Fuji Electric Frenic-HVAC Catalog

Low Voltage AC Drives for HVAC Applications

Smile to the Environment

H

VAC

High performance drives enabled by the comprehensive use of Fuji Electric Technology.

Easy maintenance for the end-user, ensures safety and protects the environment.

Opens up possiblebillities for the new generation.

24A1-E-0068c

Smile to the Environment

FRENIC-

~ Energy Saving for the Environment and the Future ~

HVAC

The first slim-type inverter specialized in

energy-saving from Fuji Electric.

Achieves a great effect on energy-saving

for fans and pumps!

Contributes drastically to cost reduction by

cutting power consumption!

Fuji Electric’s inverters save the energy consumed in fans and pumps for

HVAC operations and reduce costs.

The FRENIC-HVAC series controls water and air flow rates, pressure, and

temperature with the fan and pump optimization.

2

Contributes to Reducing Global Warming

(Environmental Protection) and Achieves with Energy Saving

50% of energy consumption in office buildings is related to air conditioning.

The FRENIC-HVAC series are inverters for HVAC that have key features, functions and performances that offer the

optimal thermal environment for the people working in the building by keeping the energy consumption in various

devices such as compressor, condenser water pump and AHU to a minimum.

Fuji Electric contributes largely to global environment by realizing carbon dioxide reduction with energy saving by

the inverter.

Wide Variation in Model Capacity

FRENIC-HVAC is designed for various type of environments, such as supply voltage, enclosures.The user gets every

key features for HVAC market in one unit, such as EMC filter is equipped as standard feature for all models and

DCR is equipped in certain capacity range.

Inverter capacity EMC filter DC reactor Enclosure

1 to 60 HP (Three-phase 230V series)

1 to 125 HP (Three-phase 460V series)

1 to 150 HP (Three-phase 575V series)

75 to 125 HP (Three-phase 230V series)

150 to 1000 HP (Three-phase 460V series)

200 to 300 HP (Three-phase 575V series)

Built-in

Built-in

Built-in

External

IP21/55

NEMA type1 / type12

IP00

Open

Optimal Control with Energy-Saving Function

• Linearization function

• Temperature difference constant control and pressure difference constant control

• Energy saving functions including wet-bulb temperature presumption control

• Automatic energy-saving operation

Slim Body

The first slim body design among the Fuji

Electric inverters.

The size is the same between UL type1 and type12

(the first in the industry).

Functions Suitable for HVAC Uses

• 4 PID control • Fire mode (forced operation)

• Pick-up operation function • Real time clock

• Torque vector control

• Filter clogging prevention function • Customized logic

• User friendly, useful keypad • Password function

Stand Alone

• The inverter can be installed independently; there is no control panel is required.

