Page 1

Page 2

Page 3

CONTENTS

Chapter 1 Specifications

1. Standard Specifications .......................................................................................... 1-2

1.1 Three-phase 230V FRENIC5000G11S Series ................................................... 1-2

1.2 Three-phase 460V FRENIC5000G11S Series ................................................... 1-3

1.3 Three-phase 230V FRENIC5000P11S Series

(for variable torque load) .................................................................................... 1-4

1.4 Three-phase 460V FRENIC5000P11S Series

(for variable torque load) ..................................................................................... 1-5

2. Common Specifications .......................................................................................... 1-6

2.1 Outline of common specifications ....................................................................... 1-6

2.2 Protective functions...........................................................................................1-10

2.3 Function settings ............................................................................................... 1-11

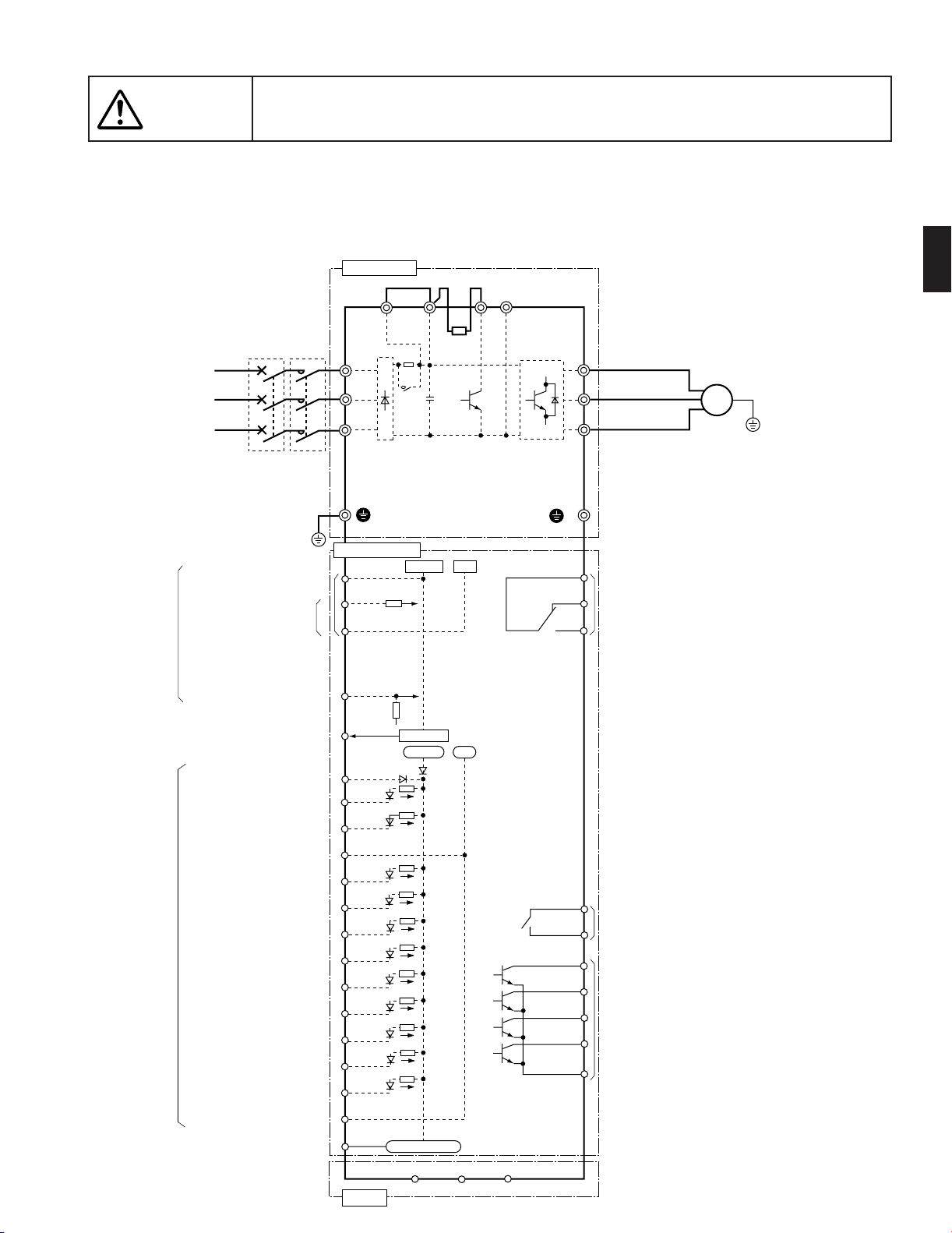

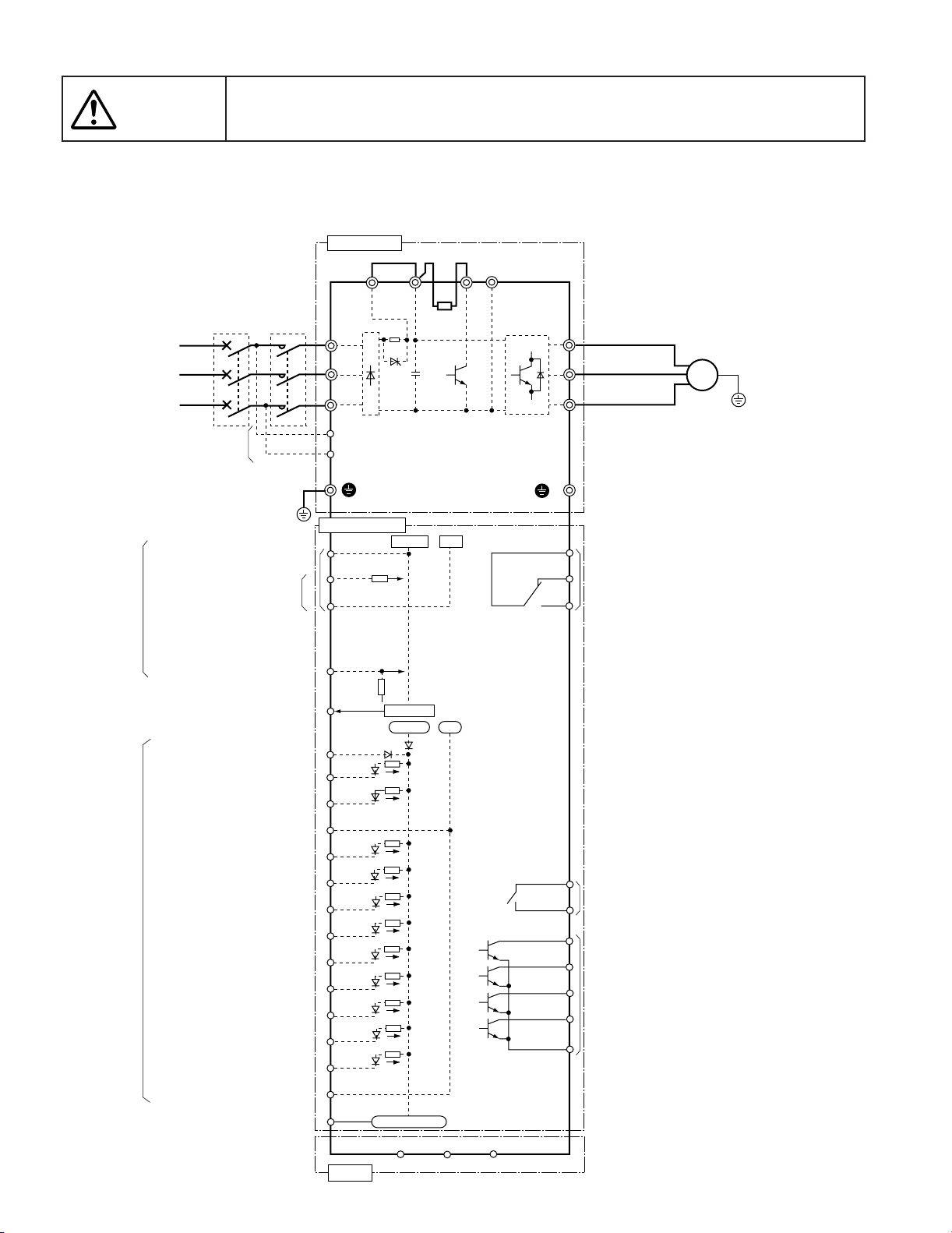

3. Wiring Diagram ..................................................................................................... 1-19

3.1 Wiring diagram before shipment from factory ................................................... 1-19

3.2 Basic wiring diagram ......................................................................................... 1-24

3.3 Wiring diagram using options............................................................................1-29

4. Terminal ................................................................................................................ 1-33

4.1 Terminal functions .............................................................................................1-33

4.2 Main circuit and control circuit terminals ........................................................... 1-37

4.2.1 Terminal block arrangement ...................................................................... 1-37

4.2.2 Main circuit terminal ................................................................................... 1-38

4.2.3 Control circuit terminal ...............................................................................1-41

Chapter 2 Operation

1. Frequency Control Operation.................................................................................2-2

1.1 Types of frequency control signal........................................................................ 2-2

1.2 Accuracy and resolution...................................................................................... 2-3

2. KEYPAD panel ........................................................................................................2-4

3. Function Explanation .............................................................................................. 2-6

3.1 Fundamental Functions ...................................................................................... 2-6

3.2 Extension Terminal Functions ........................................................................... 2-16

3.3 Control Functions of Frequency ........................................................................ 2-26

3.4 Motor Parameters ............................................................................................. 2-31

3.5 High Performance Functions ............................................................................ 2-33

3.6 Alternative Motor Parameters ........................................................................... 2-42

4. Standard RS-485 Interface ................................................................................... 2-44

4.1 Outline............................................................................................................... 2-45

4.1.1 Features..................................................................................................... 2-45

4.1.2 Function overview ...................................................................................... 2-45

4.2 Transmission specification ................................................................................ 2-45

4.3 Connection ........................................................................................................ 2-45

4.3.1 Connection method.................................................................................... 2-45

4.3.2 RS-485....................................................................................................... 2-46

4.3.3 Example of connection of FRENIC5000G11S/P11S series ...................... 2-46

4.3.4 Example of noise prevention...................................................................... 2-47

Page 4

ii Contents

4.4 Transmission method ........................................................................................2-47

4.4.1 Transmission frame.................................................................................... 2-47

4.4.2 Field description......................................................................................... 2-53

4.4.3 Procedure on the host side ........................................................................ 2-54

4.4.4 Example of communication........................................................................ 2-56

4.4.5 Communication error ................................................................................. 2-57

4.5 Functions specific for communication ...............................................................2-61

4.5.1 Command data .......................................................................................... 2-61

4.5.2 Operation command data .......................................................................... 2-61

4.5.3 Function data .............................................................................................2-62

4.5.4 Monitoring data ..........................................................................................2-63

4.6 Function data format ......................................................................................... 2-64

4.6.1 List of function data format ........................................................................ 2-64

4.6.2 Data format specification ........................................................................... 2-67

4.7 Changeover of communications ....................................................................... 2-69

4.7.1 Changeover method for communication valid/invalid................................. 2-70

4.7.2 Link function (operation selection) .............................................................2-70

4.7.3 Coexistence of link (option) and RS-485 communication ..........................2-70

4.8 Response Time................................................................................................. 2-70

4.8.1 Response interval time .............................................................................. 2-70

4.8.2 Time of receiving preparation completion .................................................. 2-71

4.9 Function ............................................................................................................ 2-71

4.10 Troubleshooting ................................................................................................. 2-72

4.11 Appendix ........................................................................................................... 2-73

4.11.1 Communication level converter .................................................................2-73

4.11.2 ASCII code list .......................................................................................... 2-73

4.11.3 Example of a control program ................................................................... 2-74

5. Using Lifetime Forecast Functions........................................................................ 2-75

5.1 Contents of lifetime forecast functions ..............................................................2-75

5.2 How to check lifetime forecast information ........................................................ 2-75

5.3 Measuring conditions of lifetime........................................................................ 2-76

Chapter 3 Peripheral Equipment

1. Inverter Input Current .............................................................................................. 3-2

2. Circuit Breakers and Magnetic Contactors ............................................................. 3-3

3. Wire Size ................................................................................................................. 3-4

3.1 FRENIC5000G11S/P11S Series ........................................................................ 3-4

3.2 Allowable current of insulation wire..................................................................... 3-8

4. Braking Unit and Braking Resistor ........................................................................3-10

5. Braking Unit and Braking Resistor (10% ED) ....................................................... 3-12

6. Rated Sensitive Current of GFCI .......................................................................... 3-14

7. Input Circuit Noise Filter (EMC Compliance Filter) ............................................... 3-15

8. Output Circuit Noise Filter (OFL- -2/4) .......................................................... 3-16

9. Output Circuit Noise Filter (OFL- -4A) .......................................................... 3-18

Page 5

10. DC REACTOR (DCR) ........................................................................................... 3-20

11. AC Reactor (ACR)................................................................................................. 3-21

12. Ferrite Ring for Reducing Radio Noise (ACL) ....................................................... 3-23

13. Power Regenerative PWM Converter (RHC) ........................................................3-23

Chapter 4 Optimal Type Selection

1. Inverter and Motor Selection ................................................................................... 4-2

1.1 Motor output torque characteristics .................................................................... 4-2

1.2 Selection procedure ............................................................................................ 4-4

1.3 Selection calculation expressions .......................................................................4-6

1.3.1 Load torque during constant speed running ................................................ 4-6

1.3.2 Acceleration and deceleration time calculation............................................ 4-7

1.3.3 Heat energy calculation of braking resistor.................................................. 4-9

1.3.4 Appendix (calculation for other than in SI Unit) ......................................... 4-10

2. Braking Unit and Braking Resistor Selection ........................................................ 4-11

2.1 Selection procedure .......................................................................................... 4-11

2.2 Notes on selection ............................................................................................ 4-11

2.3 Optional fan unit ................................................................................................ 4-11

Contents iii

Chapter 5 Option

1. Options.................................................................................................................... 5-2

1.1 Optional control cards ......................................................................................... 5-2

1.2 Other exclusive options....................................................................................... 5-2

1.3 Datailed specifications ........................................................................................ 5-3

2. Optional Peripheral Equipment .............................................................................5-14

2.1 Optional peripheral equipment .......................................................................... 5-14

2.2 Specifications and dimensions ......................................................................... 5-15

Chapter 6 Application Idea

1. Setting Items and Applications................................................................................ 6-2

2. FRENIC5000G11S/P11S Series ............................................................................ 6-4

2.1 Using with Aeration Tank Blowers .......................................................................6-4

2.2 Using with Multi-storied Automated Warehouses ............................................... 6-6

2.3 Using with Automated Parking Garages ............................................................. 6-8

2.4 Using with Vertical Circulation type Parking Facility .......................................... 6-10

2.5 Using with Bread Dough Mixers........................................................................ 6-12

2.6 Using with Commercial-use Washing Machines ............................................... 6-14

2.7 Using with Belt Conveyors ................................................................................ 6-16

2.8 Using with Grinding Machines .......................................................................... 6-18

2.9 Using with Fans for Air Conditioning Unit (1) .................................................... 6-20

2.10 Using with Fans for Air Conditioning Unit (2) .................................................... 6-22

2.11 Using with Cold/Warm Water Pumps ................................................................ 6-24

2.12 Using with Line/Inverter Changeover Operation ............................................... 6-26

Page 6

iv Contents

Chapter 7 Glossary

1. Standard Specifications .......................................................................................... 7-2

2. Common Specificationds ........................................................................................ 7-4

Chapter 8 Appendix

Appendix 1. Advantageous Use of Inverters (with regard to Electrical Noise) .............. 8-2

1.1 Effect of inverters on other devices..................................................................... 8-2

1.1.1 Effect on AM radios ..................................................................................... 8-2

1.1.2 Effect on telephones ....................................................................................8-2

1.1.3 Effect on proximity limit switches ................................................................. 8-2

1.1.4 Effect on pressure sensors ..........................................................................8-2

1.1.5 Effect on position detectors

(pulse generators; PGs, or pulse encoders) ................................................ 8-2

1.2 Noise ................................................................................................................... 8-2

1.2.1 Inverter noise ...............................................................................................8-2

1.2.2 Types of noise .............................................................................................. 8-3

1.3 Noise prevention measures ................................................................................ 8-5

1.3.1 Noise prevention treatments prior to installation.......................................... 8-5

1.3.2 Implementation of noise prevention measures ............................................8-5

1.3.3 Specific examples ........................................................................................ 8-8

Appendix 2. Effect on Insulation of General-purpose

Motor Driven with 460V Class Inverter.................................................. 8-11

2.1 Operating principle of inverter ........................................................................... 8-11

2.1.1 Main circuit configuration of inverter ..........................................................8-11

2.1.2 Control method of inverter ......................................................................... 8-11

2.2 Generating mechanism of surge voltages ........................................................ 8-11

2.3 Effect of surge voltages .................................................................................... 8-12

2.4 Countermeasures against surge voltages ........................................................ 8-12

2.4.1 Method to use motors with enhanced insulation........................................ 8-12

2.4.2 Method to suppress surge voltages ........................................................... 8-12

2.5 Regarding existing equipment .......................................................................... 8-13

2.5.1 In case of motor being driven with 400V class inverter ............................. 8-13

2.5.2 In case of existing motor driven newly with 400V class inverter ................ 8-13

Appendix 3. Example Calculation of Energy Savings .................................................. 8-14

2.1 Calculating condition ......................................................................................... 8-14

2.2 Calculation of shaft driving power .....................................................................8-14

2.3 Calculation of energy savings ........................................................................... 8-14

Appendix 4. Inverter Generating Loss .......................................................................... 8-15

Page 7

Chapter 1

Specifications

Contents

1. Standard Specifications ....................................................................................... 1-2

1.1 Three-phase 230V FRENIC5000G11S Series ................................................... 1-2

1.2 Three-phase 460V FRENIC5000G11S Series ................................................... 1-3

1.3 Three-phase 230V FRENIC5000P11S Series (for variable torque load) ............ 1-4

1.4 Three-phase 460V FRENIC5000P11S Series (for variable torque load) ............ 1-5

2. Common Specifications ....................................................................................... 1-6

2.1 Outline of common specifications .......................................................................1-6

2.2 Protective functions........................................................................................... 1-10

2.3 Function settings ............................................................................................... 1-11

