Page 1

DIFFERENTIAL PRESSURE (FLOW) TRANSMITTER

...

DATA SHEET

The FKC model of the FCX-AII V5 series of pressure transmitters accurately measures differential pressure, liquid level or

ow rate and transmits a proportional 4-20 mA output signal.

The transmitter uses an unique micro-capacitive silicon

sensor in combination with a state-of-the-art digital signal

processing to provide exceptional performances in terms of

accuracy and stability.

FEATURES

1. High accuracy up to ±0.04%

Fuji Electric’s micro-capacitive silicon sensor provides in

standard ±0,065% accuracy for all elevated or suppressed

calibration ranges without additional adjustments.

±0.04% accuracy is available in option.

2. Minimum inventory and design

Electronics unit, local indicators and electronics housing are

interchangeable among all FCX-AII V5 transmitters.

3. Minimum environmental inuence

The Advanced Floating Cell technology provides a high im-

munity against temperature variations, static pressure and

overpressure commonly found in the process industry and

substantially reduces the overall measurement error.

4. HART/Fuji Electric communication protocols

FCX-AII V5 series of pressure transmitters can communicate

using either the universal HART or the proprietary and faster

Fuji Electric communication protocol.

By the use of Device Description les, HART compatible

devices can communicate with any FCX-AII V5 transmitter.

5. Application exibility

Various options are available to address most of the process

industry applications, including :

- Full range of hazardous area approvals

- Built-in RFI lter and lightning arrester

- Analog or 5 digits local display with engineering units

- Stainless steel electronics housing

- Wide selection of wetted part materials

6. Programmable output Linearization Function

The output signal can be linearized using up to 14 pair-

points.

7. Burnout current exibility

The burnout current value can be adjusted in the ranges of

[3.2 ; 4.0] and [20.0 ; 22.5] mA and can be compliant with

NAMUR NE43 recommandations.

FKC

SPECIFICATIONS

Functional specifications

Type :

FKC : Smart, 4-20mA + HART/Fuji Electric communi-

cation protocols.

Service :

Liquid, gas, or vapour

Static pressure, span, and range limits :

Span limits kPa

Min.

0.1

0.1

0.32

1.3

5

30

0.32

1.3

5

30

500

{5000}

{1}

{1}

{3.2}

{13}

{50}

{300}

{3.2}

{13}

{50}

{300}

{m bar}

1

6

32

130

500

3000

32

130

500

3000

20000

{200000}

Max.

±1

{10}

±6

{60}

±32

{320}

±130

{1300}

±500

{5000}

±3000

{30000}

±32

{320}

±130

{1300}

±500

{5000}

±3000

{30000}

+20000,-10000

{+200000,-100000}

Static pressure

Model

FKC

FKC

FKC

FKC

FKC

FKC

FKC

FKC

FKC

FKC

FKC

Remark : To minimize environmental inuence, span should be greater than

1/40 of the max. span in most applications.

Important : For FKC#49, max possible overload pressure on LP side must be ≤

100 bar. The accuracy is not guaranteed when used at negative DP

-0.1 to +3.2

11

-0.1 to +10

22

-0.1 to +16

33

-0.1 to +16

35

-0.1 to + 16

36

-0.1 to +16

38

-0.1 to +42

43

-0.1 to +42

45

-0.1 to +42

46

-0.1 to +30

48

-0.1 to +30

49*

MPa {bar}

{-1 to +32}

{-1 to +100}

{-1 to +160}

{-1 to +160}

{-1 to +160}

{-1 to +160}

{-1 to +420}

{-1 to +420}

{-1 to +420}

{-1 to +300}

{-1 to +300}

Lower limit of static pressure (vacuum limit) :

Silicone lling oil : See Fig. 1

Fluorinated lling oil : 66 kPa abs (500 mmHg abs) at tem-

perature below 60°C

Over range limit :

To maximum static pressure limit

5

Range limits

kPa {m bar}

{±10}

{±60}

{±320}

{±1300}

{±5000}

{±30000}

{±320}

{±1300}

{±5000}

{±30000}

Fuji Electric France S.A.S.

EDSF6-134m

Date

July, 2018

Page 2

FKC

...

5

Output signal :

4-20 mA (linear or square root) with digital signal super-

imposed on the analog signal

Power supply :

10.5 to 45 V DC at transmitter terminals.

10.5 to 32 V DC with the optional arrester.

Refer to hazardous location table for specic limitations.

