Page 1

24A7-E-0069d

Page 2

Page 3

User's Manual

Page 4

Copyright © 2012-2016 Fuji Electric Corp. of America

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric

Corp. of America.

All products and company names mentioned in this manual are trademarks or registered trademarks of their

respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 5

Preface

Catalog

Instruction Manual

RS

Communication

User's Manual

This manual provides all the information on the FRENIC-HVAC series of inverters including its operating

procedure, operation modes, and selection of peripheral equipment. Carefully read this manual for proper

use. Incorrect handling of the inverter may prevent the inverter and/or related equipment from operating

correctly, shorten their lives, or cause problems.

The table below lists the other materials related to the use of the FRENIC-HVAC. Read them in conjunction

with this manual as necessary.

Name Material No. Description

24A1-E-0068

INR-SI47-1707-JE

-485

24A7-E-0021

Product scope, features, specifications, external

drawings, and options of the product

Acceptance inspection, mounting & wiring of the

inverter, operation using the keypad, running the motor

for a test, troubleshooting, and maintenance and

inspection

Overview of functions implemented by using

FRENIC-HVA C RS-485 communications facility, its

communications specifications, Modbus RTU/Fuji

general-purpose inverter protocol and functions, and

related data formats

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

The latest editions can be downloaded from our Web side at:

http://www.americas.fujielectric.com/components/drives-inverters

i

Page 6

Safety precautions

machinery related to nuclear power control, aerospace uses, medical uses or transportation. When the

Read this manual and the FRENIC-HVAC Instruction Manual (that comes with the product) thoroughly

before proceeding with installation, connections (wiring), operation, or maintenance and inspection. Ensure

you have sound knowledge of the product and familiarize yourself with all safety information and

precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

This product is not designed for use in appliances and machinery on which lives depend. Consult your Fuji

Electric representative before considering the FRENIC-HVAC series of inverters for equipment and

product is to be used with any machinery or equipment on which lives depend or with machinery or

equipment which could cause serious loss or damage should this product malfunction or fail, ensure that

appropriate safety devices and/or equipment are installed.

ii

Page 7

How this manual is organized

This manual contains Chapters 1 through 11 and Appendices.

Chapter 1 ABOUT FRENIC-HVAC

This chapter describes the features and control system of the FRENIC-HVAC series and the recommended

configuration for the inverter and peripheral equipment.

Chapter 2 SPECIFICATIONS

This chapter describes specifications of the output ratings, control system, and terminal functions for the

FRENIC-HVAC series of inverters. It also provides descriptions of the operating and storage environment,

product warranty, precautions for use, external dimensions, examples of basic connection diagrams, and

details of the protective functions.

Chapter 3 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

This chapter provides you with information about the inverter output torque characteristics, selection

procedure, and equations for calculating capacities to help you select optimal motor and inverter models.

Chapter 4 SELECTING PERIPHERAL EQUIPMENT

This chapter describes how to use a range of peripheral equipment and options, FRENIC-HVAC's

configuration with them, and requirements and precautions for selecting wires and crimp terminals.

Chapter 5 PREPARATION AND TEST RUN

This chapter details the operating environment, storage environment, installation, wiring, basic connection

examples, names and functions of the keypad components, operation using the keypad, and test run

procedure.

Chapter 6 FUNCTION CODES

This chapter contains overview tables of 12 groups of function codes available for the FRENIC-HVAC series

of inverters, function code index by purpose, and details of function codes.

Chapter 7 BLOCK DIAGRAMS FOR CONTROL LOGIC

This chapter provides the main block diagrams for the control logic of the FRENIC-H VA C series of

inverters.

Chapter 8 RUNNING THROUGH RS-485 COMMUNICATION

This chapter describes an overview of inverter operation through the RS-485 communications facility. Refer

to the RS-485 Communication User's Manual for details.

Chapter 9 TROUBLESHOOTING

This chapter describes troubleshooting procedures to be followed when the inverter malfunctions or detects

an alarm or a light alarm condition. In this chapter, first check whether any alarm code or the "light alarm"

indication (L-AL) is displayed or not, and then proceed to the troubleshooting items.

Chapter 10 MAINTENANCE AND INSPECTION

This chapter provides the instructions on how to perform daily and periodic inspections in order to avoid

trouble and keep reliable operation of the inverter for a long time.

iii

Page 8

Chapter 11 CONFORMITY WITH STANDARDS

This icon indicates information which, if not heeded, can result in the inverter not operating to

full efficiency, as well as information concerning incorrect operations and settings which can

result in accidents.

This icon indicates information that can prove handy when performing certain settings or

operations.

This icon indicates a reference to more detailed information.

This chapter sets forth the conformity with overseas standards.

Appendices

Icons

The following icons are used throughout this manual.

iv

Page 9

CONTENTS

Chapter 1 About FRENIC-HVA C

1.1 Features ..................................................................................................................................................... 1-1

1.2 Inspection of goods and product appearance .................................................................................... 1-13

1.2.1 Inspection of goods ........................................................................................................................ 1-13

1.2.2 Product appearance ....................................................................................................................... 1-15

Chapter 2 SPECIFICATIONS

2.1 Standard Model FRENIC-HVAC .............................................................................................................. 2-1

2.1.1 Three-phase 230 V class series (USA models) .................................................................................... 2-1

2.1.2 Three-phase 460 V class series (USA models) ................................................................................... 2-3

2.1.3 Three-phase 575 V class series (USA models) ................................................................................... 2-6

2.2 Common Specifications .............................................................................................................................. 2-9

2.3 Terminal Specifications ............................................................................................................................. 2-16

2.3.1 Terminal functions ............................................................................................................................ 2-16

2.3.2 Setting up the slide switches ............................................................................................................. 2-26

2.3.3 Screw specifications and recommended wire sizes ........................................................................... 2-28

2.3.3.1 Main circuit terminals ............................................................................................................... 2-28

2.3.3.2 Control circuit terminals (Common to all inverter types) ......................................................... 2-35

2.4 Conduits .................................................................................................................................................... 2- 36

2.4.1 Conduits ............................................................................................................................................ 2-36

2.5 Leakage Current of the EMC Filter........................................................................................................... 2-39

2.6 Derating of Rated Output Current ............................................................................................................. 2-42

2.7 Operating Environment and Storage Environment ................................................................................... 2-44

2.7.1 Operating environment ...................................................................................................................... 2-44

2.7.2 Storage environment ......................................................................................................................... 2-45

2.7.2.1 Temporary storage ..................................................................................................................... 2-45

2.7.2.2 Long-term storage ..................................................................................................................... 2-45

2.8 Precautions for Using Inverters ................................................................................................................. 2-46

2.8.1 Precautions in introducing inverters .................................................................................................. 2-46

2.8.2 Precautions in running inverters ........................................................................................................ 2-50

2.8.3 Precautions in using special motors .................................................................................................. 2-50

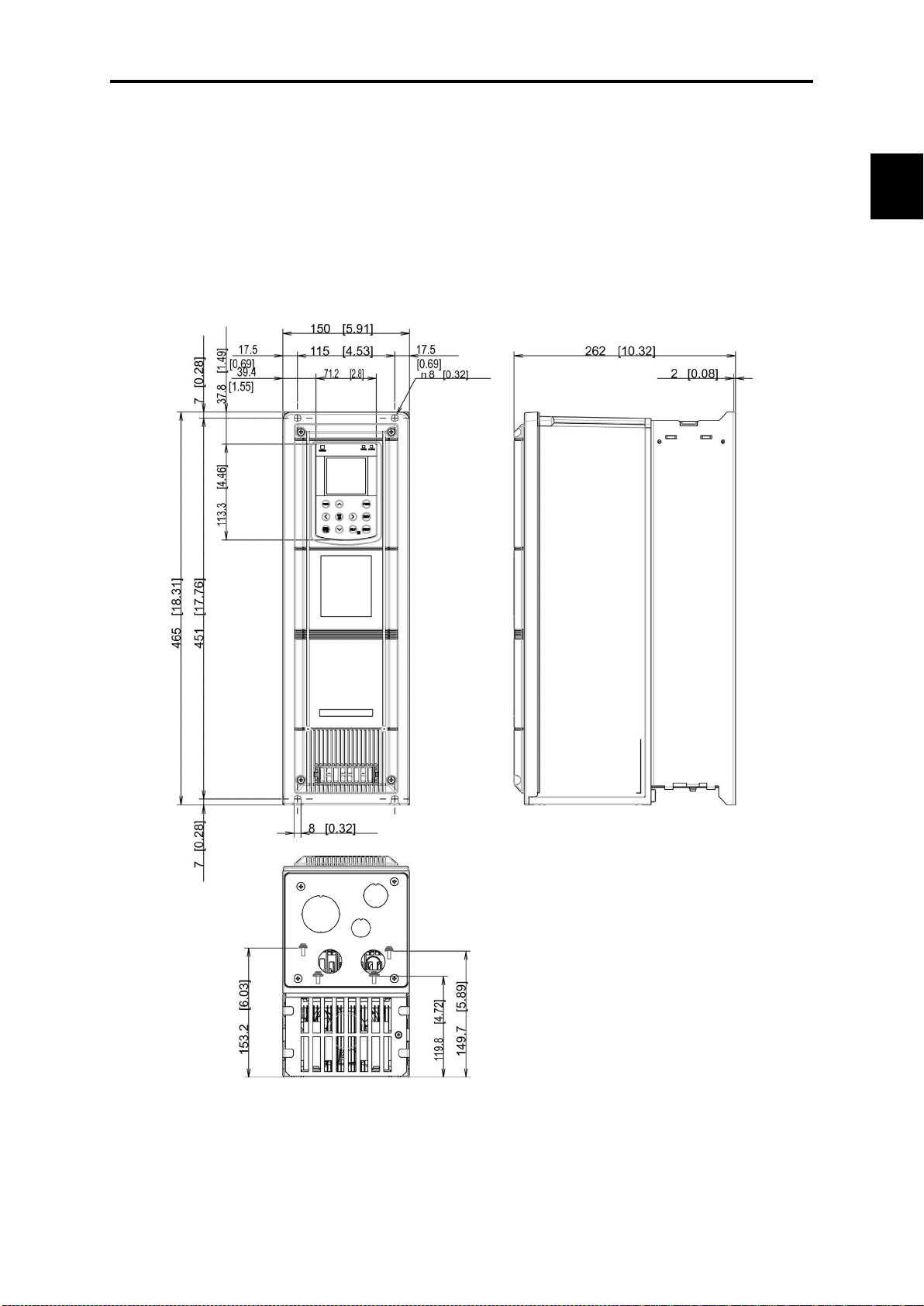

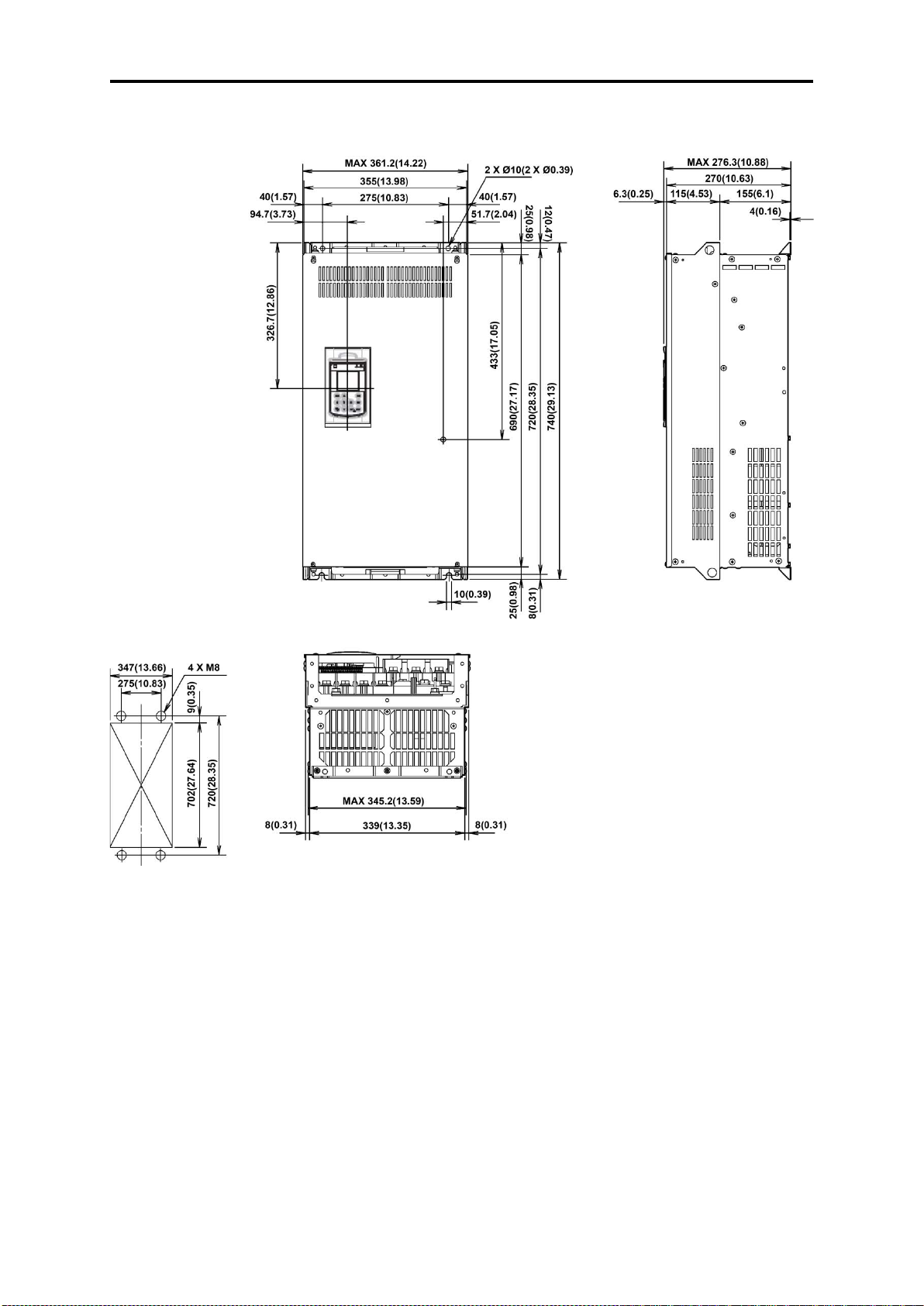

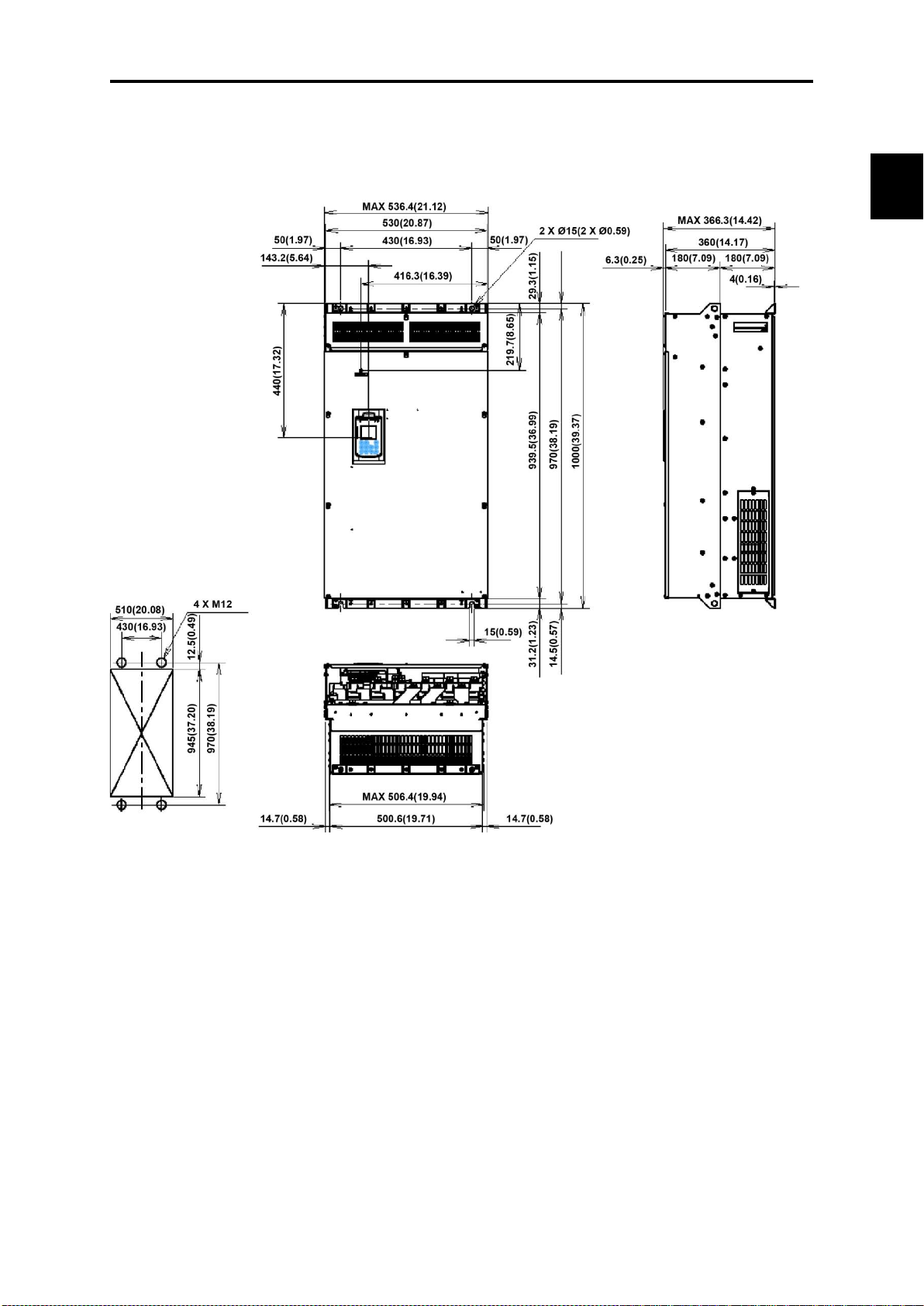

2.9 External Dimensions ................................................................................................................................. 2- 51

