Page 1

Instruction Manual

ULTRASONIC FLOWMETER

TYPE: FLV

FLW

ULTRASONIC FLOW METER

Fuji Electric Co.,Ltd.

INF-TN2FLVa-E

Page 2

PREFACE

We are grateful for your purchase of Fuji Electric’s Ultrasonic flowmeter.

• First read this instruction manual carefully until an adequate understanding is acquired,

and then proceed to installation, operation and maintenance of the converter (sensor) of

the ultrasonic flowmeter. Wrong handling may cause an accident or injury.

• The specifications of this flowmeter will be changed without prior notice for further

product improvement.

• Modification of this flowmeter is strictly prohibited unless a written approval is obtained

from the manufacturer. Fuji Electric will not bear any responsibility for a trouble caused

by such a modification.

• This instruction manual shall be stored by the person who actually uses the flowmeter.

• After reading the manual, be sure to store it at a place easier to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer:

Fuji Electric Co.,Ltd.

Type: Described in Fuji Electric’s company nameplate on main frame

Date of manufacture: Described in Fuji Electric’s company nameplate on main frame

Product nationality: Japan

Request

• It is prohibited to transfer part or all of this manual without

Fuji Electric’s permission in written format.

• Description in this manual will be changed without prior notice

for further improvement.

© Fuji Electric Co., Ltd. 1998

Issued in July, 1998

i

Page 3

About ultrasonic flowmeter

The ultrasonic flowmeter in combination with the ultrasonic sensor mounted on the external wall of

existing piping, is used to convert the amount of flow of a fluid flowing in the piping into a unified

current signal and integrated pulse signal.

Check on type and specifications

The name of type is inscribed on the specification nameplate. Check the specification nameplate to

make sure that type and specifications are correct as ordered (the nameplate is attached to the side

of the converter, the upper side of the sensor cover (small type, large type) and the side of the frame

(for high temperature).

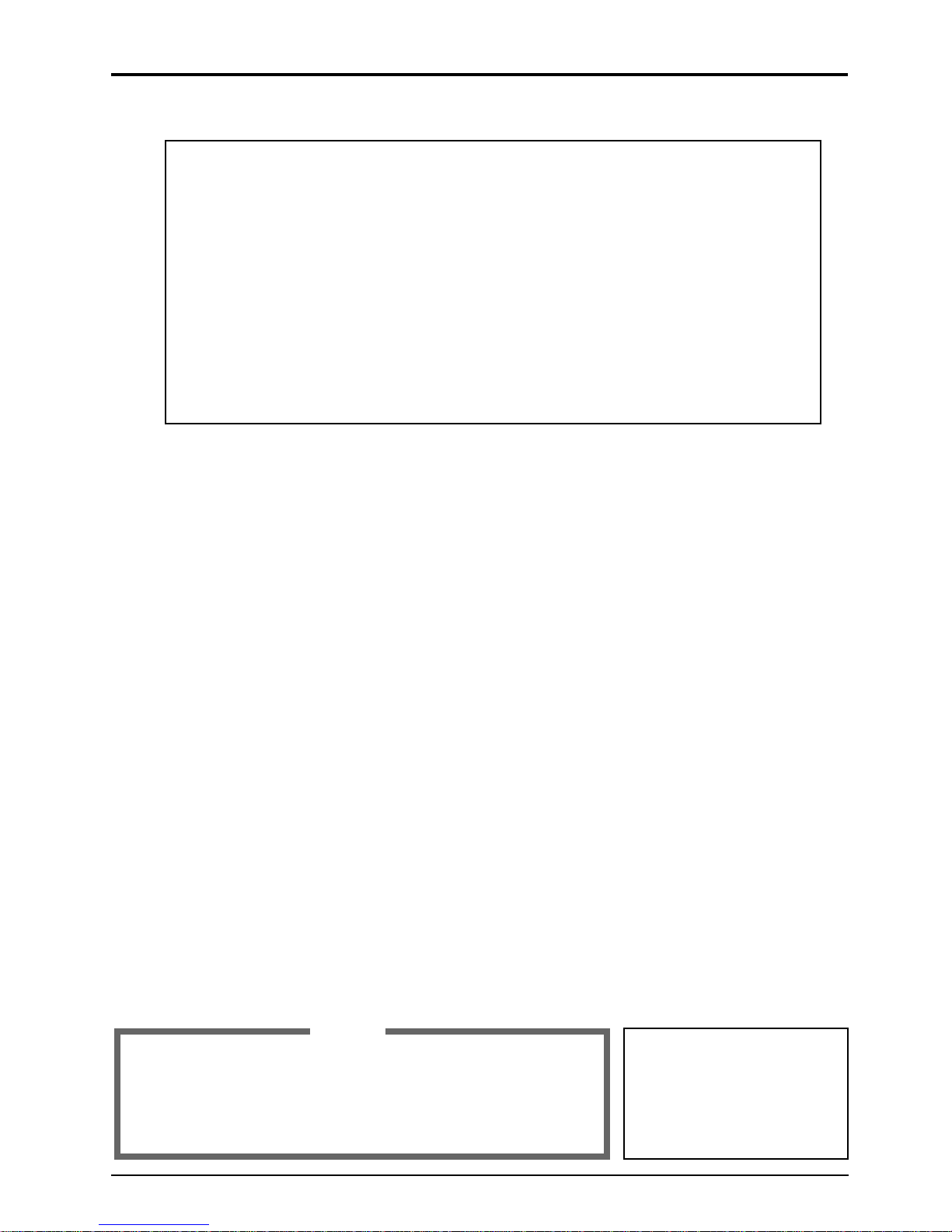

(1) Specification nameplate

Ultrasonic Flow Meter

Type

Output DC4–20mA

Power Supply

AC100–240V 50/60Hz

DC20–30V

Ser. No.

Fuji Electric Co.,Ltd.

Mfd.

Made in Japan

Ultrasonic

Flow Meter

Type

No.

FL

Fuji Electric Co., Ltd.

T19

Converter

Ultrasonic Flow Meter

Type.

Ser. No.

Mfd.

Fuji Electric Co.,Ltd.

Small type sensor

T

TK773792

Type FLW

M f d. 199 Fujielectric Co., Ltd

Large type sensor

Ser. No. T

High temperature sensor

ii

Page 4

CAUTION ON SAFETY

• The cautionary descriptions listed here contain important information about safety, so they should

always be observed. Those safety precautions are ranked 2 levels; DANGER and CAUTION.

Wrong handling may cause a dangerous situation, in which

DANGER

CAUTION

DANGER

there is a risk of death or heavy injury.

Wrong handling may invite a dangerous situation, in which

there is a possibility of medium-level trouble or slight injury

or only physical damage is predictable.

Caution on installation and wiring

• This unit is not explosion-proof type. Do not use it in a place

with explosive gases to prevent explosion, fire or other serious

accidents.

• The flowmeter should be installed in a place that meets the

• Install the flowmeter according to the instruction manual.

CAUTION

• When installing, make sure that the flowmeter interior is free

• Connect a power source of correct rating to prevent fire acci-

• Before making wiring work, be sure to turn OFF the power

• Use wiring materials of correct rating to prevent fire accidents.

operating conditions shown in this instruction manual.

Installation at an unsuited place may cause electric shock, fire or

incorrect operation.

Improper installation may lead to the cause of fall, trouble or

incorrect operation.

from cable chips and other foreign objects to prevent fire,

trouble, or incorrect operation.

dents.

supply to prevent electric shocks.

iii

Page 5

CONTENTS

PREFACE........................................................................................................................................ i

CAUTION ON SAFETY ...............................................................................................................v

CONTENTS ................................................................................................................................. vii

1. OPERATING PARTS AND THEIR FUNCTIONS............................................................... 1

2. MOUNTING OF CONVERTER............................................................................................ 2

2.1 Selection of mounting place....................................................................................................... 2

2.2 Mounting method....................................................................................................................... 2

2.3 Outline diagram (unit: in.) ......................................................................................................... 3

3. WIRING OF THE CONVERTER.......................................................................................... 4

3.1 Before wiring ............................................................................................................................. 4

3.2 Wiring ........................................................................................................................................ 4

3.3 Treatment of the wiring port ...................................................................................................... 4

3.4 Wiring to terminals .................................................................................................................... 5

4. OPERATION AND WORKS................................................................................................. 6

4.1 Before operation......................................................................................................................... 6

4.2 Power ON and status.................................................................................................................. 7

5. SETTING OF PARAMETERS .............................................................................................. 8

5.1 Outline of operating procedures................................................................................................. 8

5.2 Description of key operation...................................................................................................... 9

5.3 List of setting items.................................................................................................................. 11

5.4 Setting of parameters ............................................................................................................... 12

5.4 (1) Setting of piping specifications ................................................................................... 12

5.4 (2) Setting of analog output range..................................................................................... 14

5.4 (3) Setting of analog output limit ...................................................................................... 16

5.4 (4) Setting of burn-out....................................................................................................... 17

5.4 (5) Setting of damping.......................................................................................................18

5.4 (6) Zero adjustment ........................................................................................................... 19

5.4 (7) Setting of measurement display specifications............................................................ 20

5.4 (8) Low flow output cut .................................................................................................... 21

5.4 (9) Setting of integrated output unit and constant ............................................................. 22

5.4 (10) Setting of integral preset value .................................................................................... 23

5.4 (11) Setting of integration switch ........................................................................................ 24

5.4 (12) Selection of integral pulse output pulse width............................................................. 25

5.4 (13) Setting of measured value high and low limit switch.................................................. 26

5.4 (14) Setting of status output ................................................................................................27

5.4 (15) Calibration of measured value ..................................................................................... 28

5.4 (16) Switch of measurement unit system ............................................................................ 29

iv

Page 6

5.4 (17) Selection of language (English/Japanese) ................................................................... 30

5.4 (18) Analog output check .................................................................................................... 31

5.4 (19) Analog output calibration ............................................................................................ 32

5.4 (20) Status output check ...................................................................................................... 33

5.4 (21) Test mode..................................................................................................................... 34

6. MAINTENANCE AND INSPECTION ............................................................................... 35

6.1 Maintenance............................................................................................................................. 35

6.2 Inspection................................................................................................................................. 35

7. TROUBLESHOOTING........................................................................................................ 36

7.1 How to confirm normal operation............................................................................................ 36

7.1 (1) When checking by LCD indicator ............................................................................... 36

7.1 (2) LCD indication when power turned ON...................................................................... 36

7.1 (3) Detail check for abnormal status ................................................................................. 37

7.2 Faults and remedies.................................................................................................................. 38

7.2 (1) LCD display abnormal................................................................................................. 38

7.2 (2) Key abnormal .............................................................................................................. 38

7.2 (3) Measured value abnormal............................................................................................ 39

7.2 (4) Analog output abnormal .............................................................................................. 42

7.2 (5) Remedy for hardware fault .......................................................................................... 42

8. MOUNTING METHOD....................................................................................................... 43

8.1 Mounting of sensor .................................................................................................................. 43

8.1 (1) Mounting procedure of sensor ..................................................................................... 43

8.1 (2) Selection of mounting place ........................................................................................ 44

8.1 (3) Selection of mounting method..................................................................................... 45

8.1 (4) Processing of sensor mounting surface ....................................................................... 45

8.1 (5) Determination of mounting position (with Z method for large and small types)........ 46

8.1 (6) Cable end treatment ..................................................................................................... 47

8.1 (7) Connection of cable to small type sensor .................................................................... 48

8.1 (8) Mounting of small type sensor on pipe ....................................................................... 49

8.1 (9) Assembling procedure of the sensor............................................................................ 51

8.1 (10) Connection of cable to large type sensor..................................................................... 52

8.1 (11) Mounting of large type sensor on pipe ........................................................................ 53

8.1 (12) Mounting of high temperature sensor on pipe............................................................. 54

APPENDIX 1. SPECIFICATIONS.......................................................................................... A-1

APPENDIX 2. HOW TO MAKE GAUGE PAPER ................................................................ B-1

APPENDIX 3. COMPOSITION OF KEY OPERATION ....................................................... C-1

APPENDIX 4. PIPING DATA ................................................................................................D-1

v

Page 7

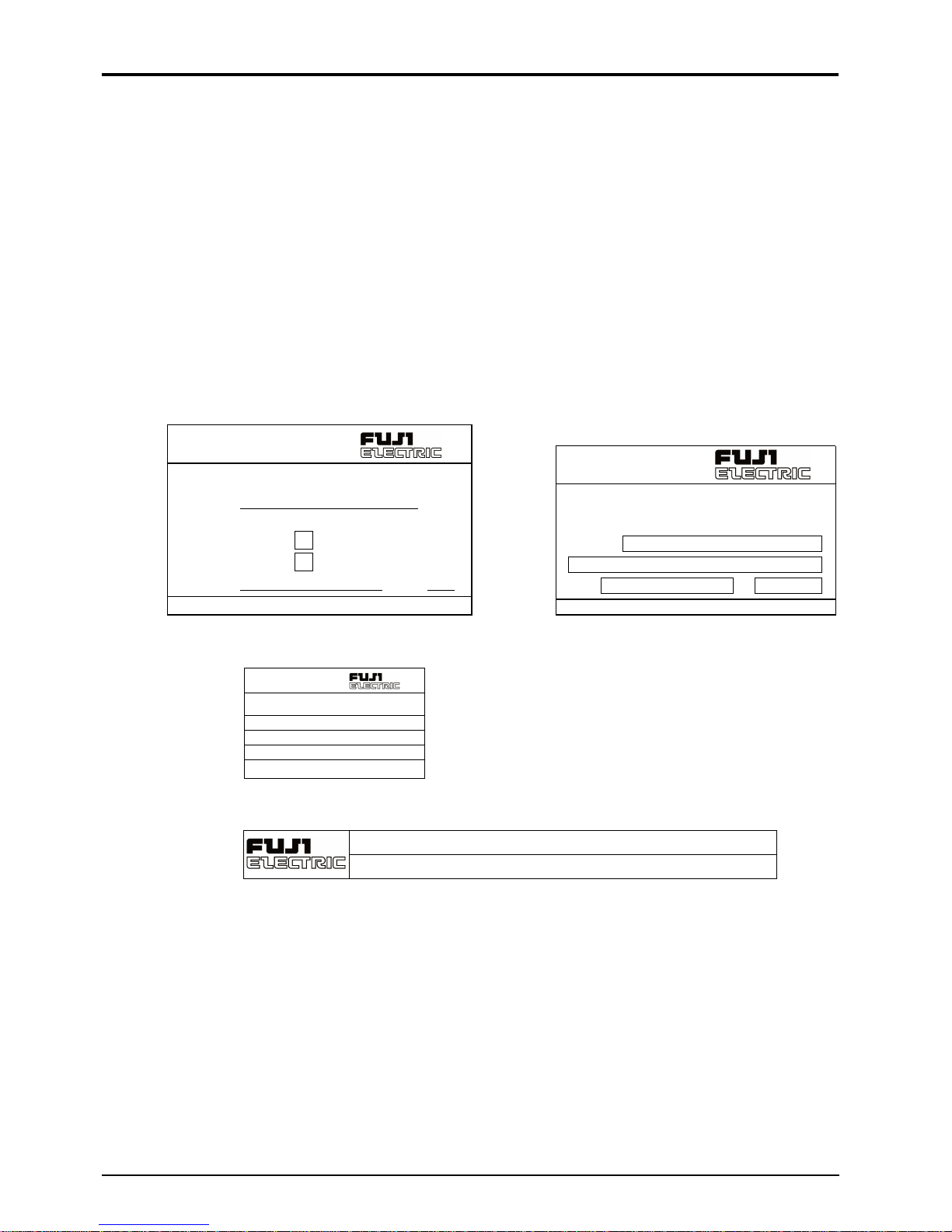

1. OPERATING PARTS AND THEIR FUNCTIONS

The names and funcitons of parts of the converter are as follows.

