Frymaster MH52, BIMH52 Installation Manual

OPERATOR’S MANUAL

FRYMASTER H52 SERIES

This equipment chapter is to be

installed in the Fryer Section of the

Equipment Manual.

TABLE OF CONTENTS

MANUFACTURED

FRYMASTER, L.L.C.

P.O. BOX 51000

SHREVEPORT, LOUISIANA 71135-1000

PHONE: 1-318-865-1711

TOLL FREE: 1-800-551-8633

1-800-24 FRYER

FAX: 1-318-219-7135

BY

GAS FRYER

FOR YOUR SAFETY

Do Not Store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WARRANTY STATEMENT...................................................................................................Page i

INTRODUCTION...................................................................................................................Page 1-1

INSTALLATION INSTRUCTIONS ........................................................................................Page 2-1

OPERATING FRYERS WITH M100B COOKING COMPUTERS.........................................Page 3-1

OPERATING FRYERS WITH THERMOSTAT CONTROLLERS .........................................Page 4-1

FILTERING............................................................................................................................Page 5-1

PREVENTIVE MAINTENANCE AND TROUBLESHOOTING ..............................................Page 6-1

Frymaster, L.L.C. 8700 Line Avenue 71106, 5489 Campus Drive 71129

P.O. Box 51000, Shreveport, Louisiana 71135-1000

TEL 318-865-1711 FAX (Parts) 318-219-7140 (Tech Support) 318-219-7135

PRINTED IN THE UNITED STATES SERVICE HOTLINE 819-5404 02/05

1-800-24-FRYER U.S. $6.00

CHAPTER 1: INTRODUCTION

1.1 General

Read the instructions in this manual thoroughly before attempting to operate this equipment. This

manual covers all configurations of models MH52 and BIH52 fryers built since December 1995.

Models designated MH52 do not have built-in filtration systems. Models designated BIH52 are

equipped with FootPrint III built-in filtration systems.

H52 Series fryers feature deep cold-zones and easy to clean, open frypots. The fryers are controlled

by multi-product cooking computers or optional thermostat controllers. Fryers in this series come in

full or split-pot arrangements, and can be purchased as single units or grouped in batteries of up to

five fryers.

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the ones

below.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

CAUTION

Example of a CAUTION box.

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

WARNING

Example of a WARNING box.

DANGER boxes contain information about actions or conditions that may cause or result in injury to

personnel, and which may cause damage to your system and/or cause your system to malfunction.

DANGER

Hot cooking oil causes severe burns. Never attempt to move a fryer containing hot

cooking oil or to transfer hot cooking oil from one container to another.

Fryers in this series are equipped with automatic safety features:

1. A high-limit thermostat causes the gas valve to close should the controlling thermostat fail or

computer temperature probe fail.

2. In BIH52 fryers, a safety switch built into the drain valve prevents the gas valve from opening

with the drain valve even partially open.

1-1

1.3 Computer Information

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been shown

to meet the Class B limits. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of the

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

The user is cautioned that any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for

additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission

helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available

from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.4 European Community (CE) Specific Information

The European Community (CE) has established certain specific standards regarding equipment of this

type. Whenever a difference exists between CE and non-CE standards, the information or instructions

concerned are identified by means of shadowed boxes similar to the one below.

CE Standard

Example of box used to distinguish CE and

Non-CE specific information.

1.5 Shipping Damage Claim Procedure

What to do if your equipment arrives damaged:

Please note that this equipment was carefully inspected and packed by skilled personnel before

leaving the factory. The freight company assumes full responsibility for safe delivery upon acceptance

of the equipment.

1. File Claim for Damages Immediately—Regardless of extent of damage.

2. Visible Loss or Damage—Be sure this is noted on the freight bill or express receipt and is signed

by the person making the delivery.

3. Concealed Loss or Damage—If damage is unnoticed until equipment is unpacked, notify Freight

Company or carrier immediately and file a concealed damage claim. This should be done within

15 days of date of delivery. Be sure to retain container for inspection.

1-2

1.6 Service Information

McDonald’s store personnel perform routine maintenance. For non-routine maintenance or repairs, or

for service information, contact your local Frymaster Authorized Service Center (FASC). Service

information may also be obtained by calling the Frymaster Technical Services Department (1-80024FRYER). The following information will be needed in order to assist you efficiently:

Model Number_________________________

Serial Number _________________________

Gas Type_____________________________

Nature of the Problem ___________________

____________________________________

____________________________________

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-3

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation Requirements

NOTE: PROPER INSTALLATION IS ESSENTIAL FOR EFFICIENT, TROUBLE-FREE

OPERATION OF YOUR FRYER. ANY UNAUTHORIZED ALTERATIONS MADE TO THIS

EQUIPMENT WILL VOID THE FRYMASTER WARRANTY.

Upon arrival, inspect the fryer carefully for visible or concealed damage. (See Shipping Damage

Claim Procedure in Chapter 1.)

CLEARANCE AND VENTILATION

The fryer(s) must be installed with a 6” (150 mm) clearance at both sides and back when installed

adjacent to combustible construction; no clearance is required when installed adjacent to noncombustible construction. A minimum of 24” (600 mm) clearance should be provided at the front of the

fryer.

One of the most important considerations of efficient fryer operation is ventilation. Make sure the

fryer is installed so that products of combustion are removed efficiently, and that the kitchen ventilation system does not produce drafts that interfere with proper burner operation.