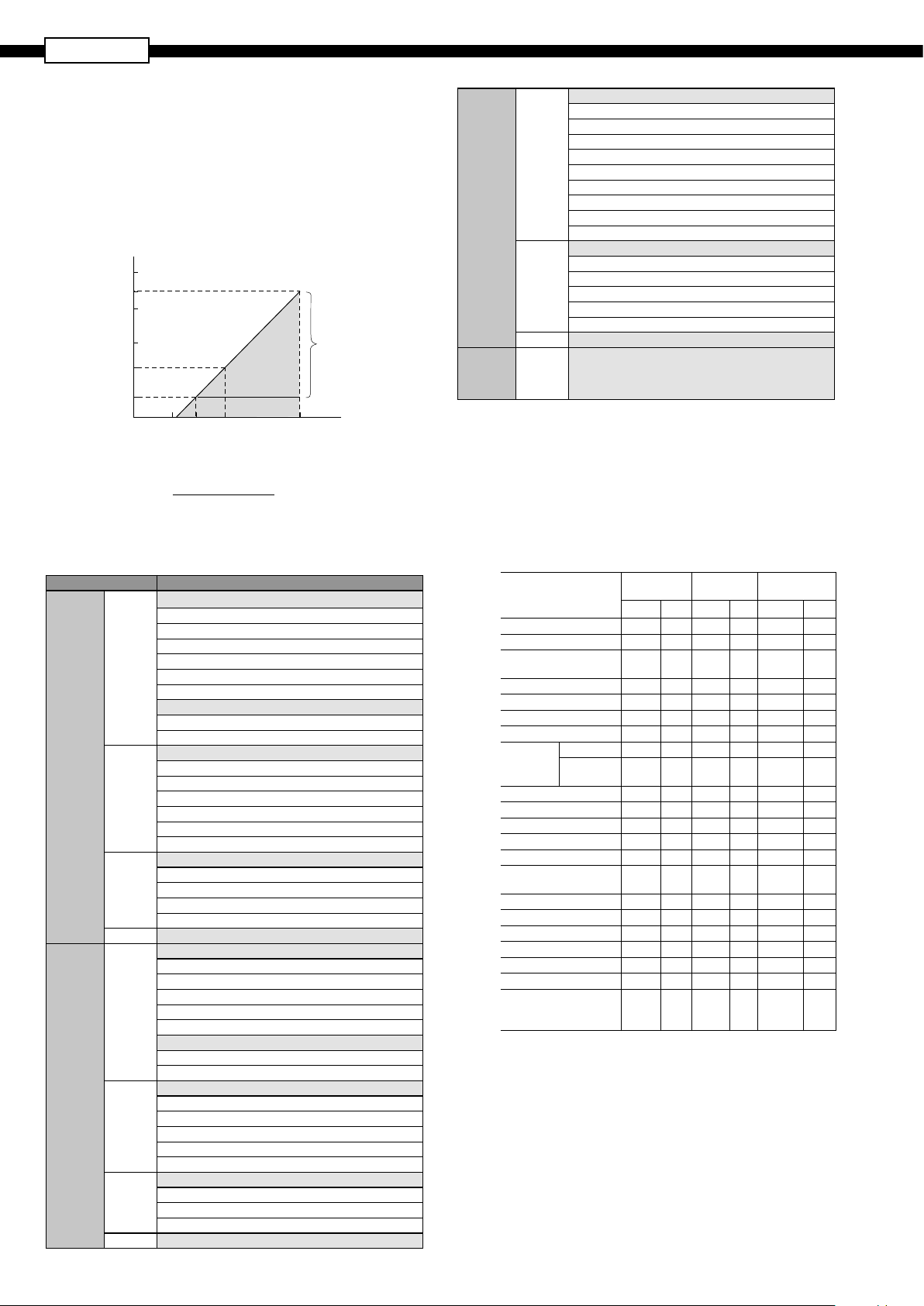

Load limitations : see gure below

R [Ω]

When the upper limit of the saturation

2000

1533

1500

1000

Load resistance

Note 1 : The load resistance varies with the upper limit of

the saturation current [I max]

Note 2 : For communication with HHC (FXW model), a minimum

load of 250 Ω is required.

current (Imax) is 21.6 mA

600

250

0

10.6 16.1

R [Ω] =

(I max [mA]+0.9)x10

Operating

area

24 45

E [V] -10.5

Communication

range with Hand

Held Communicator

(HHC)

E [V]

Power voltage

-3

Hazardous locations :

Marking (Digit 10 =) Protection type

ATEX

IECEx

Intrinsic Safety “i” :

Ex II 1G/D

Ex ia IIC T4 Ga (-40°C ≤ Ta ≤ +70°C)

Ex ia IIC T5 Ga (-40°C ≤ Ta ≤ +50°C)

Ex ia IIIC T135°C Da (-40°C ≤ Ta ≤ +70°C)

(K)

Ex ia IIIC T100°C Da (-40°C ≤ Ta ≤ +50°C)

IP 66/67

Electrical Parameters :

Ui ≤ 28 Vdc, Ii ≤ 94.3 mA, Pi ≤ 0.66 W

Ci = 26 nF

Flameproof Enclosure “d”:

Ex II 2G/D

Ex d IIC T5 Gb (-40°C ≤ Ta ≤ +85°C)

(X)

Ex d IIC T6 Gb (-40°C ≤ Ta ≤ +65°C)

Ex tb IIIC T100°C Db (-40°C ≤ Ta ≤ +85°C)

Ex tb IIIC T85°C Db (-40°C ≤ Ta ≤ +65°C)

45 Vdc max

Increased Safety “e” :

Ex II 3G/D

(P)

Ex ec IIC T5 Gc (-40°C ≤ Ta ≤ +70°C)

Ex tc IIIC T100°C Dc (-40°C ≤ Ta ≤ +70°C)

45 Vdc max

(M) Combination (K) + (X)

Intrinsic Safety “i”:

Ex ia IIC T4 Ga (-40°C ≤ Ta ≤ +70°C)

Ex ia IIC T5 Ga (-40°C ≤ Ta ≤ +50°C)

Ex ia IIIC T135°C Da (-40°C ≤ Ta ≤ +70°C)

(T)

Ex ia IIIC T100°C Da (-40°C ≤ Ta ≤ +50°C)

IP 66/67

Electrical Parameters :

