Page 1

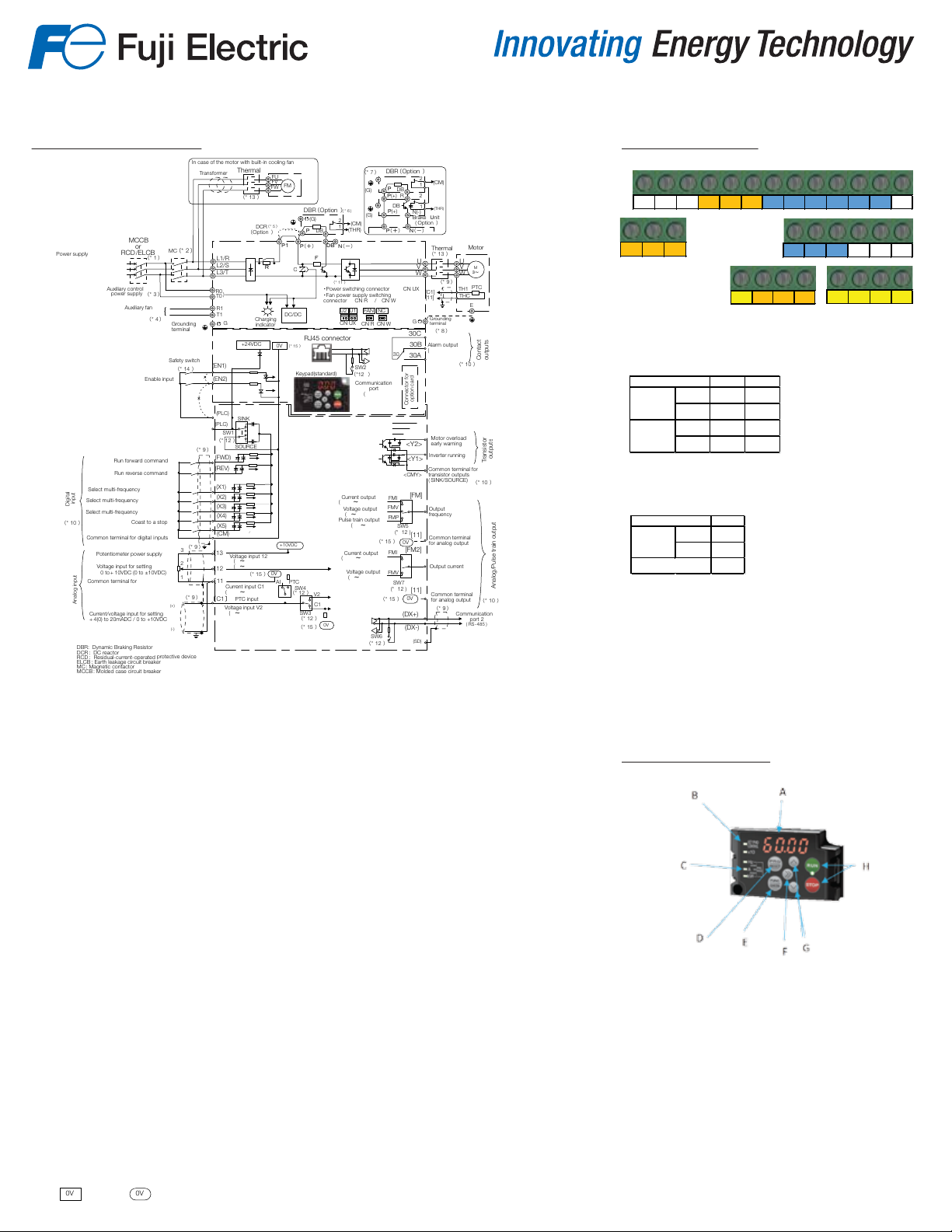

FRENIC - Ace

R

F

DBR(Option

)

DCR

(

Option

)

DB

N(-)

P(+)

P1

U

VWU

V

W

M

3

~

C

L1/R

L2/S

L3/T

MC

MCCB

or

RCD

/ELCB

G

Grounding

terminal(*1)