The fryer flue opening must not be placed close to the intake of the exhaust fan, and the fryer must

never have its flue extended in a “chimney” fashion. An extended flue will change the combustion

characteristics of the fryer, causing longer recovery time. It also frequently causes delayed ignition.

To provide the airflow necessary for good combustion and burner operation, the areas surrounding

the fryer front, sides, and rear must be kept clear and unobstructed.

Fryers must be installed in an area with an adequate air supply and adequate ventilation. Adequate

distances must be maintained from the flue outlet of the fryer to the lower edge of the ventilation

filter bank. Filters should be installed at an angle of 45º. Place a drip tray beneath the lowest edge

of the filter. For U.S. installation, NFPA standard No. 96 states, “A minimum distance of 18 in.

(450 mm) should be maintained between the flue outlet and the lower edge of the grease filter.”

Frymaster recommends that the minimum distance be 24 in. (600 mm) from the flue outlet to the

bottom edge of the filter when the appliance consumes more than 120,000 BTU per hour.

For installations in the United States, information on construction and installation of ventilating

hoods can be found in the NFPA standard cited above. A copy of the standard may be obtained

from the National Fire Protection Association, Battery March Park, Quincy, MA 02269.

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable,

tip over, and cause injury. The appliance area must be kept free and clear of com-

bustible material at all times.

2-1

NATIONAL CODE REQUIREMENTS

The type of gas for which the fryer is equipped is stamped on the data plate attached to the inside of

the fryer door. Connect a fryer stamped “NAT” only to natural gas, those stamped “PRO” only to

propane gas, and those stamped “MFG” only to manufactured gas.

Installation shall be made with a gas connector that complies with national and local codes, and,

where applicable, CE codes. Quick-disconnect devices, if used, shall likewise comply with national,

local, and, if applicable, CE codes.

ELECTRICAL GROUNDING REQUIREMENTS

All electrically operated appliances must be grounded in accordance with all applicable national and

local codes, and, where applicable, CE codes. A wiring diagram is located on the inside of the fryer

door. Refer to the rating plate on the inside of the fryer door for proper voltages.

DANGER

If this appliance is equipped with a three-prong (grounding) plug, it must be plugged

directly into a properly grounded receptacle.

Do not cut or remove the grounding prong from the plug.

DANGER

This equipment requires electrical power for operation.

Place the gas control valve in the OFF position in case of a prolonged power outage.

Do not attempt to use the equipment during a power outage.

FCC COMPLIANCE

The user is cautioned that any changes or modifications to Frymaster computers not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

Frymaster computers have been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. While these devices are verified as Class A devices, they

have been shown to meet the Class B limits. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of the equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

If necessary, the user should consult the dealer or an experienced radio and television technician for

additional suggestions.

2-2

The user may find the booklet “How to Identify and Resolve Radio-TV Interference Problems” helpful. It is prepared by the Federal Communications Commission and is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

2.2 Caster/Leg Installation

Depending upon the specific configuration ordered, your fryer may have been shipped without installed casters or legs. If casters or legs are installed, you may skip this section and proceed to section 2.3, Pre-Connection Preparations.

If your fryer requires the installation of casters/legs, install them in accordance with the instructions included in your accessory package.

2.3 Pre-Connection Preparations

DANGER

Do not connect fryer to gas supply before completing each step

in this section.

After the fryer has been positioned under the fry station exhaust hood, ensure the following has been

accomplished:

1. Adequate means must be provided to limit the movement of fryers without depending upon the

gas line connections. If a flexible gas hose is used, a restraining cable must be connected at all

times when the fryer is in use. The restraining cable and installation instructions are packed with

the flexible hose in the accessories box that was shipped with your unit.

2. Single unit fryers must be stabilized by installing restraining chains on fryers equipped with

casters or anchor straps on fryers equipped with legs. Follow the instructions shipped with the

casters/legs to properly install the chains or straps.

3. Level the fryer, if necessary, by loosening the locking screw on the caster legs and rotating the

leg to increase or decrease the exposed length. Verify that the fryer is at the proper height in the

exhaust hood. Frymaster recommends that the minimum distance from the flue outlet to the bottom edge of the hood be 24 in. (600 mm) when the appliance consumes more than 120,000 BTU

per hour.

4. Test the fryer electrical system:

a. Plug the fryer electrical cord(s) into a grounded electrical receptacle.

b. Place the power switch in the ON position.

• For fryers equipped with thermostat controls, note the illumination of the power light and

the heat light.

• For fryers having computers, note that the display reads LO-TEMP and the heat light

comes on.

• If the store is equipped with a hood interlock system, the hood exhaust fan should be on.

If not, the store hood interlock system is improperly wired and must be corrected.

c. Place the fryer power switch in the OFF position. Verify that the power and heat lights are

out, or that the display is blank.

2-3

5. Refer to the data plate on the inside of the fryer door to determine if the fryer burner is configured for the proper type of gas before connecting the fryer quick-disconnect device or piping

from the gas supply line.

6. Verify the minimum and maximum gas supply pressures for the type of gas to be used in accordance with the accompanying tables.