2.9.1 Standard models ................................................................................................................................ 2- 51

2.9.2 Keypad .............................................................................................................................................. 2-64

2.10 Connection Diagrams ................................................................................................................................ 2-65

Chapter 3 SELECTING OPTIMAL MOTOR AND INVERTER CAPACITIES

3.1 Selecting Motors and Inverters ................................................................................................................... 3-1

3.1.1 Motor output torque characteristics ..................................................................................................... 3-1

3.1.2 Selection procedure ............................................................................................................................. 3-3

3.1.3 Equations for selections ...................................................................................................................... 3-6

3.1.3.1 Load torque during constant speed running ................................................................................ 3-6

3.1.3.2 Calculation of acceleration/deceleration time ............................................................................. 3-7

3.1.3.3 Heat energy calculation of braking resistor ............................................................................... 3-10

Chapter 4 SELECTING Peripheral EQUIPMENT

4.1 Configuring the FRENIC-HVAC ................................................................................................................ 4-1

4.2 Currents flowing across the inverter terminals ............................................................................................ 4-2

4.3 Peripheral Equipment .................................................................................................................................. 4-5

v

Page 10

4.3.1 Molded case circuit breaker (MCCB), residual-current-operated protective device (RCD)/

earth leakage circuit breaker (ELCB) and magnetic contactor (MC) .................................................. 4-5

4.3.2 Surge killers for L-load ..................................................................................................................... 4-10

4.3.3 Arresters ............................................................................................................................................ 4-11

4.3.4 Surge absorbers ................................................................................................................................. 4-12

4.4 Options ...................................................................................................................................................... 4- 13

4.4.1 Selecting peripheral equipment options ............................................................................................ 4-13

4.4.1.1 Power regenerative PWM converters, RHC series .................................................................... 4-13

4.4.1.2 AC reactors (ACRs) .................................................................................................................. 4-36

4.4.1.3 DC reactors (DCRs) (Built-in or bundled as standard) ............................................................. 4-41

4.4.1.4 Surge suppression unit (SSU) .................................................................................................... 4-43

4.4.1.5 Output circuit filters (OFLs) ...................................................................................................... 4-44

4.4.1.6 Zero-phase reactors for reducing radio noise (ACLs) ............................................................... 4-48

4.4.2 Selecting options for operation and communication ......................................................................... 4-49

4.4.2.1 External frequency command potentiometer ............................................................................. 4-49

4.4.2.2 Extension cable for remote operation ........................................................................................ 4-50

4.4.2.3 Frequency meters ...................................................................................................................... 4-50

4.4.2.4 Inverter support loader software ................................................................................................ 4-51

4.4.3 Selecting Option Cards ..................................................................................................................... 4-52

4.4.3.1 List of option cards, connection ports, and applicable ROM versions ...................................... 4-52

4.4.3.2 Relay output interface card (OPC-RY) ...................................................................................... 4-53

4.4.3.3 Relay output interface card (OPC-RY2) .................................................................................... 4-55

4.4.3.4 Analog interface card (OPC-AIO)............................................................................................. 4-57

4.4.3.5 Analog current output (2 ch) interface card (OPC-AO) ............................................................ 4-61

4.4.3.6 Resistance temperature detector input card (OPC-PT) .............................................................. 4-63

4.4.3.7 CC-Link communications card (OPC-CCL) ............................................................................. 4-66

4.4.3.8 PROFIBUS-DP communications card (OPC-PDP2) ................................................................ 4-68

4.4.3.9 DeviceNet communications card (OPC-DEV) .......................................................................... 4-71

4.4.3.10 CANopen communications card (OPC-COP) ........................................................................... 4-74

4.4.3.11 LONWORKS communications card (OPC-LNW) ................................................................... 4-76

4.4.3.12 Ethernet communications card (OPC-ETH) .............................................................................. 4-77

4.5 Backup Battery .......................................................................................................................................... 4-79

4.5.1 Outline ............................................................................................................................................... 4-79

4.5.2 Loading the battery ........................................................................................................................... 4-80

4.5.3 Battery replacement procedure .......................................................................................................... 4-82

4.5.4 About air transport of batteries .......................................................................................................... 4-82

Chapter 5 PREPARATION AND TEST RUN

5.1 Mounting and Wiring the Inverter ............................................................................................................... 5-1

5.1.1 Installing the inverter .......................................................................................................................... 5-1

5.1.2 Wiring ................................................................................................................................................. 5-4

5.1.2.1 Removing and mounting the front cover and the wiring plate .................................................... 5-4

5.1.2.2 Input ferrite core diameter ........................................................................................................... 5-7

5.1.3 Screw specifications and recommended wire sizes ............................................................................. 5-7

5.1.3.1 Main circuit terminals ................................................................................................................. 5-7

5.1.3.2 Control circuit terminals (Common to all inverter types) ........................................................... 5-7

5.1.4 Conduits .............................................................................................................................................. 5-7

5.1.5 Wiring precautions .............................................................................................................................. 5-8

5.1.6 Wiring of main circuit terminals and grounding terminals.................................................................. 5-9

5.1.7 Wiring for control circuit terminals ................................................................................................... 5-16

5.1.8 Setting up the slide switches ............................................................................................................. 5-19

5.1.9 USB port ........................................................................................................................................... 5-20

vi

Page 11

5.2 Mounting and Connecting a Keypad ......................................................................................................... 5-21

5.2.1 Parts required for connection ............................................................................................................ 5-21

5.2.2 Mounting procedure .......................................................................................................................... 5-21

5.3 Operation Using the Keypad ..................................................................................................................... 5-24

5.3.1 LCD monitor, keys and LED indicators on the keypad ..................................................................... 5-24

5.4 Overview of Operation Modes .................................................................................................................. 5-28

5.5 Running Mode .......................................................................................................................................... 5-29

5.5.1 Monitoring the running status ........................................................................................................... 5-29

5.5.2 Setting up frequency and PID commands ......................................................................................... 5-32

5.5.3 Running/stopping the motor .............................................................................................................. 5-36

5.5.4 Remote and local modes ................................................................................................................... 5-36

5.5.5 Changing from keypad operation to external signal (terminal block) operation ............................... 5-37

5.5.6 Monitoring light alarms ..................................................................................................................... 5-37

5.6 Programming Mode .................................................................................................................................. 5-38

5.6.1 Quick Setup ....................................................................................................................................... 5-40

5.6.2 Start-up .............................................................................................................................................. 5-40

5.6.2.1 Set Display Language ................................................................................................................ 5-41

5.6.2.2 Function-Specific Initialization ................................................................................................. 5-42

5.6.2.3 Date/Time Settings .................................................................................................................... 5-42

5.6.2.4 Set Display ................................................................................................................................ 5-45

5.6.3 Function Codes ................................................................................................................................. 5-46

5.6.3.1 Setting up function codes .......................................................................................................... 5-47

5.6.3.2 Confirm Data ............................................................................................................................. 5-49

5.6.3.3 Confirm Changed Function Code .............................................................................................. 5-49

5.6.3.4 Copying data ............................................................................................................................. 5-49

5.6.3.5 Set Timer Operation .................................................................................................................. 5-61

5.6.3.6 Initialize Data ............................................................................................................................ 5-64

5.6.4 Inverter Information .......................................................................................................................... 5-65

5.6.4.1 Confirm Power Level ................................................................................................................ 5-65

5.6.4.2 Confirm Operational Status ....................................................................................................... 5-66

5.6.4.3 Check Status of Input/Output Signal ......................................................................................... 5-69

5.6.4.4 View Maintenance Information ................................................................................................. 5-71

5.6.4.5 View Unit Information .............................................................................................................. 5-75

5.6.5 Alarm Information ............................................................................................................................ 5-76

5.6.5.1 Confirm Alarm History ............................................................................................................. 5-76

5.6.5.2 Confirm Light Alarm History .................................................................................................... 5-80

5.6.5.3 Retry History ............................................................................................................................. 5-80

5.6.6 User Config ....................................................................................................................................... 5-81

5.6.6.1 Quick Setup ............................................................................................................................... 5-81

5.6.6.2 Password ................................................................................................................................... 5-81

5.6.7 Tools .................................................................................................................................................. 5-85

5.6.7.1 Monitor PID Control Status ...................................................................................................... 5-85

5.6.7.2 Monitor Multiple Unit Controls ................................................................................................ 5-88

5.6.7.3 Monitor Customized Logic (CLogic) ........................................................................................ 5-91

5.6.7.4 Resonance Avoidance ................................................................................................................ 5-92

5.6.7.5 Load Factor Measurement ......................................................................................................... 5-93

5.6.7.6 Communication Debug ............................................................................................................. 5-96

5.7 Alarm Mode .............................................................................................................................................. 5-97

5.7.1 Releasing the alarm and switching to Running mode ....................................................................... 5-97

5.7.2 Displaying the alarm history ............................................................................................................. 5-97

5.7.3 Displaying the status of inverter at the time of alarm ....................................................................... 5-97

5.7.4 Test run procedure ............................................................................................................................. 5-98

vii

Page 12

5.7.5 Checking prior to powering ON ........................................................................................................ 5-99

5.7.6 Powering ON and checking............................................................................................................. 5-100

5.7.7 Selecting a desired motor drive control ........................................................................................... 5-100

5.7.8 Function code basic settings < 1 > .................................................................................................. 5-101

5.7.9 Function code basic settings and tuning < 2 > ................................................................................ 5-103

5.7.10 Running the inverter for motor operation check ............................................................................. 5-106

5.7.11 Preparation for practical operation .................................................................................................. 5-107

Chapter 6 FUNCTION CODES

6.1 Overview of Function Codes ...................................................................................................................... 6-1

6.2 Function Code Tables .................................................................................................................................. 6-2

6.3 Details of Function Codes ......................................................................................................................... 6-41

6.3.1 F codes (Fundamental functions) ...................................................................................................... 6-41

6.3.2 E codes (Extension terminal functions) ............................................................................................. 6-84

6.3.3 C codes (Control functions) ............................................................................................................ 6-125

6.3.4 P codes (Motor 1 parameters) ......................................................................................................... 6-137

6.3.5 H codes (High performance functions) ........................................................................................... 6-141

6.3.6 H1 codes (High performance functions) ......................................................................................... 6-174

6.3.7 J codes (Application functions 1) .................................................................................................... 6-181

6.3.8 J1 codes (PID control 1) .................................................................................................................. 6-182

6.3.9 J2 codes (PID control 2) .................................................................................................................. 6-215

6.3.10 J5 codes (External PID control 1) ................................................................................................... 6-217

6.3.11 J6 codes (External PID control 2, 3) ............................................................................................... 6-245

6.3.12 d codes (Application functions 2) ................................................................................................... 6-249

6.3.13 U codes (Customizable logic functions) ......................................................................................... 6-249

6.3.14 U1 codes (Customizable logic functions) ....................................................................................... 6-270

6.3.15 y codes (Link functions) .................................................................................................................. 6-275

6.3.16 T codes (Timer functions) ............................................................................................................... 6-280

6.3.17 K codes (Keypad functions) ............................................................................................................ 6-284

Chapter 7 BLOCK DIAGRAMS FOR CONTROL LOGIC

7.1 Symbols Used in Block Diagrams and their Meanings ............................................................................... 7-1

7.2 Frequency Command Block ........................................................................................................................ 7-2

7.3 Drive Command Block ............................................................................................................................... 7-4

7.4 V/f Control Block ....................................................................................................................................... 7-5

7.5 PID Process Control Block ......................................................................................................................... 7-7

7.6 External PID Process Control Block ........................................................................................................... 7-9

7.7 FM1/FM2 Output Selector ........................................................................................................................ 7-11

Chapter 8 RUNNING THROUGH RS-485 COMMUNICATION

8.1 Overview on RS-485 Communication ........................................................................................................ 8-1

8.1.1 RS-485 common specifications ........................................................................................................... 8-2

8.1.2 Terminal specifications for RS-485 communication ........................................................................... 8-3

8.1.3 Connection method ............................................................................................................................. 8-4

8.1.4 Communications support devices ........................................................................................................ 8-6

8.1.5 Noise suppression ............................................................................................................................... 8-7

8.2 Overview of FRENIC Loader ..................................................................................................................... 8-8

8.2.1 Specifications ...................................................................................................................................... 8-8

8.2.2 USB port on the inverter unit .............................................................................................................. 8-9

Chapter 9 TROUBLESHOOTING

viii

Page 13

9.1 Protective Functions .................................................................................................................................... 9-1

9.2 Before Proceeding with Troubleshooting .................................................................................................... 9-2

9.3 If an Alarm Code Appears on the Monitor .................................................................................................. 9-3

9.3.1 Alarm Codes ....................................................................................................................................... 9-3

9.3.2 If the "Light Alarm" Indication Appears ........................................................................................... 9-22

9.4 Nothing appears on the monitor ................................................................................................................ 9-24

9.4.1 Abnormal motor operation ................................................................................................................ 9-24

9.4.2 Problems with inverter settings ......................................................................................................... 9-31

9.5 If Other than an Alarm Code is Displayed ................................................................................................ 9-33

Chapter 10 MAINTENANCE AND INSPECTION

10.1 Daily Inspection ........................................................................................................................................ 10-1

10.2 Periodic Inspection .................................................................................................................................... 10-1

10.3 List of Periodic Replacement Parts ........................................................................................................... 10-3

10.3.1 Judgment on service life .................................................................................................................... 10-4

10.4 Measurement of Electrical Amounts in Main Circuit ............................................................................... 10-8

10.5 Insulation Test ........................................................................................................................................... 10-9

10.6 Cooling Fan Replacement Procedure ...................................................................................................... 10-10

Chapter 11 CONFORMITY WITH STANDARDS

11.1 Compliance with European Standards ...................................................................................................... 11-1

11.1.1 Conformity to the Low Voltage Directive in the EU ......................................................................... 11-2

11.1.2 Compliance with EMC Standards ..................................................................................................... 11-8

11.1.2.1 General ...................................................................................................................................... 11-8

11.1.2.2 Recommended installation procedure ....................................................................................... 11-8

11.1.2.3 Leakage current of the EMC filter........................................................................................... 11-10

11.1.3 Harmonic Component Regulation in the EU .................................................................................. 11-14

11.1.3.1 General .................................................................................................................................... 11-14

11.1.3.2 Compliance with IEC/EN 61000-3-2 ...................................................................................... 11-14

11.1.3.3 Compliance with IEC/EN 61000-3-12 .................................................................................... 11-14

11.2 Conformity with UL Standards and cUL-listed for Canada .................................................................... 11-15

11.2.1 General ............................................................................................................................................ 11-15

11.2.2 Conformity with UL standards and cUL-listed for Canada ............................................................. 11-15

Appendices

App. A Advantageous Use of Inverters (Notes on electrical noise) ................................................................... 1

A.1 Effect of inverters on other devices ........................................................................................................ 1

A.2 Noise ...................................................................................................................................................... 3

A.3 Noise prevention .................................................................................................................................... 5

App. B Effect on Insulation of General-purpose Motors Driven with 400 V Class Inverters .......................... 13

B.1 Generating mechanism of surge voltages ............................................................................................. 13

B.2 Effect of surge voltages ........................................................................................................................ 14

B.3 Countermeasures against surge voltages .............................................................................................. 14

B.4 Regarding existing equipment .............................................................................................................. 15

App. C Inverter Generating Loss ...................................................................................................................... 16

App. D Connection Notes at Inverter Replacement Time

(Using the high power factor PWM converter, RHC series) ........................................................................ 18

ix

Page 14

Page 15

Chapter 1

About FRENIC-HVAC

This chapter describes the features, control system, outer appearance and recommended configuration of

peripheral equipment for FRENIC-HVAC.