Names of parts of converter

2

ULTRASONIC FLOW METER

PIPE

OUTPUT DAMP ZERO

7890

FLOW SW

6

TR-out1

TR-out2

I-out

2345

Green

DOWN STRUP STR

6 7

10

Confirm converter power specifications

GND8HF9GND

SH SH

Green

before connecting.

HF

Black

AC100–240V

White

White

Black

To Downstream SensorTo Upstream Sensor

DC20–30V

1

1

23

23

LN

Analog Output

1

Total or Status Output

(Transister)

TOTAL CUT OFF DISP

456

STATUS

CAL SYSTEM CHECK

123

FUNK

54

ESC

ENTER

3

1

Item Description

1

Wiring port Wiring port for power cable and signal cable

2

Data indicator Liquid crystal indicator for measurement data and set values

3

Key board Used for setting the conditions of adjustments and measurements.

4

Main board terminal block Used for connecting signal cables from sensor.

Used for connection of signal cables for analog output and status output.

5

Power terminal block Used for connecting power cable.

6

Parameter table Used for entering setting data.

1

Page 8

2. MOUNTING OF CONVERTER

2.1 Selection of mounting place

Install the converter at a place satisfying the following conditions.

1. Ambient temperature does not

exceed a range of +14°F to +140°F.

When installing outdoors, attach a

shade or put the converter in an

outdoor panel to protect it from

direct sunlight.

2. Not exposed to moisture.

Even an immersion-proof type is

not protected against entry of water.

Make arrangements so that water

can be drained quickly.

3. Not exposed to dust or corrosive gases.

4. Free from vibrations and shocks.

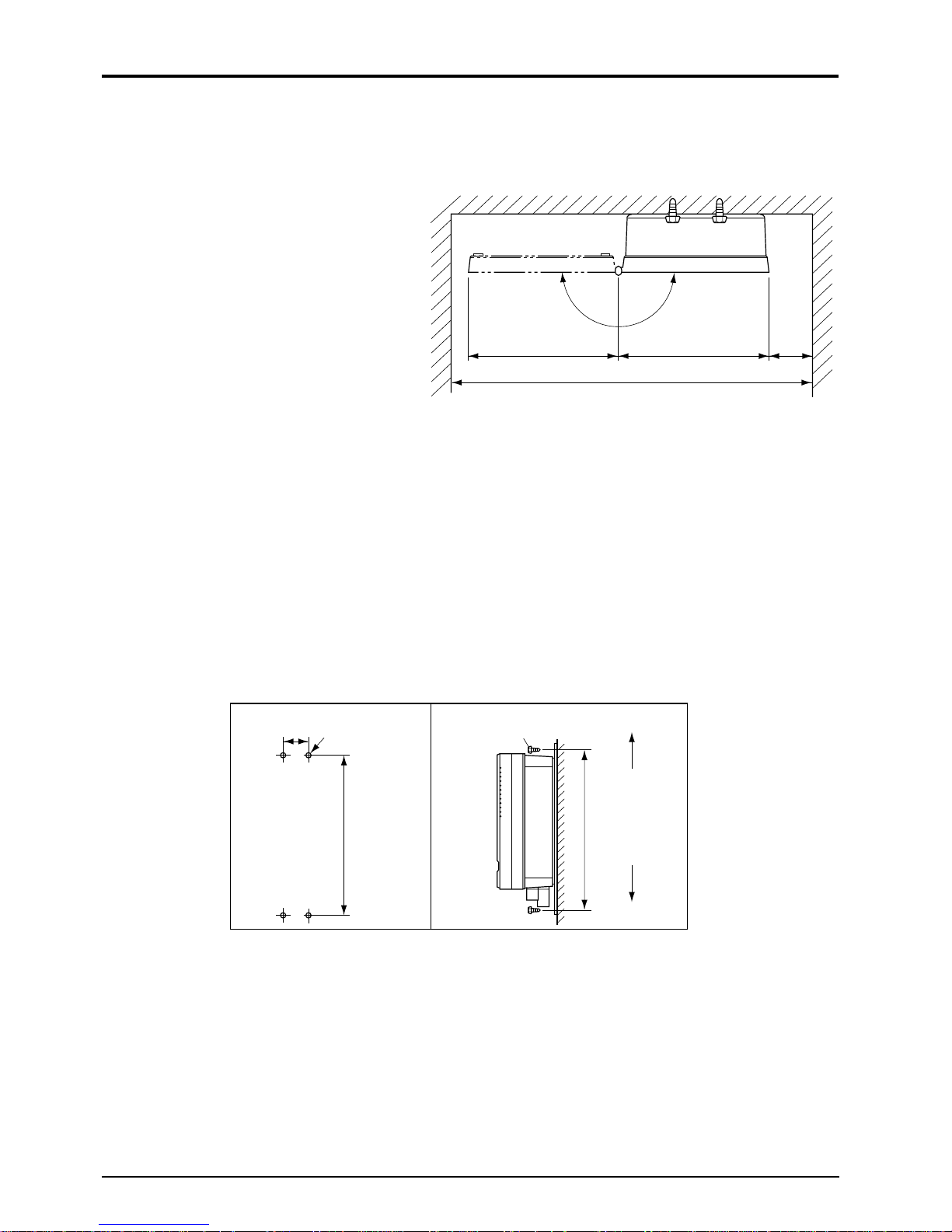

5. Space shown in Fig.2-1 is available for easy inspection and adjustment.

9.45" 9.45"

Fig. 2-1 Installation space (top view)

O

23" or more

N

E

P

4"

or more

2.2 Mounting method

Wall mounting or 2B bypass stand mounting is available for the converter.

For wall mounting, use 4-M8 bolts.

Be sure to mount the converter at correct position as shown in Fig. 2-2.

Make a hole in the wall or the like according to the cutout dimensions shown in the diagram below,

and mount the converter with M8 bolts.

312

12.28"

Top

Bottom

2.83"

4-M8

312

12.28"

Fig. 2-2 Mounting method

M8 bolt

In case of 2B pipe standing type, use U bolts (M8) on the market.

2

Page 9

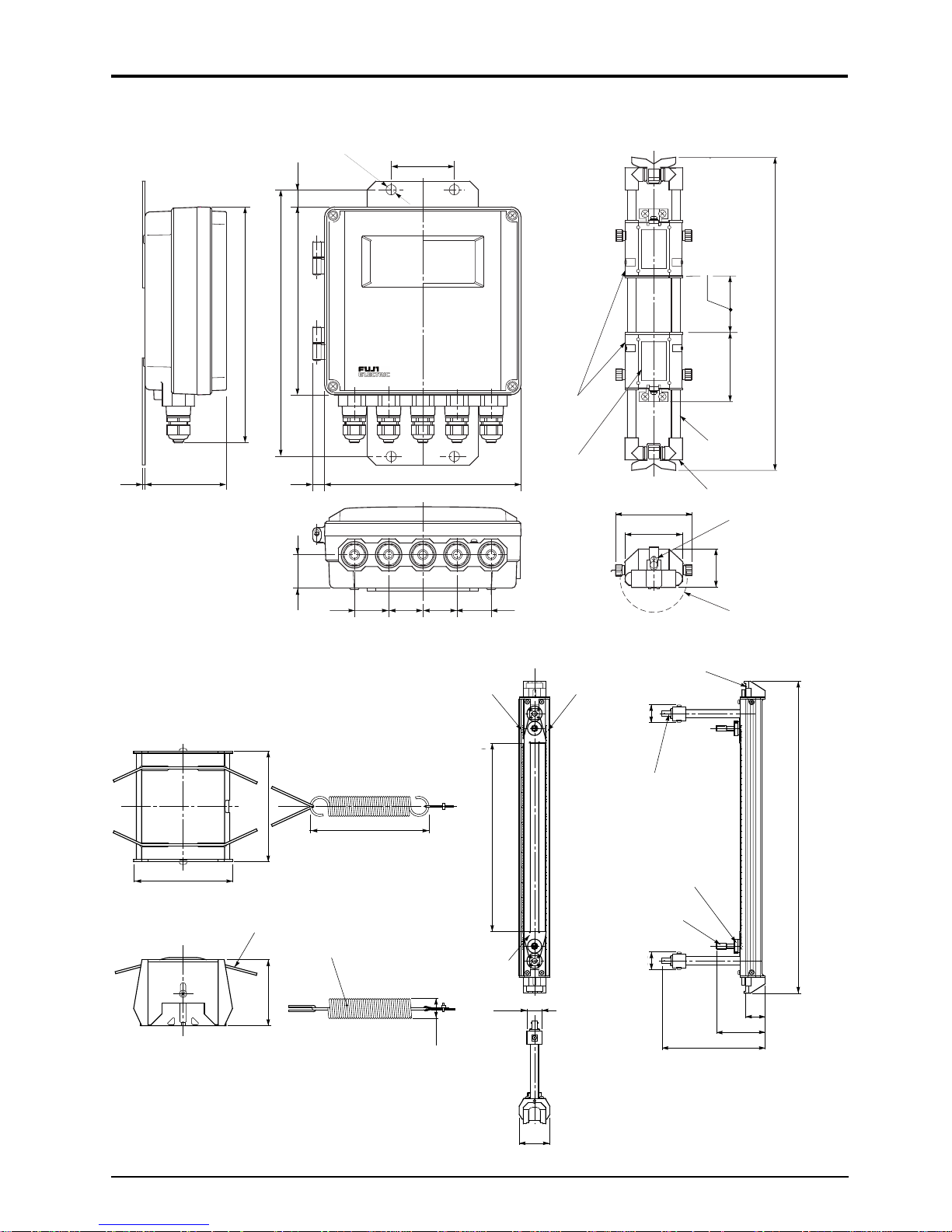

2.3 Outline diagram (unit: in.)

.08-ø.35"

.79"

8.66"

12.28"

10.91"

1/8" 3.75"

.55"

2.83"

9.06"

Sensor

Name plate

3.15"

2.36"

(50A to 250A)

Mounting Dimensions

(0 to 9.85)

Mounting dimensions

(0 to 250)

510

20.08"

72

2.83"

Pipe

Frame end

Ground terminal

3.66"

Sensor unit

1.54"

Converter FLV

104

4.09"

Wire rope

Mounting spring

62

2.44"

1.57" 1.57" 1.57" 1.57"

Scale (inch)

4.49"

Cursor

ø.75"

Sensor FLW1 (small type sensor)

Scale (mm)

Mounting dimensions 0 to 13.0"

Mounting dimensions 0 to 330

ø1.02"

Element holder

1.57"

Saddle

BNC connector

Locking unit

33 33

1.3"

8.07"

Chain & spring

20.87"

1.3"

3.54"

530

Sensor FLW5 (large type sensor)

Sensor FLD32 (high temperature sensor)

2"

3

Page 10

3. WIRING OF THE CONVERTER

3.1 Before wiring

1. For signal cable between the sensor and converter, use double-shielded coaxial cables specified

by Fuji Electric. The coaxial cable should be refrained from connecting midway.

2. The signal cable between the sensor and converter should be run in metalic conduits.

To prevent the effects of induction noise, upstream and downstream signal cables should be wired as

far away from power cable as possible.

3. An output signal cable should use shielded cable as much as possible.

4. To prevent the effects of noise, do not install signal cables together with power cable in the same

duct.

5. A power cable is provided with earth wire, it should be connected to the ground.

6. As this instrument is not equipped with a power switch, be sure to mount a power switch on the

instrument.

7. Wiring ports should be closed when they are not ready to use.

3.2 Wiring

Use the following cables:

• Power cable: 3 or 2 core cabtyre cable,

2

Nominal sectional area : 0.30 in.

Finished outside diameter : ø.43 in.

• Output signal cable: 2 core cable or multi-core cabtyre cable as needed.

Finished outside diameter : ø.43 in.

• Cable between sensor and converter:

Signal cable specified by Code Symbols

(High frequency coaxial cable with characteristic impedance of 50W)

Finished outside diameter : ø.29 in.

or more,

3.3 Treatment of the wiring port

The converter is an immersion-proof type specified by JIS C0920 “Rules for water-proof tests of

electromechanical instruments and wiring materials“. However, if the converter is to be installed in

a pit, air tightness treatment should be provided for the wiring port to prevent possible entry of

moisture, dew condensation or immersion of water.

Waterproof measures should be taken by using waterproof gland or plica tube gland furnished with

this instrument. A gland, which is not ready to be used, should be sealed by supplied cover.