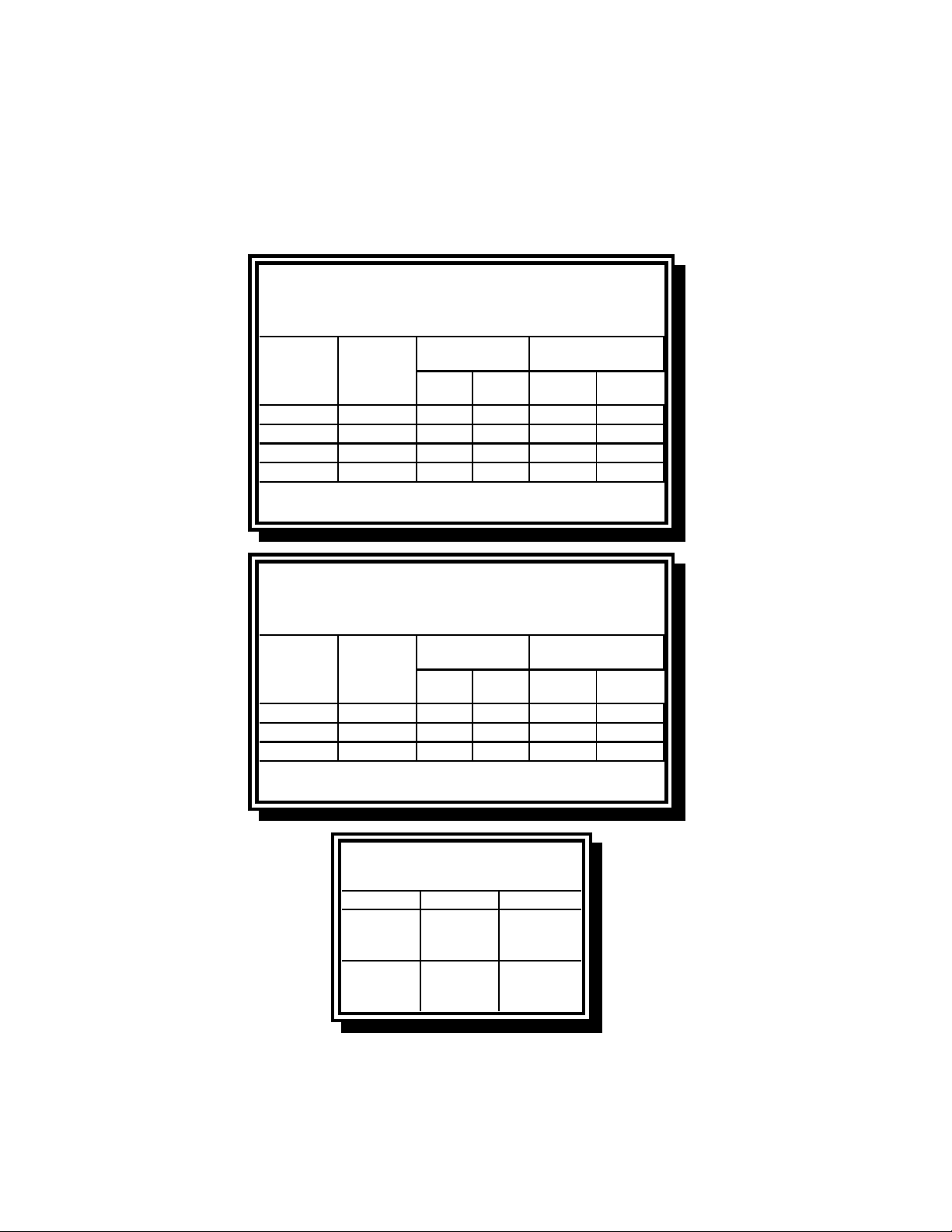

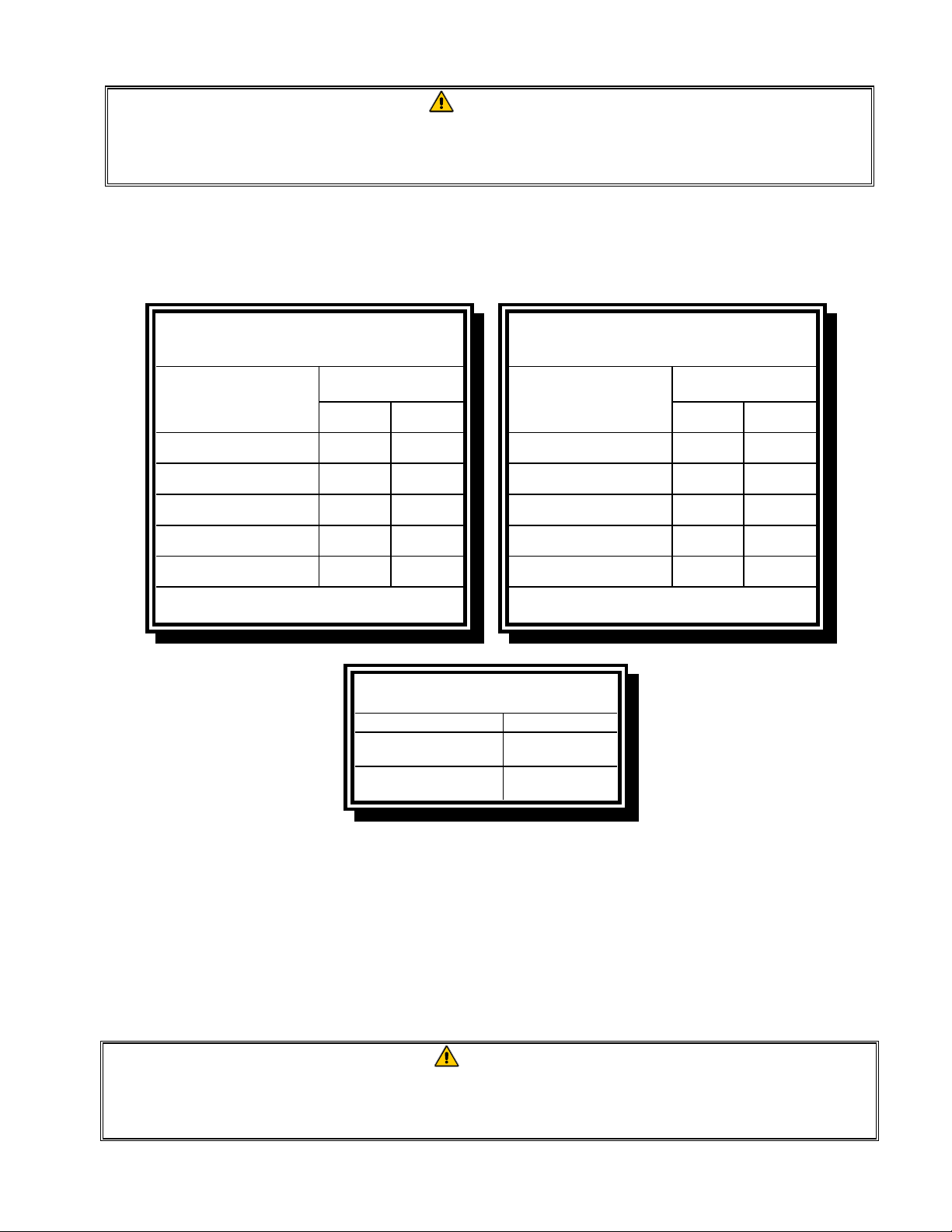

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured After April 1999

Orifice Diameter

Pressure

Gas

G20 20 2 x 3.40 2 x 3.40 7 mbar 6.5 mbar

G25 20 or 25 2 x 3.40 2 x 3.40 10 mbar 9 mbar

G30 28/30 or 50 2 x 2.05 2 x 2.05 17 mbar 17 mbar

G31 37 or 50 2 x 2.05 2 x 2.05 20 mbar 18.5 mbar

(mbar)

Single

(1)

Vat

Dual

Vat

Regulator Pressure

Single

Vat

(1) mbar = 10.2 mm H2O

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured Through April 1999

Orifice Diameter

Pressure

Gas

G20 20 2 x 3.40 2 x 3.40 7 mbar 6.5 mbar

G25 20 - 25 2 x 3.40 2 x 3.40 10 mbar 9 mbar

G31 37 - 50 2 x 2.05 2 x 2.05 20.2 mbar 18.5 mbar

(mbar)

Single

(1)

Vat

Dual

Vat

(1) mbar = 10.2 mm H2O

Regulator Pressure

Single

Vat

Dual

Vat

Dual

Vat

Non-CE Standard

for Incoming Gas Pressures

Gas Minimum Maximum

Natural

LP

6" W.C.

1.49 kPa

14.93 mbar

11" W.C.

2.74 kPa

27.37 mbar

14" W.C.

3.48 kPa

34.84 mbar

14" W.C.

3.48 kPa

34.84 mbar

7. For fryers equipped with a FootPrint III system (BIH52 models), plug the electrical cord into a

power receptacle behind the fryer.

2-4

2.4 Connection to Gas Line

The H52 Series has received the CE mark for the countries and gas categories indicated in the

accompanying table. NOTE: The nominal heat input (Qn) is 21kW except for AT, DE, LU, and for

category 3B/P under 50 mbar, which is 23kW.

