FRENIC-HVAC Quick Reference Guide

EN2

Y5A

Y5CY3Y4V2FM1

FM2X5X6

X7

X1X2X3

X4

EN1

30BY1Y2C111

30A

30C

CMY1112

DX -

13CMFWD

REV

PLC

SDCMDX +

Min. Max.

Operang

Voltage

(Sink) Off level 22V 27V

Operang

Voltage

(Sink) Off level 0V 2V

Item

Max.

Operang ON level 2V

Voltage Off level 27V

50m A

Item

Maximum Current at on.

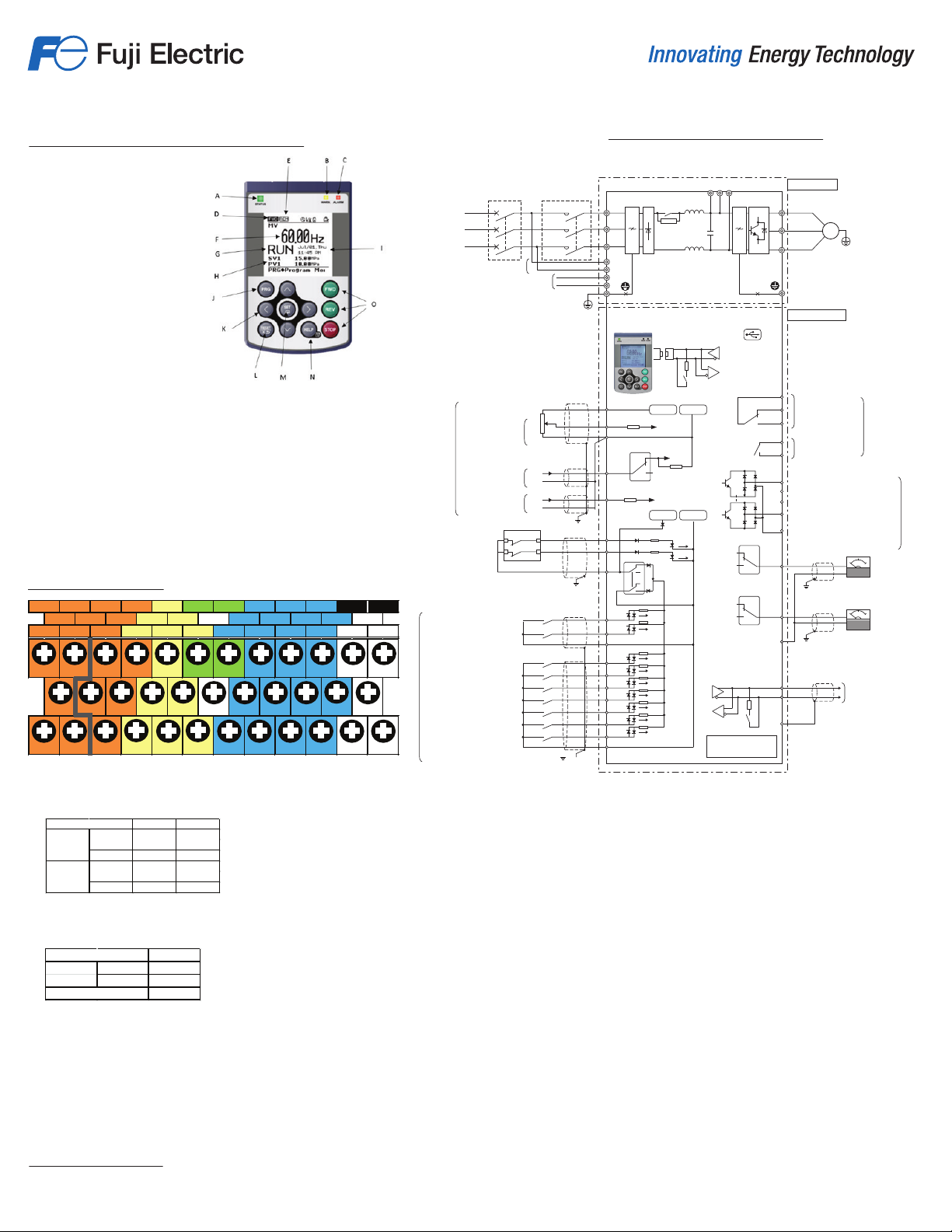

FRENIC-HVAC Multi-Function Keypad

Power supply

400V series

380V~480V

50/60Hz

Control power AUX input *1

Fan power supply auxiliary input *5

A. Run status indicator.

B. Overload Warning Indicator.

C. Alarm indicator.

D. Running direction.

E. Local Remote status monitor.

F. Main programmable Operation Monitor display.

G. Run/Stop Fault Status.

H. 2 additional programmable Operation Monitor displays.

I. Date and Time display.

J. Program button.

K. Menu navigation arrow keys.

L. Alarm reset and previous screen key.

M. Set key for storing changes.

N. Remote and Local toggle and help button.

O. Local mode control operators.

Control Card Terminals

Orange = Outputs, Yellow = Analog Inputs, Blue = Digital Inputs

• FWD, Rev, plus 7 Digital inputs.

Configurable for Source or Sink.

Analog input

Setting voltage input

Setting current input

Setting voltage input

Enable input 1

Enable input 2

FWD operation/stop command

REV operation/stop command

Digital input common

Multi-step frequency selection (0~1steps)

Multi-step frequency selection (0~3steps)

Self-hold selection

Digital input

Coast-to-stop command

Frequency setting 2/frequency setting 1

Local (keypad) instruction selection

Digital input common

MCCB

or ELCB

Potentiometer

power supply

(0~+10VDC)

(0~±10VDC)

4~20mADC

(0~20mADC)

0~±10VDC

*

3

Alarm reset

Magnetic contactor

(MC)

Ground terminal

3

2

(+)

(-)

(+)

(-)

FRENIC-HVAC Control Wiring

Main circuit

U

V

W

G

Ground terminal

Control circuit

30C

30B

Alarm relay output

30A

(for any fault)

Y5C

AX terminal

Y5A

Y1

During operation

Y2

Frequency (speed) agreement

Y3

Frequency (speed) detection

Y4

Motor overload early warning

CMY

Common terminal