Ui ≤ 28 Vdc, Ii ≤ 94.3 mA, Pi ≤ 0.66 W

Ci = 26 nF

Flameproof Enclosure “d”:

Ex d IIC T5 Gb (-40°C ≤ Ta ≤ +85°C)

Ex d IIC T6 Gb (-40°C ≤ Ta ≤ +65°C)

(R)

Ex tb IIIC T100°C Db (-40°C ≤ Ta ≤ +85°C)

Ex tb IIIC T85°C Db (-40°C ≤ Ta ≤ +65°C)

45 Vdc max

Increased Safety “e” :

Ex ec IIC T5 Gc (-40°C ≤ Ta ≤ +70°C)

(Q)

Ex tc IIIC T100°C Dc (-40°C ≤ Ta ≤ +70°C)

45 Vdc max

(N) Combination (T) + (R)

(1)

/ 36 nF

(1)

/ 36 nF

(2)

, Li = 0.6 mH

(2)

, Li = 0.6 mH

(3)

/ 0.7mH

(3)

/ 0.7mH

(4)

(4)

2

cCSAus

ATEX

IECEx

cCSAus

(1) Without optional arrester (3) Without analog indicator

(2) With optional arrester (4) With analog indicator

Intrinsic safety / Non Incendive / Class 1 Division 2 :

IS Class I Division 1, Groups ABCD Ex ia

Class II Groups EFG; Class III

NI Class I Division 2, Groups ABCD

(Per control drawing TC522873)

(J)

Class I Division 2, Groups ABCD

T4 (-40°C ≤ Ta ≤ +70°C)

T5 (-40°C ≤ Ta ≤ +50°C)

Ui ≤ 28 Vdc, Ii ≤ 94.3 mA, Pi ≤ 0.66 W

Ci = 26 nF

Explosion proof

XP Class I Division 1, Groups CD

Class II Groups EFG; Class III

(E)

T5 (-40°C ≤ Ta ≤ +85°C)

T6 (-40°C ≤ Ta ≤ +65°C)

Vmax = 42.4 Vdc

(L) Combination (J) + (E)

(W) Combination (K) + (X) + (T) + (R) + (J) + (E)

(1)

/ 36 nF

(2)

, Li = 0.6 mH

(3)

/ 0.7mH

(4)

Conguration :

Conguration of the FCX-AII V5 series of pressure transmitters

can be carried out by either using a Hand Held Communicator

(ie. Fuji Electric FXW or third party HART terminal) or the 3

push-buttons optional indicator.

A third party HART hand held communicator can be used

in combination with Fuji Electric FCX-AII V5 HART Device

Description les (https://eldcommgroup.org).

Functions

Tag Nb v v v v v v

Model Nb v v v v v v

Serial Nb & Software

revision

Engineering units v v v v v v

Upper Range Value v — v — v —

Measuring Range v v v v v v

Damping v v v v v v

Output signal type

Burnout current v v v v v v

Calibration v v v v v v

Output Adjust — v — v — v

Measuring Value v — v — v —

Self Diagnosis v — v — v —

Printer (option) v — — — — —

External Adj Screw Lock v v v v v v

Transmitter Display v v v v v v

Linearization — — v v v v

Rerange v v v v v v

Saturation Current v v v v v v

Write Protect v v v v v v

History

– Calibration History

– Ambient T° History

Note 1 : The FXW rmware revision must be higher than 7.0 in order

Note 2 : The “Linearization” function is not accessible throught the

Linear v v v v v v

Square

Root

to address FCX-AII V5 “Saturation current”, “Write protect”

and “History” functions.

3 puh-buttons optional indicator.

Fuji Electric

FXW

Display Set Display Set Display Set

v — v — v —

v v v v v v

vvv—vvv

Third party

HART HHC

—vvv—

3 push buttons

optional indicator

Zero and span adjustment :

Zero and span are adjustable with a Hand Held Commu-

nicator or locally with the external adjustment screw.

Damping :

The damping time constant can be adjusted within the

range of [0.06 to 32] seconds.

Zero elevation / suppression :

Zero can be adjusted within the range of ±100% of the

URL of the sensor.

Page 3

Normal / reverse action :

Selectable from a Hand Held Communicator

Local indicator :

One optional analog or 5-digits digital indicator.

Burnout direction and saturation currents :

If the self-diagnostic functions detect a transmitter failure,

the burnout function will drive the output signal to either

“Output Hold”, “Output Overscale” or “Output Underscale”

modes.

When “Output Hold” :

The

output signal is held as the last value just before the failure

happens.

When “Output Overscale” :

The

output signal is set within the range of [20.0 to 22.5] mA

When “Output Underscale” :

The output signal is set within the range of [3.2 to 4.0] mA

Both burnout and saturation current can be adjusted within

the range of [3.2 ; 4.0] and [20.0 ; 22.5] mA

Saturation

3.6 4

Normal operating range

3.2 3.8

Burnout

Saturation

20

20.8 22.5

Burnout

21.6 [mA]

Loop-check / xed output current :

The transmitter can be congured to provide a constant

output signal from 3.2 up to 22.5 mA.

Low ow cut-off :

The output signal is proportional to √ differential pressure

between low ow cut-off and the measuring range. Be

tween zero and low ow cut-off, the output signal is pro-

grammable to zero or linear between 0 and 20% of the ow.

Temperature limit :

Ambient :

-40 to +85°C

-20 to +80°C (with optional LCD unit)

-40 to +60°C (with optional arrester)

Please refer to the hazardous locations table for ambient

temperature limitations according to the standard and

type of protection.

