Fuji Electric Frenic-Ace Catalog

High Performance Inverter

New

FUJI ELECTRIC INVERTERS

The FRENIC-Ace Inverters are full feature drives offering great value

and maintain high performance through optimal design

for a wide range of applications for various machines and devices.

24A1-E-0042c

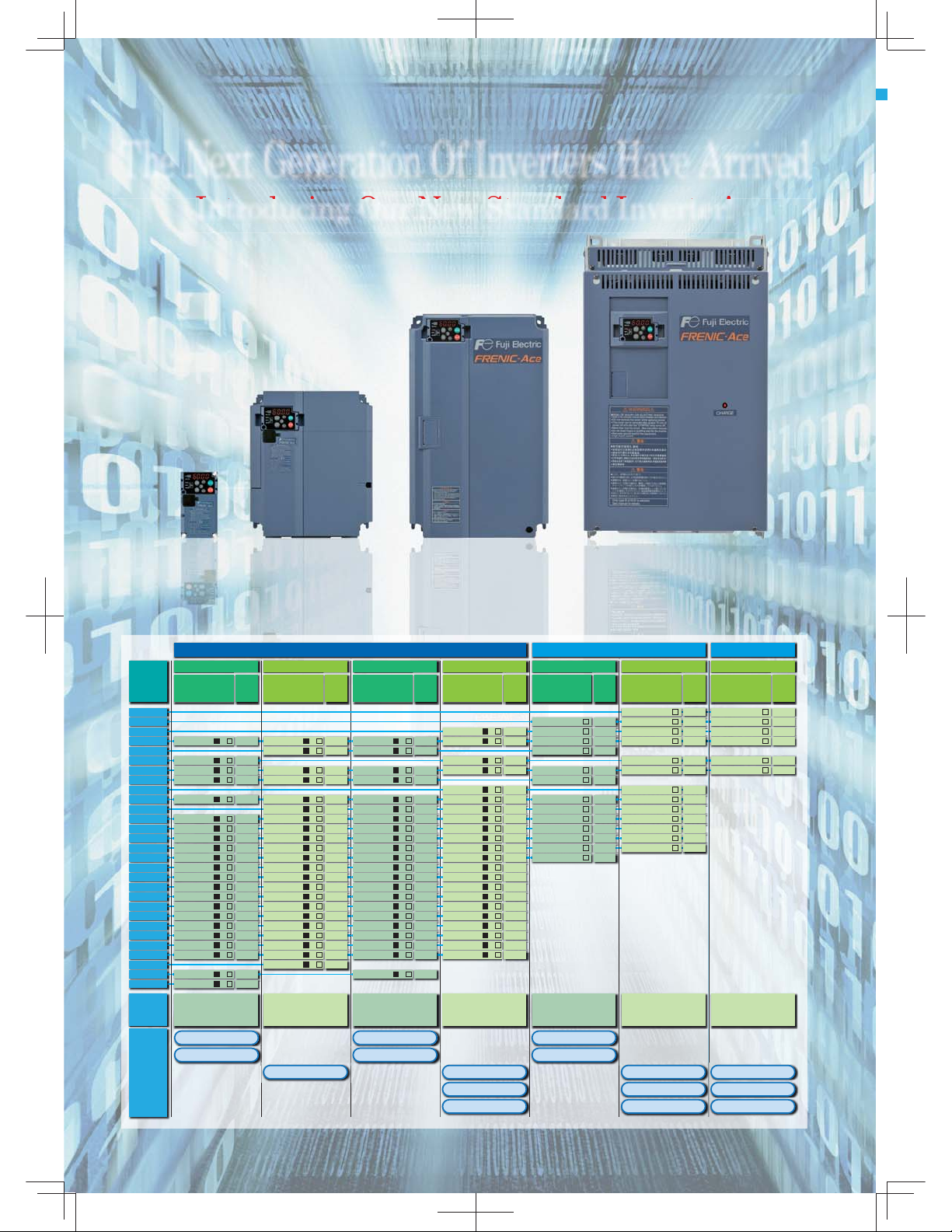

The Next Generation Of Inverters Have Arrived

Introducing Our New Standard Inverter!

Enjoy A Full Range Of Applications

The standard inverter for the next generation, the FRENIC-Ace, can be used

in most types of application—from fans and pumps to specialized machinery.

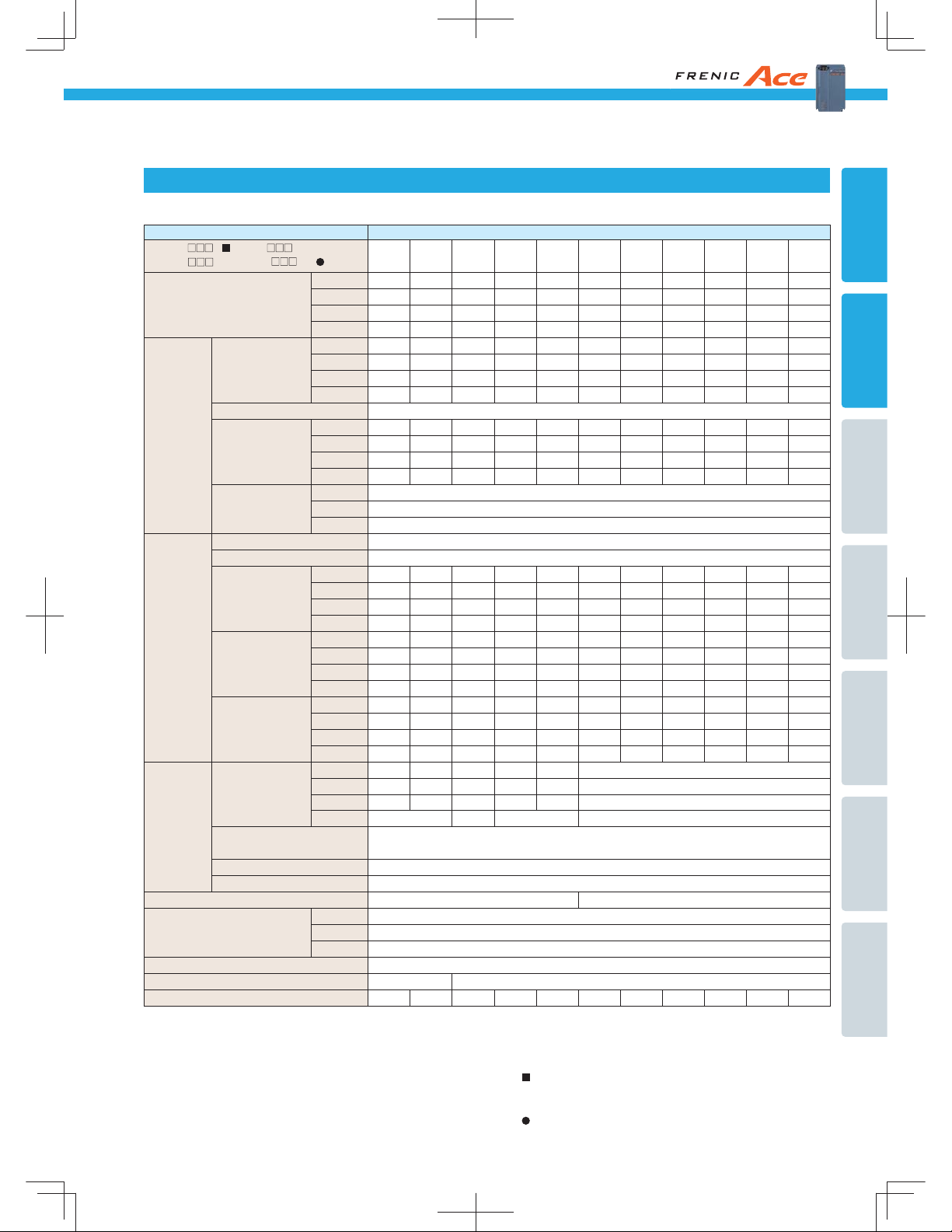

3-phase 400V series 3-phase 200V series

Nominal

applied

motor

[kW]

0.1

0.2

0.4

0.75

1.1

1.5

2.2

3

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

90

110

132

160

200

220

250

280

315

Rating

condition

Application

*3-phase 200V series supports only a product for Asia.