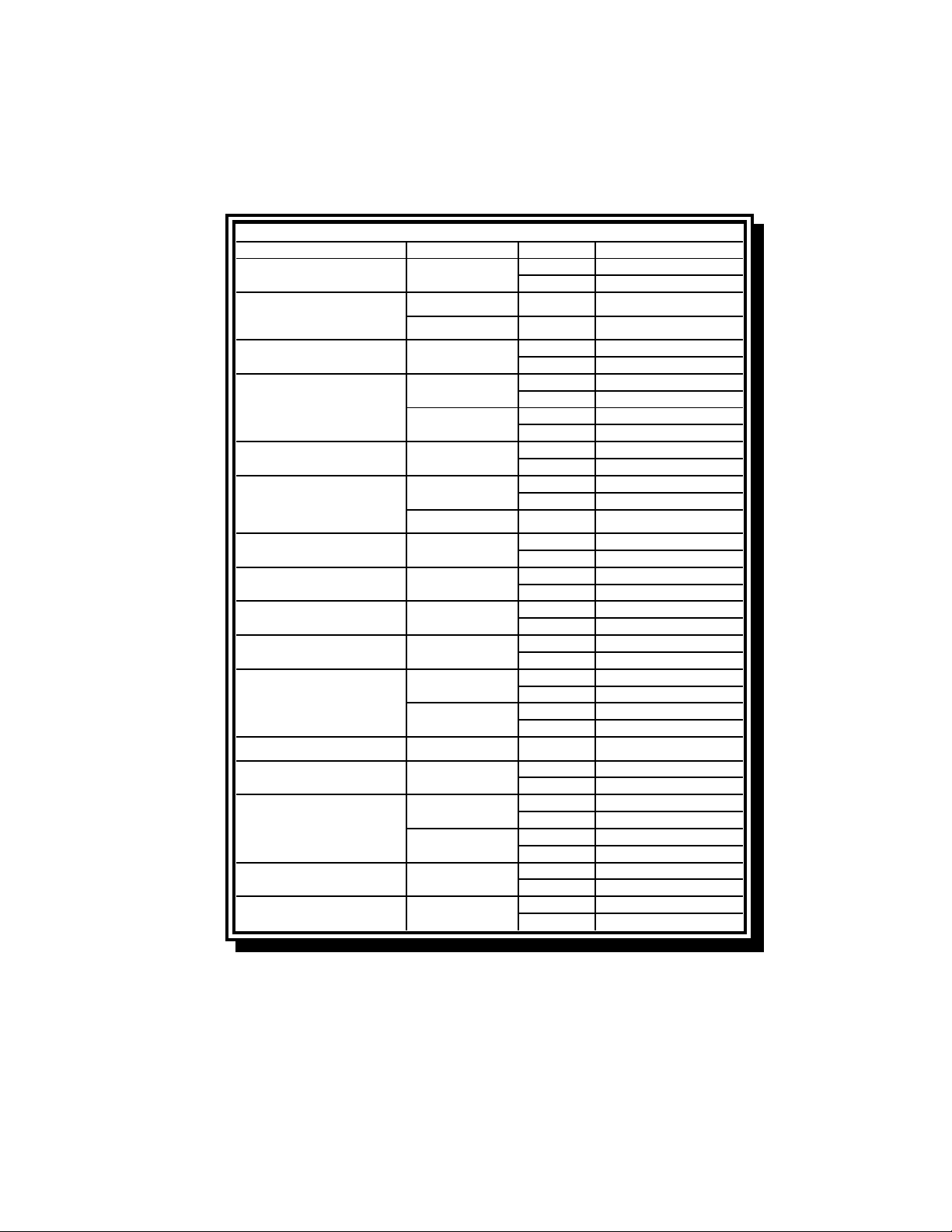

CE Approved Gas Categories by Country*

COUNTRIES CATEGORIES GAS PRESSURE (mbar)

AUSTRIA (AT)

BELGIUM (BE)

DENMARK (DK)

FRANCE (FR)

FINLAND (FI)

GERMANY (DE)

GREECE (GR)

ITALY (IT)

IRELAND (IE)

LUXEMBOURG (LU)

NETHERLANDS (NL)

NORWAY (NO)

PORTUGAL (PT)

SPAIN (ES)

SWEDEN (SE)

UNITED KINGDOM (GB)

II

2H3B/P

I

2E(R)B

I

3+

II

2H3B/P

II

2Esi3+

II

2Esi3P

II

2H3B/P

II

2ELL3B/P

I

3P

II

2H3+

II

2H3+

II

2H3+

II

2E3B/P

II

2L3P

II

2L3B/P

I

3B/P

II

2H3+

II

2H3+

II

2H3P

II

2H3B/P

II

2H3+

G20 20

G30, G31 50

G20, G25 20, 25

G30, G31 28-30, 37

G20 20

G30, G31 30

G20, G25 20, 25

G30, G31 28-30, 37

G20, G25 20, 25

G31 50

G20 20

G30, G31 30

G20, G25 20

G30, G31 50

G31 50

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 50

G25 25

G31 50

G25 25

G30, G31 30

G30, G31 30

G20 20

G30, G31 28-30, 37

G20 20

G30, G31 28-30, 37

G20 20

G31 37, 50

G20 20

G30, G31 30

G20 20

G30, G31 28-30, 37

* H152-2 units are not approved for G30 (Butane) gas.

The size of the gas line used for installation is very important. If the line is too small, the gas pressure at the burner manifold will be low. This may cause slow recovery and delayed ignition. Frymaster recommends the incoming gas supply line be a minimum of 1½” (38 mm) in diameter. Refer

to the chart on the following page for the minimum sizes of connection piping.

2-5

Gas Connection Pipe Sizes

(Minimum incoming pipe size should be 1 1/2" (38 mm))

4 or more

Gas Single Unit 2 - 3 Units

3/4

Natural

Propane 1/2" (13 mm) 3/4" (19 mm) 1" (25 mm)

Manufactured 1" (25 mm) 1 1/4" (33 mm) 1 1/2" (38 mm)

" (19 mm)

1" (25 mm) 1 1/4" (33 mm)

units*

* For distances of more than 20 feet (6 m) and/or

more than 4 fittings or elbows, increase the connection by one pipe size.

Before connecting new pipe to your unit, the pipe must be thoroughly blown out to remove any foreign particles. If these foreign particles get into the burner and controls, they will cause improper

and sometimes dangerous operation.

CE Standard

Required airflow for the combustion air supply is 2m3/h per kW.

1. Connect the quick-disconnect hose to the fryer quick-disconnect fitting under the front of the

fryer and to the building gas line.

NOTE: Some fryers are configured for a rigid connection to the gas supply line. These units are

connected to the gas supply line at the rear of the unit.

When using thread compound, use very small amounts on male threads only. Use a pipe thread

compound that is not affected by the chemical action of LP gases (Loctite™ PST56765 Sealant

is one such compound). DO NOT apply compound to the first two threads. This will ensure that

the burner orifices and control valve do not become clogged.

2. Open the gas supply to the fryer and check all piping, fittings, and gas connections for leaks. A

soap solution should be used for this purpose.