4

Page 11

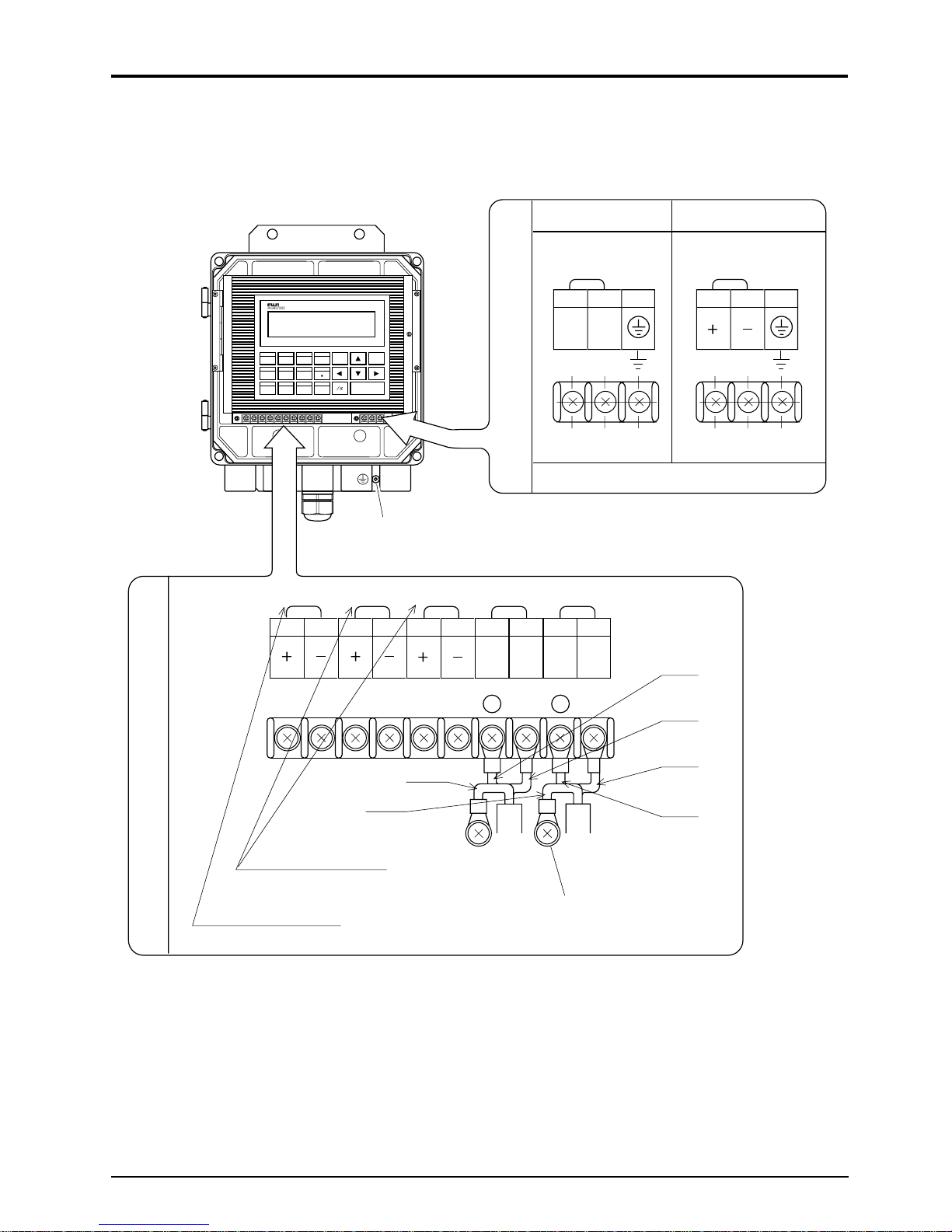

3.4 Wiring to terminals

Cables should be connected as shown in the following diagrams.

ULTRASONIC FLOW METER

PIPE

OUTPUT DAMP ZERO

7890

FLOW SW

TOTAL CUT OFF DISP

456

STATUS

CAL SYSTEM CHECK

123

FUNK

ESC

ENTER

(Note 1) Case grounding terminal

I-out

TR-out TR-out2

1 23456 7

AC power

AC power terminal

1AC23

LN

Power board terminal block

100 to 240V AC

M4 screw

DOW STRUP STR

10

GND8HF9GND

HF

SH SH

DC power

DC power terminal

1DC23

20 to 30V DC

M4 screw(Note 1)

Black

White

Main board teminal block

Total/status output

(transister contact)

Analog output signal

Note 1) Power board terminal block (for power) and case grounding terminals are available for

grounding terminals.

Be sure to earth either of them. (Class D, wiring)

Green

Green

White

Black

To sensor on

the up stream side

To sensor on the

down stream side

5

Page 12

4. OPERATION AND WORKS

4.1 Before operation

Check the following before starting operation.

1. Power

Power check See Item 4.2 (1)

2. Wiring

1) Check of main board terminal block

2) Check of power board terminal block See Item 3.4

3) Check of grounding terminal

3. Piping

1) Check that a piping is filled with fluid.

2) Check that there is no problem when water stops or flows.

}

6

Page 13

4.2 Power ON and status

1. Power specification

1) AC power

Use power supply of 100 to 240VAC ±10% (50/60 Hz).

2) DC power

A power of 20V to 30V DC is available.

2. Power ON

When the instrument is turned on, the following data are displayed on the LCD after making a

self-check of the devices.

The numerical values and symbols being displayed are as described below:

FLV-2SYSTEM

Ver FL.V2

BACK PU MEMO YR

LO DI NGA

Stab l iityWit!a

Measuring screen

000.0m/ Rs

.0000m/s3

Flow display (See Item 5.4 (7))

Flow direction

If the upstream and downstream sensors are connected reversely,

a symbol "—" appears on the LCD.

Load parameters and data from

non-volatile memory

Preparation to be taken until the measuring

conditions are met.

Display of integration, flow velocity and range %

(See Item 5.4 (7))

Status display (See Item 7.1. (1))

7

Page 14

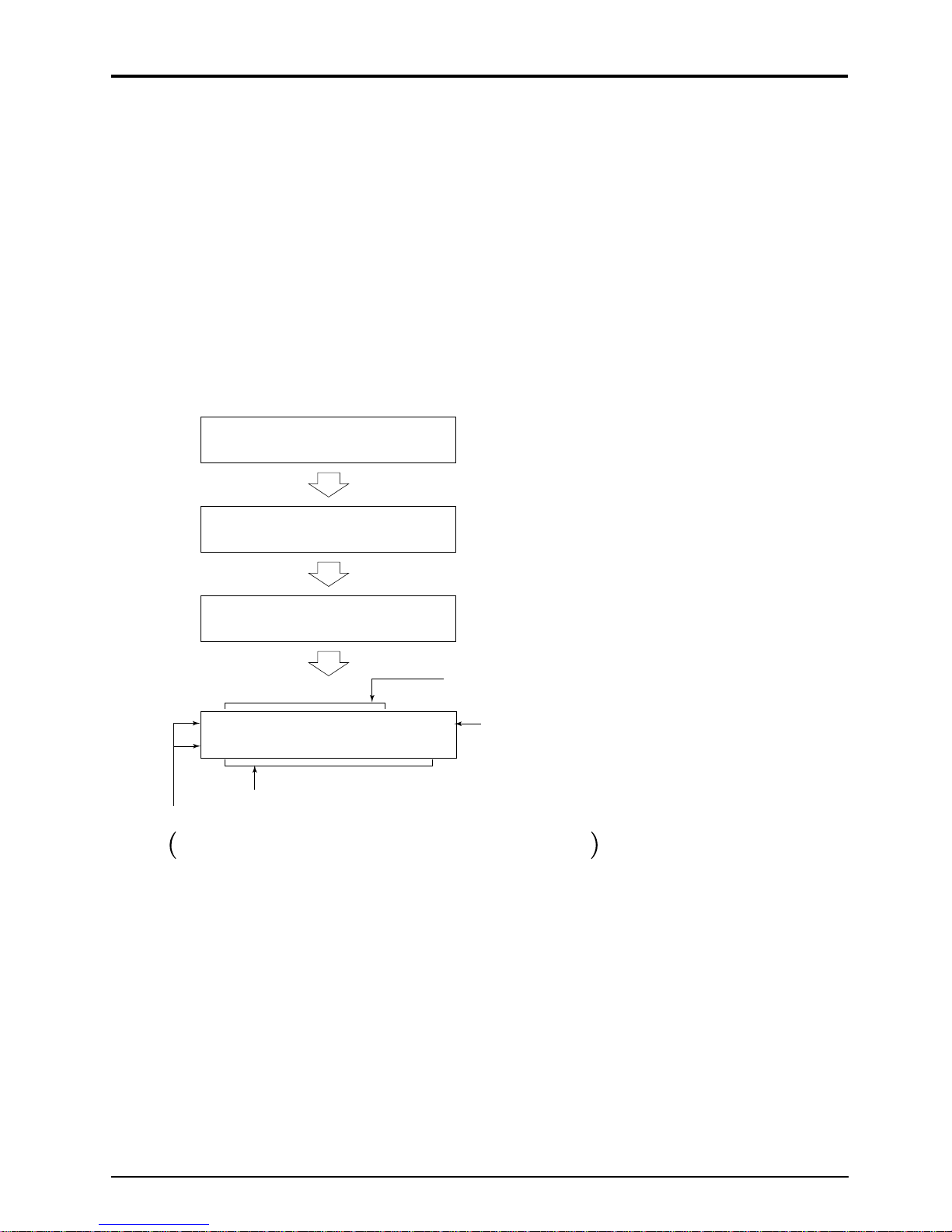

5. SETTING OF PARAMETERS

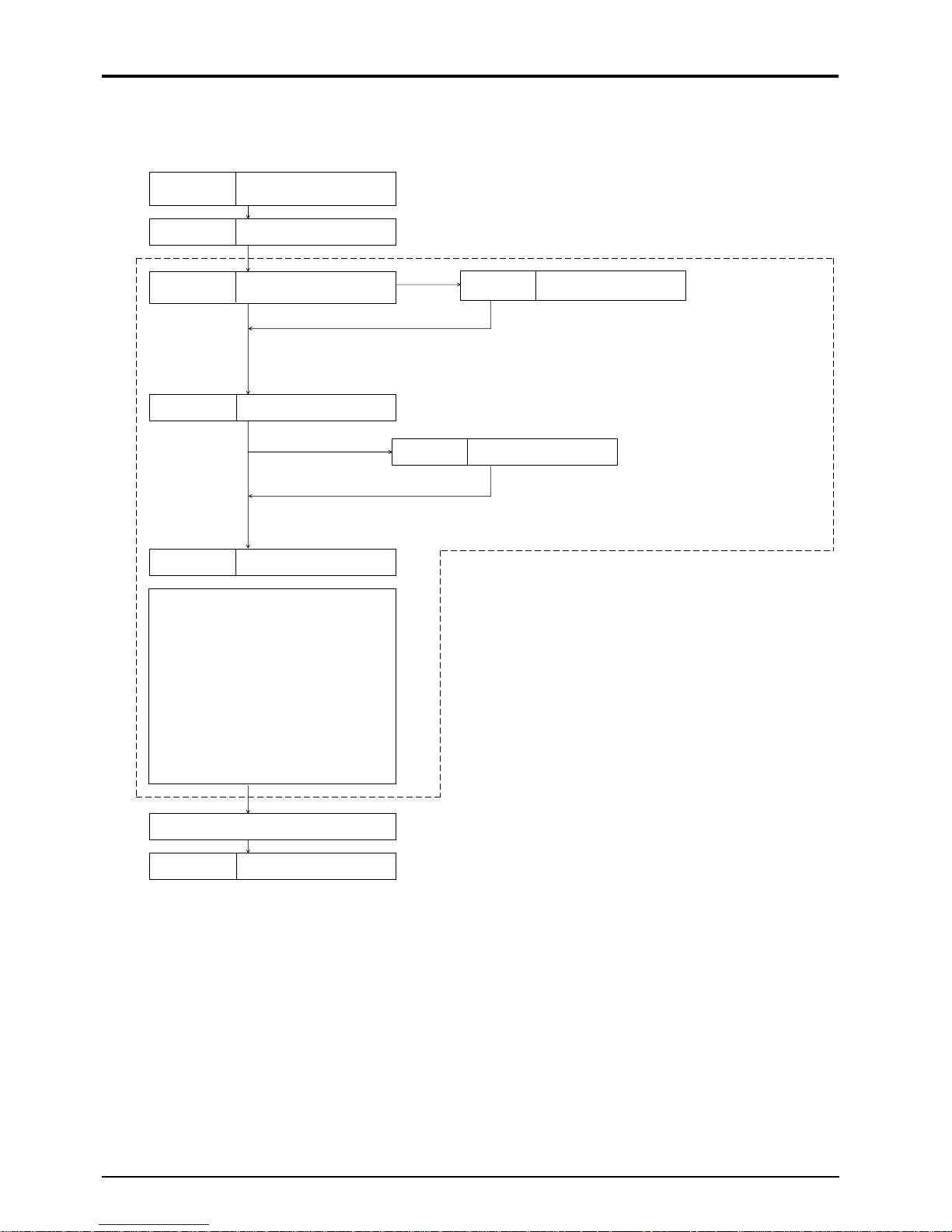

5.1 Outline of operating procedures

Proceed to the following procedure before starting measurements.

Chapter 3

Chapter 4 Power ON

5.4 (1)

Chapter 8 Installation of sensor

5.4 (6)

Output specification setting

System setting

Integration specification setting

Flow switch setting

Measuring display specification setting

Damping setting

Low flow cut setting

Output compensation setting

Status output setting

Installation and wiring

of converter

Check of piping

specification

OK

Measurement error

Measurement OK

Zero adjustment

NG

5.4 (1)

Chapter 7 Troubleshooting

Input of piping

specification

Measurement

Chapter 6 Maintenance and check

8

Page 15

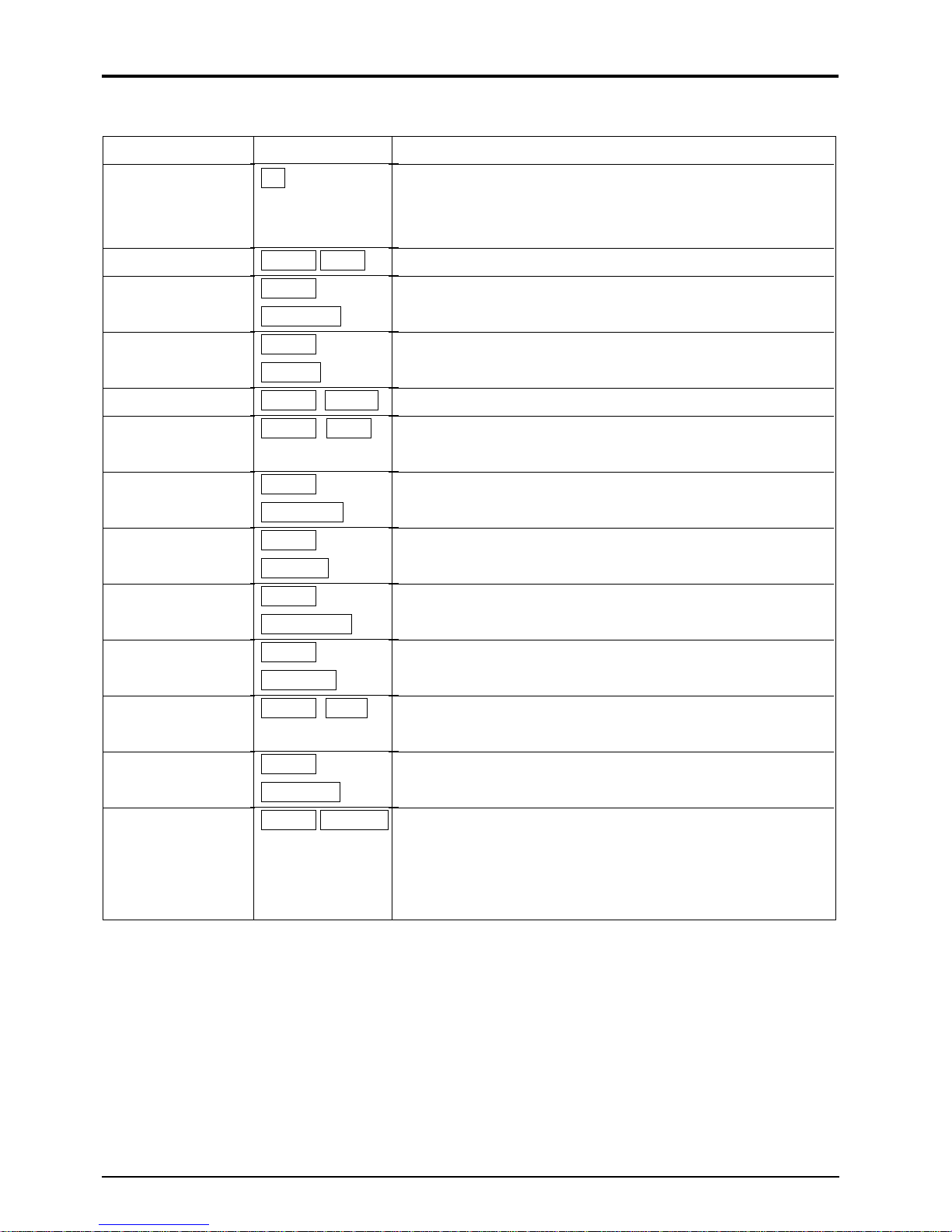

5.2 Description of key operation

Note) When adjustment is performed or setting is changed in this Chapter, be sure to enter

parameters in the list attached to the converter.