Contents

1.1 Features ...................................................................................................................................................... 1-1

1.2 Inspection of goods and product appearance ........................................................................................... 1-13

1.2.1 Inspection of goods ......................................................................................................................... 1-13

1.2.2 Product appearance ......................................................................................................................... 1-15

Page 16

Page 17

Chap. 1

About FRENIC

1 to 60 HP ( Three-phase 230V series )

■

●4PID control

●Password function

●Fire mode (Forced operation)

●Filter clogging prevention function

●Pick-up operation function

●Automatic energy-saving operation

●Customizable logic

●Wet-bulb temperature presumption control

●Regenerative avoidance control

●Linearization function

●Real time clock

●Torque vector control

●Overload avoidance control

●Commercial operation switching

●Command loss detection

●Low torque detection

●Low torque detection

●Slow flowrate stop function

1.1 Features

1.1 Features

Overview

FRENIC-HVAC is Fuji Electric’s first “slim-type inverter specially designed for saving energy.”

The device is ideal for all kinds of applications related to systems for supplying water and treating

wastewater.

Achieving significant energy savings in HVAC by the optimal control.

Wide capacity range

∙ 1 to 125 HP / 230V

∙ 1 to 1000 HP / 460V

∙ 1 to 300 HP / 575V

Protective structure

∙ NEMA UL type1/ type12

∙ Open type

Equipped with DC reactor (DCR) / EMC filter

Inverter capacity EMC filter DC reactor Enclosure

1 to 125 HP ( Three-phase 460V series )

1 to 150 HP ( Three-phase 575V series )

075 to 125 HP ( Three-phase 230V series )

150 to 1000 HP ( Three-phase 460V series )

200 to 300 HP ( Three-phase 575V series )

Built-in Built-in

Built-in

Standard

accessory

NEMA UL

type1 / type12

Open

-HVAC

DCR:IEC/EN 61000-3-2, IEC/EN 61000-3-12

Functions suitable for HVAC use

1-1

Page 18

PID1 PV

+

-

PI D1 SV

偏差

最大選択

最小選択

プロセス指令値

フィードバック値

SV:Set Value

PV:Process Value

PID

調節器

正動作/

逆動作

演算器

速度指令

選択

PID制御

キャン セル

外部PID1出力

積分・微分リセット

積分ホールド

アン チリセットワイ ンドアップ

+

-

フィードバック

選択

PID2 PV

PID2 SV

プロセス指令値

PID

調節器

速度指令

選択

PID制御

キャン セル

外部PID2出力

正動作/

逆動作

積分・微分リセット

積分ホールド

アン チリセットワイ ンドアップ

+

-

フィードバック

選択

PID3 PV

PID3 SV

プロセス指令値

PID

調節器

正動作/

逆動作

PID制御

キャン セル

外部PID3出力

積分・微分リセット

積分ホールド

アン チリセットワイ ンドアップ

速度指令

選択

External PID output

∙

∙

Feedback value

Computing

Process command

value

Feedback

selection

Process command value

Integral hold

Integral/differential reset

Anti

Integral hold

Integral/differential reset

Anti

Integral hold

Integral/differential reset

Anti

Speed

selection

regulator

reverse

Deviation

External PID1 output

Cancel PID

control 1

Feedback

selection

control 2

Cancel PID

control 3

Speed

selection

Forward/

reverse

Forward/

reverse

External PID1 output

External PID1 output

PID

regulator

PID

SV: Set Value

PV: Process Value

Process command value

Speed

PID1 PV

演算器

+

-

PI D1 SV

+

-

フィードバッ ク

選択

偏差

最大選択

最小選択

PID制御2/1切換

PID

調節器

アン チリセッ トワイ ンド アップ

積分ホールド

積分・微分リセット

速度指令

選択

渇水保護

少水量停止機能

大水量保護

高頻度運転保護

フィルタ目詰まり/噛み込み防止

正動作/

逆動作

PID制御

キャン セル

周波数指令

PID2 PV

PID2 SV

プロセス指令値

フィードバッ ク値

プロセス指令値

SV:Set Value PV:Pr ocess Value

フィードバッ ク値

PID

Speed

command

PID

PV

PID2

SV

Computing

Process command value

Feedback

Process

command value

Feedback value

Feedback value

PID control 2/1 switching

PID control

Frequency

command

PID

regulator

Forward/

reverse

Integral hold

Integral/differential reset

Anti

up

Dry pump

detection

Slow flow rate

stop function

End of curve

detection

Control of maximum

starts per hour

PID2

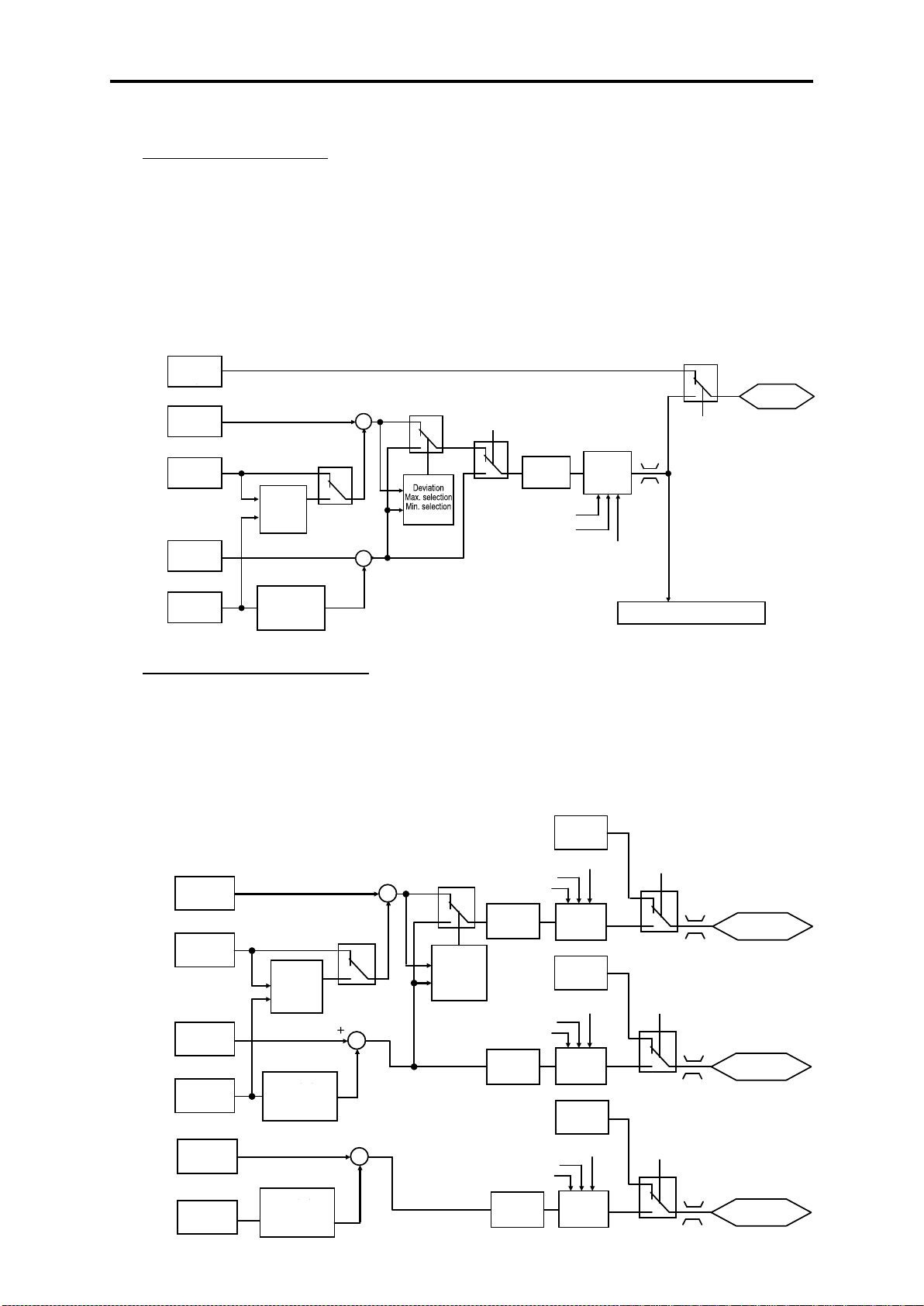

4PID control (standardly equipped with 4PID)

∙ PID control (for process)

Can be used by switching 2 types of process commands and feedback value. “Filter clogging /

anti-jam, deviation alarm / absolute value alarm output” have been added to PID regulator that

conducts temperature, pressure or flow rate control, etc. An anti-reset wind-up function to

prevent PID control overshoot and PID control function that can be easily adjusted by PID

limiter or integral fold / reset signal are furthermore employed.

PID control (process) block diagram

selection

1 SV

1

unit

-reset wind-

PV

selection

Filter clogging / anti-jam

∙ External PID control (process)

Equipped with 3 built-in external PID controllers. You can independently control external

actuators such as dampers and valves. An externally mounted PID controller is no longer

required, thereby enabling cost reduction.

External PID control (process) block diagram

command

-reset wind-up

Forward/

PID

Max. selection

Min. selection

command

-reset wind-up

Cancel PID

unit

command

selection

-reset wind-up

regulator

cancel

Y1-Y4 pins

⇒Pulse output

FM1/FM2 pins

⇒Analog output

1-2

Page 19

Chap. 1

About FRENIC

Power

source

voltage

Rotation

speed

Output

frequency

Current

Instantaneous

power failure

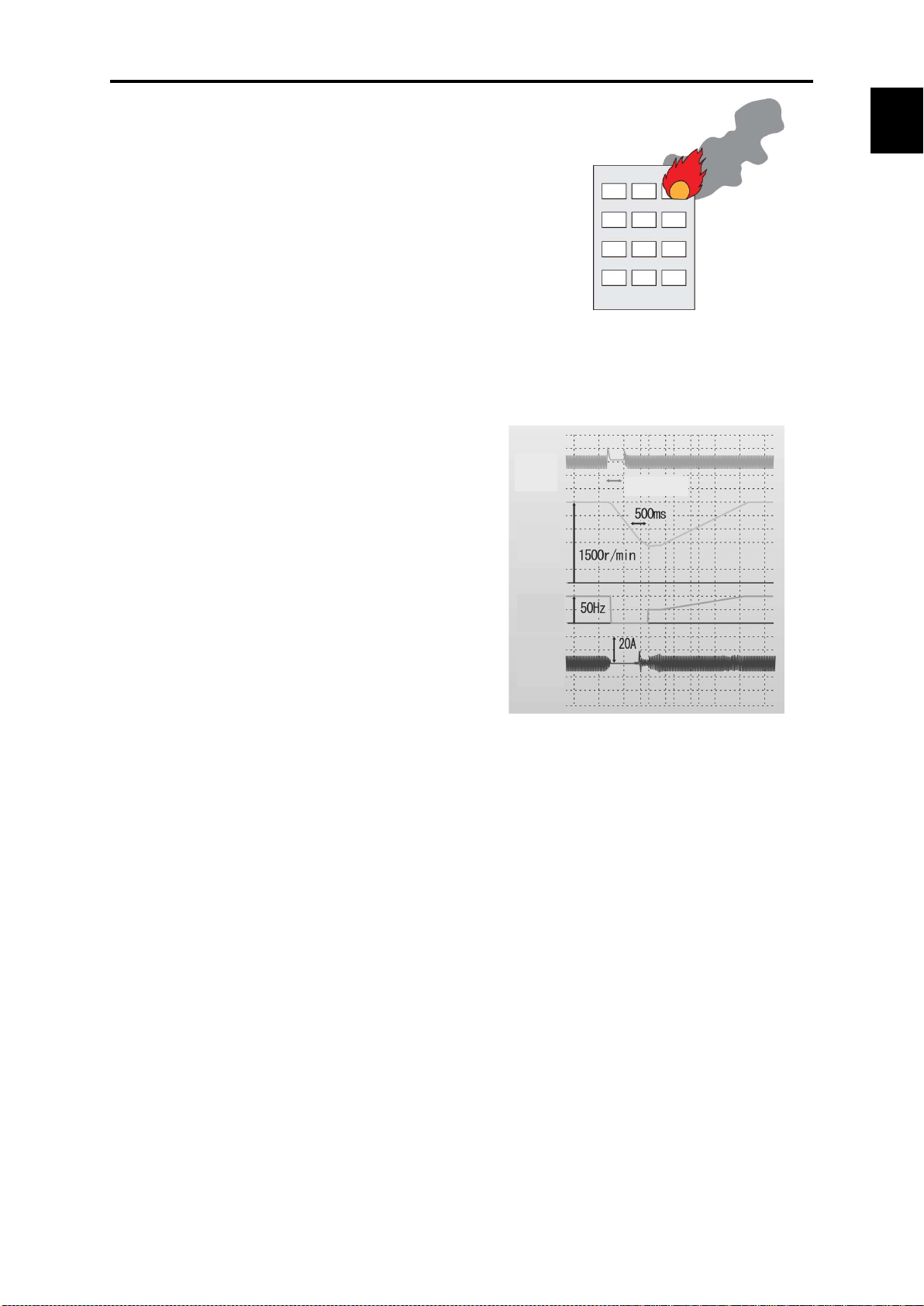

● Fire Mode (forced operation)

Alarm is ignored and operation continues

until the inverter is damaged, and evacuation

route is secured without smoke permeation.

Pick-up operation function (speed sensor)

Smooth start by pick-up function.

If operating fan while operating without a load

when the inverter is not operating, pick-up is

executed smoothly by searching for speed

regardless of rotation direction. Convenient

function when instantaneously switching from

commercial power supply to inverter or

restarting from instantaneous power failure.

1.1 Features

-HVAC

1-3

Page 20

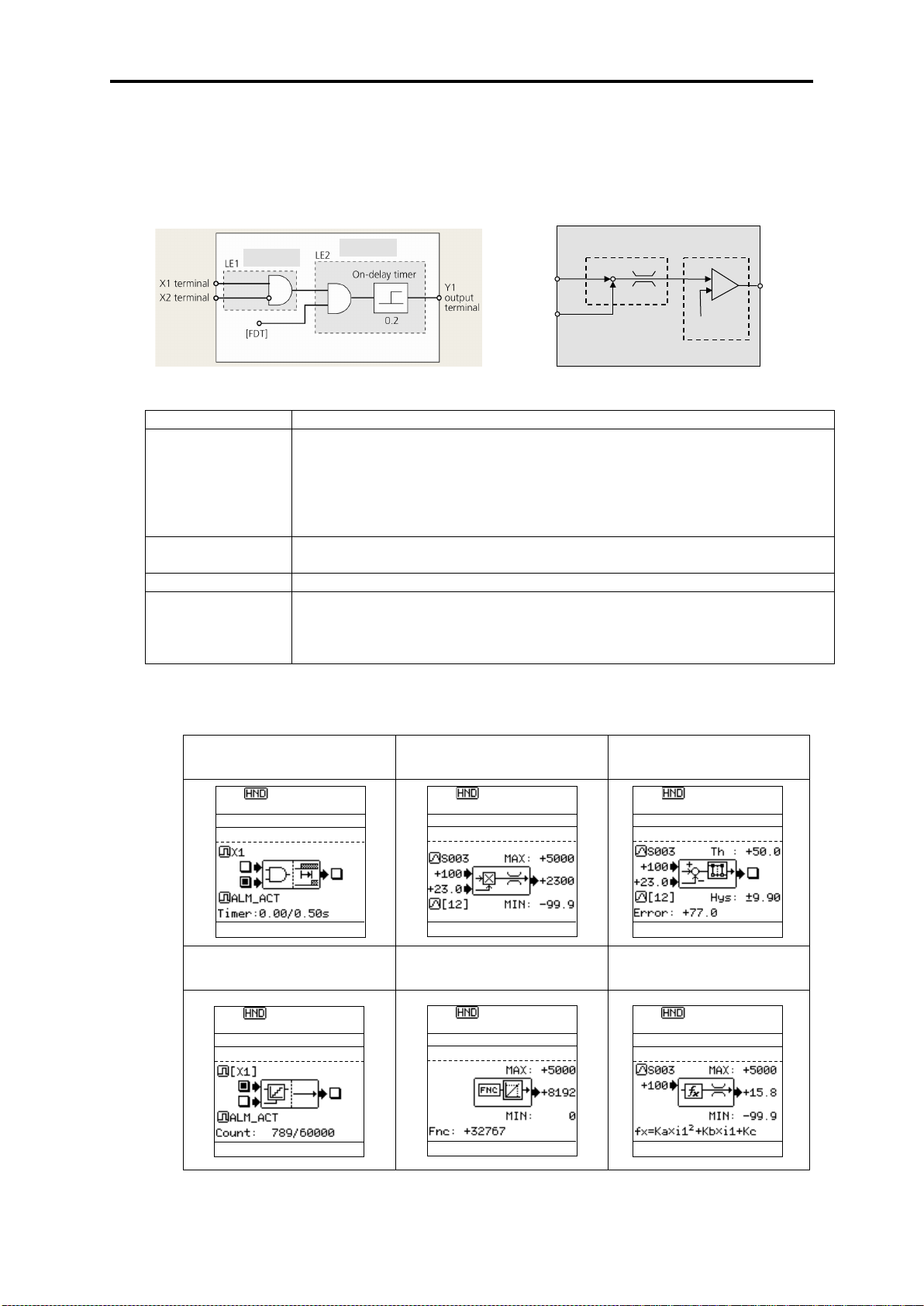

Item

Content

Logic function

<Digital>

scale conversion

General-purpose

timer

On-delay, off-delay, pulse train, etc.