ND rating

Model

FRN0002E2 -4

FRN0004E2 -4

FRN0006E2 -4

FRN0007E2 -4

FRN0012E2 -4

FRN0022E2 -4

FRN0029E2 -4

FRN0037E2 -4

FRN0044E2 -4

FRN0059E2 -4

FRN0072E2 -4

FRN0085E2 -4

FRN0105E2 -4

FRN0139E2 -4

FRN0168E2 -4

FRN0203E2 -4

FRN0240E2 -4

FRN0290E2 -4

FRN0361E2 -4

FRN0415E2 -4

FRN0520E2 -4

FRN0590E2 -4

Overload current rating

Max. ambient temp.

120% -1min

Fans, pum ps

Wire drawing

40ĆC

Rated

output

current

2.1A

4.1A

5.5A

6.9A

12A

21.5A

28.5A

37A

44A

59A

72A

85A

105A

139A

168A

203A

240A

290A

361A

415A

520A

590A

HD rating

Model

FRN0002E2 -4

FRN0004E2 -4

FRN0006E2 -4

FRN0007E2 -4

FRN0012E2 -4

FRN0022E2 -4

FRN0029E2 -4

FRN0037E2 -4

FRN0044E2 -4

FRN0059E2 -4

FRN0072E2 -4

FRN0085E2 -4

FRN0105E2 -4

FRN0139E2 -4

FRN0168E2 -4

FRN0203E2 -4

FRN0240E2 -4

FRN0290E2 -4

FRN0361E2 -4

FRN0415E2 -4

FRN0520E2 -4

FRN0590E2 -4

Overload current rating

Max. ambient temp.

150% -1min

Vert ical conve yanc e

40ĆC

Rated

output

current

1.8A

3.4A

5A

6.3A

11.1A

17.5A

23A

31A

38A

45A

60A

75A

91A

112A

150A

176A

210A

253A

304A

377A

415A

477A

HND rating

Model

FRN0002E2 -4

FRN0004E2 -4

FRN0006E2 -4

FRN0007E2 -4

FRN0012E2 -4

FRN0022E2 -4

FRN0029E2 -4

FRN0037E2 -4

FRN0044E2 -4

FRN0059E2 -4

FRN0072E2 -4

FRN0085E2 -4

FRN0105E2 -4

FRN0139E2 -4

FRN0168E2 -4

FRN0203E2 -4

FRN0240E2 -4

FRN0290E2 -4

FRN0361E2 -4

FRN0415E2 -4

FRN0520E2 -4

FRN0590E2 -4

Overload current rating

Max. ambient temp.

120% -1min

Fans, pum ps

Wire drawing

50ĆC

Rated

output

current

1.8A

3.4A

5A

6.3A

11.1A

17.5A

23A

31A

38A

45A

60A

75A

91A

112A

150A

176A

210A

253A

304A

377A

415A

520A

HHD rating

Model

output

current

FRN0002E2 -4

FRN0004E2 -4

FRN0006E2 -4

FRN0007E2 -4

FRN0012E2 -4

FRN0022E2 -4

FRN0029E2 -4

FRN0037E2 -4

FRN0044E2 -4

FRN0059E2 -4

FRN0072E2 -4

FRN0085E2 -4

FRN0105E2 -4

FRN0139E2 -4

FRN0168E2 -4

FRN0203E2 -4

FRN0240E2 -4

FRN0290E2 -4

FRN0361E2 -4

FRN0415E2 -4

FRN0520E2 -4

FRN0590E2 -4

Overload current rating

Max. ambient temp.