Stand alone

3

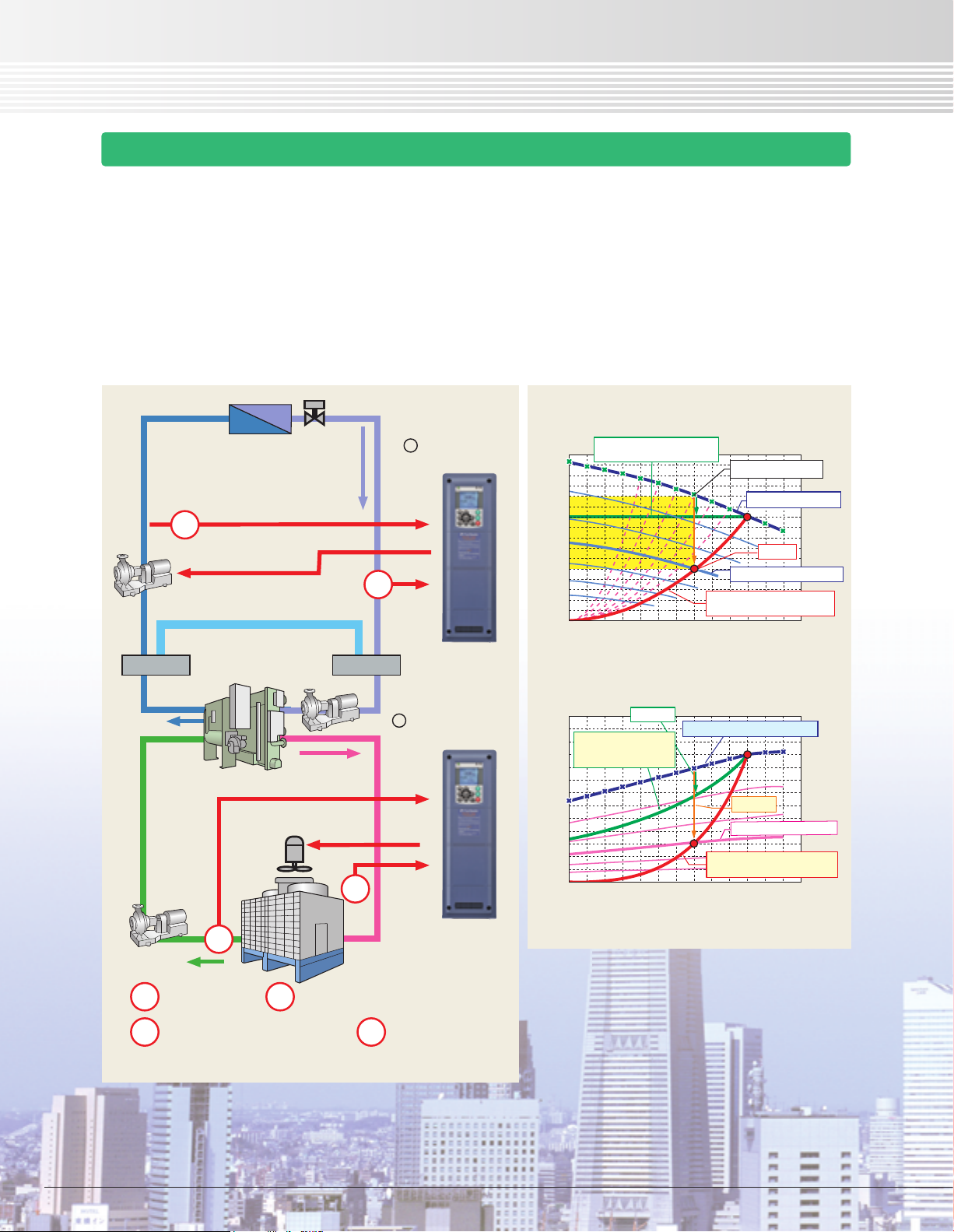

Significant Energy Savings Realized!!

For an air-conditioning heat source system, the quantity of the cooling or heating water

fluctuates generally during the seasons or days and nights. Therefore, operations continuing

in a water conveyance pressure constant control may lead to high operating pressures on

terminals at low operating state. The pump consumes an inefficient electric power for

maintaining the high water conveyance pressure.

FRENIC-HVAC inverters can perform an estimated terminal pressure control by linearization

function which estimates target pressure from a load flow rate.

It is possible to reduce the inefficient pump power consumption and to achieve energy-savings

while maintaining comfortable air conditioning.

4

Optimum Control for HVAC Facilities

• Cooling Tower Fan

The cooling tower fan is used to cool the temperature of

cooling water by emitting it into the air. The fan speed is

adjusted optimally according to the cooling water

temperature at the outlet. Moreover, the inverter

estimates the wet-bulb temperature automatically to

control the fan so that the temperature of cooling water

(wet bulb) is interlocked to the air temperature.

(Wet-bulb temperature presumption control)

• Cooling Water Pump

The cooling water pump circulates the cooling water to

the cooling tower in order to cool the heat generated by

the Refrigeration machine. The pump speed is adjusted

optimally according to the temperature and flow rate of

cooling water. Moreover, the inverter can control the

cooling pump so that the difference of the cooling

water temperature at between the inlet and outlet is

constant. (Temperature difference constant control)

(*)Use the Customized logic to the part of the control

• Chilled Water Pump

The chilled water pump circulates the chilled water

generated with the Refrigeration machine to the air

conditioner and fan coil. The pump speed is adjusted

optimally according to the header pressure. Moreover,

the pump conveyance pressure can be controlled to the

proper value by converting the flow rate signal to the

target pressure using the linearization function.