Pressing the FUNC key enables you to perform the functions shown on the upper side of the

ten-keys.

ULTRASONIC FLOW METER

PIPE

OUTPUT DAMP ZERO

7890

FLOW SW

STATUS

TOTAL CUT OFF DISP

456

CAL SYSTEM CHECK

123

Description of key (1/2)

FUNC

ESC

ENTER

Name

Ten-keys

ENTER

,

,

ESCAPE (Stop)

Key display

0 to 9 , • , ±

ENTER

,

,

ESC

Description

To enter data and numeric values of piping specifications.

By pressing this key, numeric data and selected interactive items are set. In the interactive mode, questions are

displayed.

To move the cursor to correct numeric values.

Pressing the

key allows the cursor to be moved the

left.

Pressing the key allows the cursor to be moved the

right.

Select the menu item display in an interactive message.

Pressing the

key allows the menu page to advance.

Pressing the key allows the menu page return.

To stop interactive operation.

FUNC. (Function)

FUNC

To perform the function inscribed on each ten-key.

9

Page 16

Description of key (2/2)

Name

/pi

PIPE (Pipe)

OUTPUT

(Analog output)

DAMPING

(Damping)

ZERO (Zero)

DISPLAY

(Display panel)

CUT OFF

(Low flow cut)

TOTAL

(Integration)

FLOW SW

Key display

/pi

FUNC PIPE

FUNC

OUTPUT

FUNC

DAMP

FUNC ZERO

FUNC DISP

FUNC

CUT OFF

FUNC

TOTAL

FUNC

Description

By pressing this key, the circumstance of pipe, which has

been entered, is converted into the outside diameter.

(valid only when setting the outside diameter of pipe)

To enter the size and material of the sensor piping.

To set the condition of an analog output

(units, range, limit, burn-out)

To set the damping.

To use when zero adjustment is performed.

Keys used to change items or unit system on the measurement display screen.

To set the low flow cut.

To set condition required for integration of flow rate.

(units, constant, preset value, integral switch, pulse width)

To set the measured high/low value switch

(Flow switch)

STATUS

(Status)

CAL.

(Calibration)

SYSTEM

(System)

CHECK (Check)

FLOW SW

FUNC

STATUS

FUNC CAL

FUNC

SYSTEM

FUNC CHECK

To set condition of status output (integration pulse, measuring status)

To compensate indication values of zero point and 100%

point. (Current output is effected)

To switch the measuring unit system and language, or

confirm or calibrate analog output.

To display an error message and countermeasures when

an error appears.

(An error message is displayed on the upper-right of the

LCD.)

10

Page 17

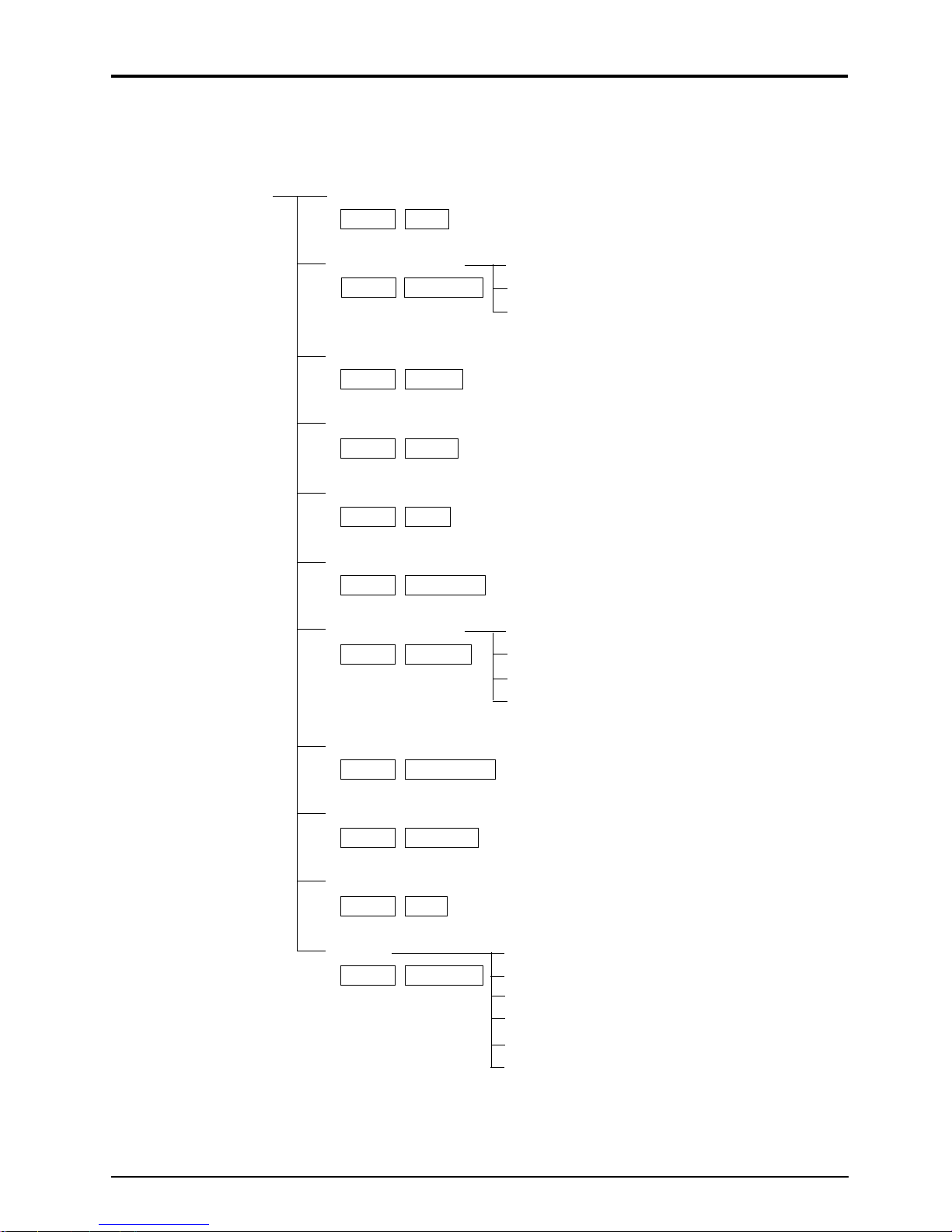

5.3 List of setting items

Measurement screen Piping specifications-----------------------------------See Item 5.4 (1)

( FUNC PIPE )

Setting of output Range------------------------See Item 5.4 (2)

( FUNC OUTPUT ) Output limit-----------------See Item 5.4 (3)

Burn-out--------------------- See Item 5.4 (4)

Damping-------------------------------------------------See Item 5.4 (5)

( FUNC DAMP )

Zero adjustment ----------------------------------------See Item 5.4 (6)

( FUNC ZERO )

Display setting------------------------------------------See Item 5.4 (7)

( FUNC DISP )

Low flow cut--------------------------------------------See Item 5.4 (8)

( FUNC CUT OFF )

Integration

Integration unit and constant -----

See Item 5.4 (9)

( FUNC TOTAL ) Integral preset -------------- See Item 5.4 (10)

Integral switch -------------See Item 5.4 (11)

Integral pulse width -------See Item 5.4 (12)

Flow switch ---------------------------------------------See Item 5.4 (13)

( FUNC FLOW SW )

Status output --------------------------------------------See Item 5.4 (14)

( FUNC STATUS )

Output compensation ----------------------------------See Item 5.4 (15)

( FUNC CAL )

System Measuring unit ------------ See Item 5.4 (16)

( FUNC SYSTEM ) Switch of language ------- See Item 5.4 (17)

Confirmation analog outpu

Analog output calibration -----

t---

See Item 5.4 (18)

See Item 5.4 (19)

Status output check ------- See Item 5.4 (20)

Test mode ------------------ See Iitem 5.4 (21)

11

Page 18

5.4 Setting of parameters

• Units are displayed in metric system.

5.4 (1) Setting of piping specifications

Description

Set the data of pipe required for measurement. The mounting dimension of the sensor is

automatically calculated. Data of each item should be entered according to the display.

Item

Outside diameter of pipe

Material of pipe

Numeric value

Selectable

Entry

Range or menu

2 in. to 236 in.

CARBON STEEL, STAINLESS STEEL, PVC,

COPPER, CAST IRON, ALUMINUM, FRP, ASBESTOS, DUCTILE IRON, PEEK, PVDF, ACRYLIC,

OTHERS*1

Pipe wall thickness

Lining (with/without)

and material

Type of fluid

Dynamic viscosity

Numeric value

Selectable

Selectable

Numeric value

0.0039 in. to 3.937 in.

NO LINING, TAR EPOXY, MORTAR, RUBBER,

TEFLON, PYREX GLASS, OTHERS *1

WATER, SEAWATER, OTHERS *1

-

0.001E

19.68 ft.2/s to 999.999E-19.68 ft.2/s *2

coefficient of fluid

Mounting method of

Selectable

V METHOD, Z METHOD

sensor

Type of sensor

Transmission voltage of

Selectable

Selectable

FLW12, FLW41, FLW50

1 TIME, 2 TIME, 4 TIME, 8 TIME

sensor

*1) Selection of “OTHERS”

Materials of piping and lining should be selected within the range of 3281 to 12,139 ft./sec.

of sound velocity and 1640 to 8202 ft./sec. of flow velocity (see Appendix).

*2) Dynamic viscosity coefficient is expressed in water (68°F: 1.004E

When more accurate data need be obtained or fluid other than water is selected, enter an

appropriate data as needed from Appendix.

-

19.68 ft.2/s)

12

Page 19

Operation (example) Outside diameter:114.3mm, pipe material:carbon steel, thickness:4.5mm,

lining material:mortar, thickness:1.25mm, fluid:heavy water, sound velocity:

1388m/s, dynamic viscosity coefficient: 1.129 x 10

method:V method, type: FLW12, Transmission voltage:8 times

-6m2

/s, sensor mounting

Key operation

FUNC PIPE

or

1 1 4 . 3 , ENTER

or , ENTER

4 . 5 , ENTER

or , ENTER

1 . 2 5 , ENTER

or , ENTER

Description

The sensor mounting dimension is

displayed.

Select “OUTER DIAMETER”.

Enter “114.3” with ten keys.

Select “CARBON STEEL”.

Enter “4.5” with ten keys.

Select :MORTAR”.

Enter “1.25” with ten keys.

Select “OTHERS”.

Display

SENSOR SPACING

0.00 mm V

OUTER DIAMETER

3mm

114.

PIPE MATERIAL

CARBON STEEL

WALL THICKNESS

5mm

4.

LINING MATERIAL

MORTAR

LINING THICKNESS

5mm

1.2

KIND OF FLUID

OTHERS

1

3 8 8 , ENTER

1 . 1 2 9 , ENTER

or , ENTER

or , ENTER

Note 3

or , ENTER

ESC ESC

Enter “1388” with ten keys.

Enter “1.129” with ten keys.

Select “V METHOD”.

Select “FLW12”.

SELECT “8 TIME”.

The sonsor mounting dimension is

displayed.

Press the key twice.

FLUID S.V.

8 m/s

138

VISCOSITY

1.129E – 6 m2/s

SENSOR MOUNTING

V METHOD

SENSOR TYPE

FLW12

TRANS. VOLTAGE

8 TIME

SENSOR SPACING

80.56 mm V

(Measurement display)

Note 3) When selecting the transmission voltage, generally choose “4 TIME”.