150% -1min,

200% -0.5sec

Vert ical conve yanc e

Winding machines

Printing machines

50ĆC

Rated

1.5A

2.5A

4.2A

5.5A

9A

13A

18A

24A

30A

39A

45A

60A

75A

91A

112A

150A

176A

210A

253A

304A

377A

415A

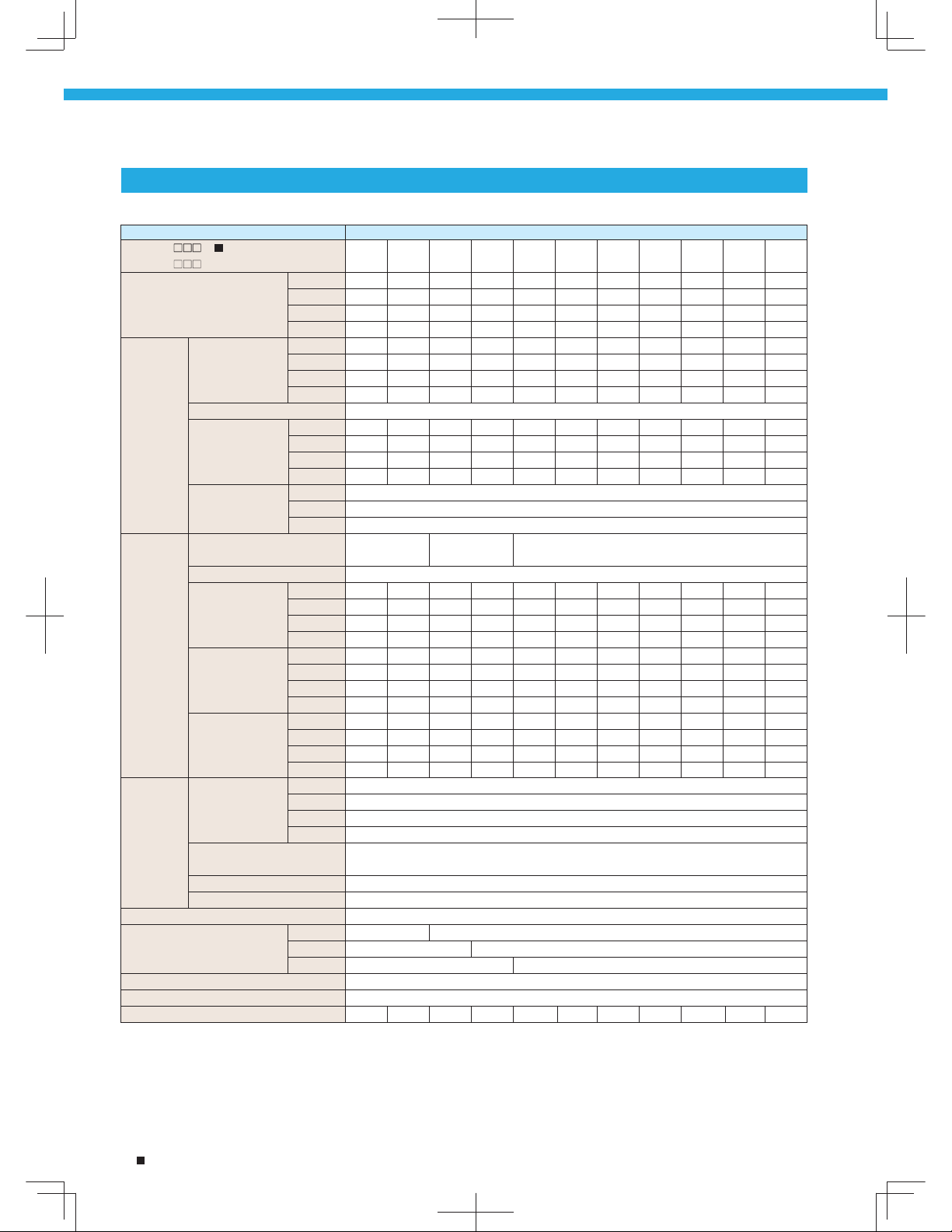

HND rating

Model

FRN0001E2S-2

FRN0002E2S-2

FRN0004E2S-2

FRN0006E2S-2

FRN0010E2S-2

FRN0012E2S-2

FRN0020E2S-2

FRN0030E2S-2

FRN0040E2S-2

FRN0056E2S-2

FRN0069E2S-2

FRN0088E2S-2

FRN0115E2S-2

Overload current rating

Max. ambient temp.

120% -1min

Fans, pum ps

Wire drawing

50ĆC

Rated

output

current

1.3A

2A

3.5A

6A

9.6A

12A

19.6A

30A

40A

56A

69A

88A

115A

HHD rating

Rated

Model

output

current

FRN0001E2S-2

FRN0002E2S-2

FRN0004E2S-2

FRN0006E2S-2

FRN0010E2S-2

FRN0012E2S-2

FRN0020E2S-2

FRN0030E2S-2

FRN0040E2S-2

FRN0056E2S-2

FRN0069E2S-2

FRN0088E2S-2

FRN0115E2S-2

Overload current rating

150% -1min,

200% -0.5sec

Vert ical conve yanc e

Winding machines

Printing machines

17.5A

Max. ambient temp.

50ĆC

1-phase 200V series

FRN0001E2S-7

0.8A

FRN0002E2S-7

1.6A

FRN0003E2S-7

3A

FRN0005E2S-7

5A

FRN0008E2S-7

8A

FRN0011E2S-7

11A

25A

33A

47A

60A

76A

90A

Overload current rating

150% -1min,

200% -0.5sec

Vert ical conve yanc e

Winding machines

Printing machines

HHD rating

Model

Max. ambient temp.

50ĆC

Rated

output

current

0.8A

1.6A

3A

5A

8A

11A

2

FUJI ELECTRIC INVERTERS

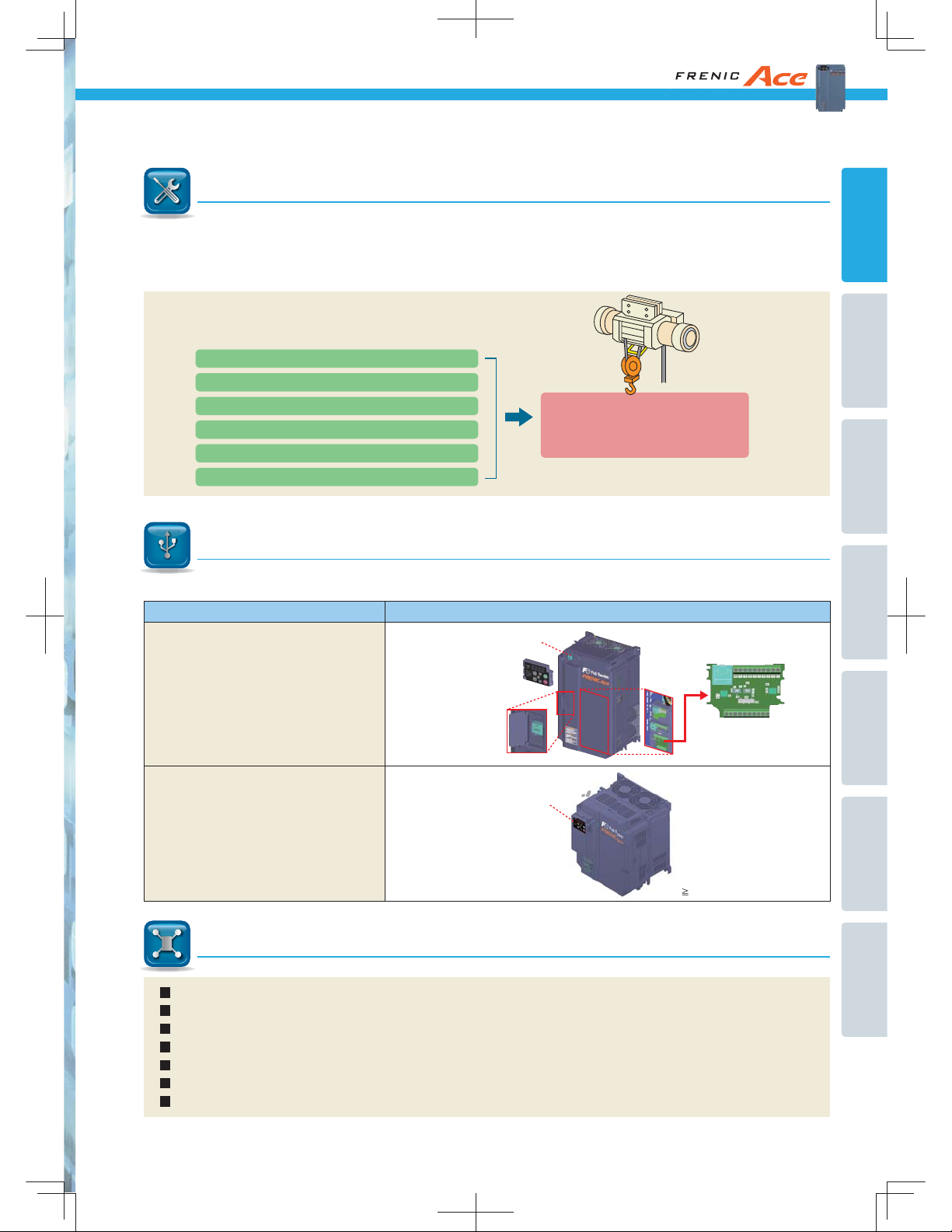

Customizable Logic

Customizable logic function is available as a standard feature. FRENIC-Ace has built-in customizable logic functions with a maximum of

200 steps including both digital and analog operation functions, giving customers the ability to customize their inverters—from simple

logic functions to full-scale programming. Fuji Electric also has plans to offer programming templates for wire drawing machines, hoists,

spinning machines, and other applications so that the FRENIC-Ace can be used as a dedicated purpose inverter.

Example: Hoist crane application

Programming the FRENIC-Ace main unit with the required logic for controlling a hoist

(1) Set speed program

Reset the alarm by using the push-button switch

(2)

(3) Mechanical limit switch function

(4) Detect load

Automatic speed drive when no load is detected

(5)

Dedicated/specialized functions for

hoist application implemented by

using customizable logic

(6) Overload stop function

Superior Flexibility

Major Functions

Standard Model Specifications

Common Specifications

FRENIC-Ace has readily available interface cards and various types of fieldbus / network to maximize its flexibility.