(

*2)

(

*5)

(*6

)

P

DB

2

1

(CM)

(THR)

(G)

N(-)

P(+)

P

DB

2

1

(CM)

(G)

2

1

(THR)

P

(+)

N(-)

DBR(Option

)

Brake

U

nit

(

Option

)

(G)

P

(+)

R

DB

(

*7)

TH1

THC

PTC

[11]

[C1]

Thermal

)

R1

T1

R0

T0

(

*3)

Auxiliary control

power supply

Auxiliary fan

(

*4)

{

(

*11)

DC/DC

(PLC)

(FWD)

(REV)

(X1)

(X2)

(X3)

(X4)

(X5)

(CM)

(EN1)

SINK

SOURCE

(EN2)

0V

+24VDC

Run forward command

Run reverse command

Select multi-frequency

Select multi-frequency

Select multi-frequency

Coast to a stop

<Y1>

<Y2>

<CMY>

Inverter running

Motor overload

early warning

[FM]

[11]

0V

G

E

Output

frequency

SW1

(

*12)

(

*8)

(

*9)

Common terminal for digital

i

nputs

Contact

Transistor

(

*10)

(

*10)

Common terminal

for analog output

Analog/Pulse train output

Common terminal for

transistor outputs

(

SINK/SOURCE)

Safety switch

SW5(*12

)

30C

30B

30A

Alarm output

(

30

Current output

(

Voltage output

(

Pulse train output

(

・

Power switching connector

“CN UX

・

Fan power supply switching

connector “CN R” / “CN W

(

*10)

(

*9)

(

*14)

(PLC)

Charging

indicator

RJ45 connector

SW2

(

*12

)

FMI

FMV

FMP

FU

FV

FW

FM

(

*13)

Transformer

Motor

In case of the motor with built-in cooling fan

Thermal

Communication

port

(

Keypad(standard)

Voltage input V2

(

〔

11

〔

12

〔

13

(

*9)

+10VDC

Current input C1

(

Current/voltage input for setting

+

4(0) to 20mADC / 0 to +10VDC

Voltage input for setting

0 to

+

10VDC (0 to ±10VDC)

0V

Analog input

3

2

1

PTC input

〔

C1〕

(

*9)

(+)

(-)

Voltage input 12

(

(

SW4

PTC

AI

(

*12)

(

*12)

SW3

C1

V2

0V

0V

0V

Enable input

DBR: Dynamic Braking Resistor

DCR

: DC reactor

RCD

: Residual-current-operated

protective device

ELCB

: Earth leakage circuit breaker

MC

: Magnetic contactor

MCCB

: Molded case circuit breaker

Grounding

terminal

Potentiometer power supply

Common terminal for

Communication

port

2

(RS-

485

)

[FM2]

SW7

(*12)

FMI

FMV

Output current

(DX+)

(DX-)

SW6

(

*

12

)

(SD)

(

*9)

Current output

(

Voltage output

(

(

*10)

[11]

0V

Common terminal

for analog output

(

*15)

(

*15)

(

*15)

(

*15)

(

*15)

U1

U2

CN UX

FAN

NC

CN R

CN W

Power supply

(

*13)

Quick Reference Guide

FRENIC - Ace Control Wiring

Control Card Terminals

SD DX- DX+ CMY Y1 Y2 CM X 1 X2 X3 X4 X 5 PLC

400V series

380 to 480V 50/60Hz

200V series

200 to 240V 50/60Hz

power supply

RS-485)

(0 to 1 step)

(0 to 3 step)

(0 to 7 step)

〕

0~+10VDC)

0~±10VDC)

〕

analog inputs

*1 Install a recommended molded case circuit breaker (MCCB) or residual-current-operated protective device (RCD)/earth

leakage circuit breaker (ELCB) (with overcurrent protection function) in the primary circuit of the inverter to protect wiring.

Ensure that the circuit breaker capacity is equivalent to or lower than the recommended capacity.

*2 Install a magnetic contactor (MC) for each inverter to separate the inverter from the power supply, apart from the MCCB or

RCD/ELCB, when necessary. Connect a surge absorber in parallel when installing a coil such as the MC or solenoid near the

inverter.