Process :

-40 to +120°C for silicone lling oil

-20 to +80°C for uorinated oil lling oil

Storage :

-40 to +90°C

Humidity limit :

0 to 100% RH (Relative Humidity)

Performance sPecifications for linear outPut

Reference conditions, silicone lling oil, SS 316L isolating diaphragms, 4 to 20 mA analog output in linear mode.

Accuracy rating :

Max span : 32 kPa to 3000 kPa models :

For spans > 1/10 of URL :

±0.065% of span or ±0.04% of span (optional)

For spans < 1/10 of URL :

± (0.015 + 0.005 x ) % of span

Max span 20 MPa models :

For spans ≥ 5 MPa :

±0.1% of span

For spans < 5 MPa :

± (0.05 + 0.05 x ) % of span

Max span 1 kPa and 6 kPa models :

For spans greater than 1/10 of URL :

±0.1% of span

For spans below 1/10 of URL :

± (0.05 + 0.005 x ) % of span

Stability :

±0.1% of the URL for 10 years for 6th digit code 3, 5, 6, 8

and 9.

Temperature effect :

Effects per 28°C changewithin the range of -40°C and +85°C

Range code

(6th digit in the

-

model code)

“1”/1 kPa {10 mbar}

“2”/6 kPa {60 mbar}

“3”/32 kPa

{320 mbar}

“5”/130 kPa

{1300 mbar}

“6”/500 kPa

{5000 mbar}

“8”/3000 kPa

{30000 mbar}

“9”/20000 kPa

{200000 mbar}

Double the effects for material code (7th digit in model code)

“H”, “M”, “T”

Static pressure effect :

Static pressure code

(5th digit in the model code)

“1” / 1 kPa {10 mbar} sensor

“2” / 6 kPa {60 mbar} sensor

Double the effects for material code (7th digit in model code)

“H”, “M”, “T”

Overrange effect :

Static pressure code

(5th digit in the model code)

“1” / 1 kPa {10 mbar} sensor

“2” / 6 kPa {60 mbar} sensor

Double the effects for material code (7th digit in model code)

“H”, “M”, “T”

(including linearity, hysteresis, and repeatability)

URL

Span

5MPa

Span

URL

Span

Zero shift

(% of span)

± (0.125+0.1 ) %

± (0.075+0.0125 ) %

“3”

“4”

“3”

“3”

“4”

“4”

URL

Span

URL

Span

Zero shift

(% of URL)

±0.2% / 3.2 MPa {32 bar}

±0.2% / 10 MPa {100 bar}

±0.035% / 6.9 MPa {69 bar}

±0.2% / 6.9 MPa {69 bar}

Zero shift (% of URL)

±0.2% / 3.2 MPa {32 bar}

±0.2% / 10 MPa {100 bar}

±0.1% / 16 MPa {160 bar} FKC35,36,38

±0.15% / 16 MPa {160 bar} FKC33

±0.25% / 42 MPa {420 bar} FKC43,45,46,48

±0.2% / 10 MPa {100 bar} FKC49

Total effect

(% of span)

± (0.15+0.1 )%

± (0.095+0.0125 ) %

URL

Span

URL

Span

FKC49

3

Page 4

FKC

...

5

Per f or m an c e sP e c if i ca t io n s for sq ua r e ro o t

outPut

Accuracy rating :

Span

Output

50 to 100%

20 to 50%

10 to 20%

±0.065 %

±0.163 %

±0.325 %

±(0.015+0.005

±2.5

×

±5

Max span 1kPa and 6kPa models :

Output Accuracy

50 to 100%

20 to 50%

10 to 20%

Temperature effect :

Effects per 28°C changewithin the range of -40°C

and +85°C

Range code Shift at 20% output point

“1” and “2”

“3” through “9”

below 0.1 × URLover 0.1 × URL

×

×

(0.015+0.005 × URL/Span)%

(0.015+0.005 × URL/Span)%

URL/Span)%

±0.1 %

±0.25%

±0.5 %

± (0.375+0.25x ) % / 28°C

± (0.24+0.03125x ) % / 28°C

URL

Span

URL

Span

co mmon Perf o r m ance sPec i f i cati o n s fo r bo t h

outPut modes

Supply voltage effect :

Less than 0.005% of calibrated span per 1 V

Update rate :

60 msec

RFI effect :

< 0,2% of the URL for the frequencies from 20 up to 1000

MHz with an electrical eld strength of 10 V/m and housing

covers in place. (Classication : 2-abc : 0.2% of span accord

ing SAMA PMC 33.1)

Response time : (63.3% of output signal without damping)

Range code

(6th digit in model codes)

“1” 0.33 sec.

“2” 0.3 sec.

“3” 0.12 sec.

“5” through “8” 0.08 sec.

Response time = time constant + dead time

Mounting position effect :

Zero shift, less than 0.12 kPa {1.2 m bar} for a 10° tilt in

any position. This error can be corrected by adjusting

Zero. (Double the effect for uorinated lling uid).

No effect on span.

Vibration effect :

< ±0.25%

of span for spans greater than 1/10 of URL.

Frequency 10 to 150 Hz, acceleration 39.2 m/sec

Material fatigue :

Please consult Fuji Electric.

Dielectric strength :

500 V AC, 50/60Hz 1 min., between circuit and earth

(except with the optional arrester)

Insulation resistance :

More than 100 MW at 500 V DC.