Option

RS485 communications card

PG interface (5V) card

PG interface (12/15V) card

DeviceNet communication card

CC-Link communication card

PROFIBUS-DP communication card (Coming Soon)

EtherNet/IP communication card (Coming Soon)

ProfiNet-RT communication card (Coming Soon)

CANopen communication card (Coming Soon)

Digital input/output interface card

Analog input/output interface card

RJ-45 connector

Optional control terminal block

Front face panel

Optional front face keypad mount

Installation type

30kW(ND): option card is built-in

Wide Variety Of Functions As A Standard Feature

Sensorless dynamic torque vector control

Motor vector control with PG (with optional card)

Synchronous motor with sensorless vector control

2-channel on-board RS485 communications port

Standard CANopen compatibility

Removable keypad device

Removable control terminal block board

Basic Wiring DiagramTerminal FunctionsExternal DimensionsOptions

Control terminal block

3

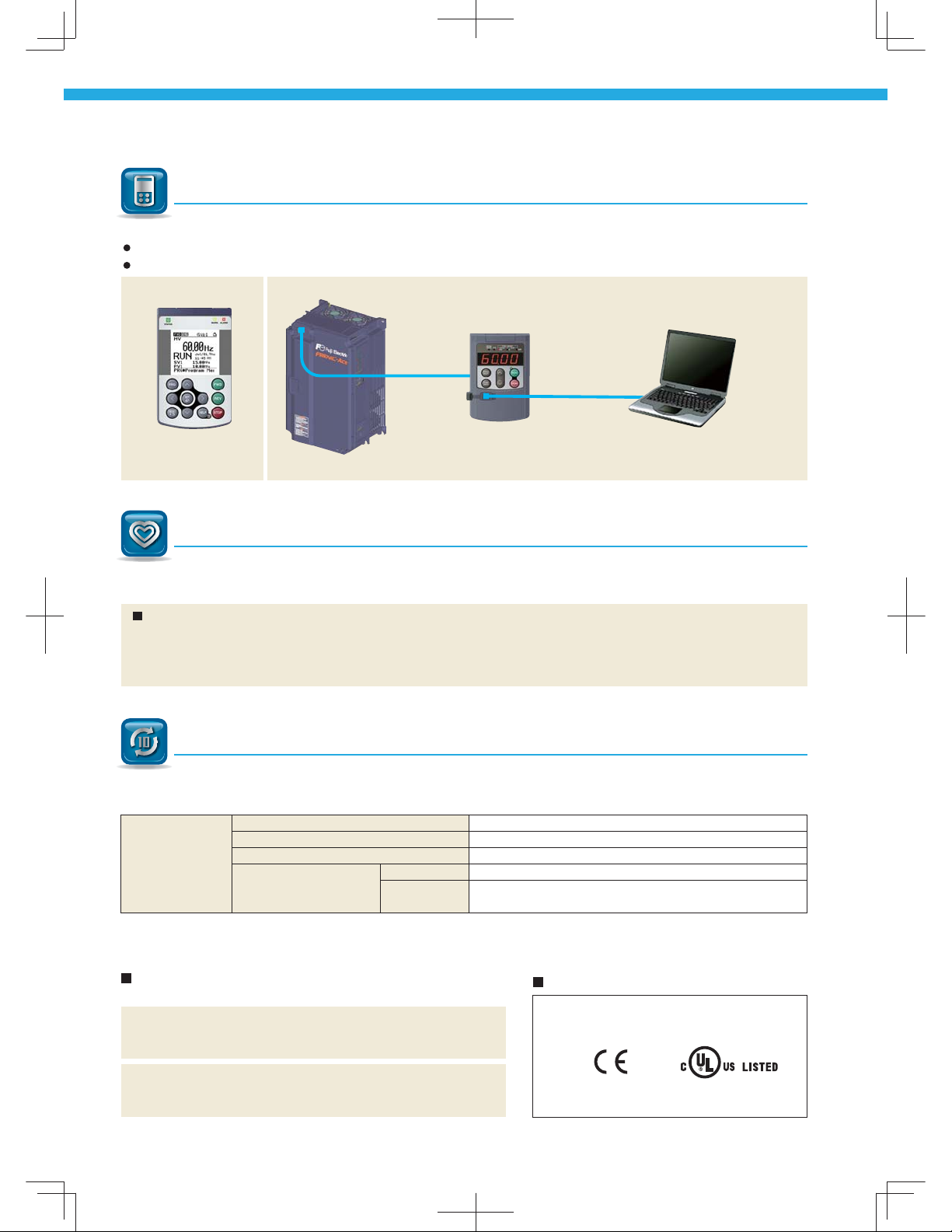

Multi-Function Keypad

(option)

FRENIC-Ace has two different multi-function keypads available

Multi-function keypad with LCD display: Enhanced HMI functionality

USB keypad: Connect to a computer for more efficient operation (set-up, troubleshooting, maintenance, etc)

LAN cable

USB–USBminiB cable

Multi-function keypad

with LCD screen

USB keypad

Functional Safety

FRENIC-Ace is equipped with STO functional safety function as a standard. Therefore output circuit magnetic contactors are not required

for safe stop implementation. Enhanced standard features position FRENIC-Ace ahead of its class (Safety input: 2CH, output: 1CH).

Complies with (coming soon)

EN ISO 13849-1: 2008, Cat.3 / PL=e

IEC/EN 60204-1: 2005/2006 Stop category 0

IEC/EN 61508-1 to -7: 2010 SIL3

IEC/EN 61800-5-2: 2007 SIL3 (Safety feature: STO)

IEC/EN 62061: 2005 SIL3

10 Years Lifetime Design

FRENIC-Ace components have a design life of ten years.

A longer maintenance cycle also helps to reduce running costs.

Main circuit capacitor

Electrolytic capacitors on PCB

Design life

* ND specifications have a rated current of two sizes higher than HHD specifications, so the life is 7 years.

Cooling fan

Life conditions

Ambient temperature

Load rate

10 years*

10 years*

10 years*

+40°C

100% (HHD specifications)

80% (HND/HD/ND specifications)

Standards

RoHS Directive

Standard compliance with European regulations that limit the use of specific hazardous substances (RoHS)

<Six hazardous

substances>

<About RoHS>

4

Lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyl

(PBB), polybrominated biphenyl ether (PBDE)

Directive 2002/95/EC, issued by the European Parliament and European

Council, limits the use of specific hazardous substances in electrical and electronic devices.

