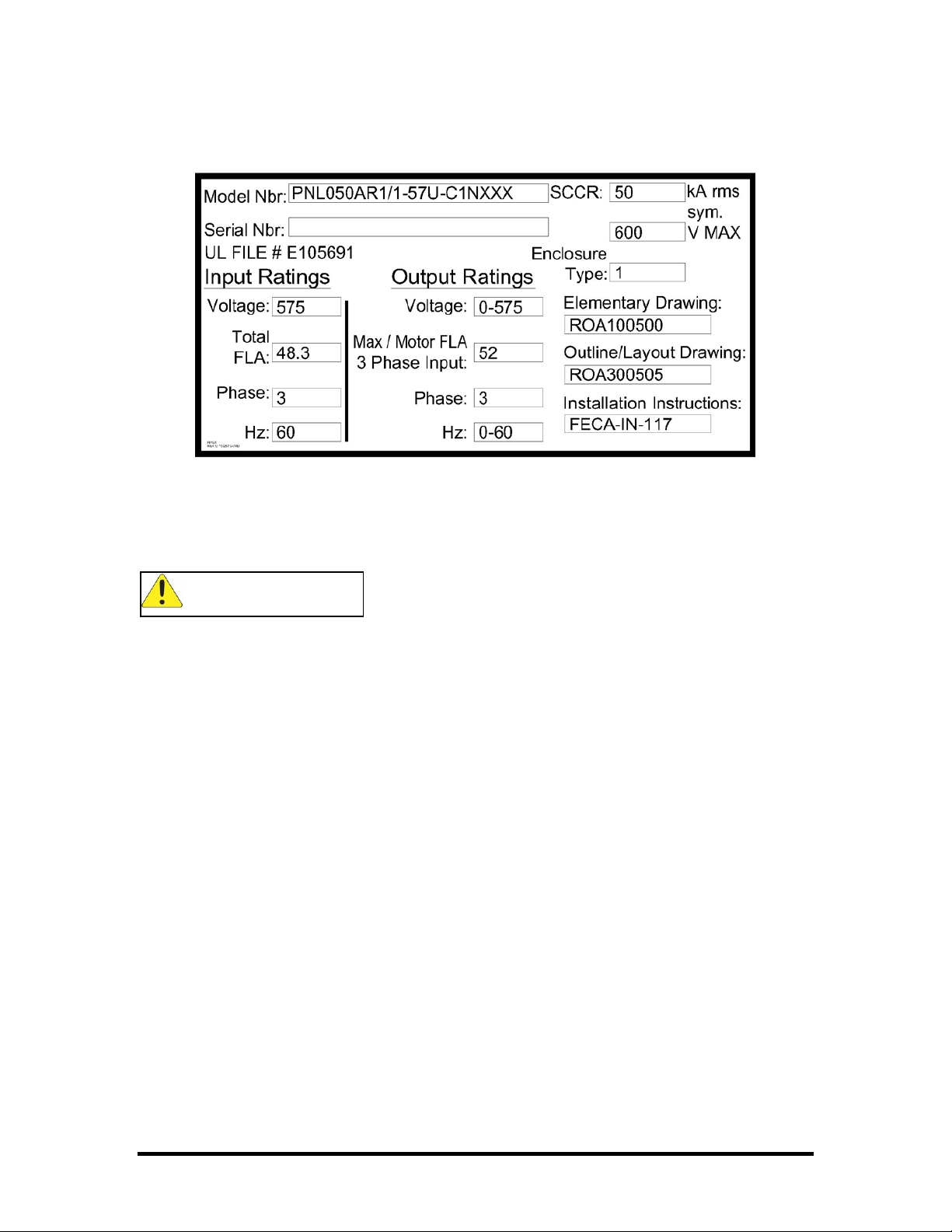

Panel Identification

Each FRENIC-HVAC Combination VFD has a nameplate label, like the example

pictured above, which contains important information about the panel. This label is

located on the inside of the hinged door or cover of the enclosure.