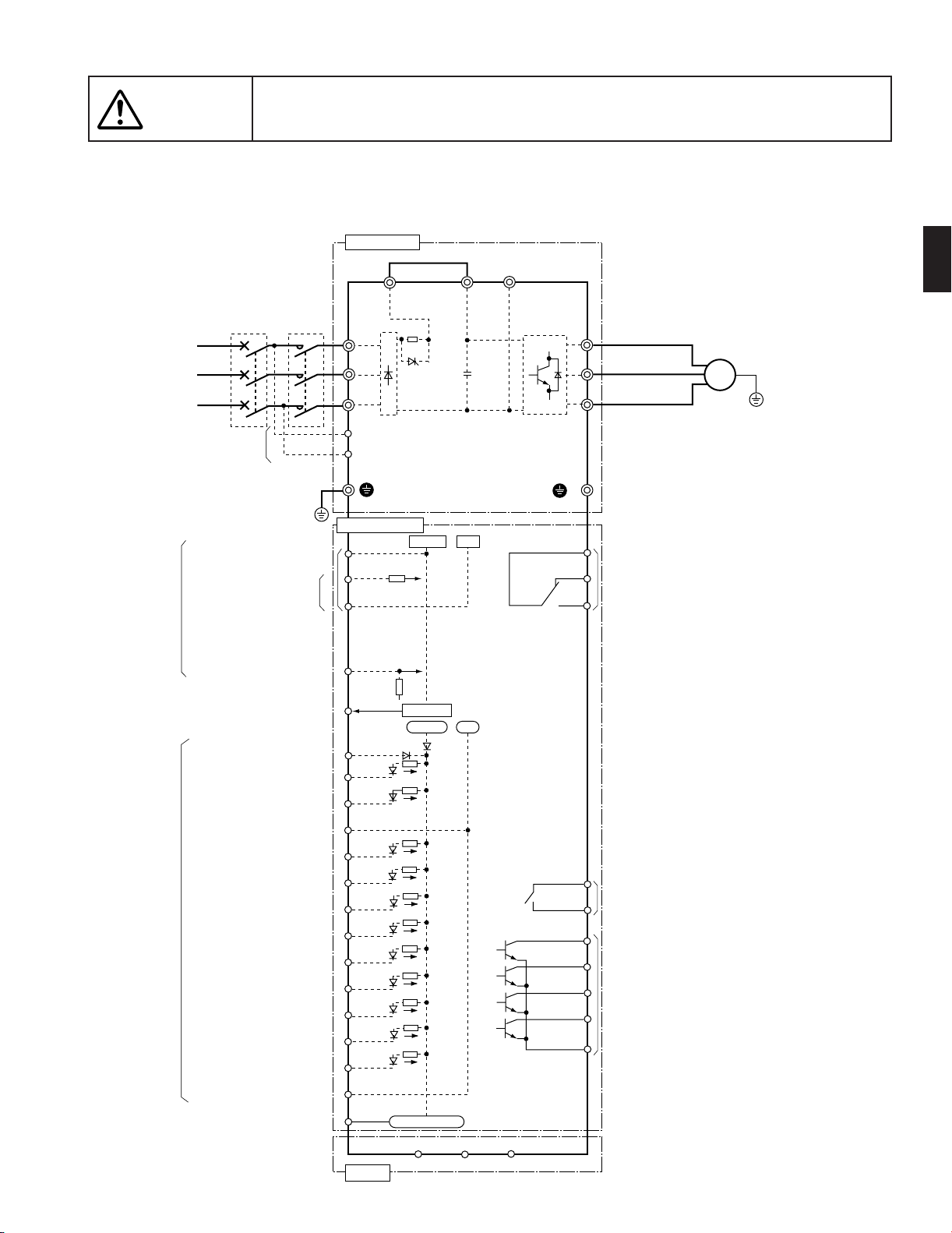

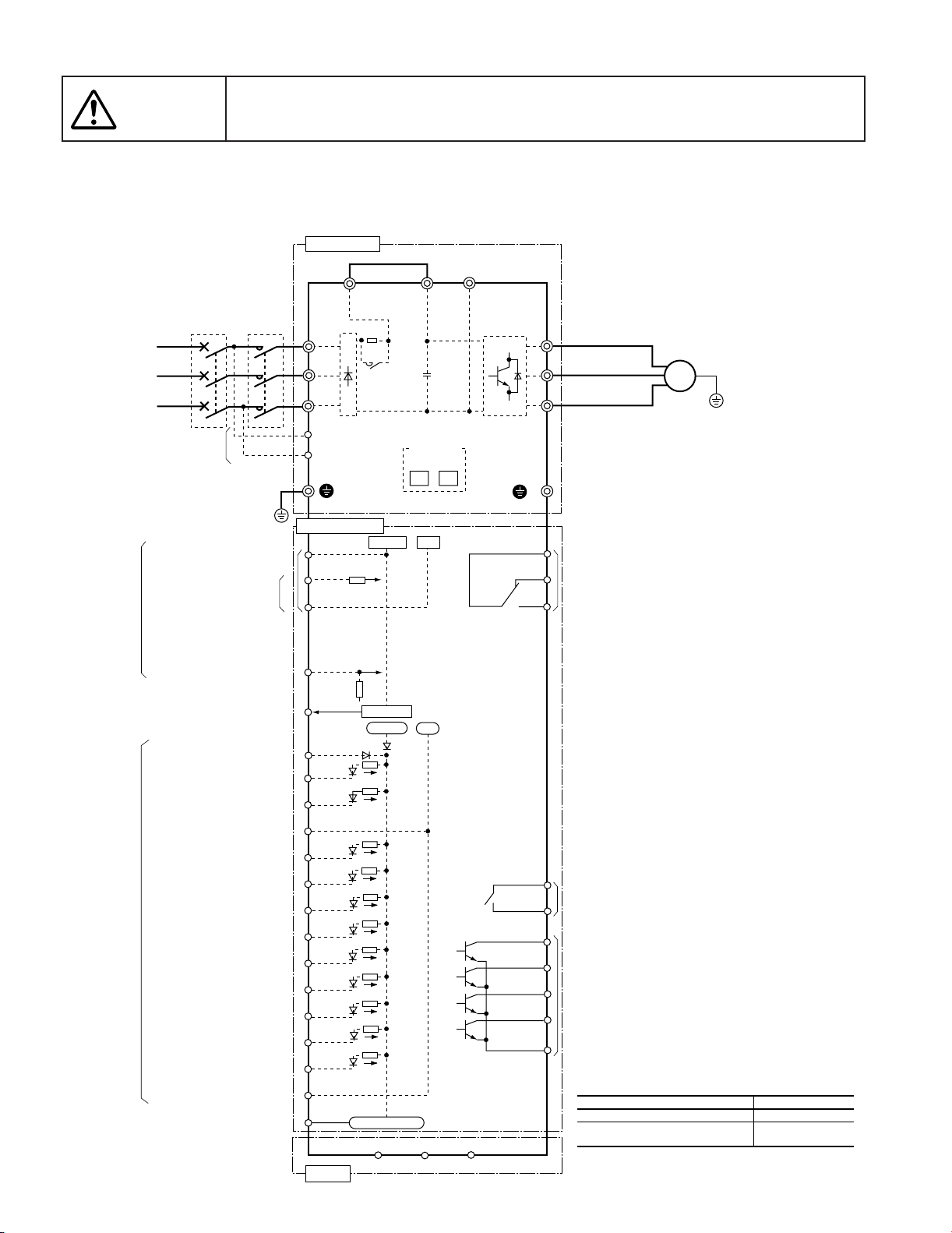

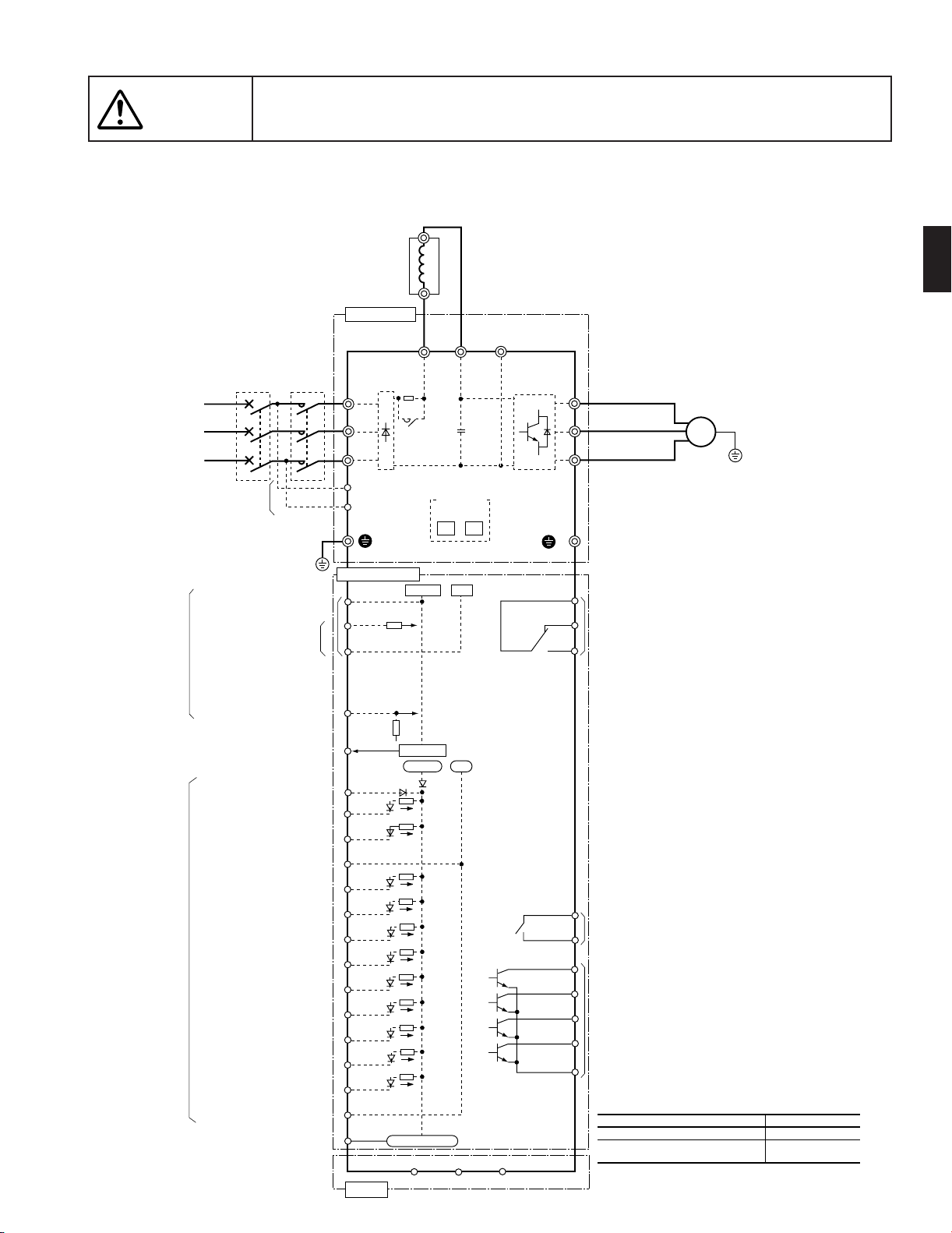

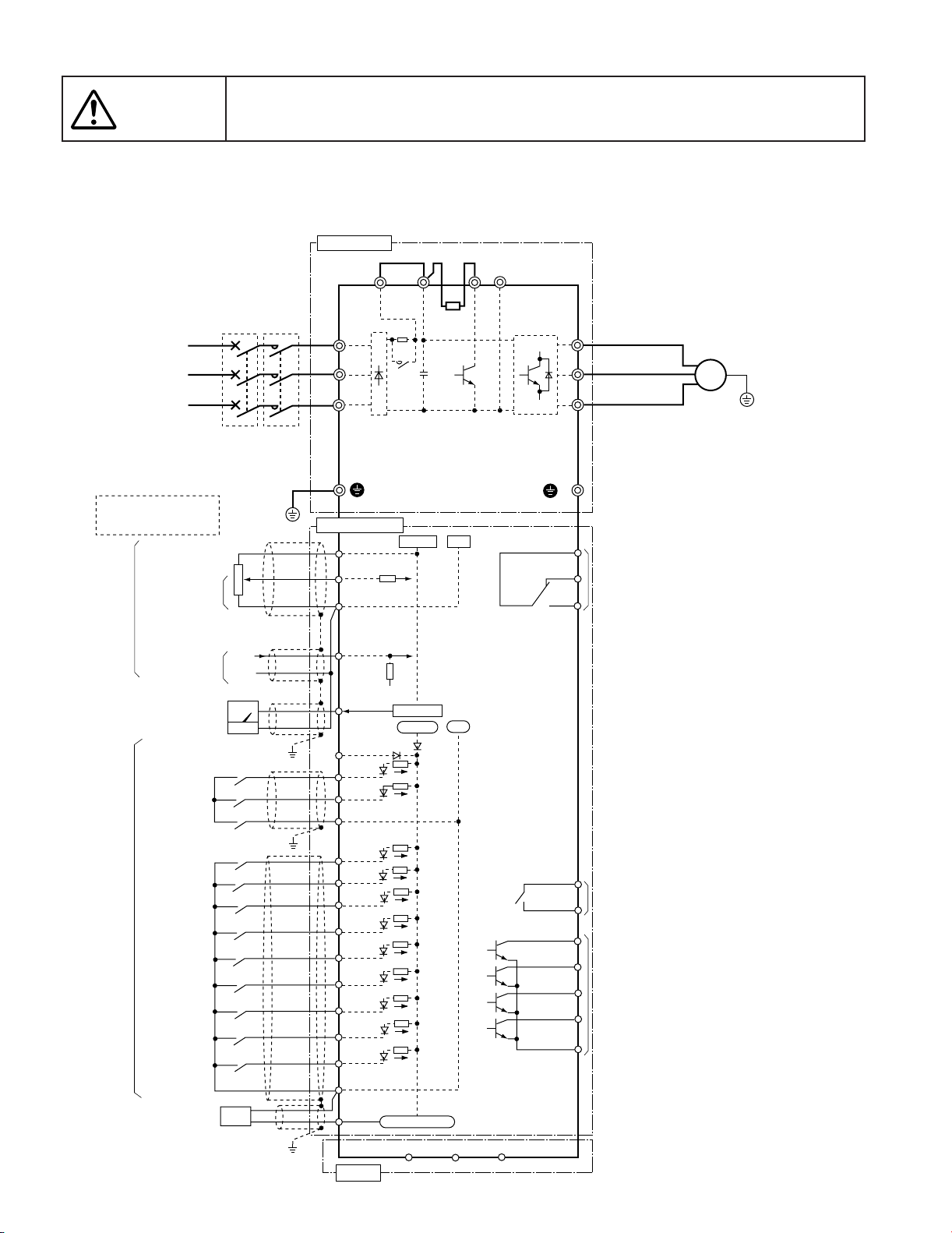

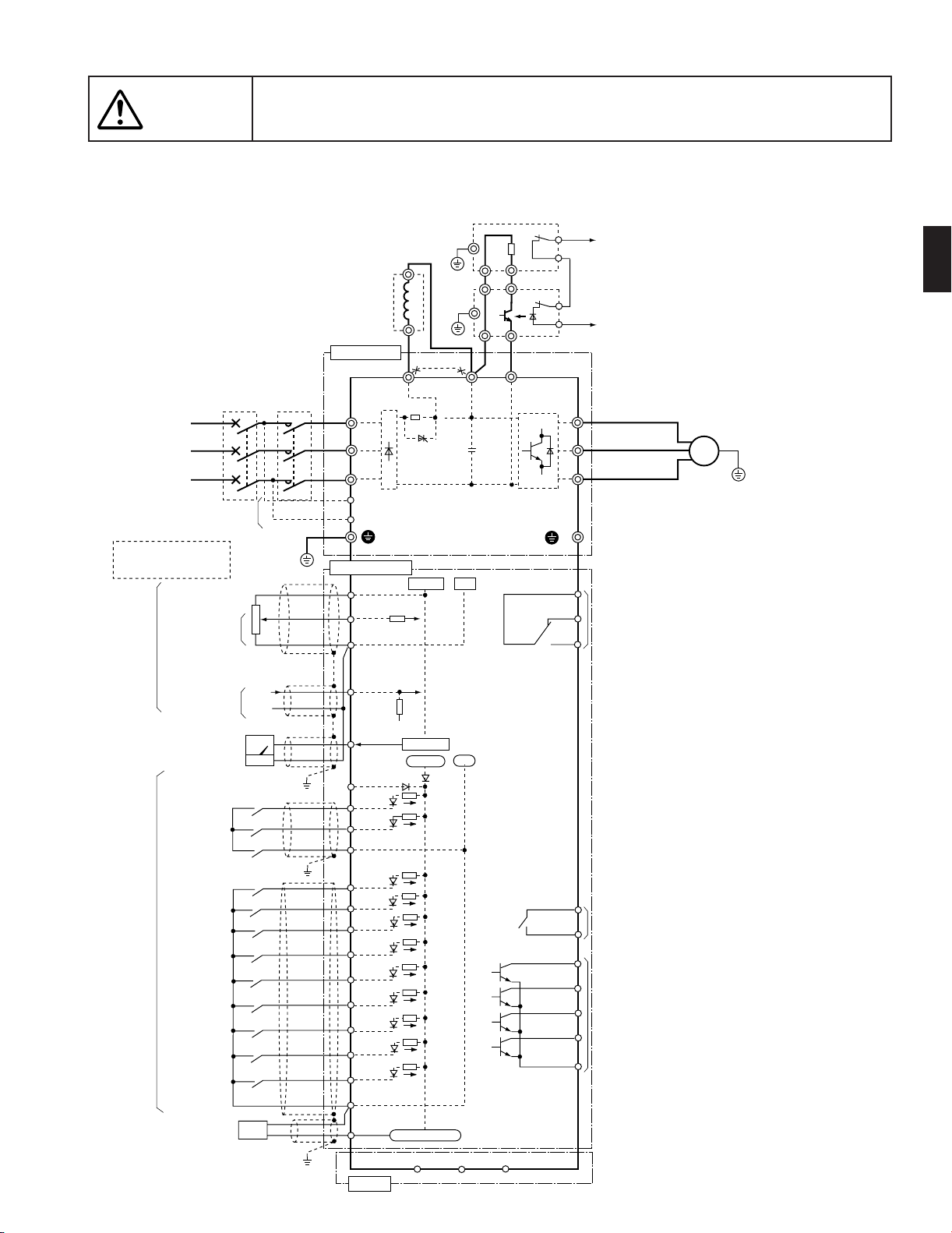

3. Wiring Diagram ................................................................................................... 1-19

3.1 Wiring diagram before shipment from factory ................................................... 1-19

3.2 Basic wiring diagram......................................................................................... 1-24

3.3 Wiring diagram using options ........................................................................... 1-29

1

4. Terminal ...............................................................................................................1-33

4.1 Terminal functions ............................................................................................. 1-33