DANGER

Never use matches, candles, or any other ignition source to check for leaks.

If gas odors are detected, shut off the gas supply to the fryer

at the main shut-off valve and contact the local gas company or an authorized

service agency for service.

3. Close the fryer drain valve and fill the frypot with water and boil-out solution to the bottom OILLEVEL line at the rear of the frypot. Light the fryer and perform the boil-out procedures that are

described in the “Lighting Instructions” and “Boiling Out the Frypot” topics found in Chapter 3

of this manual.

2-6

WARNING

“Dry-firing” your unit will cause damage to the frypot. Always ensure that melted

shortening, cooking oil, or water and boil-out solution is in the frypot before firing

your unit for any extended period.

4. It is suggested that the burner manifold pressure be checked at this time by the local gas company or an authorized service agent. Refer to “Check Burner Manifold Pressure” in Chapter 5 of

this manual for the proper procedure. The accompanying tables list the burner manifold gas

pressures for the various gas types that can be used with this equipment.

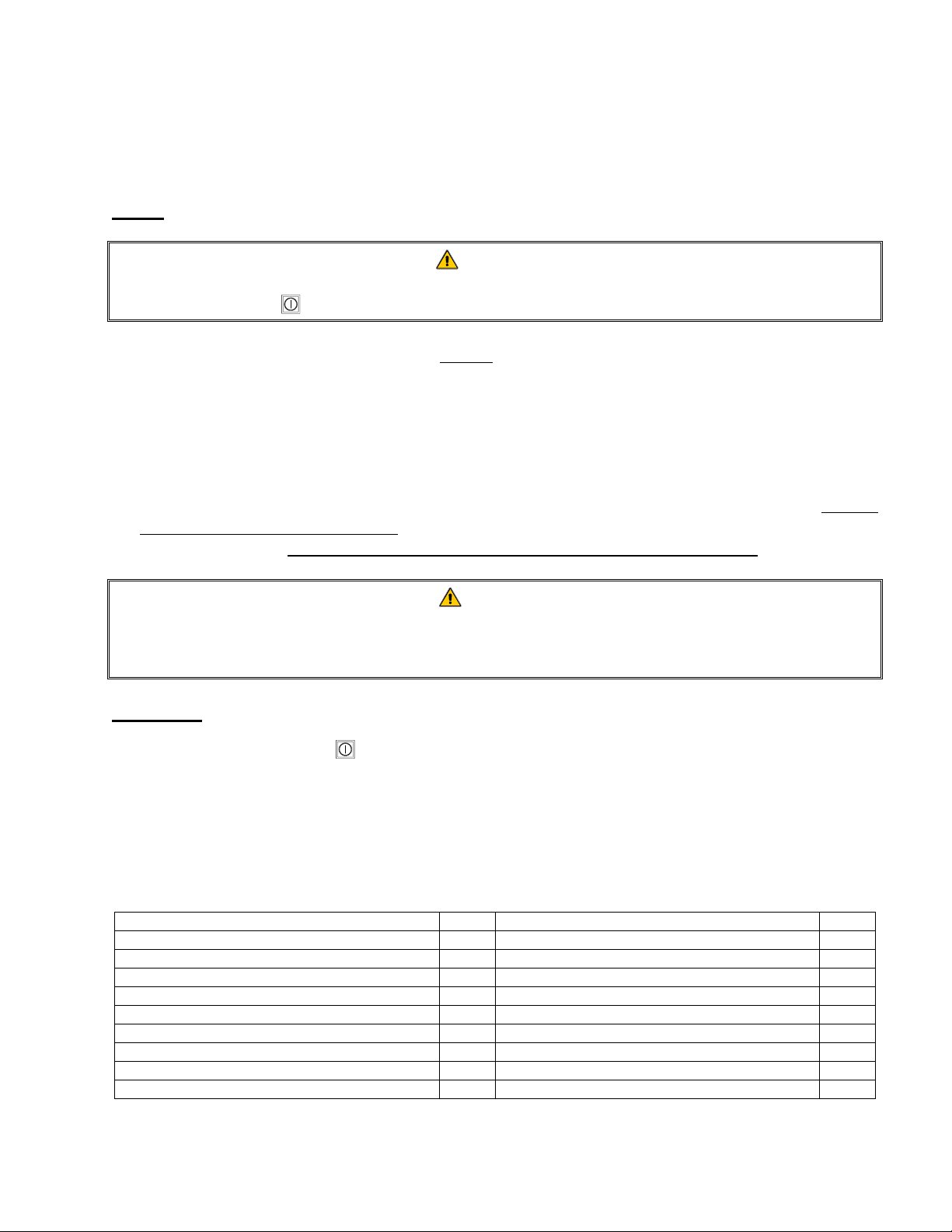

CE Standard

Burner Manifold Gas Pressures

for Fryers Manufactured After April 1999

Pressure (mbar)

Single

Gas

Natural Gas Lacq

(G20) under 20 mbar

Natural Gas Groningue *

(G25) under 25 mbar

Natural Gas Groningue

(G25) under 20 mbar

Butane

(G30) at 28/30 or 50 mbar

Propane

(G31) under 37 or 50 mbar

* Belgian G25 = 7,0 mbar (single or dual)

Vat

77

10 10

10 10

17 17

20 20

Burner Manifold Gas Pressures

for Fryers Manufactured Through April 1999

Dual

Vat

Natural Gas Lacq

(G20) under 20 mbar

Natural Gas Gronigue *

(G25) under 25 mbar

Natural Gas Gronigue

(G25) under 20 mbar

Butane

(G30) at 28/30 or 50 mbar

Propane

(G31) under 37 or 50 mbar

* Belgian G25 = 7,0 mbar (single) or 6,5 (dual)

Gas

Non-CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural

Propane

3" W.C.