Internal resistance for external eld indicator :

12 W max. (connected to test terminal CK+ and CK-)

Pressure equipment directive (PED) 2014/68/EU

Digit 5 code 1, 2, 3, 8 and 9 according to Article 4.3

Digit 5 code 4 : Category III model H1

.

Time constant

(at 23°C)

Dead time

0.12 sec.

2

.

PHYSICAL SPECIFICATIONS

Conduit connections :

1/2”-14 NPT, Pg13.5 or M20×1.5

Process connections :

Standard :

1/4”-18 NPT meets DIN 19213.

Option :

1/2”-14 NPT with oval anges

Process-wetted parts material :

Material code

(7th digit)

V Ranges 1 & 2

Ranges 3 to 8

W

H

J

M

T

Remark :

Gasket : Viton o-ring or PTFE square section gasket.

Availability of above material design depends on ranges and static

pressure according material codes V, H, M and T.

Refer to the “Model code symbols”.

Process

cover

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

Non-wetted parts material :

Electronics housing :

Low copper die-cast aluminum alloy nished with polyester

coating (standard), or SS 316 (option).

Bolts and nuts :

Cr-Mo alloy (standard).

Options :

SS 316 (L) for static pressure if 160 bar max.

SS 660 (M10) for static pressure < 160 bar.

SS 660 (M12) for static pressure > 160 bar

Filling uid :

Silicone oil (standard) or uorinated oil (option)

-

Mounting bracket :

SS 304L or 316L (option)

Environmental protection :

IEC IP66/IP67 and Type 4X

Mounting :

Without mounting bracket :

Direct mounting on manifold (optional)

With optional mounting bracket :

For Ø50 mm (2”) pipe or direct wall mounting.

Mass {weight} :

Transmitter approx. 3.5 kg without options.

Add : 0.3 kg for indicator

0.5 kg for mounting bracket

Diaphragm Wetted

SS 316L

SS 316L

Hastelloy-C

Hastelloy-C

SS 316L +

Gold coating

Monel

Tantalum

sensor body

SS 318LN

SS 316L

SS 316L

Hastelloy-C

SS 316L

Monel lining

Tantalum lining

2.0 kg for stainless steel housing (option)

Vent /

drain

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

4

Page 5

OPTIONAL FEATURES

Local indicator :

A plug-in analog indicator (2.5% accuracy) can be

mounted into the electronics compartment or the terminal

box of the housing.

An optional 5 digit indicator with engineering units is also

available.

Local conguration with the 3 push-buttons indicator :

A local conguration can be carried out with the optional 3

push-buttons 5-digits indicator.

Arrester :

A built-in arrester protects the electronics from lightning

surges.

Lightning surge immunity :

±4 kV (1.2 × 50 µs)

Oxygen service :

Special cleaning procedures are applied during the man-

ufacturing process to maintain oil free all process wetted

part. The lling uid is uorinated oil.

Chlorine service :

Same procedures and lling uid as for oxygen service.

Degreasing :

Process-wetted parts are cleaned and the lling uid is

standard silicone oil. Not for use with oxygen or chlorine

presence.

NACE specication :

Metallic materials for all pressure boundary parts comply

with NACE MR 0175/ISO 15156.

SS 660 or SS 660/660 bolts and nuts comply with NACE

MR 0175/ISO 15156.

Optional tag plate :

An extra stainless steel tag plate with customer tag data

is wired to the transmitter.

ACCESSORIES

Oval ange :

Converts process connection to 1/2”-14 NPT

Manifolds :

Available in SS 316 and in pressure rating 16 MPa or 42 MPa

Hand held communicator :

FXW model, refer to datasheet N° EDS8-47

.