Global Compliance

Standard compliance

UL Standard (cUL Certified)EC Directives (CE Mark)

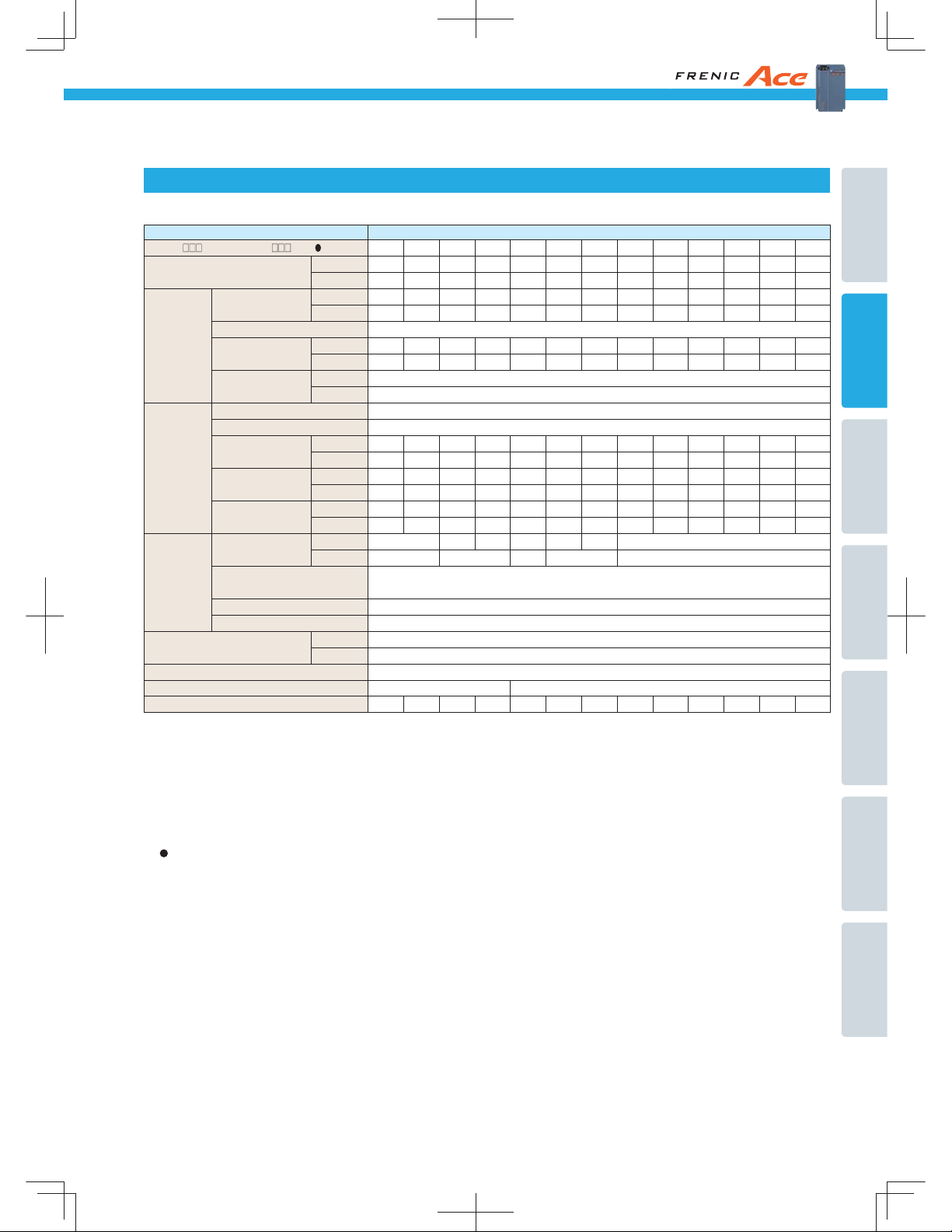

Standard Model Specifications

Three phase 400V class series

Type (FRN E2 -4E)

(FRN E2S-K(0022~)), (FRN E2S-G (0002~0012)

Nominal applied motor *1 [kW]

Output ratings

Input ratings

Braking

*9

EMC filter

DC reactor (DCR)

Enclosure (IEC60529)

Cooling method

Mass (Basic Type (EMC Filter Built-in Type)) [kg]

*1 Fuji 4-pole standard motor

*2 Rated capacity is calculated by assuming the output rated voltage as 440 V.

*3 Output voltage cannot exceed the power supply voltage.

*4 When the carrier frequency (F26) is set to below value or higher, the inverter is sure to

be necessary to derate their nominal current.

HHD spec.---type 0002 to 0012 : 8kHz, type 0022 to 0168 : 10kHz,

HND spec.---type 0002 to 0012 : 8kHz, type 0022 to 0059 : 10kHz,

HD,ND spec.---All type : 4kHz

The rated output current at HD/ND spec. is decreased 2% for every 1 °C (1.8 °F) when

ambient temperature is +40 °C (+104 °F) or more.

*5 The value is calculated assuming that the inverter is connected with a power supply with

the capacity of 500 kVA

(or 10 times the inverter capacity if the inverter capacity exceeds 50 kVA) and %X is 5%.

Be sure to use the DCR when applicable motor capacity is 75kW or above.

*10

, (FRN E2S-4A),

ND

HD

HND

HHD

ND

HD

Rated capacity [kVA]

*2

HND

HHD

Rated voltage [V]

*3

ND

HD

Rated current [A]

*4

HND

HHD

ND, HND

Overload capability

HD

HHD

Main power supply

Voltage/frequency variations

ND

Rated current

without DCR

HD

*5

HND

[A]

HHD

ND

Rated current

*5

with DCR

[A]

HD

HND

HHD

Required power

supply capacity

[kVA]

ND

HD

*6

HND

HHD

ND

Braking torque *7 [%]

HD

HND

HHD

DC braking

Braking chopper

Braking resistor

ND

HND, HD

HHD

0002

*12

)

0.75

0.75

0.75

0.4

1.6

1.4

1.4

1.1

Three-phase 380 to 480V (With AVR)

2.1

1.8

1.8

1.5

120% of nominal current for 1min

150% of nominal current for 1min

150% of nominal current for 1min or 200% of nominal current for 0.5s

Three-phase 380 to 480V (With AVR)

Voltage: +10 to -15% (Voltage unbalance:2% or less

2.7

2.7

2.7

1.7

1.5

1.5

1.5

0.85

1.1

1.1

1.1

0.6

53%

53%

53%

100% 40%

Starting frequency: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s,

Braking level: 0 to 60% (ND spec.), 0 to 80% (HD/HND spec.), 0 to 100% (HHD spec.) of nominal current

Built-in

Option

Option

Option

Option

IP20, UL open type

Natural cooling

1.2

type 0203 to 0590 : 6kHz

type 0072 to 0168 : 6kHz, type 0203 to 0590 : 4kHz

0004

1.5

1.1

1.1

0.75

3.1

2.6

2.6

1.9

4.1

3.4

3.4

2.5

4.8

3.9

3.9

3.1

2.9

2.1

2.1

1.6

2.1

1.5

1.5

1.2

50%

68%

68%

1.5

0006

2.2

2.2

2.2

1.5

4.2

3.8

3.8

3.2

5.5

5.0

5.0

4.2

7.3

7.3

7.3

5.9

4.2

4.2

4.2

3.0

3.0

3.0

3.0

2.1

48%

48%

48%

70%

Fan cooling

1.5

FUJI ELECTRIC INVERTERS

SpecificationsItems

0007

3.0

3.0

3.0

2.2

5.3

4.8

4.8

4.2

6.9

6.3

6.3

5.5

11. 3

11. 3

11. 3

8.2

5.8

5.8

5.8

4.4

4.1

4.1

4.1

3.1

29%

29%

29%

0012

5.5

5.5

*11

*11

5.5

3.7

9.1

8.5

*11

*11

8.5

6.9

12

11.1

*11

*11

11.1

9.0

16.8

16.8

*11

*11

16.8

13.0

10.1

10.1

*11

*11

10.1

7.3

7.0

7.0

*11

*11

7.0

5.1

27%

27%

*11

*11

27%

0029

0022

15

11

11

7. 5

11

7. 5

7. 5

5.5

22

16

18

13

18

13

14

9.9

28.5

21.5

23.0

17.5

23.0

17.5

18.0

13.0

*8

, Frequency: +5 to -5%)