(Shared between sink and source)

FM1

FM2

11

DX+

DX-

SD

L1/R

L2/S

L3/T

R0

T0

R1

G

T1

E1

*

4

RS-485 communications port 1

13

+10VDC

12

111

C1

SW5

V2

+24VDC

EN1

EN2

SINK

PLC

SOURCE

FWD

REV

CM

X1

X2

X3

X4

X5

X6

X7

CM

(RJ-45 connector for

keypad connection)

SW3

0V

C1

PTC

0V

SW1

P(-) P(+)

N(-)

0~10VDC

4~20mADC

(0~20mADC)

0~10VDC

4~20mADC

(0~20mADC)

RS-485

communications

port 2 (terminal

block)

4 E2

*

USB port

30

SW4

SW6

SW2

*

7

Motor

M

3~

function

frequency meter

frequency meter

Contact point output

Analog

Analog

Data send/receive

Transistor

output

*

2

ON level 0V 2V

ON level 22V 27V

• 2 0-10VDC analog inputs.

• 4-20mA analog input.

• 4 Transistor outputs.

• 2 0-10V or 4-20mA analog outputs.

• Form A contact relay

o (250VAC 0.3A, cosØ=0.3), (48VDC, .5A).

• Form C contact relay

o (250VAC 0.3A, cosØ=0.3), (48VDC, .5A).

• 24VDC max 200mA DC output power.

• 10VDC output power for potentiometer.

• 2 Source only, safe torque off Enable Inputs.

• RS-485 wiring connections.

Other Control Terminal

• RJ-45 keypad connection port.

• USB Type B connection port when using USB keypad (TP-E1U).

• 3 Option card expansion ports.

*1) To retain an alarm output signal ALM issued on inverter's programmable output terminals by the protective

function or to keep the keypad alive even if the main power has shut down,

connect these terminals to the power supply lines. Even without power supply to these terminals, the inverter

can run.

*2) Terminals [Y1] to [Y4] (transistor outputs) support both SINK and SOURCE modes.

*3) When the Enable function is not to be used, short-circuit terminals [EN1] and [PLC] and terminals [EN2] and

[PLC] using jumper wires. For opening and closing the hardware circuit between terminals [EN1] and [PLC] and

between [EN2] and [PLC], use safety components such as safety relays and safety switches. Be sure to use

shielded wires exclusive to terminals [EN1] and [PLC] and terminals [EN2] and [PLC]. (Do not put them together

with any other control signal wire in the same shielded core.)