CAUTION

• Refer to the nameplate label to determine the panel input voltage and current

requirements prior to installation and wiring.

• Refer to the nameplate label for the correct wiring diagram (Elementary Drawing).

• Sizing of field wiring conductors should be based upon the current ratings listed on

the nameplate label.

Page 4 of 37

Installation

CAUTION

The FRENIC-HVAC Combination VFD should be located:

• Away from flammable or combustible liquids, gases, and other materials

• Away from sources of severe dust, metal shavings, or other particulate

material

• Away from corrosive liq uid s , spray, or mist

• Away from sources of h eat

• Where the ambient temperature will remain between -10°C (14°F) and 40°C

(104°F)

• Where the elevation is 3300ft or lower, above this level requires derating the

current

Wall-mount panels must be mounted to a surface that is capable of supporting the

weight of the panel.

Refer to the Outline/Layout drawing that shipped with the panel for required clearances.

Routing of field wiring should be planned in coordination with choosing a mounting

location.

Disconnect – Motor branch circuit protection to be provided by customer/others per table

on next page.

Page 5 of 37

Motor Branch Circuit Protection

208/230VAC, 60Hz, 3PH

1

10A - Class J Time-Delay Fuses

2

10A - Class J Time-Delay Fuses

3

15A - Class J Time-Delay Fuses

5

25A - Class J Time-Delay Fuses

7.5

30A - Class J Time-Delay Fuses

10

50A - Class J Time-Delay Fuses

15

70A - Class J Time-Delay Fuses

20

100A - Class J Time-Delay Fuses

25

100A - Class J Time-Delay Fuses

460VAC, 60Hz, 3PH

1

3A - Class J Time-Delay Fuses

2

6A - Class J Time-Delay Fuses

3

10A - Class J Time-Delay Fuses

5

15A - Class J Time-Delay Fuses

7.5

20A - Class J Time-Delay Fuses

10

25A - Class J Time-Delay Fuses

15

30A - Class J Time-Delay Fuses

20

50A - Class J Time-Delay Fuses

25

60A - Class J Time-Delay Fuses

30

70A - Class J Time-Delay Fuses

40

100A - Class J Time-Delay Fuses

50

100A - Class J Time-Delay Fuses

575VAC, 60Hz, 3PH

1

3A - Class J Time-Delay Fuses

2

6A - Class J Time-Delay Fuses

3

6A - Class J Time-Delay Fuses

5

10A - Class J Time-Delay Fuses

7.5

15A - Class J Time-Delay Fuses

10

20A - Class J Time-Delay Fuses

15

25A - Class J Time-Delay Fuses

20

30A - Class J Time-Delay Fuses

25

40A - Class J Time-Delay Fuses

30

50A - Class J Time-Delay Fuses

40

70A - Class J Time-Delay Fuses

50

100A - Class J Time-Delay Fuses

Hp

Rating

Additional Motor Branch Circuit

Protection Maximum Amp Rating

& Type Required

Page 6 of 37

Wiring Overview

The FRENIC-HVAC Combinat ion VFD must be connected to an input power source, a

motor (output power), ground, and control may be local or by using remote devices such

as switches, potentiometers, etc….

WARNING

• Wiring should be performed by a qualified electrician using standard practices as

specified by local and national codes.

• Alway s make sure the input power source is OFF before connecting or disconnecting

any power input, output, or control wiring.

• Ground the panel, as specified by local and national codes, using the provided

grounding lugs.

• Make sure that the input power source (phases, voltage, and current capacity)

matches the requirements of the panel as stated on the nameplate.

• Never connect line voltage to the drive output terminals (U, V, and W).

• IF not using the provided conduit holes, then when making holes for conduit fittings,

be sure to cover the drive and other components to protect them from metal

shavings.

CAUTION

• All field wiring should be copper with a minimum insulation rating of 75°C.

• Sizing of field wiring conductors should be based upon the current ratings listed on

the nameplate label, in accordance with local and national codes.