Time setting: 0.0–600s

Input/output signal

Terminal input/output, inverter control function

Others

Can comprise up to 14 steps, with each step input/output occurring in

having the LCD monitor.

(AND circuit + on-delay timer)

(Multiplication circuit + vertical limiter)

(Deviation comparison 2)

(Up counter)

(Conversion 1)

Y3 pin

output

12 pin

C1 pin

U04 U05 + - U09

Step 2

Step 1

Step 2

Example: Digital (AND + on

Example: Analog (subtraction + comparison 5)

Fref 0.00Hz

PRG>6>4

Step01:0021

RESET:Back to M

RESET:Back to M

Fref 0.00Hz

PRG>6>4

Step01:2052

RESET:Back to M

Fref 0.00Hz

PRG>6>4

Step01:0110

RESET:Back to M

Fref 0.00Hz

PRG>6>4

Step01:2151

RESET:Back to M

Fref 0.00Hz

PRG>6>4

Step01:3001

RESET:Back to M

Fref 0.00Hz

PRG>6>4

Step01:2003

● Customizable logic

The customizable logic interface function is provided to the inverter body. This enables forming

of logic circuit and arithmetic circuit to the digital and analog input and output signals, allowing

simple relay sequence to be built while processing the signals freely.

-delay timer)

AND, OR, XOR, flip-flop, rise/fall detection, counter, etc.

<Analog>

Addition, subtraction, multiplication, limiter, absolute value, inverted

addition, comparison, max. value selection, min. value selection, avg.,

combination

You can check the input/output status of the various steps by the keypad

< LCD monitor example >

* Numerical values of the screen display are not the same as in actual circumstances.

Digital + digital + timer

Analog + analog + limiter

Digital + digital + counter

Function code + scale conversion Analog + 1 input + conversion

1-4

Analog + analog + comparison

Page 21

Chap. 1

About FRENIC

When operation is performed in the

When operation schedule varies

Run

command

Rotation

speed

DC

intermedi

ate circuit

voltage

Current

Time

Load status

Inverter temperature

Output frequency

OH trip

Time

1.1 Features

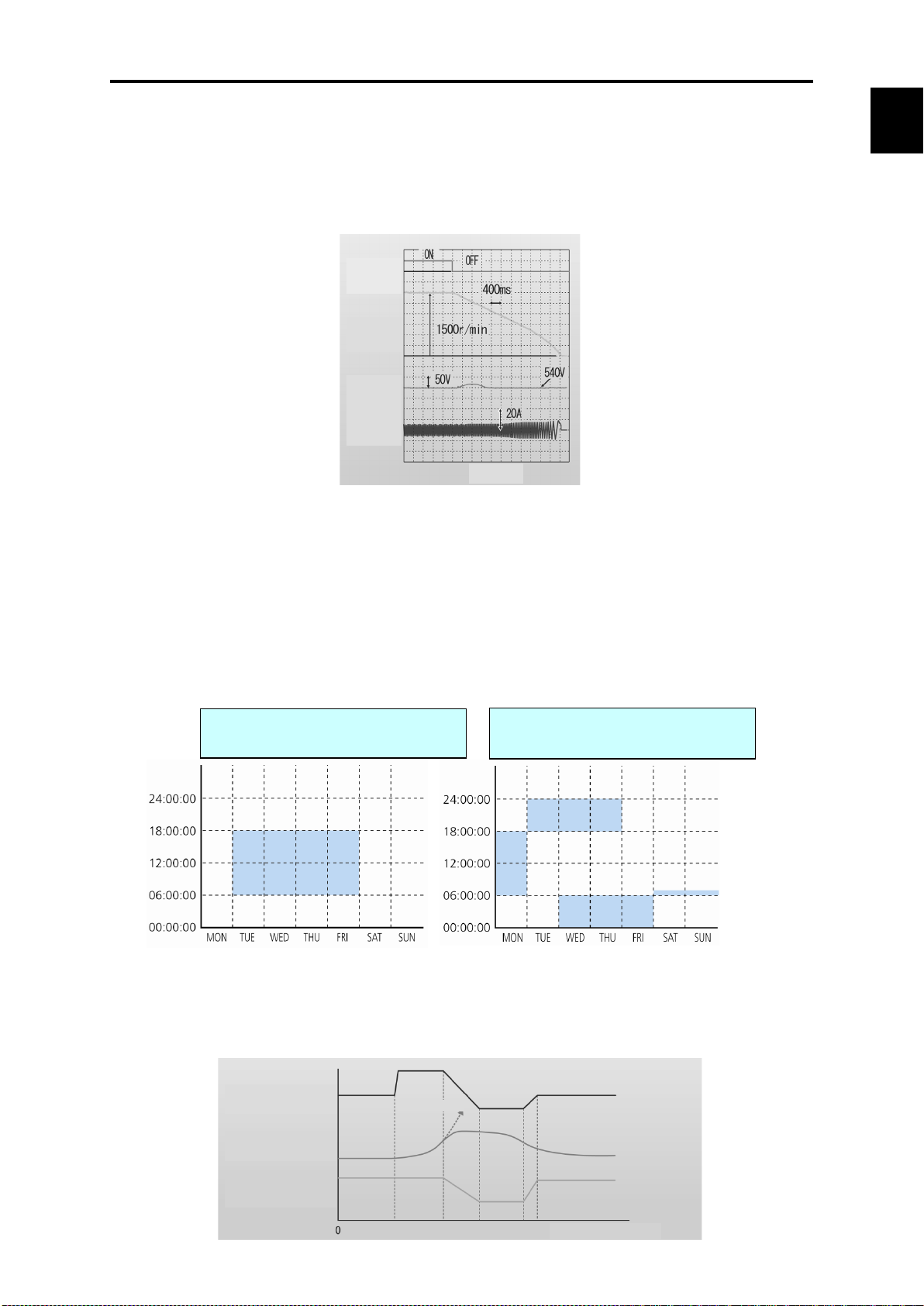

● Trip-less by regenerative avoidance control (effective for acceleration, deceleration

and fixed speed)

Because amount of energy to be regenerated to the inverter is limited and

acceleration/deceleration time is controlled, equipment can be operated without overvoltage

trip.

<Example: Operation when decelerating>

-HVAC

● Standardly equipped with Real time clock (RTC)

∙ Alarm information date/time display

∙ Timer operation function

∙ You can set up to 4 timers by units of 1 week.

∙ Holiday setting (20 days a year) is also possible.

∙ Daylight saving time auxiliary function

∙ Battery (optional) * Battery connection status displayed on the LCD monitor.

same schedule through a week

depending on the day of the week

● Continued operation of equipment by overload avoidance control

If the inverter becomes overloaded in the case where inverter internal temperature rises

radically from increased load or ambient temperature rises abnormally, operation is continued

by reducing the load by reducing motor speed.

1-5

Page 22

ELCB or

MCCB

Power

On/Off

Commercial/inverter

Built-in

Analog

equency

command

Command

loss detection

[REF OFF]

Time

Torque computation

value

Low torque

detection level

Time

Power

Transistor output

Broken

belt!

Regular frequency

setting

Output

frequency

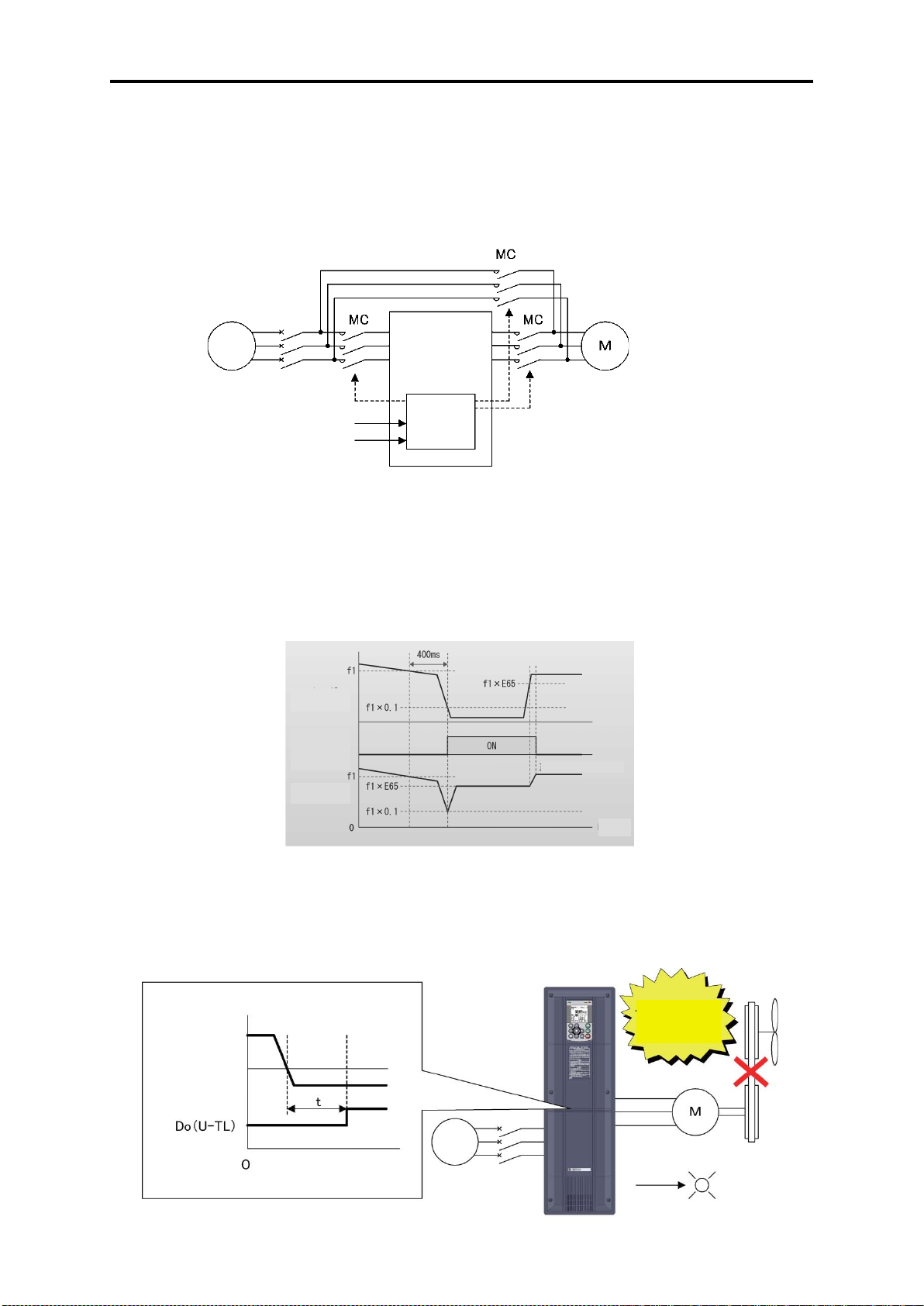

● Commercial operation switching

Because the inverter is equipped with a commercial frequency start processing function for

switching commercial / inverter operation by external sequence, peripheral equipment

configuration can be simplified. The inverter is equipped with 2 types of commercial operation

switching sequences: Fuji standard and inverter alarm automatic commercial switching

sequence.

FRENIC-HVAC

sequence

● Operation signal trouble is also avoided by command loss detection function.

If the frequency signal connected to the inverter (0 - 10V, 4 - 20 mA, multiple stage speed

operation signal, communication, etc.) is blocked, the fact that frequency command has been

lost is output as a “command loss” signal. You can furthermore set output frequency for

command loss in advance, so the equipment can continue to operate even if the frequency

signal is cut off by mechanical vibration, etc.

fr

● Low torque detection also possible

If a problem such as fan belt breaking and load connected to the motor becomes exponentially

lighter all of a sudden, detects that torque has dropped and outputs it as an output signal.

Abnormal status of the equipment can be detected using this signal, so it can be utilized as

equipment maintenance information.

1-6

Page 23

Chap. 1

About FRENIC

Inverter control (V/f control)

Required

Example of features when using damper

or valve

Energy

conservation

effect

Air flow or flow rate (%)

Inverter control

(For automatic energy

control)

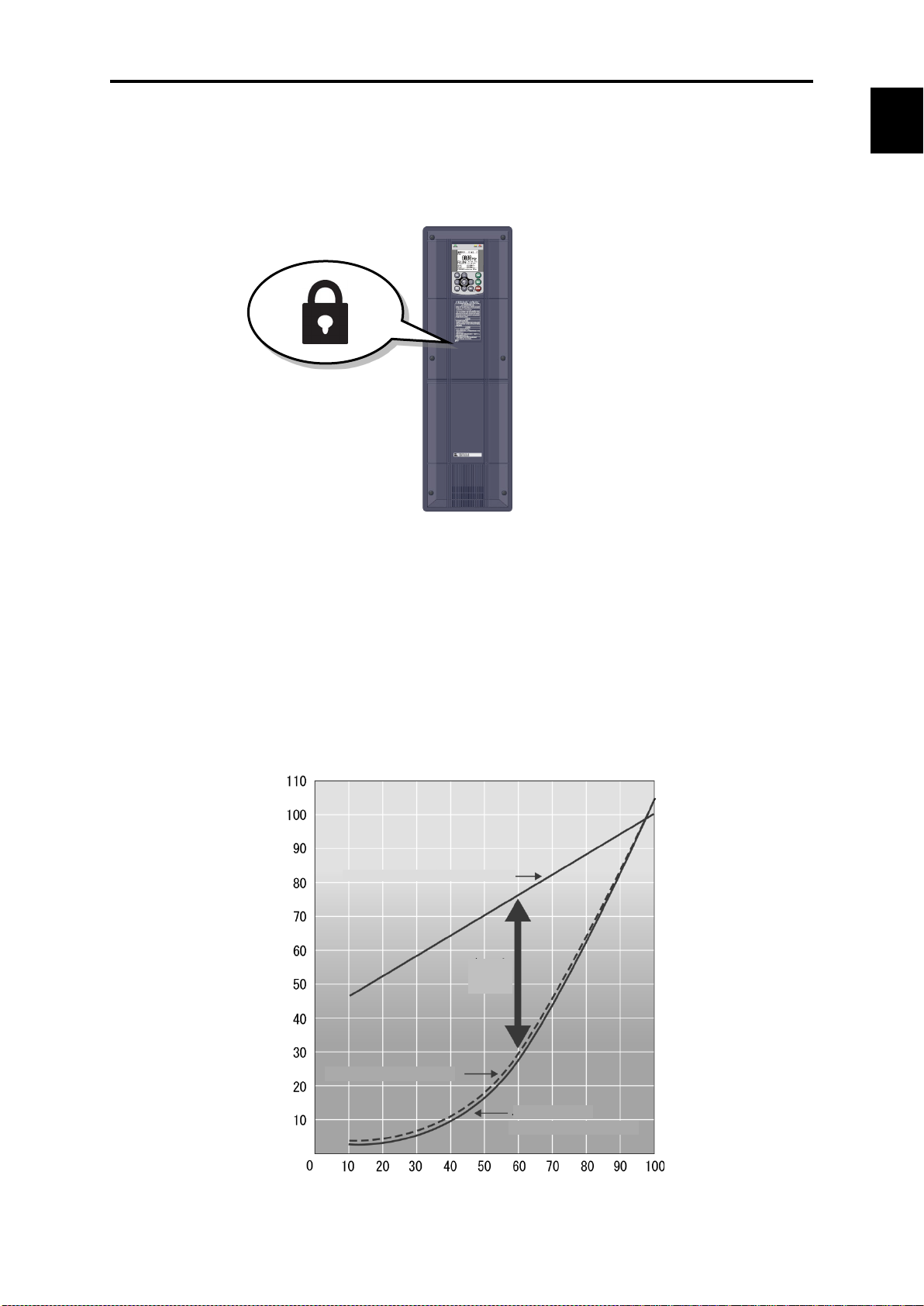

● Password function

Function codes can be read/write, displayed or hidden by setting the two passwords. This

prevents erroneous operation or overwriting of function codes. In addition, if a wrong password

was input exceeding the specified number of times, the inverter is restricted from operating as

the user is regarded as improper.