〕

4(0)~20mADC)

0~+10VDC)

4(0)~20mADC)

0~+10VDC)

25~32kp/s)

4(0)~20mADC)

0~+10VDC)

1

”

Detachable

terminal

block

”

for any alarm)

1

*3 The R0 and T0 terminals are provided for inverters of type 0059 or above(460V class) and type 0088 or above(230V class).

To retain an alarm output signal ALM issued on inverter's programmable output terminals by the protective function or to keep

the keypad alive even if the main power has shut down, connect these terminals to the power supply lines. Even if without

connecting the power supply to these terminals, the inverter can run as long as connecting the power supply to the terminals

L1/R, L2/S, L3/T.

*4 Normally no need to be connected. Use these terminals when the inverter is equipped with a high power-factor,

regenerative PWM converter (RHC series). (Type 0203 or above/460V only)

*5 When connecting an optional DC reactor (DCR), remove the jumper bar from the terminals P1 and P(+).

For types 0139 (ND spec.), 0168 (HD/ND spec.) and 0203 or bigger capacity types, it is required to connect the DCR (460V

only). Use a DCR when the capacity of the power supply transformer exceeds 500 kVA and is 10 times or more the inverter

rated capacity, or when there are thyristor-driven loads in the same power supply line.

*6 Inverters of type 0072 or below(460V class) and type 0115 or below(230V class) have a built-in braking chopper between

the terminals P(+) and DB.

*7 For inverters of type 0085 or above (460V class), need to use a braking unit to connect the braking resistor in order to

upgrade the braking capability of inverters. Be sure to connect the braking unit (option) to terminals P(+) and N(-). Auxiliary

terminals [1] and [2] have polarity. Be sure to connect as this figure.

*8 A grounding terminal for a motor. Use this terminal if needed.

*9 For control signal wires, use twisted or shielded-twisted wires. When using shielded-twisted wires, connect the shield of

them to the common terminals of the control circuit. To prevent malfunction due to noise, keep the control circuit wiring away

from the main circuit wiring as far as possible (recommended: 10 cm(3.9 inches) or more). Never install them in the same wire

duct. When crossing the control circuit wiring with the main circuit wiring, set them at right angles.

*10 The connection diagram shows factory default functions assigned to digital input terminals [X1] to [X5], [FWD] and [REV],

transistor output terminals [Y1] and [Y2], and monitor contact output terminals [FM] .

*11 The power switching connectors (CN UX) and the fan power supply switching connectors (CN R and CN W) are for type

0203(460 V class) or above.

*12 Slide switches on the control printed circuit board (control PCB). Use these switches to customize the inverter operations.

*13 Use auxiliary contacts of the thermal relay (manually restorable) to trip the molded case circuit breaker (MCCB) or

magnetic contactor (MC).

*14 When using the Enable input function, be sure to remove the jumper wire from terminals [EN1],[EN2] and [PLC].

*15 and are separated and insulated

30A 30B 30C

C1 11 FM1 FM2

CM FWD REV PLC EN1 EN2

11 11 12 13

Orange = Outputs, Yellow = Analog Inputs, Blue = Digital Inputs

• FWD, Rev, plus 5 Digital inputs. Congurable for

Source or Sink.

Operang

Voltage

(Sink)

Operang

Voltage

(Sink)

Item

Min. Max.

On level 0V 2V

Off leve l 22V 27V

On level 22V 27V

Off leve l 0V 2V

• 0-10VDC analog input.

• 4-20mA, 0-20mA or 0-10VDC analog input.

• 2 Transistor outputs.

Item

Operang

Voltage

(Sink)

Maximum Current at on 50mA

Max.

On level 2v

Off level 22V

• Form C contact relay

o (250VAC 0.3A, cosØ=0.3), (48VDC, .5A).

• 1 0-10VDC, 4-20mA, 0-20mA or 25-32kp/s analog

output.

• 1 0-10VDC, 4-20mA or 0-20mA analog output.

• 24VDC max 100mA DC output power.

• 10VDC output power for potentiometer.