4.2 Main circuit and control circuit terminals ........................................................... 1-37

4.2.1 Terminal block arrangement ...................................................................... 1-37

4.2.2 Main circuit terminal ................................................................................... 1-38

4.2.3 Control circuit terminal ...............................................................................1-41

1-1

Page 8

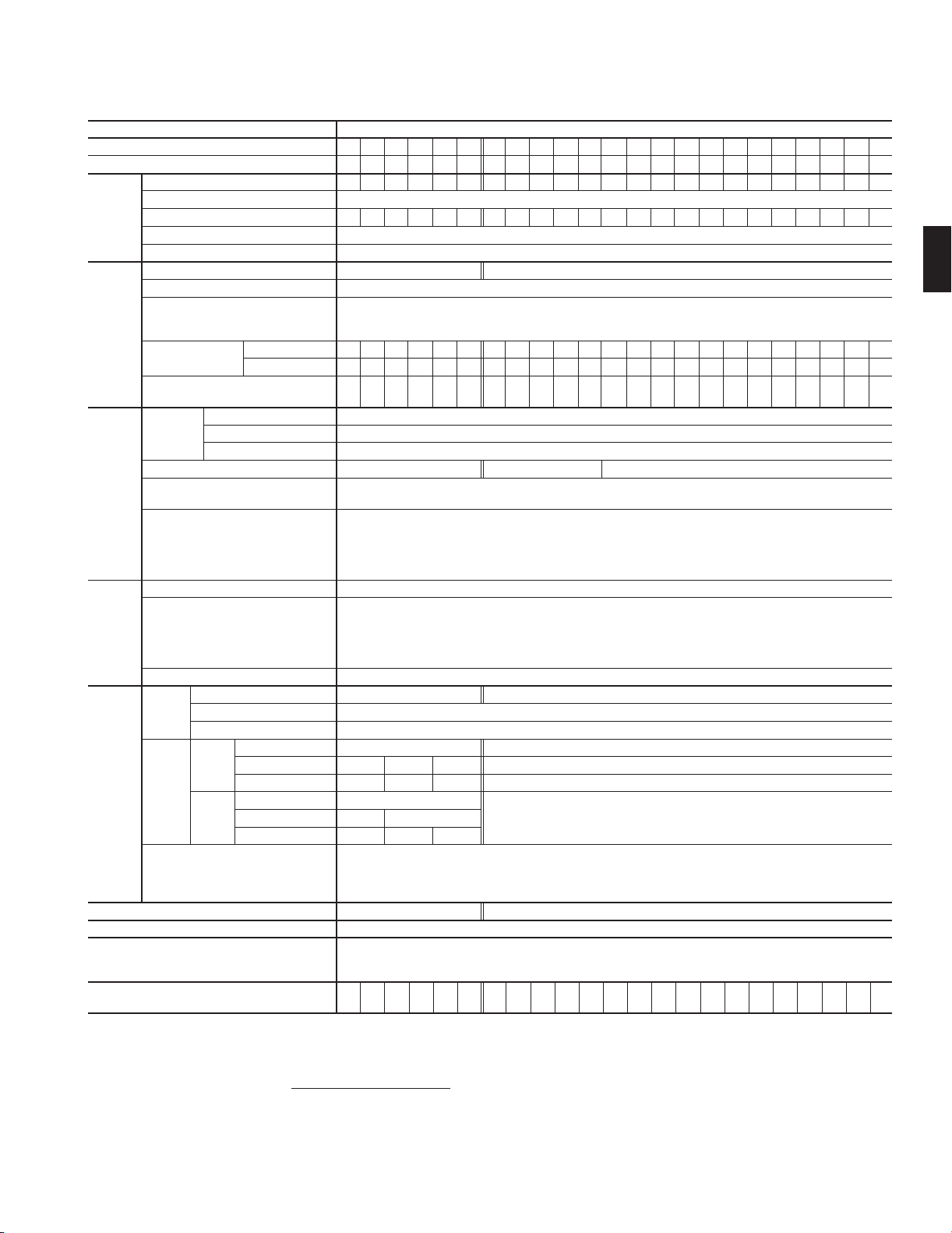

Chapter 1

1. Standard Specifications

1. Standard Specifications

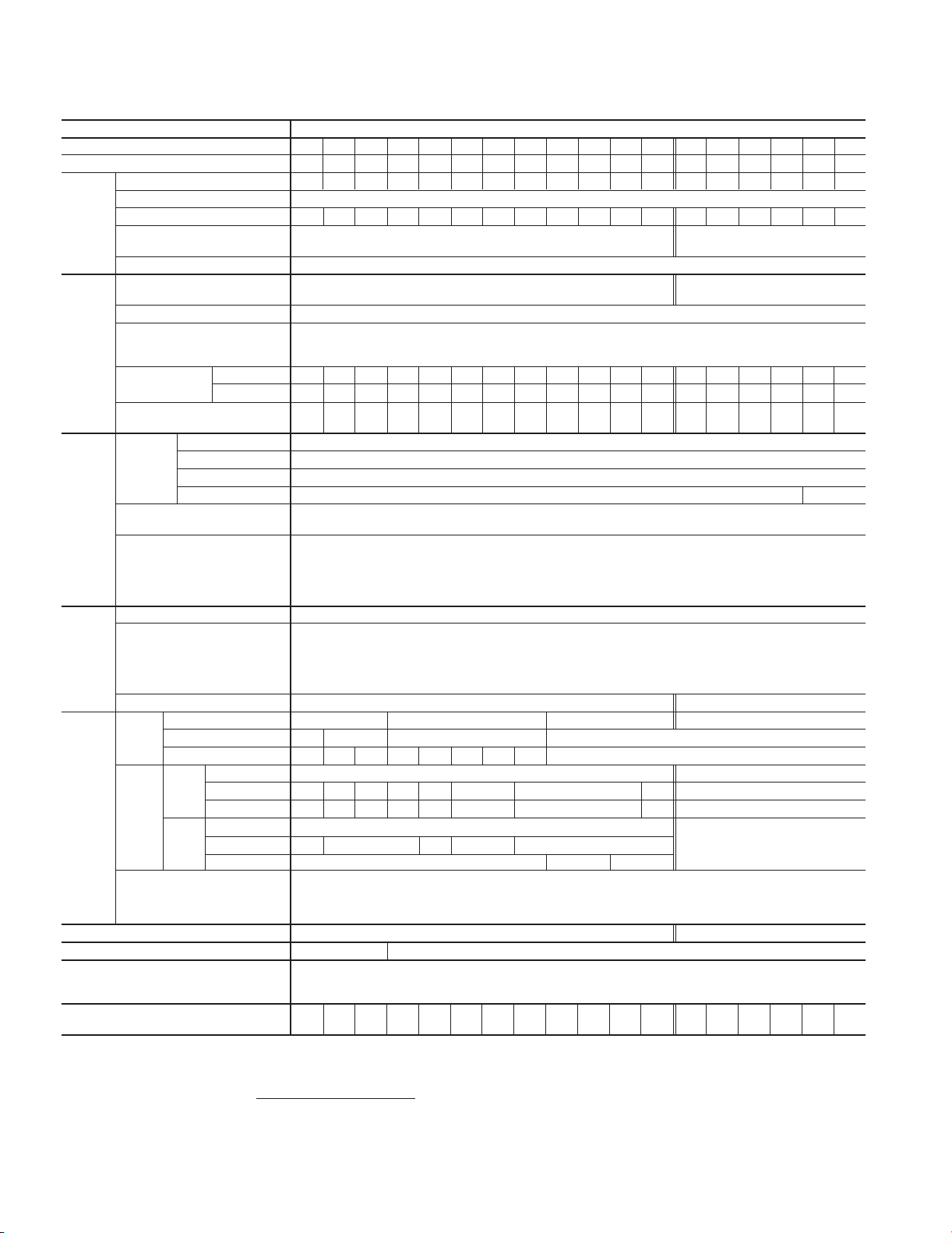

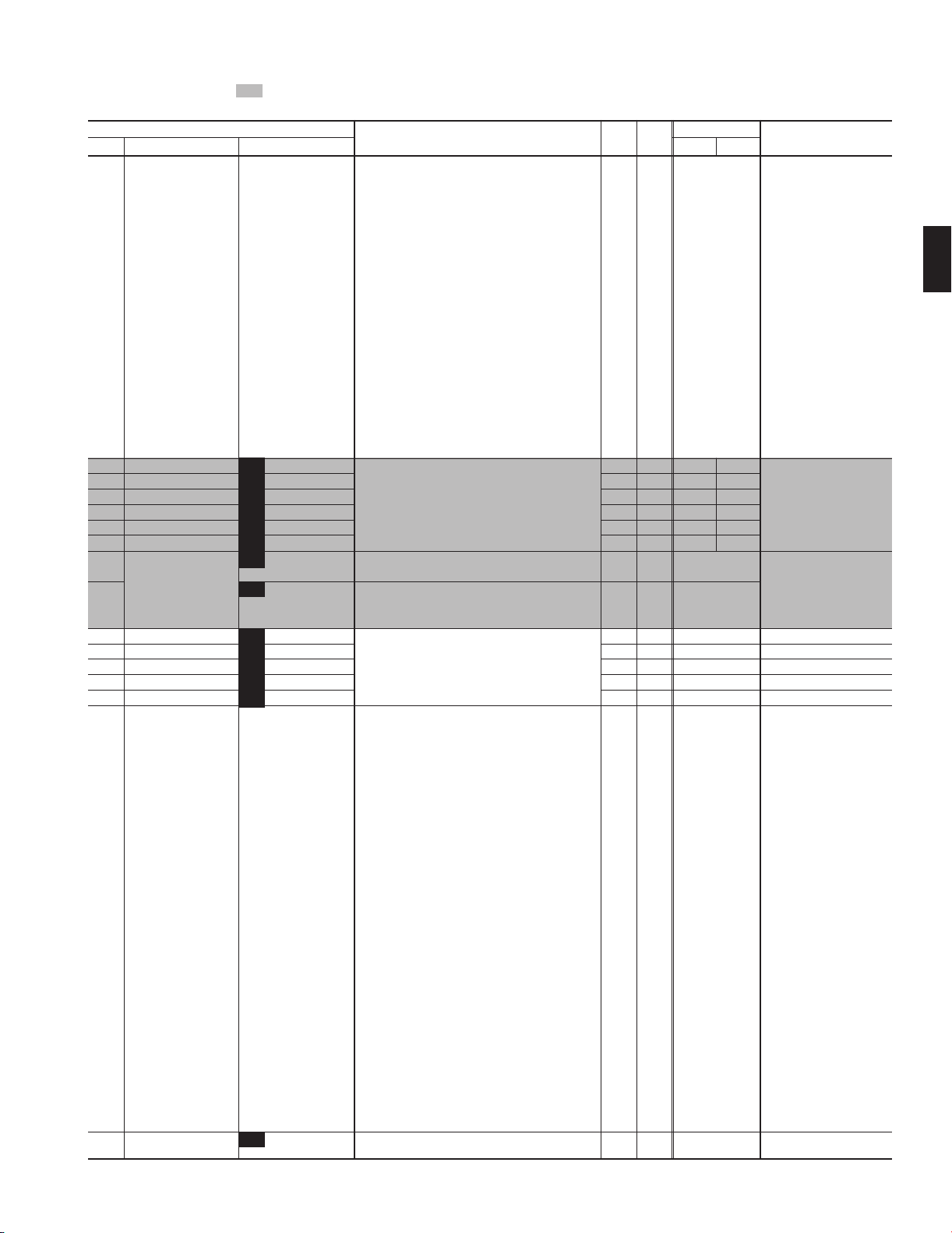

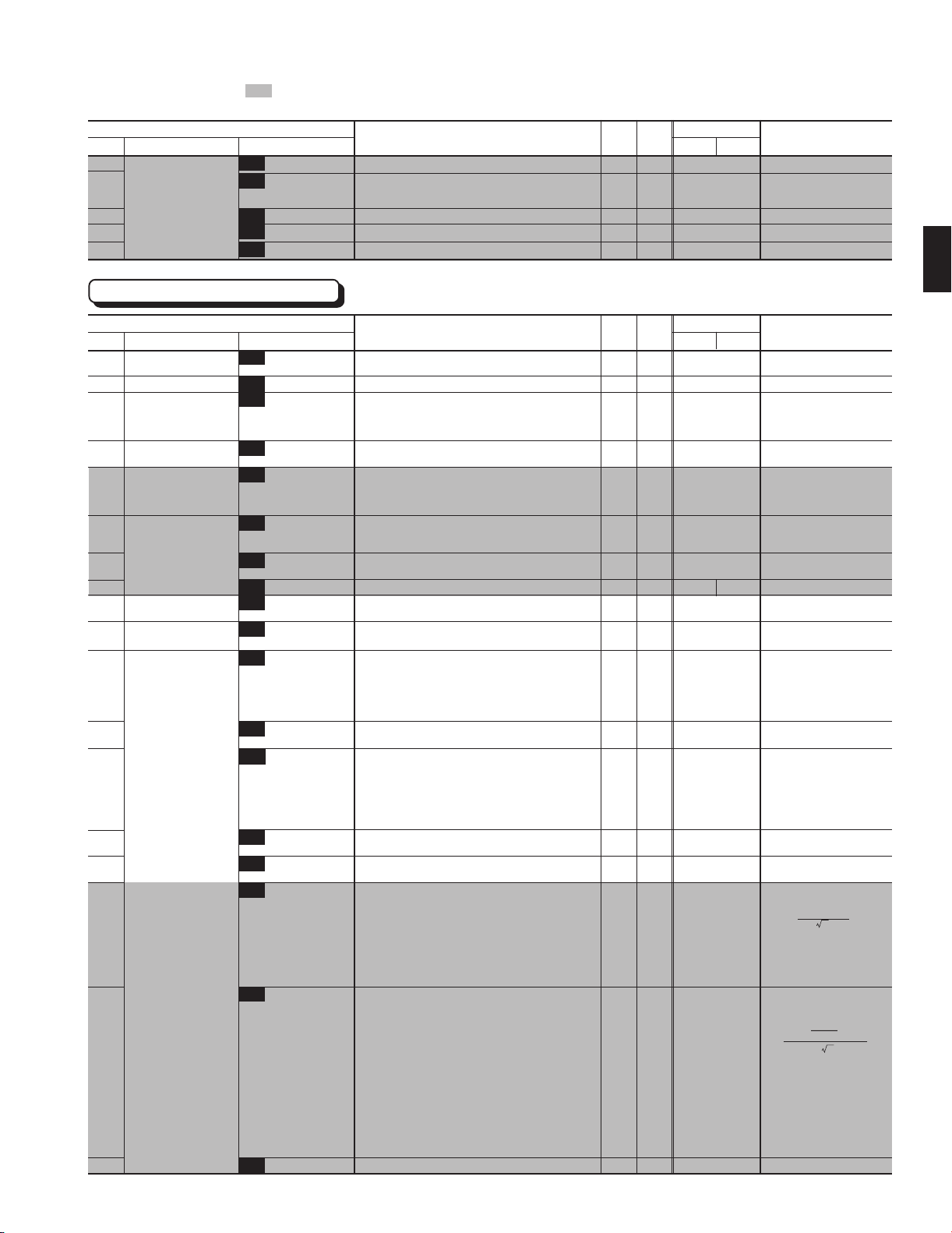

1.1 Three-phase 230V FRENIC5000G11S Series

Item Specifications

Type FRN■■■■■■G11S-2UX F25 F50 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125

Nominal applied motor HP 1/4 1/2 12357.5101520253040506075100125

Rated capacity *1) kVA 0.6 1.2 2.0 3.2 4.4 6.8 9.9 13 18 23 29 36 46 58 72 86 113 138

Rated voltage *2) V 3-phase 200V/50Hz 200, 220, 230V/60Hz

Output Rated current *3) A 1.5 3.0 5.0 8.0 11 17 25 33 46 59 74 87 115 145 180 215 283 346

ratings Overload capability 150% of rated current for 1min. 150% of rated current for 1min.

Rated frequency Hz 50, 60Hz

Phases, Voltage, Frequency 3-phase 200 to 230V 50/60Hz

Voltage / frequency variations Vo ltage : +10 to –15% (Voltage unbalance *4) : 2% or less) Frequency :+5 to –5%

Input *5) When the input voltage drops below 165V from rated voltage, the inverter can be operated for 15ms .

ratings The smooth recovery method is selectable.

Output Accuracy (Stability) •Analog setting : ± 0.2% of Maximum frequency (at 25±10°C (77±50°F))

frequency •Digital setting : ±0.01% of Maximum frequency (at –10 to +50°C (14 to 122°F))

Control 0.1 to 0.9 : Manual (for variable torque load) *9)

Braking Duty cycle

Enclosure (IEC 60529) IP 40 IP 00 ( IP 20 : Option )

Cooling method Natural cooling Fan cooling

Standards -IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

Weight lbs 4.9 4.9 5.5 8.4 8.4 8.4 13 13 22 22 23 23 64 79 97 101 154 254

NOTES:

Momentary voltage dip capability When the input voltage is 165V or more, the inverter can be operated continuously.

Rated current *6) (with DCR) 0.94 1.6 3.1 5.7 8.3 14.0 19.7 26.9 39.0 54.0 66.2 78.8 109 135 163 199 272 327

A(without DCR) 1.8 3.4 6.4 11.1 16.1 25.5 40.8 52.6 76.9 98.5 117 136 168 204 243 291 - -

Required power supply

capacity *7)

Maximum frequency 50 to 400Hz

Setting Base frequency 25 to 400Hz

Starting frequency 0.1 to 60Hz, Holding time: 0.0 to 10.0s

Carrier frequency *8) 0.75 to15kHz

Setting resolution •Analog setting : 1/3000 of Maximum frequency ex.) 0.02Hz at 60Hz, 0.04Hz at 120Hz, 0.15Hz at 400Hz

Voltage / freq. (V/f) characteristic Adjustable at base and maximum frequency, with AVR control : 80 to 240V

To rque boost To rque boost can be set, using Function code F09 and A05.

Starting torque 200% (with Dynamic torque-vector control selected)

Braking torque *10) 150% 100% 20% 10 to 15%

Standard

Time s 10 5 5 No limit

Duty cycle

Standard

Braking torque 150% 100%

Time s 90 45 45 45 30 20 10 8 10

Using

options

10%ED Braking torque 150% *12)

Time s 90 45 30 20 10

DC injection braking Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

*1) Inverter output capacity (kVA) at 230V. Rated capacity reduces when power supply voltage decreases.

*2) Output voltage cannot exceed the power supply voltage.

*3) Current derating may be required in case of low impedance loads such as high frequency motor.

*4) Use a DC REACTOR (DCR) when the voltage unbalance exceeds 2%. (This value is equivalent to FUJI’s conventional allowable value.)

Voltage unbalance (%) =

*5) Tested at standard load condition (85% load).

*6) This value is under FUJI original calculation method.

*7) When power-factor correcting DC REACTOR (DCR) is used.

*8) When inverter is operating at a carrier frequency of 10kHz or higher, the inverter may automatically reduce the carrier frequency to 8kHz for protecting inverter.

*9) When torque boost is set at 0.1, starting torque of 50% or more can be obtained.

*10) With a nominal applied motor, this value is average torque when the motor decelerates and stops from 60Hz. (It may change according to motor loss.)

*11) Order individually.

*12) Applicable to 10%ED when using options (standard)

Duty cycle

1-2

200% of rated current for 0.5s 180% of rated current for 0.5s

3-phase 200 to 220V/50Hz (220 to 230V/50Hz) *11)

200 to 230V/60Hz

kVA 0.4 0.6 1.1 2.0 2.9 4.9 6.9 9.4 14 19 23 28 38 47 57 69 95 114

•Digital setting : 0.01Hz at Maximum frequency of up to 99.99Hz (0.1Hz at Maximum frequency of 100Hz and above)

• LINK setting : Selects from the following two items.