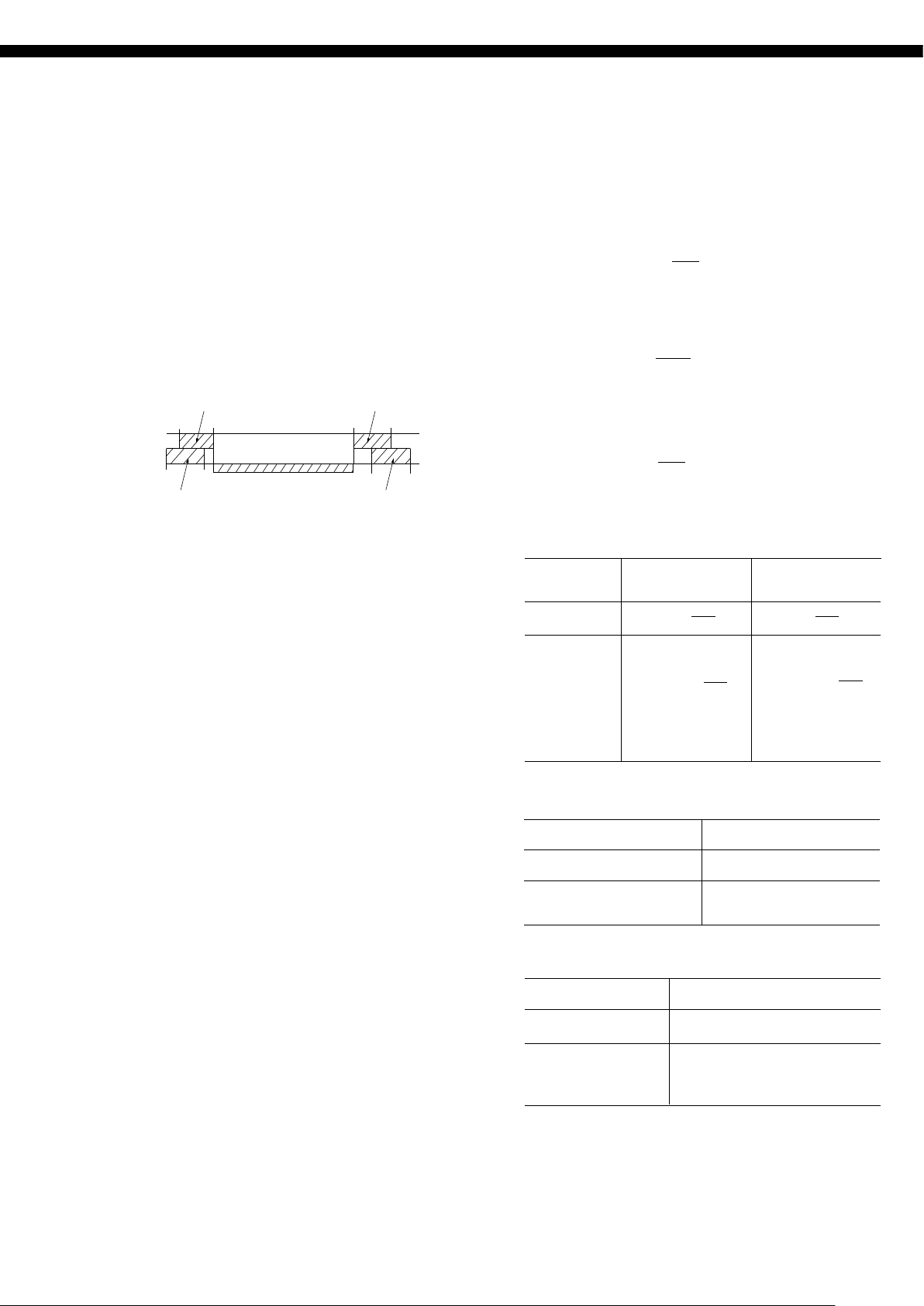

Silicone oil (Code:Y,G)

kPa abs

{mbar abs}

101

{1010}

20

{200}

4

Operating pressure

{40}

2.7

{27}

Fig. 1

Relation between process temperature and operating

Silicone oil (Code:R)

Operating area

Non operationg

area

60−40 −15 85 120

Process Temperature [°C]

pressure

5

Page 6

...

DESCRIPTION

FKC

5

MODEL CODE SYMBOLS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

F K C

M (*9)

N M10 Pg13,5

P 1/2 - 14 NPT

R (*8)

T 1/4 - 18 NPT 1/2 - 14 NPT

V (*1)

W (*1)

X

5

6

7

8

9

1 1 V

1 1 W Hastelloy C SS 318LN

1 1 J Gold coat

1 1 H Hastelloy C Hastelloy C

2 2 V

2 2 W Hastelloy C SS 318LN

2 2 J Gold coating

2 2 H Hastelloy C Hastelloy C

3 3 V SS 316L

3 3 W

3 3 H

3 3 M Monel Monel lining

3 3 J

3 3 C

3 3 T

3 5 V

3 5 W

3 5 H

3 5 M Monel Monel lining

3 5 J (*4)

3 3 C

3 5 T Tantalum Tantalum lining

3 6 V

3 6 W

3 6 H

3 6 J (*4) Gold coating SS 316L

3 6 M

3 6 T Tantalum Tantalum lining

3 8 V

3 8 W

3 8 H

4 3 V SS 316L

4 3 W

4 3 H

4 3 M

4 3 J (*4)

4 5 V SS 316L

4 5 W

4 5 H 0,13/13 m WC

4 5 M Monel Monel lining

4 5 J SS 316L

4 6 V SS 316L

4 6 W

4 6 H 0,5/50 m WC Hastelloy C

4 6 M Monel Monel lining

4 6 J

4 8 V SS 316L

4 8 W

4 8 H

4 8 J

4 9 V SS 316L

4 9 J

8 1 H (*5)

8 2 H 10/600 mm WC Hastelloy C Hastelloy C

8 3 H

8 3 M 32/3200 mm WC Monel Monel lining

8 3 T Tantalum Tantalum lining

8 5 H Hastelloy C Hastelloy C

8 5 M 0,13/13 m WC Monel Monel lining

8 5 T Tantalum Tantalum lining

8 6 H

8 6 M Monel Monel lining

8 6 T Tantalum Tantalum lining

9 1 H 10/100 mm WC

9 2 H 10/600 mm WC

9 3 H

9 3 M 32/3200 mm WC Monel Monel lining

9 3 T Tantalum Tantalum lining

9 5 H

9 5 M Monel Monel lining

9 5 T Tantalum Tantalum lining

9 6 H

9 6 M Monel Monel lining

9 6 T Tantalum Tantalum lining

5 - - -

Type

Differential pressure transmitter - Smart, 4-20 mA + HART/Fuji Electric communication protocols

Connections

Process

connections

(*9)

(*9)

(*8)

(*8)

(*12)

Rc 1/4"

(*12)

(*1)

1/4"-18 NPT

(*1)

(*12)

Ranges and materials

(*2) Static pressure

limits

(*3)

-1 to 32 bar 10/100 mm WC

(*4)