13

Page 20

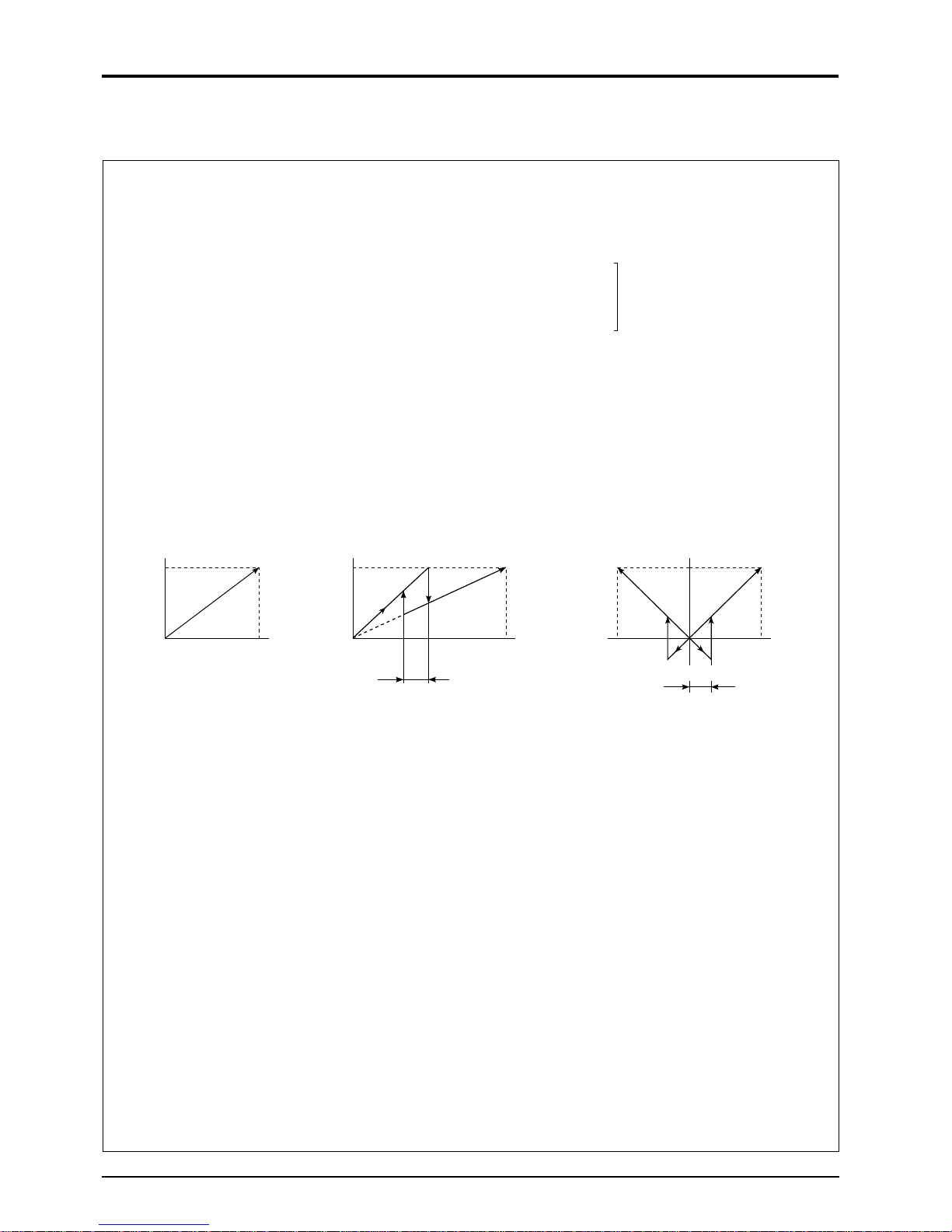

5.4 (2) Setting of analog output range

Description

An analog output range is set to provide an output of 4 to 20mA in the specified range of

measured values (flow rate or flow velocity).

[Measurement items]

1. Selection of range unit ............ m/s

Note 1)

l/s, l/m l/h, Ml/d

3

/s, m3/m, m3/h, Mm3/d

m

BBL/s, BBL/m, BBL/h, MBBL/d

2. Selection of range type

• SINGLE RANGE: Single range

• AUTO 2 RANGES: Auto 2 ranges

• BI-DIR RANGE: Auto forward/reverse range

Choose any of

the unit: METRIC system

Single range

Analog output

20mA

4mA

BASE

SCALE

FULL

SCALE

3. Setting of range

• BASE SCALE: Set flow rate value or flow velocity value for 4mA output.

• FULL SCALE: Set flow rate value or flow velocity value for 20mA output.

4. Setting of hysteresis

When selecting “AUTO 2 RANGES” or “BI-DIR.RANGE” from the type of range,

hysteresis is selectable.

Set the hysteresis within the range of 0 to 20% of full scale.

• In case of auto 2-range: Hysteresis of span size of full-scale 1 or full-scale 2, whichever

• In case of forward/reverse range: Hysteresis of span in action range

Note 1) Flow units of low flow cut, flow switch and output compensation flow units

Analog output

20mA

Flow rate

4mA

BASE

SCALE

Auto 2 range

FULL

SCALE1

Hysteresis setting

Flow rate

FULL

SCALE2

Auto range, forward/reverse range

Analog output

20mA

4mA

FULL

SCALE2

BASE SCALE

Flow velocity value should be set within the range of 0 to ±32m/s.

Flow velocity value should be set within the range of ±0.3 to ±32m/s.

is smaller

are changed with the selection of the range unit.

FULL

SCALE1

Hysteresis setting

14

Page 21

Operation (example) When setting the base scale to 0m3/h, full scale 1 to 100m3/h, full scale 2 to –

100m3/h and hysteresis to 5% in the forward/reverse range.

Key operation

FUNC OUTPUT

or , ENTER

or , ENTER

0 , ENTER

1 0 0 , ENTER

± 1 0 0 , ENTER

5 , ENTER

Description

Select “m3/h”.

Select “Forward/reverse range”.

Enter “0” with ten keys.

Enter “100” with ten keys.

Enter “–100” with ten keys.

Enter “5” with ten keys.

Display

RANGE UNIT

RANGE TYPE

BI-DIR. RANGE

BASE SCALE

0 m3/h

FULL SCALE 1

0 m3/h

10

FULL SCALE 2

0 m3/h

–10

RANGE HYSTERESIS

5%

m3/h

ESC ESC

Press the key twice.

(Measurement display)

15

Page 22

5.4 (3) Setting of analog output limit

Description

Set the high/low limits within the range of analog output of 0.8 to 23.2mA (

-

20 to 120%).

Low limit

Analog output

23.2mA

20mA

4mA

-20%

0% 100% 120%

0.8mA

High limit

Flow rate

Operation (example) Low limit : -10% (2.4mA), high limit : 110% (21.6mA)

Key operation

Description

FUNC OUTPUT

or

± 1 0 , ENTER

1 1 0 , ENTER

Select “Output limitter”.

Enter “–10”with ten keys.

Enter “110” with ten keys.

OUTPUT LIMIT

LOW – 20 %

OUTPUT LIMIT

LOW – 1

OUTPUT LIMIT

HIGH 11

Display

0 %

0 %

ESC ESC

• In case of auto 2-range :

• In case of forward/reverse range :

Press the key twice.

(Measurement display)

Low limit is limited to the small range, and High limit is limited to the large range.

The low/high limits are limited to the range of action.

(100%)20mA

(0%) 4mA

Base

scale

Auto 2 range

Full

scale 1

High limit

Full

scale 2

16

Page 23

5.4 (4) Setting of burn-out

Description

When the pipe is empty of fluid or when air bubbles are contained in fluid, the flow rate can

not be measured correctly. In such a case, the analog output needs to be set to “HOLD”,

“HIGH” limit or “LOW” limit. A burnout timer is used to set the time needed for burnout.

(Setting items)

• HOLD : Measured value is held

• HIGH : 120%t output (23.2mA) is obtained.

-

• LOW :

• Zero : 0 % output (4.0mA) is obtained.

• NOT USED : Not used.

• Liquid crystal display : Measured value is held.

• Integrated pulse output : Output stops Note)

• Internal integration : Integration stops Note)

Note) Integrated pulse output and internal integration is integrated until the burnout timer is

energized.

20% output (0.8mA) is obtained.

Operation (example) When setting the burnout to the “LOW” limit and burnout timer to 15

seconds.

Key operation

Description

Display

FUNC OUTPUT

or

or , ENTER

1 5 , ENTER

ESC ESC

Select “Burn-out”.

Select “Low limit”.

Enter “15” with ten keys.

Press the key twice.

OUTPUT BURNOUT

NOT USED

OUTPUT BURNOUT

BURNOUT TIMER

(Measurement display)

LOWER

15 sec

17

Page 24

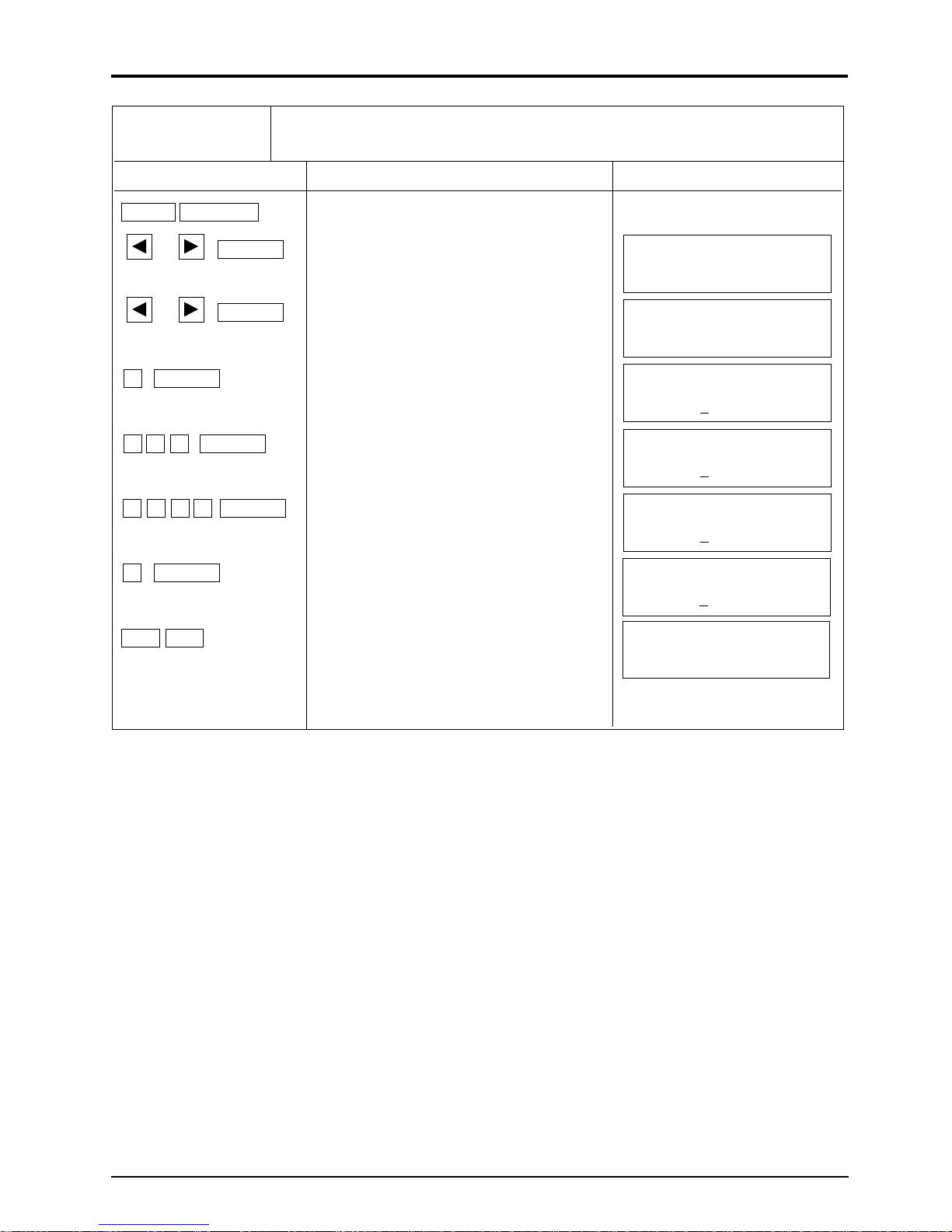

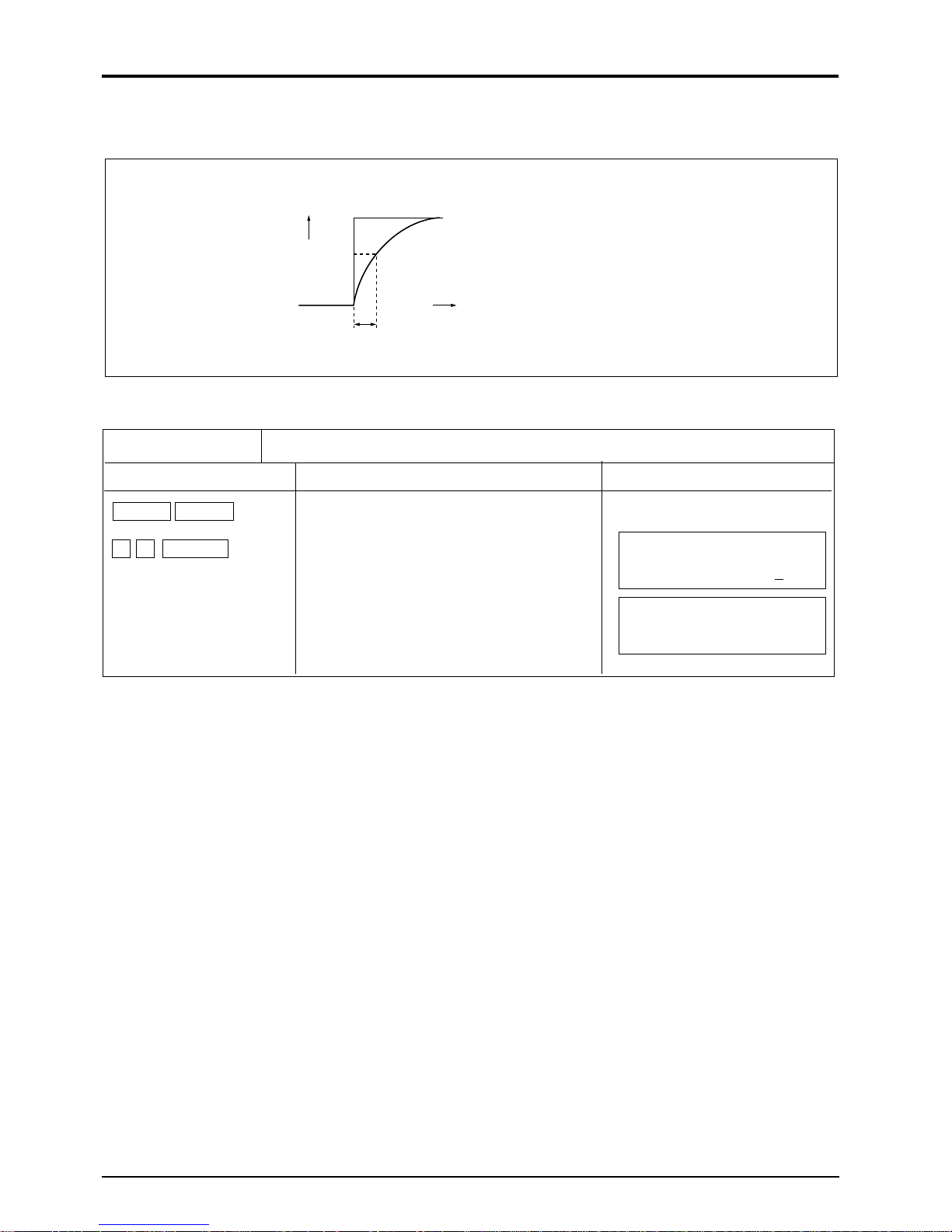

5.4 (5) Setting of damping

Description

Damping is used to suppress fluctuation of measured values.

The set value is a time constant (about 63% response time). (Setting range : 0 to 100 sec)

63%

Flow rate

Response time

Time

Unless otherwise specified in the order sheet, the setting time of damping is adjusted to 5 sec.

Operation (example) Change of set value to 20 sec.

Key operation

Description

FUNC DAMP

2 0 , ENTER

Enter “20” with ten keys.