0.0 : Automatic (for constant torque load)

1.0 to 1.9 : Manual (for propotional speed torque load)

2.0 to 20.0: Manual (for constant torque load)

%ED

10 5 353232 No limit

%ED

37 22 18 10 7 5 5 5 10

%ED

*Inverter restarts at the star ting frequency when operation command is input while braking is operating.

*DC injection braking does not operate at the time of change-over from forward to reverse operation.

*

DC injection braking does not operate when frequency setting is decreased while operation command (FWD, REV) is being input.

-UL/cUL -Low Voltage Directive -EMC Directive -TÜV (up to 30HP)

-IEC 61800-3 (EMC product standard including specific test methods)

(kg) (2.2) (2.2) (2.5) (3.8) (3.8) (3.8) (6.1) (6.1) (10) (10) (10.5) (10.5) (29) (36) (44) (46) (70) (115)

Max. voltage [V] – Min. Voltage [V]

Three-phase average voltage[V]

• 1/20000 of Maximum frequency ex.) 0.003Hz at 60Hz, 0.006Hz at 120Hz, 0.02Hz at 400Hz

• 0.01Hz (Fixed)

180% (with Dynamic torque-vector control selected)

10 10 10

x 67 (Conforming to EN61800-3 (5.2.3))

0.75 to 10kHz

Page 9

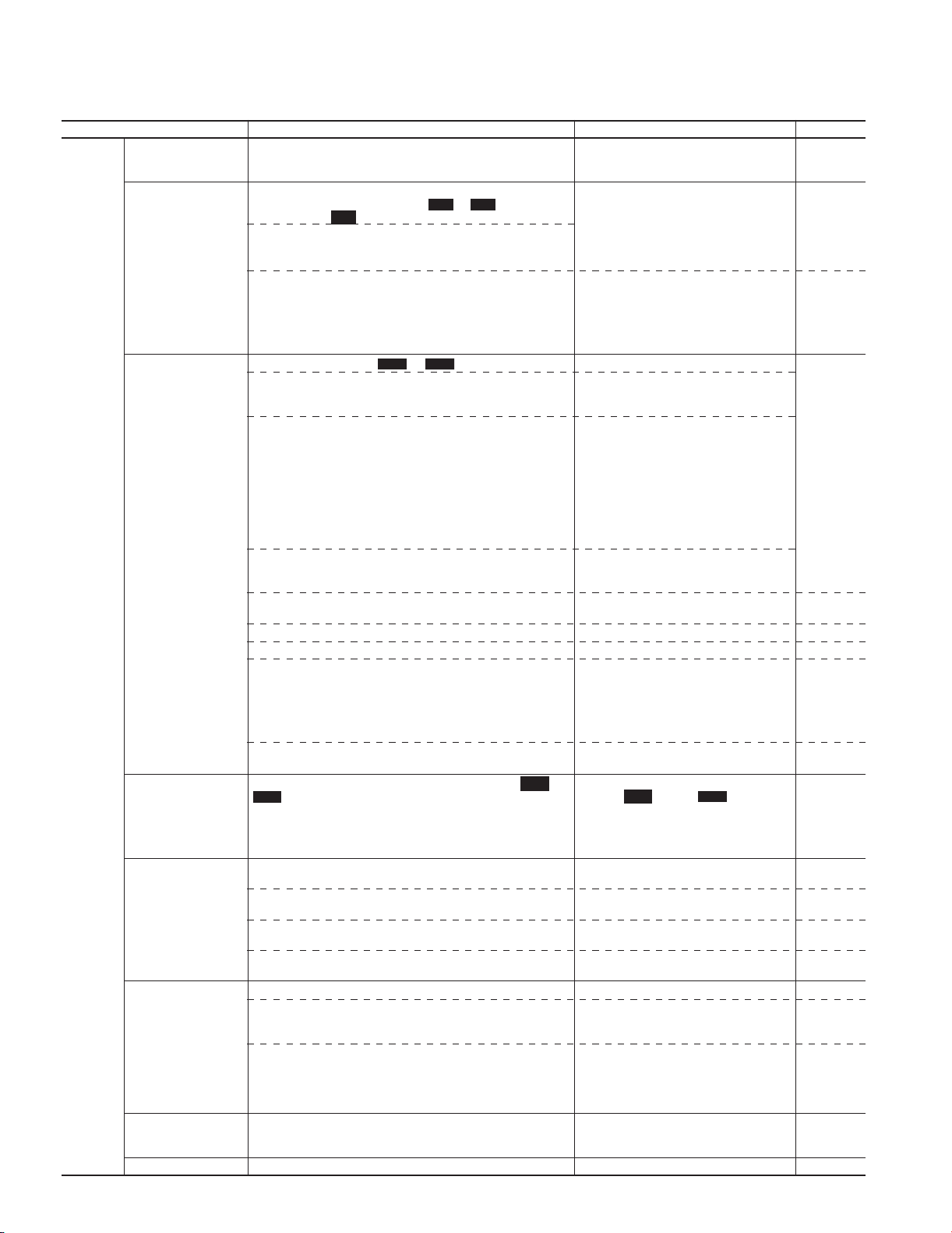

Chapter 1

1. Standard Specifications

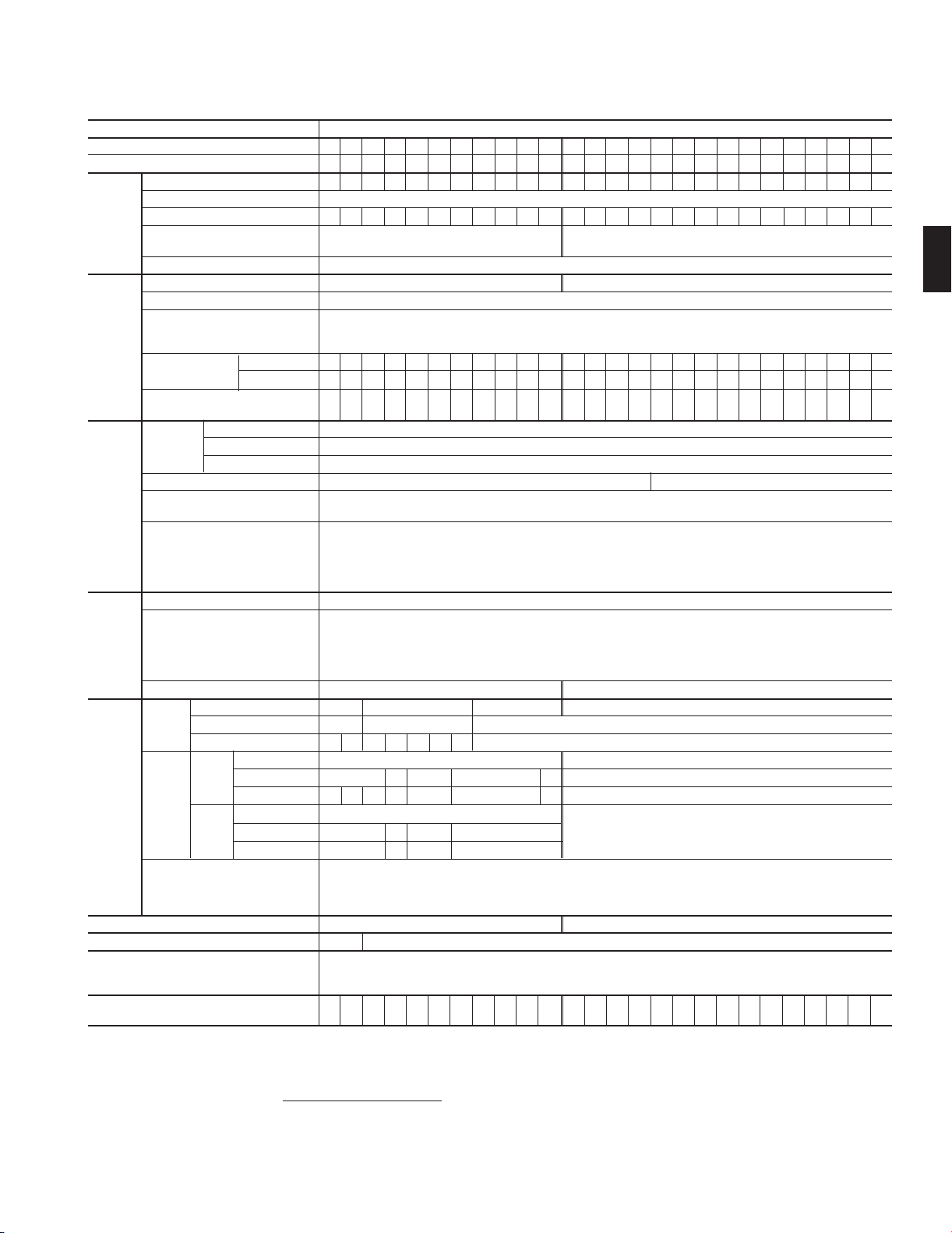

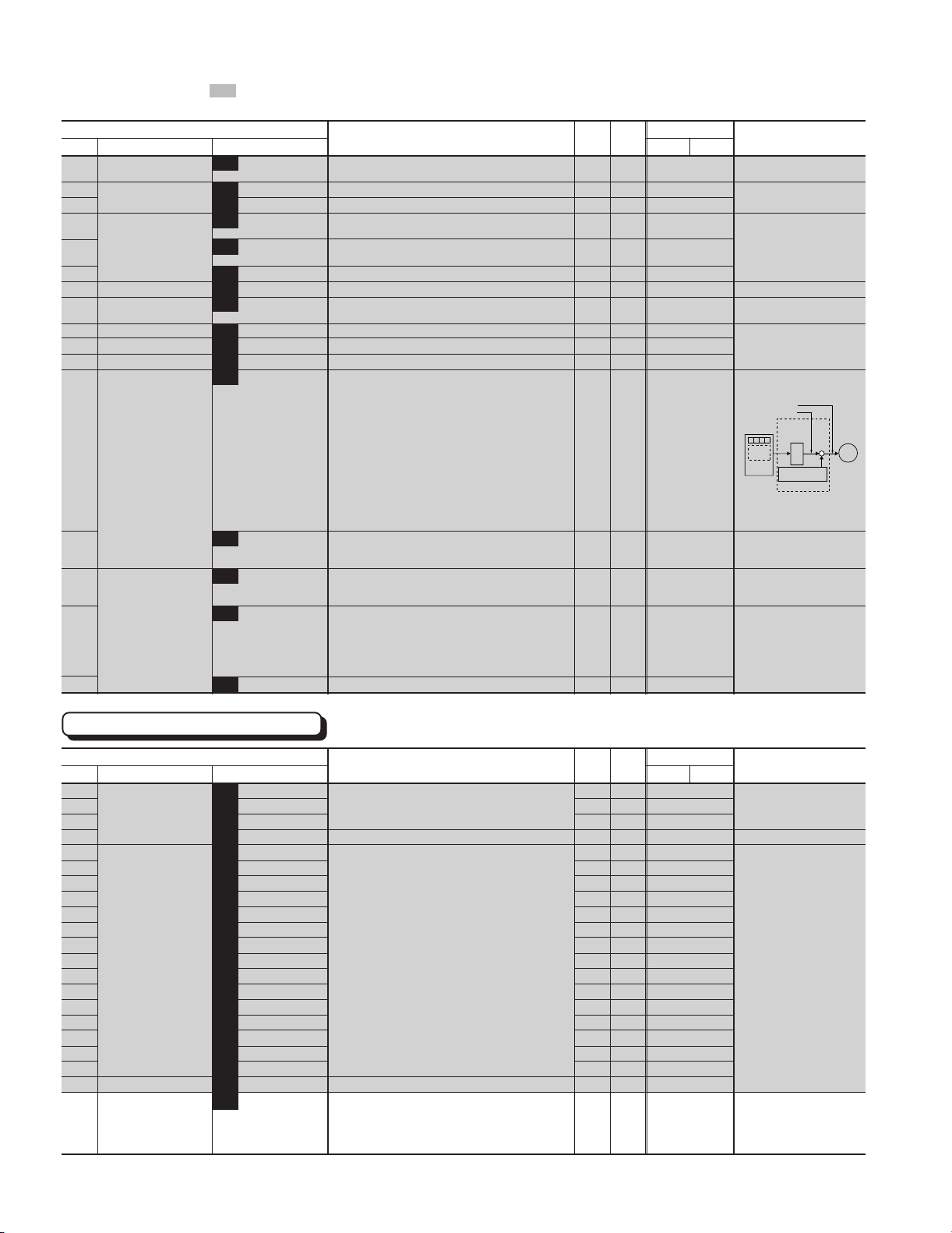

1.2 Three-phase 460V FRENIC5000G11S Series

Item Specifications

Type FRN■■■■■■G11S-4UX F50 001 002 003 005 007 010 015 020 025 030 040 050 060 075 100 125 150 200 250 300 350 400 450 500 600

Nominal applied motor HP 1/2 12357.5101520253040506075100125150200250300350400450500600

Rated capacity *1) kVA 1.1 1.9 2.8 4.1 6.8 9.9 13 18 22 29 34 45 57 69 85 114 134 160 192 231 287 316 396 445 495 563

Rated voltage *2) V 3-phase 380, 400, 415V/50Hz 380, 400, 440, 460V/60Hz

Output Rated current *3) A 1.5 2.5 3.7 5.5 9 13 18 24 30 39 45 60 75 91 112 150 176 210 253 304 377 415 520 585 650740

ratings Overload capability 150% of rated current for 1min. 150% of rated current for 1min.

Rated frequency Hz 50, 60Hz

Phases, Voltage, Frequency 3-phase 380 to 480V 50/60Hz 3-phase 380 to 440V/50Hz 380 to 480V/60Hz *4)

Voltage / frequency variations Vo ltage : +10 to –15% (Voltage unbalance *5) : 2% or less) Frequency :+5 to –5%

Input *6) When the input voltage drops below 310V from rated voltage, the inverter can be operated for 15ms .

ratings The smooth recovery method is selectable.

Output Accuracy (Stability) •Analog setting : ±0.2% of Maximum frequency (at 25±10°C (77±50°F))

frequency •Digital setting : ±0.01% of Maximum frequency (at –10 to +50°C (14 to 122°F))

Control 0.1 to 0.9 : Manual (for variable torque load) *10)

Braking Duty cycle

Enclosure (IEC 60529) IP 40 IP 00 ( IP 20 : Option )

Cooling method

Standards -IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

Weight lbs 4.9 5.5 8.4 8.4 8.4 14 14 22 22 23 64 75 86

NOTES: *1) Inverter output capacity (kVA) at 460V. Rated capacity reduces when power supply voltage decreases.

Momentary voltage dip capability When the input voltage is 310V or more, the inverter can be operated continuously.

Rated current *7) (with DCR)

A(without DCR) 1.8 3.5 6.2 9.2

Required power supply

capacity *8)

Maximum frequency 50 to 400Hz

Setting Base frequency 25 to 400Hz

Starting frequency 0.1 to 60Hz, Holding time: 0.0 to 10.0s

Carrier frequency *9) 0.75 to 15kHz 0.75 to 10kHz

Setting resolution •Analog setting : 1/3000 of Maximum frequency ex.) 0.02Hz at 60Hz, 0.04Hz at 120Hz, 0.15Hz at 400Hz

Voltage / freq. (V/f) characteristic Adjustable at base and maximum frequency, with AVR control : 320 to 480V

To rque boost To rque boost can be set, using Function code F09 and A05.

Starting torque 200% (with Dynamic torque-vector control selected) 180% (with Dynamic torque-vector control selected)

Braking torque *11) 150% 100% 20% 10 to 15%

Standard

Time s 55 No limit

Duty cycle

Standard

Braking torque 150% 100%

Time s 45 30 20 10 8 10

Using

options

10%ED Braking torque 150% *13)

Time s 45 30 20 10

Duty cycle

DC injection braking Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

*2) Output voltage cannot exceed the power supply voltage.

*3) Current derating may be required in case of low impedance loads such as high frequency motor.

*4) When the input voltage is 380 to 398V/50Hz or 380 to 430V/60Hz, the tap of the auxiliary transformer must be changed.

*5) Use a DC REACTOR (DCR) when the voltage unbalance exceeds 2%. (This value is equivalent to FUJI’s conventional allowable value.)

Voltage unbalance (%) =

*6) Tested at standard load condition (85% load).

*7) This value is under FUJI original calculation method.

*8) When power-factor correcting DC REACTOR (DCR) is used.

*9) When inverter is operating at a carrier frequency of 10kHz or higher, the inverter may automatically reduce the carrier frequency to 8kHz for protecting inverter.

*10) When torque boost is set at 0.1, starting torque of 50% or more can be obtained.

*11) With a nominal applied motor, this value is average torque when the motor decelerates and stops from 60Hz. (It may change according to motor loss.)

*12) Consult with Fuji Electric.

*13) Applicable to 10%ED when using options (standard)

200% of rated current for 0.5s 180% of rated current for 0.5s

0.82

1.5 2.9 4.2 7.1

kVA 0.6 1.1 2.1 3.0 5.0 7.0 9.4 14 19 24 28 38 47 57 70 93 111 136 161 196 244 267 341 383 433 488

•Digital setting : 0.01Hz at Maximum frequency of up to 99.99Hz (0.1Hz at Maximum frequency of 100Hz and above)

• LINK setting : Selects from the following two items.

0.0 : Automatic (for constant torque load)

1.0 to 1.9 : Manual (for propotional speed torque load)

2.0 to 20.0: Manual (for constant torque load)

%ED

5353232 No limit

%ED

22 18 10 7 5 5 5 10

%ED

(kg)

Max. voltage [V] – Min. Voltage [V]

Three-phase average voltage[V]

10 10 10 10

*Inverter restarts at the starting frequency when operation command is input while braking is operating.

* DC injection braking does not operate at the time of change-over from forward to reverse operation.

*

DC injection braking does not operate when frequency setting is decreased while operation command (FWD, REV) is being input.