-1 to 100 bar 10/600 mm WC

(*4)

(*4)

(*4)

-1 to 160 bar (*3)

(*4)

-1 to 420 bar

(*4)

(*4)

-1 to 300 bar

(*4)

(*4)

(*5)

(*5)

(*5)

(*5)

0 to 15 bar

(*5)

(*5)

(*5)

(*5)

(*5)

(*5)

(*5)

(*5)

(*5)

(*5)

(*5)

0 to 15 bar

(*5)

(*5)

(*5)

(*5)

(*5)

(*5)

Oval flange

threading

7/16 - 20 UNF

M10 or M12 (*1)

7/16 - 20 UNF

7/16 - 20 UNF

M10 or M12 (*1)

7/16 - 20 UNF

Measuring ranges

(*3)

(*2)

32 /3200 mm WC

0,13 /13 m WC

0,5/50 m WC

3/300 m WC

32/3200 mm WC

3/300 m WC Hastelloy C

50/2000 m WC

10/100 mm WC

0,5 /50 m WC

0,13 /13 m WC

0,5 /50 m WC

Electrical

connection

M20 x 1,5

M20 x 1,5 "L" shape

Pg13,5

M20 x 1,5

Pg13,5

G 1/2"

1/2 - 14 NPT

Pg13,5

M20 x 1,5

Pg13,5

Process cover Measuring

LP side HP side

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

SS 316L

PVDF Insert

PVDF Insert Hastelloy C Hastelloy C

SS 316L

Enclosure

type

"T" shape

diaphragm

SS 316L

SS 316L

Hastelloy C

Gold coating

Gold/ceramic Gold/ceramic

Tantalum Tantalum lining

SS 316L

Hastelloy C

Gold coating SS 316L

Gold/ceramic Gold/ceramic

SS 316L

Hastelloy C

Monel Monel lining

SS 316L

Hastelloy C

Hastelloy C

Gold coating

Hastelloy C

Gold coating

Hastelloy C

Gold coating

Gold coating

Gold coating

Hastelloy C Hastelloy C lining

Hastelloy C

Hastelloy C Hastelloy C

Wetted cell body

SS 316L

Hastelloy C

SS 316L

SS 316L

Hastelloy C

SS 316L

Hastelloy C

SS 316L

Hastelloy C

SS 31L63 8 J (*4) Gold coating

SS 31L6

Hastelloy C

SS 316L

SS 316L

Hastelloy C

SS 316L

SS 316L

SS 316L

Hastelloy C

SS 316L

SS 316L

Hastelloy C

6

Page 7

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

C

F

K

Notes*:

1- M12 thread if static pressure > 160 bar.

2- Turn down ratio of 100 is possible but span greater than 1/40 of the the URL is recommended for better performances.

3- For M10 bolts/nuts : maximum static pressure = 160 bar. For static pressure > 160 bar : M12 is required.

4- Gold coating on wetted parts of the measuring cell for hydrogen service. Gold/ceramic coating available upon request.

5- Process cover with PVDF insert: 1/2”-14 NPT side process connection, no vent/drain, square section PTFE gasket. Other upon request.

6- When no code can be found in the current model code, place “*” in the corresponding digit code as well as in the 16th digit.

7- SS 660 bolts/nuts are in conformity with NACE MR0175/ISO 15156

8- For static pressure = 420 bar and PTFE process cover gasket, use only code “R”, “T” or “X”.

9- Process connection on the bottom side with side vent/drain.

10- Only with digit 4 = “M”, “P”, “R”, “T”, “W”, “6”, “8”

11- Except digit 10 = “P”, “Q”

12- For static pressure = 420 bar and PTFE process cover gasket, use only code “5”, “6” or “9”

13- SS 316L enclosure not available for "T" shape version

5 - - -

5 - A

5 - B

5 - C

5 - D

5 - J

5 - E

5 - F

5 - G Yes

5 - H

5 - K

5 - L

5 - P

5 - M

5 - Q

5 - S

5 - N

5 - 1

5 - 2

5 - 3

5 - 4

5 - 5

5 - 6

A

X

K

P

M

E

J

L

R

T

Q

N

W

A

C

K

D

F

L

Y None

B Yes

C None

E Yes

Y Silicone oil

W

G Degreasing Silicone oil

A Oxygen service Fluorinated oil (only with digit 7 = J, V, W)

D Chlorine service Fluorinated oil (only with digit 7=H,T)

N (*7) NACE Silicone oil

- A Viton

- C PTFE square section for SS flange

D

-

A Carbon steel Cr-Mo - M10 for static pressure < 160 bar

U

V Carbon steel Cr-Mo - M12 for static pressure > 160 bar

W SS 660/660 - M10 for static pressure < 160 bar

W

(*6) - * special, no code available

Indicator Arrester

None

(*11)

Analog, 0-100% linear scale

(*11)

Analog, 0-100% √ scale

(*11)

Analog, Custom scale

(*11)

Analog, double scale

None

Analog, 0-100% linear scale

(*11)

Analog, 0-100% √ scale

(*11)

Analog, Custom scale

(*11)

Analog, double scale

(*11)

Digital, 0-100%

Digital, Custom scale

Digital, 0-100% √ scale

Digital, 0-100%

Digital, Custom scale

Digital, 0-100% √ scale

Digital, 0-100% with push button

Digital, Custom scale with push button

Digital, 0-100% √ scale with push button

Digital, 0-100% with push button

Digital, Custom scale with push button

Digital, 0-100% √ scale with push button

Hazardous location approvals

None

(*10)