1.1 Features

-HVAC

● Filter clogging prevention function

This function detects clogging of the fan filter with dust or other materials using the output

current and pressure sensor value. When clogging is detected, the fan is rotated in reverse

to eject dust, and then resumes rotation in forward to blow air. In addition, the function notifies

you of maintenance necessity with the alarm signal.

Equipped with function that contributes to energy conservation.

Automatic energy-saving operation

Considering that fact that “control that minimizes motor loss” has evolved and the loss of the

inverter itself, the device has been “equipped with a new type of control to minimize loss of the

motor plus the inverter” to further conserve electric power for fan and pump applications.

power (%)

*Effect differs according to motor characteristics

Example of energy saving effect characteristics

1-7

Page 24

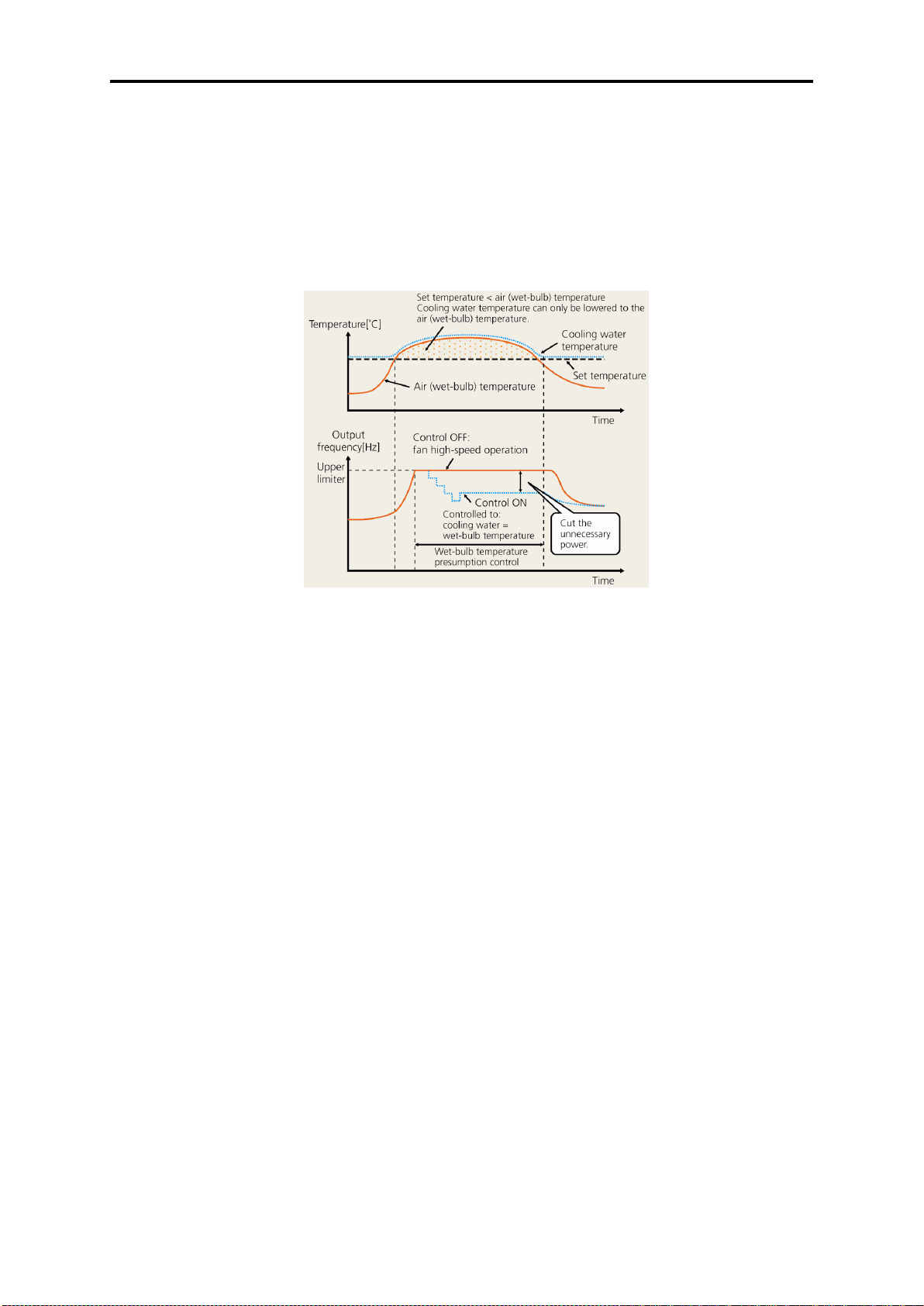

● Wet-bulb temperature presumption control

This function is optimal for controlling the fan of cooling tower. Since the wet-bulb temperature

would become higher than the set temperature when the air temperature is particularly high,

water temperature will not reach the set temperature. Therefore, the fan keeps rotating at high

speed, failing in energy-saving operation. FRENIC-HVAC automatically estimates

the wet-bulb temperature and controls the fan so that the cooling water is interlocked with the air

temperature in order not to use unnecessary electric power.

1-8

Page 25

Chap. 1

About FRENIC

Refrigeration machine

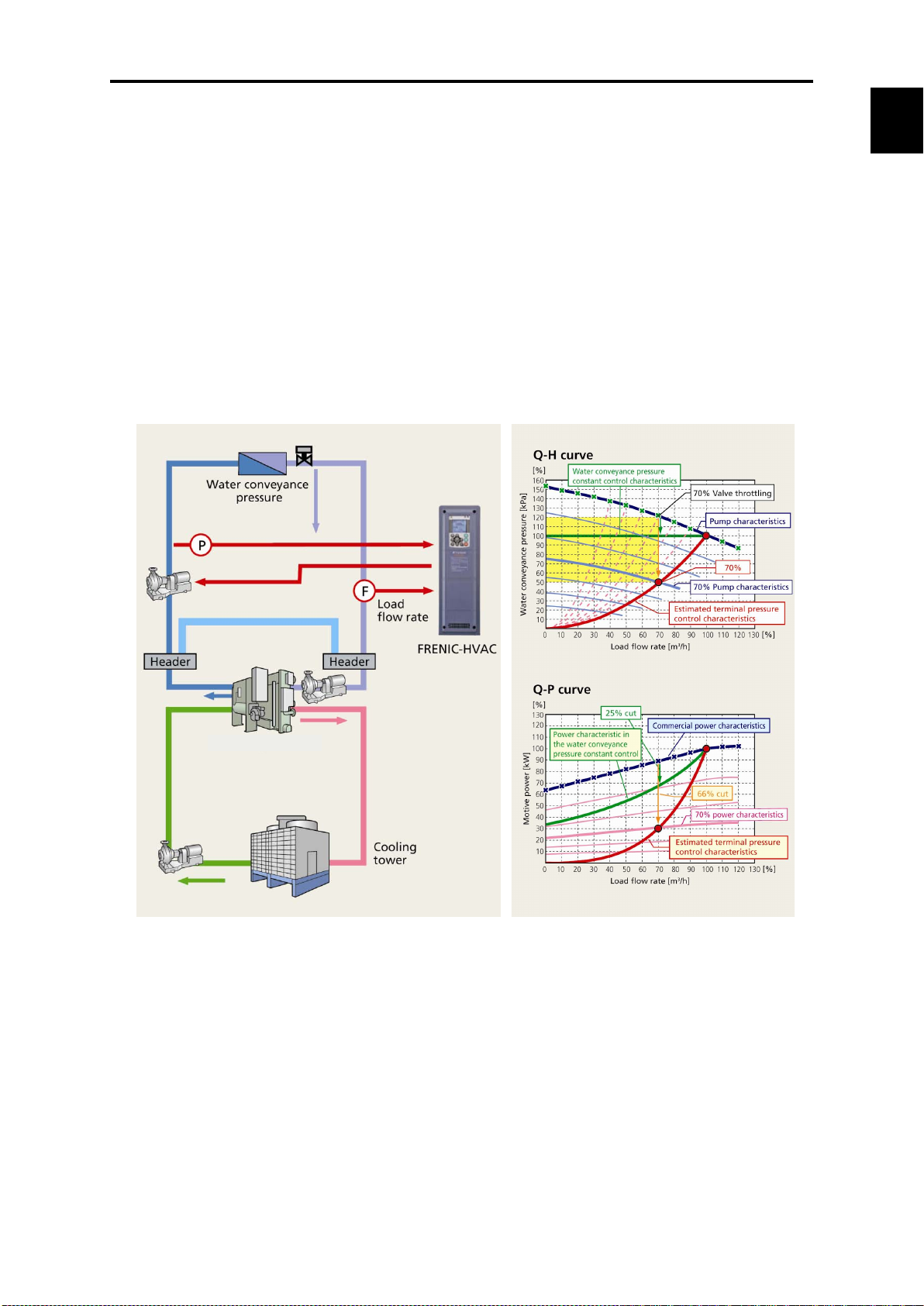

● Linearization function

This function estimates the target pressure using the load flow rate, which allows the estimated

terminal pressure to be controlled. For an air-conditioning heat source system, the needed

quantity of the cooling or heating water fluctuates generally in seasons or days and nights.

Therefore, operations continuing in a water conveyance pressure constant control may lead to

high operating unnecessary pressures on terminals at low operating state. Thus, the pump

consumes an ineffectual electric power for maintaining the high water conveyance pressure.

↓

Based on the calculated value and water conveyance pressure of estimated terminal pressure

using the detected load flow rate, PID control is performed.

↓

It is possible to reduce the ineffectual pump power consumption and to achieve a great

energy-saving effect together with maintaining comfortable current air conditioning.

1.1 Features

-HVAC

Enhanced network support

Standard equipment

∙ Modbus RTU ∙ Metasys N2 ∙ BACnet

Optional cards

∙ PROFIBUS-DP ∙ CC-Link ∙ DeviceNet ∙ CANopen

∙ LONWORKS ∙ Ethernet

1-9

Page 26

Item

Objective

Motor cumulative

Keeps track of time that equipment (motor) using the inverter is actually running.

pulleys.

Startup count (times)

Counts the number of times the inverter is turned on and off.

machinery when turned on and off.

Simple and enhanced maintenance / enhanced protective functions.

Information concerning life of consumable inverter parts is displayed.

Main circuit capacitance

Cooling fan cumulative running time

(Equipped with cooling fan ON/OFF

control compensation)

Inverter cumulative running

time

Electrolytic capacitors on PC board

Cumulative running time

Life warning signal can be output to transistor output.

Output when the end of service life of main circuit capacitors, electrolytic capacitors on PC board,

cooling fan, or real time lock battery (optional) approaches.

Information taking equipment maintenance into account is also displayed.

Information is added to maintenance information for the inverter itself and information taking

equipment maintenance into account is also displayed.

running time (h)

(Usage example)

If used for fan control, it approximates the time for replacement of belts used for

(Usage example)

Because it keeps a record of how many times the equipment is turned on and off, it

approximates the times for replacement of equipment parts that place a load on

You can check alarm history for the past 10 times (latest and 9 past times).

Detailed information can also be checked for the past 4 times.

If using a real time clock, you can check the date and time of occurrence.

Employs detachable interface board (terminal block for control signal line)

1-10

Page 27

Chap. 1

About FRENIC

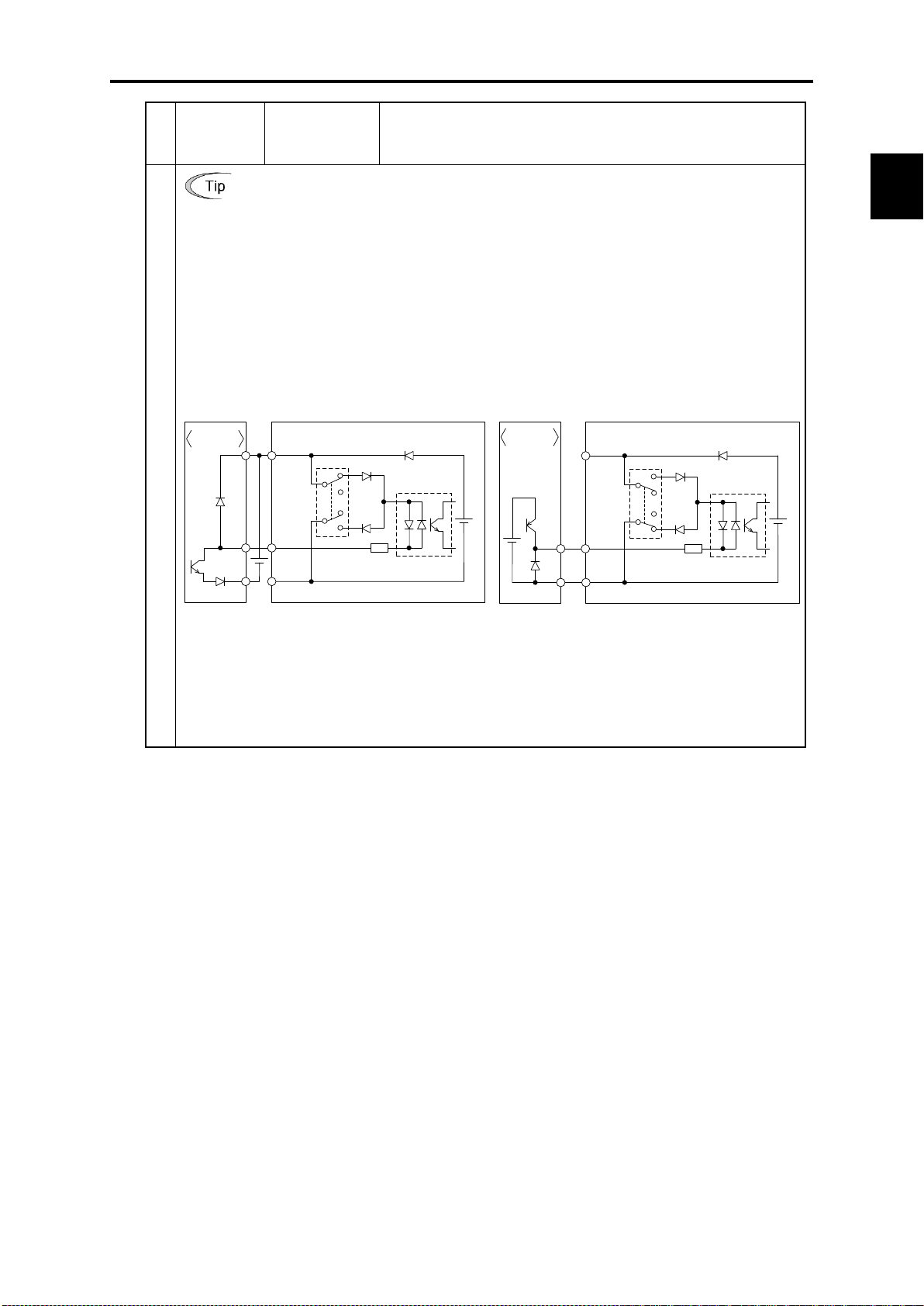

<

PTC

thermistor

Comparator

External

alarm

Resistor

(Power level)

Press knob inward.

Lift carefully.

Disconnect

the connector.

Remove the cooling fan (with case).

Remove cooling fan cable (connector).

Remove and replace the fan case and

cooling fan.