DAMPING

(Measurement display)

Display

0 sec

2

18

Page 25

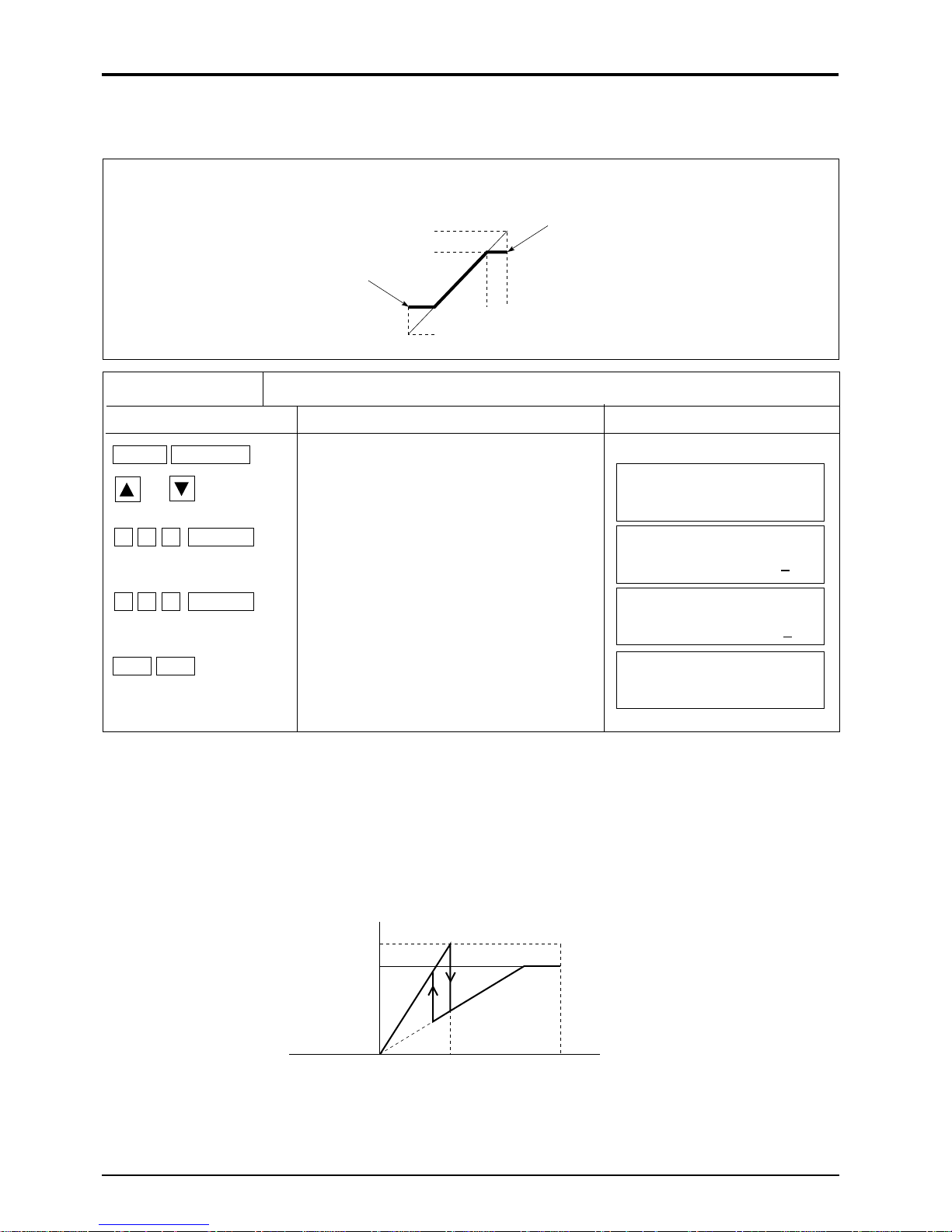

5.4 (6) Zero adjustment

Description

Zero point of measured value is adjusted.

(Setting items)

• ZERO POINT ADJUST : Stop the flow of fluid and adjust zero point.

The zero pont is the state of measurement at set point.

• ZERO POINT CLEAR : This setting is used when fluid will not stop flowing.

Adjusted zero point is cleared.

Operation (example) Zero point adjustment when fluid is in stop mode.

Key operation

Description

FUNC ZERO

Display

or , ENTER

Select “Zero point adjustment”.

ZERO MODE

SET ZERO

(Measurement display)

19

Page 26

5.4 (7) Setting of measurement display specifications

Description

Select measured value from the following.

1. Setting of measurement display 1st line

Select any one from the following 7 types for the 1st line display.

F : TOTAL : Forward integral value

R : TOTAL : Reverse integral value

TOTAL DIFF : Forward/reverse difference between integral values

F : TOTAL PULSE : Forward integral pulse counter

R : TOTAL PULSE : Reverse integral pulse counter

FLOW VELOCITY : Instantaneous flow velocity [m/s]

RANGE % : Ratio of analog output to range

2. Setting of decimal measurement display on 2nd line

On the second display is instantaneous flow rate displayed.

Select one from the following 12 units of flow rate.

l/s, l/m l/h, Ml/d,

BBL/s, BBL/m, BBL/h, MBBL/d

3. Setting of decimal point position of instantaneous flow rate display

Setting of digit display after the decimal point is available.

Select any one from the following.

Position of decimal point (digit) Range of data display

00000000. : -99999999. to 0. to 99999999.

0000000.0 : -9999999.9 to 0.0 to 9999999.9

000000.00 : -999999.99 to 0.00 to 999999.99

00000.000 : -99999.999 to 0.000 to 99999.999

0000.0000 : -9999.9999 to 0.0000 to 9999.9999

000.00000 : -999.99999 to 0.00000 to 999.99999

00.000000 : -99.999999 to 0.000000 to 99.999999

0.0000000 : -9.9999999 to 0.0000000 to 9.9999999

m3/s, m3/m, m3/h, Mm3/d

(metric system)

}

Display of integral value

1. Display of forward/reverse integral values

#

2. Display of forward/reverse difference between integral values

Difference of integrated value = forward integral value

Note : If any of integral values in the forward and reverse directions exceeds the over

flow mark, ####### is displayed.

Overflow mark

When the integral value exceeds the overflow mark.

Overflow times

0 to 9, # (exceeding 9)

Integral value

0 to 9999999

-

reverse integral value.

20

Page 27

Operation (example) Display instantaneous flow velocity and instantaneous flow unit in m3/h, and

instantanous flow rate in 3 digits after decimal point.

Key operation

Description

Display

FUNC DISP

or , ENTER

or , ENTER

or , ENTER

Select “Flow velocity”.

Select :m

Select “00000.000”.

ESC ESC

5.4 (8) Low flow output cut

Description

A low flow output can be cut.

This flowmeter will display the flow rate, when the fluid in the piping is moving with the

valve closed due to a convection current. The cutting point should be set as needed.

(Setting range : 0 to 16.4 ft./s in terms of flow velocity value)

3

/h”.

1: DISPLAY KIND

VELOCITY

2: FLOW UNIT

m3/h

2: DECIMAL POINT

00000.000 m3/h

(Measurement display)

Outlet

Flow rate

Cutting set value

Operation (example) Setting of cutting point to 0.05m/s.

Key operation

Description

FUNC CUT OFF

0 . 0 5 , ENTER

Enter “0.05” with ten keys.

Display

CUT OFF

0.05 m/s

(Measurement display)

21

Page 28

5.4 (9) Setting of integrated output unit and constant

Description

Integrated output unit is set to integrate measurement value (flow rate)

Just after setting of measured value is completed, the pulse counter begins integration by

clearing the previous integrated value.

1. Integrated unit.………Select one of the following 8 kinds of integral units.

m3, km3, Mm3, mBBL, BBL, kBBL (metric system)

ml, l,

Note : When changing the integrated unit, integral constant value and integral preset

value are cleared.

2. Integral constant

When the flow rate reaches the value set by the integral constant, integral pulse value is

displayed on the measurement screen, and the integral pulse counter provides an output of 1

pulse.

Setting range : 0 to 9999999

Operation (example) Integrated output of 100m

Key operation

Description

FUNC TOTAL

or , ENTER

or , ENTER

1 0 0 , ENTER

ESC

or , ENTER

ESC ESC

Display “TOTAL MODE”.

Select “m3”.

Enter “100” with ten keys.

Display “TOTAL MODE”.

Select “START”.

Press the key twice.

3

Display

TOTAL MODE

TOTAL STOP

TOTAL UNIT

m3

TOTAL RATE

0 m3

10

TOTAL MODE

TOTAL STOP

TOTAL MODE

TOTAL RUN

(Measurement display)

Integral mode

Stop: Integration is stopped.

Start: Integration is started (integral parameter can not be changed at a time of start).

Reset: Integral value is set to the integral preset value, and integration is stopped.

When the flowmeter is restored from power interruption, it will be operated in the integral mode that

was set before power interruption.

[Note : If measurement is abnormal, refer to burnout setting for integration.]

22

Page 29

5.4 (10) Setting of integral preset value

Description

Set integrated preset value

F: TOTAL PRESET: Forward integral preset value

R: TOTAL PRESET: Reverse integral preset value

Setting range: 0 to 9999999

Addition

Preset value

0

Time

Note: In case of setting, please keep “TOTAL MODE” suspended.

Operation (example) Forward direction : 1000m3, reverse direction : 2000m

Key operation

Description

FUNC TOTAL

or

1 0 0 0 , ENTER

ENTER

2 0 0 0 , ENTER

Select “F: TOTAL PRESET”.

Enter “1000” with ten keys.

Select “R: TOTAL PRESET”.

Enter “2000” with ten keys.

3

Display

F:TOTAL PRESET

F:TOTAL PRESET

R:TOTAL PRESET

R:TOTAL PRESET

100

200

0 m3

0 m3

0 m3

0 m3

ESC ESC

Press the key twice.

(Measurement display)

23

Page 30

5.4 (11) Setting of integration switch

Description

When an integral value exceeds the set value, the status output is provided.

F: TOTAL SW: Forward integration switch

R: TOTAL SW: Reverse integration switch

Setting range: 0 to 9999999

Note) When setting the status output, integration switch is valid only

when “F: TOTAL SW” or “R: TOTAL SW” is set.

Integration

Setting value

OFF

ON

Contact output

Note: In case of setting, please keep “TOTAL MODE” suspended.

Operation (example) Set value of forward integration switch :50000m

Key operation

Description

FUNC TOTAL

or

5 0 0 0 0 , ENTER

ESC ESC

Select “TOTAL SW”.

Enter “50000” with ten keys.

Press the key twice.

3

Display

F: TOTAL SW

F: TOTAL SW

(Measurement display)

5000

0 m3

0 m3

24

Page 31

5.4 (12) Selection of integral pulse output pulse width

Description

The following 2 types can be selected according to the counter connected.

When setting status output, set the pulse width to use “F:TOTAL” or “R:TOTAL”.

• 50msec

• 100msec

Note: In case of setting, please keep “TOTAL MODE” suspended.

Operation (example) Pulse width: 100msec.

Key operation

Description

FUNC TOTAL

Display

or

or , ENTER

Select “Pulse width”.

Select “100msec”.

PULSE WIDTH

50 msec

PULSE WIDTH

100 msec

(Measurement display)

25

Page 32

5.4 (13) Setting of measured value high and low limit switch

Description

1. Set high limit and low limit of switching point when using high limit flow or low limit flow

to set the status output.

Setting range : 0 to ±105 ft./s of flow velocity

[Relation between status output and set value]

• High limit setting and high limit flow • Low limit setting and low limit flow

–105 ft./s –105 ft./s

ON

0 ft./s 0 ft./s

OFF OFF

High limit

set value

105 ft./s

ON

Hysteresis

ON

OFF OFF

ON

Low limit

set value

2. Setting of hysteresis

Switching hysteresis can be held in the following range.

Set hysteresis within 0 to 20% of the analog output range full scale (with auto 2 range, and

forward and reverse auto range, effective for full scale 1 and 2, whichever small).

Operation (example) Low limit flow velocity: 3.5m/s, high limit flow velocity value: 12m/s,

hysteresis : 5%

Key operation

Description

Display

FUNC FLOW SW

3 . 5 , ENTER

Enter “3.5” with ten keys.

FLOW SW LOW

105 ft./s

Hysteresis

5 m/s

3.

1 2 , ENTER

5 , ENTER

Enter “12” with ten keys.

Enter “5” with ten keys.

26

FLOW SW HIGH

FLOW SW HYS.

(Measurement display)

2 m/s

1

5 %

Page 33

5.4 (14) Setting of status output

Description

• When the status of setting or integral pulse is outputted, the contents of output is set.

1. NOT USED : No output

2. SIGNAL ERROR : ON at abnormal measurement

3. F: TOTAL PULSE : Forward flow integral pulse

4. R: TOTAL PULSE : Reverse flow integral pulse

5. FLOW SW HIGH : ON when the flow rate is over the high limit set by flow switch.

6. FLOW SW LOW : ON when the flow rate is below the low low limit set by

7. F: TOTAL ALARM : ON when the flow rate is over the forward flow integration

8. R: TOTAL ALARM : ON when the flow rate is below the reverse flow integra-

9. F: TOTAL OVERFLOW : ON when the forward flow integral value overflows.

10. R: TOTAL OVERFLOW : ON when reverse flow integral value overflows.

11. FULL SCALE 2 : ON at FULL SCALE 2 RANGE in analog output range status.

12. R: FLOW DIRECTION : ON when the flow direction is reverse.

13. RANGE OVER : ON when the set value of the output span exceeds the range

14. BACK UP ABNORMAL : ON when the backup non-volatile memory is abnormal.

• Setting of status output pulse mode

Normal: effective when status output is ON.

Spot: effective when status output is OFF.

flow switch.

switch.

tion switch.

-

10 to 110%, or integral pulse output exceeds 5 pulse/

of

sec.

Operation (example) When setting the forward integral pulse and contact output in the normal

mode.

Key operation

FUNC STATUS

or , ENTER

or , ENTER

or , ENTER

ESC

Description

Select “CHANNEL 1”.

Select “F: TOTAL”.

Select “Normal”.

(Continued on next page)

27

Display

STATUS CHANEL

CHANNEL 1

STATUS SEL : CH1

F : TOTAL

STATUS MODE : CH1

NORMAL

Page 34

Operation (example) When setting the forward integral pulse and contact output in the normal mode.