Natural cooling

-UL/cUL -Low Voltage Directive -EMC Directive -TÜV (up to 30HP)

-IEC 61800-3 (EMC product standard including specific test methods)

(2.2) (2.5) (3.8) (3.8) (3.8) (6.5) (6.5) (10) (10)

10.0 13.5 19.8 26.8 33.2 39.3

14.9 21.5 27.9 39.1 50.3 59.9 69.3

• 1/20000 of Maximum frequency ex.) 0.003Hz at 60Hz, 0.006Hz at 120Hz, 0.02Hz at 400Hz

• 0.01Hz (Fixed)

(10.5) (10.5)

x 67 (Conforming to EN61800-3 (5.2.3))

54 67 81 100 134 160 196 232 282 352 385 491 552 624 704

86 104 124150 -----------

Fan cooling

23

(29) (34)

88 106 154 154 221 221 309 309 551 551 794 794

(70)(70)(48)(40)(39)

(100) (100)

(140)

(140)

(250) (250) (360)

(360)

1

1-3

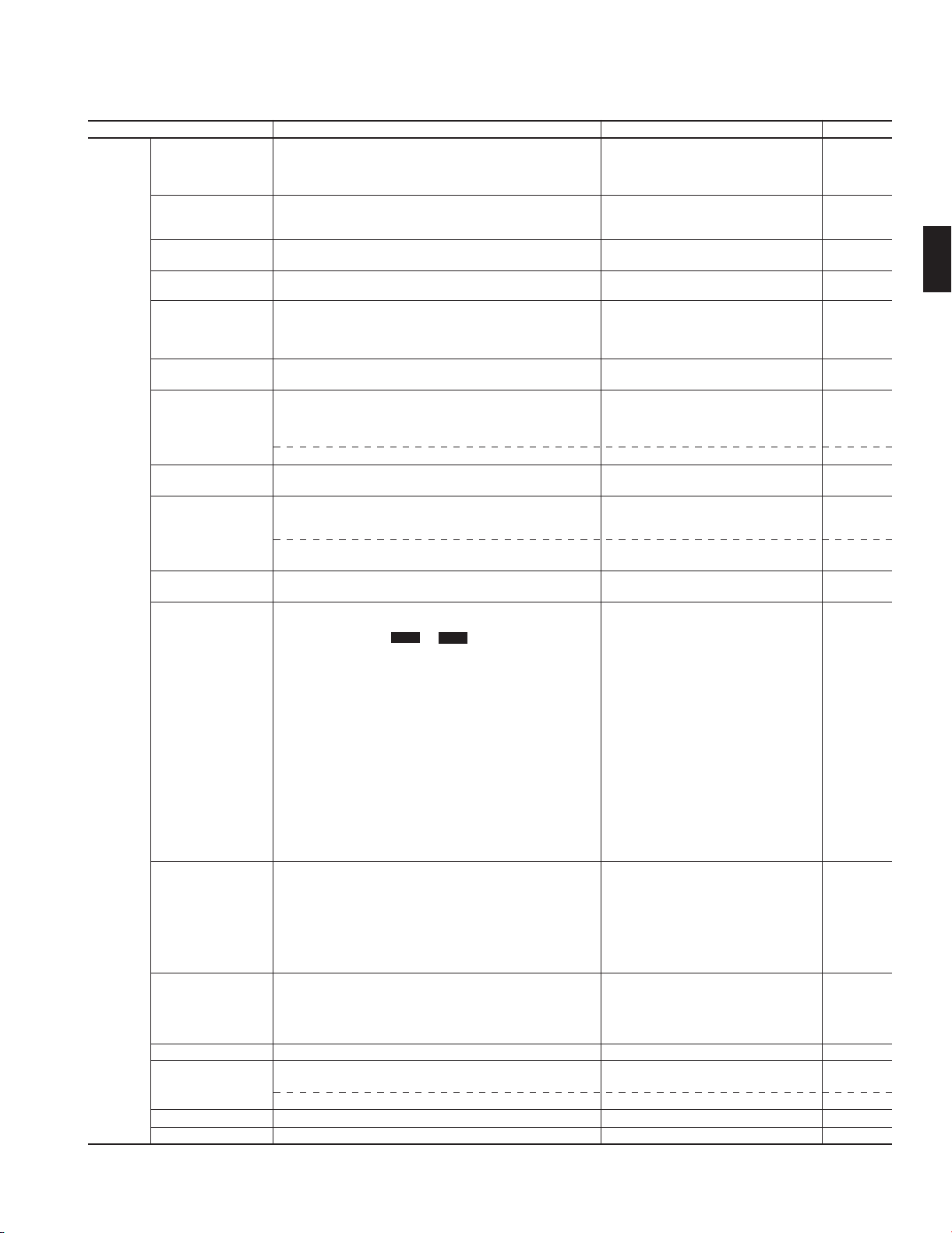

Page 10

Chapter 1

1. Standard Specifications

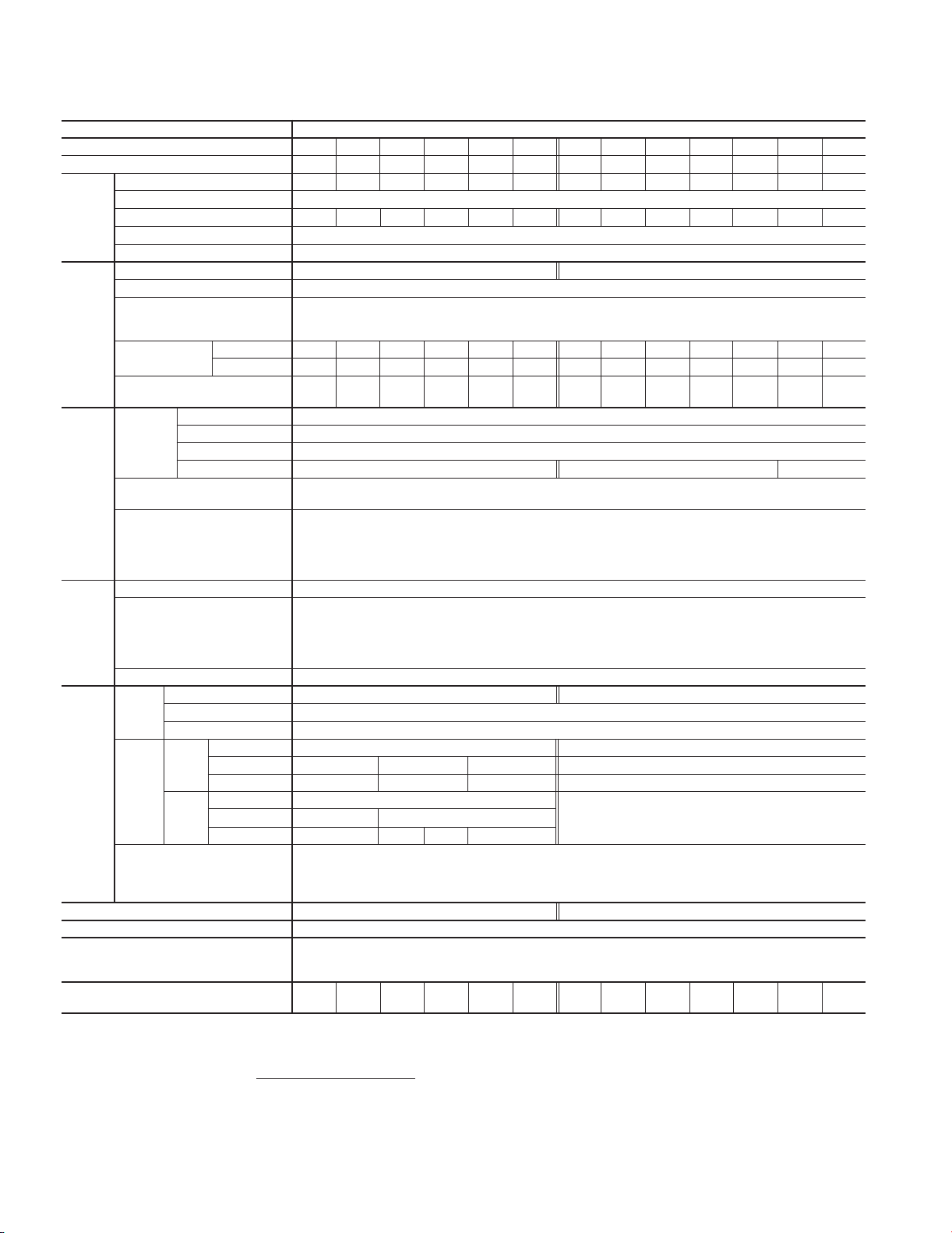

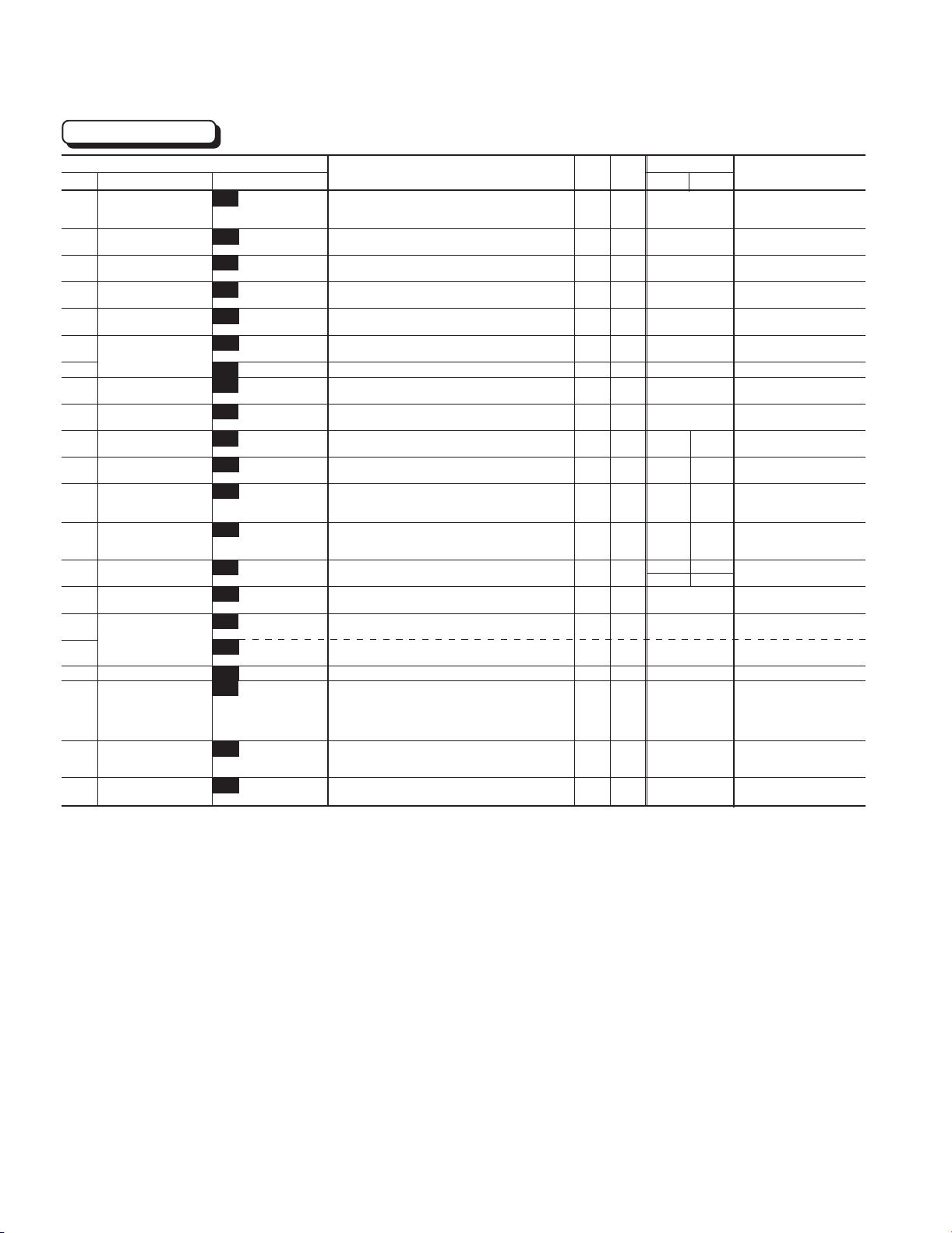

1.3 Three-phase 230V FRENIC5000P11S Series (for variable torque load)

Item Specifications

Type FRN■■■■■■P11S-2UX 007 010 015 020 025 030 040 050 060 075 100 125 150

Nominal applied motor HP 7.5 10 15 20 25 30 40 50 60 75 100 125 150

Rated capacity *1) kVA 8.8 12 17 22 27 31 46 58 72 86 113 138 165

Rated voltage *2) V 3-phase 200V/50Hz 200, 220, 230V/60Hz

Output Rated current *3) A 22 29 42 55 67 78 115 145 180 215 283 346 415

ratings Overload capability 110% of rated current for 1min

Rated frequency Hz 50, 60Hz

Phases, Voltage, Frequency 3-phase 200 to 230V 50/60Hz

Voltage / frequency variations Vo ltage : +10 to –15% (Voltage unbalance *4) : 2% or less) Frequency :+5 to –5%

Input *5) When the input voltage drops below 165V from rated voltage, the inverter can be operated for 15ms .

ratings The smooth recovery method is selectable.

Output Accuracy (Stability) •Analog setting : ± 0.2% of Maximum frequency (at 25±10°C (77±50°F))

frequency •Digital setting : ±0.01% of Maximum frequency (at –10 to +50°C (14 to 122°F))

Control 0.1 to 0.9 : Manual (for variable torque load) *9)

Braking Duty cycle

Enclosure (IEC 60529) IP 40 IP 00 ( IP 20 : Option )

Cooling method Fan cooling

Standards -IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

Weight lbs 13 13 13 22 22 23 64 64 79 97 101 154 254

NOTES: *1) Inverter output capacity (kVA) at 230V. Rated capacity reduces when power supply voltage decreases.

Momentary voltage dip capability When the input voltage is 165V or more, the inverter can be operated continuously.

Rated current *6) (with DCR) 19.7 26.9 39.0 54.0 66.2 78.8 109 135 163 199 272 327 400

A(without DCR) 40.8 52.6 76.9 98.5 117 136 168 204 243 291 - - -

Required power supply

capacity *7)

Maximum frequency 50 to 120Hz

Setting Base frequency 25 to 120Hz

Starting frequency 0.1 to 60Hz, Holding time: 0.0 to 10.0s

Carrier frequency *8) 0.75 to 15kHz 0.75 to 10kHz 0.75 to 6kHz

Setting resolution •Analog setting : 1/3000 of Maximum frequency ex.) 0.02Hz at 60Hz, 0.04Hz at 120Hz

Voltage / freq. (V/f) characteristic Adjustable at base and maximum frequency, with AVR control : 80 to 240V

To rque boost To rque boost can be set, using Function code F09 and A05.

Starting torque 50%

Braking torque *10) 20% 10 to 15%

Standard

Time s No limit

Duty cycle

Standard

Braking torque 100% 75%

Time s 15 7 8 10

Using

options

10%ED Braking torque 100% *12)

Time s 15 7

Duty cycle

DC injection braking Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

*2) Output voltage cannot exceed the power supply voltage.

*3) Current derating may be required in case of low impedance loads such as high frequency motor.

*4) Use a DC REACTOR (DCR) when the voltage unbalance exceeds 2%. (This value is equivalent to FUJI’s conventional allowable value.)

Voltage unbalance (%) =

*5) Tested at standard load condition (85% load).

*6) This value is under FUJI original calculation method.

*7) When power-factor correcting DC REACTOR (DCR) is used.

*8) When inverter is operating at a carrier frequency of 10kHz or higher, the inverter may automatically reduce the carrier frequency to 8kHz for protecting inverter.

*9) When torque boost is set at 0.1, starting torque of 50% or more can be obtained.

*10) With a nominal applied motor, this value is average torque when the motor decelerates and stops from 60Hz. (It may change according to motor loss.)

*11) Order individually.

*12) Applicable to 10%ED when using options (standard)

kVA 6.9 9.4 14 19 23 28 38 47 57 69 95 114 139

•Digital setting : 0.01Hz at Maximum frequency of up to 99.99Hz (0.1Hz at Maximum frequency of 100Hz and above)

• LINK setting : Selects from the following two items.

0.0 : Automatic (for constant torque load)

1.0 to 1.9 : Manual (for propotional speed torque load)

2.0 to 20.0 : Manual (for constant torque load)

%ED

%ED

%ED

(kg) (5.7) (5.7) (5.7) (10) (10) (10.5) (29) (29) (36) (44) (46) (70) (115)

Max. voltage [V] – Min. Voltage [V]

Three-phase average voltage[V]

3.5 3.5 4 10

10 10 10 7

* Inverter restarts at the starting frequency when operation command is input while braking is operating.

* DC injection braking does not operate at the time of change-over from forward to reverse operation.

*

DC injection braking does not operate when frequency setting is decreased while operation command (FWD, REV) is being input.

-UL/cUL -Low Voltage Directive -EMC Directive -TÜV (up to 30HP)

-IEC 61800-3 (EMC product standard including specific test methods)

• 1/20000 of Maximum frequency ex.) 0.003Hz at 60Hz, 0.006Hz at 120Hz

• 0.01Hz (Fixed)

x 67 (Conforming to EN61800-3 (5.2.3))