(Linearization function)

(*)Use the Customized logic to the part of the control

• Supply Fan / Return Fan

The speed of supply and return fans is adjusted

optimally according to the pressure, discharge

temperature, room temperature, and others. Moreover,

the highest level of carbon dioxide is selected

automatically by detecting the level in room to control it

to stay within the allowable level.

5

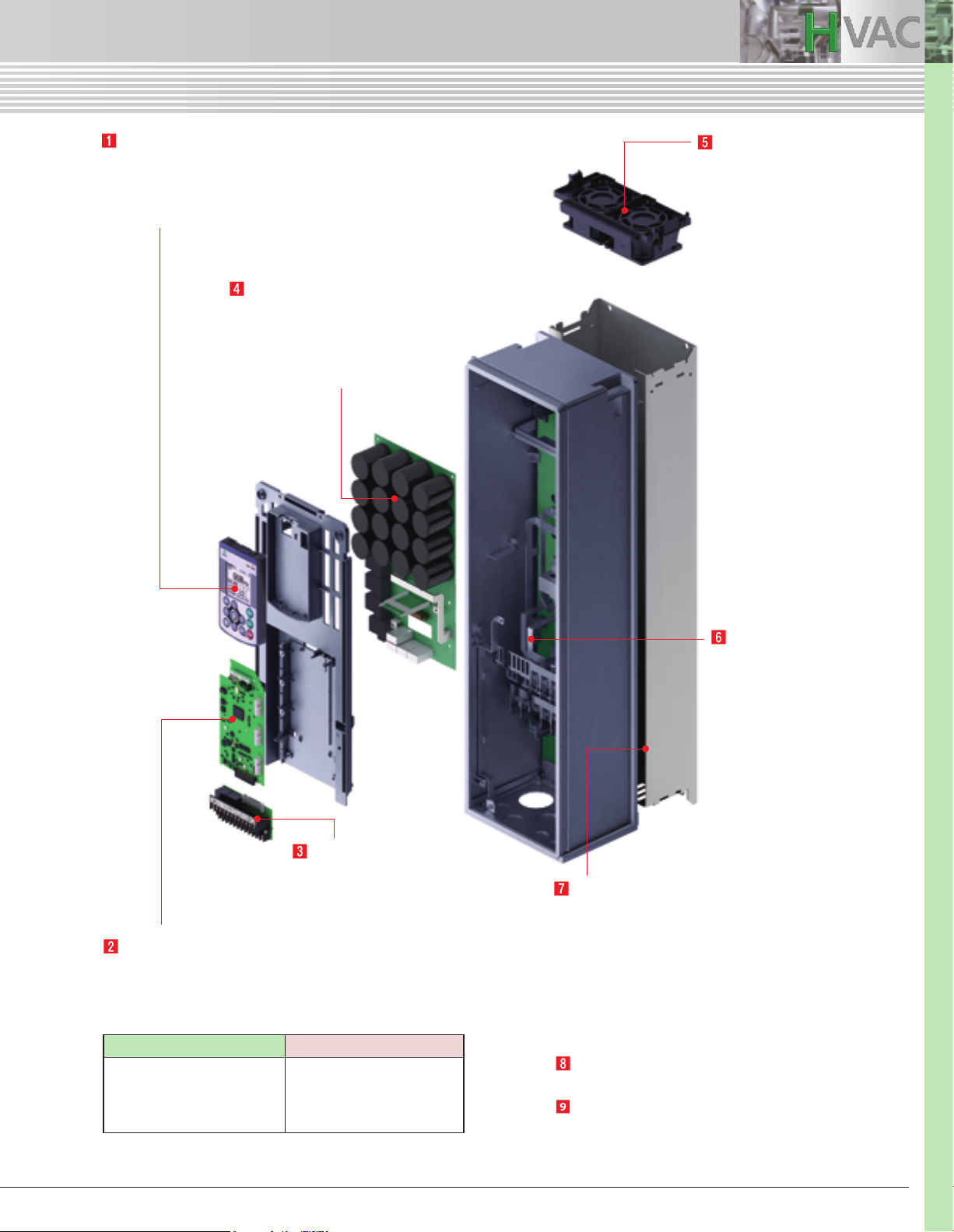

Optimal Structure Design

User Friendly, Easy to See Keypad

• The regulator is indicated by enlarging the LCD.