43.8

33.0

33.0

23.2

33.0

23.2

23.2

17.3

28.8

21.1

21.1

14.4

21.1

14.4

14.4

10.6

20

15

15

10

15

10

10

7.3

12%

15%

15%

0037

18.5

15

15

11

28

24

24

18

37.0

31.0

31.0

24.0

52.3

43.8

43.8

33.0

35.5

28.8

28.8

21.1

25

20

20

15

0044

22

18.5

18.5

15

34

29

29

23

44.0

38.0

38.0

30.0

60.6

52.3

52.3

43.8

42.2

35.5

35.5

28.8

29

25

25

20

0059

30

22

22

18.5

45

34

34

30

59.0

45.0

45.0

39.0

77.9

60.6

60.6

52.3

57.0

42.2

42.2

35.5

39

29

29

25

0072

37

30

30

22

55

46

46

34

72.0

60.0

60.0

45.0

94.3

77.9

77.9

60.6

68.5

57.0

57.0

42.2

47

39

39

29

20%

Compliant with EMC Directives, Emission and Immunity: Category C3 (2nd Env.) (EN61800-3:2004)

5.0(TBD)

1.9

5.0(TBD)

8.0(TBD)

9.0(TB D)

9.5(10.5)

10(11.2)

1.6

*6 Obtained when a DC reactor (DCR) is used.

*7 Average braking torque for the motor running alone. (It varies with the efficiency of

the motor.)

*8 Voltage unbalance (%) =(Max. voltage (V) - Min. voltage (V))/Three -phase average

voltage (V) × 67 (IEC 61800 - 3) If this value is 2 to 3%, use an optional AC reactor

(ACR).

*9 The EMC Filter Built-in Type supports only a product for EU.

*10 : S: Standard (basic type), E: EMC filter built-in type (0059 to 0590)

*11 HND spec. of the type 0007 and 0012: allowable ambient temperature 40 °C (+104 °F)

or less.

The rated output current at HND spec. is decreased 1% for every 1 °C (1.8 °F) when

ambient temperature is +40 °C (+104 °F) or more.

*12 : A: 1 CAN termi nal, 1 a nalog current outpu t

B: NONE CAN terminal, 2 analog current output

Major Functions

Standard Model Specifications

Common Specifications

Basic Wiring DiagramTerminal FunctionsExternal DimensionsOptions

5

Standard Model Specifications

Three phase 400V class series

SpecificationsItems

0240

0203

132

110

110

90

110

90

90

75

183

155

160

134

160

134

134

114

240

203

210

176

210

176

176

150

Three-phase 380 to 440V, 50Hz

Three-phase 380 to 480V, 60Hz

*8

, Frequency: +5 to -5%)

-

-

-

-

-

-

-

-

238

201

201

164

201

164

164

138

165

139

140

114

140

114

114

96

Attached as standard

Attached as standard

62(62)

40(40)

0290

0361

160

200

132

160

132

160

110

132

22

275

1

232

193

232

193

193

160

361

290

304

253

304

253

253

210

-

-

-

-

-

-

-

-

357

286

286

238

286

238

238

201

248

199

199

165

199

165

165

140

Attached as standard

95(95)

63(63)

0415

220

200

200

160

316

287

287

232

415

377

377

304

*9

-

-

-

-

390

357

357

286

271

248

248

199

96(96)

0520

280

220

220

200

396

316

316

287

520

415

415

377

-

-

-

-

500

390

390

357

347

271

271

248

130 (130 )

*1

[kW]

*5

*11

[A]

0105

0139

0085

ND

HD

HND

HHD

ND

HD

*2

HND

HHD

*3

ND

HD

*4

HND

HHD

ND, HND

HD

HHD

Three-phase 380 to

55

45

45

37

45

37

37

30

80

65

69

57

69

57

57

46

Three-phase 380 to 480V (With AVR)

105

85.0

91.0

75.0

91.0

75.0

75.0

60.0

120% of nominal current for 1min

150% of nominal current for 1min

150% of nominal current for 1min or 200% of nominal current for 0.5s

Three-phase 380 to

480V (With AVR)

0168

75

55

55

45

106

85

85

69

139

112

112

91.0

480V, 50/60Hz

90

75

75

55

128

114

114

85

168

150

150

112

Voltage: +10 to -15% (Voltage unbalance:2% or less

ND

HD

*5

HND

[A]

HHD

ND

HD

HND

HHD

ND

HD

*6

HND

HHD

ND

HD

HND

HHD

114

94.3

94.3

77.9

83.2

68.5

68.5

57.0

58

47

47

39

5 to 9%

7 to 12%

7 to 12%

10 to 15%

140

114

114

94.3

102

83.2

83.2

68.5

71

58

58

47

140

140

114

138

102

102

83.2

96

71

71

58

-

-

-

-

140

164

138

138

102

114

96

96

71

Starting frequency: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s,

Braking level: 0 to 60% (ND spec.), 0 to 80% (HD/HND spec.), 0 to 100% (HHD spec.) of nominal current

Option

Option

Compliant with EMC Directives, Emission and Immunity: Category C3 (2nd Env.) (EN61800-3:2004)

ND

HND, HD

HHD

Option

Option

Option

IP00, UL open type

Fan cooling

26(27)

25(26)

30(31)

33(33)

Type (FRN E2 -4E)

(FRN E2S-4A)

Nominal applied motor

Rated capacity [kVA]

Rated voltage [V]

Output ratings

Rated current [A]

Overload capability

Main power supply

Voltage/frequency variations

Rated current

without DCR

Input ratings

Rated current

with DCR

Required power

supply capacity

[kVA]

Braking torque *7 [%]

Braking

DC braking

Braking chopper

Braking resistor

*10

EMC filter

DC reactor (DCR)

Enclosure (IEC60529)

Cooling method

Mass (Basic Type (EMC Filter Built-in Type)) [kg]

*1 Fuji 4-pole standard motor

*2 Rated capacity is calculated by assuming the output rated voltage as 440 V.

*3 Output voltage cannot exceed the power supply voltage.

*4 When the carrier frequency (F26) is set to below value or higher, the inverter is sure to be necessary to derate their nominal current.

HHD spec.---type 0002 to 0012 : 8kHz, type 0022 to 0168 : 10kHz, type 0203 to 0590 : 6kHz

HND spec.---type 0002 to 0012 : 8kHz, type 0022 to 0059 : 10kHz, type 0072 to 0168 : 6kHz, type 0203 to 0590 : 4kHz

HD,ND spec.---All type : 4kHz

The rated output current at HD/ND spec. is decreased 2% for every 1 °C (1.8 °F) when ambient temperature is +40 °C (+104 °F) or more.

*5

The value is calculated assuming that the inverter is connected with a power supply with the capacity of 500 kVA (or 10 times the inverter capacity if the inverter capacity exceeds 50 kVA) and %X is 5%.

Be sure to use the DCR when applicable motor capacity is 75kW or above.

*6 Obtained when a DC reactor (DCR) is used.