• 2 Source only, safe torque off Enable Inputs.

• RS-485 wire terminals.

FRENIC-Ace (E2) Keypad

A. LED Display

B. Remote/Local Indicator

C. Monitoring Display Indicator

D. Program Reset Key

E. Function Data Key

F. Shift Key

G. Menu Navigation Keys

H. Local Mode Control Operators

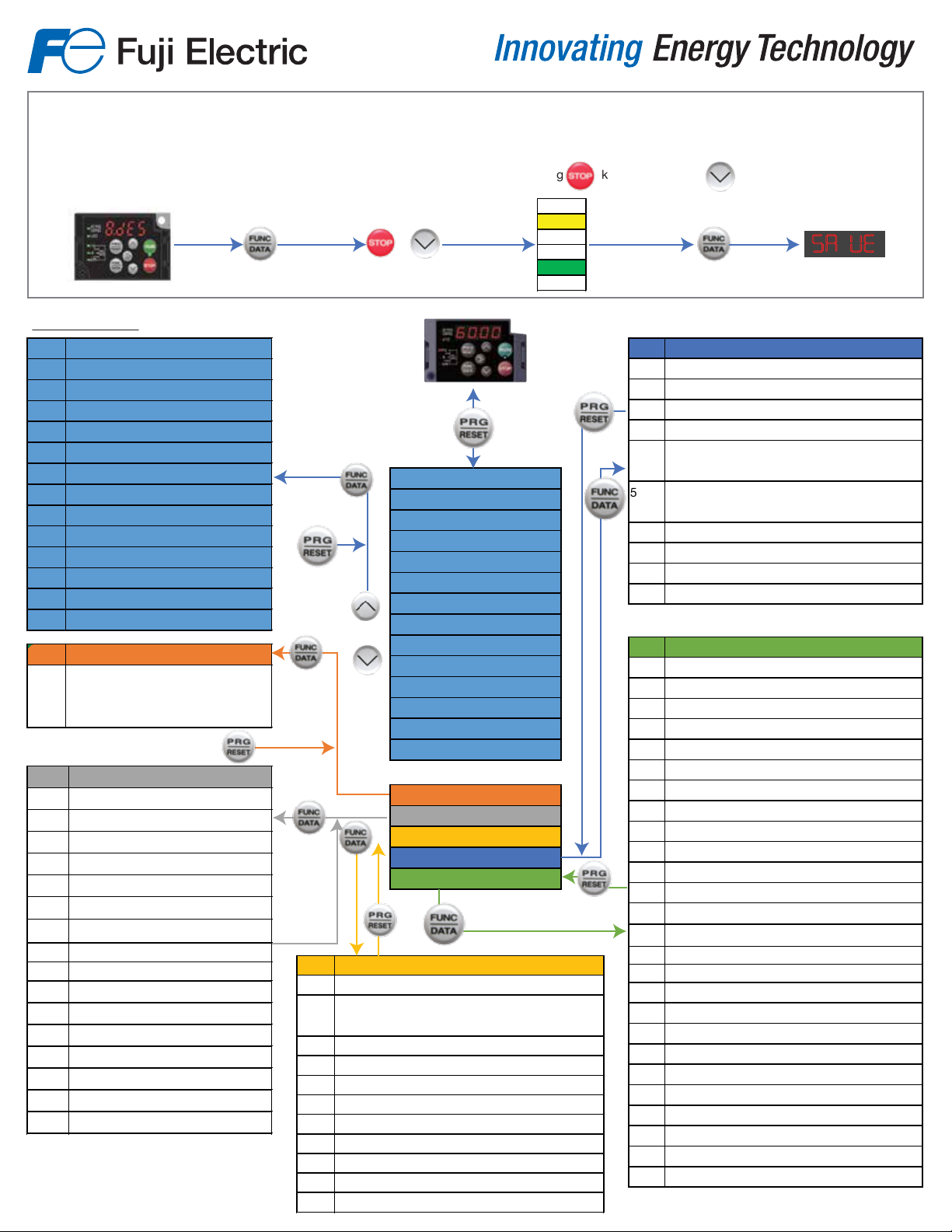

Page 2

First Power ON.