3-phase 200 to 220V/50Hz (220 to 230V/50Hz) *11) 200 to 230V/60Hz

No limit

1-4

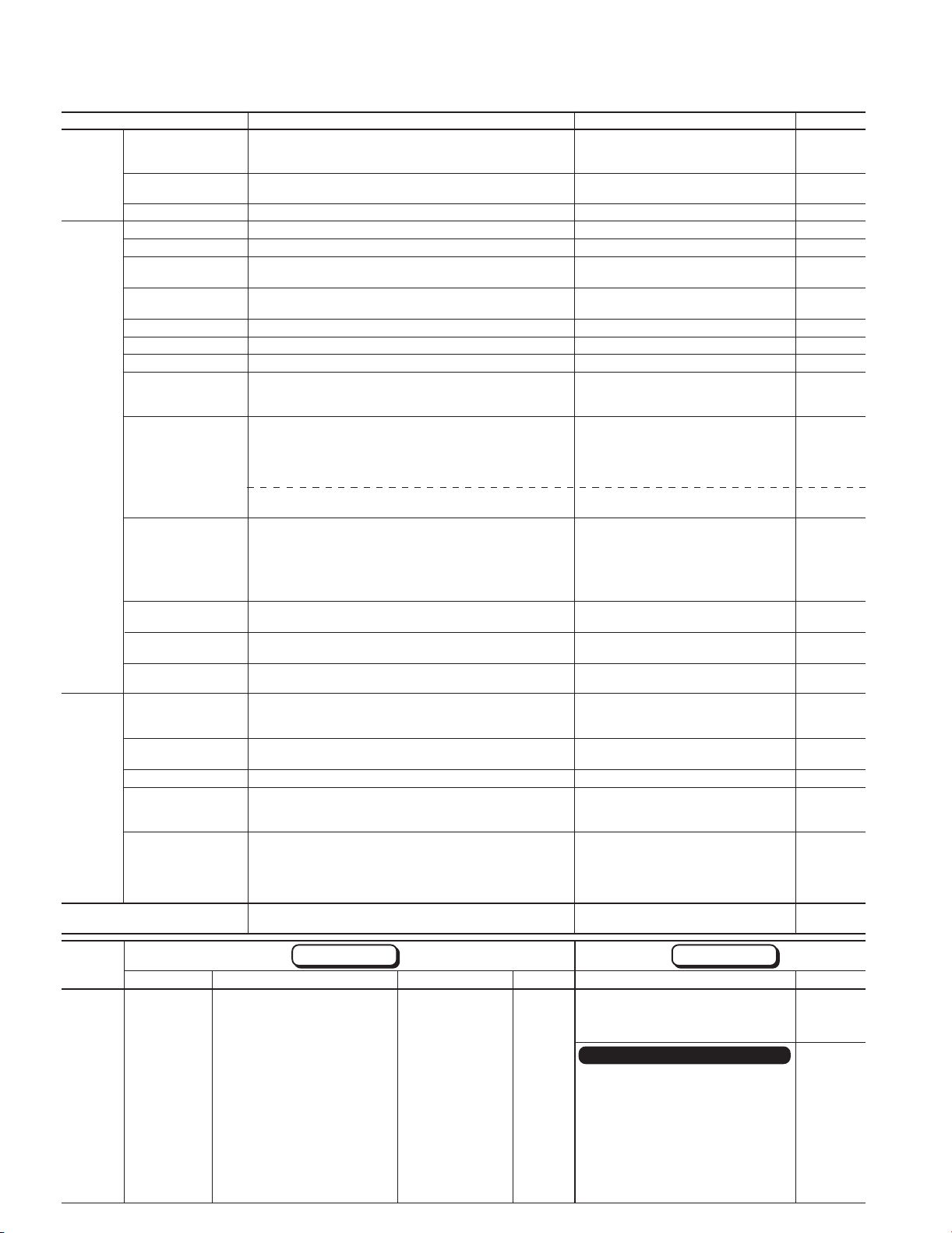

Page 11

Chapter 1

1. Standard Specifications

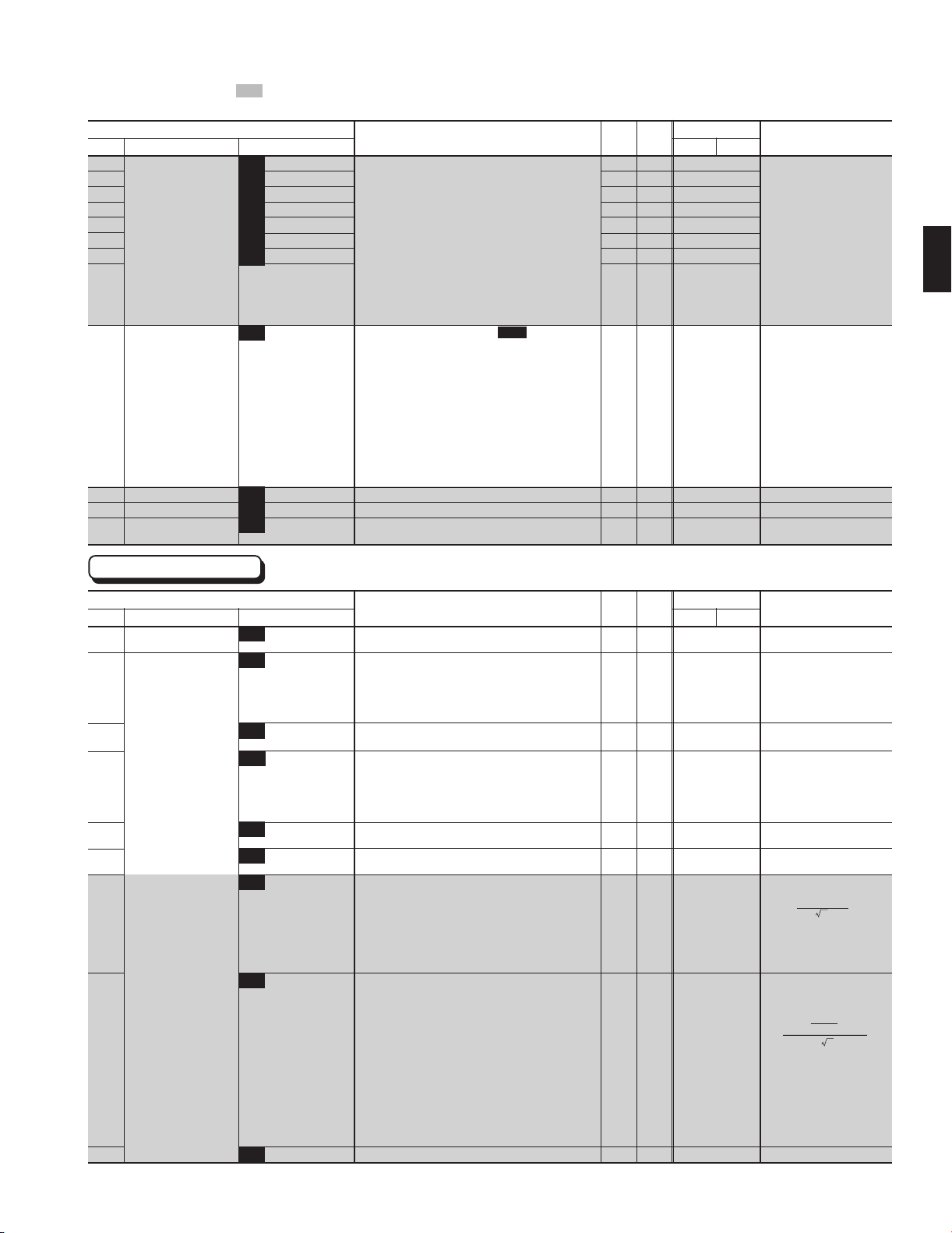

1.4 Three-phase 460V FRENIC5000P11S Series (for variable torque load)

Item Specifications

Type FRN■■■■■■P11S-4UX 007 010 015 020 025 030 040 050 060 075 100 125 150 200 250 300 350 400 450 500 600 700 800

Nominal applied motor HP 7.5 10 15 20 25 30 40 50 60 75 100 125 150 200 250 300 350 400 450 500 600 700 800

Rated capacity *1) kVA 10 13 18 24 29 35 48 60 72 89 119 140 167 201 242 300 330 386 414 517 589 668 764

Output

raitings

Input *6) When the input voltage drops below 310V from rated voltage, the inverter can be operated for 15ms .

ratings The smooth recovery method is selectable.

Output Accuracy (Stability) ·Analog setting : ±0.2% of Maximum frequency (at 25±10°C (77±50°F))

frequency ·Digital setting : ±0.01% of Maximum frequency (at –10 to +50°C (14 to 122°F))

Control 0.1 to 0.9 : Manual (for variable torque load) *10)

Braking Duty cycle

Enclosure (IEC 60529) IP 40 IP 00 ( IP 20 : Option )

Cooling method Fan cooling

Standards -IEC 61800-2 (Ratings, specifications for low voltage adjustable frequency a.c. power drive systems)

Weight lbs 13 13 13 22 22 23 64 64 75 86 88 106 154 154 221 221 309 309 309 551 551 794 794

NOTES:

Rated voltage *2) V 3-phase 380, 400, 415V/50Hz 380, 400, 440, 460V/60Hz

Rated current *3) A

Overload capability 110% of rated current for 1min

Rated frequency Hz 50, 60Hz

Phases, Voltage, Frequency

Voltage / frequency variations Voltage : +10 to –15% (Voltage unbalance *5) : 2% or less) Frequency :+5 to –5%

Momentary voltage dip capability When the input voltage is 310V or more, the inverter can be operated continuously.

Rated current *7) (with DCR)

A(without DCR)

Required power supply

capacity *8)

Maximum frequency 50 to 120Hz

Setting Base frequency 25 to 120Hz

Starting frequency 0.1 to 60Hz, Holding time: 0.0 to 10.0s

Carrier frequency *9) 0.75 to 15kHz 0.75 to 10kHz 0.75 to 6kHz

Setting resolution ·Analog setting : 1/3000 of Maximum frequency ex.) 0.02Hz at 60Hz, 0.04Hz at 120Hz

Voltage / freq. (V/f) characteristic Adjustable at base and maximum frequency, with AVR control : 320 to 480V

To rque boost Torque boost can be set, using Function code F09 and A05.

Starting torque 50%

Braking torque *11) 20% 10 to 15%

Standard

Time s No limit

Duty cycle

Standard

Braking torque 100% 75%

Time s 15 7 8 10

Using

options

10%ED Braking torque 100% *13)

Time s 15 7

Duty cycle

DC injection braking Starting frequency: 0.1 to 60.0Hz Braking time: 0.0 to 30.0s Braking level: 0 to 100% of rated current

*1) Inverter output capacity (kVA) at 460V. Rated capacity reduces when power supply voltage decreases.

*2) Output voltage cannot exceed the power supply voltage.

*3) Current derating may be required in case of low impedance loads such as high frequency motor.

*4) When the input voltage is 380 to 398V/50Hz or 380 to 430V/60Hz, the tap of the auxiliary transformer must be changed.

*5) Use a DC REACTOR (DCR) when the voltage unbalance exceeds 2%. (This value is equivalent to FUJI’s conventional allowable value.)

Voltage unbalance (%) =

*6) Tested at standard load condition (85% load).

*7) This value is under FUJI original calculation method.

*8) When power-factor correcting DC REACTOR (DCR) is used.

*9) When inverter is operating at a carrier frequency of 10kHz or higher, the inverter may automatically reduce the carrier frequency to 8kHz for protecting inverter.

*10) When torque boost is set at 0.1, starting torque of 50% or more can be obtained.

*11) With a nominal applied motor, this value is average torque when the motor decelerates and stops from 60Hz. (It may change according to motor loss.)

*12) Consult with Fuji Electric.

*13) Applicable to 10%ED when using options (standard)

Max. voltage [V] – Min. Voltage [V]

Three-phase average voltage[V]

12.5 16.5

3-phase 380 to 480V 50/60Hz

10.0 13.5 19.8 26.8 33.2 39.3

21.5 27.9 39.1 50.3 59.9 69.3

kVA 7.0 9.4 14 19 24 28 38 47 57 70 93 111 136 161 196 244 267 341 383 433 488 549 610

·Digital setting : 0.01Hz at Maximum frequency of up to 99.99Hz (0.1Hz at Maximum frequency of 100Hz and above)

· LINK setting : Selects from the following two items.

%ED

%ED

%ED

* Inverter restarts at the starting frequency when operation command is input while braking is operating.

* DC injection braking does not operate at the time of change-over from forward to reverse operation.

*

-UL/cUL -Low Voltage Directive -EMC Directive -TÜV (up to 30HP)

-IEC 61800-3 (EMC product standard including specific test methods)

(kg)

(6.1) (6.1) (6.1)

23 30 37 44 60 75 91 112 150 176 210 253 304 377 415 520 585 650 740 840 960

3-phase 380 to 440V/50Hz 380 to 480V/60Hz *4)

54 67 81 100 134 160 196 232 282 352 385 491 552 624 704 792 880

86 104 124 150 - ------------

• 1/20000 of Maximum frequency ex.) 0.003Hz at 60Hz, 0.006Hz at 120Hz

• 0.01Hz (Fixed)

0.0 : Automatic (for constant torque load)

1.0 to 1.9 : Manual (for propotional speed torque load)

2.0 to 20.0 : Manual (for constant torque load)

No limit

3.5 3.5 4 10

10 10 7

DC injection braking does not operate when frequency setting is decreased while operation command (FWD, REV) is being input.

(10) (10)

(10.5)

(29) (29) (34) (39) (40) (70) (70)

x 67 (Conforming to EN61800-3 (5.2.3))

(48)

(100) (100) (140) (140) (140) (250) (250) (360) (360)

1

1-5

Page 12

Chapter 1

FWD

2. Common Specifications

2. Common Specifications

2.1 Outline of common specifications

Item Explanation Remarks Func. code

Control Control method

Operation method F02

Frequency setting F01

(Frequency command)

Jogging operation C20

Running status signal E20 to E23

Acceleration/ F07, F08

Deceleration time E10 to E15

Active drive H19

Frequency limiter F15, F16

NOTE : ( ) or < > in the “Remarks” column indicates the abbreviation of terminal function assigned to digital input terminals X1 to X9 and

1-6

transistor output terminals Y1 to Y5C.

•V/f control (Sinusoidal PWM control)

• Dynamic torque-vector control (Sinusoidal PWM control)

•Vector control with PG ...G11S only

• KEYPAD operation :

Forward or reverse operation by

Stopping by

• Digital input signal operation :

FWD·STOP command, REV·STOP command, Coast-to-stop

command, etc.

• LINK operation :

• RS-485 (standard)

• Various Bus interface is available. (Option)

• T-Link (FUJI private link) • Devicenet • CAN open

• Profibus-DP • Modbus Plus

• Interbus-S •JPCN1

• KEYPAD operation :

• External potentiometer : Variable resistor (1 to 5kΩ 1/2W)

• Analog input : External voltage or current input

(Reversible

operation)

(Inverse

operation)

• UP/DOWN control :

Output frequency increases when UP signal is ON, and

decreases when DOWN signal is ON.

• Multistep frequency selection :

Up to 16 different frequencies can be selected by digital input signal.

• Pulse train input : 0 to 100kp/s

• Digital signal (parallel) :

• LINK operation : RS-485 (standard) (RS-485FGABus)

Programmed PATTERN operation : Max. 7 stages

This operation can be performed by KEYPAD opration (

key) or digital input signal (FWD or REV).

REV

Transistor output : RUN, FAR, FDT, OL, LU, TL, etc.

(4 points) (4 output types are selectable)

Relay output : • Same as transistor output.

(2 points) • Alarm output (for any fault)

Analog output : Output frequency, Output current,

(1 point) Output voltage, Output torque, etc.

Pulse output : Output frequency, Output current,

(1 point) Output voltage, Output torque, etc.

0.01 to 3600s

Four kinds of acceleration and deceleration times can be set

independently, and the desired time is selected by combining

digital input signal (2 points).

Selects acceleration/deceleration pattern from the following 4 types.

• Linear

• S-curve (weak)

• S-curve (strong)

• Non-linear (for variable torque load)

When the acceleration time reaches 60s, the motor output torque

is automatically reduced to rated torque. Then the motor operation

mode is changed to torque limiting operation.

High and Low frequency limiters can be preset.

key

STOP

∨

0 to +10Vdc (0 to +5Vdc)

4 to 20mAdc

: Reversible operation by polarized signal can be

selected.

0 to ± 10Vdc (0 to ± 5Vdc)

: Inverse mode operation can be selected by

digital input signal (IVS).

0 to +10Vdc → 10 to 0Vdc (terminal 12)

4 to 20mAdc → 20 to 4mAdc (terminal C1)

12-bit parallel (12-bit binary) signal can be input.

(Option) • T-Link (FUJI private link)

• Profibus-DP

• Interbus-S

• Modbus Plus

• Devicenet

or

FWD

or ∨ key

REV

key

,

Option card (PG/Hz) required.

Switching between KEYPAD operation and

digital input signal operation is enabled by

pressing STOP key and RESET key at the

same time.

(LE)

• Connect to terminals 13, 12, and 11.

• Set Function code at ”F01: 1".

• Potentiometer is required separately.

0 to +5Vdc, 0 to ± 5Vdc input is enabled

when Func. code 17 (Gain for frequency

setting) is set at 200.0%.

(UP, DOWN)

(SS1, SS2, SS4, SS8)

Option card (PG/SY) required.

Option card (DIO) required.

(LE)

Option card for open networks

<STG1, STG2, STG4, TU, TO>

• To enter jogging operation mode:

•Press

same time.

•Digital input signal : (JOG)

* During jogging operation, an indicator at

“JOG” is lit on the LCD monitor.

Coast-to-stop is selectable by Function code “H11”.

(RT1, RT2)

The acceleration time is automatically

extended up to 3 times.

STOP

key and

∨

key at the

F42, A09

H30 to H39

C05 to C19

H31 to H39

F01

C21 to C28

F02

F36

E24, E25

F31

F35

H07

Page 13

Chapter 1

∨

2. Common Specifications

Item Explanation Remarks Func. code

Control Bias frequency F18

Gain for frequency F17

setting

Jump frequency control C01 to C04

Rotating motor pick up H09

(Flying start)

Auto-restart after F14

momentary power failure

Line/Inverter

changeover operation

Slip compensation P09

Droop operation H28

Torque limiting F40, F41

Torque control H18

PID control H20 to H25

Automatic deceleration F41, E17

Second motor's setting A01 to A18

Energy saving operation H10

Fan stop operation H06

Universal DI

Universal DO

Bias frequency can be preset.

Gain for frequency setting can be preset. (0.0 to 200.0%)

ex.) Analog input 0 to +5Vdc with 200% gain results in

Maximum frequency at 5Vdc.

Jump frequency (3 points) and its common jump hysteresis width

(0 to 30Hz) can be preset.

A rotating motor(including inverse rotating mode) can be smoothly

picked up without stopping the motor. (speed search method)

Automatic restart is available without stopping motor after a

momentary power failure. (speed search method)

When "Smooth recovery" mode is selected, the motor speed drop

is held minimum.

Controls switching operation between line power and inverter.

The inverter has sequence function inside.

• The inverter output frequency is controlled according to the load

torque to keep motor speed constant.

• When the value is set at "0.00" and "Torque-vector" is set at "active", the

compensation value automatically selects the Fuji standard motor.

Slip compensation can be preset for the second motor.

The motor speed droops in proportional to output torque.(-9.9 to

0.0Hz) ...G11S only

When the motor torque reaches a preset limiting level, this function

automatically adjusts the output frequency to prevent the inverter

from tripping due to an overcurrent.

To rque limiting 1 and Torque limiting 2 can be individually set, and

are selectable with a digital input signal.

Output torque (or load factor ) can be controlled with an analog

input signal (terminal 12).

This function can control flowrate, pressure, etc. (with an analog feedback signal.)

••

• Reference signal

••

• KEYPAD operation (

Setting freq. / Maximum freq. X 100 [%]

•Voltage input (terminal 12 and V2) : 0 to 10Vdc / 0 to 100%

•Current input (terminal C1) : 4 to 20mAdc / 0 to 100%

• Reversible operation with polarity (terminal 12) :

0 to ± 10Vdc / 0 to ±100%

•Reversible operation with polarity (terminal 12 + V1) :

0 to ± 10Vdc / 0 to ± 100%

•Inverse mode operation (terminal 12 and V2) : 10 to 0Vdc / 0 to 100%

• Inverse mode operation (terminal C1) : 20 to 4mAdc / 0 to 100%

• PATTERN operation : Setting freq. / Maximum freq. X 100 [%]

•DI option input : • BCD...Setting freq. / Maximum freq. X 100 [%]

• Multistep frequency setting :

• RS-485 : Setting freq. / Maximum freq. X 100 [%]

••

• Feedback signal

••

• Terminal 12 (0 to 10Vdc / 0 to 100%, or 10 to 0Vdc / 0 to 100% )

• Terminal C1 (4 to 20mAdc / 0 to 100%, or 20 to 4mAdc / 0 to 100%)

Torque limiter 1 (Braking) is set at "F41: 0".

• In deceleration :

The deceleration time is automatically extended up to 3 times for

tripless operation even if a braking resistor is not used.

• In constant speed operation :

Based on regenerative energy, the frequency is increased, and

tripless operation is active.

This function is used for two motors switching operation.