1. Process Variable (PV)

2. Set Value (SV)

Manipulation Value (MV)

3.

4. Frequency

*Possible to show understandable indications through the unit conversion function.

*Multi-language function: 19 languages + user customized language supported

5. Output Current

6. Output Voltage

7. Torque

8. Rotation Speed

9. Power Consumption

10. Cumulative Energy

• Multi-language supported: 19 languages + user customized language

Language

Japanese

Spanish

Malay

Czech

English

Italian

Vietnamese

Swedish

Chinese

Russian

Thai

Portuguese

German

Greek

Indonesian

Dutch

Real Time Clock (RTC) is Provided as Standard.

• Alarm information with date and time

• Alarm information for last ten times is stored and

displayed with date and time.

Easy failure

analysis

French

Turkish

Polish

• Timer function

• Possible to set the maximum four timers for a week.

• Possible to set flag holidays (20 days a year).

Example

When operation is performed in the

same schedule through a week

24:00:00

18:00:00

12:00:00

06:00:00

00:00:00

MON TUE WED THU FRI SAT SUN MON TUE WED THU FRI SAT SUN

Operation schedule can be set according

to actual condition by using four timers.

When operation schedule varies depending

on the day of the week

24:00:00

18:00:00

12:00:00

06:00:00

00:00:00

• Unit conversion function between PV and SV values

• Unit conversion allows you to easily set data.

Function

Unit conversion

No conversion

3

m

/h

kPa

in-wg

PSI

Units

%

˚C

mWG

psi

RPM

mbar

mmHg

˚F

l/min

bar

kW

ppm

6

User-Friendly, Easy to See Dedicated Keypad

Multi-language supported, HELP function featured, unit

setting with SV and PV values, data copy (three kinds),

detachable and can be attached on the panel (using an

optional cable)

Capacitor Board

Outputs the life prediction signal

determining capacitor capacity

drop and cumulative running

hours. This allows the user to grasp

replacement period.

Cooling Fan

Easy replacement just by

simply removing and

attaching the part.

Prolonged life by controlling

the fan ON and OFF.

Control Terminal Block

The detachable control terminal

block is adopted. This allows the unit

to be replaced easily without

disconnecting cables.

Control Board

USB port equipped, BACnet equipped as standard.

Max. three types of built-in optional boards can be mounted all together.

Optional battery connection

Various communications options

Standard equipment

•

BACnet MS/TP

•

Modbus RTU

•

Metasys N2

Optional equipment

•

LonWorks

•

Ethernet

•

PROFIBUS-DP

*Coming soon

*

•

DeviceNet

•

CANopen

•

CC-Link

EMC Filter

Drastically reduces noise.

Provided to units of all

capacities. Conforming

to IEC61800-3.

DCR

Drastically reduces harmonic noise. Conforming to

IEC/EN61000-3-2 and IEC/EN61000-3-12. Provided

as standard to models up to 60HP (Three-phase

230V series), 125HP (Three-phase 460V series),

150HP (Three-phase 575V series), and can be

attached externally as an option to models from 75

to 125HP (Three-phase 230V series), 150 to

1000HP (Three-phase 460V series), 200 to 300HP

(Three-phase 575V series).

Environmental Immunity

3C2, IEC60721-3-3 supported

Others

Support/analysis software by loader, RTC backup by

battery (option)

7

Functions Suitable for HVAC Use

Linearization Function

This function estimates the target pressure using the load flow rate, which allows the estimated terminal

pressure to be controlled.

For an air-conditioning heat source system, the amount of the cooling or heating water fluctuates generally in

seasons or days and nights. Therefore, operations continuing in a water conveyance pressure constant control

may lead to high operating unnecessary pressures on terminals at low operating state. Thus, the pump

consumes an ineffectual electric power for maintaining the high water conveyance pressure.