Key operation

or , ENTER

or , ENTER

or , ENTER

ESC ESC

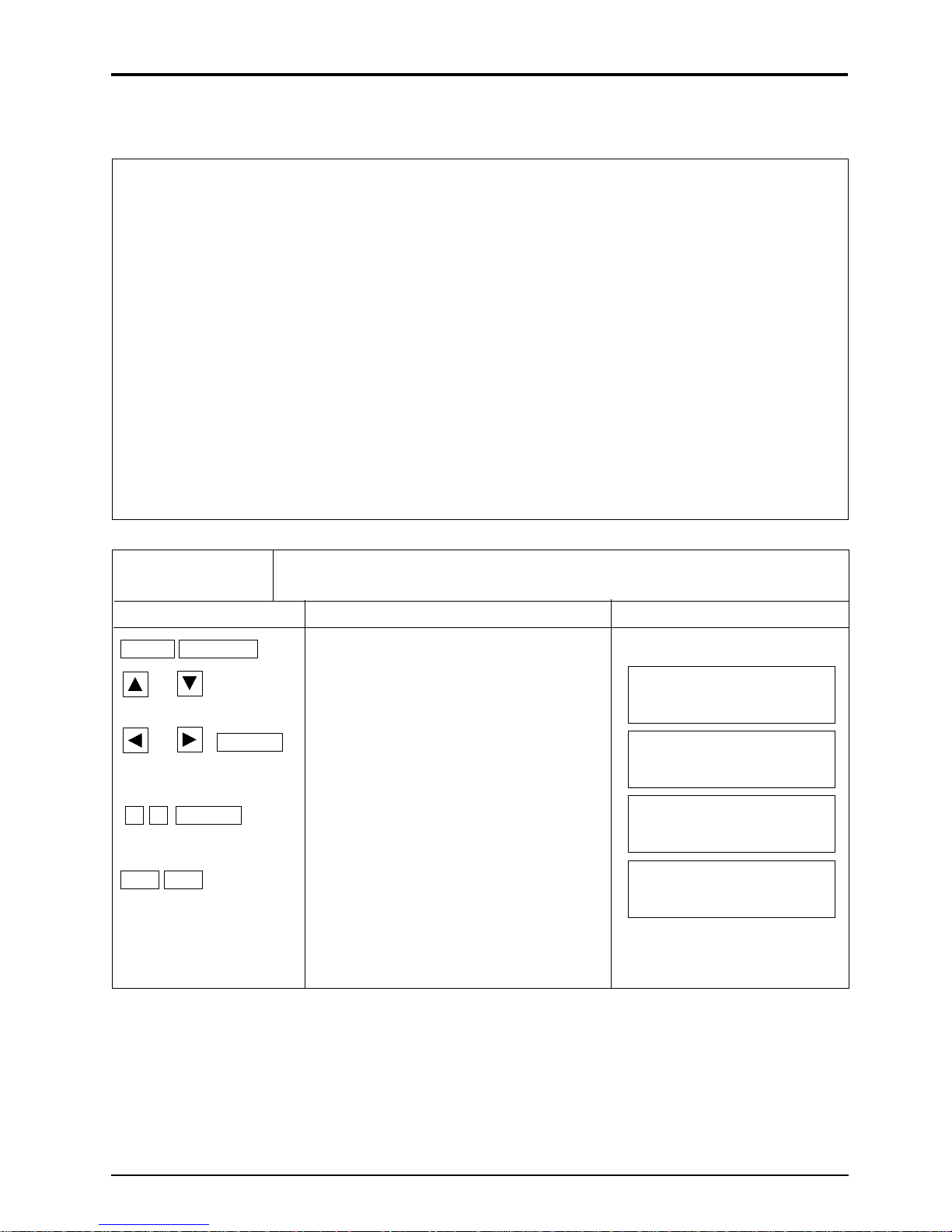

5.4 (15) Calibration of measured value

Description

Measured value (zero and span points) can be calibrated, if required.

Zero point and span point can be calibrated.

Calibration range: Zero point: ±16.4 ft./s of flow velocity

Measured value and analog output value are calculated by the following formula.

Output =

Select “CHANNEL 2”.

Select “F: TOTAL ALARM”.

Select “SPOT”.

Press the key twice.

Span: ±200%

Measured value ´ [span set value %]

Output

Description

100

Output

100%

Display

STATUS CHANEL

CHANNEL 2

STATUS SEL : CH2

F : TOTAL ALARM

STATUS MODE : CH2

SPOT

(Measurement display)

+ Zero point

0

Movement of zero point

Operation (example) Calibration of zero point to – 0.5m/s and span point 105%

Key operation

FUNC CAL

± 0 . 5 , ENTER

1 0 5 , ENTER

ESC ESC

Enter “– 0.5” with ten keys.

Enter “105” with ten keys.

Press the key twice.

Flow Flow

0

Movement of span

Description

CALIBRATION ZERO

CALIBRATION SPAN

28

Display

–0.

5 m/s

5%

10

(Measurement display)

Page 35

5.4 (16) Switch of measurement unit system

Description

Measurement units can be set in the two systems, metric system and inch system.

(Setting contents)

• Metric system

Pipe dimension ------------mm

Flow velocity unit---------m/s

Flow rate unit --------------

Integration unit ------------ml, l,

• English system

Pipe dimension ------------inch

Flow velocity unit---------ft/s

Flow rate unit --------------gal/s, gal/m, gal/h, gal/d

Integration unit ------------gal, kgal, ft

l/s, l/m l/h Ml/d

3

/s, m3/m, m3/h, Mm3/d

m

BBL/s, BBL/m, BBL/h, MBBL/d

m3, km3, Mm3, mBBL, BBL, kBBL

3

/s, ft3/m, ft3/h, Mft3/d

ft

BBL/s, BBL/m, BBL/h, MBBL/d

3

, kft3, Mft3, mBBL, BBL, kBBL

Operation (example) Change of measurement unit to inch system

Key operation

Description

FUNC SYSTEM

or , ENTER

ESC ESC

Select “Inch system”.

Press the key twice.

Display

SYSTEM OF UNITS

ENGLISH

(Measurement display)

29

Page 36

5.4 (17) Selection of language (English/Japanese)

Description

2 kinds of language, English and Japanese (Katakana) can be selected on this display, at the

time of setting.

Operation (example) Selection of English display

Key operation

FUNC SYSTEM

or

or , ENTER

ESC ESC

Description

Select “Language”.

Select “English”.

Press the key twice.

Display

LANGUAGE

JAPANESE

LANGUAGE

ENGLISH

(Measurement display)

30

Page 37

5.4 (18) Analog output check

Description

Check the analog output circuit.

Check to make sure that the output values at

Connect an ammeter to the Iout terminal as shown below.

-

20% to 120% are 0.8mA to 23.2mA.

Iout

1234

Operation (example) Check of analog output of 4mA, 8mA, 12mA, 16mA, 20mA

Key operation

TRout 1

Ammeter

Description

FUNC SYSTEM

or

0 , ENTER

Select “Analog output check”.

Enter “0” with ten keys.

OUTPUT CHECK

OUTPUT CHECK

[0% (4mA) check]

2 5 , ENTER

Enter “25” with ten keys.

OUTPUT CHECK

[25% (8mA) check]

Display

2

0 %

0 %

5 %

5 0 , ENTER

7 5 , ENTER

1 0 0 , ENTER

ESC ESC

Enter “50” with ten keys.

[50% (12mA) check]

Enter “75” with ten keys.

[75% (16mA) check]

Enter “100” with ten keys.

[100% (20mA) check]

Press the key twice.

OUTPUT CHECK

OUTPUT CHECK

OUTPUT CHECK

(Measurement display)

10

5

7

0 %

5 %

0 %

31

Page 38

5.4 (19) Analog output calibration

Description

The analog output circuit is calibrated so that the measured flow rate is set to provide an output of

4mA in the base scale and 20mA in the full scale.

Calibration should be performed by connecting an ammeter to Iout terminal as shown below.

Iout

1234

Operation (example) Calibration of output of 4mA, 20mA

Key operation

FUNC SYSTEM

or

or , ENTER

(up) or (down)

(down) or (up)

Select “Analog output calibration”.

Select “Setting”.

Fine calibration

Coarse calibration

TRout 1

Description

}

Ammeter should

indicate 4mA.

Ammeter

Display

OUTPUT ADJUST

SKIP

OUTPUT ADJUST

SETTING

OUTPUT ADJUST

4mA

, ENTER

(up) or (down)

(down) or (up)

, ENTER

ESC ESC

Note : After calibration is completed, set the calibration mode to Skip.

Fine calibration

Coarse calibration

Press the key twice.

Ammeter should

indicate 20mA.

}

OUTPUT ADJUST

20mA

(Measurement display)

32

Page 39

5.4 (20) Status output check

Description

Perform check of status output for ON-OFF operation. Status output is an open collector. A

check is performed by connecting a voltmeter to terminals, TRout 1 and TRout 2 as shown

below.

TR out 1

1234

TR out 2

Volt meter

V

Volt meter

V

Operation (example) Check of status channel 1.

Key operation

Description

FUNC SYSTEM

or

or , ENTER

Select “Status check”.

Select “Channel 1”.

Signal receiving instrument

Display

STATUS CHECK

Channel *

STATUS CHECK

Channel 1

or

ESC ESC ESC

Note: Status output changes depending upon “normal” or “Reverse” specified under the status

mode conditions.

Select “ON or OFF”.

Press the key 3 times.

33

STATUS CHECK

ON

(Measurement display)

Page 40

5.4 (21) Test mode

Description

The test mode is used to check for integrated conditions and action of the flow switch, etc. by

entering measuring flow rate simulately.

With base scale set to 0% and full scale to 100%, an arrival time from previous value to target

value can be set as shown below:

Data setting range: 0 to ±120%

Tracking time setting range: 0 to 900sec

Output

Output data

Base scale

time

Tracking time

Note: During measurement, set the test mode to “NOT USED”.

Operation (example) To set the tracking time to 15 seconds so that the target value reach from 0 to

100%.

Key operation

FUNC SYSTEM

or

or , ENTER

0 , ENTER

2 , 5 , ENTER

1 , 0 , 0 , ENTER

ESC ESC

Description

Select “Test mode”.

Select “Setting”.

Enter “0” with ten keys.

Enter “15” with ten keys.

Enter “100” with ten keys.

Press the key twice.

Display

TEST MODE

NOT USED

TEST MODE

SETTING

OUTPUT DATA

0%

TRACKING TIME

15 sec

OUTPUT DATA

100%

(Measurement display)

34

Page 41

6. MAINTENANCE AND INSPECTION

6.1 Maintenance

(1) LCD display unit

Expected service life of LCD is 7 years. It is recommended that LCD should be replaced with new

one in about 5 years since it is put into operation, or it may offer deteriorated contrast.

[Replacement procedure]

1) Power OFF

2) Remove the connector from the key panel and replace the LCD display unit (see parts list).

3) Assembly

4) Power ON

5) Check for normal operation

6.2 Inspection

(1) Daily check

Confirm the converter is operating normally by using the LCD display unit in accordance with

Item “7.1 How to confirm normal operation”.

35

Page 42

7. TROUBLESHOOTING

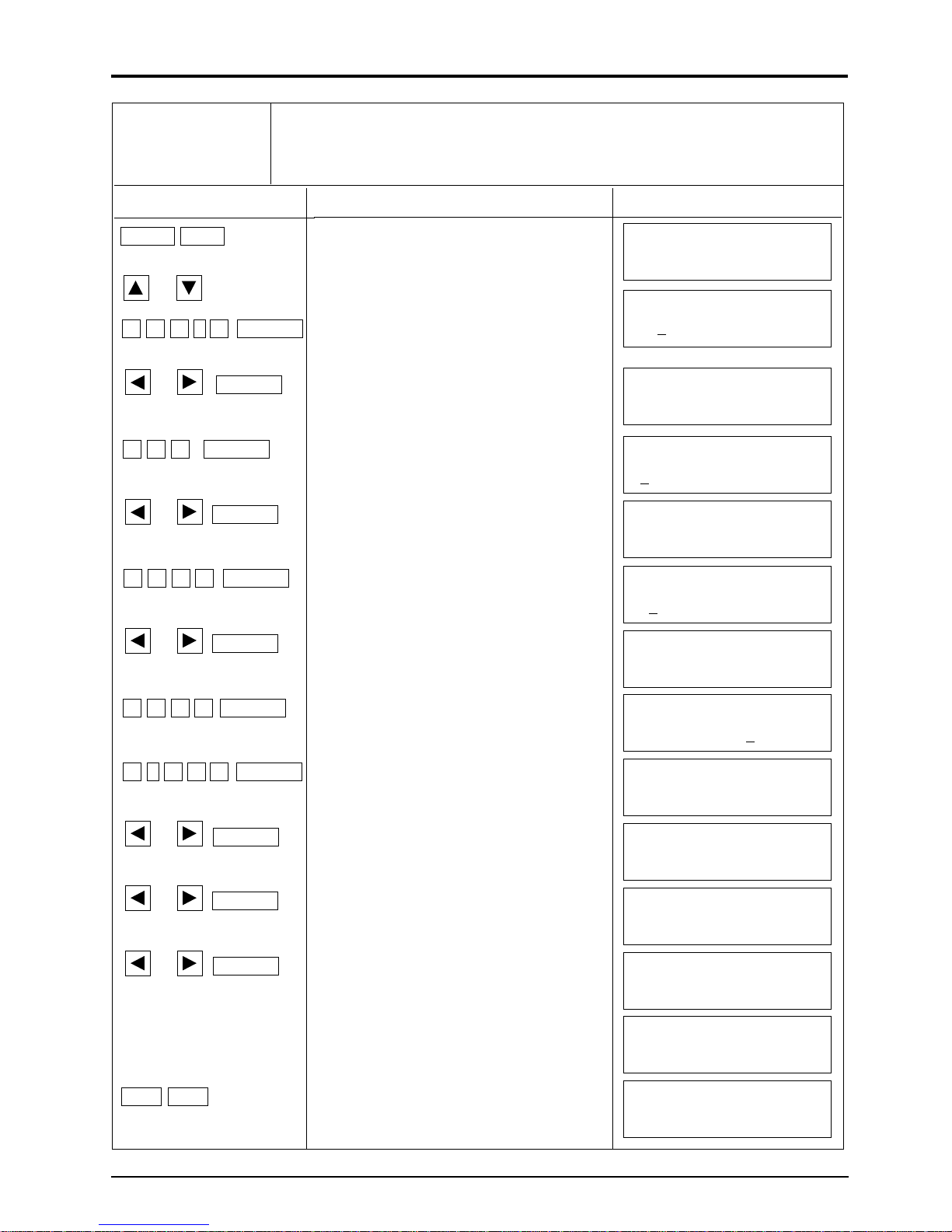

7.1 How to confirm normal operation

7.1 (1) When checking by LCD indicator

Indication

symbol

– XX. XXX m/s R

– XXXX. XXXX /s

Press ESC key if this indication

doesn't appear

C, H, W,

O, I

indication

7.1 (2) LCD indication when power turned ON

In case of no indication

System abnormal (CPU stopped)

Contact Fuji Electric.

Operation status

R Normal

E Range over

• Ultrasonic wave not

Ab-

transmitted normally

normal

inside pipe.

B

No

—

Backup error

Forward flow of fluid

Reverse flow of fluid

36

Page 43

7.1 (3) Detail check for abnormal status

Description

Status display at the upper right of the measurement screen is detailed as follows:

(Status display) (Contents of display) (Detailed Contents)

R : NORMAL

C : CAL. ERROR • Check for piping input data.