1.1 Features

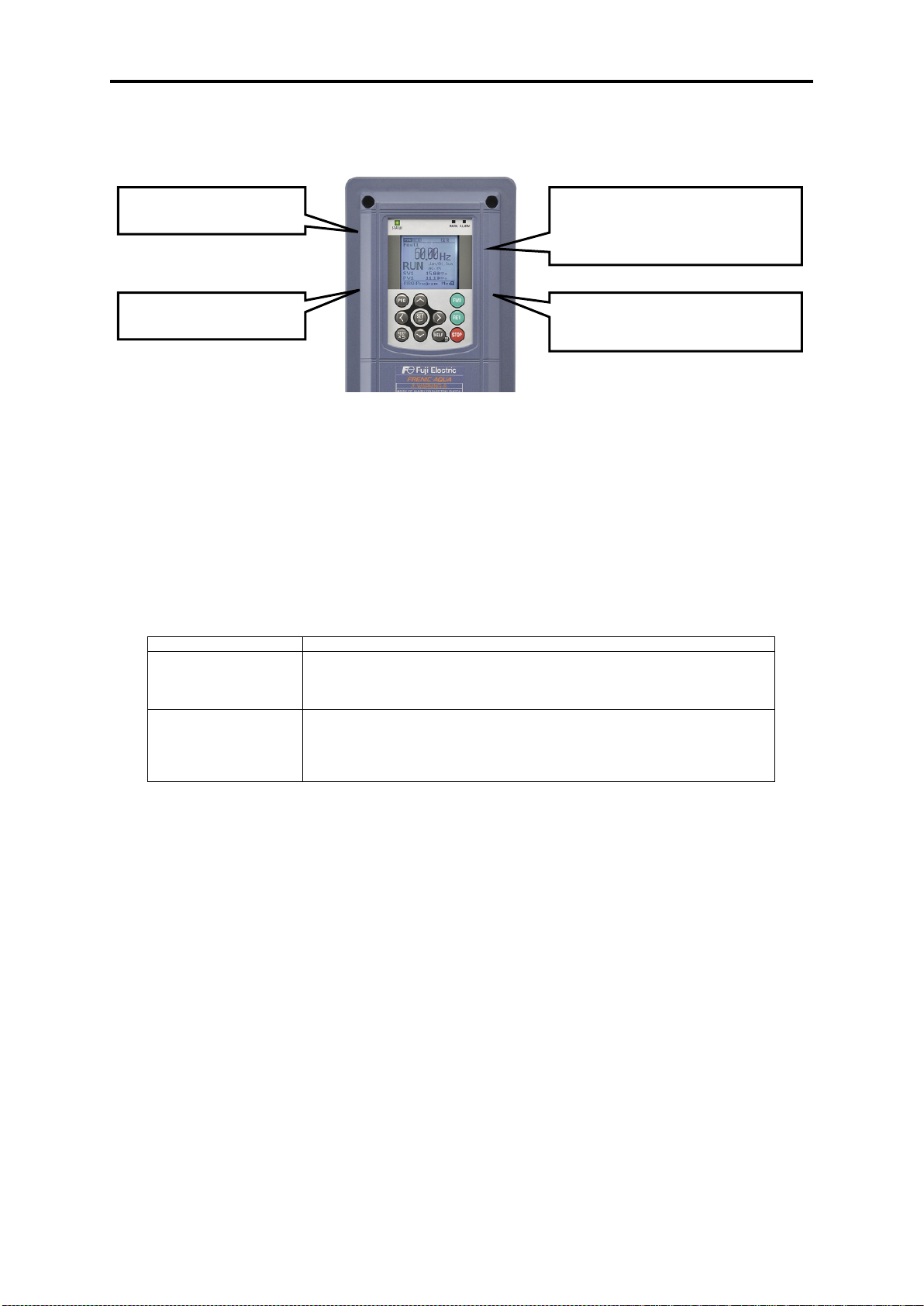

Motor protection by PTC thermistor

By connecting the Positive Temperature Coefficient (PTC) thermistor embedded in the motor to

the C1 pin, motor temperature is detected to protect the motor by shutting off the inverter before

the motor overheats. You can select whether to shut off the inverter (stop by alarm) or output

alarm from transistor output by PTC protection level.

Control circuit>

-HVAC

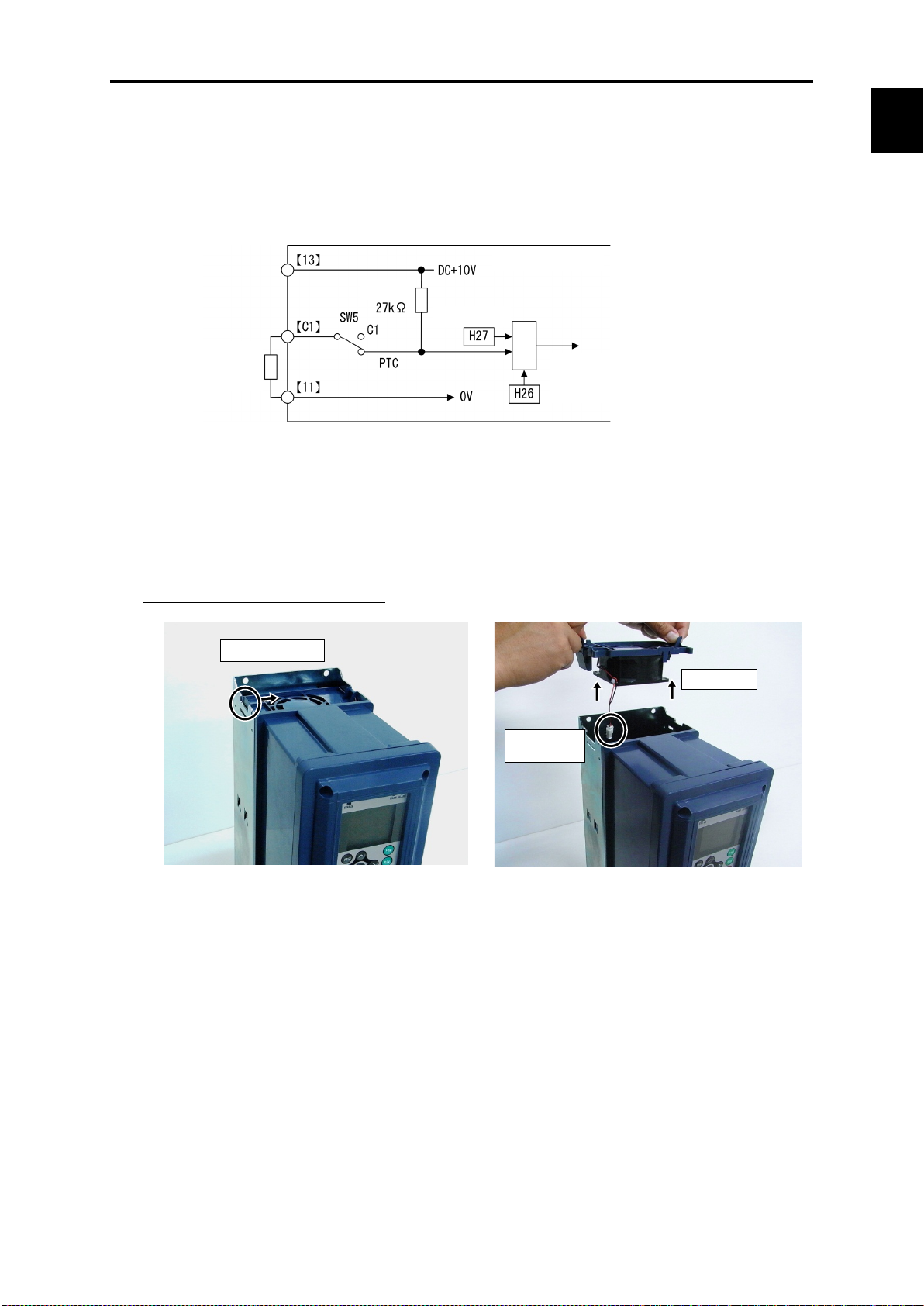

Easy cooling fan replacement

Employs configuration that allows the fan to be mounted or dismounted by one simple operation

to facilitate cooling fan replacement. (For the detailed replacement procedure, refer to Chapter 10,

Section 10.6 "Cooling Fan Replacement Procedure.")

Cooling fan replacement procedure

1-11

Page 28

Language

English

Chinese

German

French

Spanish

Italian

Russian

Greek

Turkish

Malay

Vietnamese

Thai

Indonesian

Polish

Czech

Swedish

Portuguese

Dutch

Japanese

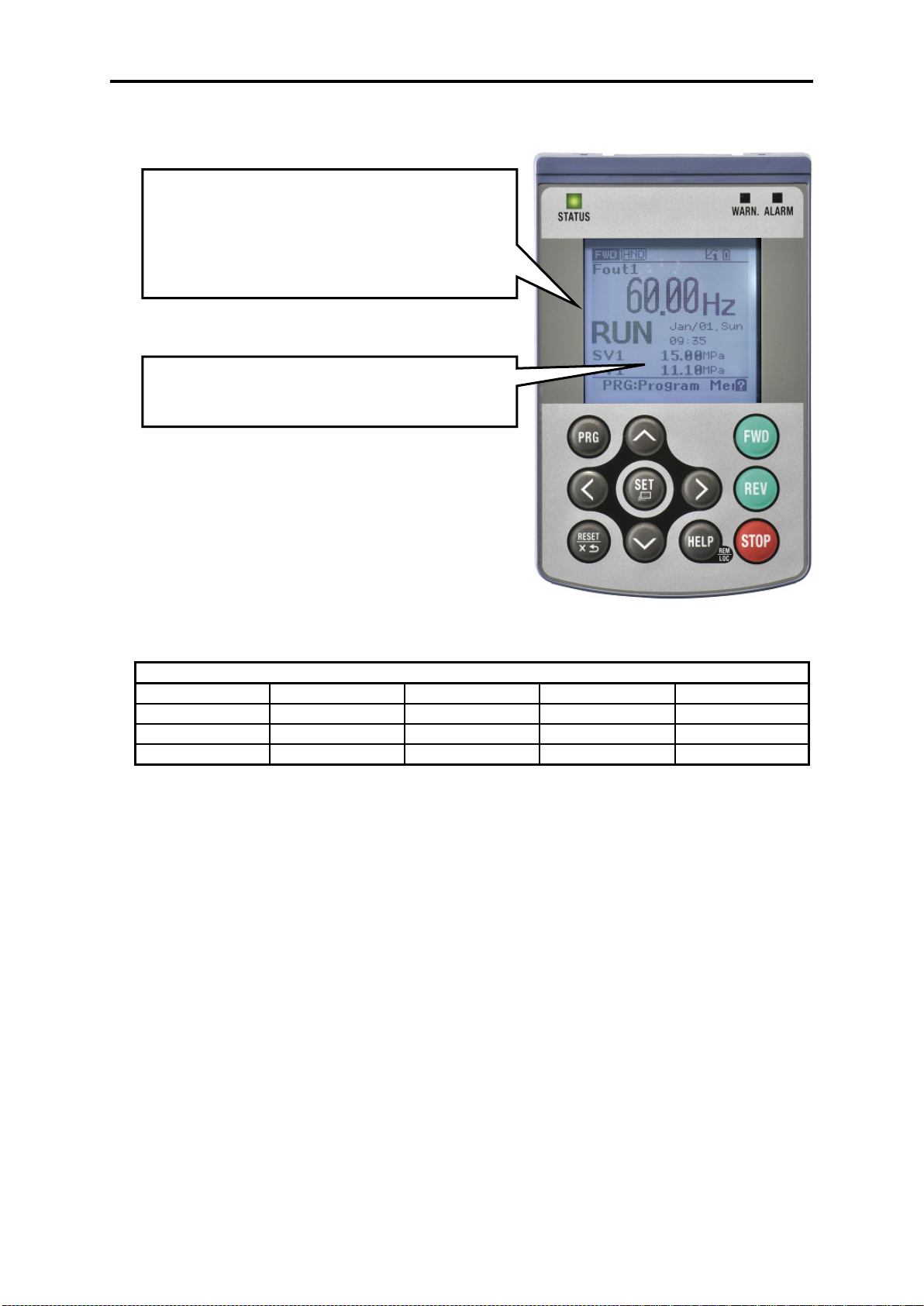

Equipped with keypad employing large LCD.

∙ Realizes regulator display by enlargement of LCD.

1. Present value (PV) 6. Output voltage

2. Setting value (SV)

3. Manipulating value (MV)

4. Frequency 9. Power consumption

5. Output current 10. Cumulative energy

7. Torque

8. Rotation speed

Unit setting function enables

easy-to-understand display.

∙ Multi-language supported: 19 languages + user customized language

1-12

Page 29

Chap. 1

About

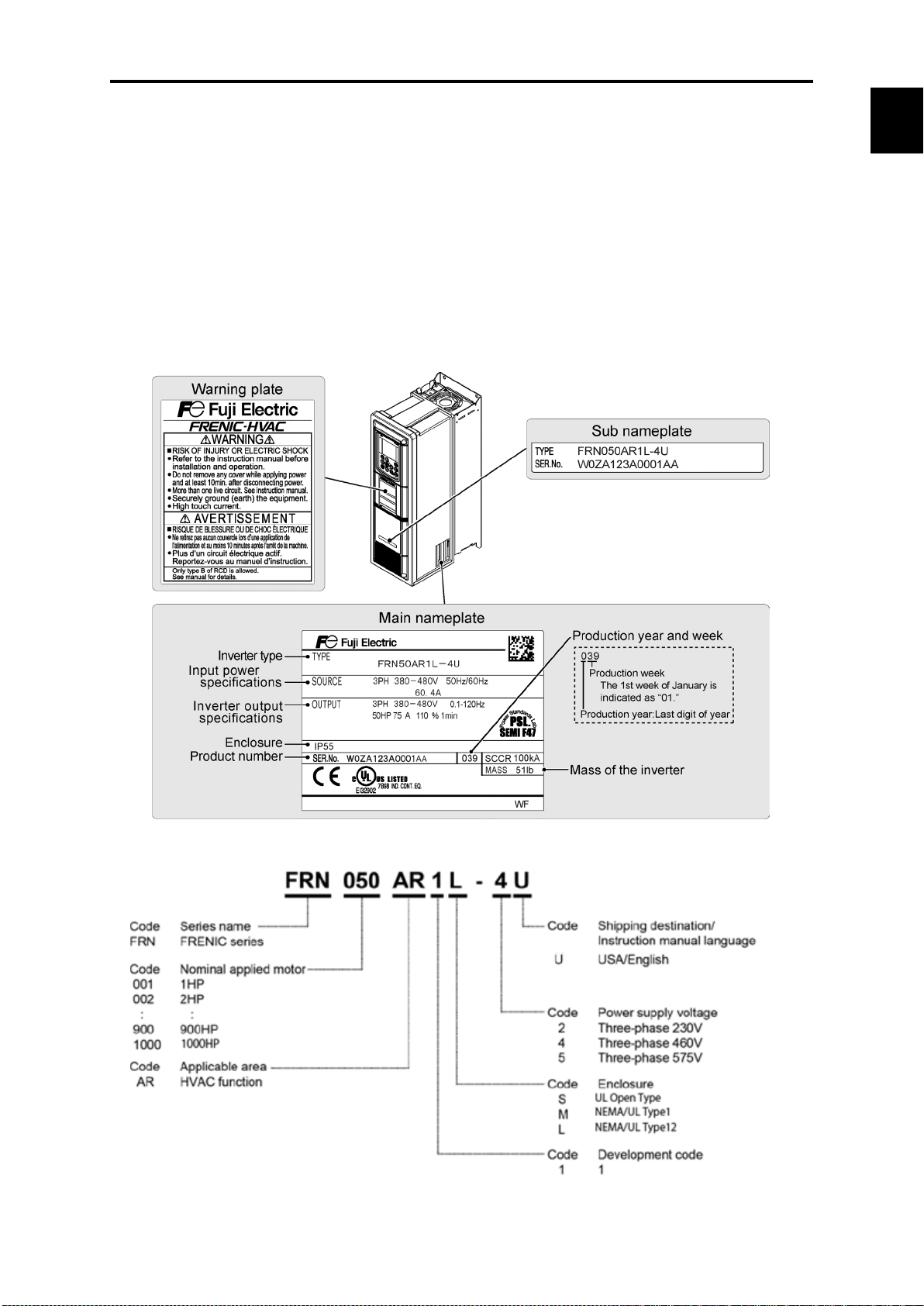

1.2 Inspection of goods and product appearance

1.2 Inspection of goods and product appearance

1.2.1 Inspection of goods

Unpack the package and check the following:

(1) An inverter and the following accessories are contained in the package.

Accessories: Instruction manual and CD-ROM manual

(2) The inverter has not been damaged during transportation—there should be no dents or parts

missing.

(3) The inverter is the type you ordered. You can check the type and specifications on the main

nameplate. (A total of four nameplates and warning plates are attached to the inverter as shown

below.)

FRENIC-HVAC

①Type: Inverter type

“Nominal applied motor” for USA models are represented in the HP unit.

1-13

Page 30

The alphabetical character that indicates protective structure goes in .

②Source: Input power source specifications

No. of input phases (3PH in the case of 3 phases), input voltage, input frequency, input current

③Output: Inverter output specifications

No. of output phases, rated output voltage, output frequency range, output rated capacity,

rated output current, overload current rating

④IP Code: Protective structure

⑤⑥Ser. No: Serial No. / Mfg. Year/week

W18A123A0001AA 039

The first week of mfg. week / January is “01.”

This indicates which week it corresponds to.

Mfg. year / last digit of year

⑦Mass: Mass

Inverter type is indicated as "FRN***AR1-2U/4U/5U" in the various tables in this document.

If there is something you do not understand about the product or there is something wrong with it,

please contact the dealership from where you purchased it or your nearest Fuji Electric sales office.