Based on the calculated value and water conveyance pressure of estimated terminal pressure using the detected

load flow rate, PID control is performed.

It is possible to reduce the ineffectual pump power consumption and to achieve a great energy-saving effect

together with maintaining comfortable current air conditioning.

Q-H curve

Water conveyance

pressure

P

Chilled water pump

Refrigeration machine

HeaderHeader

Twb

1

Chilled

water pump

F

Load

flow rate

FRENIC-HVAC

2

Cooling

tower fan.

(*)

(*)

Water conveyance pressure [%]

Motive power [%]

Water conveyance pressure

160

constant control characteristics

150

140

130

120

110

100

90

80

70

60

50

40

30

20

10

0 110 120 130

Load flow rate [%]

70% Valve throttling

Pump characteristics

70%

70% Pump characteristics

Estimated terminal pressure

control characteristics

100908020 30 40 50 60 7010

Q-P curve

130

120

Power characteristic in

110

the water conveyance

100

pressure constant control

90

80

70

60

50

40

30

20

10

0 110 120 130

25% cut

Commercial power characteristics

Load flow rate [%]

66% cut

70% power characteristics

Estimated terminal pressure

control characteristics

100908020 30 40 50 60 7010

FRENIC-HVAC

…Thermometer

T

Cooling

water pump

…Flowmeter

F

…Wet-bulb thermometer

Twb

T

Cooling

tower

…Pressare gauge

P

(*) This function needs to optional card, “OPC-PT”.