0.73 kPa

8.25" W.C.

2.5 kPa

CE Standard

Pressure (mbar)

Single

Vat

76,5

10 9

10 9

17 16,5

20,2 18,5

Dual

Vat

5. Check the programmed temperature or analog controller thermostat setting. (Refer to Chapter 3,

Operating Instructions, for the setpoint programming instructions for your particular controller.)

2.5 Converting to Another Gas Type

Your fryer is configured at the factory for either natural gas or propane (LP) gas. If you desire to

switch from one type of gas to another, a gas conversion kit must be installed by a Factory

Authorized Service Center technician.

DANGER

Switching to a different type of gas without installing the proper conversion kit may

result in fire or explosion! NEVER attach your fryer to a gas supply for which it is

not configured.

2-7

H52 Series Fryers manufactured for Non-CE countries use different burners for each type gas. The

burners in fryers built for Propane gas have a special gray-colored coating on the burner tiles to enable them to withstand the higher caloric value of the Propane gas. Burners designed for use in Propane units may be used in natural gas applications, but not vice versa.

Non-CE Gas Conversion Kits

Natural Gas to Propane (LP) Gas Propane (LP) Gas to Natural Gas

Full Vat: Part Number 826-1145 Full Vat: Part Number 826-1146

Dual Vat: Part Number 826-1147 Dual Vat: Part Number 826-1148

Units manufactured for export to CE countries are equipped with “universal” burners that may be

used with either natural (G20, G25) gas or Butane (G30) and Propane (G31) gasses.

CE Gas Conversion Kits for Units with Gas Valve 810-1011

G20 or G25 (Natural) to G30 or G31 Gas: G30 or G31 to G20 or G25 (Natural) Gas:

Part Number 826-1196 Part Number 826-1197

CE GAS CONVERSION INSTRUCTIONS

1. Between G20- and G25-type Natural Gas, adjust the gas pressure at the regulator. (Refer to the

CE Standard Burner Manifold Gas Pressure Chart.) Do not change the orifice.

2. Between a 2nd family (G20 or G25) and a 3rd family gas (G30 Butane or G31 Propane):

a. Change the orifices.

b. Change the gas valve spring (units with valve part number 810-1011only)

c. Adjust the manifold pressure.

3. Affix the new label included with the conversion kit next to the existing rating plate stating that

the gas type has been converted. Remove any references to the previously used gas from the existing rating plate. Conversion rating label PN 802-2144.

4. If the destination language changes, replace the labels. Call your local service agency or KES

for a label kit. The language of reference will be on the corner of the label.

2.6 Frypot Boil-Out

Before the fryer is first used for cooking product, it should be boiled out to ensure that any residue

from the manufacturing process has been eliminated.

In addition, after the fryer has been in use for a period of time, a hard film of caramelized vegetable

oil will form on the inside of the frypot. This film should be periodically removed by following the

boil-out procedure.

Refer to Fryers Maintenance Requirement Card (MRC) 14A for the boil-out procedure.

2-8

g

CHAPTER 3: OPERATING FRYERS

WITH M100B™ COOKING COMPUTERS

3.1 Equipment Setup and Shutdown Procedures

Setup

WARNING

Fill the frypot to the bottom oil level line with vegetable oil before pressing the

ON/OFF switch to the ON position. Failure to do so could damage the frypot.

1. Fill the frypot with vegetable oil to the bottom OIL LEVEL line located on the rear of the frypot.

This will allow for oil expansion as heat is applied. Do not fill cold oil any higher than the bottom

line; overflow may occur as heat expands the oil.

2. Ensure that the power cord(s) is/are plugged into the appropriate receptacle(s). Verify that the

face of the plug is flush with the outlet plate, with no portion of the prongs visible.

3. Ensure that the vegetable oil level is at the top OIL LEVEL line when the vegetable oil is at its

programmed cooking temperature. It may be necessary to add vegetable oil to bring the level up

to the proper mark, after the oil has reached the programmed cooking temperature.

CAUTION

Do not add vegetable oil to the fryer between the time the computer is turned on and

the time it reaches programmed cooking temperature. Doing so is likely to cause

RECOVERY LOCKOUT (REC LOCK). See Section 3.4.

Shutdown

1. Press the ON/OFF switch to the OFF position (the display will show OFF).

2. Filter vegetable oil and clean fryers.

3. Place the frypot covers on frypots.

3.2 Finding Information

How do I… Pa

Activate/deactivate the BOIL-OUT mode? 3-10 Display “use time” information? 3-14

Change computer product/temp displays? 3-9 Enter a product number in a test menu? 3-12

Change cooking temperature setpoint? 3-11 Enter the program mode? 3-8

Calibrate computer to frypot temperature? 3-9 Enter the setup mode? 3-8

Change shake, pull, or quality times? 3-10 Program test item parameters? 3-12

Change the display language? 3-8 Reset the computer to factory defaults? 3-10

Configure the computer for a gas fryer? 3-8 Suppress a shake, QA, or duty function? 3-13