Refer to the Elementary diagram that shipped with this panel and the torque table in this

Instruction Manual.

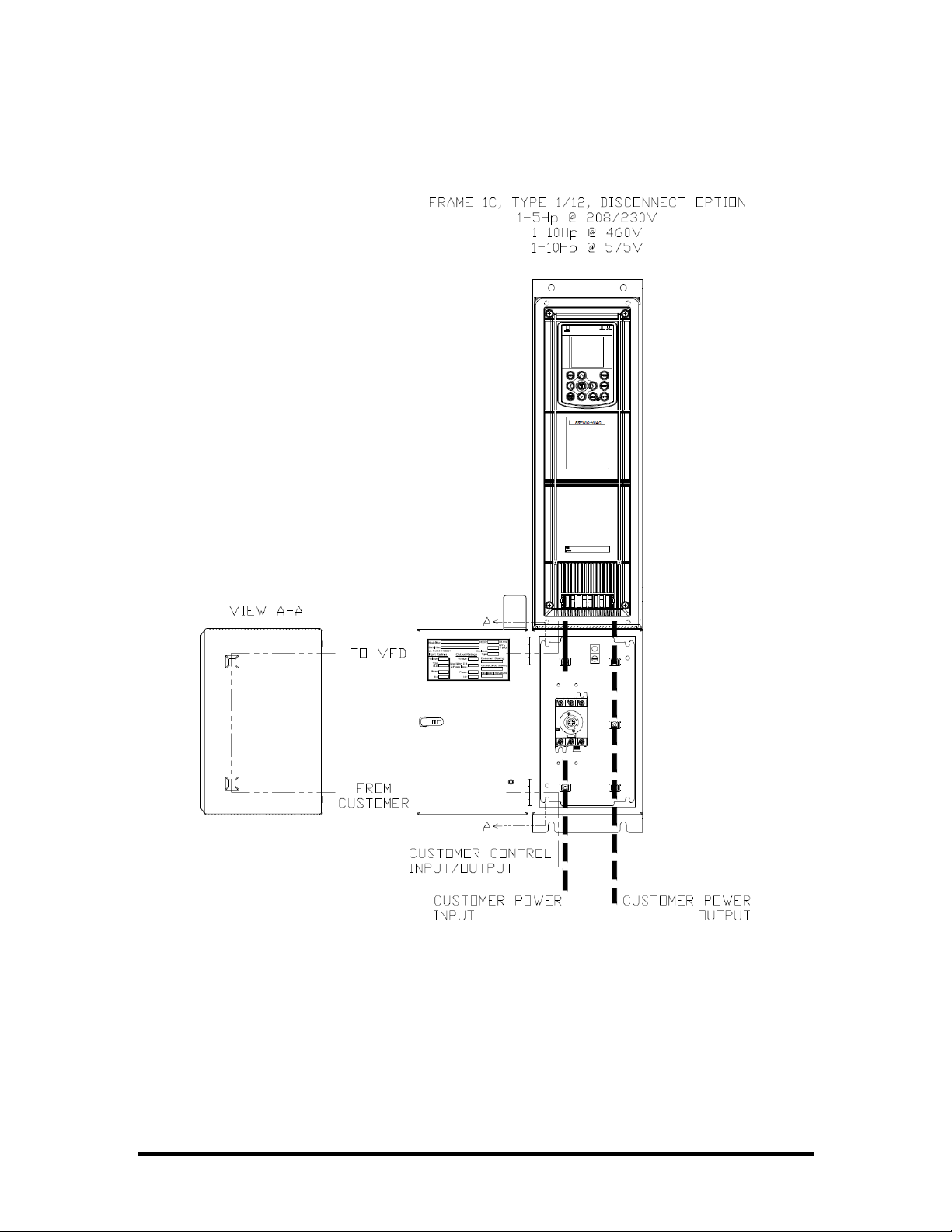

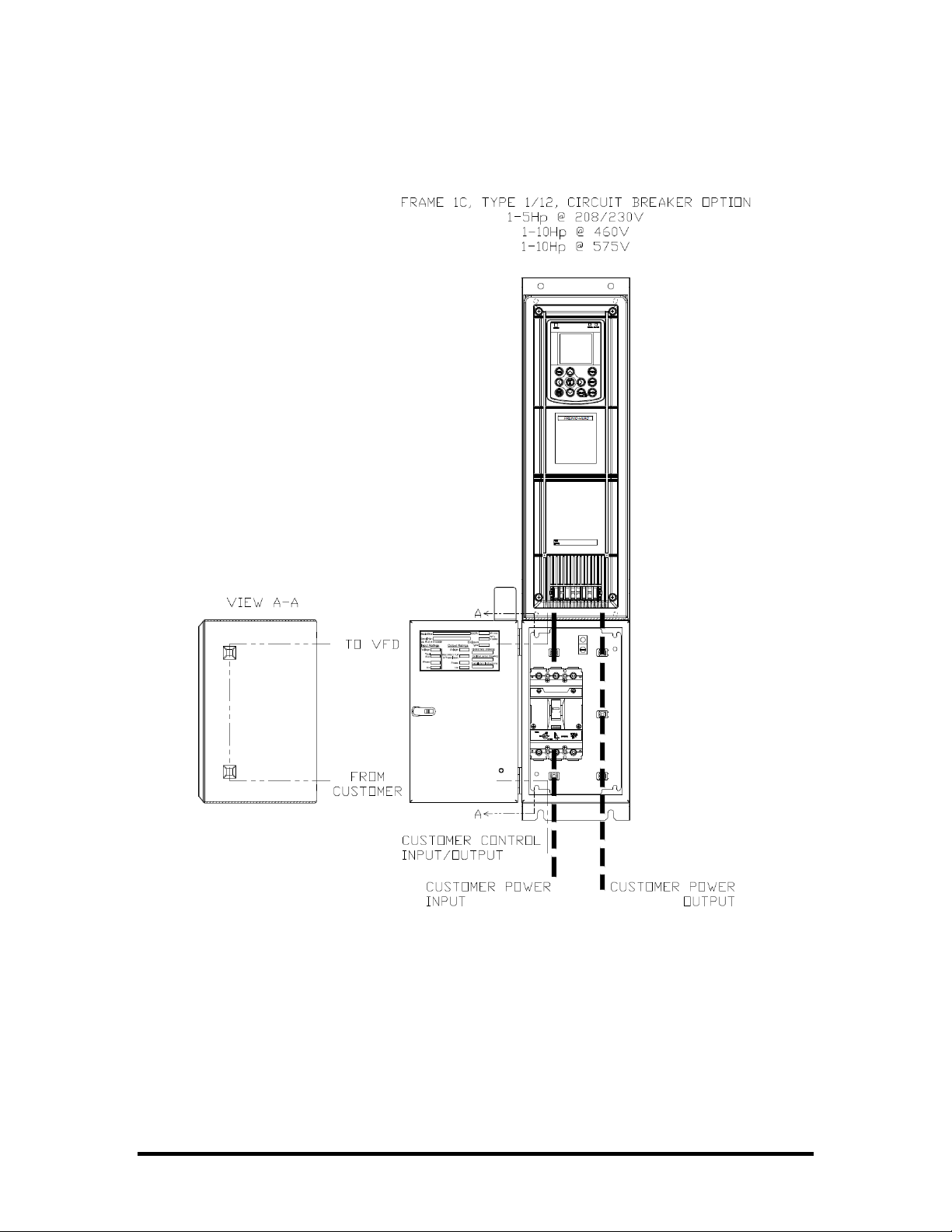

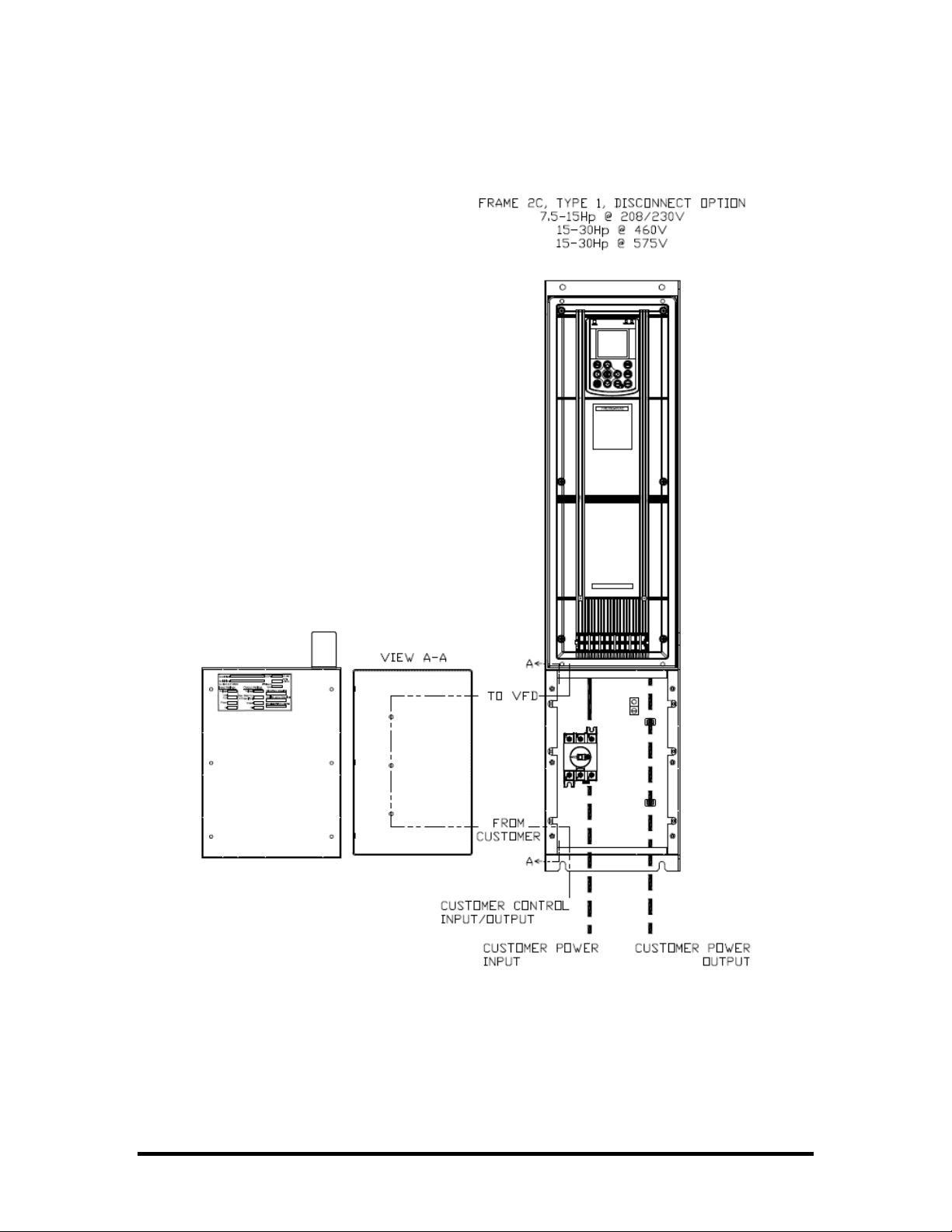