*4) Usually there is no need to do anything regarding the EMC filter.

When the leakage current due to the built-in EMC filter causes problems with the power supply system,

removing screws from terminals [E1] and [E2] may improve the problem.

Note that doing so the effect of the EMC filter is lost, and therefore the inverter is no longer compliant with the

EMC standards. To remove those screws, consult your Fuji Electric representative.

*5) Normally there is no need to connect it. Must be connected if inverter is supplied from regenerative PWM

converter (RHC Series) or from DC power supply.

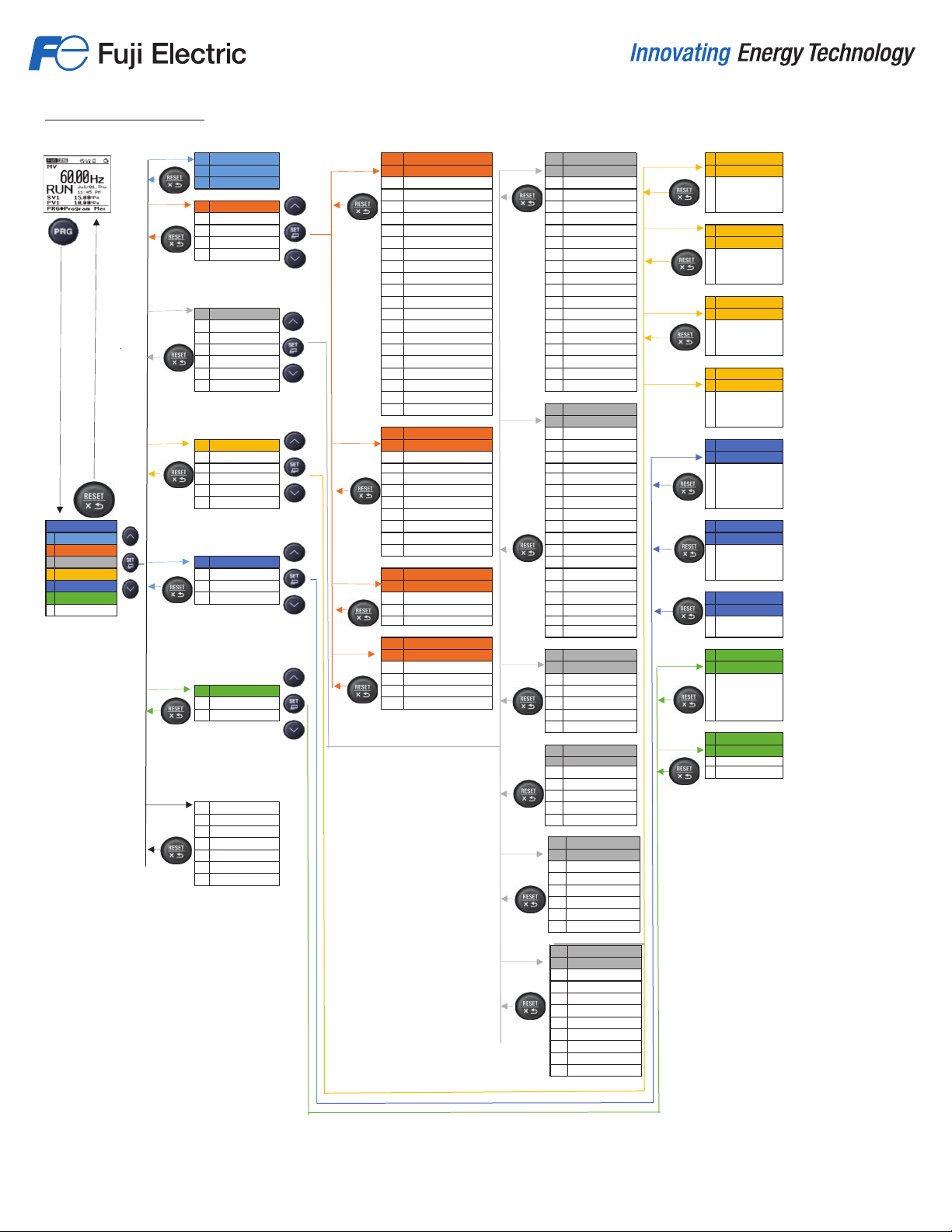

Quick Start Menus

0. Quick setup 1. Start-up 2. 3.Funcon Codes

F:

P:

Motor Param 0. FJapanese

1.