• The second motor's V/f characteristics (base and maximum frequency),

rated current, torque boost, electronic thermal relay, etc. can be preset.

• The second motor's circuit parameter can be preset, and torquevector control can be applied to both motors.

This function minimizes inverter and motor losses at light load.

• This function detects temperature inside inverter to stop cooling

fans for silent operation and extending the fans' lifetime.

•On/off status of cooling fans is output.

Transmits to main controller of LINK operation

Outputs command signal from main controller of LINK operation.

∨

or

• Binary...Full scale / 100%

(Setting of Torque limiter 2 (Braking) is same.)

key) :

Setting freq. / Maximum freq. X 100

NOTE : ( ) or < > in the “Remarks” column indicates the abbreviation of terminal function assigned to digital input terminals X1 to X9 and

transistor (relay) output terminals Y1 to Y4 (Y5A, Y5C).

When the sum of setting frequency and bias

frequency is minus value, the output

frequency rise can be delayed. (No reverse

running is performed.)

(STM)

The inverter searches the motor speed, and

smoothly returns to setting frequency.

Even if the motor circuit is temporarily opened,

the inverter operates without a hitch.

(SW50, SW60)

<SW88, SW52-1, SW52-2>

Slip compensation value can be manually

set from 0.01 to 5.00Hz instead of 0.0 for

FUJI standard motor.

P11S series doesn't have this function.

(TL2/TL1)

• Torque polarity selectable. (Hz/TRQ)

• P11S series doesn't have this function.

• PID control is selected by "H20". (Hz/PID).

• Reference signal selection is made by "F01".

In "F01", "8: UP/DOWN control 1", "9: UP/

DOWN control 2", and "11: Pulse train

input" cannot be used for the reference

signal of PID control.

• Terminal V1 is optional.

• Terminal V2: EN only

[%

]

• Feedback signal selection is made by "H21".

When the deceleration time is extended to

longer than three times the setting time, the

inverter trips.

(M2/M1)

<SWM2>

<FAN>

(U-DI)

<U-DO>

H13 to H16

E01 to E09

E20 to E24, H13

A18

E16, E17

F01

C05 to C19

H21

1

1-7

Page 14

Chapter 1

2. Common Specifications

Item Explanation Remarks Func. code

Control Zero speed control

Positioning control

Synchronized operation

Protection Overload

Overvoltage

Surge protection

Undervoltage

Input phase loss

Overheating

Short-circuit

Ground fault

Motor overload F10 to F12

(Overload early warning) E33 to E35

DB resistor overheating F13

Output phase loss

detection

Motor protection by H26, H27

PTC thermistor

Auto reset H04, H05

Condition Installation location

(Installation

and

operation)

Storage condition

Ambient temperature

Ambient humidity

Altitude

Vibration

The stopped motor holds its rotor angle. For a rotating motor, the

rotor angle is held after deceleration.

The SY option card can be used for positioning control by

differential counter method.

This function controls the synchronized operation between 2 axes with PGs.

Protects the inverter by electronic thermal and detection of inverter temperature.

Detects DC link circuit overvoltage, and stops the inverter.

Protects the inverter against surge voltage between the main

circuit power line and ground.

Detects DC link circuit undervoltage, and stops the inverter.

Phase loss protection for power line input

Protects the inverter by detection of inverter heat sink temperature.

Short-circuit protection for inverter output circuit

• Ground fault protection for inverter output circuit (3-phase current

• Zero-phase current detection method

• The inverter trips, and then protects the motor.

• Electronic thermal overload relay can be selected for standard

• The second motor's electronic thermal overload relay can be

• Before the inverter trips, outputs OL(Overload early warning)

• Prevents DB resistor overheating by internal electronic thermal

•Prevents DB resistor overheating by external thermal overload

When the inverter executes auto-tuning, detects each phase

impedance imbalance (and stops the inverter).

When the motor temperature exceeds allowable value, the inverter

trips automatically.

When the inverter is tripped, it resets automatically and restarts.

• Indoor use only.

• Free from corrosive gases, flammable gases, oil mist, dusts, and

-10 to +50˚C (14 to +122˚F) (For inverters of 30HP or smaller, remove the

ventilation covers when operated at temperature of 40˚C (104˚F)or above.)

5 to 95%RH (non-condensing)

33ft (1000m) or less. Applicable to 9800ft (3000m) with power

derating (-10% / 33ft (1000m))

3mm (vibration amplitude) at 2 to less than 9Hz

9.8m/s

2m/s2 at 20 to less than 55Hz (2m/s2 at 9 to less than 55Hz : G11S

125HP, P11S 150HP or more)

1m/s

• Temperature : -25 to +65°C (-13 to +149°F)

• Humidity : 5 to 95%RH (No-condensing)

detection method)

motor or inverter motor

preset for 2-motor changeover operation.

signal at a preset level.

overload relay. (10HP or smaller for G11S, 15HP or smaller for

P11S)

relay attached to DB resistor. (15HP or larger for G11S, 20HP or

larger for P11S)

direct sunlight.

2

at 9 to less than 20Hz

2

at 55 to less than 200Hz

A motor with PG and option card (OPCG11S-PG) are necessary. (ZERO)

P11S series doesn't have this function.

Option card (PG/SY) required

Option card is required.

230V : 400Vdc, 460V : 800Vdc

• Line voltage : 5kV

• Between power line and ground : 7kV (1.2/50µs)

230V : 200Vdc, 460V : 400Vdc

•

Operation details are selected by Function code F14.

• 30HP or smaller inverter

• 40HP or larger inverter

• Thermal time constant (0.5 to 75.0

minutes) can be preset for a special motor.

• External singnal is used for changeover.

Related transistor output : OL

<OL1, OL2>

• The inverter stops electricity discharge

operation, to protect the DB resistor.

Then, usually inverter displays "OU trip".

• Connects the relay output to the terminal

THR, to protect the DB resistor.

Then, usually the inverter displays "OH trip".

Number of Auto reset times and reset

interval can be preset.

Pollution degree 2 when complying with Low

Voltage Directive is needed.

*

When altitude is 6600ft (2000m) or higher,

interface circuit should be isolated from main

power lines, to comply with Low Voltage Directive.

F14

A06 to A08

1-8

Item Explanation Remarks Func. code Explanation Func. code

Indication Operation mode

(Running)

LED monitor

The following items can be displayed

by function setting.

• Output frequency 1 (Before slip

compensation) [Hz]

• Output frequency 2 (After slip

compensation) [Hz]

• Setting frequency [Hz]

• Output current [A]

• Output voltage [V]

• Motor synchronous speed [r/min]

• Line speed [m/min]

• Load shaft speed [r/min]

• Torque calculation value [%]

• Input power [kW]

• PID reference value

• PID reference value (remote)

• PID feedback value

• Trip history

Cause of trip of the

last 4 trips can be

retained and

displayed. (Even

when main power is

off, data is retained.)

• PG feedback value

is displayed when

PG option is used.

E43

F01

C30

LCD monitor

Languages for the LCD monitor are

selectable.

English, German, French, Spanish, Italian,

Japanese

Operation monitor & Alarm monitor

• Operation monitor

Two types of monitoring is selectable by "E45".

• Displays operation guidance

• Bargraph

• Output frequency (before slip

compensation) [%]

• Output current [A]

• Output torque [%]

• Alarm monitor

When the inverter trips, displays the alarm.

E46

E45

Page 15

Chapter 1

2. Common Specifications

Indication Stopping

Item Explanation Remarks Func. code Explanation Func. code

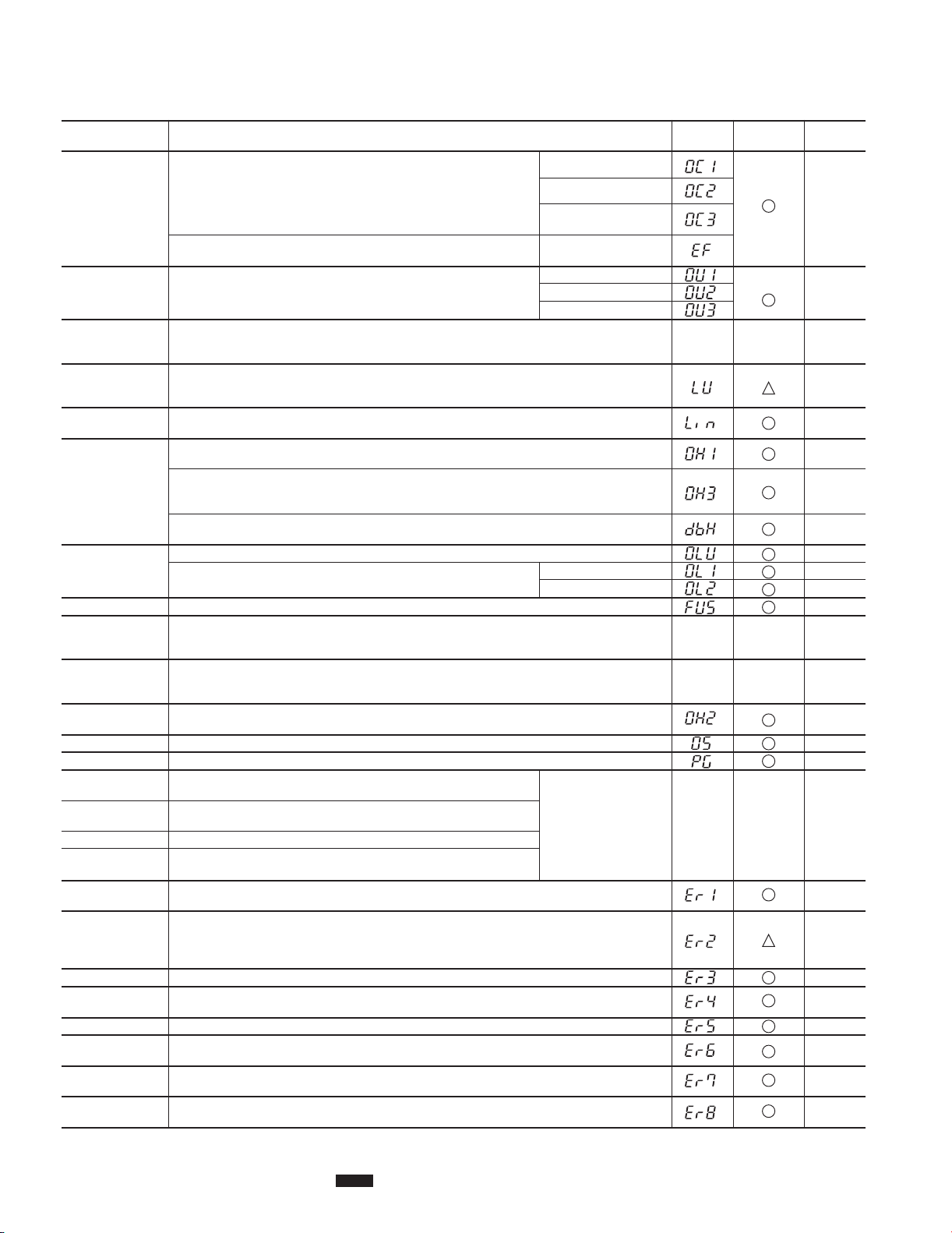

Tri p mode

Charge lamp When the DC link circuit voltage is higher than 50V, the charge lamp is ON.

LED monitor

Selected setting value or output

value

Displays the cause of trip by codes

as follows.

• OC1 (Overcurrent during

acceleration)

• OC2 (Overcurrent during

deceleration)

• OC3 (Overcurrent running at

constant speed)

• EF (Ground fault)

• Lin (Input phase loss)

• FUS (Fuse blown)

• OU1 (Overvoltage during

acceleration)

• OU2 (Overvoltage during

deceleration)

• OU3 (Overvoltage running at

constant speed)

• LU (Undervoltage)

• OH1 (Overheating at heat sink)

• OH2 (External thermal relay tripped)

• OH3 (Overtemperature at inside air)

• dBH (Overheating at DB circuit)

• OL1 (Motor1 overload)

• OL2 (Motor2 overload)

• OLU (Inverter unit overload)

• OS (Overspeed)

• PG (PG error)

• Er1 (Memory error)

• Er2 (KEYPAD panel communication error)

• Er3 (CPU error)

• Er4 (Option communication error)

• Er5 (Option error)

• Er6 (Operation procedure error)

• Er7 (Output phase loss error,

impedance imbalance)

• Er8 (RS-485 error)

• Trip history

Cause of trip of the last

4 trips can be retained

and displayed. (Even

when main power is off,

data are retained.)

E44

LCD monitor

Function setting & monitor

Selectable from the following 7 indications.

••

• Function setting

••

Displays function codes and its data or data code.

•

• Changes the data value.

••

• Operation condition monitoring

••

• Output frequency (before slip compensation)

• Output current [A]

• Output voltage [V]

• Torque calculation value [%]

• Setting frequency [Hz]

• Operation condition

• FWD or REV (Forward or reverse running)

• IL (Current limiting)

• VL or LU (Voltage limiting or stopped by

undervoltage)

• TL (Torque limiting)

• Motor synchronous speed [r/min]

• Load shaft speed [r/min]

• Line speed [m/min]

• PID reference value

• PID feedback value

• Driving torque limiter setting value [%]

• Braking torque limiter setting value [%]

••

• Tester function (I/O check)

••

Displays on/off status of digital input and

output signals, level of analog input and

pulse output signals.

•Digital I/O : ■ (ON), ■■ (OFF)

• Analog I/O: [V] , [mA], [H], [p/s]

••

• Maintenance data

••

• Operation time [h]

• DC link circuit voltage [V]

• Temperature at inside air [°C]

• Temperature at heat sink [°C]

• Maximum current [A]

• Main circuit capacitor life [%]

• Control PC board life [h]

• Cooling fan operation time [h]

• Communication error times (KEYPAD)

• Communication error times (RS-485)

• Communication error times (Option)

• ROM version (Inverter)

• ROM version (KEYPAD)

• ROM version (Option)

••

• Load factor calculation

••

• Measurement time [s]

• Maximum current [A]

• Effective current [A]

• Average braking power [%]

••

• Alarm data

••

Dispalys operation data immediately before

a trip occurs.

• Output frequency (before slip compensation)

• Output current [A]

• Output voltage [V]

• Torque calculation value [%]

• Setting frequency [Hz]

• Operation condition

• FWD or REV (Forward or reverse

running)

• IL (Current limiting)

• VL or LU (Voltage limiting or stopped by

undervoltage)

• TL (Torque limiting)

• Operation time [h]

• DC link circuit voltage [V]

• Temperature at inside air [°C]

• Temperature at heat sink [°C]

• Communication error times (KEYPAD)

• Communication error times (RS-485)

• Communication error times (Option)

• Digital input terminal condition (Remote)

Digital input terminal condition (Communication)

•

• Transistor output terminal condition

• Trip history code

• Multiple alarm exist

••

• Data copy

••

• Function code (data and data code) is

stored in one inverter and is copied to

another inverter *.

* Copying is only available to the inverter

of the same series, same voltage class,

and same capacity .

[Hz]

[Hz]

1

1-9

Page 16

Chapter 1

2. Common Specifications

2.2 Protective functions

Function Description

Overcurrent protection

(Short-circuit)

(Ground fault)

Overvoltage protection

Incoming surge

protection

Undervoltage

protection

Input phase loss

protection

Overheat protection

Electronic thermal

overload relay

(Motor protection)

Fuse blown

Stall prevention

(Momentary

overcurrent limitation)

Active drive

External alarm

input

Overspeed protection

PG error

Alarm output

(for any fault)

Alarm reset command

Alarm history memory

Storage of data on

cause of trip

Memory error

KEYPAD panel

communication error

CPU error

Option

communication error

Option error

Operation

procedure error

Output phase loss

error

RS-485 communication

error

*) ▲▲ : By function code setting, alarm output can be disabled.

NOTES :

1) Retaining alarm signal when auxiliary controll power supply is not used :

2) To issue the RESET command, press the

3) Fault history data is stored for the past four trips.

1-10

• Stops running to protect inverter from an overcurrent resulting from

overload.

• Stops running to protect inverter from an overcurrent due to a short-circuit

in the output circuit.

• Stops running to protect inverter from an overcurrent due to a ground

fault in the output circuit.

• Stops running to protect inverter from an overcurrent resulting from ground fault

in the output circuit by detecting zero-phase current. (30kW or larger model only)

• The inverter stops when it detects an overvoltage in the DC link circuit.

(230V : 400Vdc or more, 460V : 800Vdc or more)

•

Protection is not assured if excess AC line voltage is applied inadvertently.

• Protects the inverter against surge voltage between the main circuit power line and ground.

• Protects the inverter against surge voltage in the main circuit power line.

• The inverter may be tripped by some other protective function.

• Stops the inverter when the DC link circuit voltage drops below undervoltage level.

(230V series : 200V DC or less, 460V series : 400V DC or less)

• Alarm signal is not output even if the DC link circuit voltage drops, when “F14 : 3 to 5” is selected.

• The inverter is protected from being damaged when open-phase fault occurs.

• Stops the inverter when it detects excess heat sink temperature in case of cooling fan failure or

overload.

• Stops the inverter when it detects an abnormal rise in temperature in the inverter unit caused by

insufficient ventilation in cubicles or an abnormal ambient temperature.

• Stops the inverter when it detects an abnormal rise in temperature inside the inverter.

• When the built-in or external braking resistor overheats, the inverter stops discharging and running.

•

Function data appropriate for the resistor type (built-in/external) must be set. (G11S: 10HP or smaller only)

• This function stops the inverter by detecting an inverter overload.

• This function stops the inverter by detecting an overload in a standard

motor or inverter motor.

When a blown fuse is detected, the inverter stops running. (40HP or larger model only)

•

• When an output current exceeds the limit during acceleration, this function lowers output frequency

to prevent the occurrence of an OC1 trip.

• The stall prevention function can be disabled.

• During running in which acceleration is 60s or longer, this function increases the acceleration time to

prevent the occurrence of an OLU trip.

• The acceleration time can be prolonged up to three times the preset time.

• The inverter stops on receiving external alarm signals.

• Use THR terminal function (digital input).

• Stops the inverter when the output frequency exceeds the rated maximum frequency by 20%.

• If disconnection occurs in pulse generator circuits, the inverter issues an alarm.

• The inverter outputs a relay contact signal when the inverter issued an

alarm and stopped.

• An alarm-stop state of the inverter can be cleared with the RESET key or

by a digital input signal (RST).

• Store up to four instances of previous alarm data.

• The inverter can store and display details of the latest alarm history data.

• The inverter checks memory data after power-on and when the data is written. If a memory error is

detected, the inverter stops.

• If an error is detected in communication between the inverter and KEYPAD when the Keypad panel

is being used, the inverter stops.

• When operated by external signals, the inverter continues running. The alarm output (for any fault) is

not output. Only Er2 is displayed.

• If the inverter detects a CPU error caused by noise or some other factor, the inverter stops.

• If a checksum error or disconnection is detected during communication, the inverter issues an alarm.

• If a linkage error or other option error is detected, the inverter issues an alarm.