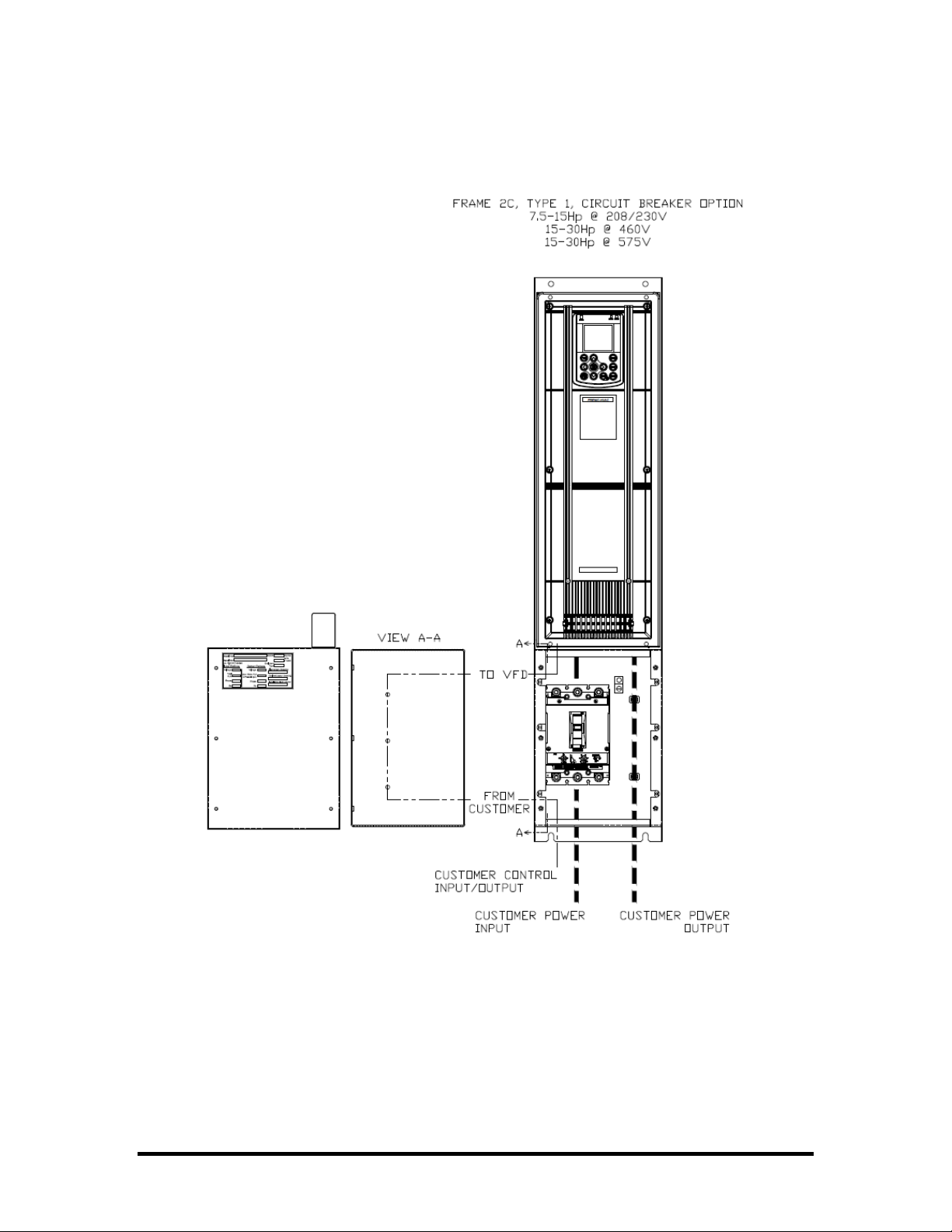

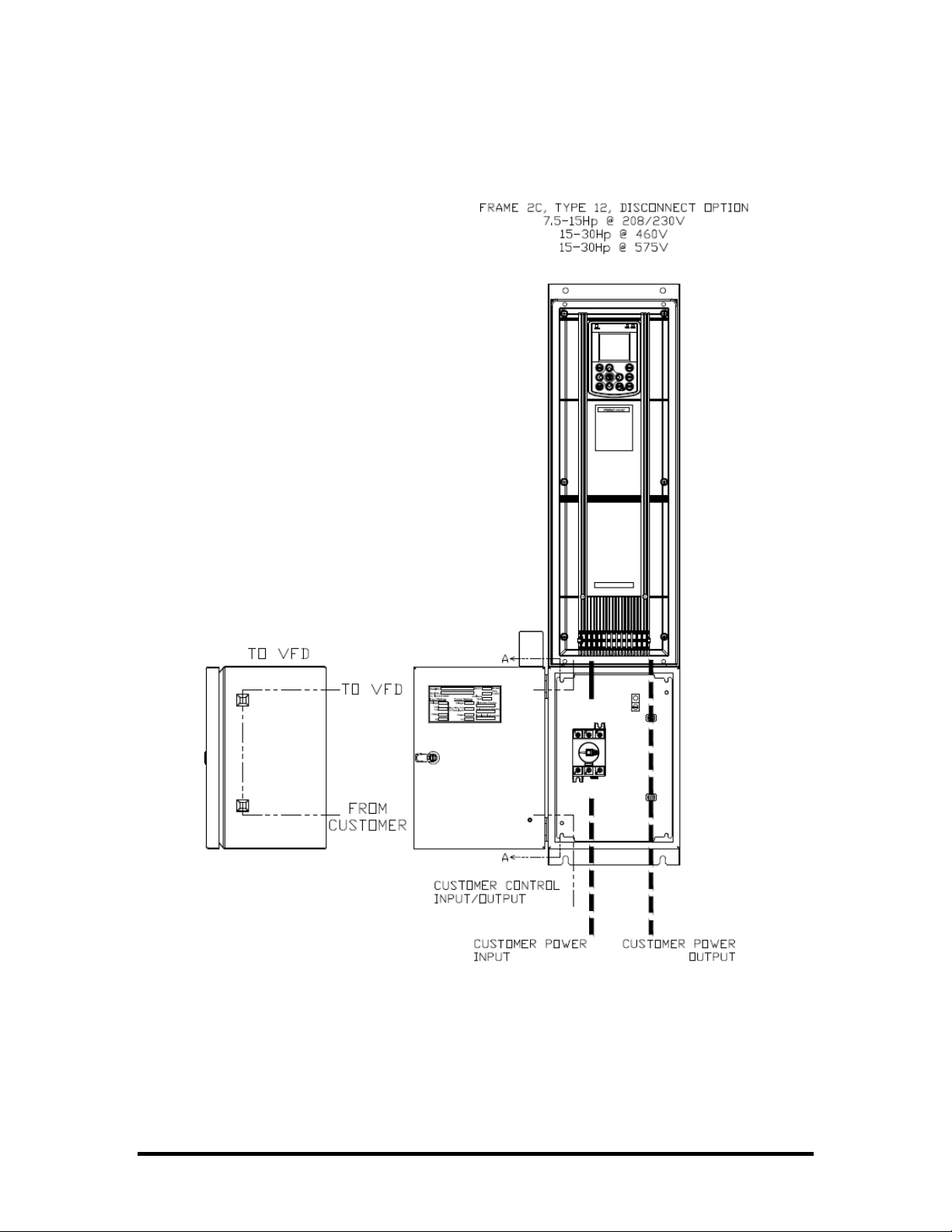

Refer to the diagrams on the following pages for general component layout and for

general routing of power input, power output (motor connections), and control wiring for

your panel. Power input wiring should be routed away from power output wiring, and

both should enter the panel from separate conduit. Control wiring should be routed away

from power wiring, and should enter the panel from separate conduit.

Refer to the following section Control Wiring for descriptions of the control connections.

Page 7 of 37

Wiring Overview (cont’d)

UL/NEMA Type 1 & 12 (Typical Wire Routing)

Page 8 of 37

Wiring Overview (cont’d)

UL/NEMA Type 1 & 12 (Typical Wire Routing)

Page 9 of 37

Wiring Overview (cont’d)

UL/NEMA Type 1 (Typical Wire Routing)

Page 10 of 37

Wiring Overview (cont’d)

UL/NEMA Type 1 (Typical Wire Routing)

Page 11 of 37

Wiring Overview (cont’d)

UL/NEMA Type 12 (Typical Wire Routing)

Page 12 of 37

Loading...

Loading...