*7 Average braking torque for the motor running alone. (It varies with the efficiency of the motor.)

*8 Voltage unbalance (%) =(Max. voltage (V) - Min. voltage (V))/Three -phase average voltage (V) × 67 (IEC 61800 - 3) If this value is 2 to 3%, use an optional AC reactor (ACR).

*9 The 400 V class series with type 0203 or above is equipped with a set of switching connectors (male) which should be configured according to the power source voltage and frequency.

*10 The EMC Filter Built-in Type supports only a product for EU.

6

*11 : S: Standard (basic type), E: EMC filter built-in type (0059 to 0590)

0590

315

250

280

220

450

364

396

316

590

47

7

520

415

-

-

-

-

559

443

500

390

388

307

347

271

140 (140)

Standard Model Specifications

Three phase 200V class series (Basic Type)

Type (FRN E2S-2A(0030~))

*9

, (FRN E2S-2G (0001~0020))

Nominal applied motor *1 [kW]

*2

*3

*4

Output ratings

Rated capacity [kVA]

Rated voltage [V]

Rated current [A]

Overload capability

Main power supply

Voltage/frequency variations

Input ratings

Rated current

without DCR

Rated current

with DCR

Required power

supply capacity

*5

[A]

*5

[A]

*6

[kVA]

Braking torque *7 [%]

Braking

DC braking

Braking chopper

Braking resistor

DC reactor (DCR)

Enclosure (IEC60529)

Cooling method

Mass [kg]

*1 Fuji 4-pole standard motor

*2 Rated capacity is calculated by assuming the output rated voltage as 220 V.

*3 Output voltage cannot exceed the power supply voltage.

*4 When the carrier frequency (F26) is set to below value or higher, the inverter is sure to be necessary to derate their nominal current.

HHD spec.---type 0001 to 0020 : 8kHz, type 0030 to 0115 : 10kHz,

HND spec.---type 0001 to 0020 : 4kHz, type 0030 to 0069 : 10kHz, type 0088,0115 : 4kHz

*5 The value is calculated assuming that the inverter is connected with a power supply with the capacity of 500 kVA

(or 10 times the inverter capacity if the inverter capacity exceeds 50 kVA) and %X is 5%.

*6 Obtained when a DC reactor (DCR) is used.

*7 Average braking torque for the motor running alone. (It varies with the efficiency of the motor.)

*8 Voltage unbalance (%) =(Max. voltage (V) - Min. voltage (V))/Three -phase average voltage (V) × 67 (IEC 61800 - 3)

If this value is 2 to 3%, use an optional AC reactor (ACR).

*9 Three phase 200V class series supports only a product for Asia

*10 HND spec. of the type 0012 and 0020: allowable ambient temperature 40 °C (+104 °F) or less.

The rated output current at HND spec. is decreased 1% for every 1 °C (1.8 °F) when ambient temperature is +40 °C (+104 °F) or more.

*11 : A: 1 CAN terminal, 1 analog current output

B: NONE CAN terminal, 2 analog current output

HND

HHD

HND

HHD

HND

HHD

HND

HHD

HND

HHD

HND

HHD

HND

HHD

HND

HHD

HND

HHD

*11

0001

0.2

0.1

0.5

0.3

0002

0.4

0.2

0.8

0.6

0004

0.75

0.4

1.3

1.1

0006

1.1

0.75

2.3

1.9

0010

2.2

1.5

3.7

3.0

Three-phase 200 to 240V (With AVR)

9.6

6.0

3.5

2.0

1.3

8.0

5.0

3.0

1.6

0.8

120% of nominal current for 1min

150% of nominal current for 1min or 200% of nominal current for 0.5s

Three-phase 200 to 240V, 50/60Hz

Voltage: +10 to -15% (Voltage unbalance:2% or less

12.8

6.7

4.9

2.6

1.8

9.

5.3

3.1

1.8

1.1

4.3

3.0

1.6

0.93

0.57

0.4

0.2

75%

150%

1.6

0.93

1.1

0.6

0.6

0.4

53%

100% 40%

3.0

1.5

1.1

68%

8.3

5.7

2.9

2.0

48%

70%

Starting frequency: 0.0 to 60.0Hz, Braking time: 0.0 to 30.0s,

Braking level: 0 to 60% (ND spec.), 0 to 80% (HD/HND spec.), 0 to 100% (HHD spec.) of nominal current

Built-in

Option

Option

Option

IP20, UL ope n type

Naturalural cool

0.8

0.6

0.5

0.5

1.5

0012

3.0

2.2

4.6

4.2

12

11

17.9

5

13.2

11.7

8.3

4.1

2.9

29%

Fan cooli ng

1.5

SpecificationsItems

0020

*11

*11

5.5

3.7

*11

*11

7. 5

6.7

*11

*11

19.6

17.5

*8

, Frequency: +5 to -5%)