• Turn ON/OFF the power.

H : RECEIVED SIGNAL ERROR • Check for air bubbles in pipe

• Check for particles in pipe

W : WINDOW ERROR • Check for piping input data.

O : RECEIVED SIGNAL OVERFLOW • Check for the sensor mount-

ing method.

I : NO RECEIVED SIGNAL • Check for piping input data.

• Check for sensor installation.

• Check for cable connections.

• Check for type of sensor.

E : RANGE OVER • Check for output setting.

• Check for integral constant.

B : BACKUP ERROR • Non-volatile memory fault.

Operation (example) I appears at the upper right of the measurement screen.

Key operation

FUNC CHECK

ENTER

(Contens of display)

(Detailed contents)

(Detailed contents)

(Detailed contents)

Description

I : NO RECEIVED SIGNAL

CHECK

INPUT PIPE DATA

CHECK

SENSOR MOUNT

CHECK

CABLE CONNECT

CHECK

SENSOR TYPE

(Detailed contents)

ESC ESC

Press the key twice.

Display

(Measurement display)

37

Page 44

7.2 Faults and remedies

7.2 (1) LCD display abnormal

Status

No indication

appears.

Dark indication on

upper side.

Cause

• Power is not turned ON.

• Power voltage is low.

• Fuse is burnout.

• LCD is abnormal. Take remedy in “7.2 (5) Remedy for

hardware fault”

• DC power supply polarity is connected reversely.

• Power voltage is low.

• LCD is abnormal. Take remedy in “7.2 (5) Remedy for

hardware fault”

• DC power supply polarity is connected reversely.

• Hardware fault. Take remedy in “7.2 (5) Remedy for

hardware fault”

Random indication

Unclear display

Whole is dark

7.2 (2) Key abnormal

Status

No response at press

of input key

Specific keys can not

be operated.

Key operation is

• Ambient temperature low. (less than-10°C)

Increase the temperature.

• LCD indicator is worn out. Replace the LCD.

• Ambient temperature is high. (60°C or more)

Decrease the temperature.

Cause

• Hardware fault. Take remedy in “7.2 (5) Remedy for

hardware fault”

different from that

defined.

38

Page 45

7.2 (3) Measured value abnormal

Status

Minus (

-

) symbol

indicated on measured value

Measured value

fluctuates though

flow rate is constant.

Measured value is not

changed with change

in flow rate.

Cause

Remedy

• Connection between transmitter

and sensor is reversed. Connect correctly.

(Upstream and down stream

detectors should be connected

reversely)

• Flow of fluid is reversed.

• Straight pipe length is inadequate.

Move instrument to a place

where 10D can be maintained on upstream and 5D

on downstream.

• Pump, valve etc. which disturbs Attach instrument at

flow is located nearby. least 30D away

• There is pulsation in the Set the damping to increase

flow the response time.

Ultrasonic wave is not transmitted

inside pipe but measured value

remains unchanged (HOLD).

1. Installation is improper

• Error in piping specifica-

tions

• Sensor attached to welded

part

• Error in sensor mounting

dimensions

• Error in silicon appliance at

the time of mounting the

sensor

• Error in connection of the

sensor cable.

2.Problem with piping, fluid

Pipe not filled with fluid

Bubbles included in the fluid

If measured value becomes

normal when flow has

stopped, it indicates that

bubbles are contained in the

fluid.

When the sensor is mounted

right after the valve, cavitation may occur in the pipe,

resulting in entry of air

bubbles.

(Contined)

After confirming the cause,

remove the sensor and

apply sufficient amount of

silicone to the sensor.

Then, mount the sensor

again at a position slightly

away from previous position.

Fluid out a pipe filled with

fluid on the same pipeline,

and relocate the sensor to

the pipe.

• Attach the sensor to the

lowest place on the pipeline.

Eliminate the bubbles.

• Raise the level of the pump

well.

• Check the shaft seal of the

pump.

• Retighten the flange of

negative pressure pipe.

• Arrange so that fluid doesn’t

fall into the pump well

Move the sensor to a place

where no bubbles are

contained.

• Pump inlet side

• Upstream side of valve

39

Page 46

Status

Cause

Remedy

(Continued)

Turbidity is high.

Turbidity is higher than inflow

water contamination or return

sludge.

Scale deposits on the inside of

old pipe

Thick lining

Mortar lininig is several ten

millimeters thick

Separation of lining

This is gap between lining and

pipe.

Sensor is mounted on bent or

tapered pipe.

3. Effect of external noise

•There is a radio broadcast

station nearby.

•Measurement conducted near a

passage of vehicles or electric

cars.

• Change sensor

mounting from V

method to Z method.

• Move sensor to a

place of smaller

diameter on the

same pipeline.

• Relocate sensor to

another place or pipe

line.

Mount sensor on a

straight pipe.

• Keep the cable

between converter

and sensor as short

as possible.

• Ground the converter and piping.

Measured value not

zero when fluid stops

flowing.

• Mounting of sensor incorrect

• Mounting dimensions

• Sensor is separated from pipe

4. Hardware fault

• Fluid forms a convection inside

the pipe.

• Zero point adjustment

• Pipe is not full of water or it is

empty of water when water

stops flowing.

• Mount sensor parallel with pipe at the

correct position.

• Press sensor so it is

securely mounted on

the pipe.

Refer to Item “7.2(5)

Remedy for hardware

fault”.

This is normal.

• Readjust the zero

point after fluid has

stopped flowing.

This is normal.

• The value may vary

at Item “5.4(4) Setting

of output at abnormal

measurement”.

40

Page 47

Status

Cause

Remedy

Error in measured

value

• Input piping specifications

differ from the actual ones.

• Scale deposits on old pipe

• Length of straight pipe is inadequate. (should be at least 10D

upstream and 5D downstream.)

Error of about 3%

occurs when inner

diameter differs by

1%.

• Input the correct

specifications

• Input scale as a

lining.

Change the sensor to

another mounting

position (upstream of

disturbing objects)

No disturbing objects

in flow within 30D

upstream without

pump, valve, combined pipe, etc.

• Try mounting the

sensor at various

angles versus the

pipe section, and

mount it where

average value is

obtained.

• Pipe is not filled with fluid or

sludge is deposited in the pipe.

Occurs particularly

where sectional area

is small.

• Move sensor

to a vertical pipe.

41

Page 48

7.2 (4) Analog output abnormal

Status

Current output is not

matched though

indication value is not

0.

Output is 0mA.

Output is below 4mA

when indication is 0.

Output is greater than

20mA.

Indication is changed

but analog output

remains the same.

Indication does not

agree with analog

output.

Analog output

doesn’t change even

after it has been

adjusted.

Cause

Range setting is not

performed.

Cable is disconnected.

Zero adjustment of analog

output has deviated.

E is displayed on LCD

indicator. Note)

Span adjustment is incorrect.

Output load is greater than

1kW.

Zero or span of analog output

has deviated.

Hardware falut

Remedy

• Set.

Adjust the analog output.

Range over:

• Reset analog output range

data.

• Adjust the analog output.

• Reduce the load to 1kW

or less.

Adjust the analog output.

Contact Fuji Electric.

Note: When the base scale is not set to 0 within the range of an analog output, the flow

display may not be matched with the analog output.

7.2 (5) Remedy for hardware fault

When hardware is in trouble after following “6. Maintenance and inspection” and “7.

Troubleshooting”, details of trouble and self-check should be notified to Fuji Electric.

42

Page 49

8. MOUNTING METHOD

8.1 Mounting of sensor

8.1 (1) Mounting procedure of sensor

Mount the sensor on the pipe, and perform the following works in order before making

measurement.

8.1 (2)

8.1 (3) Selection of mounting method

8.1 (4)

8.1 (5)

8.1 (6)

8.1 (7) Connection of cable

8.1 (8) Mounting of small type

Selection of mounting place

Processor of sensor

mounting surface

Determination of

mounting position

Cable end termination

to small type sensor and

sensor with small

diameter

sensor and pipe with

small diameter on pipe

8.1 (10) Connection of signal

cable to large type

sensor

8.1 (11) Mounting of large type

sensor on pipe

8.1 (12) Mounting of high

temperature sensor

on pipe

8.1 (9) Assembly procedure

of sensor

43

Page 50

8.1 (2) Selection of mounting place

Mounting place for the sensor, i. e. conditions of piping where flow rate is measured, has considerable influence on measurement accuracy.

A place satisfying the following conditions should be selected.

1) A place where there is a straight pipe portion of 10D or more on upstream side and of 5D or

more on the downstream side.

2) A place where there are no factors which disturb the flow (pumps, valves, etc.) within 30D on

upstream side.

3) Pipe must be filled up with fluid. No bubbles should be contained.

4) Make sure that a maintenance space is provided around the piping where the sensor is

mounted. (See Fig. 8-1.)

Note) A space should be provided so that maintenance work can be made with workers

standing on both sides of the piping.

8" or

more

more

200 or

Note

Note

8" or

more

more

200 or

D + 48" or more

24" or

more

D

24" or

more

D : Pipe diameter

Fig.8-1 Space required for mounting sensor

CAUTION

1. Where a horizontal pipe is used, install the sensor within ±45° from the horizontal plane.

Where a vertical pipe is used, the sensor can be installed anywhere.

Pipe

45°

Horizontal

45°

2. Avoid installing the sensor on a deformed portion of pipe or welded portion of pipe, or on

flange.

2,000 or more

80" or more

Welded portion Flange or weld Welded portion

44

Page 51

8.1 (3) Selection of mounting method

There are two ways for mounting the sensor, the V method and the Z method (See Fig. 8-2).

Approx. D

Sensor

D

V method

D

Approx. D/2

Sensor

Z method

Fig. 8-2 Mounting method

The Z method should be used in the following cases.

• Where a mounting space is not available. (As shown in the figure above, the mounting dimension with the Z method is about half of that with the V method).

• When measuring fluid of high turbidity such as sewage.

• When the pipe has a mortar lining.

• When the pipe is old and has a thick accumulation of scale on its inner wall.

Selection standard

For a large size sensor with inside diameter of more than 12 in., the Z method is recommended for mounting.

Sensor

Small type

sensor

Type : FLW12

Large type

sensor

Type : FLW51

High temperature

sensor

FLW32

Z

method

V

method

Z

method

V

method

: Range noted in specifications

: Range specified with piping material

(FRP, PVC or other plastic materials)

8.1 (4) Processing of sensor mounting surface

Using thinner and/or sandpaper, remove pitch, rust and unevenness over a width of (L) + 8 in. on

the pipe circumference where the sensor is mounted.

Note) If there is a jute winding on the pipe circumference, remove it and carry out the above

processing.

Jute winding

1" 2" 4" 8" 12" 16" 40" 120" 240"

Inside diameter (inches)

Pipe

L + 8"

45

Page 52

8.1 (5) Determination of mounting position (with Z method for large and small types)

Edge should be even.

Straight line A

Carry out the following to determine the mounting position.

Gauge paper is necessary for this work. (Refer to Appendix 1. “How to make gauge paper”.)

1. Align the edge of gauge paper with a point about 4 in. from

one end of the processed section, and wrap the paper around

the pipe so that the line drawn on the paper is parallel with the

pipe shaft. (The paper should be taped to prevent slipping.)

At this time, make sure that the paper edge is even.

2. Extended the line drawn on the paper and mark a straight line A

on the pipe.

3. Mark a line along on edge of the paper. Assume the intersection

of the line and the straight line A is A

.

0

4 in.

A

0

V method

Example) L = 8 in.

8 in.

A

0

A

2

4. Remove the gauge paper and measure

the mounting dimension from A

.

0

Then , draw a line which crosses the

straight line A (determine the position

A

).

2

A0 and A2 are the mounting position.

Z method

B

0

A

0

Straight line B

B0,B

1

A0,A

A

1

B

1

4. Measure the circumference of the pipe from the

point A

between the point B

, and mark a line (straight line B)

0

and B1 obtained at 1/2 of

0

the circumference.

Example) L = 4 in.

4 in.

B2B

0

A

0

B

B

0

2

5. Put a mark at point B0 and remove the gauge

paper.

Measure the mounting dimension from B

and

0

mark a line crossing the straight line B

(determine the position B

).

2

In this way, the mounting position is determined.

and B2 are the mounting position.

A

0

1

46

Page 53

8.1 (6) Cable end treatment

The end of coaxial cable is treated at the factory prior to delivery. If the cable needs to be cut

before use, the conductor and the shielding wires should be treated using clamp terminals.

Outer shielding wire (green)

Note) When cutting the coaxial cable, make sure that the upstream side and the downstream side

are the same in length.

Shielding wire (black, G)Conductor (white, +)

Clamp terminal

47

Page 54

8.1 (7) Connection of cable to small type sensor

Cable clamp

G

+

1. Loosen the earth screw and the retaining knob on

the sensor using a screwdriver, then remove the

cover from the sensor.

Cover

Loosen

Retaining knob

2. Select a mounting position on the pipe.

Note) Mount the sensors so that the upstream and

downstream sensors can be distinguished with

each other.

Remove the cable clamp and insert the coaxial

cable through the cable lead-in port.

4. Secure the coaxial cable with the cable clamp.

5. Remove foreign matters from the terminals, and

mold the while terminal block with silicone filler.

• Cut off the tip of the silicone filler tube.

Apply silicone to the terminal block while

pressing the head of the tube against the bottom of

terminals.

At this time, care should be taken to prevent entry

of air bubbles.

3. Connect the cable to the terminal (G, +) and the

earth screw.

Note) After connecting the outer shielding wire to

the earth screw, be sure to bend the amplifier

terminal.

Outer shielding

terminal

Outer shielding wire

Silicone filler

Bend

Earth screw

Terminal

6. Put the cover on the sensor.

Coaxial cable

48

Page 55

8.1 (8) Mounting of small type sensor on pipe

The small type sensor is mounted on pipe with a diameter of ø50 to 250 (V method) or ø150 to

400 (Z method) for measurements.

1. Mounting of sensor (V method)

Mounting the sensor using the following procedure.

For mounting, prepare a scale or a slide calipers.

1. Loosen the retaining knob A (4 places), slide the

sensor so as to match the mounting dimension,

place a scale on the mounting dimension reference

surface C and adjust the dimension, then tighten

the retaining knob A.

Mounting dimension

reference surface C

Retaining

knob A

Mounting

dimension

Scale

2. Spread silicone filler over the whole transmitting

side of the sensor. Care should be taken to

prevent entry of air bubbles.

3. Raise the end of the pipe fitted with the sensor,

and attach the yellow ring on the chain to the

hook.

Pipe end Wire

Yellow

Red

Spring

Ring

Attach the other chain to the other hook of sensor,

and secure it loosely.