ATEX - Flameproof

ATEX - Intrinsic Safety

ATEX - Increased Safety

(*10)

ATEX - Combination Flameproof and Intrinsic Safety

(*10)

cCSAus - Explosion proof

cCSAus - Intrinsic Safety and Non Incendive

(*10)

cCSAus -Combination Explosion proof, Intrinsic Safety and Non Incendive

IECEx - Flameproof

(*10)

IECEx - Intrinsic Safety

IECEx - Increased Safety

(*10)

IECEx - Combination Flameproof and Intrinsic Safety

IECEx - ATEX - cCSAus - Explosion/flameproof, Intrinsic Safety and Non Incendive

(*10)

Side vent/drain Mounting bracket

None (standard)

Yes

Stainless steel parts

TAG plate Housing

(*13)

(*13)

(*5)

(*3)

(*7)

(*7)

Special applications & filling fluid

Treatment Filling fluid

None

Process cover gasket

PTFE square section for PVDF insert

Bolts/screws material

SS 316L / 316L - M10 for static pressure < 160 bar

SS 660/660 - M12 for static pressure > 160 bar

Special options

DESCRIPTION

None

SS 304L

SS 316L

None

SS 304L

SS 316L

None

Yes

Fluorinated oil

None

None

Yes

None

Yes

7

Page 8

FKC

...

5

OUTLINE DIAGRAM

ITH ANALOG INDICATOR

W

W

ITH DIGITAL INDICATOR

IGH PRESSURE CONNECTION

H

(unit : mm) <7th digit code : V, H, M, T>

1/4 NPT

M

OUNTING BRACKET FOR

P

IPE

Ø50 MM (2”)

(X11 = C)

VALE FLANGE SCREW

O

(

SEE TABLE

L

OW PRESSURE CONNECTION

1)

1/4 NPT

V

ENT

/ D

A

RAIN

E

O

ø18.5

VAL FLANGE SCREW

7/16-20 UNF

7/16-20 UNF

M10 or M12

M10 or M12

7/16-20 UNF

Code X=4

R

T

V

W

X

ø15

D

ONDUIT CONNECTION

C

M20x1.5

1/2-14NPT

Pg13.5

M20x1.5

Pg13.5

E GD

16

16

10,5

16

10,5

Table 1

W

EIGHT

: - 3,5 KG (

DD

: - 0,3 KG

A

- 2 KG

FOR STAINLESS STEEL HOUSING OPTION

- 0,5 KG

G

2.5

8

ø7

WITHOUT OPTION

FOR INDICATOR OPTION

FOR MOUNTING BRACKET

)

U-

BOLT

M8

D

IMENSIONS

A

B

C

198,5 225,5 38,5

194 221 37

198,5 225,5 38,5

8

Page 9

C

ONDUIT CONNECTION

(

SEE TABLE

1)

B

C

Zero/Span adjustment screw

Vent / drain

9

Page 10

Fuji Electric France S.A.S.

46 rue Georges Besse - ZI du brézet - 63039 Clermont ferrand

Tél : 04 73 98 26 98 - Fax : 04 73 98 26 99

Mail : sales.dpt@fujielectric.fr - web : www

...

FKC

5

CONNECTION DIAGRAM

ELECTROMAGNETIC COMPATIBILITY

All FCX-AII series of pressure transmitters are in conformity with the provision of the EMC Directive 2014/30/EU on the

harmonization of the laws of the Members States relating to electromagnetic compatibility.

All these models of pressure transmitters are in accordance with the following harmonized standards :

• EN 61326-1 (Electrical equipment for measurement, control and laboratory use - EMC requirements Part 1: General requirements).

• EN 61326-2-3 (Particular requirements - Test conguration, operational conditions and performance criteria for tranducers

with integrated or remote signal conditioning).

Emission limits (according to EN 55011 / CISPR 11, Group 1 Class A)

Frequency range (MHz) Limits Basic standard

30 to 230 40 dB (µV/m) quasi peack, measured at 10 m distance Passed

230 to 1000 47 dB (µV/m) quasi peack, measured at 10 m distance

Immunity

Phenomenon Test value Standard Required Result

Performance criteria of criteria

Electrostatic Discharge ±4 kV (Contact) EN/IEC 61000-4-2 B A

±8 kV (Air)

Radiated, Electromagnetic 10 V/m (0.08 to 1.0 GHz) EN/IEC 61000-4-3 A A

Field 3 V/m (1.4 to 2.0 GHz)

1 V/m (2.0 to 2.7 GHz)

Fast transients (burst) 2 kV (5/50 ns, 5 kHz EN/IEC 61000-4-4 B A

Surge Transients 1 kV Line to line EN/IEC 61000-4-5 B A

2 kV Line to ground

Conducted RF Disturbances 3 Vrms (150 kHz to 80 MHz) EN/IEC 61000-4-6 A A

80% AM @ 1 kHz

Power Frequency 30 A/m (50 Hz, 60 Hz) EN/IEC 61000-4-8 A A

Magnetic Field

Performance criteria (A & B): according to IEC 61326

.fujielectric.fr

Fuji Electric can accept no responsibility for possible errors in catalogues, brochures and other printed material. Fuji Electric reserves the right to alter its products without notice. This

also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed. All trademarks

in this material are property of the respective companies. All rights reseved.

Loading...

Loading...