Configure the computer for full- or split-vat? 3-9 Turn factory-programmed menu item on/off? 3-14

Display Product Cycle Accumulator info? 3-14 Use the filter countdown time? 3-15

e How do I… Page

3–1

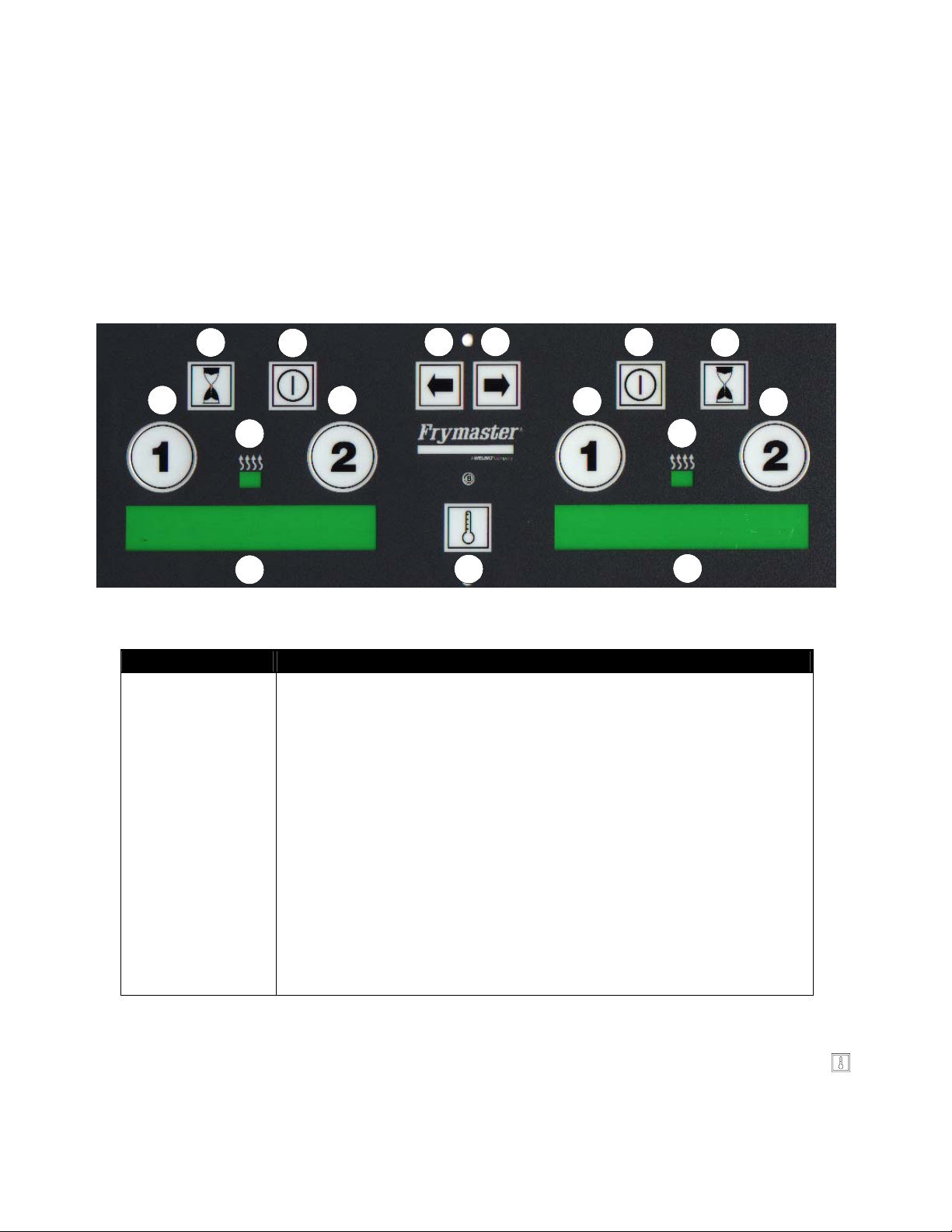

3.3 Introduction To The M-100B™ Cooking Computer

The M-100B cooking computer, illustrated below, automatically maintains fryer temperature to cook

products according to preprogrammed cooking specifications. The computer also acts as a cooking

process timer, displaying the remaining cooking time for each product and alerting the operator by

sound and display message to shake or pull the product at the correct time. It also signals quality

control (hold-time) limits. The computer automatically adjusts cooking times to compensate for

variances in product temperature and basket load so that, for example, a full basket of cold fries will

be cooked to the same quality as half a basket of fries at room temperature.

H

D

L

E

J

B

N

O

F

A

M

I

G

K

C

ITEM DESCRIPTION

A Temperature Display Switch

B Left LED Display

C Right LED Display

D Cook Switch #1, Left

E Cook Switch #2, Left

F Cook Switch #1, Right

G Cook Switch #2, Right

H Recovery/Use Time Recall Switch, Left

I Recovery/Use Time Recall Switch, Right

J Light - Left Heating Mode Indicator

K Light - Right Heating Mode Indicator

L Switch - Left ON/OFF

M Switch - Right ON/OFF

N Switch - Left Product Selection

O Switch - Right Product Selection

To quickly determine the software version number and the current configuration of an M-100B

computer, with the computer turned OFF (OFF in both displays) press the temperature check

switch. The displays will automatically cycle through the version number, power configuration (gas

or electric), EPRA configuration (On or Off), and frypot configuration (full or split).

3–2

Loading...

Loading...