Er6 is indicated only when the inverter is forcedly stopped by [STOP1] or [STOP2] operation in E01 to

E09 (Set value: 30 or 31)

If an unbalance of output circuits is detected during auto-tuning, this function issues an alarm (and

stops the inverter).

• If an RS-485 communication error is detected, the inverter issues an alarm.

If the inverter power supply is cut off while an internal alarm signal is being output, the alarm signal cannot be retained.

LED monitor

During acceleration

During deceleration

While running at constant

speed

Groung fault

During acceleration

During deceleration

While running at constant speed

Motor 1 overload

Motor 2 overload

• Output terminals:

30A, 30B, and 30C

• Use the RST terminal

function for signal input.

• Even if main power

input is turned off, alarm

history and trip-cause

data are retained.

key on the KEYPAD panel or connect terminals RST and CM and disconnect them afterwards.

RESET

Alarm output Func. code

(30Ry) *)

F14

F13

F10 to F12

A06 to A08

F40, F41

E16, E17

––

H12

F36

F02

Page 17

Chapter 1

∨

2. Common Specifications

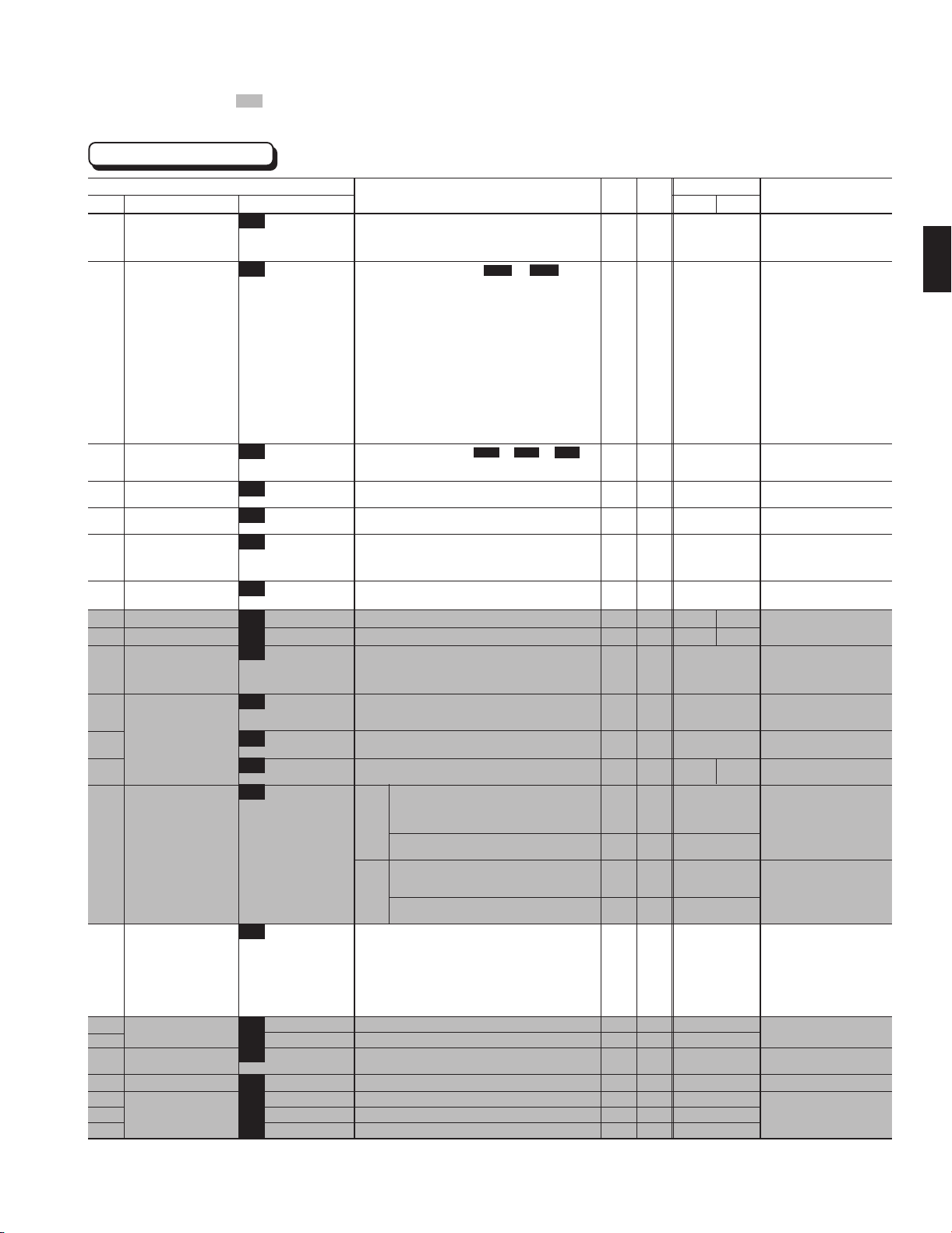

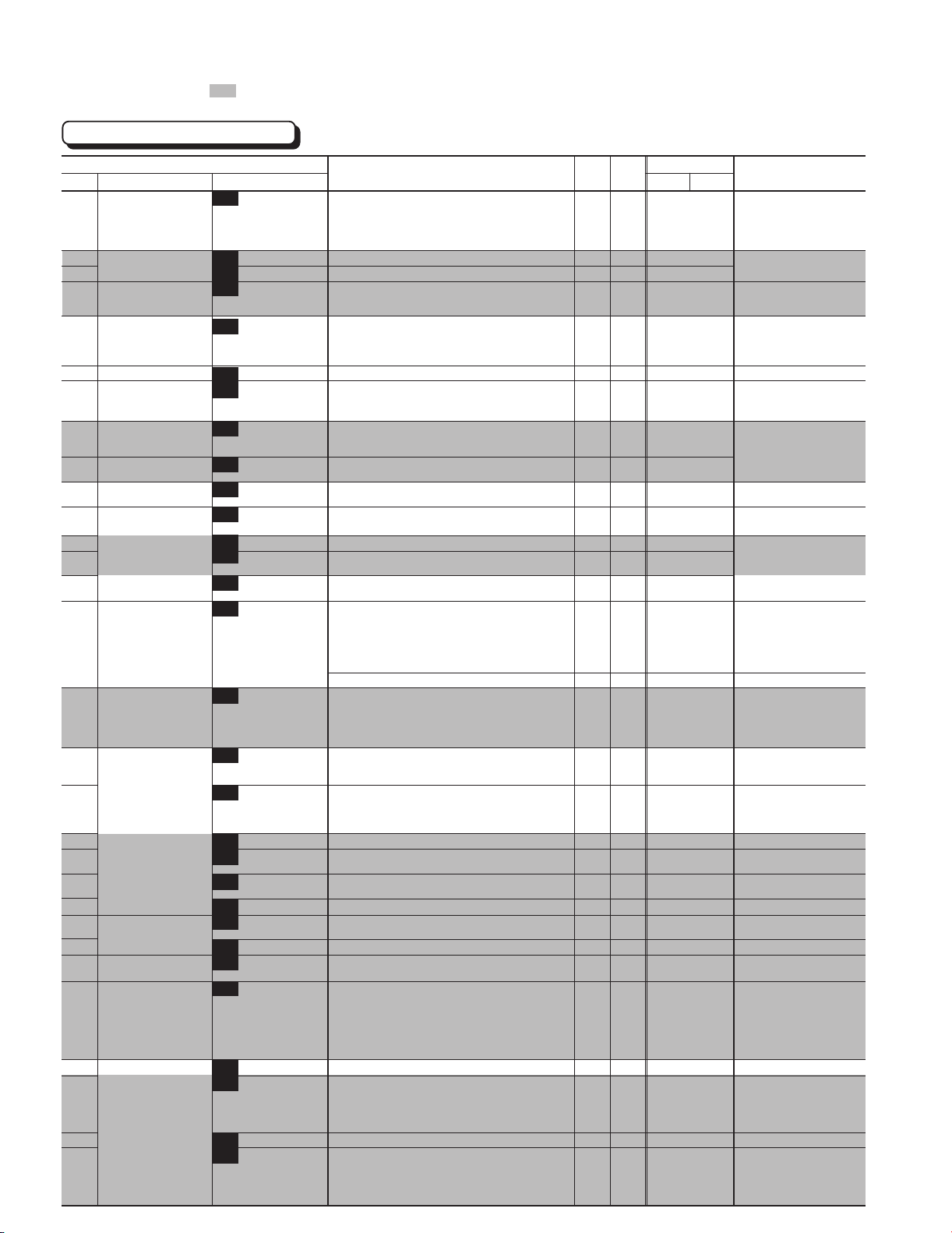

2.3 Function settings

The function marked can be set while the inverter is running. Other functions must be set while the inverter is

stopped.

Fundamental Functions

Function

Code Name LCD monitor unit 30HP 40HP

F00 Data protection F00 DATA PRTC 0:Data change enable

F01 Frequency command 1 F01 FREQ CMD 1 0 : KEYPAD operation (∨ or

F02 Operation method F02 OPR METHOD 0 : KEYPAD operation (

F03 Maximum frequency 1 F03 MAX Hz-1 G11S : 50 to 400Hz

F04 Base frequency 1 F04 BASE Hz-1 G11S : 25 to 400Hz

F05 Rated voltage 1 F05 RATED V-1 0V : The output voltage in proportion to the power

(at Base frequency 1 ) 80 to 240V : AVR active (230V)

F06 Maximum voltage 1 F06 MAX V-1 80 to 240V : AVR active (230V)

(at Maximum frequency 1) 320 to 480V : AVR active (460V)

F07 Acceleration time 1 F07 ACC TIME1 0.01 to 3600s

F08 Deceleration time 1 F08 DEC TIME1 0.01 to 3600s

F09 Torque boost 1 F09 TRQ BOOST1 0.0 : Automatic (for constant torque load)

F10 Electronic (Select) F10 ELCTRN OL1 0 : Inactive

thermal 1 : Active (for 4-pole standard motor)

overload relay 2 : Active (for 4-pole inverter motor)

F11 for motor 1 (Level) F11 OL LEVEL1 Approx. 20 to 135% of rated current of the inverter

F12 (Thermal time constant) F12 TIME CNST1 0.5 to 75.0 min

F13 Electronic thermal F13 DBR OL G11S [10HP or smaller]

overload relay 0 : Inactive

(for braking resistor) 1 : Active (for built-in braking resistor)

F14 Restart mode (Select) F14 RESTART 0 : Inactive (Trip and alarm when power failure occurs.)

after momentary 1 : Inactive (Trip, and alarm when power recovers.)

power failure 2 : Inactive (Deceleration stop, and alarm)

F15 Frequency (High) F15 H LIMITER G11S : 0 to 400Hz P11S : 0 to 120Hz

limiter (Low) F16 L LIMITER G11S : 0 to 400Hz P11S : 0 to 120Hz

F16

F17 Gain (for frequency F17 FREQ GAIN 0.0 to 200.0%

F18 Bias frequency F18 FREQ BIAS G11S : -400.0 to 400.0Hz P11S : -120.0 to 120.0Hz

F20 DC brake(Starting freq.) F20 DC BRK Hz 0.0 to 60.0Hz

F21 (Braking level) F21 DC BRK LVL G11S : 0 to 100% P11S : 0 to 80%

F22 (Braking time) F22 DC BRK t 0.0 (DC brake inactive), 0.1 to 30.0s

setting signal)

1:Data protection

Voltage input (terminal 12) (0 to 10Vdc, 0 to 5Vdc)

1:

2:Current input (terminal C1) (4 to 20mAdc)

3:Voltage and current input (terminals 12 and C1)

4:Reversible operation with polarity

(terminal 12) (0 to ± 10Vdc)

5:Reversible operation with polarity

(terminal 12 and V1) (0 to ± 10Vdc)

6:Inverse mode operation (terminal 12)

(+10 to 0Vdc)

7:Inverse mode operation (terminal C1)

(20 to 4mAdc)

8:UP/DOWN control 1 (initial freq. = 0Hz)

9:UP/DOWN control 2 (initial freq. = last value)

10 : PATTERN operation

11 : DI option or Pulse train input

1:External signal input (digital input)

(Operation by FWD or REV command)

P11S : 50 to 120Hz

P11S : 25 to 120Hz

supply voltage is set.

320 to 480V : AVR active (460V)

0.1 to 0.9 : Manual (for variable torque load)

1.0 to 1.9 : Manual (for proportional torque load)

2.0 to 20.0 : Manual (for constant torque load)

rated current, in Ampere

2 : Active (for external braking resistor)

[15HP or larger]

0 : Inactive

P11S [15HP or smaller]

0 : Inactive

2 : Active (for external braking resistor)

[20HP or larger]

0 : Inactive

Active (Smooth recovery by continuous operation mode)

3:

4:Active (Momentarily stops and restarts at output

frequency of before power failure)

5:Active (Momentarily stops and restarts at

starting frequency)

Setting range Unit

key)

or

or

FWD

REV

STOP

key)

Min. Factory setting

-- 0

-- 0

-- 0

Hz 1 60

Hz 1 60

V1

230:(230V class)

V1230:(230V class)

s 0.01 6.0 20.0

s 0.01 6.0 20.0

- 0.1 G11S : 2.0

-- 1

A 0.01 Motor rated

min 0.1 5.0 10.0

-- 1

-- 0

-- 0

-- 0

-- 0

Hz 1 70

Hz 1 0

% 0.1 100.0

Hz 0.1 0.0

Hz 0.1 0.0

% 1 0

s 0.1 0.0

460:(460V class)

460:(460V class)

P11S : 2.0

current

Remarks

Setting can be made so that

a set value cannot be easily

changed by KEYPAD panel

operation.

Sets the operation

command input method.

Sets the maximum output

frequency for motor 1.

Sets the base frequency for

motor 1.

Sets the output voltage at

the Base frequency 1 “F04”.

Sets the output voltage at the

Maximum frequency 1 “F03”.

During deceleration, Coastto-stop can be selected by

setting of “H11”.

Torque boost for motor 2

can also be set by “A05”.

Selection fo motor 2 can

also be made by “A06”.

Level setting for motor 2 can

also be made by “A07”.

Setting for motor 2 can also

be made by “A08”.

Not provided with models

15HP or larger.

Not provided with models

20HP or larger.

For detailed setting

procedure, see “H13” to

“H16”.

Minus bias setting is possible.

1

1-11

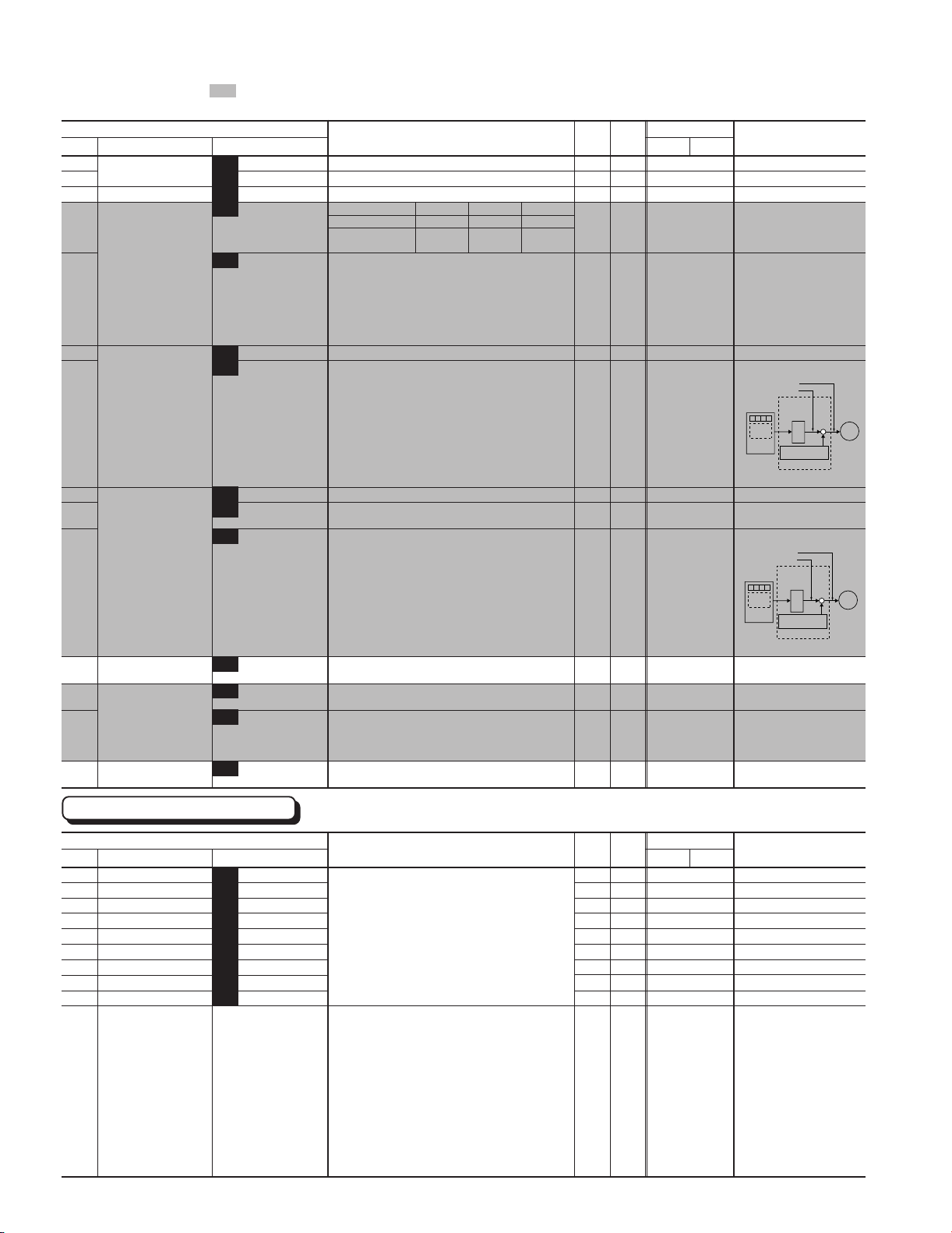

Page 18

Chapter 1

2. Common Specifications

The function marked can be set while the inverter is running. Other functions must be set while the inverter is

stopped.

Function

Code Name LCD monitor unit 30HP 40HP

Setting range Unit

F23 Starting frequency (Freq.) F23 START Hz 0.1 to 60.0Hz

F24 (Holding time) F24 HOLDING t 0.0 to 10.0s

F25 Stop frequency F25 STOP Hz 0.1 to 6.0Hz

F26 Motor sound (Carrier freq.) F26 MTR SOUND 0.75-15kHz 0.75-10kHz 0.75-6kHz

G11S -75HP 100HP –

P11S -30HP 40-100HP 125HP

F27 (Sound tone) F27 MTR TONE 0 : Level 0

1: Level 1

2: Level 2

3: Level 3

F30 FMA (Voltage adjust) F30 FMA V-ADJ 0 to 200%

F31 (Function) F31 FMA FUNC 0 : Output frequency 1 (Before slip compensation)