Upon powering the drive on for the rst time you must set the region in Menu 8.des, for Americas by setting the value to amer

After initial start-up you may change the region by setting the value of H101. See page 4-4 of FRENIC-ACE Instructional Manual INR-SI47-1733f-E For

more details.

Changing the regional from default value

Quick Start Menus

1.F Fundamental Functions

1.E Extension Terminal Functions

1.C Control Functions of Frequency

1.P Motor 1 Parameters

1.H High Performance Functions

1.H1 High Performance Functions

1.A Motor 2 Functions

1.J Application Functions

1.J1 PID Functions

1.d Application Functions 2

1.U Customizable Logic

1.U1 Customizable Logic

1.Y Link Functions

1.k Keypad Functions

2. rEP (Data Check)

Displays function codes that

have been changed from

factory default

3. oPE (Operations Monitor)

3_00 Output frequency Before Slip

3_01 Output frequency After Slip

3_02 Output Current

3_03 Output Voltage

3_04 Calculated Torque

3_05 Reference Frequency

3_06 Rotation Direction

3_07 Running Status

3_08 Motor Speed r/min

3_09 Load Shaft speed

3_10 PID SV

3_11 PID PV

3_12 Torque Limit Value A

3_13 Torque Limit Value B

3_14 Ratio Setting

3_15 Line Speed r/min

Fuji Electric Corp. of America

47520 Westinghouse Drive, Fremont, CA 94539

Phone: 510-440-1060

www.americas.fujielectric.com

asia to amer requires pressing and holding key while pressing

jpn

asia

+

1.F _ _

1.E _ _

1.C _ _

1.P _ _

1.H _ _

1.H1 _ _

1.A _ _

1.J _ _

1.J1 _ _

1.d _ _

1.U _ _

1.U1 _ _

1.Y _ _

1.k _ _

To access menus 2-6 change function code E52-2

2. rEP

3. oEP

4. I_O

5. CHE

6. AL

4. I_O (I/O Check)

4_00 I/O Signals on the Control Card Terminals

4_01 I/O Signals on the Control Card Terminals

under Communications.

4_02 Input Voltage on Terminal 12

4_03 Input Current on Terminal C1

4_04 Output Voltage on Terminal FMV

4_05 Output Voltage on Terminal FM2

4_06 Output Frequency on Terminal FMP

4_07 Input Voltage on Terminal C1

4_08 Output Current on Terminal FMI

4_09 Output Current on Terminal FM2

4_2

4 Cutomizable Logic Timer

chn

eu

amer

kor

5. CHE (Maintenacne Info)

5_00 Accumulated Run Time

5_01 DC Link Bus Voltage

5_03 Max Temperature of Heat Sink

5_04 Max Effectice Current

5_05 Capacitance of the DC Link Bus

Capacitance

5_06 Accumutated Run Time of Electolytic

Capacitors on the PCB

5_07 Accumulated Run Time of Cooling Fan

5_08 Number of Starts (Drive)

5_09 Input Watt-Hour

5_10 Input Watt-Hour Data

6. AL (Alarm Info)

6_00 Output Frequency

6_01 Output Current

6_02 Output Voltage

6_03 Calculated Torque

6_04 Reference Frequency

6_05 Rotational Ditection

6_06 Running Status

6_07 Accumulated Running Time

6_08 Number of Startups

6_09 DC Link Bus Voltage

6_10 Temperature Inside the Inverter

6_11 Max. Temperature of Heat Sink

6_12

Terminal I/O Status

6_13 Terminal Input Signal Status in HEX

6_14 Terminal Output Status in Hex

6_15

Number of Consecutice Occurrces

6_16 Overlapping Alarm 1

6_17 Overlapping Alarm 2

6_18 Communication Terminal Status I/0

6_19 Communication Terminal Status Input

6_20 Communication Terminal Status Output

6_21 Sub-Code

6_22 Running Status 2

6_23 Detected Speed

6_24 Running Status 3

6_25 Multiple Alarm Sub-Code

sav ue

Loading...

Loading...