*11

*11

31.9

22.2

*11

*11

19.9

14.0

*11

*11

6.9

4.9

*11

*11

27%

1.8

0030

7. 5

5.5

9.5

30

25

42.7

31.5

28.8

21.1

10

7.3

15%

20%

5.0

FUJI ELECTRIC INVERTERS

0056

15

11

21

18

56

47

80.0

60.7

57.6

42.2

20

15

8.0

0069

18.5

97.0

80.0

71.0

57.6

0040

11

7. 5

11

15

13

40

33

60.7

42.7

42.2

28.8

15

10

5.0

9.0

0115

0088

30

22

22

18.5

15

44

34

26

34

29

23

115

88

69

90

76

60

Major Functions

Standard Model Specifications

151

112

112

97.0

114

84.4

84.4

71.0

40

30

25

30

25

20

Common Specifications

Basic Wiring DiagramTerminal FunctionsExternal DimensionsOptions

10

9.5

7

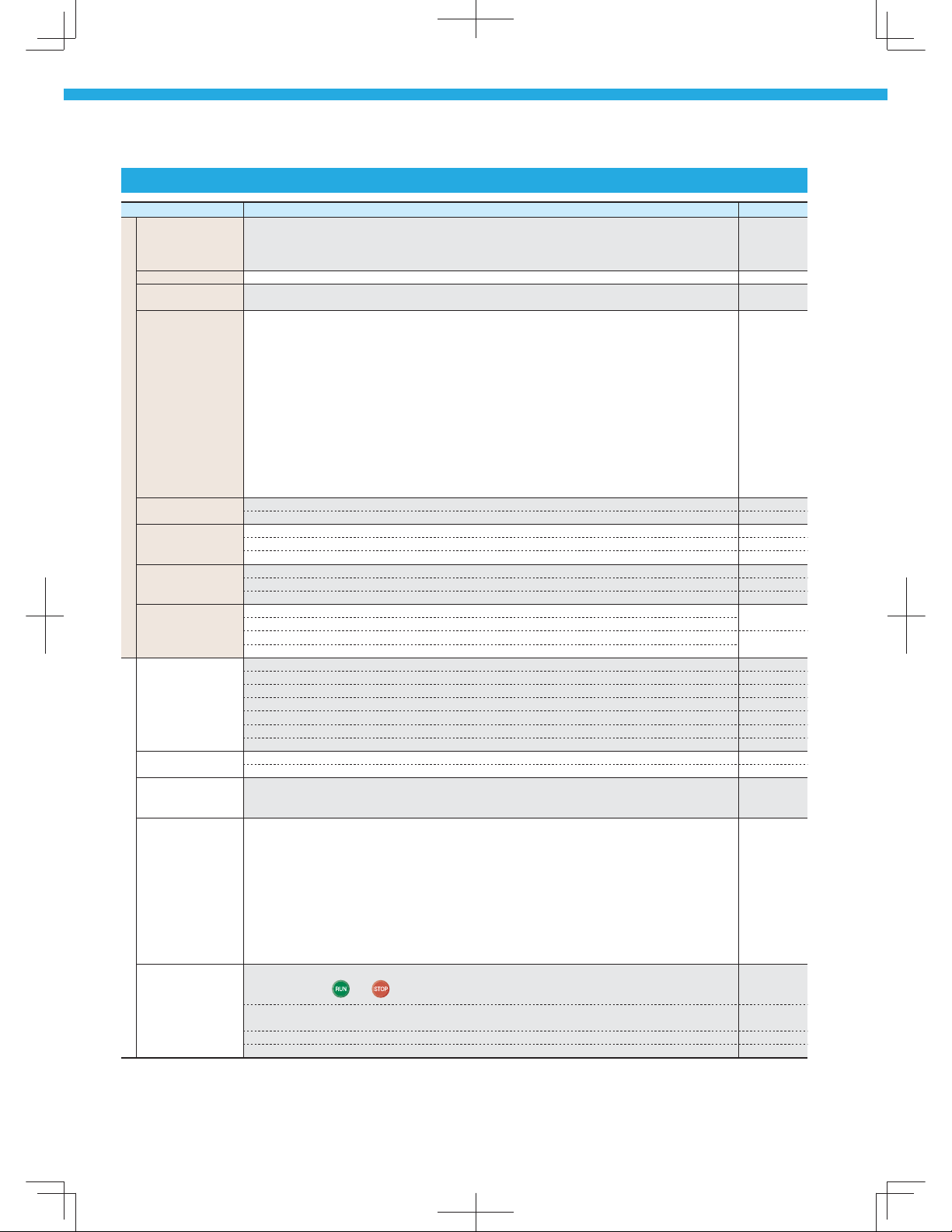

Common Specifications

Items

- HHD/HND/ HD spec.: 25 to 500 Hz varia ble

Maximum frequency IMPG-VC

Base frequency

Starting frequency IMPG-VC

Carrier frequency

OutputControl

Output frequency

accuracy (Stability)

Frequency setting

resolution

Speed control range IMPG-VF

Speed control

accuracy

Control method

Voltage/Frequency

characteristic

Torque boost

Starting torque

Start/Stop operation

(V/f control mode, Magneti c pole position sensorl ess vector contro l mode)

(Up to 200 Hz un der vecto r contro l with speed senso r)

- ND spec.: 25 to 120 Hz vari able (all c ontrol mode)

25 to 500 Hz variable (in conjunction with the maximum frequency)

0.1 to 60.0 Hz variable

(0.0 Hz unde r vector co ntrol wit h speed sensor)

Three ph ase 400V class

- Type 0002 to 00 59:

- 0.75 to 16kHz variable ( HHD/HND/ HD spec.)

- 0.75 to 10kHz variable (ND spec.)

- Type 0072 to 0168:

- 0.75 to 16kHz variable ( HHD spec.)

- 0.75 to 10kHz variable (HND/HD spec.)

- 0.75 to 6kHz variable (ND spe c.)

- Type 0203 or above t ype of cap acity:

- 0.75 to 10kHz variable (HHD spec.)

- 0.75 to 6kHz variable (HND/HD/ND spec.)

Three ph ase 200V cl ass

- Type 0030,0040,0056,0 069

- 0.75 to 16kHz variable ( HHD/HND/ s pec.)

Note: Carrier frequency dro ps automa tically to p rotect th e inverte r depending on envi ronmental tempe rature and

output cu rrent. ( This a uto drop fu nction c an be canceled.)

- Analog setting: ±0.2% of ma ximum fre quency 25±10°C

- Keypad setting: ±0.01% of maximum frequency -10 to +50°C

- Analog setting: 0.05% of maximum frequency

- Keypad setting: 0.01 Hz (99.99 Hz or less), 0.1 Hz (100.0 to 500.0 Hz)

- Link setting: 0.005% of maximum frequency or 0.01 Hz (fixed)

- 1 : 1500 (Minim um speed : Nominal speed, 4 -pole, 1 to 1500 rpm)

- 1 : 100 (Minimu m speed : N ominal s peed, 4-pole, 15 to 1500 rpm)

- 1 : 10 (Minimum speed : Nominal spe ed, 6-pole, 180 to 1800 rp m)

- Analog setting: ±0.2% of ma ximum fre quency or below 25 ±10°C

- Digital setting: ±0.01% of maximum frequency or below -10 to +50°C

- Analog setting: ±0.5% of base fr equency or below 25 ±10°C

- Digita l setting: ±0.5% of base f requen cy or below -10 to +50°C

- V/f control

- Speed sensor le ss vector control ( Dynami c torque vector control)

- V/f control w ith slip compens ation active

- V/f control w ith spee d senso r (The P G option card is req uired.)

- V/f Control w ith spee d senso r (+Auto Torque Boos t) (The P G option ca rd is req uired.)

- Vector control with speed sensor ( The PG opti on card is required.)

- Vector control without magnetic pole position sensor

- Possible to set output voltage at base frequency and at maximum output frequency (160 to 500 V).

- Non-linear V/f set ting (3 po ints): Free vol tage (0 to 50 0 V) and freque ncy (0 to 500 Hz) can be set.

- Auto torque b oost (For consta nt torque lo ad)

- Manual to rque boo st: Torque boos t value can be set bet ween 0.0 an d 20.0%.

- Select application load with the function code. (Var iable torque load o r consta nt torque l oad)

Three ph ase 400V class

- 200% or above (HHD spec.:type 0072 or below) / 150% or higher (HHD spec.:type 0085 or above) at reference

freque ncy 0.5Hz

- 120% or higher at r eference frequ ency 0.5Hz, (HND/ND s pec.)

- 150% or higher at referen ce frequ ency 0.5H z, (HD spec.)

(Base frequency 50 Hz, wi th activat ing the slip compen sation and the auto tor que boost mode, app lied motor

is Fuji 4-p ole stan dard moto r.)

Three ph ase 200V cl ass

- 200% or above ( HHD spec .:type 0 069 or be low) at refe rence fr equency 0.5Hz

- 120% or higher at r eference frequ ency 0.5Hz, (HND spe c.)

(Base frequency 50 Hz, wi th activat ing the slip compen sation and the auto tor que boost mode, app lied motor

is Fuji 4-p ole stan dard moto r.)

- Keypad:

Start and stop with and keys (Standar d keypad)

- Exter nal sign als (digi tal inpu ts): Forward (Rever se) rotation, stop co mmand (capable of 3 -wire op eratio n),

coast-to- stop command, exter nal alar m, alarm r eset, etc.

- Link ope ration: O perati on via built-in RS- 485 or fi eld bus (option) com munica tions

- Switchin g operation comm and: Remote/loc al switching, link switching

Specifications Remarks

IMPG-VC

PM-SVC

IMPG-VC

PM-SVC

VF

IM-SVC(DTV)

VF with SC

IMPG-VF

IMPG-ATB

IMPG-VC

PM-SVC

8

Loading...

Loading...