8

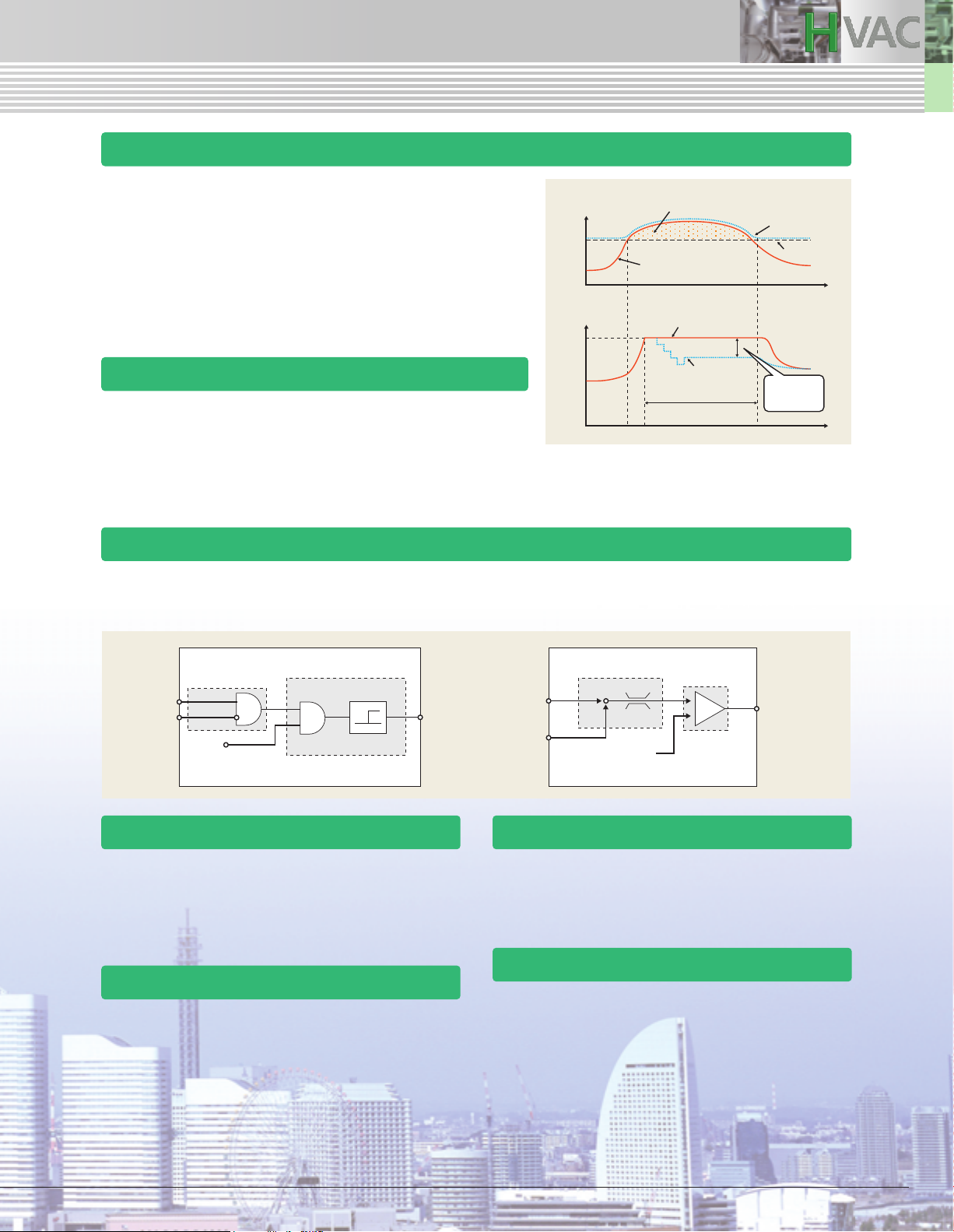

Wet-Bulb Temperature Presumption Control

This function is optimal for controlling the fan of cooling tower.

Since the wet-bulb temperature would become higher than the

set temperature when the air temperature is particularly high,

water temperature will not reach the set temperature.

Therefore, the fan keeps rotating at high speed, failing in

Temperature[˚F]

Set temperature < air (wet-bulb) temperature

Cooling water temperature can only be lowered to the

air (wet-bulb) temperature.

Air (wet-bulb) temperature

Cooling water

temperature

Set temperature

energy-saving operation. FRENIC-HVAC automatically estimates

the wet-bulb temperature and controls the fan so that the

cooling water is interlocked with the air temperature in order

not to use unnecessary electric power.

Filter Clogging Prevention Function

This function detects clogging of the fan filter with dust or

other materials using the output current and pressure sensor

Output

frequency[Hz]

Upper

limiter

Control OFF:

fan high-speed operation

Control ON

Controlled to:

cooling water =

wet-bulb temperature

Wet-bulb temperature

presumption control

Time

Cut the

unnecessary

power.

Time

value. When clogging is detected, the fan is rotated in reverse

to eject dust, and then resumes rotation in forward to blow air.

In addition, the function notifies you of maintenance necessity

with the alarm signal.

Customized Logic

The customized logic interface function is provided to the inverter body. This enables forming of logic circuit and

arithmetic circuit to the digital and analog input and output signals, allowing simple relay sequence to be built

while processing the signals freely.

Example

Step 1

U04

+

-

U05

U04

Step 2

Y3

output

terminal

X1 terminal

X2 terminal

Step 1

[FDT]

Step 2

On-delay timer

0.2

Y1

output

terminal

12 terminal

C1 terminal

Standard 4 PID Control Fire Mode (Forced Operation)

The 4 PID control is featured as standard. One PID

module is used to control the output frequency of the

inverter, and the other three PIDs can be used to

control the external system. To utilize all of four PIDs,

the optional card (OPC-AIO) needs to be mounted.

This mode ignores (retry) the inverter protection

function to continue the operation. In that way, the

inverter keeps operating the fan and pump as much as

possible in case of emergency such as fire.

Pick-up Operation Function

Password

Function codes can be read/write, displayed or hidden

by setting the two passwords. This prevents erroneous

operation or overwriting of function codes. In addition,

if a wrong password was input exceeding the specified

number of times, the inverter is restricted from

operating as the user is regarded as improper.

The pick-up operation function enables smooth starts.

If you wish to run a fan currently not run by the

inverter and in idle mode, this function searches the

speed regardless of the direction of rotation and pick

up the motion smoothly. This function allows for

smooth operation such as when switching the power

supply from the commercial power to inverter in a

momentary action.

9

Loading...

Loading...