Start-up 2. German C Control

1. 3.Language French P Motor Param

2. 4.App Select HSpanish 3.High Perform

3.

4.

2.

1.

2.

4. 16.Data Copy Malay o Opon

5. 17.Timer Setup TVietnamese 3.Timer

6.

1.

3. 2.I/O Check Motor Prm H4.High Perform

5.

Start-up 73. Usage Pu1 J62EXT PID 2/3

3

5

6

Tools 2. oAdjust Opon 3.3.Retry History

4.Funcon Code dAlarm Info

1.INV Info 1.Alarm History Start-up U4Custom Logic

2.Alarm Info 3.Warn.History U1Date/Time

3.User Config 1.Retry History Disp Format y 4.Link

5.

1. 4.Select Q.Setup 3.Disp at Stop -> K12

2.

6.

2.

3.2.C Logic Monitor

4.

5.

6. Com Debug

ck Portuguese U13.Custom Logic

Op Monitor 1. PAll Data Motor Param

Unit Info 11. Jw/0 Link

Password 4.5.Maintenance

Tools 4.1.KP <-> INV Verify

Mul-Op Mon

Resonant Adv.

Load Factor

1.Fundamental 1.Language (K01) 1.Data Set

1.

5.Date/Time H1Italian 2.High Perform

6.Disp Seng JChinese

8.

9. Greek J2 PID 2

10. J5Turkish Ext PID 1

11. Polish J6 3.EXT PID 2/3

12.Funcon Codes Czech d 4.Applicaon 2

13.Data Set USwedish

14.Data Che

15.Changed Data Dutch y Link

18.Inialize KThai 5.Keypad

19.

Indonesia

100.

1.

Start-up F3.Fundamental

2.INV Info EApp Select (H03) 4.Extension

0.Energy Monitor Disable C Control 1.2.Alarm History

10.Maintenance H1Inialize RTC

12.

71.Main Menu J2Usage Cp1 P

72.Quick Setup J5Usage Fan Ext PID 1 2.1Warn.History

1.

Start-up

4. 2.Disp Seng 5.Funcon Codes

1.

2.

3.User Config 2.Select Speed -> K11 Op Monitor

Fundamental

EEnglish

Extension

Applicaon 1

J1Russian PID 1

Custom Logic

2.U.C.L

Funcon Codes

2.

Data Check

High Perform

Applicaon 1

J1CLR C Logic PID 1

ID 2 4.0Alarm Info

Applicaon 2

Custom Logic

TDST Sengs

Timer

K

Keypad

3.Disp Mode-> K15 1.Changed Data

1.Main Monitor -> K10

Energy Monitor

I/O Check

Unit Info

2.

4.

1. 6. Set PW2KP->INV I.Write

2.3.INV _> KP Read

KP->INV Write

5.PID Monitor

KP Data Check

Funcon Codes

5.

Timer Setup

1.

Timer 1

2.3.Timer 2

Timer 3

4. Timer 4

5. Pause da y

6.2.Overview

Funcon Codes

6.

Inialize (H03)

0.

Disable

1.2.All Data

Motor Prm

10.

Inialize RTC

11.

w/0 Link

12.

CLR C Logic

71.

Usage Cp1

Usage Fan

72.

73.

Usage Pu1

INV Info

Energy Monitor

Last 48 days of

energy

consumpon.

INV Info

Op Monitor

Real me display

of operaons.

INV Info

Maintenance

Maintenance

informaon for

the inverter.

INV Info

Unit Info

Type

Serial # Rom

Version

Alarm Info

Last ten alarms,

Date of alarm,

Number of

occurrences

- Overload

Warning

History

Alarm Info

Auto-restart

History

User Config

Select Q.Setup

Opon to add

Funcon codes

to Quick set

menu.

5.

User Config

2. Funcon Codes

Password

4.Data Copy Set PW1

Fuji Electric Corp. of America

47520 Westinghouse Drive, Fremont, CA 94539

Phone: 510-440-1060

www.americas.fujielectric.com

FECA-HVACQRG

Loading...

Loading...