1-14

Page 31

Chap. 1

About

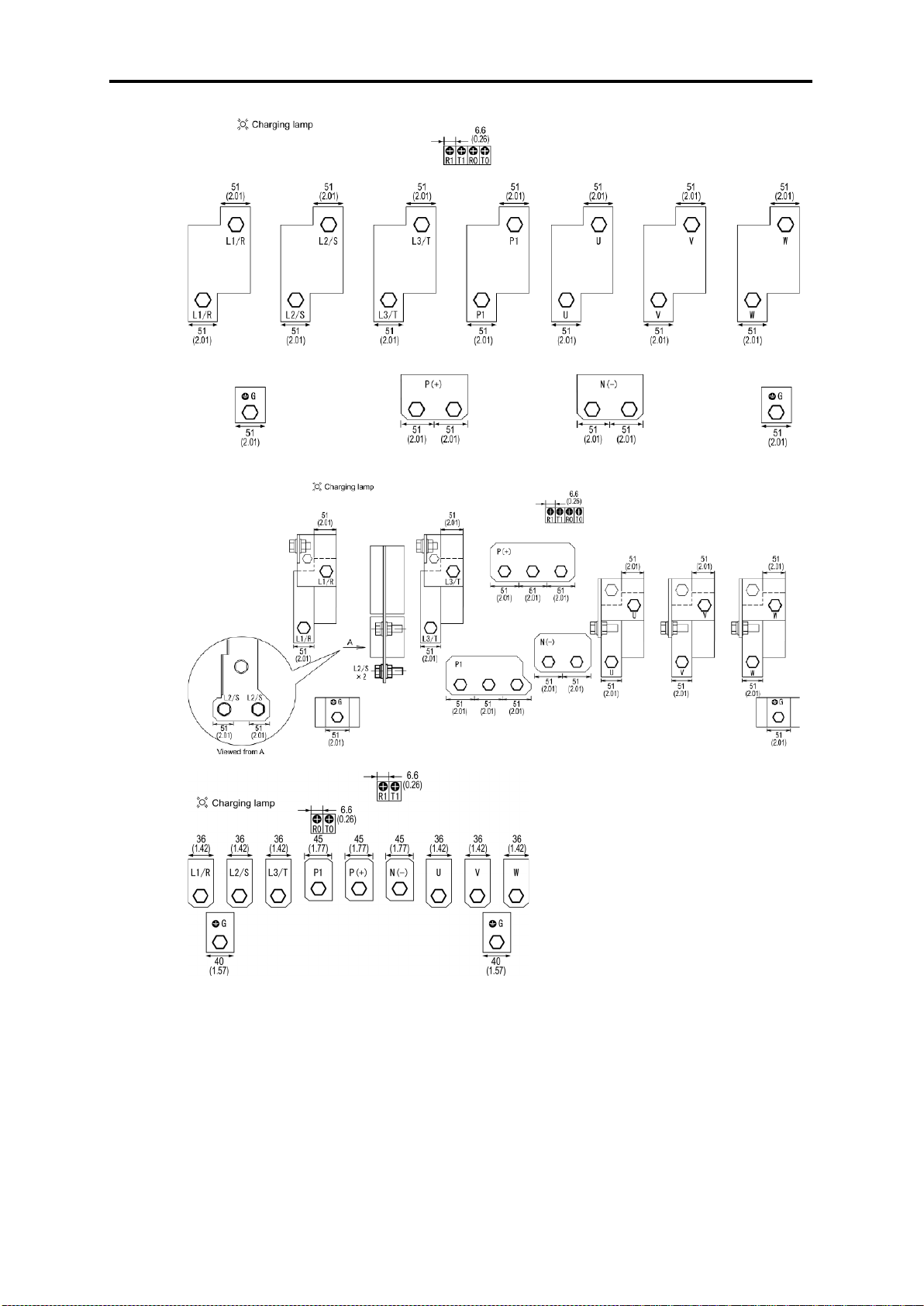

Fig. 1.1 FRN001AR1M-4U (NEMA/UL type1)

Fig. 1.2 FRN300AR1S-4U (UL open type)

Cooling fan

Front cover

Caution label

Ratings label

Main circuit terminal block

Control circuit terminal block

Front cover

Front cover

mounting screw

Keypad

Internal

agitator fan

1.2.2 Product appearance

1.2 Inspection of goods and product appearance

FRENIC-HVAC

Note: Refer to external drawings in chapter 2 for other capacities.

1-15

Page 32

Chapter 2

SPECIFICATIONS

This chapter describes specifications of the output ratings, control system, and terminal functions for the

FRENIC-HVAC series of inverters. It also provides descriptions of the operating and storage environment,

precautions for using inverters, external dimensions, examples of basic connection diagrams, and details of

the protective functions.

Contents

2.1 Standard Model FRENIC-HVAC .............................................................................................................. 2-1

2.1.1 Three-phase 230 V class series (USA models) .................................................................................... 2-1

2.1.2 Three-phase 460 V class series (USA models) ................................................................................... 2-3

2.1.3 Three-phase 575 V class series (USA models) ................................................................................... 2-6

2.2 Common Specifications .............................................................................................................................. 2-9

2.3 Terminal Specifications ............................................................................................................................. 2-16

2.3.1 Terminal functions ............................................................................................................................ 2-16

2.3.2 Setting up the slide switches ............................................................................................................. 2-26

2.3.3 Screw specifications and recommended wire sizes ........................................................................... 2-28

2.3.3.1 Main circuit terminals ............................................................................................................... 2-28

2.3.3.2 Control circuit terminals (Common to all inverter types) ......................................................... 2-35

2.4 Conduits .................................................................................................................................................... 2- 36

2.4.1 Conduits ............................................................................................................................................ 2-36

2.5 Leakage Current of the EMC Filter........................................................................................................... 2-39

2.6 Derating of Rated Output Current ............................................................................................................. 2-42

2.7 Operating Environment and Storage Environment ................................................................................... 2-44

2.7.1 Operating environment ...................................................................................................................... 2-44

2.7.2 Storage environment ......................................................................................................................... 2-45

2.7.2.1 Temporary storage ..................................................................................................................... 2-45

2.7.2.2 Long-term storage ..................................................................................................................... 2-45

2.8 Precautions for Using Inverters ................................................................................................................. 2-46

2.8.1 Precautions in introducing inverters .................................................................................................. 2-46

2.8.2 Precautions in running inverters ........................................................................................................ 2-50

2.8.3 Precautions in using special motors .................................................................................................. 2-50

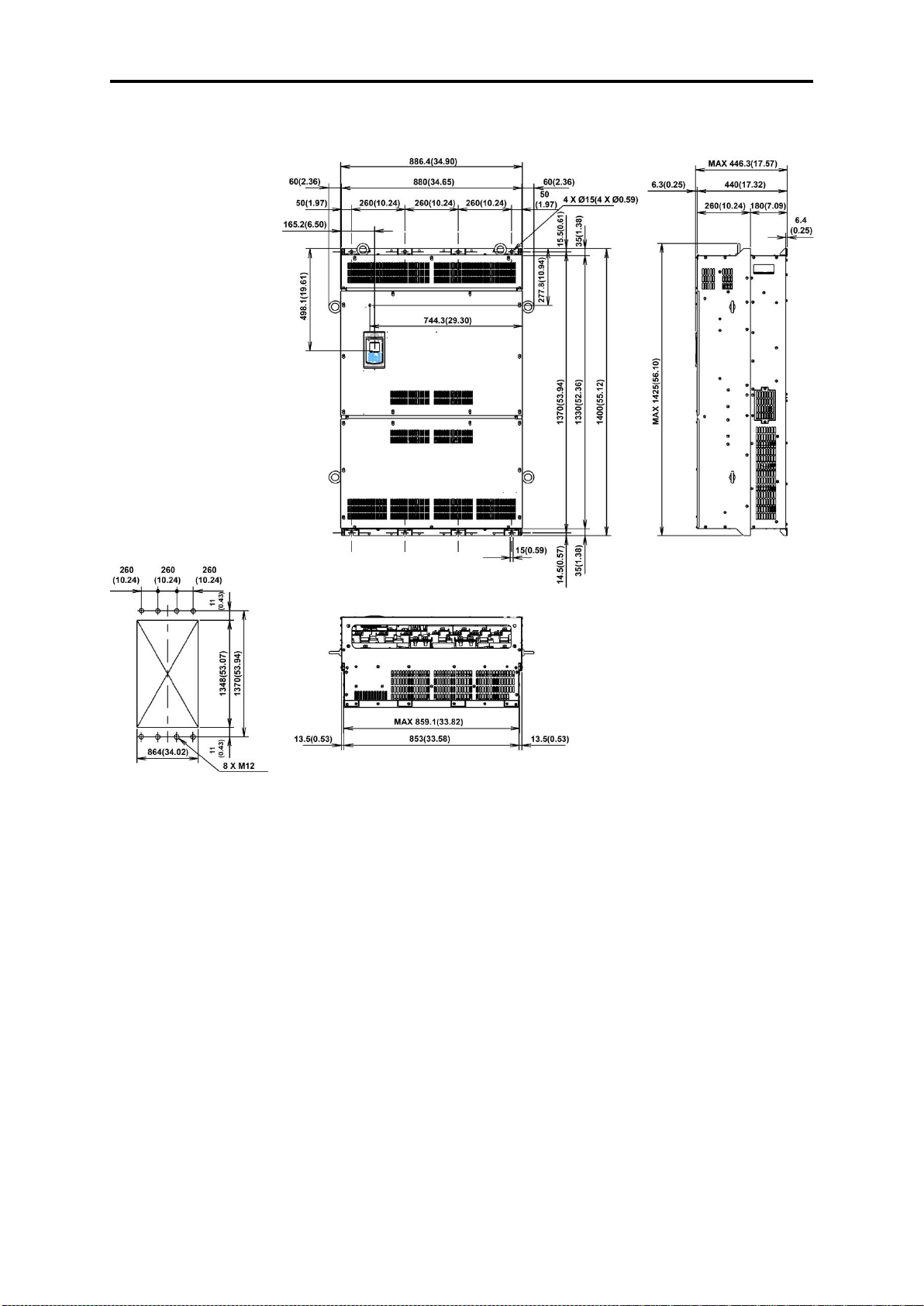

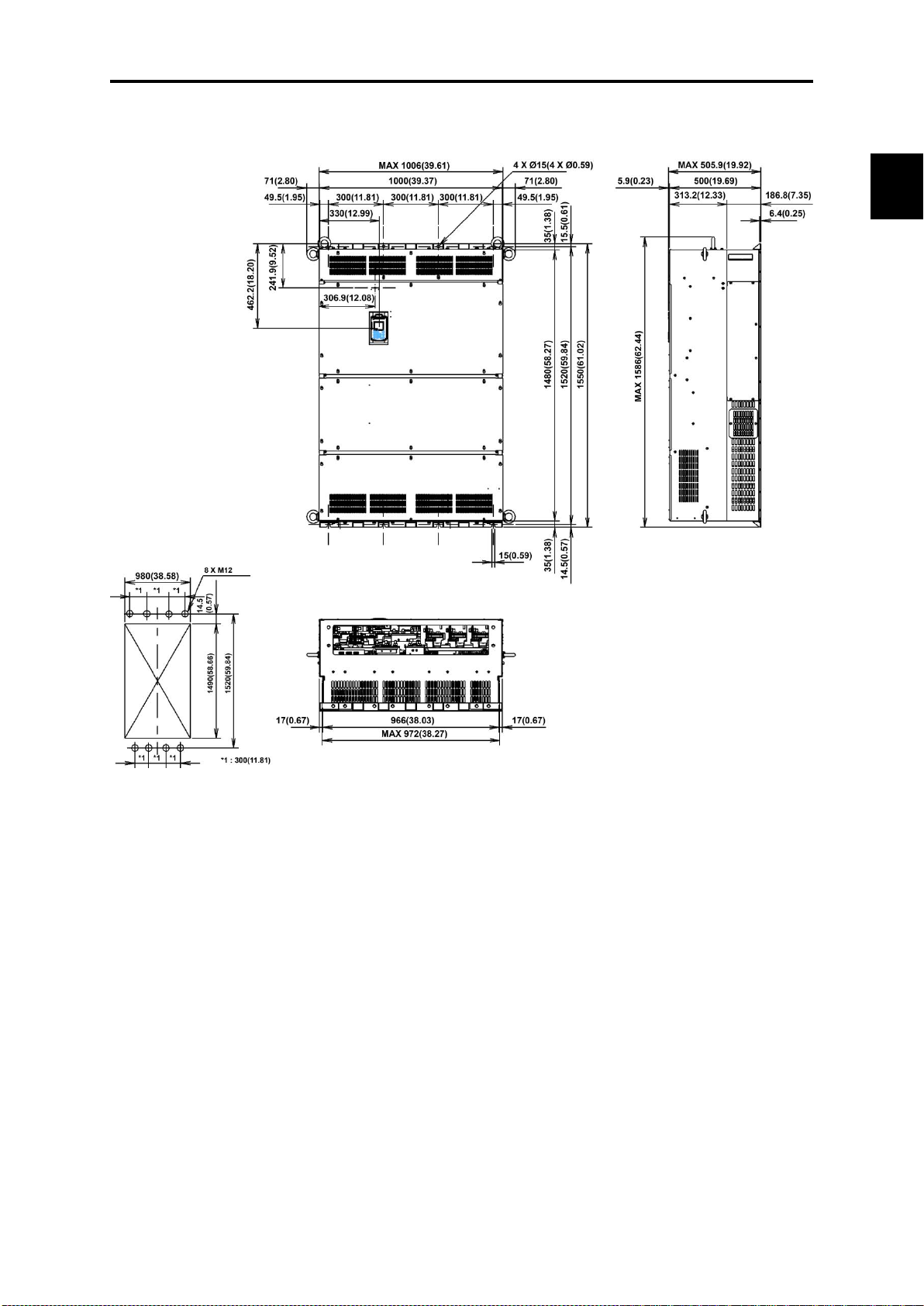

2.9 External Dimensions ................................................................................................................................. 2- 51

2.9.1 Standard models ................................................................................................................................ 2- 51

2.9.2 Keypad .............................................................................................................................................. 2-64

2.10 Connection Diagrams ................................................................................................................................ 2-65

Page 33

Page 34

Chap. 2

SPECIFICATIONS

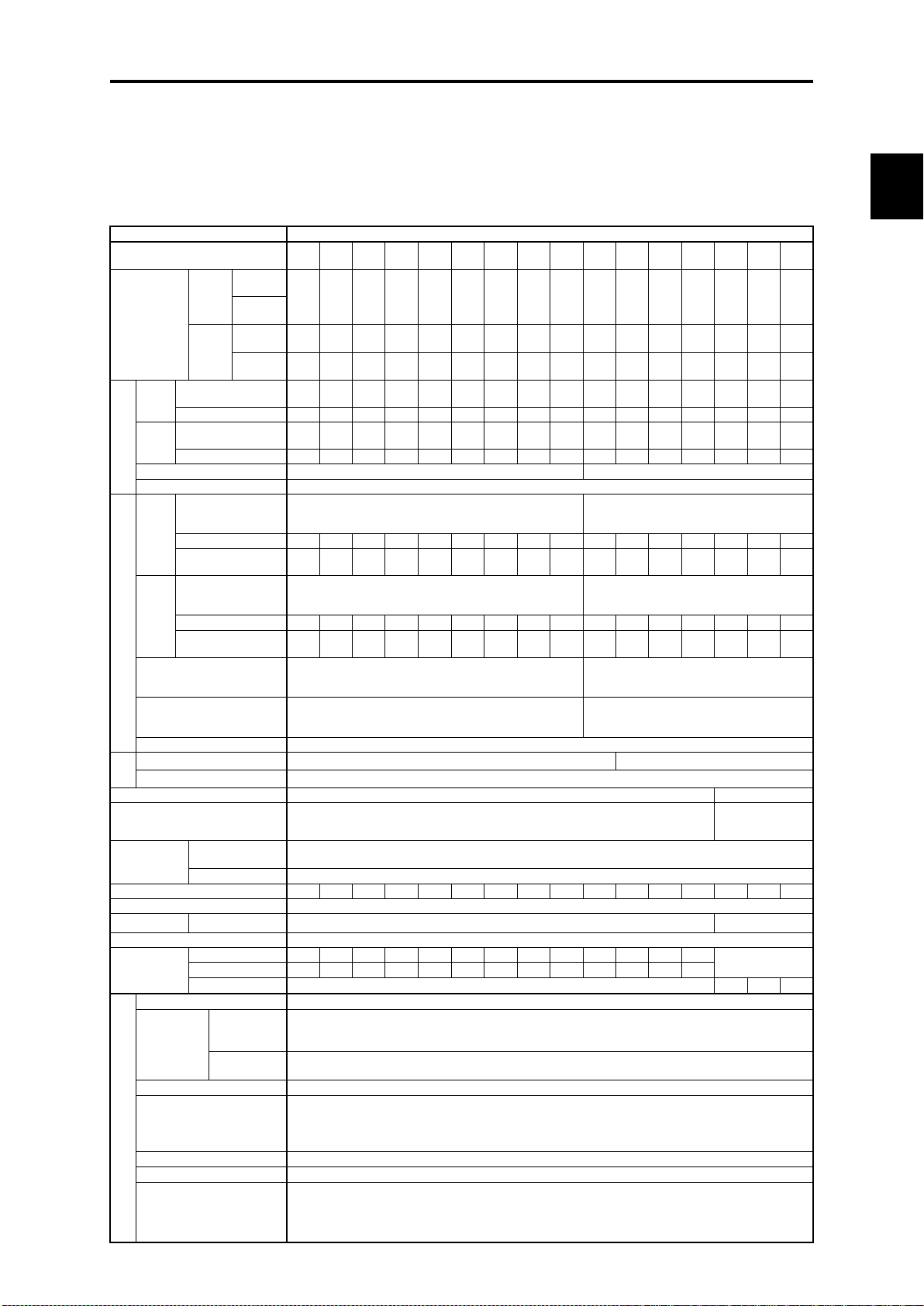

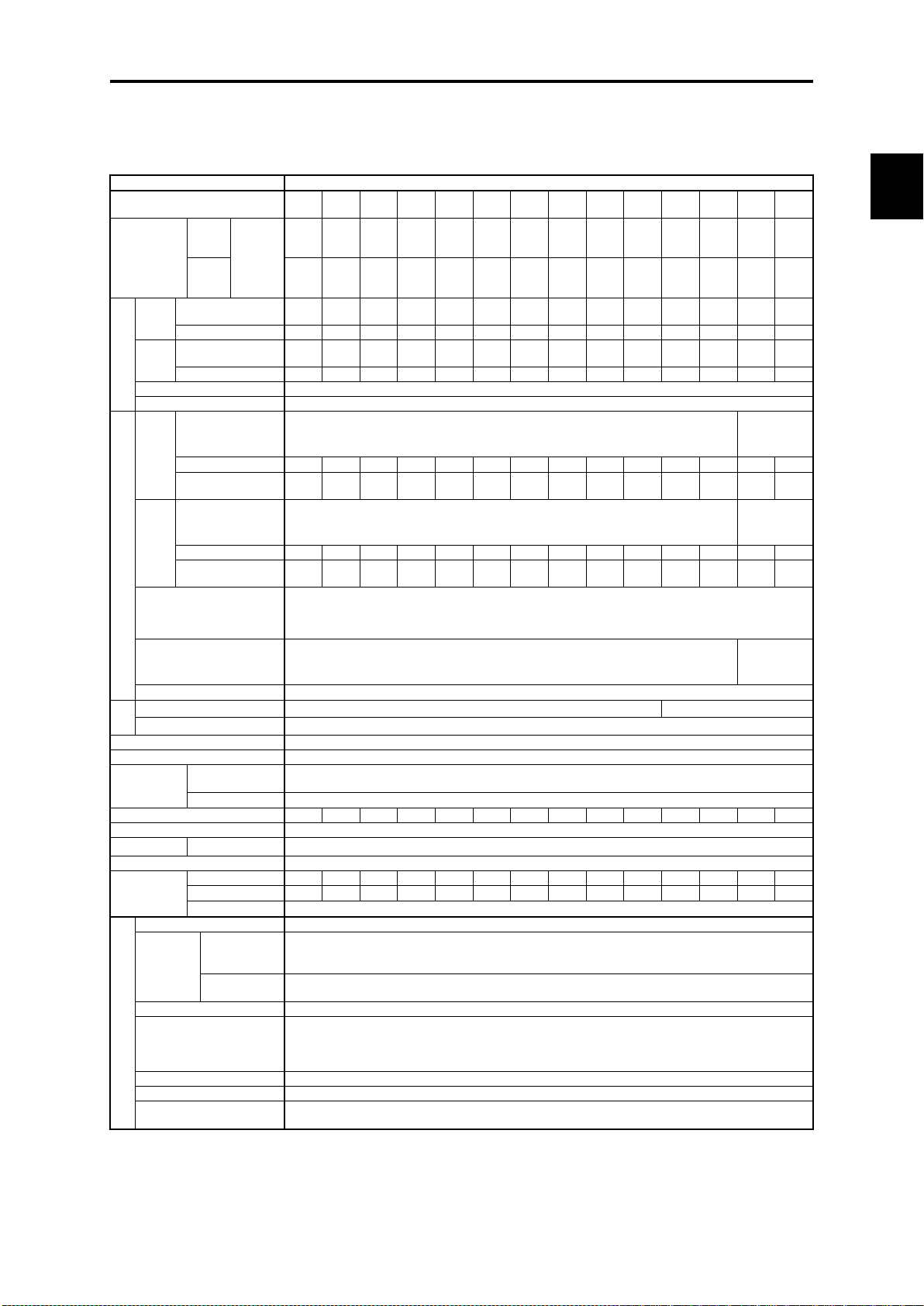

Item

Specifications

Type

(FRN_ _ _AR1-2U) (*1)

Nominal

Three

AC208V

motor

AC230V

motor

Single

AC208V

motor

AC230V

motor

Three

Rated capacity (kVA)

(*3)

Rated current (A)

5 8 11

18

27

31.8

46.2

59.4

74.8

88

115

146

180

215

283

346

Single

Rated capacity (kVA)

(*3)

Rated current (A)

1.9

3.1

4.2 7 10.5

12.4

18

23.1

29.1

34.3

44.8

56.9

70.2

95

102

131

Rated voltage (V) (*4)

Three-phase, 200 to 240 V (with AVR function)

Three-phase, 200 to 230 V (with AVR function)

Overload capability

110%-1 min (Overload interval: Compliant with IEC 61800-2)

Main power supply

voltage, frequency)

Rated current (A) (*5)

2.8

5.3

7.5

12.9

18.0

24.2

36.0

48.6

60.0

71.5

96.9

121

145

177

246

291

Required power

supply capacity [kVA]

Main power supply

voltage, frequency)

Rated current [A] (*5)

2.8

5.3

7.5

12.9

18.0

24.2

36.0

48.6

60.0

71.5

96.9

121

145

177

246

291

Required power

supply capacity [kVA]

Auxiliary control power supply:

frequency)

Auxiliary main power supply

frequency) (*6)

Voltage, frequency variations

Voltage: +10 to -15% (Interphase voltage unbalance : 2% or less) (*9), Frequency: +5 to -5%

Brak-

ing

Braking torque [%] (*7)

DC injection braking

EMC filter (IEC/EN 61800-3) (*8)

EMC standards compliance : Category C2 (emission) / 2nd Env. (Immunity)

C3/ 2nd

Standard

(IEC/EN61000-3-12)

load)

Fundamental wave

power factor

Total power factor

≥ 0.90

Efficiency (at the rated load) (%)

97

97

97

97

97

98

98

98

98

98

98

98

98

98

98

98

Applicable (safety) standards

UL 508C, C22.2 No. 14, IEC/EN 61800-5-1 SEMI F47-0706

Cooling method

Fan cooling

Weight / Mass

NEMA/UL Type 1

22

22

22

22

40

40

40

51

51

110

110

154

154

NEMA/UL Type 12

22

22

22

22

40

40

40

51

51

110

110

154

154

UL open type

-

93

95

137

Site location

Indoors

UL open type /

UL Type 1

NEMA/

UL Type 12

Relative humidity

5 to 95% (No condensation)

The inverter must not be exposed to dust, direct sunlight, corrosive gases, flammable gases, oil mist, vapor or water

drops. Pollution degree 2 (IEC/EN 60664-1) (*12)

The atmosphere can contain a small amount of salt. (0.01 mg/cm2 or less per year)

The inverter must not be subjected to sudden changes in temperature that will cause condensation to form.

Altitude

3,300 ft max. (*13)

Atmospheric pressure

86 to 106 kPa

60 HP or less

75 to 100 HP

1 m/s2 55 to less than 200 Hz

125 HP

2.1 Standard Model FRENIC-HVAC

2.1.1 Three-phase 230 V class series (USA models)

(001 to 125 HP)

001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125

2.1 Standard Model

applied motor

[HP] (*2)

phase

input

(Rated output)

phase

input

phase

input

phase

input

Output ratings

(number of phases,

Three

phase

input

(number of phases,

Single

phase

input

Input power

(number of phases, voltage,

(number of phases, voltage,

1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125

- 1/2 3/4 1.5 2 3 5 5 7.5 10 10 15 20 30 30 40

- 1/2 1 2 3 3 5 7.5 10 10 15 20 25 30 30 50

1.9 3.1 4.3 7.1 10 12 18 23 29 35 45 58 71 85 112 137

0.7 1.2 1.6 2.7 4.1 4.9 7.1 9.2 11 13 17 22 27 37 40 52

Three-phase, 200 to 240 V, 50/60 Hz

Three-phase, 200 to 220 V, 50 Hz

Three-phase, 200 to 230 V, 60 Hz

1.2 2.2 3.0 5.2 7.2 10 15 20 24 29 39 49 58 71 98 116

Single-phase, 200 to 240 V, 50/60 Hz

Single-phase, 200 to 220 V, 50 Hz

Single-phase, 200 to 230 V, 60 Hz

0.7 1.3 1.8 3.0 4.2 5.6 8.3 12 14 17 23 28 34 41 57 67

Single-phase , 200 to 240 V, 50/60 Hz Single-phase, 200 to 230 V, 50/60 Hz

-

Single-phase, 200 to 220 V, 50 Hz

Single-phase, 200 to 230 V, 60 Hz

20 10 to 15

Braking start frequency: 0.0 to 60.0 Hz; Braking time: 0.0 to 30.0 s; Braking operation level: 0 to 60%

DC reactor (DCR) (*8) Built-in (IEC/EN 61000-3-2(*10), IEC/EN 61000-3-12)

Power factor

(at the rated

> 0.98

accessory

Enclosure NEMA/UL 50 NEMA/UL Type 1, NEMA/UL Type 12(*11) UL open type

[lbs]

Ambient

NEMA/

14 to 122°F

-

temperature

14 to 104°F

Atmosphere

Environmental Requirements

Vibration

3 mm 2 to less than 9 Hz

10 m/s2 9 to less than 200 Hz

3 mm 2 to less than 9 Hz

9.8 m/s2 9 to less than 20 Hz

2 m/s2 20 to less than 55 Hz

3 mm 2 to less than 9 Hz

2 m/s

1 m/s

2

9 to less than 55 Hz

2

55 to less than 200 Hz

2-1

Page 35

Altitude

3300 ft or lower

3300 to 4900 ft

4900 to 6600 ft

6600 to 8200 ft

8200 to 9800 ft

Output current derating factor

1.00

0.97

0.95

0.91

0.88

(*1) A box () replaces an alphabetic letter depending on the enclosure.

Enclosure: M (NEMA/UL Type1), L (NEMA/UL Type12) or S (UL Open Type)

(*2) US 4-pole standard induction motor.

(*3) Rated capacity is calculated by assuming the output rated voltage as 230 V.

(*4) Output voltage cannot exceed the power supply voltage. At single-phase input use, the output voltage may be lower than three-phase input.

(*5) The value is calculated on assumption that the inverter is connected with a power supply 230V, 50Hz and Rsce=120.

(*6) The auxiliary power input is used as an AC power input when combining the unit to DC power supply such as high power factor PWM converter

with power regenerative function. (Generally not to be used.)

(*7) Average braking torque for the motor running alone. (It varies with the efficiency of the motor.)

(*8) EMC filters and DCR does not conform to each corresponding standards when single phase input use.

(*9) Voltage unbalance [%] = (Max. voltage [V] - Min. voltage [V])/Three-phase average voltage [V] x 67 (See IEC/EN61800-3.)

If this value is 2 to 3%, use an optional AC reactor (ACR).

(*10) It is applicable when the power supply is supplied from 3-phase 200V series transformer which is through 3-phase 400V series transformer.

(*11) NEMA/UL Type 12 offers protection for short water jets. Do not use outdoors or in places where long-term waterproofing is required.

(*12) Do not install the inverter in an environment where it may be exposed to lint, cotton waste or moist dust or dirt which will clog the heat sink of the

inverter. If the inverter is to be used in such an environment, install it in a dustproof panel of your system.

(*13) If you use the inverter in an altitude above 3300 ft, you should apply an output current derating factor as listed in the table below.

2-2

Page 36

Chap. 2

SPECIFICATIONS

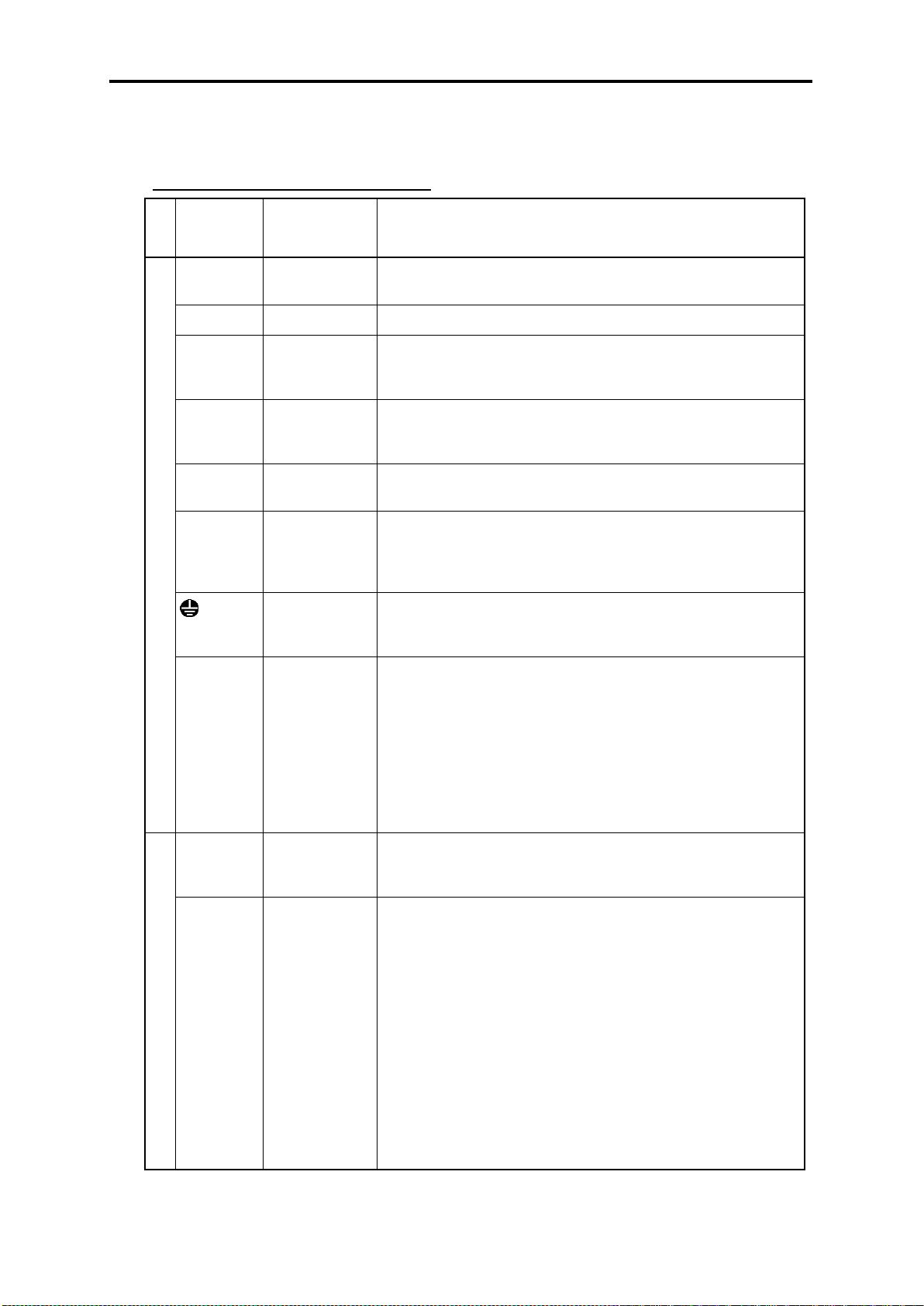

Item

Specifications

Type

(FRN_ _ _AR1-4U) (*1)

Nominal

Three

input

AC460V

Single

input

Three

Rated capacity (kVA)

(*3)

Rated current (A)

2.5

4.1

5.5

9.0

13.5

18.5

24.5

32

39

45

60

75

91

112

Single

Rated capacity (kVA)

(*3)

Rated current (A)

-

1.5

2.1

3.5

5.2

7.2

9.5

12.4

15.2

17.5

23.4

29.2

35.4

43.6

Rated voltage (V) (*4)

Three-phase, 380 to 480 V (with AVR function)

Overload capability

110%-1 min (Overload interval: Compliant with IEC 61800-2)

Three

Main power supply

Three-phase, 380

phase, 380

to 480 V, 60 Hz

Rated current (A) (*5)

1.4

2.7

3.8

6.5

9.0

12.1

18.0

24.3

30.0

35.8

48.5

60.4

72.3

88.7

Required power

supply capacity [kVA]

Single-phase, 380

to 480 V, 60 Hz

Rated current [A] (*5)

-

2.7

3.8

6.5

9.0

12.1

18.0

24.3

30.0

35.8

48.5

60.4

72.3

88.7